Method for preparing loaded catalyst for heterogeneous phase ozone oxidizing

A supported catalyst, ozone oxidation technology, applied in the direction of heterogeneous catalyst chemical elements, metal/metal oxide/metal hydroxide catalyst, physical/chemical process catalyst, etc., can solve unused problems and achieve the use Effects of long life, reduced molding cost, and reduced operating cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] In order to make the technical problems, technical solutions and beneficial effects solved by the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

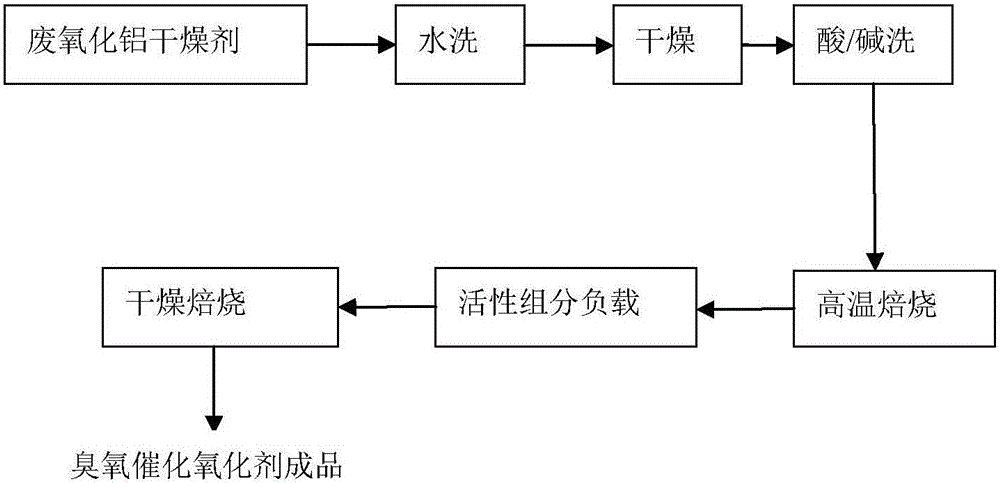

[0045] A preparation method for a supported catalyst for heterogeneous ozone oxidation, comprising the following features:

[0046]Step (1), washing with water: washing the discarded alumina desiccant in water until the pH of the solution remains unchanged;

[0047] Step (2), drying: separate the alumina desiccant after cleaning in step (1) from water, let it dry naturally at room temperature for 2-4 hours, and then dry it at 100°C-110°C for 3-5 hours, Obtain clean alumina desiccant;

[0048] Step (3), pickling and / or alkali washing, then take out the clean alumina des...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| chemical oxygen demand (mass) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com