Patents

Literature

3371 results about "Drying Agents" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The term drying agent has different meanings: Drying agent may refer to: Desiccant absorbs water or moisture from solids. Oil drying agents for compounds that speed up the hardening of oils, often used in painting.

Sequential release pharmaceutical formulations

InactiveUS20070141147A1Efficient coordinationBiocideHydroxy compound active ingredientsControlled releaseImmediate release

A mixed-release tablet or capsule formulation including vehicles for the delivery of a plurality of drugs in various combinations of immediate release, extended release, and / or delayed release modes over a predetermined time period have been developed, which provide for controlled release not just of the drugs, but controlled release that is designed to create more effective coordination between the drugs being delivered. The drugs can be any medically and / or physiologically appropriate combination of drugs and active ingredients, preferably decongestant drugs, antihistamines, expectorants, antitussives, cough suppressants, and drying agents.

Owner:AURIGA LAB

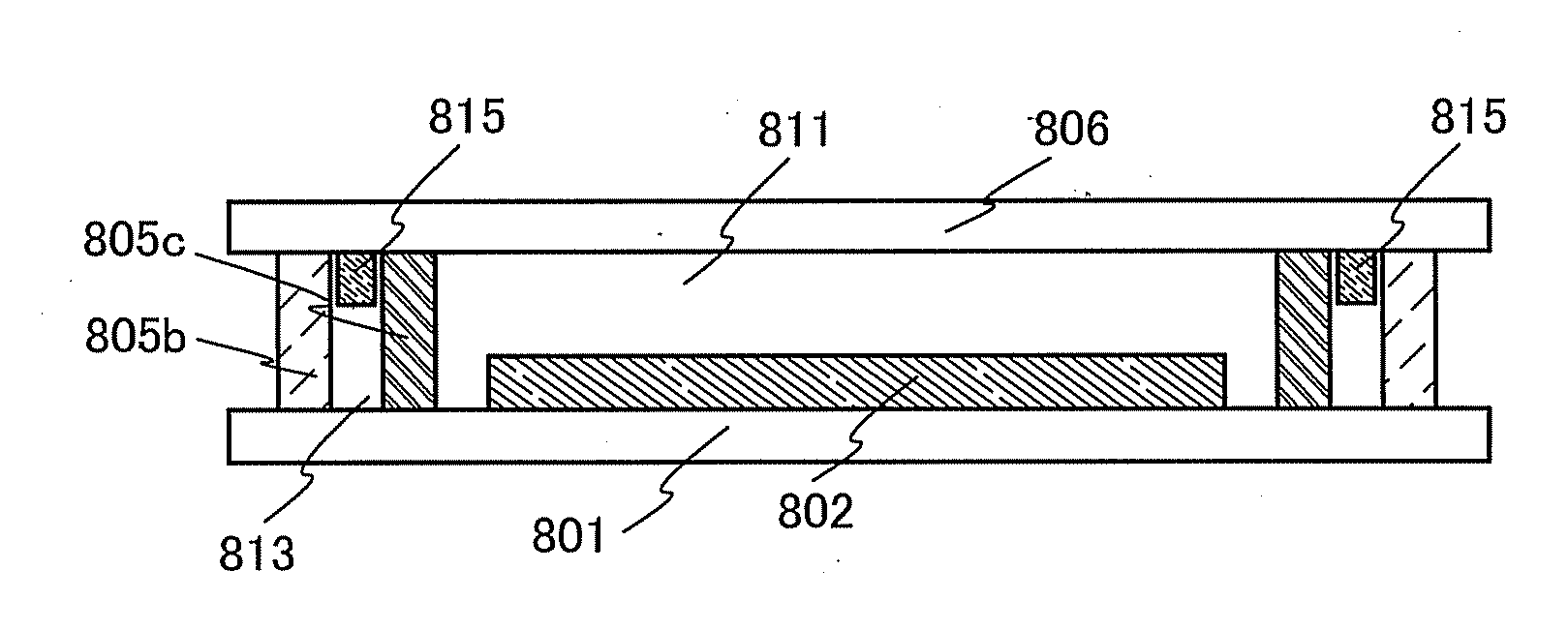

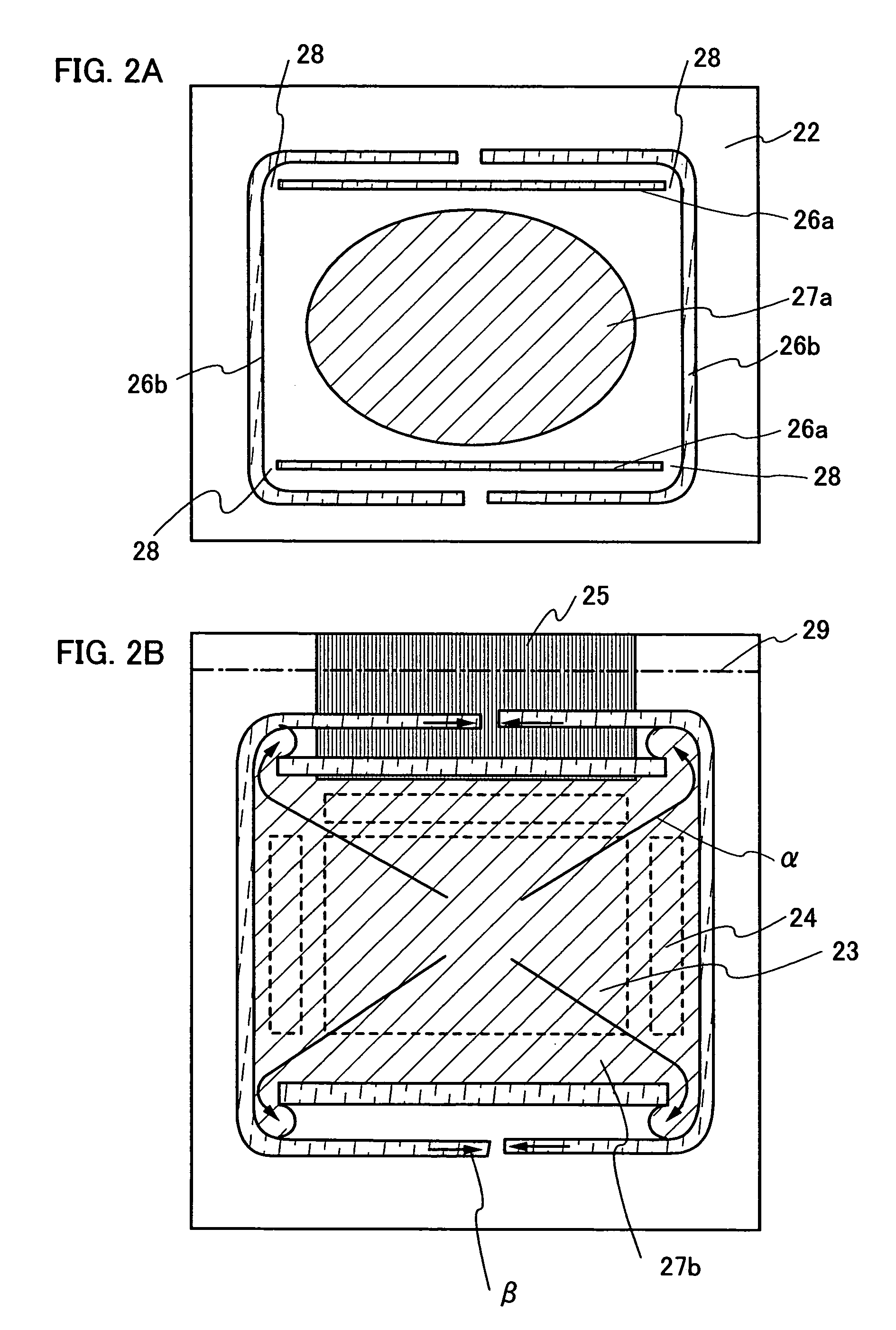

Light emitting device and method for manufacturing the same

ActiveUS20050040762A1Decrease in luminanceSolution to short lifeDischarge tube luminescnet screensElectroluminescent light sourcesEngineeringSealant

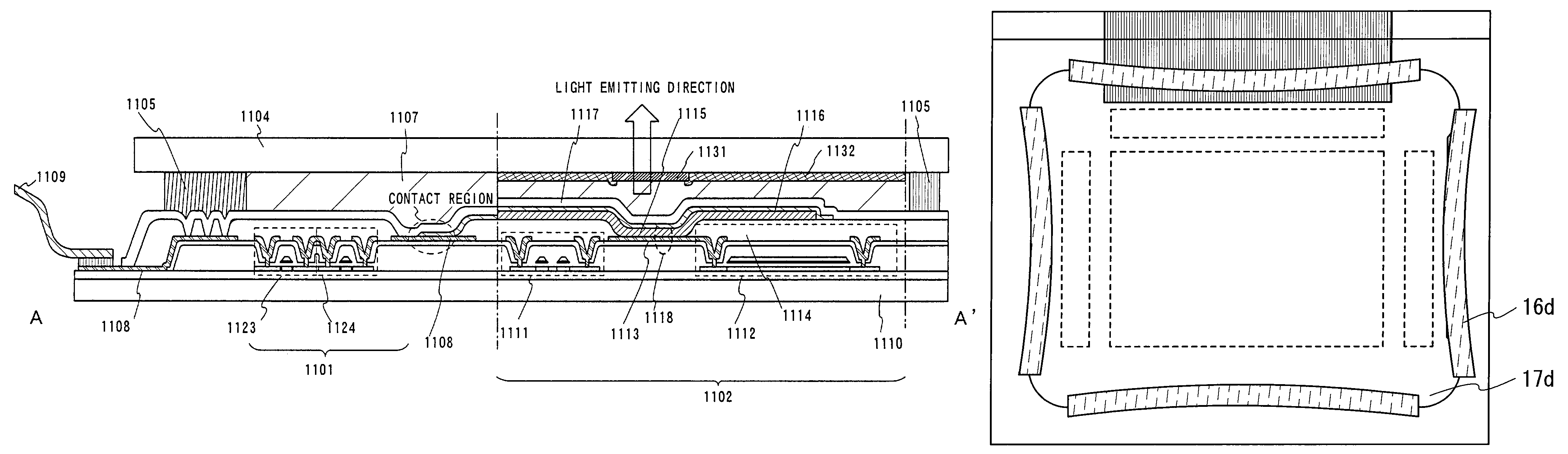

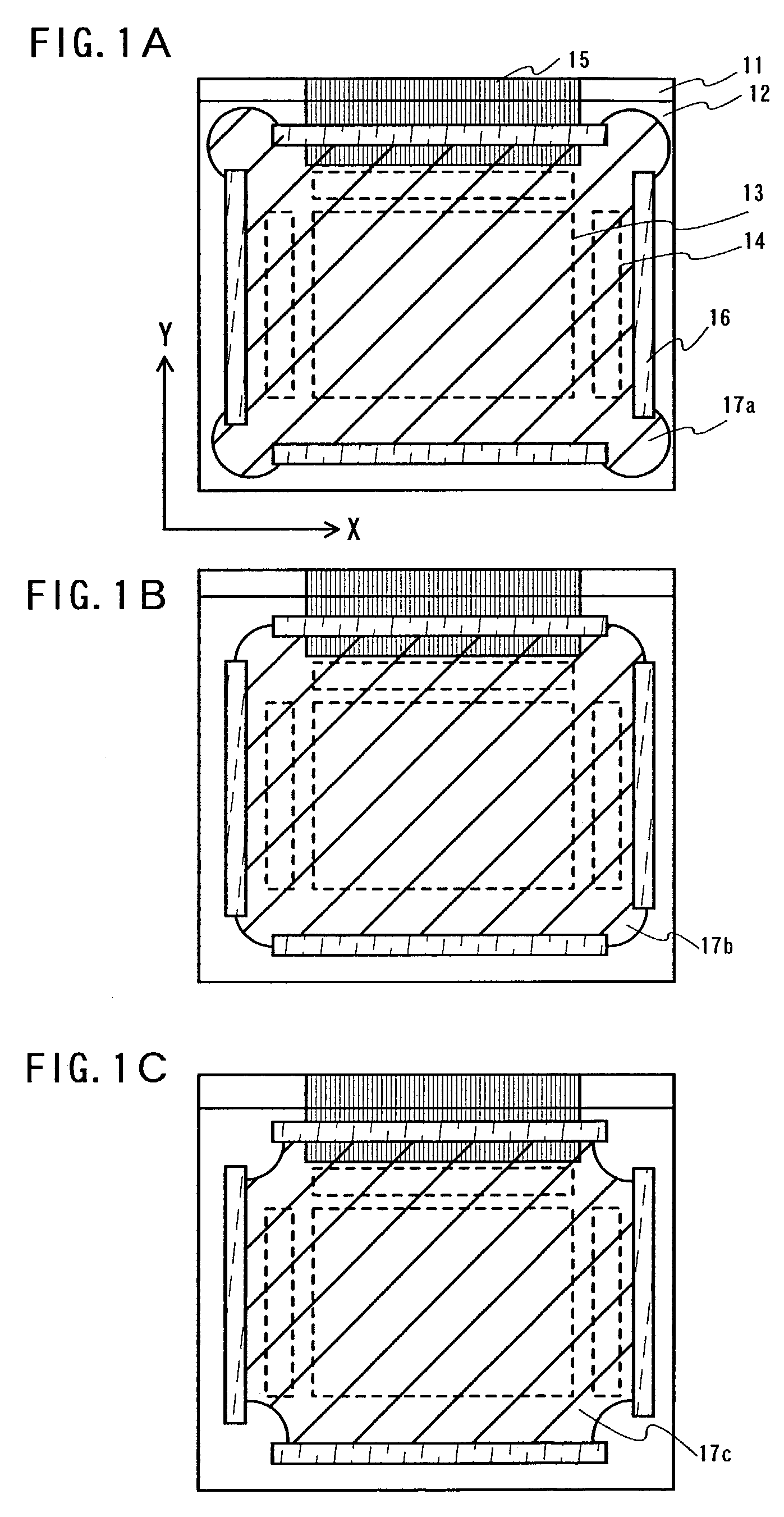

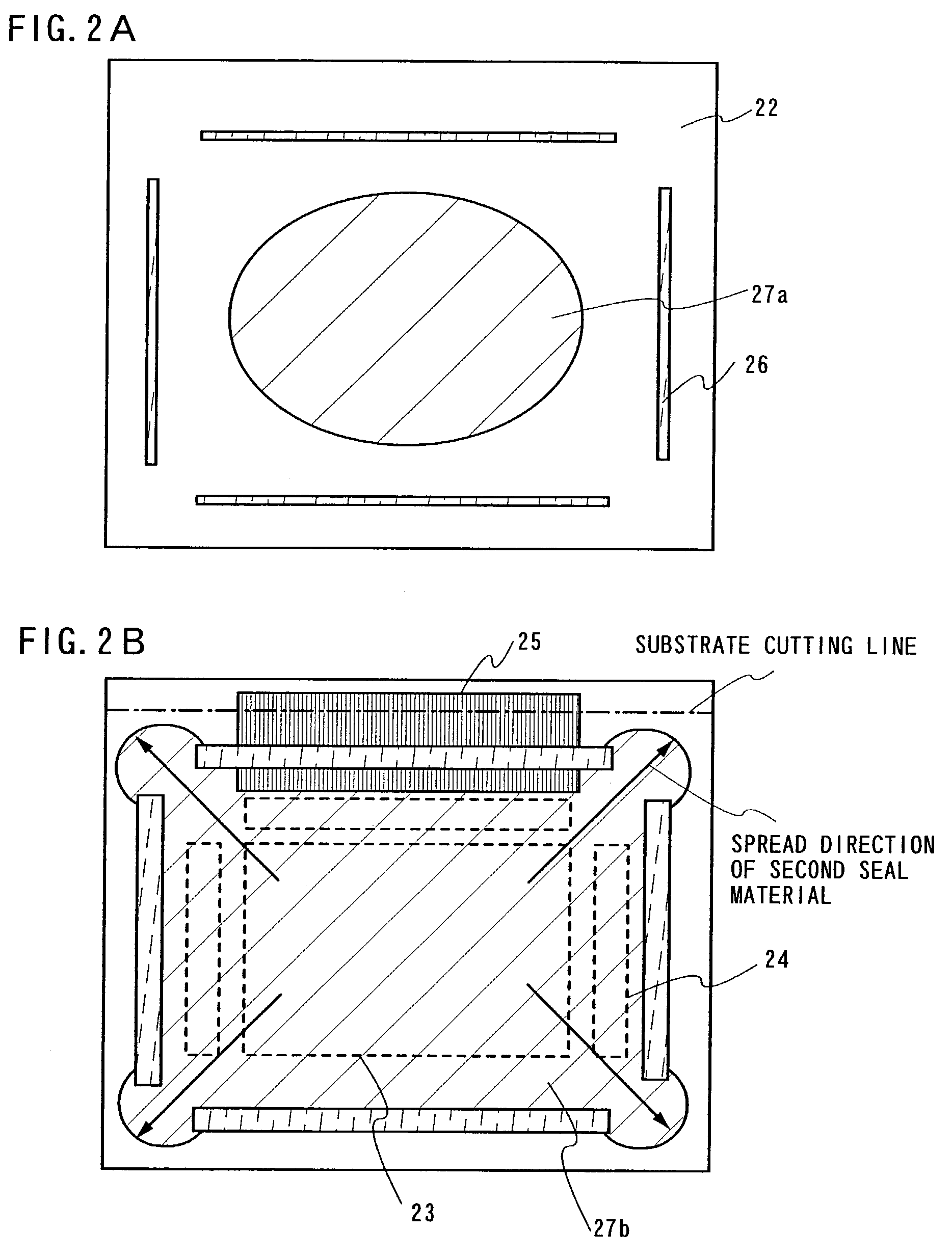

When attaching a substrate with an EL element formed thereon and a transparent sealing substrate, the periphery of a pixel portion is surrounded with a first sealing agent that maintains a gap between the two pieces of substrates, an entire surface of the pixel portion is covered with a second transparent sealing agent so that the two pieces of substrate is fixed with the first sealing agent and the second sealing agent. Consequently, the EL element can be encapsulated by curing the first sealing agent and the second sealing agent without enclosing a drying agent and doing damage to the EL element due to UV irradiation even when a sealing device only having a function of UV irradiation is used.

Owner:SEMICON ENERGY LAB CO LTD

Light-Emitting Device, Electronic Device, Lighting Device, and Method for Manufacturing the Light-Emitting Device

ActiveUS20130048967A1DeteriorationReduce pressureElectroluminescent light sourcesSolid-state devicesDrying AgentsEngineering

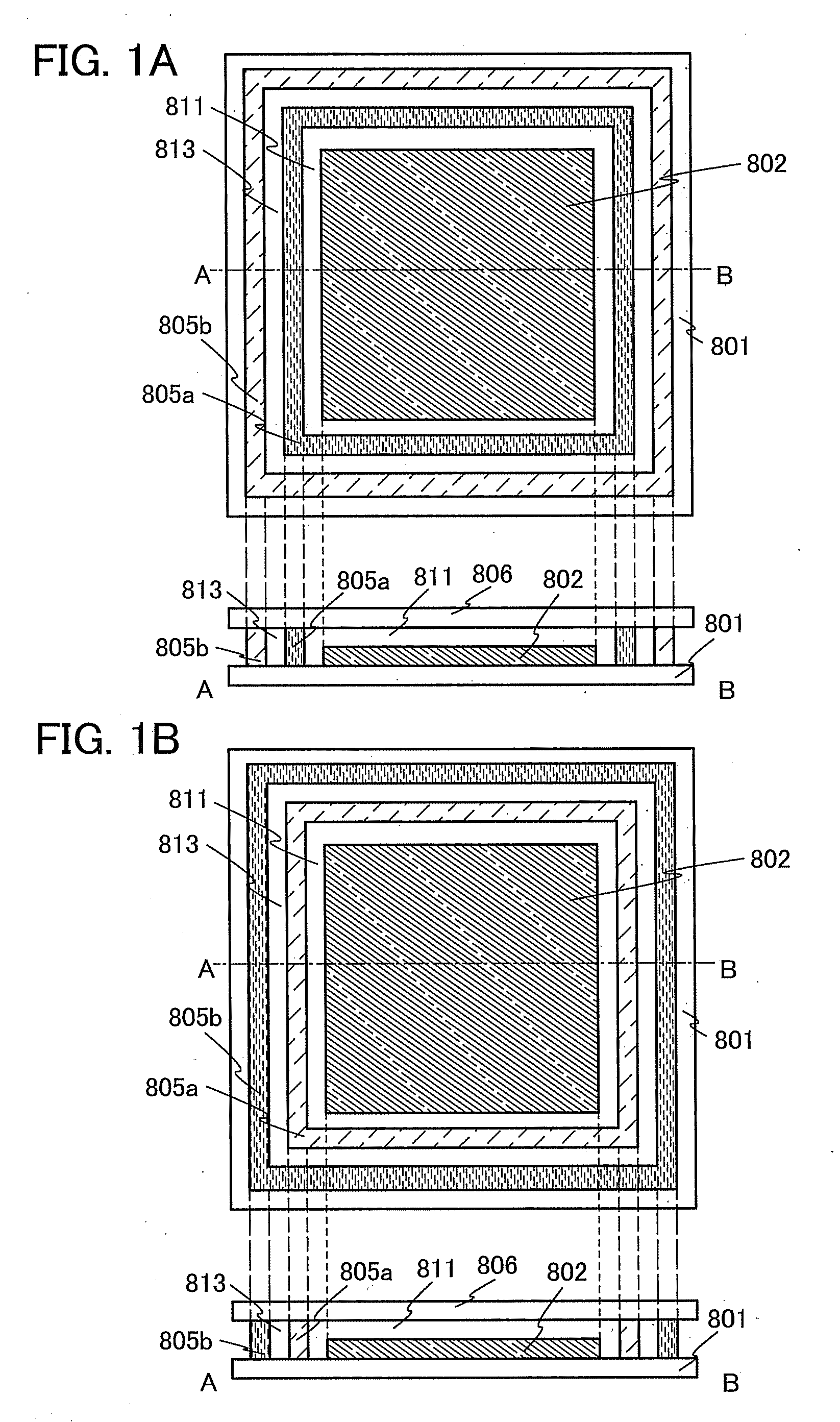

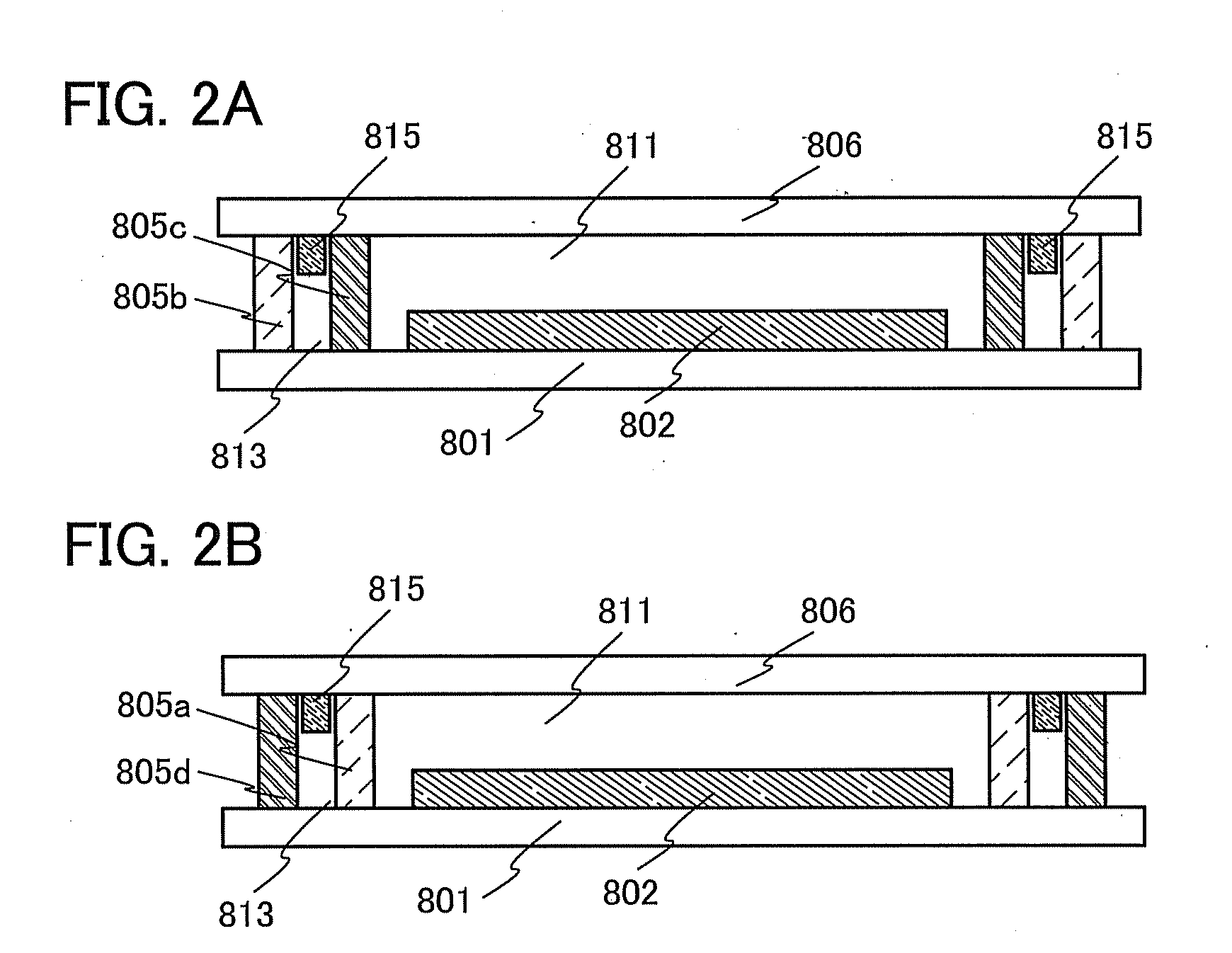

A light-emitting device in which deterioration of an organic EL element due to impurities such as moisture or oxygen is suppressed is provided. The light-emitting device includes a first substrate and a second substrate facing each other, a light-emitting element provided over the first substrate, a first sealant provided so as to surround the light-emitting element, and a second sealant provided so as to surround the first sealant. One of the first sealant and the second sealant is a glass layer and the other is a resin layer. A dry agent is provided in a first space surrounded by the first sealant, the second sealant, the first substrate, and the second substrate, or in the resin layer. The light-emitting element is included in a second space surrounded by the first sealant, the first substrate, and the second substrate.

Owner:SEMICON ENERGY LAB CO LTD

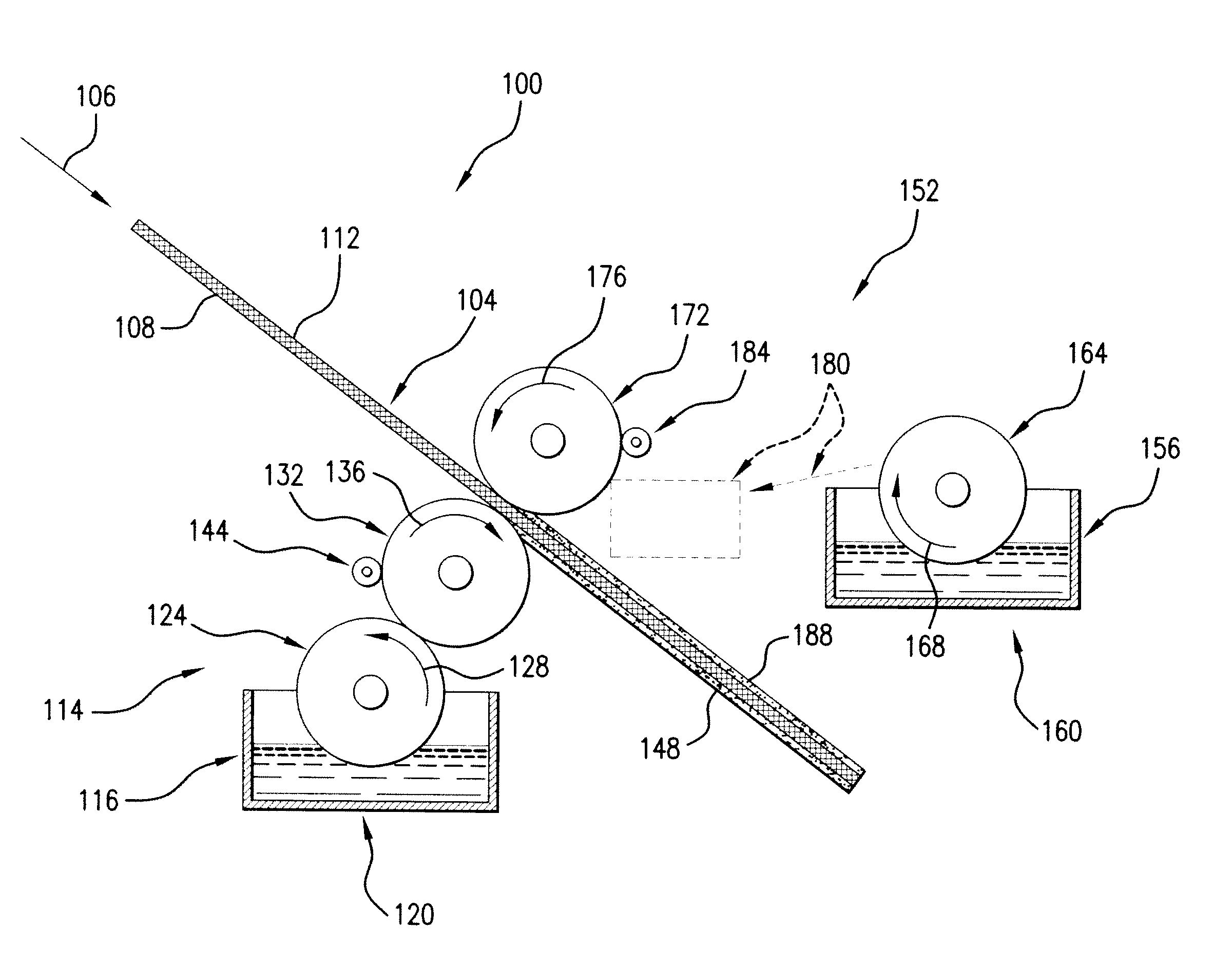

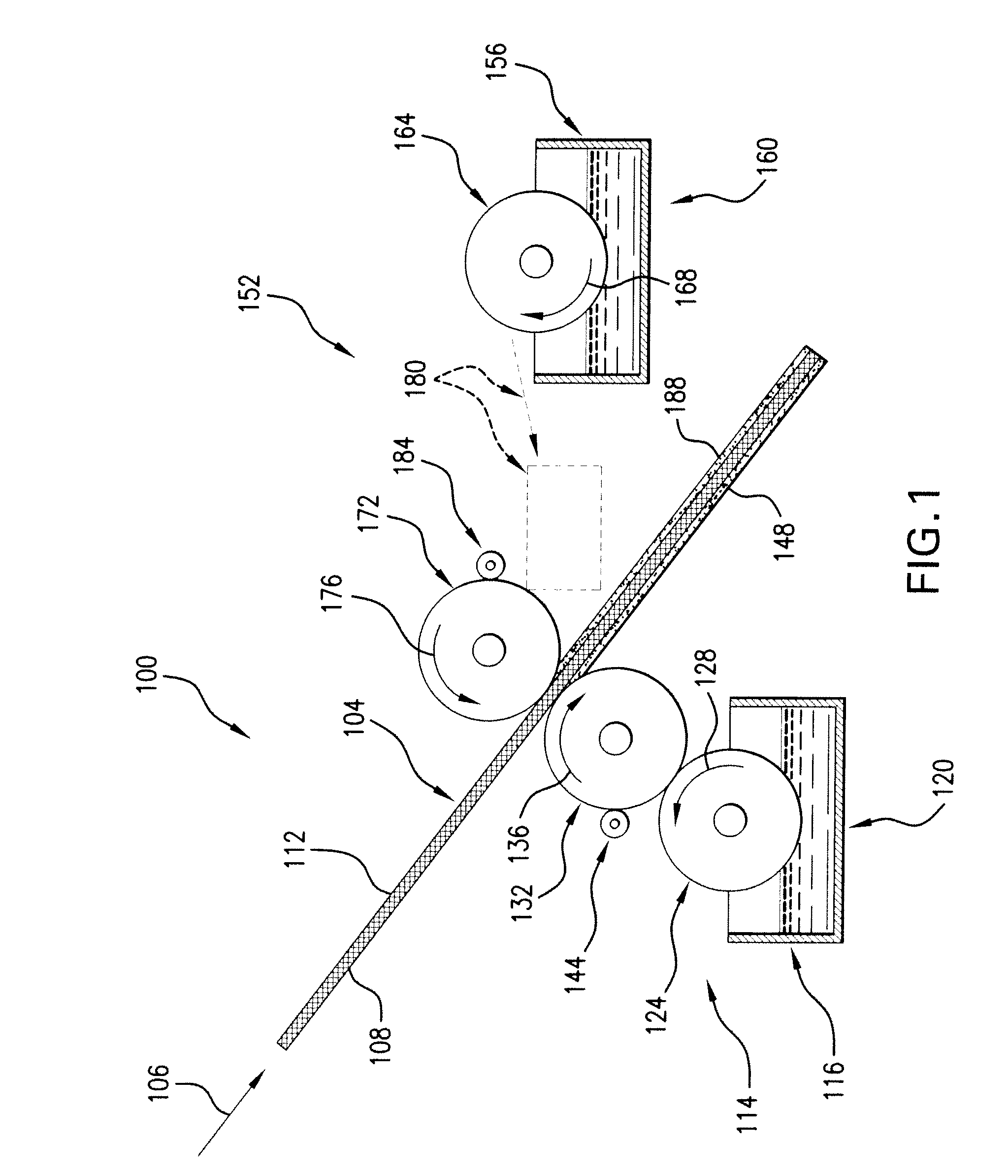

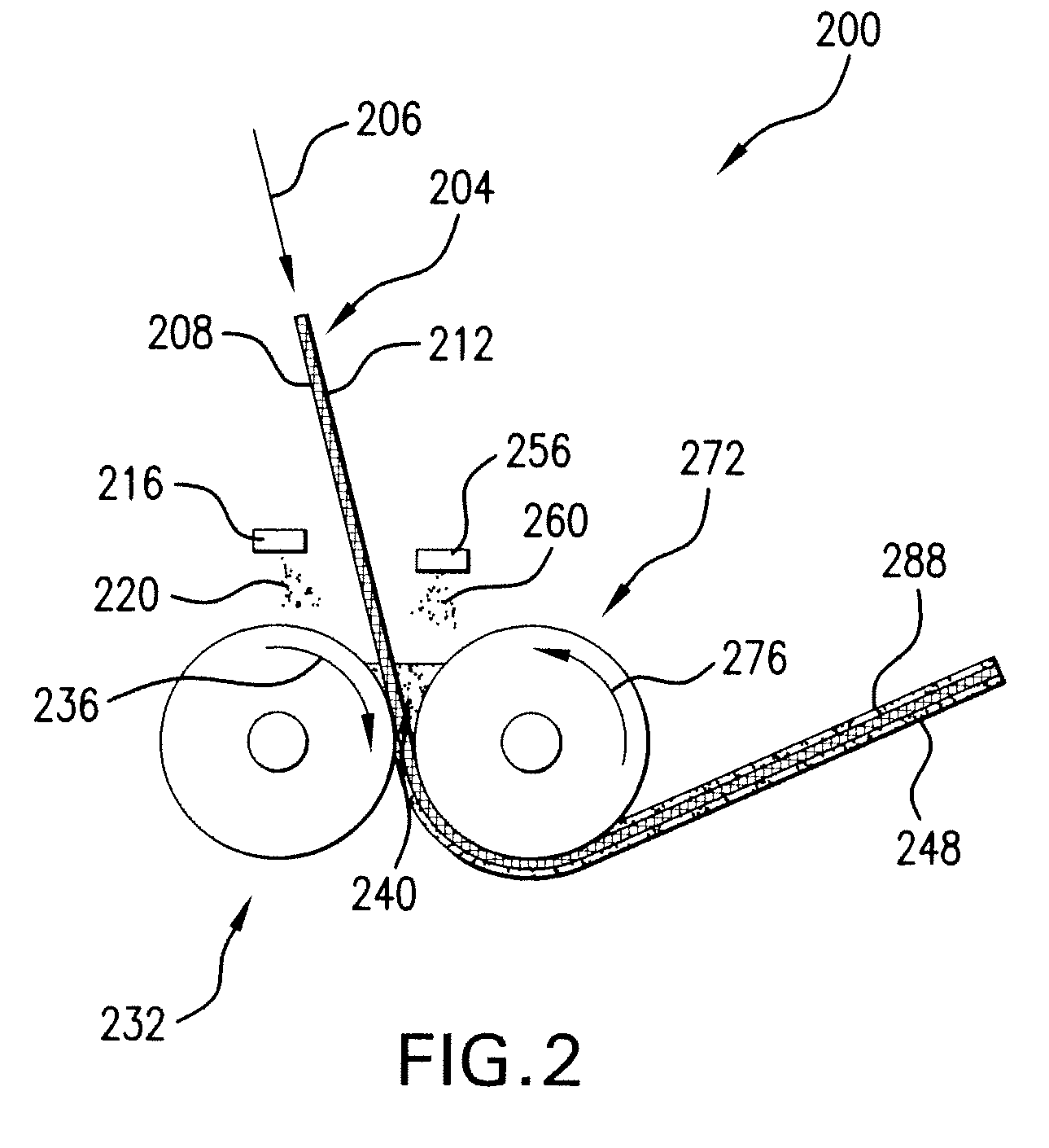

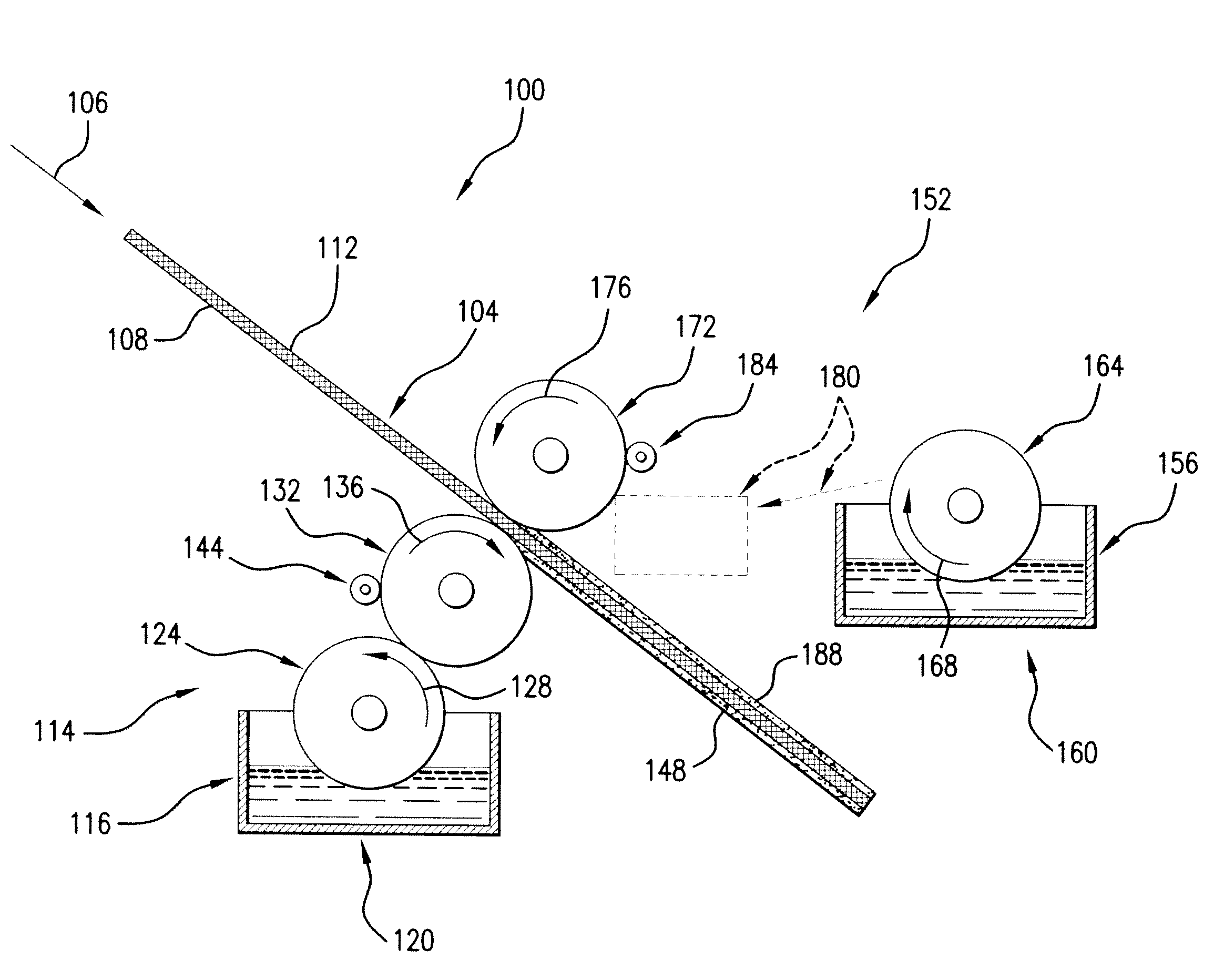

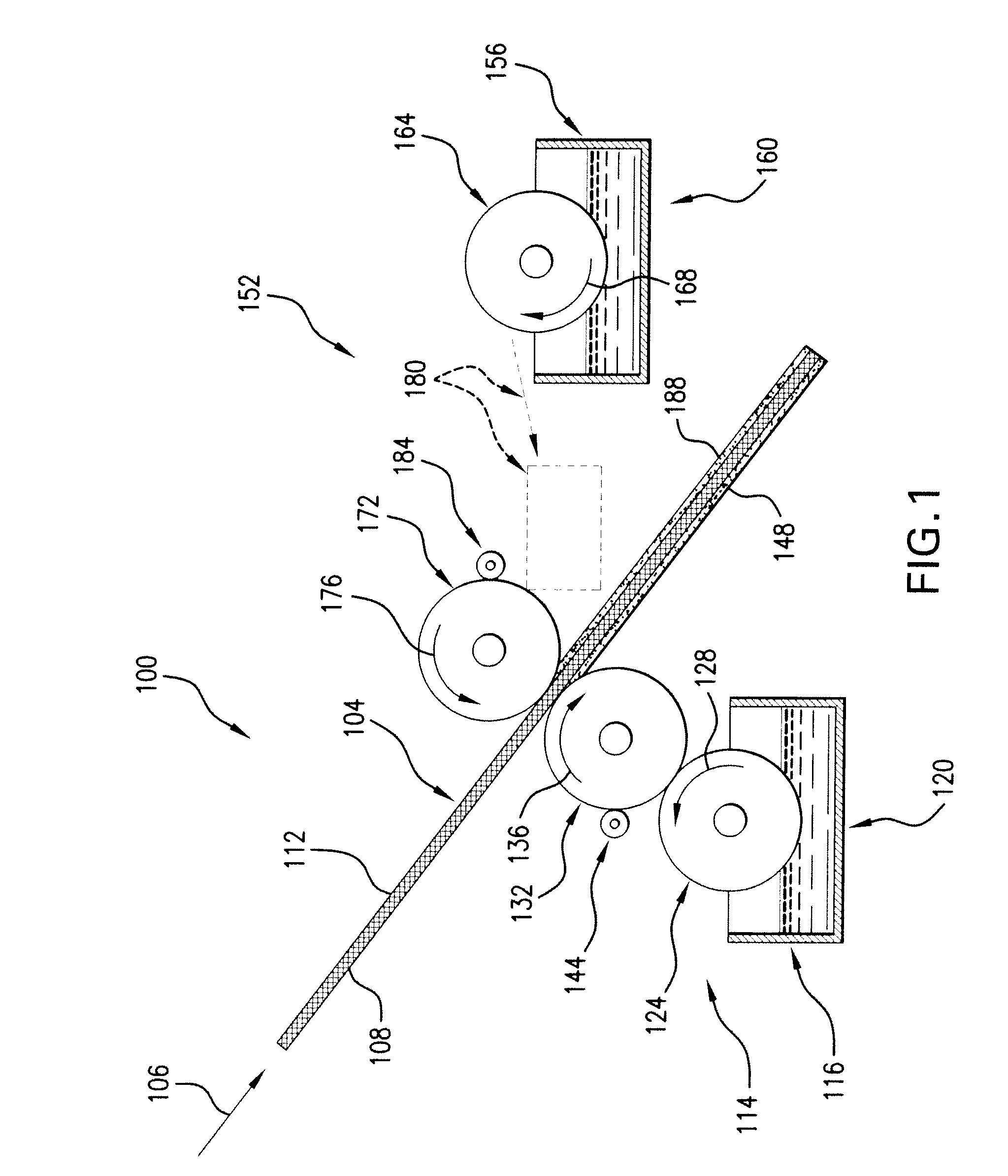

Fast dry coated inkjet paper

Disclosed are a coating composition, coated article, and a method for treating one or more sides of the printable web with the composition, for providing improved printing ink dry time and gloss. The coating composition comprises: a calcium carbonate pigment component comprising a mixture high and low surface area calcium carbonate pigment; a metal salt drying agent; and a cationic dye fixing agent; a pigment binder; optionally a plastic pigment; and optionally an optical brightener; and which provides: a solids content of at least about 25%; a ratio of high to low surface area calcium carbonate in the range of from about 0.5:1 to about 20:1; and a ratio of calcium carbonate pigment component to pigment binder in the range of from about 4:1 to about 50:1.

Owner:GLOBAL HLDG II INC

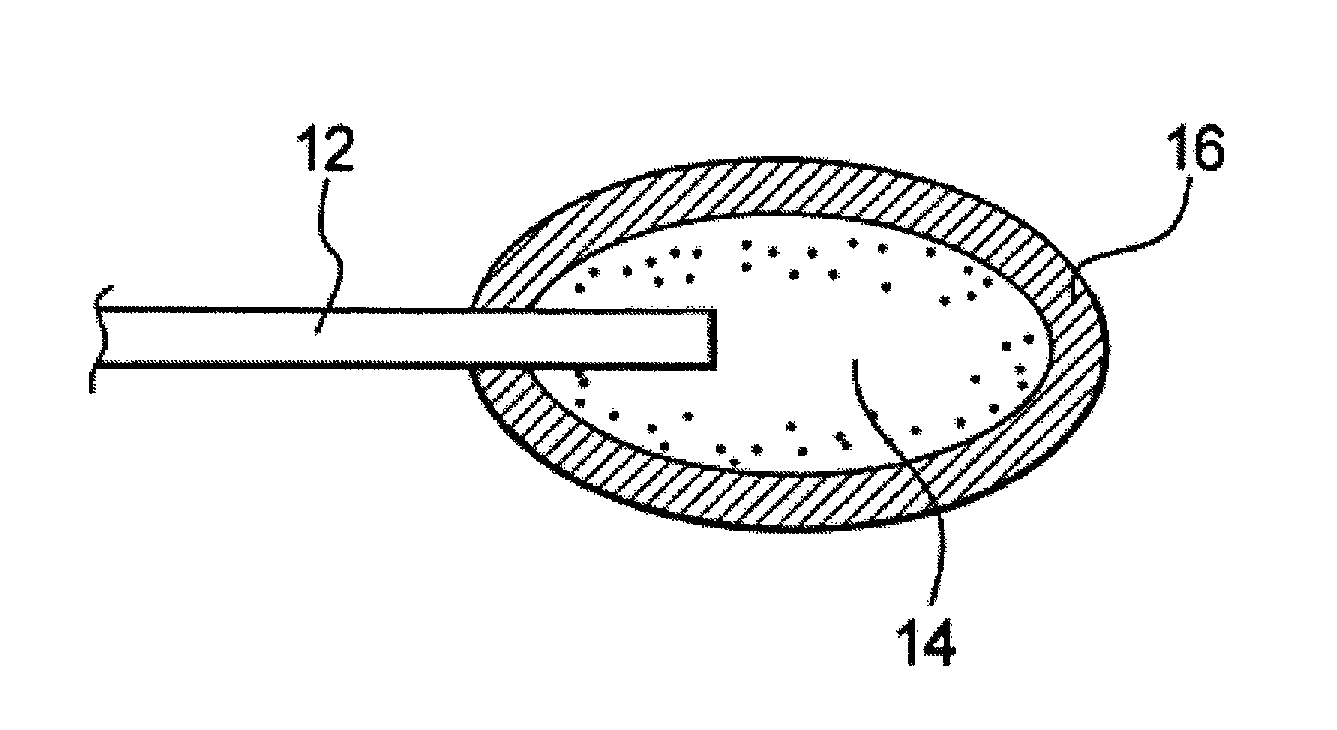

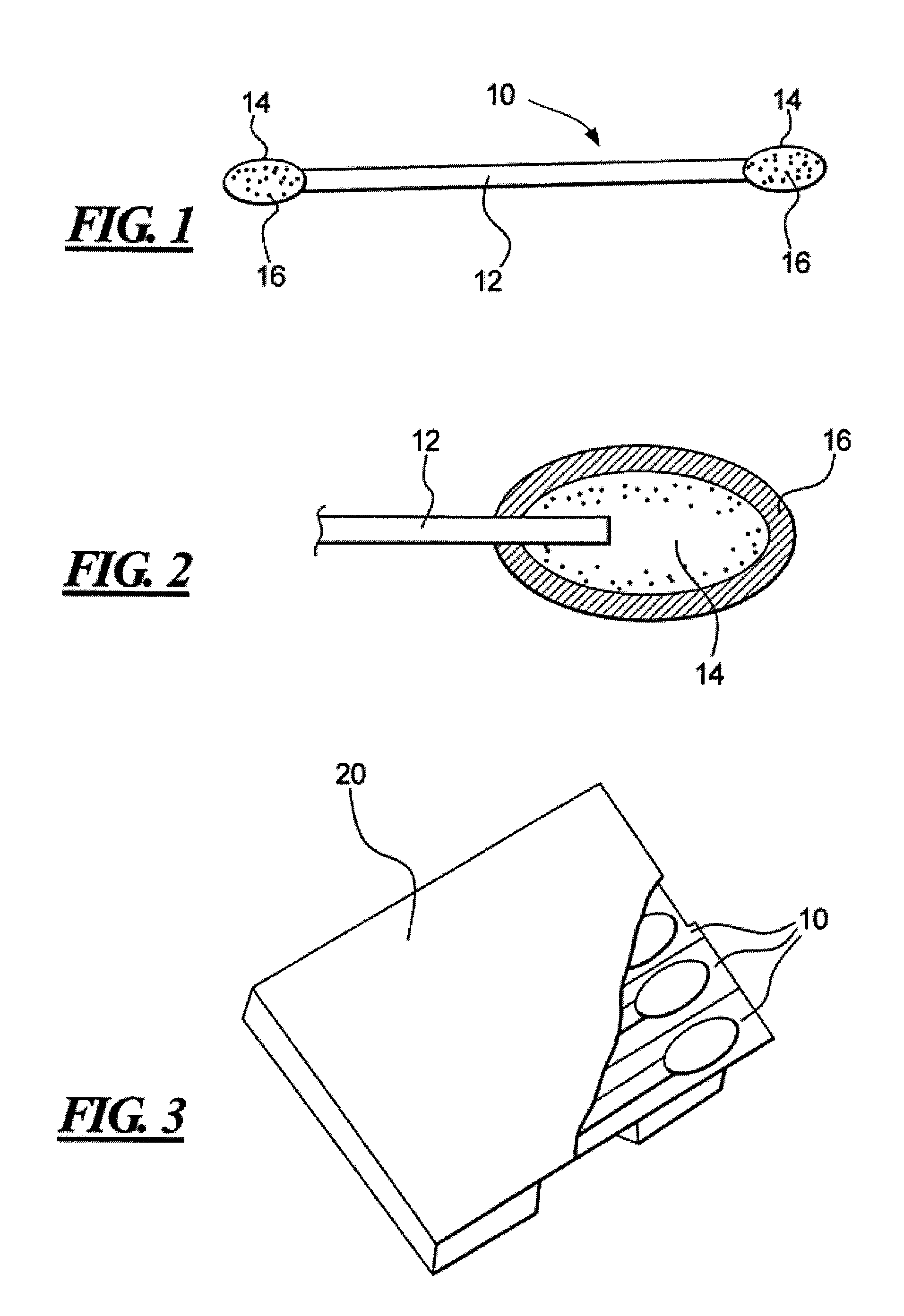

Prepared medication applicator including a swab and a pharmacological active agent

A disposable swab tipped medication applicator containing one or more pharmacologically active agents in an anhydrous crystalline or powdered form at the swab. A method for use of the swab tipped applicator provides for delivery the pharmacological agent(s) to an area of the skin, such as the external auditory canal, preferably after showering or bathing, so that the dry agent is dampened so as to treat conditions of the skin. A package of the prepared applicators is provided in one embodiment, while in another embodiment applicators having two different medicaments are provided in a single package for treatment of a condition.

Owner:VAN ACKER TED GERARD

Water industrial paint based on organosilicon acrylic acid epoxy ester water dispersion and preparation method thereof

InactiveCN1927968AImprove corrosion resistanceGood physical propertiesEmulsion paintsEpoxyDefoaming Agents

The present invention provides one kind of water thinned industrial paint based on water dispersed organosilicon epoxy acrylate. The water thinned industrial paint is prepared with water dispersed organosilicon epoxy acrylate, inert antirust pigment, active antirust pigment, nanometer material modified antirust pigment, stuffing, dispersant, wetting agent, thickener, drying agent, mildew inhibitor, preservative, defoaming agent, deionized water and other materials. The water thinned industrial paint with water dispersed organosilicon epoxy acrylate as base material can form coating with the features of high mechanical strength and high anticorrosive performance similar to that of epoxy resin as well as the features of high weather resistance and good decoration performance like acrylate resin. The water thinned industrial paint has convenient use and wide application range.

Owner:广州市允升环保科技有限公司

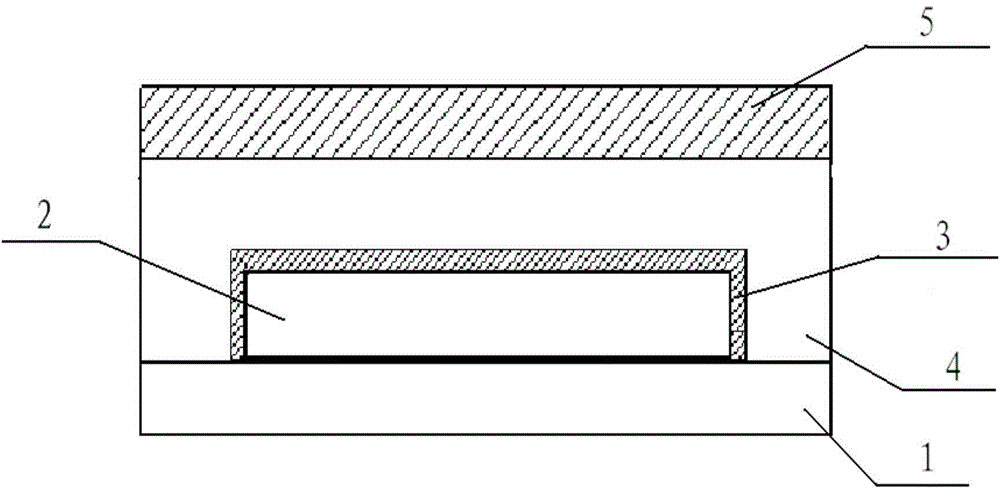

OLED device encapsulation structure

The invention relates to the encapsulation technical field, and discloses an OLED device encapsulation structure. The OLED device encapsulation structure comprises an upper substrate and a lower substrate, wherein the upper substrate and the lower substrate are arranged opposite to each other. An OLED device is arranged on the lower substrate, and an encapsulation thin film is arranged on the OLED device. The edge of the lower substrate is connected with the edge of the upper substrate in a sealed mode through a retaining wall. The edge of the side, facing the upper substrate, of the lower substrate is provided with a groove. The end, connected with the lower substrate, of the retaining wall is located in the groove of the lower substrate, and the periphery of the encapsulation thin film is sealed in the groove of the lower substrate through the retaining wall. The periphery of the encapsulation thin film is located in the groove formed in the edge of the lower substrate and is sealed in the groove through the retaining wall, a cavity between the upper substrate and the encapsulation thin film is filled with nitrogen or inert gas or resin or drying agents and the like to reduce water vapor and oxygen making contact with the encapsulation thin film, therefore, the influence of the water vapor and oxygen on the OLED device is lowered, and the service life of the OLED device is prolonged.

Owner:BOE TECH GRP CO LTD

Light emitting device and method for manufacturing the same

ActiveUS7109655B2Avoid problemsLarge heightDischarge tube luminescnet screensElectroluminescent light sourcesSealantIrradiation

When attaching a substrate with an EL element formed thereon and a transparent sealing substrate, the periphery of a pixel portion is surrounded with a first sealing agent that maintains a gap between the two pieces of substrates, an entire surface of the pixel portion is covered with a second transparent sealing agent so that the two pieces of substrate is fixed with the first sealing agent and the second sealing agent. Consequently, the EL element can be encapsulated by curing the first sealing agent and the second sealing agent without enclosing a drying agent and doing damage to the EL element due to UV irradiation even when a sealing device only having a function of UV irradiation is used.

Owner:SEMICON ENERGY LAB CO LTD

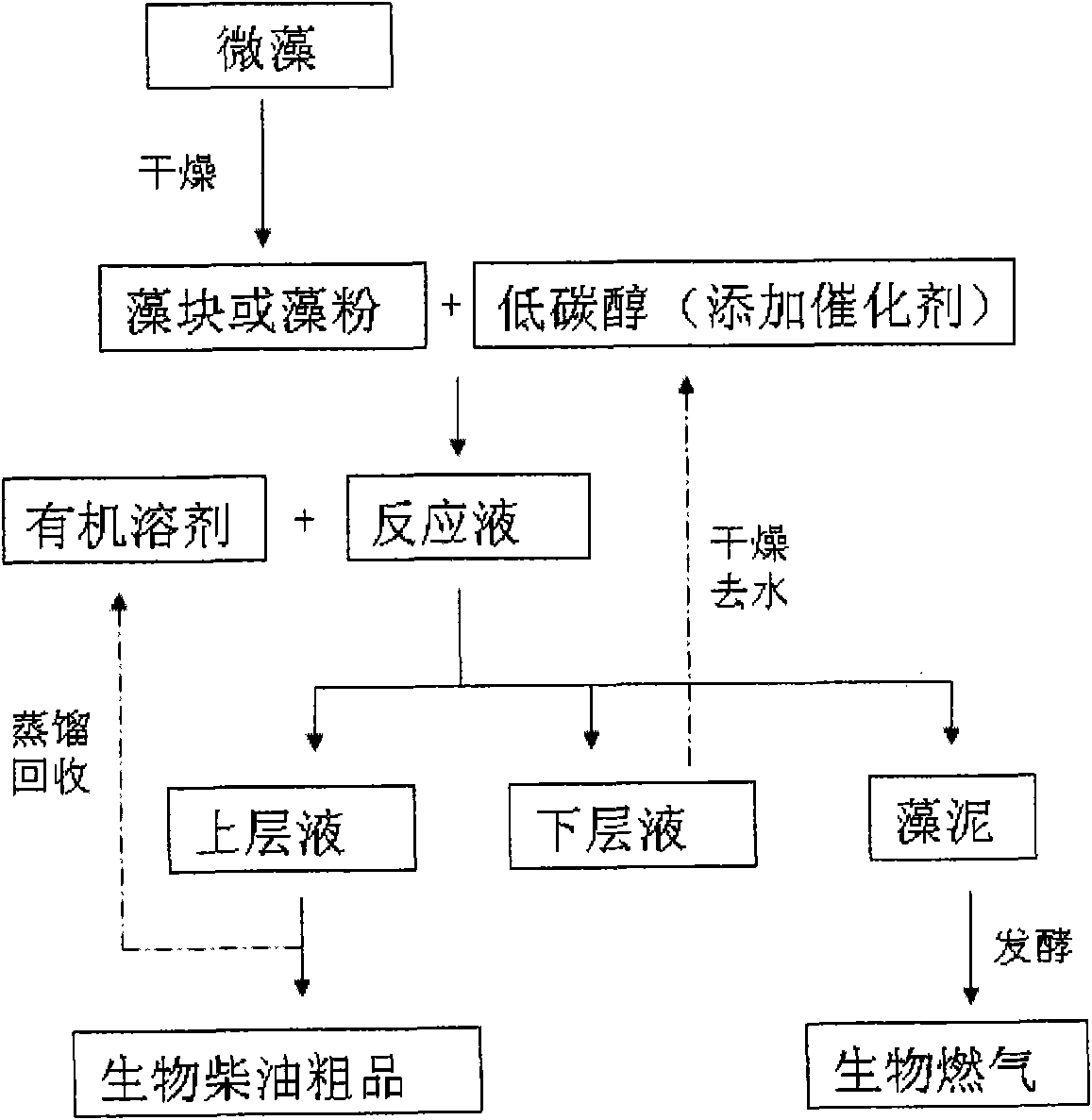

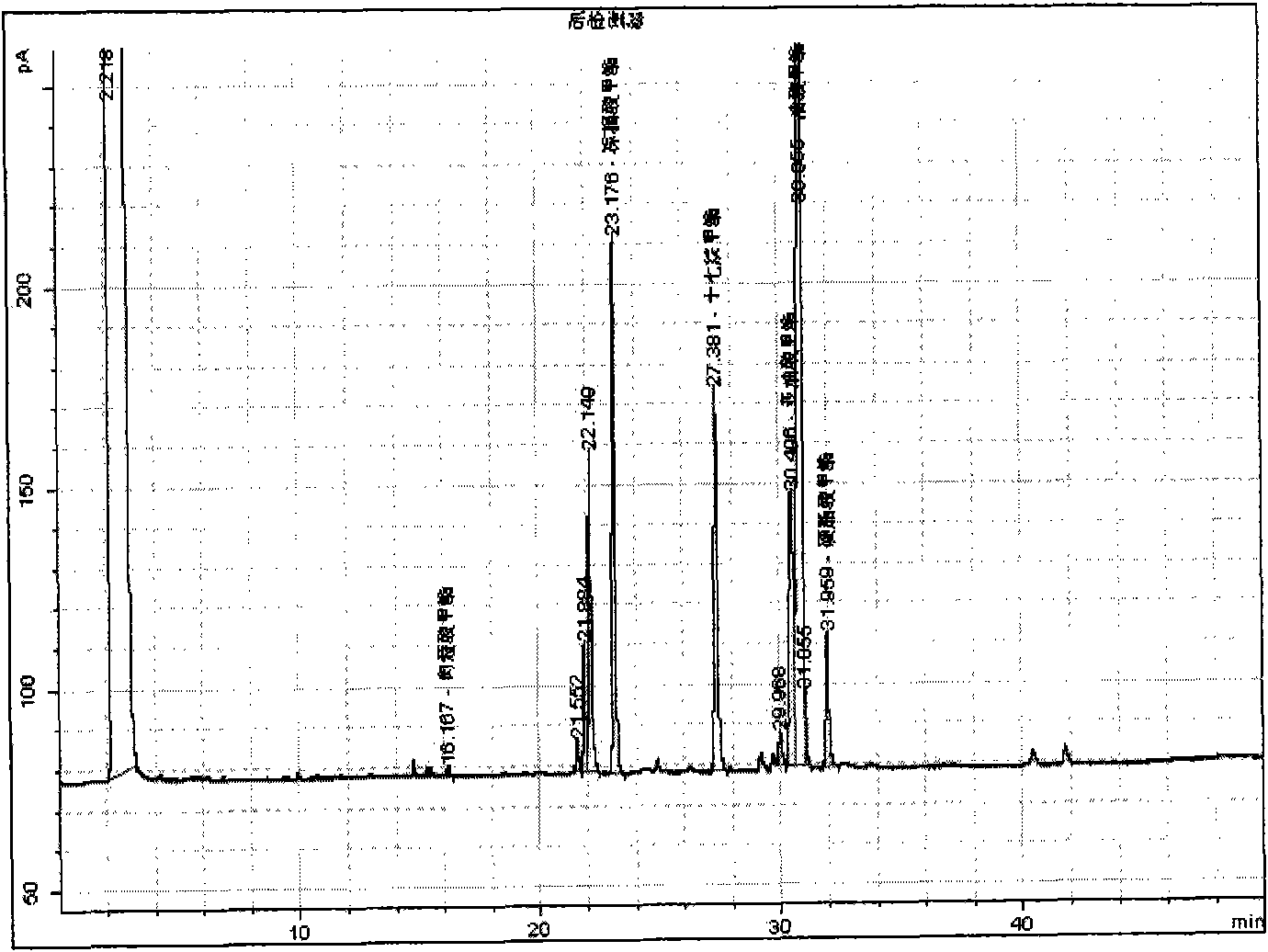

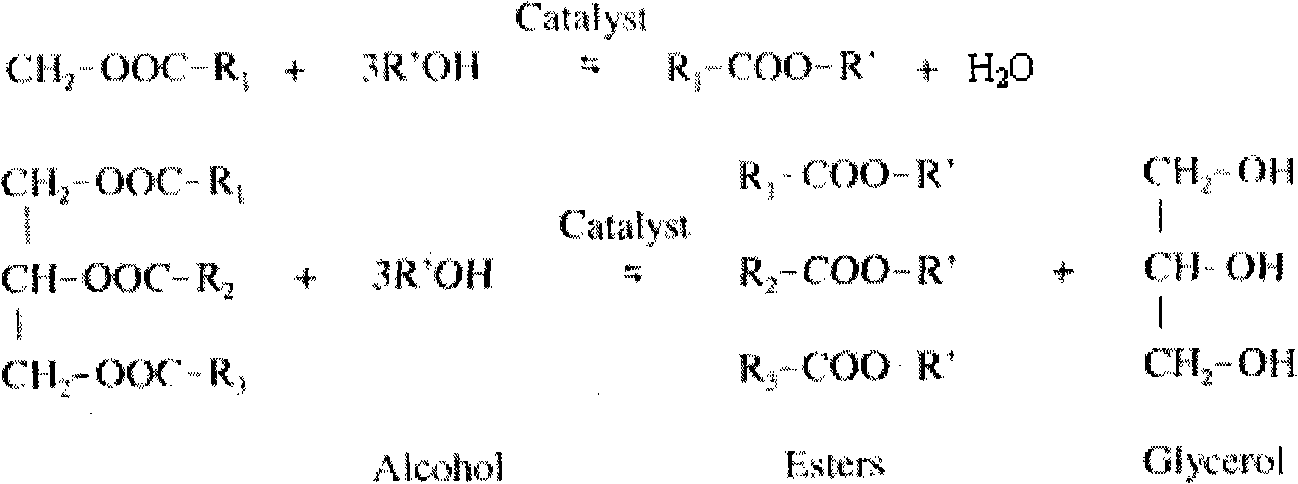

Biomass energy prepared by one-step method of microalgae

ActiveCN101580857AWon't happenRelieve pressurePreparation by ester-hydroxy reactionBiofuelsDownstream processingBiodiesel

The invention provides a method for preparing biodiesel from microalgae. The method comprises the following steps of: a. changing collected microalgae from the wet algae into algae block or algae powder; b. mixing a catalyst into low-carbon alcohol, directly adding the algae block or the algae powder obtained by the step a, and carrying out ester exchange reaction to prepare the biodiesel; c. after the reaction is stopped, adding an organic solvent for extracting reaction solution which is divided into organic solvent phase used for extraction, low-carbon alcohol water-adding phase and algae mud; and d. after the extraction is completed, collecting the organic solvent phase used for extraction, removing the organic solvent by distillation, and obtaining oily liquid, namely crude products of the biodiesel. After preparing the biodiesel, the steps that the low-carbon alcohol water-adding phase is used circularly after dewatered by a solid drying agent, and the produced algae mud is used for producing biogas by biological fermentation are added. The invention completes the oil extraction of microalgae and biodiesel production by one step, simplifies the technique steps and equipment, saves cost; the sulphuric acid and low-carbon alcohol used for production can be recovered, then dewatered by drying, then utilized repeatedly, the cost is reduced, the final product is neutral, does not need washing and reduces the downstream processing pressure; and simultaneously, chlorophyll is mainly concentrated in the low-carbon alcohol, reduces the interference of the chlorophyll to the color of the product and does not need the step of decoloring.

Owner:ENN SCI & TECH DEV

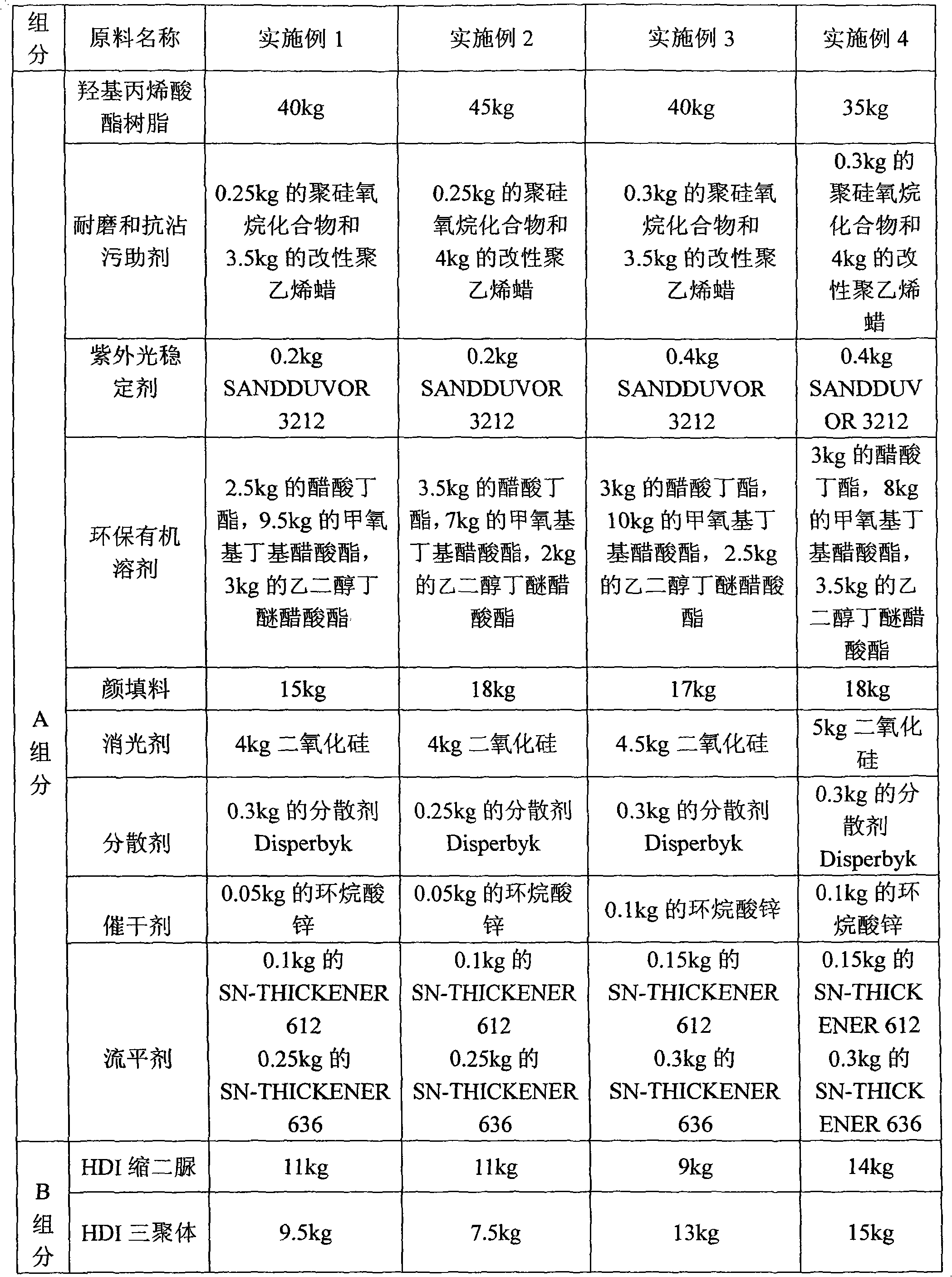

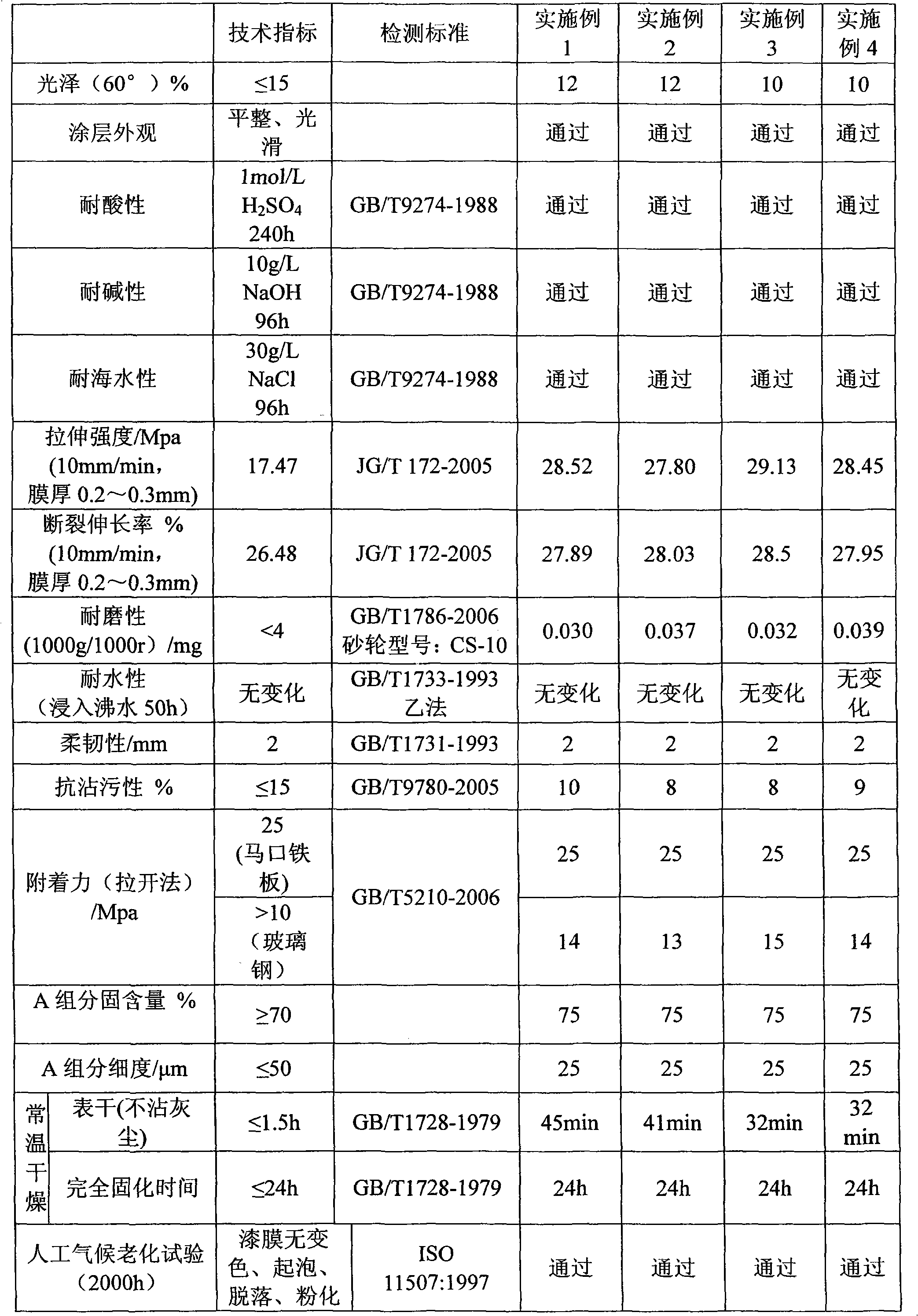

Protective coating for aerogenerator vanes and preparation method thereof

InactiveCN101613564AGood weather resistanceStrong UV resistanceMachines/enginesPolyurea/polyurethane coatingsOrganic solventPliability

The invention relates to a protective coating for aerogenerator vanes and a preparation method thereof, wherein the protective coating has the advantages of excellent ultraviolet radiation resistance, abrasion resistance, stain resistance, corrosion resistance, adhesive force and flexibility. The preparation method uses hydroxyl acrylate resin as a base material of the surface protective coating for the aerogenerator vanes and uses the mixture of HDI biuret and HDI tripolymer as a curing agent. The coating consists of a component A and a component B, wherein the component A comprises the following materials in portion by weight: 10 to 55 portions of the hydroxyl acrylate resin, 1 to 5 portions of abrasion resistant and stain resistant auxiliary agent, 0.2 to 0.4 portion of ultraviolet stabilizer, 10 to 15 portions of environment-friendly organic solvent, 15 to 20 portions of pigments and fillers, 2 to 5 portions of delustering agent, 0.15 to 0.55 portion of dispersing agent, 0.01 to 0.3 portion of drying agent, and 0.25 to 0.55 portion of levelling agent; the component B comprises 1 to 15 portions of the HDI biuret and 1 to 15 portions of the HDI tripolymer; and the mass ratio of the component A to the component B is 2-6:1. When in use, the components A and B are mixed and stirred evenly in proportion, and then the mixture is adjusted to proper viscosity for construction by using a spraying method.

Owner:SOUTHEAST UNIV

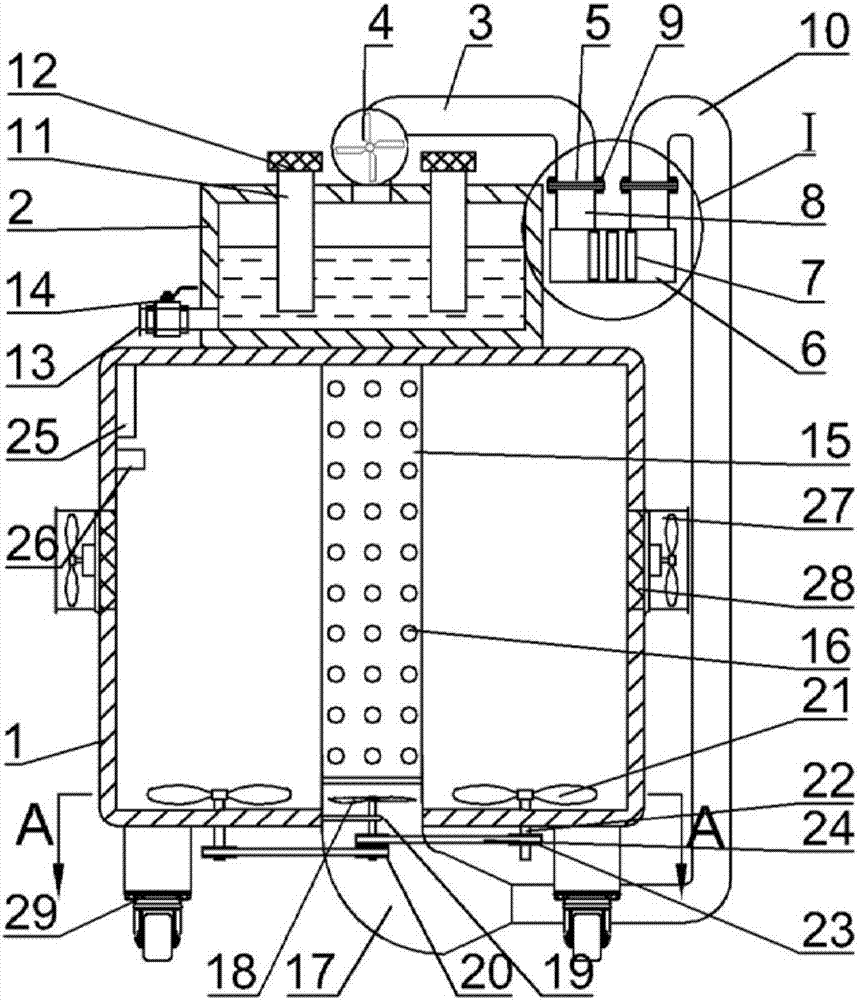

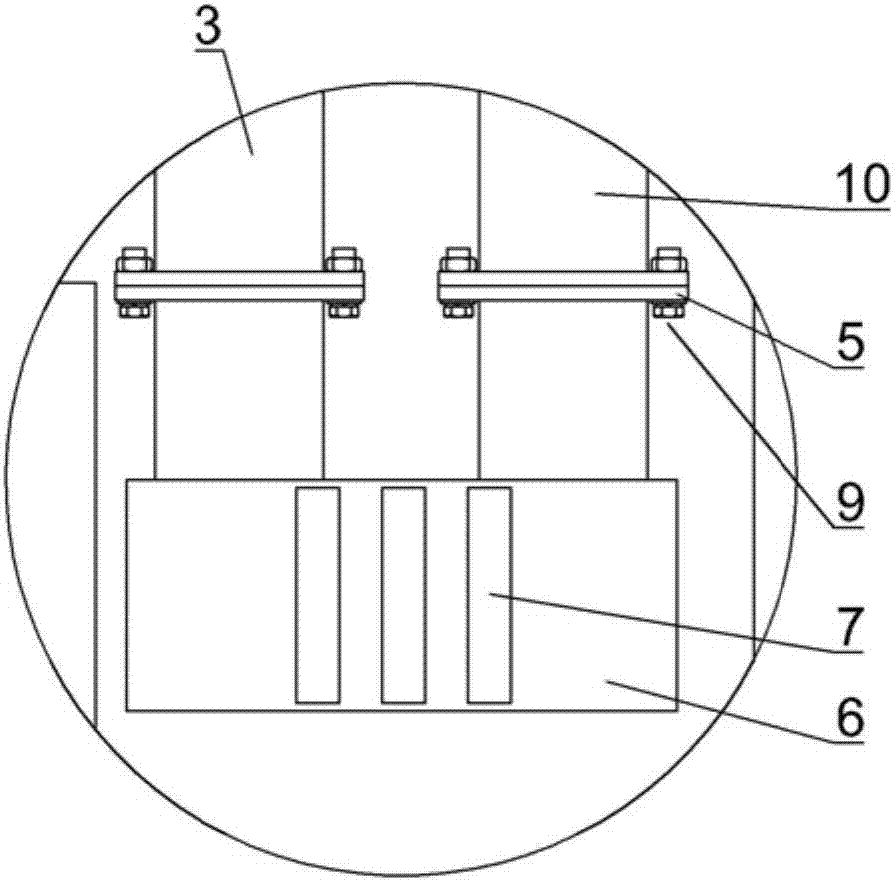

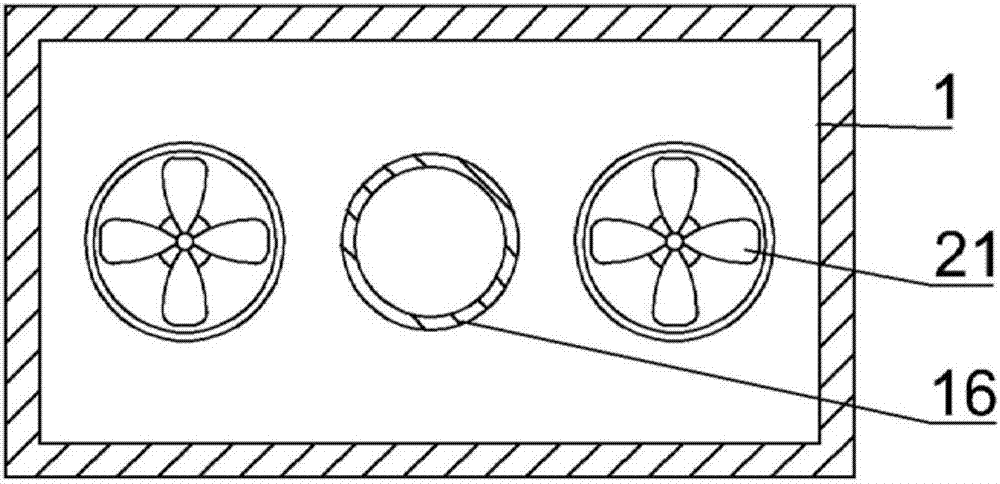

Dustproof and heat radiation type electric power equipment power distribution cabinet

ActiveCN106972382AImprove cooling efficiencyQuick releaseSubstation/switching arrangement cooling/ventilationSubstation/switching arrangement casingsImpellerElectric power equipment

The invention discloses a dustproof and heat radiation type electric power equipment power distribution cabinet comprising a cabinet body, a heat radiation blower, a negative pressure blower, a water tank and a drying agent placing box. The water tank is fixedly connected on the upper part of the cabinet body. The negative pressure blower is fixedly connected in the middle of the upper side wall body of the water tank. The air inlet end of the negative pressure blower is fixedly communicated with the upper side wall body of the water tank. The output end of the negative pressure blower is fixedly communicated with an output pipe. The beneficial effects of the dustproof and heat radiation type electric power equipment power distribution cabinet are that when a temperature sensor in the cabinet body senses certain temperature, the negative pressure blower is enabled to be electrified and started, and the air is secondarily filtered so that the dust in the air can be effectively reduced. The drying agent placing box can be rapidly detached and installed by detaching and installing a bolt component, and cleaning is facilitated. When the drying agent requires to be replaced, the drying agent box is directly pulled out and a new drying agent box is put in so that replacing is rapid and operation is convenient. A propeller impeller is enabled to rotate by the air entering an air pipeline so that fan blades are enabled to rotate, and the heat radiation efficiency in the cabinet body can be enhanced.

Owner:珠海市万晟电气有限公司

Method for regulating dissolving speed of water-soluble film

A process for preparing the water-soluble film with regulatable soluble speed includes proportionally mixing partly alcoholzed polyvinyl alcohol, fully alcoholyzed polyvinyl alcohol, starch, plasticizer, surfactant, and drying agent at 85-95 deg.C and doctor blading. Its soluble speed can be regulated by controlling the ratio of partly alcoholyzed polyvinyl alcohol, fully alcoholyzed polyvinyl alcohol, and starch. Said film has good water soluability and bio-degradation.

Owner:郝喜海

Methods and kits for removing, treating, or preventing lice with driable pedicul ostatic agents

InactiveUS6303581B2Prevent removalImprove efficiencyBiocideCosmetic preparationsPediculus capitisMedicine

Methods and kits for removing, treating or preventing head lice infestations in patients in need of such treatment are disclosed and include topically applying to the lice-infested area an effective amount of a driable pediculostatic agent for a time sufficient to immobilize the lice, drying the agent onto the application site and removing the dried agent, thereby removing the lice and nits.

Owner:PEARLMAN DALE L

Nano-antibacterial gravure aqueous printing ink and preparation method thereof

The invention provides a nano-antibacterial gravure aqueous printing ink, comprising 65-70wt% of water-soluble resin, 15-20wt% of deionized water, 5-10wt% of aqueous organic pigment, 3-6wt% of ethanol, 1-2wt% of antiseptic, 1-2wt% of dispersant, 0-1wt% of slow drying agent, 0.5-1wt% of aqueous levelling agent, 0.5-1wt% of aqueous wax emulsion, 0.5-1wt% of organic amine, and 0.5-1wt% of antifoaming agent. The invention further provides a preparation method of the nano-antibacterial gravure aqueous printing ink. According to the invention, the problems of bad antibacterial effect, impact on people' health, environmentally unfriendly property, etc. of gravure aqueous printing inks in the prior art are overcome, and the nano-antibacterial gravure aqueous printing ink disclosed herein satisfies the idea of green circular economy, has high-efficiency antibacterial property, can effectively cut off the propagation approach of pathogens and guarantee people' health, and has good market prospect, etc.

Owner:GUANGDONG ZHUANGLI COLOR PRINTING

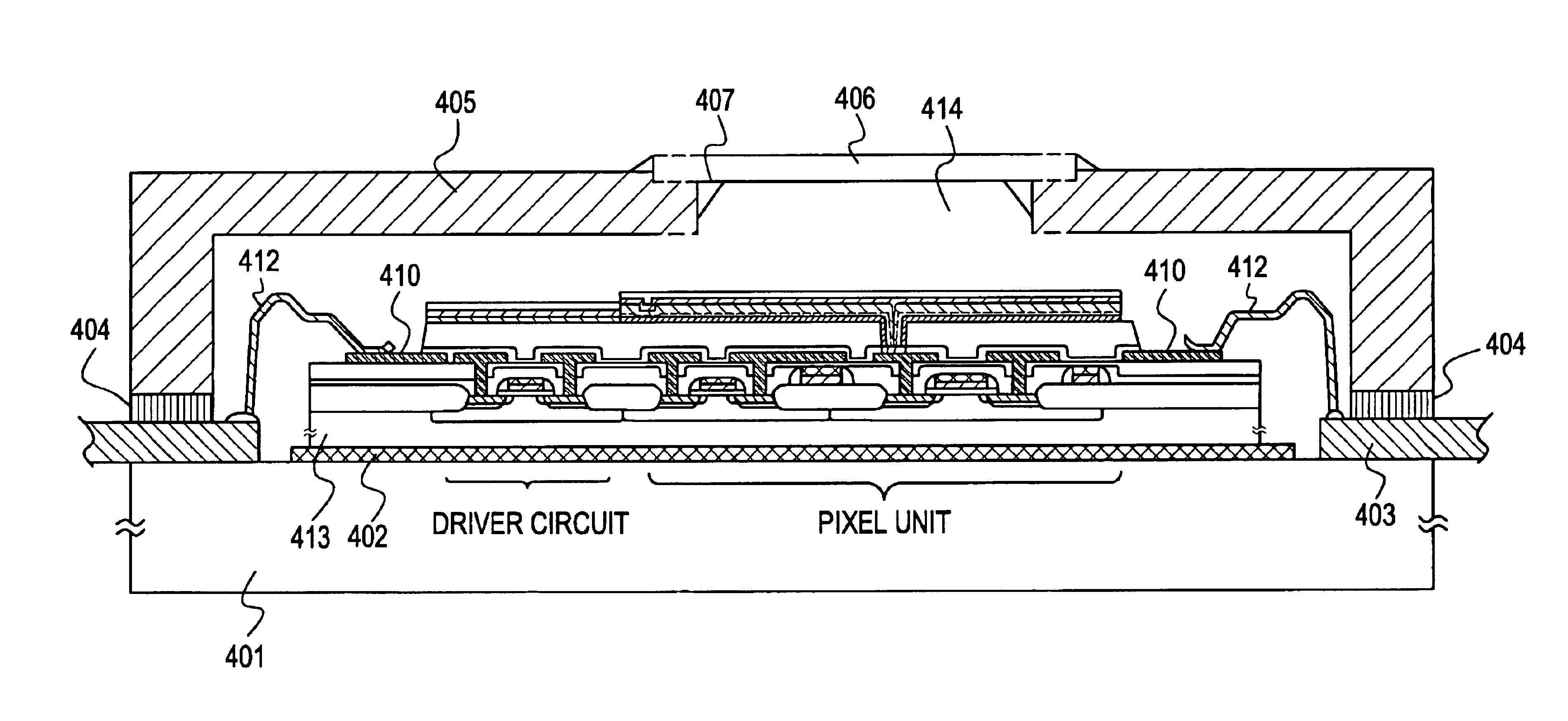

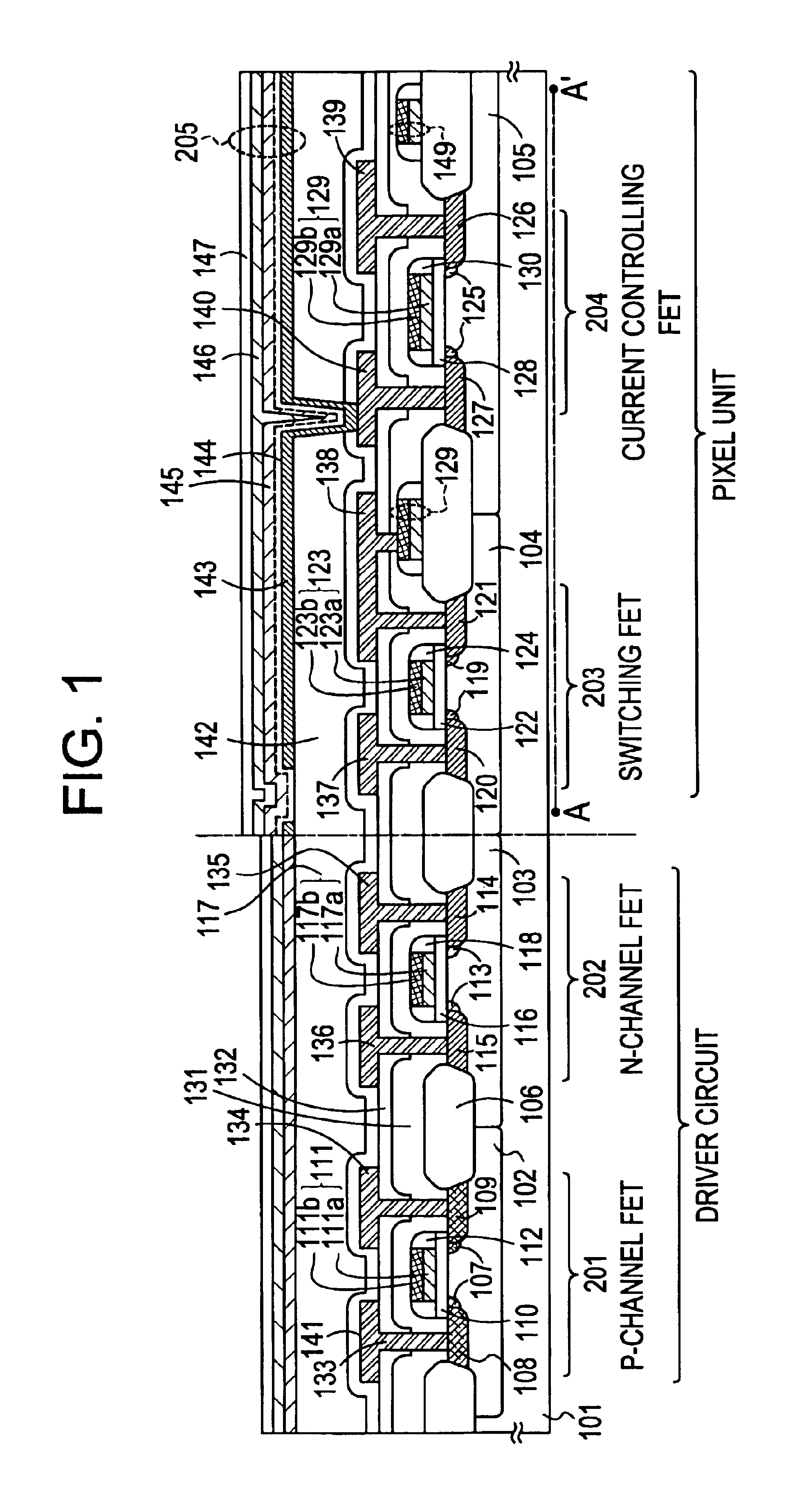

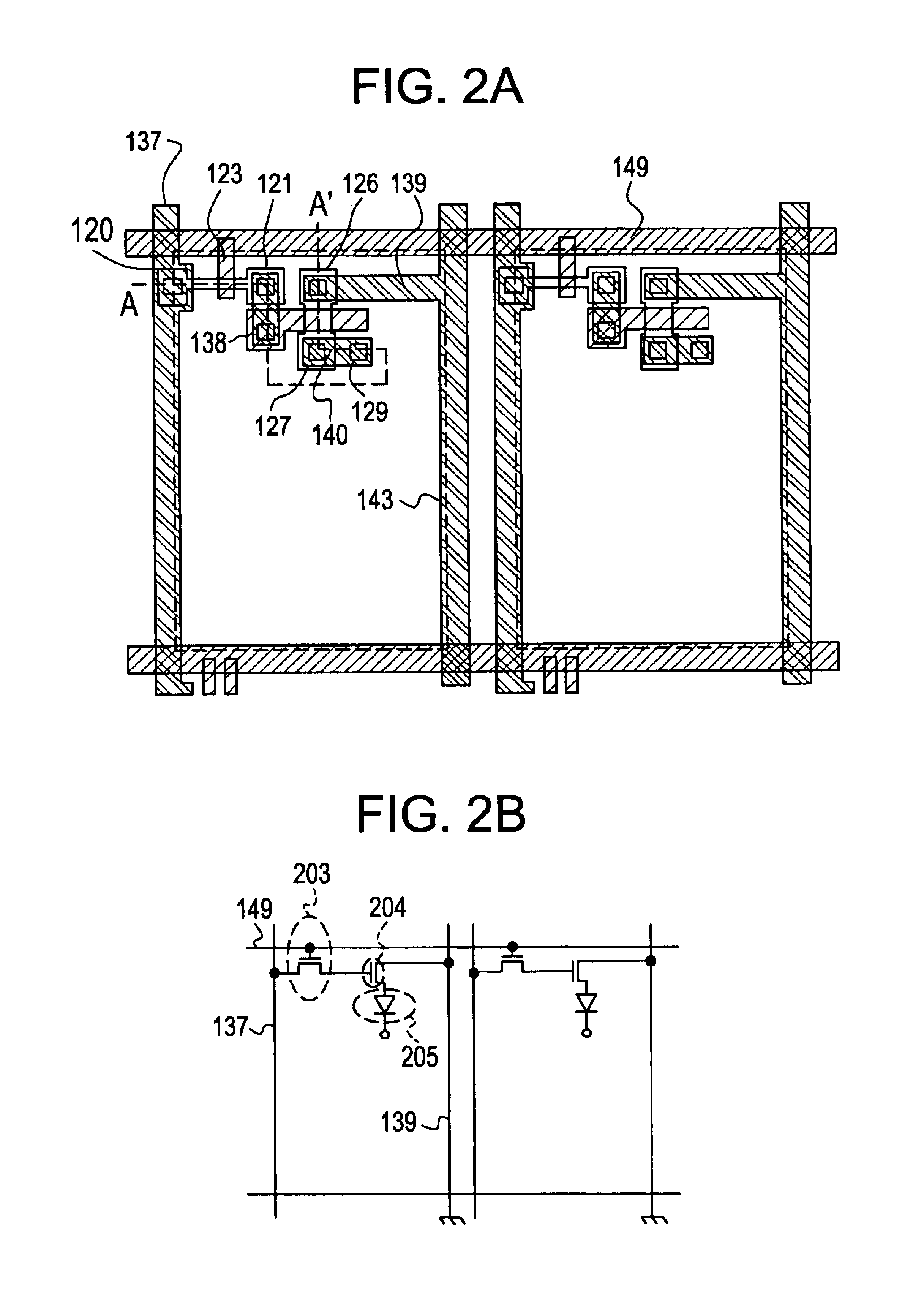

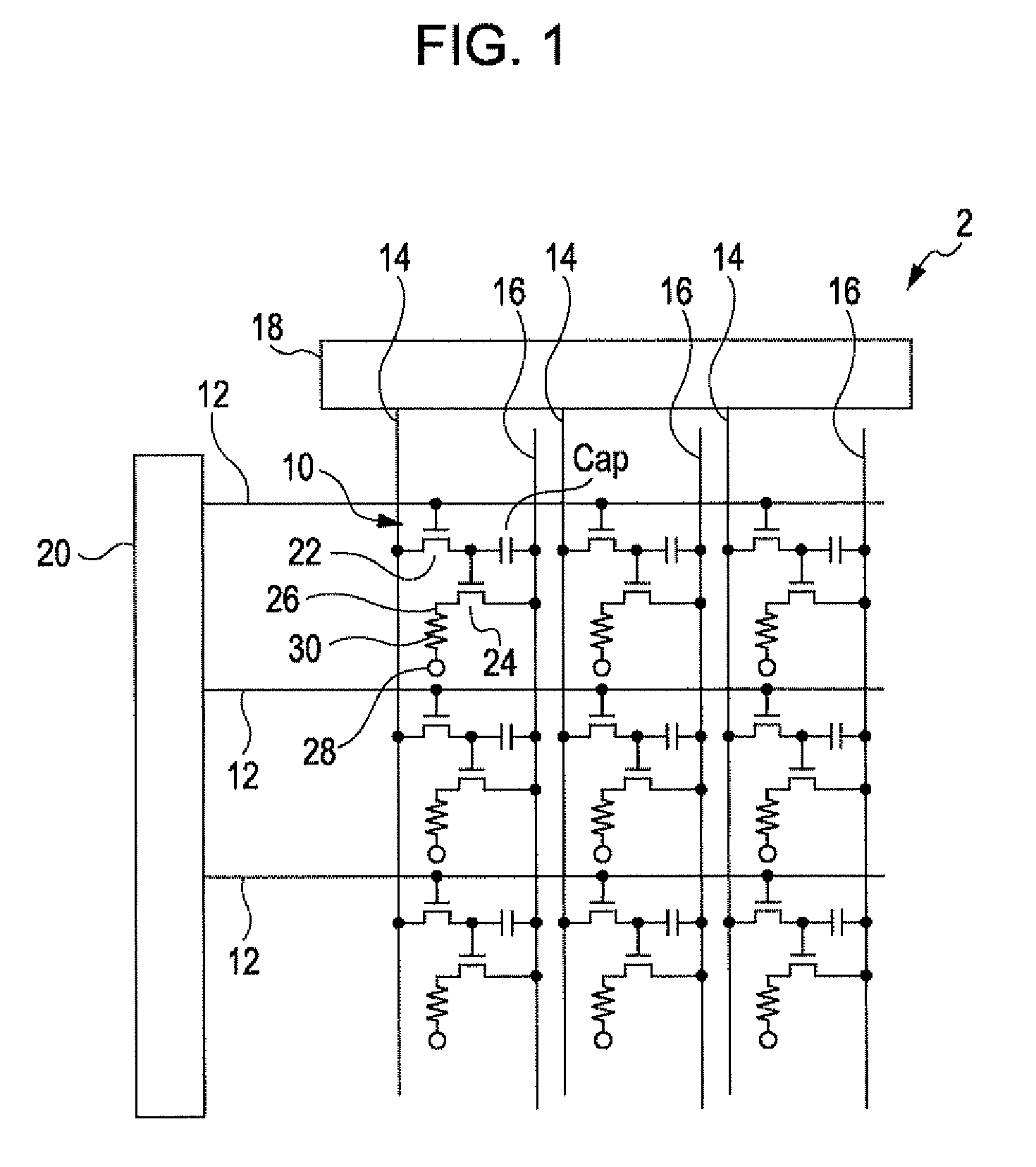

Organic electroluminescent display device

InactiveUS6876145B1Improve reliabilityDischarge tube luminescnet screensElectroluminescent light sourcesActive matrixSingle crystal

An organic EL display device of active matrix type wherein insulated-gate field effect transistors formed on a single-crystal semiconductor substrate are overlaid with an organic EL layer; characterized in that the single-crystal semiconductor substrate (413 in FIG. 4) is held in a vacant space (414) which is defined by a bed plate (401) and a cover plate (405) formed of an insulating material, and a packing material (404) for bonding the bed and cover plates; and that the vacant space (414) is filled with an inert gas and a drying agent, whereby the organic EL layer is prevented from oxidizing.

Owner:SEMICON ENERGY LAB CO LTD

Acidified zeolite

The invention discloses an acidified zeolite. The technical scheme is as follows: the acidified zeolite is composed of zeolite, attapulgite clay, magnesia, hydrochloric acid, instant sodium silicate, polyvinyl alcohol, hydroxypropyl methylcellulose and sodium carbonate. The acidified zeolite materials are input into a mill and milled, and the milled powder is the acidified zeolite. The production method of acidified red mud adopts acidification before composite proportioning, thereby avoiding the chemical reaction between the sulfuric acid and the instant sodium silicate, polyvinyl alcohol, hydroxypropyl methylcellulose and sodium carbonate; and the acidified zeolite can effectively remove ammonia, iron, fluorine, phosphides and micro pollutants in domestic sewage, and can be used for removing or recovering heavy metal ions and treating radioactive waste. The acidified rear has the characteristics of favorable thixotropy, favorable heat stability, favorable plasticity and favorable binding property, and is suitable for producing drying agents, adsorptive separation agents, molecular sieves, catalysts, defluorination soil improvers, deodorizers and firefighting products.

Owner:江苏世澳非金属应用科技有限公司

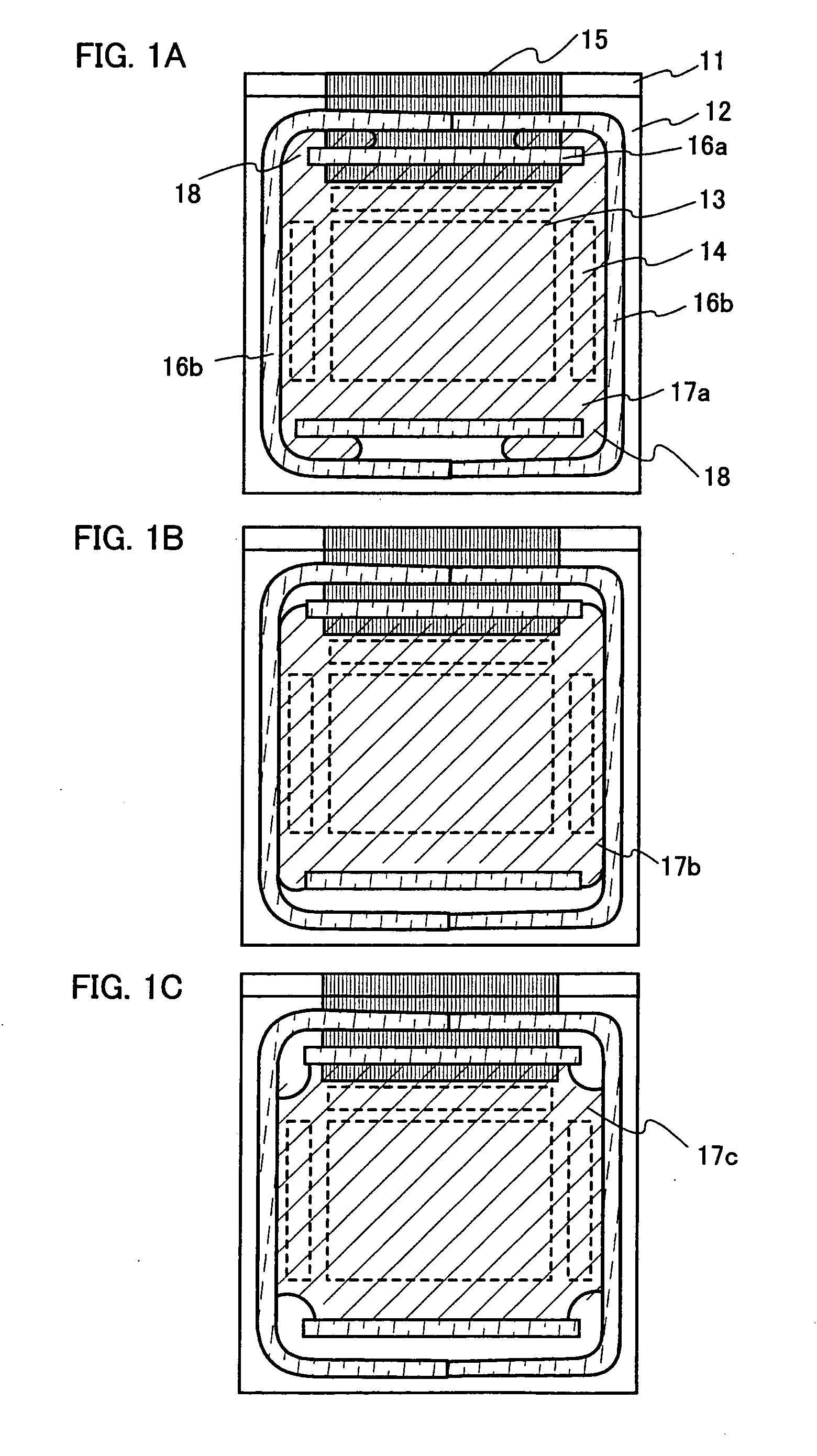

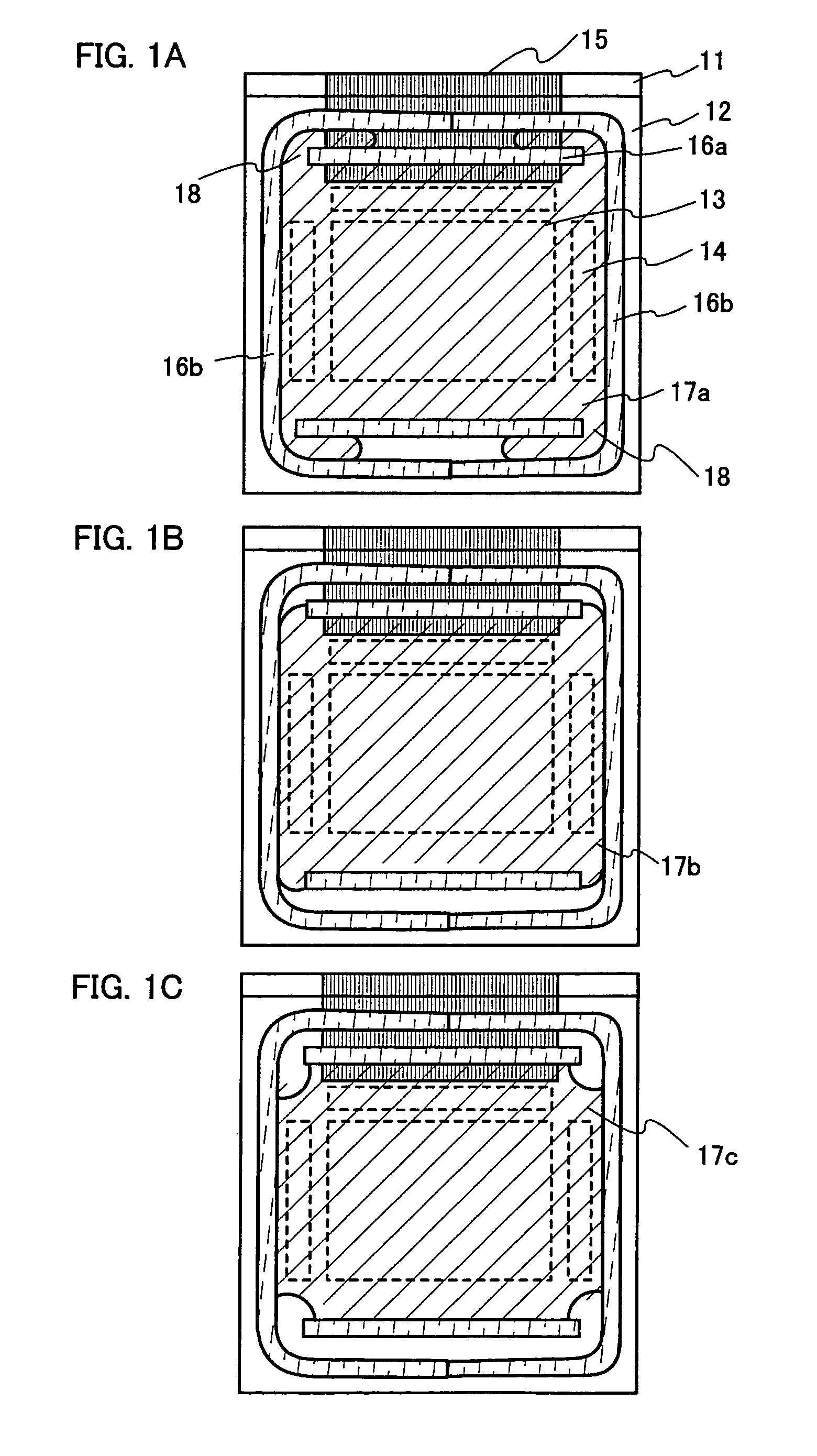

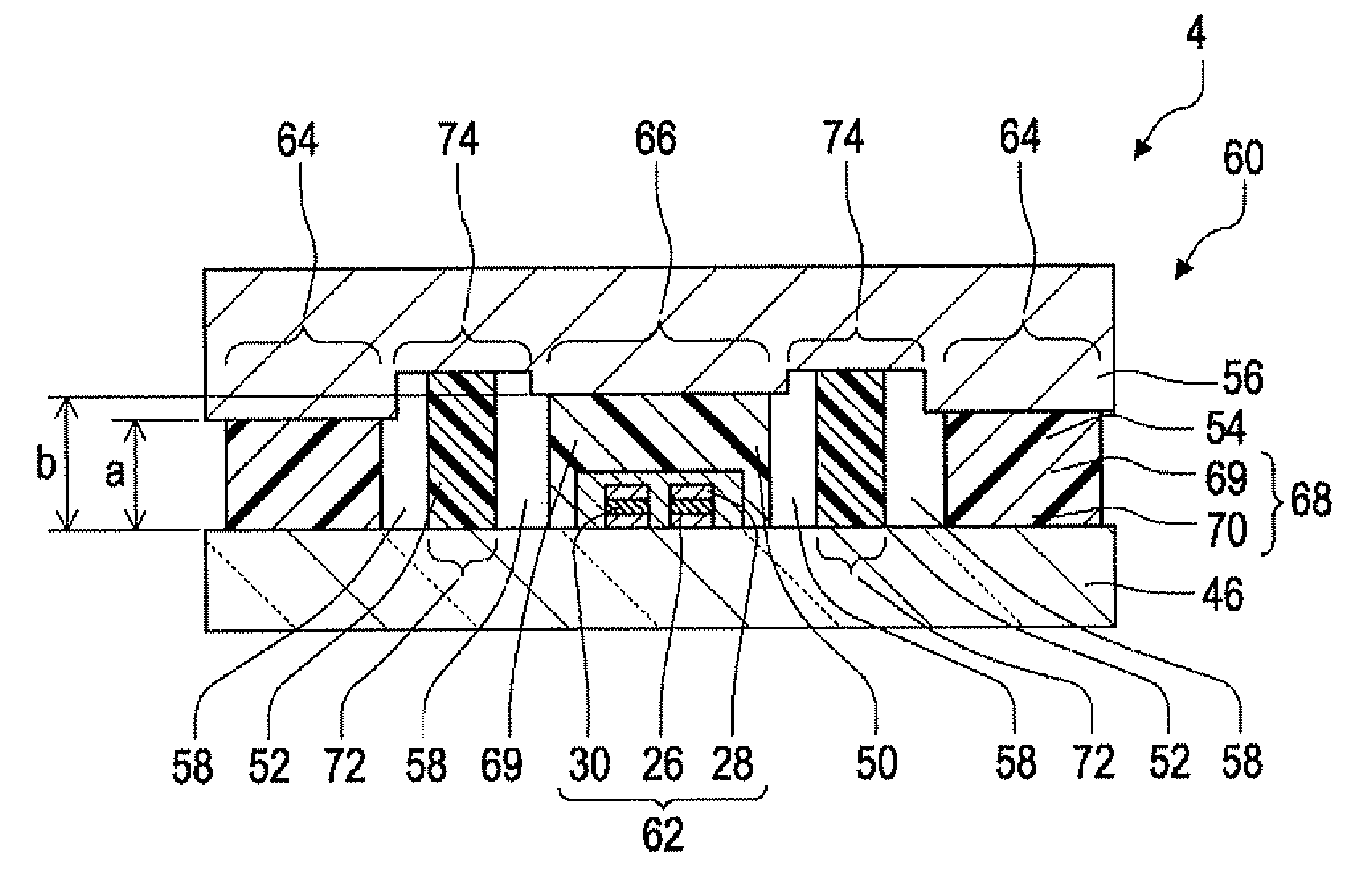

Light emitting device having pixel portion surrounded by first sealing material and covered with second sealing material

InactiveUS7700958B2High viscosityLow viscositySemiconductor/solid-state device detailsElectroluminescent light sourcesOxygenMoisture

A light emitting device having a structure in which oxygen and moisture are prevented from reaching light emitting elements, and a method of manufacturing the same, are provided. Further, the light emitting elements are sealed by using a small number of process steps, without enclosing a drying agent. The present invention has a top surface emission structure. A substrate on which the light emitting elements are formed is bonded to a transparent sealing substrate. The structure is one in which a transparent second sealing material covers the entire surface of a pixel region when bonding the two substrates, and a first sealing material (having a higher viscosity than the second sealing material), which contains a gap material (filler, fine particles, or the like) for protecting a gap between the two substrates, surrounds the pixel region. The two substrates are sealed by the first sealing material and the second sealing material. Further, reaction between electrodes of the light emitting elements (cathodes or anodes) and the sealing materials can be prevented by covering the electrodes with a transparent protective layer, for example, CaF2, MgF2, or BaF2.

Owner:SEMICON ENERGY LAB CO LTD

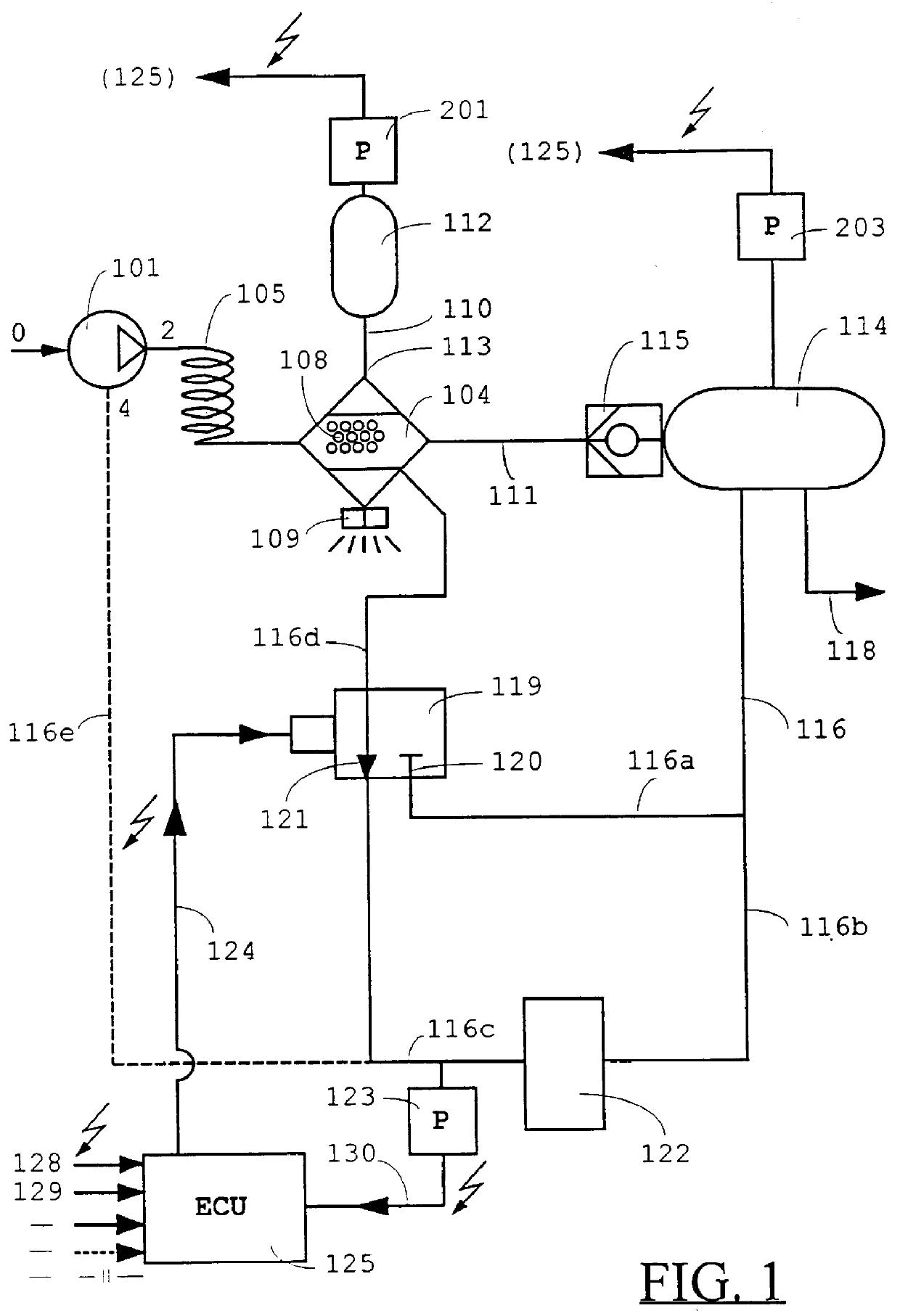

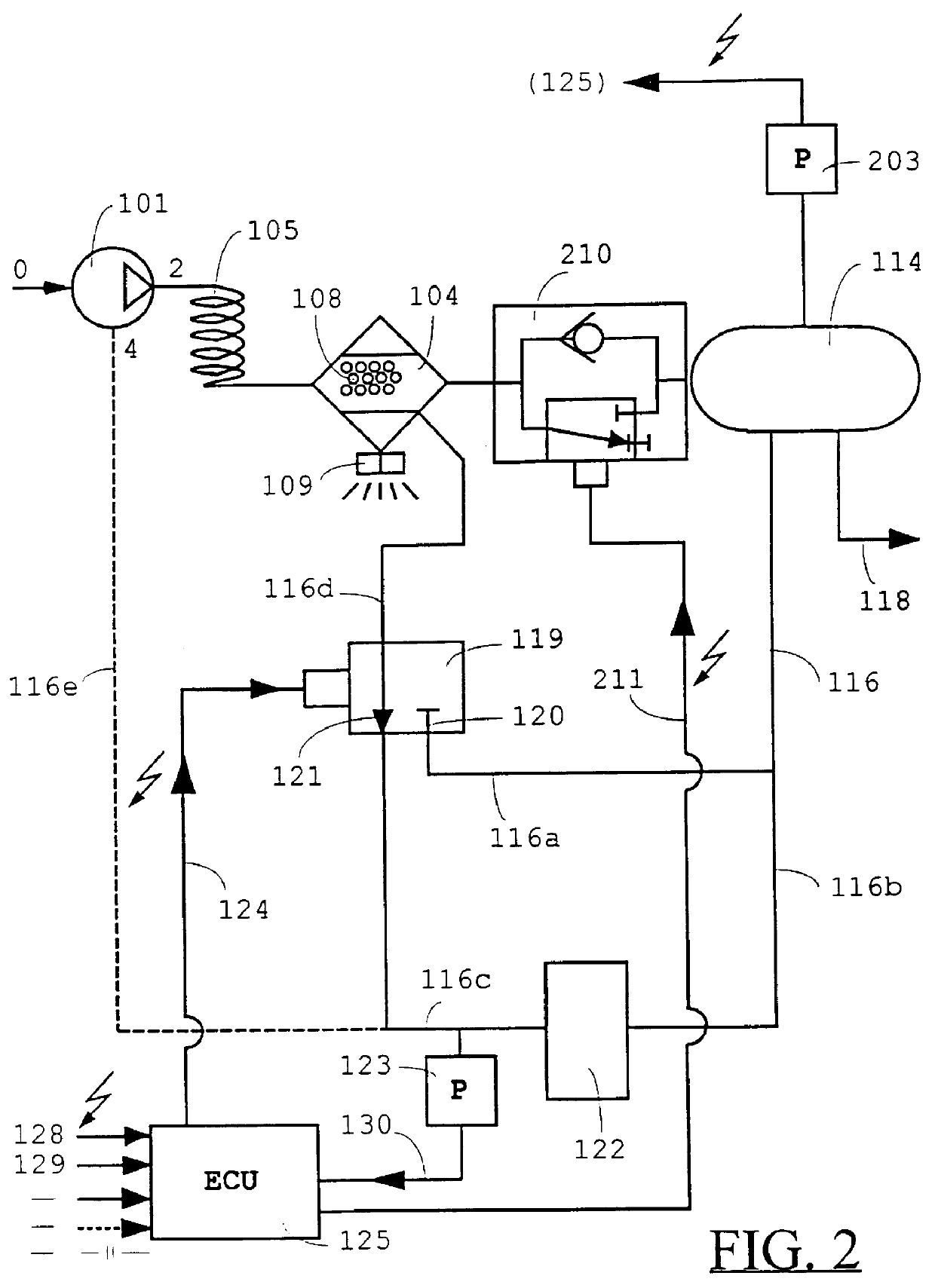

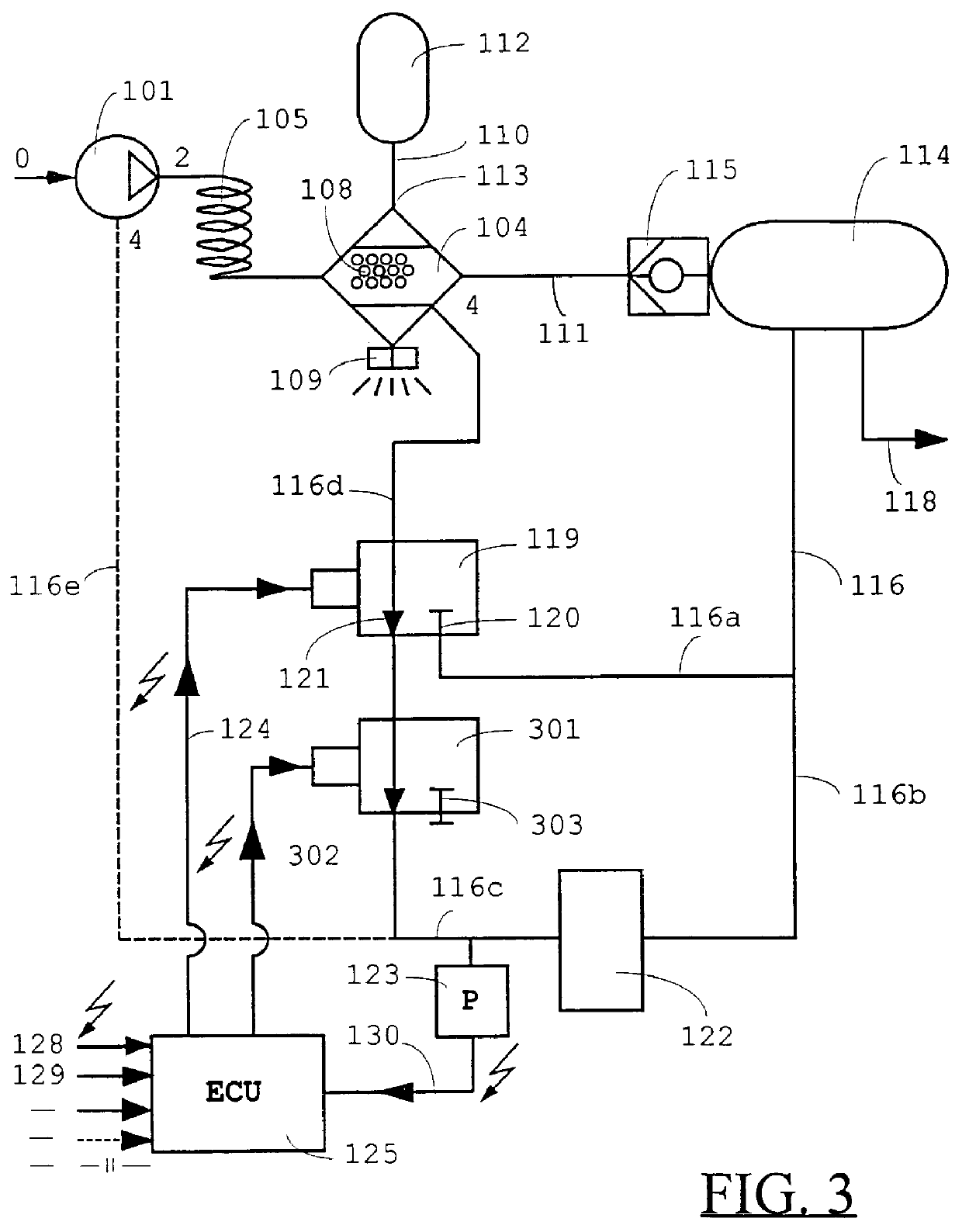

Air drying device for a pneumatic system

PCT No. PCT / SE96 / 01162 Sec. 371 Date Jun. 10, 1998 Sec. 102(e) Date Jun. 10, 1998 PCT Filed Sep. 20, 1996 PCT Pub. No. WO97 / 11274 PCT Pub. Date Mar. 27, 1997Device and method for the regeneration of a drying agent in compressed air system. The wetting degree of the drying agent is estimated and recorded by a control unit. The control unit ensures that the drying agent is dehumidified as soon as the wetting degree has reached a certain wetting degree. This certain wetting degree may be set to different levels for different operational condition.

Owner:AB VOLVO

Fast Dry Coated Inkjet Paper

Disclosed are a coating composition, coated article, and a method for treating one or more sides of the printable web with the composition, for providing improved printing ink dry time and gloss. The coating composition comprises: a calcium carbonate pigment component comprising a mixture high and low surface area calcium carbonate pigment; a metal salt drying agent; and a cationic dye fixing agent; a pigment binder; optionally a plastic pigment; and optionally an optical brightener; and which provides: a solids content of at least about 25%; a ratio of high to low surface area calcium carbonate in the range of from about 0.5:1 to about 20:1; and a ratio of calcium carbonate pigment component to pigment binder in the range of from about 4:1 to about 50:1.

Owner:GLOBAL HLDG II INC

Dental Appliance Cleansing Composition

ActiveUS20090042756A1Effective compositionEasy to cleanInorganic/elemental detergent compounding agentsBiocideChloramine BAlkaline earth metal

A novel and safe composition has been discovered that is effective for cleaning dental appliances (e.g. removable braces, retainers, dentures, etc.). This composition bleaches, disinfects, and deodorizes the appliance, while removing plaque that has accumulated on the appliance during wear. The composition comprises a chloramine bleaching agent that liberates hypochlorous acid upon contact with water, a surfactant, a water-soluble carboxylic acid and an alkaline base to produce effervescence and regulate pH, a sequestering agent for alkaline earth metal ions, a drying agent, and an indicator dye that signifies the end of the cleansing process. In a preferred method of using this invention, the premixed components are added to water, and the dental appliance is submerged in the resulting effervescent solution until a color change indicates that cleaning is complete. This invention provides a safe, effective, and convenient method for cleansing and disinfecting dental appliances.

Owner:LMA SOLUTIONS

Anticorrosive paint for weather-resistant corrosion-resistant steel pipe outer wall

ActiveCN102120909AFast dryingDry fastGeneral water supply conservationAnti-corrosive paintsEpoxyWeather resistance

The invention relates to an anticorrosive paint for a weather-resistant corrosion-resistant steel pipe outer wall, which is prepared from 30-50 parts of alkyd resin, 2-5 parts of epoxy resin, 10-15 parts of terpene resin, 30-50 parts of hydrocarbon solvent, 3-8 parts of anticorrosive agent and 1-3 parts of drying agent. The paint provided by the invention can be applied by brushing, spraying, dipcoating, curtain coating or the like, and is naturally dried at normal temperature. The terpene resin adopted in the invention has high stability for oxygen, heat and light, and has excellent ageing resistance, so that the paint has excellent weather resistance. The rust inhibitor adopted in the invention can form a compact protective layer with high adhesive force on the surface of a steel pipe,and thus, prevents or slows the permeation of oxygen and water in the environment under the isolation action, thereby inhibiting the generation of corrosion microcells and performing a favorable anticorrosive protection function.

Owner:TIANJIN COLOROAD COATING & CHEM

Titanate coupling agent modified pollution-flashover-preventing fluorocarbon paint and preparation method thereof

InactiveCN103242718ASolve the problem of pollution flashoverImprove hydrophobicityCoatingsPolymer sciencePolymer chemistry

The invention discloses titanate coupling agent modified pollution-flashover-preventing fluorocarbon paint which comprises the following components in parts by weight: 30-50 parts of fluorocarbon resin, 10-30 parts of filler, 1-10 parts of pigment, 3.5-10 parts of curing agent, 2-10 parts of coupling agent, 0.03-3 parts of assistant, 35-45 parts of solvent and 0.001-0.1 part of drying agent. The invention also discloses a preparation method of the fluorocarbon resin paint. The static contact angle theta of the fluorocarbon resin paint can be up to 118 degrees; and the fluorocarbon resin paint has favorable hydrophobicity and hydrophobic migration performance and high pollution flashover preventing performance, thus ensuring that the physical / chemical properties and electric properties of a prepared coating can meet pollution flashover preventing conditions. The invention is used for insulator pollution flashover prevention, and solves the problem of insulator pollution flashover of a high-voltage transmission line.

Owner:ELECTRIC POWER RES INST OF GUANGDONG POWER GRID +1

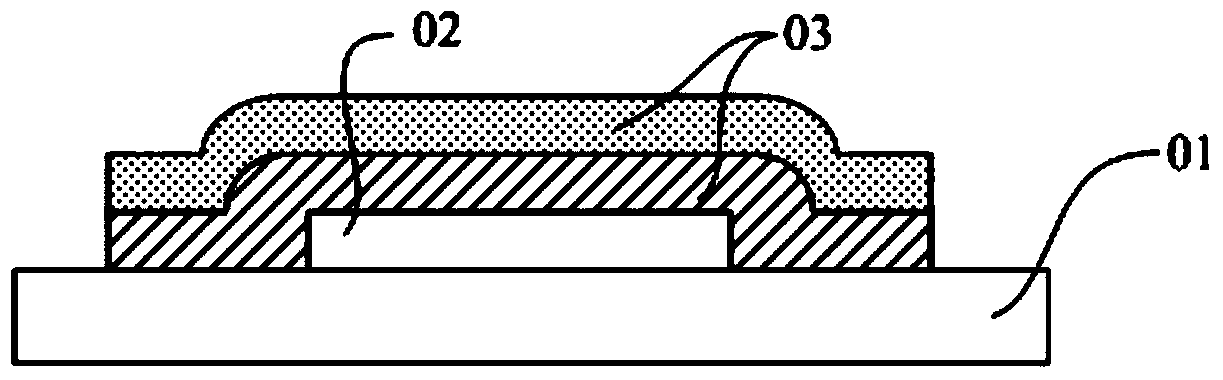

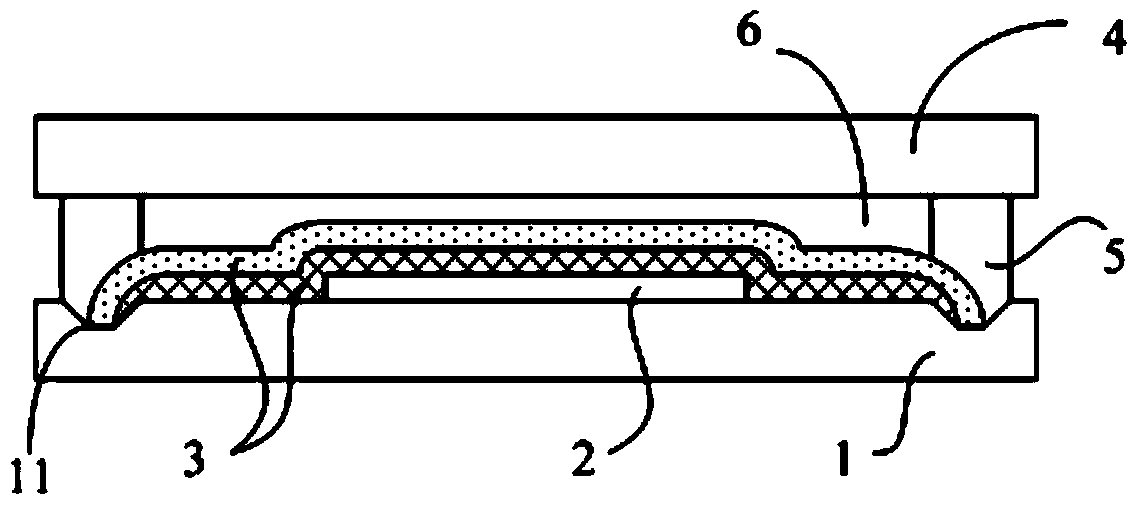

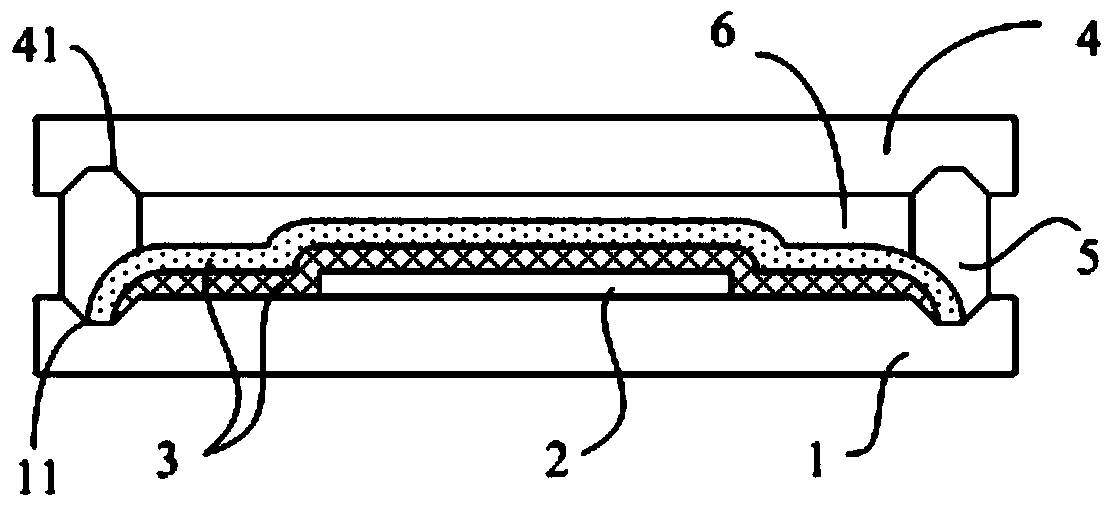

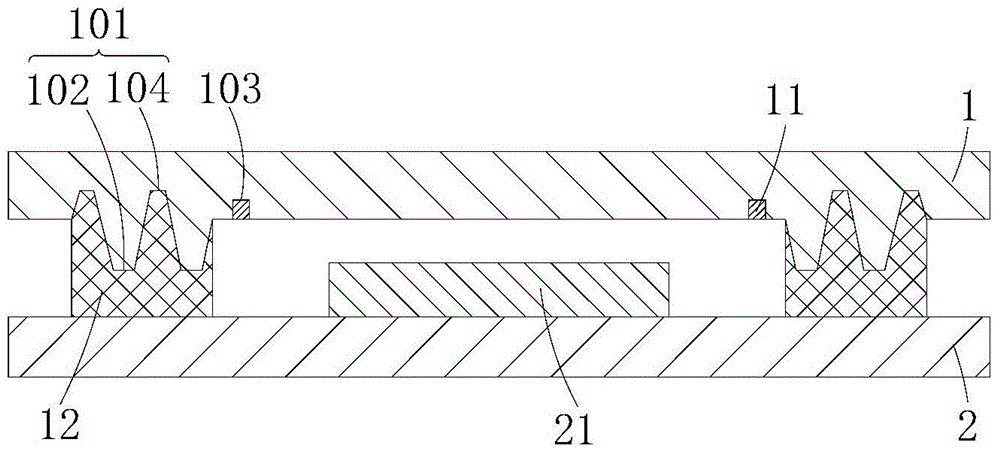

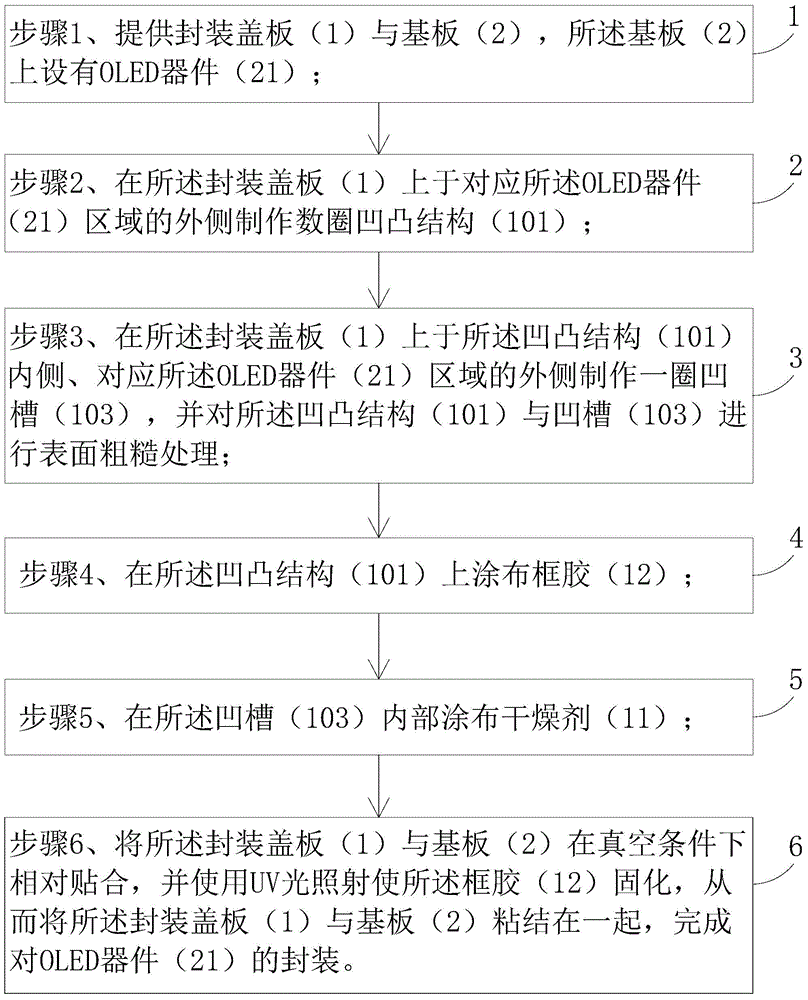

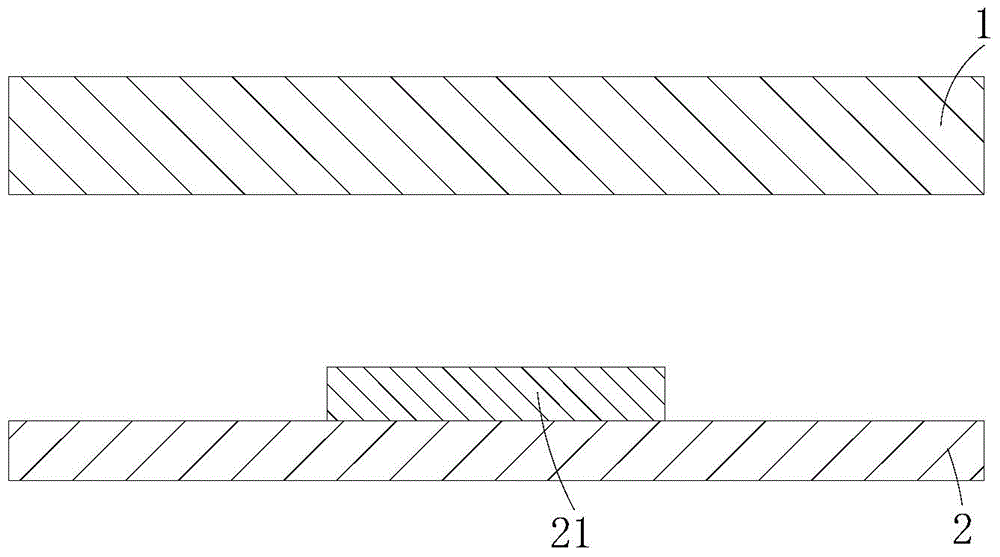

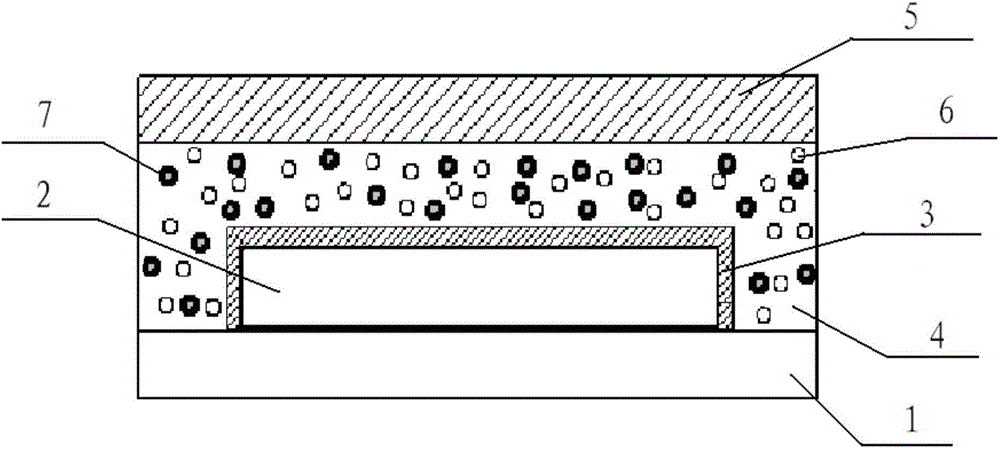

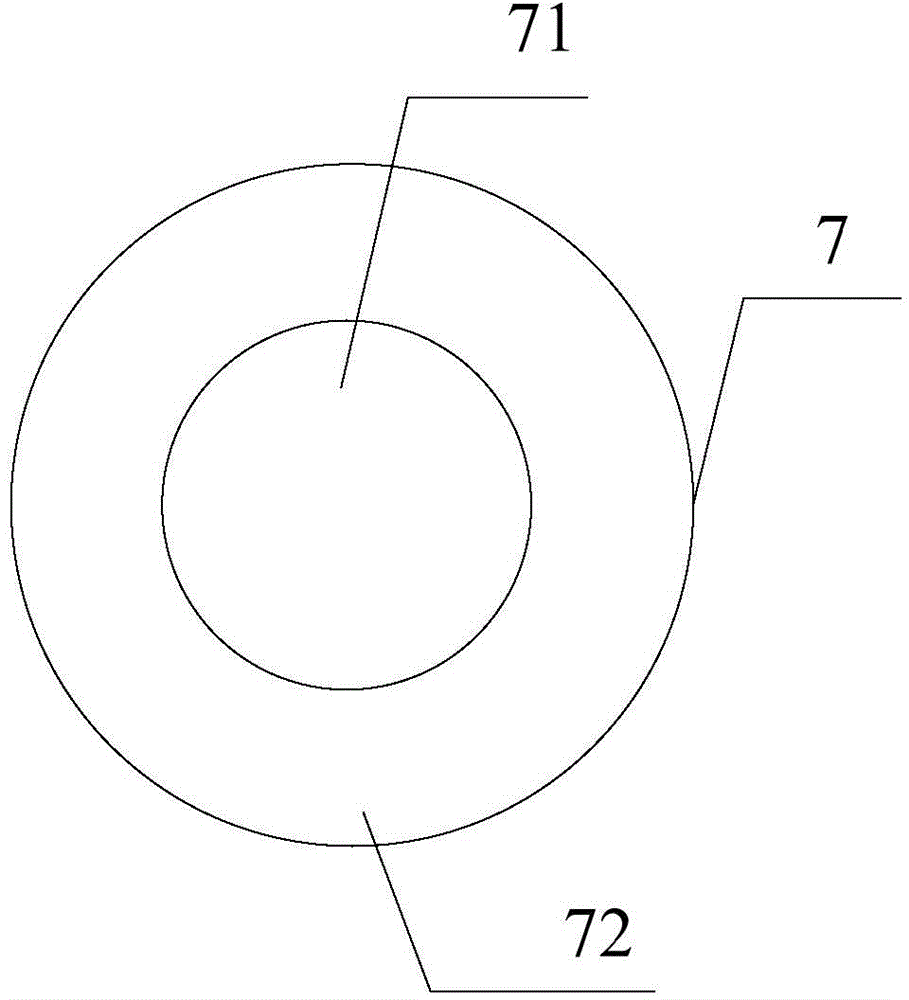

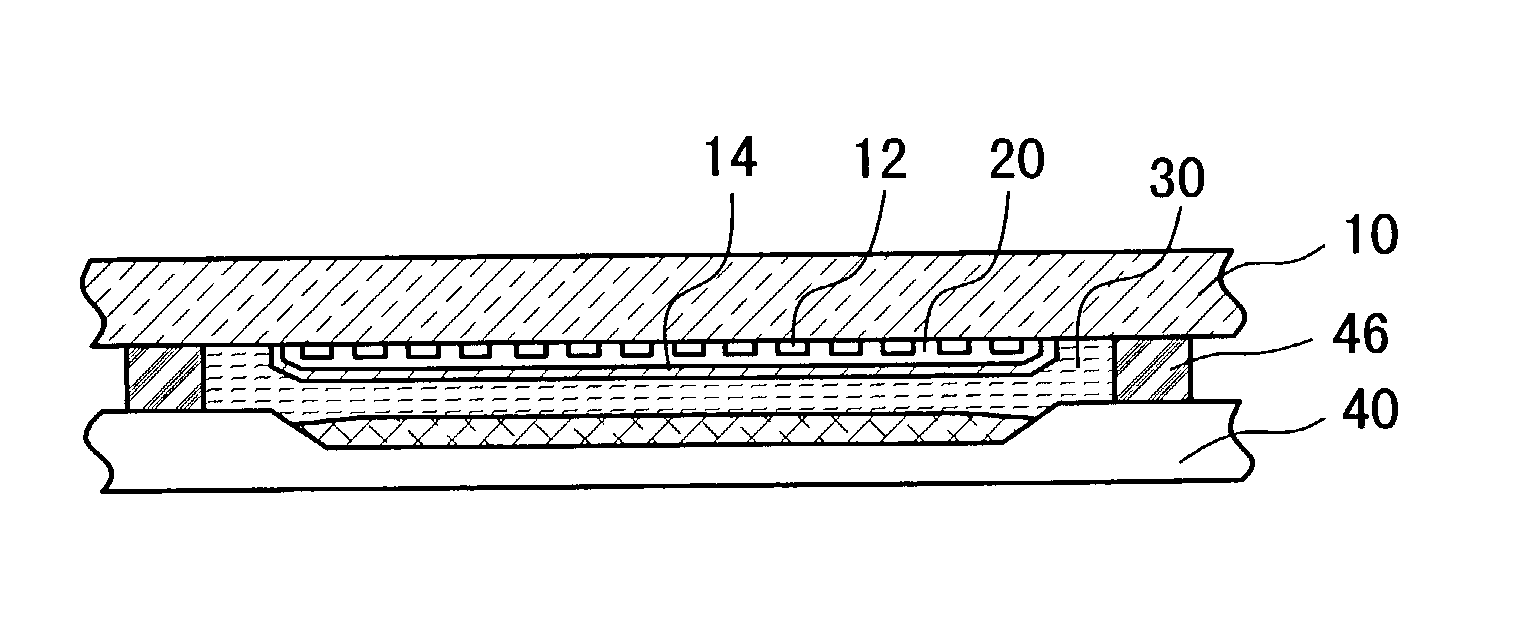

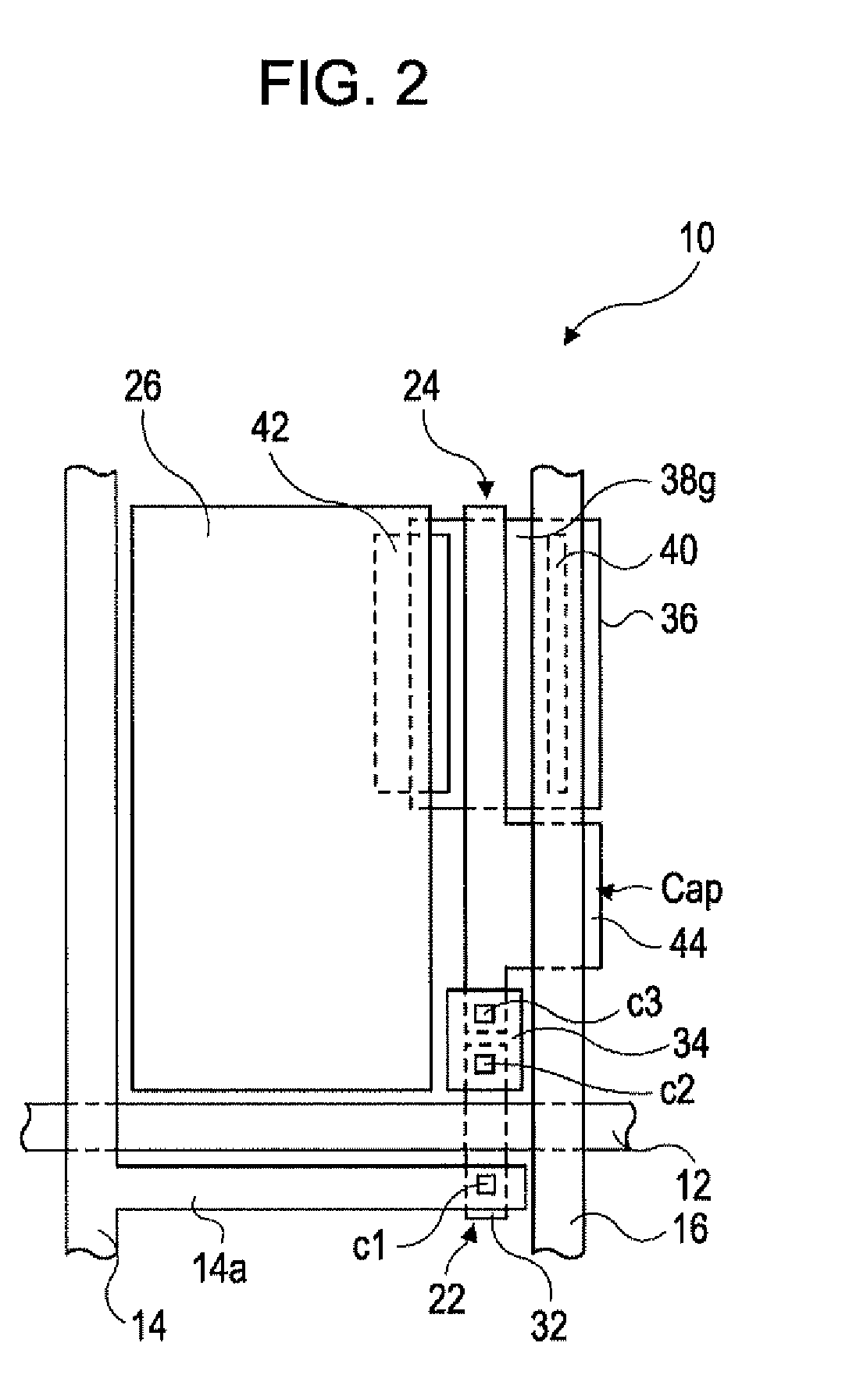

OLED packaging structure and OLED packaging method

InactiveCN104538555AHigh bonding strengthReduce distanceSolid-state devicesSemiconductor/solid-state device manufacturingDrying AgentsBonding strength

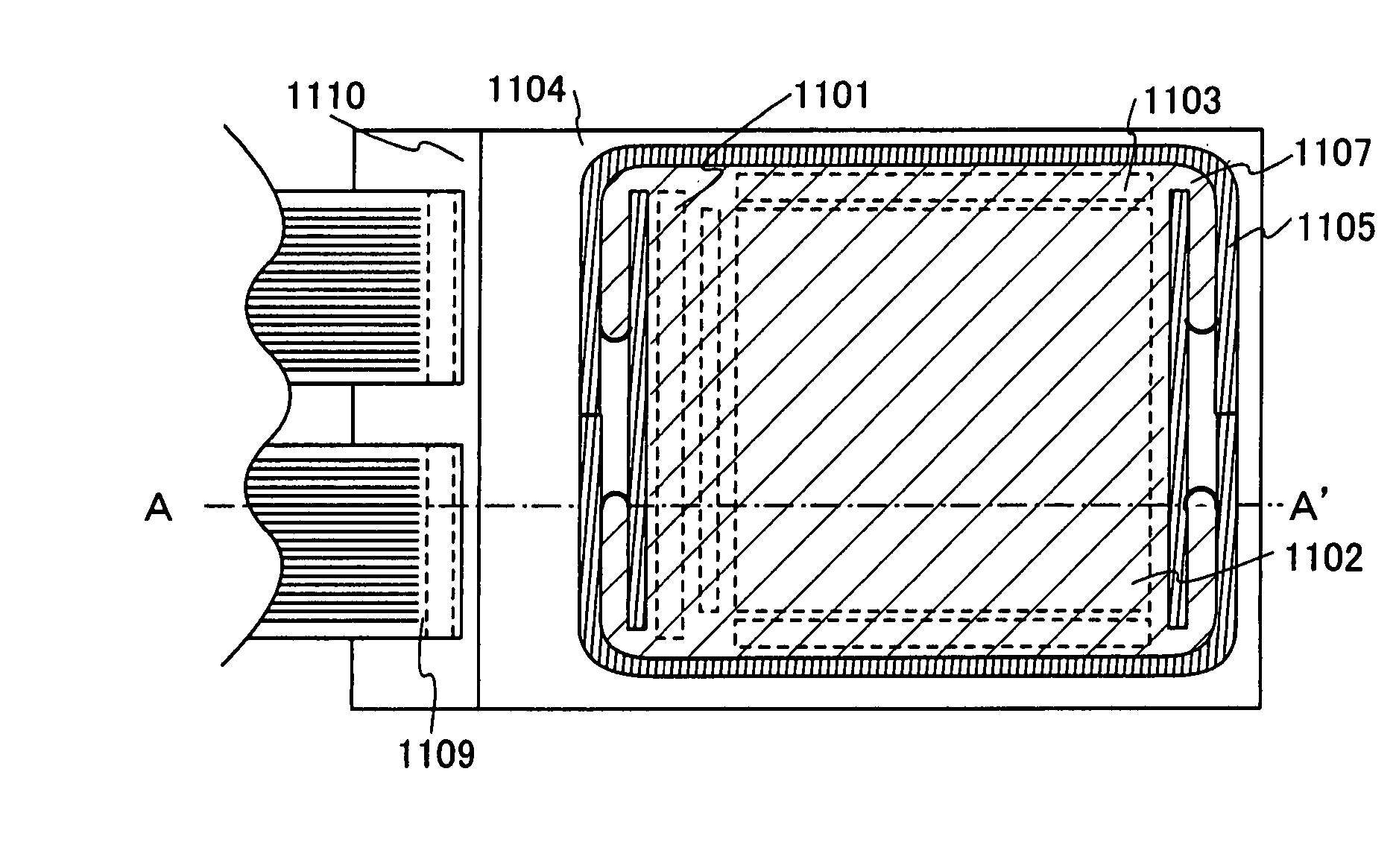

Provided in the invention is an OLED packaging structure and an OLED packaging method. The OLED packaging structure comprises a packaging cover plate (1), a substrate (2), an OLED device (21), a drying agent (11), and a frame adhesive (12); and the drying agent (11) located at the periphery of the OLED device (21) is arranged on the packaging cover plate (1) and the frame adhesive (12) located at the periphery of the drying agent (11) is used for bonding the packaging cover plate (1) and the substrate (2). A loop of groove (103) is formed in the periphery, corresponding to the area of the OLED device (21), of the packaging cover plate (1); and multiple loops of concave-convex structures (101) are formed at the periphery of the groove (103). The drying agent (11) is arranged in the groove (103); and the frame adhesive (12) is arranged between the concave-convex structures (101) and the substrate. According to the OLED packaging structure, the bonding strength between the packaging cover plate and the substrate can be improved and the distance between the packaging cover plate and the substrate is reduced; and thus infiltration of the moisture and oxygen can be effectively blocked.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

Organic luminescent device and organic luminescence display apparatus

ActiveCN104091890AAvoid damageImprove thermal conductivitySolid-state devicesSemiconductor/solid-state device manufacturingOrganic light emitting deviceEngineering

The invention belongs to the field of a display technology, and provides an organic luminescent device and an organic luminescence display apparatus, for solving the problems of overheated organic luminescence device and affected service life which are caused by poor heat conduction performance of packaging glue layers in a conventional organic luminescent device and a conventional organic luminescence display apparatus. The packaging glue layers in the organic luminescent device and the organic luminescence display apparatus are provided with heat conduction particles and drying agent particle. The heat conduction particles can improve the heat conduction capabilities of the packaging glue layers so as to prevent the service life from being affected and the device from being damaged due to overheating of an organic luminescence unit after long-time energization; and the drying agent particles, when the moisture and oxygen obstructing performance of the packaging glue layer is decreased, absorb moisture to prevent the moisture from being diffused to the organic luminescence unit so as to prevent the service life from being affected.

Owner:BOE TECH GRP CO LTD

Novel strongly and weakly alkaline anion exchange resin and preparation method thereof

The invention discloses a novel strongly and weakly alkaline anion exchange resin with adsorption and ion exchange functions and a preparation method thereof, and relates to the field of anion exchange resin and a preparation process thereof. The novel anion exchange resin with the adsorption and ion exchange functions comprises a strong alkali group and a weak alkali group, the exchange capacityof strong alkali is 2.9 to 5.7meq for each gram of dry agent, and the exchange capacity of weak alkali is 2.8 to 3.2meq for each gram of dry agent. The preparation method of the resin comprises the following steps of: performing nucleophilic substitution reaction on macroporous chloromethylated polystyrene resin serving as a raw material and an alcohol amine compound, and reacting with thionyl chloride for further quaternization to obtain the strongly and weakly alkaline anion exchange resin.

Owner:溧阳常大技术转移中心有限公司

Double-component solvent-free polyurethane adhesive

ActiveCN105778847AHigh strengthImprove adhesionNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesRefrigerator carPolyester

The invention relates to a double-component solvent-free polyurethane adhesive.The double-component solvent-free polyurethane adhesive is prepared from a component A and a component B at the mass ratio of (1-4):1.The component A is prepared from, by weight, 5-15% of polyether polyol, 20-40% of polyester polyol, 1-5% of an accelerant, 2-6% of a coupling agent, 30-60% of filler, 5-10% of a drying agent and 0.05-0.2% of a catalyst.The component B is prepared from, by weight, 50-80% of isocyanate, 10-30% of polyester polyol and 1-10% of a chain extender.A preparing method of the double-component solvent-free polyurethane adhesive includes the following first step of preparation of the component A, the second step of preparation of the component B and the third step of mixing of the component A and component B.The double-component solvent-free polyurethane adhesive is used for adhesion of compartment structural members in refrigerator car compartments and truck compartments, is capable of achieving long opening time, has high initial adhesion force and adhesion strength, high base material applicability and excellent adhesion force on various base materials, and is long in storage life and high in stability.

Owner:上海都昱新材料科技有限公司

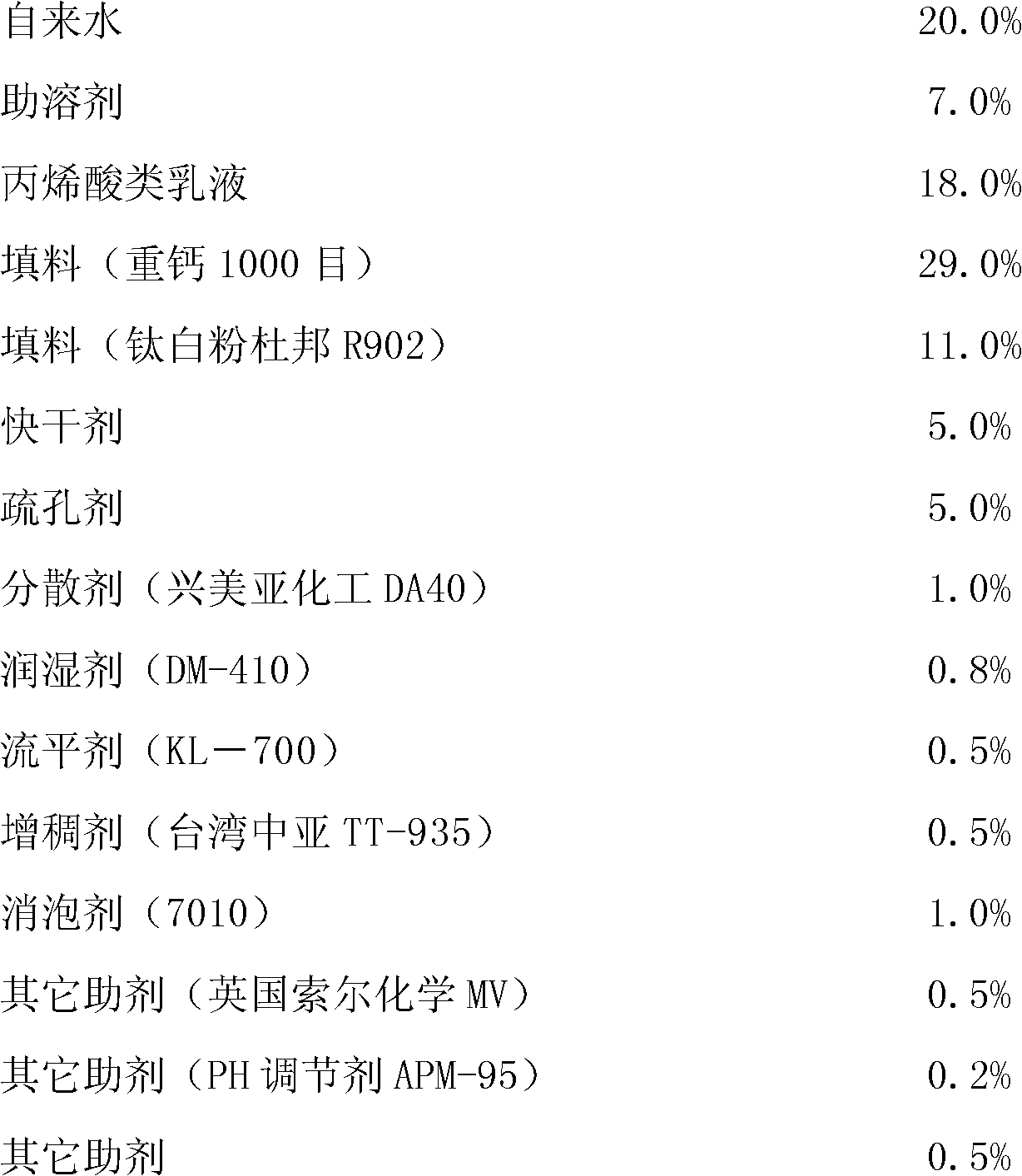

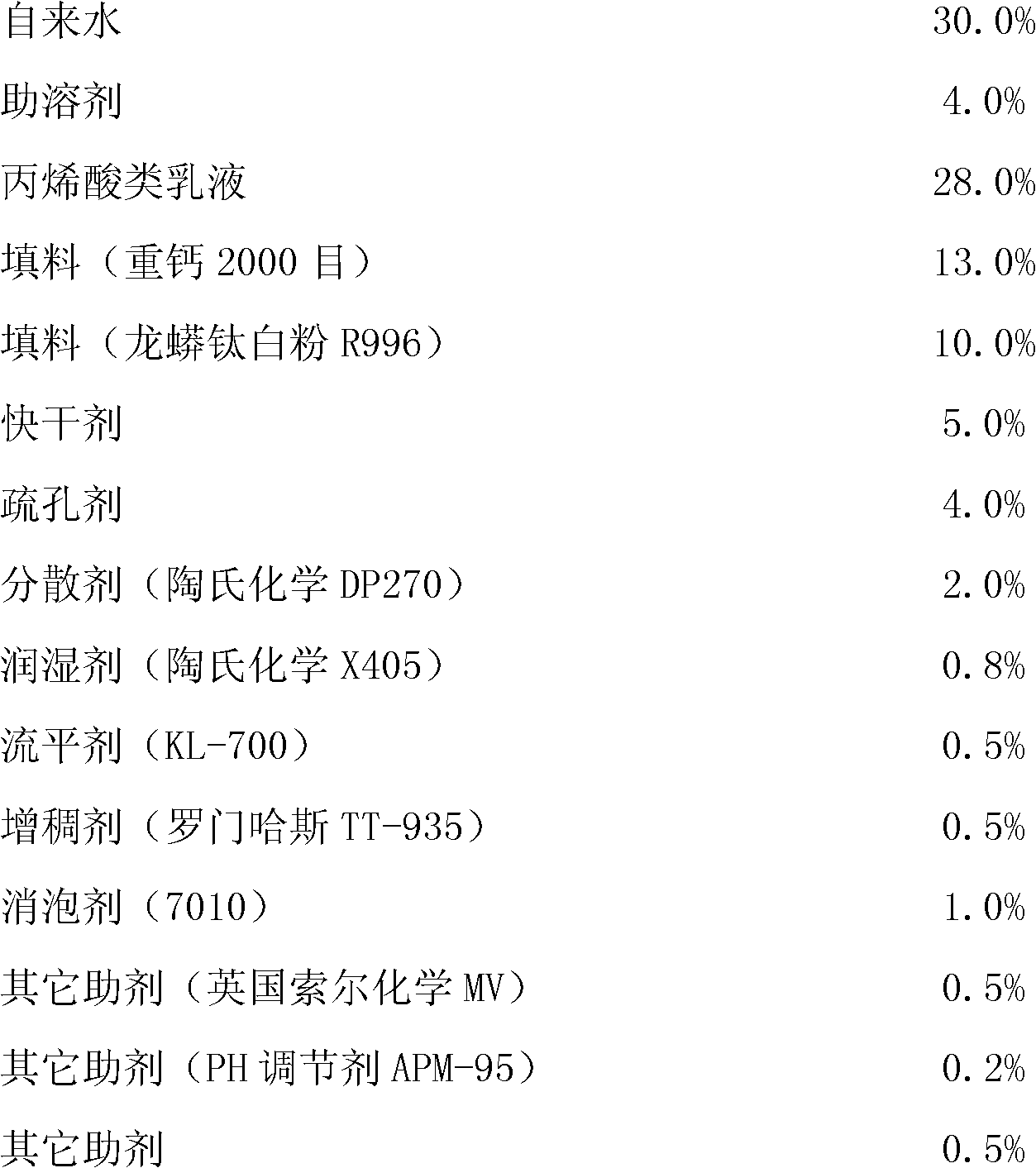

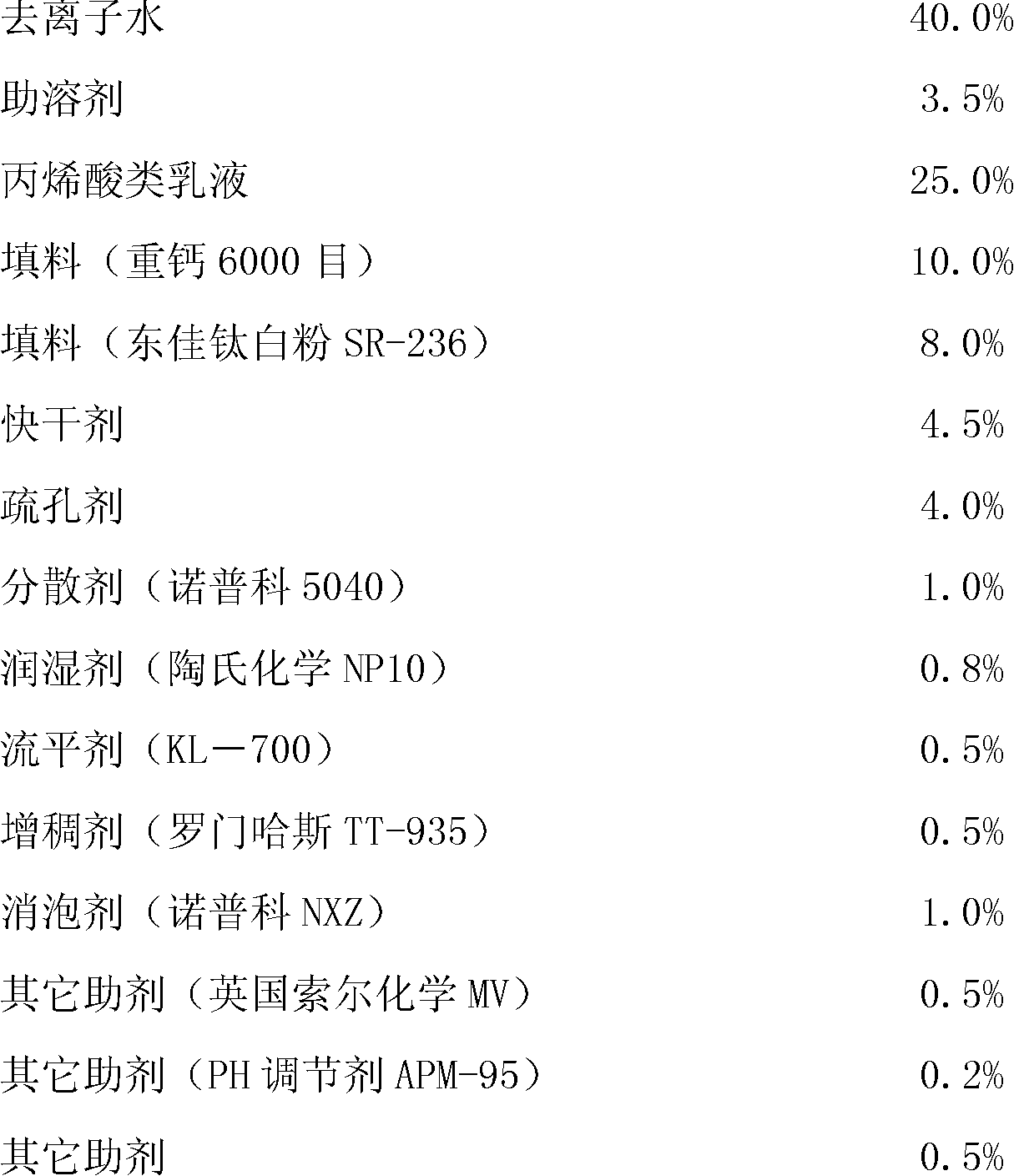

Quick-dry thin acrylic-acid protective coating and HDPE (high-density polyethylene) self-adhesive film waterproof roll protective coating layer

The invention discloses a quick-dry thin acrylic-acid protective coating, which mainly consists of water, cosolvent, acrylic-acid like emulsion, filler, quick dry agent, hole forming agent, dispersing agent, wetting agent, defoamer, flatting agent and thickener and the like. The invention further discloses an HDPE (high-density polyethylene) self-adhesive film waterproof protective coating layer, which is formed after the quick-dry thin acrylic-acid protective coating is sprayed on a HDPE self-adhesive layer uniformly by a reciprocating mechanical spraying method and drying the same. The quick-dry thin acrylic-acid protective coating is environment-friendly and non-toxic and can be dried quickly and has excellent flatting performance, and an HDPE self-adhesive film waterproof roll prepared by the HDPE self-adhesive film waterproof roll protecting layer has excellent pre-paving anti-adhesive effect with post-cast concrete, and the HDPE self-adhesive film waterproof roll protective layer and the post-cast concrete can be guaranteed to be adhered stably and firmly.

Owner:BEIJING ORIENTAL YUHONG WATERPROOF TECH CO LTD +1

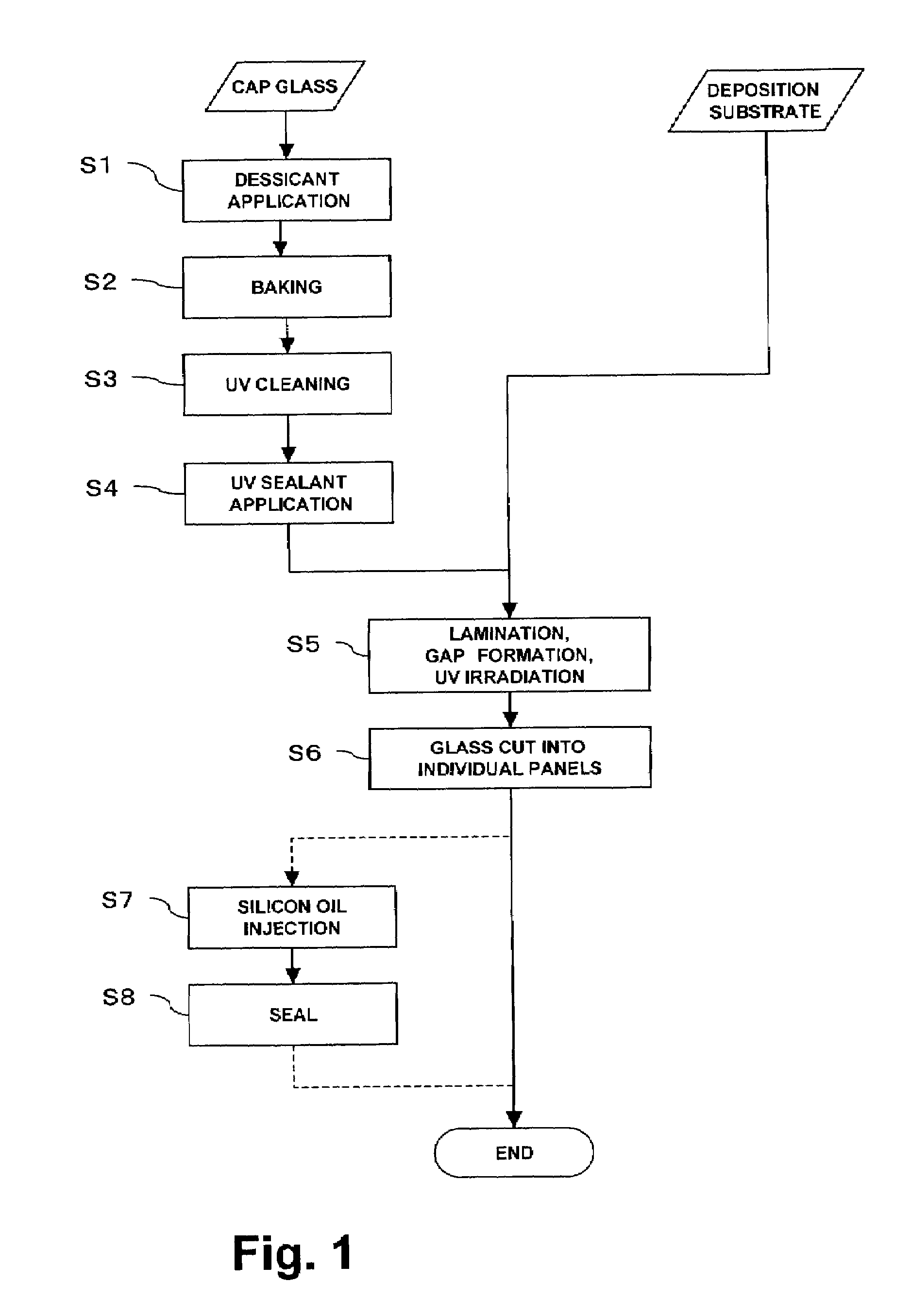

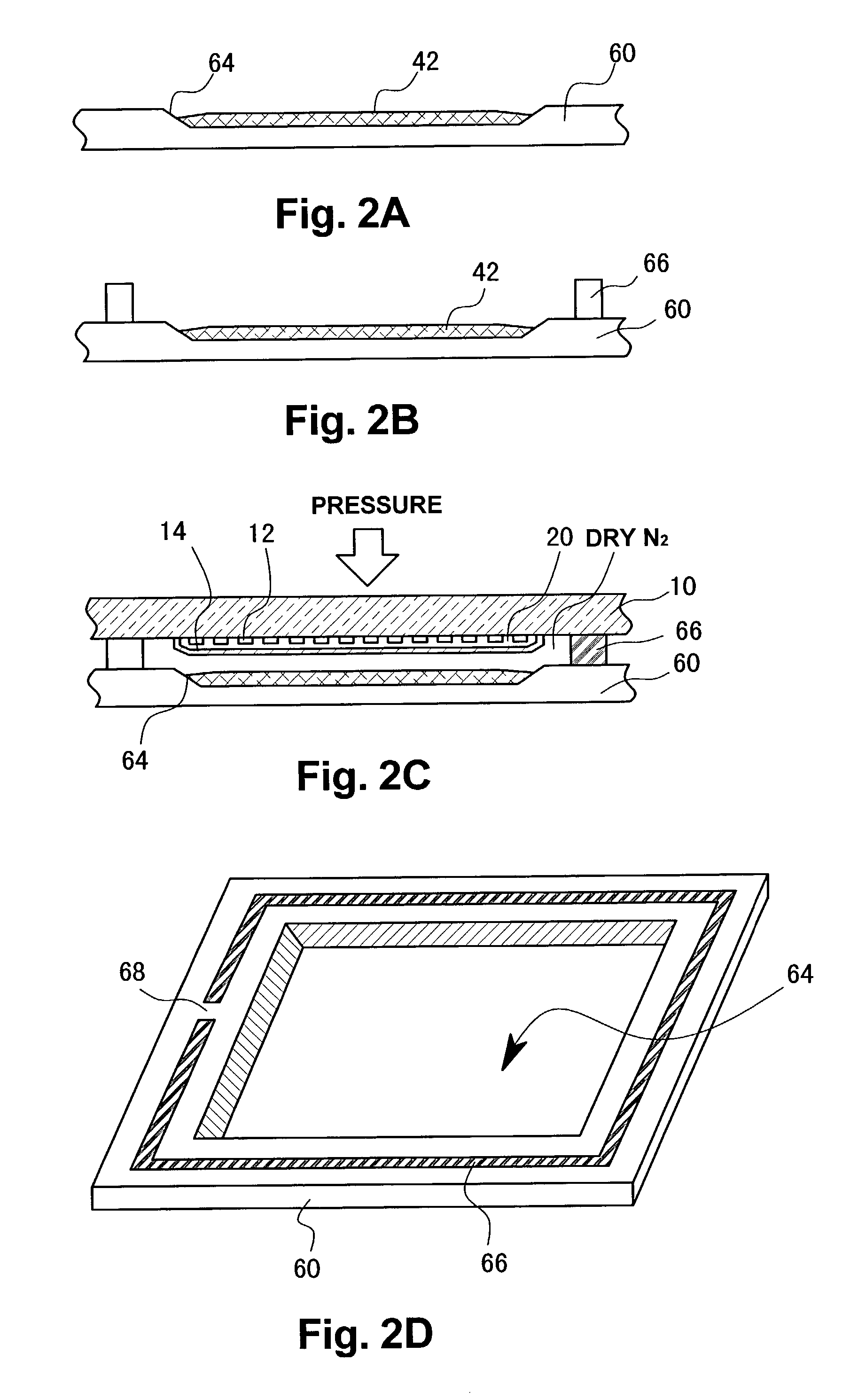

Method of manufacturing electroluminescence panel

InactiveUS7097527B2Improve protectionEasy to manufactureElectroluminescent light sourcesSolid-state devicesEngineeringSealant

An opposing substrate which is subjected to desiccant application, baking, UV cleaning, UV sealant application, or the like and an element substrate having EL elements formed thereon are affixed together by applying a sealing liquid such as silicon oil in a vacuum. Subsequently, when exposed to a normal atmosphere, the opposing substrate and the element substrate are adsorbed to each other while a predetermined gap is maintained in between. In this state, the UV sealant is cured with UV irradiation. It is thus possible to enclose the sealing liquid between the opposing substrate and the element substrate using a simple manufacturing method.

Owner:SANYO ELECTRIC CO LTD

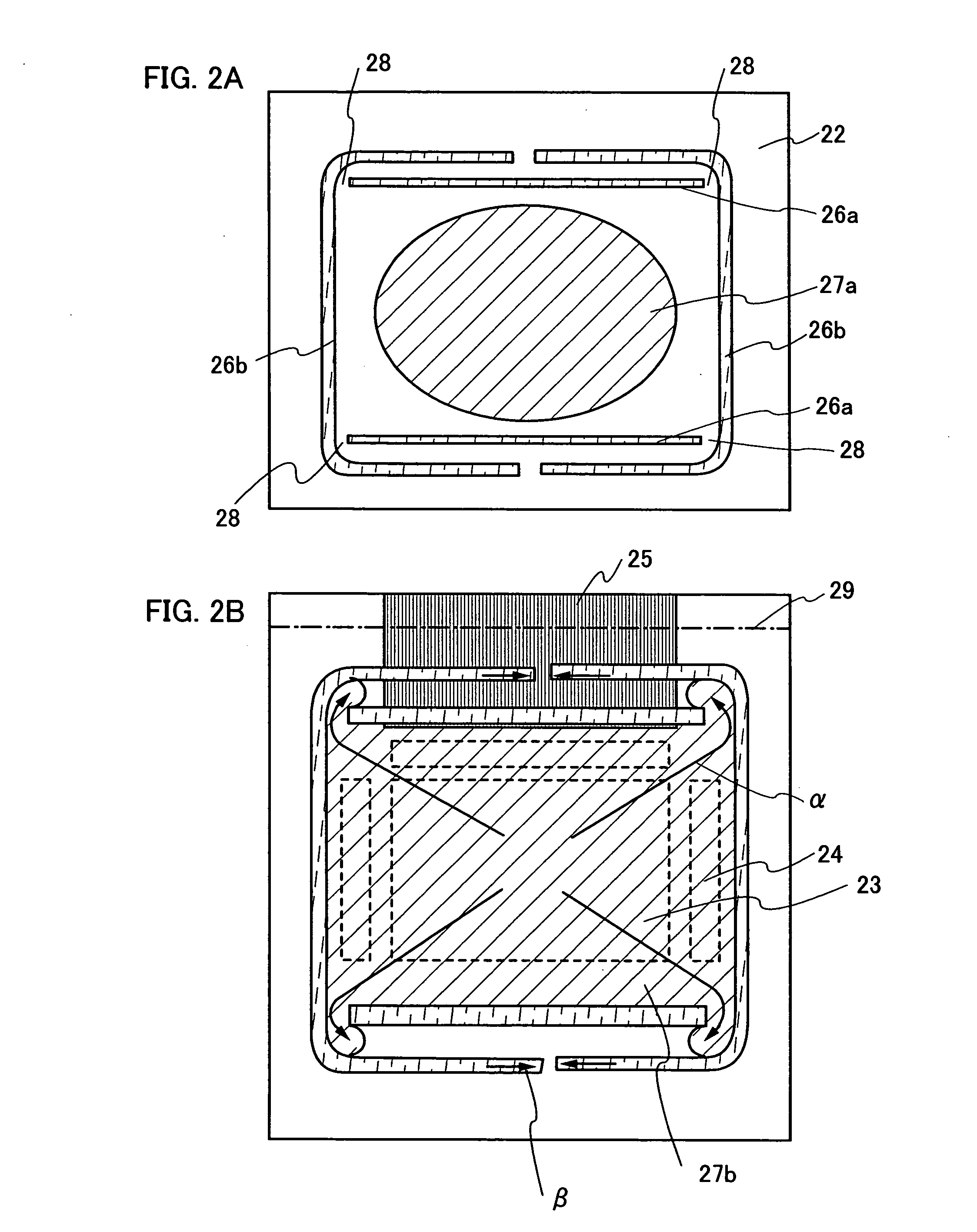

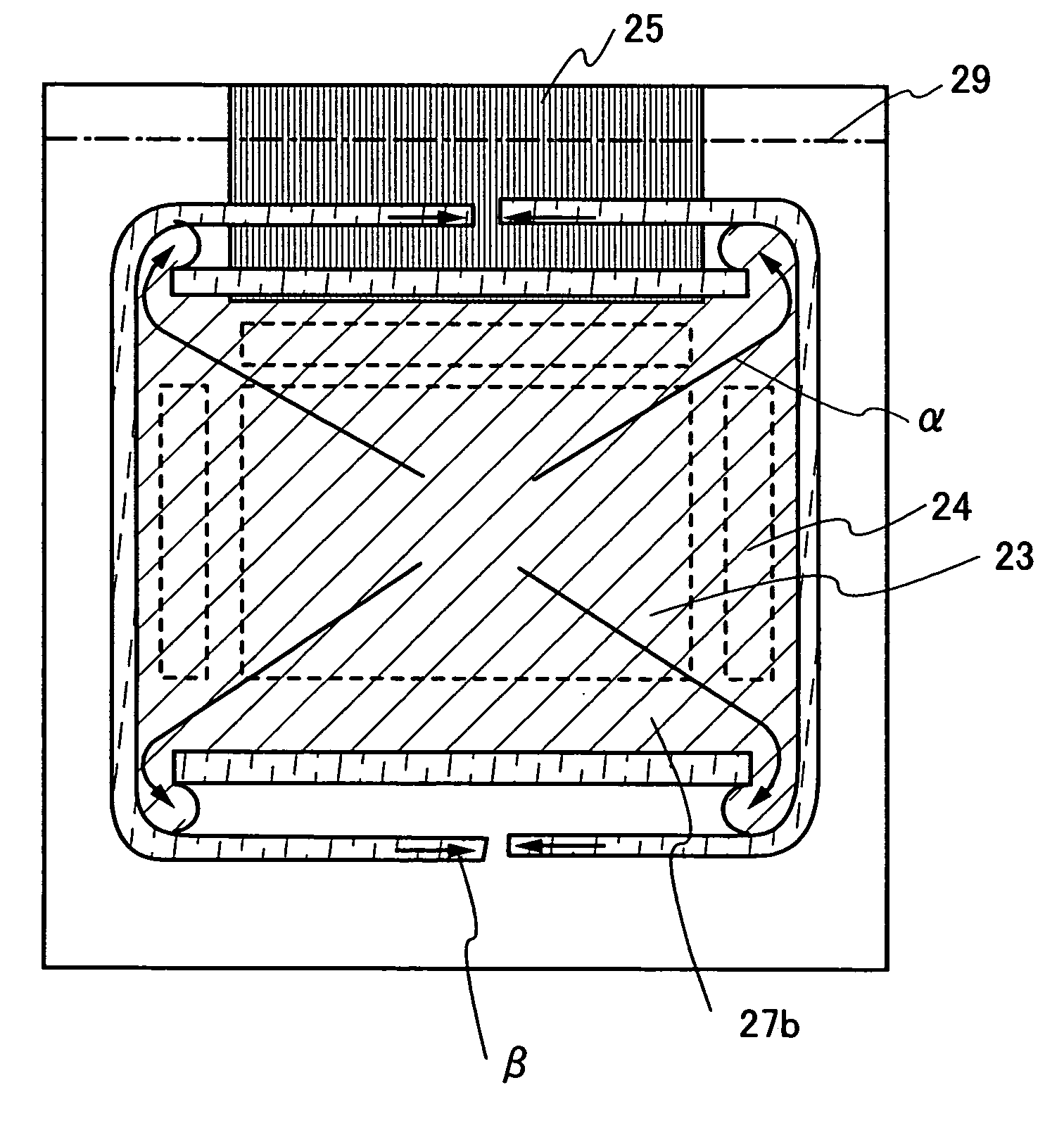

Organic electroluminescent apparatus

InactiveUS20090261719A1Increase load weightImproves sealing reliabilityDischarge tube luminescnet screensLamp detailsOrganic electroluminescenceDrying Agents

An organic electroluminescent apparatus includes a first substrate and a second substrate facing each other, a first sealing portion that seals the first and second substrates so as to form a closed space between the first and second substrates, an organic light-emitting element that is disposed on the first substrate in the closed space and includes an organic light-emitting layer mainly composed of an organic light-emitting material, a second sealing portion that is disposed on the organic light-emitting element and seals the organic light-emitting element, and a drying agent film that is formed in a region surrounded by the first and second sealing portions and is mainly composed of a drying agent.

Owner:SEIKO EPSON CORP

Double-component elastic-handfeel paint and preparation method thereof

InactiveCN102120911AGood compatibilityImprove alcohol resistancePolyurea/polyurethane coatingsAlcoholSolvent

The invention relates to a double-component elastic-handfeel paint and a preparation method thereof. The double-component elastic-handfeel paint comprises a component A and a component B, wherein the component A comprises the following ingredients in parts by weight: 25-40 parts of elastic resin, 1-5 parts of extinction powder, 1-5 parts of elastic powder, 0.2-0.5 part of drying agent, 0.5-3 parts of assistant and 40-60 mixed solvent; the component B is an aliphatic polyisocyanate curing agent; and the proportion of the component A to the component B is 10:(1-2). The preparation method comprises the following steps: adding resin and part of solvent, and dispersing; adding powder, and dispersing; and adding assistant and the rest of the solvent, and dispersing. The film formed by the double-component elastic-handfeel paint has special handfeel, and can satisfy the requirements of resistance testing for high-grade products in the aspects of alcohol resistance, wear resistance and environmental control.

Owner:深圳市深赛尔股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com