Patents

Literature

207results about How to "Save processing power" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

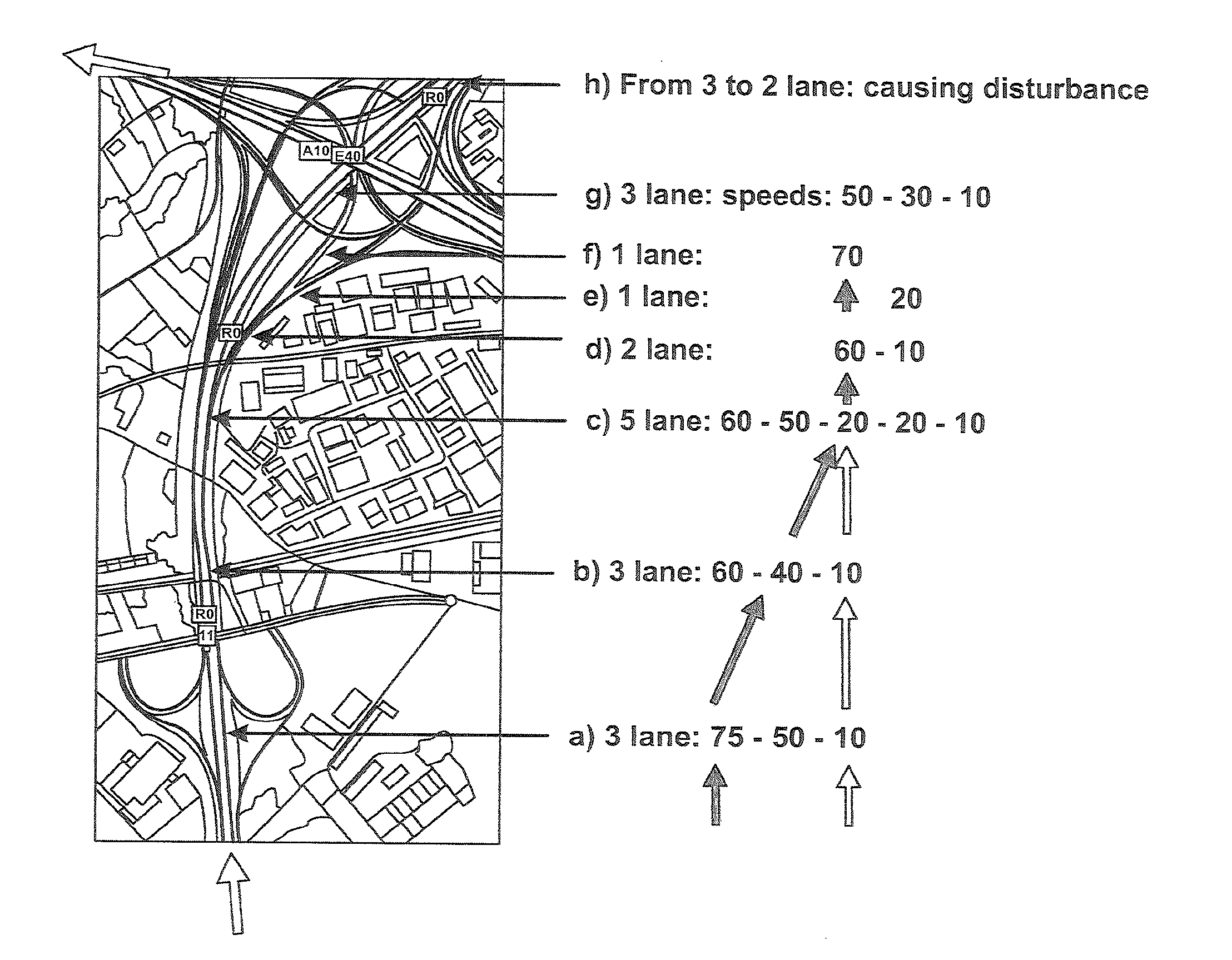

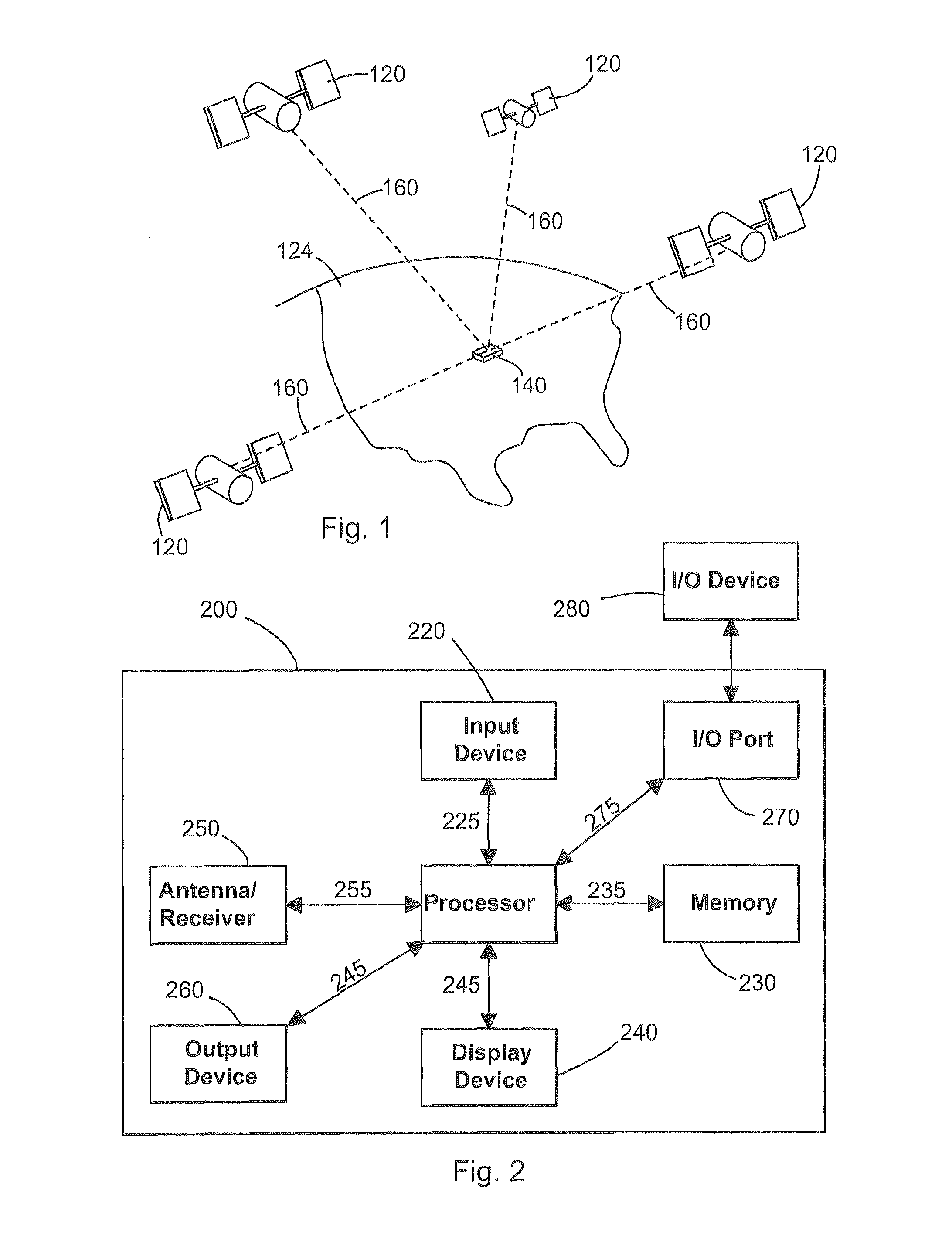

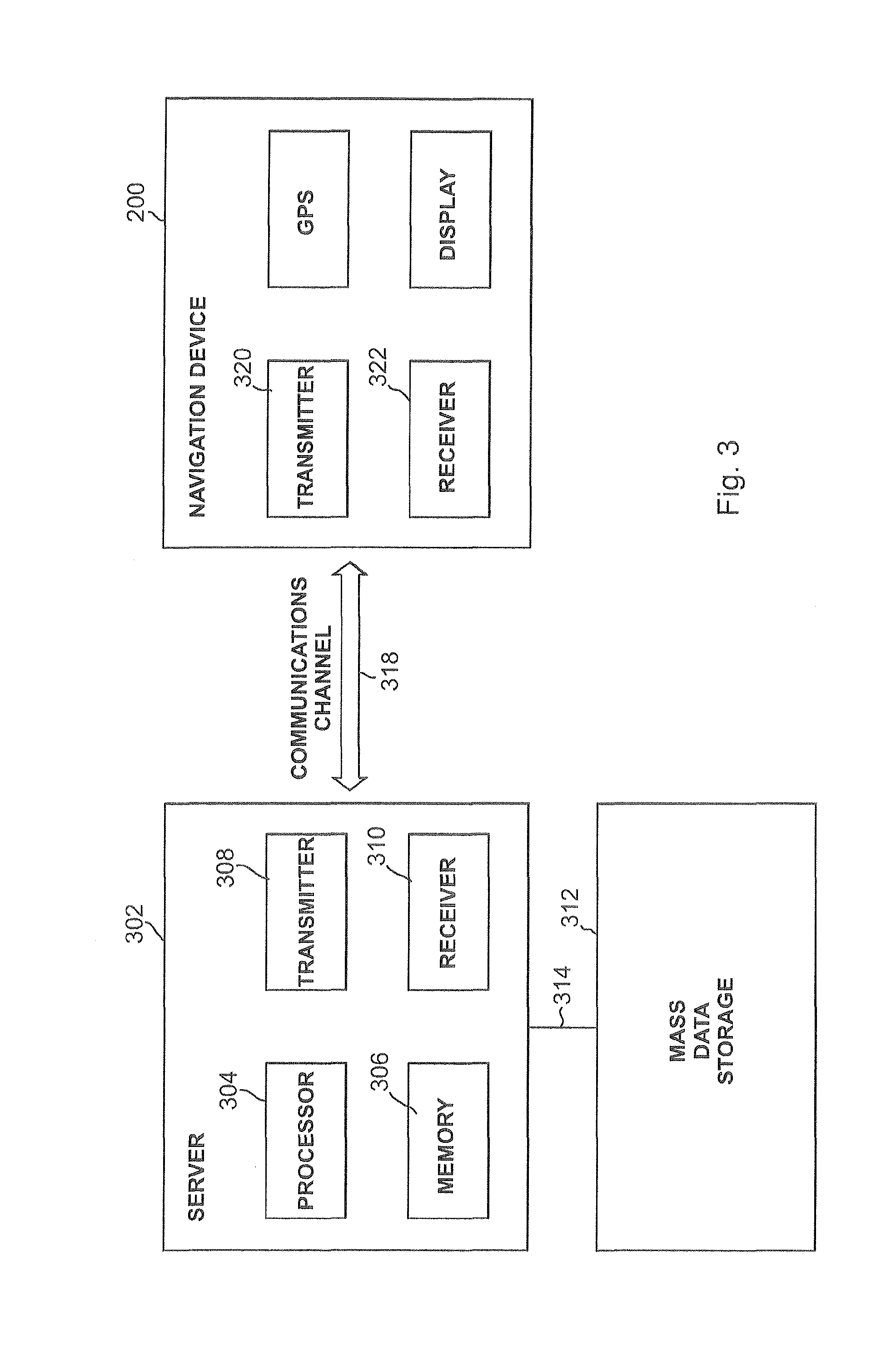

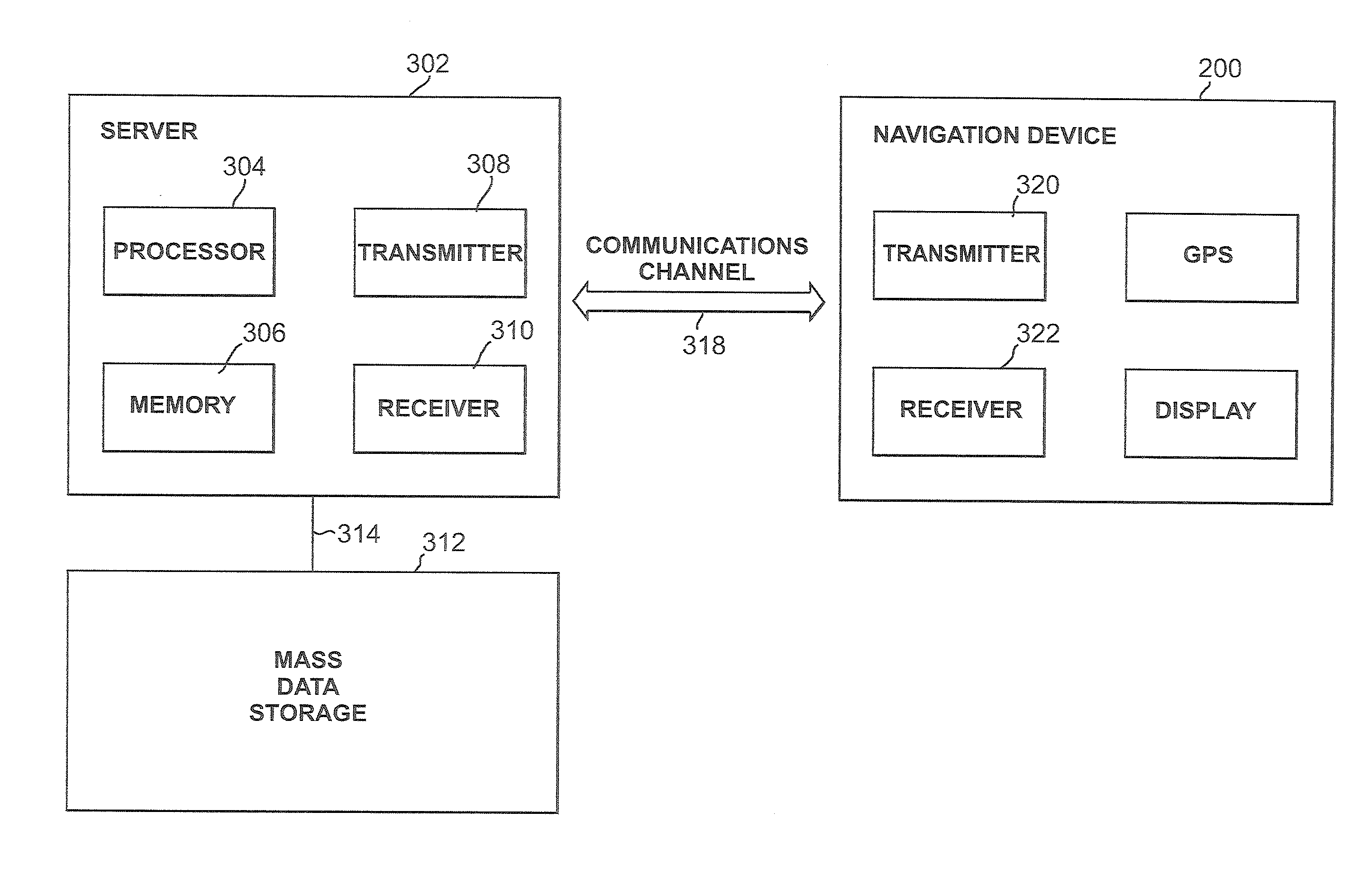

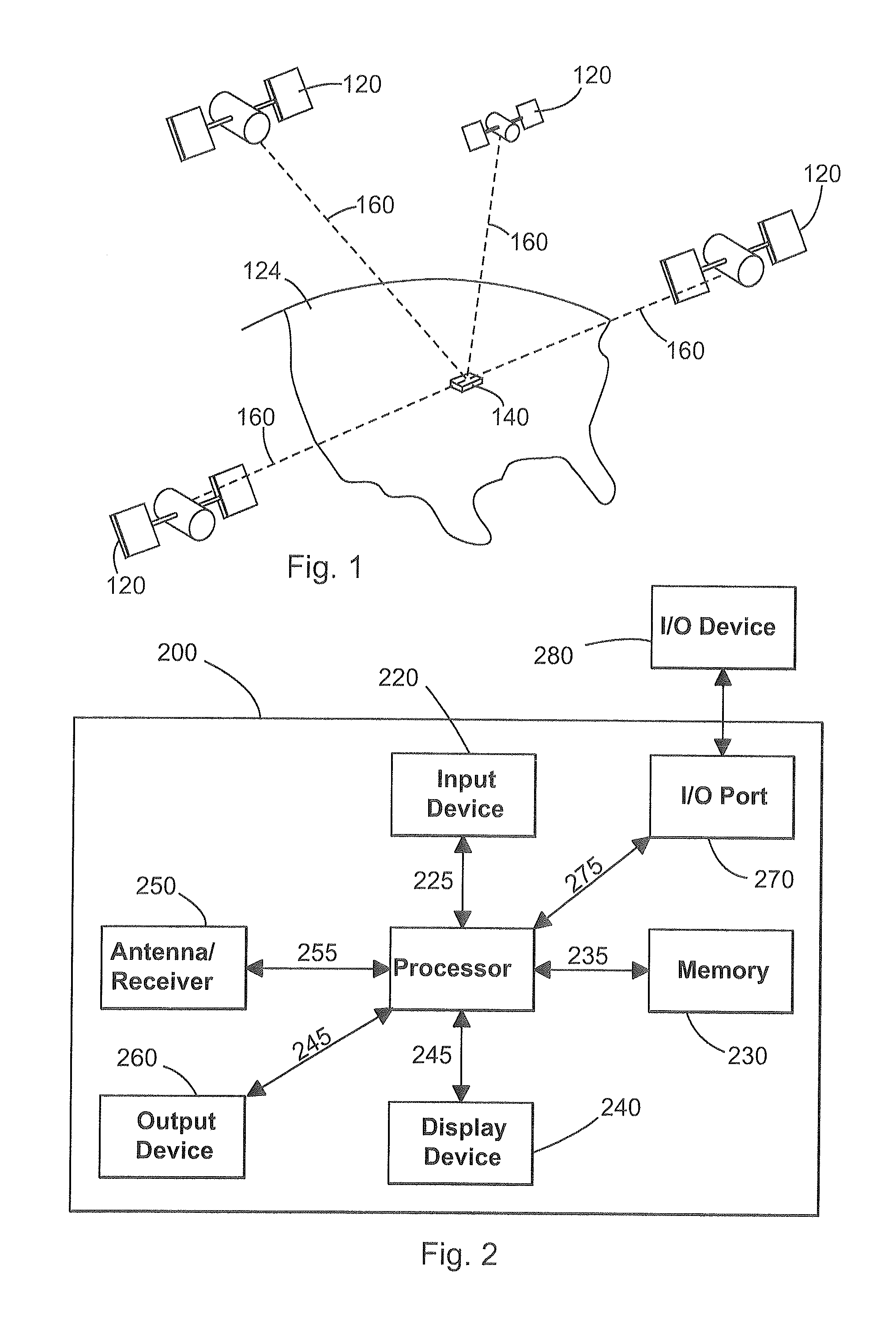

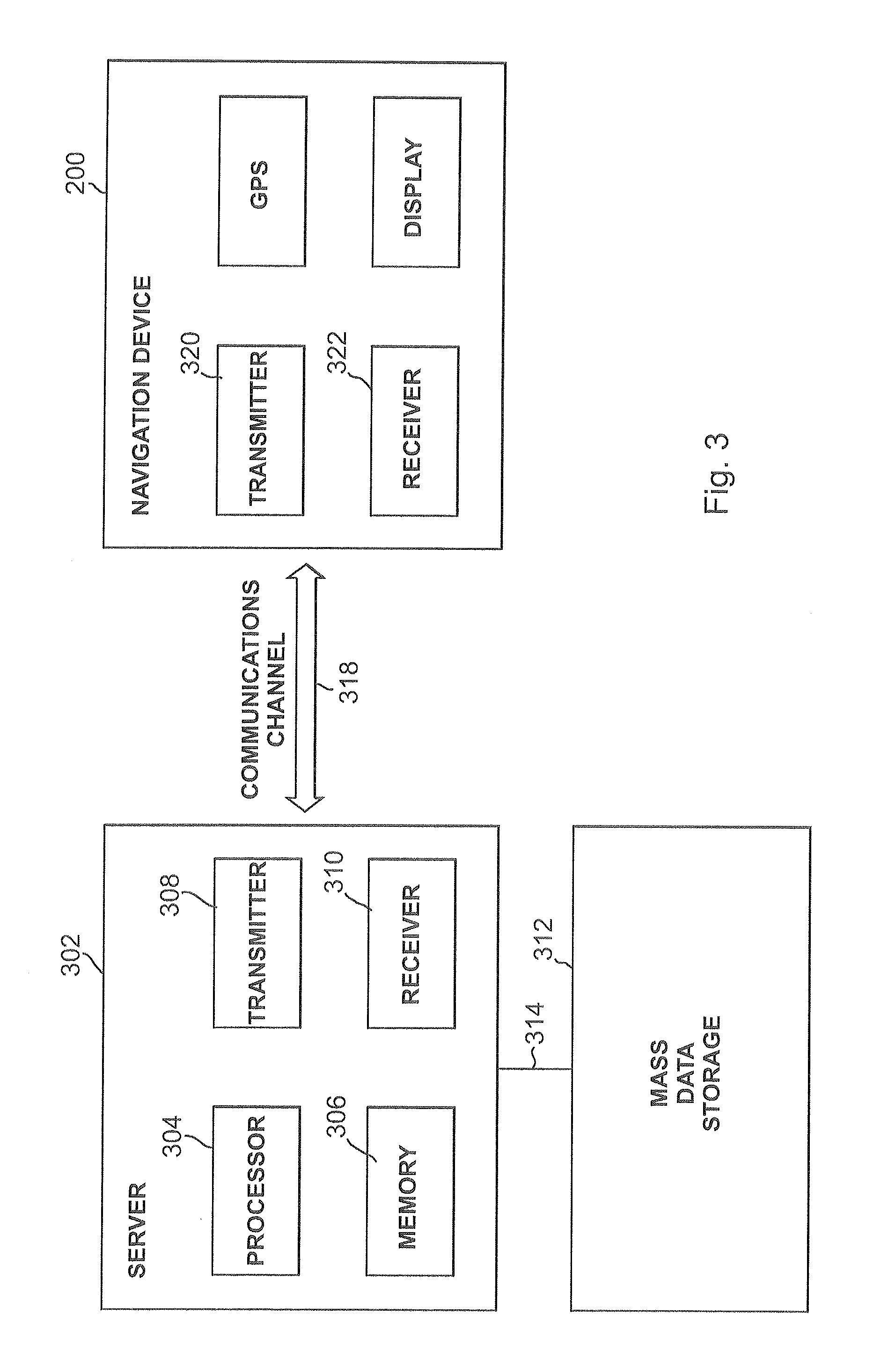

Systems and methods for obtaining and using traffic flow information

InactiveUS20130282264A1Save processing powerImprove the display effectAnalogue computers for vehiclesInstruments for road network navigationEngineeringTraffic flow

A method of determining historical lane speed profiles for each of a plurality of individual lanes of a multi-lane road section is described. The plurality of individual lanes are lanes for the same given direction of travel. The method involves collecting vehicle probe data relating to the movement of individual vehicles on the road section for a specific time of day, and using the probe data to derive an aggregate speed profile for travel along each lane at the relevant time. The method may involve using the historical lane speed profiles to provide lane guidance instructions to the user of a navigation apparatus.

Owner:TOMTOM NAVIGATION BV

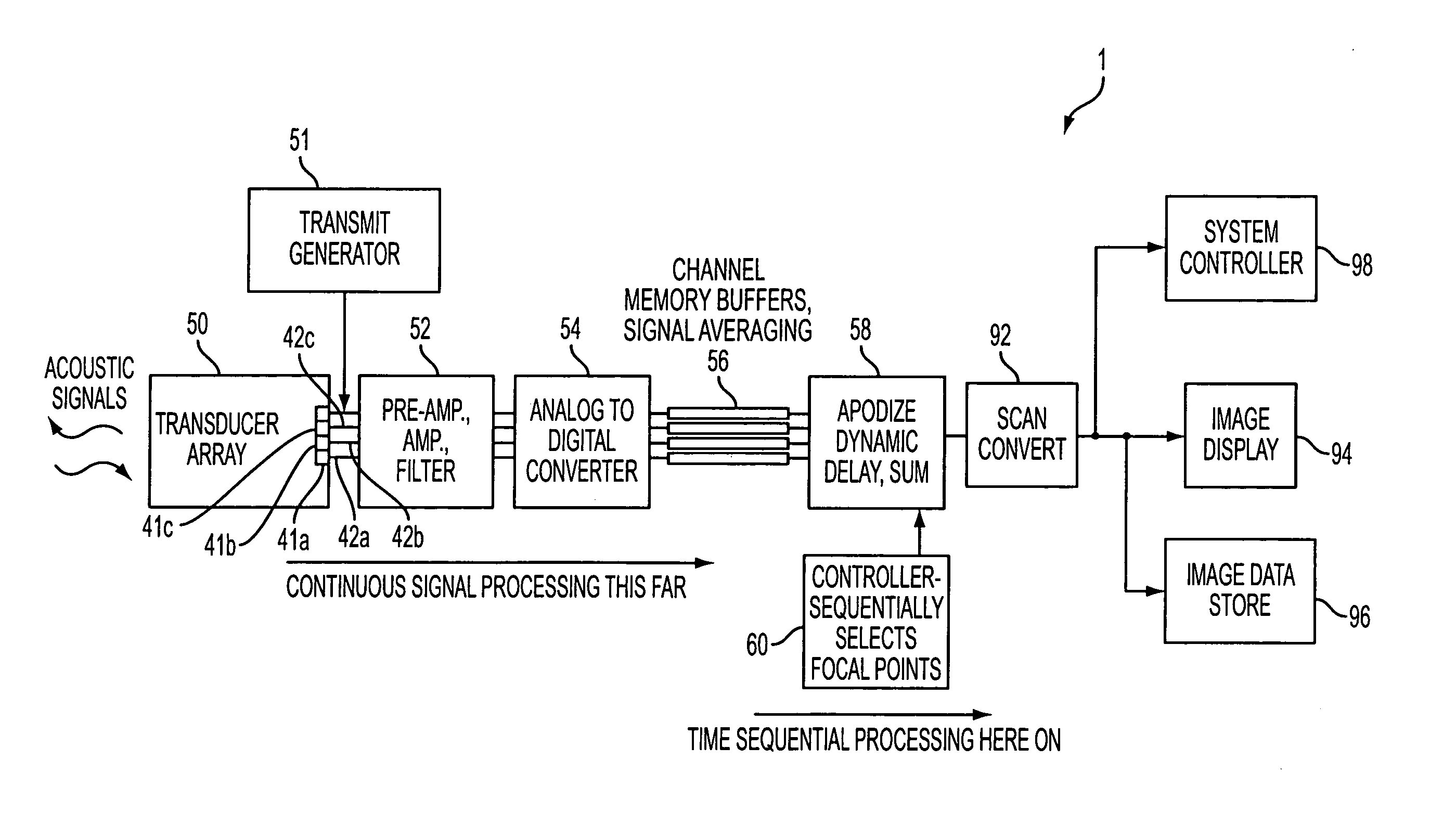

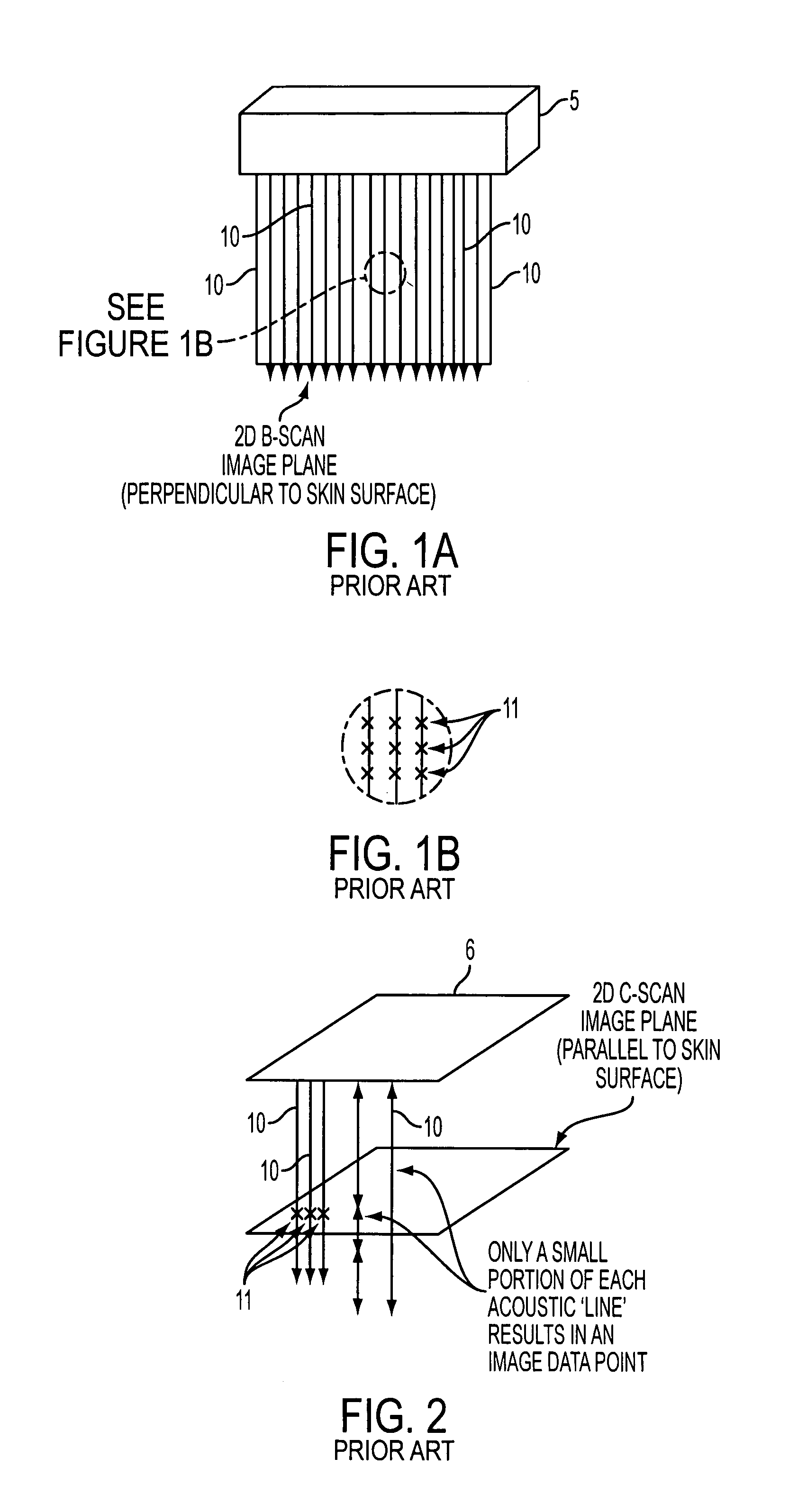

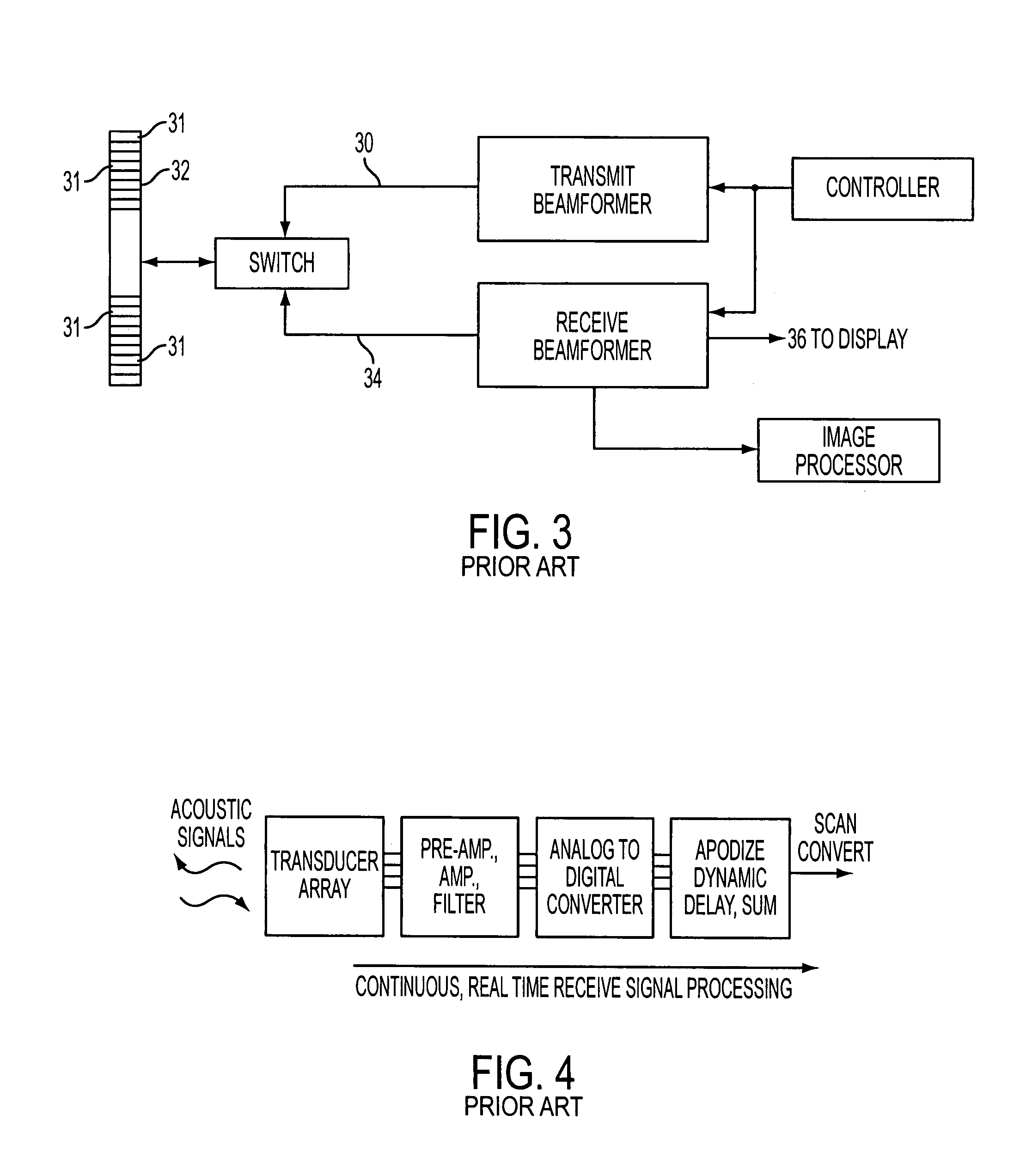

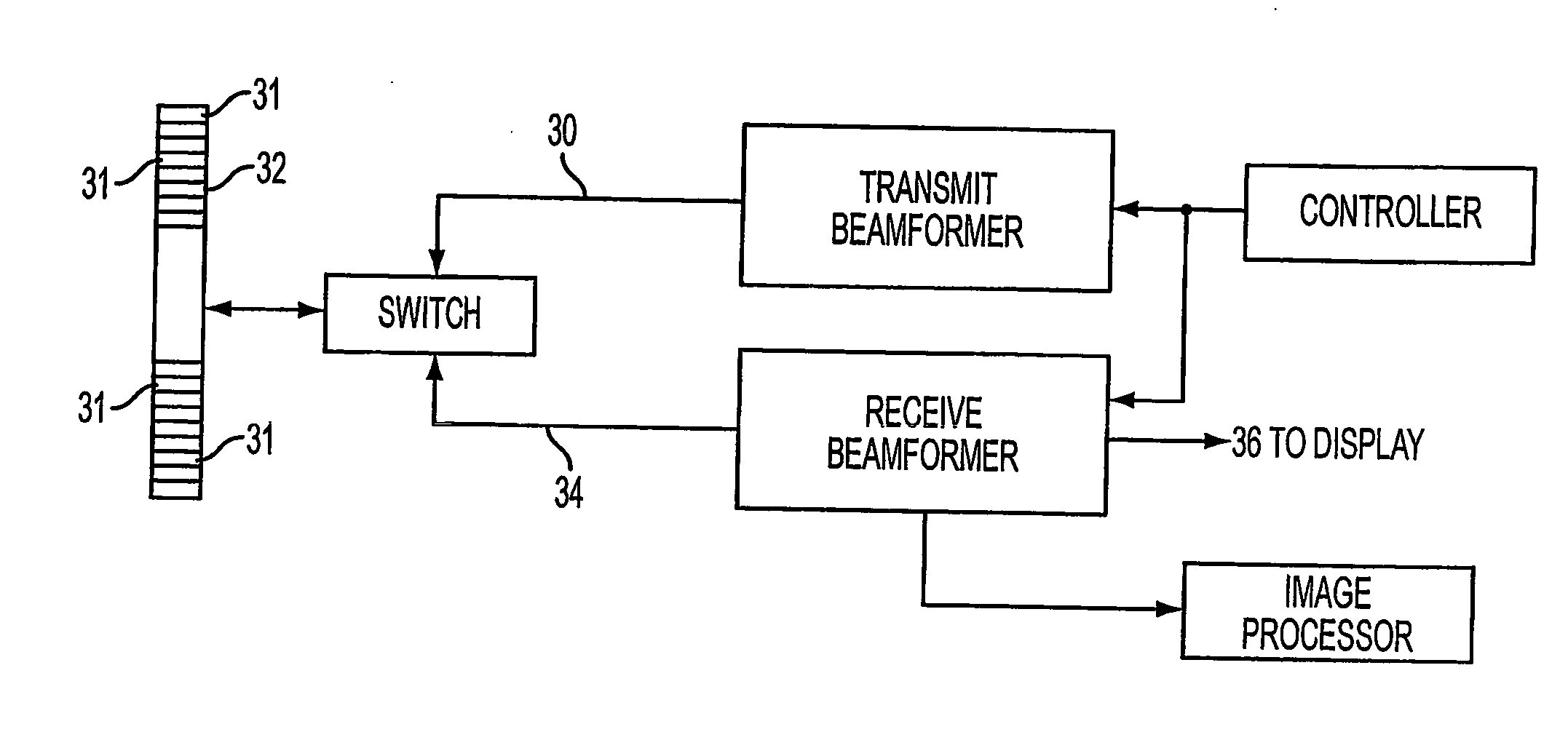

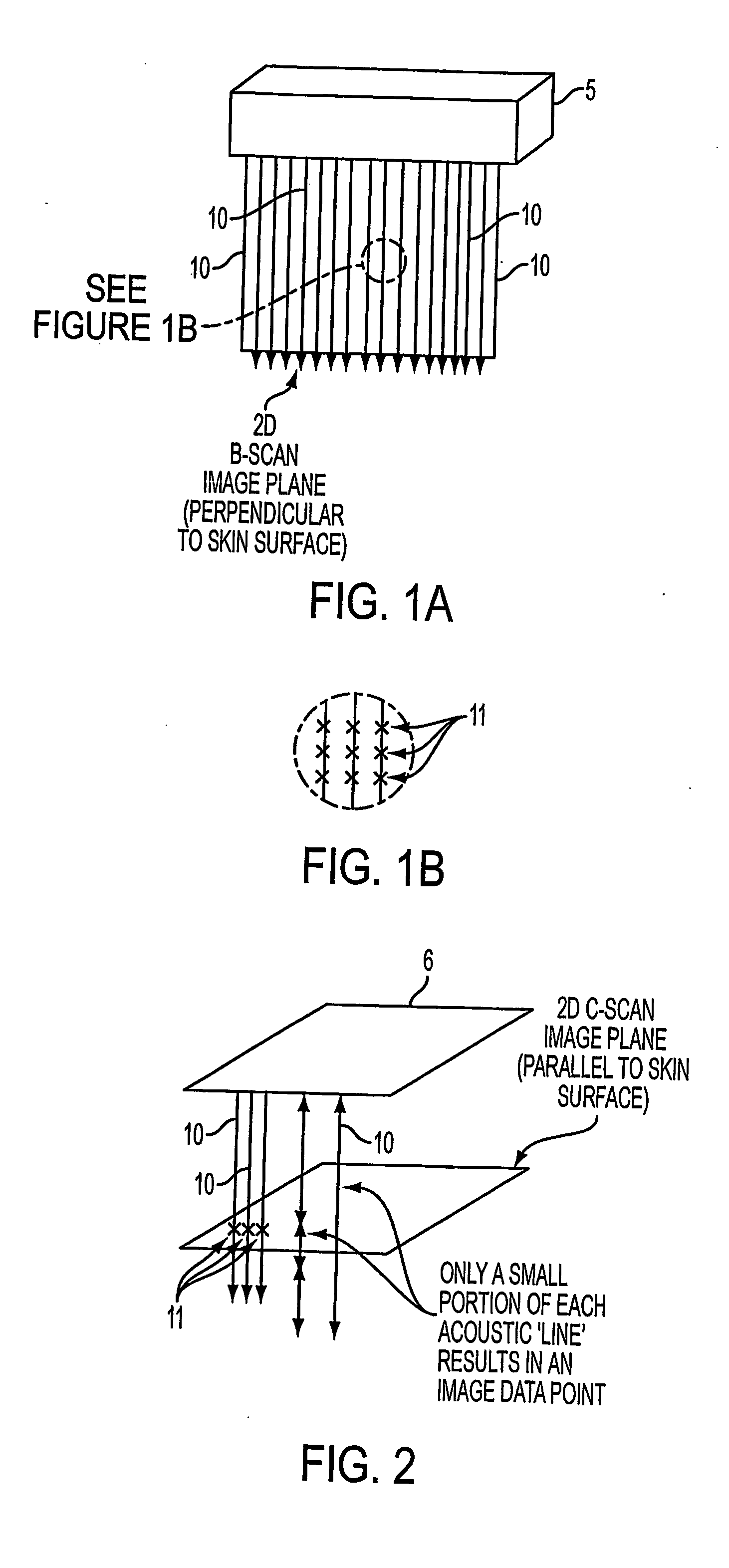

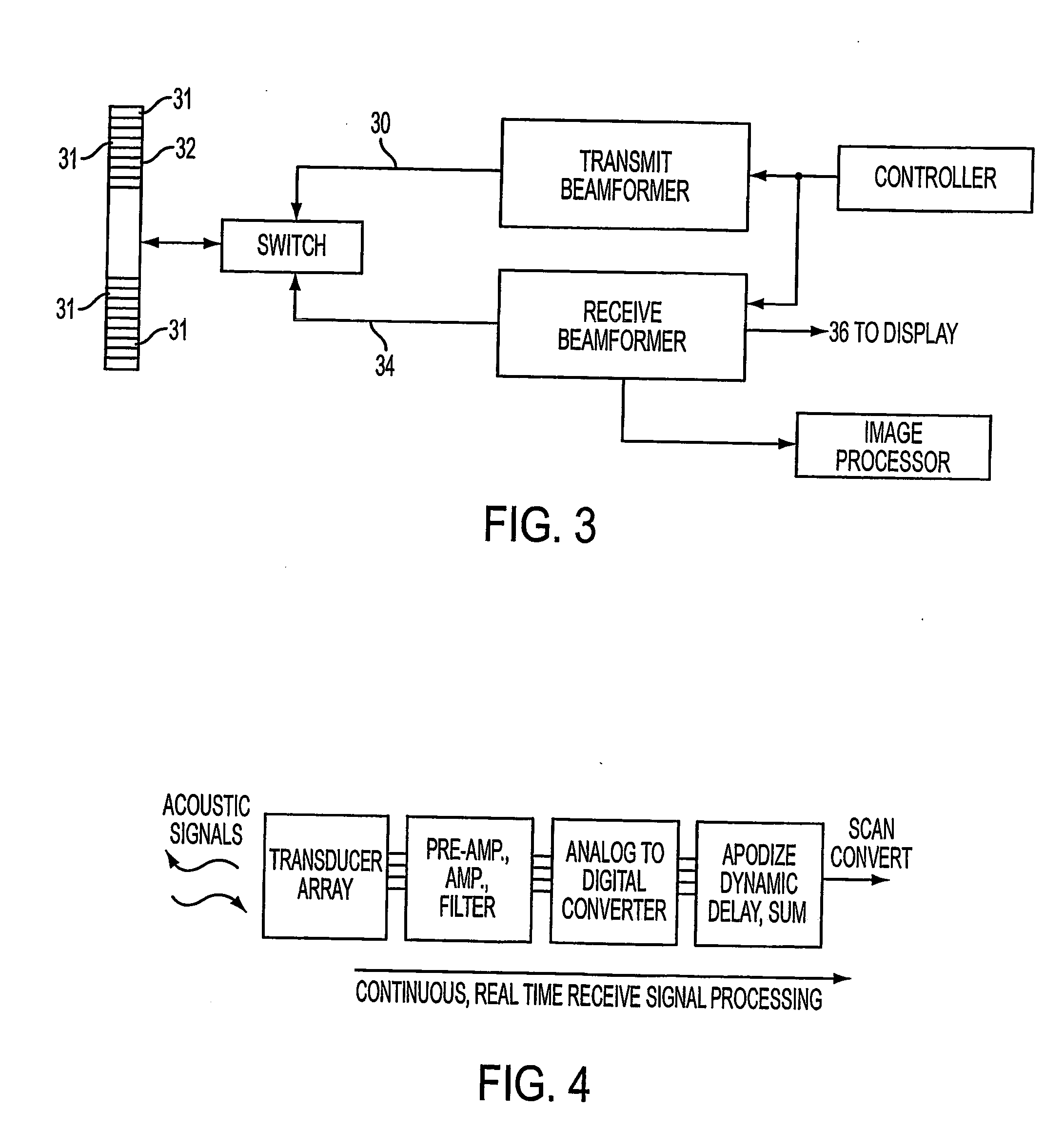

Efficient ultrasound system for two-dimensional C-scan imaging and related method thereof

ActiveUS7402136B2Save processing powerLow costHeart/pulse rate measurement devicesInfrasonic diagnosticsSonification3d image

An ultrasound system and related method for forming 2D C-scan images and / or collecting 3D image data from 2D transducer arrays. The system including in part a 2D transducer array of elements, transmit voltage generation means for each element, a memory buffer with or part of channels for each element, and a receive beamformer. On a time serial or sequential basis, several times for each line of firing, the contents of the per element memory buffer are read into the beamformer with different focusing values for each buffer reading cycle. In this way, the beamformer can calculate beamformed image values for multiple points per line firing cycle—or per each line of signals between the transducer array and receive beamformer.

Owner:UNIV OF VIRGINIA ALUMNI PATENTS FOUND

Efficient ultrasound system for two-dimensional c-scan imaging and related method thereof

ActiveUS20060052697A1Minimal costLow costHeart/pulse rate measurement devicesInfrasonic diagnosticsData bufferVoltage

An ultrasound system and related method for forming 2D C-scan images and / or collecting 3D image data from 2D transducer arrays. The system including in part a 2D transducer array of elements, transmit voltage generation means for each element, a memory buffer with or part of channels for each element, and a receive beamformer. On a time serial or sequential basis, several times for each line of firing, the contents of the per element memory buffer are read into the beamformer with different focusing values for each buffer reading cycle. In this way, the beamformer can calculate beamformed image values for multiple points per line firing cycle—or per each line of signals between the transducer array and receive beamformer.

Owner:UNIV OF VIRGINIA ALUMNI PATENTS FOUND

Navigation methods and systems

ActiveUS20130275033A1Extension of timeMaximise time availableAnalogue computers for vehiclesInstruments for road network navigationSimulationCarriageway

Lane speed profiles are determined for each of a plurality of individual lanes of a multi-lane road section. The plurality of individual lanes are lanes for a given direction of travel. The lane speed profiles are determined using real-time vehicle probe data. The speed profiles are used to determine a timing for provide an instruction to a user of a navigation apparatus to change lane. The timing may be determined to provide a quickest route through at least a part of the road section, to increase the time available for the user to perform the lane change, or to enable a user to pass an incident affecting a lane most quickly.

Owner:TOMTOM INT BV

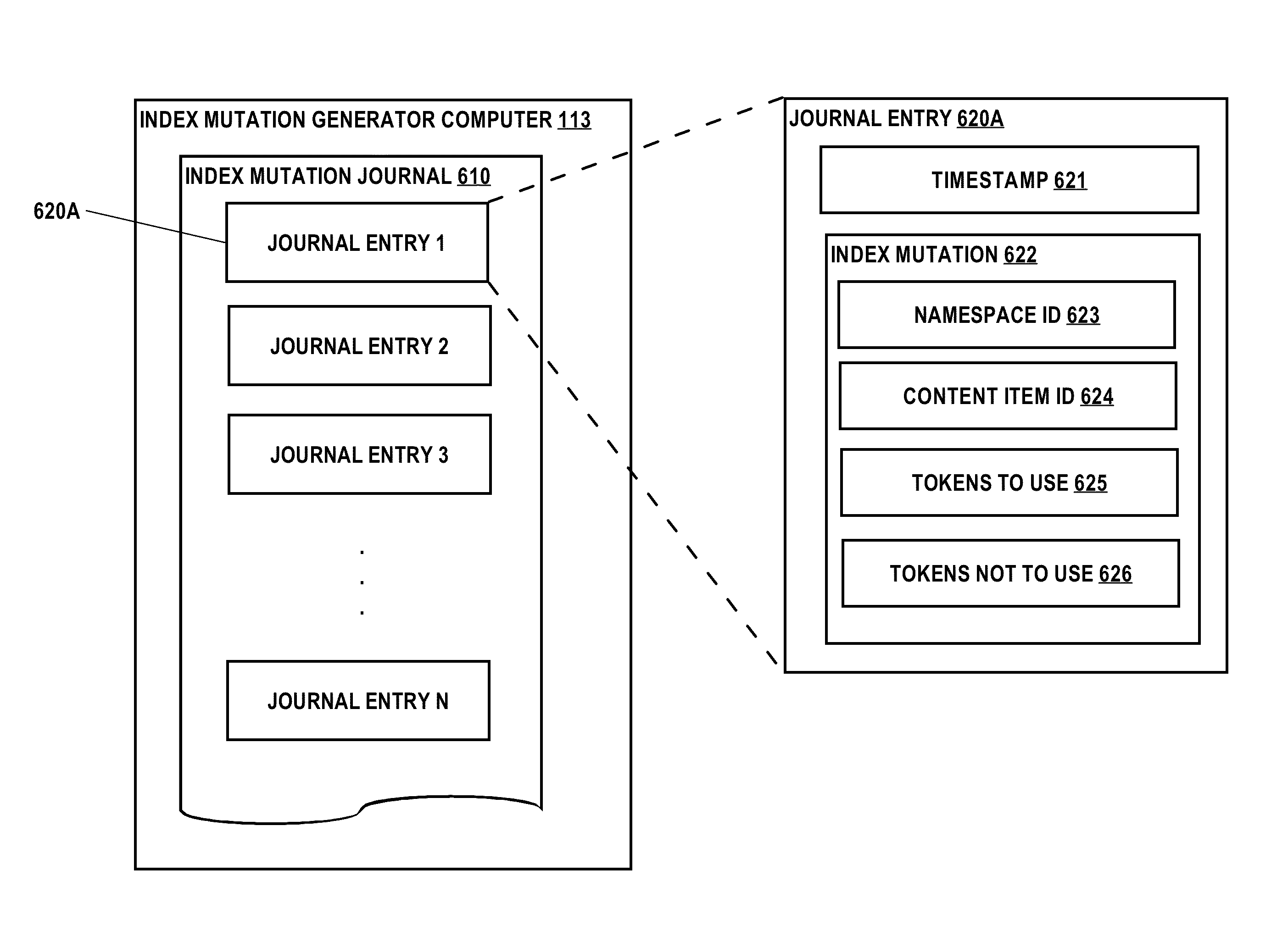

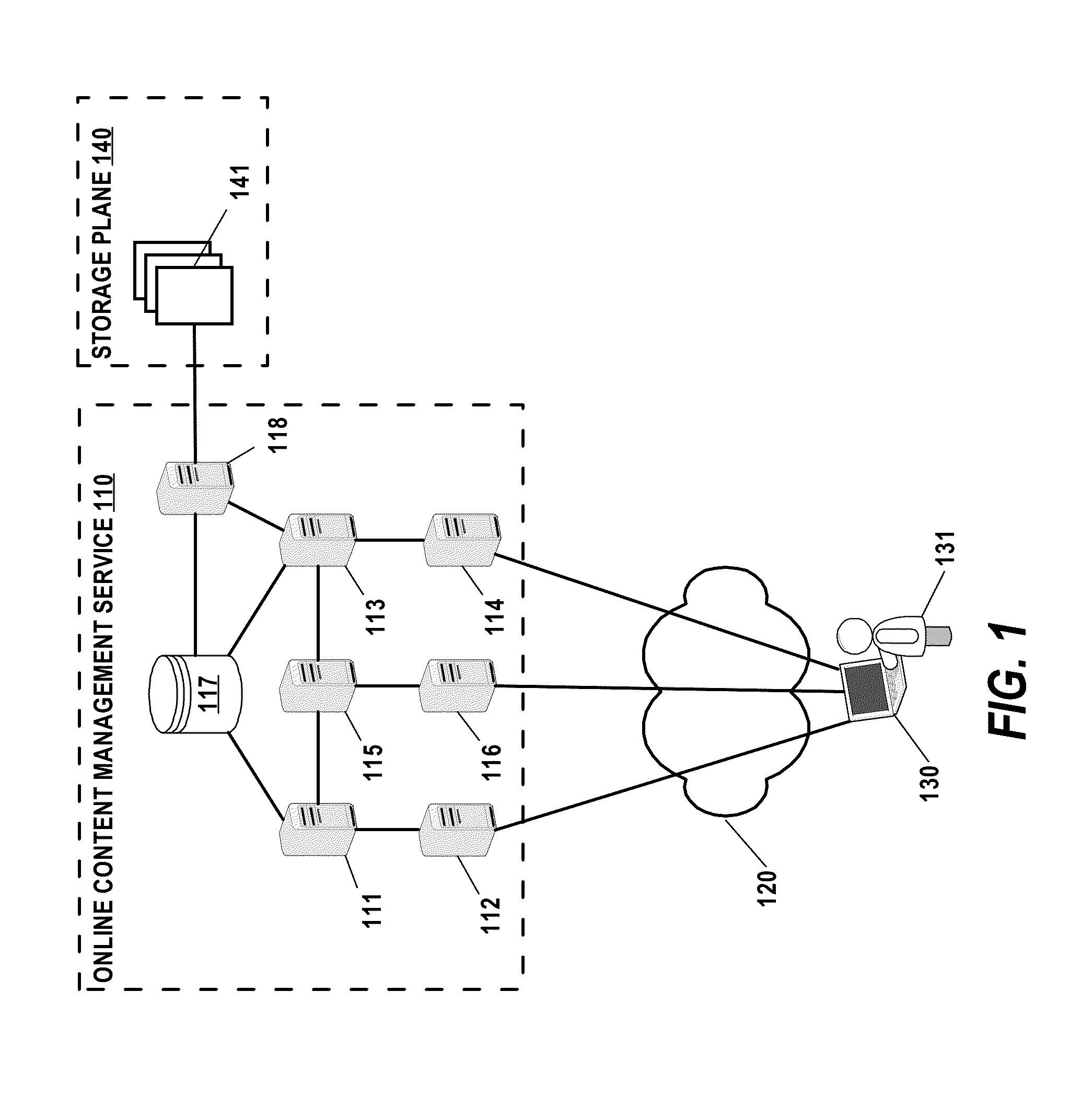

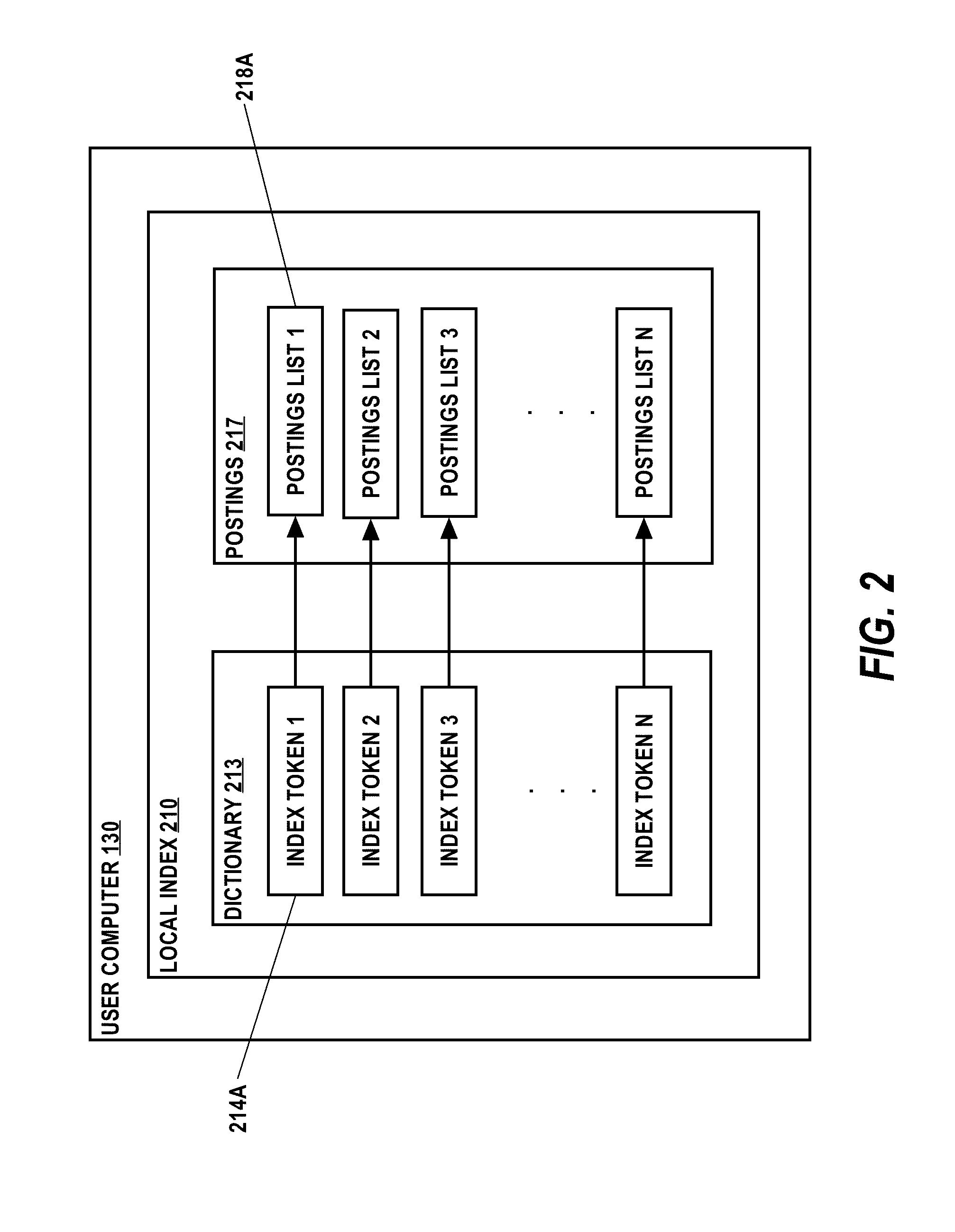

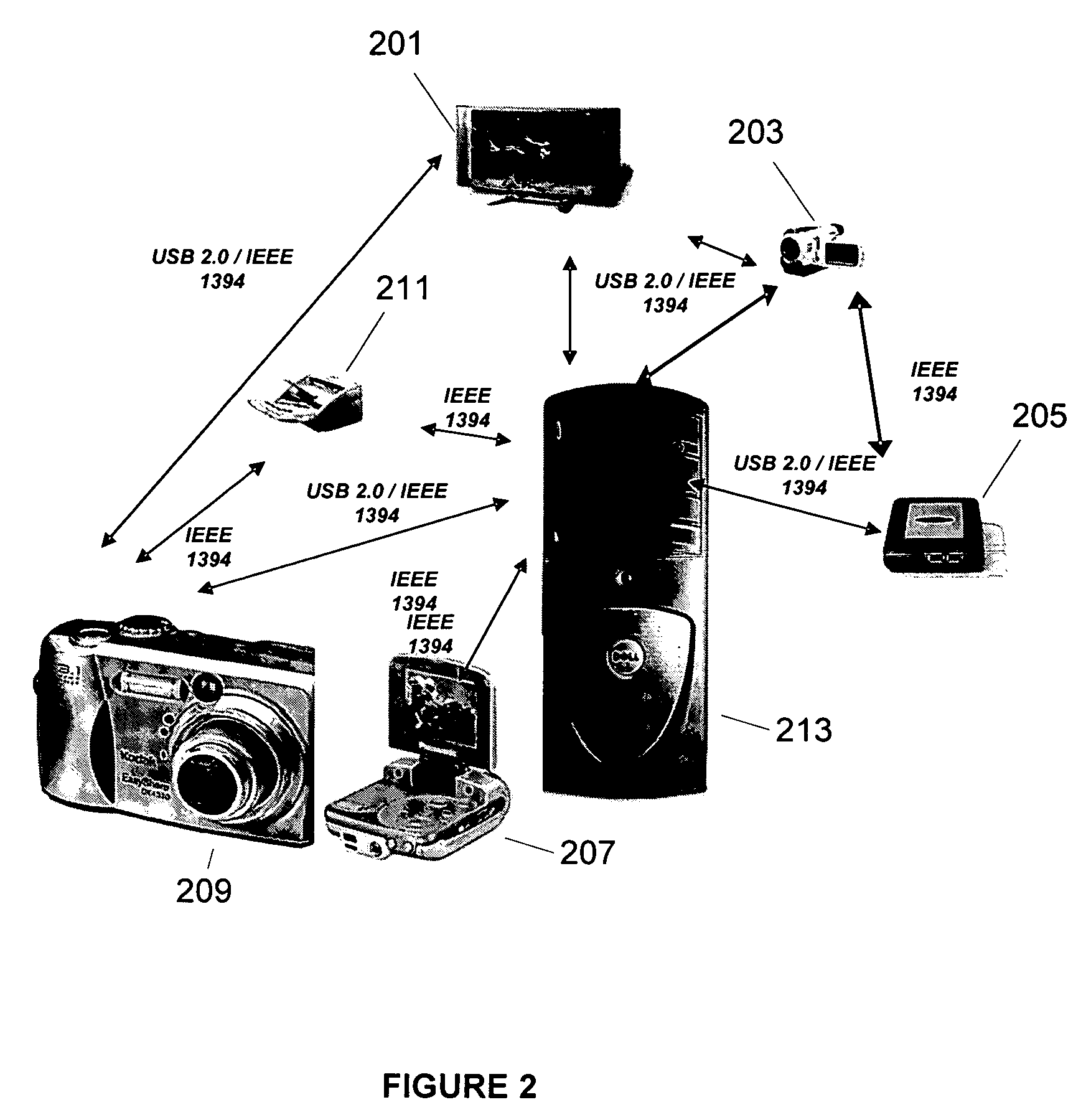

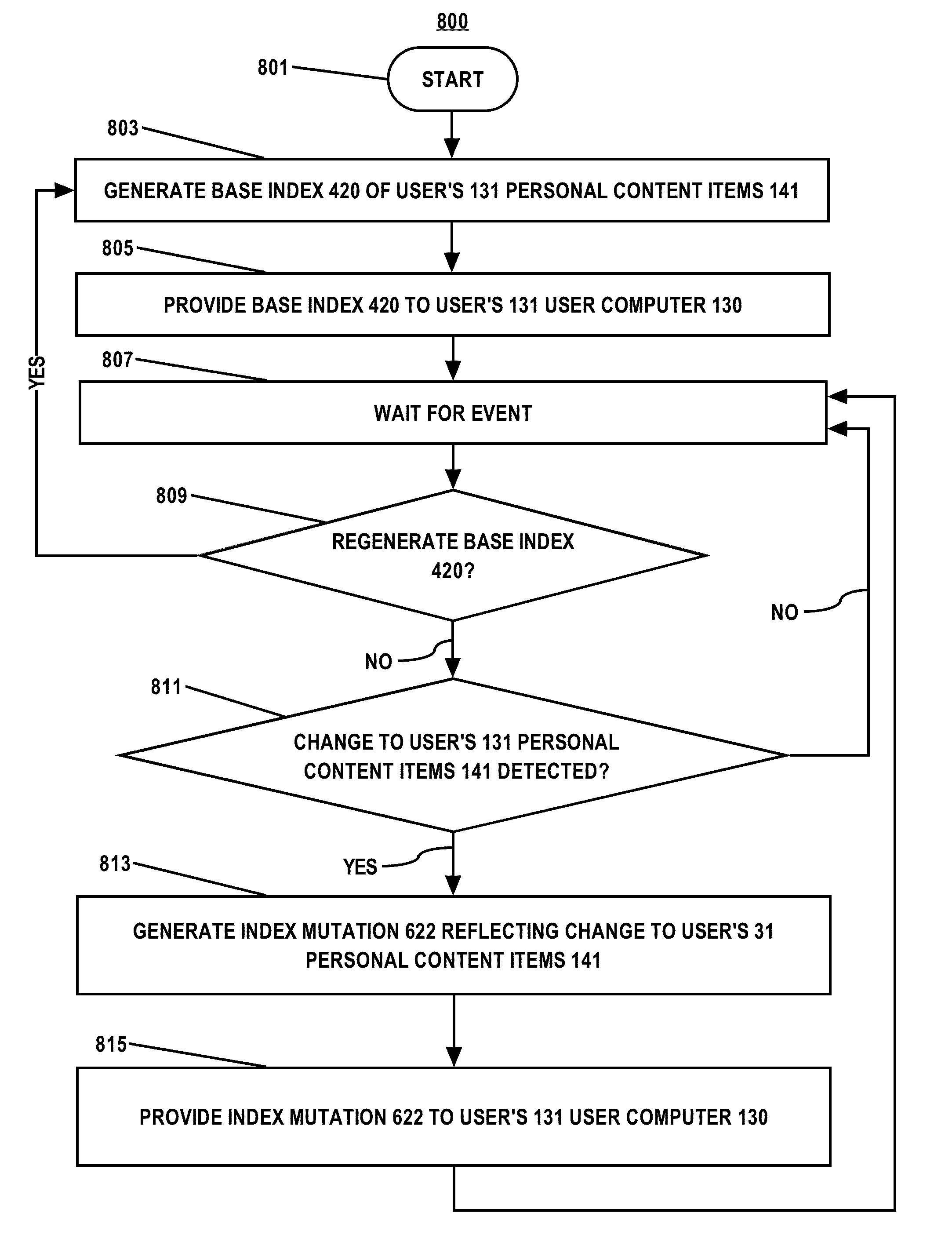

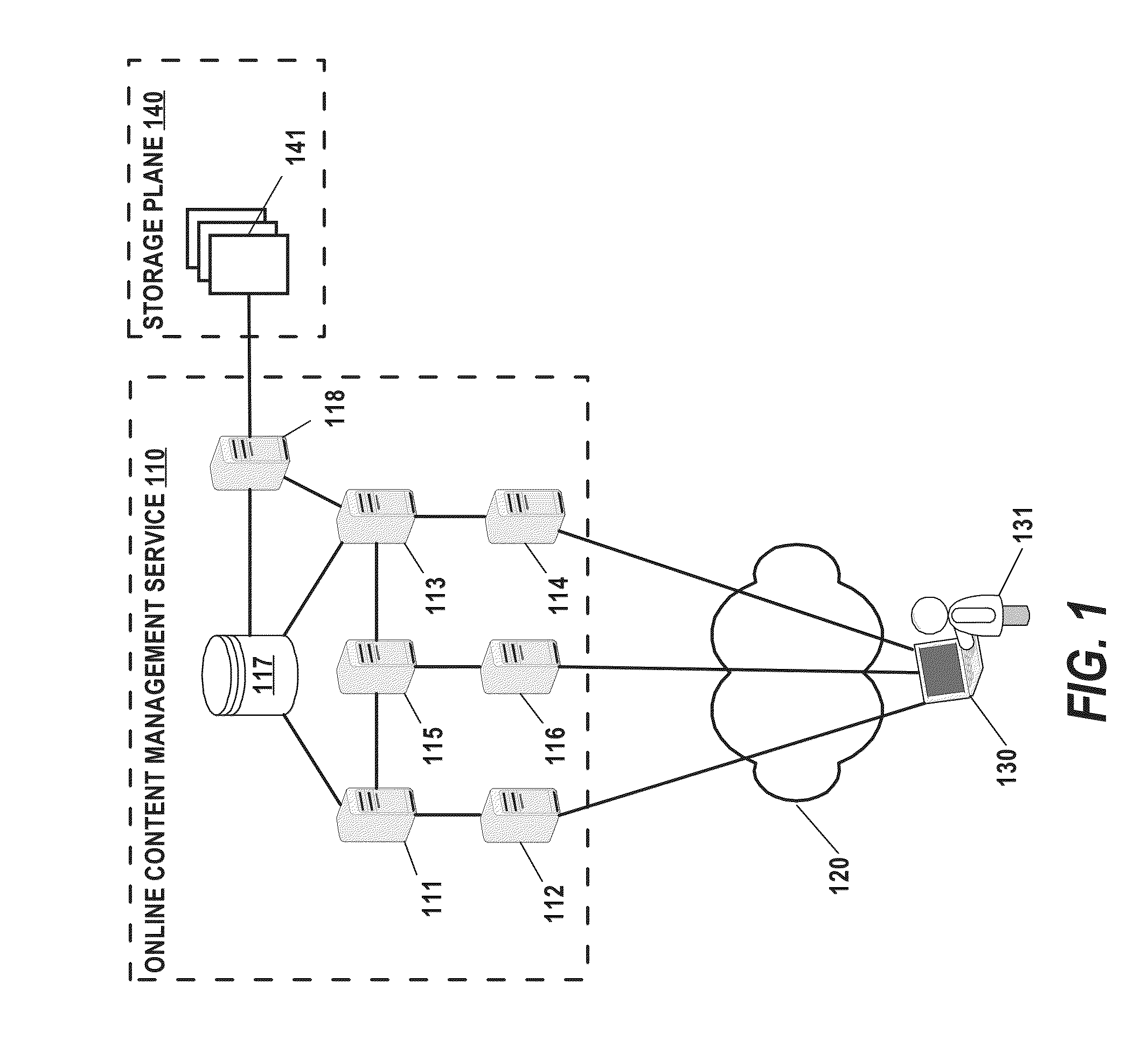

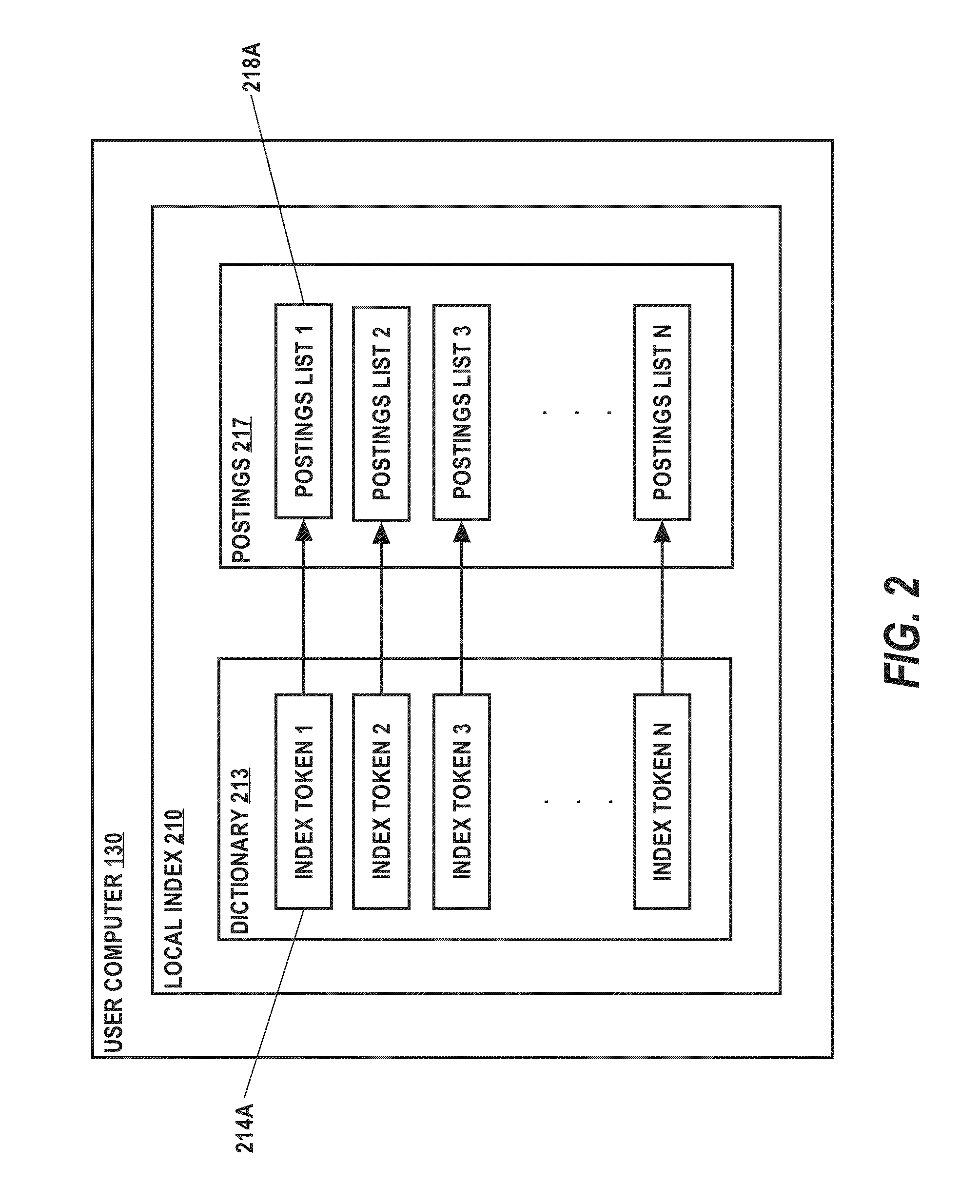

Personal content item searching system and method

ActiveUS9183303B1Provided to the user more quicklyProvide quicklyDatabase updatingWeb data indexingIndexing ServiceContent management

A system and method for enabling a user to use a user computer to search the user's personal content items hosted by an online content management service, the online content management service having an indexer computer configured to generate a base index of the user's content items hosted by the service, a base index server computer configured to transmit the generated base index over a network to the user computer, an index mutation generator computer configured to generate index mutations for subsequent changes to user's hosted content items, and an index mutation sever computer configured to transmit the generated index mutations over the network to the user computer. In one aspect, the system and method enable searches of the user's hosted content items and changes thereto to be conducted at the user computer using an index local to the user computer constructed based on the base index and the index mutations received by the user computer.

Owner:DROPBOX

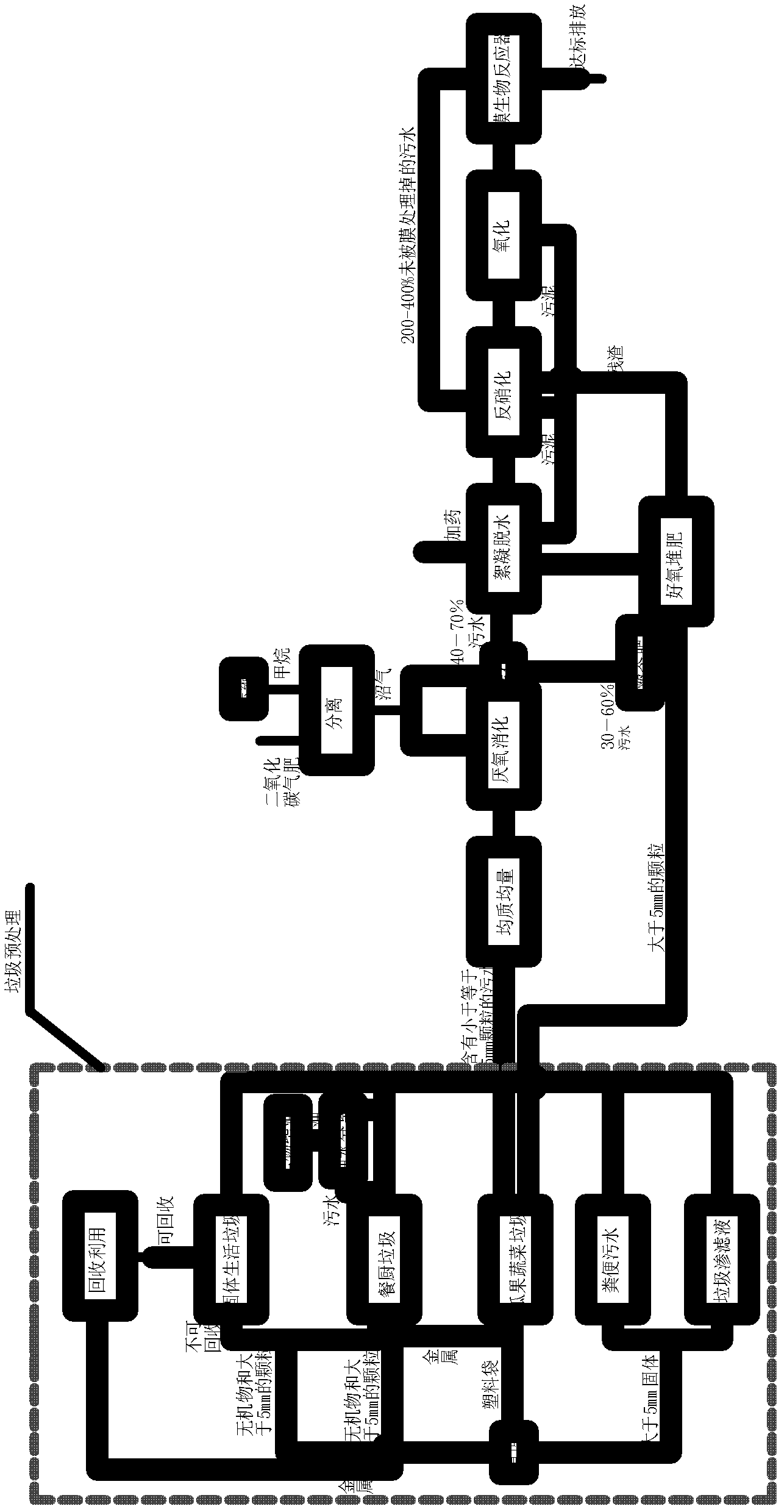

Method for jointly treating different garbage

ActiveCN102531295ASave processing powerProportional balanceBio-organic fraction processingWaste processingFlocculationBiodiesel

The invention discloses a method for jointly treating different garbage. In the implementation process, different garbage is subjected to pretreatment, homogenization, anaerobic digestion, flocculation dewatering, denitrification, oxidation treatment, membrane bioreactor treatment, aerobic composting and biodiesel production, treated sewage can reach the third grade Standard of Water Pollutants Discharge of DB11 / 307-2005, the process flow is greatly shortened, the cost is reduced, and methane generated in the treatment process and the recovered waste oil are subjected to deep processing to beutilized as green energy.

Owner:北京昊业怡生科技有限公司

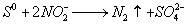

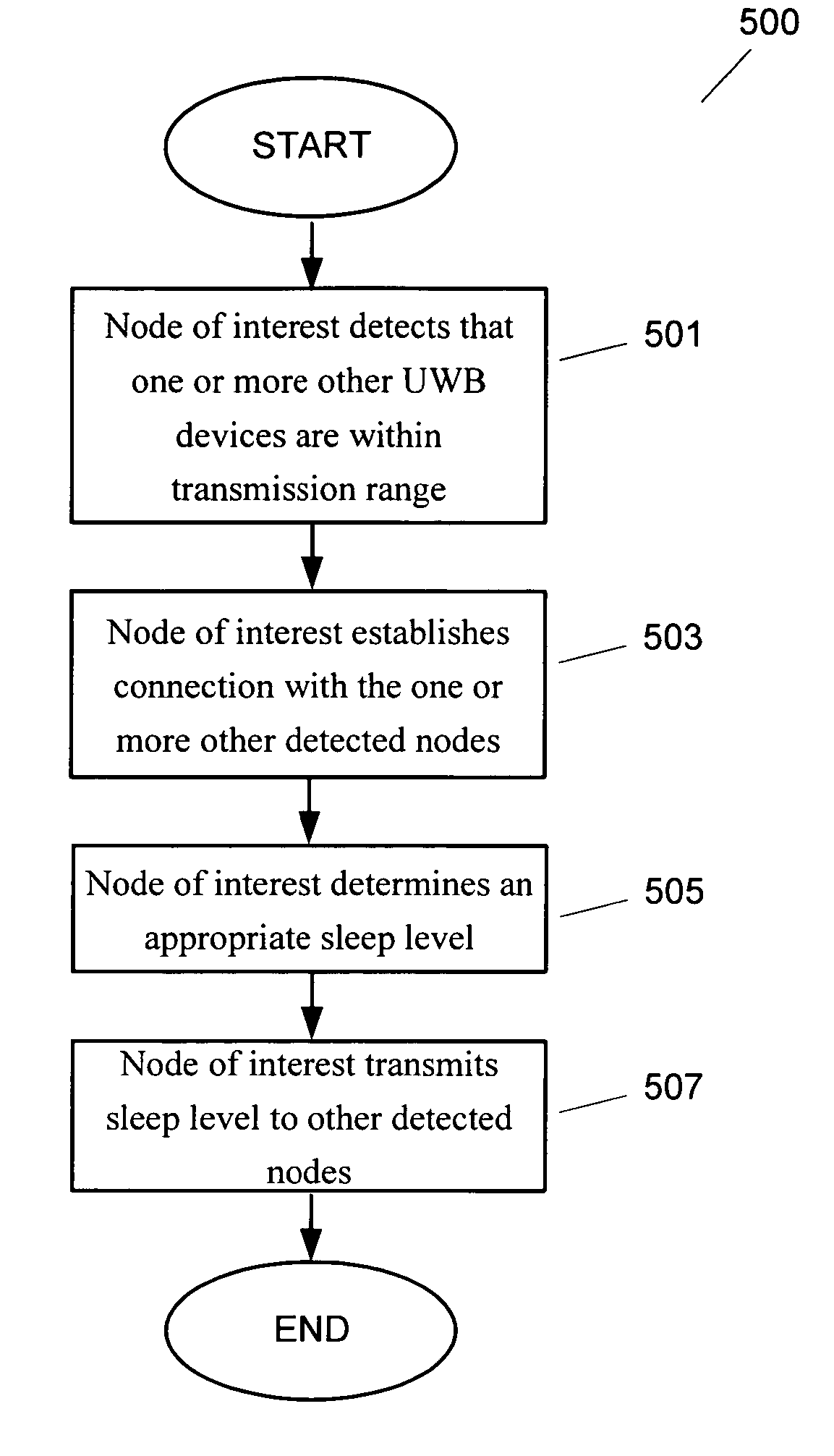

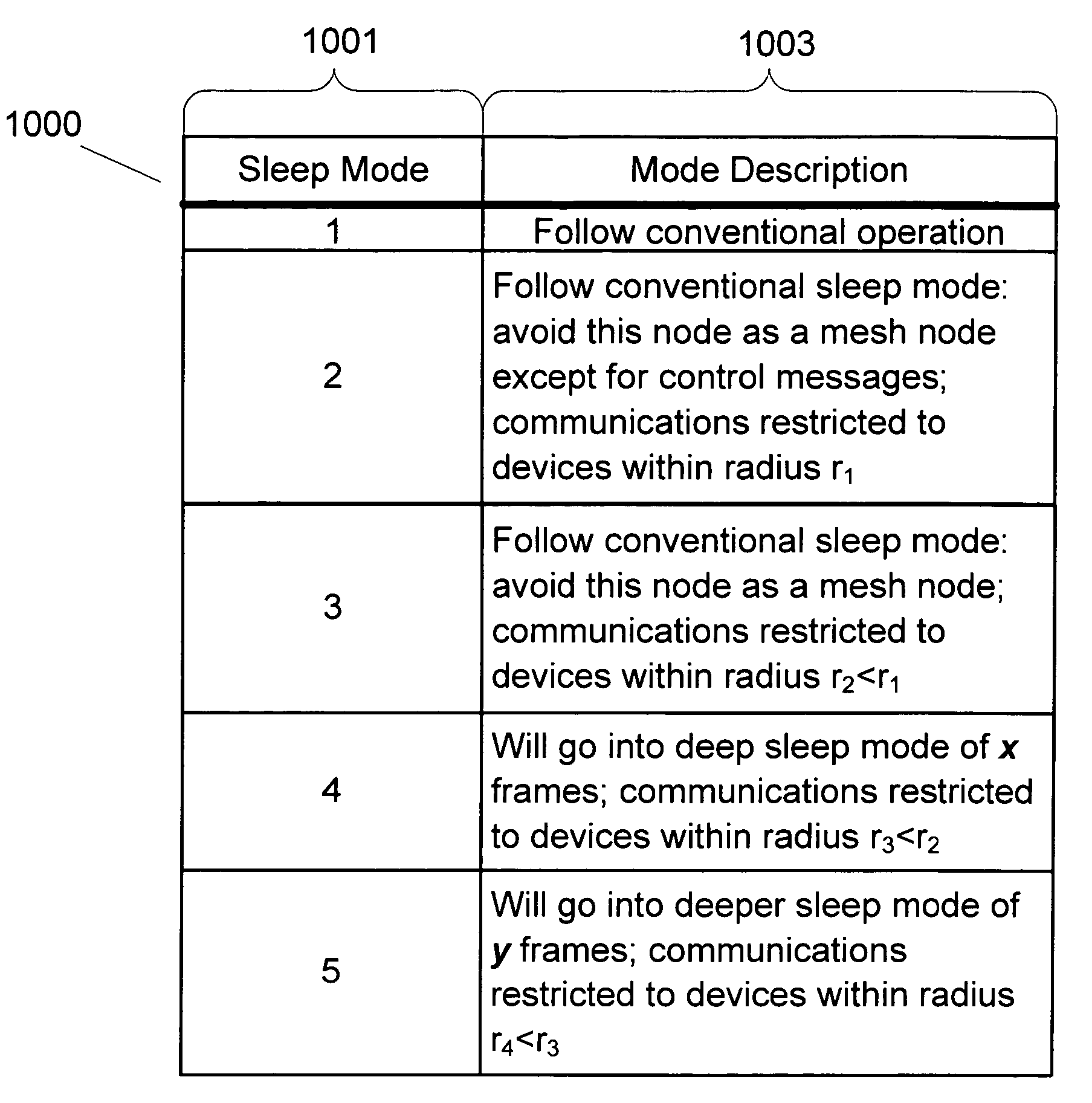

Ultra wide band power save

ActiveUS20060129850A1Improve battery lifeMore powerPower managementEnergy efficient ICTBroadbandWide band

A network node selects a “sleep” level based on its current or projected battery capacity. In an embodiment of the invention, sleep levels define the physical radius within which the wireless network node will engage other devices. The node in question communicates its selected sleep level to the rest of the network so that the other network nodes can communicate accordingly with the node.

Owner:MICROSOFT TECH LICENSING LLC

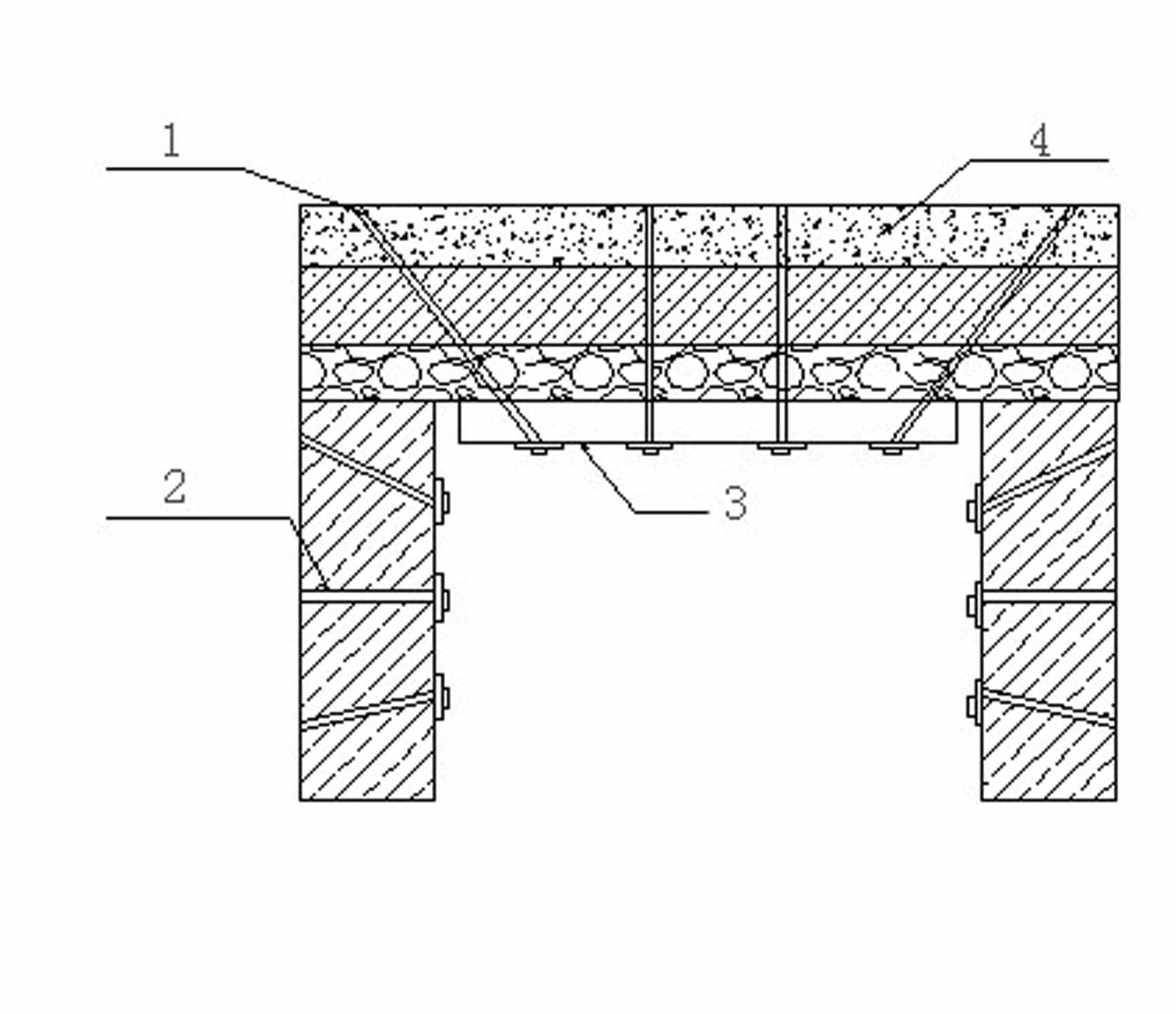

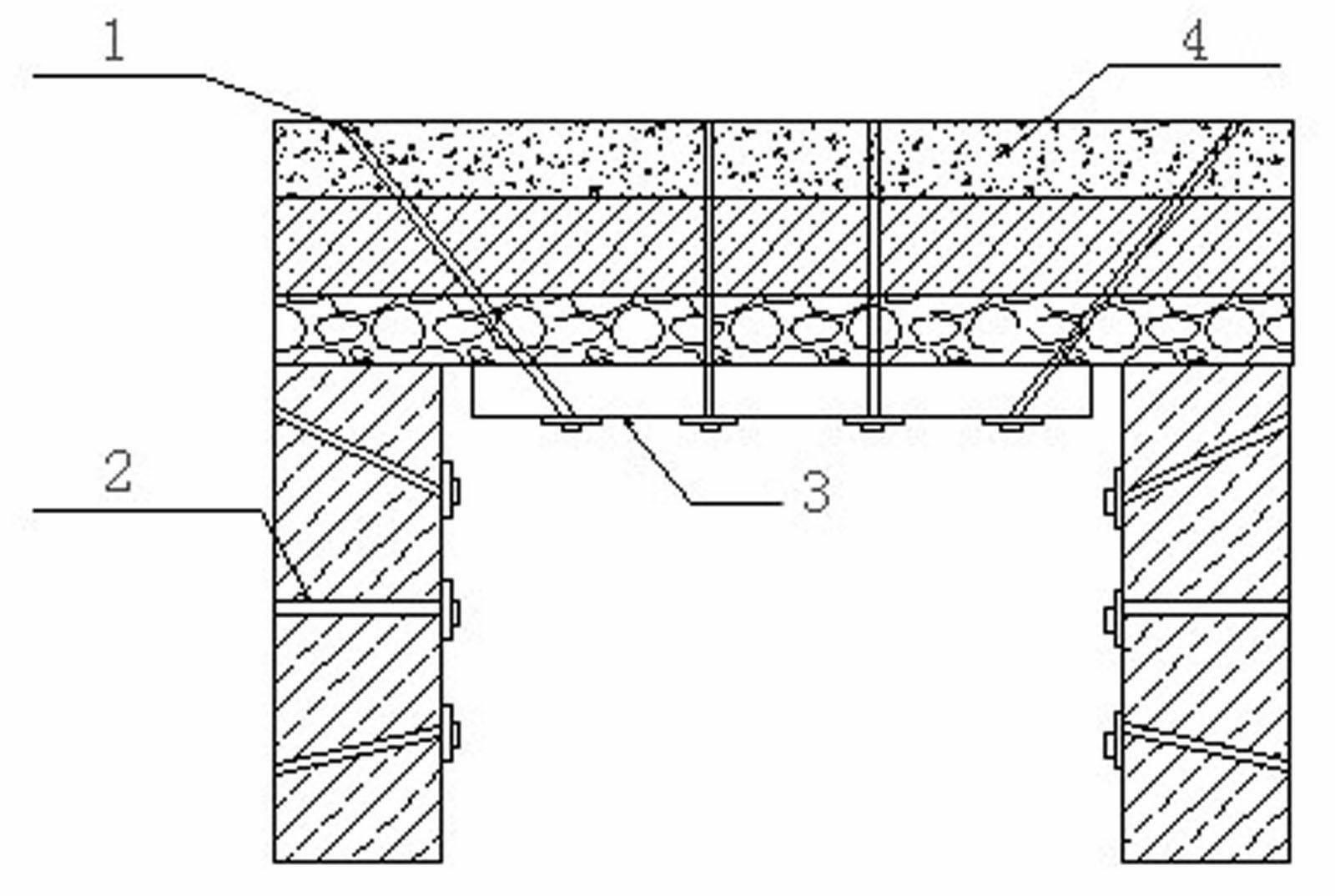

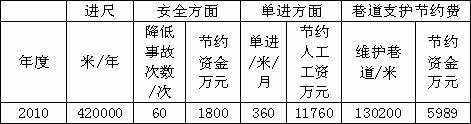

Supporting method of laneway under multiple goafs in ultra-close coal seam group

InactiveCN102425438ASolve the technical problems of roadway supportSolve support technical problemsAnchoring boltsProtective coversSocial benefitsEngineering

The invention specifically relates to a supporting method of a laneway under multiple goafs in an ultra-close coal seam group, which can be used for solving the problem of incomplete support of the laneway under the multiple goafs in the ultra-close coal seam group. The supporting method of the laneway under the multiple goafs in the ultra-close coal seam group comprises the following steps: performing preparation work, performing temporary supporting, laying a steel wire mesh, loading steel beams, mounting an anchor rod of a top plate, mounting the anchor rod of an upper part, mounting an anchor rope of the top plate and the like. By utilizing the effective supporting scheme according to the invention, the technical difficult problem of supporting the laneway under the multiple goafs in the ultra-close coal seam group in Datong mining area is solved, and the great safety economic effect and the great social benefits are achieved.

Owner:DATONG COAL MINE GRP

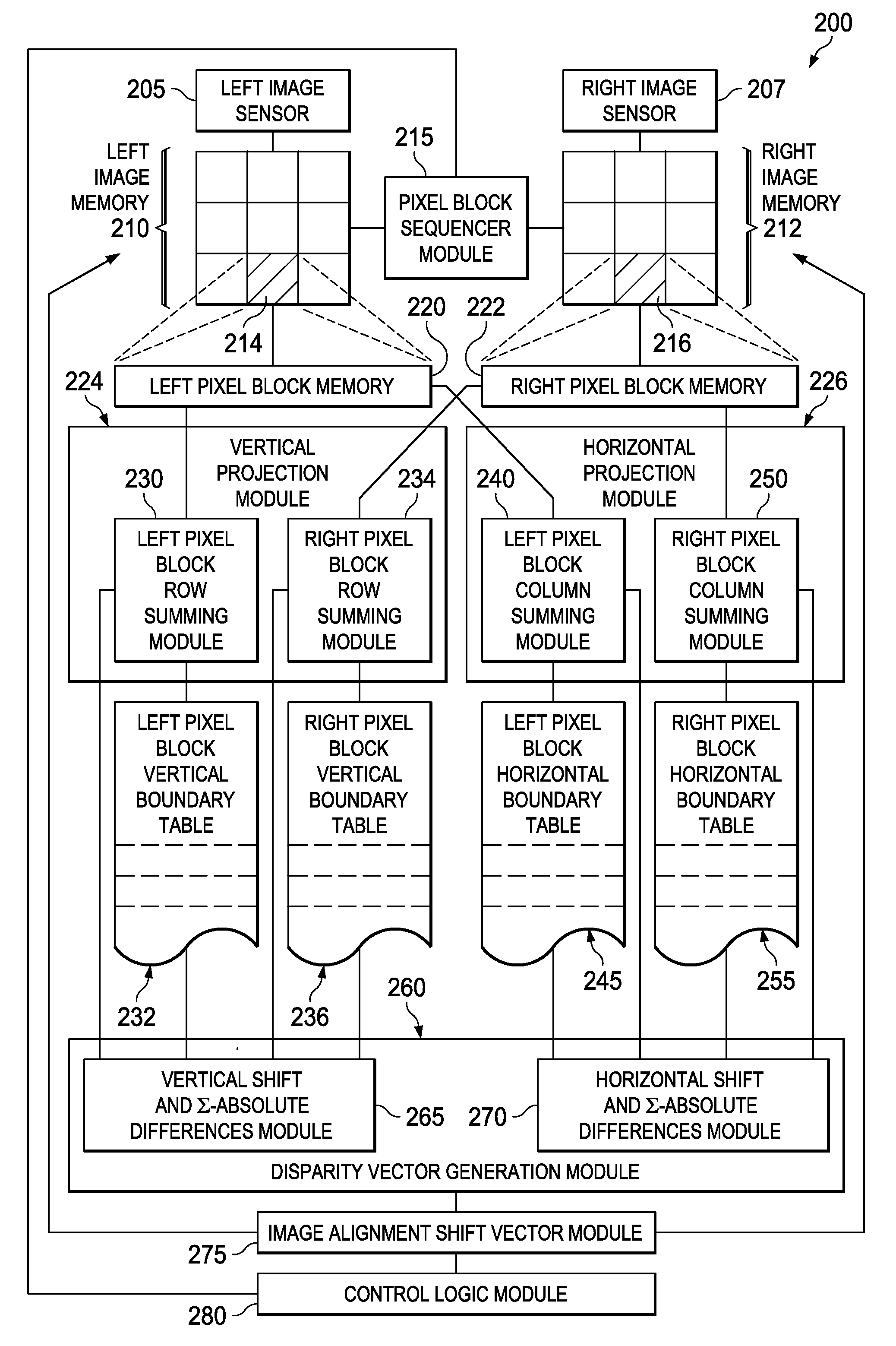

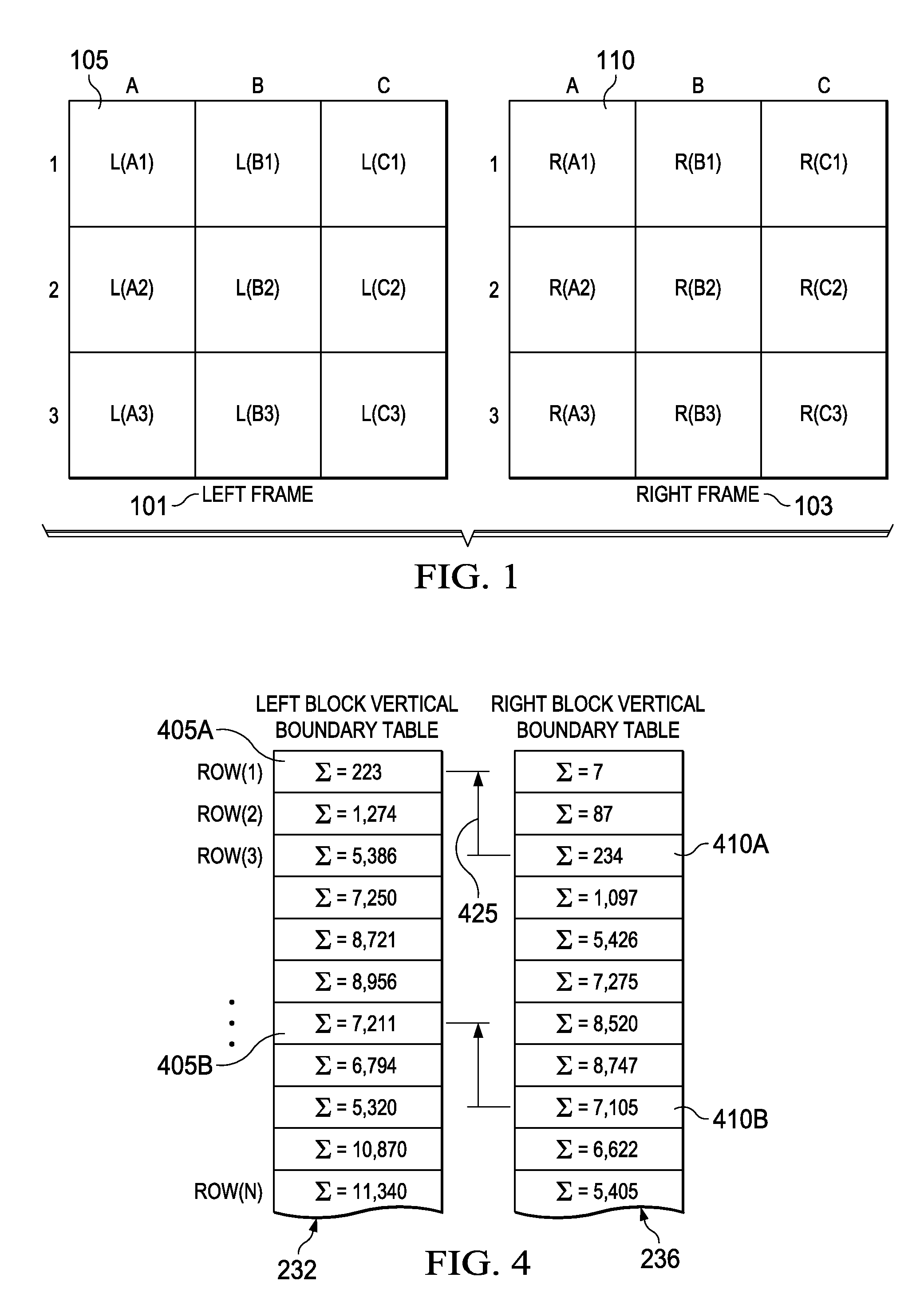

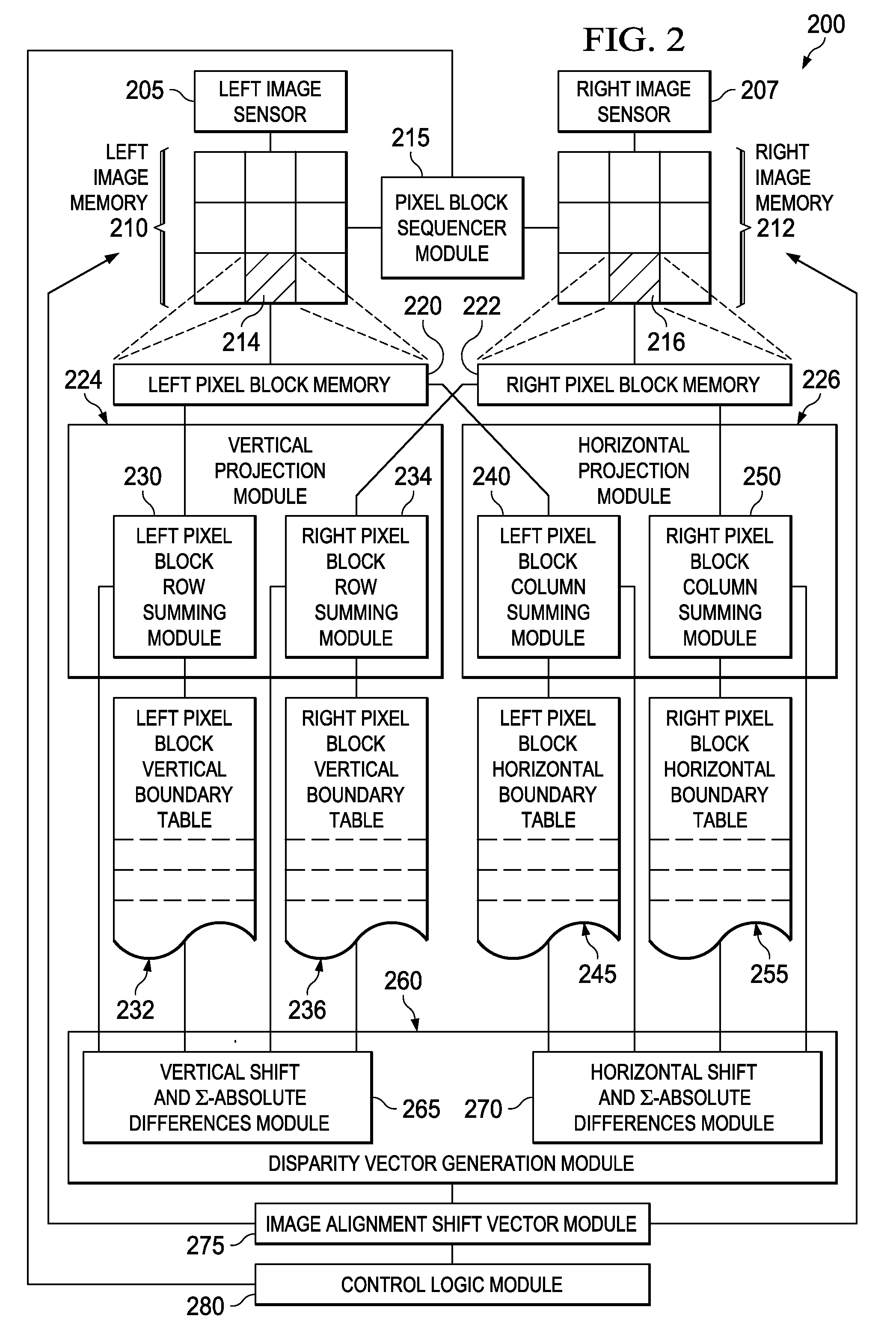

Stereoscopic image pair alignment apparatus, systems and methods

InactiveUS20110249889A1Reduce and eliminate and componentSave processing powerImage enhancementImage analysisParallaxImage alignment

Apparatus, systems, and methods disclosed herein operate to produce an image alignment shift vector used to shift left and right image portions of a stereoscopic image with respect to each other in order to reduce or eliminate undesirable horizontal and vertical disparity components. Vertical and horizontal projections of luminance value aggregations from selected left and right image pixel blocks are correlated to derive vertical and horizontal components of a disparity vector corresponding to each left / right pixel block pair. Disparity vectors corresponding to multiple image blocks are algebraically combined to yield the image alignment shift vector. The left and / or right images are then shifted in proportion to the magnitude of the image alignment shift vector at an angle corresponding to that of the image alignment shift vector.

Owner:TEXAS INSTR INC

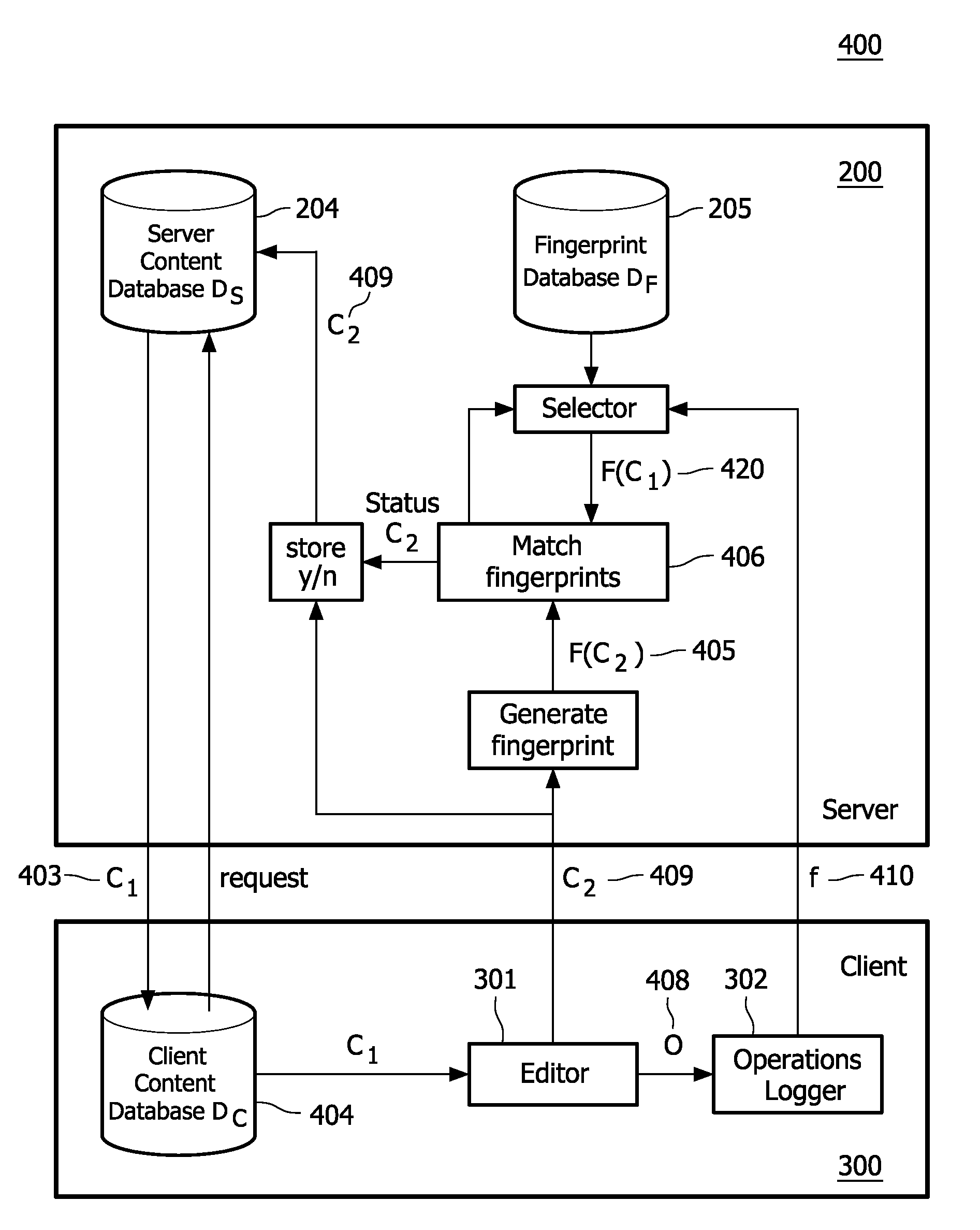

Method and a system for identifying elementary content portions from an edited content

InactiveUS20100287201A1Easy to identifyComputationally efficientPulse modulation television signal transmissionDigital data processing detailsRelevant featureData science

This invention relates to a method and a system for identifying elementary content portions from an edited content. A log is generated indicating the elementary content portions used in the edited content. Fingerprints are obtained from the elementary content portions as indicated in the log. Characteristic information is determined about the elementary content portions by comparing the fingerprints to fingerprints of registered content having associated characteristic information.

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

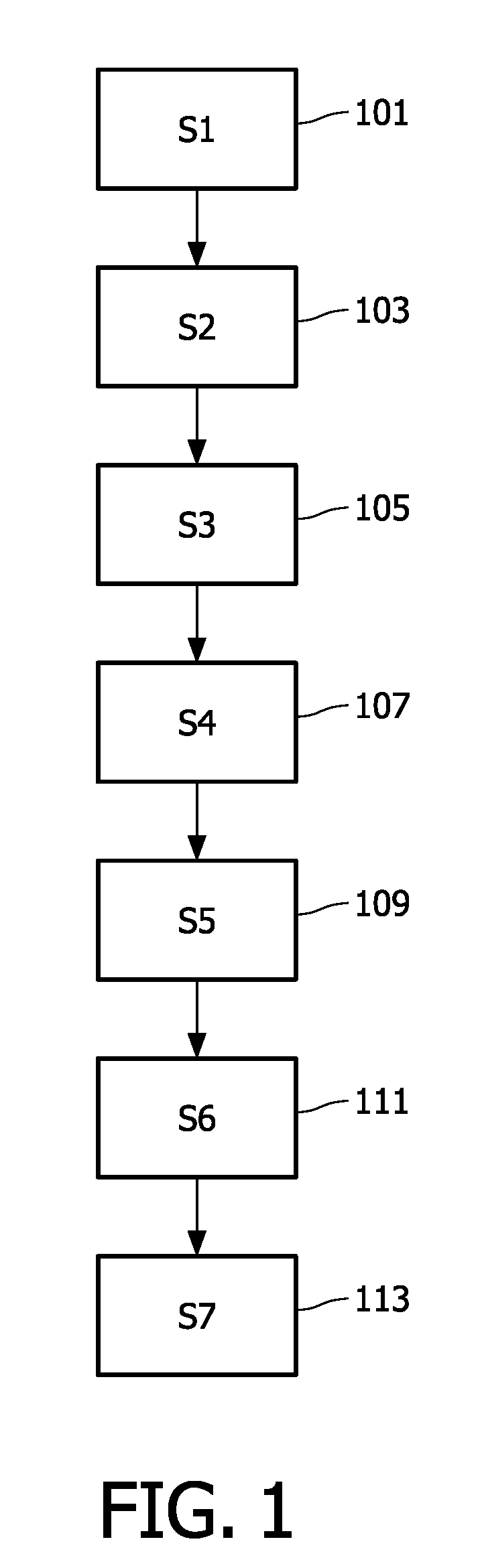

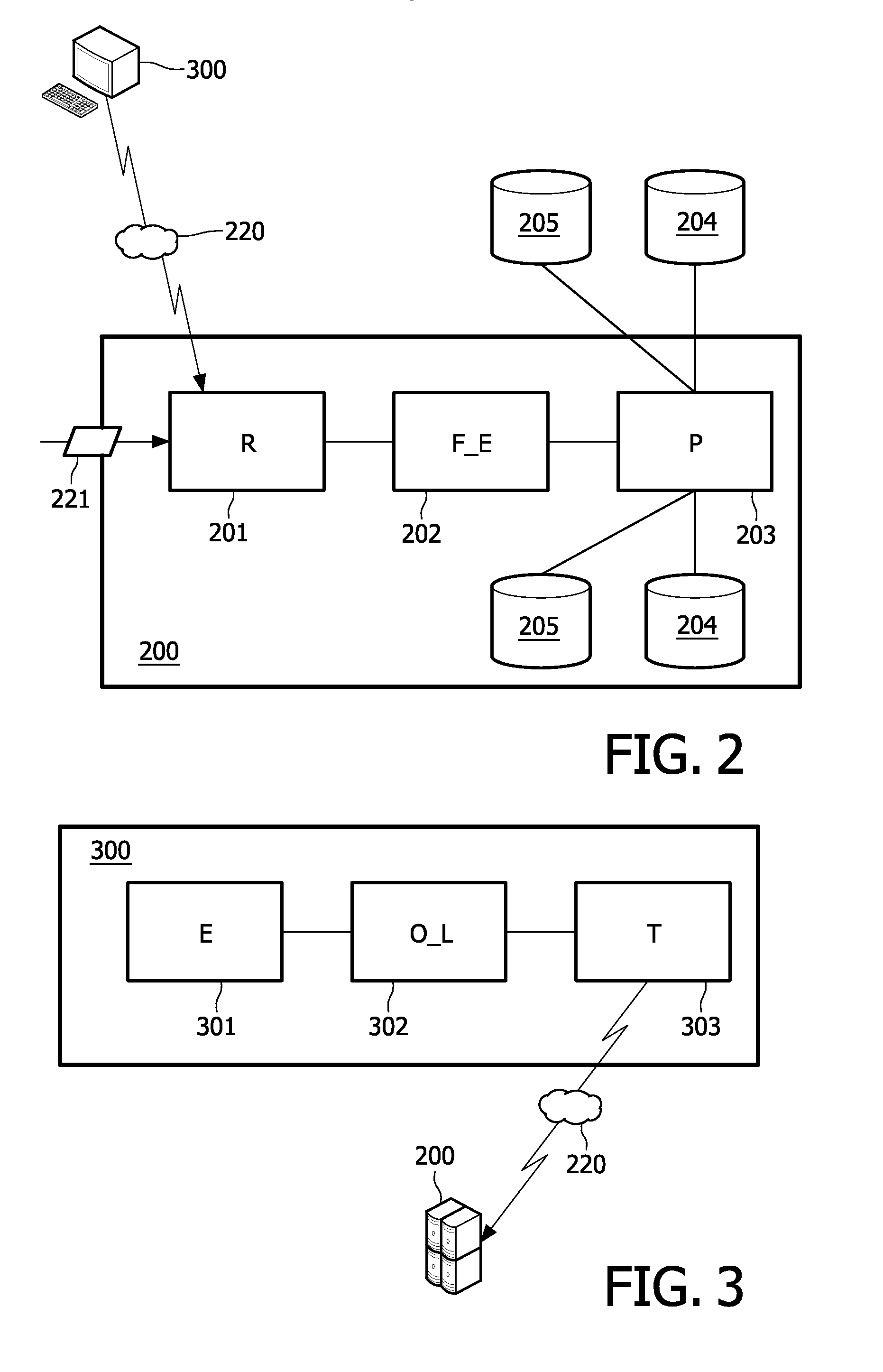

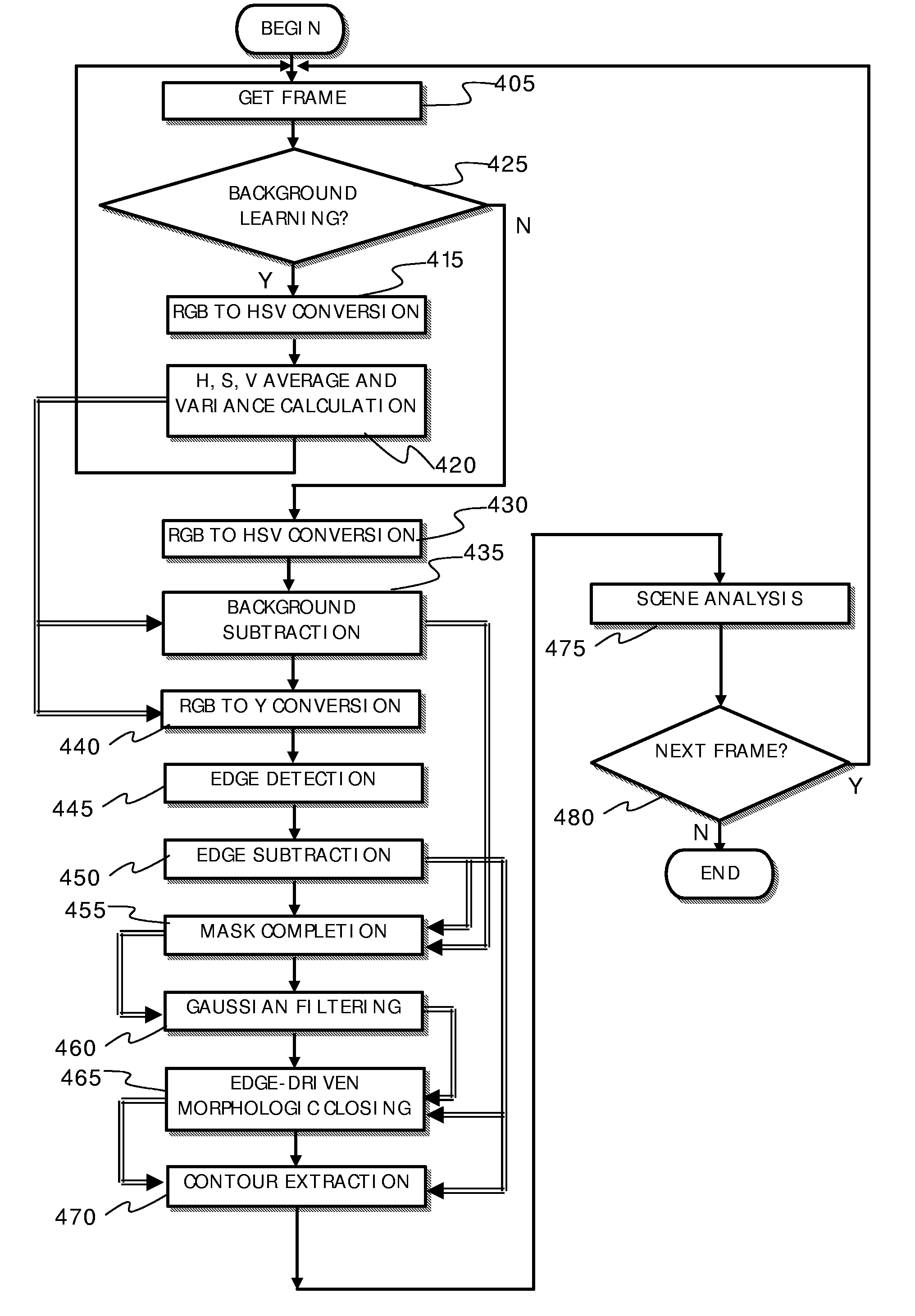

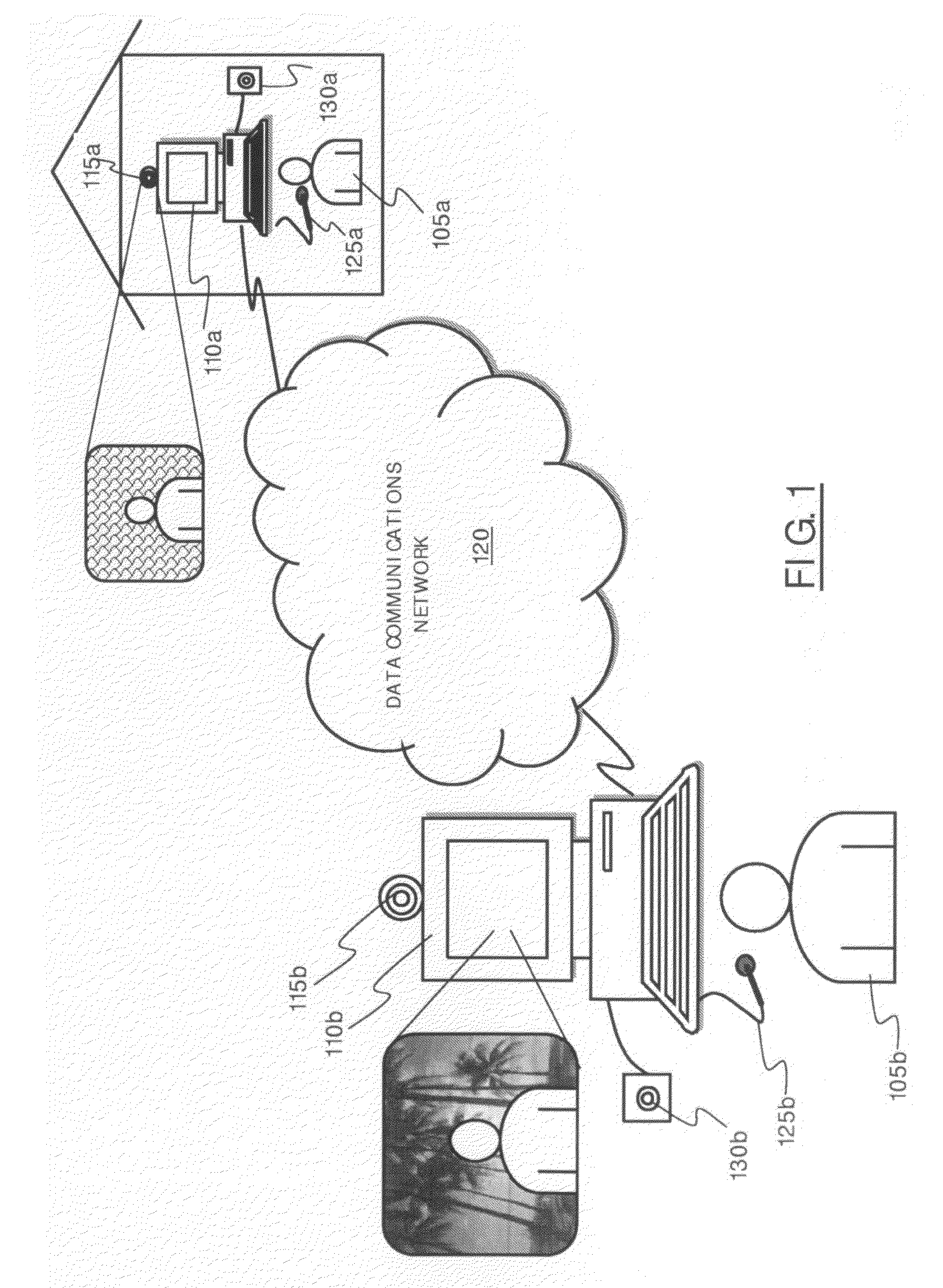

Segmentation of Video Sequences

InactiveUS20090028432A1Save CPU processing powerLess versatileImage enhancementImage analysisGraphicsMethod of images

A method of image processing, includes: providing a data processing apparatus, including a central processing unit and a graphics processing unit; feeding at least one video frame of a video sequence to the data processing apparatus, the at least one video frame including at least one foreground subject and a background; and processing the at least one video frame in the data processing apparatus so as to separate the at least one foreground subject from the background. The processing is at least partially performed by the processors of the graphics processing unit.

Owner:TELECOM ITALIA SPA

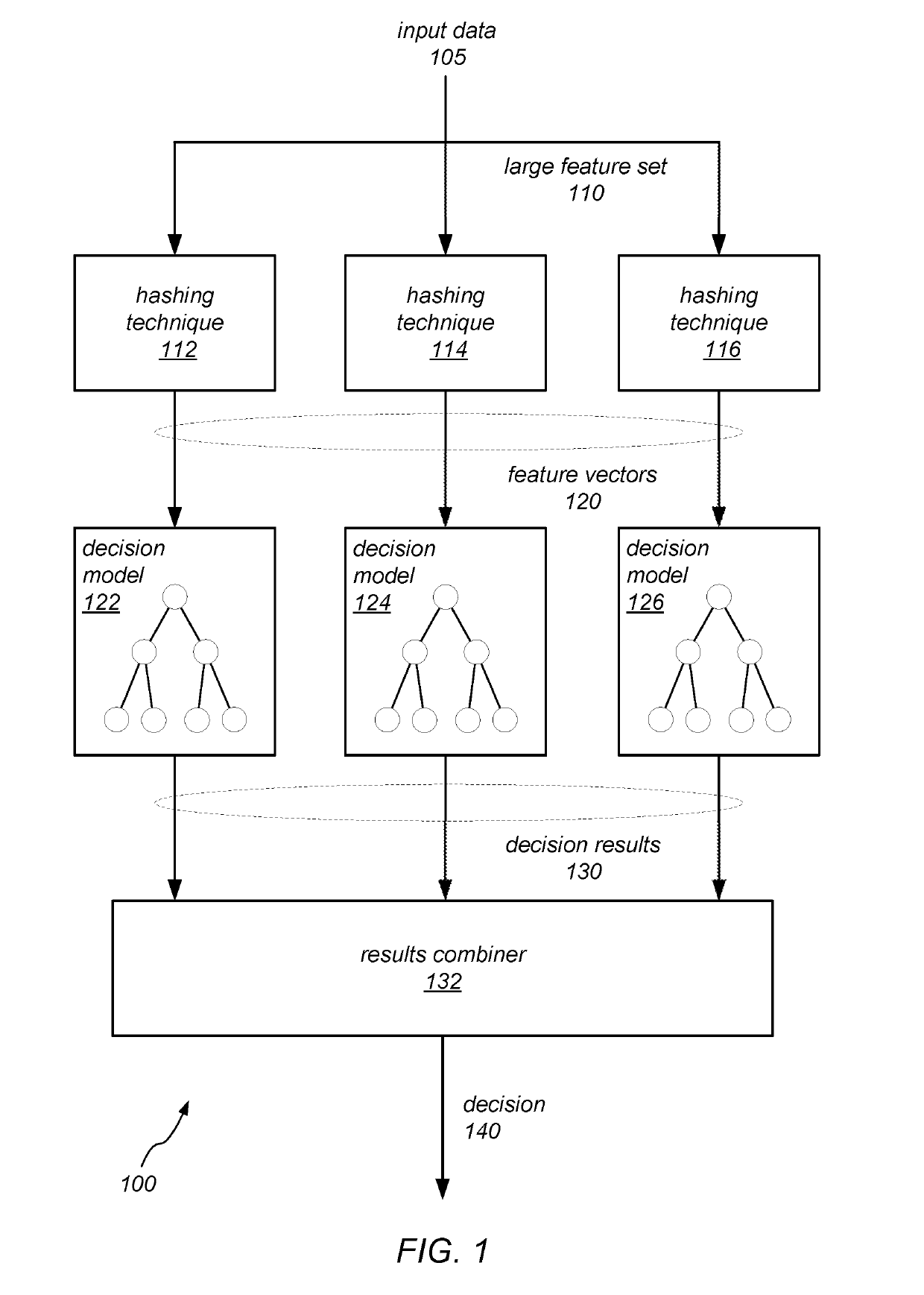

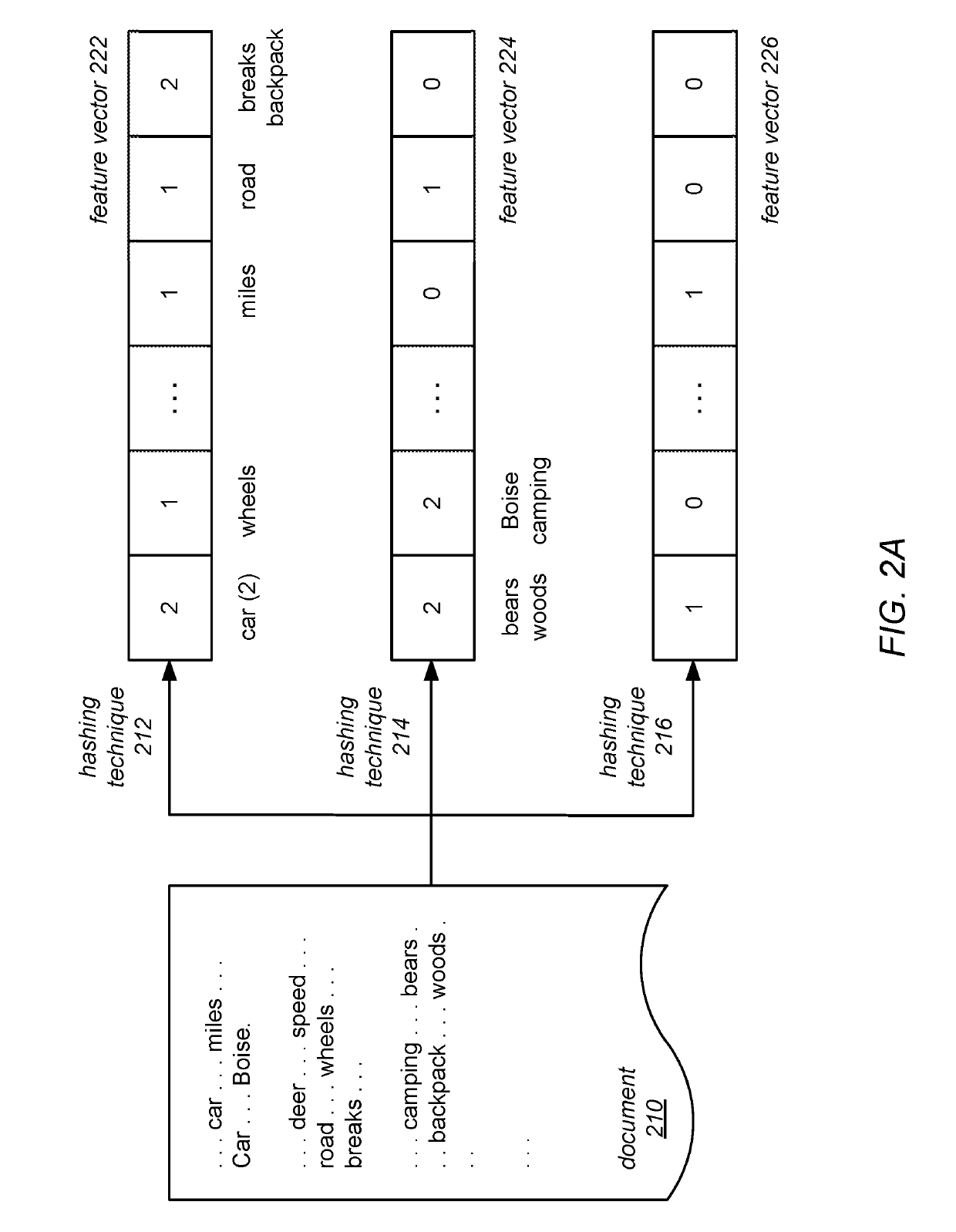

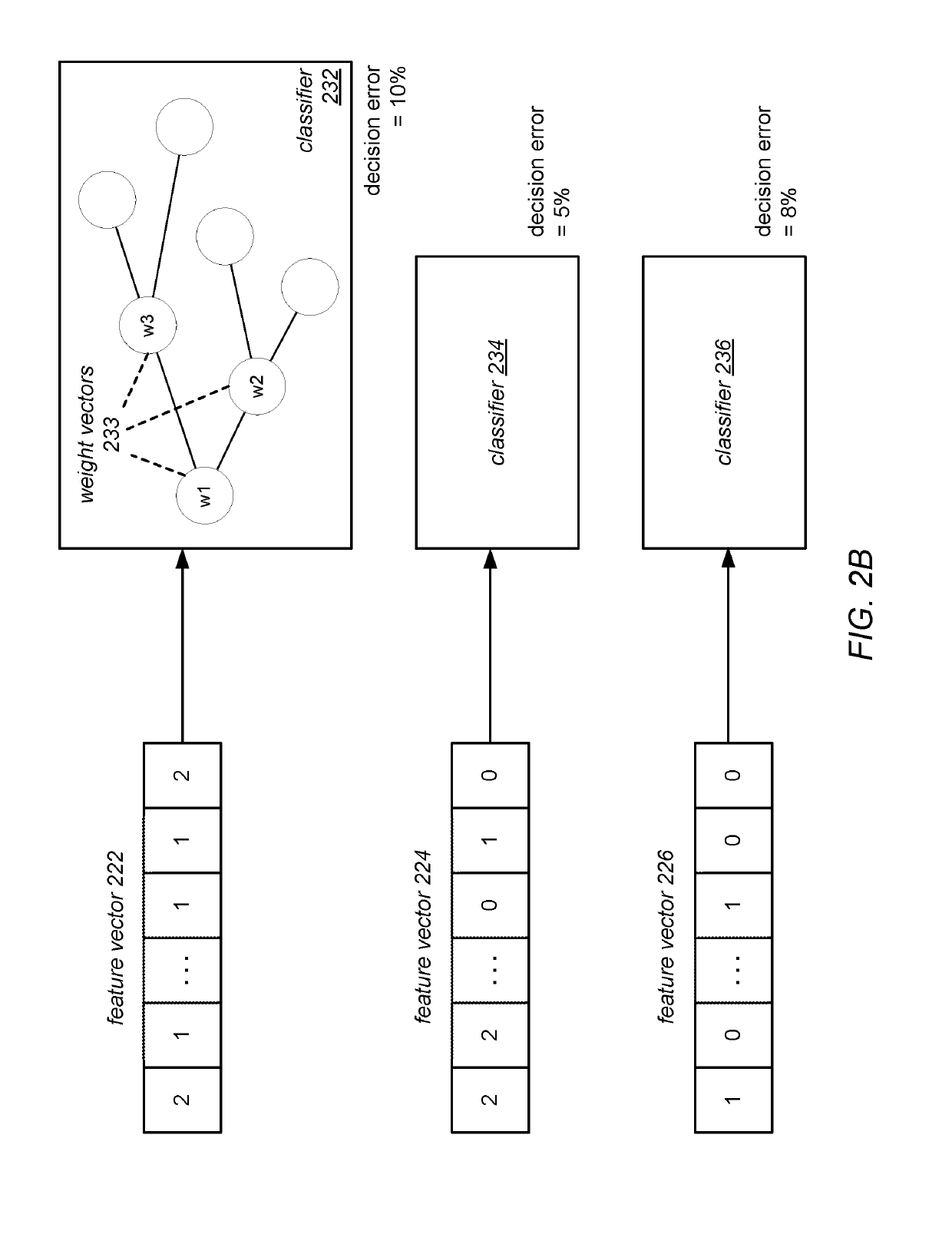

Ensembled Decision Systems Using Feature Hashing Models

ActiveUS20190095805A1Reducing feature space dimensionalitySave processing powerEnsemble learningInference methodsFeature vectorDecision model

Systems and methods are disclosed to build and execute a decision system based on multiple machine learned decision models. In embodiments, the decision system performs a hashing technique to reduce relevant features of the input data into a feature vector for each decision model. The feature vector reduces the dimensionality of the feature universe of the input data, and its use allows the decision models to be trained and executed using less computing resources. In embodiments, the decision system implements an ensembled decision model that makes decisions based on a combination function that combines the decision results of the individual models in the ensemble. The decision models employ different hashing techniques to hash the input features differently, so that errors caused by the feature hashing of individual models are reduced in the aggregate.

Owner:ORACLE INT CORP

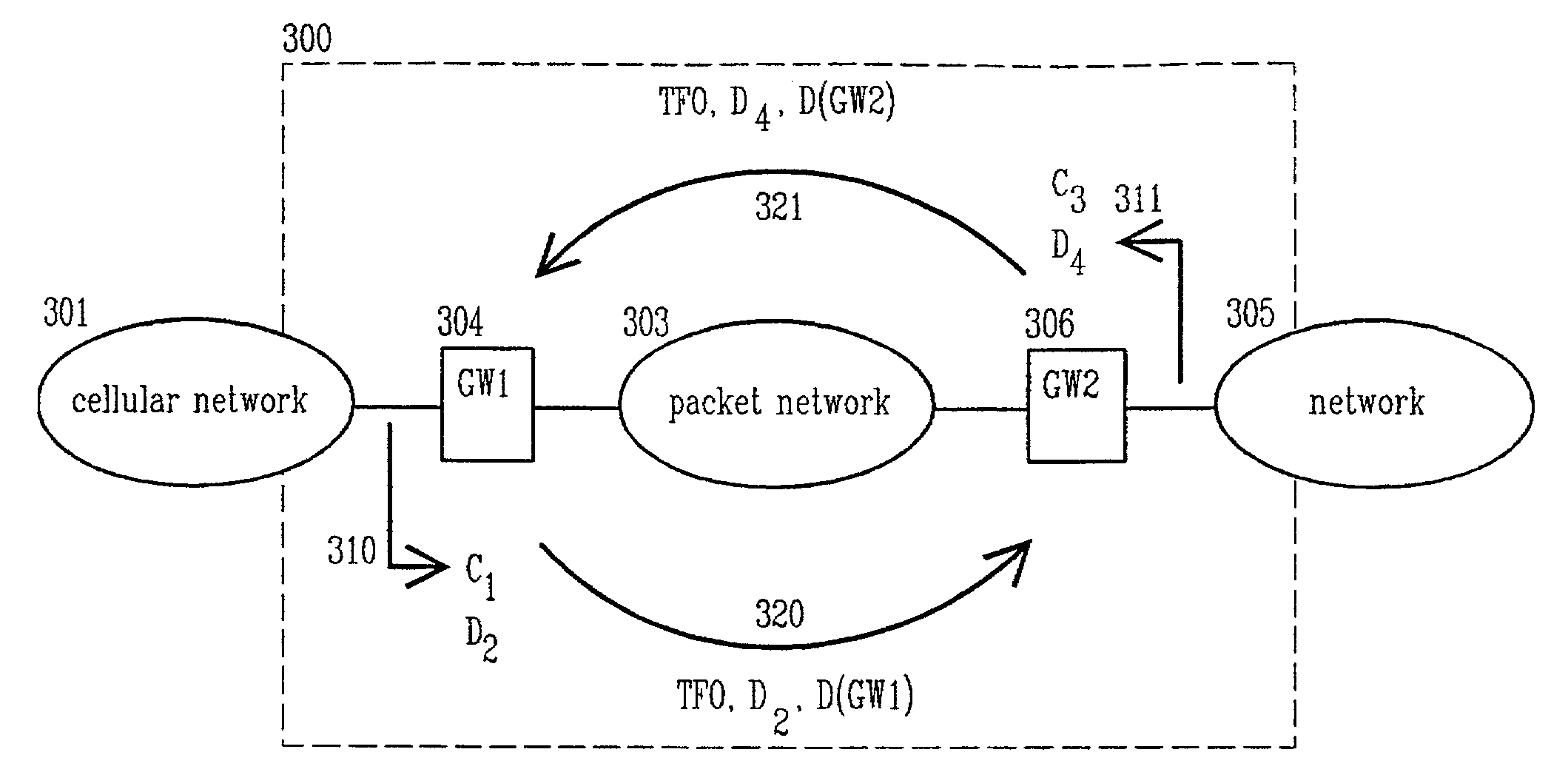

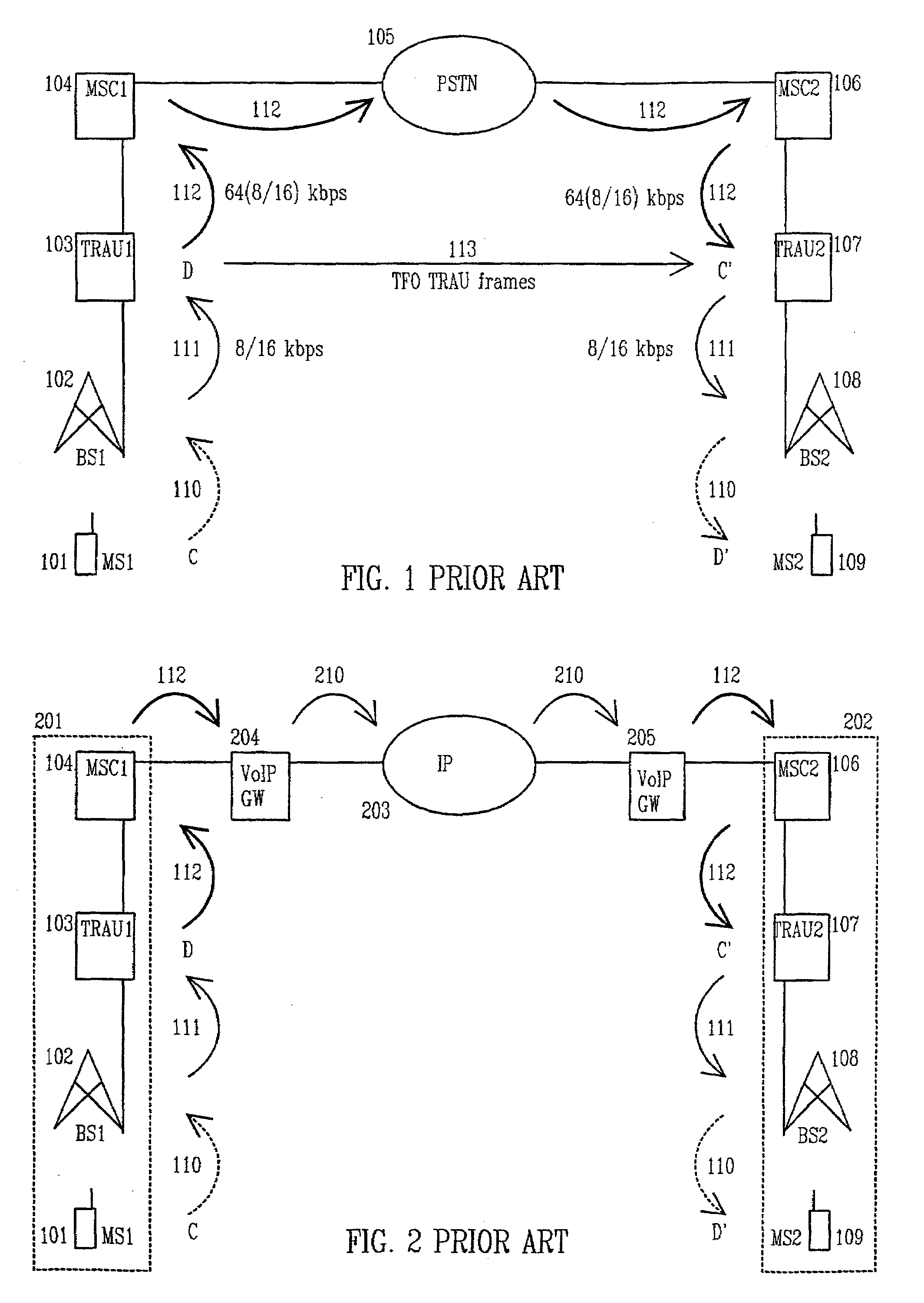

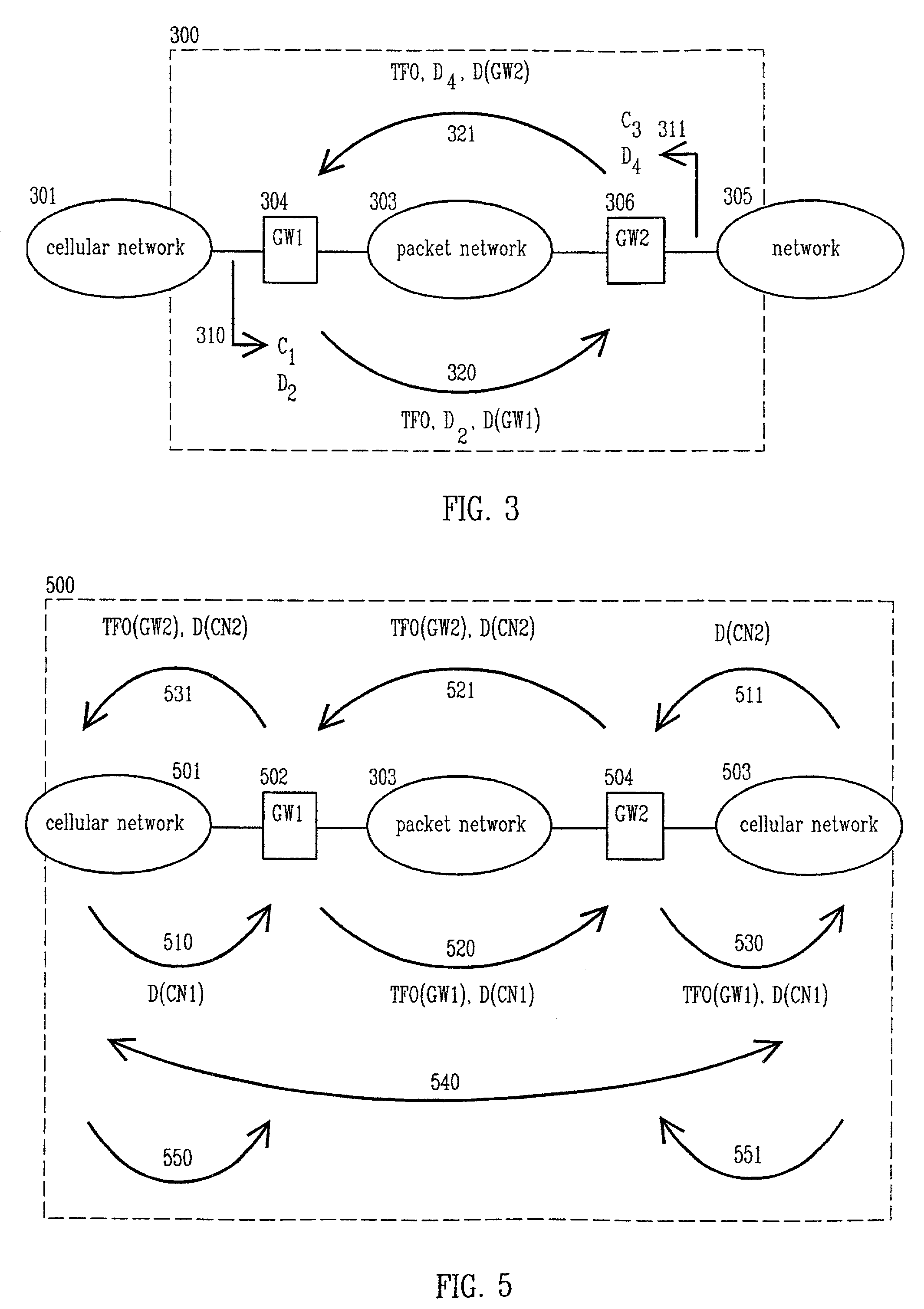

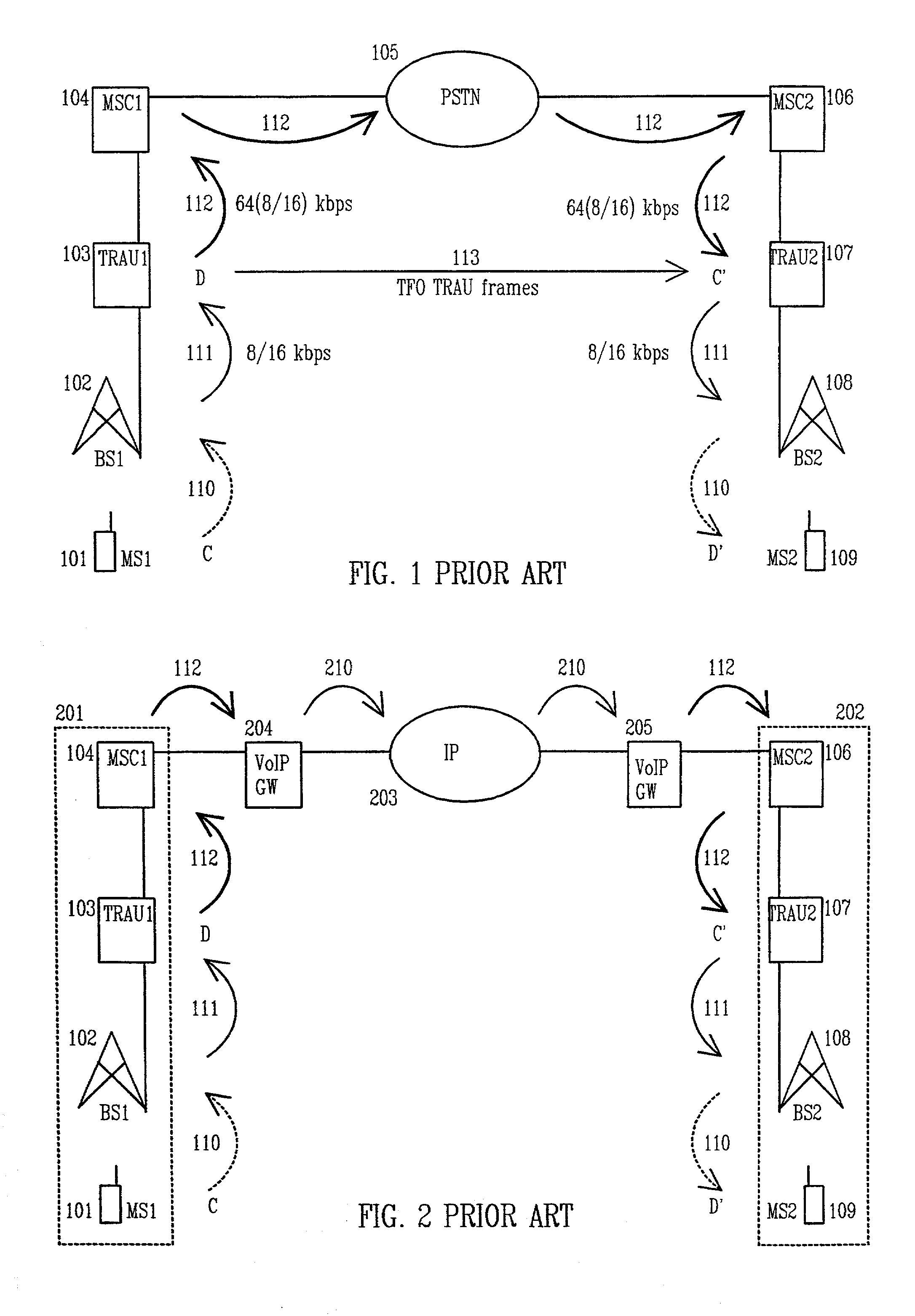

Method for transmitting coding information over packet data network

ActiveUS7136375B1Extend tandem free operationEasy to operateTime-division multiplexData switching by path configurationCellular networkInformation transmission

The invention relates to a method (300, 400, 500) for transmitting information related to tandem free operation, where a cellular network comprising a tandem free operation capable coding-decoding unit is connected to a packet network, an entity, which can be a second network or a terminal, is connected to the packet network and data is transmitted over the packet network between said coding-decoding unit on a first side of the packet network and said entity on a second side of the packet network. The method according to the invention is characterized in that information about the decoding capabilities and tandem free operation capabilities on the first side of the packet network is transmitted (320, 420, 520) over the packet network to the second side of the packet network. The invention relates also to a decoding information exchange arrangement (611), to a gateway (610), to a decoding information transmission arrangement (601) and to a cellular network element (600).

Owner:NOKIA TECHNOLOGLES OY

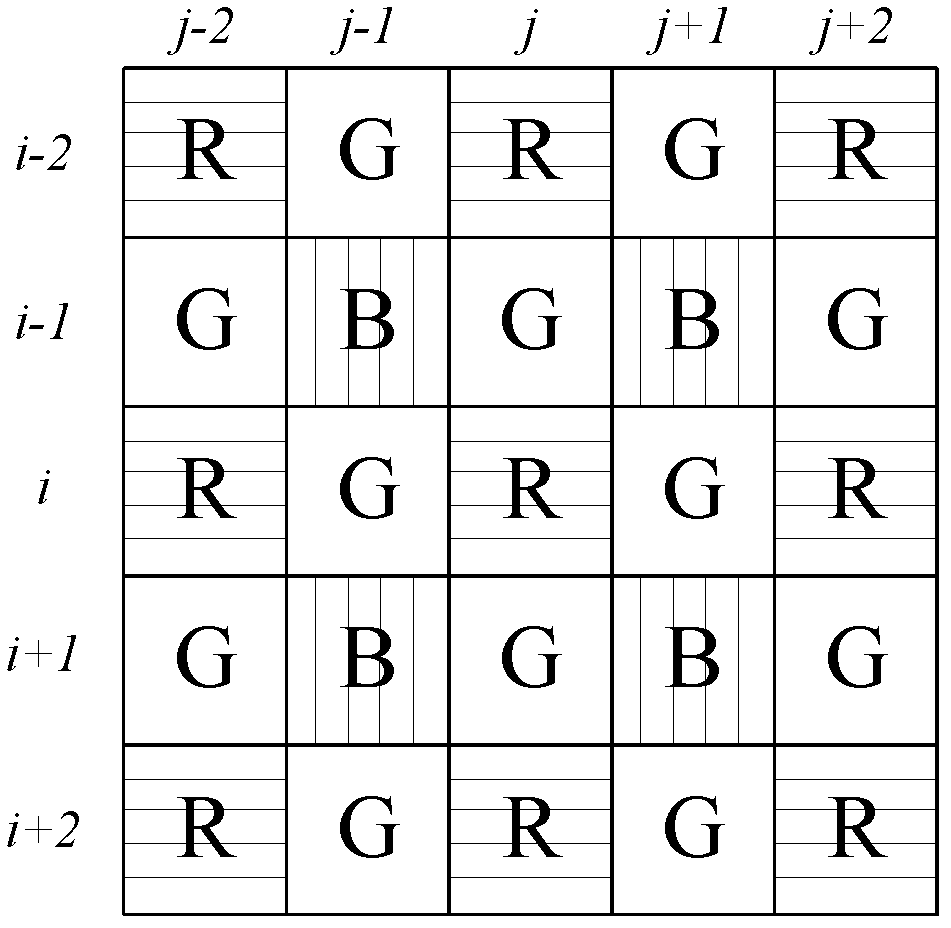

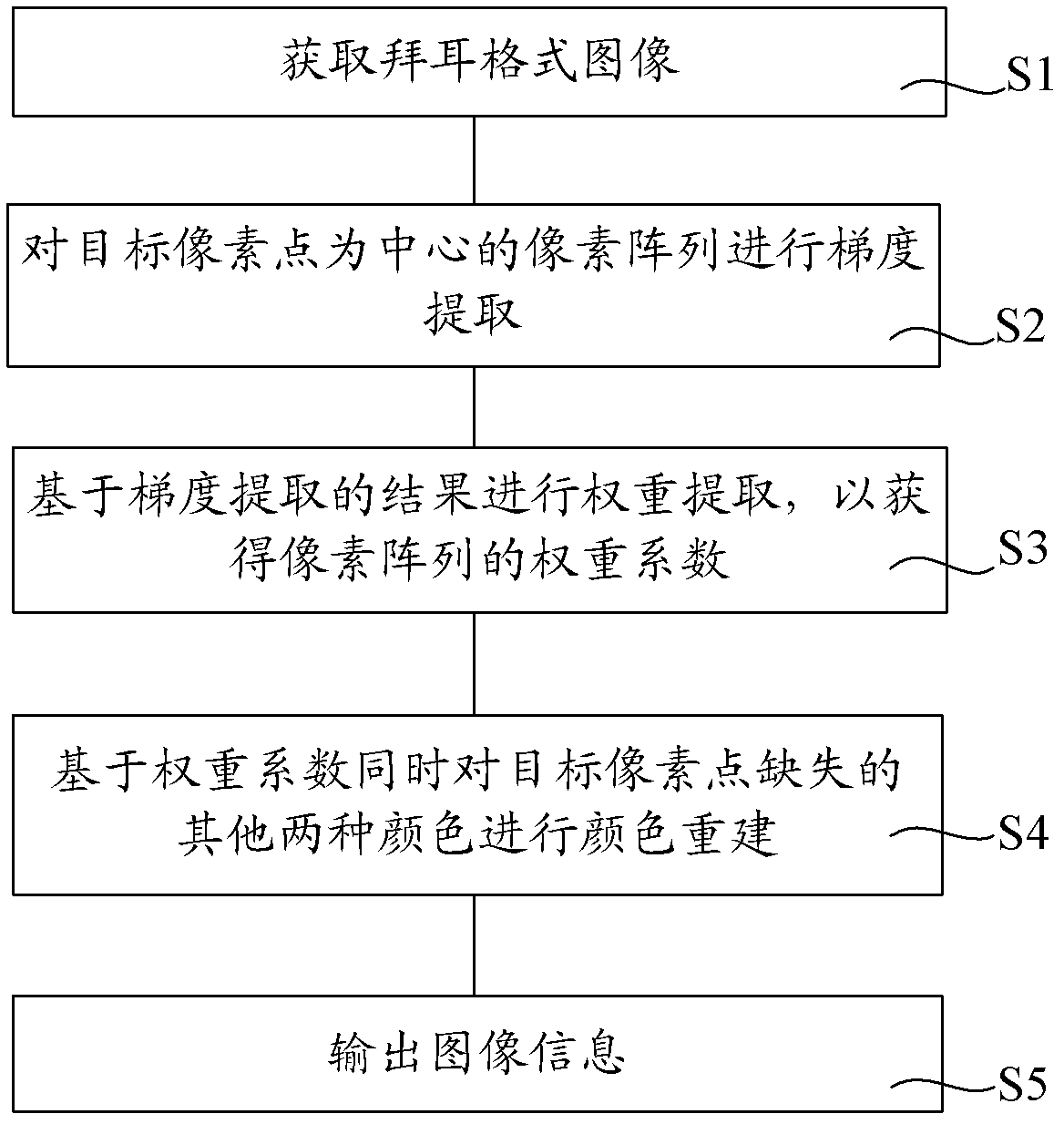

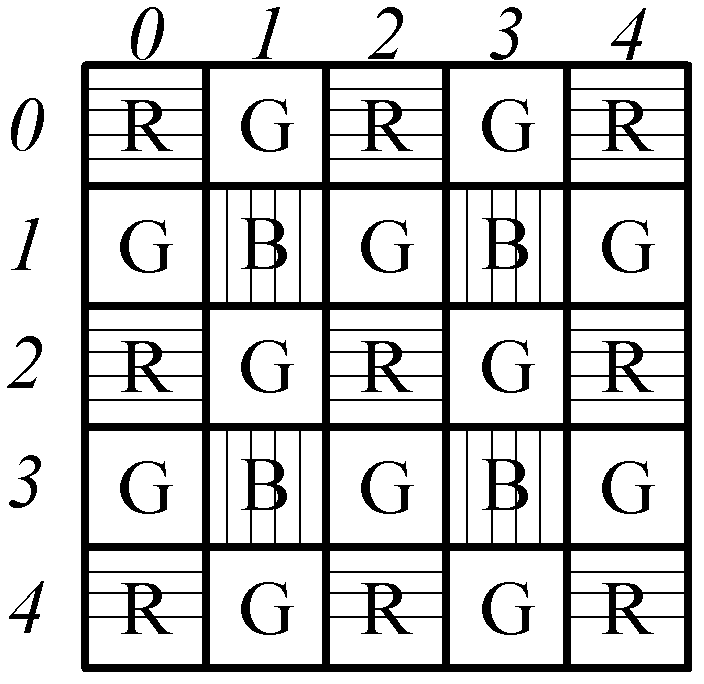

Method and device for demosaicking

ActiveCN102630018AImprove throughputImprove demosaic efficiencyImage enhancementColor signal processing circuitsImaging processingWeight coefficient

The invention relates to a method and a device for demosaicking. The method comprises the following steps of: acquiring a Bayer-format image; carrying out gradient extraction on a pixel array which takes a target pixel point as the center; carrying out weight extraction on the basis of a gradient extraction result to obtain a weight coefficient of the pixel array; on the basis of the weight coefficient, simultaneously carrying out color reconstruction on other two colors missed by the target pixel point; and outputting image information. The device comprises an image acquisition unit, a gradient extraction unit, a weight extraction unit, a color reconstruction unit and an image output unit, wherein the image acquisition unit is used for acquiring the Bayer-format image; the gradient extraction unit is used for carrying out gradient extraction on the pixel array which takes the target pixel point as the center; the weight extraction unit is used for carrying out weight extraction according to the gradient extraction result to obtain the weight coefficient of the pixel array; the color reconstruction unit comprises two color reconstructors connected with the weight extraction unit and is used for simultaneously carrying out color reconstruction on other two colors missed by the target pixel point according to the weight coefficient; and the image output unit is used for outputting the image information obtained after color reconstruction. According to the invention, the image processing efficiency can be improved.

Owner:GALAXYCORE SHANGHAI

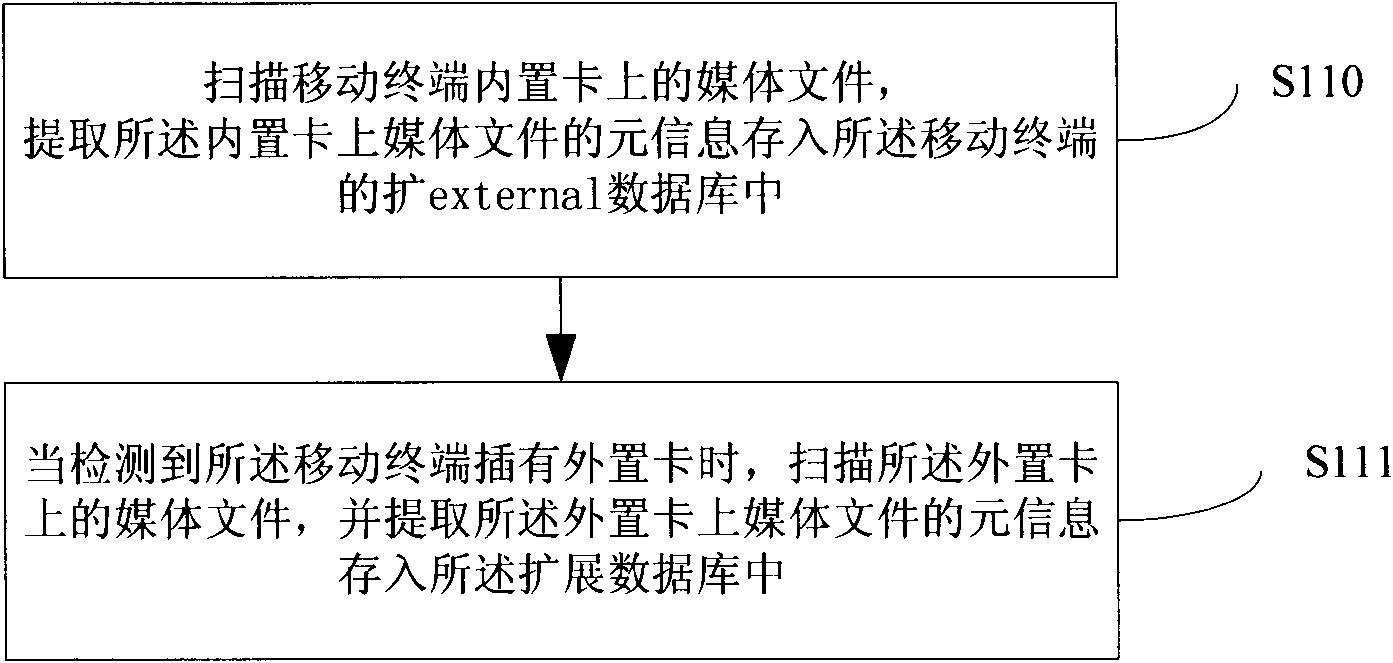

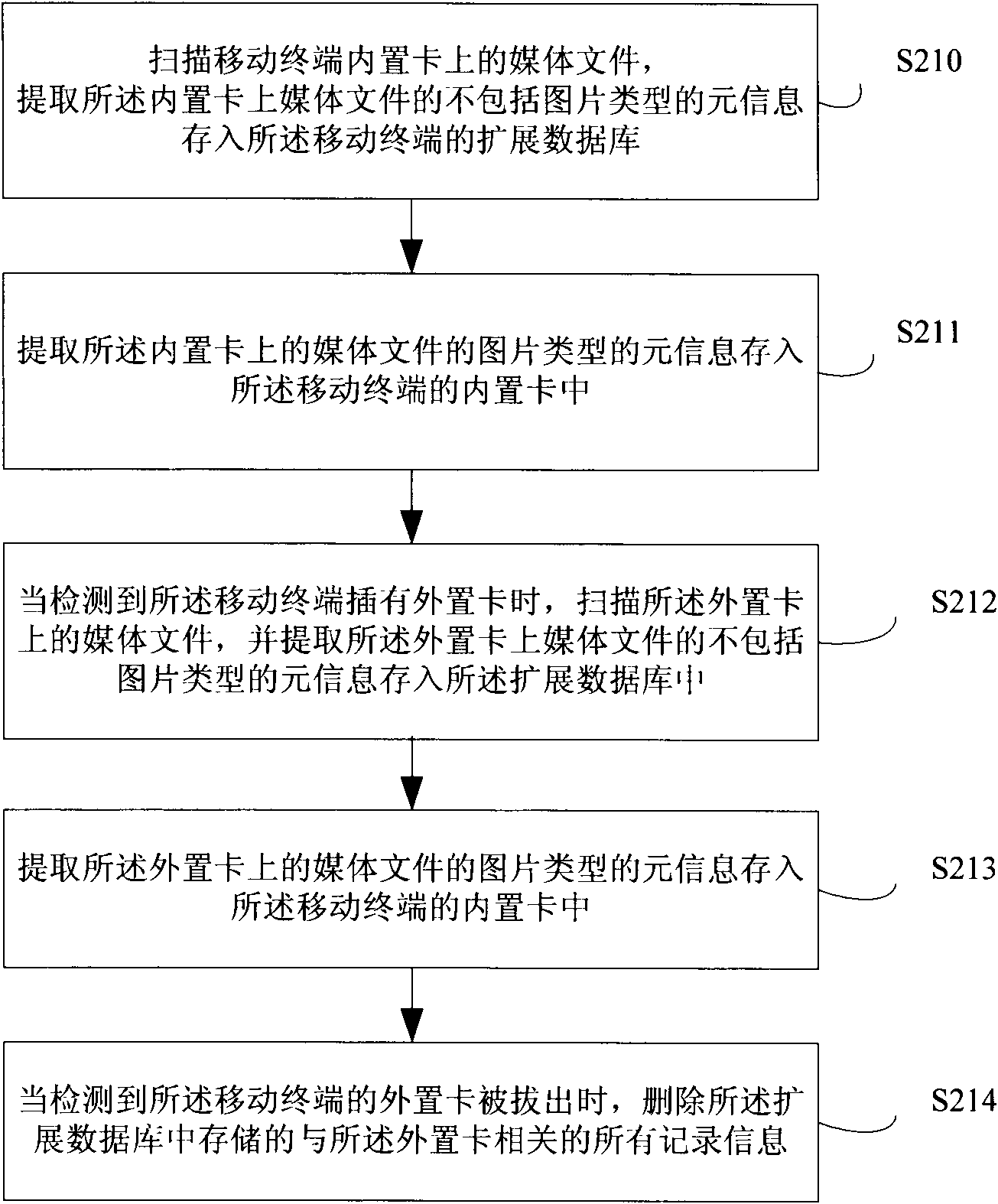

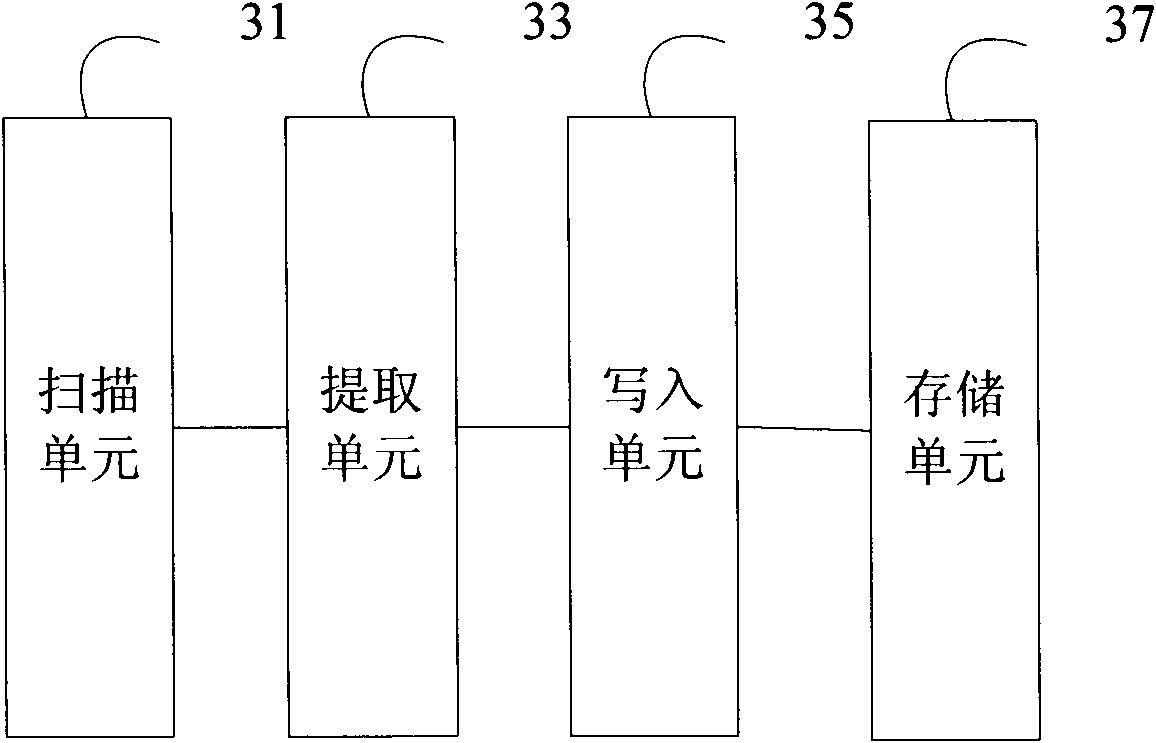

Data storage method of media files and mobile terminal

ActiveCN101957854ASave resourcesSave processing powerSubstation equipmentSpecial data processing applicationsComputer terminalData library

The embodiment of the invention provides a data storage method of media files and a mobile terminal. The data storage method comprises the following steps of: scanning the media files on a built-in card of the mobile terminal, and extracting metainformation of the media files on the built-in card and saving the metainformation in an expansion database of the mobile terminal. By the embodiment of the invention, the media files on the built-in card of the mobile terminal and records of a system database are synchronized.

Owner:YULONG COMPUTER TELECOMM SCI (SHENZHEN) CO LTD

Neutral blocking remover composition for oilfield oil extraction and preparation method thereof

ActiveCN104293333AImprove plugging efficiencyRestore permeabilityDrilling compositionButanedioic acidMethyl lactate

The invention relates to a neutral blocking remover composition for oilfield oil extraction, which is prepared from the following components in parts by weight: 30-35 parts of acrylic acid-methyl acrylate copolymer, 44-50 parts of diethylene triamine pentaacetic acid, 30-35 parts of sodium polyepoxysuccinate, 30-35 parts of amine malate, 10-14 parts of sodium alkyl sulfonate, 5-8 parts of amine hydroxy ethylidene diphosphate, 10-14 parts of hydrolyzed polyacrylamide, 12-17 parts of atlapulgite, 20-25 parts of sodium persulfate, 7-10 parts of sodium lignosulfonate, 5-8 parts of tannin, 12-16 parts of sodium malate, 5-8 parts of sodium sulfosuccinate, 5-8 parts of starch, 9-12 parts of methyl lactate, 0.2-0.3 part of vanadium pentoxide and 0.1-0.3 part of diisobutyl carbinol. The neutral blocking remover composition for oilfield oil extraction has the advantages of high blocking removal speed, no corrosivity due to neutrality and no dead area, can quickly dissolve the material scales, clean the oilfield stratum and remove blocking, and does not generate the phenomenon of precipitation or secondary blocking; and the cleaning waste liquid does not need to be subjected to sewage treatment after returning to the ground.

Owner:兰州熙瑞化工科技有限公司

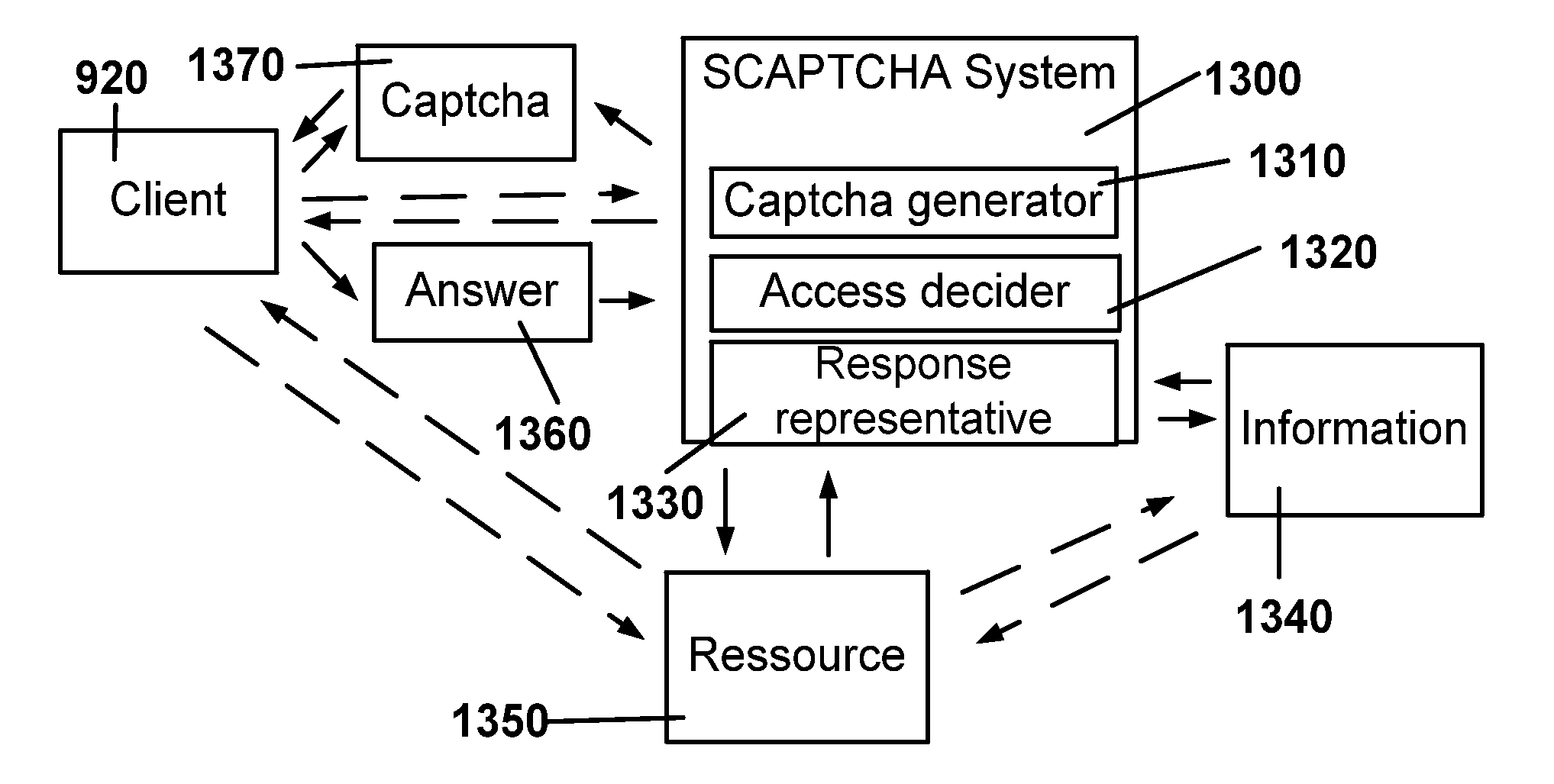

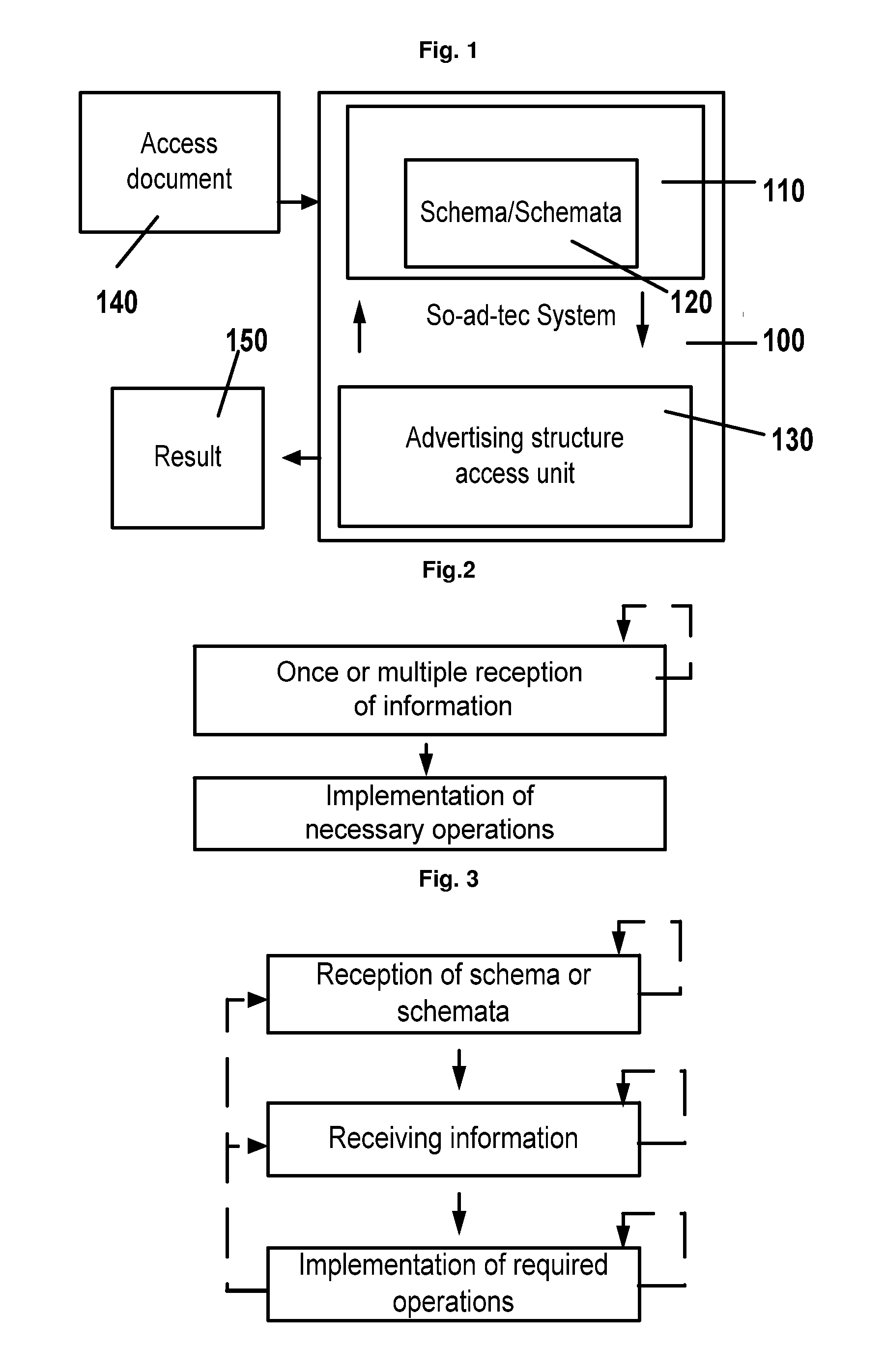

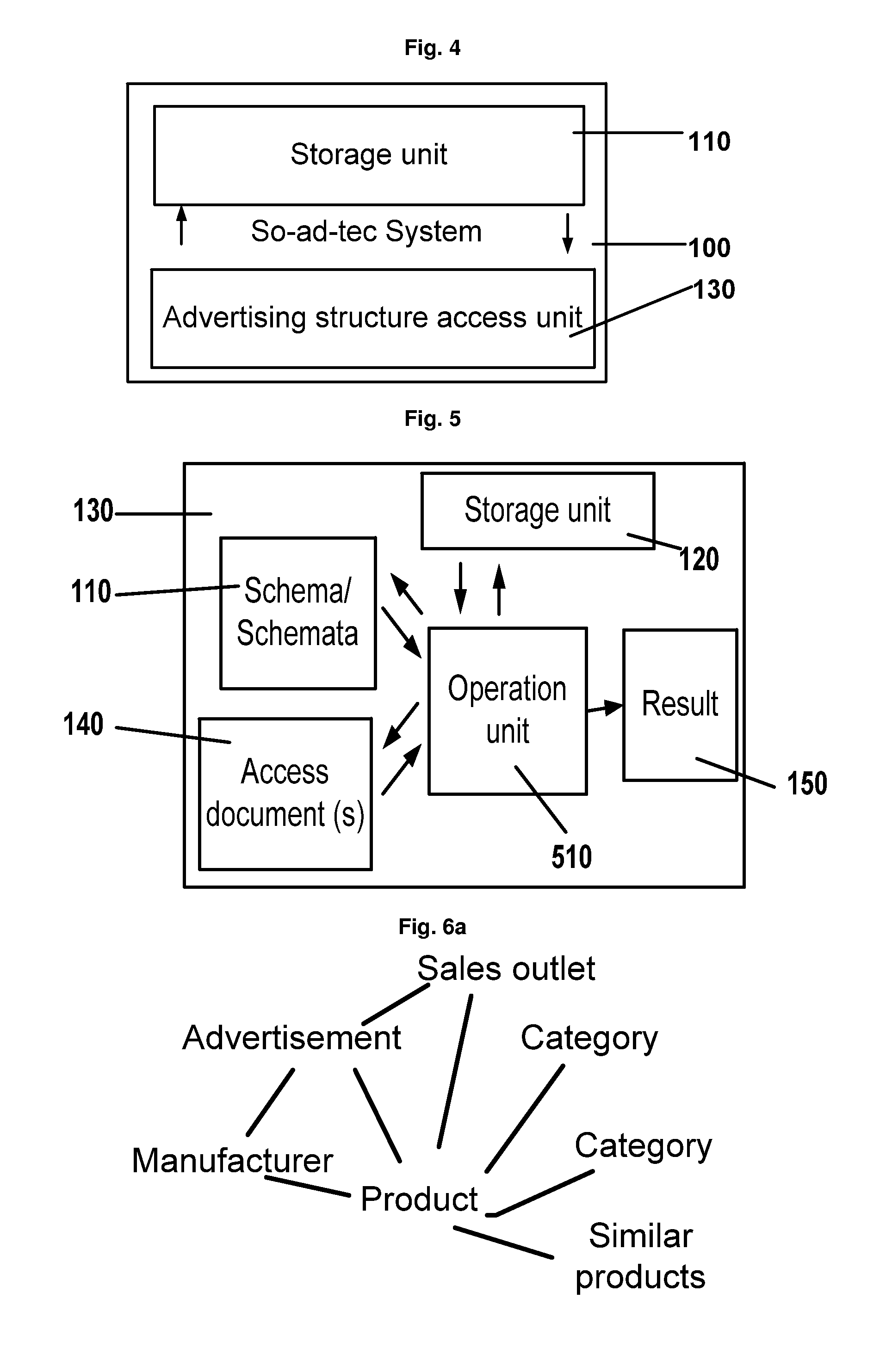

Social advertising technology (so-ad-tec) system and method for advertising for and in documents, and other systems and methods for accessing, structuring, and evaluating documents

InactiveUS20130035996A1Save processing powerSave energyOffice automationMarketingStructure of Management InformationLibrary science

The invention relates to system to access advertisement and / or associated information that can be stored in a So-ad-tec system. The So-ad-tec system includes an access unit which is designed to process at least one access having resources to access details of at least one schema or the information derived thereof or the schema (120) or the structure itself. The So-ad-tec system is designed to manage advertisement and other associated or related information, in at least one schema.

Owner:FREY TIM

Neutral blockage removing agent composition used for oil recovery formation in oilfield and preparation method thereof

ActiveCN104194758ALow corrosion rateUnblocking safetyDrilling compositionButanedioic acidSuccinic acid

The invention relates to a neutral blockage removing agent composition used for an oil recovery formation in an oilfield. The neutral blockage removing agent composition is prepared from the following raw materials in parts by weight: 10-14 parts of polyepoxysuccinic acid amine, 35-40 parts of diethylenetriaminepentaacetic acid amine, 33-37 parts of hydroxyl succinic acid amine, 20-25 parts of polyacrylamide, 7-10 parts of sodium polyaspartate, 10-14 parts of sodium gluconate, 10-15 parts of activated clay, 20-25 parts of potassium peroxodisulfate, 9-11 parts of hydroxyl butanedioic acid amine, 4-7 parts of sodium salicylate, 5-9 parts of hexamethylene tetramine, 0.2-0.3 part of vanadium pentoxide, 2-5 parts of starch, 5-8 parts of alpha-sulphonated fatty acid methyl ester and derivative thereof (MES) and 0.1-0.3 part ofdiethyl ethanolamine. The neutral blockage removing agent composition is used for the blockage removal of an oil pumping well and a screw pump well in the oilfield, can effectively solve the problems of cleaning blockage removal of the oil pumping well and the screw pump well in the oilfield and the corrosion of oil recovery equipment, has high blockage removing speed, is neutral and is free of corrosion; waste liquid for blockage removal can be degraded and does not need to be discharged onto the ground to be subjected to sewage treatment, no corrosion, dead angle, precipitation or secondary well blockage are generated, and more safety and more reliability are realized as compared with traditional pickling blockage removing, biological blockage removing and solvent blockage removing.

Owner:兰州熙瑞化工科技有限公司

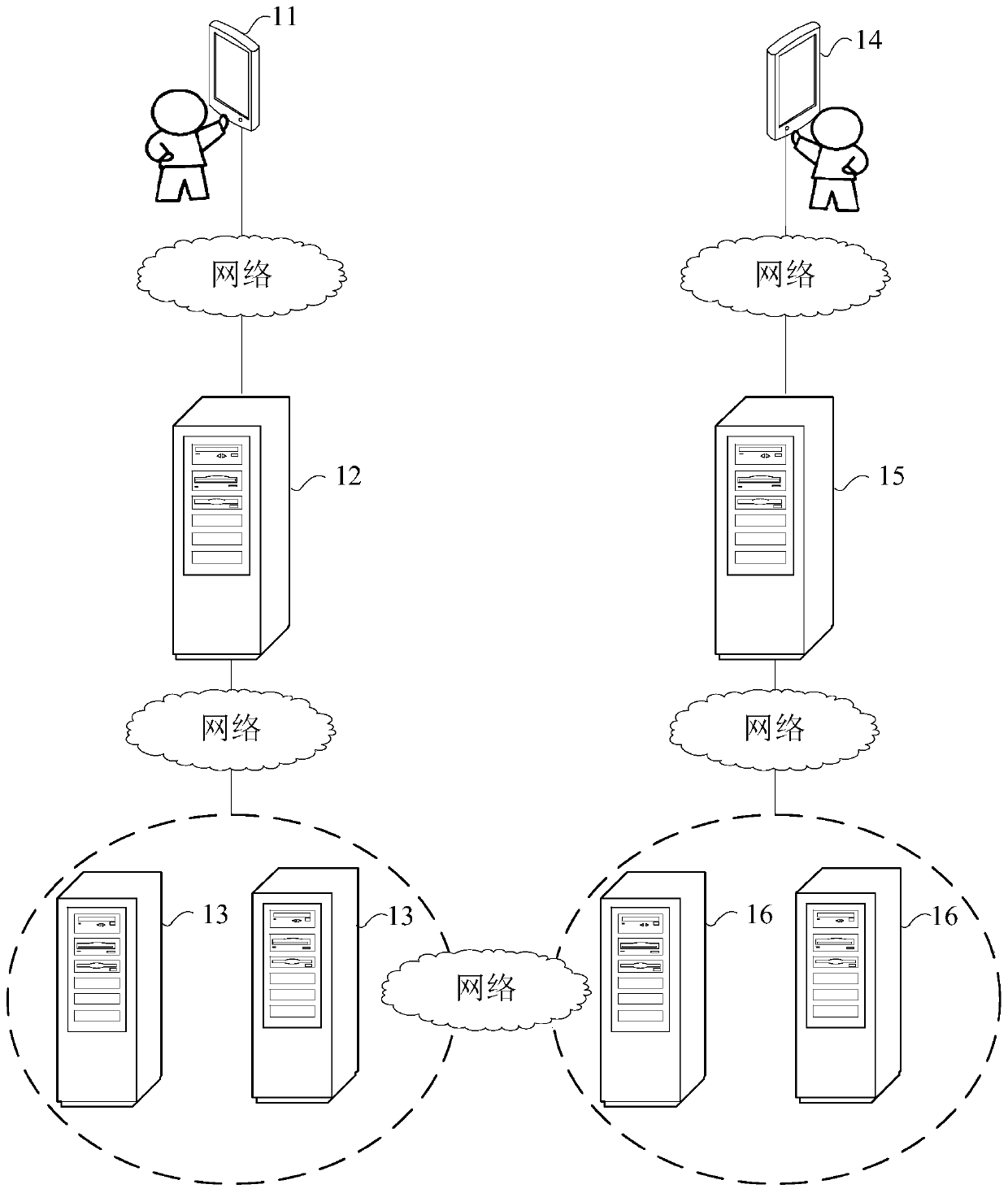

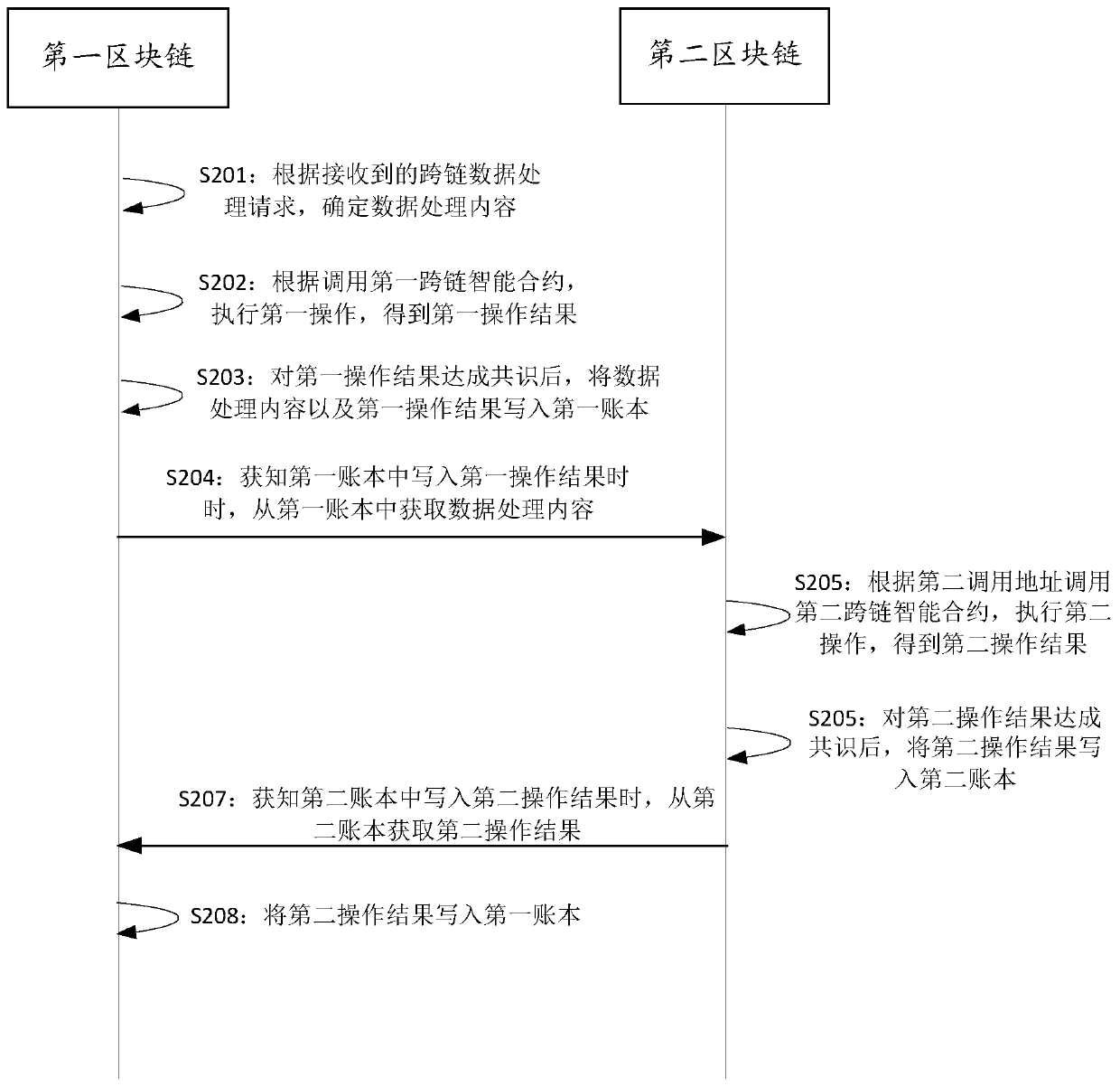

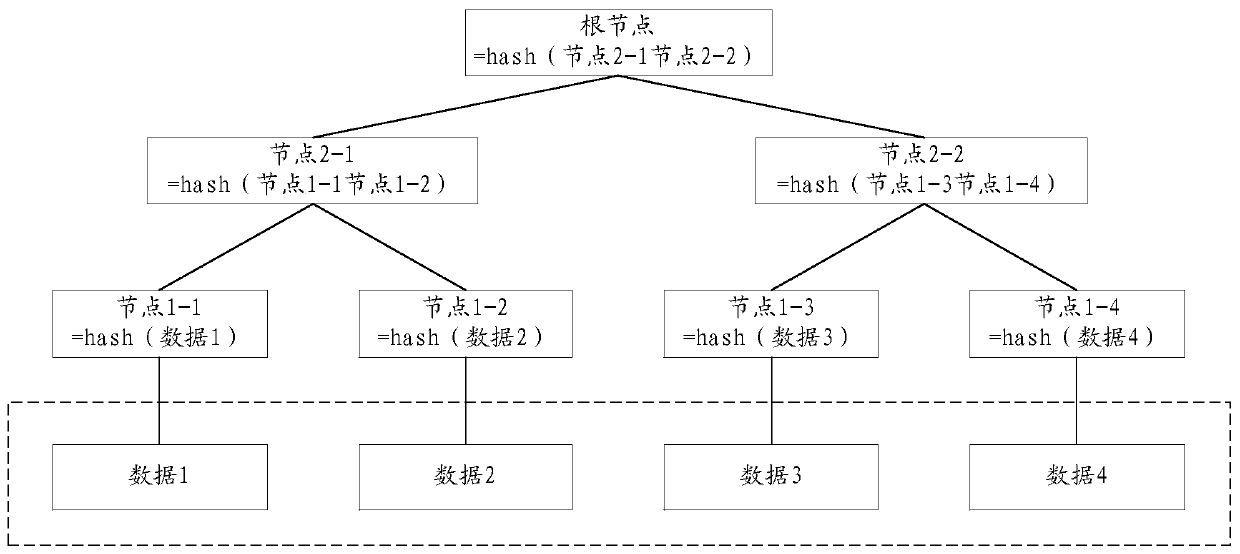

Cross-chain data processing method and device based on block chain

ActiveCN110442652ARealize processingFlexible processing timeDatabase distribution/replicationPayment protocolsResource consumptionThe Internet

The invention relates to the technical field of the Internet, and discloses a cross-chain data processing method and device based on a block chain, which are used for improving the efficiency in the cross-chain data processing process and reducing the resource consumption, and the method comprises the following steps: a first block chain determining data processing content according to a receivedcross-chain data processing request; the first block chain calling a first cross-chain smart contract according to the first call address, and executing a first operation corresponding to the first block chain in the data processing content to obtain a first operation result; the first block chain writing the data processing content and the first operation result into a first account book after reaching a consensus of the first operation result; when the first block chain knows that a second operation result is written into a second account book of a second block chain, obtaining the second operation result from the second account book; and the first block chain writing the second operation result into the first account book.

Owner:TENCENT TECH (SHENZHEN) CO LTD

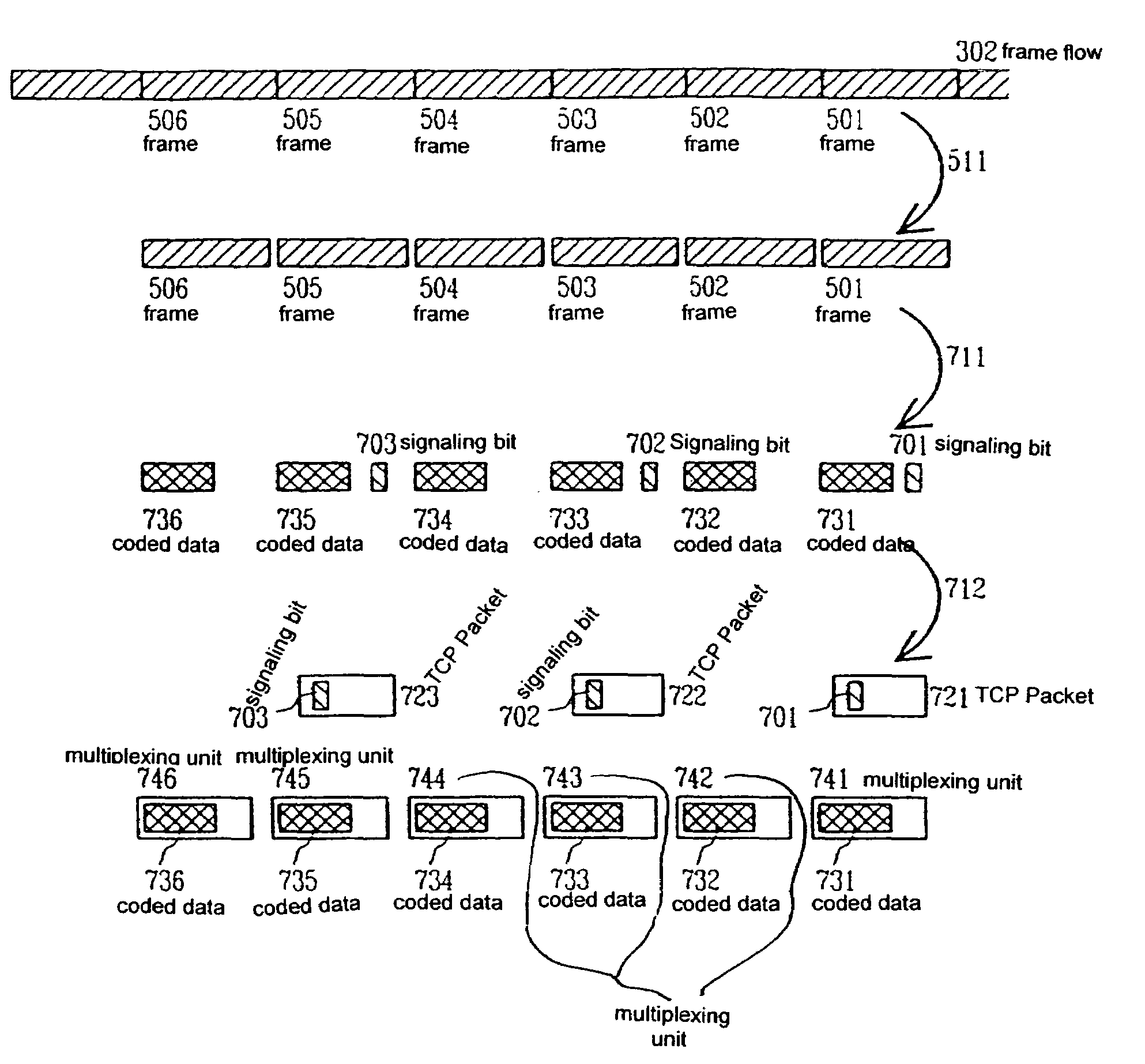

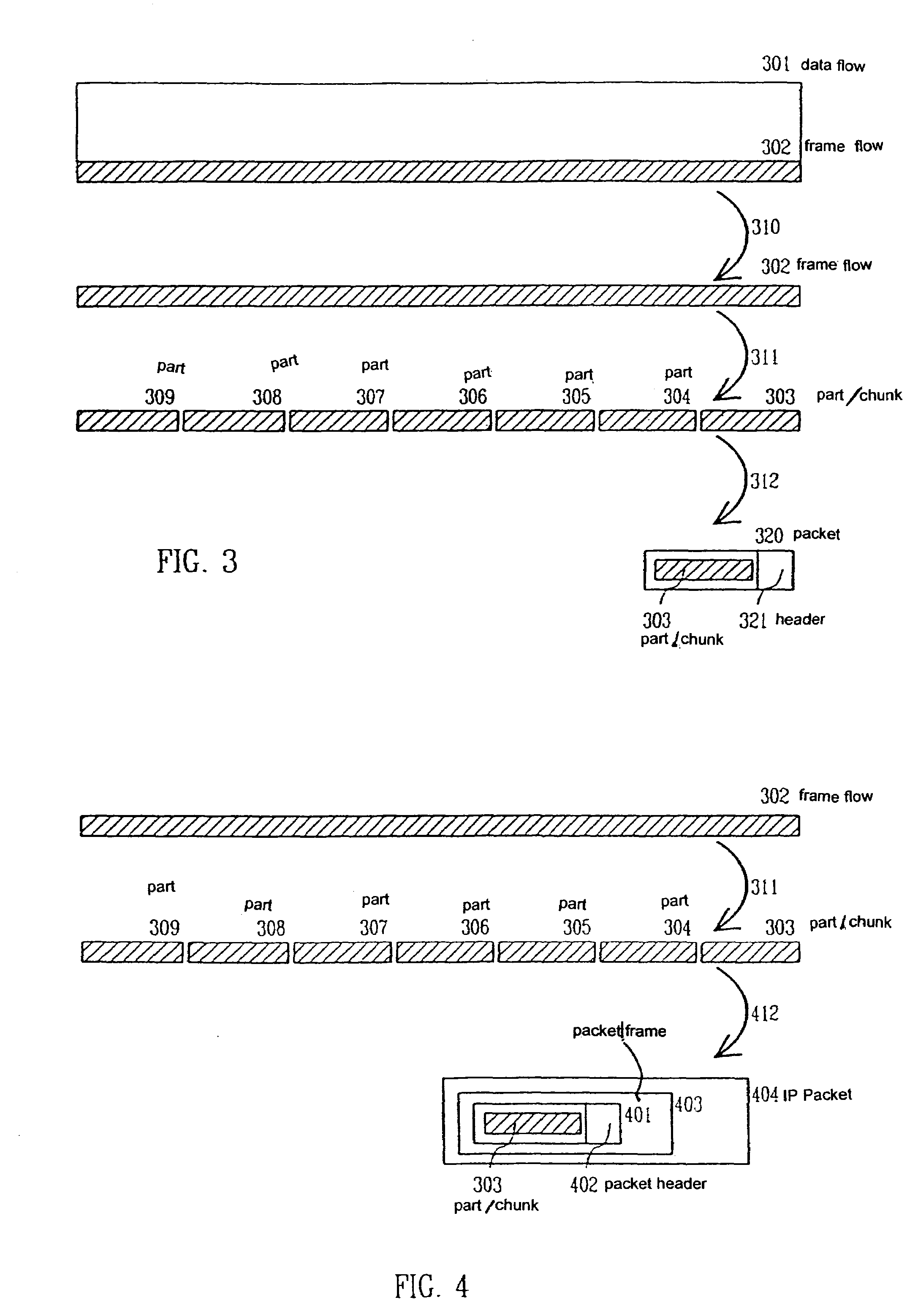

Method for transmitting calls over packet network

InactiveUS7257114B1Quality improvementSave processing powerTime-division multiplexData switching by path configurationNetworked Transport of RTCM via Internet ProtocolTelephone network

A transmitting / receiving arrangement, gateway and method for transmitting data over packet network, where a cellular network is connected to a packet network and uplink data frames which carry coded data and certain signaling information related to the coding are transmitted from the cellular network towards the packet network, wherein at least all non-redundant information from the uplink data frames is extracted from the frames and transmitted over the packet network. The gateway connects a packet network to a telephony network.

Owner:META PLATFORMS INC

Personal content item searching system and method

ActiveUS20160224677A1Provided to the user more quicklyProvide quicklyDatabase updatingWeb data indexingIndexing ServiceContent management

Enable using a user computer to search the user's personal content items hosted by an online content management service, the online content management service having an indexer computer configured to generate a base index of the user's content items hosted by the service, a base index server computer configured to transmit the generated base index over a network to the user computer, an index mutation generator computer configured to generate index mutations for subsequent changes to user's hosted content items, and an index mutation sever computer configured to transmit the generated index mutations over the network to the user computer. In one aspect, the system and method enable searches of the user's hosted content items and changes thereto to be conducted at the user computer using an index local to the user computer constructed based on the base index and the index mutations received by the user computer.

Owner:DROPBOX

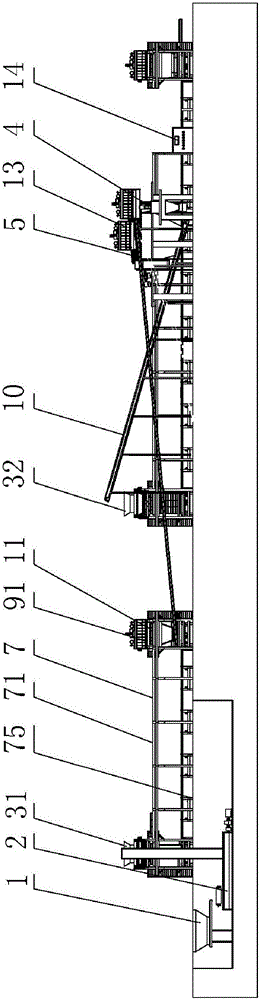

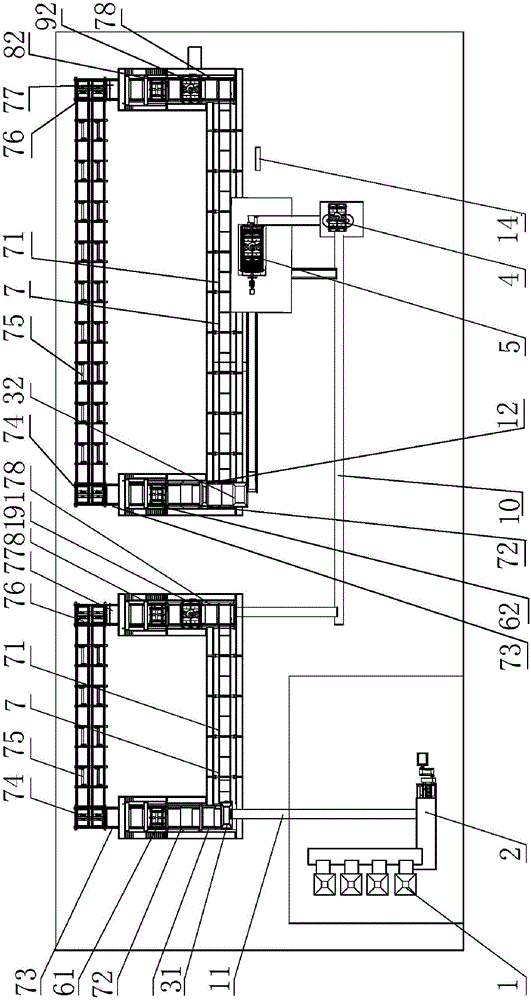

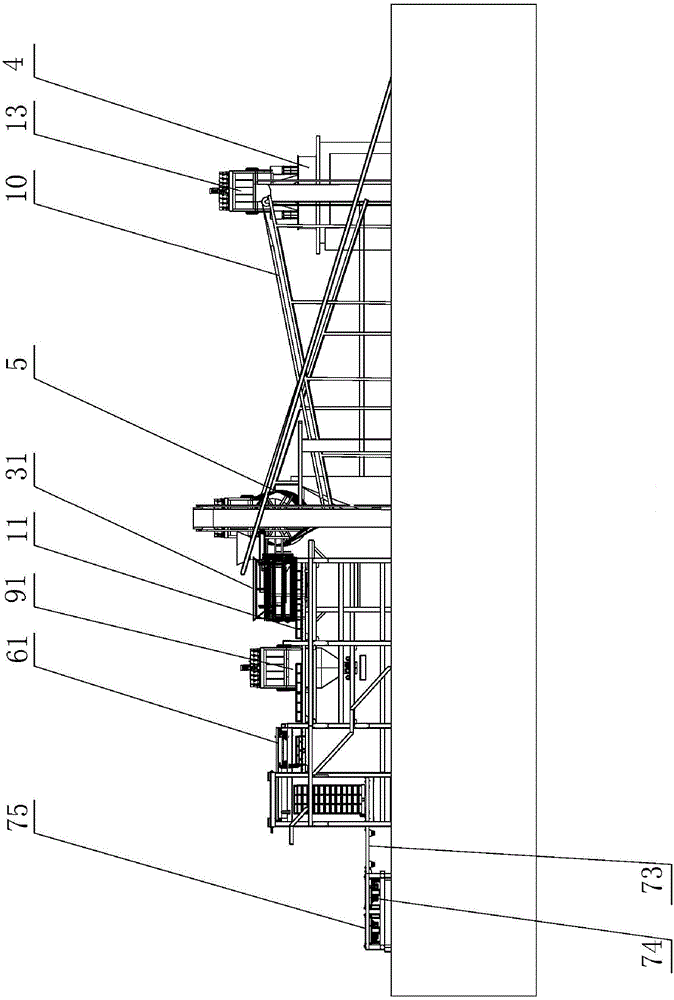

Tray type stereoscopic organic material fermentation system and fermentation method

ActiveCN105060958ASolve the problem of secondary environmental pollutionSave processing and production landBio-organic fraction processingClimate change adaptationStackerFermentation system

The invention relates to a tray type stereoscopic organic material fermentation system and fermentation method. The fermentation system comprises tray loading equipment, tray stackers, tray unstackers and tray-dumping unloaders which are mounted sequentially as well as rolling equipment mounted on the tray loading equipment, tray conveying equipment connected among the tray loading equipment, the tray stackers, the tray unstackers and the tray-dumping unloaders and fermentation trays moving and circulating among the tray loading equipment, the tray stackers, the tray unstackers and the tray-dumping unloaders through the tray conveying equipment. Organic materials are loaded in the fermentation trays by the tray loading equipment, the fermentation trays are conveyed to the tray stackers by the tray conveying equipment to be stacked to form a tray stack, the organic materials are subjected to aerobic fermentation in the fermentation trays stacked in the tray stack and conveyed to the tray unstackers through the tray conveying equipment, the fermentation trays are taken out from the tray stack, the trays are conveyed to the tray-dumping unloaders by the tray conveying equipment, the materials are poured out from the fermentation trays, and the empty fermentation trays are conveyed back to the tray loading equipment by the tray conveying equipment.

Owner:GUANGXI LIYUANBAO SCI & TECH

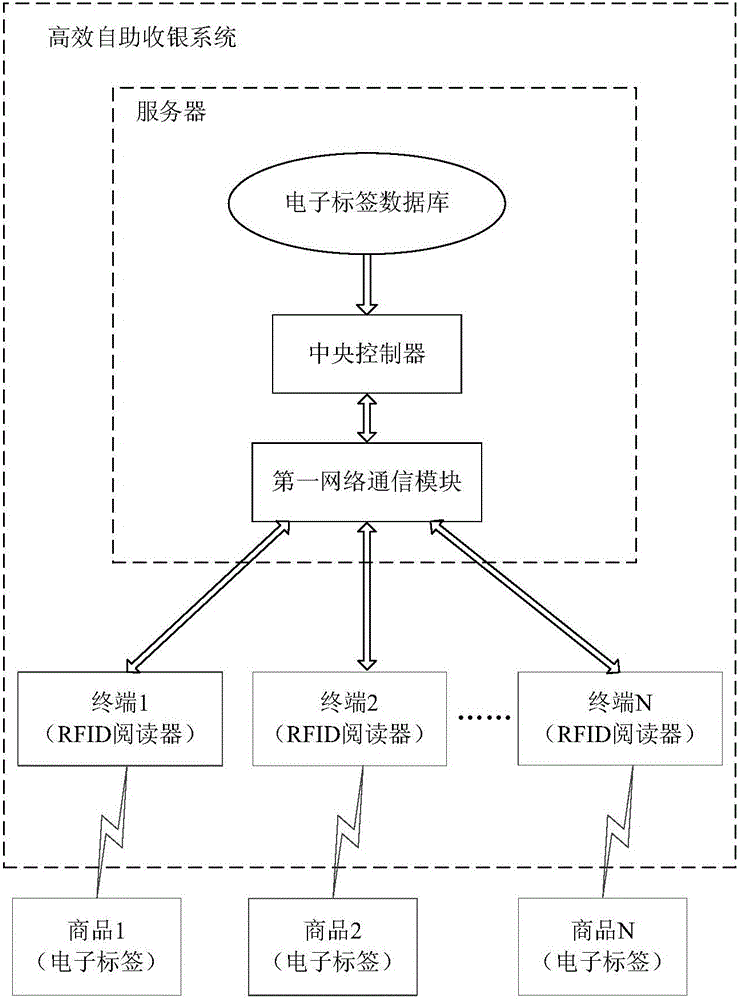

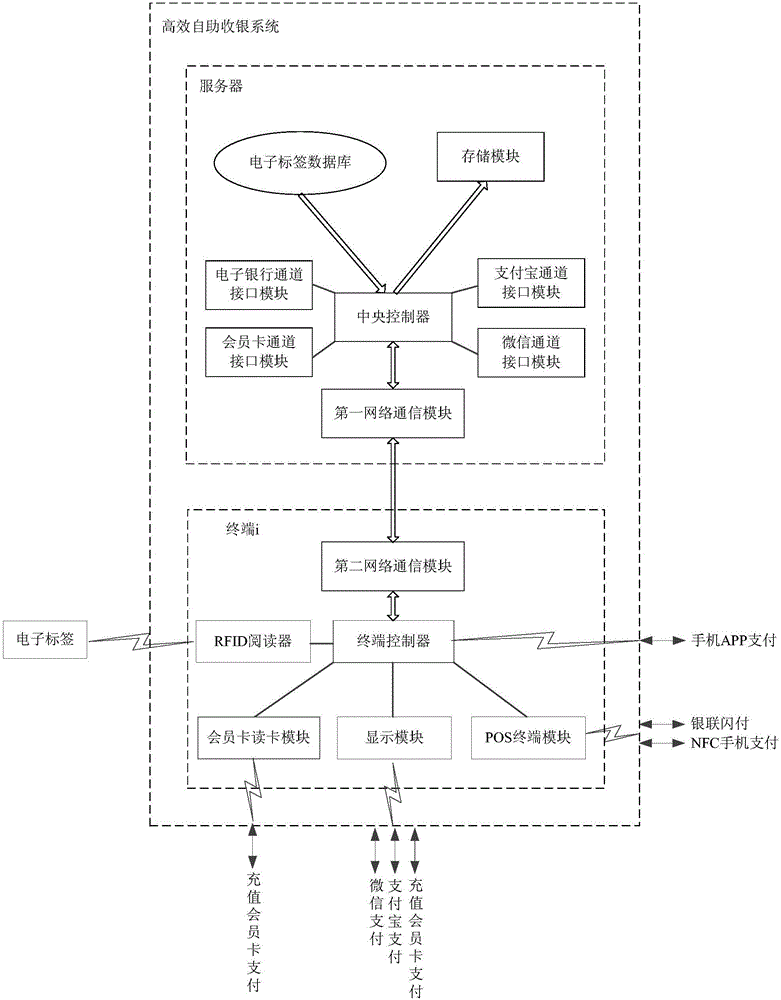

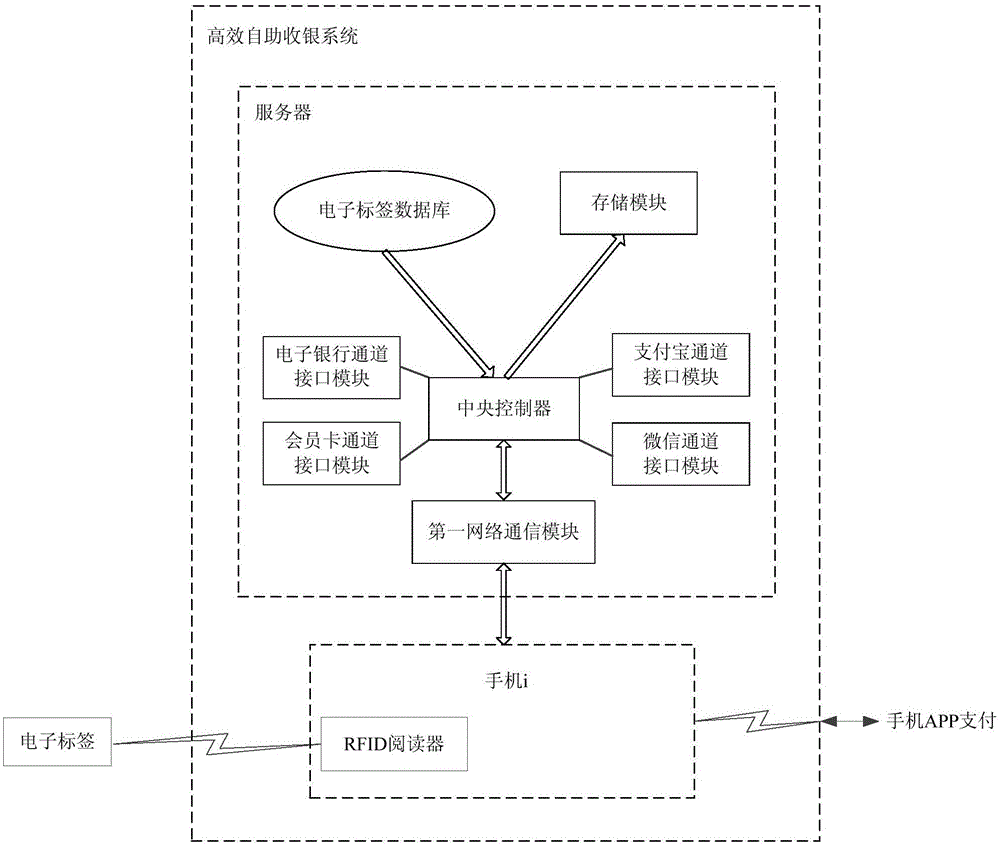

Efficient self-service cashing system and method

InactiveCN105976542AConvenient anti-theft monitoring and alarmIncreased security level against theftCash registersPoint-of-sale network systemsPaymentComputer terminal

The present invention relates to a high-efficiency self-service cash register system and method. The system includes a server and several terminals. The server includes an electronic tag database, a central controller and a first network communication module. Get the product electronic tag information, the central controller controls the receipt of the product electronic tag information through the first network communication module, reads the corresponding product detailed information in the electronic tag database and creates a product shopping list and then returns to the terminal, the server controls and establishes the corresponding product through the central controller The payment channel and the information of the payment channel are fed back to the terminal. After receiving the successful payment information, the server controls and updates the status of the electronic tag of the product through the central controller to release the alarm and update the detailed information of the product in the electronic tag database. The system proposed by the invention is compatible with multiple information flow channel communication architectures, and improves efficiency, flexibility, reliability and adaptability.

Owner:BEIJING SCI & TECH LLC

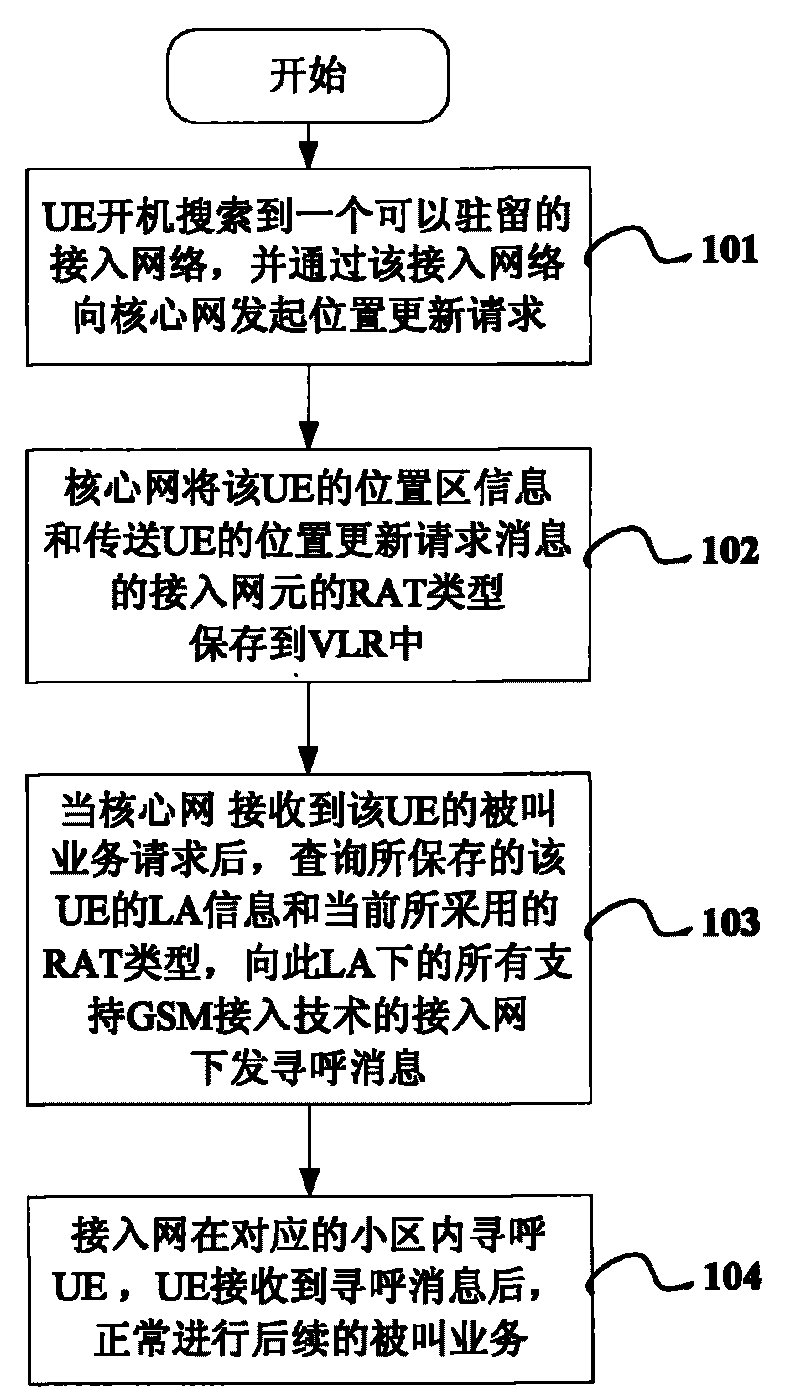

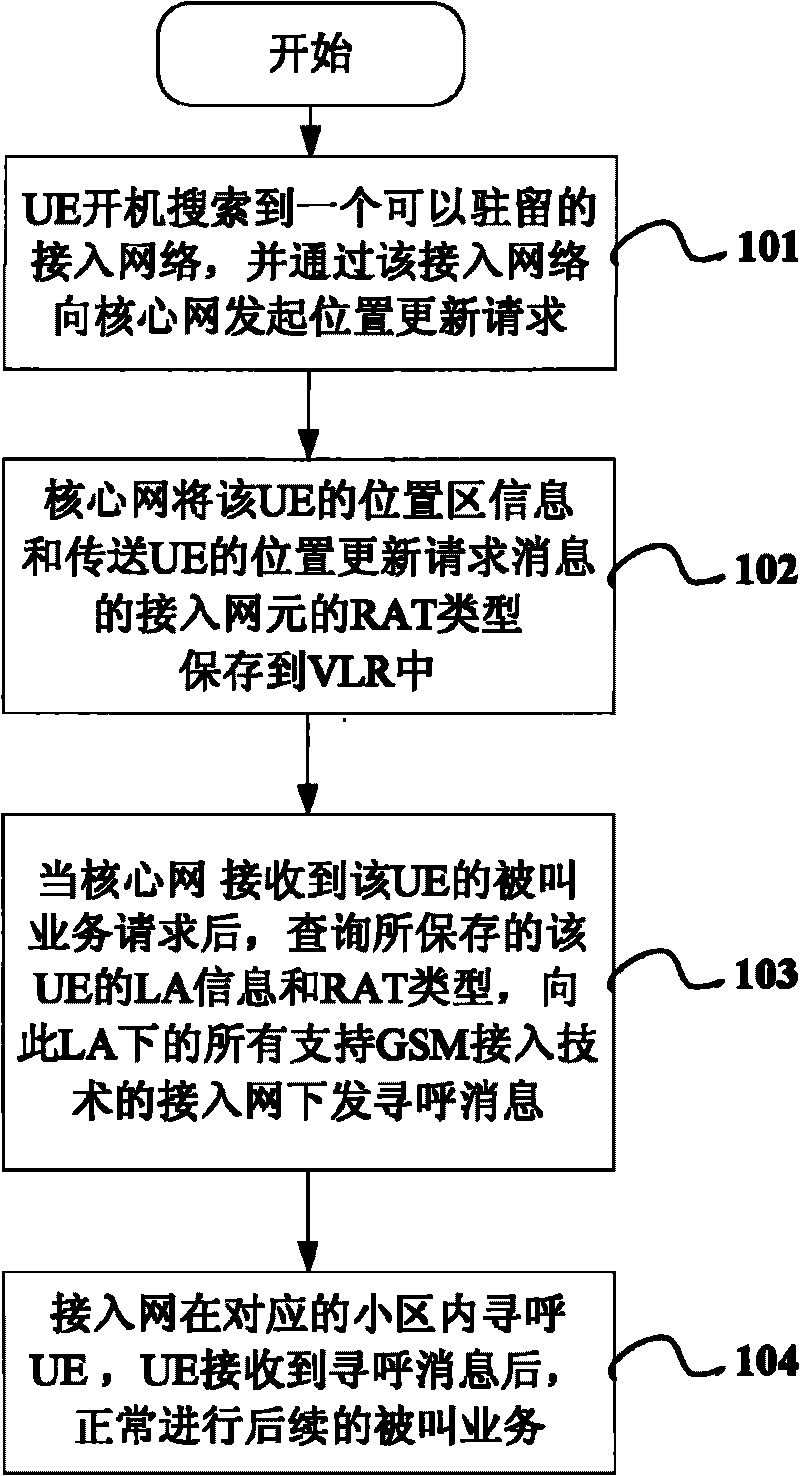

Paging method in mobile communication system

InactiveCN101742676ASave bandwidth resourcesSave processing powerConnection managementAccess networkMobile communication systems

The invention discloses a paging method in a mobile communication system, relating to a mobile communication system. The method of the invention is applicable to a mixed network containing a plurality of standard mobile access networks, comprising the following steps: in the process of starting position updating by user equipment through the access network, a core network stores position information of the user equipment and the wireless access technique type of the access network; after receiving the service request in which the target device is the user equipment, the core network reads the prestored position information of user equipment and the wireless access technique type, and sends paging information to the access networks in support of the wireless access technique type in the position region indicated by the position information; and the access network receiving the paging information pages the user equipment. The technical scheme of the invention effectively saves bandwidth resources and processing load of the mobile network under the premise that the called service of UE is not influenced.

Owner:ZTE CORP

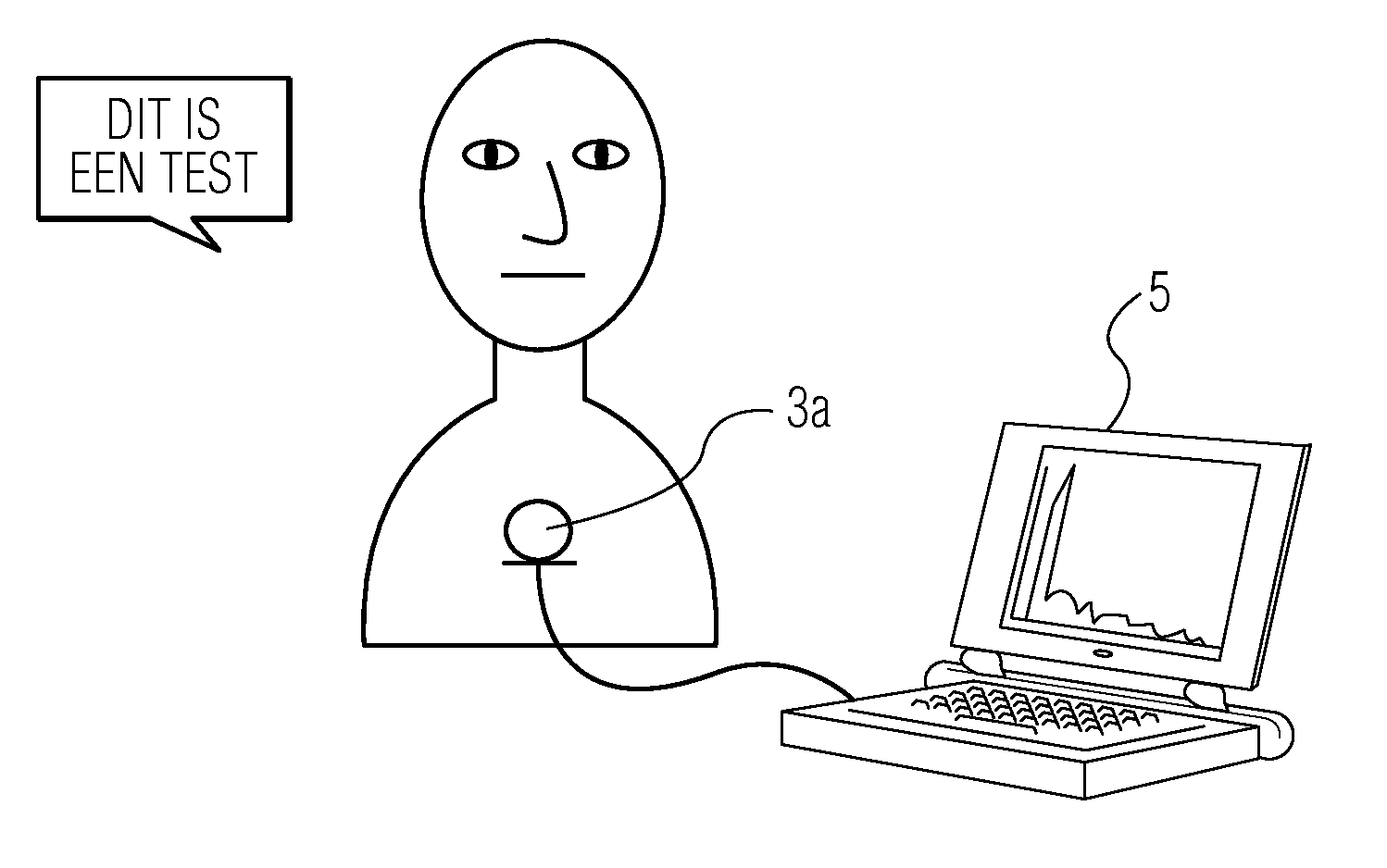

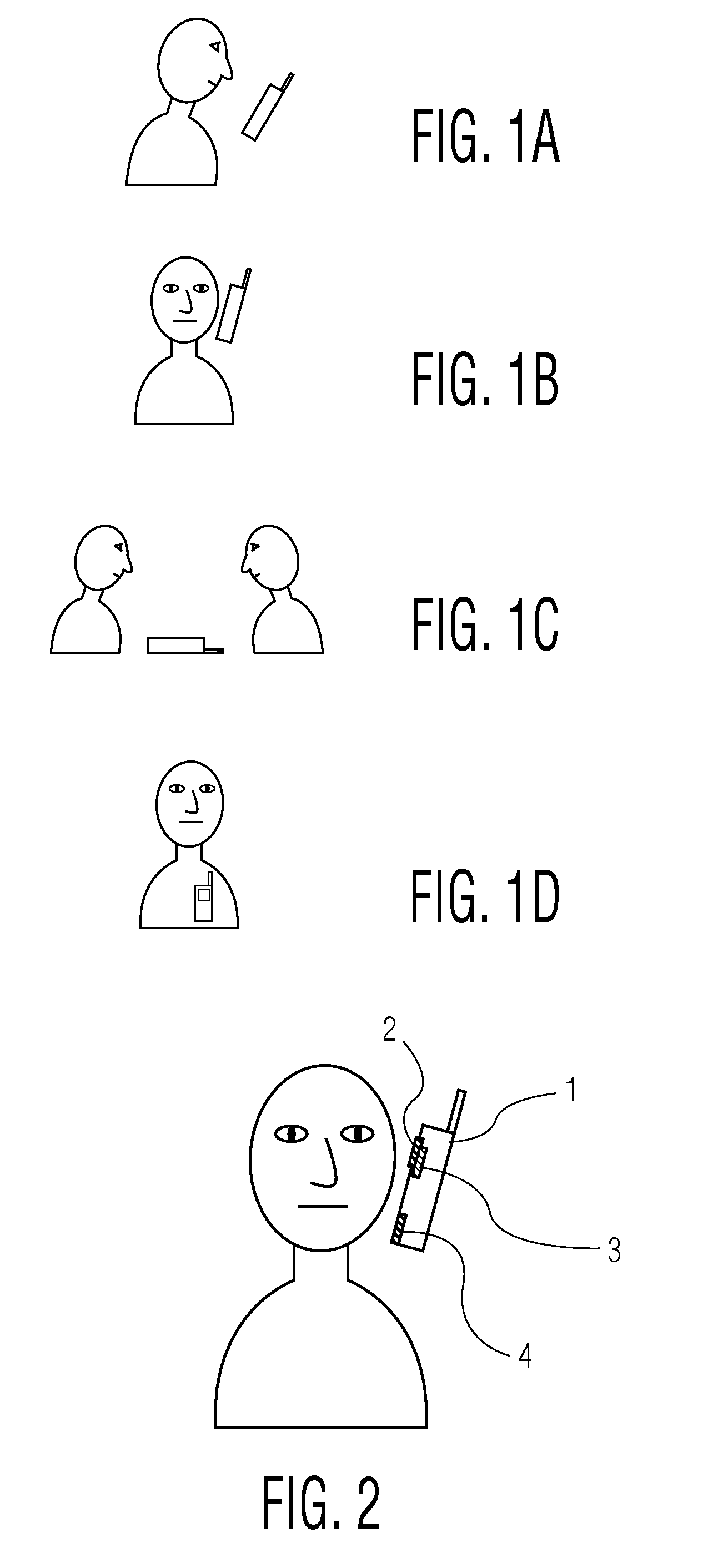

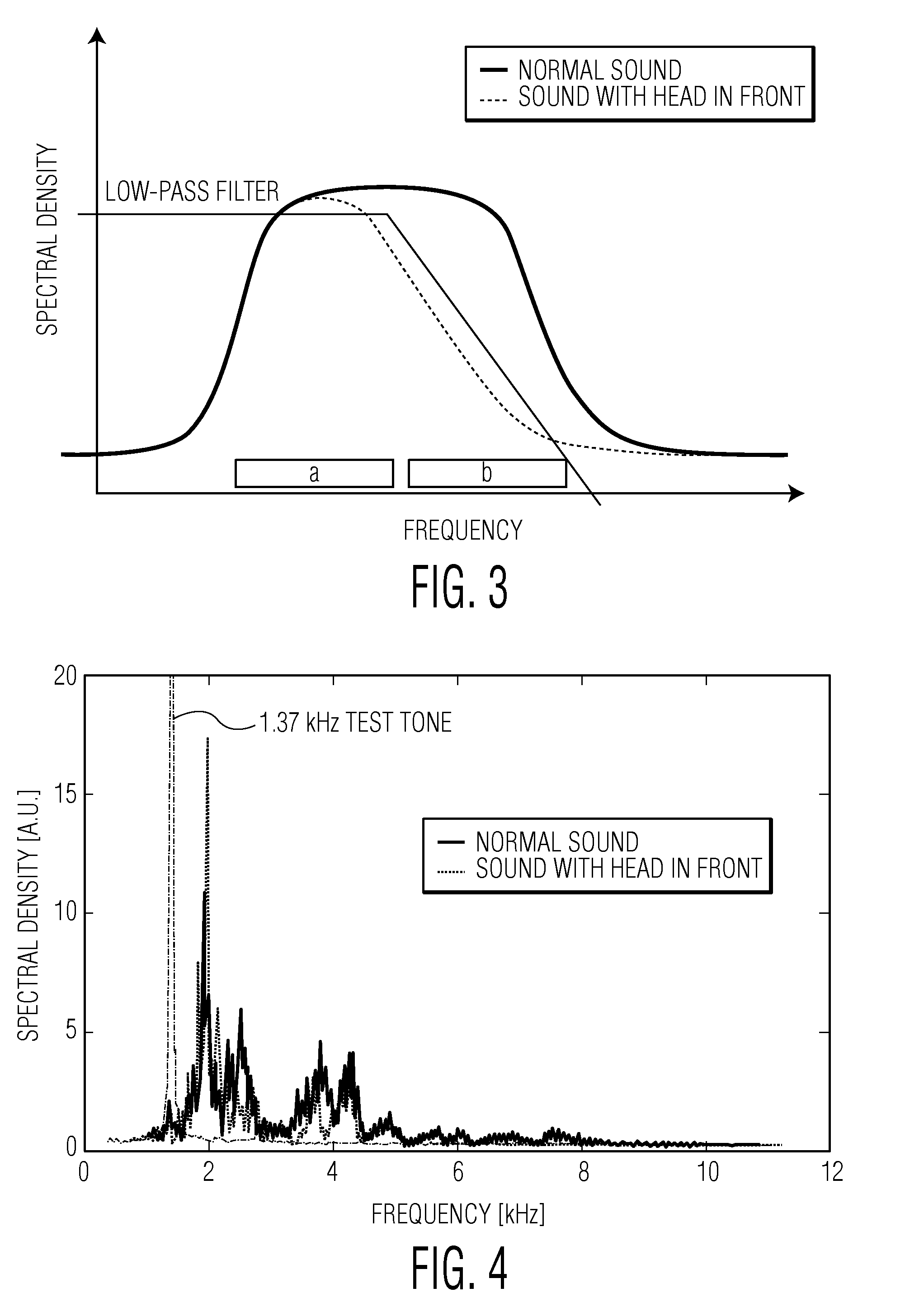

Apparatus and method for detecting usage profiles of mobile devices

InactiveUS20110003615A1Save processing powerEasy to handleDevices with sensorSubstation equipmentProximity sensorFrequency spectrum

A proximity sensor arrangement is provided comprising at least one first and at least one second acoustic transducer and at least one comparing means. The acoustic transducers are adapted to receive acoustic signals and convert the received acoustic signals into electric signals. The comparing means are adapted to compare the spectra received by the acoustic transducers. If the device comprising the proximity sensor arrangement is held at a user's ear, the signal received by the covered microphone is low-pass filtered due to human tissue and / or the presence of the human head, resulting in a spectral difference between several microphones. Furthermore a method is provided comprising the steps of receiving an acoustic signal at least two locations distant from each other. In a second step, said received acoustic signals are converted into electric signals. Subsequently, the actual proximity and / or coverage situation is deduced from the spectral difference between the electric signals.

Owner:KNOWLES ELECTRONICS ASIA

Ultra wide band power save

ActiveUS7689843B2Improve battery lifeMore powerPower managementEnergy efficient ICTWide bandBattery capacity

Owner:MICROSOFT TECH LICENSING LLC

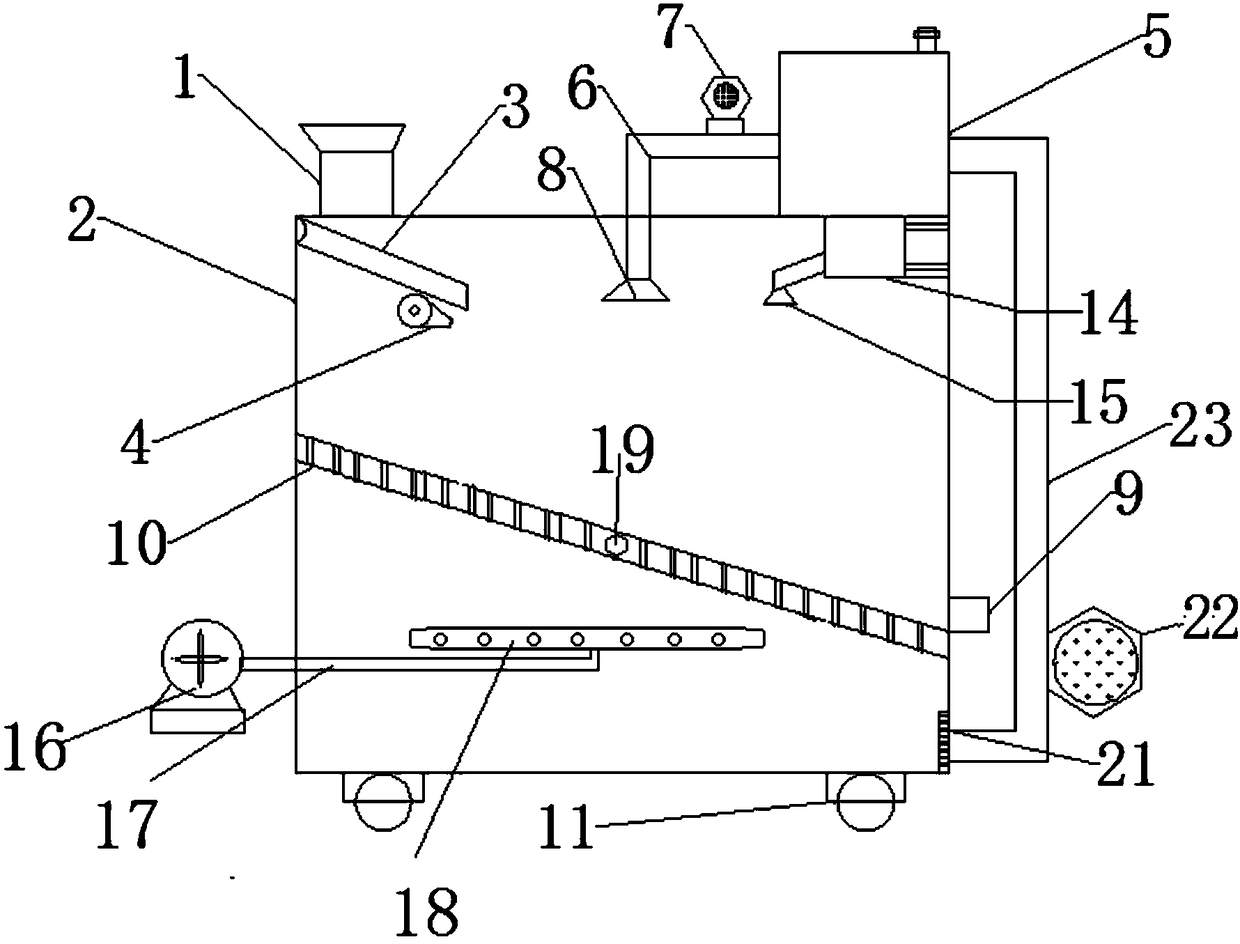

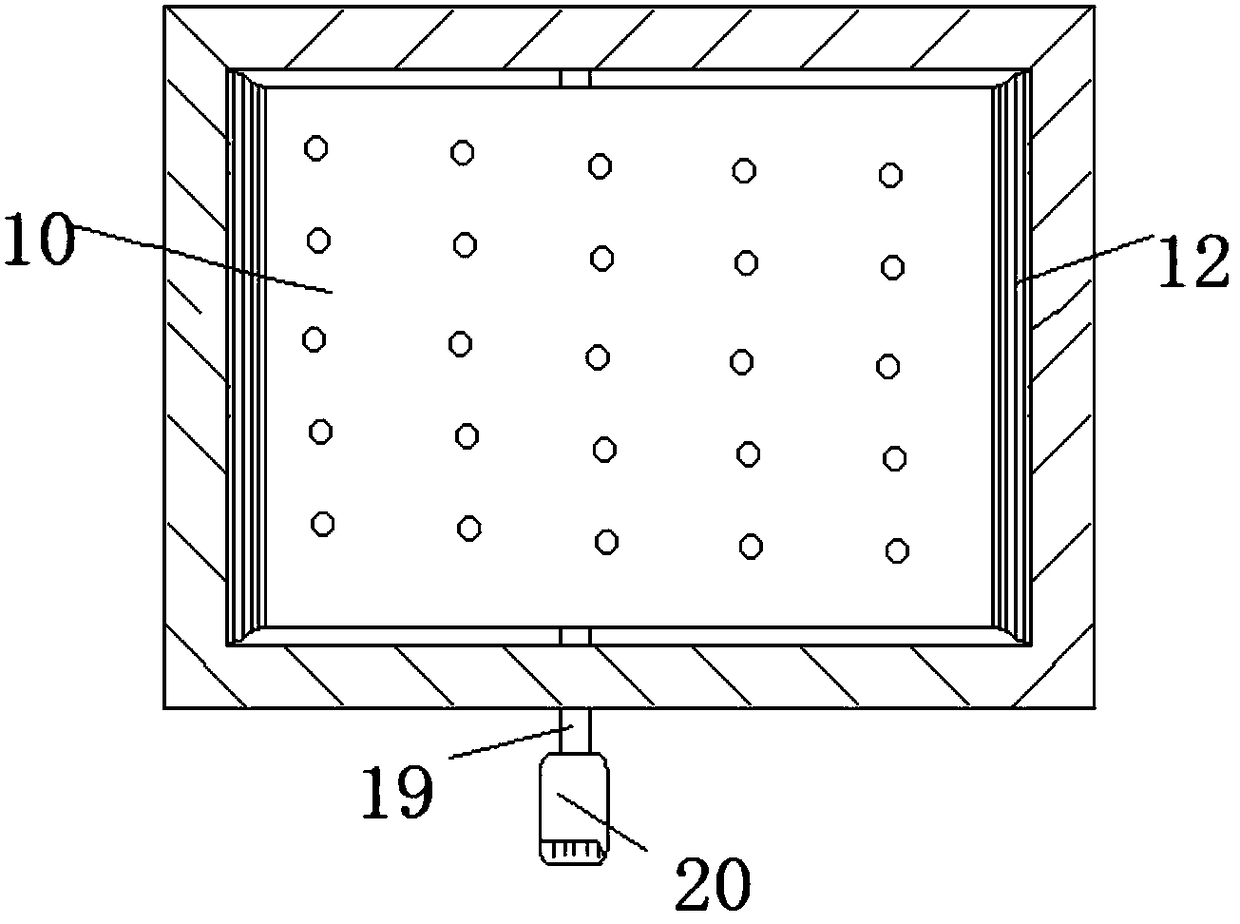

Ore efficient aeration vibration cleaning device

The invention discloses an ore efficient aeration vibration cleaning device which comprises a feeding pipe, a treatment box, a material shake plate, a water storage box, a water spray pipe, a screen plate, a dust collector, an aeration machine, a center rotating shaft and a backflow pipe. The feeding pipe is arranged at the top end of the treatment box. The material shake plate is further arrangedin the treatment box. The water storage box is mounted at the top end of the treatment box. The water spray pipe is arranged on the water storage box. A spray head is arranged at the outlet end of the water spray pipe. The dust collector is mounted on the inner wall of the top end of the treatment box. The screen plate is obliquely arranged in the treatment box. An ore discharging pipe is arranged on the side wall of the treatment box. The center rotating shaft is fixedly arranged at the center position of the screen plate. One end of the center rotating shaft penetrates the side wall of thetreatment box to be connected with an output shaft of a forward and reverse rotation motor. The treatment box communicates with the aeration machine. According to the ore efficient aeration vibrationcleaning device, safety is improved; the ore surfaces can be cleaned conveniently; the work efficiency and effect are improved; water is cyclically used; energy is saved; the use cost is reduced; thestructure is simple; use is convenient; and popularization is facilitated.

Owner:ZHENGZHOU GERUITA ELECTRONICS INFORMATION TECH CO LTD

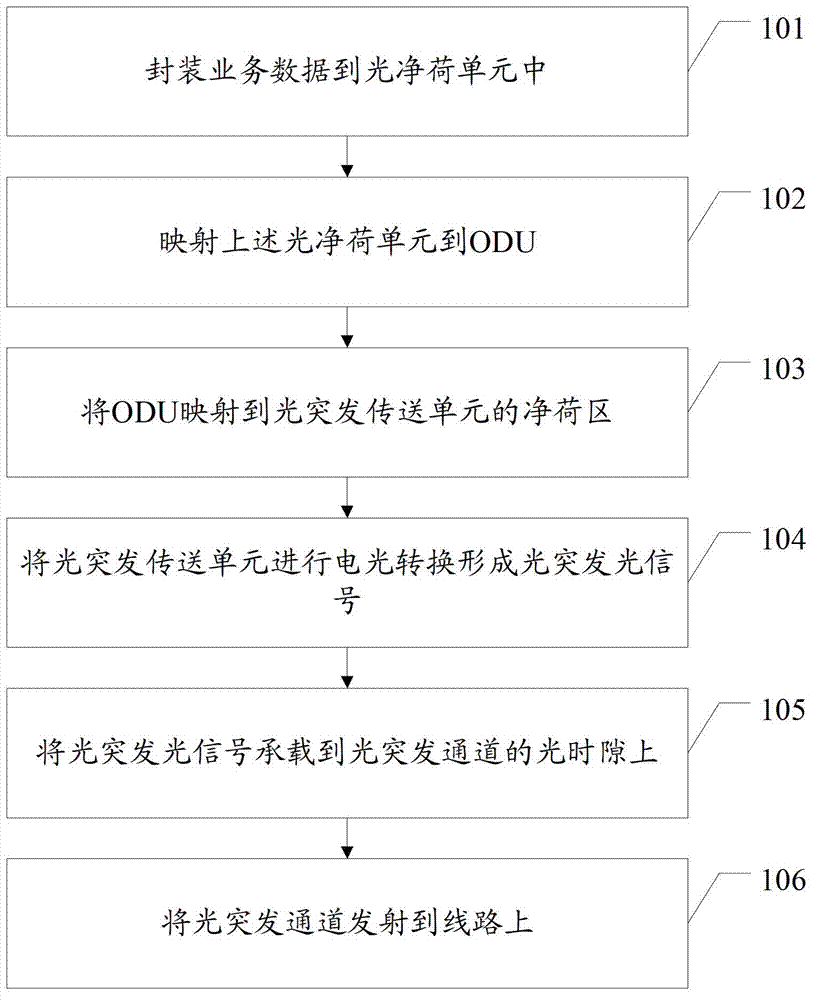

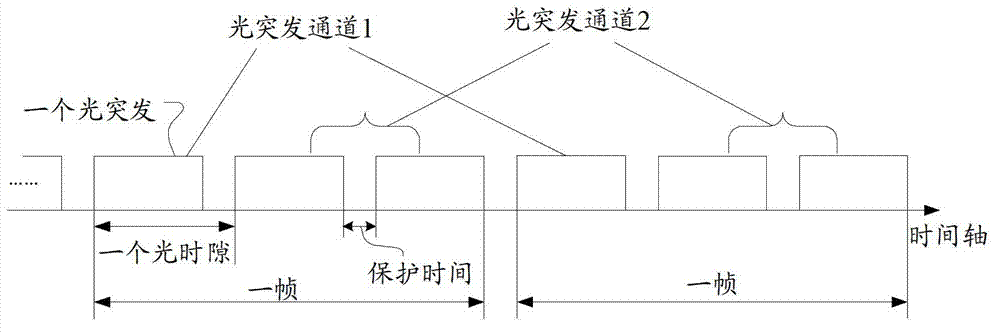

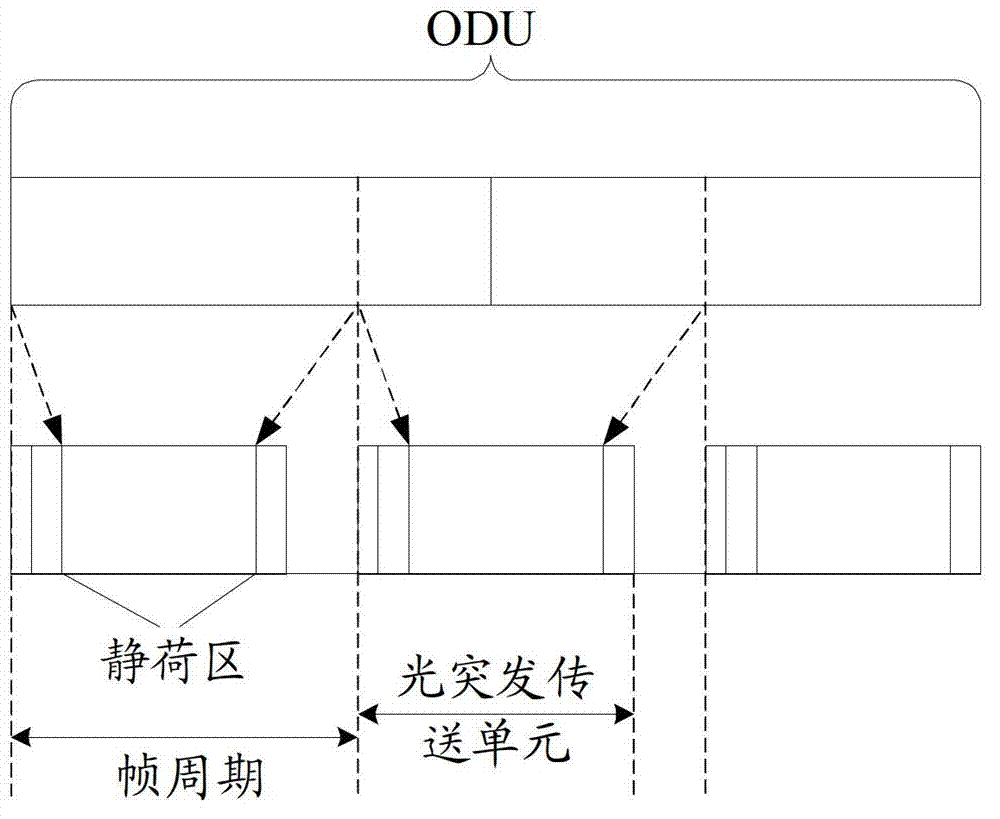

Data processing method in optical transport network, and related device and system

ActiveCN102783178AEasy to handleReduce processing delayMultiplex system selection arrangementsTime-division multiplexChannel dataTime delays

Provided are a data processing method in an optical transport network, and a related device and system. The data processing method in an optical transport network includes: encapsulating service data into an optical payload unit; mapping the optical payload unit to an optical channel data unit; mapping the optical channel data unit to the payload area of an optical burst transport unit; photo-electrically converting the optical burst transport unit to form an optical burst optical signal; bearing the optical burst optical signal onto the optical slot of an optical burst channel; and transmitting the optical burst channel onto a line. The technical solutions provided in the present invention can simplify the data processing process effectively and reduce the data processing time delay.

Owner:HUAWEI TECH CO LTD

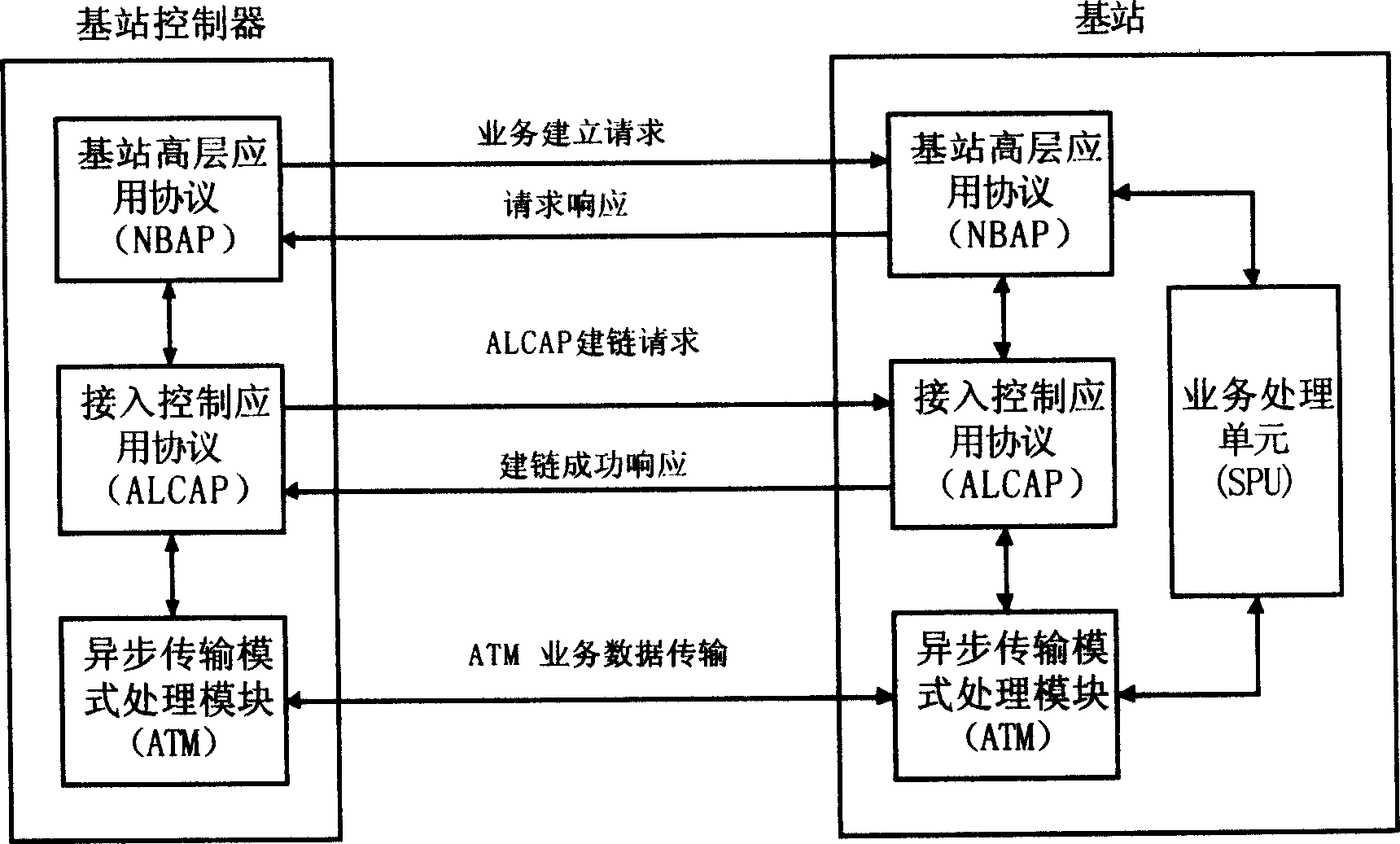

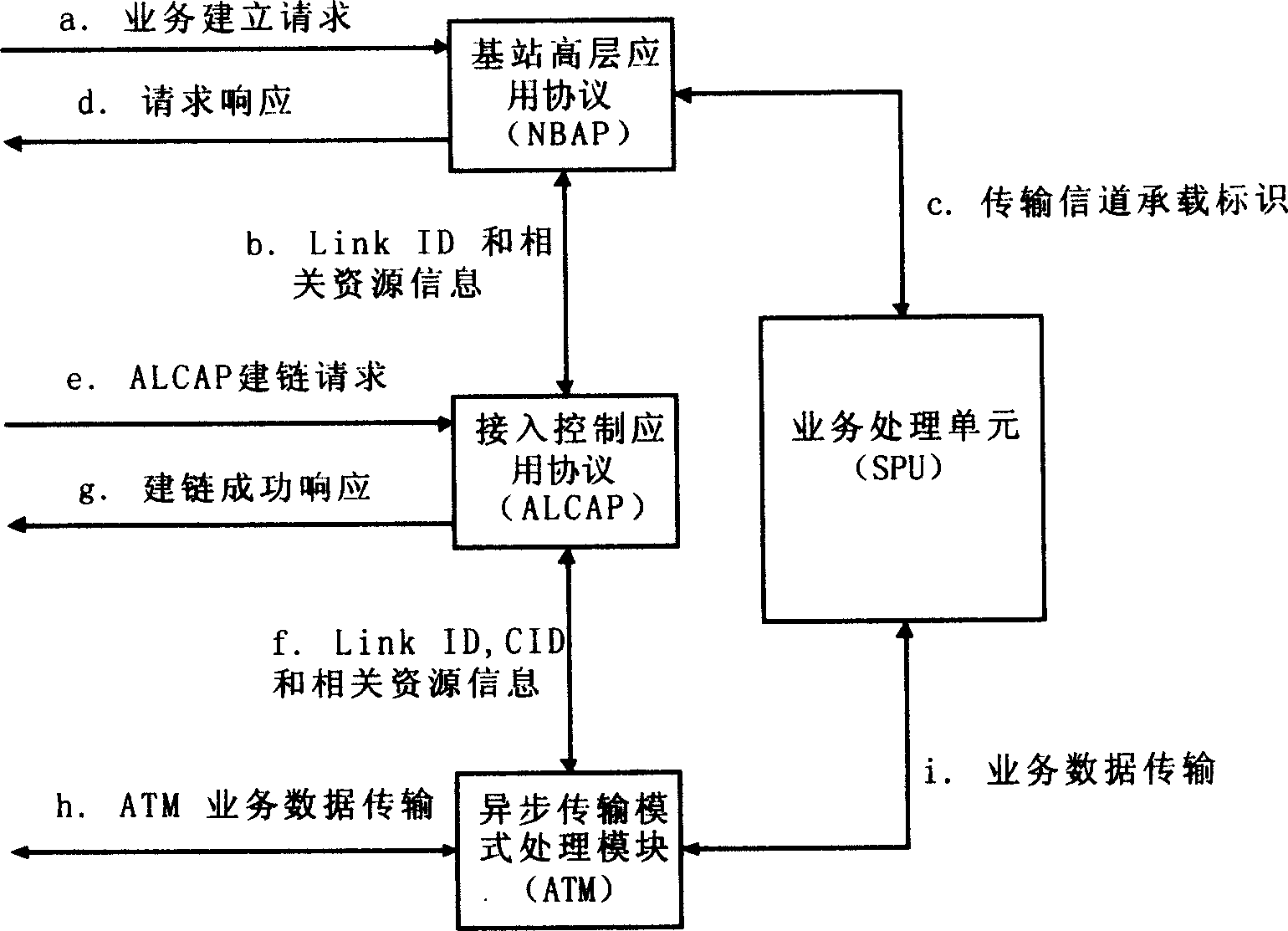

A method for external link identification mapping and processing within base station

InactiveCN1545288AImprove processing speed and processing efficiencySave processing steps and timeTransmissionALCAPData Linkage

The invention is a base station inner and outer link mapping and processing method, used for wireless access net base station in an ATM transmission based mobile communication system and for ALL2 data linkage between base station controllers. It sets a parameter, as well as Binding ID, processing sub-course index number, transmission channel supporting identification, and other parameters, where their byte number can be different but their values all are equal to the set parameter's. Because it uses only a parameter in all the courses: NBAP high-layer signaling course, ALCAP link setup course, etc, it can omit many index processing courses of mapping relations, accordingly enhancing internal data processing speed and efficiency.

Owner:ZTE CORP

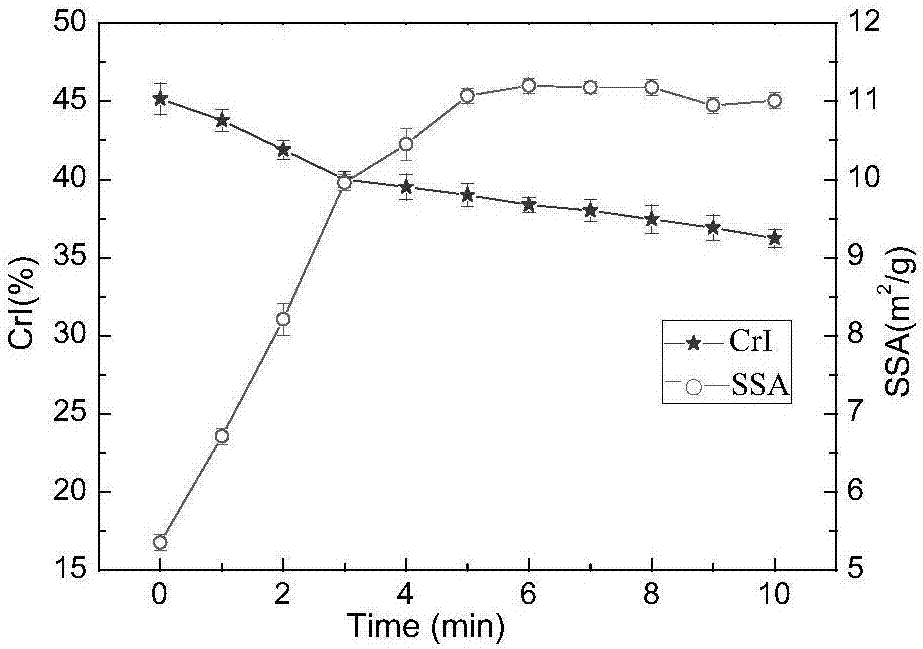

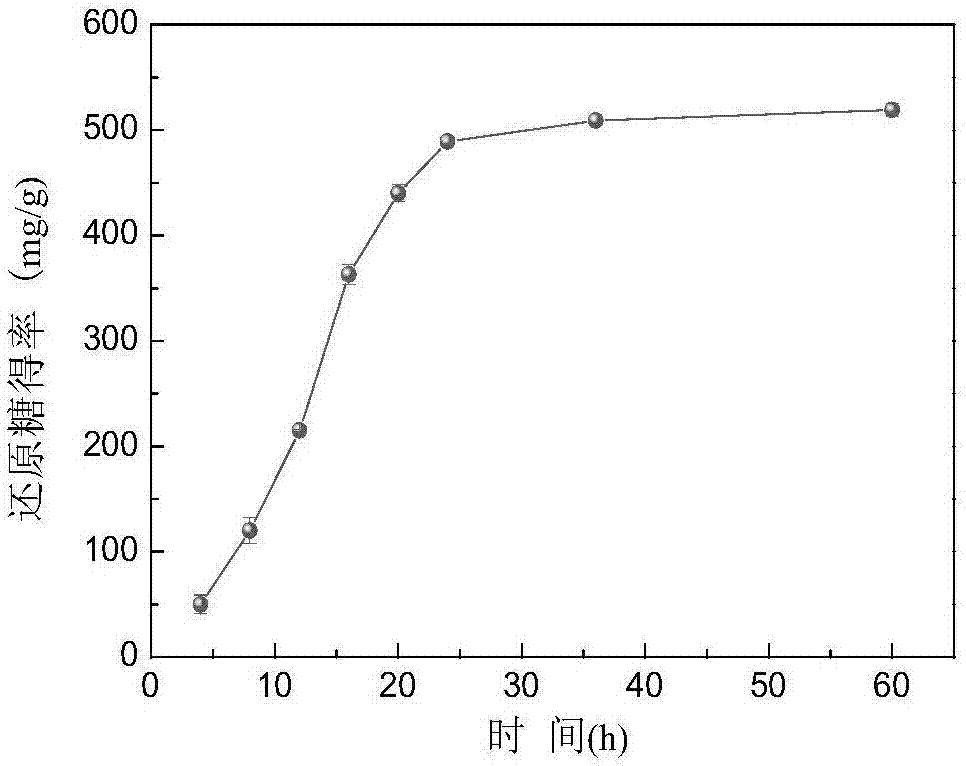

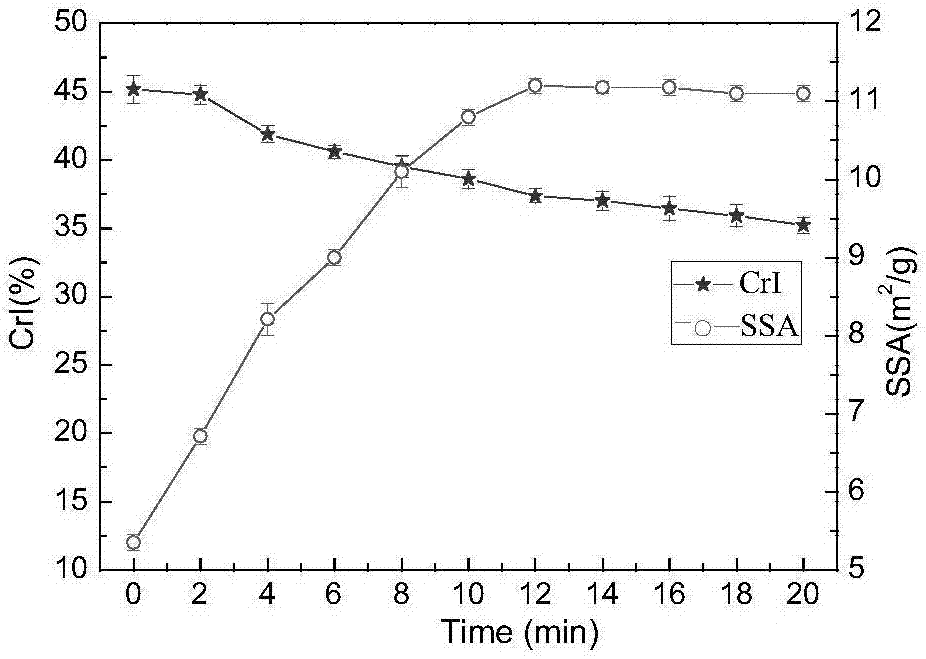

Method for promoting enzymolysis saccharification of lignocellulose

The invention relates to a method for promoting enzymolysis saccharification of lignocellulose. The method comprises the steps of soaking hair in an acetic acid solution which is 85-95 DEG C firstly, regulating the pH value to be 6-7, conducting filtration, and drying filtrate to obtain hair protein powder; then smashing and screening lignocellulose biomass to obtain lignocellulose biomass powder; soaking the lignocellulose biomass powder in deionized water for irradiation treatment; extracting the lignocellulose biomass powder after irradiation treatment, adding a citric acid-sodium citrate buffer solution, conducting uniform mixing to obtain a mixed solution, and adding cellulose and the hair protein powder to the mixed solution to obtain enzymatic hydrolysate; and conducting enzymatic hydrolysis reaction on the enzymatic hydrolysate for 3-24 h at 30-45 DEG C to promote enzymolysis saccharification of lignocellulose. The structure of lignocellulose is changed through irradiation treatment to facilitate enzymolysis saccharification, the hair protein powder is used as an enzymolysis assistant, non-specificity absorption of cellulose by lignin is reduced, and higher efficiency can be realized within a shorter period of time.

Owner:YULIN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com