Patents

Literature

464results about How to "Reduce mold cost" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

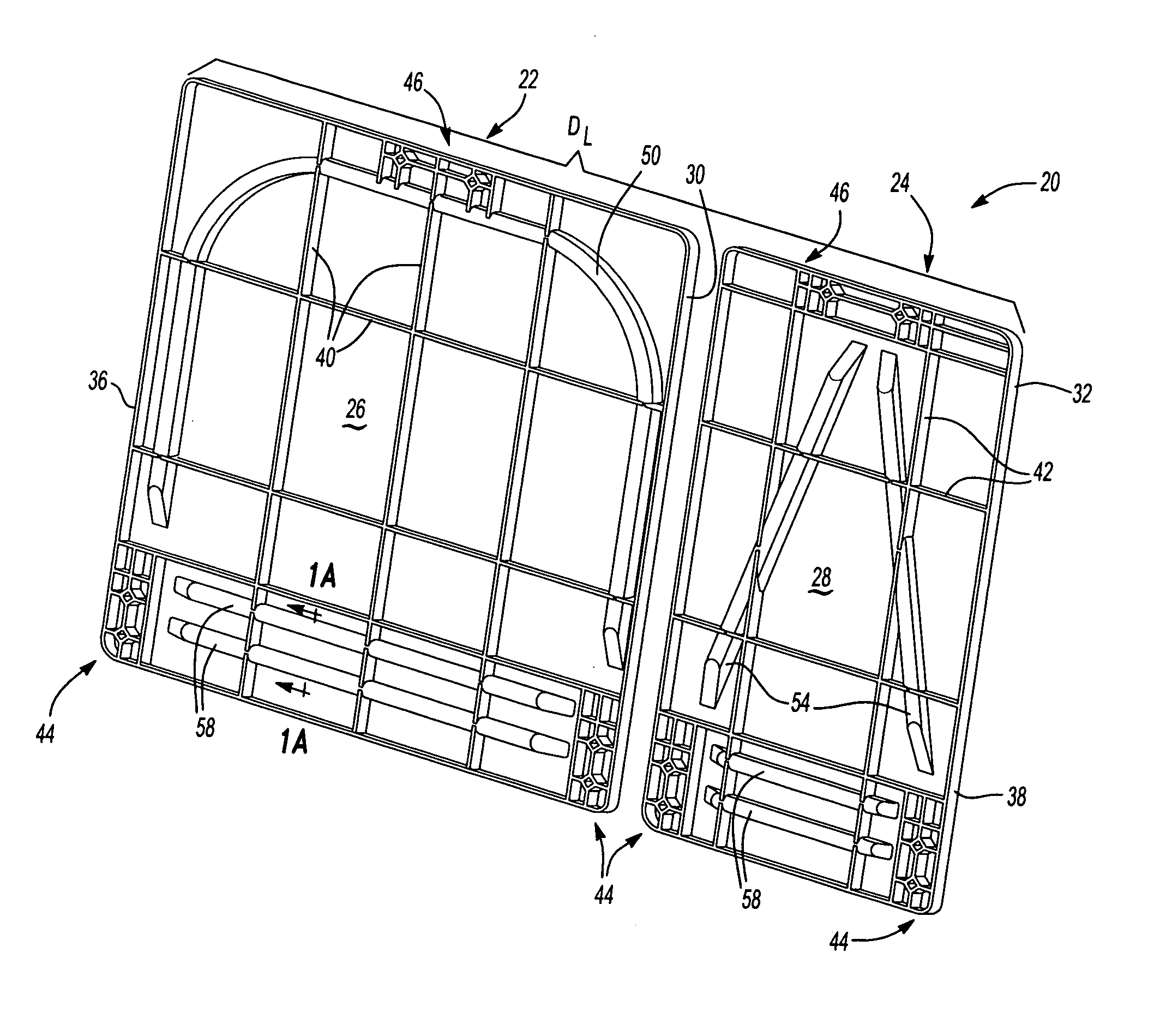

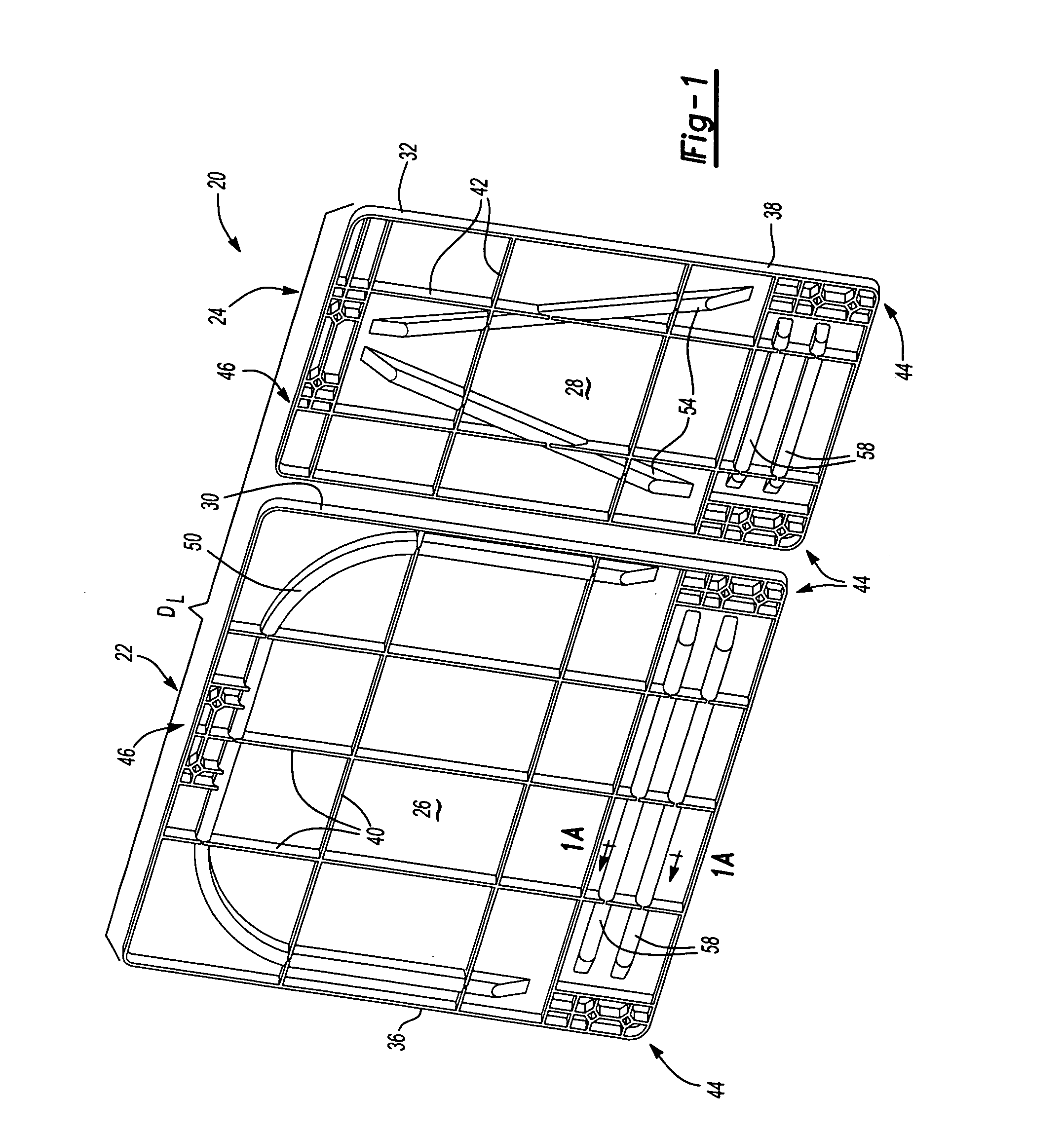

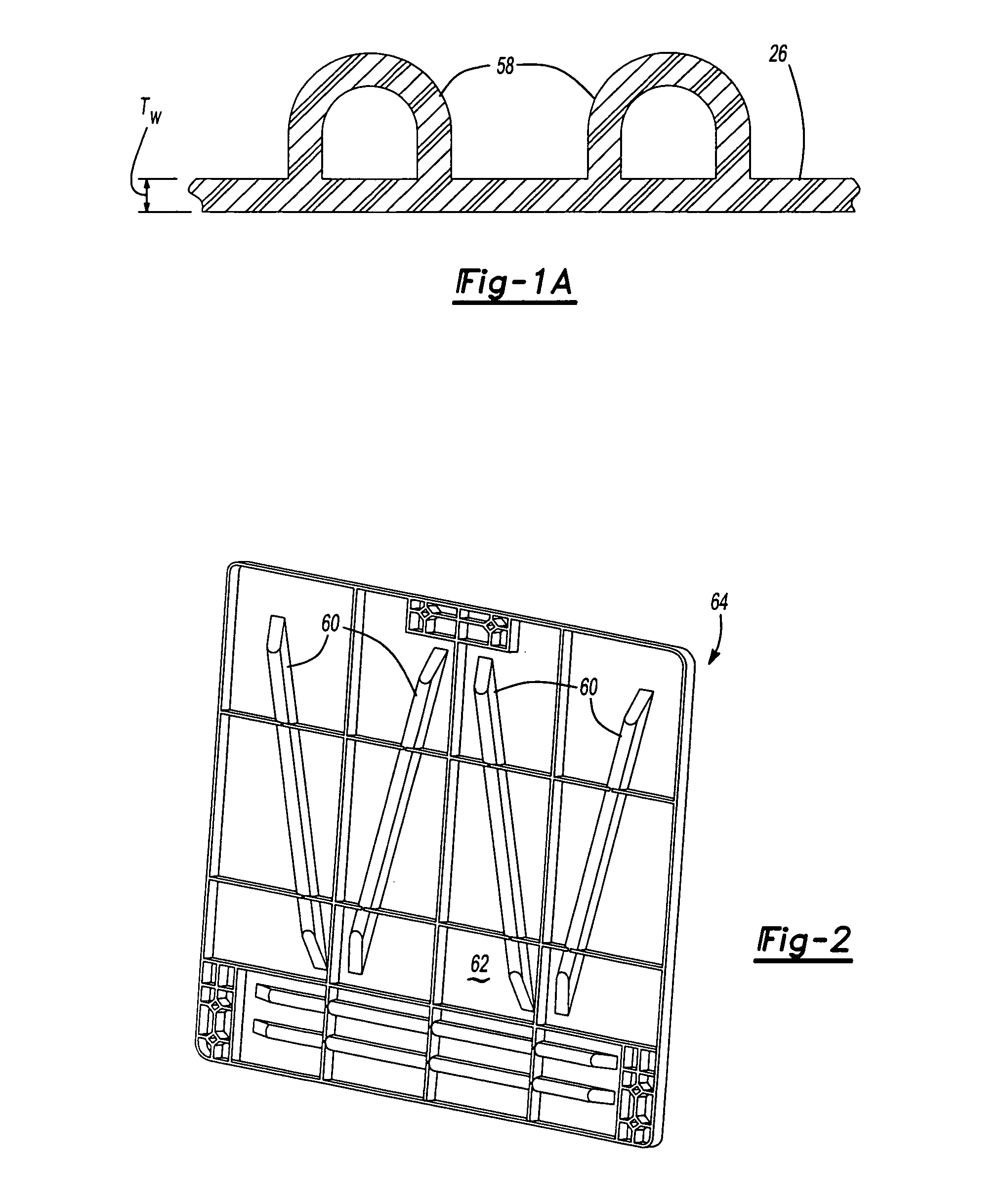

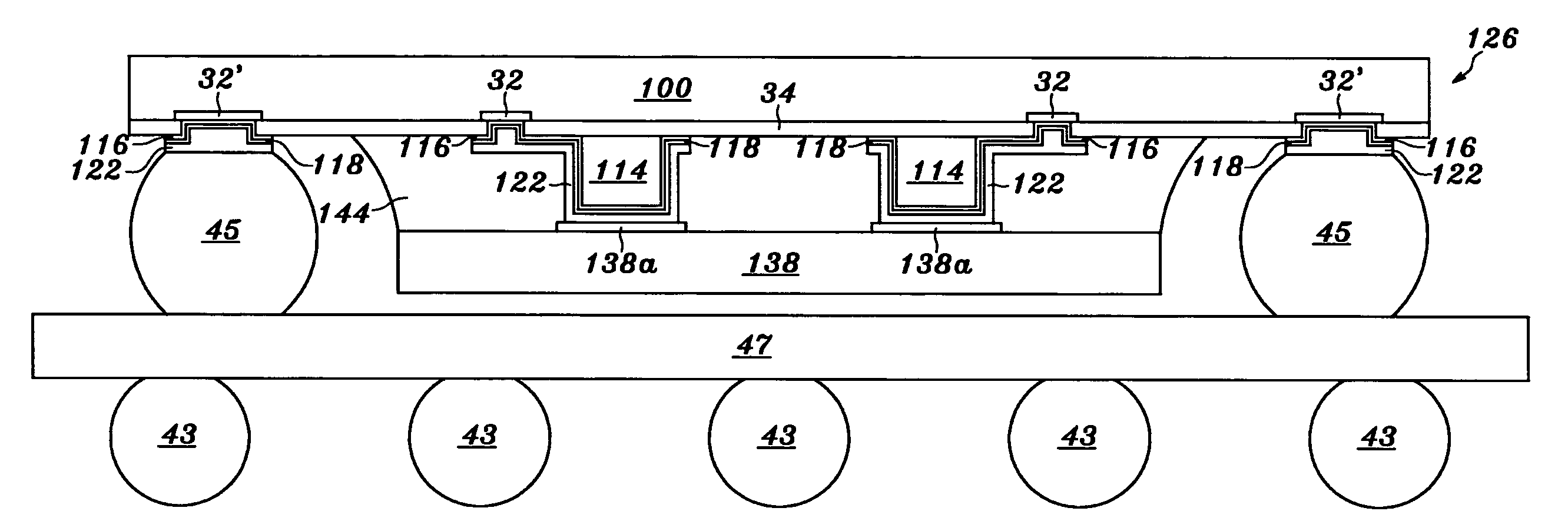

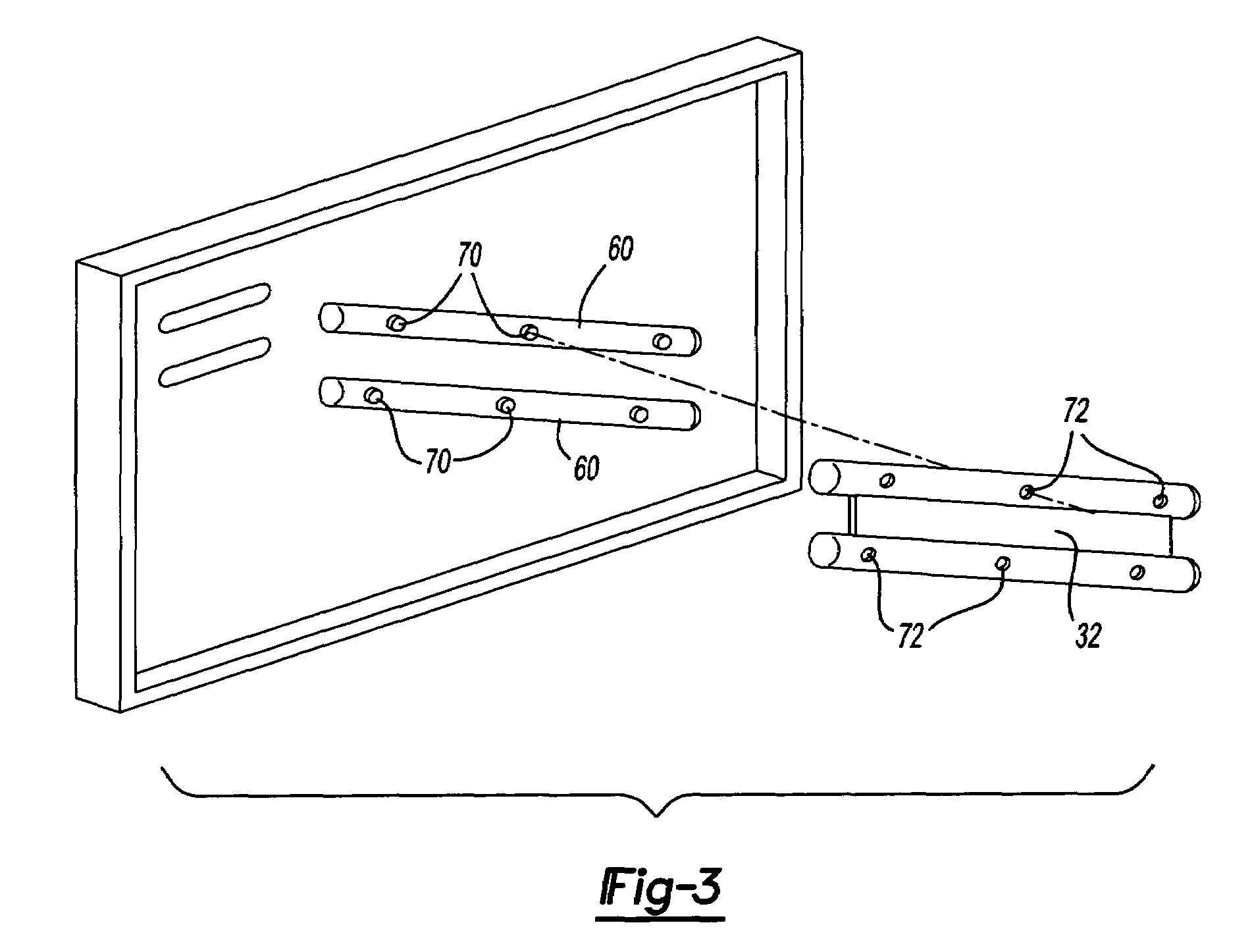

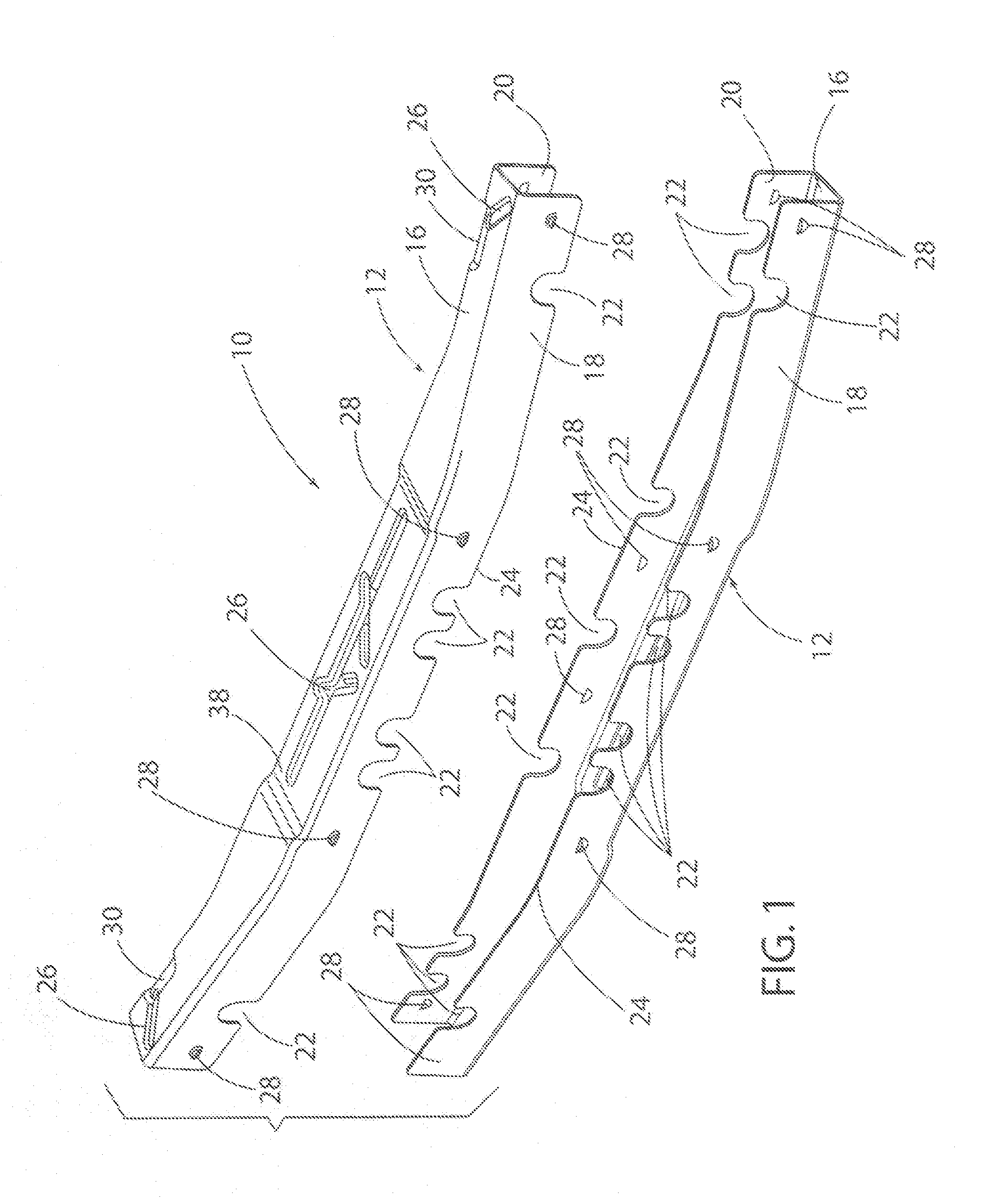

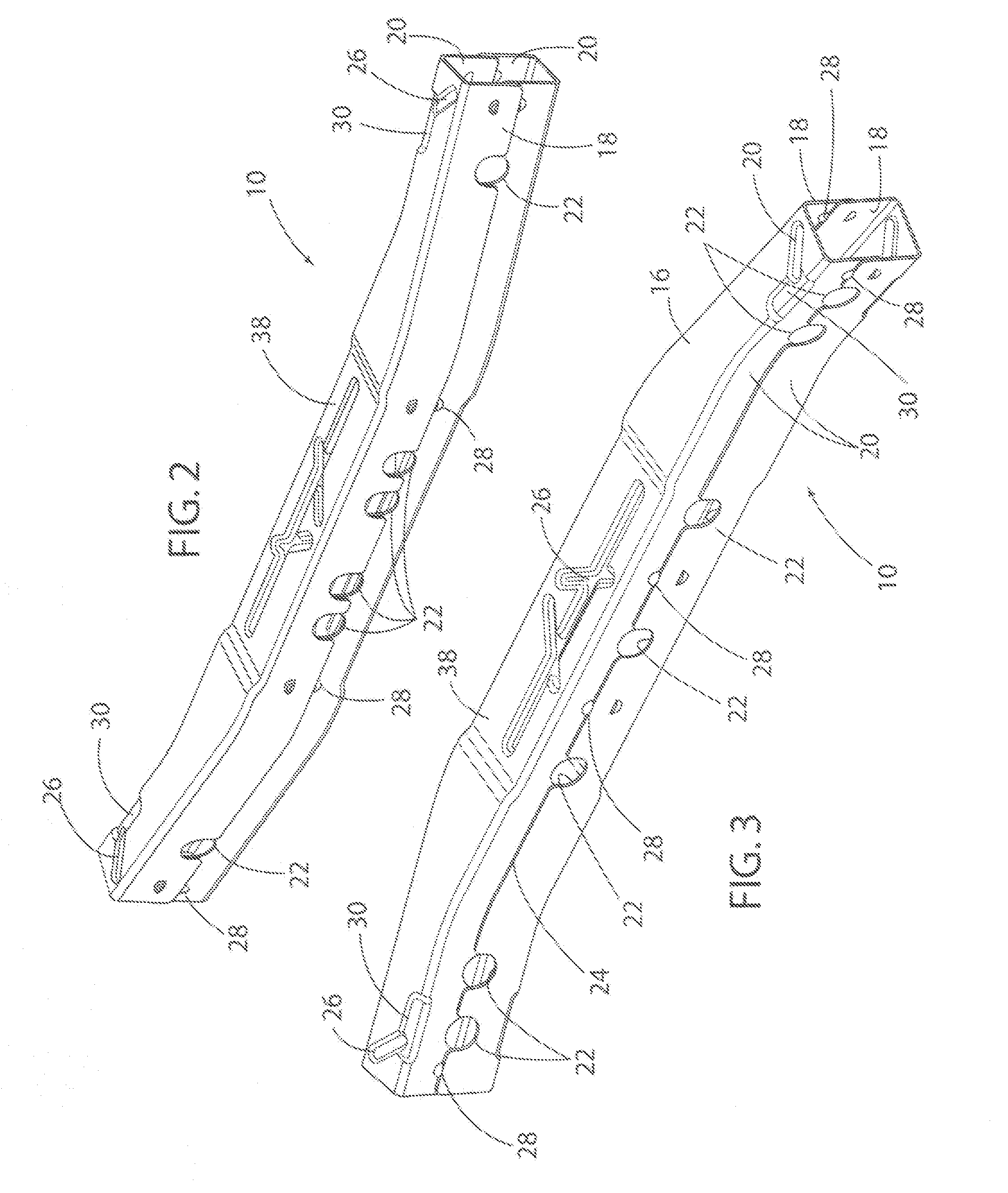

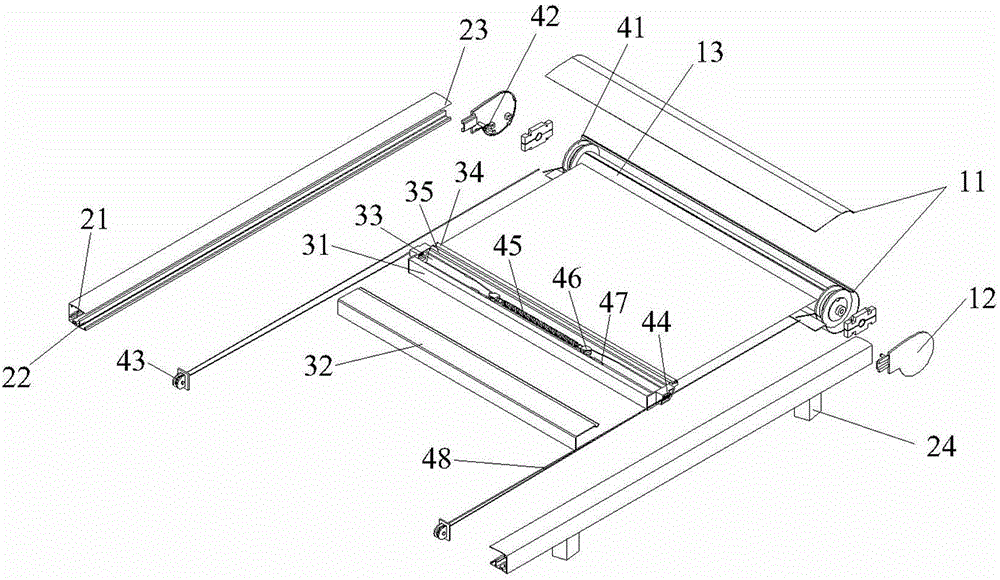

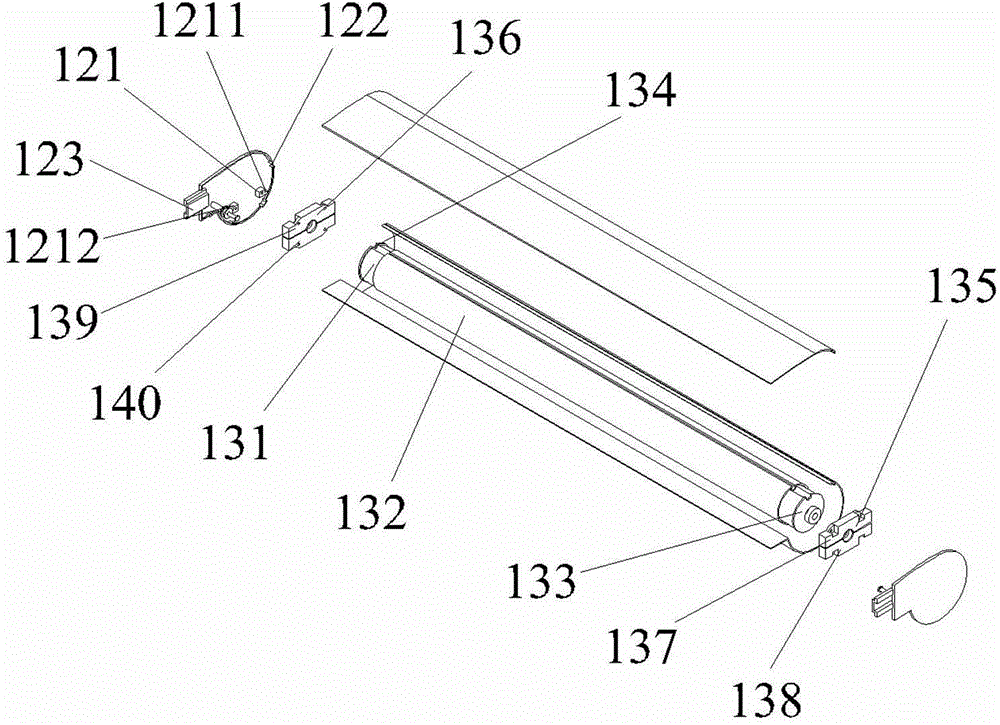

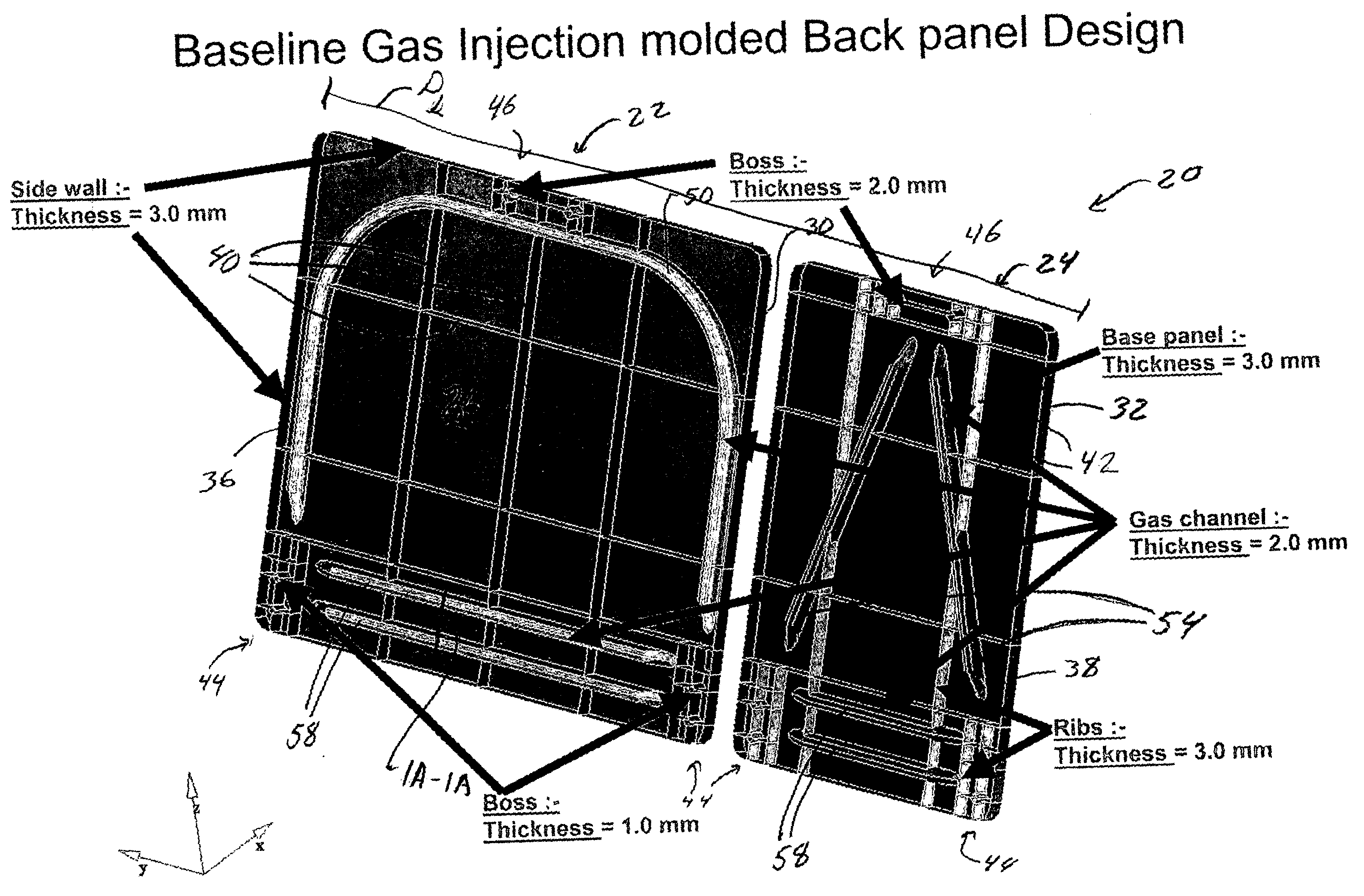

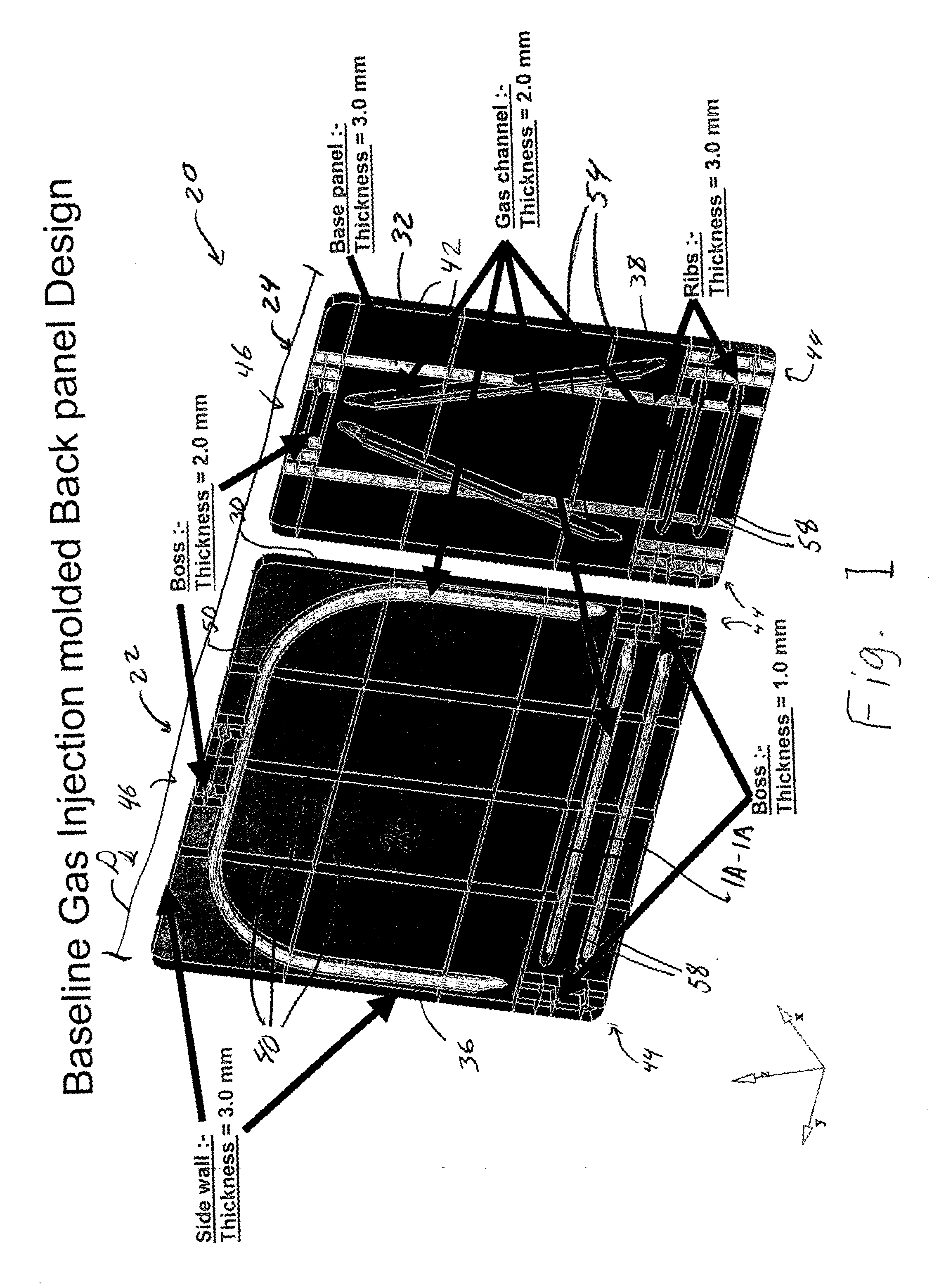

Seating system and method of forming same

InactiveUS7128373B2Provide strengthEasy to manufactureSeat framesStoolsMechanical engineeringEngineering

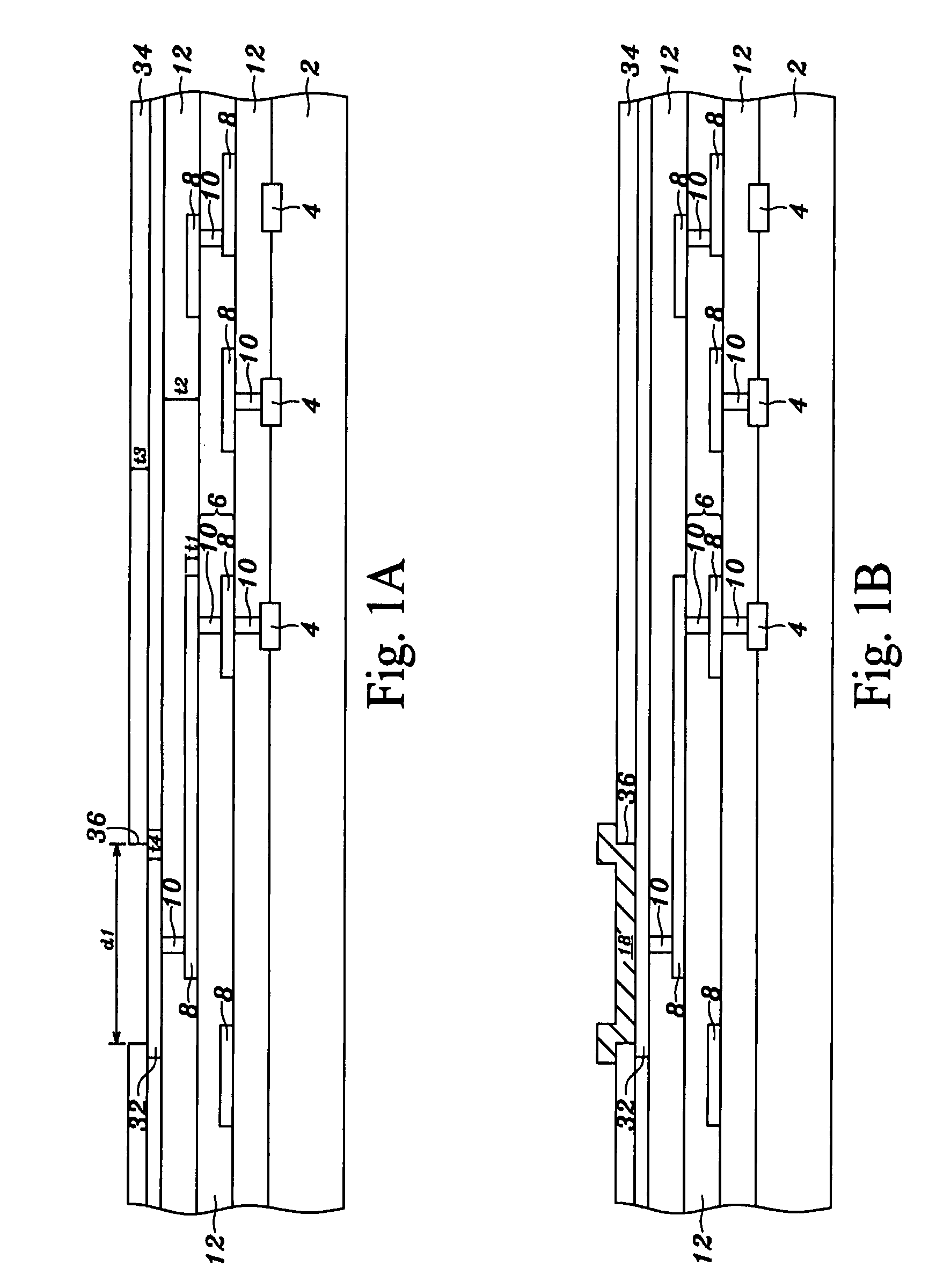

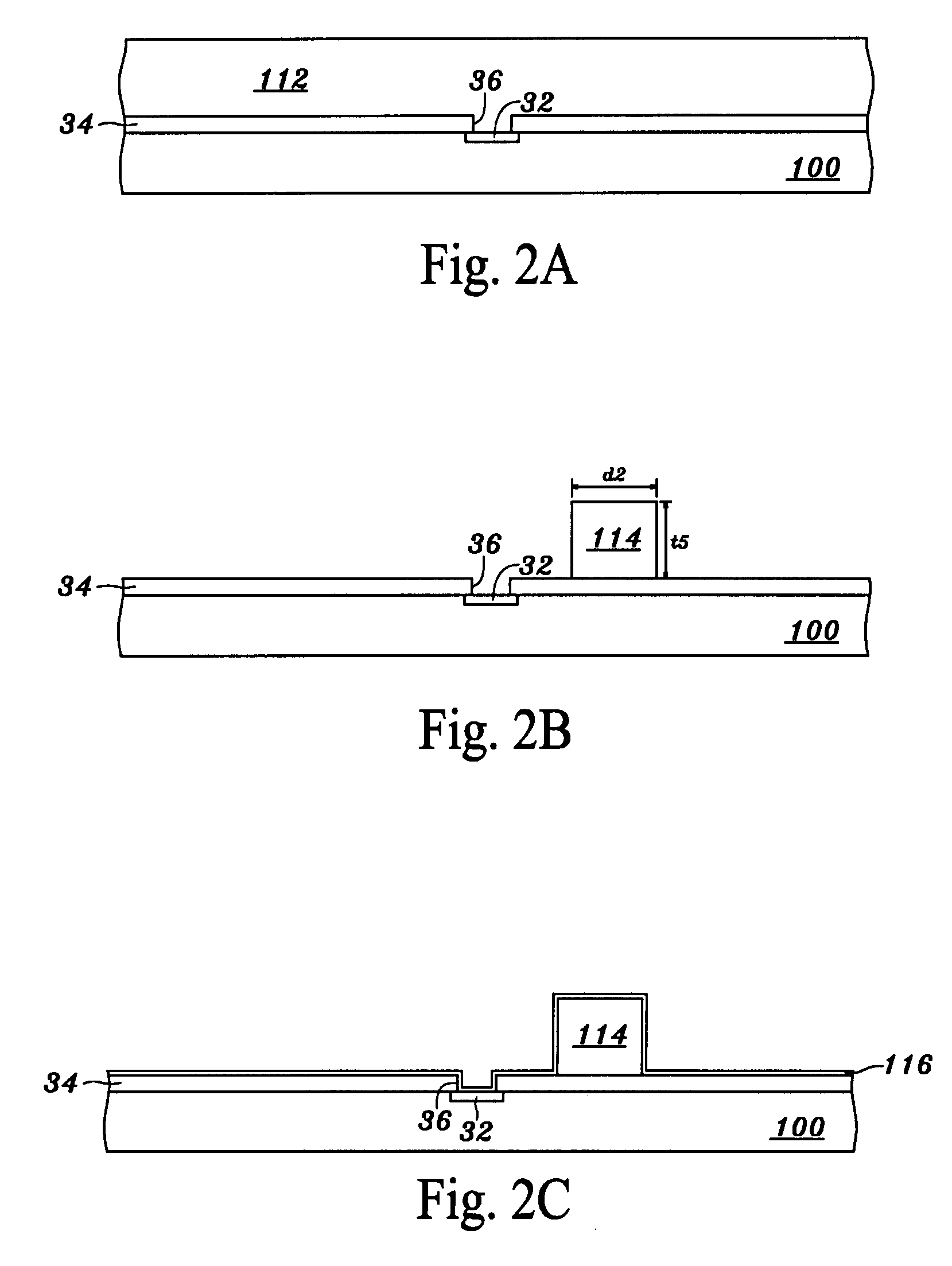

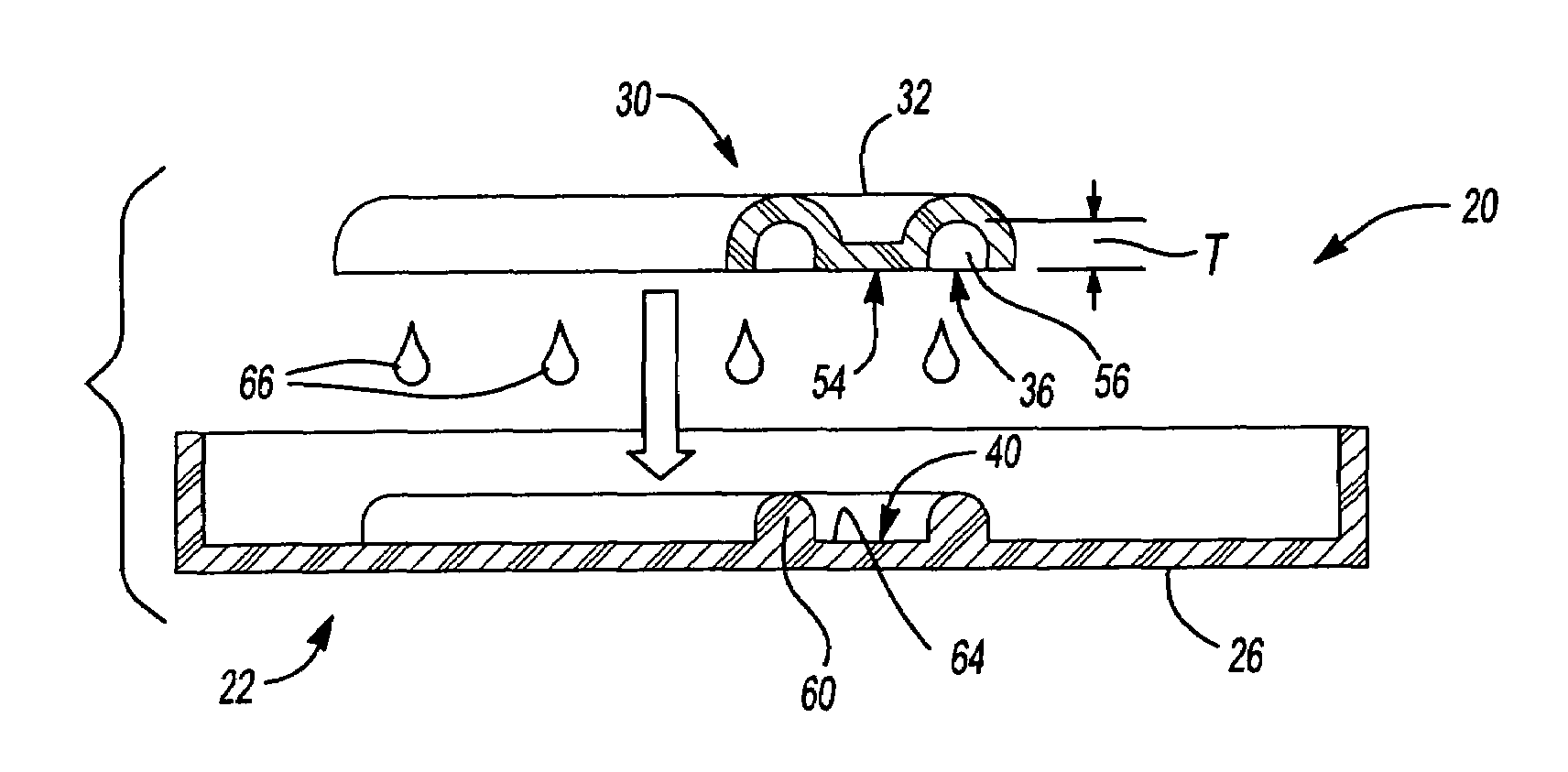

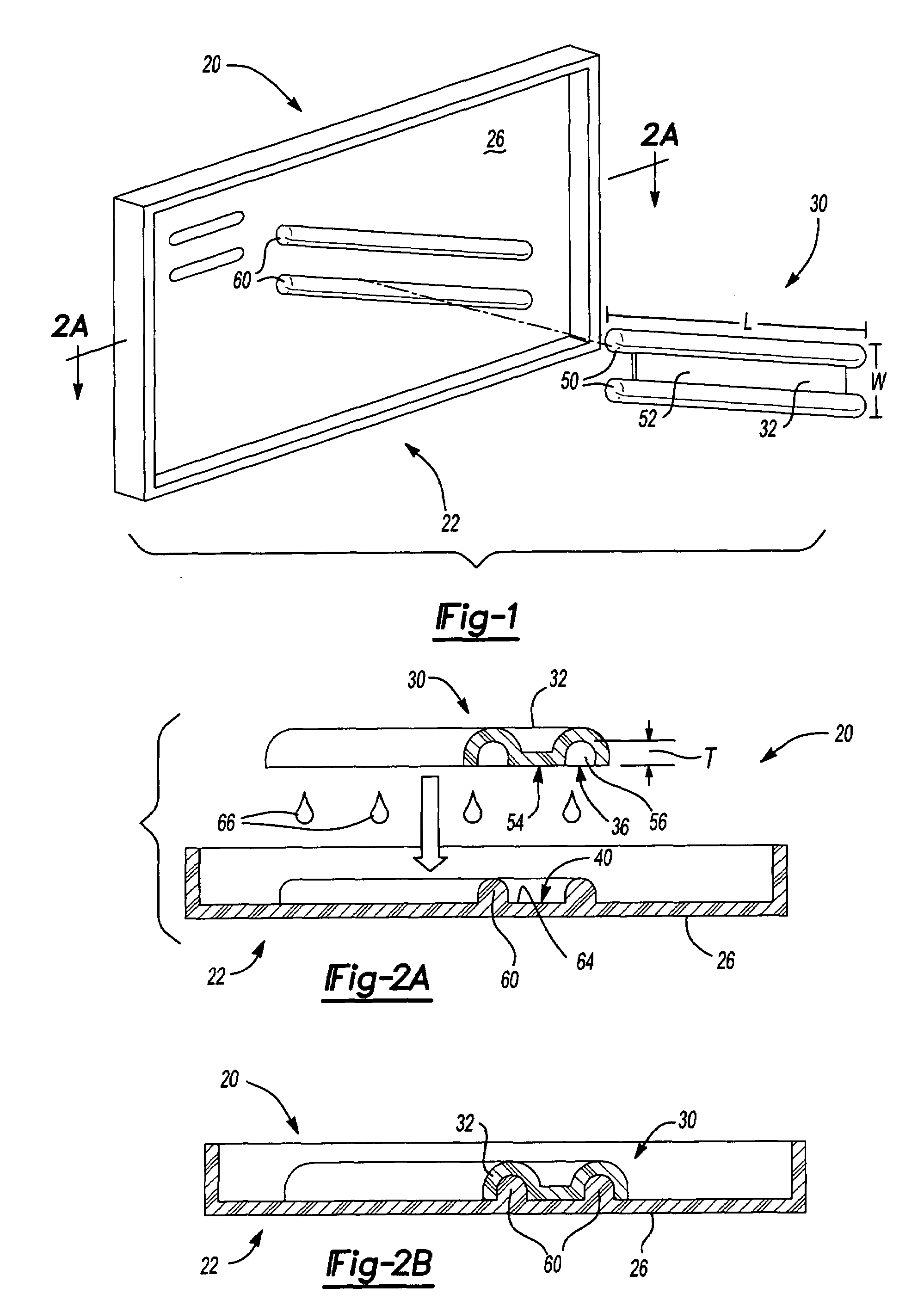

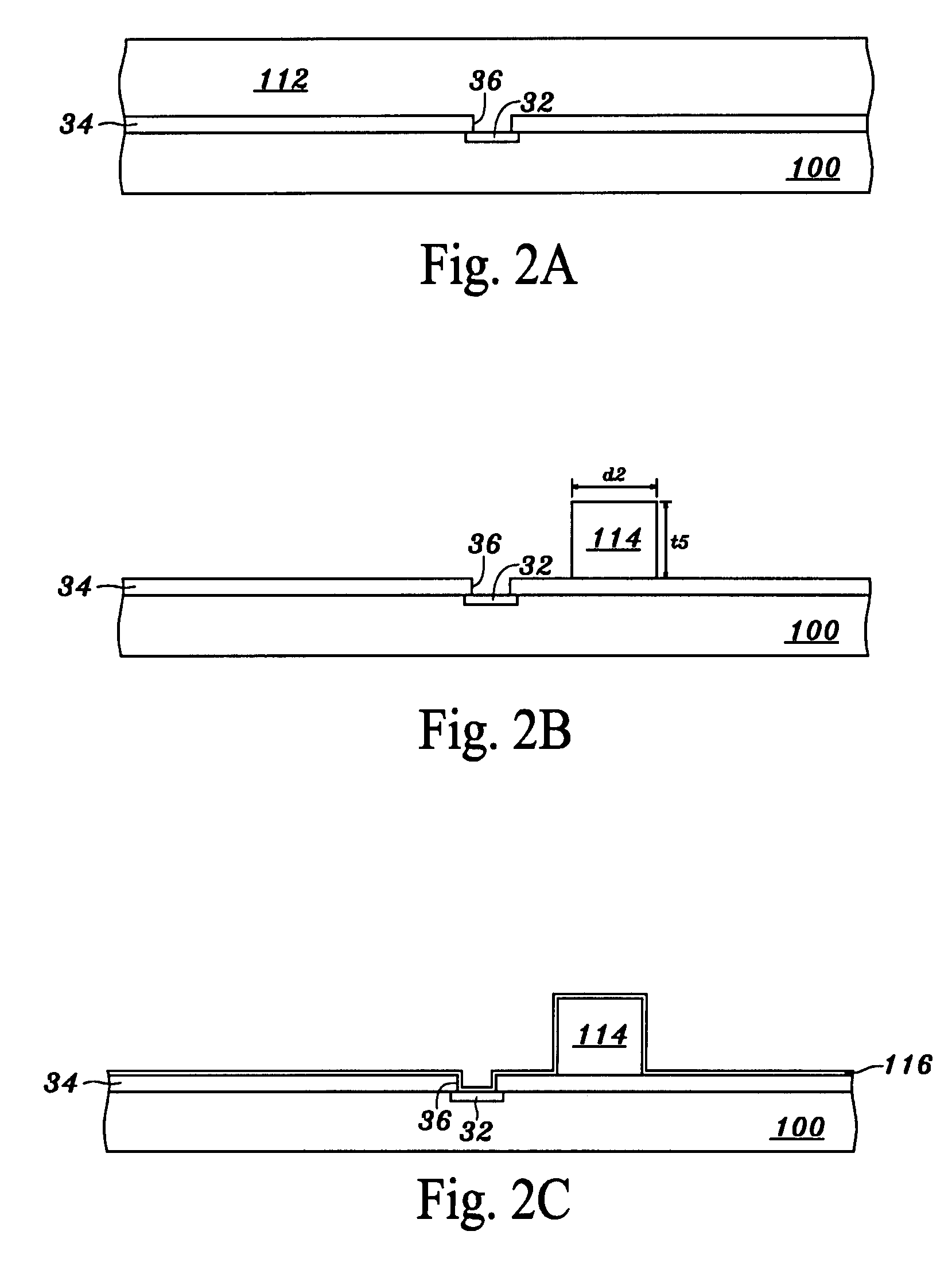

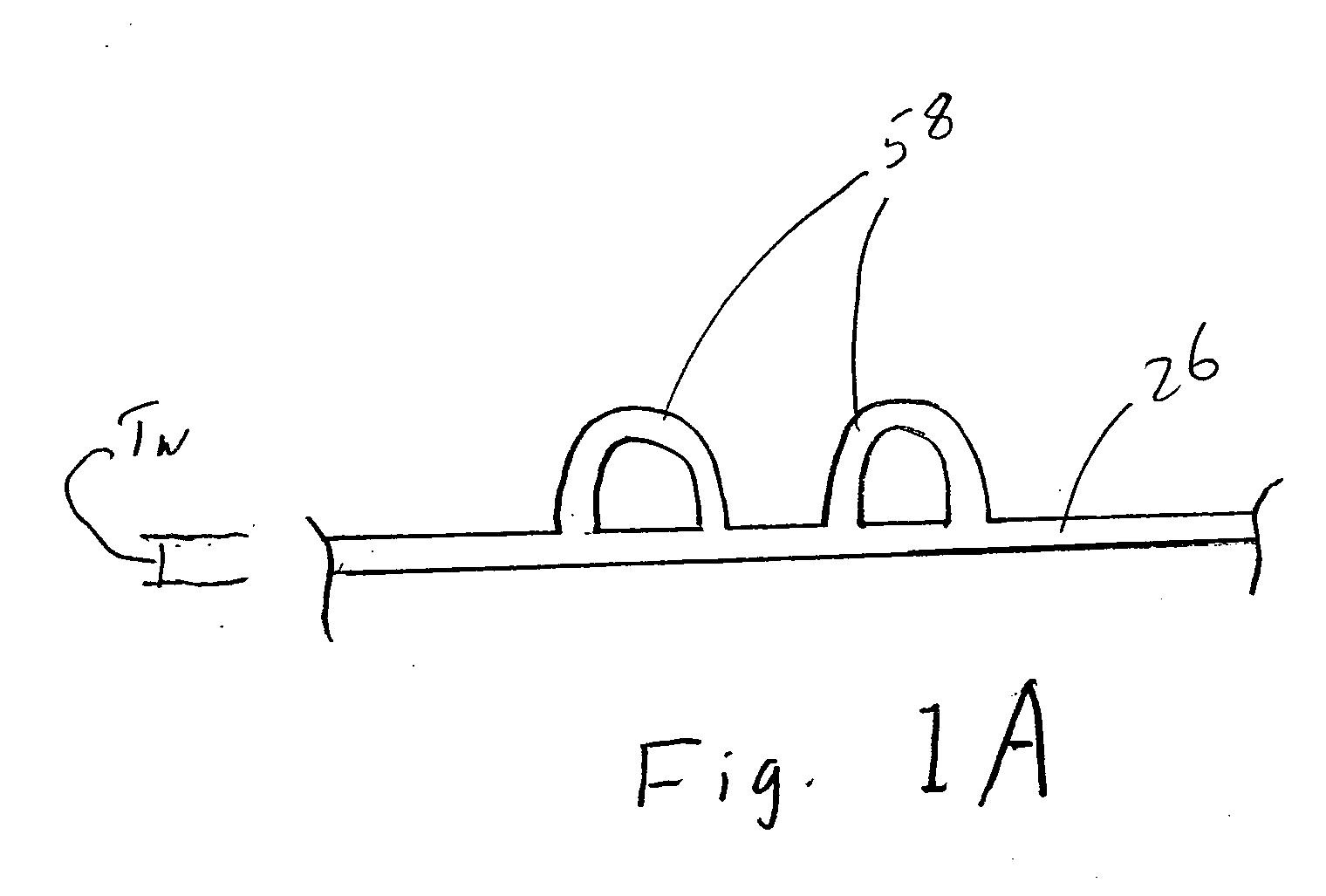

The present invention discloses a seating system that includes a seat back (20) with one or more plastic panels (22, 24) that extend across a lateral distance (D2) of the seat back (20). The seat back (20) preferably includes one or more channel forming ribs (50, 54, 58). Optionally the seat back (20) will be anchored to a body of an automotive vehicle with an improved attachment system (100).

Owner:DOW GLOBAL TECH LLC

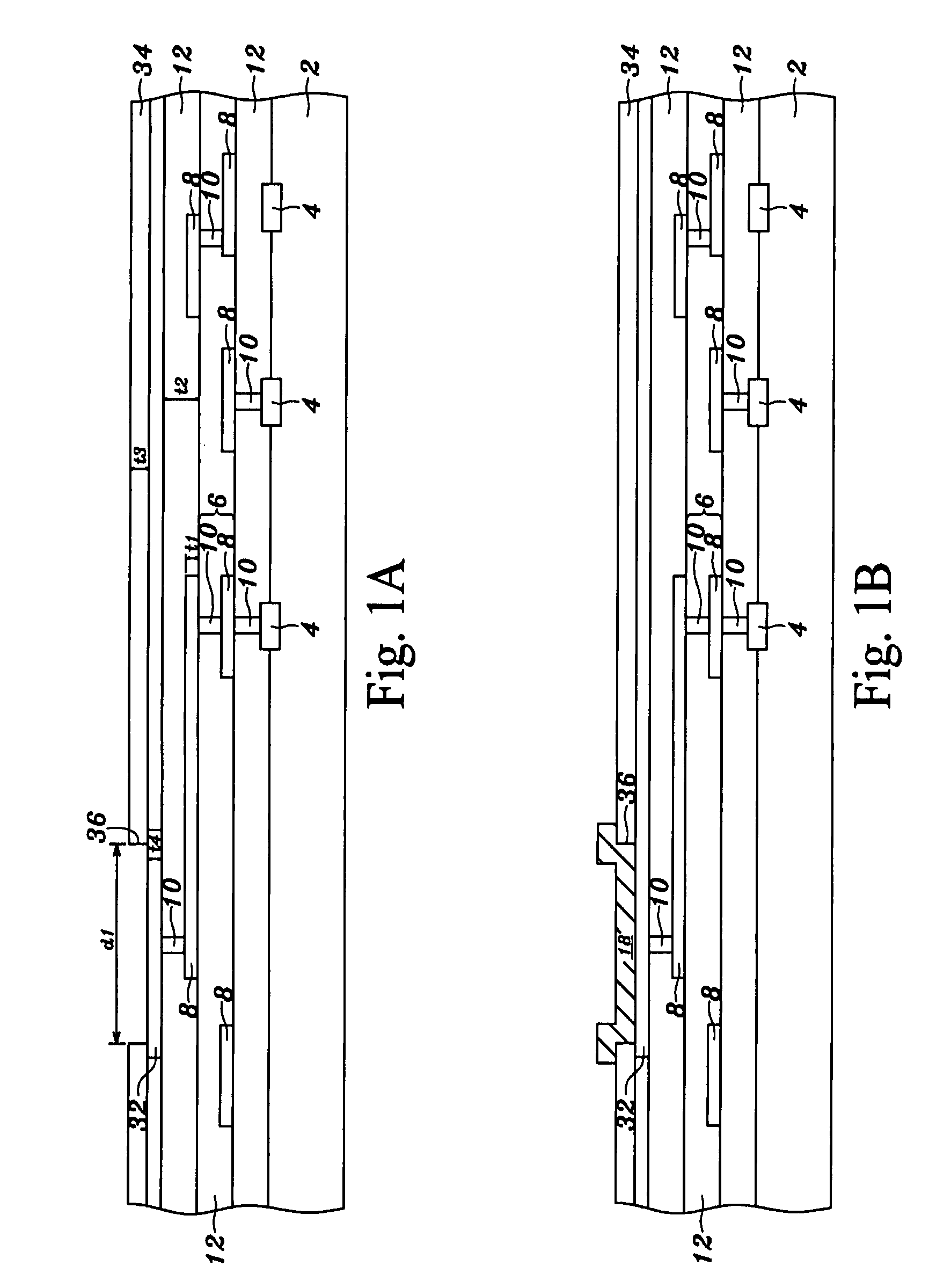

Semiconductor chip and method for fabricating the same

ActiveUS20080054457A1Reduce mold costSemiconductor/solid-state device detailsSolid-state devicesMicrometerSemiconductor chip

A semiconductor chip includes a silicon substrate, a first dielectric layer over said silicon substrate, a metallization structure over said first dielectric layer, wherein said metallization structure comprises a first metal layer and a second metal layer over said first metal layer, a second dielectric layer between said first and second metal layers, a passivation layer over said metallization structure and over said first and second dielectric layers, an opening in said passivation layer exposing a pad of said metallization structure, a polymer bump over said passivation layer, wherein said polymer bump has a thickness of between 5 and 25 micrometers, an adhesion / barrier layer on said pad exposed by said opening, over said passivation layer and on a top surface and a portion of sidewall(s) of said polymer bump, a seed layer on said adhesion / barrier layer; and a third metal layer on said seed layer.

Owner:QUALCOMM INC

Method of forming a seating system

InactiveUS7250091B2Easy to manufactureEasily attachedGlass/slag layered productsCellulose adhesivesMechanical engineering

The present invention discloses a seating system that includes a seat back (20) with one or more plastic panels (22) that extend across a lateral distance of the seat back (20). The seat back (20) preferably includes one or more reinforcements (30) attached to the plastic panels (22).

Owner:DOW GLOBAL TECH LLC

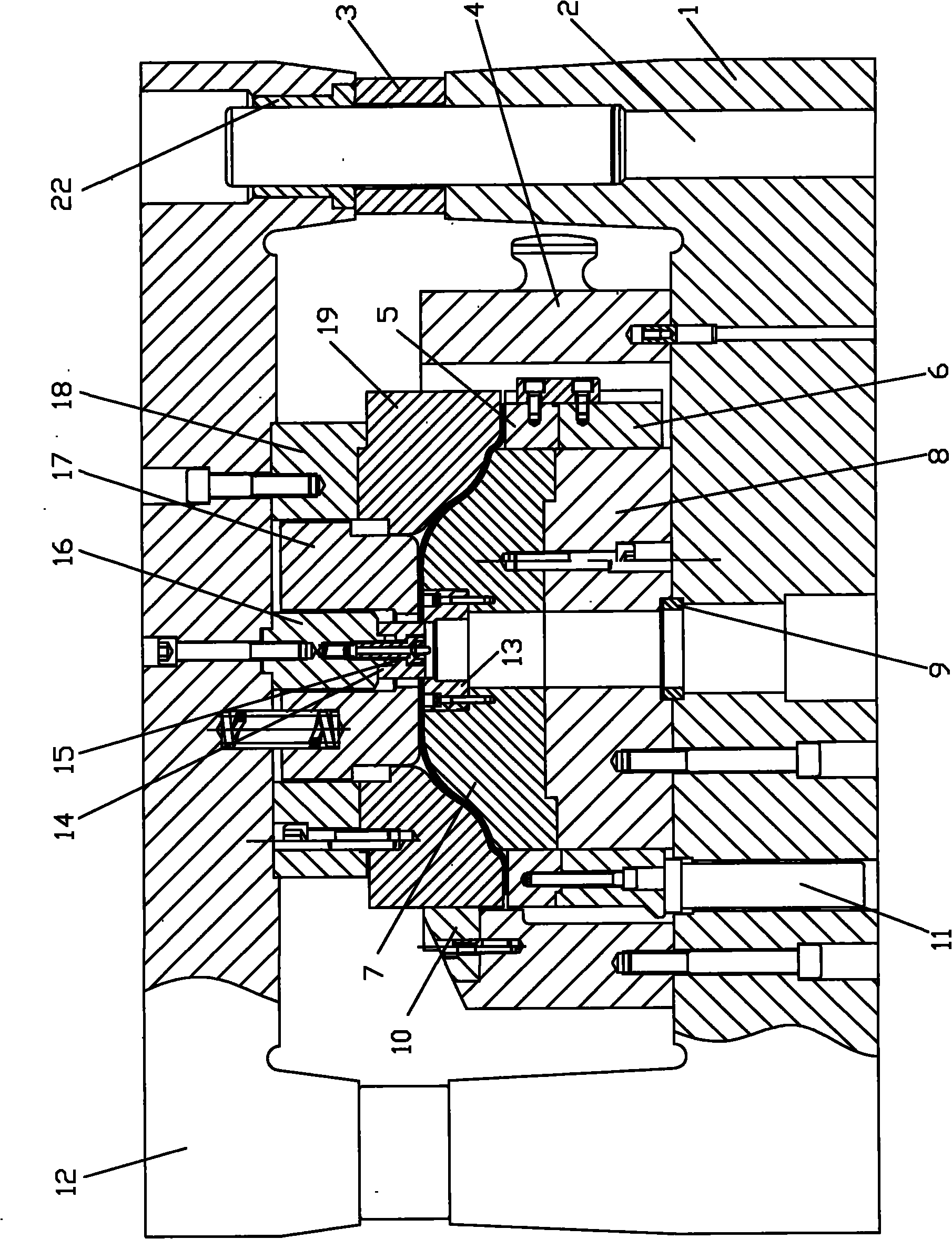

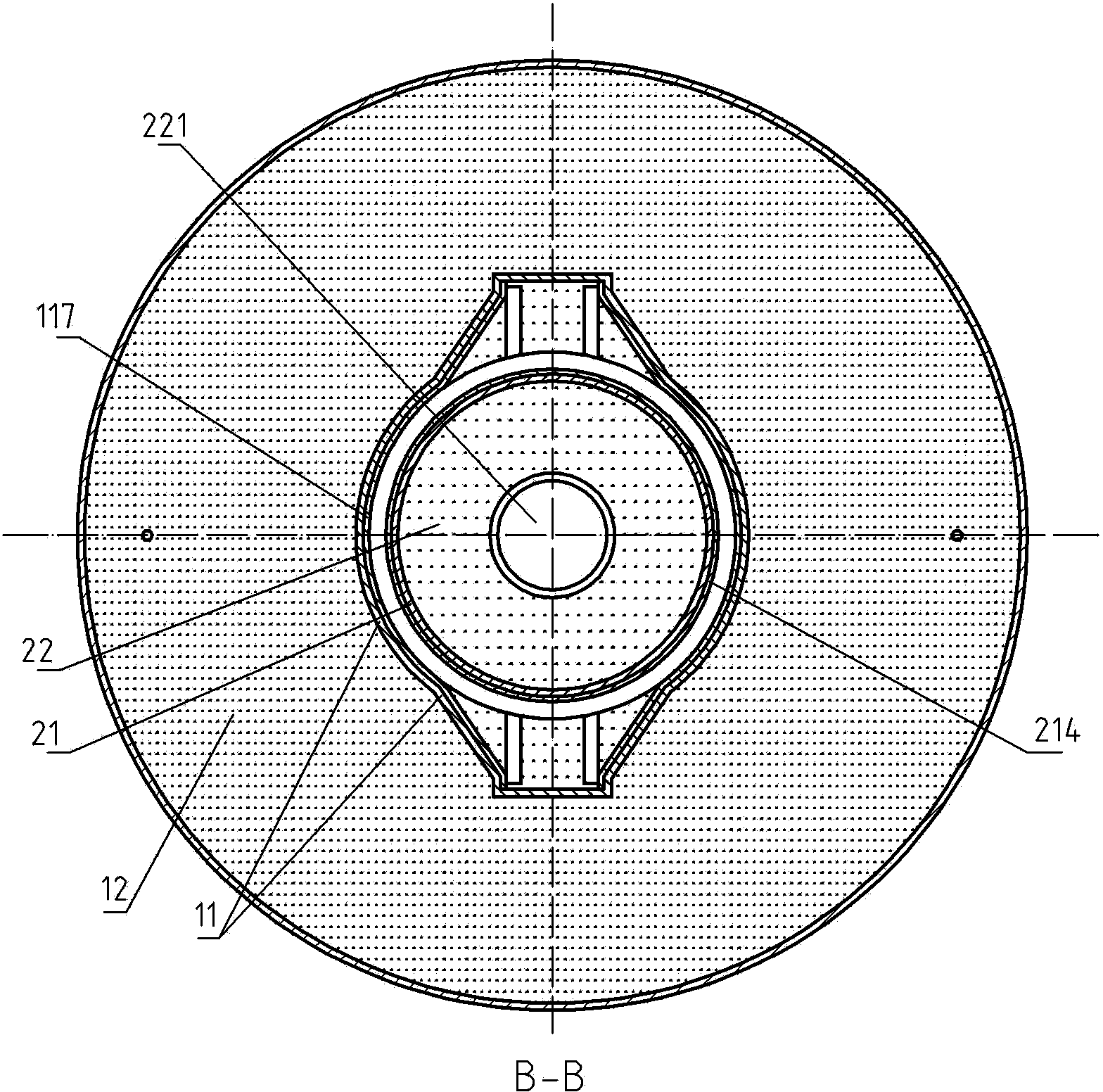

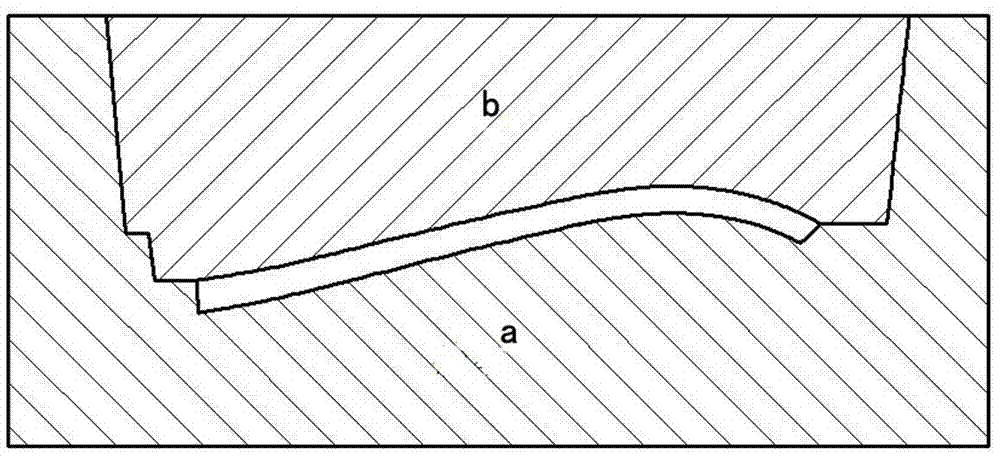

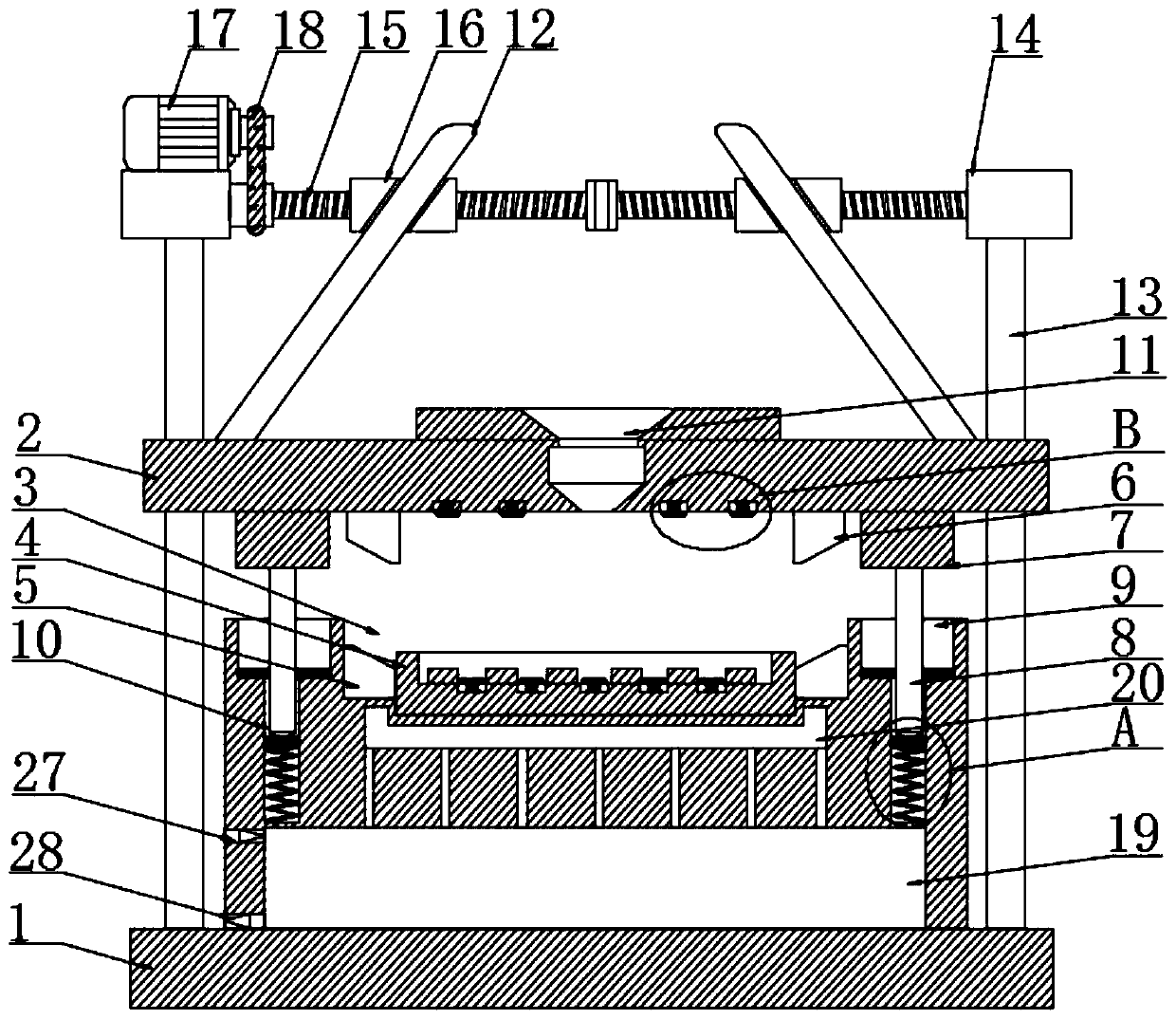

Steel wheel spoke stamping process for passenger car and processing mould

The invention relates to a steel wheel spoke stamping process for a passenger car, comprising the following steps of: (1) cutting a panel veneer: placing the rectangular panel veneer on a material support, the left and right ends as well as the front end of which are positioned by a set rule; when a press descends, cutting the panel veneer at the same time by using a peripheral cutting edge at the lower part of the outer edge of an upper mold core and a trim blade to form a spoke panel veneer; (2) stretching the panel veneer: placing the trimmed spoke panel veneer on a blank pressing ring, and pressing down the spoke panel veneer through the upper mold core and the blank pressing ring, wherein in the descending process of the press, the middle part of the spoke panel veneer firstly contacts the lower mold core to prevent the middle part of the spoke panel veneer from descending, and the peripheral part of the spoke panel veneer without being blocked continuously stretches the spoke panel veneer along with the descending of the upper mold core and the blank pressing ring; (3) punching central holes of the spoke; and (4) resetting and discharging. The invention integrates the blanking and stretching processes, adopts the one-step positioning way to ensure the concentricity of the central hole of the spoke and the outer edge of the spoke to ensure the processing quality of the spoke and reduces one process compared with the prior art, thereby greatly improving the production efficiency.

Owner:SHANGHAI BAOSTEEL WHEEL

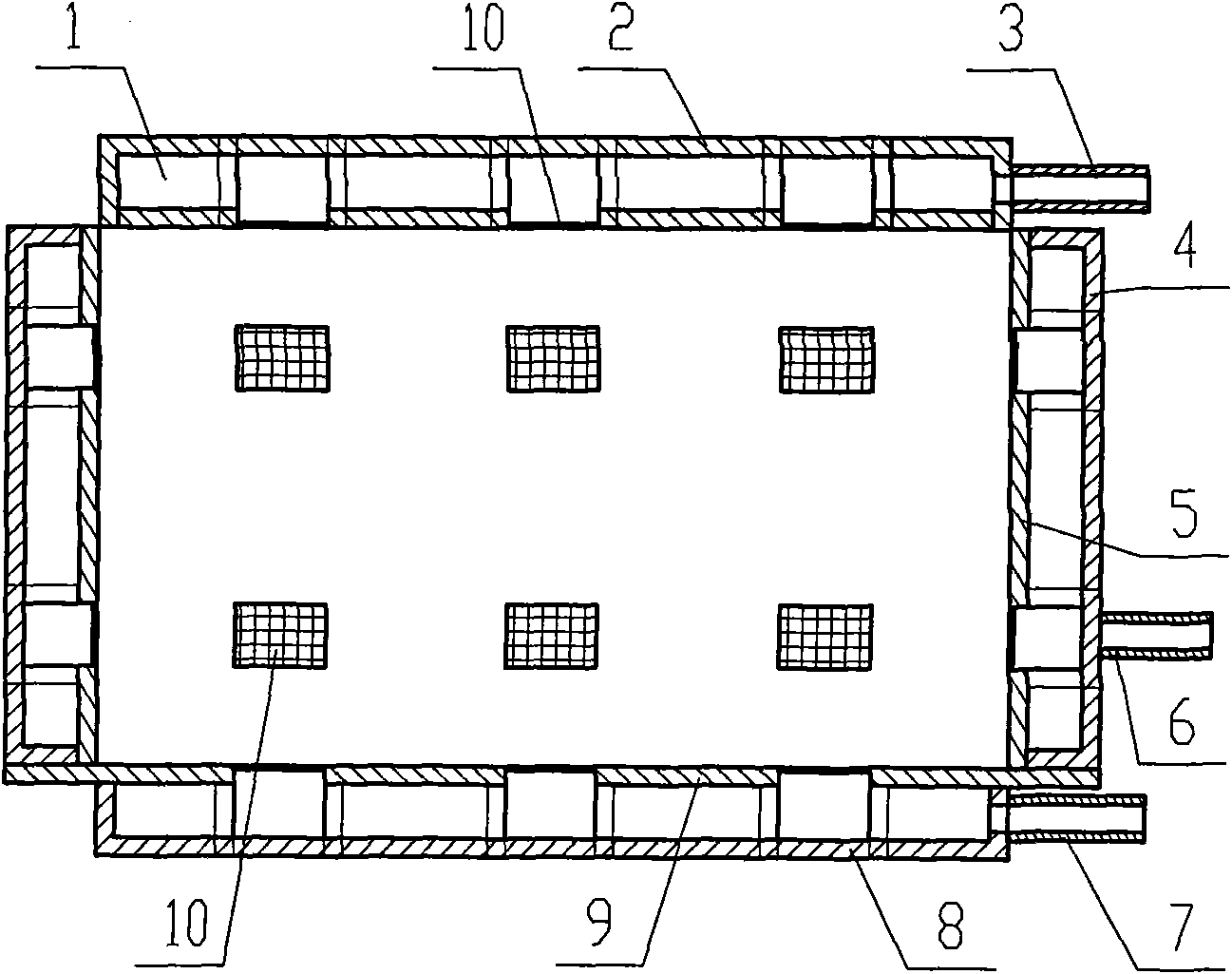

Vacuum expendable pattern casting (V-EPC) molding method of large complex castings

ActiveCN101607299AGood product qualityAvoid driftingFoundry mouldsFoundry coresLost-foam castingMolding sand

The invention discloses a vacuum expendable pattern casting (V-EPC) molding method of large complex castings. A flask for molding comprises three parts including flask bottom, a flask body and an up draught pneumatic hoist press bar; each part is provided with an independent vacuum air duct. The molding procedures comprise the following steps: filling sand and carrying out vibrating molding on the bottom of the expendable pattern, turning over the flask, removing a supporting plate and a tire plate rack and placing the up draught pneumatic hoist press bar, filling the sand, exerting pressure for vibrating molding, sealing the flask and carrying out pouring after vacuumizing. The parts with blind holes and grooves are filled with resin sand and core irons and a floating crane is employed to fix the core irons; local compaction is carried out on loose parts. Being adopted, the method of the invention ensures compact and uniform molding sand, solves the difficult problems frequently appearing in the process of V-EPC of large castings, including sand crushing, sand drop, sand inclusion and deformation, can ensure the accuracy of the blind holes, deep grooves and entire castings, can enable the pattern to be almost free from floating and deformation in the process of vibration and can produce high quality large complex castings.

Owner:BOTOU QINGFENG MACHINERY

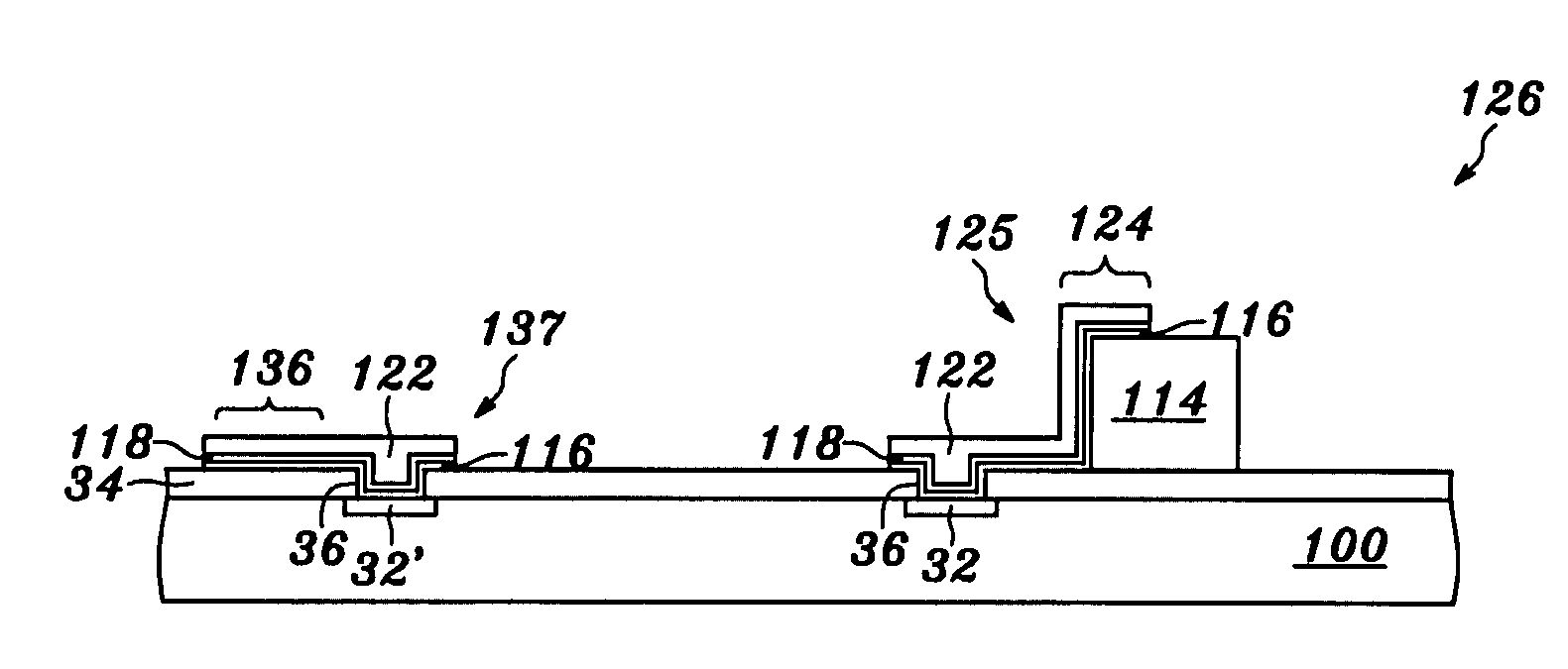

Semiconductor chip and method for fabricating the same

ActiveUS7582966B2Reduce mold costSemiconductor/solid-state device detailsSolid-state devicesMicrometerSemiconductor chip

A semiconductor chip includes a silicon substrate, a first dielectric layer over said silicon substrate, a metallization structure over said first dielectric layer, wherein said metallization structure comprises a first metal layer and a second metal layer over said first metal layer, a second dielectric layer between said first and second metal layers, a passivation layer over said metallization structure and over said first and second dielectric layers, an opening in said passivation layer exposing a pad of said metallization structure, a polymer bump over said passivation layer, wherein said polymer bump has a thickness of between 5 and 25 micrometers, an adhesion / barrier layer on said pad exposed by said opening, over said passivation layer and on a top surface and a portion of sidewall(s) of said polymer bump, a seed layer on said adhesion / barrier layer; and a third metal layer on said seed layer.

Owner:QUALCOMM INC

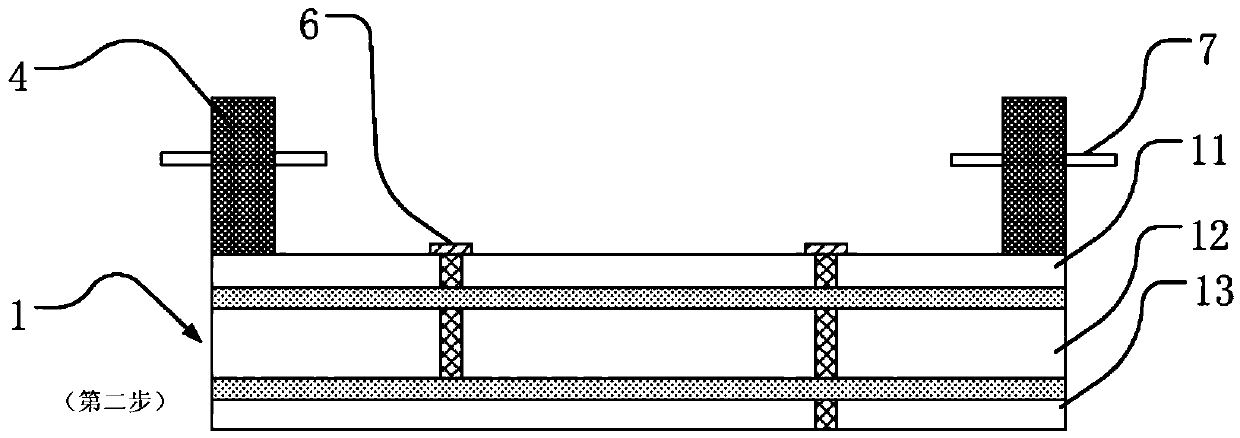

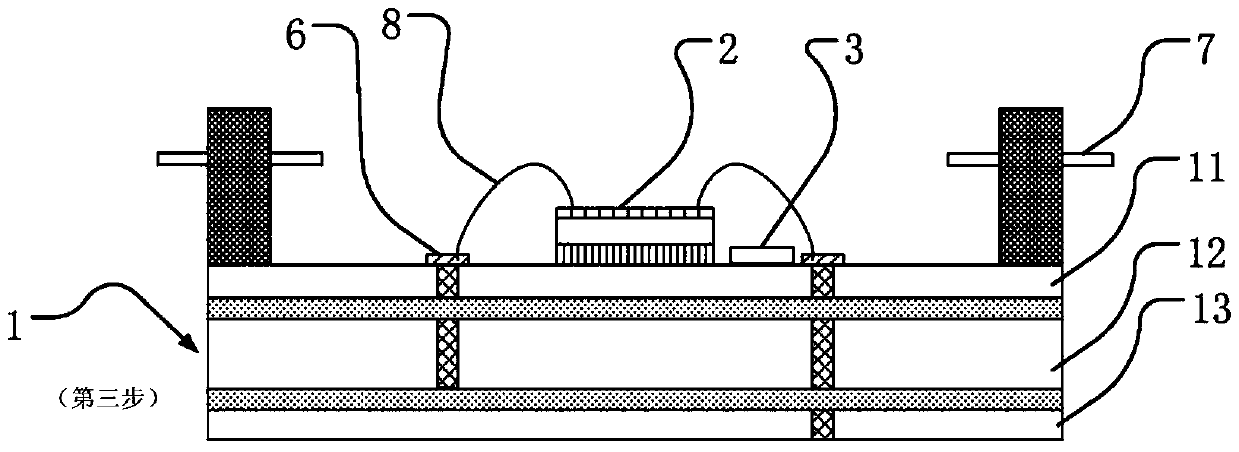

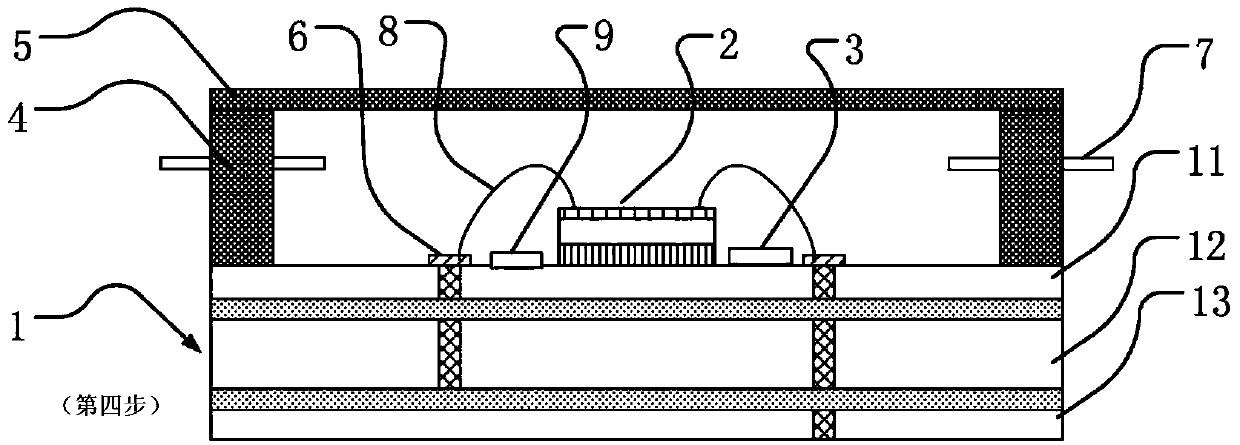

MEMS (Micro-Electromechanical System) sensor encapsulation structure and encapsulation method thereof

ActiveCN103950886ACompact structureReduce electrical connectionsDecorative surface effectsSolid-state devicesHigh densityThermal expansion

The invention relates to an MEMS sensor encapsulation structure and an encapsulation method thereof, which are used for encapsulating an MEMS sensor. The MEMS sensor encapsulation structure is characterized by comprising a ceramic base, a side wall and a top cap, wherein a plurality of metal bonding pads are respectively arranged on a top layer and a bottom layer of the ceramic base; the metal bonding pads on the top layer of the ceramic base are connected with leads of the MEMS sensor; the MEMS sensor is arranged on the ceramic base; the metal bonding pads on the bottom layer of the ceramic base are connected with an external circuit; the ceramic base adopts one-layer or multi-layer perpendicularly interconnected structure; the side wall and the top cap are both made of kovar alloy. According to the invention, the ceramic base of which coefficient of thermal expansion is approximate to that of the MEMS sensor material is selected as the encapsulation material, in order to reduce influence of the base expansion stress to the MEMS sensor; meanwhile, the ceramic base can be utilized to realize one-layer perpendicular interconnection or multi-layer perpendicular interconnection; the system-level integration between the MEMS sensor and the peripheral circuit can be realized within a small area; high-density system-level encapsulation can be realized; the encapsulation flexibility and the expansibility of the MEMS sensor can be realized.

Owner:INST OF GEOLOGY & GEOPHYSICS CHINESE ACAD OF SCI

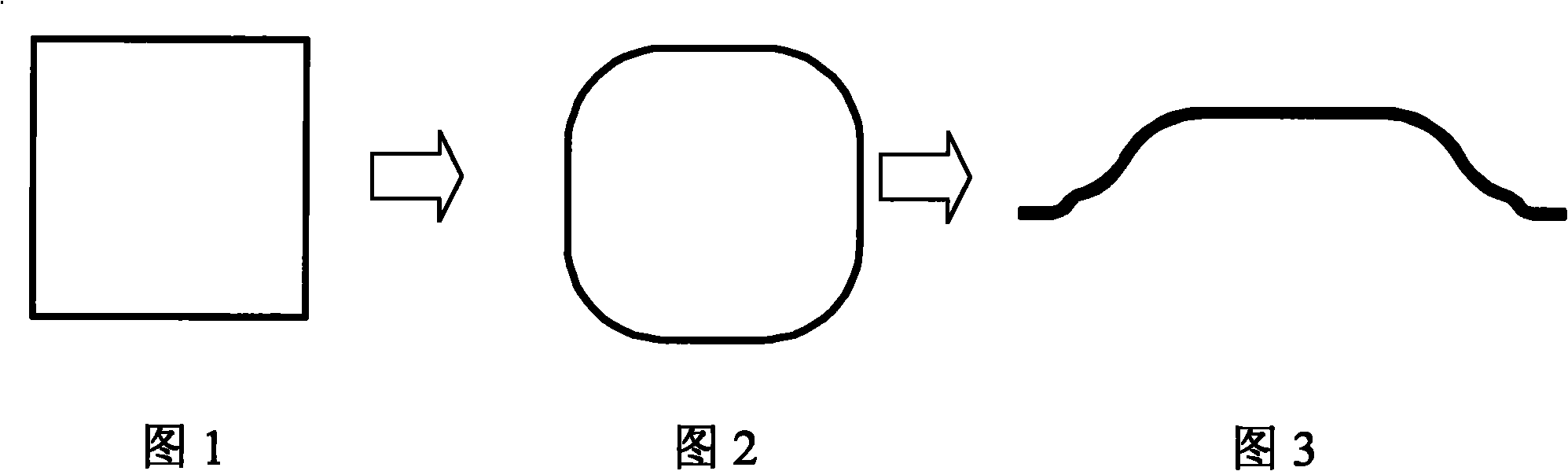

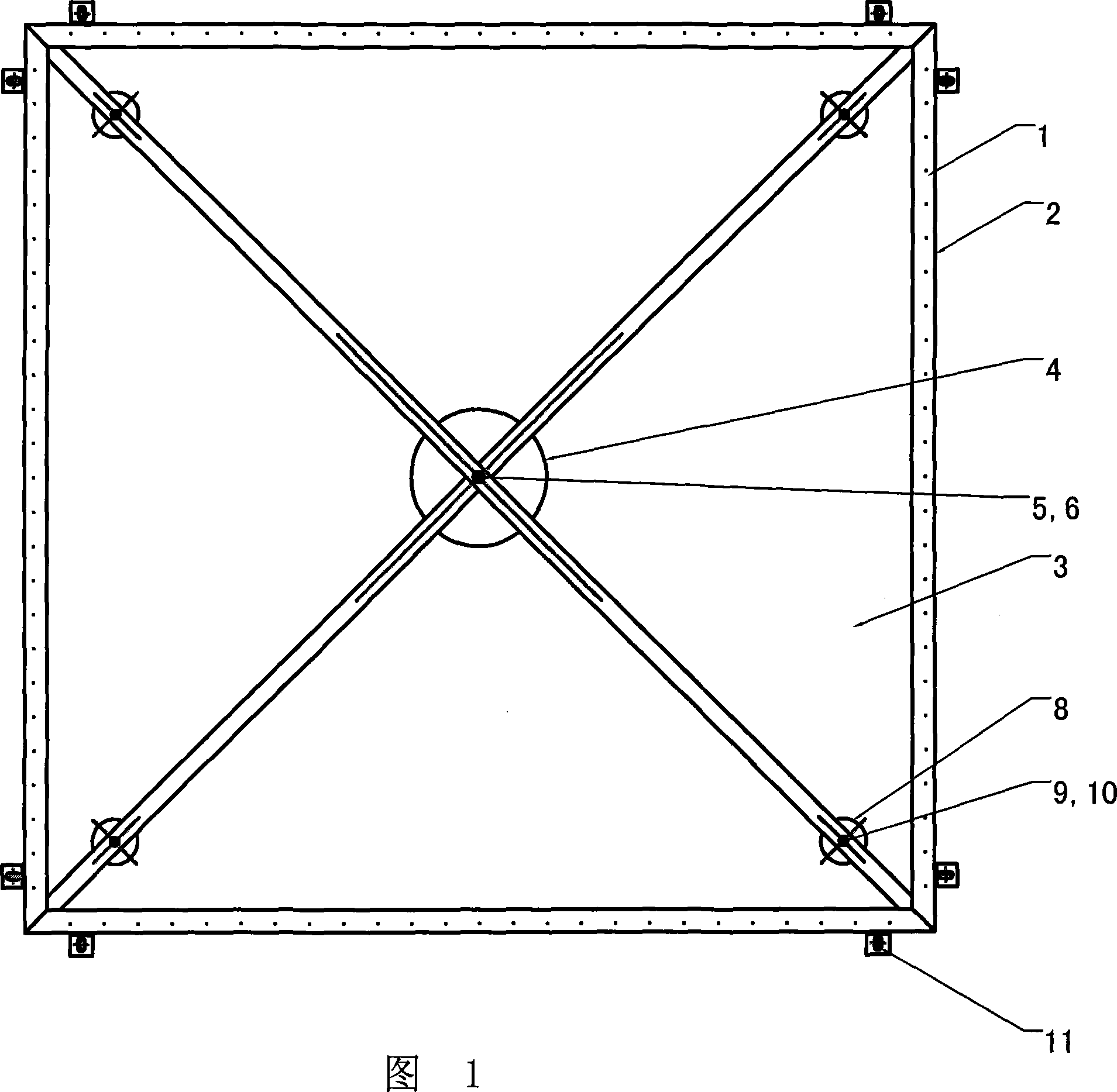

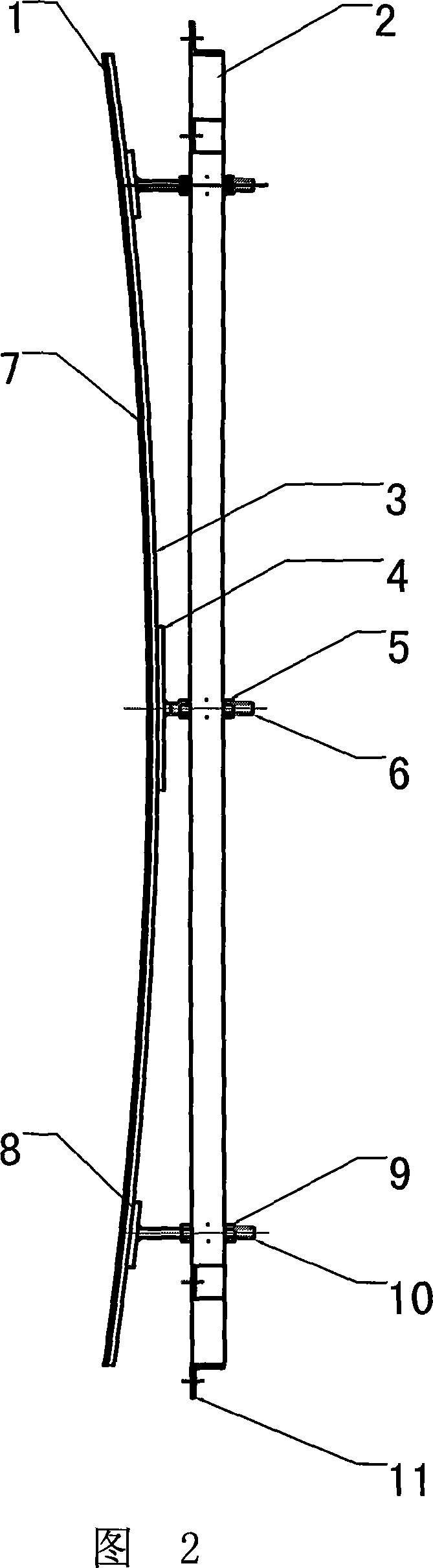

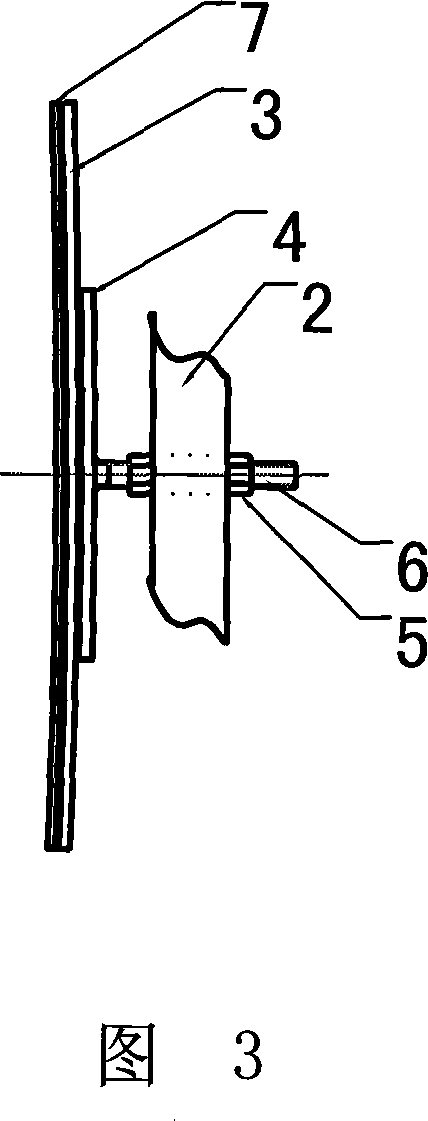

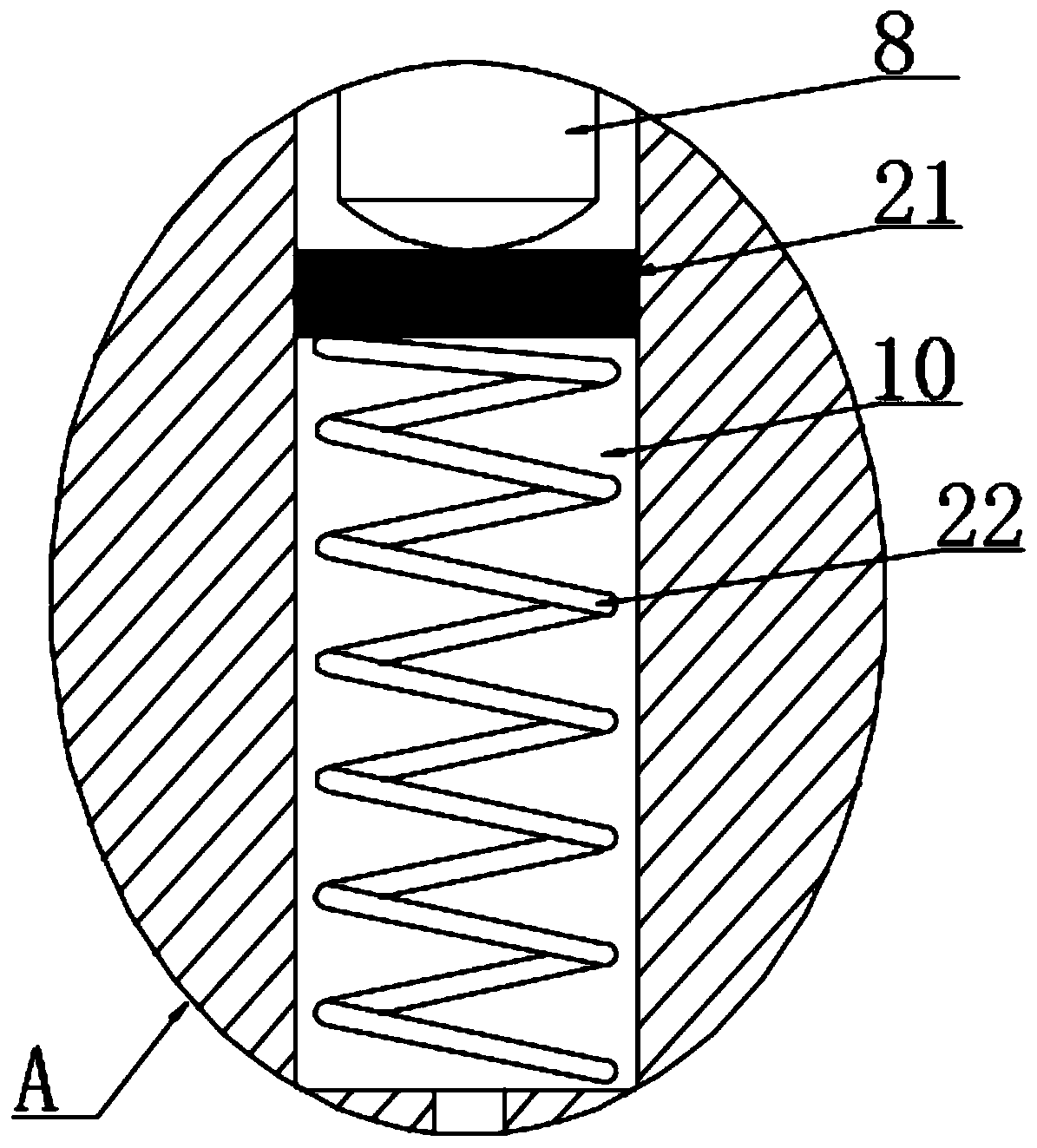

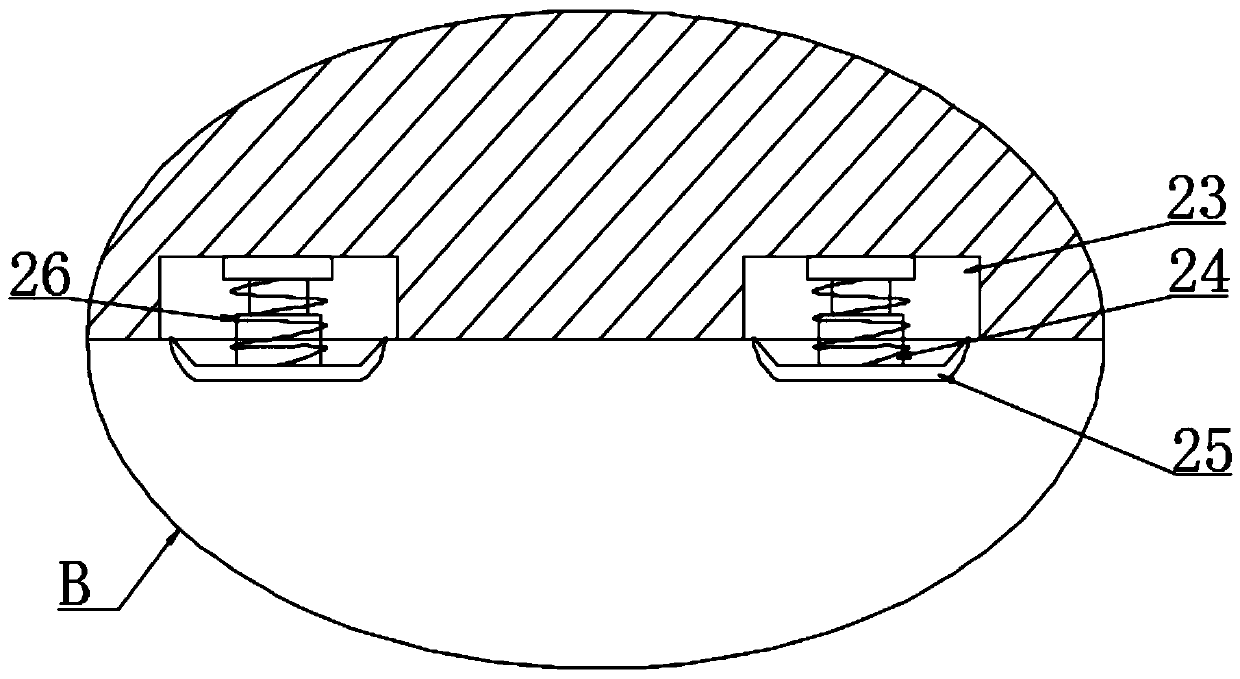

Heliostat with glass micro-arc curved surface mirror forming process structure

InactiveCN101058474AReduce mold costEasy to operateSolar heat devicesGlass reforming apparatusHeliostatEngineering

The invention discloses a heliostat through glass micro-arc mirror shaping technique in the solar utilizing technical domain, which is composed of curved mirror composite adjusting device and a group of single-chip glass micro-arc curved mirror shaping adjusting device, wherein the glass mirror rack of the single-chip glass micro-arc curved mirror shaping adjusting device is connected with the glass mirror through three groups of adjustable connecting devices at two ends or in the middle; two ends of each single-chip glass micro-arc curved mirror shaping adjusting device are fixed on the main frame of the curved mirror composite adjusting device through at least two groups of locking fixing piece, which are arranged adjacently; the incidence adjusting device is loaded near two groups of locking fixing piece adjacent to the main frame.

Owner:张耀明 +2

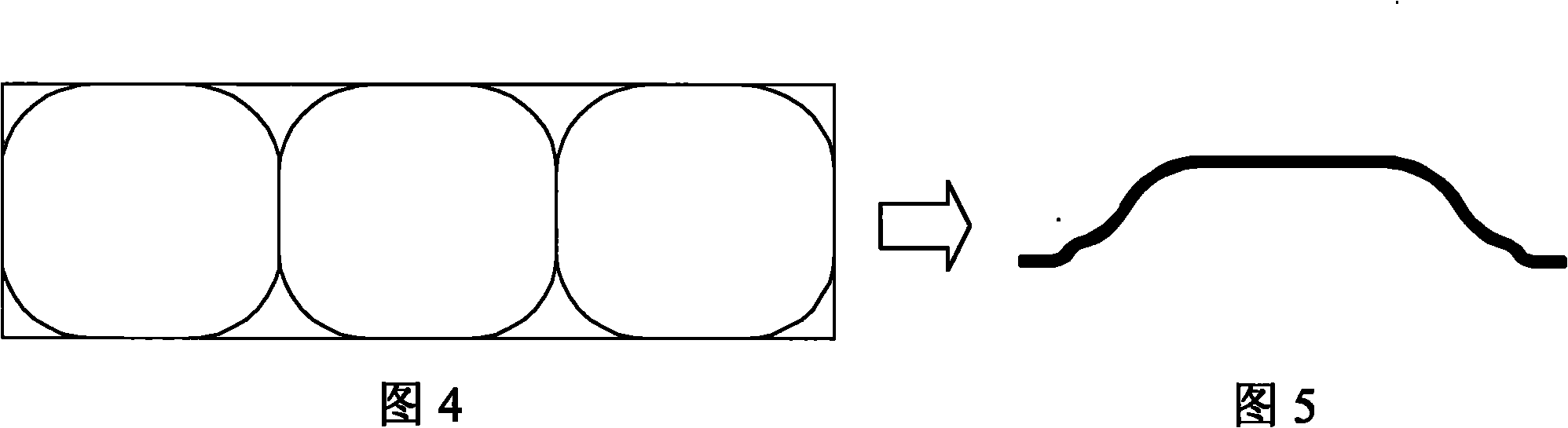

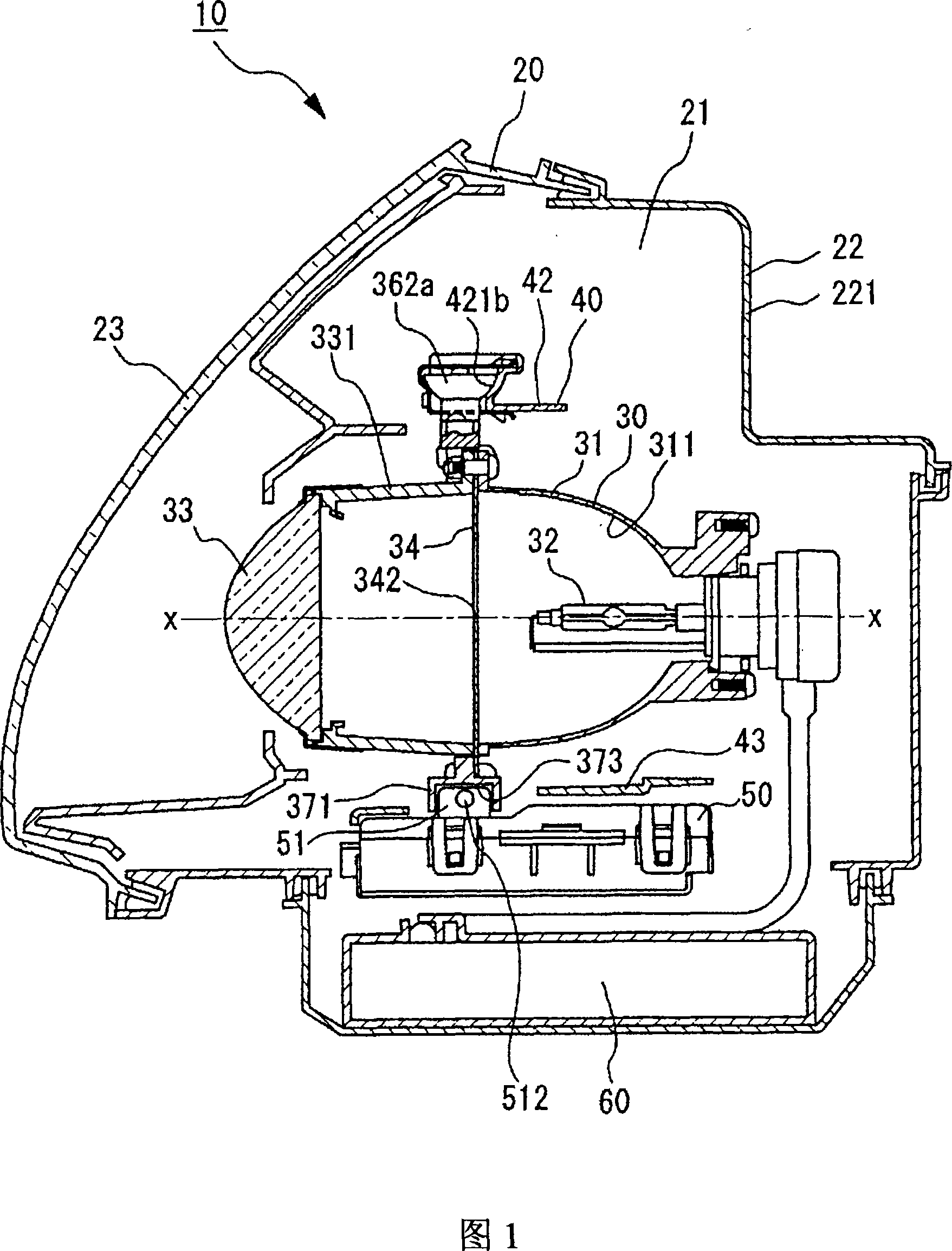

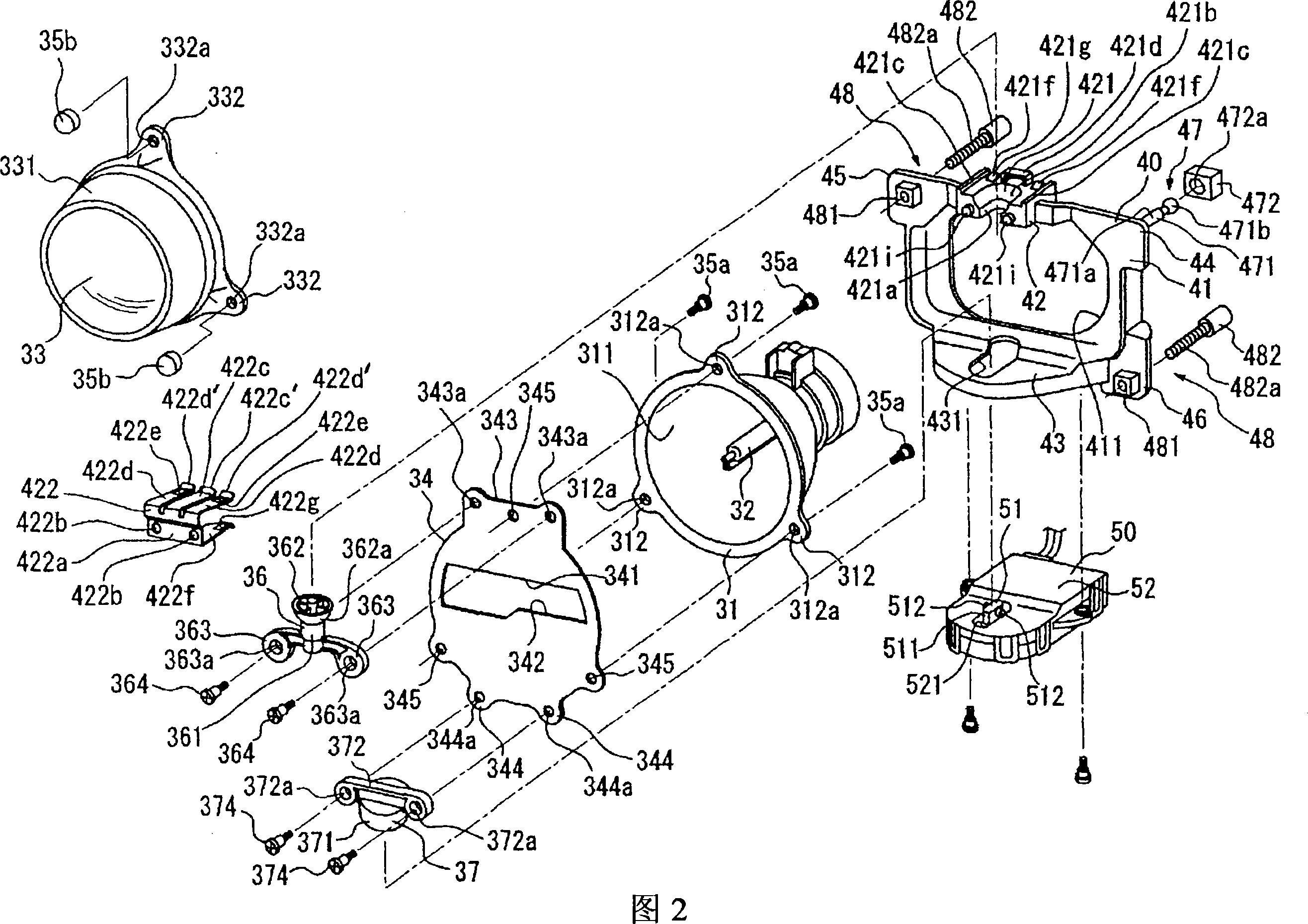

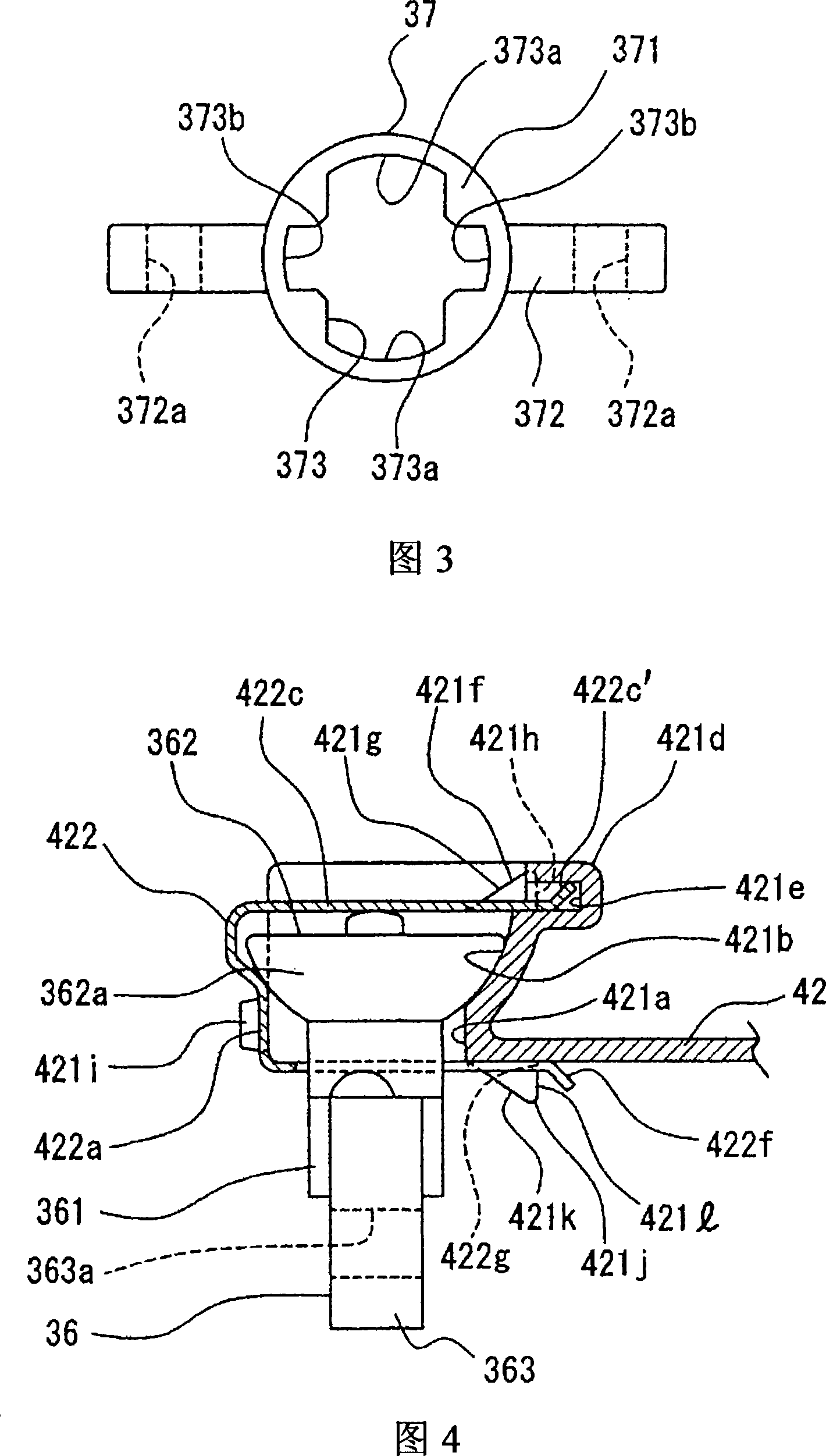

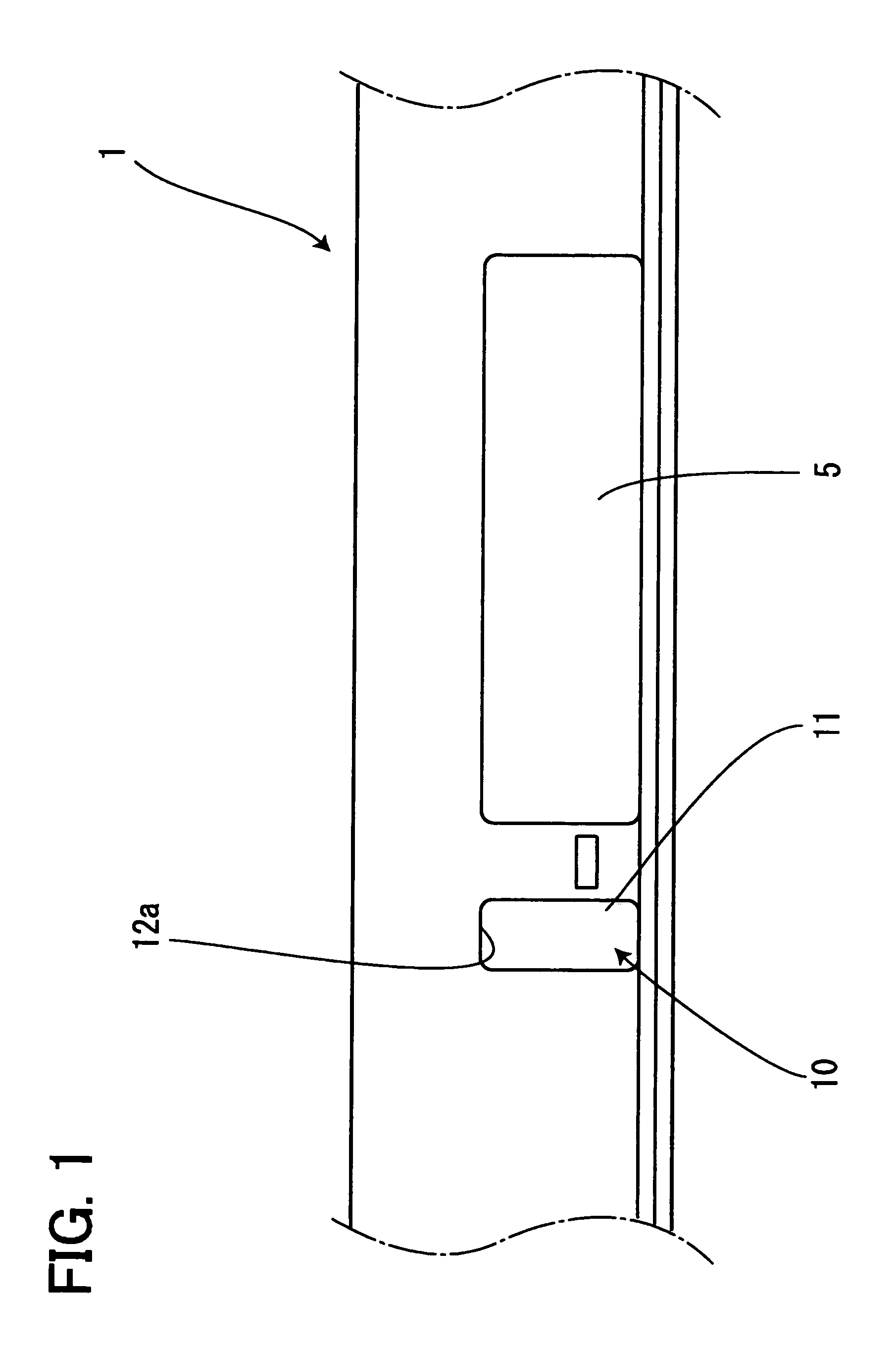

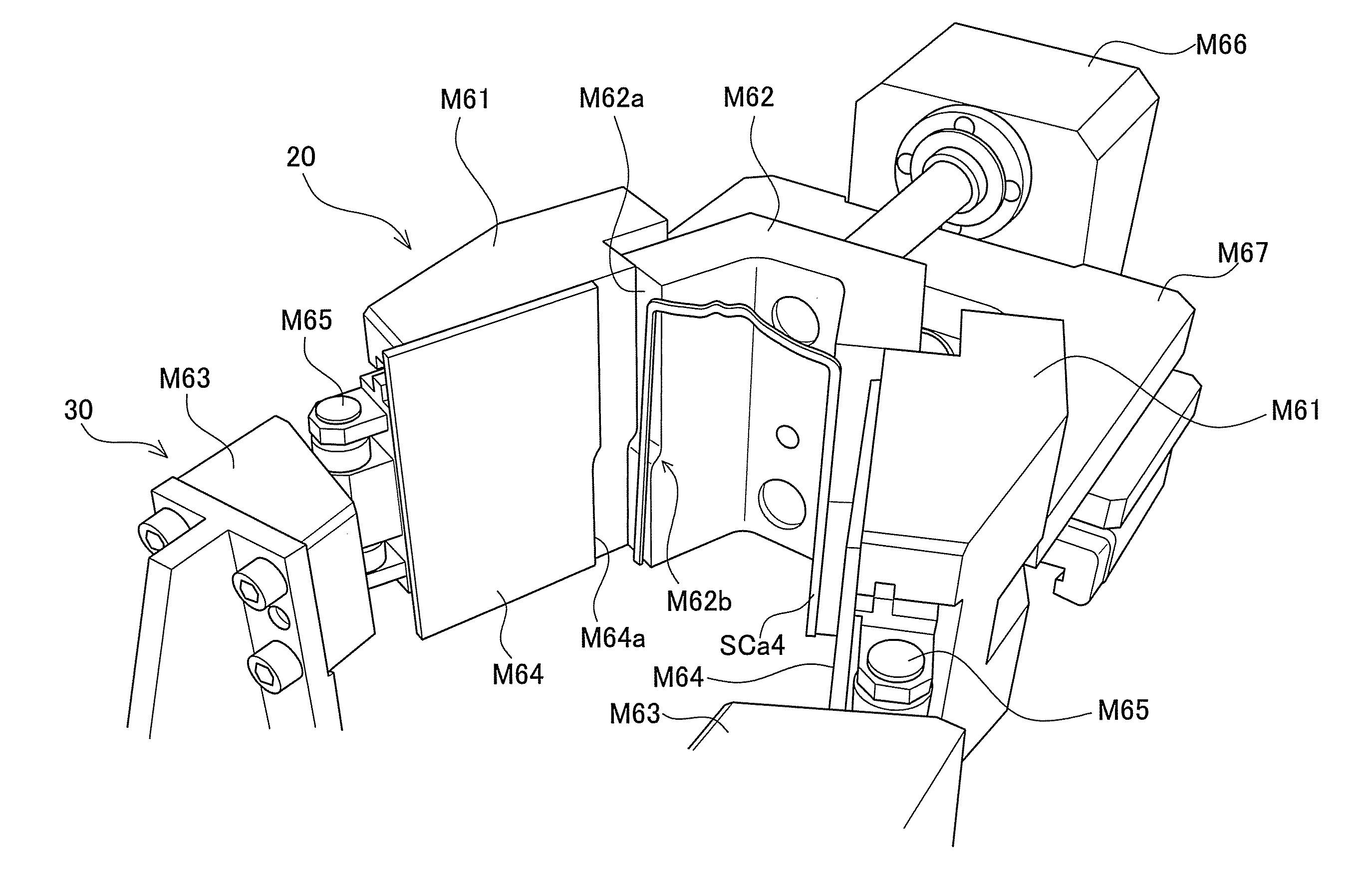

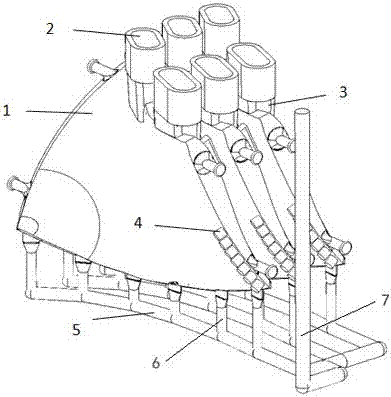

Lamp for vehicle

The present invention provides a lamp for a vehicle, which can change the irradiation direction in any direction up, down, left and right, reduces the number of parts, and can accurately control the irradiation direction without applying an extra load to the drive unit. The vehicle headlamp (10) has: a lamp unit (30), which is arranged in a lamp chamber (21) formed by a lamp body (22) and a transparent cover (23) closing the front side of the lamp body, and facing forward irradiating light; and an irradiating direction adjusting device (50), which makes the lamp unit tilt up and down and left and right, and the lamp unit is suspended and supported in the lamp room in a state of being able to move up and down, left and right, and the irradiating direction adjusting device has an output shaft ( 51), which can move in the front-back direction and rotate in the left-right direction at the same time. The output shaft is connected to the lower end of the lamp unit, and the rotation in the left-right direction of the output shaft can be transmitted to the lamp unit. Rotation occurs between the axis and the luminaire unit.

Owner:KOITO MFG CO LTD

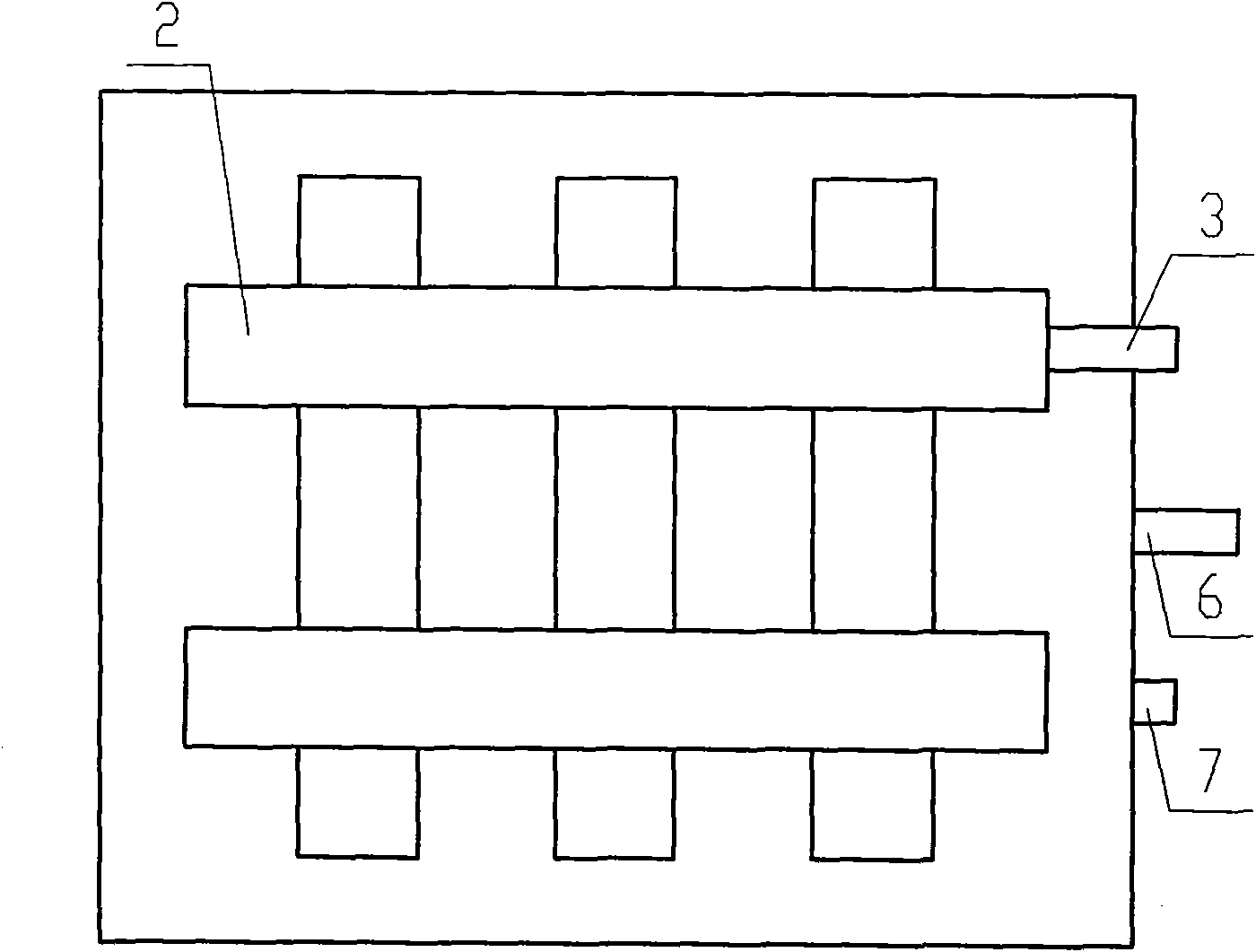

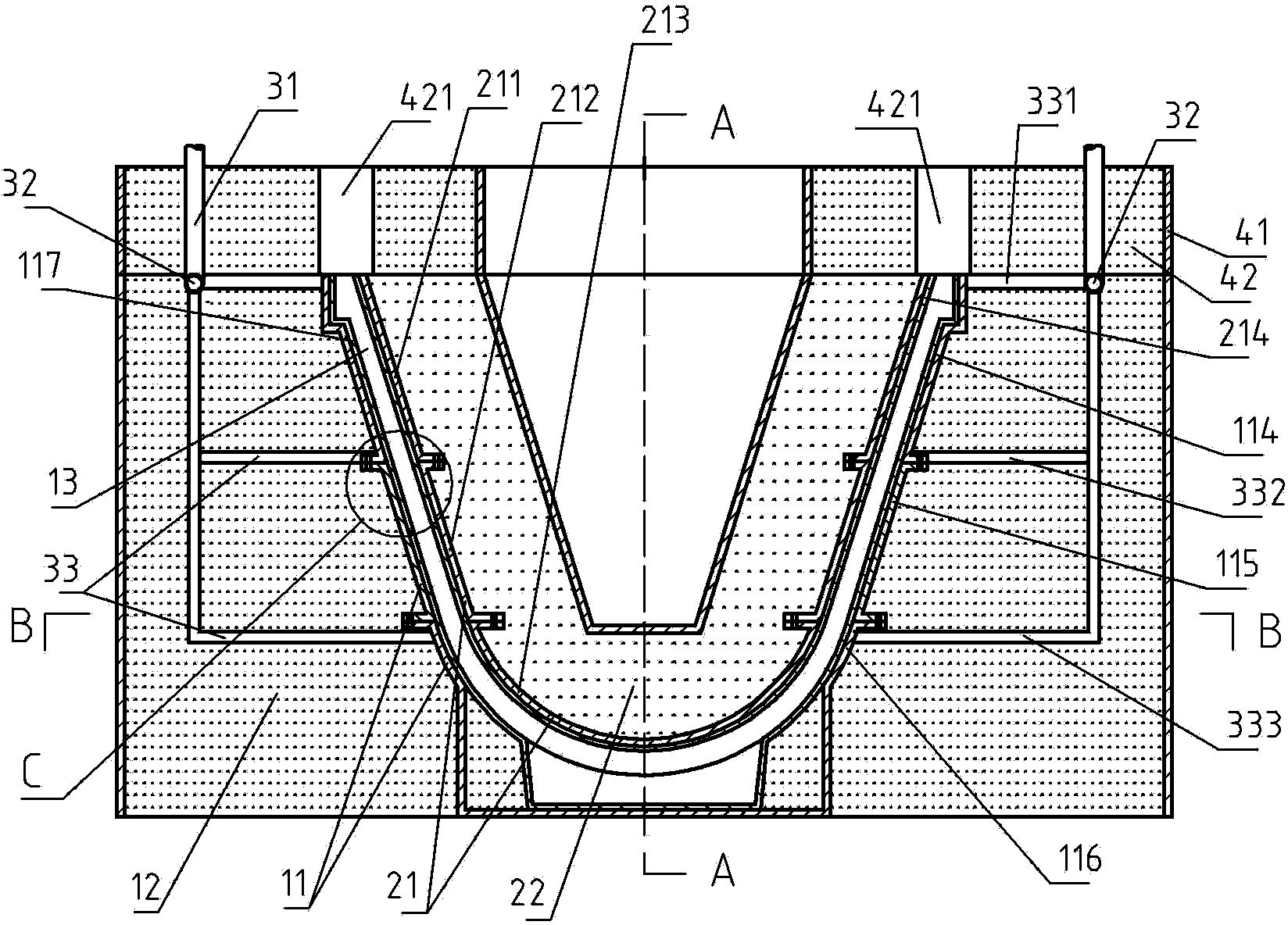

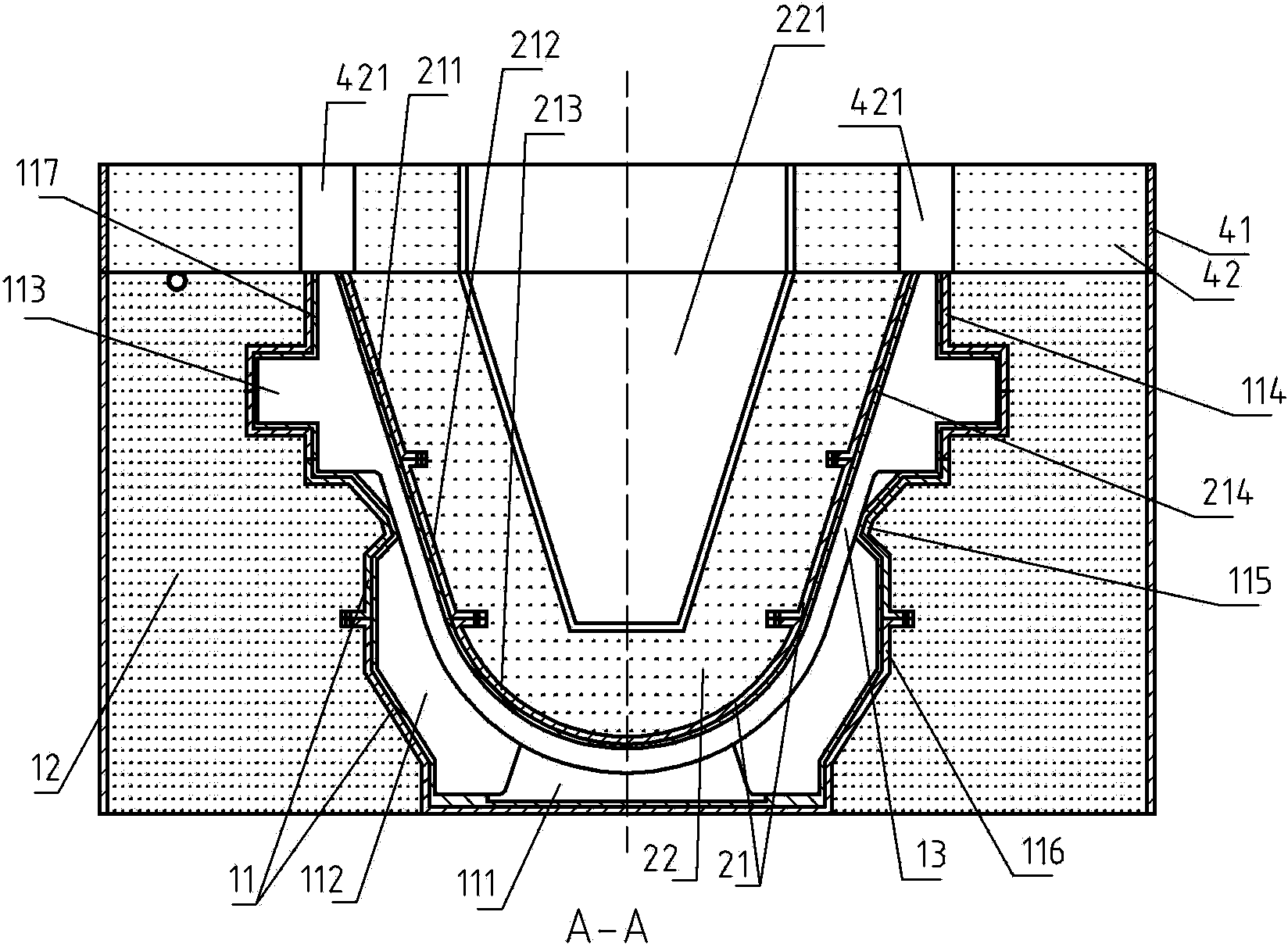

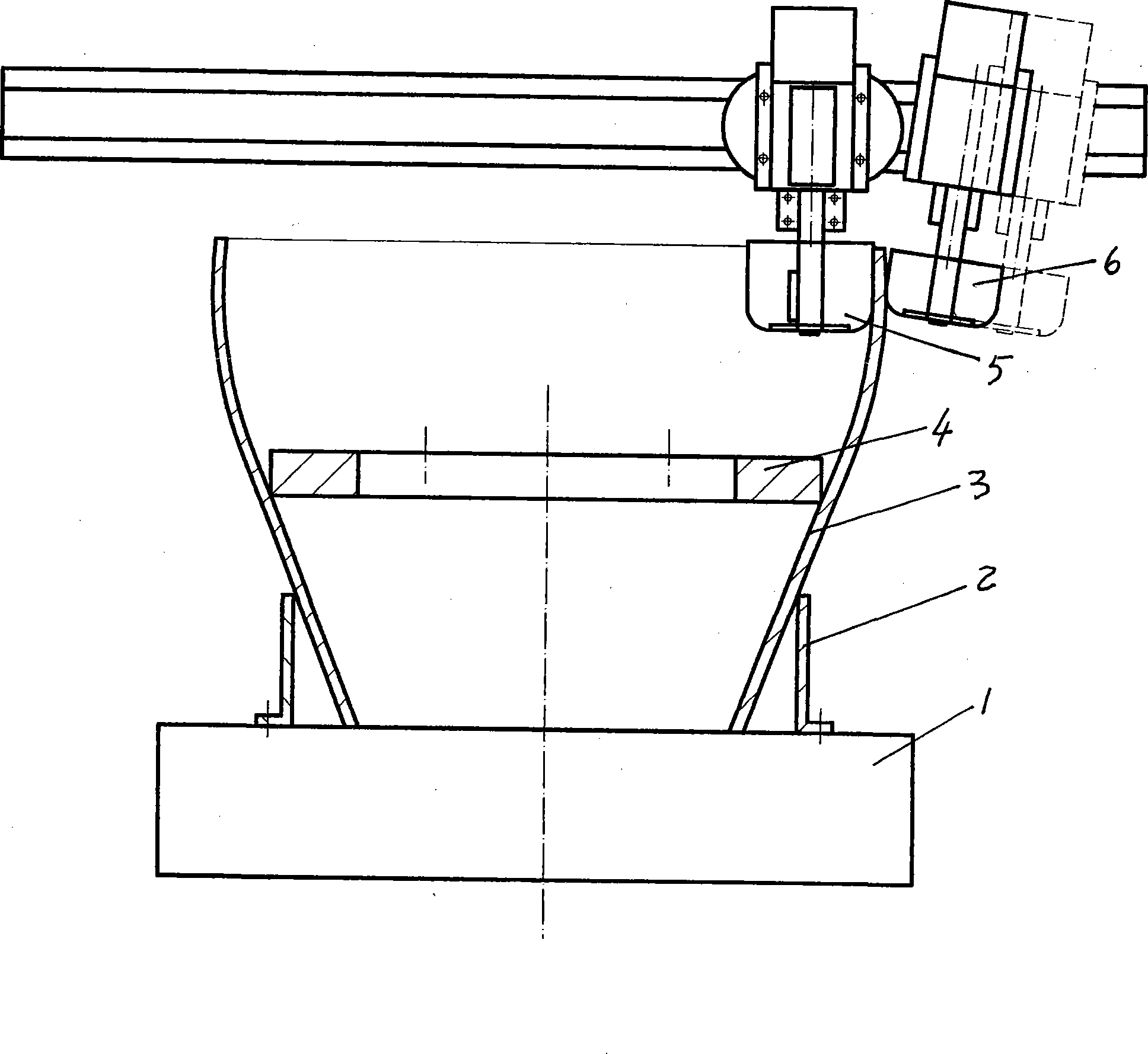

Casting method of slag ladle and casting mold

InactiveCN104226916ANo shrinkage porosity defectsHigh yieldMelt-holding vesselsMolten metal pouring equipmentsSlagCasting mold

The invention discloses a casting method of a slag ladle and a dedicated casting mold for implementing the method. The method comprises the following technical steps: 1. manufacturing the casting mold: (1) designing a pit: designing and manufacturing a casting pit; (2) manufacturing a casting external mold of the slag ladle and a pouring gate system, preparing an external wall cold mold (11) of the slag ladle, connecting the pouring gate system well, and filling an outer sand mold (12); (3) manufacturing a casting inner mold of the slag ladle and a feed head mold, manufacturing an inner wall cold mold (21) of the slag ladle, installing the inner wall cold mold (21) of the slag ladle in the outer wall cold mold (11) of the slag ladle, and defining a slag ladle casting cavity (13) between the inner wall cold mold and the outer wall cold mold, wherein the outer wall cold mold (11) of the slag ladle and the inner wall cold mold (21) of the slag ladle are both made of iron; (4) drying of the mold: drying the mold with hot air till dry; 2. pouring: pouring the casting liquid in the slag ladle casting cavity (13), cooling, and at last obtaining the slag ladle.

Owner:衡阳中钢衡重铸锻有限公司

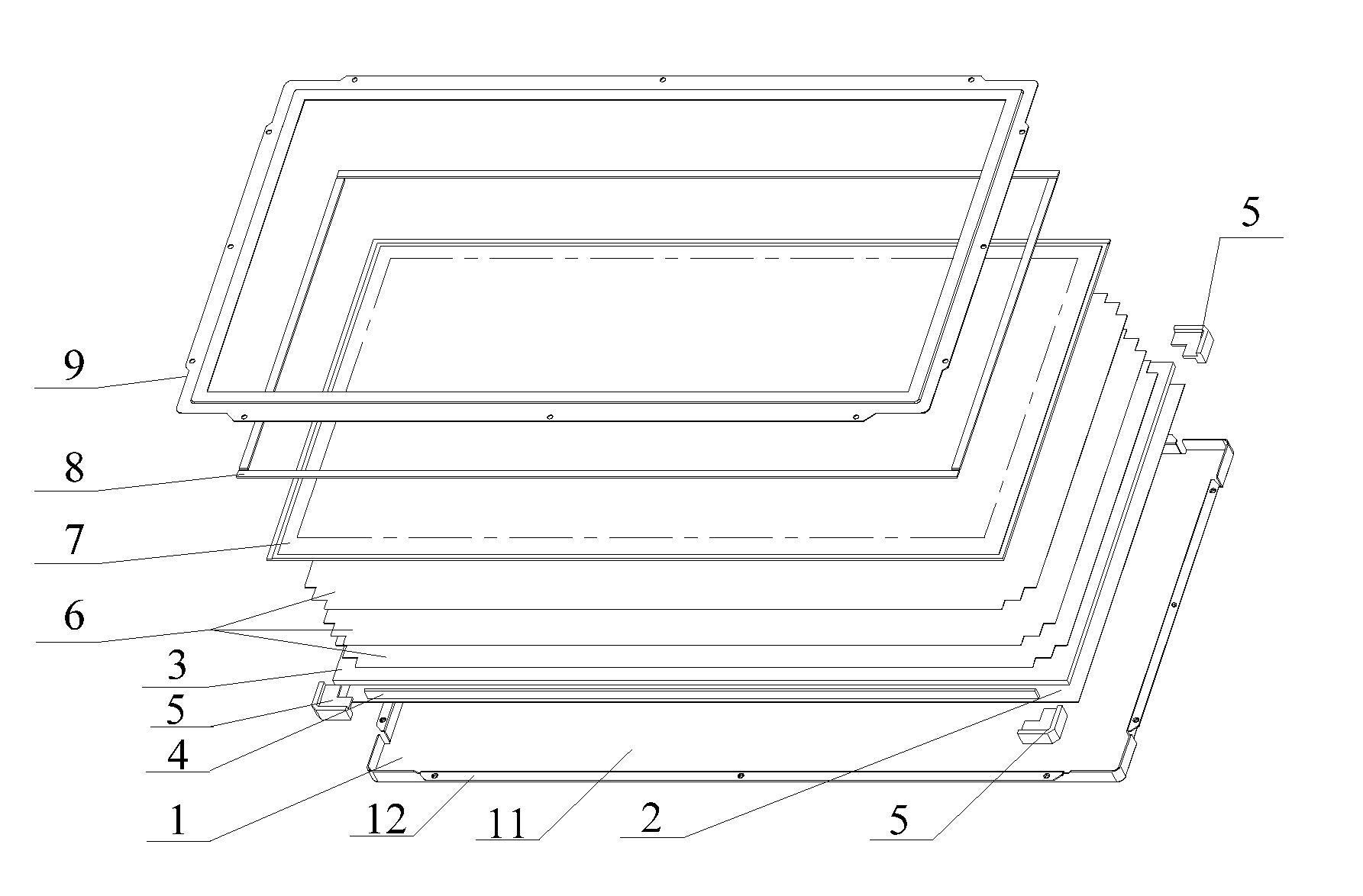

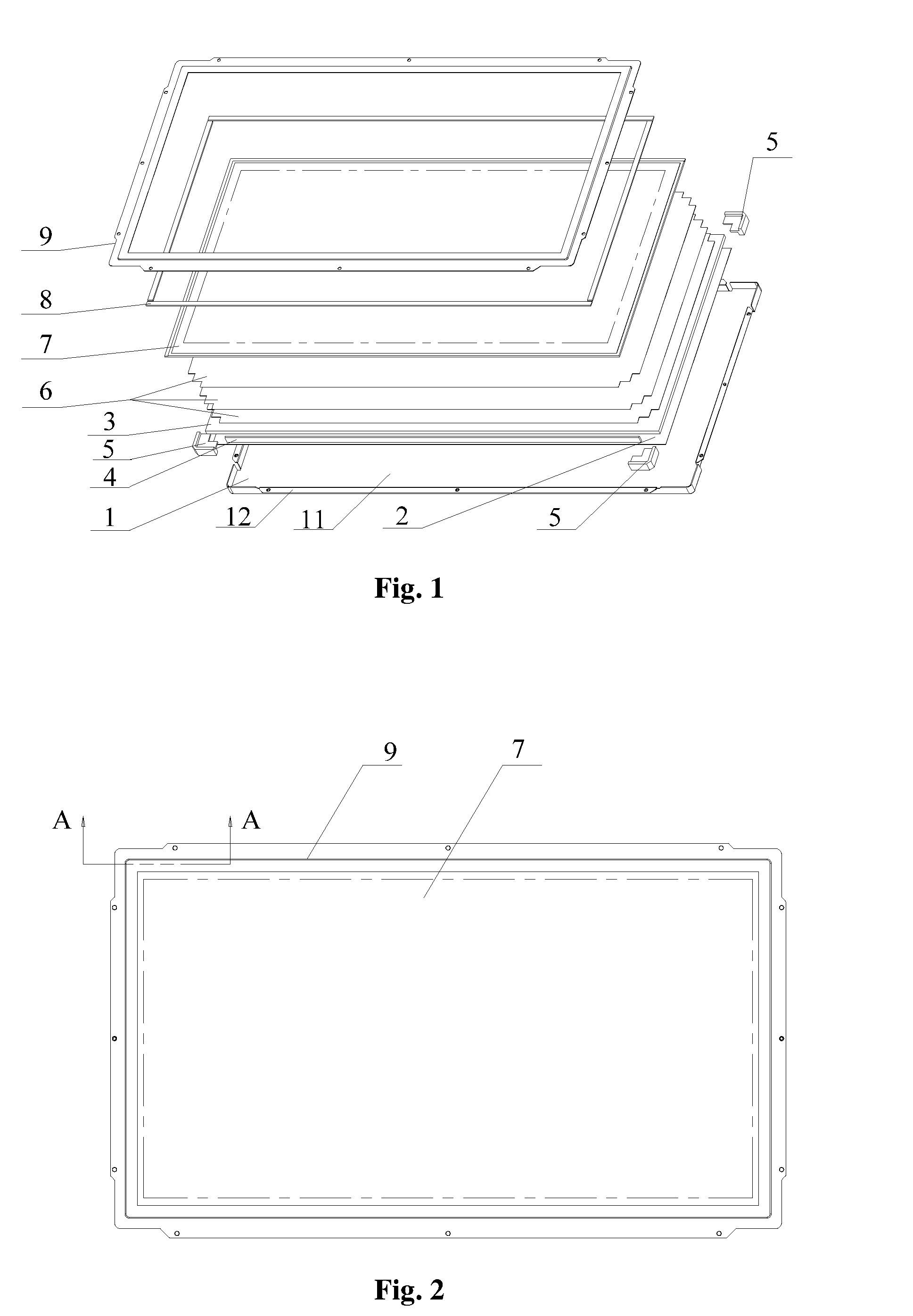

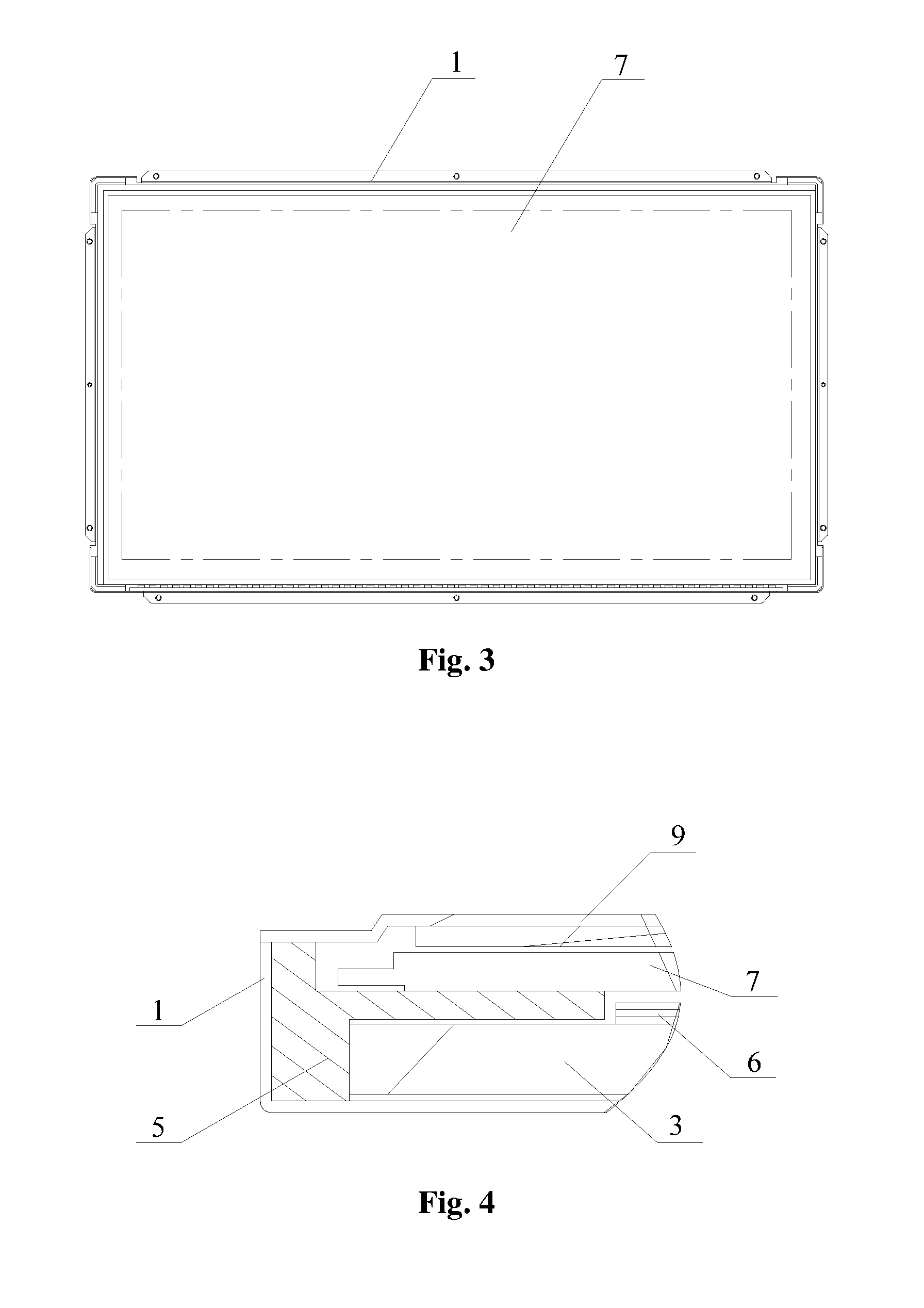

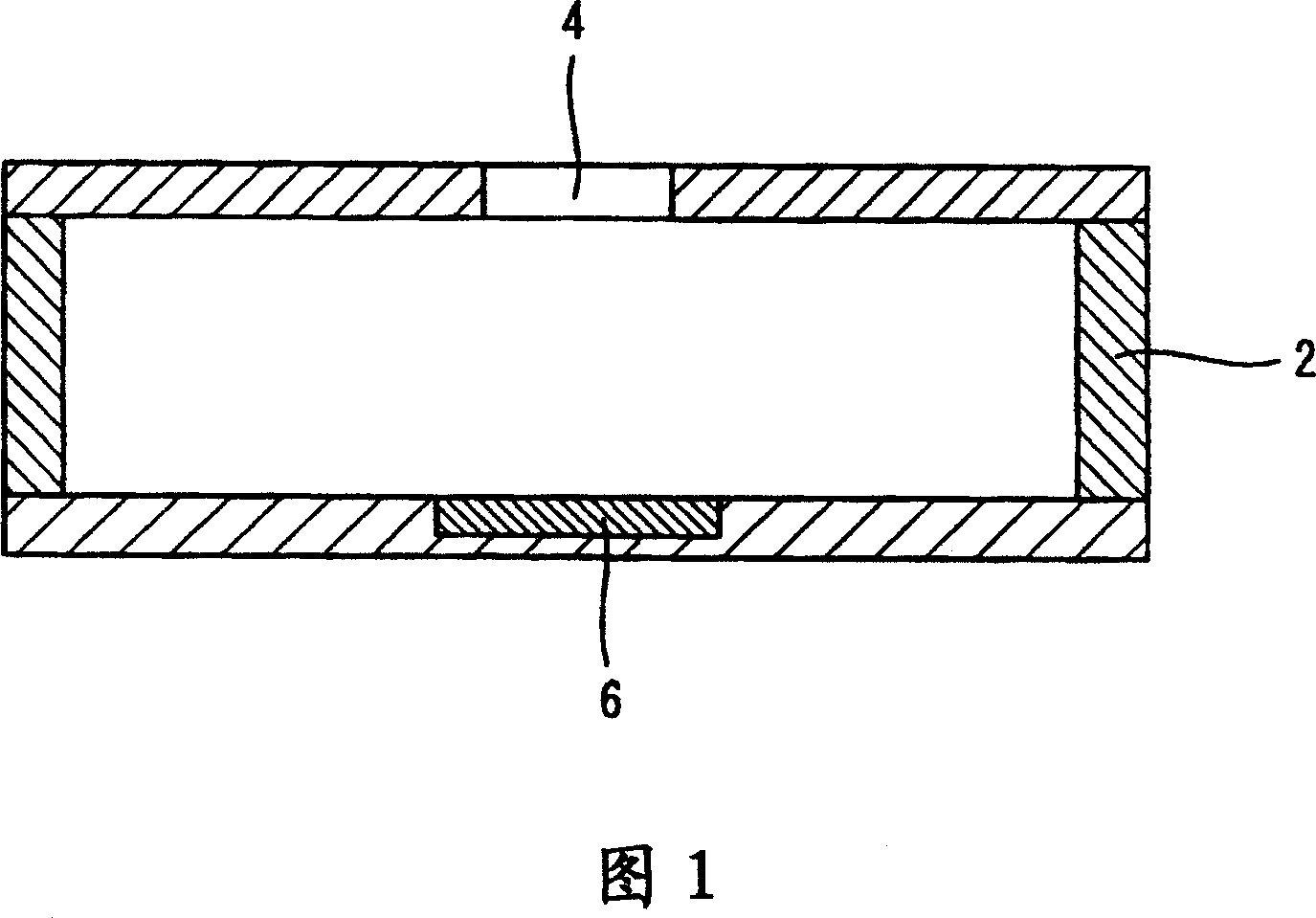

Backlight module and liquid crystal display

ActiveUS20130033657A1Reduce mold costLow production costMechanical apparatusLight guides for lighting systemsCushioningLiquid-crystal display

A backlight module comprises a back frame, a light guide plate disposed in the back frame, and elastic corner parts for locating the light guide plate. The elastic corner parts are disposed at diagonal corners of the backlight module and sandwiched between the back frame and the light guide plate. The elastic corner parts can locate the light guide plate in the back frame, and the desirable cushioning performance and appropriate hardness of the elastic corner parts provide a desirable space for thermal expansion and contraction of the light guide plate. Meanwhile, the elastic corner part corresponding to the light incident side is greater than that of the non-light-incident sides for ensuring the light mixing distance between the LEDs and the light incident side of the light guide plate, which can improve the light unitization factor of the LEDs and save both the product cost and the mold cost.

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS TECH CO LTD

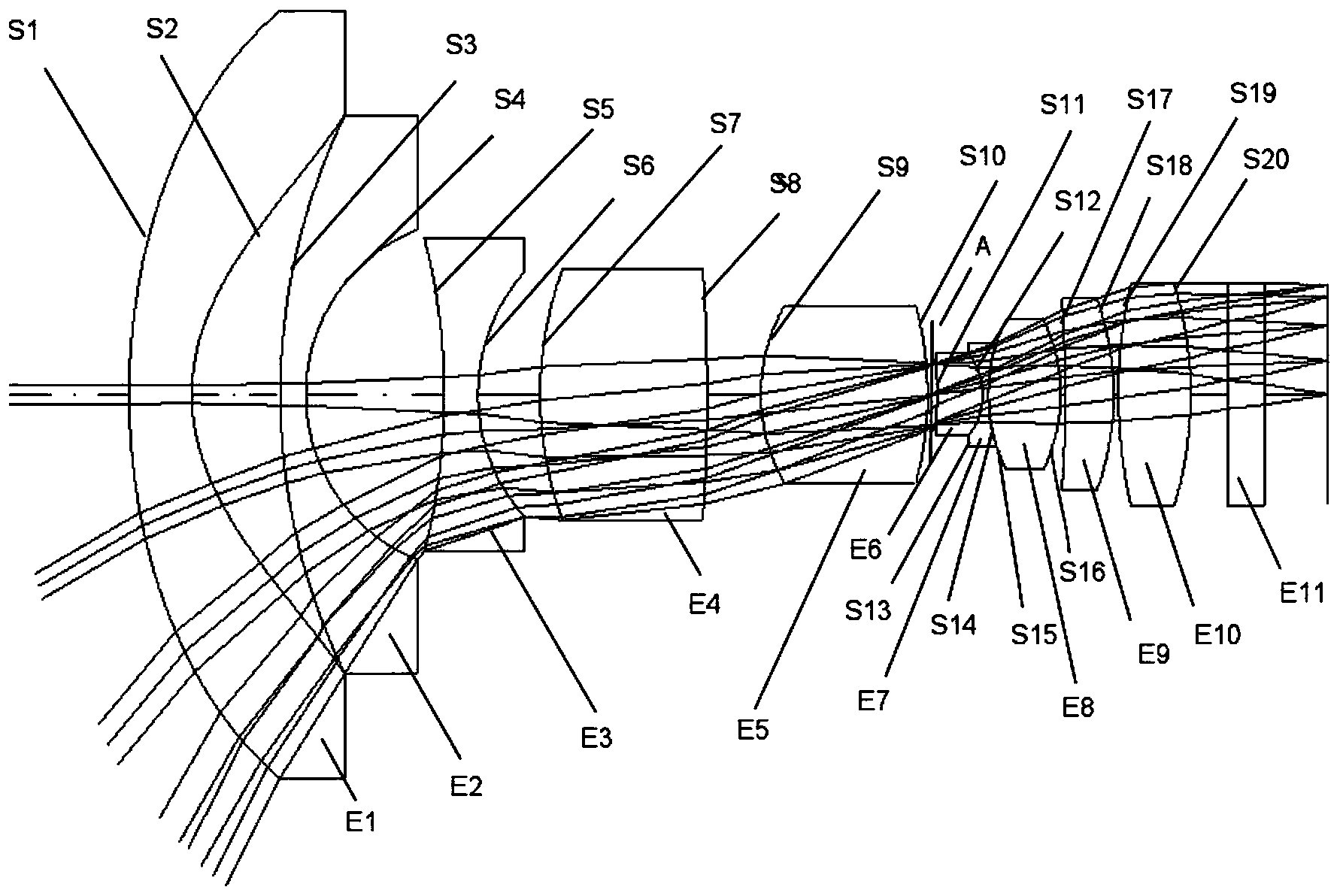

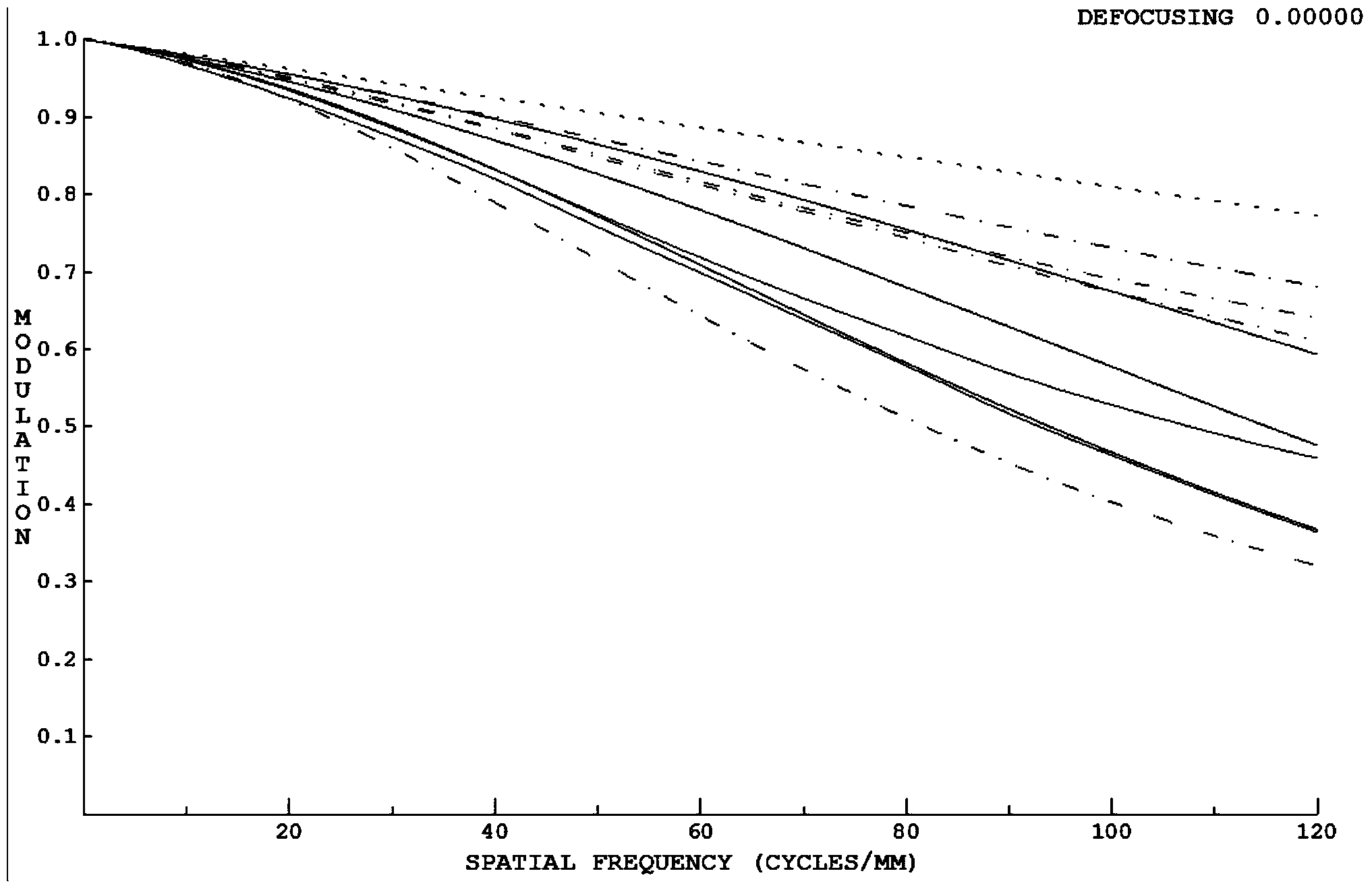

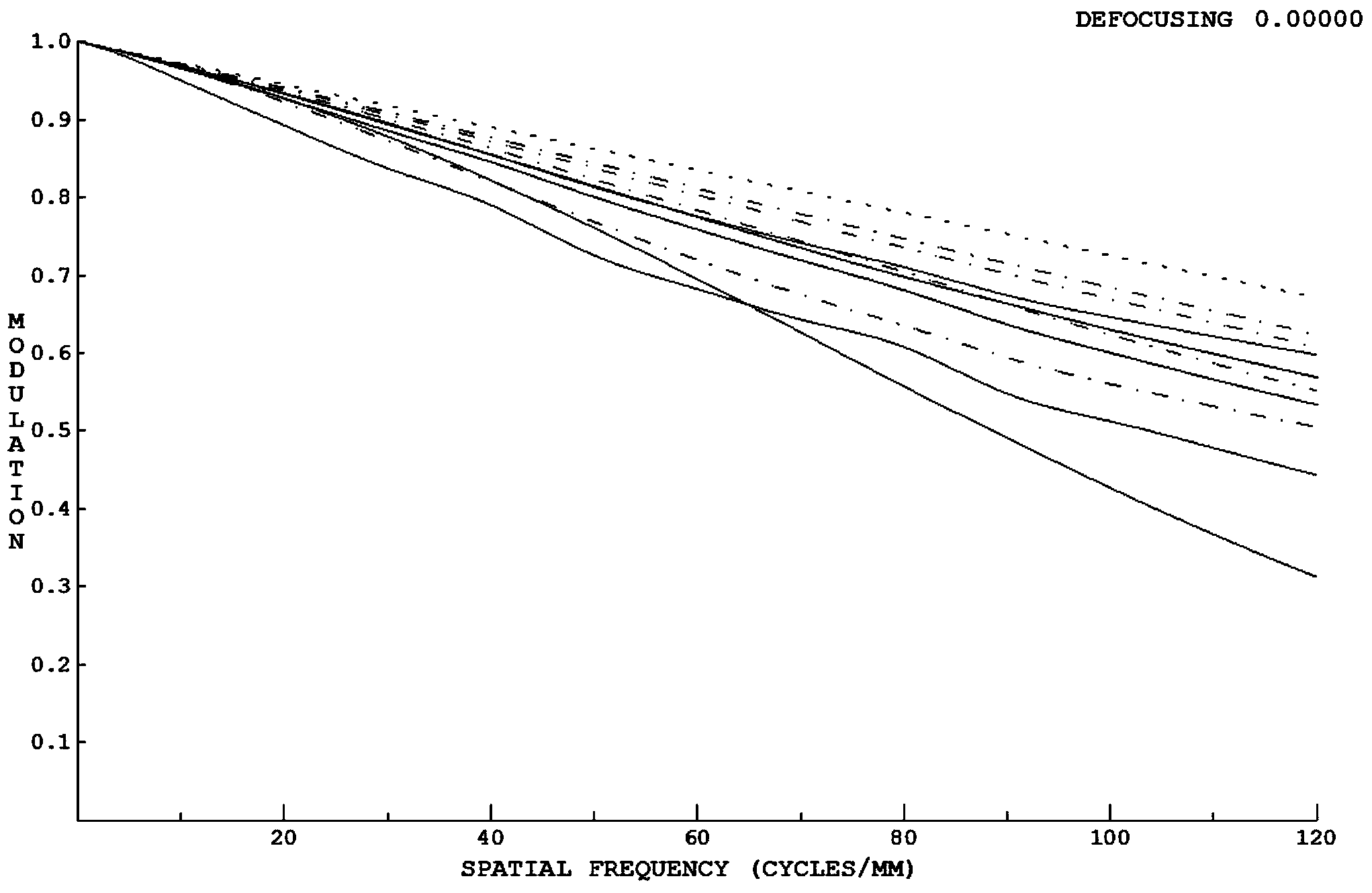

Wide-angle distortion-removing dual-band confocal optical lens

The invention provides a wide-angle distortion-removing dual-band confocal optical lens which comprises a front group, a diaphragm, a back group and an optical filter. The wide-angle distortion-removing dual-band confocal optical lens is characterized in that the front group is a Galileo optical system and comprises a first negative lens, a second negative lens, a third negative lens, a first positive lens and a second positive lens in sequence from a near object side, the back group has positive focal power and comprises a third positive lens, a fourth negative lens, a fourth positive lens, a fifth positive lens and a sixth positive lens in sequence from the near object side, the third positive lens, the fourth negative lens and the fourth positive lens are tightly connected into a tight-connecting group, and the lenses are all glass lenses. According to the wide-angle lens, ten lenses are used, elements are arranged reasonably, the structure is simple, production difficulty and cost are lowered, the requirement that a view field angle reaches 126 degrees, and distortion is smaller than 5% is met, imaging quality is high, wave bands are visible bands and near-infrared bands, and the optical lens can be used for a monitoring camera for day and night.

Owner:GOERTEK OPTICAL TECH CO LTD

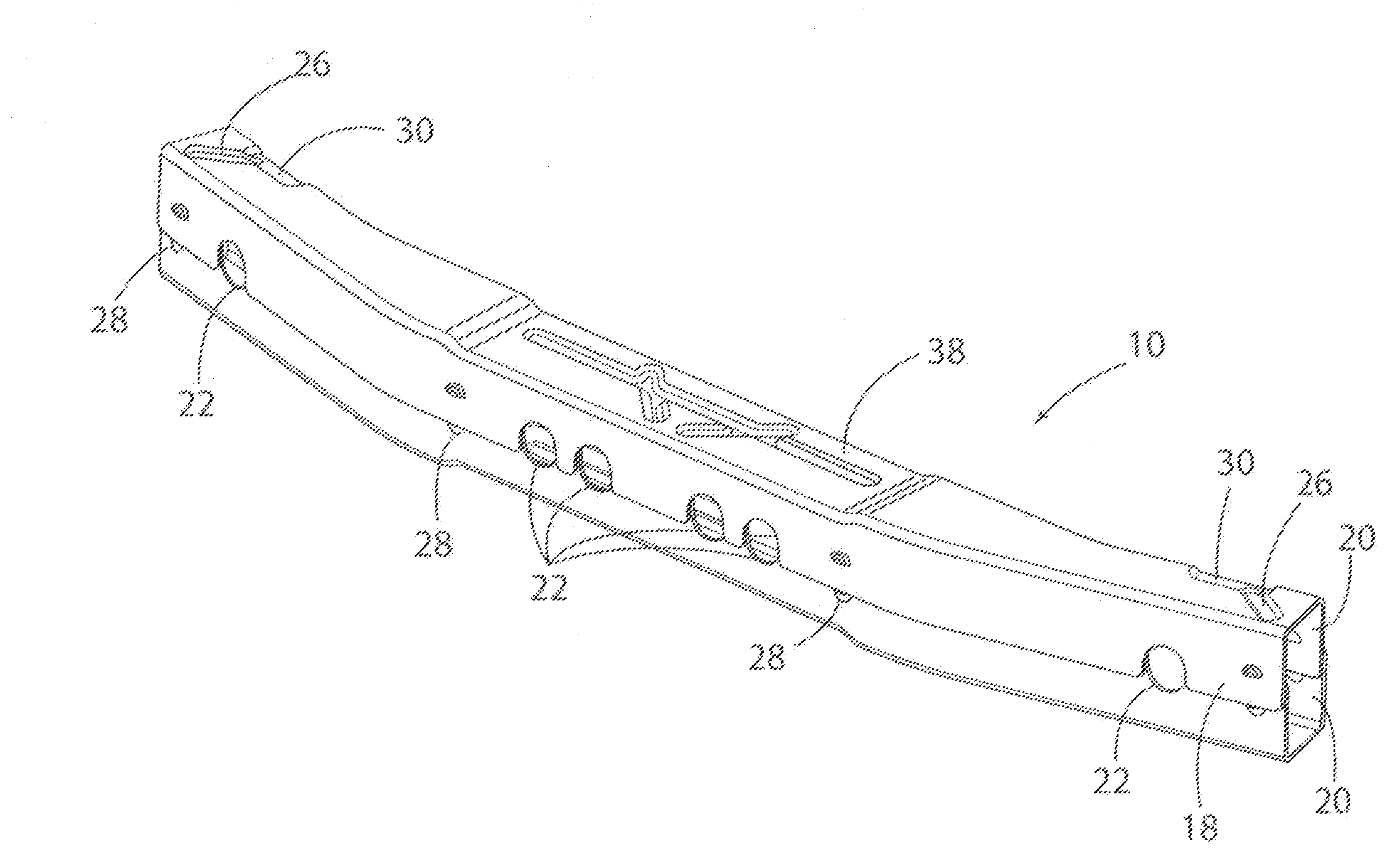

Vehicle bumper and method of making same

A vehicle bumper and a method for making a vehicle bumper formed of first and second members. Each of the first and second members are formed of substantially similar first and second U-shaped members positioned such that the respective sidewalls of the first and second U-shaped members are positioned adjacent one another. The bumper including a plurality of apertures therein formed by cutouts extending inward from the peripheral edge of each of the first and second U-shaped members.

Owner:SKD AUTOMOTIVE GRP

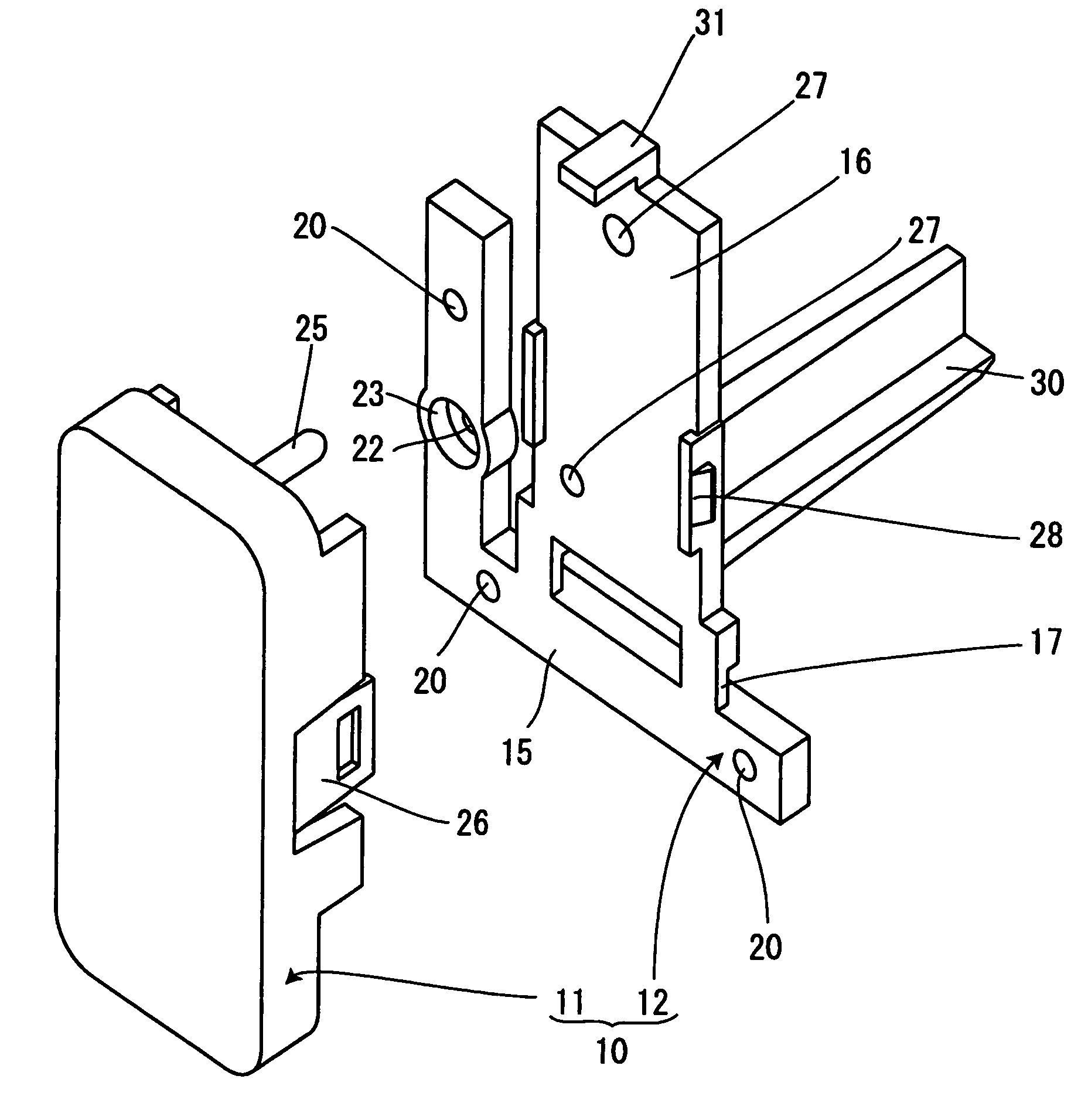

Electronic device with manual operation button

The invention provides a manual operation button having a large operable area. A manual operation button is composed of a manual operation plane, a holder for assembling the manual operation plane and a stopper for fixing the holder to a casing. The casing has a mounting hole having substantially the same size and shape as the manual operation plane, so that when the manual operation plane is assembled to the mounting hole, the manual operation plane forms a substantially continuous flat plane with the casing. The holder includes a substantially L-shaped mounting portion for mounting to the casing, a flat plate-like mounting plane for mounting the manual operation plane, and a hinge portion connecting the mounting portion and the mounting plane. The whole width of the hinge portion is disposed within the outer projection plane of the manual operation plane.

Owner:ORION ELECTRIC CO LTD

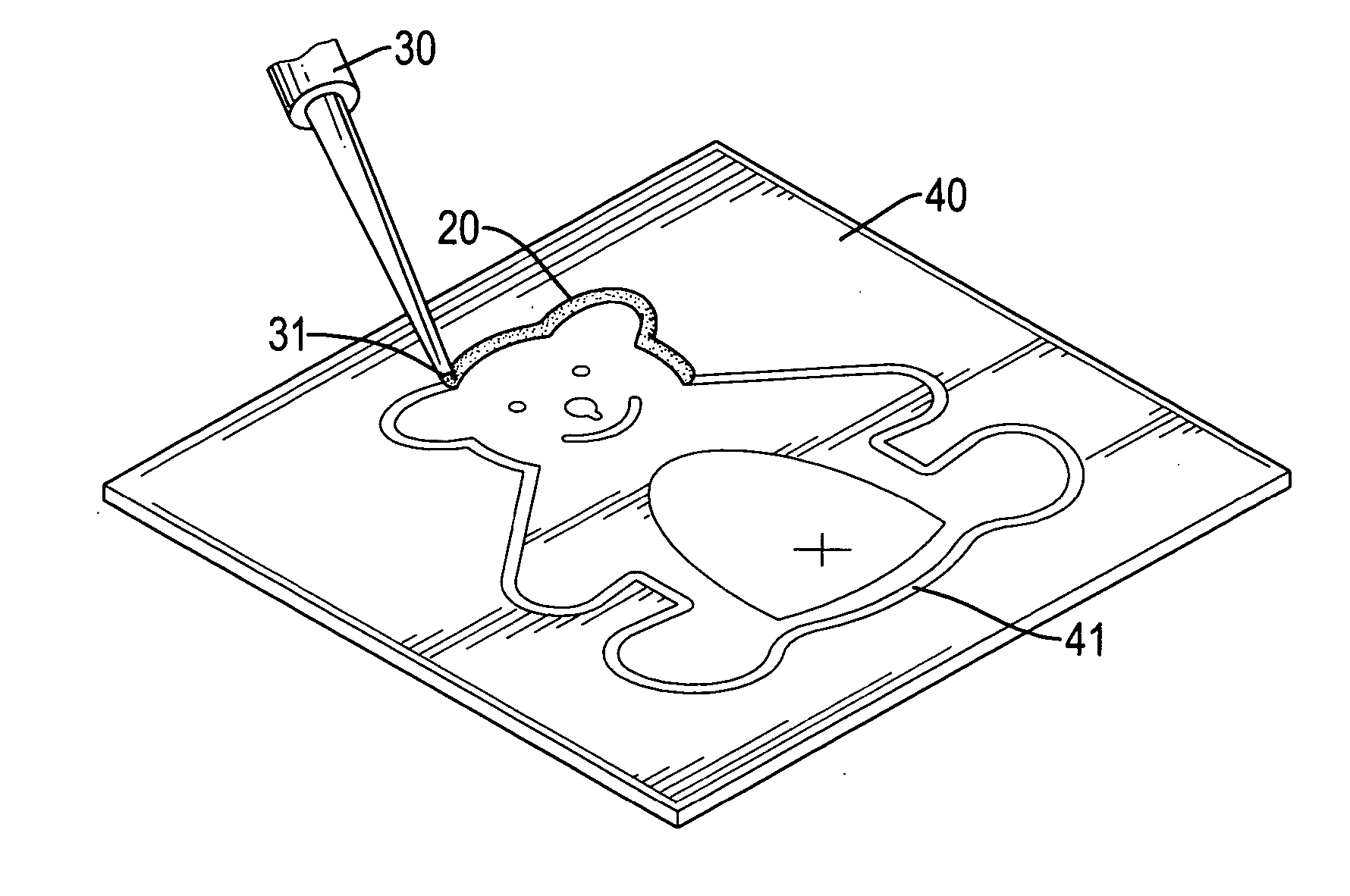

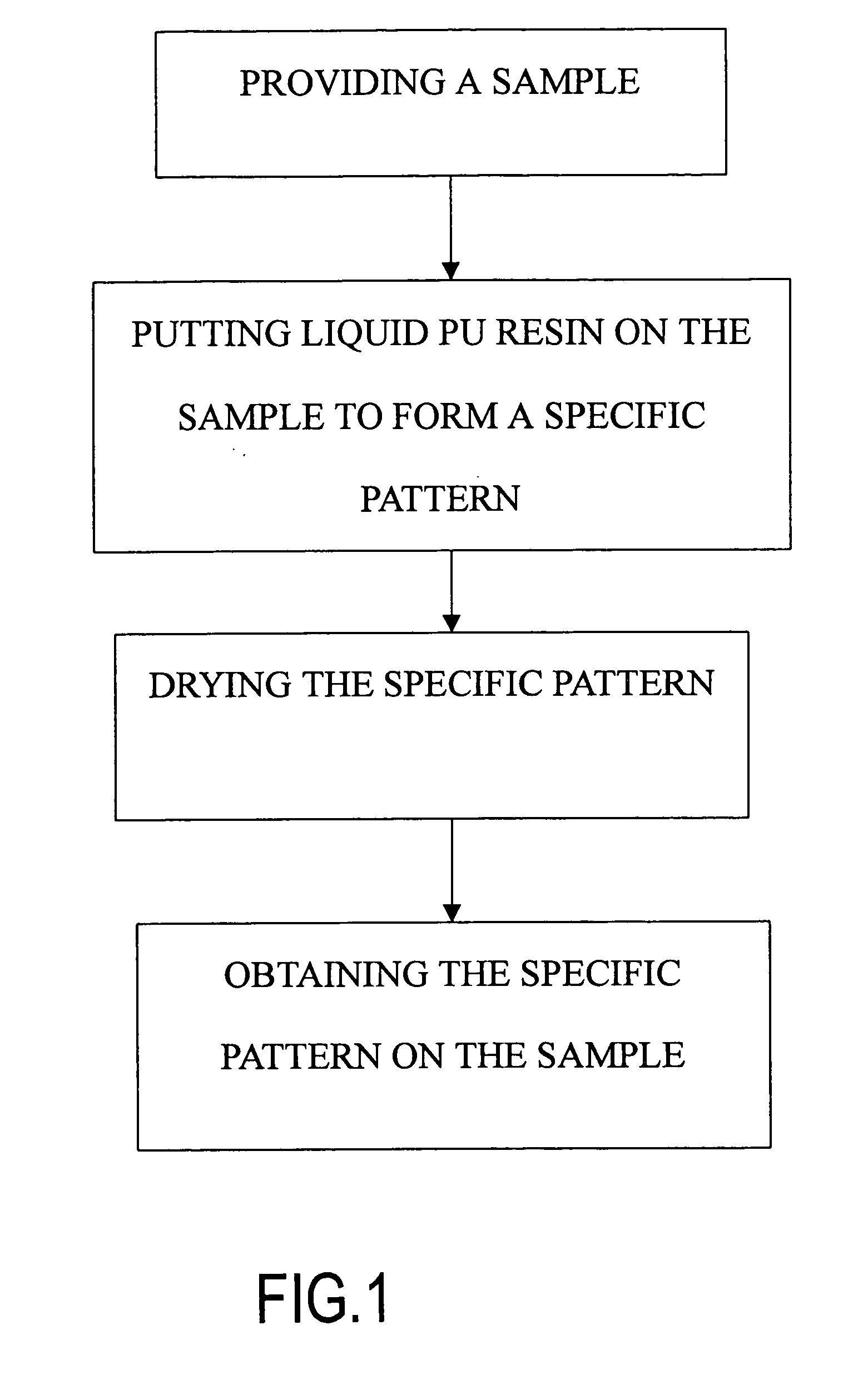

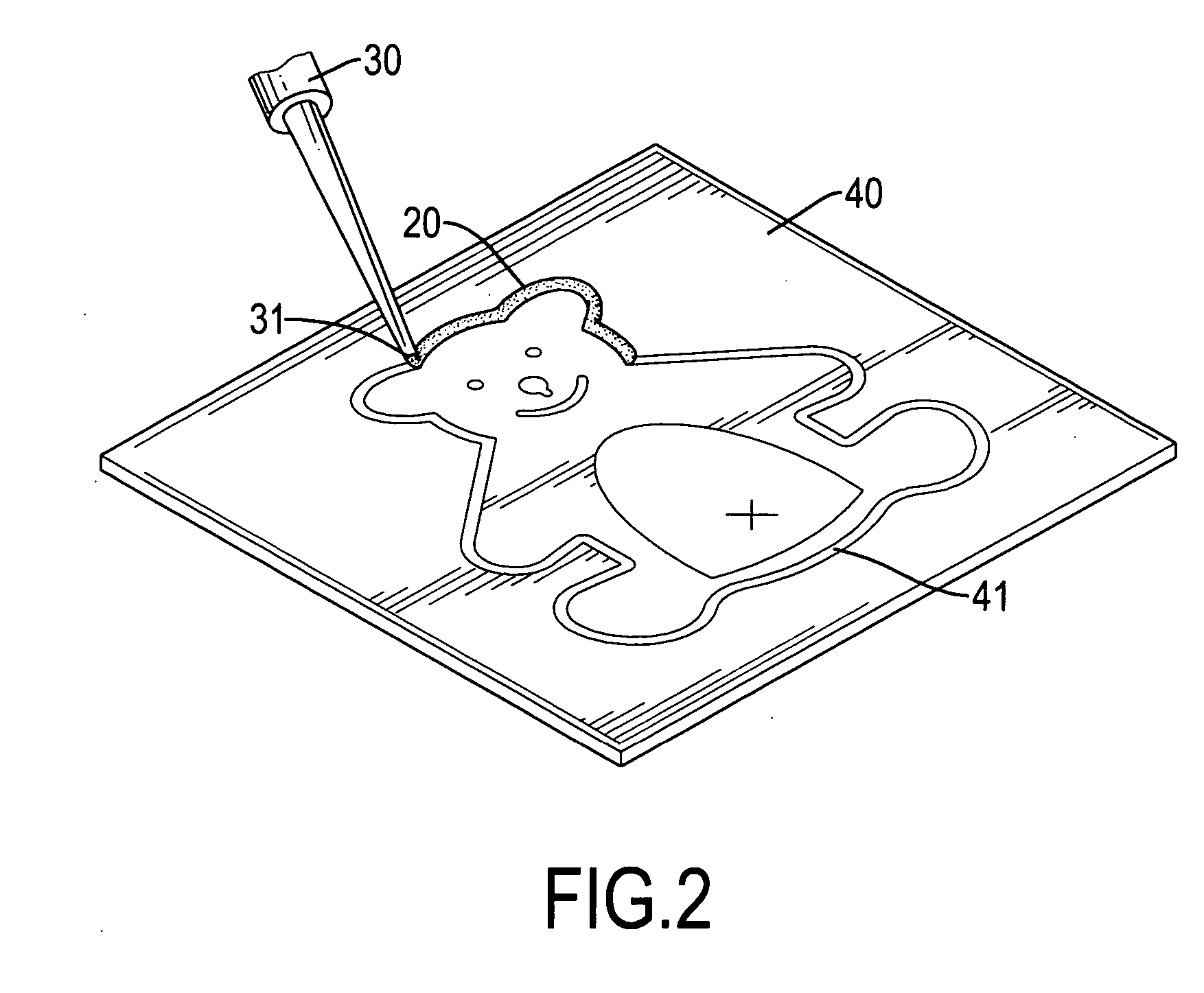

Method for applying surface ornamentation on material of shoes, bags or clothing

InactiveUS20070098898A1Easy to implementNot time-consumePretreated surfacesSpecial artistic techniquesEngineering

A method for applying surface ornamentation on material of shoes, bags or clothing involves the steps of: providing a sample, putting liquid PU resin on the sample to form a specific pattern, drying the specific pattern and obtaining the specific pattern on the sample. The present invention provides a way to form the specific pattern without a mold, so that the pattern is not limited by the mold. Furthermore, the cost for forming a pattern is reduced.

Owner:WU CHI KUNG

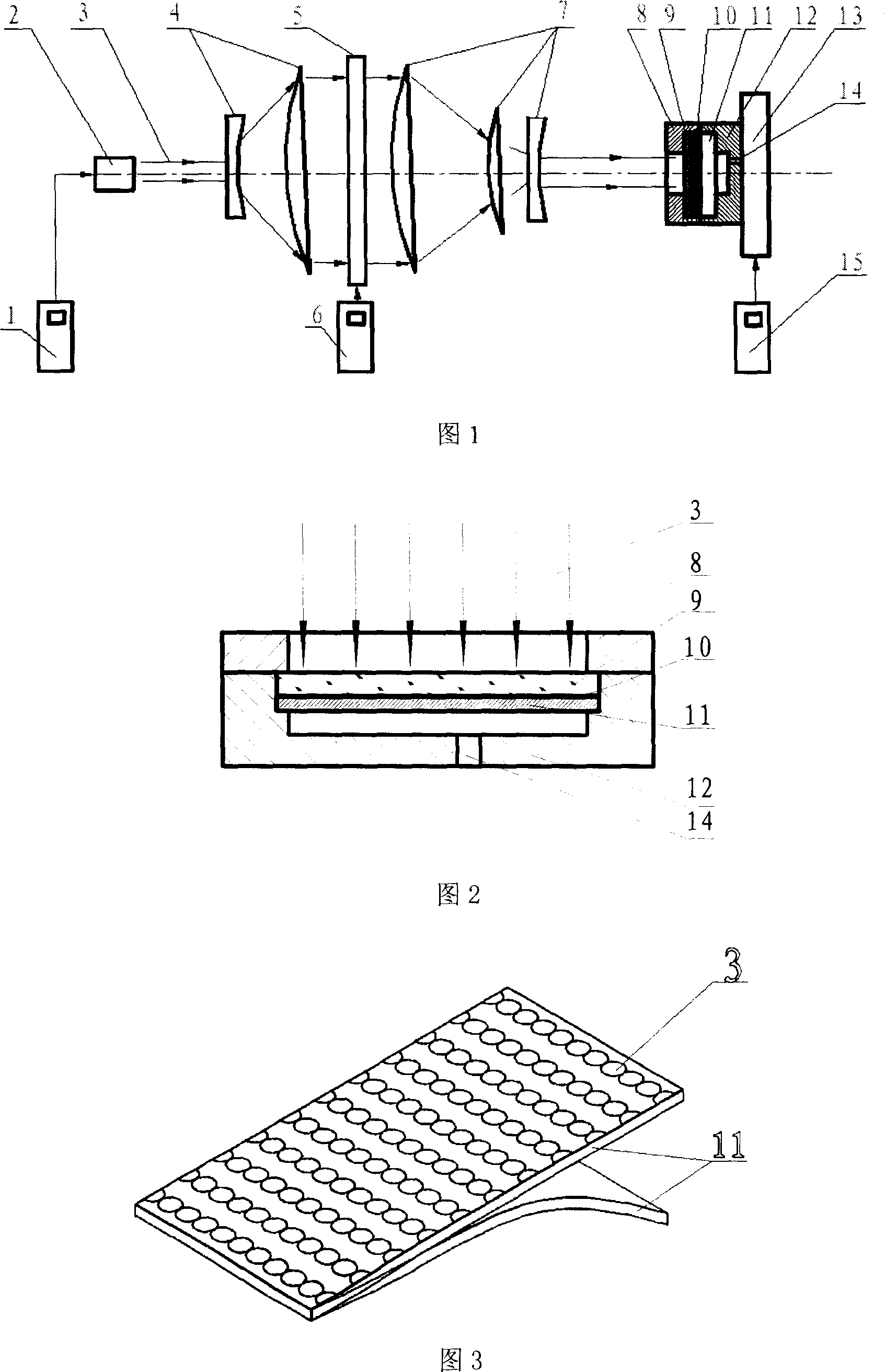

Method and device of laser impact sheet metal mouldless shaping based on liquid crystal mask

InactiveCN100999038ARealize three-dimensional distributionDifferent transmittanceLaser beam welding apparatusManufacturing technologyMetallic materials

The present invention belongs to the field of machinery manufacture technology, in particular, it relates to a laser impacted sheet formation method base on liquid crystal mask and its equipment. It is applicable to precision formation of metal sheet (whose thickness is 50 micrometers-4 mm). The invented equipment includes successively-connected laser generator control device, laser generator, beam-expanding system, liquid crystal display screen and display screen control device, focusing system, workpiece clamping apparatus system and digital control system connected with laser generator control device. Display screen control device and working table control device.

Owner:JIANGSU UNIV

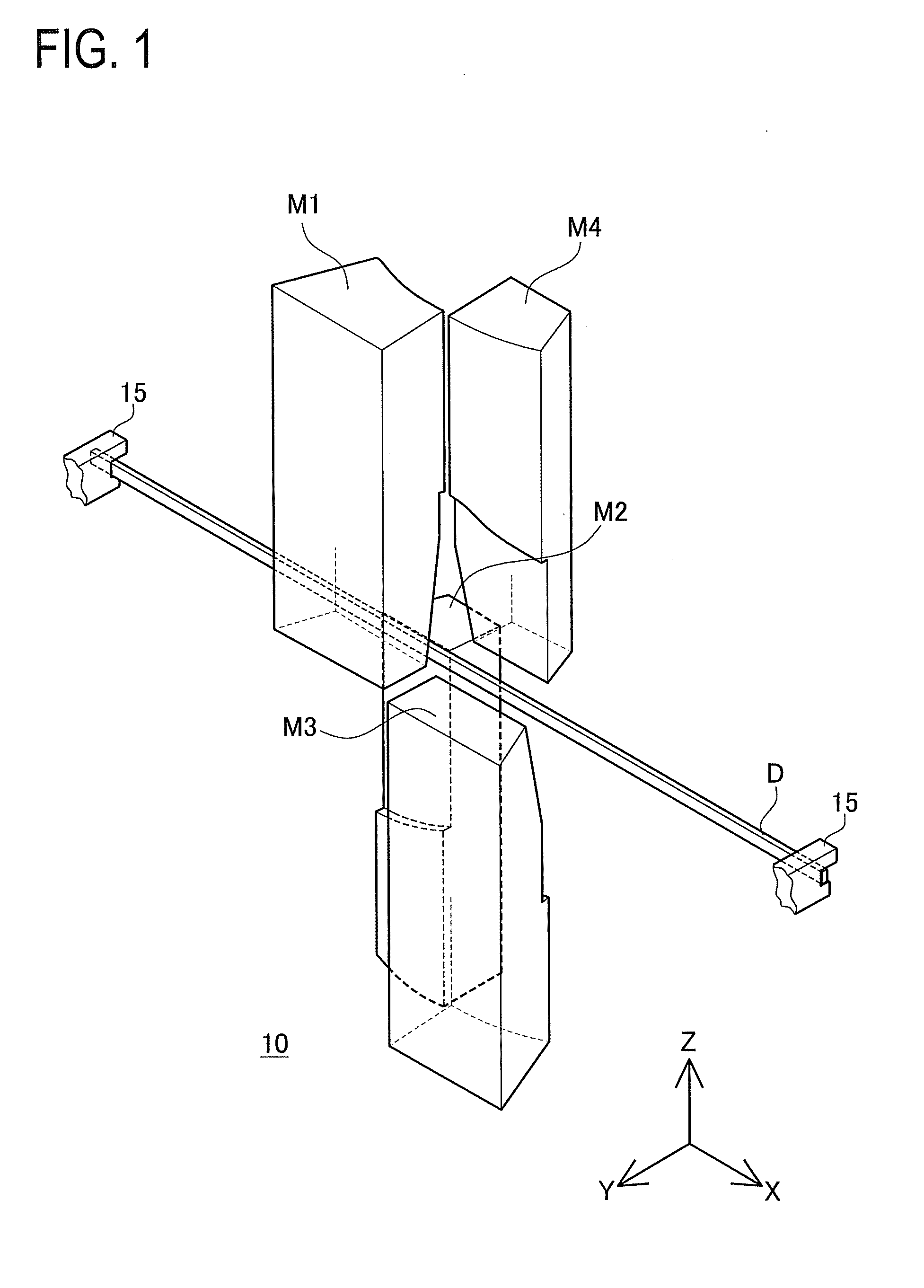

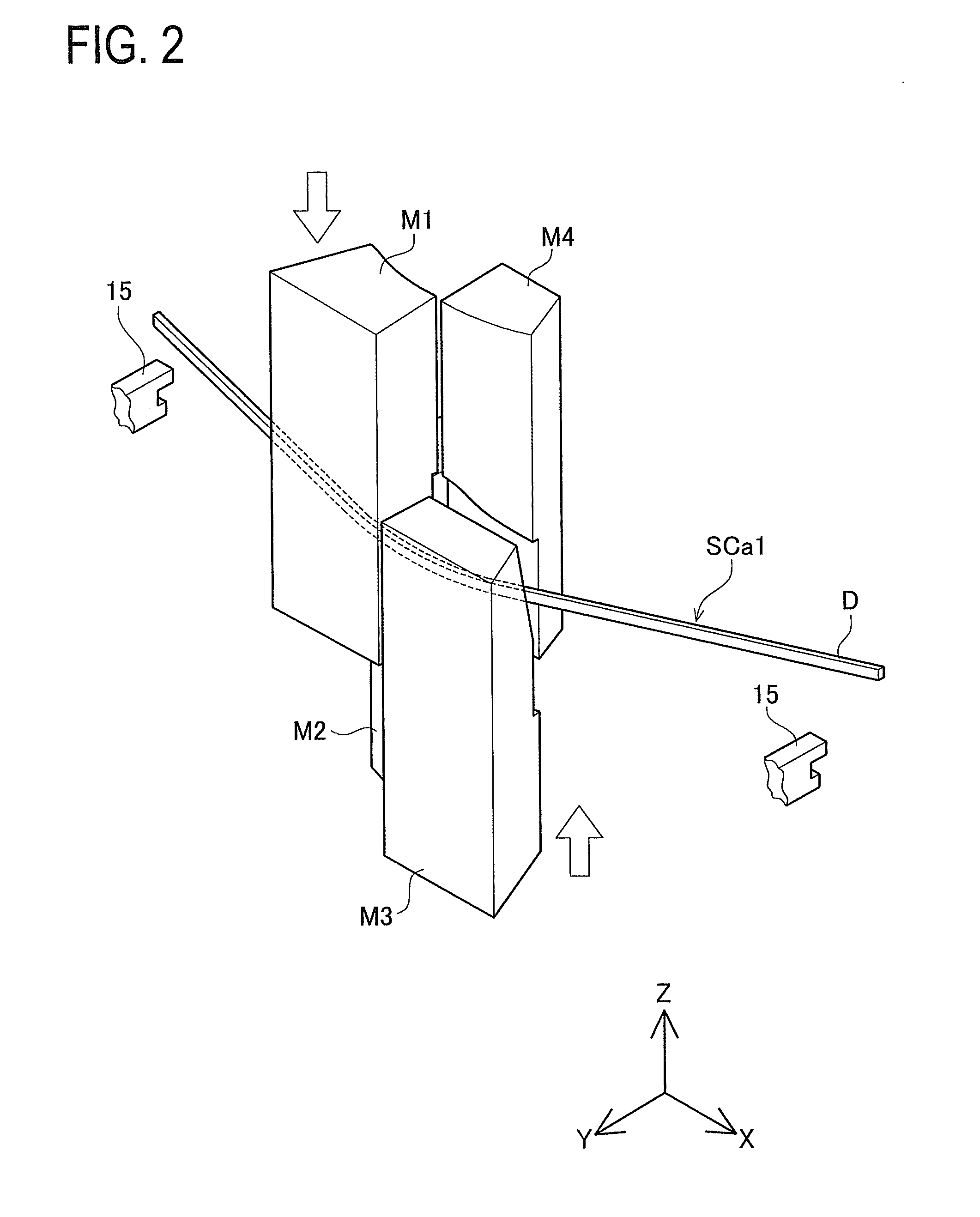

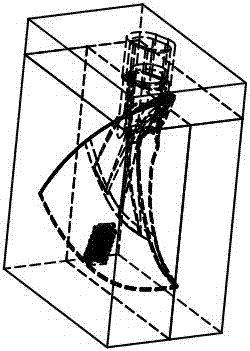

Segmented-coil manufacturing method, segmented-coil manufacturing device, and segmented coil manufactured using the method and the device

ActiveUS20140223727A1Shorten cycle timeLow costManufacturing dynamo-electric machinesCoils manufactureElectrical conductorEngineering

In a segment coil manufacturing method for manufacturing a segmented coil by bending a flat rectangular conductor using a forming die so that the segmented coil has a circular arc section, a crank section, and a protrusion-shaped section, the forming die includes an outer peripheral surface forming upper die, an inner peripheral surface forming upper die, an inner peripheral surface forming lower die, and an outer peripheral surface forming lower die, and the method includes forming the circular arc section, the crank section, and the protrusion-shaped section while holding at least two surfaces of the outer peripheral surfaces of the flat rectangular conductor by the outer peripheral surface forming upper die, the inner peripheral surface forming upper die, the inner peripheral surface forming lower die, and the outer peripheral surface forming lower die.

Owner:TOYOTA JIDOSHA KK +1

Mould using for organic binder, molding sand composition and mould

ActiveCN101104194AIncrease the number of casting shapesImprove productivityFoundry mouldsFoundry coresCarbamateOrganic solvent

The invention provides an organic adhesive used in casting which can assure excellent casting intensity when phenolic aldehyde carbamate is cast, and can solve or reduce the sand-sticking problem that the sclerosis molding sand composition sticks on the surface of a mould. The organic adhesive of the invention is used in the gas sclerosis casting and the molding of the self- sclerosis casting of the phenolic aldehyde carbamate. The invention is characterized in that: the organic adhesive adopts a condensation product of unsaturated fatty acid with alcoholic hydroxyl, phenol formaldehyde resin, polyisocyanate compound, and organic solvent as the essential components.

Owner:ASAHI YUKIZAI KOGYO CO LTD

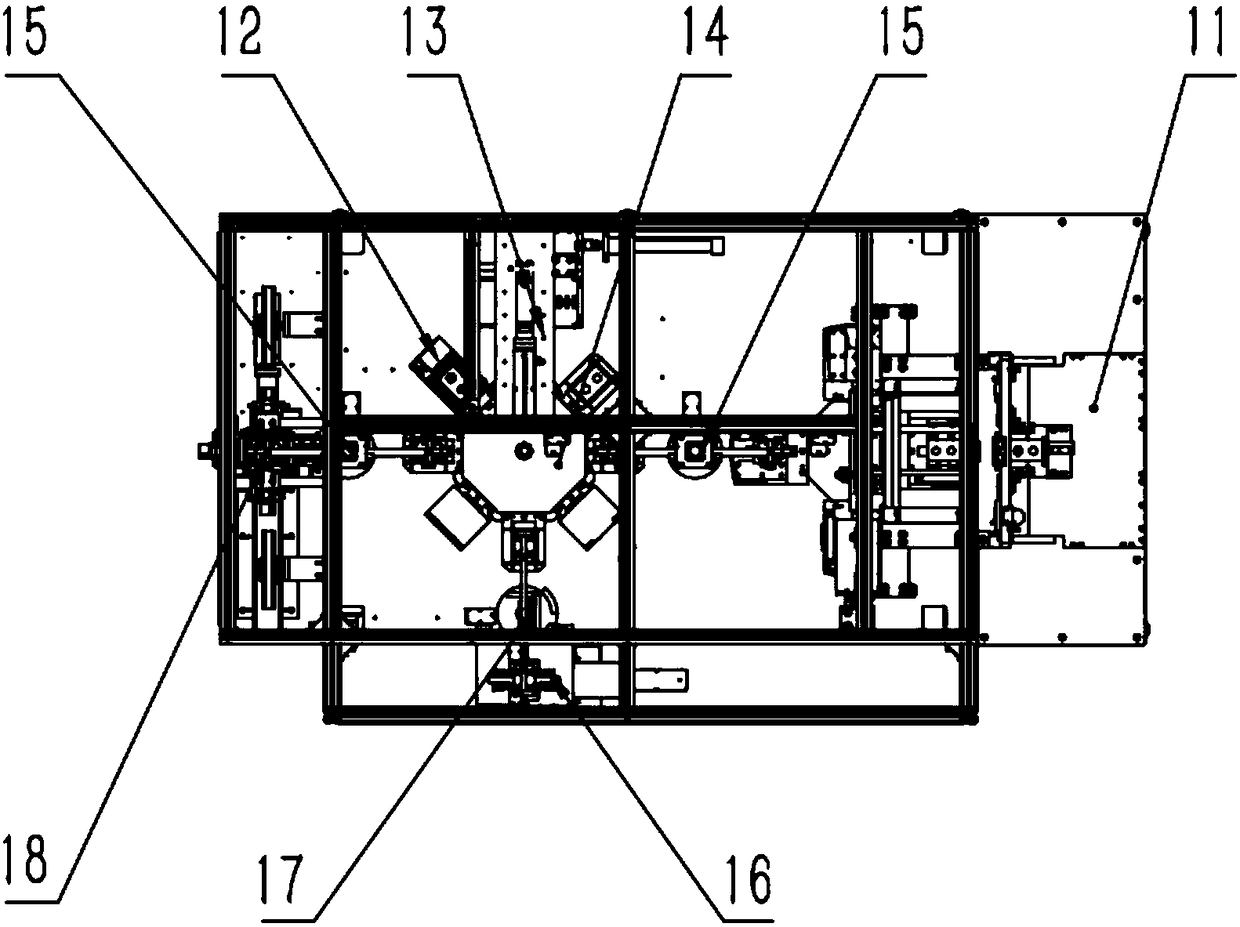

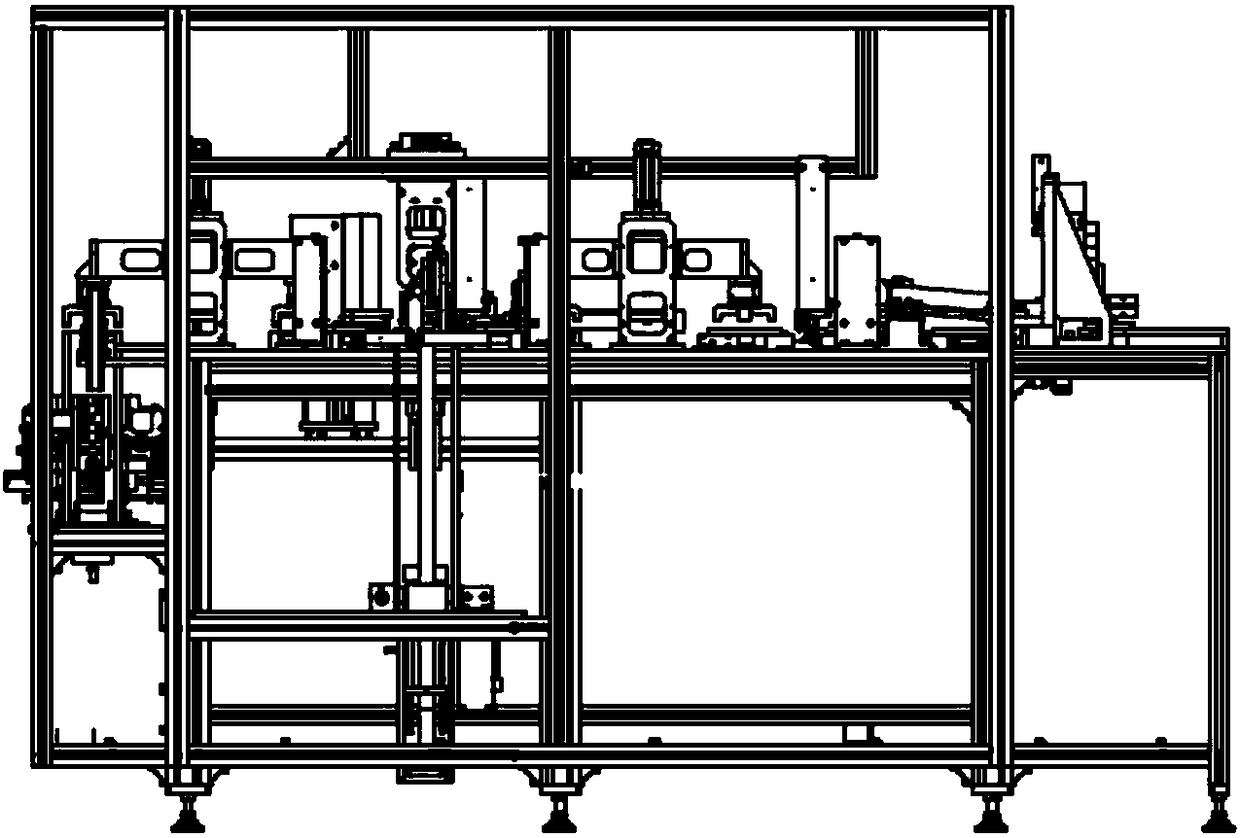

Paper box inner box forming equipment and forming method thereof

PendingCN108466449AReduce manufacturing costLow application costBox making operationsPaper-makingEngineeringMachining process

The invention discloses a paper box inner box forming equipment and a forming method thereof, and belongs to the technical field of packaging equipment. An enclosing strip mold forming mechanism, an inner box forming rotary plate mechanism, an inner box pressure maintaining rubberizing mechanism and other mechanisms are arranged for completing processing of all links in the inner box forming process correspondingly, the inner box forming process is conducted on a rotary plate, a plurality of inner box forming cavities are formed in the rotary plate and correspondingly provided with a lower cover charging mechanism, a lower cover gluing mechanism, an upper cover charging mechanism and the parts for completing charging and machining processes of all materials in the inner box forming processing, and thus inner box forming is completed. According to the paper box inner box forming equipment and the forming method thereof, through coordinate operation of the multiple mechanisms or devices,unintermittent inner box precise forming can be achieved, compared with traditional manual forming techniques, the precision in the inner box forming process is effectively ensured, the inner box forming efficiency is improved, the production cost of inner boxes even paper boxes is lowered, and the paper box inner box forming equipment and the forming method thereof have great application value.

Owner:SINOTECHO WUHAN INTELLIGENT TECH CO LTD

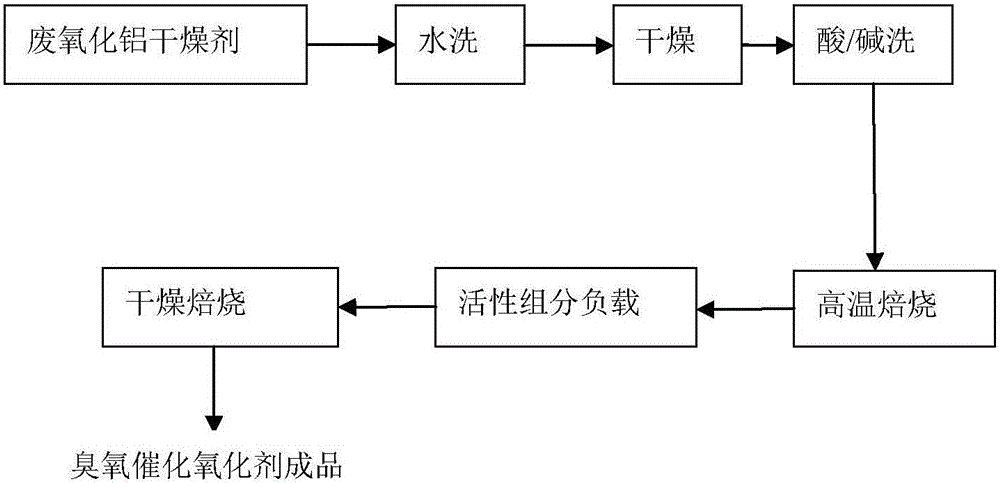

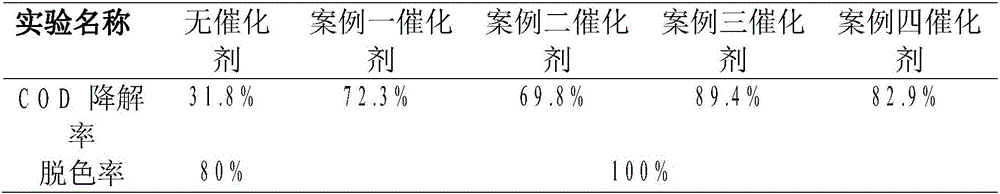

Method for preparing loaded catalyst for heterogeneous phase ozone oxidizing

InactiveCN105771968AWide variety of sourcesLow priceHeterogenous catalyst chemical elementsMetal/metal-oxides/metal-hydroxide catalystsActive ingredientPollution

The invention discloses a method for preparing a loaded catalyst for heterogeneous phase ozone oxidizing. The method is characterized by including the following steps of 1, washing; 2, drying; 3, pickling and / or alkaline cleaning; 4, roasting; 5, active ingredient loading; 6, drying and roasting. A waste aluminum oxide drying agent used in the method is wide in source and low in cost, and is used as a carrier, secondary pollution caused by solid waste is avoided, and resource use of waste can be further achieved; as the waste aluminum oxide drying agent is kept spherical, forming cost is greatly reduced, and the use cost of the catalyst is radically reduced; the service life of the catalyst is long; when reacting is conducted for a period of time and the treatment efficiency is reduced, the catalyst can be recycled again, and operating cost can be further reduced.

Owner:BEIJING JINDAYU ENVIRONMENT TECH CO LTD

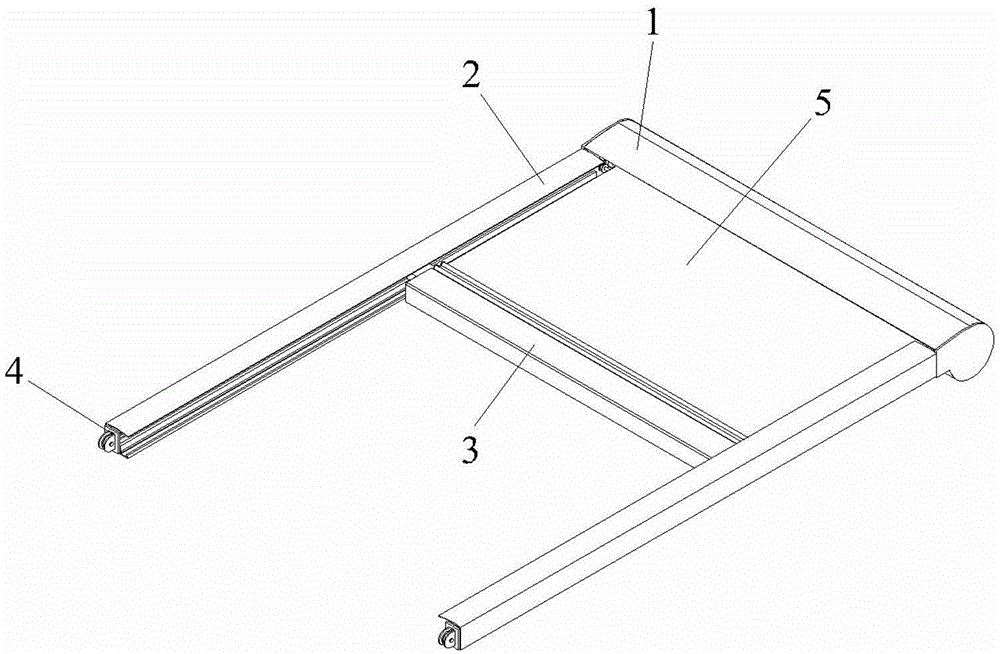

Seamless canopy awning

The invention relates to a seamless canopy awning and belongs to the technical field of outdoor automatic sun-shading. The seamless canopy awning comprises a cloth winding device, a guide rail structure, a sun-shading cloth bottom beam and a traction structure. The cloth winding device is provided with sun-shading cloth. The guide rail structure comprises a traction space containing the traction structure and a bottom beam moving space formed beside the traction space to contain the end of the sun-shading cloth bottom beam. The bottom beam moving space is connected with an extension stop part. According to the scheme, the seamless canopy awning can shade people from sun completely.

Owner:浙江恒红节能科技有限公司

Seating system and method of forming same

InactiveUS20050040690A1Cost reductionEasily manufactureSeat framesStoolsEngineeringMechanical engineering

The present invention discloses a seating system that includes a seat back (20) with one or more plastic panels (22, 24) that extend across a lateral distance (D2) of the seat back (20). The seat back (20) preferably includes one or more channel forming ribs (50, 54, 58). Optionally the seat back (20) will be anchored to a body of an automotive vehicle with an improved attachment system (100).

Owner:DOW GLOBAL TECH LLC

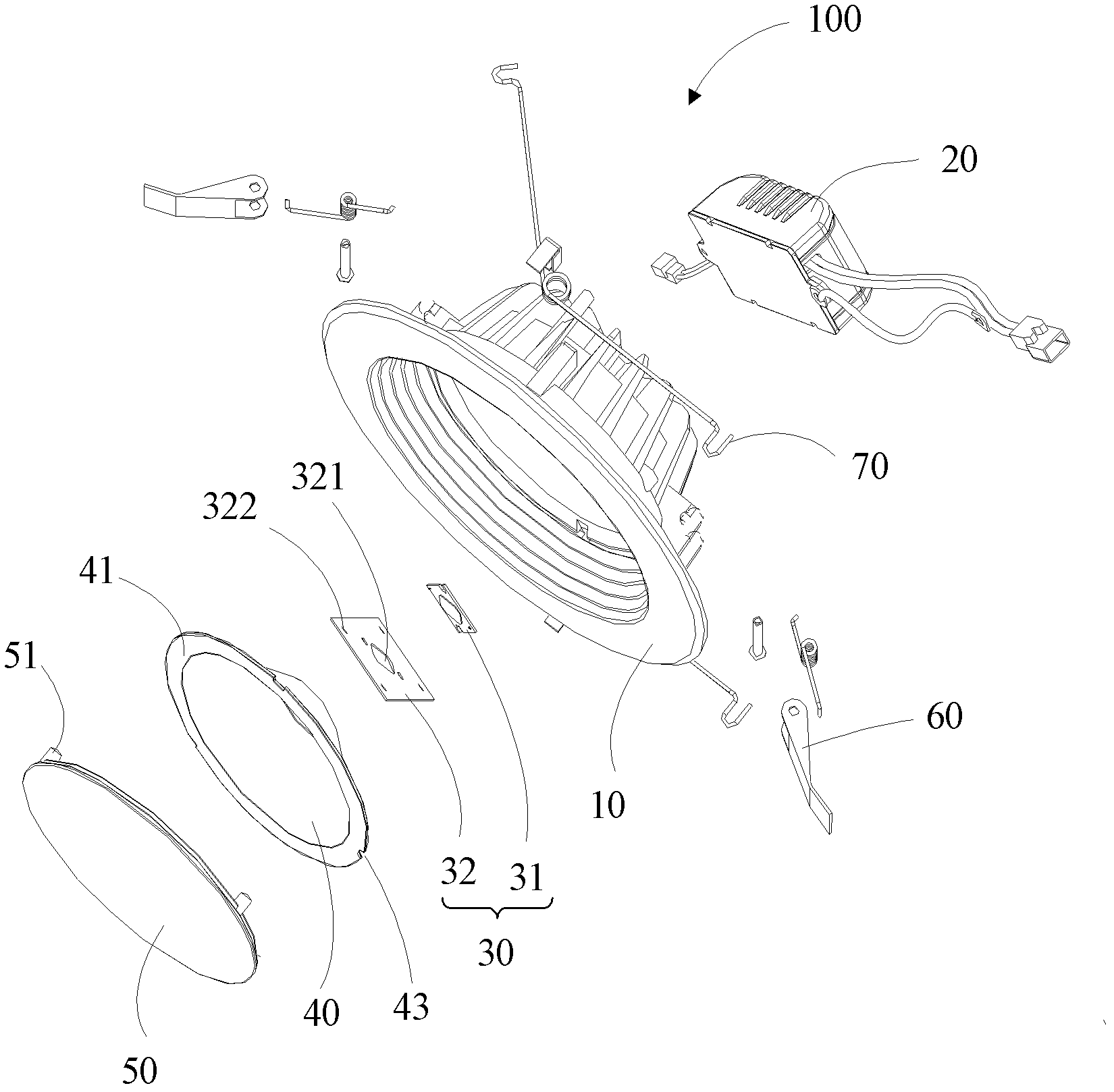

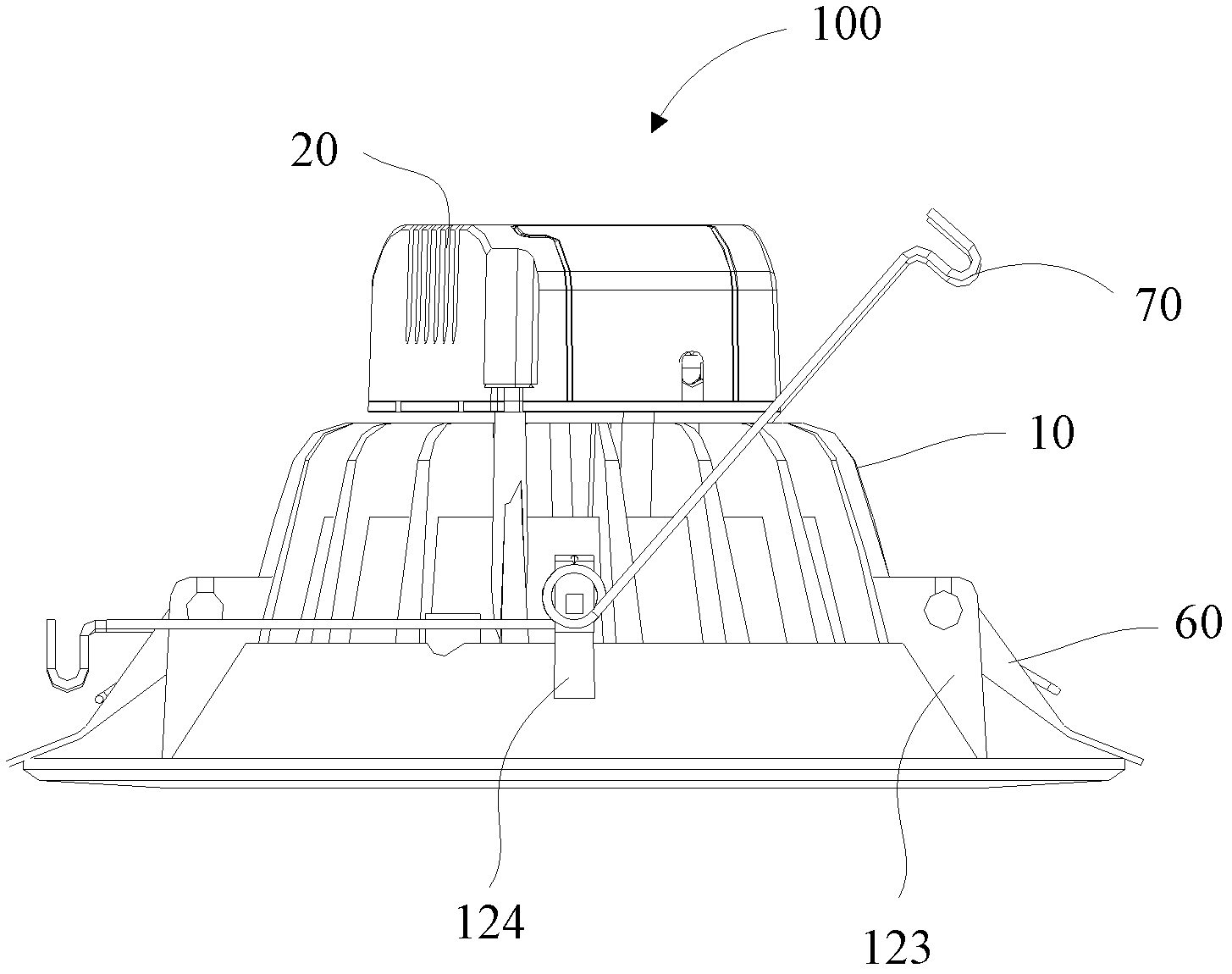

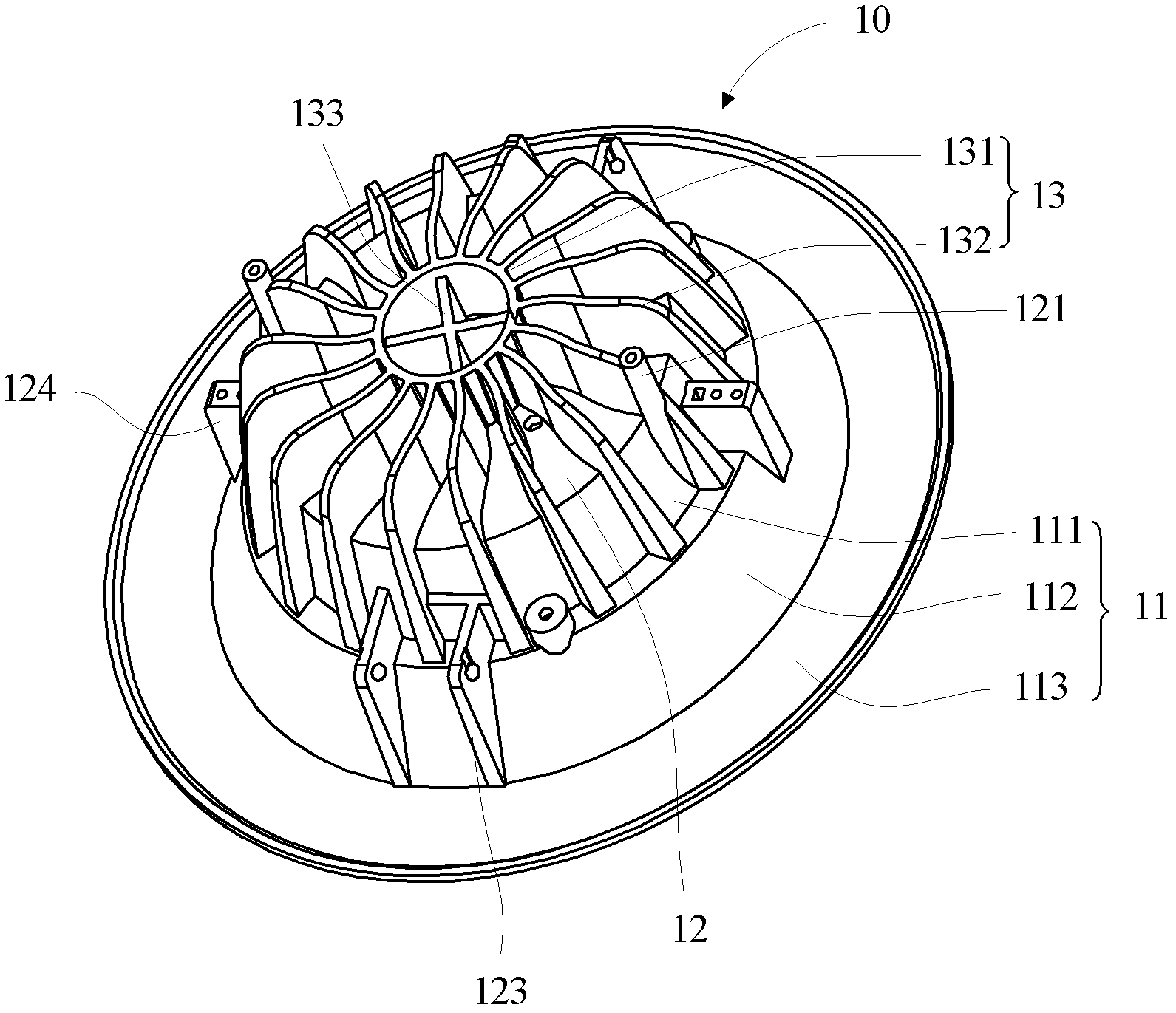

led downlight and its lamp body

InactiveCN102287727AImprove general performanceStrong matchingPoint-like light sourceLighting heating/cooling arrangementsEngineeringHeat sink

The invention relates to a lamp body of an LED downlight, which comprises a cylinder body, a cover plate and a radiator. One end of the barrel is open, the other end is covered with the cover plate, and the radiator is formed on the outer surface of the cover plate. The cylindrical body includes a first cylindrical portion connected to the cover plate and a second cylindrical portion connected to an end of the first cylindrical portion away from the cover plate. A stepped surface facing the opening direction of the cylinder body is formed between the inner surfaces of the first cylinder part and the second cylinder part. An annular groove and a plurality of fixing holes are formed on the step surface. The lamp body can be matched with the traditional LED lamp board, and also can be matched with the integrated LED light source, which has strong compatibility. In addition, the present invention also provides an LED downlight having the above-mentioned lamp body.

Owner:ニンボードゥジャライティングテクノロジーカンパニーリミテッド

Sand core structure of water turbine blade steel castings

PendingCN107138683AThe overall thickness is thinReduce thicknessFoundry mouldsFoundry coresWater turbineSand granules

The invention relates to a sand core structure of water turbine blade steel castings in the technical field of casting. The sand core structure comprises a plurality of sand cores which are sequentially spliced and combined, and a casting cavity is formed after every two adjacent sand cores are combined. After the sand cores are sequentially spliced and combined, the multiple casting cavities are formed. Core heads spliced in a matched manner are arranged on the peripheries of the outlines of the adjacent sand core cavities. Each core head is provided with a positioning structure. The sand cores share one pouring system. A dead head feeding structure is arranged on the top of each sand core. According to the sand core structure of a water turbine blade, the beneficial effects that the water turbine blade plane size is large, and the thickness is small are utilized, one combined sand core structure is adopted, the multiple casting cavities are formed, one-time box burying modeling and one-time pouring are conducted to form the multiple castings, the sand-iron rate is greatly reduced, the thickness of single sand cores is reduced, and the overall casting technology efficiency is improved.

Owner:KOCEL STEEL

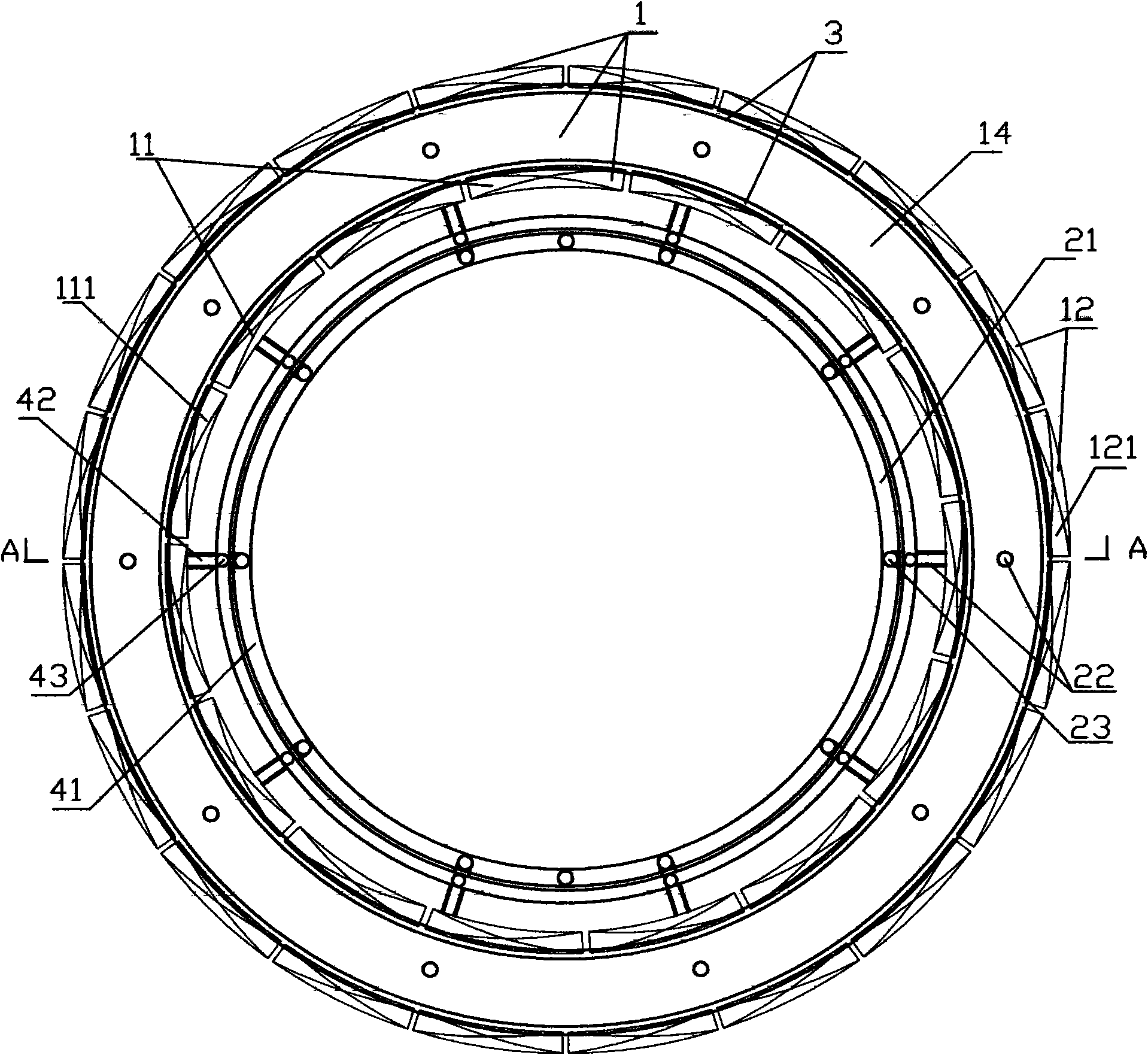

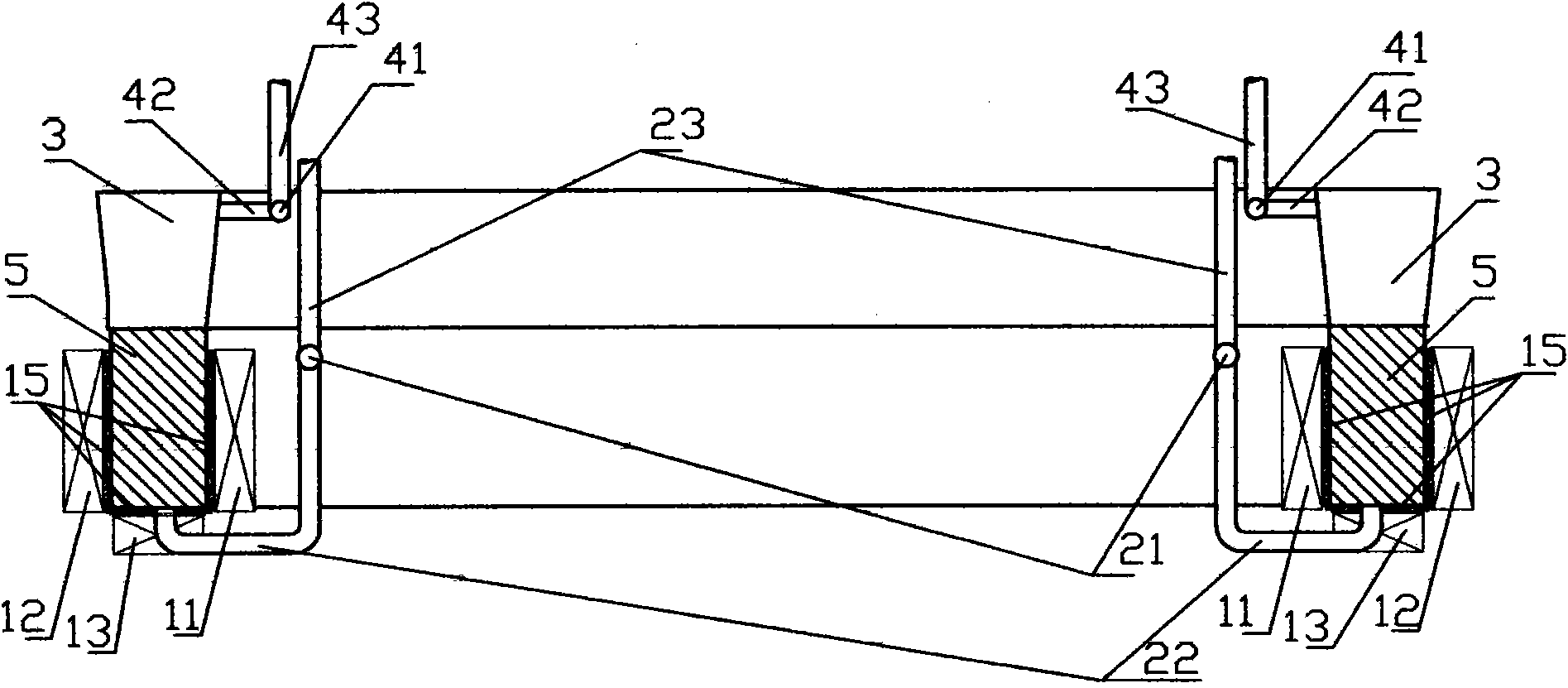

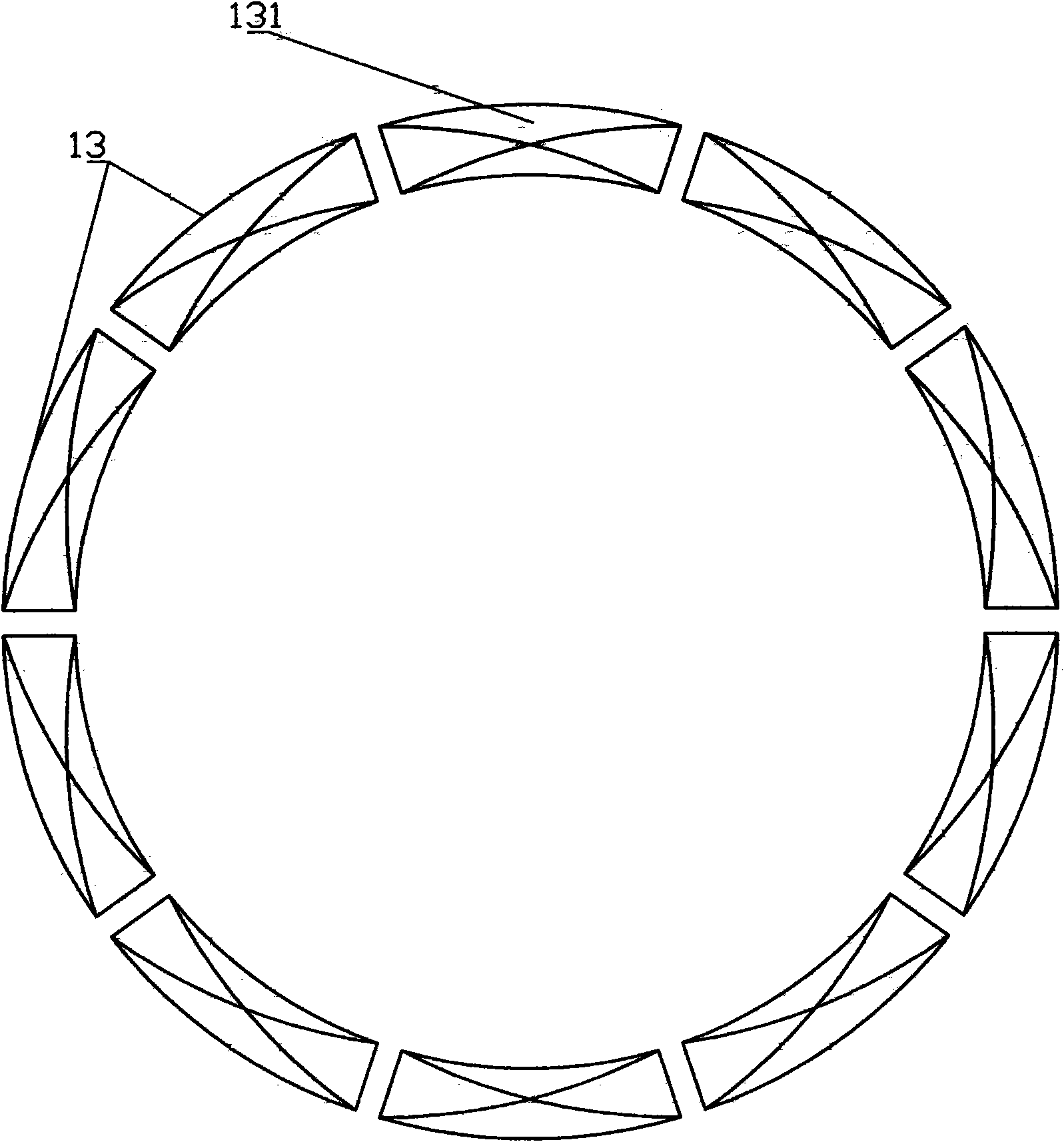

Tyre casting method and casting die

InactiveCN101837432ANo shrinkage cavity shrinkage defectHigh yieldFoundry mouldsFoundry coresMaterials scienceShrinkage porosity

The invention discloses a tyre casting method, comprising a toroidal flute cast (1), a bottom casting runner system, a feeder head (3) and a feeder head point casting runner system, wherein, the toroidal flute cast (1) comprises a toroidal inner wall (11), a toroidal outer wall (12) and a toroidal bottom mat (13) which are all composed of a plurality of blocks with different quantities; the bottom casting runner system comprises a bottom casting cross runner (21), a bottom casting ingate (22) and a bottom casting sprue (23). The invention discloses a method for casting a tyre by utilizing a tyre casting cold die. The method has high process yield, and the tyre casting produced by the method has no shrinkage porosity, shrinkage cavity and crack defects.

Owner:衡阳中钢衡重铸锻有限公司

Spinner

A spinning press tool for forming a cylindrical body from a conic barrel on a vertical lathe is composed of a fixing circular barrel with a diameter matched with the external diameter of the middle part of a conic barrel to be shaped, a turnover plate on the bottom of said circular barrel and with a screw hole, a pressing plate in said conic barrel and with a screw hole, a screw bolt for fixing said conic barrel to the bench of said vertical lather via said pressing plate, a cylindrical main roller arranged to upper mouth of said conic barrel, and an axle for said cylindrical main roller and connected to lower part of tool carrier.

Owner:河南科隆石化装备有限公司

Injection mould for studying tool box stationery series

The invention discloses an injection mould for studying tool box stationery series, and particularly relates to the technical field of moulds. The injection mould for the studying tool box stationeryseries comprises a lower mould seat. An upper mould seat is arranged at the top of the lower mould seat, a first groove is formed in the top end of the lower mould seat, a clamping groove is formed inthe middle of the first groove, an injection mould plate is movably connected into the clamping groove, and a first clamping block is movably connected between the inner wall of the first groove andthe injection mould plate. According to the injection mould for the studying tool box stationery series, the clamping groove is connected with the injection mould plate in a clamped mode, the injection mould plate is fixed through the first clamping block, the mould plate is conveniently replaced, the mould manufacturing cost is lowered, the motor rotates and is connected with a connecting threaded rod in a transmission mode through a conveyor belt, thus two moving sleeves move oppositely, a pulling rod slides in a sliding sleeve, the upper mould seat is pulled to slide on the outer side of the sliding rod, the lower mould seat and the upper mould seat conveniently work in a corresponding mode, the production efficiency is improved, a raised block is matched with a second groove, a limiting pin and a limiting hole are matched, the raised block, the second groove, the limiting pin and the limiting hole are matched with a buffering cushion to reduce vibration, the upper mould seat is stabilized advantageously, mould crushing is avoided, and the injection quality is improved.

Owner:福建省靖虹模具科技有限公司

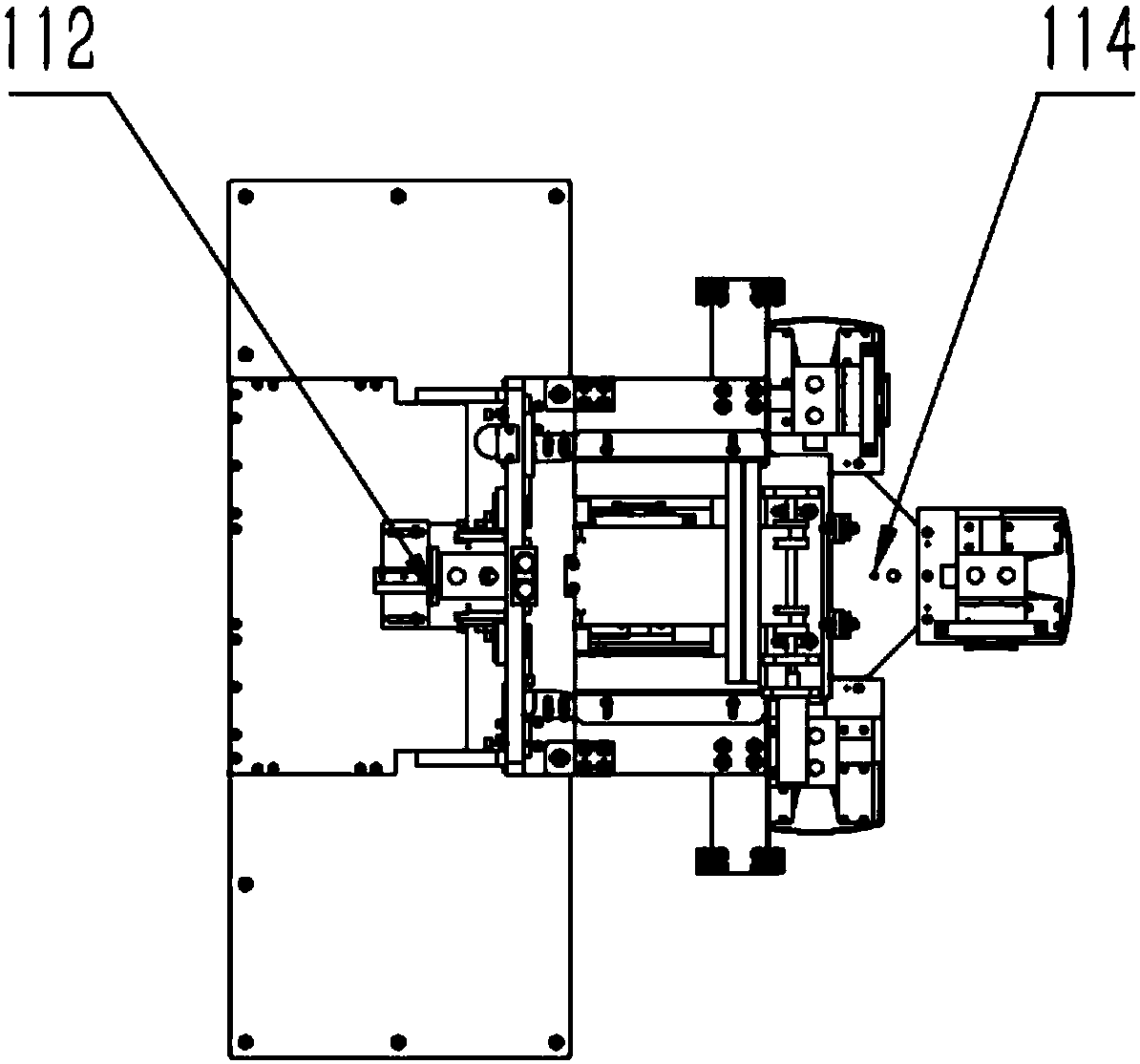

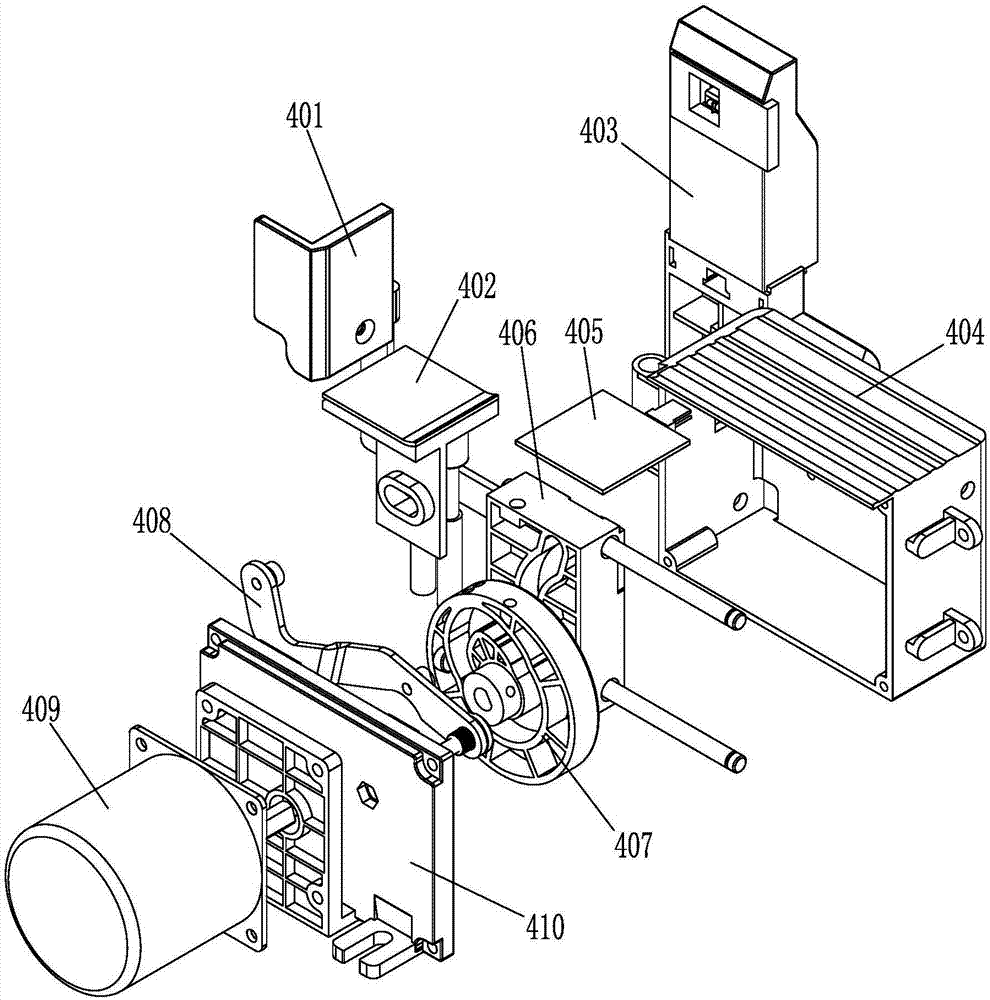

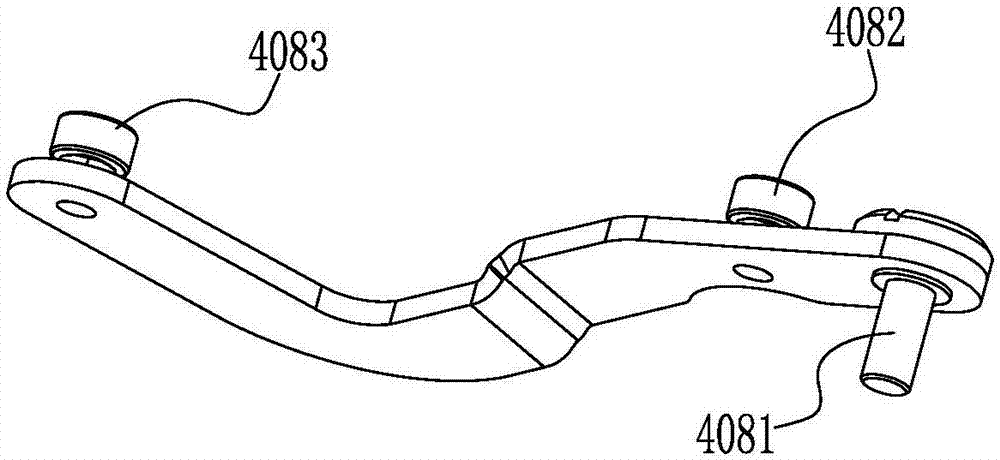

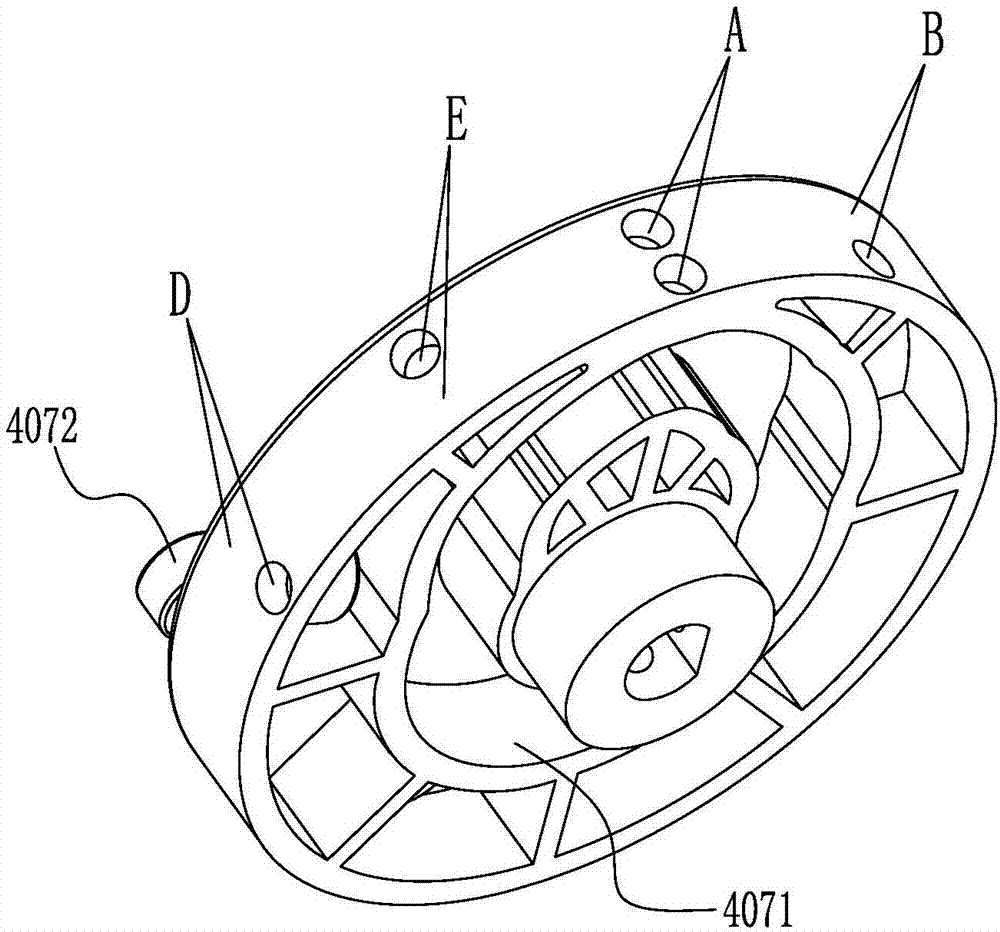

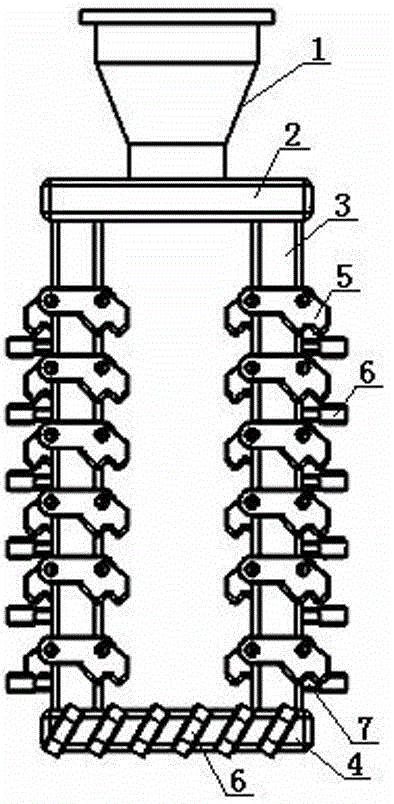

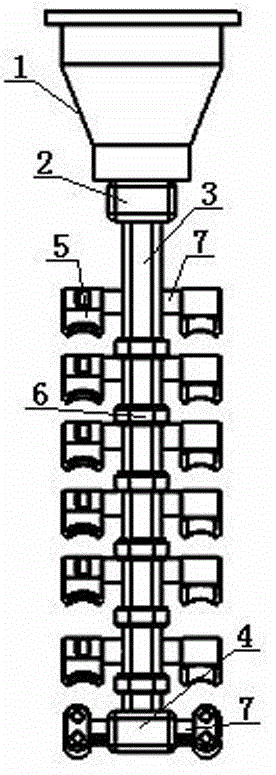

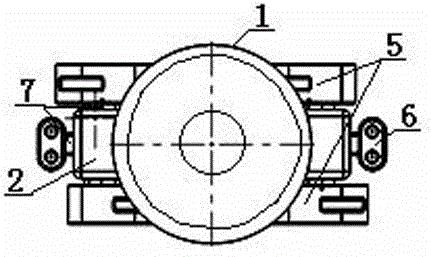

Mahjong machine, stacking and pushing device thereof and method for stacking and pushing mahjong tiles

ActiveCN107281748AVarious ways to playImprove experienceIndoor gamesElectric machineryIndustrial engineering

The invention discloses a mahjong machine, a stacking and pushing device thereof and a method for stacking and pushing mahjong tiles. Two different sets of linkage matching relationships are adopted by a tile-pushing head and a tile-supporting table. When two mahjong tiles are stacked and pushed, two stacked tiles are intervened in advance by arranging the tile-pushing head in order to prevent a third mahjong tile from being sent out. Therefore, a conventional motor is utilized for selecting the rotation direction of the motor. The stacking and pushing device can be rapidly switched to stack and push two mahjong tiles or stack and push three mahjong tiles. As a result, the same stacking and pushing device can stack and push three mahjong tiles and two mahjong tiles. Therefore, the staking and pushing device and the mahjong machine become more universal. Mold opening cost and manufacturing cost are reduced. The mahjong machine offers many ways of playing so that a user can have better experience and feels more comfortable in playing mahjong.

Owner:ZHEJIANG CHAOSHENG ELECTROMECHANICAL TECH CO LTD

Precise CRDM part casting forming method

ActiveCN104874739AImprove yieldUniform structure and long-term wear resistanceFoundry mouldsFoundry coresStellite alloyInvestment casting

The invention discloses a precise CRDM part casting forming method. The precise CRDM part casting forming method comprises the steps that 1, a ceramic mold shell matched with design shape is manufactured in an investment mode according to the design shape of a CRDM claw and / or a connecting rod; 2, the ceramic mold shell is preheated under the condition of the temperature ranging from 850 DEG C to 1100 DEG C, the temperature is kept for 1-5 hours, and temperature uniformity of all positions of the ceramic mold shell is ensured; a stellite ingot is molten under the condition of the temperature ranging from 1400 DEG C to 1500 DEG C and is cast into the well-preheated ceramic mold shell, and a casting is formed after solidification; 3, mold shell is cleaned, and the casting is subjected to heat preservation under the condition of the temperature ranging from 850 DEG C to 950 DEG C and then is subjected to air cooling for 610 hours. The forming of the connecting rod and / or the claw part for a CRDM is reliably achieved by means of an investment casting technology, forming operation is easy, finished product rate is high, and a formed connecting rod and / or the claw part has even texture, is long-acting and abrasion-resistant, is reliable and stable in use and can effectively meet the technological requirements.

Owner:DONGFANG TURBINE CO LTD

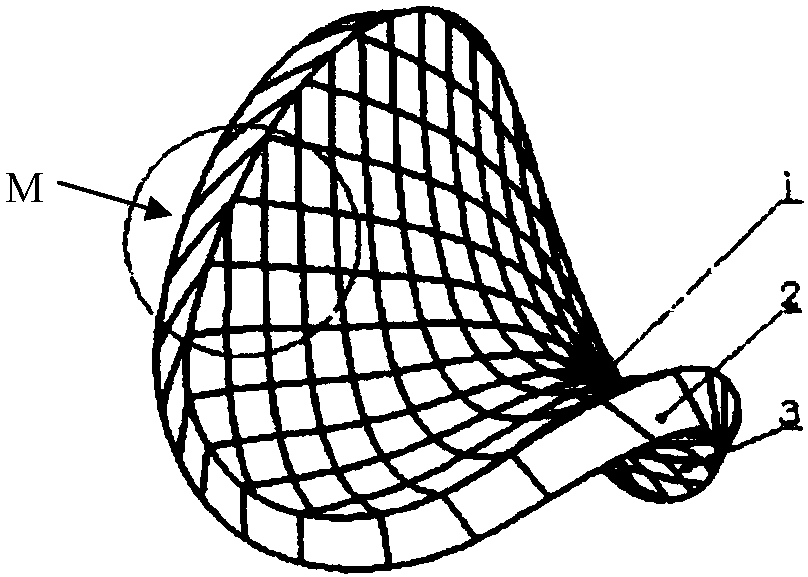

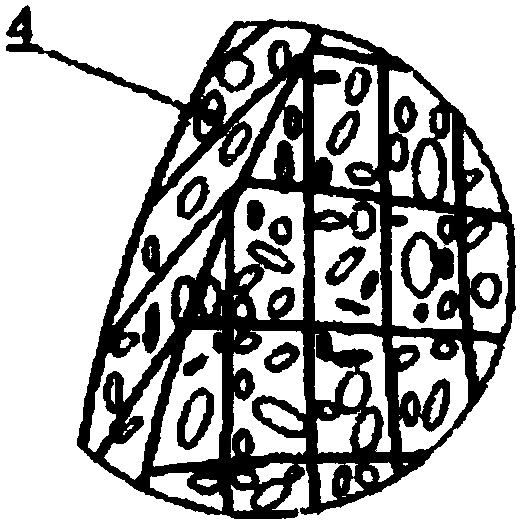

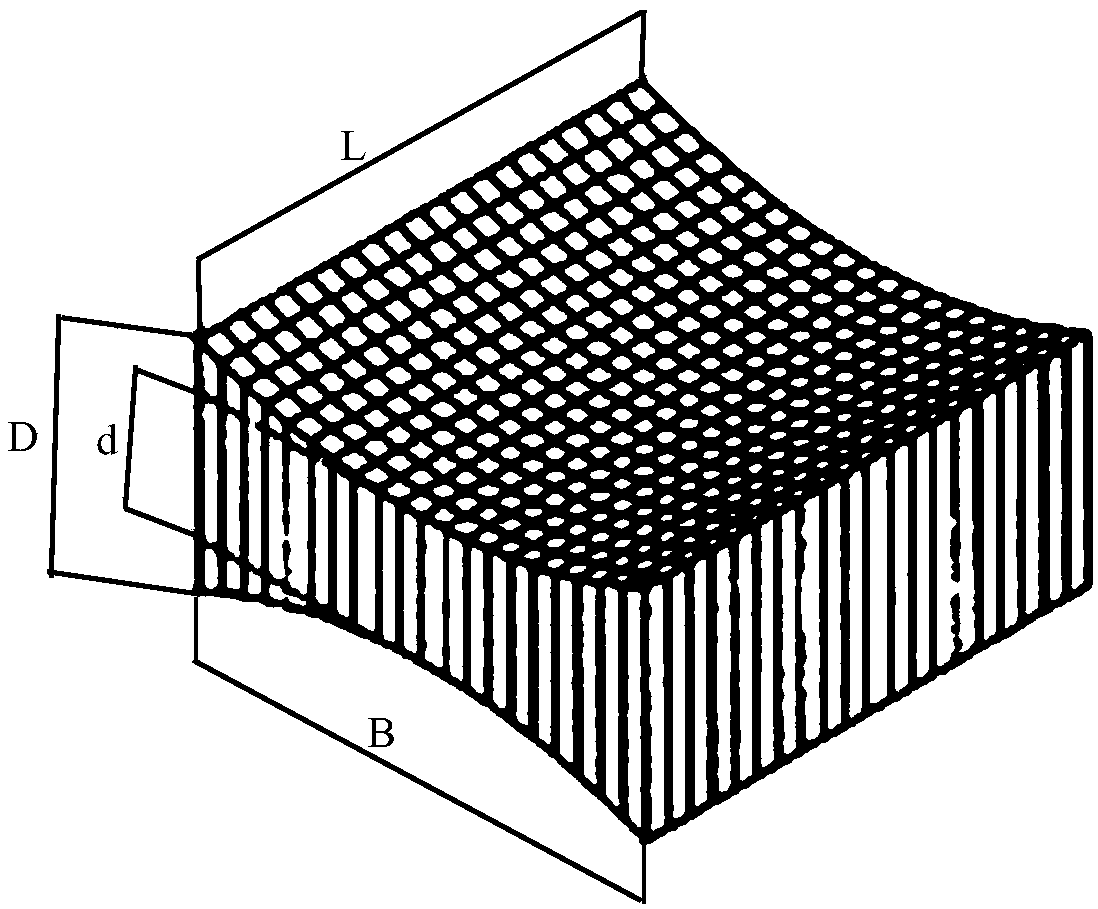

Three-dimensional warp-knitted spacer fabric reinforcing special-shape foam material and preparing method thereof

The invention discloses a three-dimensional warp-knitted spacer fabric reinforcing special-shape foam material and a preparing method thereof, and relates to foam reinforcing materials. The three-dimensional warp-knitted spacer fabric reinforcing special-shape foam material is composed of a matrix and a reinforcing body, wherein the matrix is an organic foam material, the reinforcing body is three-dimensional spacer fabric, and the three-dimensional spacer fabric and the organic foam material are compounded. The preparing method comprises the steps of 1, selecting the three-dimensional spacerfabric, a polymer, a foaming agent and an additive; 2, placing the three-dimensional spacer fabric into a mold after cutting the three-dimensional spacer fabric, deforming the three-dimensional spacerfabric and fixing the shape in the mold; 3, preparing the organic foam material, wherein the polymer, the foaming agent and the additive which are selected in the step 1 are stirred and uniformly mixed; 4, casting raw materials which are uniformly mixed in the step 3 into the three-dimensional spacer fabric, and conducting foam enriching, curing and demolding to obtain the three-dimensional warp-knitted spacer fabric reinforcing special-shape foam material.

Owner:福建福联精编有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com