Patents

Literature

106results about How to "With thermal shock resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing ligh high strength aluminium oxide hollow ball ceramic

InactiveCN1554616AWith shrinkageWith thermal shock resistanceCeramicwarePhosphoric acidShock resistance

The light high-strength alumina ceramic ball has phosphoric acid solution as binding agent, alpha-alumina powder as basic material and hollow alumina ball as aggregate. Compared with dense refractory material, it has low density, high heat shock resistance, good heat insulating performance, low heat capacity and other features; and compared with common heat insulating material, it has high compression strength, high loaded softening temperature, low re-burning linear shrinkage and other features. It may be used as heat insulating material directly and may be also used in direct contact with flame, such as being used as lining material in high temperature furnace and kiln. In addition, its strength may be further raised in secondary sintering.

Owner:ZHEJIANG UNIV

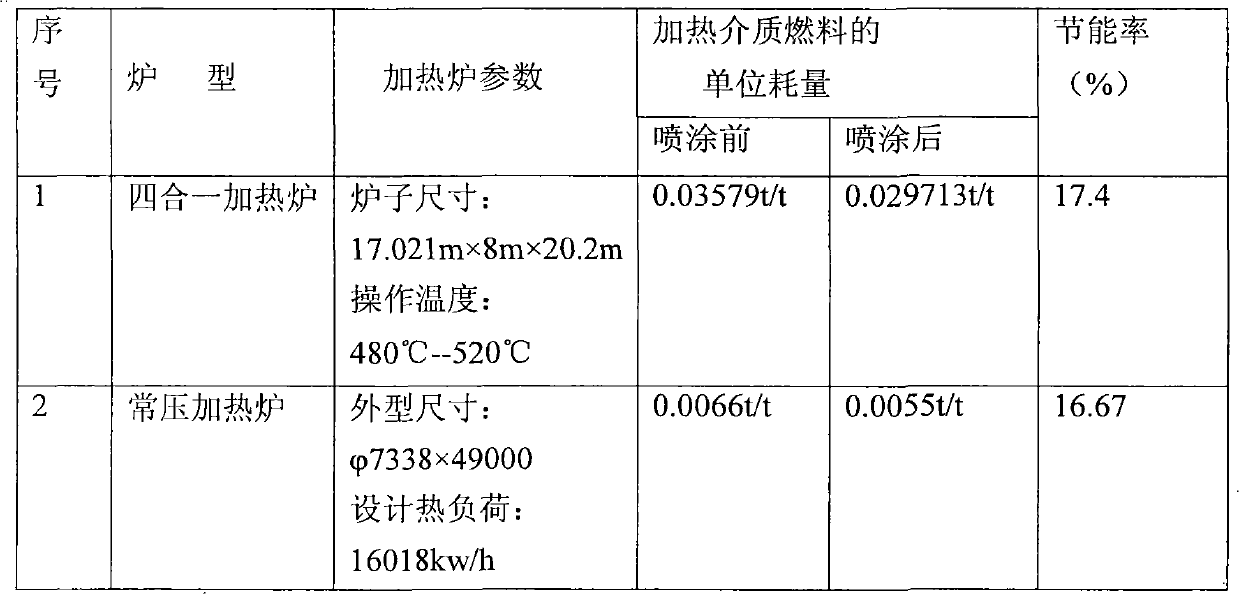

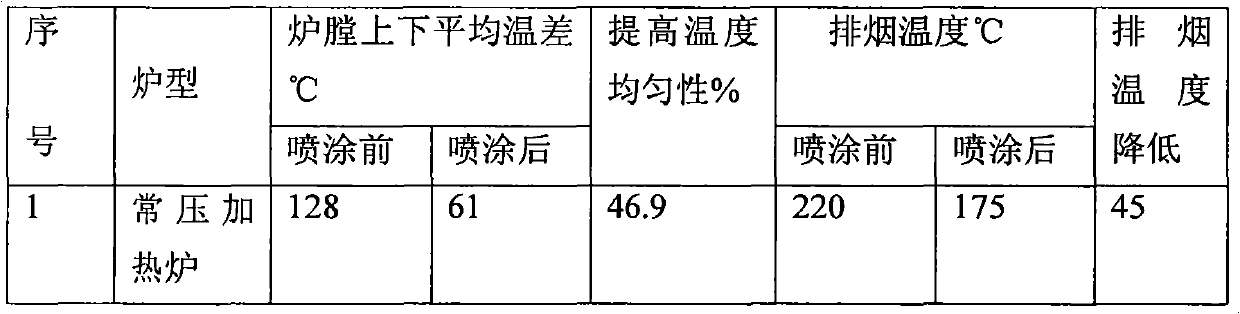

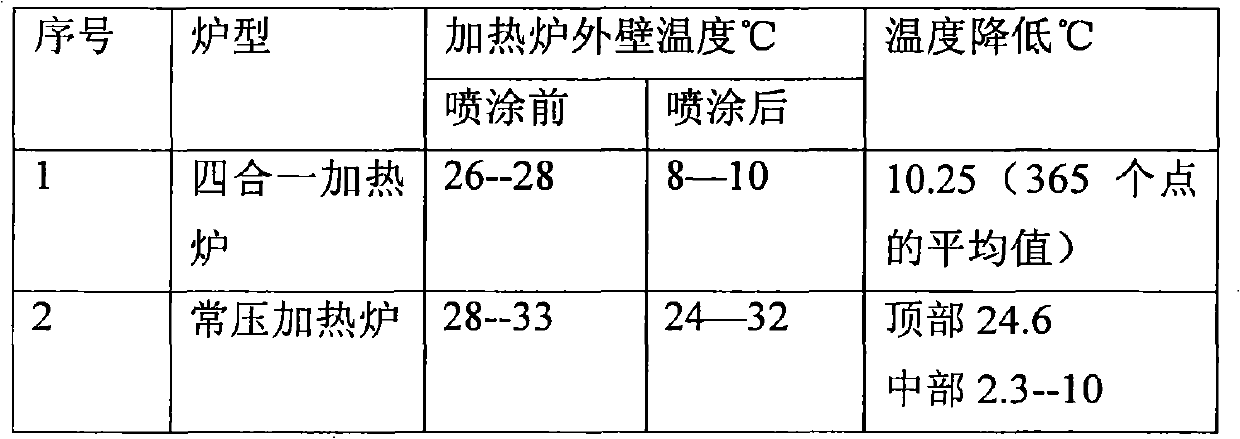

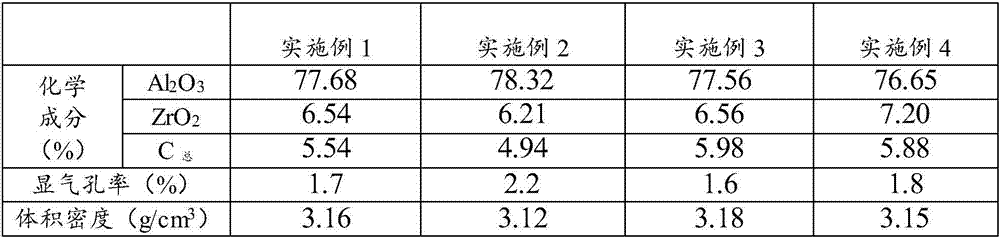

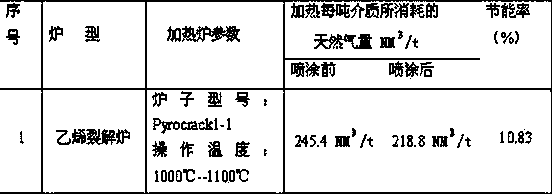

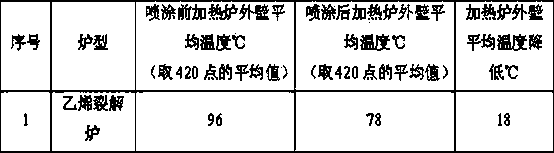

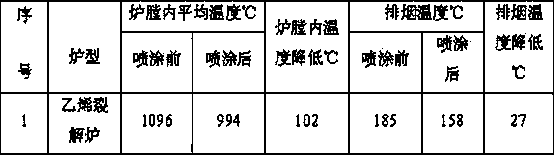

Ceramic coating used for heating furnace

InactiveCN102020475AExtended service lifeHas high temperature oxidation resistanceEmissivityRadiance

The invention relates to ceramic coating used for a heating furnace. The ceramic coating comprises the following components: ceramic micro powder, an inorganic bonding agent and a linear thermal expansivity regulator. The invention also provides a method for preparing the ceramic coating for the heating furnace. The ceramic coating has the characteristics of having improved radiance and thermal shock resistance, being efficient and energy-saving, prolonging the service life of furnace linings and furnace tubes, improving temperature uniformity and the like, as defined below: (1) the energy consumption is reduced, the energy is saved by more than 3 percent and pollutant discharge is reduced; (2) the temperature uniformity in the heating furnace is improved: (3) the metallurgy stability of the furnace tube of the heating furnace is improved, the coking and scaling of the furnace tub are delayed, and the absorbing capacity of the furnace tube can be maximized; (4) the emissivity of the surface of the refractory lining layer can be maximized so as to increase the secondary radiation of radiant heat (energy) and increase the efficiency of the radiant section; and (5) the outer wall temperature and the exhaust gas temperature of the heating furnace can be reduced by more than 5 percent.

Owner:北京安泰恒业科技有限公司

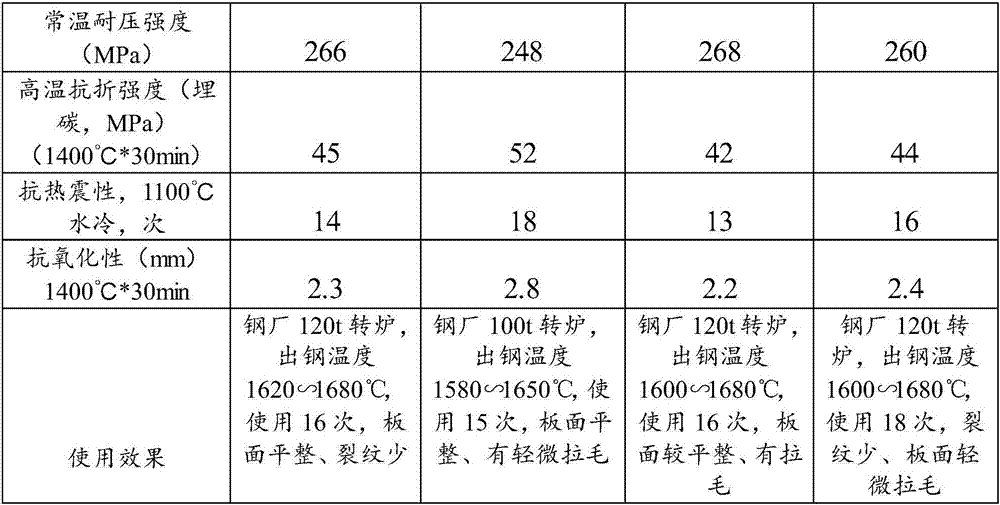

Slide plate brick for slag stopping of converter, and production method thereof

The invention provides a slide plate brick for slag stopping of a converter. The slide plate brick is produced from, by mass, 45-60% of tabular corundum, 10-30% of zirconia mullite, 6-14% of alumina micro-powder, 4-10% of metallic aluminum powder, 2-8% of silicon carbide, 1-3% of clay, 1-3% of carbon black, 0.5-1.5% of boron carbide, 0.5-1.5% of aluminum fibers and 4-6% of a composite resin binder. The slide plate brick for slag stopping of the converter is produced through selecting specific kinds and proportions of the raw materials without high temperature calcination, can be used multiple times, and has good resistance to corrosion, scour, oxidation and thermal shock.

Owner:HUNAN XIANGGANG RUITAI TECH

Heat treatment method for high ferrochrome roll requiring stepped hardness of roll body

ActiveCN102321795ALow thermal conductivitySmall heat capacityFurnace typesHeat treatment process controlFiberHardness

The invention discloses a heat treatment method for a high ferrochrome roll requiring stepped hardness of a roll body. The method mainly comprises the following steps of: before the roll is preheated, coating ceramic fibers on parts, which have low hardness requirement on the roll body, close to the roll necks of the roll; performing preheating treatment, differential temperature heat treatment and quenching treatment; before tempering, removing the ceramic fibers on two end parts of the roll; and performing tempering treatment on the roll in a low temperature tempering furnace. By the heat treatment method, the technical requirement that the roll body of the roll has stepped hardness can be met.

Owner:SINOSTEEL XINGTAI MACHINERY & MILL ROLL

Aluminum silicon carbide carbon brick for torpedo tank and preparation method thereof

The invention relates to an aluminum silicon carbide carbon brick for a torpedo tank and a preparation method thereof. The aluminum silicon carbide carbon brick comprises the raw materials by weight percent: 10-30% of special grade alumina, 15-35% of sub-white fused alumina being 1-3mm, 5-15% of silicon carbide, 2-10% of andalusite, 5-15% of crystalline flake graphite, 5-15% of 325-mesh sub-white fused alumina, 1-10% of nitride, 2-3% of metal aluminum powder and 3-5% of phenolic resin. The aluminum silicon carbide carbon brick is prepared by mixing the raw materials in the proportion, molding and drying. According to the invention, a corundum mullite phase is formed in the process of using the finished product and combined with nitride by adjusting the composition of the raw materials and adding nitride, so that the corrosion resistance, the scouring resistance and the high-temperature volume stability of the brick can be improved; compared with the common Al2O3-SiC-C (ASC) brick, the aluminum silicon carbide carbon brick improves the furnace age by about 15%.

Owner:北京首钢耐材炉料有限公司

Method for maintaining coke dry quenching furnace

The invention discloses a method for maintaining a coke dry quenching furnace. The method comprises the following steps of: firstly, carrying out construction preparation; then, building an isolation shed to achieve the safety requirement on simultaneous construction in a plurality of construction areas; sequentially carrying out constructions of applying an interfacial agent, ramming a liner which consists of firm plasticizing materials and anchoring bricks, and treating a working surface of the liner; and finally baking the furnace. The invention has the advantage that by adopting the isolation shed, construction mode on areas required to be maintained are changed from a traditional rotating maintenance mode into a simultaneous maintenance mode on a plurality of areas, thereby shortening the maintenance period, and enhancing the work efficiency; by adopting the liner consisting of the firm plastic materials and the anchoring bricks, the furnace body has the excellent performances ofhigh strength, good structure, strong wear-resisting property, thermal shock resistance and the like, thereby the service life of the furnace body is prolonged.

Owner:宜兴市炉顶密封工程有限公司

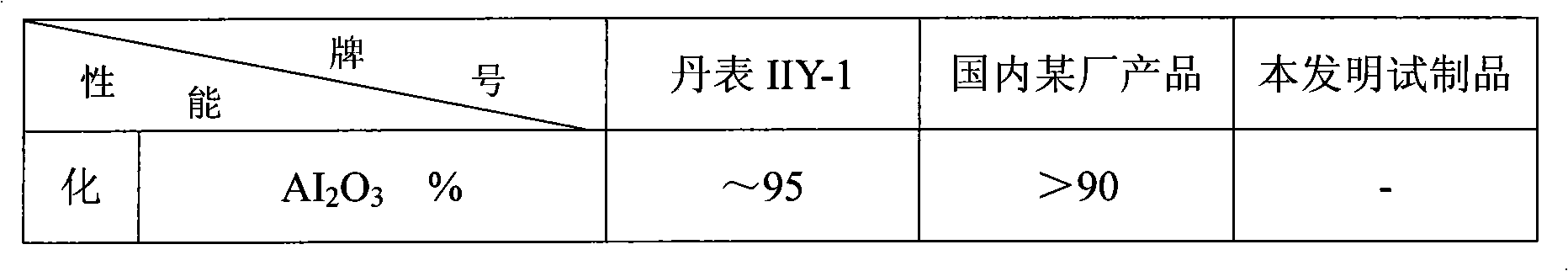

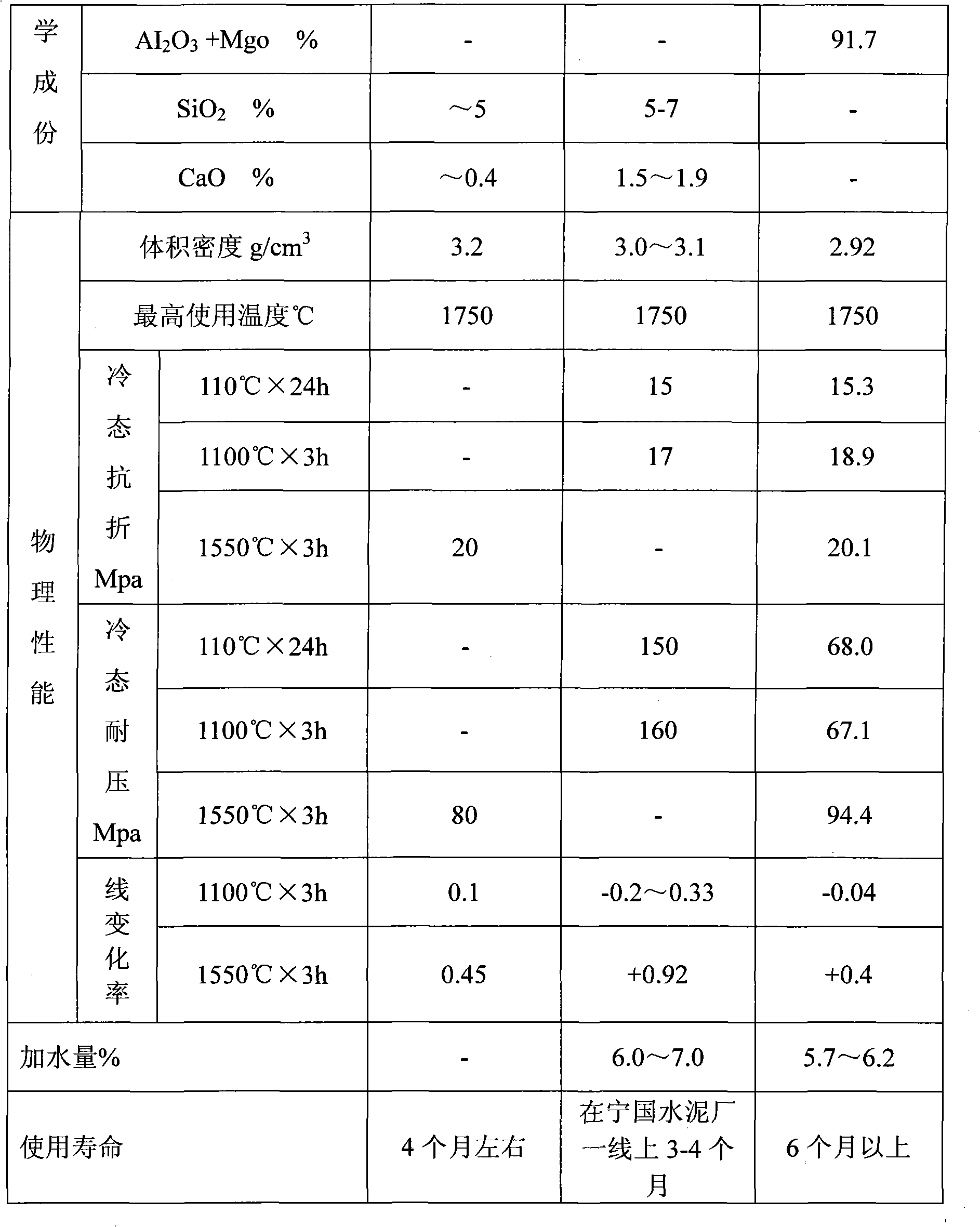

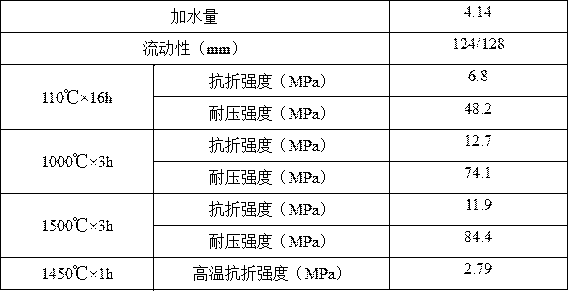

Cement kiln coal injection pipe castable

The invention provides a cement kiln coal injection pipe castable, which adopts high purity aluminium magnesium spinel as main raw material, selects pure calcium aluminate cement as bonding agent, alumina superfines as additive. The invention integrates the advantages of high refractoriness, high resistance to thermal shocks, high strength and abrasion resistance, meanwhile the service life can break down the record of the 4 month of the external product and exceed 8 month.

Owner:ANHUI NINGHUO NEW MATERIAL

Anti-erosion iron runner castable for large blast furnace

InactiveCN111574206APrevent penetrationLow apparent porosityCeramicwareOxidation resistantCarbon black

The invention relates to an anti-erosion iron runner castable for a large blast furnace. The material comprises, according to weight percentage, 58-64 parts of compact brown fused alumina particles, 2-5 parts of white corundum particles, 16-23 parts of silicon carbide, 5-7 parts of aluminum oxide micro-powder, 2-3 parts of pure calcium aluminate cement, 2-3 parts of silicon dioxide micro-powder, 1.5-2.5 parts of spherical asphalt particles, 0.5-1.2 parts of carbon black powder, 1.5-3.5 parts of metal silicon powder, 0.2-0.6 part of boron carbide, 0.1-0.2 part of metal aluminum powder, 0.15-0.2part of a water reducing agent, 0.6-1 part of an anti-erosion agent and 0.05-0.08 part of explosion-proof fibers. According to the castable, the service life of a primary runner of a main runner is prolonged, and the stability of safe operation of an iron runner is improved. It is verified that the requirements for rapid baking without cracking, erosion resistance, oxidation resistance, slag adhesion resistance and iron flux can be met, the iron flux can reach 180000 tons or above without repairing, and good application prospects are achieved.

Owner:TANGSHAN GUOLIANG SPEICAL REFRACTORY MATERIAL

Magnesium spinel refractory product

InactiveCN103214255AHigh temperature resistantWith thermal shock resistanceTemperature resistanceCement kiln

The invention discloses a magnesium spinel refractory product which is prepared by the following steps of: reacting polyacrylic acid with a magnesium oxide containing material at the room temperature to generate magnesium polyacrylic acid, and reacting magnesium alumina spinel at high temperature reacts with a composite powder consisting of grinding iron alumina spinel, an active alumina micropowder and active iron oxide which are added in advance, so as to form a solid solution. The material of the magnesium spinel refractory product has high temperature resistance, and thermal shock resistance, and good property of adhering coating. The magnesium spinel refractory product can be used in large-size cement kiln calcining zones.

Owner:郑州瑞泰耐火科技有限公司

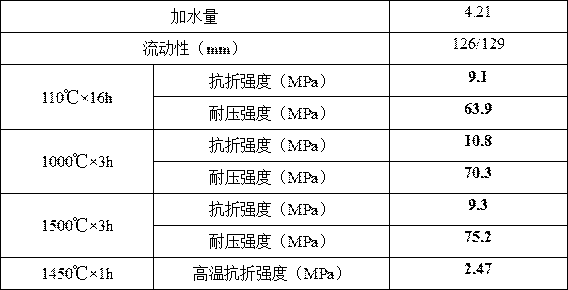

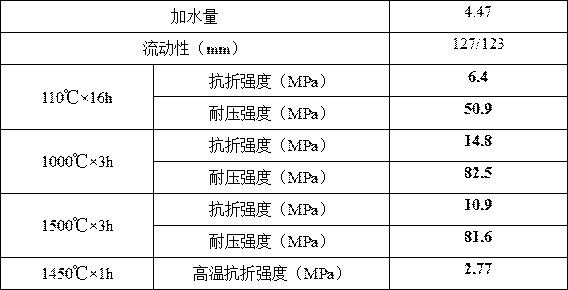

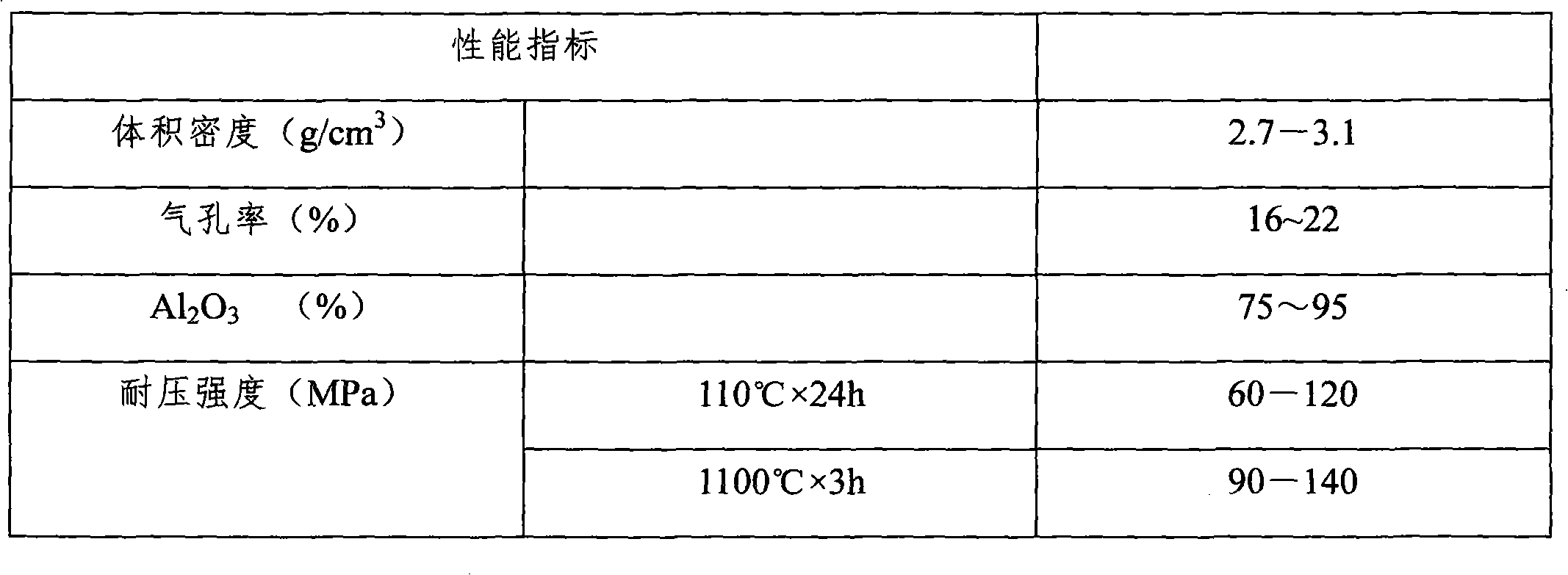

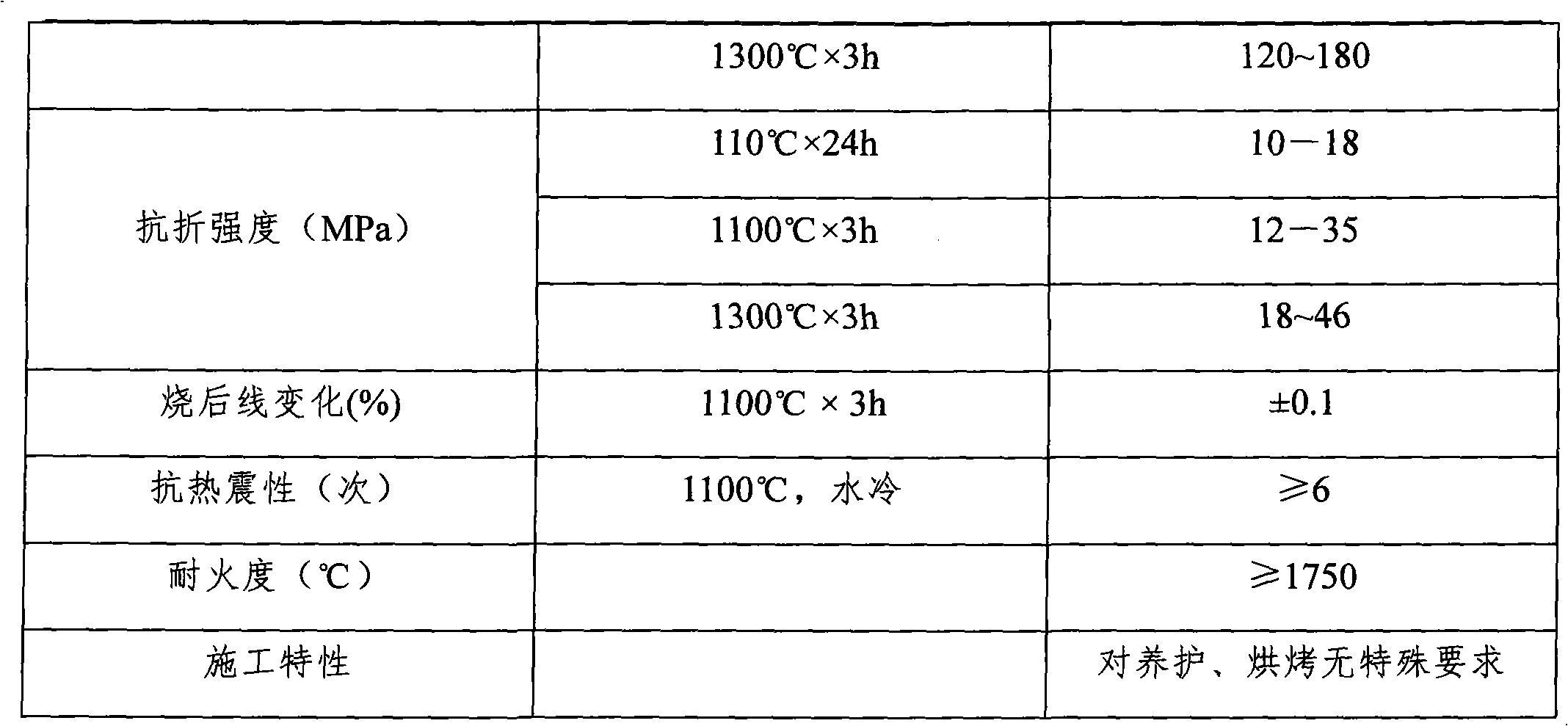

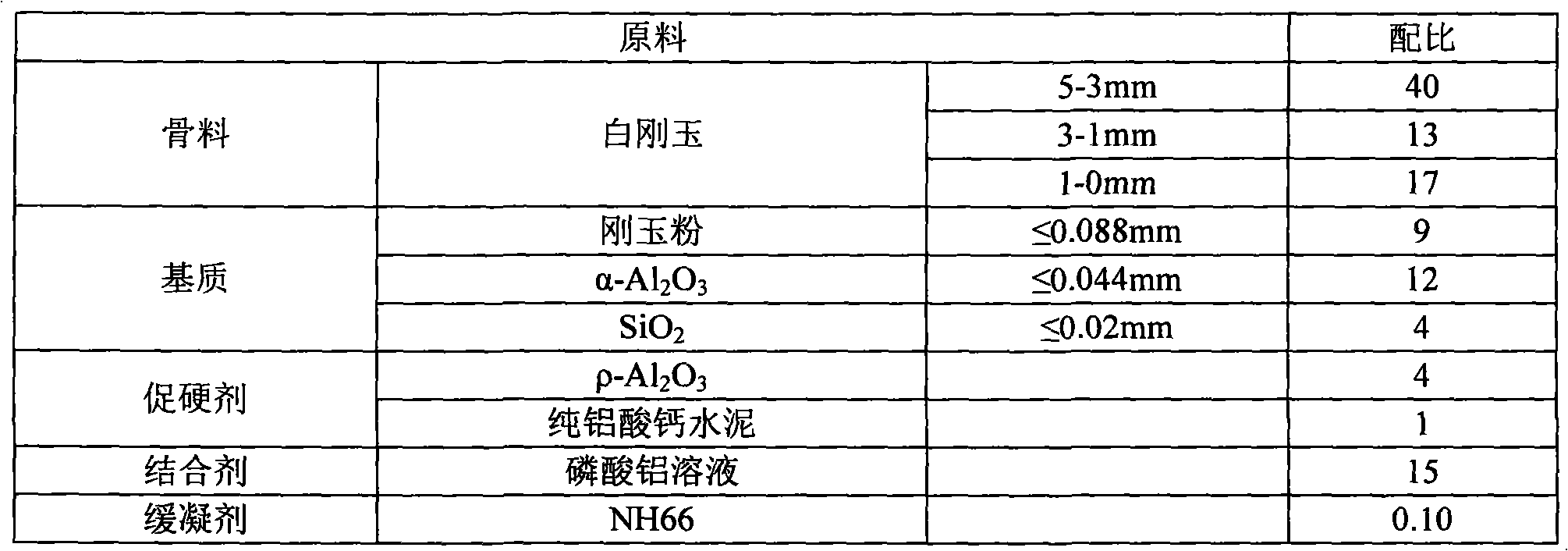

Phosphate bonded castable adopting composite hardening accelerator

ActiveCN102503460AImprove high temperature resistanceReduce cement contentPhosphateALUMINUM PHOSPHATE

The invention relates to a phosphate bonded castable adopting a composite hardening accelerator, belonging to the technical field of refractory materials. The phosphate bonded castable is prepared from the following main raw materials in percentage by mass: 55-75wt% of aggregate, 9-40wt% of powder material, 5-16wt% of composite hardening accelerator, 0.1-0.25wt% of corrosive inhibitor and 8-18wt% of bonding agent, wherein the aggregate is corundum or high-aluminum bauxite; the powder material comprises 0-37wt% of corundum powder, 0-37wt% of bauxite powder, 1-8wt% of SiO2 micropowder and 3-12wt% of alpha-Al2O3 micropowder; the composite hardening accelerator is pure calcium aluminate cement and rho-Al2O3 micropowder; the corrosive inhibitor is an NH66 type inhibitor, and comprises the main chemical component of bismuth oxyiodotannate; and the bonding agent is phosphate (aluminum phosphate solution), and the P2O5 / Al2O3 ratio is 1 / 2.5-1 / 3.8. The phosphate bonded castable has the advantages of high strength, wear resistance, thermal shock resistance, short stripping time, capability of being quickly baked and the like, and has excellent high-temperature resistance.

Owner:RUITAI MATERIALS TECHNOLOGY CO LTD

Foam glass produced by lens glass waste material and its preparing method

InactiveCN1587148AWell mixedUniform structureSolid waste disposalHeat conductingVolumetric Mass Density

The present invention produces foamed glass with the leftover from producing glasses lens in 96.1-98.6 wt%, boric acid 1.0-3.0 wt%, Sb2O3 as assistant 0.2-0.4 wt% and common carbon black as foaming agent 0.2-0.5 wt%, and through ball milling to form compounded material, grinding to finer than 80 micron, spreading in refractory steel mold, covering with isolating refractory steel plate and forming in common technological process to obtain the foamed glass with homogeneous structure. The foamed glass has density of 130 kg / cu m, water absorption less than 0.5 vol%, compression strength and folding strength higher than 0.6 MPa and heat conducting coefficient of 0.046-0.052 w / (m.k). It is one excellent kind of heat insulating material, and may be used widely in petroleum industry, tunnel engineering, outer building wall, etc.

Owner:BEIJING UNIV OF TECH

Environment-friendly ceramic material

The invention discloses an environment-friendly ceramic material which comprises the following components in parts by weight: 100-150 parts of kaolin, 20-30 parts of silicon carbide, 30-40 parts of active carbon powder, 10-15 parts of nano zirconium dioxide, 25-50 parts of glass fibers, 20-30 parts of carbon fibers, 80-100 parts of dolomite powder, 5-10 parts of octaphenyl polyoxyethyiene, 5-10 parts of polydimethylsiloxane and 10-15 parts of trimethyl hexanediamine. The environment-friendly ceramic material is subjected to high-temperature sintering and has the characteristics of high hardness, corrosion resistance, good thermal change resistance, thermal shock resistance, impact resistance and the like; an adsorption material capable of adsorbing toxic and harmful substances is added into ceramics, so that when the ceramic material is used, the toxic and harmful substances can be adsorbed to some degree, thus cleaning the environment and improving the living quality of human beings.

Owner:陈新棠

Self-lubricating wear-resistant ceramic for cutting tools and preparation method thereof

ActiveCN104387071AImprove high temperature resistanceImprove carrying capacityPolyoxyethylene castor oilWear resistant

The invention relates to a self-lubricating wear-resistant ceramic for cutting tools, which is prepared from the following raw materials in parts by weight: 2-3 parts of bismuth sulfide, 2-3 parts of diethanolamine, 2-3 parts of ammonium sulfate, 2-3 parts of magnesium chloride, 2-3 parts of calcium carbide sludge, 2-3 parts of graphene oxide, 0.6-0.8 part of KOH, 0.2-0.3 part of polyoxyethylene castor oil, 3-4 parts of magnesium oxide, 36-40 parts of titanium boride, 4-5 parts of nano tungsten trioxide, 30-35 parts of titanium carbide, 3-5 parts of beryllium oxide, 1-2 parts of silver powder, a right amount of ethanol, a right amount of deionized water, 1-1.5 parts of polyacrylic acid, 1.2-1.6 parts of polyethyleneglycol and 4-5 parts of antiwear assistant. The added nano tungsten trioxide enhances the high temperature resistance of the ceramic. The ceramic has the characteristics of high temperature resistance, high carrying capacity, self lubrication, thermal shock resistance, high wear resistance and the like, and is suitable for manufacturing cutting tools. The antiwear assistant can enhance the wear resistance and heat resistance of the ceramic.

Owner:枣庄科顺数码有限公司

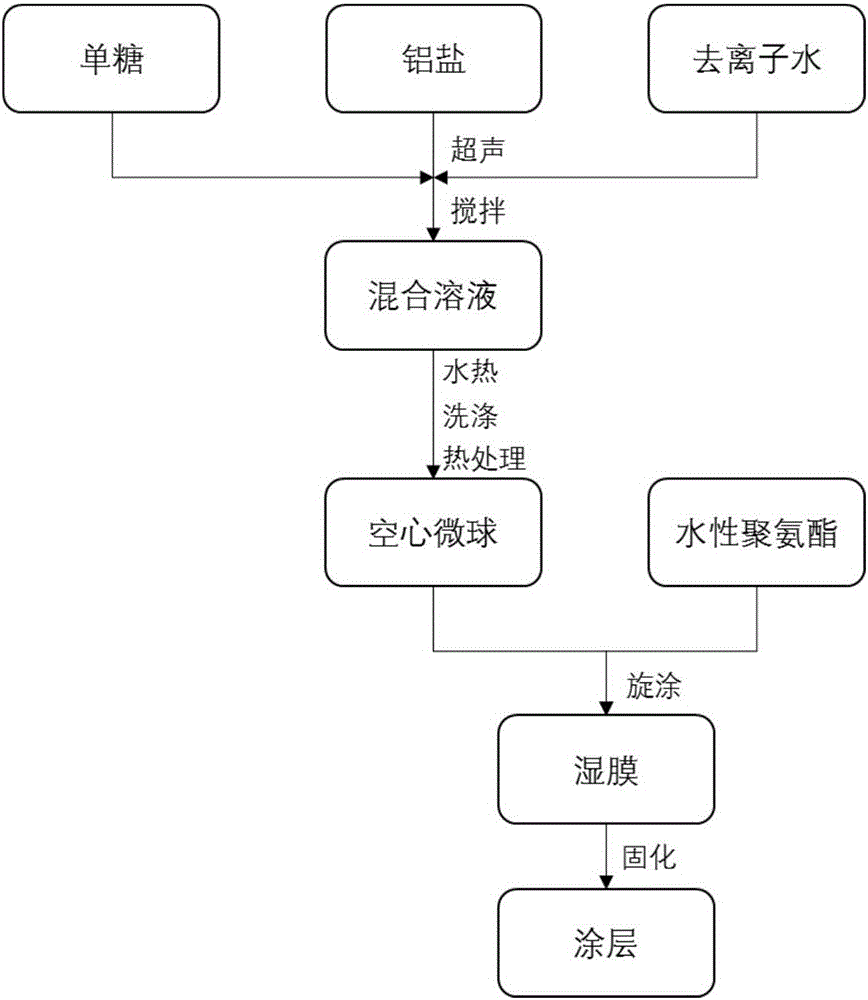

Preparation method of hollow aluminum oxide ceramic microsphere modified polyurethane coating

InactiveCN106634514AHigh strengthHigh hardnessAnti-corrosive paintsPolyurea/polyurethane coatingsMicrosphereMaterials science

The invention relates to a preparation method of a hollow aluminum oxide ceramic microsphere modified polyurethane coating. The preparation method comprises the following steps: preparing hollow aluminum oxide ceramic microspheres, namely treating aluminum nitrate and monosaccharide raw materials by virtue of steps of ultrasound, magnetic stirring, hydrothermal treatment, heat treatment and the like to obtain the hollow aluminum oxide ceramic microspheres with uniform particle size; and blending the obtained ceramic microspheres with waterborne polyurethane, and carrying out high-speed dispersion, ultrasound, spin coating and curing to obtain a composite coating. The preparation method provided by the invention has the advantages that nontoxic and easily available raw materials are adopted, a preparation process is simple, technology is controllable, cost is low, repeatability is good, and the hollow aluminum oxide ceramic microspheres are uniformly distributed. The prepared composite coating has the characteristics of environmental friendliness, light weight, high strength, high hardness, high wave transmission, low thermal conductivity, low infrared emissivity, excellent wear resistance, excellent weather resistance and the like and can be applied to the fields of heat insulation coatings, infrared stealth and the like.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

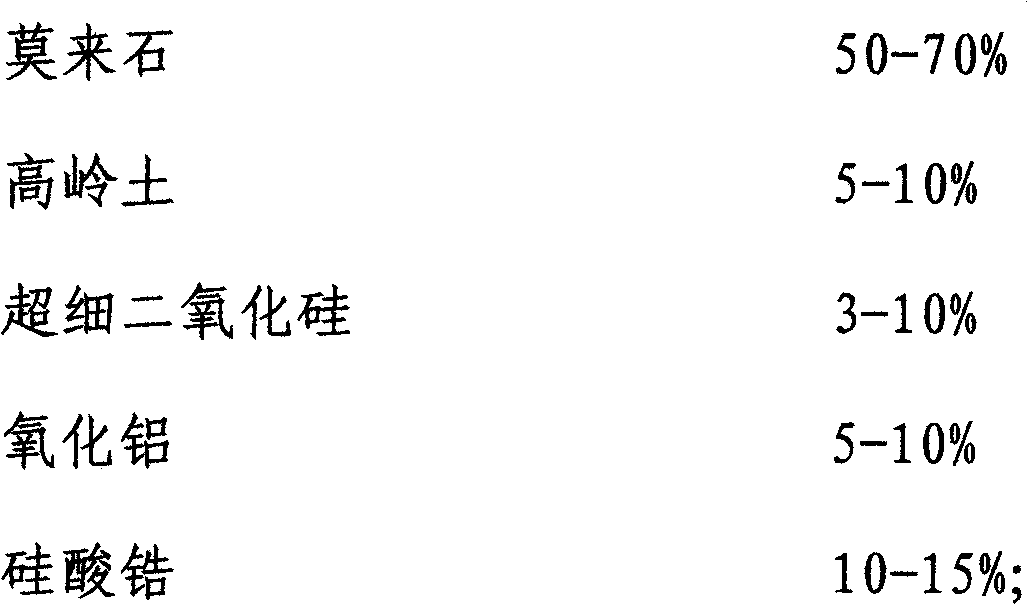

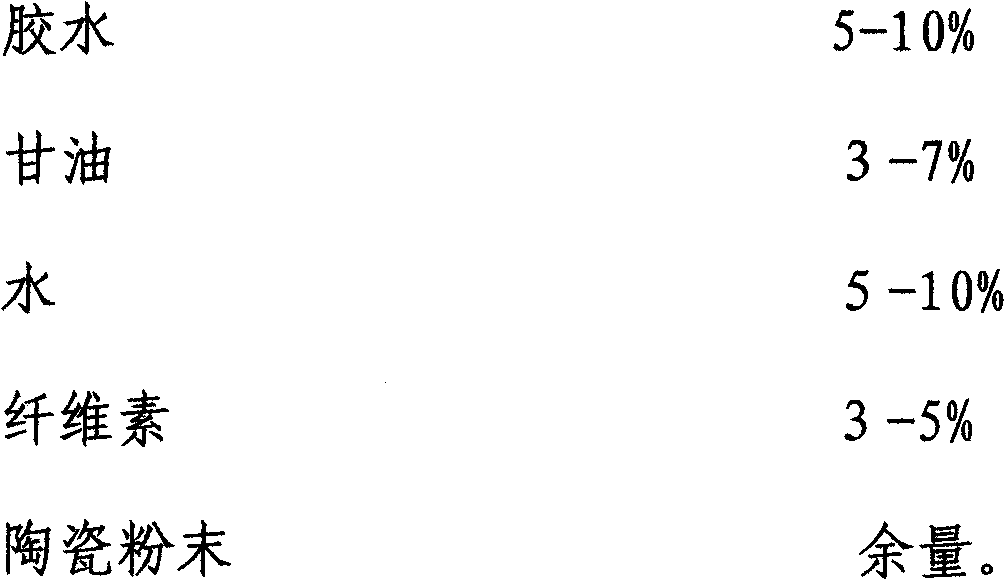

Honeycomb ceramic filter and preparation method thereof

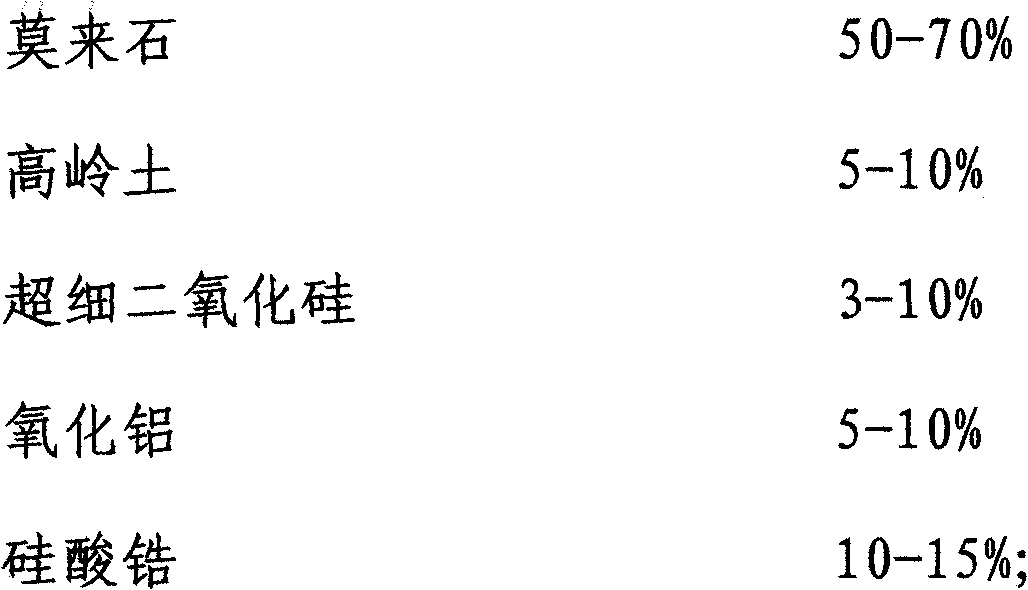

The invention discloses a honeycomb ceramic filter and a preparation method thereof, and belongs to the field of inorganic nonmetal. The honeycomb ceramic filter is obtained after ceramic powder and plastic pug are sequentially subjected to ball milling, mixing, decaying, vacuum pugging and extrusion forming, dry cutting and sintering, wherein the ceramic powder is prepared by mixing mullite, kaolin, ultrafine silicon dioxide, aluminum oxide and zirconium silicate according to the proportion, and the plastic pug is prepared by mixing auxiliary materials composed of a glue, glycerol and hydrate cellulose. The honeycomb ceramic filter has good high-temperature strength and good thermal shock resistance. The method has the characteristics of low cost and simplicity in operation and is suitable for industrial production.

Owner:晋城市富基新材料股份有限公司

Al2O3-SiO2 tundish permeable brick and preparation method thereof

InactiveCN102320845AAvoid room temperature decompositionGuaranteed decentralizationAluminum fluorideBrick

The invention relates to an Al2O3-SiO2 tundish permeable brick and a preparation method thereof. 65-78 wt% of tabular corundum particles, 7-20 wt% of mullite particles, 2-10 wt% of white corundum fine powder, 1-4 wt% of rho-Al2O3 fine powder, and 1-3 wt% of silicon micropowder are used as raw materials; 0.10-0.20 wt% of mixtures of sodium hexametaphosphate and sodium tripolyphosphate, 0.05-0.20 wt% of yellow dextrin, 0.01-0.20 wt% of azodicarbonamide, 1-4 wt% of Al2O3-SiO2 gel powder, and 0.20-1.0 wt% of aluminium fluoride are used as additives. The preparation method comprises the following steps: premixing the additives and silicon micropowder uniformly according to the contents, adding the tabular corundum particles and the mullite particles, mixing and grinding, adding the white corundum fine powder and rho-Al2O3 fine powder, mixing and grinding, adding 5-7 wt% of water, stirring, casting, molding, performing heat preservation at 110-200 DEG C for 12-48 hours, and finally sintering at 1200-1500 DEG C for 3 hours. The prepared permeable brick has good permeability and high strength, and is erosion-resistant and environment-friendly.

Owner:WUHAN UNIV OF SCI & TECH

High-temperature nano radiation coating for heating furnace and preparation process thereof

The invention provides a high-temperature nano radiation coating for a heating furnace and a preparation process thereof. The coating comprises radiation function powder particles, an inorganic adhesive and an expansion coefficient regulator. The preparation process comprises the following steps: preparing the radiation function powder particles, preparing the expansion coefficient regulator, synthesizing the inorganic adhesive, mixing the radiation function powder particles, the inorganic adhesive and the expansion coefficient regulator, and filtering and grinding the obtained mixture so as to obtain the high-temperature nano radiation coating for the heating furnace. The high-temperature-resistant nano radiation coating disclosed by the invention has the characteristics of capability of increasing the radiance and the thermal shock stability, energy conservation and environmental friendliness, corrosion resistance, and capability of prolonging the service life of the heating furnace and raising the temperature uniformity, and the like. The technical indexes of the products provided by the invention are as follows: a temperature of 1800 DEG C can be resisted, the radiance epsilon is greater than or equal to 0.92, the thermal shock resistance (1300 DEG C) is greater than or equal to 5 times, the thickness of the coating is 0.1-0.2 mm, and the service life is greater than or equal to 6 years.

Owner:BDES BEIJING ENERGY SAVING TECH SERVICE

Large-sized special-shaped composite magnesium aluminate spinel product and technique for producing the same

ActiveCN101434492AHigh temperature resistantWith thermal shock resistanceMagnesium AluminateTemperature resistance

The invention relates to large or specific compound magnesium-aluminum spinel products with the formula of 48 to 56 percent of 5-1mm magnesium-aluminum spinel, 12 to 22 percent of 1-0.088mm magnesium-aluminum spinel, 16 to 25 percent of magnesium-aluminum spinel with d90 less than 0.088mm, 3 to 6 percent of magnesium-aluminum spinel with d90 less than 0.010mm, 3 to 15 percent of beta alumina powder with d95 less than 0.020mm, 2 to 6 percent of hydratable alumina, 1 to 5 percent of magnesium promoter, 0.05 to 0.4 percent of external efficient water reducing agents (polycarboxylic acid plus sulfonation naphthaldehyde polymer plus sulfonation melamine polymer), 1 to 6 percent of latex of the system of external polyacrylic acid and 1 to 6 percent of external water. The magnesium-aluminum spinel composite combined refractory has the following chemical compositions: 72 to 87 percent of Al2O3, 12 to 27 percent of MgO, 0.2 to 1.5 percent of Na2O and 0.1 to 0.5 percent of SiO2. The raw materials are weighed according to the ratios, and are mixed, molded and maintained to make billets, and then are subjected to the processes of drying, firing at the temperature of 1430 to 1650 DEG C and inspection and the like so as to make products of large or specific compound magnesium-aluminum spinel refractory. The magnesium-aluminum spinel product has excellent manufacturing performance and excellent performances of high-temperature resistance, erosion resistance and creep resistance. As the products are casted and moulded, large and specific products can be produced.

Owner:青岛中瑞泰旭催化剂有限公司

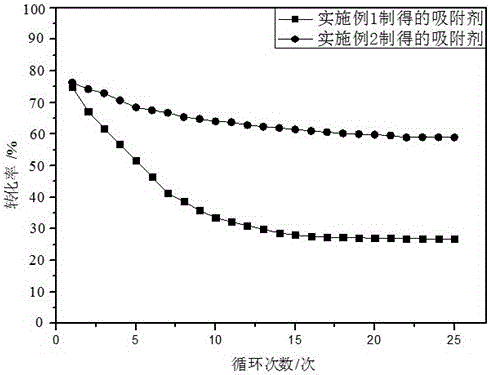

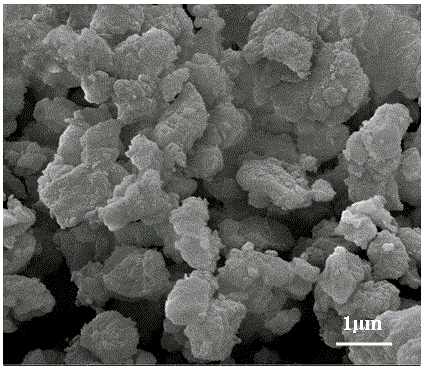

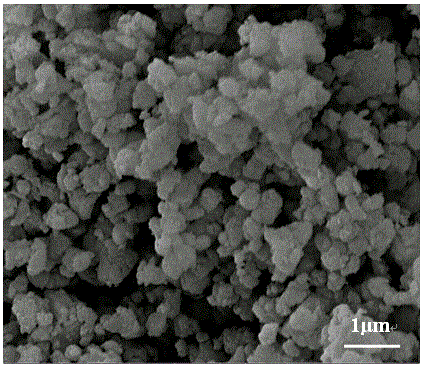

Preparation method and application of calcium-based adsorbent

ActiveCN105903458AAntioxidantHigh temperature strengthGas treatmentOther chemical processesDesorptionSorbent

The invention discloses a preparation method of a calcium-based adsorbent. According to the preparation method, natural quartz stone powder (including a main component SiO2) and active carbon powder are taken as raw materials for preparing silicon oxynitride by adopting a carbon thermal reduction method; and silicon oxynitride is used as an inert supporting material and is treated by a process of immersing, drying and calcining to load CaO so as to prepare the calcium-based adsorbent. By controlling the CaO precursor and calcining conditions, relatively good circulating stability is obtained. The raw material has a wide source, the preparation method is simple and convenient and the operability is strong; and the problem that the adsorption capacity of the high-temperature CO2 calcium-based adsorbent is reduced after a plurality of times of CO2 adsorption / desorption cycles is improved very well.

Owner:KUNMING UNIV OF SCI & TECH

Preparation method of tundish air brick

InactiveCN103787670AHigh Durability Thermal Shock ResistantExcellent thermal shock resistanceAzodicarbonamideCorundum

The invention discloses a preparation method of a tundish air brick. The preparation method comprises the following steps of: (1) placing 45-55 parts by weight of tabular corundum granules, 10-14 parts by weight of mullite granules and 5-8 parts by weight of chromic oxide granules into a mixer, and mixing for 5-8 minutes; (2) placing 4-6 parts by weight of white corundum fine powder, 2-3 parts by weight of alpha-Al2O3 fine powder and 1.5-3.5 parts by weight of silica micropowder into the mixer, and mixing for 10-15 minutes; (3) adding a mixture prepared from the step (1) to the mixer used in the step (2), mixing for 10-15 minute again, adding 0.4-0.6 part by weight of sodium hexametaphosphate, 0.3-0.5 part by weight of yellow dextrin, 0.1-0.3 part by weight of azodicarbonamide, 0.2-0.4 part by weight of boric acid and 0.1-0.3 part by weight of aluminum fluoride, and then mixing for 10-15 minutes again; (4) ageing for 1-2 hours, pressing for forming by using a press machine, and drying into a drying kiln at 200 DEG C for 24 hours; (5) firing under the condition of 1250-1350 DEG C for 2-3 hours.

Owner:WUXI CHENGBO SCI & TECH DEV

Repair welding method for magnesium alloy casting oil way

InactiveCN105537735AWith thermal shock resistanceSmall coefficient of thermal expansionWelding accessoriesGraphiteTemperature resistance

The invention relates to a repair welding method for a magnesium alloy casting oil way. A graphite material is used as a repair welding base plate for carrying out repair welding on defects of a casting, so that the purpose of repair is achieved. The characteristics of softness, easy removal, high temperature resistance and thermal shock resistance of graphite are utilized, in the using process, the repair welding base plate can bear acute changes of temperature so that damage and cracks can be prevented, and has various properties needed by an argon arc welding base plate, it is possible to repair the defects of the magnesium alloy casting oil way part, and the purpose of saving the casting is achieved.

Owner:HARBIN DONGAN ENGINE GRP

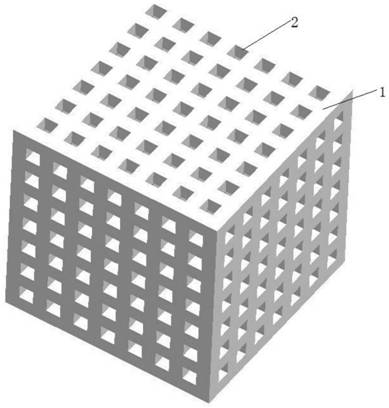

Preparation method of refractory high-entropy alloy skeleton-copper spontaneous perspiration composite structure

ActiveCN112024902AGood mechanical propertiesHigh strengthAdditive manufacturing apparatusSelective laser meltingHigh entropy alloys

The invention discloses a preparation method of a refractory high-entropy alloy skeleton-copper spontaneous perspiration composite structure. The method comprises the following steps of: smelting a refractory high-entropy alloy raw material to obtain an alloy ingot, and preparing refractory high-entropy alloy powder from the alloy ingot by using a plasma rotating electrode atomization method; forming the refractory high-entropy alloy powder into a preset porous skeleton structure through an electron beam or selective laser melting additive manufacturing process; and infiltrating metal copper into the porous skeleton structure by adopting an infiltration process, thereby obtaining the refractory high-entropy alloy skeleton-copper spontaneous perspiration composite structure. The structure has the characteristic of spontaneous perspiration, and is suitable for high-temperature parts such as rocket engine nozzle throat inserts, thrust chamber injector panels, missile warhead nose cones and electromagnetic gun tracks. The prepared composite structure has the advantages that the forming process is simple, the porosity can be conveniently designed and adjusted according to actual requirements, the mechanical property is good, high temperature resistance and thermal shock resistance can be achieved, and high practical value is achieved.

Owner:JIANGSU UNIV OF SCI & TECH +2

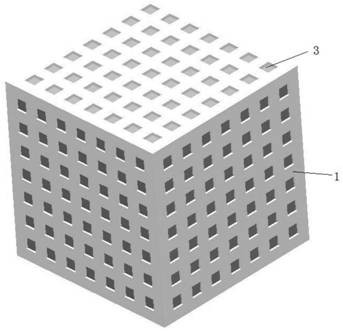

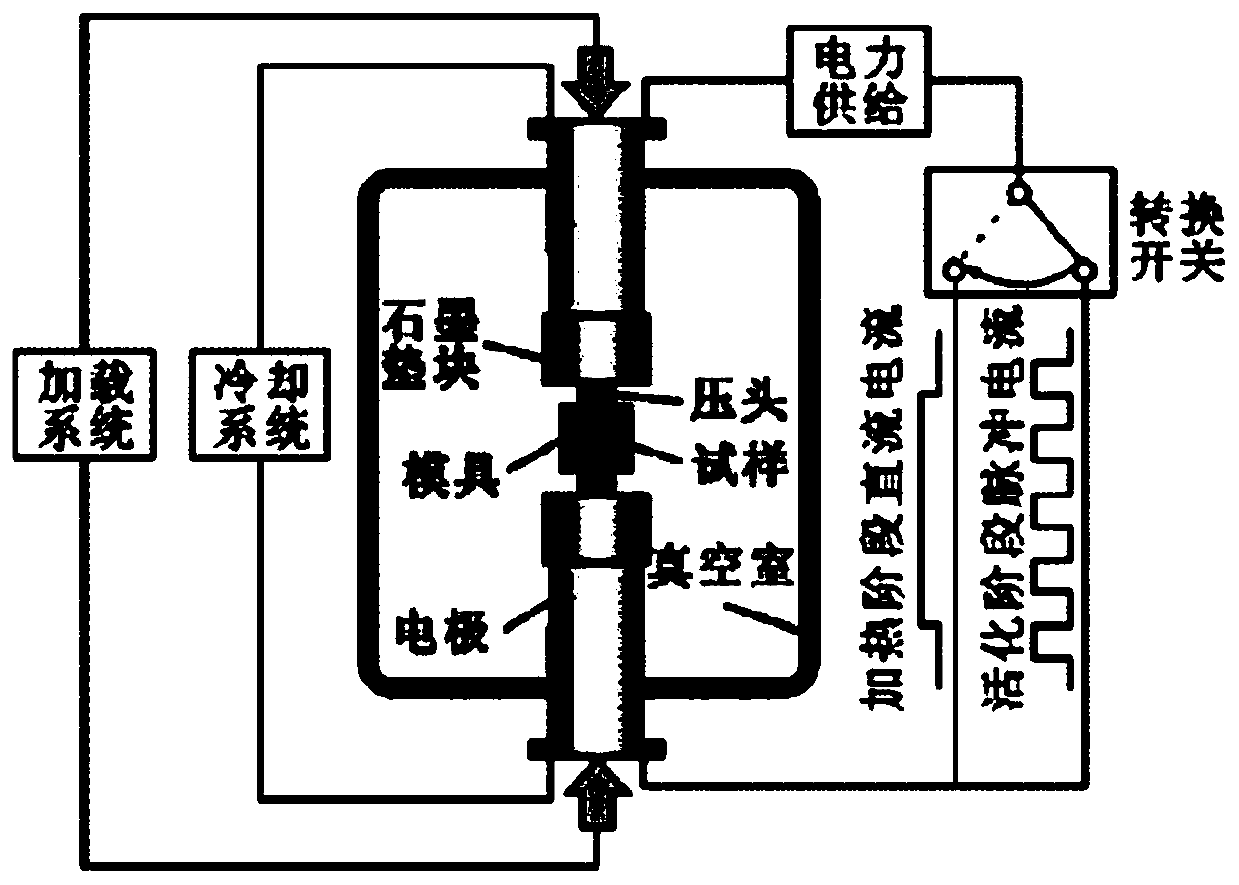

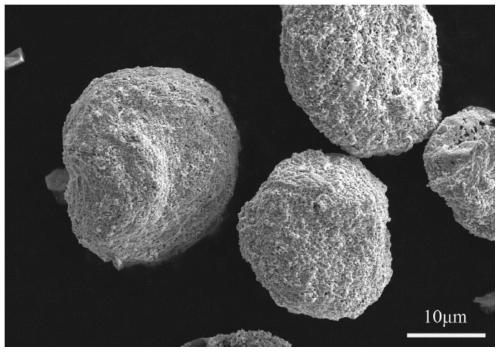

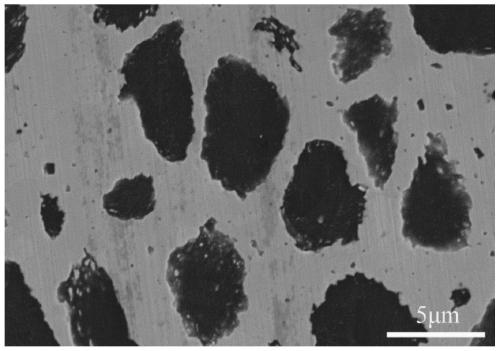

Silicon carbide reinforced carbon matrix composite material and preparation method

The invention discloses a silicon carbide reinforced carbon matrix composite material and a preparation method. Mesocarbon microbeads are adopted as the matrix, and silicon carbide ceramic is adoptedas the reinforcement phase and is evenly distributed among the carbon microbeads so as to form a three-dimensional network silicon carbide skeleton reinforced isotropic structure. Technically, siliconpowder particles and the mesocarbon microbeads are taken as the raw materials to prepare uniform and thickness controllable silicon carbide coating coated mesocarbon microbead powder by molten salt method, after pre-press molding, discharge plasma sintering is carried out at 1600-1900DEG C to form a uniform three-dimensional network silicon carbide ceramic skeleton, while the strength, ablation resistance, oxidation resistance and thermal shock resistance of the carbon matrix are improved, the thermal conductivity of the matrix is also improved, therefore the isotropic carbon matrix compositematerial characterized by low cost, low density and excellent mechanical properties, sintering properties, thermal shock resistance, ablation resistance and thermal conductivity can be formed. Because of the excellent comprehensive performance, the silicon carbide reinforced carbon matrix composite material can be widely applied to aerospace, national defense, electronic packaging and other fields, and has broad application prospects.

Owner:XI AN JIAOTONG UNIV

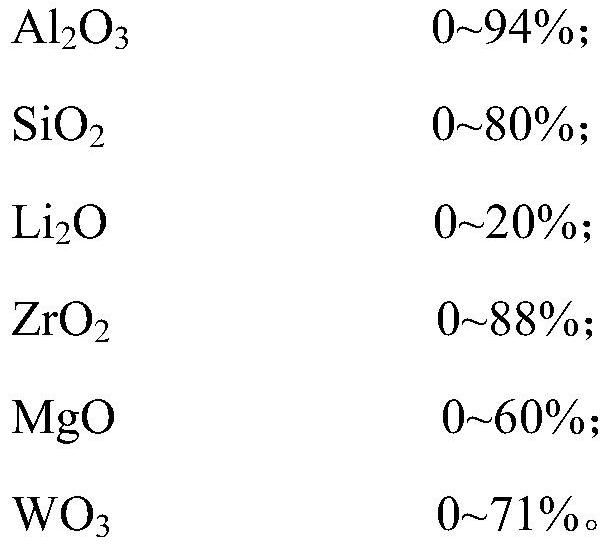

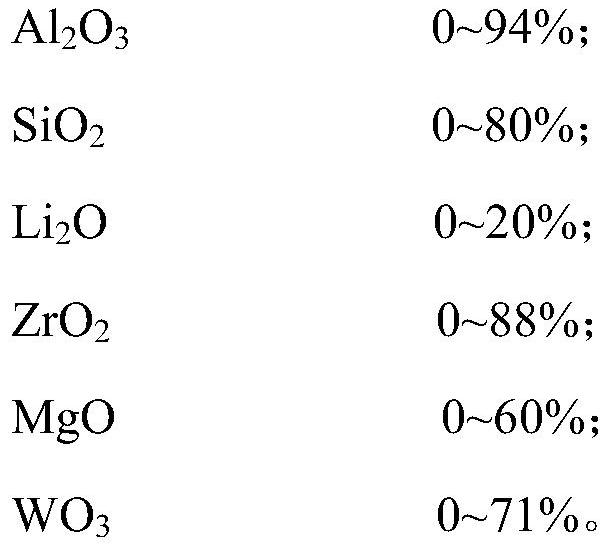

Sagger for positive electrode material of lithium ion battery

PendingCN112028650AHas erosive propertiesReduce consumptionCharge supportsThermal dilatationElectrical battery

The invention discloses a sagger for a positive electrode material of a lithium ion battery. The sagger is composed of a low-thermal-expansion material and / or a negative-thermal-expansion material anda lithium ion battery positive electrode material corrosion-resistant material, wherein the low-thermal-expansion material and / or the negative-thermal-expansion material and the lithium ion battery positive electrode material corrosion-resistant material are mixed and molded into a sagger blank, and the sagger blank is sintered to obtain the sagger for the positive electrode material of the lithium ion battery. The sagger disclosed by the invention has the characteristics of thermal shock resistance and lithium ion battery positive electrode material erosion resistance, the service life of the sagger is greatly prolonged, the refractory material consumption of the lithium ion battery positive electrode material is reduced, and the environment is protected. The sagger provided by the invention does not need an additional coating to protect the sagger, so a production process, required equipment and manpower are greatly reduced; and the sagger can be produced only by simple forming equipment and annealing equipment, so production efficiency is improved.

Owner:广州粤瓷新材料有限公司

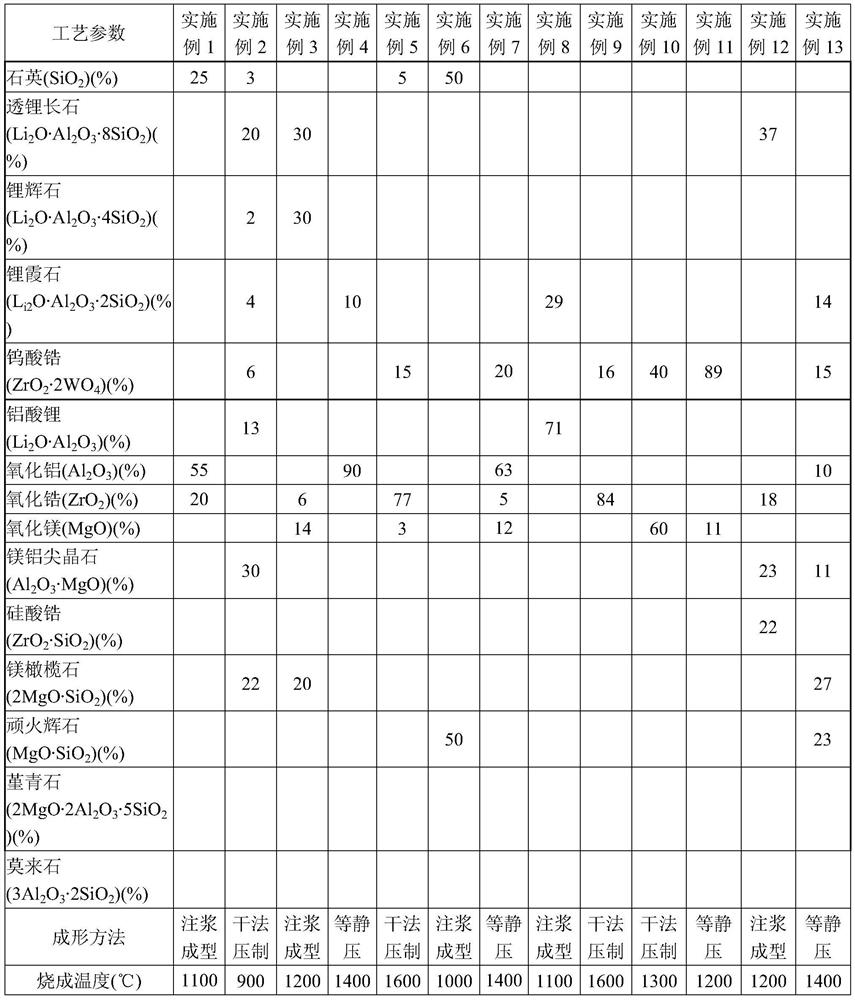

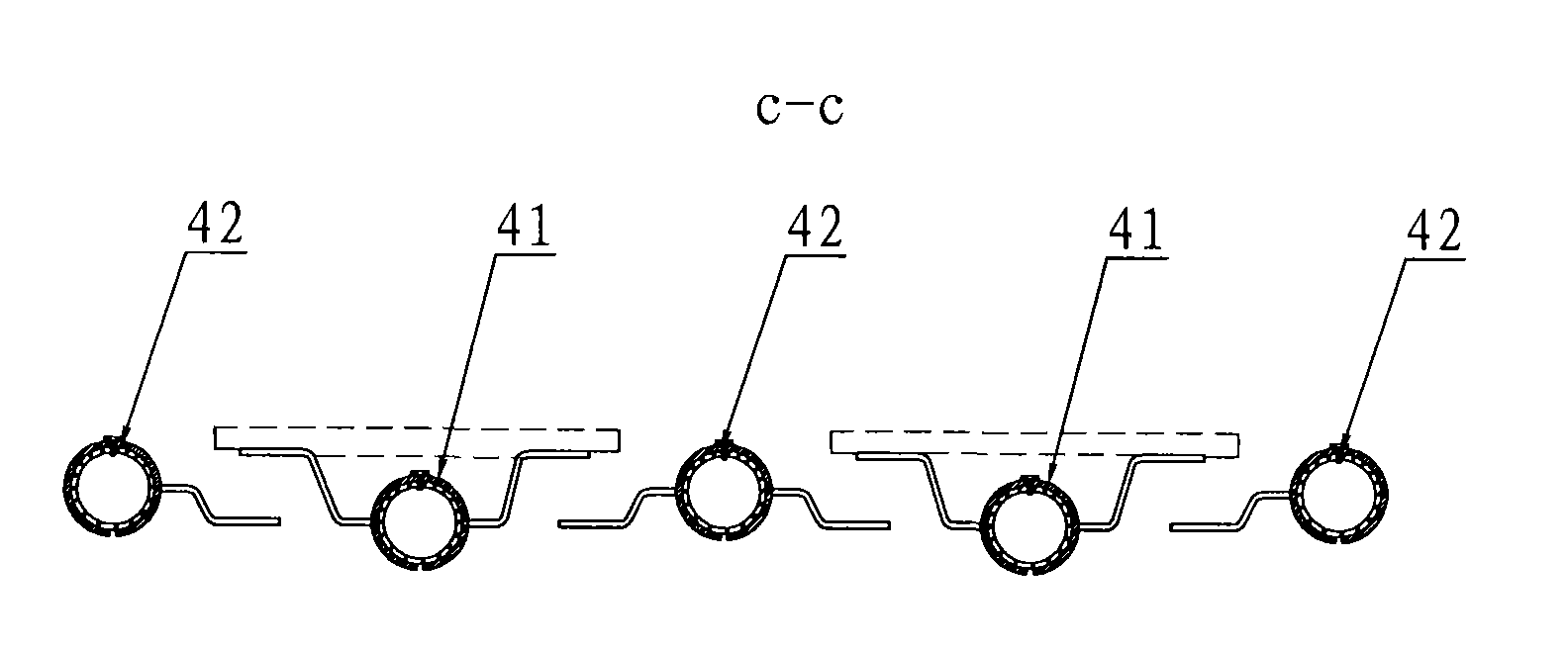

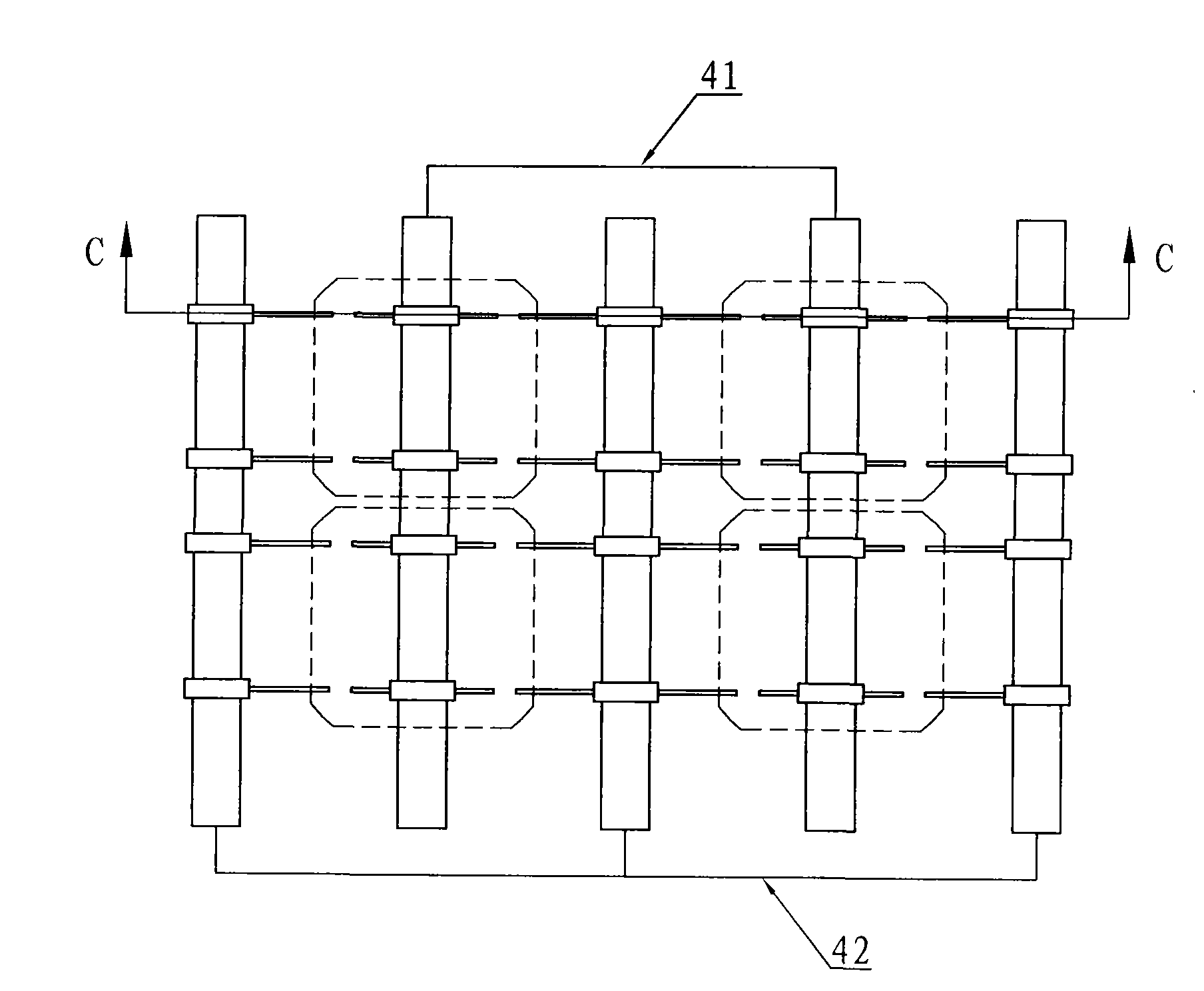

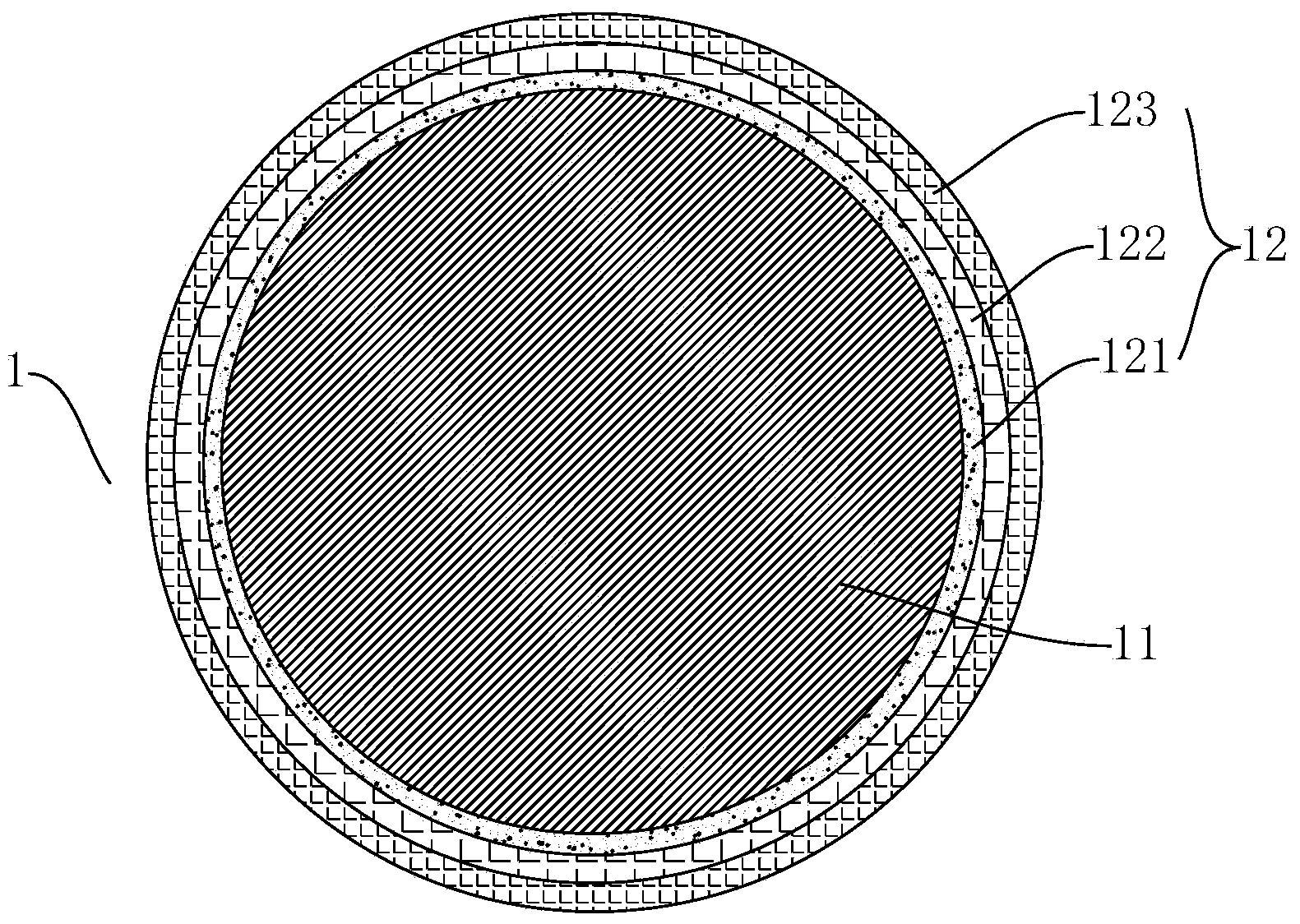

Quartz glass tube silicon chip bracket component

ActiveCN102032777AHigh strengthMeet the intensityFinal product manufactureFurnace typesCeramic coatingTemperature resistance

The invention provides a quartz glass tube silicon chip bracket component for a mesh belt-free silicon chip sintering furnace. The component comprises a quartz glass tube, metal sleeves, support legs and limiting screws, wherein the support legs are fixed on the metal sleeves; the metal sleeves are provided with threaded holes and are fixed on the quartz glass tube at equal intervals through the limiting screws; the support legs are made of steel wires; and the surfaces of the steel wires are coated with ceramic coatings. The quartz glass tube has the advantages of high intensity, high temperature resistance, low expansion coefficient, thermal shock resistance, acid resistance, chemical stability, high electrical insulating property, small heat absorption capacity and the like and is very suitable to be taken as a silicon chip bracket. The support legs are made of steel wires and the surfaces of the steel wires are coated with ceramic coatings, so that the requirements on intensity, high temperature resistance and wearing resistance of the support leg are met and metal ion pollution of a silicon chip caused by metal contact in a sintering process is reduced. Each metal sleeve is provided with an opening and a threaded hole, so that the metal sleeve is convenient to fix on the quartz glass tube.

Owner:EGING PHOTOVOLTAIC TECHNOLOGY CO LTD

Surface glass used for preparing an optical fiber faceplate

The invention discloses surface glass used for preparing an optical fiber faceplate, relates to the field of optical fibers, and overcomes a problem that sealing between an optical fiber faceplate and other parts is bad. Raw materials of the surface glass comprise 45-75% by mass of silica, 1-15% by mass of calcium oxide, 1-18% by mass of boric oxide, 0.1-2% by mass of magnesium fluoride, 1-14% by mass of aluminum oxide, 0.1-2% by mass of bismuth oxide and 0.1-4% by mass of barium oxide. The optical fiber faceplate prepared from the surface glass is high in cathode sensitivity, compatible with photocathode materials and capable of resisting thermal shock and mechanical vibration, and is advantageous in that sealing between the optical fiber faceplate and other parts is good.

Owner:中建材光芯科技有限公司

Anti-scaffolding composite coating

ActiveCN104044304AWear-resistantHigh temperature resistantFurnace typesHeat treatment furnacesAlloyThermal shock

The invention discloses an anti-scaffolding composite coating which is characterized by comprising at least three layers of sub-coatings, which are respectively an alloy layer coated on the surface of a base body, a first metal ceramic layer coated on the surface of the alloy layer, and a second metal ceramic layer coated on the surface of the first metal ceramic layer. The anti-scaffolding composite coating provided by the invention has the properties of resisting abrasion, high temperature, oxidation, thermal shock, scaffolding and the like; the quality of a steel plate manufactured by a furnace roller sprayed with the coating is greatly improved.

Owner:SHANGHAI JUSN SURFACE TECH ENG

Carbon/ceramic heat-resistant composite material and preparation process thereof

InactiveCN1793037AObvious advantagesObvious positive effectCeramic shaping apparatusRoom temperatureFree cooling

The invention relates to a carbon / ceramic heat proof compounding material and the manufacturing method. The wt% of the material is C squama 25-65, ceramic powder SiC+B4C 30-60, of which SiC: SiC+B4C=5:1, TiO2 5-13, adopting acetone phenolic resin as binding agent. Mixing the constituents, molding at the pressure of 30-50MPa, keeping the temperature and cooling to room temperature, the material would be gained. The invention has the feature of light, high intensity, high toughness, antifriction, high temperature poof, and anti-oxidation.

Owner:NORTHEASTERN UNIV

Dispersion strengthened ceramic composite material and preparation method thereof

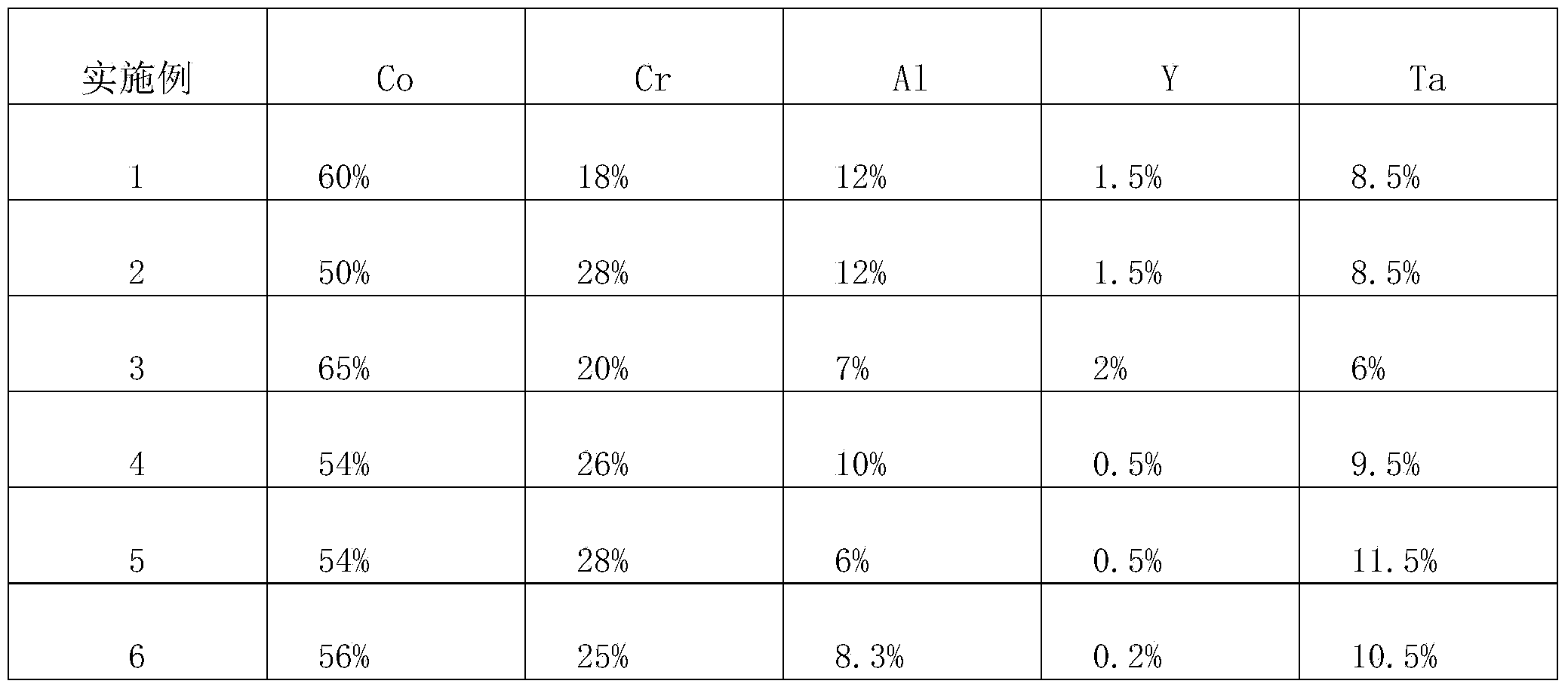

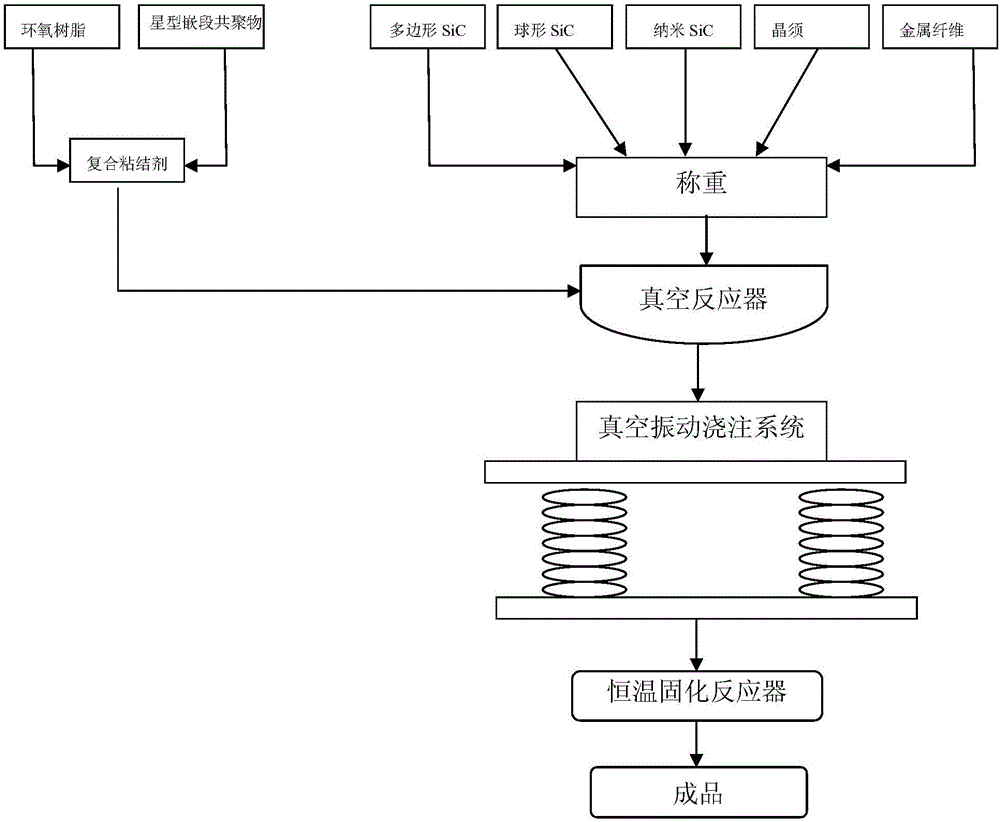

The invention discloses a dispersion strengthened ceramic composite material and a preparation method thereof and belongs to the field of composite materials and engineering ceramic materials. The composite material is formed by compounding silicon carbide of different forms, calcium sulfate whiskers, metal fibers and a composite adhesive, wherein the silicon carbide of different forms, the calcium sulfate whiskers, the metal fibers and the composite adhesive are interweaved and distributed. The preparation method comprises the following steps: 1) uniformly mixing the silicon carbide, the calcium sulfate whiskers, the metal fibers and the composite adhesive under vacuum conditions so as to prepare slurry; 2) vibrating and casting the slurry in a mold under vacuum; and 3) curing the mold and cast slurry, thereby obtaining the dispersion strengthened ceramic composite material. According to the method disclosed by the invention, the problems of wear and corrosion of highly corrosive solid-liquid media on pump materials during transport are effectively solved, and the prepared composite material has the characteristics of high metal matrix adhesion force, high hardness, wear resistance, corrosion resistance, oxidation resistance, thermal shock resistance and the like and is applied to the fields of chemical industry, pharmacy, papermaking and the like.

Owner:NORTHEASTERN UNIV +1

Ceramic paint

InactiveCN104211372AHas high temperature oxidation resistanceWith thermal shock resistanceClaywaresGlycerolSilicon oxide

The invention discloses a ceramic paint which is composed of following raw materials including 20-50 parts of ceramic fiber, 50-80 parts of silicon micro-powder, 60-95 parts of hollow glass microbeads, 200-250 parts of kaolin, 6-8 parts of di-(2-ethylhexyl) phthalate, 10-12 parts of glycerol, 2-3 parts of dimethylbenzene, 5-8 parts of epoxy resin, 6-9 parts of sodium hexametaphosphate, 12-15 parts of sodium hydroxide, 5-10 parts of trisodium phosphate, 3-10 parts of sodium carboxymethylcellulose, 2-5 parts of hydroxyethyl cellulose, 5-10 parts of hydroxypropyl methyl cellulose, 3-10 parts of titanium carbide, 5-10 parts of titanium dioxide, 3-5 parts of zirconium nitride, 6-10 parts of titanium hydride, 5-8 parts of sodium carbonate, 8-15 parts of calcium carbonate, 12-15 parts of silicone oil, 12-15 parts of polydimethylsiloxane, 10-15 parts of carbon black, 15-20 parts of paraffin, 12-15 parts of graphene, 5-10 parts of magnesium nitride, 5-10 parts of magnesium oxide, 3-6 parts of silicon oxide, 3-8 parts of nano silicon dioxide and 300-350 parts of pure water. In the ceramic paint, the raw materials are reasonably blended. The paint has a high-temperature anti-oxidation property and a thermal shock resistant property when being sprayed on or brushed on a lining layer.

Owner:李兆源

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com