Patents

Literature

135results about How to "Reduce cutting heat" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

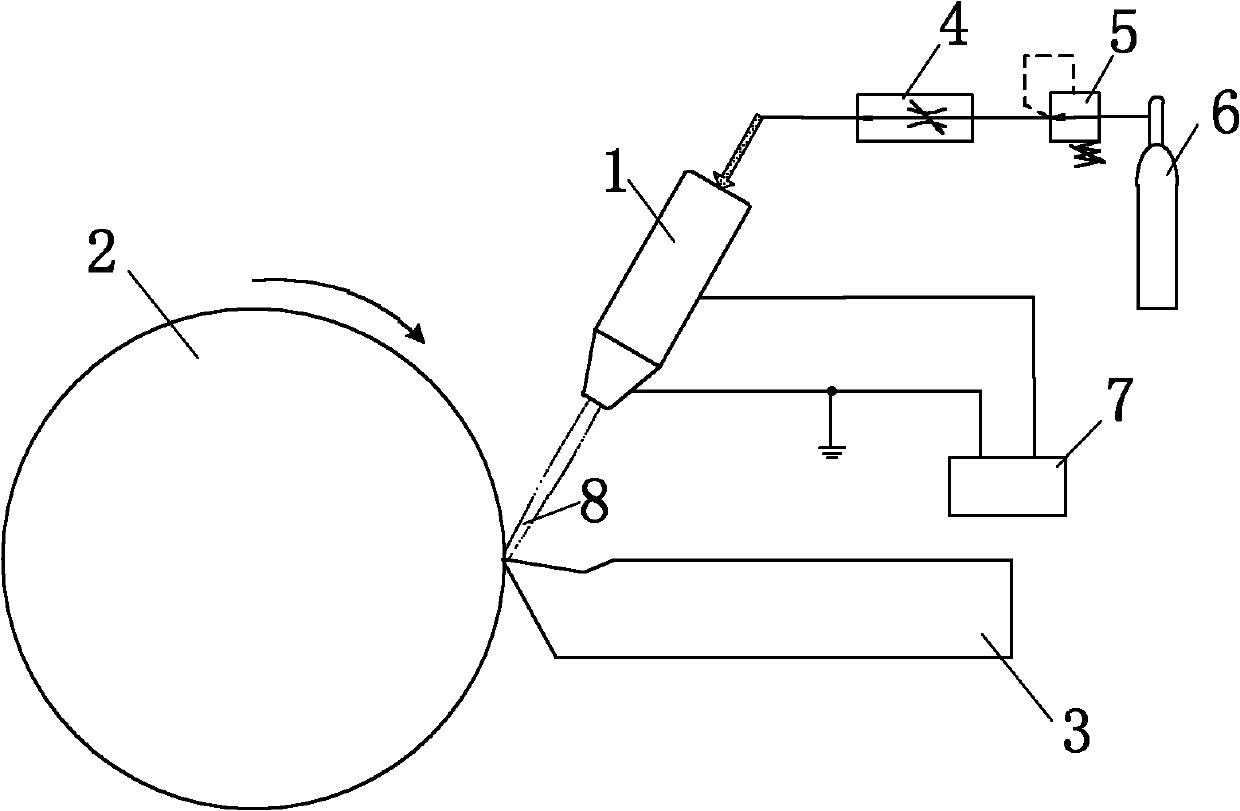

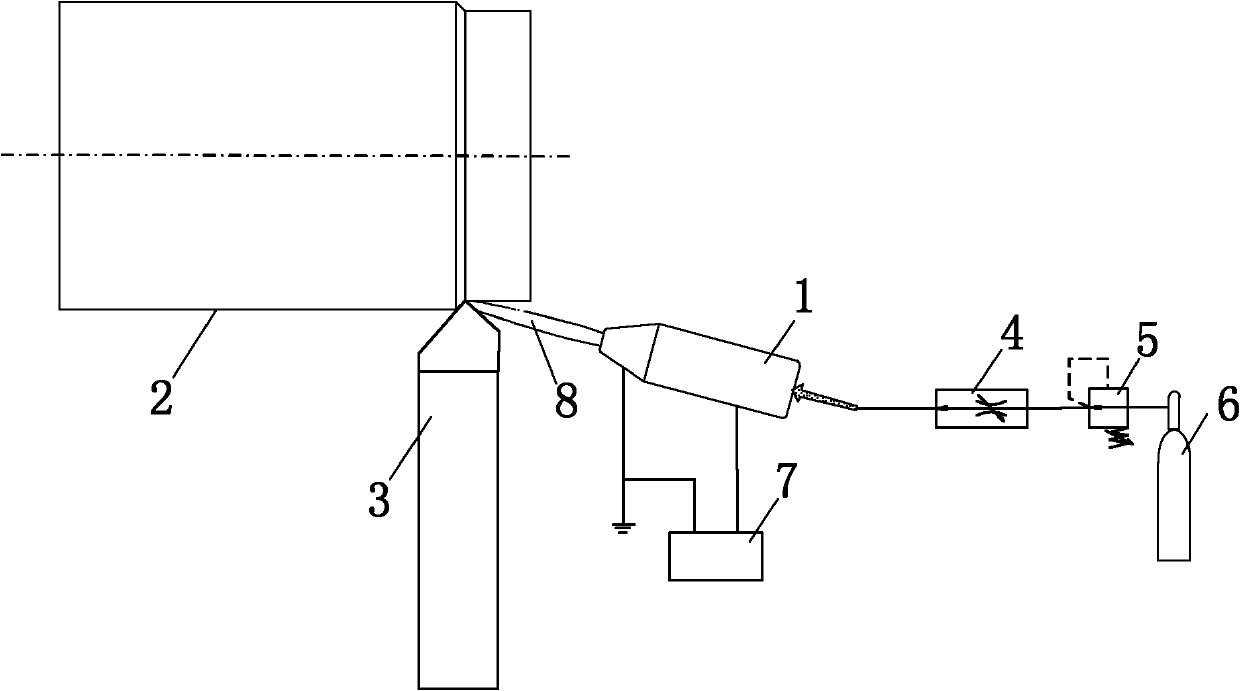

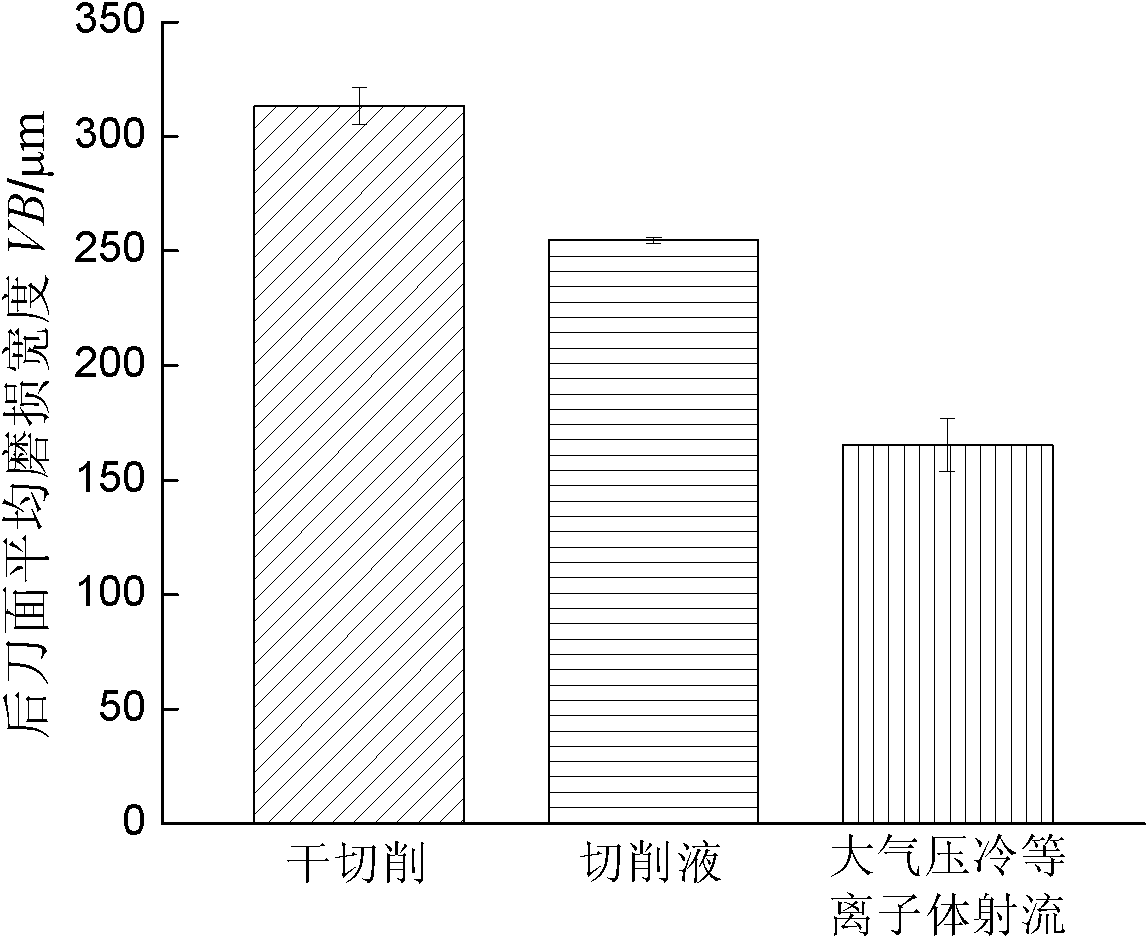

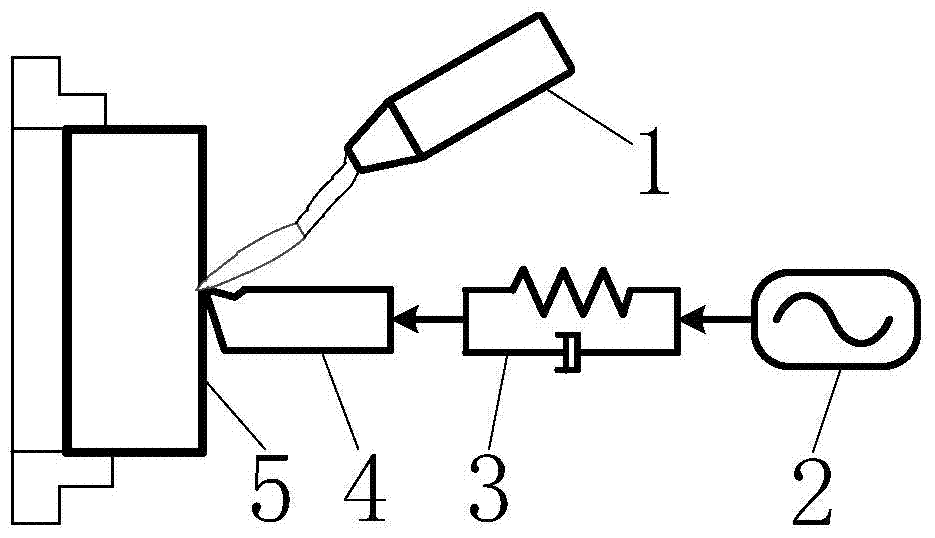

Atmospheric cold plasma jet auxiliary cutting method

ActiveCN102601677AReduce plastic deformation resistanceExtend your lifeMaintainance and safety accessoriesPlasma jetCooling effect

The invention provides an atmospheric cold plasma jet auxiliary cutting method. Cold plasma jet generated under atmospheric pressure is used as a lubricating cooling medium during material cutting. Working gas enters a cold plasma jet generator from a working gas source via a pressure reducing valve and an adjustable flow meter, the flow of the working gas and output voltage of a high-voltage power source are adjusted so that uniform cold plasma jet is sprayed out from a nozzle outlet of the cold plasma jet generator, the temperature of the jet is the room temperature or is slightly higher than the room temperature, and a tool and workpiece interface and a tool and chip interface are always soak in the cold plasma jet during cutting by means of adjusting a spraying angle. Plasma can be generated in a dielectric barrier discharge mode, a suspension electrode discharge mode or a bare electrode discharge mode. The atmospheric cold plasma jet auxiliary cutting method is an environment-friendly cutting method, an excellent lubricating and cooling effects for various metal and nonmetal materials can be realized during cutting, accordingly, cutting force is reduced, the service life of a tool is prolonged, and the quality of the surface of a workpiece is enhanced.

Owner:DALIAN UNIV OF TECH

Turning method and turning tool

The invention provides a turning method. The method comprises the following step: turning the outer surface of a niobium alloy target material or a niobium alloy target material by adopting a turning tool, wherein the front angle of the turning tool is 20-40 degrees, the rear angle is 4-15 degrees, the main deflection angle is 45-60 degrees, the auxiliary deflection angle is 45-90 degrees, and the blade inclination angle is 10-25 degrees. By selecting the front angle, rear angle, main deflection angle, auxiliary deflection angle and blade inclination angle of the turning tool, cuttings can be discharged from processed surfaces, so that the cuttings are prevented from sticking to the tool, and the cutting difficulty is lowered. The invention further provides a turning tool. The front angle of the turning tool is 20-40 degrees, the rear angle is 4-15 degrees, the main deflection angle is 45-60 degrees, the auxiliary deflection angle is 45-90 degrees, and the blade inclination angle is 10-25 degrees.

Owner:NINGXIA ORIENT TANTALUM IND

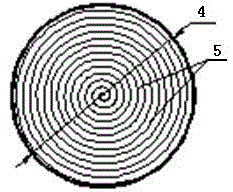

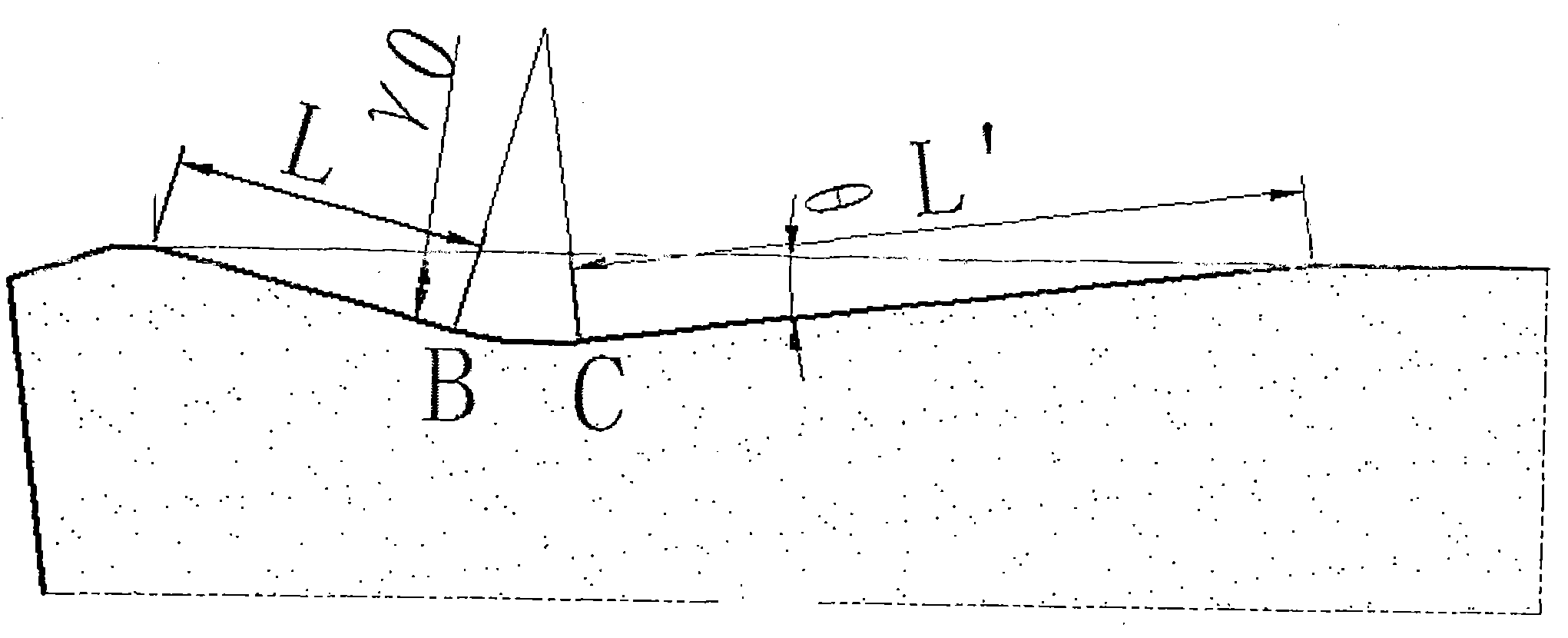

Production method of brazed diamond wire saw

InactiveCN101596749AIncrease productivityReduce manufacturing costFine working devicesStone-like material working toolsDiamond wire sawInduction welding

The invention relates to a production method of a brazed diamond wire saw, comprising the following process steps: 1. a steel wire enters a vessel stored with paste solder; 2. the steel wire adhered with solder enters a first wire-drawing die to facilitate the steel wire passing through the first wire-drawing die to be evenly coated with a layer of solder; 3. the steel wire adhered with solder enters a sealed dust box which contains diamond powder with diameter being 20-30 mum, a blower device blows the diamond fine powder, and the steel wire adhered with solder is evenly coated with a layer of diamond powder after passing through the dust box; 4. the steel wire adhered with solder enters a second wire-drawing die and is evenly and tightly coated with a layer of diamond powder; 5. the steel wire adhered with solder enters the center of a coil of high frequency induction welding, the solder melts down instantly, and diamond and the wire are fixedly and metallurgically bonded; and 6. a roll-up wheel evenly winds the finished diamond wire by welding. The method of the invention has quick production speed, and the prepared brazed diamond wire saw has long service life.

Owner:江苏中博钻石科技有限公司

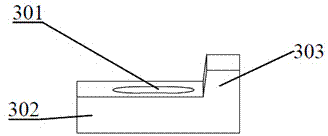

Radially-adjustable heavy-duty cutting layer milling cutter

InactiveCN104841994ARaise the natural frequencyChange milling forceTransportation and packagingMilling cuttersMilling cutterEngineering

The invention discloses a radially-adjustable heavy-duty cutting layer milling cutter applicable to the field of heavy-type milling processing, and aims to solve the problems that during heavy-duty milling water chamber end enclosing, surfaces of workblanks are uneven, multi-defective and poor in machinability; cutting blades are prone to being damaged by impacts during rough machining or hogging machining; during milling, cutting depth changes frequently, which results in that not all cutter teeth are involved in cutting, utilization rate of the milling cutter is low, the cutting layer milling cutter of a fixed radial stepped structure is short in service life, machining efficiency is influenced and the like. Cutter teeth of the cutting layer milling cutter are designed in a stepped distribution, by means of increasing cutting depth, metal removal rate is increased, and machining efficiency is improved; by the aid of a radial adjusting mechanism, the cutting blades in an upper layer are enabled to move radially, a proper overhang amount can be selected, and strength of the cutting blades is enhanced. A radially-adjustable cutter pad is positioned by a pad block, auxiliary time including cutter amounting time, cutter adjusting time and the like is saved; up-warp chip holding grooves are formed in a cutter body in design, the depths of the positions, close to the cutting blades, of the chip holding grooves are far larger than that of the positions, distant from the cutting blades, of the chip holding grooves, up-warp slopes are formed in the chip holding grooves, and when cutting chips flow in the chip holding grooves, the chips can be separated from the cutter body quickly, friction between the chips and the cutter body is reduced, and service life of the cutter body is prolonged.

Owner:HARBIN UNIV OF SCI & TECH

Perforating process of composite carbon fiber material product

ActiveCN1986145ASolve the hole layering problemGuarantee the quality of hole makingAutomatic control devicesTransportation and packagingAlloyCutting force

The perforating process of composite carbon fiber material product includes the following main steps: sorting hard alloy drilling bit with helix angle of 20 deg, vertex angle not smaller than 120 deg and chisel width of 0.06-0.1 D; drilling the guide hole based on the cutting force formula F=CFdxffYFvZFN; reaming at medium speed; and statically withdrawing the reamer. The improved perforating process has no delamination of the composite material, high production efficiency and high product quality.

Owner:CHENGDU AIRCRAFT INDUSTRY GROUP

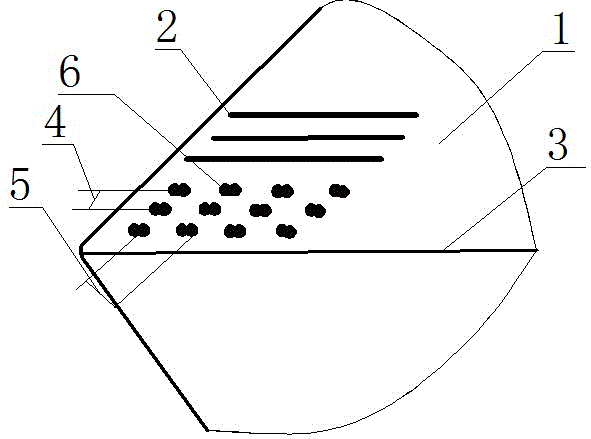

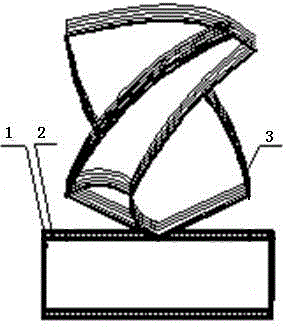

Tool provided with cutting chip flow guiding capillaries and functions and machining method of tool

InactiveCN106270582AExtend your lifeQuality improvementCutting insertsTurning toolsCapillary TubingEngineering

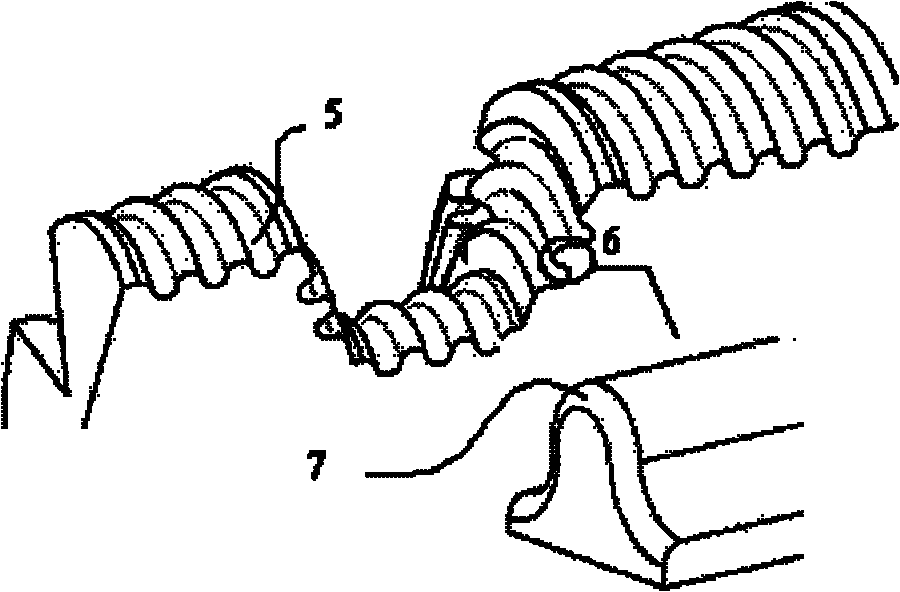

The invention discloses a tool provided with cutting chip flow guiding capillaries and functions and a machining method of the tool, relates to the tool in which the flow guiding capillaries are formed initiatively at the bottoms of cutting chips, and belongs to the field of mechanical manufacturing. The tool is characterized in that a texture array is arranged on the surface (1), on one side of the flowing direction of the cutting chips, of the tool; the texture array is formed by combination of micro-bulge (6) arrays and micro-groove (2) arrays; and the micro-bulge (6) arrays and the micro-groove (2) arrays are sequentially arranged along the flowing direction of the cutting chips. According to the tool, when a wet cutting machining mode is adopted, the direction of pouring or spraying is aligned with the direction of the capillaries or micro-grooves. Friction between the tool and the cutting chips is reduced; and cutting fluid reaches a bonding zone and a sliding zone, so that cutting force and cutting heat are lowered, and the service life of the tool is prolonged.

Owner:JIANGSU UNIV

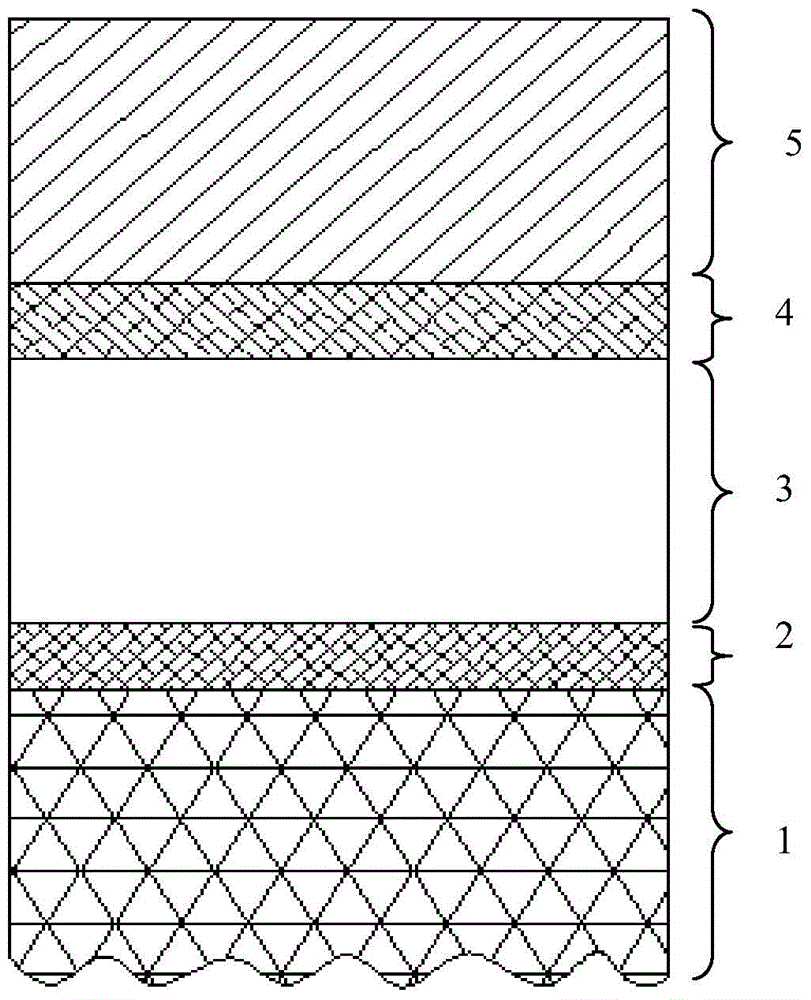

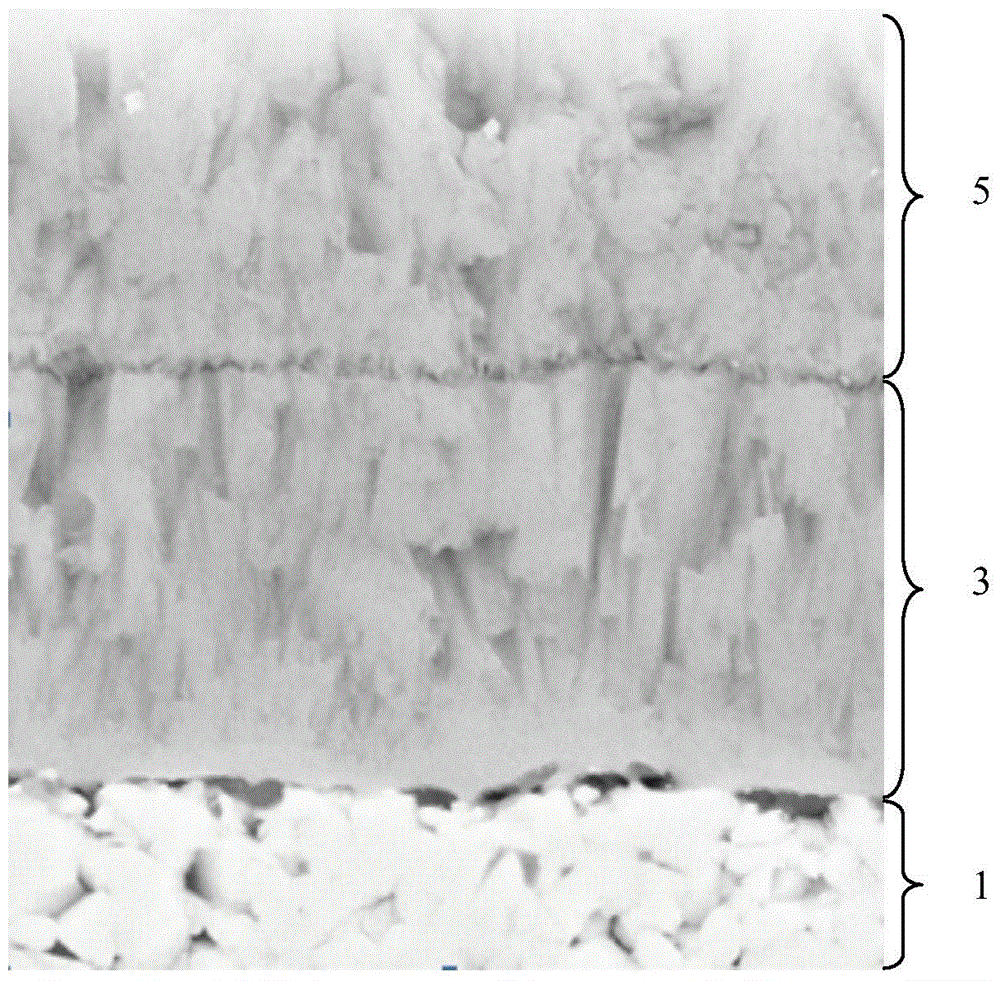

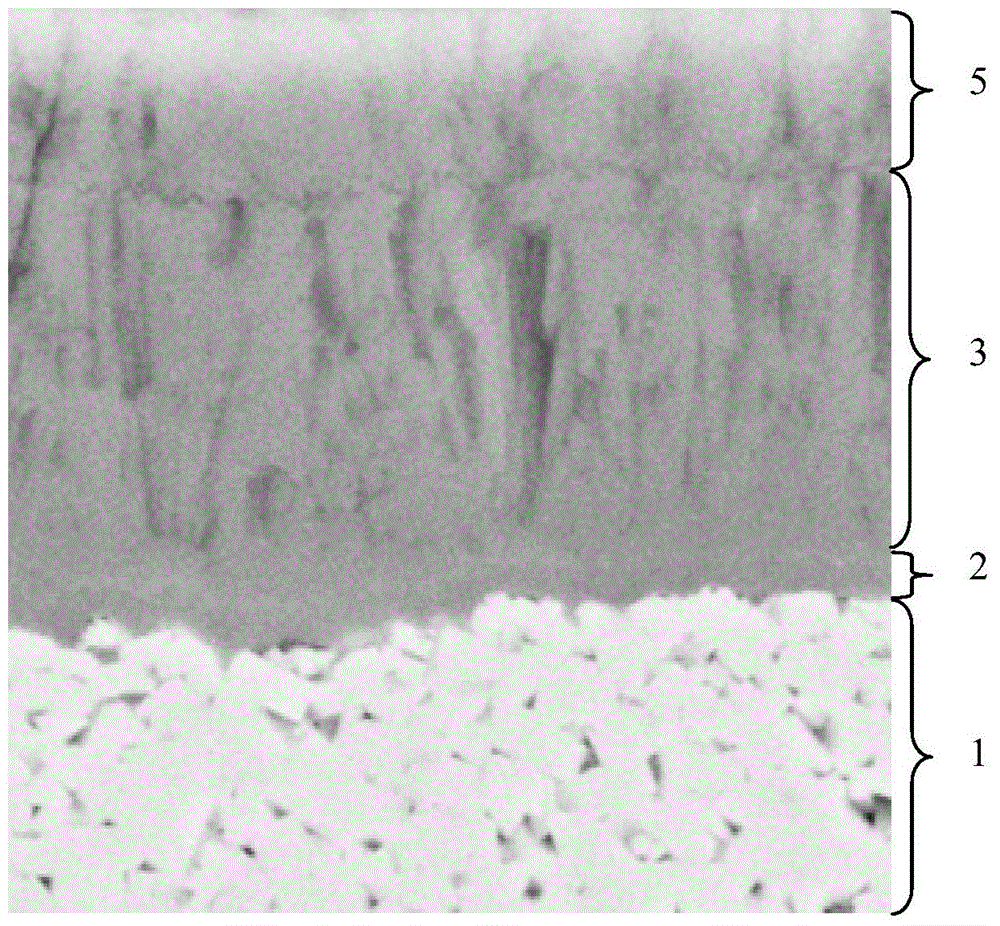

Cutting blade with improved coating structure and manufacturing method of cutting blade

ActiveCN105269010AImprove toughnessGood wear resistanceTurning toolsChemical vapor deposition coatingSurface finishingOxide

The invention discloses a cutting blade with an improved coating structure and a manufacturing method of the cutting blade. The cutting blade comprises a matrix A and a coating deposited on the matrix A. The coating is a multi-layer coating and at least comprises an inner layer C and an outer layer D. The inner layer C is composed of carbon-nitrogen oxide of transition elements of the IV B group or carbonitride of transition elements of the IV B group. The outer layer D is a (TiaAlb)(CiNjOk) layer, the thickness of the outer layer D is 1-20 [mu]m. Both the inner layer C and the outer layer D are of face-centered cubic structures. The manufacturing method comprises the steps of manufacturing the matrix A, selectively depositing a transition layer B, depositing the inner layer C, selectively depositing a transition layer E, depositing the outer layer D, and conducting surface treatment. The cutting blade is good in tenacity, abrasion resistance and oxidation resistance, the cutting blade has excellent cutting performance in machining of materials such as steel and stainless steel, and the manufacturing method is simple, convenient to implement, and easy to operate and control.

Owner:ZHUZHOU CEMENTED CARBIDE CUTTING TOOLS CO LTD

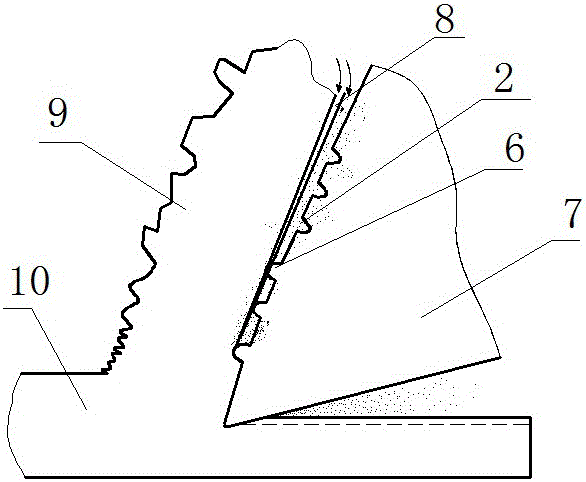

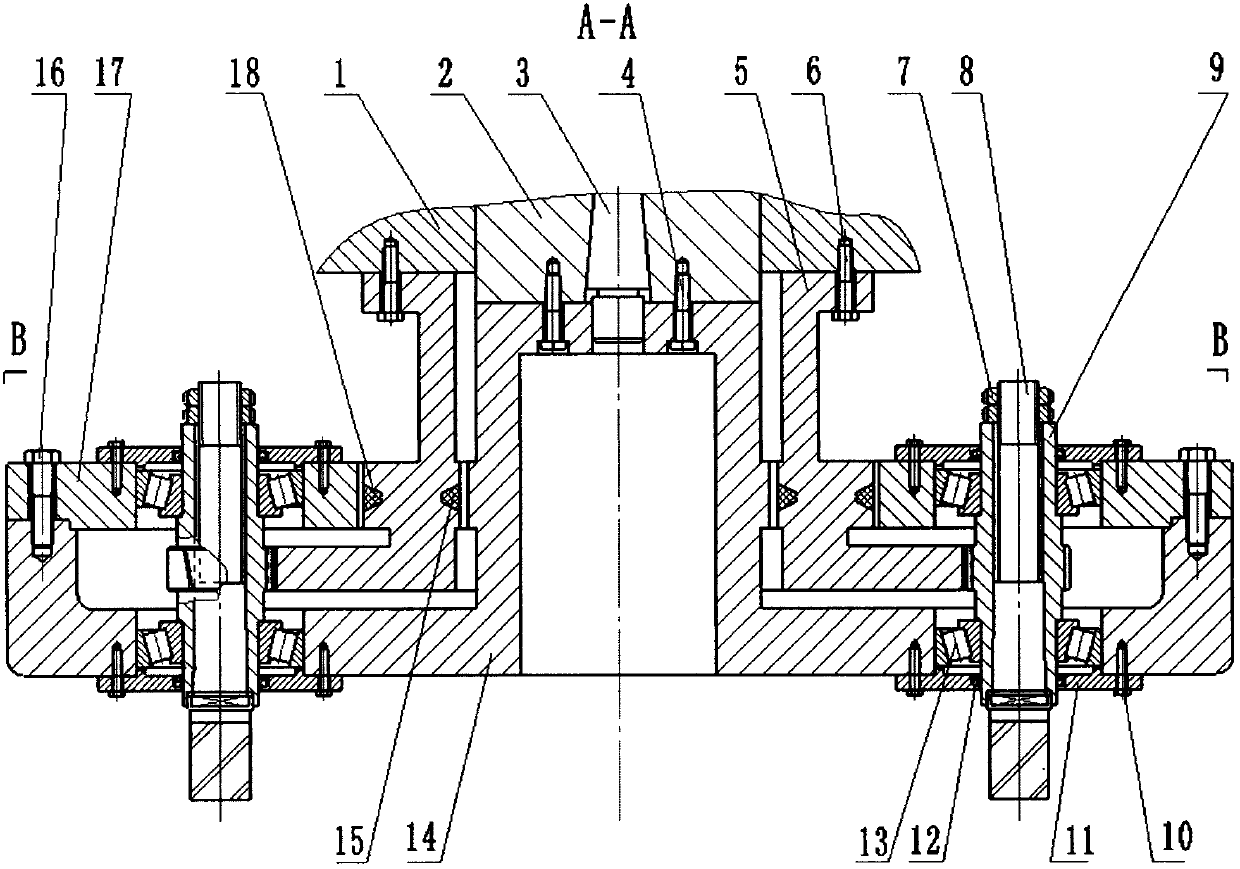

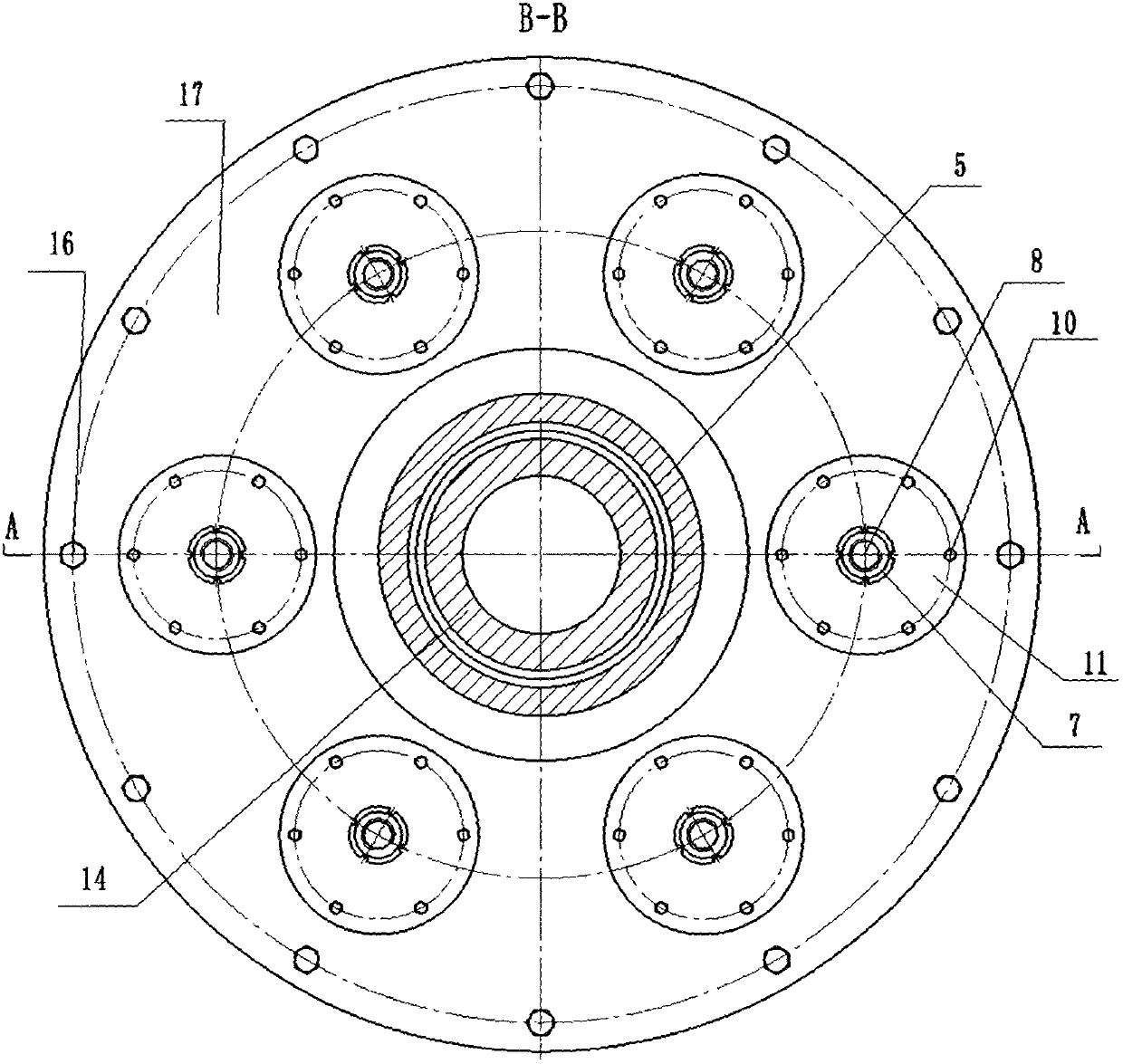

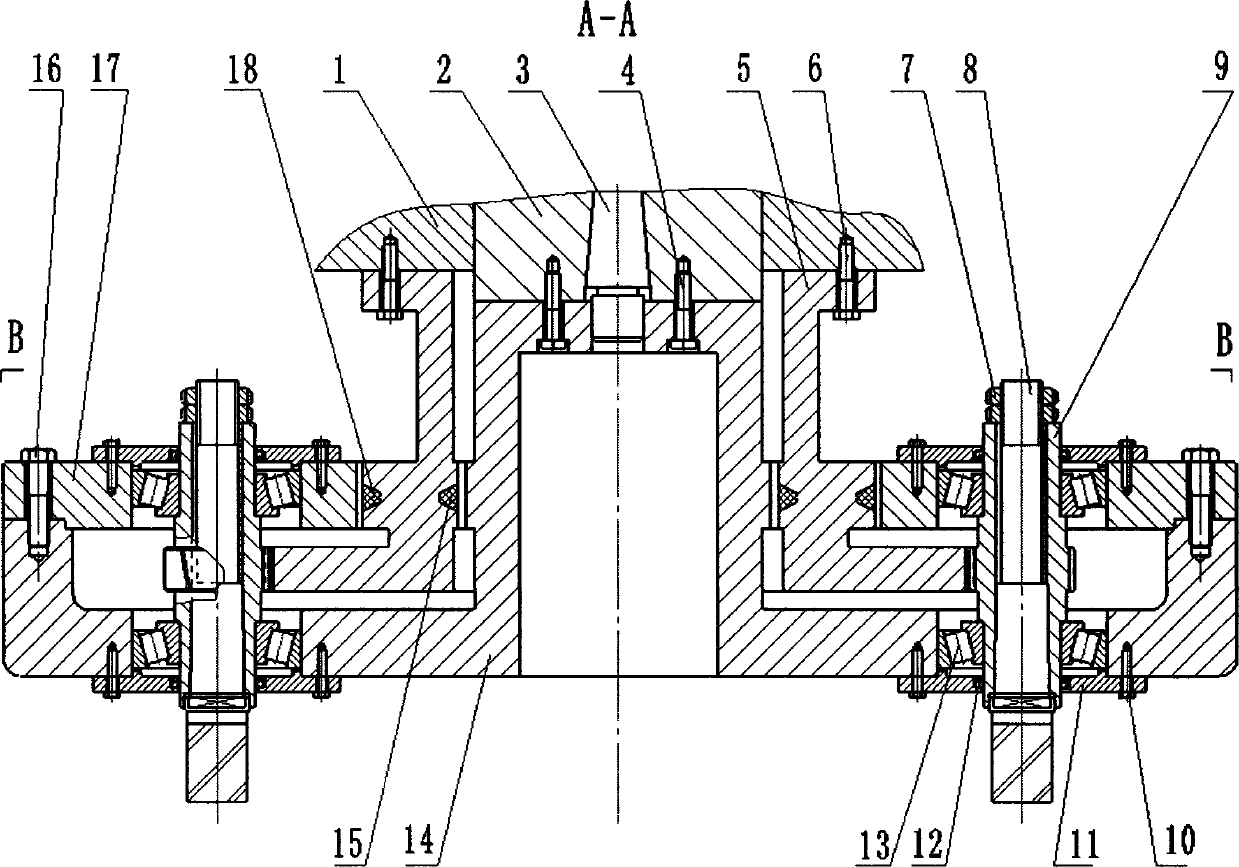

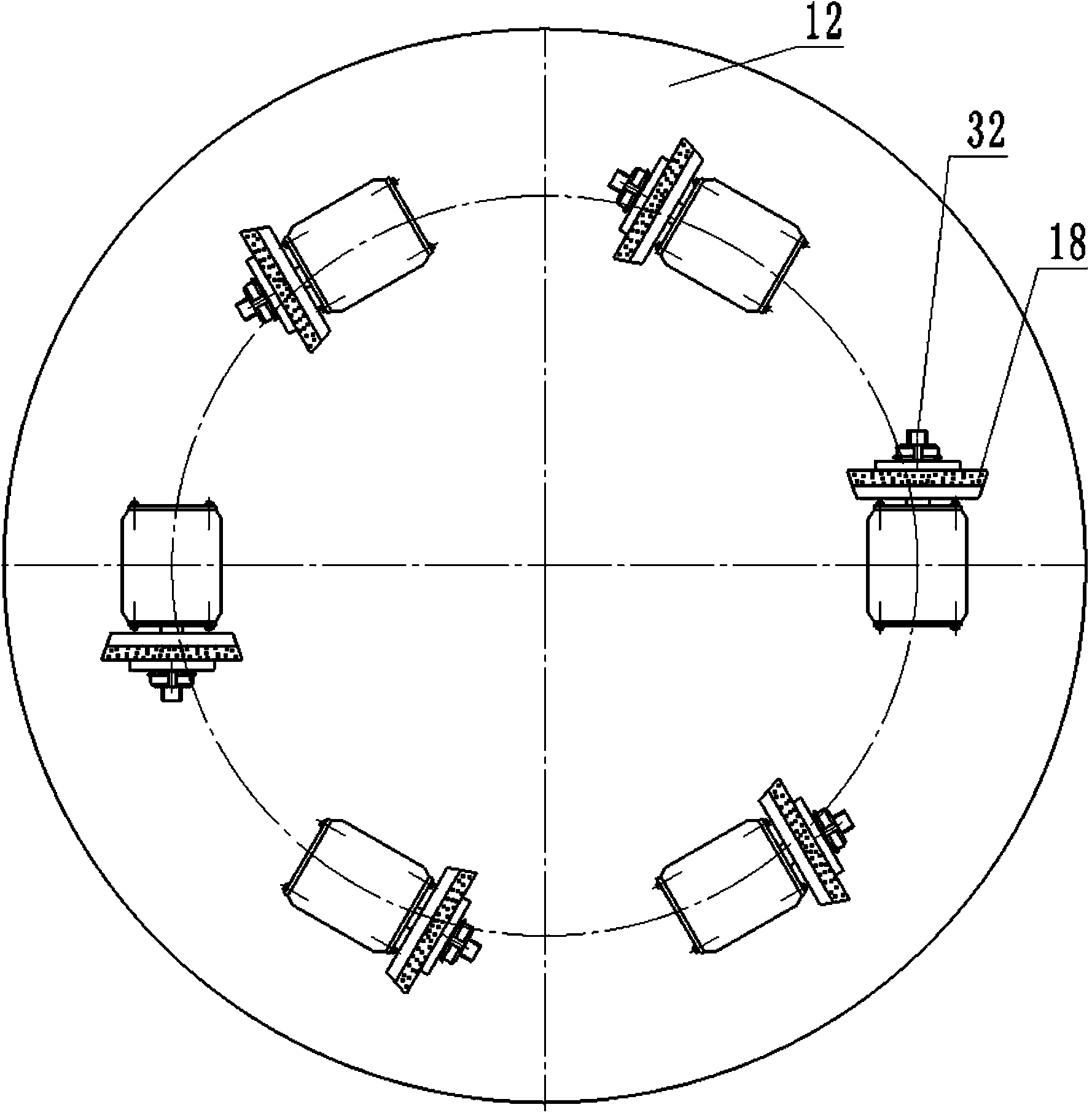

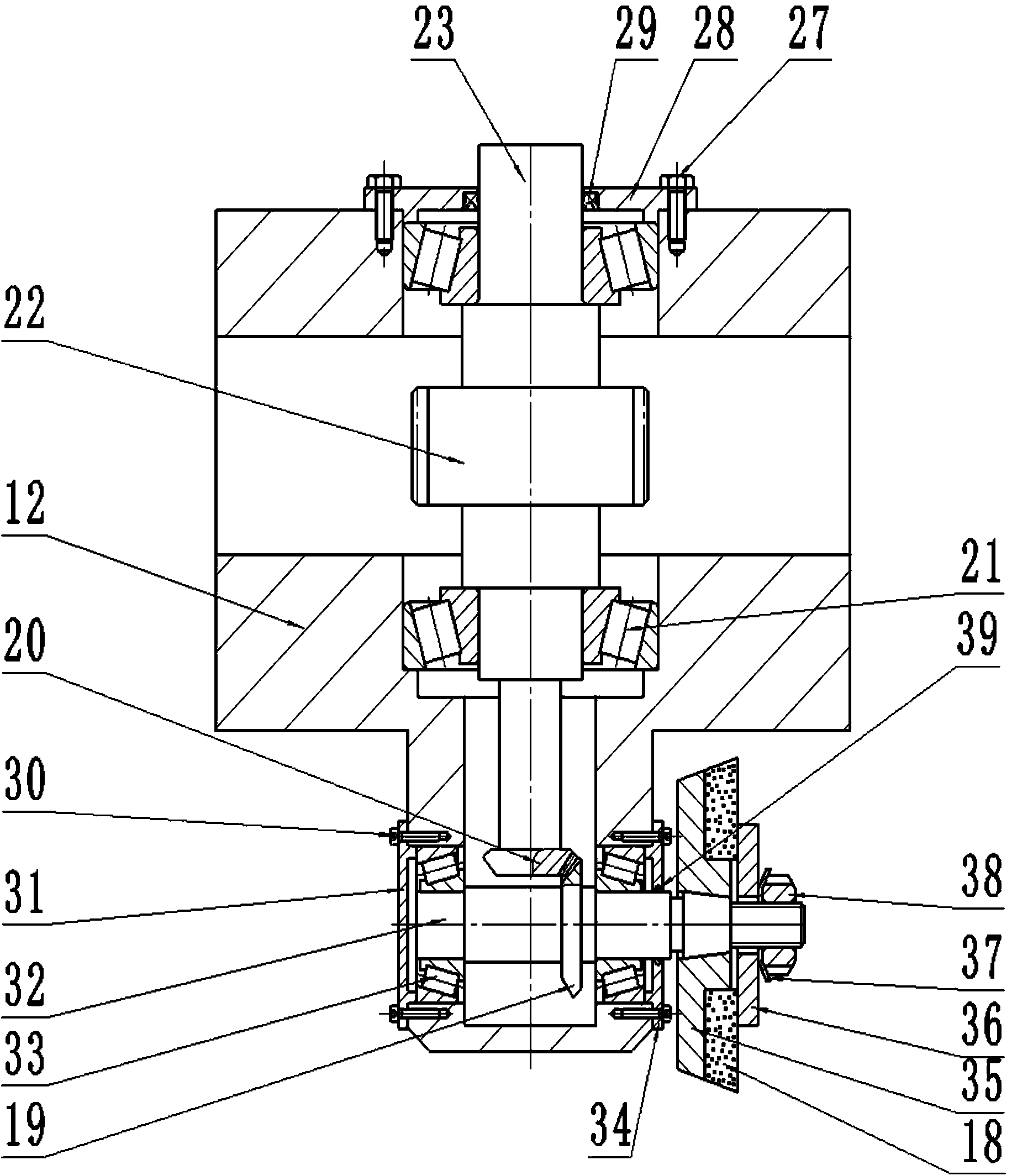

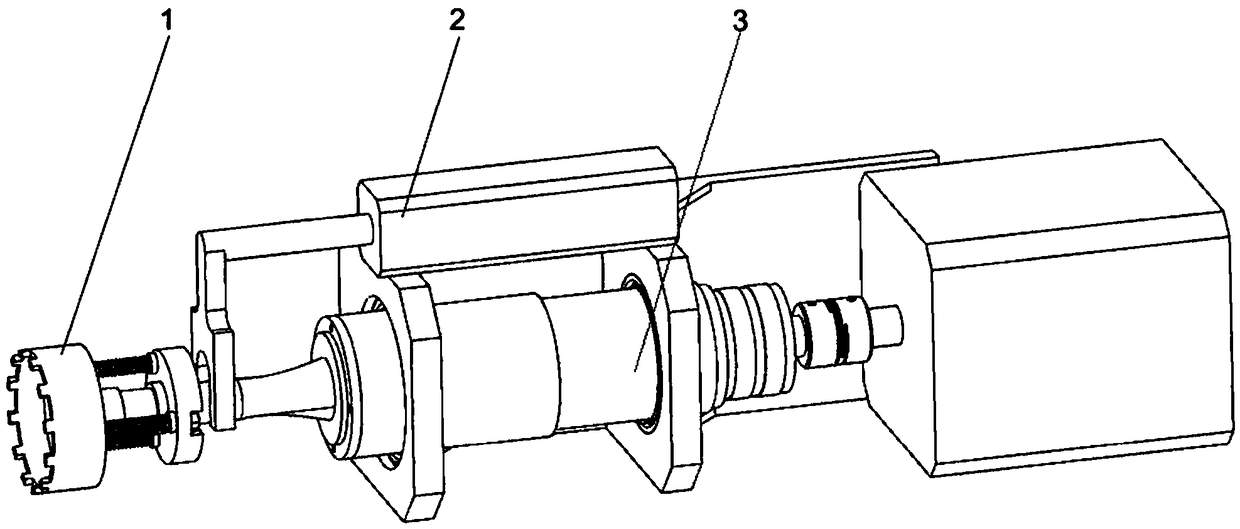

Planetary milling cutter

InactiveCN102653015AIncreased durabilityReduce cutting forceMilling equipment detailsDriving apparatusMilling cutterEngineering

The invention discloses a planetary milling cutter, which is mainly applied to high-efficiency milling for planes during machining. The planetary milling cutter comprises a main shaft box 1, a rotating main shaft 2, a positioning central shaft 3, fastening screws 4, a central bracket 5, bracket bolts 6, circular nuts 7, branch milling cutter shafts 8, planetary sleeve shafts 9, gland screws 10, bearing glands 11, oil seals 12, bearings 13, a rotating cutter disk 14, bracket inner oil seals 15, bolts 16, cover boards 17 and bracket outer oil seals 18, wherein the rotating cutter disk 14 rotates continuously under the driving of the rotating main shaft 2 which rotates continuously; the branch milling cutter shafts 8 rotate around the axis of the rotating main shaft 2 and also rotate around the respective axes; and the rotating machining motion of the planetary milling cutter is synthesized by the rotating motion of the rotating cutter disk 14 and the rotating motions of the branch milling cutter shafts 8. According to the planetary milling cutter, cutting force can be effectively reduced, cutting heat can be reduced, the durability of the cutter is improved, and the plane milling efficiency is improved.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Compound milling cutter for machining fir tree type blade root wheel groove

InactiveCN101804478AHelps reduce chip breakingHelps reduce chip removalMilling cuttersMilling cutterEngineering

The invention related to a compound milling cutter for machining a fir tree type blade root wheel groove, which belongs to the technical field of machinery manufacture. The compound milling cutter comprises a shank part and a cutting part, wherein the tail end of the shank part is fixed with the cutting part, and a spiral groove and a cutting edge are arranged on the cutting part; the spiral groove is spirally arranged on the cutting edge, and a spiral angle is greater than 5 DEG but less than 10 DEG. In the invention, a V-shaped rough milling cutter, a deepen milling cutter and a semi-finish cutter in an original process are combined through optimum design of the cutting edge, rough machining and semi-finish machining of a supercritical steam turbine of 1000MW are completed, tooling and cutter changing time is reduced, and the cutting speed and the feed rate are increased so that the productivity is improved, and the production cost is reduced.

Owner:SHANGHAI JIAO TONG UNIV

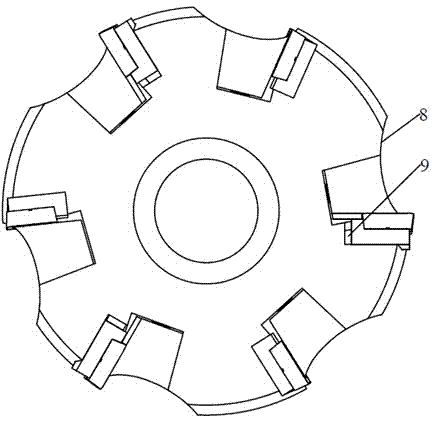

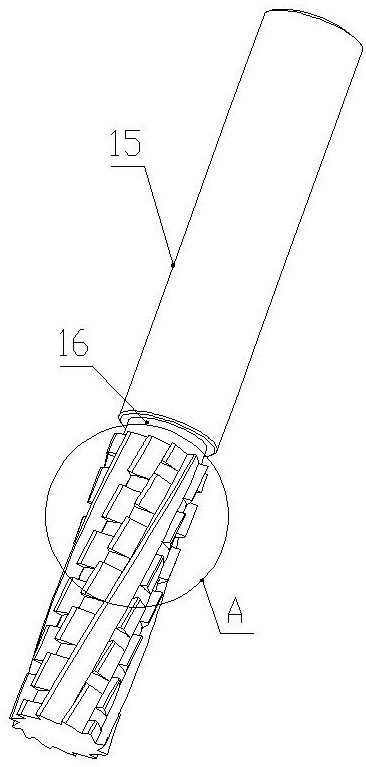

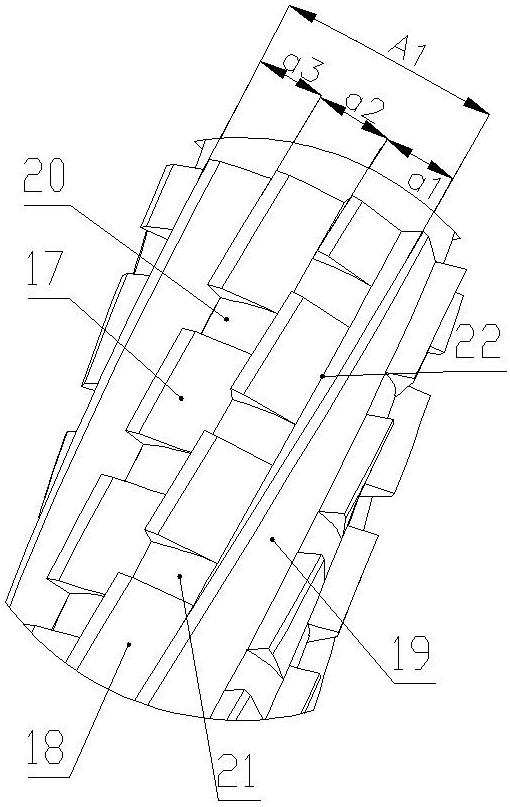

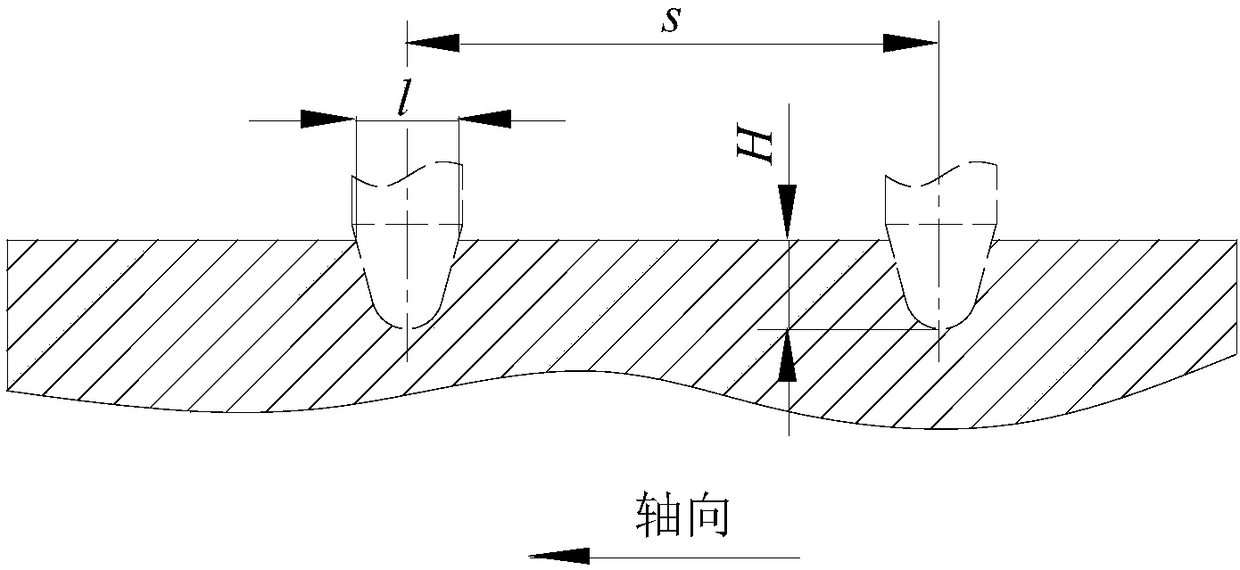

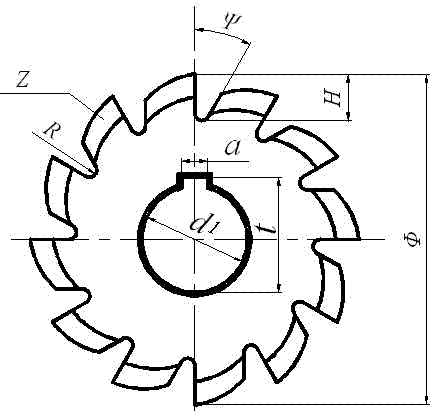

Stream turbine rotor blade root arc groove roughing milling cutter

InactiveCN101628347AExtended service lifeIncrease productivityMilling cuttersMilling cutterEngineering

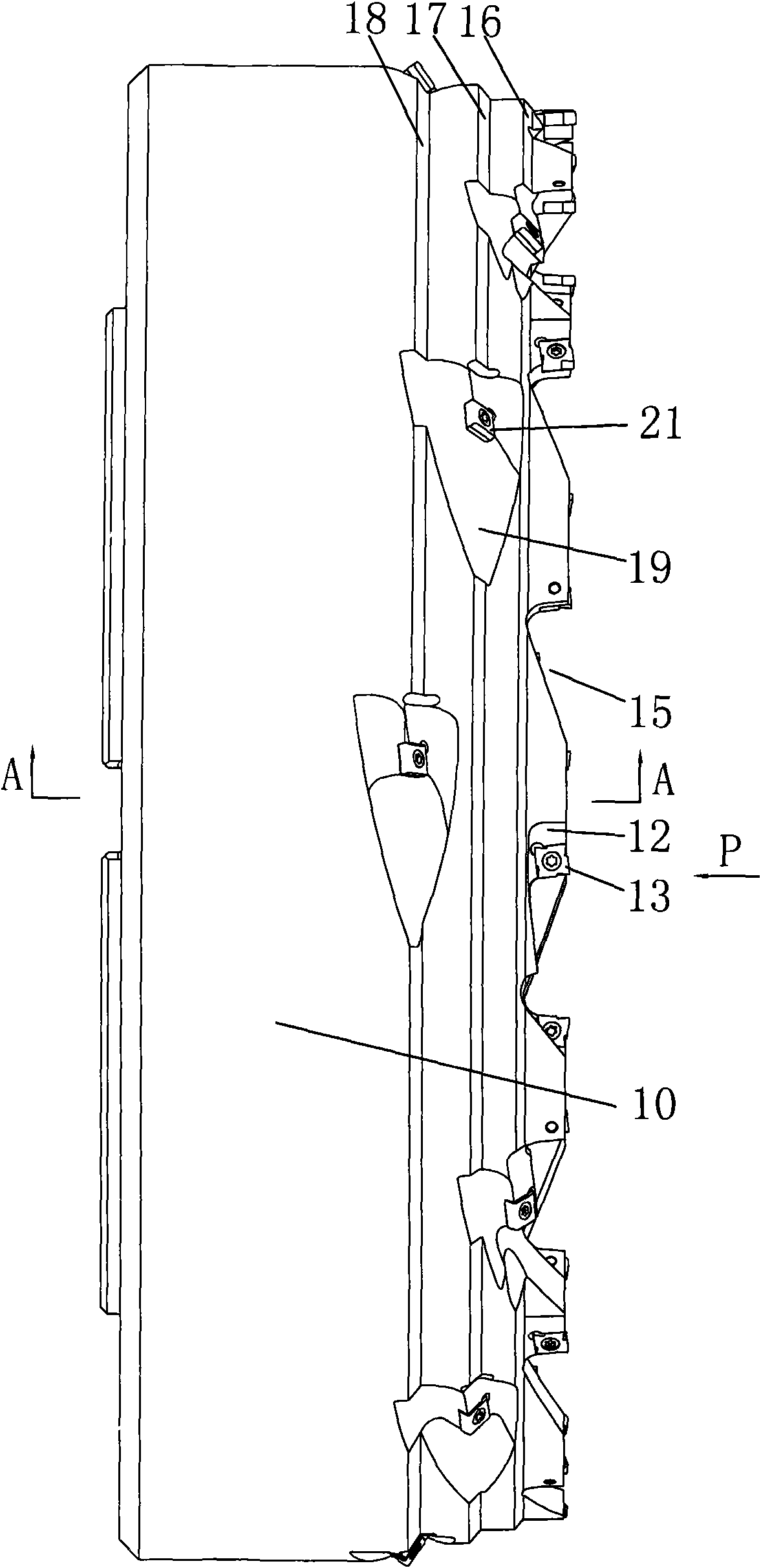

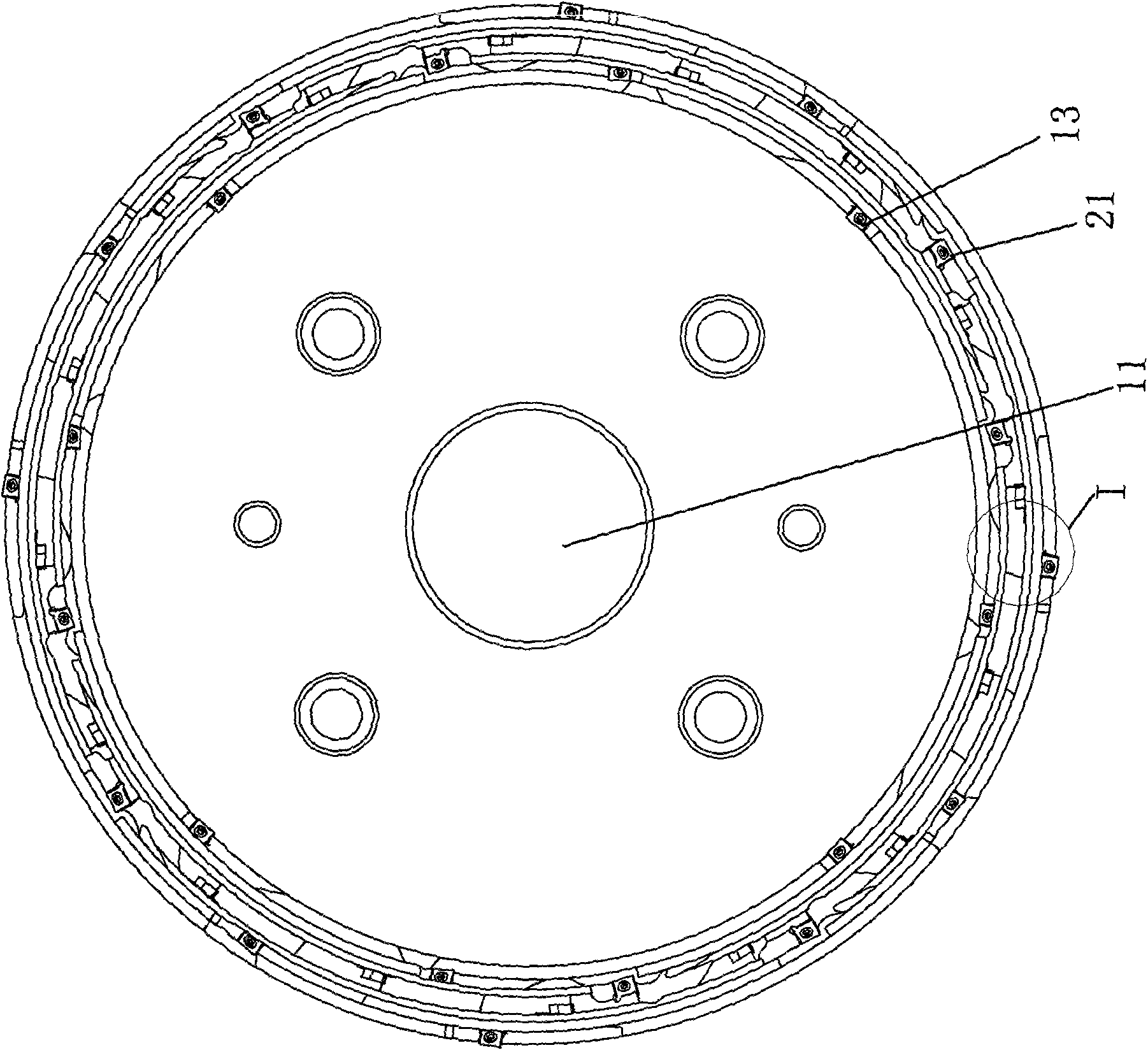

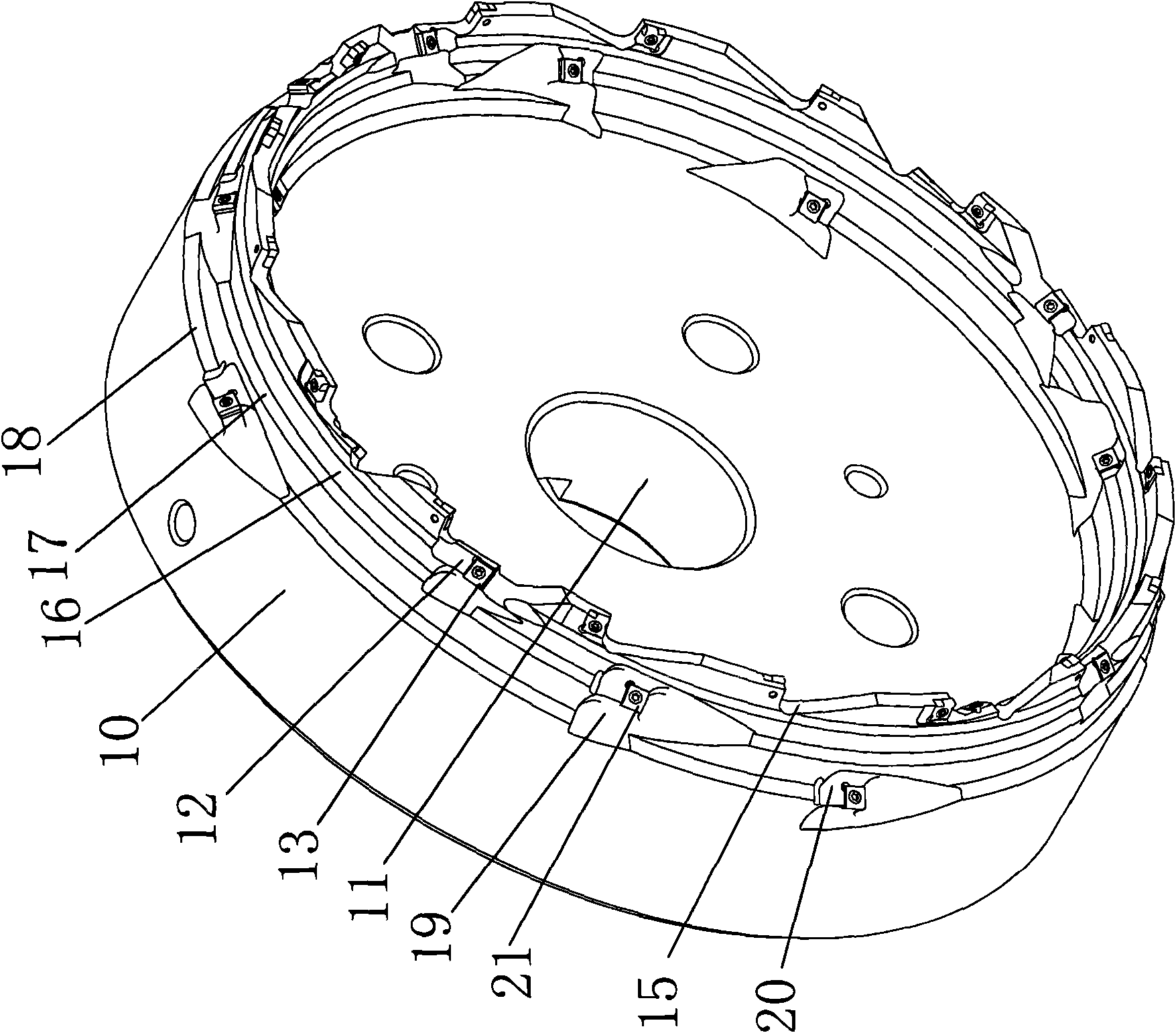

The invention relates to a stream turbine rotor blade root arc groove roughing milling cutter comprising a cylindrical cutter body, wherein the upper end face of the cutter body in the same circumference is provided a plurality of blade bearings at intervals on which end face cutting blades are arranged; one of the end face cutting blades of any two adjacent blade bearings is arranged on the outer side face of the blade bearing fixed with the end face cutting blade, and the other one of the end face cutting blades is arranged on the inner side face of the blade bearing fixed with the end face cutting blade; the outer periphery and the inner periphery of the cuter body are provided with a plurality with steps symmetrically from top to bottom, wherein the radius of the steps on the outer periphery from top to bottom increases by effect, the periphery of the steps on the inner periphery and the outer periphery is provided with a plurality of cuttings chutes which are sunken towards the wall surface of the cutter body, and the root parts of the cuttings chutes are provided with a tool apron on which a step cutting blade is arranged. The invention has the advantage of high processing efficiency and long service life.

Owner:常州市西夏墅工具研究所有限公司

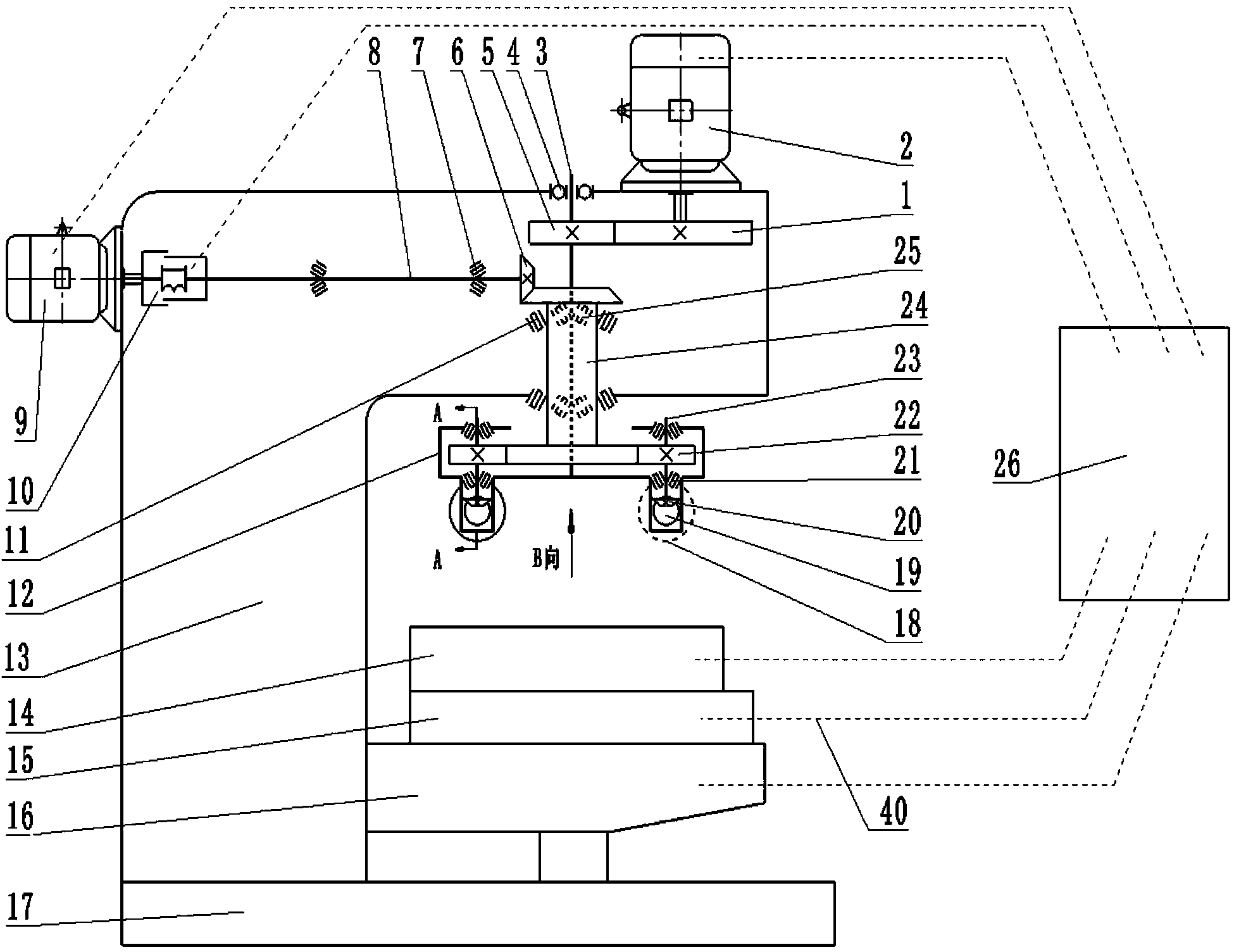

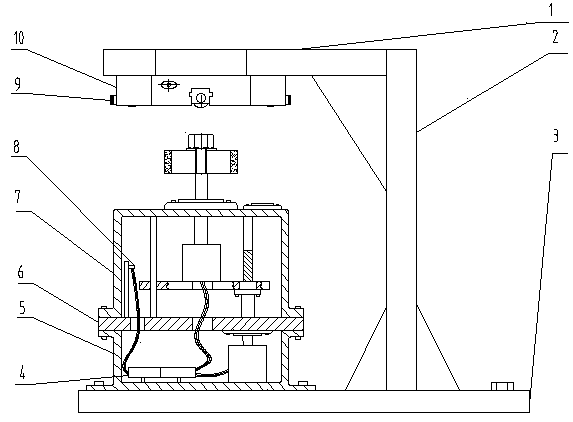

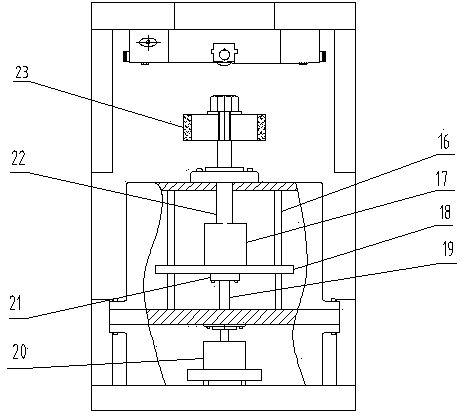

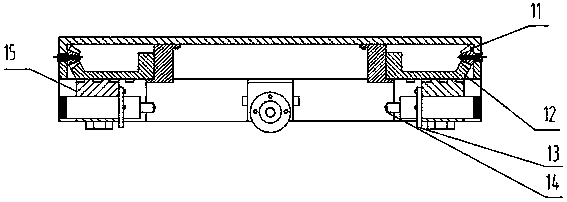

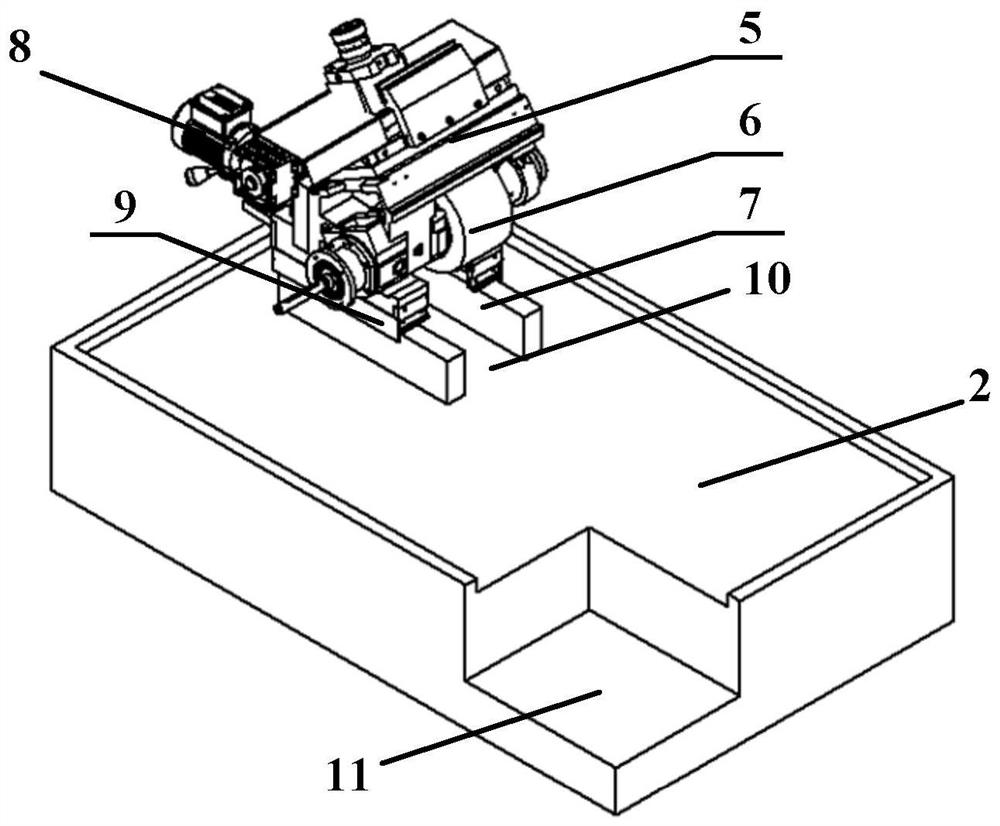

Differential stepless speed-regulation multimode hobbing machine tool

InactiveCN103769677ARealize three-way mobile functionIncreased durabilityShearing machinesElectromagnetic clutchCutting force

The invention belongs to the technical field of mechanical machining, and particular relates to a stepless speed-regulation hobbing machine tool. The differential stepless speed-regulation multimode hobbing machine tool adopts the technical scheme as follows: a control driving system (26) is connected with a main shaft speed regulation motor (2), a speed regulation motor (9), an electromagnetic clutch (10), a transverse feeding worktable (14), a longitudinal feeding worktable (15) and a machine tool lift platform (16) through a data area driving line (40), the speed variation and direction changing of the main shaft speed regulation motor (2) and the speed regulation motor (9), the opening and closing of the electromagnetic clutch (10), the inward-outward motion of the transverse feeding worktable (14), the leftward-rightward motion of the longitudinal feeding worktable (15) and the up-down motion of the machine tool lift platform (16) are controlled and driven according to an input command. By adopting the differential stepless speed-regulation multimode hobbing machine tool, different cutting forms can be realized, the cutting force can be effectively reduced, the cutting heat can be reduced, the duration of the cutter can be improved, smoothness in clippings discharging is realized, and the clippings can be cut off in time.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Automobile clutch pressure plate vertical turning special-purpose water-based milling liquid and production method

The invention discloses a water-based cutting fluid specialized for merry-go-round machine in automobile clutch platen which can reduces cutting temperature and force to maximum extent, improves cutting process efficiency, ensures cutting precision and surface quality, prolongs life of cutting tool, reduces cost, satisfies environmental protection requirements, and method for making the same. Raw materials of specialized water-based fluid and corresponding weight percentage are phytic acid 2.8-3.2%, sodium benzoate 9-11%, triethanolamine 9-11%, sodium carbonate 2.5-3.5%, hyposulfite of soda 0.8-1.2%, polyethyleneglycol 5.5-6.5%, glycyl alcohol 5.5-6.5%, 2-methyl-3(2H)-Isothiazolone 0.4-0.6%, de-ionize water 58-63%. The production process is synthesis with stirring under condition of normal temperature - medium temperature - normal temperature.

Owner:DALIAN SANDAAOKE CHEM

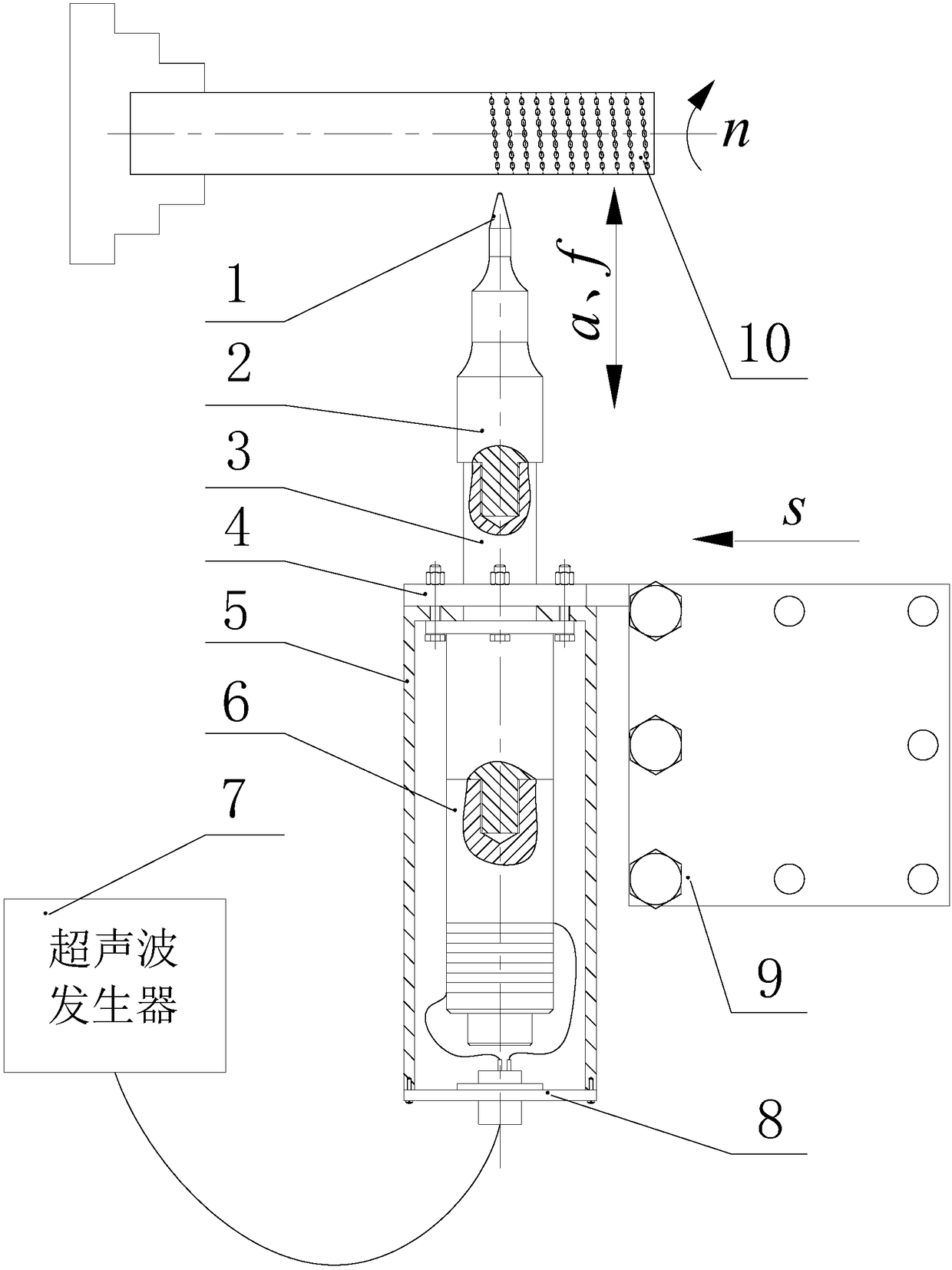

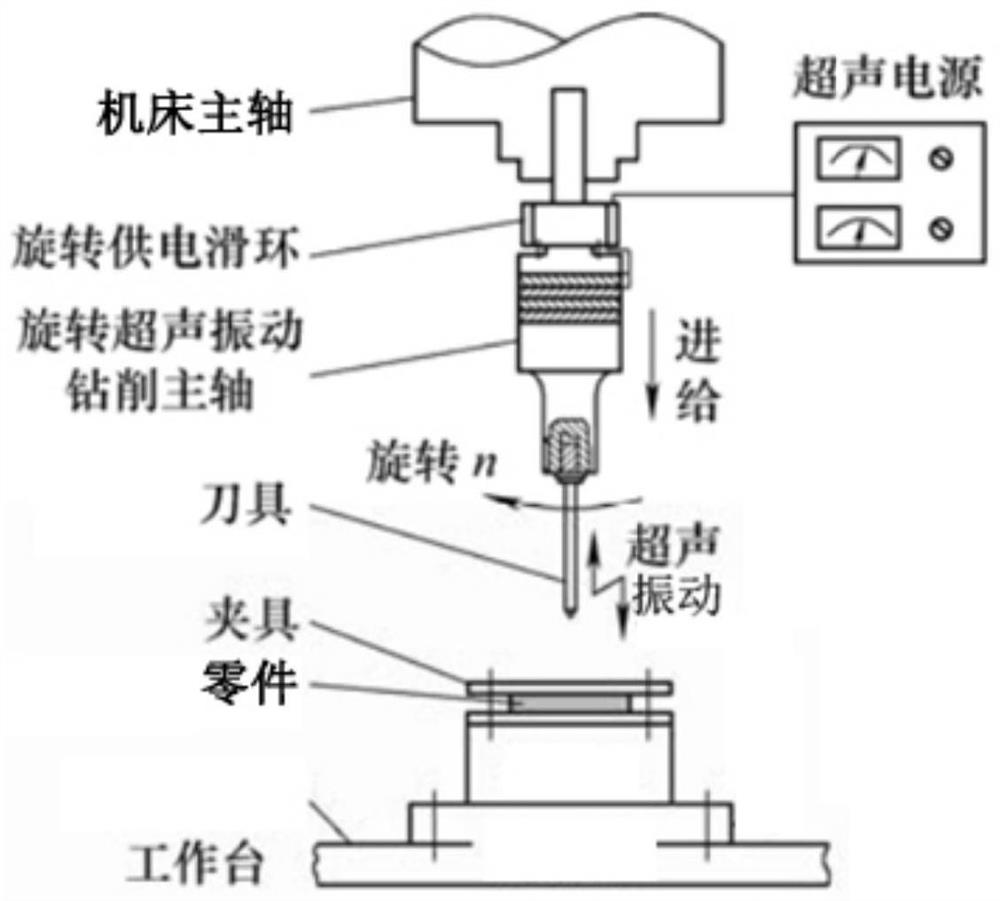

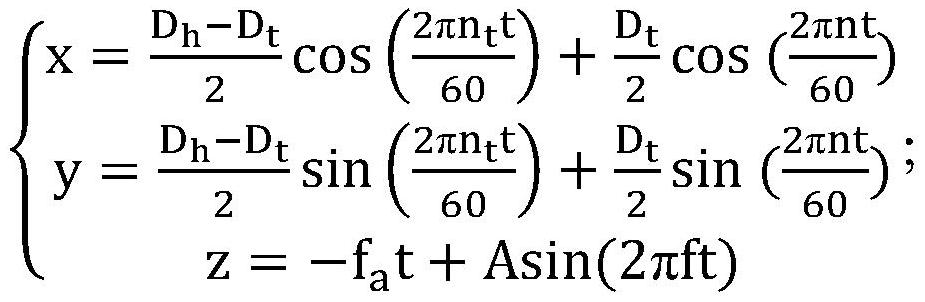

Ultrasonic vibration machining device and method for aluminum-based silicon carbide composite material

ActiveCN112548175AImprove quality and efficiencyImprove processing efficiencyMilling equipment detailsCarbide siliconMachine parts

The invention discloses an ultrasonic vibration machining device and method for an aluminum-based silicon carbide composite material. The ultrasonic vibration machining device comprises a computer, alaser auxiliary heating part, an ultrasonic vibration machining part, a machine tool workbench, a machine tool spindle and a micro-edge milling cutter, wherein the ultrasonic vibration machining partcomprises an ultrasonic generator, a transducer and an amplitude-change pole; the lower end of the machine tool spindle is connected with the transducer, the lower end of the transducer is connected with the amplitude-change pole, the upper end of the micro-edge milling cutter is clamped at the lower end of the amplitude-change pole, and the ultrasonic generator is connected with the transducer through a wire; a clamp holder is arranged on the machine tool workbench, a workpiece made of the aluminum-based silicon carbide composite material is clamped on the clamp holder, and the clamp holder is connected with a three-way dynamometer; and the laser auxiliary heating part is used for heating a to-be-machined part of the workpiece. In the milling operation process, chip removal can be accelerated, flutter of a cutter is eliminated, abrasive abrasion and adhesive abrasion are reduced, milling force and cutting heat are reduced, the machining size precision is guaranteed, the workpiece surface quality and the machining efficiency are improved, and the machining cost is saved.

Owner:HENAN POLYTECHNIC UNIV

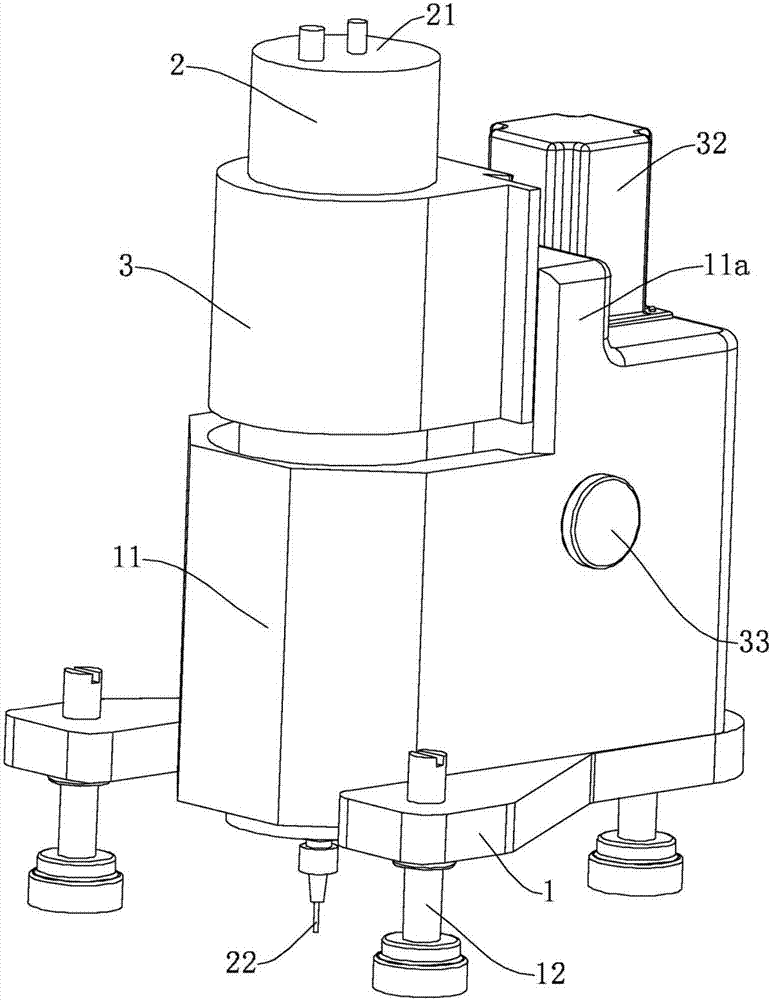

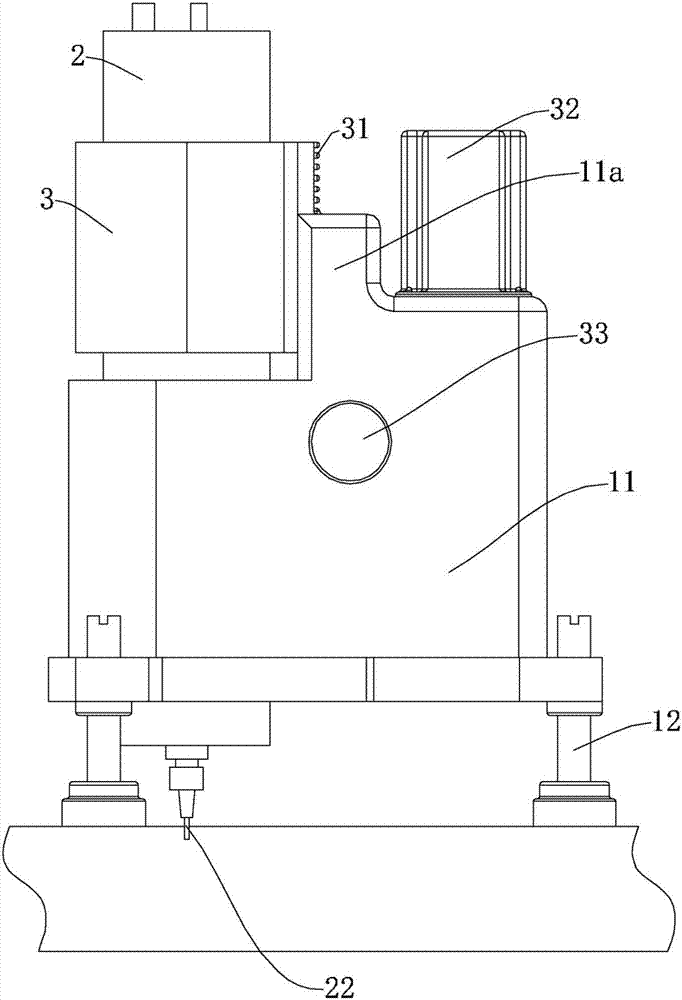

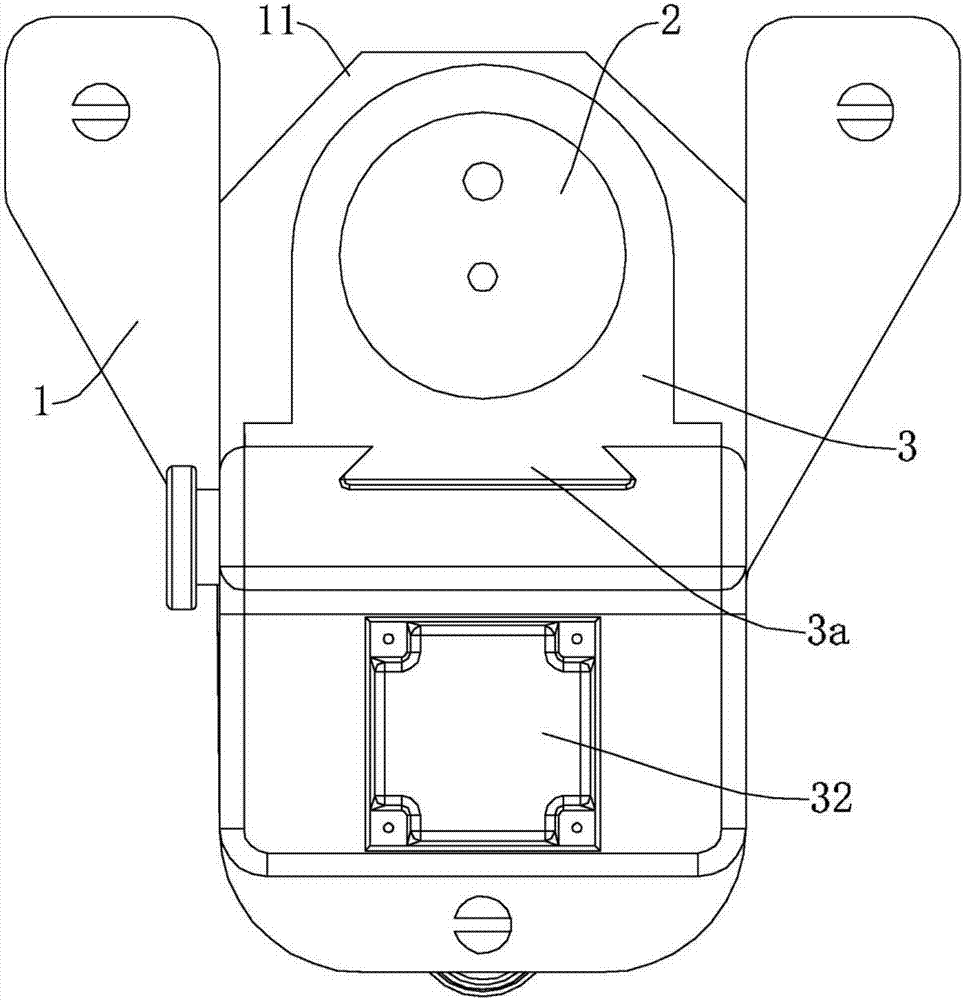

Automatic diamond grinding wheel trimming device

ActiveCN103962960AShorten dressing timeImprove processing efficiencyAbrasive surface conditioning devicesPhysicsDiamond grinding

The invention discloses an automatic diamond grinding wheel trimming device which is mainly composed of a working table, a chuck and a cylinder body. The chuck is fixed below an upper top plate of the working table and comprises a small bevel gear (11) and a big bevel gear (12) which are meshed with each other. The big bevel gear is connected with a sliding block (15). An energy converter (9), an amplitude-change pole (13) and a diamond stylus (14) are arranged on the sliding block. The energy converter is connected with an ultrasonic generator. A ball screw penetrates through a fixed supporting plate to be connected with a servo motor. A guide shaft penetrates through a movable supporting plate to be connected with an upper cylinder body and the fixed supporting plate. A three-phase asynchronous motor is connected with a grinding wheel (23) through a main shaft. One end of a circuit board is connected with a proximity switch, and the other end of the circuit board is respectively connected with the servo motor and the three-phase asynchronous motor. By means of the automatic diamond grinding wheel trimming device, ultrasonic elliptic vibration of the diamond stylus can be achieved, machining efficiency and machining accuracy of the grinding wheel are improved, rigidity and stability of a cutting system are enhanced, the service life of the diamond stylus can be prolonged, and the automatic diamond grinding wheel trimming device is relatively suitable for trimming grinding wheels made of hard materials.

Owner:CONPROFE TECH GRP CO LTD +1

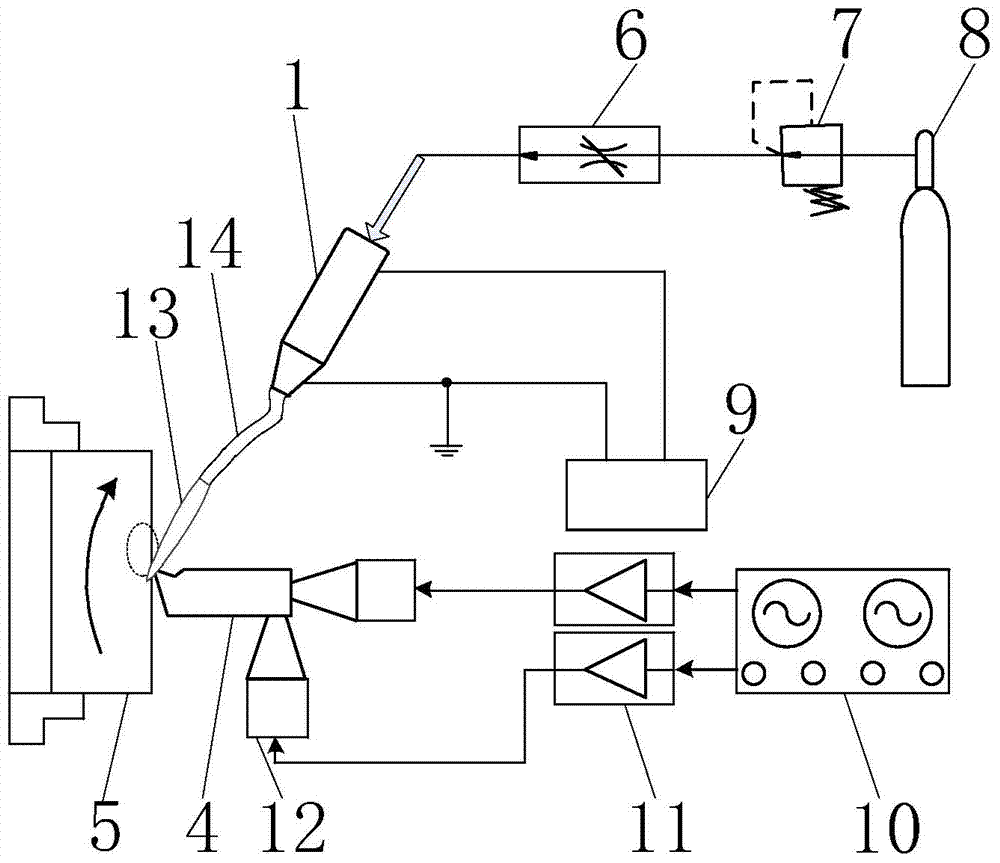

Method for cutting black metal by diamond tool

ActiveCN103691969ALow macro temperatureReduce cutting forceAuxillary equipmentMaintainance and safety accessoriesIonActive carbon

The invention provides a method for cutting black metal by a diamond tool. A barometric pressure cold plasma jet regulated and controlled cutting interface is combined with ultrasonic vibration auxiliary cutting. Under a barometric pressure condition, a cold plasma jet generated by discharging a graphite needle naked electrode is led out by an insulating guide pipe and then is conveyed to a cutting region so as to effectively regulate and control a contact interface of the diamond tool and black metal. Active carbon particles in the jet are gathered on the contact interface of the diamond tool and the black metal; active particles adsorbed on the surface of the black metal can be used for preventing the diamond tool from being directly contacted with the black metal so as to inhibit chemical abrasion of the diamond tool. The cavitation effect of ultrasonic vibration forms a high pressure and a complicated thermodynamic effect in the cutting process is used for promoting the active particles in the cold plasma jet to be reacted with the surface of the newly-generated black metal to generate a substance, and the chemical affinity between the substance and a diamond is lower than that between the substance and the black metal; the effect of inhibiting the abrasion of the diamond tool is enhanced.

Owner:DALIAN UNIV OF TECH

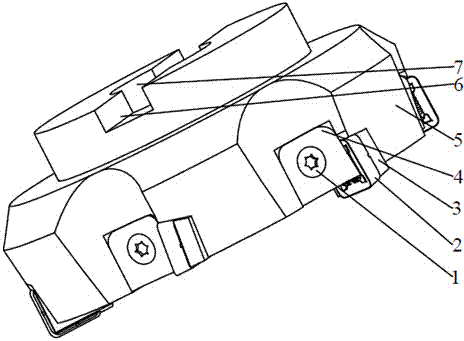

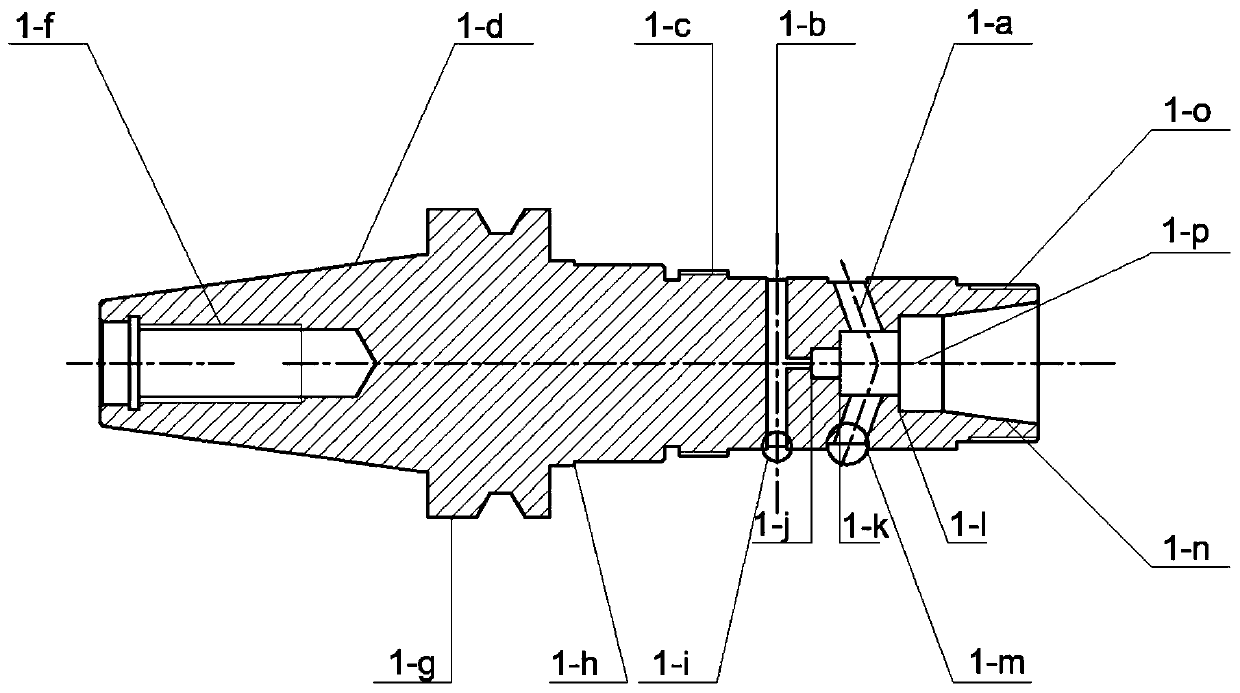

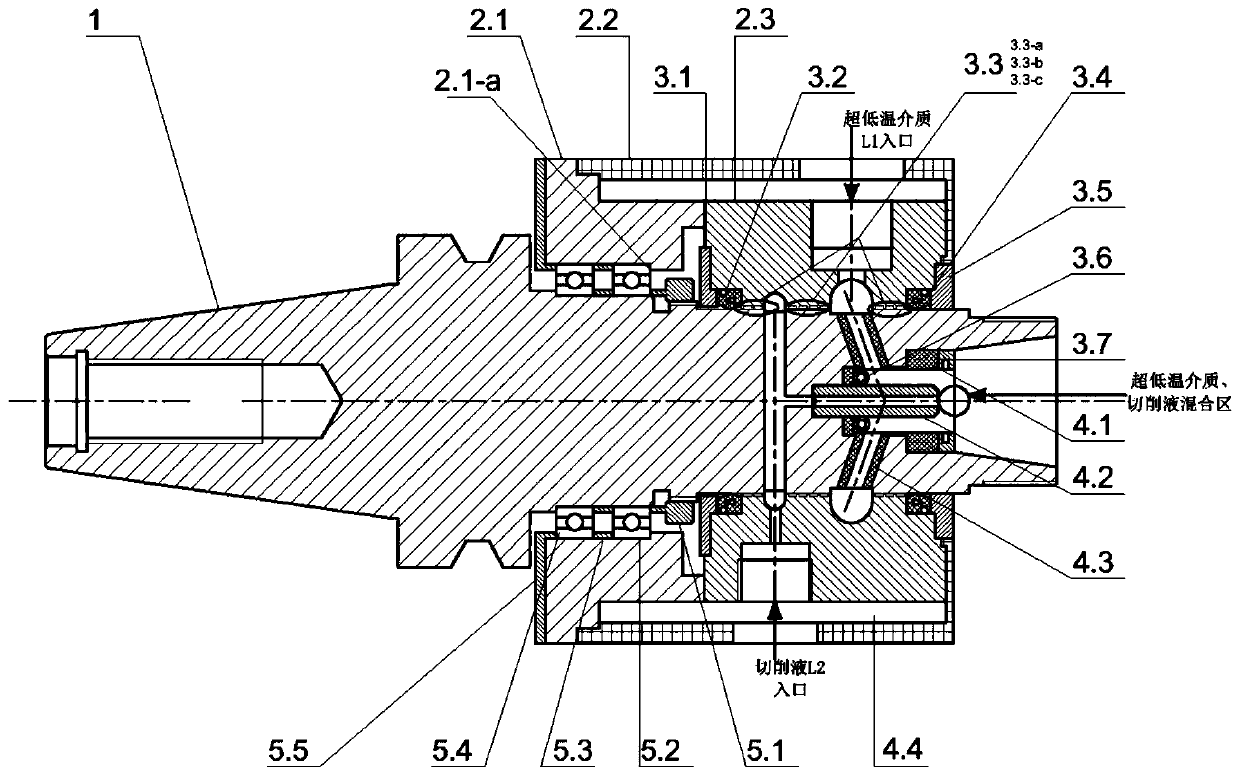

Knife handle suitable for low-temperature minimal quantity lubrication

ActiveCN110883591ASolve problems not suitable for low temperature MQL cuttingOvercome tightnessMilling cuttersAdverse effect compensationNumerical controlCooling effect

The invention provides a knife handle suitable for low-temperature minimal quantity lubrication, and belongs to the technical field of cooling and lubrication of numerical control machine tools. The knife handle comprises a knife handle body, a peripheral static structure, a multi-layer sealing structure, a heat insulation structure and a bearing supporting structure. The problems that in the minimal quantity lubrication technology, the cooling performance is insufficient, and lubrication is insufficient in the low-temperature cooling machining technology are solved, the oxygen isolation protection effect of an ultralow-temperature medium, the cooling effect of the ultralow-temperature medium and the anti-attrition lubrication effect of minimal quantity lubrication are integrated, and therefore a good machining effect is achieved on the aspect of materials difficult to machine. The knife handle can be used for machining the materials difficult to machine through a traditional numericalcontrol machine tool, the application range of an outer rotating inner knife handle is widened, the cutting heat of the materials difficult to machine in the cutting machining process is effectivelyreduced, the service life of a knife is prolonged, traditional cutting fluid is replaced, and green manufacturing is achieved.

Owner:DALIAN UNIV OF TECH

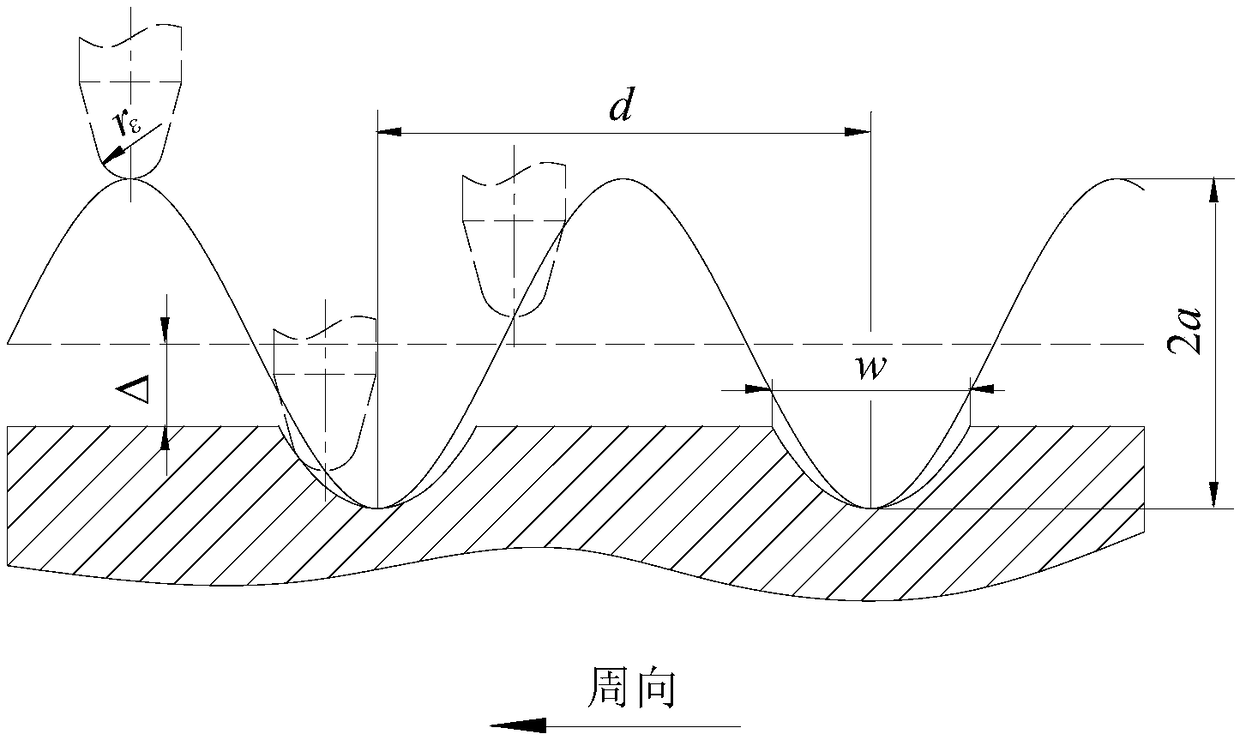

Surface texturing device based on ultrasonic vibration impact and texturing method

InactiveCN108555317AAdjust coverageIncreased texture depthAutomatic/semiautomatic turning machinesDesign optimisation/simulationNumerical controlTransducer

The invention discloses a surface texturing device based on ultrasonic vibration impact. The surface texturing device based on ultrasonic vibration impact comprises an ultrasonic generator and an ultrasonic vibration system. The ultrasonic vibration system comprises a tool bit, a tool bar, an amplitude-change pole and a transducer. The tool bit is welded at the top end of the tool bar, and the tool bar and the transducer are connected to the two ends of the amplitude-change pole in a threaded mode correspondingly. A transducer shell is connected with the exterior of the transducer in a sleeving mode, and the front end face of the transducer shell is fixedly connected with the flange end face on the amplitude-change pole through bolts. A shell end cover is arranged at the rear end of the transducer shell, the shell end cover and the transducer shell are fixedly connected together through screws, and the transducer shell is installed on a tool rest of a numerical control lathe through aclamp. A workpiece is installed on the numerical control lathe through a three-jaw chuck, and the height of the axis of the workpiece is equal to that of the tool nose of the tool bit. The invention further discloses a method of texturing by the use of the surface texturing device based on ultrasonic vibration impact.

Owner:XIAN UNIV OF TECH

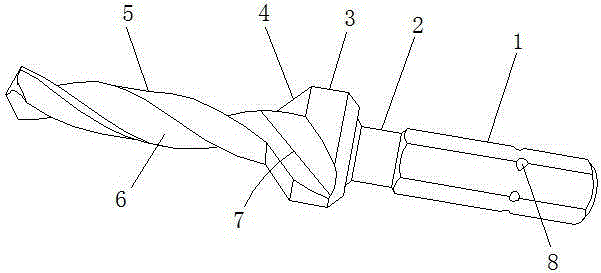

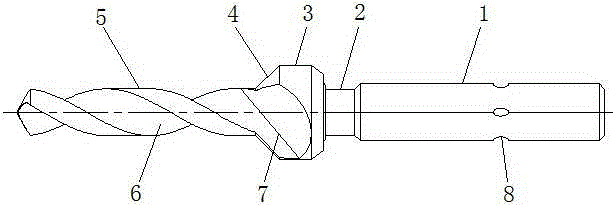

Drilling and chamfering synthesis tool and manufacturing method thereof

InactiveCN106670550AExtended service lifeIncrease productivityTransportation and packagingOther manufacturing equipments/toolsHardware toolEngineering

The invention discloses a drilling and chamfering synthesis tool and a manufacturing method thereof, belongs to the technical field of hardware tool manufacturing, and is novel in structure and clear in working principle. A drill bit part can be used for general drilling; a conical surface part can be used for hole port chamfering; a cylinder part also can be used for counter bore machining; the machining steps can be performed smoothly; the machining procedures are reduced; the machining cost is saved; and the machining efficiency is improved; the chamfering is excellent in centering and high in precision and smoothness; as a V-shaped chip discharge groove is formed in a cylinder surface, and is communicated with a double-spiral groove at the head part, the cutting is quicker and lighter in the drilling process, the chip removal is more smooth, a lot of cutting head is reduced in the machining process, the cutter service life is prolonged, and the production efficiency is improved.

Owner:YANGZHOU SHILI HARDWARE TOOL IND & TRADE CO LTD

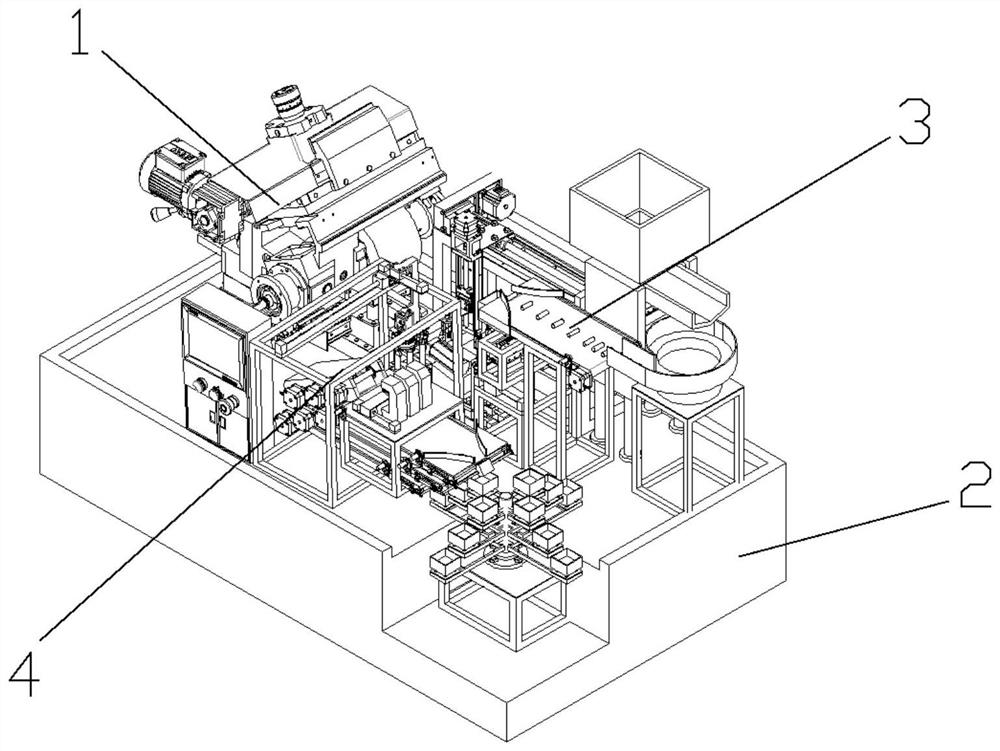

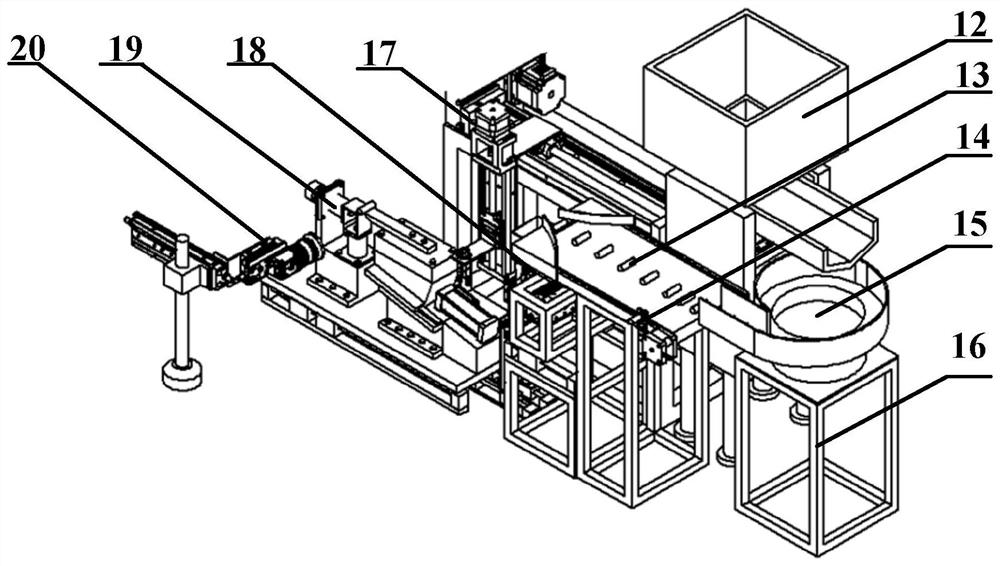

Full-automatic grinding machine for ultrasonic vibration auxiliary grinding of outer circle of hard and brittle single crystal cylinder

ActiveCN111805309ARealize automatic feeding processImprove work efficiencyGrinding carriagesGrinding feed controlMachine partsEngineering

The invention discloses a full-automatic grinding machine for ultrasonic vibration auxiliary grinding of an outer circle of a hard and brittle single crystal cylinder, and relates to the technical field of mechanical equipment. The full-automatic grinding machine aims to solve the problems in the prior art that when the outer circle surface of the hard and brittle single crystal cylinder is ground, the adopted grinding liquid is alkaline or acidic, a machine tool can be corroded after long-term use, the clamping precision of a workpiece is reduced, the surface precision of a machined part is reduced, and the working efficiency is low due to the fact that feeding is carried out in a manual mode. An automatic feeding mechanism and an automatic classifying and storing mechanism are distributed in parallel, the full-automatic grinding machine is perpendicular to the automatic feeding mechanism and the automatic classifying and storing mechanism, a storage mechanism base table is arranged at one corner of the upper surface of a grinding machine base, and the upper surface of the storage mechanism base table is lower than the upper surface of the grinding machine base and is used for containing the automatic classifying and storing mechanism. The full-automatic grinding machine is suitable for grinding the outer circle surface of the hard and brittle single crystal cylinder.

Owner:HARBIN INST OF TECH

Machining method for 5-12 oz thick copper power circuit board drilling

InactiveCN104607684AAvoid glitchesThere will be no problem of blocking the vacuum lineThermodynamicsCopper

The invention belongs to a machining method for 5-12 oz thick copper power circuit board drilling. The machining method is characterized by comprising the following steps that firstly, when the drilling diameter is larger than 2.0 mm , a drill bit 3 with the diameter phi of 1.55 mm is selected, and a first pre-drill hole 4 with the diameter phi 1of 1.55 is drilled; secondly, after the first pre-drill hole 4 with the diameter phi 1 of 1.55 is drilled and when the difference between the designed drilling diameter and the diameter of 1.55 mm of the first pre-drill hole is larger than 0.45-0.6 mm, a drill bit with the diameter phi 2 of 1.55 mm plus 0.45-0.6 mm is selected to drill a second pre-drill hole; thirdly, equally, when the difference between the diameter of the second pre-drill hole and the designed hole diameter is larger than 0.45-0.6 mm, a drill bit with the diameter phi3 to which phi 2 plus 0.45-0.6 mm equals is selected to drill a third pre-drill hole; fourthly, the rest can be done in the same manner till the difference between the pre-drill hole diameter and the designed hole diameter is smaller than or equal to 0.45-0.6 mm, and a drill bit with the diameter equal to the designed hole diameter is selected to finish the final sequential machining. Copper scraps do not block a vacuum pipe, the machining precision is high, and cost is saved.

Owner:DALIAN CHONGDA CIRCUIT

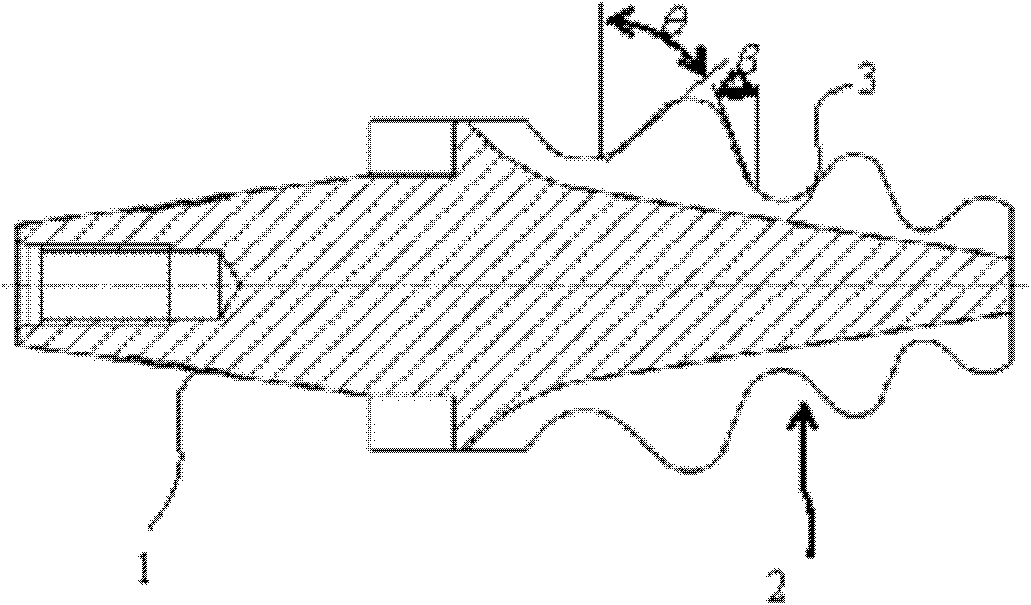

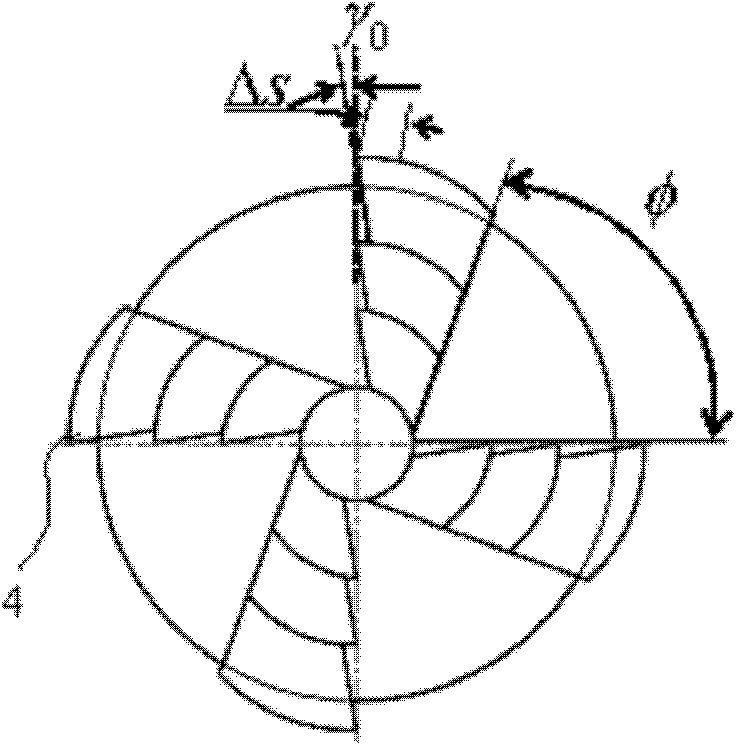

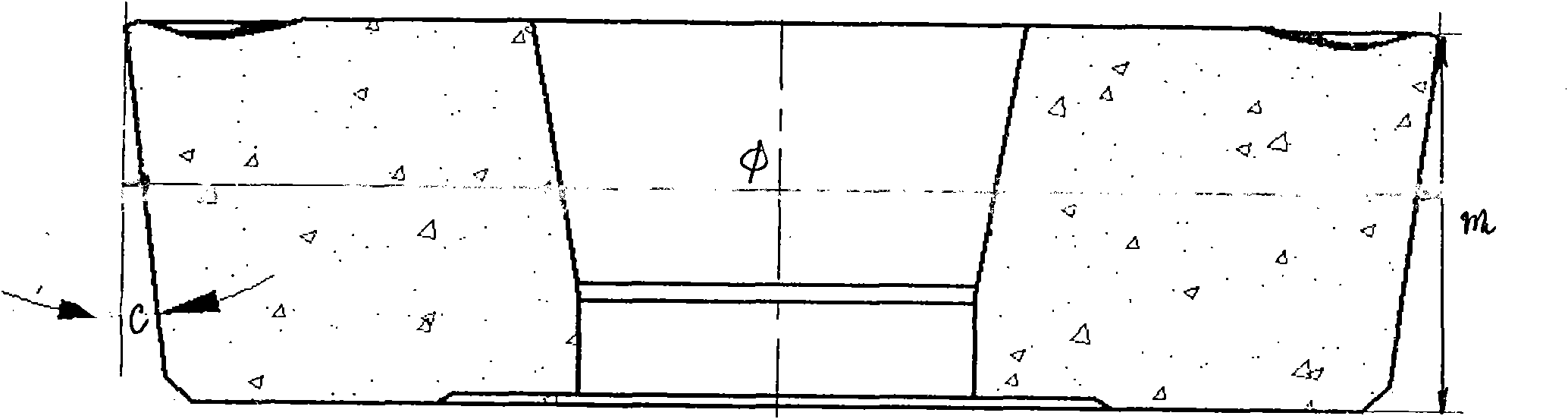

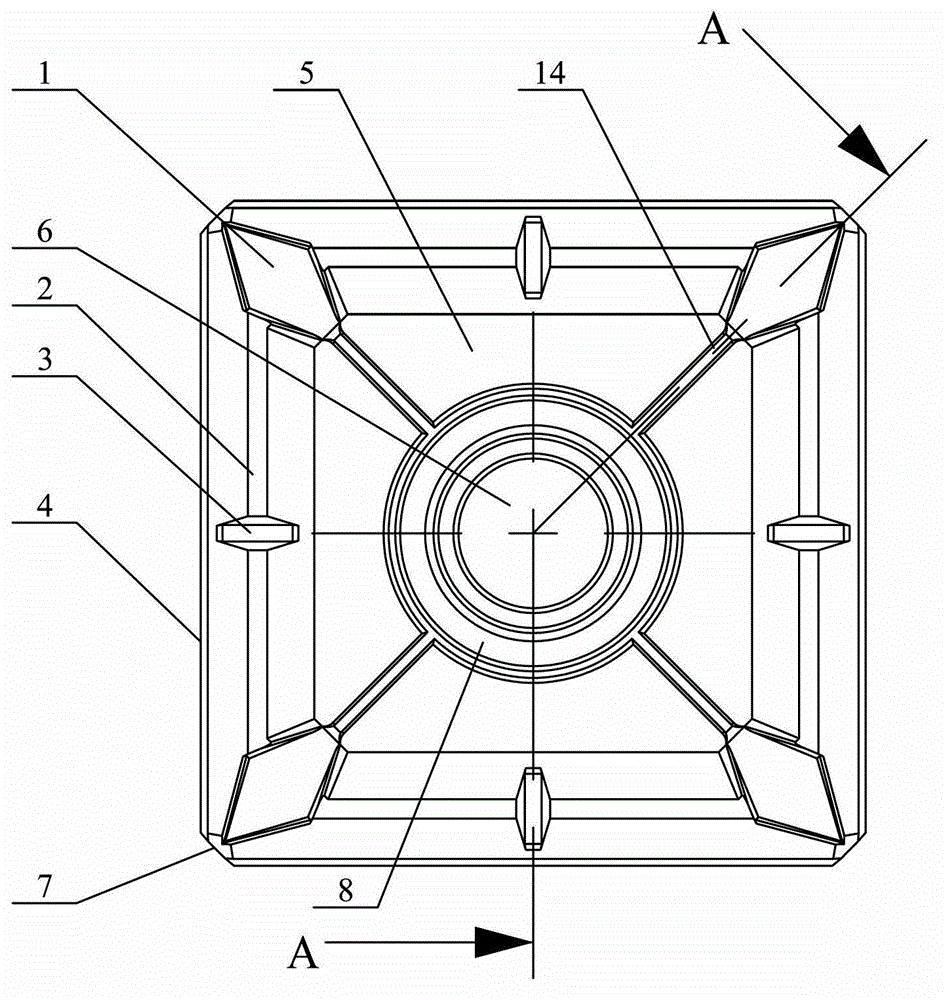

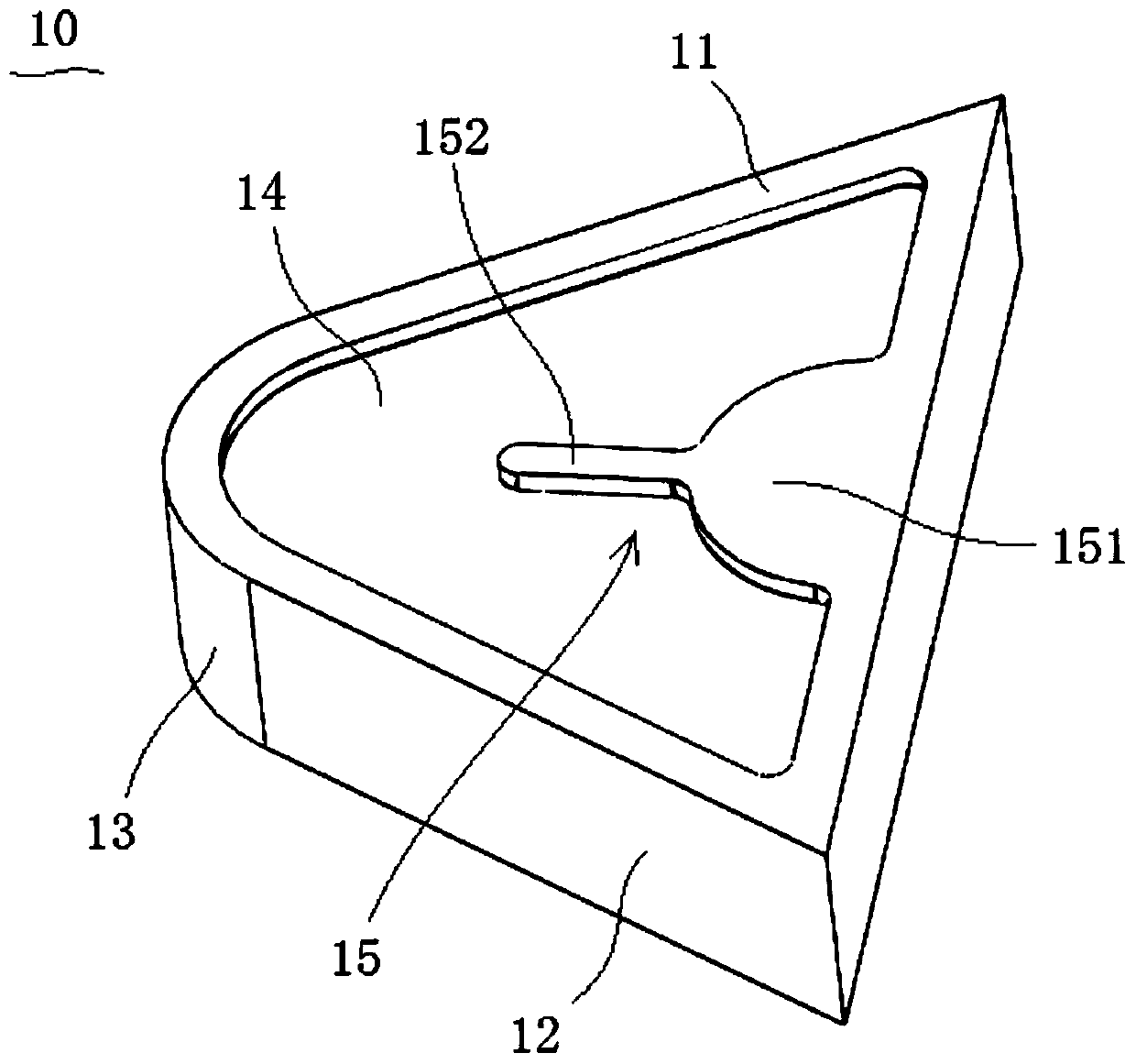

Disc-shaped cutting tool

InactiveCN101890528AGood chip breaking effectImprove product qualityMilling cuttersCircular surfaceBiomedical engineering

The invention provides a disc-shaped cutting tool, which solves the problem of poor chip breaking performance of conventional cutting tools. A chip breaker groove consists of a front tool face, a circular surface and a reverse chip surface, wherein the front tool face and the reverse chip surface are coaxial conical surfaces and are in tangential connection with the circular surface; an included angle gamma0 between the front tool face and a front end face is 15 to 17 DEG; an included angle theta between the reverse chip surface and the rear end face is 15 to 17 DEG; a rear end face is 0.1 to 0.2mm higher than the front end face, namely the height h of a cutting edge is 0.1 to 0.2mm; a plurality of bosses (1) are uniformly distributed on the coaxial periphery of the reverse chip surface; and bumps (2) are arranged between every two adjacent bosses.

Owner:CHENGDU TOOL RES INST

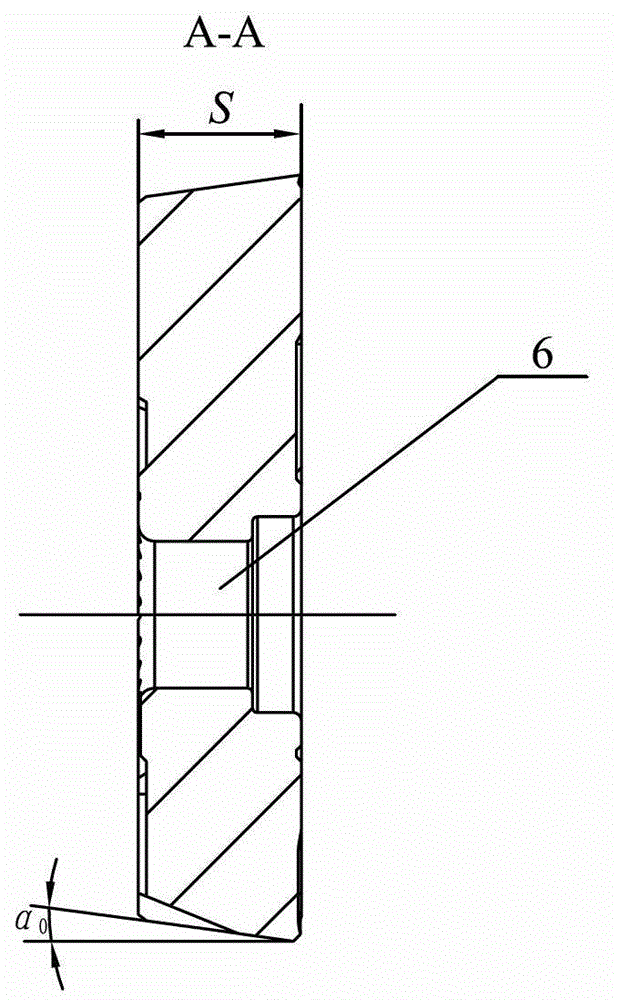

Special blade for roughly processing large axial forge piece with V-shaped tool noses

The invention discloses a special blade for roughly processing a large axial forge piece with V-shaped tool noses, and belongs to the technical field of tools for turning, in order to solve the problems that during the course of roughly milling a hydrogenation shell ring of an ultra large axial forge piece, fracture failure is caused due to the fact that a tool bears load-variable and frequency-variable mechanical shock, and during the course of cutting, the tool is bonded with chips, and chip cutting and chip breaking are difficult due to the fact that a heat dissipation condition is poor and a tool body is softened resulting from high temperature. Four negative chamfered cutting edges are processed at four external rims of a blade rake face; the V-shaped tool noses are processed at connection parts between every two adjacent negative chamfered cutting edges; trapezoid chip breaker grooves are formed in the blade rake face; four rhombic bulges are arranged on the blade rake face, and are close to the four V-shaped tool noses; a tightening screw counter bore is processed in a bulge platform, and positioned in a geometric center; a circular heat-dissipation groove is processed at the periphery of the tightening screw counter bore in the bulge platform; and diagonal heat-dissipation grooves are processed in four diagonal lines of the bulge platform. The special blade is used for large knifing turning in rough processing of a large forge piece blank.

Owner:HARBIN UNIV OF SCI & TECH

Workpiece residual stress detection method based on ultrasonic driven boring

InactiveCN107356358AReduce the error valueReduce cutting forceApparatus for force/torque/work measurementEngineeringCutting force

The invention discloses a workpiece residual stress detection method based on ultrasonic driven boring. The method comprises the following steps: 01) polishing workpiece test point surface; 02) pasting a strain rosette to the polished position; 03) connecting the strain rosette and a wiring terminal, and connecting the strain rosette to a corresponding channel of a strain gauge; 04) moving a plane drilling platform onto the surface of a sample, installing a high-precision microscope on the plane drilling platform and carrying out position calibration through the high-precision microscope; 05) dismounting the high-precision microscope and mounting an ultrasonic motorized spindle; 06) after the residual stress value displayed on a computer display screen is stable, adjusting the residual stress value to zero; 07) after turning on a power supply of an ultrasonic motorized spindle driving module, turning on the power supply of a positioning drive module, and controlling drilling feed rate and rotation speed according to a program; and 08) recording and keeping the data after the data is stable. The method can reduce cutting force and can reduce additional stress and additional heat caused by boring itself.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

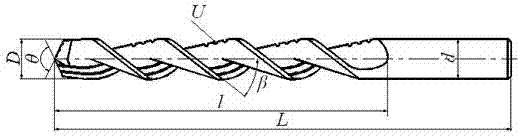

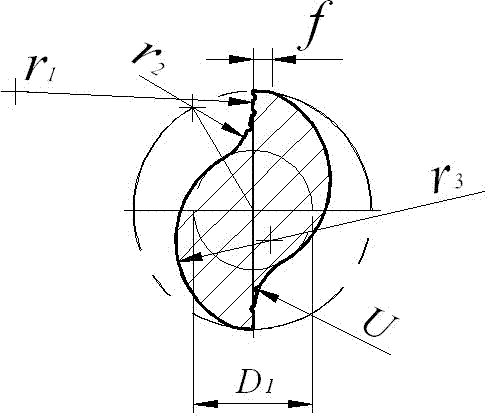

Self-lubricating twist drill and machining method thereof

InactiveCN102922010ABig spaceHigh strengthMilling equipment detailsTwist drillsEngineeringMachining process

The invention relates to a self-lubricating twist drill and a machining method of the self-lubricating twist drill. The invention provides the twist drill with a lubricating groove, which has the advantages of high strength, large scrap containing space, primary machining formation of the groove and a back, and capability of being designed according to different machining materials. Particularly, in a deep hole machining process, self-lubricating cutting is carried out without the cooling and lubricating effect of cutting liquid, so that the cutting friction is reduced and the effective scrap removing and scrap cutting are carried out. The technical scheme is as follows: an axial section of the self-lubricating twist drill is formed by a cutting circular arc, a scrap coiling circular arc and a tooth back circular arc; the structural size comprises an outer diameter D, a drilling core diameter D1, a blade belt f, a cutting circular arc r1, the scrap coiling circular arc r2, the tooth back circular arc r3, and the lubricating groove U on the cutting circular arc r1; the cutting circular arc r1 is smoothly tangent with the scrap coiling circular arc r2; the scrap coiling circular arc r2 is smoothly tangent with the tooth back circular arc r3; the scrap coiling circular arc r2 and the tooth back circular arc r3 are tangent with the drilling core diameter D1; and the cutting circular arc is provided with no less than one lubricating groove.

Owner:XIAN TECHNOLOGICAL UNIV

Manufacturing method for heavy-load grinding wheel

The invention discloses a manufacturing method for a heavy-load grinding wheel. The method includes the following steps that 1) raw materials are taken and mixed to obtain molding materials; 2) the molding materials are put in an inner cavity of a die and uniformly spread, and prepressing pre-profiling is carried out; 3) pre-profiling blanks are put in a drying tunnel to be preheated for 1-2 hours to reach the temperature of 115-120 DEG C; 4) preheated pre-profiling blanks are placed in the die to continue to be heated to the temperature of 195 DEG C-200 DEG C, and the grinding wheel is formed through hot pressing; 5) the hot press molding grinding wheel is placed in a drying oven heated to the temperature of 200 DEG C to be solidified for 12 hours and then naturally cooled to the room temperature to be taken out, and a finished product is manufactured. According to the method, toughness of the heavy-load grinding wheel can be improved, cutting heat is reduced, and the cutting ratio is increased.

Owner:CHANGSHU JULI GRINDING WHEEL

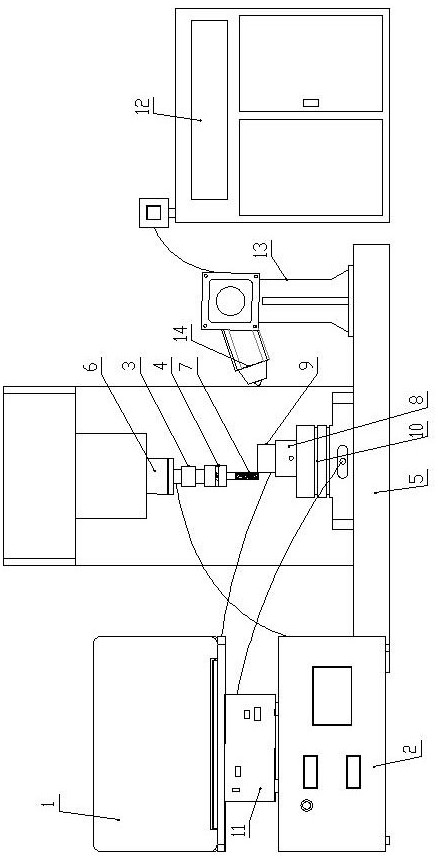

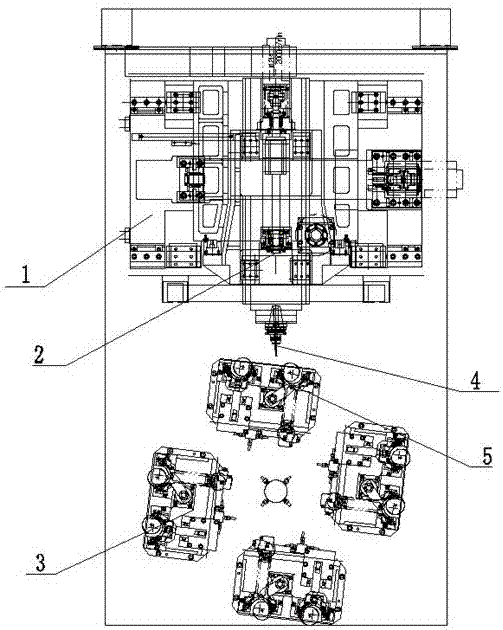

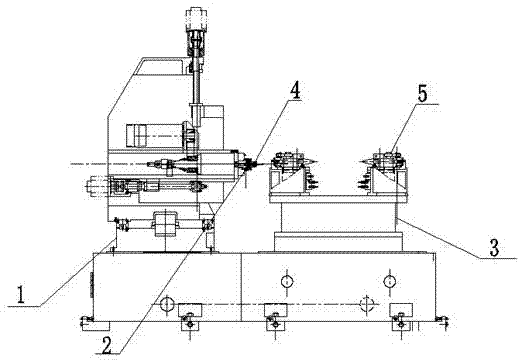

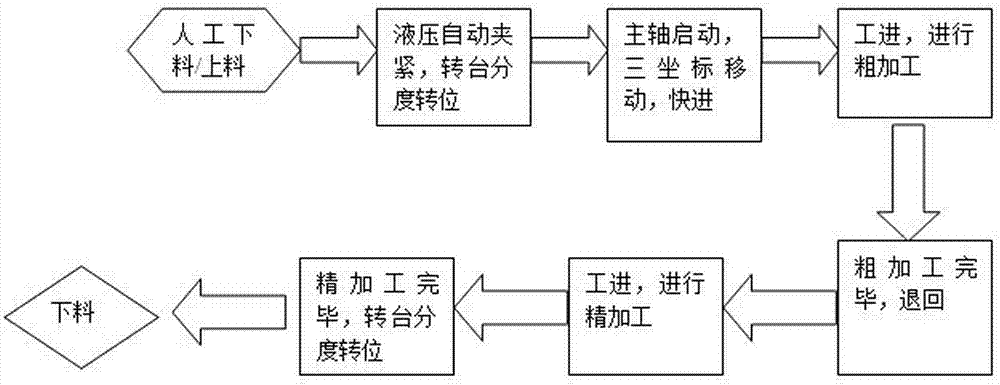

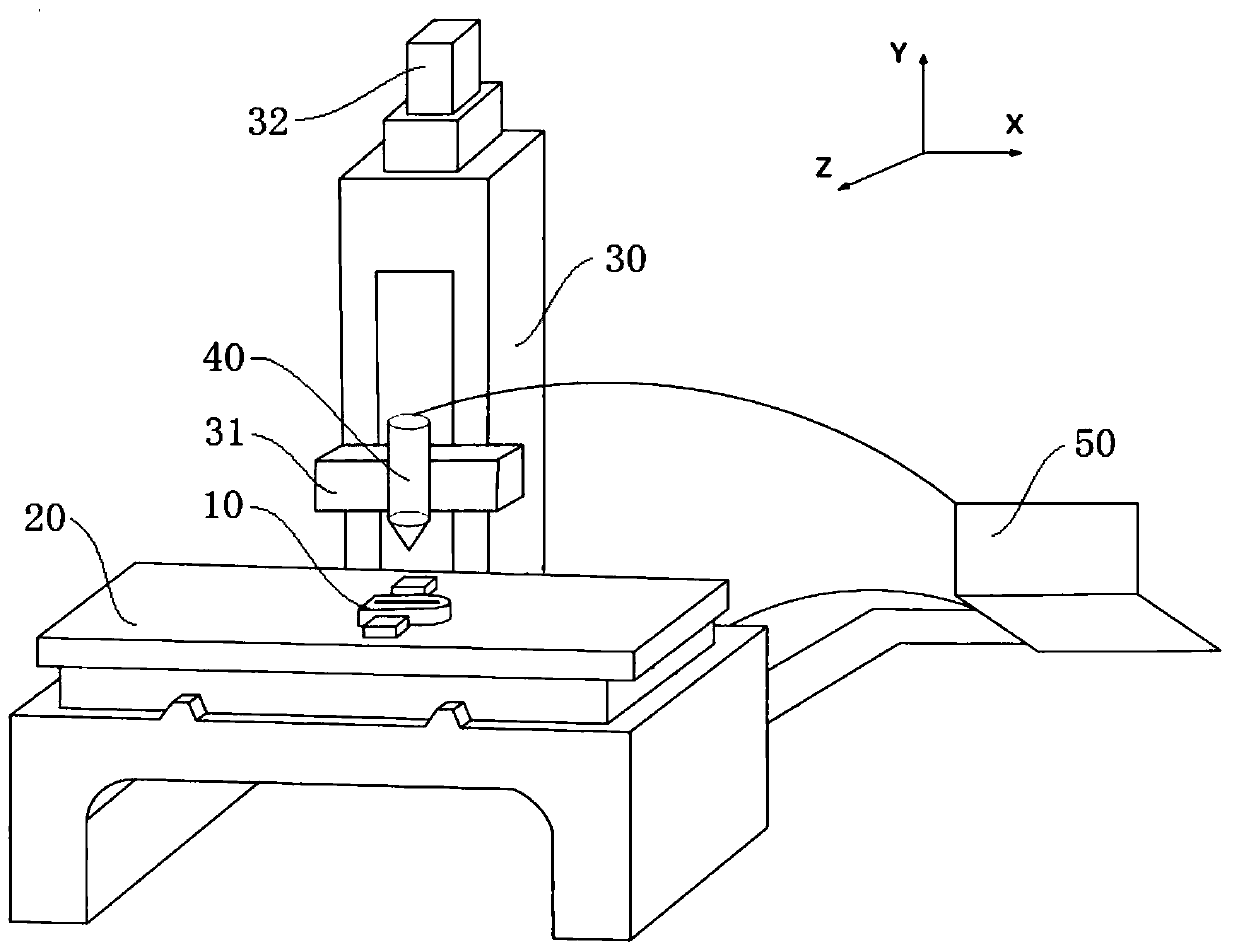

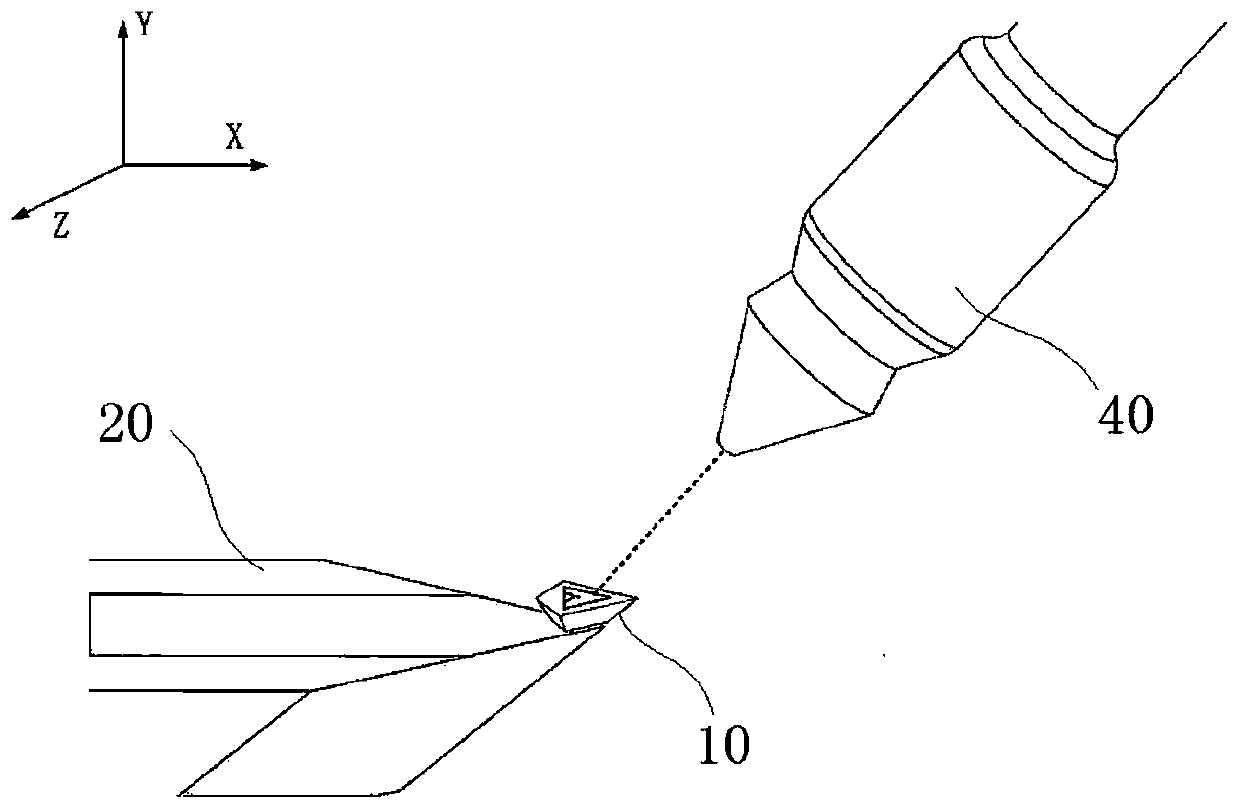

Chamfering machining equipment and chamfering machining method for curved surfaces of orifices of oil holes of connecting rods

PendingCN107127381AImprove chamfering efficiencyHigh chamfering precisionMilling equipment detailsMilling cutterSurface roughness

The invention discloses chamfering machining equipment and a chamfering machining method for curved surfaces of orifices of oil holes of connecting rods, and relates to the field of machining technologies for connecting rods of engines. The chamfering machining equipment comprises a horizontal three-coordinate driving mechanism, a servo spindle driving mechanism and an indexing worktable. The servo spindle driving mechanism is arranged on the horizontal three-coordinate driving mechanism and can be driven by the horizontal three-coordinate driving mechanism to move, a milling cutter shank is arranged at an end of the servo spindle driving mechanism, and a milling cutter is fixed onto the milling cutter shank. The chamfering machining equipment and the chamfering machining method for the curved surfaces of the orifices of the oil holes of the connecting rods have the advantages that the chamfering efficiency and the precision of the profile tolerance of the machined curved surfaces can be improved, and the chamfering consistency and the surface roughness can be enhanced.

Owner:四川普什宁江机床有限公司

FRP tank perforating device

InactiveCN109129681AEfficient quality openingContinuous holeMetal working apparatusDischarge efficiencyDriven element

The invention relates to a FRP tank perforating device which is used in cooperation with a propelling device and locating clamp. The FRP tank perforating device comprises a cup-shaped cutter, an ultrasonic rotary main shaft and a waste discharging mechanism. The waste discharging mechanism comprises an ejection ring which is arranged in an inner cavity of the cup-shaped cutter in a matched manner,at least two ejector rods which perpendicularly penetrate through the end face of the cup-shaped cutter and are connected with the ejection ring, a synchronizing plate which is connected with the end, far away from the ejection ring, of each ejector rod, a drive element used for drying the synchronizing plate to linearly move so as to drive the ejection ring to conduct ejection and springs whichare arranged on the ejector rods in a sleeving manner and can achieve resetting of the ejection ring. The ultrasonic rotary main shaft comprises an ultrasonic amplitude-change pole and a main shaft motor used for providing rotation power for the ultrasonic amplitude-change pole. The ultrasonic amplitude-change pole penetrates through the synchronizing plate and then is connected with the center ofthe cup-shaped cutter. The FRP tank perforating device is high in locating precision, good and stable in perforating quality and capable of discharging cutting chips in time, improves the cutting efficiency and improves the waste discharging efficiency.

Owner:WUHAN UNIV OF TECH

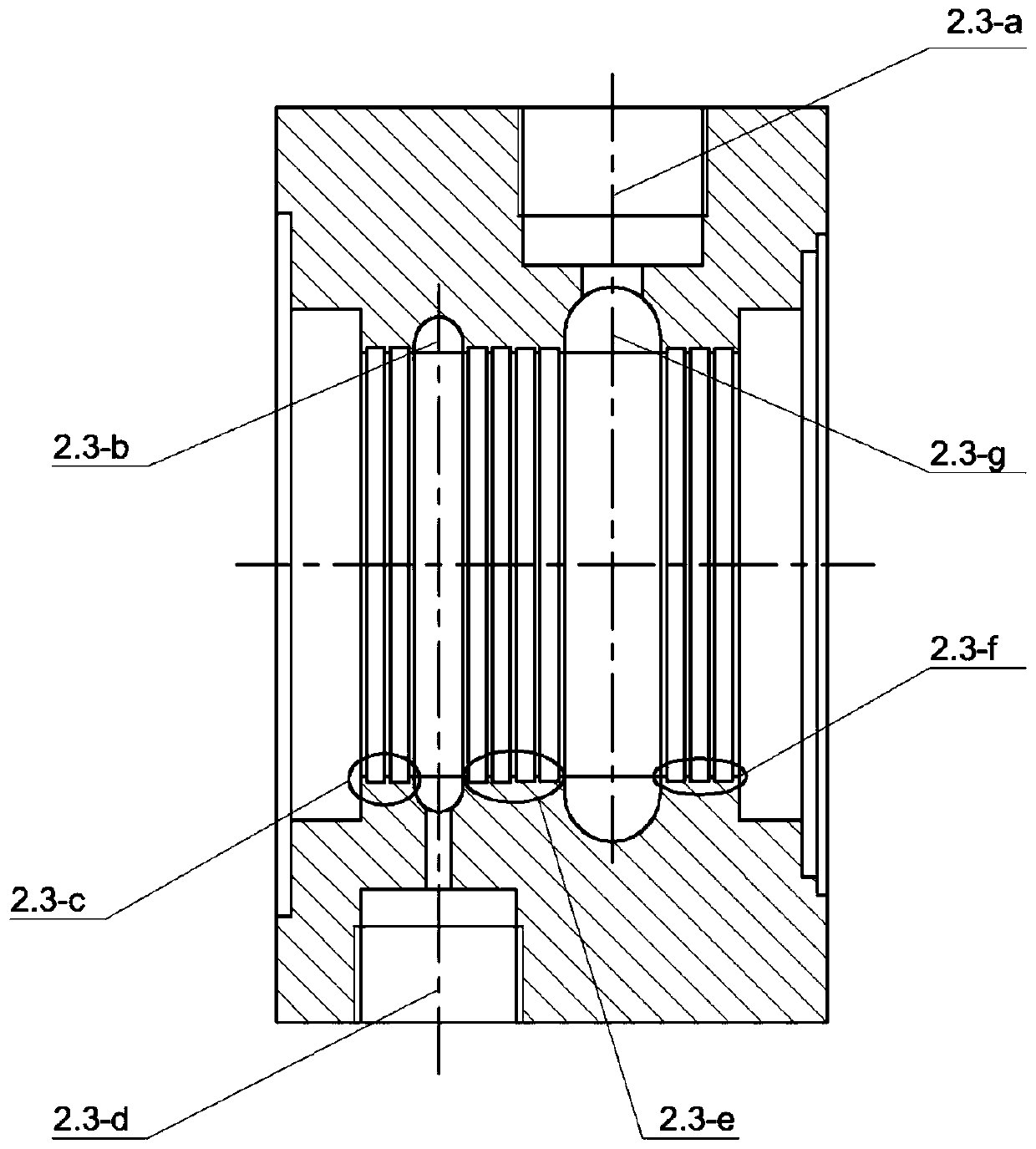

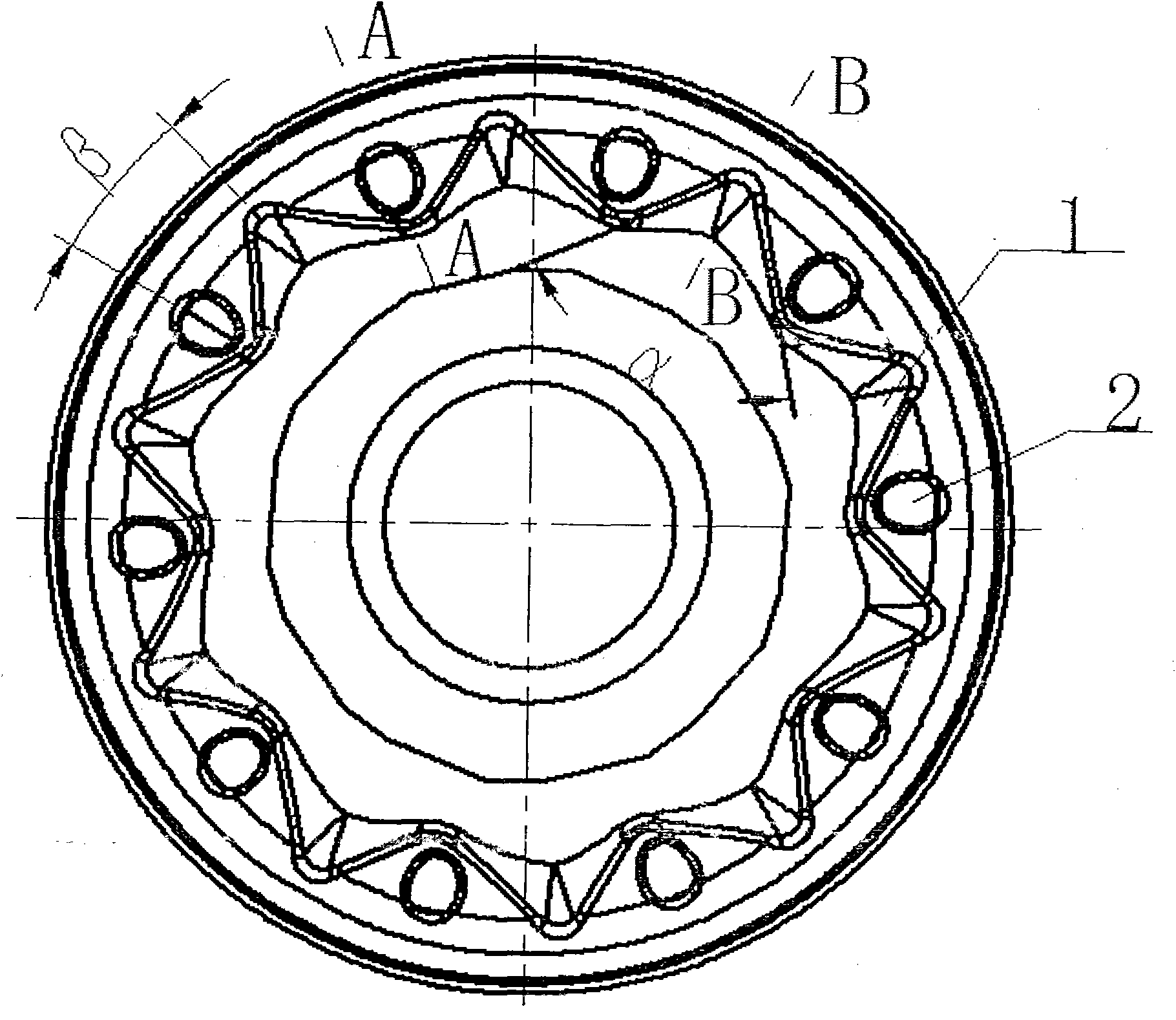

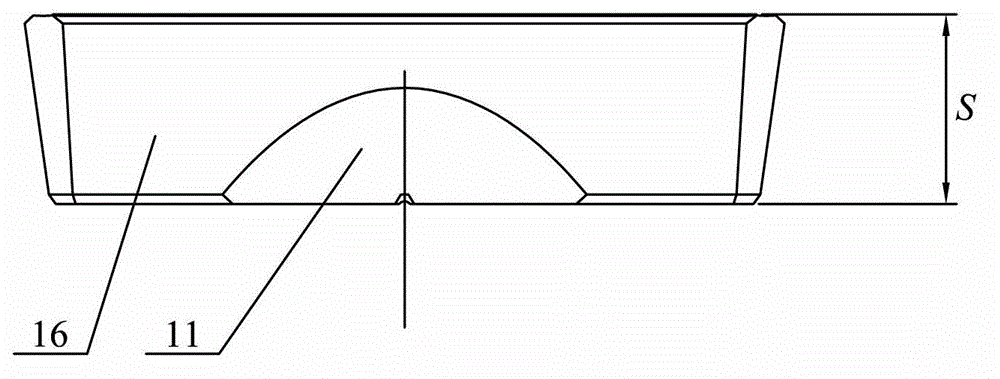

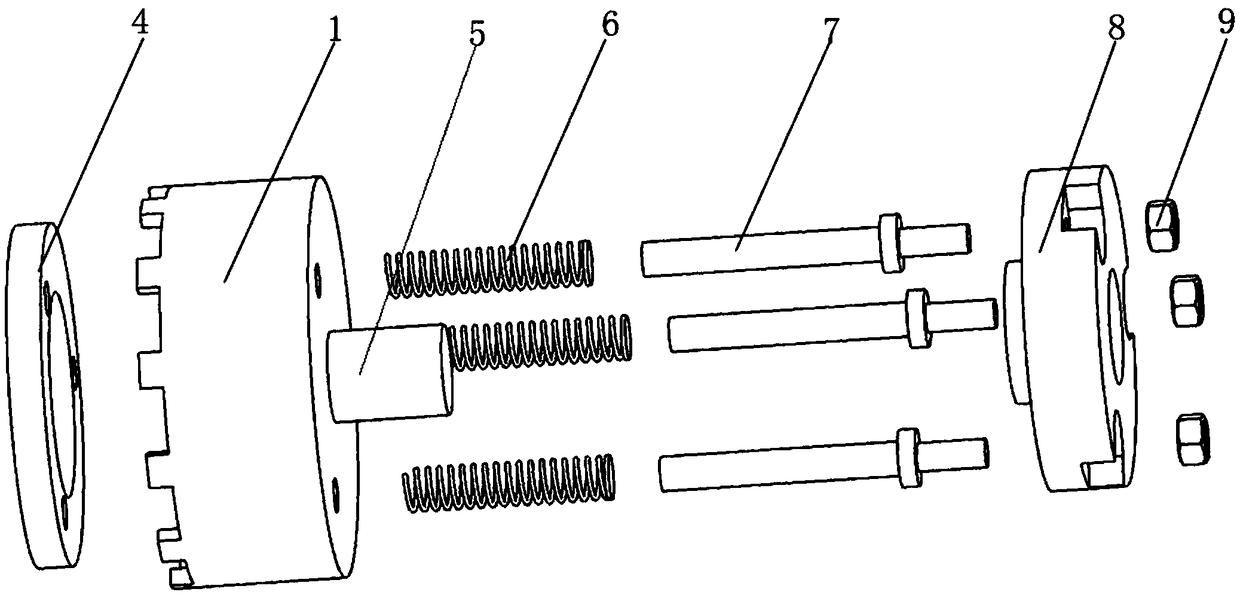

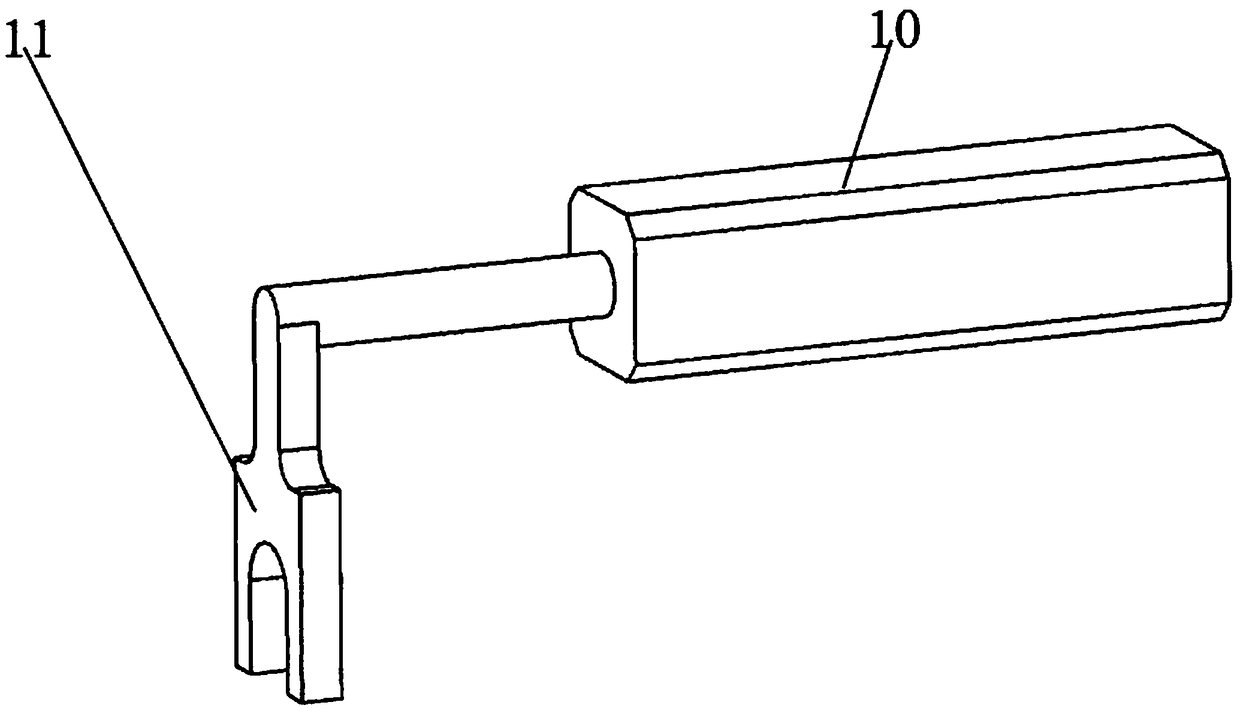

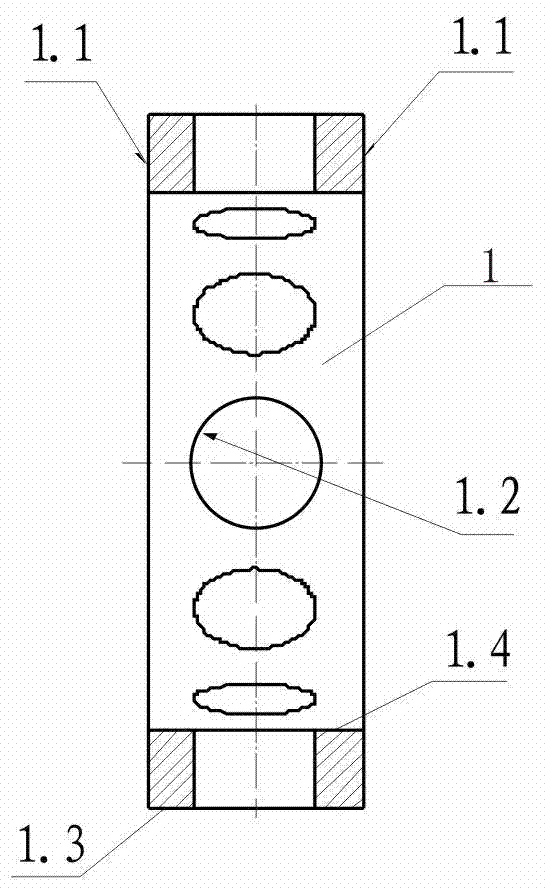

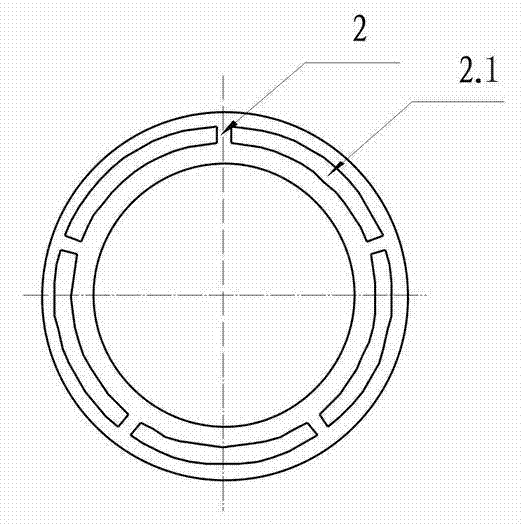

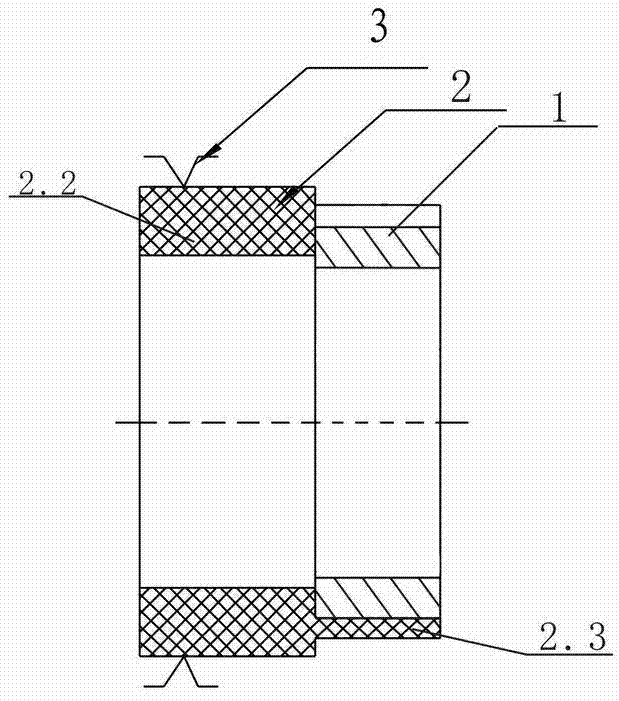

Processing method of aramid fiber reinforced polytetrafluoroethylene holder

ActiveCN103089818AImprove processing pass rateHigh card loading accuracyBearing componentsEngineeringAramid

The invention discloses a processing method of an aramid fiber reinforced polytetrafluoroethylene holder. The aramid fiber reinforced polytetrafluoroethylene holder (1) comprises two lateral end faces (1.1), a pocket (1.2), an outer-diameter end face (1.3) and an inner-diameter end face (1.4); stable treatment I, semi-finish turning on the outer-diameter end face, semi-finish turning on the inner-diameter end face and stable treatment II are added on the basis of the conventional processing; a bakelite expander (2) is used in the semi-finish turning on the outer-diameter end face and semi-finish turning on the inner-diameter end face; the bakelite expander comprises a lathe clamping section (2.2) and a holder fixing section (2.3); and the whole processes of rough turning on the inner-diameter end face, rough turning on the outer-diameter end face, stable treatment I, turning on the two lateral end faces, semi-finish turning on the outer-diameter end face, semi-finish turning on the inner-diameter end face, distributing and drilling pocket, stable treatment II, finish turning on the inner-diameter end face, finish turning on the outer-diameter end face, and final detection are finally formed. The demands on the processing environment temperature are provided, so that the manufacturing percent of pass of the aramid fiber reinforced polytetrafluoroethylene holder is improved to 80% from below 20% in the prior art.

Owner:LUOYANG BEARING RES INST CO LTD

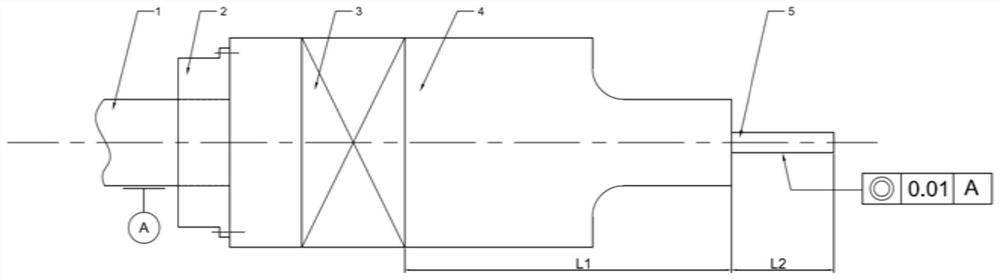

Aluminum-based silicon carbide thread precision machining method

ActiveCN112059535AHigh quality and efficient processingReduce wearCarbide siliconLongitudinal vibration

The invention discloses an aluminum-based silicon carbide thread precision machining method. The method comprises the following steps that an ultrasonic longitudinal vibration machining cutter handleis installed on a machine tool, an ultrasonic power source is connected with the ultrasonic longitudinal vibration machining cutter handle, and a workpiece is clamped on a machine tool workbench; a 2mm-10 mm drill bit is installed at the tail end of the ultrasonic longitudinal vibration machining cutter handle, and threaded bottom hole machining of the workpiece is completed; the 2 mm-10 mm drillbit is replaced with a diamond coating hard alloy cutter for thread machining, and an ultrasonic power source is started; the frequency of the ultrasonic power source and the amplitude of the diamondcoating hard alloy cutter carried at the tail end of the ultrasonic longitudinal vibration machining cutter handle are adjusted to meet the separation condition of the ultrasonic technology; a milling machine tool is started, and the diamond coating hard alloy cutter spirally mills a threaded hole of the workpiece according to a set spiral track; and the ultrasonic power source is shut off, and thread inlet and outlet chamfers of the workpiece are milled. By means of the aluminum-based silicon carbide thread precision machining method, threaded hole surface and hole inlet and outlet quality is improved, the machining efficiency is improved, and meanwhile cutter abrasion is reduced.

Owner:BEIJING SATELLITE MFG FACTORY

Microstructure superhard cutter and manufacturing method thereof

PendingCN111496278AIncrease cooling areaReduce cutting heatCutting insertsTurning toolsErbium lasersBatch production

The invention discloses a microstructure superhard cutter and a manufacturing method thereof. The microstructure superhard cutter comprises a cutter body and a cutter head connected with the cutter body, wherein the cutter head comprises a rake face, a flank face and a tip; a microstructure depressed downwards is arranged on the rake face; and a chip breaking structure for cutting off accumulatedchips is arranged on one side, away from the tip, of the microstructure. The manufacturing method of the microstructure superhard cutter comprises the following steps: S1, adjusting the relative position of a laser and the to-be-machined cutter; S2, turning on the laser to irradiate the rake face of the to-be-machined cutter; S3, controlling the laser to move along a predetermined path. The microstructure with high precision can be machined on the cutter with high hardness, the cutter is suitable for suitable for batch production; and the cutter with the micro structure ahs the advantages thatthe heat dissipation area in the cutting process can be increased, cutting heat is reduced, and the service life of the cutter is prolonged.

Owner:SHENZHEN UNIV +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com