Patents

Literature

203 results about "Linear shrinkage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Linear shrinkage is the decrease in length of a soil sample when oven-dried, starting with a moisture content of the sample at the liquid limit. • 100 mm spatula. • Shrinkage moulds in the form of semi-cylindrical troughs 250 mm long and 25 mm diameter, with brazed-on square ends.

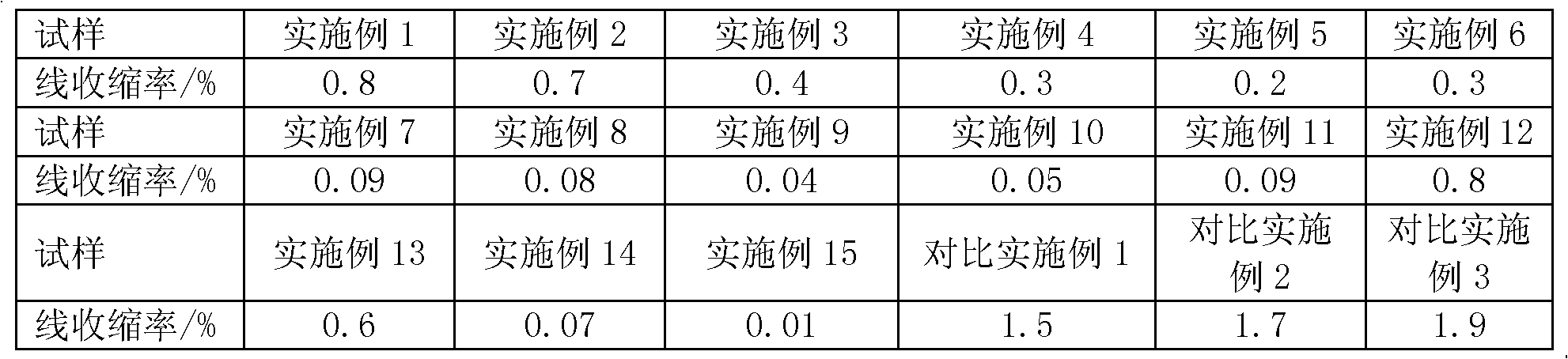

Cast magnesium alloy of low linear shrinkage

The invention discloses a cast magnesium alloy of low linear shrinkage, which belongs to the field of magnesium alloys. The magnesium alloy consists of Mg, Al, Zn, Mn, rare earth, Nb, Li and M element, wherein the materials have the following weight percentage composition: 1.5-25 percent of Al, 0.1-3.5 percent of Zn, 0.1-2.2 percent of Mn, 0.0002-16 percent of rare earth, 0.0002-4 percent of Nb, 0.0002-9 percent of Li, 0.0002-2 percent of M element and the balance Mg; and the M element is at least one of Zr, Ti, Sr, Ca, C and B. According to the heat-resistant magnesium alloy, the rare earth element and the Nb element are added into the magnesium alloy, so that the structure of beta phase is changed; the Zr element and the M element are added to refine crystal grains; due to combined action of the elements, latent heat of crystallization during alloy solidification is changed; and the magnesium alloy which has superior mold-filling capacity, low shrinkage, superior mechanical property and good machinability, fluidity and die-cast performance and is suitable for casting is obtained.

Owner:嘉兴佳斯贝特新材料有限公司

Precisive ornament casting moulding material

ActiveCN101074320AHigh hardnessLow shrinkageFoundry moulding apparatusMINERAL WAXMicrocrystalline wax

A precision-casting mold material for ornament consists of hydrogenated microcrystalline wax, paraffin, petroleum resin, high-molecular polymer, mineral wax and animal and vegetable wax. It has better bending strength, surface hardness, thermal stability, fluidity, reutilization and less linear shrinkage rate. It can be used for gold and silver ornaments.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for preparing ligh high strength aluminium oxide hollow ball ceramic

InactiveCN1554616AWith shrinkageWith thermal shock resistanceCeramicwarePhosphoric acidShock resistance

The light high-strength alumina ceramic ball has phosphoric acid solution as binding agent, alpha-alumina powder as basic material and hollow alumina ball as aggregate. Compared with dense refractory material, it has low density, high heat shock resistance, good heat insulating performance, low heat capacity and other features; and compared with common heat insulating material, it has high compression strength, high loaded softening temperature, low re-burning linear shrinkage and other features. It may be used as heat insulating material directly and may be also used in direct contact with flame, such as being used as lining material in high temperature furnace and kiln. In addition, its strength may be further raised in secondary sintering.

Owner:ZHEJIANG UNIV

Crack-resisting mortar for insulation of modified rubber powder and preparation method thereof

ActiveCN102225856AHigh compressive strengthImprove flexural strengthSolid waste managementCellulosePolymer science

The invention provides crack-resisting mortar for insulation of a modified rubber powder and a preparation method thereof. The crack-resisting mortar for insulation comprises the following raw materials in parts by weight: 5-60 parts of modified rubber powder, 50-110 parts of cement, 10-50 parts of sand, 0.5-2 parts of polypropylene fiber, 0.5-3 parts of dispersible latex powder, 2-3 parts of quick lime, 0.1-1 part of cellulose ether and 0.01-0.03 part of air entraining agent. The preparation method comprises the following steps: preparing a modifier; preparing the modified rubber powder; carrying out air-drying for later use; and carrying out mix preparation so as to obtain the crack-resisting mortar for the insulation of the modified rubber powder. Compared with the crack-resisting mortar for the insulation of the unmodified rubber powder, the compression strength, rupture strength and flexural toughness of the crack-resisting mortar in the invention are improved under the same flowability condition, wherein the rupture strength is larger than 450kpa, the compression strength is larger than 700KPa, the bonding strength is more than 180KPa, linear shrinkage is less than 1%, and the softening coefficient is more than 0.9. The crack-resisting mortar in the invention has a huge effect in the building field and a wide market prospect.

Owner:CHINA XINXING BAOXIN CONSTR CORP

Method for preparing micro expanded inorganic heat insulation mortar

ActiveCN102010166AWide variety of sourcesLow priceSolid waste managementCeramicwareMethyl celluloseEther

The invention discloses a method for preparing micro expanded inorganic heat insulation mortar. Materials such as common silicate cement, desulfuration ash, calcium carbonate powder, re-dispersible latex powder, hydroxypropyl methyl cellulose ether, wood fiber, polypropylene fiber, surfactant, foam stabilizer, water, vitrified micro bubbles and the like are adopted; and the mortar is obtained by adopting the steps of stirring, mixing, shaping, curing and the like. The method has the advantages of low cost, early micro expansion, low later linear shrinkage rate, fire resistance, durability and the like, is easy to construct, and achieves good effect of preparing the I-type building heat insulation mortar by using the III-class vitrified micro bubbles.

Owner:CHONGQING SIBEIKEN ENERGY SAVING TECH DEV +1

Grinding material for precision casting

The invention relates to a precise casting mold material, which comprises: petroleum wax, petroleum resin, high polymer, mineral wax and animal-plant wax. This product has high bending strength, superficial hardness, small linear shrinkage and ash, and well other properties, overcomes opposite in prior art, and fits to manufacture large-scale thin-wall integral fine-casting structure part.

Owner:CHINA PETROLEUM & CHEM CORP +1

Packing mold material used in investment precision casting

InactiveCN102876054ALow linear shrinkageHigh strengthFoundry moulding apparatusWaxInvestment casting

The invention relates to a packing mold material used in investment precision casting, which comprises starch serving as a packing material, and further comprises petroleum wax, organic superpolymer, rosin and 5 to 20 percent by mass of tapioca. As tapioca is added in the packing mold material, the shrinkage ratio and the expansion ratio of the packing mold material can be controlled effectively, which is very important for controlling casting dimensional precision in investment precision casting. The tapioca is wide in source, and lower in cost than other packing mold materials, and does not react with an investment casting shell. The packing mold material has the advantages that the linear shrinkage ratio and the ash content are low and the strength, the smearing property and the flowability are better, thereby being suitable for manufacturing model wax of large thin-walled investment precision casting and ornamental article casting with higher surface quality requirements.

Owner:GUANGXI UNIV

Aluminum alloy automobile hub casting process

The invention discloses an aluminum alloy automobile hub casting process which comprises the following steps: a, metal melting: smelting an Al-Si-Mg ternary alloy aluminum material into an alloy liquid; and b, casting: adopting low-pressure casting, controlling a casting temperature at 600-700 DEG C, mould-filling pressure to 0.02-0.03MPa, mould-filling time to 7-9 seconds, freezing and pressure-maintaining pressure to 0.05-0.06MPa, pressure-maintaining time to 8-10 minutes, and de-molding after releasing pressure and cooling. In this way, the aluminum alloy automobile hub casting process is simple and easy to control; the Al-Si-Mg ternary alloy aluminum material which is self-formulated is adopted for low-pressure casting and forming, so that the alloy liquidity is good, the linear shrinkage is small, and hot cracking tendency is avoided, and therefore, the cast automobile hub has relatively high strength, good plasticity and high impact toughness; and a casting piece is good in surface quality, and follow-up mechanical processing is not required.

Owner:SUZHOU HUACHONG PRECISION MACHINERY

Low-density molding compound

ActiveUS20060258781A1Improve performanceSynthetic resin layered productsCellulosic plastic layered productsParticulatesCompound a

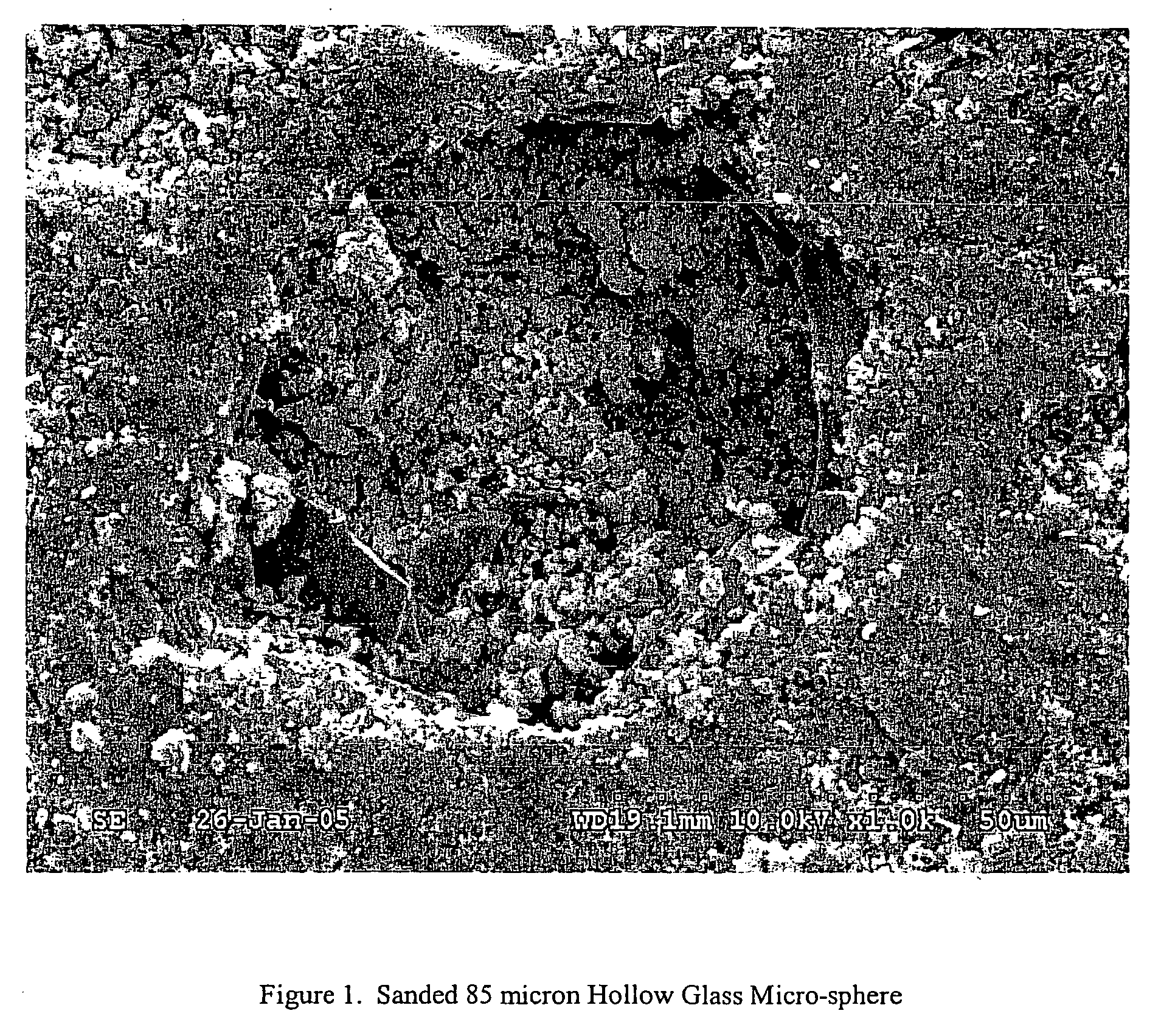

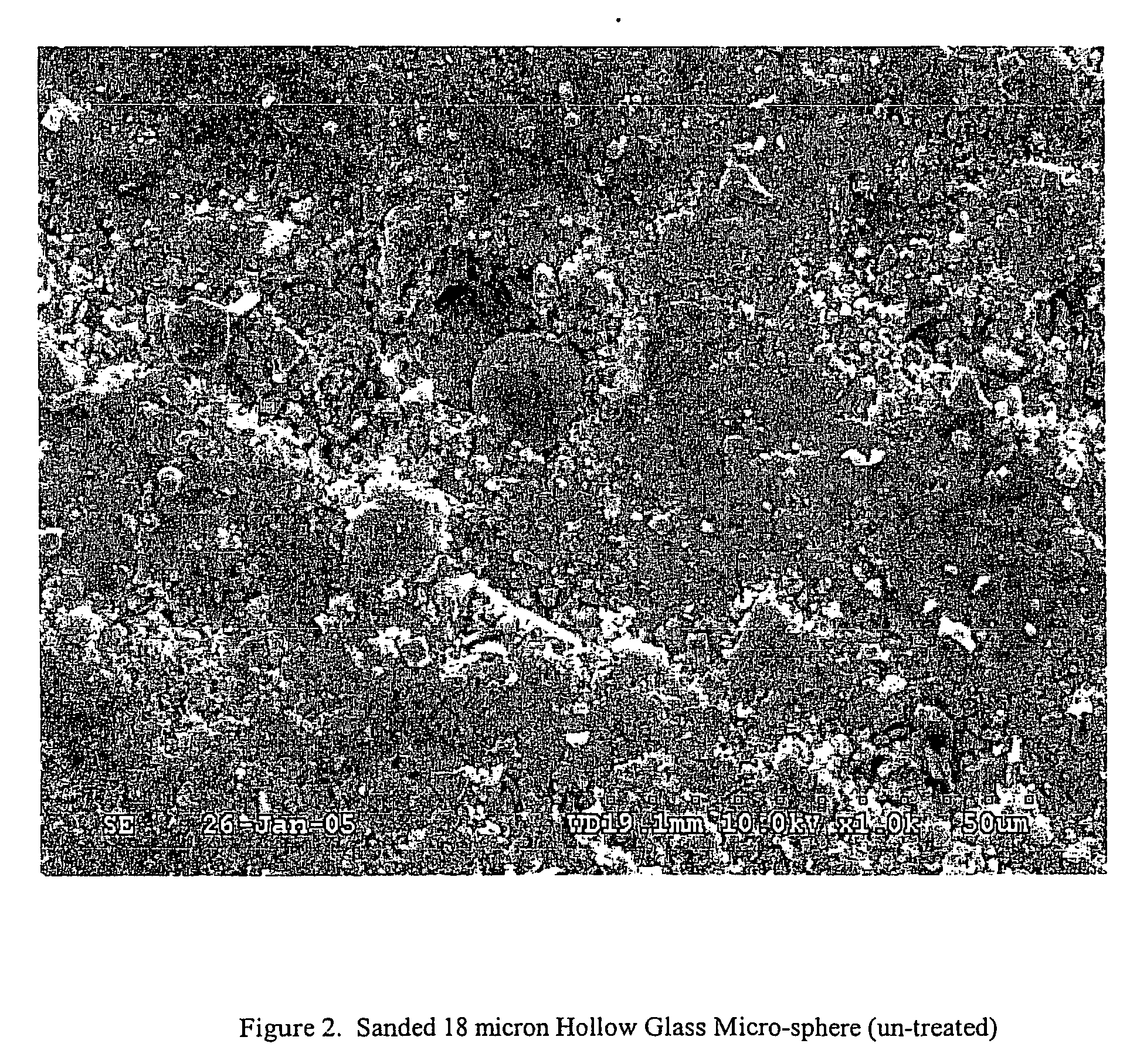

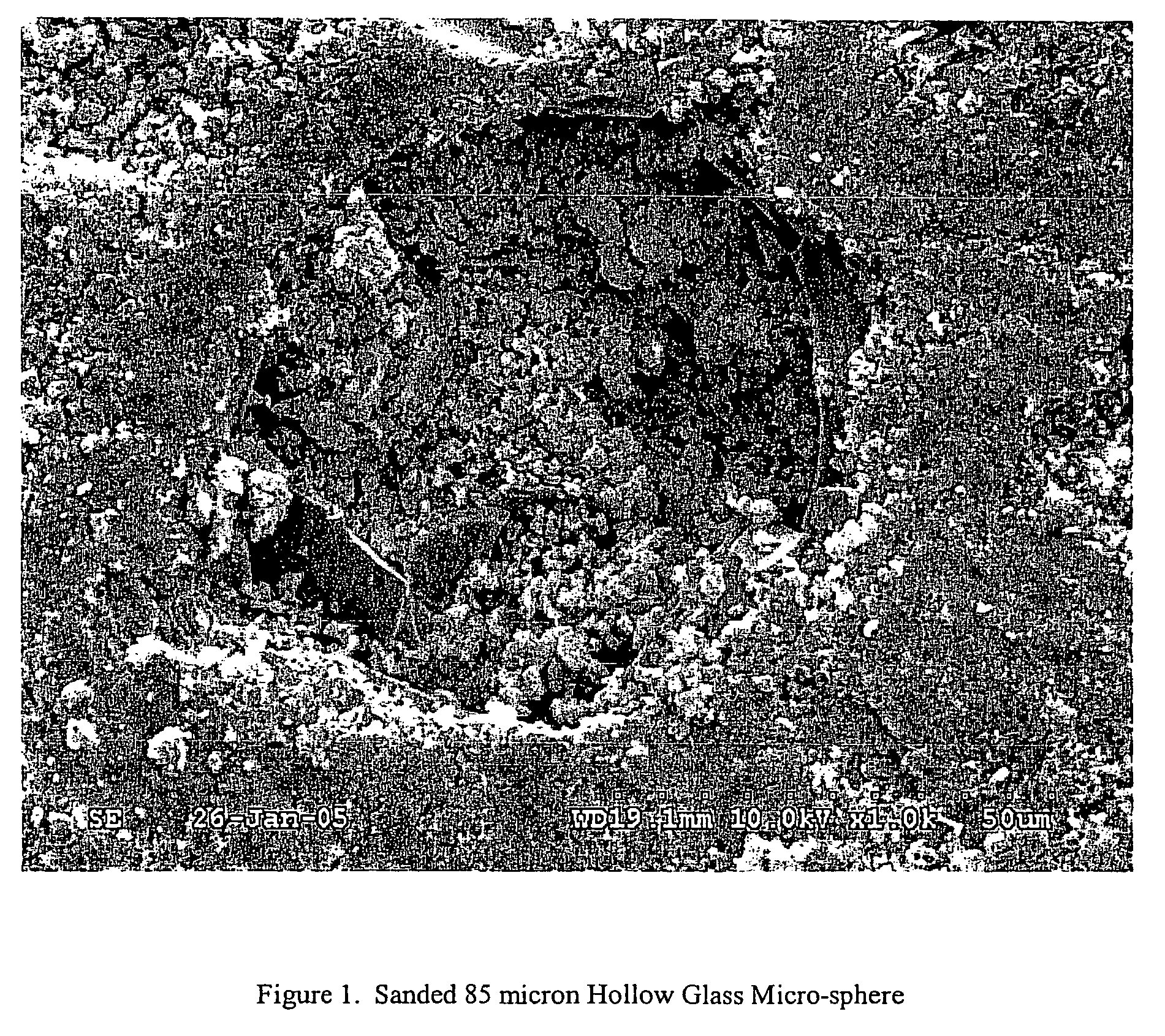

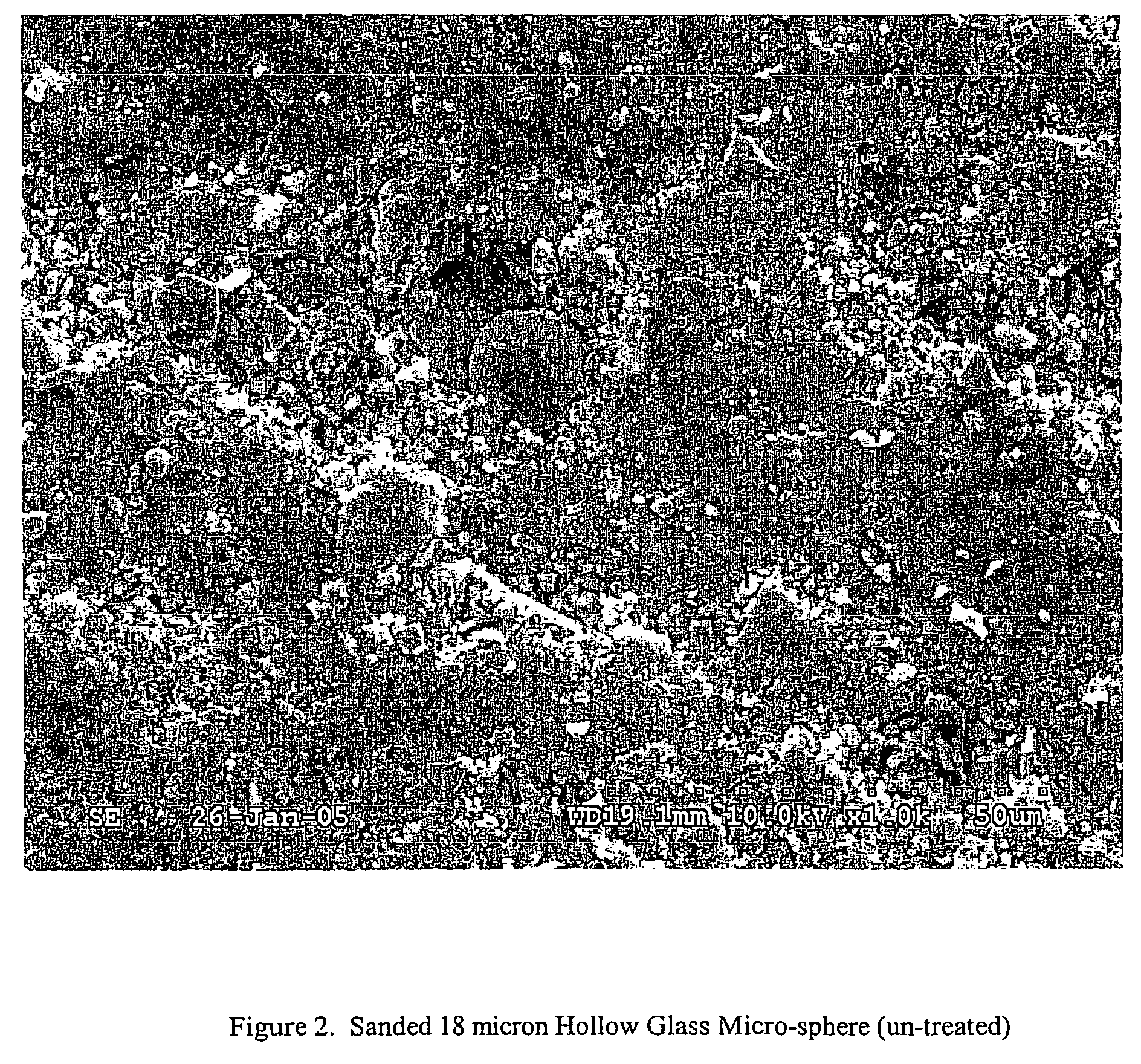

A molding composition formulation includes a thermoset cross-linkable polymeric resin. Glass microspheroids are present such that upon cure of the resin the resulting article has a linear shrinkage of less than ±0.06% and a density of less than 1.65. An article formed from such a composition is further strengthened by the addition of a surface activating agent bonded to the surface of the glass microspheroids. Conventional particulate fillers when added to an inventive formulation provide enhanced performance when the filler particle has a size sufficiently small to insert within adjacent microspheroid interstitial voids. An unsaturated polyester resin so formed is particularly well suited for the formation of sheet molding compound formulations.

Owner:CONTINENTAL STRUCTURAL PLASTICS INC

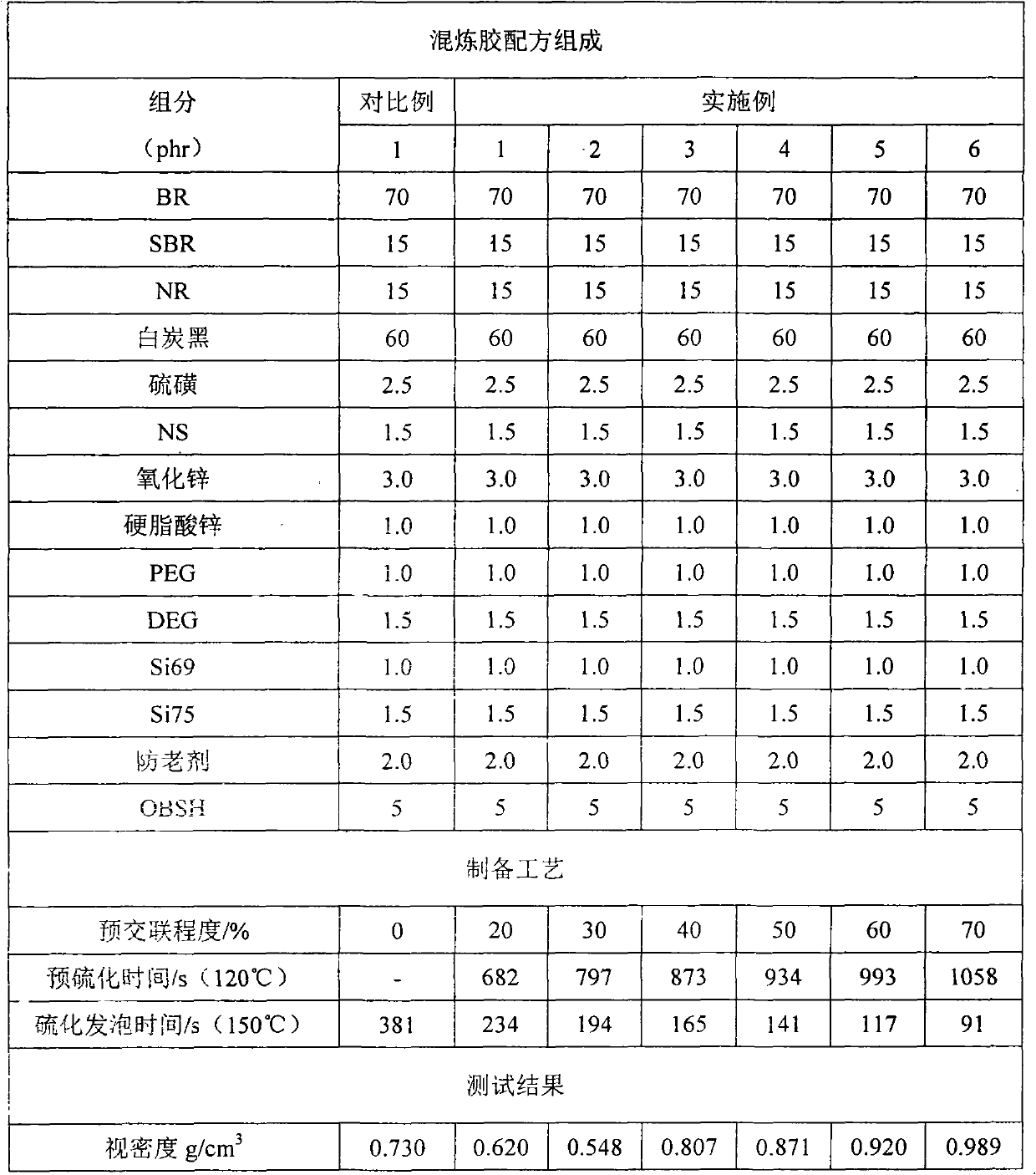

Production process for rubber foam material by means of compression molding

The invention provides a production process for a rubber foam material by means of compression molding, which integrates a rotor-free vulcameter with a practical compression molding method, and introduces a pre-crosslinking degree accurate control method into a traditional two-step compression molding foaming production process of rubber, so that prevulcanization of the rubber is realized. Adopting different pre-crosslinking degrees to control a starting point of vulcanization effectively realizes mutual match of vulcanization and foaming, and the rubber foam material with the apparent density of 0.523-0.909g / cm3 and linear shrinkage of 3.88%-9.55% can be prepared by the process. The production process has the advantages that the match point of vulcanization and foaming can be quickly and accurately found, the use ratio of foaming agents is increased, profit margin is increased, and energy is saved. Besides, the production process can effectively decrease the linear shrinkage of the rubber foam material, and improve dimensional stability of products.

Owner:CHINA LEATHER & FOOTWEAR IND RES INST

Bicomponent addition type room curing silicon rubber and preparation method thereof

The invention discloses a bicomponent addition type room curing silicon rubber and a preparation method thereof. A component A of the room curing silicon rubber comprises the following components in part by weight: 30 to 60 parts of allyl-terminated organic polysiloxane of which the viscosity is 450 to 1,000 mPa.s, 15 to 30 parts of 400-1,000-mesh quartz powder, 23 to 35 parts of 600-1,200-mesh aluminum oxide, 0.1 to 5 parts of coloring agent, and 0.5 to 3 parts of platinum catalyst; a component B comprises the following components in part by weight: 30 to 55 parts of the allyl-terminated organic polysiloxane of which the viscosity is 450 to 1,000 mPa.s, 20 to 30 parts of the 400-1,000-mesh quartz powder, 18 to 30 parts of the 600-1,200-mesh aluminum oxide, 0.1 to 5 parts of inhibiting agent, 0.5 to 3 parts of hydrogen-containing silicone oil containing 0.17 to 1.2 parts of hydrogen, 0.5 to 6 parts of viscosity increaser, 0.3 to 1 part of anti-settling agent and the like. The prepared bicomponent addition type room curing silicon rubber has high heat conductivity and fluidity and can achieve cohesive failure by being bonded with metals such as aluminum, copper, stainless steel and the like and plastics such as PBT, ABS, PC, epoxy resin and the like, the bonding strength can be over 0.5 MPa, and the properties such as viscosity, hardness, density, strength, linear shrinkage and the like of a liquid silicon rubber are basically not influenced.

Owner:TONGJI UNIV

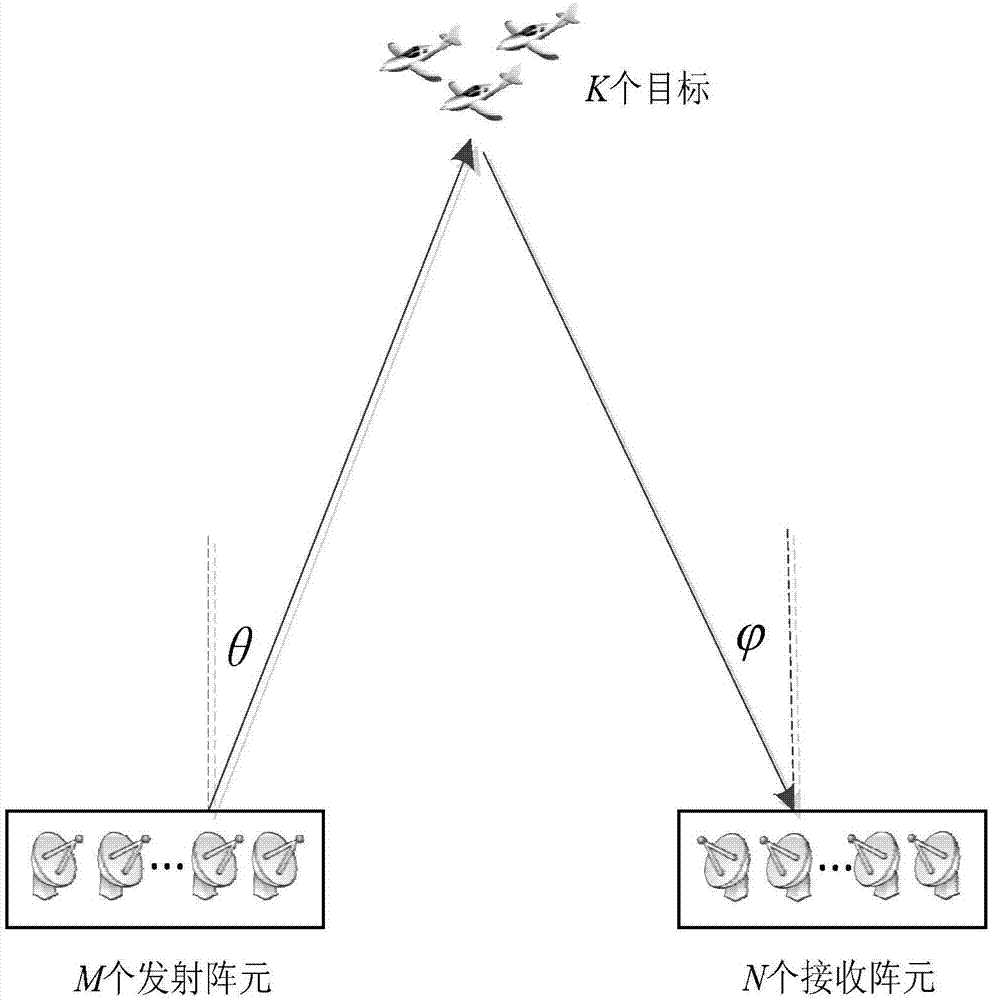

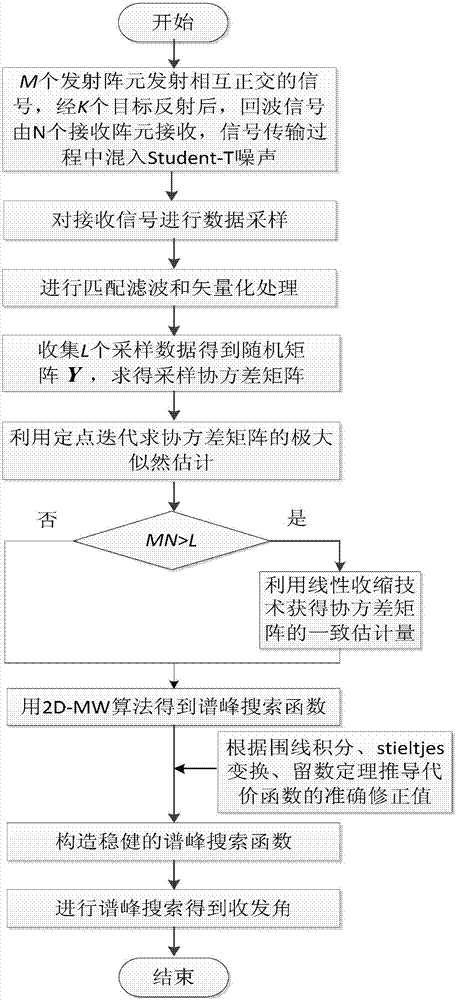

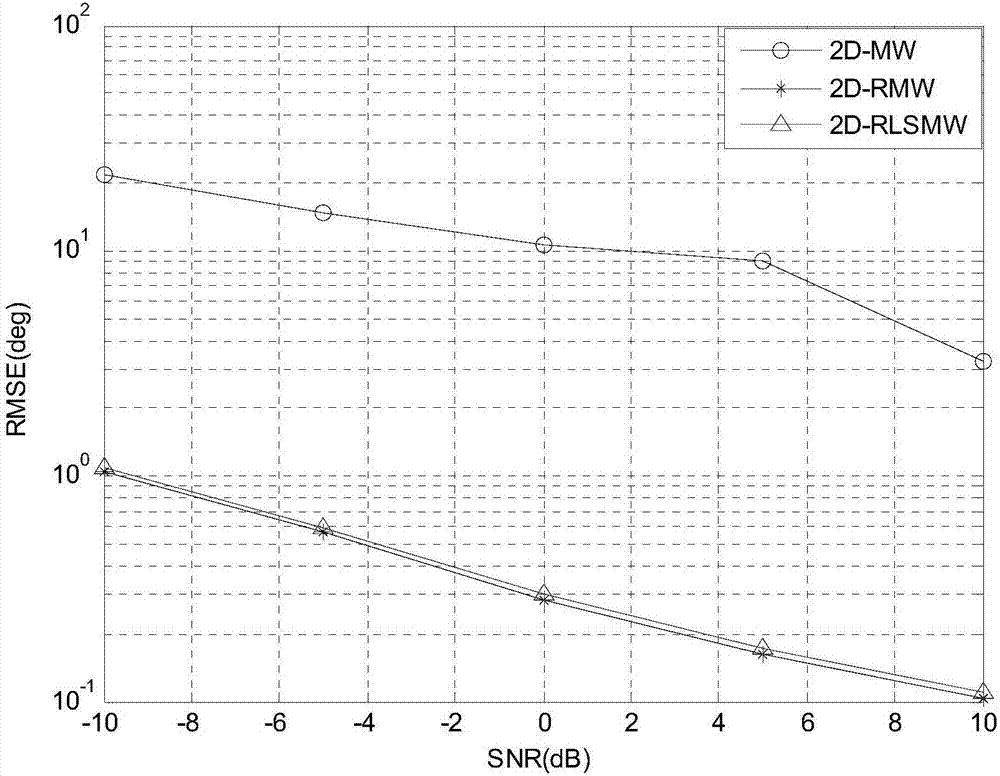

Robust large-array MIMO target transmitting and receiving angle joint estimation method

ActiveCN107167785ASolve the problem of inaccurate estimation of receiving and receiving anglesSolve the missing rank problemWave based measurement systemsEstimation methodsRadar

The invention provides a robust large-array MIMO target transmitting and receiving angle joint estimation method, and belongs to the field of multiple-input multiple-output radar target parameter estimation. The method provided by the invention is based on linear shrinkage and a random matrix theory. Implementation of the method comprises the steps of building a random matrix model of observed data by using echo signals, solving maximum likelihood estimation of a covariance matrix through fixed-point iteration under the non-Gaussian noise background, acquiring robust covariance matrix estimation by using a linear shrinkage technology when the number of transmitting and receiving array elements is greater than the number of snapshots, building a robust cost function by using contour integration, Stieltjes transform and a residue theorem, and performing spectrum peak search on the cost function so as to solve the target transmitting and receiving angle. The method provided by the invention has the advantages that the method has robust estimation performance under the non-Gaussian noise background, and the method is applicable to a large-array system with the number of transmitting and receiving array elements being greater than the number of snapshots at the same time.

Owner:JILIN UNIV

Light-weight and heat-isolation mullite bricks and preparation method thereof

The invention particularly relates to light-weight and heat-isolation mullite bricks and a preparation method thereof. The technical scheme is that the light-weight and heat-isolation mullite bricks are prepared from the following raw materials in percentage by weight: 40 to 48 percent of flint clay, 14 to 38 percent of kyanite, 6 to 16 percent of clay and 14 to 24 percent of alpha-Al2O3 fine powder, wherein a bonding agent is 15 to 20 percent by weight of the raw materials, and a pore-forming agent is 45 to 60 percent by weight of the raw materials. The preparation method comprises the following steps of firstly mixing the alpha-Al2O3 fine powder with the pore-forming agent, and carrying out wet grinding for 8 to 10 hours to obtain homogenized mud; uniformly stirring the homogenized mud, the flint clay, the kyanite, the clay and the bonding agent; carrying out aging, forming and baking; and preserving the heat at 1,325 to 1,450 DEG C for 3 to 5 hours to obtain the light-weight and heat-isolation mullite bricks. The light-weight and heat-isolation mullite bricks and the preparation method thereof have the advantages of saving resources, being simple in process, and being environmentally-friendly; and the prepared light-weight and heat-isolation mullite bricks are high in heat stability, low in heat conduction coefficient, low in volume density, low in after-burning linear shrinkage ratio, high in compression strength and good in heat insulation and isolation effect.

Owner:WUHAN UNIV OF SCI & TECH

Alumina fiber reinforced alumina closed-cell foamed ceramic and preparation method thereof

The invention discloses alumina fiber reinforced alumina closed-cell foamed ceramic and a preparation method thereof. Service temperature of the alumina fiber reinforced alumina closed-cell foamed ceramic is lower than 1700 DEG C, compressive strength is 7 MPa to 10 MPa, heating permanent linear shrinkage under 1600 DEG C is less than 1.5 percent multiplied by 24 hours, a heat conductivity coefficient of a hot surface of 1000 DEG C is 0.40 to 0.60 W / m.K, volume density is 0.7 to 1.0 g / cm<3>, and porosity is 75 to 83 percent; content of Al2O3 of chemical compositions is not less than 95 wt%; a principal crystalline phase of the foamed ceramic is alpha-Al2O3; a micro phase also comprises mullite produced by high-temperature reaction between silica sol and alpha-Al2O3. According to the alumina fiber reinforced alumina closed-cell foamed ceramic and the preparation method thereof disclosed by the invention, in a manner of combining pore-forming agent adding with a foaming method, the prepared foamed ceramic is of a closed-cell structure, and is high in porosity and has good mechanical property; the alumina fiber reinforced alumina closed-cell foamed ceramic can be used as a fire-proof insulating material, and is applied to the fields of high-temperature electric furnace linings, building materials and the like.

Owner:JIANGSU HIGH TECHNO THERMAL EQUIP CO LTD

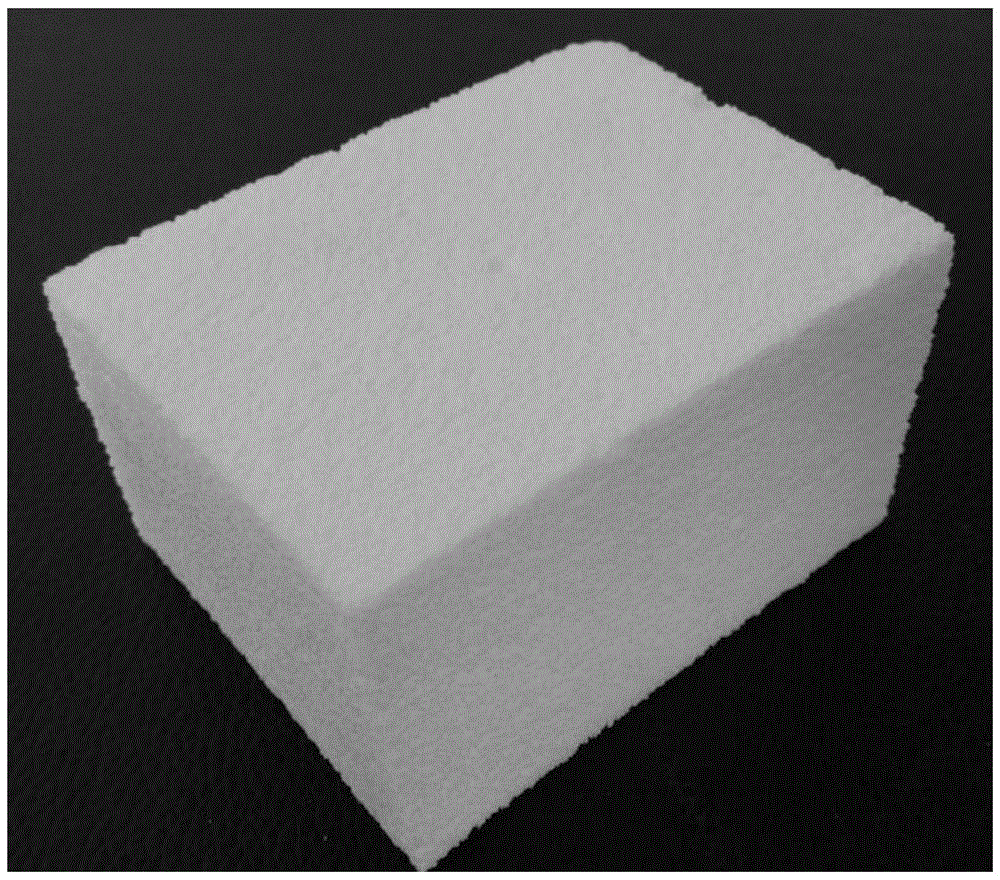

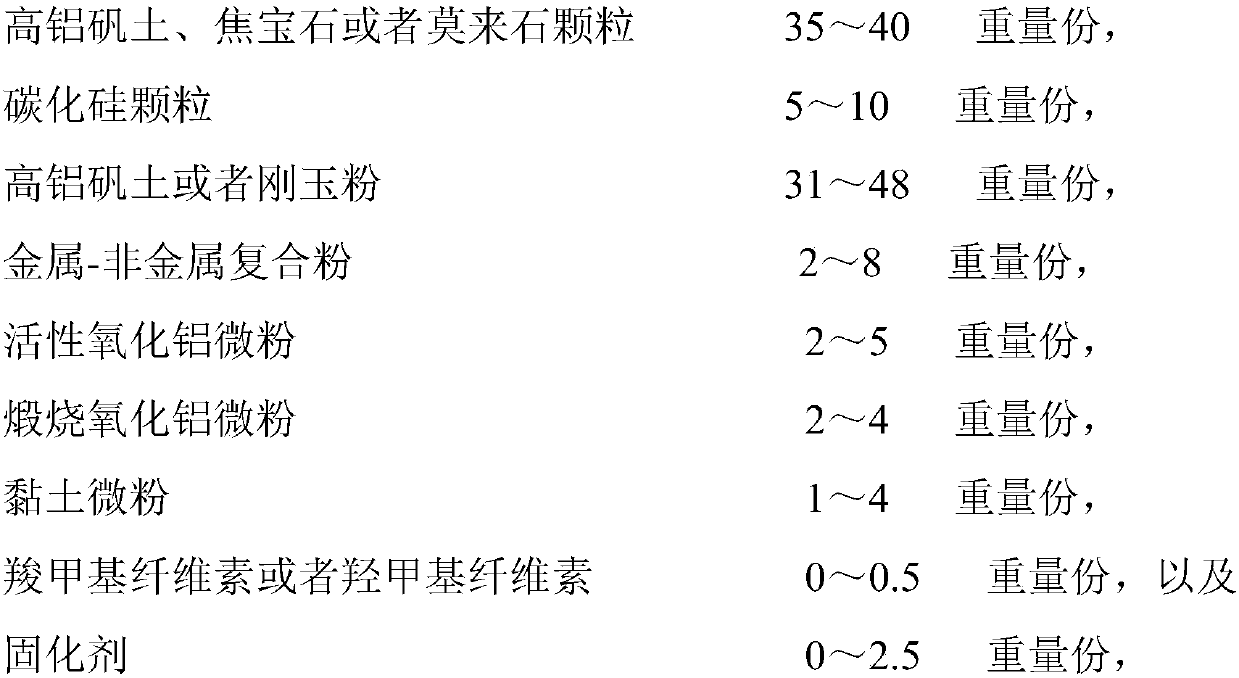

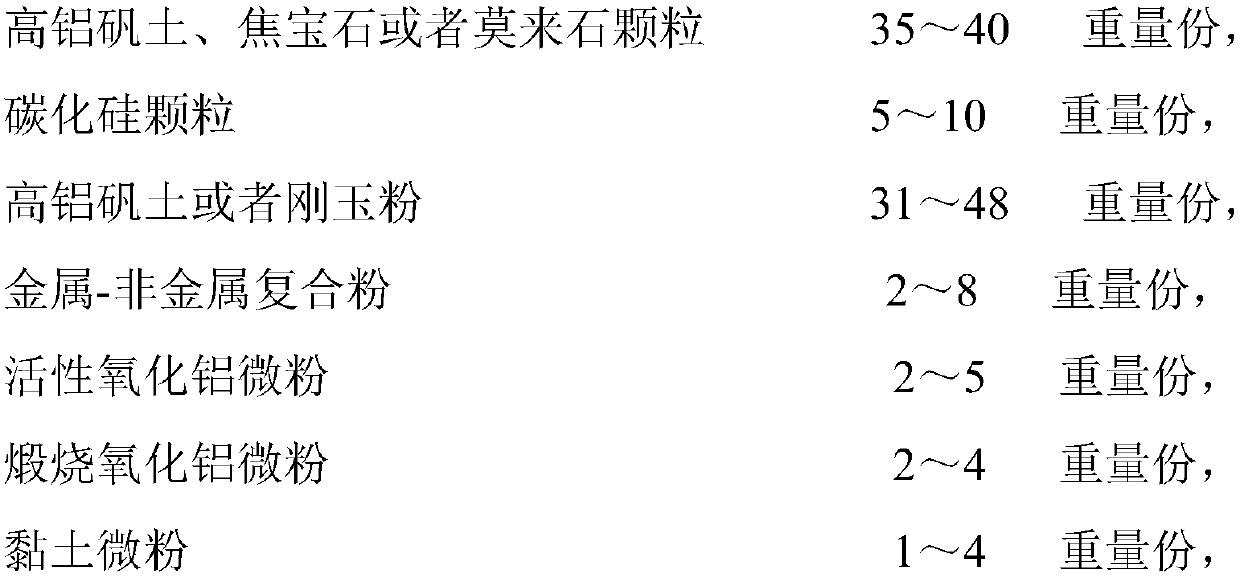

Hot-blast furnace pipe packing material and preparation method therefor

ActiveCN107698266AImprove high temperature performanceGood solid state sintering propertiesBlast furnace detailsProcess efficiency improvementResource utilizationMullite

The invention discloses a hot-blast furnace pipe packing material and a preparation method therefor. The packing material is prepared from the ingredients in parts by weight: 100 parts of dry mattersand 10-25 parts of silica sol, wherein the 100 parts of dry matters comprise high bauxite, flint clay or mullite particles, silicon carbide particles, high bauxite or corundum powder, metal-nonmetal composite powder, activated alumina micropowder, calcined alumina micropowder, clay micropowder, carboxymethyl cellulose or hydroxymethyl cellulose and a curing agent. The packing material disclosed bythe invention is pollution-free to environments, is good in fluidity in construction time, is not prone to settlement, can be thoroughly packed into small slits during pressed-in repair, can be constructed at high temperatures and can also be cured at normal temperatures; the packing material can be tightly bonded to a material of a pressed-in area; the packing material has good strength propertyat all temperatures; the packing material has low linear shrinkage in service temperature intervals and has good thermal shock stability; and industrial wastes of other industries are utilized, so that the utilization ratio of resources is increased.

Owner:CHINA JINGYE ENG +2

Method for preparing silicon aluminum composite aerogel material with high temperature resistance and high formability

The invention relates to a method for preparing a silicon aluminum composite aerogel material with high temperature resistance and high formability. The method comprises the following steps: preparing pure alumina sol on a water area heater at the temperature of over 60 DEG C, cooling and stirring until the solution restores to room temperature after the sol is clarified; adding a silicon precursor, a catalyst and other solvents into the solution, stirring for several minutes, and standing, wherein the obtained wet gel is subjected to aging modification and replacement of one part of hydrolyzed aluminum alkoxide solution; and finally, performing high-temperature superfluid modification and drying, thereby obtaining massive aerogel, and performing high-temperature treatment at the temperature of 1200 DEG C, thereby obtaining the silicon aluminum composite aerogel of which the linear shrinkage is less than 8 percent. According to the preparation method of the composite material, wide application of the high-temperature-resistant aerogel material in the fields of aerospace, military affairs and civil use is further accelerated.

Owner:SHANGHAI GRAND SOUND BEYOND NOISE NEW MATERIAL

Low-density molding compound

ActiveUS7700670B2Improve performanceSynthetic resin layered productsCellulosic plastic layered productsParticulatesCompound a

A molding composition formulation includes a thermoset cross-linkable polymeric resin. Glass microspheroids are present such that upon cure of the resin the resulting article has a linear shrinkage of less than ±0.06% and a density of less than 1.65. An article formed from such a composition is further strengthened by the addition of a surface activating agent bonded to the surface of the glass microspheroids. Conventional particulate fillers when added to an inventive formulation provide enhanced performance when the filler particle has a size sufficiently small to insert within adjacent microspheroid interstitial voids. An unsaturated polyester resin so formed is particularly well suited for the formation of sheet molding compound formulations.

Owner:CONTINENTAL STRUCTURAL PLASTICS INC

Flame-retardant polyether glycol and preparation method thereof, combined polyether and polyurethane foam

InactiveCN102070412AImprove flame retardant performanceEasy to operateEther preparation from oxiranesRing-opening polymerizationLinear shrinkage

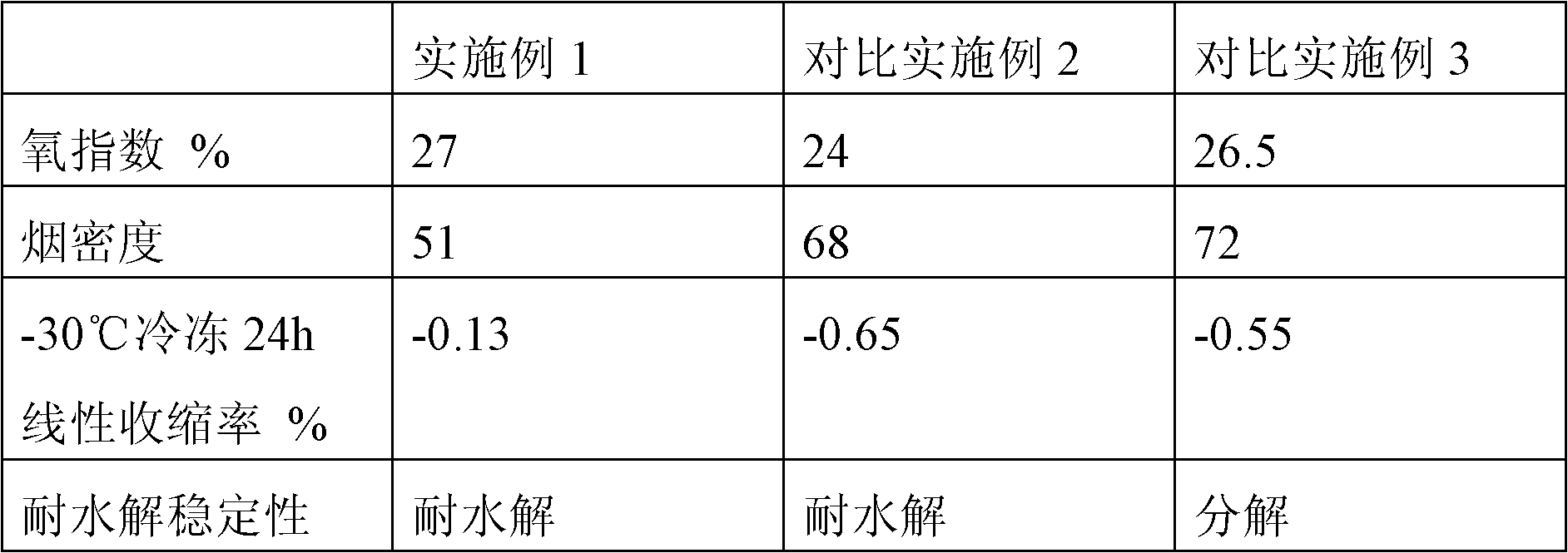

The invention provides a method for preparing flame-retardant polyether glycol, which comprises the step of: under the oxygen-free condition in the atmosphere of inert gas and the action of weak amine catalyst, performing opening polymerization reaction on polyol having the functionality of 3 to 8 and tetrabromo phthalic anhydride-diol, which are used as compound starting agents, and an epoxy compound. The flame-retardant polyether glycol overcomes the defect of low fire retardance of the conventional polyether glycol, and has better fire retardance; the polyurethane hard foam plastic prepared from the flame-retardant polyether glycol has higher oxygen index (more than 25), lower smoke density and perfect size stability (the linear shrinkage rate of the plastic after being frozen at -30 DEG C for 24 hours is -0.13 to -0.25 percent), and has outstanding economic benefit and social benefit. The preparation method for the polyether glycol is simple in operation, and the yield rate is over 98 percent.

Owner:SHANGHAI DONGDA POLYURETHANE

Gypsum mold formula for casting magnesium alloy and preparation method thereof

The invention discloses a gypsum mold formula for casting a magnesium alloy and a preparation method thereof, relating to preparation of a gypsum mold for casting a magnesium alloy. The gypsum mold formula comprises an additive component consisting of four basic components, including alpha-semihydrated gypsum, quartz powder, bauxite and magnesium sulfate as well as seven substances such as trisodium orthophosphate, barium chloride, a water reducing agent and the like. The invention further discloses a preparation method for the gypsum mold formula. Due to the adoption of scale graphite, oxidation of the magnesium alloy is effectively prevented; the water reducing agent is added into the formula, so that the fluidity of gypsum slurry is improved, the water consumption is lowered by 30 percent simultaneously, and the gypsum mold strength and drying efficiency are increased; the linear shrinkage of the gypsum mold can be remarkably lowered by using the gypsum mold formula together with barium chloride and urea; moreover, a solvent component consisting of tap water is adopted, so that the problems of high water consumption, poor fluidity, low strength, large size deformation, difficulty in breaking and the like existing in an ordinary gypsum mold are solved; and meanwhile, the problems of oxidization and combustion of the magnesium alloy are solved.

Owner:HUAZHONG UNIV OF SCI & TECH

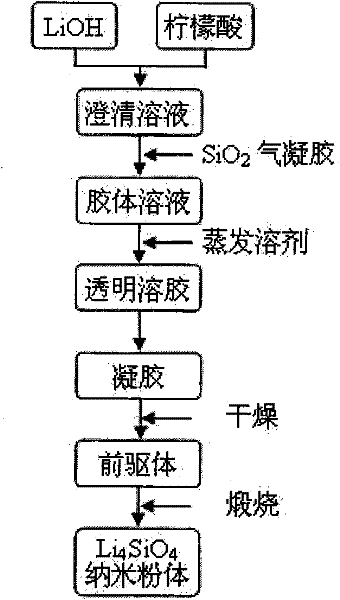

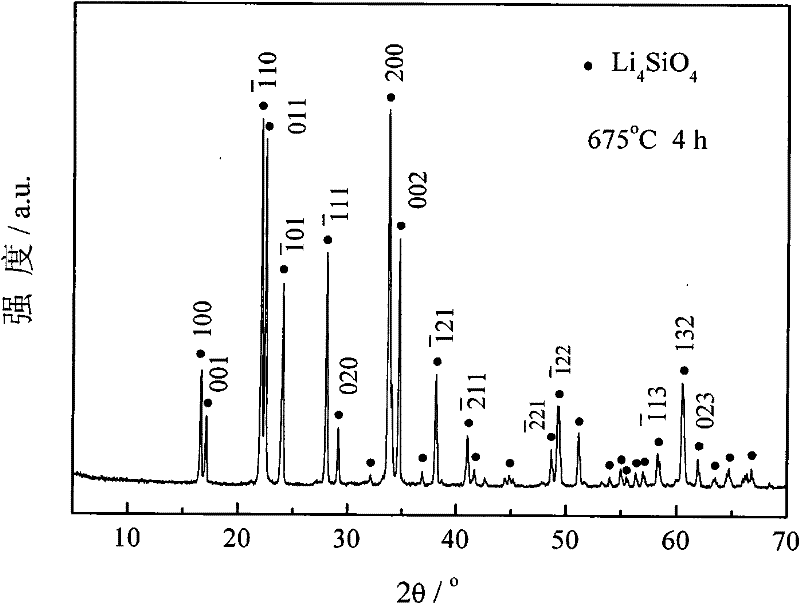

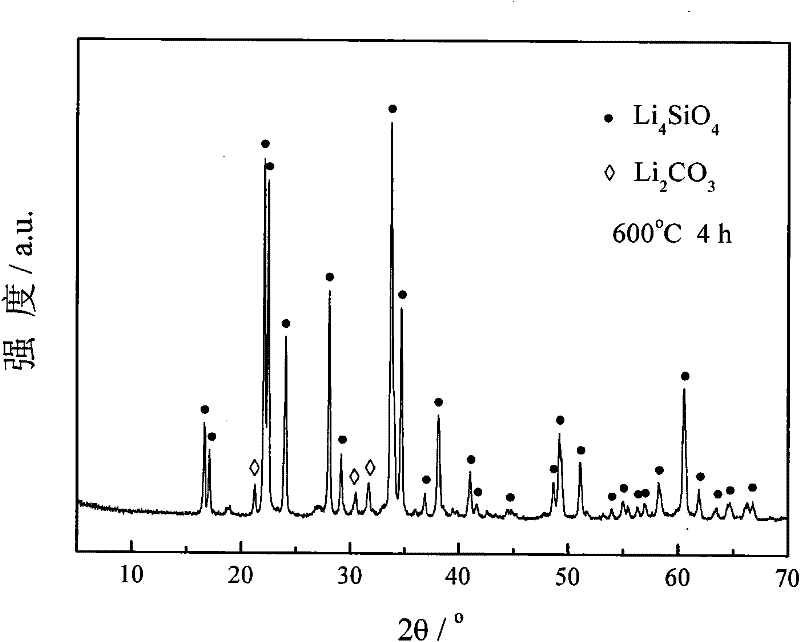

Method for preparing Li4SiO4 ceramic powder by water-based sol-gel process

The invention belongs to the field of ceramic materials and relates to a method for preparing lithium orthosilicate ceramic powder by a water-based sol-gel process. In the invention, a soluble lithium compound is used as a lithium source, SiO2 aerogel is used as a silicon source, citric acid is used as a complexing agent and a pH regulator for the solution, deionized water is used as a reaction medium, Li4SiO4 nano powder is synthesized at 550 to 700 DEG C, the pure-phase Li4SiO4 can be obtained by controlling some preparation conditions, the nano powder has high sintering activity, and the linear shrinkage at a temperature between room temperature and 1,000 is 3 times higher than that of Li4SiO4 powder prepared by a solid-phase reaction process. In the method, the raw materials are readily available and cheap, water is used as a reaction medium, and cost is lowered; and the reaction temperature is over 200 DEG C lower than that of the solid-reaction process, and energy is saved. The relative density of ceramic prepared by using Li4SiO4 nano powder is up to 82.9 percent, which is much higher than that of ceramic prepared by the solid-phase reaction process.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

Composite fireproof thermal-insulation board for fire barrier of external thermal insulation system for outer wall and preparation method of the board

The invention discloses a composite fireproof thermal-insulation board for a fire barrier of an external thermal insulation system for an outer wall and a preparation method of the board, and relates to a fireproof thermal-insulation board and a preparation method of the board. The board solves a technical problem that fireproofing security of the external thermal insulation system for the outer wall in the prior art is low. The fireproof thermal-insulation board provided by the invention is prepared from expanded perlite, floating beads, anti-crack fibers, a water repellent, an air entraining agent, water glass, re-dispersible rubber powder, cement, sodium fluosilicate and water. The preparation method comprises the steps of mixing raw materials, placing raw materials in a mold, solidifying the mold, demolding to obtain a blank, and heating and drying the blank to obtain the board. The fireproof thermal-insulation board provided by the invention has the characteristics of bulk density of 250-290kg / m<3>, compressive strength larger than 0.15MPa, thermal conductivity not larger than 0.060W / (m*k), water absorption not larger than 2%, hydrophobic rate not less than 98.0%, linear shrinkage not larger than 0.3%, 28d softening coefficient not less than 0.5, 50 times freezing and thawing cycle strength loss not larger than 15%, and mass loss not larger than 2.5%.

Owner:葛兆明 +6

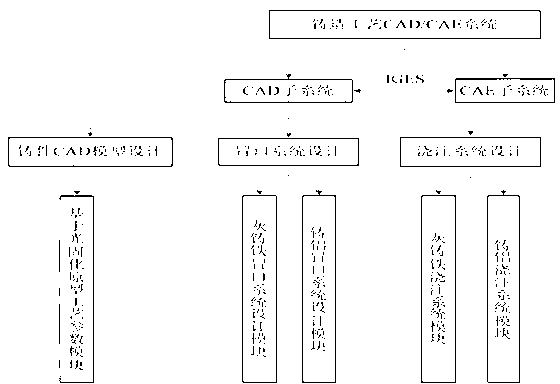

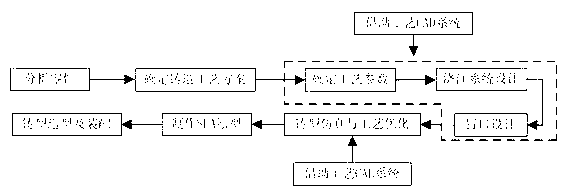

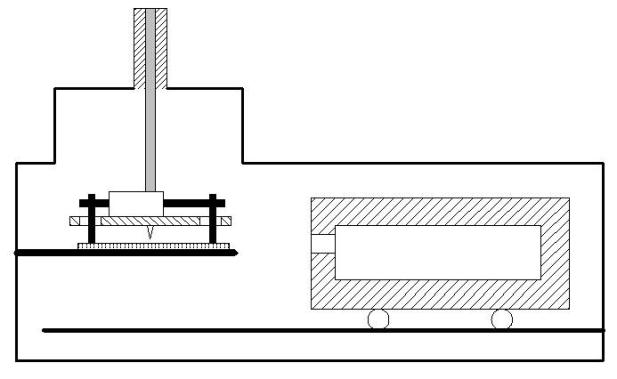

Cast manufacturing method of rapid sand casting based on SLA prototype

ActiveCN103310068AImprove efficiencyHigh precisionFoundry mouldsFoundry coresShrinkage rateMaterial resources

The invention discloses a cast manufacturing method of a rapid sand casting based on an SLA prototype, which combines the SLA rapid prototyping technology based on a conventional cast manufacturing method. The method comprises the following steps: in a whole cast design, exploiting a cast technology CAD system software as a main auxiliary application tool, and conducting cast simulating and technology optimization through a technology CAE system; and after finishing the cast design, manufacturing an SLA prototype piece through a light curing model mechanism, forming the cast by the modeling and the assembling of the cast, and manufacturing metal products by pouring. Meanwhile, by modifying the linear shrinkage and the draft angle of the cast, and adopting technical ways of phenol-urethane resin bonded sand molding, and the like, the efficiency and the accuracy of design and manufacturing of a casting technology designer are improved; manpower and material resources are saved; the engineering time is shortened, so as to facilitate the popularization and application of the rapid casting technology.

Owner:SOUTHWEAT UNIV OF SCI & TECH

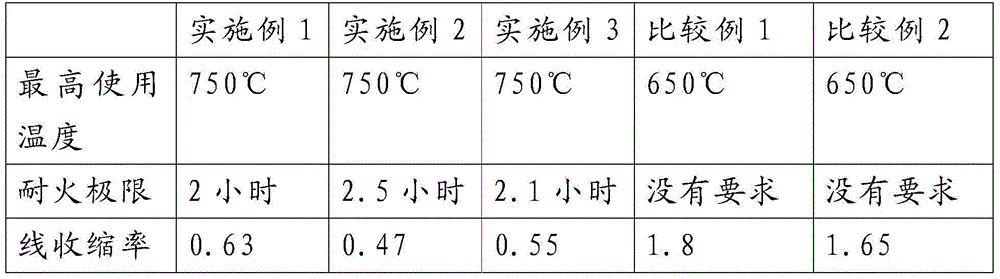

Preparation method of black rock wool

The invention provides a preparation method of black rock wool. The preparation method comprises the following steps: melting the following components in parts by weight: 300-400 weight parts of basalts, 200-300 weight parts of iron ores, 130-220 weight parts of blast furnace slag and 150-250 weight parts of coke, wherein the introducing amount of oxygen in the melting process accounts for 3-5% of the total mass of the basalts, the iron ores, the blast furnace slag and the coke; centrifuging and blowing off melts to be fibers; and performing wool collection, superposition and pressurized pleating on the fibers, and performing high-temperature pressurized molding in a curing oven to obtain the black rock wool. According to the prepared black rock wool provided by the invention, the temperature of a softening point can be increased, and the heat resistance can also be improved. Experimental results show that the maximum service temperature of the prepared black rock wool provided by the invention can reach 750 DEG C, the duration of fire resistance is more than 2 hours, and the linear shrinkage rate is less than 1.

Owner:山东鲁阳玄武岩纤维有限公司

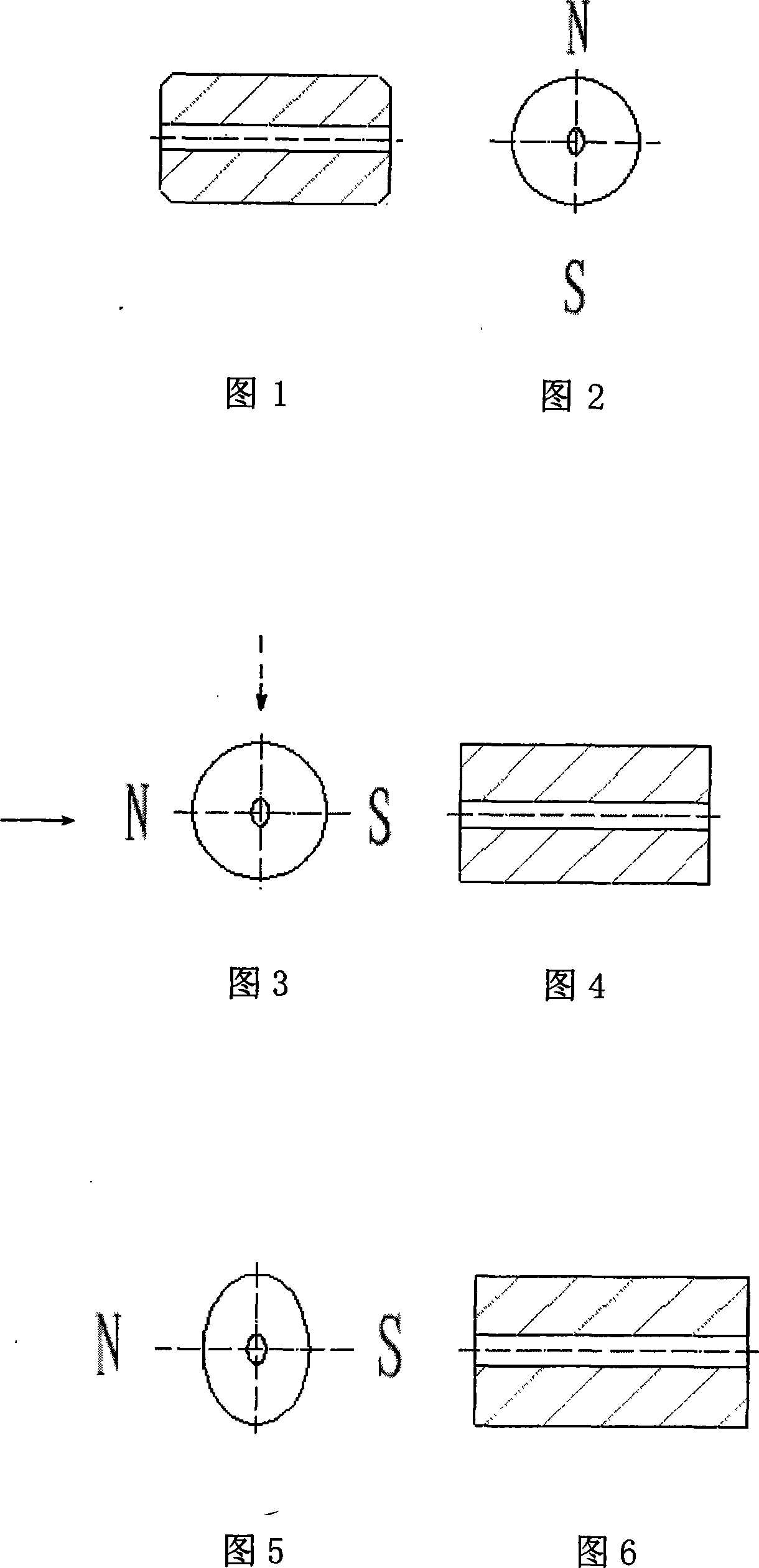

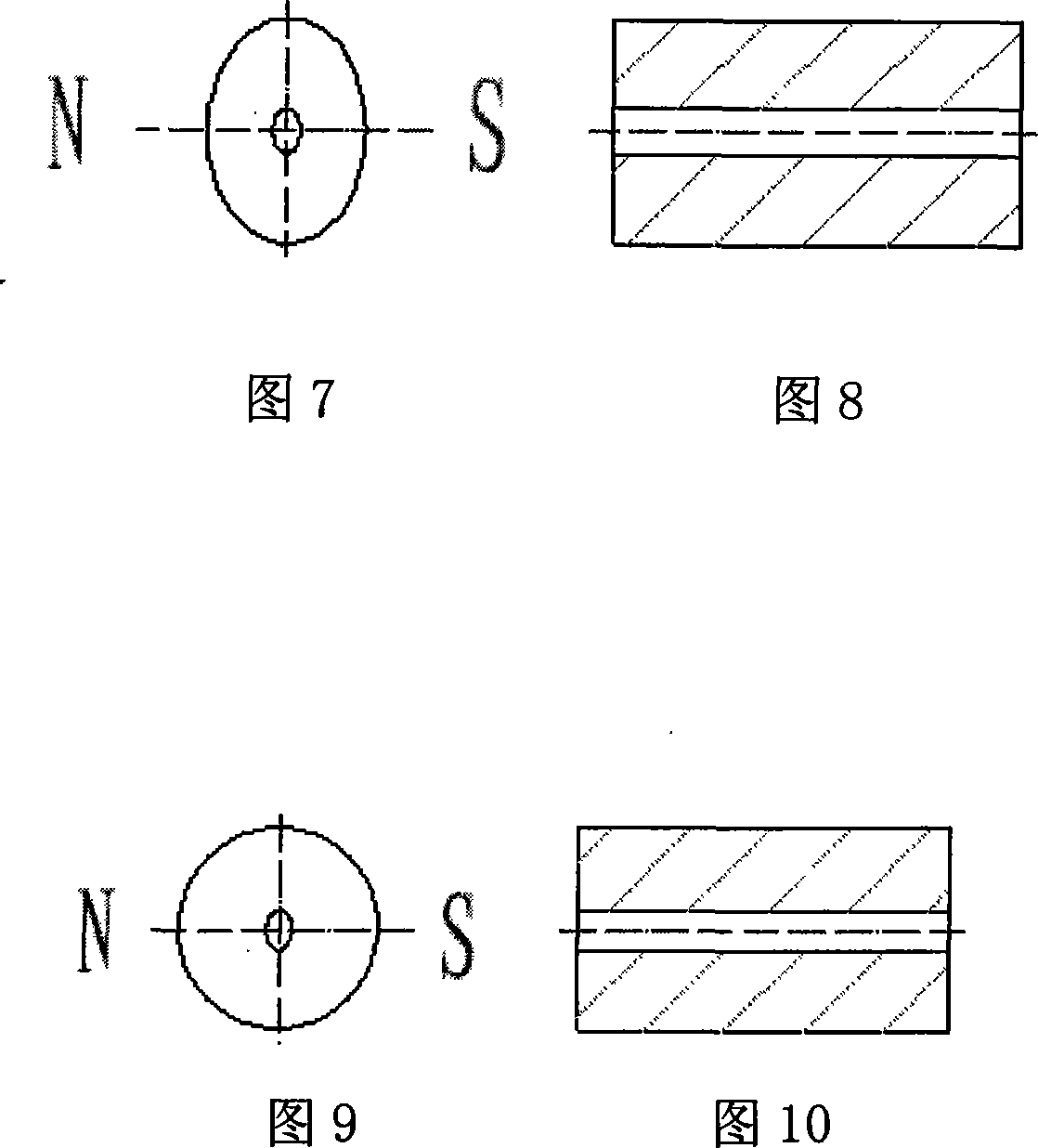

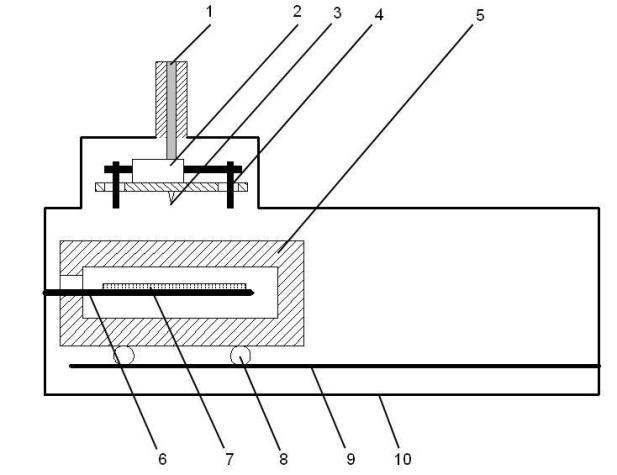

Method for making radial direction orientation permanent ferrite rotor

InactiveCN101202486AReduce lossGrinding convenienceInorganic material magnetismManufacturing stator/rotor bodiesMaterials scienceGrinding process

The invention discloses a manufacture method of a permanent magnetic ferrite rotor with radial orientation. The invention is made by the processes of powder making, green body pressing, sintering, grinding, cleaning and classification, injection and magnetizing; the pressed green body is pressed into a cylinder with elliptic section according to different linear shrinkage ratio of alignment direction and non-alignment direction in the sintering process of the permanent magnetic ferrite with radial orientation; the cylinder has the cylindrical shape after being sintered. The invention has the advantages that the produced blank pieces overcome the defects of the round pressing process; the pressed blank pieces are contracted into round shape after being sintered; the round blank piece brings a plurality of convenience for the grinding process, improves the working efficiency of the grinding process, improves magnetic performance and reduces the loss of raw material.

Owner:许正民

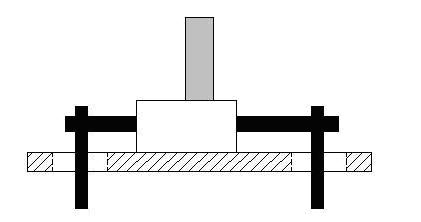

Method and device for measuring linear shrinkage rate and thermal stress of metal solidification process

ActiveCN102661966ASolve for uniformityTroubleshoot testing difficultiesInvestigating phase/state changeShrinkage rateCrucible

The invention relates to a method and a device for measuring a linear shrinkage rate and a thermal stress of a metal solidification process, which can solve the problems that the temperature is not uniform and the test is difficult in the existing method for measuring the shrinkage rate and the thermal stress of a black metal solidification process. The method comprises the following steps of: after smelting a sample in a crucible in situ, solidifying to realize the solidification under different cooling conditions; uniformly solidifying the sample in a temperature reducing process, wherein an axial temperature gradient is low and the measured linear shrinkage rate and thermal stress are accurate; and simultaneously measuring the linear shrinkage rate and the thermal stress in the solidification process through a stress sensor and a displacement sensor to realize continuous real-time measurement and correspond to those in an actual solidification process. According to the method and the device disclosed by the invention, the solidification and shrinkage properties of the metal can be accurately and reasonably measured, and the method and the device have important meanings of determining a casting and continuous casting process, improving relative equipment parameters and accelerating the quality and the yield of a casting blank and a casting piece.

Owner:SHANGHAI UNIV

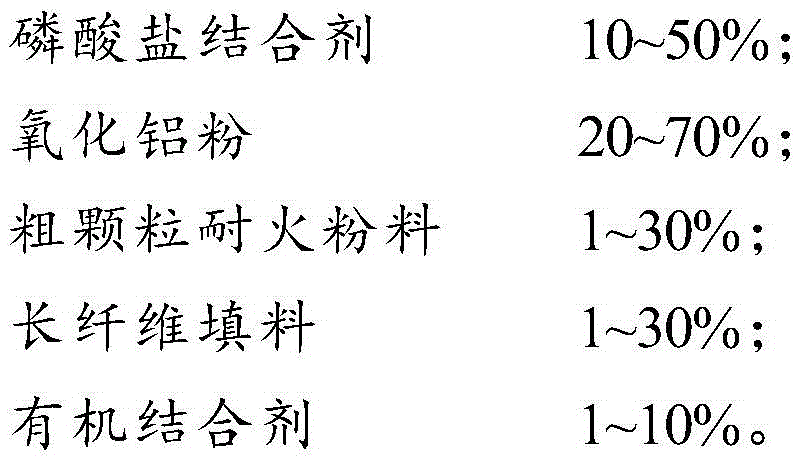

Novel composite coating layer and preparation method thereof

The invention provides a novel composite coating layer; a selected binder is high-temperature-resistant phosphate, and a filler is selected from a high-temperature refractory powder and fibers (including high-temperature-resistant inorganic silicate fibers and related organic fibers); the novel composite coating layer comprises, by the weight percentage, 10-50% of a phosphate binder, 20-70% of an alumina powder, 1-30% of a coarse-particle refractory powder, 1-30% of a long fiber filler, and 1-10% of an organic binder. The novel composite coating layer comprises the following main performance indexes: the volume weight after the novel composite coating layer is dried at room temperature is 1500-2500 kg / m<3>, the compressive strength is 1-26 MPa, the breaking strength is 1-15 MPa, the heating linear shrinkage is 0-3%, the solid content is 60-95%, the discretionary reduction is 2-30%, the viscosity is 10000-100000 MPa*s, and the using temperature is 800-1400 DEG C. The novel composite coating layer has the advantages of excellent thermal shock resistance and air flow scouring resistance, prevents a fiber furnace lining in a high temperature furnace from directly making contact with a severe environment in the furnace, so as to prolong the service life of the furnace lining, and improve furnace heat-preservation and heat-insulation effects.

Owner:LUYANG ENERGY SAVING MATERIALS CO LTD

Mullite light heat-insulation brick based on flint clay and preparation method of brick

ActiveCN105503209AEasy to form large-scale industrial productionLow costCeramic materials productionClaywaresFiberBrick

The invention particularly relates to a mullite light heat-insulation brick based on flint clay and a preparation method of the brick. According to the technical scheme, the mullite light heat-insulation brick is prepared from the raw materials of 20-38 wt% of the flint clay, 20-32 wt% of kyanite, 20-32 wt% of clay and 14-26 wt% of alpha-alumina micro powder, and saw dust accounting for 30-50% of the weight of the raw materials, mullite fibers accounting for 5-11% of the weight of the raw materials and a binding agent accounting for 10-35% of the weight of the raw materials are additionally added; the materials are stirred for 6-8 h at room temperature, and then material aging, shaping and natural drying are conducted; an obtained product is baked for 12-24 h at the temperature ranging from 110 DEG C to 210 DEG C, heat preservation is conducted for 2-5 h at the temperature ranging from 1,150 DEG C to 1,450 DEG C, and the mullite light heat-insulation brick based on the flint clay is prepared. The preparation method has the advantages of being low in cost and simple in technology, and the prepared mullite light heat-insulation brick based on the flint clay has the advantages of being low in heat conductivity coefficient, low in volume density, low in linear shrinkage rate after burning and high in compressive strength.

Owner:WUHAN UNIV OF SCI & TECH

Polyurethane board and preparation method thereof

The invention discloses a polyurethane board and a preparation method thereof. The manufacturing method comprises the following steps of uniformly mixing a component A, a component B and compound filler to prepare a foaming material, injecting the foaming material into a die for compression molding, and finally demoulding to form a polyurethane board product, wherein the component A comprises a polyether polyol auxiliary a and a polyester polyol auxiliary b; the component B is isocyanate; the filler is prepared from an inorganic powder material, a plant powder material and a fiber material. According to the manufacturing method, the polyurethane board product is manufactured by uniformly mixing the compound polyester polyol, the isocyanate and the compound filler, injecting the mixture into the die and carrying out heat-preservation pressing. The obtained product is high in mechanical performance strength, low in linear shrinkage rate during storage and use, is not easy to warp after long-term storage and high in production and secondary processing precision, does not easily absorb water and can be applied to the field having high requirement on size precision.

Owner:昆山市柳鑫电子有限公司

Low dielectric constant low temperature fired ceramics

ActiveUS7160823B2Low dielectric lossWell formedSemiconductor/solid-state device detailsSolid-state devicesElectricityDielectric ceramics

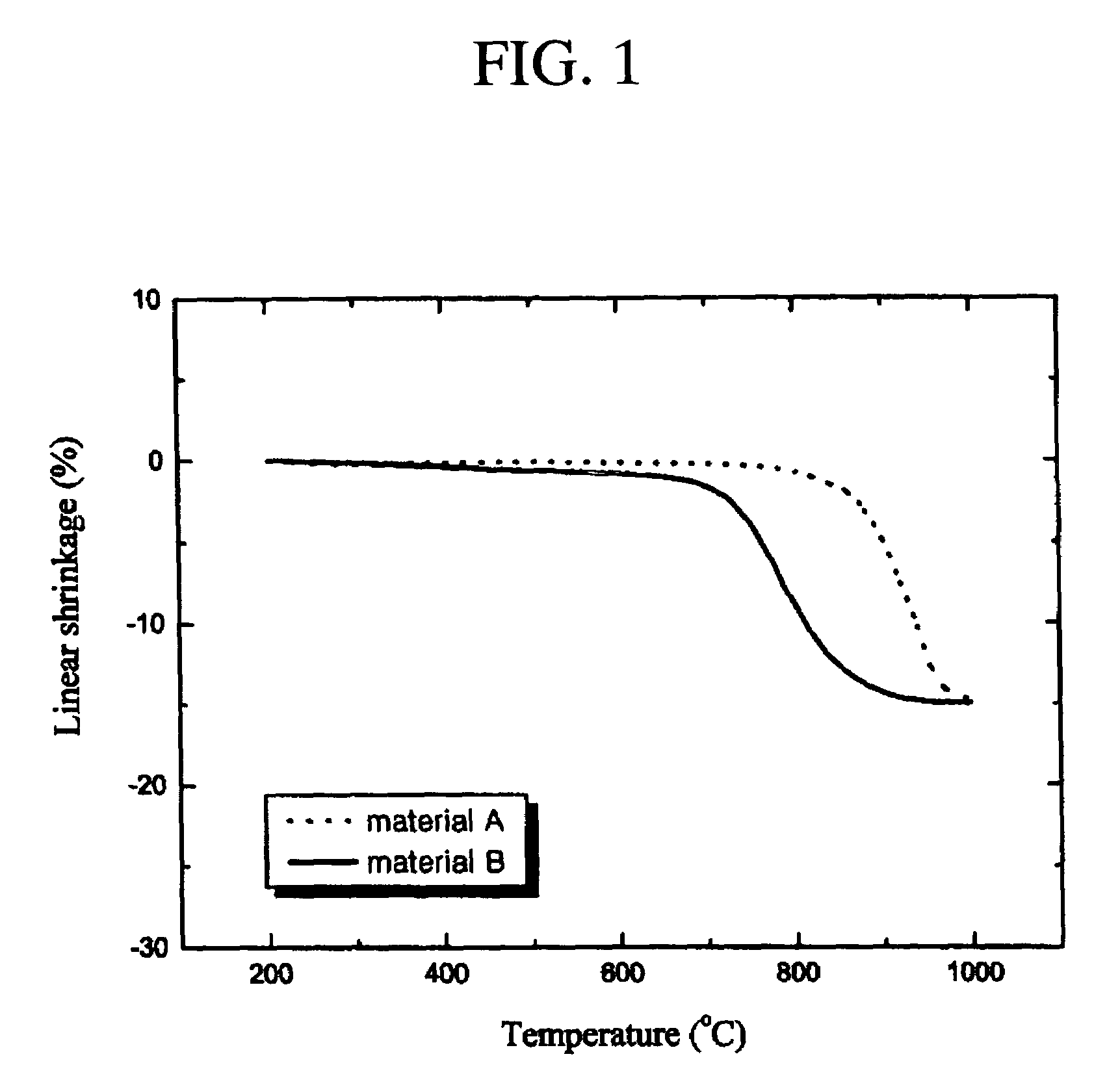

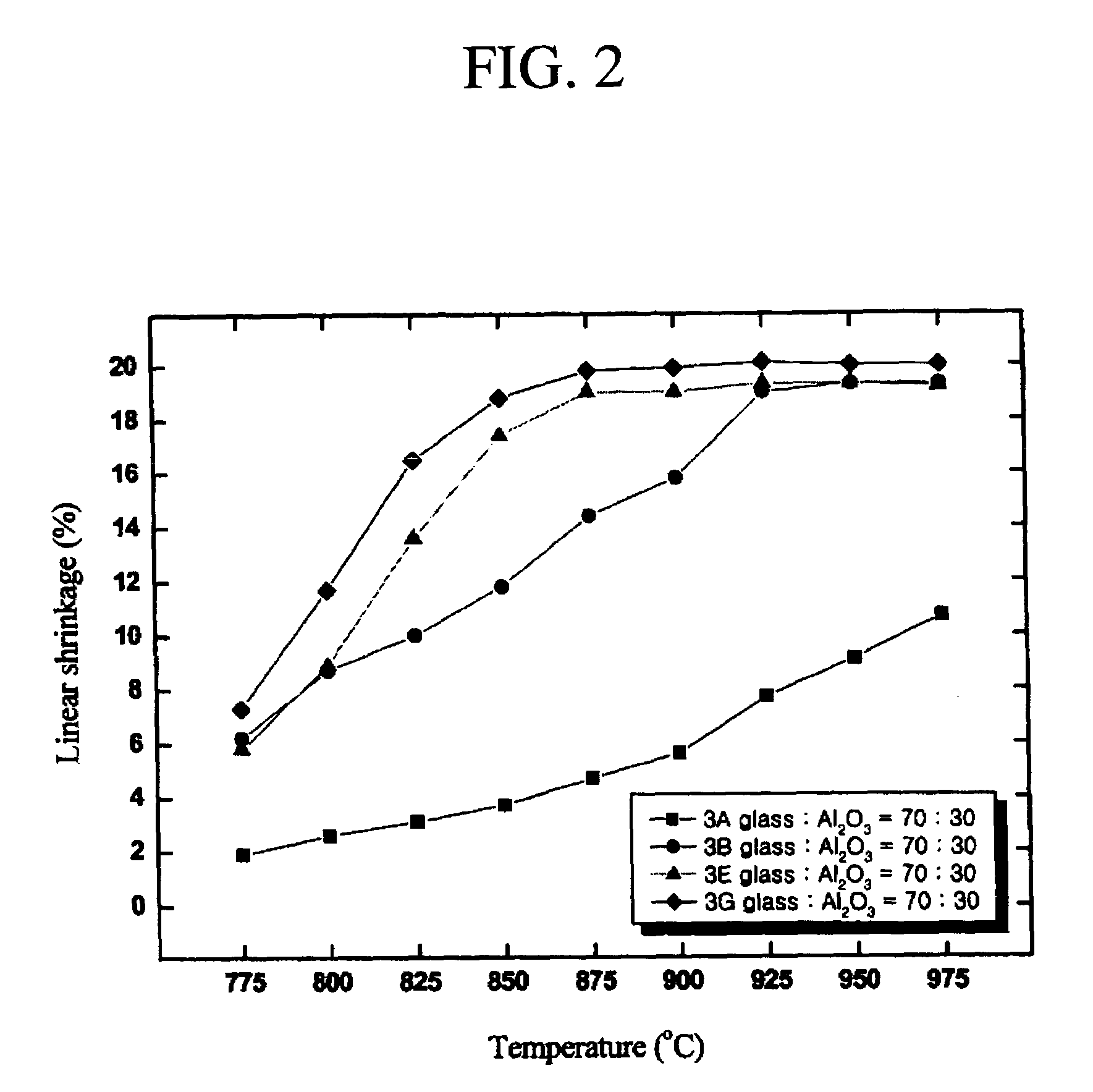

Low dielectric constant dielectric ceramics for a borosilicate-based low temperature fired multi-layer substrate is disclosed which can be fired at a wide temperature range of above and below 900° C. and exhibits a low loss electrical property. By controlling the types and addition amount of the alkaline earth metal oxide, the linear shrinkage behavior can be considerably controlled while maintaining the electrical property unchanged. The composition facilitates matching a linear shrinkage with a heterogeneous material having certain shrinkage characteristics.

Owner:KOREA INST OF SCI & TECH

Bulk silicon carbide polymer precursor ceramic and blending-cracking preparation method thereof

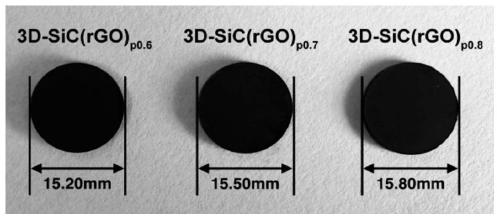

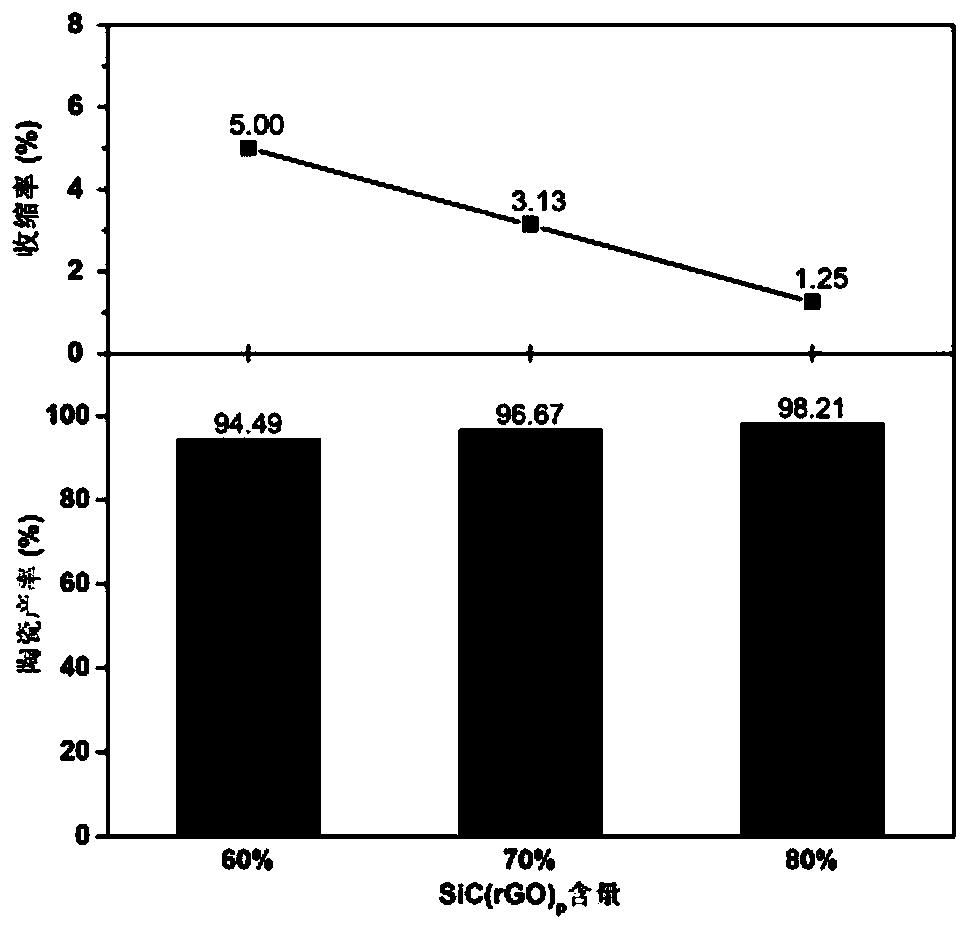

The invention provides a bulk silicon carbide polymer precursor ceramic and a blending-cracking preparation method thereof, belonging to the field of preparation of ceramic materials. The bulk siliconcarbide polymer precursor ceramic is named as 3D-SiC(rGO) ceramic and is composed of beta-SiC, SiO<x>C<y>, SiO<2>, rGO, and free carbon, wherein beta-SiC nanocrystals are dispersed in a SiO<x>C<y> / C<free> amorphous phase, and SiO2 grains are inlaid in a beta-SiC / SiO<x>C<y> / C<free> matrix. The homemade modified polymer precursor polycarbosilane-vinyltriethoxysilane-graphene oxide is used as a rawmaterial and is mixed with SiC(rGO) powder obtained after cracking the precursor in proportion, and then ball milling and re-cracking are carried out so as to prepare the ceramic. The ceramic has high ceramic yield, low linear shrinkage, good hardness and fracture toughness, uniform and dense microstructure, few pores, microcracks and interfaces, and good practicality and reliability.

Owner:中科德胜(常州)电子科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com