Process design method of upper casting for large ship

A technology of process design and casting, which is applied in the field of process design of large-scale marine castings, can solve problems such as the failure of the butt joint between the rib plate of the casting and the steel plate of the hull, the repair welding is not allowed at the position of the shaft hole, and the poor feeding of the lower part of the casting, etc., to achieve The effect of increasing the amount of process correction, saving trimming time, and saving the cost of repeated manual trimming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Gross weight of the casting in this embodiment: 10200kg, material: carbon-manganese steel, outline size: 1770mm*870mm*1180mm;

[0042] The process design method of the large-scale marine upper casting in this embodiment is optimized on the basis of the existing process, and specifically includes the following steps:

[0043] (1) Selection of line shrinkage rate: line shrinkage rate is selected as 1.95%;

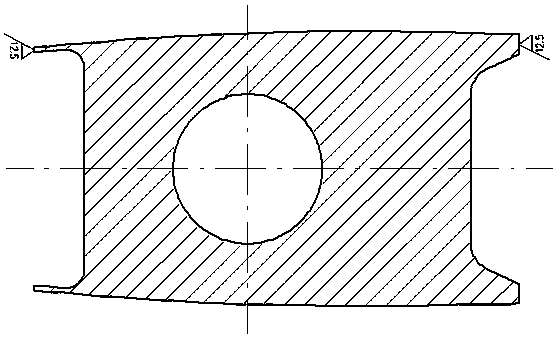

[0044] (2) Increase the processing allowance: increase the knife inspection at the rib plate that is in contact with the hull of the welded steel plate, and the amount of knife inspection is 10mm. figure 1 ;

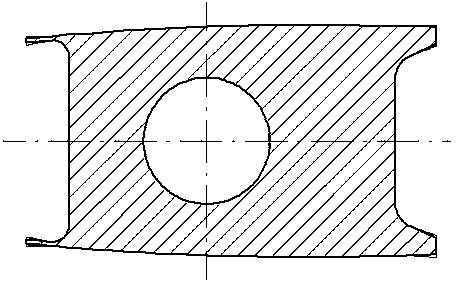

[0045] (3) Add process correction amount: add process correction amount at the rib plate, see figure 2As shown, both sides of the ribs transition from +5mm to 0, and the length of the transition area is 300mm;

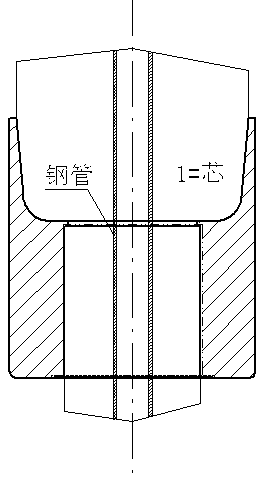

[0046] (4) Improve the model design: lay the exhaust steel pipe in the middle of the mud core, wrap the grass rope around the holes cut around it, an...

Embodiment 2

[0053] Gross weight of the casting in this embodiment: 23000kg; material: carbon-manganese steel; outline size: 2350mm*2075mm*1390mm;

[0054] The process design method of the large-scale marine upper casting in this embodiment is optimized on the basis of the existing process, and specifically includes the following steps:

[0055] (1) Selection of line shrinkage rate: line shrinkage rate is selected as 1.85%;

[0056] (2) Increase the processing allowance: increase the knife inspection at the rib plate that is in contact with the hull of the welded steel plate, the knife inspection amount is 15mm, see the added knife inspection figure 1 ;

[0057] (3) Add process correction amount: add process correction amount at the rib plate, see figure 2 As shown, both sides of the ribs transition from +8mm to 0, and the length of the transition area is 300mm;

[0058] (4) Improve the model design: put the exhaust steel pipe in the middle of the mud core, wrap the grass rope around t...

Embodiment 3

[0065] Gross weight of the casting in this embodiment: 32000kg; material: carbon-manganese steel; outline size: 2285mm*1650mm*1820mm;

[0066] The process design method of the large-scale marine upper casting in this embodiment is optimized on the basis of the existing process, and specifically includes the following steps:

[0067] (1) Selection of line shrinkage rate: line shrinkage rate is selected as 1.8%;

[0068] (2) Increase the processing allowance: increase the knife inspection at the rib plate that is in contact with the hull of the welded steel plate, and the amount of knife inspection is 20mm. figure 1 ;

[0069] (3) Add process correction amount: add process correction amount at the rib plate, see figure 2 As shown, both sides of the ribs transition from +8mm to 0, and the length of the transition area is 300mm;

[0070] (4) Improve the model design: lay the exhaust steel pipe in the middle of the mud core, wrap the grass rope around the holes cut around it, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com