Antifouling clamping block of continuous tube injection head and manufacturing method thereof

A clamping block and injection head technology, which is applied in the direction of drill pipe, casing, earthwork drilling and mining, etc., can solve the problems of clamping block clamping performance degradation, etc., to reduce the loss of clamping performance and reduce the clamping contact area , Guarantee the effect of clamping performance stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

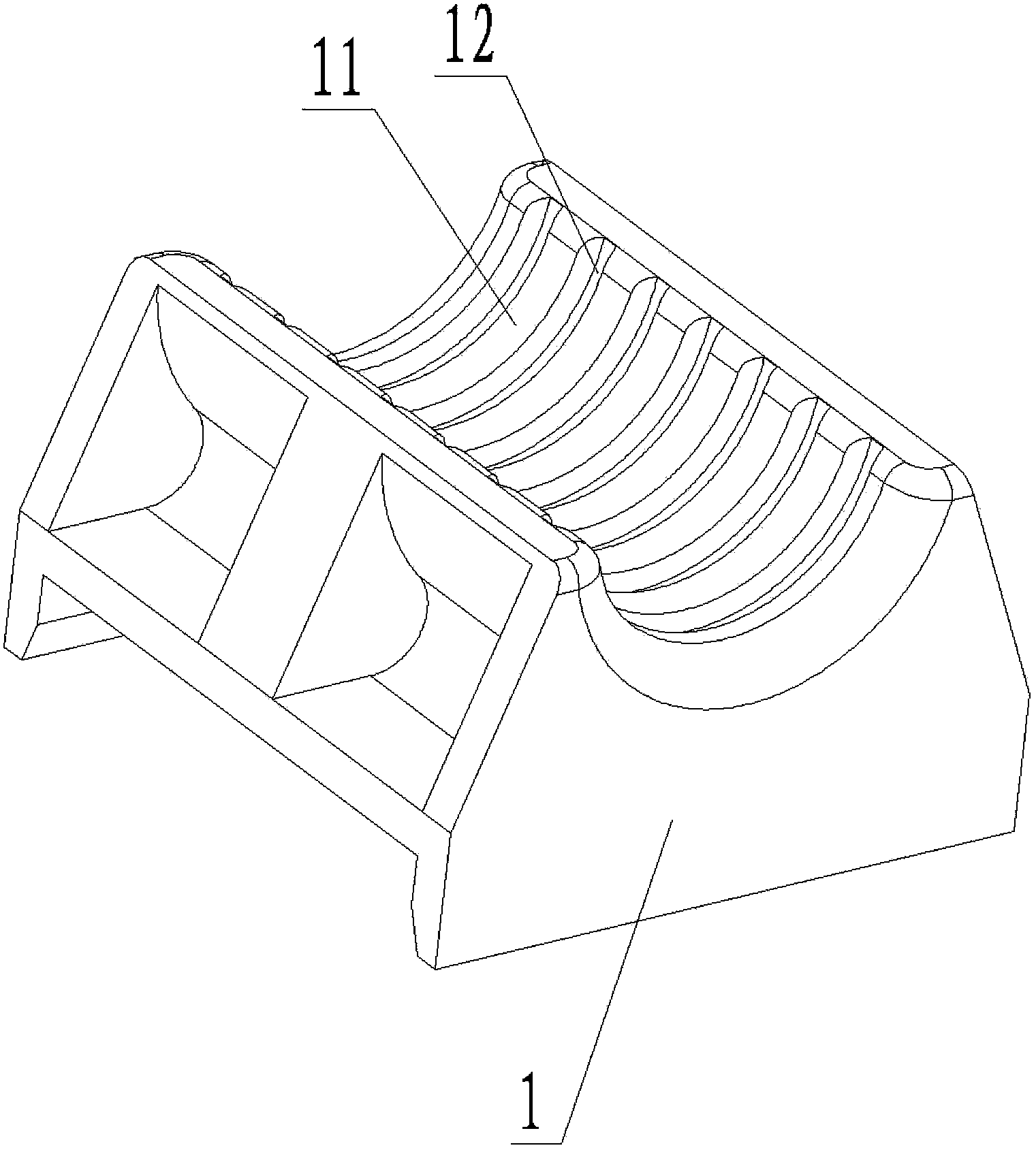

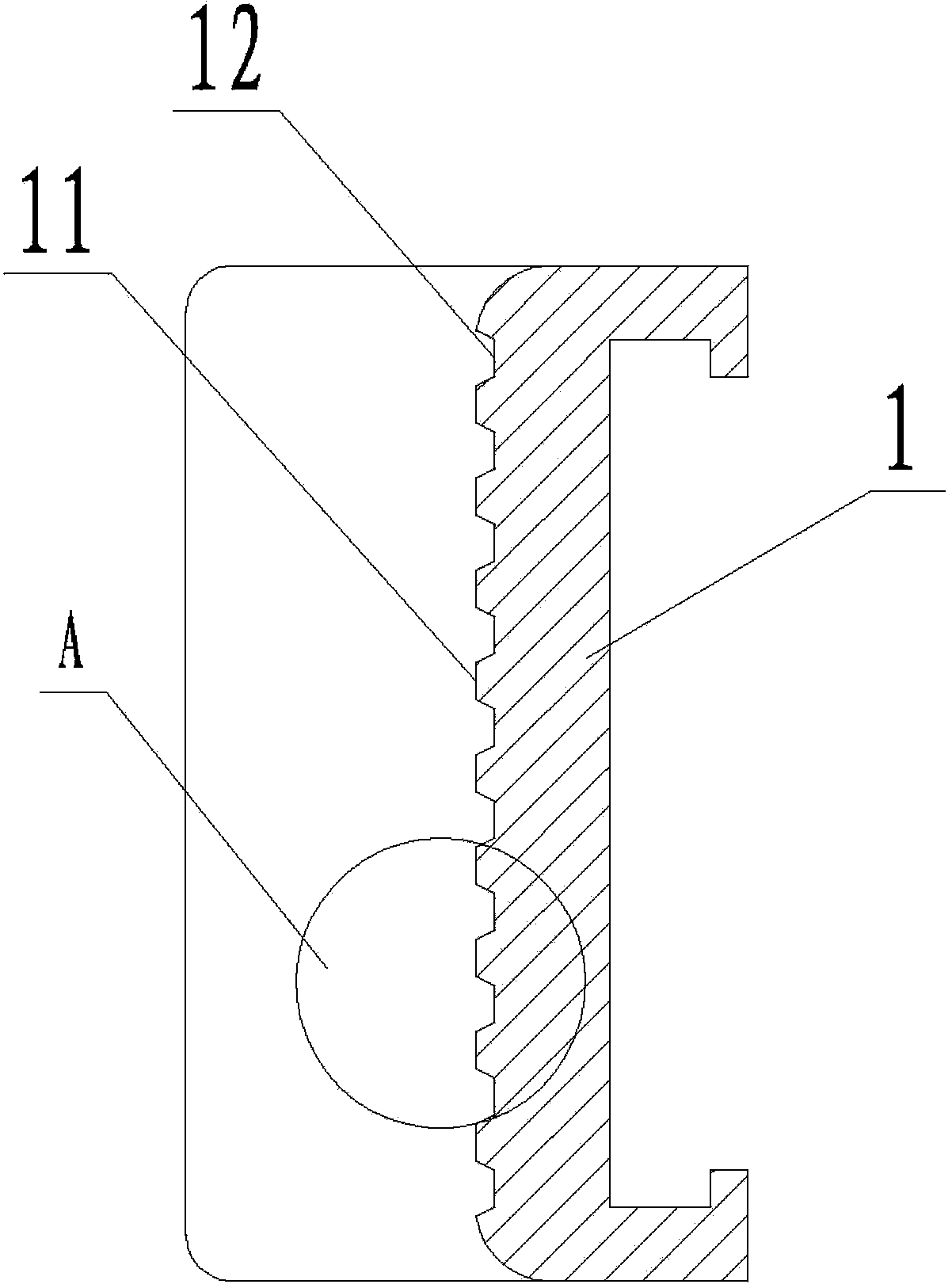

[0024] This embodiment provides a kind of anti-fouling clamping block of coiled tubing injection head, see figure 1 , figure 2 and image 3 , the anti-pollution clamping block includes: a clamping block body 1, the clamping block body 1 has a concave arc clamping surface 11, the concave arc clamping surface 11 and another concave arc clamping surface 11 or anti-pollution Other parts of the clamping block cooperate to clamp the injection head of the coiled tubing.

[0025] A transverse groove 12 is processed on the concave arc clamping surface 11, that is, the transverse groove 12 is arranged radially along the concave arc clamping surface 11, and multiple transverse grooves 12 are spaced apart on the concave arc clamping surface 11 It is set that the distance between every two transverse grooves 12 is 5mm-10mm. Preferably, the depth of the transverse groove 12 is 1.5 mm to 2.5 mm, and the width is 3.0 mm to 8.0 mm, and the bottom surface from the concave circular arc clamp...

Embodiment 2

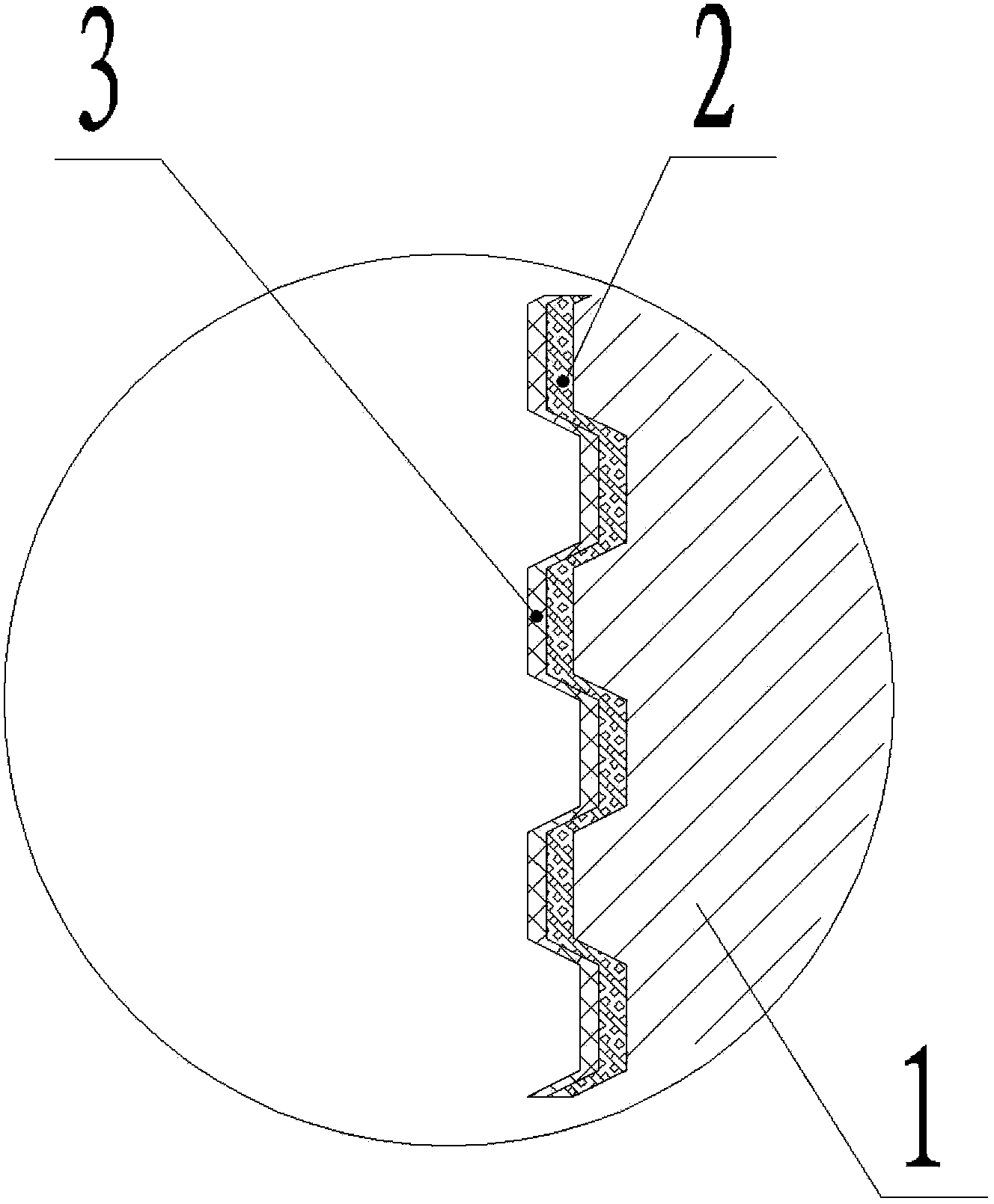

[0028] The embodiment of the present invention provides a method for manufacturing an anti-fouling clamping block of a coiled tubing injection head, the method mainly includes a method of arranging a frictional coating 2 and a corrosion-resistant and anti-fouling coating 3 on the anti-fouling clamping block. see figure 1 , figure 2 and image 3 , the friction coating 2 is set on the concave arc clamping surface 11 and the bottom surface and side wall of the transverse groove 12 by spraying, including:

[0029] S701, cleaning, degreasing and sandblasting roughening of the concave arc clamping surface 11 first, the roughening degree is Ral2.5. In this way, oil stains and scales on the surface of the concave arc clamping surface can be effectively removed, so that the adhesion of the friction coating on the concave arc clamping surface is better.

[0030] S702, using 325 mesh to 500 mesh WC-Co alloy powder for supersonic spraying, the process parameters during spraying are: O...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com