Patents

Literature

45results about How to "Shorten dressing time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Process of dressing glass disk polishing pads using diamond-coated dressing disks

InactiveUS6254461B1Rapidly but accurately removeEasy to takePolishing machinesGrinding drivesMagnetic memoryCerium

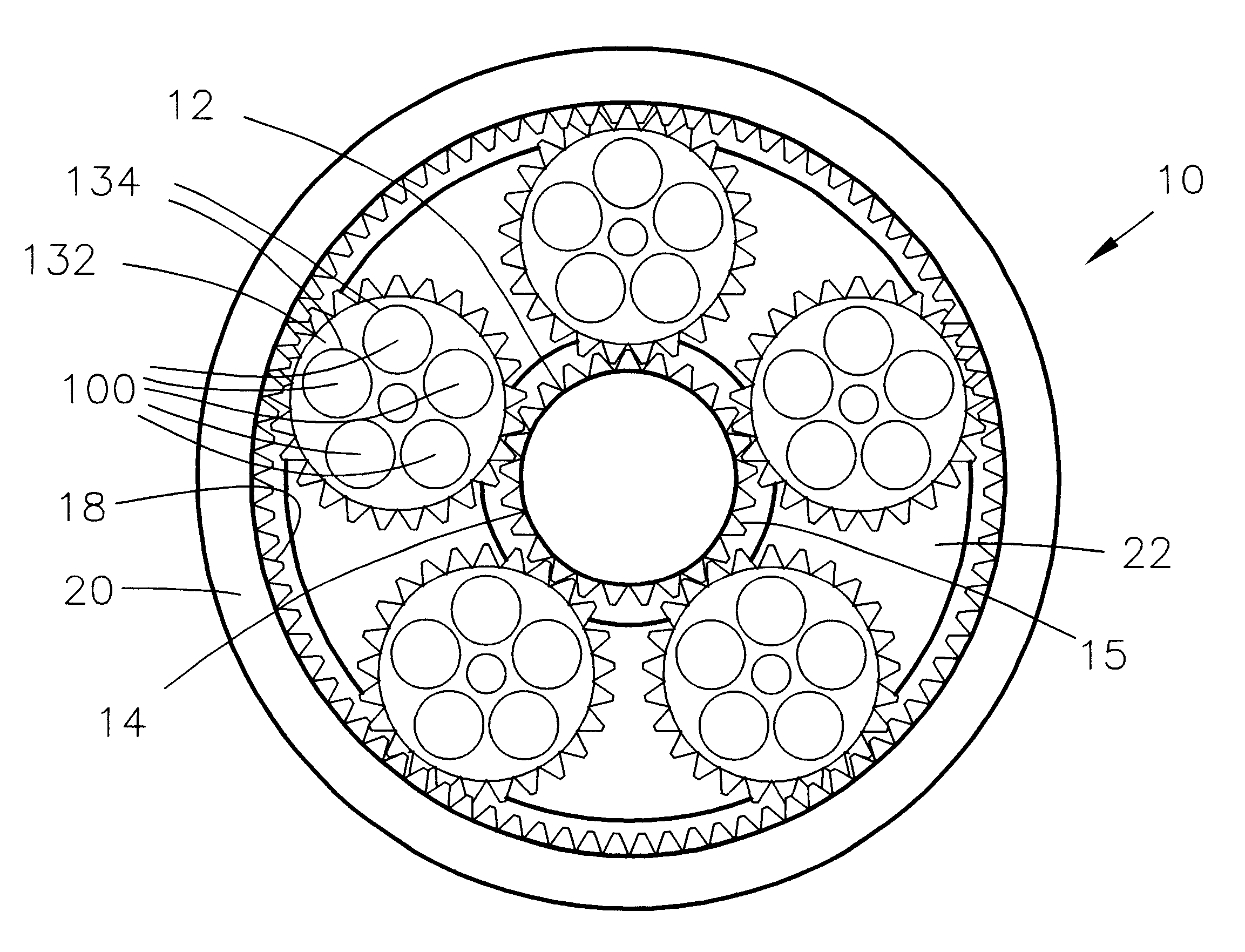

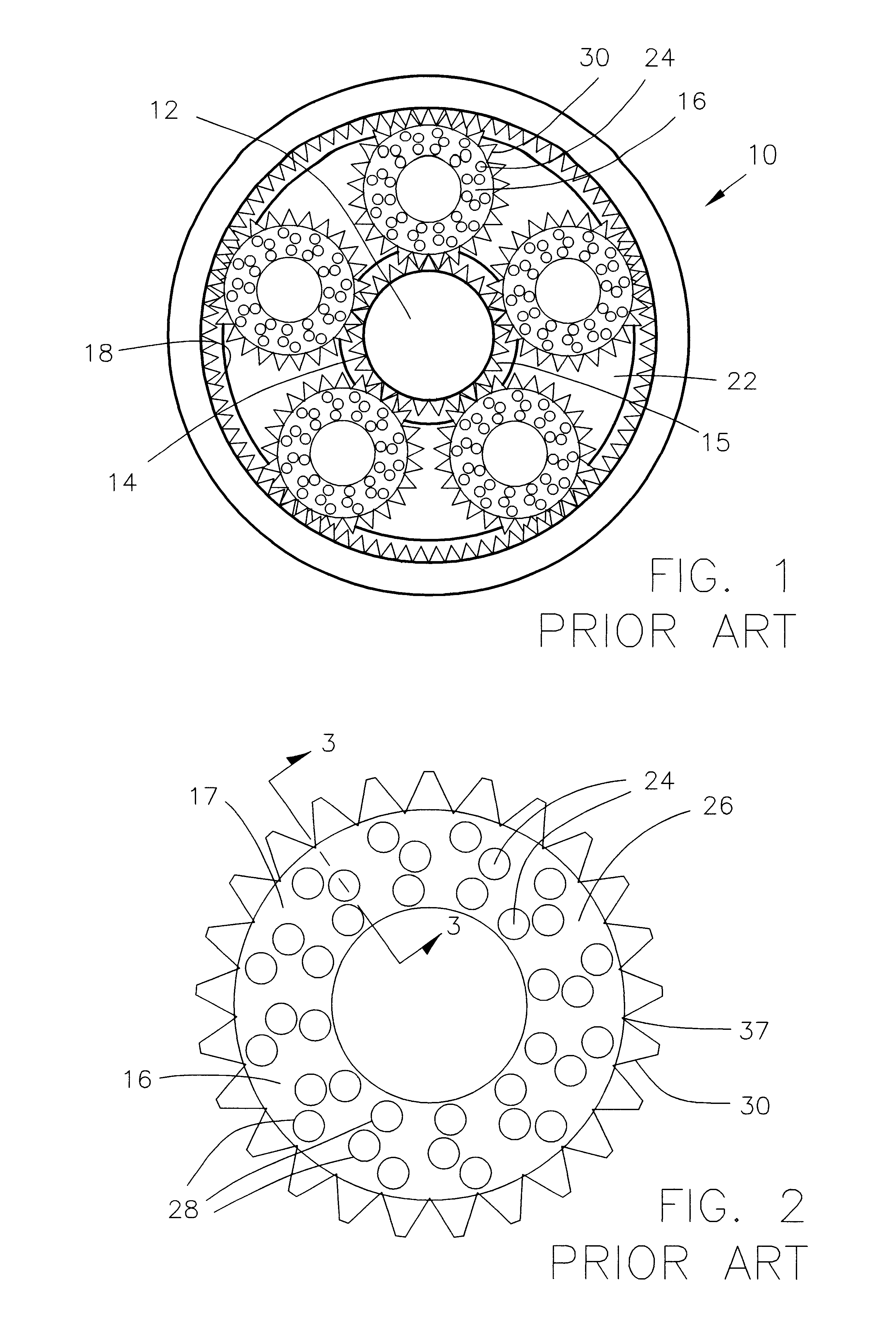

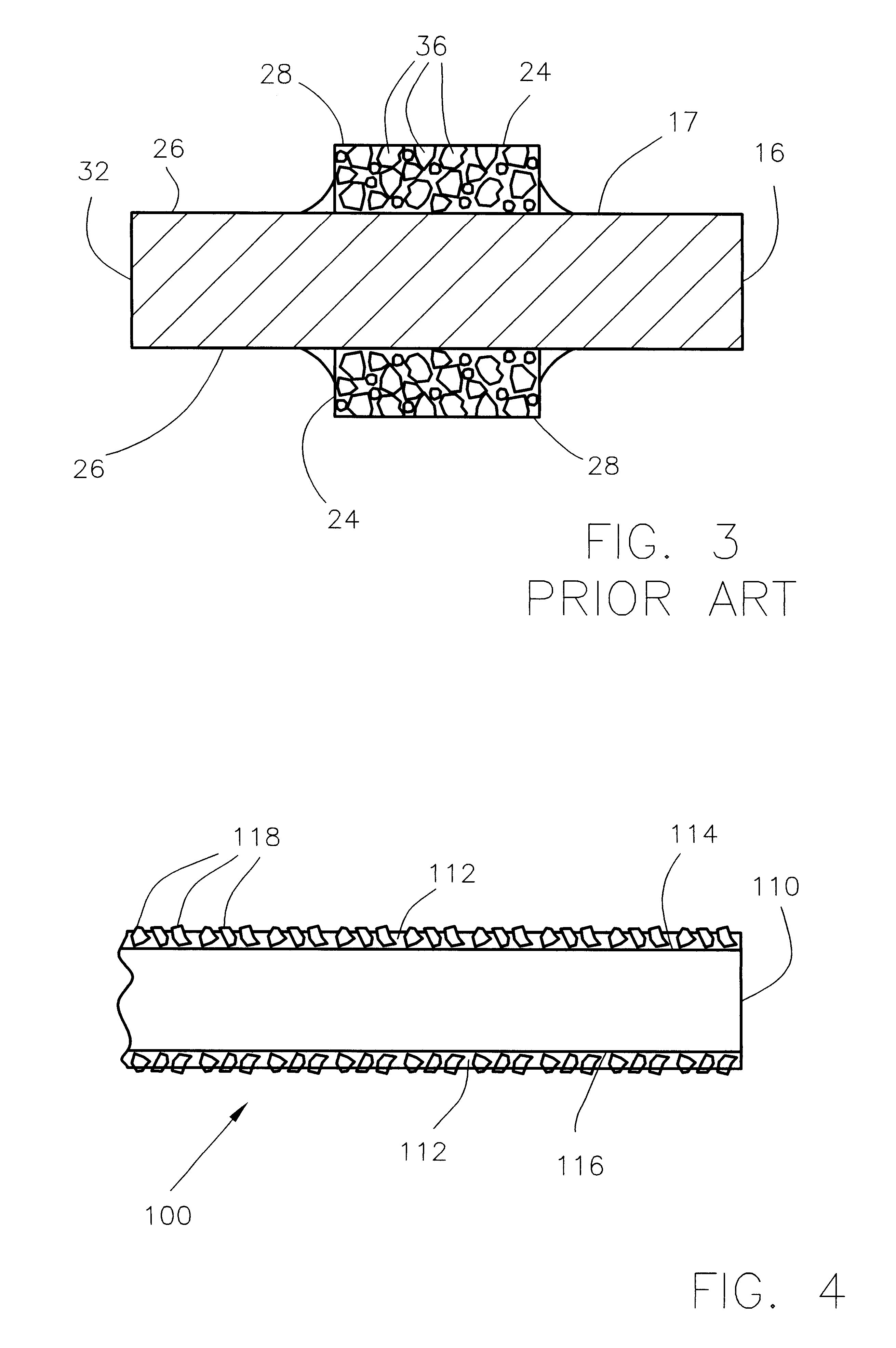

A dressing disk for dressing and reconditioning the polishing pad of a planetary disk polishing machine is fabricated by plating a nickel / diamond matrix layer onto a stainless steel disk wherein the matrix layer thickness is developed or plated to a thickness which leaves exposed about 25 percent of the fine diamond particles, thereby forming a surface that has the look and feel of medium to coarse sandpaper. The dressing disks are inserted into the holes in a disk carrier of a planetary polishing machine and driven by its central rotary drive. While being so driven under a flow of water to carry away abraded particles, a pair of polishing pads are engaged with the disk surfaces and forced together with a loading or down force to cause the disks to abrade or grind away a thin surface layer of the polishing pad, thereby removing glazing and exposing cerium particles embedded in the urethane matrix of the polishing pad to engage the glass disks to be polished to a very smooth surface for use as substrates for magnetic memory disks useable in disk drives.

Owner:IBM CORP

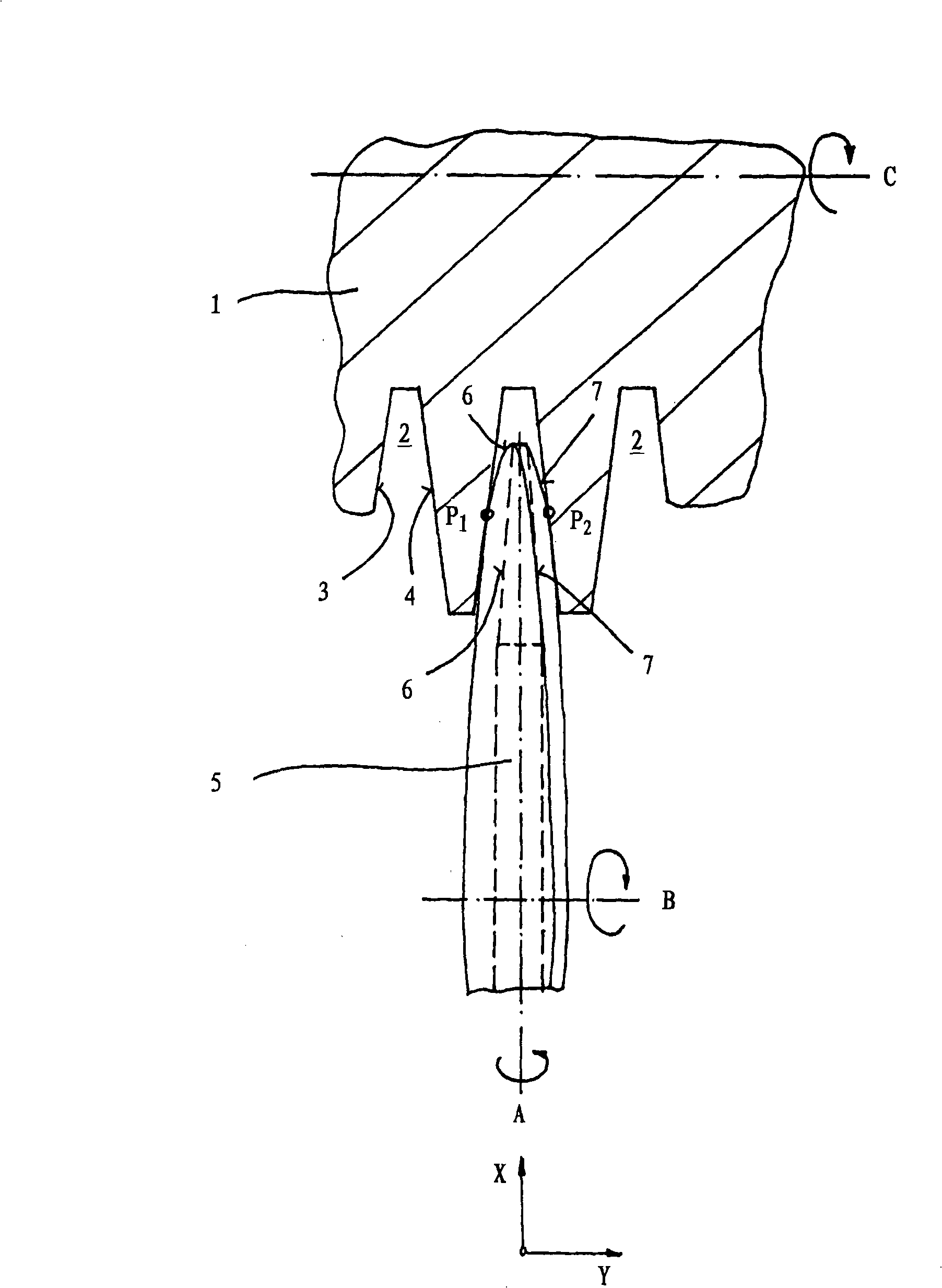

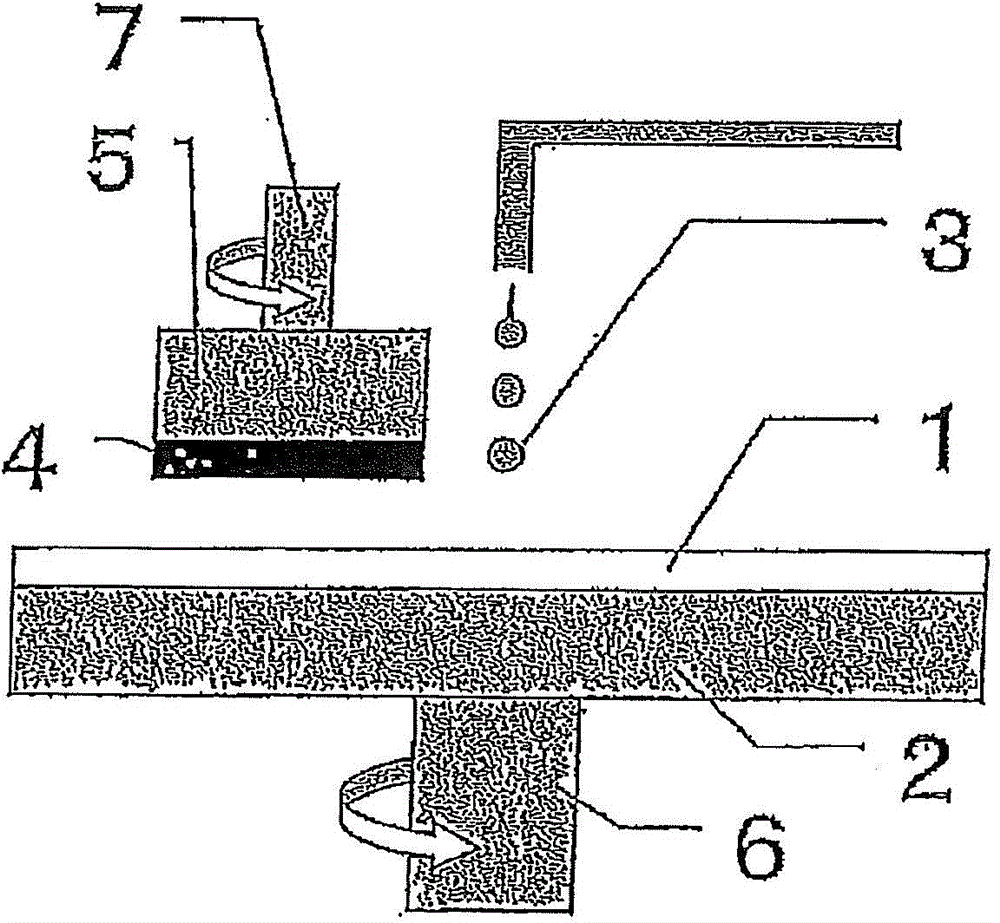

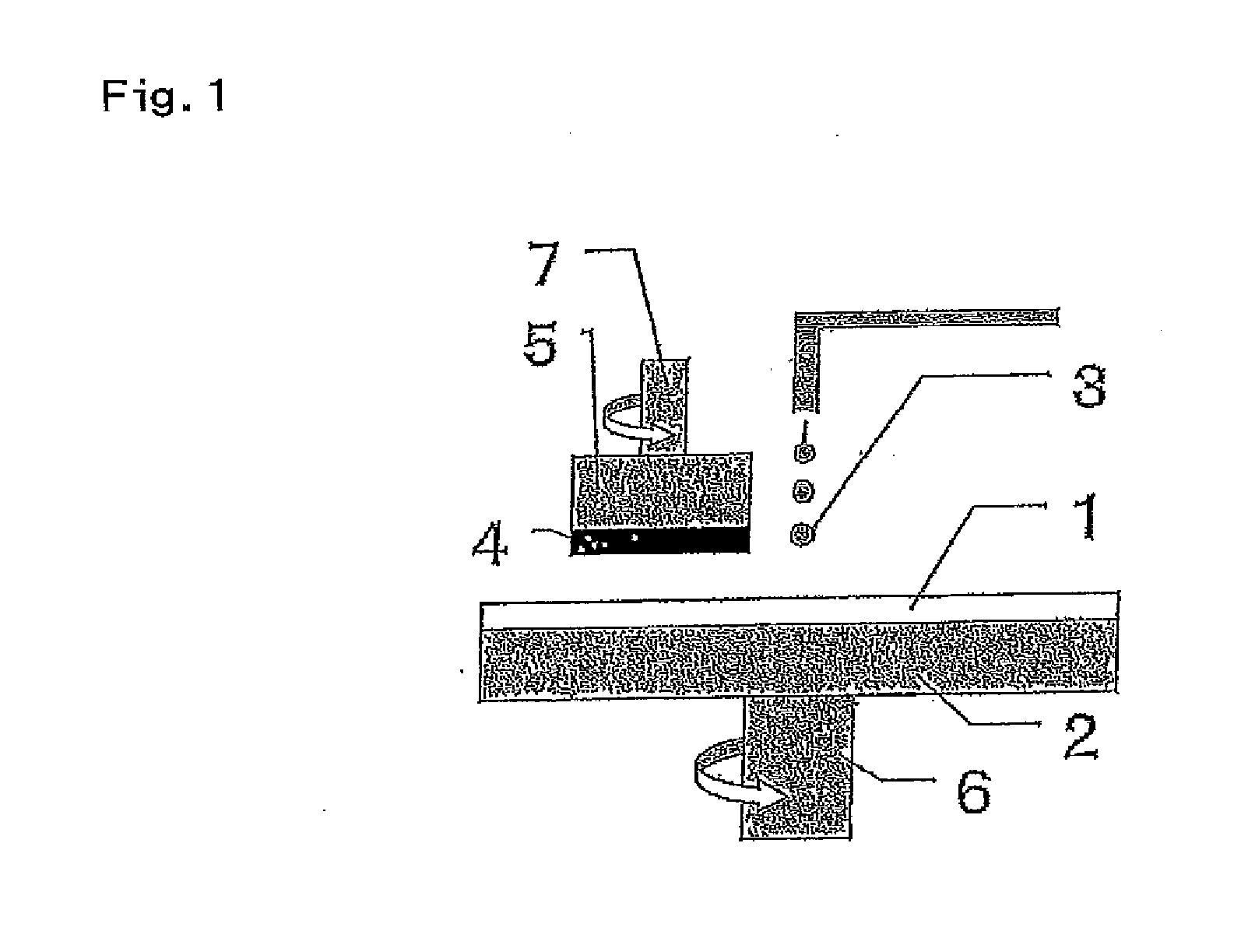

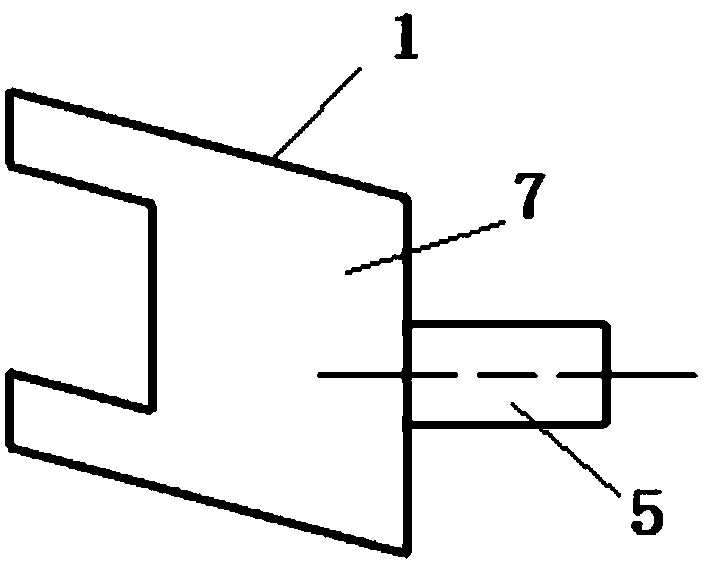

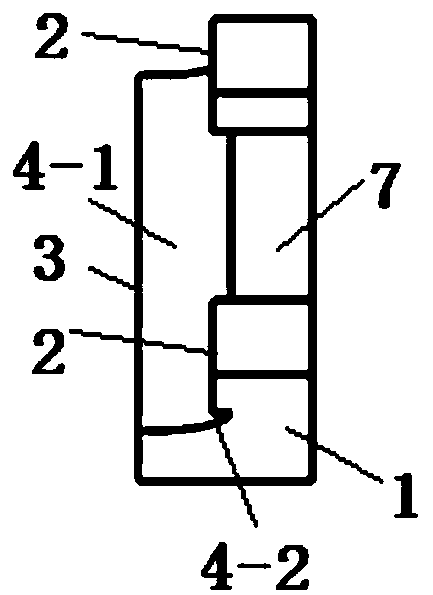

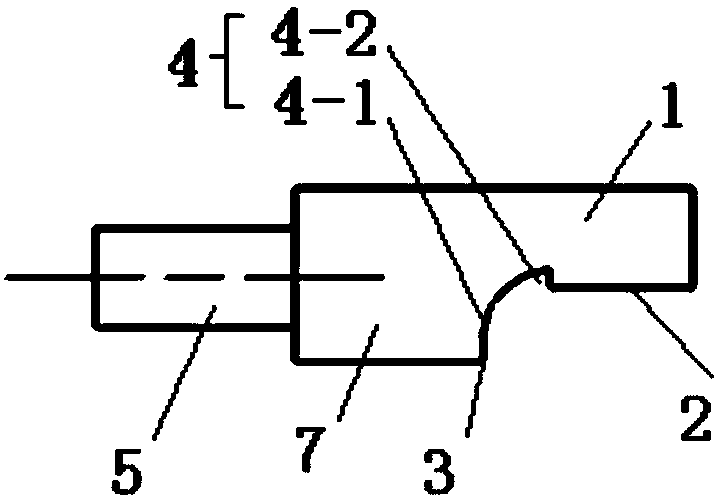

Method and grinding machine for profiling a grinding tool

ActiveCN101293290AAchieve reductionShorten dressing timeAbrasive surface conditioning devicesGear-cutting machinesMetallurgy

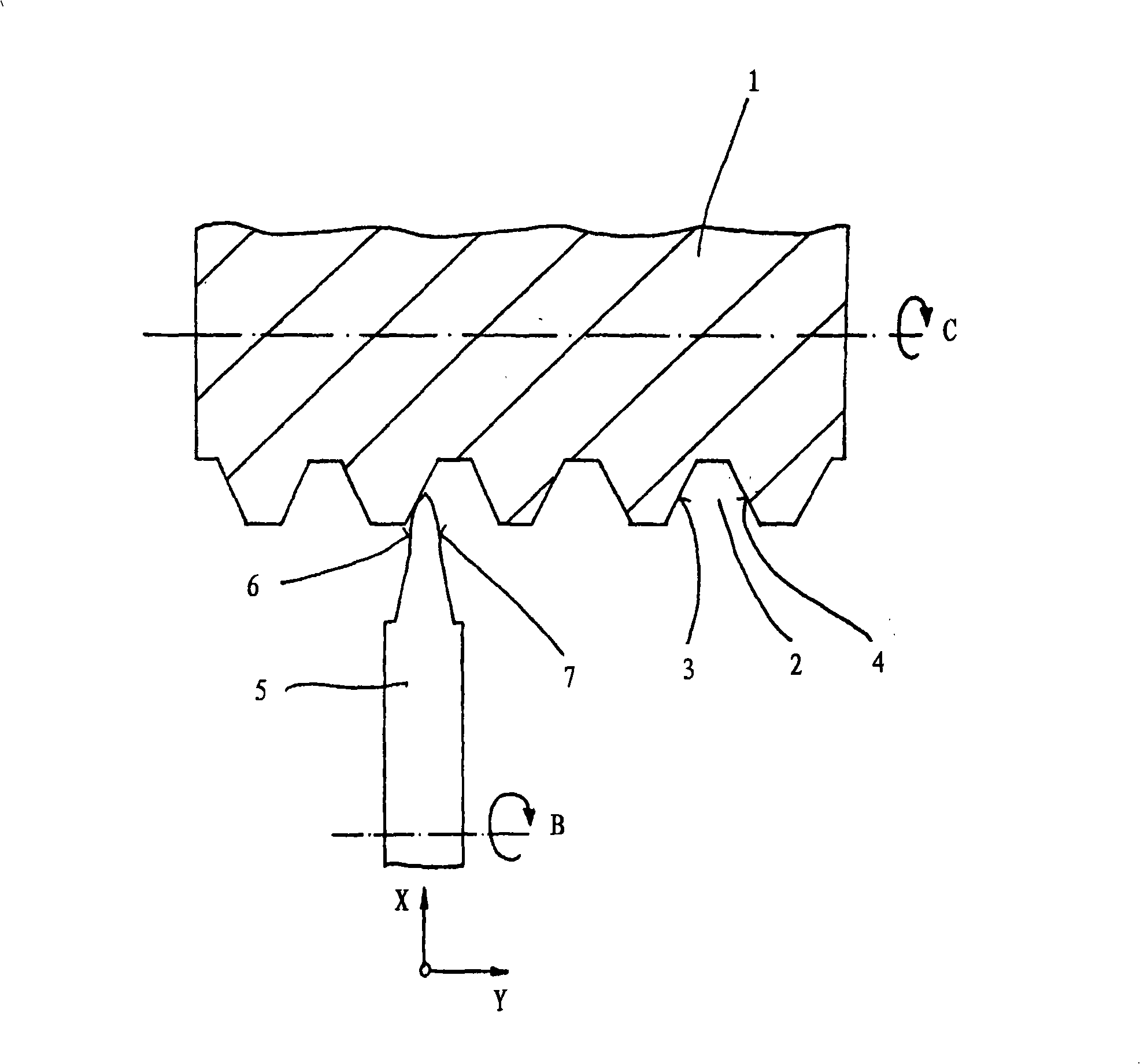

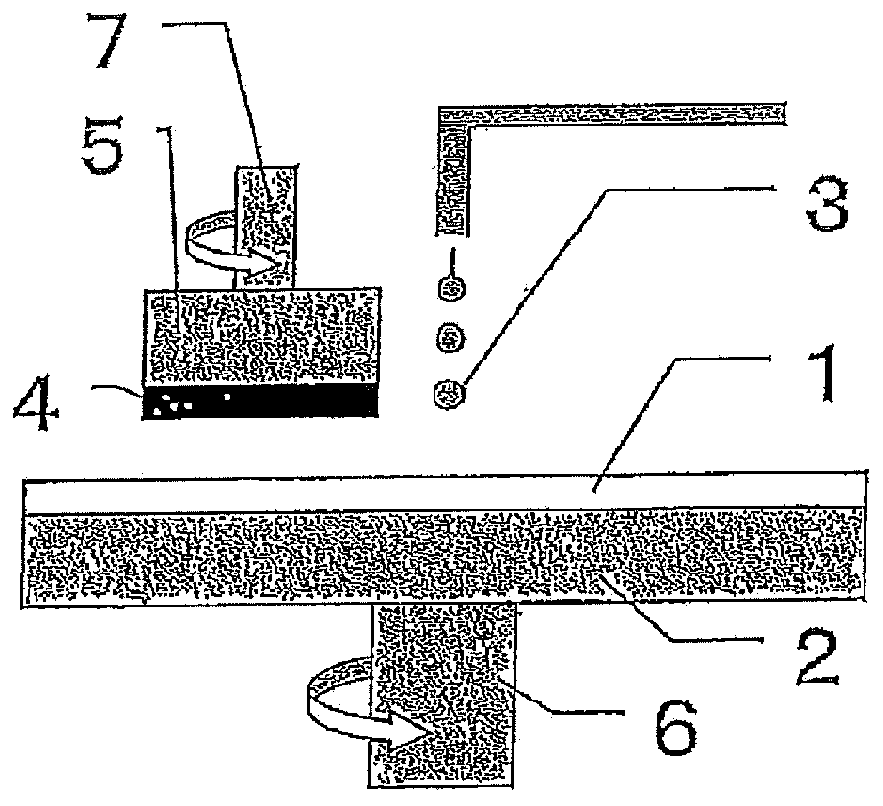

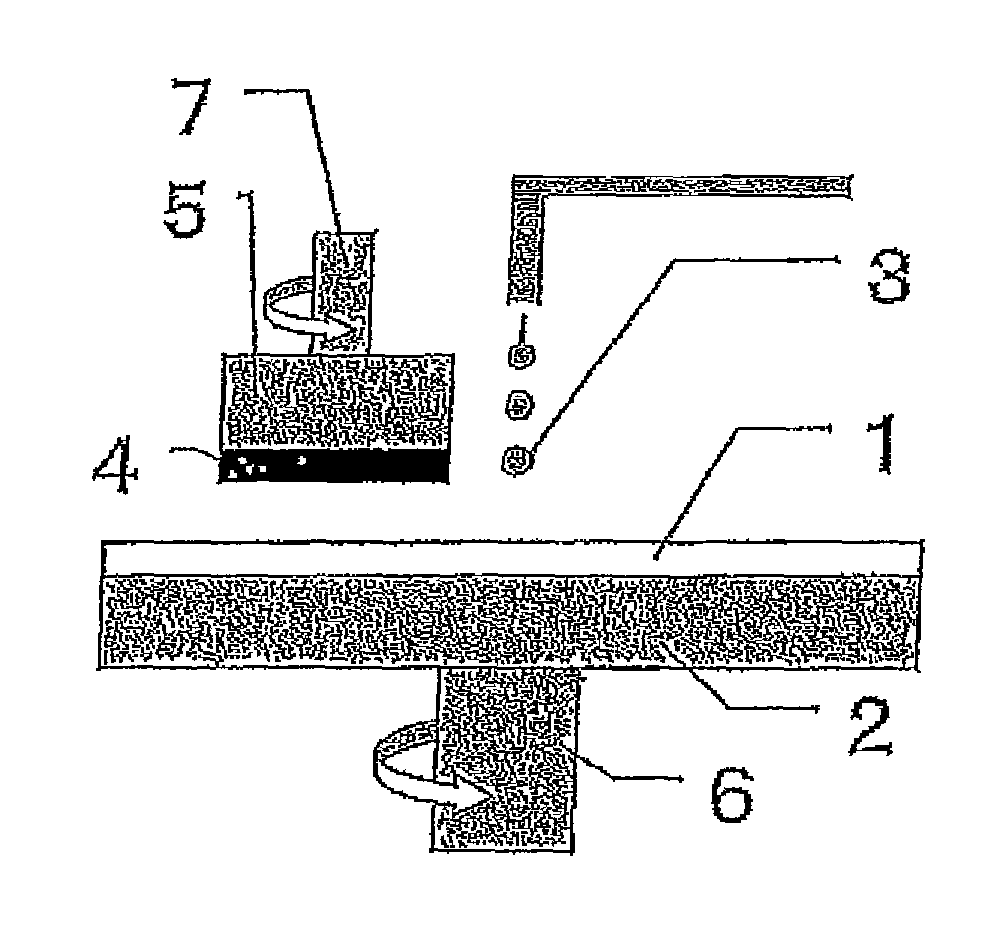

The invention relates to a method and machine for the dressing of a grinding tool ( 1 ), which has at least one tooth-shaped profile ( 2 ) with a first flank ( 3 ) and an opposing second flank ( 4 ). A disk-shaped dressing tool ( 5 ) used for dressing of the grinding tool ( 2 ) has a first abrasive area ( 6 ) and a second abrasive area ( 7 ). To allow a faster and thus more economical dressing of the grinding tool, the first abrasive area ( 6 ) contacts the first flank ( 3 ) and the second abrasive area ( 7 ) contacts the second flank ( 4 ) simultaneously, and the disc-shaped dressing tool ( 5 ) and / or the grinding tool ( 1 ) are pivoted relatively to another around an axis (A) being arranged perpendicular to the axis of rotation (C) of the grinding tool ( 1 ), so that both flanks ( 3, 4 ) are dressed simultaneously.

Owner:KAPP GMBH & CO KG WERKZ MASCHFAB

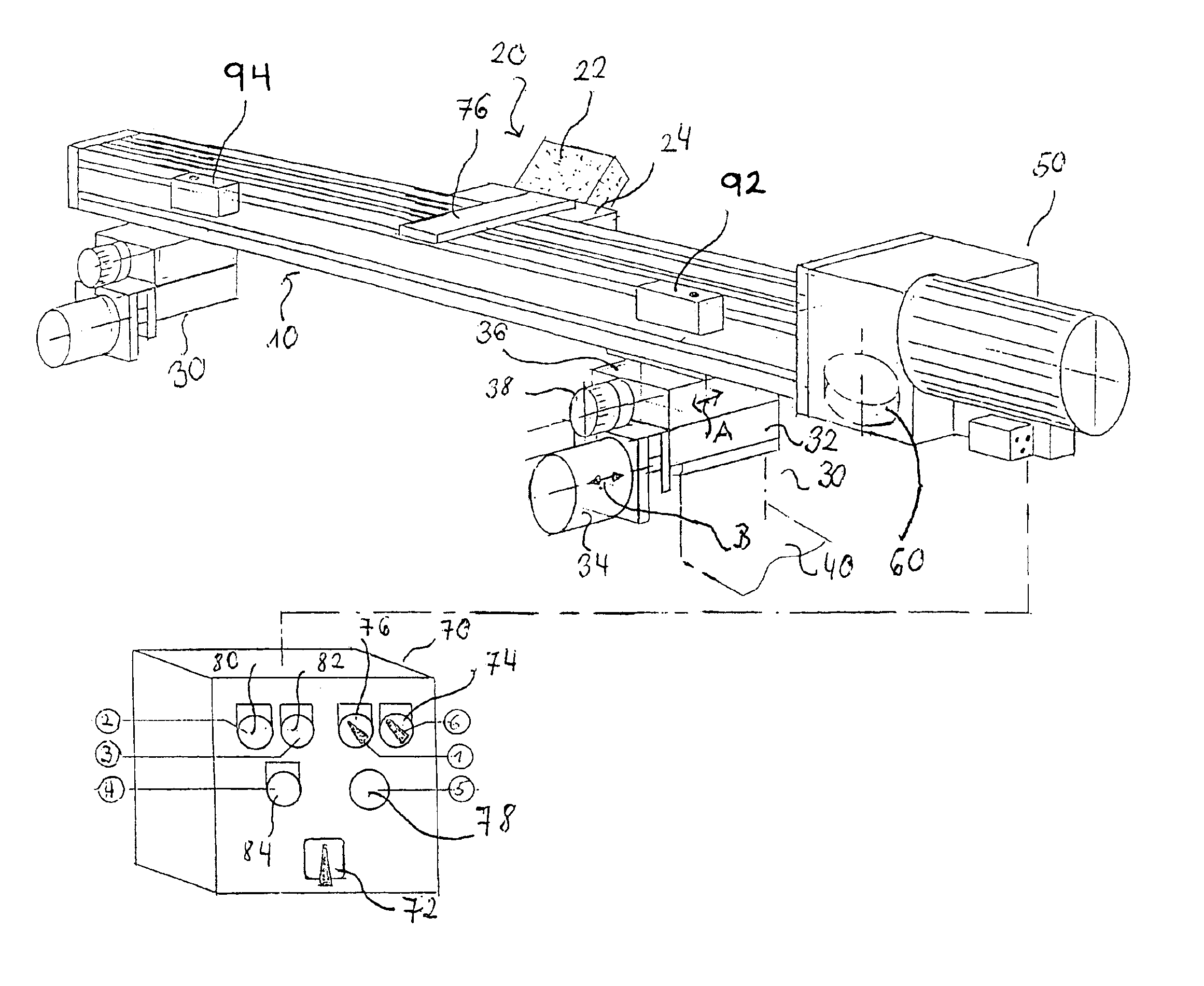

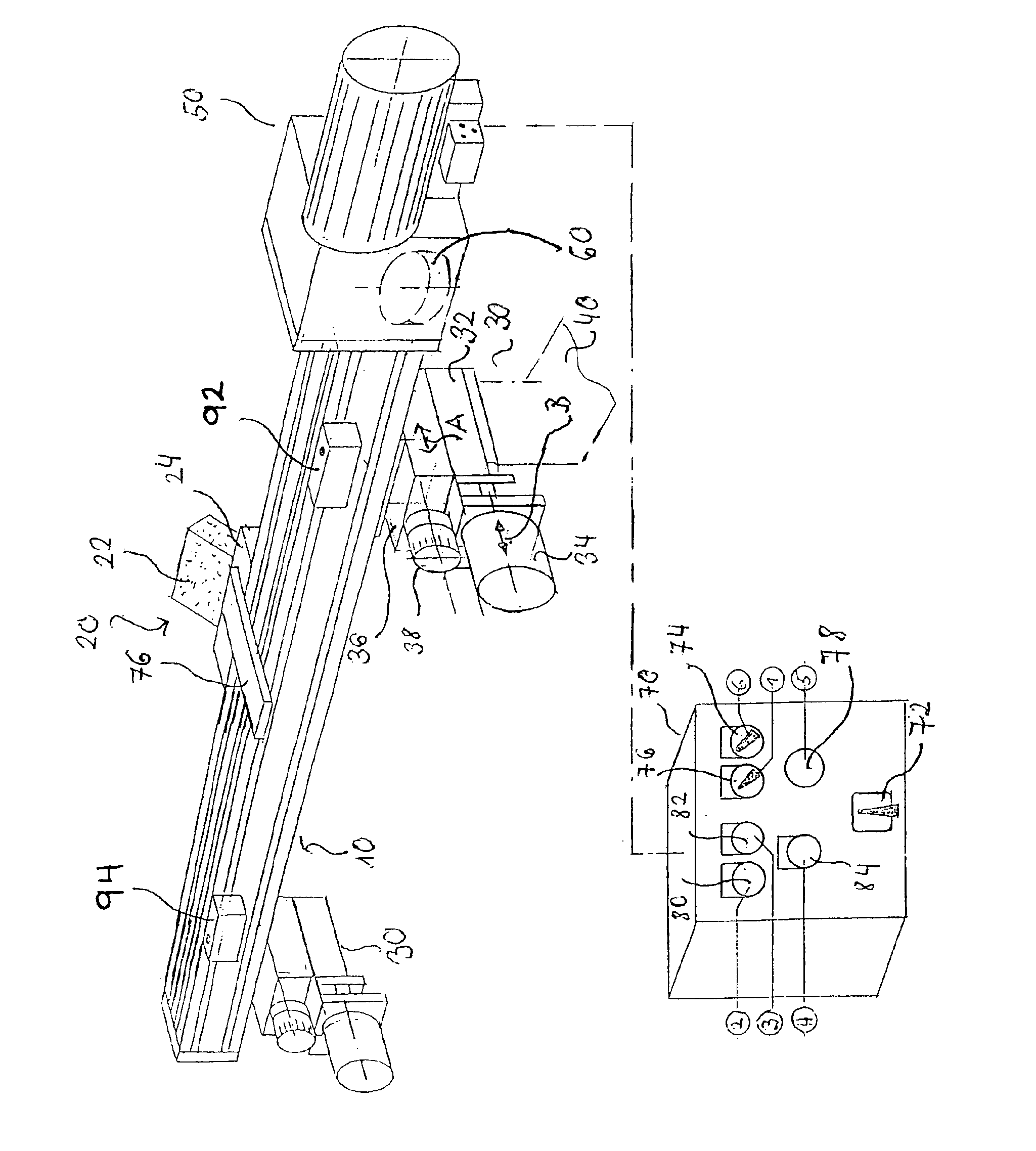

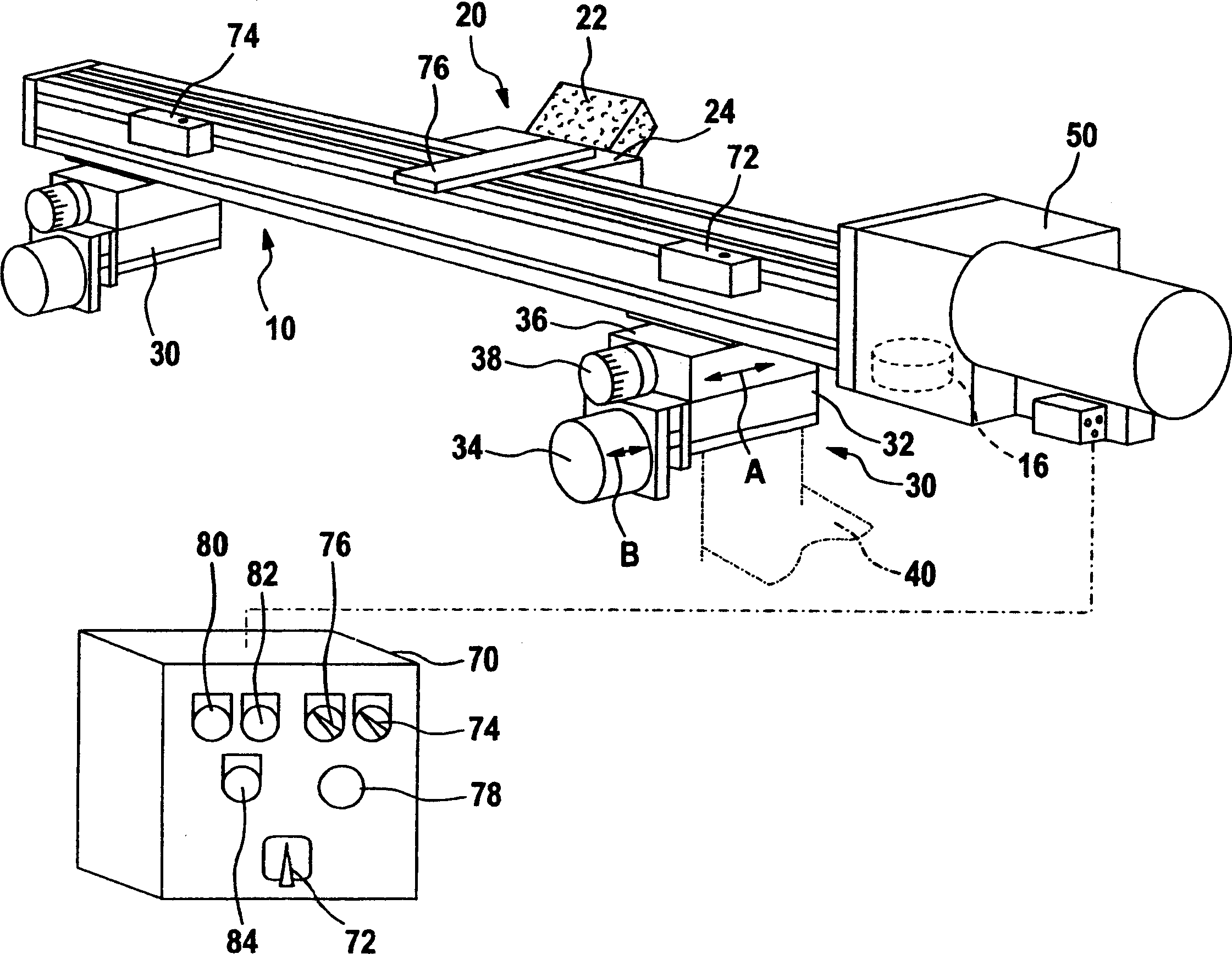

Device and methods for dressing card clothing

InactiveUS6863591B2Shorten dressing timeGuaranteed to workCarding machinesPlane surface grinding machinesRemote controlEngineering

A device for dressing a card clothing, especially an all-steel sawtooth clothing, drawn over a preferably cylindrical drum, with a dressing system that can be moved along a path predetermined by a guide element, so that at least one element of the dressing system can be advanced in a direction that runs transversely, especially perpendicularly, to the predetermined path. The device has a remote-controlled advancing mechanism for advancing the one or more elements of the dressing system.

Owner:GRAF CIE AG

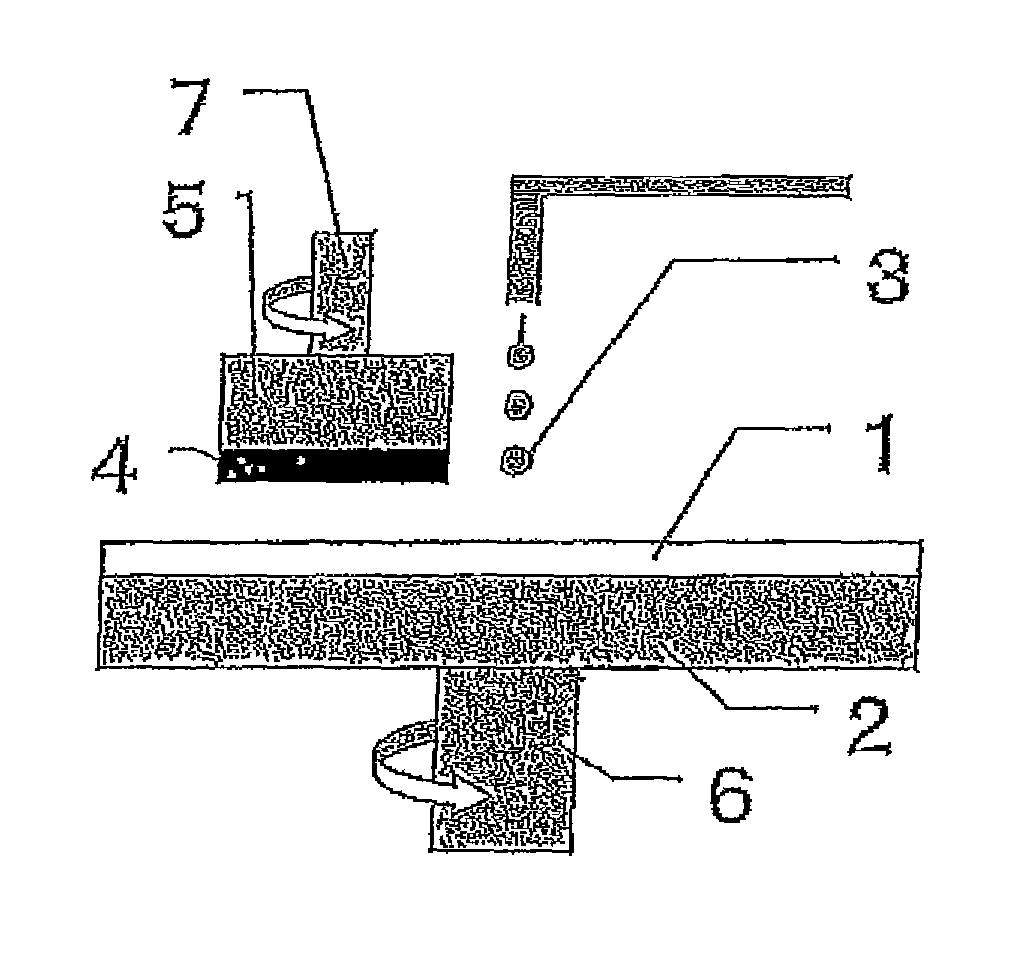

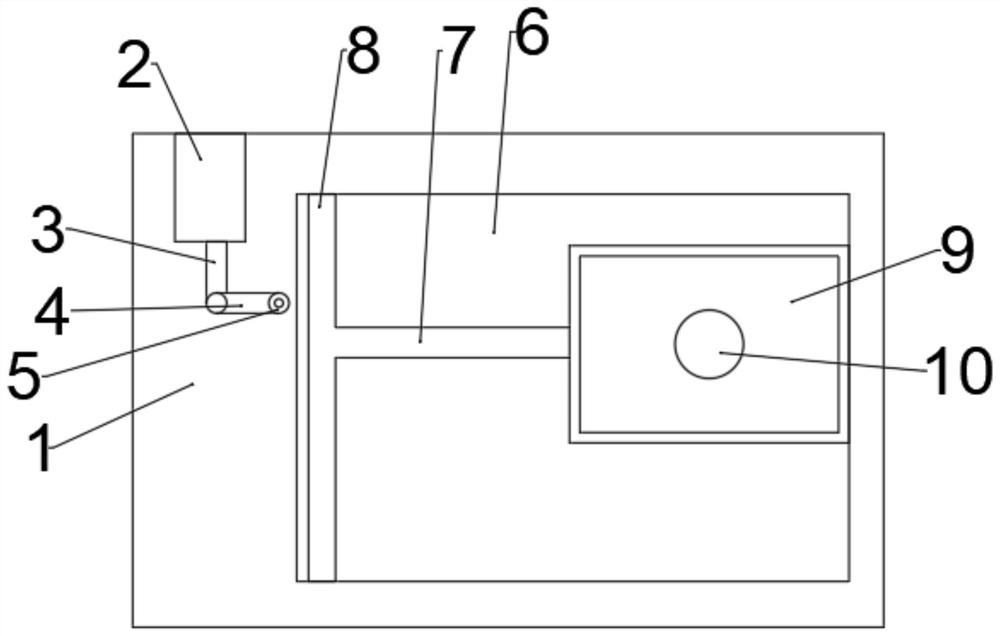

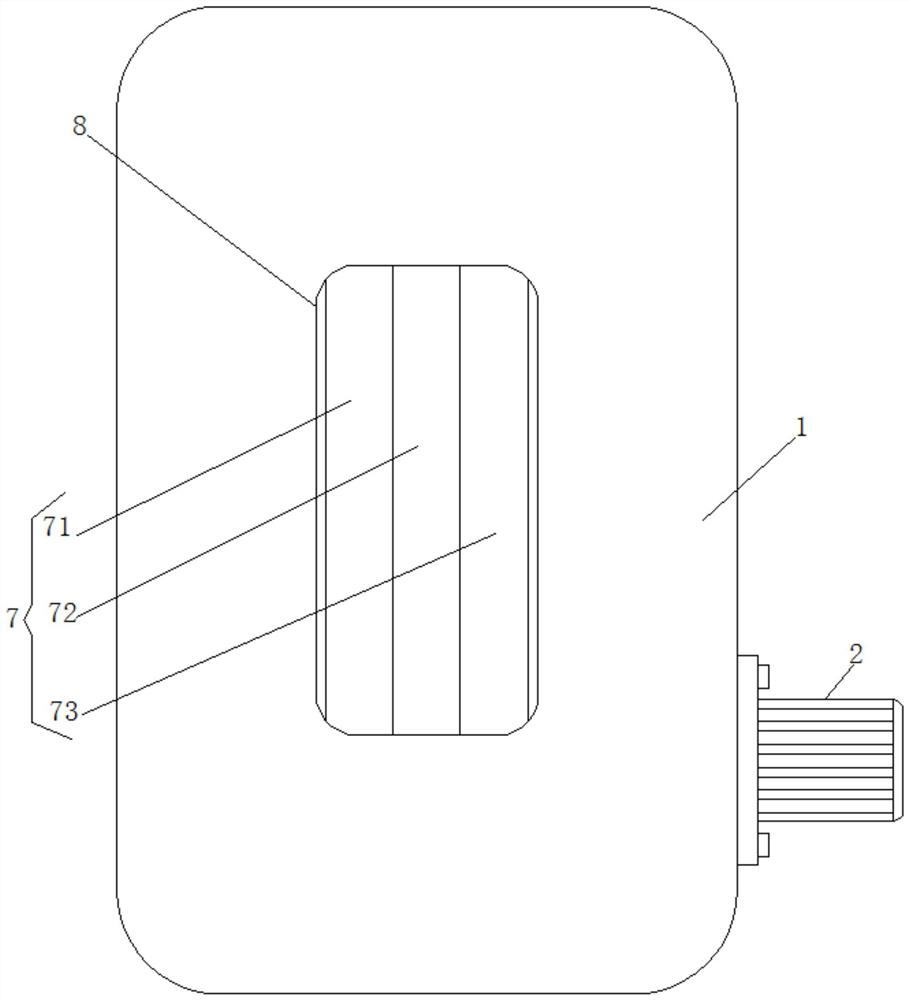

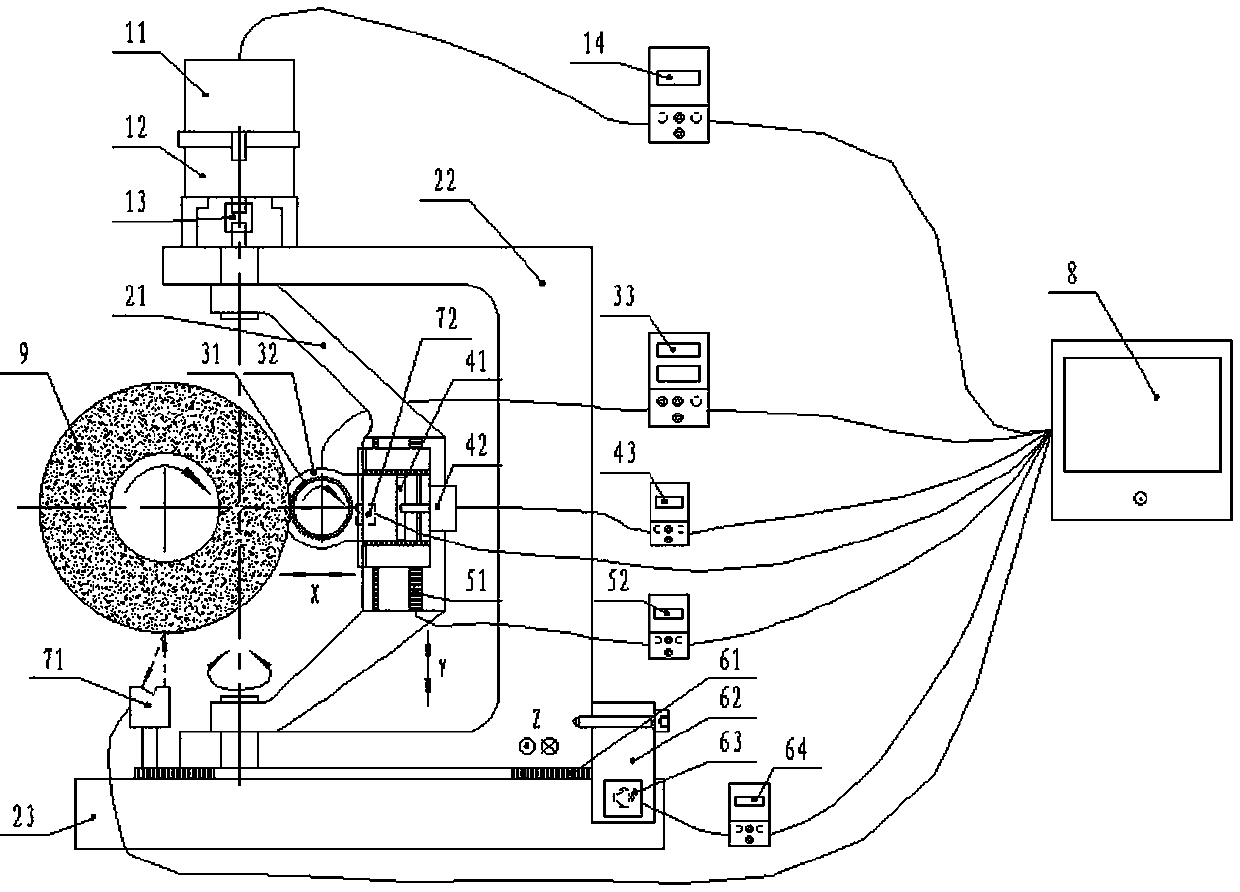

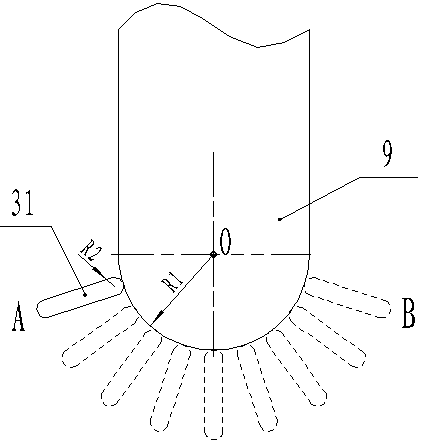

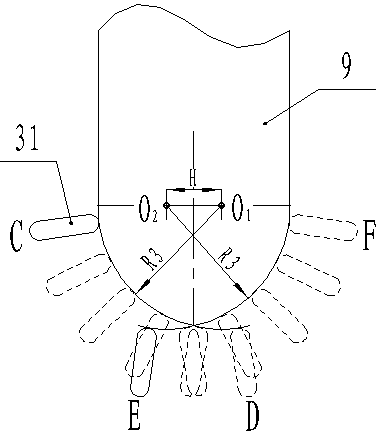

Groove grinding wheel profile automatic detection and regulation trimming device and method

ActiveCN110421486AHigh precisionImprove product qualityGrinding feed controlAbrasive surface conditioning devicesAnalytical controlEngineering

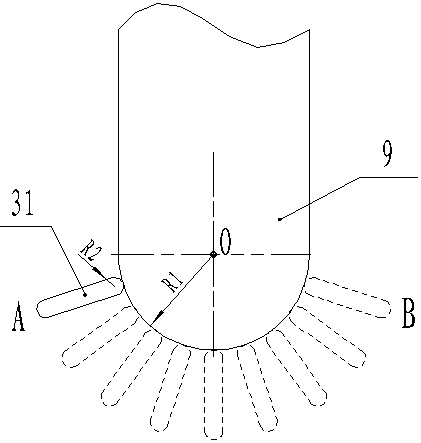

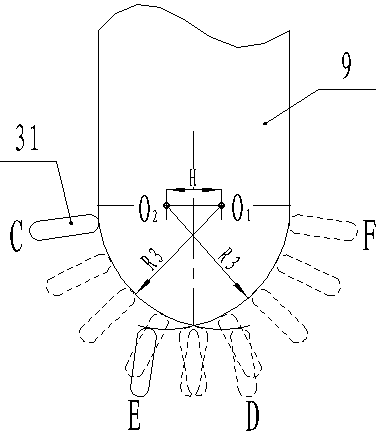

The invention discloses a groove grinding wheel profile automatic detection and regulation trimming device and method. The device comprises a C-shaped support frame, a swing trimming frame, a swing driving mechanism, a trimming tool assembly and an analysis controller, wherein the swing driving mechanism is used for providing rotary power for the swing trimming frame, and the analysis controller is connected with a displacement detection assembly used for detecting displacement and a displacement regulation assembly used for adjusting the movement of the trimming tool assembly in a controllingmode; the C-shaped support frame is erected on the outer side of the swing trimming frame, the swinging driving mechanism is arranged at the upper end of the C-shaped supporting frame, connecting mandrels of the upper end of the swinging trimming frame and the upper end of the swinging driving mechanism penetrate through a rotating hole of the upper end of the C-shaped supporting frame, and a connecting mandrel of the lower end of the swinging trimming frame penetrates through a rotating hole of the lower end of the C-shaped supporting frame. The profile of a grinding wheel is detected on line, the trimming process is regulated in real time according to detection results, the purpose of automatic trimming on the profile of the wheel grinding is achieved, the trimming time is saved, the trimming cost is reduced, and the efficiency is improved.

Owner:ZHENGZHOU RES INST FOR ABRASIVES & GRINDING CO LTD

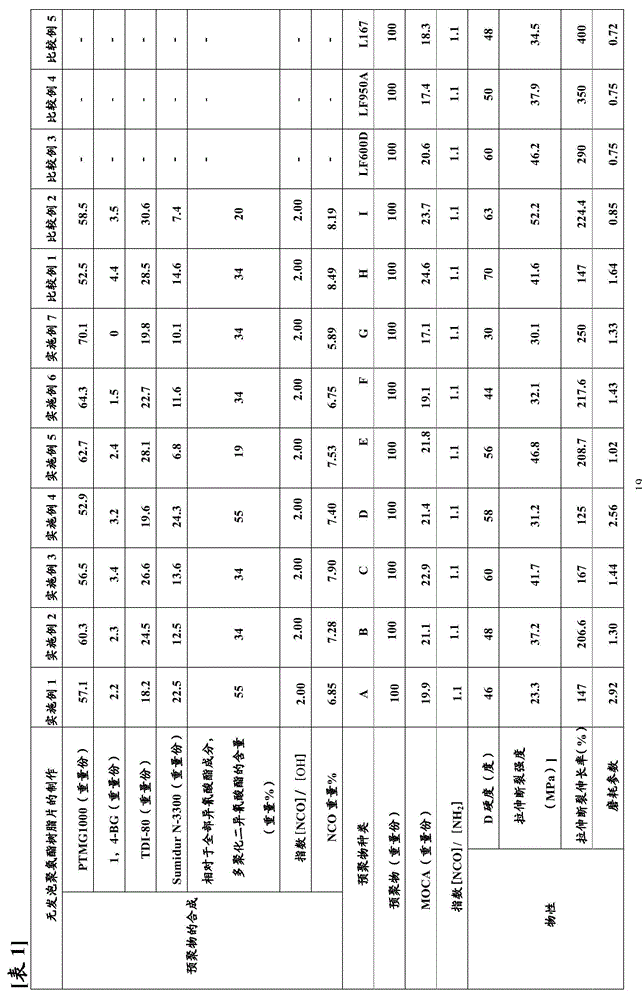

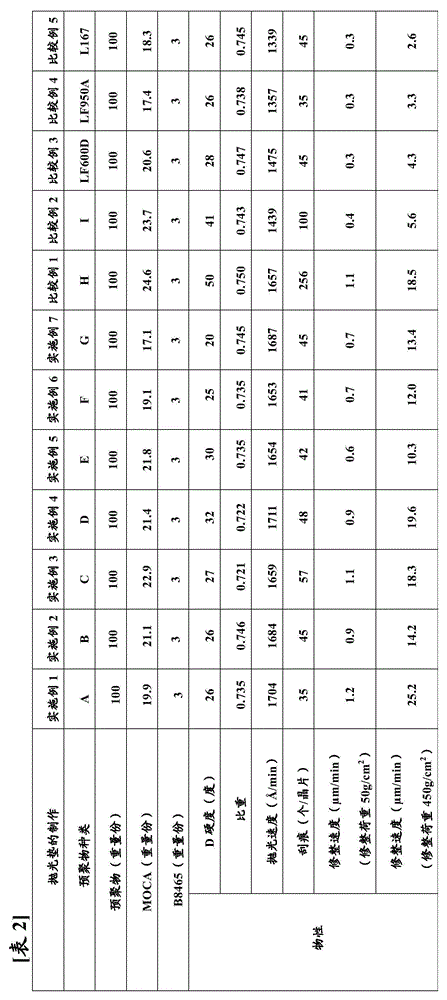

Polishing pad

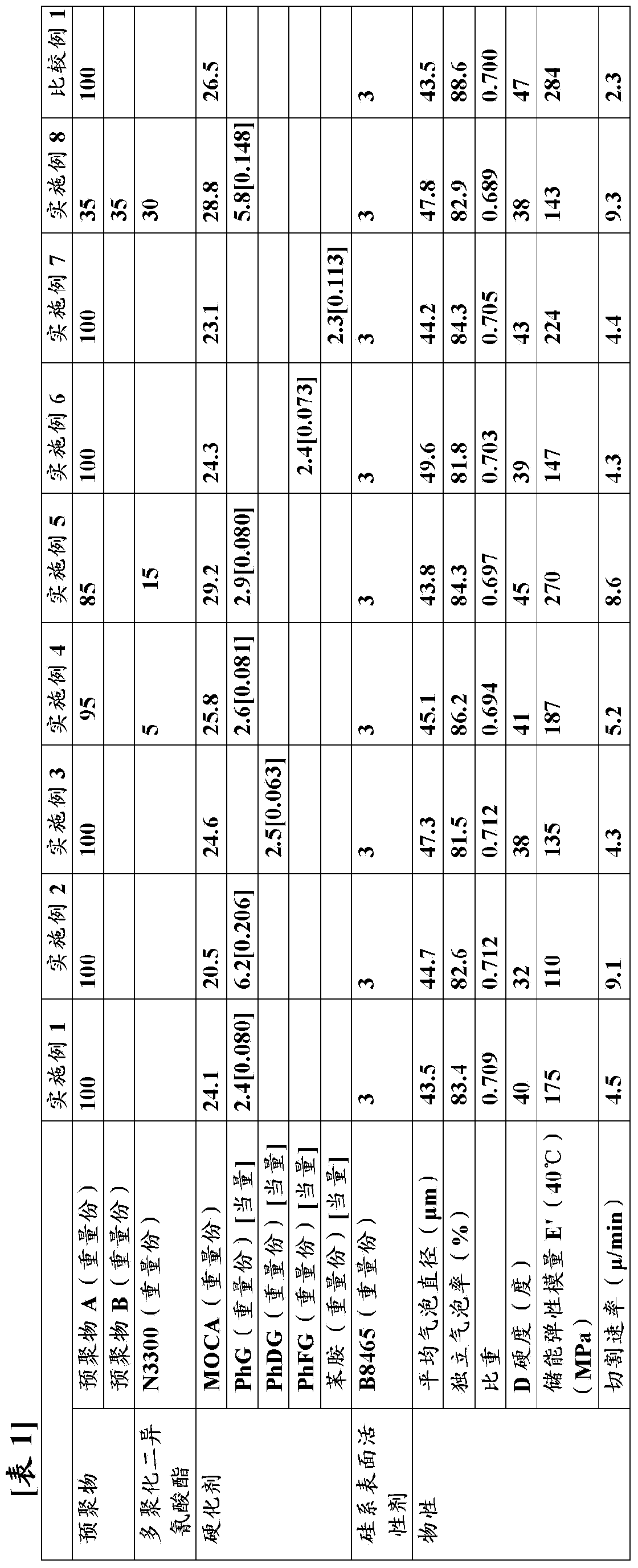

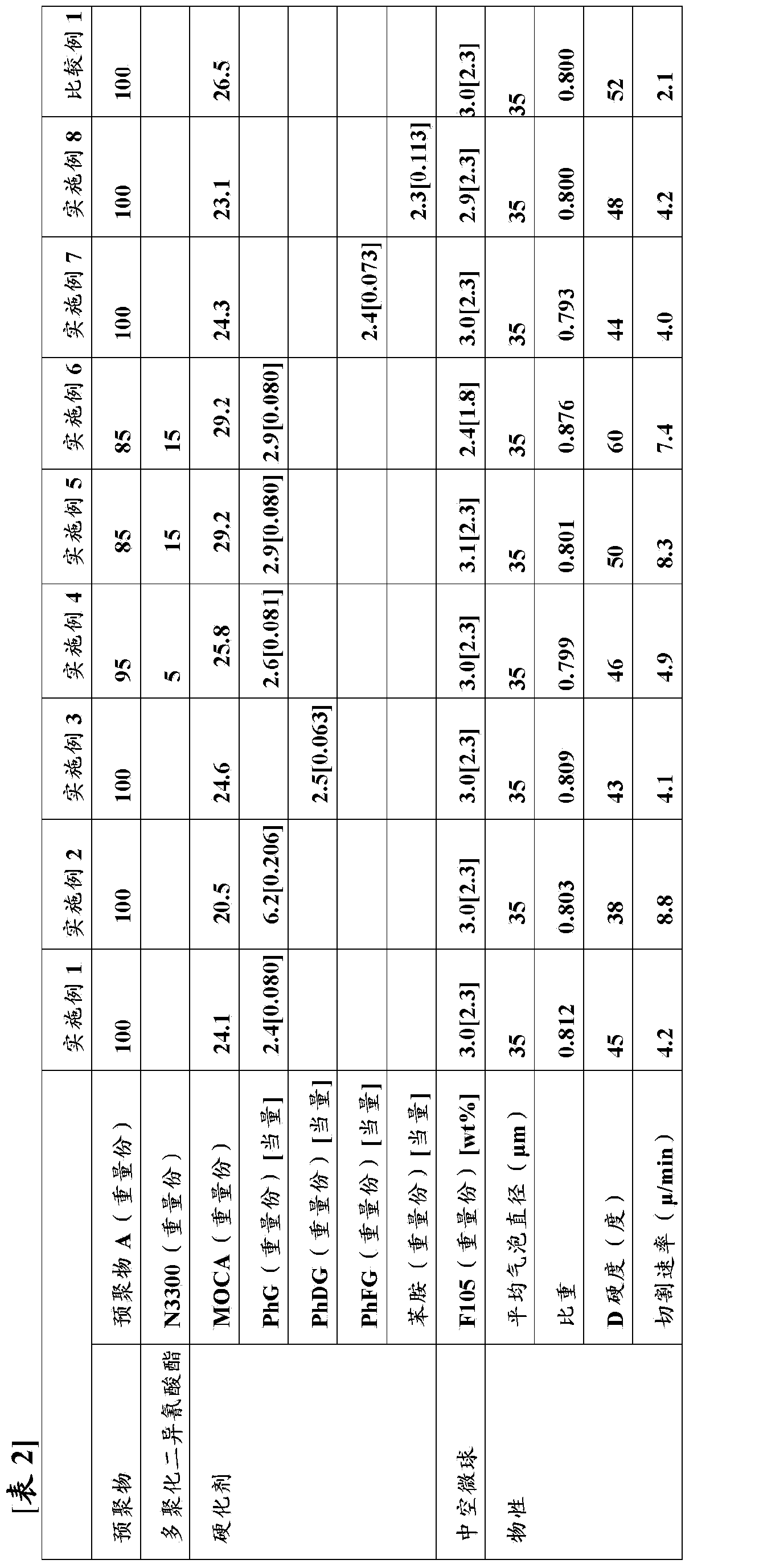

InactiveCN103958125ALow hardness and softLarge wear parametersAbrasion apparatusSemiconductor/solid-state device manufacturingBreaking strengthHardness

An aim of the present invention is to provide a polishing pad which generates almost no scratches on the surface of an object to be polished, and has improved dressability. Another aim of the present invention is to provide a semiconductor device manufacturing method using the polishing pad. The polishing pad according to the present invention comprises a polishing layer formed of a microbubble-containing polyurethane resin foam. The polyurethane resin foam contains a polyurethane resin whose asker D hardness is between 20 degrees and 60 degrees, and whose wear parameter, which is expressed by the following formula, is between 1 and 3. Wear parameter = {1 / (tensile breaking strength [MPa] tensile breaking elongation [%] / 100)} 100

Owner:ROHM & HAAS ELECTRONICS MATERIALS CMP HLDG INC

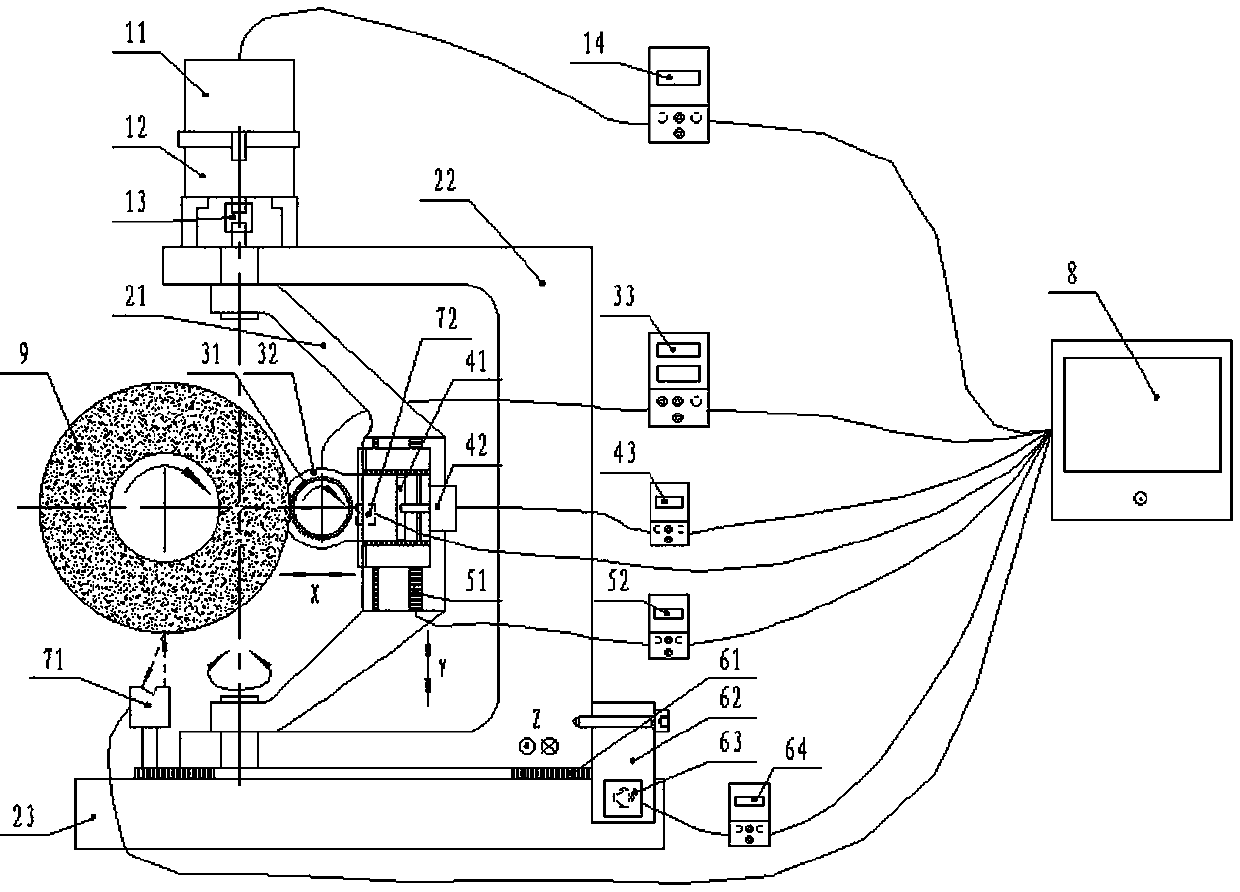

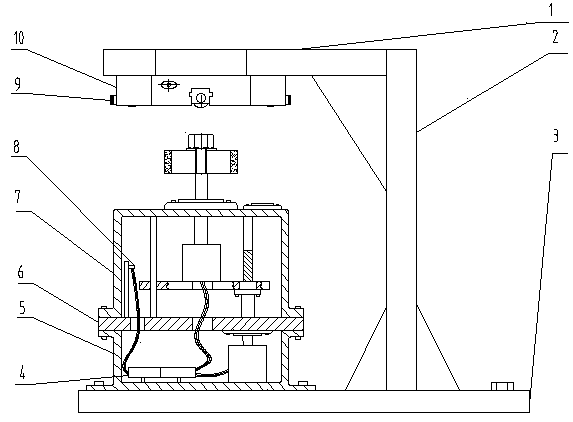

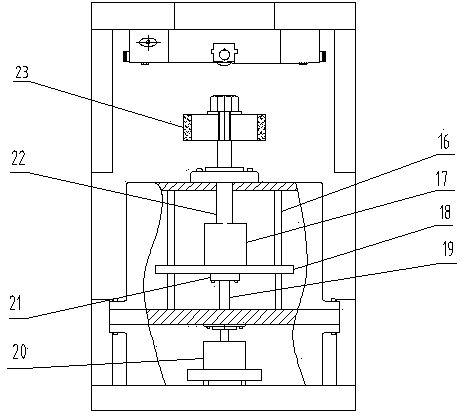

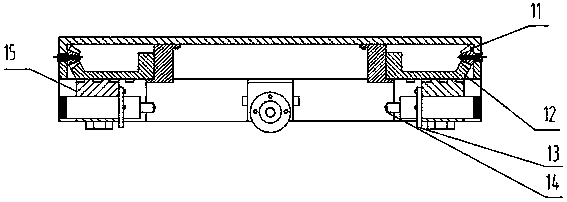

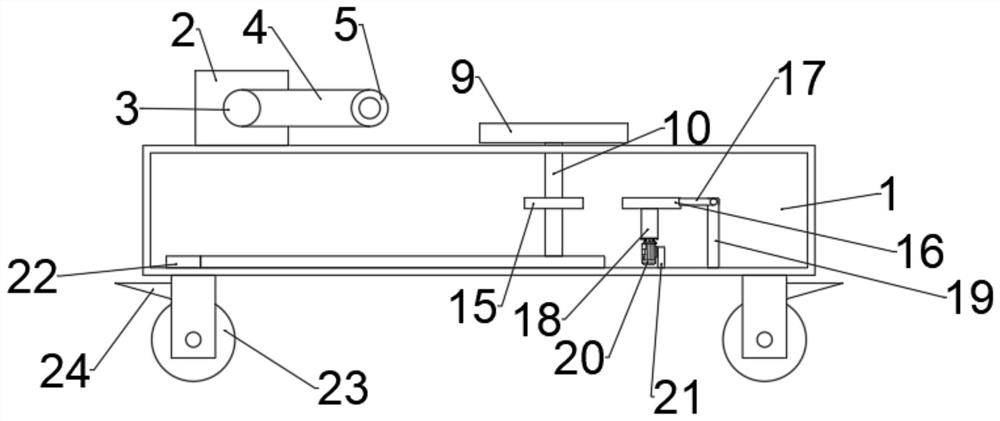

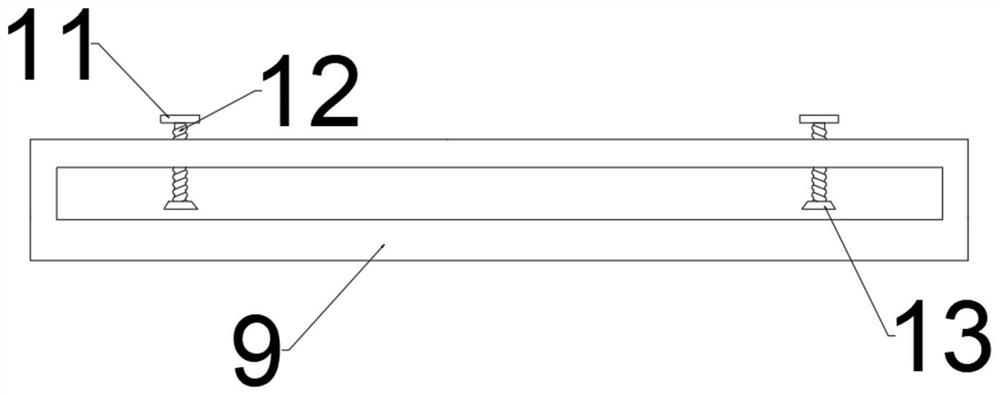

Automatic diamond grinding wheel trimming device

ActiveCN103962960AShorten dressing timeImprove processing efficiencyAbrasive surface conditioning devicesPhysicsDiamond grinding

The invention discloses an automatic diamond grinding wheel trimming device which is mainly composed of a working table, a chuck and a cylinder body. The chuck is fixed below an upper top plate of the working table and comprises a small bevel gear (11) and a big bevel gear (12) which are meshed with each other. The big bevel gear is connected with a sliding block (15). An energy converter (9), an amplitude-change pole (13) and a diamond stylus (14) are arranged on the sliding block. The energy converter is connected with an ultrasonic generator. A ball screw penetrates through a fixed supporting plate to be connected with a servo motor. A guide shaft penetrates through a movable supporting plate to be connected with an upper cylinder body and the fixed supporting plate. A three-phase asynchronous motor is connected with a grinding wheel (23) through a main shaft. One end of a circuit board is connected with a proximity switch, and the other end of the circuit board is respectively connected with the servo motor and the three-phase asynchronous motor. By means of the automatic diamond grinding wheel trimming device, ultrasonic elliptic vibration of the diamond stylus can be achieved, machining efficiency and machining accuracy of the grinding wheel are improved, rigidity and stability of a cutting system are enhanced, the service life of the diamond stylus can be prolonged, and the automatic diamond grinding wheel trimming device is relatively suitable for trimming grinding wheels made of hard materials.

Owner:CONPROFE TECH GRP CO LTD +1

Polishing pad

InactiveCN103764346AImprove trimming effectImprove production efficiencySemiconductor/solid-state device manufacturingLapping machinesPolyolHardness

Owner:ROHM & HAAS ELECTRONICS MATERIALS CMP HLDG INC

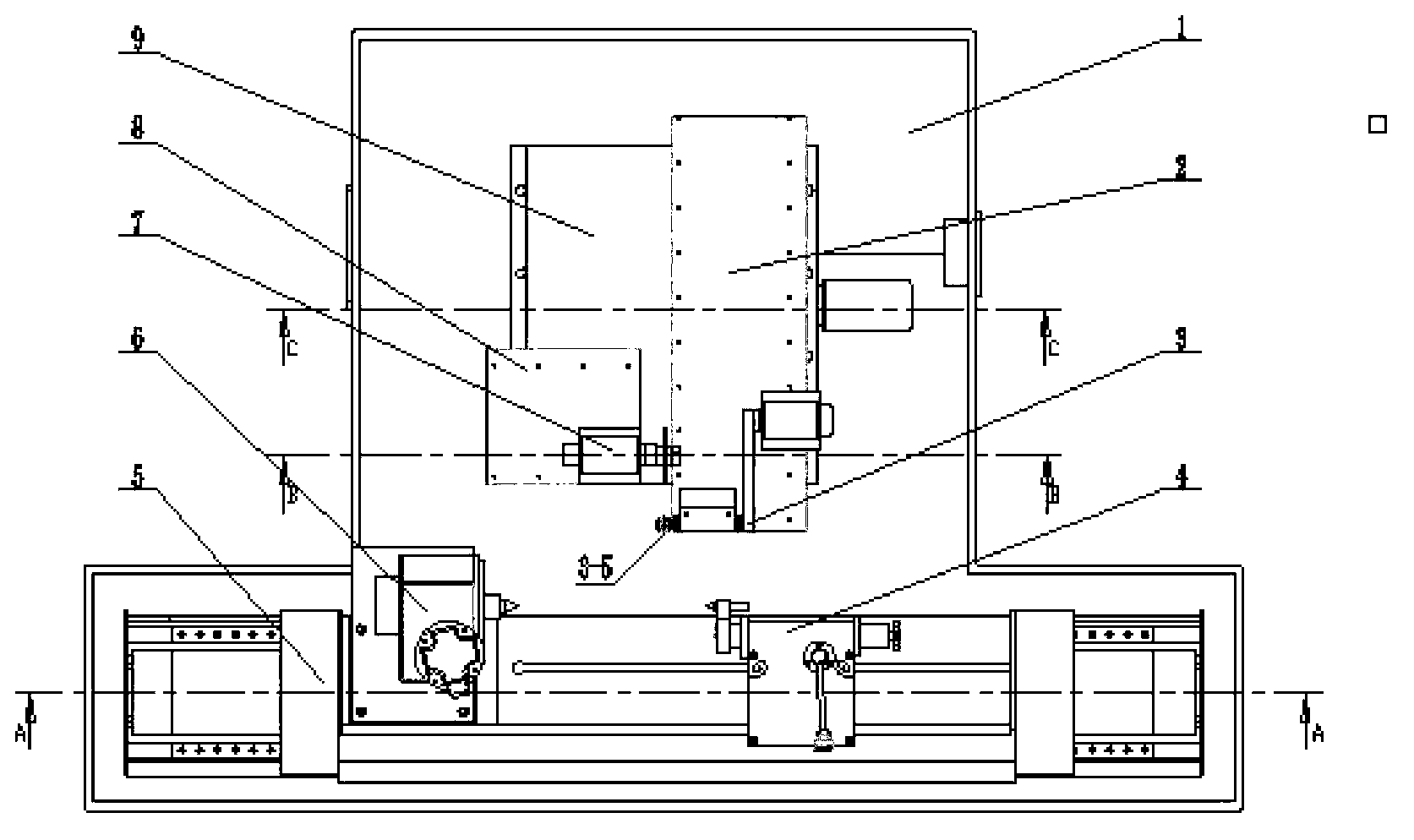

Numerical-control relief grinding machine

InactiveCN103286687AAchieve movementImprove accuracyGrinding drivesAbrasive surface conditioning devicesNumerical controlGrating

The invention discloses a numerical-control relief grinding machine, and relates to the field of numerical-control machining equipment. A Z-direction moving device and a rotating worktable are arranged on a machine body of the numerical-control relief grinding machine, and an X-direction moving device and a Y-direction moving device are arranged on the rotating worktable and can rotate along with the rotation of the rotating worktable. According to the numerical-control relief grinding machine, the Z-direction moving device, the X-direction moving device and the Y-direction moving device are driven by a linear motor, and the linear motor is matched with an optical grating to position the movement of the moving devices, and therefore the accuracy of movement is improved. An indexing component is provided with a round optical grating to form a closed loop to accurately position the rotary movement. The numerical-control relief grinding machine adopts the direct-driving motor technology and the closed loop control technology to reduce the movement errors generated in the moving process of the machine, and shortens the time for relief grinding correction.

Owner:WUXI TAINUO TOOL

Polishing pad

ActiveUS20140378031A1Improve dress propertyImprove productionSemiconductor/solid-state device manufacturingLapping machinesIsocyanateChemistry

The purpose of the present invention is to provide: a polishing pad which has improved dressing properties, while maintaining the hardness; or a polishing pad which does not easily make a scratch on the surface of an object to be polished, while having improved dressing properties. A polishing pad of the present invention is characterized by having a polishing layer that is formed of a polyurethane resin foam or an unfoamed polyurethane resin, and is also characterized in that the polyurethane resin foam or the unfoamed polyurethane resin contains, as starting material components, (A) an isocyanate component, (B) a polyol component and (C) an aromatic compound that has one hydroxyl group and / or an aromatic compound that has one amino group.

Owner:ROHM & HAAS ELECTRONICS MATERIALS CMP HLDG INC

Apparatus and method for trimming card clothing

InactiveCN1508305ANo harmShorten dressing timeCarding machinesGrinding machinesRemote controlMechanical engineering

A device for dressing a card clothing, especially an all-steel sawtooth clothing, drawn over a preferably cylindrical drum, with a dressing system that can be moved along a path predetermined by a guide element, so that at least one element of the dressing system can be advanced in a direction that runs transversely, especially perpendicularly, to the predetermined path. The device has a remote-controlled advancing mechanism for advancing the one or more elements of the dressing system.

Owner:GROB & CO AG

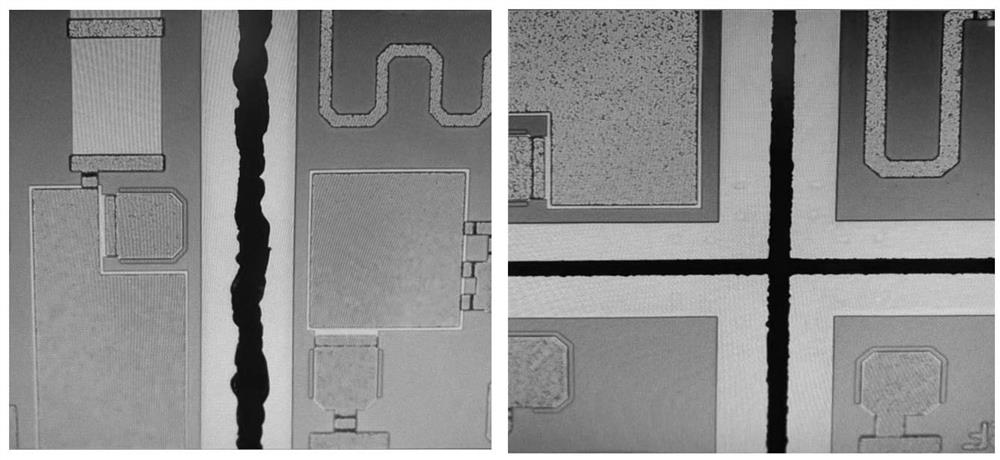

Dicing knife trimming method for gallium arsenide wafer

InactiveCN111633479AShorten dressing timeReduce positive collapseGrinding drivesOther manufacturing equipments/toolsGallium arsenateEngineering

The invention discloses a dicing knife trimming method for a gallium arsenide wafer. The method comprises the steps that S1, a sharpening plate is fixed, and a dicing knife is mounted; S2, knife sharpening is performed, as the number of sharpening the knife increases, the depth of cutting into the sharpening plate is gradually increased, the feeding speed is gradually increased, and a total of 20-40 cuts is carried out; S3, a gallium arsenide dummy is fixed; S4, sharpening is carried out, the depth of cutting into the gallium arsenide dummy gradually increases along with the increase of the number of sharpening the knife, the feeding speed is gradually increased, and a total of 20-50 cuts is carried out; and S5, cutting quality test is carried out, the seam width and the positive disintegration size are measured, if both the seam width and the positive disintegration size meet the requirements, trimming is completed; and if the seam width or the positive disintegration size exceeds thequality requirements, rework or scrapping is carried out. It is ensured that the dicing knife has good initial cutting quality, and after the 100% cutting performance test is added, the cutting quality is more stable on a customer site.

Owner:ZHENGZHOU RES INST FOR ABRASIVES & GRINDING CO LTD

Method for quickly dressing grinding wheel

ActiveCN104476400AShorten dressing timeGuaranteed flatnessAbrasive surface conditioning devicesMicrometerSingle crystal

The invention discloses a method for quickly dressing a grinding wheel. The method for quickly dressing the grinding wheel includes steps that (1) fixing the grinding wheel to be dressed; (2) setting an initial point; (3) dressing the cup-shaped grinding wheel; (4) finishing dressing the cup-shaped grinding wheel. The method for quickly dressing the grinding wheel is capable of greatly reducing the cup-shaped grinding wheel dressing time, the cup-shaped grinding wheel dressing time is reduced to 20 minutes from the original dressing time of 4 hours, and the single equipment capacity is improved by 7.4% per day; because the change of the cup-shaped grinding wheel dressing mode enables the inner edge of a grinding wheel blade to be flat, the different sizes due to the rugged diagonal line are avoided, and the single crystal size fluctuation of an SiS156G Okamoto integrated machine is reduced; the flatness of the cup-shaped grinding wheel is guaranteed, and the error between the highest point and lowest point of the cup-shaped grinding wheel is smaller than 50 micrometers.

Owner:TIANJIN ZHONGHUAN SEMICON CO LTD

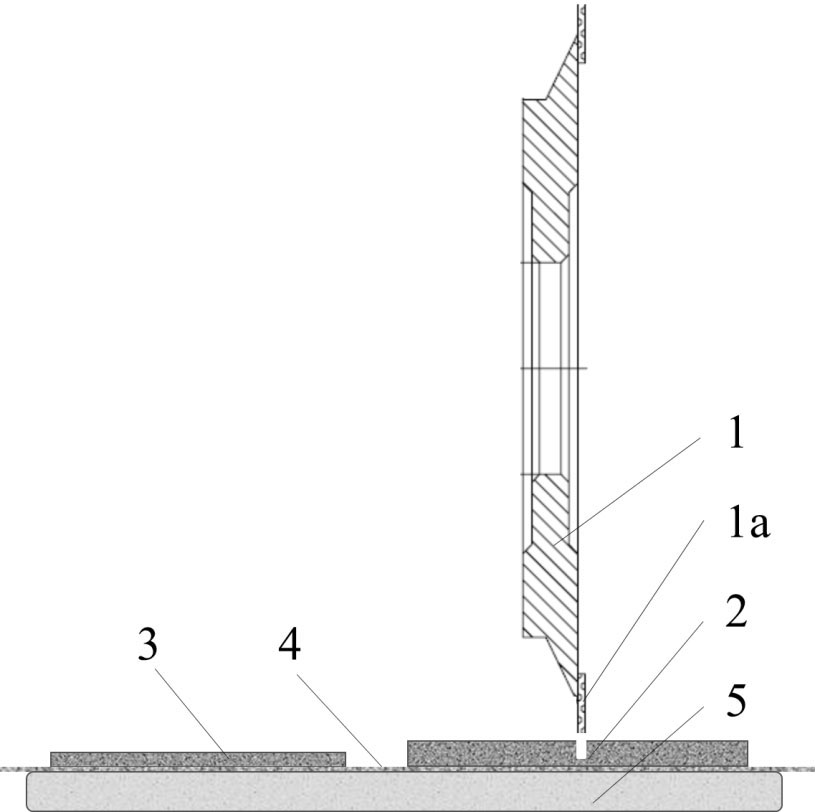

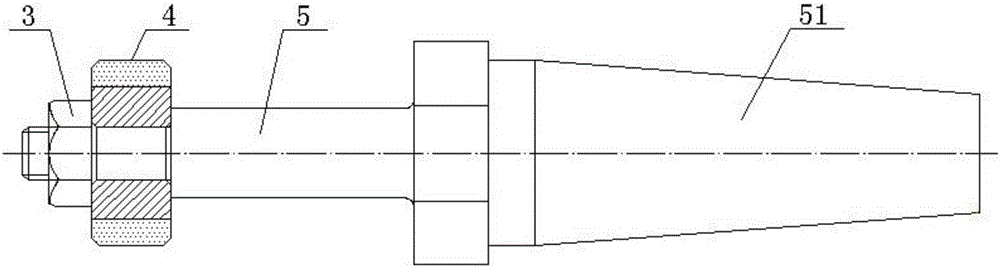

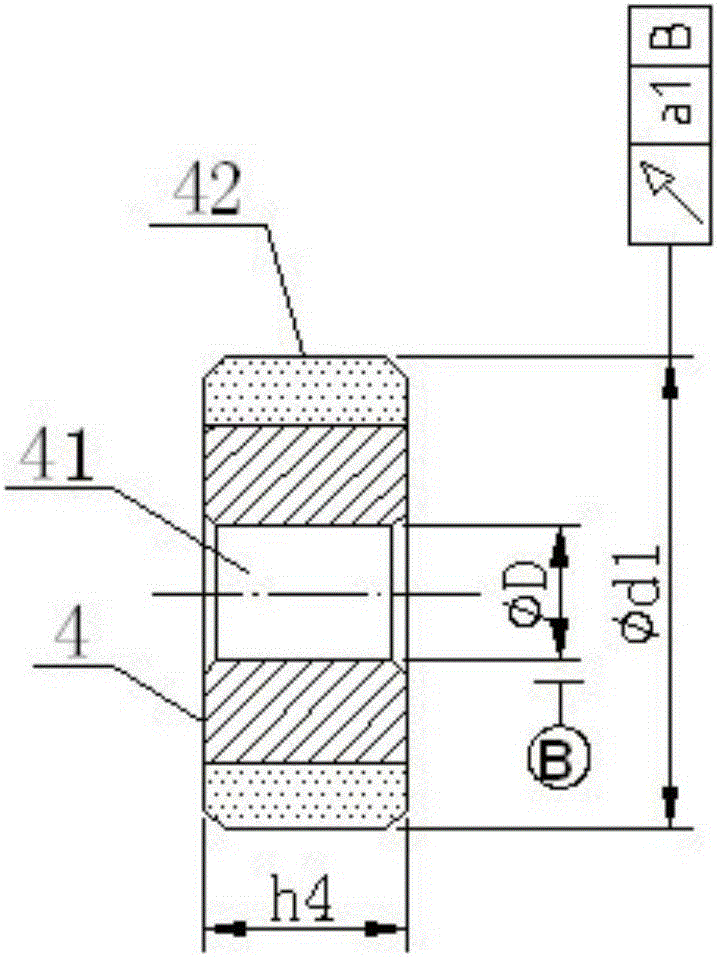

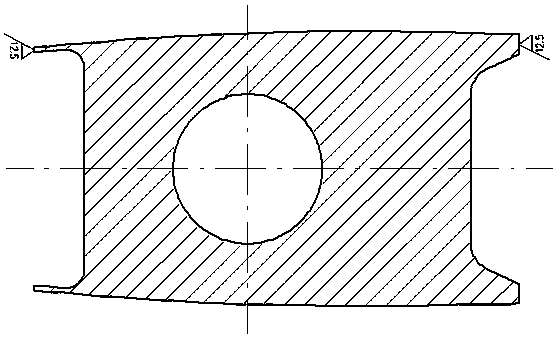

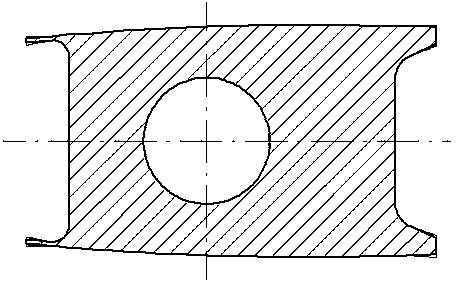

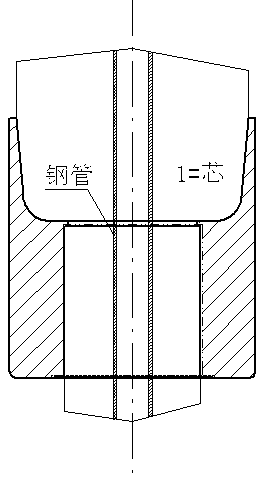

Machining device and machining method of forming hole

InactiveCN105171543AImprove processing productivityImprove pass rateGrinding wheel securing apparatusRevolution surface grinding machinesInterference fitEngineering

The invention provides a machining device and method of a forming hole. The machining device comprises a grinding wheel (4) and a grinding wheel rod (5), wherein the grinding wheel (4) is fixedly connected with a grinding wheel mounting part (52) at one end of the grinding wheel rod (5); a grinding wheel mounting hole (41) in the grinding wheel (4) is in interference fit with the grinding wheel mounting part (52) on the grinding wheel rod (5); the other end of the grinding wheel rod (5) is provided with a grinding wheel rod clamping part (51); the axial width of the grinding wheel (4) is smaller than the axial width of the forming hole; the diameter tolerance of the grinding wheel mounting hole (41) is 0-0.01 mm; and the diameter tolerance of the grinding wheel mounting part (52) is 0.01-0.02. When the machining device is used for grinding the forming hole, the machining of the forming hole by a longitudinal reciprocating and transverse feeding grinding mode can be realized, so that a lot of grinding wheel finishing time and grinding tool setting time are saved, and the machining productivity of the forming hole is greatly improved.

Owner:自贡中兴耐磨新材料有限公司

Numerical control relief-grinding machine

InactiveCN105290887AAchieve movementImprove accuracyGrinding drivesMilling cuttersNumerical controlClosed loop

The invention discloses a numerical control relief-grinding machine and relates to the field of numerical control machining equipment. A machine body of the numerical control relief-grinding machine is provided with a Z-direction movement device and a rotary workbench. The rotary workbench is provided with an X-direction movement device and a Y-direction movement device, and the X-direction movement device and the Y-direction movement device can rotate along with the rotation of the rotary workbench. According to the numerical control relief-grinding machine, the Z-direction movement device, the X-direction movement device and the Y-direction movement device are driven by linear motors and locate movement in coordination with rasters, so that the accuracy of movement is improved. An indexing component is provided with a circular raster, and a closed loop is formed to accurately locate rotational movement. According to the numerical control relief-grinding machine, the direct driving motor technology and the closed loop control technology are adopted to reduce kinematic errors generated in the movement process of the machine and shorten the relief-grinding dressing time.

Owner:CHONGQING DACHENG GRACE NC TECH CO LTD

Polishing pad

ActiveUS9079289B2Improved dressing propertyIncrease productivitySemiconductor/solid-state device manufacturingLapping machinesHardnessChemistry

The purpose of the present invention is to provide: a polishing pad which has improved dressing properties, while maintaining the hardness; or a polishing pad which does not easily make a scratch on the surface of an object to be polished, while having improved dressing properties. A polishing pad of the present invention is characterized by having a polishing layer that is formed of a polyurethane resin foam or an unfoamed polyurethane resin, and is also characterized in that the polyurethane resin foam or the unfoamed polyurethane resin contains, as starting material components, (A) an isocyanate component, (B) a polyol component and (C) an aromatic compound that has one hydroxyl group and / or an aromatic compound that has one amino group.

Owner:ROHM & HAAS ELECTRONICS MATERIALS CMP HLDG INC

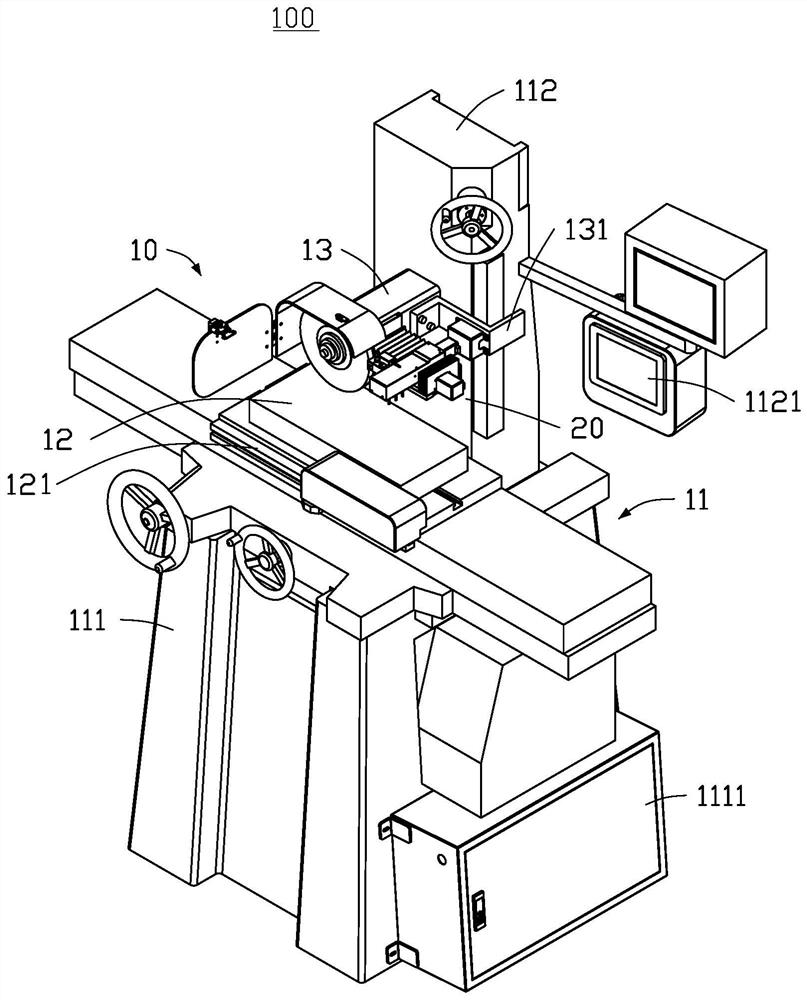

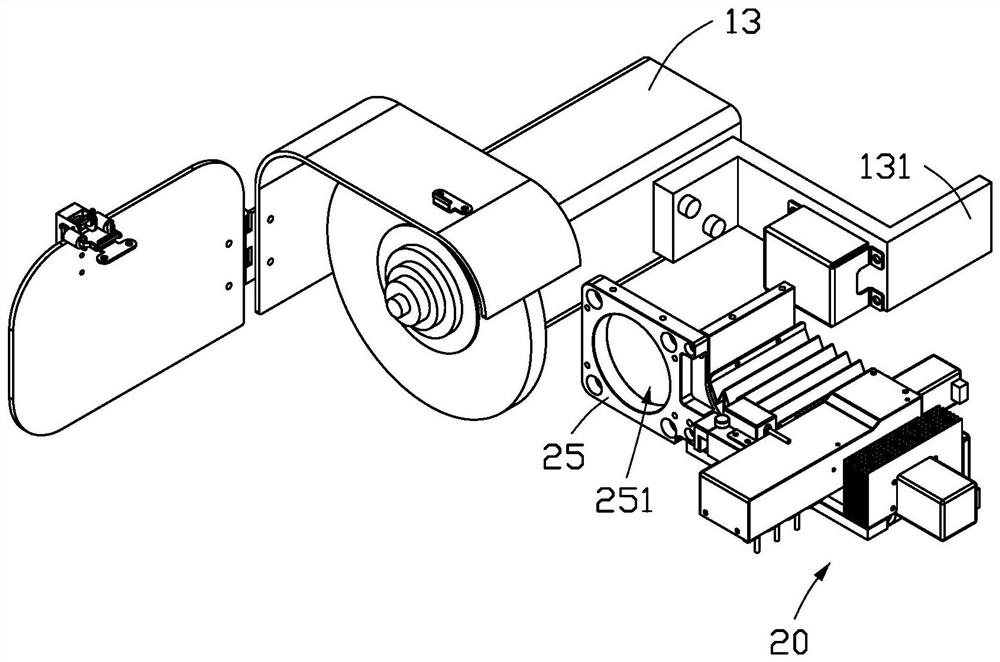

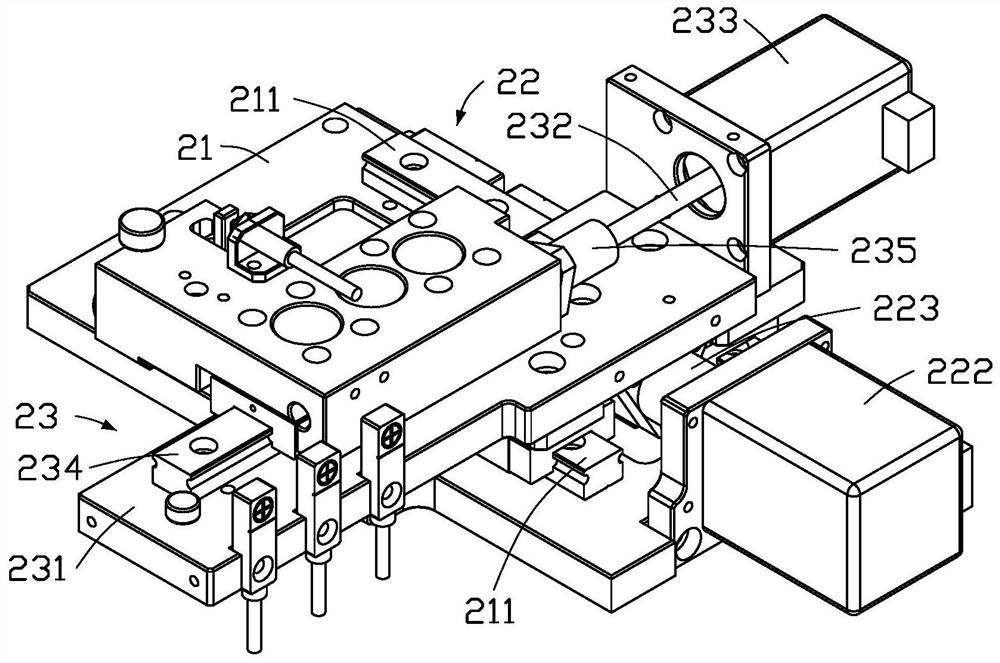

Grinding wheel dressing device, control system and control method

PendingCN113492360AShorten dressing timeAccurately control the dressing amountAbrasive surface conditioning devicesNumerical controlControl systemGrinding wheel

The invention discloses a grinding wheel dressing device. The grinding wheel dressing device comprises a rotating device, a main body, a first sliding mechanism, a second sliding mechanism and a repairing mechanism, the rotating device is fixed to one side of the main body and used for fixing and driving a grinding wheel to rotate, the first sliding mechanism is arranged on the main body, the second sliding mechanism is arranged on the first sliding mechanism in a sliding mode, the repairing mechanism comprises a sliding seat, a detection contact and a repairing cutter, the detection contact and the repairing tool are arranged on the sliding seat, the sliding seat is arranged on the second sliding mechanism in a sliding mode, the detection contact is used for detecting the diameter and the position of the grinding wheel, and the first sliding mechanism and the second sliding mechanism drive the repairing cutter to move to the detected position of the grinding wheel to trim the grinding wheel. According to the grinding wheel dressing device, dressing time is shortened, efficiency is improved, the system and set parameters of a rough dressing grinding wheel and a fine dressing grinding wheel are controlled, the dressing amount of the grinding wheel is accurately controlled through the control method, the cutting amount of the grinding wheel is effectively reduced, and materials are saved.

Owner:FU TAI HUA IND SHENZHEN

Method for fire polishing of rhinestone pearl blank by means of composite powder medium

ActiveCN105382673AImproved roundness and efficiencyShorten dressing timeEdge grinding machinesPolishing machinesMetal cylinderFiber

The invention discloses a method for fire polishing of a rhinestone pearl blank by means of a composite powder medium, and belongs to the technical field of rhinestone pearl blank machining. The method comprises the step that the composite powder medium and the rhinestone pearl blank are added into a rotary metal cylinder after being evenly mixed and are heated and subjected to fire polishing, wherein the composite powder medium comprises graphite powder and inorganic powder, and the weight ratio of the graphite powder to the inorganic powder to the rhinestone pearl blank is (1-4):(1-6):(93-96). According to the method for fiber polishing of the rhinestone pearl blank by means of the composite powder medium, the fire polishing circular degree and efficiency of the rhinestone pearl blank can be improved, the rhinestone spheroidizing and finishing time can be shortened, the working efficiency of a fire polishing furnace can be improved, meanwhile, the composite powder medium can be recycled, graphite powder oxidation consumption can be reduced, the production environment can be improved, and the spheroidized rhinestone pearl blank can be easy to clean.

Owner:YANCHENG INST OF TECH

Process design method of upper casting for large ship

InactiveCN111390106AImprove product qualityEliminate stomatal defectsFoundry mouldsFoundry coresPipeRudder

The invention discloses a process design method of an upper casting for a large ship, which is formed by optimizing on the basis of an existing process. The process design method comprises the following steps that (1), the linear shrinkage is selected as 1.8%-2.0%; (2), cutter leveling is additionally carried out a rib plate of a welding steel plate making contact with a ship body; (3), a processcorrection amount is added to the rib plate; (4), an air exhaust steel pipe is horizontally placed in the middle of a loam core, straw ropes are wound outside peripheral cutting holes, and a wood realsample is subjected to pattern draft according to a ratio of 1:20; (5), a riser is designed by adopting a hot pitch circle method, and spot casting is carried out at the riser; (6), upper and lower middle surfaces are selected as parting surfaces; (7), sand-hanging external chill is horizontally placed on the back surface of the riser; and (8), proper wrapping holes and quantity are selected according to gross weight and maximum height of the casting. By the adoption of the process design method, the casting quality of the upper casting can be guaranteed, the using requirement of a shipyard is met, meanwhile, the production efficiency is improved, the production cost is reduced, and the process design method is suitable for lower castings, upper and lower rudder knobs, rudder stock bearings and dumb braces.

Owner:石钢京诚装备技术有限公司

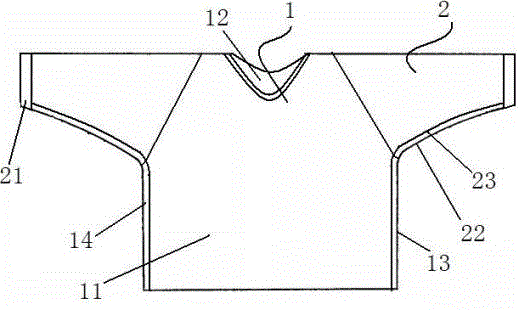

Upper garment for infant and convenient to wear

InactiveCN105533835AEasy to dressThe process of wearing clothes is comfortableGarmentsBaby linensEngineeringCuff

The invention discloses an upper garment for an infant and convenient to wear. The upper garment comprises an upper garment body and sleeves, wherein the sleeves are connected to the upper garment body, the upper garment body comprises a front piece and a back piece, the waist side seams of the front piece and the back piece are not sewn, an elastic ring is arranged on the cuff of each sleeve, the sleeve seam, from the elastic ring to the oxter, of the sleeve is not sewn, each waist side seam is spliced and closed through a splicing tape I, each sleeve seam is spliced and closed through a splicing tape II, and the distance between the front end edge of the elastic ring to the front end edge of the splicing tape I is 0.5-3 cm. According to the upper garment, due to the arrangement of the waist side seams and the sleeve seams, when the infant wears the upper garment, only the head of the infant needs to extend into and be sleeved by the upper garment, the whole wearing process is completed by splicing the splicing tapes I and the splicing tapes II through hands, and the arms of the infant do not need to be bent, therefore, the wearing time is shortened, and the wearing process is relatively comfortable; due to the arrangement of the elastic rings, the splicing tapes I can not be pulled open when the infant pulls the sleeves, therefore, the heat retention property is good, and the infant is protected against a cold.

Owner:谭映林

Blade mortise adhesive tape repair device and method

The invention belongs to the technical field of aircraft engine blade mortise repair, and particularly relates to a blade mortise adhesive tape repair device and method. The repair device comprises arepair block, and the repair block is provided with a first positioning surface for being attached to and positioned with an end face locking block of a mortise, a second positioning surface for beingattached to and positioned with the bottom surface of the mortise and a mold portion matched with an adhesive tape of a grading adhesive tape portion of the mortise for repairing the adhesive tape ofthe grading adhesive tape portion, and a separation space used for being separated from an adhesive tape of the bottom face non-repair portion of the mortise is arranged on the portion, close to thesecond positioning surface, of the mold portion. The mold portion can repair the gradient part of the adhesive tape in the gumming process of an aircraft engine blade, and the separation space used for being separated from the adhesive tape of the bottom face non-repair portion of the mortise is arranged on the portion, close to the second positioning surface, of the mold portion, so that the erroneous contact with the non-repair portion is avoided, and the repairing effect can be ensured.

Owner:AECC AVIATION POWER CO LTD

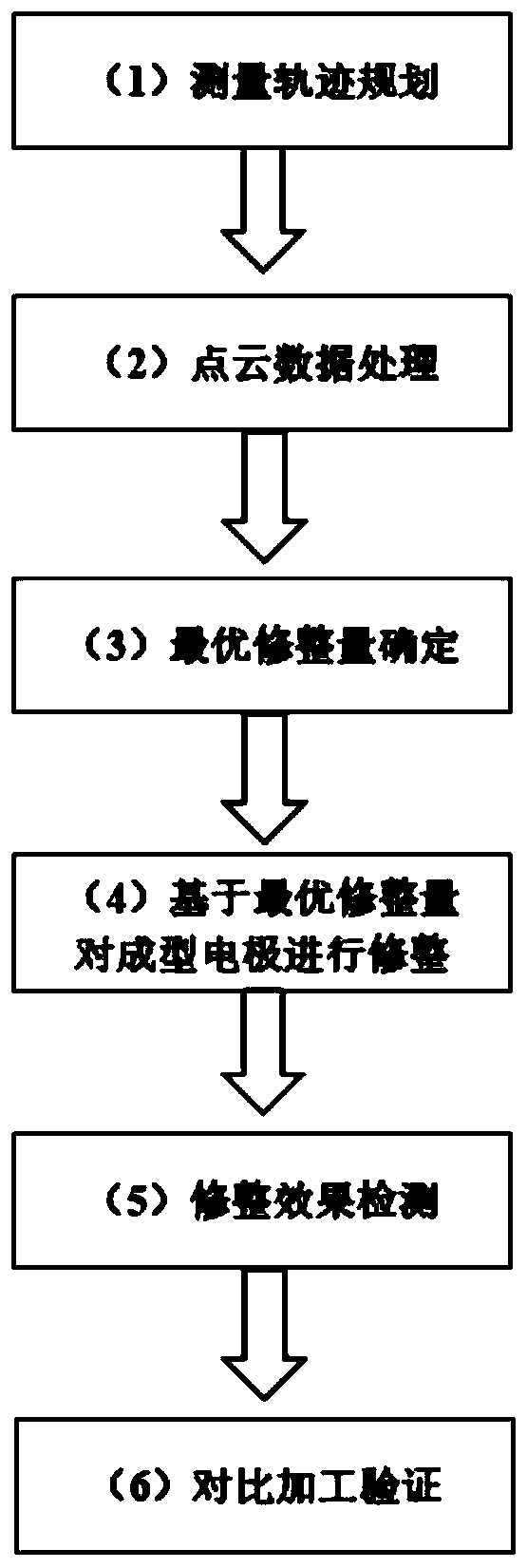

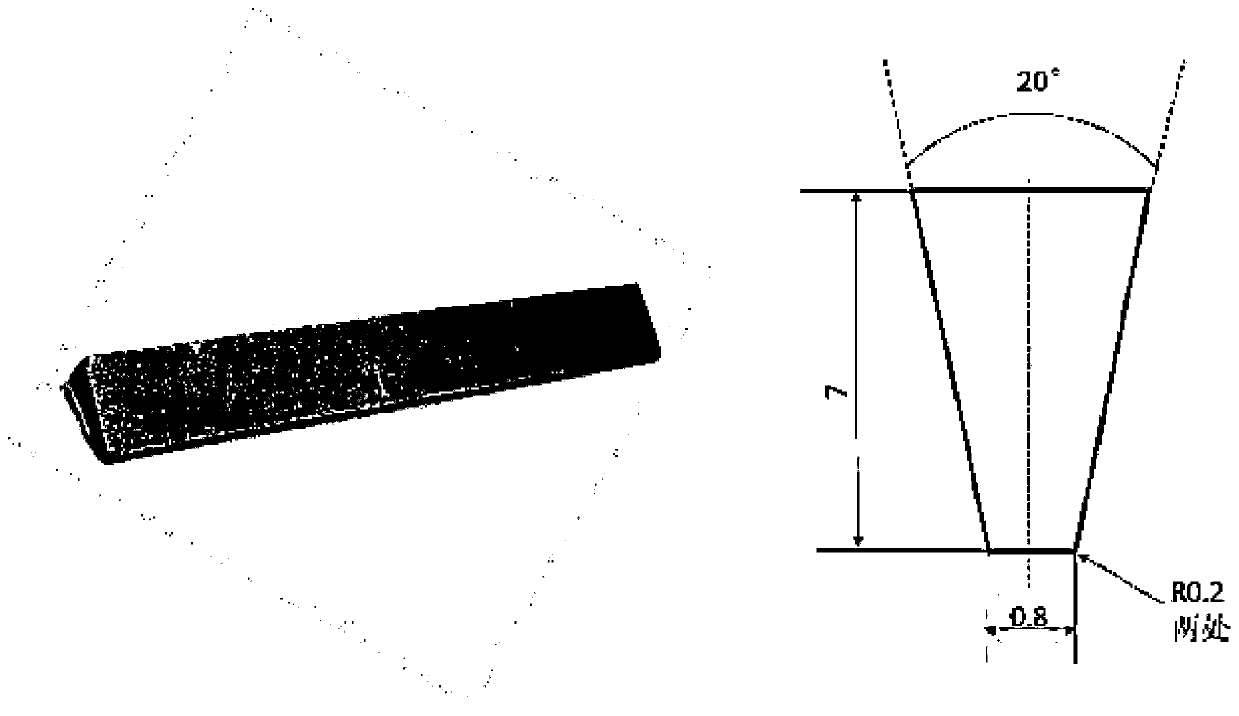

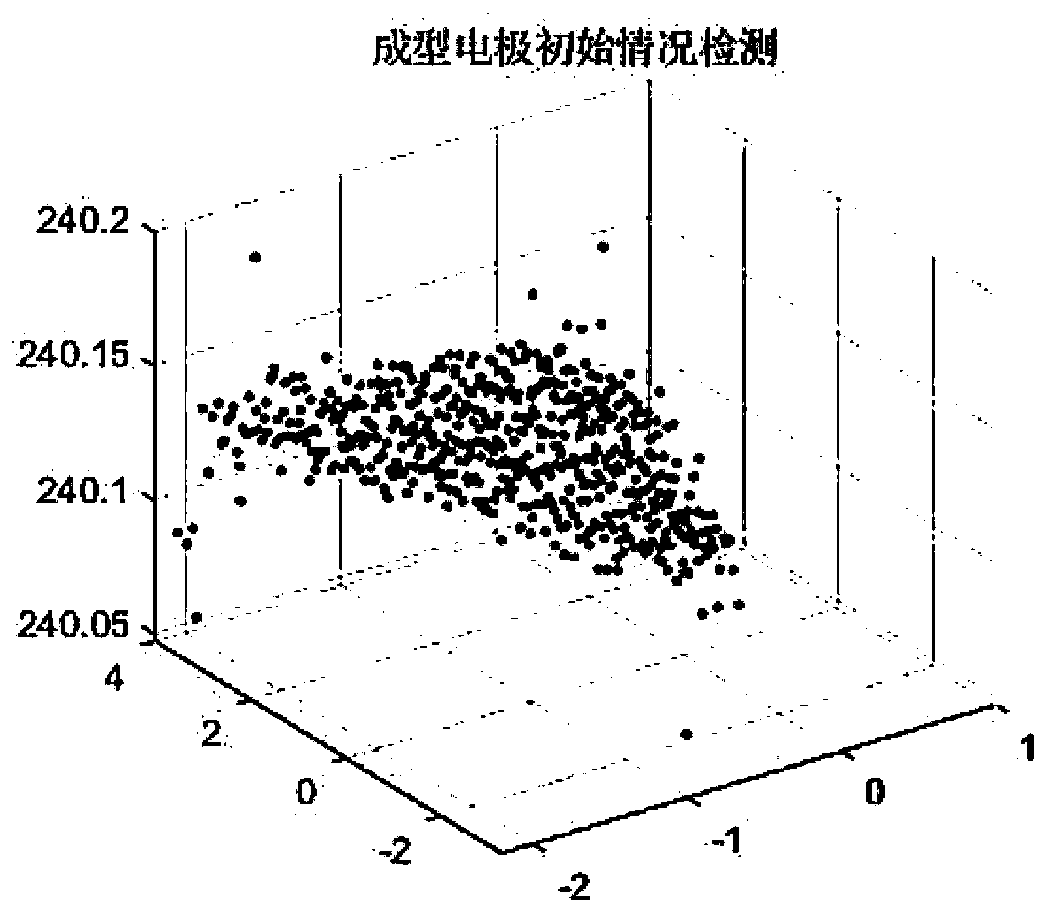

Method for realizing optimal finishing amount of formed electrode loss based on point cloud data processing

ActiveCN110977064AAccurately determineImprove processing efficiencyUsing optical meansElectrical-based machining electrodesProcess engineeringCoordinate-measuring machine

The invention discloses a method for realizing the optimal finishing amount of the formed electrode loss based on point cloud data processing. The formed electrode loss situation is measured through alaser three-coordinate measuring machine, point cloud data are obtained, and the point cloud data are transformed from a machine tool coordinate system to a workpiece coordinate system and denoised;and then approximate plane fitting is conducted through a least square method to obtain the optimal finishing amount, and by adopting a reverse-forming finishing technology and combining the optimal finishing amount, a dissipated formed electrode is finished through a reverse copying block. The optimal finishing amount of the tool electrode loss in electric spark non-traditional machining can be accurately determined, the machining efficiency is improved, and the finishing quality is ensured.

Owner:SHANGHAI JIAO TONG UNIV

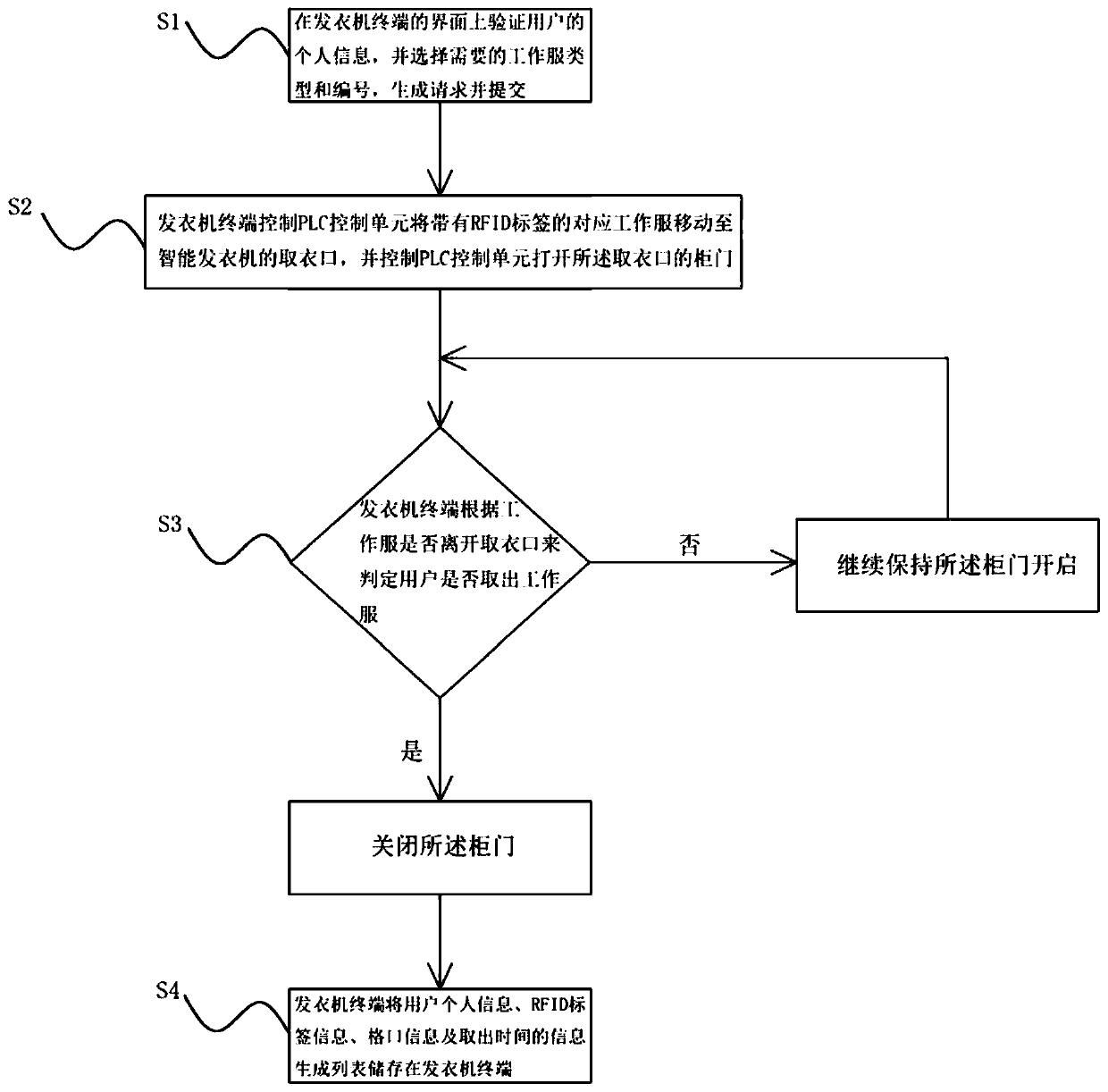

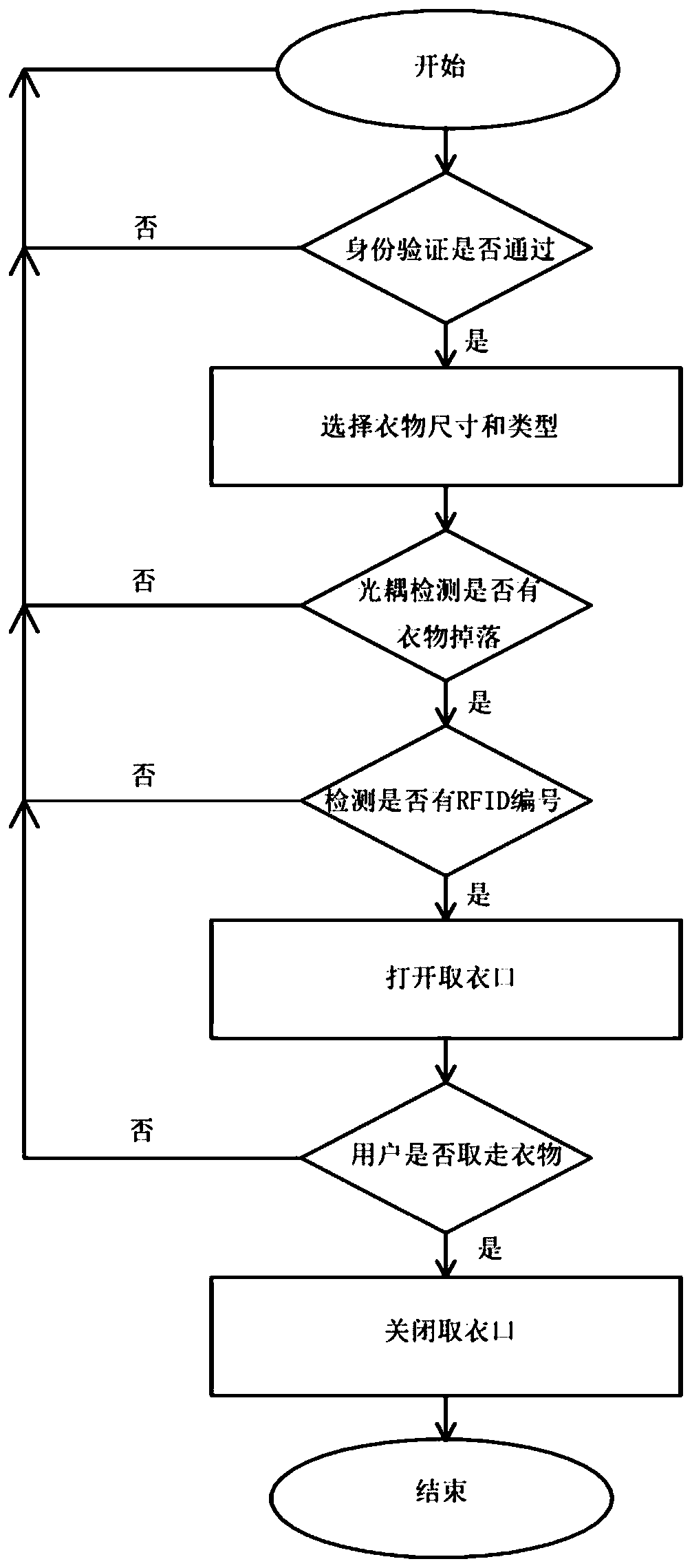

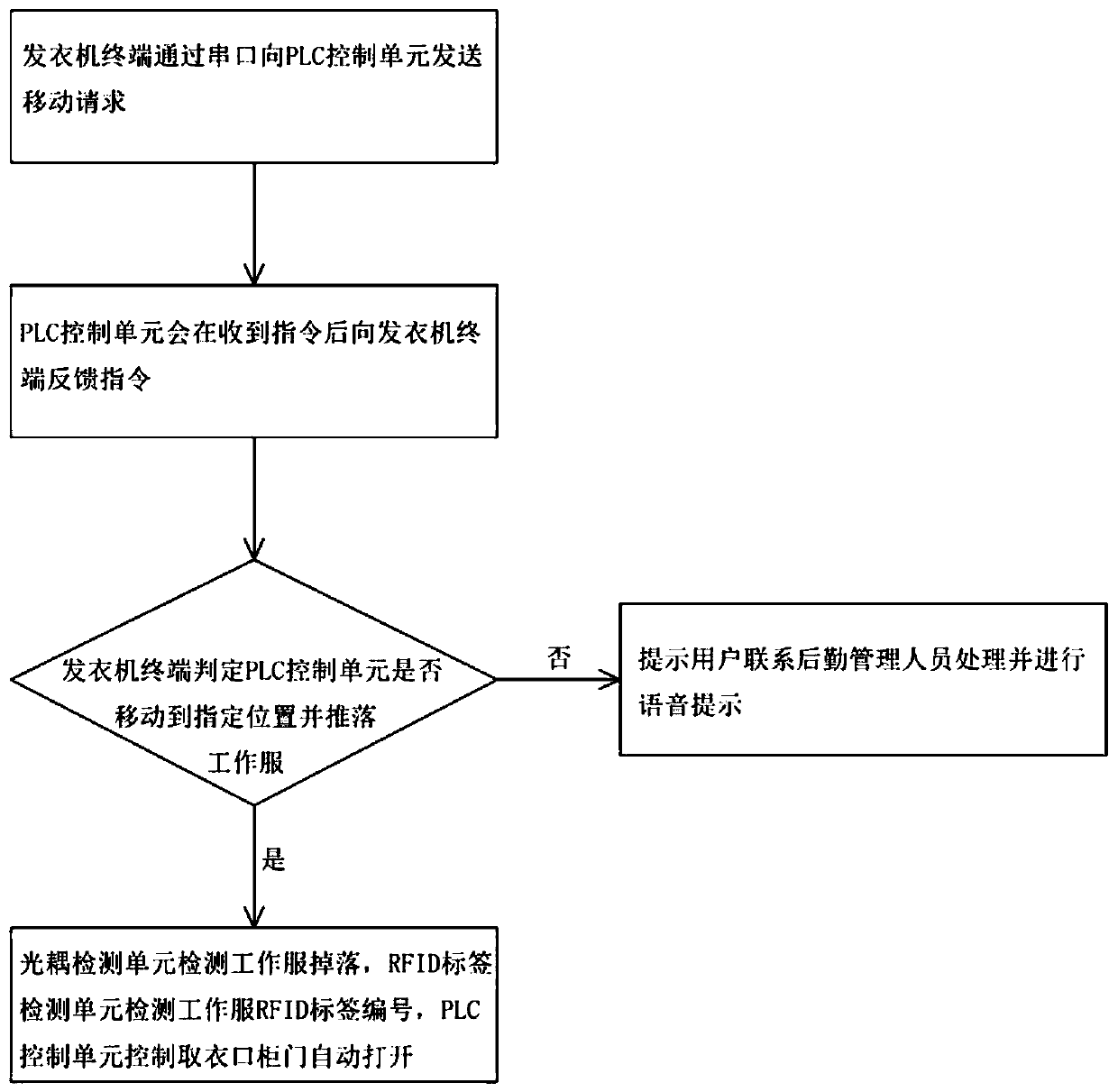

Delivery method and system of intelligent clothes dispenser

PendingCN110705668AImprove timelinessReduce labor costsCo-operative working arrangementsDigital data authenticationControl engineeringControl cell

The invention discloses a shipment method and a system for an intelligent clothes dispenser, and the method comprises the following steps: S1, a user verifies the personal information, and selects thetype and model of work clothes; S2, the clothes sending machine terminal controls a PLC control unit to move the work clothes with the RFID tag to a clothes taking opening of the intelligent clothessending machine, and a cabinet door of the clothes taking opening is opened; s3, the clothes sending machine terminal judges whether the work clothes leave the clothes taking opening, and if yes, thecabinet door is closed; if not, keeping the cabinet door open; and S4, the clothes sending machine terminal transmits the data to a data monitoring center for storage. The method has the advantages that self-service access is achieved in the whole process, excessive manual interference is not needed, the timeliness of work clothes getting is higher, and the labor cost is lower. Work clothes conforming to the specification can be received by selecting the corresponding size according to the requirements of a user, use is convenient and fast, and the clothes changing time of workers is greatly shortened.

Owner:SHENZHEN ZHILAI SCI & TECH

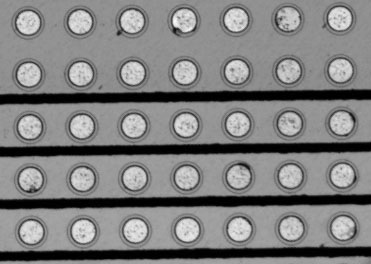

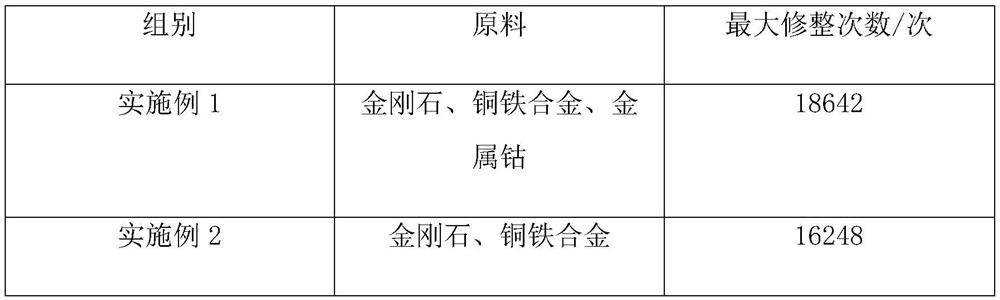

Preparation method of diamond roller for efficiently trimming CBN grinding wheel

ActiveCN112548881AImprove wear resistanceShorten dressing timeAbrasion apparatusGrinding devicesMetal sheetAlloy

The invention provides a preparation method of a diamond roller for efficiently trimming a CBN grinding wheel. The preparation method comprises the following steps that S1, diamond particles and copper-iron alloy powder are taken and put into a micro stirrer for being stirred to obtain mixed powder, a lubricant is added into a mixture, and continuing stirring is carried out to obtain a mixture; S2, the mixture is put into a graphite mold, the mixture is pressed into a metal sheet, put into a medium-frequency sintering machine for sintering, and is cooled to obtain a diamond alloy sheet; S3, aroller base body is machined, the diamond alloy sheet is put into a high-frequency heating machine to be heated, the diamond alloy sheet is taken out and rapidly sleeves the roller base body, and thediamond roller is obtained after cooling; and S4, the diamond roller obtained in the S3 is polished, dynamic balance is carried out, cleaning and drying are carried out, antirust oil is sprayed, packaging and storing are carried out. In conclusion, the preparation method of the diamond roller for efficiently trimming the CBN grinding wheel has the advantages of novelty, convenience in operation, low cost, long product service life and the like.

Owner:西安博奥达金刚石工磨具有限公司

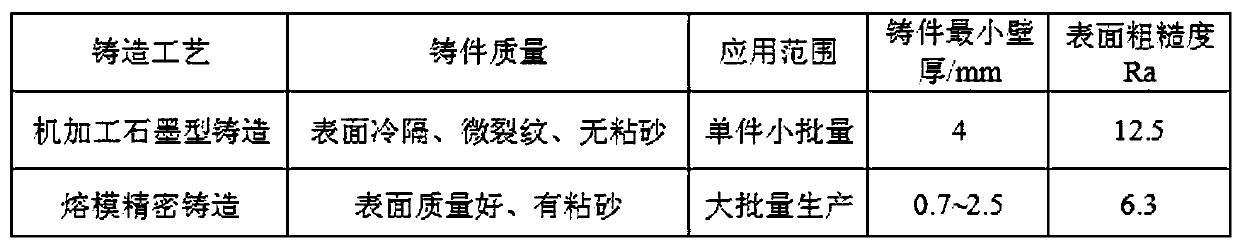

A graphite mold casting method for large thin-walled titanium alloy castings

ActiveCN105880464BImprove surface qualityIncrease filling limitFoundry mouldsFoundry coresSpray coatingSurface roughness

Owner:LUOYANG SUNRUI TI PRECISION CASTING

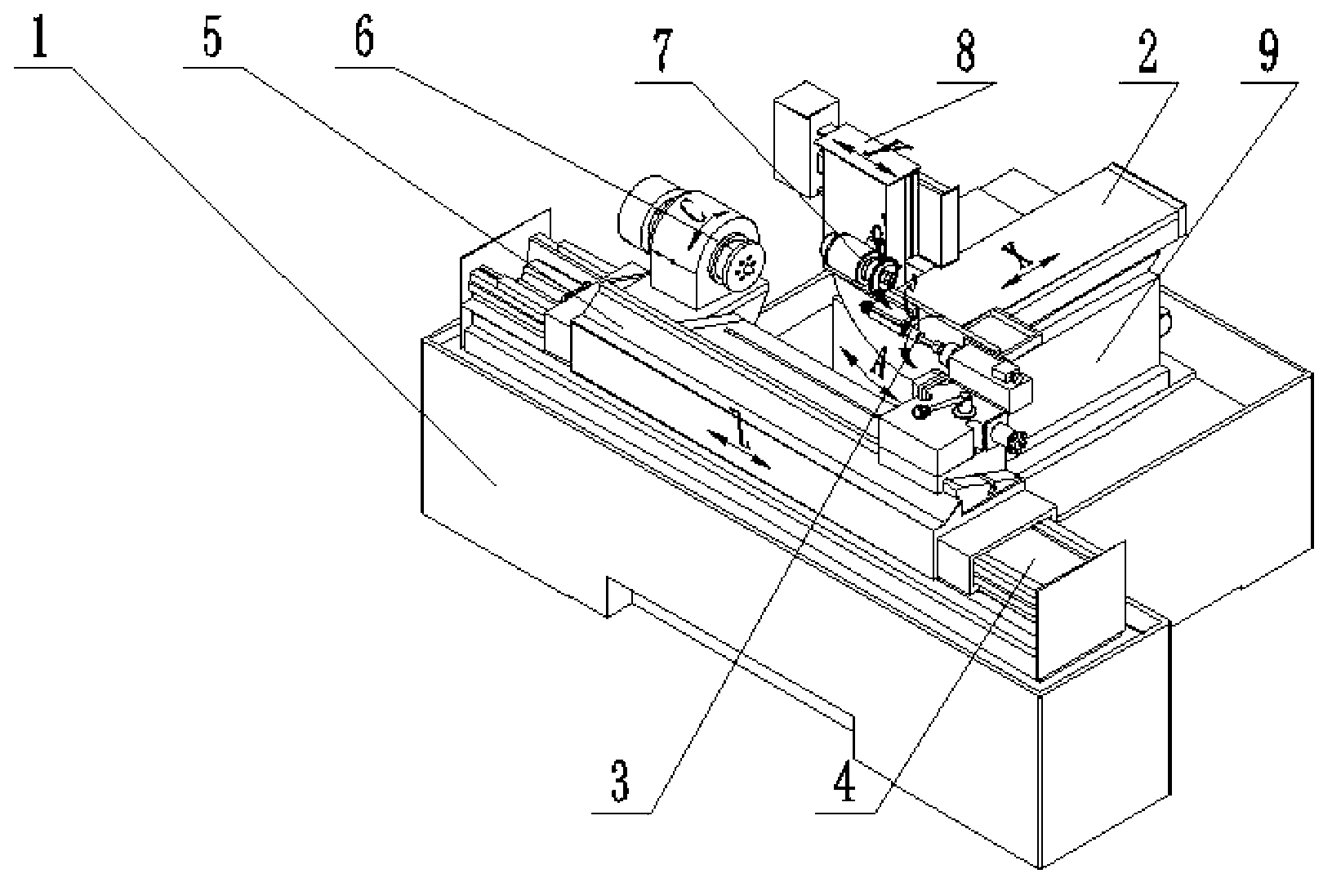

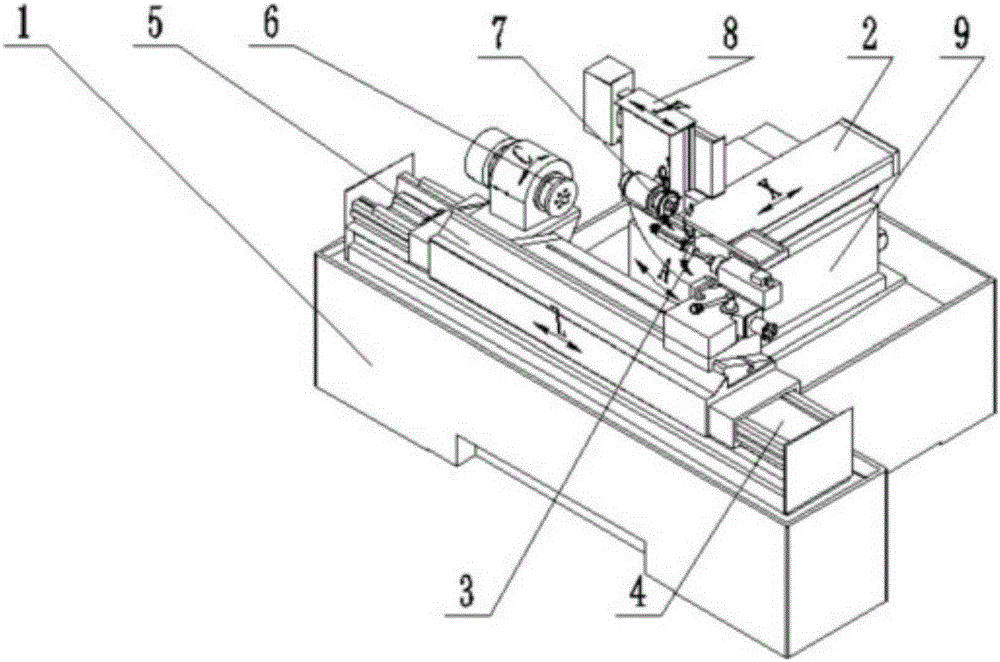

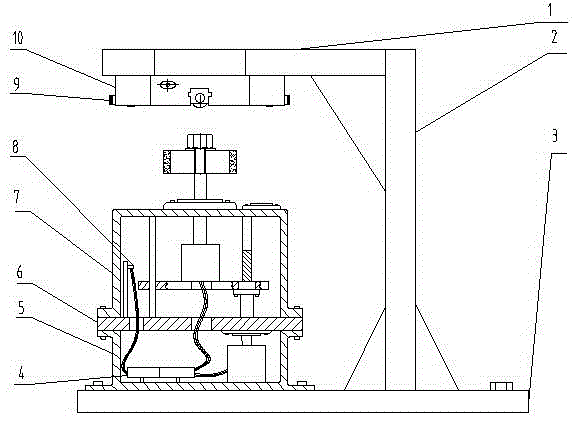

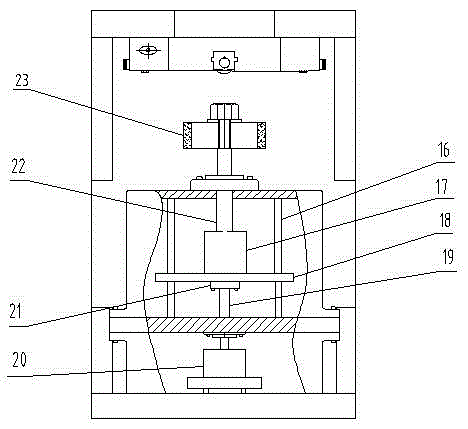

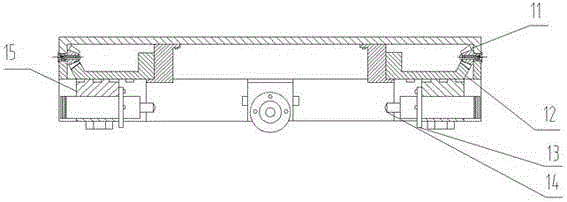

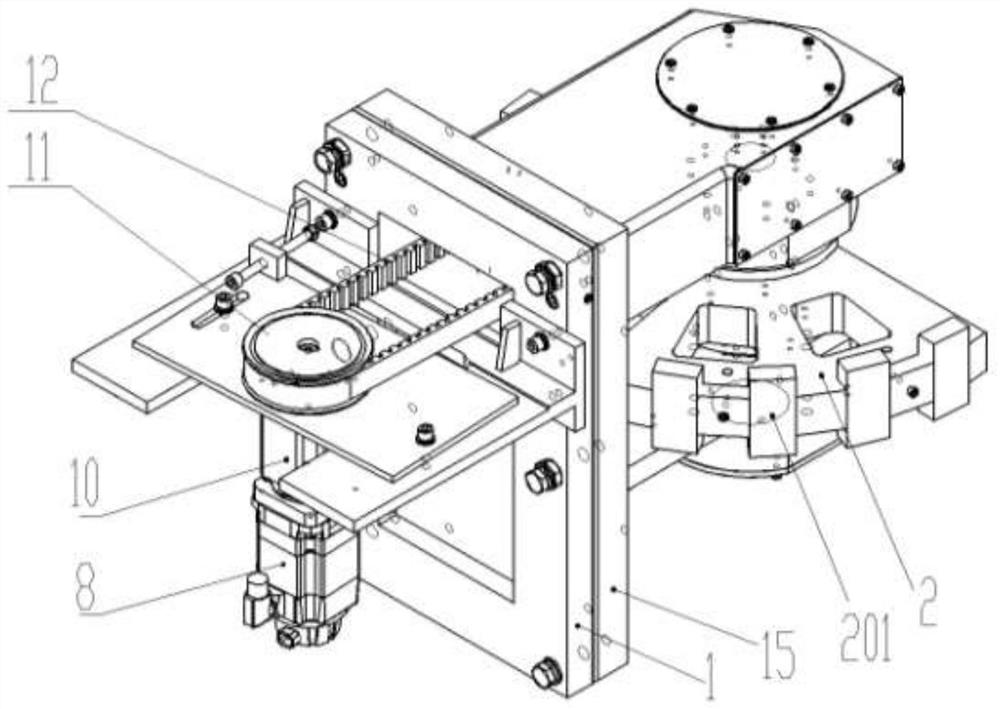

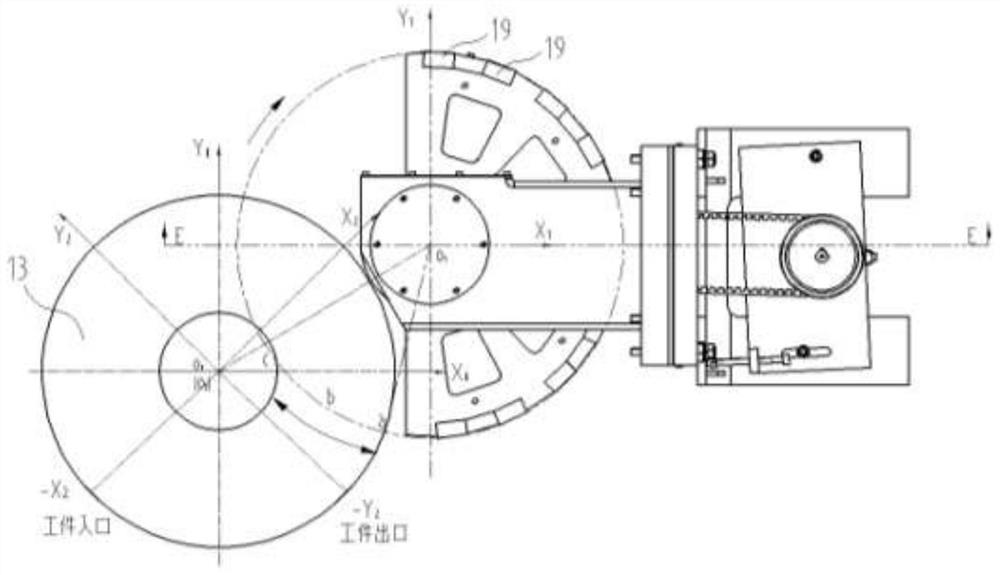

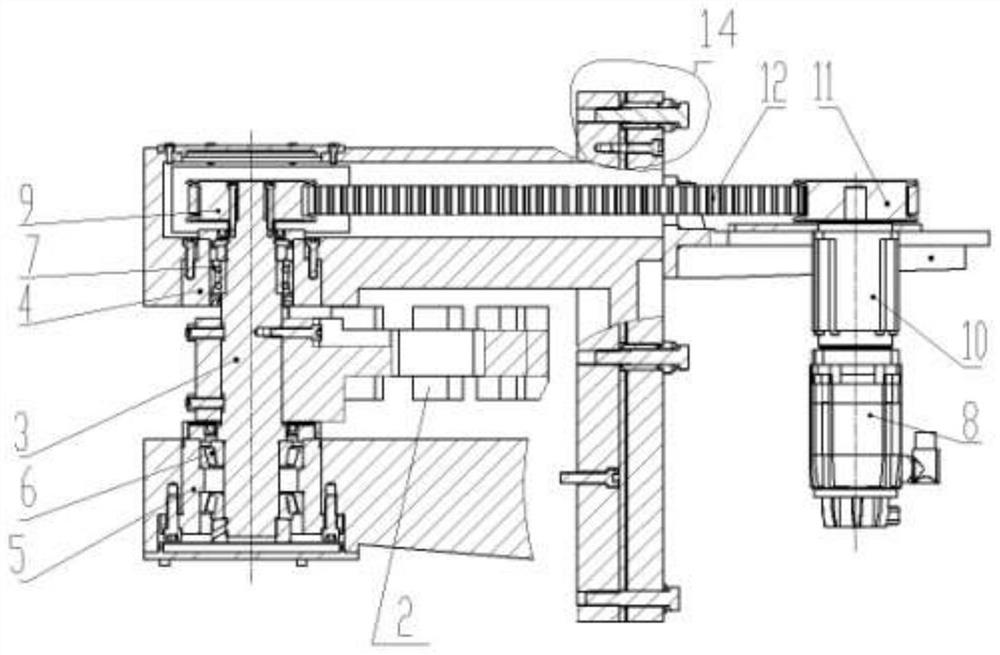

Automatic Dressing Device for Diamond Grinding Wheel

ActiveCN103962960BShorten dressing timeImprove processing efficiencyAbrasive surface conditioning devicesGear wheelEllipse

The invention discloses an automatic dressing device for a diamond grinding wheel, which is mainly composed of a workbench, a chuck, and a cylinder body. The chuck is fixed under the upper top plate of the workbench. The gear (12), the large bevel gear is connected with the slider (15), the transducer (9), the horn (13) and the diamond pen (14) are installed on the slider, and the transducer is connected with the ultrasonic generator , the ball screw is connected to the servo motor through the static support plate, the guide shaft is connected to the upper cylinder and the static support plate through the dynamic support plate, the three-phase asynchronous motor is connected to the grinding wheel (23) through the main shaft, and one end of the circuit board is connected to the The proximity switch is connected, and the other end is connected with the servo motor and the three-phase asynchronous motor respectively. The invention can realize the ultrasonic elliptical vibration of the diamond pen, improve the processing efficiency and precision of the grinding wheel, enhance the rigidity and stability of the cutting system, prolong the service life of the diamond pen, and is more suitable for dressing of the hard grinding wheel.

Owner:CONPROFE TECH GRP CO LTD +1

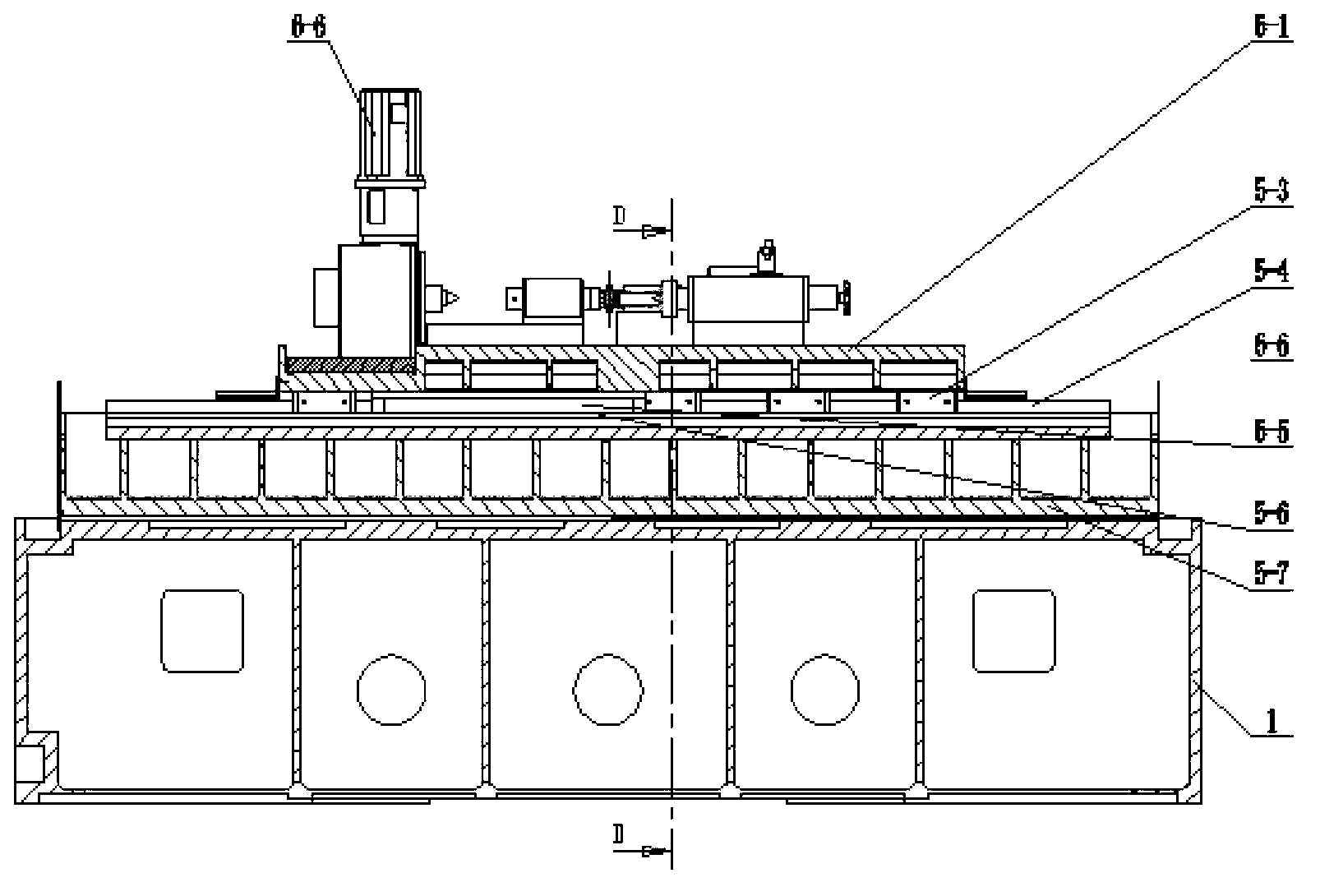

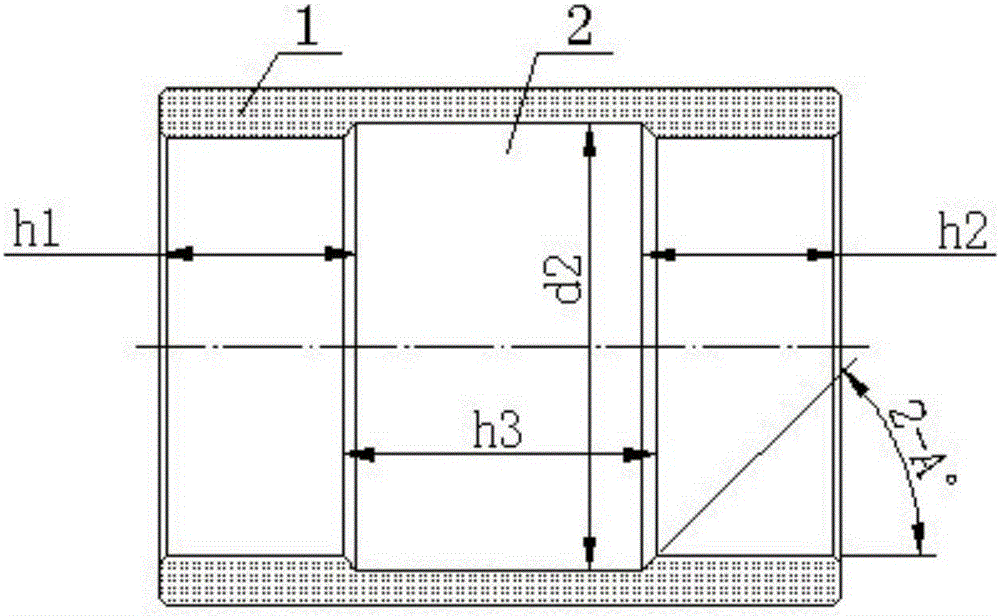

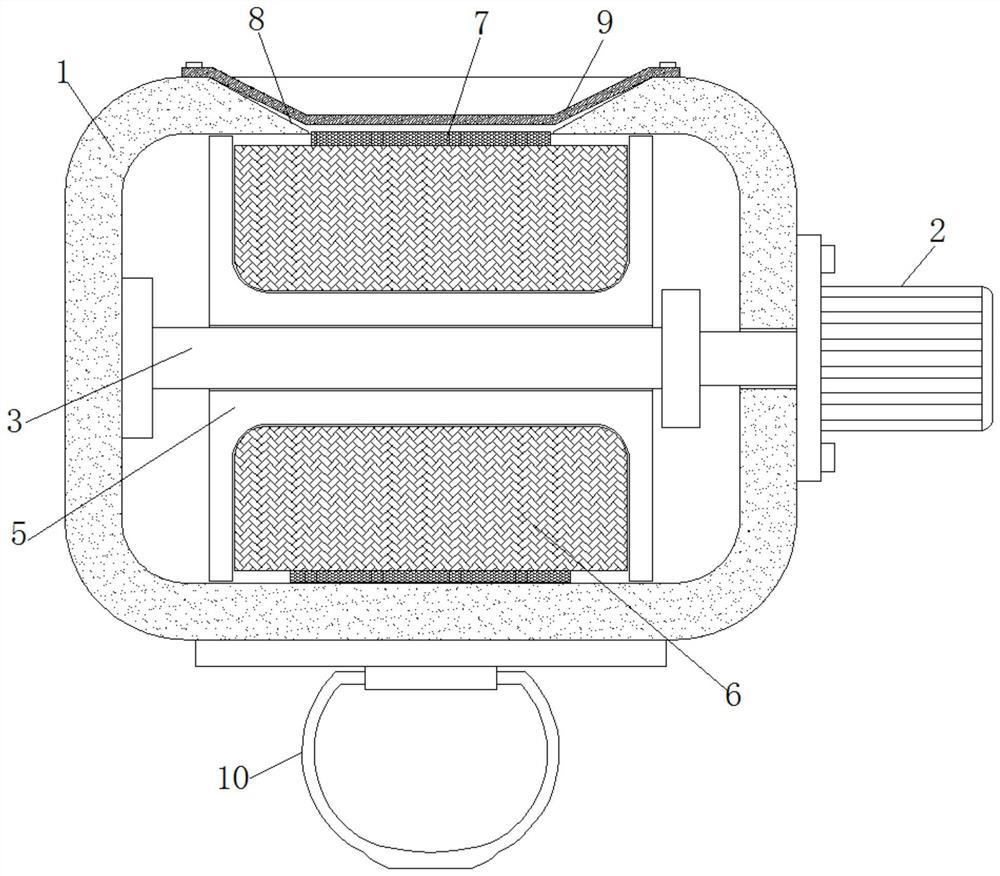

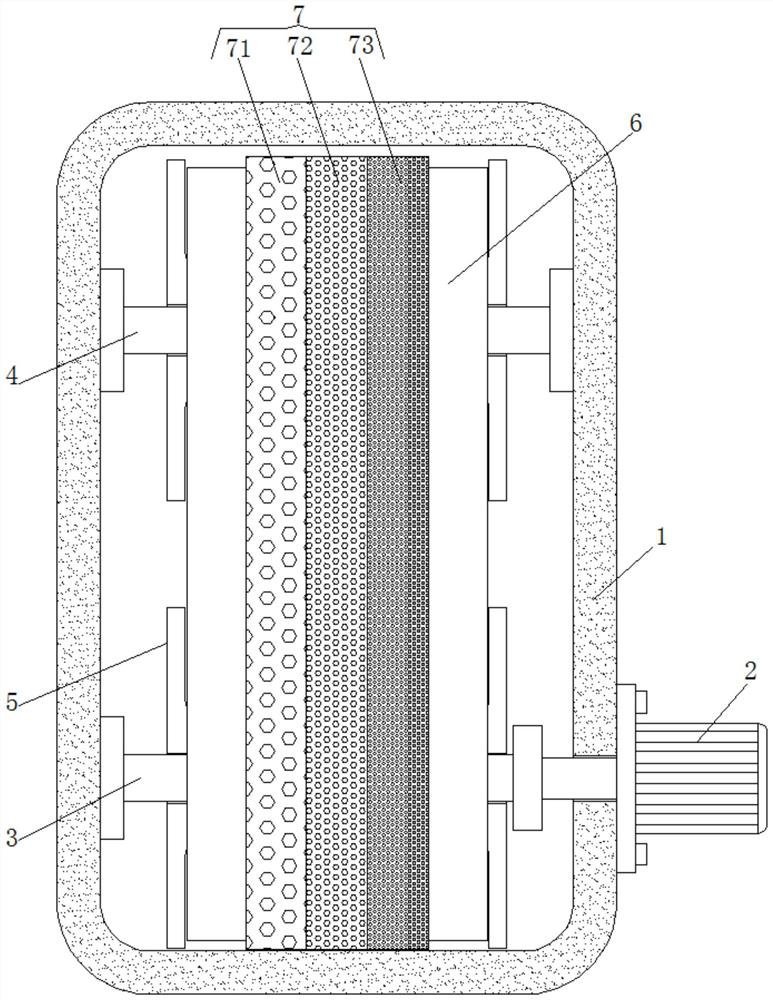

Double-end-face grinding machine dressing device

ActiveCN113580011AGood sharpness retentionGood self-sharpeningAbrasive surface conditioning devicesGrinding wheelMachine tool

The invention provides a double-end-face grinding machine dressing device. The double-end-face grinding machine dressing device comprises a main body, a power mechanism, a transmission mechanism and a dressing mechanism, wherein the power mechanism drives the dressing mechanism to rotate through the transmission mechanism; the dressing mechanism comprises a dressing shaft and a dressing disc; the dressing disc is mounted on the dressing shaft; a plurality of dressing oil stones are arranged in the peripheral direction of the dressing disc; one end of each dressing oil stone protrudes out of the upper surface of the dressing disc and the other end of each dressing oil stone protrudes out of the lower surface of the dressing disc; and the main body is provided with an adjusting mechanism for adjusting a swinging center of the dressing disc to be parallel to a rotary center of a grinding wheel. According to the double-end-face grinding machine dressing device, the sharpness retentivity of the grinding wheel is better and the self-sharpening performance is better; more workpieces can be ground between two times of dressing frequencies; and the size precision and the surface precision of the machined workpieces can be improved. The dressing time is saved and the utilization rate of a machine tool is improved. The dressing device is mounted on a grinding machine box body and an adjustable structure is adopted, so that the parallelism of a dressing center and the center of the lower grinding wheel is easy to guarantee, and furthermore, the whole manufacturing difficulty of the machine tool is reduced and the assembling efficiency is improved.

Owner:YUHUAN CNC MACHINE TOOL

The Method of Fire-throwing Water Drilling Bead Blank Using Composite Powder Medium

ActiveCN105382673BPlay a role in isolationLubricateEdge grinding machinesPolishing machinesFiberGraphite

The invention discloses a method for fire polishing of a rhinestone pearl blank by means of a composite powder medium, and belongs to the technical field of rhinestone pearl blank machining. The method comprises the step that the composite powder medium and the rhinestone pearl blank are added into a rotary metal cylinder after being evenly mixed and are heated and subjected to fire polishing, wherein the composite powder medium comprises graphite powder and inorganic powder, and the weight ratio of the graphite powder to the inorganic powder to the rhinestone pearl blank is (1-4):(1-6):(93-96). According to the method for fiber polishing of the rhinestone pearl blank by means of the composite powder medium, the fire polishing circular degree and efficiency of the rhinestone pearl blank can be improved, the rhinestone spheroidizing and finishing time can be shortened, the working efficiency of a fire polishing furnace can be improved, meanwhile, the composite powder medium can be recycled, graphite powder oxidation consumption can be reduced, the production environment can be improved, and the spheroidized rhinestone pearl blank can be easy to clean.

Owner:YANCHENG INST OF TECH

Burr trimming device for blockboard

PendingCN112059809AShorten dressing timeImprove dressing efficiencyEdge grinding machinesGrinding carriagesWood plankMechanical engineering

The invention discloses a burr trimming device for a blockboard. The burr trimming device comprises a bottom plate, a sliding cavity is formed in the upper portion of the bottom plate, a placing plateis arranged in the sliding cavity, a sliding shaft is arranged on the lower part of the placing plate, a transverse sliding groove is formed in the center of the sliding cavity, a longitudinal sliding groove is formed in the left side of the inner part of the sliding cavity, and the sliding shaft slides in the transverse sliding groove and the longitudinal sliding groove; and a hydraulic pipe isarranged on the rear part of the left side of the bottom plate, a first connecting rod is arranged on the front side of the hydraulic pipe, and a second connecting rod is arranged at the end, away from the hydraulic pipe, of the first connecting rod. A wood plate is placed on the placing plate, the wood plate can rotate in the sliding cavity through the sliding shaft, the grinding range of a grinding wheel can be enlarged through the hydraulic pipe, burr trimming can be carried out on the wood plate at multiple angles and in a larger range, after trimming is completed, the placing plate can bereset and rotated, and the other side of the wood plate is trimmed; and trimming can be carried out on the wood plate at multiple angles and in a larger range, trimming time is shortened, the trimming efficiency is accelerated, and the burr trimming device is suitable for large-scale popularization.

Owner:桃江县福丰木业有限公司

A handheld nail trimming device

The invention relates to the technical field of nail trimming equipment, and discloses a hand-held nail trimming device. The right side of the body is fixedly connected with a micro motor through a small bolt, and the output shaft of the micro motor runs through the right side of the body and passes through a coupling. The torque shaft is fixedly connected, and the torque shaft is movably connected to the inner wall on the left side of the body at the end far away from the micro-motor. There is a rubber transmission belt connected between the two connecting wheels. The outer surface of the rubber transmission belt is bonded with trimming sandpaper. There is a rectangular groove in the middle of the top of the body. The rectangular groove on the top of the body is fixed and connected by small screws. There is a limit plate, and the middle position of the bottom of the body is fixedly connected with a finger buckle. The handheld nail trimming device shortens the trimming time of the nail trimming surface and greatly reduces the difficulty of trimming the nail trimming surface.

Owner:佛山市佳蔓达电器有限公司

A trimming device and method for automatic detection and regulation of groove frosted contour

ActiveCN110421486BTo achieve the purpose of automatic trimmingShorten dressing timeGrinding feed controlAbrasive surface conditioning devicesControl theoryGrinding wheel

The invention discloses a groove grinding wheel profile automatic detection and regulation trimming device and method. The device comprises a C-shaped support frame, a swing trimming frame, a swing driving mechanism, a trimming tool assembly and an analysis controller, wherein the swing driving mechanism is used for providing rotary power for the swing trimming frame, and the analysis controller is connected with a displacement detection assembly used for detecting displacement and a displacement regulation assembly used for adjusting the movement of the trimming tool assembly in a controllingmode; the C-shaped support frame is erected on the outer side of the swing trimming frame, the swinging driving mechanism is arranged at the upper end of the C-shaped supporting frame, connecting mandrels of the upper end of the swinging trimming frame and the upper end of the swinging driving mechanism penetrate through a rotating hole of the upper end of the C-shaped supporting frame, and a connecting mandrel of the lower end of the swinging trimming frame penetrates through a rotating hole of the lower end of the C-shaped supporting frame. The profile of a grinding wheel is detected on line, the trimming process is regulated in real time according to detection results, the purpose of automatic trimming on the profile of the wheel grinding is achieved, the trimming time is saved, the trimming cost is reduced, and the efficiency is improved.

Owner:ZHENGZHOU RES INST FOR ABRASIVES & GRINDING CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com