Patents

Literature

39results about How to "Low hysteresis loss" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

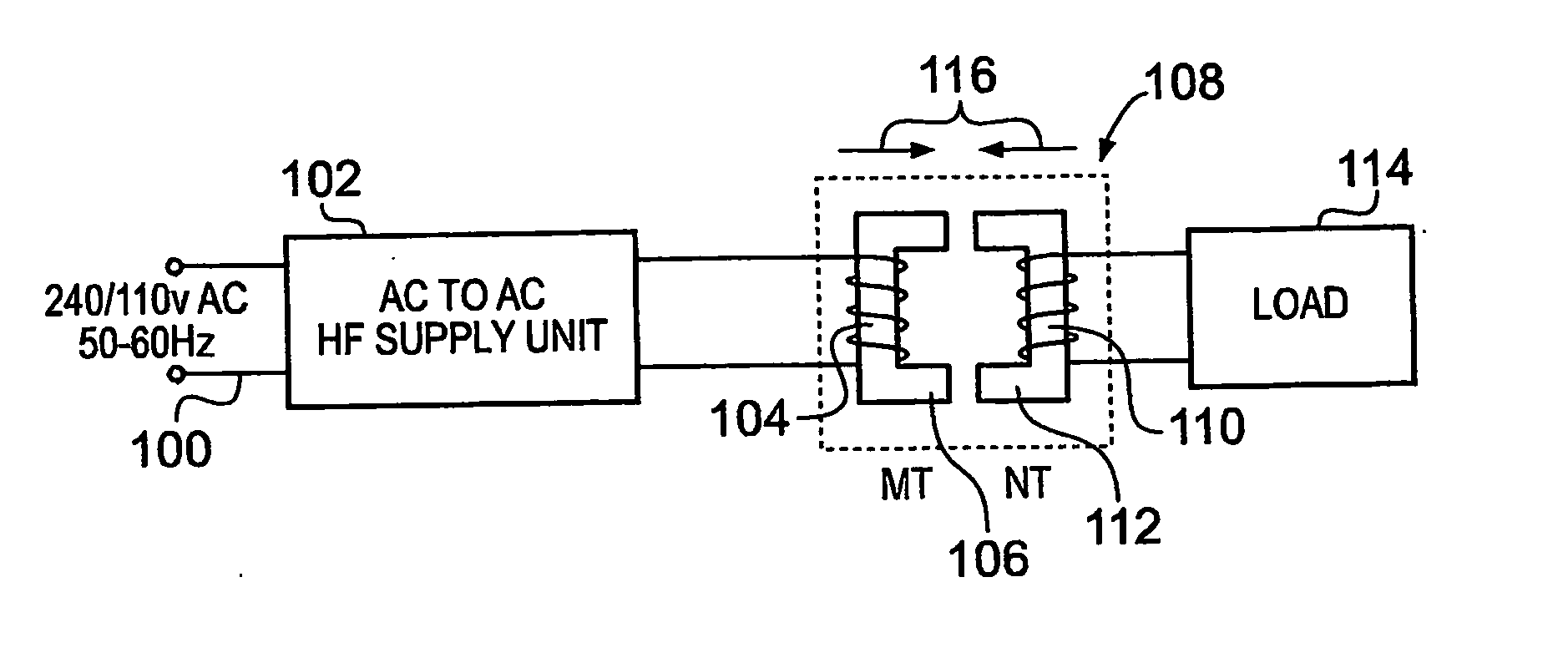

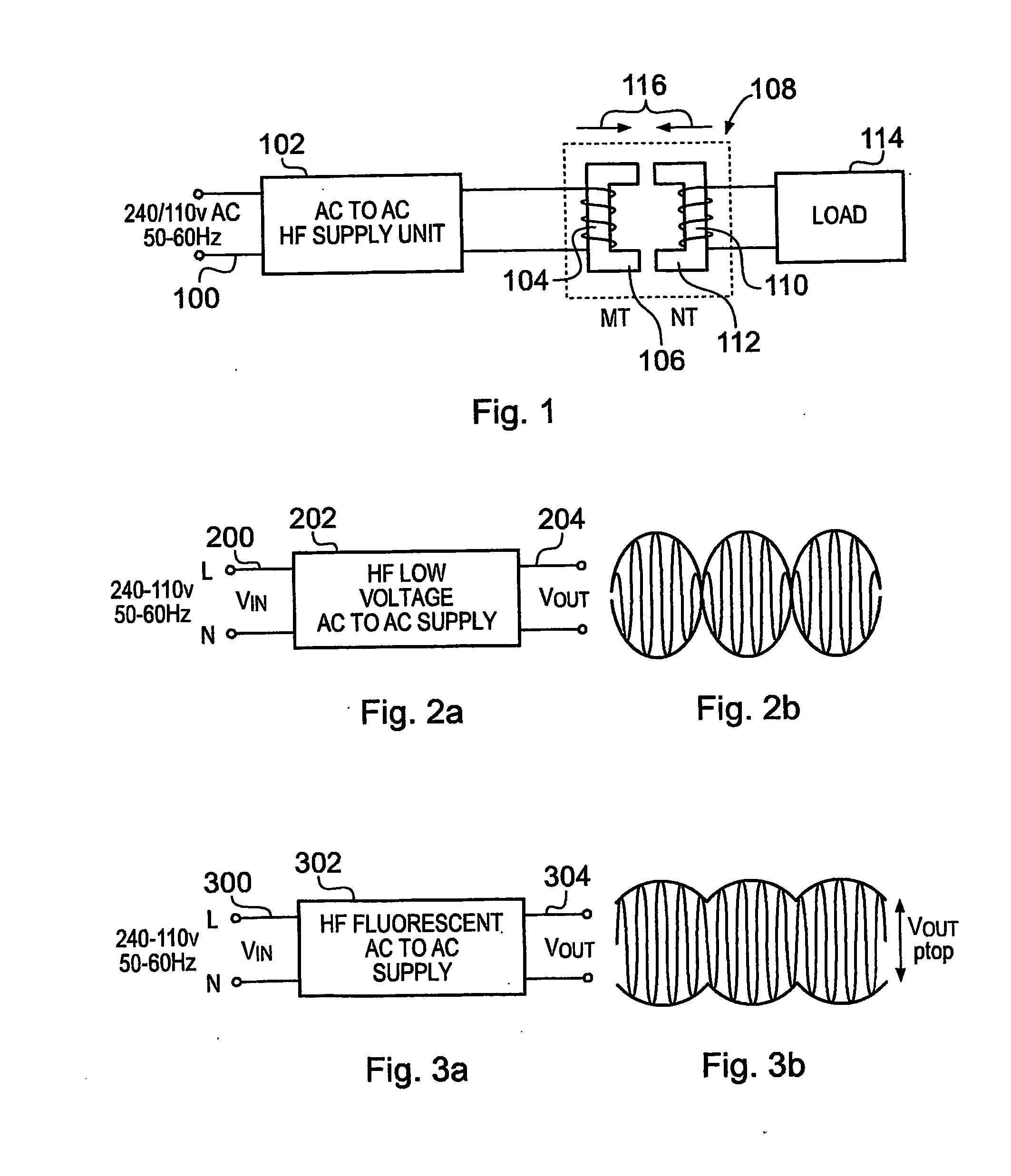

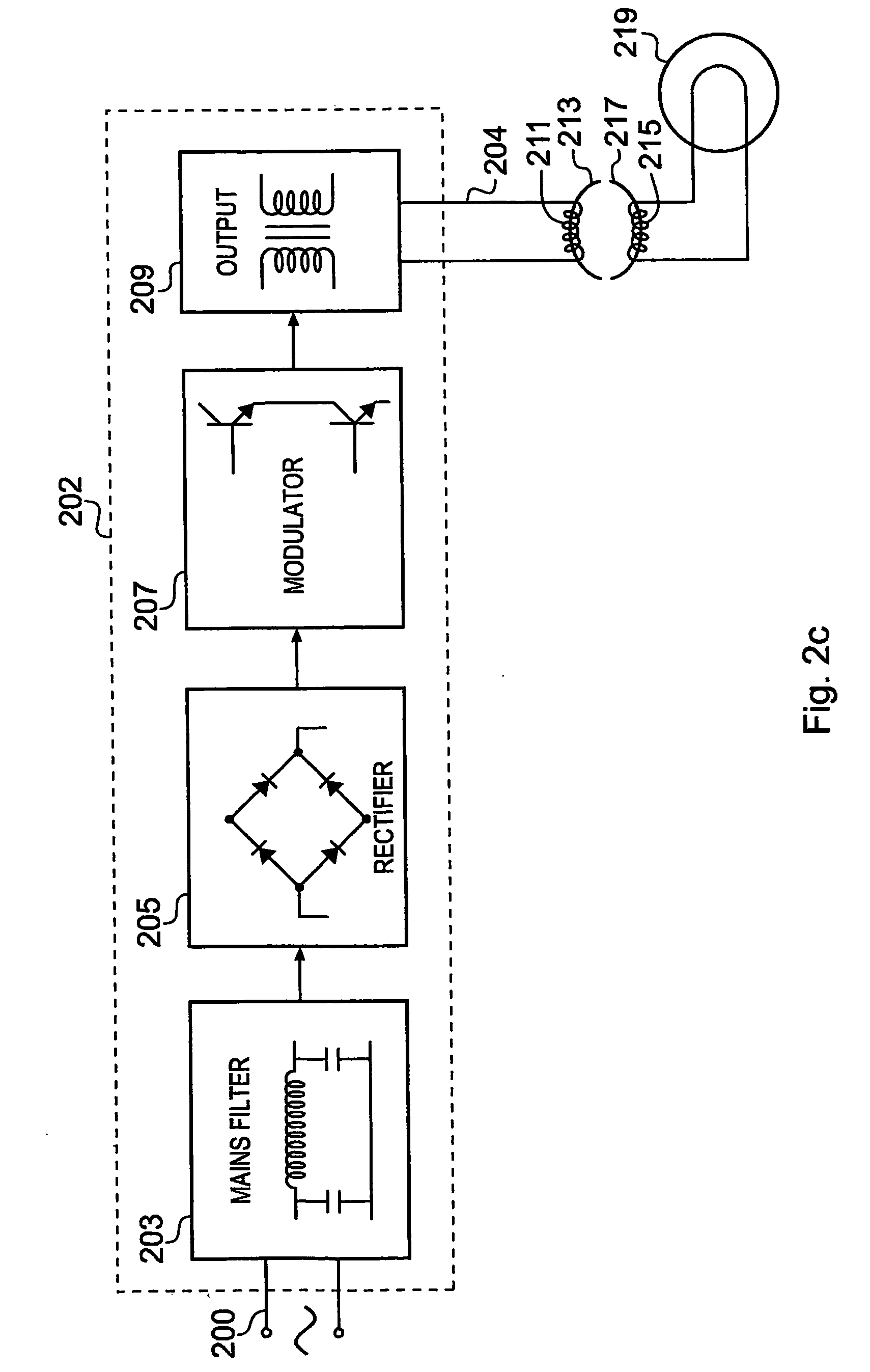

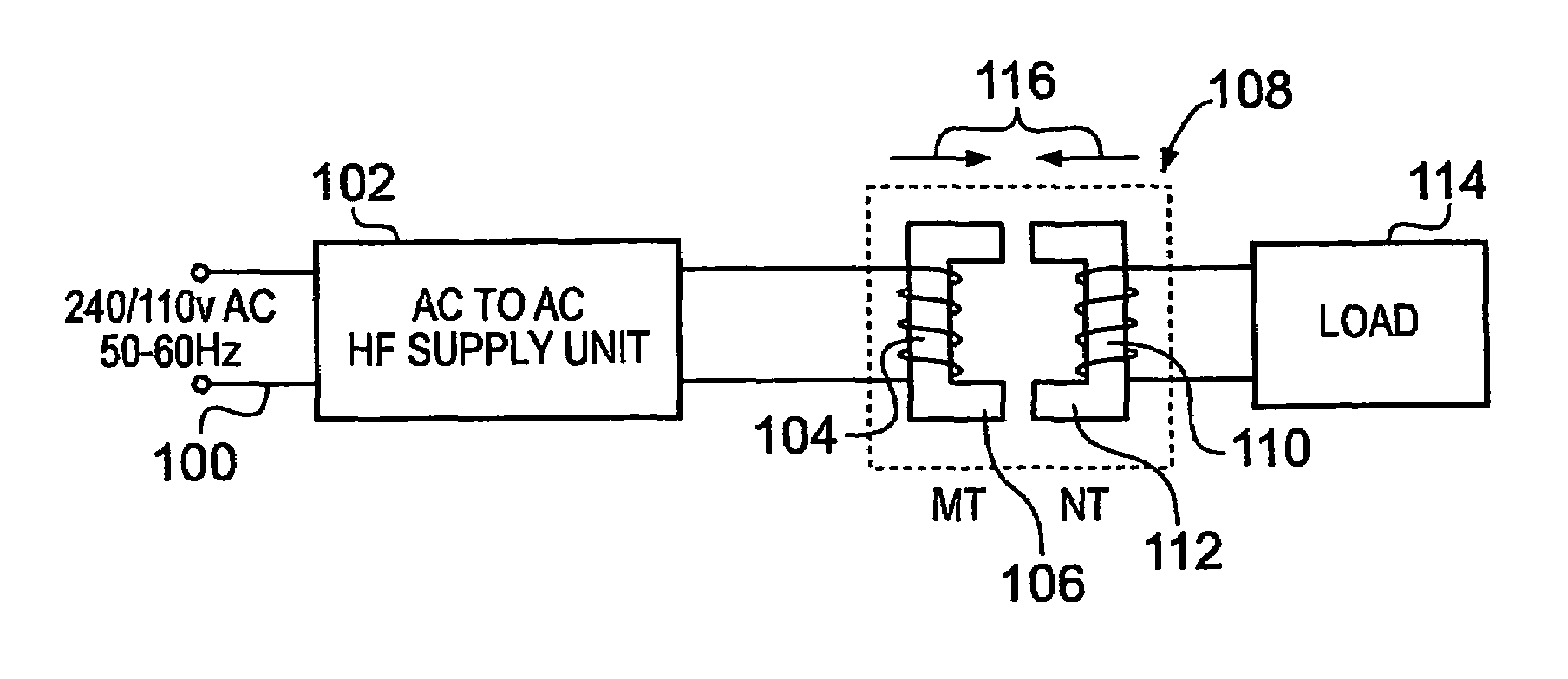

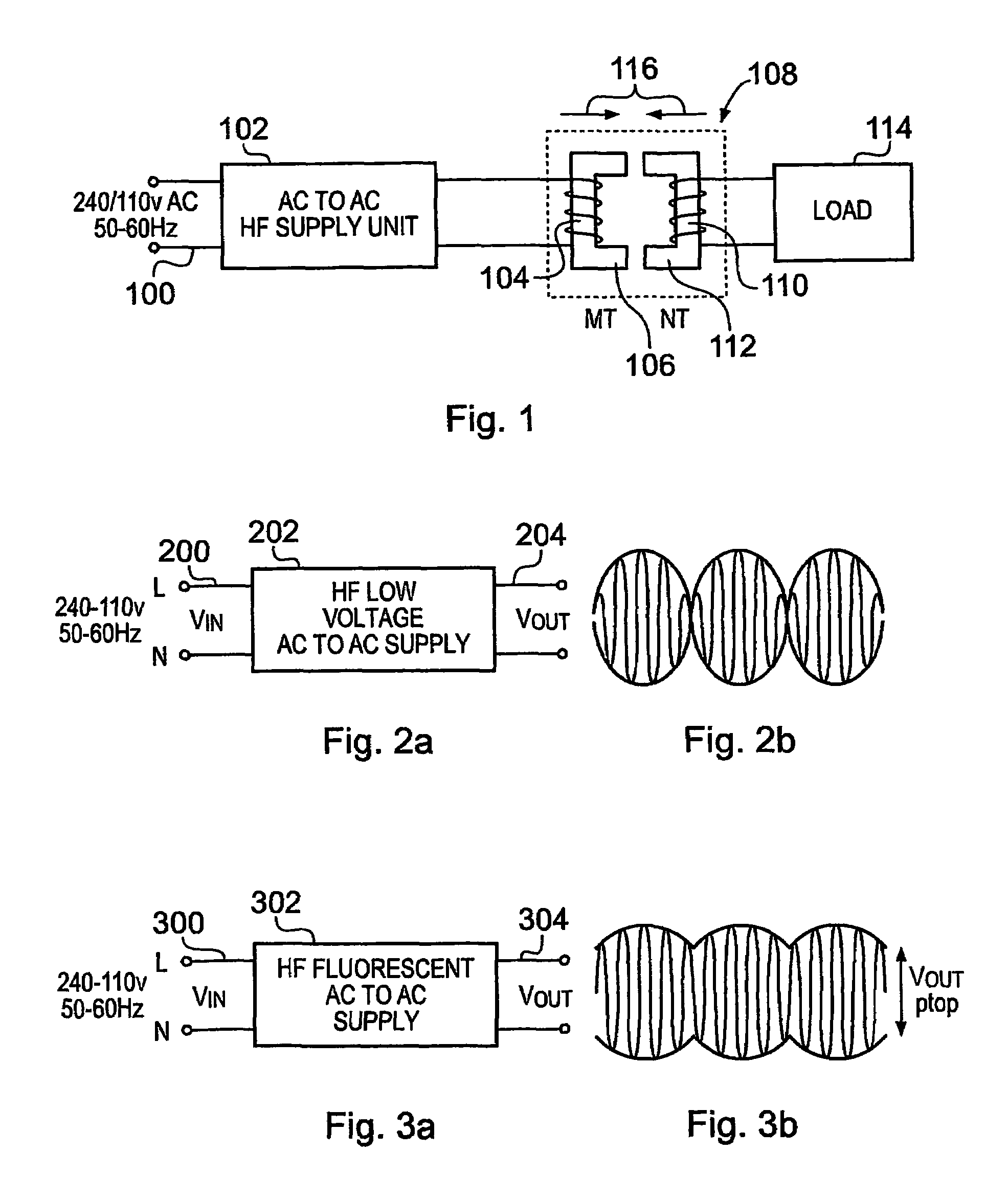

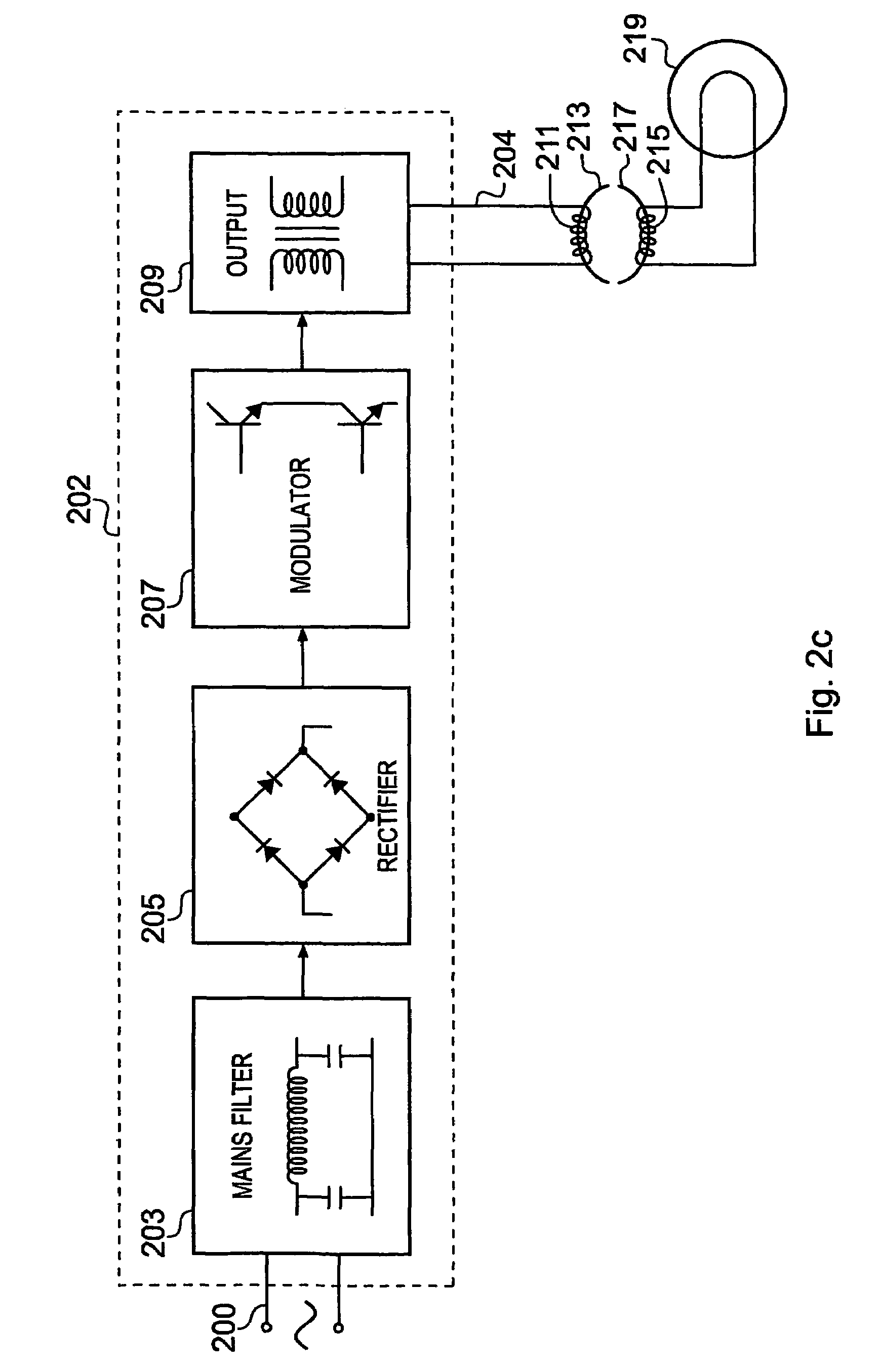

Apparatus for supplying energy to a load and a related system

InactiveUS20070076459A1Avoid eddy currentsImprove system efficiencyPoint-like light sourceConversion with intermediate conversion to dcLow voltageTransformer

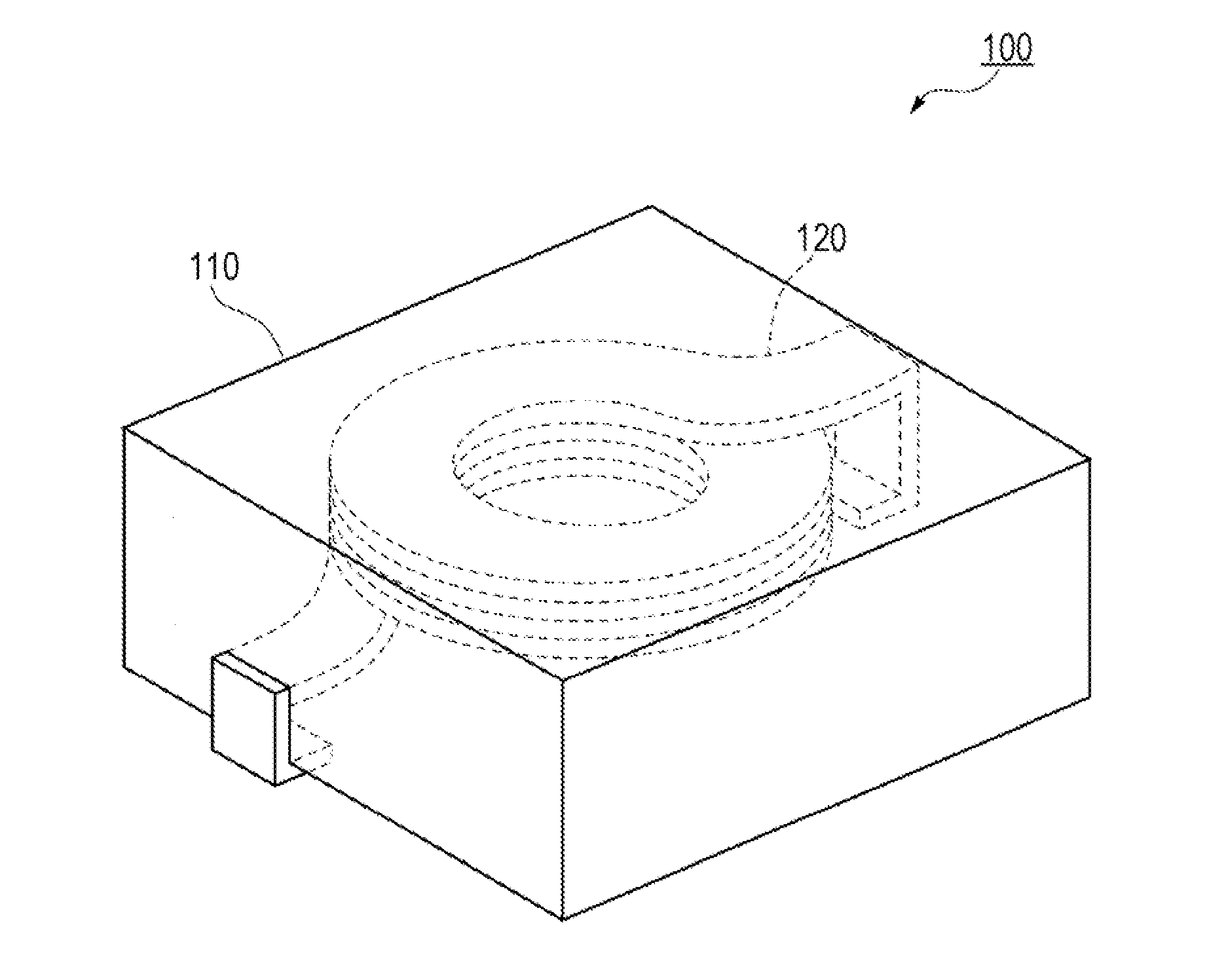

Apparatus for supplying energy to a load, comprises a power supply unit (102) e.g. a switched mode electronic transformer or electronic ballast having an input for receiving current at mains frequency and a means for stepping-up said mains frequency to a higher frequency e.g. 30-50 kHz and an output for delivering energy at the higher frequency. A two part connector (108) has a first core portion (106) that has a primary winding (104) connected to the output of the power supply unit and a mating second core portion (112) that has a secondary winding (110) for delivery of energy to a load (114), the core portions being of a high resistivity material, e.g. a ferrite having a resistivity of at least 104 Ωcm. The apparatus may be used to power e.g. low voltage halogen or other incandescent lighting, fluorescent lighting, or an electric motor, a power supply for a computer, radio, television or like electronic device, a heater or the like.

Owner:LIMPKIN GEORGE A +1

Conjugated diolefin (co)polymer rubber, process for producing (co)polymer rubber, rubber composition, composite, and tire

InactiveCN1578790ALow hysteresis lossLow abrasion resistanceSpecial tyresRolling resistance optimizationHysteresisPolymer science

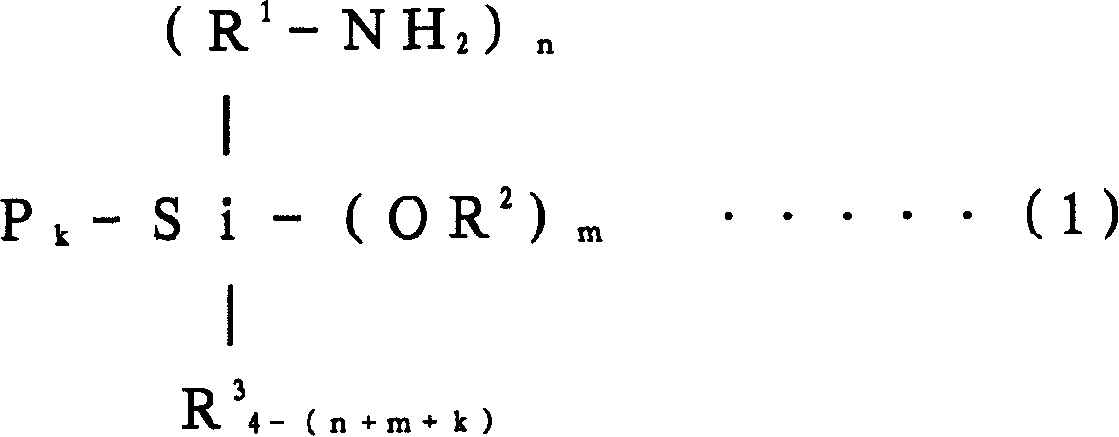

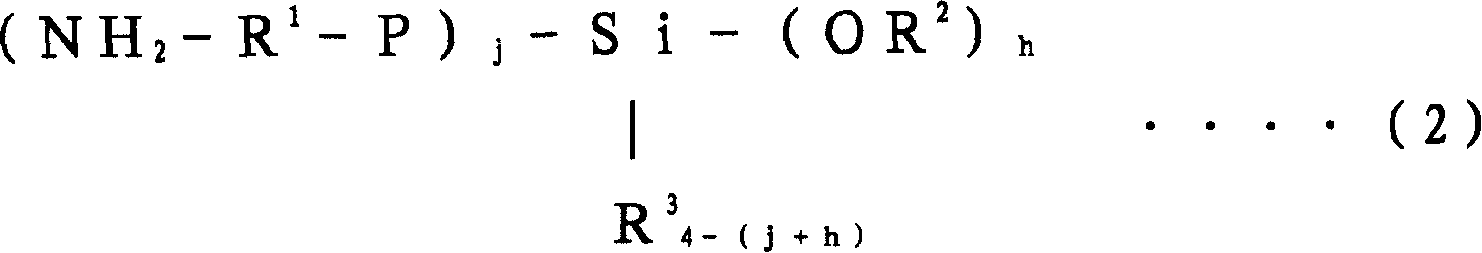

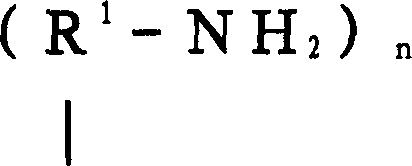

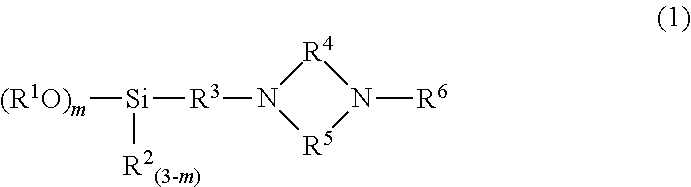

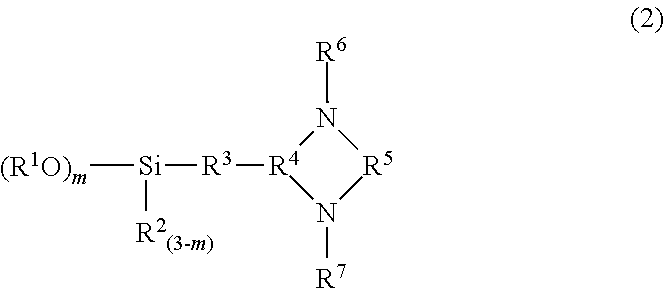

Disclosed are a conjugated diolefin (co)polymer rubber formed from either a conjugated diolefin or a conjugated diolefin and an aromatic vinyl compound, wherein the (co) polymer rubber has a primary amino group and an alkoxysilyl group which are bonded to a (co)polymer chain; a process for producing the same; a rubber composition; a composite; and a tire. The (co) polymer rubber has satisfactory processability, and can give an automotive tire tread having a balance among wear resistance, failure characteristics, low hysteresis loss and wet-skid characteristics.

Owner:JSR CORPORATIOON

Conjugated diolefin (co)polymer rubber, process for producing (co)polymer rubber, rubber composition, composite, and tire

InactiveCN1789293ALow hysteresis lossLow abrasion resistanceSpecial tyresRolling resistance optimizationPolymer scienceAlkoxy group

Disclosed are a conjugated diolefin (co)polymer rubber formed from either a conjugated diolefin or a conjugated diolefin and an aromatic vinyl compound, wherein the (co) polymer rubber has a primary amino group and an alkoxysilyl group which are bonded to a (co)polymer chain; a process for producing the same; a rubber composition; a composite; and a tire. The (co) polymer rubber has satisfactory processability, and can give an automotive tire tread having a balance among wear resistance, failure characteristics, low hysteresis loss and wet-skid characteristics.

Owner:JSR CORPORATIOON

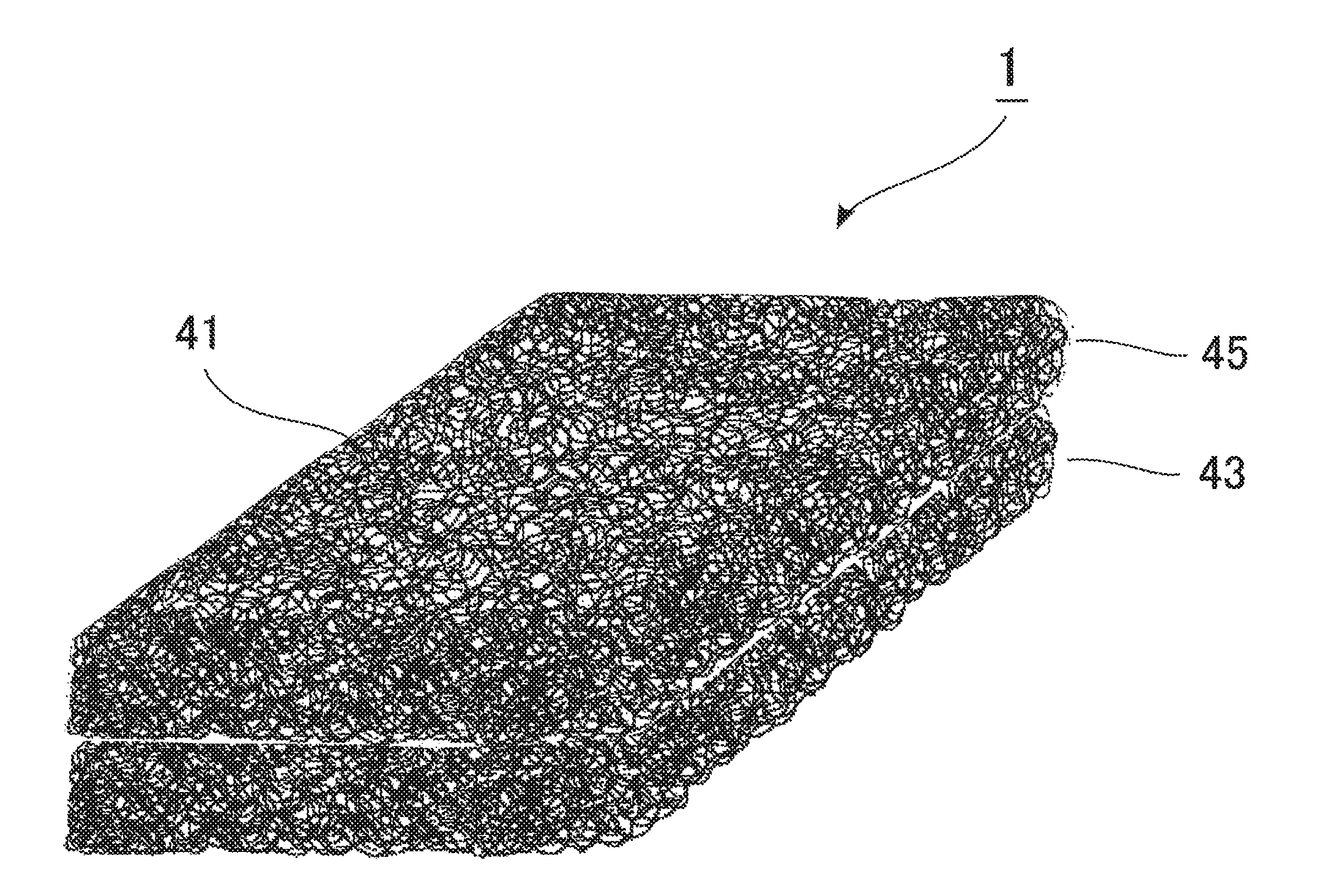

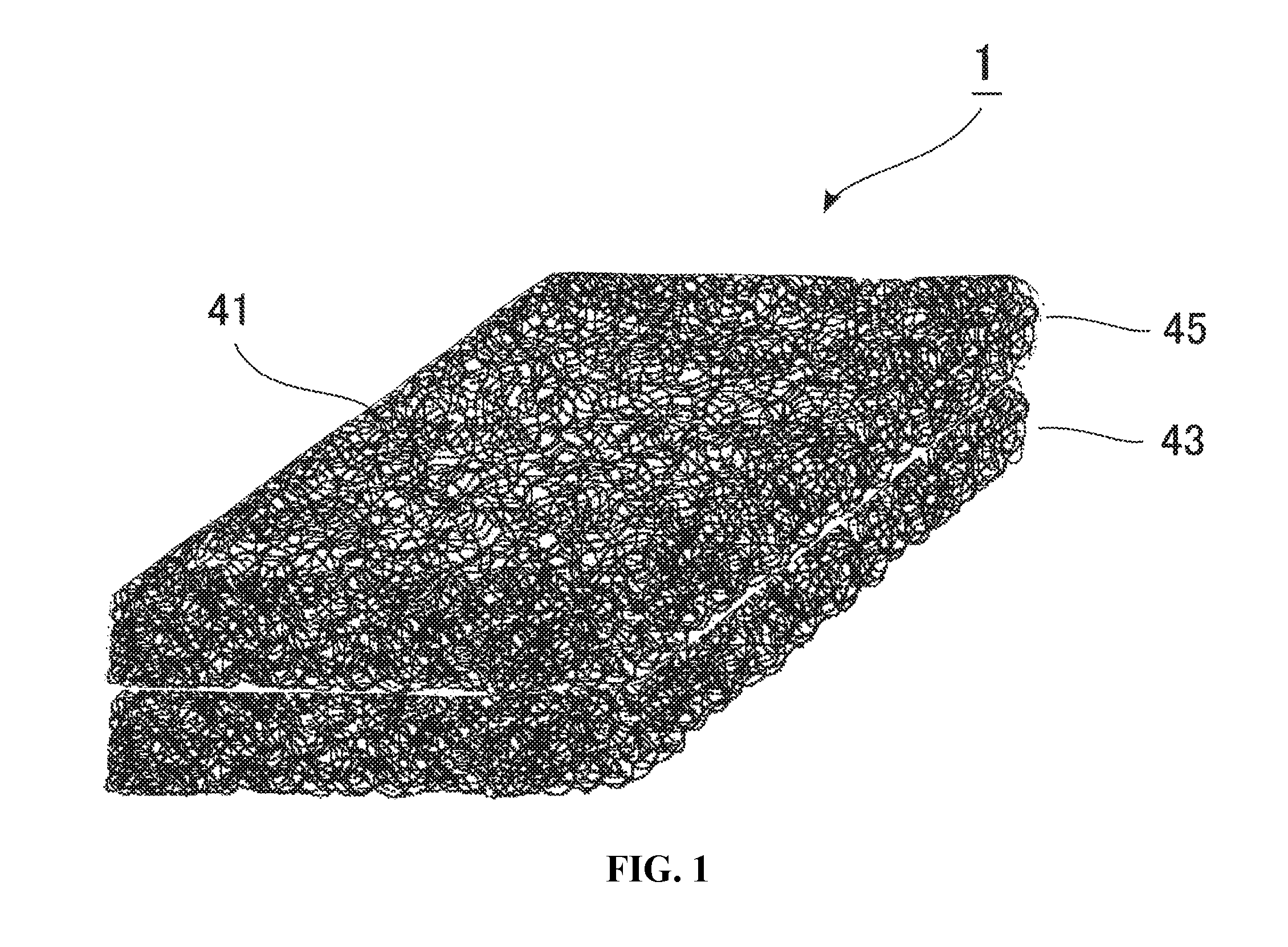

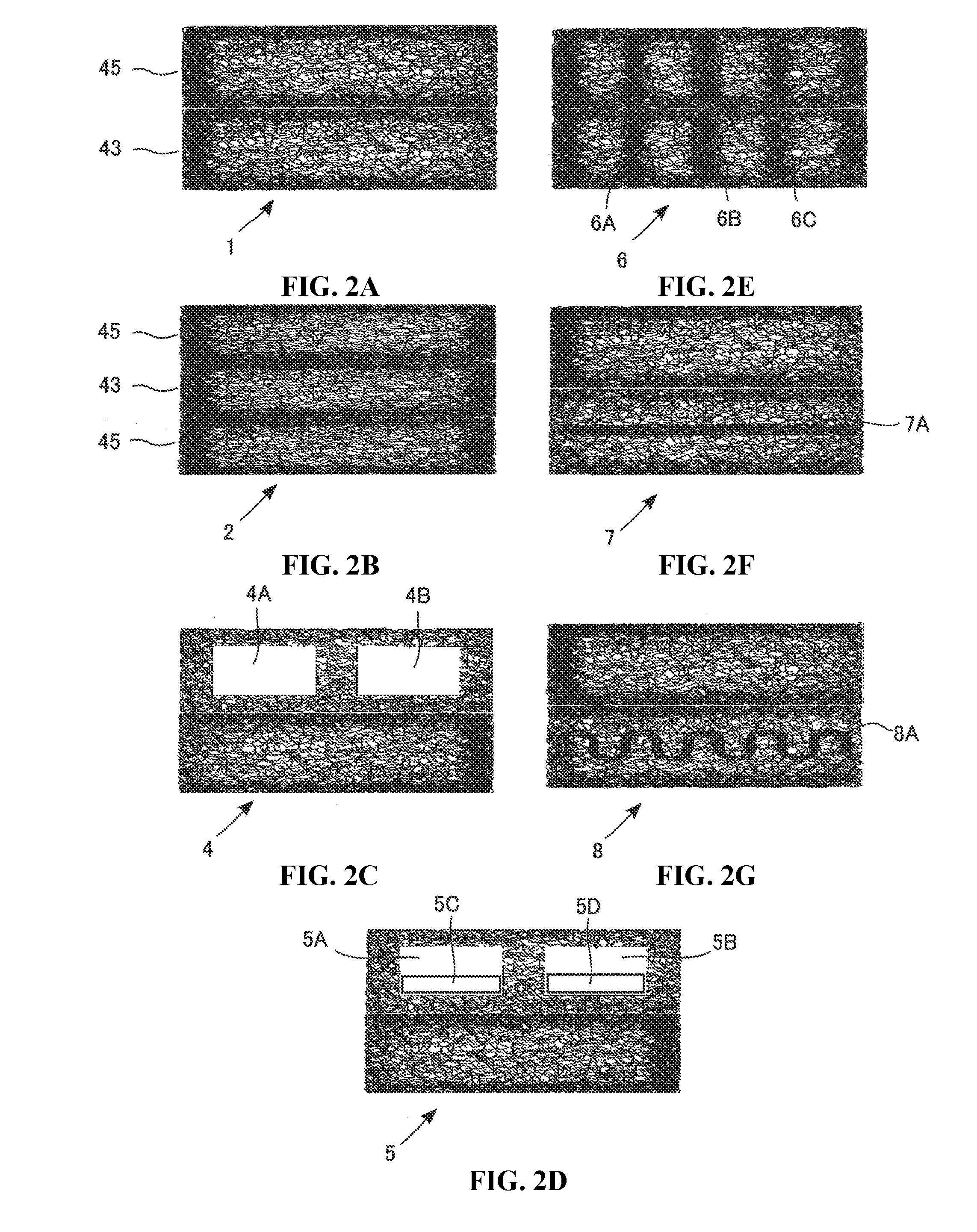

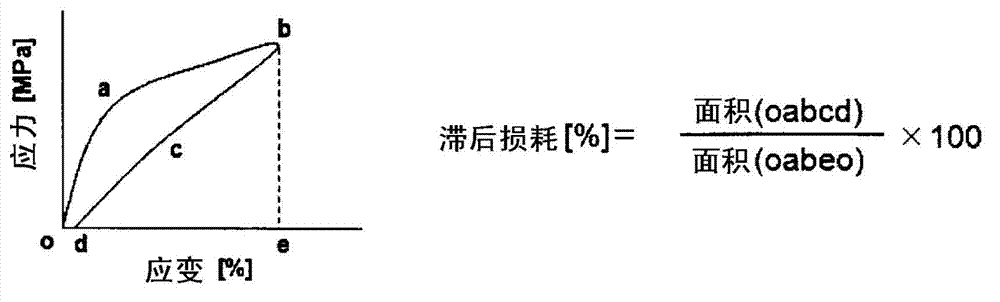

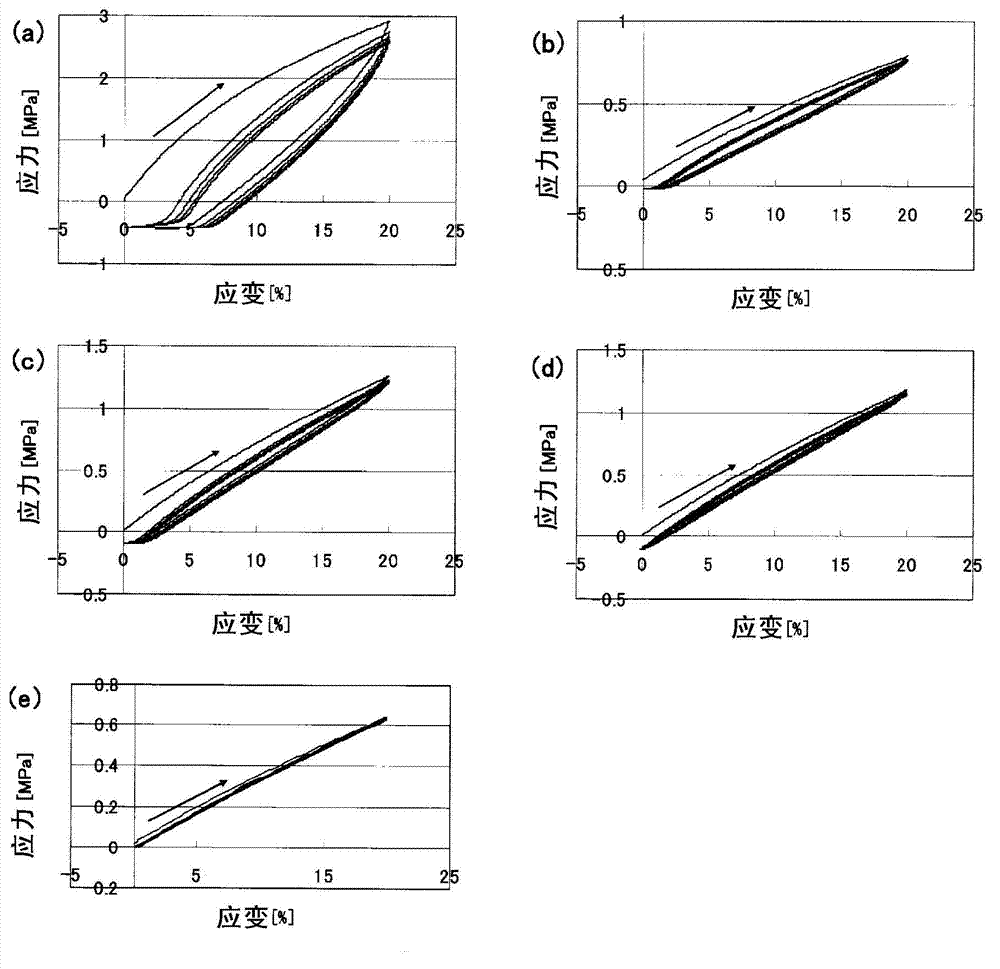

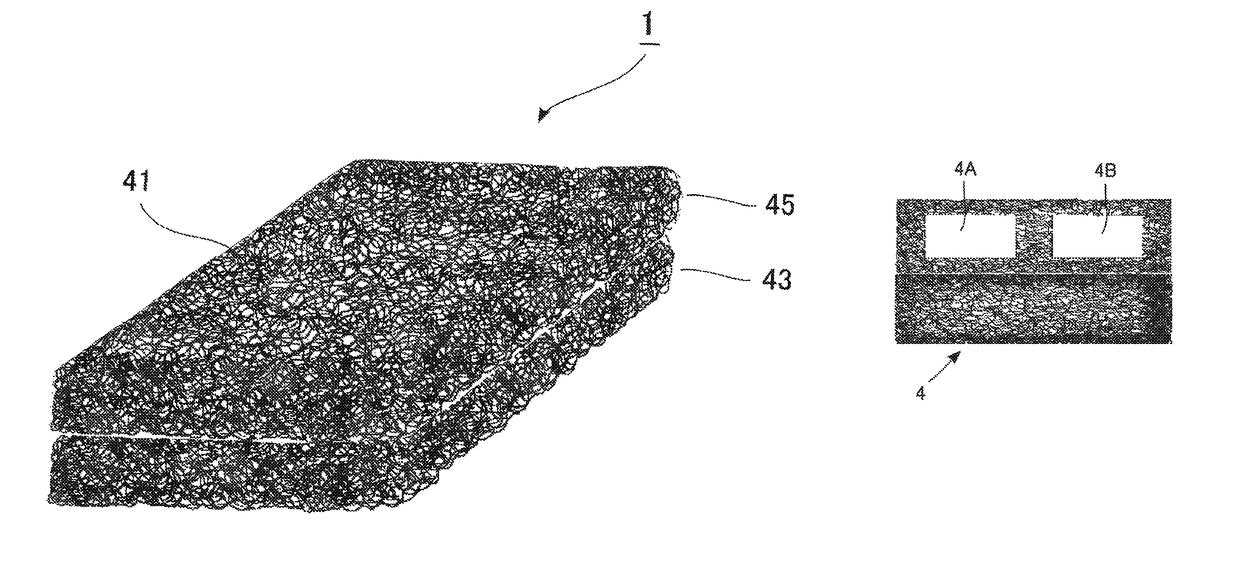

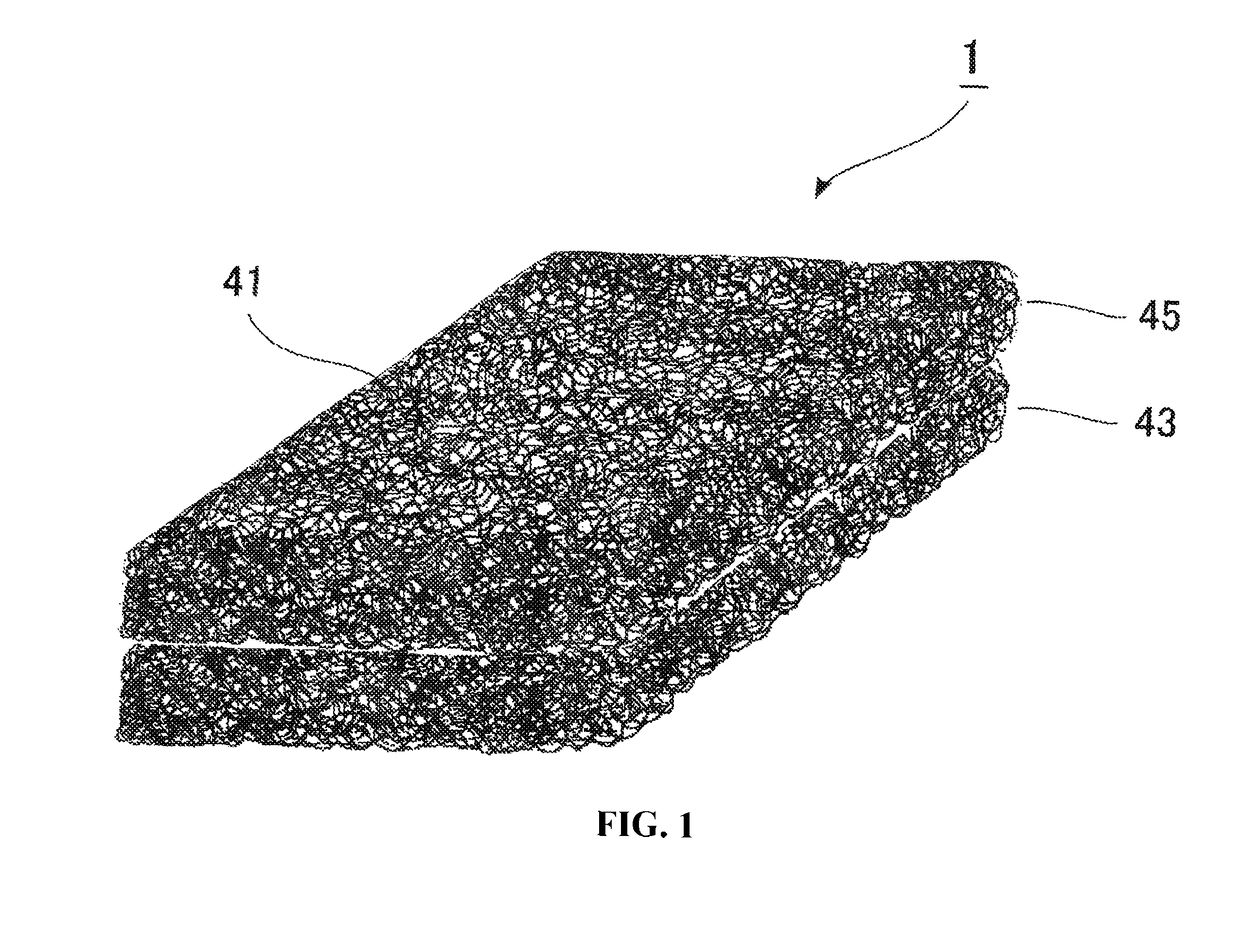

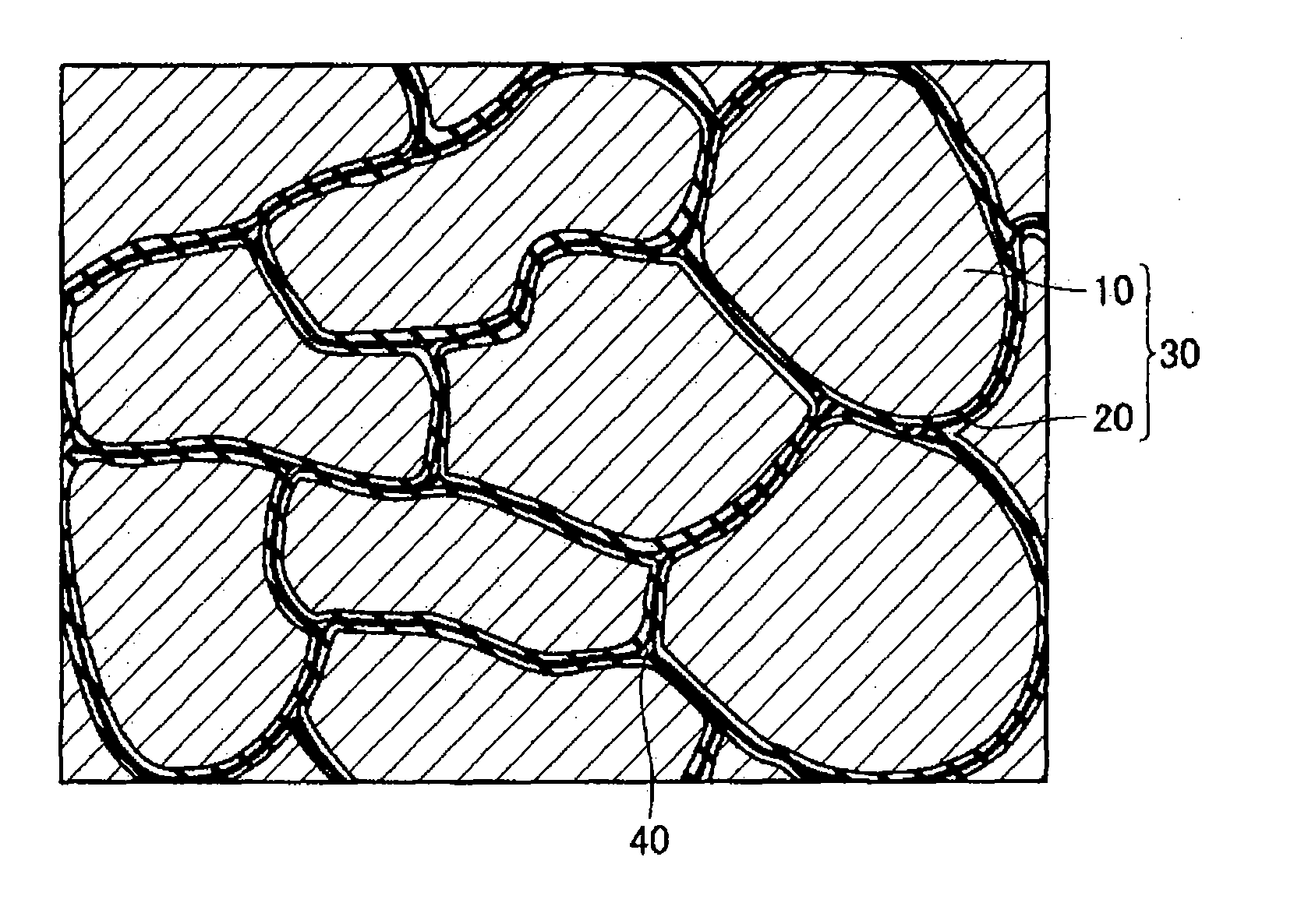

Core material for cushion, and cushion

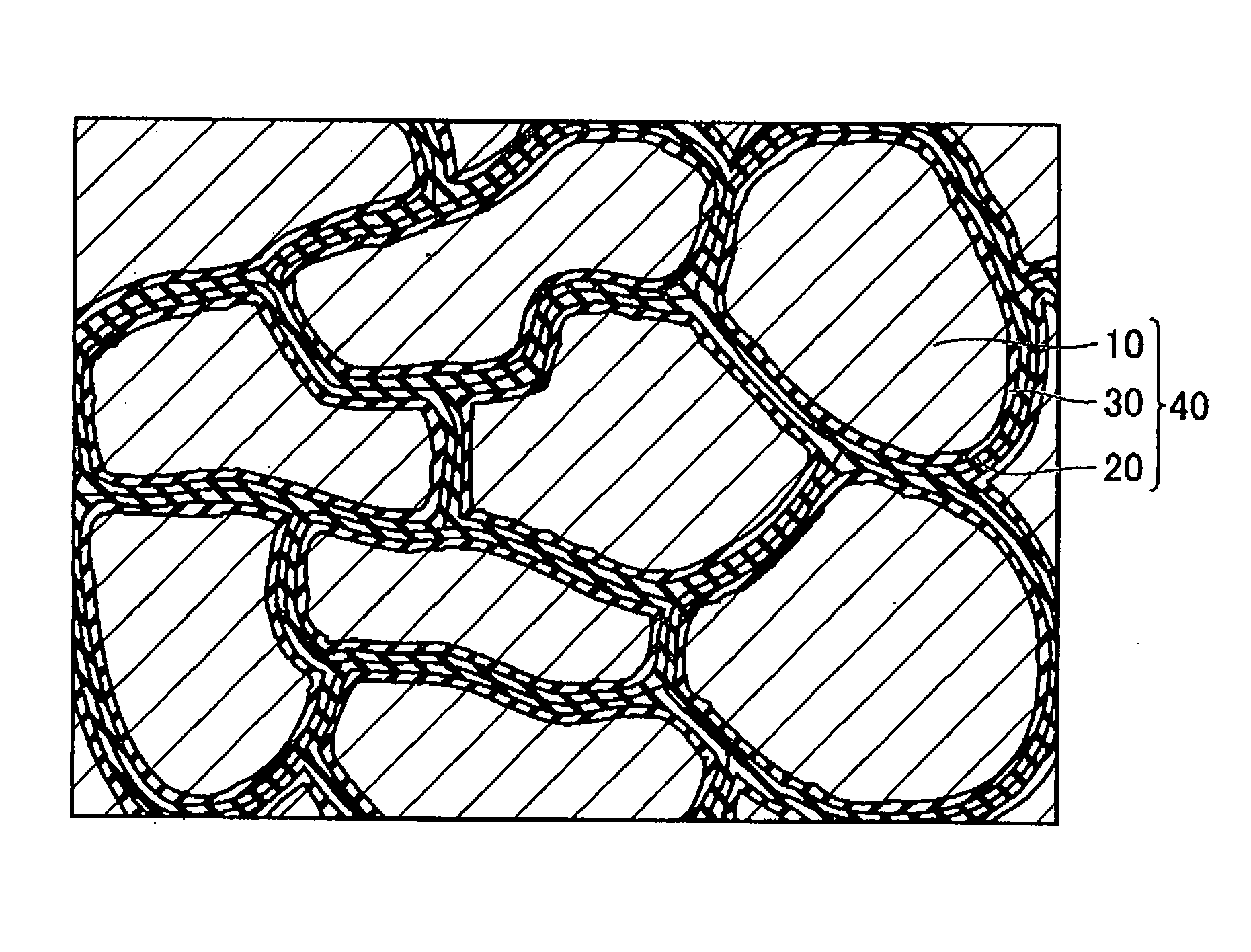

ActiveUS20160174725A1Solve the lack of resistanceSuppress shrinkage of the cushion and wrinkles of the coverStuffed mattressesDomestic upholsteryThermoplasticPolyester

An object is to provide a hygienic cushion that has an adequate thickness to provide the repulsive force of or above a specified level and the body-holding property, is light in weight, has excellent air permeability and is washable with water. The core material for cushion 1 comprising the three-dimensional net-like structure, which is comprised of a polyethylene thermoplastic resin, a polyester thermoplastic elastomer or a mixture of a polyethylene thermoplastic resin and a polyethylene thermoplastic elastomer. The three-dimensional net-like structure has a first layer that includes a thermoplastic resin and a second layer that is stacked on a single surface or both surfaces of the first layer and includes a thermoplastic resin different from the thermoplastic resin of the first layer. The three dimensional net-like structure has an impact resilience of not lower than 13 cm, a hysteresis loss of not higher than 34% and not lower than 13%, and a thermal expansion rate of 0 to 8% in the longitudinal direction before and after a hot-air drying test that is performed at a temperature of 90° C. for 30 minutes with regard to the polyethylene thermoplastic resin, that is performed at a temperature of 130° C. for 30 minutes with regard to the polyester thermoplastic elastomer and that is performed at a temperature of 90° C. for 30 minutes with regard to the mixture of the polyethylene thermoplastic resin and the polyethylene thermoplastic elastomer.

Owner:C ENG CO LTD

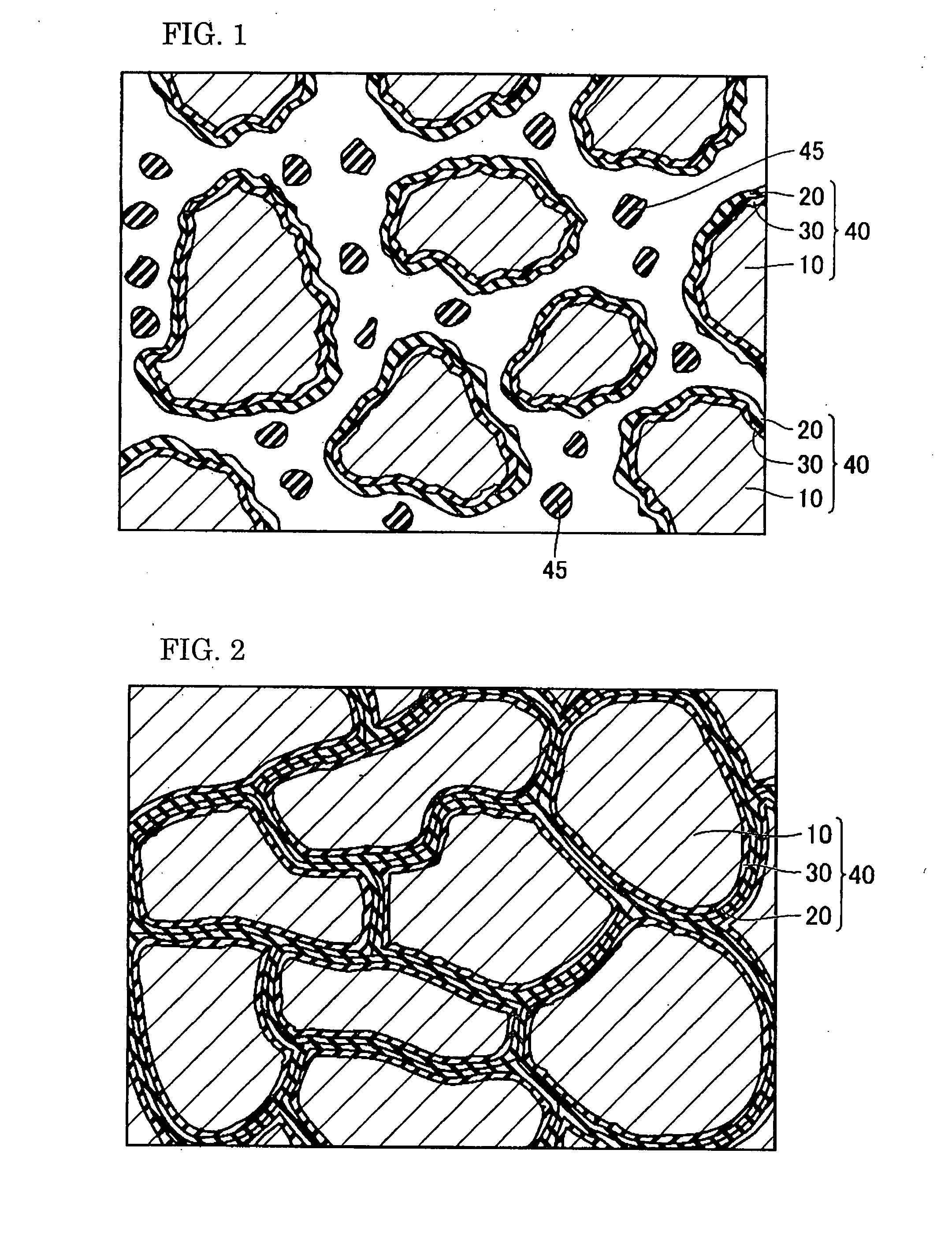

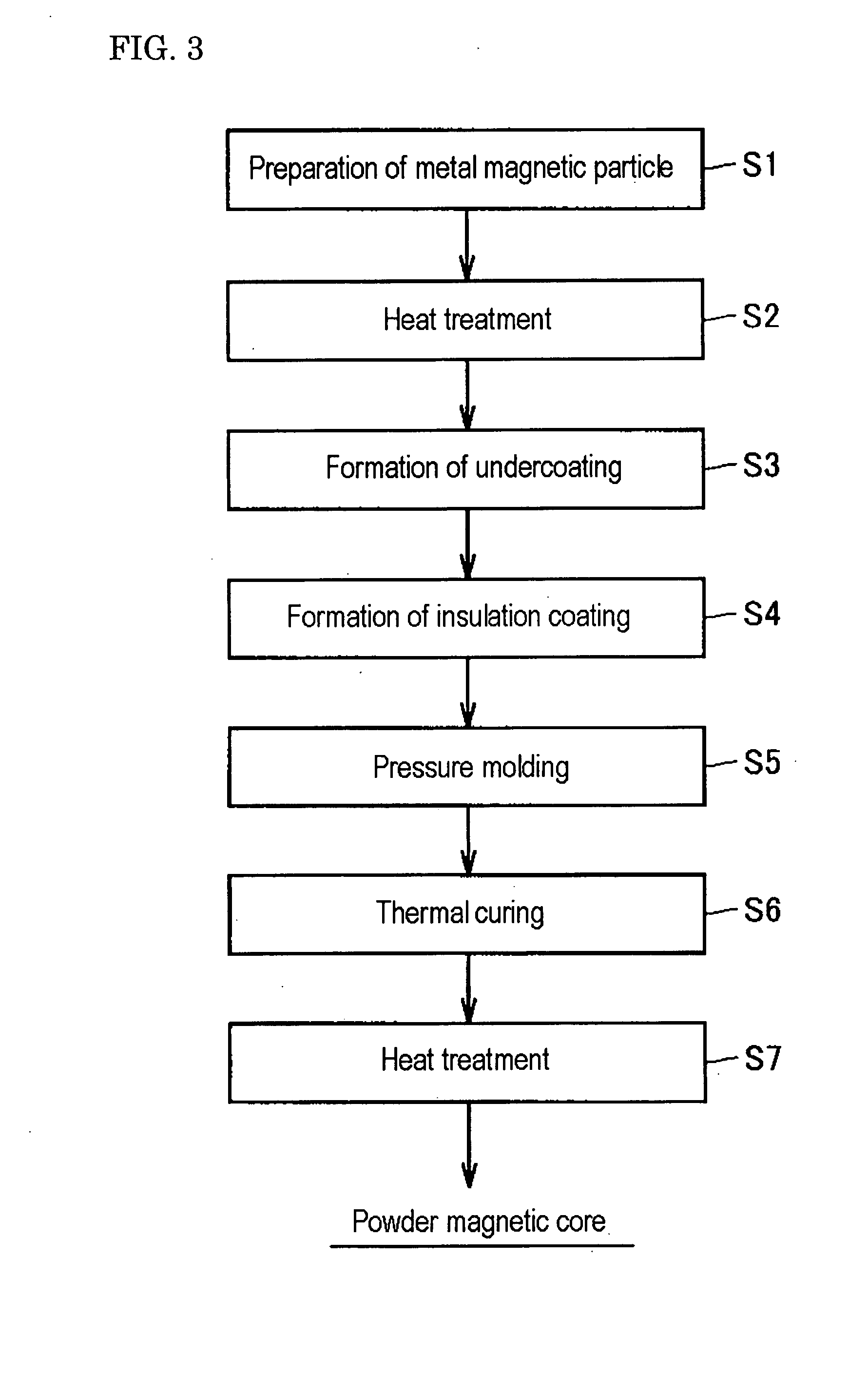

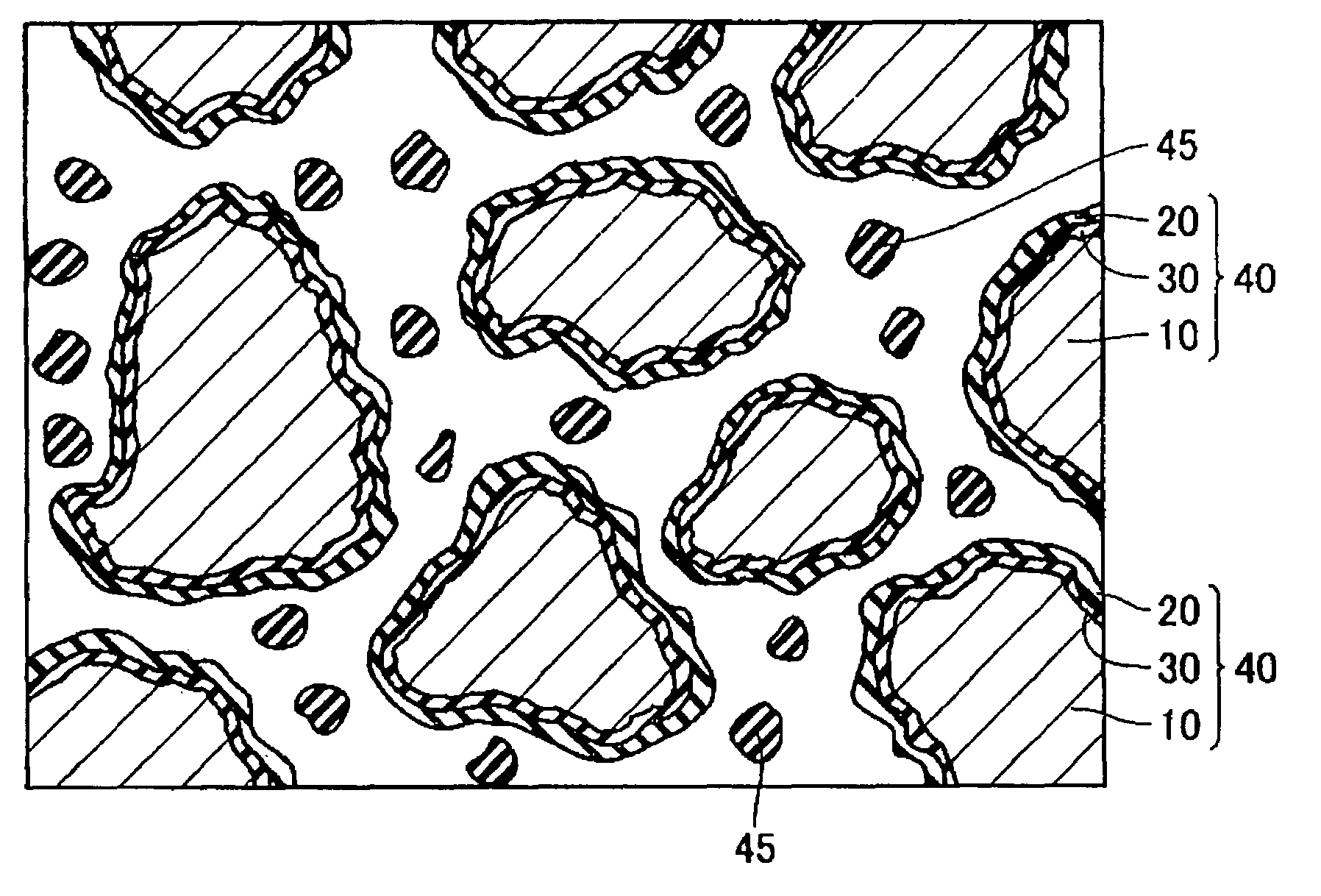

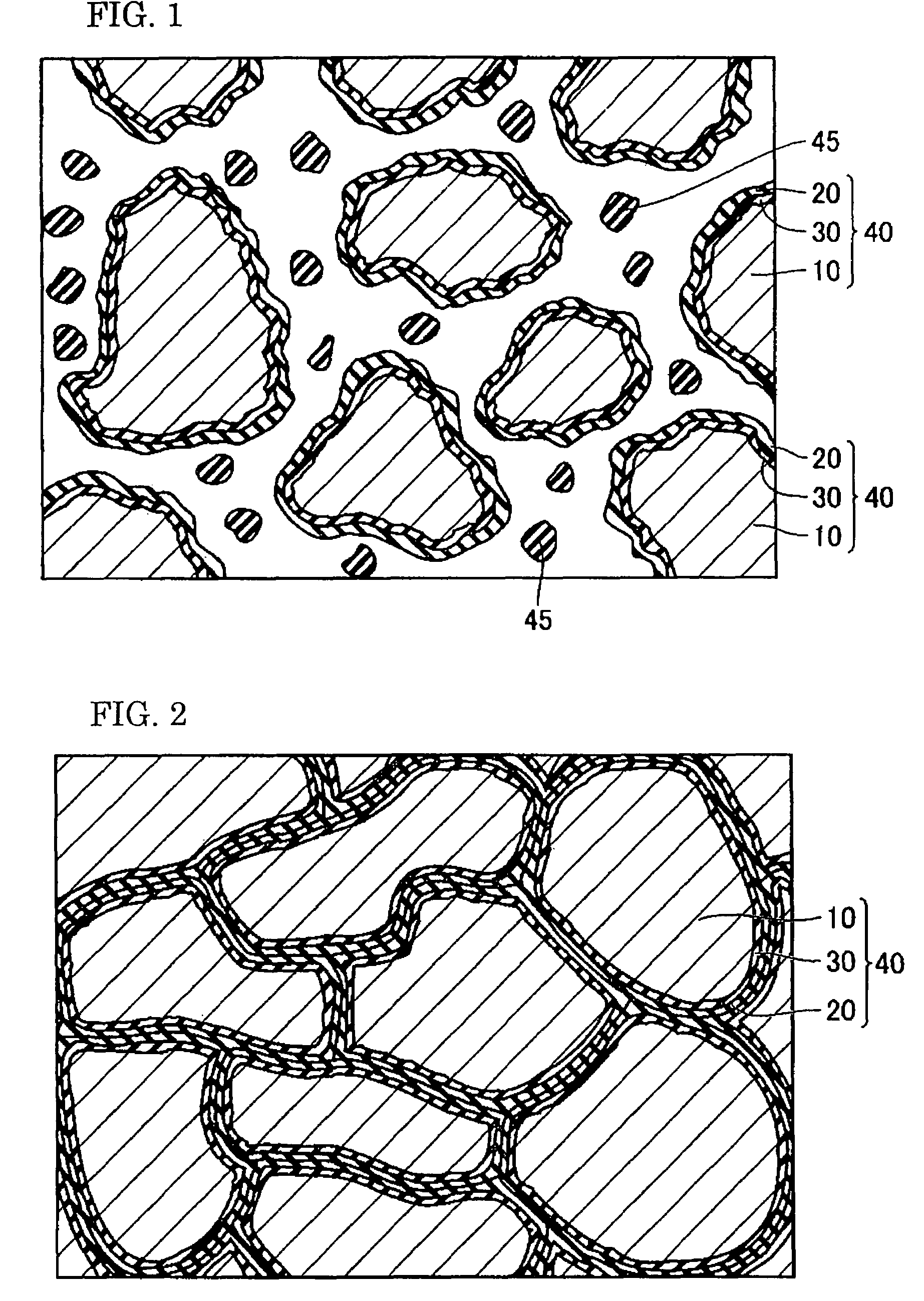

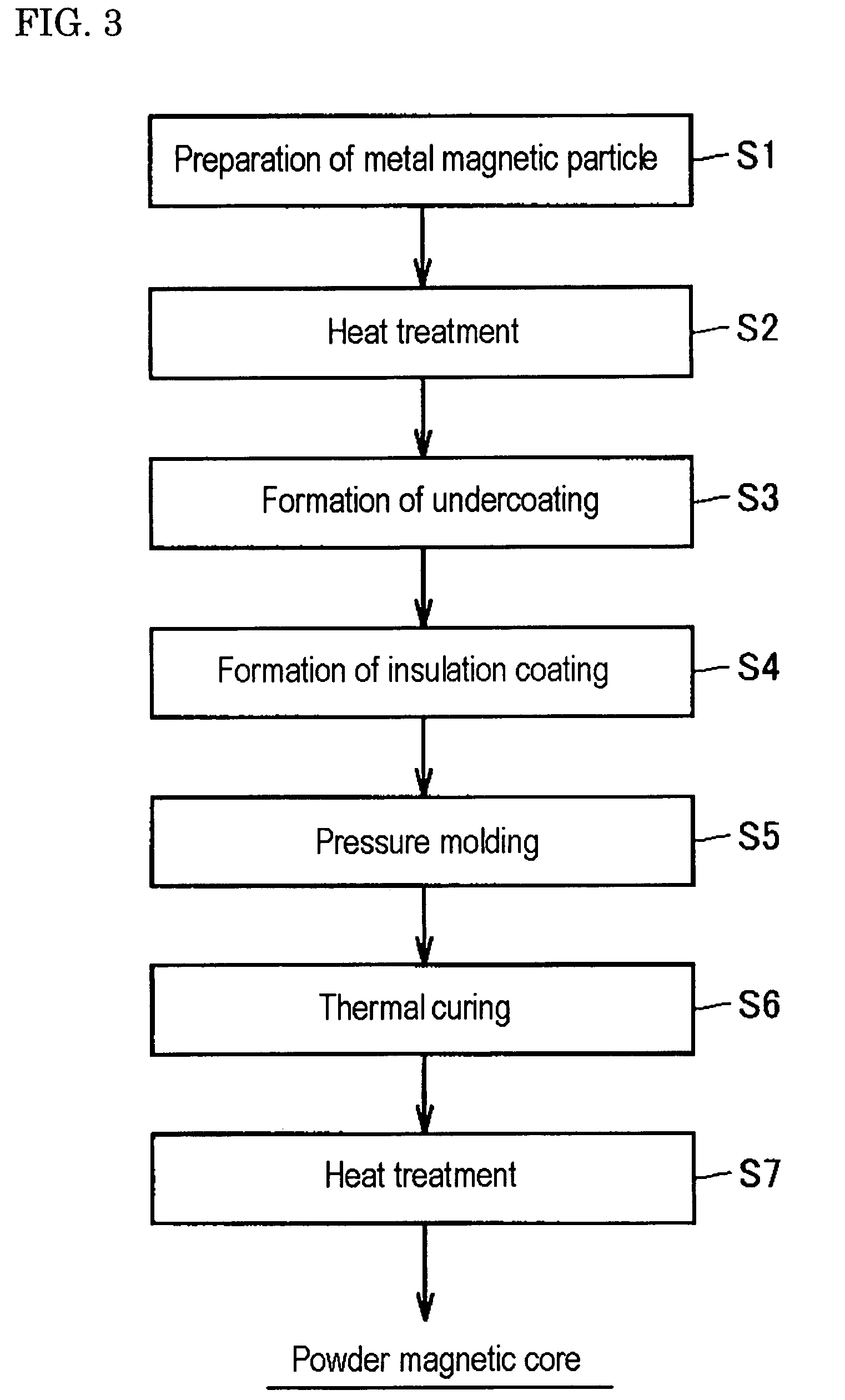

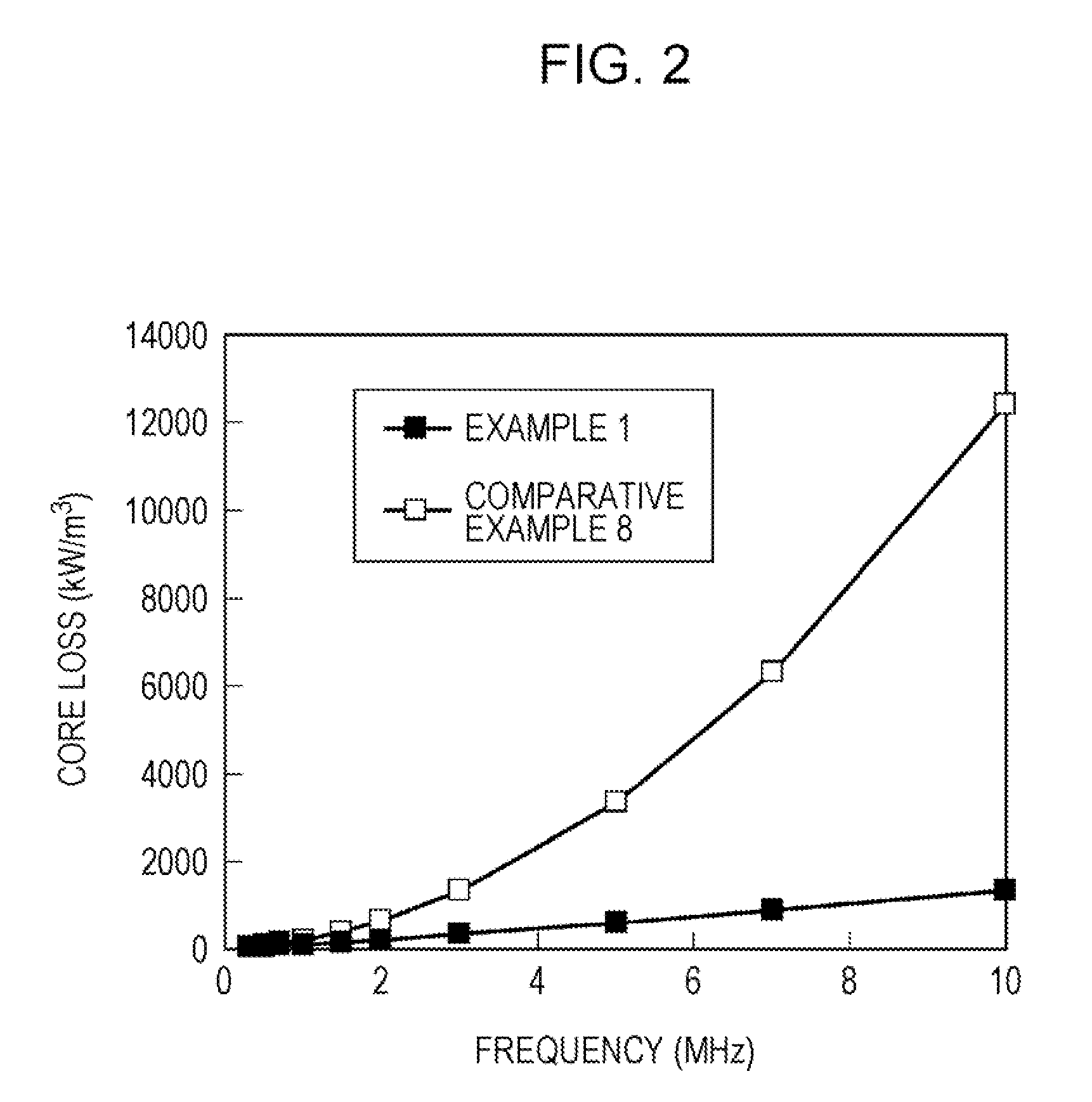

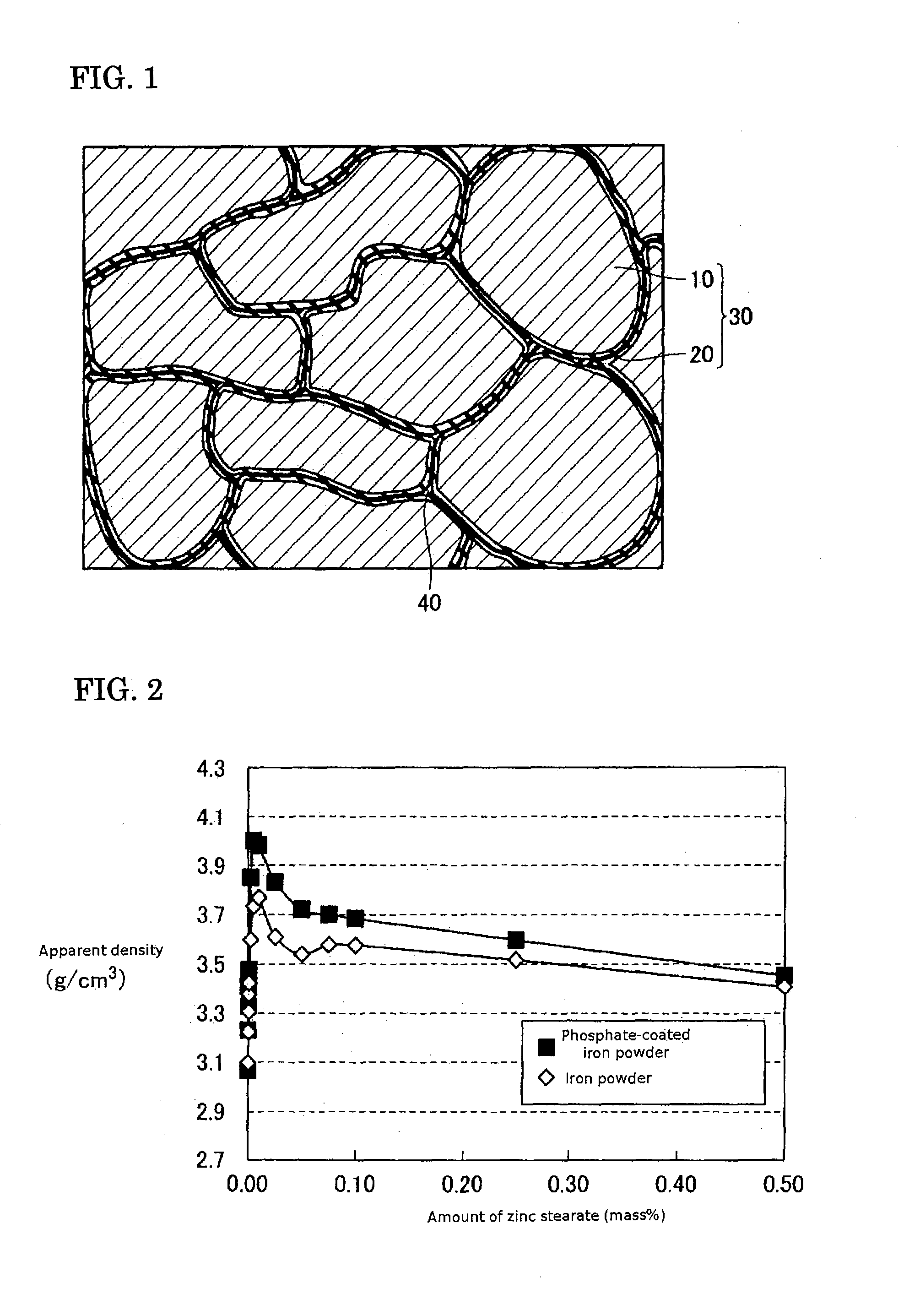

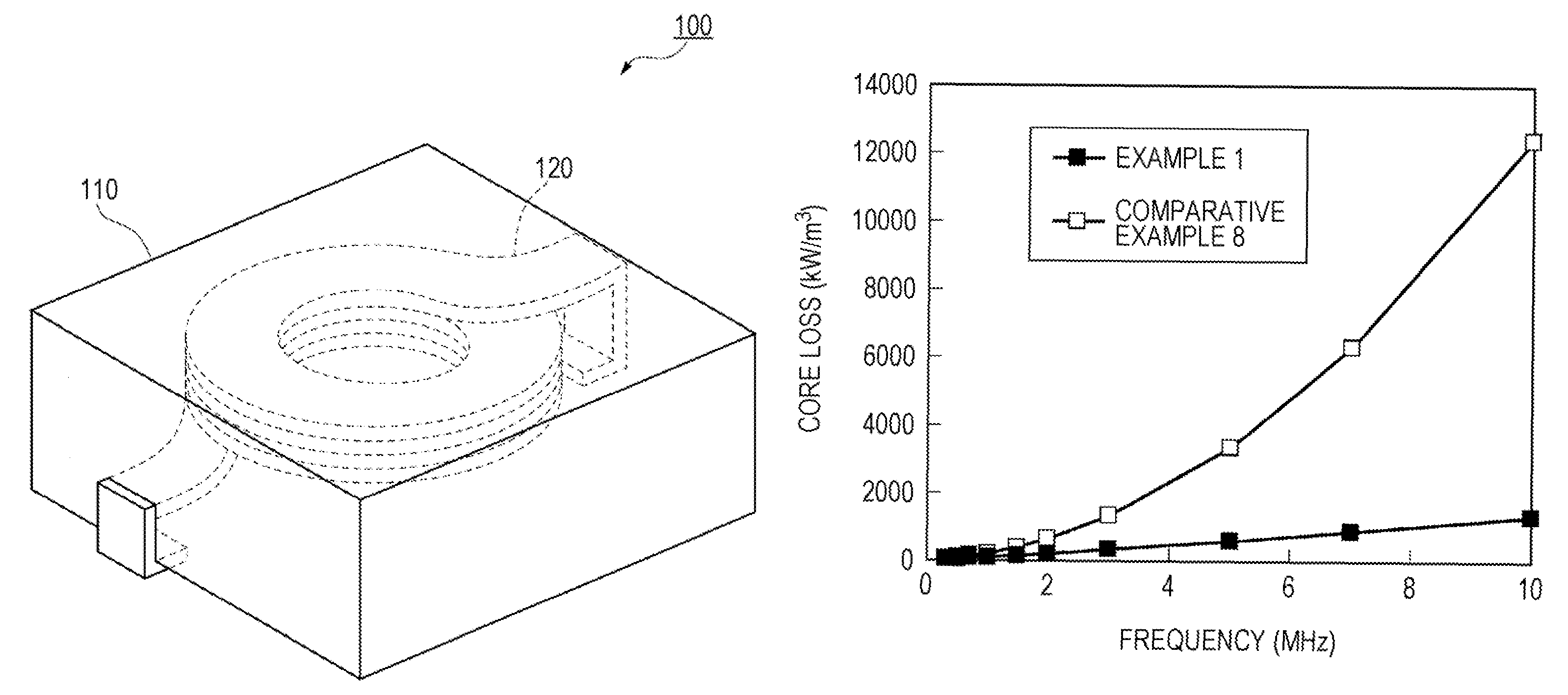

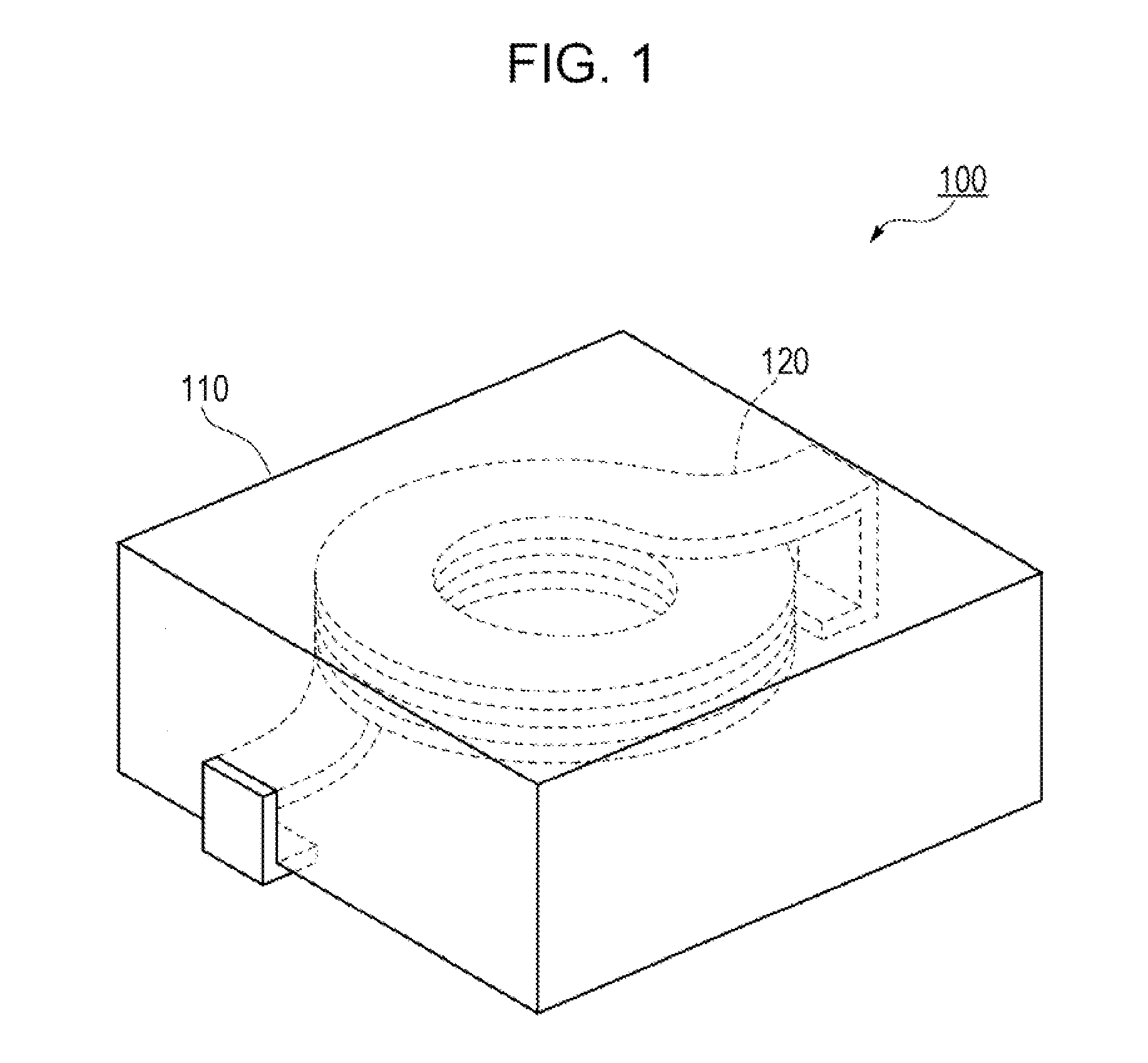

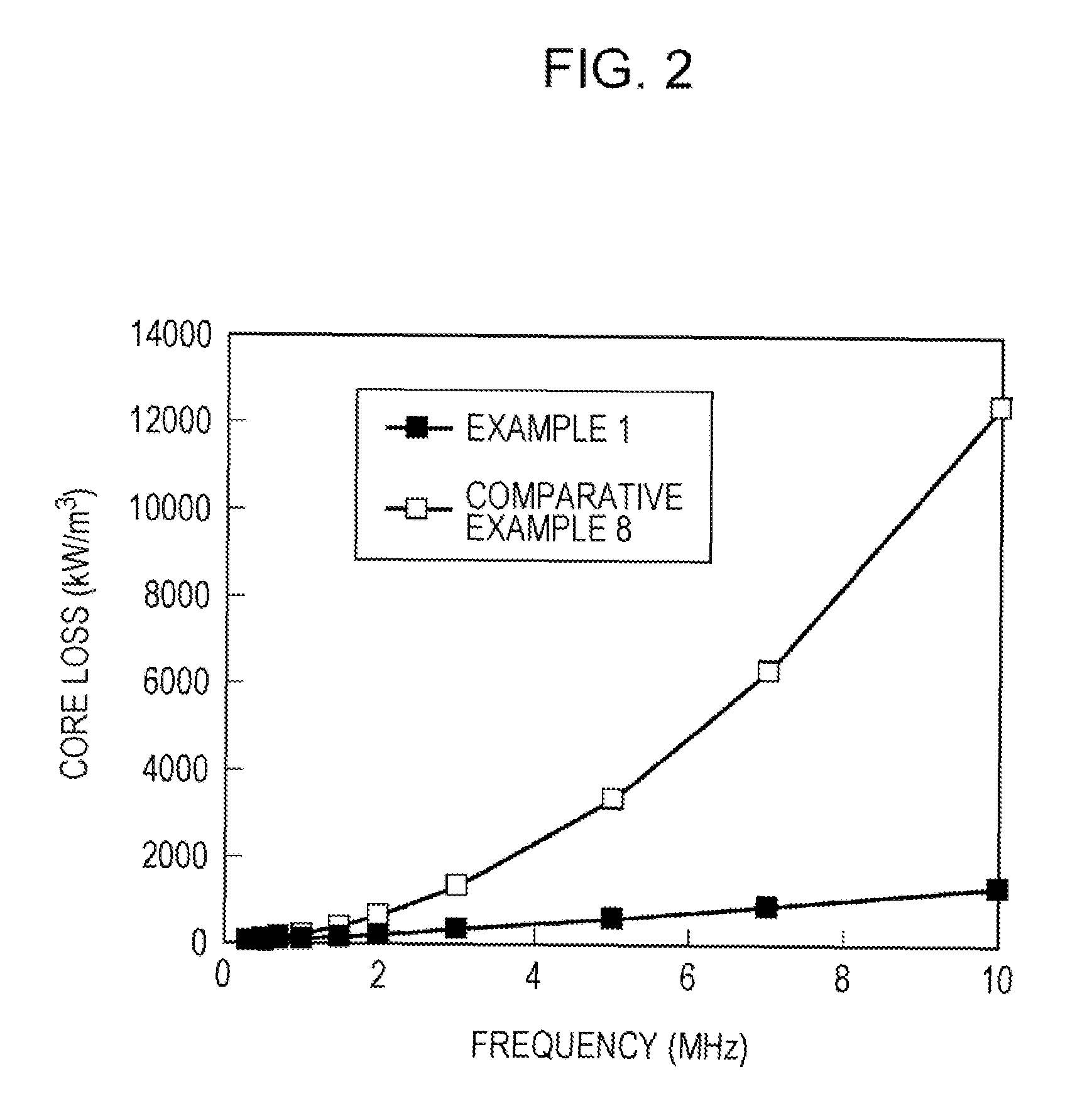

Soft Magnetic Material, Powder Magnetic Core, Method for Manufacturing Soft Magnetic Material, and Method for Manufacturing Powder Magnetic Core

InactiveUS20080044679A1Increase in eddy-current lossHigh strengthMagnetic paintsMetal-working apparatusHysteresisEddy current

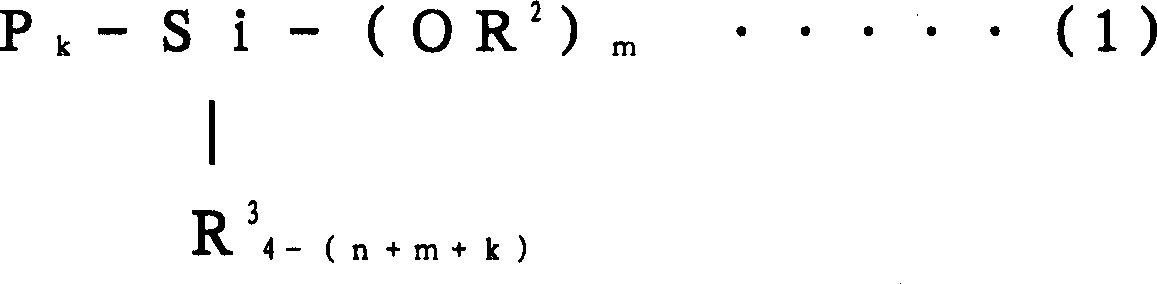

A soft magnetic material includes a plurality of composite magnetic particles (40) each including a metal magnetic particle (10) and an insulation coating (20) covering the surface of the metal magnetic particle (10), wherein the insulation coating (20) contains Si (silicon), and 80% or more of Si contained in the insulation coating constitutes a silsesquioxane skeleton. Therefore, it is possible to effectively decrease a hysteresis loss while suppressing an increase in eddy-current loss.

Owner:SUMITOMO ELECTRIC IND LTD

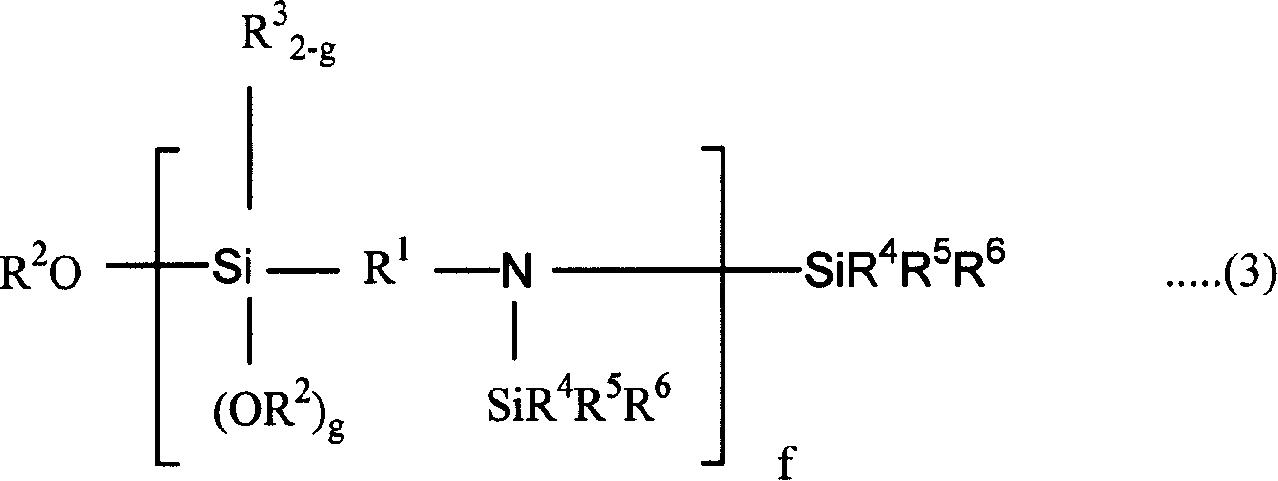

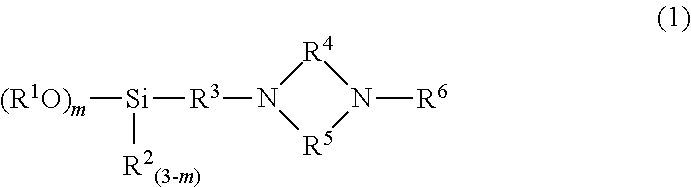

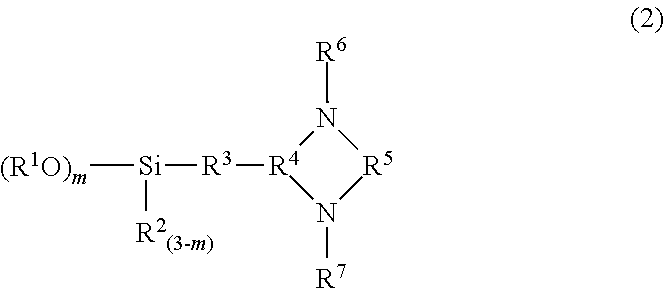

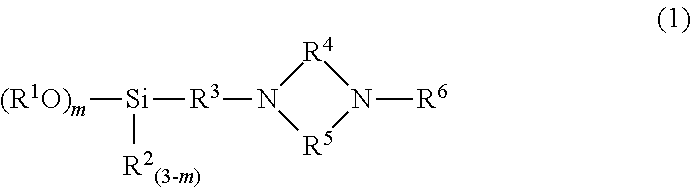

Modified conjugated diene-based polymer, method for producing the same, modified conjugated diene-based polymer composition, and tire

There is provided a modified conjugated diene-based polymer having a silyl group substituted with one or more alkoxy groups, and one or more nitrogen atoms on the chain ends of a conjugated diene-based polymer, the modified conjugated diene-based polymer being obtained by polymerizing a conjugated diene compound, or copolymerizing a conjugated diene compound with an aromatic vinyl compound, by using a polyfunctional anionic polymerization initiator prepared from a polyvinyl aromatic compound and an organolithium compound in a range of a molar ratio (the polyvinyl aromatic compound / the organolithium compound) of from 0.05 to 1.0, so as to obtain the conjugated diene-based polymer, and by reacting a living polymer end of the conjugated diene polymer with the compound having a silyl group substituted with two or more alkoxy groups, and one or more nitrogen atoms.

Owner:ASAHI KASEI CHEM CORP

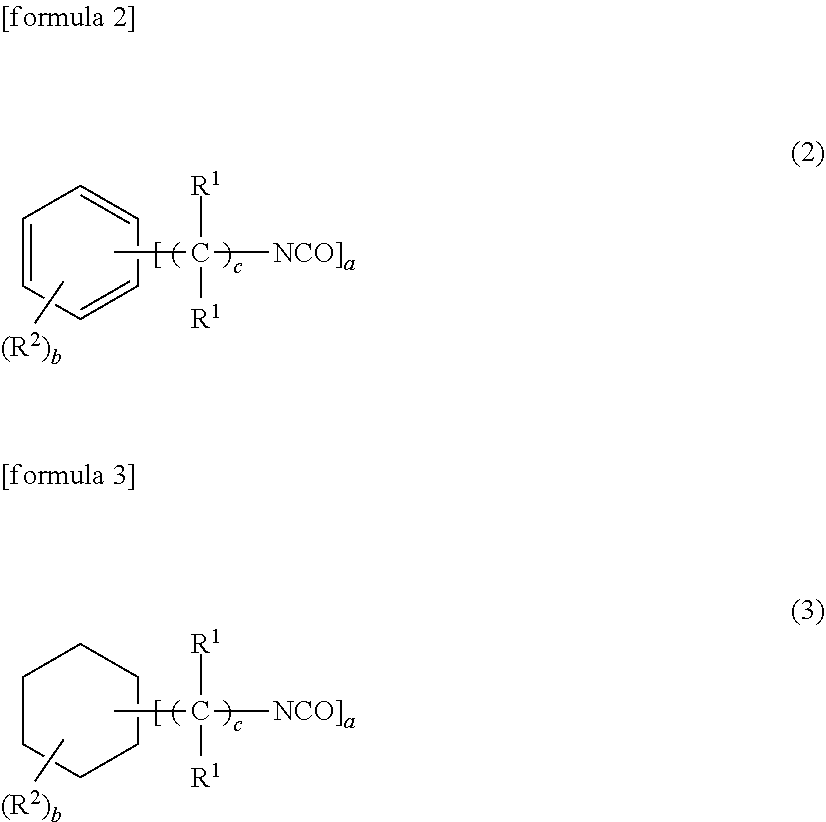

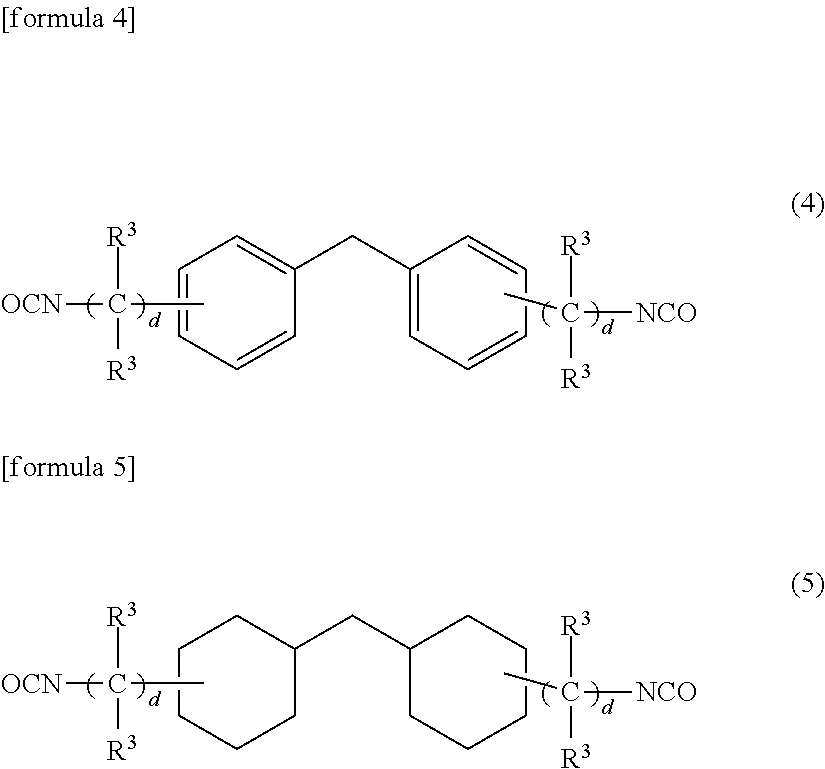

Photocrosslinkable polyrotaxane, composition comprising the photocrosslinkable polyrotaxane, crosslinked body derived from the composition, and methods for producing same

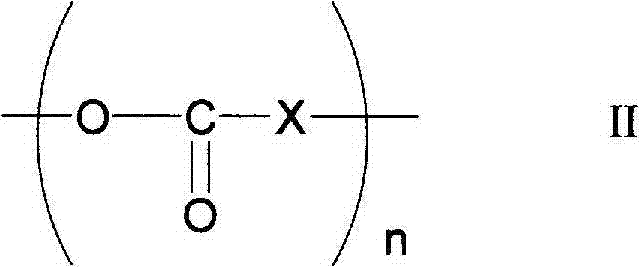

Disclosed are: a photocrosslinkable polyrotaxane having a high scratch resistance, low hysteresis loss and so on; a composition comprising the photocrosslinkable polyrotaxane and so on; a crosslinked body obtained from the composition; and methods for producing the same. Specifically disclosed are: a photocrosslinkable polyrotaxane comprising a cyclic molecule of polyrotaxane, wherein pseudo-polyrotaxane is formed by piercing the opening of a cyclic molecule by a straight-chain molecule to form a clathrate therewith and blocking groups are positioned at both ends of the pseudo-polyrotaxane to prevent the withdrawal of the cyclic molecule, said cyclic molecule of polyrotaxane having a group represented by -M-Y (wherein M is represented by formula II; X represents a straight-chain alkylene group having 1-8 carbon atoms, etc.; n is 1-10 on average; and Y represents a group having a photopolymerizable group); a composition comprising the photocrosslinkable polyrotaxane and so on; a crosslinked body derived from the composition; and methods for producing the same.

Owner:株式会社ASM

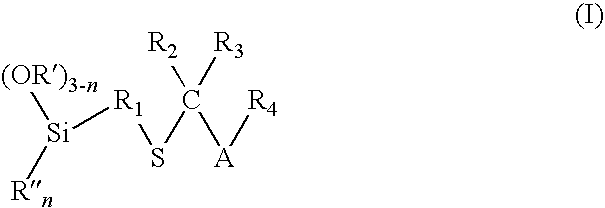

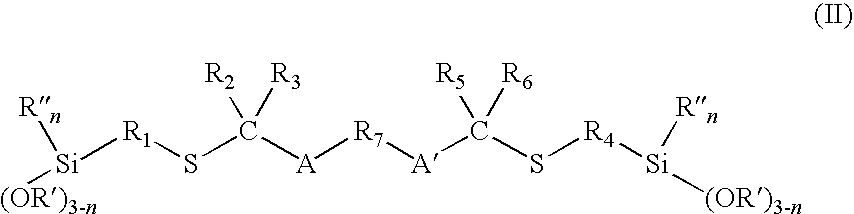

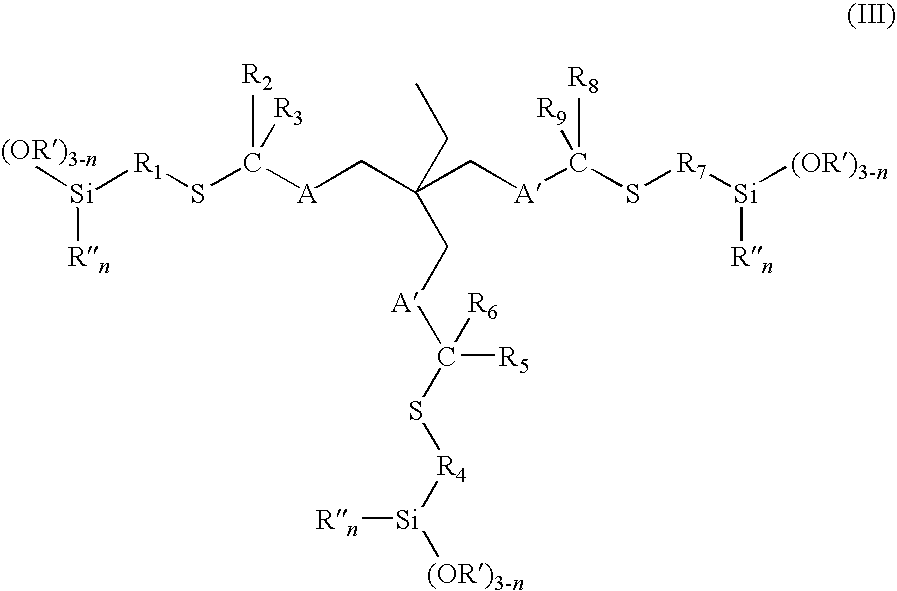

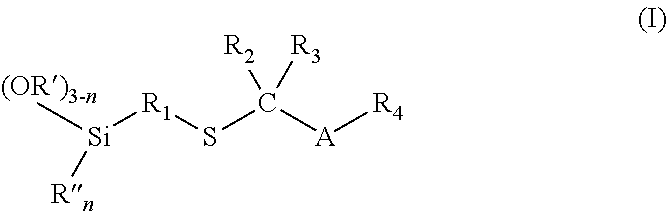

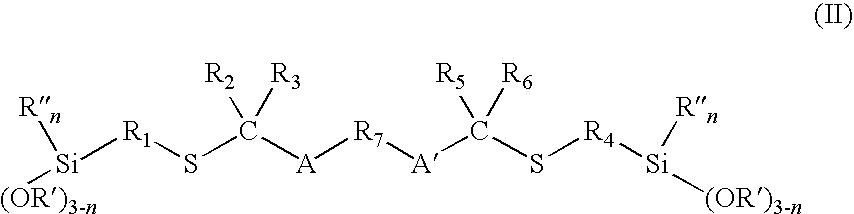

Mercapto silane

ActiveCN1807434AImprove wear resistanceReduce releaseGroup 4/14 element organic compoundsRolling resistance optimizationSilanesAlkoxylation

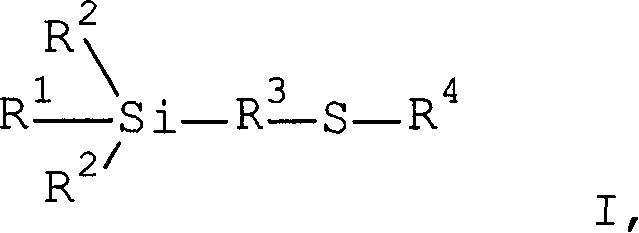

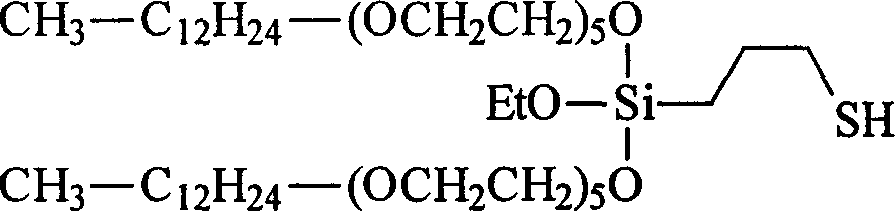

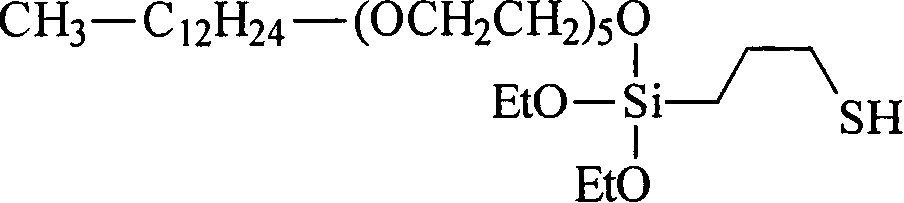

The invention relates to mercaptosilane of the general formula I, wherein R<1> is an alkyl polyether group -O-(R<5>-O)-R<6>. They are prepared by a procedure in which a silane of the general formula II is subjected to a catalytic reaction with an alkyl polyether R<1>-H with the same specification as the above, R<7>-OH being split off, the molar ratio of the alkyl polyether R<1>-H to the silane of the general formula II is at least 0.5 and R<7>-OH is separated off from the reaction mixture continuously or discontinuously. They can be used in shaped articles.

Owner:EVONIK OPERATIONS GMBH

Rubber masterbatch, method for producing the same, and rubber composition obtained from the same

There are provided a rubber masterbatch which can give a vulcanized rubber having a low hysteresis loss while having a low electrical resistance (low volume electrical resistance value); and a method for producing the rubber masterbatch. The rubber master-batch is a rubber masterbatch including a diene rubber, a carbon nanotube, and a silane coupling agent, and the carbon nanotube shows a weight loss proportion of 10 to 30% by weight in a range from 200 to 600° C. in a thermogravimetry of the carbon nanotube.

Owner:TOYO TIRE & RUBBER CO LTD

Apparatus for supplying energy to a load and a related system

InactiveUS7646279B2Efficient couplingInhibit currentPoint-like light sourceConversion with intermediate conversion to dcLow voltageTransformer

Apparatus for supplying energy to a load, comprises a power supply unit (102) e.g. a switched mode electronic transformer or electronic ballast having an input for receiving current at mains frequency and a means for stepping-up said mains frequency to a higher frequency e.g. 30-50 kHz and an output for delivering energy at the higher frequency. A two part connector (108) has a first core portion (106) that has a primary winding (104) connected to the output of the power supply unit and a mating second core portion (112) that has a secondary winding (110) for delivery of energy to a load (114), the core portions being of a high resistivity material, e.g. a ferrite having a resistivity of at least 104 Ωcm. The apparatus may be used to power e.g. low voltage halogen or other incandescent lighting, fluorescent lighting, or an electric motor, a power supply for a computer, radio, television or like electronic device, a heater or the like.

Owner:LIMPKIN GEORGE A +1

Soft magnetic material, powder magnetic core, method for manufacturing soft magnetic material, and method for manufacturing powder magnetic core

InactiveUS7622202B2Suppressing an increase in eddy-current lossHigh strengthSynthetic resin layered productsMetal-working apparatusHysteresisEddy current

Owner:SUMITOMO ELECTRIC IND LTD

Core material for cushion, and cushion

ActiveUS9615670B2Solve the lack of resistanceSuppress shrinkage of the cushion and wrinkles of the coverStuffed mattressesDomestic upholsteryPolyesterThermoplastic

An object is to provide a hygienic cushion that has an adequate thickness to provide the repulsive force of or above a specified level and the body-holding property, is light in weight, has excellent air permeability and is washable with water. The core material for cushion 1 comprising the three-dimensional net-like structure, which is comprised of a polyethylene thermoplastic resin, a polyester thermoplastic elastomer or a mixture of a polyethylene thermoplastic resin and a polyethylene thermoplastic elastomer. The three-dimensional net-like structure has a first layer that includes a thermoplastic resin and a second layer that is stacked on a single surface or both surfaces of the first layer and includes a thermoplastic resin different from the thermoplastic resin of the first layer. The three dimensional net-like structure has an impact resilience of not lower than 13 cm, a hysteresis loss of not higher than 34% and not lower than 13%, and a thermal expansion rate of 0 to 8% in the longitudinal direction before and after a hot-air drying test that is performed at a temperature of 90° C. for 30 minutes with regard to the polyethylene thermoplastic resin, that is performed at a temperature of 130° C. for 30 minutes with regard to the polyester thermoplastic elastomer and that is performed at a temperature of 90° C. for 30 minutes with regard to the mixture of the polyethylene thermoplastic resin and the polyethylene thermoplastic elastomer.

Owner:C ENG CO LTD

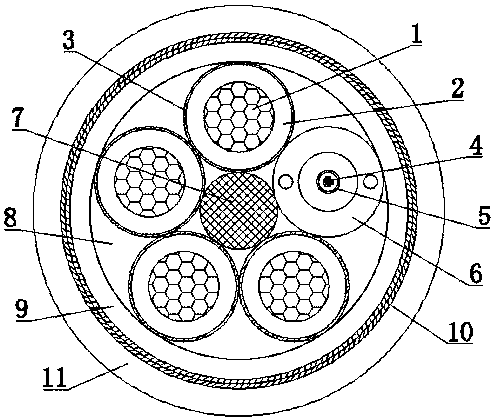

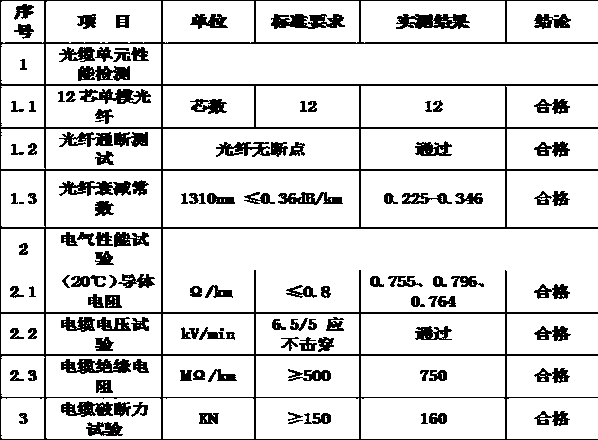

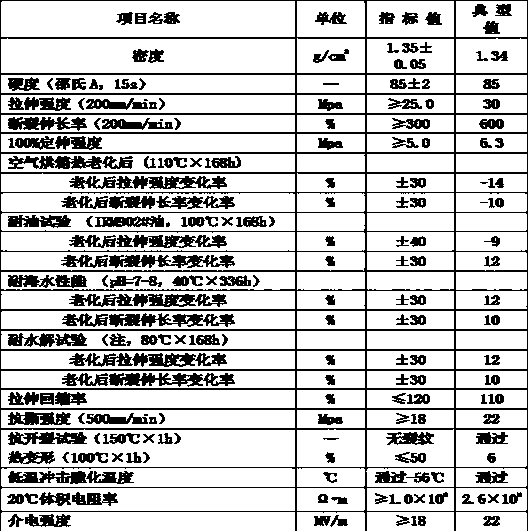

Flexible optical fiber composite submarine cable and preparation method thereof

PendingCN108074657AHigh tensile strengthHigh power transmission efficiencyNon-insulated conductorsConductive materialPower cableCopper wire

A flexible optical fiber composite submarine cable comprises four power cable cores, a communication optical cable, an aramid reinforcing rib, a polyurethane filling layer, an inner protecting layer,an aramid braiding layer and a polyurethane outer protecting layer, wherein the power cable cores, the communication optical cable and the aramid reinforcing rib are located in the middle, and the polyurethane filling layer, the inner protecting layer, the aramid braiding layer and the polyurethane outer protecting layer are located on the outer side. The aramid reinforcing rib is arranged at thecenter of a torus formed by the four power cable cores and the communication optical cable; each power cable core comprises a class-V oxygen-free copper flexible conductor, a butyronitrile-PVC compound insulating layer and a copper wire braiding shielding layer in sequence from inside to outside, and each class-V oxygen-free copper flexible conductor is formed by twisting multiple tinned annealedsoft copper wires; a twelve-core optical fiber is arranged in the communication optical cable, and the outer layer of the twelve-core optical fiber is provided with a stainless steel tube, a PE protecting bush and a polyurethane protecting layer in sequence; the polyurethane filling layer is arranged between the inner protecting layer and the power cable cores and the communication optical cable.The flexible optical fiber composite submarine cable has the advantages of being good in waterproofness, flexibility and creep resistance, light in weight, small in size, high in tensile strength andthe like.

Owner:万达集团股份有限公司 +1

Modified conjugated diene-based polymer, method for producing the same, modified conjugated diene-based polymer composition, and tire

ActiveUS8946339B2Improve balanceLow hysteresis lossSpecial tyresActive polymerOrganolithium compounds

There is provided a modified conjugated diene-based polymer having a silyl group substituted with one or more alkoxy groups, and one or more nitrogen atoms on the chain ends of a conjugated diene-based polymer, the modified conjugated diene-based polymer being obtained by polymerizing a conjugated diene compound, or copolymerizing a conjugated diene compound with an aromatic vinyl compound, by using a polyfunctional anionic polymerization initiator prepared from a polyvinyl aromatic compound and an organolithium compound in a range of a molar ratio (the polyvinyl aromatic compound / the organolithium compound) of from 0.05 to 1.0, so as to obtain the conjugated diene-based polymer, and by reacting a living polymer end of the conjugated diene polymer with the compound having a silyl group substituted with two or more alkoxy groups, and one or more nitrogen atoms.

Owner:ASAHI KASEI CHEM CORP

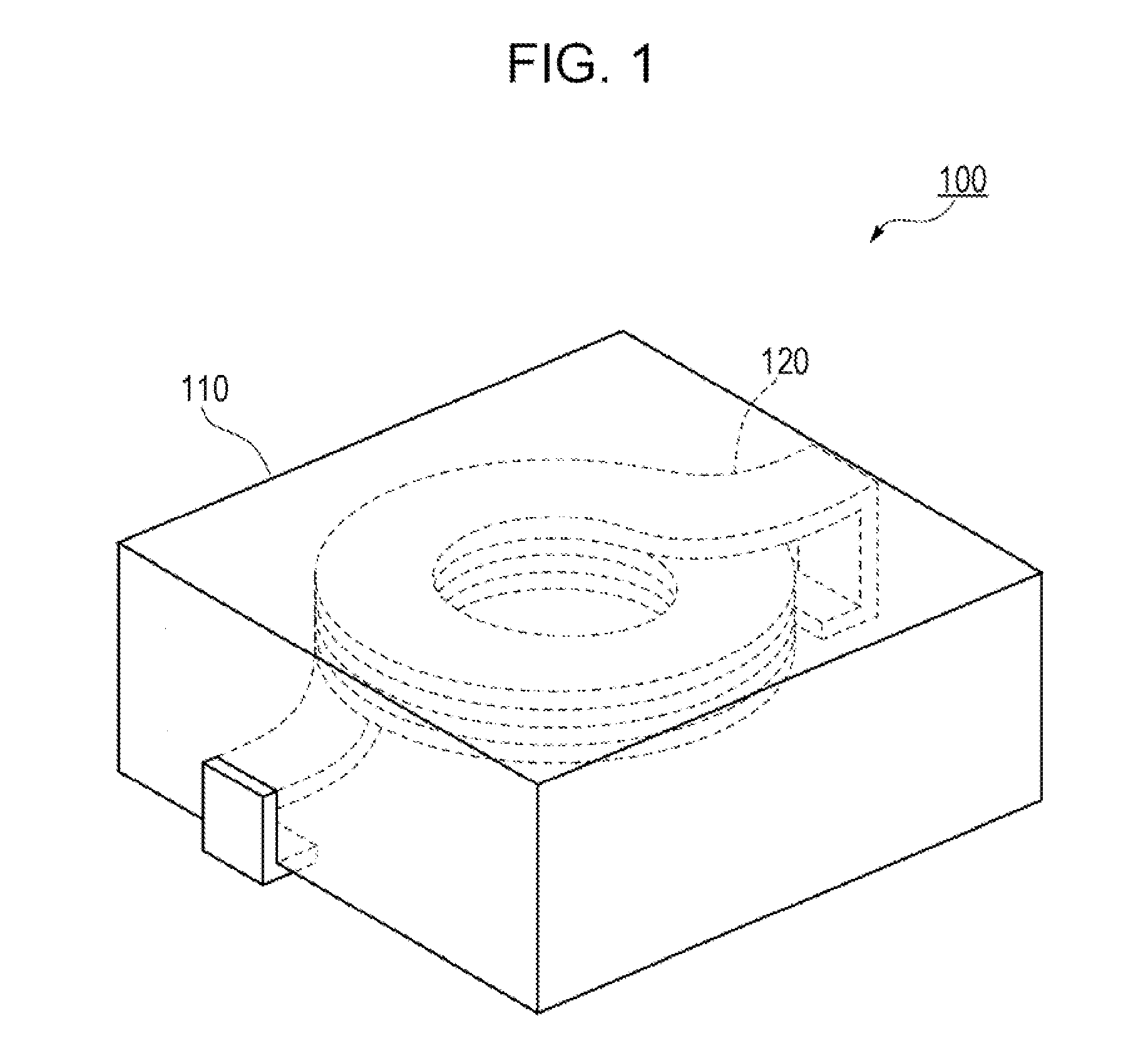

Soft magnetic alloy powder, compact, powder magnetic core, and magnetic element

ActiveUS20130265127A1Reduce lossImprove corrosion resistancePermanent magnetsInorganic material magnetismMagnetic coreMagnetic alloy

Provided are a soft magnetic alloy powder, a compact made from the soft magnetic alloy powder, a powder magnetic core including the compact, and a magnetic element including the powder magnetic core. The soft magnetic alloy powder contains Fe—Ni-based particles containing 38% to 48% by mass Ni, 1.0% to 15% by mass Co, and 1.2% to 10% by mass Si relative to the total mass of Fe, Ni, Co, and Si, the remainder being Fe. The Fe—Ni-based particles have an average size of more than 1 μm to less than 10 μm.

Owner:TDK CORPARATION

Rubber composition containing modified conjugated diene polymer and tire

ActiveUS20060217470A1Enhanced interactionImprove wear resistanceSpecial tyresHysteresisPolymer science

This invention relates to a rubber composition having a high interaction between rubber component and carbon black, a good wear resistance and an excellent low heat buildup (low hysteresis loss), and more particularly to a rubber composition comprising (A) 100 parts by mass of a rubber component containing not less than 10% by mass of a conjugated diene polymer having a polymer chain with at least one functional group selected from the group consisting of particular substituted amino group and cyclic amino group, (B) not less than 20 parts by mass of carbon black and (C) not more than 1.0 part by mass of a polycyclic aromatic compound (PCA).

Owner:BRIDGESTONE CORP

Method for producing a rubber composition

A method for producing a rubber composition, the method including: preparing a modified natural rubber by releasing protein from rubber particles in a natural rubber latex by adding at least one organic compound selected from formaldehyde, paraformaldehyde, formalin, and glyoxal to the above mentioned natural rubber latex and then drying so as to include the released protein therein; and mixing at least one selected from carbon black and silica in this modified natural rubber. Such method reduces viscosity and improves molding processibility of the rubber composition, as well as reducing hysteresis loss.

Owner:YOKOHAMA RUBBER CO LTD

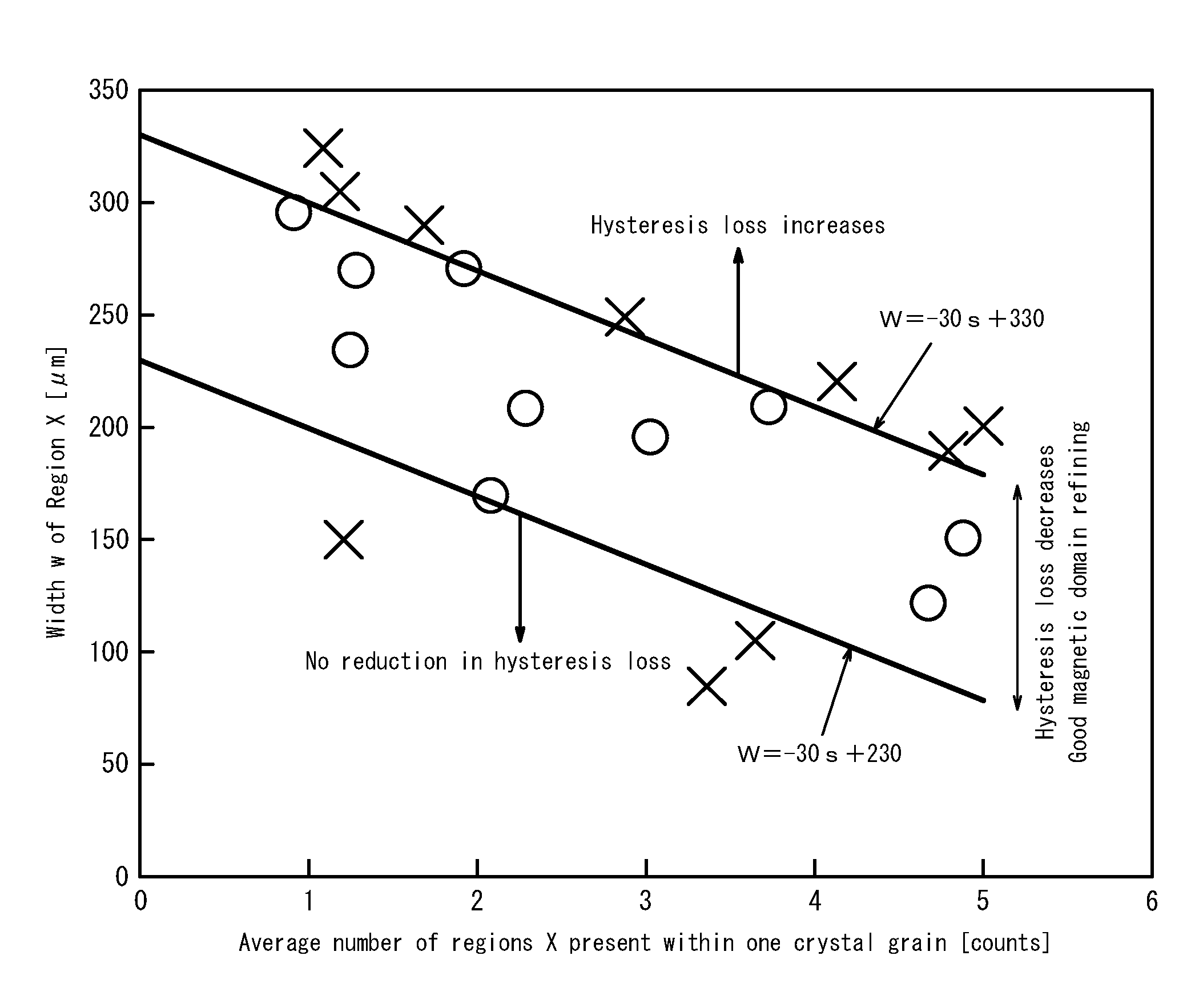

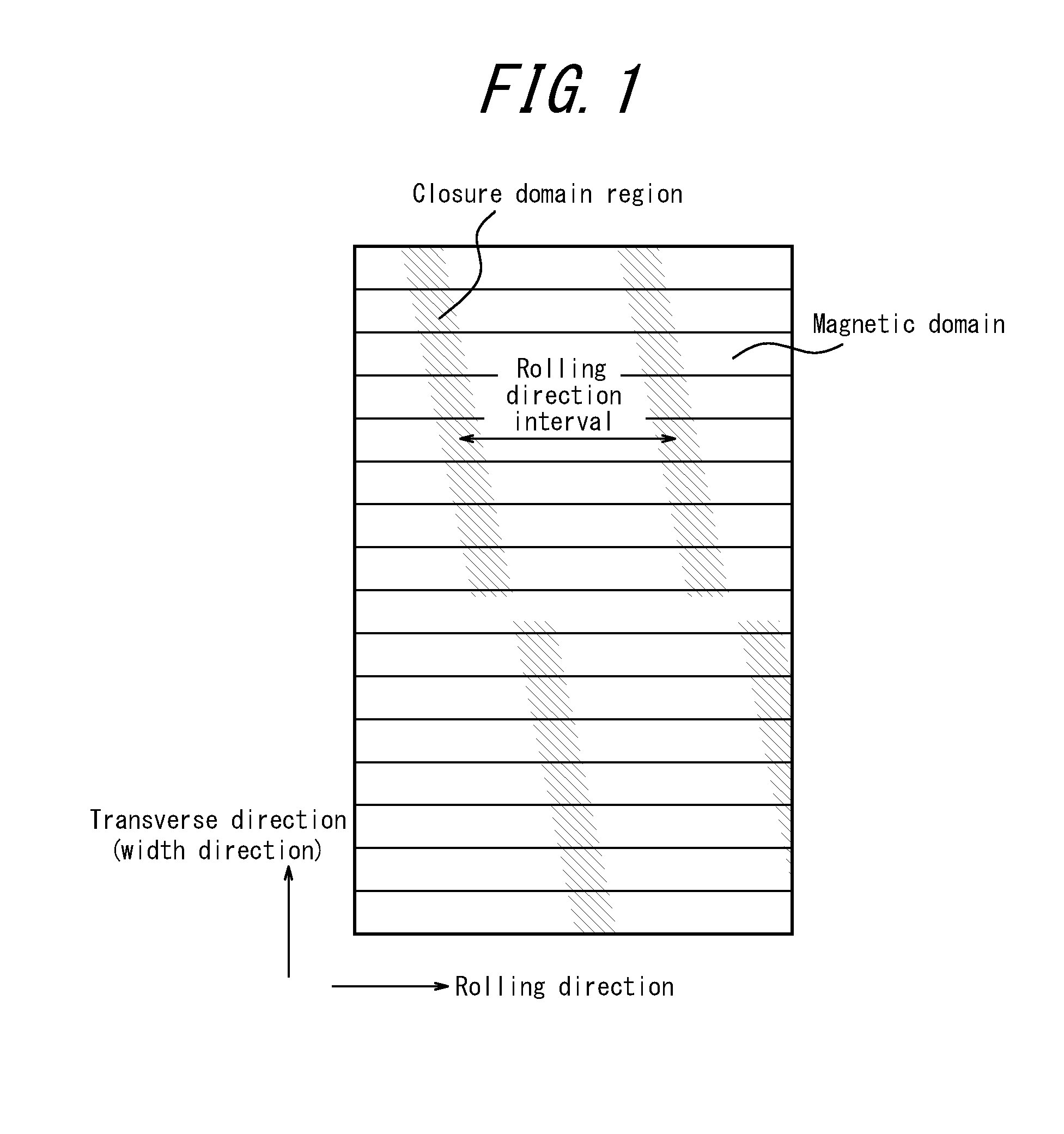

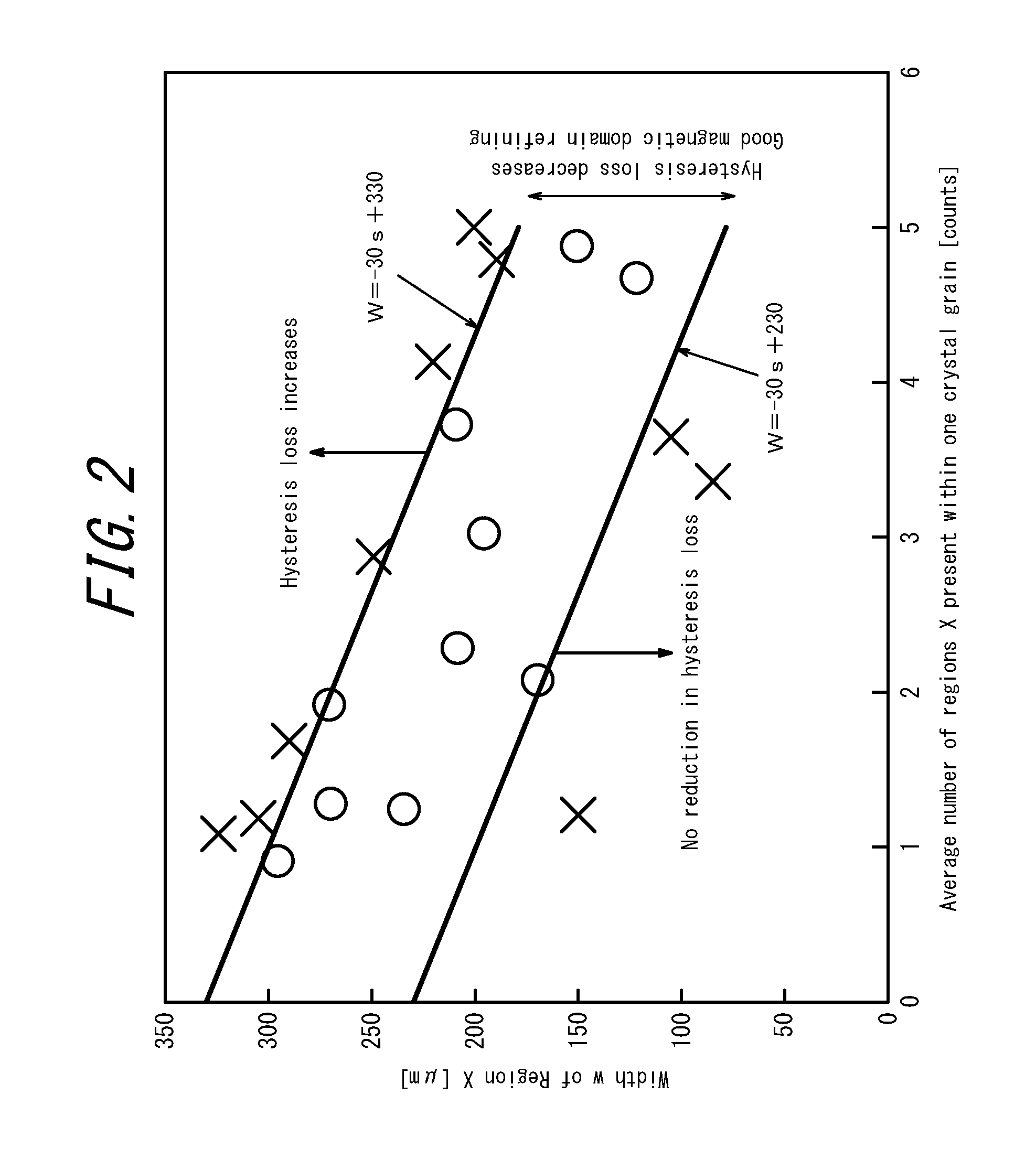

Grain-oriented electrical steel sheet and method for producing same

ActiveUS20150034211A1Total current dropImprove energy efficiencyInorganic material magnetismHysteresisElectrical steel

Disclosed is a grain-oriented electrical steel sheet exhibiting low hysteresis loss and low coercive force, in which an increase in hysteresis loss due to laser irradiation or electron beam irradiation, which has been a conventional concern, is effectively inhibited. The grain-oriented electrical steel sheet has closure domain regions (X) formed to divide the magnetic domains in a rolling direction, from one end to the other in the width direction of the steel sheet, provided that Expression (1) is satisfied:−(500t−80)×s+230≦w≦−(500t−80)×s+330 Expression (1),where t represents a sheet thickness (mm); w represents a smaller one of the widths (μm) of the regions measured on the front and rear surfaces of the steel sheet, respectively, by using a Bitter method; and s represents an average number of the regions present within one crystal grain.

Owner:JFE STEEL CORP

Urethane resin comprising a polyrotaxane and polishing pad

ActiveUS20190263961A1Appropriate hardnessGood elasticity recoveryAbrasion apparatusPolyurea/polyurethane coatingsHydrogenPolyrotaxane

To provide a urethane resin for sliding members which has high abrasion resistance and is considered that crosslinking points are uniformly dispersed so that molecular motion is suitably possible. Particularly, to provide the urethane resin can be advantageously used as a polishing pad.There is provided the urethane resin for polishing is obtained by polymerizing a polymerizable composition comprising (A) a polyrotaxane having a composite molecular structure formed by an axial molecule and a plurality of cyclic molecules clathrating the axial molecule and side chains having an active hydrogen group introduced into at least some of the cyclic molecules and (B) a polyiso(thio)cyanate compound.

Owner:TOKUYAMA CORP

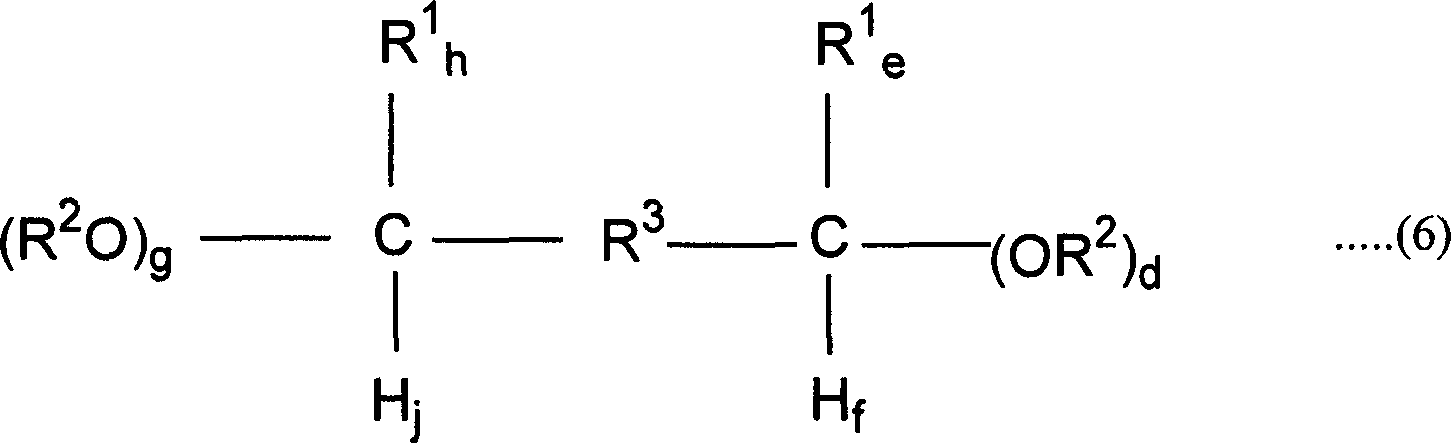

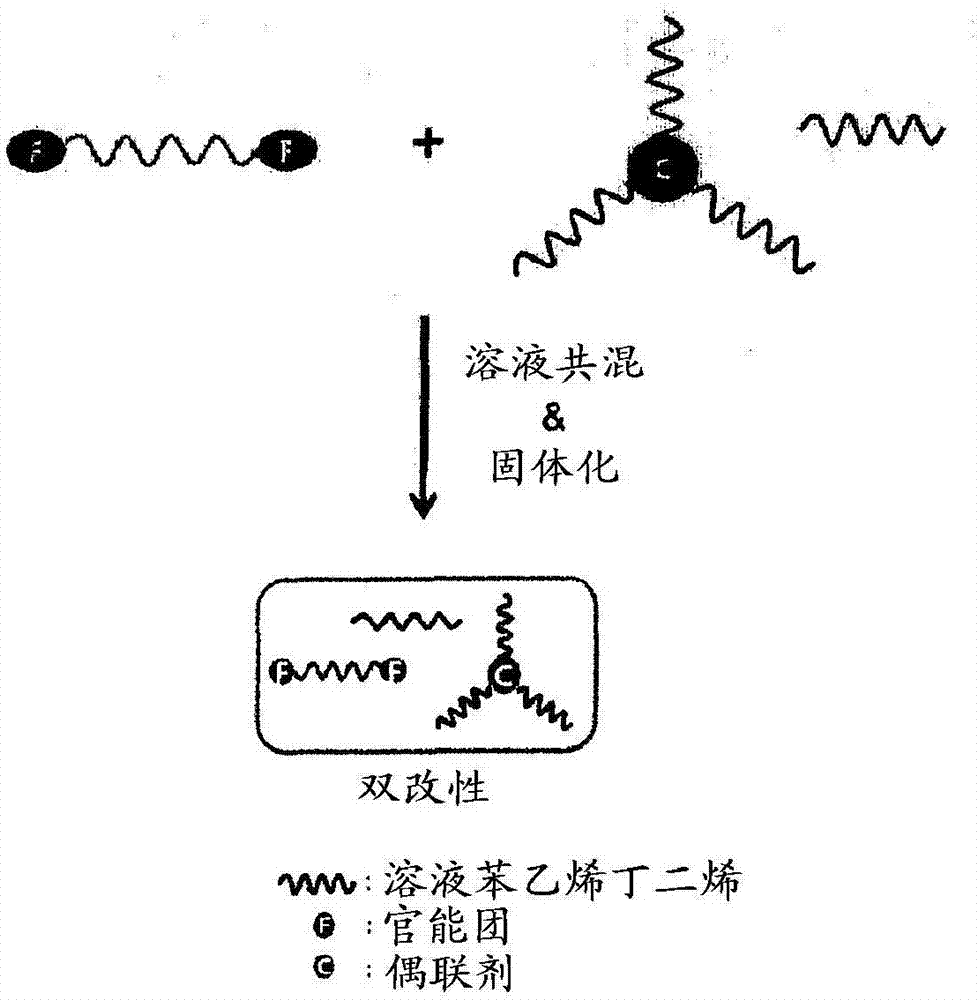

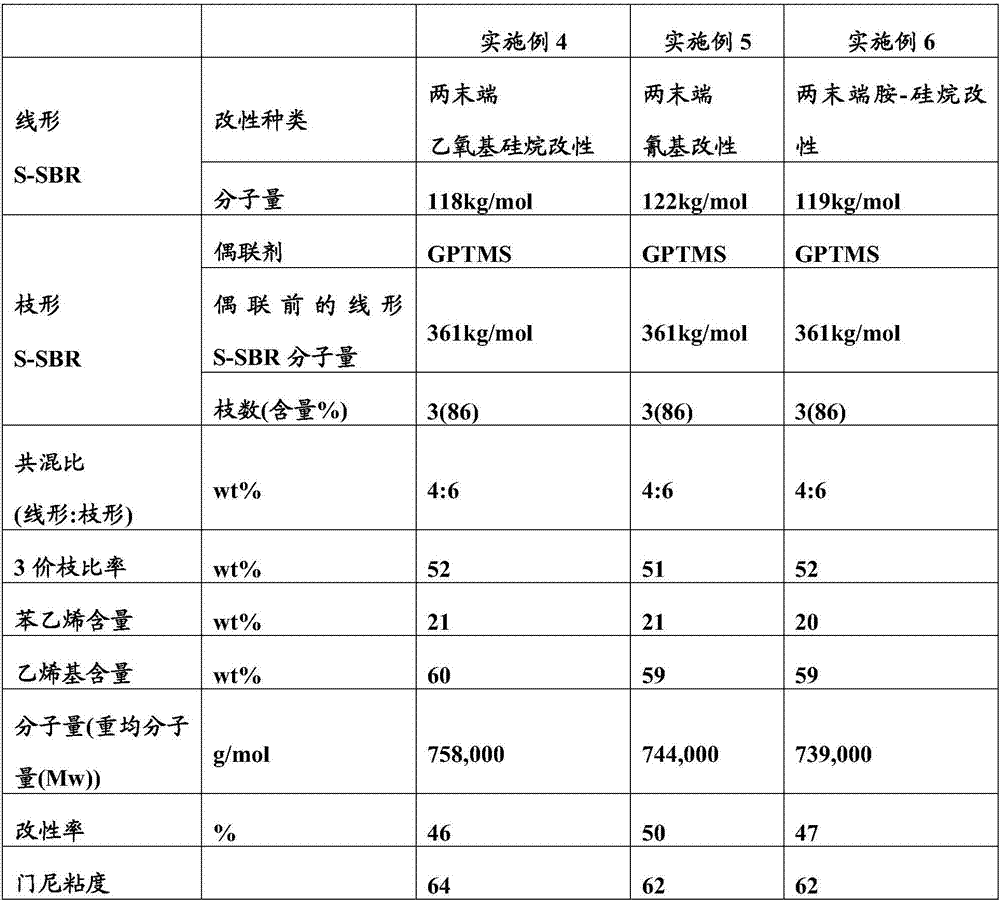

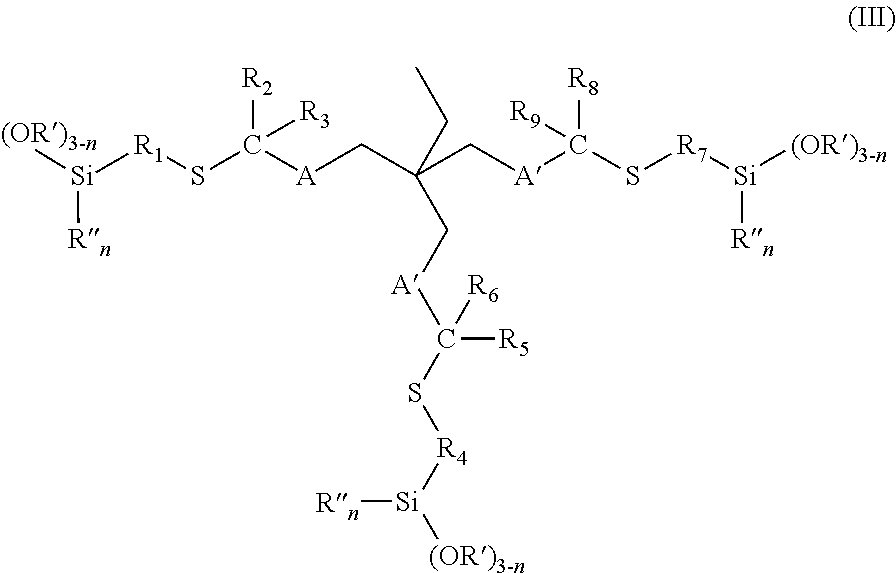

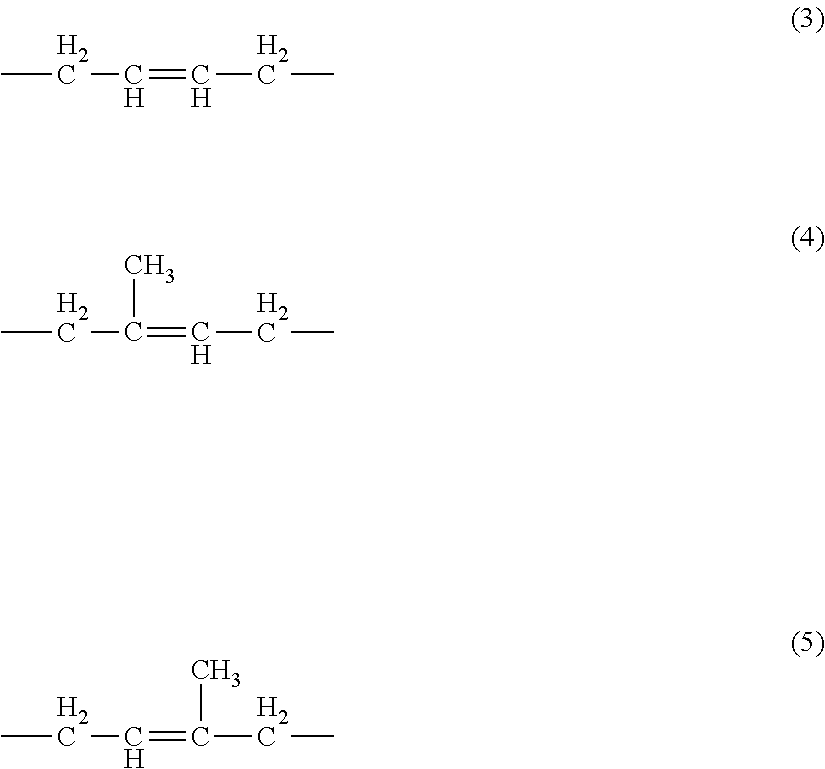

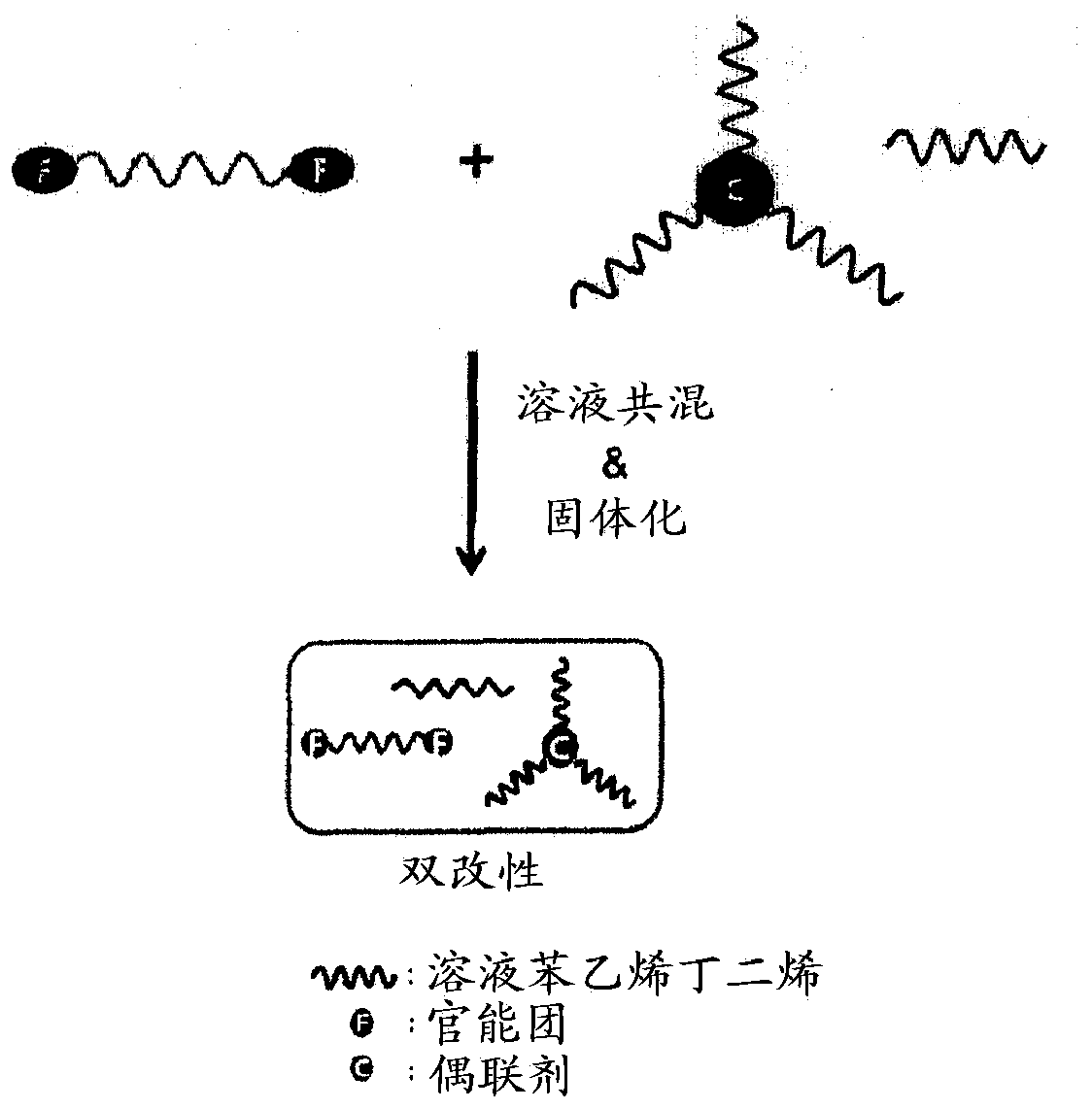

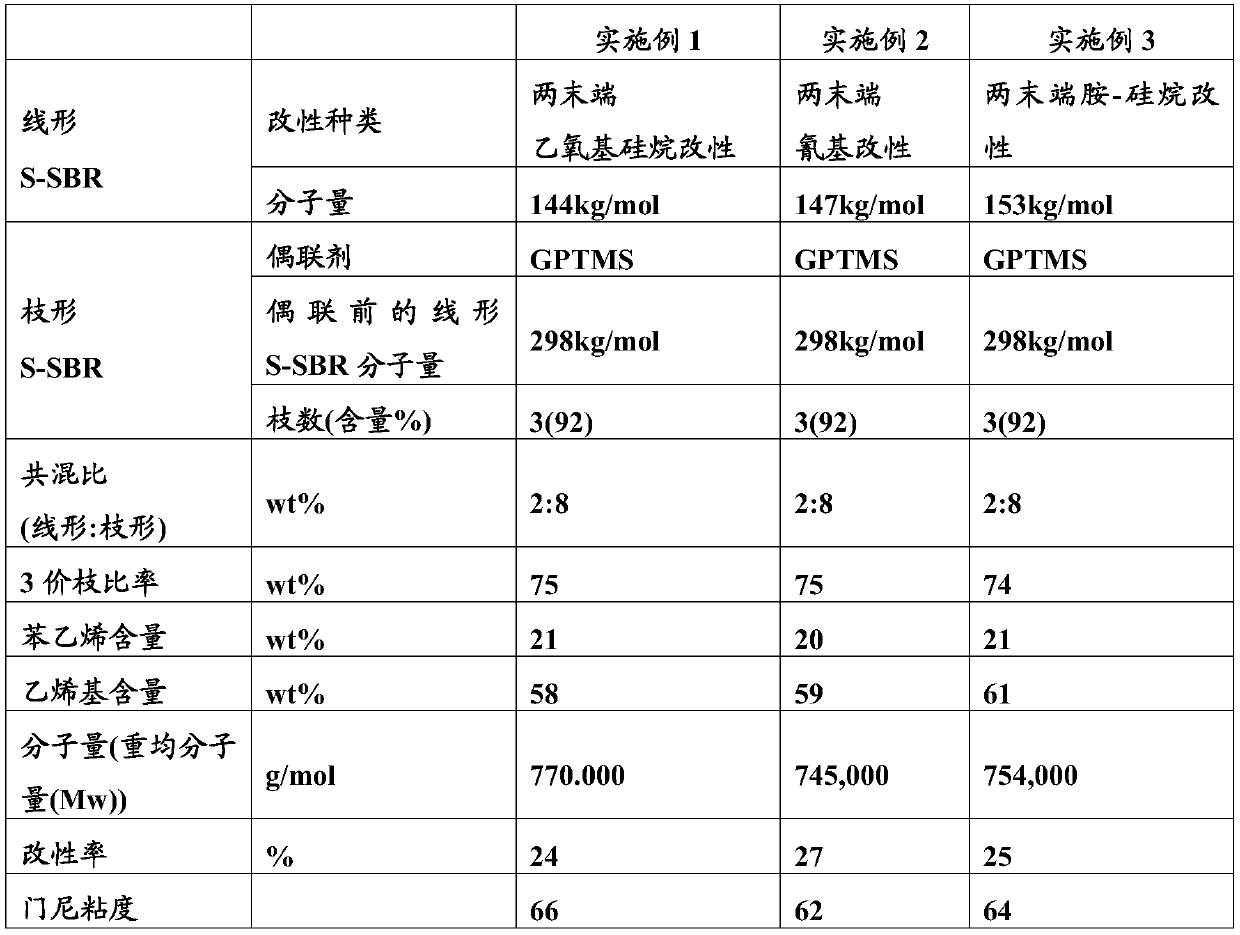

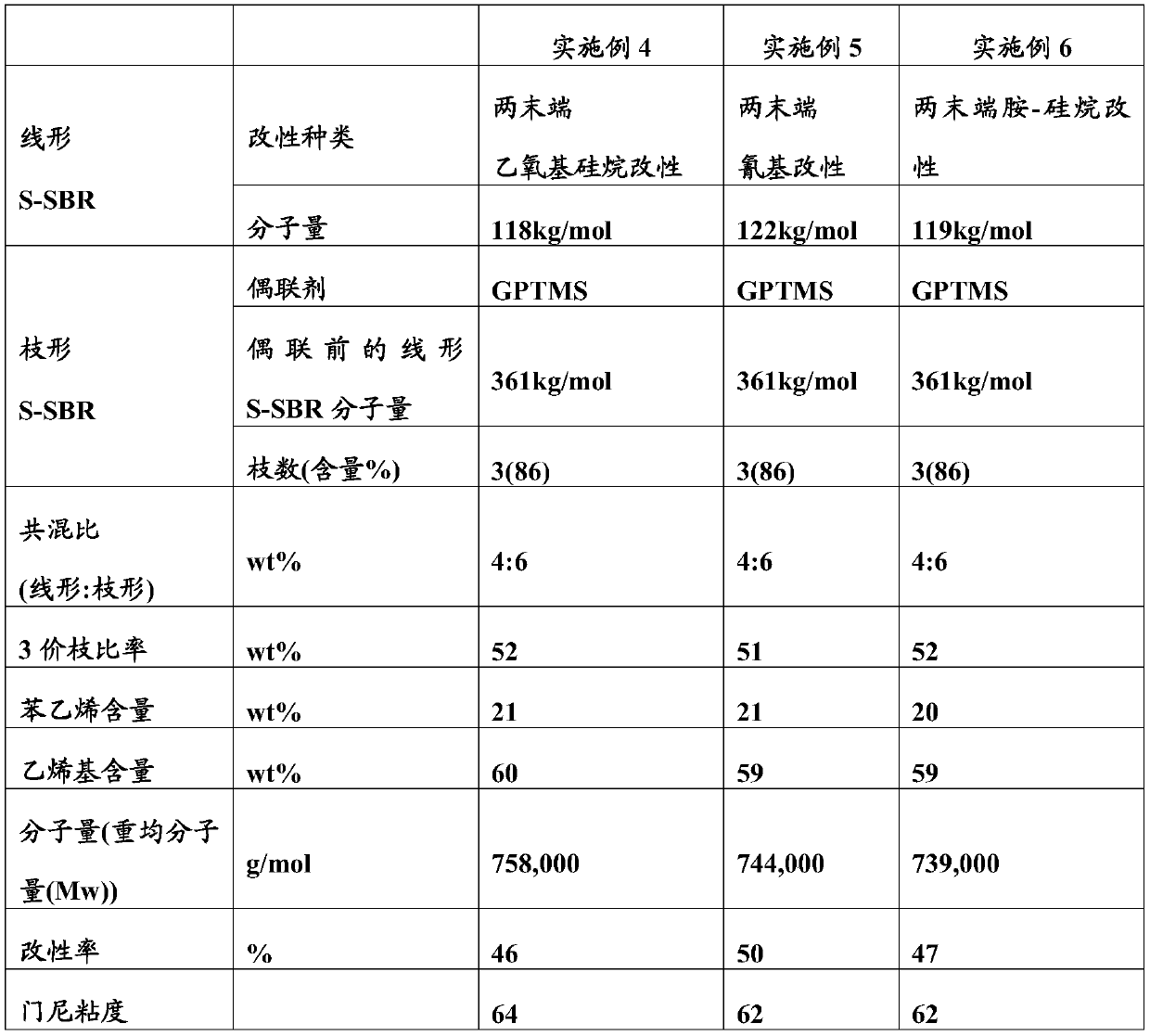

Modified conjugated diene-based polymer and a tire rubber composition using the same

ActiveCN106995541AImprove wet skid performanceLow hysteresis lossSpecial tyresChemistryConjugated diene

The invention relates to modified conjugated diene-based polymer and a tire rubber composition using the same. Raw materials of modified conjugated diene-based polymer are provided. Through utilization of anionic polymerization technique in which an amphoteric initiator is effectively used, a rubber composite material is produced by a conjugated diene-based polymer having a combination of a linear structure modified by two special-structured terminals and having good silica compatibility and a branched conjugated diene-based polymer. It is possible to improve the dispersibility of the inorganic substance through increase of affinity with an inorganic filler.

Owner:한화토탈에너지스주식회사

Rubber composition containing modified conjugated diene polymer and tire

This invention relates to a rubber composition having a high interaction between rubber component and carbon black, a good wear resistance and an excellent low heat buildup (low hysteresis loss), and more particularly to a rubber composition comprising (A) 100 parts by mass of a rubber component containing not less than 10% by mass of a conjugated diene polymer having a polymer chain with at least one functional group selected from the group consisting of particular substituted amino group and cyclic amino group, (B) not less than 20 parts by mass of carbon black and (C) not more than 1.0 part by mass of a polycyclic aromatic compound (PCA).

Owner:BRIDGESTONE CORP

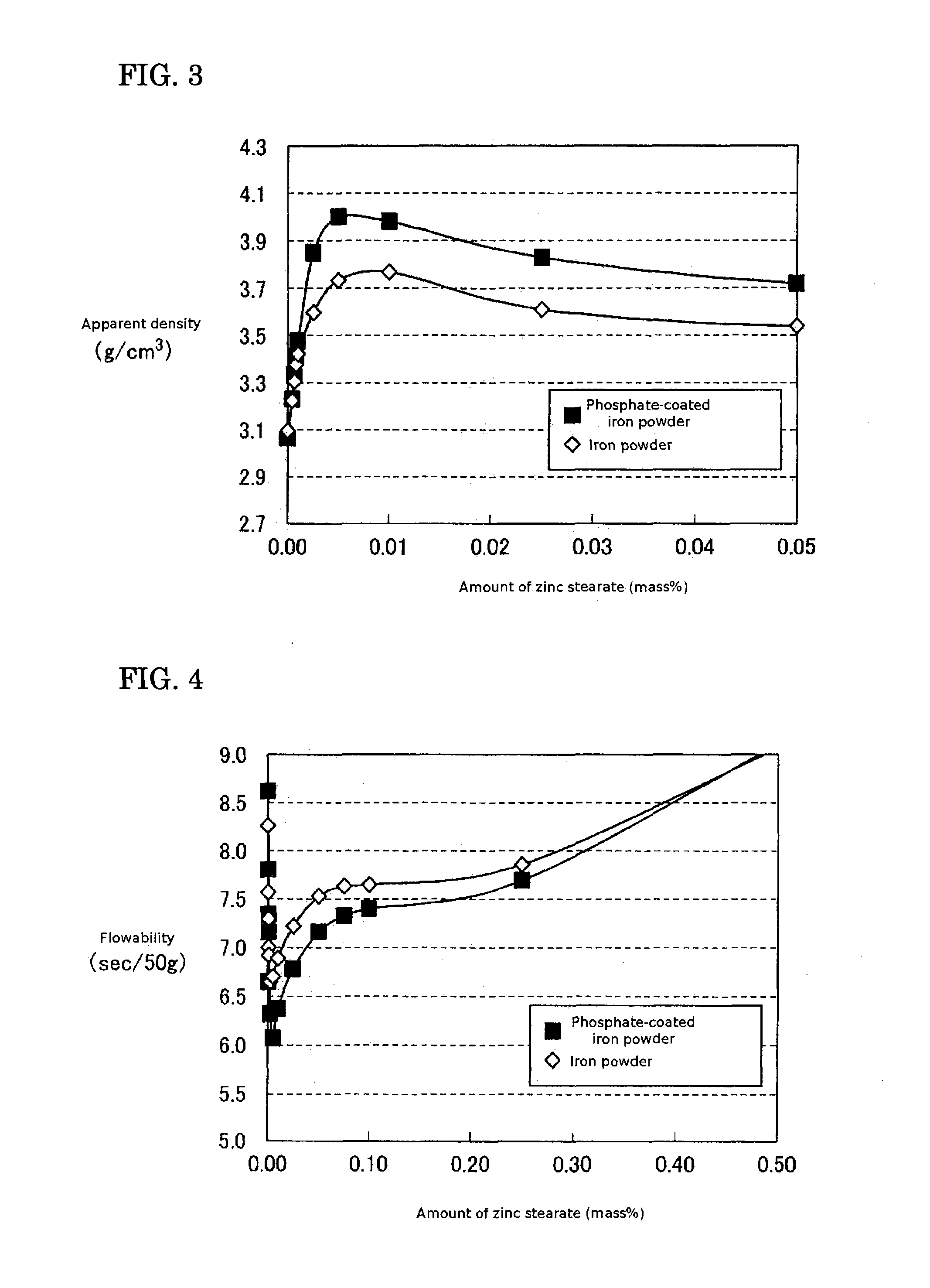

Soft magnetic material and powder magnetic core

ActiveUS20070194267A1Reduce distortionLow hysteresis lossTransportation and packagingMetal-working apparatusMagnetic coreLubrication

A soft magnetic material includes: a plurality of composite magnetic particles formed from a metal magnetic particle and an insulative coating surrounding a surface of the metal magnetic particle and containing metallic salt phosphate and / or oxide; and a lubricant formed as fine particles added at a proportion of at least 0.001 percent by mass and no more than 0.1 percent by mass relative to the plurality of composite magnetic particles. With this structure, superior lubrication is provided during compacting and desired magnetic characteristics can be obtained after compacting.

Owner:SUMITOMO ELECTRIC IND LTD

Sulfur-containing conjugated diolefin copolymer rubber, and rubber composition comprising the same

InactiveUS20100179280A1Good processabilityEasy to processSilicon organic compoundsSpecial tyresConjugated dieneSulfur containing

Disclosed is a sulfur-containing conjugated diolefin copolymer rubber composed of a conjugated diolefin and an aromatic vinyl compound, wherein (1) the content of sulfur bound to the rubber is 0.01 mmol % or more, (2) the content of the aromatic vinyl compound polymerization unit is not less than 5 wt % and less than 45 wt % relative to the amount of the copolymer rubber, and (3) the content of a vinyl bond (a 1,2-bond) in the conjugated diolefin polymerization unit is 30 mol % or more relative to the amount of the conjugated diolefin polymerization unit. In the the copolymerization between the conjugated diolefin and the aromatic vinyl compound, a specific sulfur-containing polymerization terminator is used to terminate the reaction of the copolymerization. The sulfur-containing conjugated diolefin copolymer rubber has good processability and a good balance among wear resistance, fracture properties and low hysteresis loss.

Owner:YOKOHAMA RUBBER CO LTD

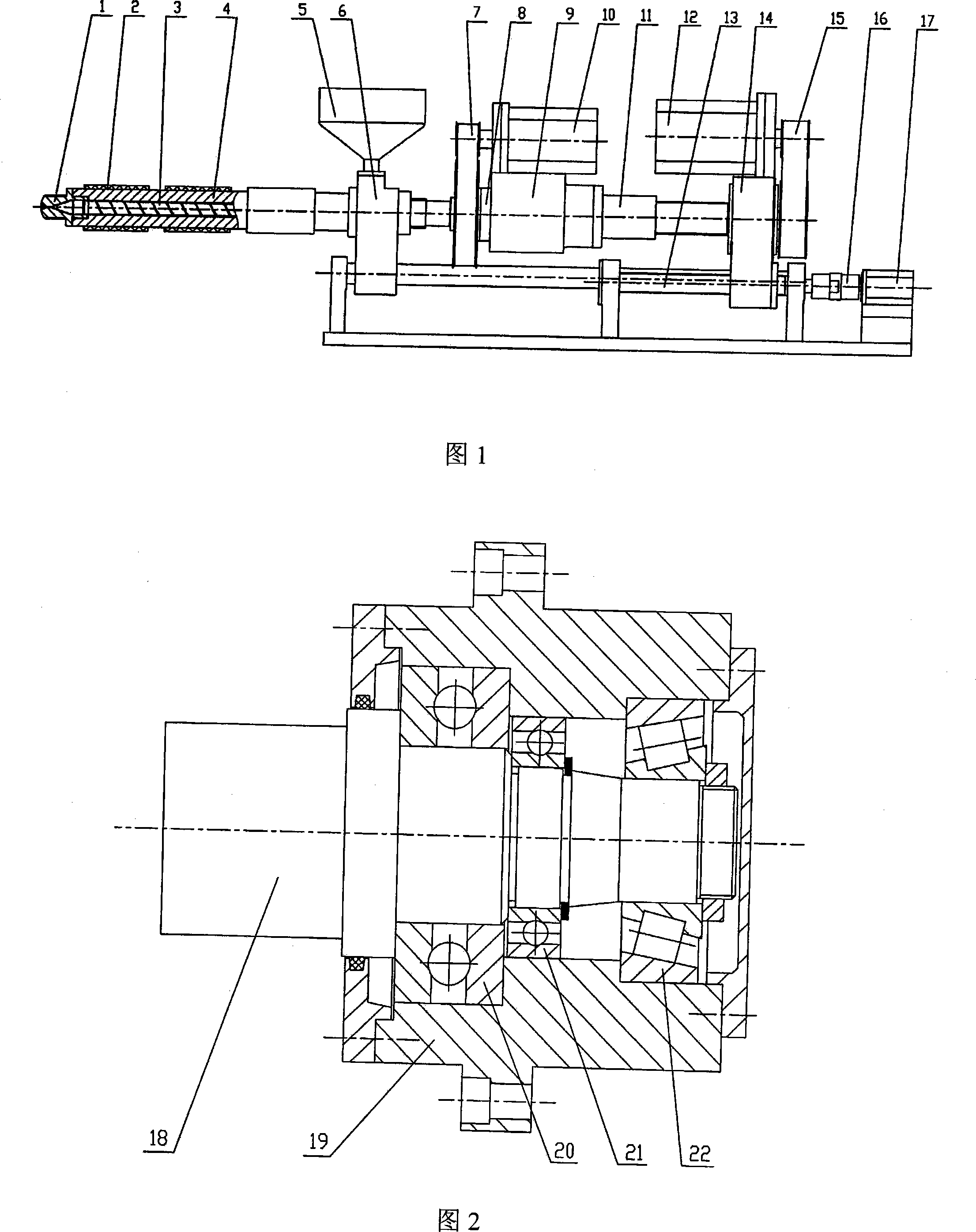

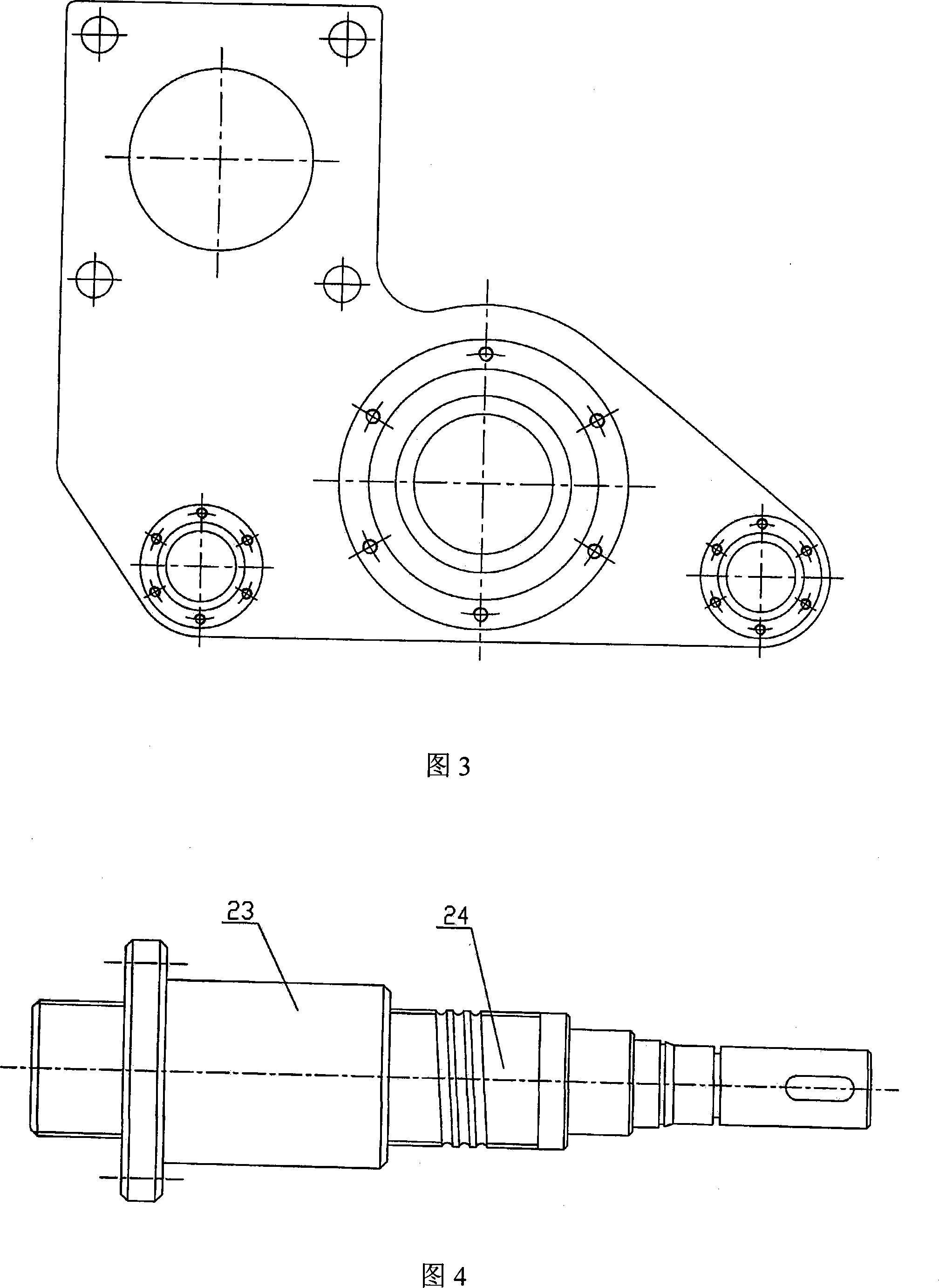

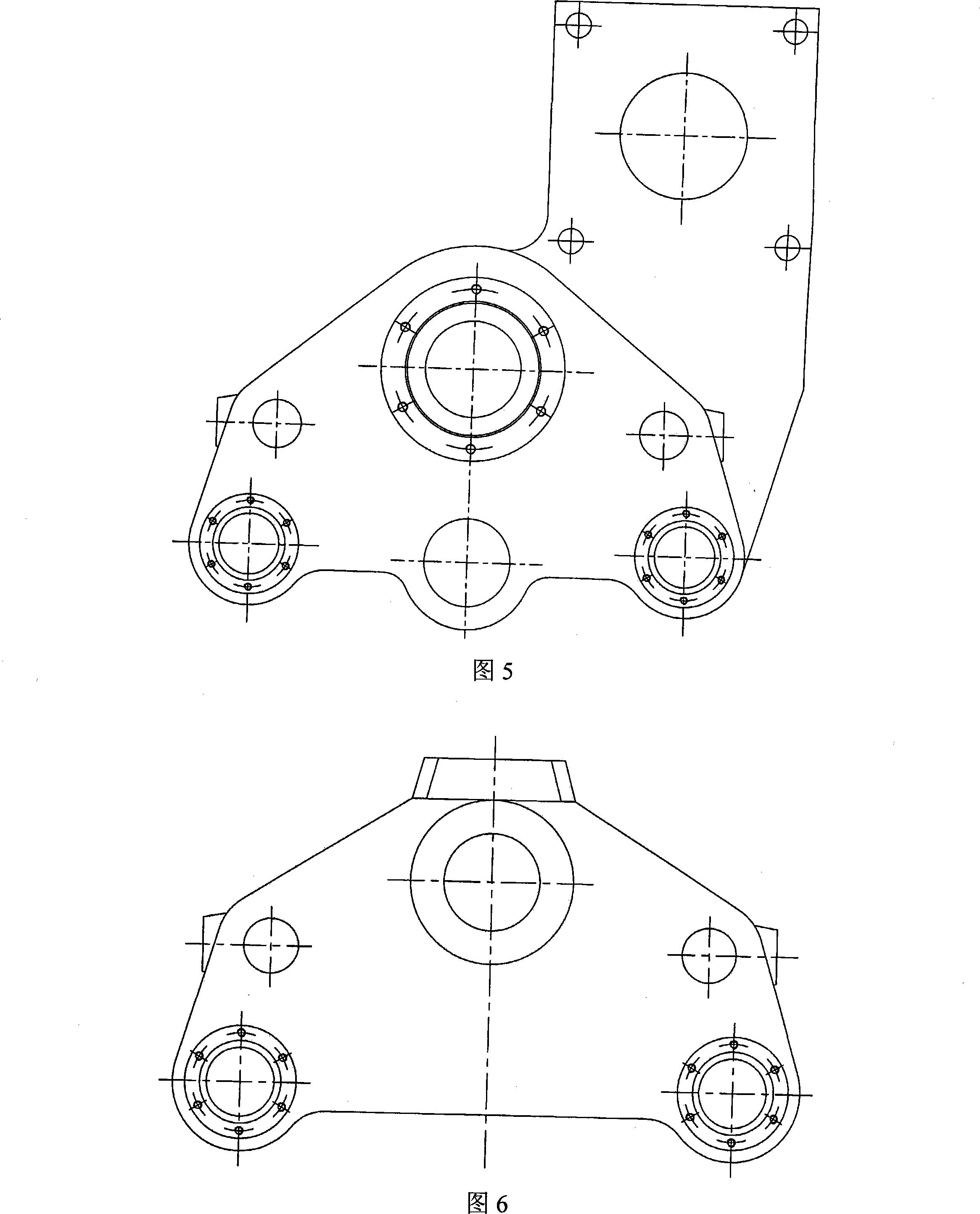

Electrical ejection forming method and device for bonded permanent magnet

InactiveCN101197208AReduce frictional resistanceImprove energy savingCeramic shaping apparatusInductances/transformers/magnets manufactureStructural symmetryDrive shaft

The invention relates to an electric operated injection molding method for bonded permanent-magnets and a device thereof. The method is that: an AC servomotor drives a timing belt and a ball screw to complete plasticization metering, stepless injection molding and guaranteeing the pressure to make up shrinks of a screw to mixed feeding of the bonded permanent-magnets. The device mainly comprises a screw rod, a charging barrel, the timing belt, a transmission shaft, a motor and the ball screw. When the pressure of fusion feeding of the bonded permanent-magnets in the charging barrel reaches the set value, load of the injection servomotor is increased and current of the injection servomotor is increased correspondingly, the injection servomotor rotates reversely to drive the screw rod to retreat in order to realize the plasticization metering of the permanent-magnets feeding; when the fusion feeding of the bonded permanent-magnets in the charging barrel reaches the value of the plasticization metering, the injection servomotor rotates positively to drive the timing belt and the ball screw, the transmission shaft is utilized to make the screw rod advance axially so as to realize the stepless injection molding and guaranteeing the pressure to make up shrinks of the permanent-magnets feeding. The whole device of the invention has good symmetrical structure and movement stationarity, low energy consumption, short injection molding period, and high magnetic performance and dimensional precision.

Owner:WUYI UNIV

Method for producing a rubber composition

A method for producing a rubber composition, the method including: preparing a modified natural rubber by releasing protein from rubber particles in a natural rubber latex by adding at least one organic compound selected from formaldehyde, paraformaldehyde, formalin, and glyoxal to the above mentioned natural rubber latex and then drying so as to include the released protein therein; and mixing at least one selected from carbon black and silica in this modified natural rubber. Such method reduces viscosity and improves molding processibility of the rubber composition, as well as reducing hysteresis loss.

Owner:THE YOKOHAMA RUBBER CO LTD

Soft magnetic alloy powder, compact, powder magnetic core, and magnetic element

ActiveUS9245676B2Reduce lossImprove corrosion resistanceTransformers/inductances casingsTransformers/inductances coils/windings/connectionsMetallurgyAverage size

Provided are a soft magnetic alloy powder, a compact made from the soft magnetic alloy powder, a powder magnetic core including the compact, and a magnetic element including the powder magnetic core. The soft magnetic alloy powder contains Fe—Ni-based particles containing 38% to 48% by mass Ni, 1.0% to 15% by mass Co, and 1.2% to 10% by mass Si relative to the total mass of Fe, Ni, Co, and Si, the remainder being Fe. The Fe—Ni-based particles have an average size of more than 1 μm to less than 10 μm.

Owner:TDK CORPARATION

Sulfur-containing conjugated diolefin copolymer rubber, and rubber composition comprising the same

InactiveUS8148473B2Easy to processLow hysteresis lossSilicon organic compoundsSpecial tyresAlkeneSulfur containing

Disclosed is a sulfur-containing conjugated diolefin copolymer rubber composed of a conjugated diolefin and an aromatic vinyl compound, wherein (1) the content of sulfur bound to the rubber is 0.01 mmol % or more, (2) the content of the aromatic vinyl compound polymerization unit is not less than 5 wt % and less than 45 wt % relative to the amount of the copolymer rubber, and (3) the content of a vinyl bond (a 1,2-bond) in the conjugated diolefin polymerization unit is 30 mol % or more relative to the amount of the conjugated diolefin polymerization unit. In the copolymerization between the conjugated diolefin and the aromatic vinyl compound, a sulfur-containing polymerization terminator is used to terminate the reaction of the copolymerization.

Owner:THE YOKOHAMA RUBBER CO LTD

Modified conjugated diene polymer, modified conjugated diene polymer composition, tire, and method for producing modified conjugated diene polymer

ActiveUS10822446B2Improve balanceLow hysteresis lossSpecial tyresTyre tread bands/patternsPolymer scienceConjugated diene

A modified conjugated diene polymer satisfying the following conditions (I) to (IV):(I) at least two peaks are observed in a molecular weight distribution curve;(II) when a peak of the highest molecular weight is defined as a peak (B), a peak of the largest peak area except for the peak (B) is defined as a peak (T), a peak molecular weight of the peak (B) is from 500,000 to 2,500,000 and a peak molecular weight of the peak (T) is from 150,000 to 600,000;(III) an area of the peak (T) is from 30% to 80% and a total value of an area of the peak (B) and the area of the peak (T) is 65% or more; and(IV) a proportion of a modified polymer chain(s) in a region ranging from a low-molecular-weight side to a point of 5% cumulative area is from 60% to 99%.

Owner:JAPAN ELASTOMER CO LTD

Preparation method of high-performance room temperature complex-phase magnetic cooling material

InactiveCN101768677BImprove magnetocaloric performanceImprove corrosion resistanceMagnetic materialsHysteresisRare earth

The invention relates to a preparation method of a high-performance room temperature complex-phase magnetic cooling material. The complex-phase magnetic cooling material comprises amorphous ferrous alloy and crystalline rare earth based alloy. The preparation method comprises the following steps of: (1) preparing the amorphous ferrous alloy by adopting a melt-spun process, mechanically crushing and then carrying out ball milling to prepare powder; (2) preparing the crystalline rare earth based alloy by adopting an ingot casting process, a fast-hardening and strip-casting process or a melt-spun process, mechanically crushing after heat treatment, and then carrying out ball milling to prepare powder; or preparing alloy powder by directly adopting a mechanical alloying process; (3) evenly mixing the amorphous ferrous alloy powder and the crystalline rare earth based alloy powder in the protection atmosphere or vacuum; (4) carrying out compression molding on mixed powder in the protectionatmosphere or vacuum; and (5) preparing a pressed blank into amorphous / crystalline complex-phase blocky alloy by adopting a rapid sintering process below the crystallization temperature and in the protection atmosphere or vacuum. The prepared complex-phase magnetic cooling material has high magneto-thermal performance, high decay resistance performance, low hysteresis lag and cost and simple process, and is suitable for large-scale batch production.

Owner:JIANGSU UNIV

Modified conjugated diene polymer and tire rubber composition using same

ActiveCN106995541BImprove wet skid performanceLow hysteresis lossSpecial tyresPolymer scienceSilicon dioxide

The invention relates to modified conjugated diene-based polymer and a tire rubber composition using the same. Raw materials of modified conjugated diene-based polymer are provided. Through utilization of anionic polymerization technique in which an amphoteric initiator is effectively used, a rubber composite material is produced by a conjugated diene-based polymer having a combination of a linear structure modified by two special-structured terminals and having good silica compatibility and a branched conjugated diene-based polymer. It is possible to improve the dispersibility of the inorganic substance through increase of affinity with an inorganic filler.

Owner:HANWHA TOTAL ENERGIES PETROCHEMICAL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com