Medium-strength fiber and processing method thereof

A processing method and high-strength technology, applied in stretch spinning, artificial filament heat treatment, textiles and papermaking, etc., can solve the problems of low stretch setting temperature, low orientation, low crystallinity, poor dimensional stability, etc., and achieve molecular structure Stable, good dimensional stability, dimensional stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Embodiment 1: the processing of strong yarn in chip spinning 840dtex / 192f

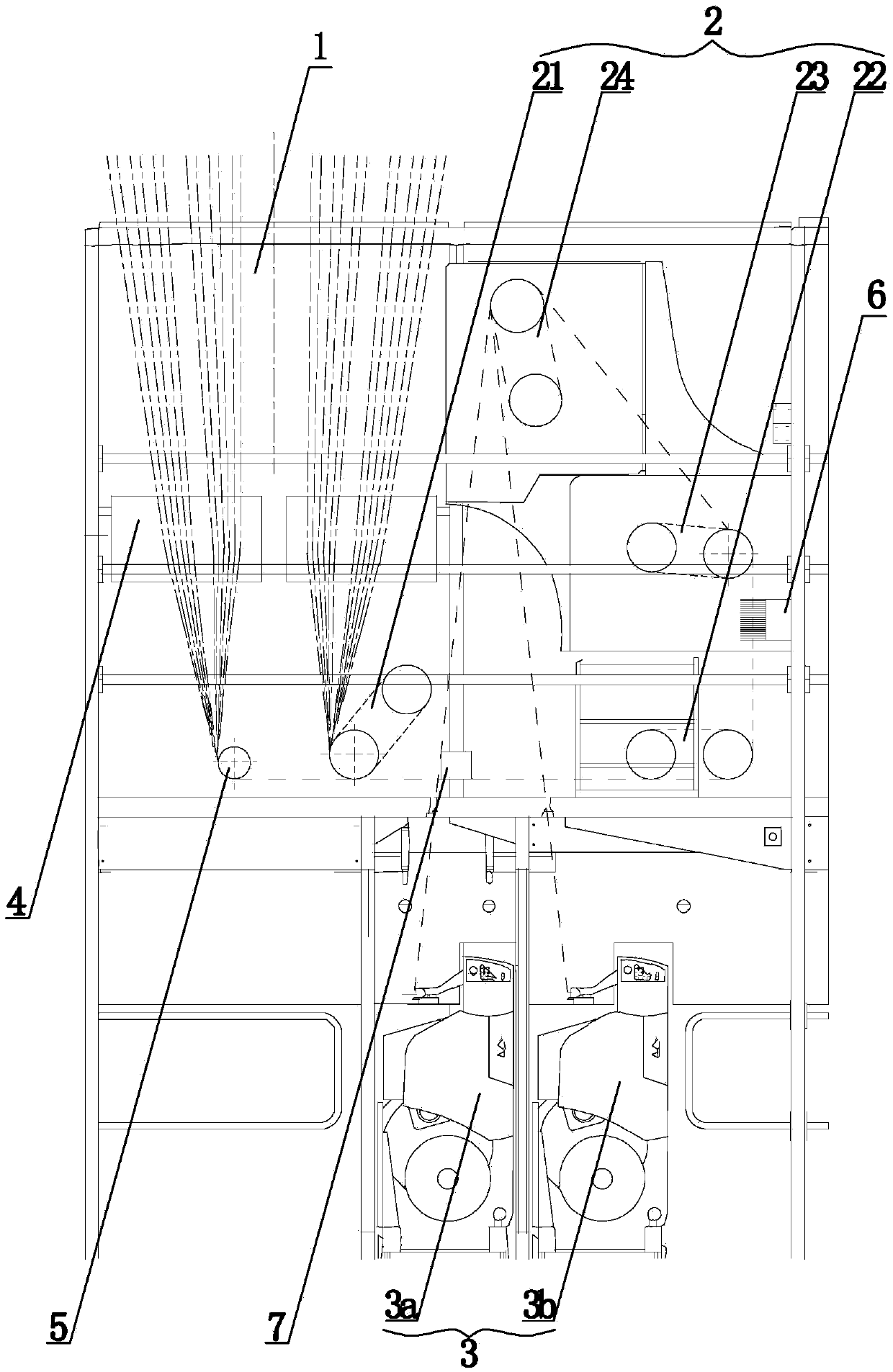

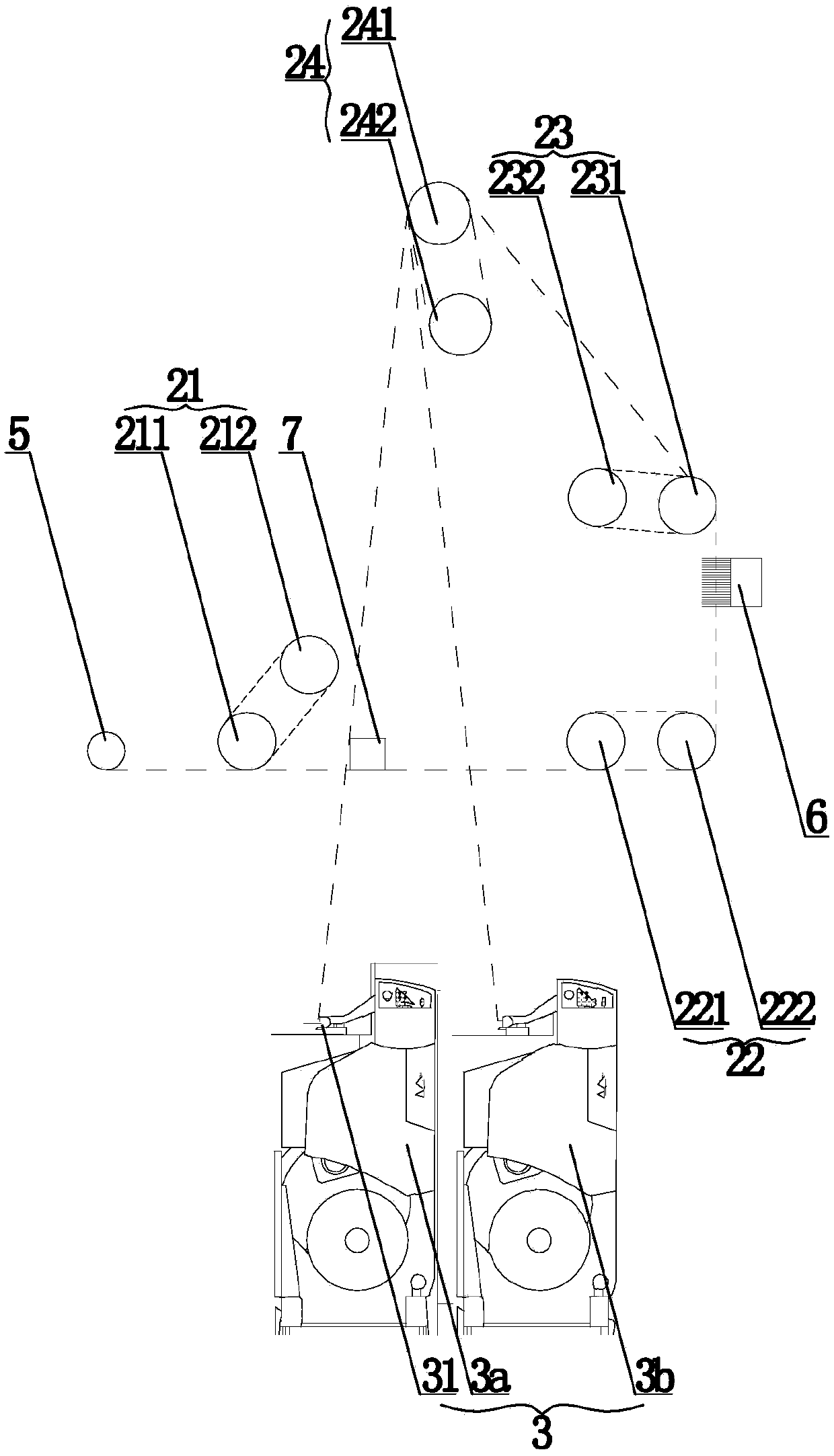

[0028] A kind of processing method of medium-strength wire of the present embodiment, combines figure 1 and figure 2 , with slices as the initial material, the processing flow is: spinning → cooling → oiling → multi-stage stretching heat setting (first stage medium temperature stretching → second stage high temperature stretching → third stage high temperature stretching) → network → winding .

[0029] Chip viscosity 0.85dl / g, b value ≤ 2.0, water content ≤ 20ppm.

[0030] (1) Spinning stage:

[0031] Zone 1 temperature: 285°C

[0032] Zone 2 temperature: 295°C

[0033] Zone 3 temperature: 292°C

[0034] Zone 4 temperature: 290°C

[0035] Zone 5 temperature: 285°C

[0036] Metering pump front pressure: 51.4bar

[0037] Pressure after metering pump: 162.5bar

[0038] Metering pump speed: 12.44rpm

[0039] Biphenyl box temperature: 298°C

[0040] Post heating 1: 340 / 340°C

[0041] Sp...

Embodiment 2

[0065] Embodiment 2: the processing of the strong yarn in the chip spinning 555dtex / 96f

[0066] The setting and working principle of this embodiment are the same as that of Embodiment 1, the difference is that:

[0067] (1) Spinning stage:

[0068] Zone 1 temperature: 288°C

[0069] Zone 2 temperature: 298°C

[0070] Zone 3 temperature: 295°C

[0071] Zone 4 temperature: 292°C

[0072] Zone 5 temperature: 288°C

[0073] Metering pump front pressure: 55bar

[0074] Pressure after metering pump: 150bar

[0075] Metering pump speed: 12.56rpm

[0076] Biphenyl box temperature: 300°C

[0077] Post heating 1: 330 / 330°C

[0078] Spinning assembly: the precision of the filter element is 20 μm, the number of spinneret holes is 2*48, and the size of the spinneret hole is 0.3*1.1mm.

[0079] (2) Cooling stage:

[0080] Cooling adopts side blowing: wind temperature 25°C, relative humidity 5%, wind speed 1.0m / s.

[0081] (3) Oiling stage:

[0082] Oiling agent model: GXM-100,...

Embodiment 3

[0097] Embodiment 3: Melt spinning 840dtex / 192f medium strong yarn processing

[0098] The setting and working principle of this embodiment are the same as that of Embodiment 1, the difference is that:

[0099] In this embodiment, polyester melt is used as raw material, and the viscosity of the raw material is 0.85-1.10dl / g.

[0100] (1) Spinning stage:

[0101] Metering pump front pressure: 45bar

[0102] Pressure after metering pump: 160bar

[0103] Biphenyl box temperature: 290-298°C

[0104] Post heating 1: 330 / 330°C

[0105] Spinning assembly: the precision of the filter element is 20 μm, the number of spinneret holes is 2*96 holes, and the size of the spinneret hole is 0.4*1.2mm.

[0106] (2) Cooling stage:

[0107] Cooling adopts side blowing: wind temperature 18°C, relative humidity 10%, wind speed 0.5m / s.

[0108] (3) Oiling stage:

[0109] Oiling agent model: GXM-100, oil concentration 93%; oil pump speed 30rpm.

[0110] (4) Drafting stage:

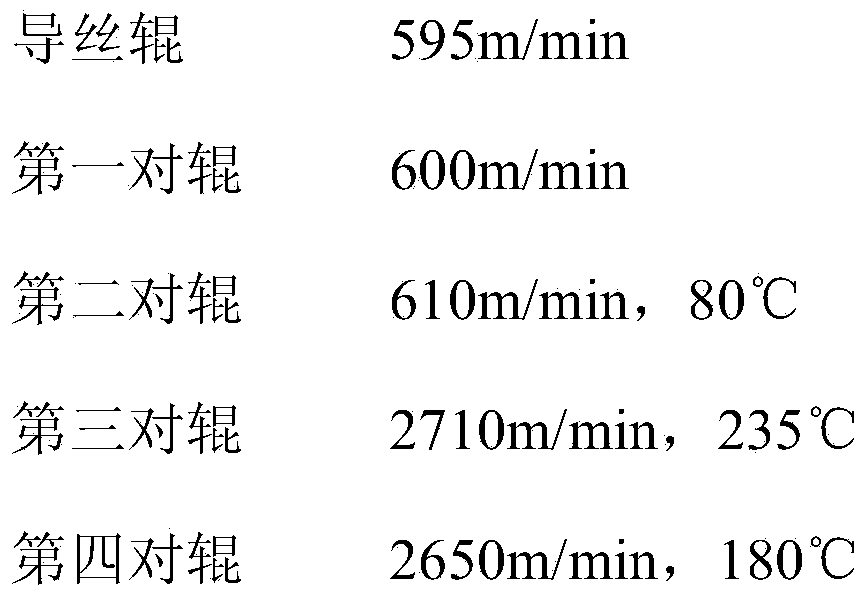

[0111]

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

| shrinkage | aaaaa | aaaaa |

| shrinkage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com