Patents

Literature

476 results about "Biodiesel production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

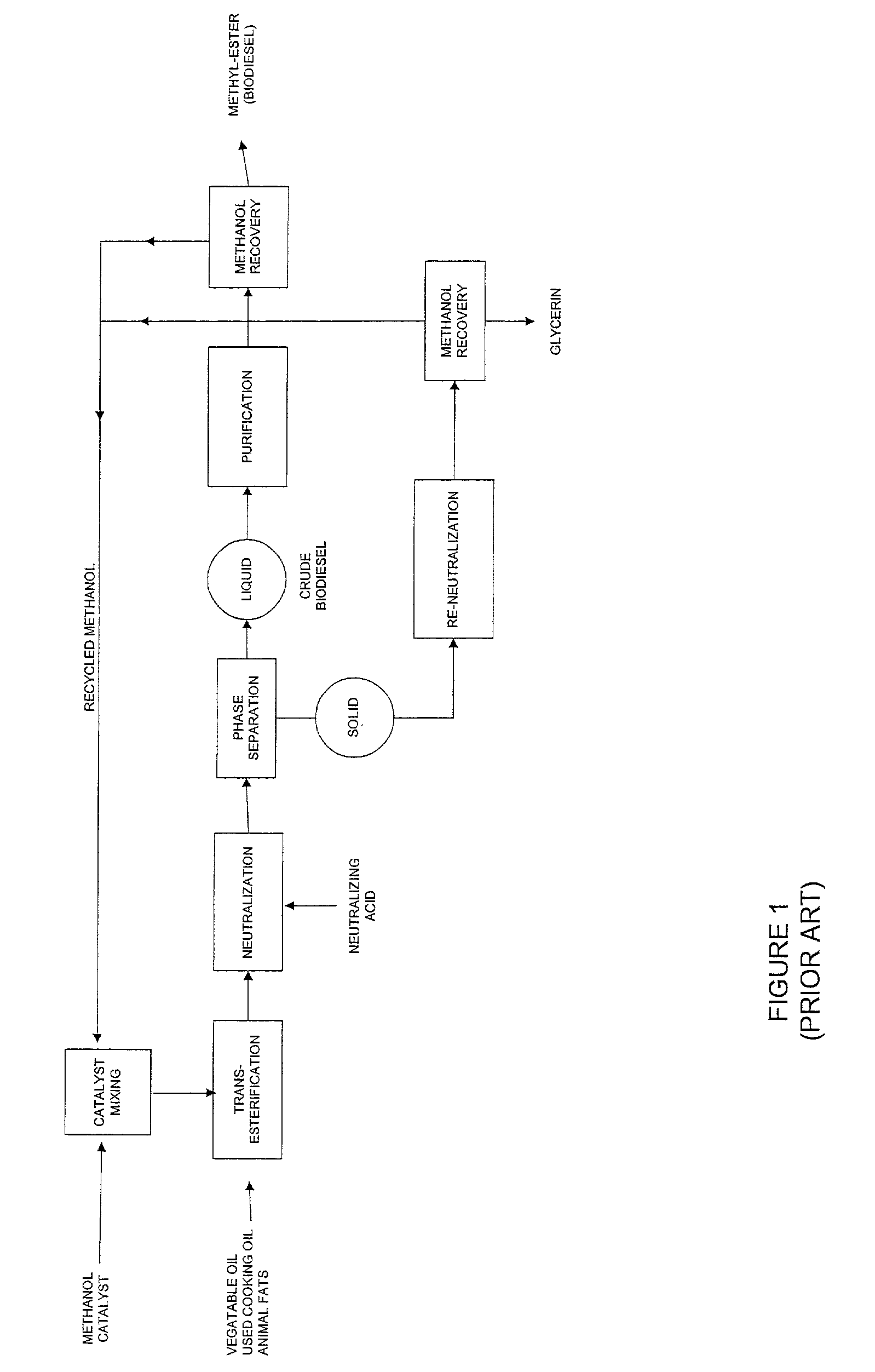

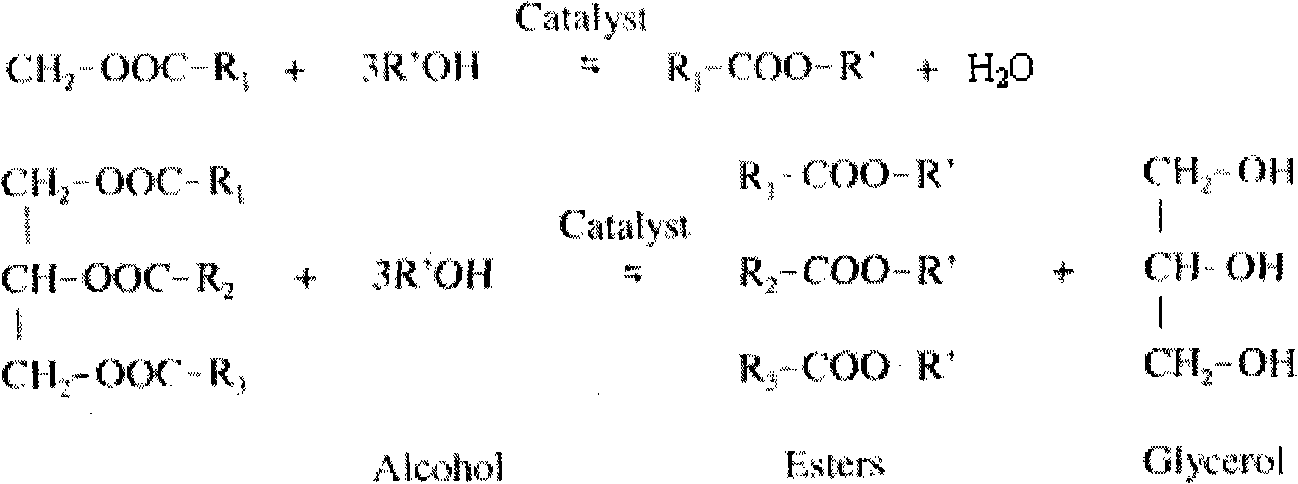

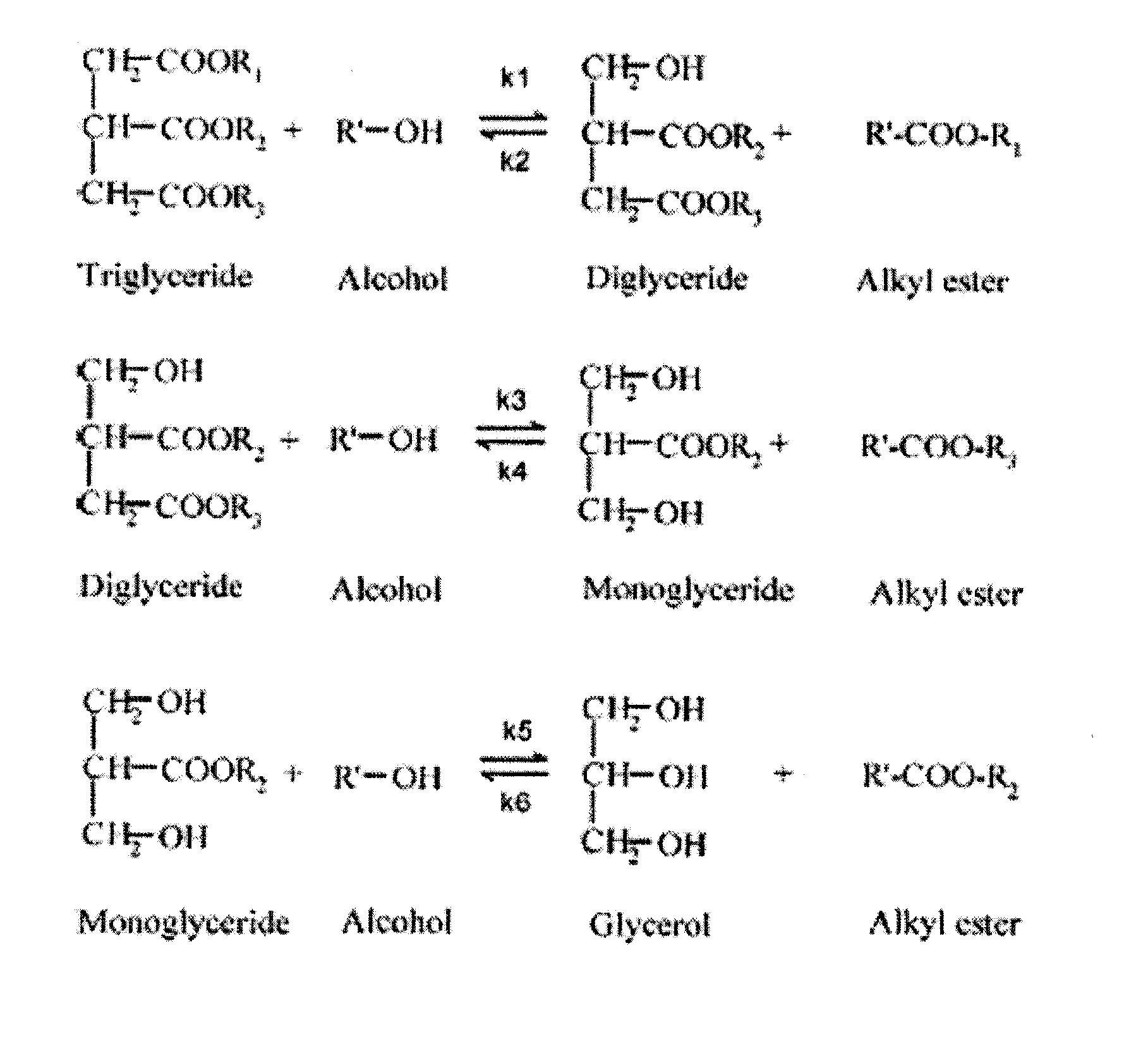

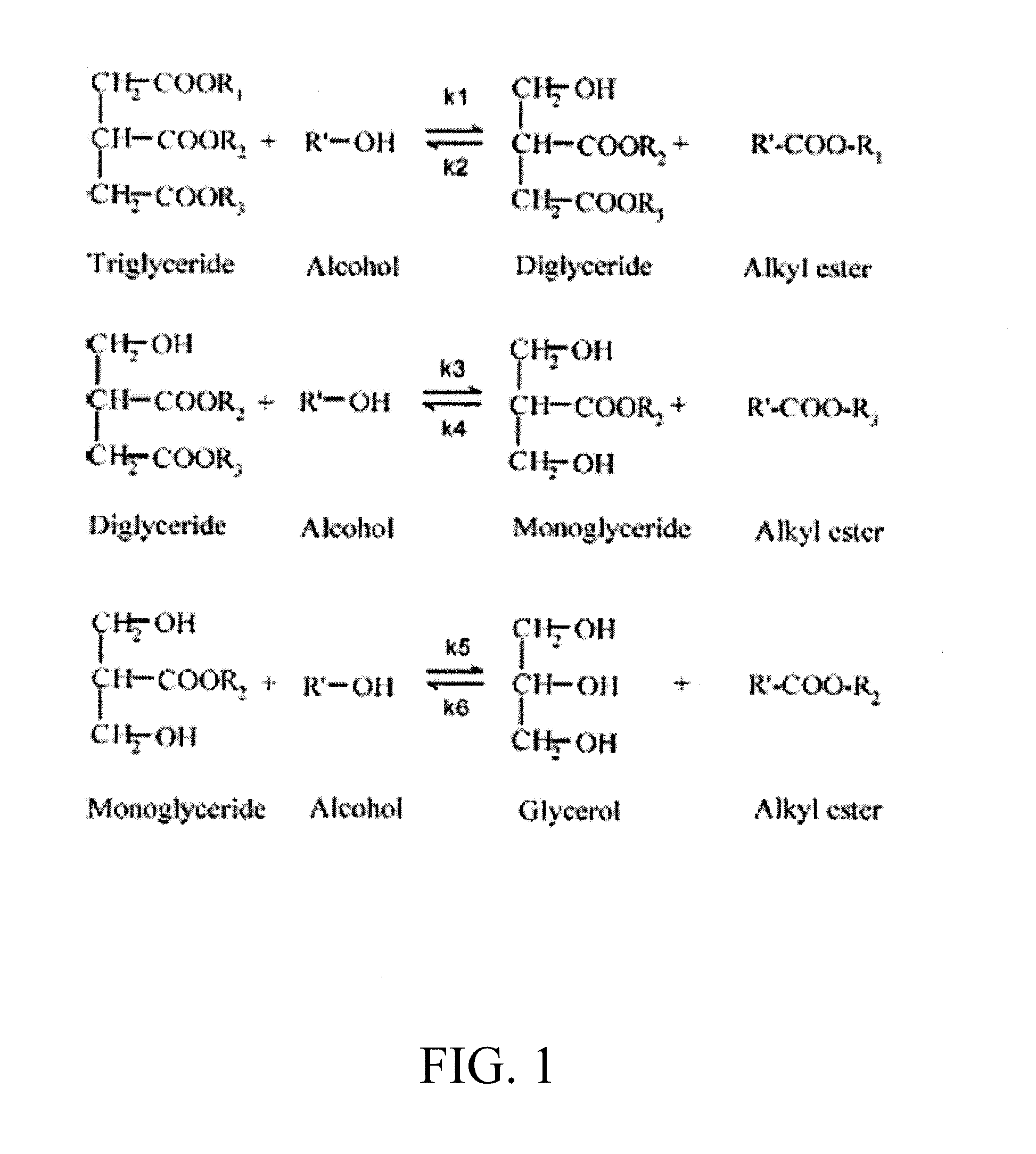

Biodiesel production is the process of producing the biofuel, biodiesel, through the chemical reactions of transesterification and esterification. This involves vegetable or animal fats and oils being reacted with short-chain alcohols (typically methanol or ethanol). The alcohols used should be of low molecular weight. Ethanol is the most used because of its low cost, however, greater conversions into biodiesel can be reached using methanol. Although the transesterification reaction can be catalyzed by either acids or bases, the base-catalyzed reaction is more common. This path has lower reaction times and catalyst cost than those acid catalysis. However, alkaline catalysis has the disadvantage of high sensitivity to both water and free fatty acids present in the oils.

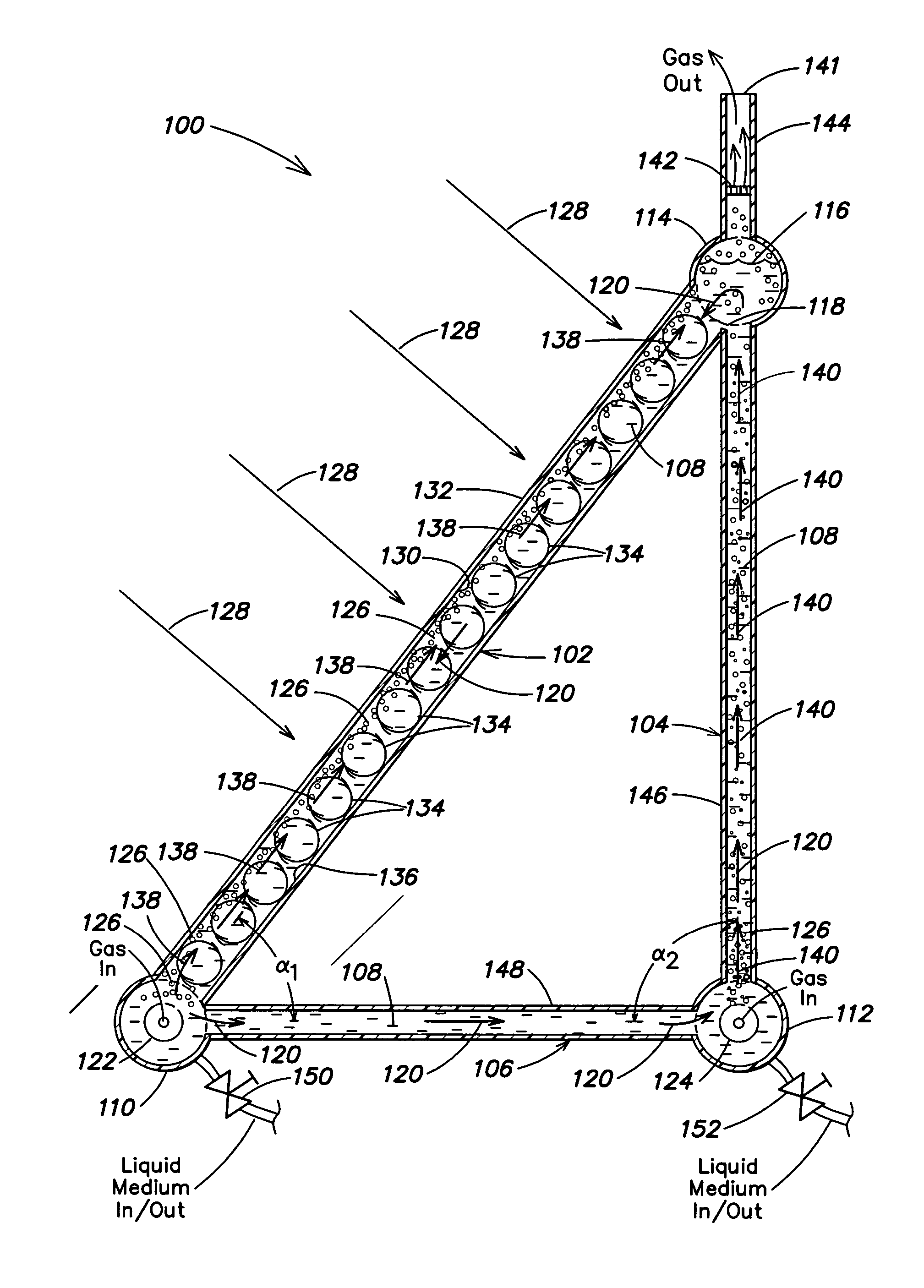

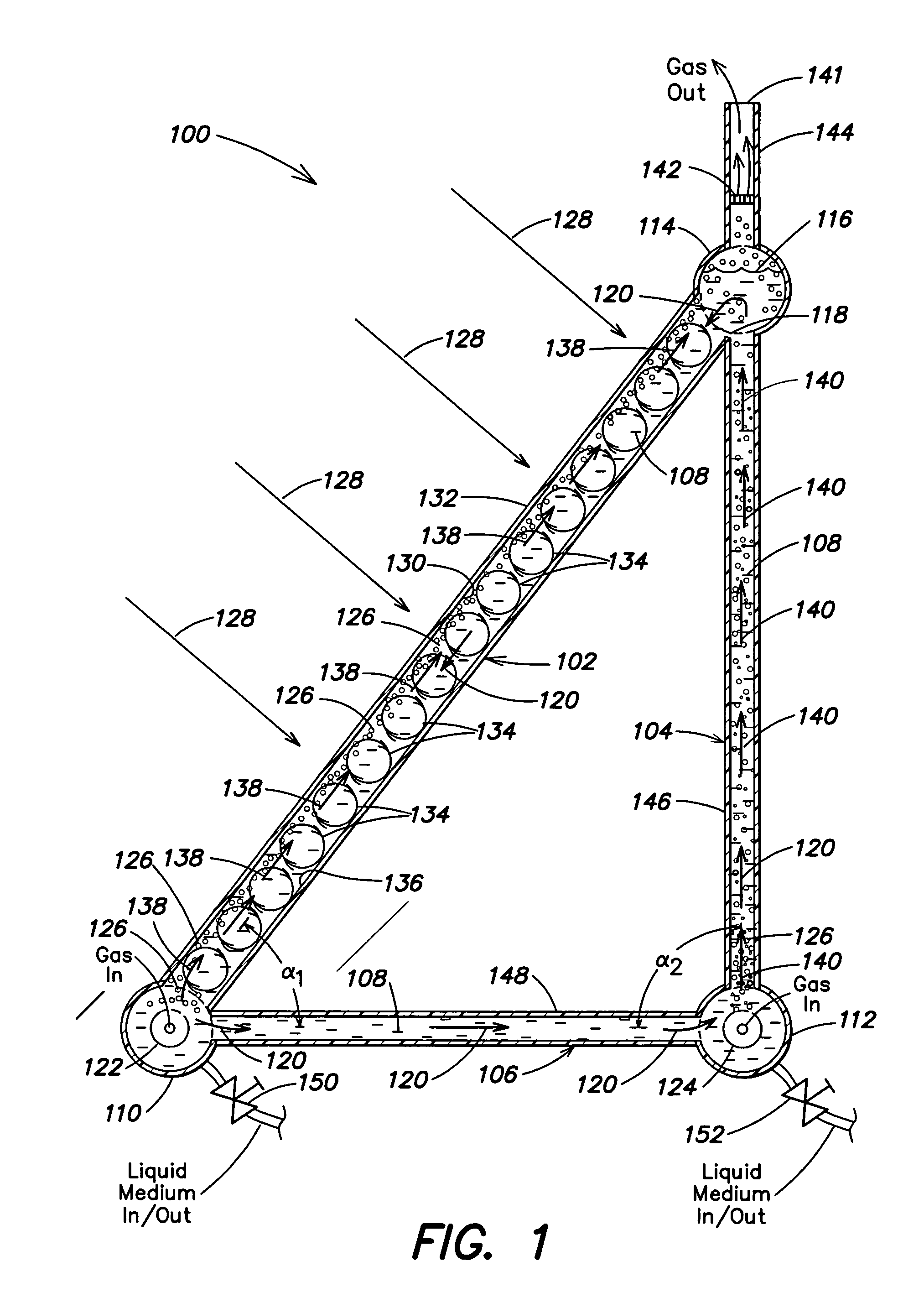

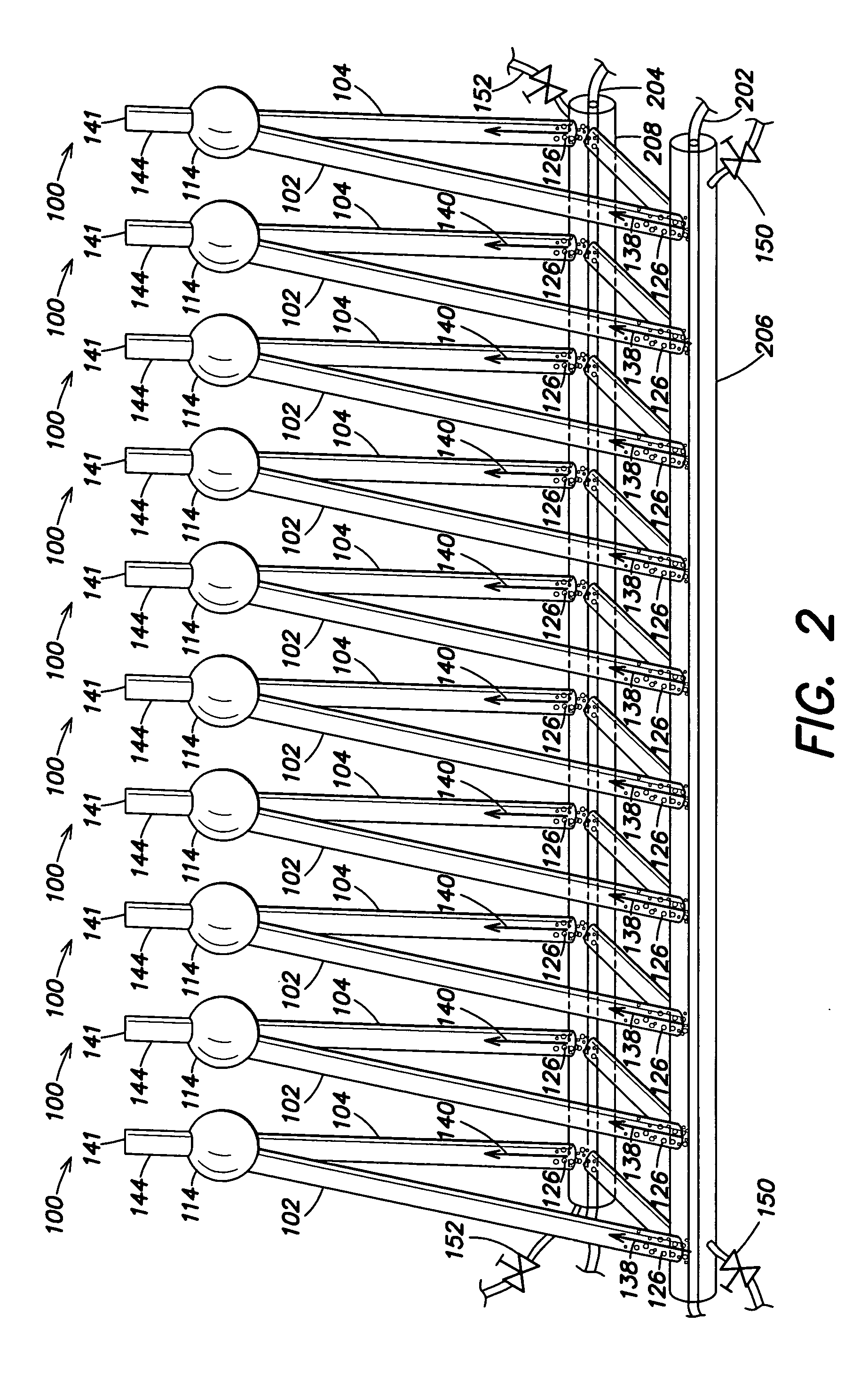

Synthetic and biologically-derived products produced using biomass produced by photobioreactors configured for mitigation of pollutants in flue gases

InactiveUS20050239182A1Bioreactor/fermenter combinationsBiological substance pretreatmentsBiodieselLiquid medium

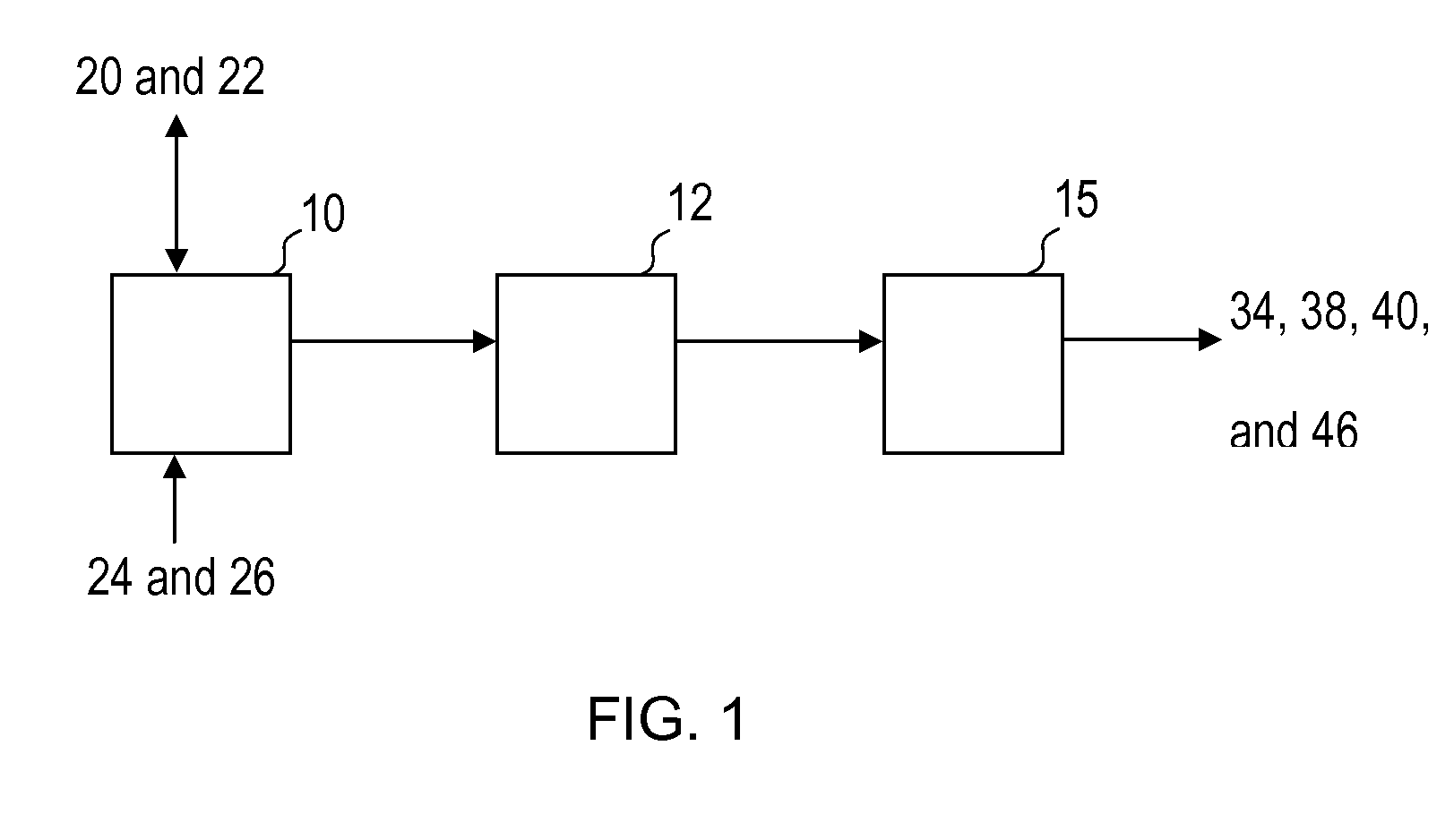

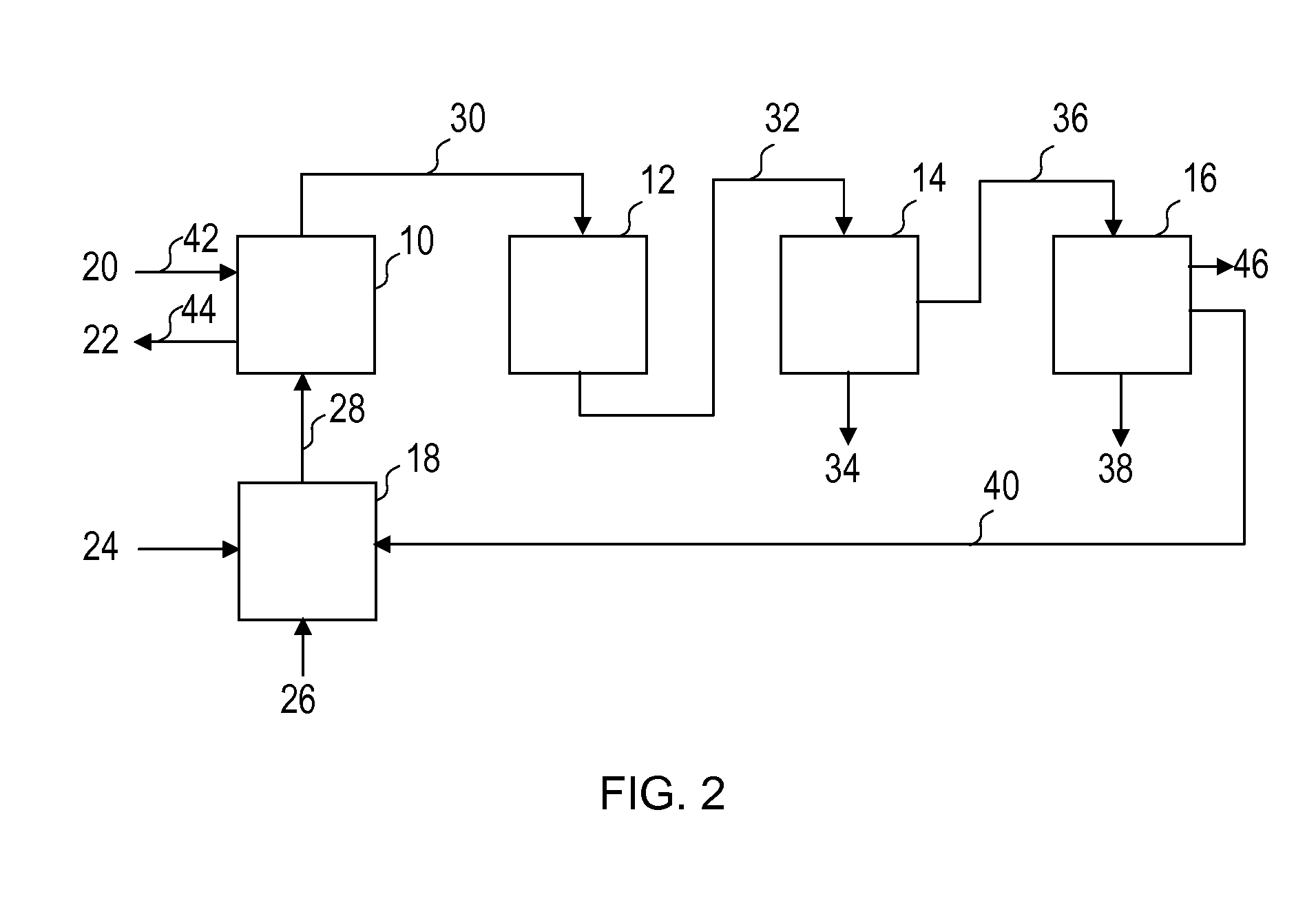

Certain embodiments and aspects of the present invention relate to photobioreactor apparatus designed to contain a liquid medium comprising at least one species of photosynthetic organisms therein, and to methods of using the photobioreactor apparatus as part of a production process for forming an organic molecule-containing product, such as a polymeric material and / or fuel-grade oil (e.g. biodiesel), from biomass produced in the photobioreactor apparatus. In certain embodiments, the disclosed organic molecule / polymer production systems and methods, photobioreactor apparatus, methods of using such apparatus, and / or gas treatment systems and methods provided herein can be utilized as part of an integrated combustion and polymer and / or fuel-grade oil (e.g. biodiesel) production method and system, wherein photosynthetic organisms utilized within the photobioreactor are used to at least partially remove certain pollutant compounds contained within combustion gases, e.g. CO2 and / or NOx, and are subsequently harvested from the photobioreactor, processed, and utilized as a source for generating polymers and / or organic molecule-containing products (e.g. fuel-grade oil (e.g. biodiesel)) and / or as a fuel source for a combustion device (e.g. an electric power plant generator and / or incinerator).

Owner:GREENFUEL TECHNOLOGIES CORPORATION

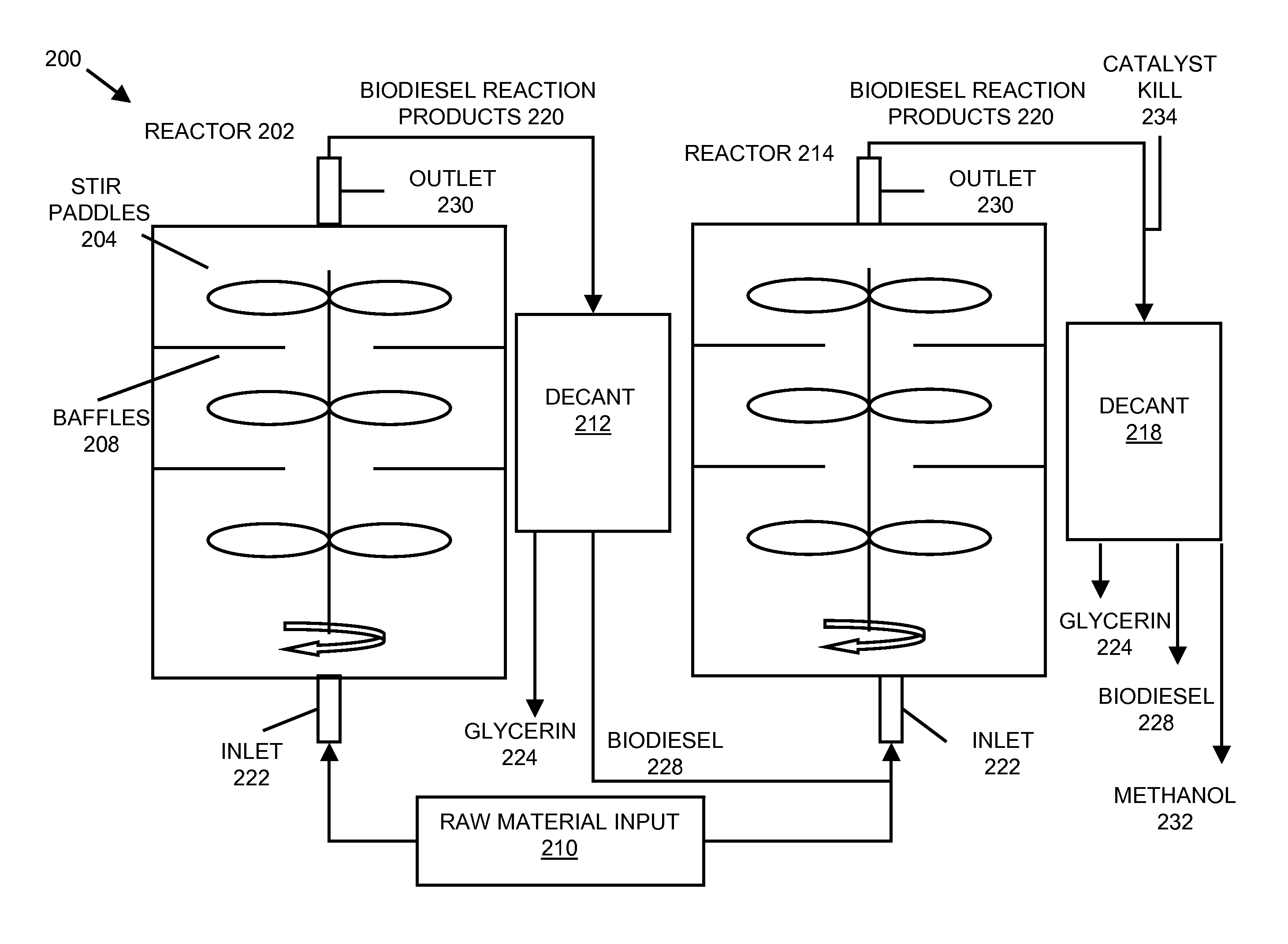

System and process for producing biodiesel

InactiveUS20080282606A1Reducing filter blocking tendencyEnhance biodiesel stabilityFatty acid esterificationFatty acids production/refiningBiodieselDistillation

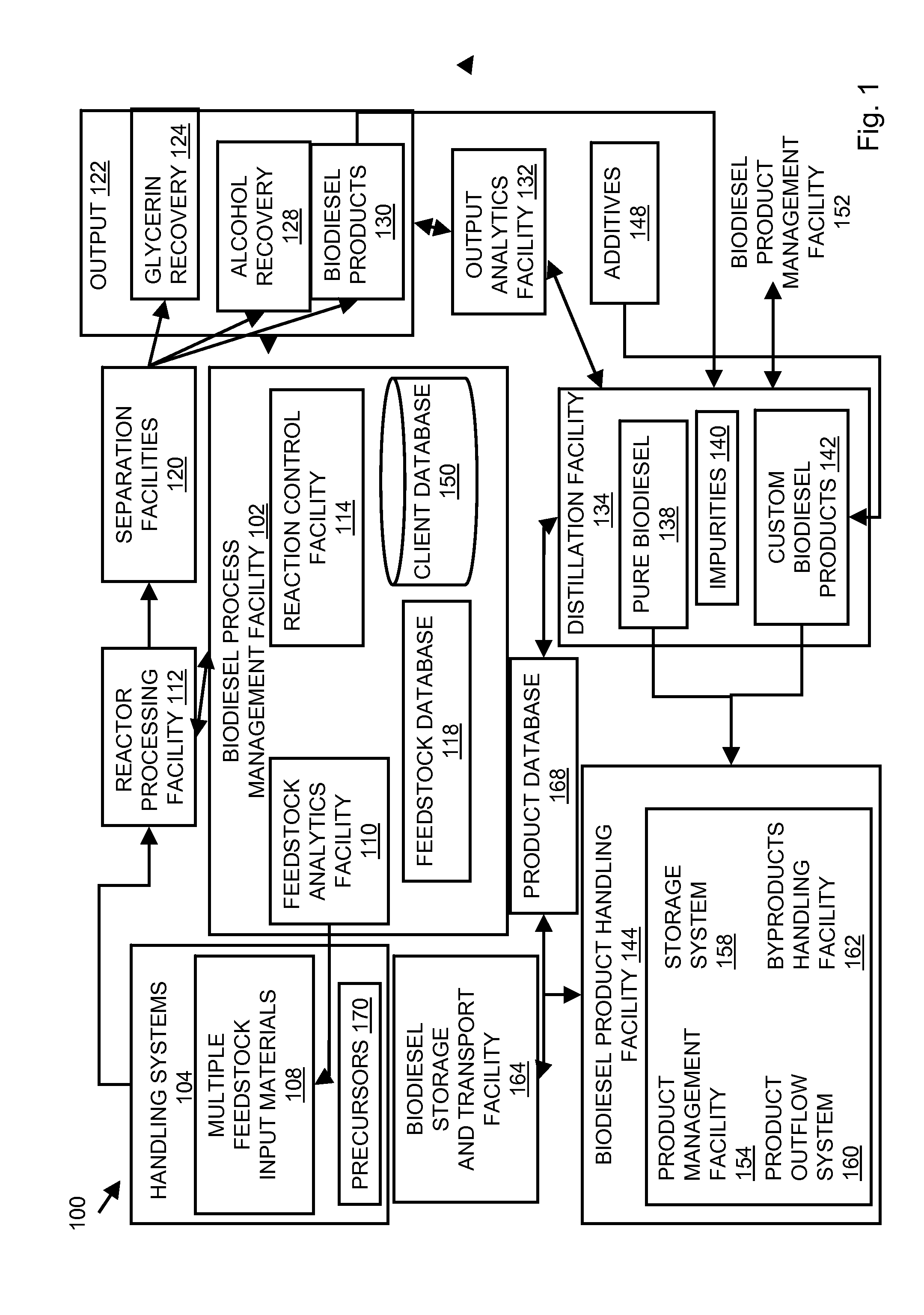

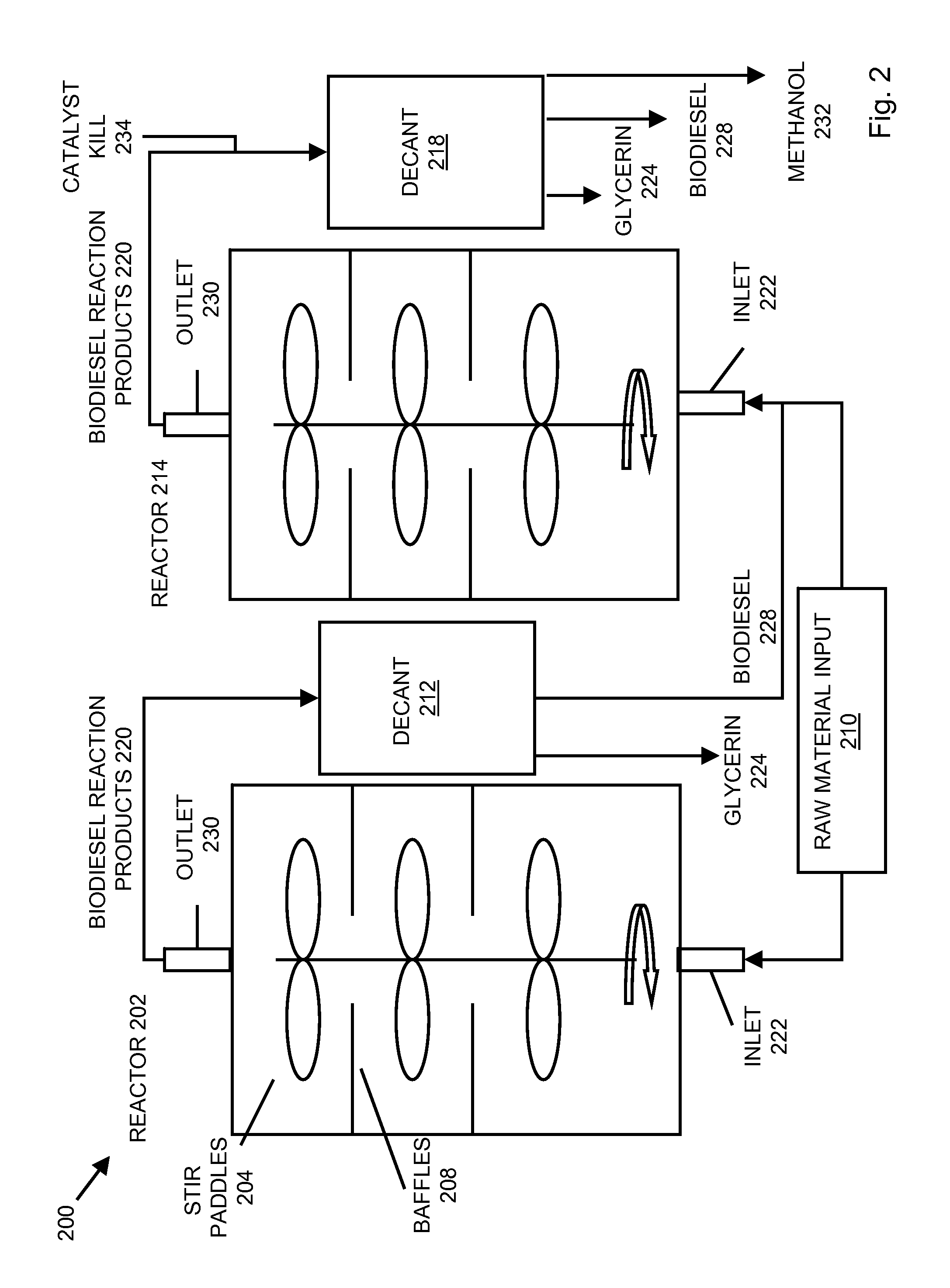

In embodiments of the present invention, systems for producing a biodiesel product from multiple feedstocks may include a biodiesel reactor, a decanter, a flash evaporator and a distillation column. In other embodiments of the present invention, a process for producing a biodiesel comprises distilling a biodiesel reaction product to remove tocopherols and sterol glucosides and, optionally, adding biodiesel stabilizers to the resultant biodiesel to enhance thermal stability. The components of the system are interrelated so that parameters may be regulated to allow production of a custom biodiesel product.

Owner:IMPERIUM PROCESS TECH

Purification of glycerin

InactiveUS7126032B1Low costEfficient recyclingOrganic compound preparationOxygen compounds purification/separationAlcoholWash water

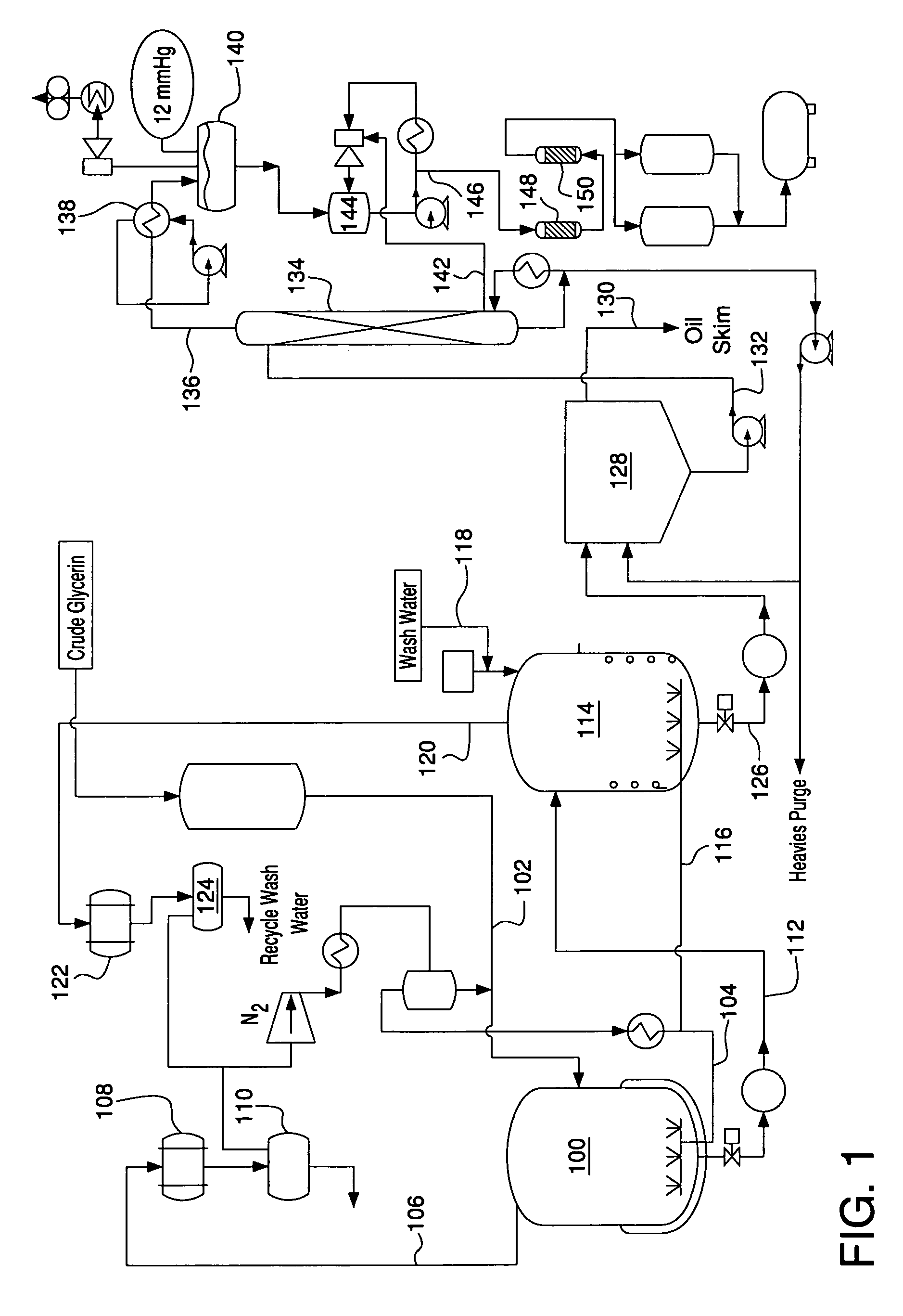

A process for purifying glycerin recovered as a byproduct of biodiesel production comprises heating a glycerin effluent stream containing a low molecular weight alcohol, water and fatty acid esters of the low molecular weight alcohol to cause transesterification of the fatty acid esters to glycerides and additional low molecular weight alcohol. The reaction mixture is sparged with nitrogen to help remove water and low molecular weight alcohol, which drives the transesterification reaction towards glyceride formation. A wash water stream may also be added to the recovered glycerin stream from biodiesel production. Either before or following the transesterification reaction, an oil layer can be separated from the recovered glycerin stream by reducing the pH of the stream to below 7. Following separation of the oil layer and transesterification the glycerin stream is flash distilled to separate glycerin from water, salts, and glycerides.

Owner:SUNOCO INC (R&M)

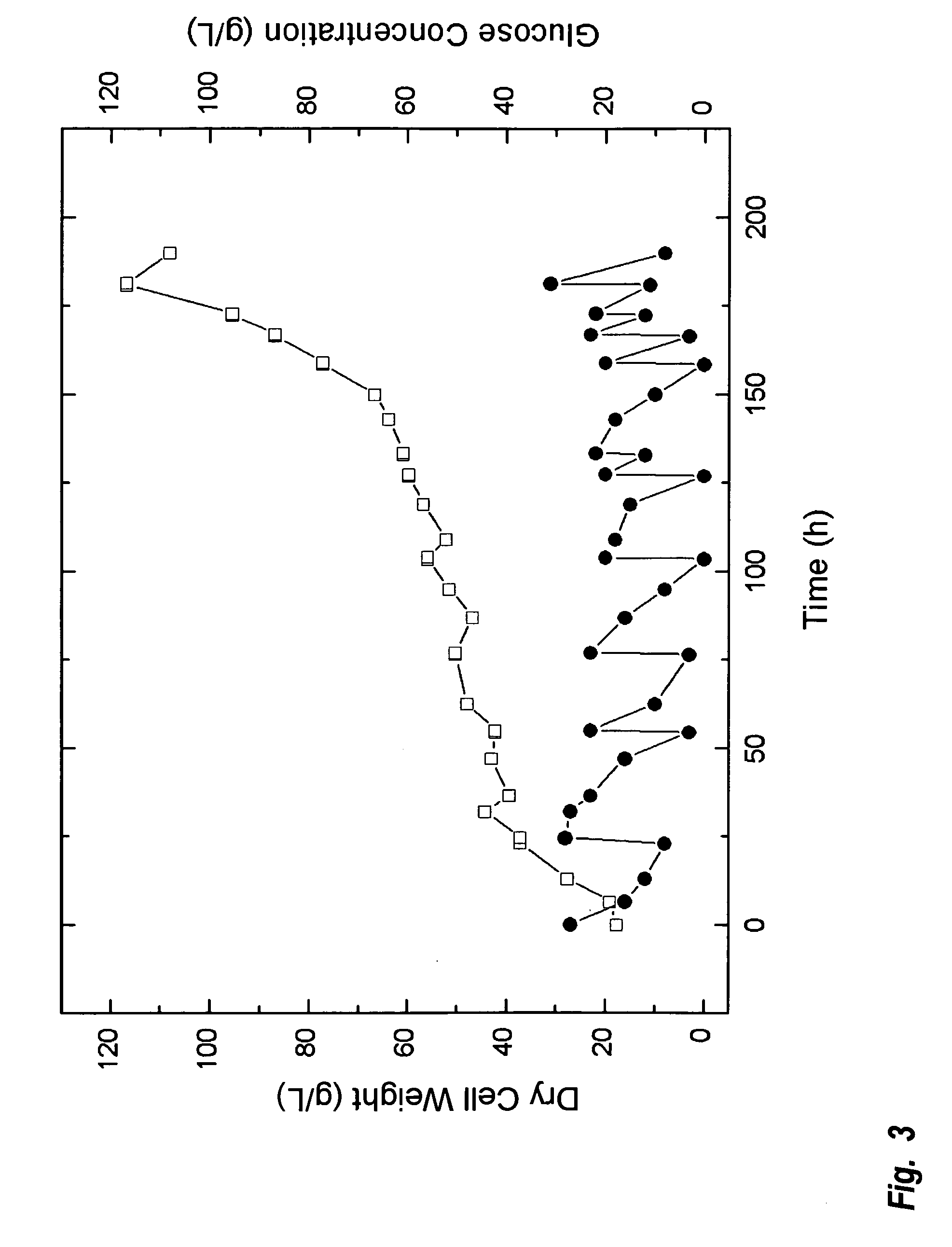

Method for producing biodiesel from an alga

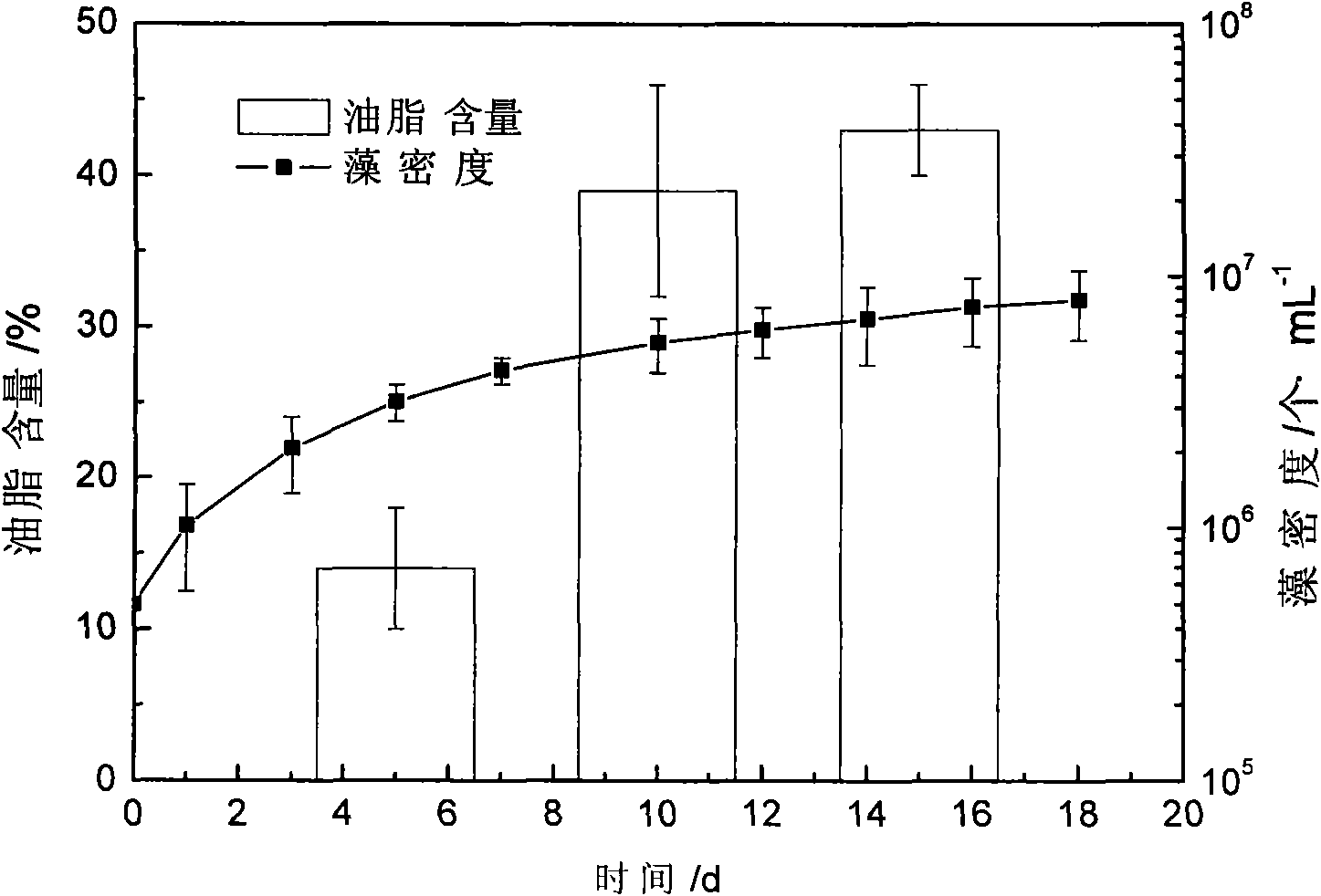

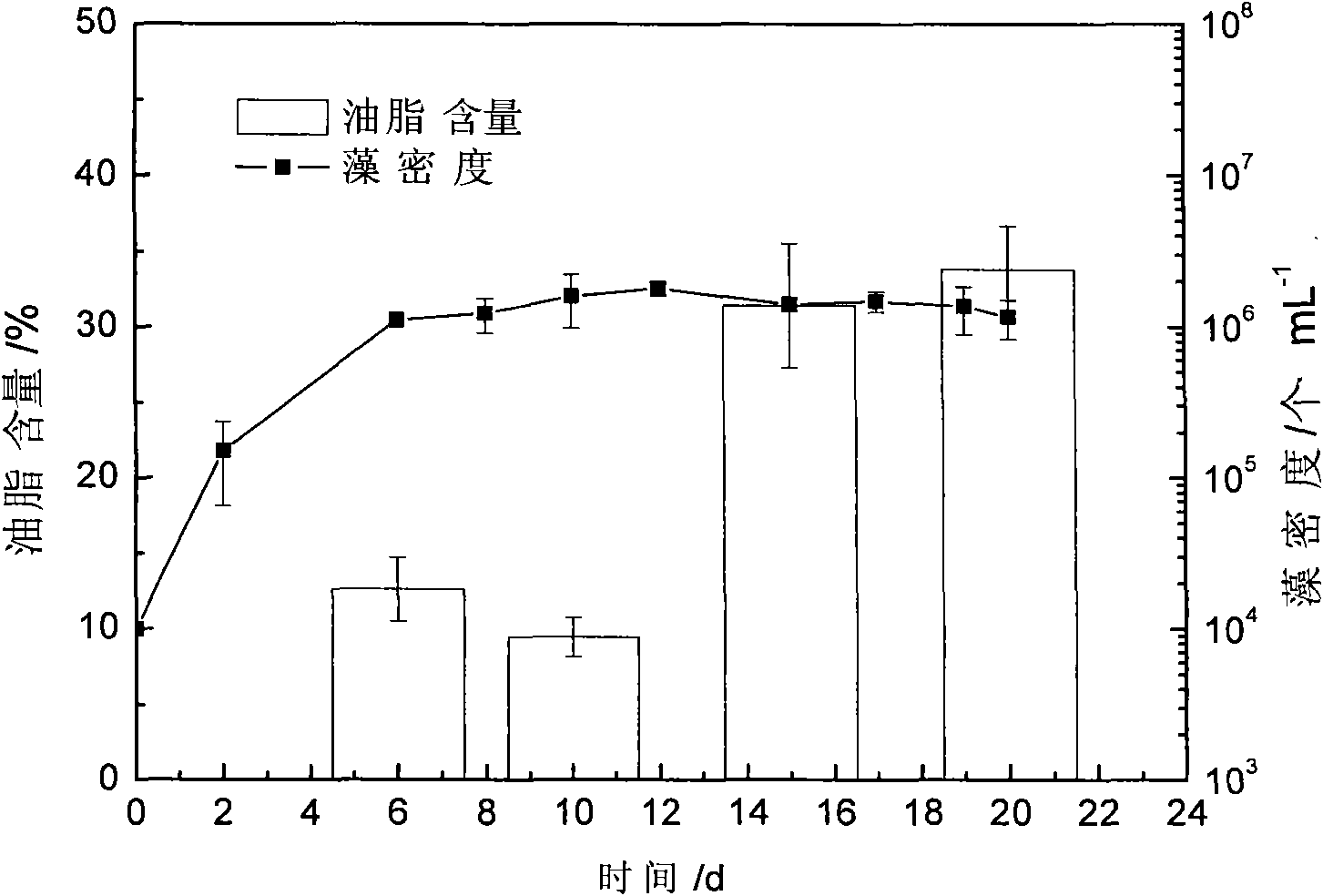

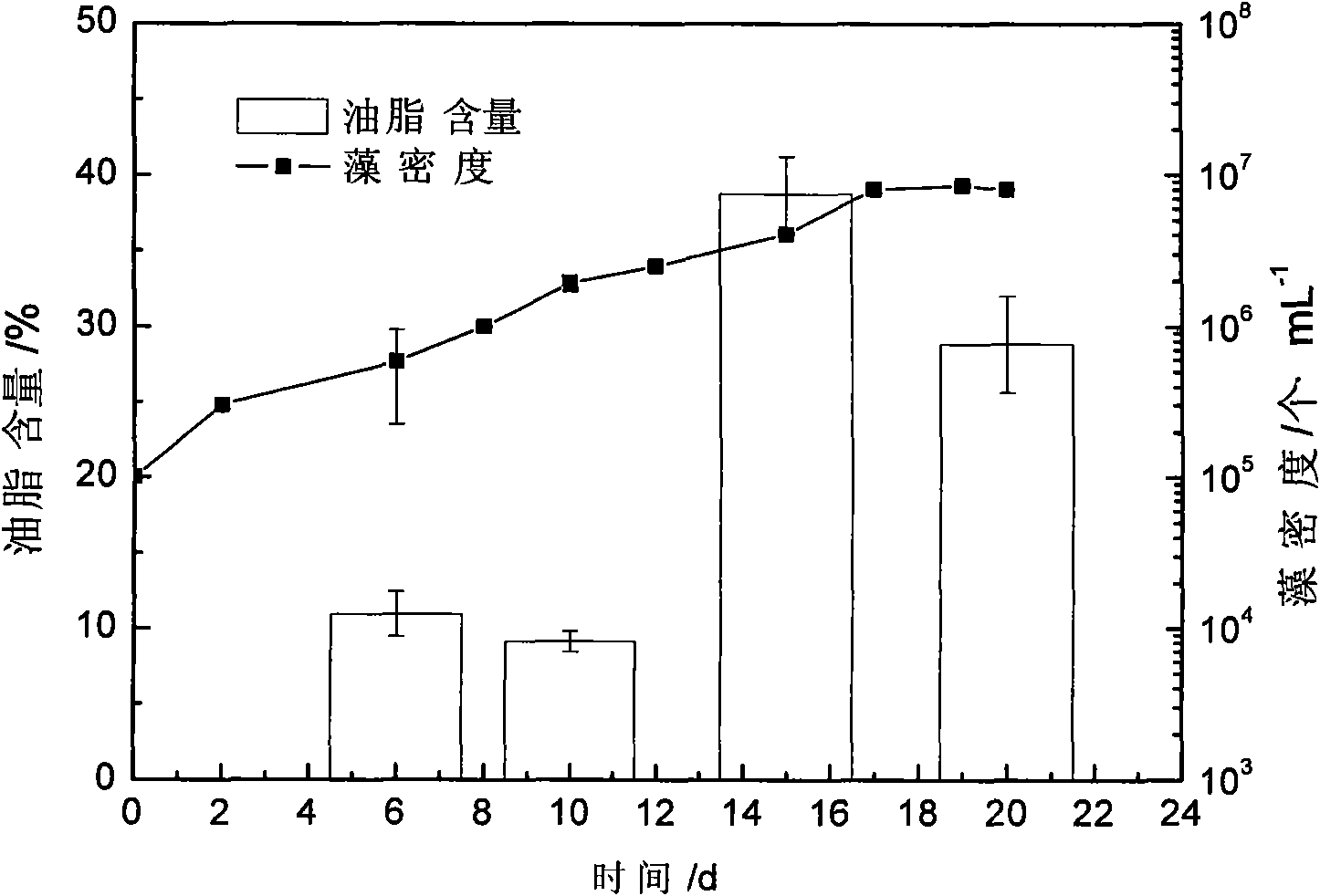

InactiveUS20090298159A1Avoid Microbial ContaminationOrganic chemistryFatty acid esterificationMembrane lipid metabolismOrganism

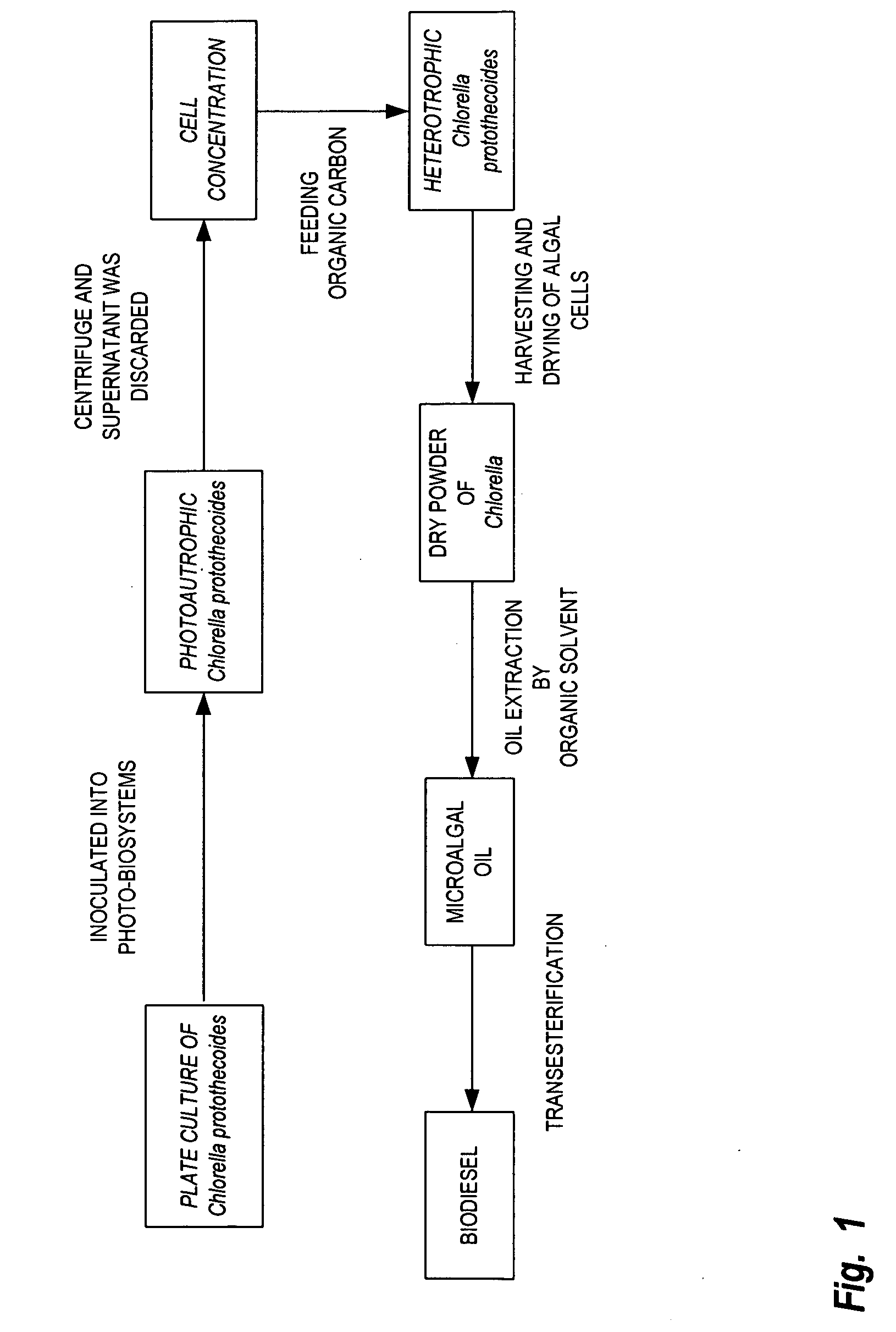

A method is provided to produce biodiesel from algae using a two-stage, autotrophic and heterotrophic cultivations of chlorella for biodiesel production. This method includes a sequence of procedures: cultivating photoautotrophic algae, concentrating cells and then transferring them to a fermentor for heterotrophic cultivation. During the photoautotrophic cultivation stage, the culture is exposed to a light source, such as sunlight with carbon dioxide obtained from a carbon dioxide source or from air. antibacterial agents may be added to prevent contamination from undesired microorganisms. Organic carbons are added during heterotrophic cultivation stage. Fermentation conditions are optimized for maximizing lipid synthesis. High biomass is achieved to about 108 g / L with lipid content reaching about 52% of dry cell weight. After cultivation, biodiesel is made through extraction and transesterification of algae lipids.

Owner:TSINGHUA UNIV

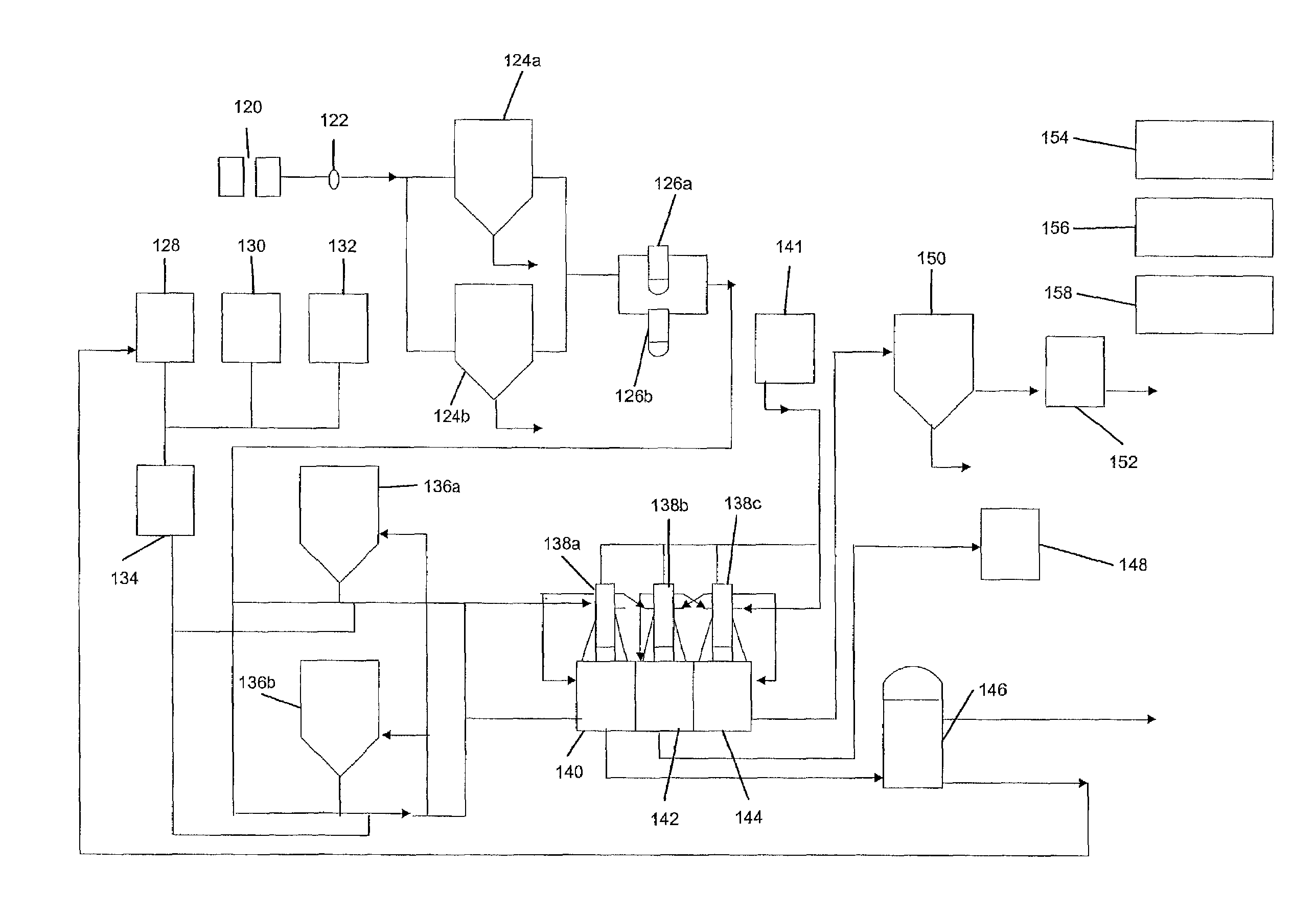

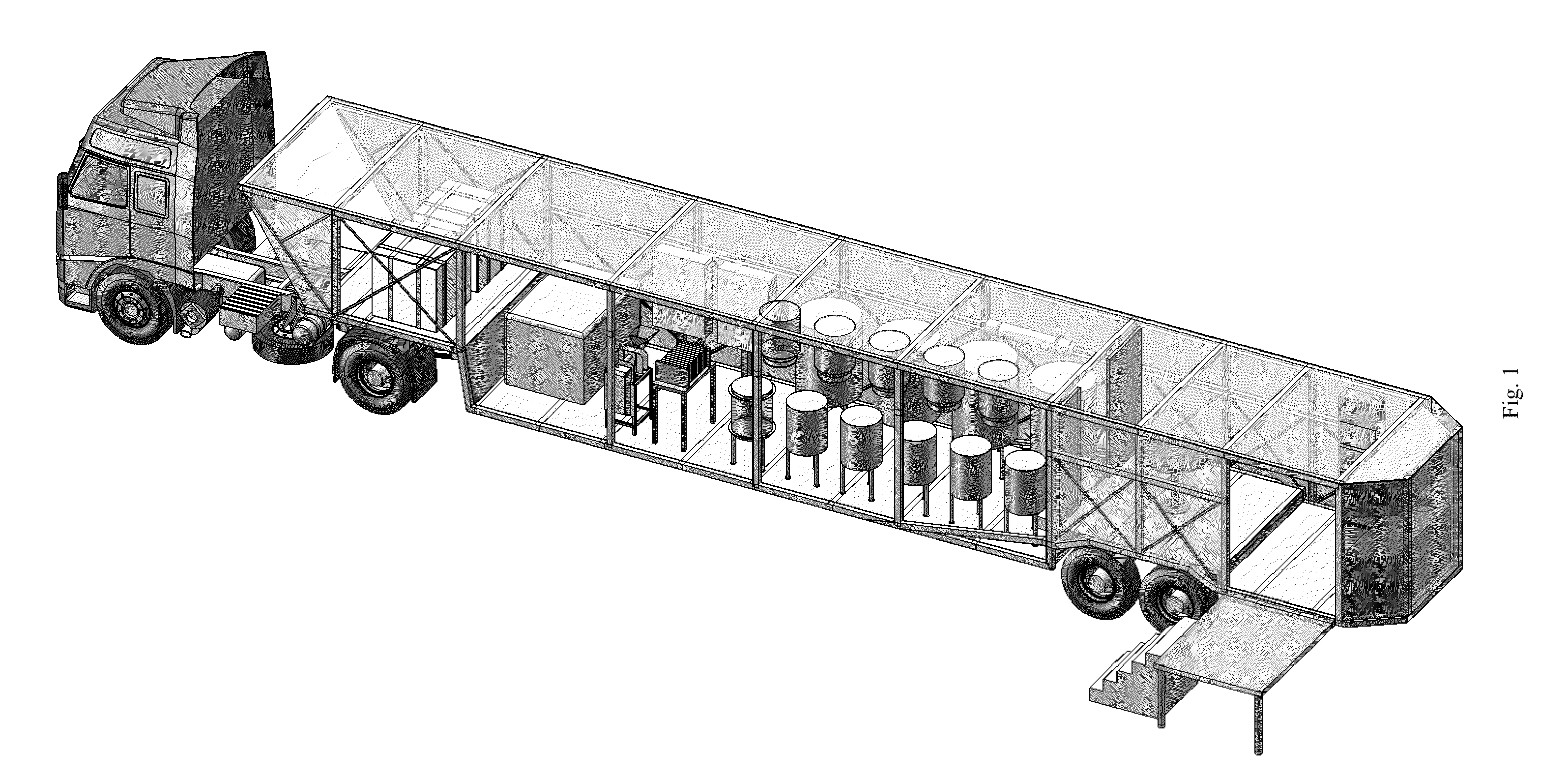

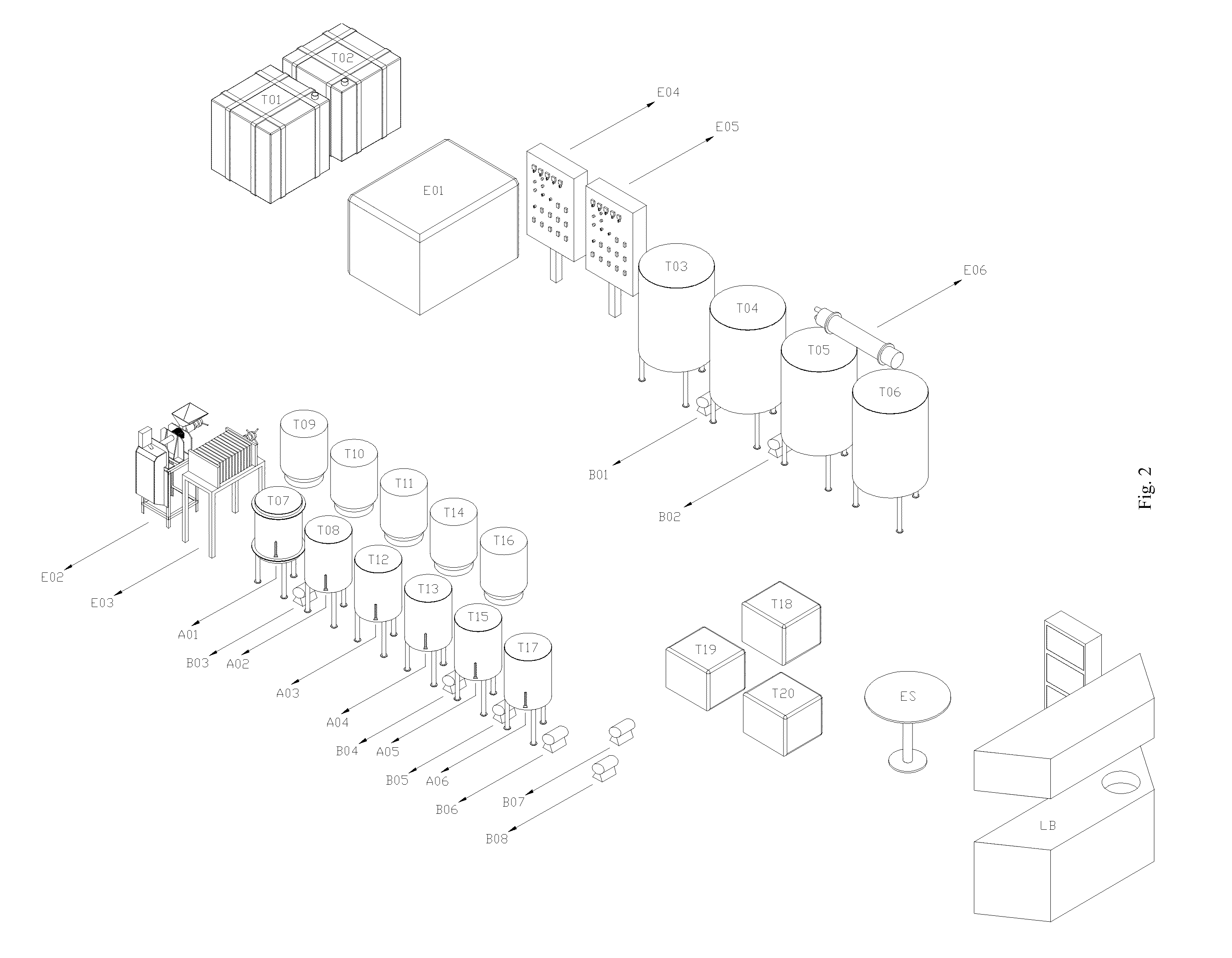

Biodiesel production unit

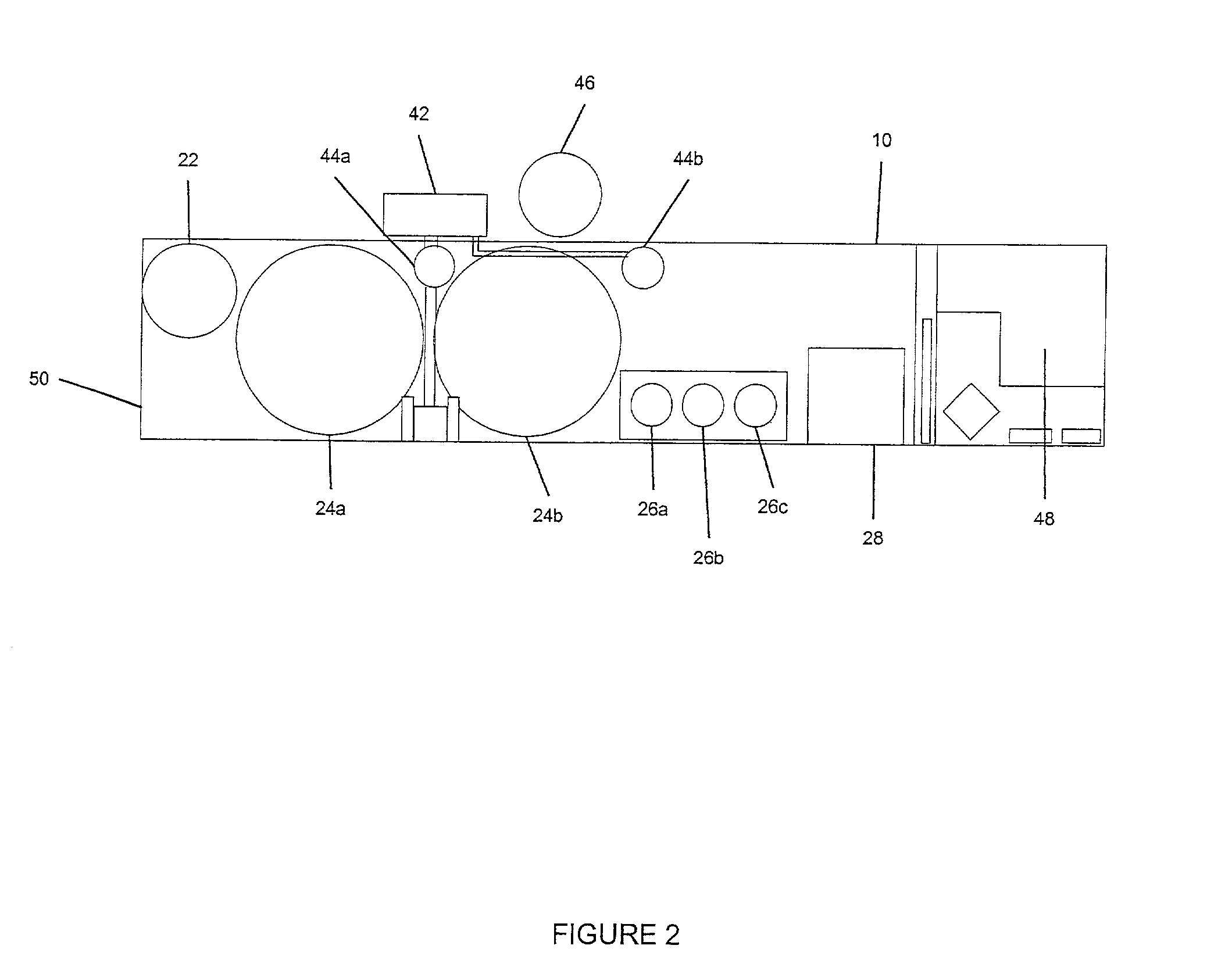

In a first aspect, systems and methods for producing biodiesel fuel include a modular production unit incorporated onto a single platform or into a housing for ease of relocatability. The modular production unit preferably includes a mixing unit, a reactor unit, a separation unit, a distillation unit, and a filtering unit, all incorporated onto or into a self-contained platform or housing that is able to be easily relocated. In a second aspect, the modular production unit is combined with additional fixed and / or relocatable components to provide a biodiesel processing plant. In a third aspect, a raw materials processing system and method includes a roller barrel adapted for recovery, transportation, and introduction of recycled oil feedstock into a biodiesel manufacturing process. The raw materials processing system preferably includes a hot box for filtering and heating the raw recycled oil feedstock.

Owner:BIODIESEL IND

Continuous algal biodiesel production facility

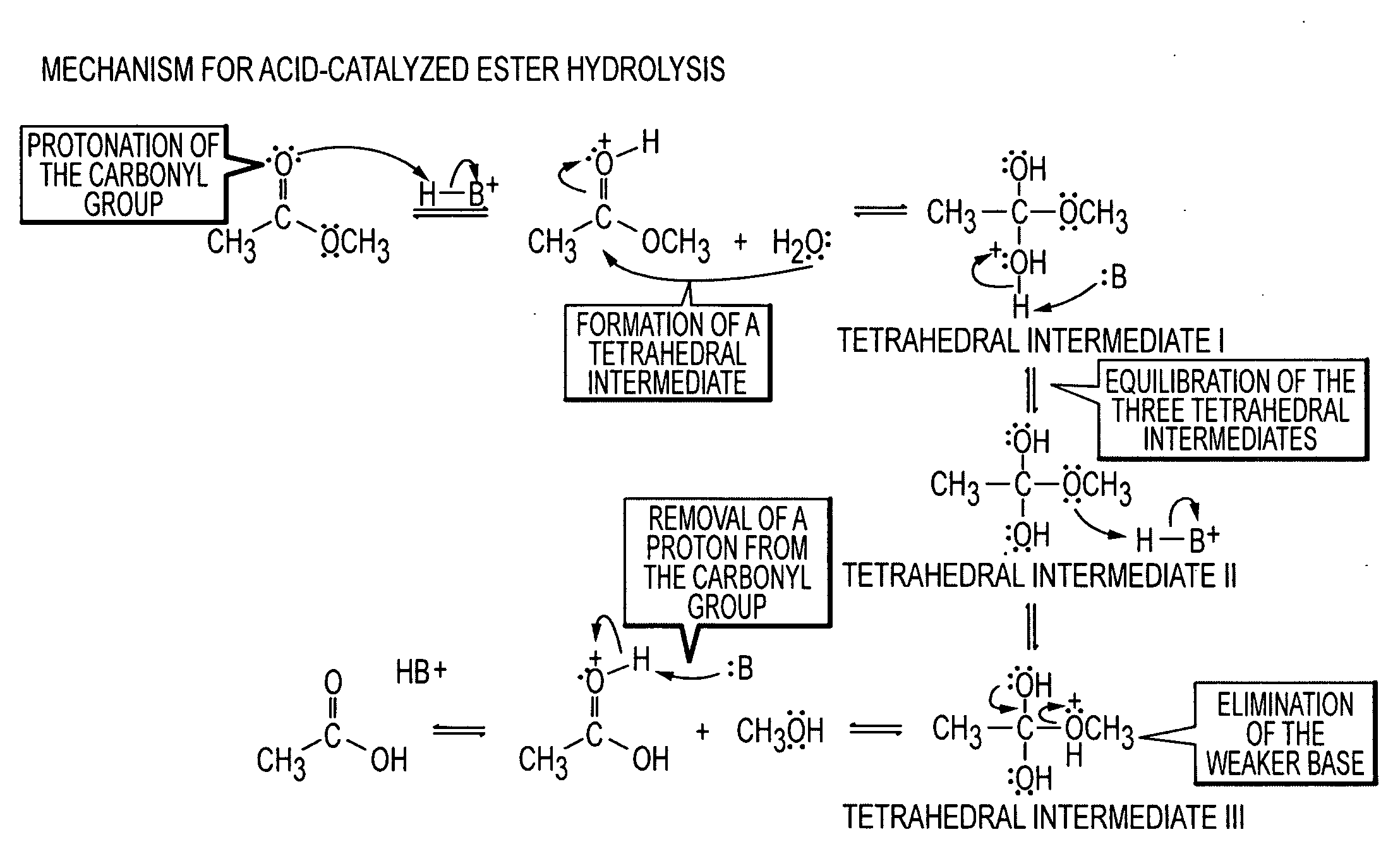

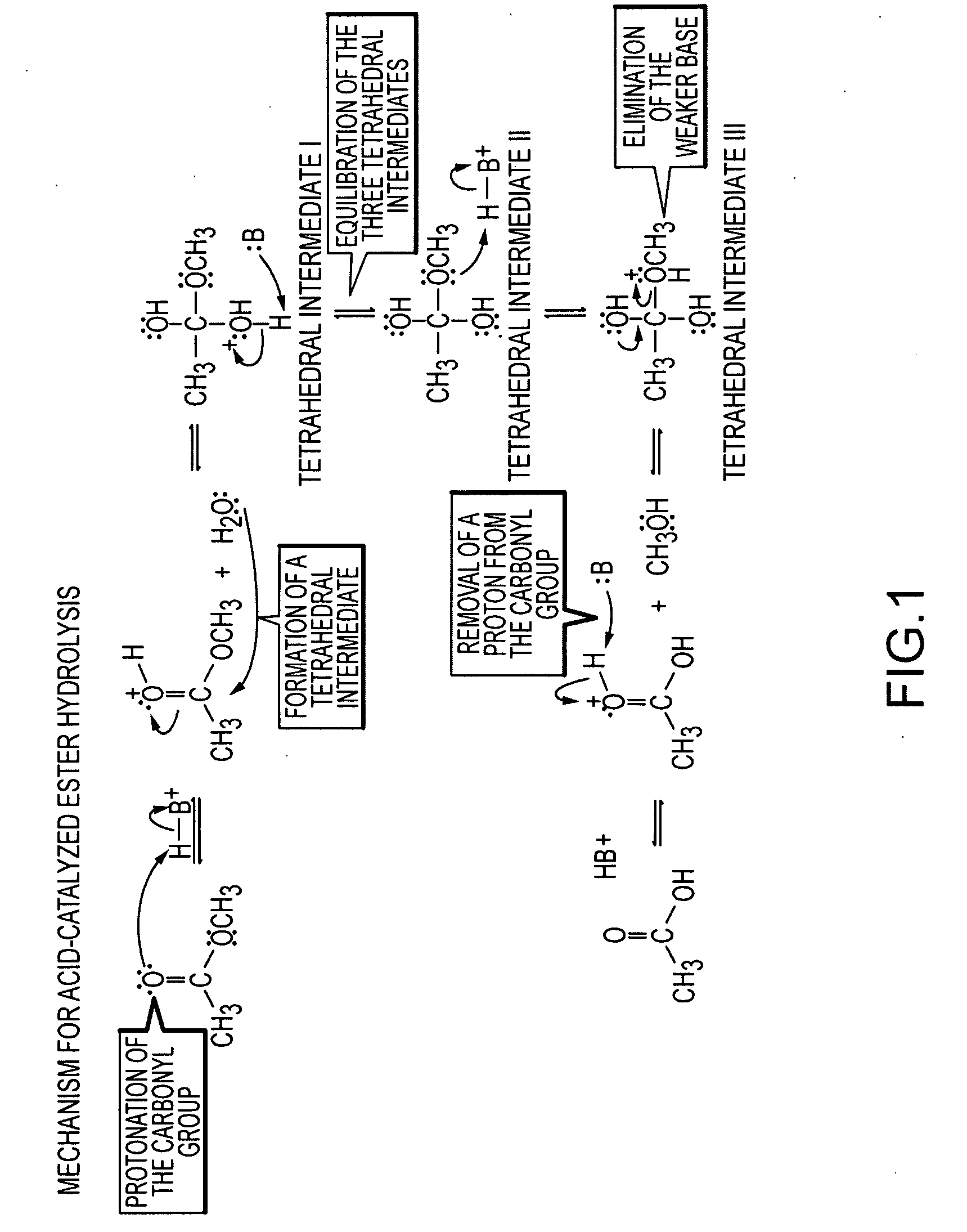

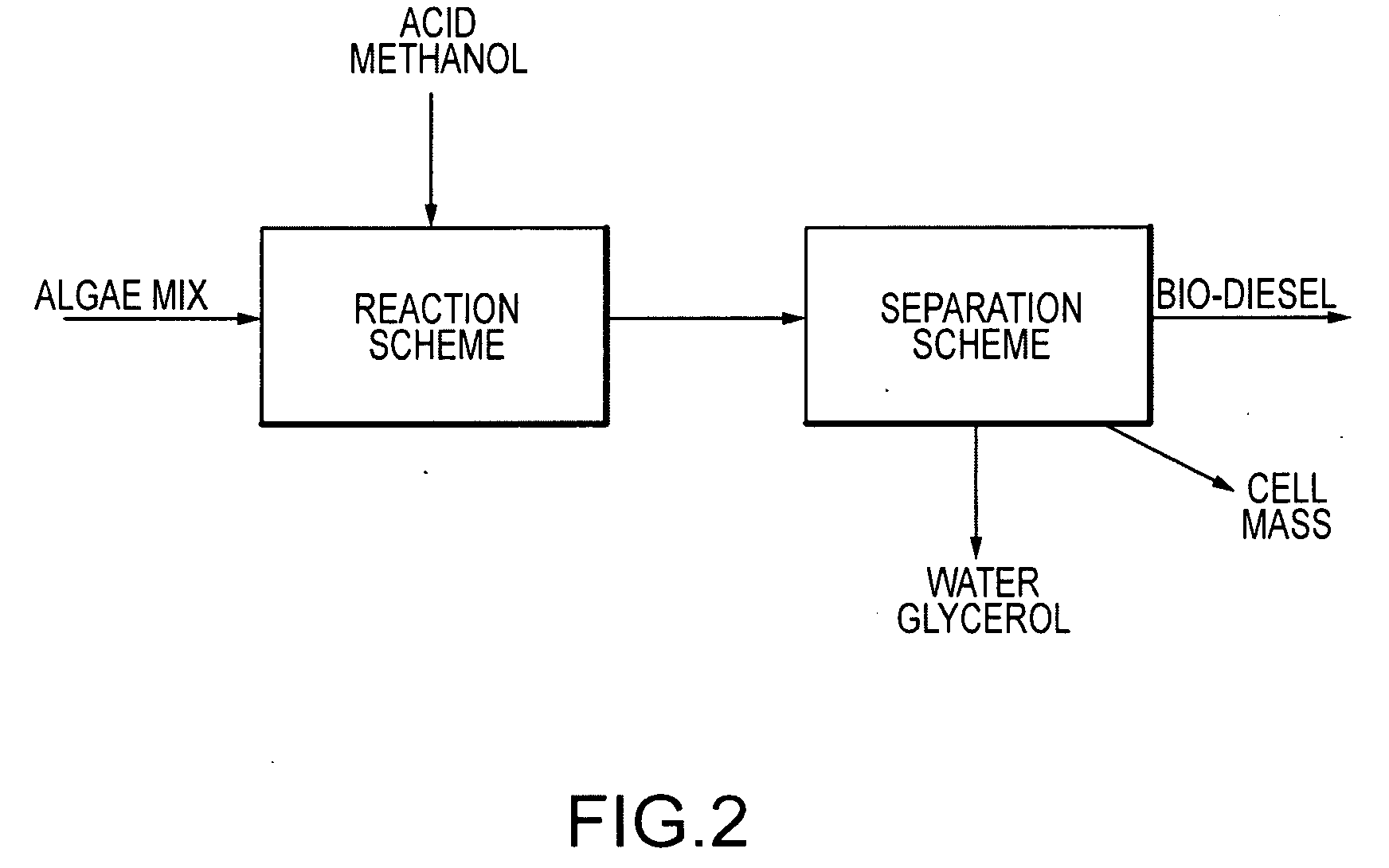

Embodiments of the present invention concern methods, compositions, and apparatus for the continuous conversion of algal lipids into biodiesel. In some embodiments, the biodiesel is formed in a multi-step sequence, the first steps occurring in the presence of water and a strong acid wherein the lipids are released from the algae by means of mechanical and chemical action and are then hydrolyzed to free fatty acids. In a subsequent step, this free fatty acid mixture is reacted with methanol to generate fatty acid methyl esters (also known as biodiesel). Such methods produce biodiesel from algal lipids without the requirement for separate algal cell lysis or lipid extraction or purification prior to the acid catalysis sequence. In other embodiments, the multi-step acid catalysis sequence occurs at 100° C. at two atmospheres of pressure.

Owner:COLORADO STATE UNIVERSITY +1

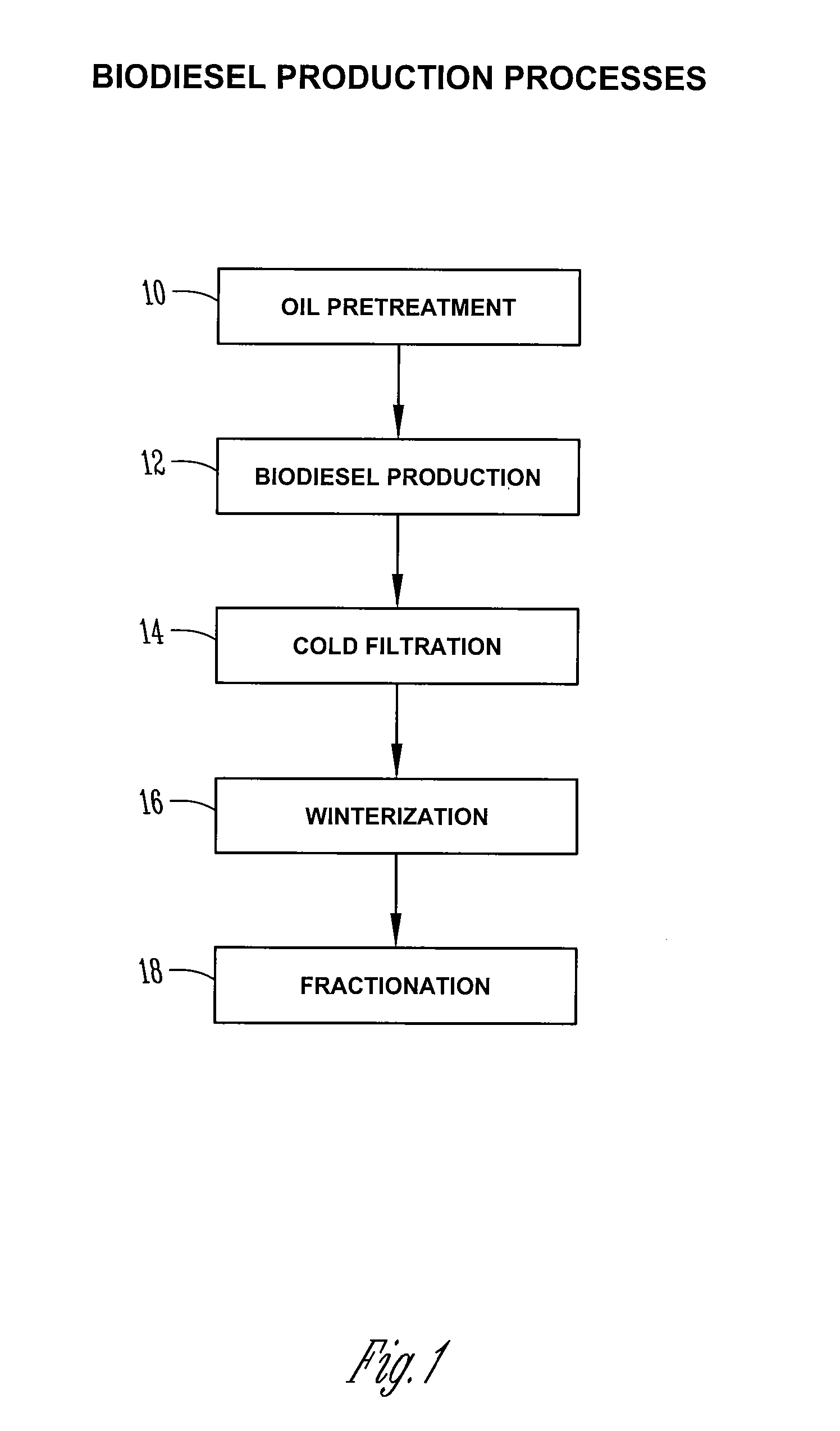

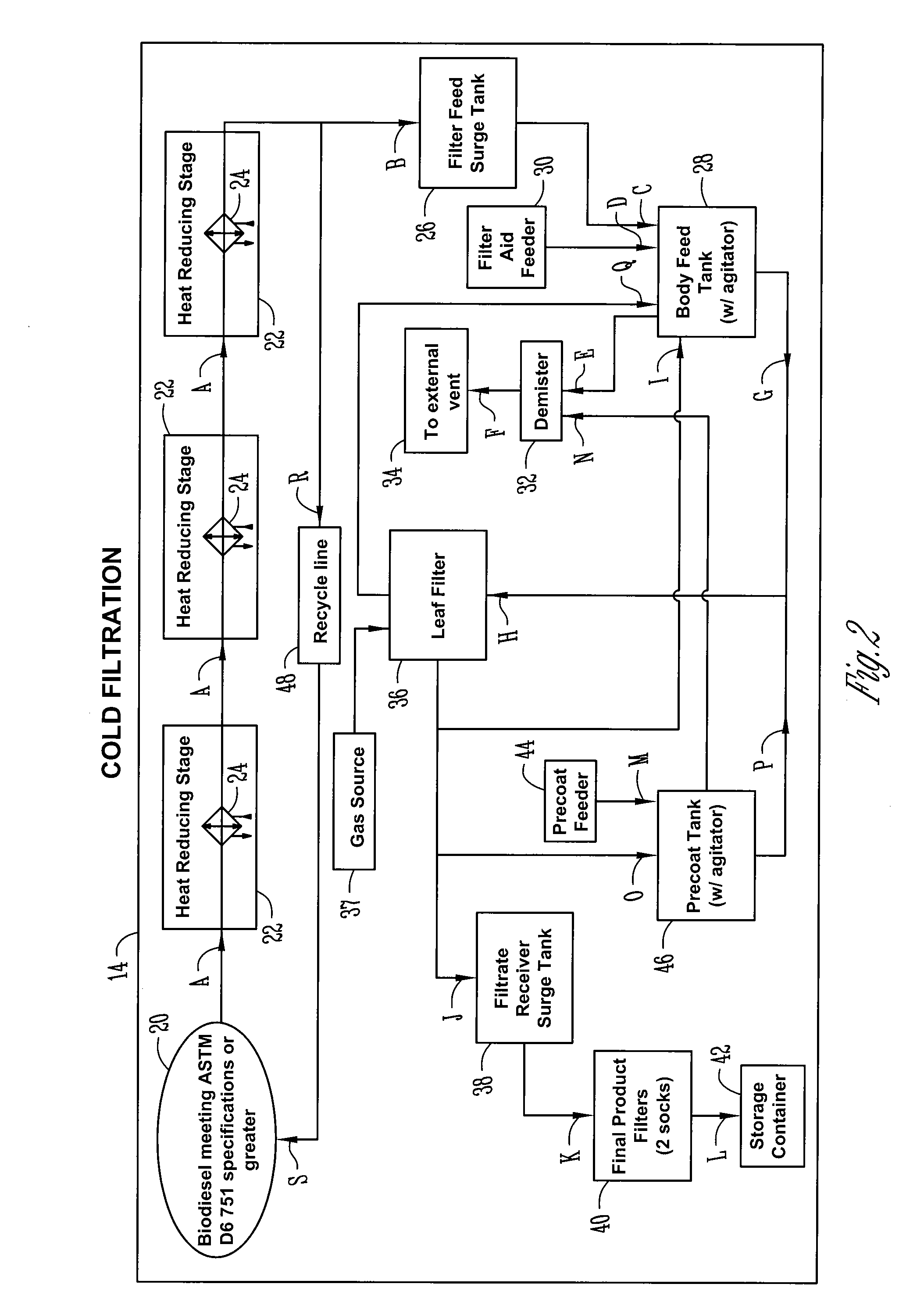

Biodiesel cold filtration process

An improved biodiesel production process includes the steps of processing a feedstock to produce biodiesel, cooling the biodiesel so as to form sediment, and filtering the biodiesel to remove the sediment. The resulting biodiesel from the cold filtration process avoids problems of sediment formation during storage and transportation.

Owner:REG BIOFUELS

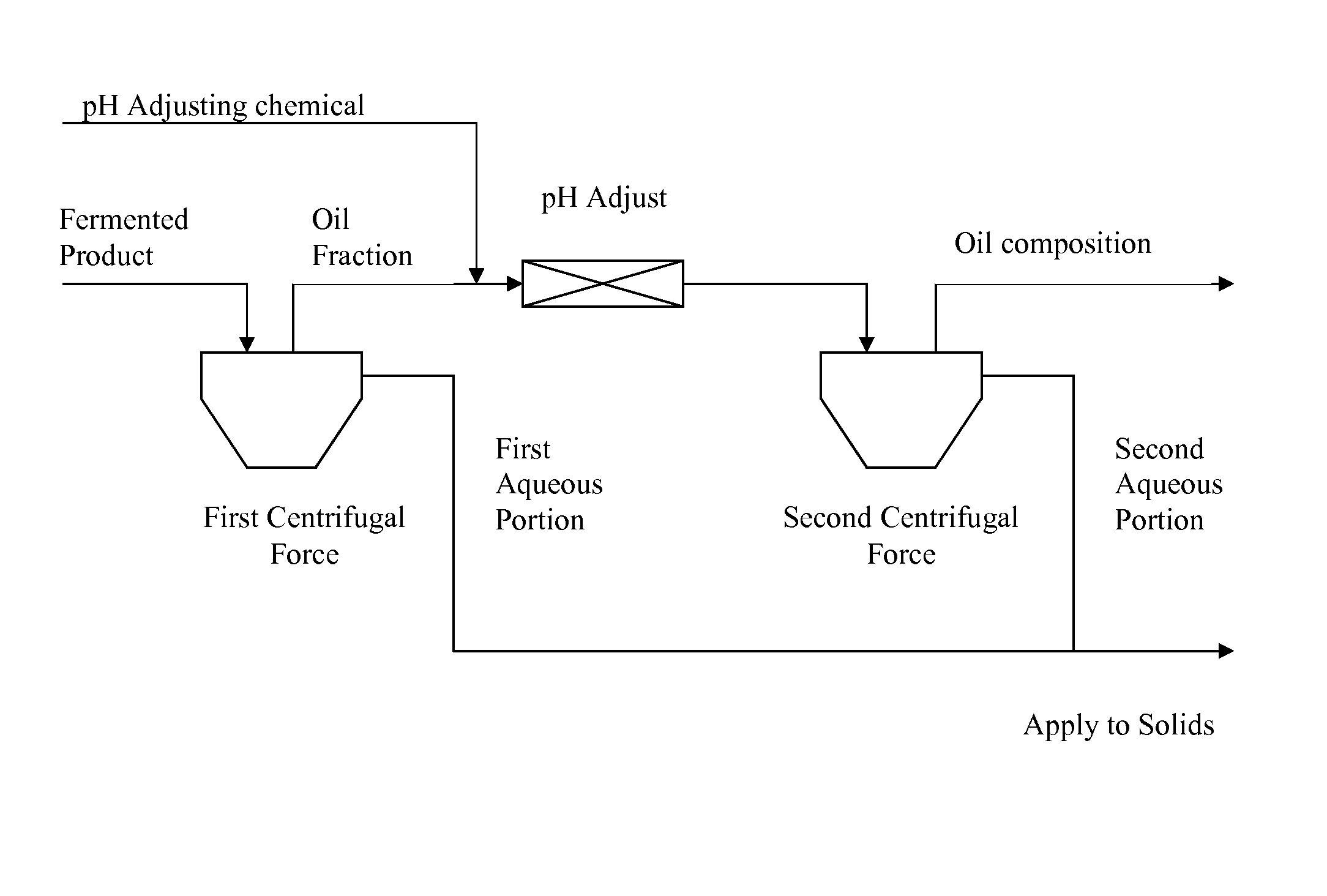

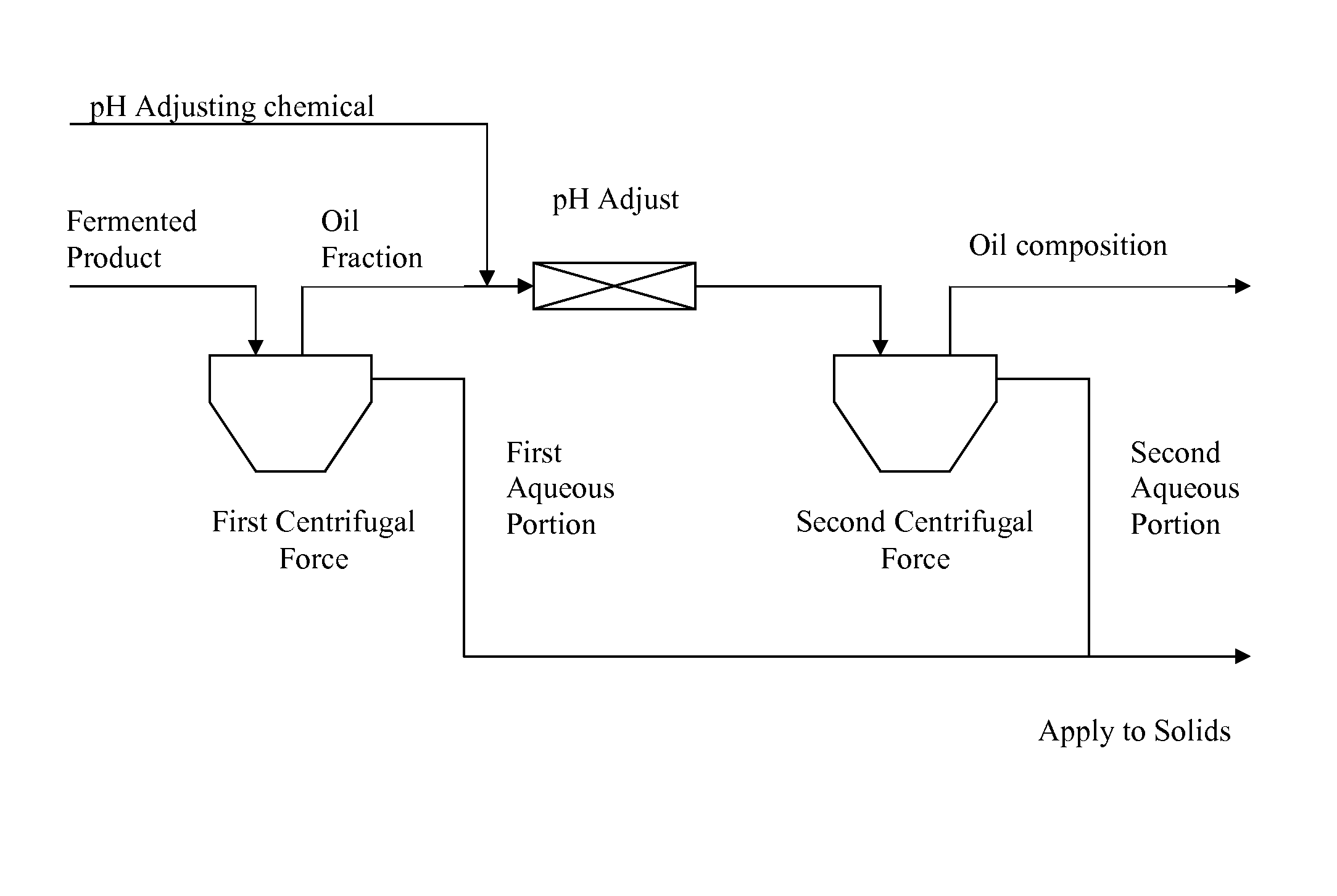

Oil composition and method of recovering the same

ActiveUS20100058649A1Low in unsaponifiablesFatty acids production/refiningBiofuelsBiodieselFermentation

The present invention generally relates to oil compositions and methods of producing such oil compositions. More particularly, the present invention relates to an oil composition recovered from a fermentation product as well as methods of recovering such oil compositions for use in various processes such as bio-diesel production as well as in various edible applications.

Owner:POET RES INC

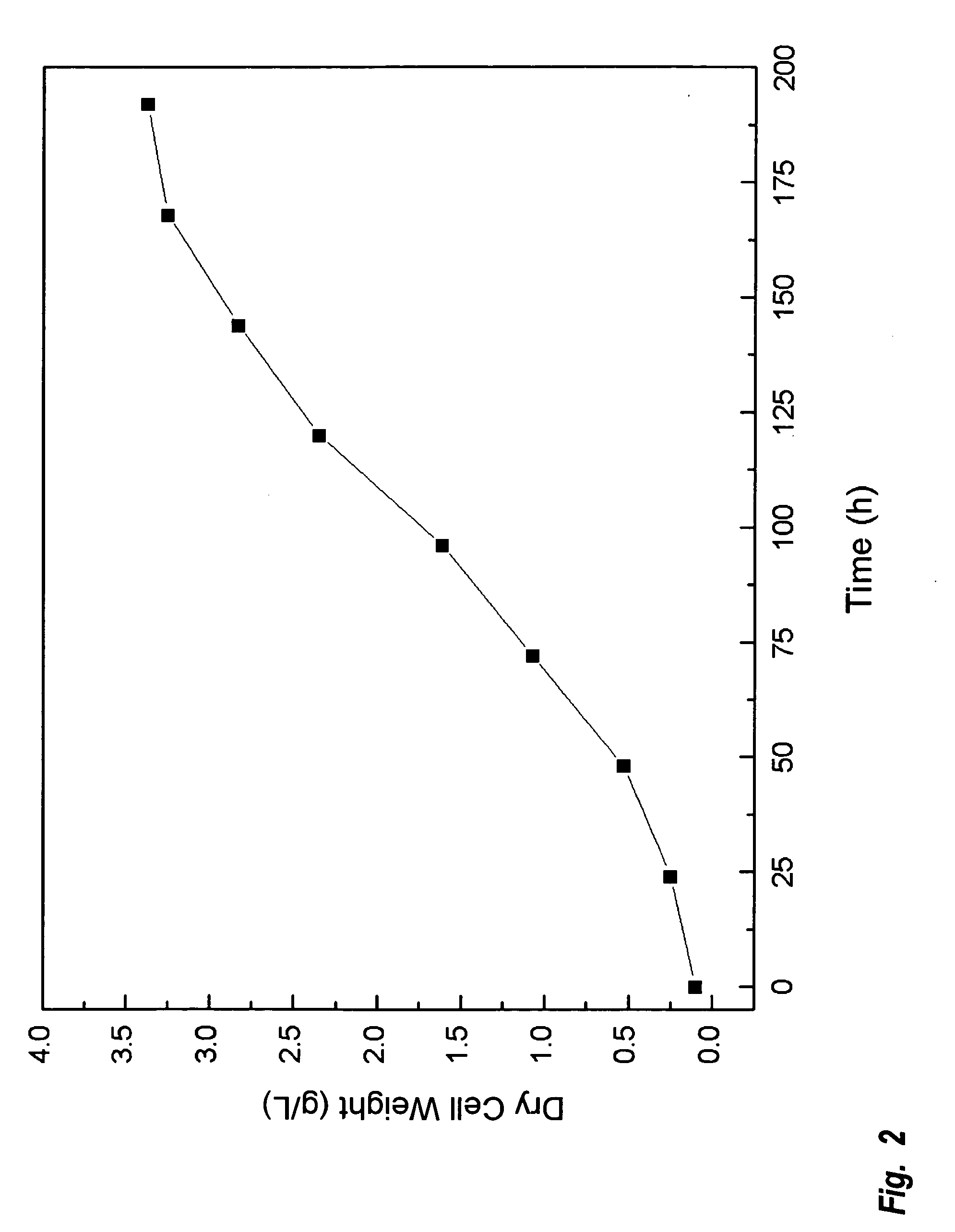

Heterotrophic algal high cell density production method and system

InactiveUS20090209014A1Increase cell densityIncrease biomassUnicellular algaeBiofuelsHigh cellHigh density

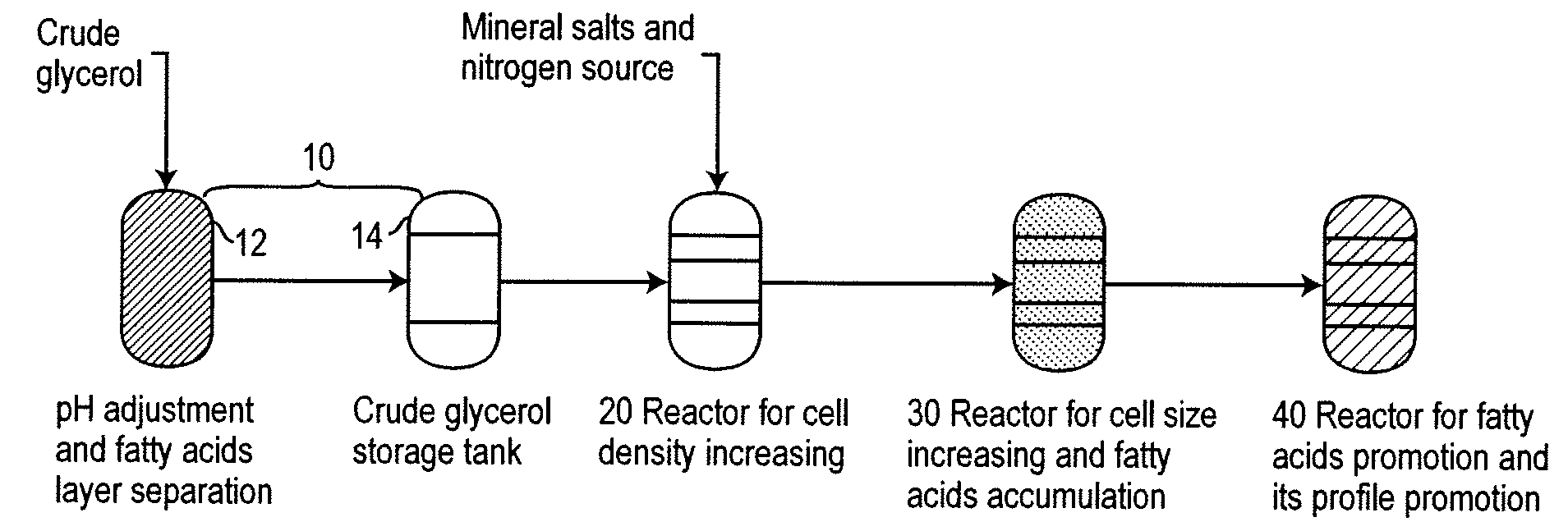

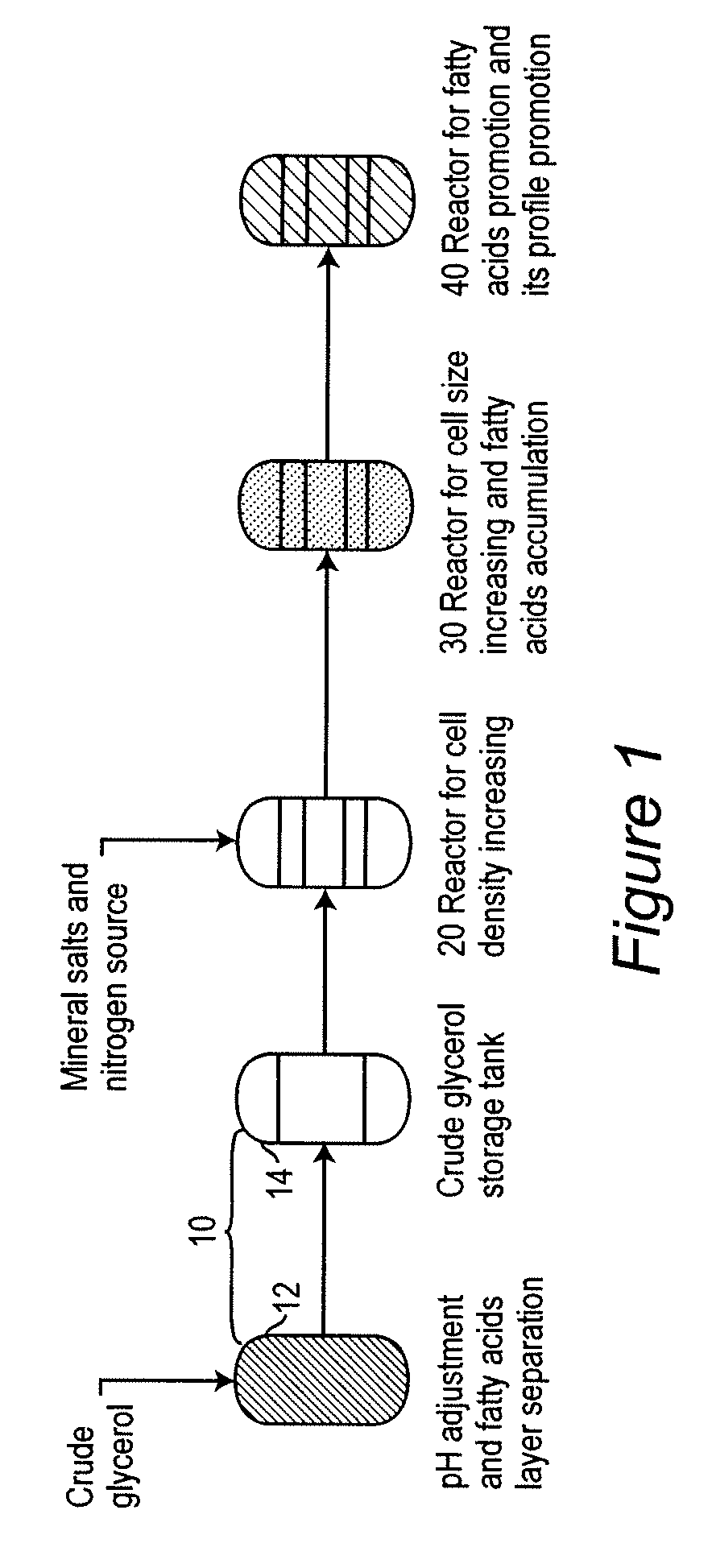

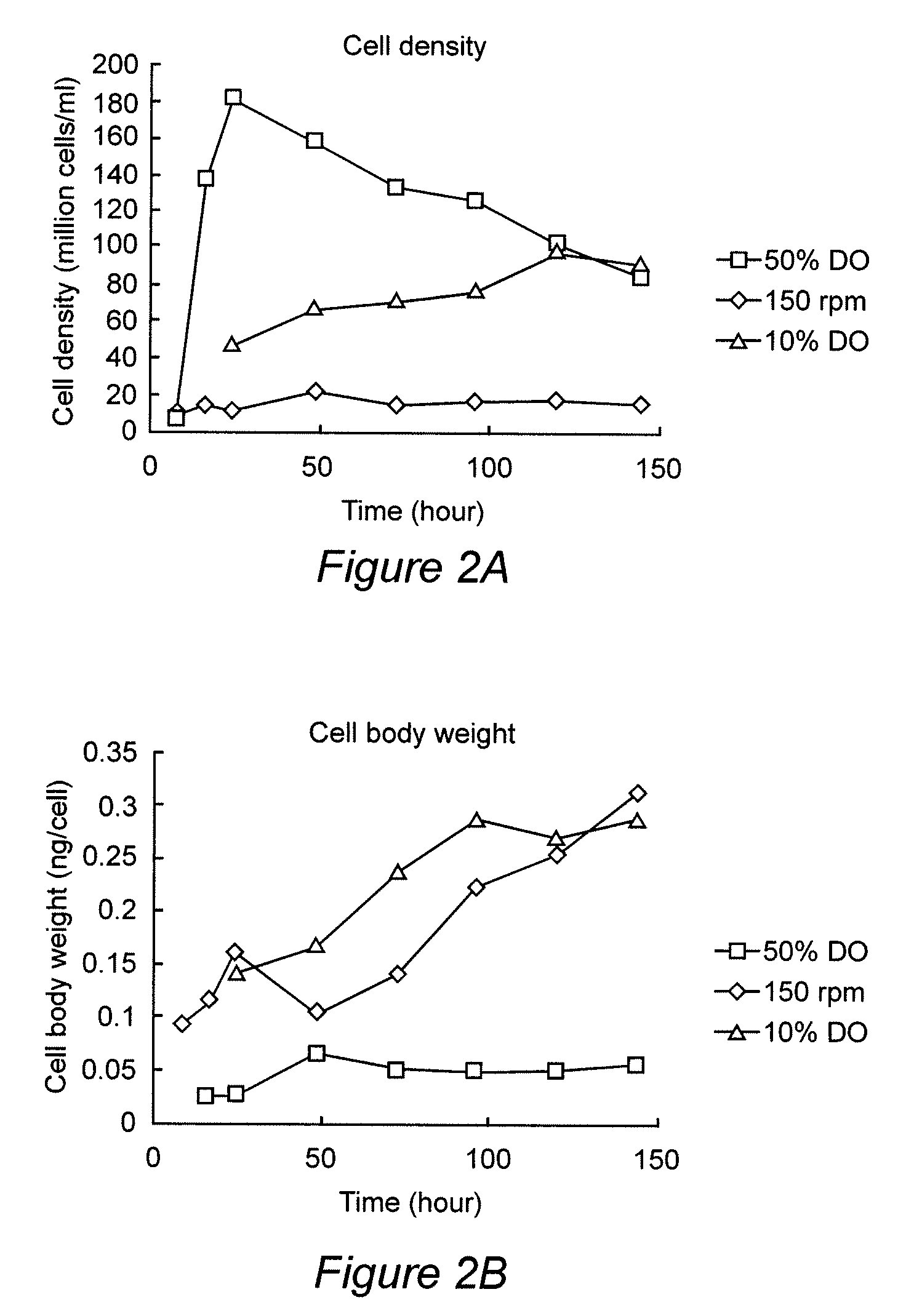

A multiphase culturing process for high density heterotrophic microalgal growth uses crude glycerol as the primary carbon source and produces ω-3 fatty acids. The process uses multiphase growth conditions that decouple the phases of increasing cell density and increasing cell size and fatty acid production. The entire process is integrated with biodiesel production.

Owner:WASHINGTON STATE UNIV RES FOUND INC

Process for producing biodiesel fuel products

A method for producing a biodiesel fuel product from biological material is disclosed which comprises extracting lipids from the biological material with a pure or alcohol-modified supercritical fluid in an extractor, passing the extract directly into a reactor wherein a transesterification reaction is induced between the extracted lipids and alcohol with additional alcohol added if needed, forming glycerol and fatty acid alkyl esters, passing the mixture into one or more separators to remove the glycerol and fatty acid alkyl ester products, removing wastes, and recycling the critical fluid solvent and unreacted alcohol to the extractor. An improvement to biodiesel preparation is afforded by the simplification of the extraction and reaction processes into a single flowing system. According to the invention, a biodiesel fatty acid alkyl ester product can be prepared directly from biological material feedstock, such as oil-containing seeds, without the need for prior isolation of the oil.

Owner:AEROPHASE

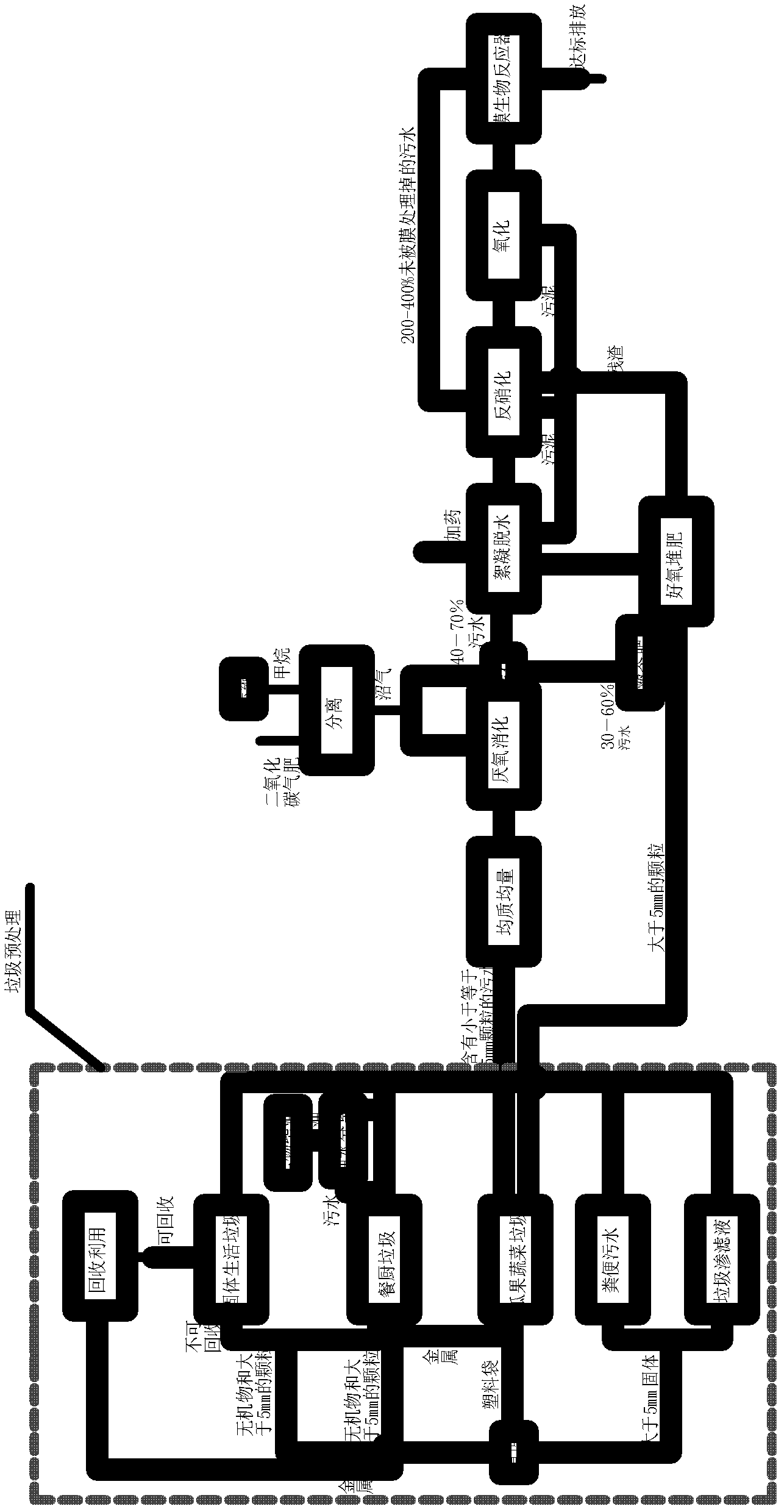

Method for jointly treating different garbage

ActiveCN102531295ASave processing powerProportional balanceBio-organic fraction processingWaste processingFlocculationBiodiesel

The invention discloses a method for jointly treating different garbage. In the implementation process, different garbage is subjected to pretreatment, homogenization, anaerobic digestion, flocculation dewatering, denitrification, oxidation treatment, membrane bioreactor treatment, aerobic composting and biodiesel production, treated sewage can reach the third grade Standard of Water Pollutants Discharge of DB11 / 307-2005, the process flow is greatly shortened, the cost is reduced, and methane generated in the treatment process and the recovered waste oil are subjected to deep processing to beutilized as green energy.

Owner:北京昊业怡生科技有限公司

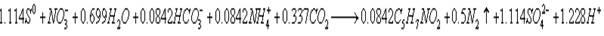

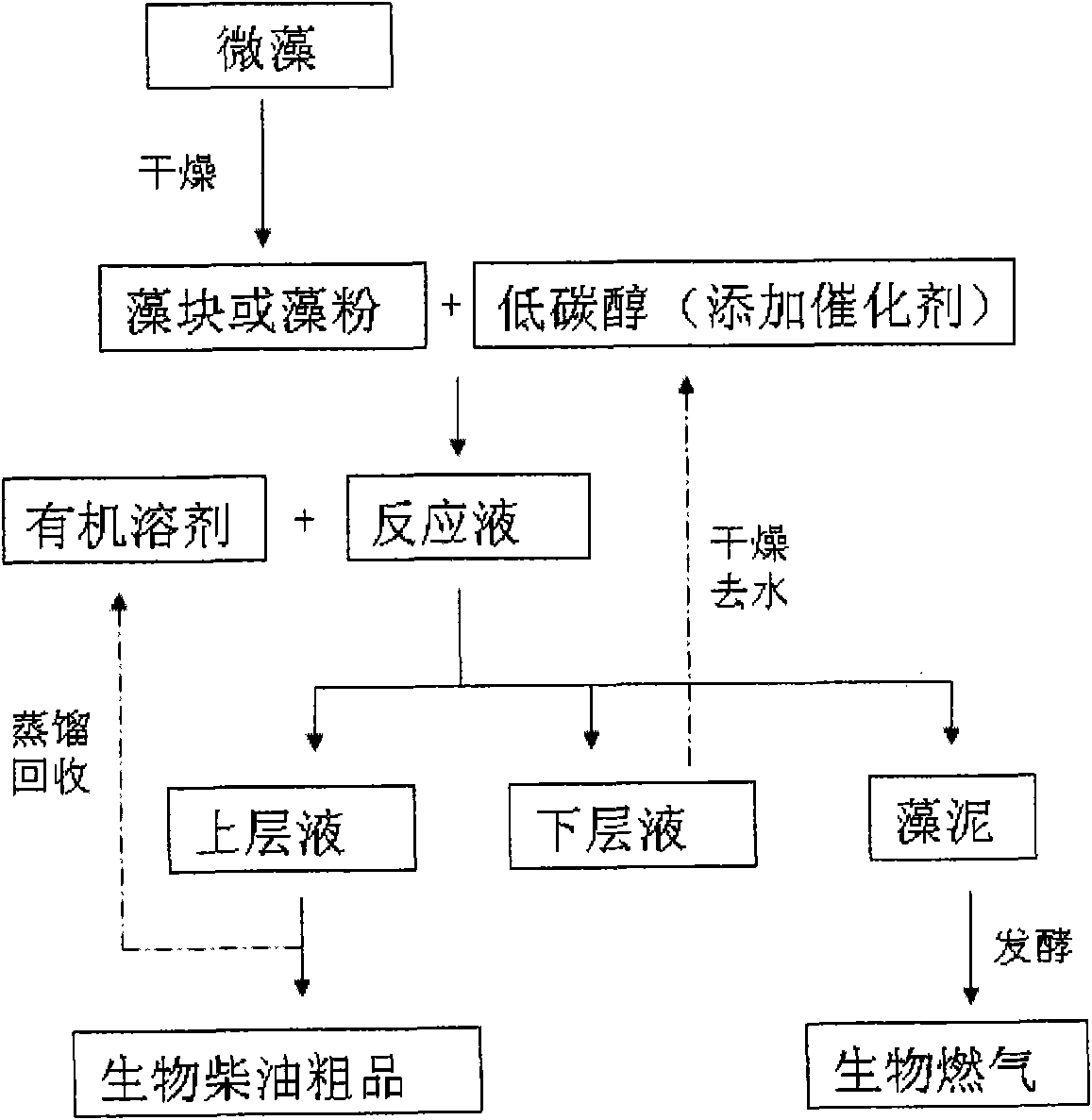

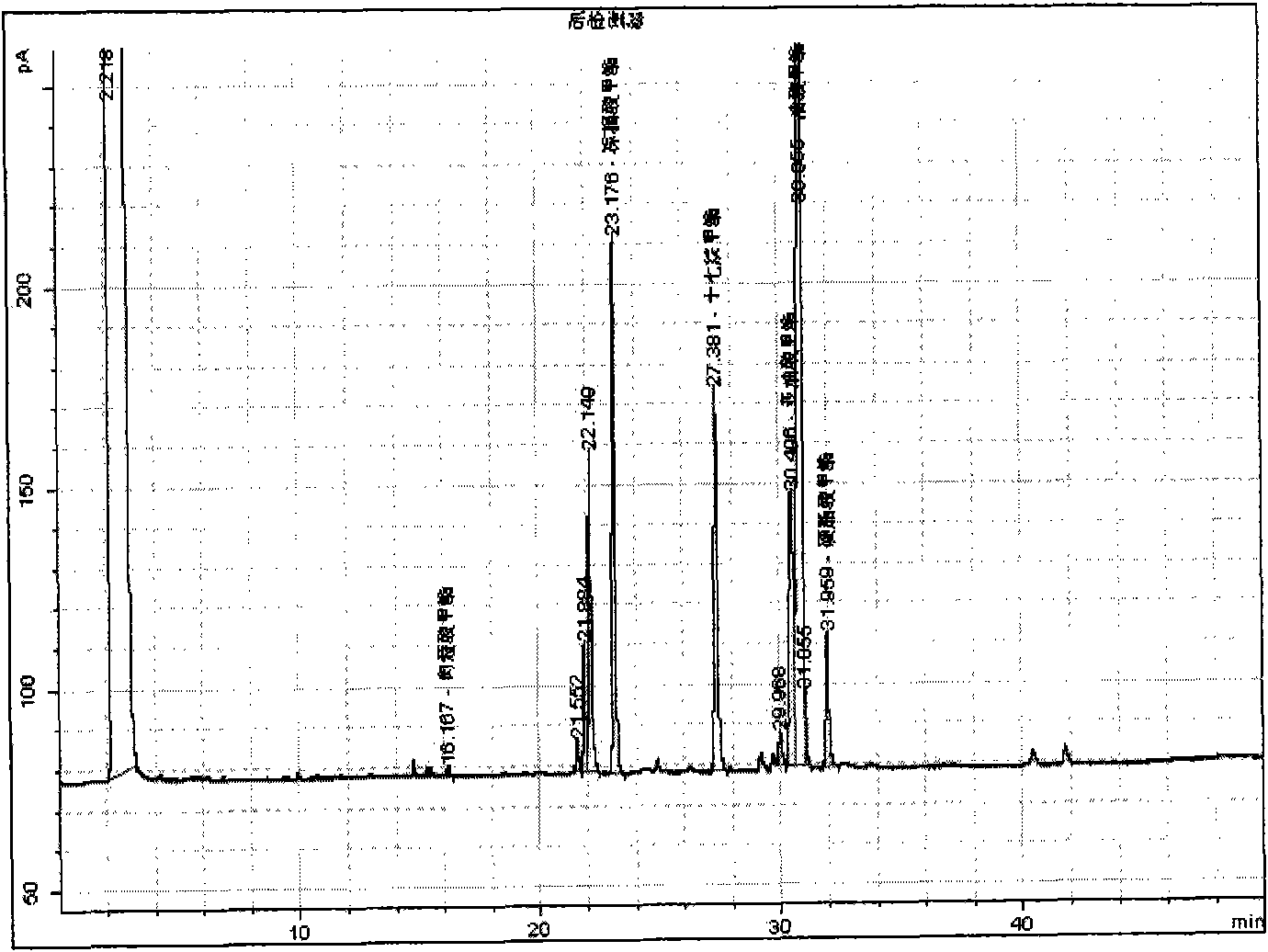

Biomass energy prepared by one-step method of microalgae

ActiveCN101580857AWon't happenRelieve pressurePreparation by ester-hydroxy reactionBiofuelsDownstream processingBiodiesel

The invention provides a method for preparing biodiesel from microalgae. The method comprises the following steps of: a. changing collected microalgae from the wet algae into algae block or algae powder; b. mixing a catalyst into low-carbon alcohol, directly adding the algae block or the algae powder obtained by the step a, and carrying out ester exchange reaction to prepare the biodiesel; c. after the reaction is stopped, adding an organic solvent for extracting reaction solution which is divided into organic solvent phase used for extraction, low-carbon alcohol water-adding phase and algae mud; and d. after the extraction is completed, collecting the organic solvent phase used for extraction, removing the organic solvent by distillation, and obtaining oily liquid, namely crude products of the biodiesel. After preparing the biodiesel, the steps that the low-carbon alcohol water-adding phase is used circularly after dewatered by a solid drying agent, and the produced algae mud is used for producing biogas by biological fermentation are added. The invention completes the oil extraction of microalgae and biodiesel production by one step, simplifies the technique steps and equipment, saves cost; the sulphuric acid and low-carbon alcohol used for production can be recovered, then dewatered by drying, then utilized repeatedly, the cost is reduced, the final product is neutral, does not need washing and reduces the downstream processing pressure; and simultaneously, chlorophyll is mainly concentrated in the low-carbon alcohol, reduces the interference of the chlorophyll to the color of the product and does not need the step of decoloring.

Owner:ENN SCI & TECH DEV

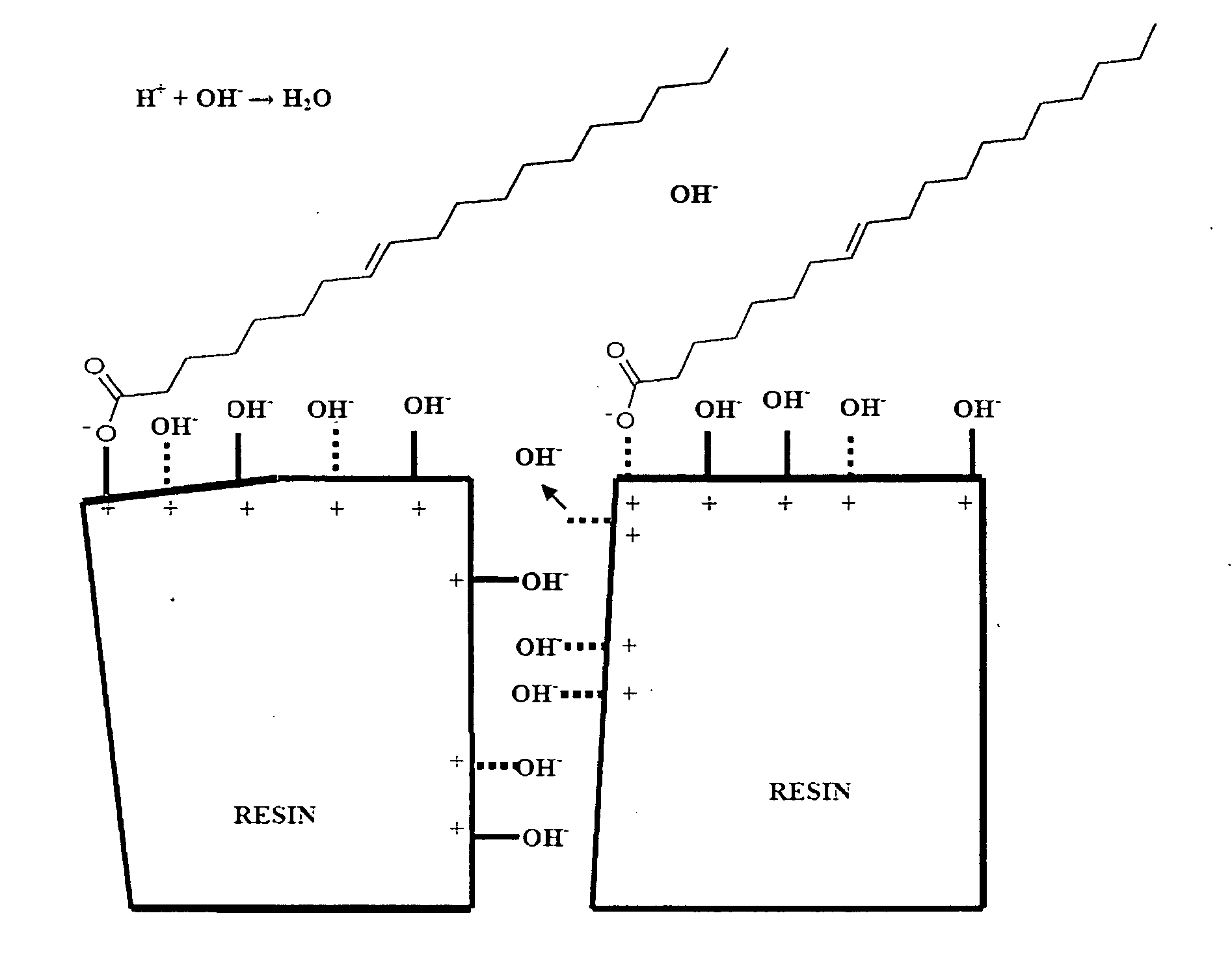

Process for Desalting Glycerol Solutions and Recovery of Chemicals

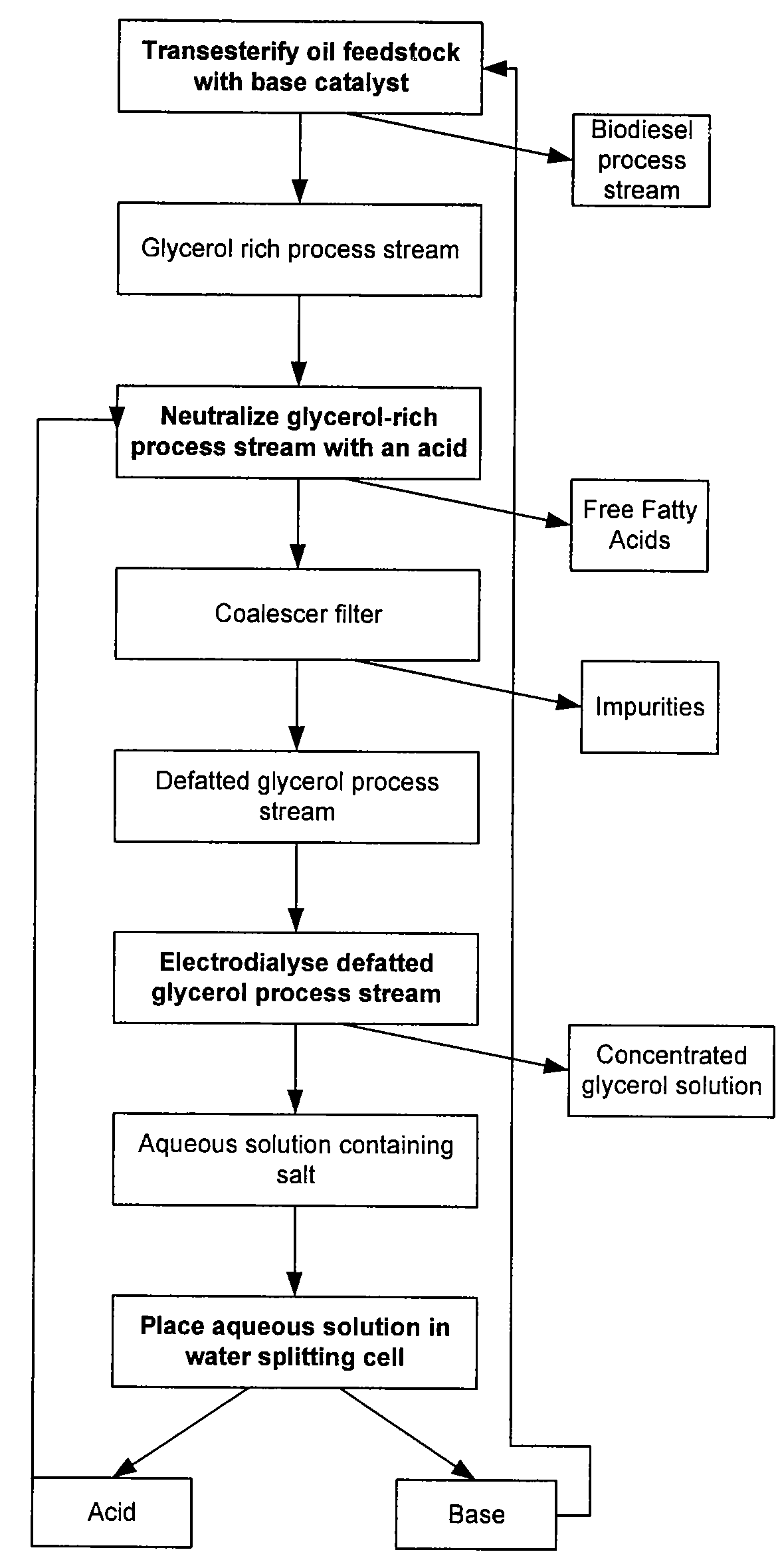

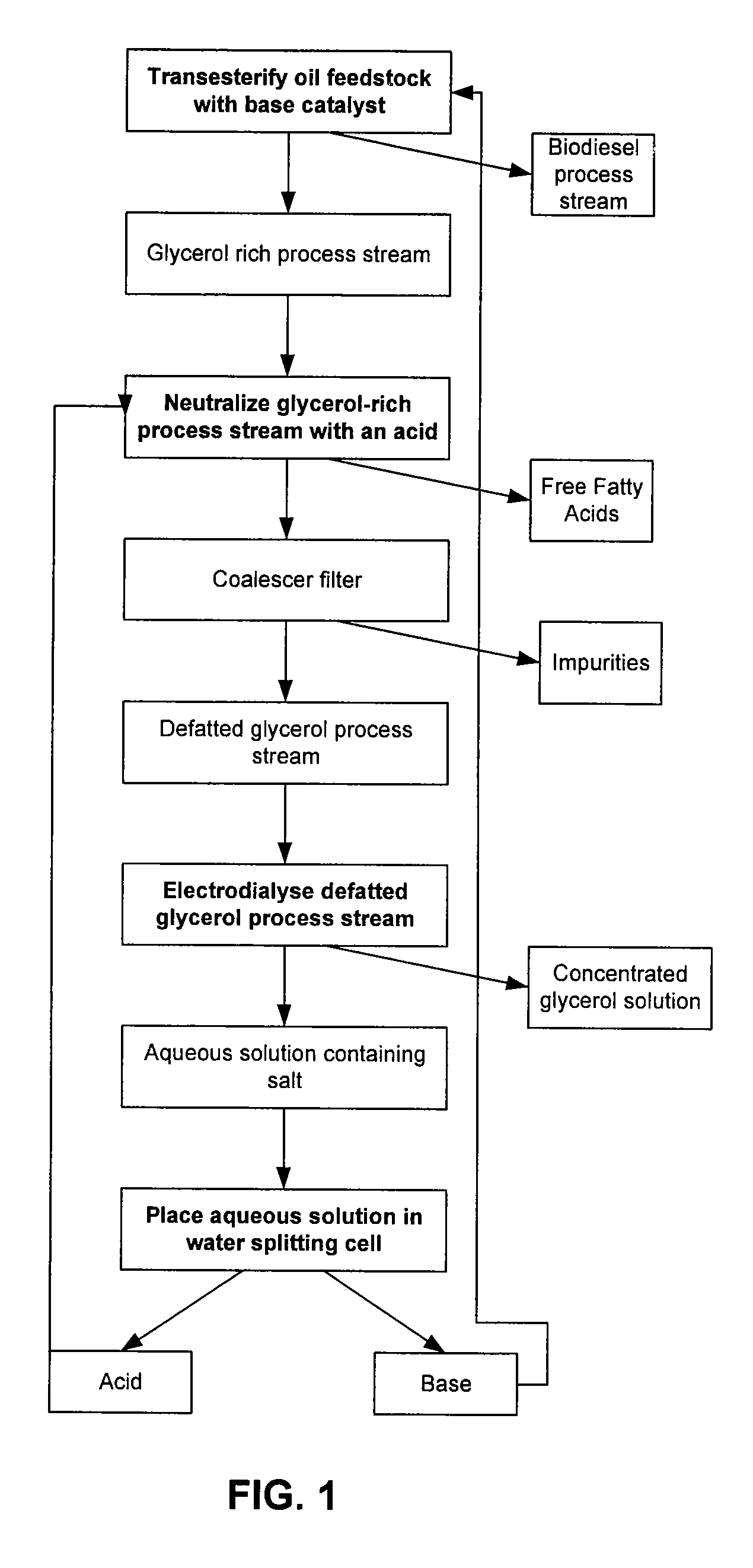

Processes for desalting glycerol-rich solutions or process streams using electrodialysis are provided. The glycerol-rich process streams are typically byproducts from the production of biodiesel. Following electrodialysis, the resulting aqueous salt solution is placed in a water splitting cell to recover the acid and base components of the salt. These acid and base components, in turn, can be reused in other processes, such as biodiesel production.

Owner:ARCHER DANIELS MIDLAND CO

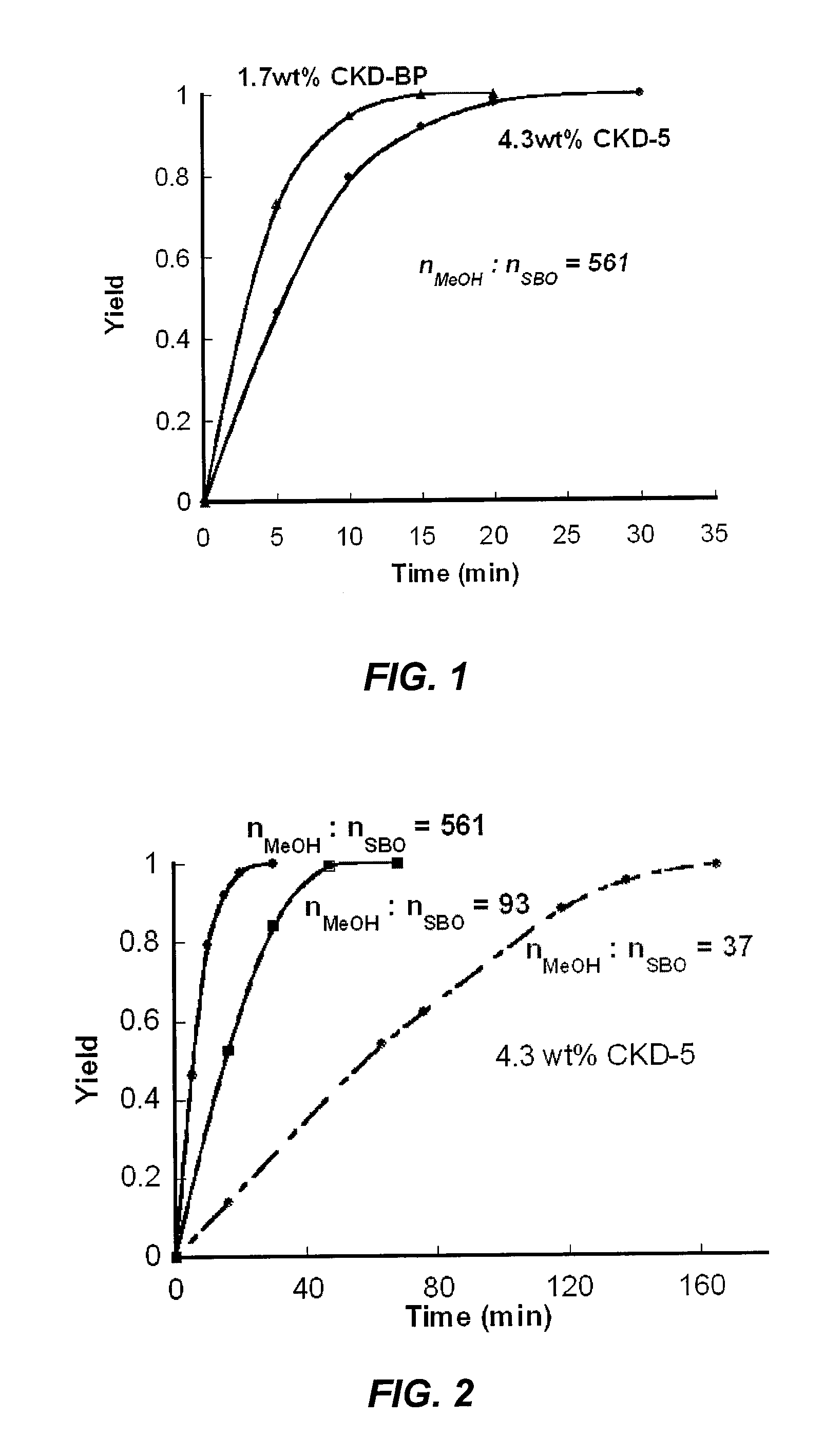

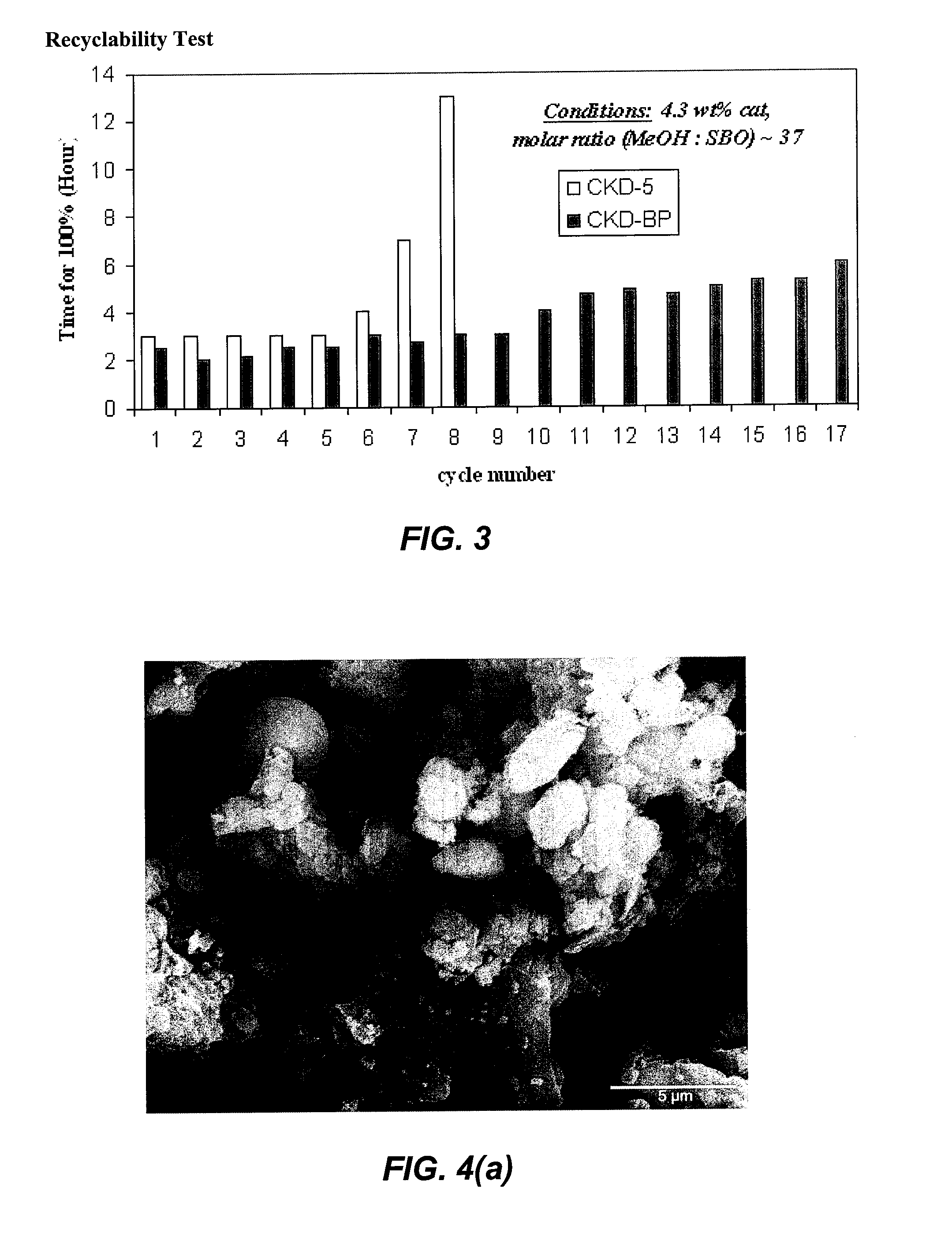

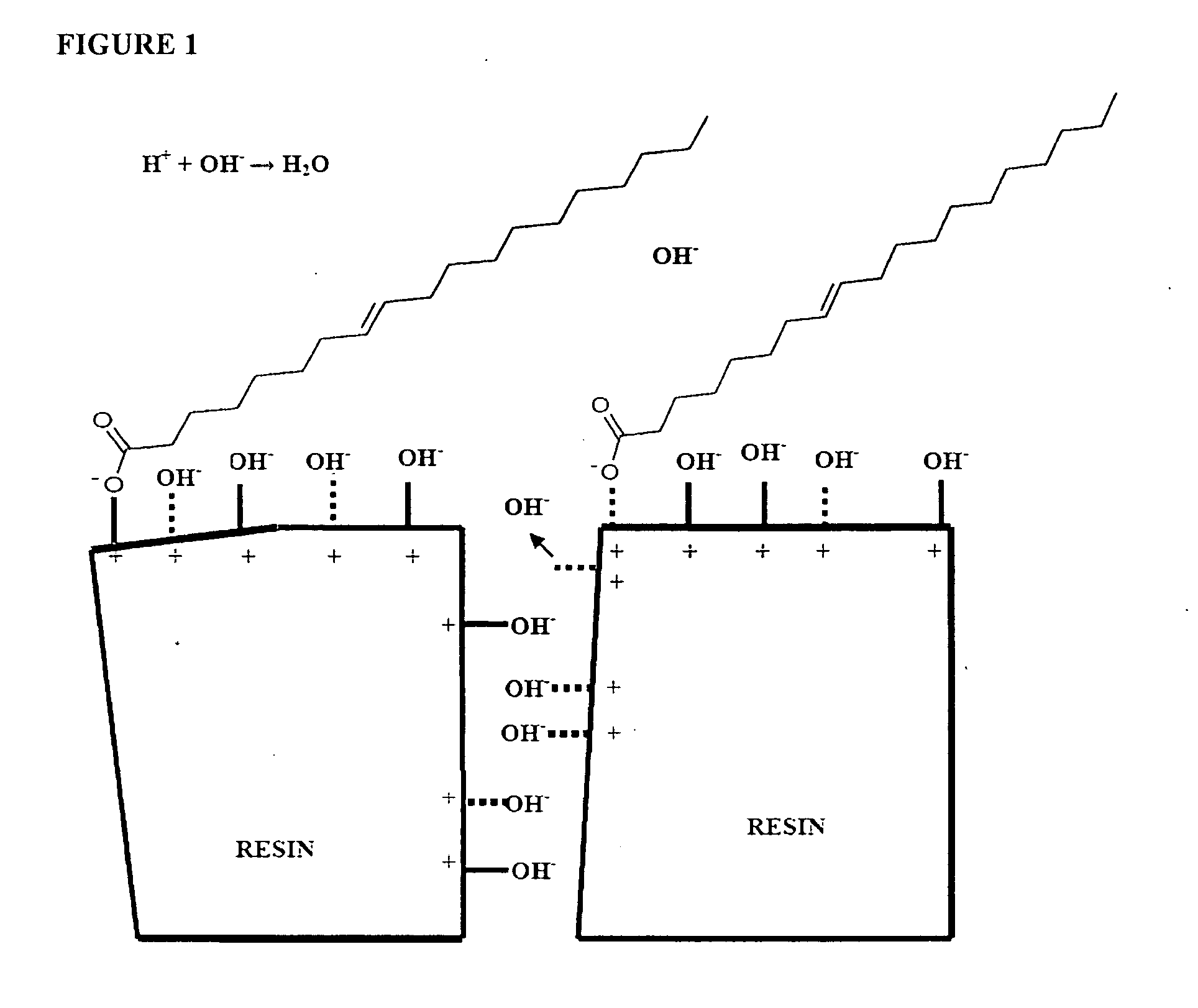

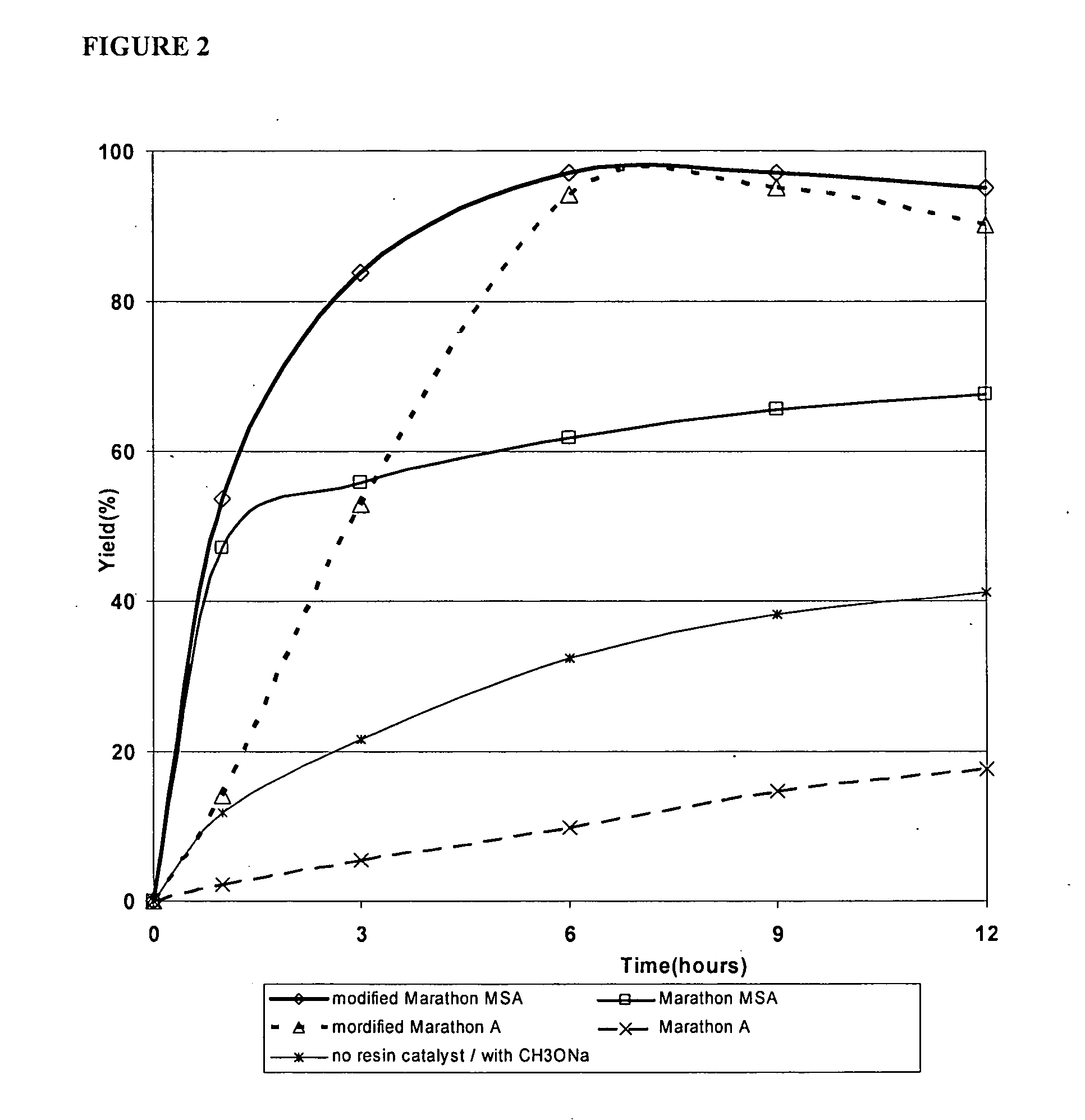

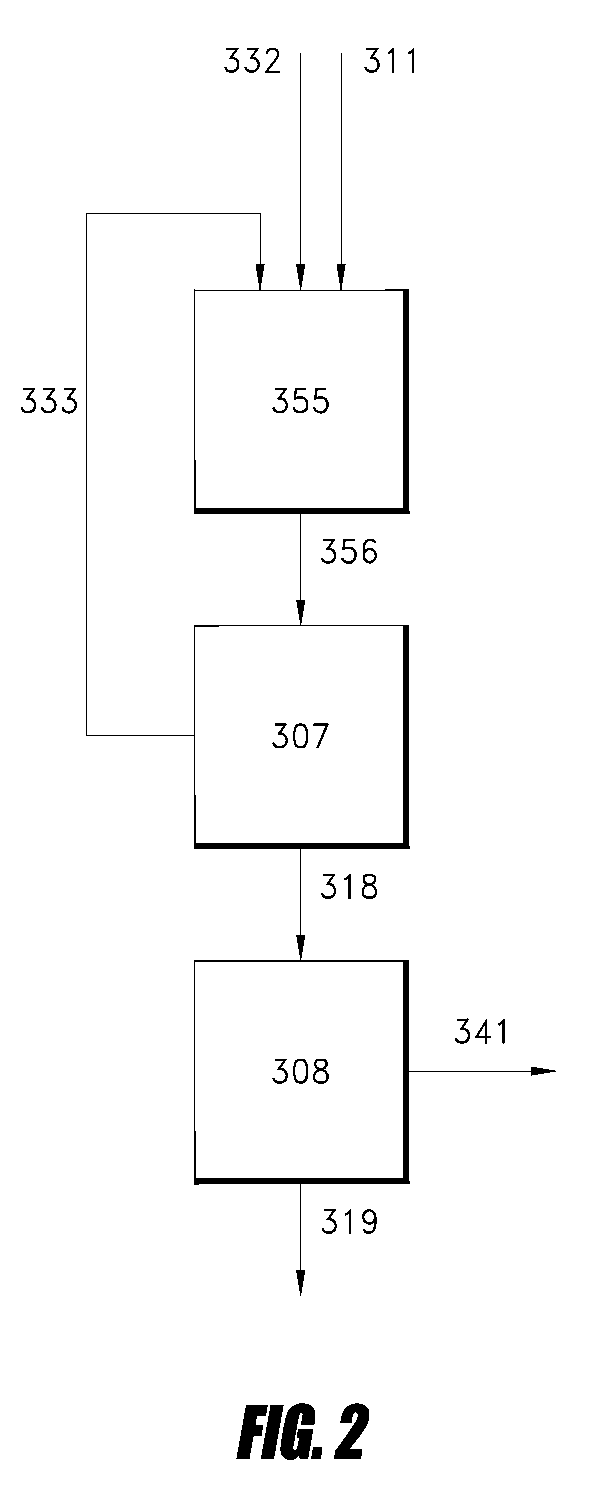

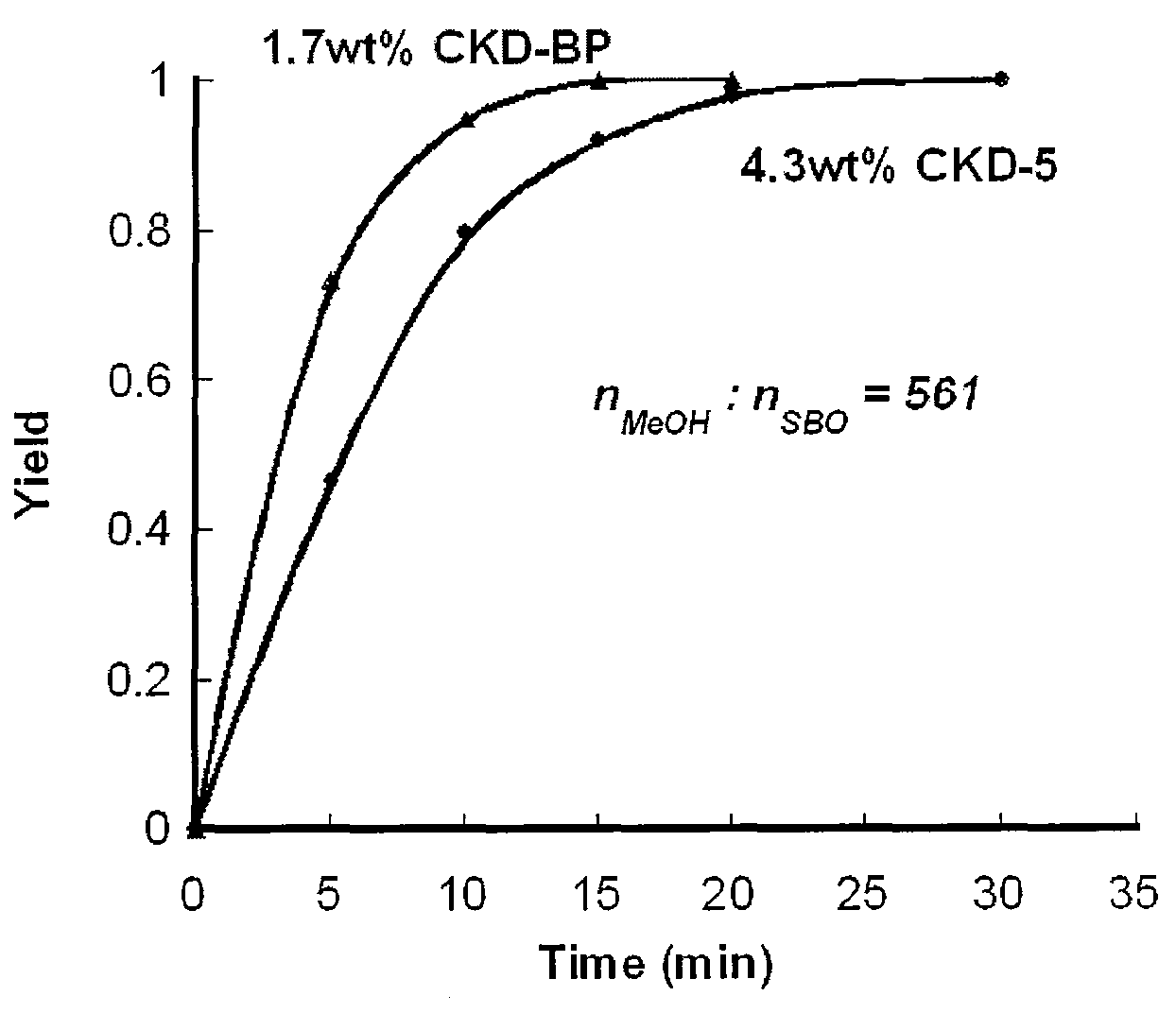

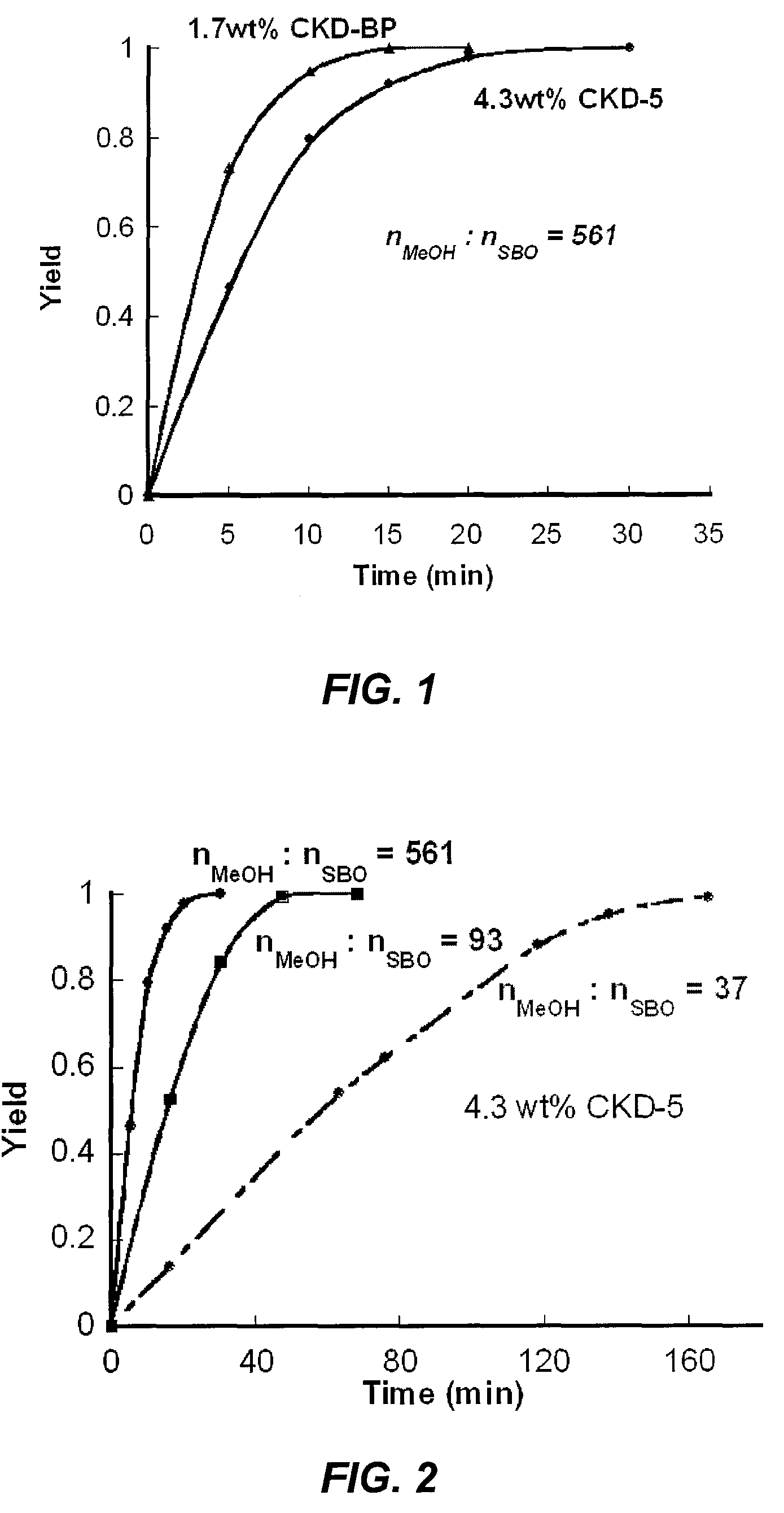

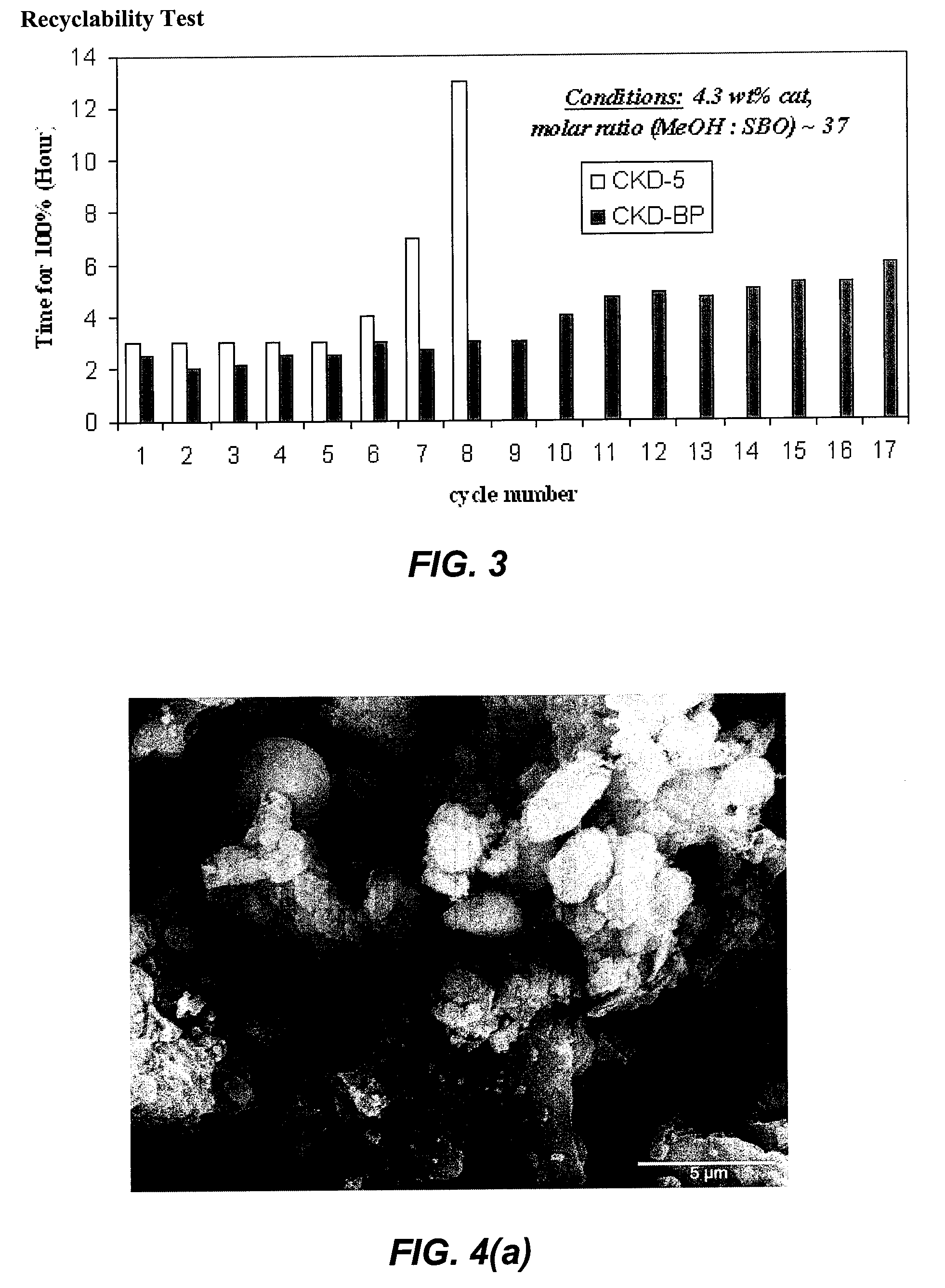

Solid catalyst system for biodiesel production

ActiveUS20090112007A1Increase contact areaRapid responseFatty acid chemical modificationFatty acids production/refiningMETHYL SOYATEVegetable oil

The invention provides efficient, inexpensive, and environmental friendly catalysts and catalyst systems. The catalysts can be used to catalyze esterification and / or transesterification reactions, for example, for the preparation of biodiesel. Kiln dust, such as cement kiln dust (CKD) or lime kiln dust (LKD) can be used to convert a variety of feedstock acids and / or esters to biodiesel in high yield under mild conditions. The CKD and LKD catalyst systems are recyclable esterification or transesterification catalysts that can be used to prepare biodiesel, such as methyl soyate, from various feedstocks, including vegetable oils and animal fats.

Owner:PINNAVAIA THOMAS J PH D +1

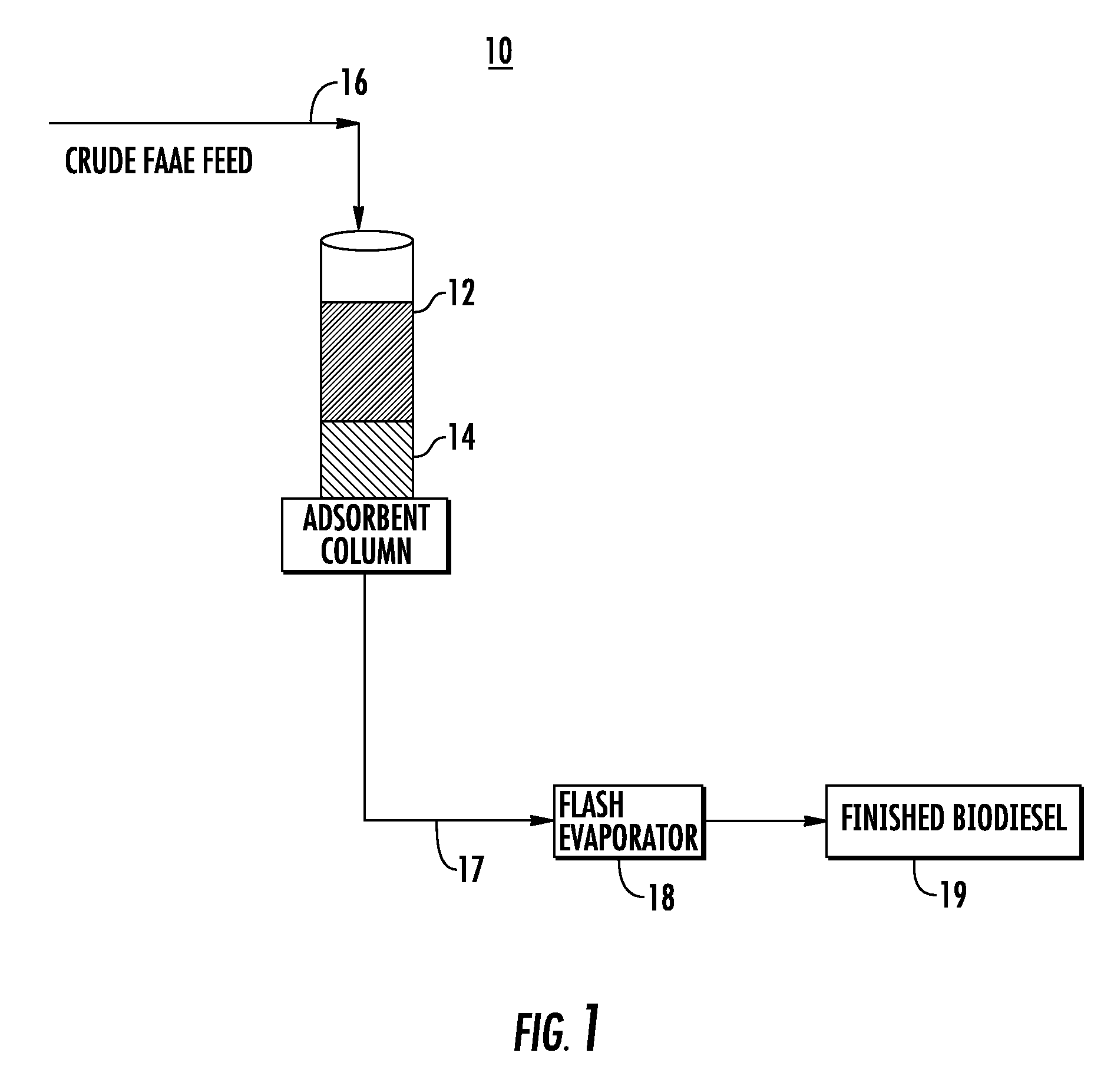

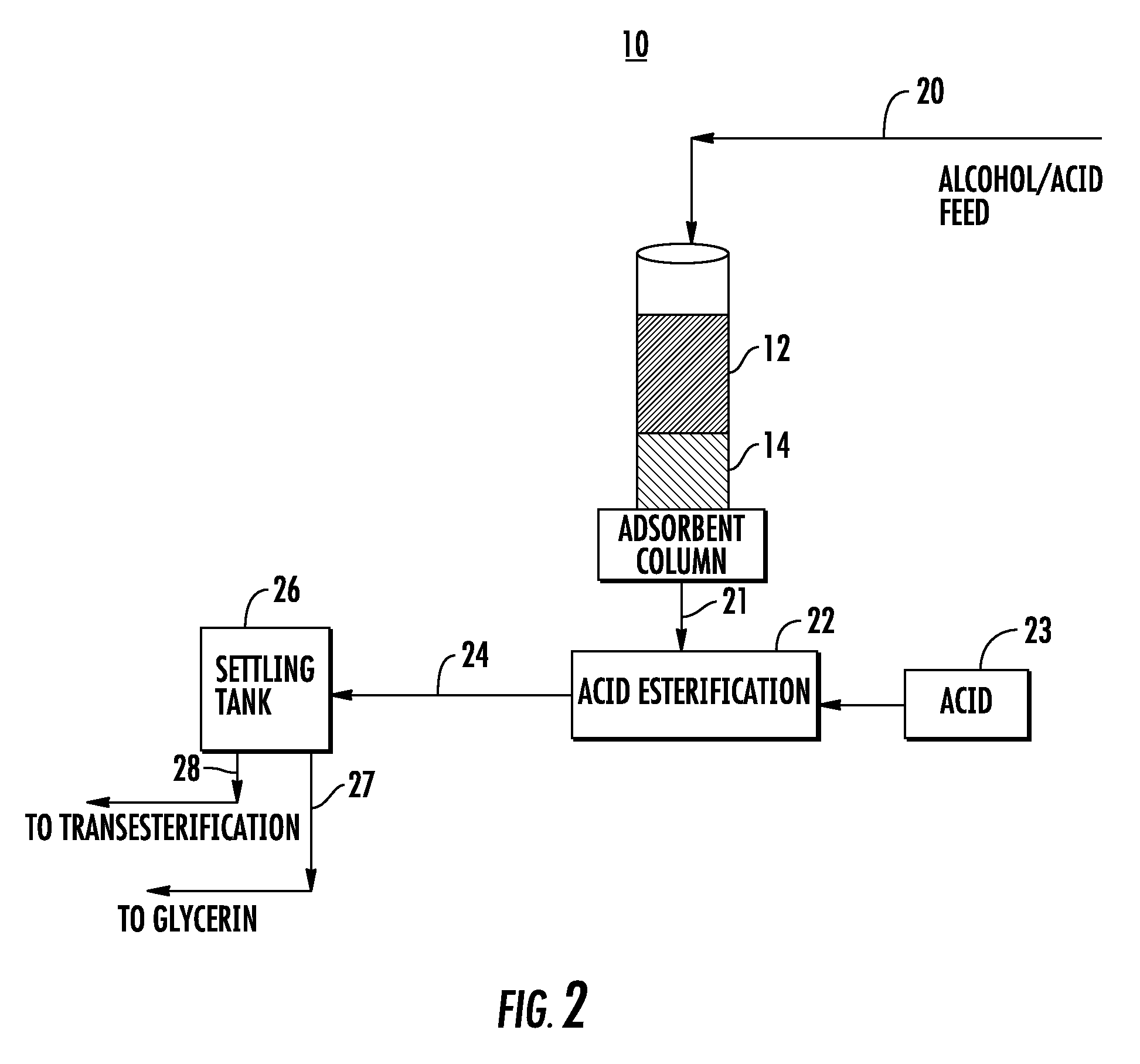

Biodiesel purification by a continuous regenerable adsorbent process

ActiveUS20090199460A1Reduced stabilityLarge amount of removalOrganic anion exchangersLoose filtering material filtersFiltrationSorbent

A quick, economical and environmentally friendly, “green”, process for the continuous purification of biodiesel (fatty acid alkyl esters (FAAE)) is described using a powdered, granulated or extruded adsorbent. The adsorbent is contained in a column system and is regenerated for reuse multiple times. The process employs an adsorbent such as, but not limited to, carbon, silica, clay, zeolite or a metal silicate contained in a column to remove the impurities from fatty acid alkyl esters (FAAE) or crude biodiesel in a continuous process. The process utilizes the adsorbent column system for the purification of biodiesel, rather than water or filtration, to remove soaps and other impurities entrained in a crude biodiesel. The crude biodiesel is contacted with an adsorbent packed into a column, or multiple columns in series, for a sufficient amount of time to remove impurities such as, but not limited to, soaps, metals, free glycerin, sterol glucosides and many of the other impurities that reduce the stability of biodiesel. The resulting finished biodiesel exiting the column(s) is ready for the methanol recovery process. Once the adsorbent no longer removes the desired amount of impurities, it is regenerated for reuse. The solvent used for the regeneration process is reclaimed and reused by recycling it back to the transesterification reaction.

Owner:DALLAS GROUP OF AMERICA

Chlorella, cultivating method and application thereof in producing biodiesel

InactiveCN101565675AReduce manufacturing costReduce water burdenUnicellular algaeBiofuelsBiodieselWater resources

The invention discloses a chlorella which belongs to the technical field of producing biodiesel and a cultivating method thereof. The chlorella is named as Chlorella YJ1, and the registration number of the spawn preservation is CGMCC No. 3037. The invention also discloses the application of the chlorella in producing biodiesel. Second-grade effluent water of municipal sewage is taken as the culture medium to grow the chlorella without adding nutrient elements such as nitrogen, phosphorus and the like, thus reducing the cost of producing biodiesel and lightening the burden of water resource. The chlorella is used for establishing the process of municipal sewage deep treatment, and the biodiesel can be obtained at the same time of the sewage treatment, which is a sewage recycling and biodiesel producing technology with eco-friendliness and low cost.

Owner:TSINGHUA UNIV

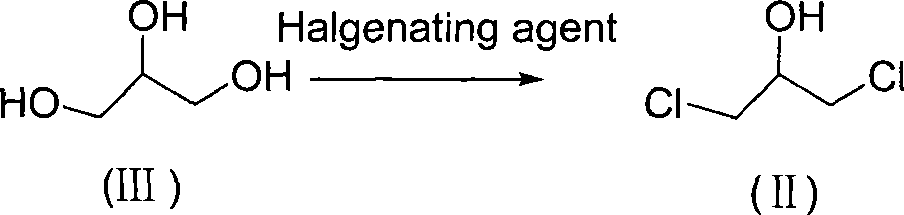

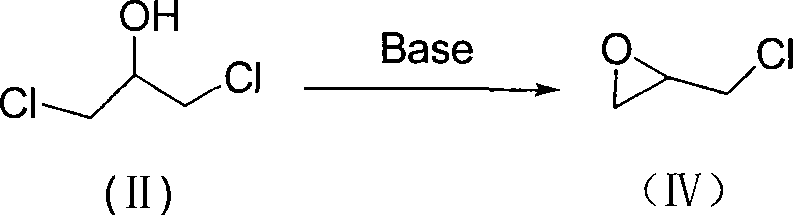

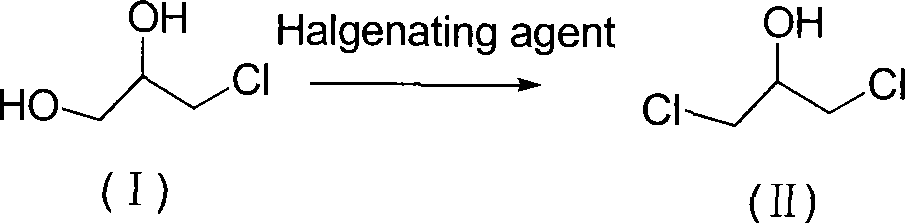

Method for synthesizing epichlorohydrin

The invention relates to a synthesis method of epichlorohydrin, which is a reclaim utilization method of R-3-chloro-1, 2-propanediol during the separation and the preparation of S-epichlorohydrin by utilizing the dynamics of epichlorohydrin and a utilization method of utilizing glycerin which is the byproduct in the production of biodiesel. The R-3-chloro-1, 2-propanediol is reacted with chlorinating agent with the catalysis of the acid catalyst to generate the 1, 3-dichloro propanol, the obtained 1,3-dichloro propanol is reacted with alkali to generate the epichlorohydrin; the glycerin is reacted with the chlorinating agent with the catalysis of the acid catalyst to generate the 1,3-dichloro propanol, and the obtained 1,3-dichloro propanol is reacted with alkali to generate the epichlorohydrin. The synthesis method of the invention is simple, which can effectively convert the highly toxic waste R-3-chloro-1, 2-propanediol and the crude glycerin into the epichlorohydrin, the yield is high, the production cost is low, the environment pollution is reduced, so the synthesis method is an ideal method for industrialization reclaiming and utilization of R-3-chloro-1, 2-propanediol and the crude glycerin.

Owner:WUHAN UNIV OF TECH

Combined homogeneous and heterogeneous catalytic transesterification process for biodiesel production

InactiveUS20090145022A1Fatty acid esterificationPreparation by ester-hydroxy reactionAlcoholTransesterification

In one aspect, a process for producing a biofuel comprises reacting a feed material that comprises a glyceride with an alcohol in the presence of a catalytic composition such that at least some of the glyceride in the feed material is converted into a biofuel mixture that comprises glycerol and the corresponding alcoholic ester of the glyceride. The catalytic composition comprises a heterogeneous catalyst and a homogeneous catalyst. The heterogeneous catalyst and the homogeneous catalyst have a synergistic effect in catalyzing the reaction of the glyceride in the feed material with the alcohol.

Owner:WAYNE STATE UNIV

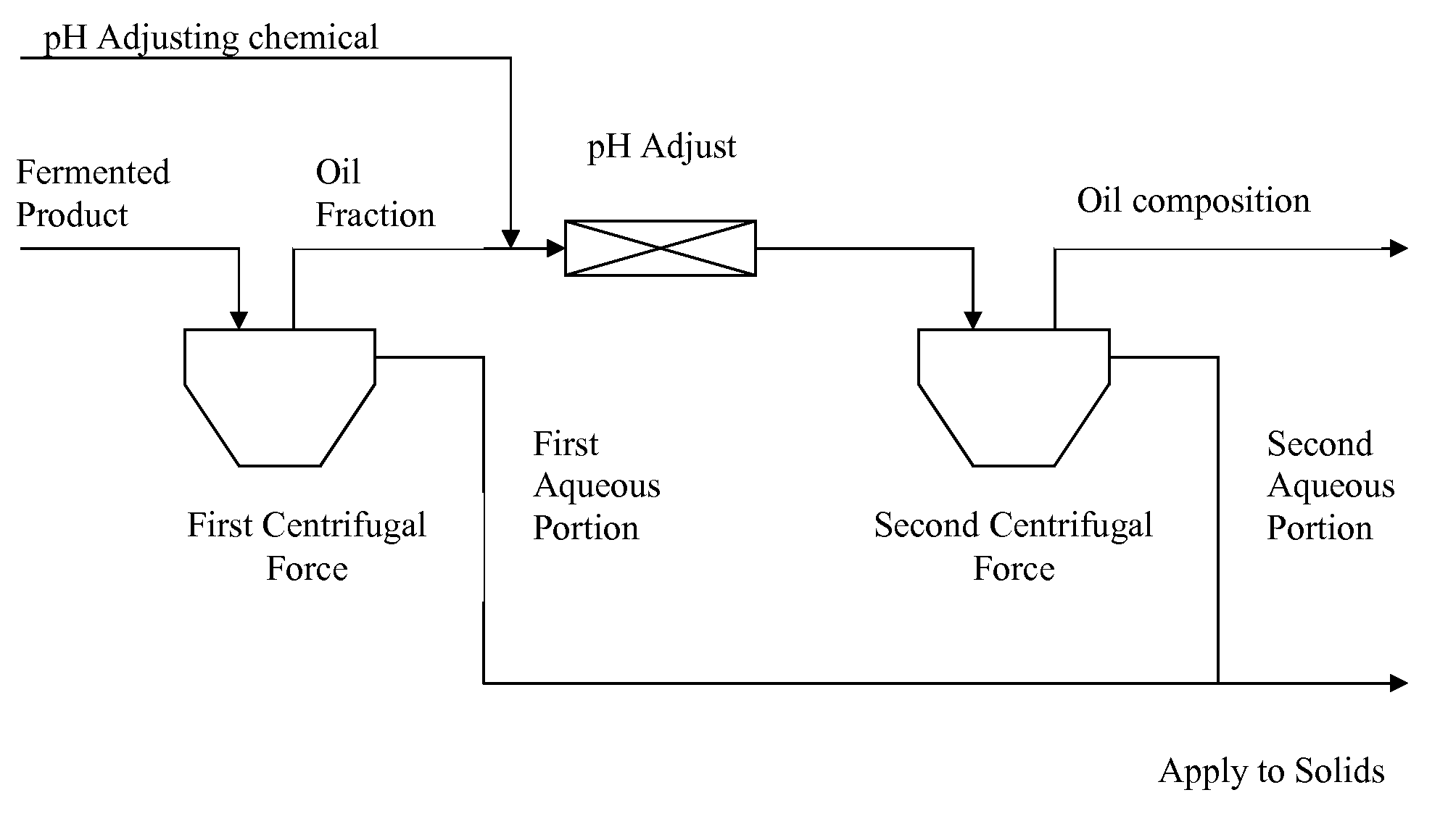

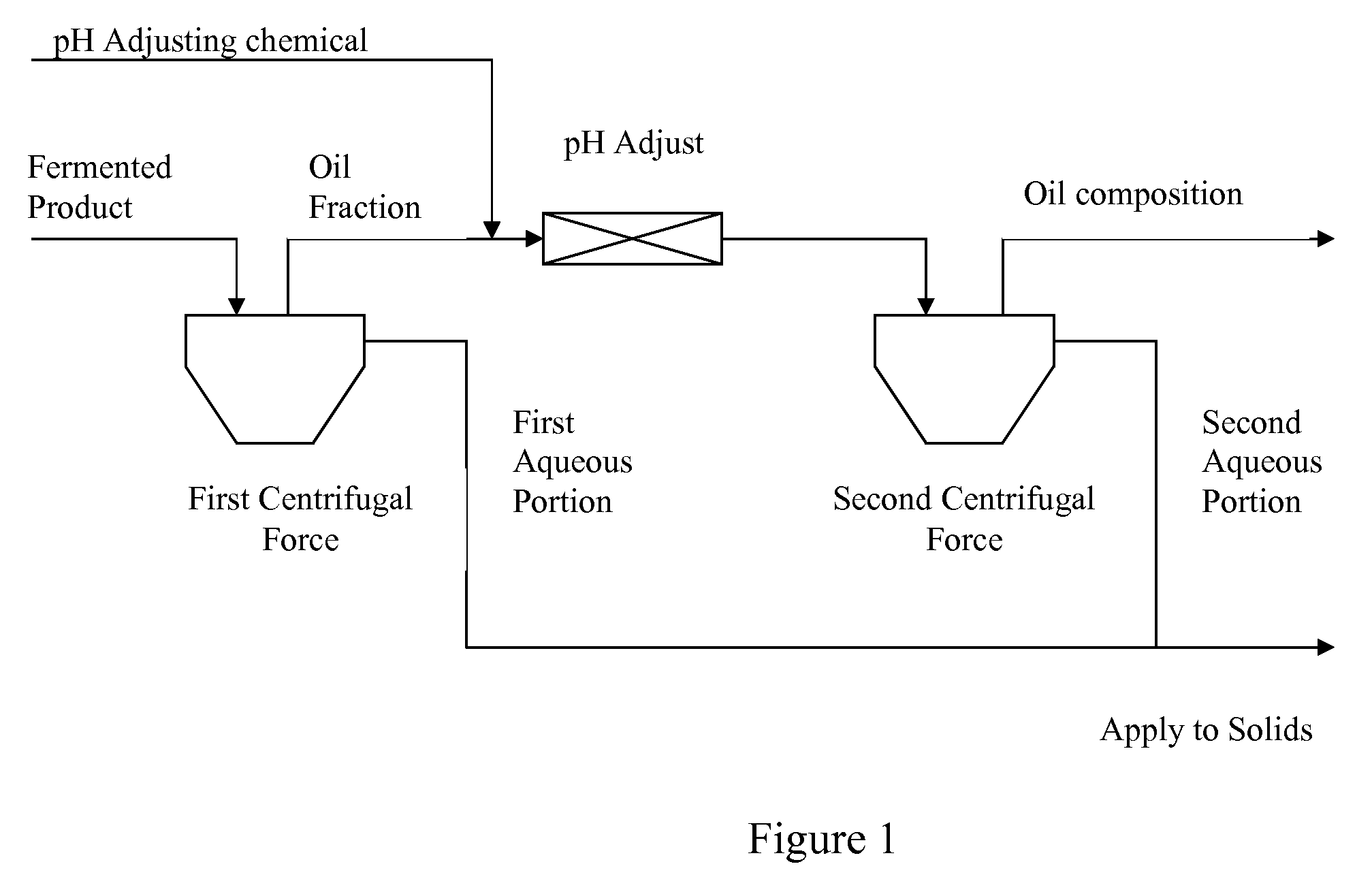

Oil composition and method of recovering the same

The present invention generally relates to oil compositions and methods of producing such oil compositions. More particularly, the present invention relates to an oil composition recovered from a fermentation product as well as methods of recovering such oil compositions for use in various processes such as bio-diesel production as well as in various edible applications.

Owner:POET RES INC

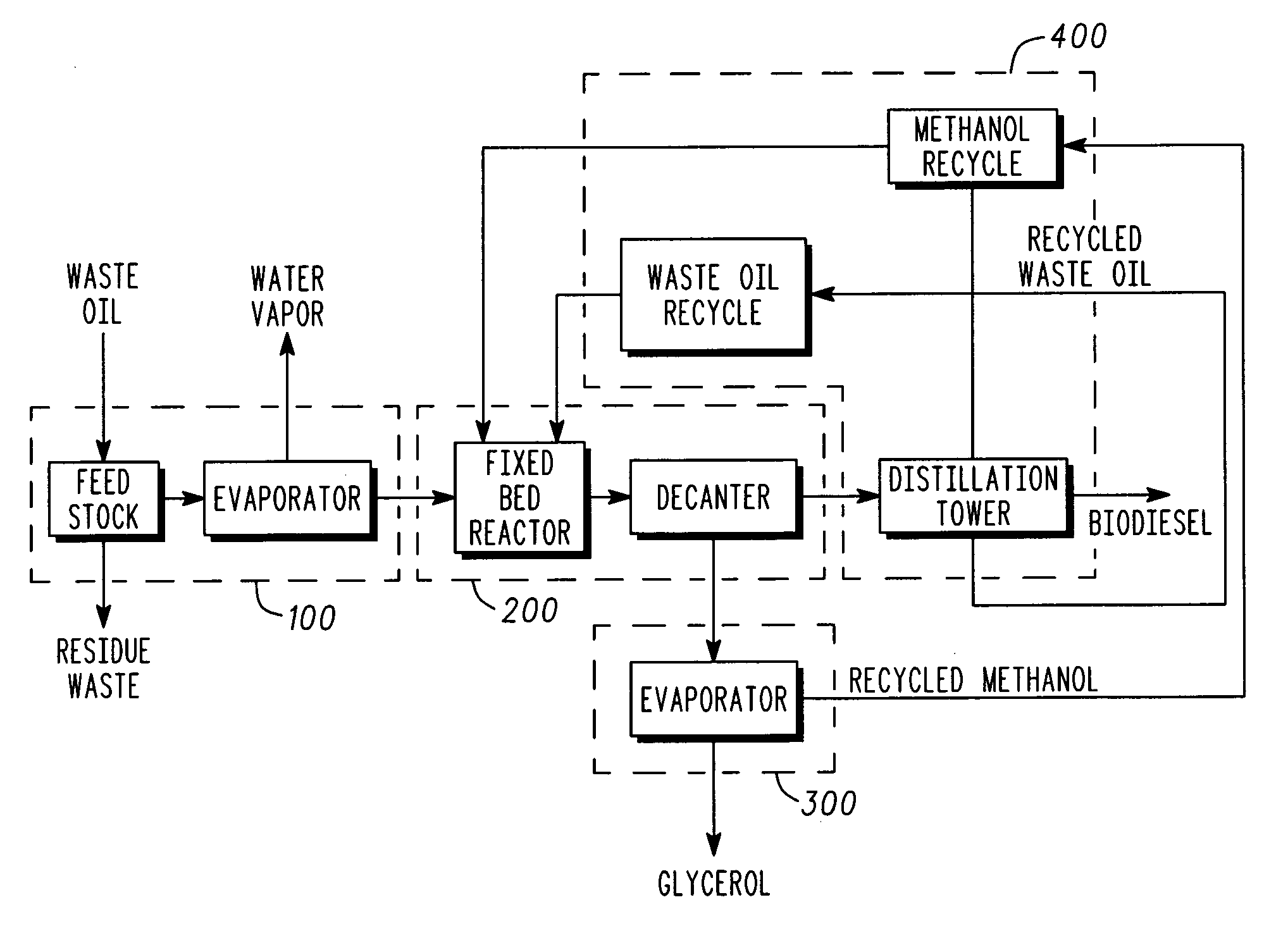

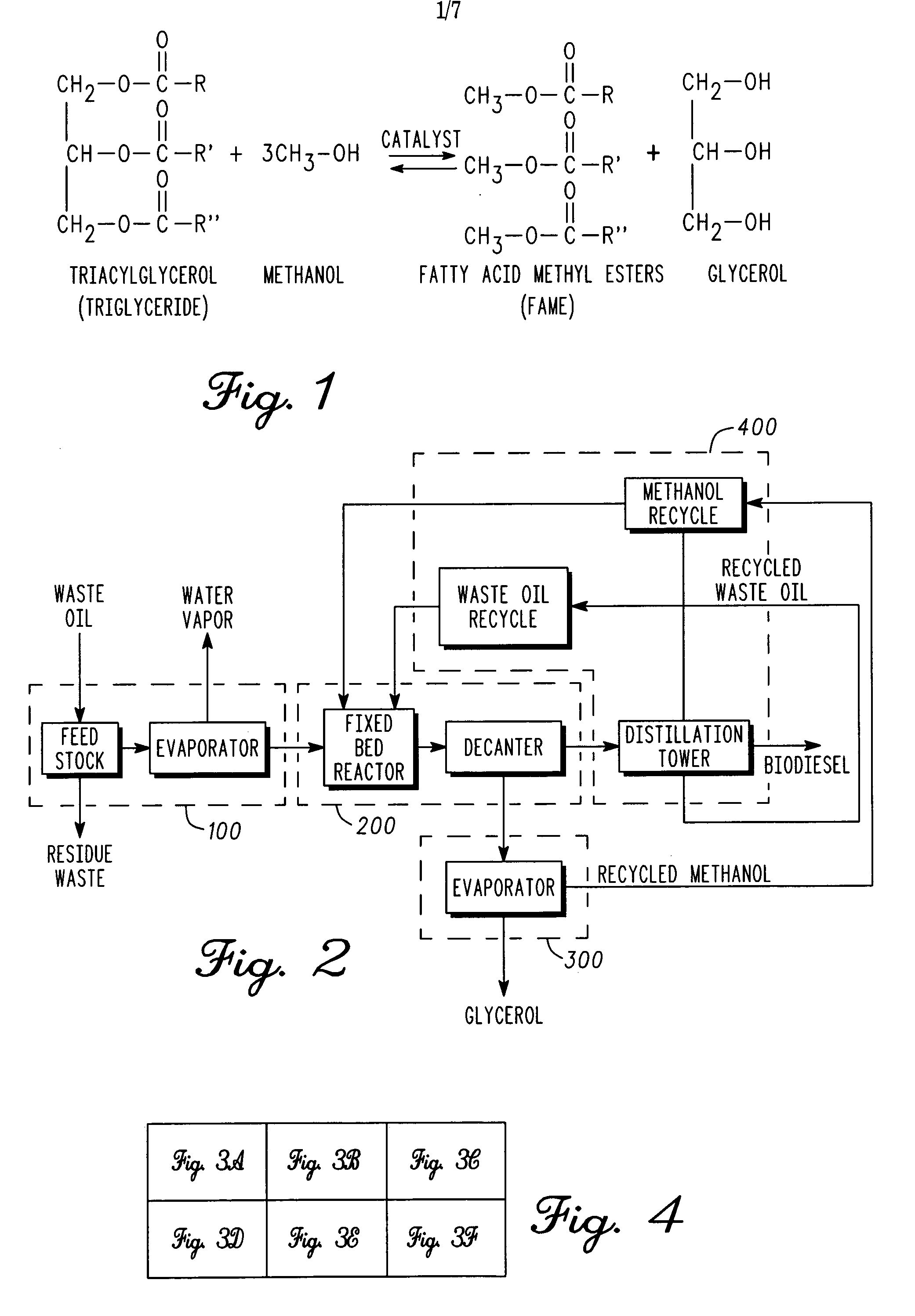

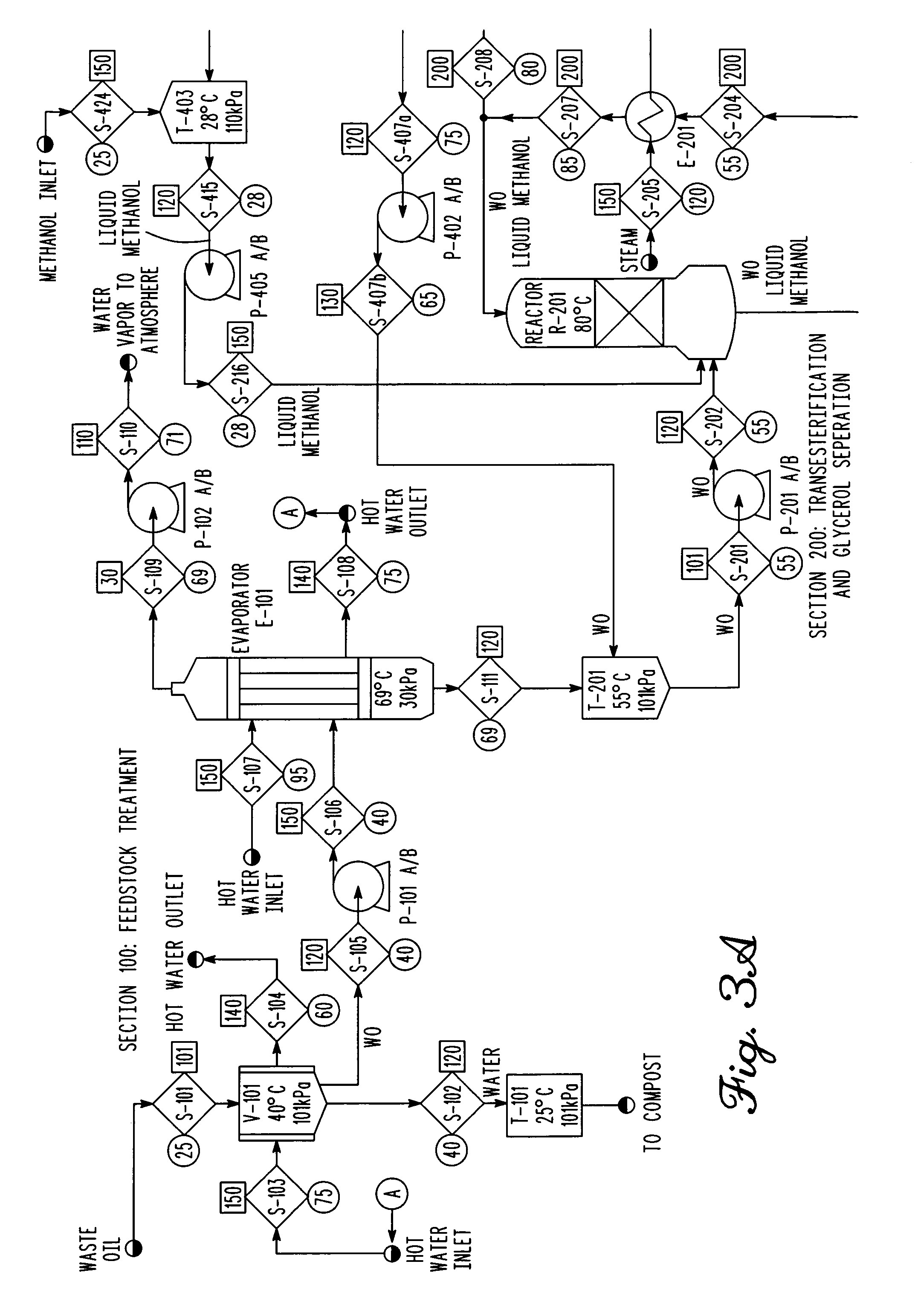

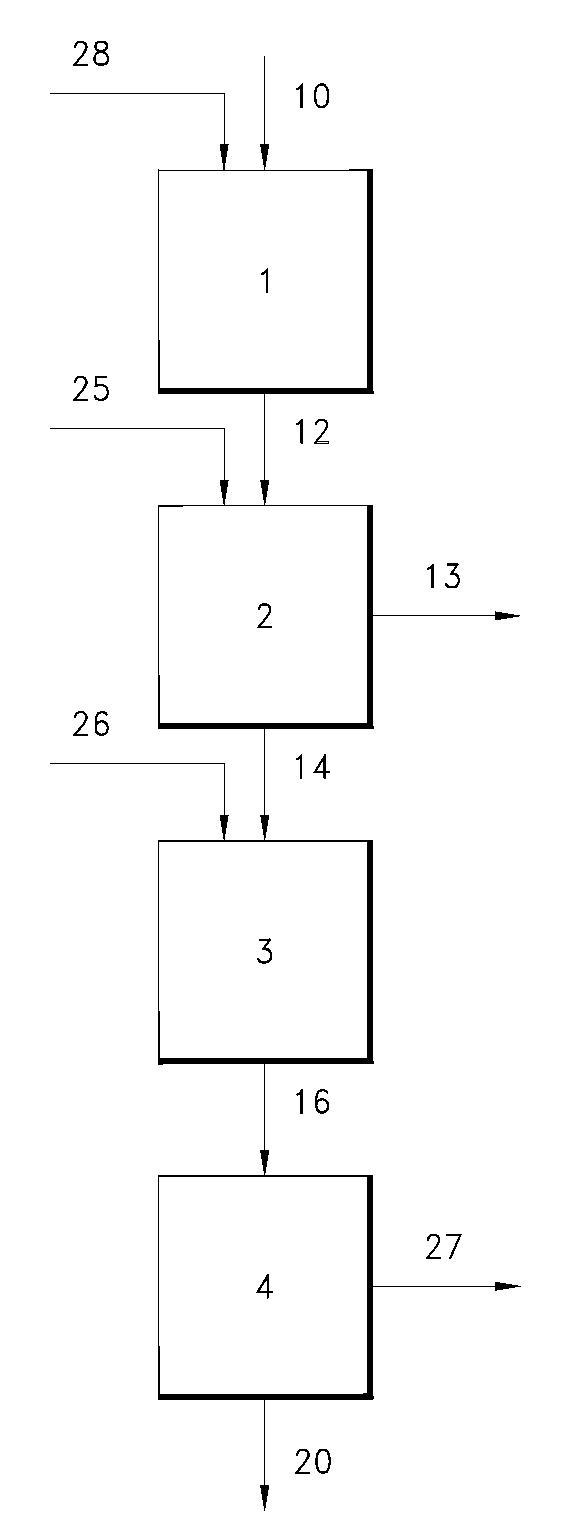

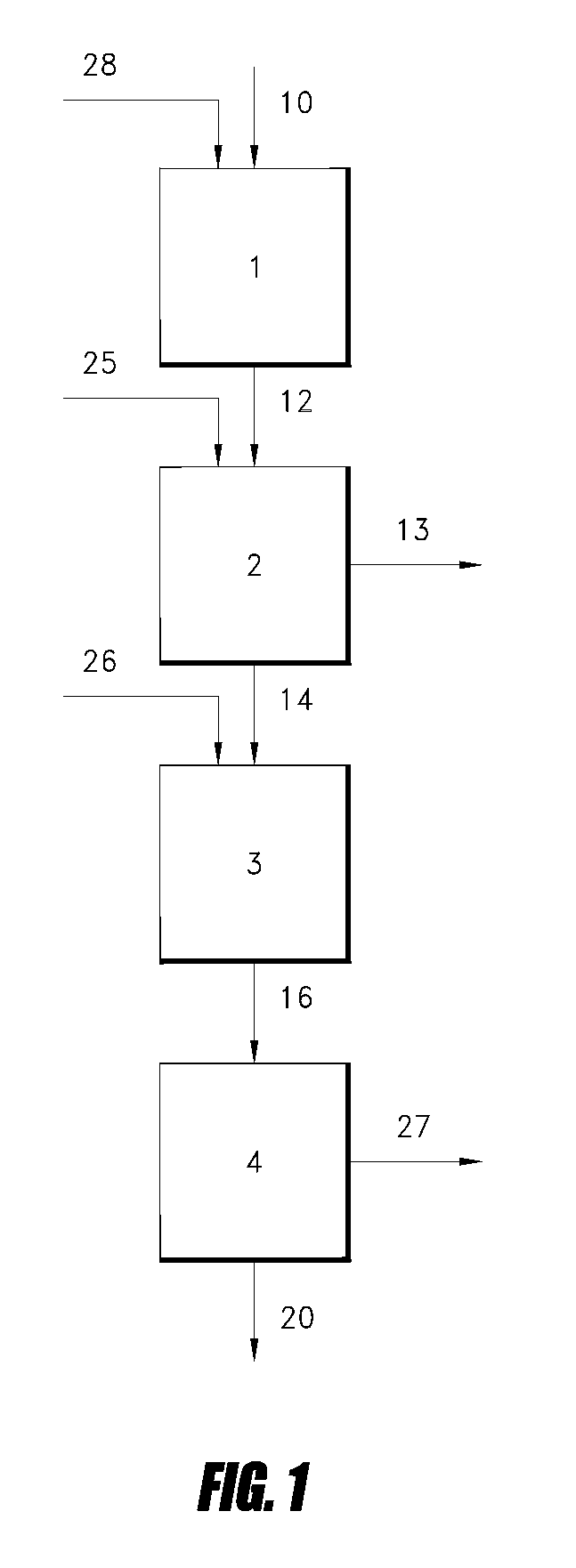

System and process of biodiesel production

ActiveUS20100166620A1Optimizing overall efficiency of processMinimal negative impactFatty acid esterificationBiofuelsTransesterificationGlycerol

A system and process for continuous production of fatty acid methyl esters (FAME) from the fatty acid triglycerides of waste oil via transesterification in the presence of a reusable sugar-based catalyst. The system and process incorporates re-cycling and re-use of waste bi-product streams to result in a near-zero emissions, with a 97% product yield mix consisting of almost pure biodiesel and a very small percentage of impurities including glycerol.

Owner:GURSKI STEPHANIE MARIE +3

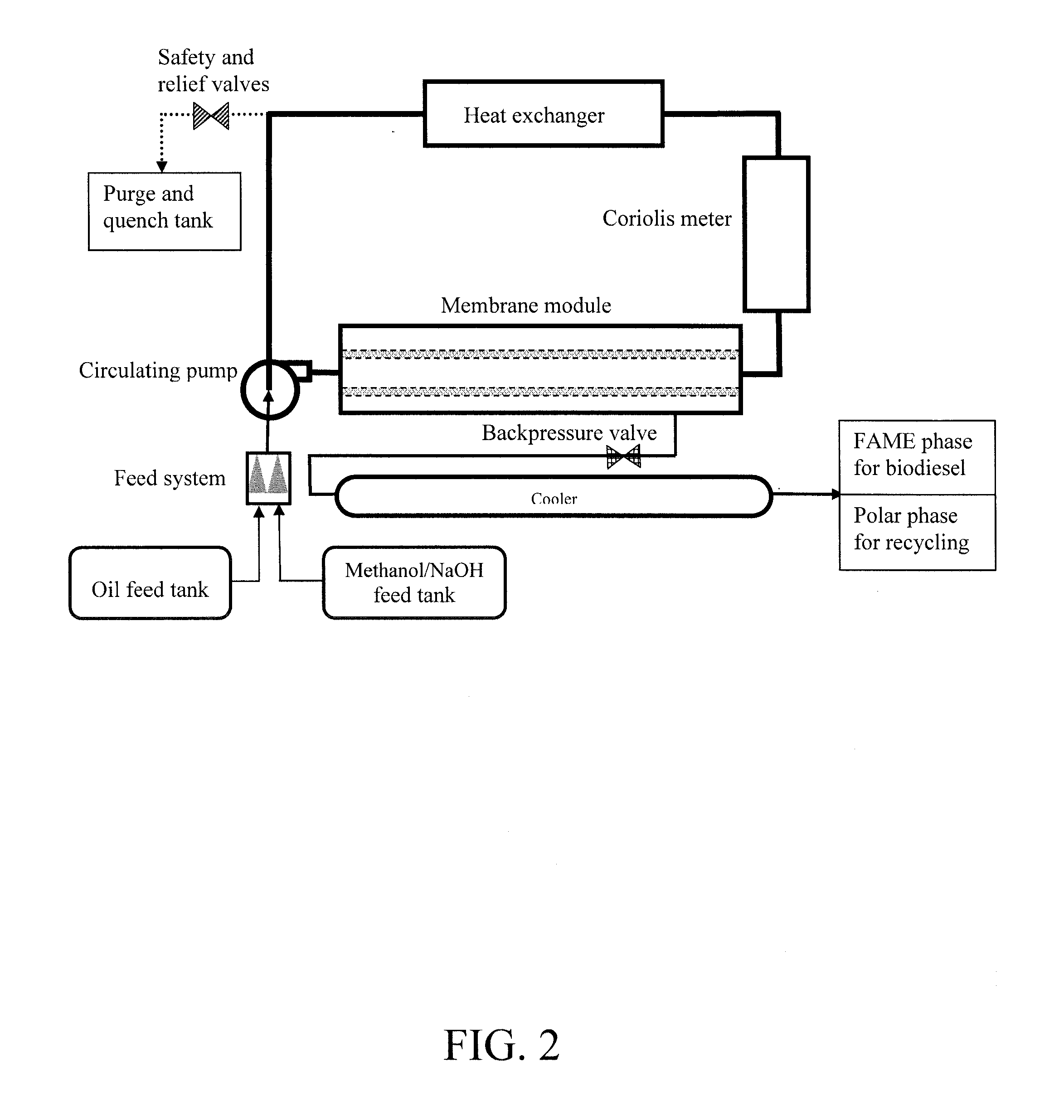

Biodiesel production using ultra low catalyst concentrations in a membrane reactor

InactiveUS20100307051A1Good colorReduce the amount requiredFatty oils/acids recovery from wasteFatty acid esterificationBiodieselEmulsion

A method for producing a fuel or fuel additive comprising providing a reaction mixture comprising oil and an alcohol in an oil-in-alcohol emulsion and a catalyst for converting the oil to the fuel or the fuel additive. The oil and the alcohol are reacted in the presence of the catalyst, at a concentration below that used in a conventional batch process, to produce the fuel or fuel additive. This low level of catalyst reduces the formation of diols and oxidation products that can diminish the quality of the fuel or fuel additive. The fuel or fuel additive produced is continuously removed during the reaction, effectively de-coupling the concentration of catalyst used from the rate of the two phase reaction.

Owner:UNIVERSITY OF OTTAWA

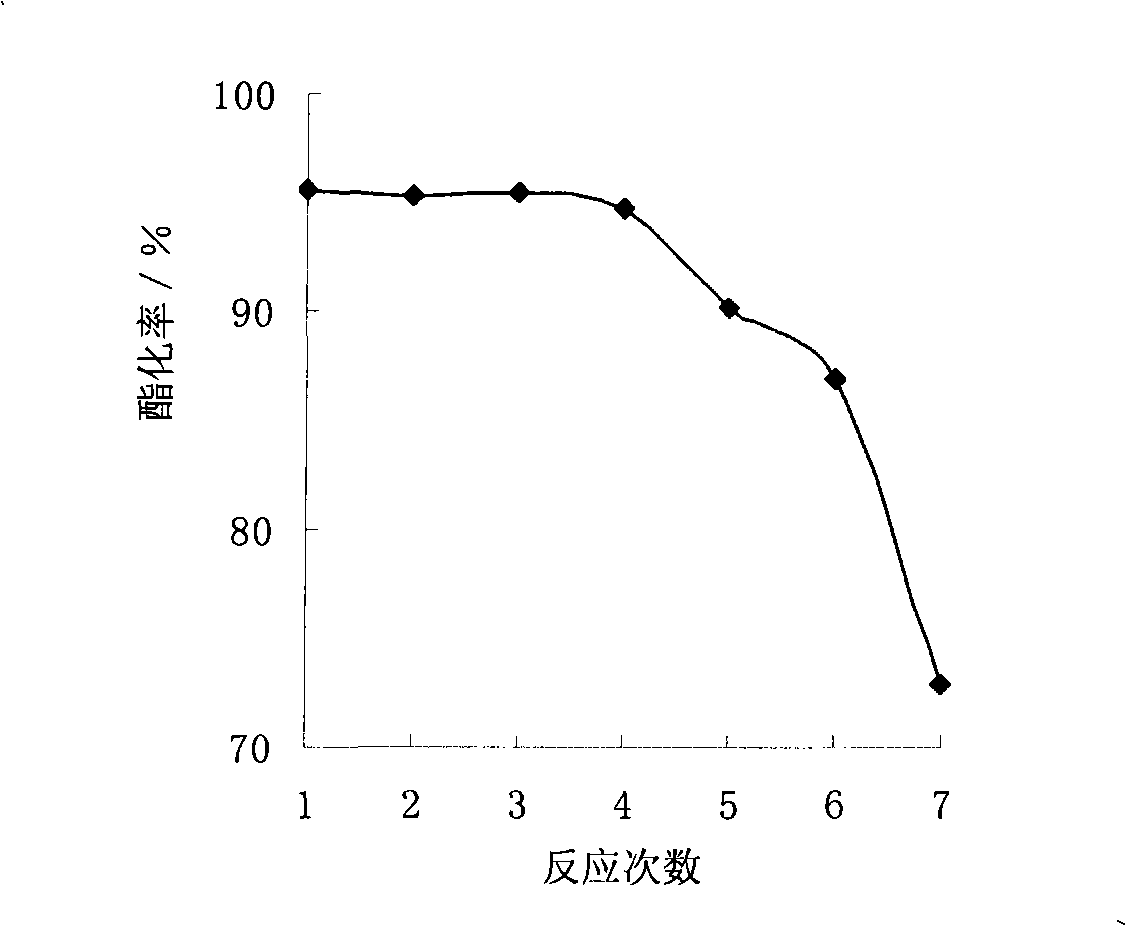

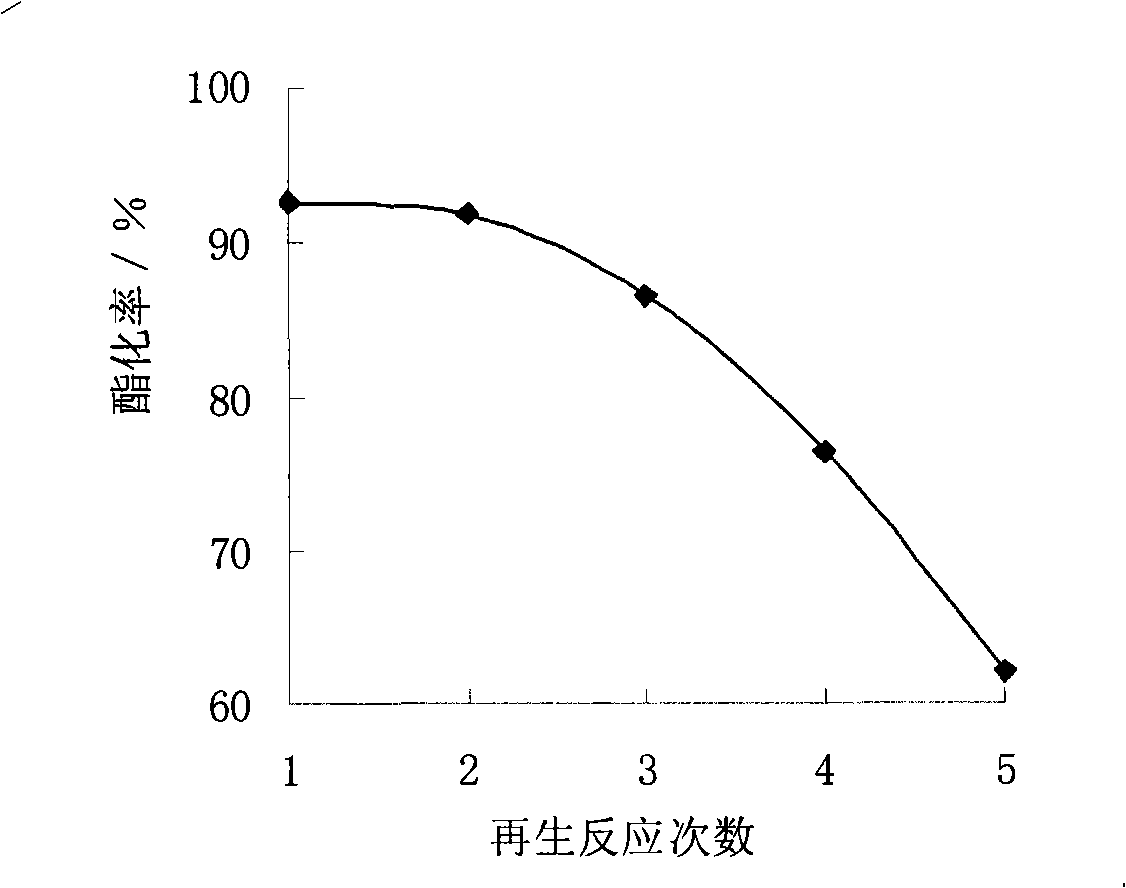

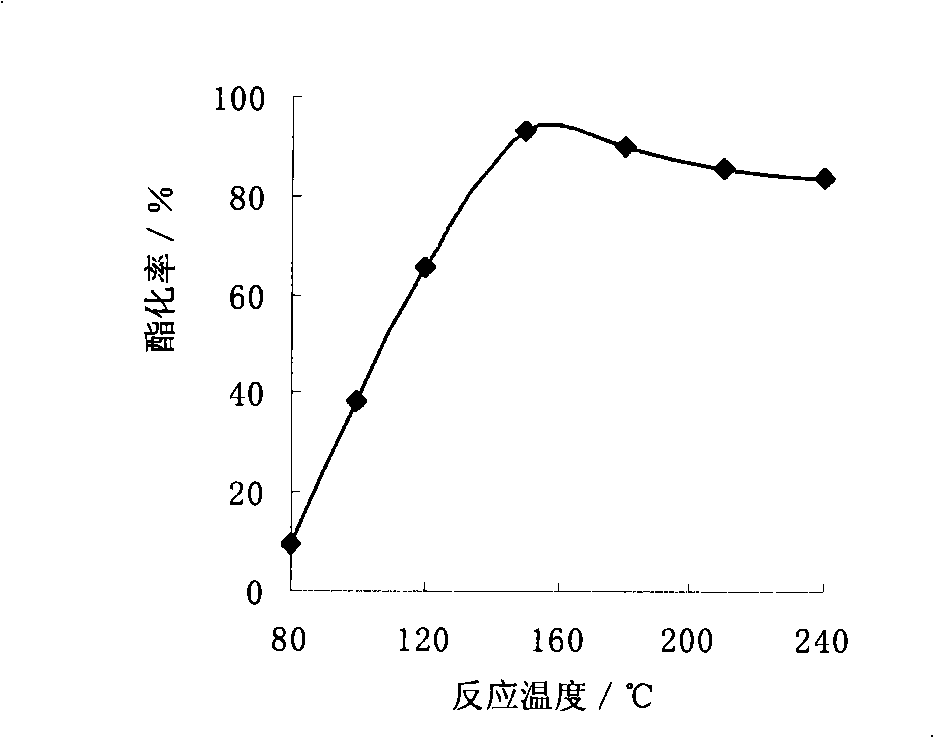

Method for producing biodiesel by using tallowseed oil and special solid catalyst thereof

InactiveCN101492603AHigh activityHigh strengthPhysical/chemical process catalystsFatty acid esterificationBiodieselAlcohol

The invention belongs to the biodiesel preparation technical field, in particular to a method for producing the biodiesel by tallow seed oil and a special magnetic nanometer difunctional solid catalyst suitable for the method. The invention is characterized in that: the tallow seed oil and a low-carbon alcohol are put in a reaction system and react under the catalysis of the catalyst; wherein the catalyst is magnetic nanometer solid acid or / and alkali with the particle size of 30-200nm, the low-carbon alcohol is methyl alcohol, and the reaction is esterification and / or ester exchange reaction; the usage of the catalyst is 1-8% of the weight of the tallow seed oil, the alcohol / oil mol ratio is maintained to be 5-45:1, and the reaction temperature is 60-180 DEG C; the reaction lasts 1-10h at normal pressure, glycerol is separated, the methyl alcohol is evaporated out, so that the prepared biodiesel is neutral. With the invention adopted, the magnetic nanometer difunctional solid catalyst having the advantages of high activity, good intensity, long service life and good regenerability is obtained; in addition, the post process of biodiesel production is simple, the yield is high, thus meeting the production requirement of environmental protection.

Owner:HUAZHONG AGRI UNIV

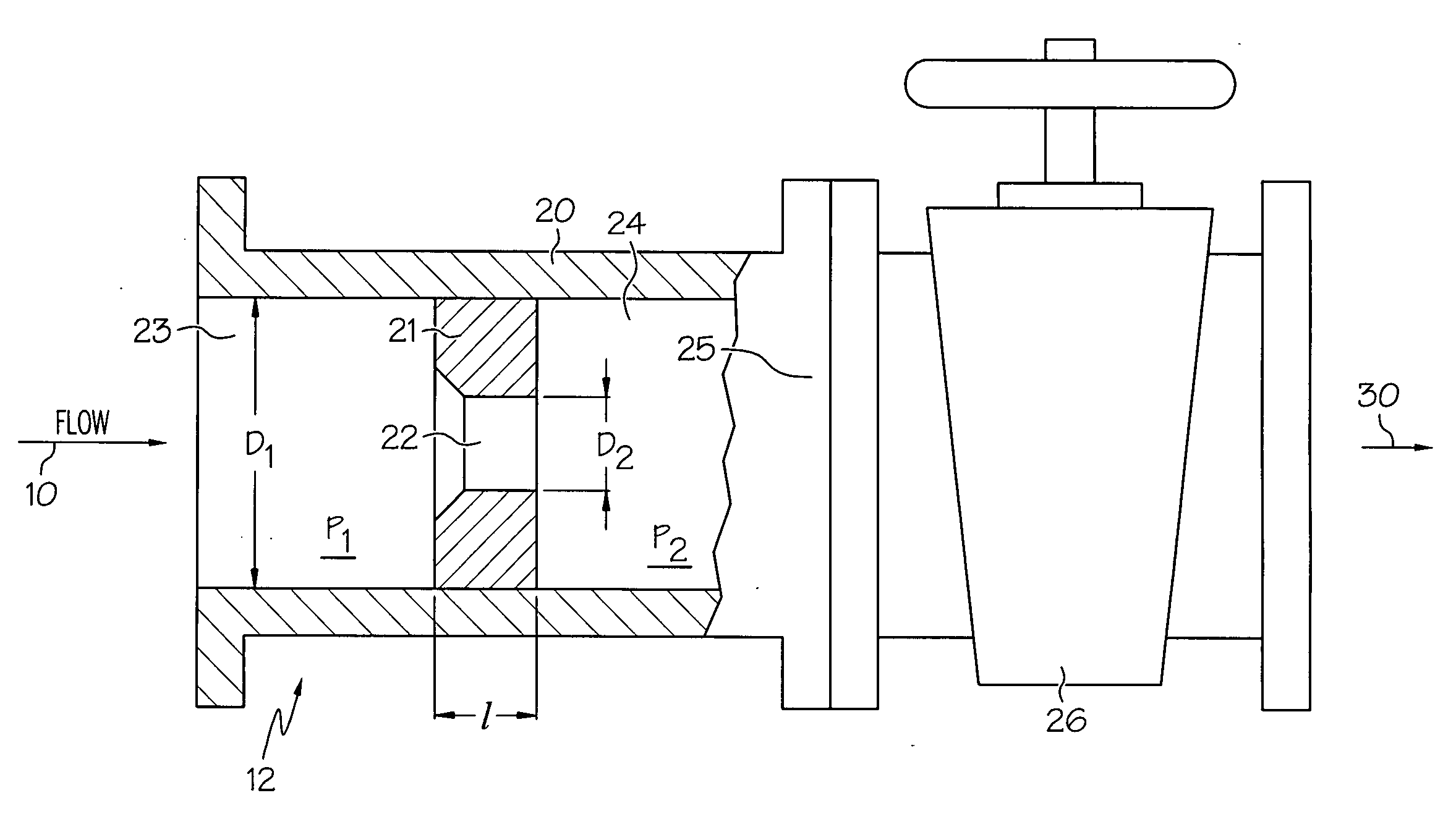

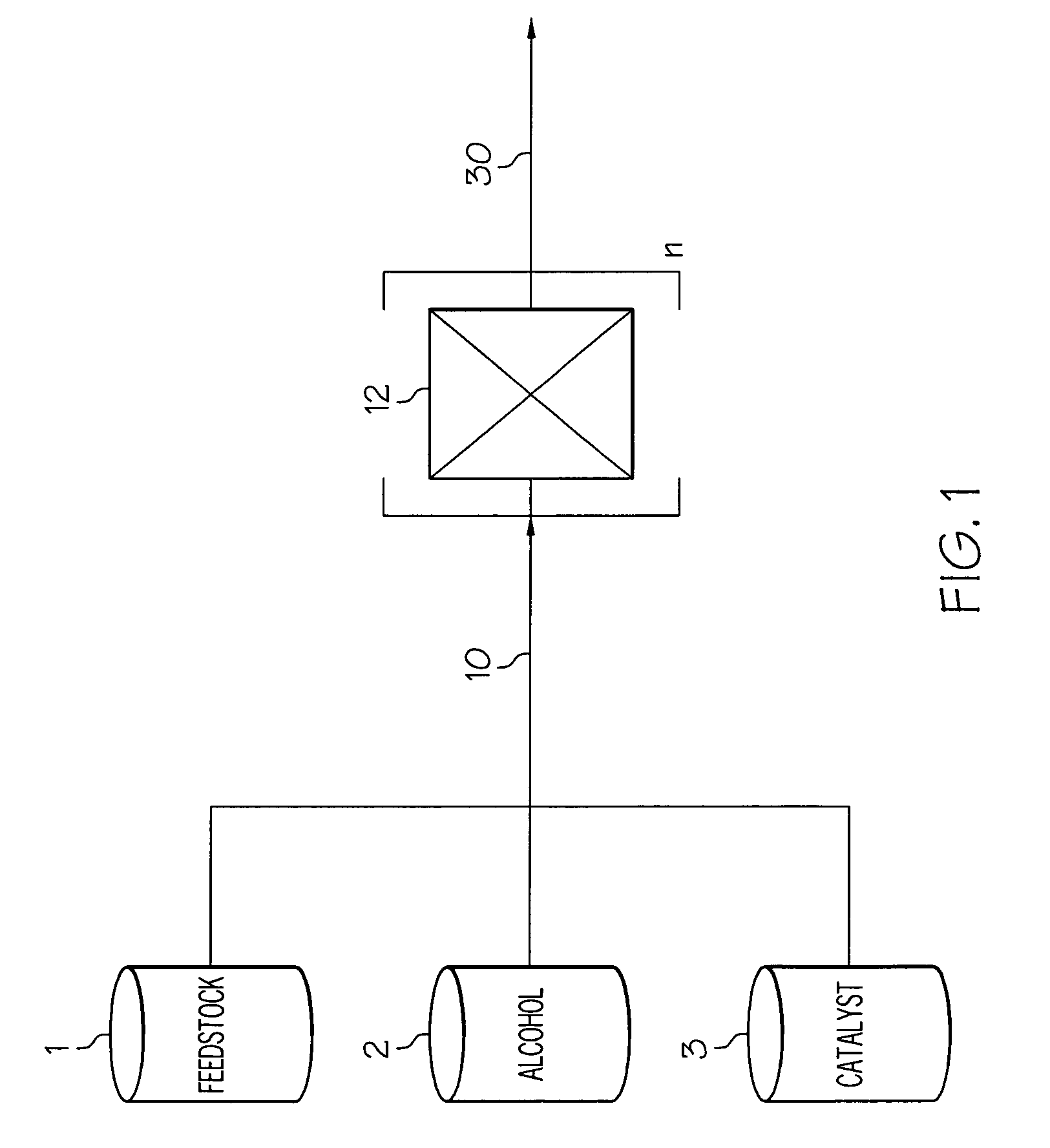

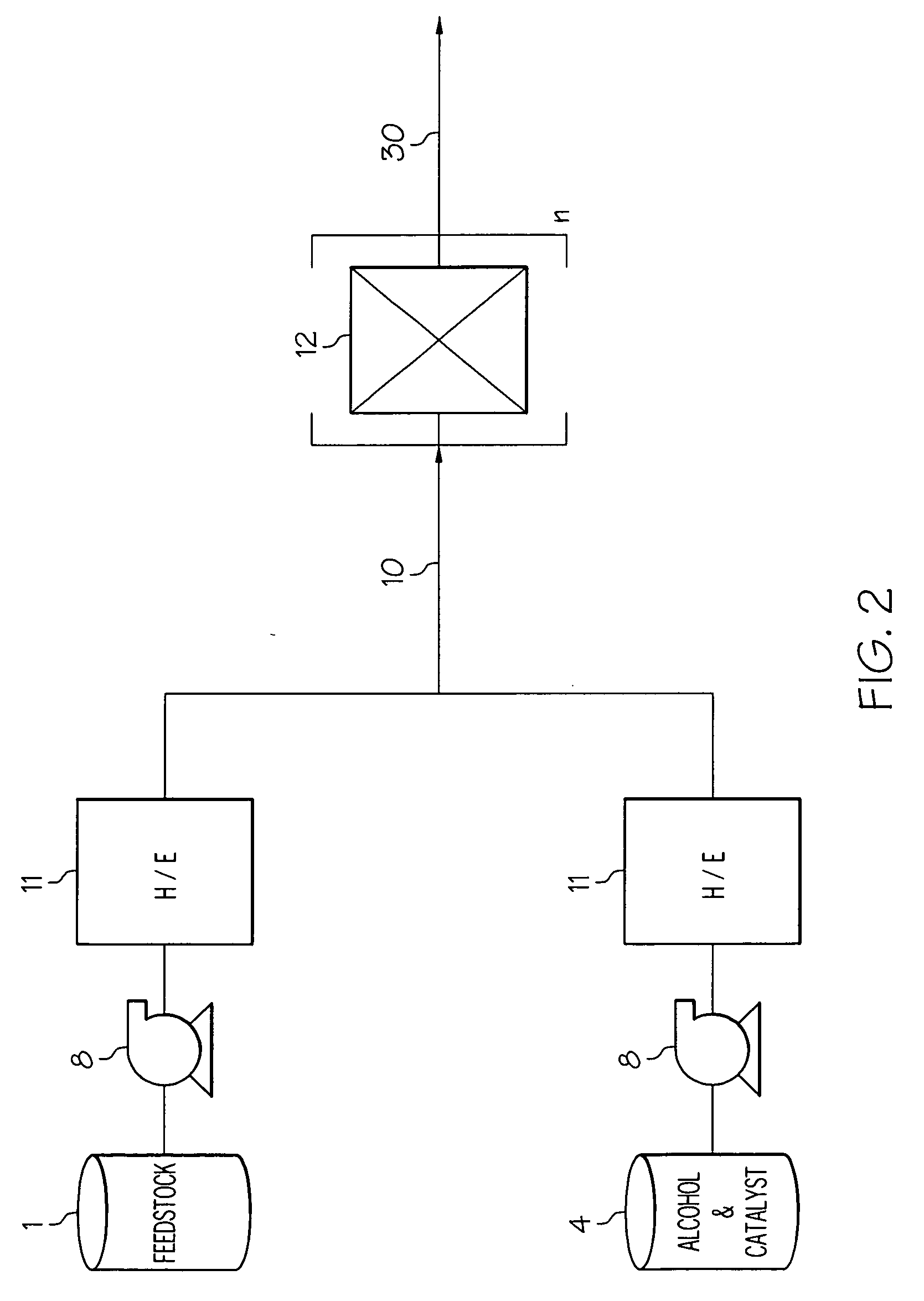

Apparatus and method for producing biodiesel from fatty acid feedstock

InactiveUS20090043118A1Improve conversion rateConversion rateFatty acid esterificationFatty acids production/refiningCavitationBiodiesel

A method comprising applying a controlled flow cavitation apparatus to a biodiesel production process in order to increase fatty acid alkyl ester yield. A feedstock comprising free fatty acids can be passed through a controlled flow cavitation apparatus at a velocity capable of generating a hydrodynamic cavitation zone where the free fatty acids can be esterified. One or more controlled flow cavitation apparatuses can be applied at various points of a biodiesel production process.

Owner:ARISDYNE STSTEMS INC

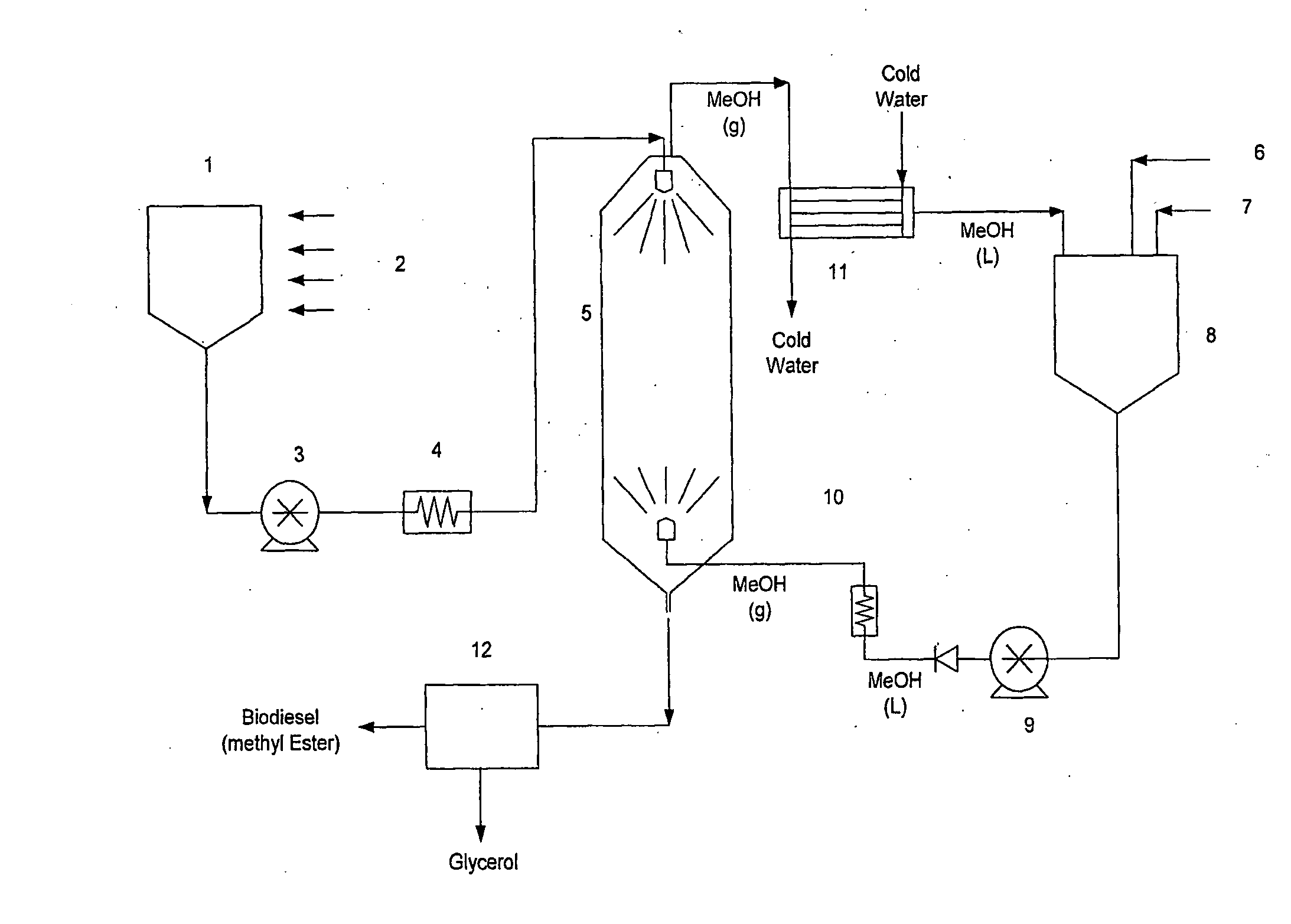

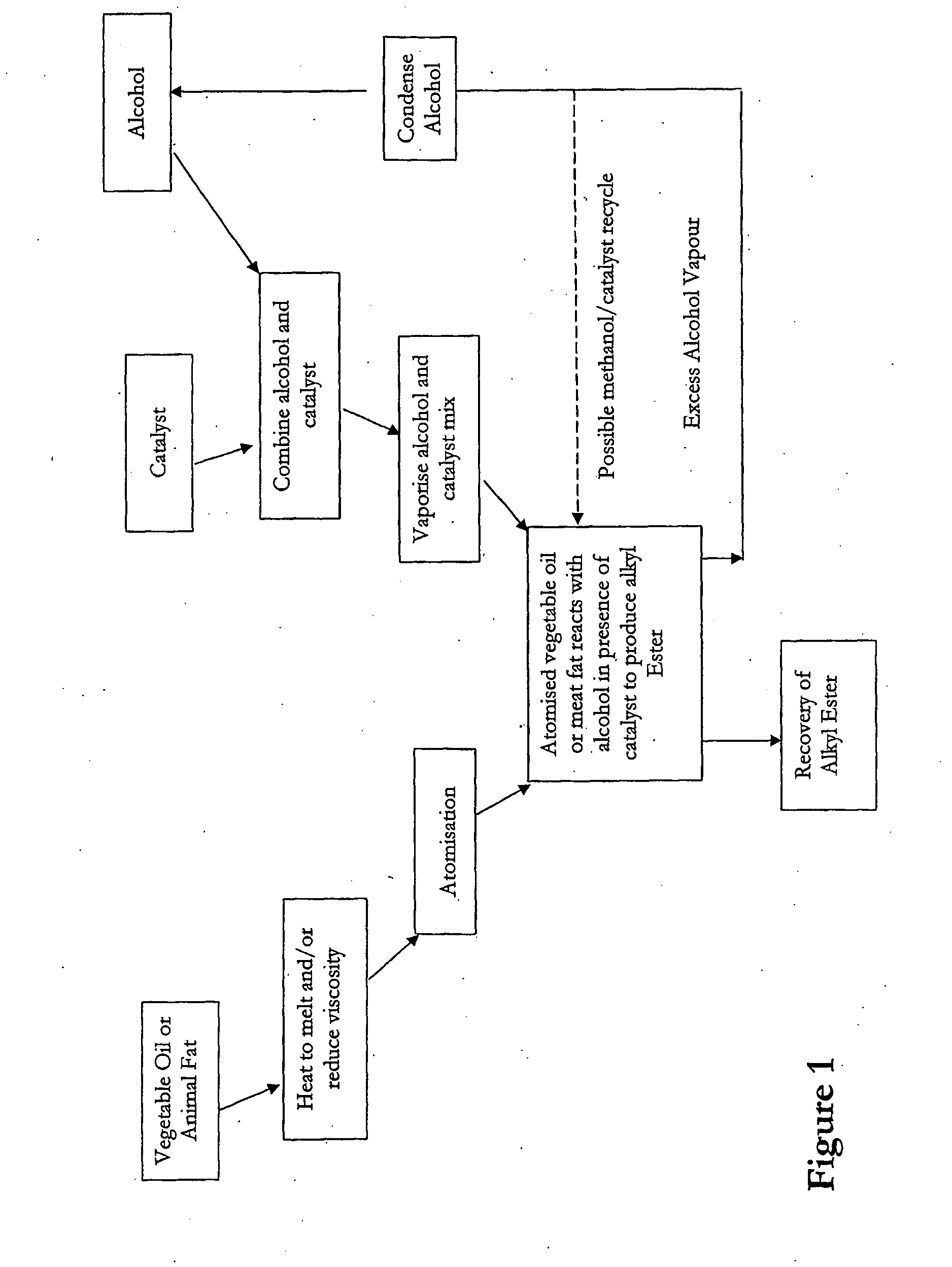

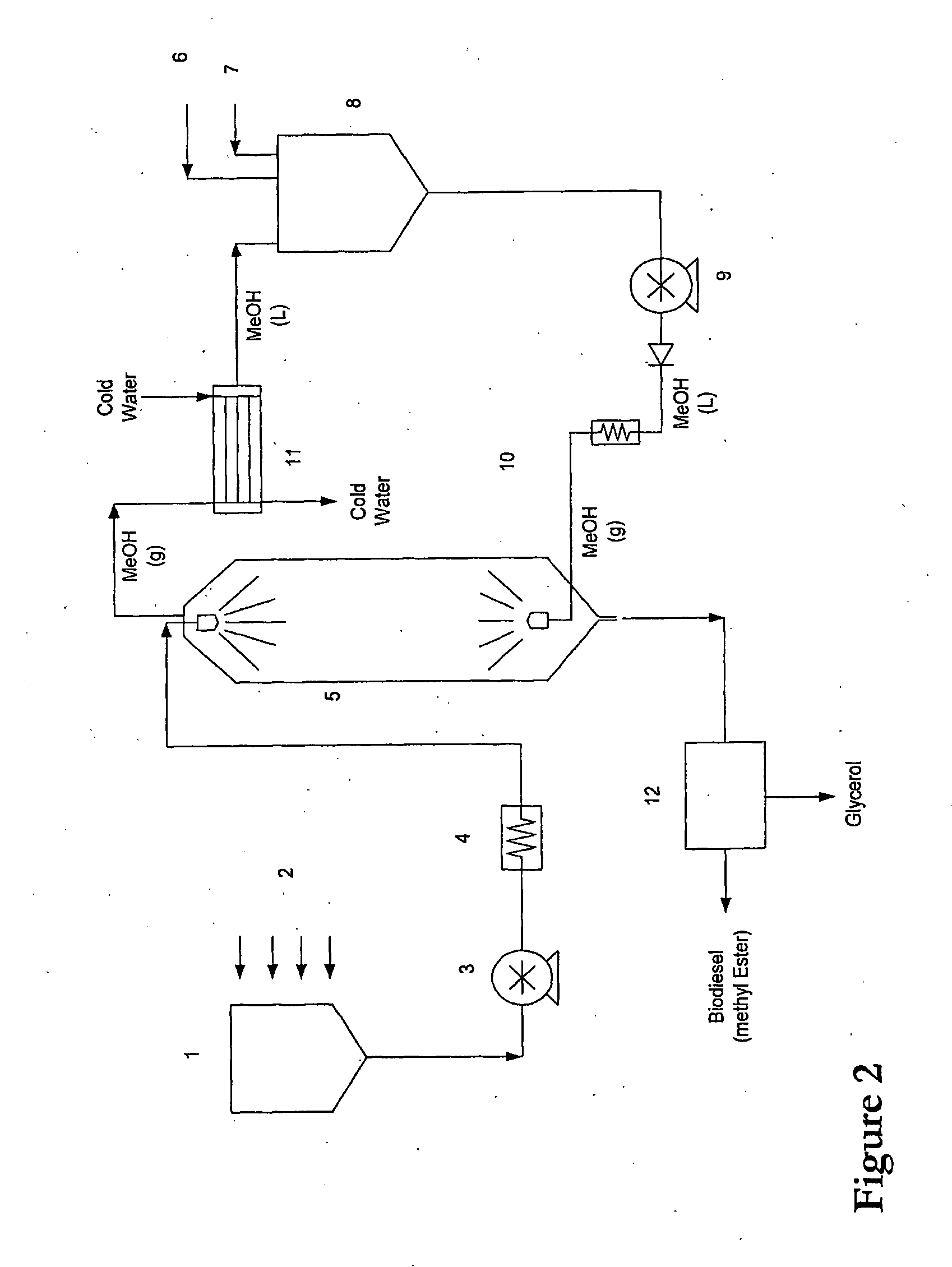

Method of Biodiesel Production

InactiveUS20090038209A1Physical/chemical process catalystsFatty acid esterificationBiodieselVegetable oil

The invention relates to a process of producing biodiesel via transesterification reaction where the feed of vegetable oil and / or animal fat is atomised prior to the reaction. The process is suitable for continuous production of biodiesel.

Owner:AUCKLAND UNISERVICES LTD

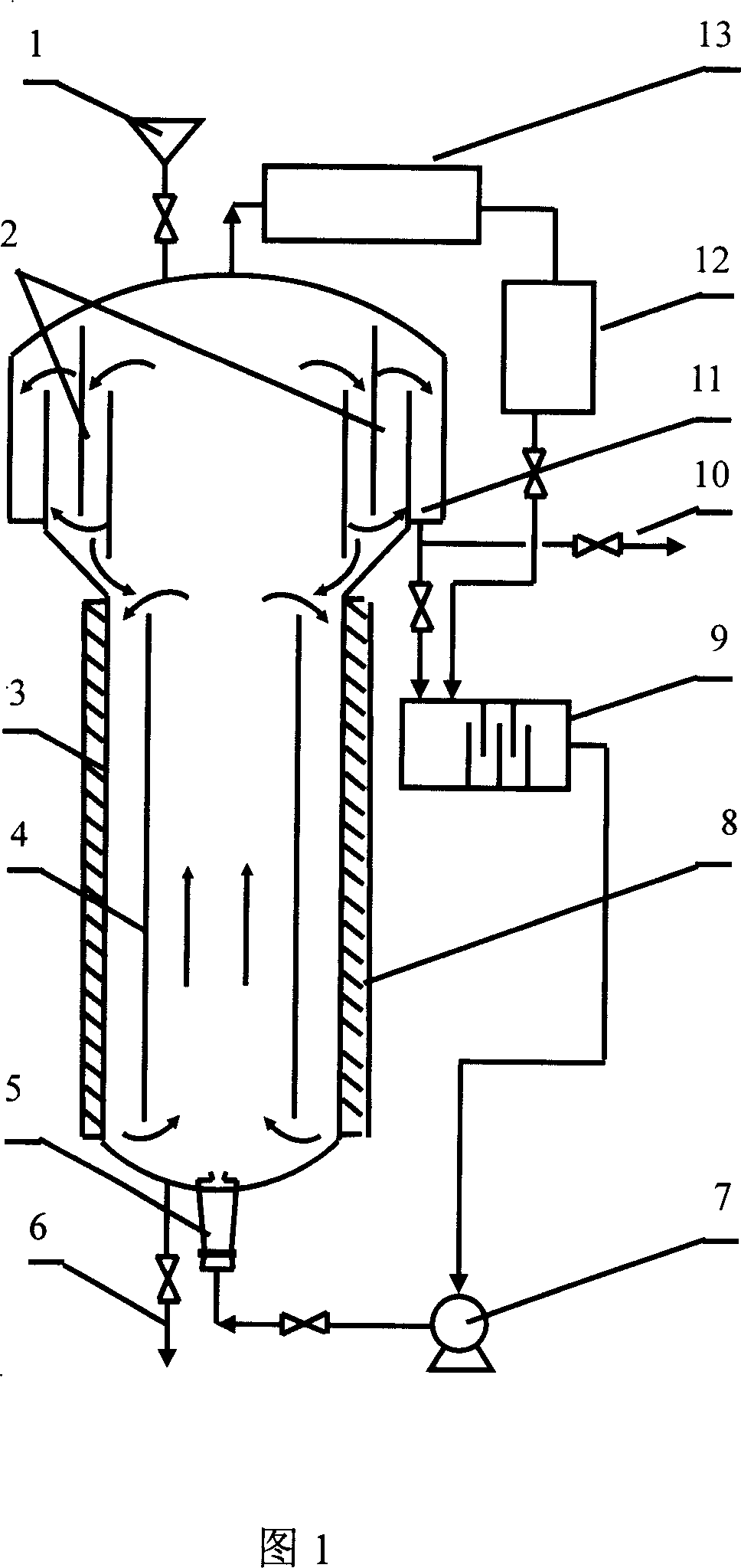

Process for preparing biological diesel oil by using loop reactor

InactiveCN1970692AAchieve recyclingEliminate the "dead zoneBiofuelsLiquid hydrocarbon mixture productionOil and greaseBiodiesel

The invention discloses a manufacturing method of biological diesel in the circulating reactor, which comprises the following steps: adopting circulating reactor and auxiliary equipment with reflux condenser, high-level groove, static blender and pump; dissolving solid alkaline catalyst or solid acid catalyst in the carbinol; adding catalyst into circulating reactor from the top; blending carbinol and grease in the static blender into circulating reactor through pump and cavitation injector; proceeding ester exchange reaction at 50-70 deg.c or 100-160 deg.c under 0.3-1.5Mpa; circulating carbinol from the top of circulating reactor; obtaining glycerin and biological diesel from the bottom of circulating reactor.

Owner:TIANJIN UNIV

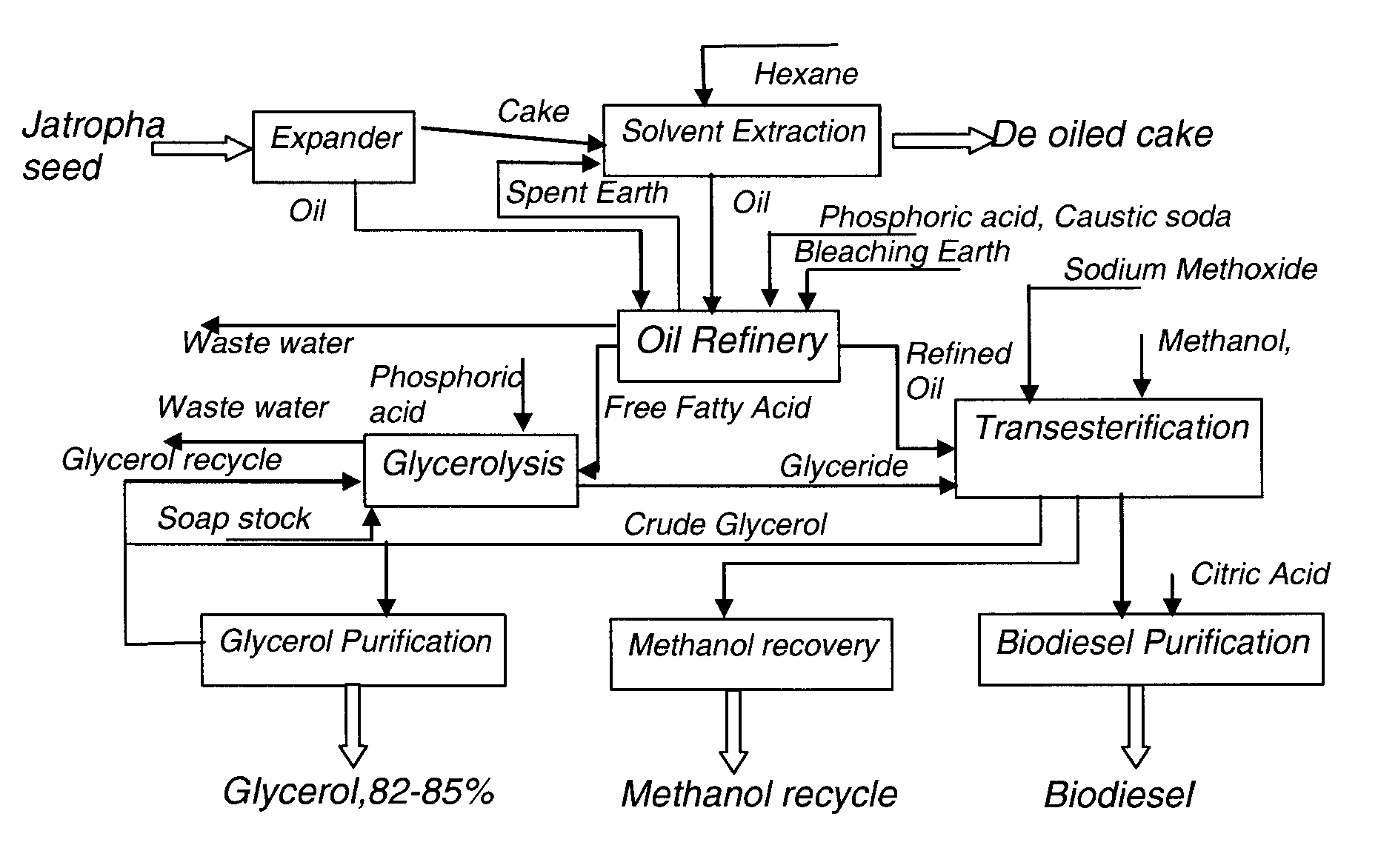

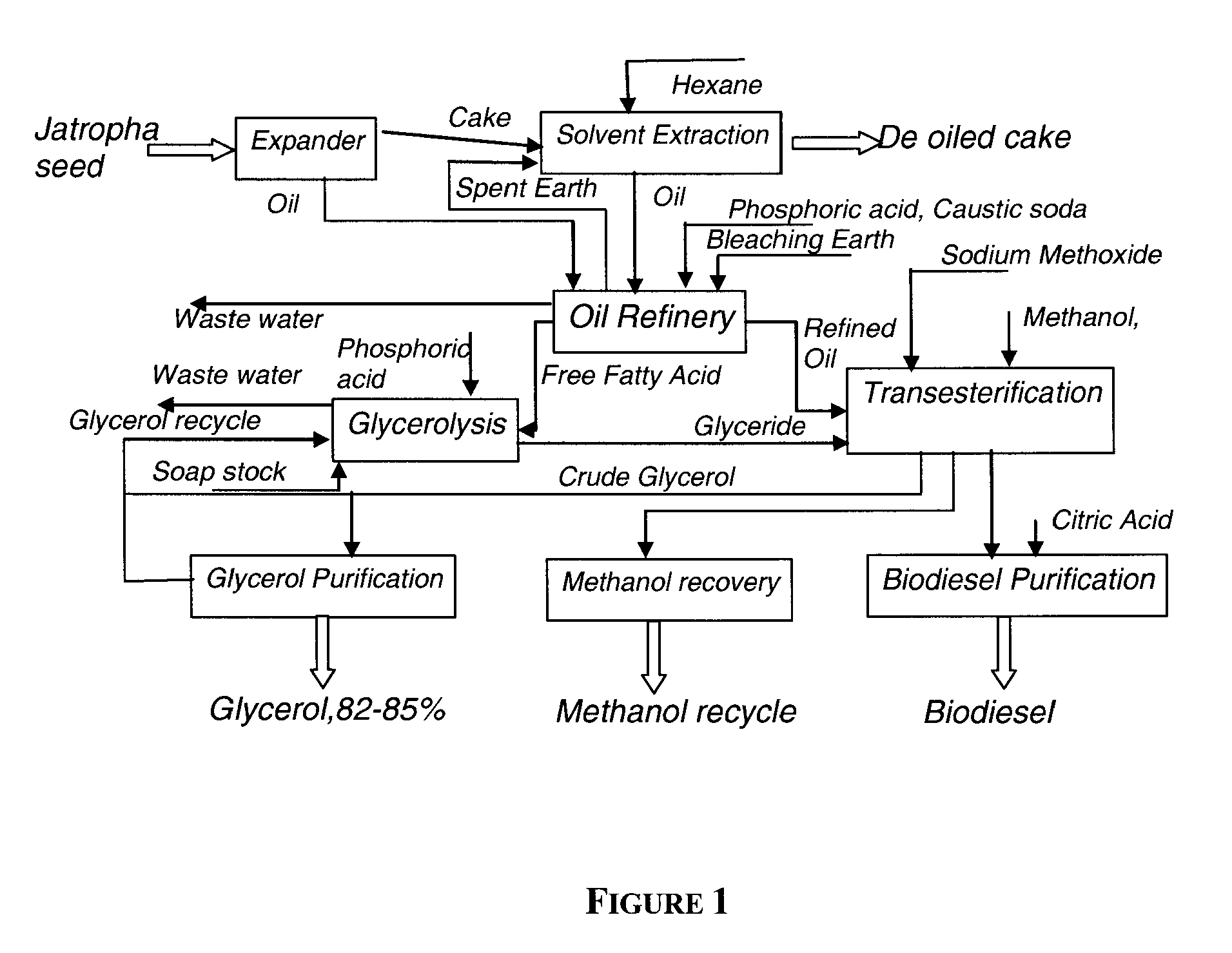

Integrated Process for the Preparation of Fatty Acid Methyl Ester (Biodiesel)

InactiveUS20080269513A1Fatty oils/acids recovery from wasteFatty acid esterificationVegetable oilGlycerol ester of wood rosin

The disclosure provides methods and systems for the production of biodiesel from biological feedstocks such as vegetable oils or animal fats. In particular, the disclosure is directed to the product of biodiesel from seeds such as non-edible oil seeds. Methods for maximizing oil recovery from the feedstocks are provided, as well as methods to convert free fatty acids in the feedstocks into glycerides amenable to transesterification. Thus the methods and systems provide for efficient biodiesel production.

Owner:RELIANCE LIFE SCI PVT

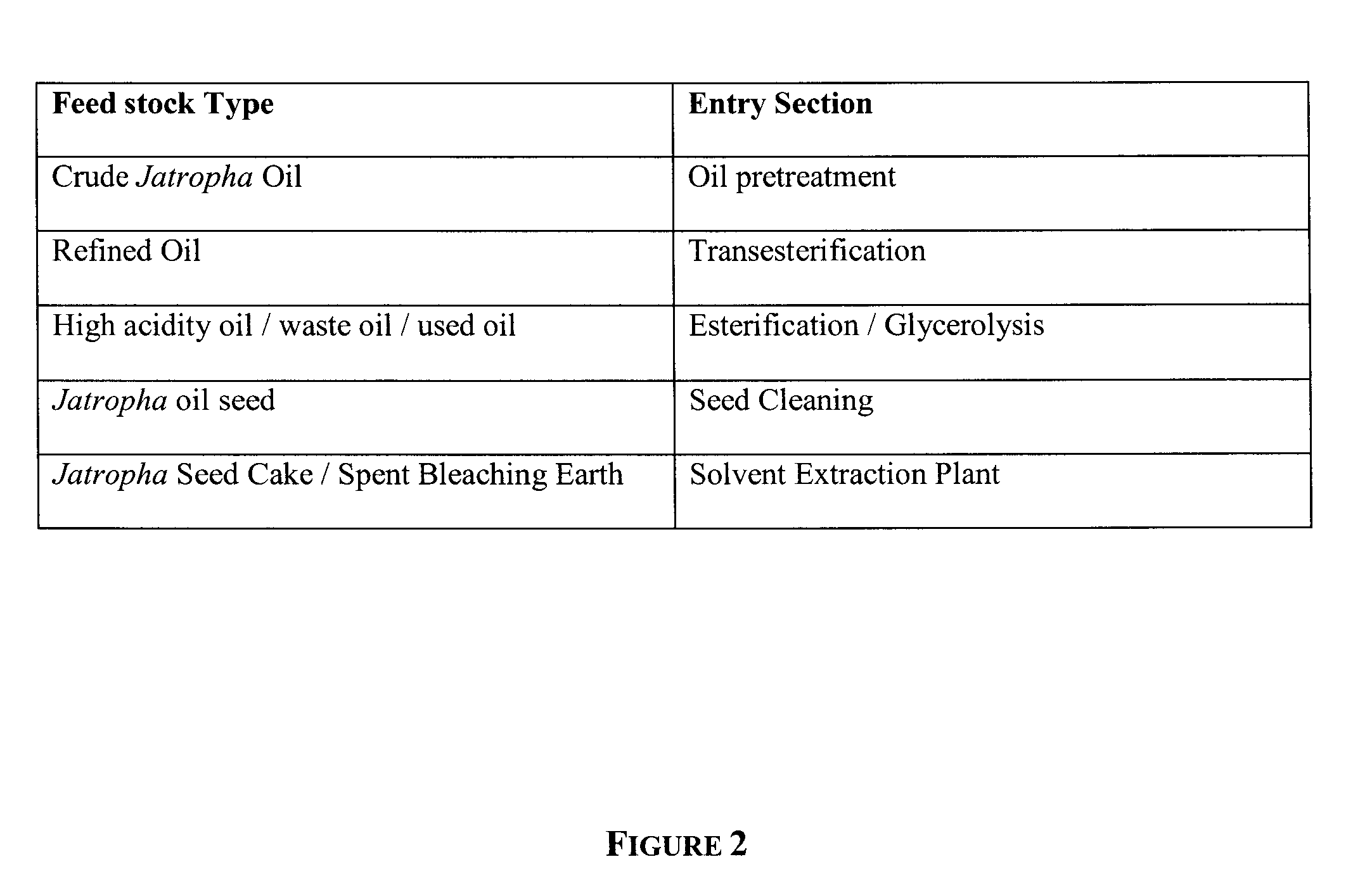

Self-sustainable mobile biodiesel production plant and method

InactiveUS20110167712A1High technicalHigh economic sustainability environmentFatty acid esterificationExhaust apparatusElectricityBiodiesel

The “MOBILE PLANT FOR SELF-SUSTAINABLE BIODIESEL PRODUCTION AND MOBILE PROCESS FOR BIODIESEL PRODUCTION” characterized by a compact equipment arrangement for the biodiesel production in a way intended to reduce waste generation and, additionally, allow reuse / application of some of them; it is organized and arranged over a chassis with axle and wheels that can be attached and taken to various locations, presents a self-sustainable format to use its own fuel to generate electricity to supply the entire plant, if necessary.

Owner:BIOMINAS ENGENHARIA E INDA DE ENERGIA

Process for preparing supported solid catalyst for use in production of bio-diesel oil

InactiveCN1962824ASimple production processMild conditionsBiofuelsLiquid hydrocarbon mixture productionProduction ratePolymer science

The invention discloses a preparing method of load alkaline catalyst to manufacture biological diesel, which comprises the following steps: allocating the material with at least one hydrotalcite or hydrotalcite load KF, CaF2, ZnF2, NaF or K2CO3 with density at 3-20%; sintering at 400-800 Deg C for 2-10h; grinding. The invention makes the production rate by over 94%, which recycles residual carbinol to avoid huge waste of difficult separation of by-product and carbinol.

Owner:XIANGTAN UNIV

Gas phase process for monoalcohol production from glycerol

InactiveUS20090005614A1Economically viableOrganic compound preparationOxygen compounds preparation by reductionGlycerolBiodiesel production

Owner:BIOFUEL SOLUTION I MALMO

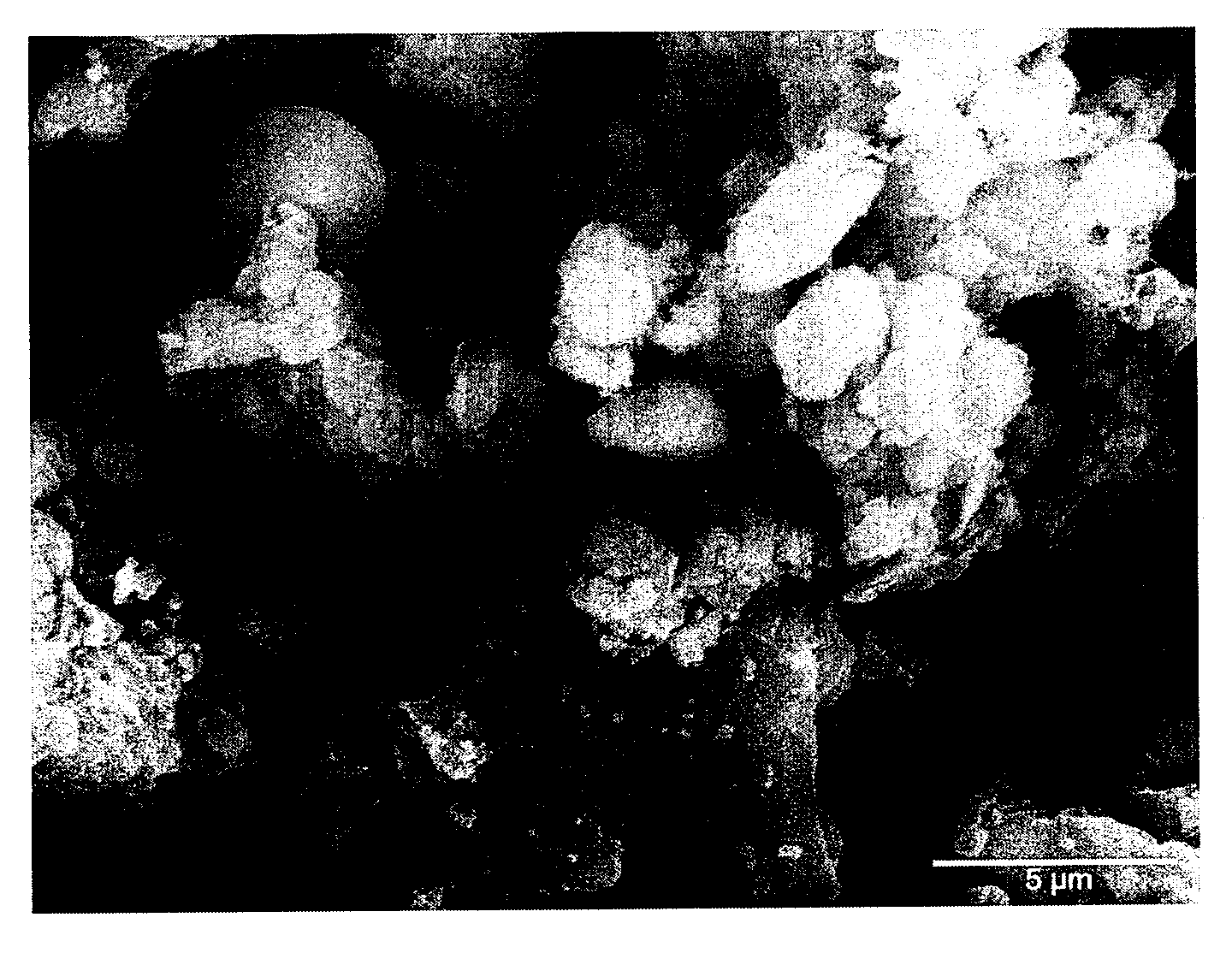

Solid catalyst system for biodiesel production

ActiveUS7906665B2Fatty acid chemical modificationFatty acids production/refiningMETHYL SOYATEVegetable oil

The invention provides efficient, inexpensive, and environmental friendly catalysts and catalyst systems. The catalysts can be used to catalyze esterification and / or transesterification reactions, for example, for the preparation of biodiesel. Kiln dust, such as cement kiln dust (CKD) or lime kiln dust (LKD) can be used to convert a variety of feedstock acids and / or esters to biodiesel in high yield under mild conditions. The CKD and LKD catalyst systems are recyclable esterification or transesterification catalysts that can be used to prepare biodiesel, such as methyl soyate, from various feedstocks, including vegetable oils and animal fats.

Owner:PINNAVAIA THOMAS J PH D +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com