Patents

Literature

2871 results about "Ethanolamine" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ethanolamine (2-aminoethanol, monoethanolamine, ETA, or MEA) is an organic chemical compound with the formula HOCH₂CH₂NH₂ (C₂H₇NO). The molecule is bifunctional, containing both a primary amine and a primary alcohol. Ethanolamine is a colorless, viscous liquid with an odor reminiscent of ammonia. Its derivatives are widespread in nature; e.g., lipids, as precursor of a variety of N-acylethanolamines (NAEs), that modulate several animal and plant physiological processes such as seed germination, plant–pathogen interactions, chloroplast development and flowering, as well as precursor, combined with arachidonic acid (C₂₀H₃₂O₂; 20:4, ω-6), to form the endocannabinoid Anandamide (AEA: C₂₂H₃₇NO₂; 20:4, ω-6).

Proteinic drug delivery system using membrane mimetics

A mixed liposome pharmaceutical formulation with multilamellar vesicles, comprises a proteinic pharmaceutical agent, water, an alkali metal lauryl sulphate in a concentration of from 1 to 10 wt. / wt. %, at least one membrane-mimetic amphiphile and at least one phospholipid. The membrane-mimetic amphiphile is hyaluronic acid, pharmaceutically acceptable salts of hyaluronic acid, lauramidopropyl betain, lauramide monoisopropanolamide, sodium cocoamphopropionate, bishydroxypropyl dihydroxypropyl stearammonium chloride, polyoxyethylene dihydroxypropyl stearammonium chloride, dioctadecyldimethylammonium chloride, sulphosuccinates, stearamide DEA, gamma-linoleic acid, borage oil, evening of primrose oil, monoolein, sodium tauro dihydro fusidate, fusidic acid, alkali metal isostearyl lactylates, alkaline earth metal isostearyl lactylates, panthenyl triacetate, cocamidopropyl phosphatidyl PG-diammonium chloride, stearamidopropyl phosphatidyl PG-diammonium chloride, borage amidopropyl phosphatidyl PG-diammonium chloride, borage amidopropyl phosphatidylcholine, polysiloxy pyrrolidone linoleyl phospholipid, trihydroxy-oxo-cholanylglycine and alkali metal salts thereof, and octylphenoxypolythoxyethanol, polydecanol X-lauryl ether, polydecanol X-oleyl ether, wherein X is from 9 to 20, or combinations thereof. The phospholipid is phospolipid GLA, phosphatidyl serine, phosphatidylethanolamine, inositolphosphatides, dioleoylphosphatidylethanolamine, sphingomyelin, ceramides, cephalin, triolein, lecithin, saturated lecithin and lysolecithin, or a combination thereof. The amount of each membrane mimetic amphiphile and phospholipid is present 1 to 10 wt. / wt. % of the total formulation, and the total concentration of membrane mimetic amphiphiles and phospholipids is less than 50 wt. / wt. % of the formulation.

Owner:GENEREX PHARMA

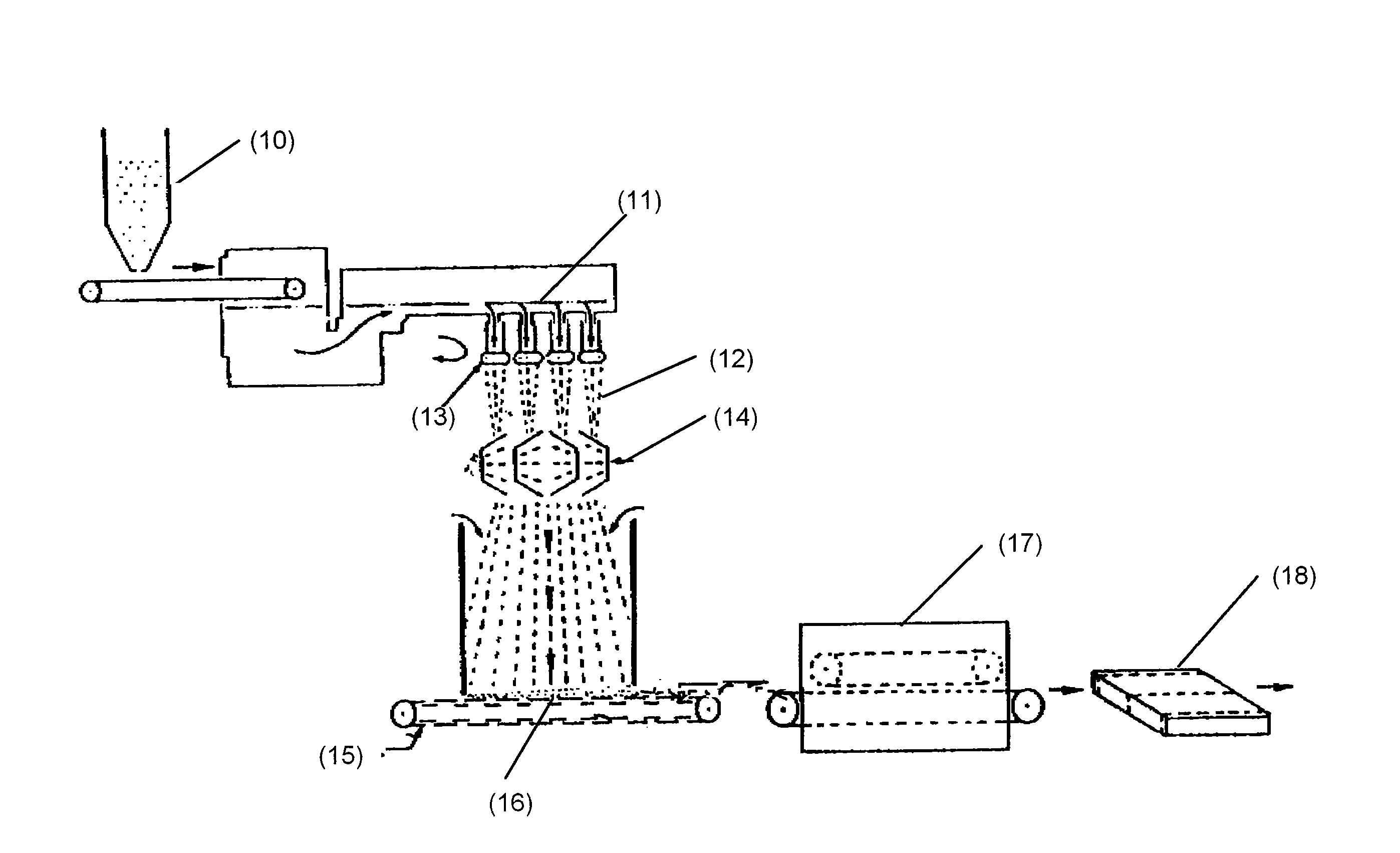

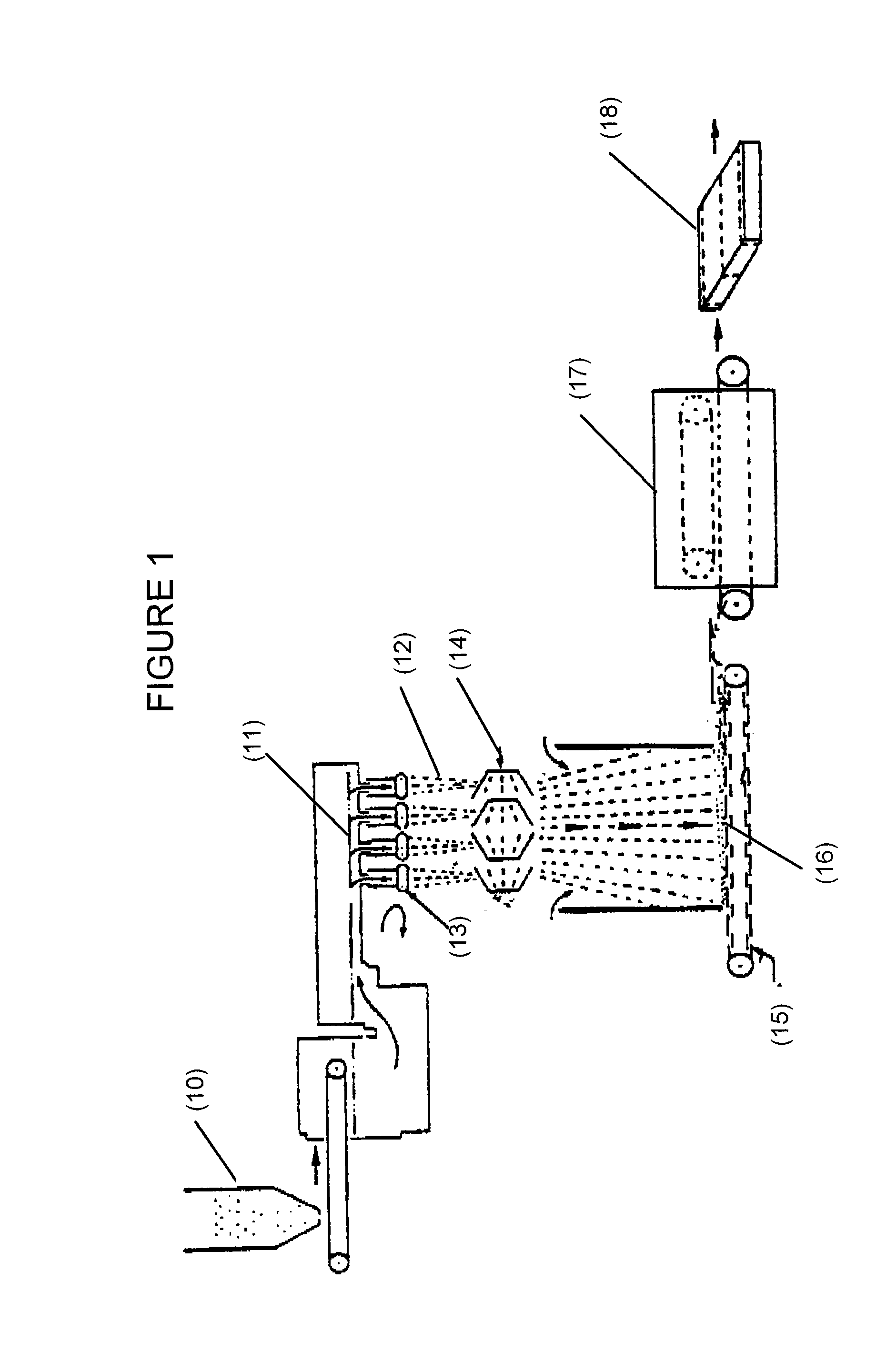

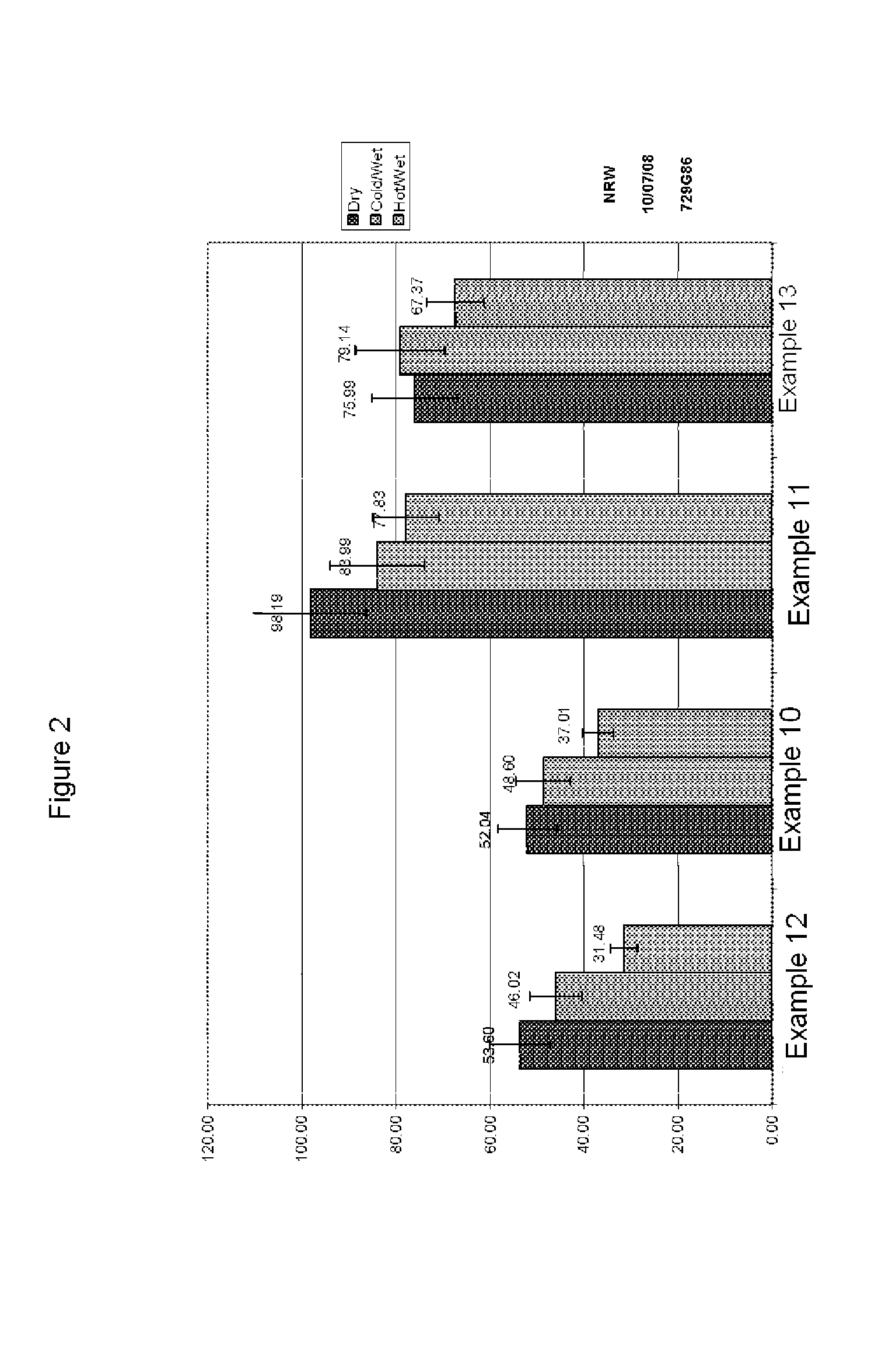

Formaldehyde free binder

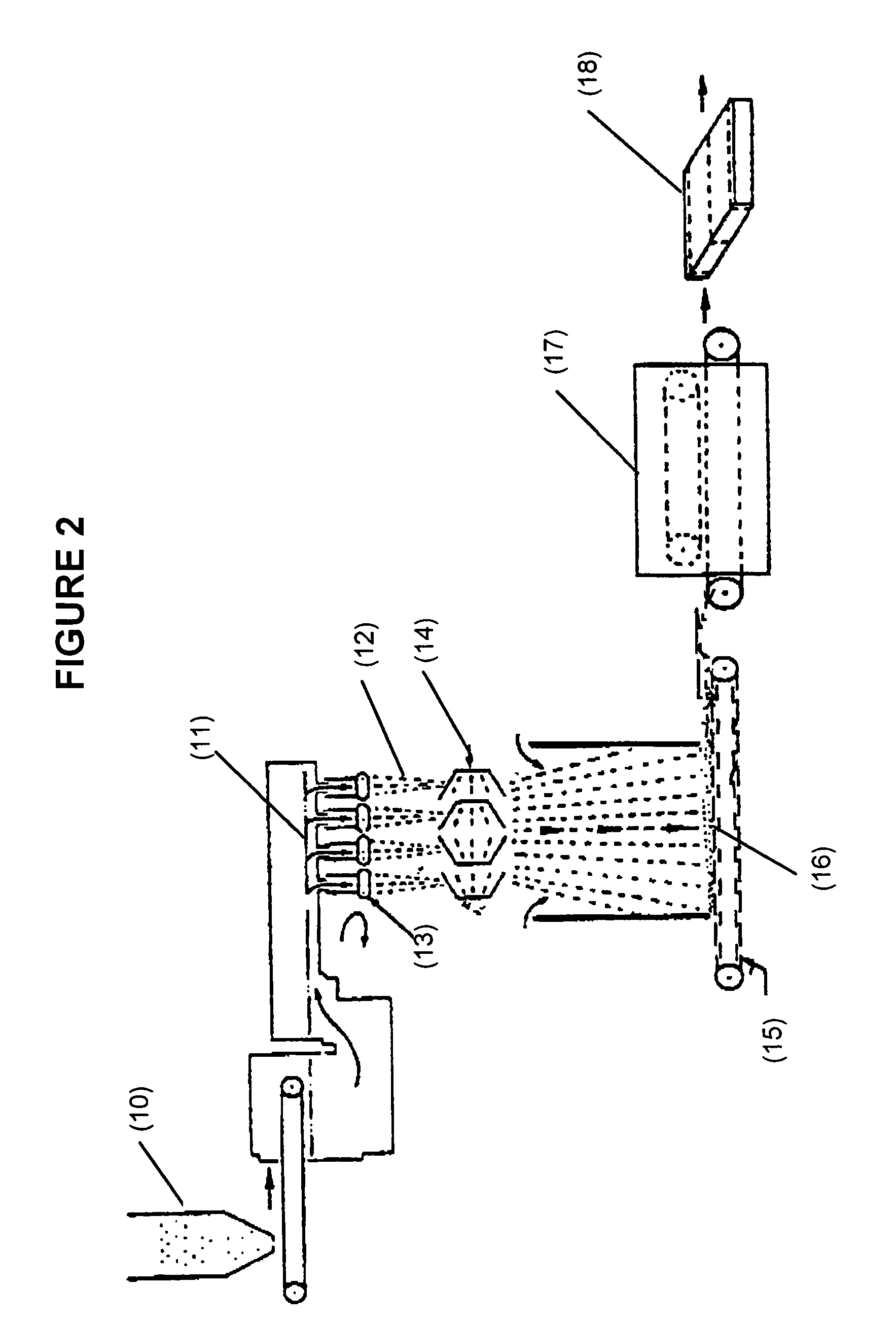

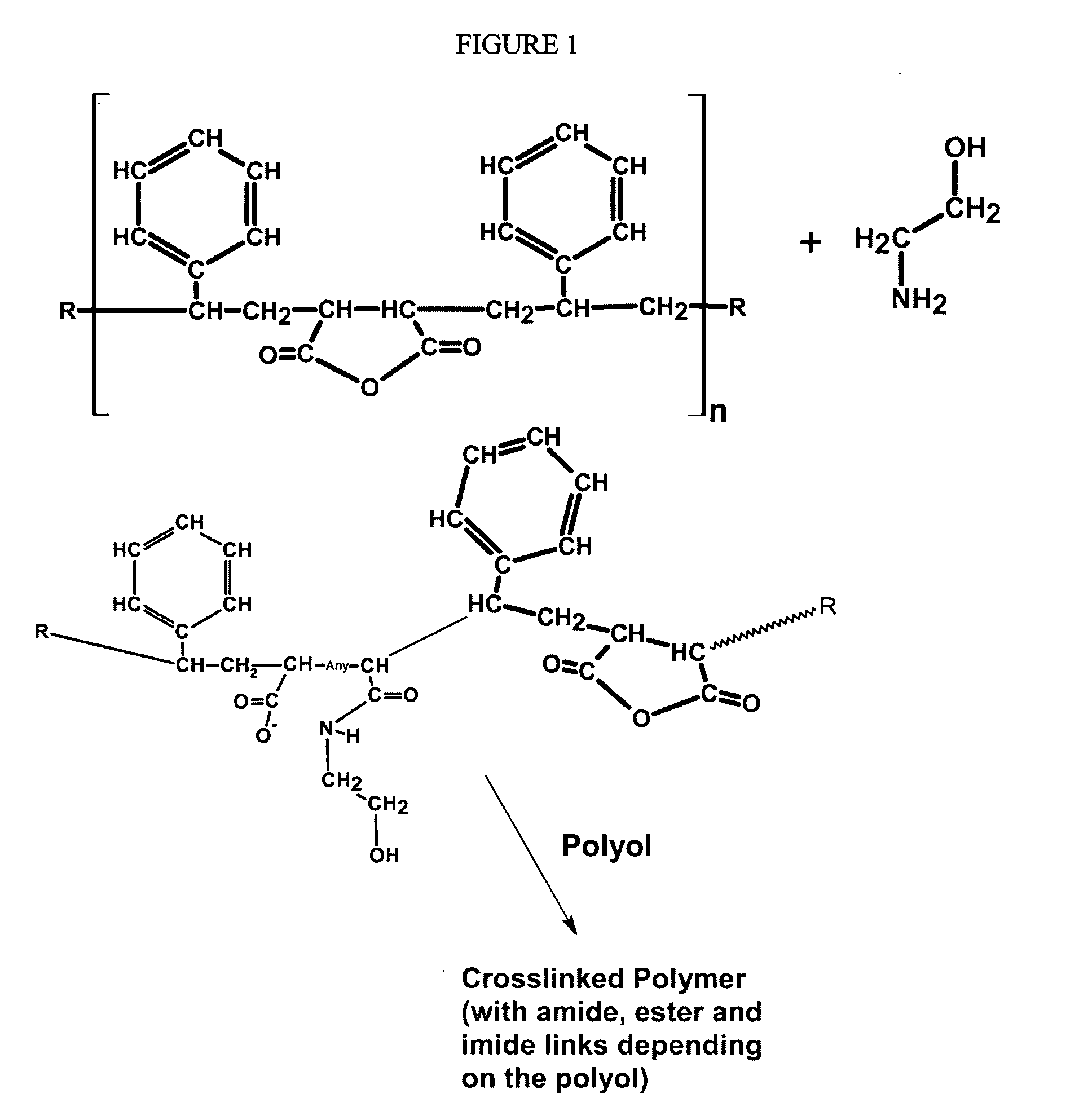

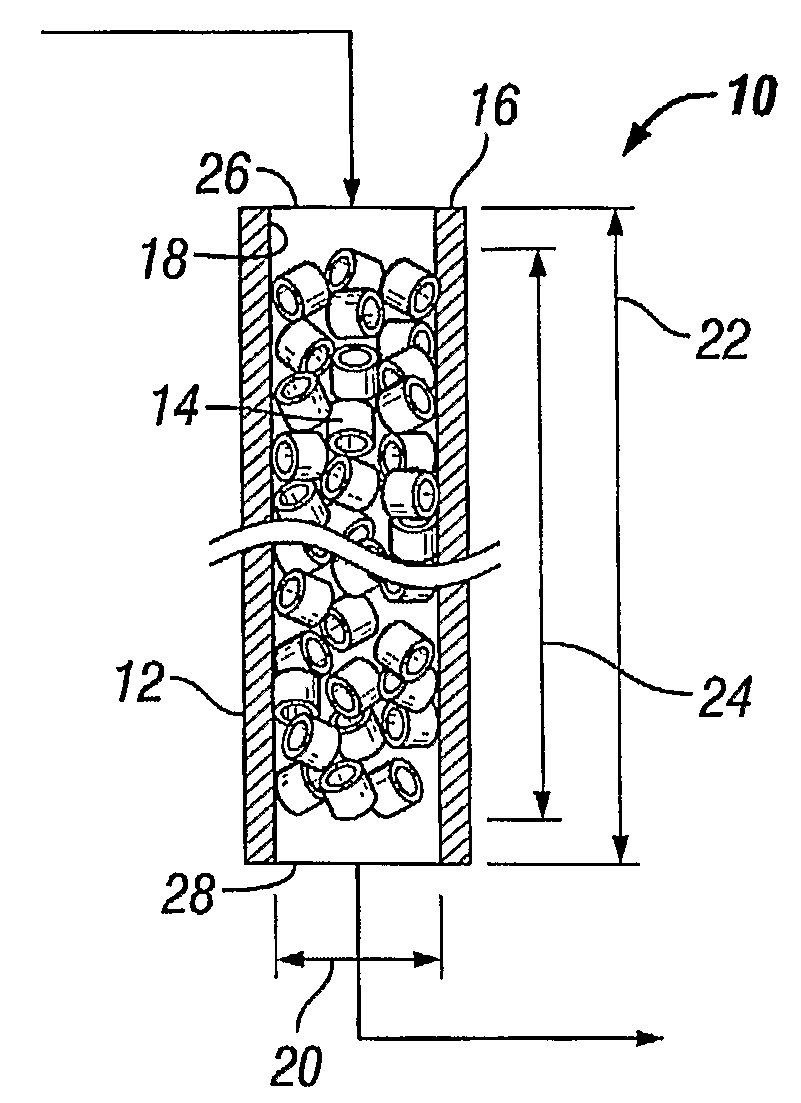

An aqueous binder composition, useful for making fiber products, especially fiberglass insulation, comprising an aqueous substantially alkaline (pH of at least 5.0) solution of a polyol and a hydrolyzed (solubilized) copolymer of maleic anhydride and a vinyl aromatic compound, preferably styrene (i.e., a SMA copolymer); the copolymer is solubilized using ammonia, an ammine, a primary alkanolamines (preferably monoethanolamine), a secondary alkanolamine (preferably diethanolamine (DEA)), a tertiary alkanolamine (preferably triethanolamine (TEA)), or a mixture thereof and the binder composition is cured as a consequence of cross-linking, esterification reactions between pendant carboxyls on the solubilized (hydrolyzed) copolymer (SMA) chains and hydroxyl groups of the polyol, including the diethanolamine and / or triethanolamine preferably used in the solubilization of the SMA.

Owner:GEORGIA PACIFIC CHEM LLC

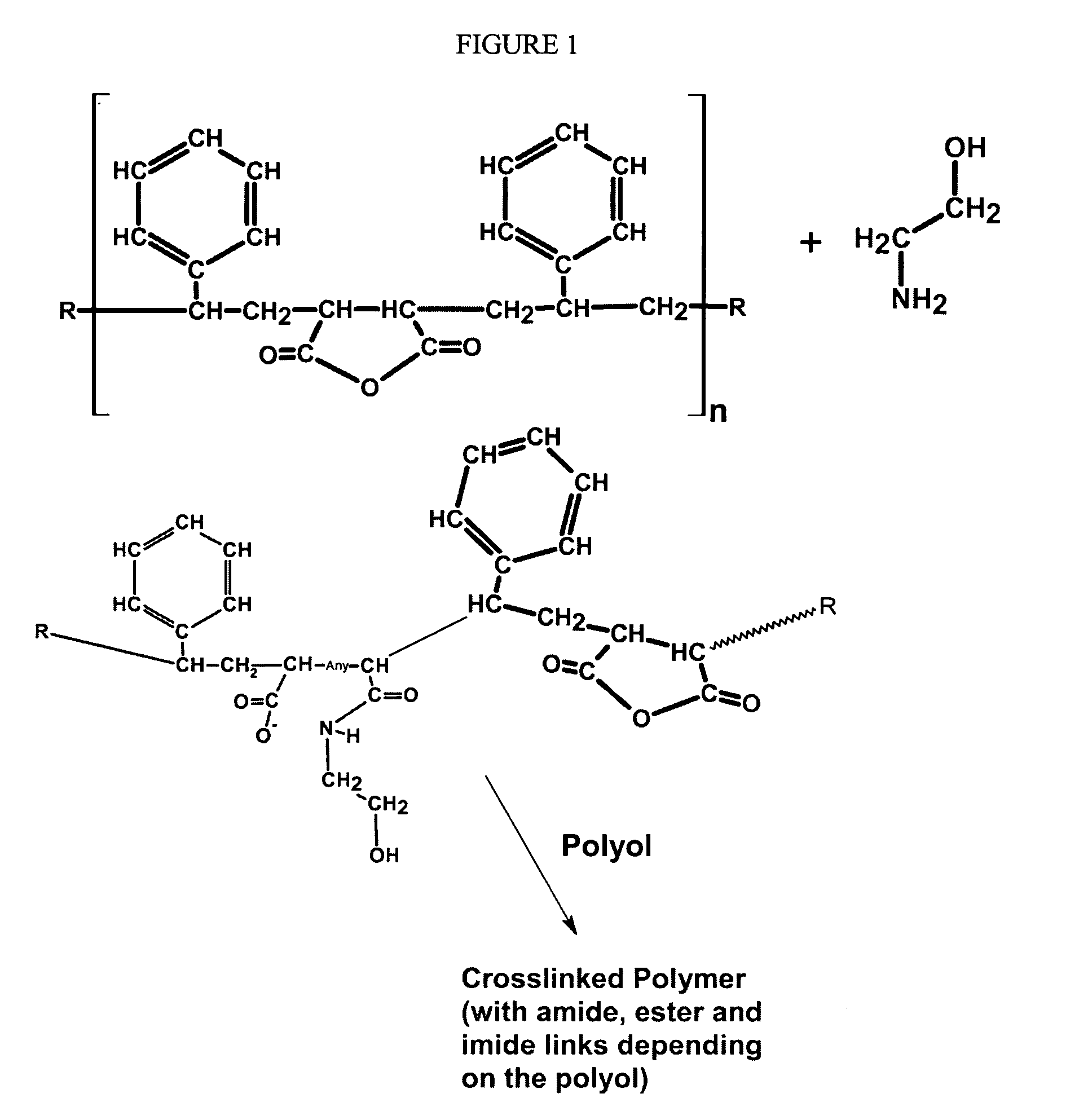

Formaldehyde free binder

An aqueous, formaldehyde-free binder composition comprising a modified copolymer of maleic anhydride and a vinyl aromatic compound such as styrene, the copolymer being modified by reaction with a primary alkanolamine, such as monoethanolamine (MEA), to produce a modified copolymer that is self-curing and cures as a consequence of cross-linking, esterification reactions between pendant carboxyls and hydroxyl groups on the solubilized (hydrolyzed) modified copolymer chains; the invention also relates to the corresponding method of using the binder composition for making fiber products, especially fiberglass insulation.

Owner:GEORGIA PACIFIC CHEM LLC

Formaldehyde free binder

An aqueous, formaldehyde-free binder composition comprising a modified copolymer of maleic anhydride and a vinyl aromatic compound such as styrene, the copolymer being modified by reaction with a primary alkanolamine, such as monoethanolamine (MEA), to produce a modified copolymer that is self-curing and cures as a consequence of cross-linking, esterification reactions between pendant carboxyls and hydroxyl groups on the solubilized (hydrolyzed) modified copolymer chains; the invention also relates to the corresponding method of using the binder composition for making fiber products, especially fiberglass insulation.

Owner:GEORGIA PACIFIC CHEM LLC

Environment-friendly type alkali-free liquid accelerator for sprayed concrete and preparation method thereof

The invention belongs to the technical field of building materials, and in particular relates to an environment-friendly alkali-free liquid quick-setting agent used for shotcrete and a method for preparing the same. The alkali-free liquid quick-setting agent is a light green viscous liquid prepared from aluminum sulfate, sodium fluoride, triethanolamine and polyacrylamide, wherein the aluminum sulfate and the sodium fluoride are main quick-setting components, the aluminum sulfate can significantly reduce the initial setting time of cement, while the sodium fluoride can significantly shorten the final setting time of the cement, promote the formation of a hydrate structure, and improve the shear strength of the concrete and the binding power of a reinforcing steel bar. The triethanolamine shortens the setting time of the concrete to csertain extent and greatly improves the 1d compressive strength of mortar, and the polyacrylamide is an organic tackifying component to improve the thickness of a primarily sprayed layer, improve the bond strength between the concrete and a substrate, reduce the rebound loss in the spraying process, and save materials. The environment-friendly alkali-free liquid quick-setting agent has the advantages of wide source of raw materials, low cost, simple production method, and high production efficiency, and is suitable for industrial mass production.

Owner:TONGJI UNIV

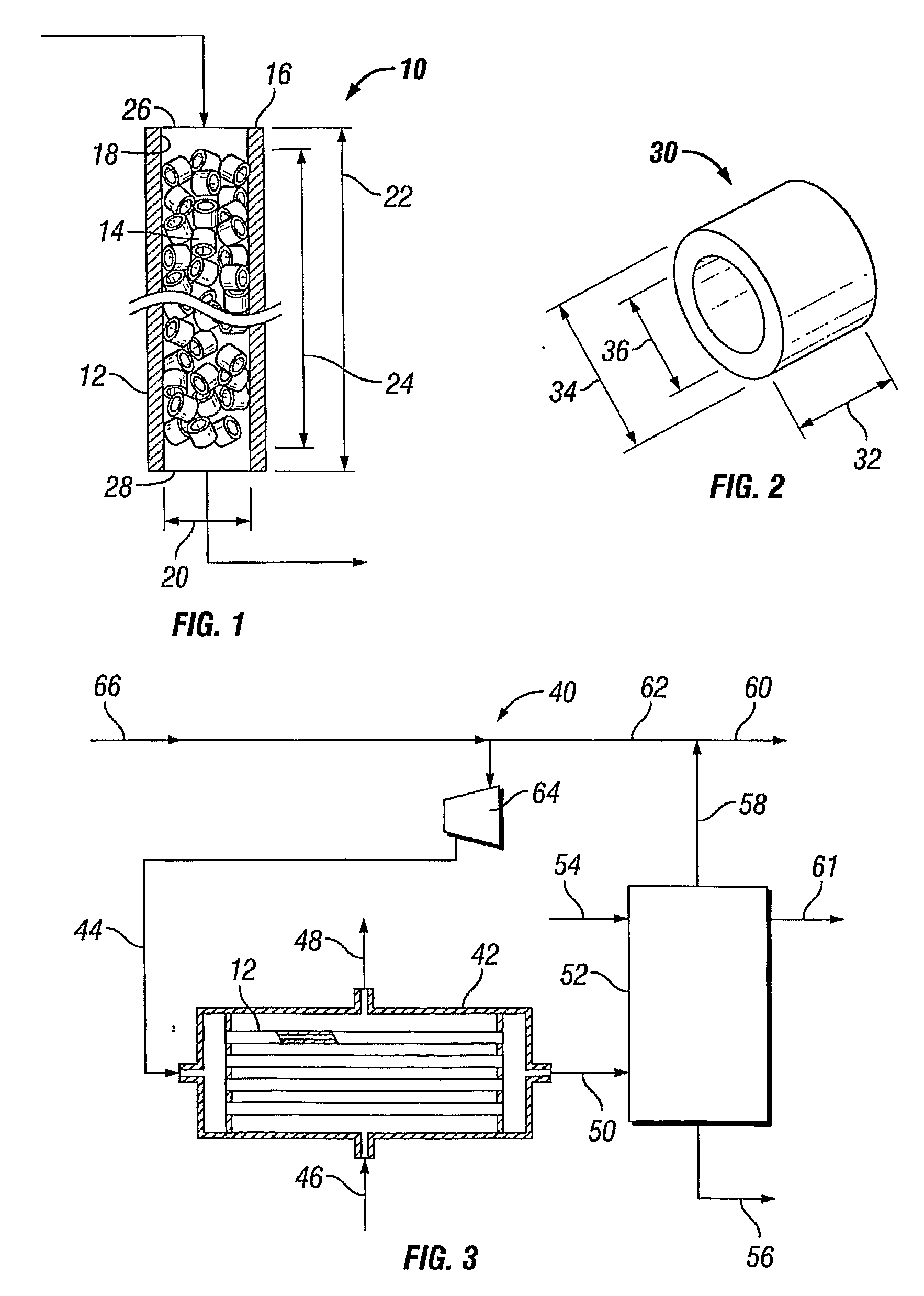

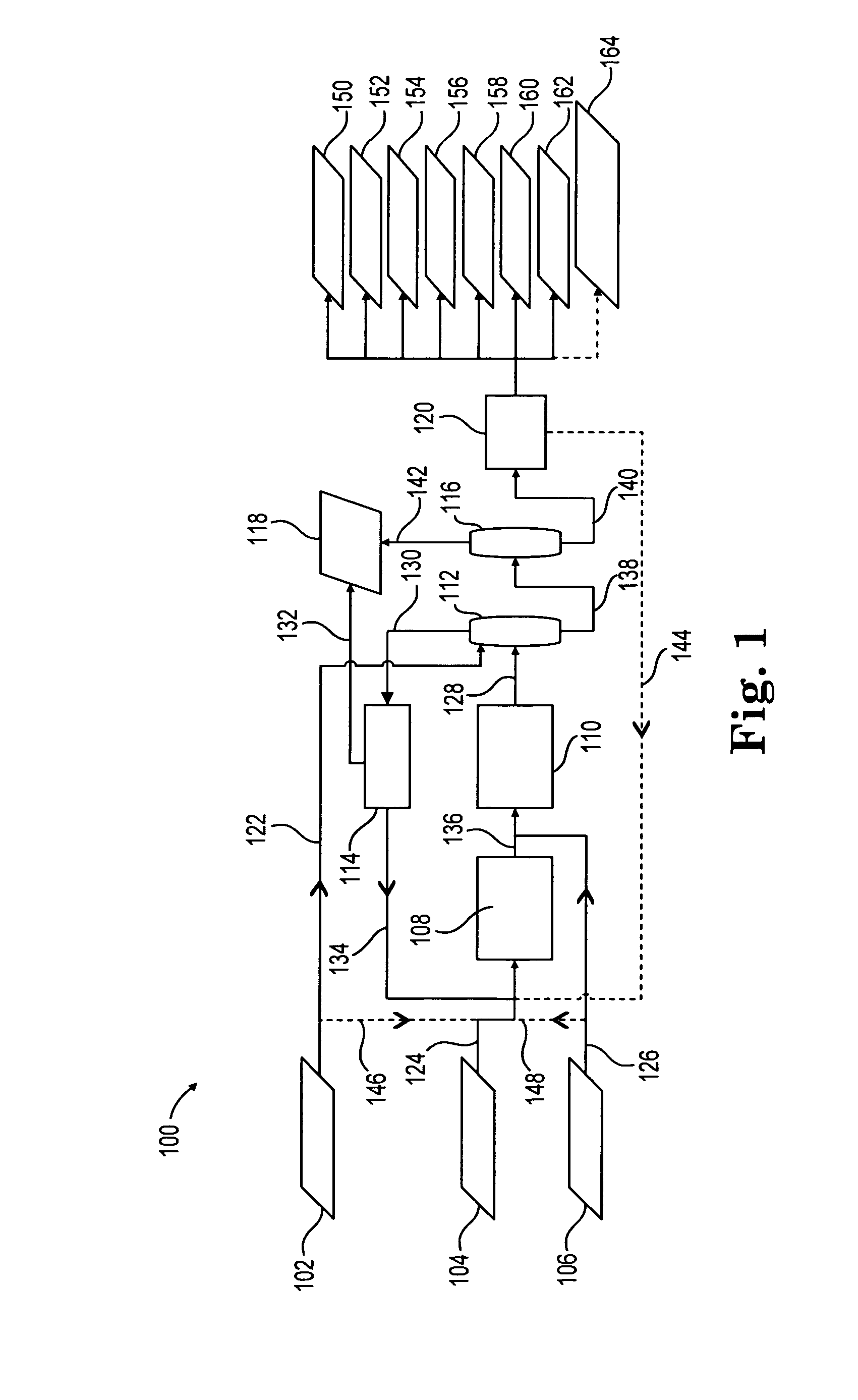

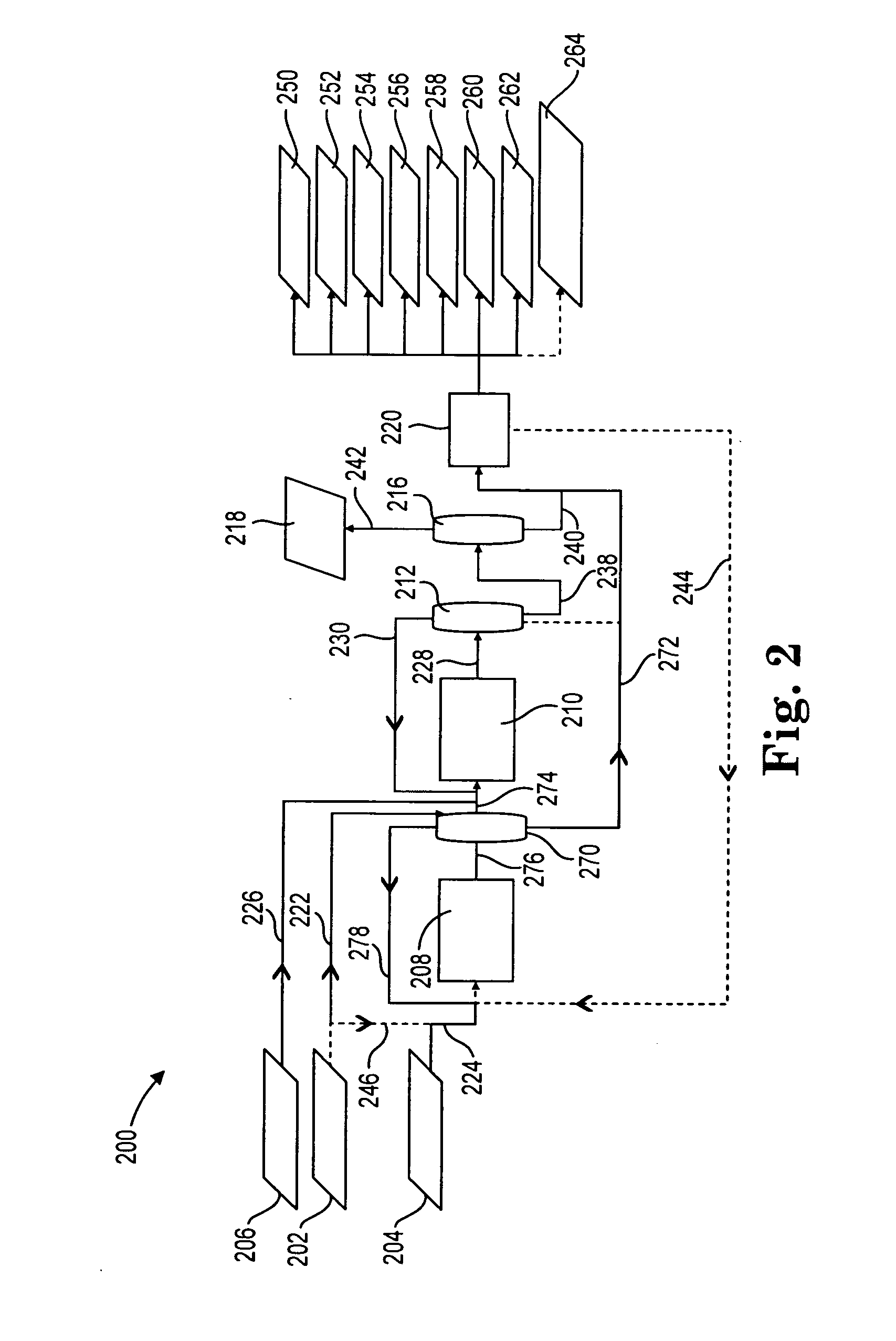

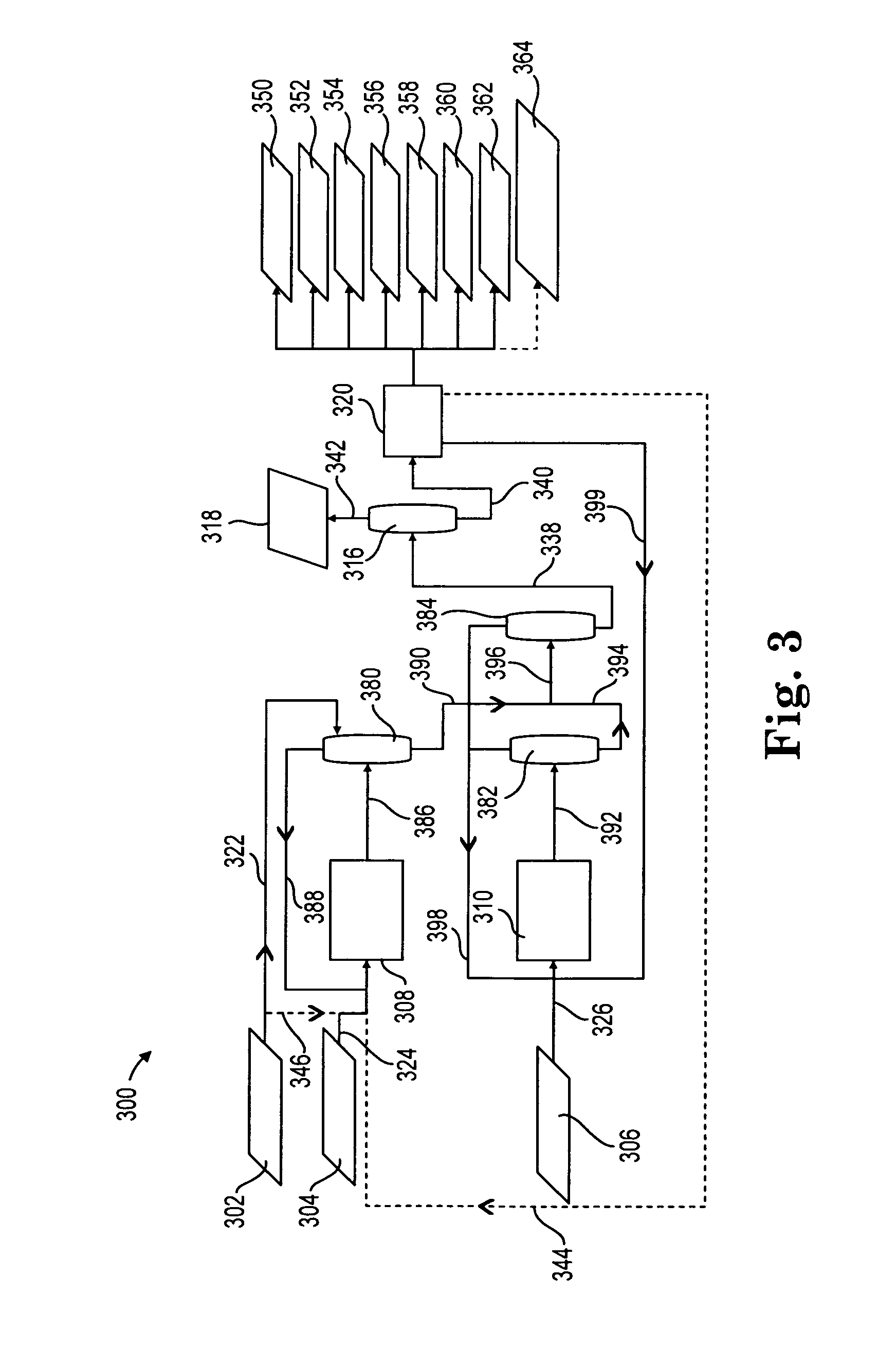

Reactor System and Process for the Manufacture of Ethylene Oxide

A reactor system for the epoxidation of ethylene, which reactor system comprises an elongated tube having an internal tube diameter of more than 40 mm, wherein contained is a catalyst bed of catalyst particles comprising silver and a promoter component deposited on a carrier, which promoter component comprises an element selected from rhenium, tungsten, molybdenum and chromium; a process for the epoxidation of ethylene comprising reacting ethylene with oxygen in the presence of the catalyst bed contained in the reactor system; and a method of preparing ethylene glycol, an ethylene glycol ether or an ethanol amine comprising obtaining ethylene oxide by the process for the epoxidation of ethylene, and converting the ethylene oxide into ethylene glycol, the ethylene glycol ether, or the ethanol amine. Preferably, the internal tube diameter is at least 45 mm.

Owner:SHELL OIL CO

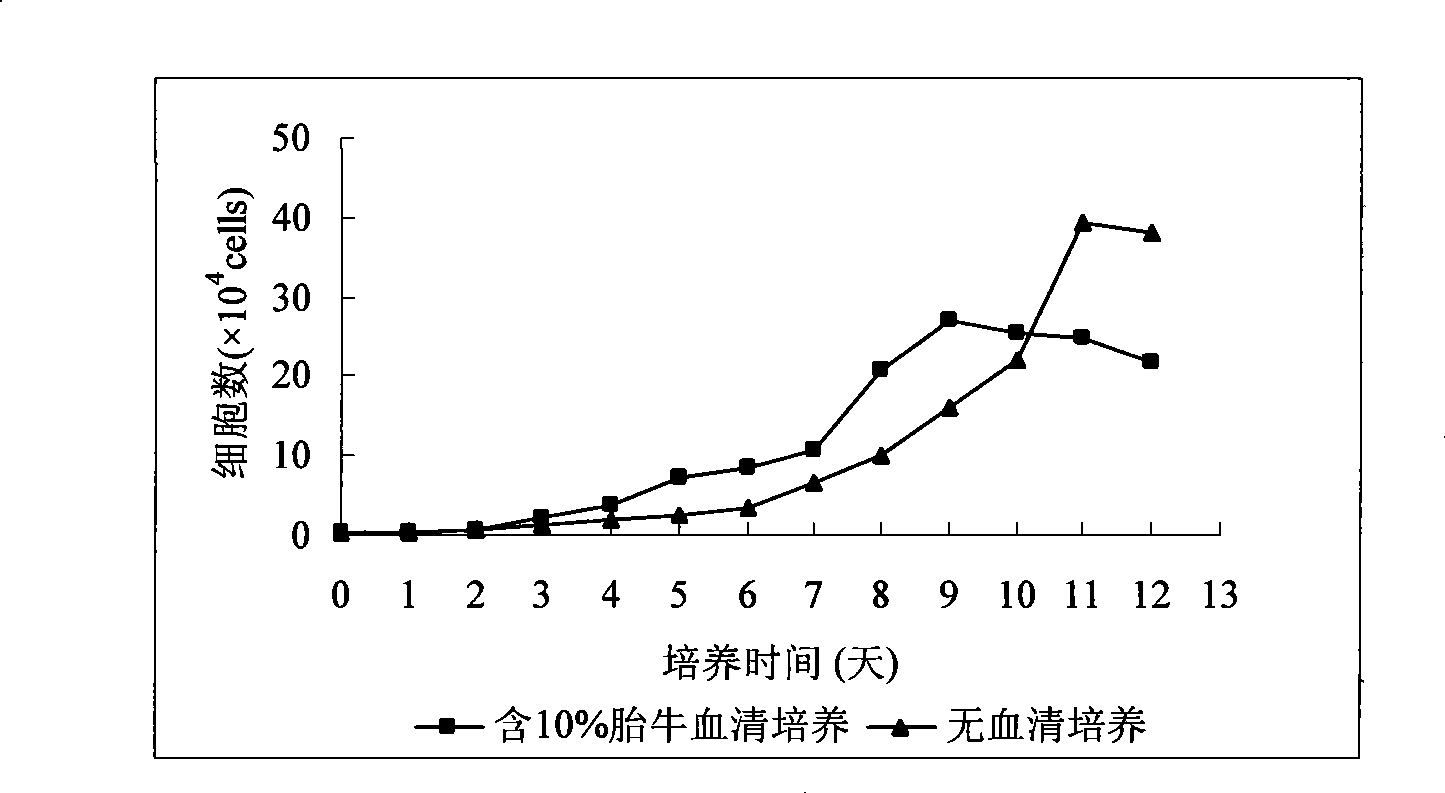

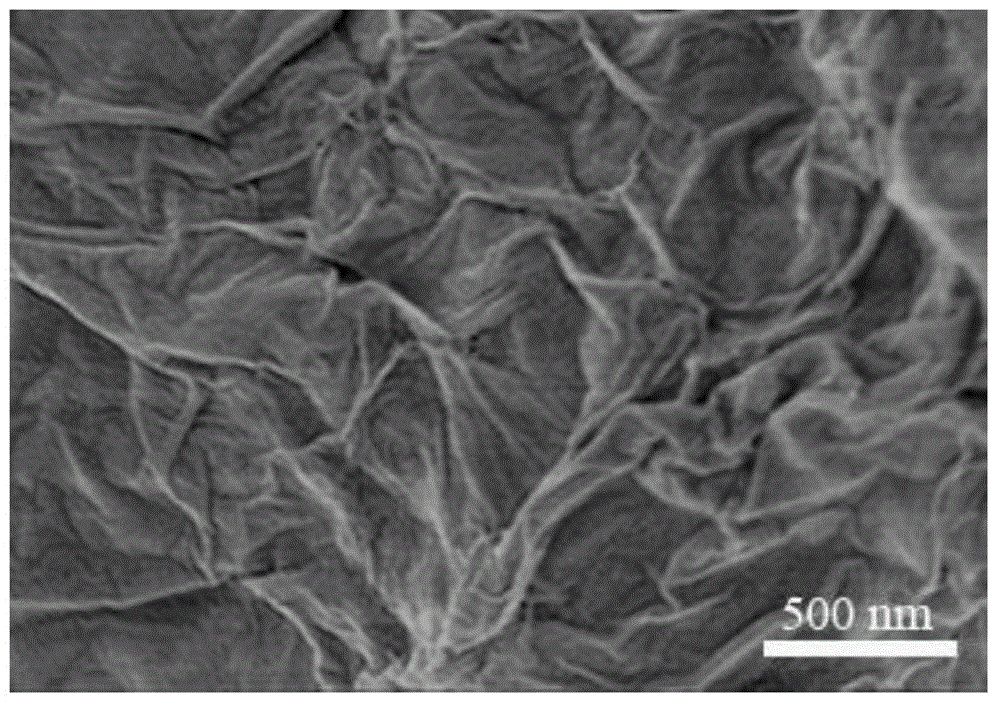

Serum-free medium for in vitro cultivation and amplification of mesenchymal stem cells

ActiveCN101412985AResidue reductionMaintain multilineage potentialSkeletal/connective tissue cellsSerum free mediaAntioxidant

The present invention belongs to the field of biotechnology, and discloses a serum-free culture medium with specific chemical compositions for in vitro culture and amplification of bone marrow mesenchymal stem cells. By adding insulin, transferrin, ethanolamine, sodium selenite, growth factors, adherent factors, hormone, putrescine, inorganic salt, vitamin, albumin and antioxidant into a basic culture medium, the bone marrow mesenchymal stem cells can attach to the culture medium under a serum free condition, so the in vitro culture and amplification are realized, the potential of multi-directional differentiation is maintained, and the amplified cells can be induced to be osteoblast and lipocyte in vitro. The serum-free culture medium has the advantages that the clinic level cell products for human produced by the serum free culture medium can effectively avoid the potential risk of producing cell products by serum culture medium. The drawing appended is a photo of the confluence of the bone marrow mesenchymal stem cells cultured by the serum-free culture medium.

Owner:EAST CHINA UNIV OF SCI & TECH

Methods for making ethanolamine(s) and ethyleneamine(s) from ethylene oxide and ammonia, and related methods

ActiveUS20100087684A1Minimizes numberReduce equipment footprintAmino compound purification/separationOrganic compound preparationEthylenediamineEthylene oxide

The present invention relates to processes for the manufacture of one or more ethanolamines and one or more ethyleneamines starting from the reaction of ethylene oxide with ammonia to produce one or more ethanolamines and the conversion of the ethanolamine(s) to ethyleneamine(s). The present invention also relates to separating alkylethyleneamines from ethyleneamines.

Owner:DOW GLOBAL TECH LLC

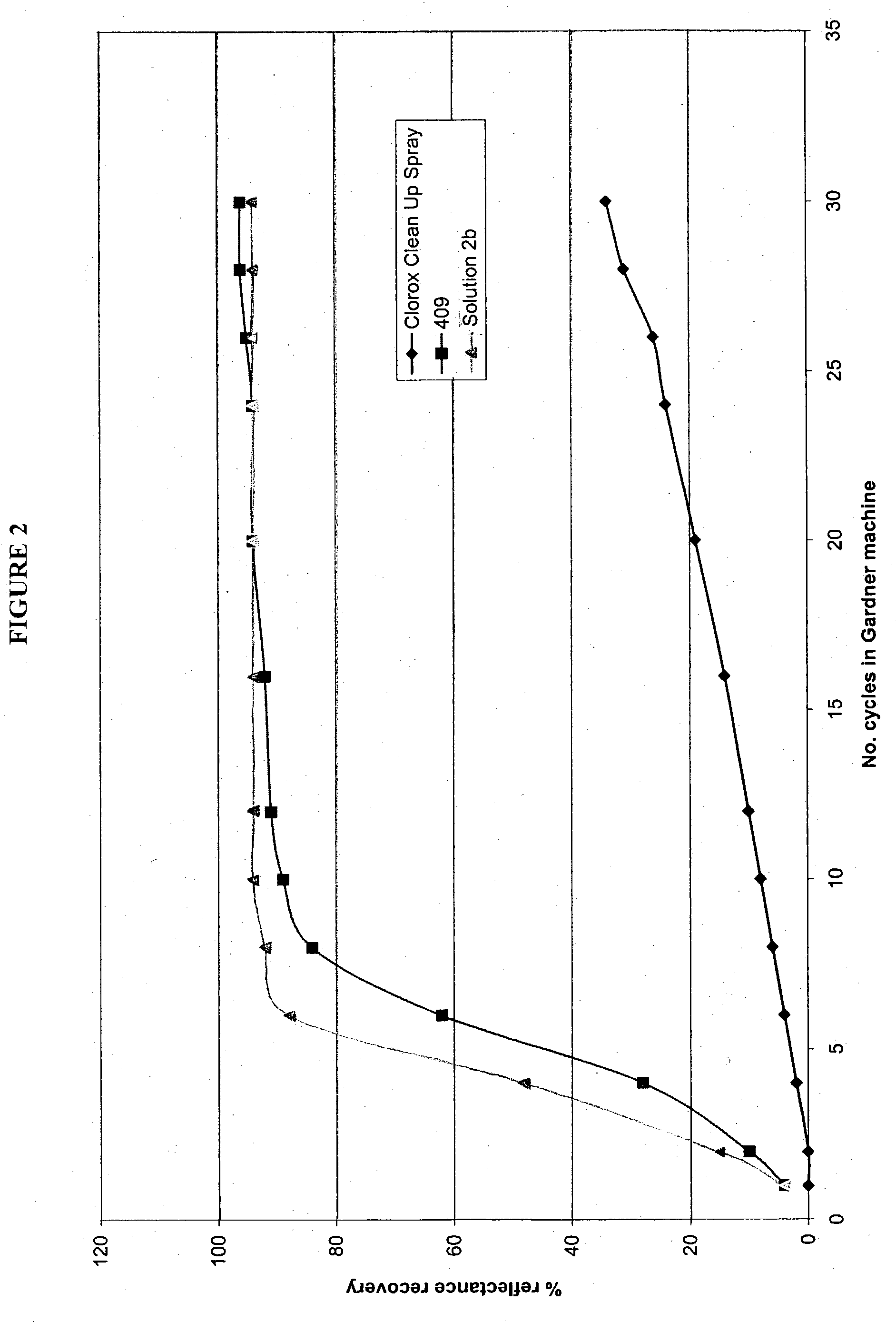

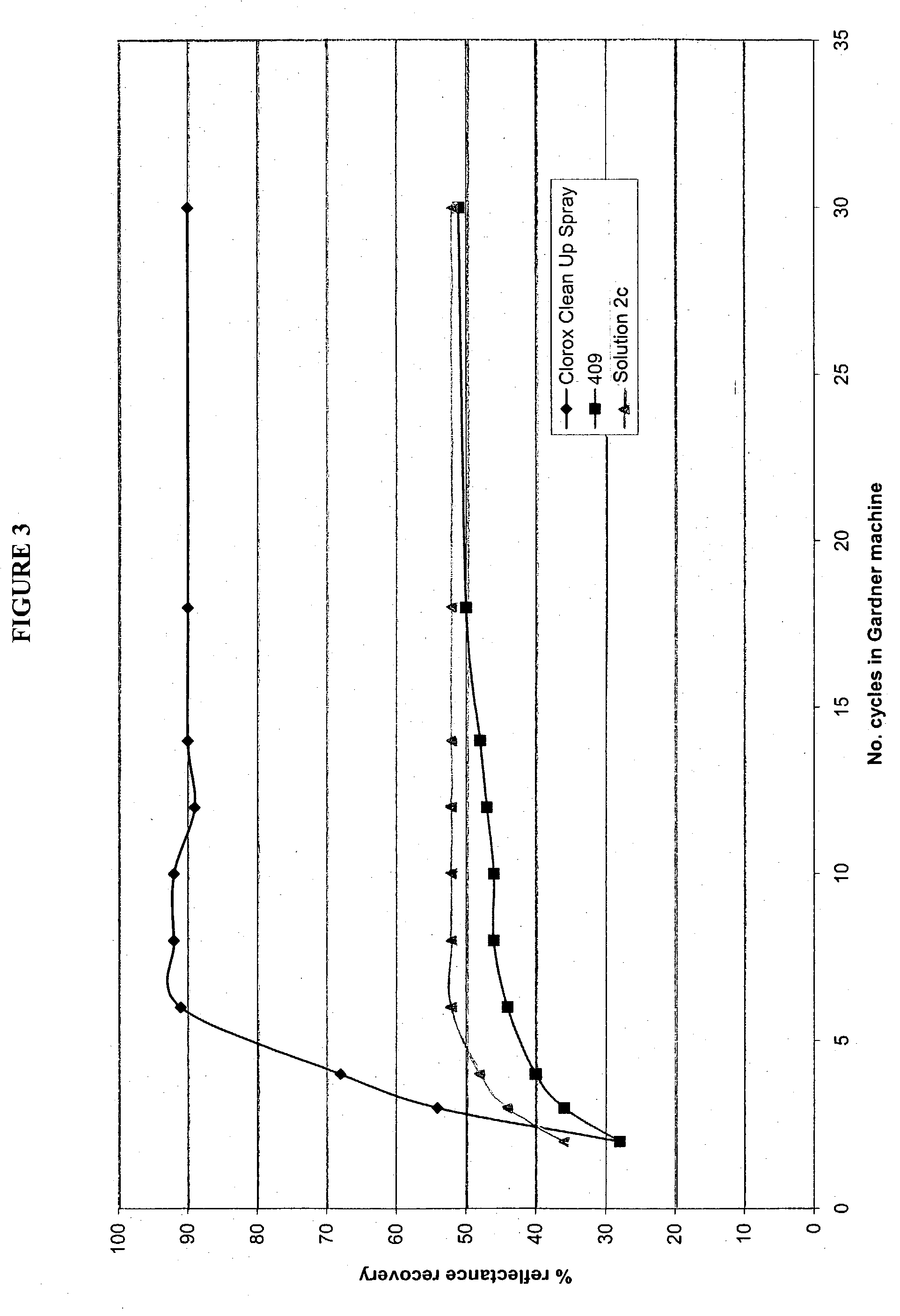

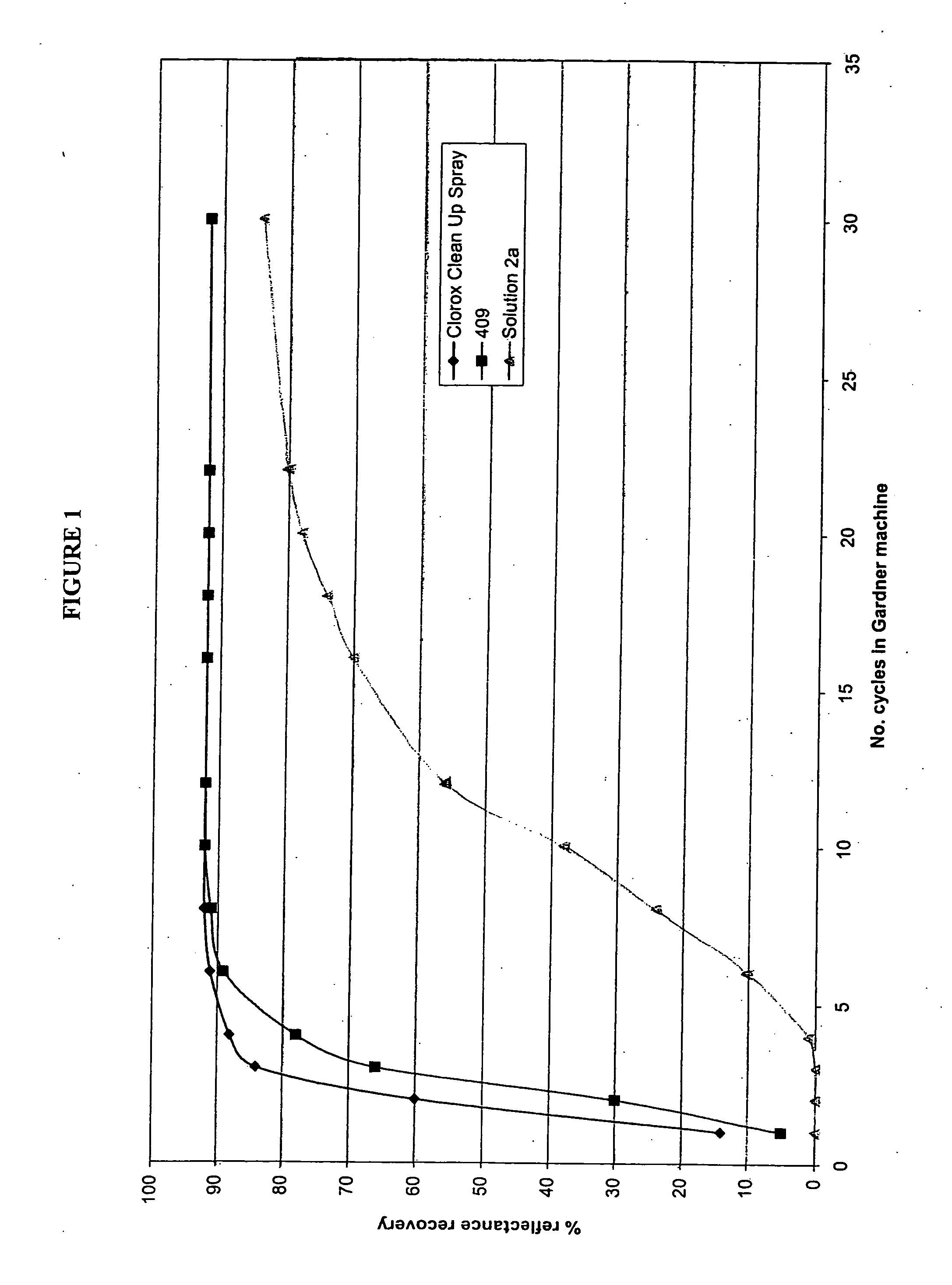

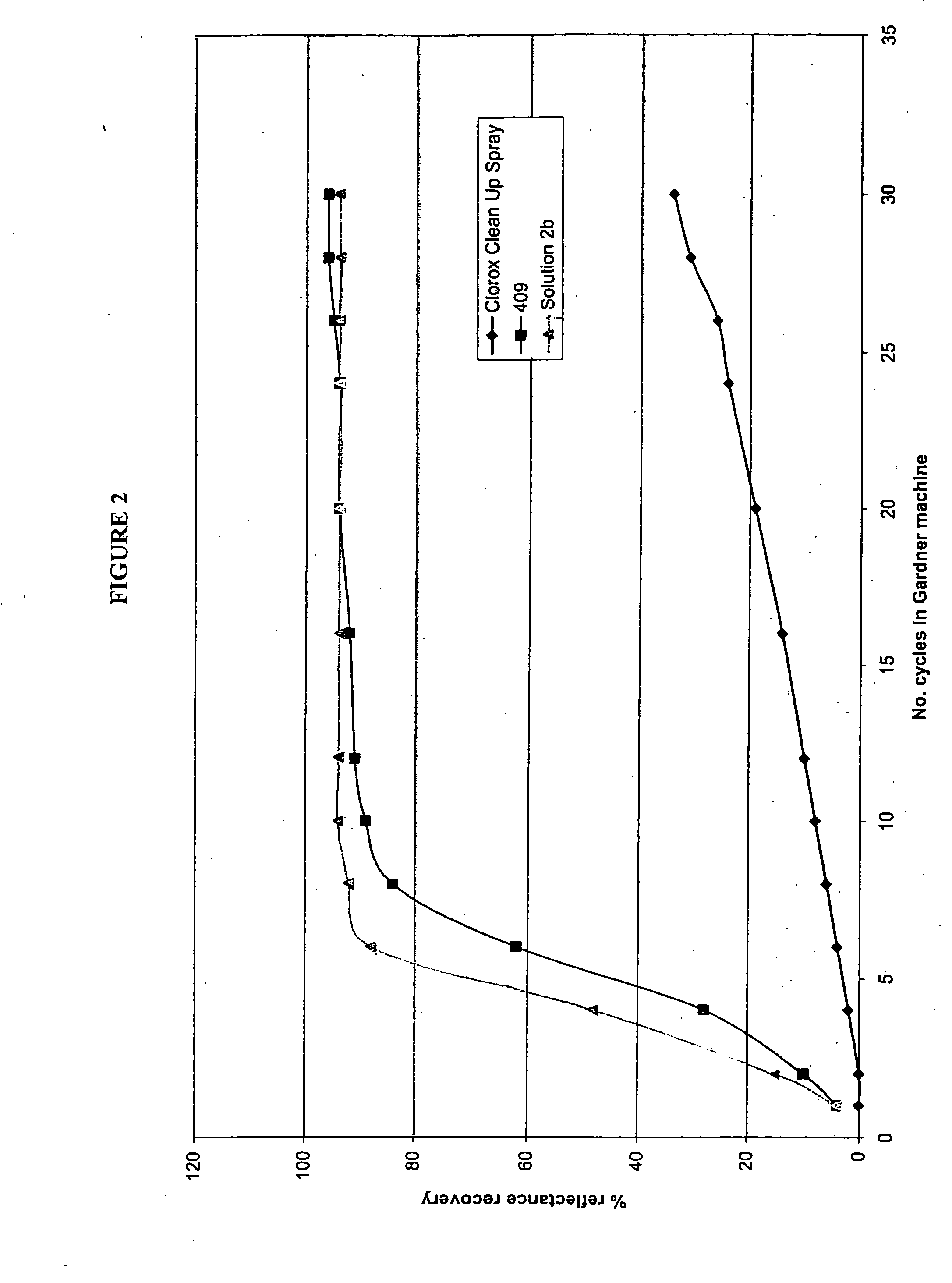

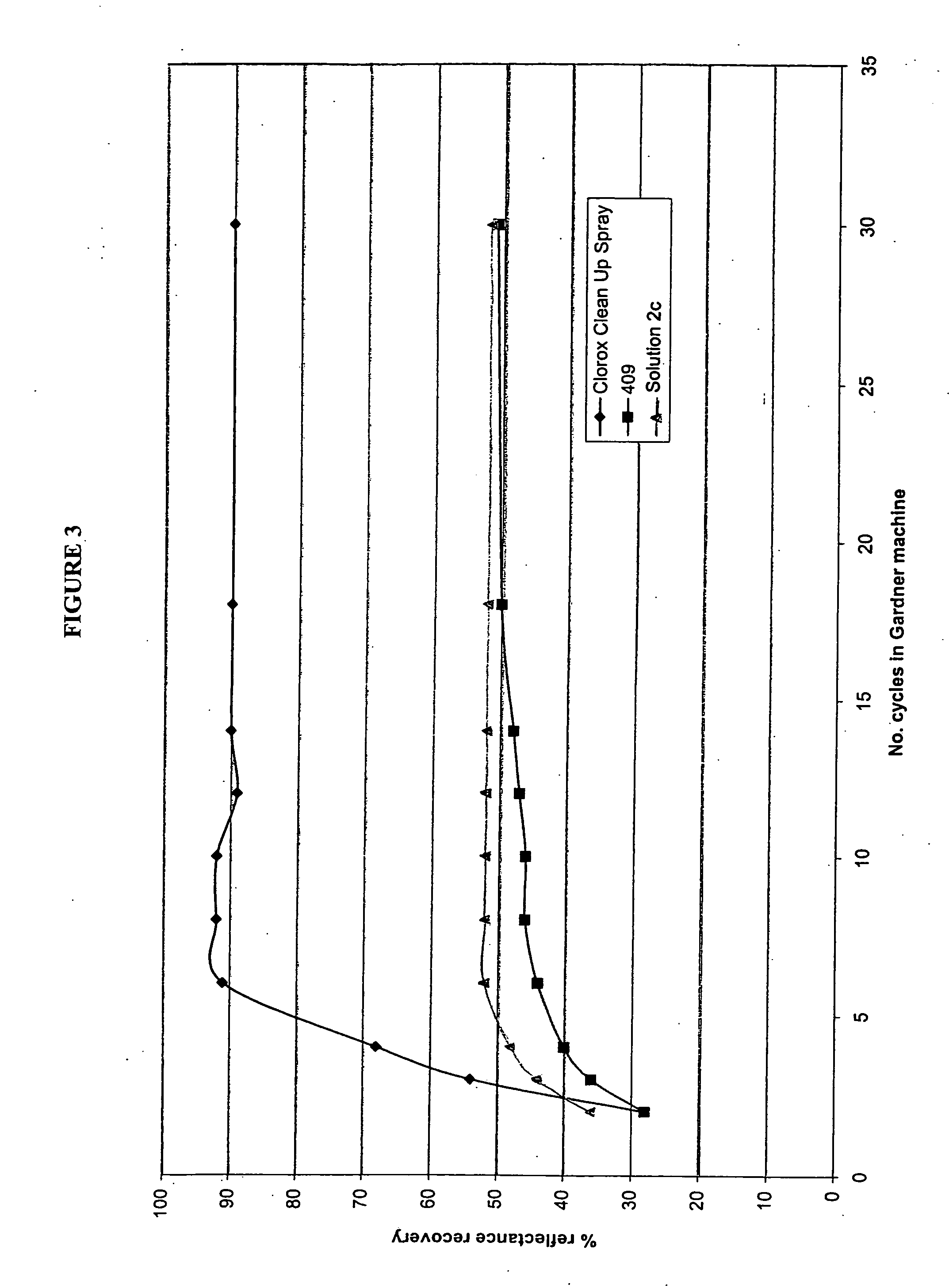

Methyl ester-based microemulsions for cleaning hard surfaces

A cleaning composition containing: (a) from about 1.0 to about 15.0% by weight of a monoethanolamine salt of an alkyl sulfonic acid; (b) from about 3 to about 50% by weight of a C6-C14 methyl ester primary solvent; (c) from about 1.0 to about 15.0% by weight of a short-chain cosurfactant; (d) from about 1 to about 25% by weight of a polar solvent having a water solubility of from about 1 to 5 g / 100 ml; (e) up to about 10.0% by weight of a nonionic surfactant; (f) from about 0.05 to about 3.0% by weight of a thickening agent selected from the group consisting of hydroxypropyl cellulose, hydroxypropyl methylcellulose, and mixtures thereof; and (g) remainder, water, all weights being based on the total weight of the composition, and wherein the composition is terpene-free.

Owner:COGNIS IP MANAGEMENT GMBH

Sulfur removal agent suitable for production of oil-gas well

InactiveCN102698576ASimple recipeAffect normal productionDispersed particle separationPropanolAlcohol

The invention relates to a sulfur removal agent suitable for the production of an oil-gas well. The sulfur removal agent comprises the following components in percentage by mass: 10 to 25 percent of hexahydro-1,3,5-tris(hydroxyethyl)-s-triazine, 5 to 20 percent of alcohol amine, 5 to 20 percent of small molecular alcohol and the balance of water. The alcohol amine is one or a mixture of more thantwo of monoethanolamine, ethyleneglycol amine, diisopropanolamine, methyldiethanolamine and triethanolamine; and the small molecular alcohol is one or a mixture of more than two of methanol, ethanol and propanol. The sulfur removal agent has a simple formula, can be soluble with water, and can effectively reduce the content of hydrogen sulfide in crude oil or natural gas; simultaneously, productsgenerated by the sulfur removal agent and the hydrogen sulfide are water-soluble, and cannot block a mineshaft and influence the normal production of the oil-gas well; and the sulfur removal agent can achieve effects at the temperature of 30 to 120 DEG C and can be quickly reacted with the hydrogen sulfide.

Owner:SOUTHWEST PETROLEUM UNIV

Enhanced activity hydrogen peroxide disinfectant

An enhanced activity aqueous disinfecting solution having a pH of from about 0.5 to about 6 and consisting essentially of (i) hydrogen peroxide in a concentration of from about 0.05 to about 8 w / w % of the solution; (ii) at least one anionic surfactant selected from the group consisting of C8 to C16 alkyl aryl sulfonic acids and alkali metal, ammonium, ethanolamine, calcium and magnesium salts thereof, sulfonated C12 to C22 carboxylic acids and alkali metal, ammonium, calcium and magnesium salts thereof, C6 to C22 alkyl diphenyl oxide sulfonic acids and alkali metal, ammonium, ethanolamine, calcium and magnesium salts thereof, naphthalene sulfonic acids and alkali metal, ammonium, calcium and magnesium salts thereof, C8 to C22 alkyl sulfonic acids and alkali metal, ammonium, calcium and magnesium salts thereof, alkali metal, ammonium, calcium and magnesium C8 to C18 alkyl sulfates, alkyl or alkenyl esters or diesters of sulfosuccinic acid in which the alkyl or alkenyl groups independently contain from six to eighteen carbon atoms and alkali metal, ammonium, calcium and magnesium salts thereof, and mixtures thereof, in a concentration range of from about 0.02 to about 8 w / w % of the solution. Optionally, the solution may contain (iii) at least one additional ingredient chosen from a monocarboxylic acid, a polycarboxylic acid, and mixtures thereof, in a concentration of from about 0.05 to about 4 w / w % of the solution; and (iv) at least one further additional ingredient chosen from benzyl alcohol, an alcohol comprising one to six carbon atoms, and mixtures thereof, in a concentration of from about 0.1 to about 10 w / w % of the solution.

Owner:TRIKON TECH LTD +1

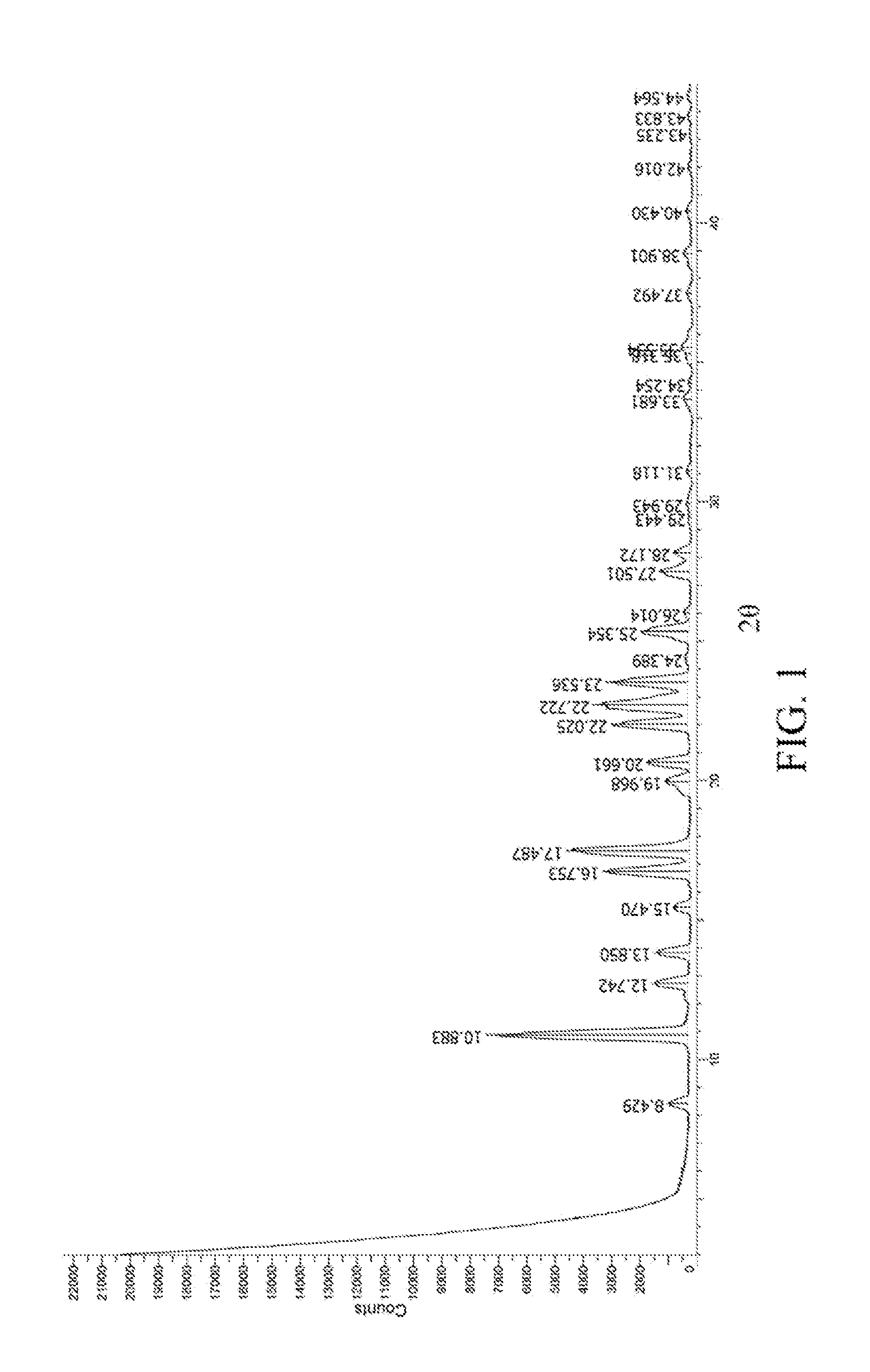

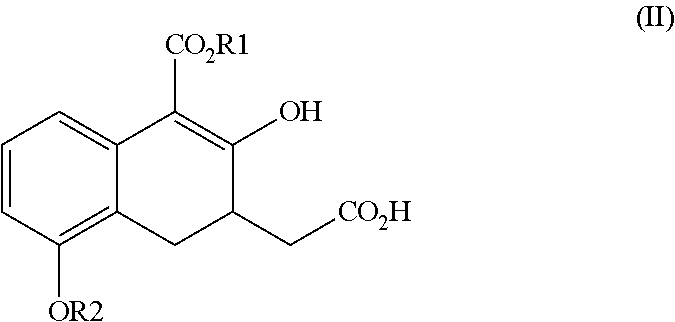

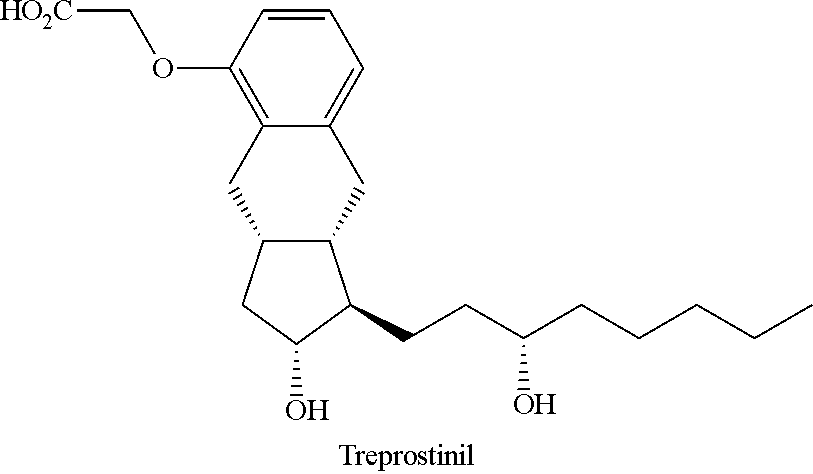

Novel intermediate for synthesizing treprostinil diethanolamine and method for preparing the same

ActiveUS20160152548A1High optical purityHigh purityOrganic compound preparationPreparation by ester-hydroxy reactionCombinatorial chemistryEthanolamine synthesis

The present invention relates to a method for treprostinil diethanolamine synthesis. The present invention also relates to a novel intermediate used in the method for treprostinil diethanolamine synthesis. The novel intermediate is shown in the following formula (II):wherein R1 and R2 are described in the description.

Owner:EVERLIGHT CHEMICAL INDUSTRIAL CORPORATION

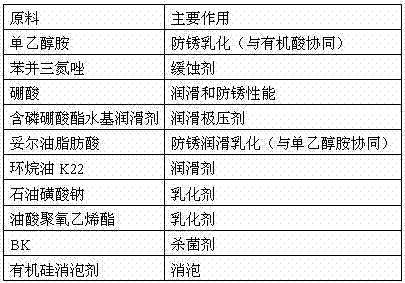

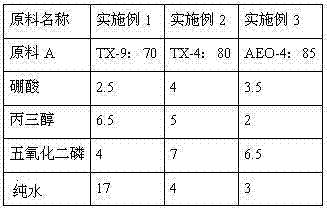

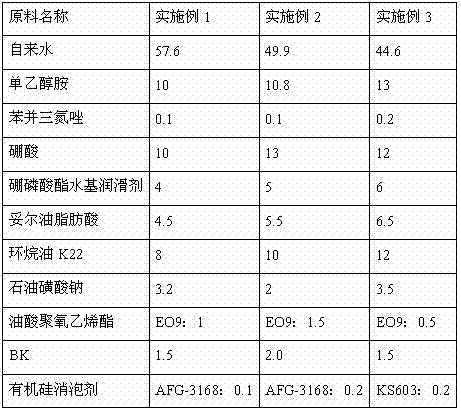

Multi-effect semi-synthetic cutting solution

ActiveCN102899152AReduce dosageHigh lubricating extreme pressure performanceLubricant compositionWater basedPhosphate

The invention discloses a multi-effect semi-synthetic cutting solution. The solution is prepared by uniformly mixing the following raw material components in percentage by total mass of 100%: 10 to 14% of monoethanolamine for industrial use, 0.1 to 0.2% of benzotriazole for industrial use, 10 to 13% of boric acid for industrial use, 4 to 6% of phosphate-borate-containing water-based lubricant, 4 to 7% of tall oil fatty acid for industrial use, 8 to 12% of naphthenic oil K22, 2 to 4% of petroleum sodium sulfonate No.55, 0.5 to 1.5% of oleic acid polyoxyethylene ester for industrial use, 1.5 to 2% of 1,3,5-tri(2-hydroxyethyl)-hexahydrotriazine for industrial use, 0.1 to 0.2% of organic silicon defoamer for industrial use and the balance of water. The solution has high lubrication extreme pressure performance and is biodegradable and environment-friendly.

Owner:无锡纳润特科技有限公司 +1

Cleaning sheet

InactiveUS6624135B2Good quality finishEasy to cleanOrganic detergent compounding agentsLiquid soapsMorpholineActive agent

A cleaning sheet having high cleaning ability and with which finished quality of a surface after cleaning is excellent. A cleaning sheet comprising a sheet base material impregnated with an aqueous cleaning composition that has a pH value of 8 to 11, the composition comprising (A) at least one compound selected from monoethanolamine, morpholine and morpholine derivative compounds, (B) a saturated or unsaturated fatty acid having 14 to 22 carbon atoms, (C) a terpene-type hydrocarbon, and (D) a surfactant.

Owner:SC JOHNSON & SON INC

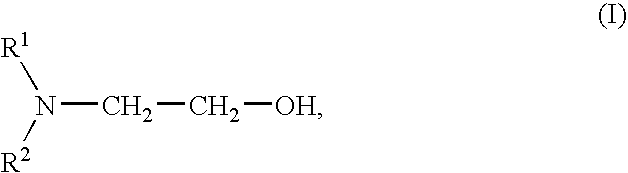

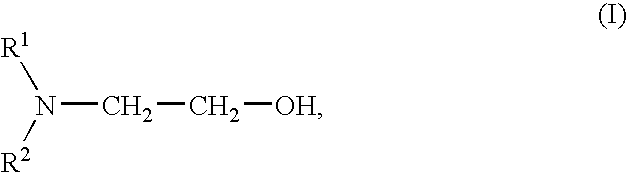

Compositions comprising an ethanolamine derivative and organic metal salts

InactiveUS20050238730A1Combating and treating effectEffective treatmentCosmetic preparationsBiocideETHANOLAMINE DERIVATIVESZinc

This invention relates to compositions comprising an ethanolamine derivative and an organic salt of zinc and / or magnesium. It further relates to the use of such compositions in topical formulations, in particular in anti-aging formulations. The invention further relates to the use of such compositions to promote human dermal fibroblasts growth and to combat the effects of skin aging.

Owner:JOHNSON & JOHNSON CONSUMER FRANCE SAS

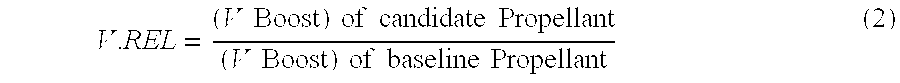

Premixed liquid monopropellant solutions and mixtures

Nondetonable, or low detonation sensitivity, substantially nontoxic liquid monopropellants are provided. The liquid propellants are formed from aqueous solutions of solid oxidizers in liquid oxidizers and water soluble liquid fuels and formulated to have a freezing point less than −10° C. Liquid oxidizers may be inorganic or organic aqueous solutions, with hydrogen peroxide being preferred. Preferred solid oxidizers are water soluble nitrates including ammonium dinitramide, aminoguanidine dinitrate, ammonium nitrate, hydroxylamine nitrate, hydrazine nitrate, guanidine nitrate and aminoguanidine nitrate. Preferred liquid fuels are water soluble alcohols, amines and amine nitrates, hydroxyethyl hydrazine, hydroxyethylhydrazine nitrate, cyanoguanidine, guanidines, aminoguanidines, triaminoguanidines, and their nitrate salts, ethanolamine dinitrate, ethylenediamine dinitrate, polyvinyl nitrate, and aziridine.

Owner:AEROJET GENERAL CORP

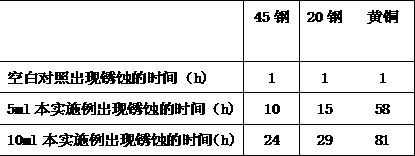

Metal rust-preventive oil comprising butyl acrylate

ActiveCN103214886AGood gas phase anti-rust effectExcellent contact rust resistanceAnti-corrosive paintsMeth-Composite film

The invention discloses metal rust-preventive oil comprising butyl acrylate. The oil is prepared from the raw materials of: No.120 solvent oil, paraffin, methyl diethanolamine, epoxy octyl stearate, magnesium naphthenate, a silane coupling agent KH560, a silane coupling agent A171, microcrystalline wax, aluminum stearate, magnesium lanolin soap, monoethanolamine, barium petroleum sulfonate, sodium lauryl sulfate, trioctyl trimellitate, benzotriazole, 2-aminoethyl heptadecenyl imidazoline, zinc stearate, an antioxidant BHT, an antioxidant 1010, dipropylene glycol, phytic acid, butyl acrylate, modified nano-grade dolomite powder, a composite film-forming material, and ferrocene. The rust-preventive oil provided by the invention has excellent contact rust resistance and good gas-phase rust resistance. The rust-preventive oil provided by the invention provides good gas-phase rust resistance and contact rust resistance for steel and brass.

Owner:SHANTOU HONGSHENG BOLT IND CO LTD

Process for the preparation of rice bran oil low in phosphorous content

InactiveUS6706299B2Simple and economical and fast processReduce processing stepsFatty-oils/fats refiningCheese manufacturePhosphoric acidPulp and paper industry

Owner:COUNCIL OF SCI & IND RES

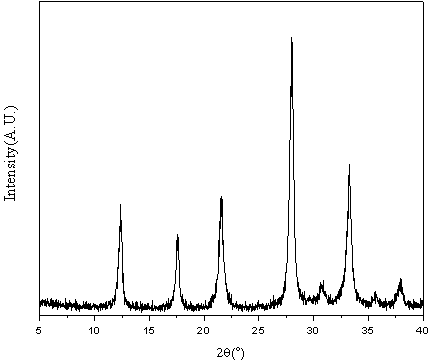

Method for preparing P type molecular sieve by using coal ash as raw material

InactiveCN104291349AInhibition of dissolutionCause dissolutionCrystalline aluminosilicate zeolitesMolecular sieveSodium aluminate

The invention relates to a method for preparing a P type molecular sieve by using coal ash as a raw material. The method for preparing the P type molecular sieve by using coal ash as the raw material comprises the following steps: I, pre-treating and activating coal ash; II, preparing sodium silicate and sodium metaaluminate by using activated coal ash; and III, synthesizing the P type molecular sieve: firstly, uniformly mixing a sodium silicate solution with a sodium salt, then, dropwise adding the sodium metaaluminate solution into the mixed liquid, and finally, adding an organic steric hindering agent and a proper amount of deionized water to form a reaction mixture, wherein the molar ratios of the reaction mixture are as follows: SiO2 / Al2O3=0.4-1.8, M / Al2O3=1-5, Na2O / Al2O3=2-4 and H2O / SiO2=20-150 and the organic spatial steric hindering agent is at least one of ethanol amine, diethanol amine and triethanol amine; packing the mixed materials in a polytetrafluoroethylene container, stirring, then putting in a stainless steel reaction kettle, and carrying out hydro-thermal synthesis for 2-8 hours; and taking out products in the reaction kettle, carrying out centrifugal separation and washing by deionized water, and drying to obtain the P type molecular sieve. The method provided by the invention is short in synthetic cost, short in crystallization time and high in yield of the P type molecular sieve.

Owner:NORTHEAST GASOLINEEUM UNIV

Natural gas pipeline drag-reducing agent and preparation method thereof

InactiveCN102443022ASource directlyEasy to operateGroup 5/15 element organic compoundsPipeline systemsEsterification reactionFatty alcohol

Owner:CHINA NAT OFFSHORE OIL CORP +2

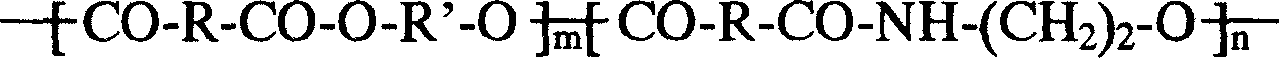

Degradable unsaturated polyesteramide resin and synthesis method thereof

The invention adopts a melt polycondensation method. A few of monomers of C2-5 aliphatic dibasic alcohol, diethylene glycol, polyglycol, fumaric acid, maleic anhydride, lactic acid, glycolic acid, ethanolamine, C2 to C12 aliphatic diamine, glutamic acid, lysine, glycine, etc. are taken as basic materials to be synthesized to obtain non toxic unsaturated polyester-amide resin with adjustable degradation rate and lower cost; wherein, the partial fumaric acid or maleic anhydride can be replaced with phthalic anhydride, isophthalic acid, or adipic acid. The resin yearns for being used as matrix resin of medical bone internal fixation material, tissue engineering scaffold material, bone tissue temporary substitutes, environmental protection type bonding agent, environmental protection type fiberglass reinforced plastics, environmental protection type coating material, disposable tableware, packing material, shopping bags, disposable bags, drug coating or capsule, drug delivery (controlled-release) material, agricultural mulching films, etc., and can be recovered to be utilized.

Owner:HUNAN UNIV

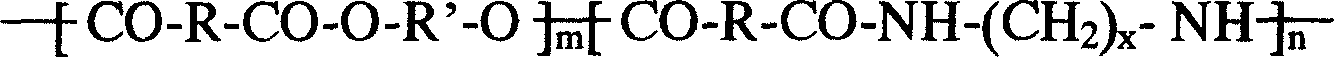

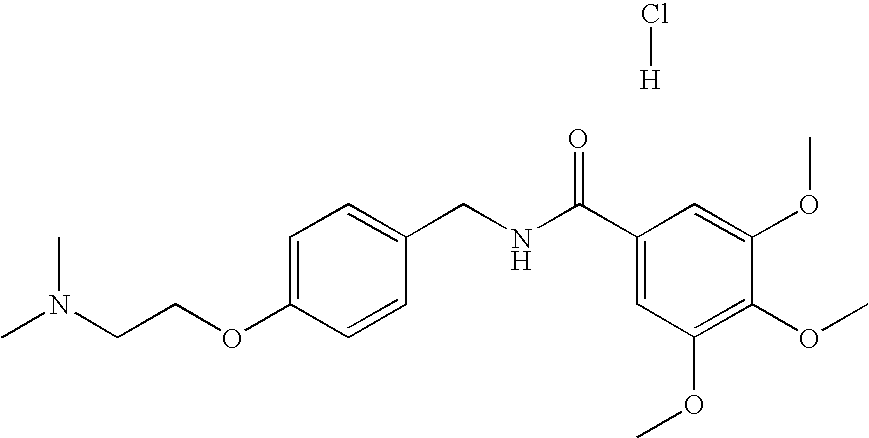

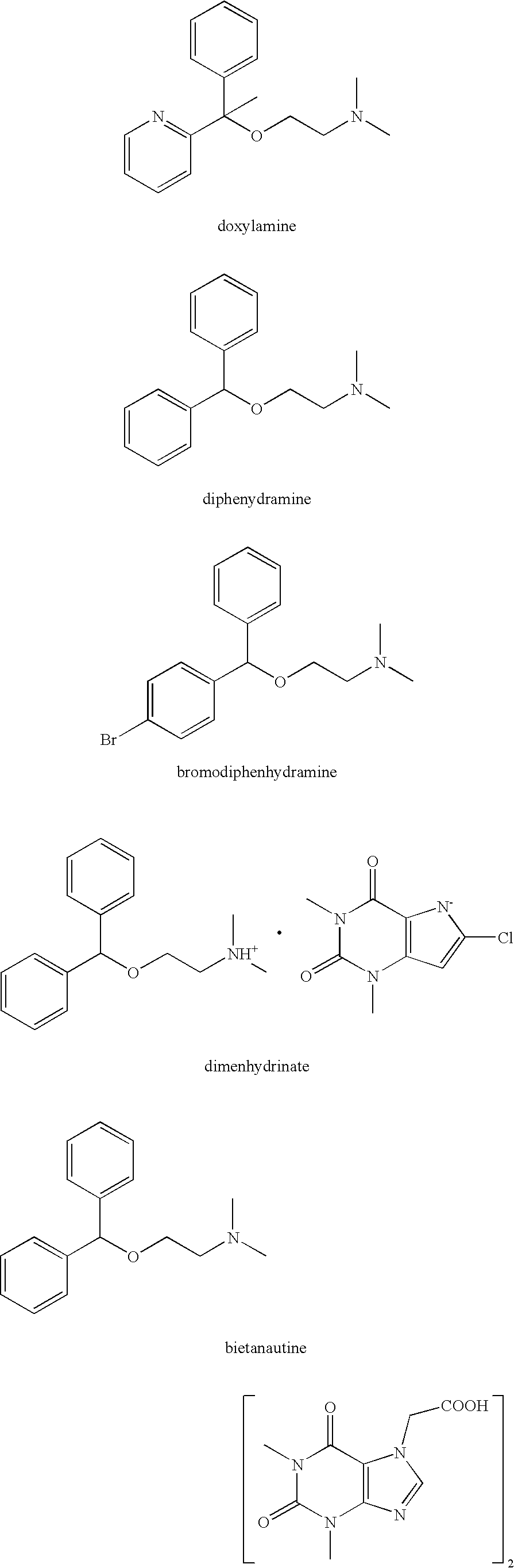

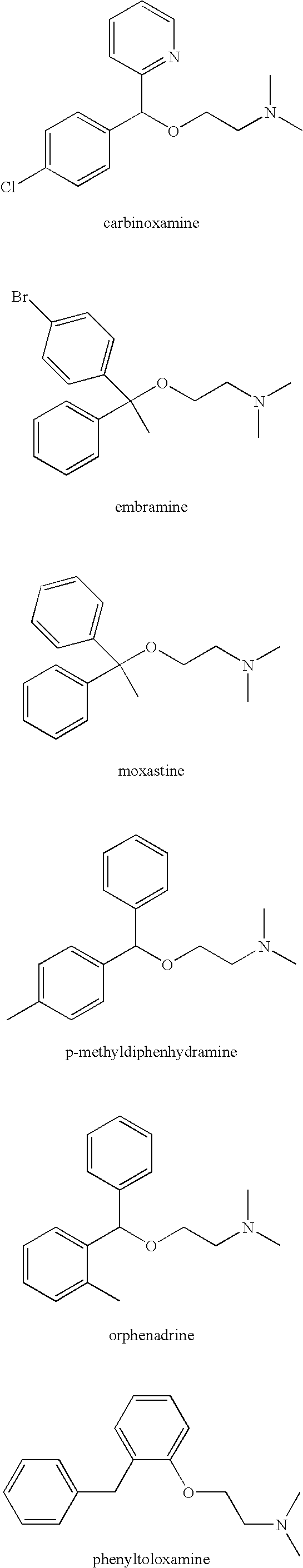

Methods and composition for treatment of migraine and symptoms thereof

Compositions, methods and kits are provided for the treatment of migraines. The compositions, methods and kits include an effective dose of trimethobenzamide and an ethanolamine antihistamine that, when administered to an individual suffering from migraine headaches, will alleviate symptoms associated with the migraine headaches. Compositions, methods, and kits for the treatment of migraines include pharmaceutical compositions of trimethobenzamide and diphenhydramine.

Owner:SALEHANI FOAD

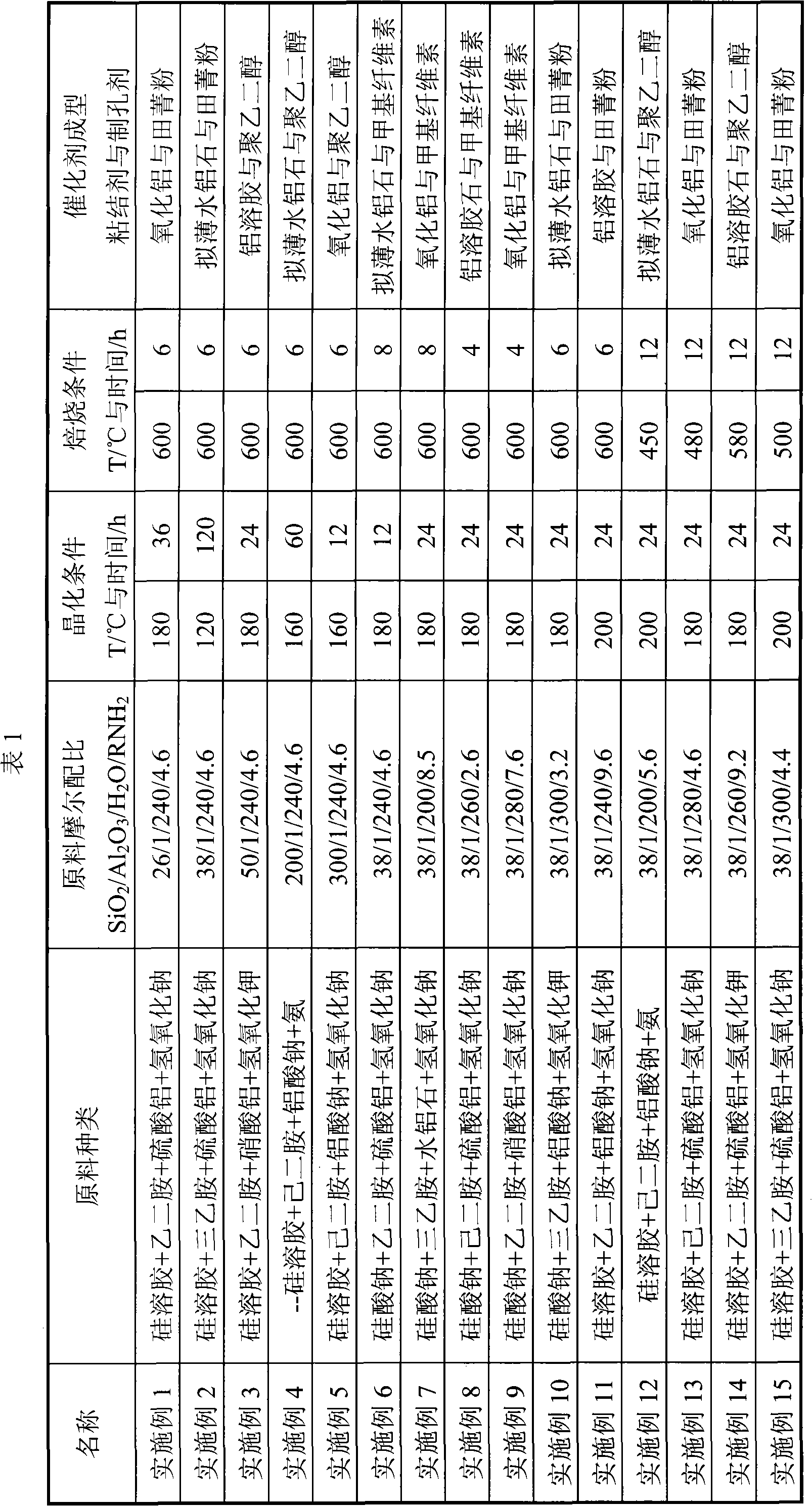

Amination catalyst and preparation method thereof

ActiveCN101406845AHigh catalytic activityImprove catalytic selectivityMolecular sieve catalystsOrganic compound preparationDodecaneMordenite

The invention discloses an amination catalyst and a preparation method thereof, which aims to solve the problem that the amination catalyst is not high in activity and selectivity. The compositions in weight percentage of the amination catalyst are: 15 to 25 percent of A, 5 to 10 percent of B, 1 to 3 percent of C, 0.1 to 1.5 percent of D, and the balance being h-type mordenite, wherein the A is alumina; the B is titanium oxide; the C is metallic ion W<6+>, Re<7+> or Bi<3+>; the D is metallic ion Cs<+>; and the metals exist in the form of elements or oxides. The preparation method comprises the following steps of loading the components C and D on the h-type mordenite, well mixing the components C and D with the alumina and ethanolamine titanate dodecane alcohol ester, molding, roasting and activating the mixture. The catalyst is used for synthesizing ethylene dimine under the conditions of ethanolamine and ammonia phase.

Owner:XIAN MODERN CHEM RES INST

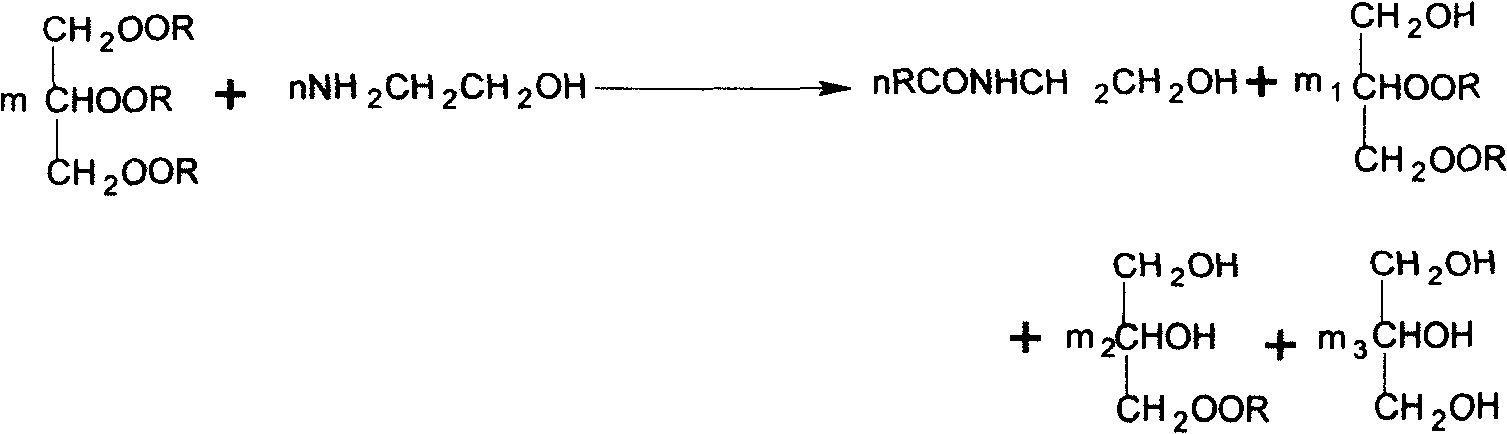

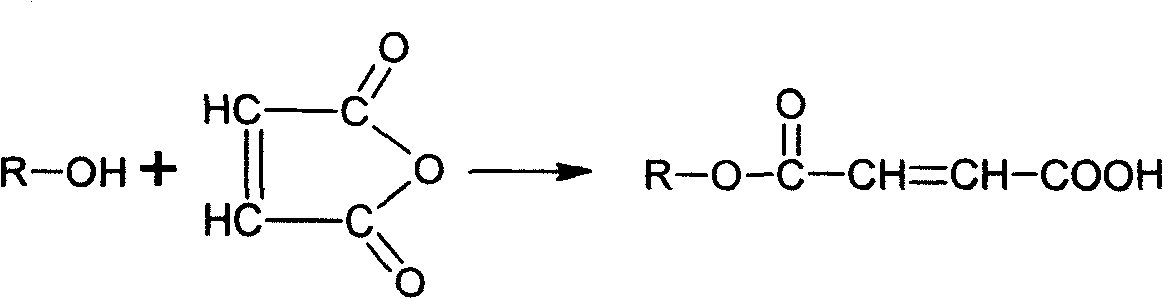

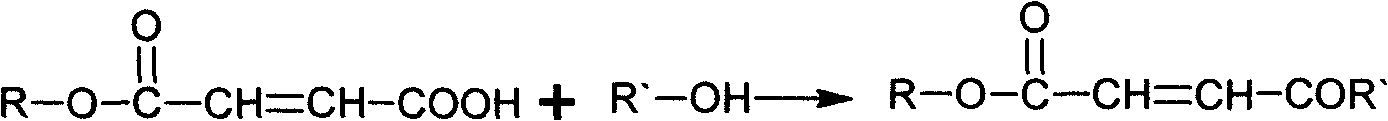

Composite sulfited vegetable oil leather fat-liquoring agent and method for preparing same

InactiveCN101285107AGood low temperature storageGood fatliquoring performanceLeather impregnationMaleic anhydrideSOYBEAN SEED OIL

The invention relates to a complex sulfited vegetable oil leather fat liquor and a method for preparing the same. The complex fat liquor contains sulfited vegetable oil, granulesten, chloridized soybean oil methyl ester, alkyl sulfonyl amine, liquid paraffin and auxiliary emulsifying agent. Firstly, vegetable oil is reacted with monoethanol amine to obtain amidated vegetable oil, the amidated vegetable oil is reacted with maleic anhydride to obtain succinic acid monoester, then the succinic acid monoester undergoes an esterification reaction with low carbon alcohol to obtain succinic acid diester, and the succinic acid diester is reacted with sodium bisulfite to obtain the sulfited vegetable oil. Then the granulesten, the chloridized soybean oil methyl ester, the alkyl sulfonyl amine, the liquid paraffin and the auxiliary emulsifying agent are imported into the sulfited vegetable oil, and the complex sulfited vegetable oil leather fat liquor can be obtained by emulsifying and adjusting contents of effective substances. The product has strong electrolyte-resistant ability, leather using the product to make a fat liqoring is soft and moist and has good elasticity, and the fat-liquoring effect can be maintained for a long time.

Owner:WENZHOU UNIVERSITY

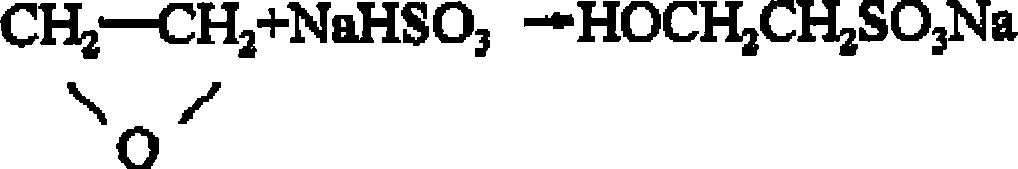

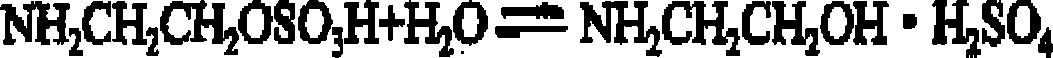

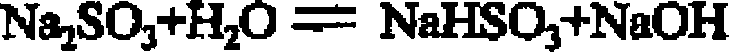

Method for synthesizing taurine

InactiveCN101100449ANo escapeImprove economySulfonic acid preparationTaurine synthesisChemical synthesis

Synthesis of taurine is carried out by: reducing esterified product of cholamine with ammonium sulfite as reducer, separating to generate crude product, and re-crystallizing to obtain final product. It's economical, has no SO2 gas discharge and has friendly production environment and can separate out taurine and sulfate at low temperature.

Owner:JIANGSU YUANYANG PHARMA

Method for producing o-chloroaniline

InactiveCN101333169AHigh yieldLow costOrganic compound preparationAmino compound preparationEthylenediamineO-nitrochlorobenzene

An o-chloroaniline production method takes o-nitrochlorobenzene as raw material and is characterized in that the o-nitrochlorobenzene is dissolved in alcohol solvent in the presence of catalyst and additive and reacted with hydrogen at 10-120 DEG C and under 0.3-4.0 MPa; the reaction process is continuous reaction; after the completion of the reaction, the o-chloroaniline is obtained through treatment, wherein, the catalyst can be selected from one of the following: Ni / Al2O3, Raney Ni, Pt / C and Pd / C; while the additive can be selected from one, or two, or three of the following compounds: cyclohexylamine, ethylenediamine, ethanolamine, diethanolamine, triethanolamine, pyridine, liquid ammonia, ammonium bicarbonate, ammonium carbonate, sodium carbonate, sodium bicarbonate, potassium bicarbonate, potassium carbonate, potassium hydrogen phosphate, potassium dihydrogen phosphate, sodium hydrogen phosphate and sodium dihydrogen phosphate; the dosage of the catalyst takes up 0.05% to 20% of the mass of the o-nitrochlorobenzene; the dosage of the additive takes up 0. 5% to 20% of the mass of the o-nitrochlorobenzene; the alcohol can be methanol or ethanol; the dosage of alcohol takes up 30% to 150% of the dosage of the o-nitrochlorobenzene; the continuous reaction is realized through 1 to 6 tank reactors which are connected in series.

Owner:淮安嘉诚高新化工股份有限公司

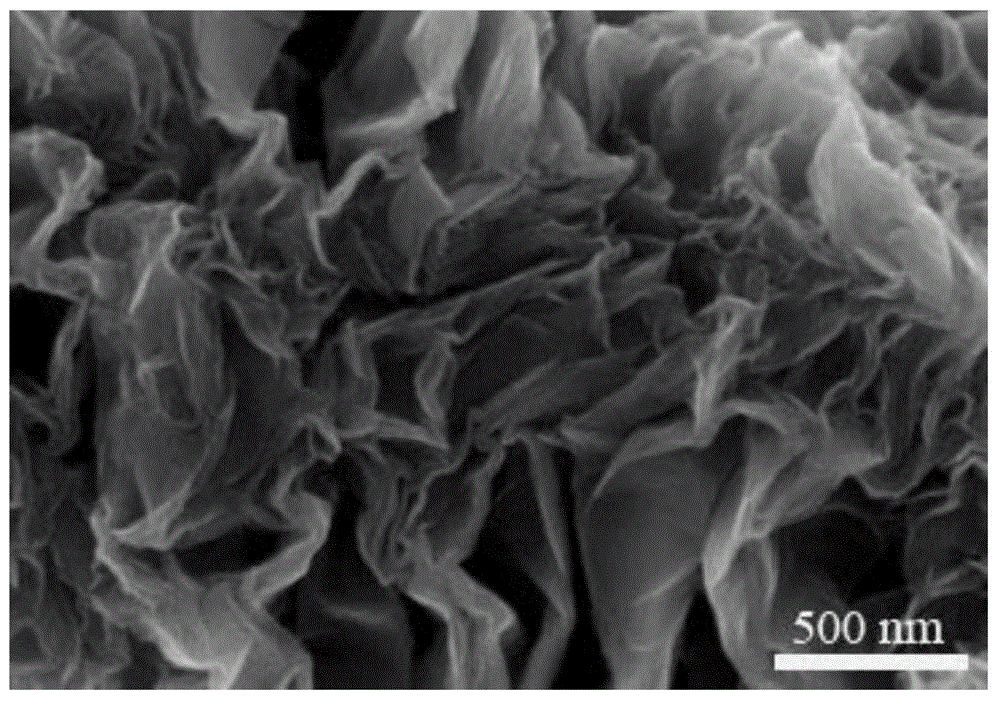

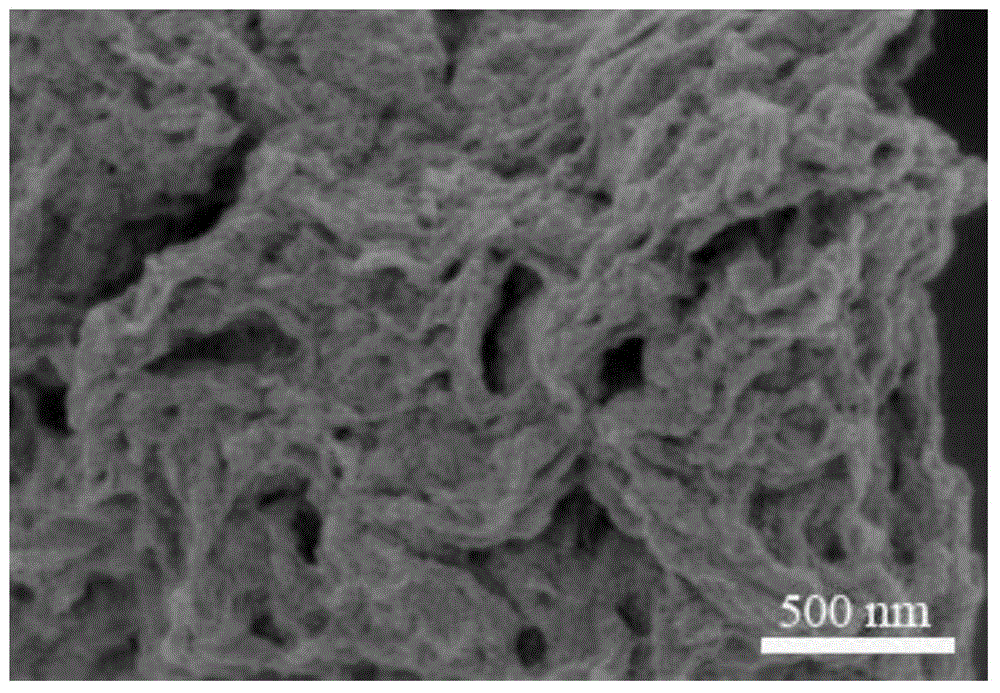

Graphene-poly ionic liquid composite material, and preparation method and application thereof

InactiveCN103980424AImprove conductivityLarge specific surface areaMaterial electrochemical variablesCvd grapheneIonic liquid

Owner:JIAXING UNIV

Catalyst for gas phase synthesis of ethylenediamine and preparation method thereof

ActiveCN1962058AHigh catalytic activityImprove stabilityMolecular sieve catalystsOrganic compound preparationEthylenediamineHydrogen

The invention relates to a catalyst used to composite ethanediamine from gas phase and relative production, wherein it comprises 20-30% alumina, 5-15% metal ion, and left is hydrogen mordenite treated by acid, while metal ion can be one of Zr4+, Nb5+, Mo6+, Sn4+, Sb5+ with one of Zn2+, Fe3+, while their mol ratio is 1-10:1. And its production comprises loading the metal ion on the treated hydrogen mordenite, drying, and mixing with alumina, compressing, baking and activating. The invention is used to composite ethanediamine from ethanolamine and ammonia gas.

Owner:XIAN MODERN CHEM RES INST

Enhanced activity hydrogen peroxide disinfectant

InactiveUS20070059380A1Commercially acceptable stability and cleaning abilityWithout usingAntibacterial agentsBiocideMagnesium saltDisinfectant

An enhanced activity aqueous disinfecting solution having a pH of from about 0.5 to about 6 and consisting essentially of (i) hydrogen peroxide in a concentration of from about 0.05 to about 8 w / w % of the solution; (ii) at least one anionic surfactant selected from the group consisting of C8 to C16 alkyl aryl sulfonic acids and alkali metal, ammonium, ethanolamine, calcium and magnesium salts thereof, sulfonated C12 to C22 carboxylic acids and alkali metal, ammonium, calcium and magnesium salts thereof, C6 to C22 alkyl diphenyl oxide sulfonic acids and alkali metal, ammonium, ethanolamine, calcium and magnesium salts thereof, naphthalene sulfonic acids and alkali metal, ammonium, calcium and magnesium salts thereof, C8 to C22 alkyl sulfonic acids and alkali metal, ammonium, calcium and magnesium salts thereof, alkali metal, ammonium, calcium and magnesium C8 to C18 alkyl sulfates, alkyl or alkenyl esters or diesters of sulfosuccinic acid in which the alkyl or alkenyl groups independently contain from six to eighteen carbon atoms and alkali metal, ammonium, calcium and magnesium salts thereof, and mixtures thereof, in a concentration range of from about 0.02 to about 8 w / w % of the solution. Optionally, the solution may contain (iii) at least one additional ingredient chosen from a monocarboxylic acid, a polycarboxylic acid, and mixtures thereof, in a concentration of from about 0.05 to about 4 w / w % of the solution; and (iv) at least one further additional ingredient chosen from benzyl alcohol, an alcohol comprising one to six carbon atoms, and mixtures thereof, in a concentration of from about 0.1 to about 10 w / w % of the solution.

Owner:JOHNSONDIVERSEY INC

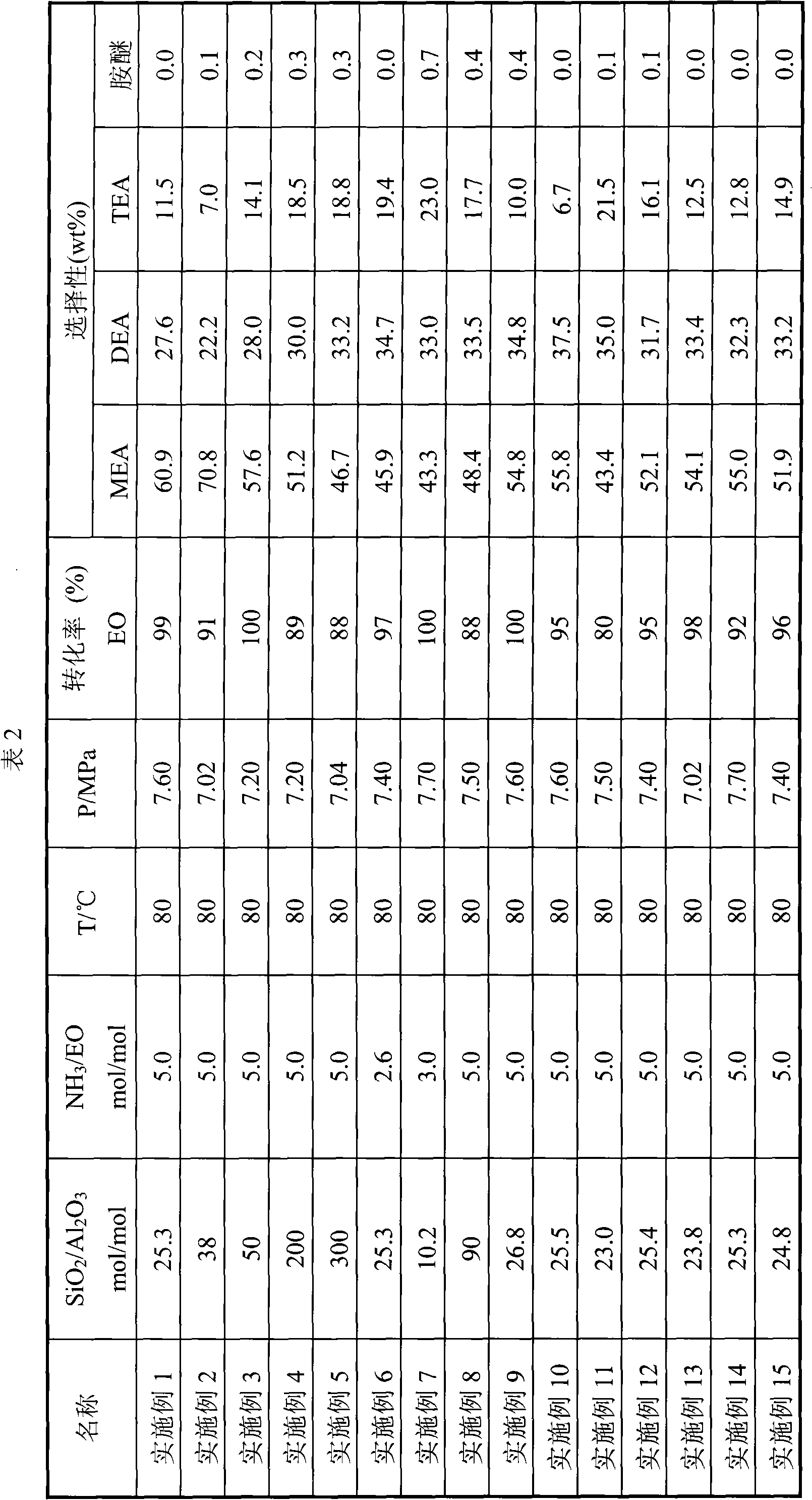

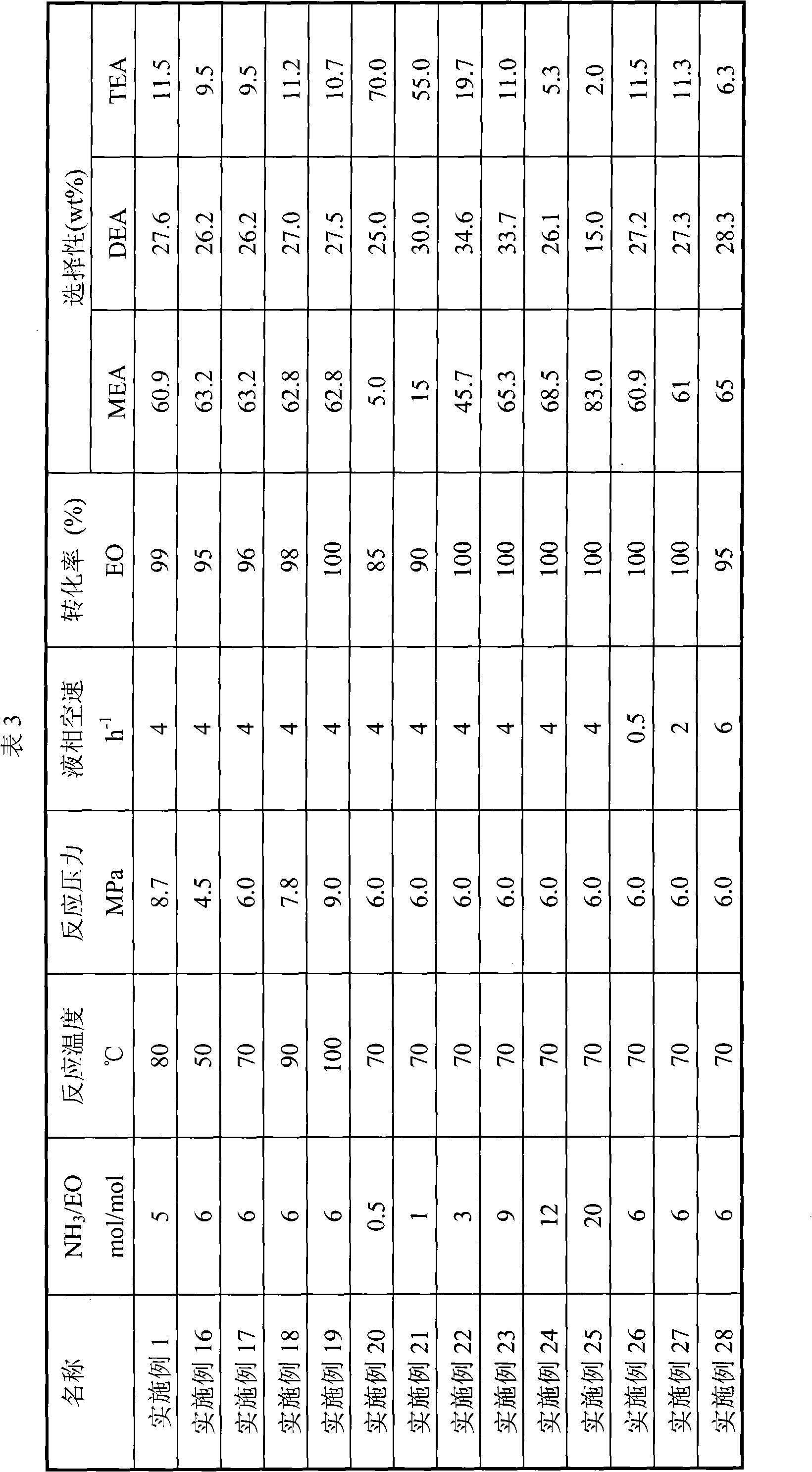

Method for producing ethanolamine

ActiveCN101885686AGood acidity distributionPromote regenerationMolecular sieve catalystsOrganic compound preparationEthylene oxideReaction temperature

The invention relates to a method for producing ethanolamine, mainly solving the technical problem of high reaction temperature and high system pressure in the prior art. The technical problem is well solved by using a technical scheme in which ethylene oxide and ammonia are used as raw materials and ZSM-5 is taken as a catalyst for reaction to produce ethanolamine under the conditions that the mole ratio of ammonia to ethylene oxide is 0.5-15, the reaction temperature is 50-100 DEG C, the system pressure is 4-12 MPa, and liquid-phase space velocity is 0.5-4h<-1>. The method can be used in the industrial production of the ethanolamine.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com