Patents

Literature

1402results about How to "Excellent abrasion resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Coating composition for multiple hydrophilic applications

InactiveUS20030203991A1Tough and durable and printable surfaceImprove wettabilityOther chemical processesSynthetic resin layered productsColloidWear resistance

A coating composition is disclosed which comprises an aqueous polymeric matrix, a hydrophilic polymer, a colloidal metal oxide and a crosslinker. The coating composition when applied on medical devices is hydrophilic, shows improved lubricity, abrasion resistance and substrate adhesion on metallic or plastic substrates. The coating also shows improved water sheeting thus providing the coated substrates with anti-fog properties. The coating absorbs aqueous dye or stain solutions making the substrate suitable for printing.

Owner:HYDROMER INC

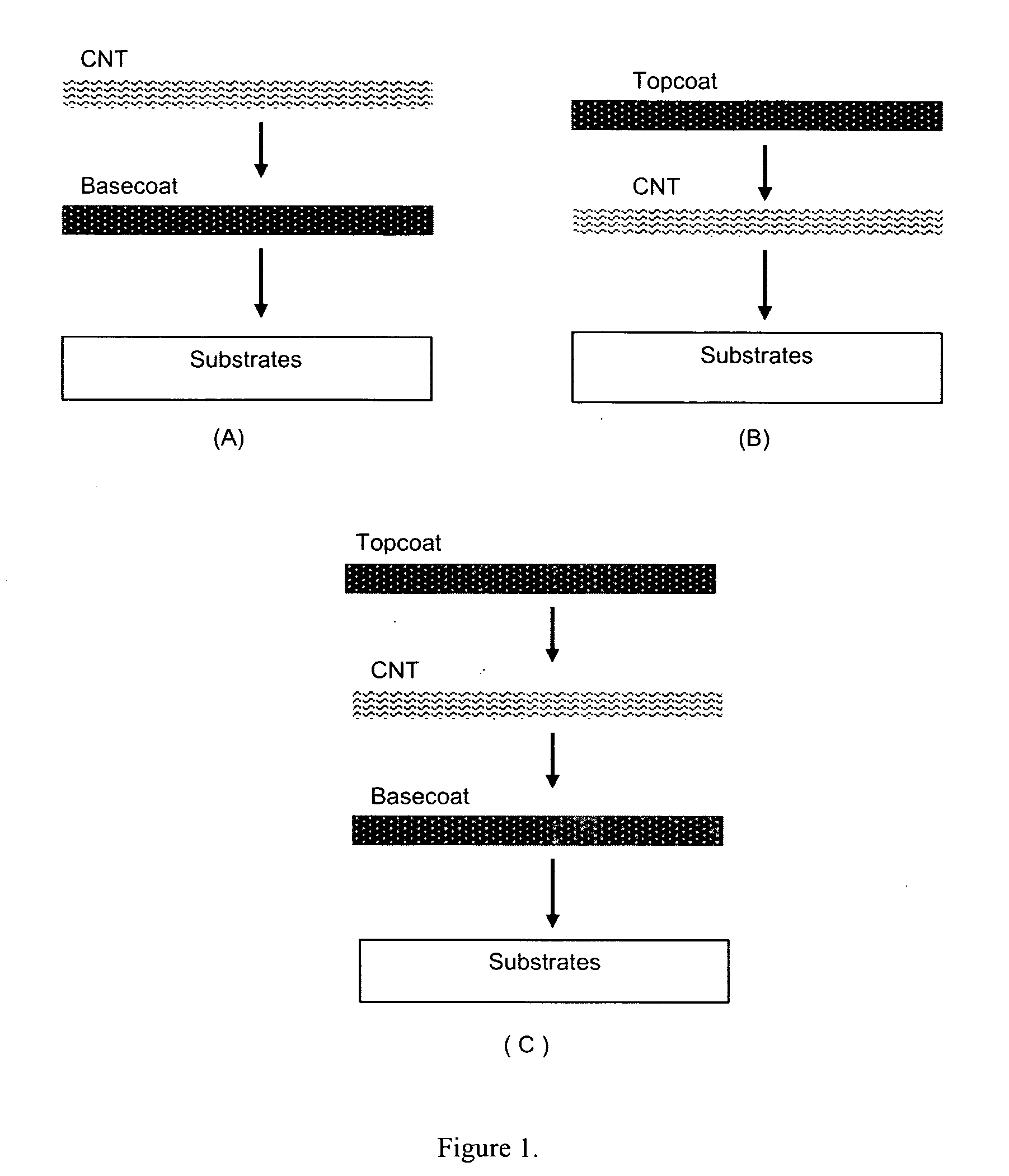

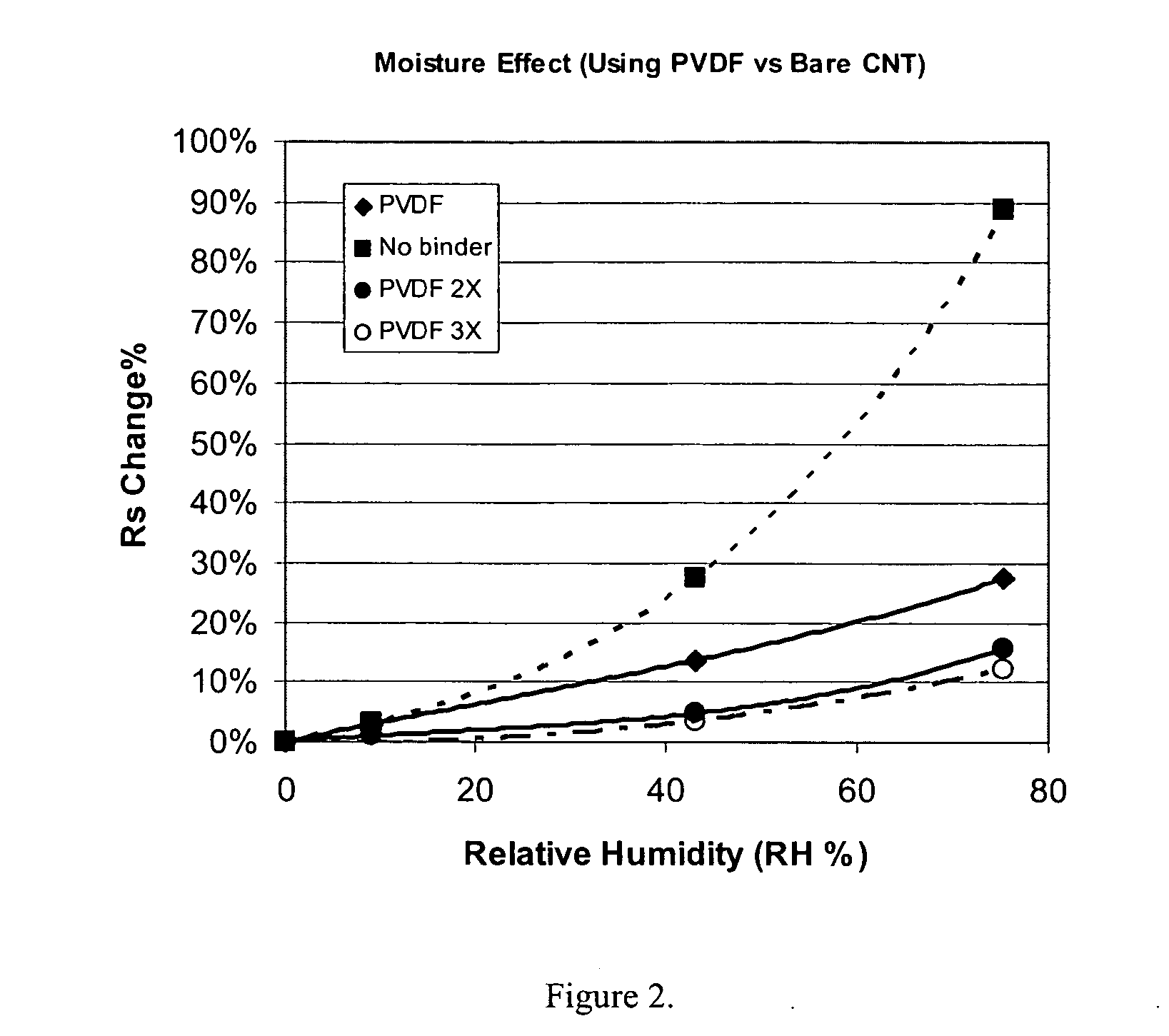

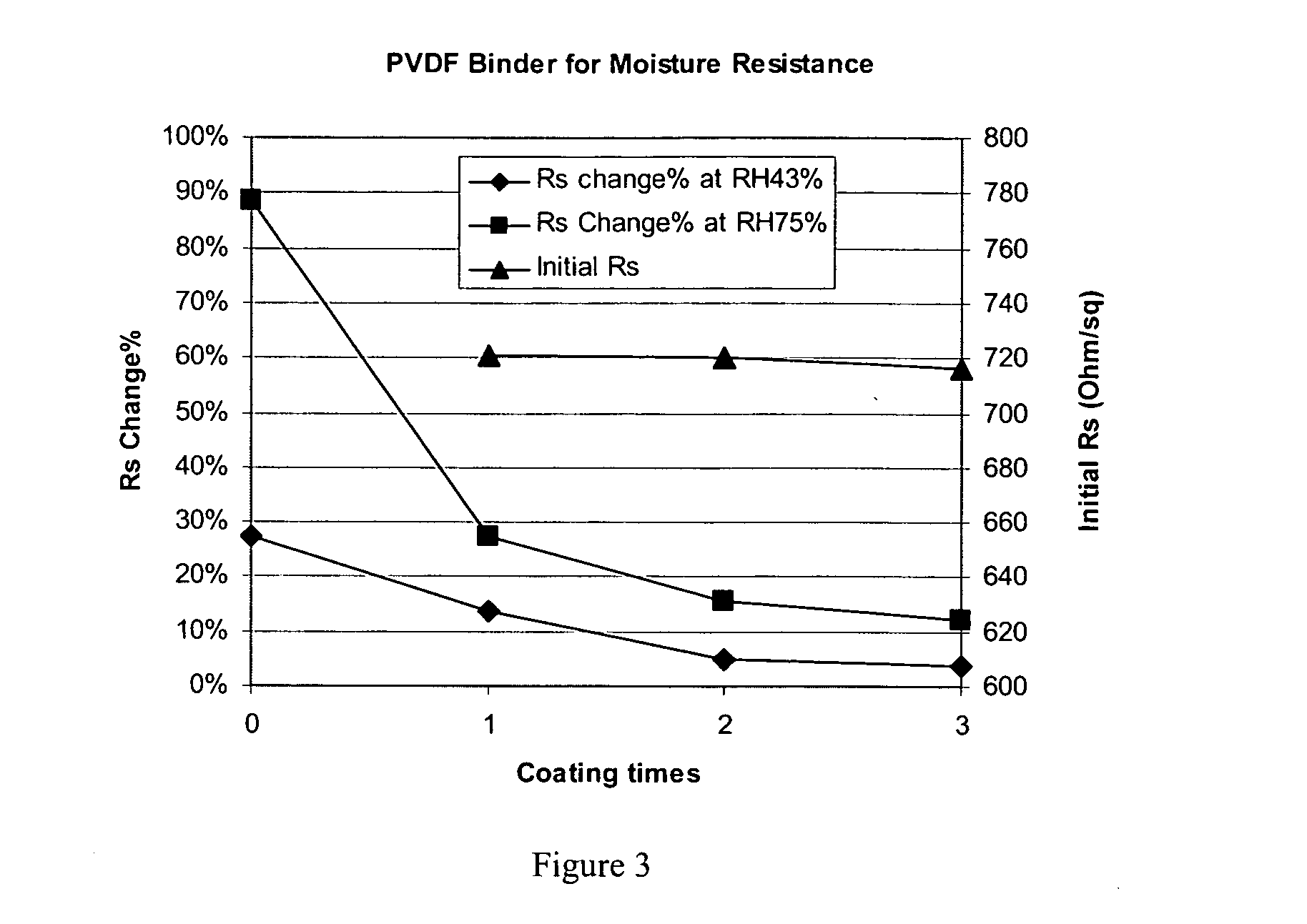

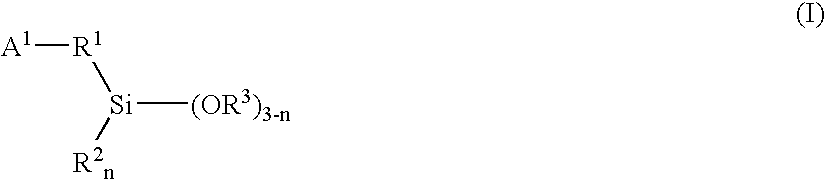

Polymer binders for flexible and transparent conductive coatings containing carbon nanotubes

InactiveUS20050209392A1Decrease in optical transparencyDecrease in surface conductivityMaterial nanotechnologySpecial tyresThermoplasticCarbon nanotube

This invention relates to flexible, transparent and conductive coatings and films formed using single wall carbon nanotubes and polymer binders. Preferably, coatings and films are formed from carbon nanotubes (CNT) applied to transparent substrates forming one or multiple conductive layers at nanometer level of thickness. Polymer binders are applied to the CNT network coating having an open structure to provide protection through infiltration. This provides for the enhancement of properties such as moisture resistance, thermal resistance, abrasion resistance and interfacial adhesion. Polymers may be thermoplastics or thermosets, or any combination of both. Polymers may also be insulative or inherently electrical conductive, or any combination of both. Polymers may comprise single or multiple layers as a basecoat underneath a CNT coating, or a topcoat above a CNT coating, or combination of the basecoat and the topcoat forming a sandwich structure. Binder coating thickness can be adjusted by changing binder concentration, coating speed and / or other process conditions. Resulting films and articles can be used as transparent conductors for flat panel display, touch screen and other electronic devices.

Owner:EIKOS

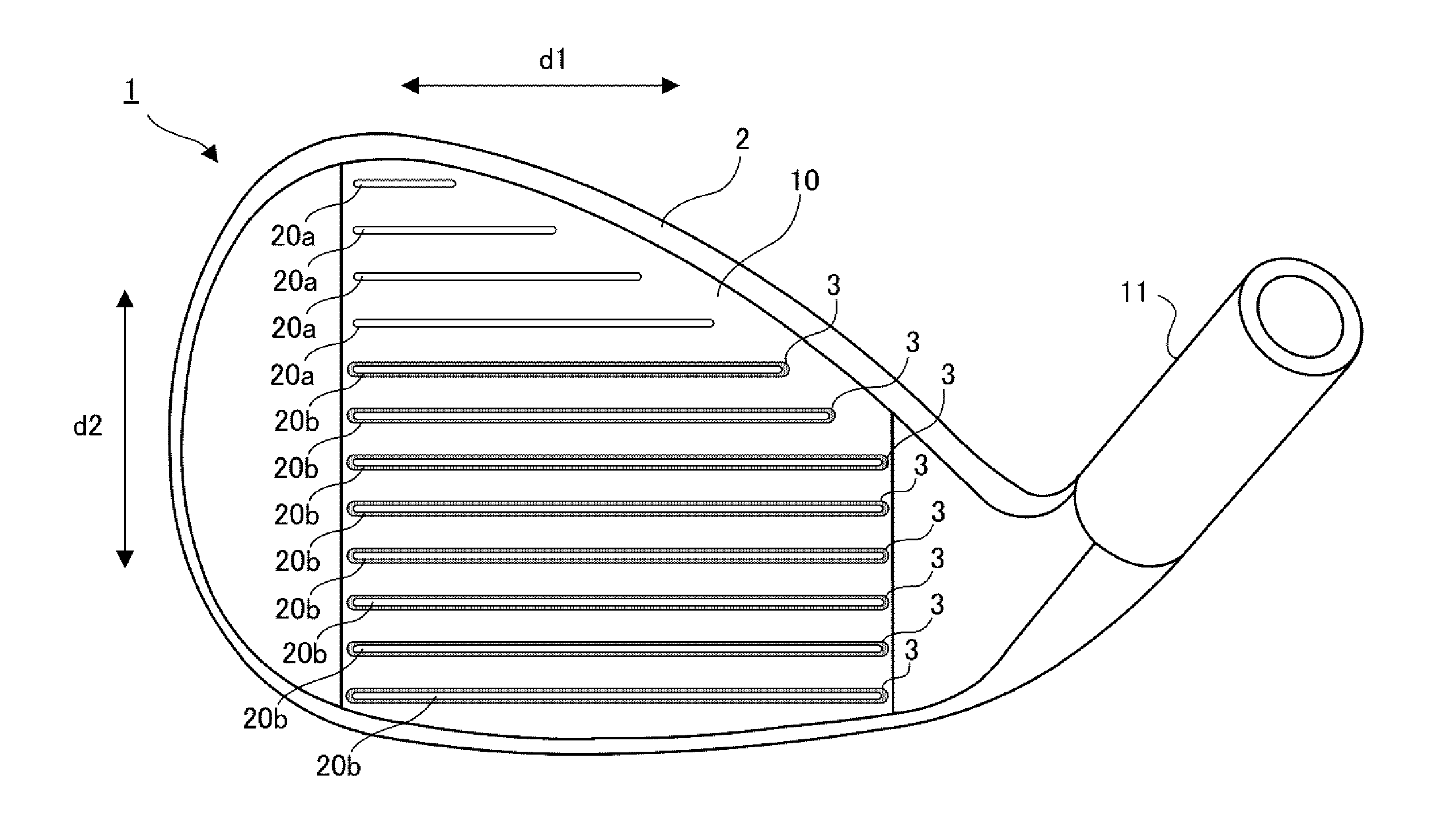

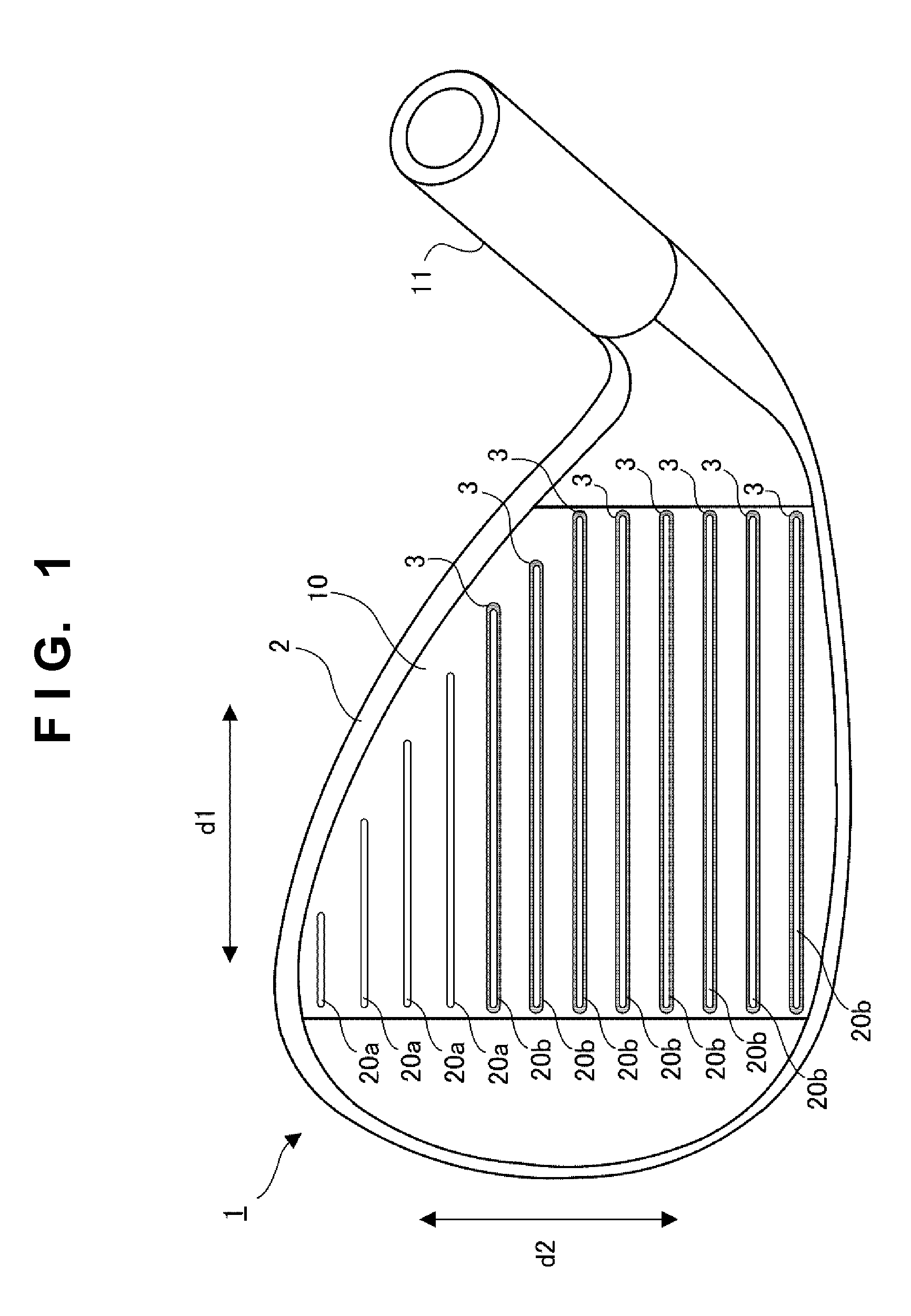

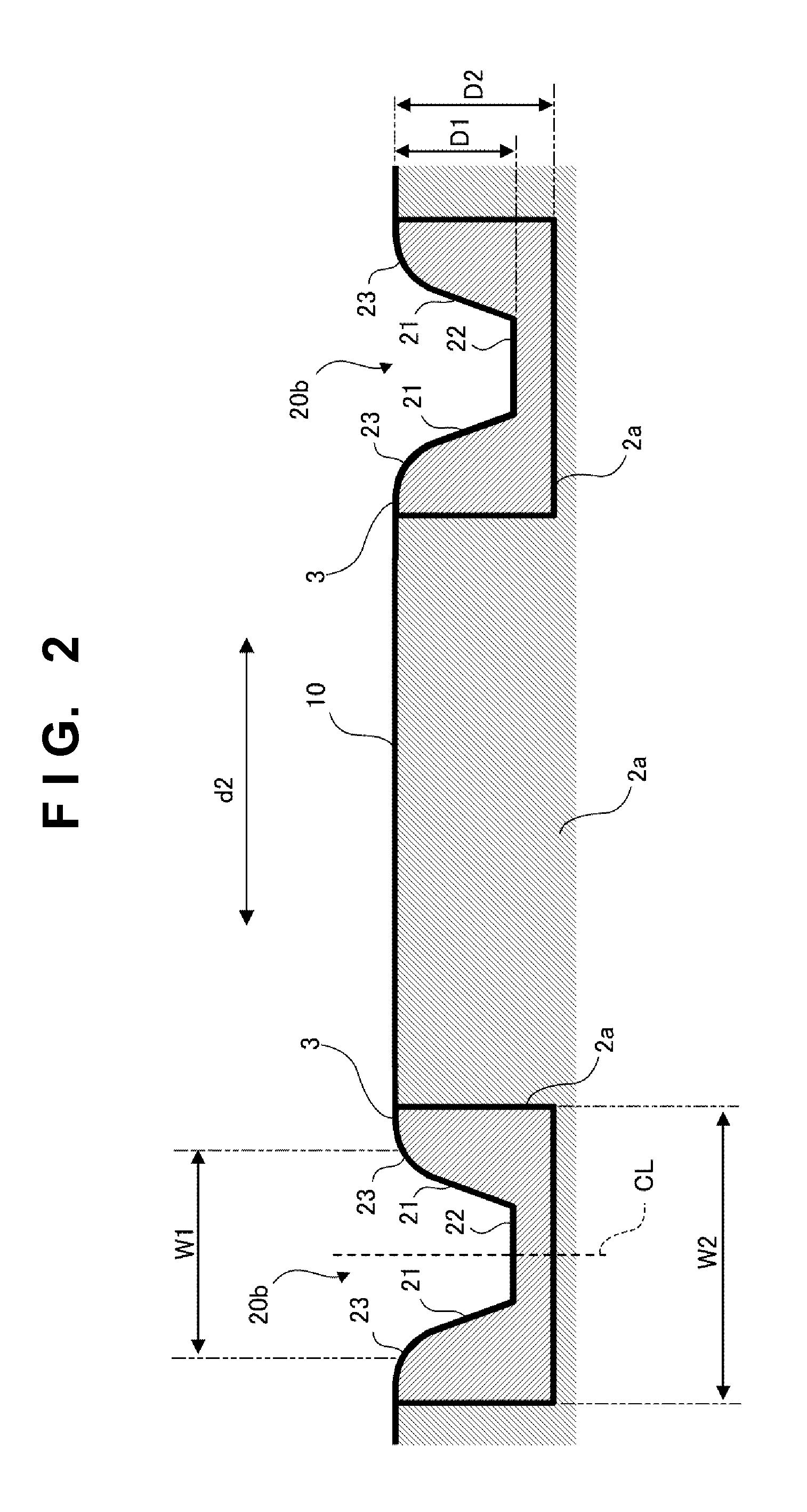

Manufacturing method and golf club head

ActiveUS20130303303A1Excellent abrasion resistanceImprove impact feelMetal rolling stand detailsMetal working apparatusEngineeringGolf Ball

This invention provides a method of manufacturing a golf club head including a face surface. This manufacturing method includes a step of forming a plurality of recessed portions in the face surface, included in a first member, to extend in the toe-to-heel direction, a fixing step of fixing, to the recessed portions, second members which are formed by a material different from that of the first member, and fill the recessed portions, and after the fixing step, a scoreline forming step of forming at least one scoreline in each of the second members, while not forming the scoreline in a portion, between the recessed portions, of the face surface of the first member.

Owner:BRIDGESTONE SPORTS

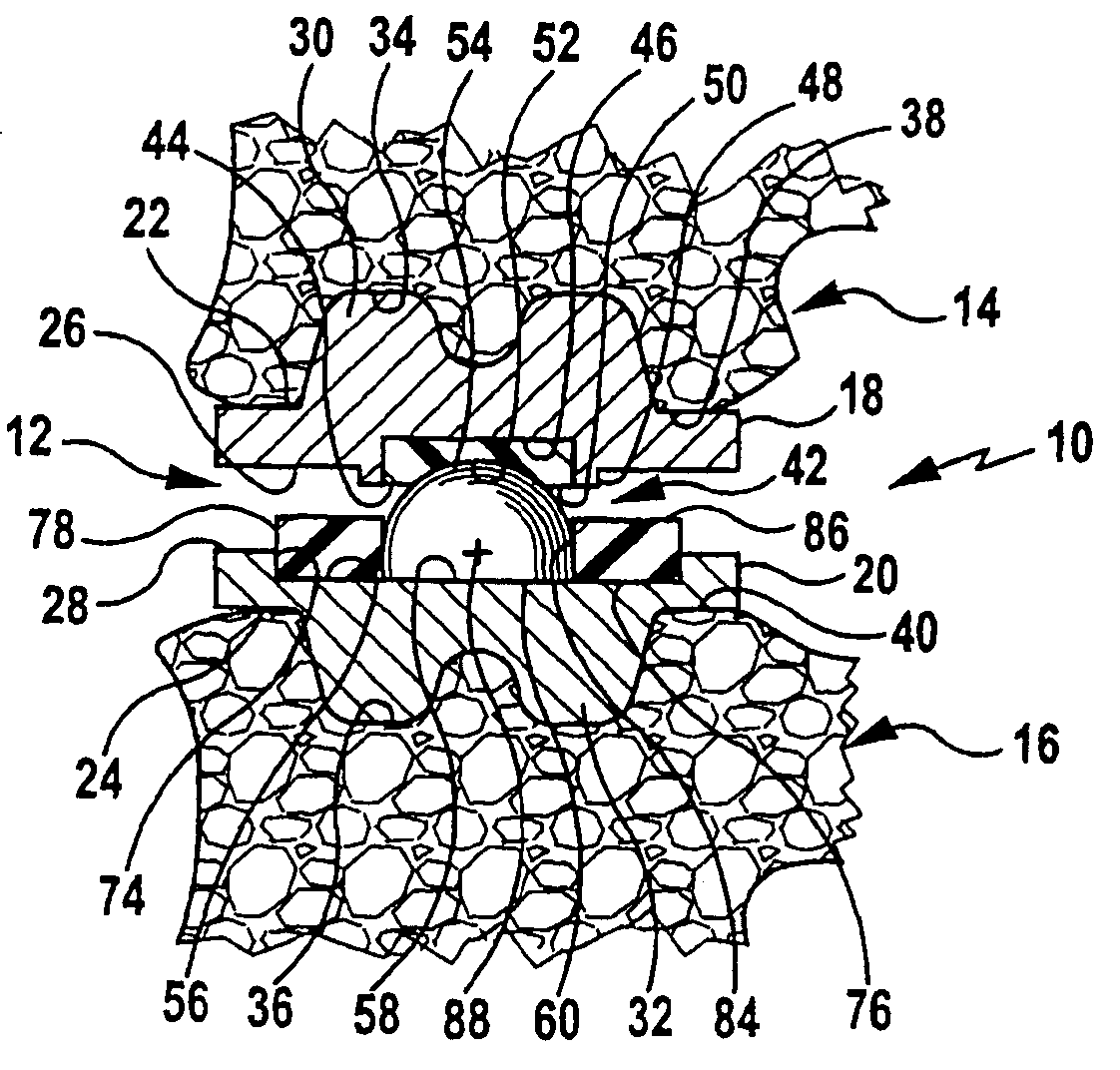

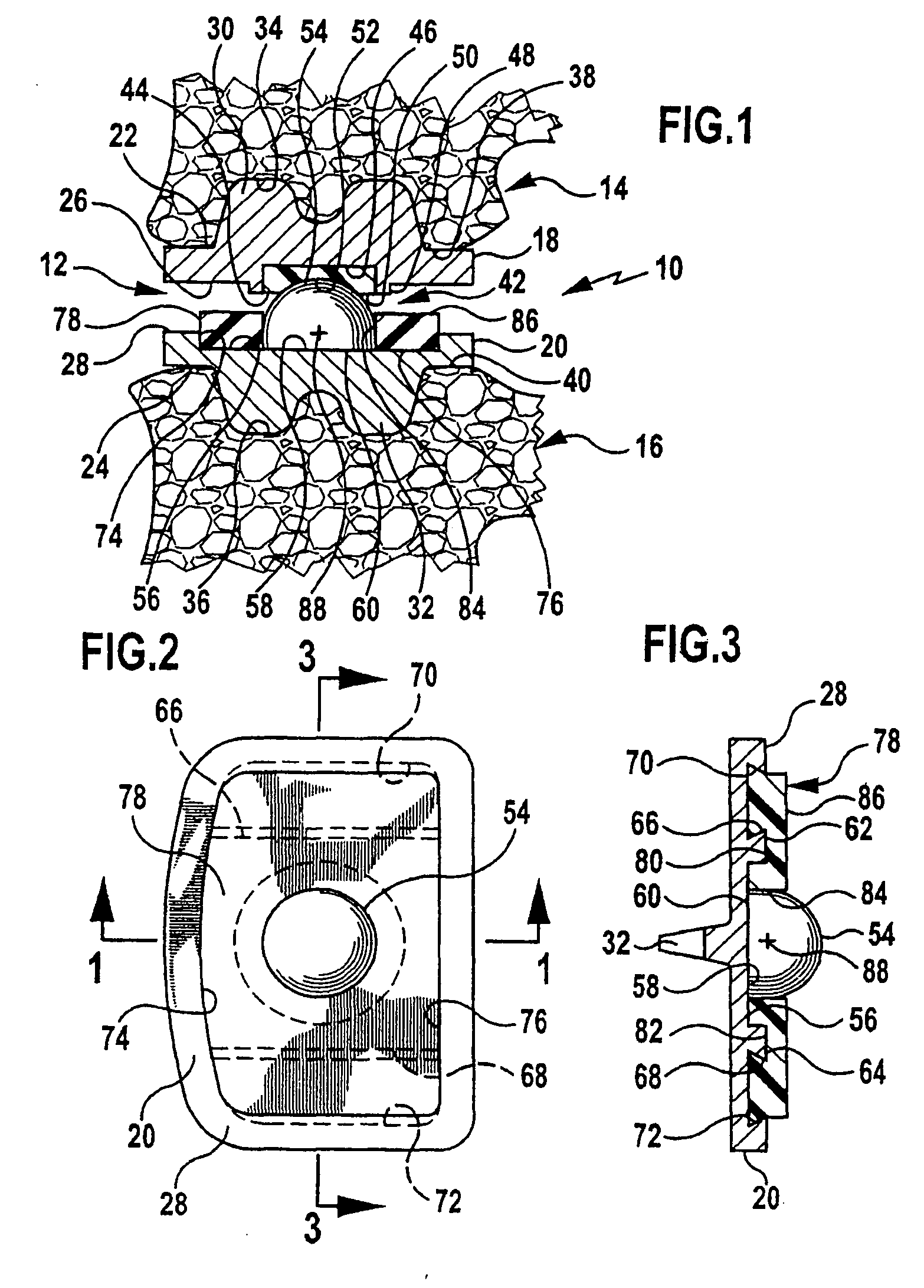

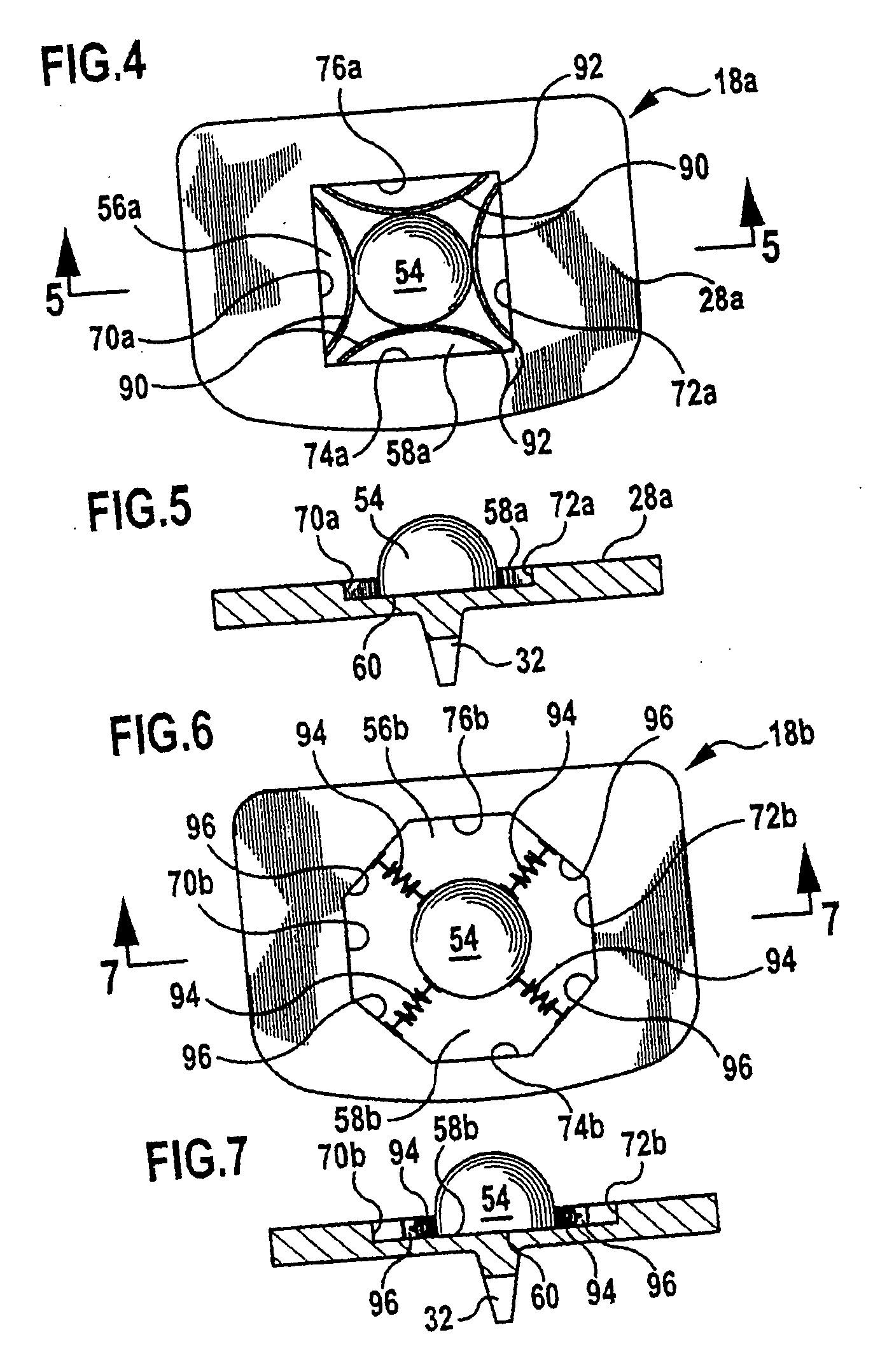

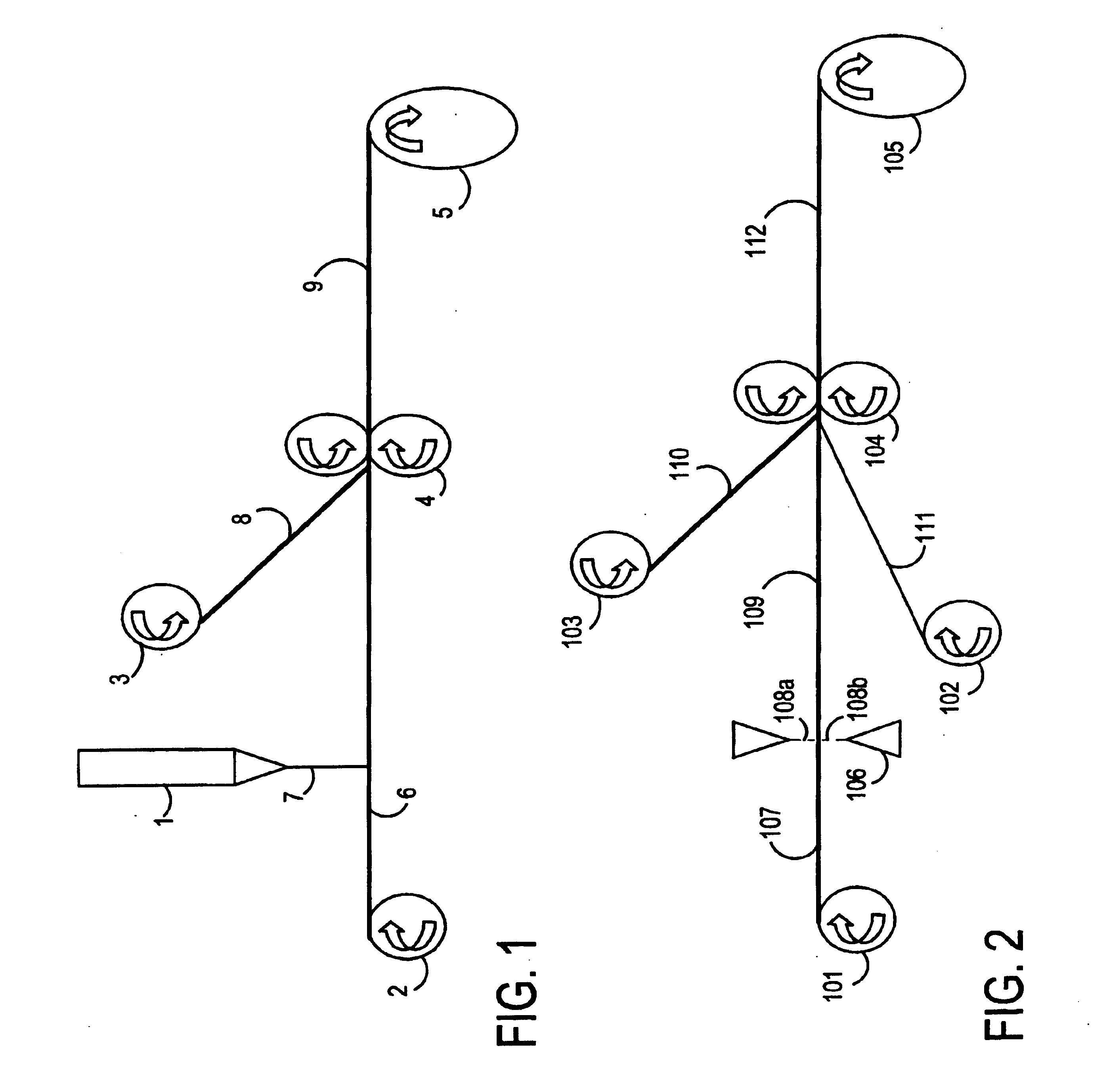

Intervertebral implant

InactiveUS20050080488A1Excellent abrasion resistanceImprove stabilityJoint implantsSpinal implantsIntervertebral spaceSacroiliac joint

An intervertebral implant is provided for insertion between a first vertebral body and a second vertebral body defining an intervertebral space. The implant includes a first anchoring part for anchoring at the first vertebral body, a second anchoring part for anchoring at the second vertebral body, and a joint configured to connect the first and second anchoring parts together. The joint includes a first joint part carried by the first anchoring part, and a second joint part carried by the second anchoring part. The implant further includes at least one restoring device adapted to exert a restoring force on the first or second joint part. The restoring force of the at least one restoring device transfers the first or second joint part from a deflected position back to a normal position and / or limits movement of the first or second joint part away from the normal position.

Owner:AESCULAP AG

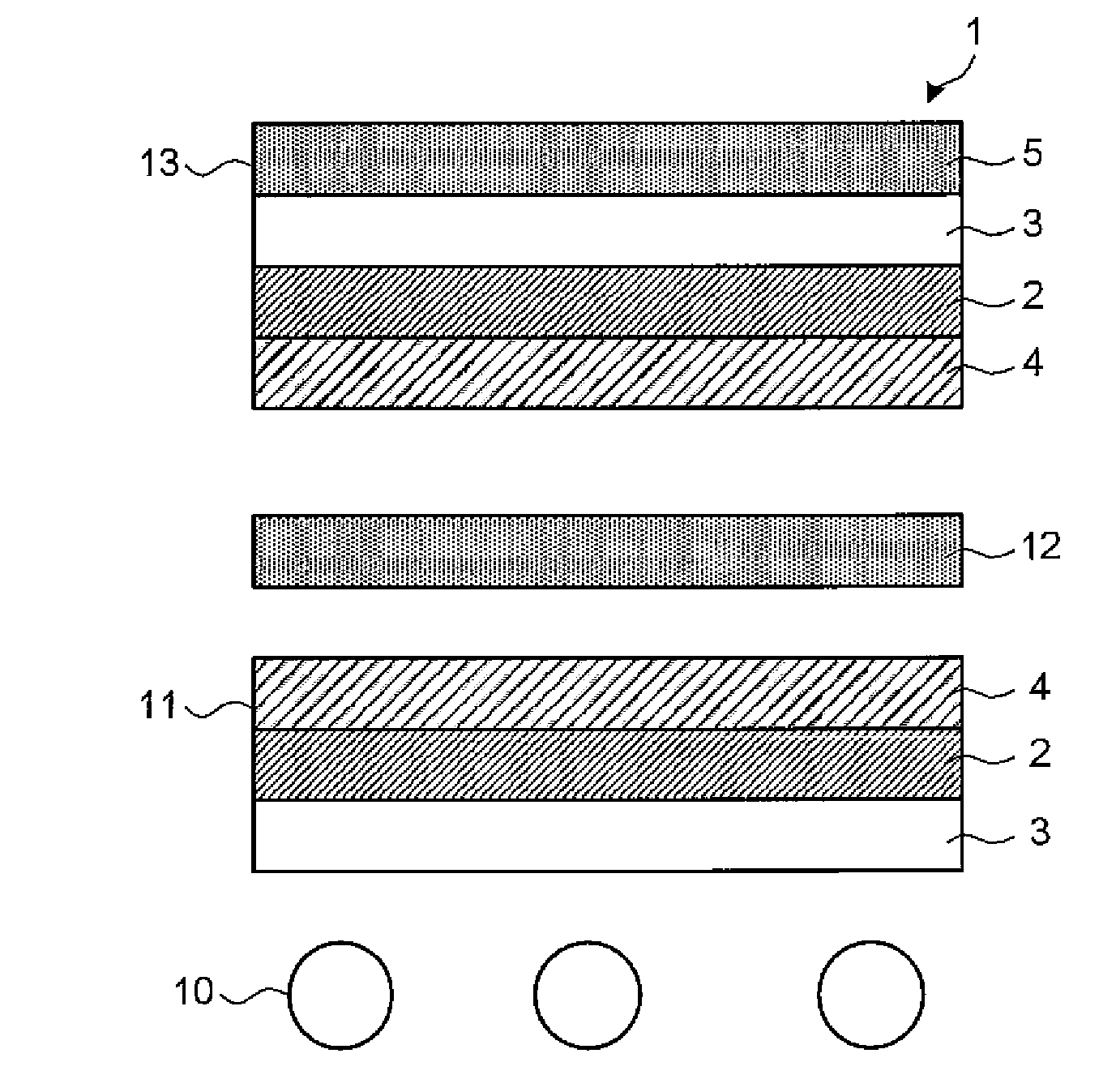

Fully elastic nonwoven-film composite

InactiveUS20050106980A1Excellent abrasion resistanceImprove conformitySynthetic resin layered productsLaminationEngineeringNonwoven fabric

This invention concerns an elastic multilayer composite, comprising an elastic film layer sandwiched between a first elastic nonwoven layer and an optional second elastic nonwoven layer, and a process for making the same. The laminate is stabilized via bonding according to either: adhesive bonding between the film and nonwoven layer(s), direct extrusion lamination of the film to one or more nonwoven layer(s), or attachment of the film to one or more of the nonwoven layers at a plurality of points via thermopoint bonding. This invention also concerns a process for manufacturing an elastic multilayer composite, comprising: bonding under neutral tension or substantially neutral tension at least one elastic film layer to at least one elastic nonwoven layer. This invention also concerns a process for manufacturing an elastic multilayer composite, comprising: bonding under differential tension or stretch at least one elastic film layer to at least one elastic nonwoven layer, where either the film or the nonwoven or both are stretched Further the invention relates to a process whereby the elastic nonwoven(s), the film, the composite or any combination is activated, especially stretch activated, to create or enhance elasticity or the touch of the nonwoven, to create pores in the elastic film, or to soften the composite.

Owner:ADVANCED DESIGN CONCEPTS GMBH

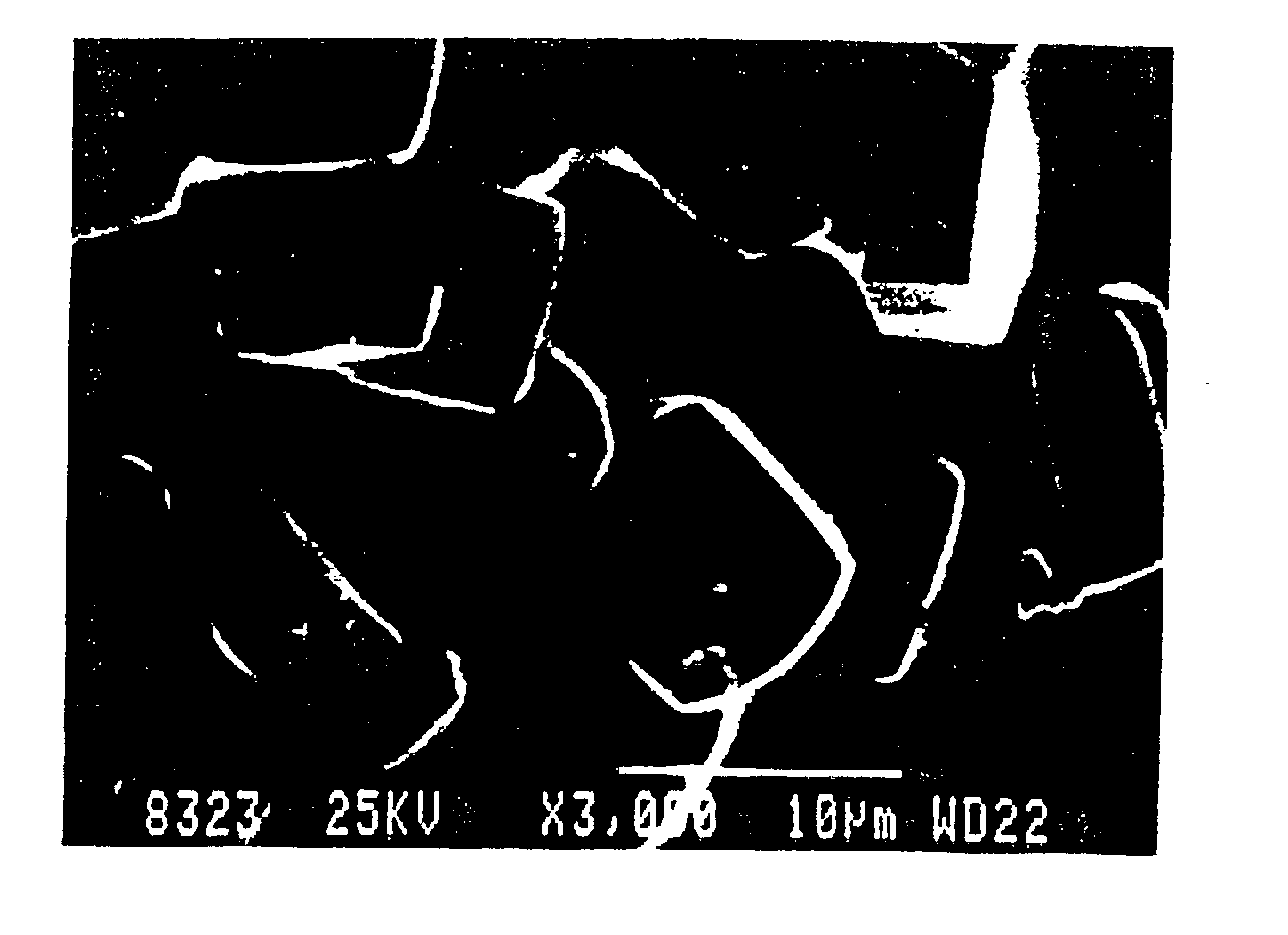

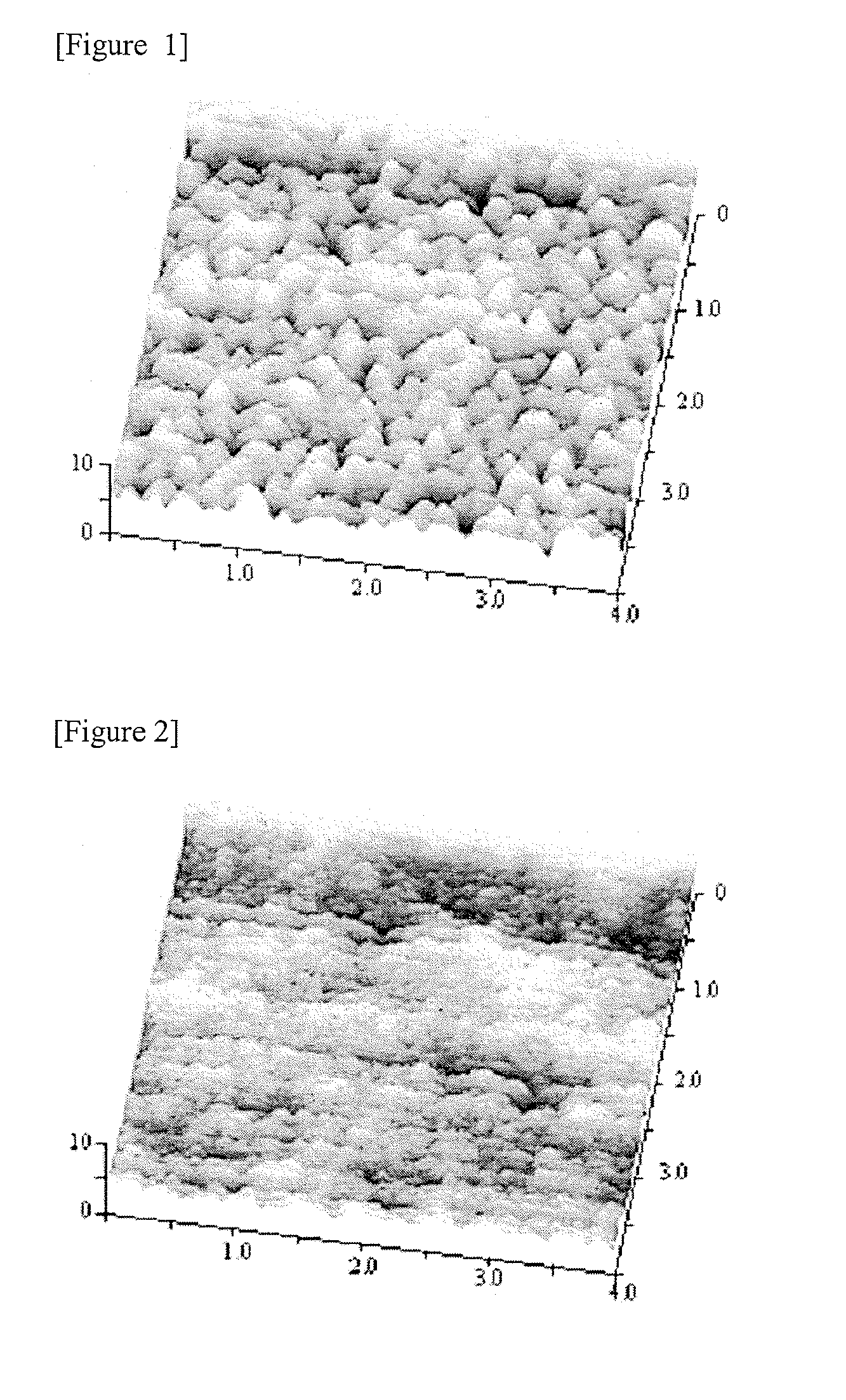

Glass ceramic and metal substrates with a self-cleaning surface, method for the production and use thereof

InactiveUS6872441B2Improve self-cleaningExcellent abrasion resistanceFouling preventionPretreated surfacesRough surfaceGlass-ceramic

The invention relates to glass, ceramic and metal substrates with at least one self-cleaning surface, comprising a layer with a micro-rough surface structure which is arranged on the substrate and made at least partly hydrophobic. The layer contains a glass flux and structure-forming particles with a mean particle diameter within the 0.1 to 50 μm range; the glass flux and structure-forming particles are present in a volume ratio within the 0.1 to 5 range, and the micro-rough surface structure has a ratio of mean profile height to mean distance between adjacent profile tips within the 0.3 to 10 range.To produce the subject of the invention the substrate is coated with a composition containing a glass flux and structure-forming particles, and the layer is burnt in and made hydrophobic.

Owner:FERRO GMBH

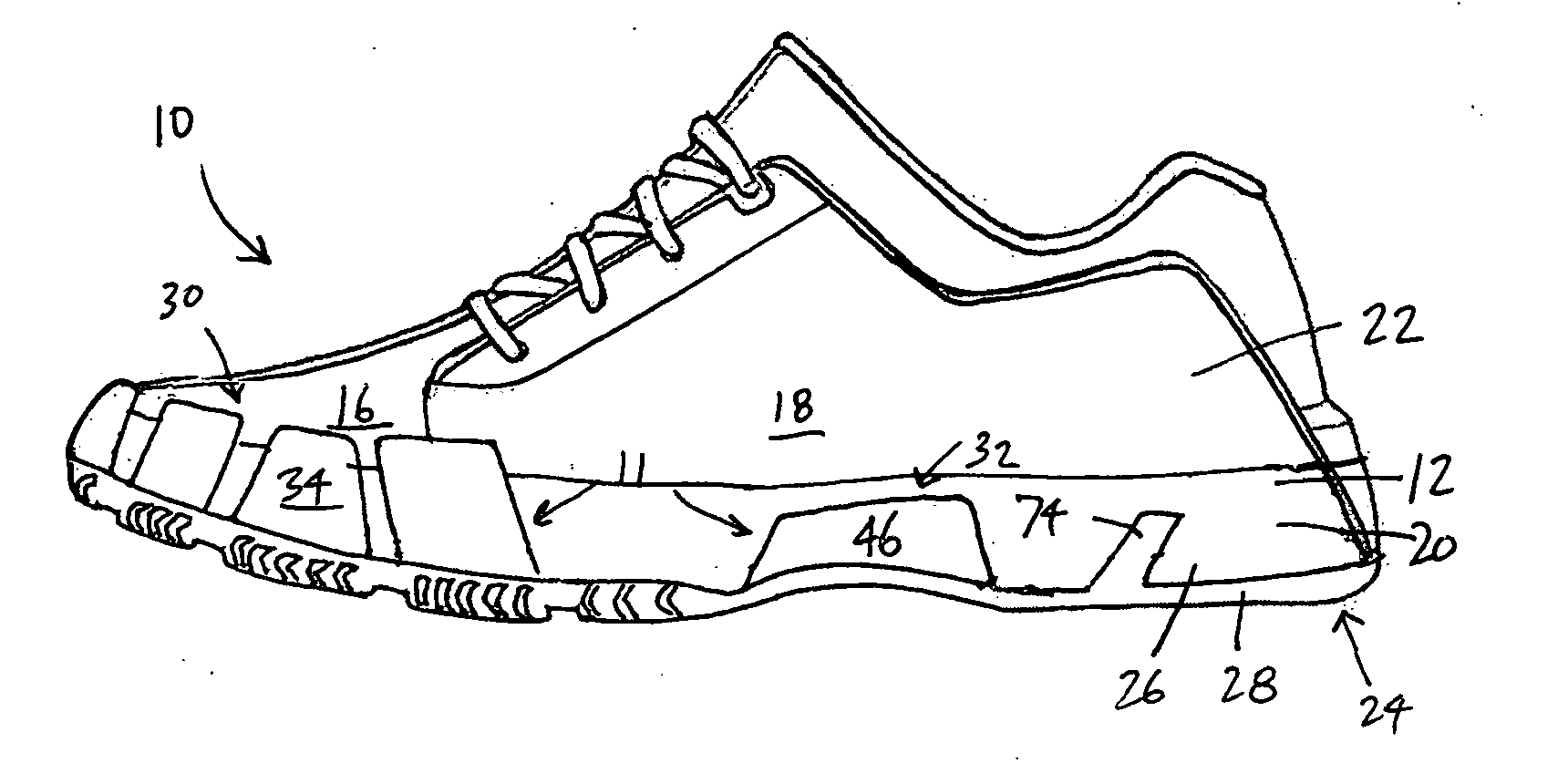

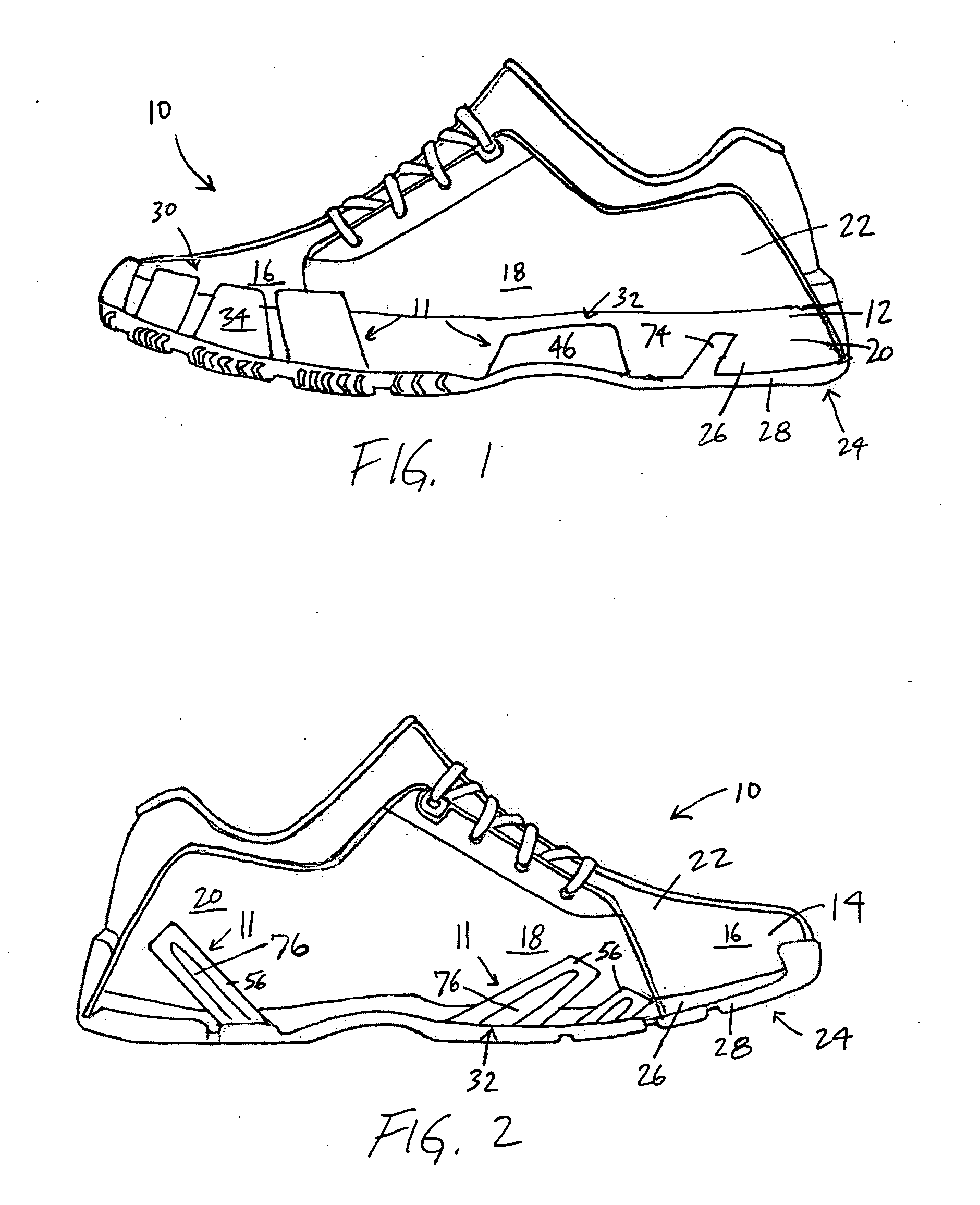

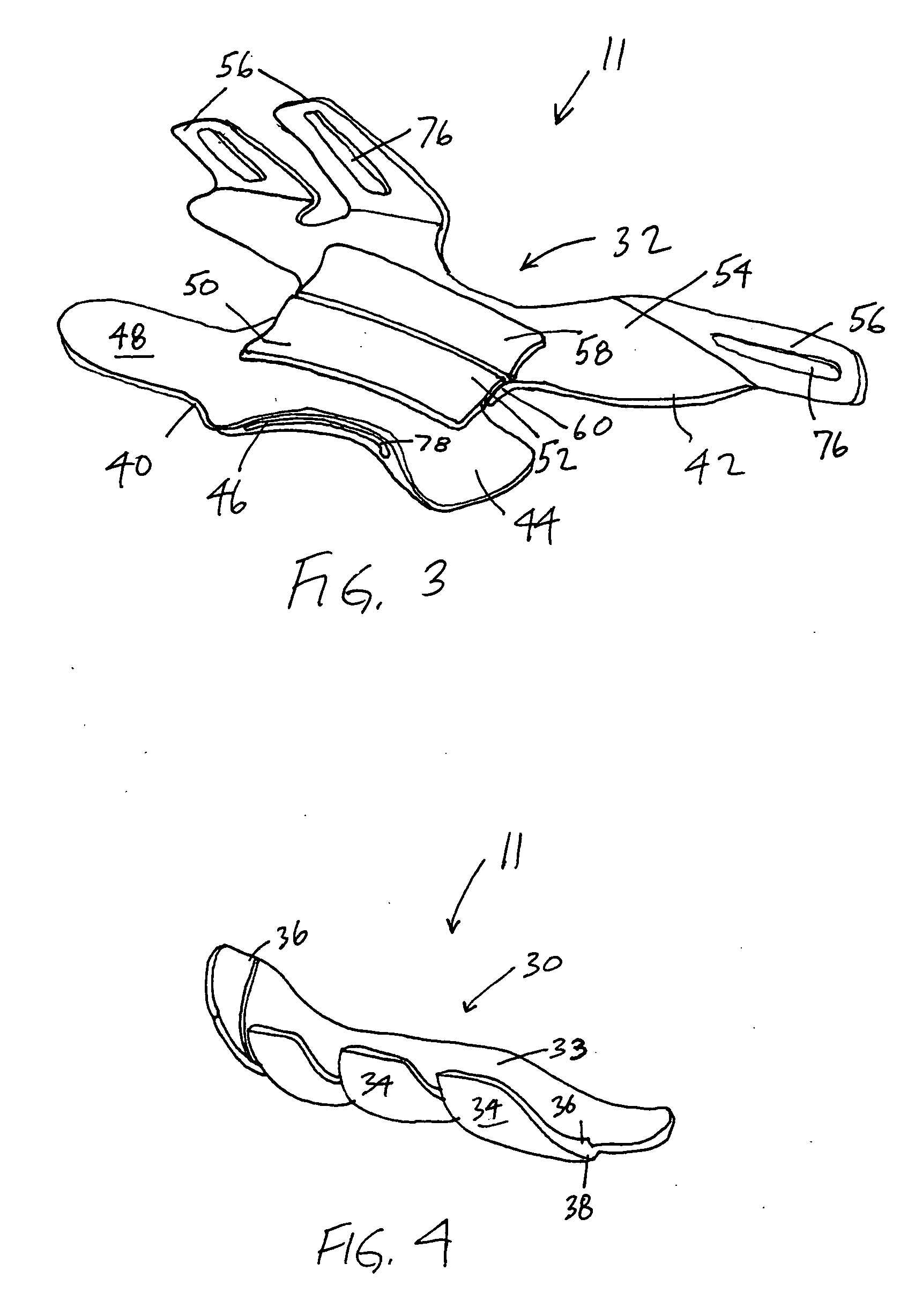

Article of footwear with sole plate

An article of footwear includes a sole assembly and an upper secured to the sole assembly. A sole plate is positioned between the upper and the sole assembly. The sole plate includes a midfoot member comprising a medial member having a base plate and at least one medial pillar extending upwardly from a medial edge of the base plate; with the base plate having a substantially planar finger extending forwardly and configured to extend under a foot of a user; and a lateral member having at least one lateral pillar extending upwardly from a lateral edge thereof. A forefoot member has at least one finger extending upwardly along an exterior surface of the upper.

Owner:NIKE INC

Heat-shrinkable polymeric films

InactiveUS6908687B2High and predictable and controlled shrinkage characteristicGood optical claritySynthetic resin layered productsSausage casingsOptical transparencyControl layer

The present invention relates to oriented or hot-blown shrink films which may be manufactured from by a number of processes. The oriented films may be manufactured by double bubble, LISIM, tape bubble, trapped bubble or tenter framing processes. The films of the present invention are useful as a shrink film to package and label a variety of products. The films exhibit a high degree of MD shrinkage in a very controlled and consistent manner while providing a number of other positive characteristics such as optical clarity, puncture and abrasion resistance, controlled gauge, and superior web winding and handling characteristics. The shrink control layers of the films of the present invention contain a modifier component selected from plastomers and / or metallocene catalyzed ethylene-propylene copolymers and blends thereof.

Owner:JINDAL INNOVATION CENT SRL

Highly wearable vacuum coating ultraviolet curing coatings

ActiveCN101157808AImprove adhesionImproved RCA wear performancePolyurea/polyurethane coatingsWear resistantLacquer

The invention relates to the electronic application-coating field, in particular to uv-curing coating with high wearing resistance and vacuum coating. The compositions and contents of the invention are: 10 wt percent to 30 wt percent of difunctional group polyurethane acrylate, 10 wt percent to 40 wt percent of high functional group polyurethane acrylate, 5 wt percent to 20 wt percent of high functional group acrylate monomer, 0 wt percent to 15 wt percent of monofunctional group acrylate monomer, 1 wt percent to 10 wt percent of acid adhesive promoter, 1 wt percent to 6 wt percent of photoinitiator, 0 wt percent to 5 wt percent of nano wearing resistance materials, 0.1 wt percent to 2 wt percent of additive and 10 wt percent to 50 wt percent of solvent. The invention is designed for providing surface protection for vacuum coating parts of electric products such as mobile phone, MP3, and digital camera, etc., and is characterized by good surface effect, good performances of ultrawear-resistance, high temperature and humidity resistance, anti-cold thermal cycling and anti-yellowing, etc., wherein, RCA wear can be up to more than 1500 times, which can effectively improve the service life of electric products. The invention effectively enhances the adhesion and wearing resistant performance of the uv-curing and vacuum coating dope, solves the matching problem of the bottom and surface lacquer of the uv-curing and vacuum coating dope, and has broad university.

Owner:HUNAN SOKAN NEW MATERIAL

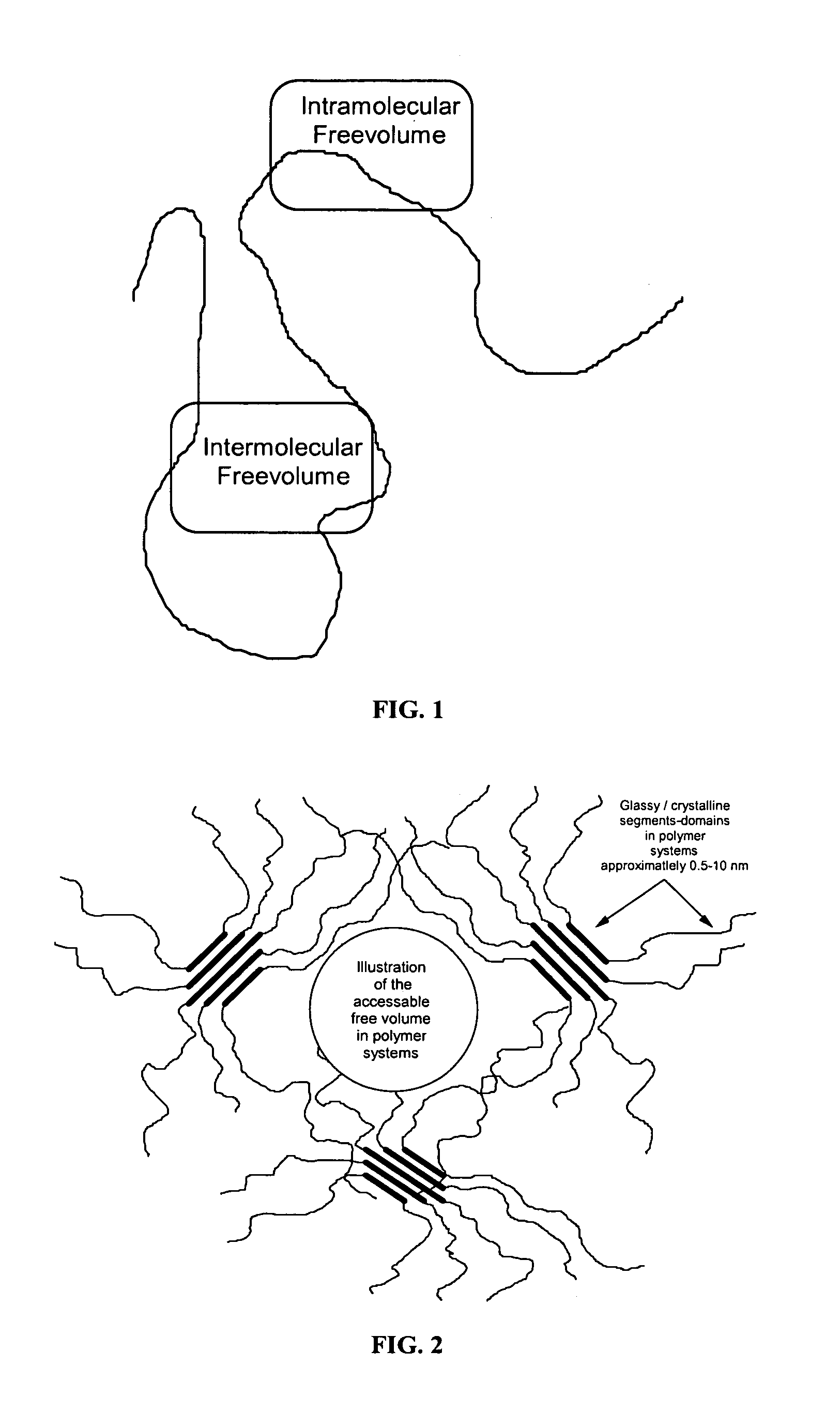

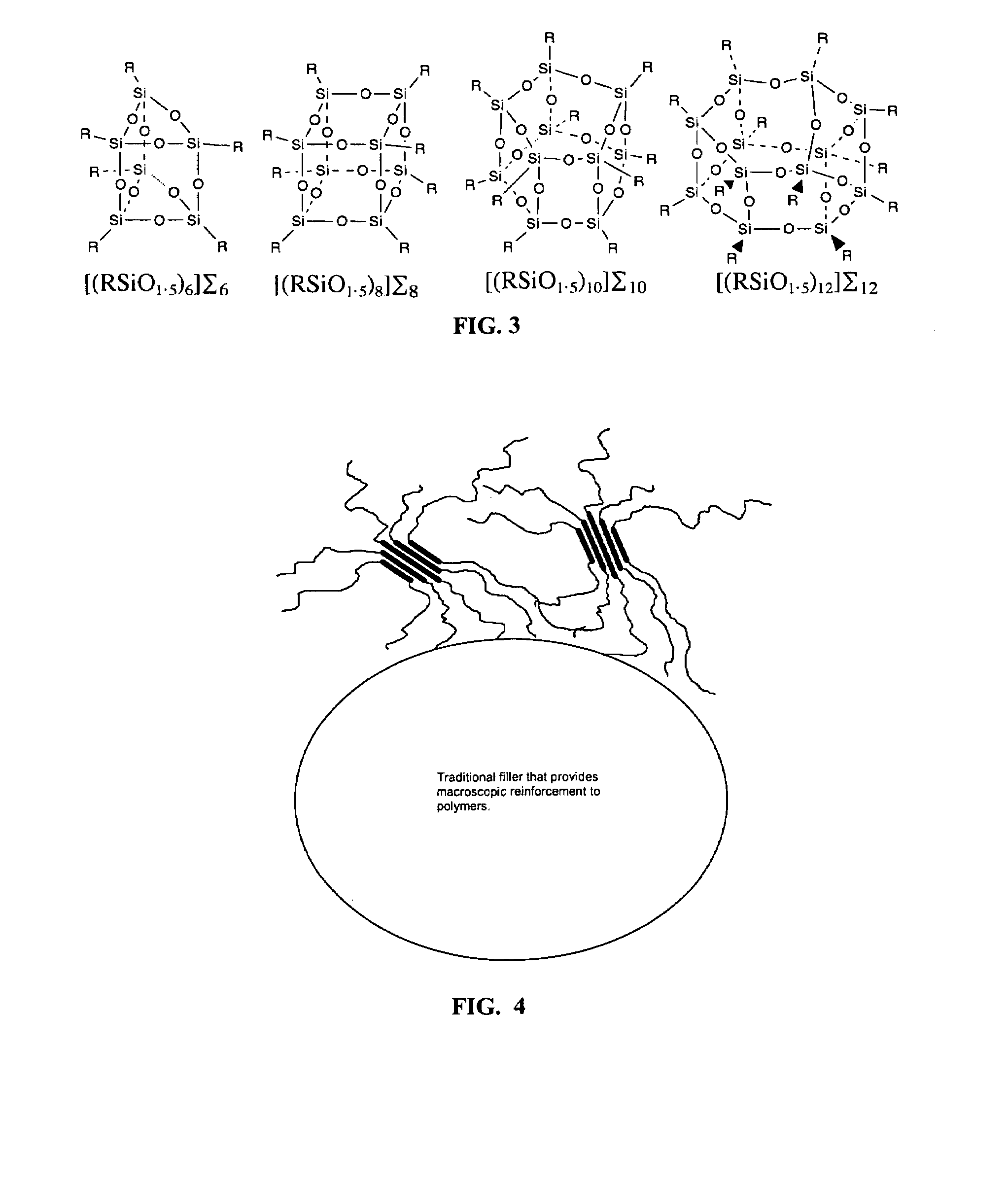

Nanostructured chemicals as alloying agents in fluorinated polymers

InactiveUS7193015B1Reduce melt viscosityLow dielectric constantMaterial nanotechnologyMolecular levelCompression set

A method of using nanostructured chemicals as alloying agents for the reinforcement of flouropolymer microstructures, including polymer coils, domains, chains, and segments, at the molecular level. Because of their tailorable compatibility with fluorinated polymers, nanostructured chemicals can be readily and selectively incorporated into polymers by direct blending processes. Properties most favorably improved are time dependent mechanical and thermal properties such as heat distortion, creep, compression set, shrinkage, modulus, hardness and abrasion resistance. In addition to mechanical properties, other physical properties are favorably improved, including lower thermal conductivity, fire resistance, and improved oxygen permeability. These improved properties may be useful in a number of applications, including space-survivable materials and creep resistant seals and gaskets. Improved surface properties may be useful for applications such as anti-icing or non-wetting surfaces or as low friction surfaces.

Owner:THE UNITED STATES OF AMERICA AS REPRESETNED BY THE SEC OF THE AIR FORCE

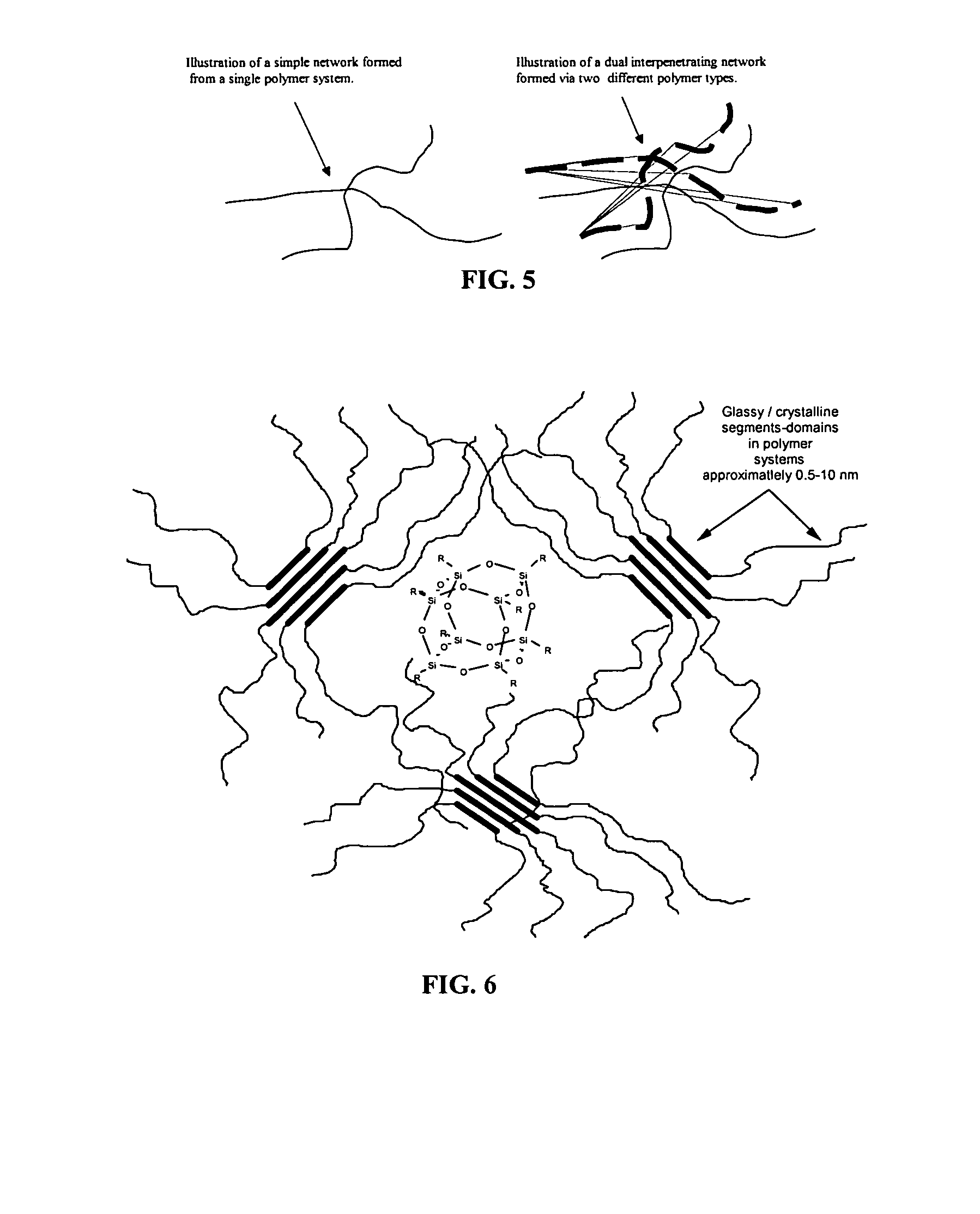

Cross-linkable polymers, method for the production thereof, and shaped bodies made of cross-linked polymers

InactiveUS6528585B1Low levelExtended maintenance periodPlastic/resin/waxes insulatorsCross-linkPolymer science

The invention relates to a process for preparing crosslinkable polymers containing silane groups having at least one hydrolyzable radical by free-radical-initiated grafting of the base polymers with an olefinically unsaturated silane having at least one hydrolyzable radical, wherein the grafting is carried out in the presence of(a) an alkylsilane of the formula I, whereR1 is a monovalent hydrocarbon radical having from 1 to 33 carbon atoms or a divalent hydrocarbon radical having from 4 to 24 carbon atoms,R2 is a hydrocarbon radical having from 1 to 10 carbon atoms,X are identical or different hydrolyzable radicals,n is 0, 1 or 2 andm is 1 or 2 and / or(b) a fluoroalkylsilane of the formula whereR3 is a fluoroalkyl radical,R4 is an alkyl radical andX is a hydrolyzable radical,x is an integer from 1 to 3,y is 0, 1 or 2 andz is an integer from 1 to 3, with the proviso that the sum x+y+z=4.

Owner:EVONIK DEGUSSA GMBH

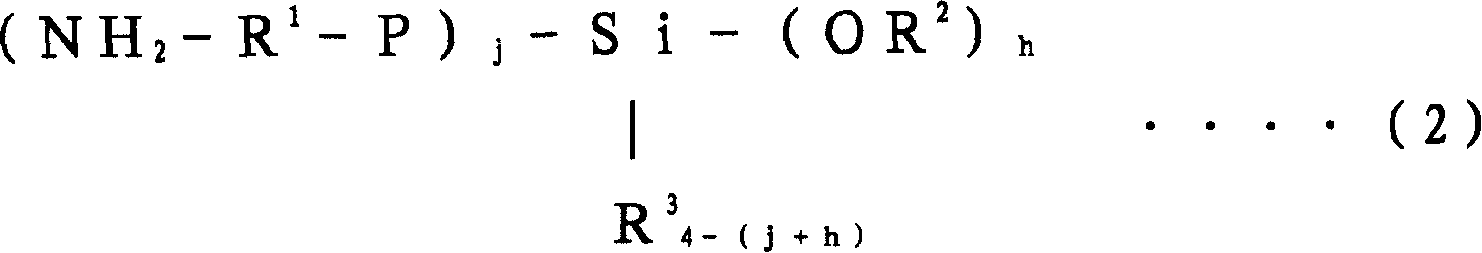

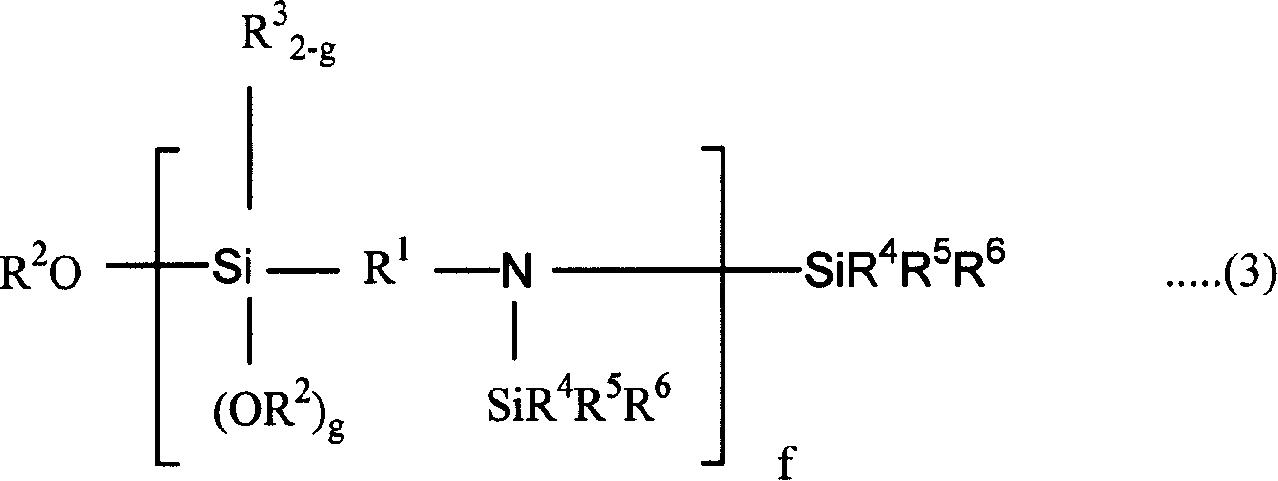

Process for producing modified polymer, modified polymer obtained by the process, and rubber composition

InactiveUS20050159554A1Raise fracture characteristicExcellent abrasion resistanceSpecial tyresPolymer scienceActive site

The present invention relates to a process for producing a modified polymer, comprising modifying a polymer having an active site of an organometal type in a molecule by reacting the site thereof with a hydrocarbyloxysilane compound and adding a condensation accelerator to the reaction system in the middle of the above reaction and / or after completion thereof and a rubber composition comprising the modified polymer obtained by the process described above, preferably a rubber composition comprising 100 parts by weight of (A) a rubber component containing at least 3% by weight of the above modified polymer and 10 to 100 parts by weight of (B) silica and / or carbon black. According to the present invention, capable of being provided is a silica and / or carbon black-blended rubber composition which enhances interaction with silica and carbon black and which elevates the fracture characteristic, the abrasion resistance and the low heat buildup property and can exhibit a good workability.

Owner:BRIDGESTONE CORP

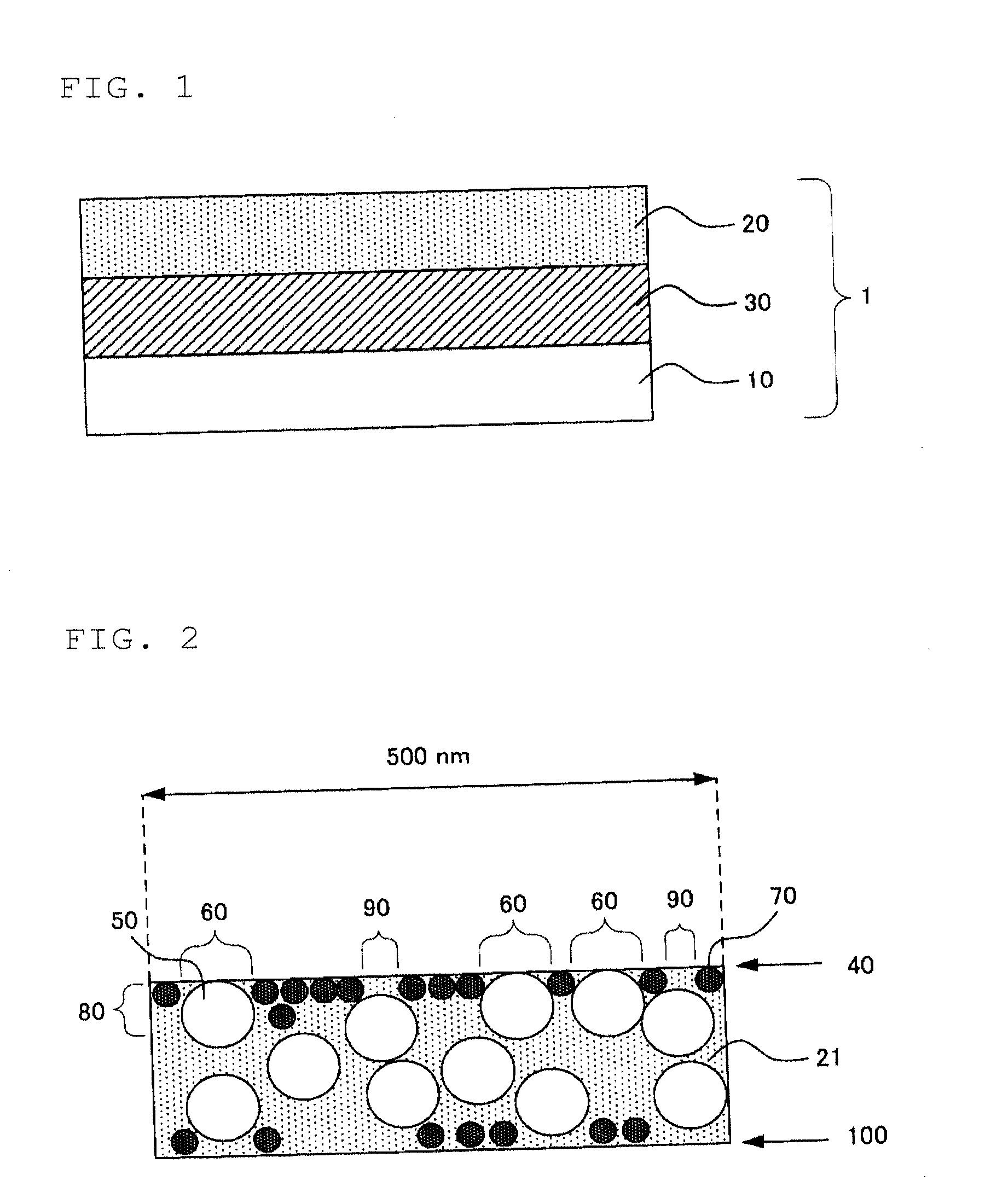

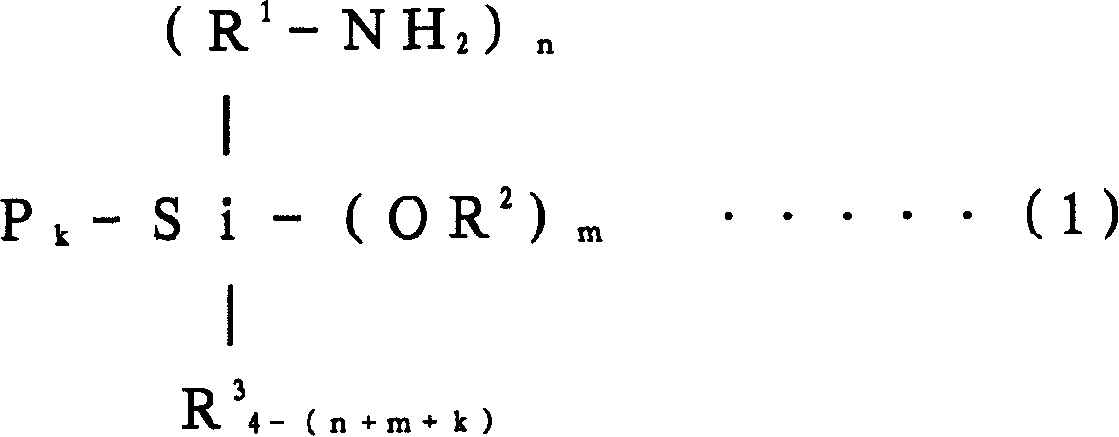

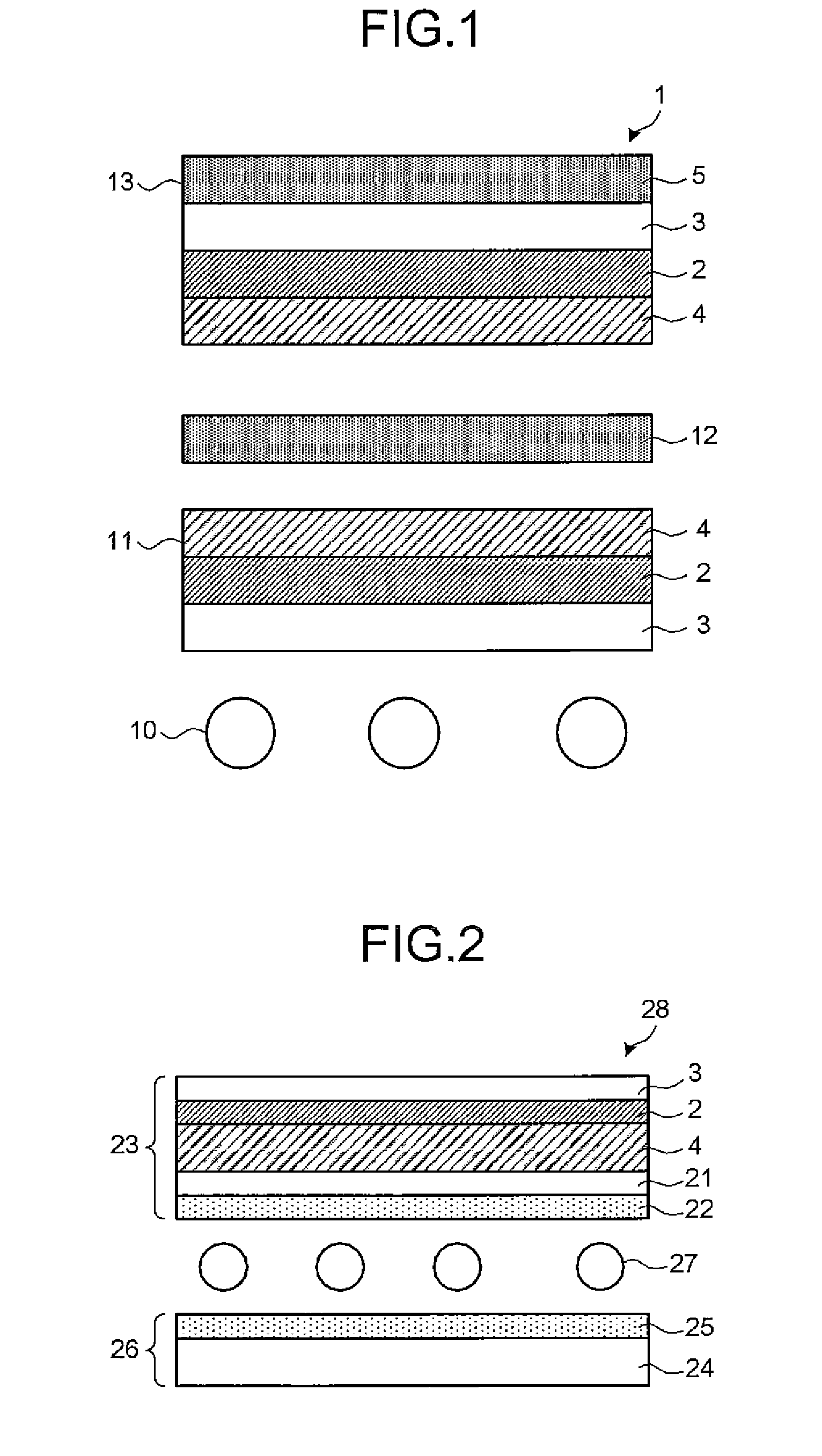

Optical film and display panel

ActiveUS20120200933A1Improve wear resistanceImprove anti-reflection abilityCoatingsNon-linear opticsRefractive indexDisplay device

An optical film having an optically-transparent substrate, and a low refractive index layer having a thickness d on one side of the optically-transparent substrate, a polarizing plate and a display panel provided with the same, and a display provided with the same.

Owner:DAI NIPPON PRINTING CO LTD

Conjugated diolefin (co)polymer rubber, process for producing (co)polymer rubber, rubber composition, composite, and tire

InactiveCN1578790ALow hysteresis lossLow abrasion resistanceSpecial tyresRolling resistance optimizationHysteresisPolymer science

Disclosed are a conjugated diolefin (co)polymer rubber formed from either a conjugated diolefin or a conjugated diolefin and an aromatic vinyl compound, wherein the (co) polymer rubber has a primary amino group and an alkoxysilyl group which are bonded to a (co)polymer chain; a process for producing the same; a rubber composition; a composite; and a tire. The (co) polymer rubber has satisfactory processability, and can give an automotive tire tread having a balance among wear resistance, failure characteristics, low hysteresis loss and wet-skid characteristics.

Owner:JSR CORPORATIOON

Optical element having antireflection film

InactiveUS6919134B2Excellent abrasion resistanceGood adhesivenessLayered productsSpecial surfacesHeat resistanceTransmittance

The present invention is directed to an optical element having an antireflection film formed on a plastic substrate, wherein the reflectance of the antireflection film is low while the transmittance thereof is high. The impact resistance, the adhesiveness, the heat resistance, the abrasion resistance and the alkali resistance of the antireflection film on the plastic substrate are superior.The optical element having an antireflection film has at least one layer of the antireflection film that is a hybrid layer made of an inorganic substance and an organic substance.

Owner:HOYA CORP

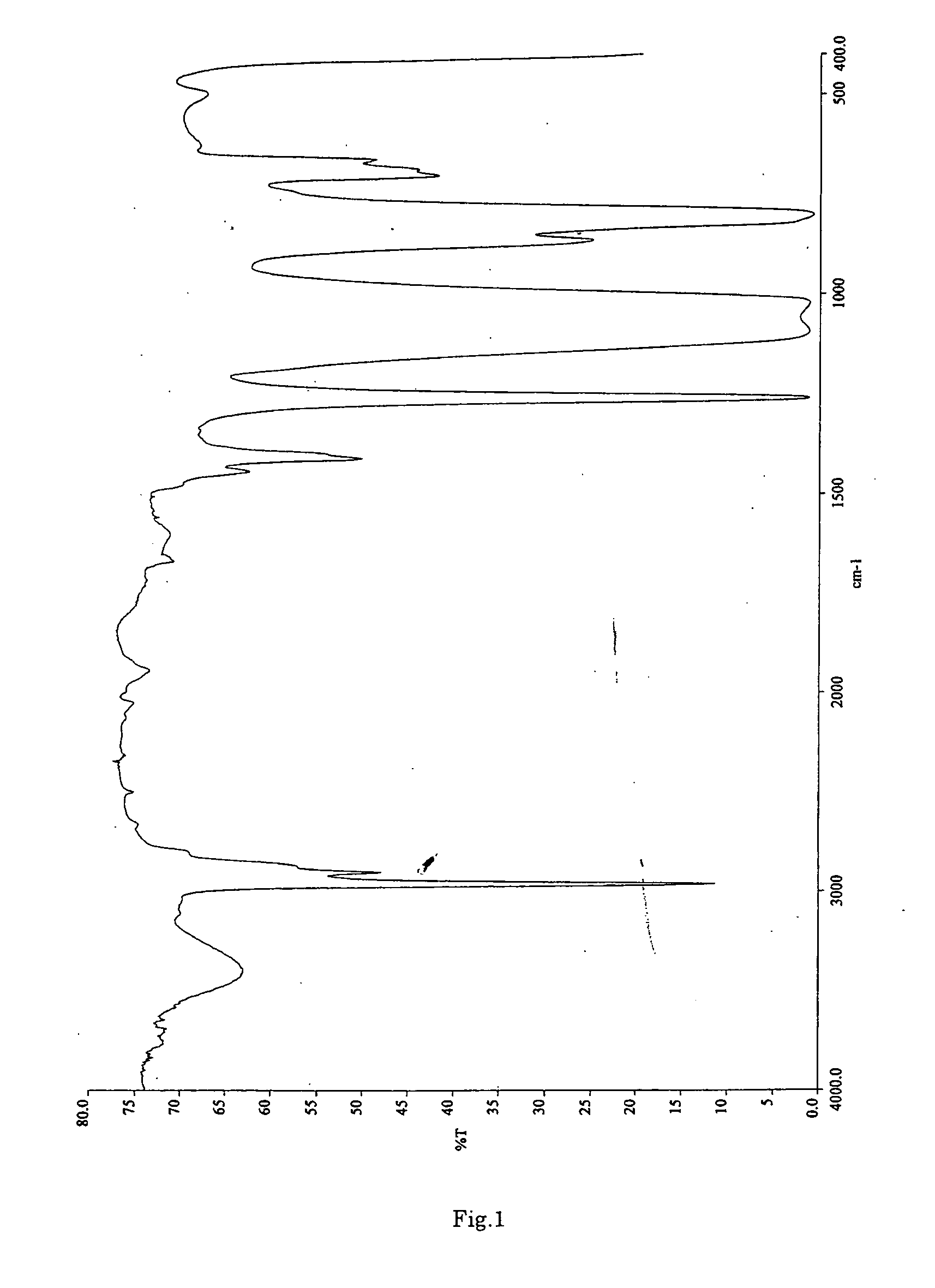

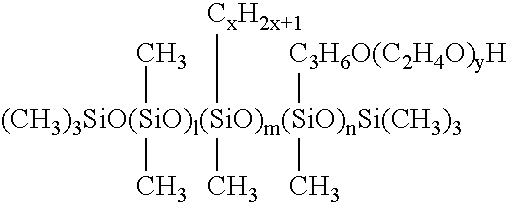

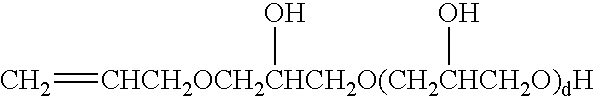

Alternating copolymer of organopolysiloxane with grycerol derivative and a cosmetic comprising the same

InactiveUS20050008600A1Reduce viscosityLight spreadabilityCosmetic preparationsHair cosmeticsGlycerol DerivativesCopolymer

Owner:SHIN ETSU CHEM IND CO LTD

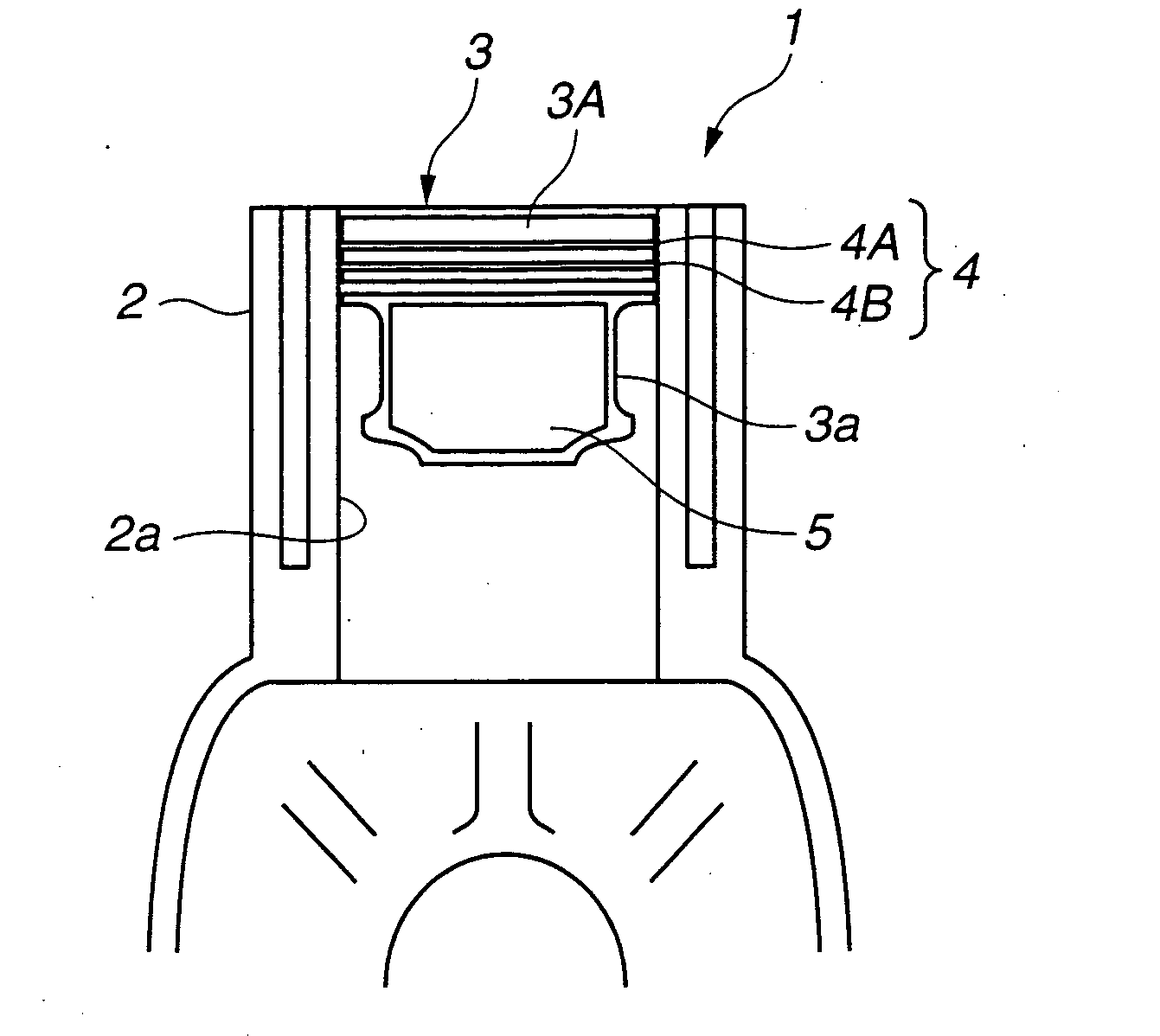

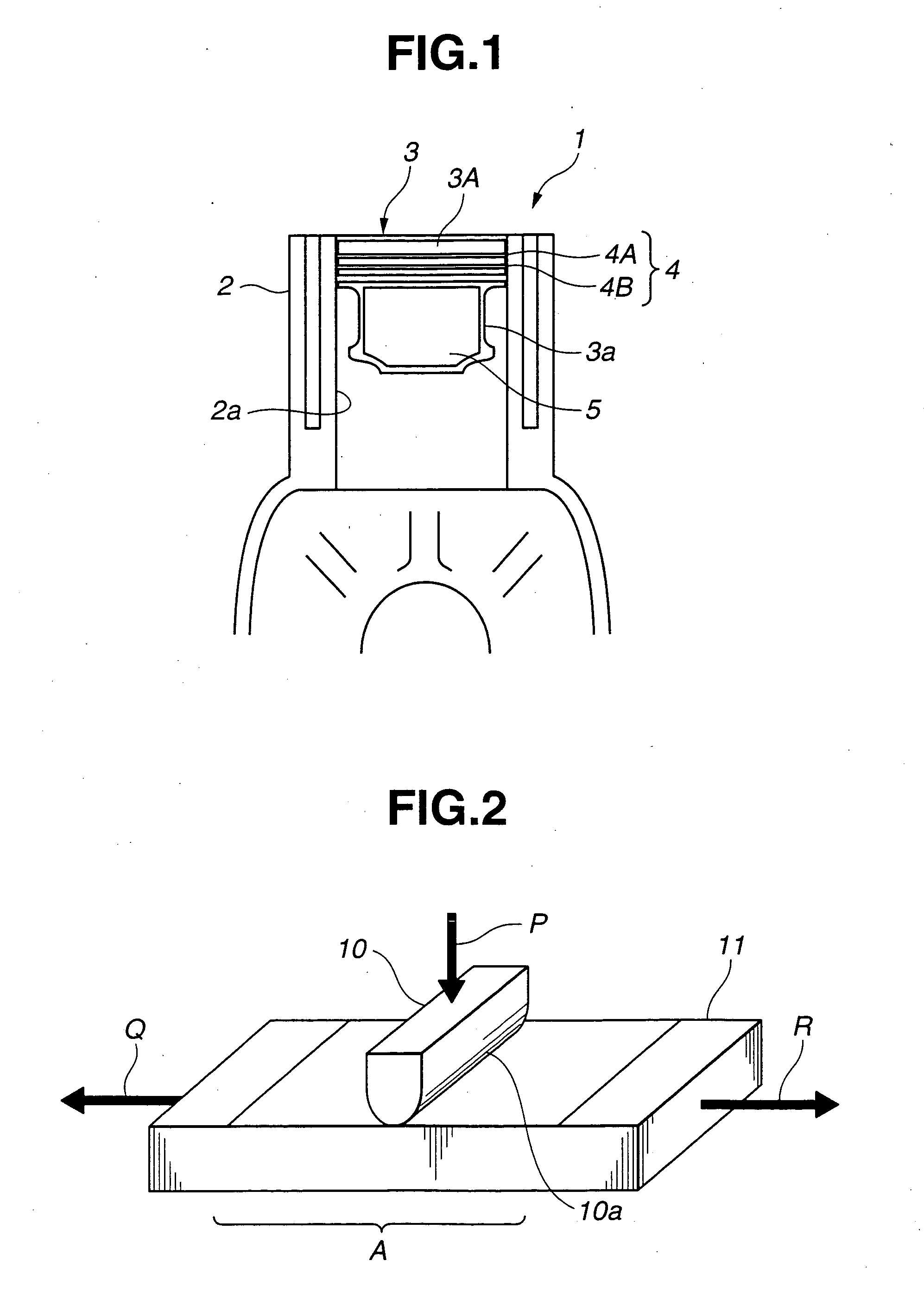

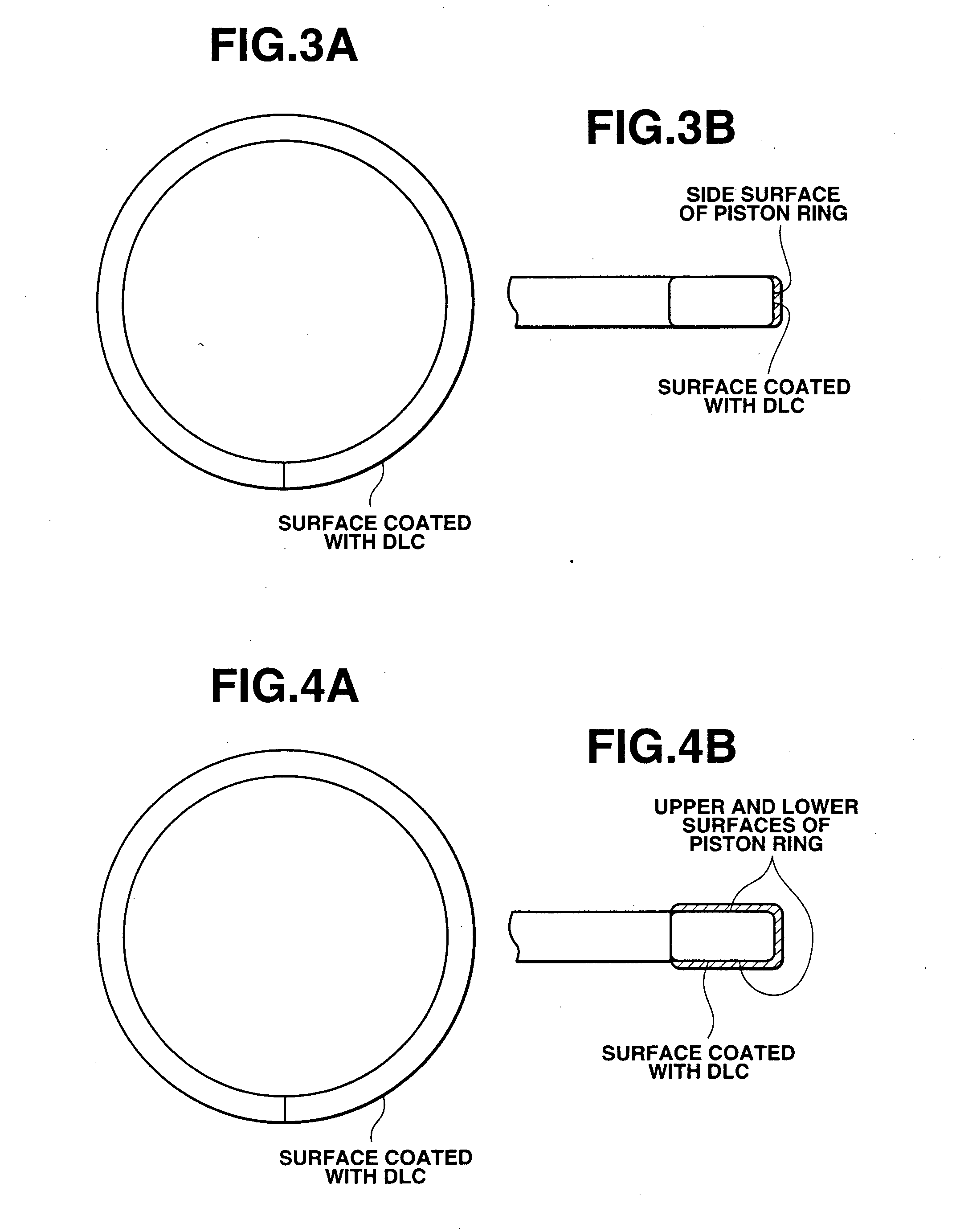

Piston for internal combustion engine

ActiveUS20050005892A1Excellent abrasion resistanceReduce coefficient of frictionCasingsPlungersPiston ringAliphatic amine

A piston for an internal combustion engine of an automotive vehicle. The piston has a piston ring and a piston skirt section each of which has a sliding section in slidable contact with a cylinder bore section of a cylinder block in presence of a lubricating oil. The cylinder bore section is formed of eutectic or hyper-eutectic aluminum alloy. Additionally, a hard carbon thin film is coated on the sliding section of the piston and contains hydrogen atom in an amount of not more than 1 atomic %. Here, the lubricating oil contains at least one selected from the group consisting of ashless fatty acid ester friction modifier, ashless aliphatic amine friction modifier, polybutenyl succinimide, derivative of polybutenyl succinimide, zinc dithiophosphate, and derivative of zinc dithiophosphate.

Owner:NISSAN MOTOR CO LTD

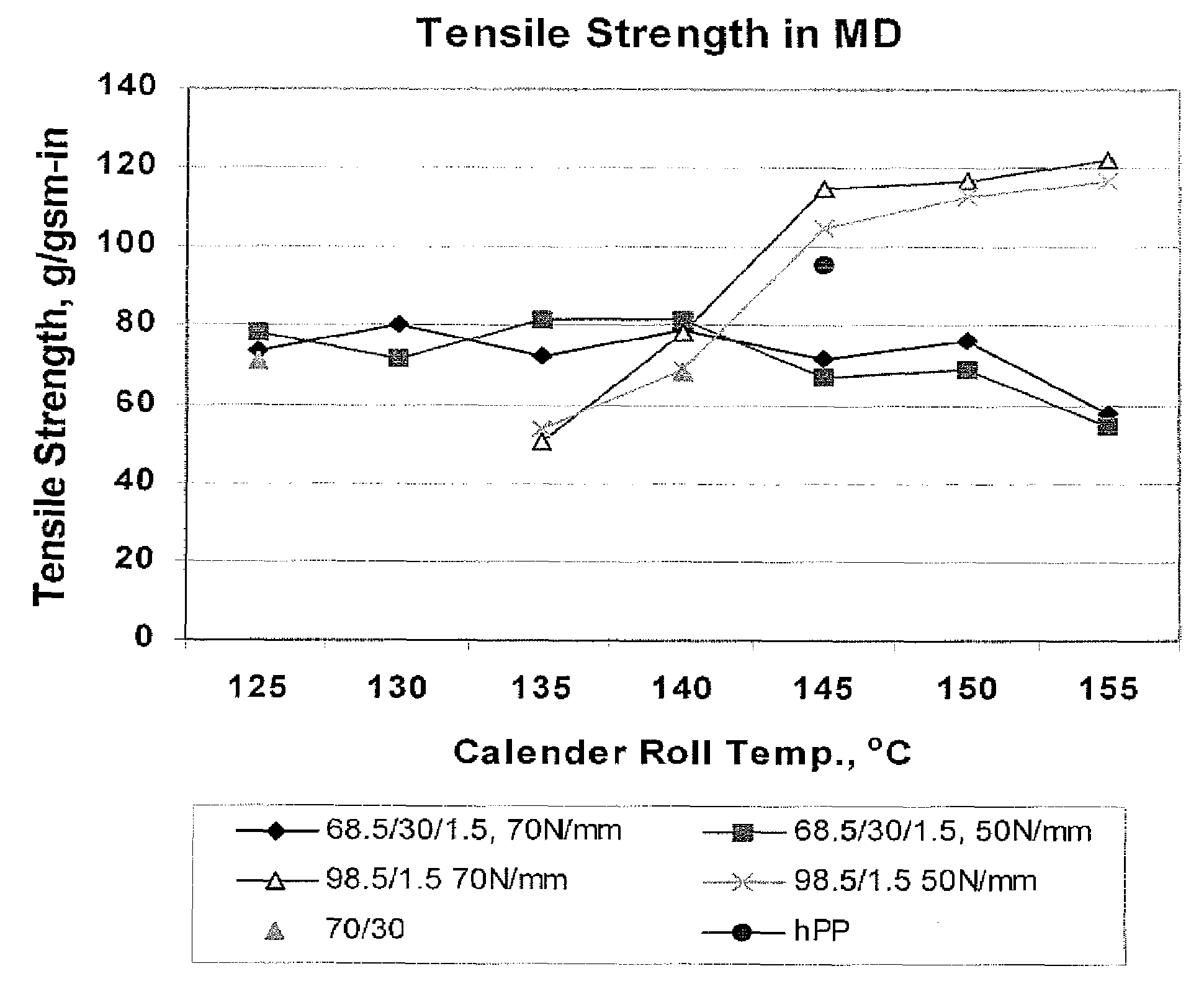

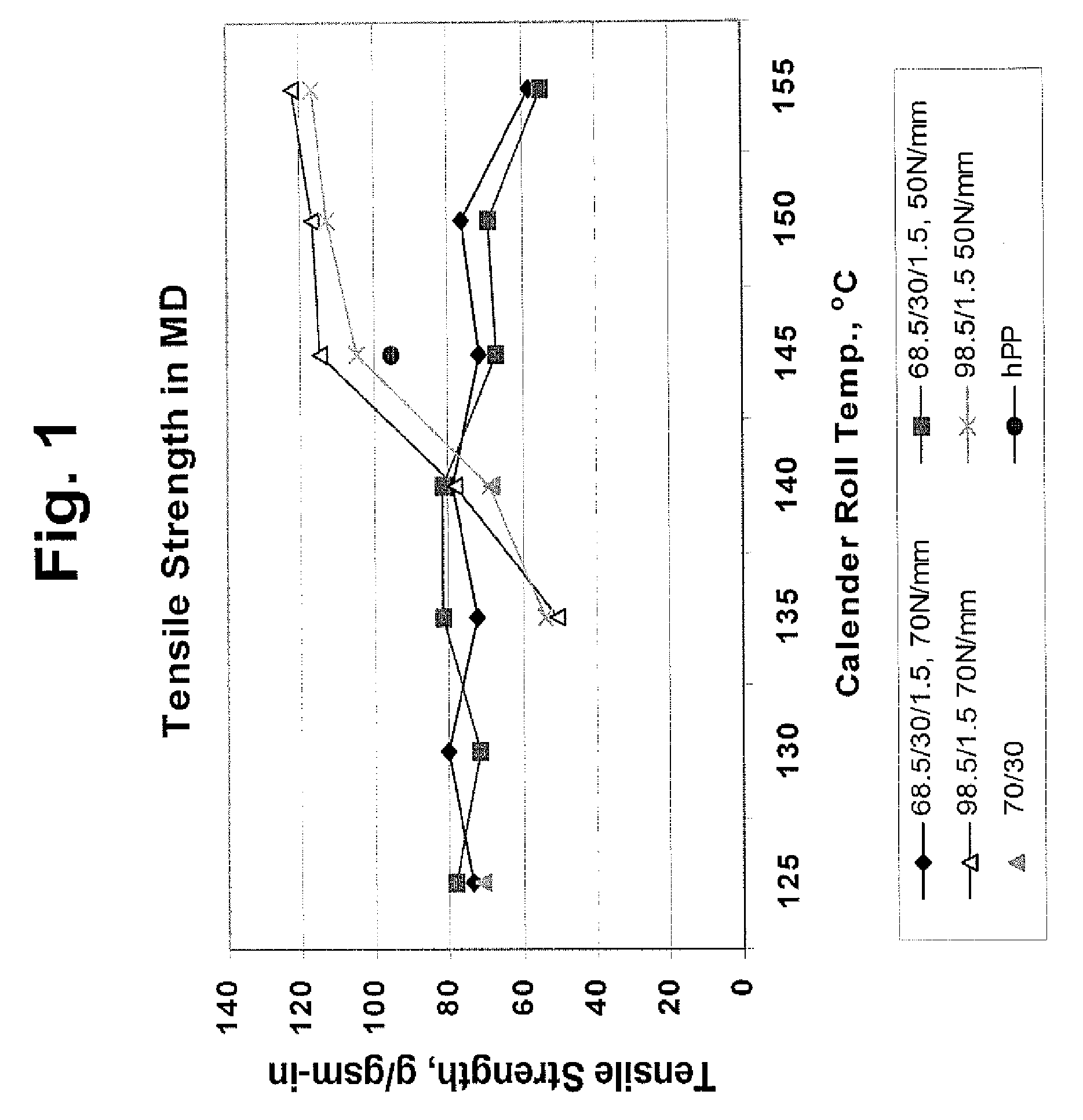

Soft and extensible polypropylene based spunbond nonwovens

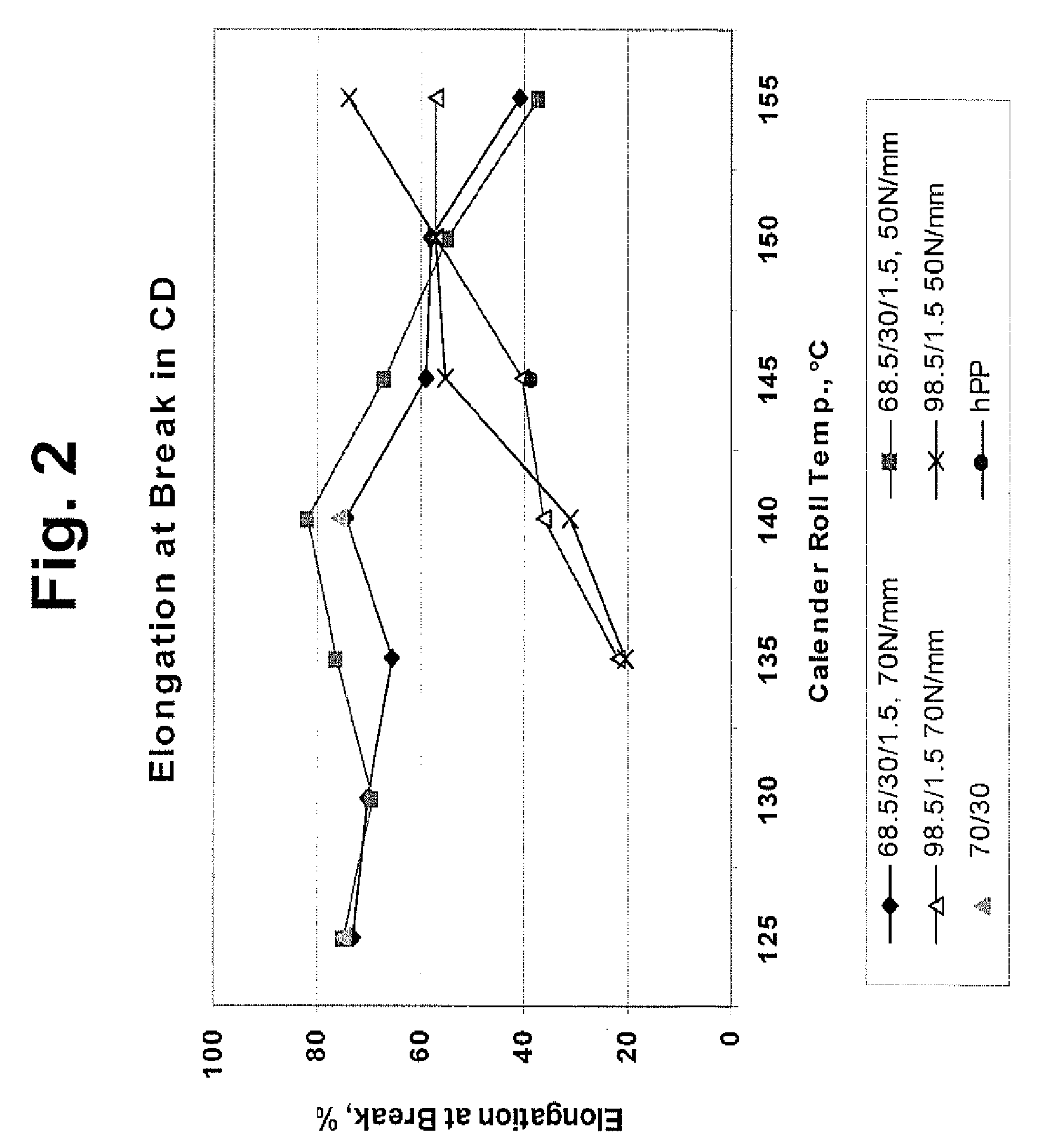

InactiveUS20090111347A1Excellent abrasion resistanceIncrease softnessSynthetic resin layered productsWoven fabricsPolypropyleneWeight distribution

The present invention relates to nonwoven webs or fabrics. In particular, the present invention relates to nonwoven webs having superior abrasion resistance and excellent softness characteristics. The nonwoven materials comprise fibers made from of a polymer blend of isotactic polypropylene and reactor grade propylene based elastomers or plastomers together with from about 100 to about 2500 ppm (by weight of the fiber) of a slip agent. The isotactic polypropylene can be homopolymer polypropylene, and / or random copolymers of propylene and one or more alpha-olefins. The reactor grade propylene based elastomers or plastomers have a molecular weight distribution of less than about 3.5, and a heat of fusion less than about 90 joules / gm. In particular, the reactor grade propylene based elastomers or plastomers contains from about 3 to about 15 percent by weight of units derived from an ethylene and a melt flow rate of from about 2 to about 200 grams / 10 minutes. Erucamide is the preferred slip additive.

Owner:DOW GLOBAL TECH LLC

Thermal spray material and process for preparing same

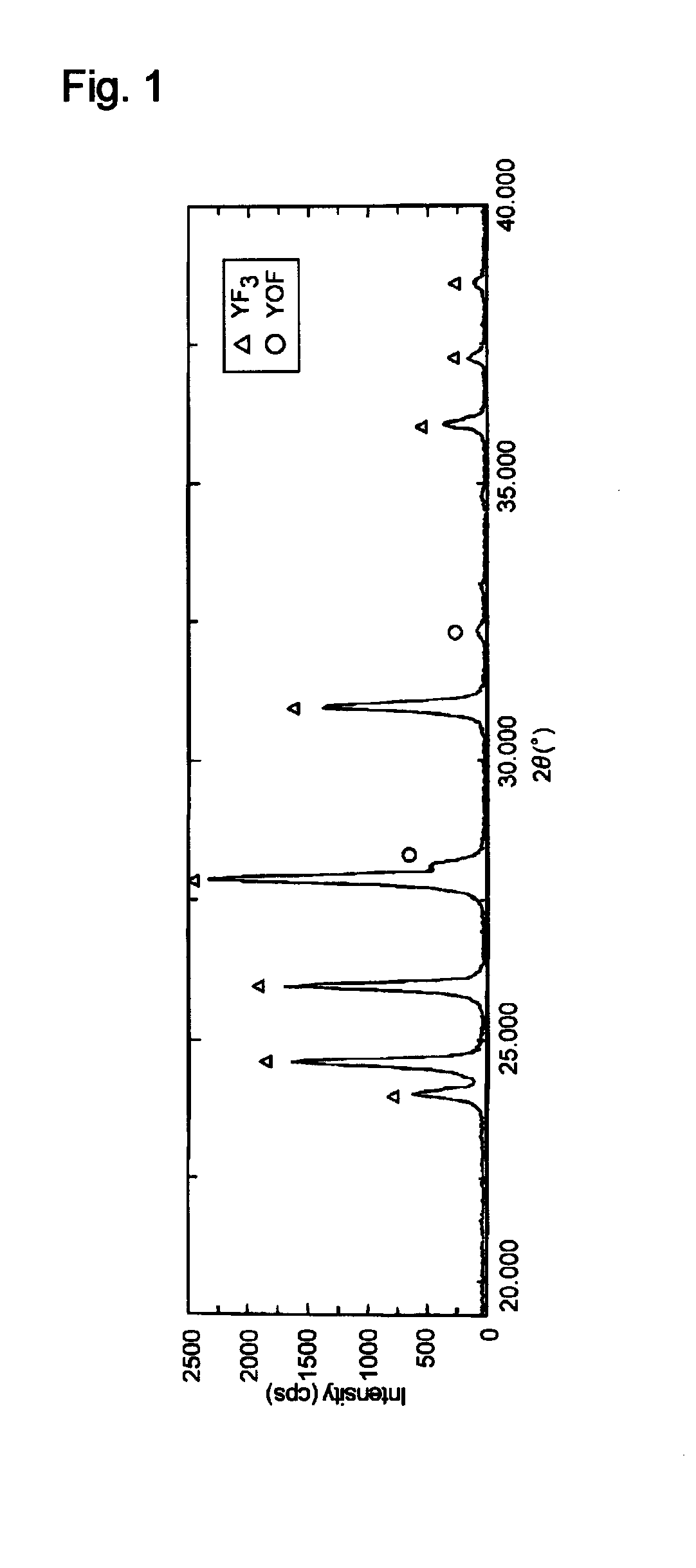

ActiveUS20150096462A1Smooth thermal spray coatingFormed with easeMolten spray coatingRare earth metal compoundsRare-earth elementThermal spraying

A thermal spray material includes granules of an oxyfluoride of yttrium (YOF). The granules may contain a fluoride of yttrium (YF3). The granules preferably have an oxygen content of 0.3 to 13.1 mass %. The granules preferably have a fracture strength of 0.3 MPa or more and less than 10 MPa. Part of yttrium (Y) of the granules may be displaced with at least one rare earth element (Ln) except yttrium, the molar fraction of Ln relative to the sum of Y and Ln being preferably 0.2 or less.

Owner:NIPPON YTTRIUM

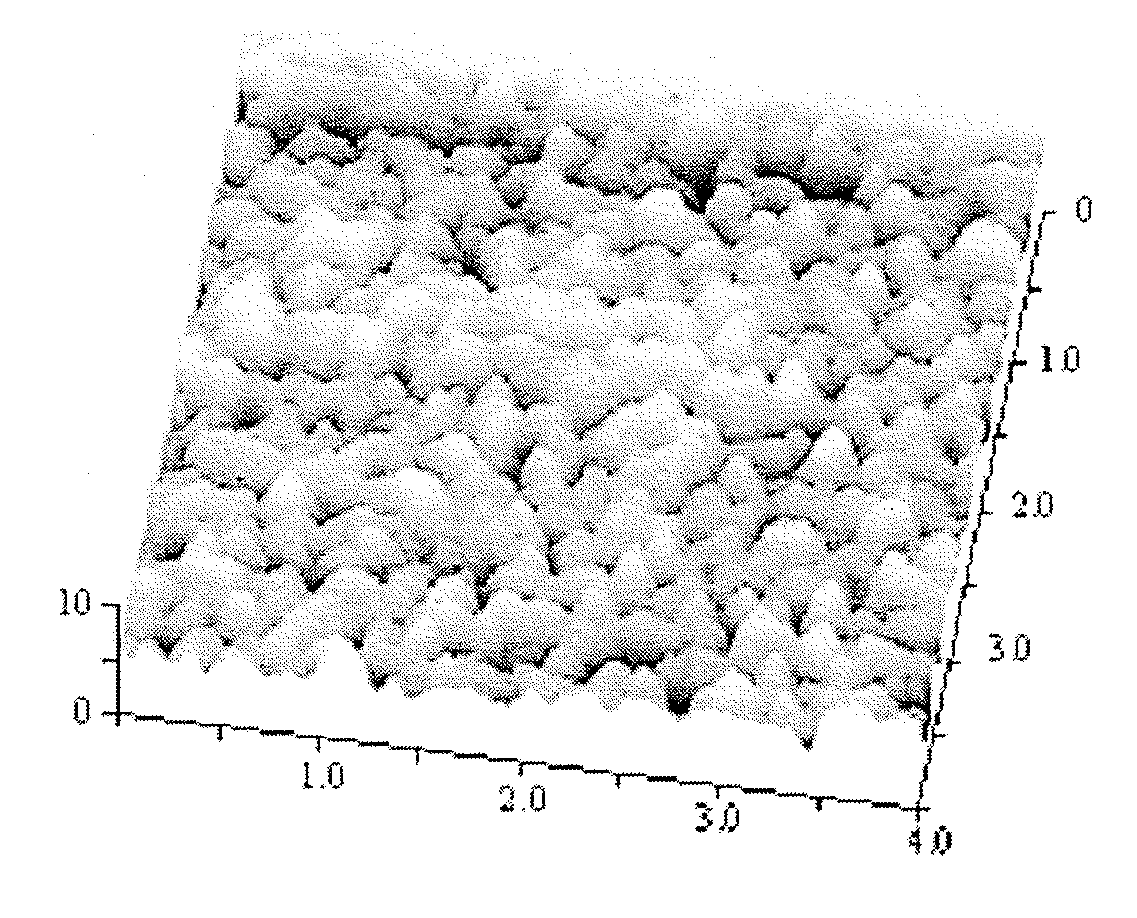

Method For Modifying Surface Of Substrate, Substrate Having Modified Surface, And Method For Producing Same

InactiveUS20080138611A1Excellent abrasion resistanceGood chemical resistanceSilicaSynthetic resin layered productsPolysilazaneOrganic group

A method for modifying the surface of a substrate includes the following steps: (1) a step for forming a polysilazane coating by applying a polysilazane onto the surface of a substrate; (2) a step for applying an organic compound of which main backbone comprises an organic group represented by the following formula [1]: —[(R)mO]n— (wherein R represents an alkylene group, and m and n respectively represent a positive number of not less than 1) onto the surface of the polysilazane coating; and (3) a step for heating the substrate having undergone the steps (1) and (2), thereby converting the polysilazane to silica and bonding the organic compound to the silica of the silica layer.

Owner:UNIVERSITY OF TOKUSHIMA

High-hardness hypereutectic high chromium, manganese, molybdenum and tungsten alloy wear resistant steel material and use thereof

The invention discloses a high-hardness hypereutectic high Cr-Mn-Mo-tungsten alloy abrasion-resistant steel and iron material which adopts multivariant alloying and has the advantages of good hardenability, high hardness, better abrasion-resistance and wear resistance, and the like compared with the prior high-chromium cast iron especially the addition of C, Cr, Mn, Mo and tungsten, thereby enlarging the application range of materials. The invention is suitable for preparing wearing and corrosive wearing parts, in particular to parts used for impacting corrosive wearing working conditions.

Owner:JINAN UNIVERSITY

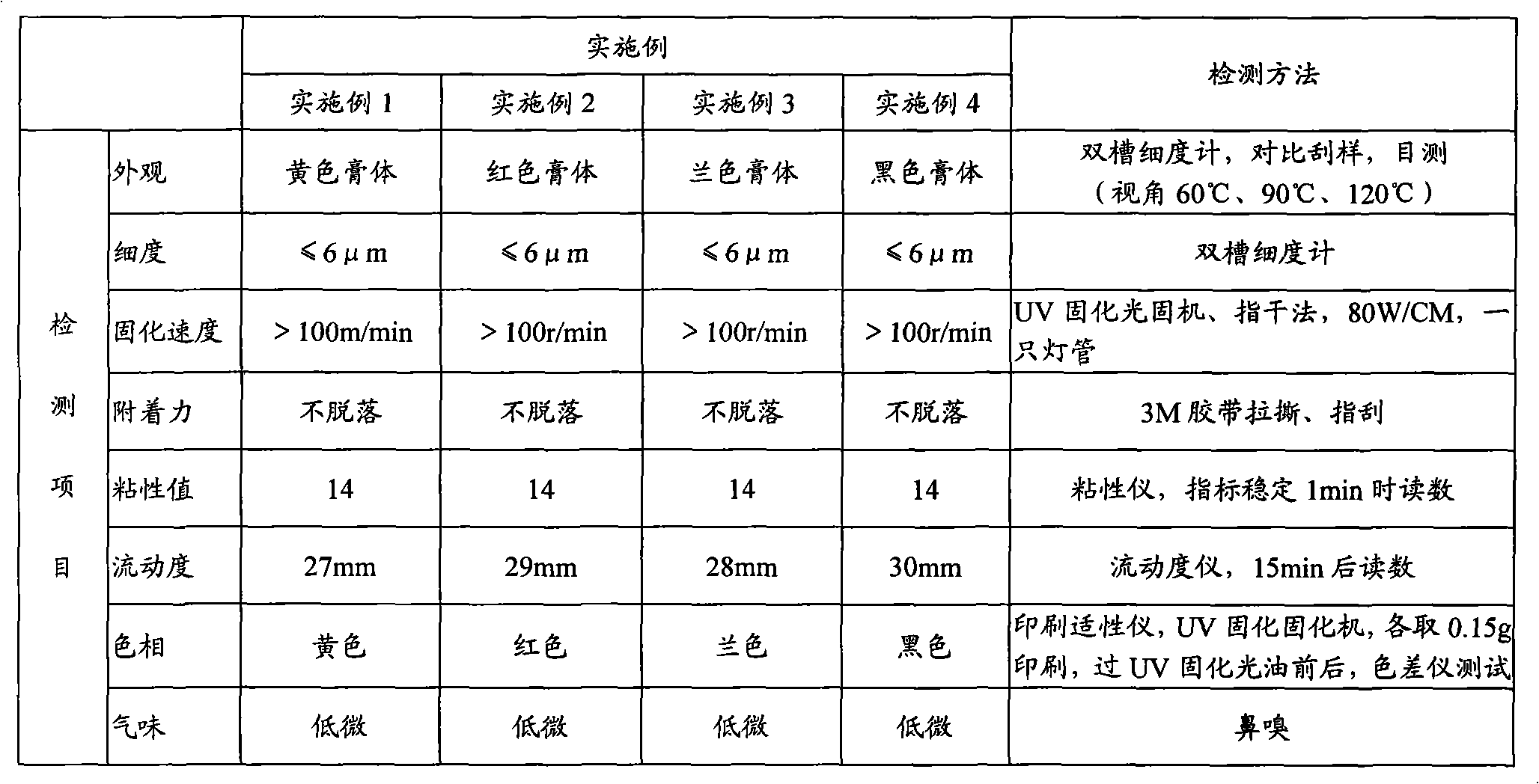

UV curing offset printing ink and use

The invention relates to UV cured lithographic ink and purposes thereof. The ink is a compound which comprises the following components by the weight percent: 30 to 50 of polyester acrylic ester, 0 to 15 of epoxy acrylic ester, 2 to 22 of high-viscosity monofunctional polyurethane acrylic ester, 0 to 10 of acrylic monomer, 10 to 15 of photoinitiator, 2 to 5 of filler and 16 to 22 of pigment. The UV curing glue printing ink of the invention can be cured at high speed, can meet the requirements of high-speed packaging, printing and environment protection, does not contain VOC, has little irritation to the human skin, and can be used as lithographic ink for the high-speed printing, and paper and plastic printing of packaging and printing.

Owner:深圳市美丽华科技股份有限公司

Polarization plate, liquid crystal display device and protective film

ActiveUS20090257003A1Sufficient visibilityExcellent abrasion resistanceAdhesive processesMirrorsTectorial membraneVisibility

Provided are a polarization plate which has a high mechanical strength, which does not impair a visibility even under a high temperature and high humidity, which is excellent in flexibility and abrasion resistance, and which reduces a visible disturbance such as color unevenness due to a size change, as well as a liquid crystal display device using the polarization plate. A film composed of a plurality of layers composed mainly of thermoplastic resins is used as a first protection film used for a visible side of the polarization plate, and at least one surface layer of this first protection film is composed mainly of an acrylic resin. Furthermore, a second protection film having a specific property is disposed at a side of a liquid crystal cell.

Owner:ZEON CORP

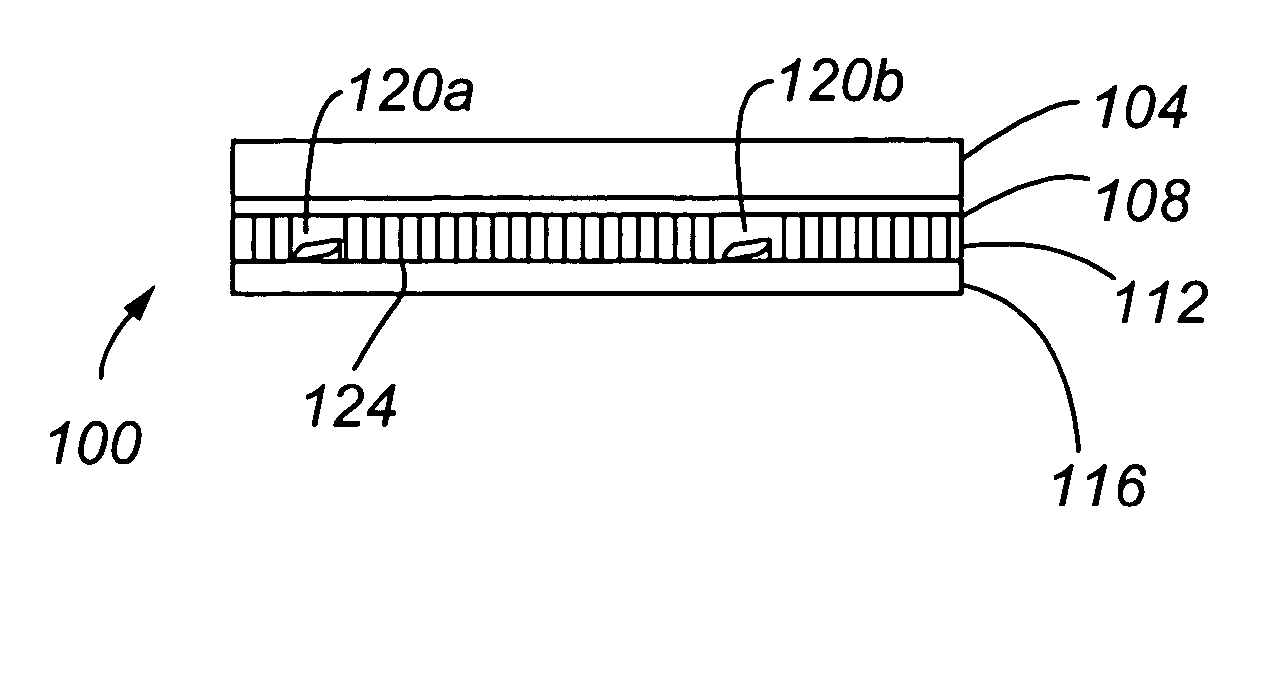

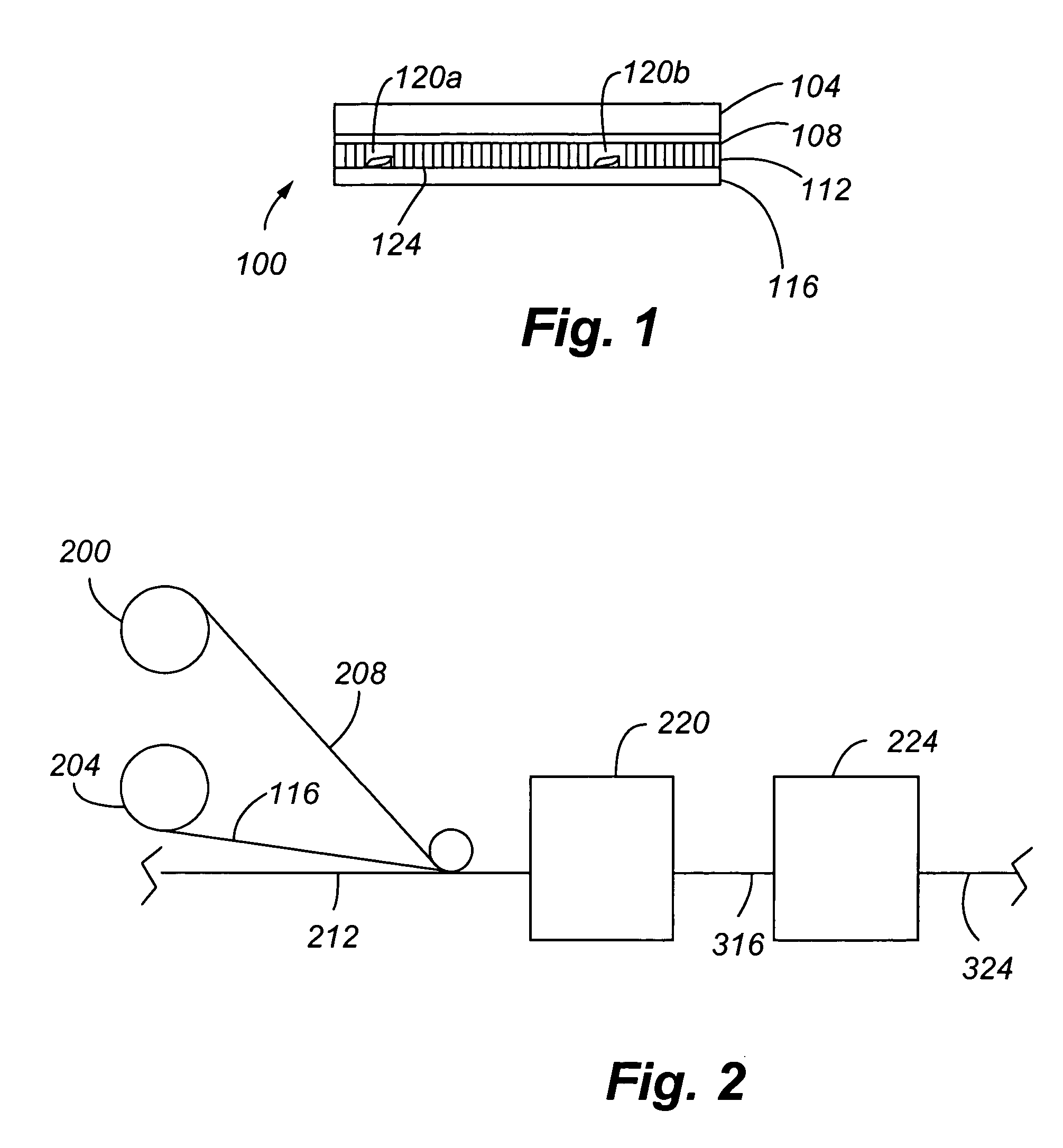

Polyurethane in intimate contact with fibrous material

InactiveUS7267288B2Excellent abrasion resistanceImprove adhesionRecord information storageLight beam reproducingFiberPolymer science

A sprayable polymeric material and a process for preparing the material which contains a fibrous material, dispersed throughout the polymeric material. A restriction free spray nozzle is provided for mixing and spraying the polymeric material having a fibrous material, the nozzle having a restriction free check valve. A reinforced structure, and a method of making the structure are provided, the structure having layers of the polymeric material (both film and foam) containing the fibrous material. A flexible liner is provided of a porous geotextile fabric and a polyurethane composition comprising the fibrous material sprayed over the geotextile fabric.

Owner:NEVADA SUPPLY CORP

Silica containing rubber composition

InactiveUS20050209370A1Enhanced snow/ice tractionReduce rolling resistanceSpecial tyresOrganic dyesElastomerHydrocarbon solvents

This invention discloses a method for preparing rubber compositions that exhibit unique combinations of properties that are desirable for tire tread applications for enhanced snow / ice and wet traction, low rolling resistance and increased treadwear performance in comparison with conventional silica compounds. Specifically, a high reactively silane coupling agent, such as a mercaptosilane, is used in combination with a silane coupling typically used for silica tread compounds such as bis(triethoxylsilylpropyl)disulfide to treat silica pellets in a hydrocarbon solvent at elevated temperatures. The treated silica is then blended with solution elastomer cement in a hydrocarbon solvent. The deposited reactive silanes partially react with the elastomer molecules forming a layer of polymer grafted on the silica surfaced. This structure significantly improves the silica retention during the steam stripping operation. Almost 100% (99+%) silica retention has been achieved by this invention. After solvent removal from steam stripping, the treated silica / elastomer mixer is dewatered and dried using conventional equipment such as shaker screens, expellers and expanders to form a well-dispersed silica masterbatch. This technique results in silica compounds with excellent silica dispersion and increased filler-polymer interaction, hence enhanced compound performance such as better physical properties, more desirable dynamic properties (low hysteresis at high temperatures and high hysteresis at low temperatures) and increased abrasion resistance.

Owner:THE GOODYEAR TIRE & RUBBER CO

Process for producing rubber composition for tire tread

InactiveCN101622303AExcellent abrasion resistanceEasy to processSpecial tyresPolymer scienceVulcanization

A process for producing a rubber composition for tire treads which includes: a masterbatch kneading step in which 100 parts by mass of a rubber ingredient (A) comprising at least one of natural rubber and synthetic diene rubbers is kneaded together with 20-150 parts by mass of silica (B), 1-30 parts by mass of a silane coupling agent (C), and a compound (D) accelerating the reaction between the silica and the silane coupling agent; and a final kneading step in which the resultant masterbatch, a vulcanizing agent, and a vulcanization accelerator are kneaded. The rubber composition obtained by the process gives a tire having improved wearing resistance and is improved in processability and productivity in kneading steps and an extrusion step.

Owner:BRIDGESTONE CORP

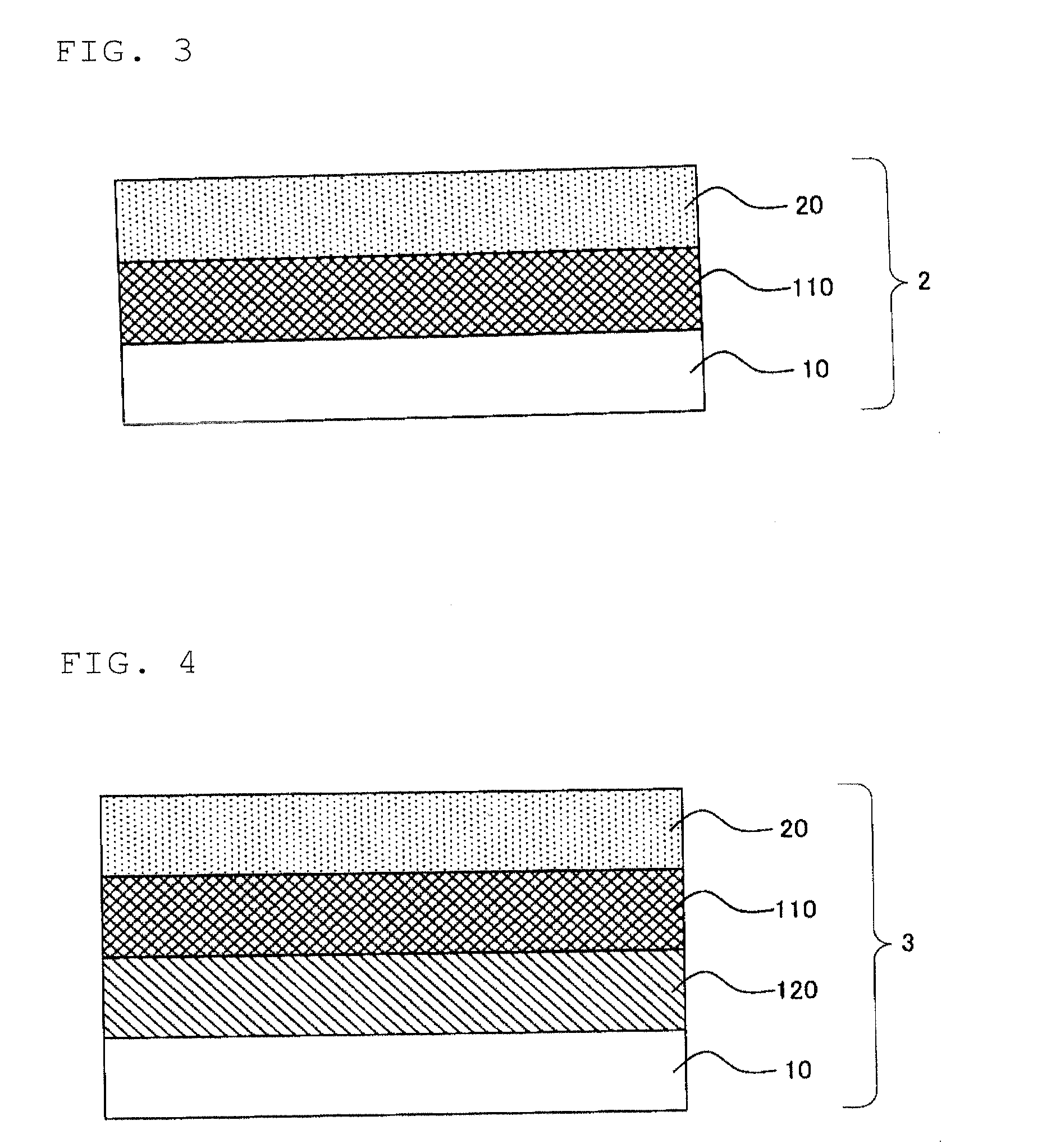

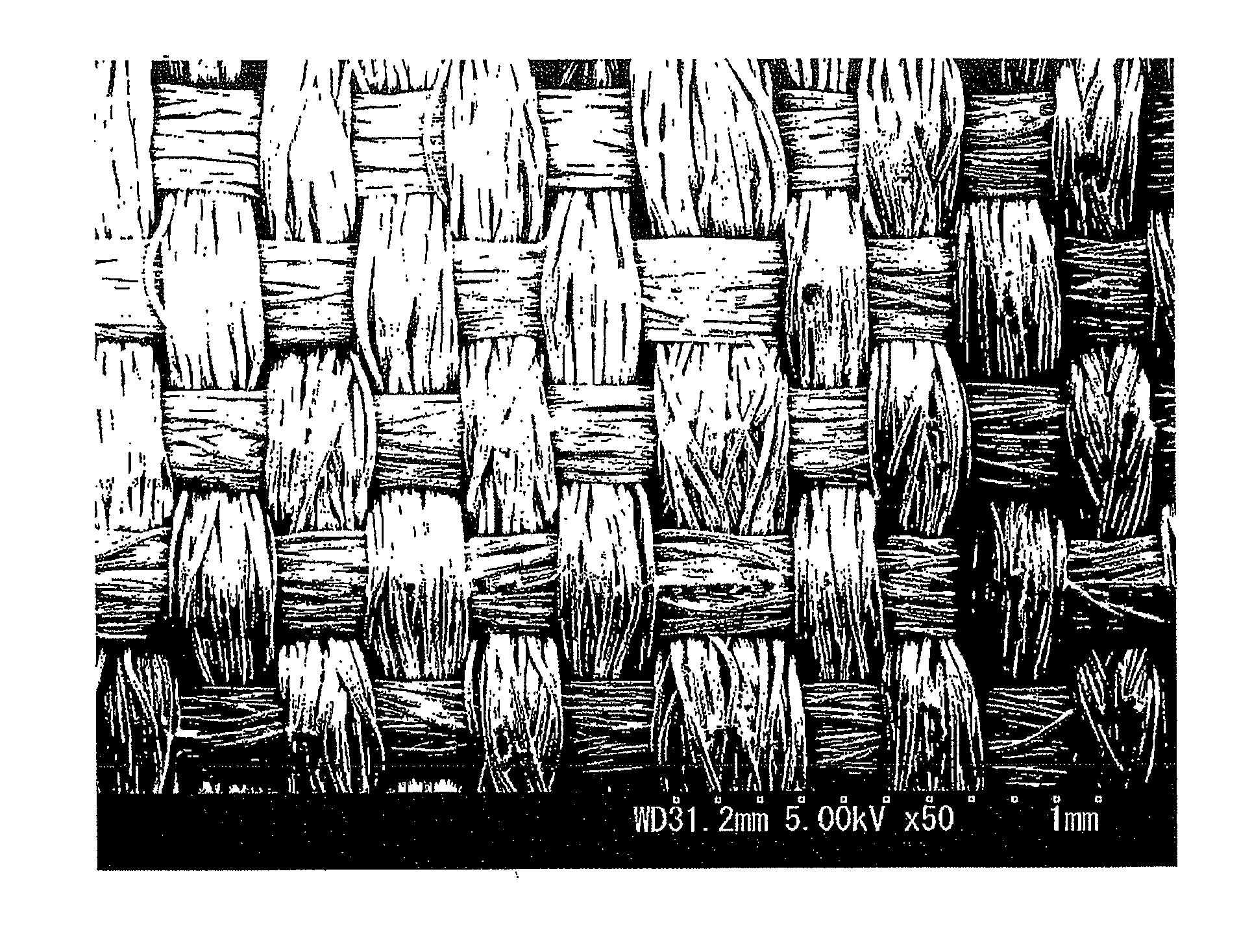

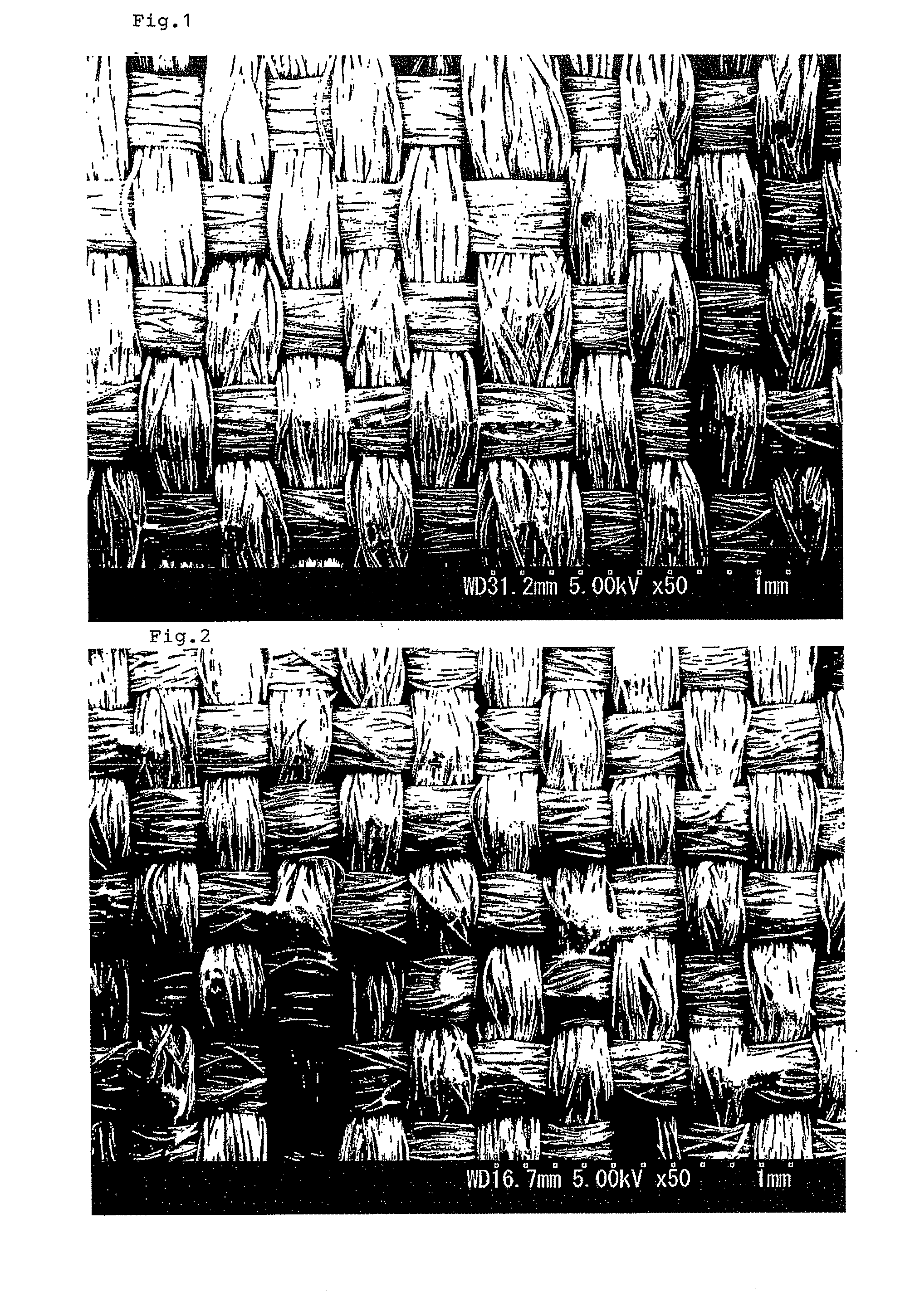

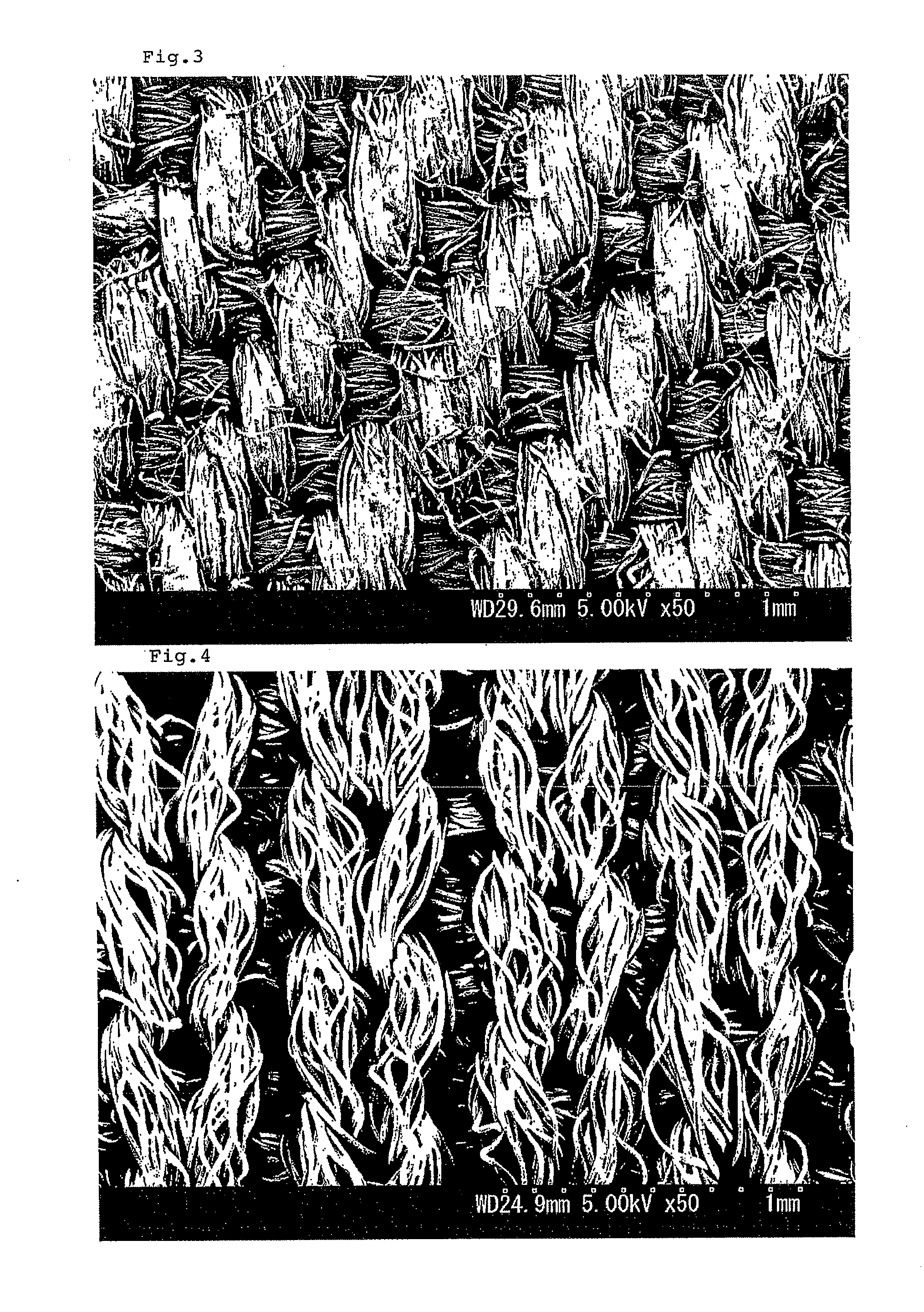

Fabric, Composite Fabric, and Textile Product Excellent in Abrasion Resistance, and Process of Producing the Same

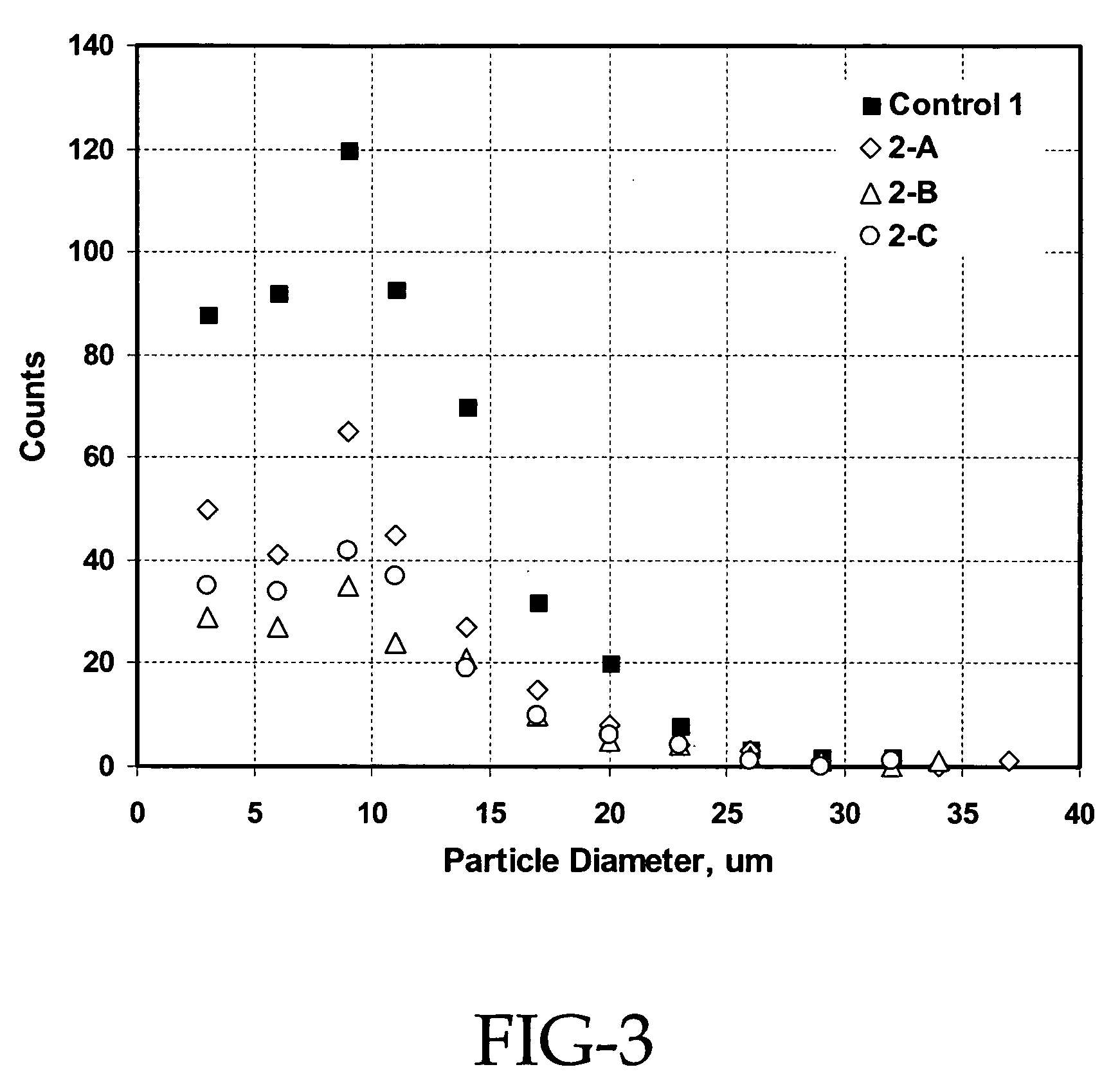

InactiveUS20100071115A1Excellent abrasion resistanceImpairing appearanceFibre typesSynthetic resin layered productsMaximum diameterEngineering

A first objective of the present invention is to provide a technology for improving the abrasion resistance of a fabric or a composite fabric for use in textile products such as clothing products and the like without impairing the appearance thereof, and further, a second objective of the present invention is to provide a technology for achieving both the abrasion resistance and the lightweightness of a fabric or a composite fabric without impairing the appearance and the texture thereof.By coating a surface of a fabric with polymer dots as an abrasion-resistant resin and causing the average maximum diameter of the polymer dots to be equal to or less than 0.5 mm, the abrasion resistance of the fabric can be improved without impairing the appearance of the fabric. Further, by causing the surface-coating amount of the polymer dots to range from 0.2 g / m2 to 3.0 g / m2, both the abrasion resistance and the lightweightness can be achieved.

Owner:JAPAN GORE TEX INC

Non-stick coating composition comprising diamond particles and substrate having the composition applied thereto

ActiveUS20070134488A1Excellent abrasion resistanceImprove wear resistanceCooking-vessel materialsSynthetic resin layered productsMicrometerFluoropolymer

A non-stick coating composition comprising diamond particles of relatively large size, i.e., greater than 1 micrometer, preferably greater than 10 micrometers, and a fluoropolymer, can be applied to a substrate. In addition, a structure comprising a substrate and an undercoat is applied to the substrate, where the undercoat comprises a primer layer comprising a heat resistant non-fluoropolymer polymer binder and diamond particles, and optionally a midcoat also comprising diamond particles.

Owner:THE CHEMOURS CO FC LLC +1

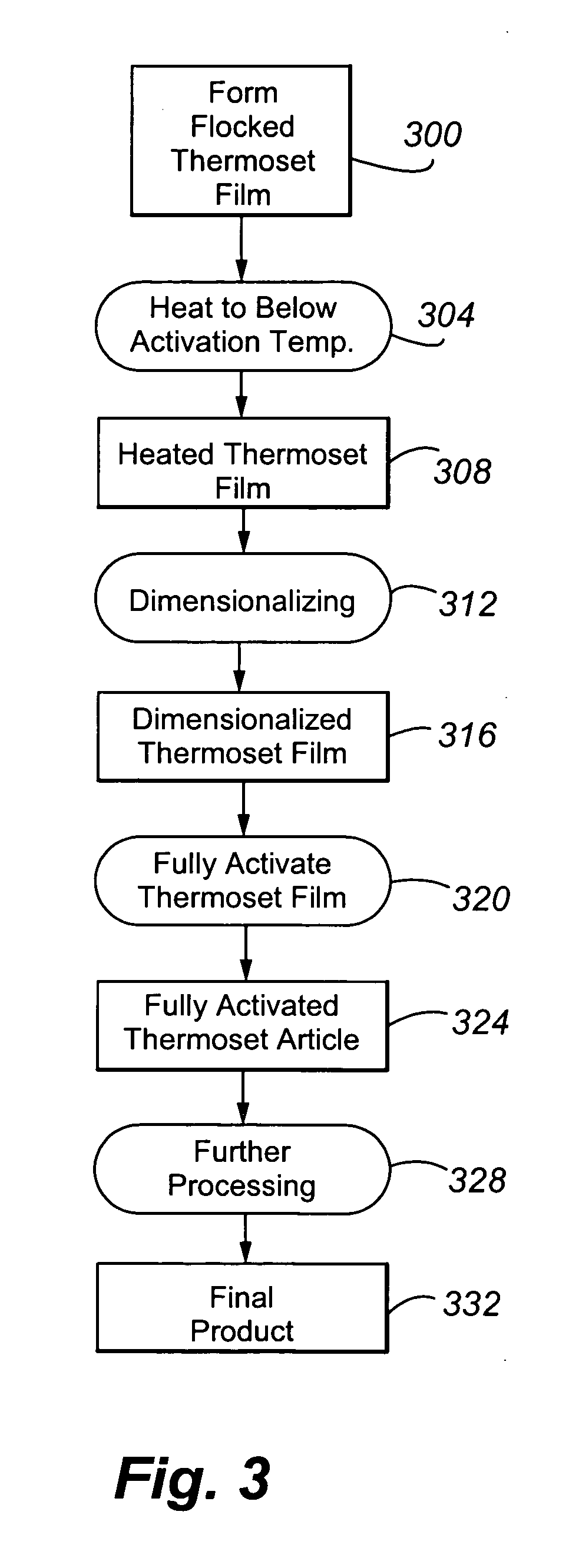

Process for dimensionalizing flocked articles or wear, wash and abrasion resistant flocked articles

InactiveUS20050158508A1Excellent abrasion resistanceImprove wear resistanceLiquid surface applicatorsLamination ancillary operationsFiberPolymer science

In one embodiment, a method for producing a decorative article, comprising: (a) providing a flocked surface, the flocked surface comprising a plurality of flock fibers and an activatable adhesive, wherein the activatable adhesive is less than 50% activated; (b) dimensionalizing the plurality of flock fibers, such that a first set of fibers is embedded to a greater distance in the activatable adhesive than a second set of fibers; and (c) after dimensionalizing, at least substantially fully activating the activatable adhesive to form the decorative article.

Owner:HIGH VOLTAGE GRAPHICS

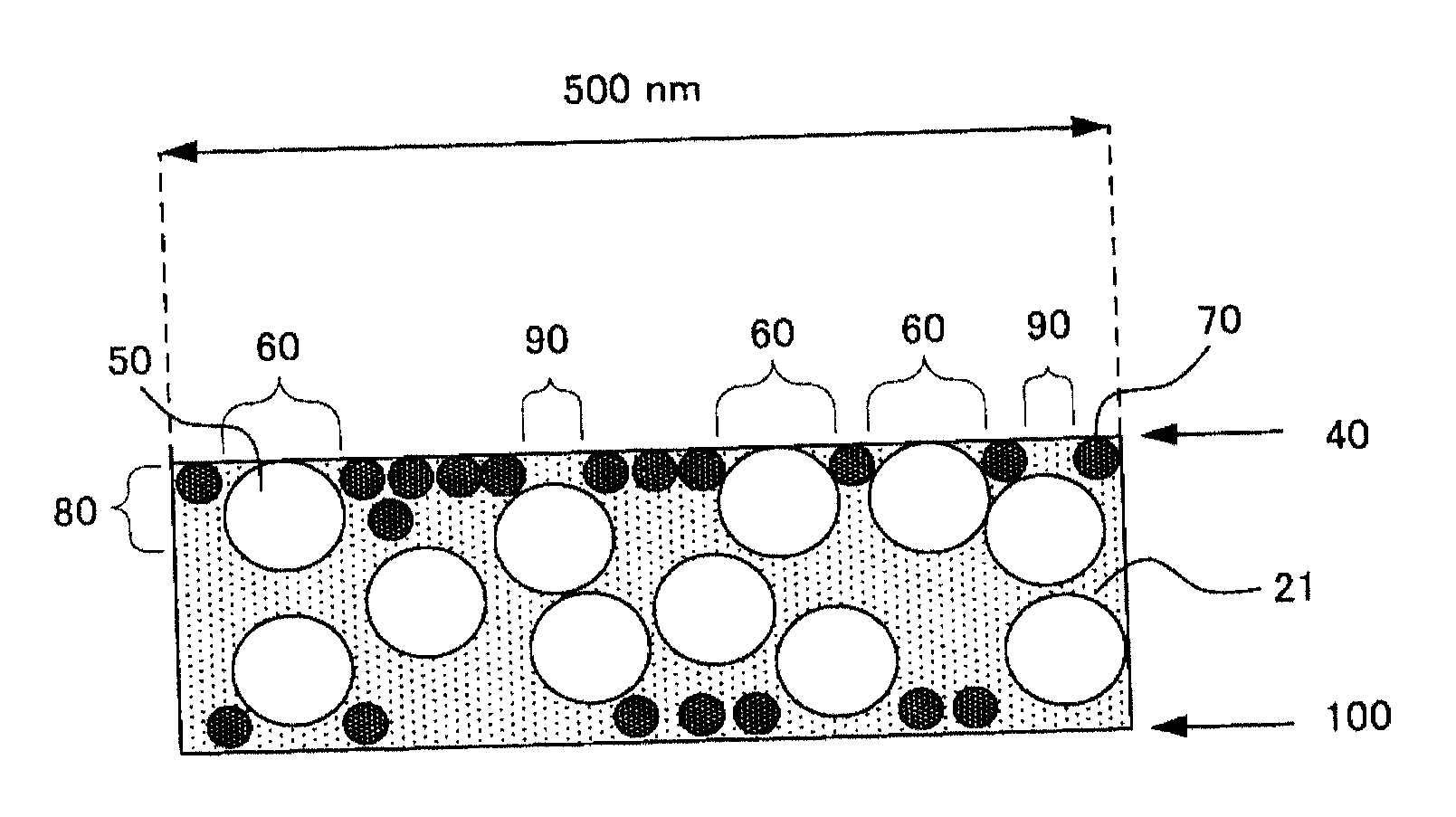

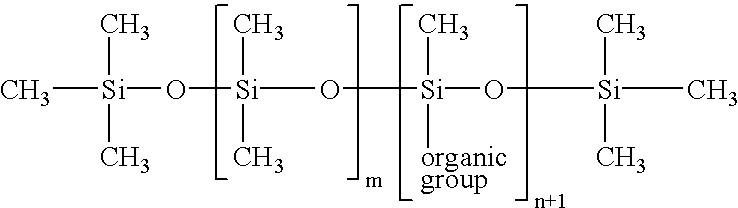

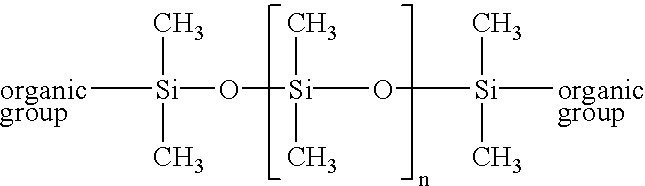

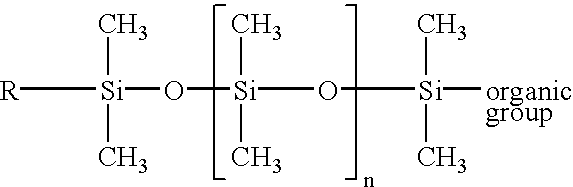

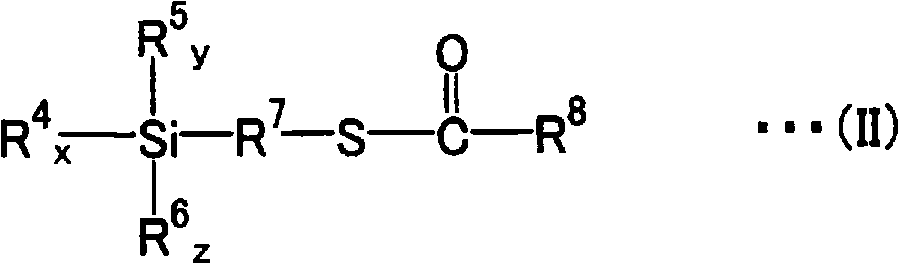

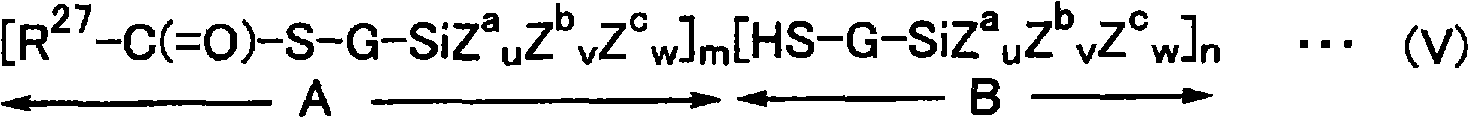

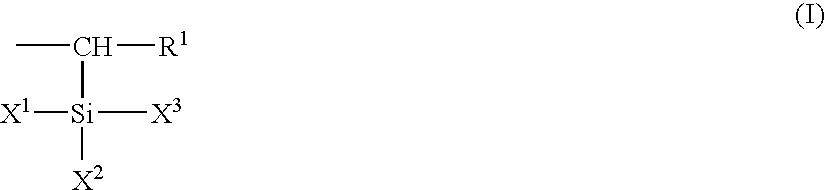

Conjugated diene polymer, conjugated diene polymer composition, and process for producing conjugated diene polymer

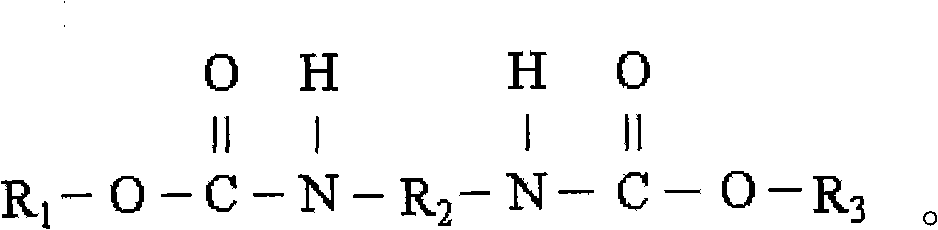

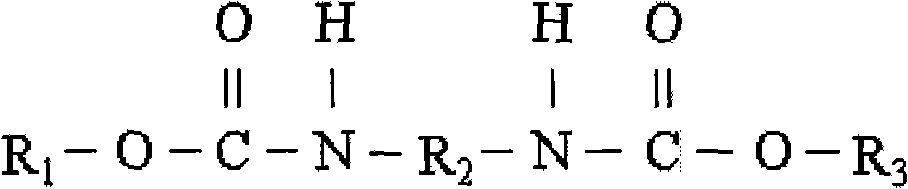

A conjugated diene polymer is provided that includes a conjugated diene-based constituent unit and a group represented by Formula (I) below at both termini of a polymer chain.(In the formula, R1 denotes a hydrogen atom, a hydrocarbyl group having 1 to 20 carbons, or a substituted hydrocarbyl group having 1 to 20 carbons, X1, X2, and X3 independently denote a group represented by Formula (II) below, a hydroxy group, a hydrocarbyl group, or a substituted hydrocarbyl group, and at least one of X1, X2, and X3 is a group represented by Formula (II) below or a hydroxy group.)(In the formula, R2 and R3 independently denote a hydrocarbyl group having 1 to 6 carbons, a substituted hydrocarbyl group having 1 to 6 carbons, a silyl group, or a substituted silyl group, and R2 and R3 may be bonded so as to form, together with the N atom, a ring structure.)There are also provided a conjugated diene polymer composition formed by combining the conjugated diene polymer and a filler, a process for producing the conjugated diene polymer, a process for producing the conjugated diene polymer composition, a vulcanizate, and a process for producing the vulcanizate.

Owner:SUMITOMO CHEM CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com