Patents

Literature

120results about How to "Creep resistant" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Poly(ether-ether-ketone) composite material, production method and application of sealing member

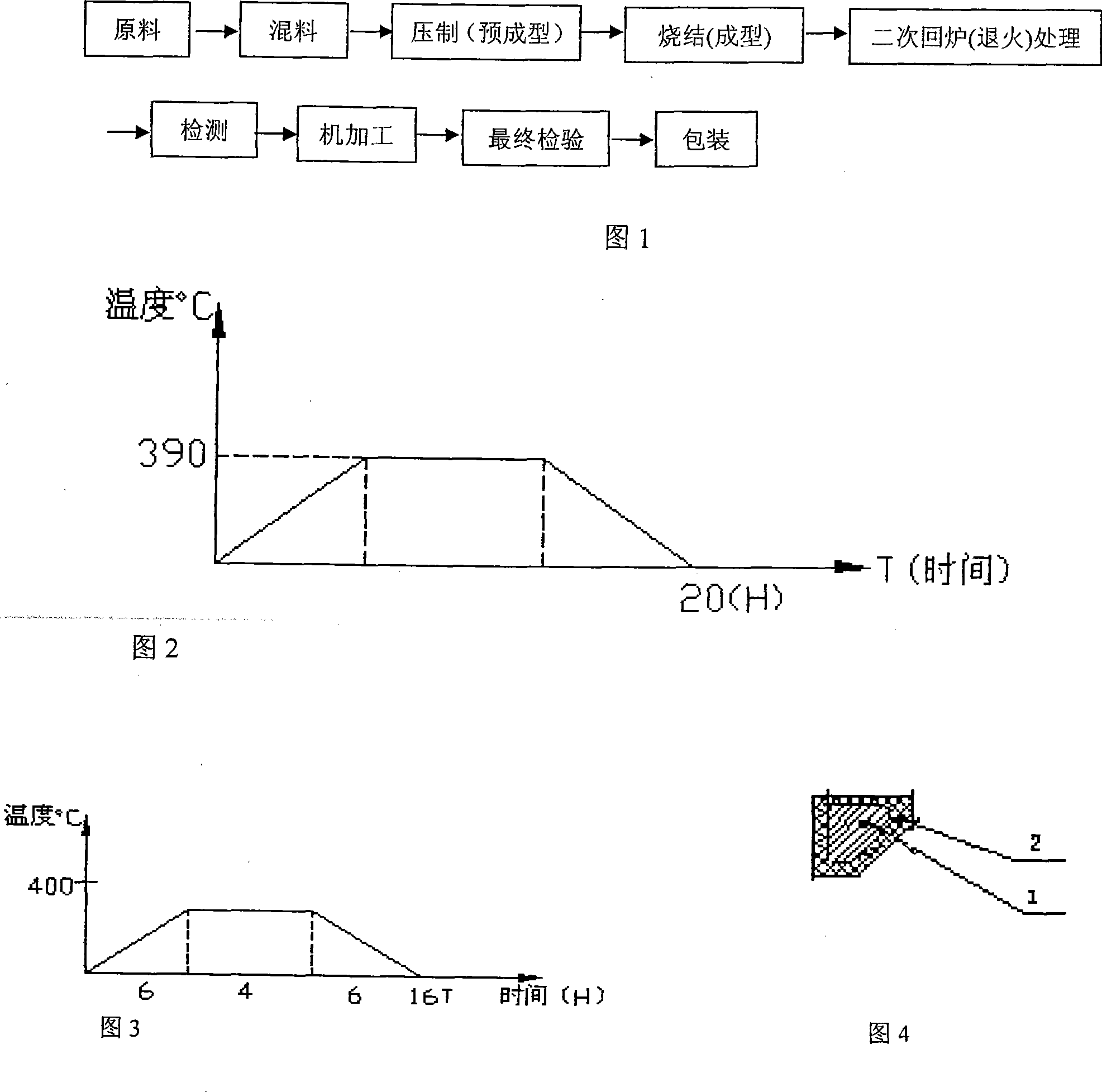

The invention relates to a polyether-ether-ketone composite material which consists of polyether-ether-ketone, nanoparticles, filling materials and addition agent materials. The composite material comprises 75 to 95 portions of polyether-ether-ketone powders, 5 to 10 portions of the nanoparticles, 10 to 20 portions of the filling materials and 2 to 5 portions of the additive agents by weight. The filling materials are glass fiber, carbon fiber, quartz powder and MoS2 or toner. A method of compression moulding forming adopted is that: materials is prepared according to the formula; materials are mixed: the materials prepared according to designed requirements poured into an automatic material mixing machine for evenly mixing, the mixing time is between 0.5 minute and 3 minutes, then compressing process is carried out, and the blended mixture is sent to a mould cavity for moulding. The material can be used for sealing materials products. Various valve sealing elements produced by the invention has properties of creep resisting, corrosion resistance, heat resistance and pressurization, etc.; the ability of pressurization and wear resistance of the material are improved, and at the same time the cost is lowered by 10 to 20 percent or even higher, thus being beneficial to using and promotion of the materials.

Owner:NANJING COMPTECH COMPOSITES CORP

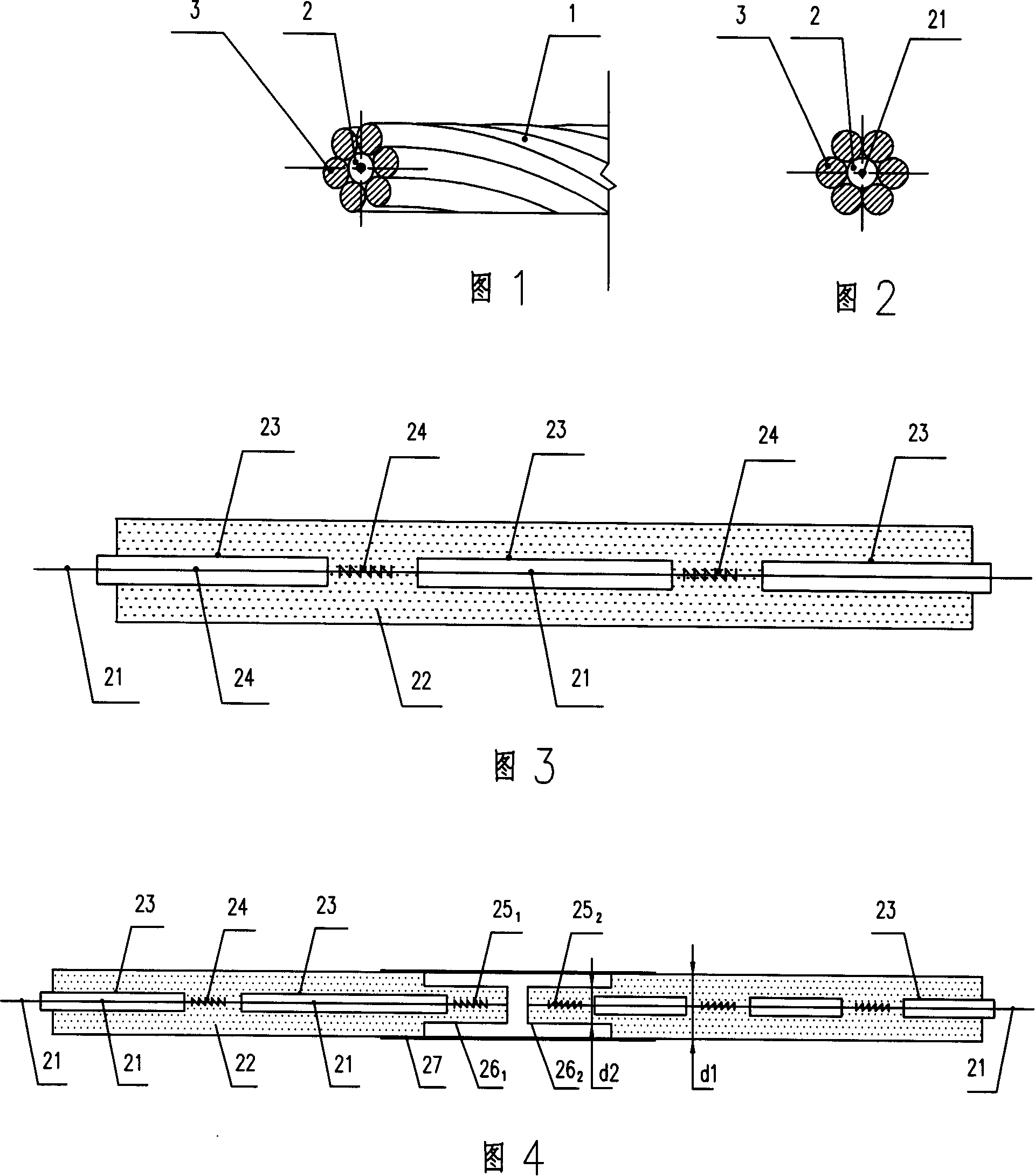

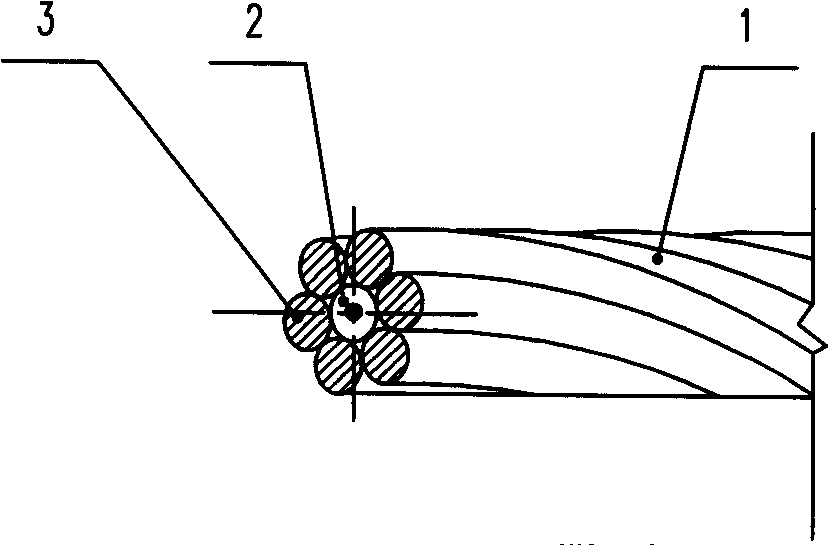

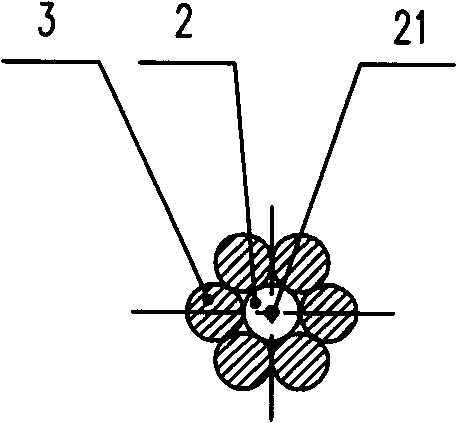

Optical fiber grating intelligent steel strand and its manufacture method

ActiveCN101210983AEffective protectionSo as not to damageForce measurement by measuring optical property variationCoupling light guidesGratingStress conditions

An intellectual steel strand for fiber lattice, which is molded by the stranding of central wire and wires around the central wire, the central wire is the enhanced composite intellectual rib of fiber lattice of a fiber lattice sensor; the intellectual rid comprises a fiber enhanced rid and fiber distributed along the lengthwise direction of the fiber enhanced rib, the fiber lattice sensor; a plastic sleeve is sleeved around the fiber without lattice, separates from the fiber and is connected with the fiber enhanced rib; the fiber transmitted by the fiber lattice sensor is led out from the head of the steel strand; a preparation method of the steel strand comprises the following steps of: firstly preparing the fiber lattice fiber enhanced composite intellectual rib; scattering stranding machines with the same length with the intellectual rib and substituting the central wire of the steel strand with fiber lattice fiber enhanced composite intellectual rib and finally molding the wire through stranding. The invented intellectual steel strand has self sensing property with all the advantages of fiber lattice, which can easily grasp the stress condition of the steel strand in the construction and service periods and instruct the tensioning of initial stress and the construction.

Owner:LIUZHOU OVM MASCH CO LTD

Electromagnetic flexible composite deposition direct preparation forming method of multifunctional gradient component

InactiveCN102962451ARealize free and flexible creationQuality improvementMetallic material coating processesHigh energyCam

The invention relates to an electromagnetic flexible composite deposition direct preparation forming method of a multifunctional gradient component, and the method is characterized in that high-energy beams or electric arc with high efficiency and low cost are used as a basic heat source, a static magnetic field or an alternating magnetic field is introduced or the static magnetic field and the alternating magnetic field are simultaneously introduced in the electric arc three-dimensional deposition process, under the support of computer-aided design (CAD) / computer-aided manufacturing (CAM) software, a computer controls a deposition fun or a workpiece to move according to a set space orbit, an electromagnetic composite energy field acting on a molten pool and a nearby micro area is used for heating and melting a material with ideal gradient ratio, the free and flexible adjustment and control of a deposition shape and a component tissue space distribution of the multifunctional gradient component can be realized, and the multifunctional gradient component is used for the development and production of the high-performance component with multiple functions such as oxidation resistance, creep resistance, fatigue resistance in fields such as aerospace, ships, automobile engine or energy.

Owner:HUAZHONG UNIV OF SCI & TECH

Ultrahigh molecular weight polyethylene/polyvinyl chloride composite pipe and manufacture method thereof

InactiveCN101696754AHighlight substantiveSignificant progressFlexible pipesPolyvinyl chlorideUltrahigh molecular weight

The invention relates to an ultrahigh molecular weight polyethylene / polyvinyl chloride composite pipe and a manufacture method thereof. The ultrahigh molecular weight polyethylene / polyvinyl chloride composite pipe is manufactured by compounding an ultrahigh molecular weight polyethylene inner pipe and a polyvinyl chloride outer wall, wherein the ultrahigh molecular weight polyethylene inner pipe comprises the following raw material components in parts by weight: (1) 100 parts of the ultrahigh molecular weight polyethylene with viscosity-average molecular weight larger than or equal to 1.5 million, 2.1-10 parts of polyvinyl chloride with the molecular weight of 2,000-10,000; and the polyvinyl chloride outer wall comprises 100 parts of polyvinyl chloride resin (PVC), 5-15 parts of impact modifiers, 0.5-8 parts of heat stabilizers, 0.07-1 part of lubricants and the balance of dyestuff. The invention provides an ideal ultrahigh molecular weight polyethylene / polyvinyl chloride composite pipe with friction resistance, corrosion resistance, high strength, creep resistance and firm fastening of the inner pipe and the outer wall and the manufacture method thereof with firm compound and low production cost. The invention is suitable for transporting corrosive, adhesive, high abrasive materials.

Owner:SHANDONG KELI NEW MATERIAL CO LTD

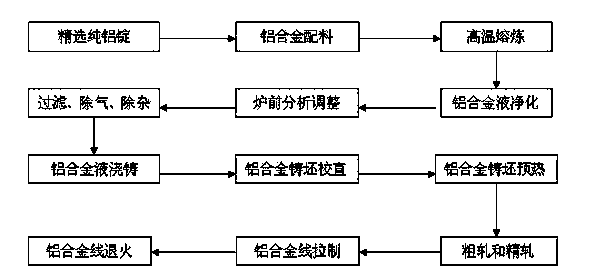

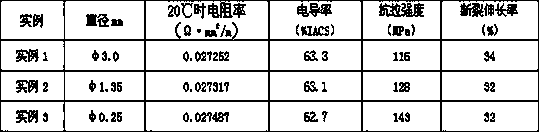

Energy-saving high-elongation soft aluminum alloy wire and preparation method thereof

InactiveCN104032191AUniform compositionGuaranteed mass productionMetal/alloy conductorsImpurityEnergy analysis

The invention relates to an energy-saving high-elongation soft aluminum alloy wire and a preparation method thereof. The aluminum alloy wire is mainly composed of the following components in percentage by weight: 0.05-0.40% of Cu, 0.10-0.40% of Zr, 0.25-1.00% of Fe, 0.01-0.22% of Mg, 0.001-0.15% of Si, 0.05-0.15% of Y, 0.05-0.10% of Sc, and the balance of Al and other inevitable impurity elements. The amount of each element in the other inevitable impurity elements does not exceed 0.03%, and the total amount of all the other inevitable impurity elements does not exceed 0.15%. The aluminum alloy wire has the advantages of favorable creep resistance, high elongation percentage, favorable bending property and the like, is easy for machine-shaping, and can ensure the stability of the electrical connection.

Owner:JIANGSU CHANGFENG CABLE

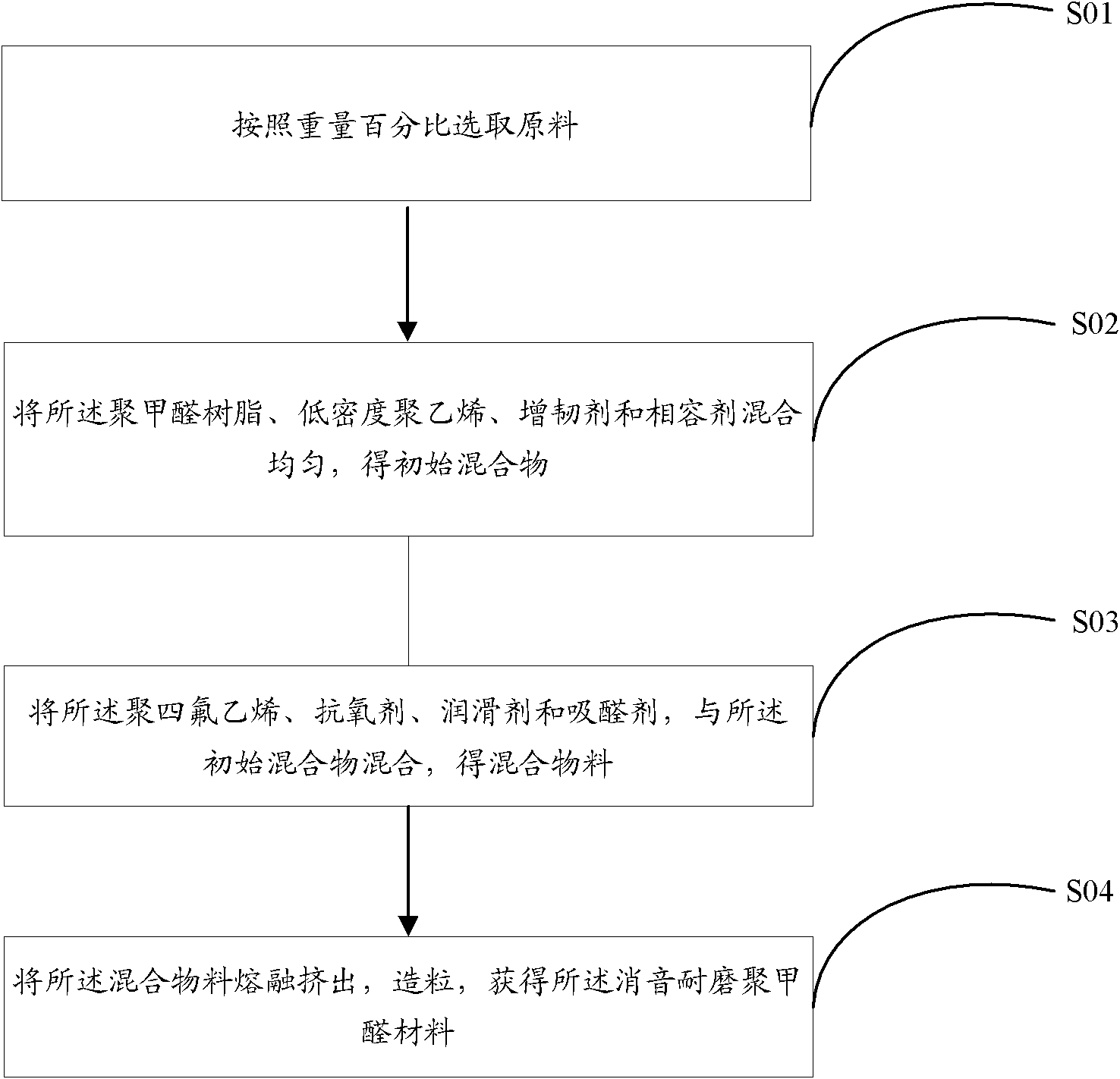

Sound-attenuating and wear-resistant polyformaldehyde material and preparation method thereof

The invention provides a sound-attenuating and wear-resistant polyformaldehyde material. The material comprises the following components in percentage by weight: 55 to 75 percent of polyformaldehyde resin, 5 to 10 percent of low density polyethylene, 3 to 10 percent of toughening agent, 10 to 20 percent of polytetrafluoroethylene, 2 to 5 percent of compatilizer, 0.2 to 0.4 percent of antioxidant, 0.2 to 0.6 percent of lubricating agent and 0.2 to 0.6 percent of aldehyde absorbing agent. The invention also provides a method for preparing the sound-attenuating and wear-resistant polyformaldehyde material. The sound-attenuating and wear-resistant polyformaldehyde material has high strength, dimensional stability, creep resistance, fatigue resistance, and high self-lubricating property, sound-attenuating property and wear resistance; and the preparation method for the material is simple, convenient to operate, high in benefit, low in cost and suitable for industrial production.

Owner:徐东

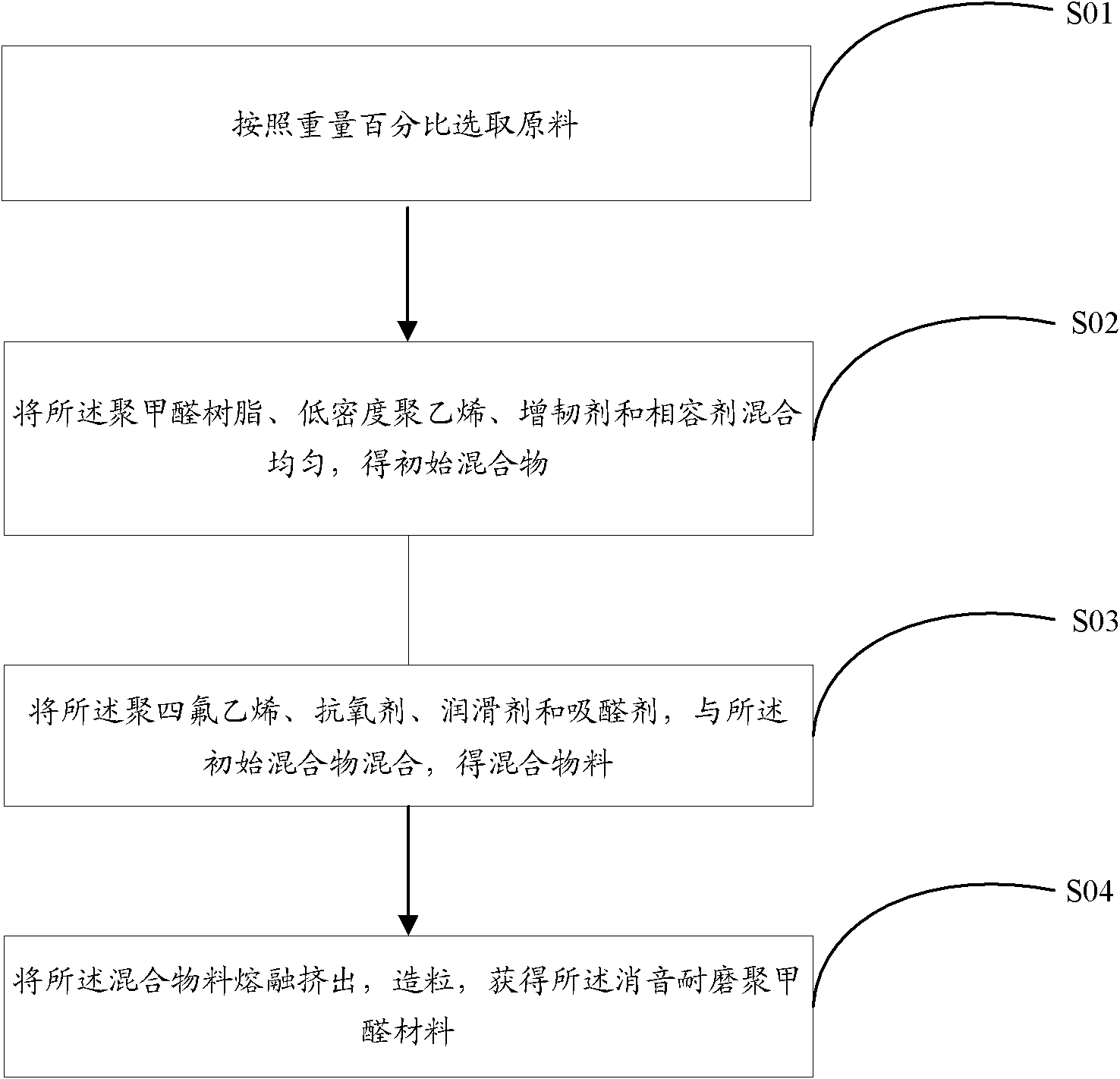

Sliding layer for bridge trackway longitudinal spacer assembly

ActiveCN101139817AReduce coefficient of frictionReduce frictionBridge structural detailsTrackwayEngineering

The invention provides a slide layer for longitudinal isolation devices on bridge tracks. The slide layer is arranged below a longitudinal partition wall between a track and a bridge; the slide layer is positioned in the direction of the bridge length; both ends of the slide layer can be expanded to limit table across an abutment; the width of the slide layer is bigger than that of the track; the slide layer comprises an top-arranged film layer, an intermediate sliding film and a bottom-arranged film layer; the top face of the top-arranged film layer of the slide layer is adhered to the bottom face of the longitudinal partition wall; the bottom face of the bottom-arranged film layer is stuck to the top face of the bridge beam body. The invention has advantages of anti-friction, tensile resistance, anti-freezing, creep-resisting, anti-corrosion and having weather ability performances; meanwhile, the invention can meet the requirements for lower friction factor and low friction loss. Besides, the invention also has advantages of perfect processing performance, being economic and practical and low price. Therefore, the invention meet requirements of bridge track longitudinal isolation devices for slide layers.

Owner:CHINA RAILWAY ERYUAN ENG GRP CO LTD

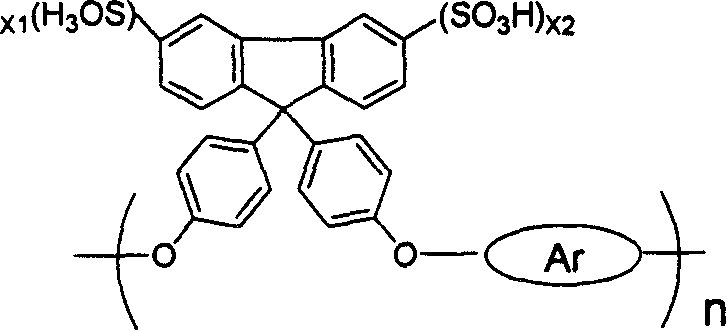

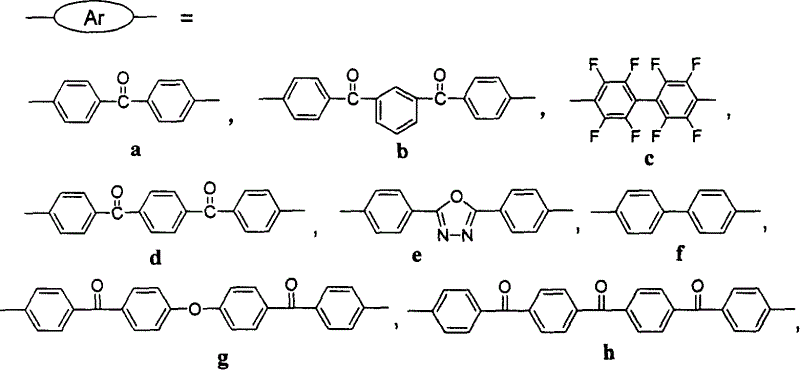

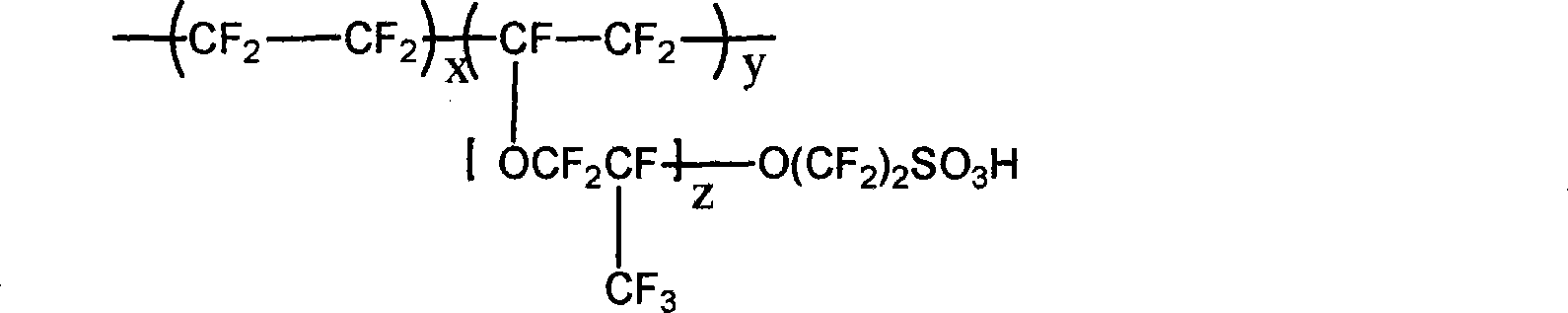

Sulfonated fluorine-containing poly-arylether (arone) and its preparing method and use

InactiveCN1621431ALow costLow priceChemical recyclingFuel cell detailsComposite filmChlorosulfuric acid

The present invention relates to one kind of sulfonated fluorene-containing polyaryl ether (ketone) and its application in preparing proton exchanging film. The sulfonated fluorine-containing polyaryl ether (ketone) may be prepared through polymerization of 9, 9-(4, 4-dihydroxyphenyl) fluorene and chloric or fluorous arone (arene) to form polyaryl ether (ketone); and the subsequent sulfonation with chlorosulfonic acid in the controlled consumption for controlled product sulfonation degree. The sulfonated fluorine-containing polyaryl ether (ketone) may be dissolved in different polar solvents before being cast to form single-component film, or be mixed with other polymer material for preparing composite film, or be mixed with heteropoly acid and other inorganic matter for preparing hetero film; and all these kinds of film have the advantages of low cost, high stability, high water absorption, small equivalent molecular weight, etc. and are expected to find use in fuel cell.

Owner:SUN YAT SEN UNIV

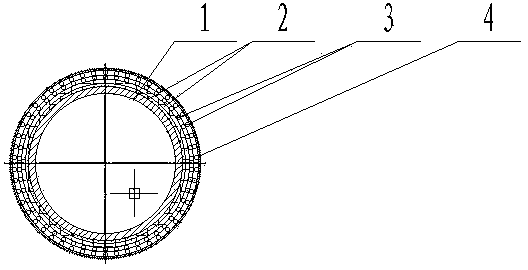

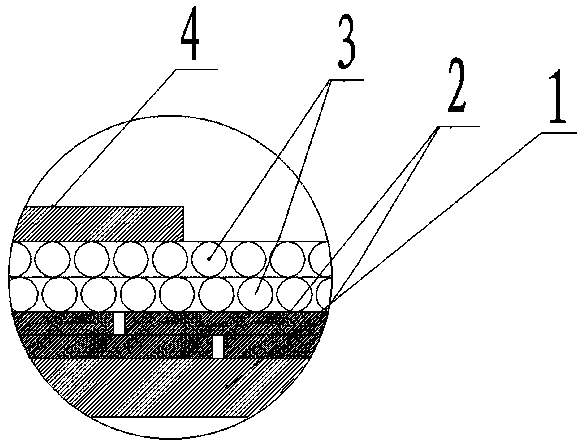

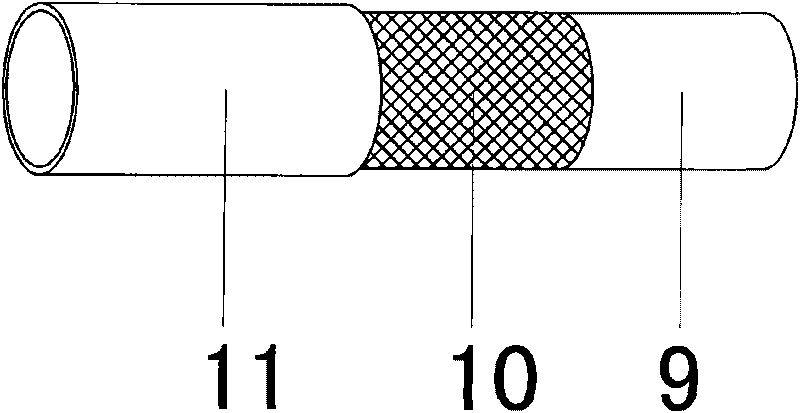

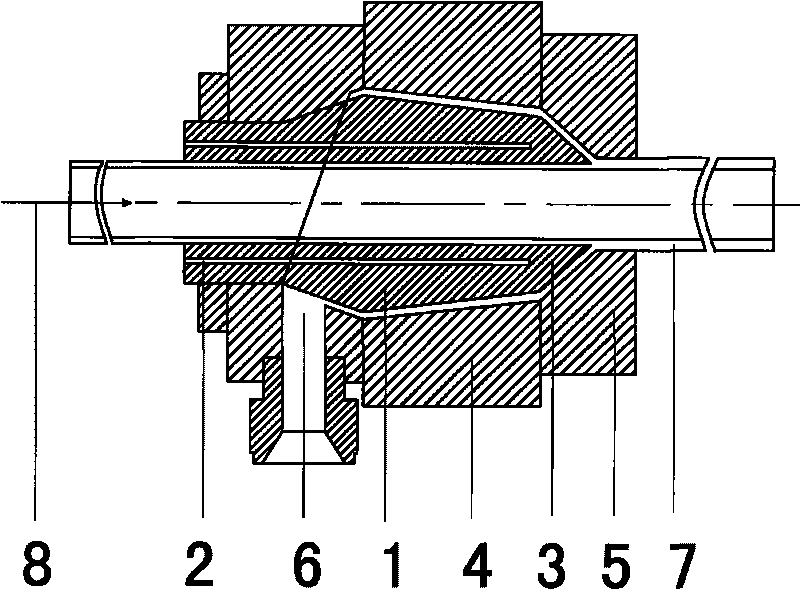

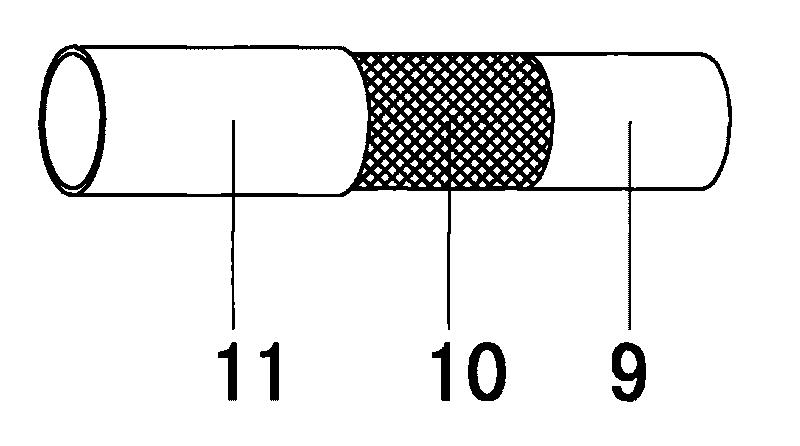

Flexible composite high-pressure delivery pipe

The invention discloses a flexible composite high-pressure delivery pipe. The flexible composite high-pressure delivery pipe comprises a media transmission layer, at least one enhanced layer and a protective layer which are integrally formed by means of heating and pressurization, the enhanced layers are arranged between the media transmission layer and the protective layer and are arranged as fiber enhanced layers, metal enhanced layers or a combination of the fiber enhanced layers and the metal enhanced layers, the fiber enhanced layers and the metal enhanced layers are of banded structures formed by gel mould coated with hot melt glue, an angle of 50-60 degrees is formed between each of the fiber enhanced layers and the metal enhanced layers and a central axis of the pipe, and the enhanced layers are of a bidirectional fiber band and metal band intersection winding structure comprising a left spiral winding layer and a right spiral winding layer. The flexible composite high-pressure delivery pipe has the advantages of reasonable structural design, high pressure bearing capacity, high resistance to low-temperature impact, small friction coefficient, good flexibility, environmental protection and long service life.

Owner:JIANGSU SHENSHI NEW MATERIAL TECH

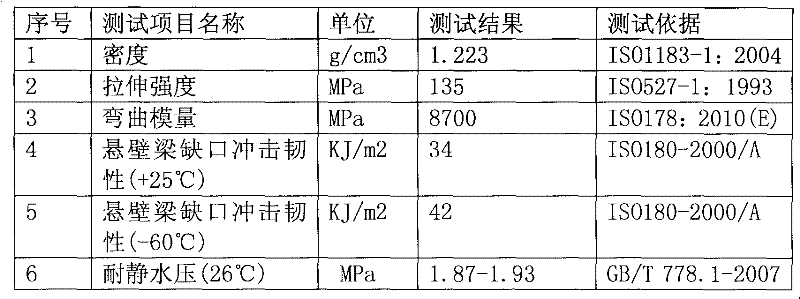

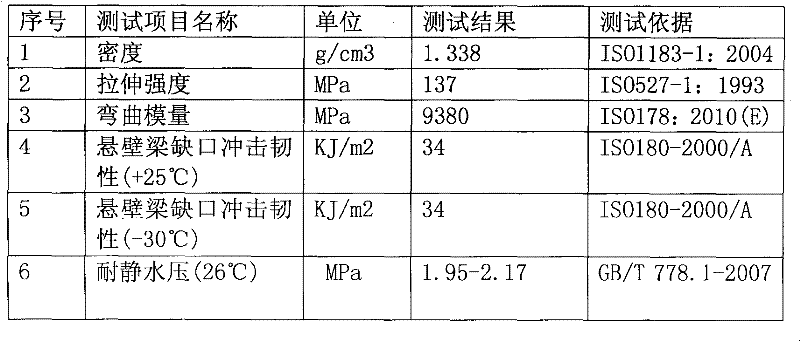

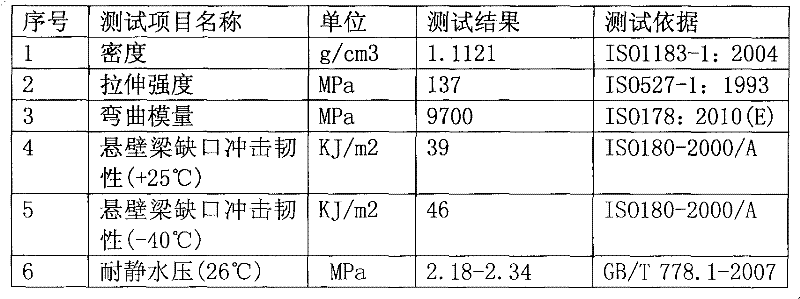

Long glass fiber enhanced polypropylene composite material water meter casing and manufacture method thereof

InactiveCN102504405AGood low temperature resistanceHigh low temperature impact resistanceVolume meteringHeavy metalsAntioxidant

The invention discloses a long glass fiber enhanced polypropylene composite material water meter casing and a manufacture method of the long glass fiber enhanced polypropylene composite material water meter casing. A thermal plastic composite material water meter casing comprises the following ingredients: blending alloy, auxiliary agents, color powder, antioxidants and ultraviolet absorbers, wherein the blending alloy consists of glass fiber, polypropylene and / or polypropylene modified materials. The thermal plastic composite material water meter casing made by adopting an injection molding forming process has the characteristics of high-temperature resistance, low-temperature resistance, impact resistance, creep deformation resistance, water pressure resistance, hydrolysis resistance, no heavy metal, long service life, low cost, environmental-friendly effect and the like, is easy to process and conforms to the industrial standard of the national plastic water meter casing material, so the thermal plastic composite material water meter casing is particularly suitable for large-scale industrial production and wide popularization and application.

Owner:BEIJING NASHENGTONG ADVANCED MATERIAL & TECH CO LTD

High-elasticity durable automobile rubber shock absorbing material

InactiveCN109161042AStrong heat resistanceImprove wear resistanceEpoxy resin coatingsWear resistantAntioxidant

The invention discloses a high-elasticity durable automobile rubber shock absorbing material. The high-elasticity durable automobile rubber shock absorbing material comprises a shock absorbing material body and a wear-resistant coating which coats the outer side of the shock absorbing material body; the shock absorbing material body is prepared from the following raw materials in parts by weight:20 to 30 parts of EPDM, 20 to 25 parts of butyl rubber, 10 to 15 parts of butadiene rubber, 4 to 7 parts of talcum powder, 2 to 5 parts of a toughening agent, 2 to 4 parts of an antioxidant, 1 to 4 parts of an anti-aging agent, 1 to 3 parts of a coupling agent, 3 to 9 parts of epoxidized soybean oil, 3 to 6 parts of a maleic anhydride compatilizer, 3 to 7 parts of paraffin, 5 to 8 parts of nano-barium sulphate, 2 to 5 parts of modified nano silicon nitride, 1 to 3 parts of potassium stearate, 2 to 5 parts of an accelerant, 2 to 4 parts of a coupling agent, 1 to 2 parts of zinc borate and 3 to7 parts of sulphur. According to the high-elasticity durable automobile rubber shock absorbing material, the wear resistance and the durability of a shock absorbing piece are greatly improved by the wear-resistant coating on the outer side of the shock absorbing material body.

Owner:ANHUI WEIWEI RUBBER PARTS GRP

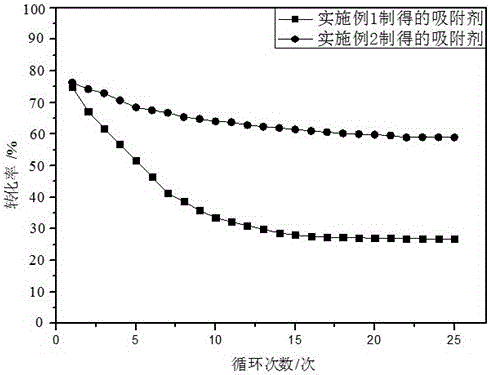

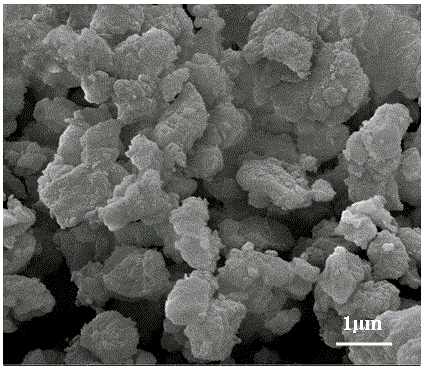

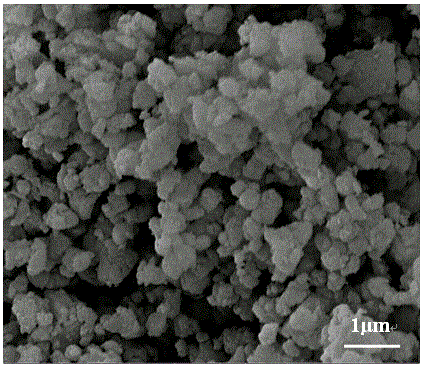

Preparation method and application of calcium-based adsorbent

ActiveCN105903458AAntioxidantHigh temperature strengthGas treatmentOther chemical processesDesorptionSorbent

The invention discloses a preparation method of a calcium-based adsorbent. According to the preparation method, natural quartz stone powder (including a main component SiO2) and active carbon powder are taken as raw materials for preparing silicon oxynitride by adopting a carbon thermal reduction method; and silicon oxynitride is used as an inert supporting material and is treated by a process of immersing, drying and calcining to load CaO so as to prepare the calcium-based adsorbent. By controlling the CaO precursor and calcining conditions, relatively good circulating stability is obtained. The raw material has a wide source, the preparation method is simple and convenient and the operability is strong; and the problem that the adsorption capacity of the high-temperature CO2 calcium-based adsorbent is reduced after a plurality of times of CO2 adsorption / desorption cycles is improved very well.

Owner:KUNMING UNIV OF SCI & TECH

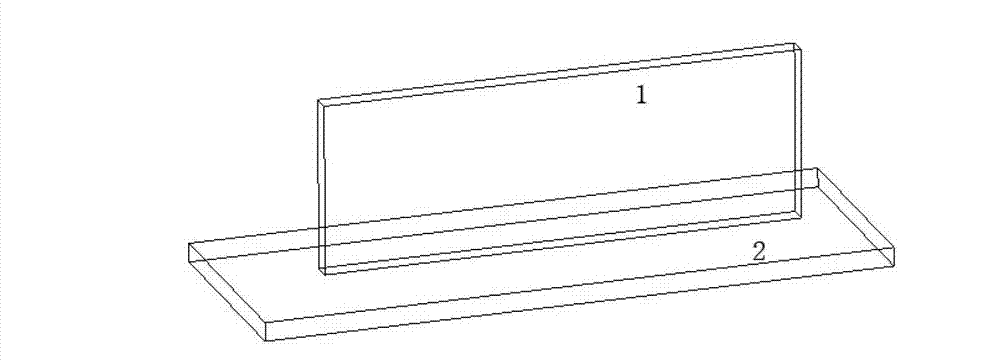

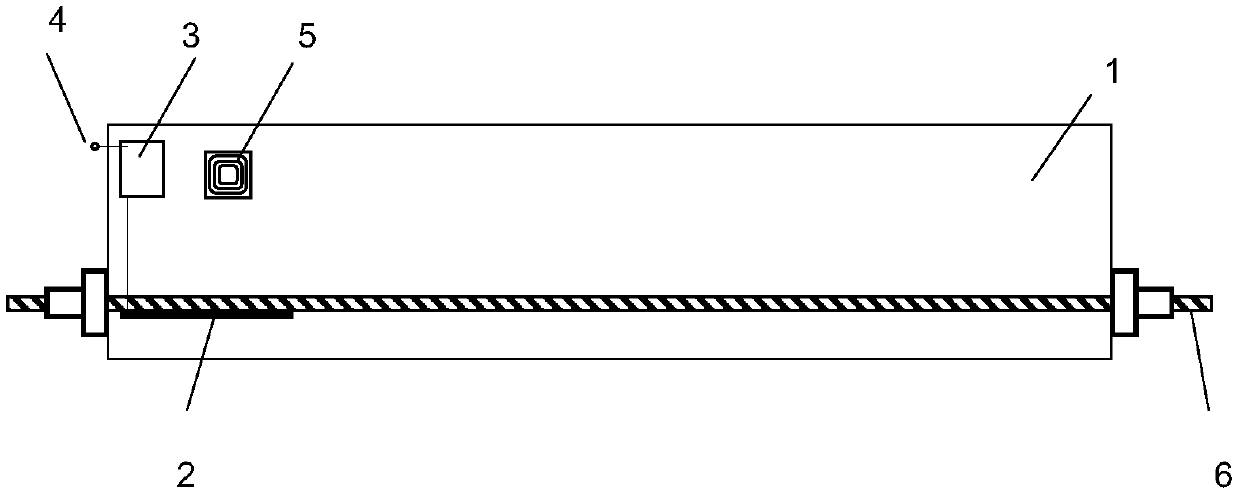

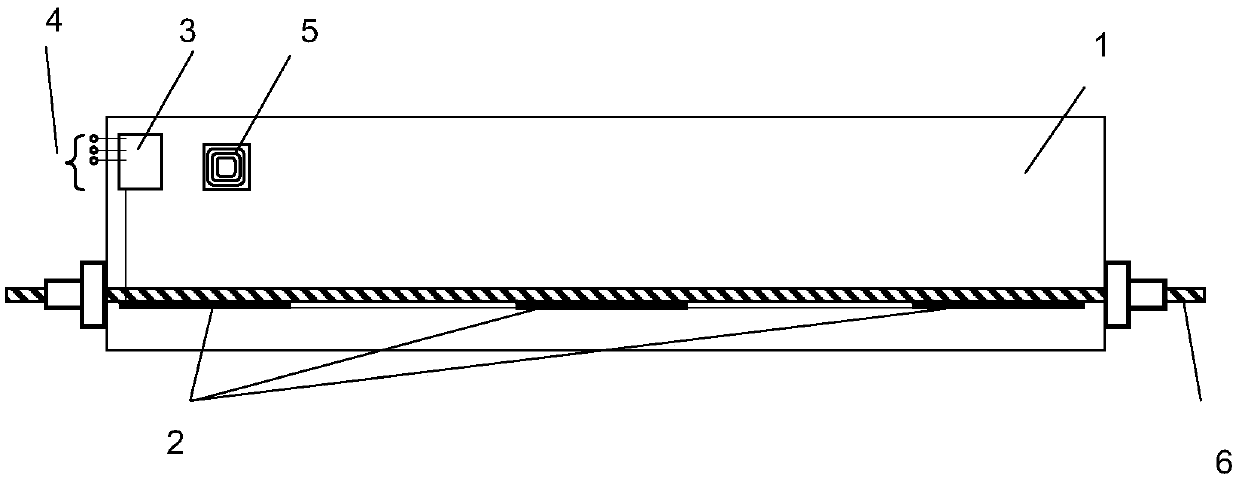

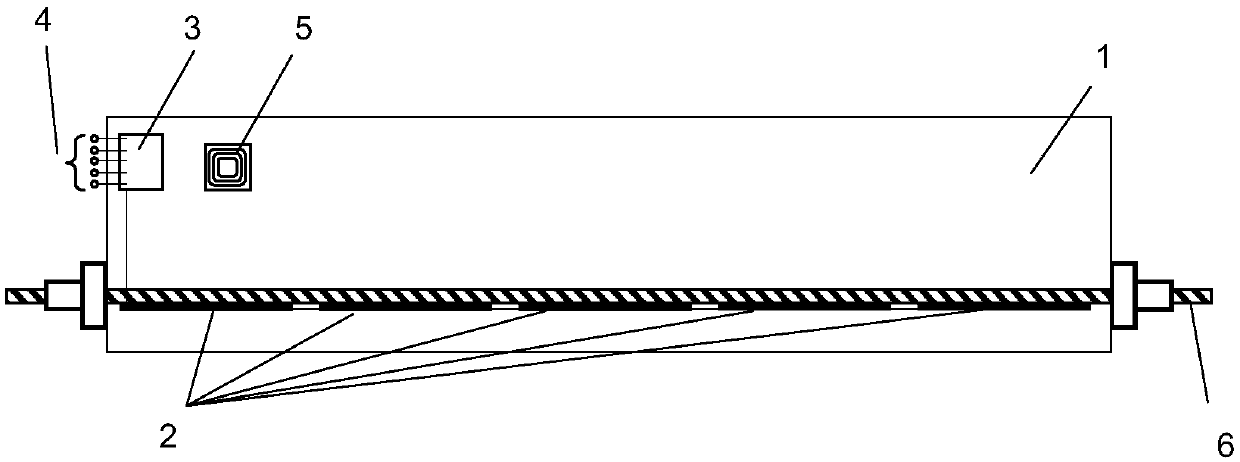

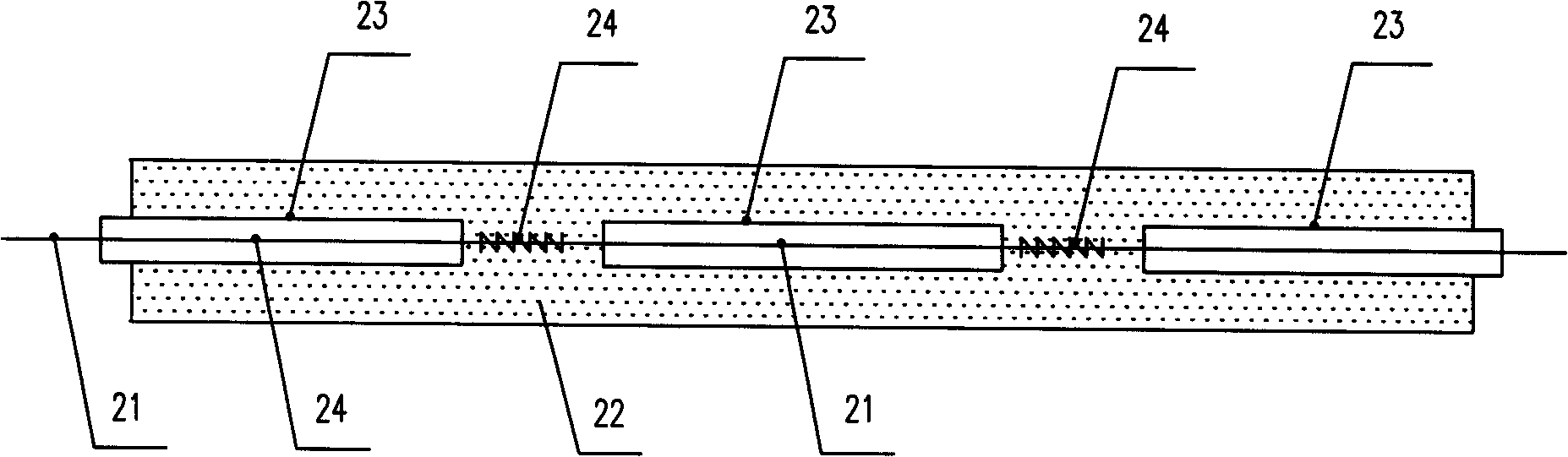

Prestress member capable of being monitored, prestress loss monitoring method and manufacturing method

PendingCN109577477AGuaranteed accuracyCorrosion resistanceCo-operative working arrangementsBuilding constructionsCarbon fibersPre stress

The invention discloses a prestress member capable of being monitored, a prestress loss monitoring method and a manufacturing method. The prestress member capable of being monitored comprises a prestress member body, long-gauge-distance carbon fiber strain sensing units, an electronic tag unit, a micro circuit board and a prestress member surface output port. Each long-gauge-distance carbon fiberstrain sensing unit arranged on the surface of a prestress reinforcing bar comprises at least one long-gauge-distance carbon fiber strain sensing element distributed on the surface of the reinforcingbar in the axial direction of the reinforcing bar; after parallel connection of the micro circuit board in the prestress member, signals of the long-gauge-distance carbon fiber strain sensing units are obtained from the prestress member surface output port; built-in electronic tags are also used, so that production information, use conditions, directions, positions and other information of the prestress member are conveniently read, the requirements for real-time positioning, tracking and monitoring of the prestress member are met, and therefore intelligent fine management can be achieved in the using process of the prestress member.

Owner:南京东智安全科技有限公司 +1

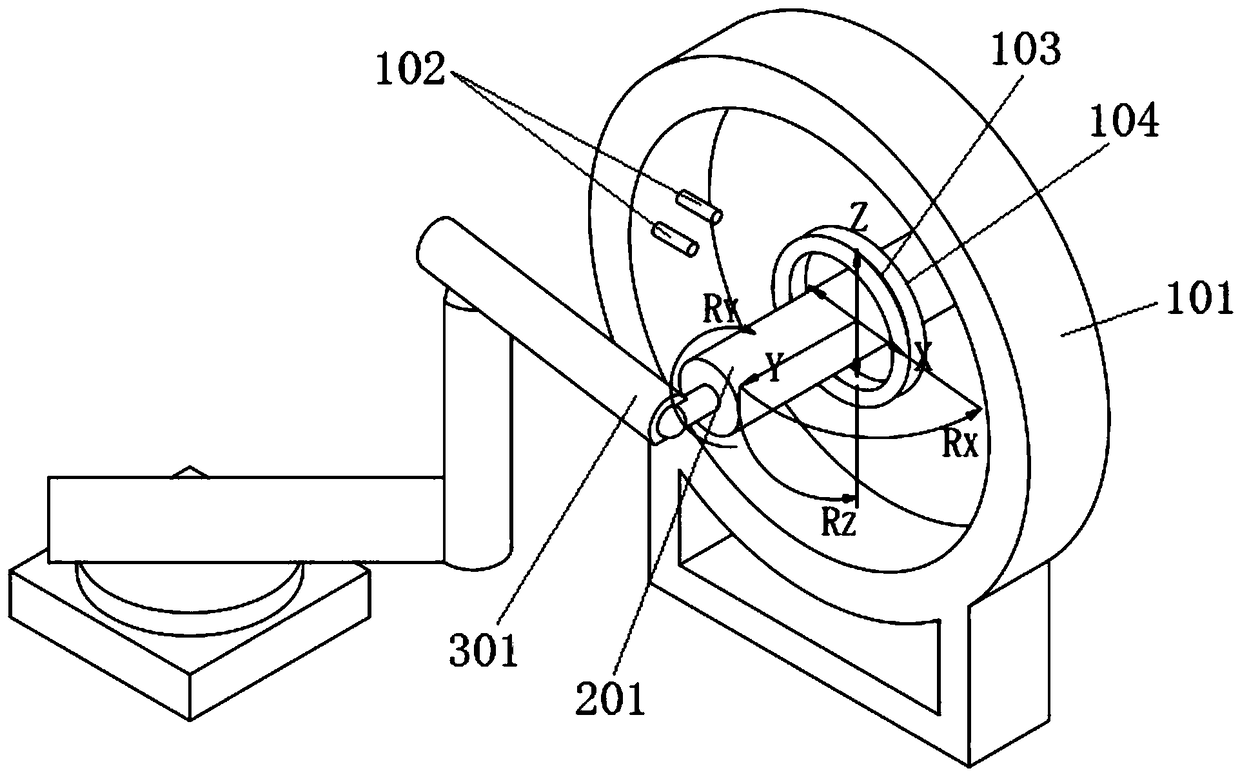

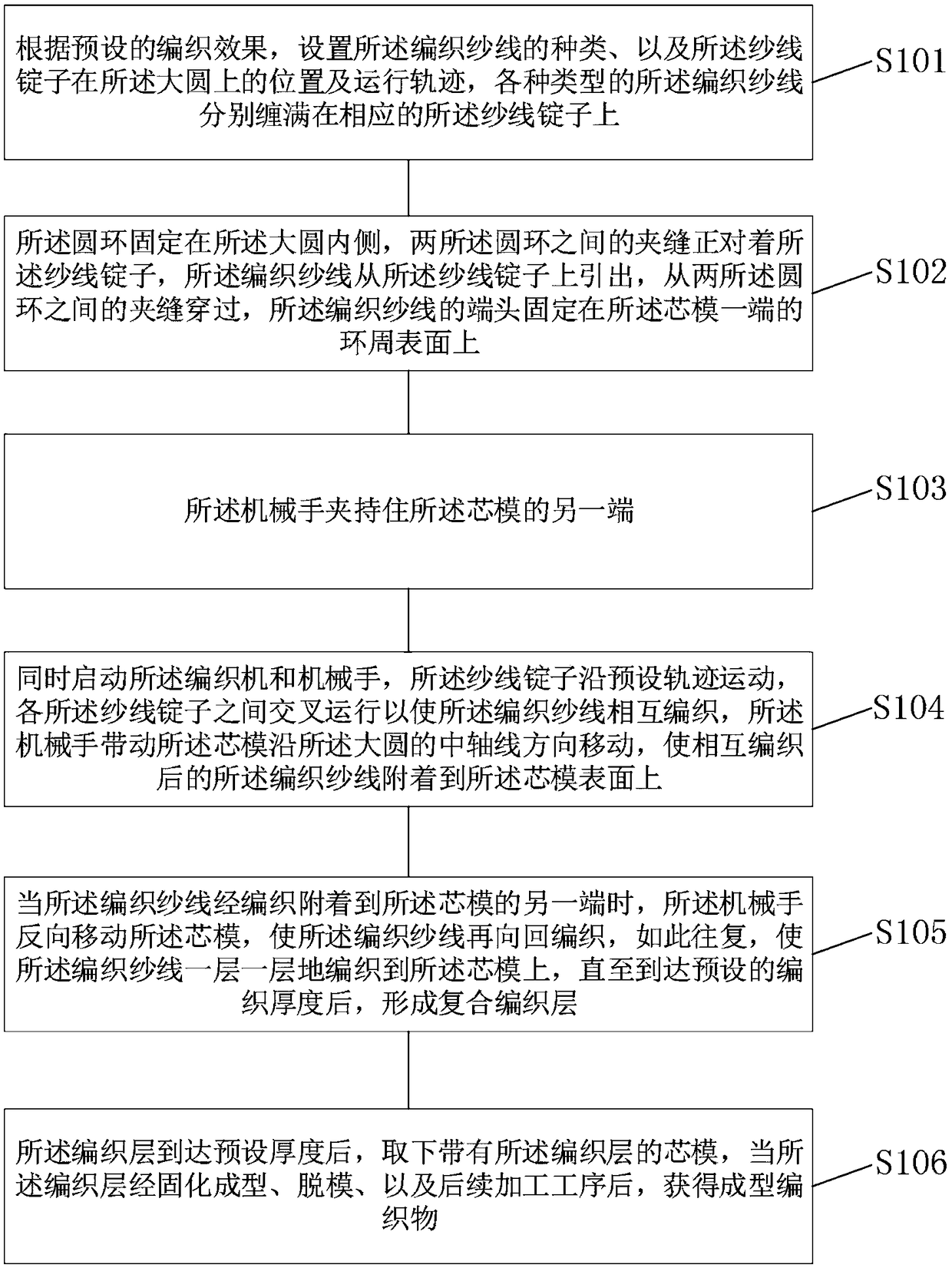

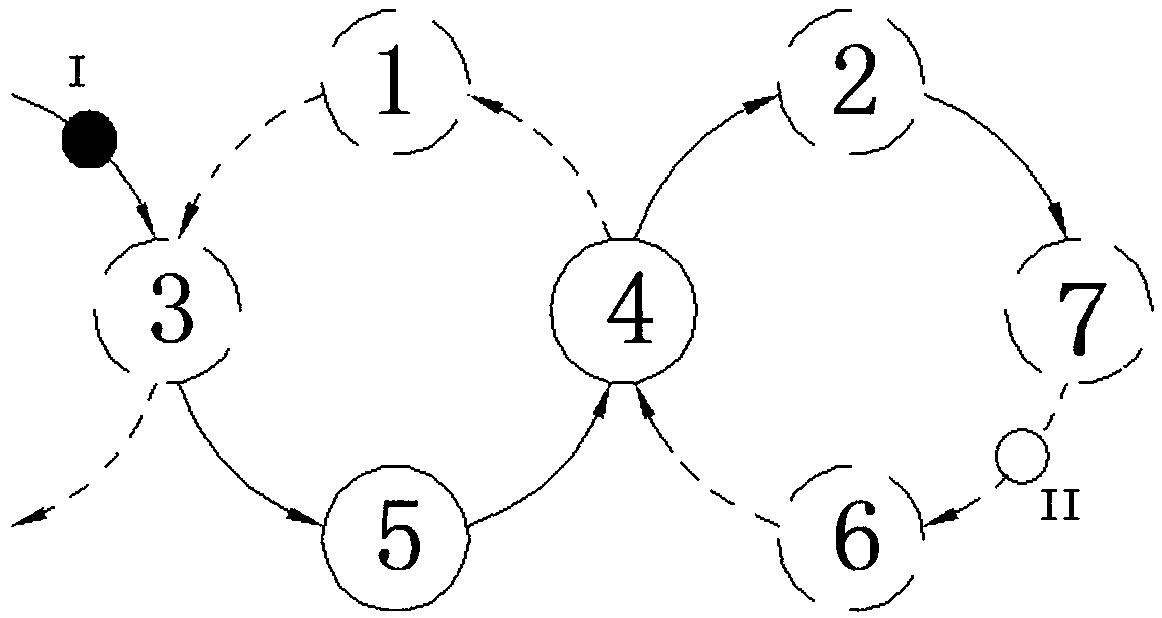

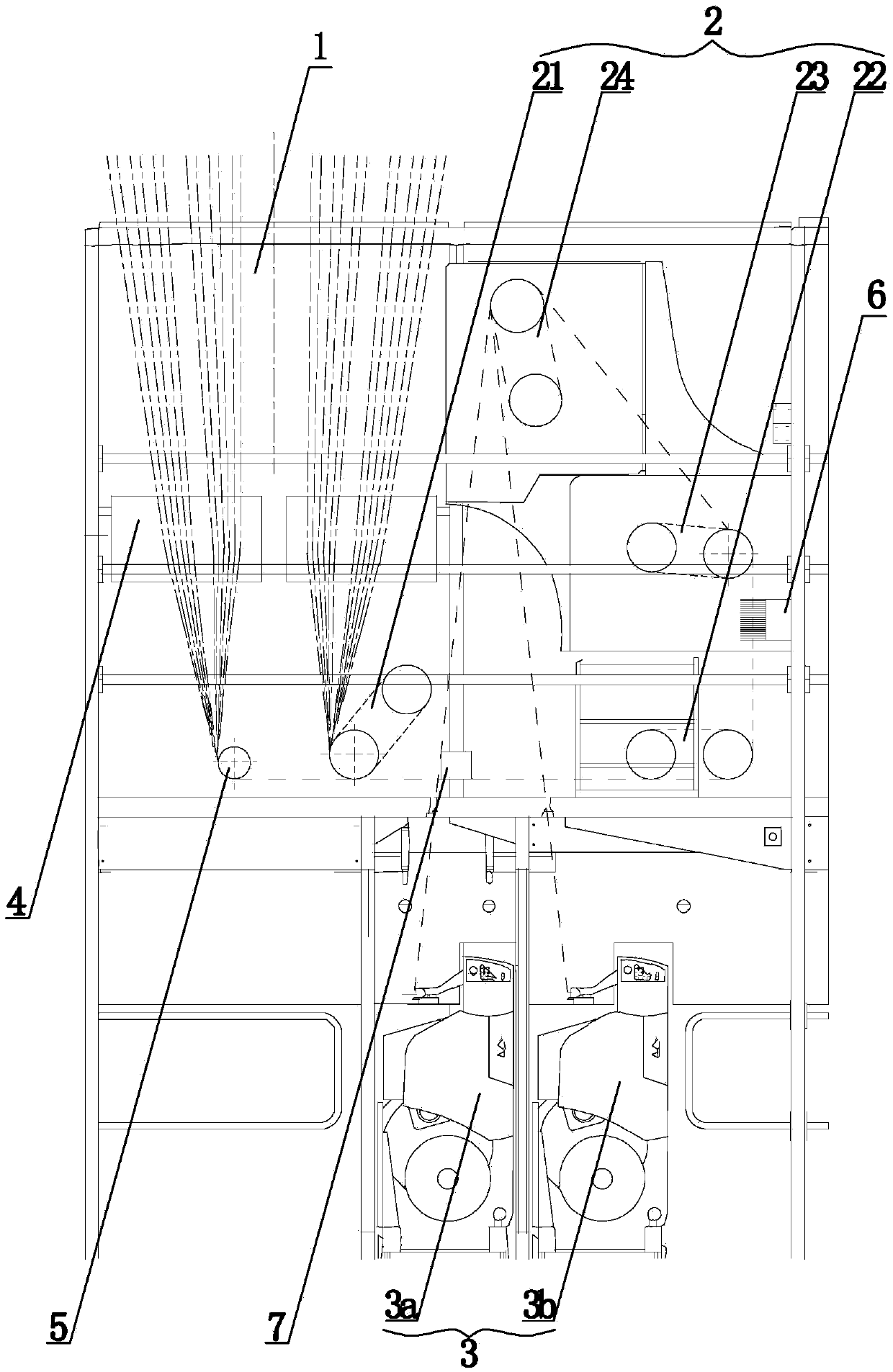

Equipment and process for weaving composite material

The invention provides equipment and a process for weaving a composite materials; the equipment comprises a knitting machine and a mechanical arm, the knitting machine comprises a large circle, yarn spindles, two circular rings and a core mould; the yarn spindles are arranged on the inner side wall of the large circle, and are uniformly arranged along the circumferential direction of the inner side wall of the large circle; the two circular rings are arranged side by side, the two circular rings coincide with the central axis of the large circle, and a preset distance is reserved between the two circular rings, so that woven yarns can pass through the preset distance; the core mould is arranged in the circular rings in a penetrating mode, one end of the core mould is connected with the mechanical arm, and the mechanical arm is used for driving the core mould to do reciprocating motion along the central axis direction of the large circle; the type of the yarn spindles is at least two, the yarn spindles of all types rotate synchronously with the large circle, and the large circle revolves according to a preset trajectory. An insulation operating rod produced by the weaving process and the equipment is higher in fiber density compared with other insulating rod formed by other processes, internal air bubbles are fewer, the insulation operating rod has the advantages of being lighter in weight, better in mechanical and insulating performance and capable of being applied to overhauling work of extra-high voltage electric power engineering.

Owner:STATE GRID CORP OF CHINA +3

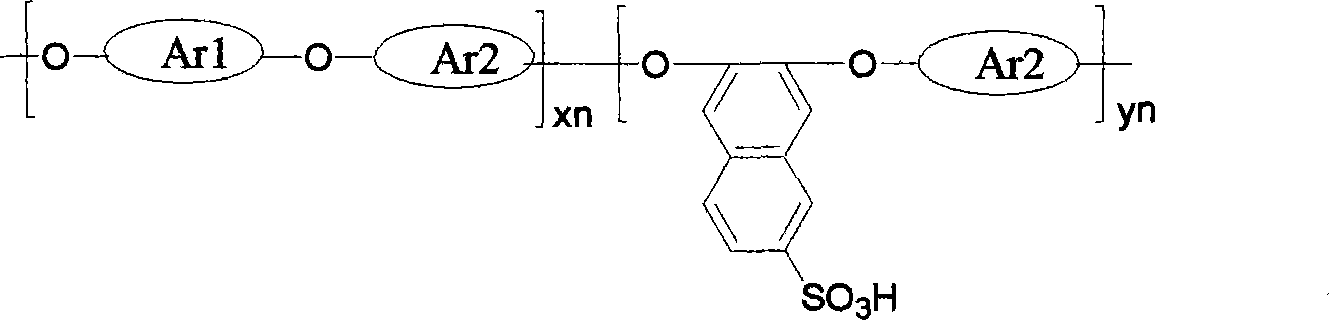

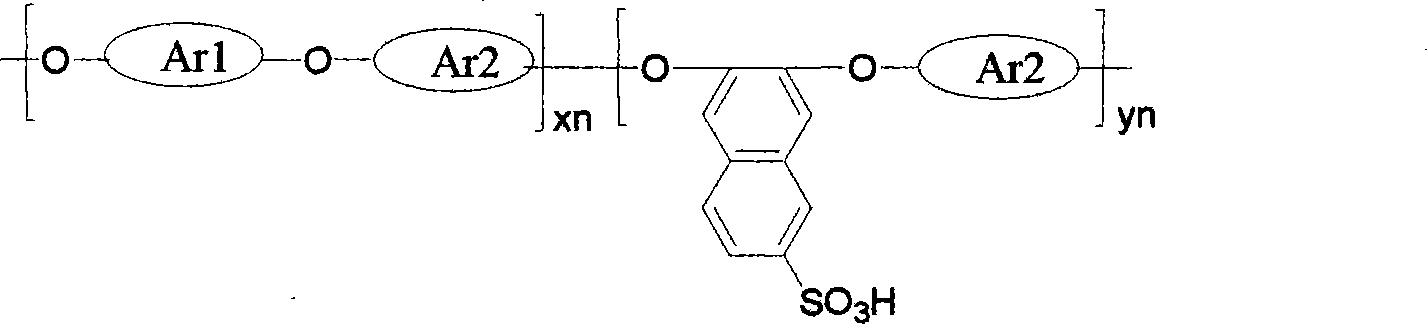

Sulfonated polyarylether with sulfonic group at side chain naphthalene ring and preparation method thereof

A sulfonated poly aryl ether with sulfonic group on naphthalene ring of side chain and preparation thereof, which is capable to solve technical problems of complexity in synthesis, hardness in controlling sulphonation position and degree, high possibility of side reaction in sulphonation, complexity in sulphonation and hardness to realize indutrialzation. The introduces binaphthyl bisphenol monomer on side-chain benzene ring of sulfonic group on molecular level, prepares sulfonated poly aryl ether with sulfonic group only on naphthalene ring of side chain, so that ensures chemical stability of main chain with high molecular weight, while having no influence on mechanical property thereof. Because of existence of conjugate benzene ring on side-chain of polymer material, sulfonic group has little impact on the main chain after introduction of sulfonic group, thus stability of the main chain is improved. The sulfonic group is linked to conjugate benzene ring, which make it easier to ionize to release hydrogen proton, so that proton exchange membrane produced from the material exhibits a good electricity conductivity. The electricity conductivity thereof is comparable to Nafion membrane.

Owner:SHENZHEN UNIV

Ultra high molecular weight polyethylene and polyvinyl chloride composite pipe embedded with reinforced steel filaments and manufacturing method thereof

InactiveCN101699119AHigh composite strengthSolve binding problemsRigid pipesPolyvinyl chlorideHot melt

The invention discloses an ultra high molecular weight polyethylene and polyvinyl chloride composite pipe embedded with reinforced steel filaments and a manufacturing method thereof. The ultra high molecular weight polyethylene and polyvinyl chloride composite pipe is characterized in that: an inner layer is an ultra high molecular weight polyethylene pipe; an outer layer is a polyvinyl chloride pipe; the steel filaments are arranged between the inner layer and the outer layer; more than one fifth of the diameter of the steel filaments is embedded into the outer wall of the inner layer ultra high molecular weight polyethylene pipe, wherein the polyvinyl chloride outer wall is added with an impact modifier, a heat stabilizer, a lubricant and other PVC processing aids. The invention provides the ultra high molecular weight polyethylene and polyvinyl chloride composite pipe, which not only has the characteristics of wear resistance, corrosion resistance and difficult adhesion of the ultra high molecular weight polyethylene pipe, but also has the good performance of high strength and creep resistance of the reinforced polyvinyl chloride material; the inner and outer wall of the pipe are corrosion resistant; and the pipe is compounded by hot melting the ultra high molecular weight polyethylene inner pipe, the polyvinyl chloride outer wall and the embedded steel filaments, the combined strength of the three materials is greatly improved, and the problem of combination of different materials is radically solved when the three materials are firmly combined.

Owner:SHANDONG KELI NEW MATERIAL CO LTD

Optical fiber grating intelligent steel strand and its manufacture method

ActiveCN101210983BEffective protectionSo as not to damageForce measurement by measuring optical property variationCoupling light guidesGratingStress conditions

Owner:LIUZHOU OVM MASCH CO LTD

Carbon fiber-reinforced halogen-free flame-retardant PA66 composite and preparation method thereof

The invention relates to a carbon fiber-reinforced halogen-free flame-retardant PA66 composite and a preparation method thereof. The composite comprises, by weight, 52.1 to 68.1% of PA66, 15 to 20% of a halogen-free fire retardant, 10 to 30% of carbon fibers, 2 to 4% of a grafting type toughening modifier, 0.4% of an anti-oxidant and 0.5% of a lubrication dispersing agent. The invention also relates to a preparation method for the carbon fiber-reinforced halogen-free flame-retardant PA66 composite. The PA66 composite provided by the invention is developed to meet special requirements of electric appliance products on antistatic performance and flame resistance of electromagnetic-shielding materials. Compared with the prior art, the PA66 composite provided by the invention has the advantages of high mechanical strength, surface resistance of 10<-2> to 10<6> omega, electromagnetic shielding performance, no halogen, environmental protection, flame-retardation performance reaching the level UL-94V0, good appearance and excellent comprehensive properties, and is especially applicable to thin-wall products with high requirements on precision.

Owner:HEILONGJIANG XINDA ENTERPRISE GRP

Abrasion-resisting and high-temperature-resisting power box housing and preparation method thereof

InactiveCN107686939AHigh hardnessChange the shape of the organizationSubstation/switching arrangement detailsMetallic material coating processesCeramic coatingImpurity

The invention discloses an abrasion-resisting and high-temperature-resisting power box housing and a preparation method thereof. The housing comprises a power box housing metal substrate and a ceramiccoating. Raw materials of the power box housing metal substrate comprise the following components of C, Al, B, Si, Mn, Cr, Ni, Cu, Ti, Zr, Nb, Mo, Sc, Nd, Y, La and the balance Fe and inevitable impurities. Raw materials of the ceramic coating comprise BC, SiC, Cr3C2, B2O3, ZrO2 and BN. The abrasion-resisting and high-temperature-resisting power box housing and the preparation method thereof havethe advantages of being resistant to a high temperature and creep deformation, good in tenacity, good in corrosion resistance, long in service life and the like.

Owner:芜湖锐华暖通科技股份有限公司

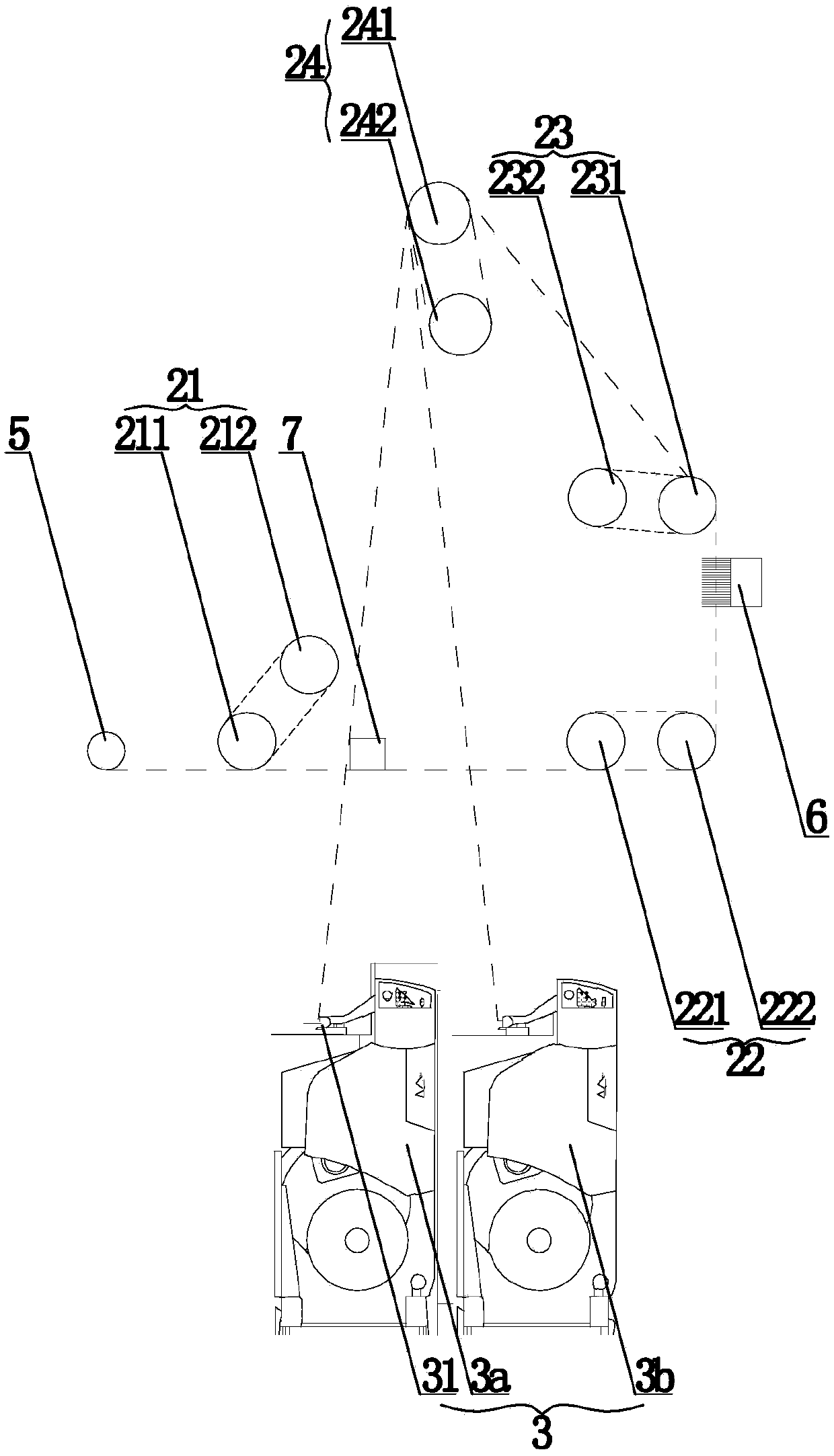

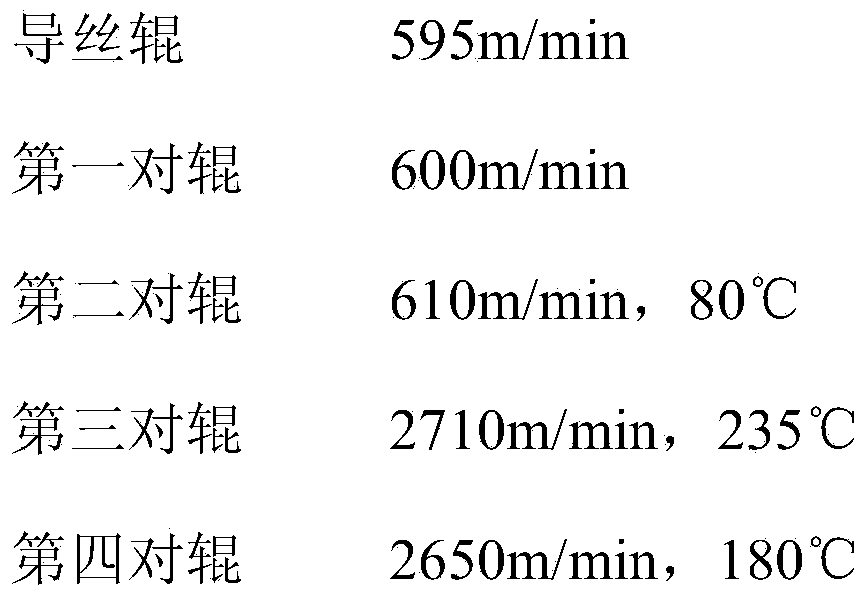

Medium-strength fiber and processing method thereof

InactiveCN105369375AStable physical propertiesDimensionally stableArtificial thread manufacturing machinesArtificial filament heat treatmentBreaking strengthEngineering

The invention relates to a medium-strength fiber and a processing method thereof, and belongs to the fiber manufacture technical field; the method uses slices or melt as primary material, and the fiber is formed by the following steps: spinning, cooling, oiling, and multistage stretching heat setting; the multistage stretching heat setting is completed in four pairs of rollers; the first pair of rollers are cold rollers; the second, third, and fourth pairs of rollers are hot rollers. The method is applied to medium-strength fiber processing, stable in spinning condition, low in waste fiber rate, and high viscosity slices are employed in the medium-strength fiber processing, thus obtaining the medium-strength fiber with high breaking tenacity, good dimension stability, and stable mechanical property.

Owner:ZHEJIANG GUXIANDAO IND FIBER +1

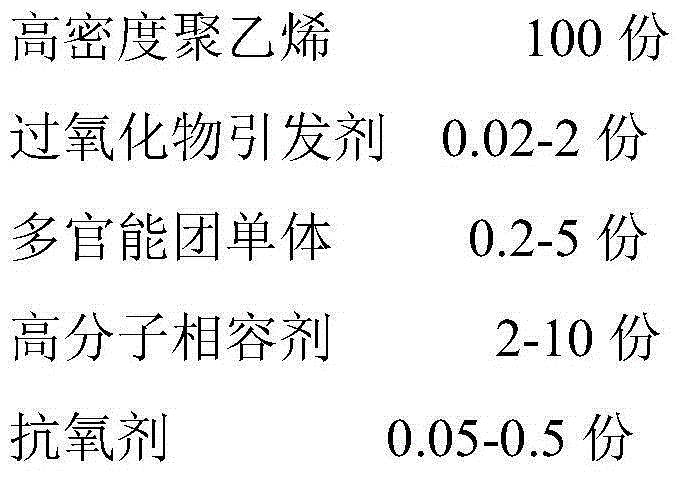

Manufacturing method of carbon fiber reinforced HDPE double-wall winding pipe

The invention discloses a manufacturing method of a carbon fiber reinforced HDPE double-wall winding pipe; firstly, a high-density polyethylene mixture is prepared by high-density polyethylene, a peroxide initiator, polyfunctional group monomers, a high molecular compatilizer and antioxidant; and modified carbon fibers are prepared by carbon fibers and a silane coupling agent. Then, the high-density polyethylene mixture and the modified carbon fibers are reacted and coextruded through a double-screw extruder, and are extruded by a mold and shaped in vacuum to obtain a carbon fiber reinforced HDPE hollow square pipe; and then, the carbon fiber reinforced HDPE hollow square pipe is spirally wound and welded by plastic hot melt adhesive to manufacture the carbon fiber reinforced HDPE double-wall winding pipe. As carbon fiber reinforced HDPE is adopted to manufacture the hollow square pipe, the creep resistance, the modulus, the impact resistance, the scratch resistance, the slow-speed crack expansibility resistance, the environmental stress cracking resistance and the high-temperature resistance are all greatly improved; and the double-wall winding pipe totally has enough gap tensile strength, so that the whole performance of the pipe is effectively improved.

Owner:WUHAN QINGYUAN PIPE CO LTD +1

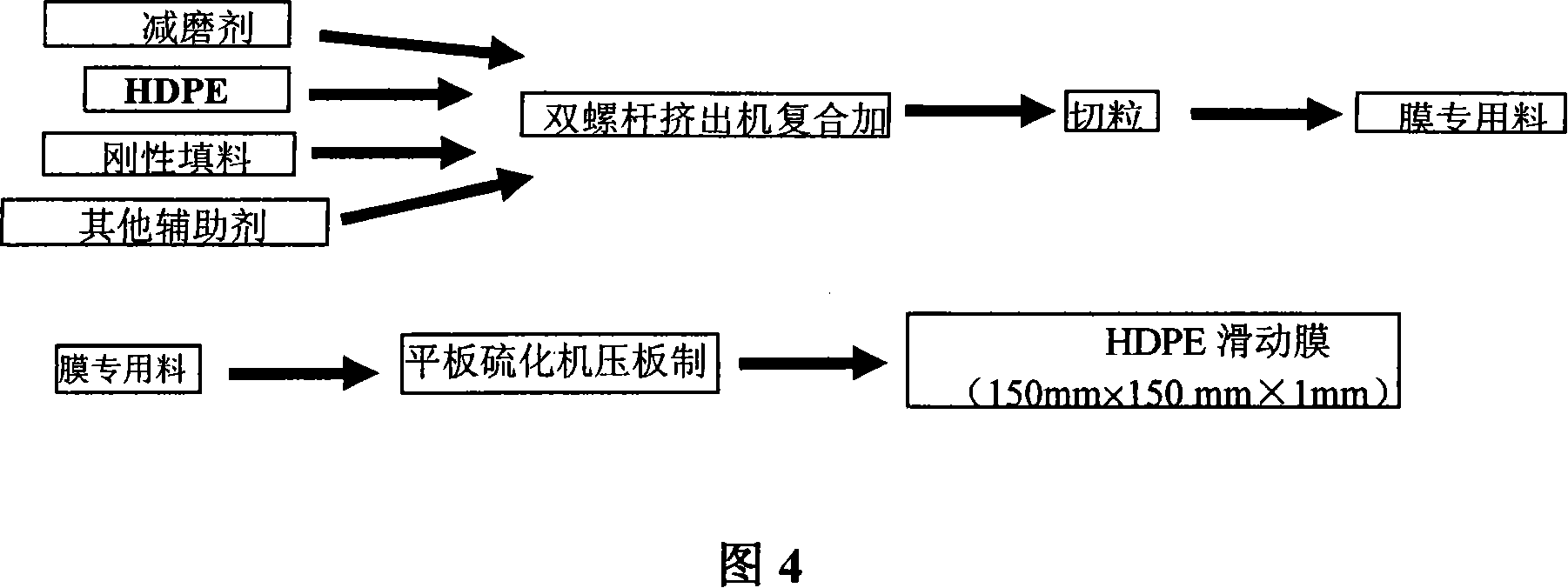

Glass fiber enhanced high-density polyethylene (HDPE) double-walled winding pipe and manufacture method thereof

ActiveCN102691832BImprove performanceImprove creep resistanceRigid pipesFiberLow-density polyethylene

The invention relates to a glass fiber enhanced high-density polyethylene (HDPE) double-walled winding pipe, which is formed by spirally winding a glass fiber enhanced HDPE plastic pipe and welding the glass fiber enhanced HDPE plastic pipe by plastic hot melt adhesives, wherein the glass fiber enhanced HDPE plastic pipe is a hollow rectangular glass fiber enhanced HDPE plastic pipe with the long glass fiber content being 5 percent to 40 percent by weight. A manufacture method of the glass fiber enhanced HDPE double-walled winding pipe comprises the following steps that HDPE mixed materials are prepared, modified long glass fiber is prepared, the HDPE mixed materials and the modified long glass fiber take reaction and are coextruded into a hollow square pipe, and the hollow square pipe is made into the glass fiber enhanced HDPE double-walled winding pipe through spiral winding and plastic hot melt adhesive welding. The glass fiber enhanced HDPE double-walled winding pipe has the advantages that the creep resistance, the modulus, the impact resistance, the scratch resistance, the slow crack expansion resistance, the environment stress cracking resistance and the high-temperature resistance are good, the whole body has sufficient sewing stretching intensity, and the integral performance of pipelines is effectively improved.

Owner:SHANGHAI QINGYUAN PIPE TECH

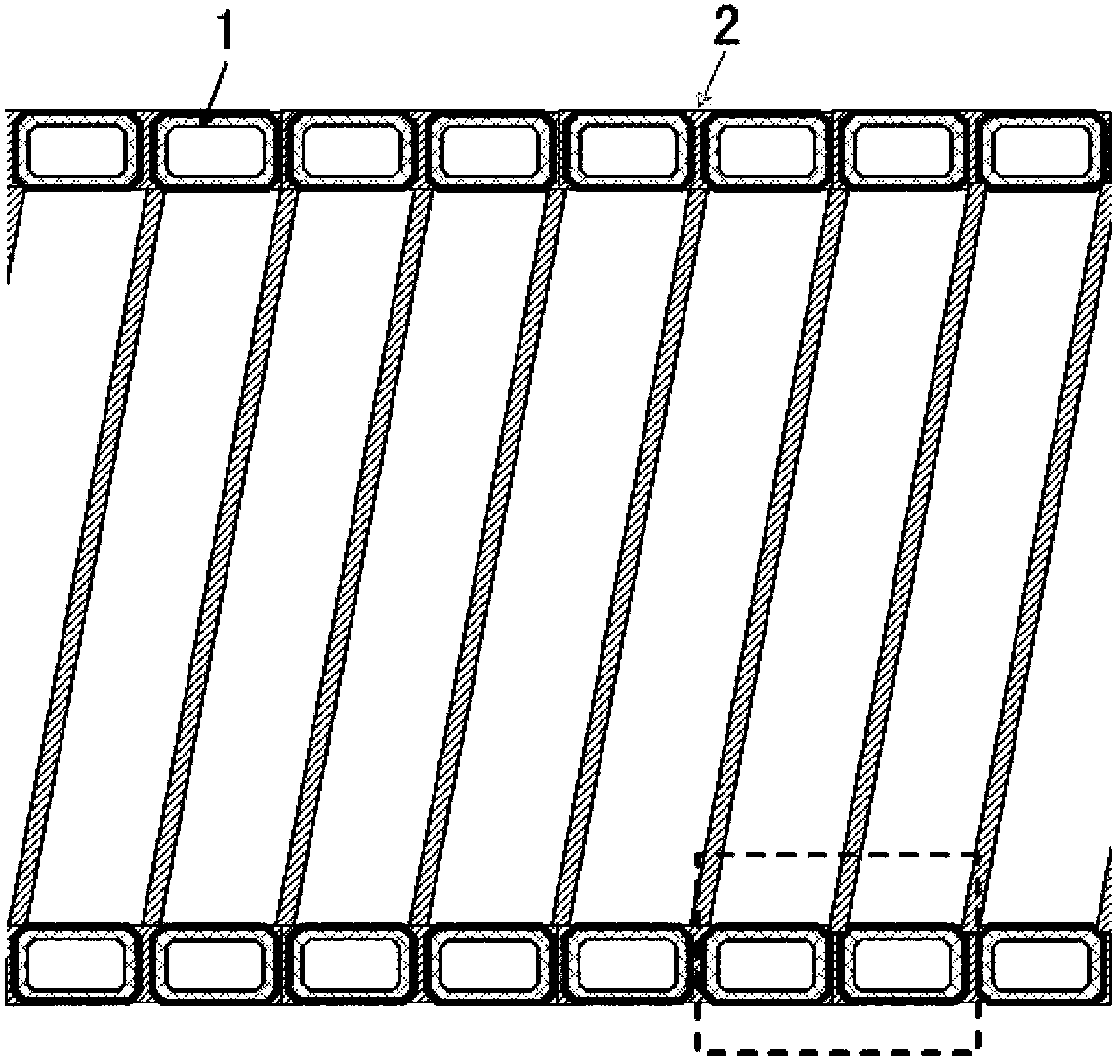

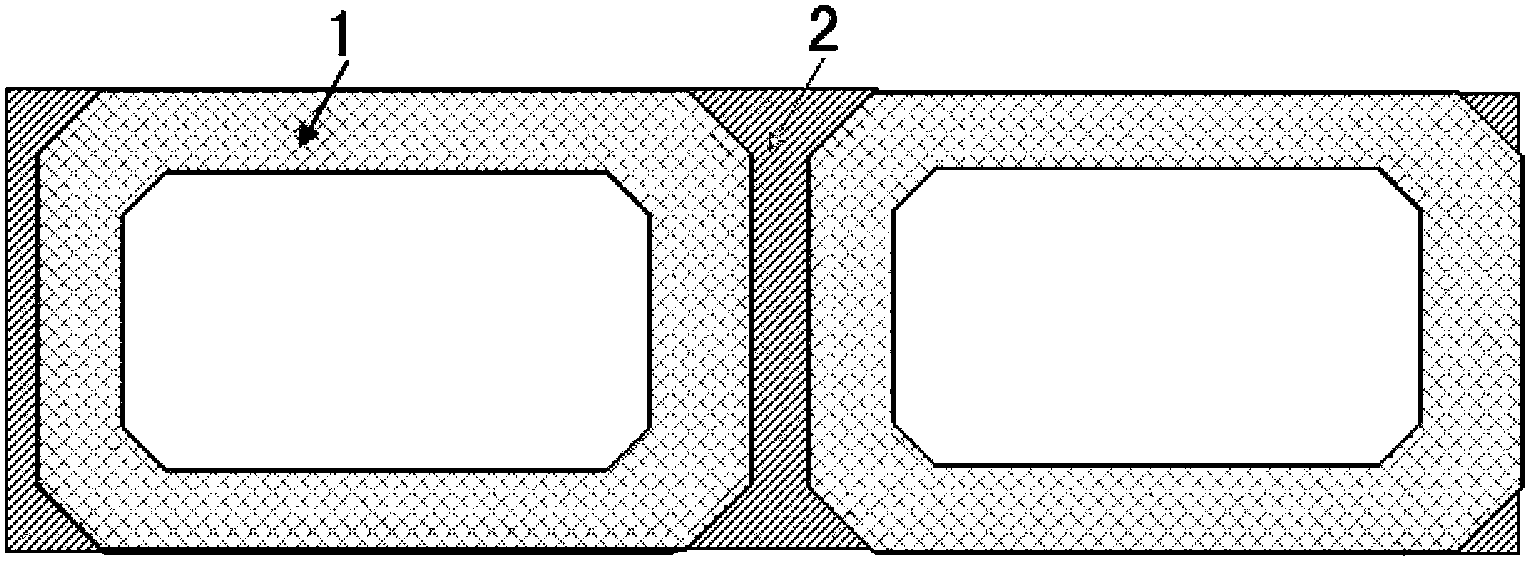

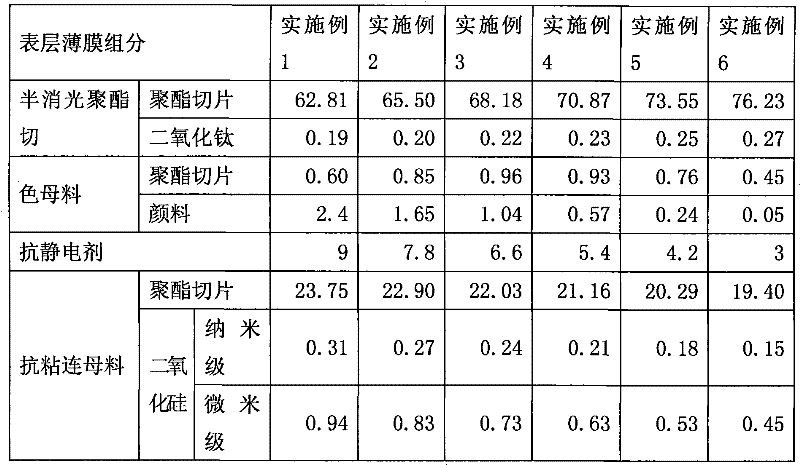

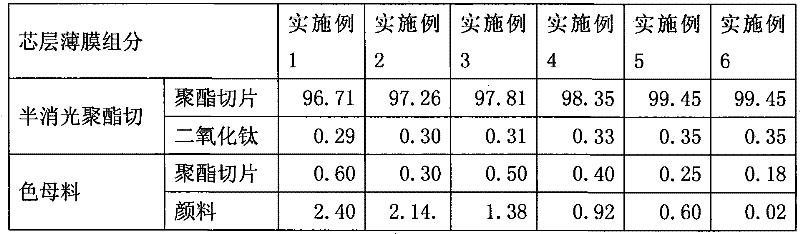

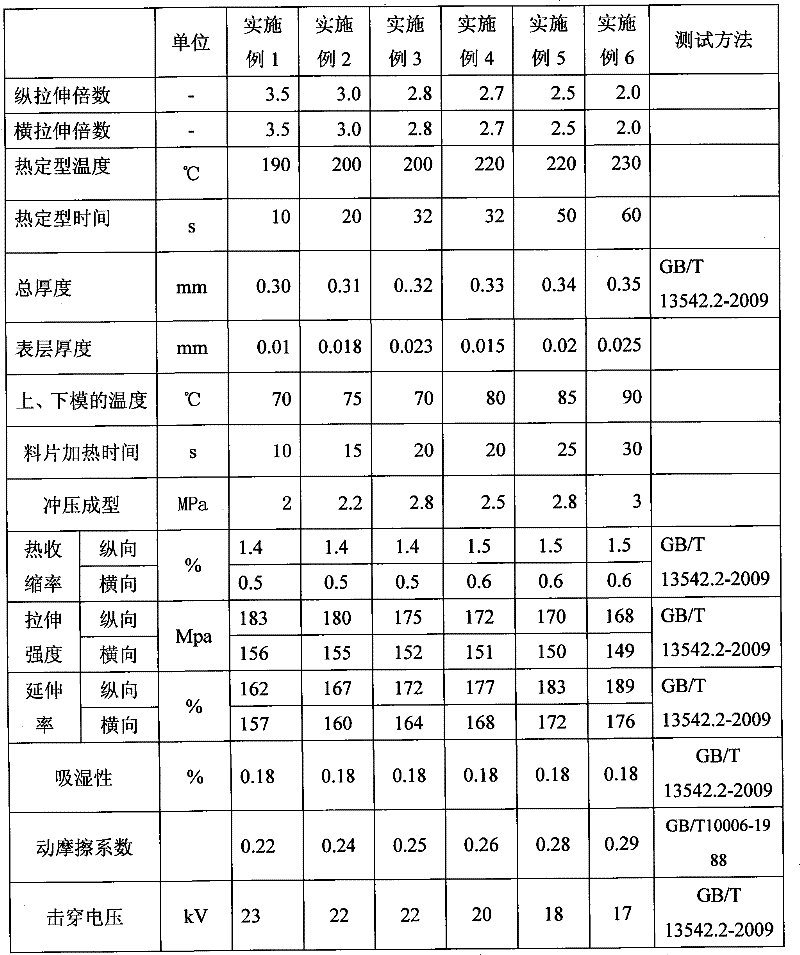

Polyester film harness wire and preparation method thereof

ActiveCN101942727BRigidHas acid and alkali resistanceSynthetic resin layered productsHealdsMasterbatchPolyester

The invention relates to a polyester film harness wire which is prepared by the following steps: forming a three-layer film by two surface layers extruded mutually and a core layer arranged between the two surface layers; and drawing the three-layer film. The surface layer film comprises 63-76.5% of semi-dull polyester chip by weight percent, 3-9% of antistatic agent by weight percent, 0.5-3% of color masterbatch by weight percent and 20-25% of anti-adhesion master batch by weight percent; the core layer film comprises 97-99.8% of semi-dull polyester chip by weight percent and 0.2-3% of colormasterbatch by weight percent; and the total thickness of the polyester film harness wire is 0.30-0.35mm, and the thickness of the isopachous surface layers is between 0.10-0.025mm. The invention hasthe characteristics of high comprehensive mechanical strength and good wear-resisting property.

Owner:JIANGSU YUXING FILM TECH

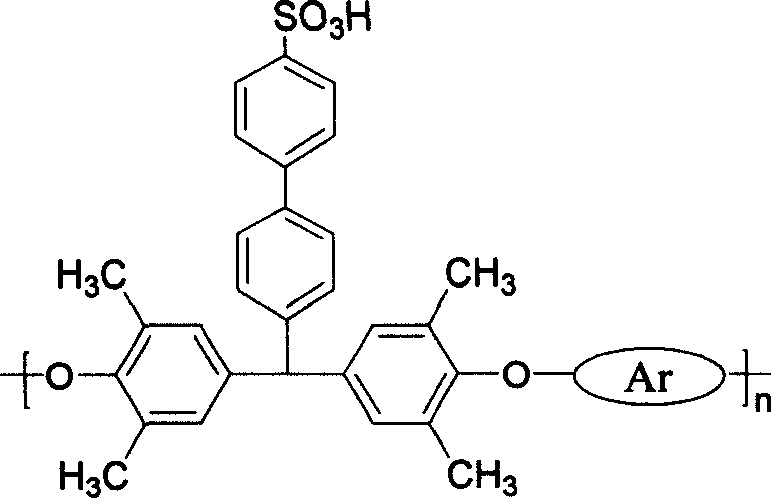

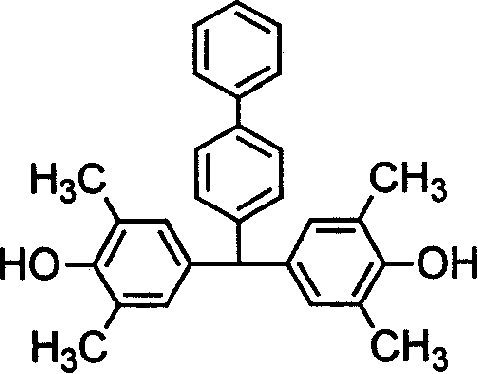

Sulfomated polyarylether containing conjugation structure, preparation method and intermediate

A sulfonated polyarylether containing conjugated structure and its intermediate are disclosed. Its preparing process includes such steps as mixing diphenol monomer, difluoro monomer and anhydrous potassium carbonate in non-protonic polar solvent, reaction to obtain its intermediate, dissolving it in polar solvent, dripping the solution of chlorosulfonic acid, and reaction. Its advantages are high resistance to high temp and creep, strength, toughness, stability, hydroscopicity and proton exchange capacity.

Owner:GUANGZHOU INST OF GEOCHEMISTRY - CHINESE ACAD OF SCI

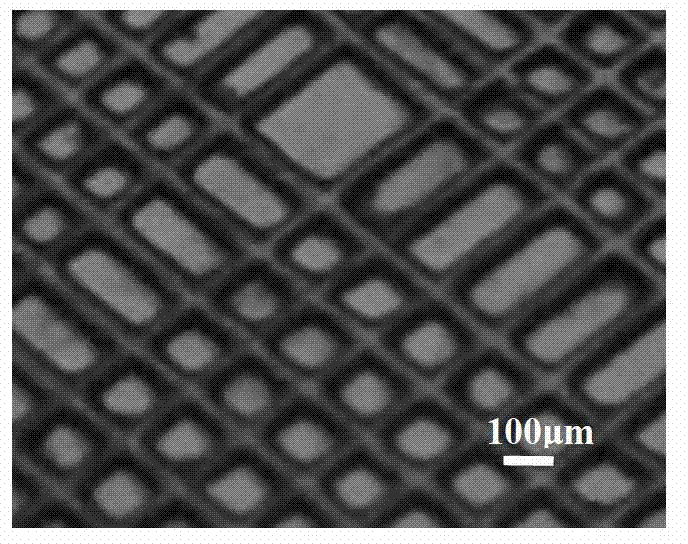

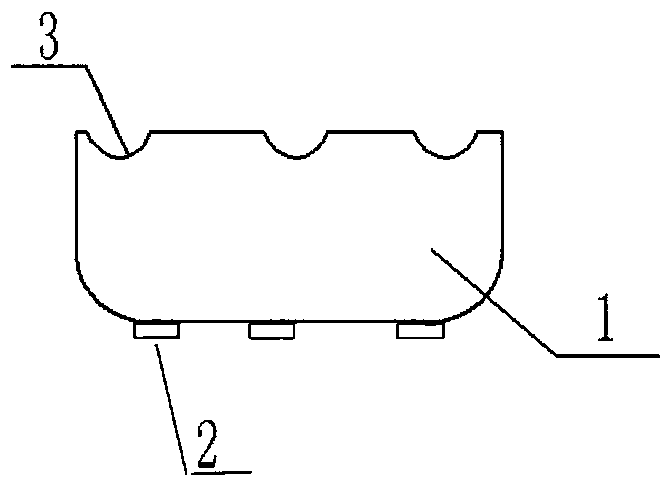

Method of using ceramic precursors to prepare patterned ceramic

The invention relates to patterned ceramic, in particular to a method of using ceramic precursors to prepare patterned ceramic. The method includes: mixing polydimethylsiloxane with crosslinking agent, adding the mixture into a metal box, heating, placing in a master pattern, heating until PDMS (polydimethylsiloxane) is solidified, adding liquid PDMS, placing in a drying oven for solidification, and taking out the master pattern to obtain a PDMS mould with a mould cavity identical to the master pattern in shape; mixing the ceramic precursors with initiator, injecting the mixture into the mould cavity of the PDMS mould, and stripping the PDMS mould after the ceramic precursors in the mould cavity are solidified to obtain solidified patterned ceramic precursors; heating the solidified patterned ceramic precursors, and taking out the solidified patterned ceramic precursors after cooling to obtain patterned ceramic. The method is simple, feasible, safe, efficient and applicable to various ceramic precursors, can be used for preparing crack-free and high-precision three-dimensional ceramic with various fine patterns, and can be widely applied to the fields of high-temperature MEMS (micro electromechanical system) devices, engine parts, micro engine combustors, chemical reactors and the like.

Owner:LVNA TECH CO LTD

Wear-resistant and anti-ageing automotive rubber damping piece material

The invention discloses a wear-resistant and anti-ageing automotive rubber damping piece material. The wear-resistant and anti-ageing automotive rubber damping piece material comprises the following raw materials in parts by weight: 20-30 parts of natural rubber, 20-25 parts of butyl rubber, 10-15 parts of butadiene rubber, 20-25 parts of wear-resistant polyvinyl chloride masterbatches, 4-7 partsof talcum powder, 2-5 parts of a toughener, 2-4 parts of an antioxidant, 1-4 parts of an anti-ageing agent, 1-3 parts of a coupling agent, 3-9 parts of mineral oil, 3-6 parts of a maleic anhydride compatilizer, 3-7 parts of paraffin, 5-8 parts of nano barium sulfate, 2-5 parts of modified nano silicon nitride, 1-3 parts of potassium stearate, 2-5 parts of a promotor, 2-4 parts of a crosslinking agent, 1-2 parts of zinc borate and 3-7 parts of sulphur. The wear-resistant and anti-ageing automotive rubber damping piece material is reasonable in formula, the compatibility of various components isgood, and the prepared damping material has the advantages of high damping coefficient, high resilience force, damping ability, high temperature resistance, ageing resistance, creep resistance, wearresistance, good flame retardant and the like, and is suitable for automotive damping products.

Owner:ANHUI WEIWEI RUBBER PARTS GRP

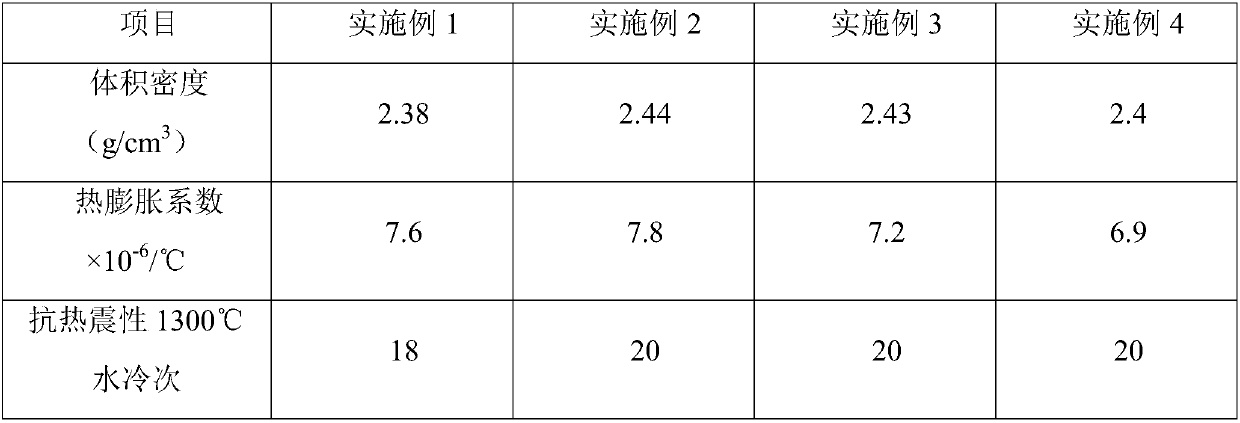

Preparation method of high-temperature corundum mullite crucible

The invention relates to a preparation method of a high-temperature corundum mullite crucible, and belongs to the field of silicate crucible preparation. The crucible comprises, by mass, 10-50% of calcined alumina powder, 5-20% of kyanite powder, 20-40% of kaolin powder and 5-30% of white corundum particles. The preparation method having five steps has the advantages of scientificity, reasonability, simplicity and easiness in operation, and convenience in industrial production; the prepared crucible has the advantages of long service life, high temperature resistance, high creep resistance andthe like.

Owner:山东铭特陶瓷材料有限公司

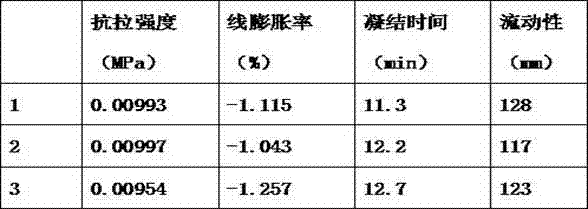

Carbon fiber reinforcing tyre casting gypsum powder and preparation method thereof

Provided are carbon fiber reinforcing tyre casting gypsum powder and a preparation method thereof. The gypsum powder is prepared by the following raw materials by weight: 10-15 parts of alpha gypsum, 15-25 parts of beta gypsum, 17-23 parts of coal ash powder, 10-20 parts of carbon fiber, 0.001-0.002 part of retarder, 0.01-0.05 part of ammonium chloride and 0.2-0.5 part of antifoaming agents. The preparation method of carbon fiber reinforcing tyre casting gypsum powder is further provided. Products manufactured by the carbon fiber reinforcing tyre casting gypsum powder are high in product strength, good in heat-conducting performance, and good in physical performance and chemical performance. The preparation method is simple, easy to operate, low in production cost and beneficial to industrialized production.

Owner:XIANGFU NEW BUILDING MATERIAL HUNAN

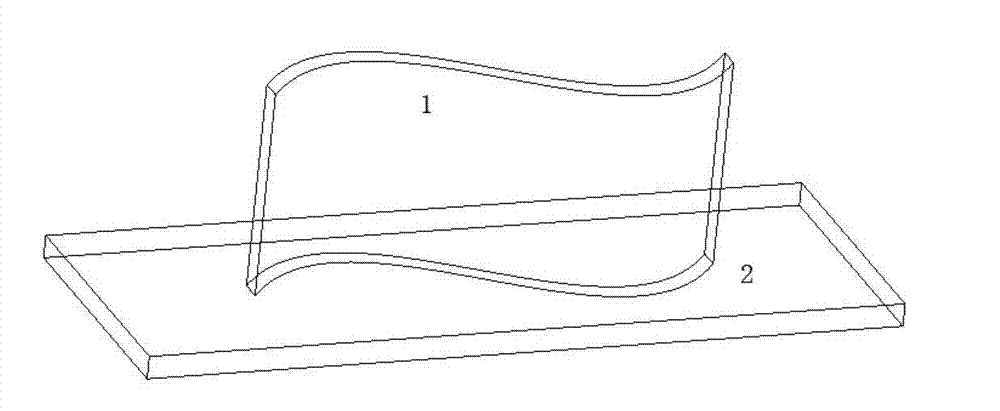

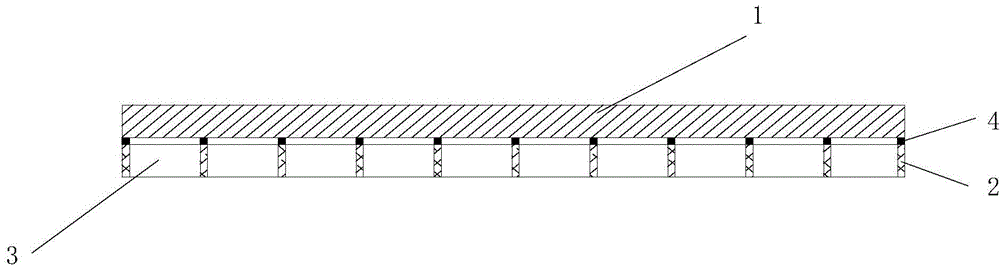

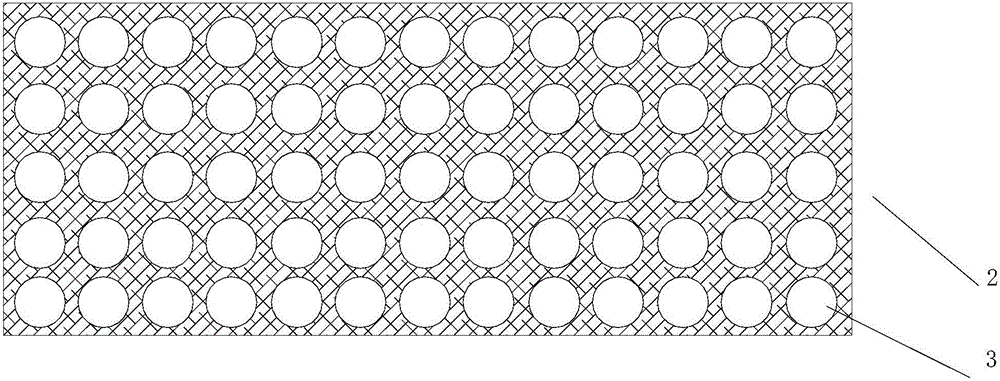

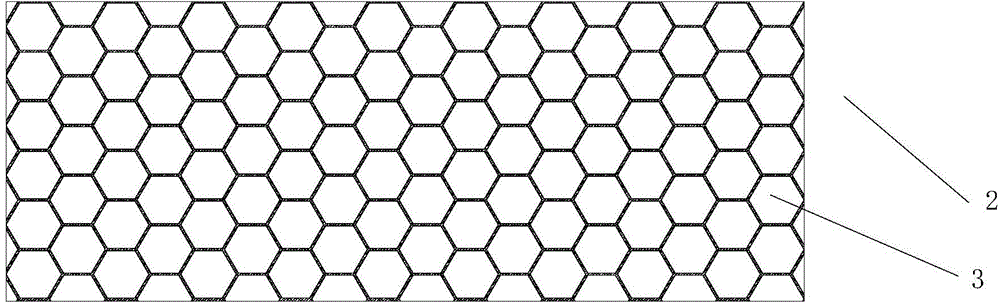

Stone composite plate free of glue failure

InactiveCN106284904AUse is not affectedWith adhesive strength No.Covering/liningsLayered productsSurface layerWater vapor

The invention discloses a stone composite plate free of glue failure. The stone composite plate free of glue failure comprises a stone face plate and a base material, wherein the base material is provided with top-to-bottom through holes at intervals in a hollowed-out manner and is glued with the stone face plate through glue. The stone composite plate free of glue failure has the advantages that the base material is glued with a stone material linearly after being hollowed out, so that cracks and hollows caused by thermal expansion and cold shrinkage resulting from retention of planar gluing water vapor and air are avoided; through thinning of the surface layer of the stone material and compositing of the stone material with other low-cost light hollowed-out base materials, decoration effects are guaranteed, cost is reduced and decoration materials are lightened; through wet combining, daub or cement enters the hollowed-out base material to glue the base material with a surface material for the second time, so that the composite plate free of glue failure permanently is obtained.

Owner:吴华茂

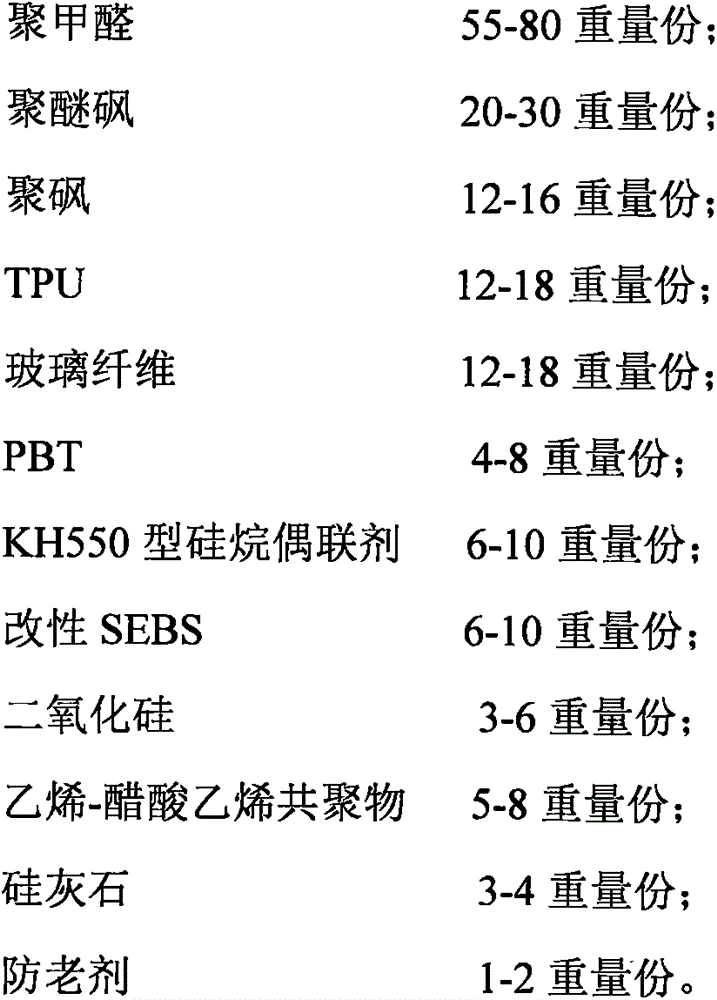

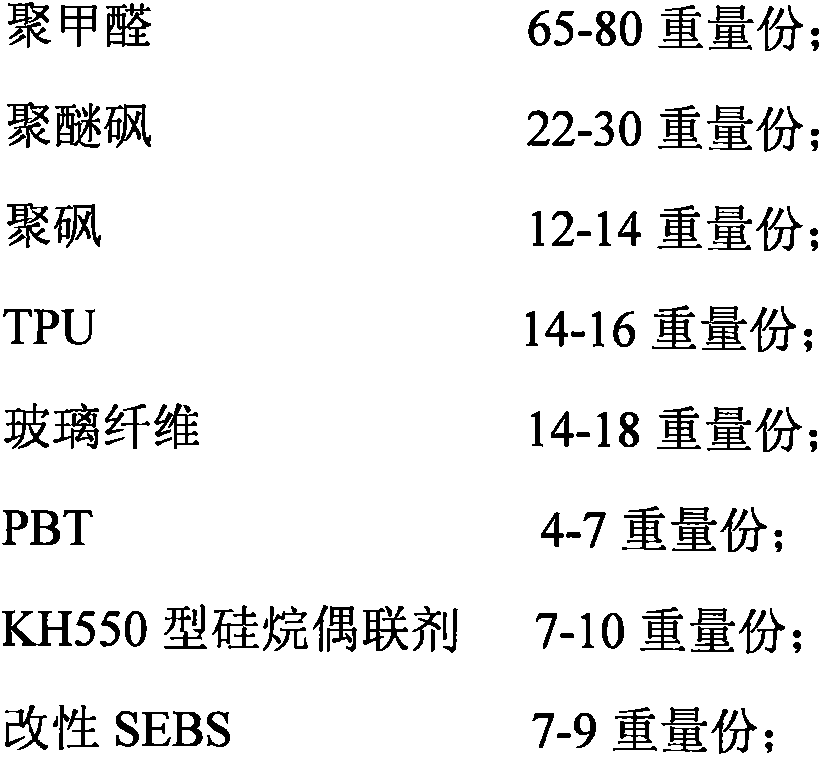

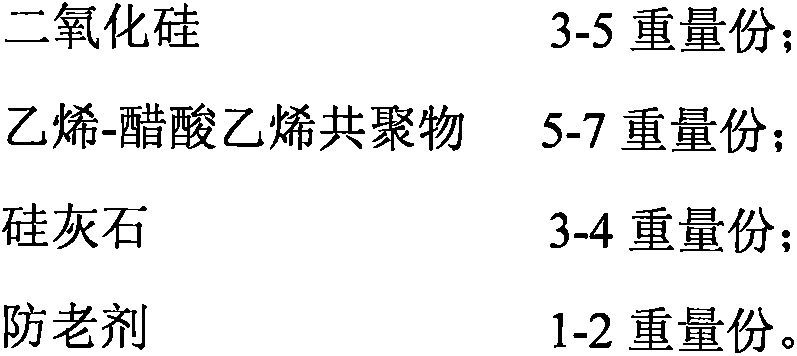

Plastic alloy for washing machine cover plate and preparation method of plastic alloy

The invention provides a plastic alloy for a washing machine cover plate and a preparation method of the plastic alloy. The following raw materials are adopted: polyformaldehyde, polyether sulfone, polysulfone, TPU, glass fiber, PBT, a KH550 type silane coupling agent, modified SEBS, silica, an ethylene-vinyl acetate copolymer, wollastonite and an anti-ageing agent. The TPU has extremely high adhesion so that the oil resistance and solvent resistance of the whole elastomer are obviously improved, and a molecular chain contains polarity and active carbamate, carbimide and various radicals, and can be interspersed into the SEBS; the polyether sulfone has the comprehensive properties of being good in size stability, resistant to corrosion, resistant to creep and the like, and the heat resistance of the polyformaldehyde system is improved; the polysulfone improves the hardness and strength of the polyformaldehyde system; and the modified SEBS is easy to form a network structure, so that the whole system has excellent processing fluidity. The experiment result shows that the plastic alloy for the washing machine cover plate, prepared by the preparation method, has good processing fluidity and mechanical properties.

Owner:宁波海飞电器有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com