Patents

Literature

50results about How to "Good quality finish" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Cleaning sheet

InactiveUS6624135B2Good quality finishEasy to cleanOrganic detergent compounding agentsLiquid soapsMorpholineActive agent

A cleaning sheet having high cleaning ability and with which finished quality of a surface after cleaning is excellent. A cleaning sheet comprising a sheet base material impregnated with an aqueous cleaning composition that has a pH value of 8 to 11, the composition comprising (A) at least one compound selected from monoethanolamine, morpholine and morpholine derivative compounds, (B) a saturated or unsaturated fatty acid having 14 to 22 carbon atoms, (C) a terpene-type hydrocarbon, and (D) a surfactant.

Owner:SC JOHNSON & SON INC

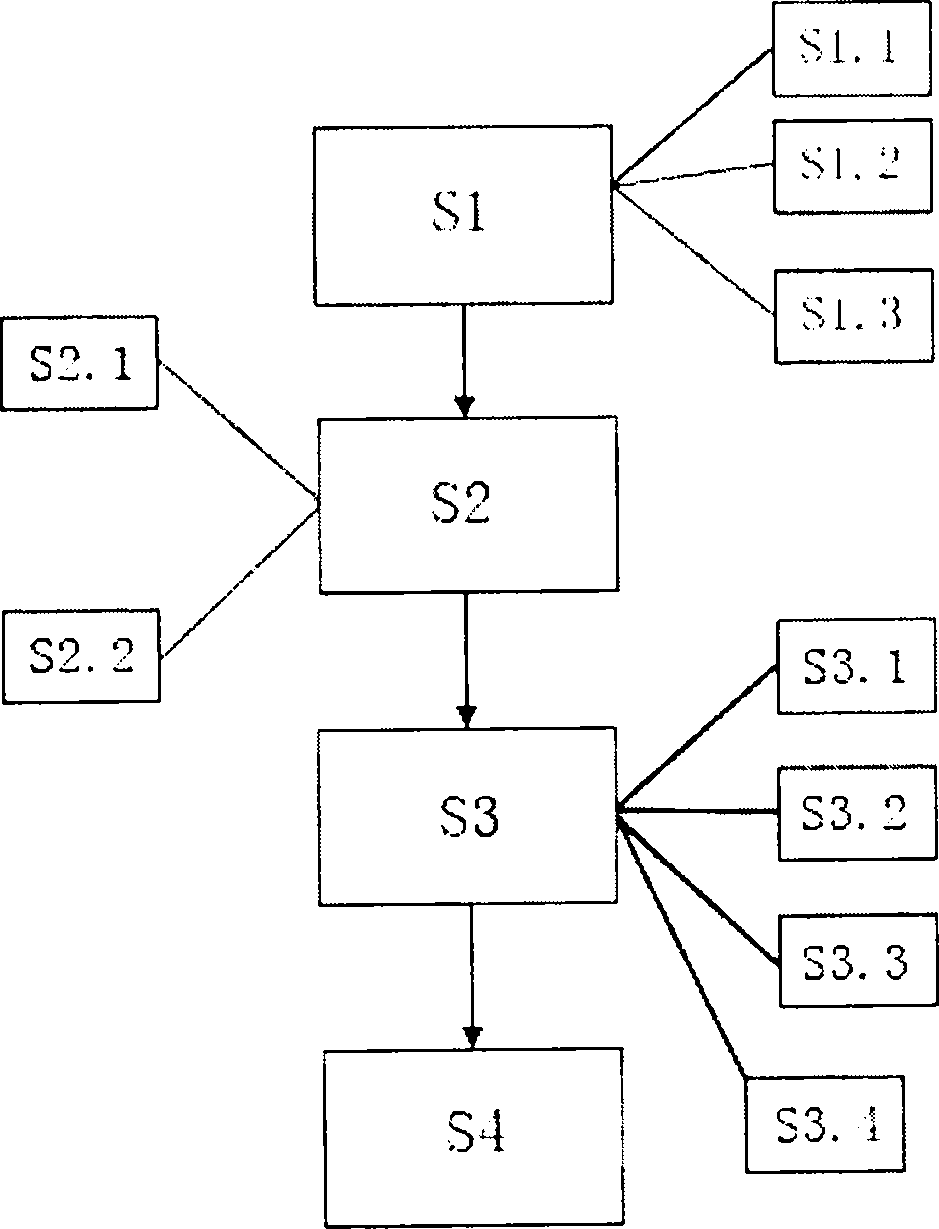

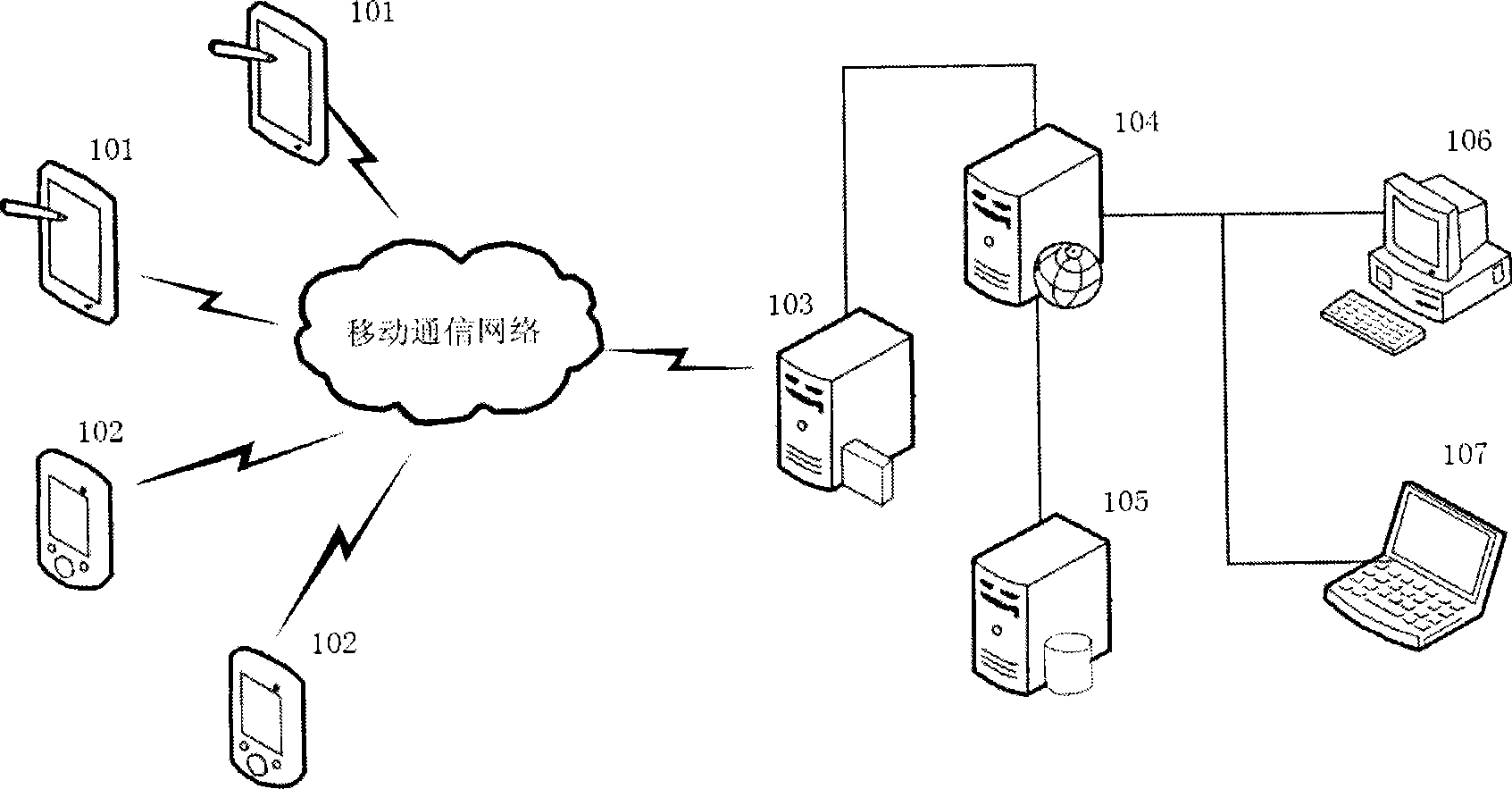

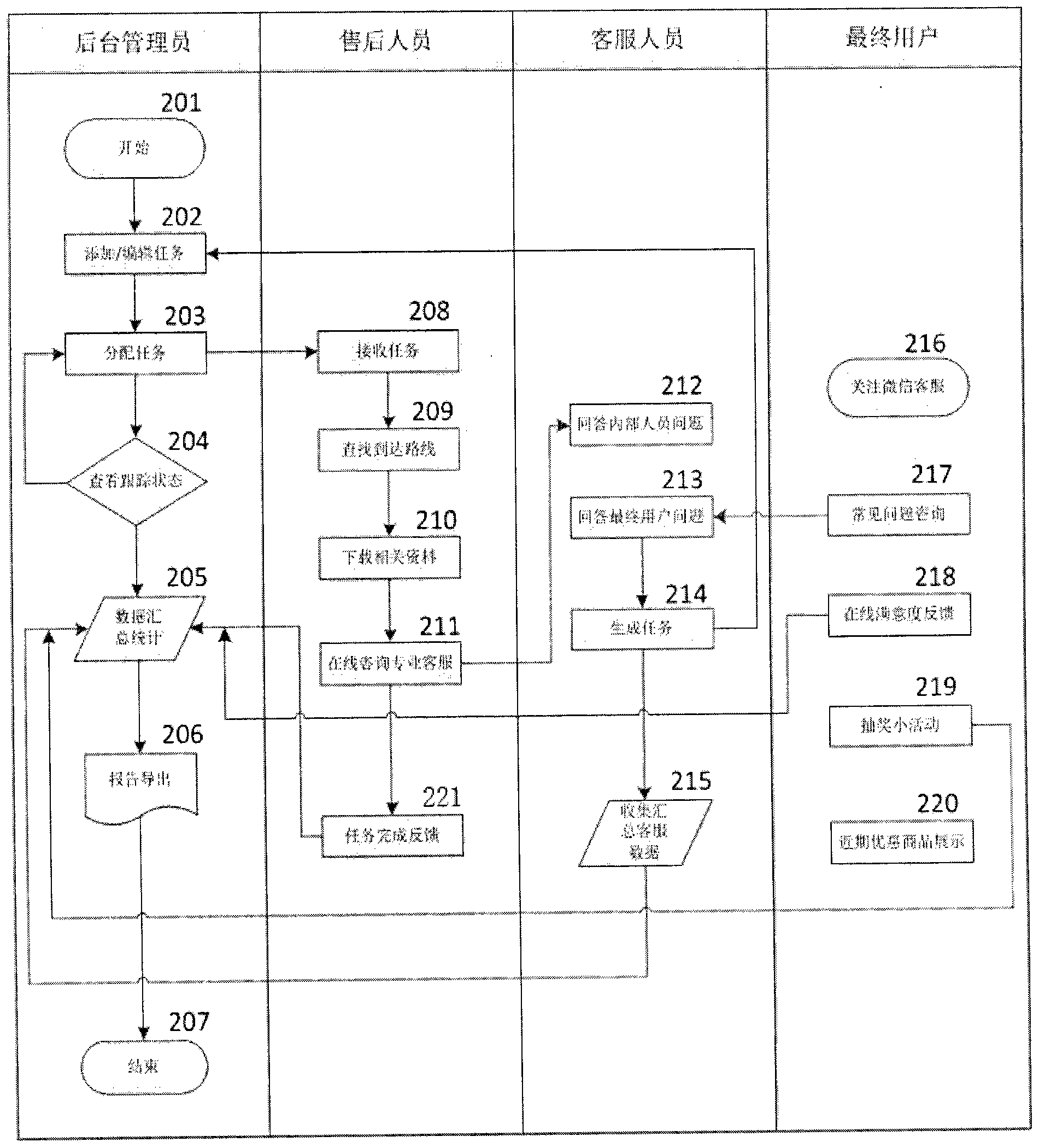

Mobile after-sales service method

ActiveCN104066053AGood quality finishIncrease stickinessResourcesLocation information based serviceService personnelApplication server

The invention relates to a mobile after-sales service method. An application server transmits data or an instruction to a client of after-sales service personnel regularly or irregularly. The client of after-sales service personnel responds to the transmitted data or instruction, and uploads verification data and / or after-sales data to the application server, or the client of the after-sales service personnel actively uploads the verification data and / or after-sales data to the application server regularly or irregularly. The application server can evaluate the state of the after-sales service personnel through combining with the transmitted data or instruction according to the verification data and / or after-sales data. The after-sales service personnel receive a task, inquire a route and download data through an after-sales APP. Moreover, if there is a problem, a user can timely consult customer service staff, thereby improving the efficiency and quality of the after-sale service. In addition, the method achieves the real-time monitoring of the working state of the after-sales service personnel, and can verify the authenticity and rationality of the working state.

Owner:饶渐平

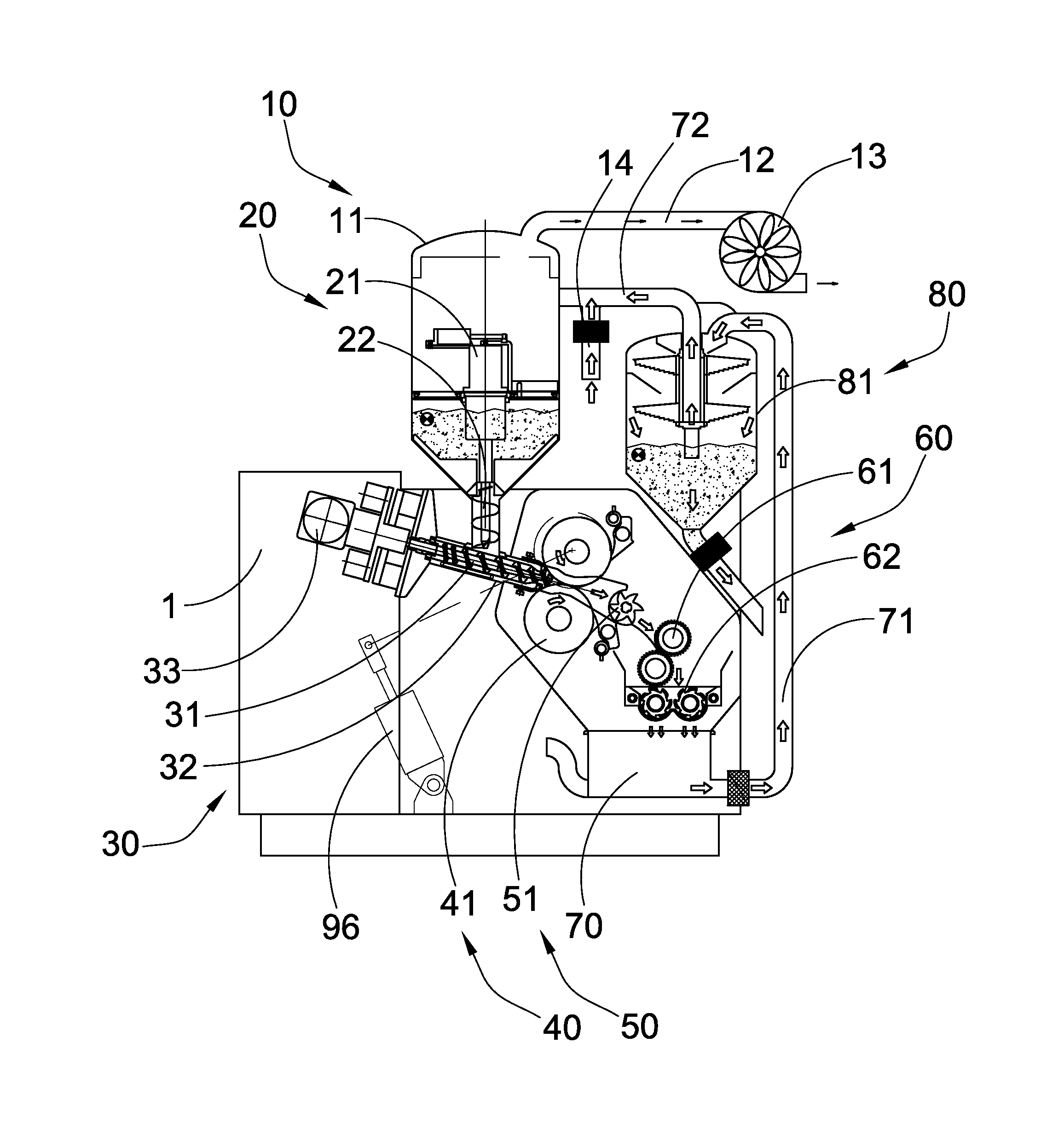

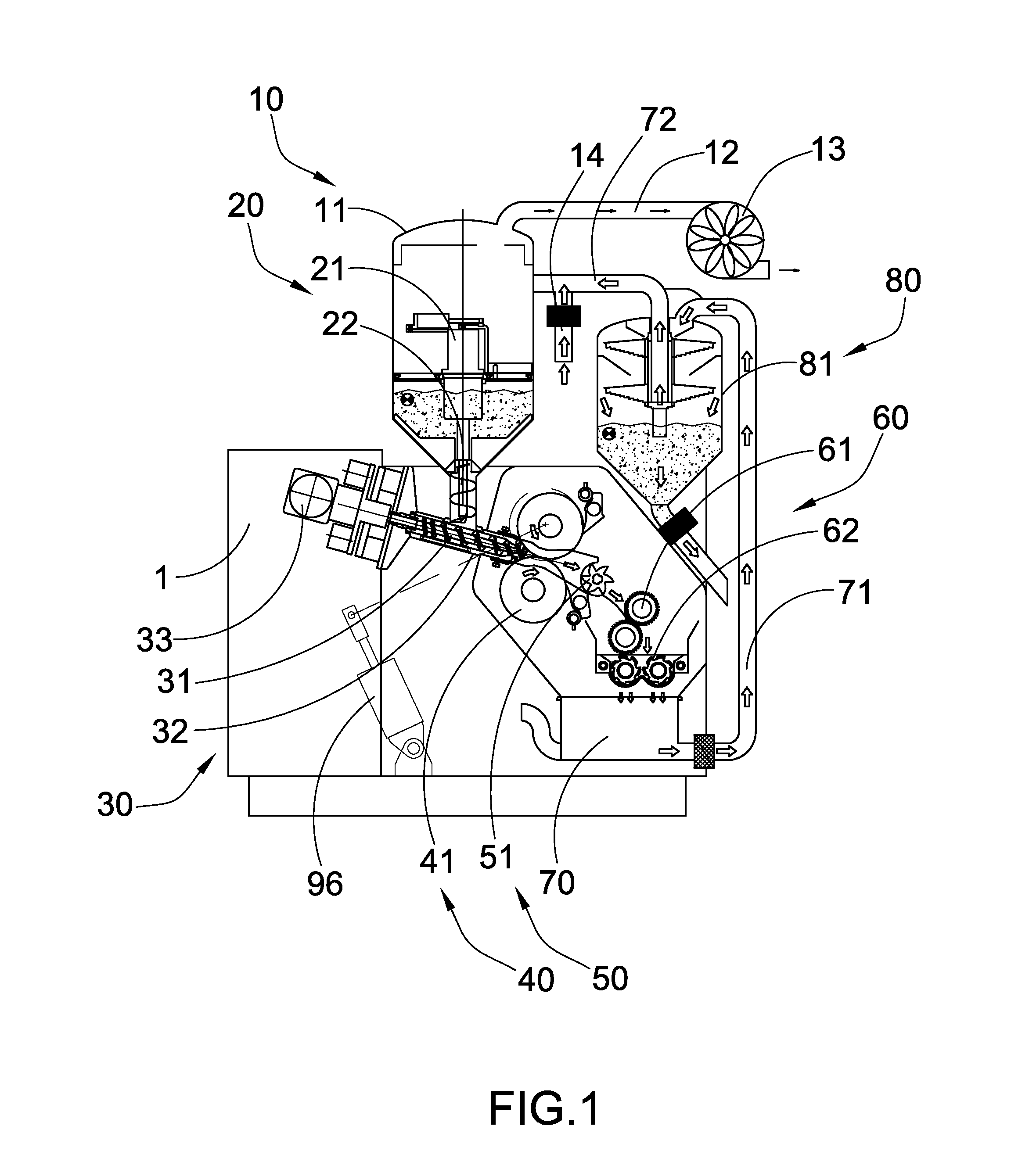

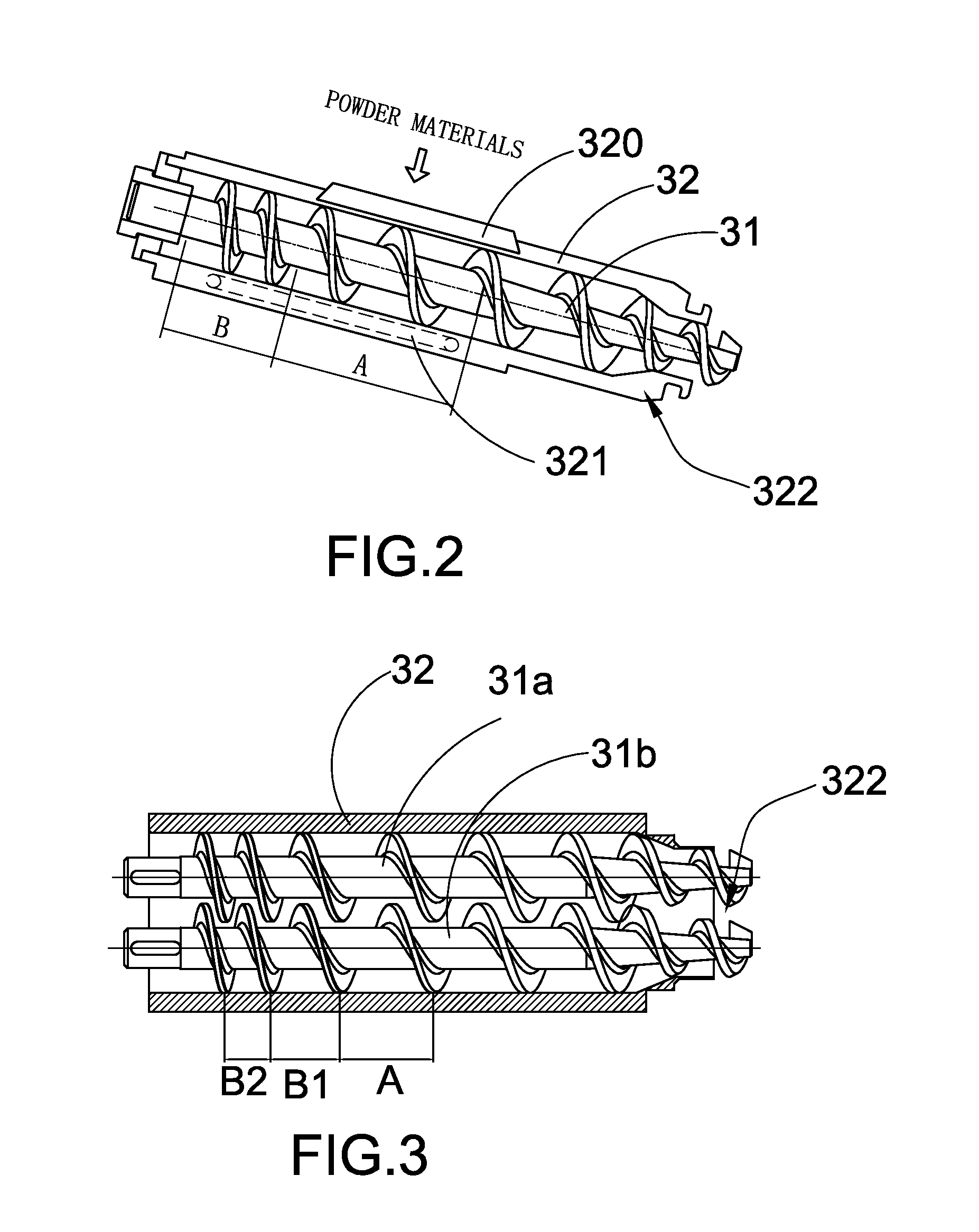

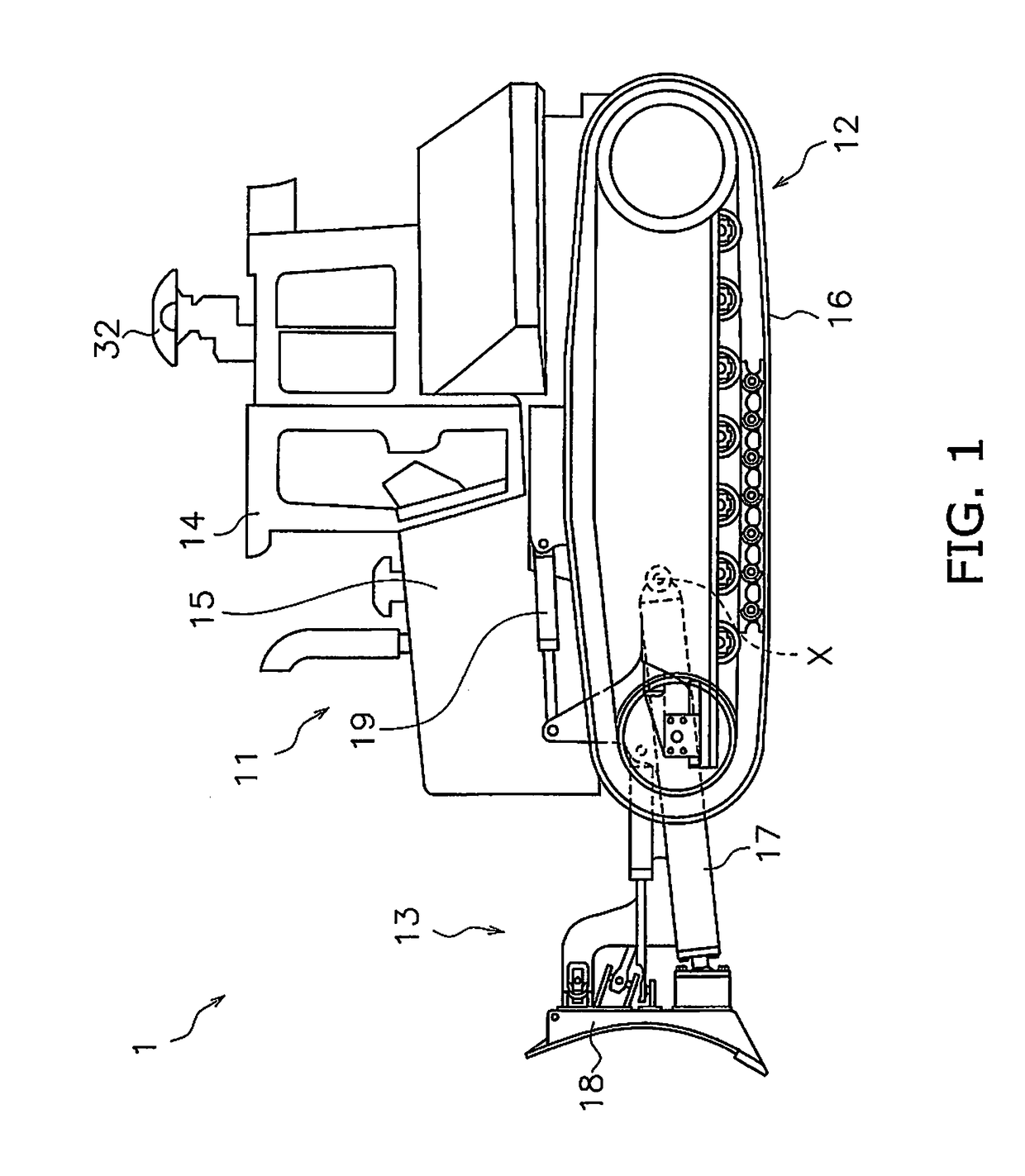

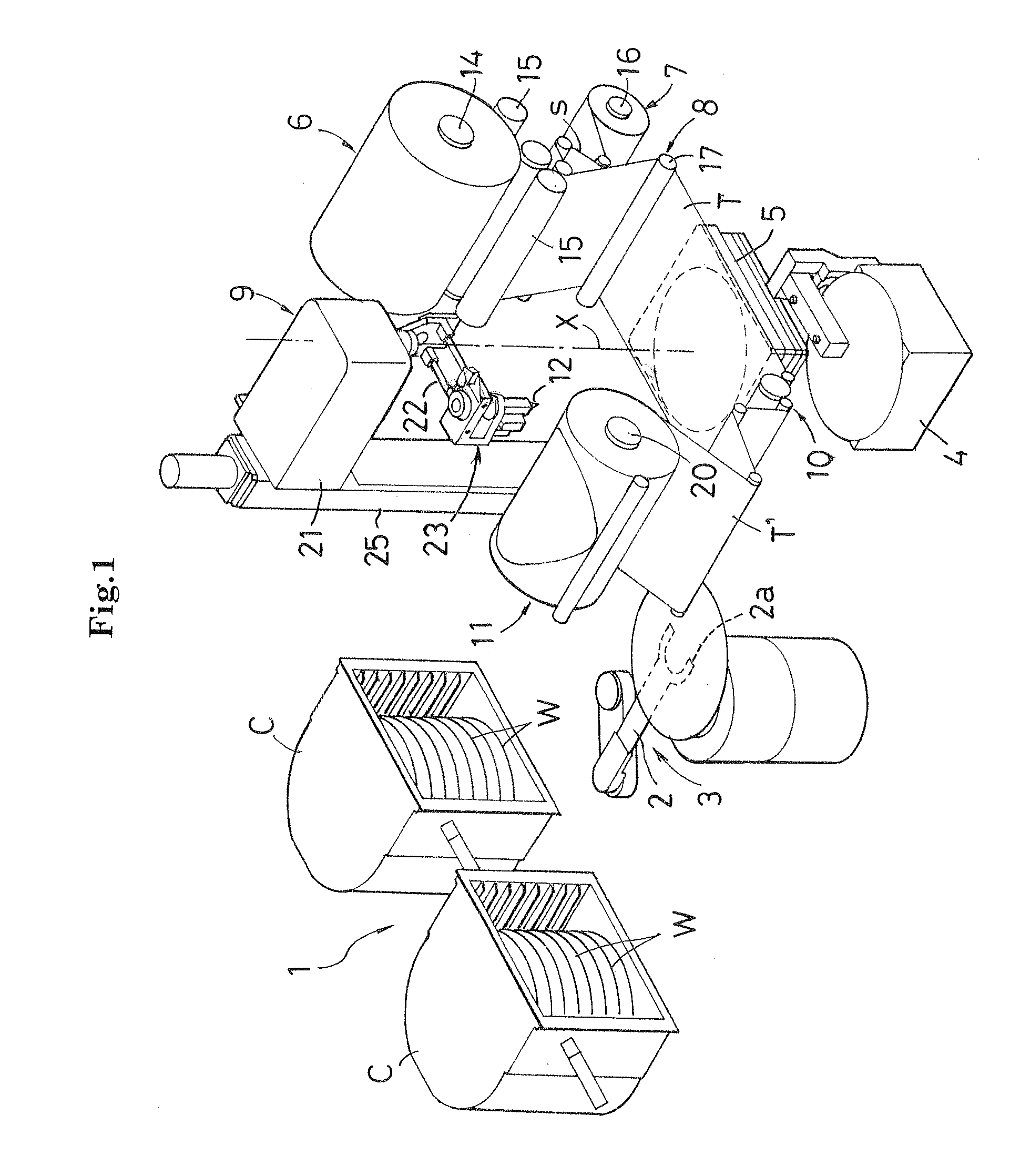

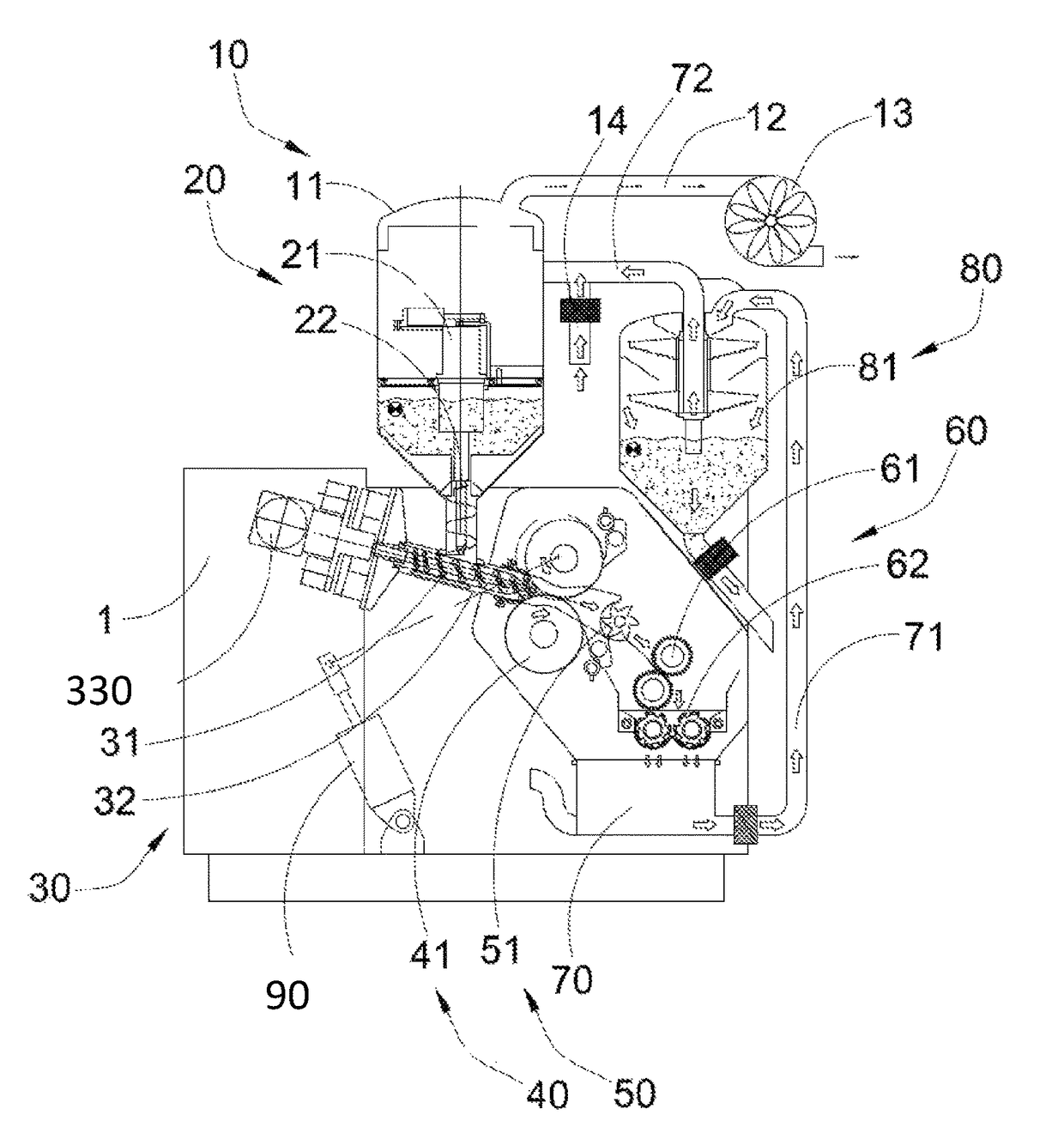

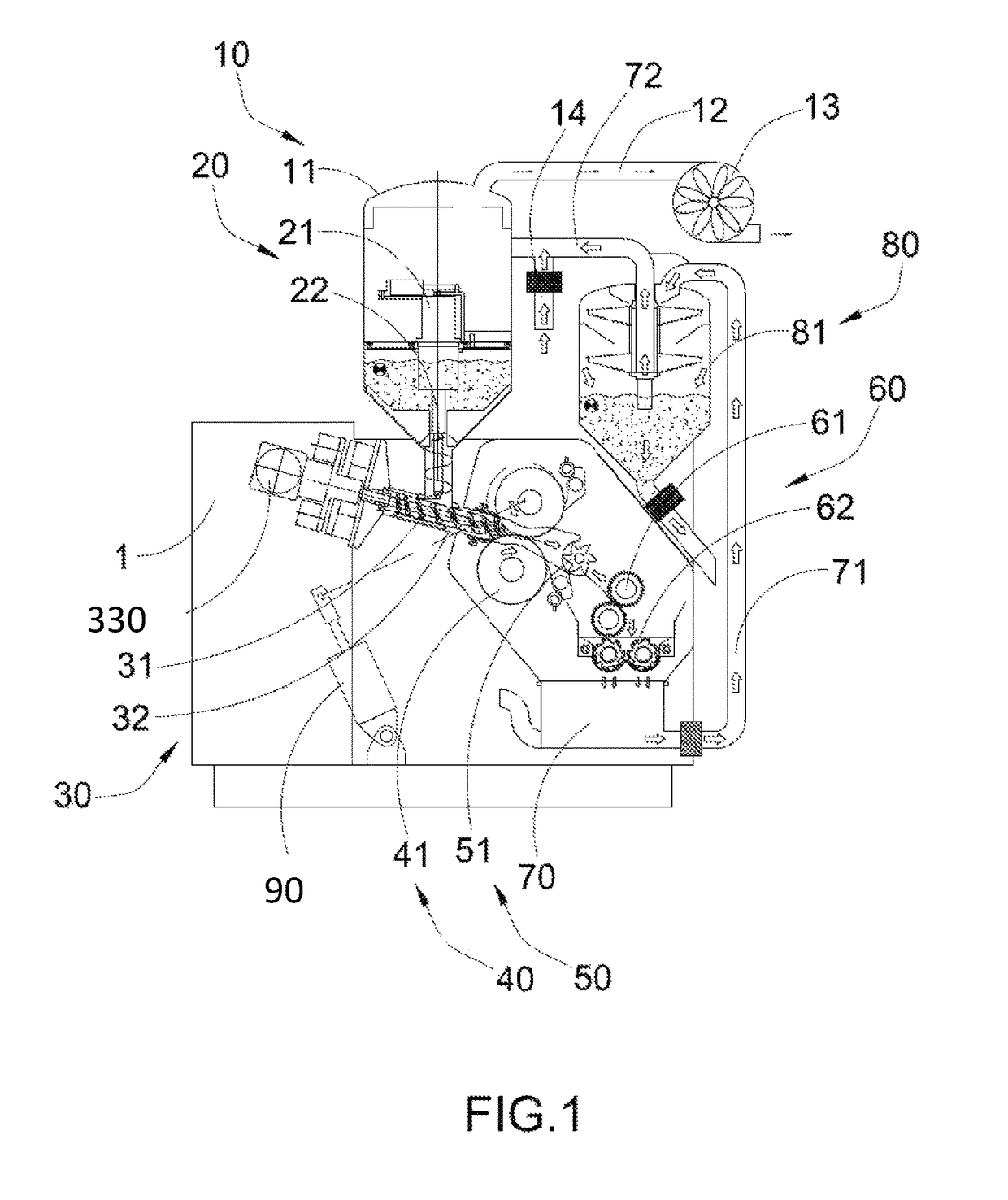

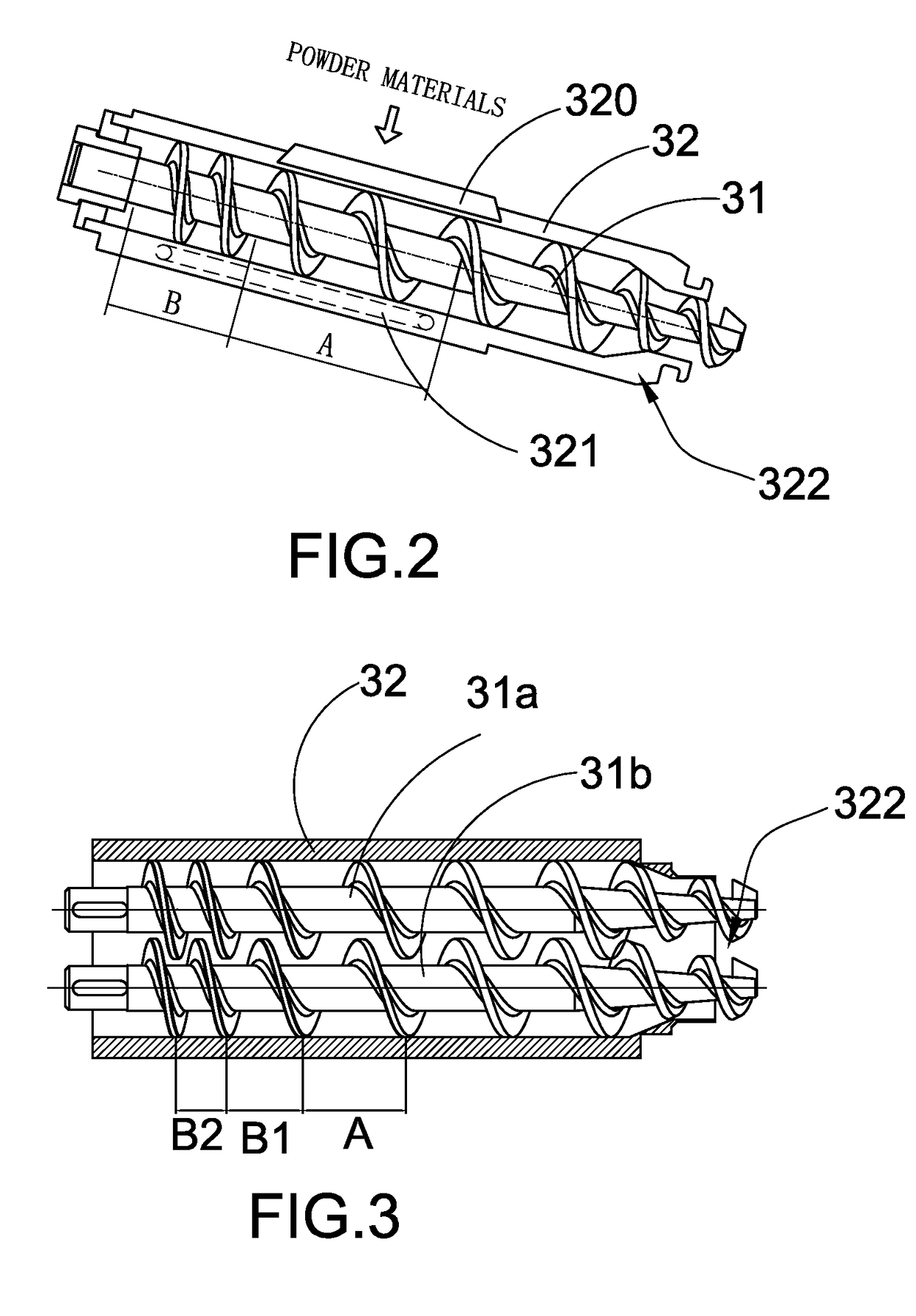

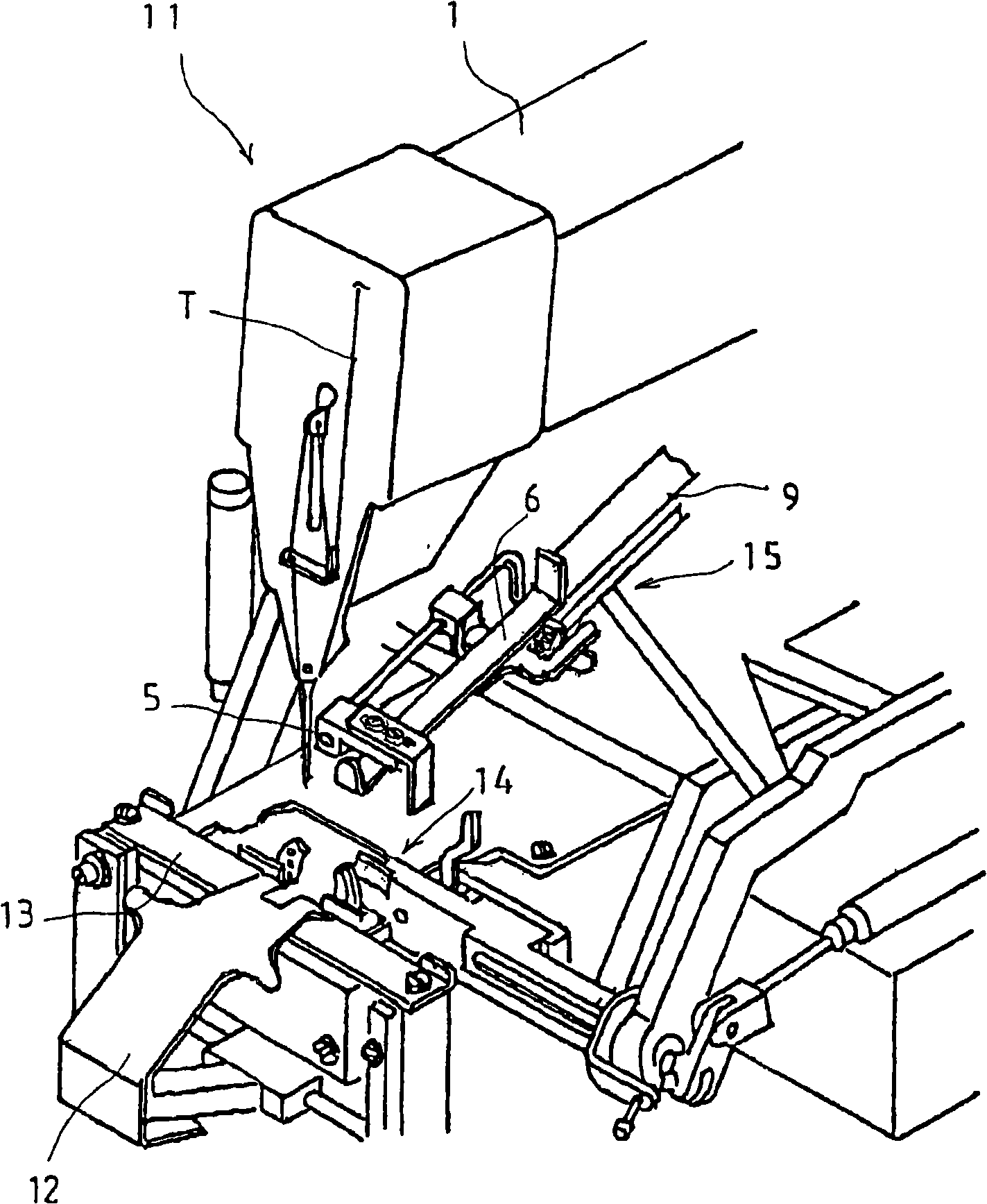

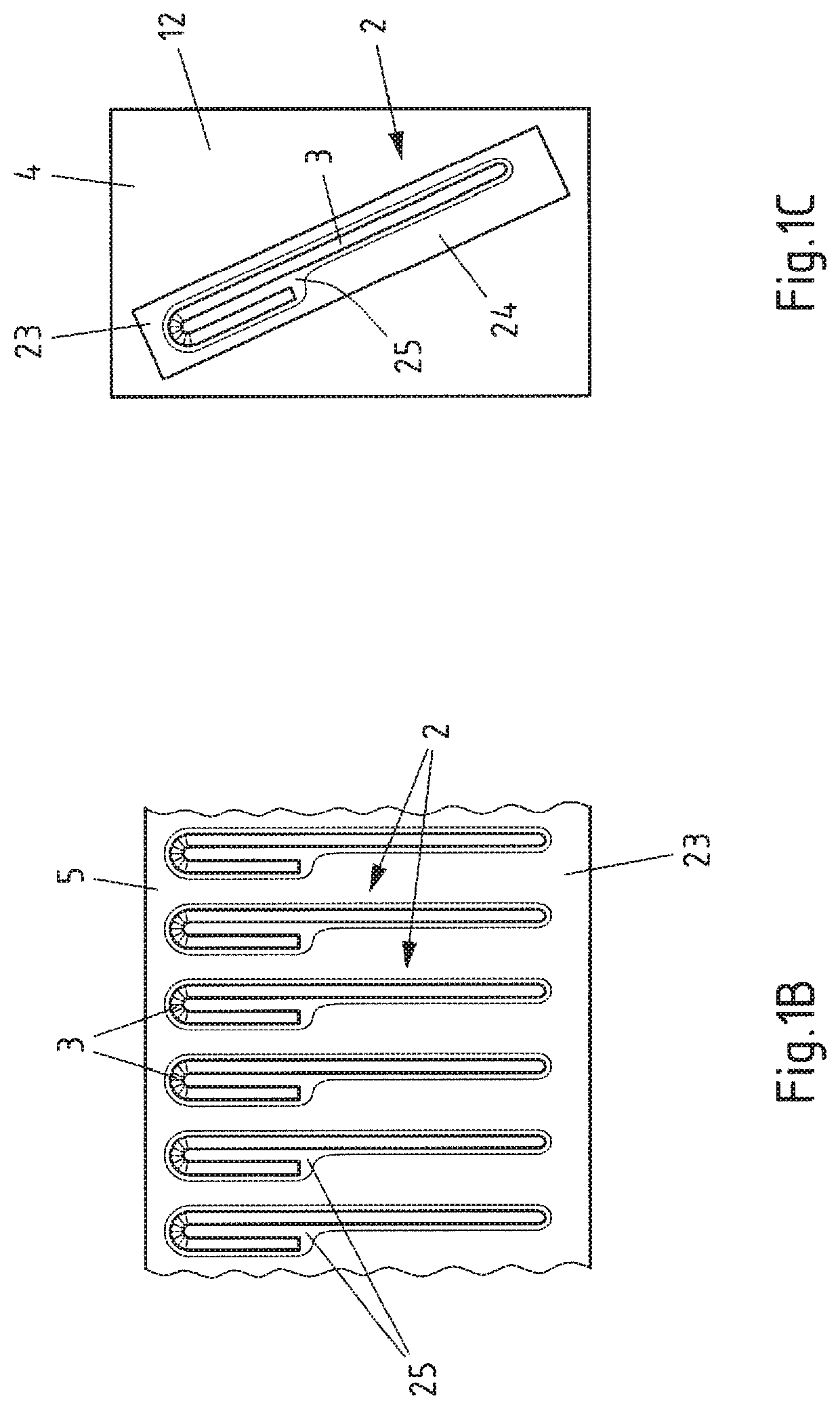

Dry Granulator

ActiveUS20150239152A1Compact structureImprove sealingDough homogenizationFrozen sweetsHardnessMaterials science

A dry granulator includes a feeding mechanism applied to suck powder materials into the material tanks; a vertical feeding mechanism to deliver the power materials to a bottom outlet of the material tank; a pressing mechanism to compress the powder materials into powder sheets with qualified hardness and thickness; an oblique feeding mechanism to deliver the powder materials to from the vertical feeding mechanism to the pressing mechanism; a crushing mechanism to crush the powder sheets into crushed powder sheets; a granulating mechanism to granulate the crushed powder sheet into finished particles products, so as to deliver to a collection storage; a sieving mechanism to separate the finished particle products with fine powders; a pressing wheel regulator applied to adjust an axial position of the lower and the upper pressing wheel; and a floating sealing device applied to provide a reliable sealing effect for the feeding mechanism.

Owner:ZHEJIANG FUTURE MACHINERY

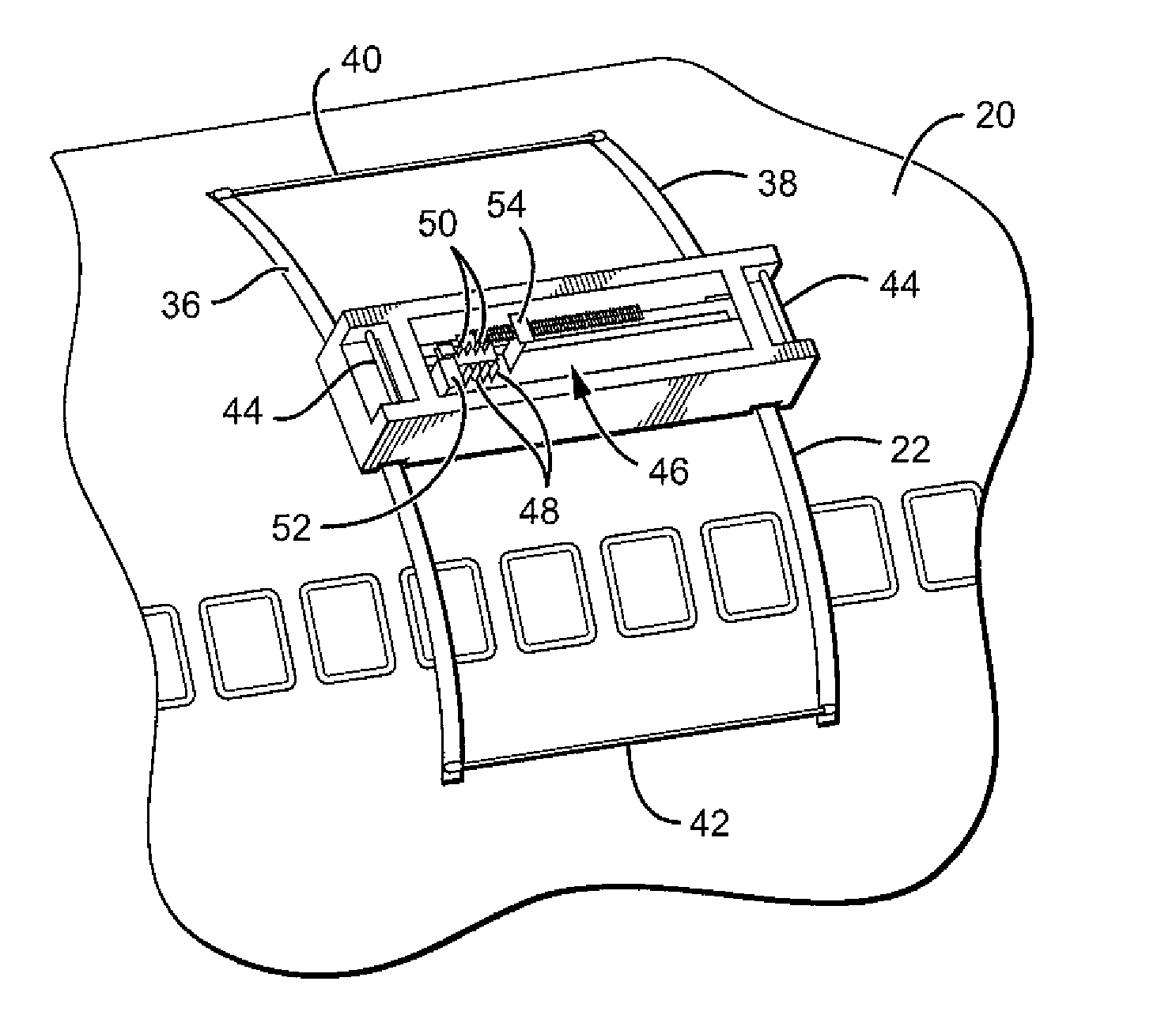

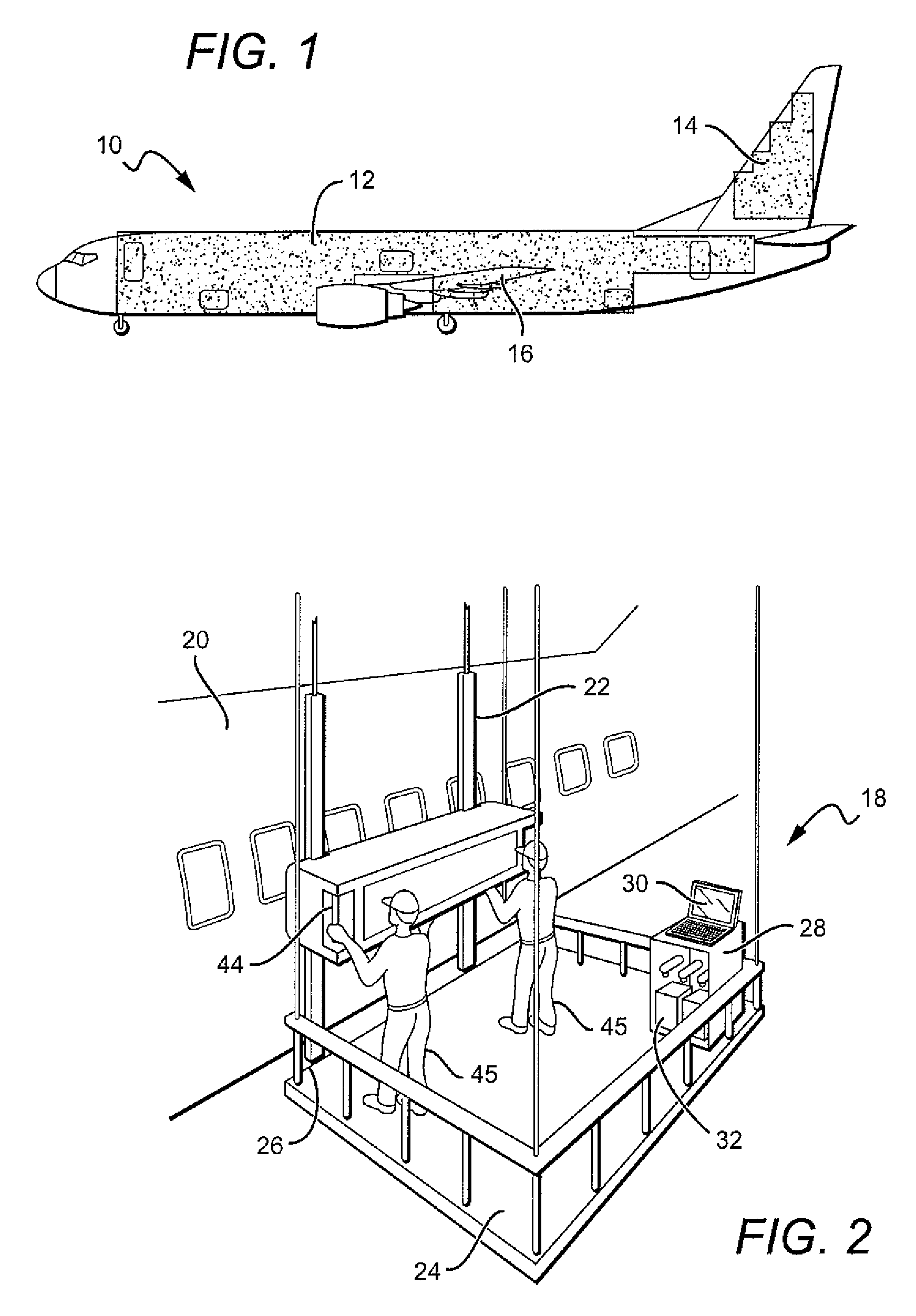

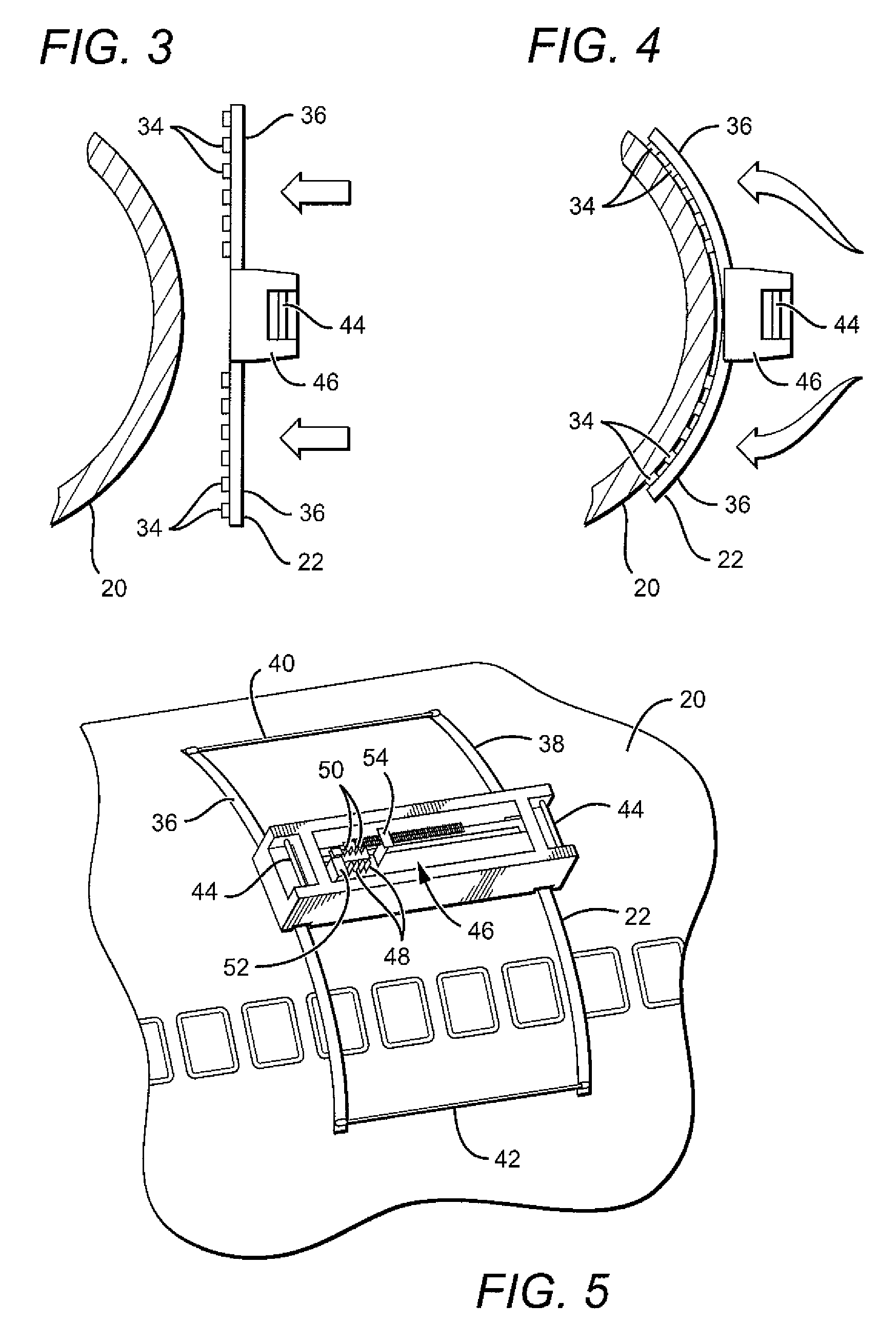

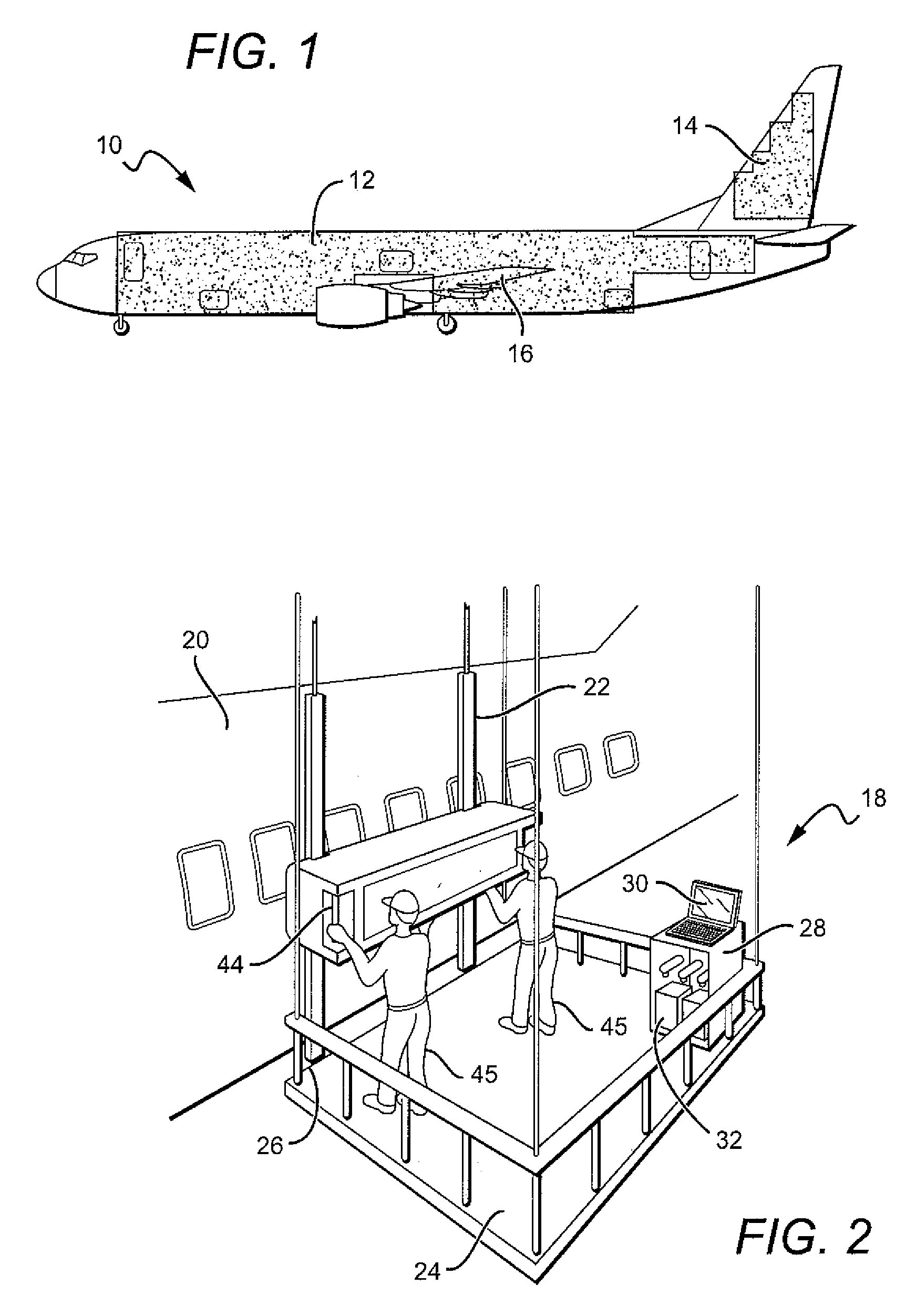

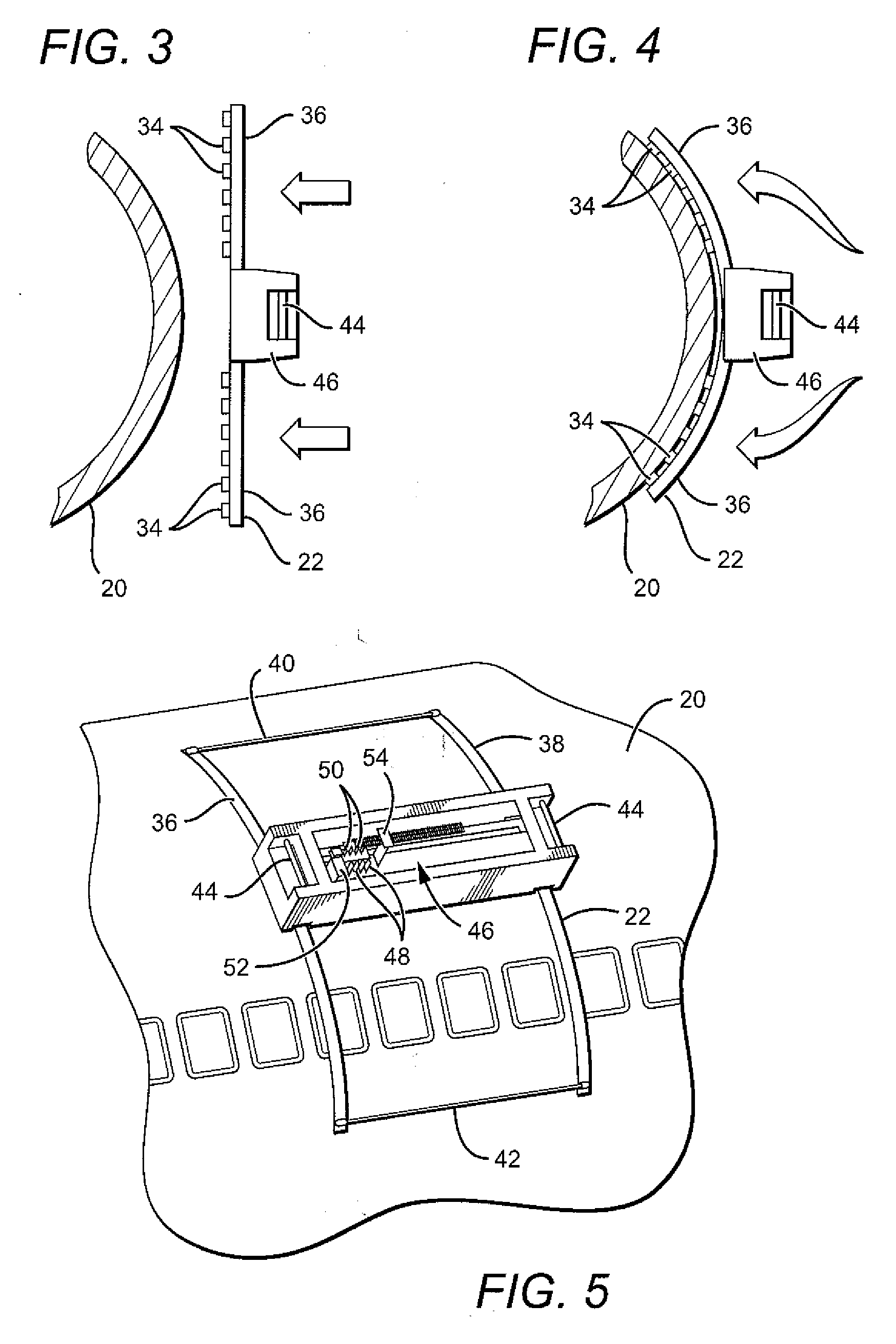

Method for application and accurate positioning of graphics on a surface

ActiveUS7922272B2Reduce labor costsFast curingDigitally marking record carriersLiquid surface applicatorsGraphicsPositioning system

There is provided a method of applying an accurately positioning at least one graphic image on a large contoured surface using an apparatus comprising a flexible-rail positioning system mounted on a portion of the surface on which the graphic image is to be applied, a graphic image application system, software to operate the positioning system, and software to operate the graphic image application system.

Owner:THE BOEING CO

Viscous Cosmetic

ActiveUS20070251541A1Improve storage conditionsLight evenlyCarpet cleanersDispensing apparatusFront edgeBiomedical engineering

A viscous cosmetic product that realizes smooth application thereof to application target areas and that prevents liquid dripping thereof onto a surface of a viscous cosmetic substance container and is free from stickiness at use thereof, enabling clean use thereof. A viscous cosmetic substance containing 1.0 to 10.0 wt % of silicic anhydride is accommodated in a tubular accommodation part. A front edge wall of the accommodation part is furnished with one or more distribution ports for the viscous cosmetic substance, and an application face is provided outside the front edge wall. Furthermore, the accommodation part thereinside is fitted with an inner tray that enables pressing the viscous cosmetic substance accommodated in the accommodation part so as to enable the viscous cosmetic substance to be pushed outward through the distribution ports.

Owner:SHISEIDO CO LTD

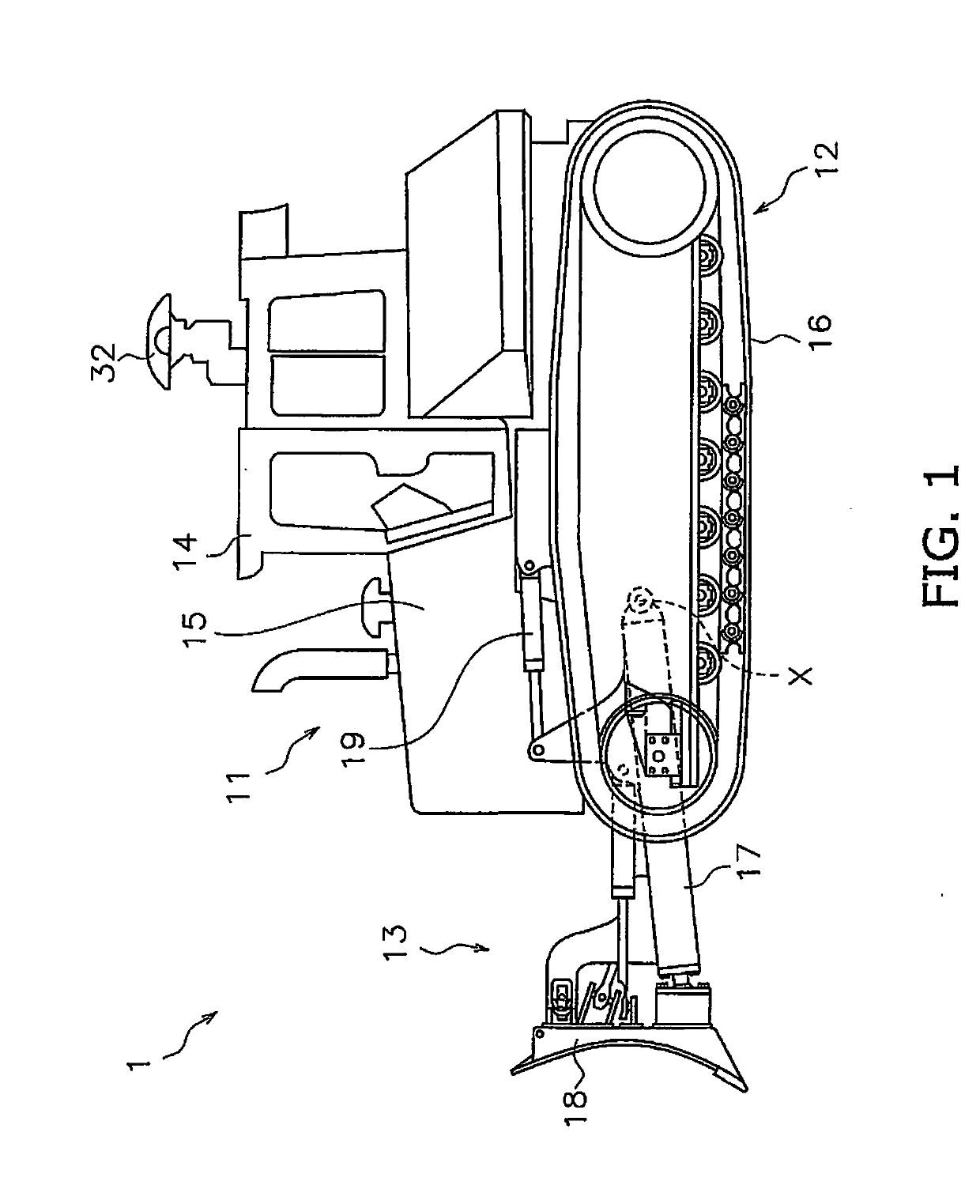

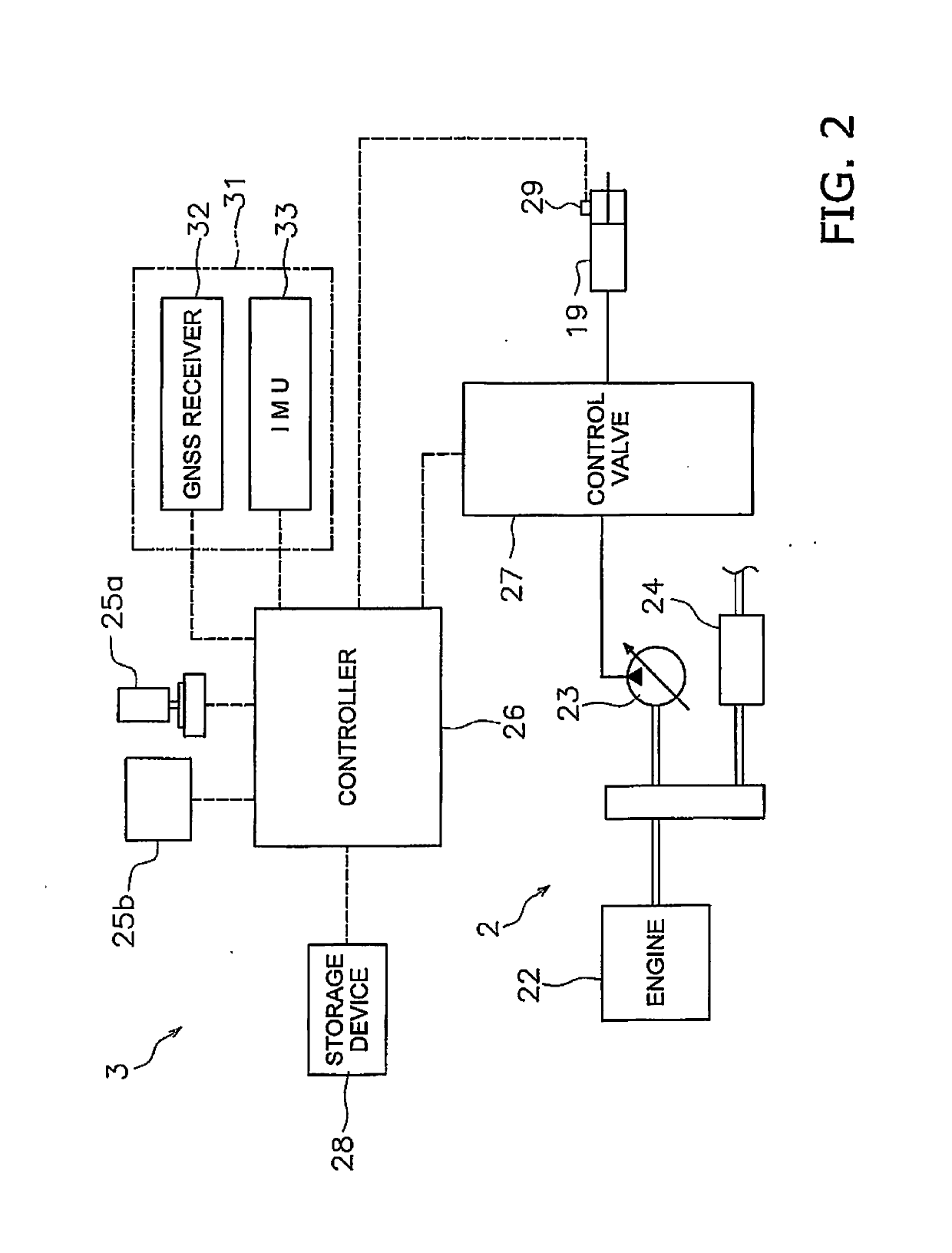

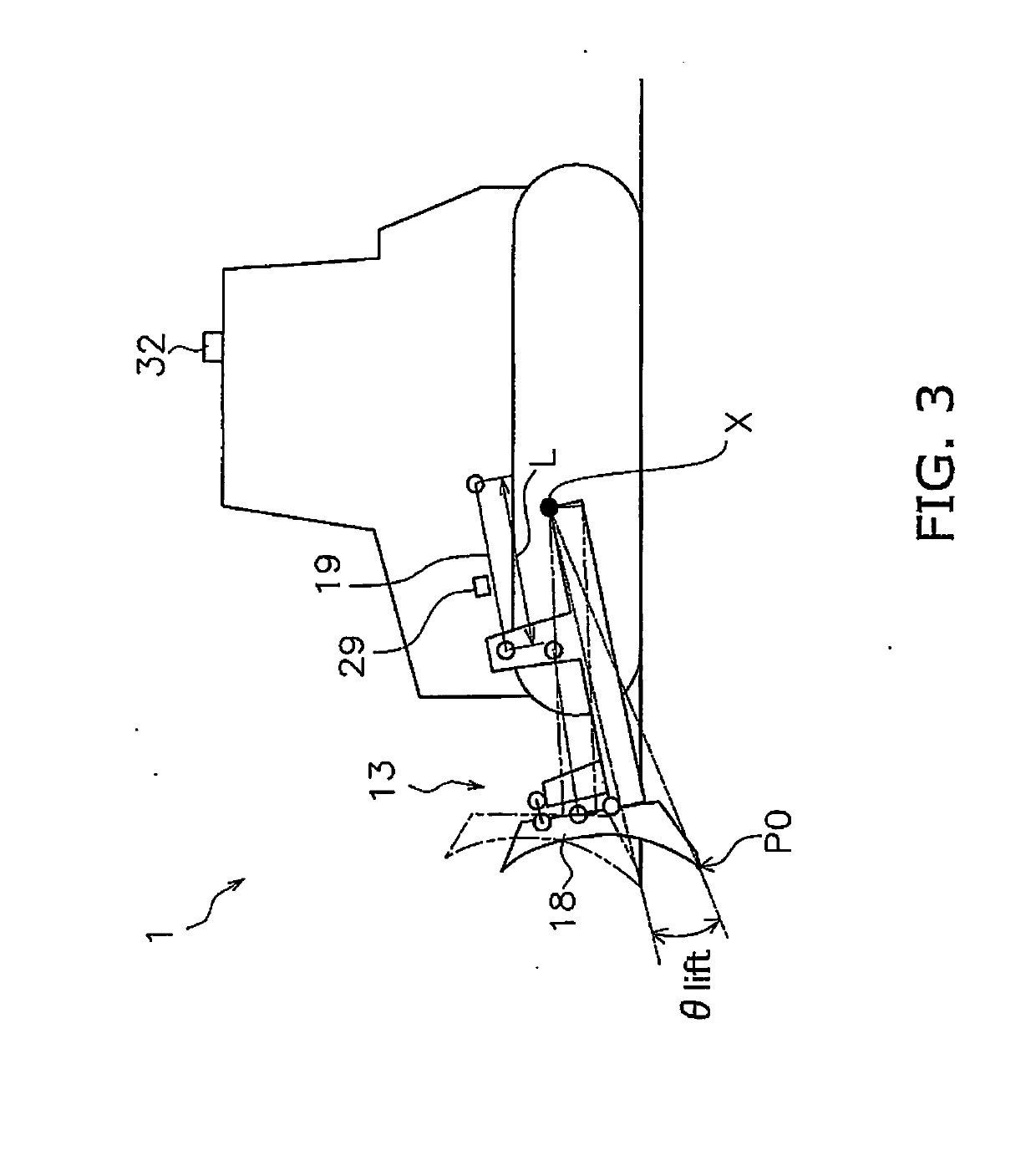

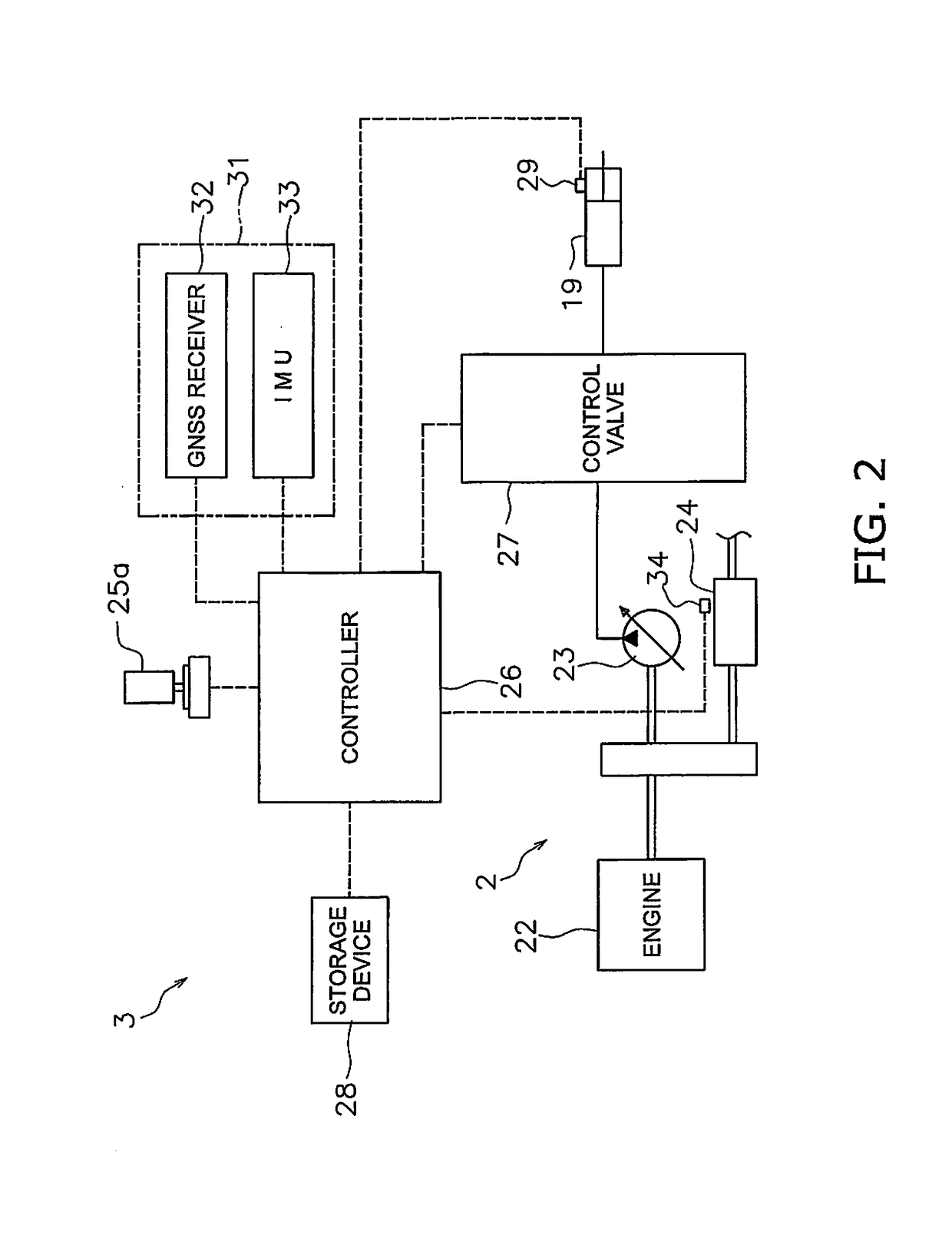

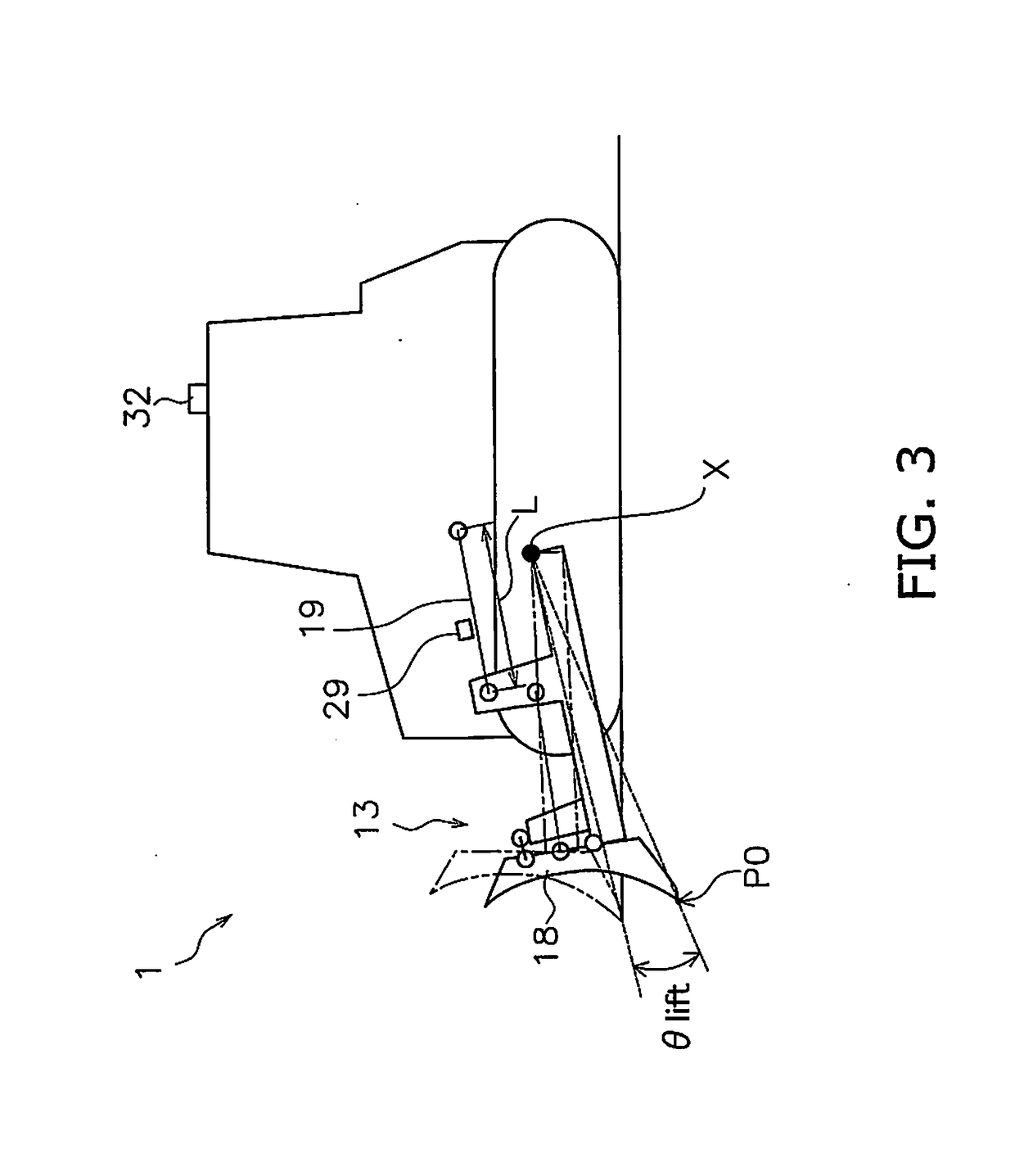

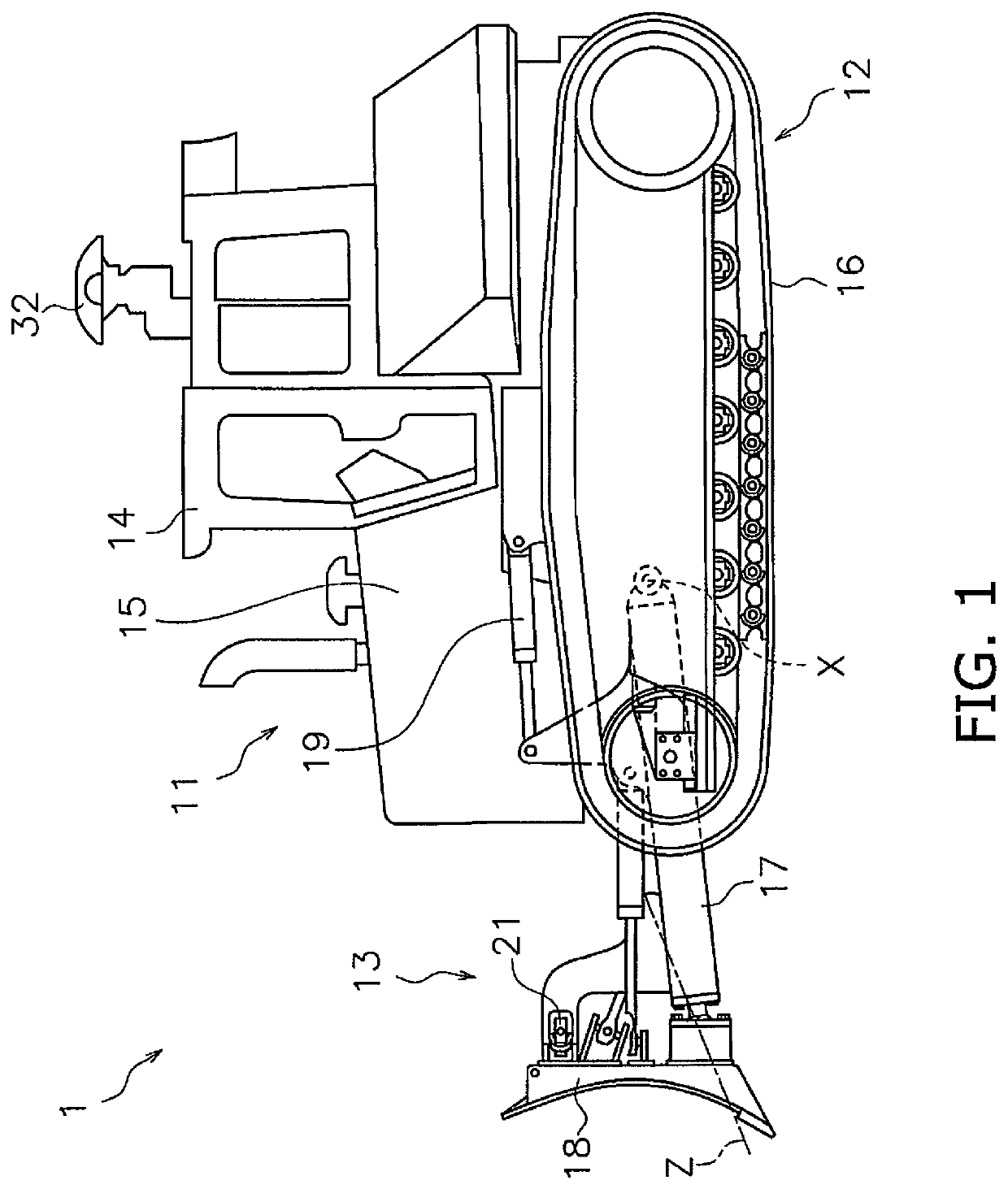

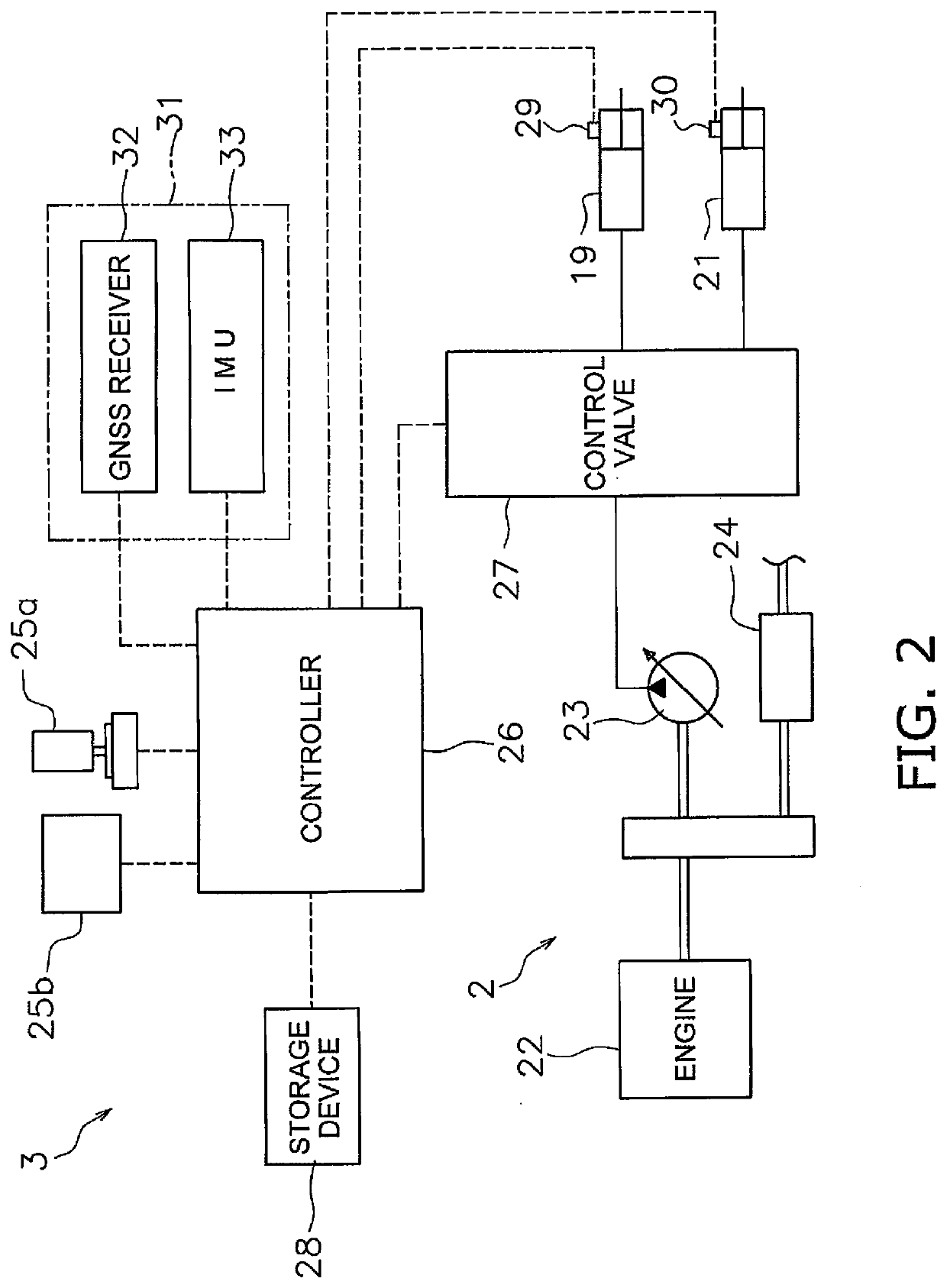

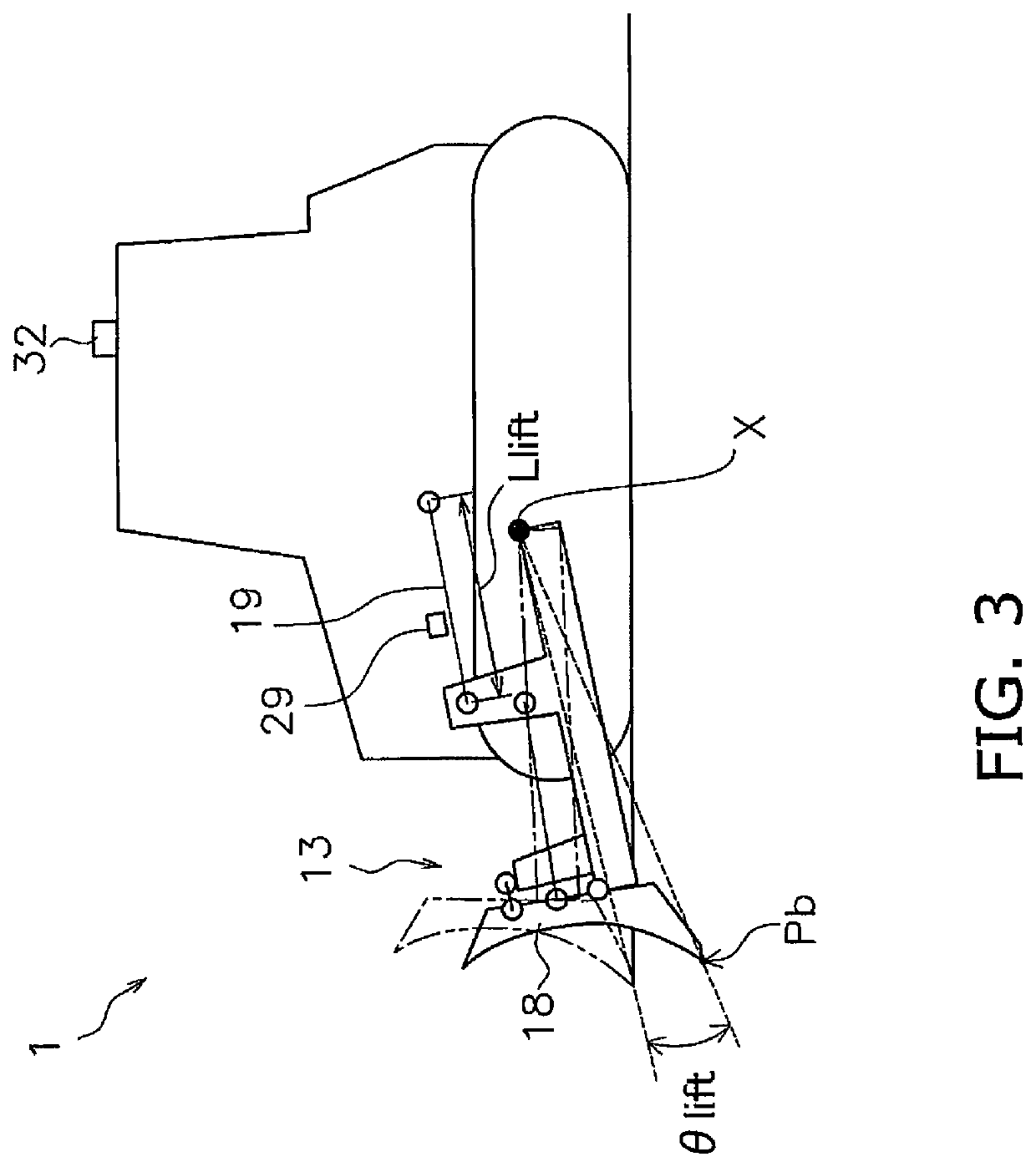

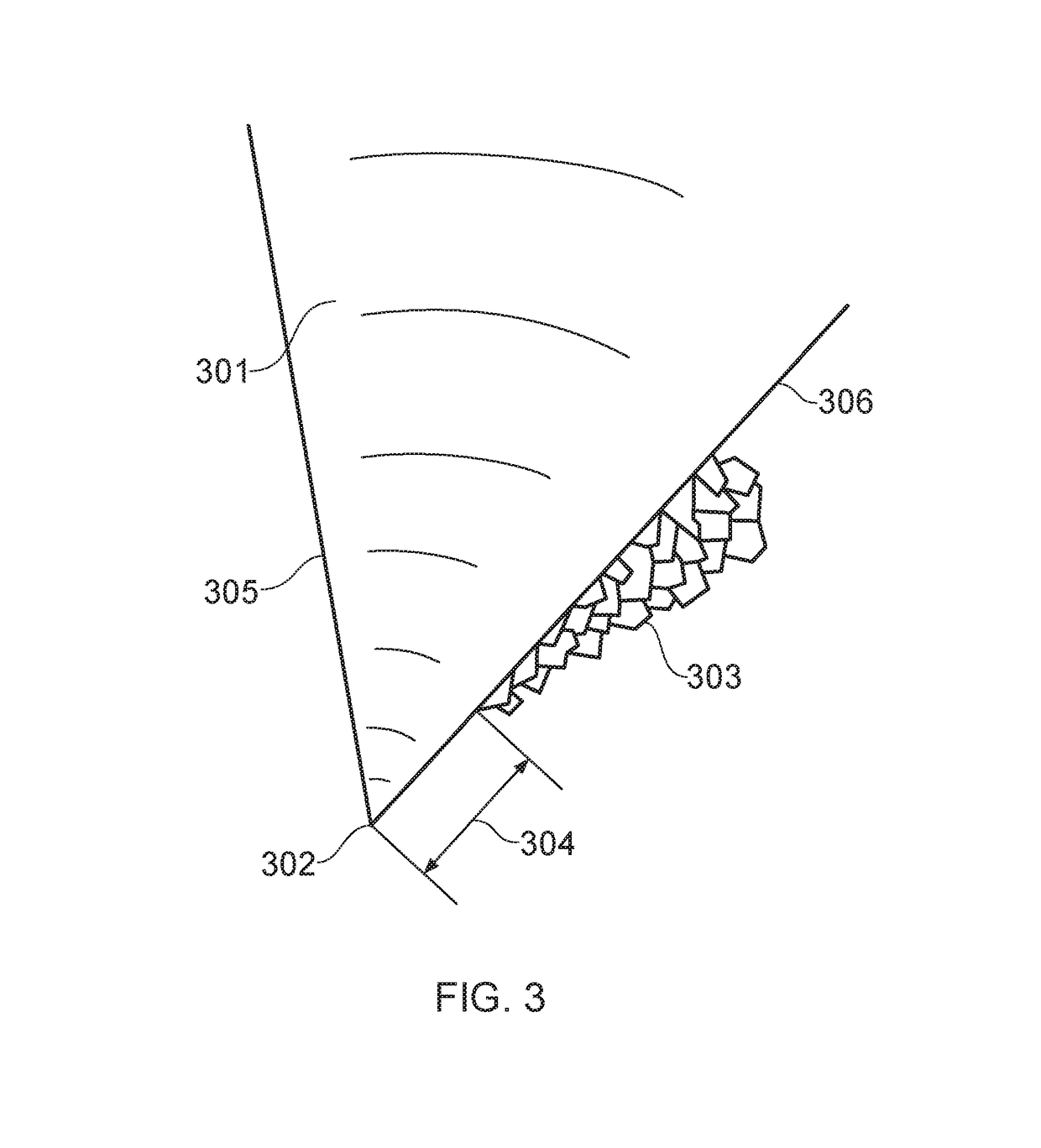

Control system for work vehicle, and method for setting trajectory of work implement

ActiveUS20190218745A1Good quality finishGuaranteed to workMechanical machines/dredgersVehicle position/course/altitude controlTerrainControl system

A control system includes a controller. The controller acquires current terrain data that indicates the current terrain to be worked. The controller decides on a target design terrain that is displaced vertically from the current terrain by referring to target displacement data. The target displacement data indicates the target displacement of a work implement according to the amount of movement from a work start position. The controller generates a command signal to move the work implement toward the target design terrain.

Owner:KOMATSU LTD

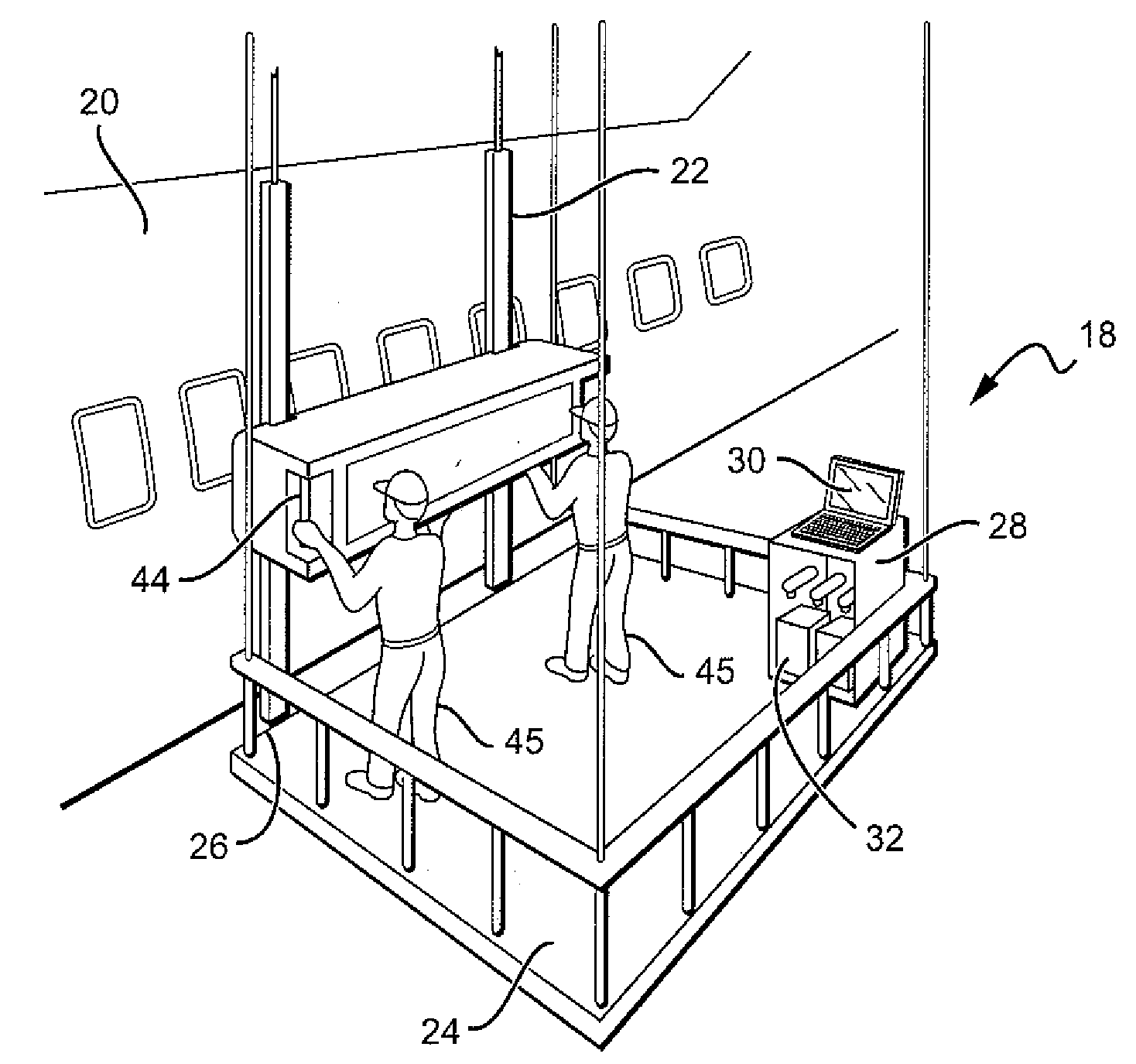

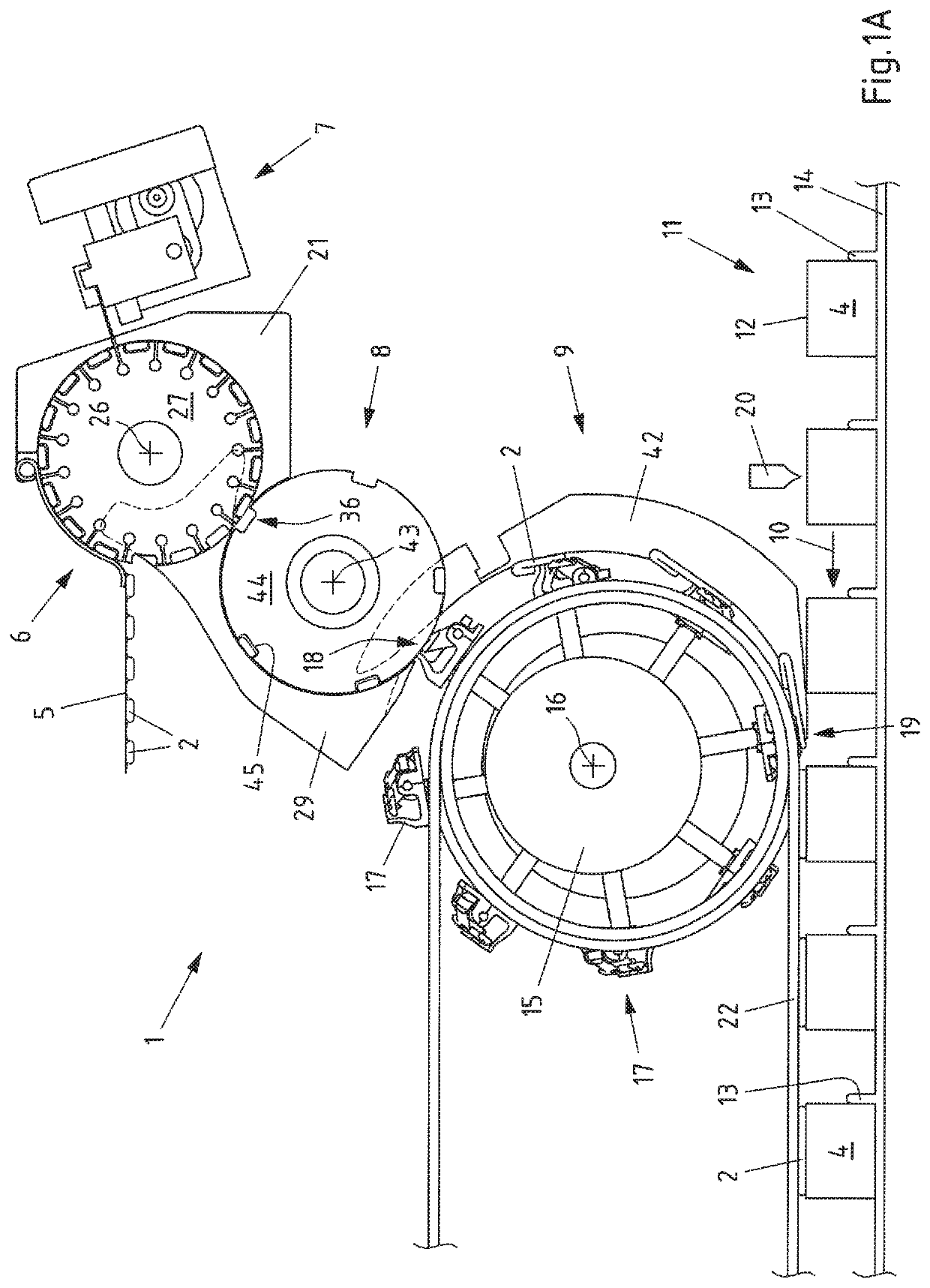

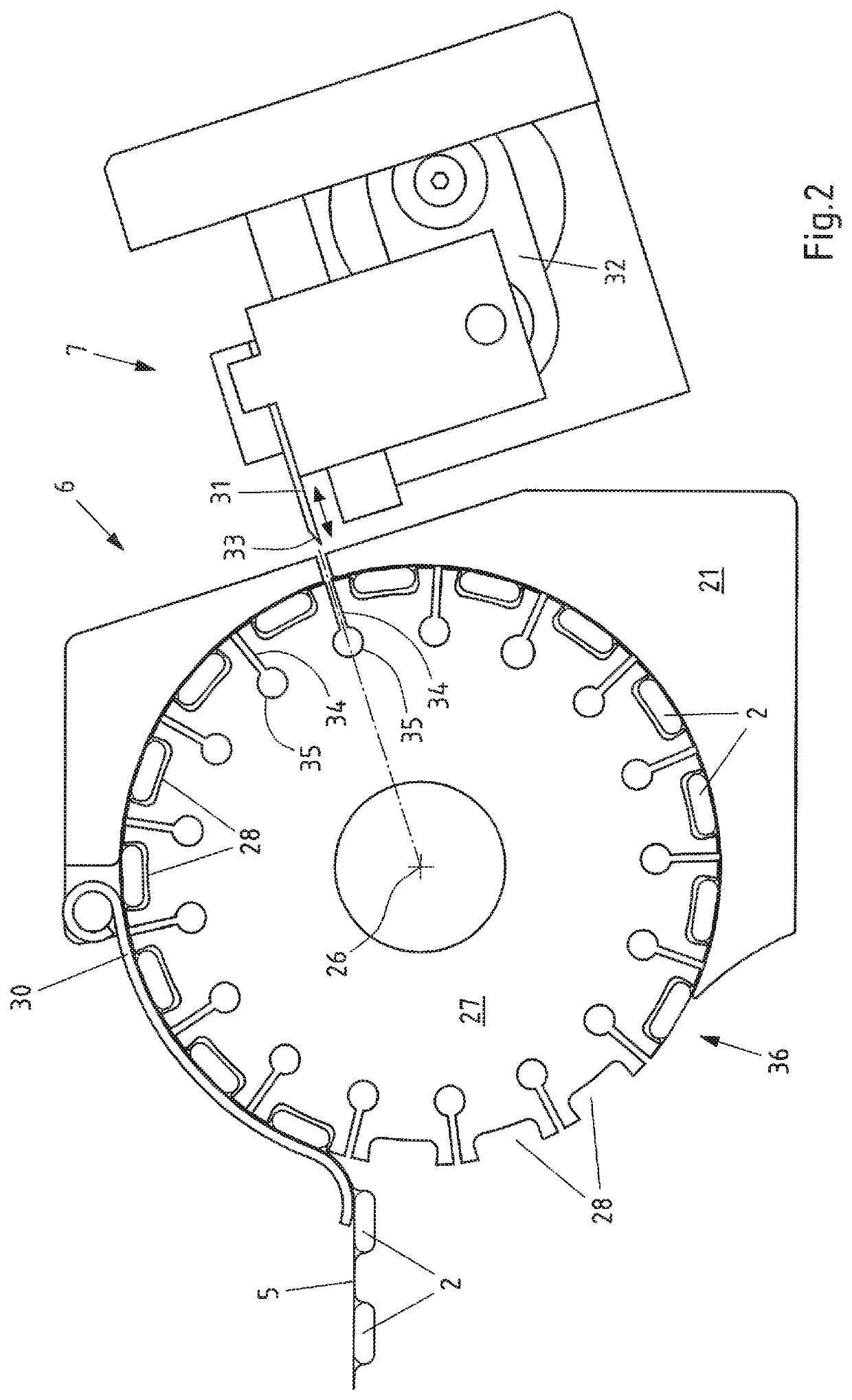

Apparatus and method for application and accurate positioning of graphics on a surface

ActiveUS20090257070A1Reduce labor costsFast curingDigitally marking record carriersLiquid surface applicatorsGraphicsPositioning system

In an embodiment of the invention, there is provided an apparatus for application and accurate positioning of at least one graphic image on a large contoured surface, comprising a flexible-rail positioning system mounted on a portion of the surface on which the graphic image is to be applied, a graphic image application system, software to operate the positioning system, and software to operate the graphic image application system. In another embodiment of the invention, there is provided a method of applying and accurately positioning at least one graphic image on a large contoured surface.

Owner:THE BOEING CO

Viscous cosmetic

ActiveUS7878728B2Improve storage conditionsLight evenlyCarpet cleanersDispensing apparatusFront edgeBiomedical engineering

Owner:SHISEIDO CO LTD

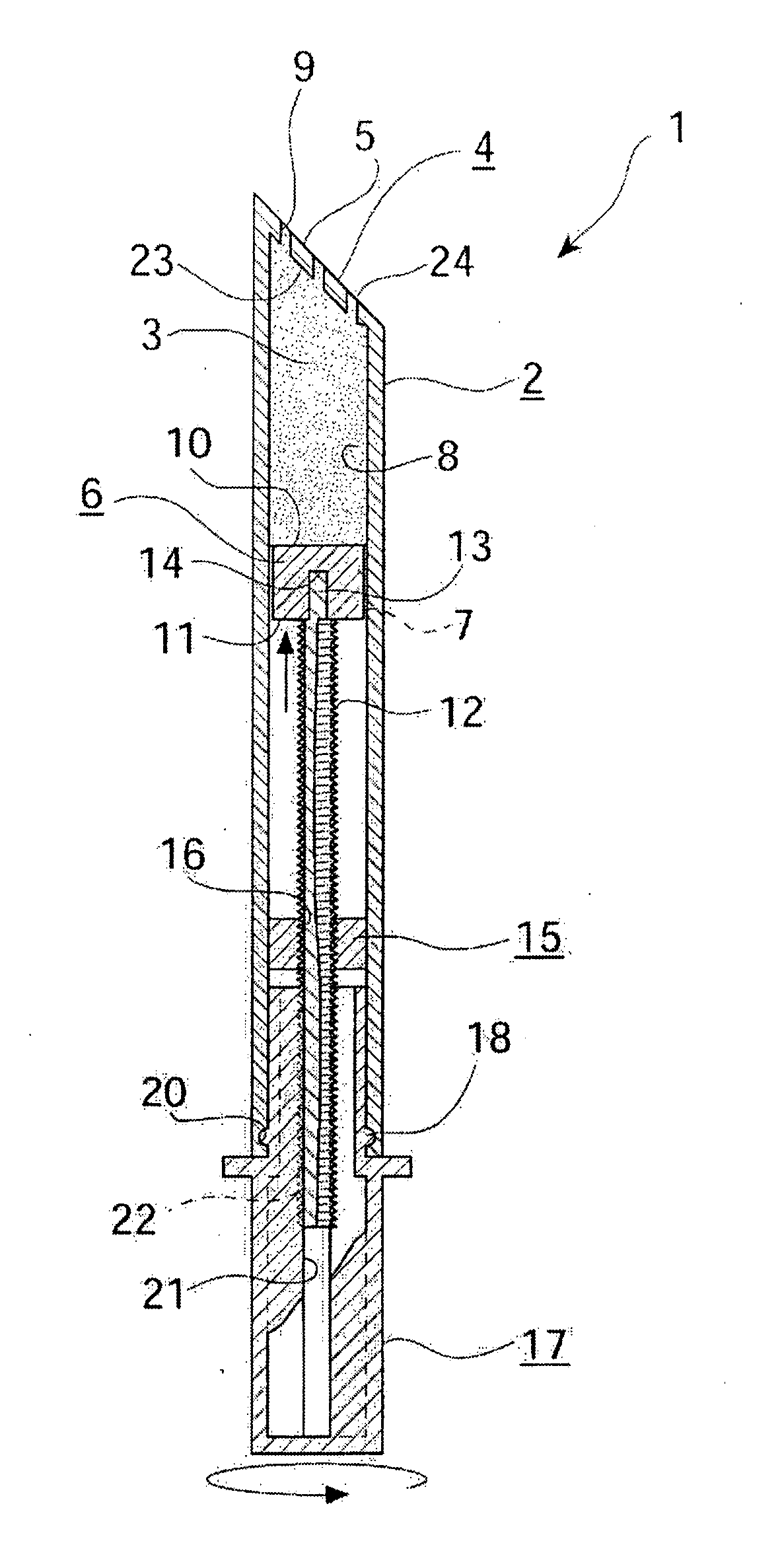

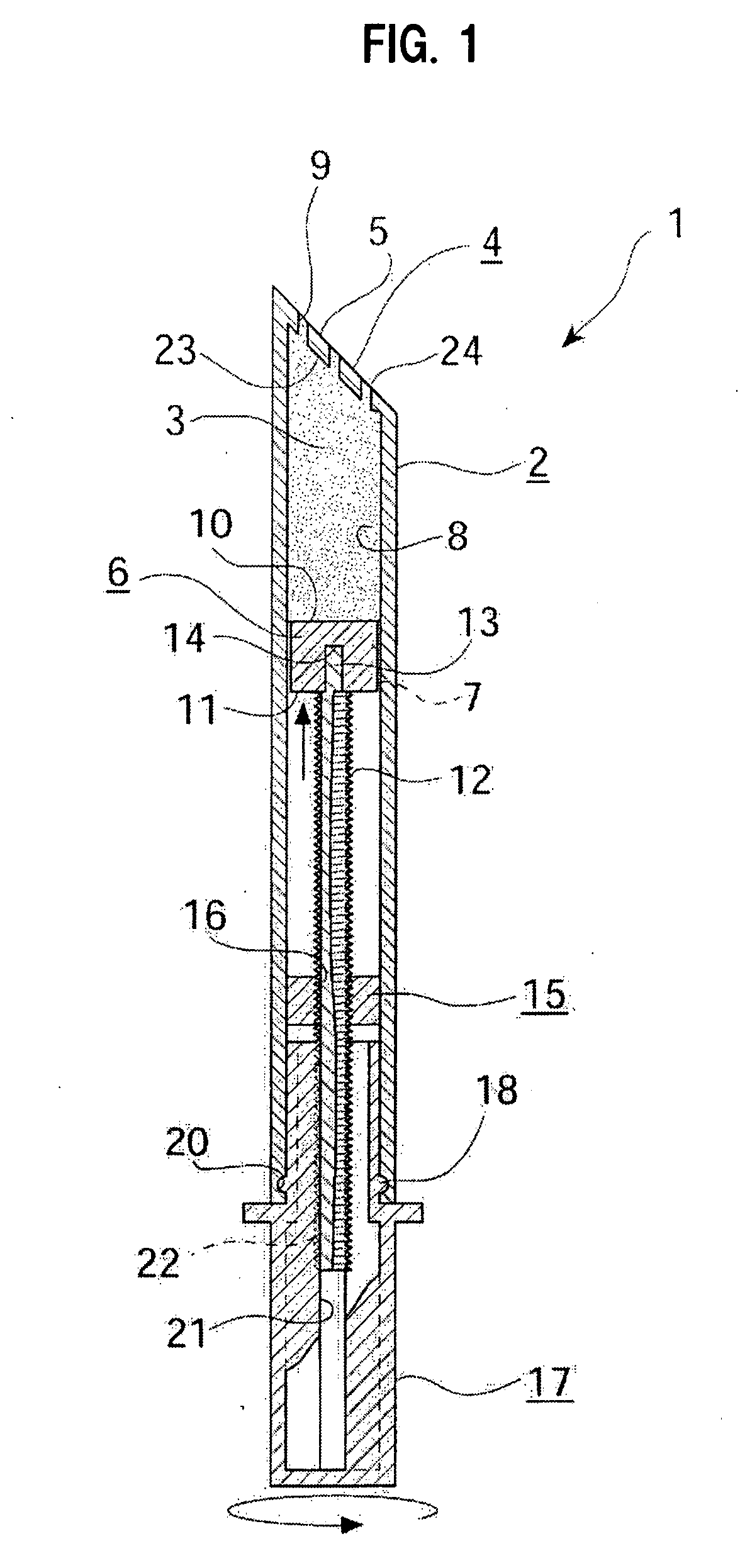

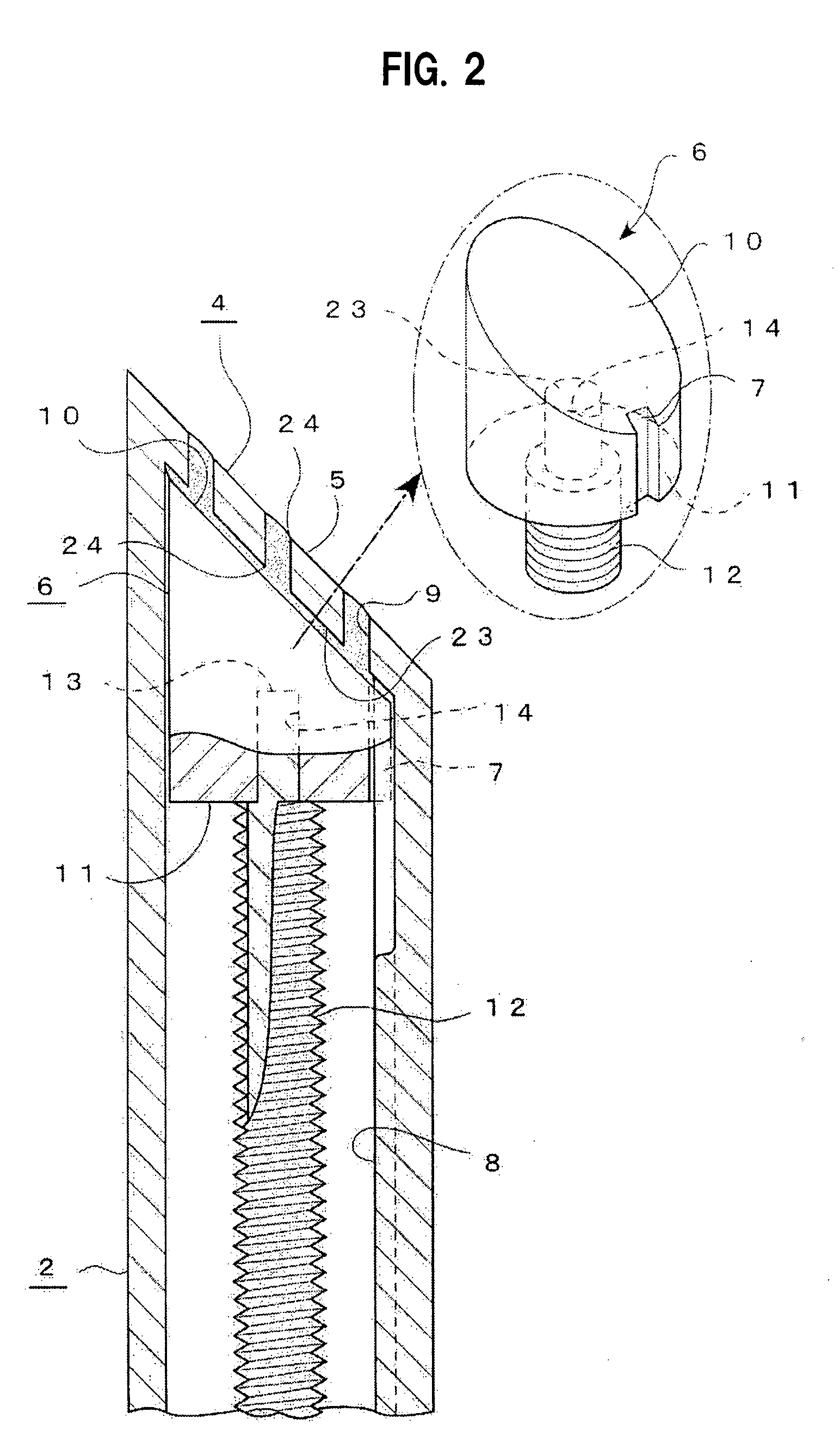

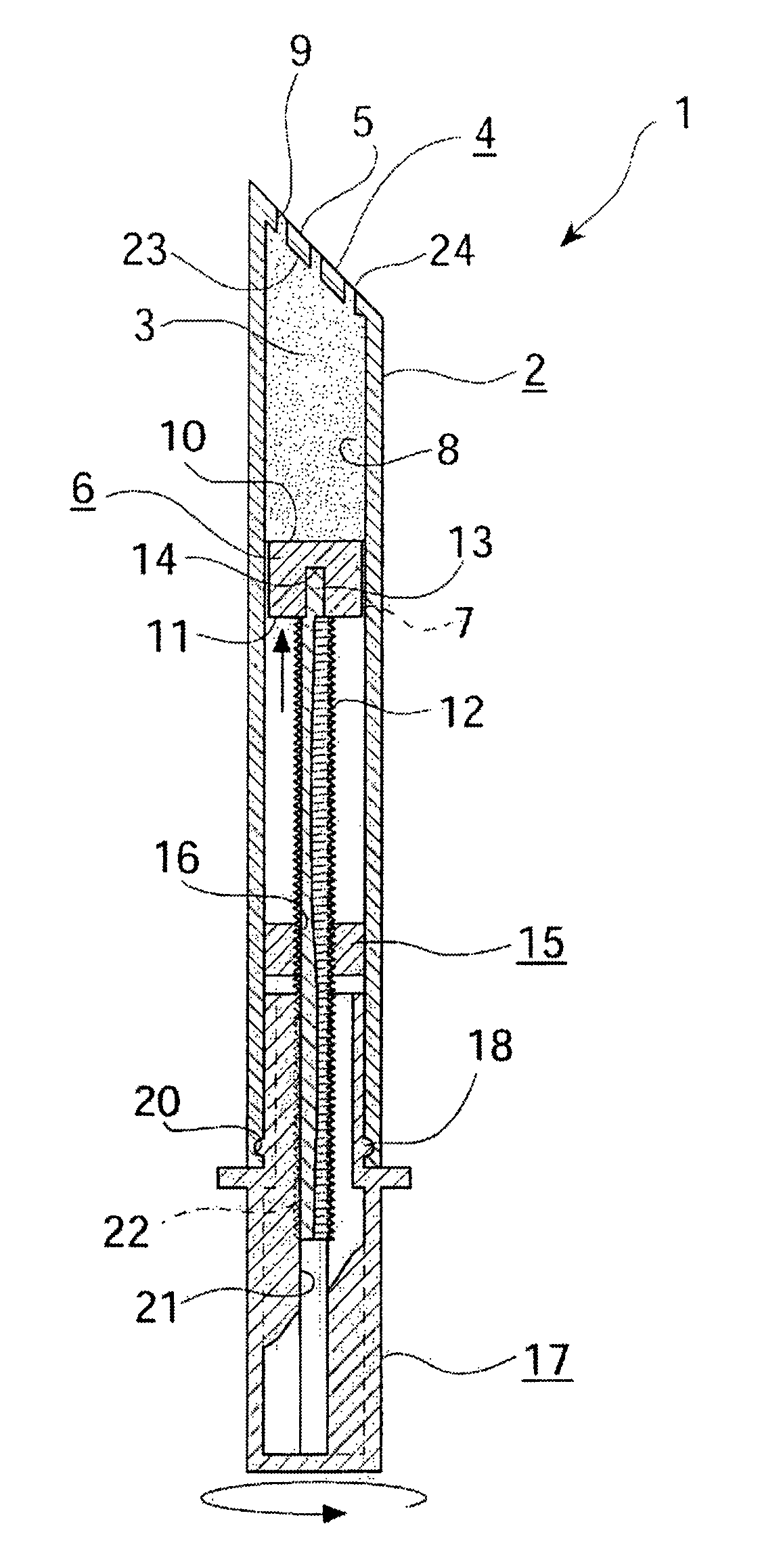

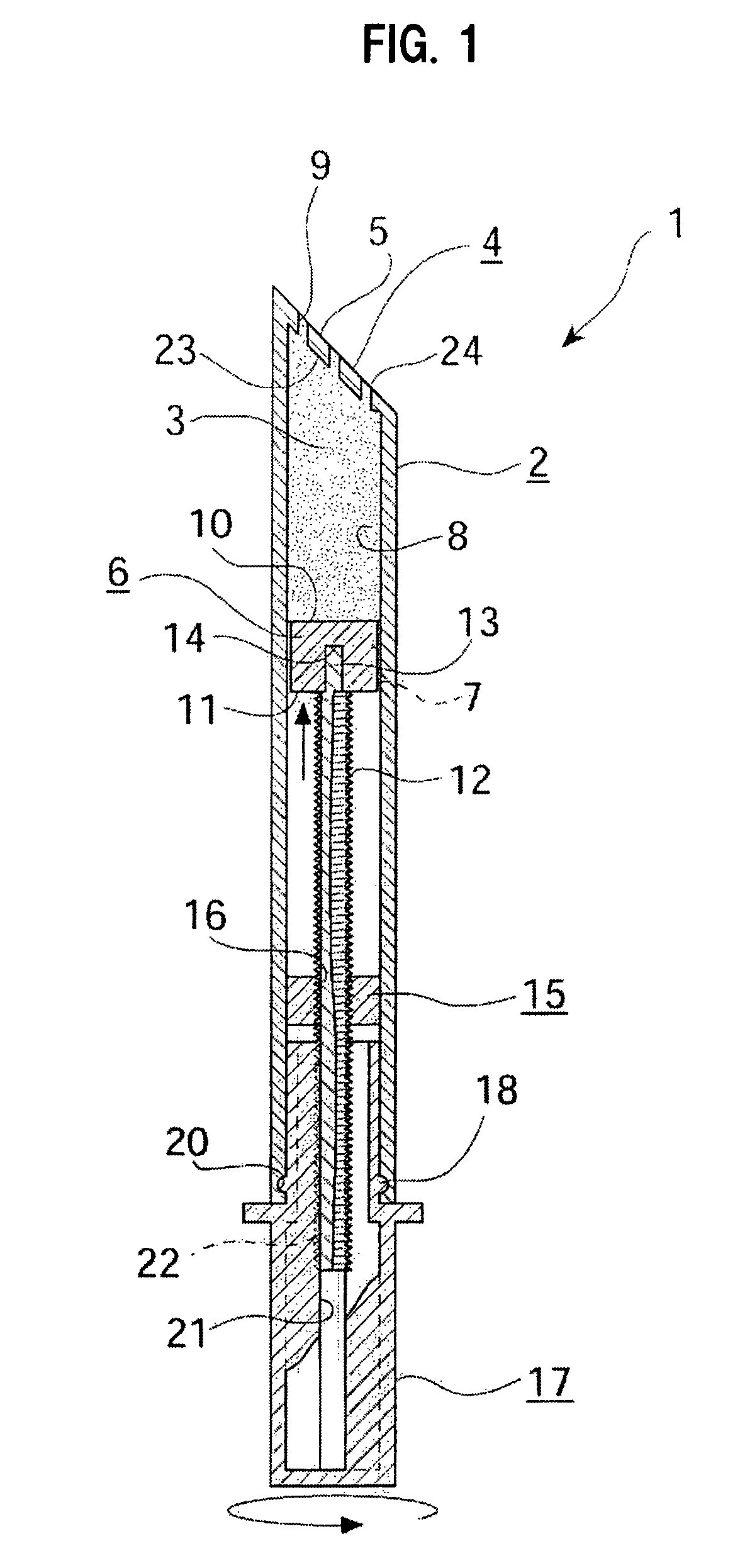

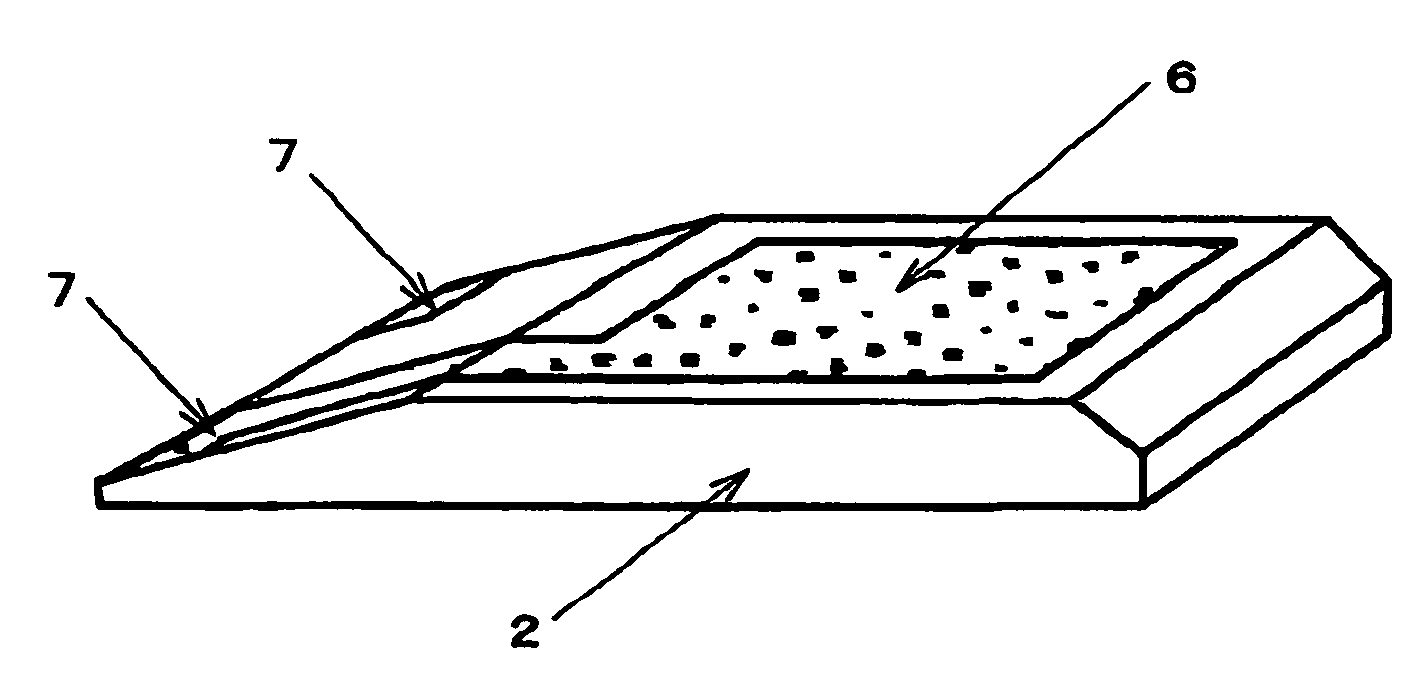

Crystal unit

InactiveUS7298069B2Quality improvementMaintained satisfactorilyPiezoelectric/electrostriction/magnetostriction machinesImpedence networksConductive materialsRock crystal

A crystal unit has a crystal blank provided with a pair of excitation electrodes and a pair of extension electrodes extended from the excitation electrodes, and a casing having a recess. A pair of connection terminals is formed on the bottom face of the recess. An inclined surface is formed at one end of a first principal surface of the crystal blank and the second principal surface of the crystal blank is flat-shaped. A conductive material is disposed between the connection terminals and the extension electrodes so that the extension electrodes are extended toward the end at which the inclined surface is formed and the second principal surface faces the mounting member, and the crystal blank is thereby held by the mounting member at the position of the end at which the extension electrodes are extended and electrically connected to the connection terminals.

Owner:NIHON DEMPA KOGYO CO LTD

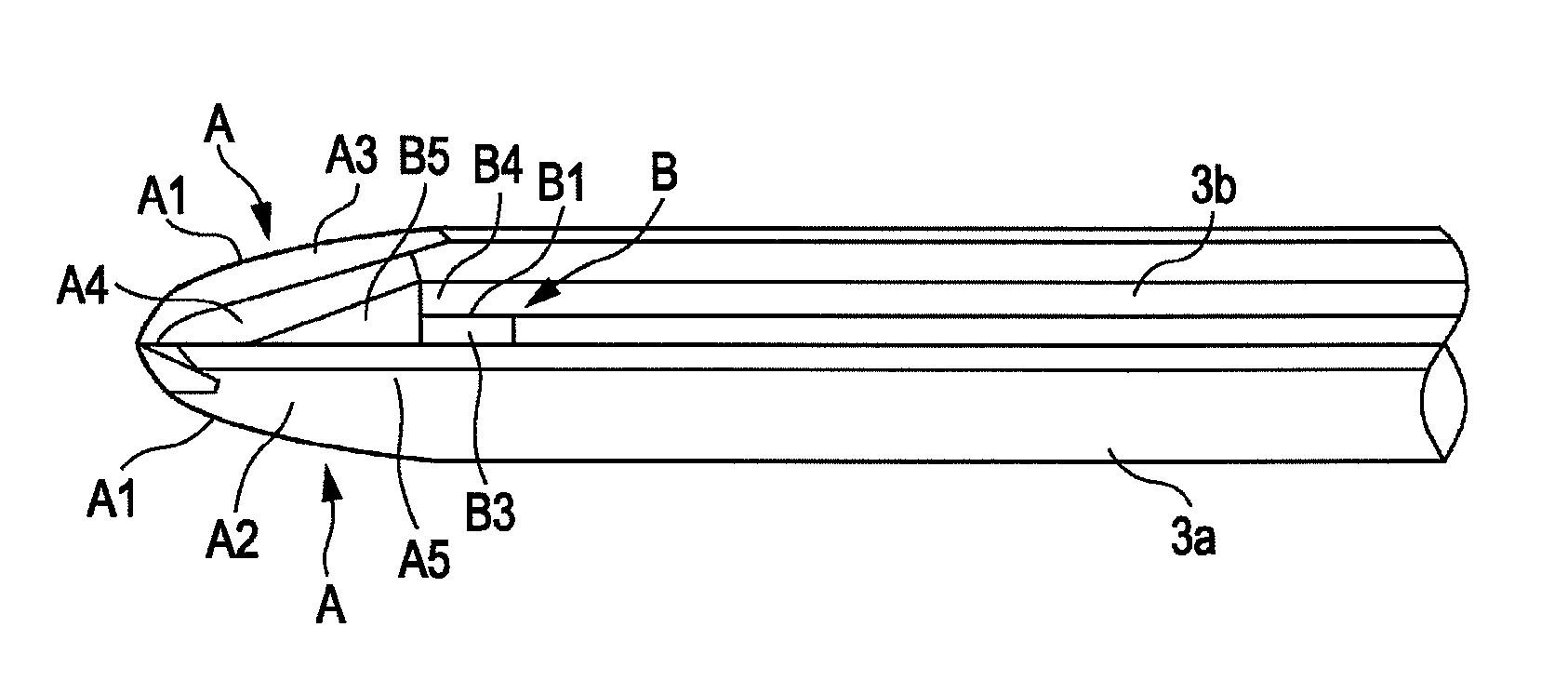

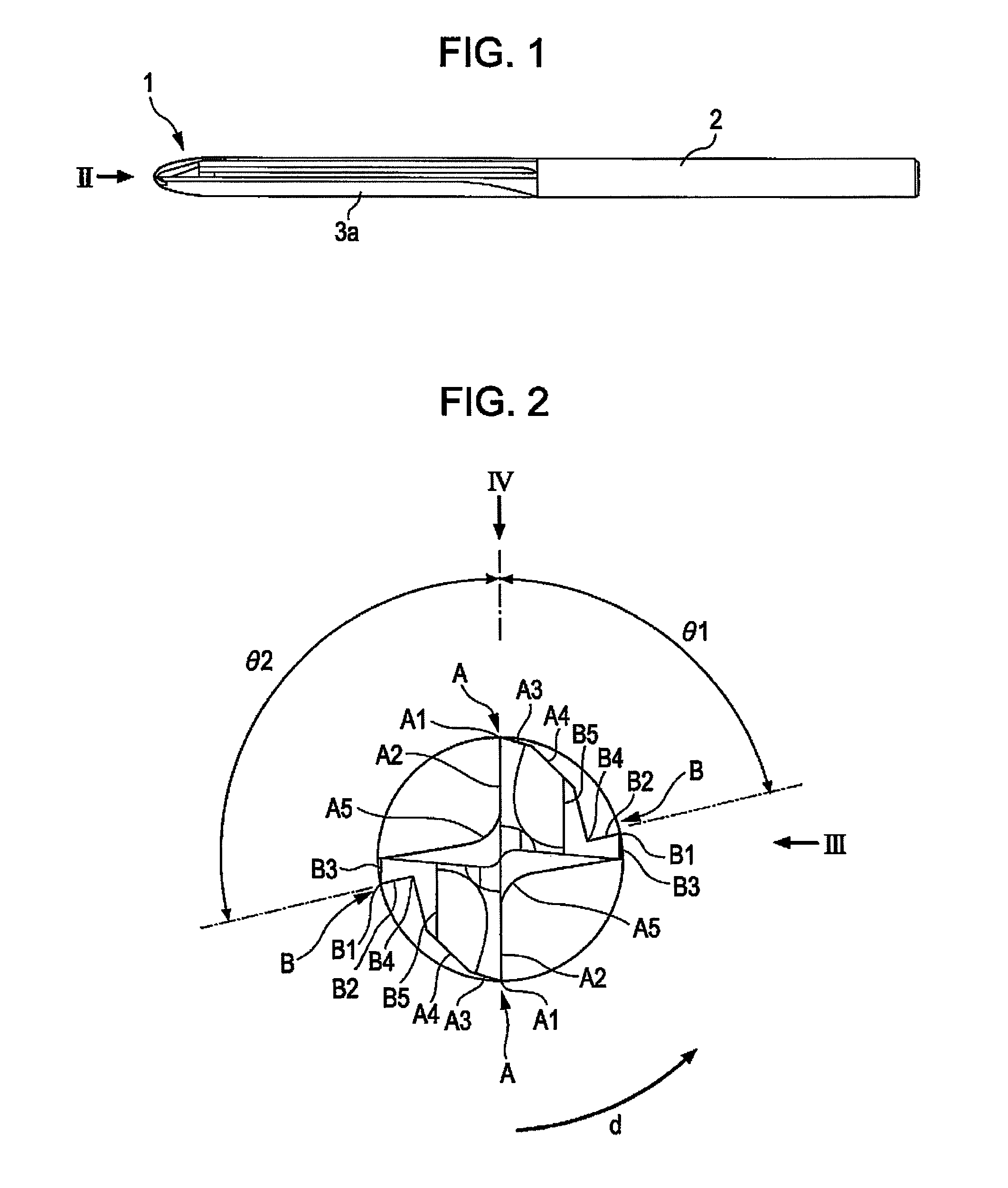

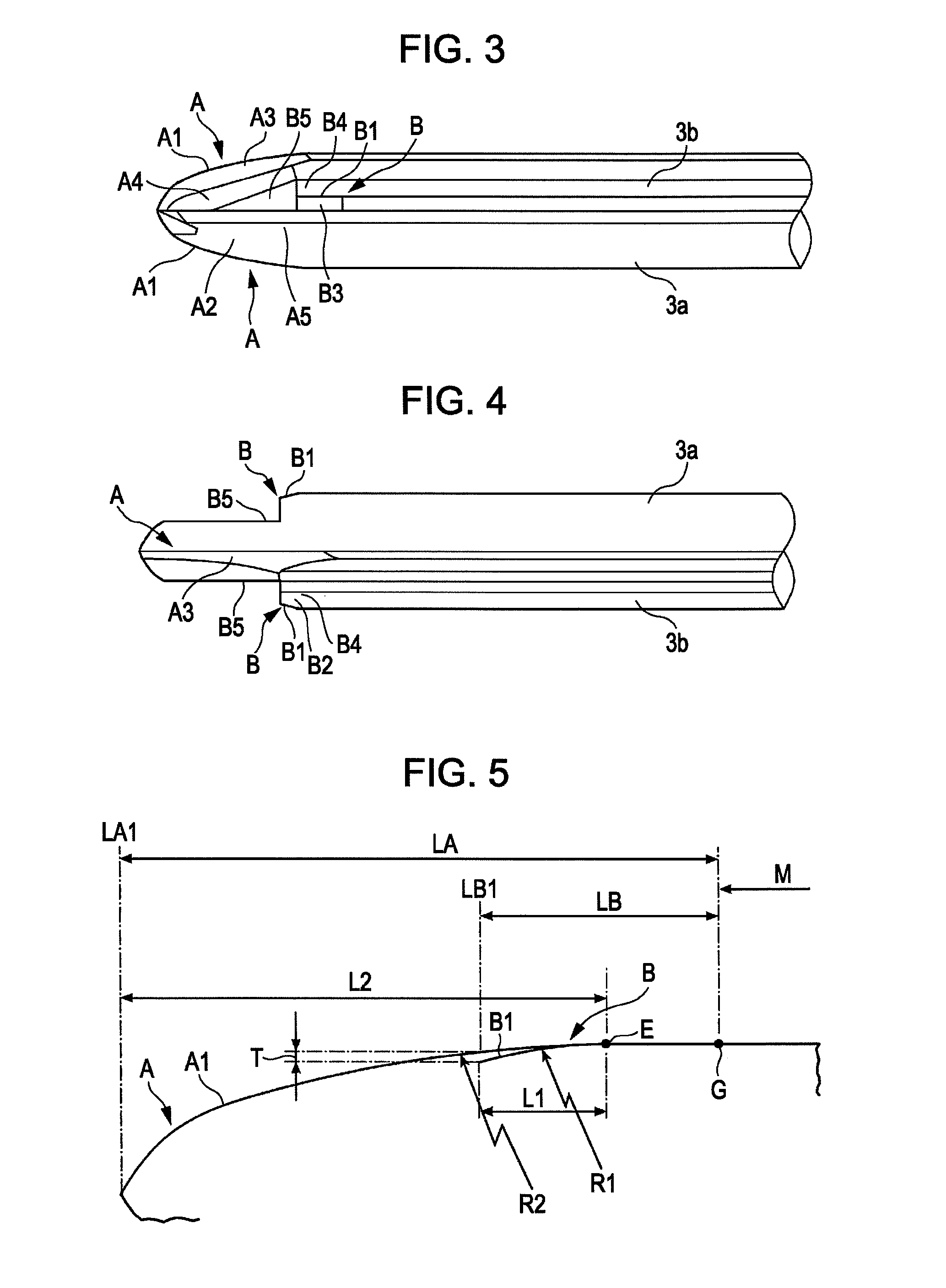

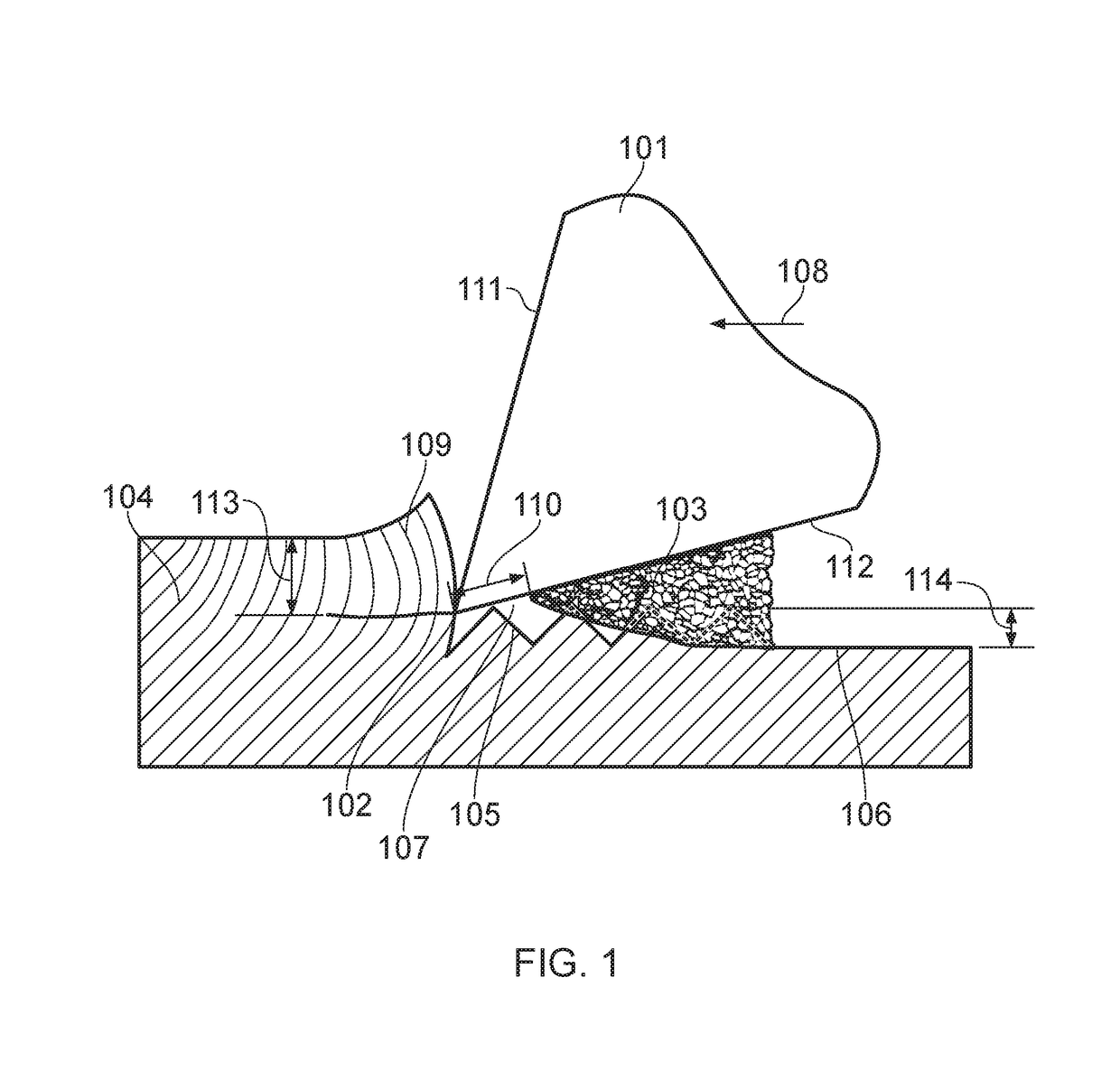

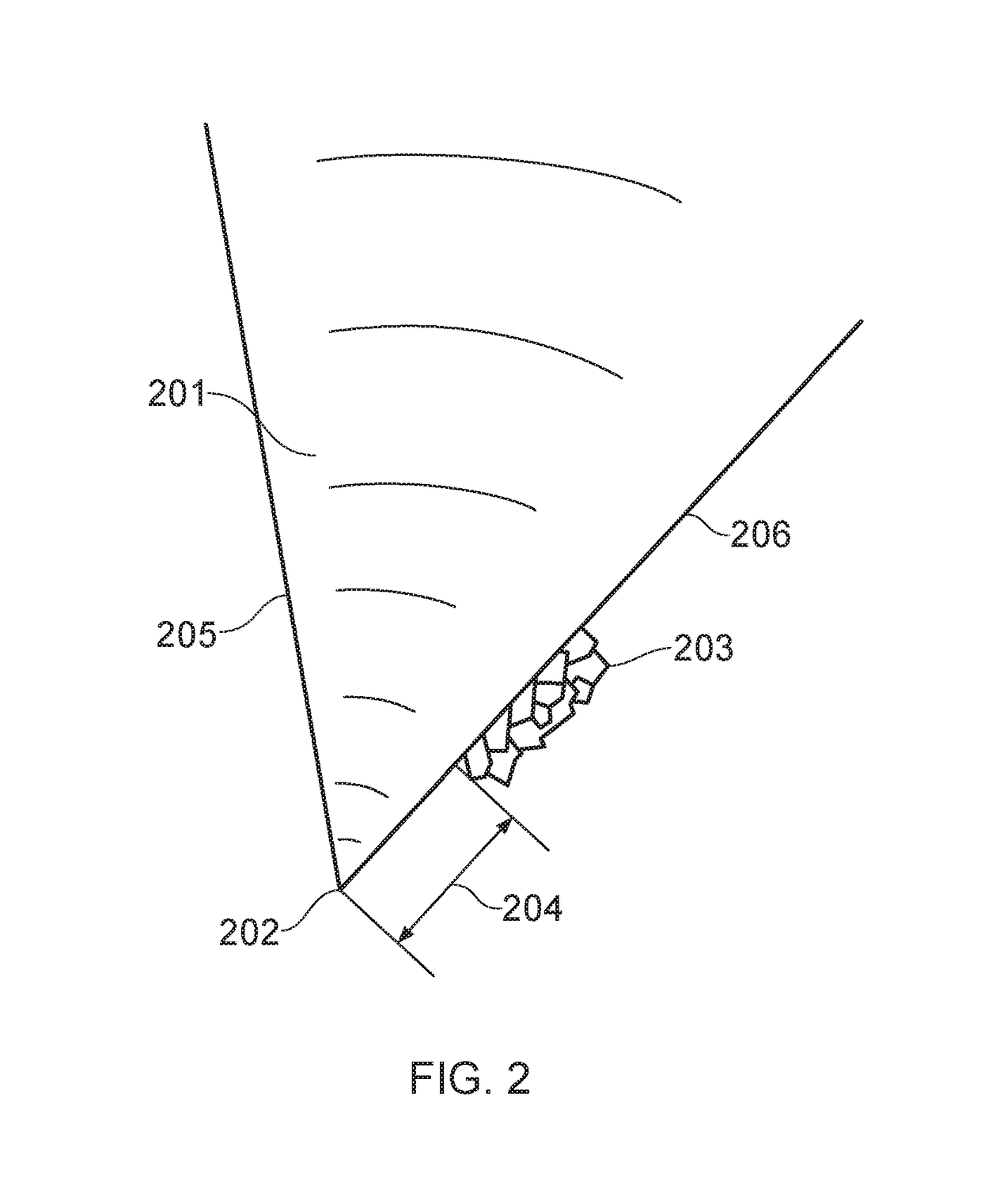

Drill

ActiveUS8734067B2Improve hole qualityExtended service lifeWood turning toolsTransportation and packagingHigh rateDistal portion

A drill includes a pair of main cutting edges extending from a distal portion of the drill to a position close to a proximal end of the drill to entirely define a two-edge configuration, and a pair of auxiliary cutting edges extending between positions at the distal and proximal sides of a maximum diameter position to partly define a four-edge configuration. A ridgeline of each auxiliary cutting edge is located within an angle smaller than 90° from a ridgeline of the corresponding main cutting edge toward the rear in a rotation direction of the drill. The point angle of the auxiliary cutting edges increases at a higher rate than the point angle of the main cutting edges in a predetermined range from the maximum diameter position toward a distal end of the drill.

Owner:SUBURU CORP +1

Control system for work vehicle, method for setting trajectory of work implement, and work vehicle

ActiveUS20180355587A1Guaranteed to workGood quality finishMechanical machines/dredgersPosition/course control in two dimensionsTerrainControl system

A control system for a work vehicle includes a controller. The controller acquires the travel direction of the work vehicle. The controller acquires current terrain data indicating a current terrain existing in the travel direction of the work vehicle. The controller decides a target profile of a work site based on the current terrain data. The controller generates a command signal to operate a work implement according to the target profile. The controller updates the travel direction of the work vehicle. The controller updates the target profile based on the updated travel direction.

Owner:KOMATSU LTD

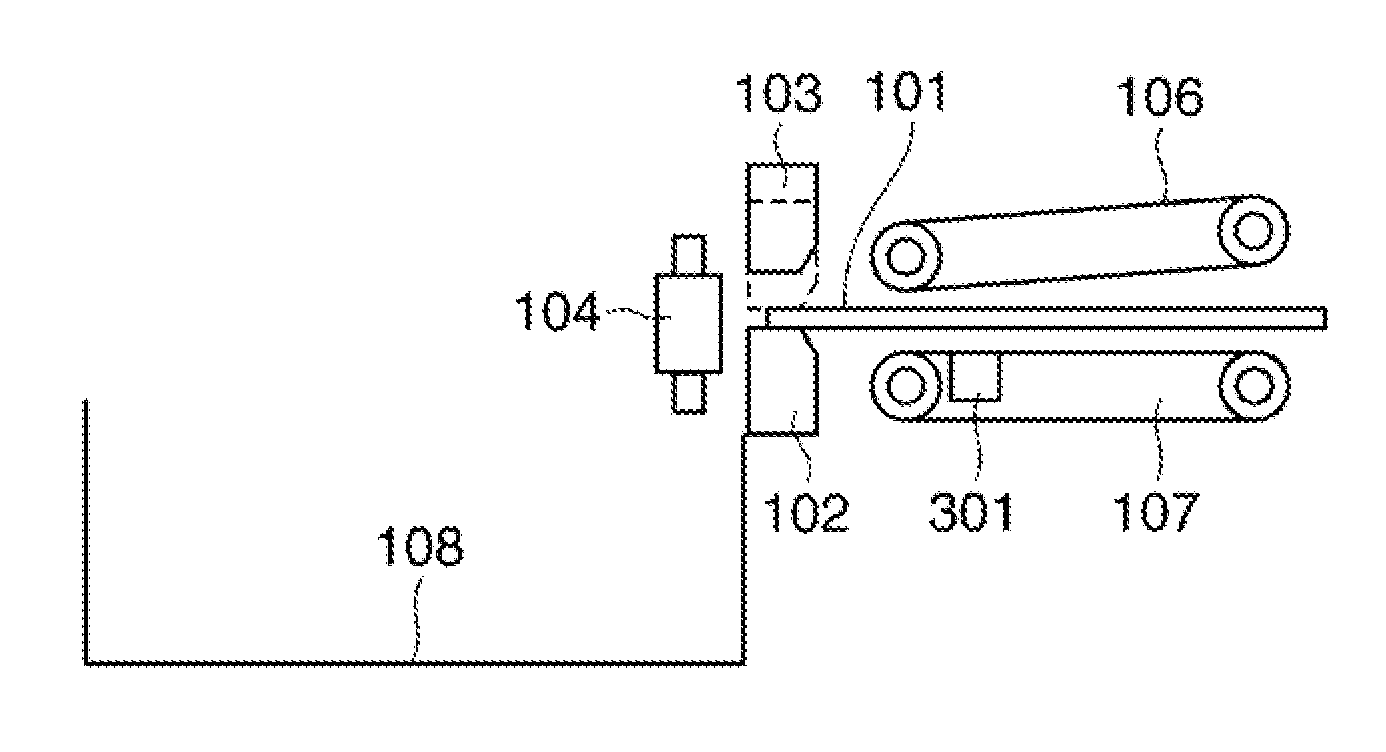

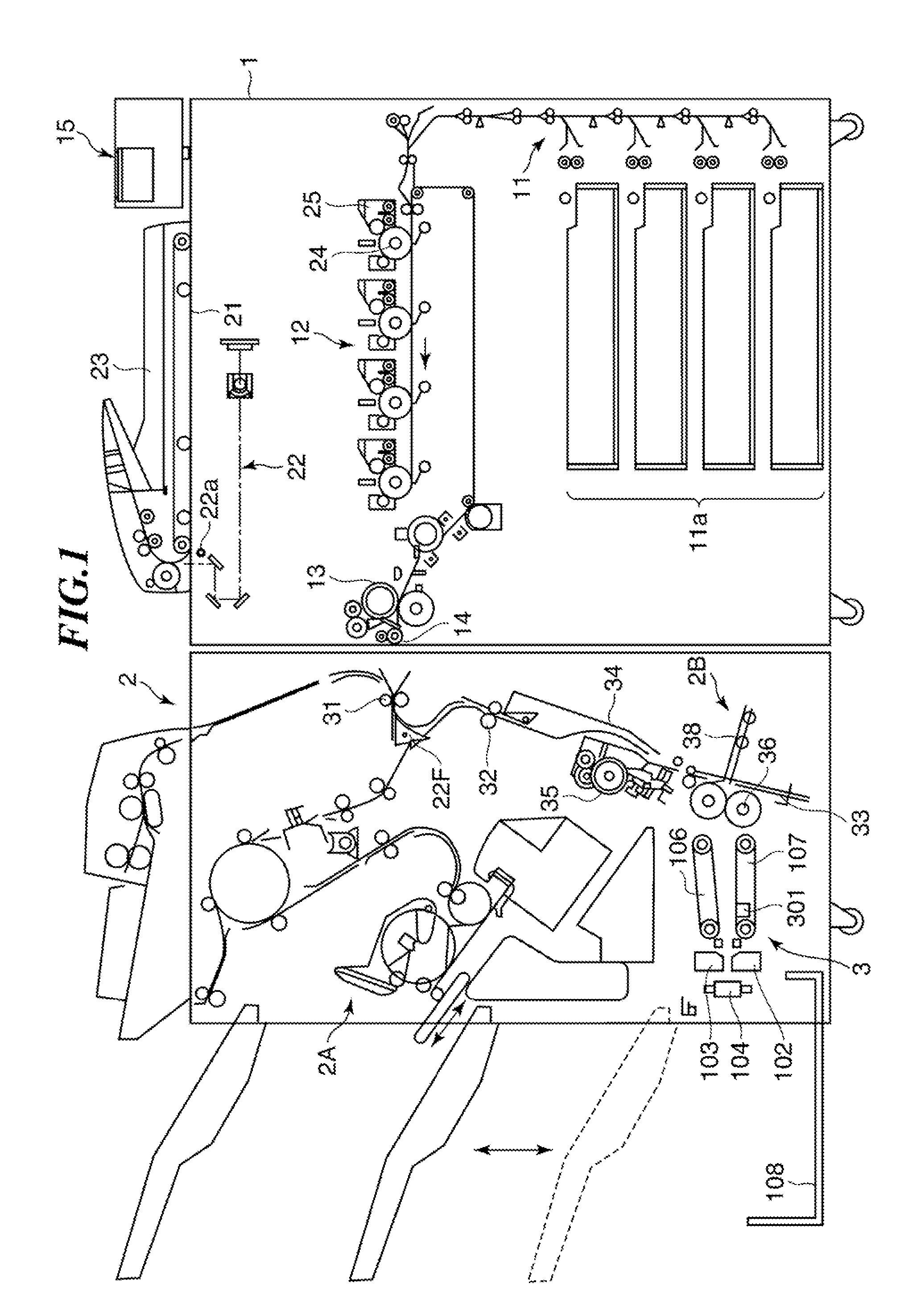

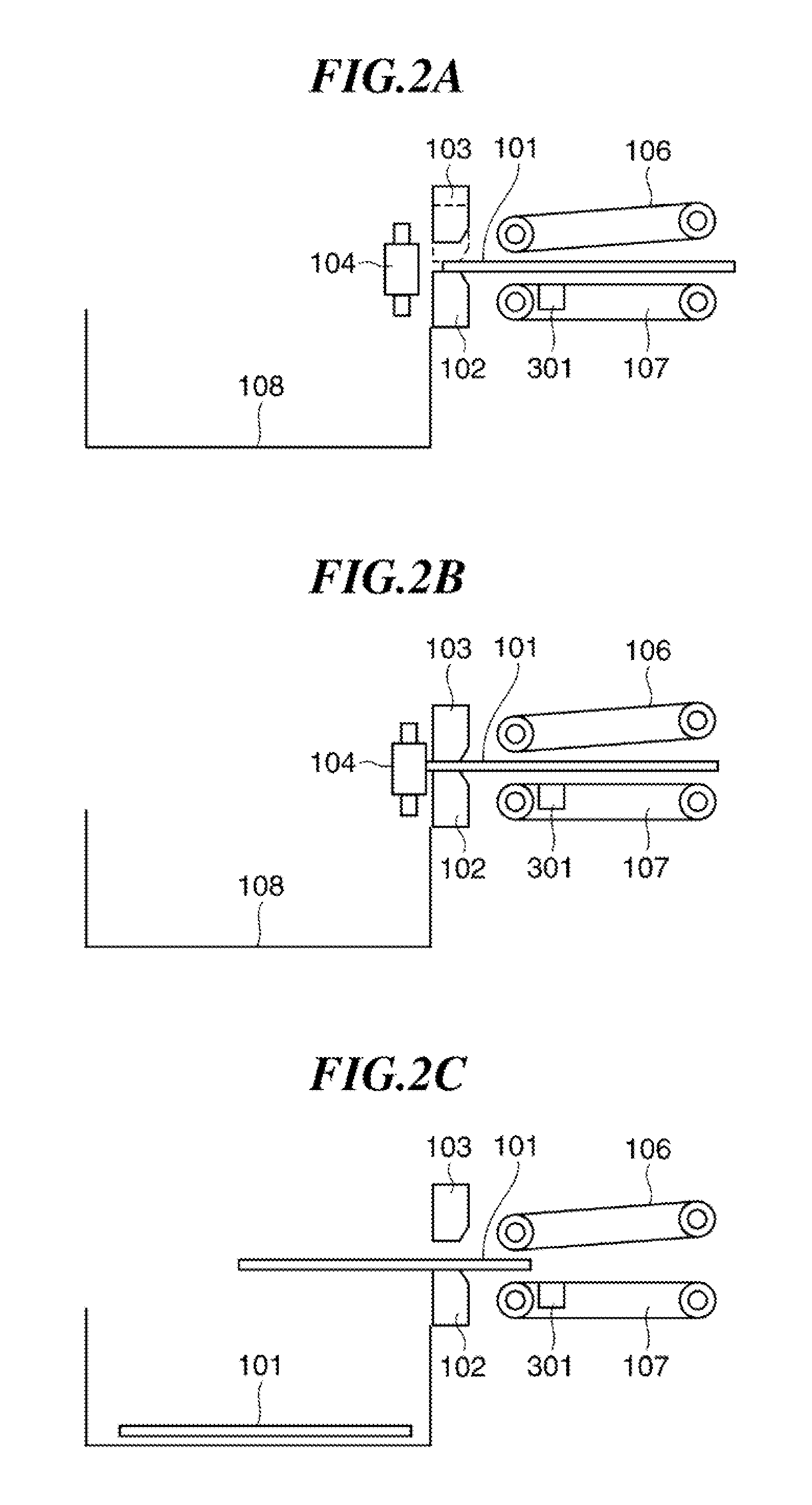

Sheet processing apparatus that flattens folded spine of sheet bundle and image forming apparatus including the sheet processing apparatus

InactiveUS20120252649A1Stable quantityGood quality finishFunction indicatorsFolding thin materialsEngineeringSheet material

A sheet processing apparatus which is capable of stabilizing a stop position of the sheet bundle, to thereby enable creation of a high finish quality product, and is compact in size and can be manufactured at low costs. Conveyance belts convey the sheet bundle to a flattening position. A pressing roller flattens the folded spine of the sheet bundle by pressing the folded spine. Clampers hold the sheet bundle such that the sheet bundle is not moved when flattening is performed. A CPU starts to stop driving of the conveyance belts when the sheet bundle is conveyed to a predetermined location upstream of the flattening position in the conveying direction of the sheet bundle, and stops the sheet bundle at the flattening position by holding the sheet bundle with the clampers before the conveyance of the sheet bundle is stopped.

Owner:CANON KK

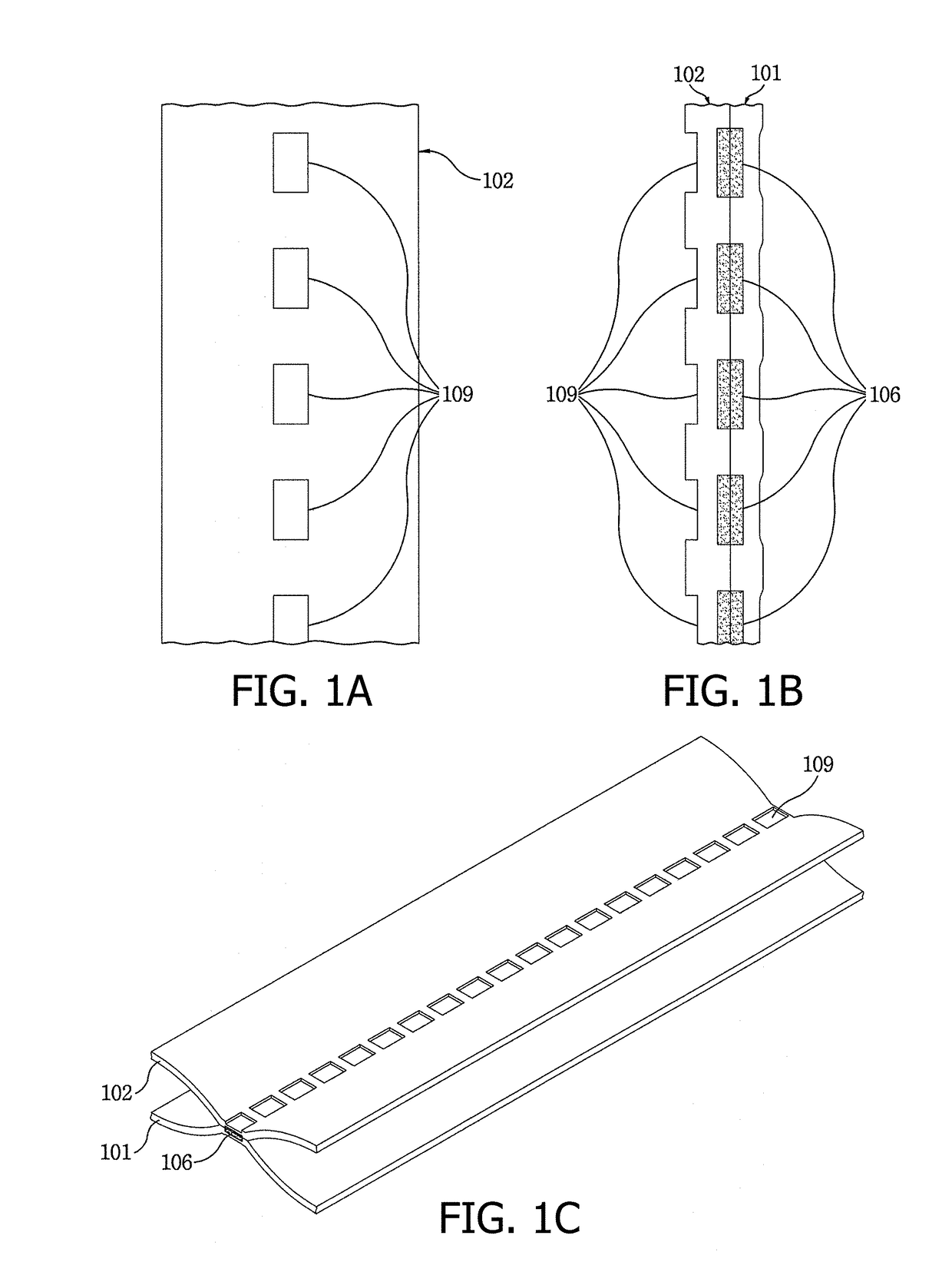

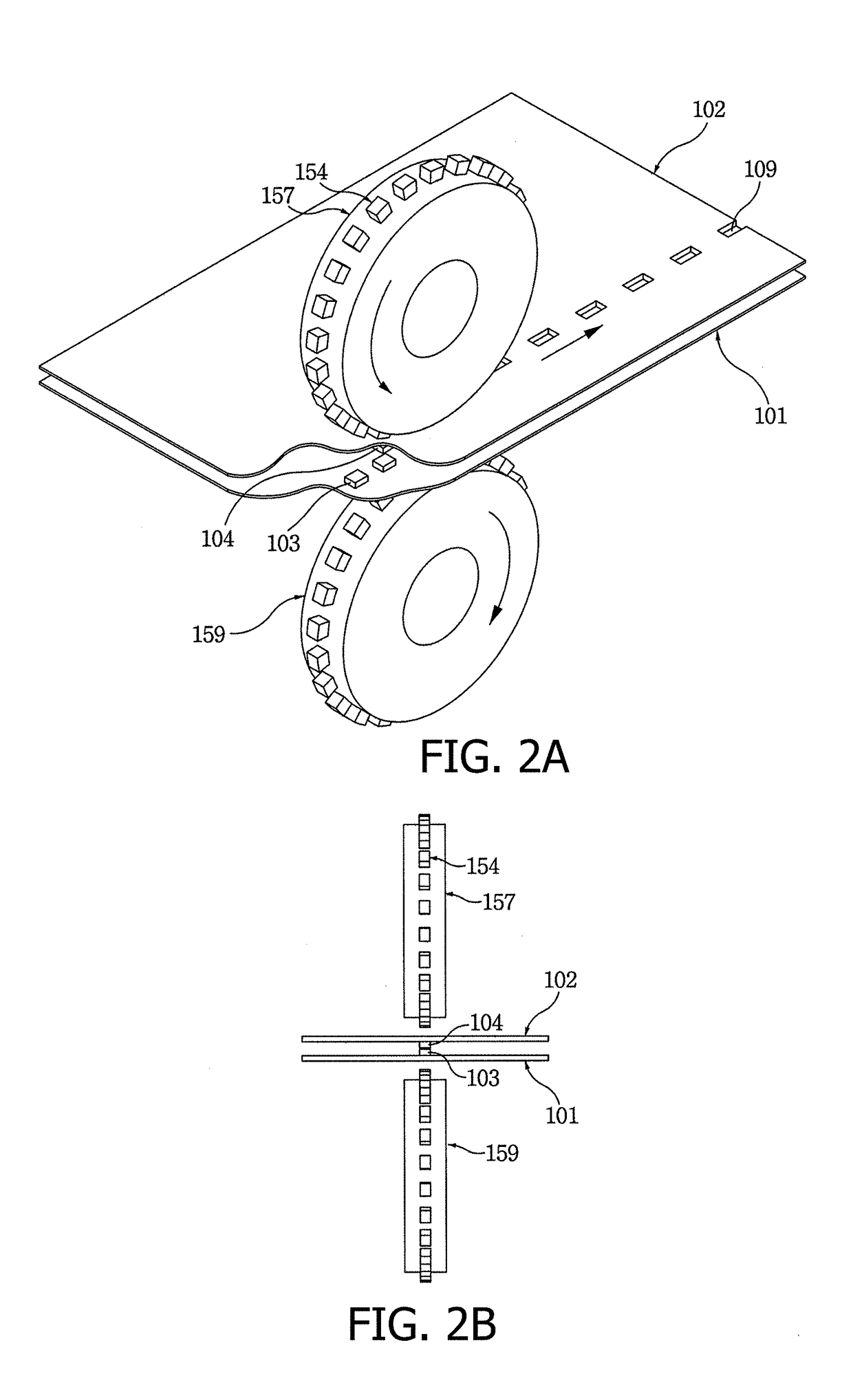

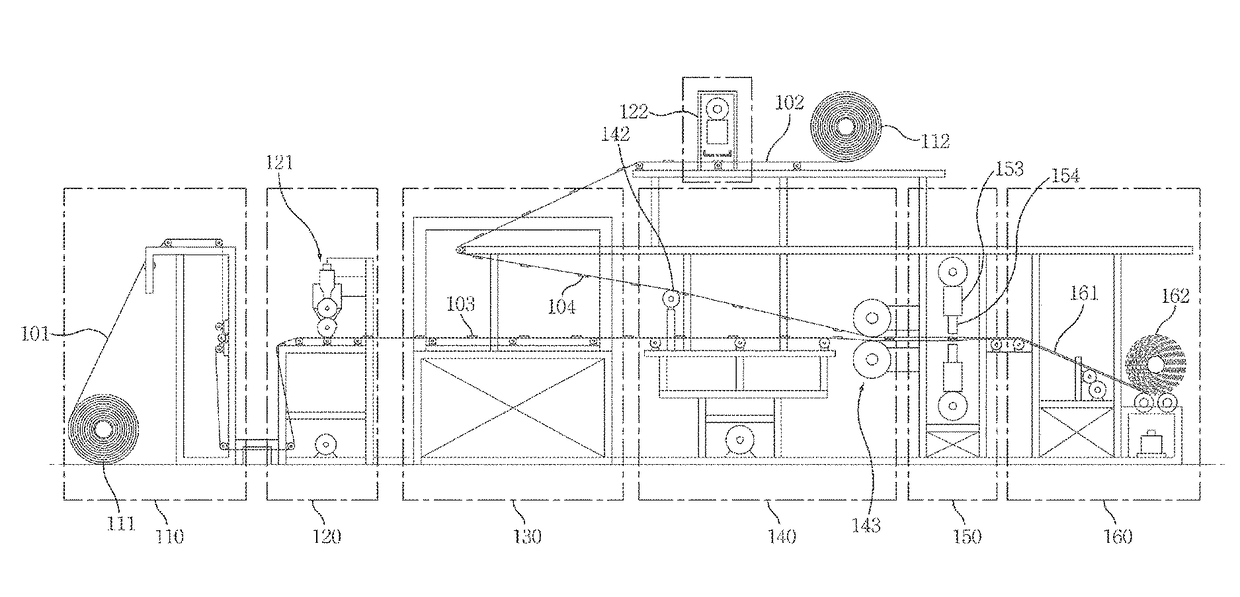

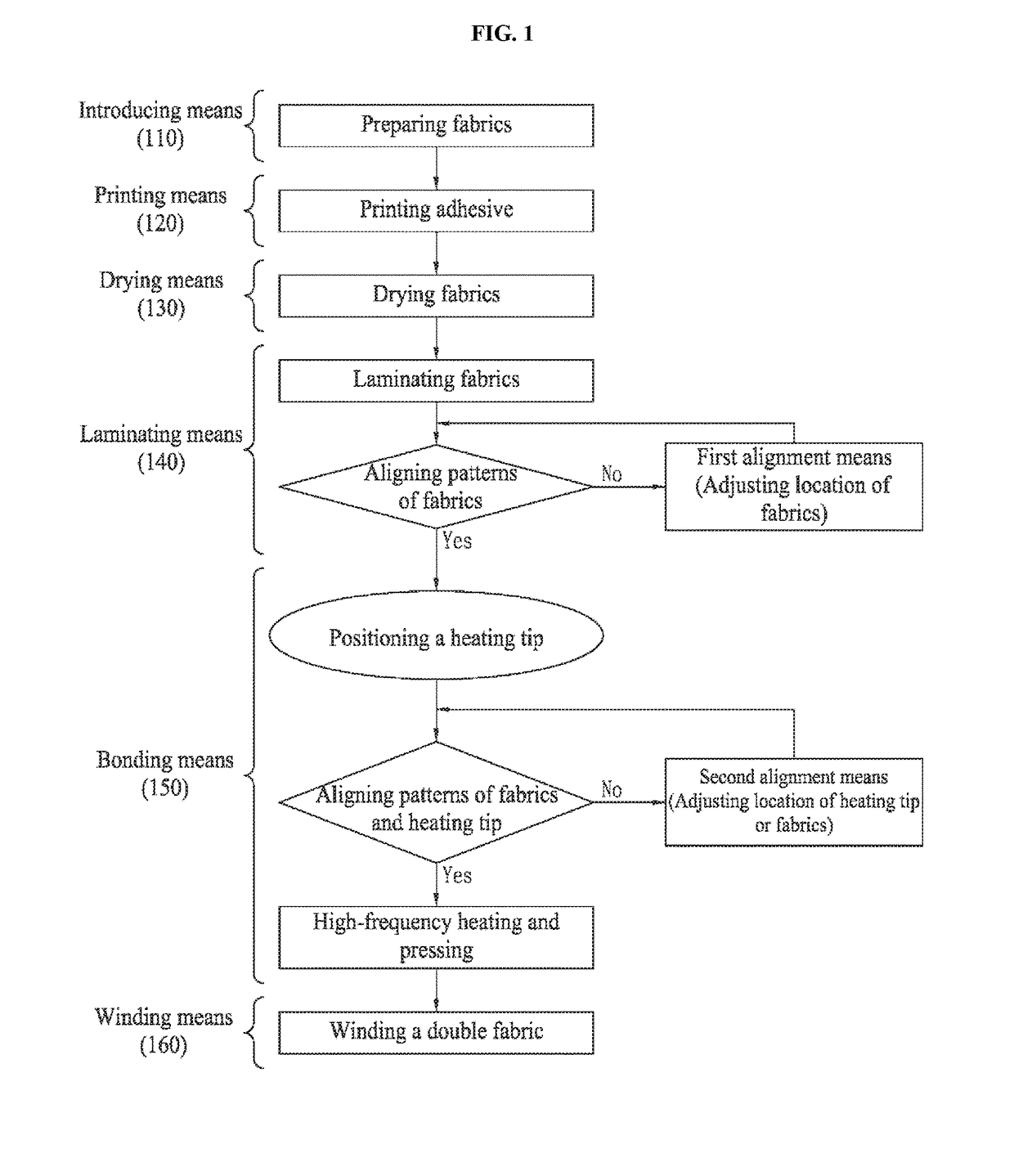

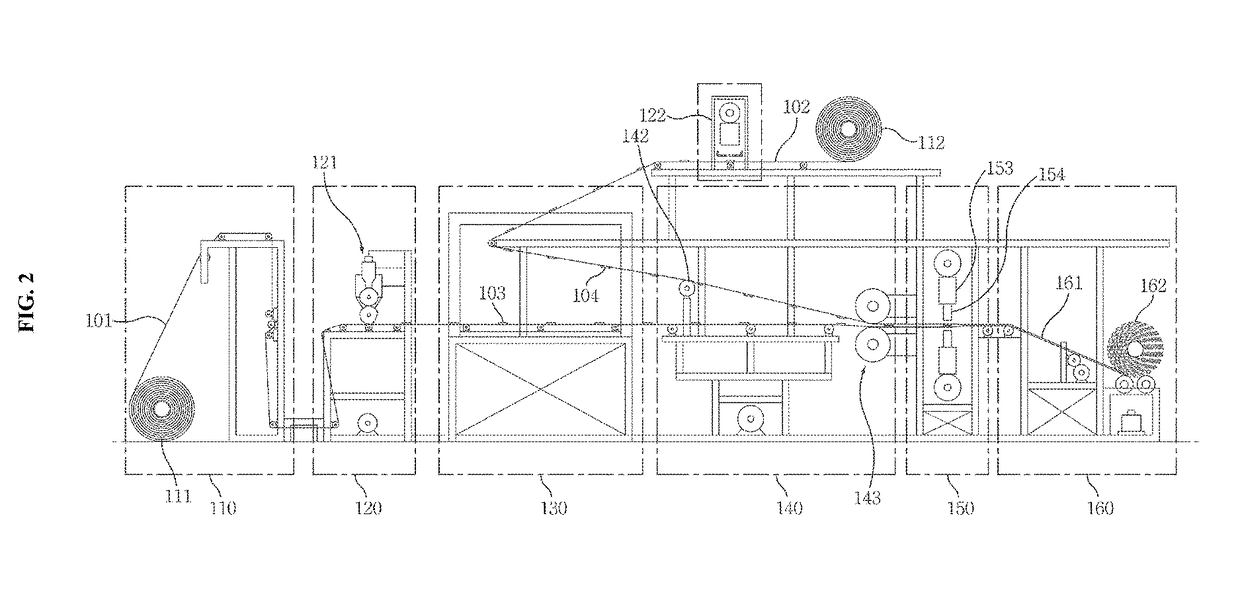

Method for seamlessly coupling fabric using bonding pattern line formed by high-frequency bonding technique

InactiveUS20180201005A1Good adhesivenessIncreased durabilityPattern makingFibre treatmentAdhesiveEngineering

The present invention can combine fabrics in a seamless manner by forming at least one bonding pattern line by a process comprising: printing and drying a heat-reactive adhesive on the inner surface of an inner fabric, and / or an outer fabric or an optional mesh material in a predetermined pattern, laminating said inner fabric, optional reinforced material and outer fabric, and then high-frequency heating them under pressing with a pressing pattern the same as the printing pattern to bond the inner fabric, and outer fabric.Since the present invention combines fabrics by employing a high-frequency bonding manner in which a heat-reactive adhesive is used, it is possible to combine fabrics in a seamless manner with a bonding pattern line which is composed of a bonding line with excellent adhesiveness and durability and an aesthetically excellent pattern line with a good clearness and finishing quality.

Owner:HOJEON

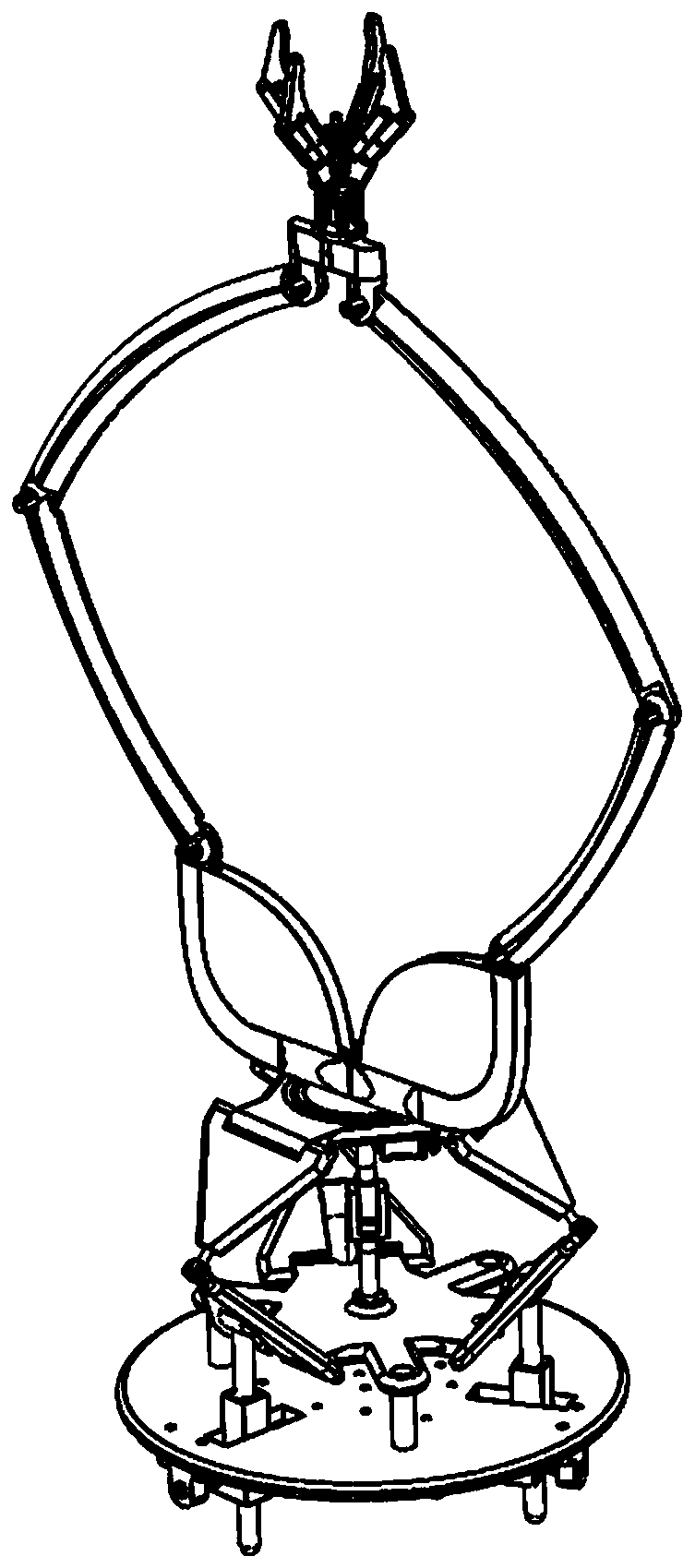

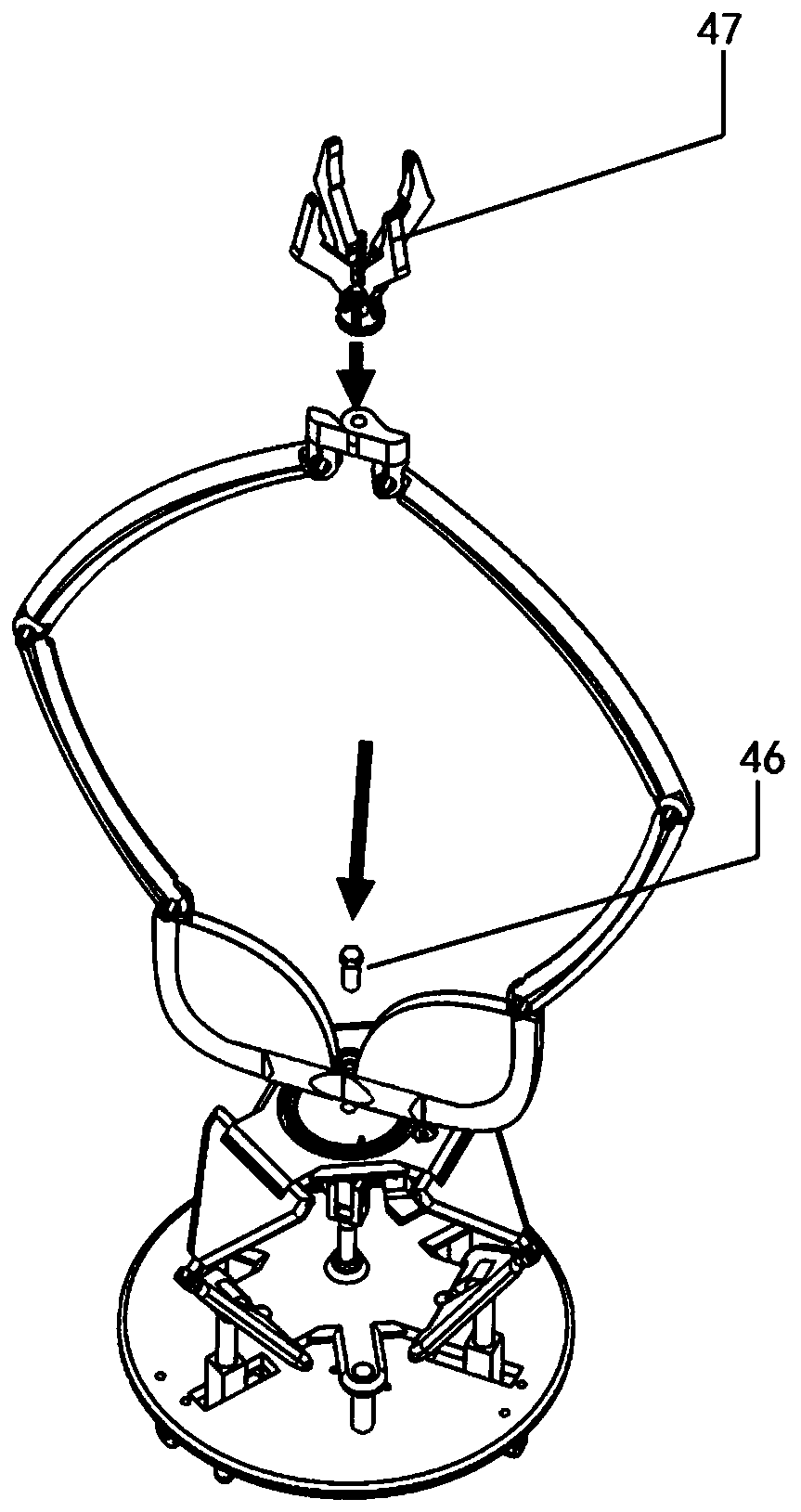

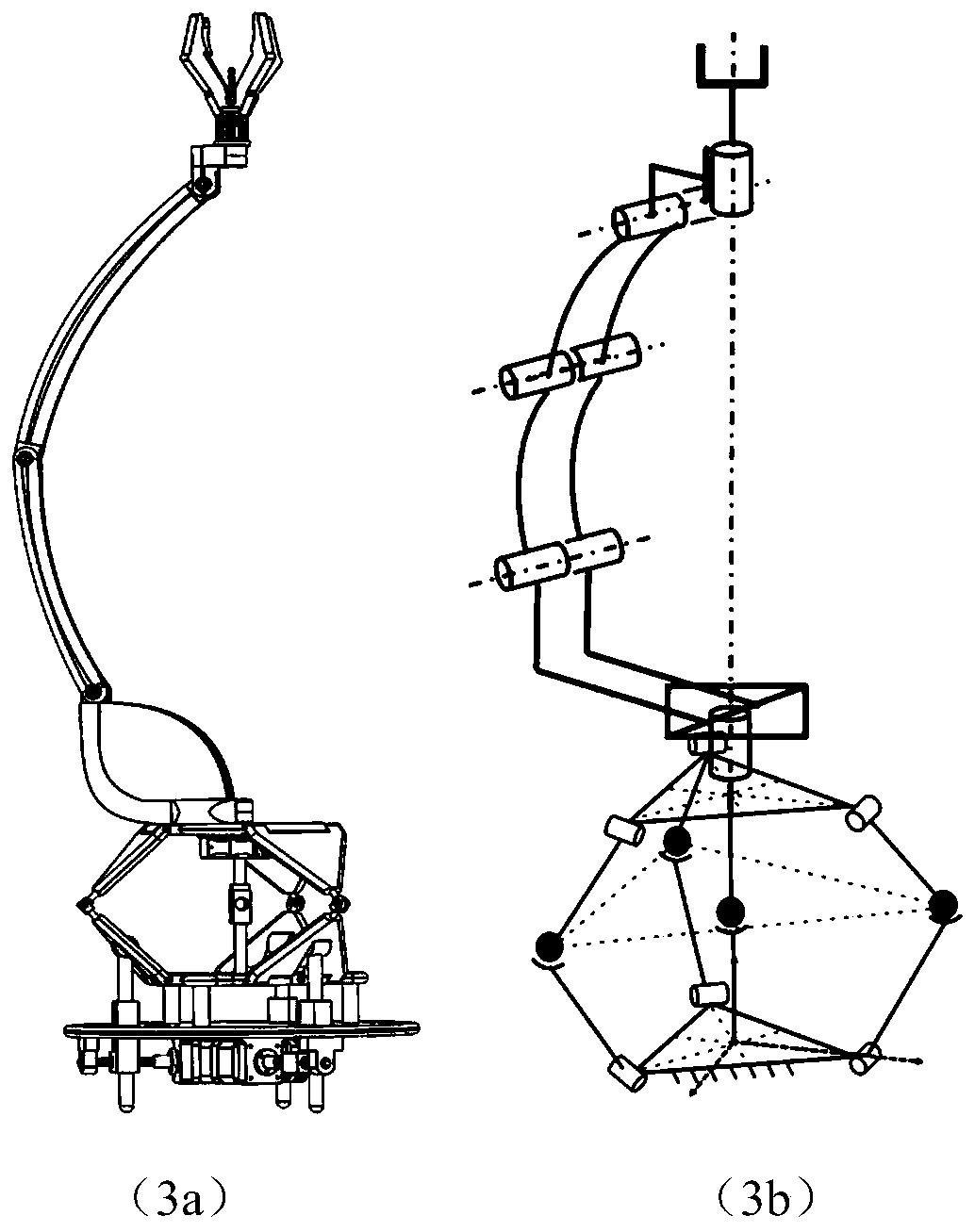

Multi-mode series-parallel mechanical arm based on movement bifurcation mechanism

ActiveCN110103202AStrong environmental adaptabilityImprove work efficiencyProgramme-controlled manipulatorEngineeringMode switching

The invention relates to a multi-mode series-parallel mechanical arm based on a movement bifurcation mechanism. The multi-mode series-parallel mechanical arm based on the movement bifurcation mechanism comprises an end executor, an arm and a parallel connection base seat which are connected in sequence, wherein the arm is an eight-pole and single-ring movement bifurcation mechanism, and comprisestwo arm branch chains which are symmetrically arranged, two ends of one arm branch chain are respectively movably connected with two ends of the other arm branch chain so as to form a single-ring andclosed-chain structure, each arm branch chain comprises four connection rods which are movably connected in sequence, the parallel connection base seat is a double-rotational-freedom space parallel mechanism, and a mode switching mechanism used for achieving series connection and parallel connection switching of the two arm branch chains is installed on the parallel connection base seat. Comparedwith the prior art, the multi-mode series-parallel mechanical arm based on the movement bifurcation mechanism has the advantages of being high in work efficiency, small in structure dimension, and high in overall stability.

Owner:SHANGHAI UNIV OF ENG SCI

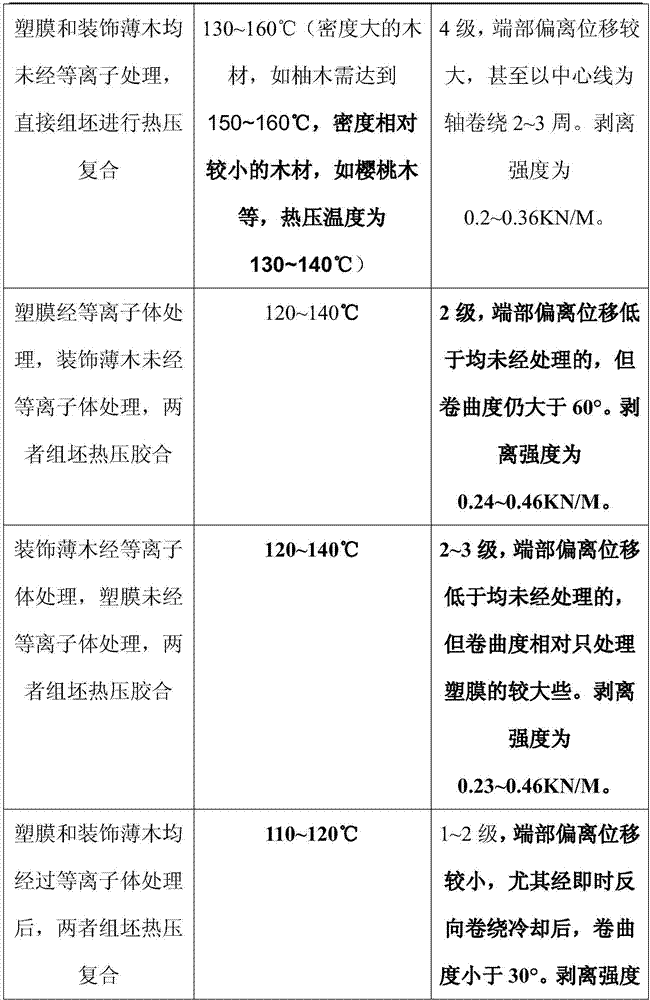

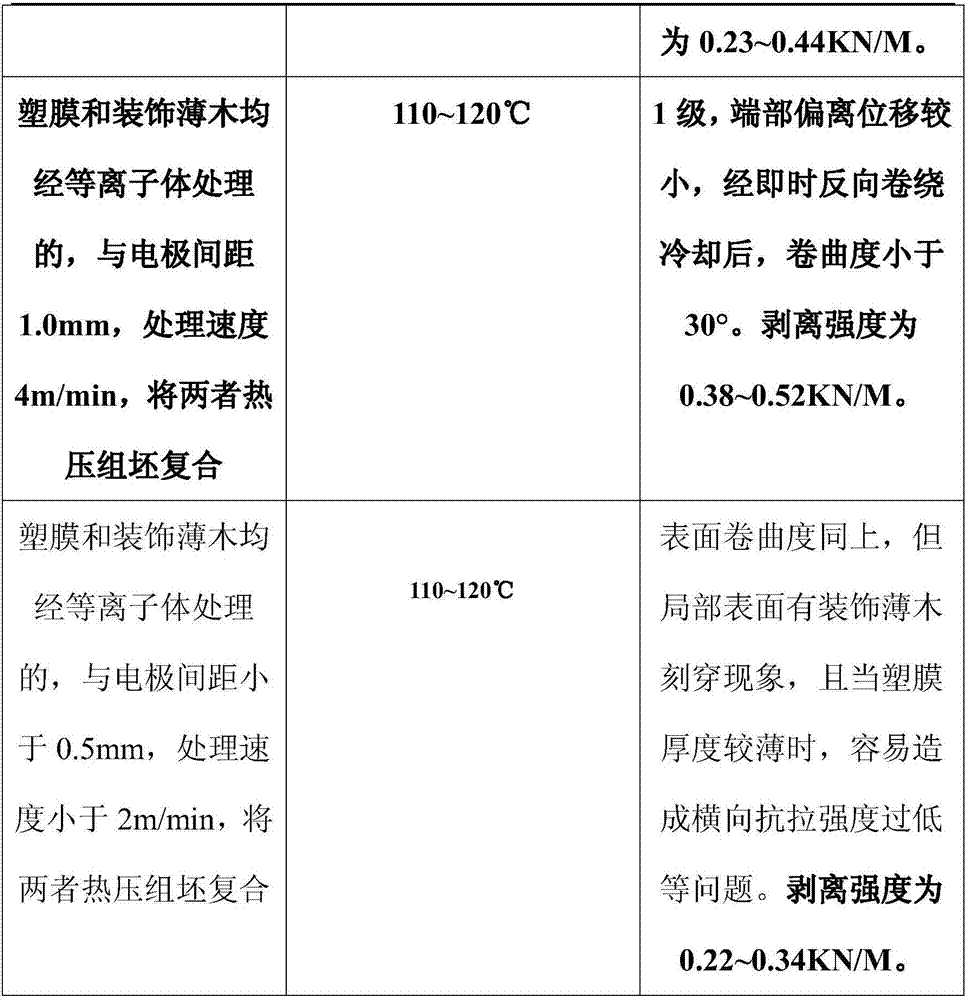

Method for improving interface bonding performance between composite flexible decorative veneer and surface facing through plasma modification

ActiveCN107030802AResolve curlSolve discolorationLayered product treatmentElectric wood treatmentAdhesiveEngineering

The invention discloses a method for improving the interface bonding performance between composite flexible decorative veneer and surface facing through plasma modification. The method sequentially comprises the following technology steps that surface pretreatment of the decorative veneer, low-temperature plasma treatment of the surface of the decorative veneer, low-temperature plasma treatment of the surface of a plastic film, assembly and hot pressing of the decorative veneer and the plastic film, and facing hot-pressing of the plastic-film-reinforced flexible decorative veneer. By the adoption of the method for improving the interface bonding performance between the composite flexible decorative veneer and the surface facing through plasma modification, woodwork surface facing is conducted through the plastic-film-reinforced flexible decorative veneer manufactured through plasma modification treatment, an adhesive is not needed, the procedure of applying the adhesive can be omitted, the bonding strength of the facing surface of the product can be improved by 10%-70%, the adhesive force of a paint film can be improved by 20%-40%, the production cost can be reduced by 10%-50%, energy is saved, environmental friendliness is achieved, operation is easy and convenient, and efficiency is high.

Owner:INST OF WOOD INDUDTRY CHINESE ACAD OF FORESTRY

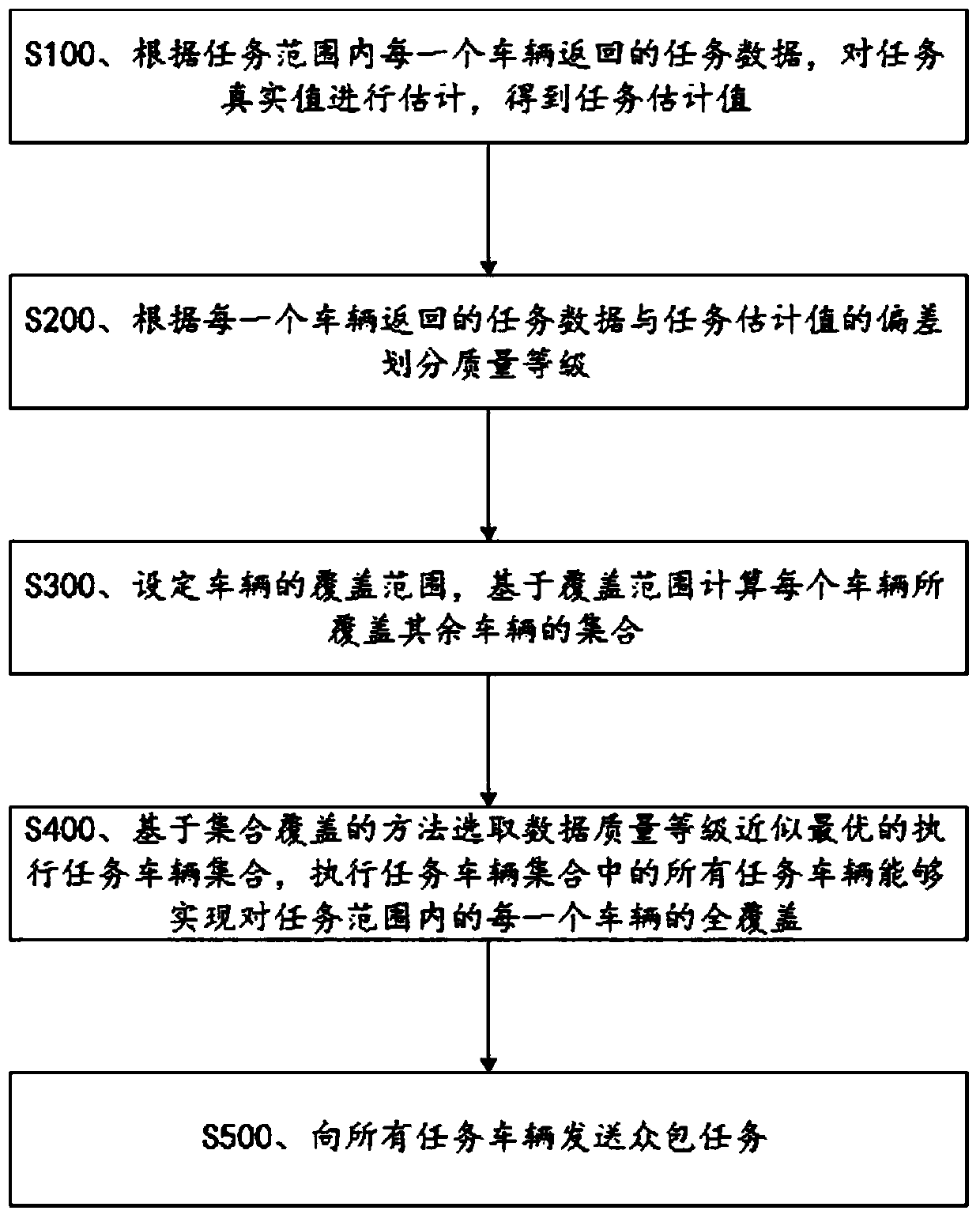

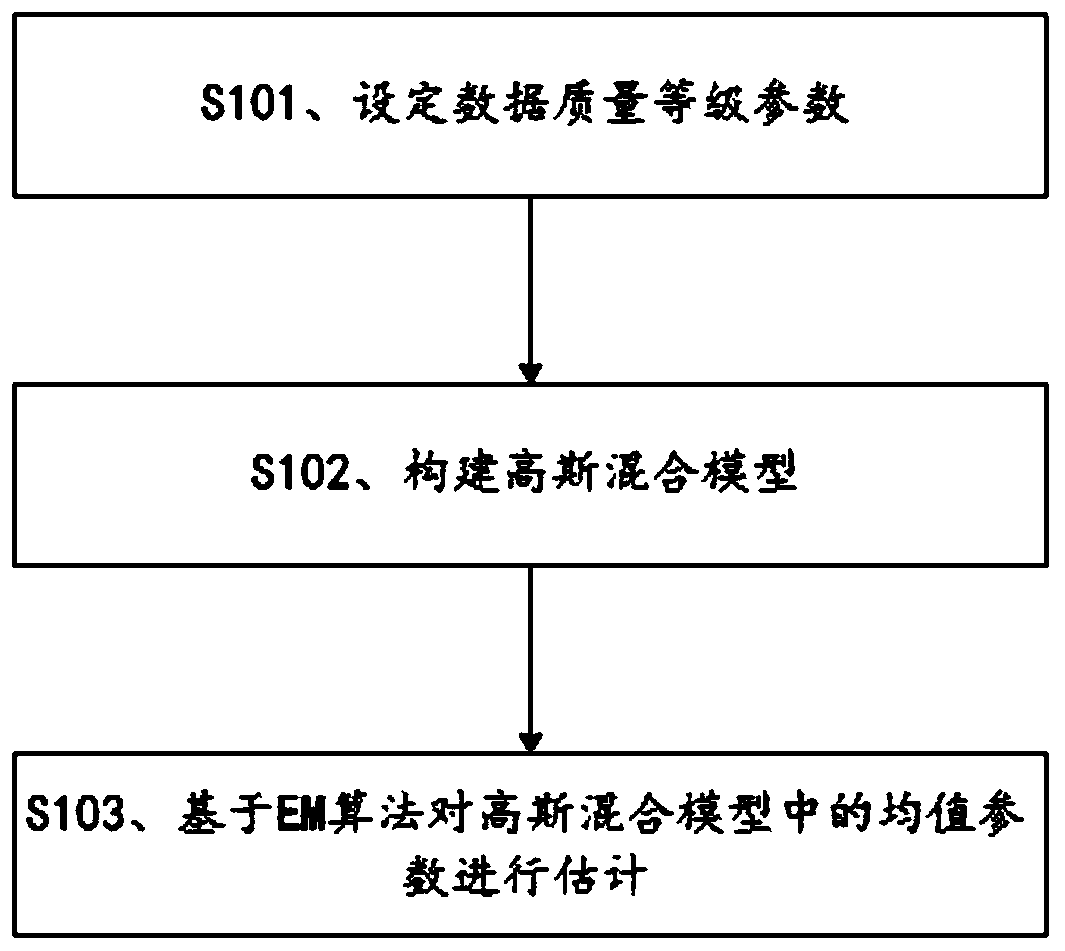

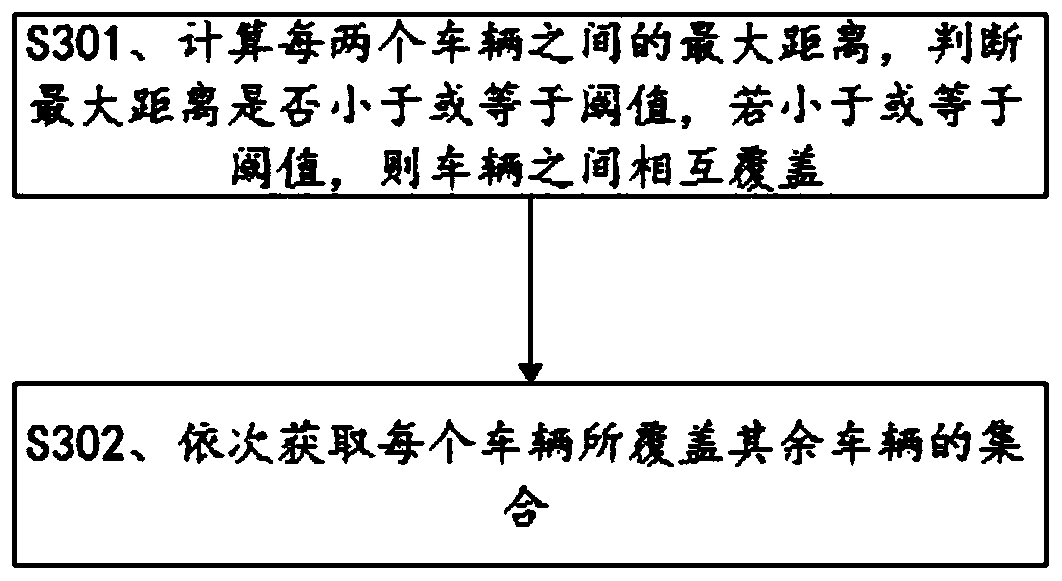

Crowdsourcing service-oriented task allocation method and system for Internet of Vehicles

ActiveCN111582641AReaction done good or badImprove execution qualityInternal combustion piston enginesResourcesSimulationThe Internet

The invention discloses a crowdsourcing service-oriented task allocation method and system for the Internet of Vehicles, and the method comprises the steps: obtaining a task estimation value accordingto task data returned by each vehicle in a task range; dividing quality grades according to the deviation between the task data returned by each vehicle and the task estimation value; setting a coverage range of the vehicles, and calculating a set of other vehicles covered by each vehicle based on the coverage range; selecting a task execution vehicle set with an approximately optimal data quality grade based on a set coverage method, wherein all task vehicles in the task execution vehicle set can realize full coverage of each vehicle in a task range; and sending the crowdsourcing task to allthe task vehicles. According to the invention, the data quality of the vehicle can be estimated in real time, and task allocation is performed on the request of the user according to the data qualitygrade and the vehicle relative position; and the data quality grade of the selected task vehicle is high, so that the purposes of reducing crowdsourcing answer redundancy and reducing system transmission overhead can be achieved.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Control system for work vehicle, method, and work vehicle

ActiveUS20210108395A1Improve efficiencyGood quality finishMechanical machines/dredgersControl systemControl engineering

A work vehicle includes a work implement. A control system for the work vehicle includes an operating device that outputs an operation signal indicative of an operation by an operator, and a controller that communicates with the operating device and controls the work implement. The controller determines a target design topography indicative of a target topography. The controller generates a command signal to operate the work implement in accordance with the target design topography. When a tilt angle of the work implement is changed with an operation of the operating device, the controller corrects the tilt angle of the work implement in accordance with the changed tilt angle.

Owner:KOMATSU LTD

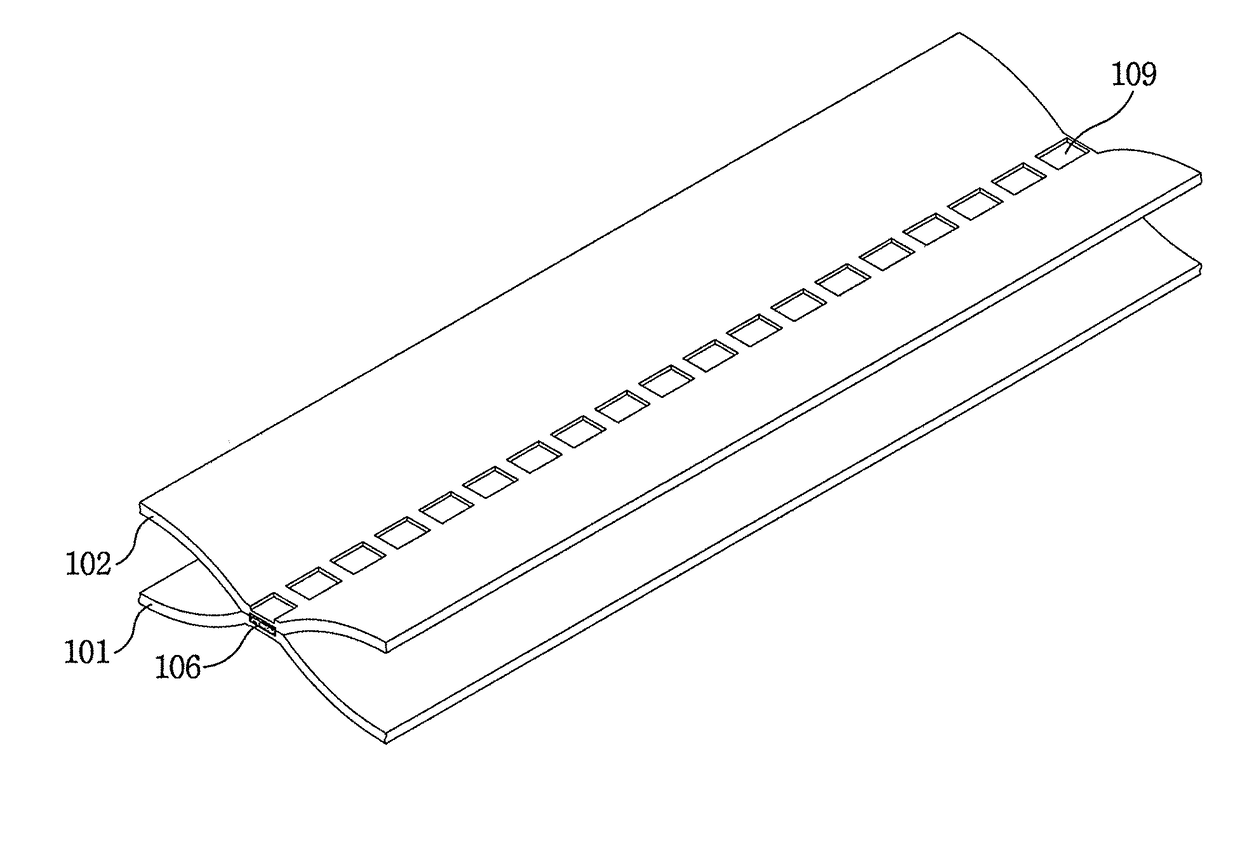

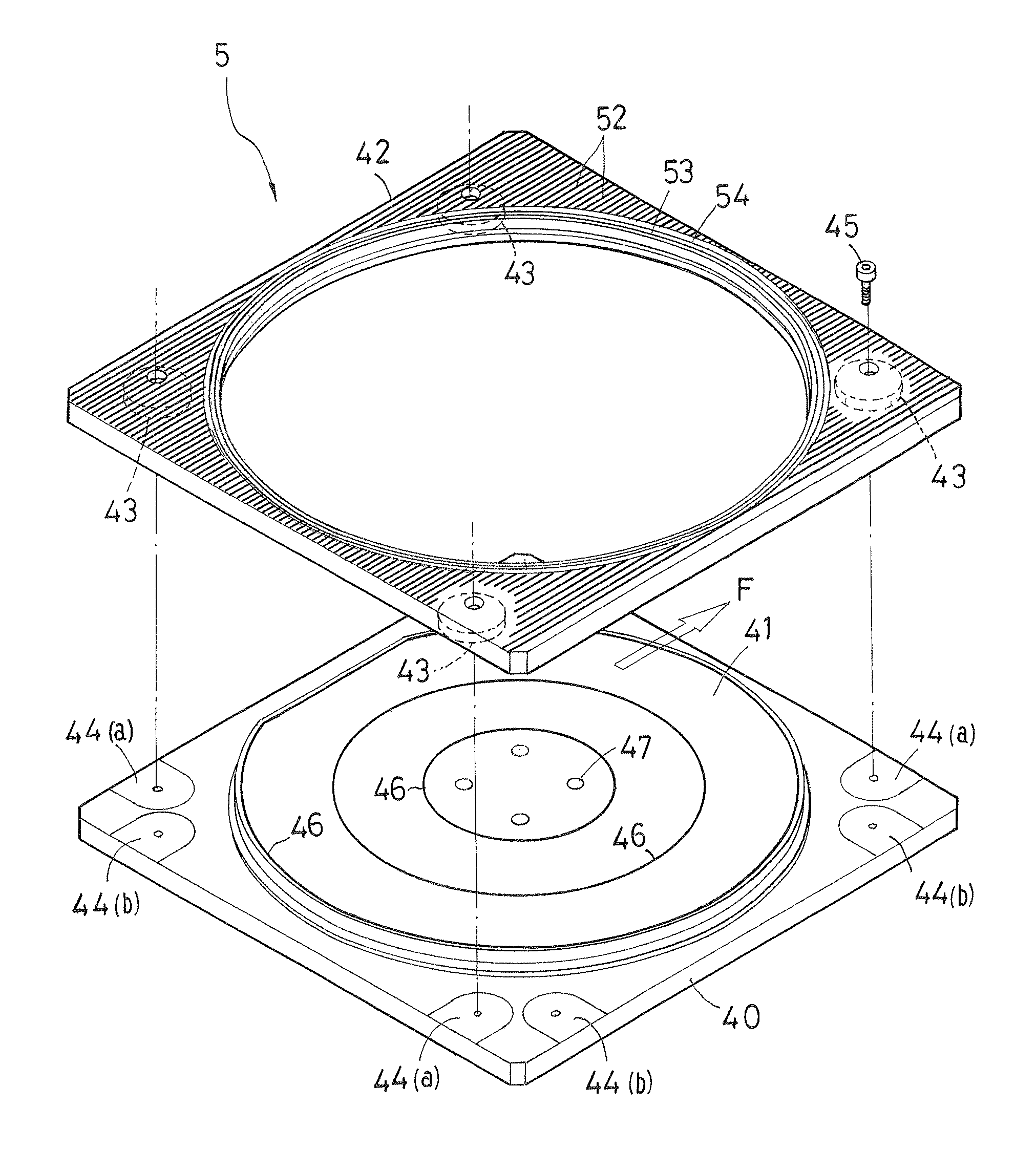

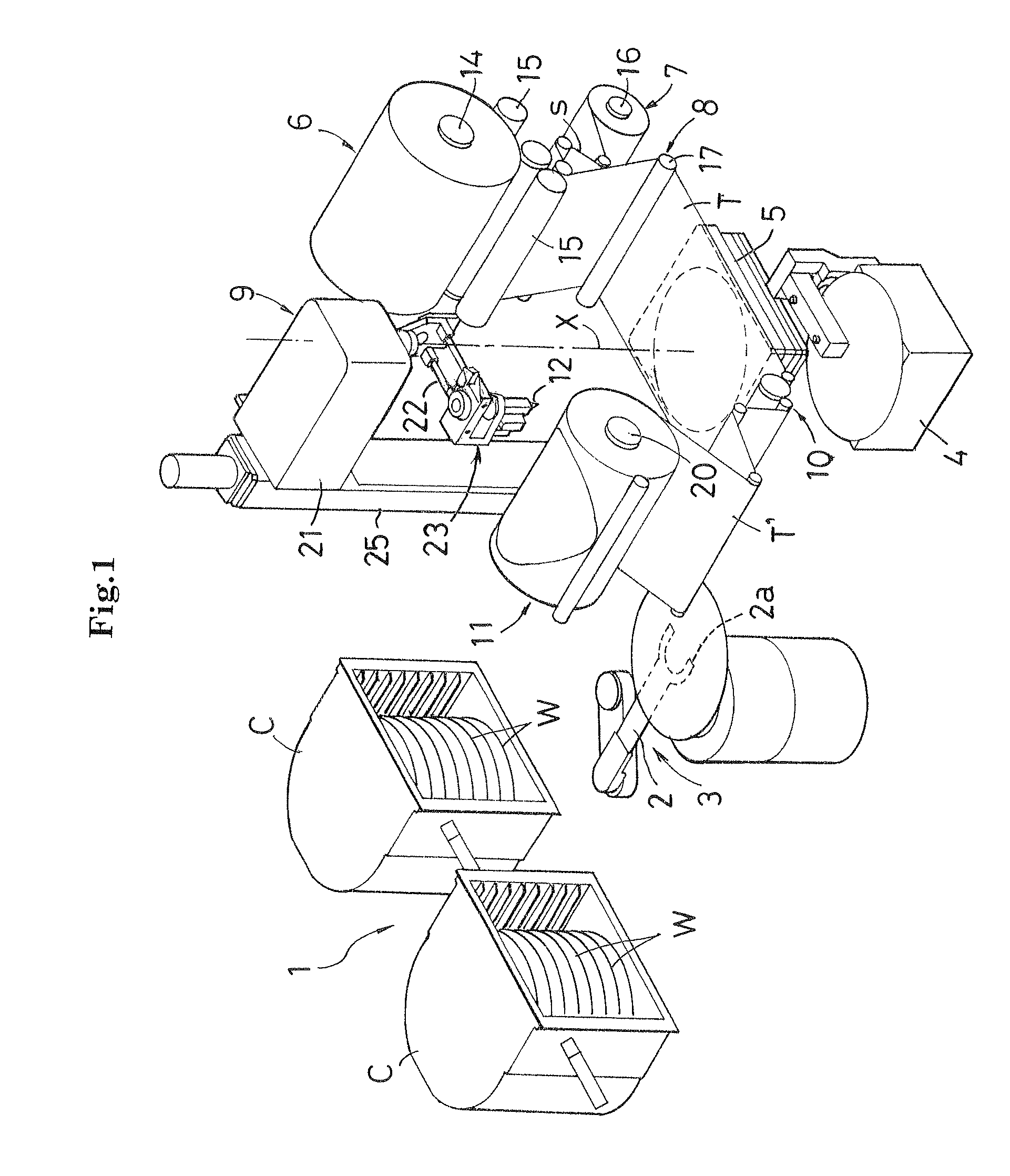

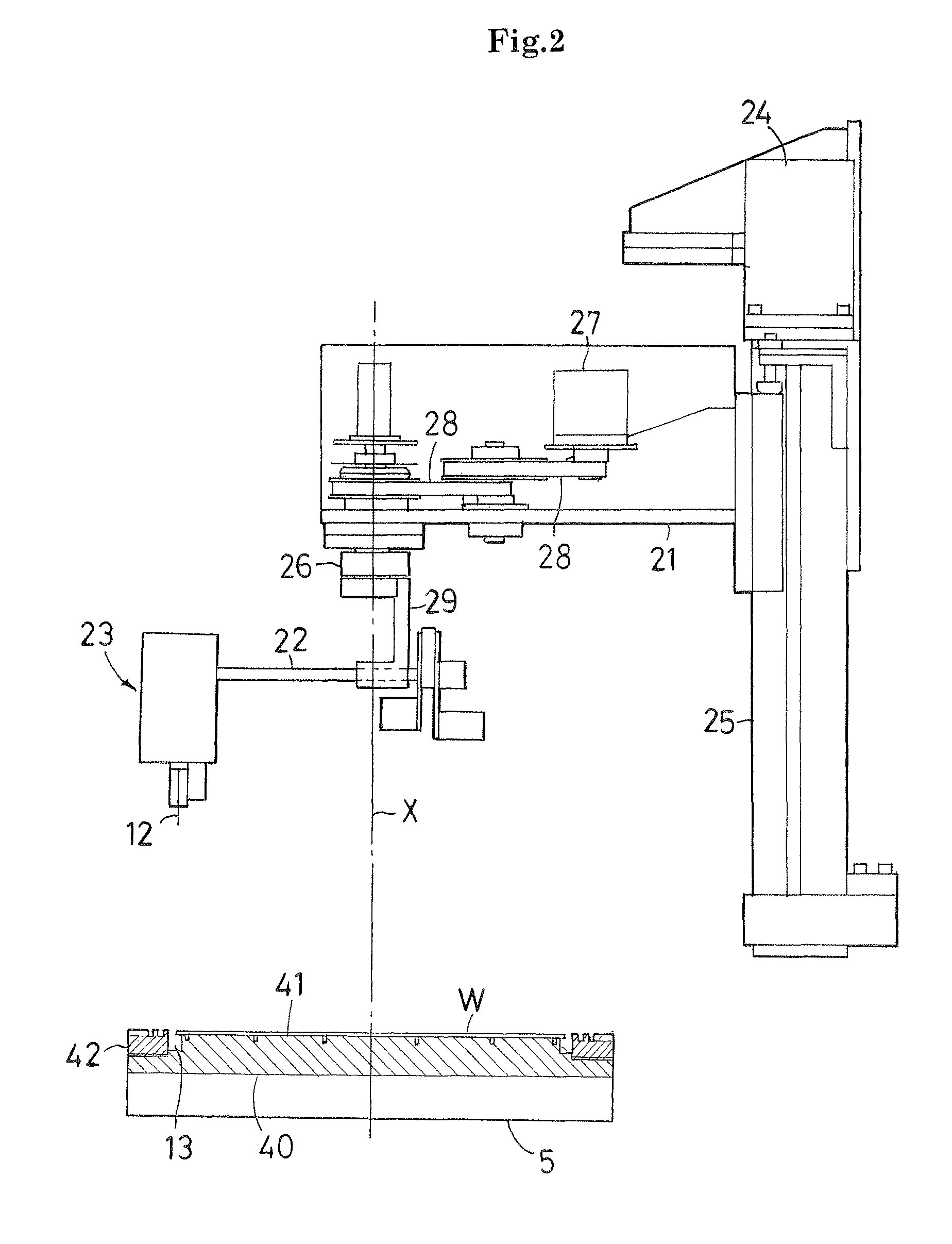

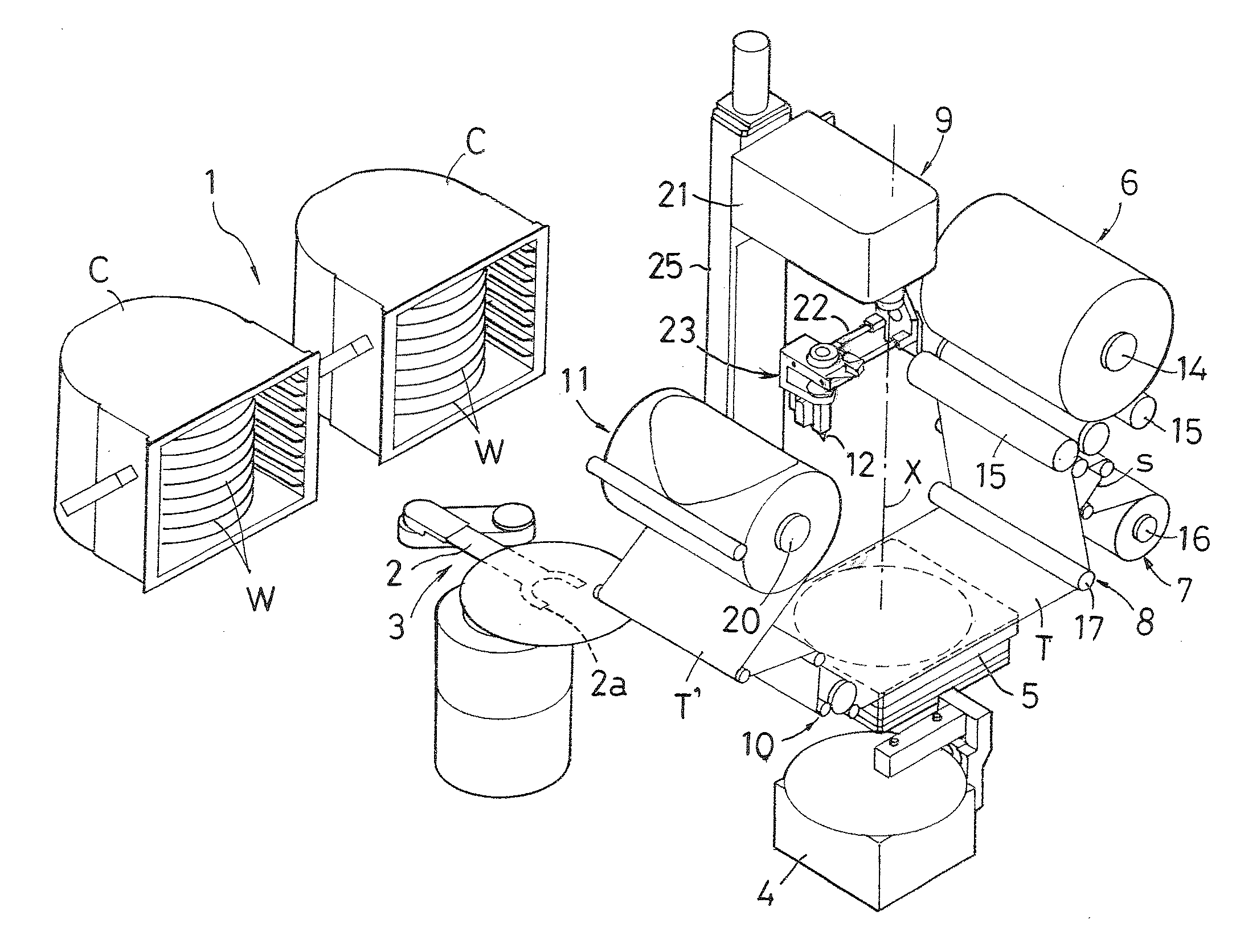

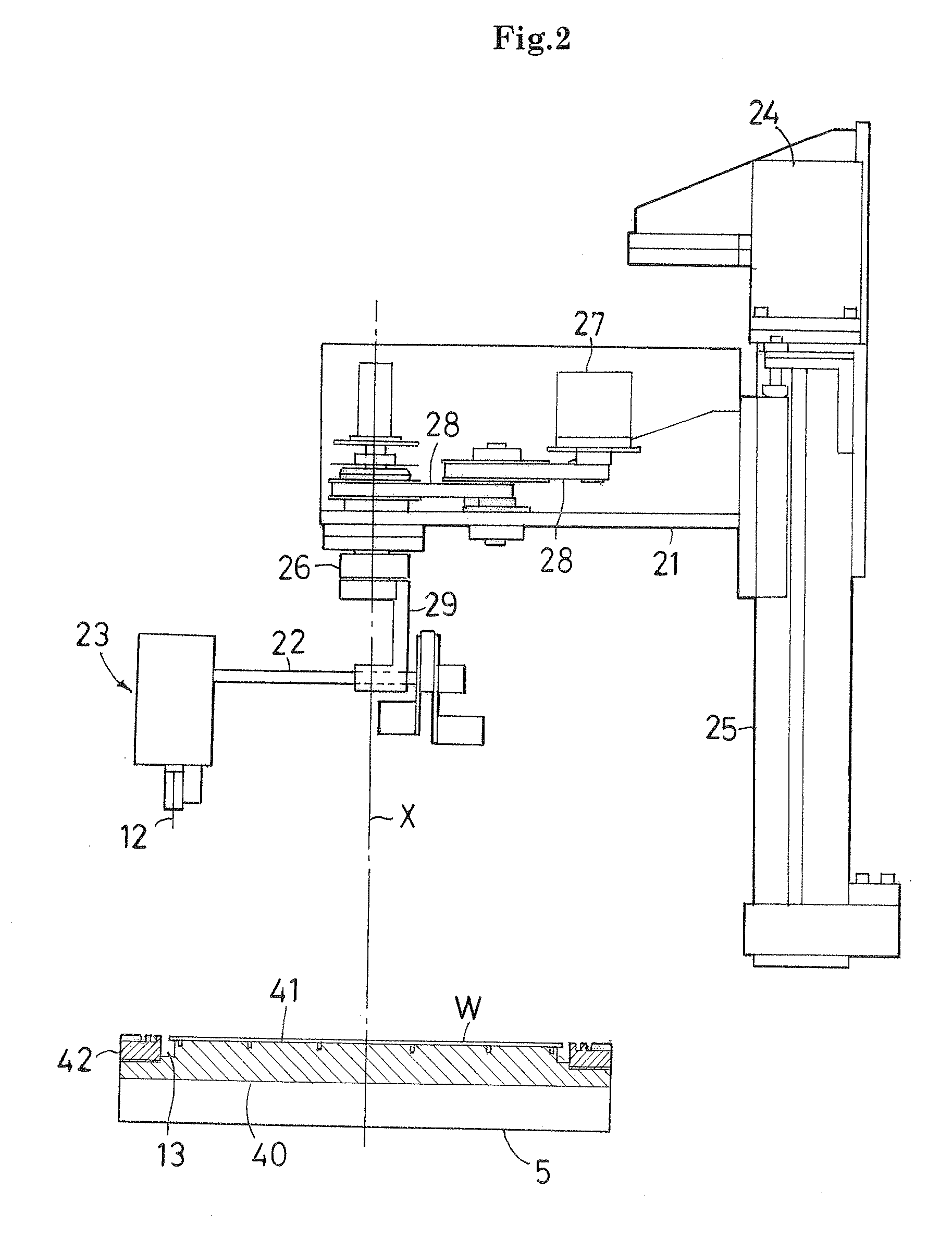

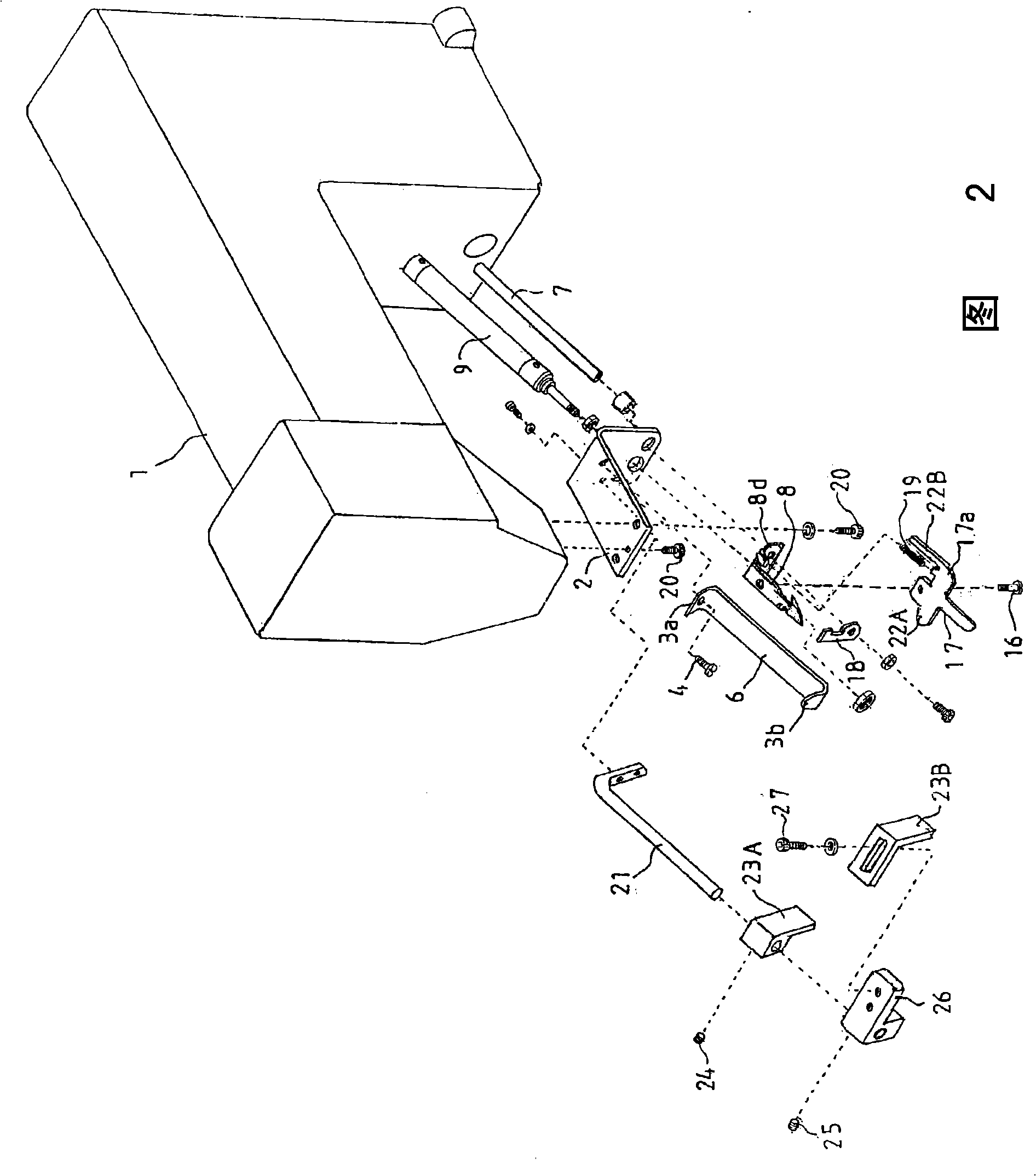

Protective tape joining apparatus

InactiveUS7987886B2Good quality finishEasy to separateLamination ancillary operationsLaminationEngineeringMechanical engineering

Owner:NITTO DENKO CORP

Protective tape joining apparatus

InactiveUS20090272496A1Change heightSlow changeLamination ancillary operationsLaminationBraced frameEngineering

A chuck table is configured with a table main body having a wafer placement part holding a wafer placed thereon, and an annular tape support frame provided outside the wafer placement part with a cutter blade traveling groove being interposed therebetween. The tape support frame has, at a top face thereof, a plurality of linear grooves arranged in parallel in a tape joining direction, a large number of linear tape support parts each located between the linear grooves, and an annular tape support part supporting the protective tape at an outer side of the cutter blade traveling groove.

Owner:NITTO DENKO CORP

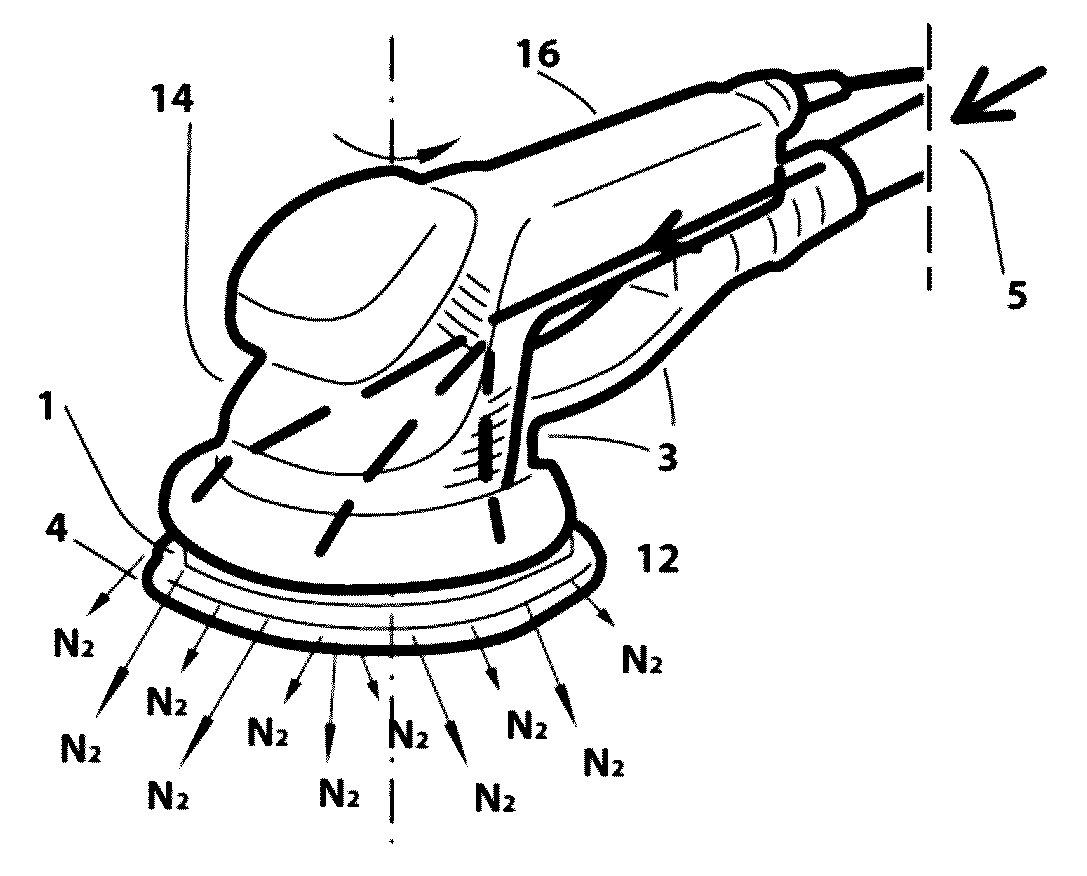

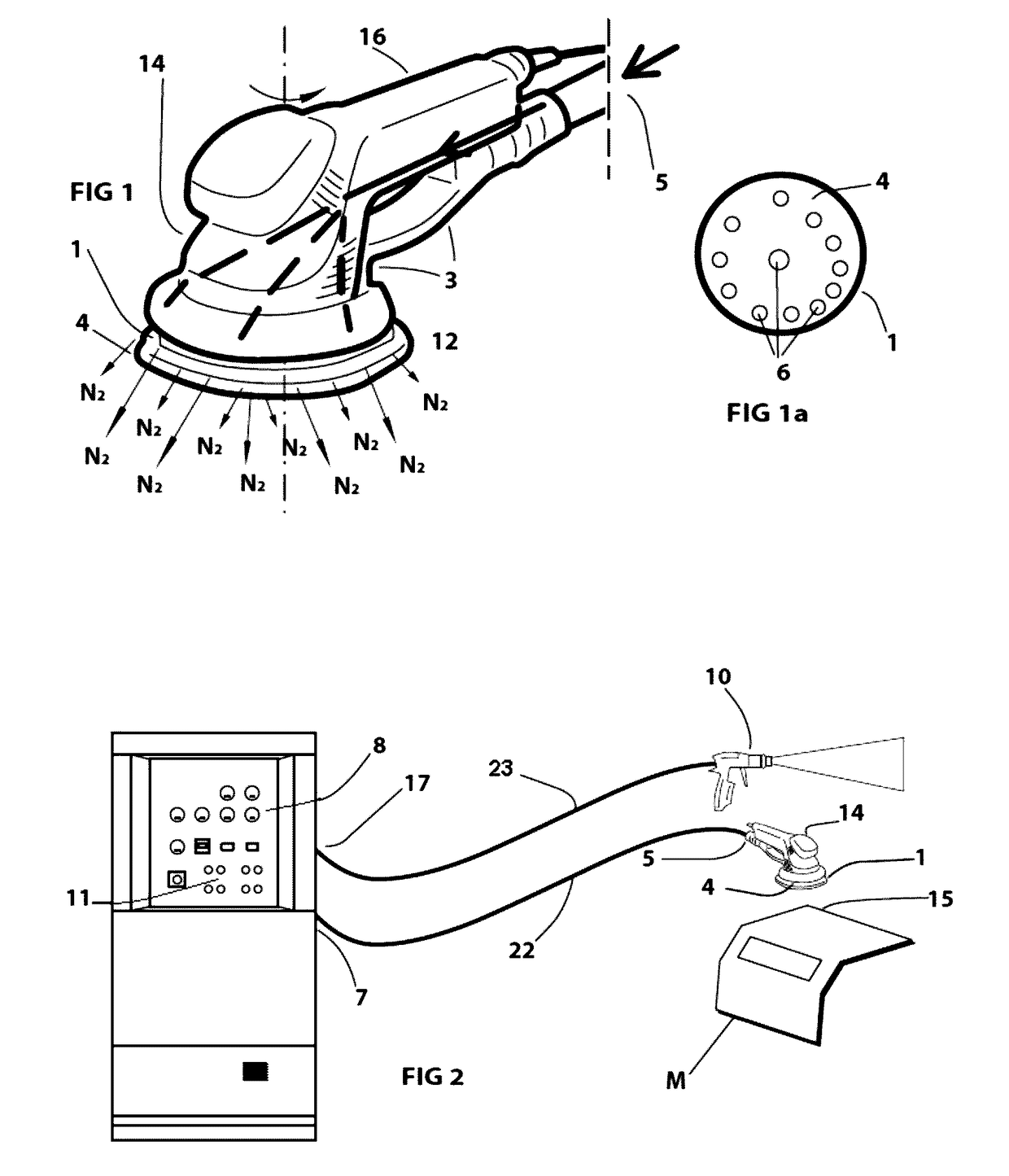

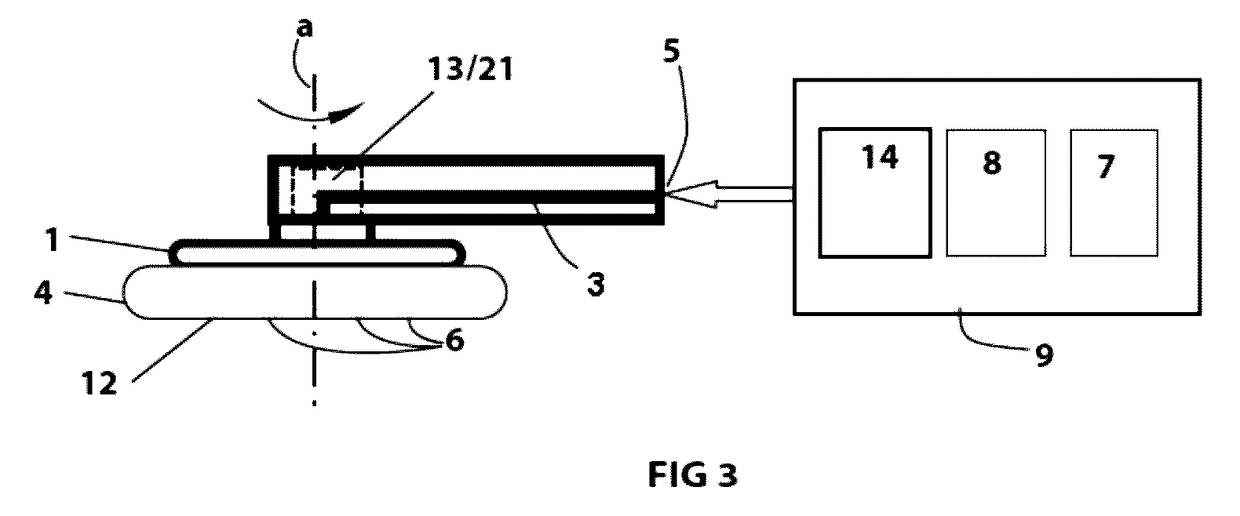

Device and method for polishing or abrading products

InactiveUS20170165807A1Risk of damage to the polished surface, and in particular to the film of paint, is extremely reducedReduce risk of damageLapping machinesPortable grinding machinesEngineeringGaseous nitrogen

A device for polishing or abrading products (M), includes: a polishing element (1) provided with an operating surface (4) designed to perform a polishing or sanding movement, preferably a circular or orbital movement;motor elements (13) operatively connected to the polishing element (1) for impressing on the operating surface (4) the polishing movement;one or more air ducts (3) extending from an inlet opening (5), which communicates with a source (7) of a flow of treated air, for example dried air, gaseous nitrogen, or modified air rich in nitrogen, to one or more outlets (6) of the flow distributed in an area corresponding to the operating surface (4); andelements (8) for regulating the temperature of the flow of treated air at a value comprised between −5° C. and +20° C.

Owner:EUROSIDER S DI MILLI OTTAVIO & C

Dry granulator

ActiveUS9827571B2Compact structureImprove sealingGranulation by pressingGrain treatmentsHardnessMaterials science

Owner:ZHEJIANG FUTURE MACHINERY

Apparatus for manufacturing double-layer fabric for down products having pattern joining line formed by high-frequency bonding

ActiveUS20170282528A1Good adhesivenessIncreased durabilityLamination ancillary operationsLayered product treatmentEngineeringMechanical engineering

A device for preparation of double fabric for down products comprises a printing means that can print an adhesive in a predetermined printing pattern on fabric; a drying means that can dry or fix the adhesive; a laminating means that can stack and laminate the fabrics on which an adhesive is printed; and a bonding means that can bond the fabrics with a cured adhesive by pressing with a predetermined pressing means and high-frequency heating to cure the adhesive; wherein said printing pattern and the pressing pattern are the same in pattern (shape), can be overlapped on the basis of the center line and have a difference in size (width) of 20% or less. Consequently, double fabric for down products thus manufactured has an excellent adhesiveness and durability and an aesthetically excellent pattern line with good clearness and finishing quality.

Owner:HOJEON

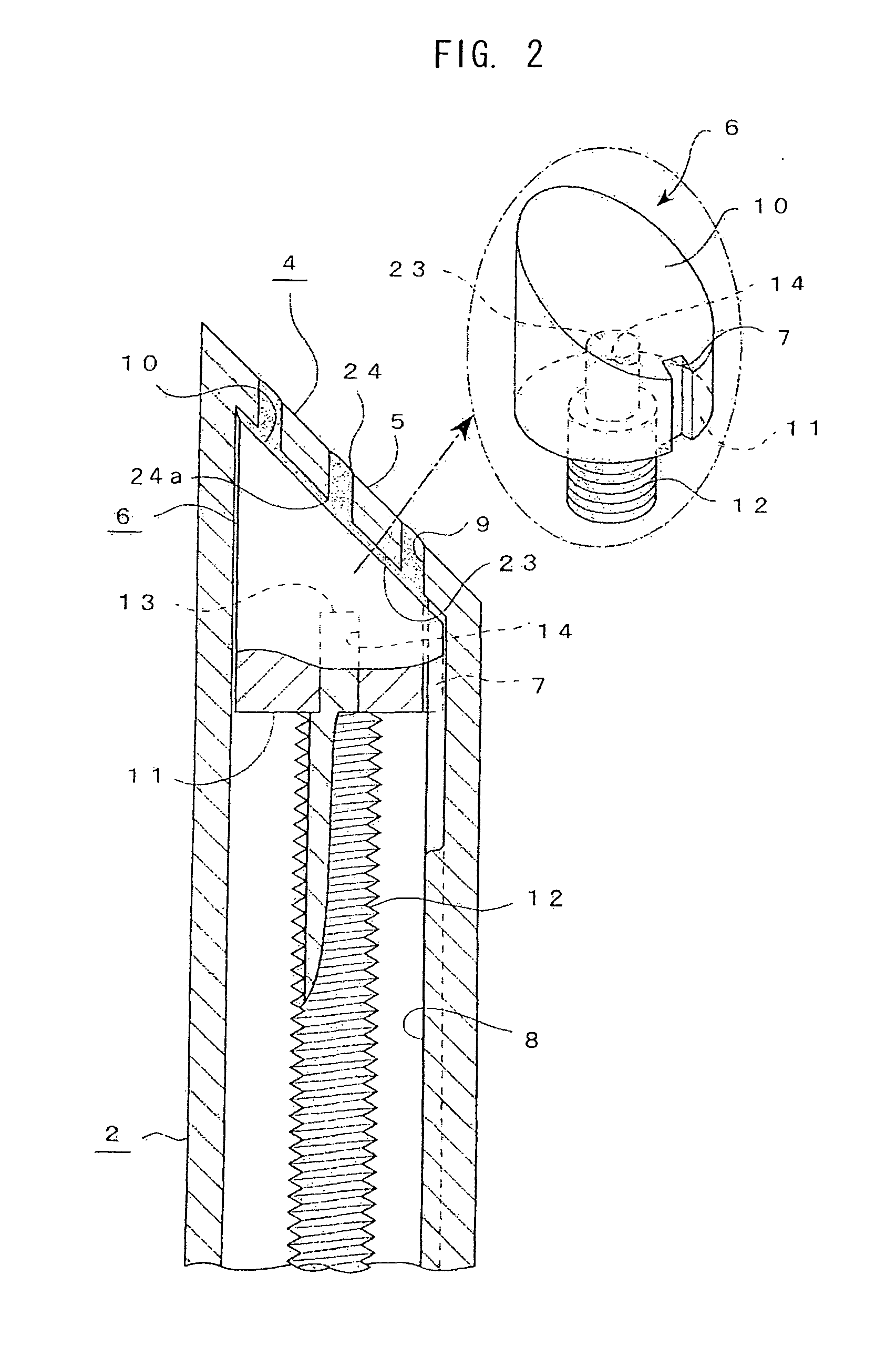

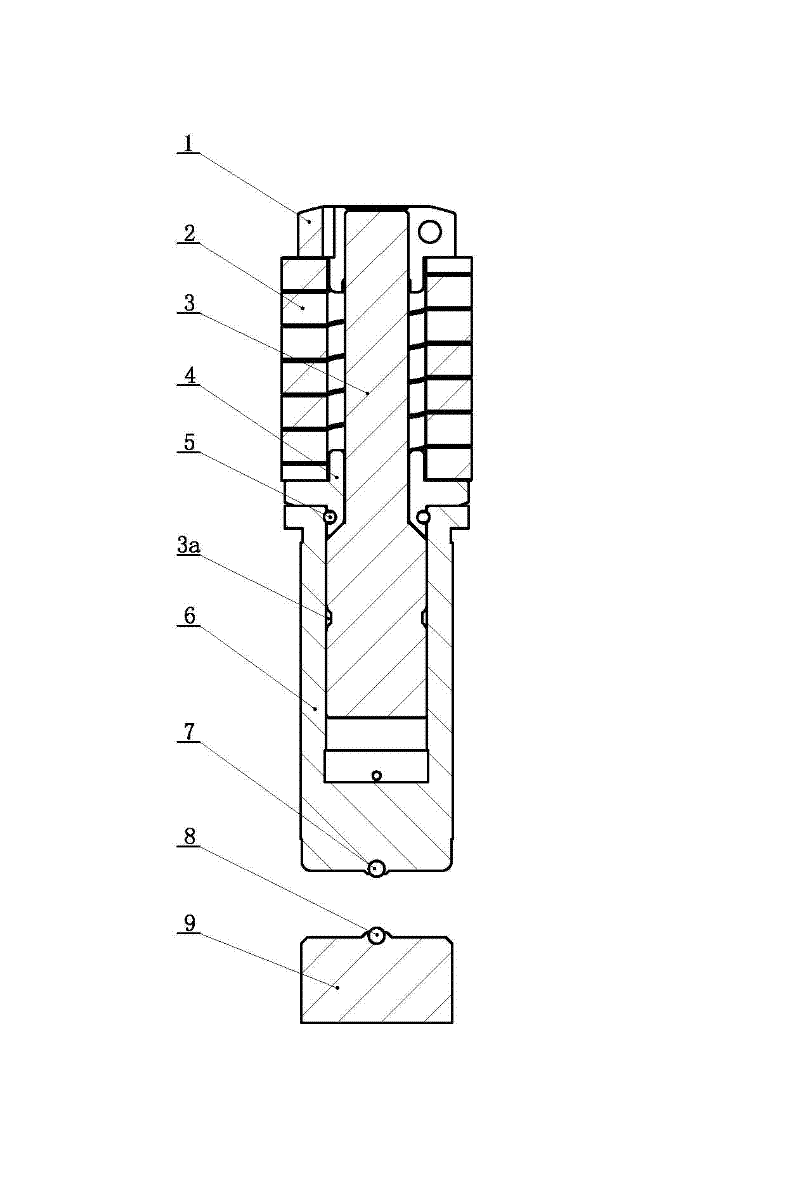

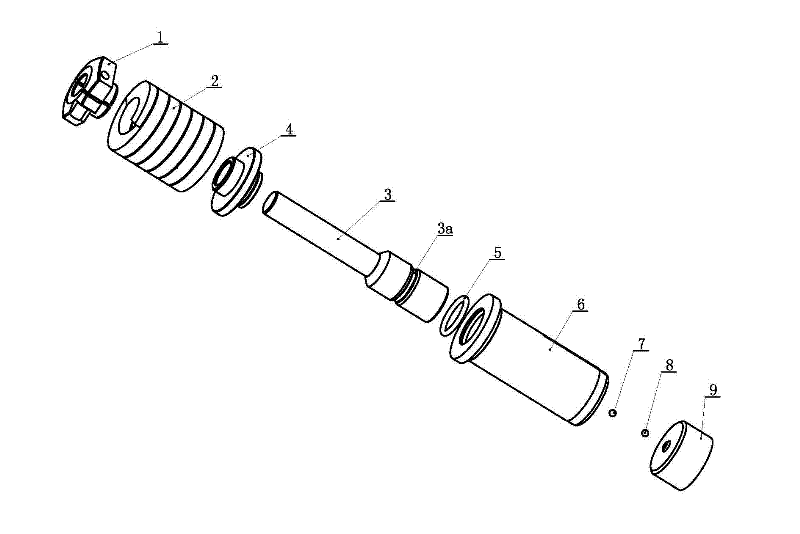

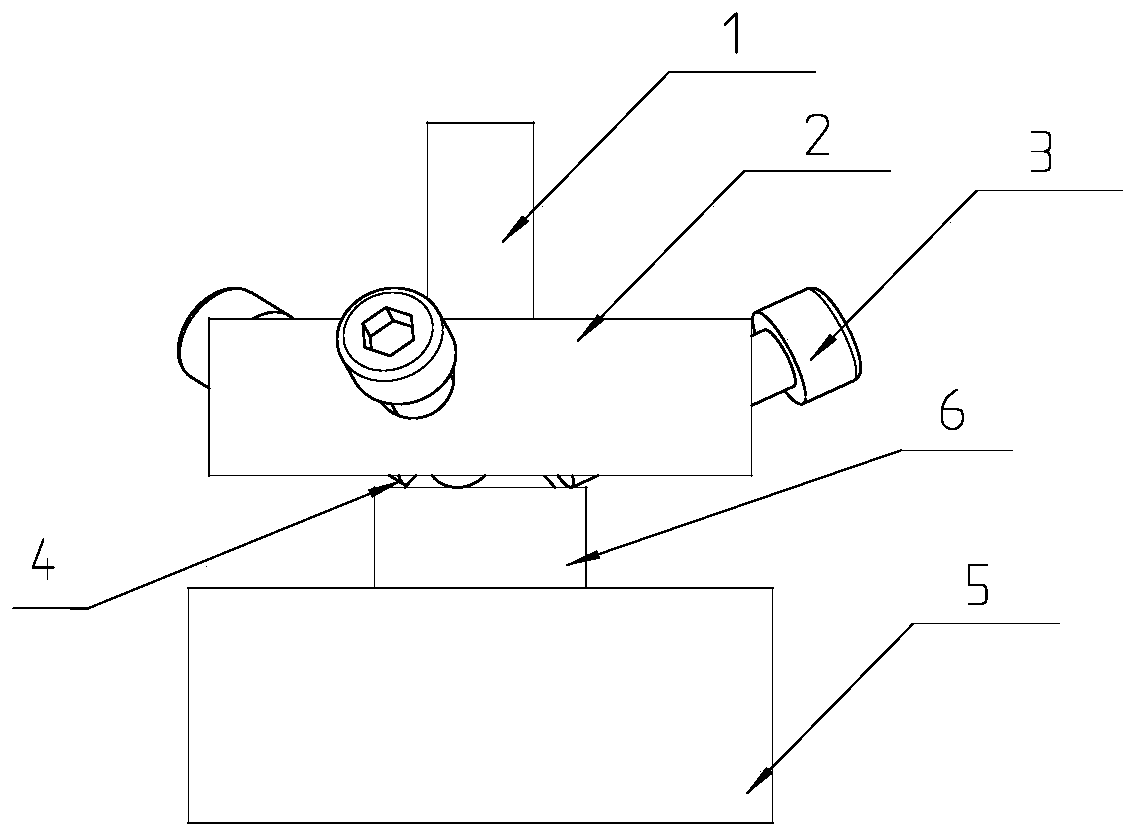

Deburring die for numerical control turret punch press

The invention relates to a deburring die for a numerical control turret punch press. The die comprises an upper die and a lower die, wherein an upper die rod is in a stepped cylinder shape with a small upper part and a large lower part; the middle part of the upper die rod is provided with a conical surface for connecting the upper part with the lower part in a transition mode; a die nut, an upper die spring and a spring seat are sleeved on the upper part of the upper die rod from top to bottom in turn; the die nut is screwed at the upper end of the upper die rod and presses the upper die spring; the lower end of the upper die spring is supported on a convex ring of the spring seat; the lower end face of the spring seat is supported on the conical surface on the middle part of the upper die rod; the lower side of the convex ring of the spring seat is supported on a flange at the upper port of a guide sleeve; the lower part of the upper die rod is inserted into the guide sleeve and canmove up and down along an inner hole of the guide sleeve; an upper ball is embedded in the center of the lower end face of the guide sleeve; the lower die comprises a lower die seat and a lower ball;the lower ball is embedded in the center of the upper end face of the lower die seat; and the upper ball and the lower ball are positioned on the axes of the upper die and the lower die. The die has a high deburring speed, does not generate iron scrap or dust, and can walk along any edge of a punched hole.

Owner:JIANGSU JINFANGYUAN CNC MACHINE CO LTD

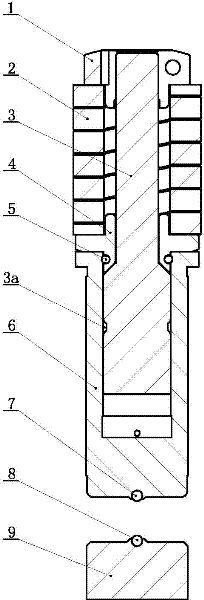

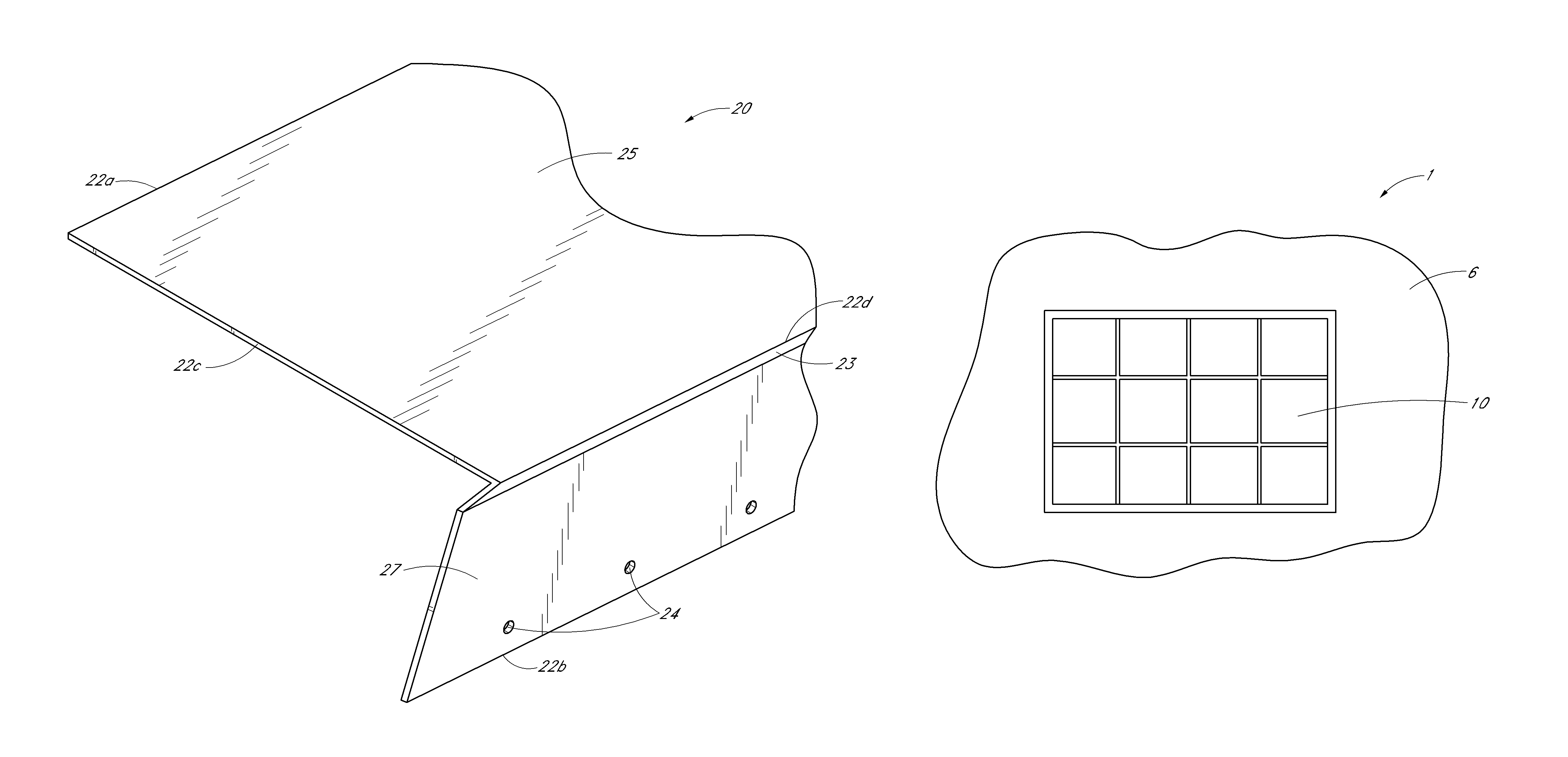

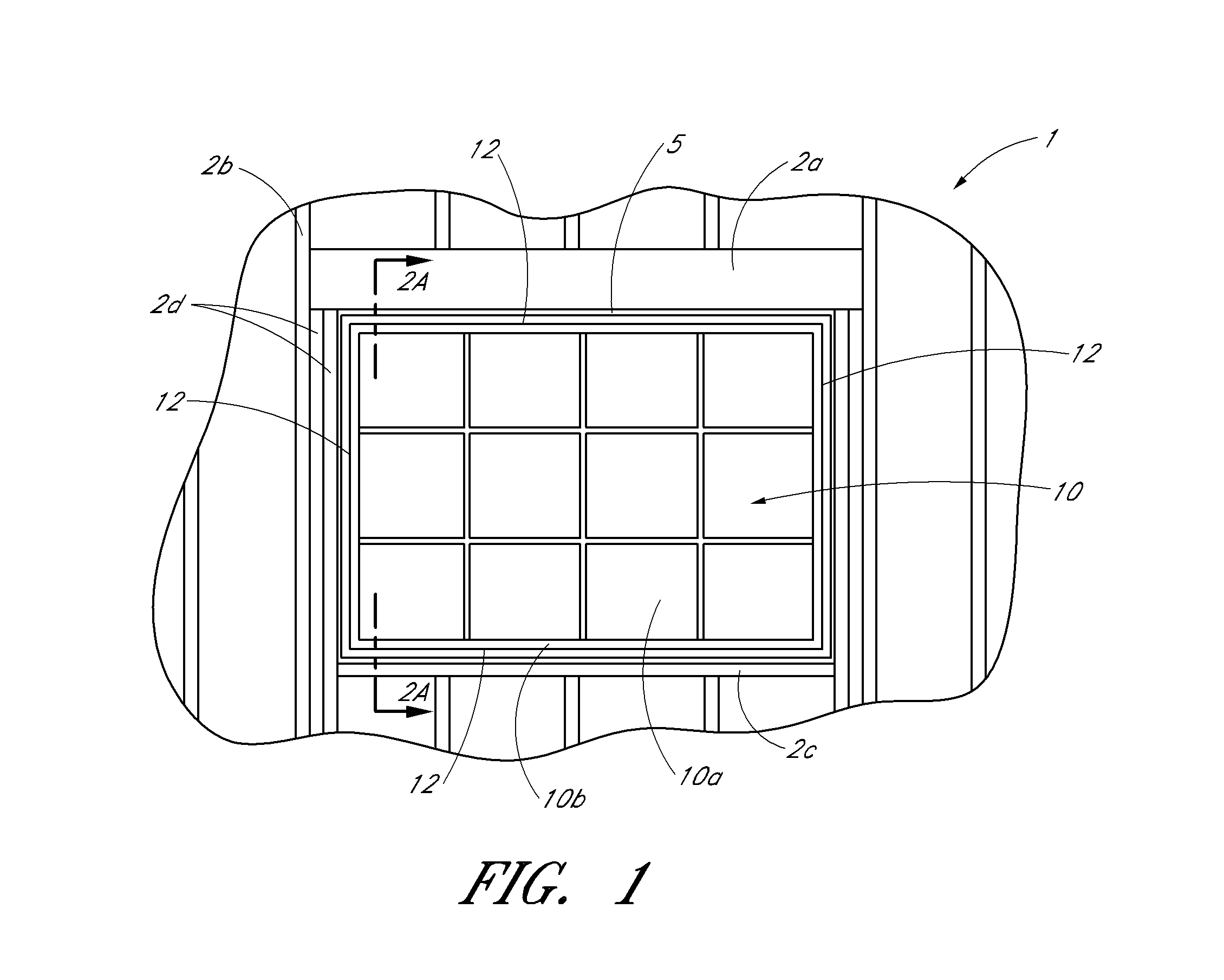

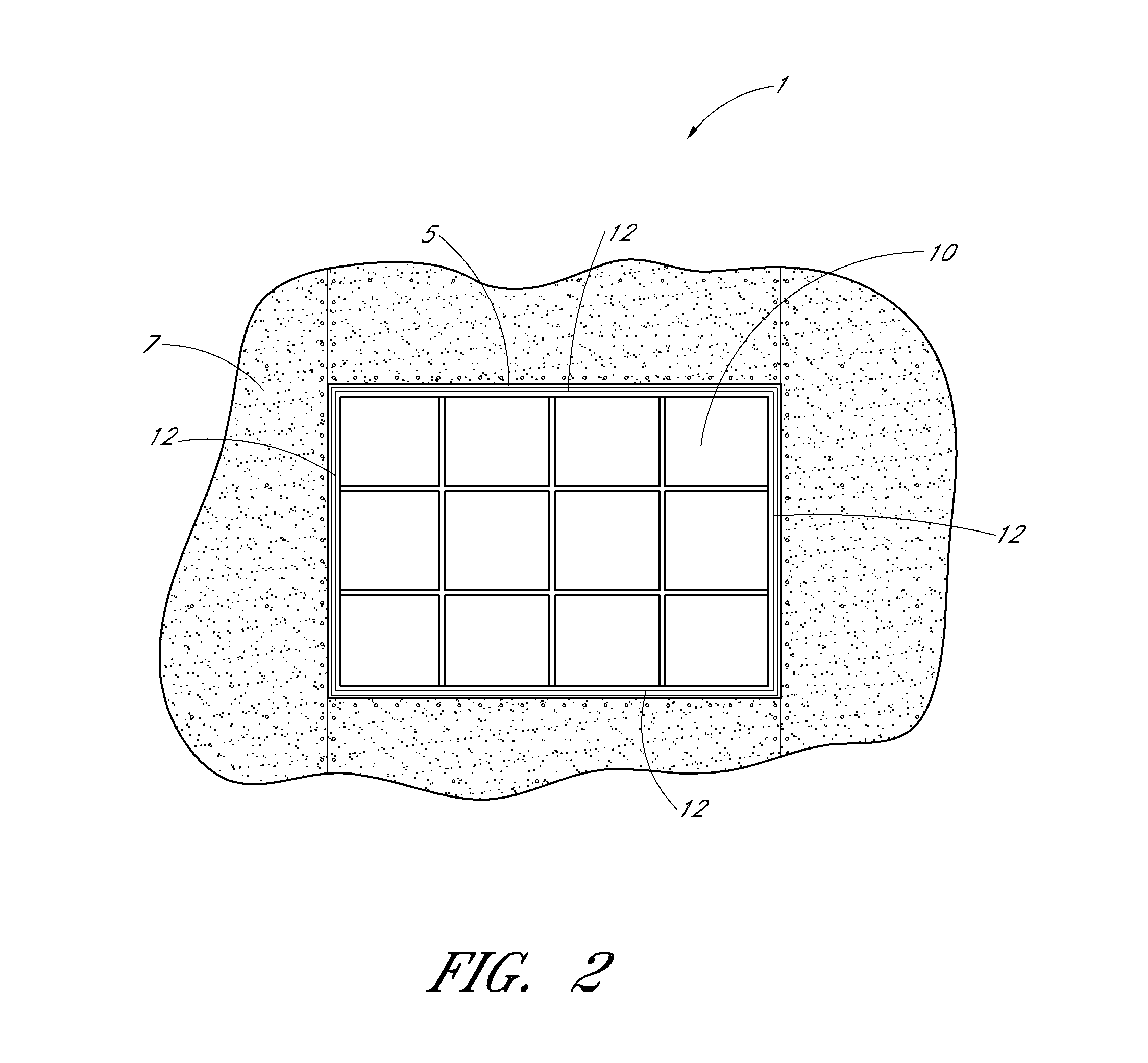

Window reveal systems and methods

InactiveUS8826612B2Easy to handleSimplerShutters/ movable grillesFrame fasteningEngineeringReveal system

Owner:PERFECT WINDOW REVEAL

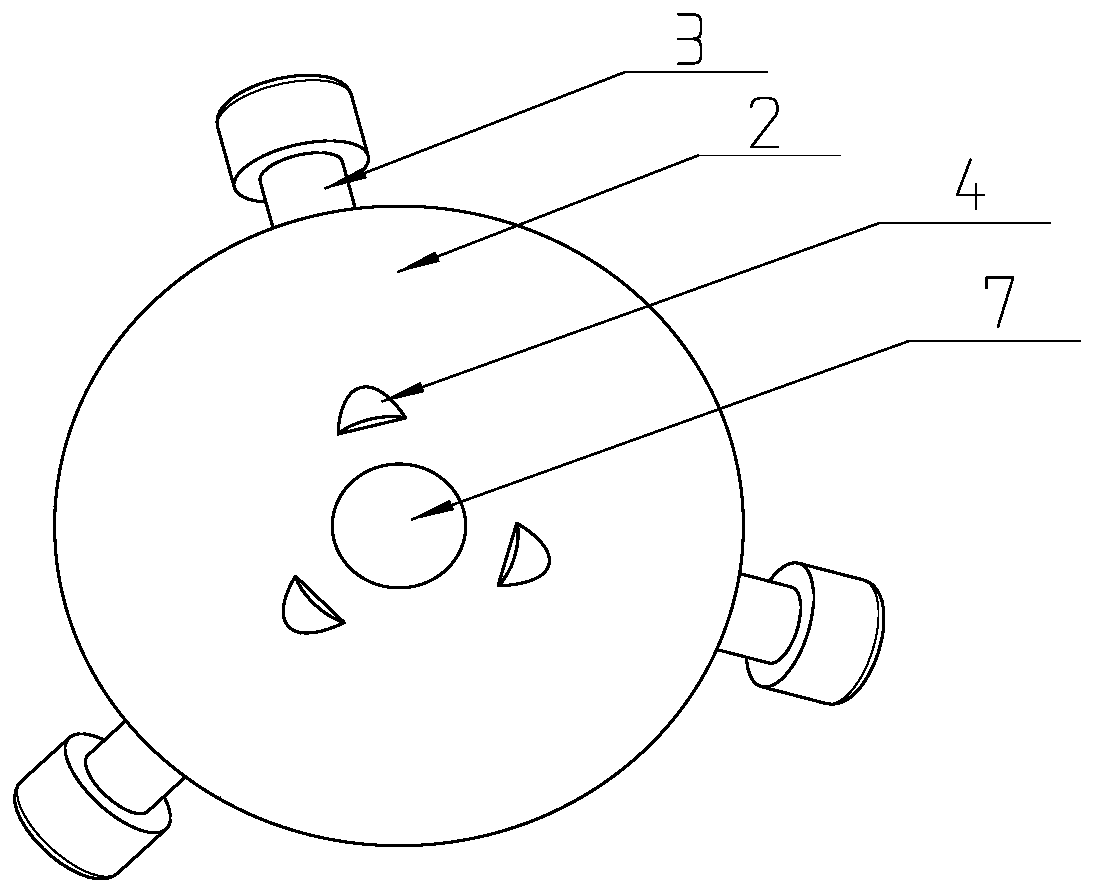

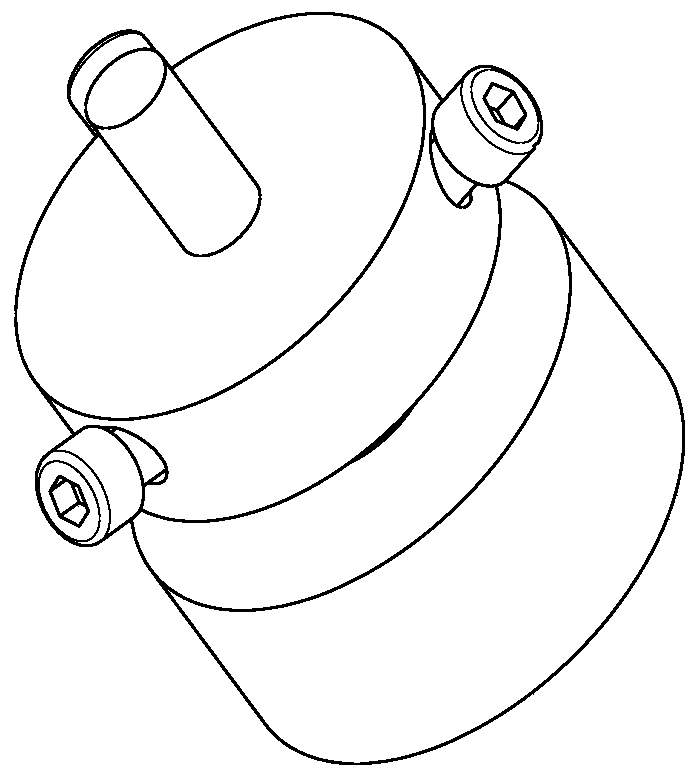

Roller type bearing spinning closing-in device and using method thereof

ActiveCN110947814AReduce the difficulty of structure manufacturingLow costStructural engineeringMechanical engineering

The invention relates to a roller type bearing spinning closing-in device. The device comprises a tool handle, a spinning head, embedded bolts, a bolt rod, a round frame base and a guide shaft. A plurality of bolt holes are formed in the spinning head, the bolt holes run through the spinning head, the bolt holes are formed at equal angles with the central axis of the spinning head as the axis, theincluded angle between each bolt hole and the horizontal plane is 25 degrees, the tool handle is perpendicular to the spinning head and located in the middle of the spinning head, the guide shaft iscylindrical, the outer circle diameter of the guide shaft is matched with the size of an inner hole of a to-be-machined bearing, and the length of the guide shaft is matched with the thickness of theto-be-machined bearing. The guide shaft is cylindrical, the outer circle diameter of the guide shaft is matched with the size of the inner hole of the to-be-machined bearing, and the length of the guide shaft is matched with the thickness of the to-be-machined bearing. The device is simple in structure, self-manufacturing and reconstruction can be realized, production is simple and convenient, themachining mode is simple, abrasion of the closing-in device is reduced, and the service life of the closing-in device is effectively prolonged.

Owner:AVIC SAC COMML AIRCRAFT

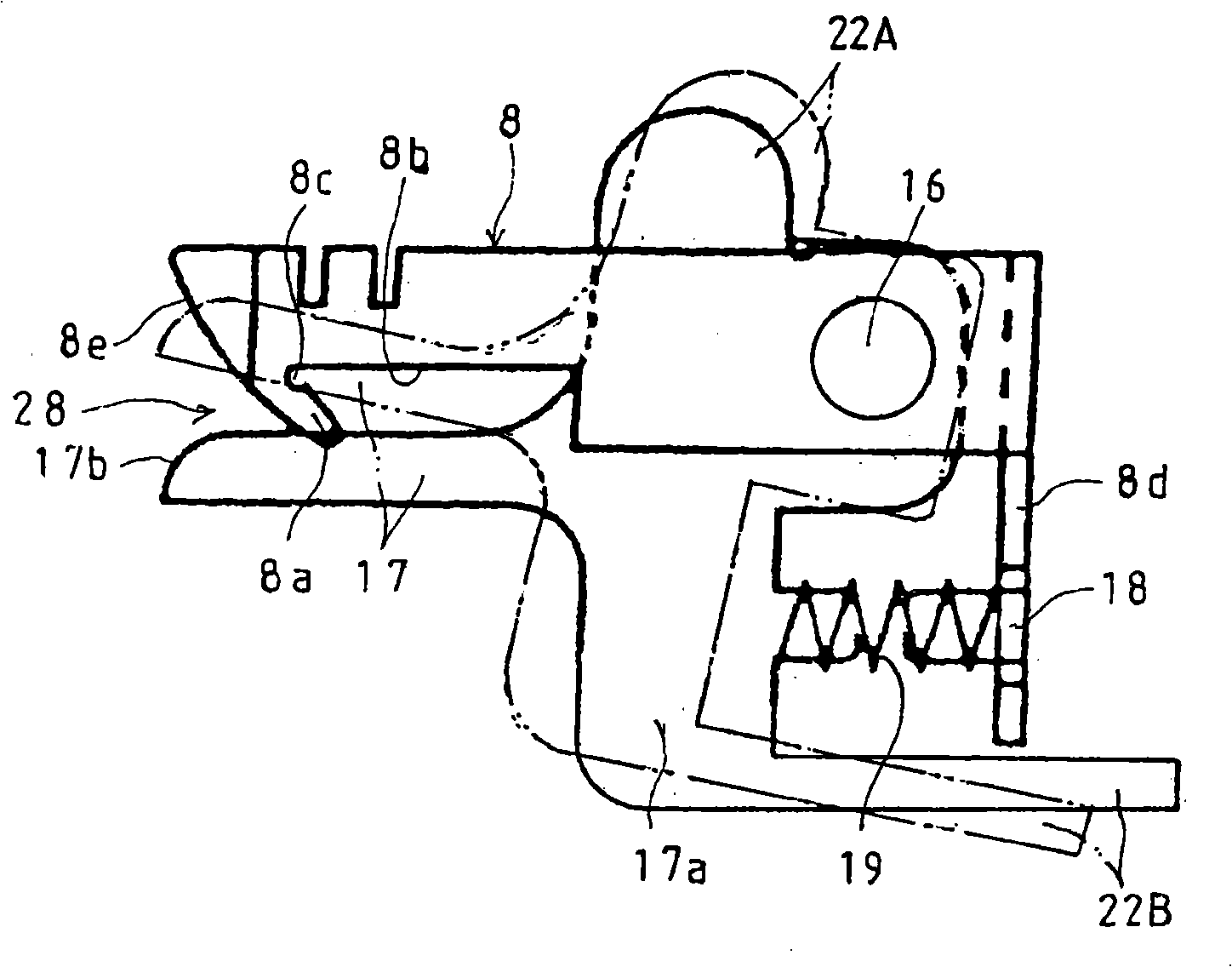

Thread hooking apparatus of button-sewing machine

InactiveCN101324013APrevent disengagementReliable formationNeedle severing devicesThread-break detectorsCut needleEngineering

The invention provides a catch-thread device for a button sewing machine, wherein a thread trailer capable of being folded and unfolded in a swinging manner is arranged on the open side of the catch-thread part on the front end of the catch-thread device. The thread is reliably caught on the catch-thread part by the movement of the thread trailer together with the catch-thread device along the motion path of a needle under the swing and open state, then the thread trailer draws an atresia and forcibly holds the needle thread between the atresia and the catch-thread device, simultaneously, the thread trailer and the catch-thread device perform the withdrawing motion towards the side direction so as to exert the function of separating the cut needle thread reliably towards the side direction after achieving the button sewing operation, furthermore, by means of maintaining the length of the separated thread in a certain value, the trace of a first stitch for the next sewing can be formed reliably with high quality.

Owner:YAMATO SEWING MASCH MFG CO LTD

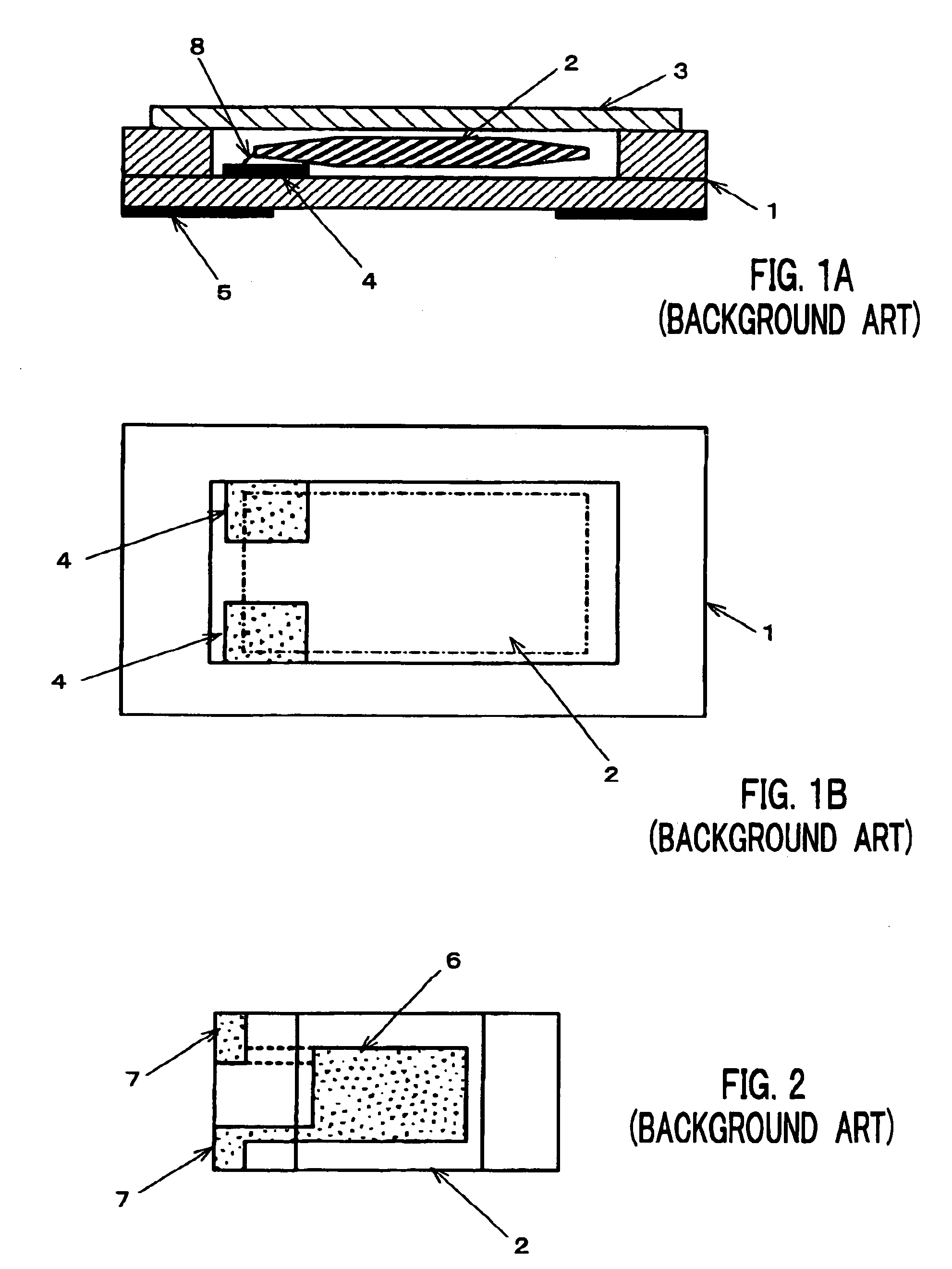

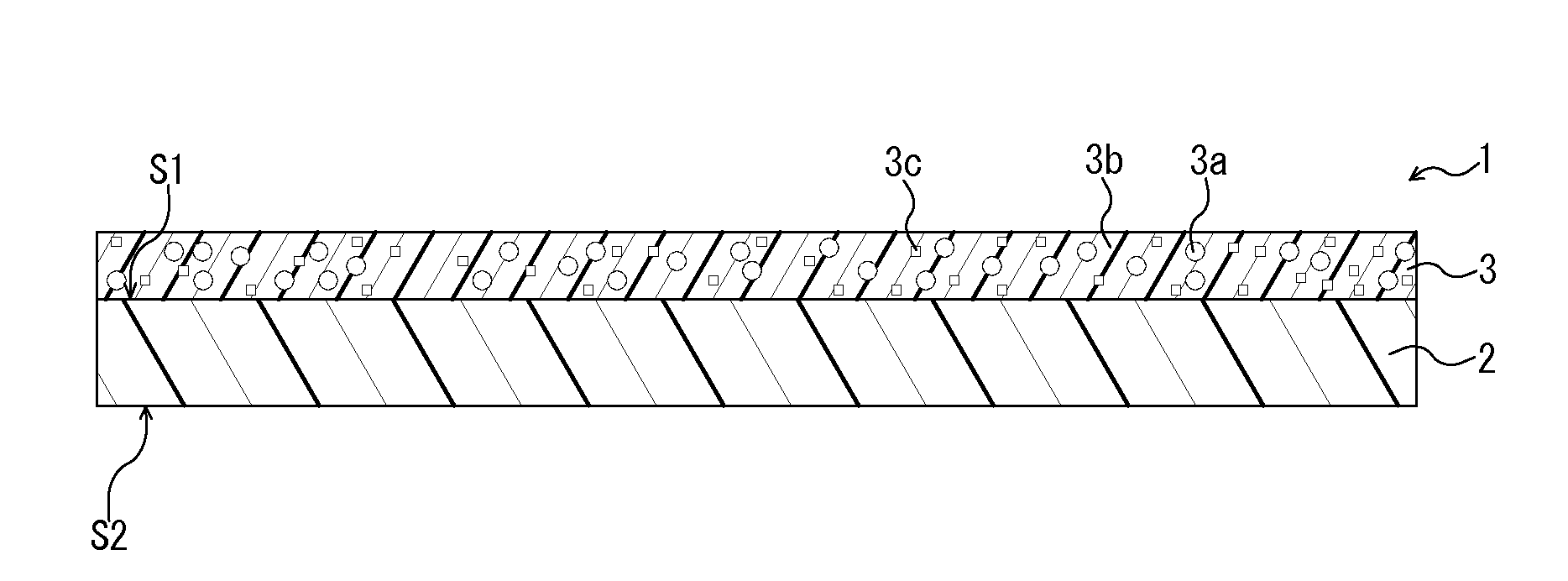

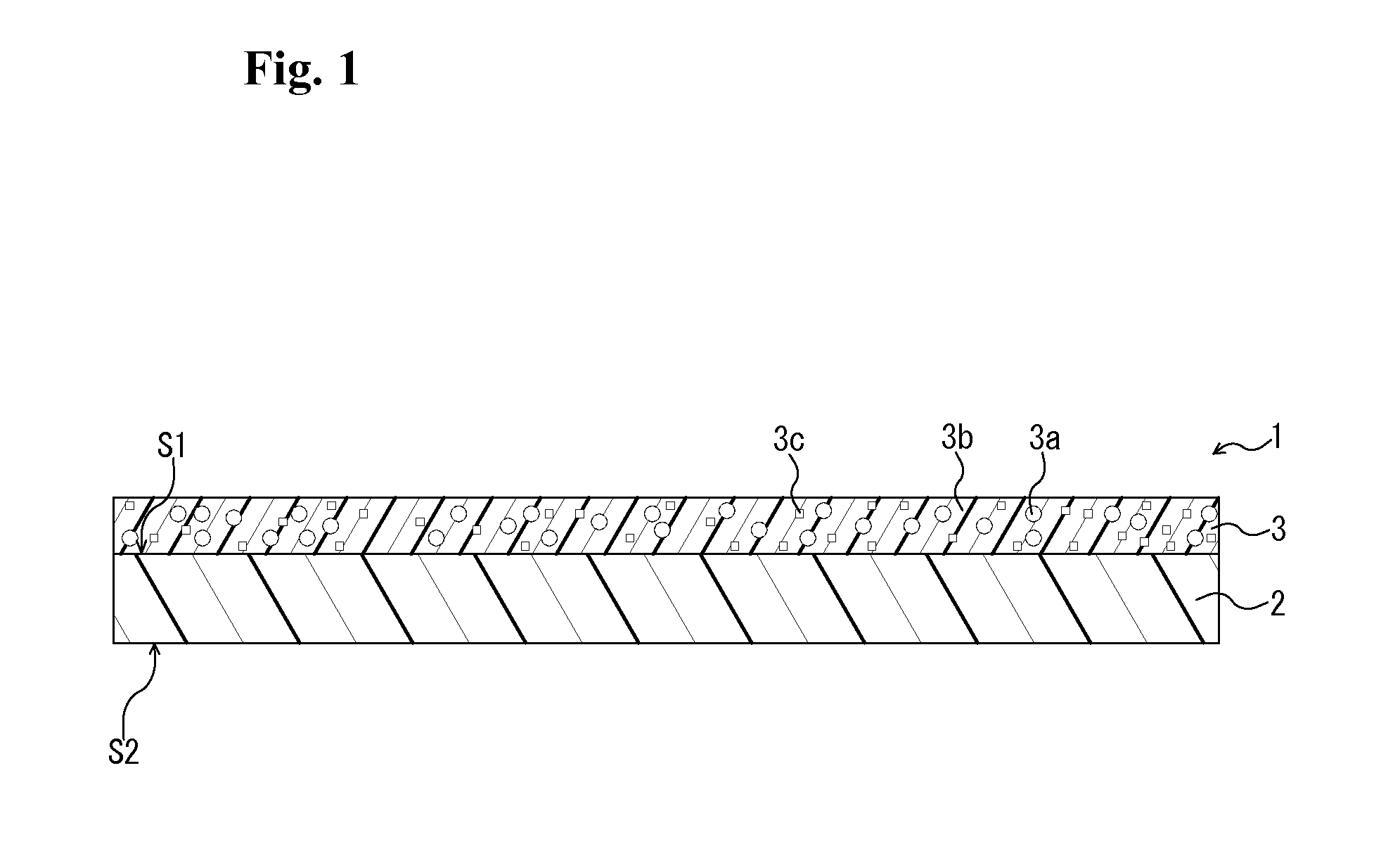

Polishing film

InactiveUS20140311044A1Good adhesionGood quality finishOther chemical processesAbrasion apparatusImpurity ionsMaterials science

The present invention provides a polishing film with which, even when water containing impurity ions is used as a polishing liquid, the abrasive particles comprising SiO2 are less apt to adhere to the polished surface, e.g., the polished surface of an end of an optical fiber itself, and which is less apt to cause the optical loss attributable to scratches or edge chips in the polished surface. The polishing film hence renders good finish-polishing quality possible. This polishing film is characterized by comprising a substrate and an abrasive layer which has been disposed on a surface of the substrate and which comprises abrasive particles comprising SiO2, a binder resin, and an adhesion inhibitor containing a phosphorus compound.

Owner:BANDO CHEM IND LTD

Composite machining tool

ActiveUS20180361484A1Good quality finishImprove the level ofTransportation and packagingMilling cuttersMachiningEngineering

A composite machining tool includes a tool body with at least one cutting edge and at least one grinding region. The grinding region is located adjacent to the cutting edge such that there is a gap between the grinding region and the cutting edge and such that when the tool performs a machining action the cutting edge and the grinding region act together on a material surface.

Owner:NORTHUMBRIA UNIVERSITY

Method and device for applying additive packaging material

Presented and described are a device for separately applying additive packaging material, preferably wrapped straws, supplied as an additive packaging material continuous belt, to packages, in particular cardboard composite packages, having a separating organ for separating the additive packaging material of the additive packaging material continuous belt, a supply means for supplying the additive packaging material continuous belt to the separating organ and for relaying the additive packaging material separated by the separating organ, an application means for applying the separated additive packaging materials to the packages and a transport means for transporting the packages along a package transport path to the application means. So that the separation and application of the additive packaging materials can be carried out quickly, with high quality and reliably, it is provided that a transfer means is provided for picking up the additive packaging material relayed from the supply means and for accelerating the transferred additive packaging material to a speed adapted to the application means.

Owner:SIG TECH AG

Decorated glass sheet and manufacturing method thereof

A decorated glass sheet comprising an essentially flat sheet body with a pair of opposite plane and parallel faces; in which a first face of the pair of faces of the sheet body has a satin finish, and in which a second face of the pair of faces is provided with:at least one decorative layer made of one or more colored paints defining a non-uniform decorative pattern replicating the aspect of marble, anda cover layer made from a substantially non-transparent colored paint, arranged above and in direct contact with the decorative layer so that the decorative layer is interposed between the sheet body and the cover layer.

Owner:OMNI DECOR SRL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com