Preparation method and application of calcium-based adsorbent

A calcium-based adsorbent, silicon oxynitride technology, applied in separation methods, chemical instruments and methods, gas treatment, etc., can solve problems such as reduced adsorption performance, and achieve the effects of easy regeneration, low cost, and extended service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

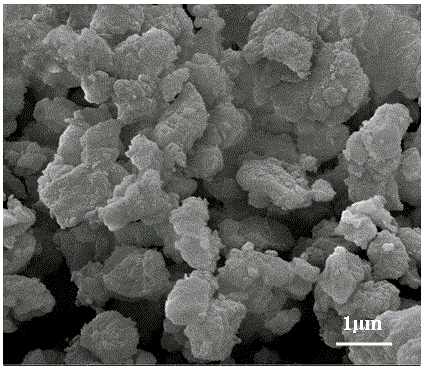

[0023] Instead of using silicon oxynitride as a carrier, calcium acetate monohydrate (C 4 h 6 CaO 4 ·H 2 O) Preparation of calcium-based adsorbent for CaO precursor, the operation steps are as follows:

[0024] Dissolve calcium acetate monohydrate in distilled water to make a saturated solution. After stirring continuously for 12 hours in a constant temperature water bath at 80°C, place it in an oven and dry it overnight at 110°C until it becomes a uniform powder, and then place it in a muffle furnace. It can be obtained by calcining at 700°C for 4 hours in an air atmosphere.

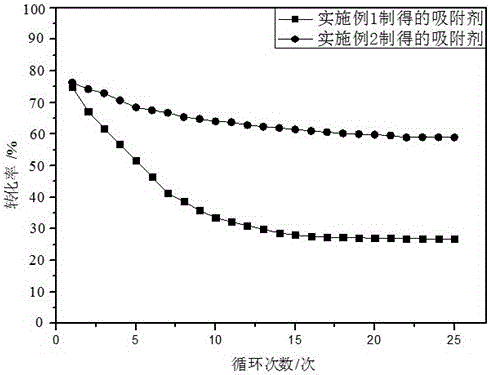

[0025] CO 2 Cyclic adsorption stability test: put the prepared adsorbent in a thermogravimetric analyzer, 2 N 2 In the atmosphere, the temperature was raised from room temperature to 750 °C at a rate of 25 °C / min, and the adsorption was carried out at a constant temperature for 10 min (50% CO 2 , and the rest are N 2 ), desorption for 5min (100% N 2 ) cyclically adsorbed CO 2 . Test results s...

Embodiment 2

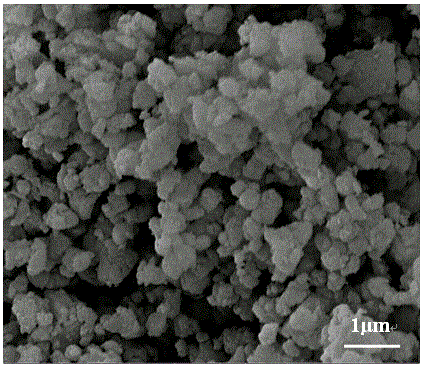

[0027] Calcium acetate monohydrate (C 4 h 6 CaO 4 ·H 2 O) is the precursor of CaO, with Si 2 N 2 O is a carrier to prepare a loaded calcium-based adsorbent, and the operation steps are as follows:

[0028] (1) Preparation of Si 2 N 2 O carrier: take natural quartz stone powder and activated carbon powder according to SiO 2 : C mass ratio is 1:3 batching, adds the SrO of natural quartz stone powder and active carbon powder total amount 2wt% simultaneously, places in the vacuum tube furnace after mixing, in N 2 1350°C in air for 4 hours, N 2 The flow rate is 1.5L / min, and then placed in a muffle furnace and calcined at 700°C for 6h in an air atmosphere;

[0029] (2) Preparation of calcium-based adsorbent: Dissolve 0.56g of calcium acetate monohydrate in distilled water to make a saturated solution, and take 1g of Si prepared in step (1) 2 N 2 The O carrier was placed in a saturated solution of calcium acetate monohydrate, stirred continuously in a constant temperature...

Embodiment 3

[0032] Calcium acetate monohydrate (C 4 h 6 CaO 4 ·H 2 O) is the precursor of CaO, with Si 2 N 2 O is a carrier to prepare a loaded calcium-based adsorbent, and the operation steps are as follows:

[0033] Get 9.44g calcium acetate monohydrate and be dissolved in distilled water and make saturated solution, get the Si prepared by step (1) in 1g embodiment 2 2 N 2 The O carrier was placed in a saturated solution of calcium acetate monohydrate, stirred continuously in a constant temperature water bath at 100°C for 12 hours, then dried in an oven at 120°C overnight until it became a uniform powder, and then placed in a muffle furnace in air Calcined at 800°C for 6h under the atmosphere to obtain it.

[0034] CO 2 The cycle adsorption stability test method is the same as in Example 1, and the test results: the first adsorption CaO conversion rate is 78.2%, after 25 CO 2 After the adsorption / desorption cycle, the CaO conversion rate was 60.5%, and the CaO conversion rate o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com