Patents

Literature

335results about How to "Appropriate hardness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Oral cavity disintegrating tablet and method of producing the same

ActiveUS20100278930A1Easy to produceDisintegrates quicklyBiocideOrganic active ingredientsSucroseOrally disintegrating tablet

The invention provides an orally disintegrating tablet containing (a) one or more saccharides or sugar alcohols selected from the group consisting of mannitol, lactose, xylitol, sucrose, erythritol and glucose and (b) low substituted hydroxypropylcellulose and substantially free of a starch disintegrant, which tablet is produced by steps of granulating a composition containing the above-mentioned components (a) and (b) by an agitation granulation method, and compression-molding the obtained granulation product. The invention also provides a method of producing an orally disintegrating tablet substantially free of a starch disintegrant, including steps of granulating a composition containing the above-mentioned components by an agitation granulation method, and compression-molding the obtained granulation product.

Owner:SAWAI PHARMA

Transparent solid oil cosmetics

ActiveUS20060280763A1High transparencyLarge transmittanceCosmetic preparationsHair removalWaxDiisostearyl malate

A solid cosmetic comprising components (A), (B), (C), and (D) below: (A) a polyamide resin; (B) diisostearyl malate; (C) a polyglyceryl isostearate; and (D) a liquid oil; and not containing a wax when the component (A) comprises only an ester-terminated polyamide resin.

Owner:KOKYU ALCOHOL KOGYO

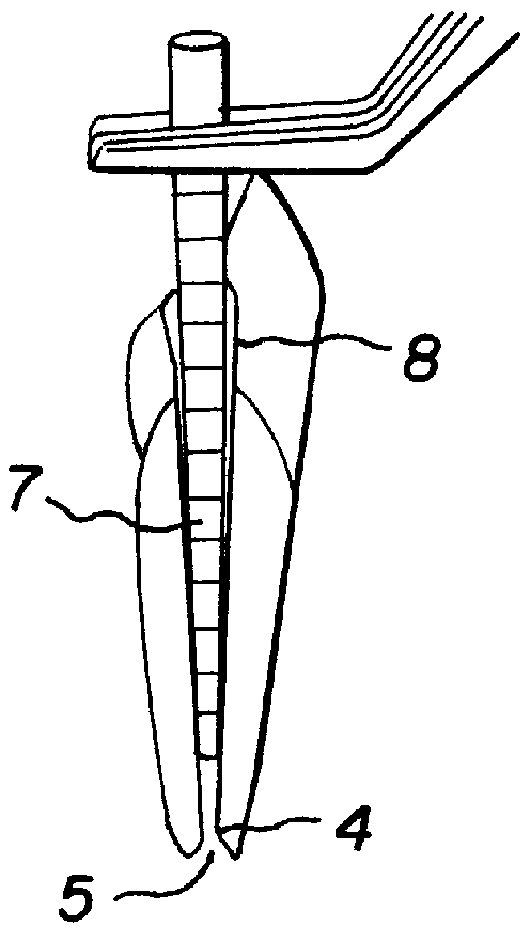

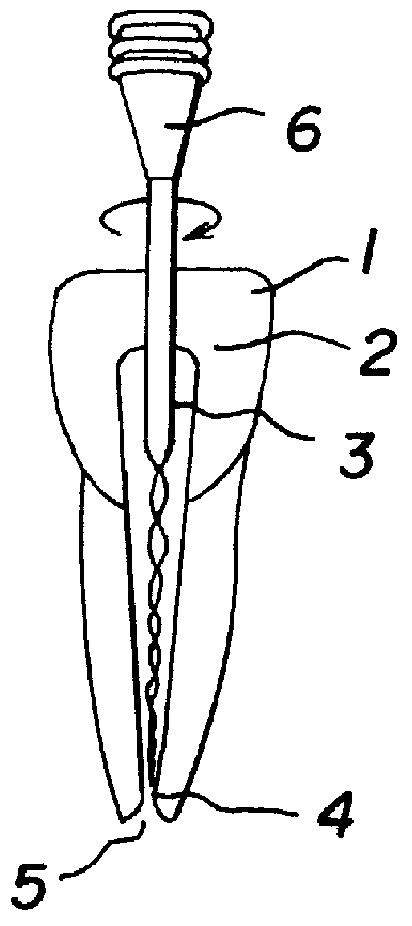

Root canal filling point

InactiveUS6024569AEasy-to-use and physicochemically stableLow antigenicityTeeth fillingTeeth cappingCopolymerEthylene

A new root canal filling point which is physicochemically stable, is not toxic to periapical tissue, can be sterilized and x-rayed; and has high elasticity and fracture resistance which enables the root canal filling point to be pressure-inserted into an even narrow or curved root canal. The root canal filling point is made of a copolymer consisting of propylene and ethylene, and a contrast medium.

Owner:AYTEC JAPAN CORP

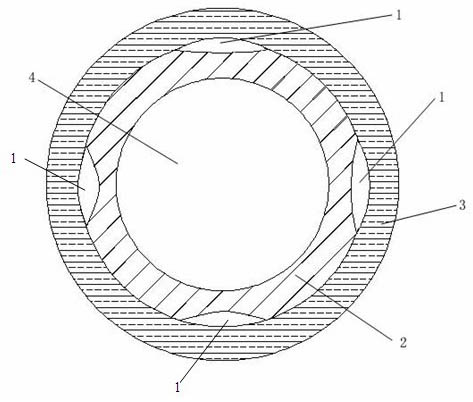

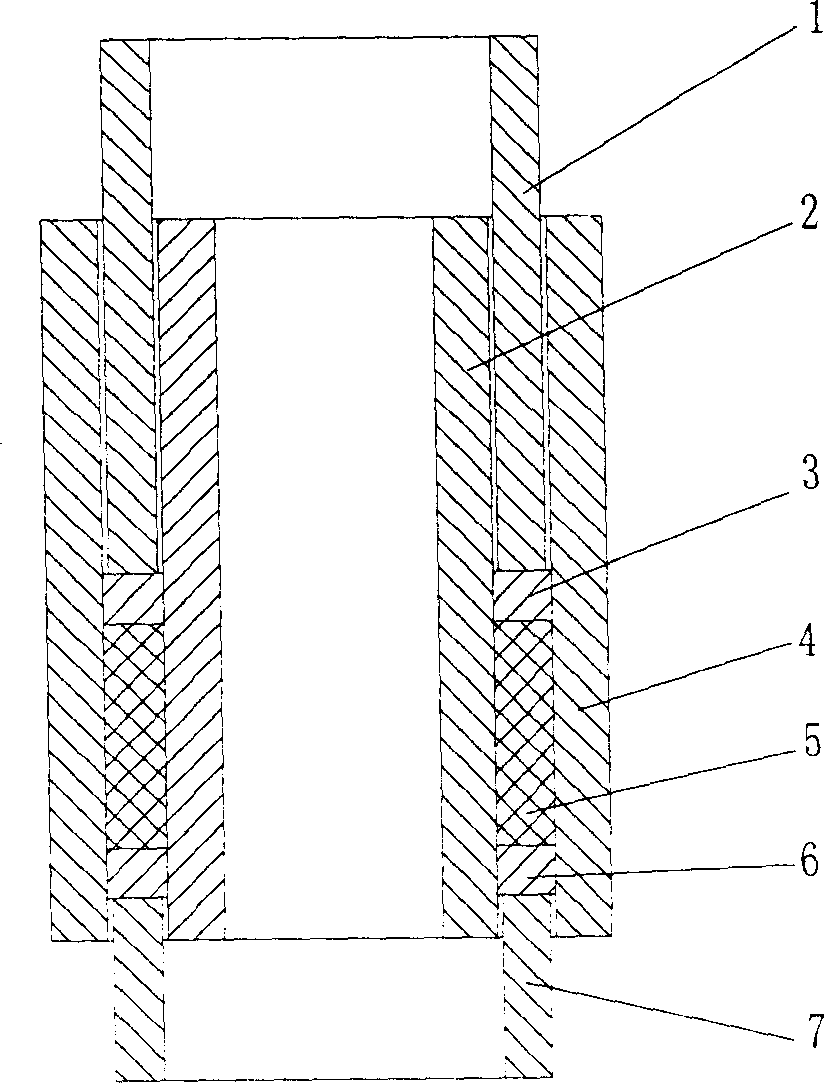

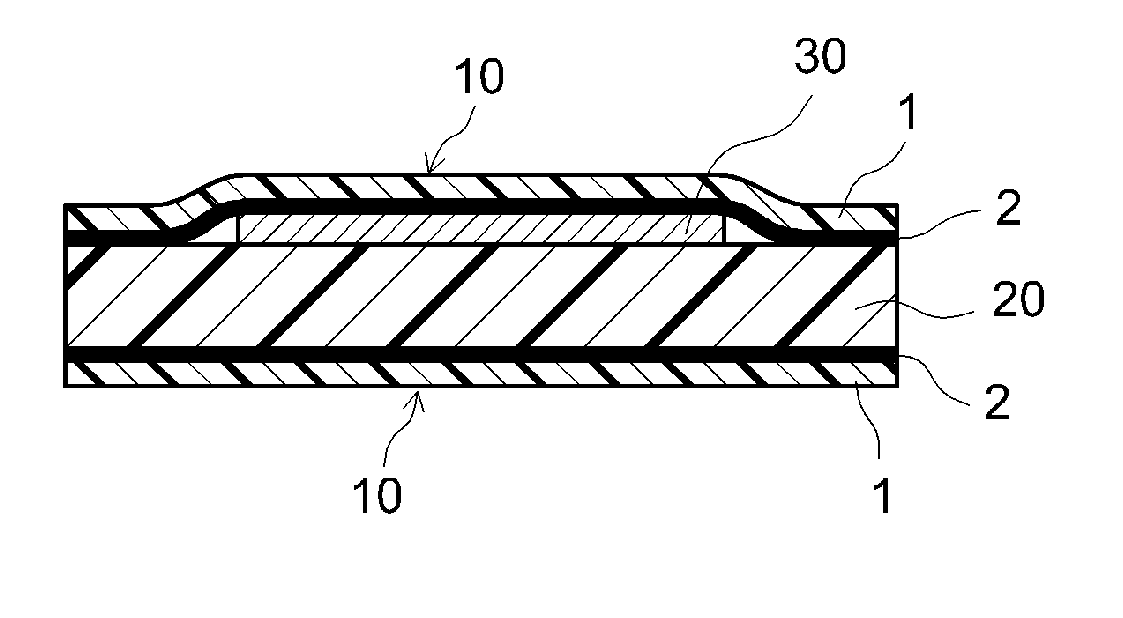

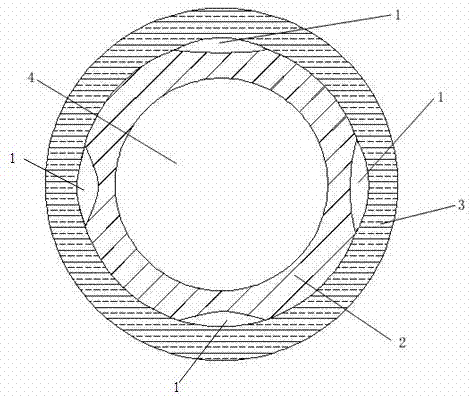

Nerve conduit and preparation method thereof

ActiveCN102688076AAddress barriers to developmentModerate intensitySurgeryCatheterCatheterNerve repair

The invention discloses a nerve conduit and a preparation method thereof. The nerve conduit consists of an inner layer, an outer layer and at least one minitype cavity for storing a bioactive factor solution, wherein the inner layer is of a hydrophilic cell scaffold layer, and the outer layer is of a hydrophobic nerve conduit scaffold layer. The nerve conduit can further comprise a transition layer between the inner layer and the outer layer. The preparation method of the nerve conduit comprises the steps of preparing the inner layer by adopting an electrostatic spinning method, then adding the material for preparing the cavity, then preparing the outer layer, and taking out or dissolving the material for preparing the cavity, thus obtaining the nerve conduit. The nerve conduit has the minitype cavity, so that bioactive factors can be loaded by a manner of injection, soaking and the like as required before operation, thus not only leading the production quality to be easily controlled, but also being capable of greatly improving the survival rate of the bioactive factors, more efficiently promoting the regeneration of nerves, and enhancing the restoration effect of nerves.

Owner:MEDPRIN REGENERATIVE MEDICAL TECH

Process for preparing composite modified water polyurethane emulsion

During the preparation of organic and inorganic silicon compound modified water-thinned polyurethane emulsion, organic silicon compound is introduced into polyurethane in the high molecular synthesis or water emulsifying chain expansion, and inorganic silicon compound in certain amount is added into the emulsion for further chain expansion and crosslinking. The method of the present invention is convenient in operation, and the prepared water-thinned polyurethane emulsion can form film with high water resistance, high brightness, proper hardness and other advantages. Compared with un-modified water-thinned polyurethane paint, the present invention has obviously raised technological performance and may be used for wood ware, etc.

Owner:GUANGZHOU INST OF GEOCHEMISTRY - CHINESE ACAD OF SCI

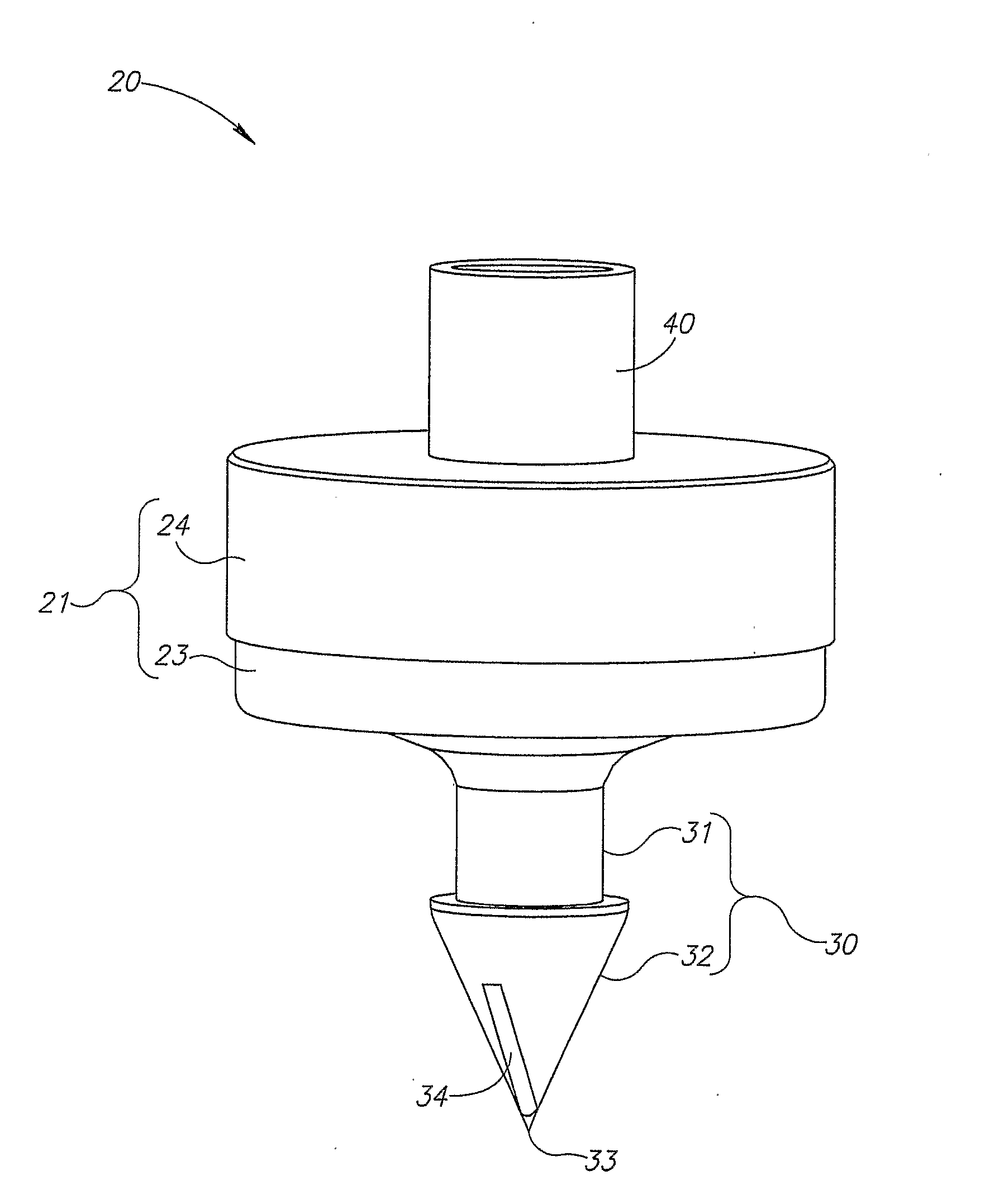

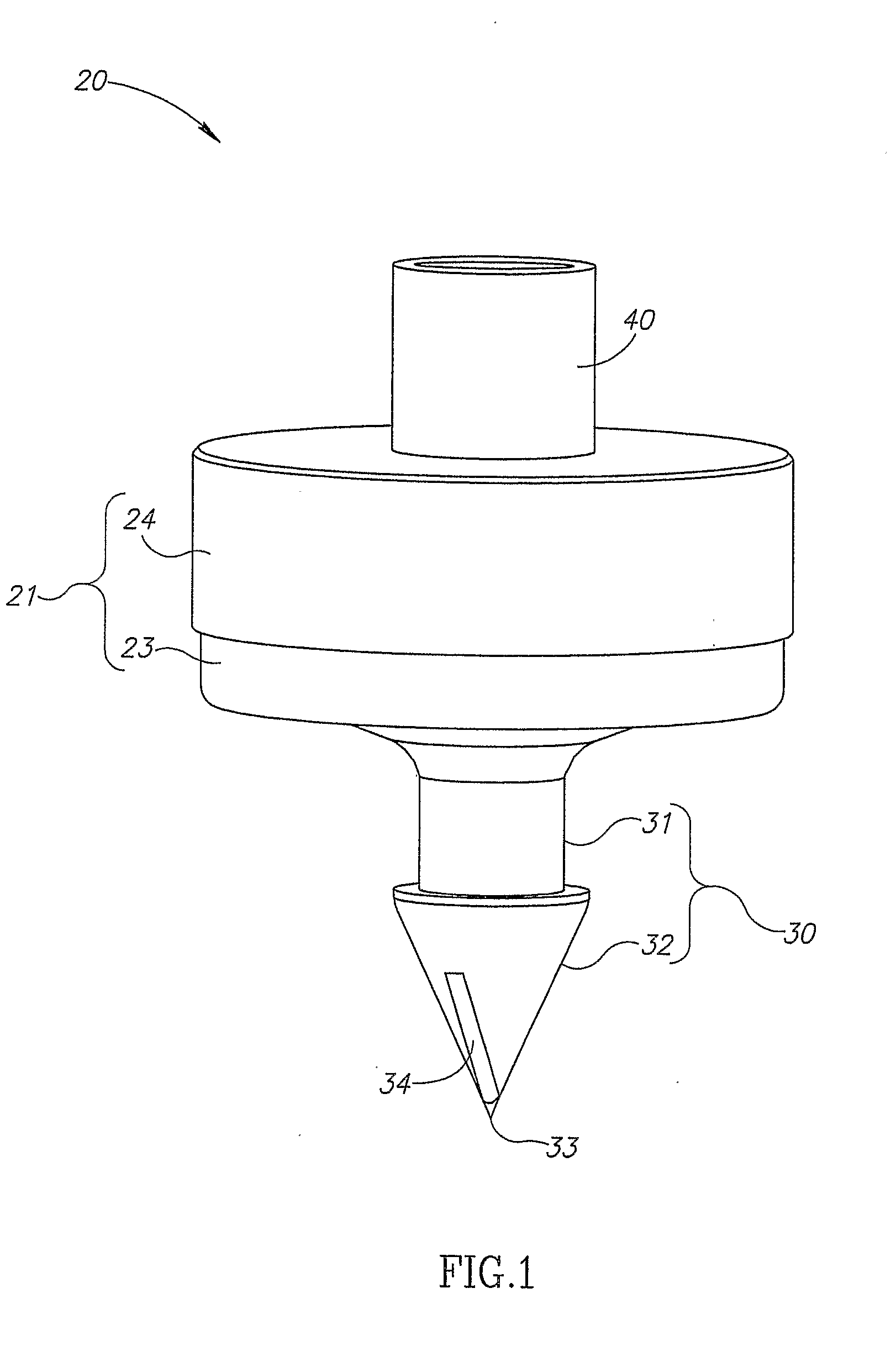

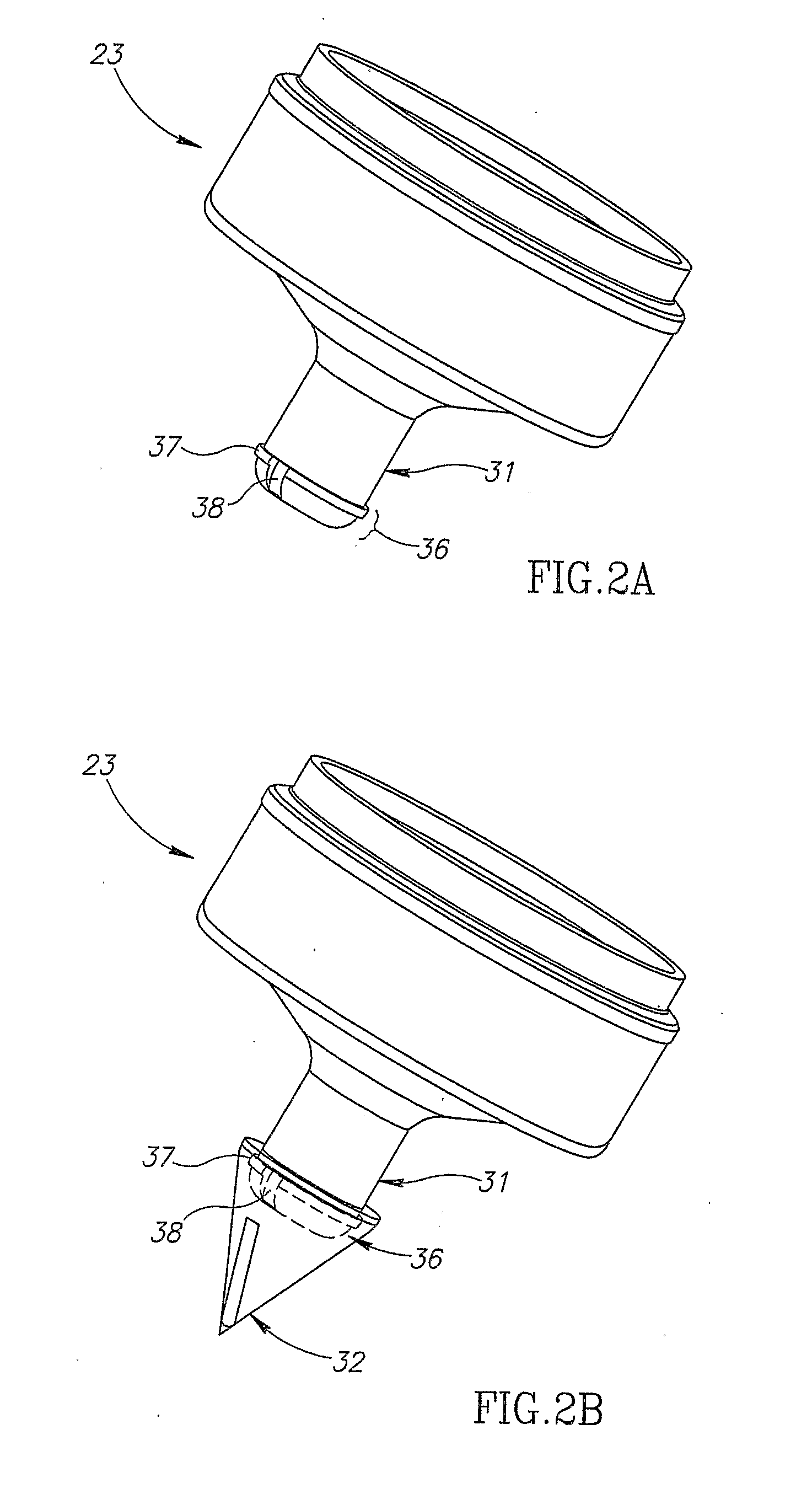

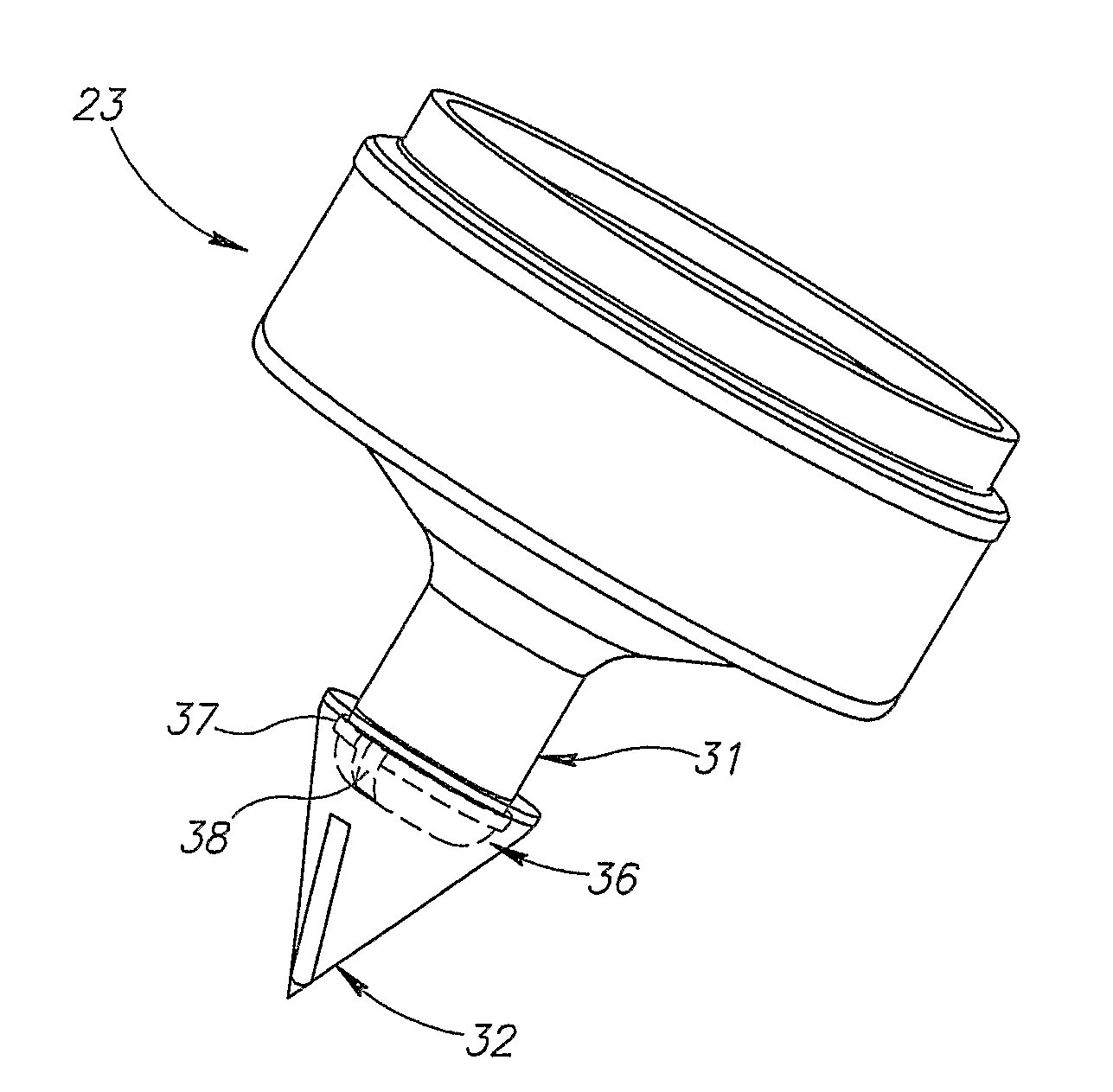

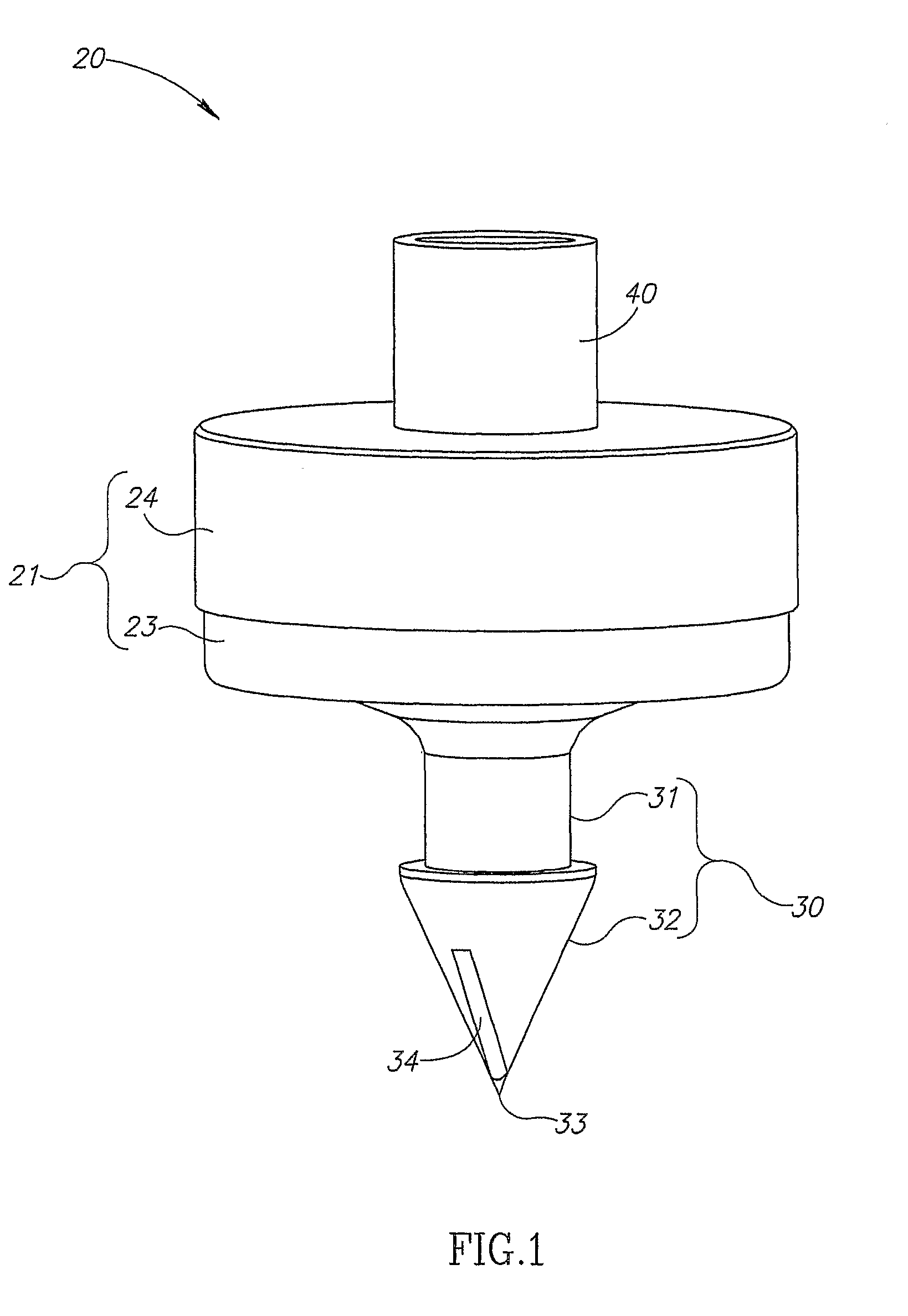

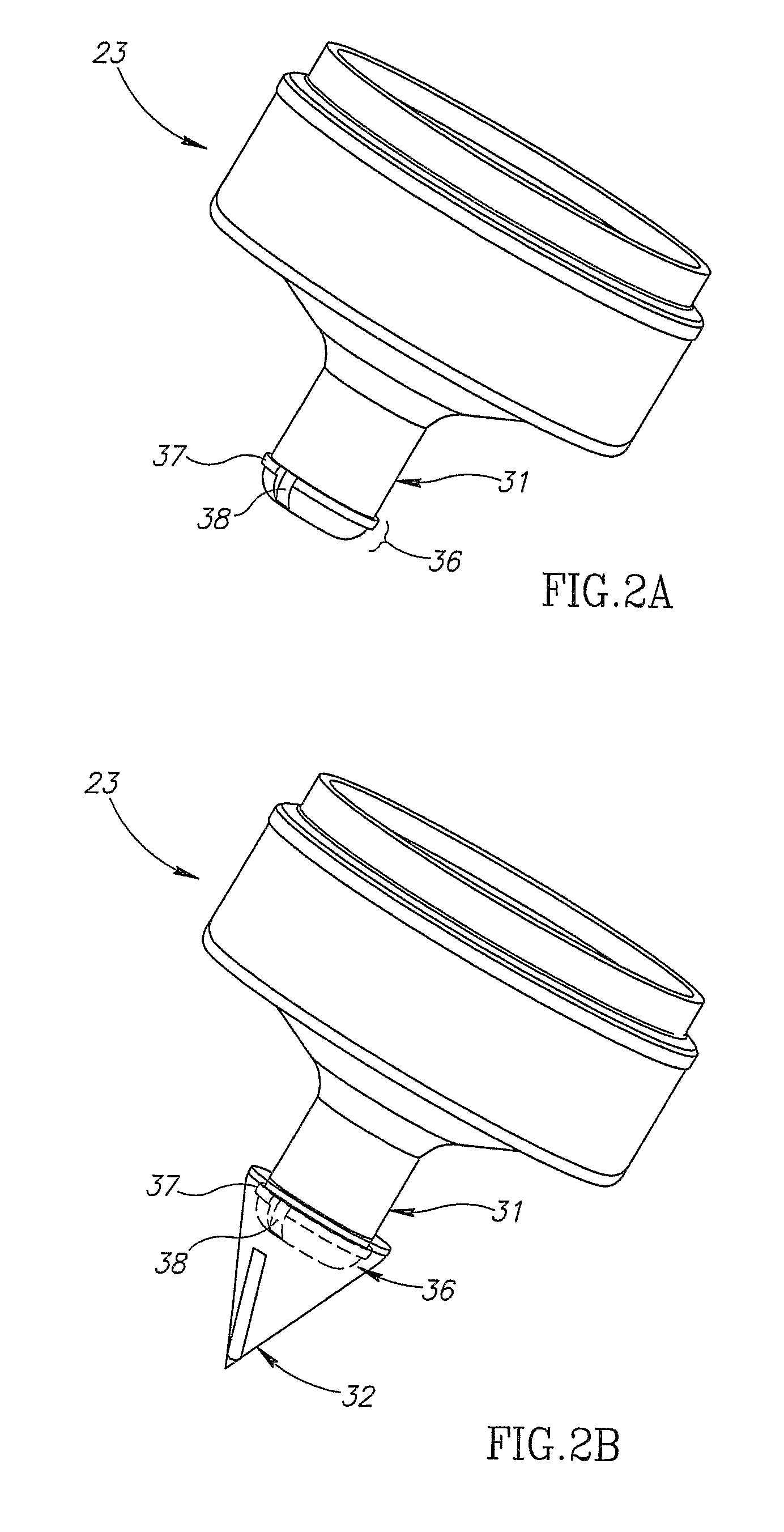

Drippers and pipe couplers

ActiveUS20090243146A1Efficiently useSolve the lack of rigidityClimate change adaptationWatering devicesEngineeringDrip irrigation

A drip irrigation device for distributing a portion of the water flowing in an irrigation pipe to a plant, the device comprising: a housing formed from a relatively soft plastic; and a connector for coupling the housing to the irrigation pipe comprising a bayonet for puncturing the irrigation pipe formed from a relatively hard material over-molded onto a feature of the housing made from the soft plastic.

Owner:NETAFIM LTD

Drippers and pipe couplers

ActiveUS8091800B2Solve the lack of rigiditySharpness sufficientClimate change adaptationWatering devicesWater flowDrip irrigation

A drip irrigation device for distributing a portion of the water flowing in an irrigation pipe to a plant, the device comprising: a housing formed from a relatively soft plastic; and a connector for coupling the housing to the irrigation pipe comprising a bayonet for puncturing the irrigation pipe formed from a relatively hard material over-molded onto a feature of the housing made from the soft plastic.

Owner:NETAFIM LTD

Oil base and external preparation containing same

ActiveUS20070269470A1Appropriate hardnessAppropriate spreadabilityCosmetic preparationsBiocideGlycerolHydroxystearic Acid

[Problems to be Solved] To provide an oil base having appropriate hardness and viscosity and excellent spreadability, a process for producing same, and a cosmetic material containing the oil base [Solution means] The oil base of the present invention is an oil base containing an ester condensate obtained by a reaction between polyglycerol, 12-hydroxystearic acid, and hydrogenated dimer acid, the oil base having a three-dimensional network structure in which hydrogenated dimer acid is condensed with a hydroxyl group of each of the polyglycerol and 12-hydroxystearic acid.

Owner:KOKYU ALCOHOL KOGYO

Finish for pre-coating coiled material

InactiveCN1473898AReasonable branched chain structureReasonable collocationPolyester coatingsIsocyanateSolvent

The finish for pre-coating coiled material consists of saturated polyester resin with linear and / or branched chain structure and acid value less than 5 mg KOH / g 10-50 wt%, amino resin 1-30 wt%, polyisocyanate closed with at least two kinds of closing agent with active hydrogen 1-30 wt%, pigment slurry 40-87 wt% and assistant 0.1-5.0 wt%. It is homogeneous white ropy liquid mixture, and has coating-4 viscosity at 23 deg.c 20-200 sec and solid content 40-80 wt%. It is coated and stoved at 200-260 deg.c for 20-90 sec to form dry film of 8-35 micron thickness. The film can fulfill the requirement for pre-coating coiled material.

Owner:CNOOC CHANGZHOU PAINT & COATINGS IND RES INST +1

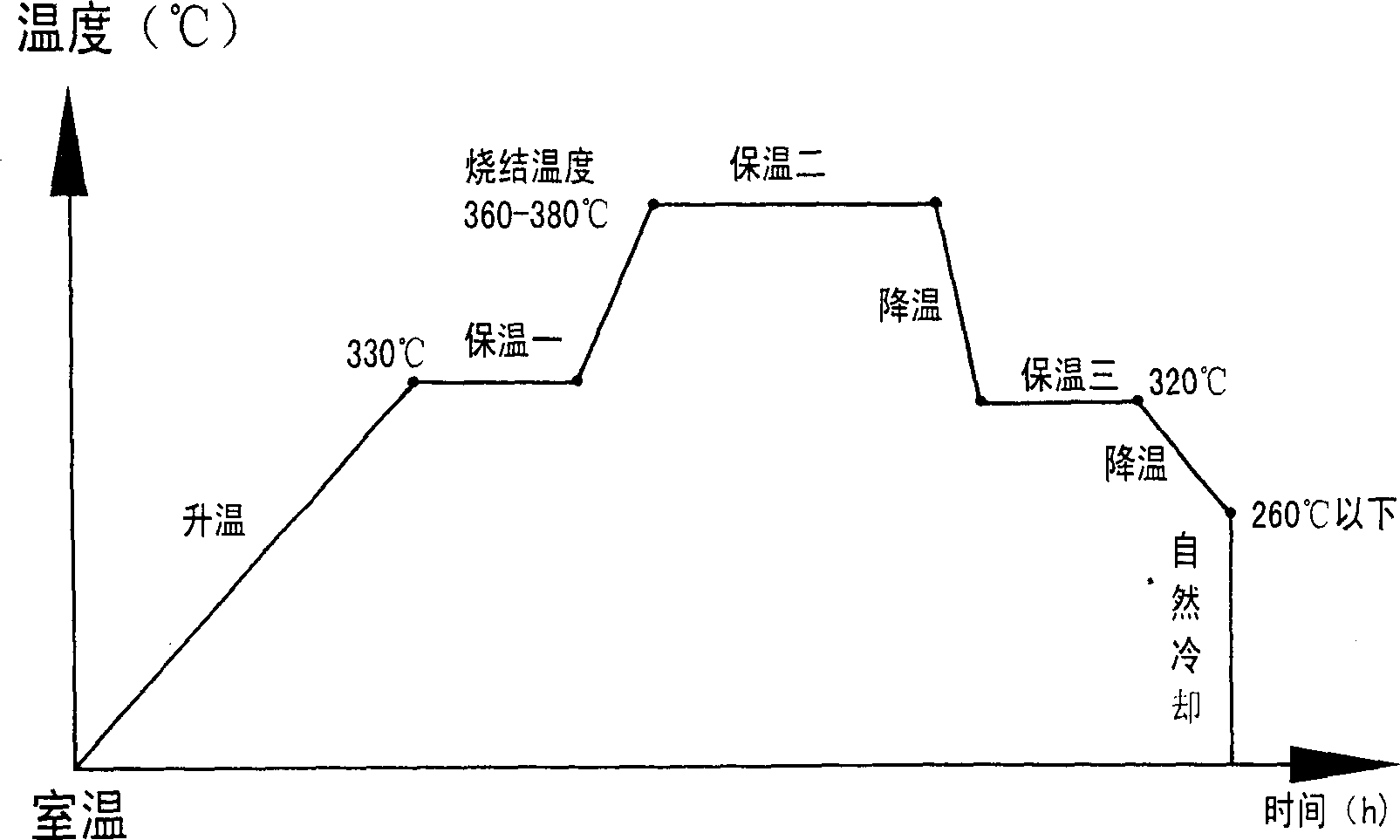

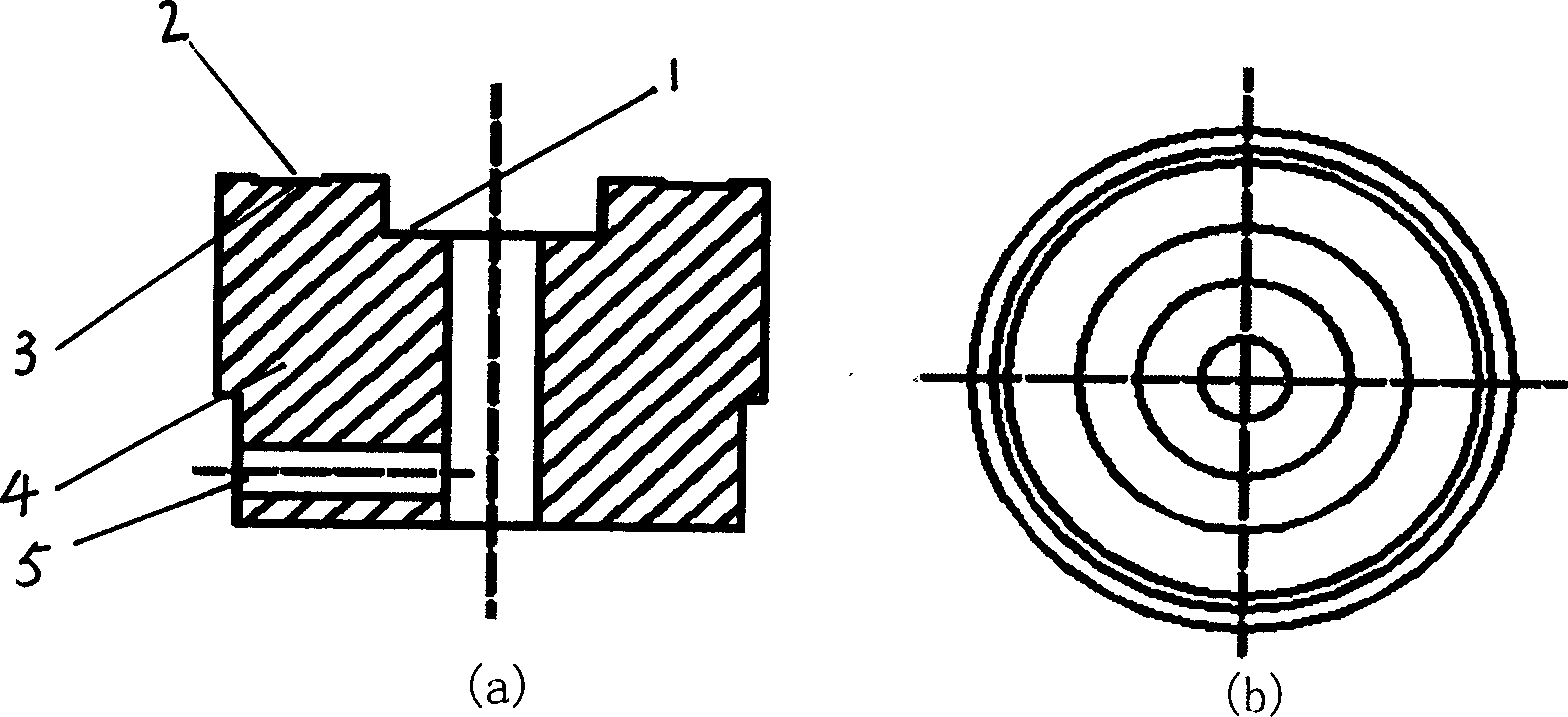

Filling up Teflon friction ring and its preparing method

A filled friction ring of teflon for oiless lubricating is prepared from teglon (100 wt. portions), graphite (1-10%), carbon black (20-50%), glass fibre (0-30%) and MoS2 (0-5%) through mixing, die pressing under 40-70 MPa for 5-40 min, sintering and machining. Its advantages are high lubricating performance and long service life.

Owner:广州宝力特液压技术有限公司

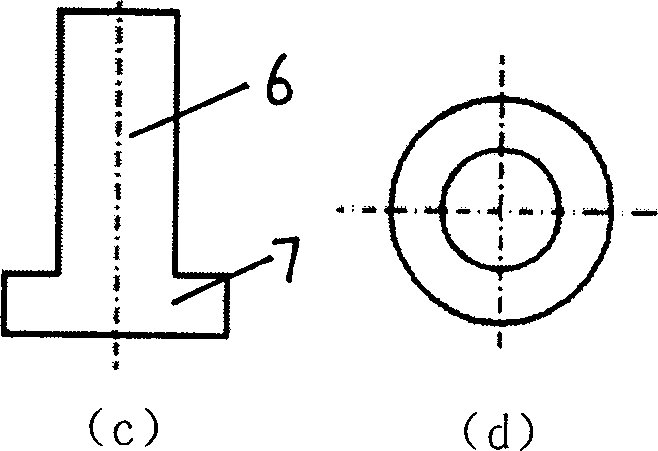

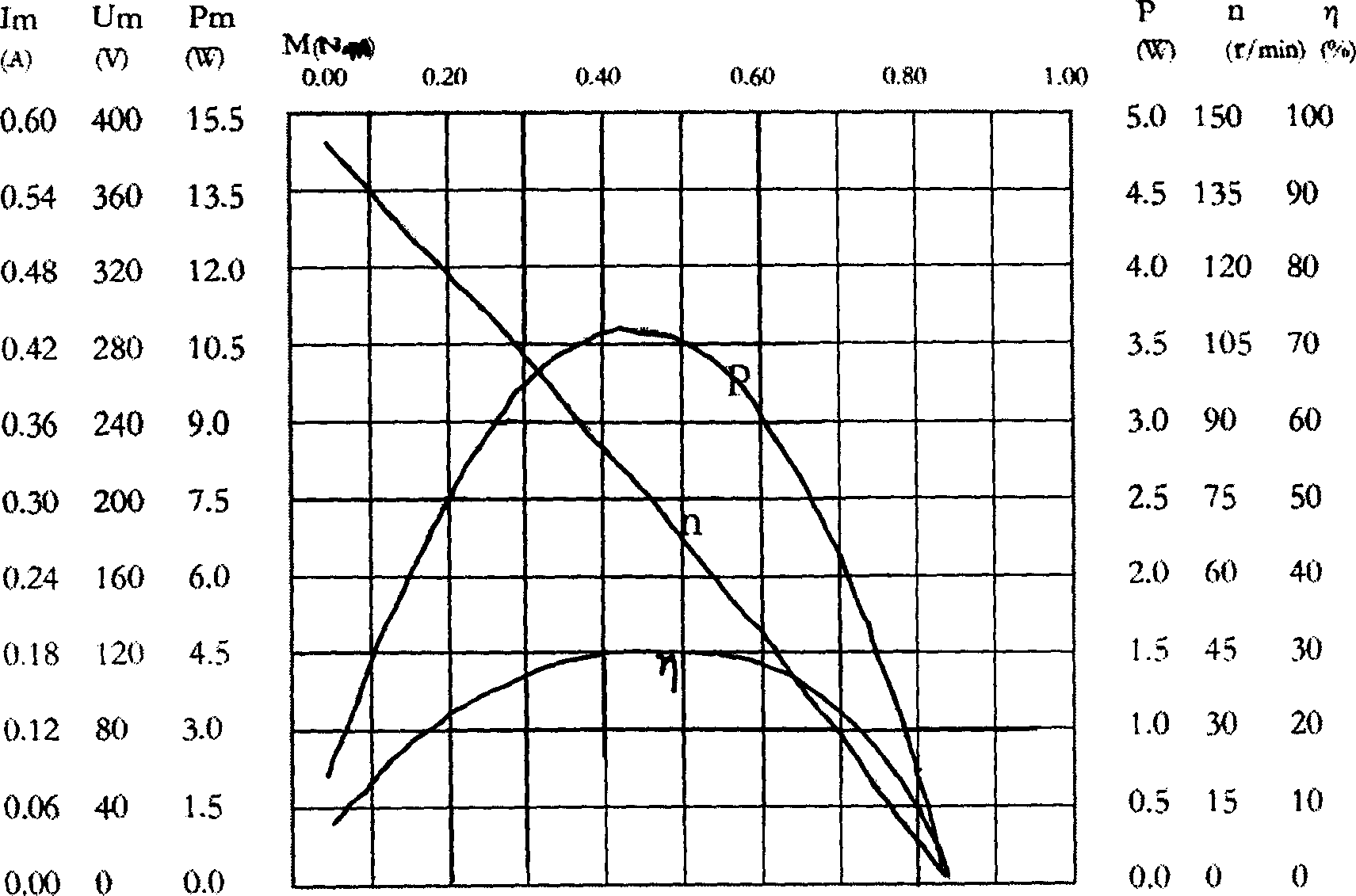

Supersonic motor thermosetting resin base friction material and friction layer manufacturing method and auxiliary tool

The invention relates to an ultrasound dynamo thermosetting resin radical friction material and friction layer making method and the assistant tools. The material is made up of 35-80% thermosetting resin, 0-34% curing agent, 5-15% nanometer antifriction powder, 5-15% carbon fiber, 0-10% copper oxide, 0-5% polytetrafluoroethylene, 5-10% copper powder, 2-10% graphite, 0-5% nitrile butadiene rubber, and 0-10% mineral substance. The invention has excellent wear resistance, suitable rigidity, good output characteristic, etc. And the method is low cost and simple. The assistant tool is made up of moving bar and base.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Steel wire rod for high-strength boron-contained and annealing-free fastening piece and preparation method thereof

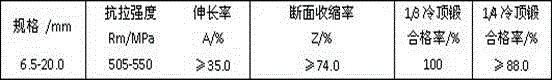

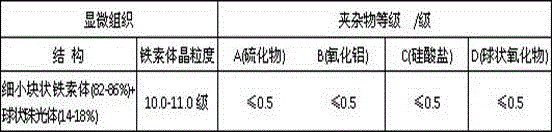

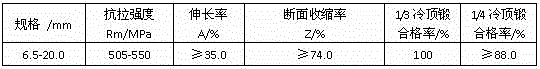

The invention discloses a steel wire rod for a high-strength boron-contained and annealing-free fastening piece and a preparation method thereof. The steel wire rod for the high-strength boron-contained and annealing-free fastening piece comprises the following chemical components in percentage by weight: 0.20-0.24 wt% of C, Si not more than 0.04 wt%, 0.50-0.70 wt% of Mn, 0.25-0.35 wt% of Cr, 0.035-0.055 wt% of Ti, 0.035-0.055 wt% of Als, 0.0045-0.0060 wt% of B, S not more than 0.004 wt%, P not more than 0.012 wt%, O not more than 0.0015 wt%, H not more than 0.00015 wt%, and the balance of Fe and inevitable impurities. The preparation method comprises the steps of molten iron pretreatment desulfurization, molten steel smelting, deoxidation alloying, molten steel LF furnace refining, molten steel VD furnace vacuum refining, molten steel pouring, steel blank heating and controlled rolling and controlled cooling. The steel wire rod for high-strength boron-contained and annealing-free fastening piece is high in cleanness, few in inclusions, excellent in hardenability, proper in strength and hardness and excellent in ductility and toughness and cold heading and upsetting deformation capacity, can directly form a 10.9-grade high-level standard part through cold heading without needing spheroidizing annealing, reduces the processing procedures and the steel consumption, and reduces the production cost.

Owner:WUKUN STEEL

Protective sheet for glass etching

InactiveUS20140158300A1Appropriate hardnessEfficient use ofFilm/foil adhesivesSemiconductor/solid-state device manufacturingHydrogen atomMethyl group

This invention provides a protective sheet for glass etching, having excellent etching solution penetration resistance, non-contaminating property and peeling efficiency. The protective sheet comprises a substrate and a PSA layer provided on one face of the substrate, such that, when the protective sheet is adhered to a non-etching area when etching glass, it protects the non-etching area from an etching solution. The PSA layer is constituted with a PSA having a gel fraction of 60% or higher. The PSA is an acrylic PSA comprising an acrylic polymer as a primary component. The acrylic polymer is synthesized by polymerizing starting monomers comprising, as a primary monomer, a monomer represented by a formula: CH2═CR1COOR2 (R1 is a hydrogen atom or a methyl group, and R2 is an alkyl group). The primary monomer comprises as a primary component a monomer with R2 being an alkyl group having 6 or more carbons.

Owner:NITTO DENKO CORP +1

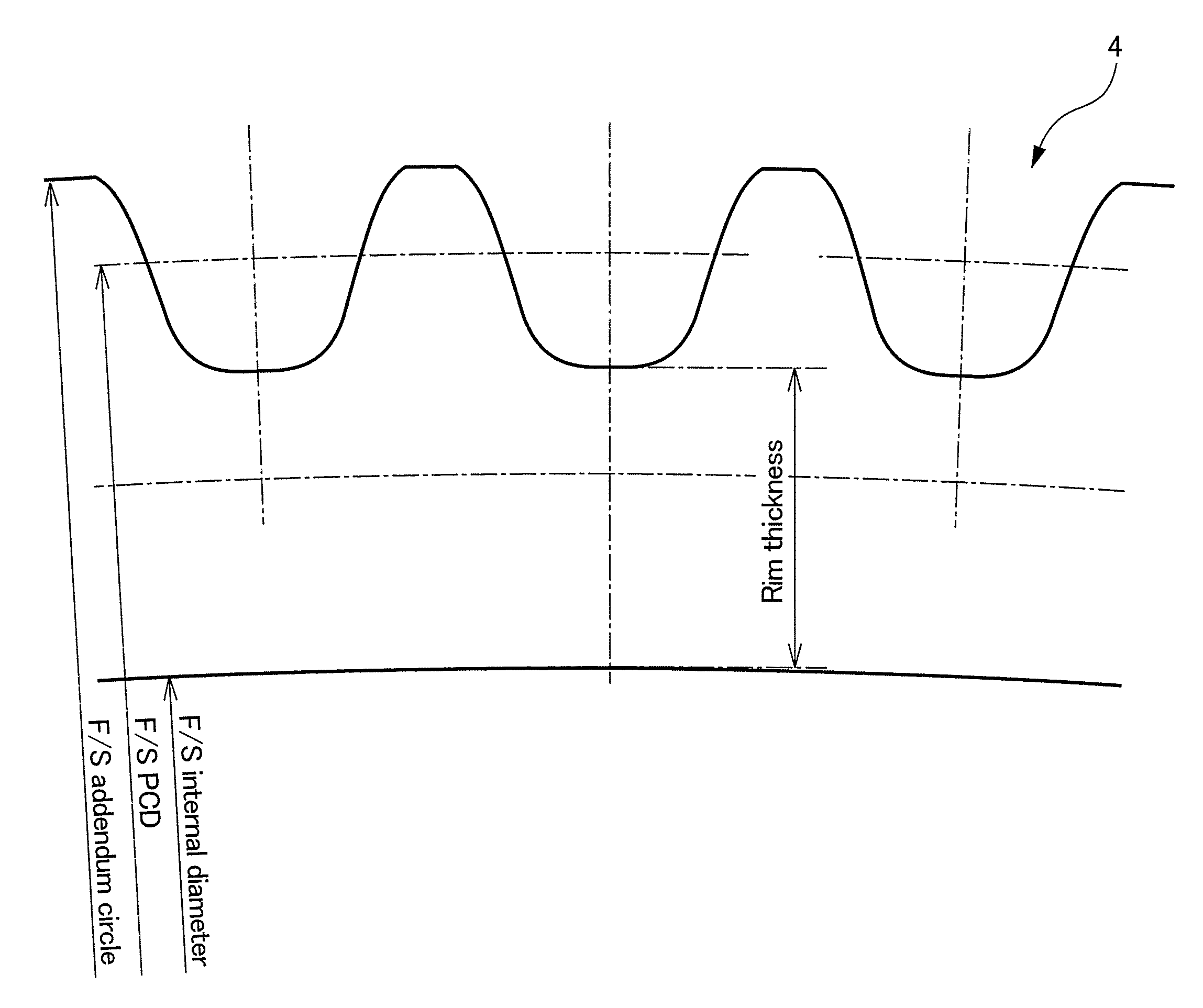

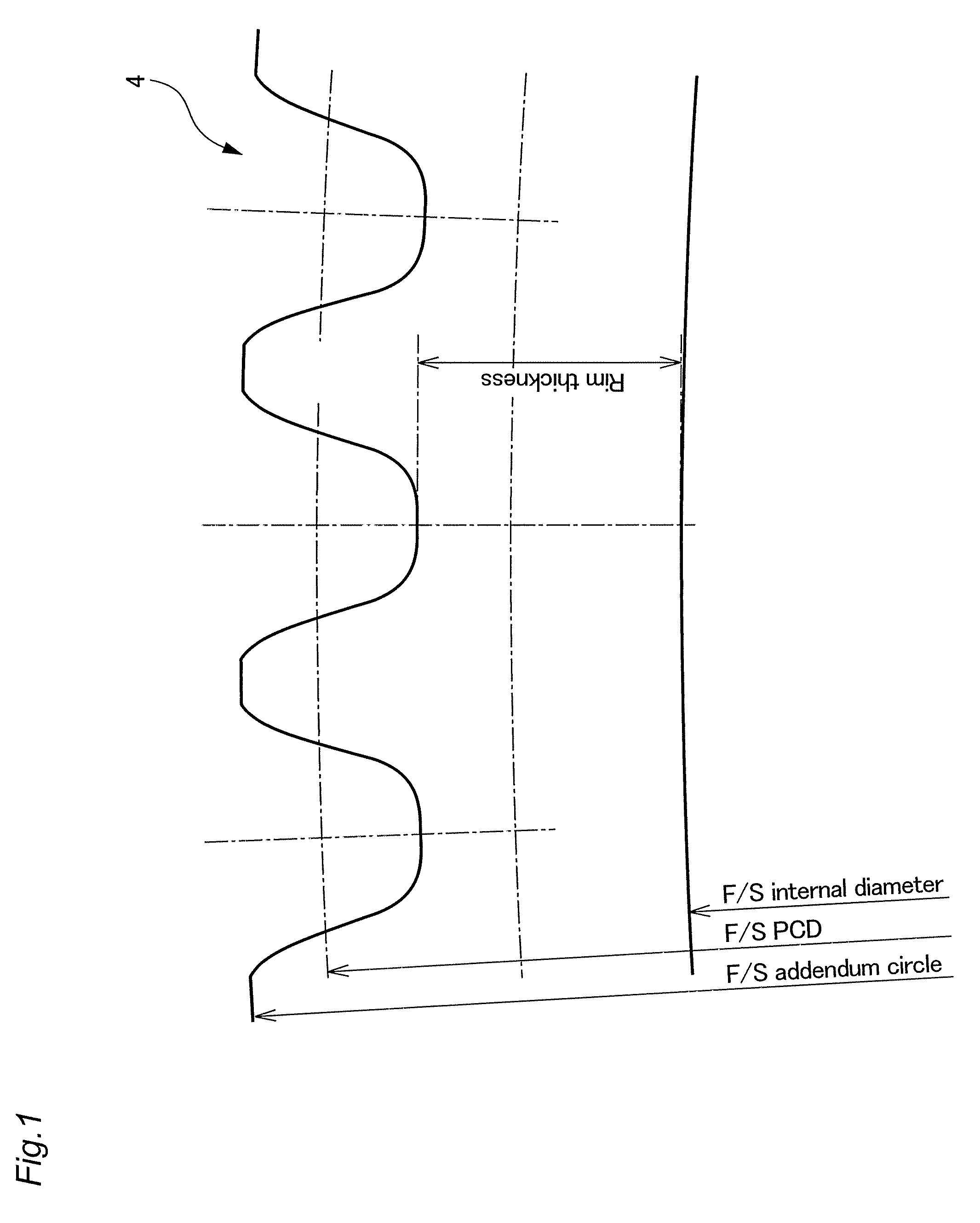

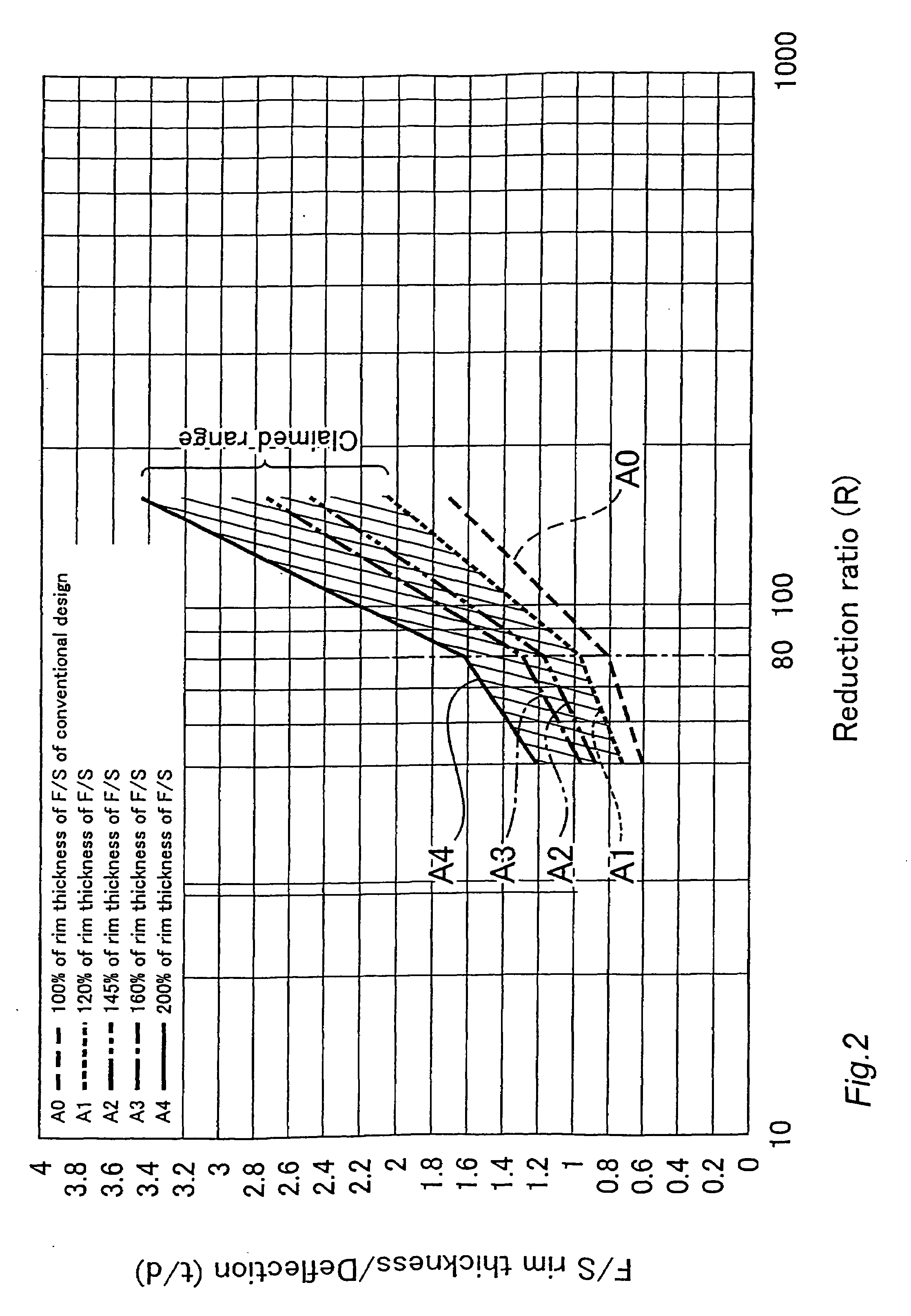

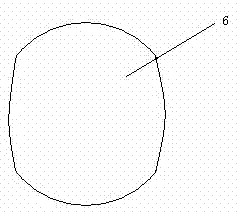

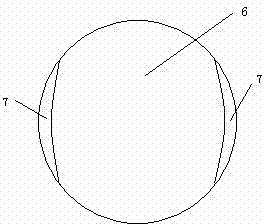

Flat type wave gear device

ActiveUS20080173130A1Improve root strengthIncrease load capacityGearingPortable liftingGear wheelReduction ratio

A flat type wave gear device is realized having a much improved load capacity. When d is an amount of radial flexing at a major axis location of a rim neutral circle of the flexible external gear of a flat type wave gear device flexed into an elliptical shape and t is the rim thickness of the flexible external gear, then(0.5237 Ln(R)−1.32)d≦t≦(0.8728 Ln(R)−2.2)d when the reduction ratio R of the wave gear device is less than 80, and(1.5499 Ln(R)−5.8099)d≦t≦(2.5832 Ln(R)−9.6832)d when the reduction ratio R of the wave gear device is 80 or more. Using this setting makes it possible to increase the tooth root fatigue limit strength of the flexible external gear, thereby making it possible to improve the load capacity of the flexible external gear.

Owner:HARMONIC DRIVE SYST IND CO LTD

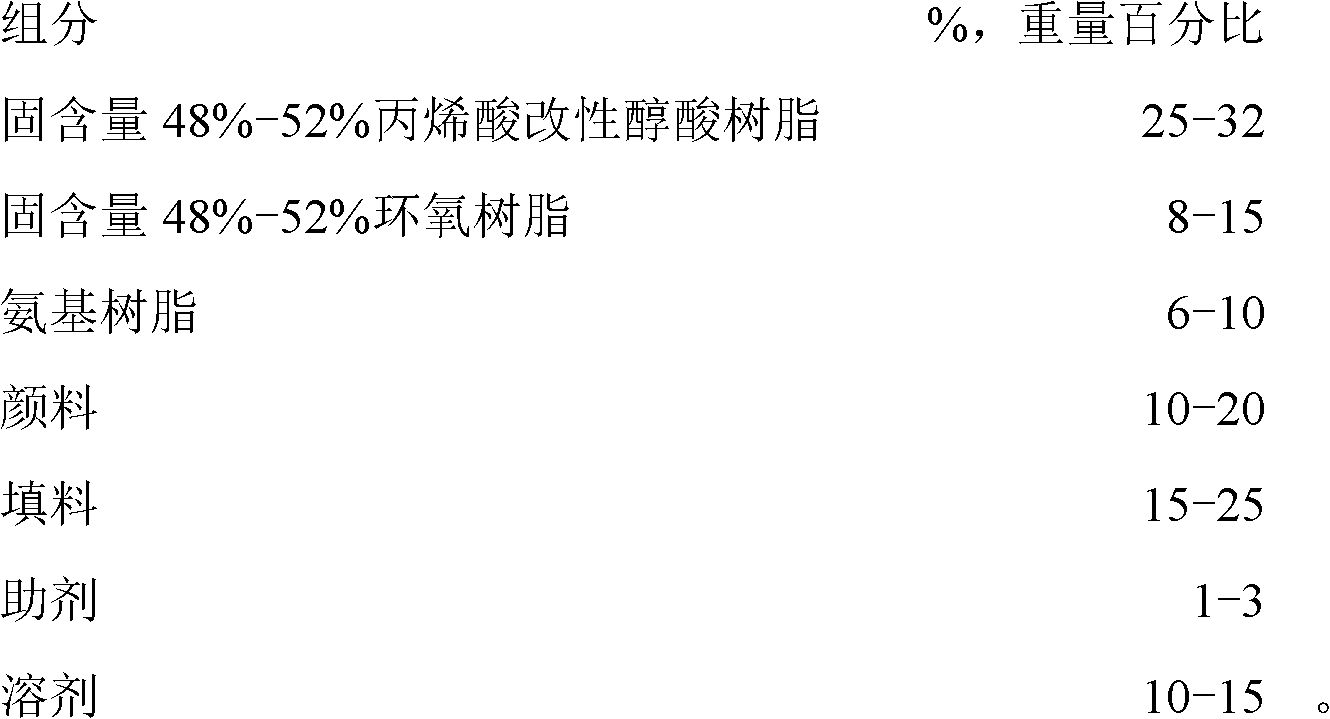

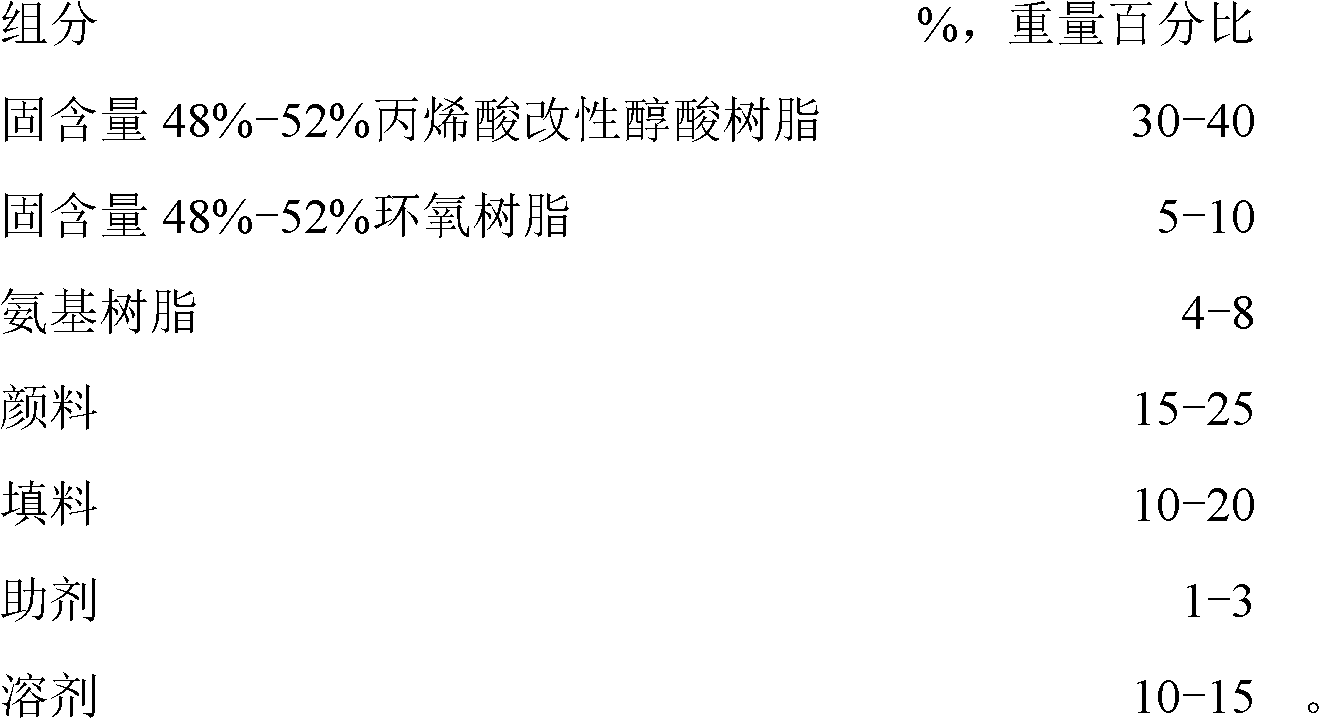

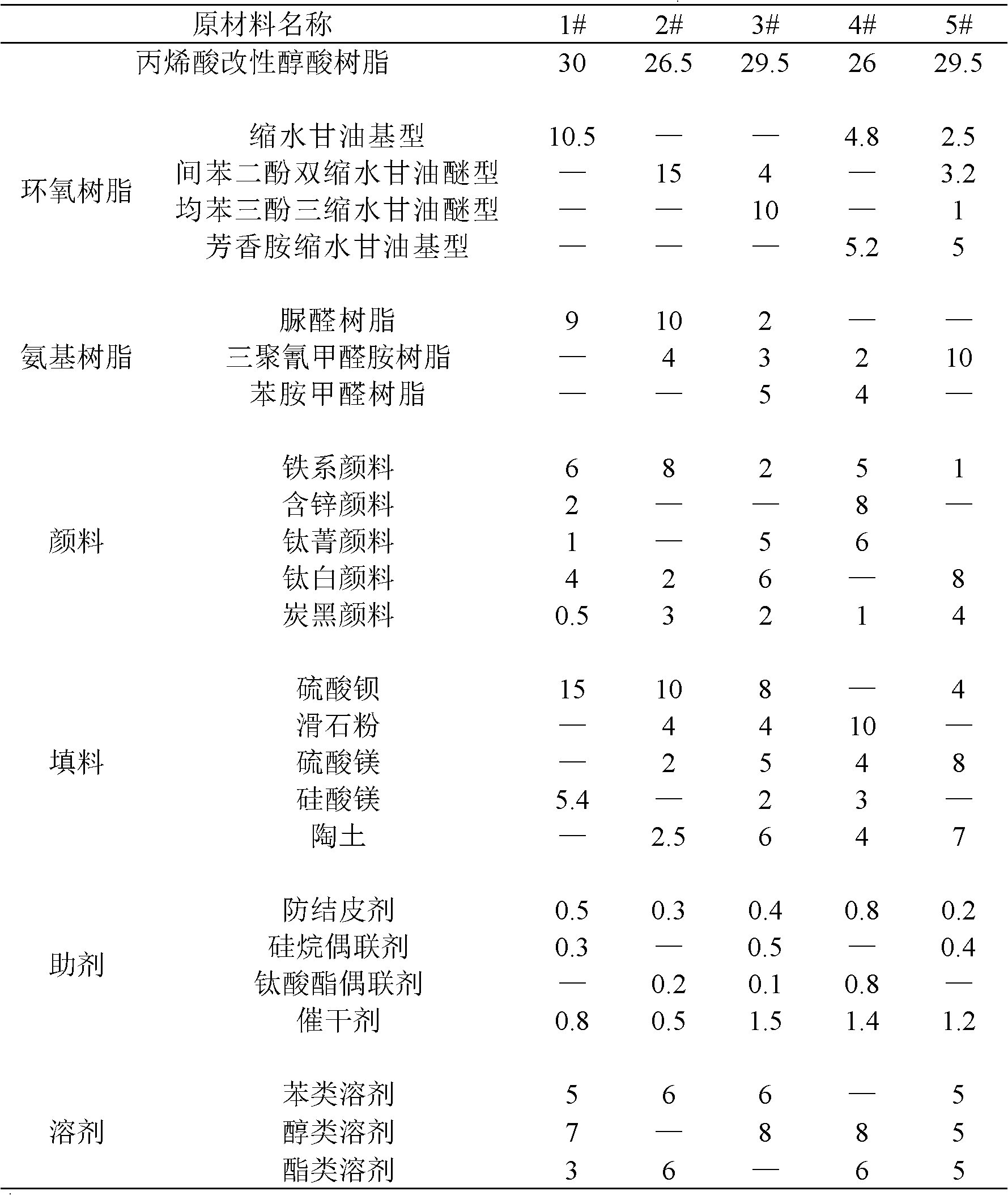

Mirror back protective coating for colored coated mirror

InactiveCN102492356ARealize the coupling effectGood construction performanceEpoxy resin coatingsPolyester coatingsEpoxyHeavy metal compound

The invention discloses a mirror back protective coating for a colored coated mirror. The mirror back protective coating for the colored coated mirror comprises a primer and a finish, wherein the primer comprises 25 to 32 weight percent of acrylic modified alkyd resin with the solid content of 50 percent, 8 to 15 weight percent of epoxy resin with the solid content of between 48 and 52 percent, and 6 to 10 weight percent of amino resin; and the finish comprises 30 to 40 weight percent of acrylic modified alkyd resin with the solid content of 50 percent, 5 to 10 weight percent of epoxy resin with the solid content of between 48 and 52 percent, and 4 to 8 weight percent of amino resin. Heavy metal compounds with anticorrosion performance are not used in the mirror back protective coating, so the coating is environment-friendly. The coating can be prepared by a large-scale curtain coating molding process, can be quickly oven-dried, can be completely cured after being roasted at the temperature of between 80 and 100 DEG C for 4 to 6 minutes, has excellent physical and chemical properties, and is favorable for large-scale industrialized production.

Owner:常州市弘可利办公用品有限公司

Rubber composition for golf balls

InactiveUS20120165475A1Increase elasticityAppropriate hardnessGolf ballsSolid ballsSolubilityPolymer science

The invention provides a rubber composition for golf balls which includes (A) a base rubber containing a polybutadiene having a cis-1,4 bond content of at least 60 wt %, (B) an unsaturated carboxylic acid and / or a metal salt thereof, and (C) two or more organic peroxides which include (C-1) an organic peroxide having a solubility parameter (SP) of 9 or less and (C-2) an organic peroxide having a solubility parameter (SP) of 10 or more. The golf ball rubber composition of the invention enables a high-quality molded and crosslinked product having a suitable hardness and a high resilience to be obtained.

Owner:BRIDGESTONE SPORTS +1

Antifouling coating composition, antifouling coating film formed using the composition, coated article having the coating film on the surface, and antifouling treatment method to form the coating film

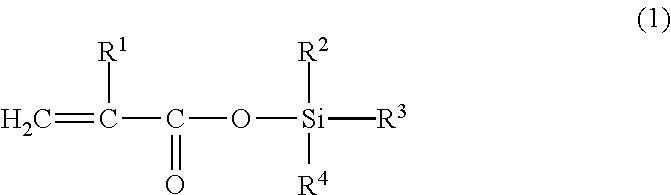

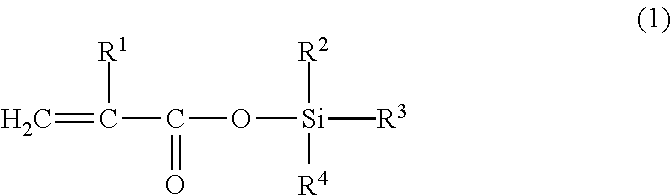

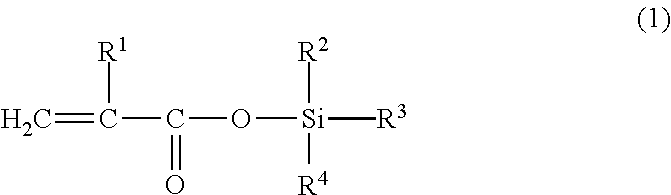

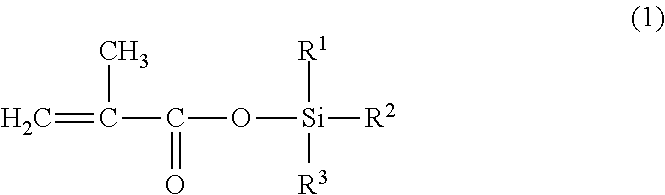

ActiveUS20110172325A1Prevents and inhibits attachmentImprove waterproof performanceFireproof paintsAntifouling/underwater paintsMethacrylateMeth-

An object of the present invention is to provide a composition for forming an environment friendly antifouling coating film that is unlikely to cause a hairline crack and like coating film defects even when immersed in seawater for a long time, and that prevents or inhibits attachment of slime. An antifouling coating composition of the invention comprises: (A) a triorganosilyl ester-containing copolymer obtained by a mixture of (a) a triorganosilyl (meth)acrylate monomer represented by a general formula (1): R1 is a hydrogen atom or a methyl, and R2, R3, and R4 are equal or different each other, and each represent an alkyl group having 3 to 6 carbons and branched on α-position or a phenyl group, and (b) an ethylenically unsaturated monomer copolymerizable with the triorganosilyl (meth)acrylate monomer, (B) a modified rosin salt which is a salt of a modified rosin and zinc and / or copper, the modified rosin containing, in an amount of 80 weight % or more, two or more members selected from the group consisting of dihydroabietic acid, tetrahydroabietic acid, dehydroabietic acid, pimaric acid, isopimaric acid, and dihydropimaric acid.

Owner:NITTO KASEI CO LTD

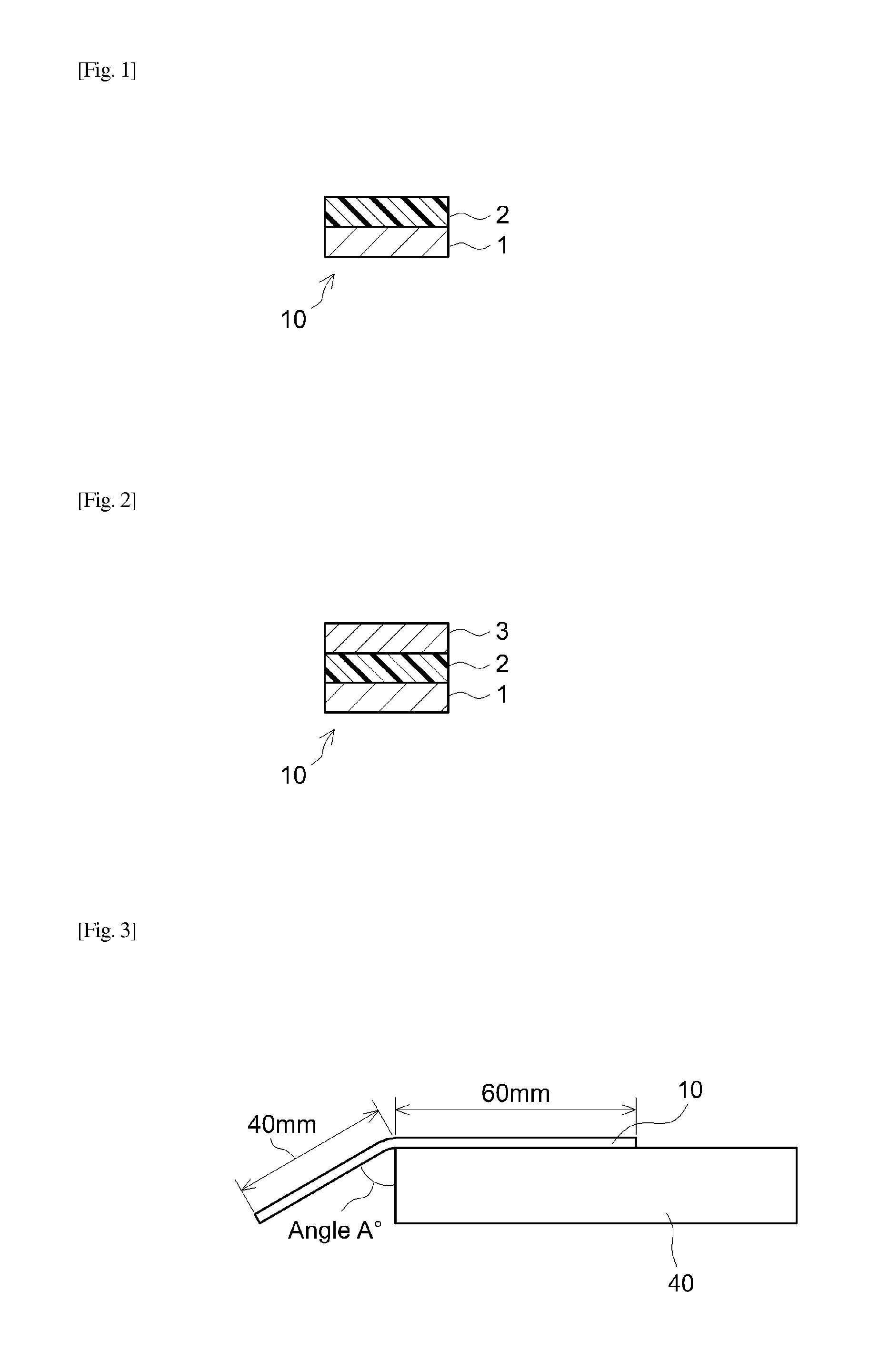

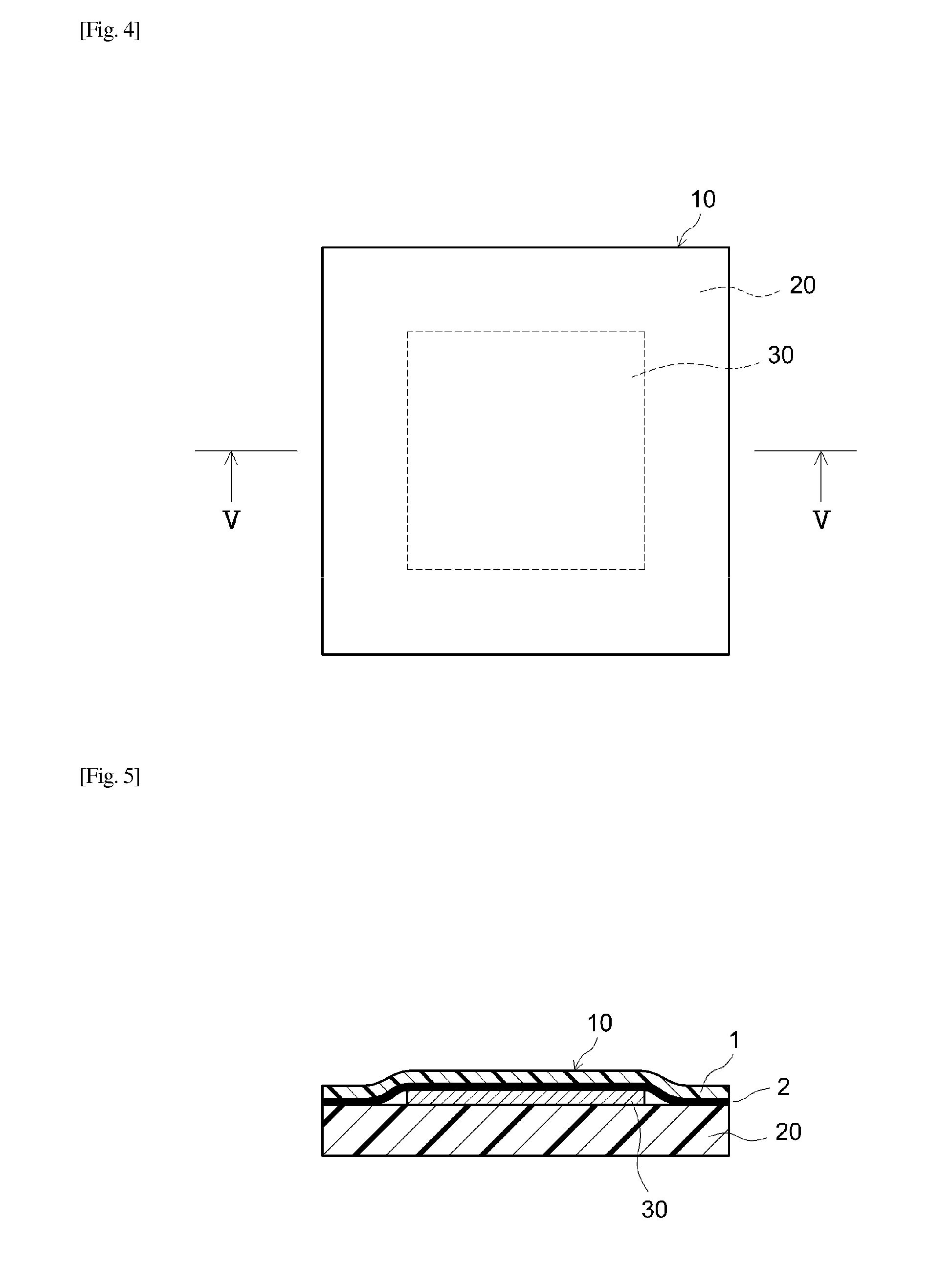

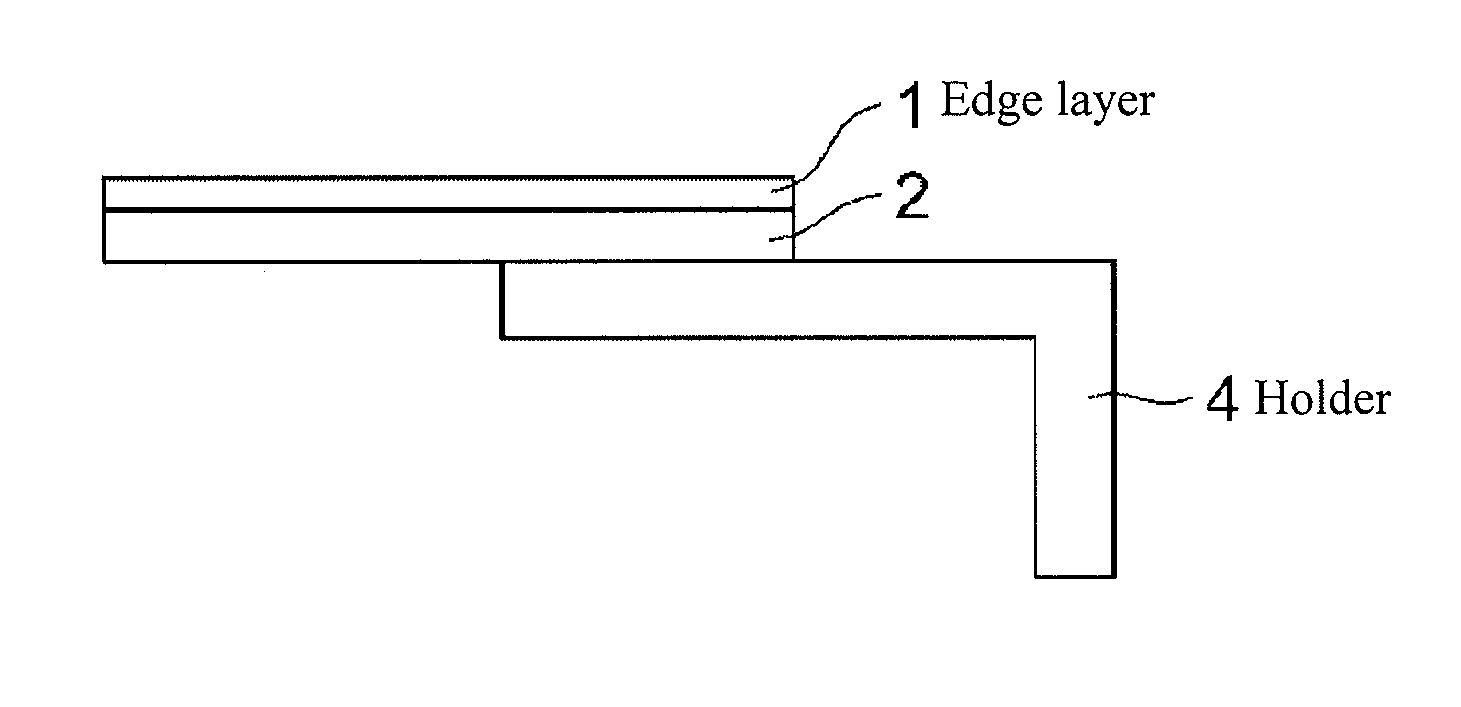

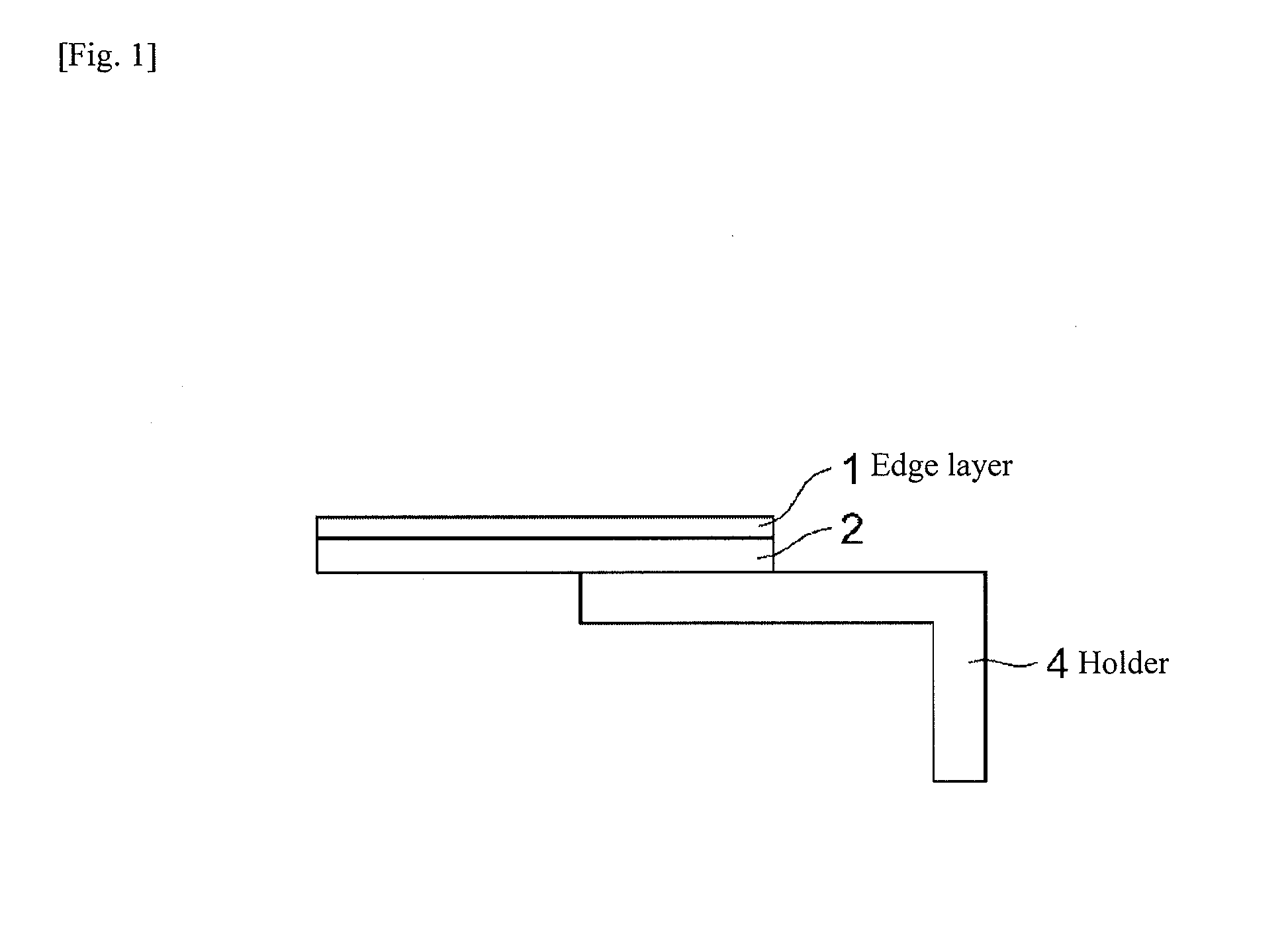

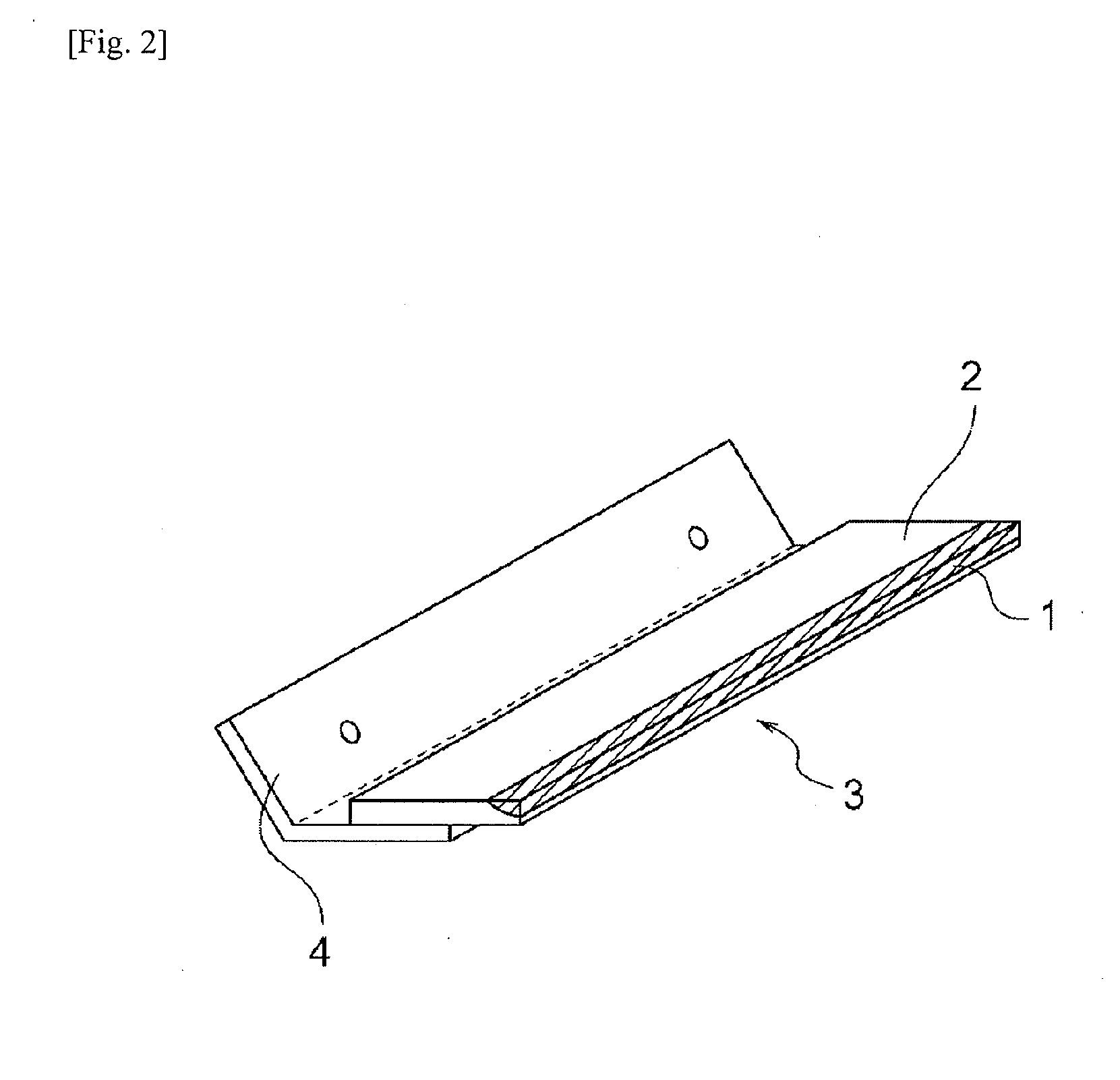

Blade for electrophotographic device and method for manufacturing the blade

An object of the present invention is to provide a blade for an electro-photographic device formed by two layers, which undergoes minimal permanent deformation and offers excellent mechanical strength, wear resistance and compliance to the use environment.A blade for an electro-photographic device whose edge and base are constituted by different materials, wherein such blade for an electro-photographic device is characterized in that at least the edge is made of ester polyurethane and the base other than the edge is made of ether polyurethane.

Owner:BANDO CHEM IND LTD

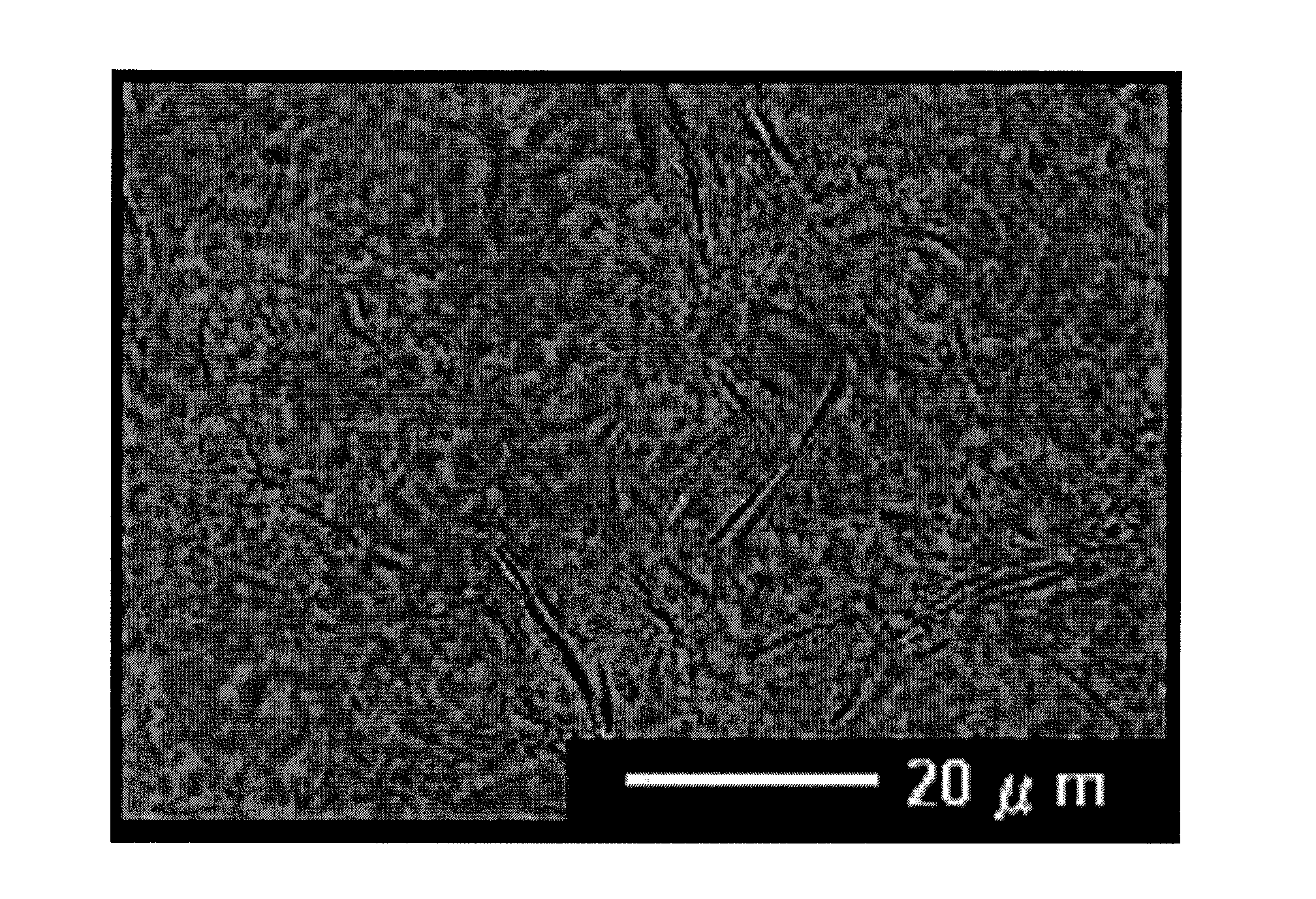

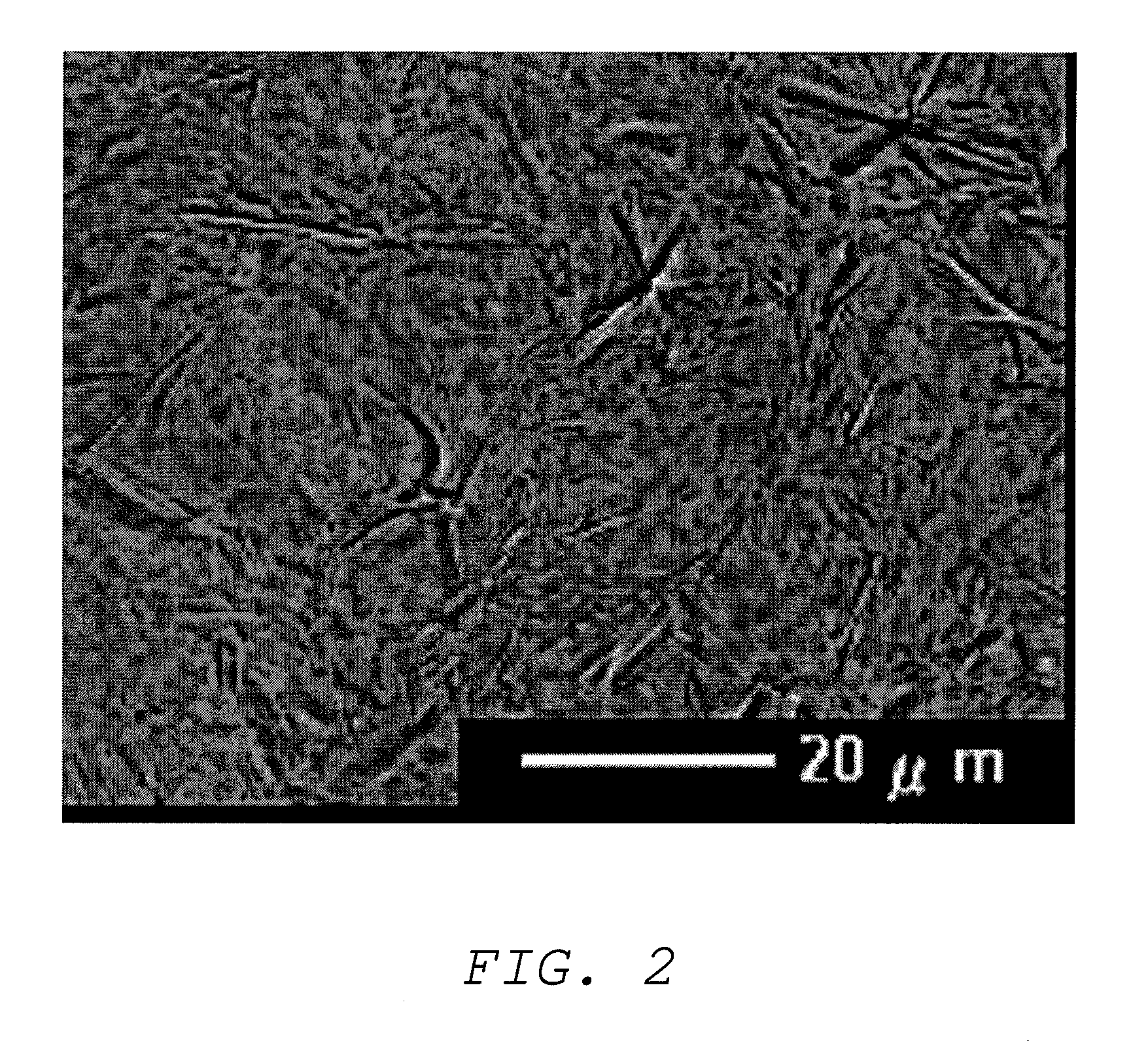

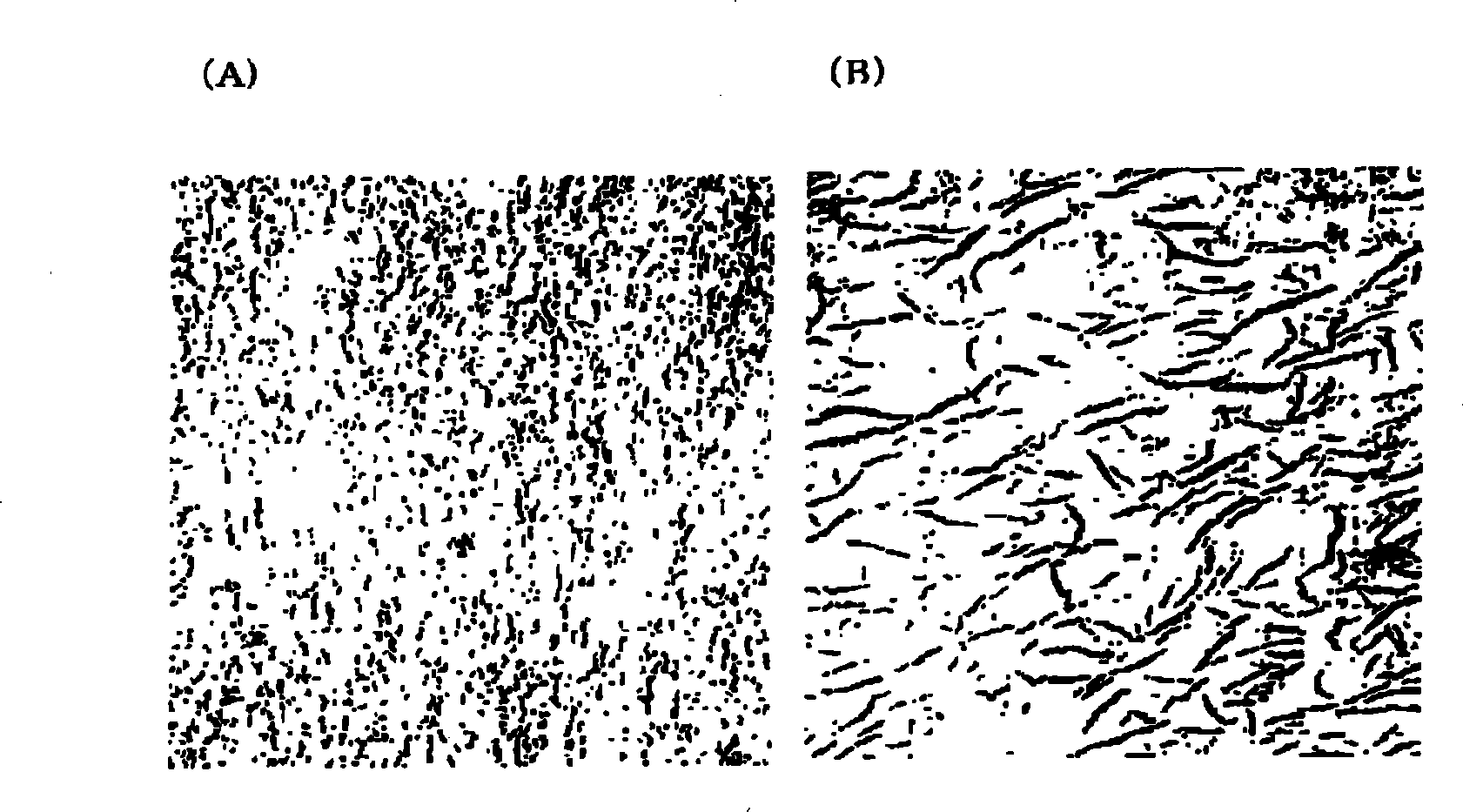

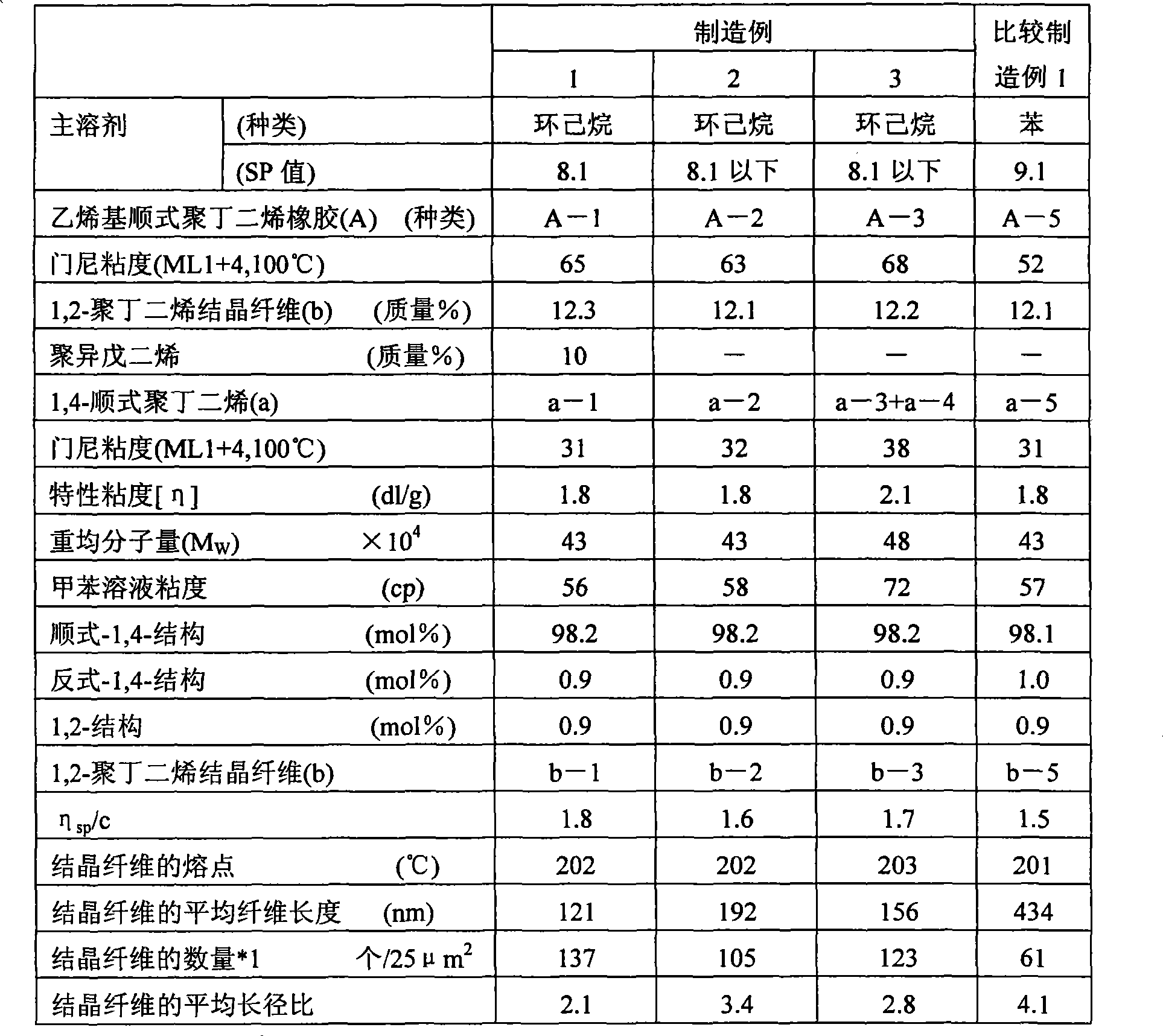

Rubber composition for shoe sole and rubber foam composition

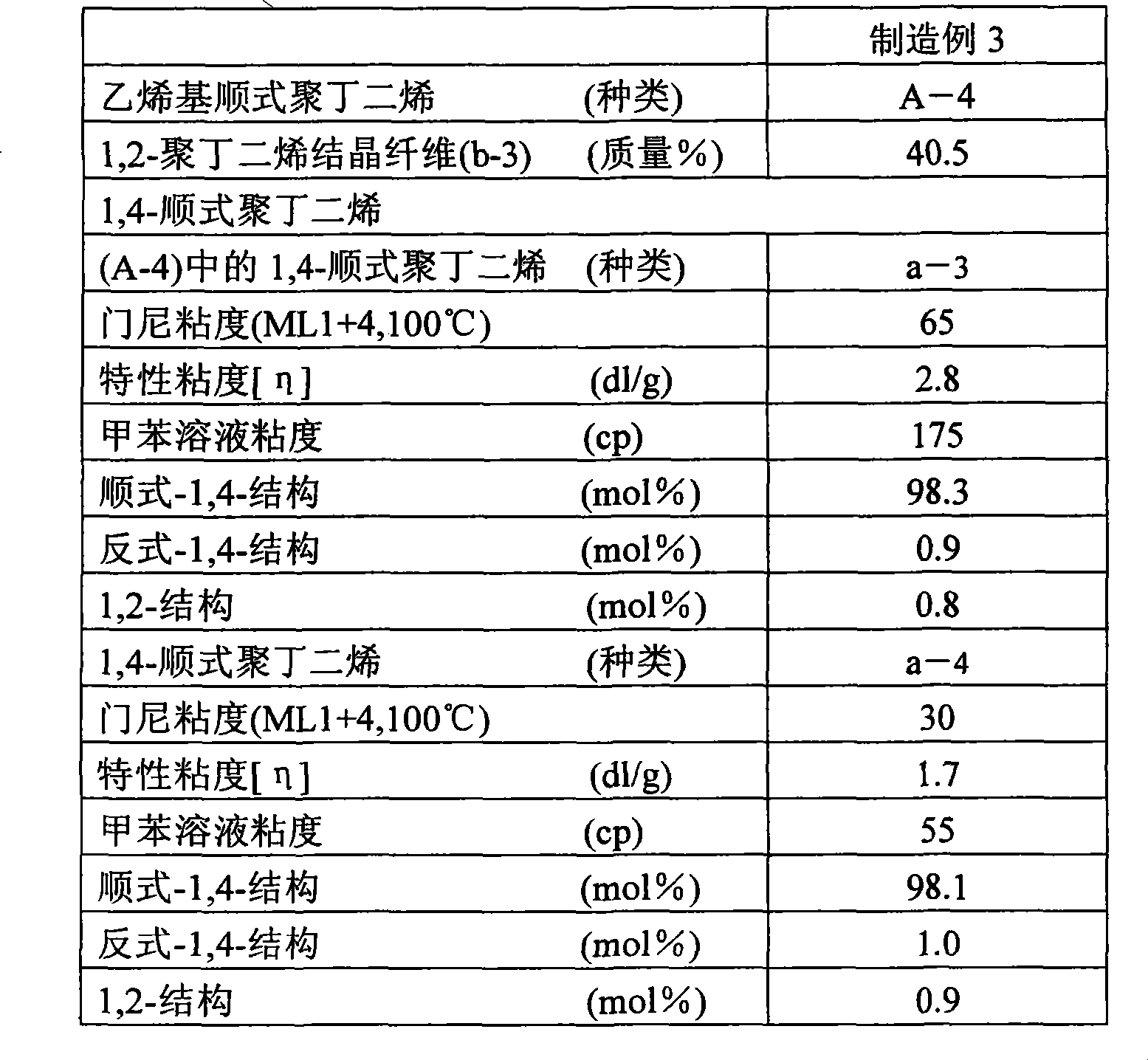

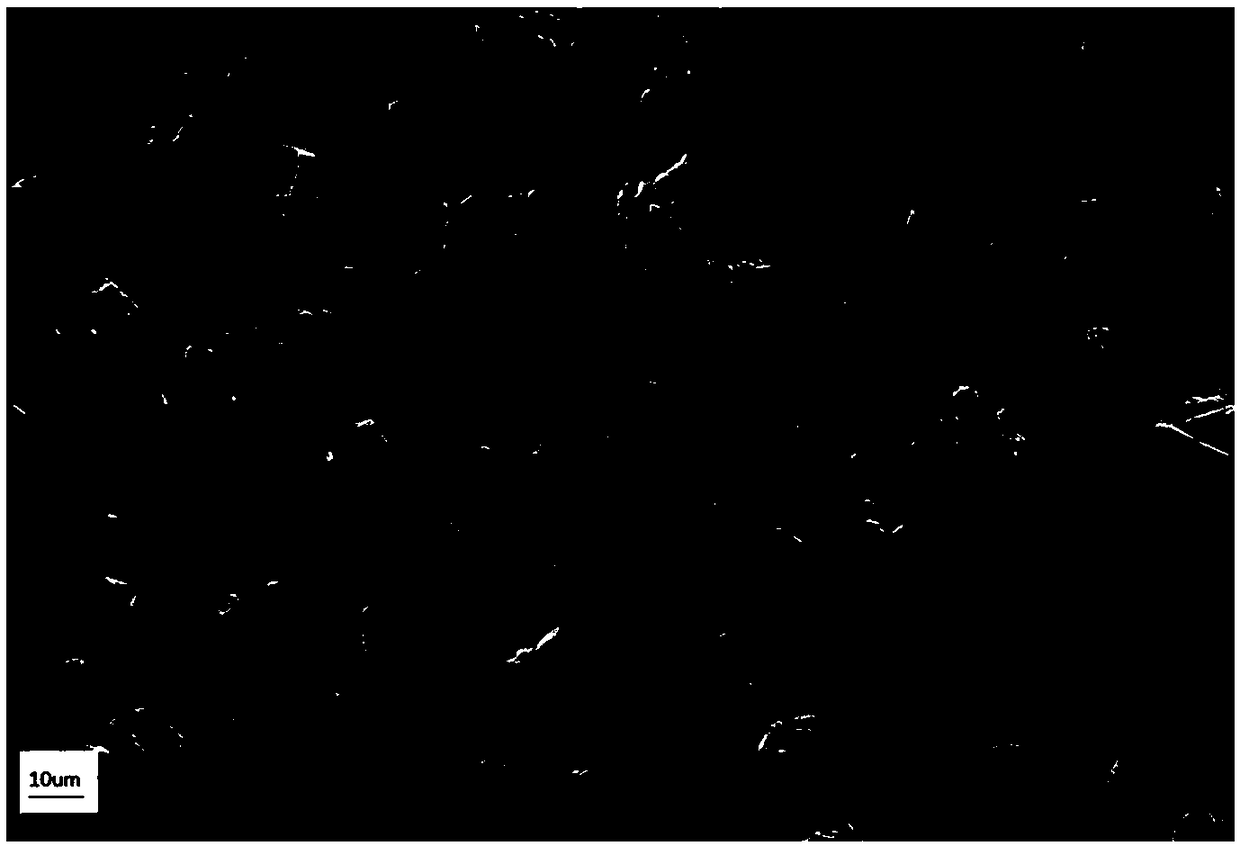

A rubber composition for shoe soles characterized by being obtained by compounding 100 parts by mass of a polymer ingredient which comprises 10-90 mass% vinyl / cis-polybutadiene rubber (A) comprising 1,4-cis-polybutadiene (a) and 1,2-polybutadiene crystal fibers (b) which have an average fiber length of 200 nm or shorter, an average aspect ratio of 10 or lower, and a melting point of 170 DEG C or higher and in which the number of the crystal fibers having a fiber length of 200 nm or shorter is 90 or more per 25 [mu]m<2>, 10-50 mass% diene rubber (B) other than the rubber (A), and 2-50 mass% thermoplastic polymer (C) with 2-50 parts by mass of a rubber reinforcement (D). This rubber composition for shoe soles is lightweight, has a moderate hardness, is excellent in tensile strength, tear strength, wearing resistance, and gripping properties, and has excellent dimensional stability after foaming. It is suitable for use as the outer soles of shoes.

Owner:UBE IND LTD

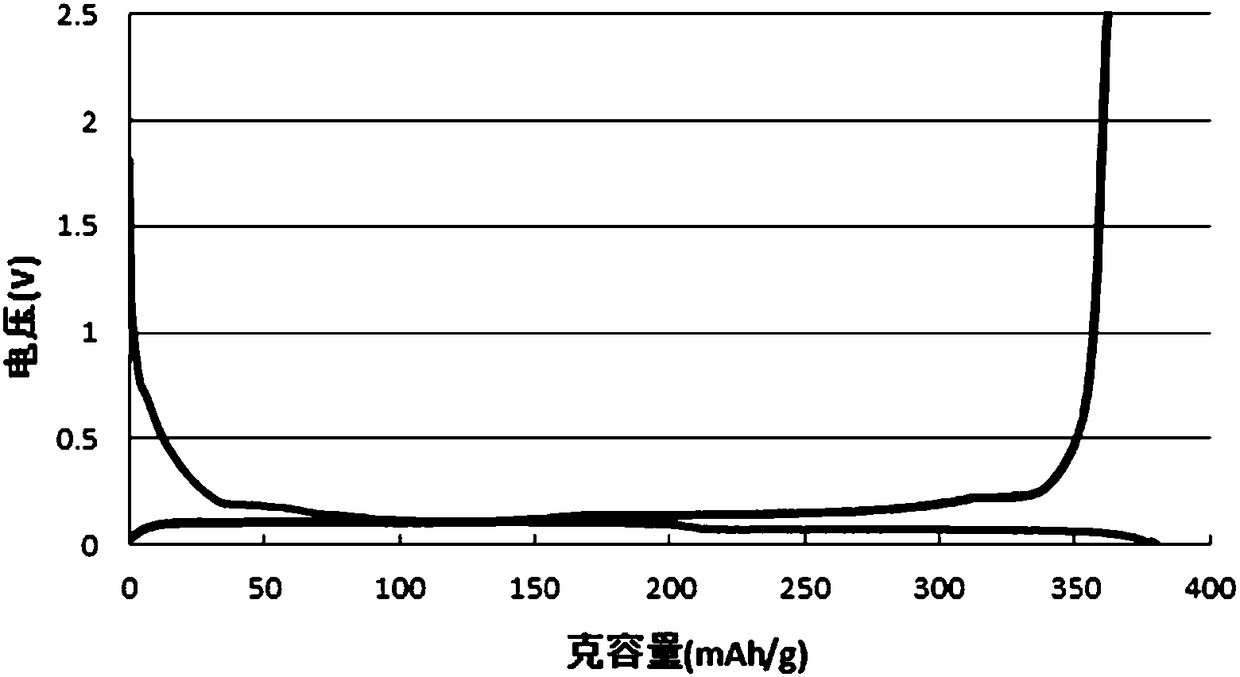

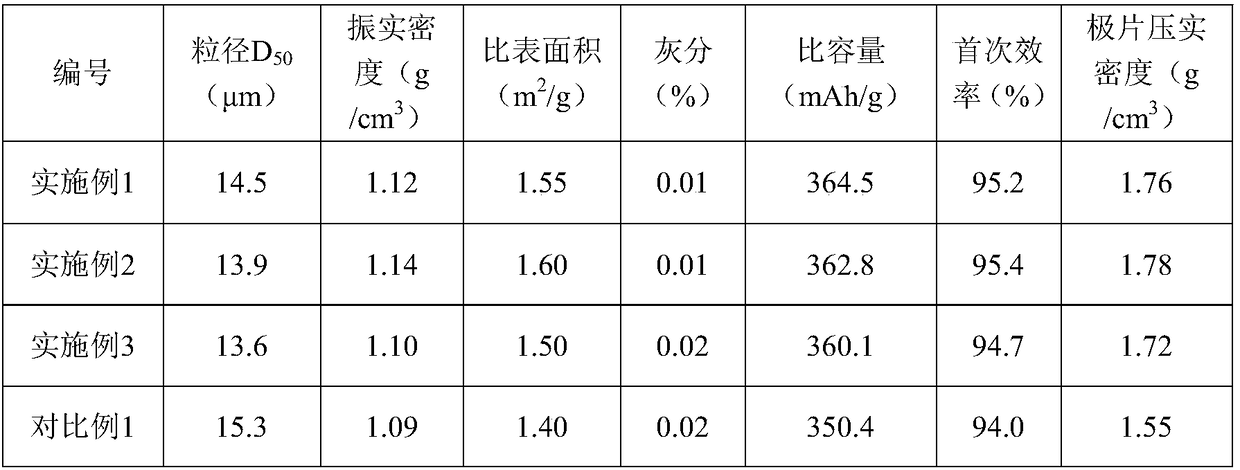

High-capacity and high-compaction artificial graphite negative electrode material, preparation method thereof and lithium ion battery

InactiveCN108550850AIncrease compaction densitySolve the problem of easy overvoltageCell electrodesSecondary cellsMixed materialsGraphite

The invention relates to a high-capacity and high-compaction artificial graphite negative electrode material, a preparation method thereof and a lithium ion battery. The preparation method comprises the steps of selecting at least two of pitch coke, petroleum coke and needle coke as graphite raw materials, and uniformly mixing with a coating agent to obtain a mixed material; and performing graphitization on the mixed material at 3,000-3,300 DEG C under a protection atmosphere to obtain the high-capacity and high-compaction artificial graphite negative electrode material. According to the preparation method of the high-capacity and high-compaction artificial graphite negative electrode material, the problem that the material is easy to press excessively due to inappropriate selection of theraw material cokes is solved by selection and matching of raw material cokes with different hardness, and the prepared graphite negative electrode material has appropriate hardness and rebound rate.A pole plate prepared from the artificial graphite negative electrode material is high in compaction density, an electrolyte is rapidly immersed, and the electrochemical performance of the lithium ionbattery is prolonged.

Owner:CHINA AVIATION LITHIUM BATTERY LUOYANG +1

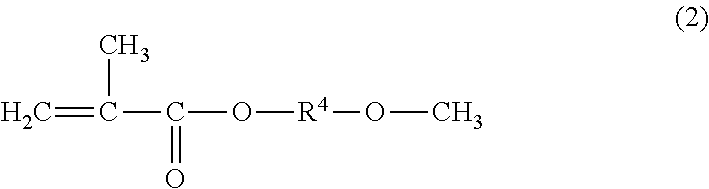

Antifouling coating composition, antifouling coating film formed from the composition, coated object having the coating film on surface, and method of antifouling by forming the coating film

ActiveUS20110166253A1Inhibit and prevent attachmentExhibit some effectFireproof paintsAntifouling/underwater paintsMethacrylateRosin

An object of the present invention is to provide a composition for forming an environment friendly antifouling coating film that can effectively exhibit an antifouling effect in seawater for a long period of time and furthermore exhibits a small temperature dependency of the coating film dissolving amount. The present invention provides an antifouling coating composition comprising: (A) a triorganosilyl ester-containing copolymer obtained by a mixture of (a) a triorganosilyl methacrylate monomer represented by a general formula (1) in which R1, R2, and R3 are equal or different each other, and each represent an alkyl group having 3 to 6 carbons and branched on α-position or a phenyl group, and (b) a methoxyalkyl methacrylate monomer represented by a general formula (2) in which R4 represents an alkylene group having 2 to 4 carbons, wherein a content ratio of the monomer (a) in the mixture is 45 to 65 weight %, and a total content of the monomer (a) and the monomer (b) in the mixture is 80 weight % or more, and a copper salt that is at least one member selected from the group consisting of rosin copper salts and copper salts of rosin derivatives.

Owner:NITTO KASEI CO LTD

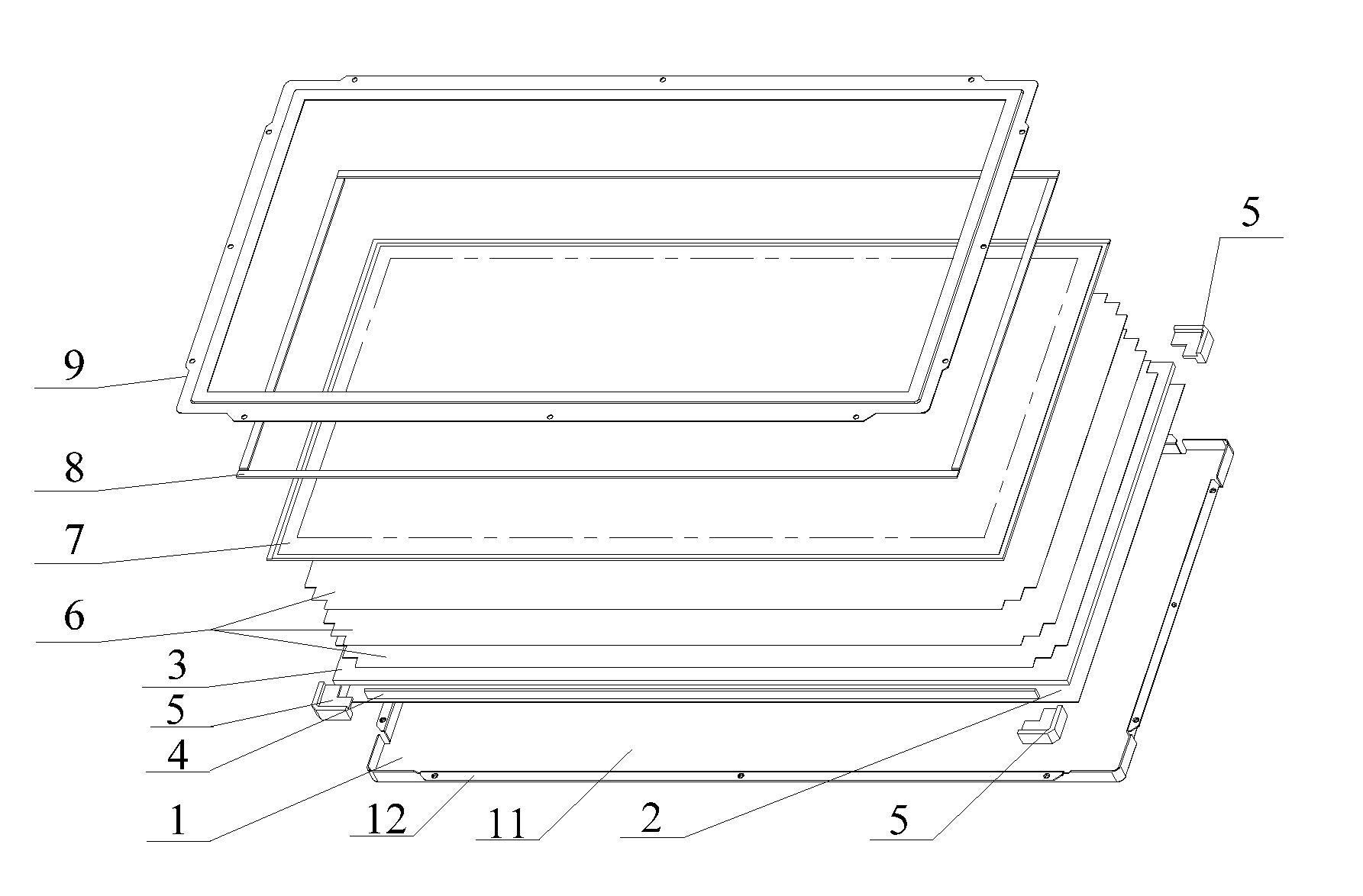

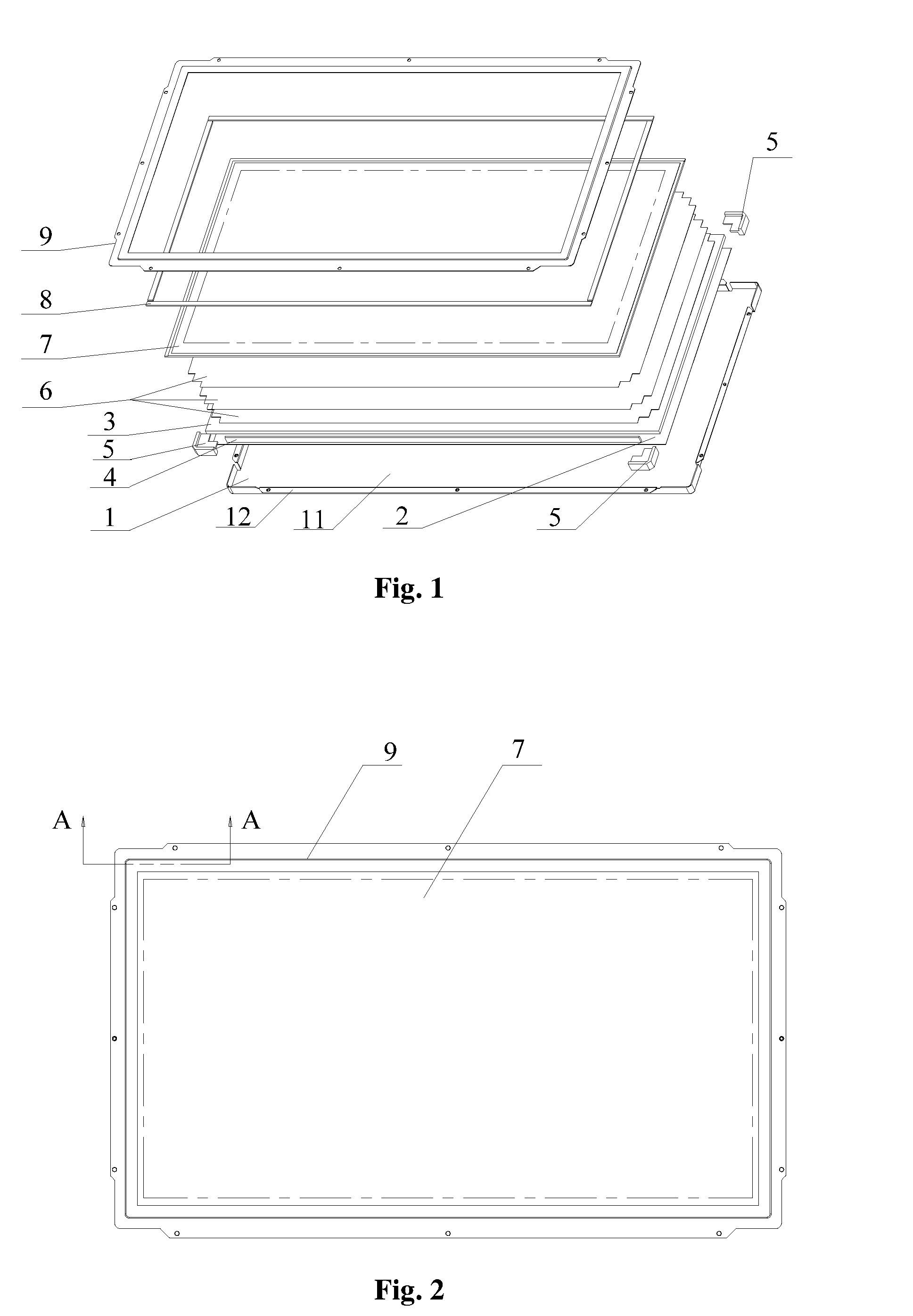

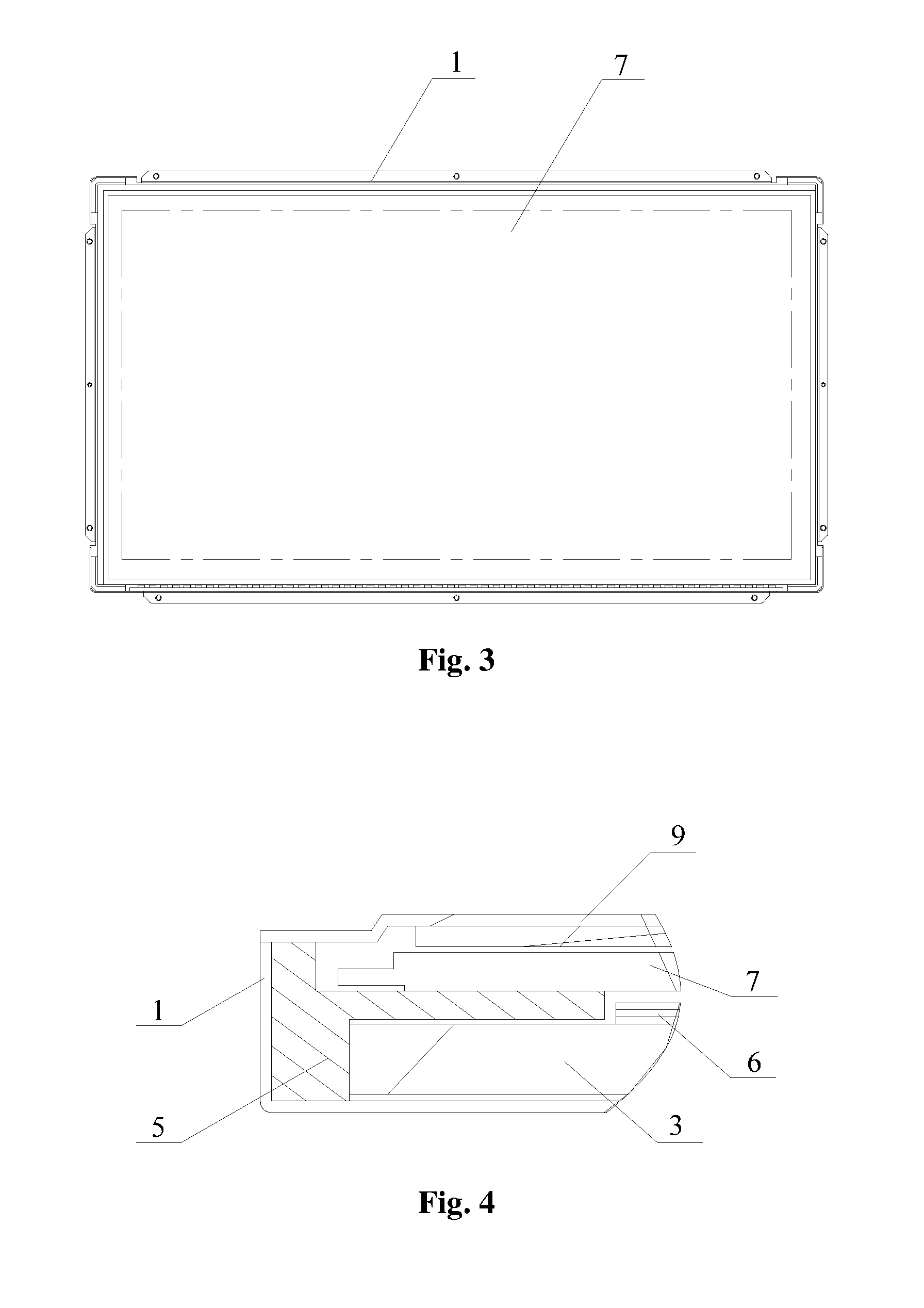

Backlight module and liquid crystal display

ActiveUS20130033657A1Reduce mold costLow production costMechanical apparatusLight guides for lighting systemsCushioningLiquid-crystal display

A backlight module comprises a back frame, a light guide plate disposed in the back frame, and elastic corner parts for locating the light guide plate. The elastic corner parts are disposed at diagonal corners of the backlight module and sandwiched between the back frame and the light guide plate. The elastic corner parts can locate the light guide plate in the back frame, and the desirable cushioning performance and appropriate hardness of the elastic corner parts provide a desirable space for thermal expansion and contraction of the light guide plate. Meanwhile, the elastic corner part corresponding to the light incident side is greater than that of the non-light-incident sides for ensuring the light mixing distance between the LEDs and the light incident side of the light guide plate, which can improve the light unitization factor of the LEDs and save both the product cost and the mold cost.

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS TECH CO LTD

Rubber Composition for Tires

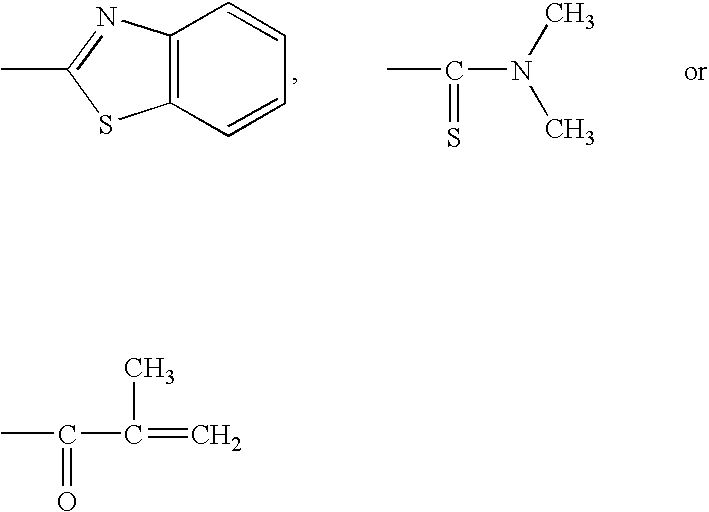

InactiveUS20080033103A1Appropriate hardnessWet strengthSpecial tyresRolling resistance optimizationPolymer scienceRolling resistance

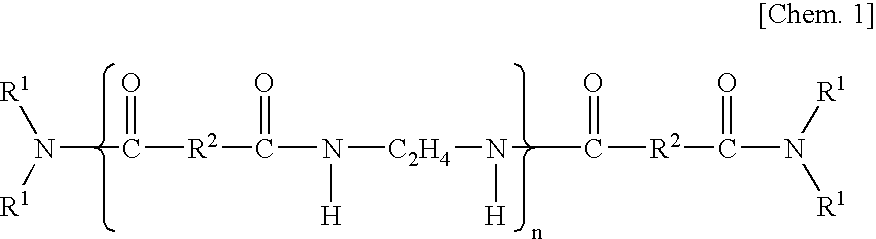

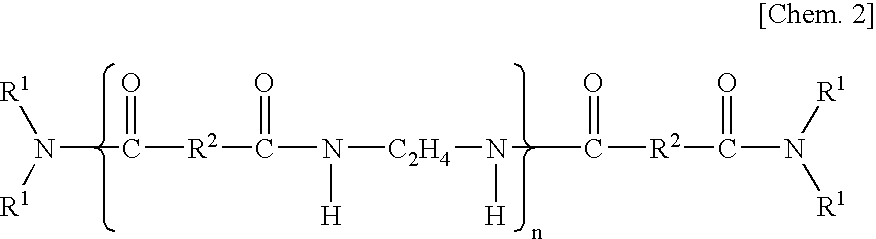

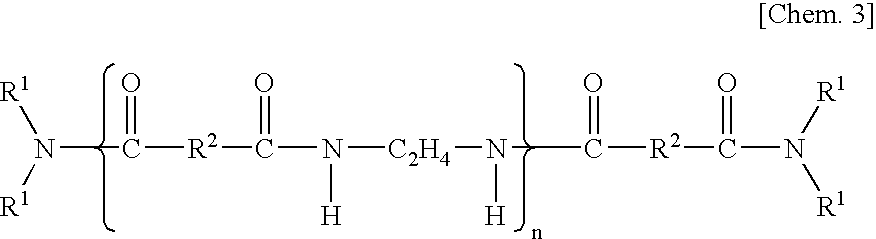

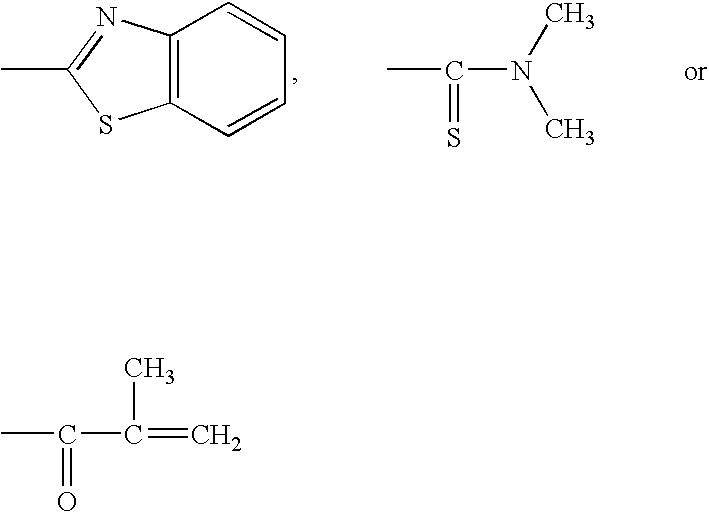

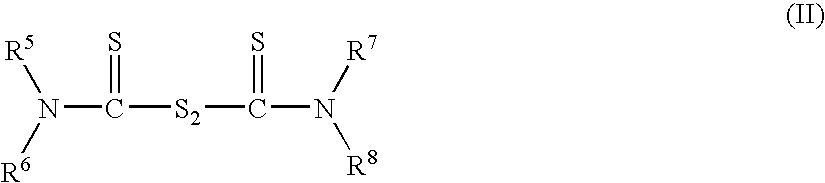

A rubber composition for a tire having greatly shortened vulcanization time, good silica dispersibility and, after vulcanization, superior braking capability, abrasion resistance and low rolling resistance, comprising (A) 100 parts by weight of a conjugated diene-based rubber, (B) 90 to 150 parts by weight of a reinforcing filler containing silica, (C) 0 to 40 parts by weight of an oil, (D) 4 to 20% by weight, based upon the weight of the silica, a silane coupling agent having the formula (I):Y3Si—CnH2nA (I)wherein Y indicates a C1 to C25 alkyl or alkoxyl group or a chloro group, the three Y's may be the same or different, n is an integer of 1 to 6, A is a mercapto group or SmZ group, where Z is the group:and m is an integer of 1 to 6)(E) sulfur, and (F) 0.05 to 5 parts by weight of a thiuram disulfide-based vulcanization accelerator having the formula (II):wherein R5, R6, R7 and R8 are independently hydrocarbon groups having 2 to 18 carbon atoms, is provided.

Owner:THE YOKOHAMA RUBBER CO LTD

Low temperature-stable creamy wash composition

Creamy wash composition containing (A) at least one N-long-chain-acyl acidic amino acid or a salt thereof, (B) at least one polyhydric alcohol, (C) at least one nonionic surfactant, (D) at least one salt of a divalent or higher cation and a monovalent or higher anion, and (E) water are stable at a low temperature and exhibit good foaming properties and a good feeling upon use.

Owner:AJINOMOTO CO INC

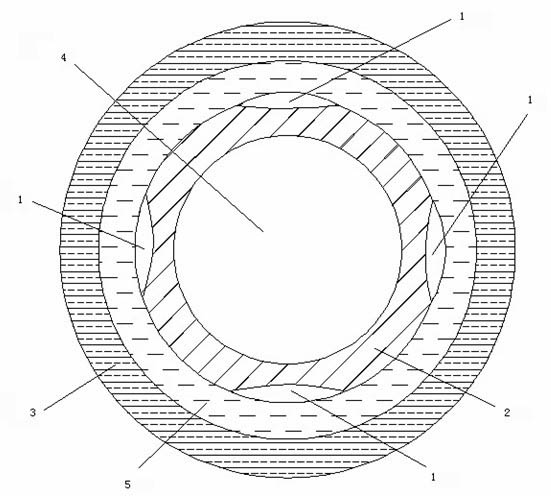

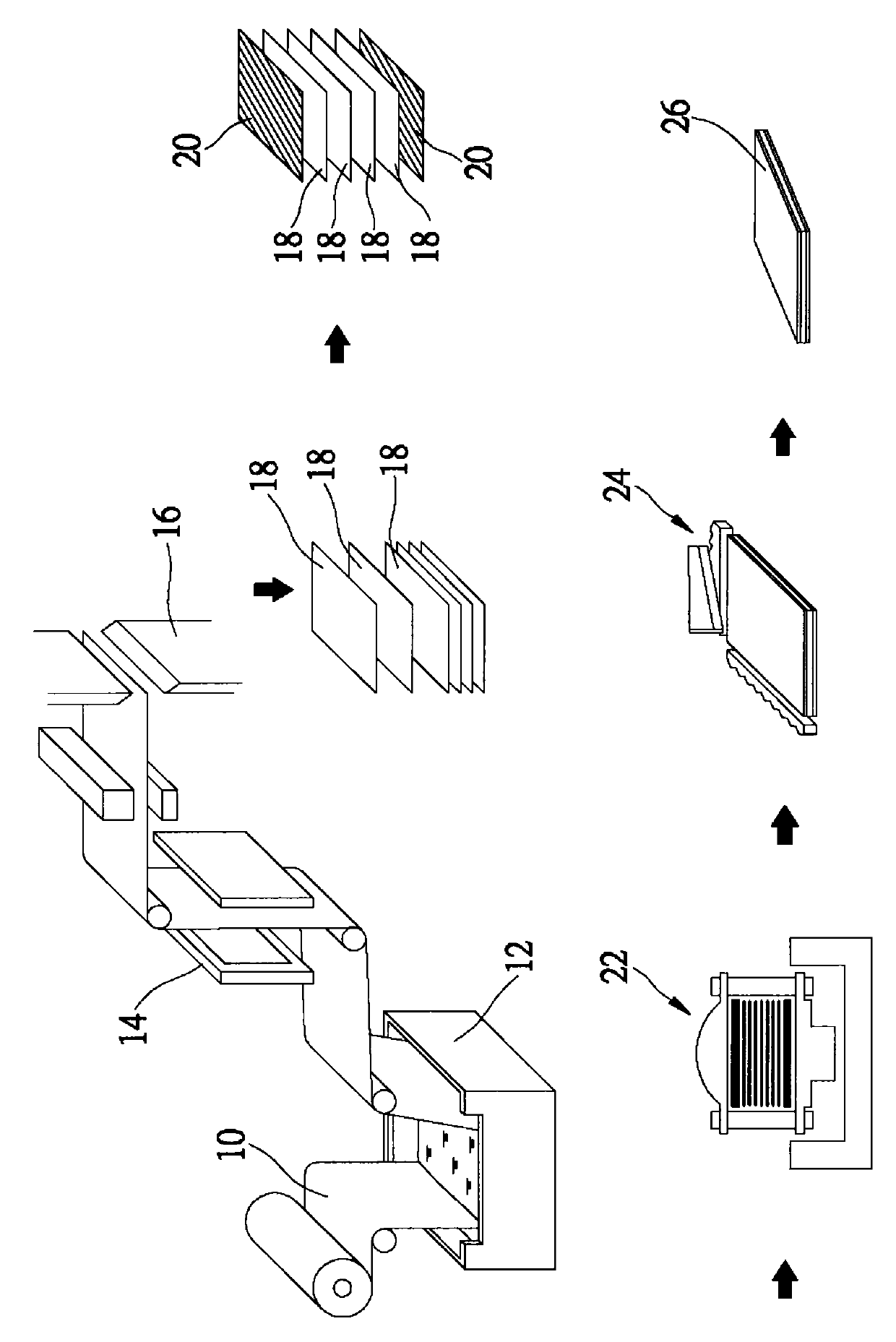

Nerve conduit and preparation method thereof

The invention discloses a nerve conduit and a preparation method thereof. The nerve conduit comprises an inner layer, a transition layer, an outer layer and at least one cavity used for storing a bioactive factor solution, wherein the outer surface of the inner layer is sequentially coated with the transition layer and the outer layer; the cavity is positioned between the inner surface of the outer layer and the outer surface of the transition layer and / or between the outer surface of the inner layer and the inner surface of the transition layer; the inner layer is a hydrophilic cytoskeleton layer made by adopting an electrostatic spinning method; and the outer layer is a hydrophobic nerve conduit scaffold layer made by adopting the electrostatic spinning method. The nerve conduit can be used for loading bioactive factors before an operation in a required mode, such as injection, soaking and the like due to the miniature cavity, so that the production quality of the product is easy to control, the survival rate of the bioactive factor can be greatly improved, the nerve regeneration can be promoted in high efficiency, and the nerve repairing effect can be reinforced.

Owner:MEDPRIN REGENERATIVE MEDICAL TECH

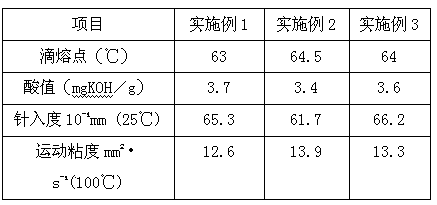

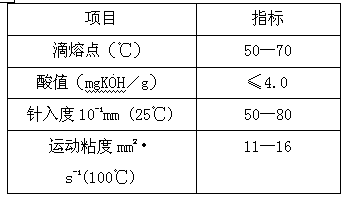

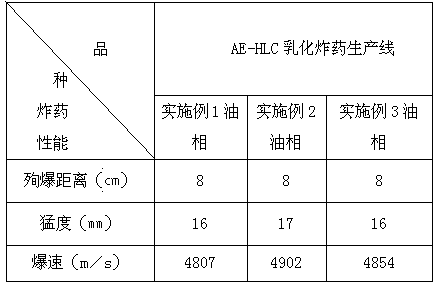

Plant type compound oil phase for emulsion explosive

ActiveCN103694068ASimple production processProduct quality is easy to controlNon-explosive/non-thermic compositionsWaxVegetable oil

The invention discloses a plant type compound oil phase for an emulsion explosive. The compound oil phase comprises main components of plant wax and plant oil, and is characterized by comprising the following materials by mass: 20%-50% of the plant wax, 10%-25% of the plant oil, 10%-25% of light dewaxing paste, 20%-35% of an emulsifier and 5%-15% of additives, wherein the total mass percentage of the materials is 100%. The compound oil phase prepared from the plant wax and the plant oil is applied to the industrial explosive production, so that a production process is simplified, and the production process quality is conveniently controlled; the compound oil phase is proper in drop melting point, acid value, needle penetration degree and kinematic viscosity, and is an ideal emulsion explosive oil phase material; the produced emulsion explosive is good in explosion performance; the plant oil phase material is clean, environment-friendly, low in price and highly available, and can effectively reduce the production cost; the compound oil phase used for producing the emulsion explosive has good economic and social benefits and is convenient for industrialization production and application.

Owner:FUZHOU GUOTAI COMPOSITE MATERIAL CO LTD

Copper clad laminate and impregnation liquid for making same

The invention relates to a copper clad laminate comprising a glass fiber substrate and at least one copper foil combined on at least one side surface of the glass fiber substrate, wherein the glass fiber substrate is formed by the steps of impregnating a piece of glass fiber cloth in an impregnation liquid to prepare a half-solid film and then combining the half-solid film with the copper foils to prepare the copper clad laminate through pressuring and heating, wherein the impregnation liquid comprises a resin and a filler of 5-80 PHR (Parts per Hundreds of Resin), and the filler is a non-crystalline net-structured composite material which is co-constituted by silicon dioxide and one or more of IIA or IIIA metallic oxides. The copper clad laminate has appropriate hardness and linear expansion coefficient.

Owner:SIBELCO ASIA

Organic-inorganic compound fertilizer for high-yield paddy rice

InactiveCN105384527AIncrease productionProduct environmental protectionFertilizer mixturesSeabirdPesticide residue

The invention discloses an organic-inorganic compound fertilizer for high-yield paddy rice. The organic-inorganic compound fertilizer is prepared from the following raw materials in parts by weight: 20 to 50 parts of urea, 5 to 20 parts of monoammonium phosphate, 30 to 50 parts of potassium polyphosphate, 30 to 50 parts of seabird droppings, 15 to 35 parts of fermented paddy rice straws, 5 to 18 parts of fermented cow dung, 15 to 30 parts of bone dregs, 5 to 15 parts of humic acid, 2 to 8 parts of modified turf, 1 to 7 parts of paddy rice straws, 15 to 19 parts of coal ash, 5 to 12 parts of attapulgite, 1 to 6 parts of kaolin, 1 to 3 parts of manganese sulfate, 1 to 2 parts of ferrous sulfate, 1 to 4 parts of carbonic lime, 0.01 to 0.07 part of compound enzyme and 0.01 to 0.05 part of compound bacteria. A product of the organic-inorganic compound fertilizer is environment-friendly, less in pesticide residue, balanced in nutrition and high in yield of paddy rice.

Owner:高青山

Edible tableware and preparation process thereof

The invention provides edible tableware and belongs to the technical field of new materials of food. The edible tableware comprises a tableware-shaped biscuit main body, wherein the surface of the biscuit main body is covered with an edible waterproofing membrane. The biscuit main body comprises the following raw materials in parts by weight: 20-30 parts of wheat flour, 10-15 parts of sorghum flour, 5-8 parts of rice flour, 5-8 parts of starch, 6-12 parts of eggs and 0-4 parts of a flavoring agent, and the flavoring agent is natural fruit and vegetable products. A preparation process comprisesthe following steps: S1, adding water to the raw materials of the biscuit main body, performing mixing, then performing pressing to obtain a tableware-shaped biscuit main body, performing cooking toobtain the biscuit main body, and forming the waterproofing membrane on the surface of the biscuit main body. The edible tableware provided by the invention can be substituted for disposable tablewarein use, such as plastic bowls, plastic spoons, disposable chopsticks, plastic or fibrous dinner plates, plastic water cups and the like, and the edible tableware is healthy, safe and environment-friendly and has economic value, social value and broad application prospects.

Owner:众智汇(厦门)生物科技有限公司

Rubber composition for shoe sole and rubber foam composition

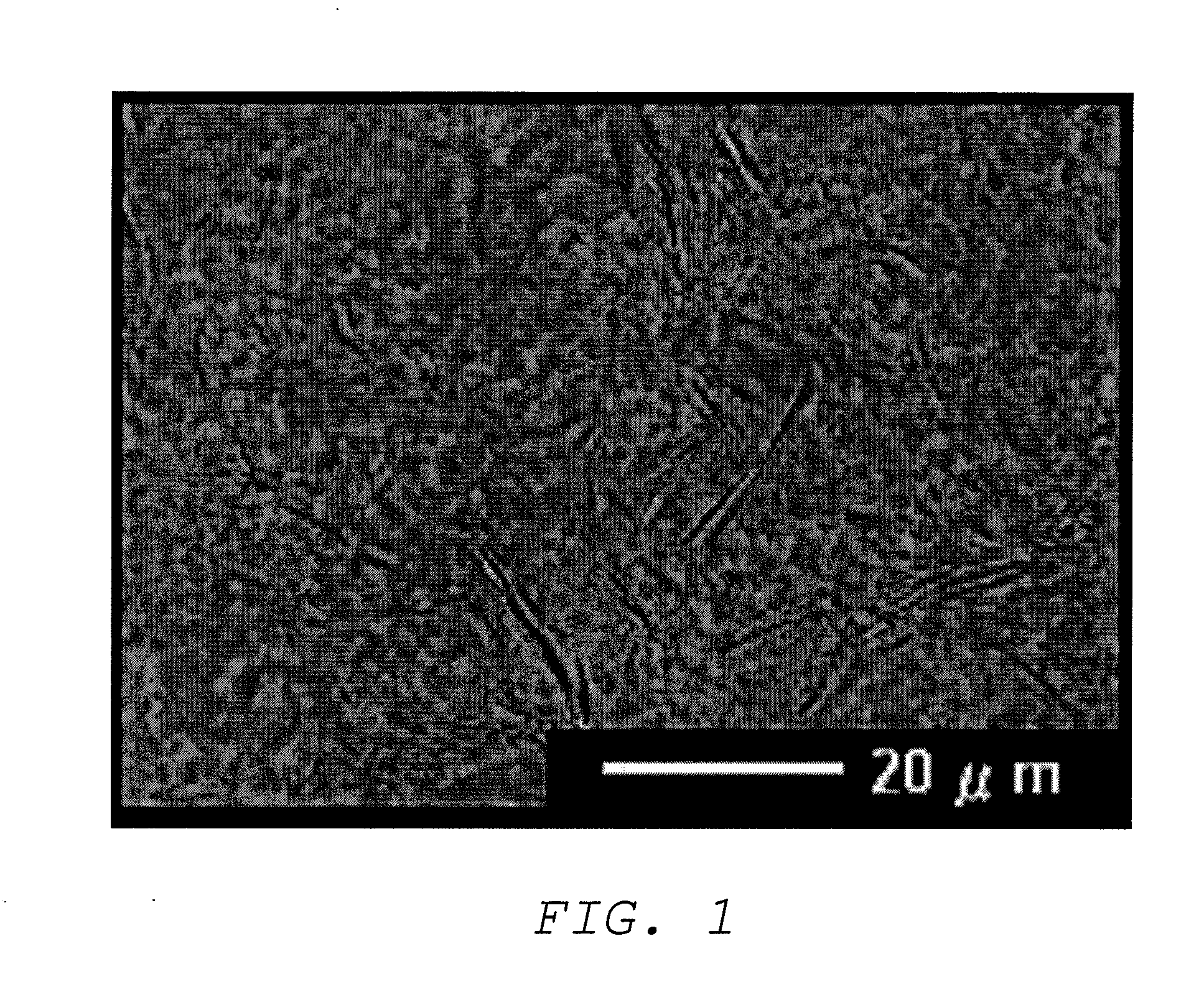

InactiveUS20090239965A1Excellent in tensile strength , tear strength , abrasion resistance and grip propertyAppropriate hardnessSolesSpecial tyresAspect ratioHardness

Provided is a rubber composition for shoe soles prepared by blending 100 mass parts of a polymer component comprising 10 to 90 mass % of a vinyl / cis-polybutadiene rubber (A) comprising 1,4-cis-polybutadiene (a) and 1,2-polybutadiene crystalline fibers (b) in which the crystalline fibers have an average fiber length of 200 nm or less and an average aspect ratio of 10 or less, in which the number of the crystalline fibers having a fiber length of 200 nm or less is 90 fibers or more per 25 μm2 and in which a melting point is 170° C. or higher, 10 to 50 mass % of a diene base rubber (B) other than the polybutadiene rubber (A) and 2 to 50 mass % of a thermoplastic polymer (C) with 2 to 50 mass parts of a rubber reinforcing material (D).The above rubber composition for shoe soles has a light weight and an appropriate hardness and is excellent in a tensile strength, a tear strength, an abrasion resistance and a gripping property and excellent as well in a dimensional stability after foaming, and it is suited as an outsole for shoes.

Owner:UBE IND LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com