Device and method for polishing or abrading products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

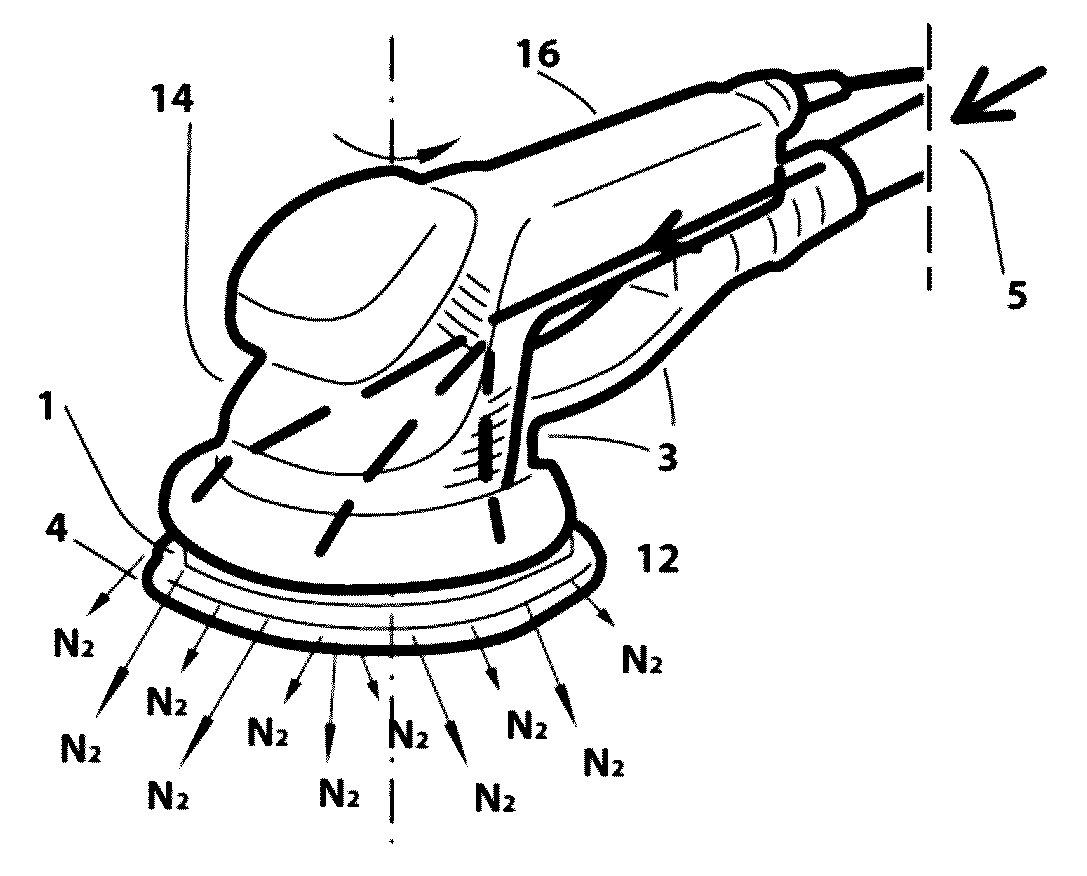

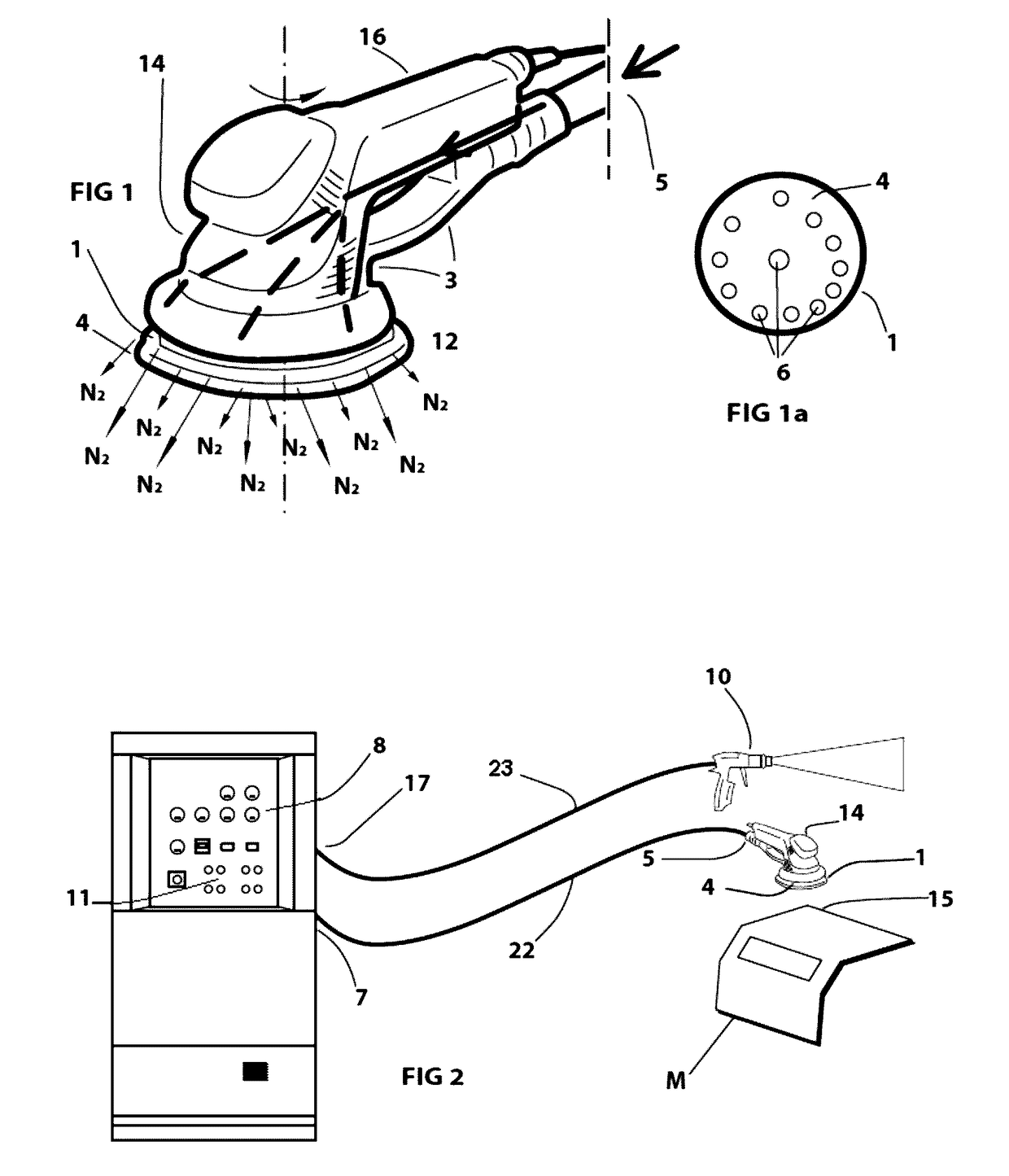

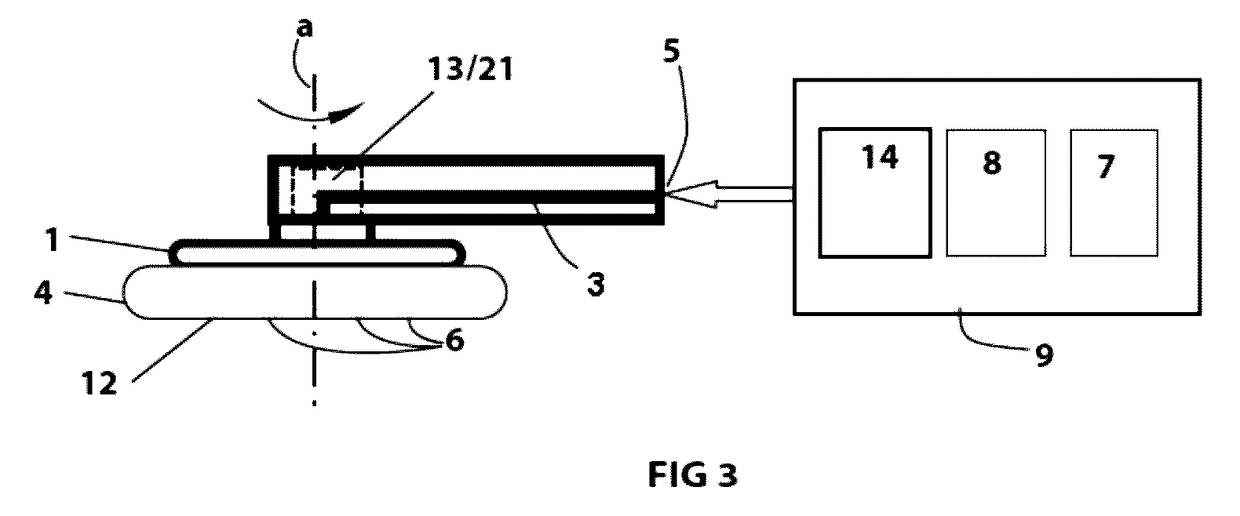

[0022]With reference to the attached drawings, there now follows a description of a device for polishing and / or sanding products M, in particular but in a non-limiting way, painted products.

[0023]The device comprises a disk 1 provided with an operating surface 4, which, in use, assumes a circular or orbital movement obtained with appropriate means 13, for example an electric or pneumatic motor, capable of impressing the polishing motion on the operating surface 4.

[0024]Preferably, removably applied on the surface 4 of the disk is a polishing pad 12 permeable to a flow of gas.

[0025]According to the invention, the device comprises a source 7 of a flow of treated air, for example cooled dry air, or nitrogen, or nitrogen-rich modified air, and one or more air ducts 3 extending from an inlet opening 5, which communicates with the source 7 by means of ducts 22, to one or more outlets 6 for the flow of treated air, located on the operating polishing surface 4, for example in areas correspo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com