Antiskid rubber outsole and manufacturing method of same

A technology of anti-skid rubber and outsole, which is applied to shoe soles, other household appliances, footwear, etc., can solve the problems of easy-to-stick rollers, difficult to process, general anti-skid effect, and difficulty in blending and compatibility, and achieves good physical and mechanical properties. Improved anti-slip effect and easy blending effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

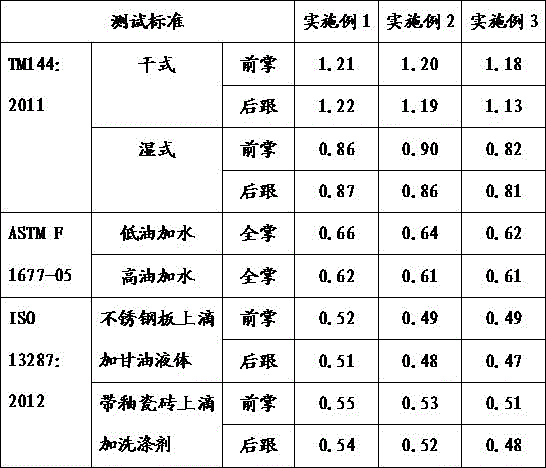

Embodiment 1

[0050] A non-slip rubber outsole consisting of the following raw material components: 60 parts of nitrile rubber (Lanxess krynac 4450 F); 25 parts of integrated rubber (Beijing Yanshan Petrochemical Company 2502); 15 parts of solution-polymerized styrene-butadiene rubber (JEC Asaprene E10) ; Modified liquid polybutadiene rubber (Cray Valley Ricobond) 8 parts; Fumed silica 30 parts; DOS 3 parts; Anti-aging agent (1010) 1.2 parts; Petroleum resin 2 parts; PEG4000 active agent 3 parts; Si-69 2 parts of coupling agent; 1 part of polyethylene wax; 3 parts of zinc oxide; 2.5 parts of sulfur; 1.5 parts of accelerator DM; 1.2 parts of accelerator D.

[0051] The manufacturing process of the anti-skid rubber outsole comprises the following steps:

[0052] Step 1. Accurately weigh nitrile rubber, integrated rubber, solution-polymerized styrene-butadiene rubber, modified liquid polybutadiene rubber, DOS, petroleum resin, antioxidant, PEG2000, Si69, polyethylene wax according to the above...

Embodiment 2

[0056]A non-slip rubber outsole, composed of the following raw material components: 60 parts of nitrile rubber (Lanxess krynac 4560 C); 20 parts of integrated rubber (Beijing Yanshan Petrochemical Company Research Institute 2502); solution-polymerized styrene-butadiene rubber (Lanxess VSL 2438) 20 parts; 7 parts of modified liquid polybutadiene rubber (Cray Valley Ricobond); 20 parts of fumed silica; 1 part of DADI; 1.2 parts of antioxidant (1076); 2.2 parts of petroleum resin; 3.5 parts of PEG4000 active agent; 2 parts of Si-69 coupling agent; 1.2 parts of polyethylene wax; 3.5 parts of zinc oxide; 3 parts of sulfur; 1.5 parts of accelerator DM; 1 part of accelerator NS.

[0057] The manufacturing process of the non-slip rubber outsole in Example 2 is the same as that in Example 1, the difference is that in Step 1 of Example 2, the mixed rubber is derived when the mixing temperature reaches 120°C.

Embodiment 3

[0059] A non-slip rubber outsole, composed of the following raw material components: 60 parts of nitrile rubber (Lanxess krynac 4560 C); 23 parts of integrated rubber (Beijing Yanshan Petrochemical Company Research Institute 2535); solution polystyrene butadiene rubber (Lanxess VSL 2438) 17 parts; 6 parts of modified liquid polybutadiene rubber (Cray Valley Ricobond); 25 parts of fumed silica; 3 parts of DOA; 1.2 parts of antioxidant (SP); 3 parts of petroleum resin; 4 parts of PEG4000 active agent; 2 parts of Si-69 coupling agent; 1.5 parts of polyethylene wax; 4 parts of zinc oxide; 3.5 parts of sulfur; 1 part of accelerator TS; 1.2 parts of accelerator NS.

[0060] The manufacturing process of the non-slip rubber outsole of embodiment 3 is consistent with the manufacturing process of embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com