Patents

Literature

3728results about "Abrasive surface conditioning devices" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

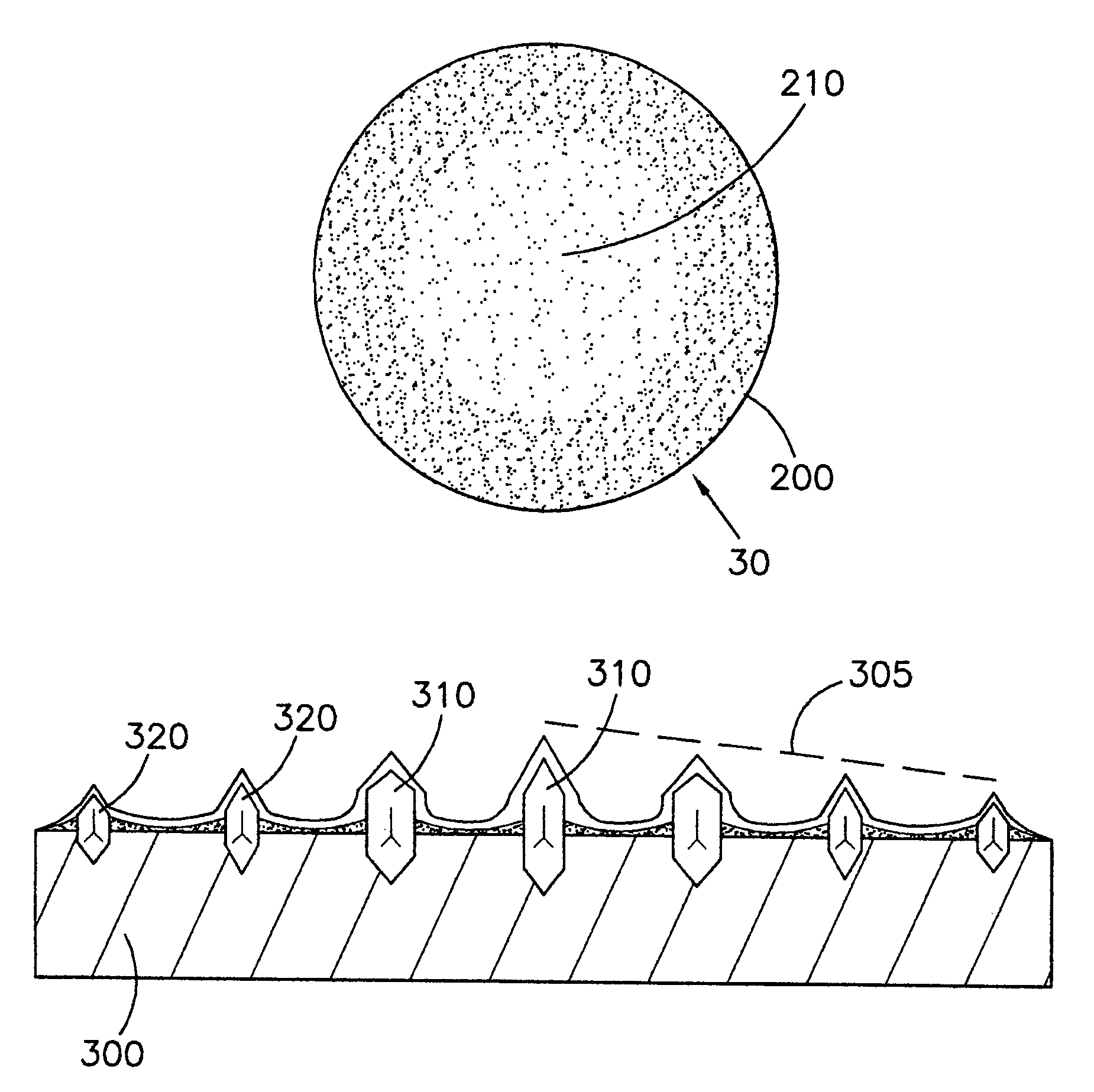

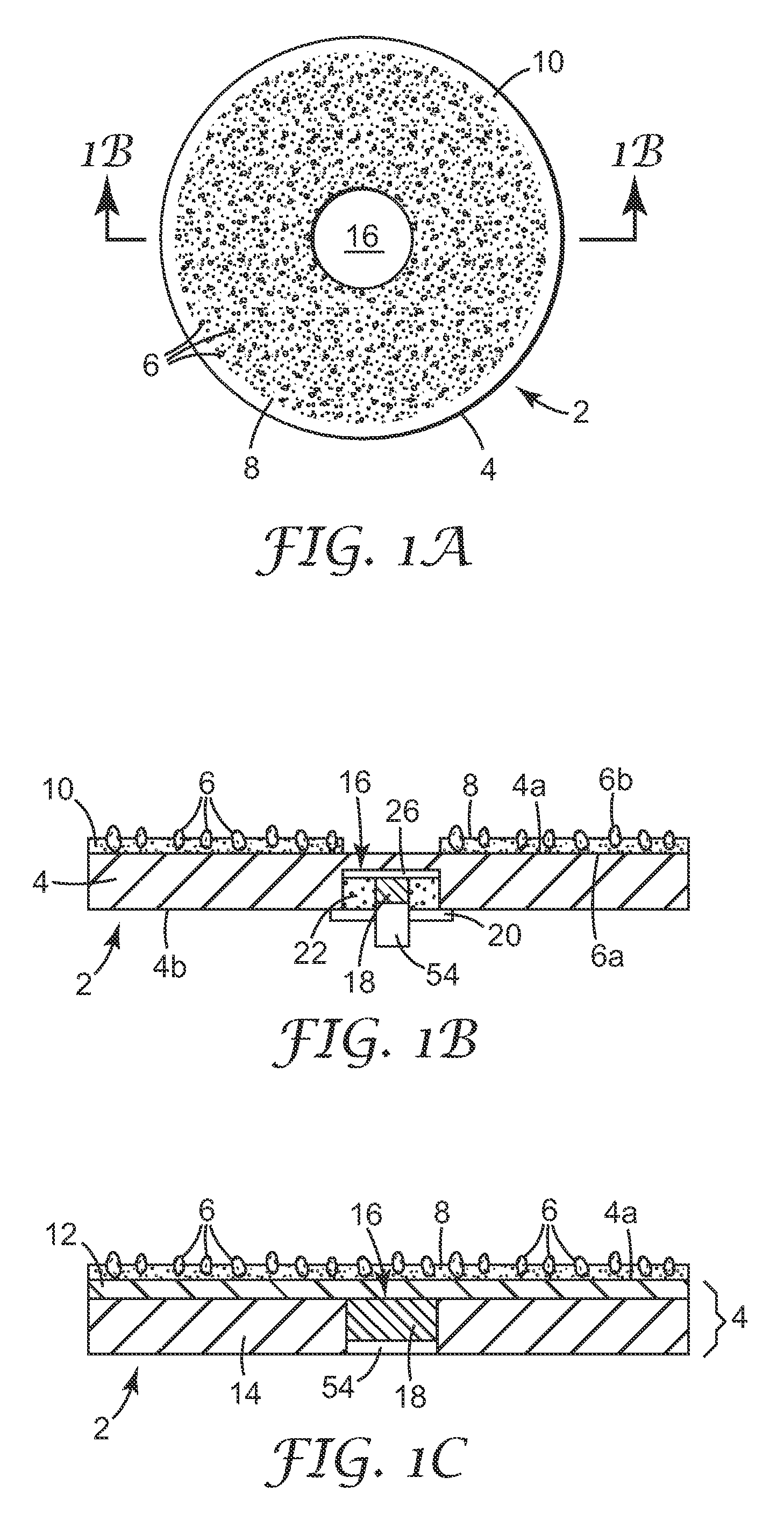

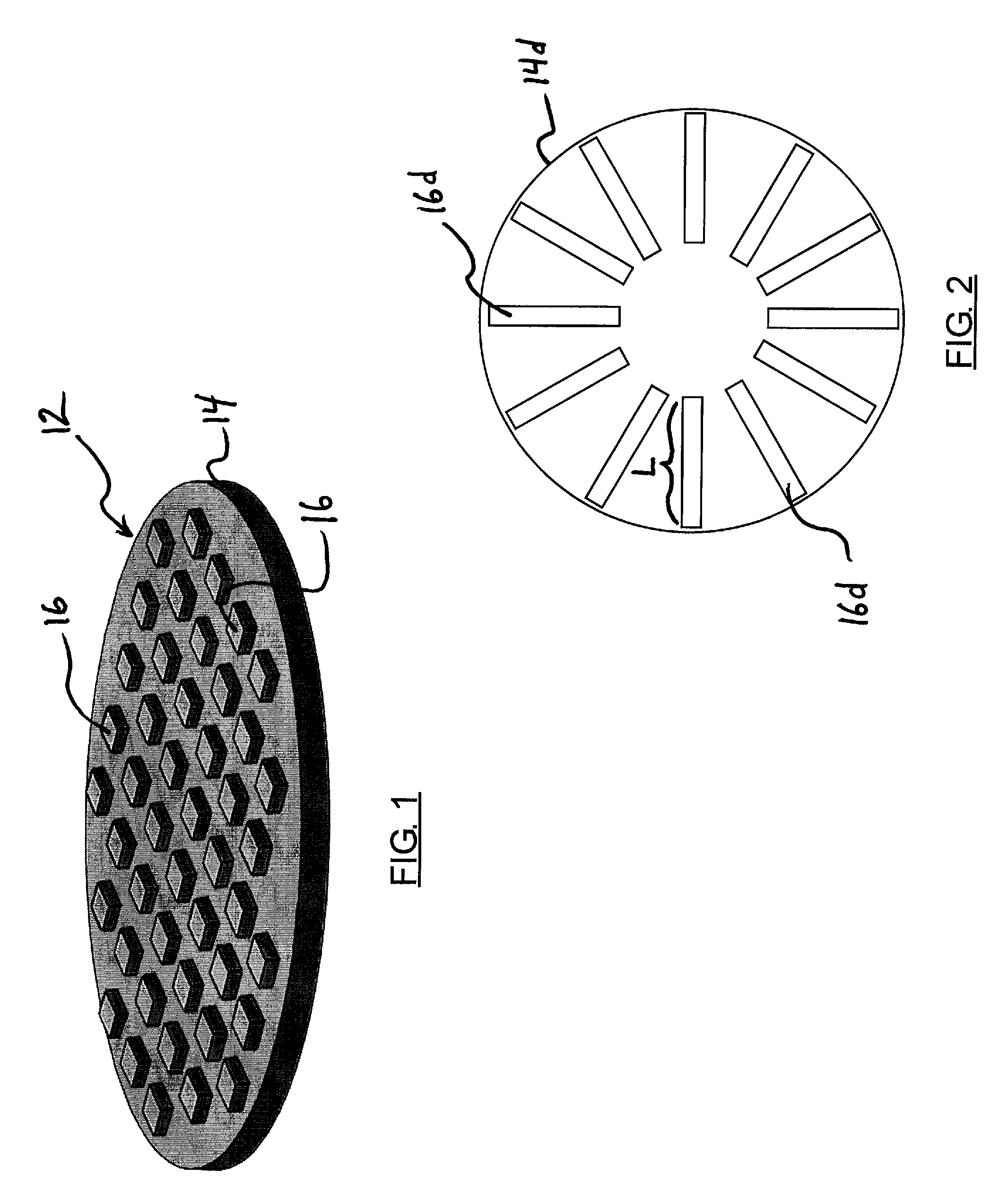

Diamond grid CMP pad dresser

InactiveUS6368198B1Improve polishing efficiencyExtended service lifePolishing machinesRevolution surface grinding machinesSuperhard materialDiamond-like carbon

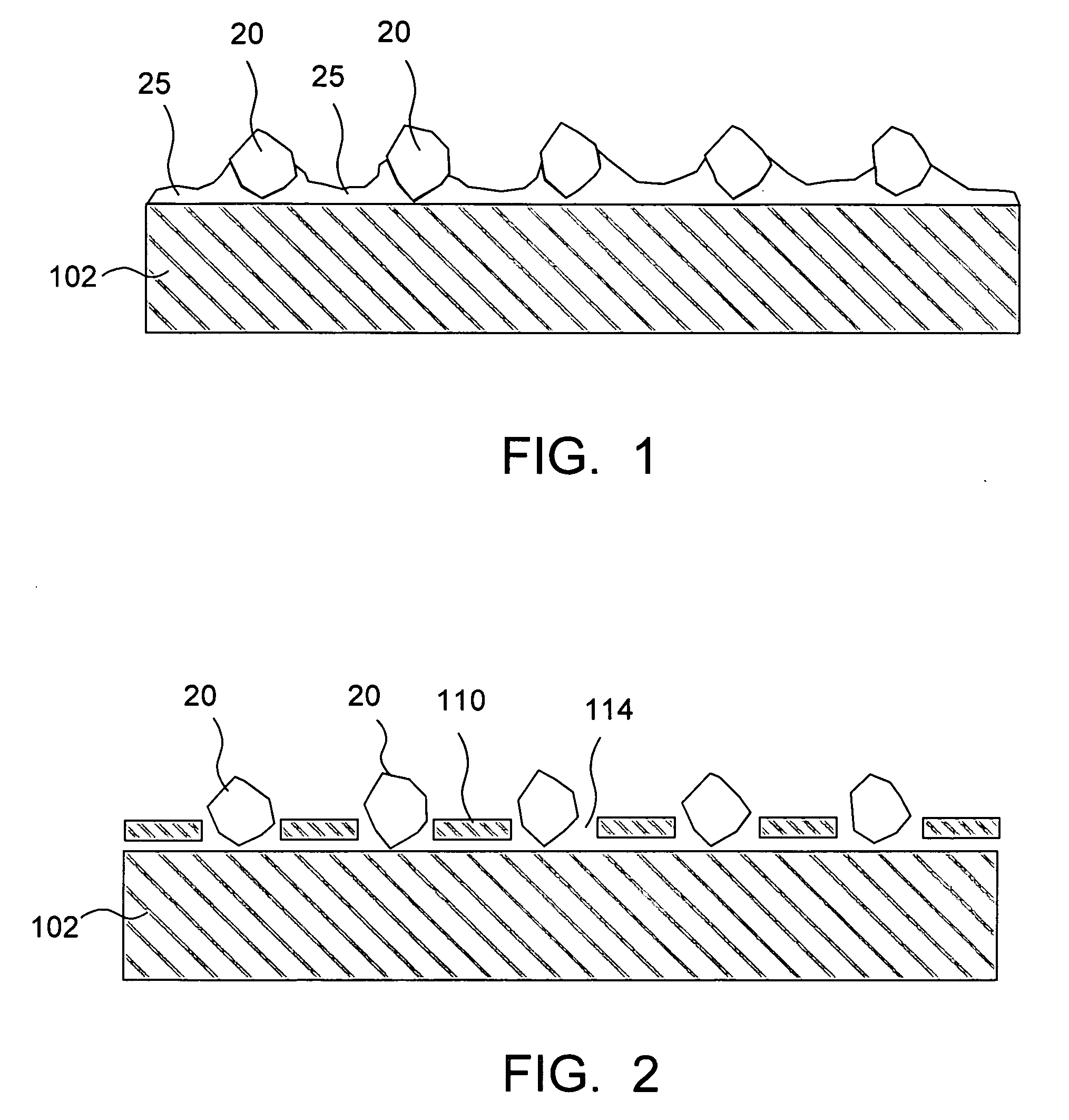

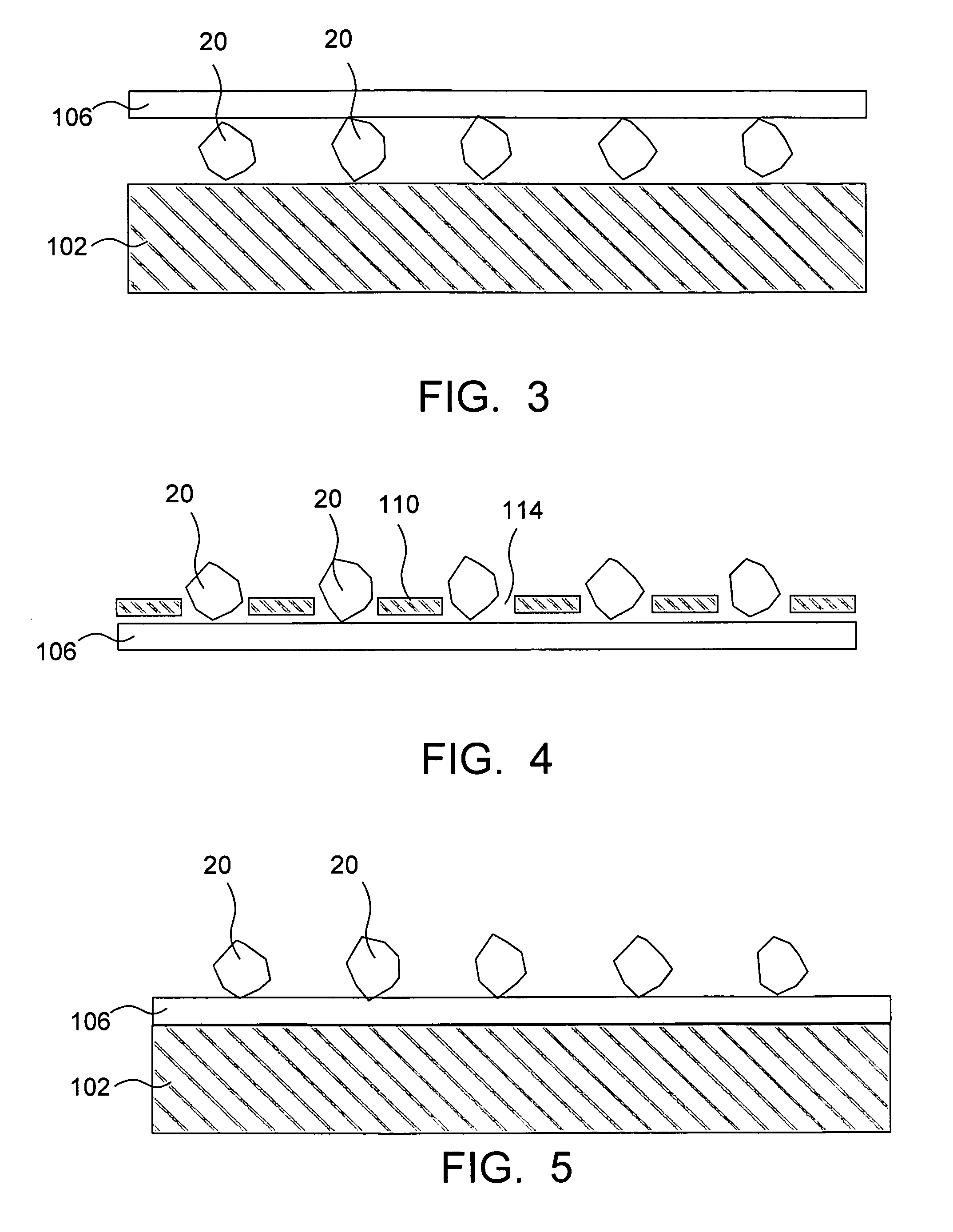

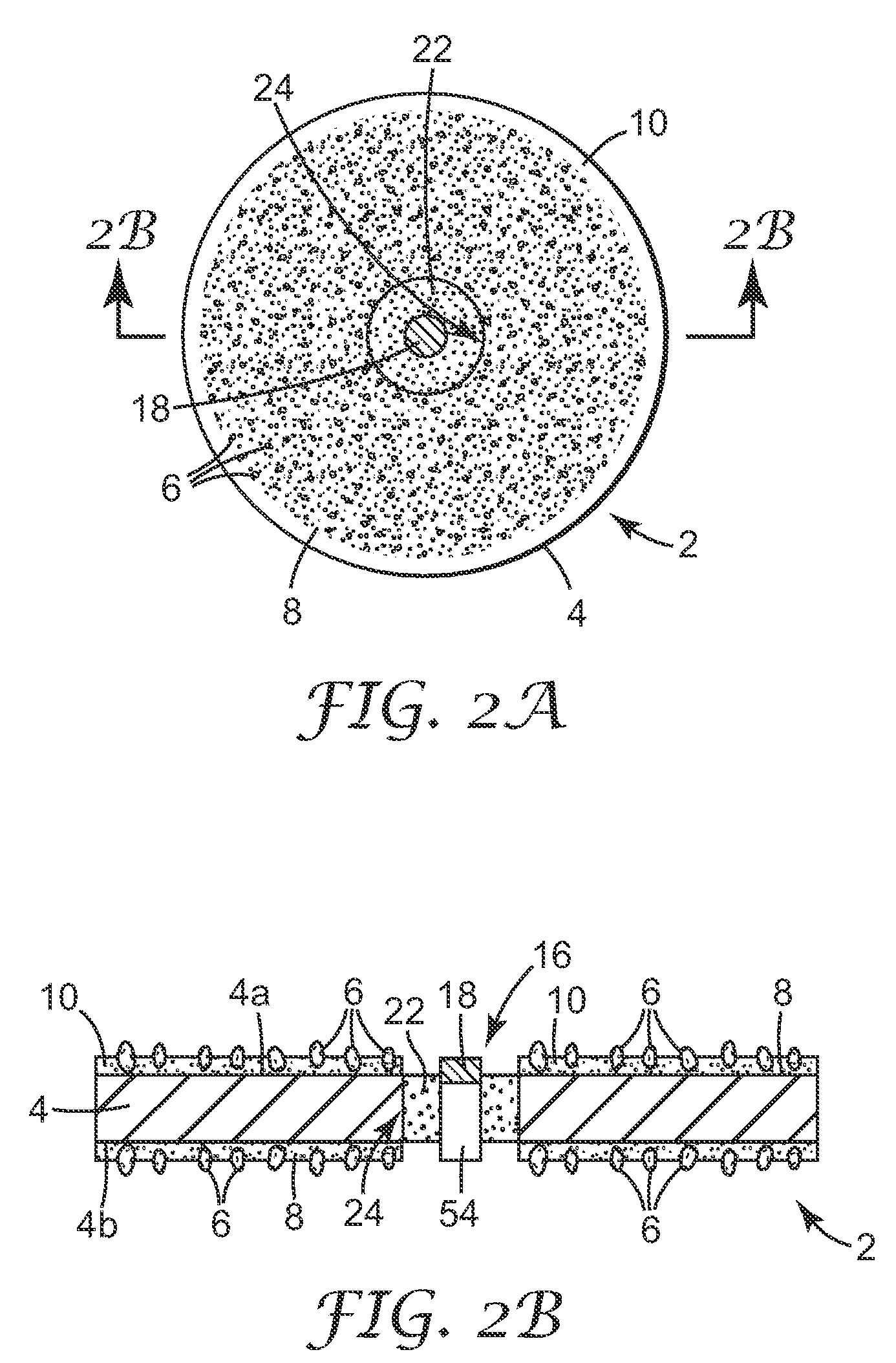

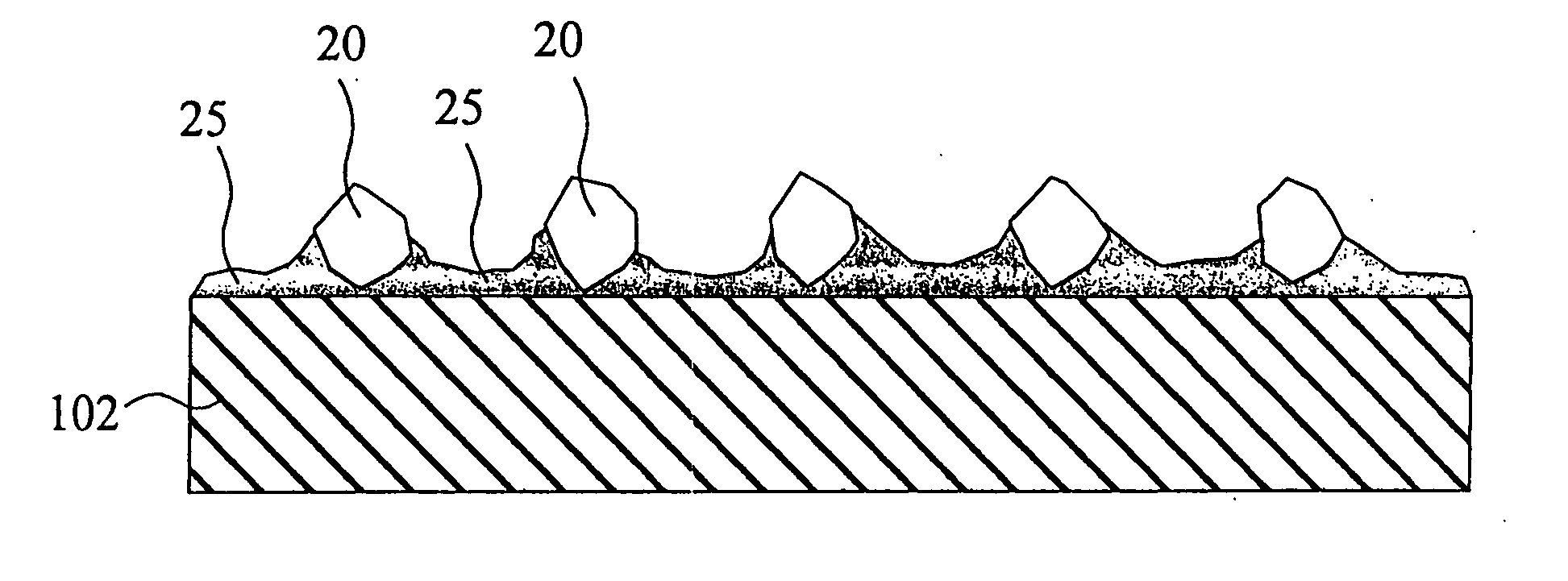

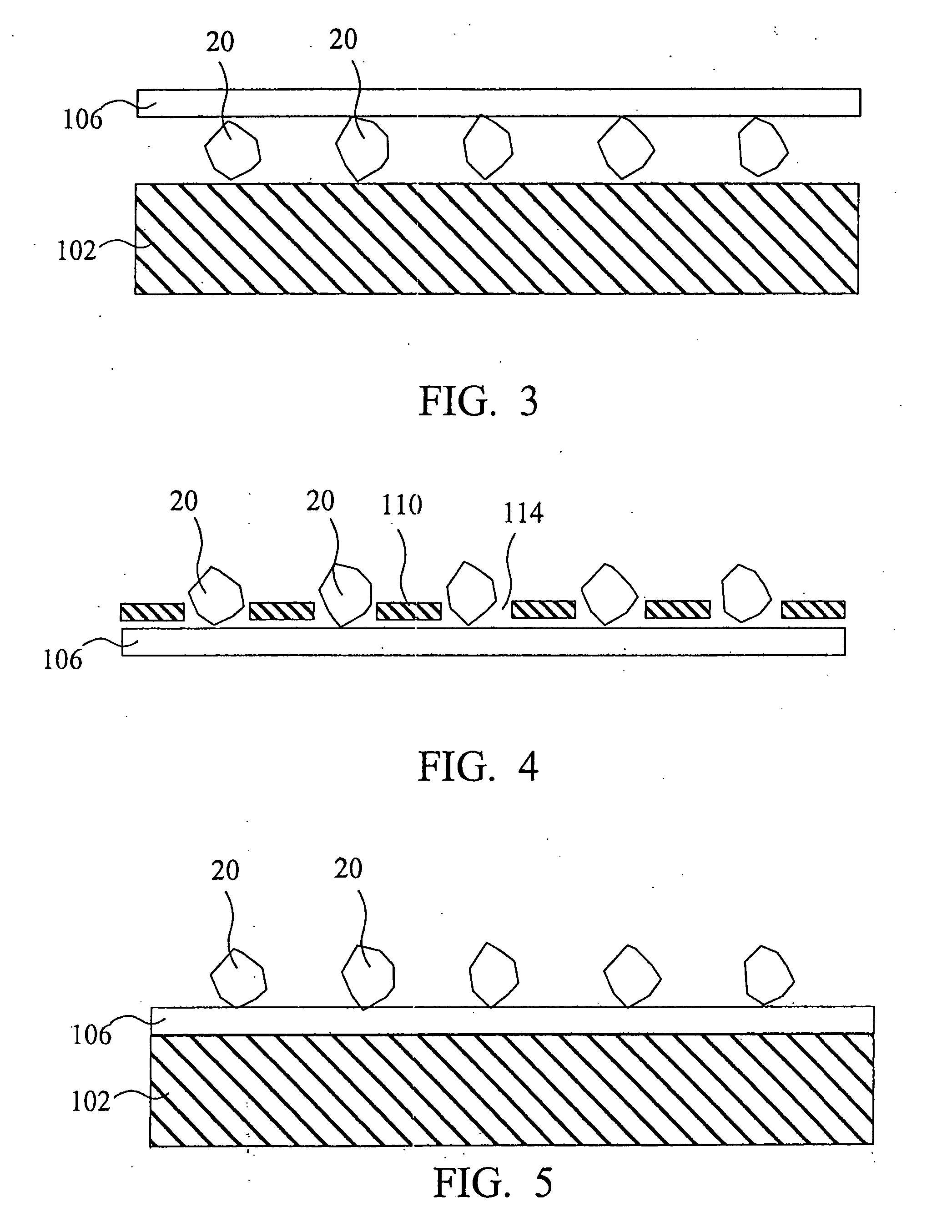

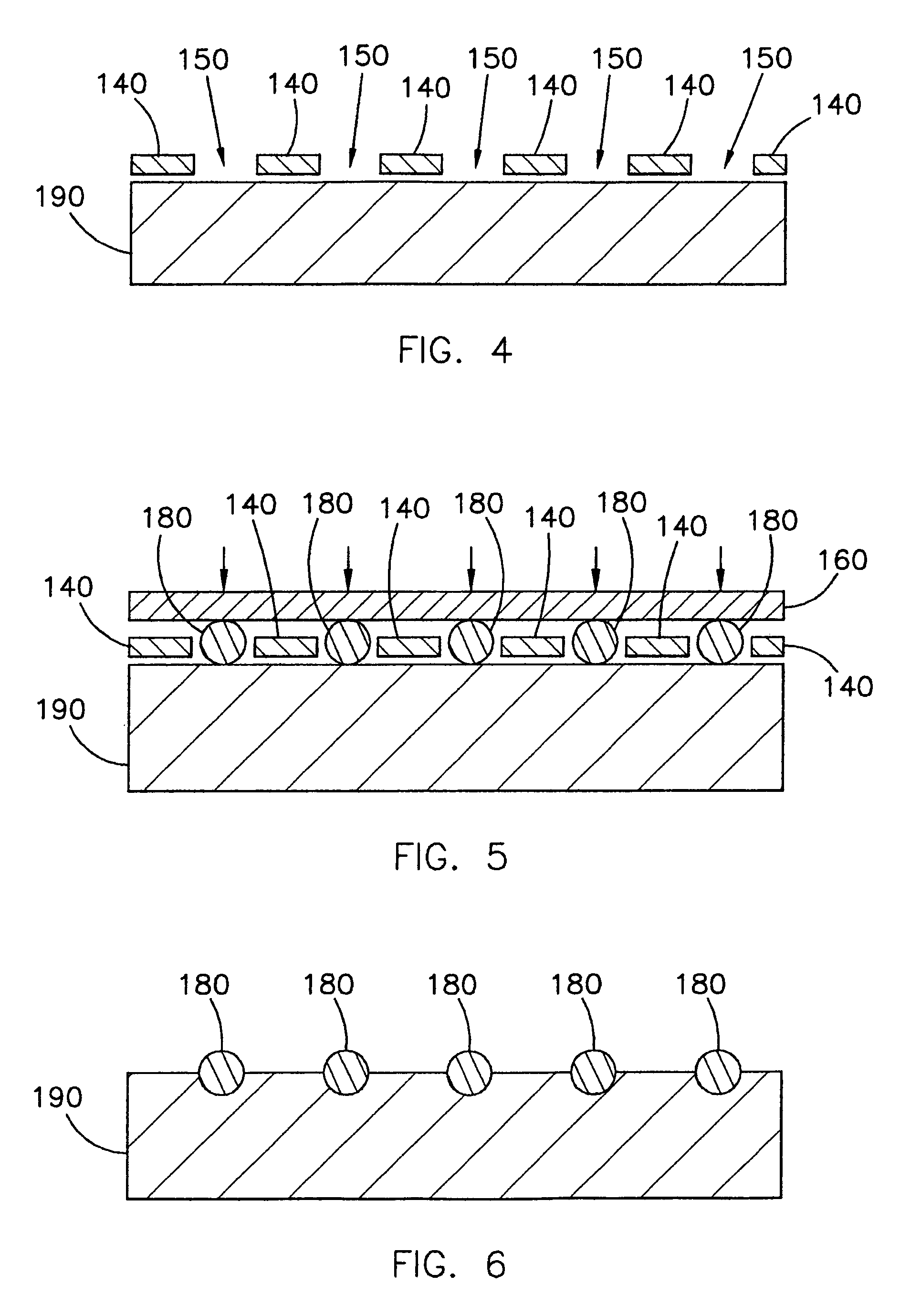

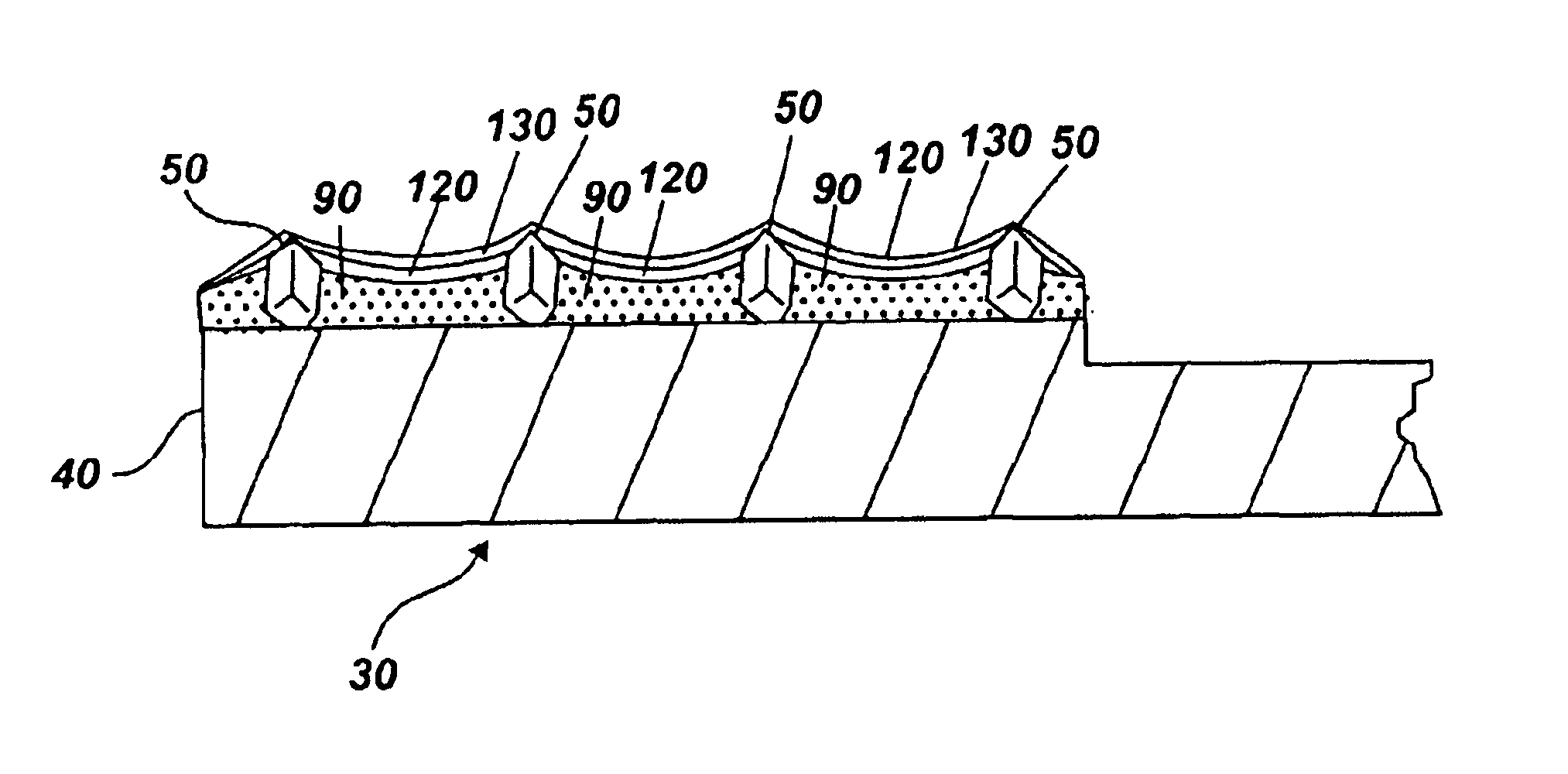

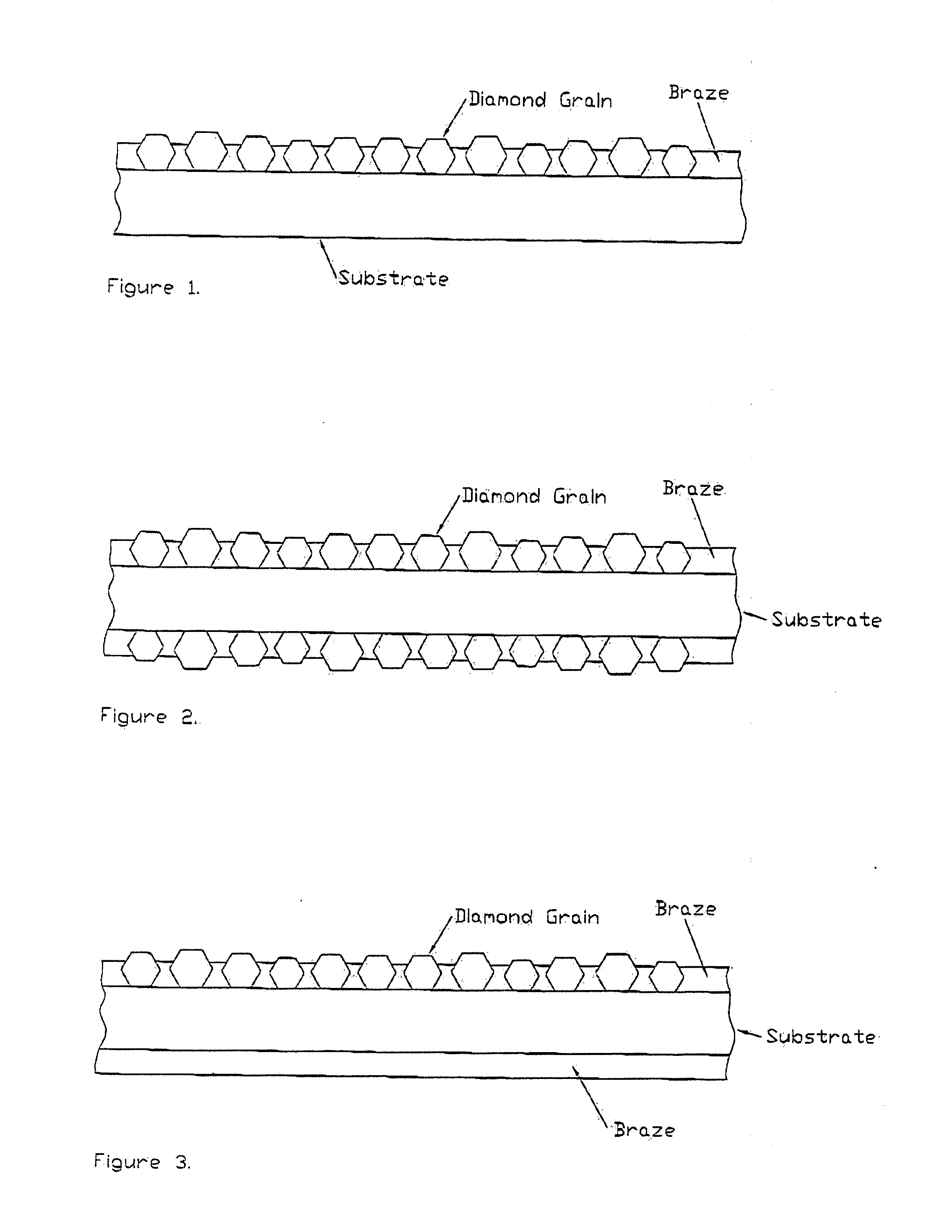

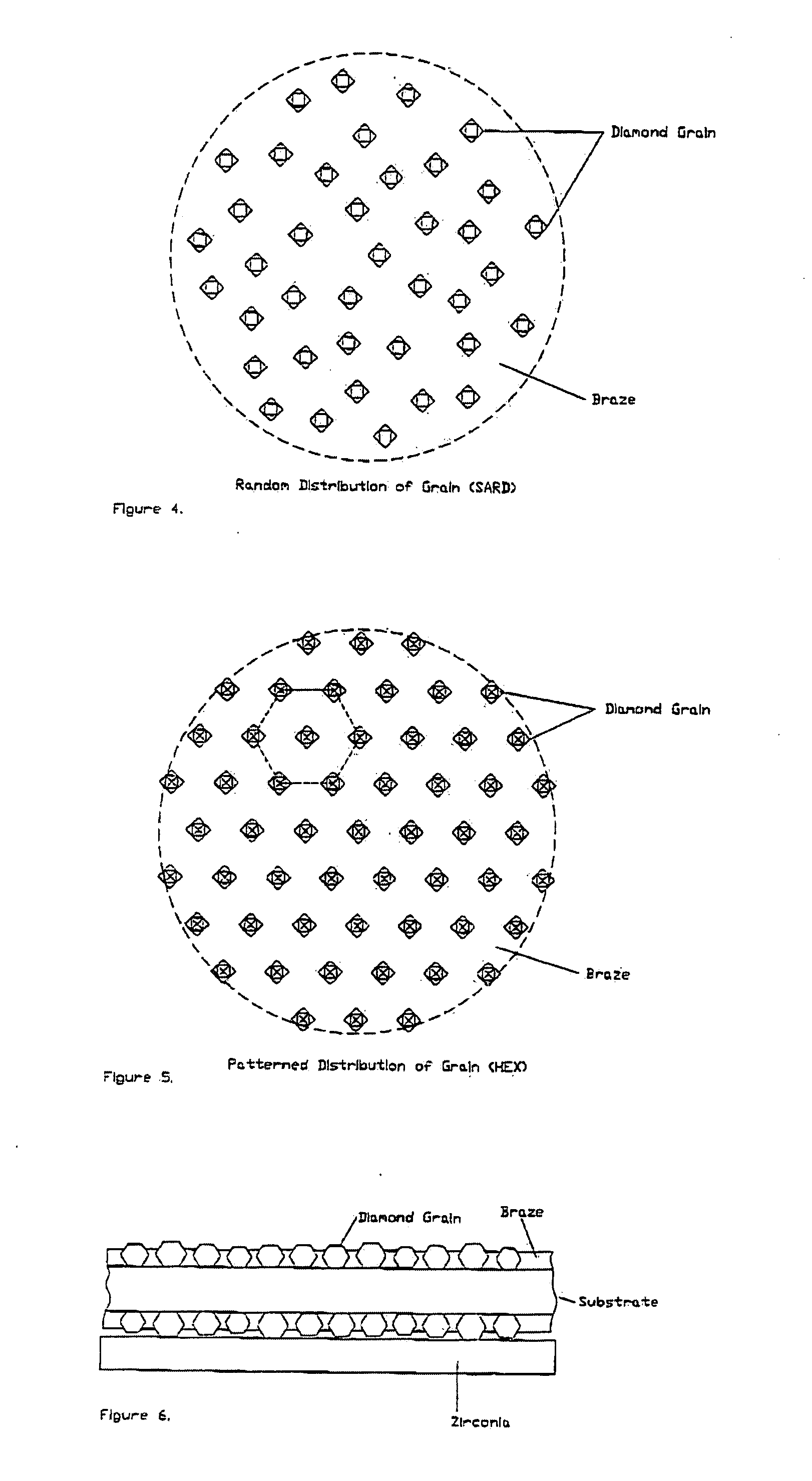

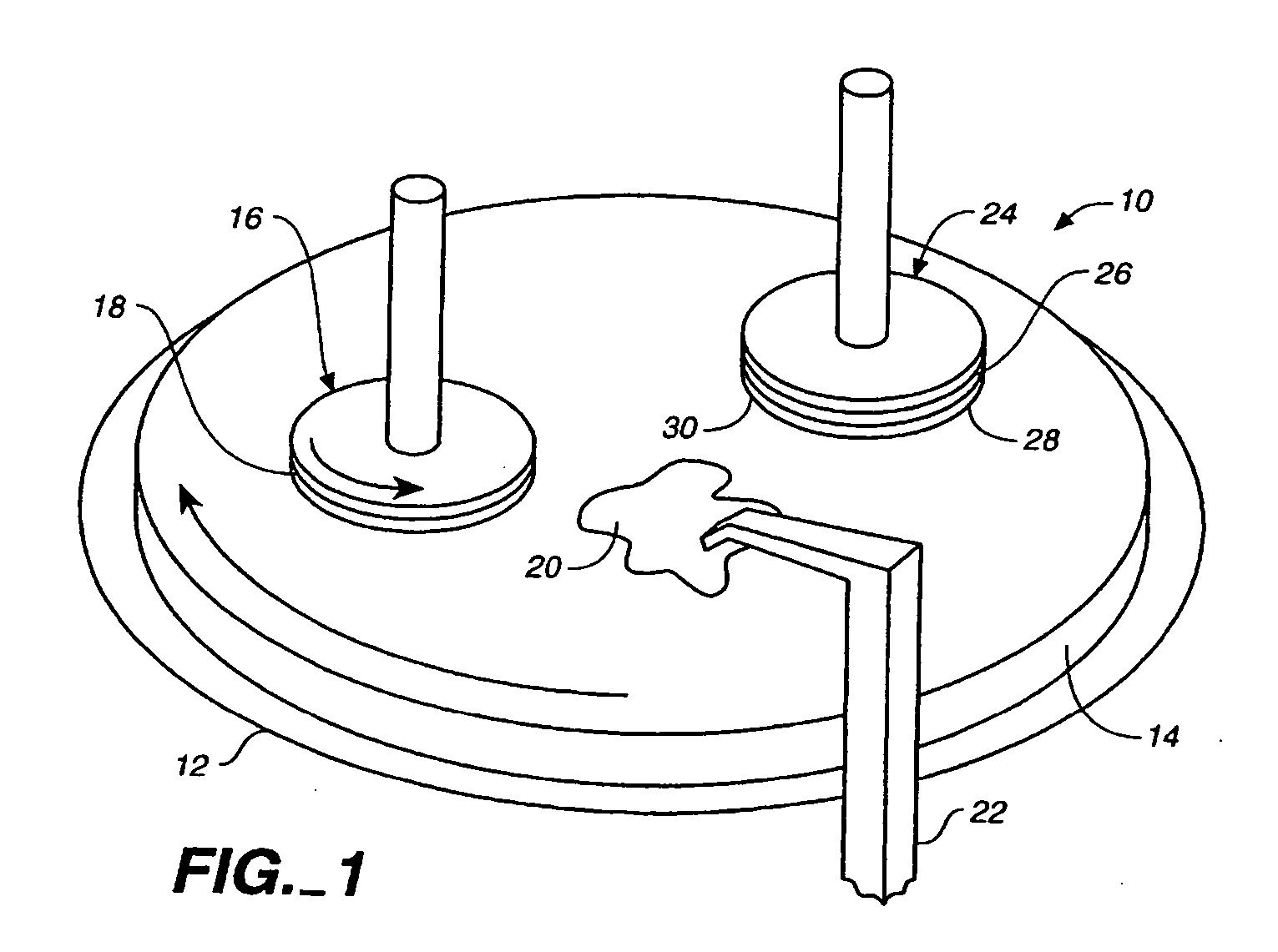

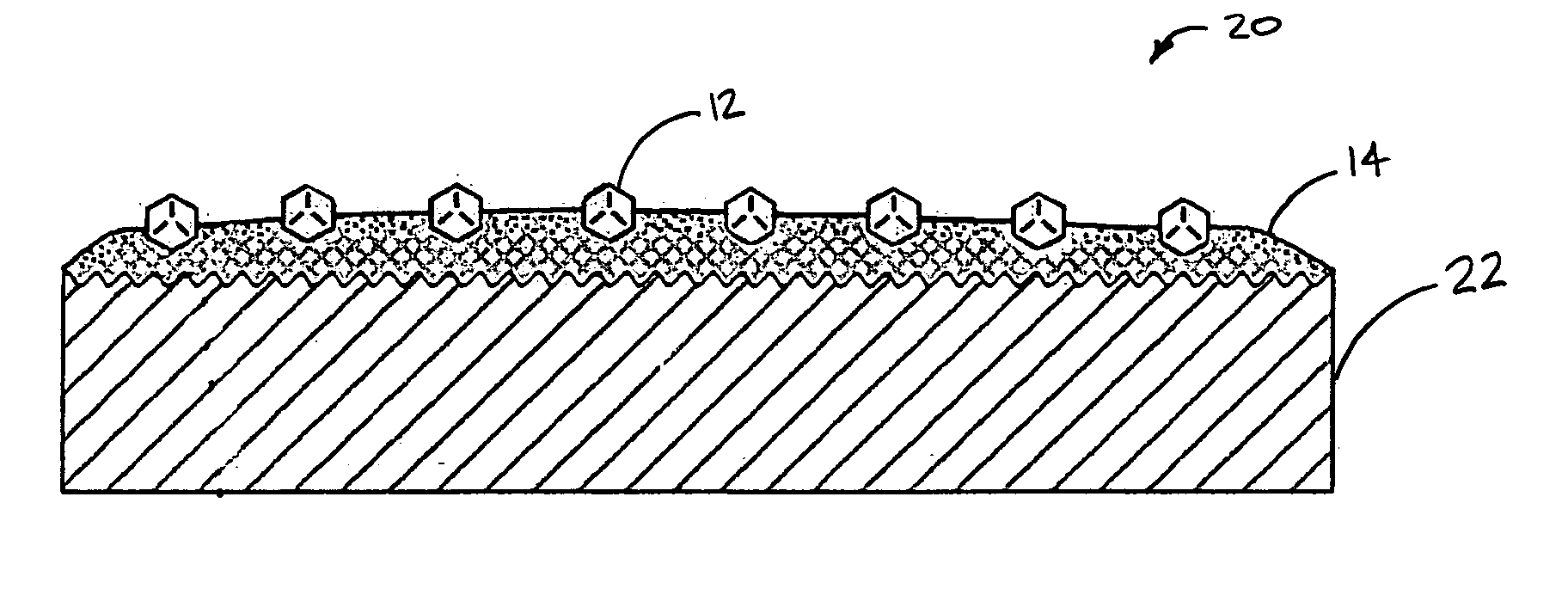

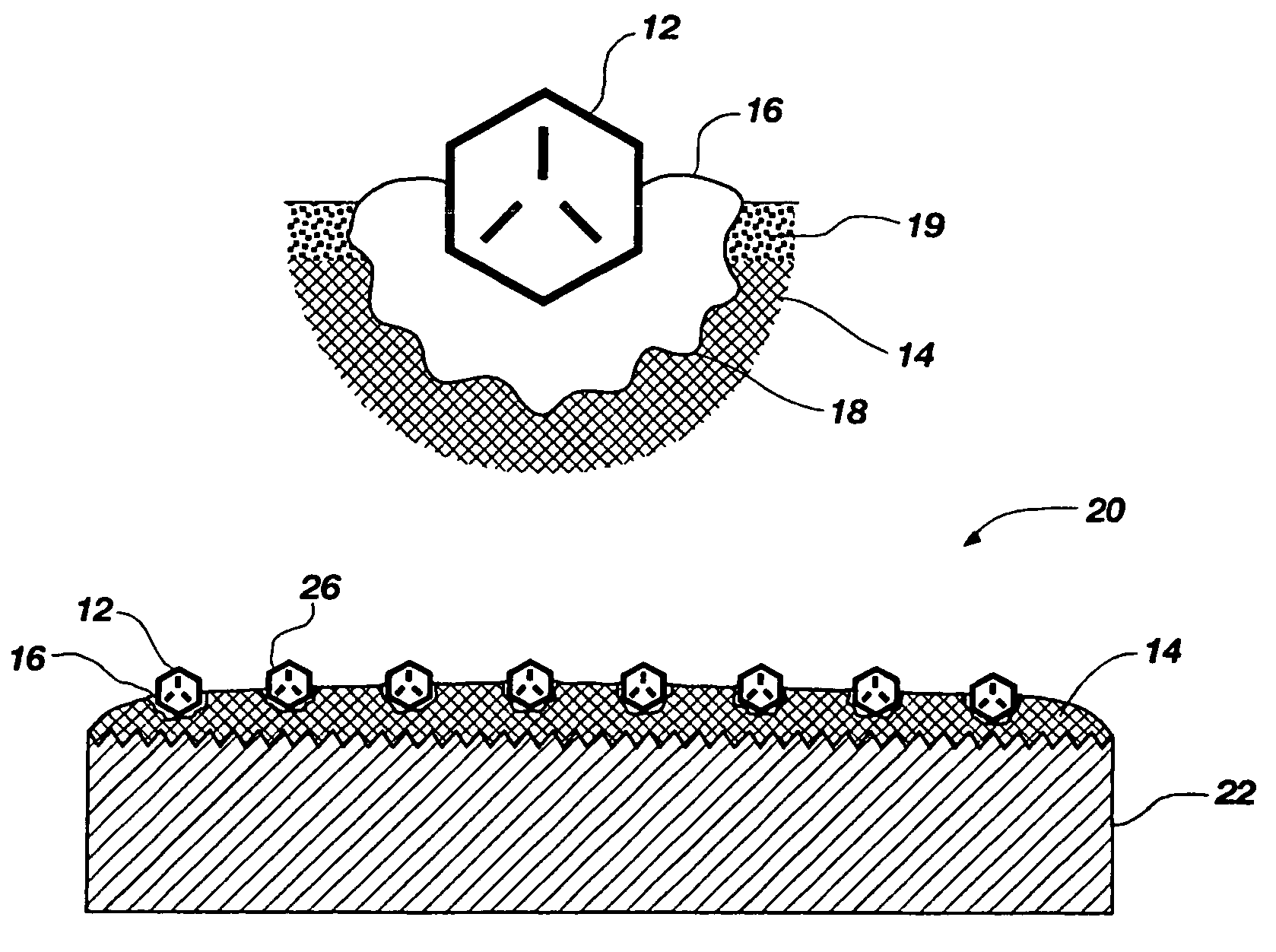

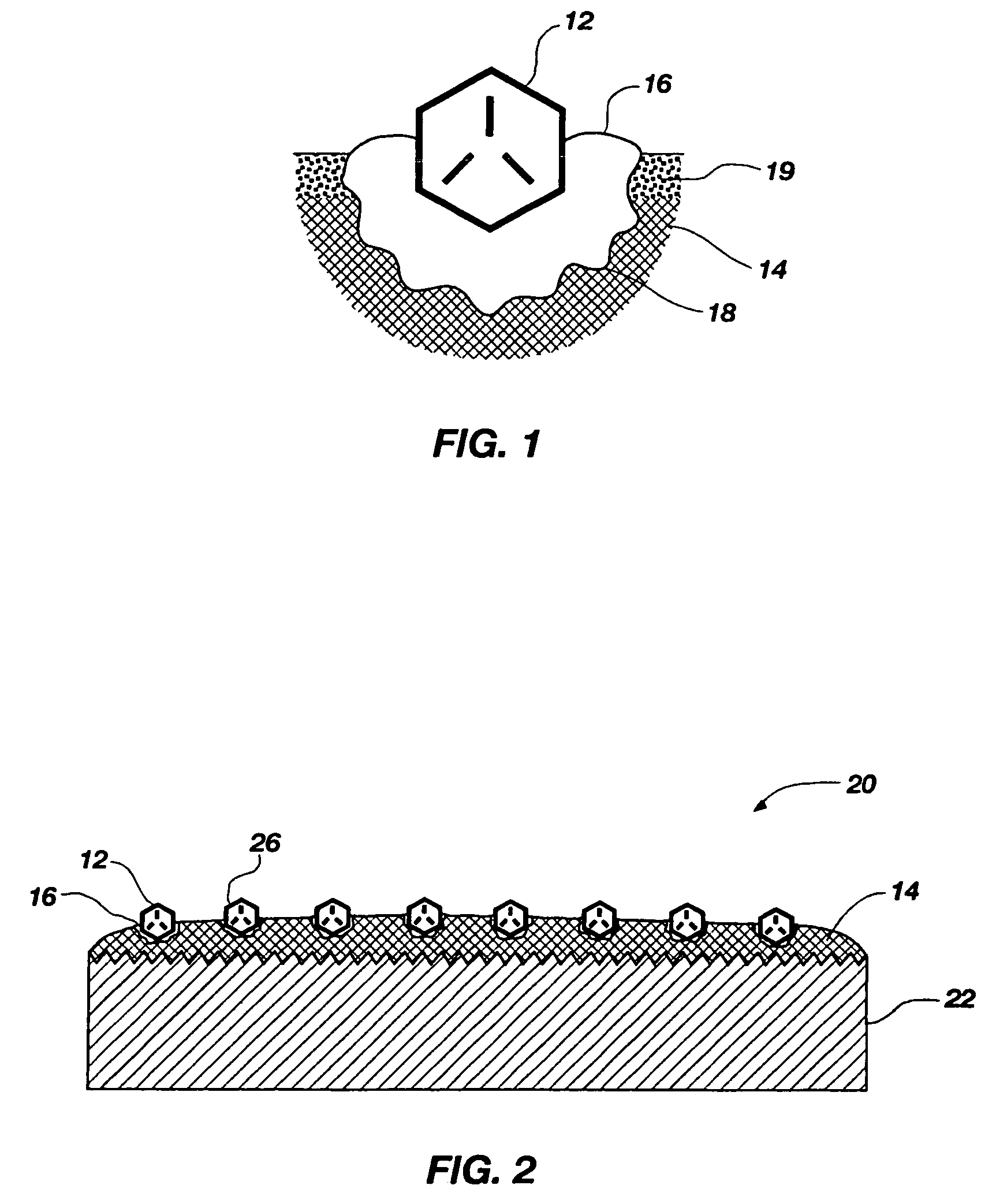

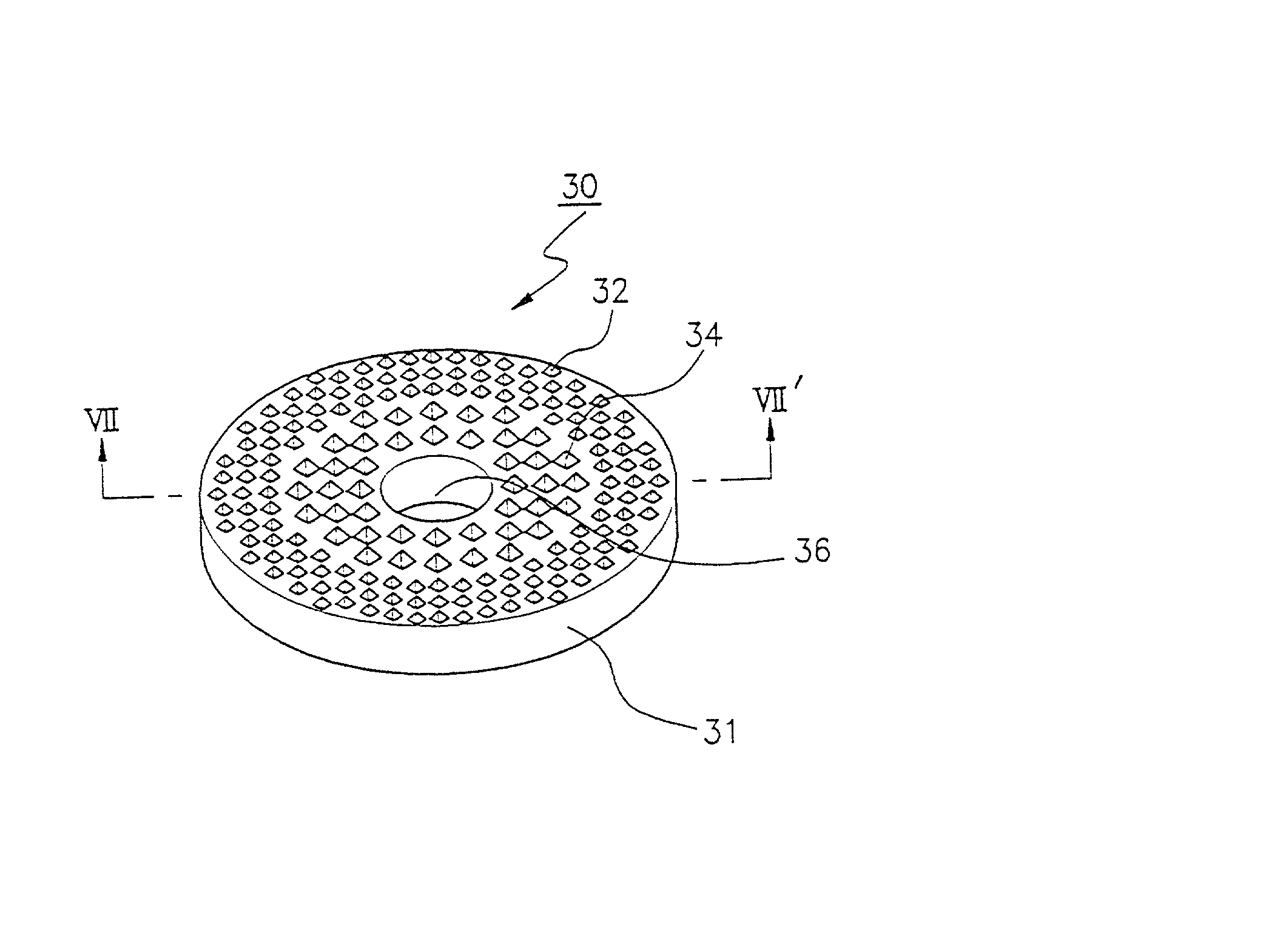

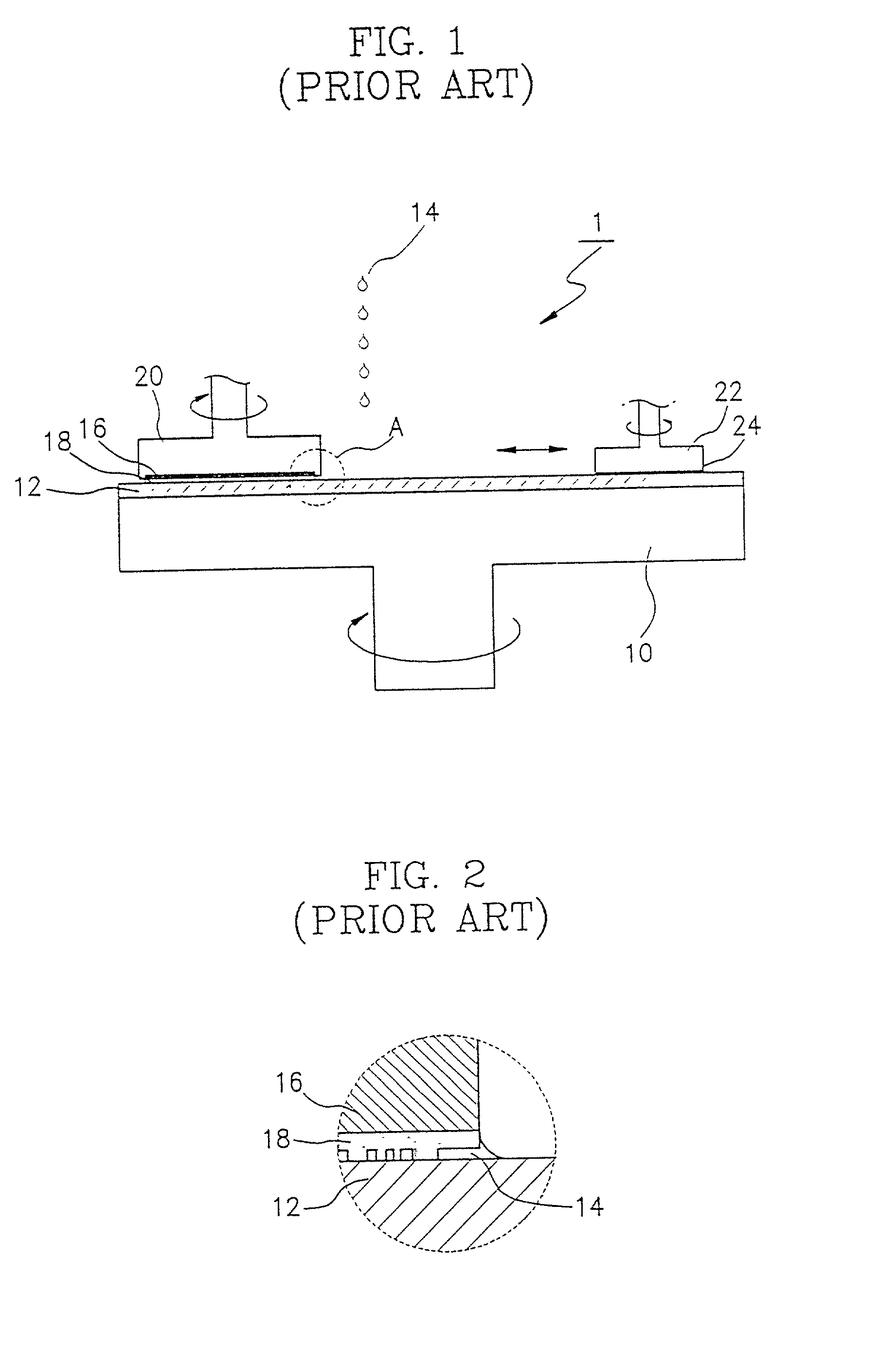

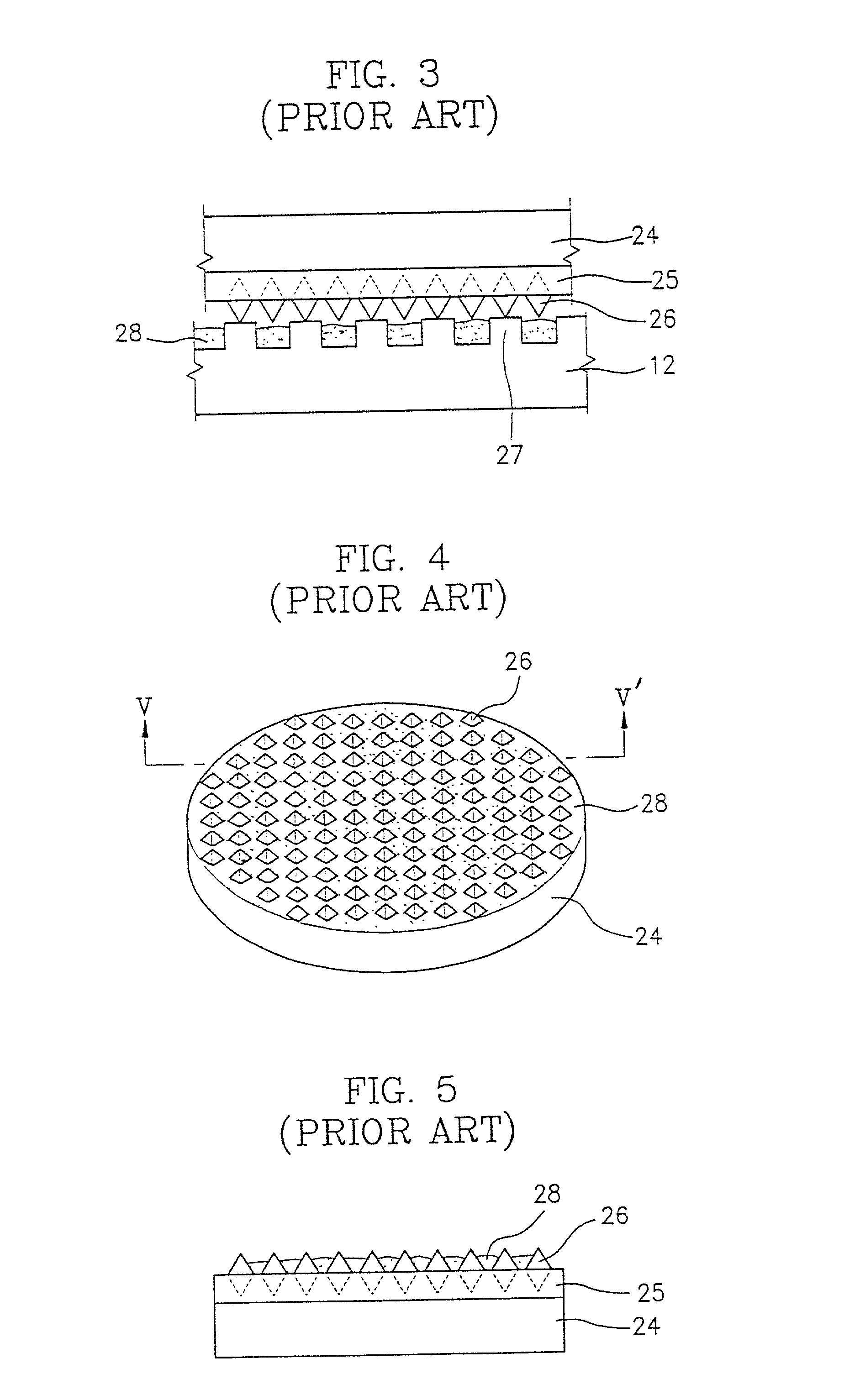

The present invention discloses a CMP pad dresser which has a plurality of uniformly spaced abrasive particles protruding therefrom. The abrasive particles are super hard materials, and are typically diamond, polycrystalline diamond (PCD), cubic boron nitride (cBN), or polycrystalline cubic boron nitride(PcBN). The abrasive particles are brazed to a substrate which may be then coated with an additional anti-corrosive layer. The anti-corrosive layer is usually a diamond or diamond-like carbon which is coated over the surface of the disk to prevent erosion of the brazing alloy by the chemical slurry used in conjunction with the CMP pad. This immunity to chemical attack allows the CMP pad dresser to dress the pad while it is polishing a workpiece. In addition to even spacing on the substrate, the abrasive particles extend for a uniform distance away from the substrate, allowing for even grooming or dressing of a CMP pad both in vertical and horizontal directions. A method of producing such a CMP pad dresser is also disclosed.

Owner:KINIK

Brazed diamond tools and methods for making the same

Owner:SUNG CHIEN MIN

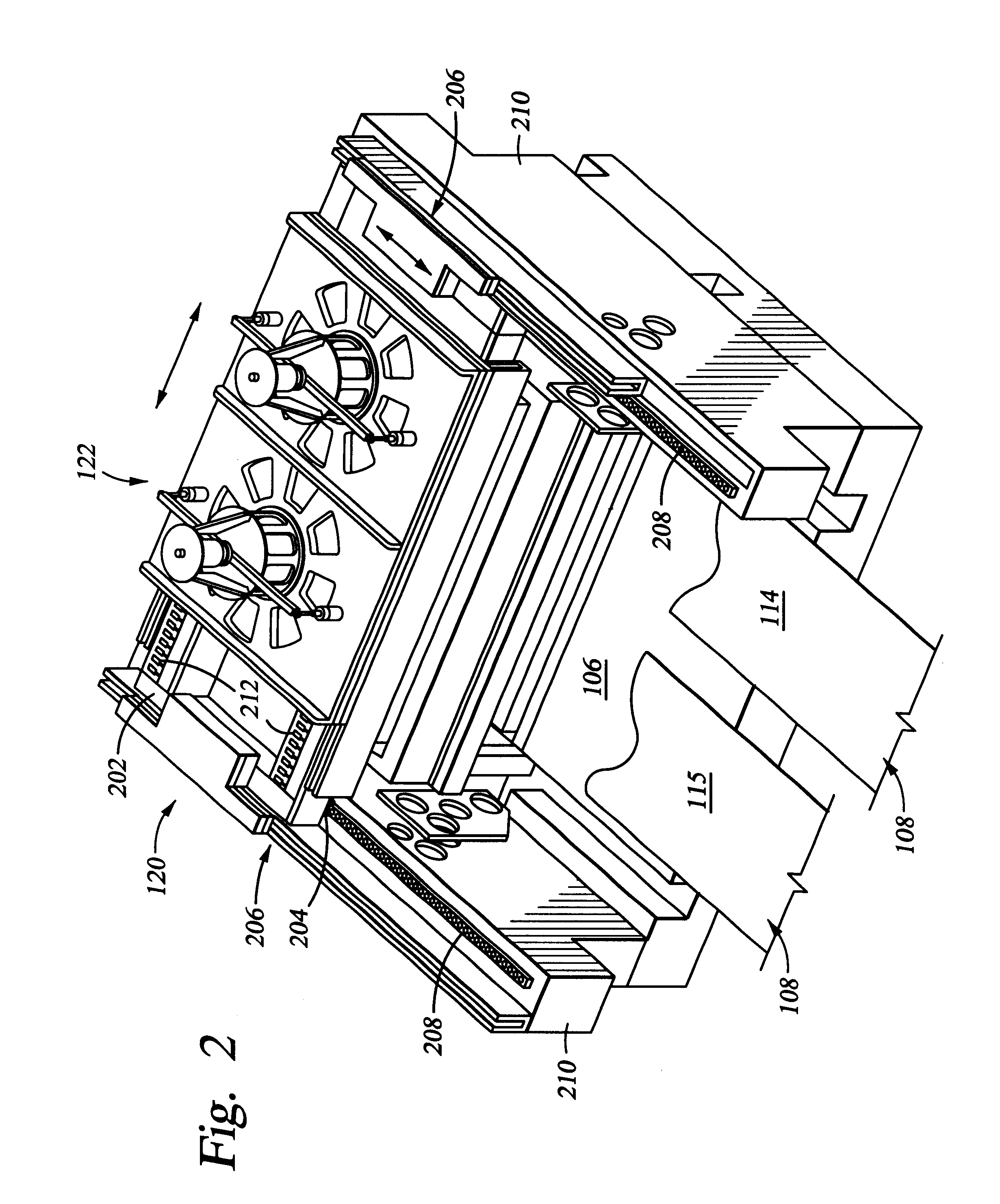

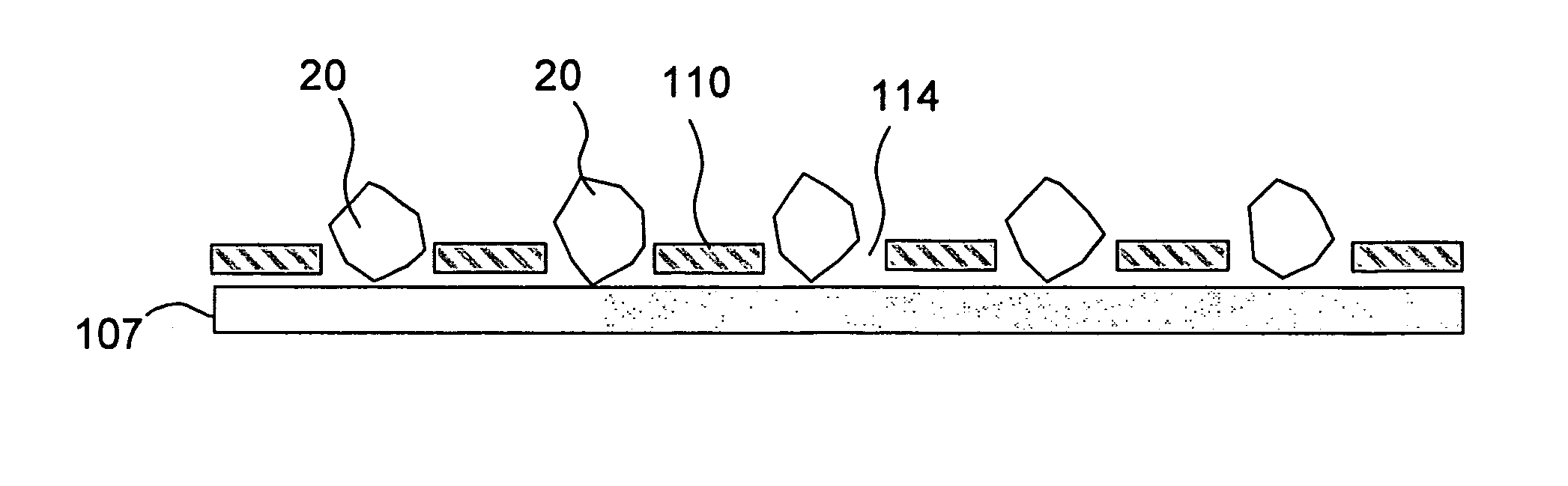

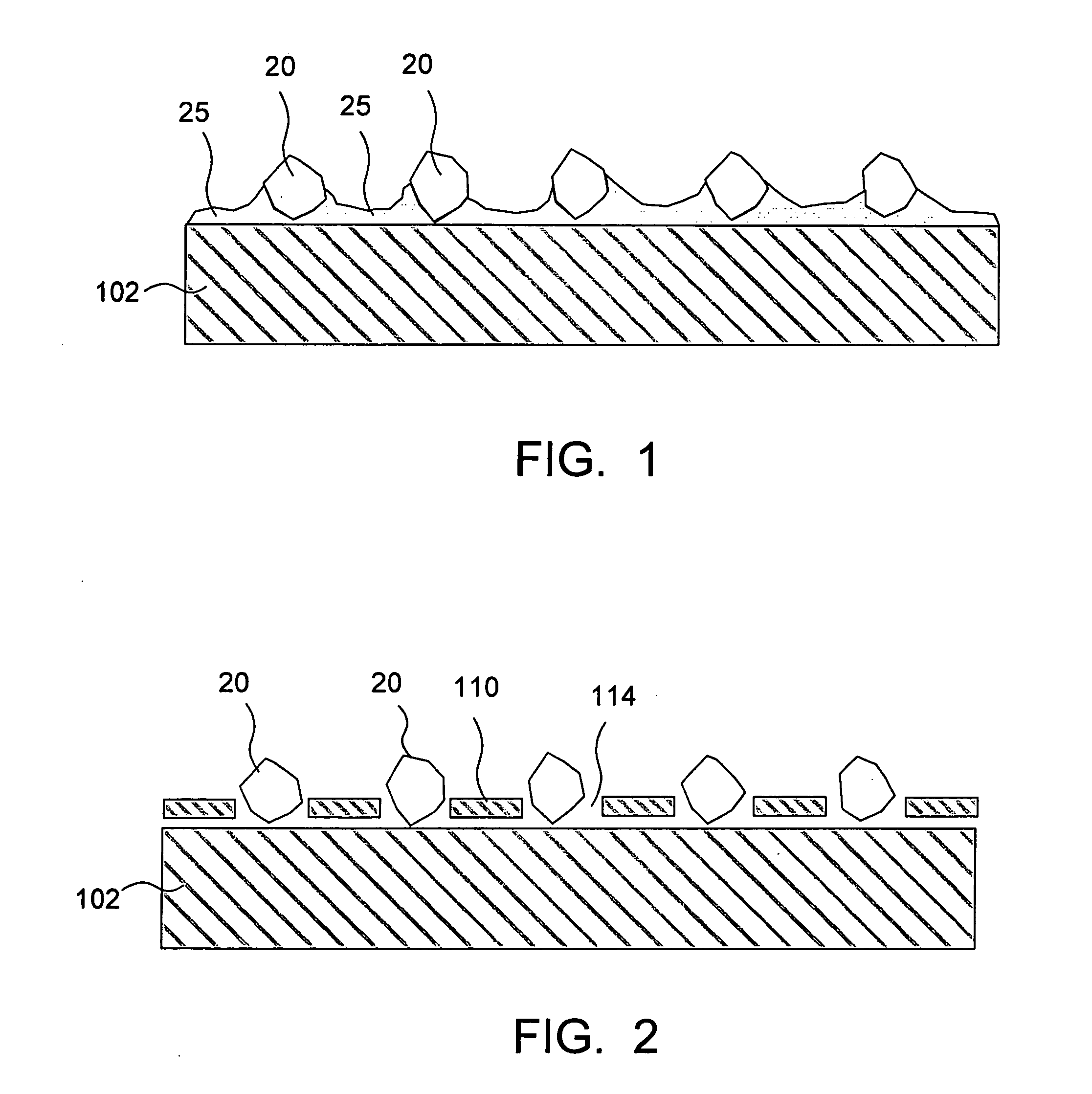

Abrasive Articles, CMP Monitoring System and Method

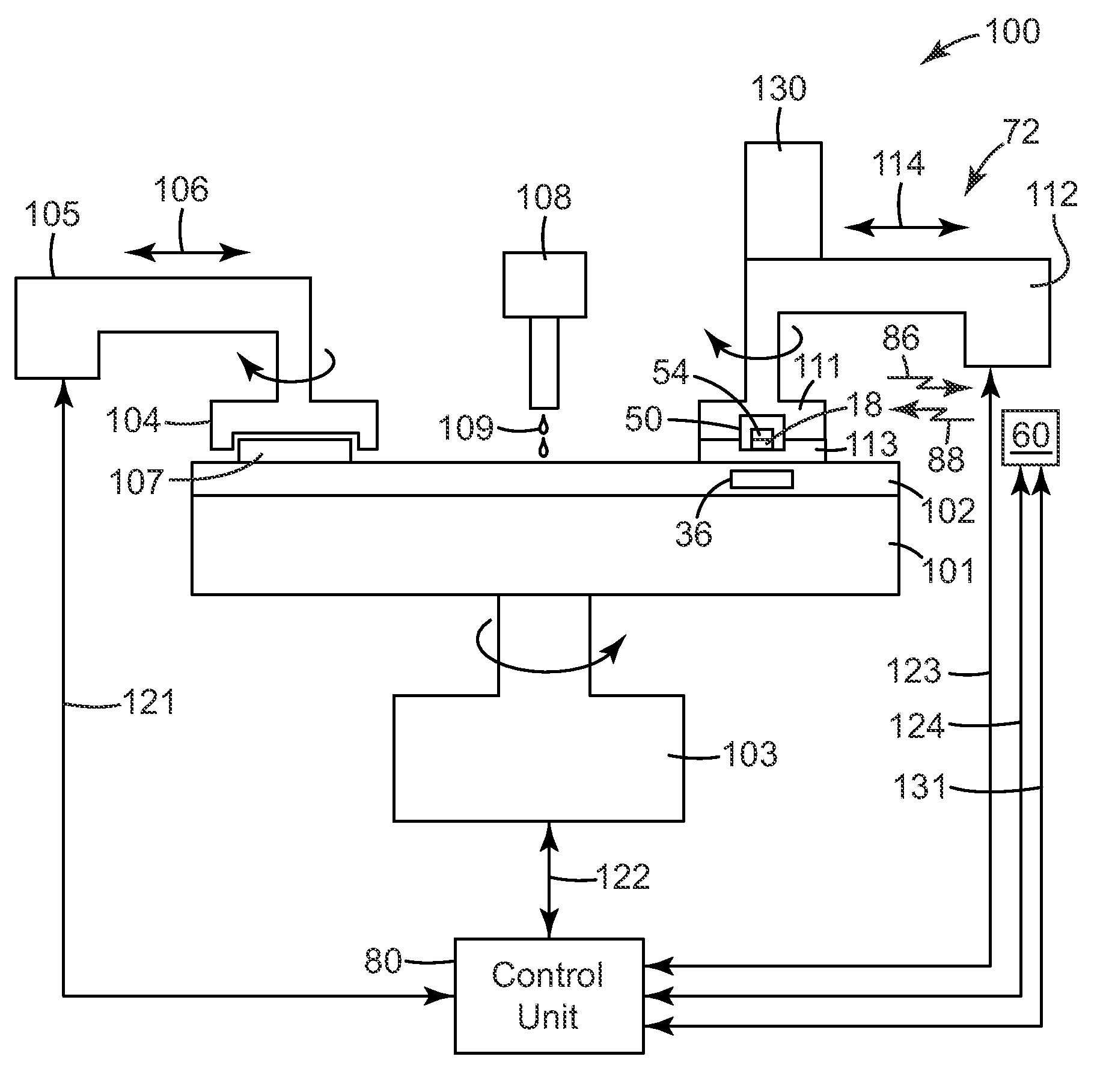

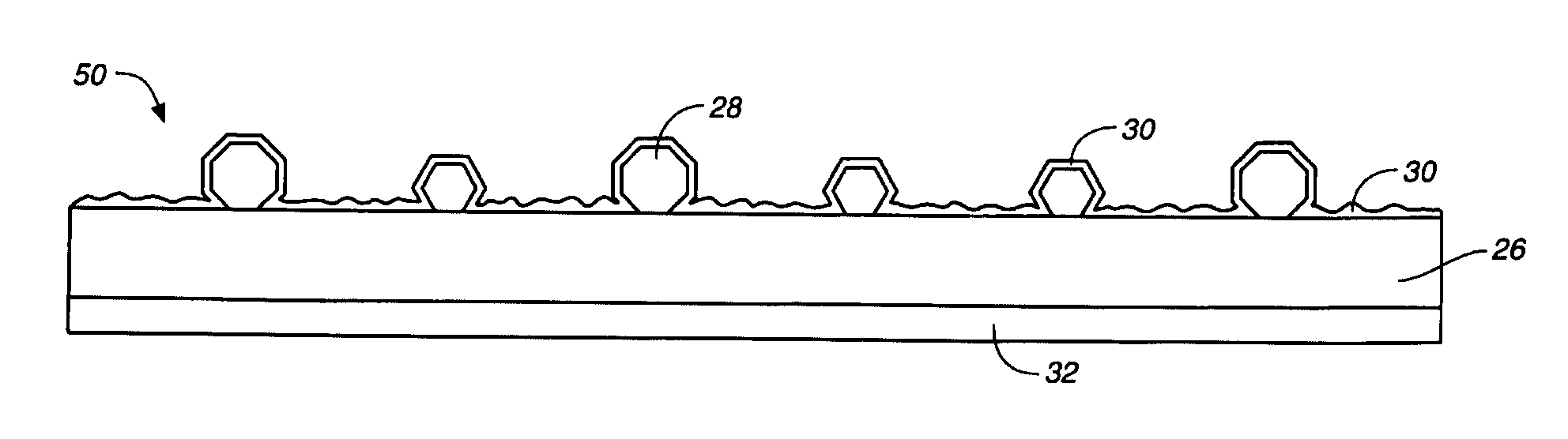

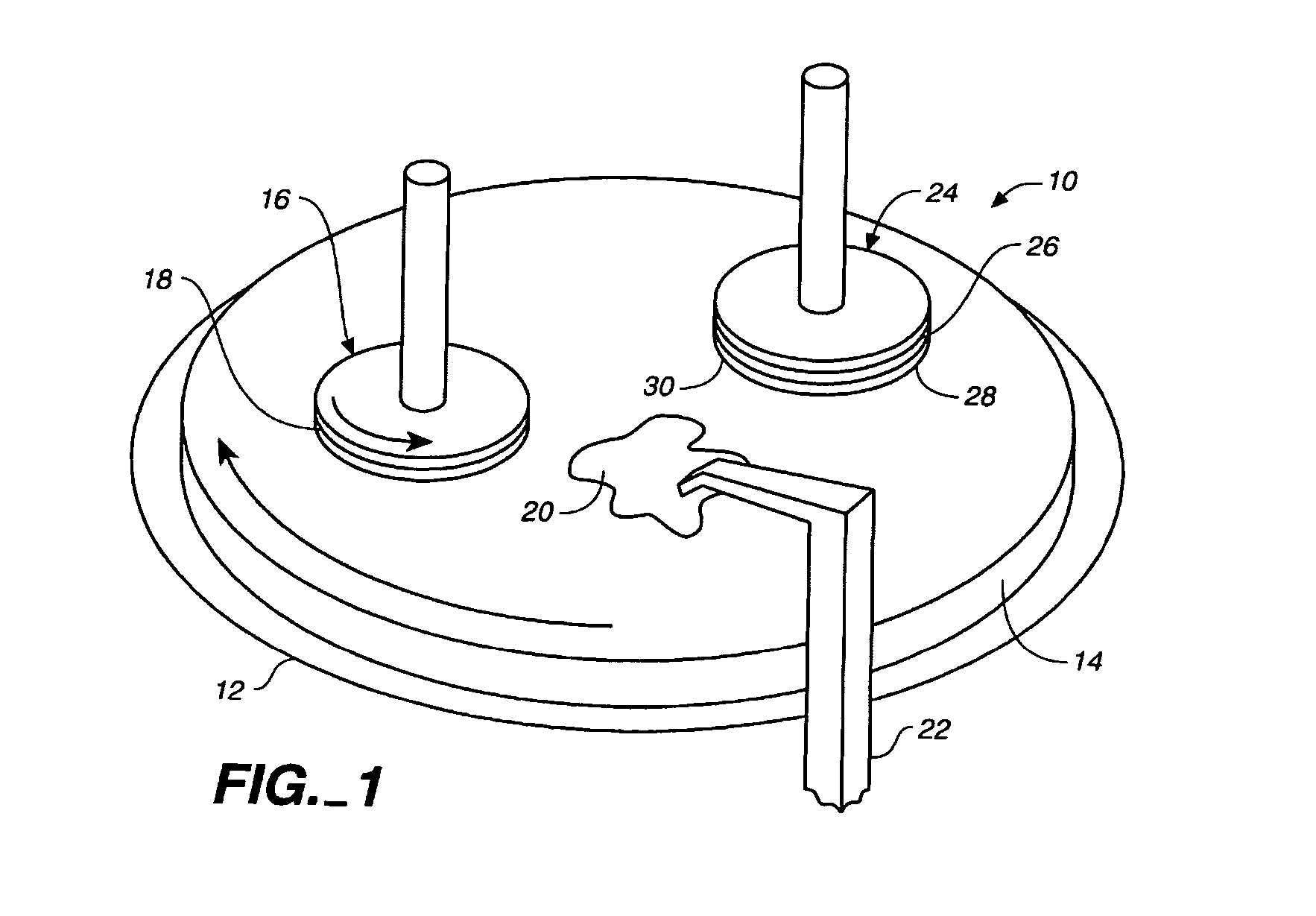

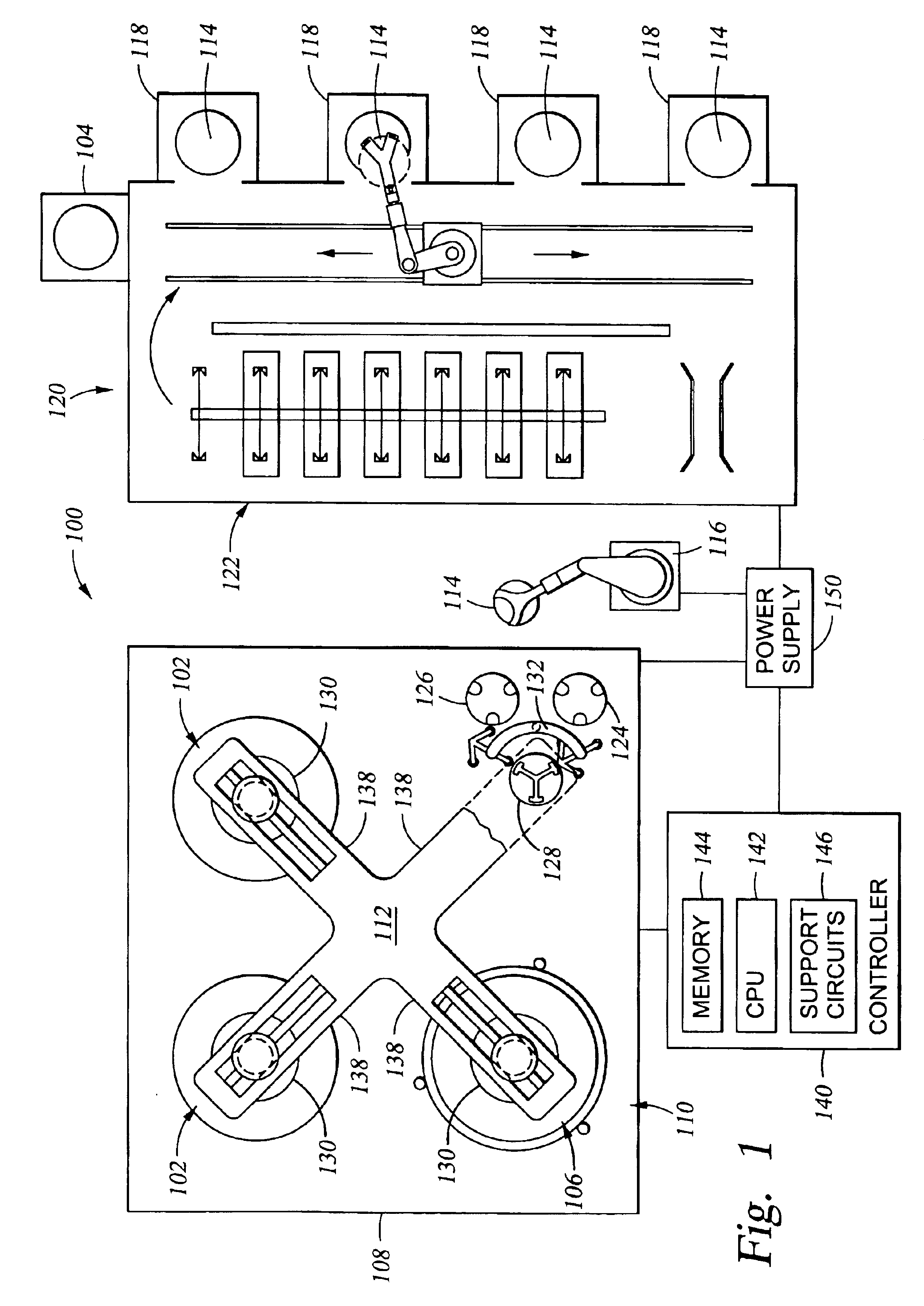

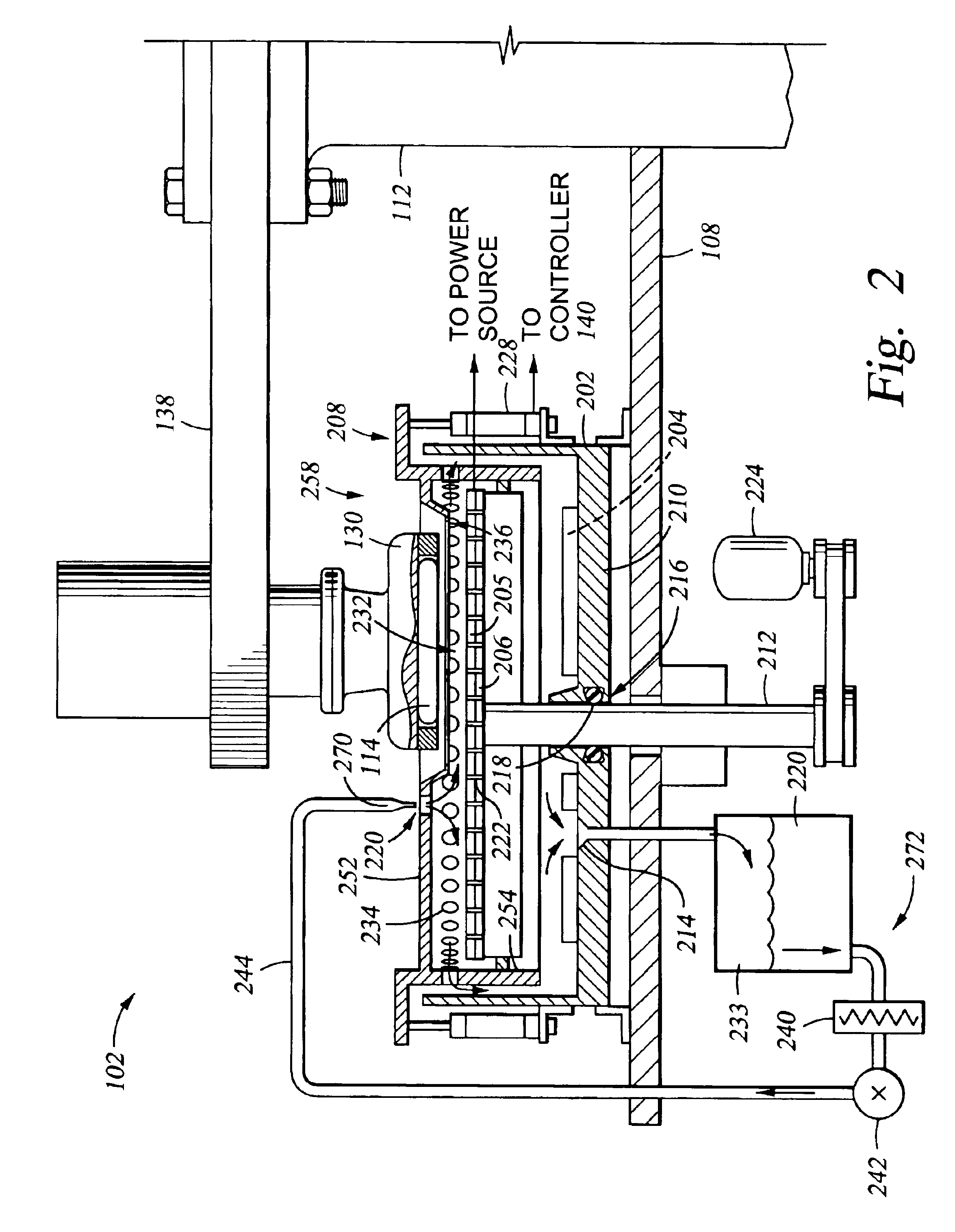

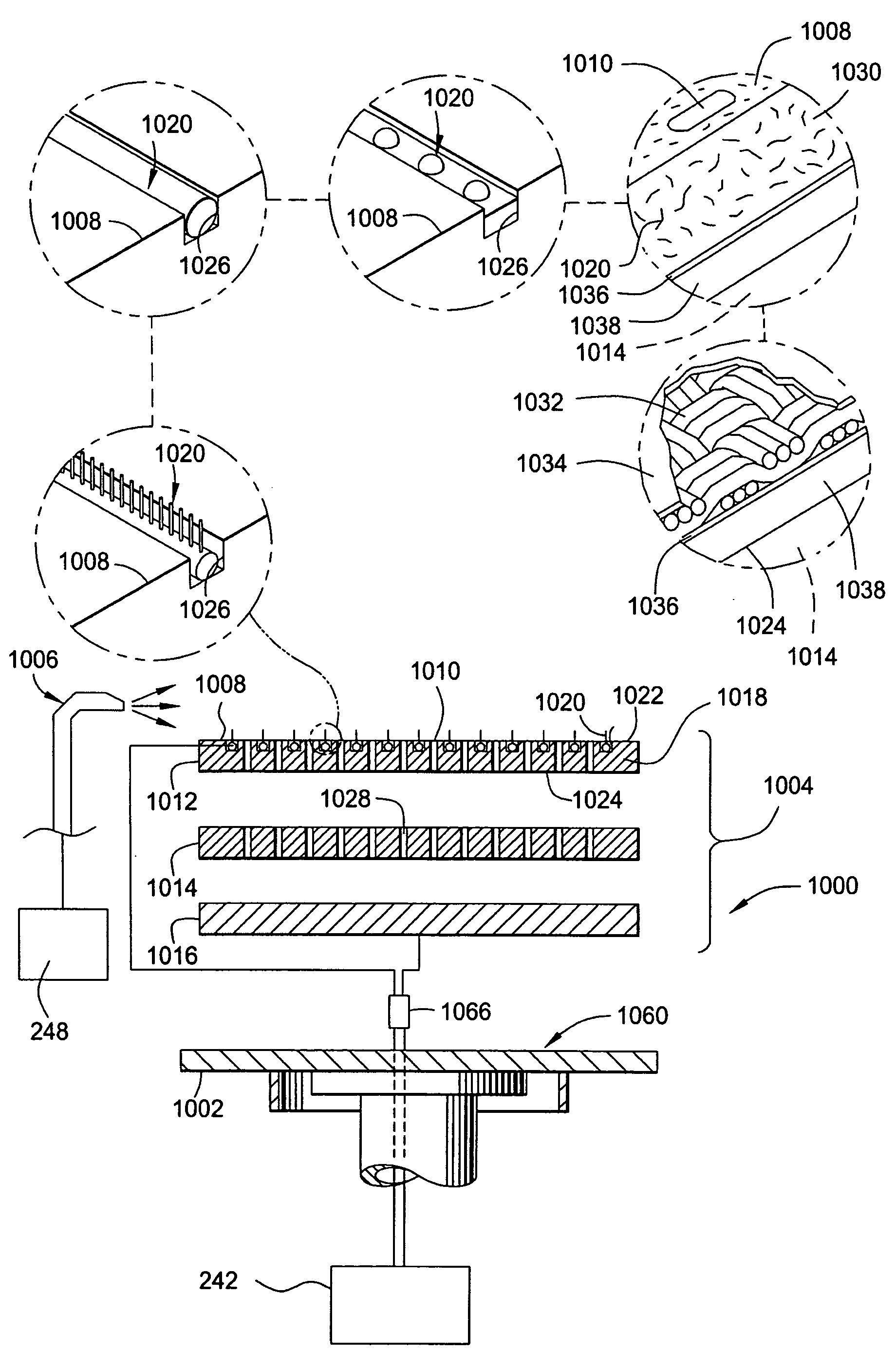

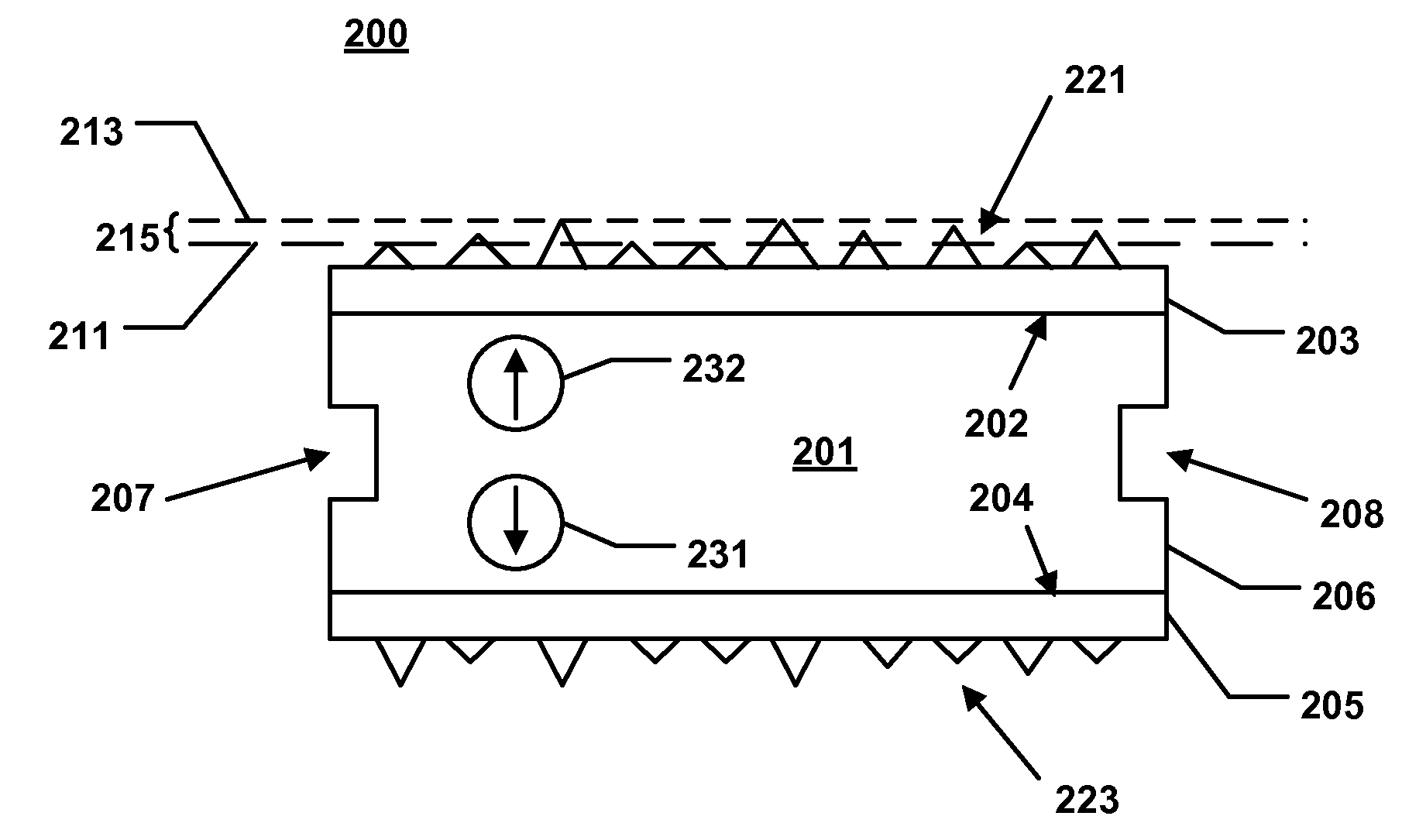

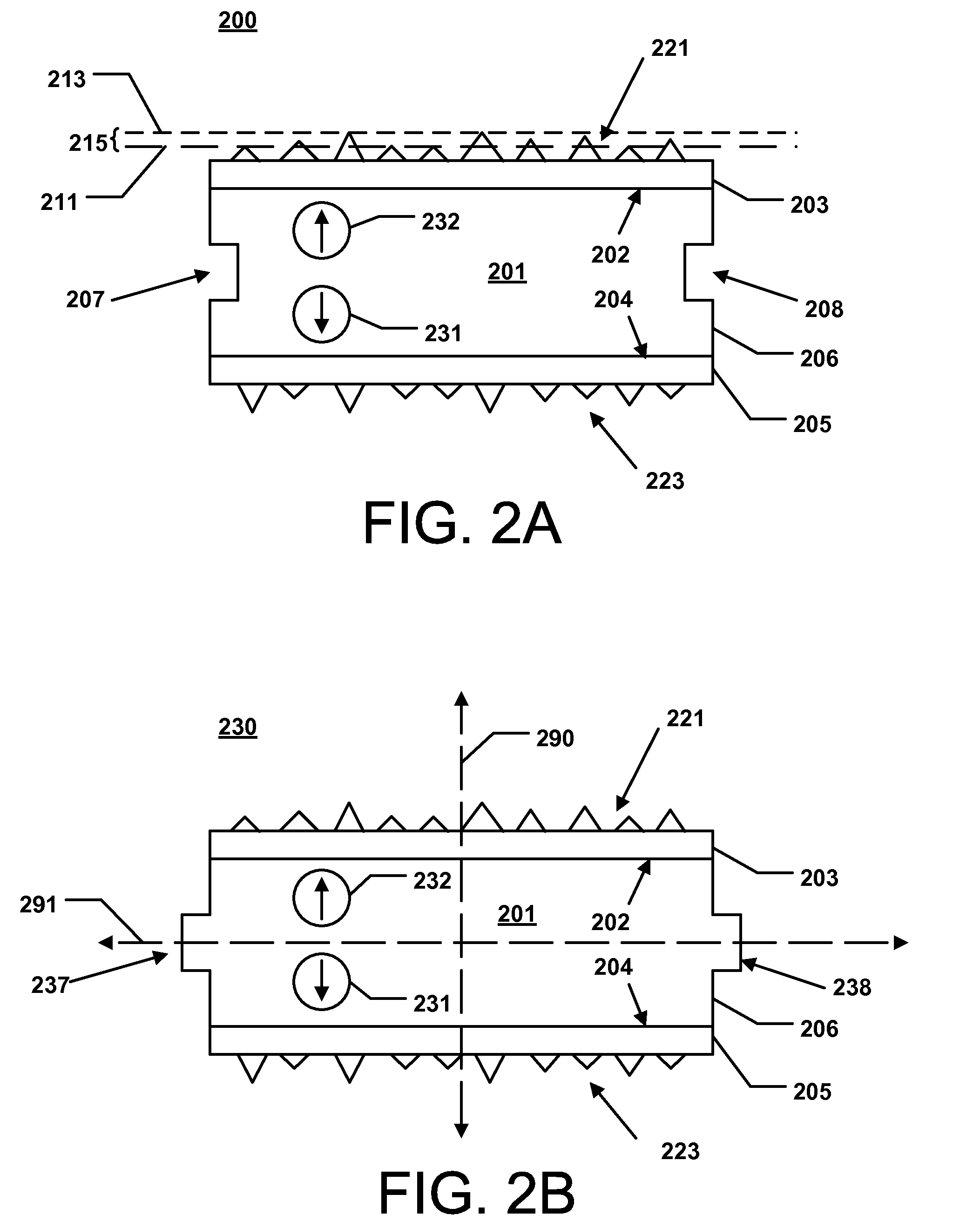

ActiveUS20080004743A1Easy to operate the machineAvoid damageGrinding drivesBelt grinding machinesMonitoring systemEngineering

The disclosure relates to abrasive articles useful in chemical-mechanical polishing (CMP), the articles including a substrate with opposite major surfaces, an abrasive material overlaying at least a portion of at least one of the major surfaces, a means for providing CMP information positioned near the substrate, and a transmitter positioned near the substrate and adapted to transmit the CMP information to a remote receiver. The disclosure also relates to a CMP pad conditioner having a means for communicating CMP information, a CMP process monitoring system, and a method for conditioning a CMP pad.

Owner:3M INNOVATIVE PROPERTIES CO

Customized polishing pads for CMP and methods of fabrication and use thereof

ActiveUS20060276109A1Easy to controlImpact on polishing propertyAdditive manufacturing apparatusLapping machinesPorositySurface engineering

The present application relates to polishing pads for chemical mechanical planarization (CMP) of substrates, and methods of fabrication and use thereof. The pads described in this invention are customized to polishing specifications where specifications include (but not limited to) to the material being polished, chip design and architecture, chip density and pattern density, equipment platform and type of slurry used. These pads can be designed with a specialized polymeric nano-structure with a long or short range order which allows for molecular level tuning achieving superior themo-mechanical characteristics. More particularly, the pads can be designed and fabricated so that there is both uniform and nonuniform spatial distribution of chemical and physical properties within the pads. In addition, these pads can be designed to tune the coefficient of friction by surface engineering, through the addition of solid lubricants, and creating low shear integral pads having multiple layers of polymeric material which form an interface parallel to the polishing surface. The pads can also have controlled porosity, embedded abrasive, novel grooves on the polishing surface, for slurry transport, which are produced in situ, and a transparent region for endpoint detection.

Owner:CMC MATERIALS INC

Method of grinding an axially asymmetric aspherical mirror

InactiveUS6537138B2Improve accuracyReliably madeEdge grinding machinesOptical surface grinding machinesNumerical controlSurface roughness

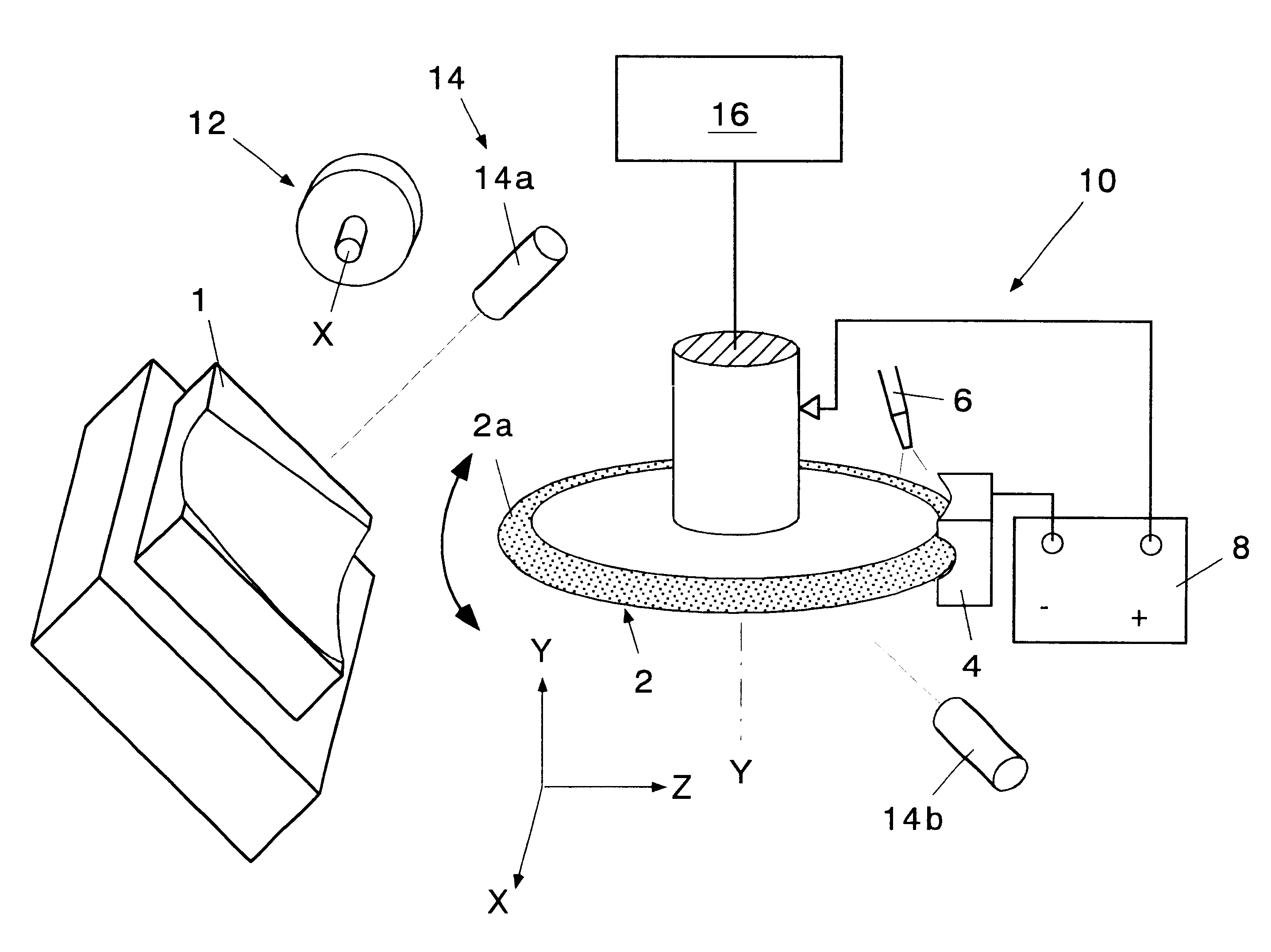

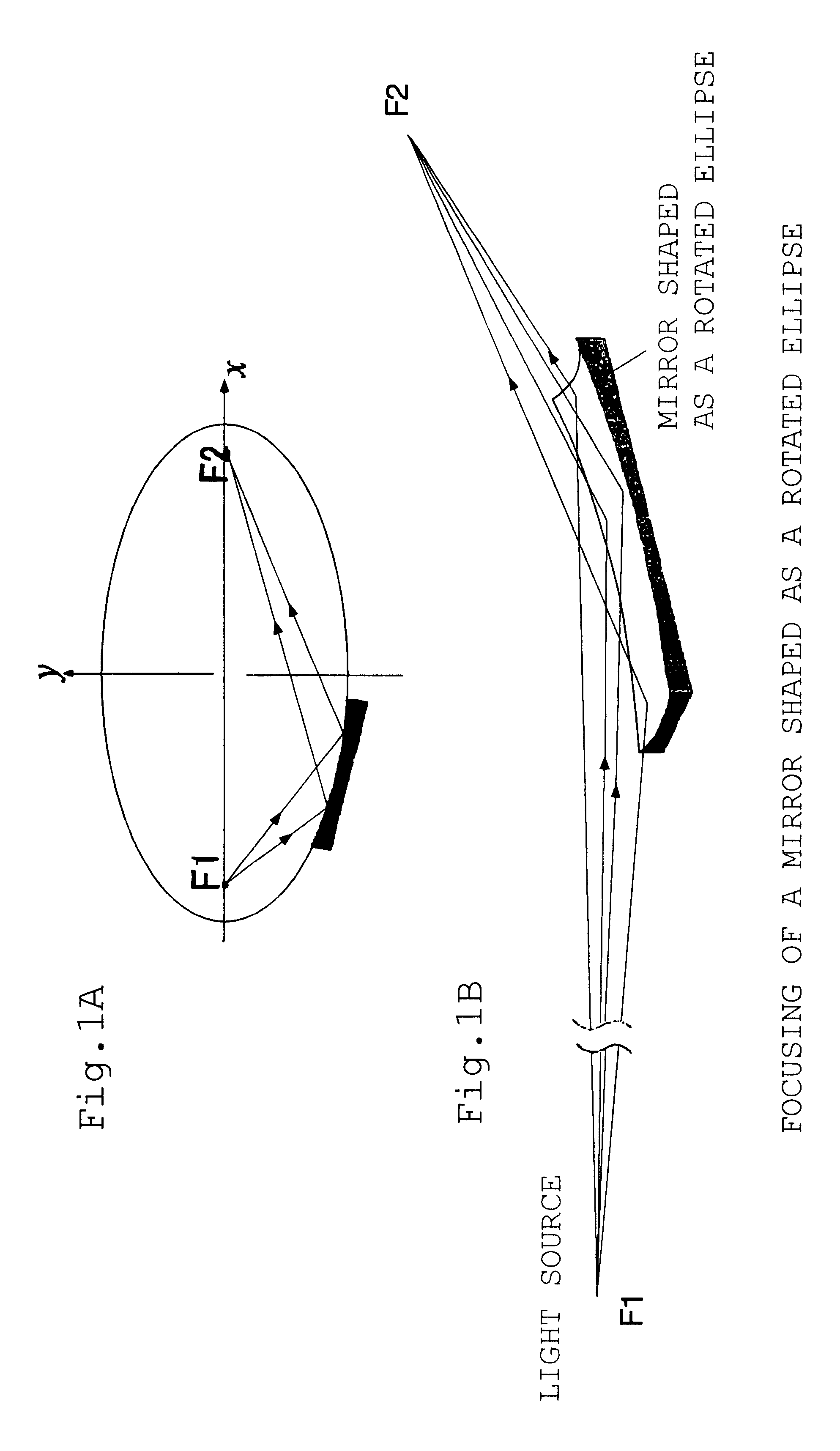

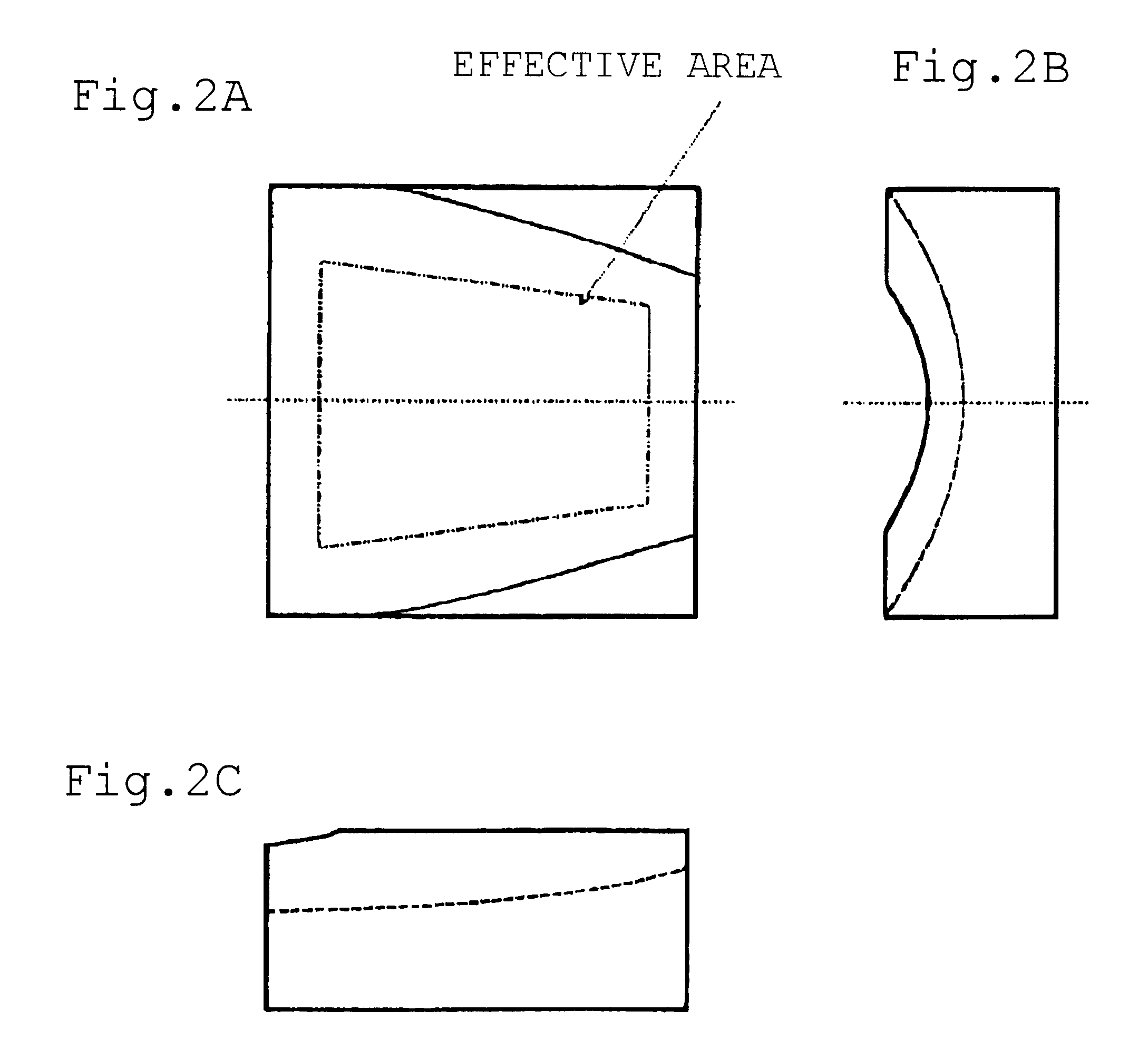

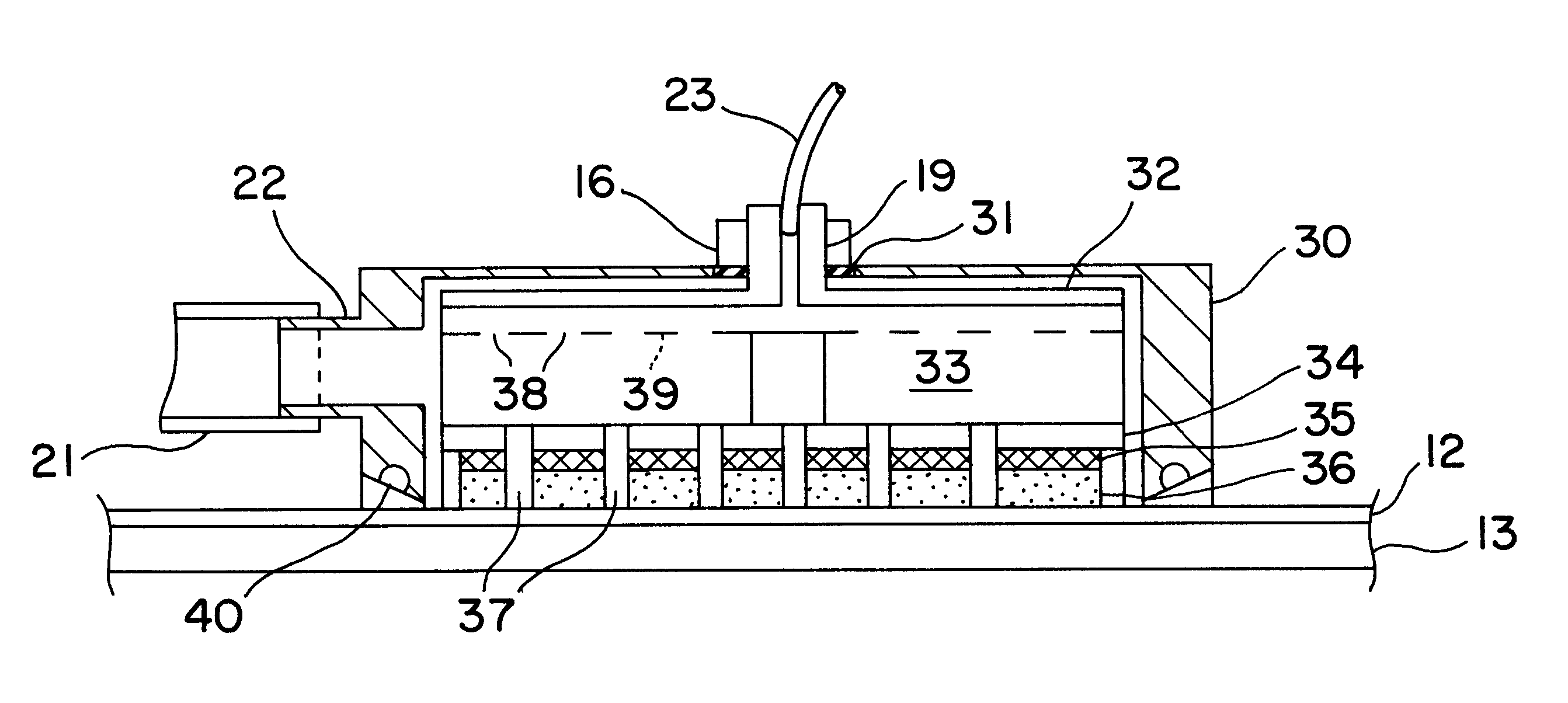

An electrolytic in-process dressing device 10 is provided with a disk-shaped metal-bonded grindstone 2 with a surface 2a with a circular arc shape with a radius R at its outer periphery and a numerical control device 16. The disk-shaped metal-bonded grindstone 2 rotates around an axis Y, and the grindstone is dressed electrolytically while the device 10 grinds the workpiece 1. The numerical control device 16 is provided with a rotary truing device 12 that rotates around the X axis that orthogonally crosses the axis of rotation Y and trues the circular arc surface 2a, a shape measuring device 14 for measuring the shape of the circular arc surface of the grindstone and the shape of the processed surface of workpiece 1 on the machine, and controls the grindstone numerically in the three directions along the axes X, Y and Z. The numerical control device 16 moves the grindstone in three axial directions and repeats the operations of truing, grinding and measurements on-line. Thus, an axially asymmetrical aspheric mirror with a highly accurate shape and extremely low surface roughness, that can precisely reflect or converge light can be manufactured within a short time with a high accuracy.

Owner:RIKEN +1

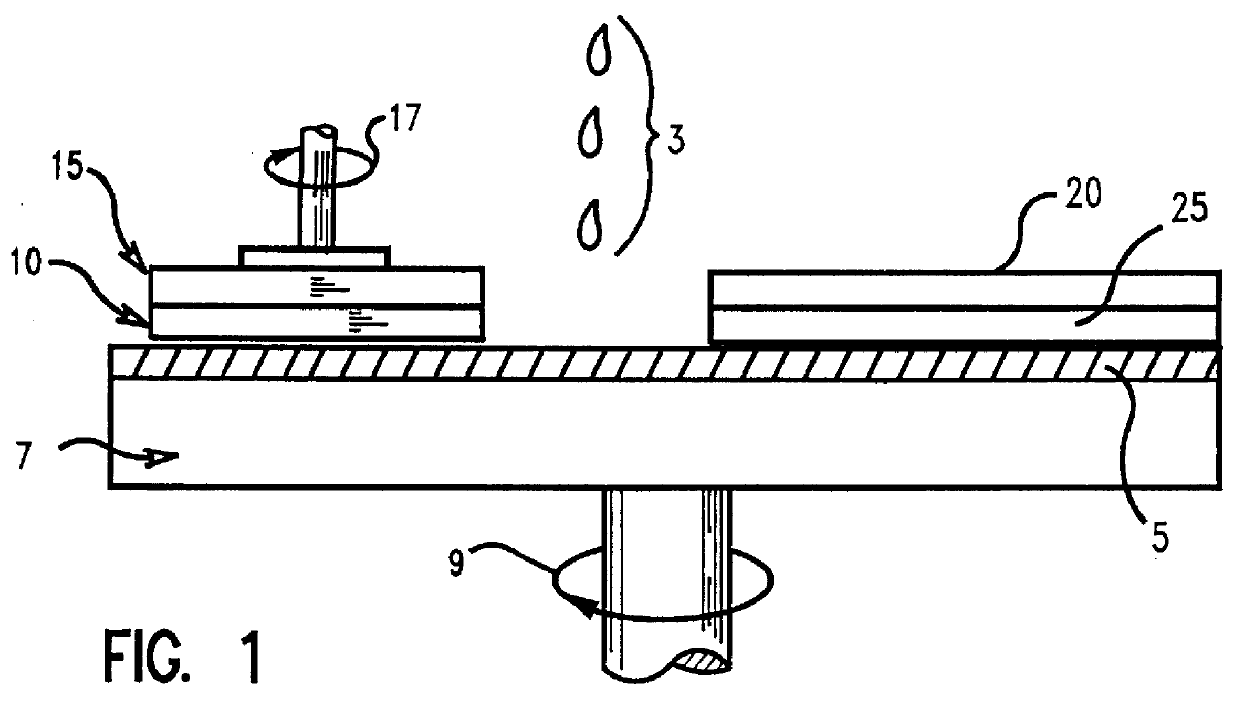

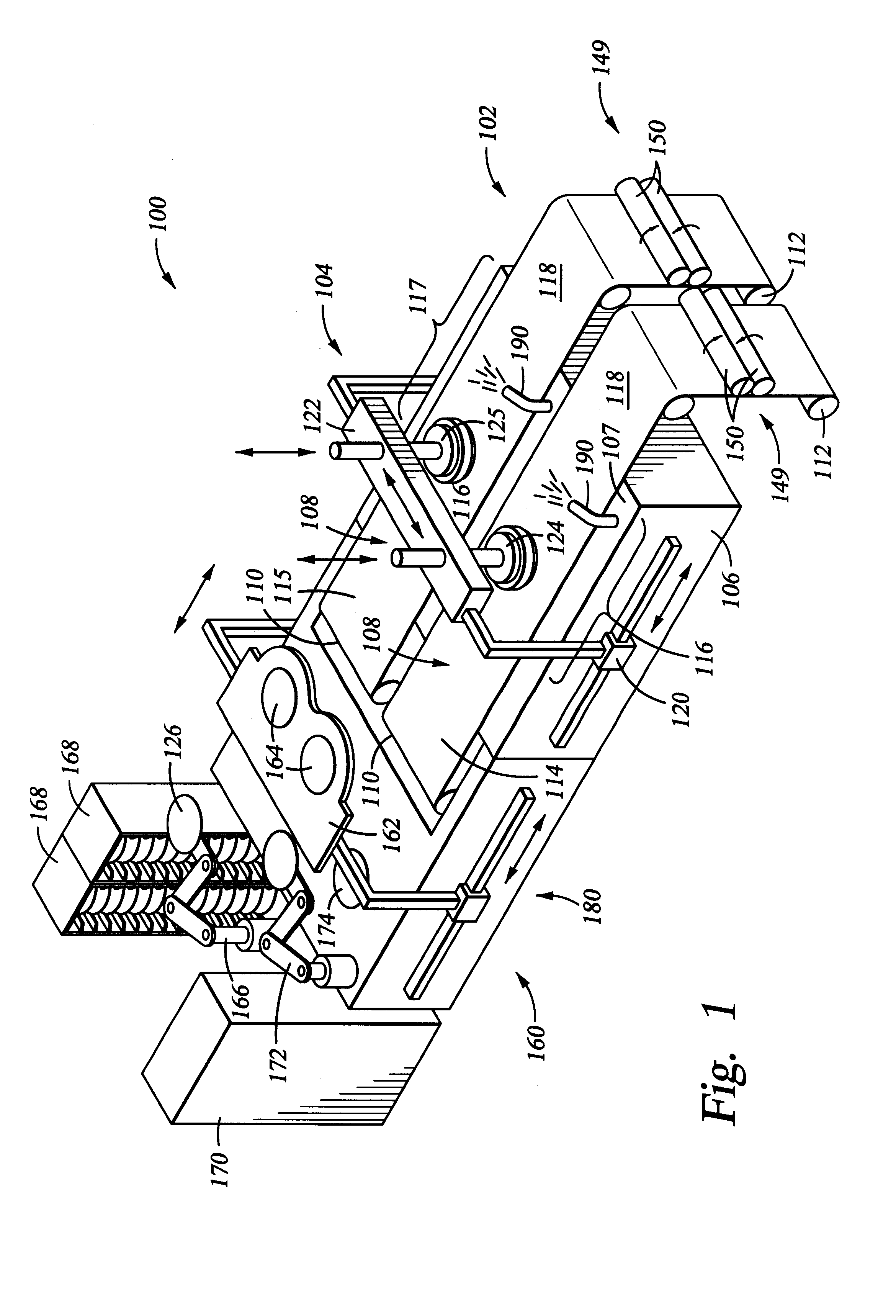

Polishing pad conditioning system

InactiveUS6508697B1Polishing machinesRevolution surface grinding machinesPiezo electricWaste material

A system for conditioning rotatable polishing pads used to planarize and polish surfaces of thin film integrated circuits deposited on semiconductor wafer substrates, microelectronic, and optical system. The system has a pad conditioning apparatus, process fluids, a vacuum capability to pull waste material out of the conditioning pad, self-contained flushing means, and a piezo-electric device for vibrating the pad conditioning apparatus.

Owner:BENNER ROBERT LYLE +2

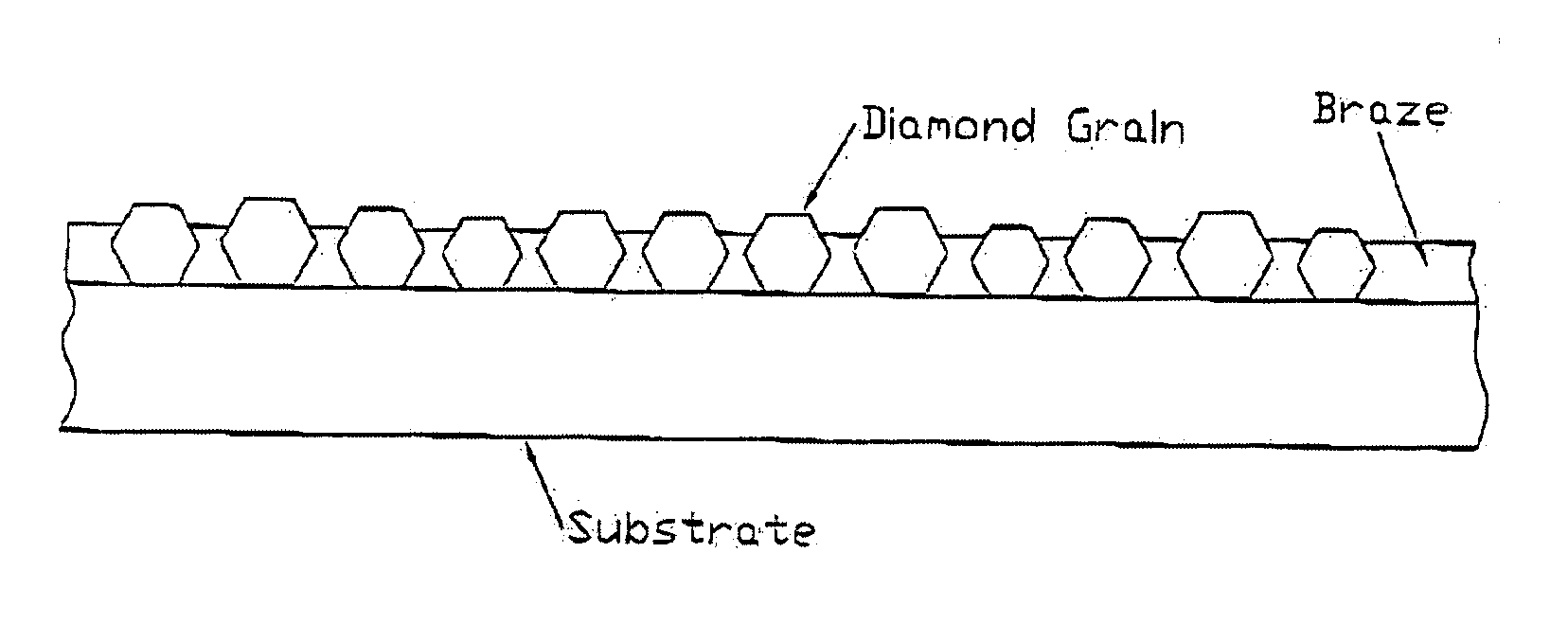

Brazed diamond tools and methods for making the same

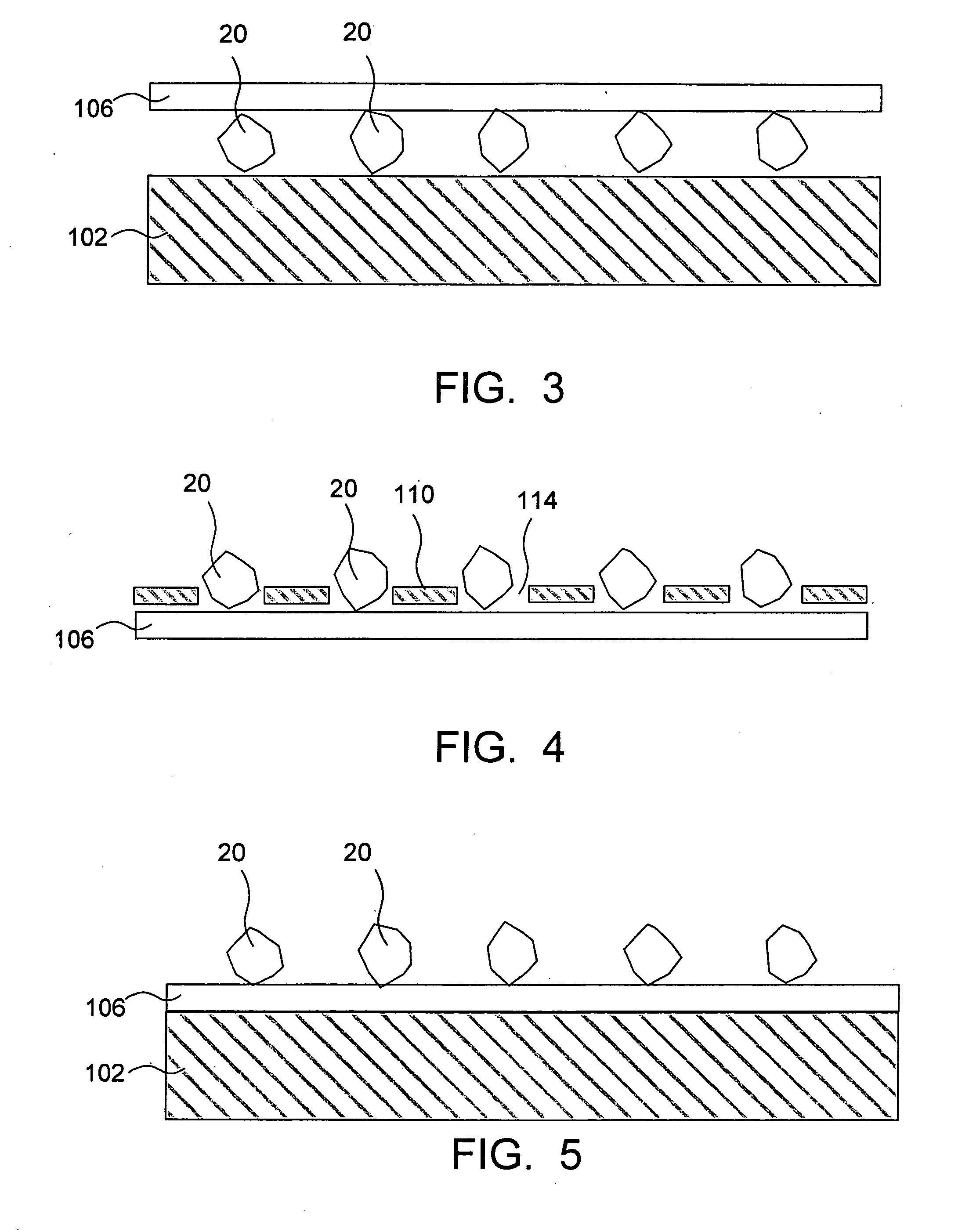

InactiveUS20040112359A1Avoid large movementsImprove cutting efficiencyDrill bitsConstructionsChemical LinkageBraze alloy

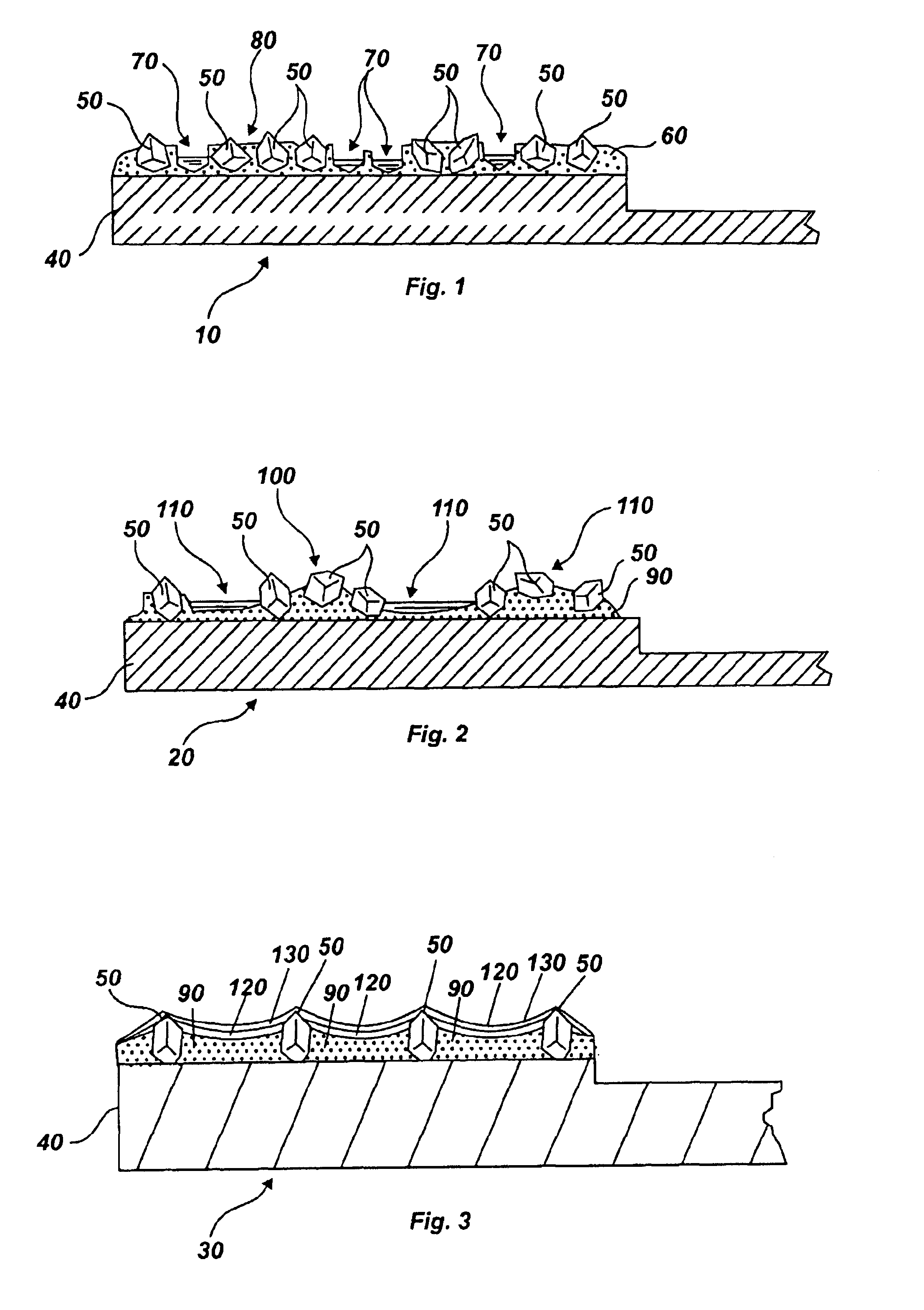

Superabrasive tools and methods for the making thereof are disclosed and described. In one aspect, superabrasive particles are chemically bonded to a matrix support material according to a predetermined pattern by a braze alloy. The brazing alloy may be provided as a powder, thin sheet, or sheet of amorphous alloy. A template having a plurality of apertures arranged in a predetermined pattern may be used to place the superabrasive particles on a given substrate or matrix support material.

Owner:SUNG CHIEN MIN

CVD diamond-coated composite substrate containing a carbide-forming material and ceramic phases and method for making same

InactiveUS20050025973A1Improve adhesionLow costPigmenting treatmentEngine sealsReaction bonded silicon carbideComposite substrate

The present invention relates to a composite material and the method of making same, which comprises a CVD diamond coating applied to a composite substrate of ceramic material and an unreacted carbide-forming material of various configurations and for a variety of applications. One example of the composite material is a composite of SiC and free silicon metal known as Reaction-Bonded Silicon Carbide. Several examples of applications of the invention include: 1) heads or disks for conditioning polishing pads, including pads used in Chemical-Mechanical-Planarization, 2) cutting and dressing tool inserts and tips, 3) heat spreaders for electronic devices, and 4) wear components including mechanical seals and pump seals.

Owner:MORGAN ADVANCED CERAMICS

Method, system and medium for process control for the matching of tools, chambers and/or other semiconductor-related entities

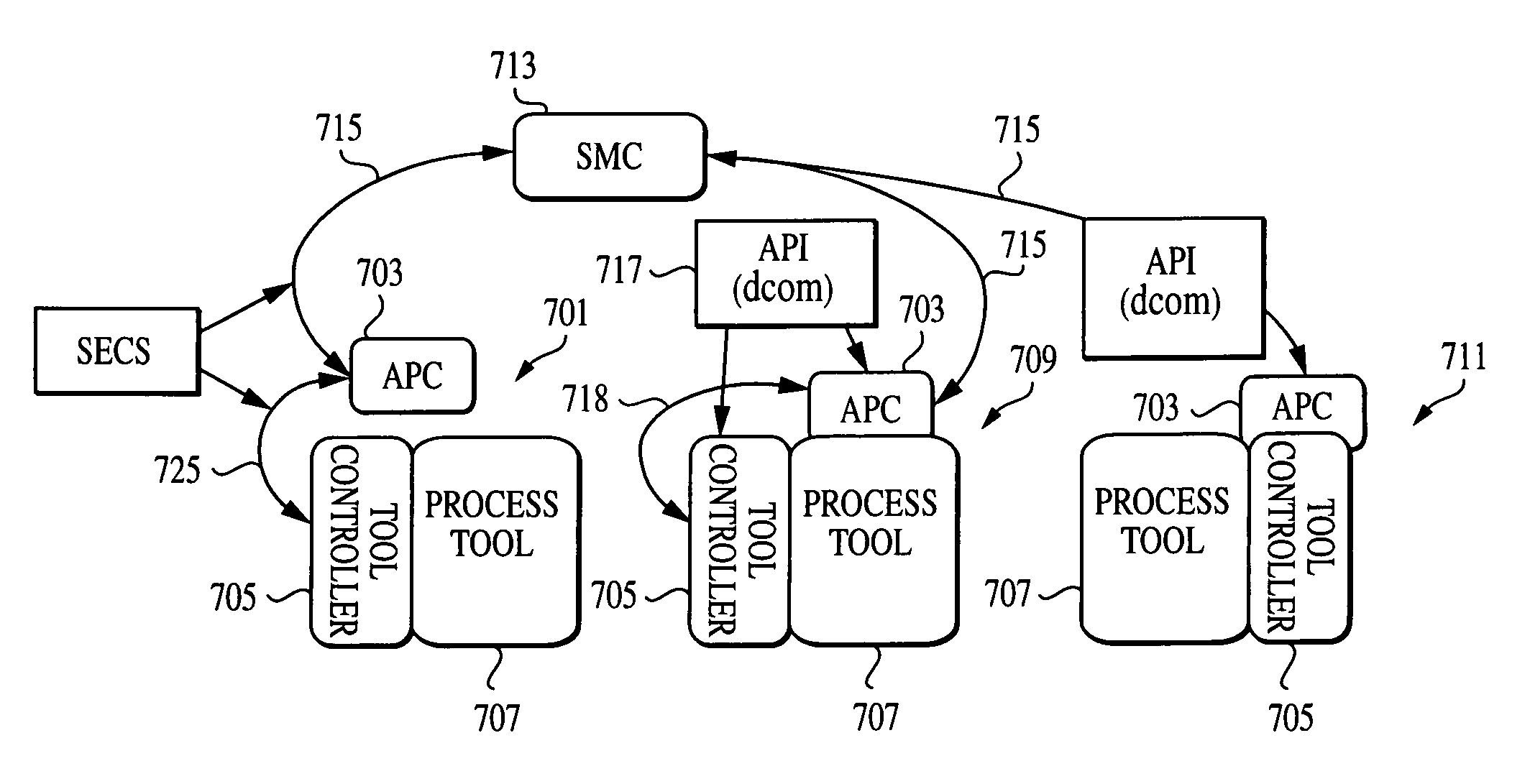

InactiveUS7082345B2Improve consistencySimple structureSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device manufacturingComputer moduleAssembly line

The invention relates to a method, system and computer program useful for producing a product, such as a microelectronic device, for example in an assembly line, where the production facility includes parallel production of assembly lines of products on identically configured chambers, tools and / or modules. Control is provided between such chambers. Behaviors of a batch of wafers (or of each wafer) are collected as the first batch (or each wafer) is processed by one of the identically configured chambers in one assembly line to produce the microelectronic device. The information relating to the behavior is shared with a controller of another one (or more) of the identically configured chambers, process tools and / or modules, to provide an adjustment of the process tool and thereby to produce a second batch (or next wafer) which is substantially identical, within tolerance, to the first batch (or wafer).

Owner:APPLIED MATERIALS INC

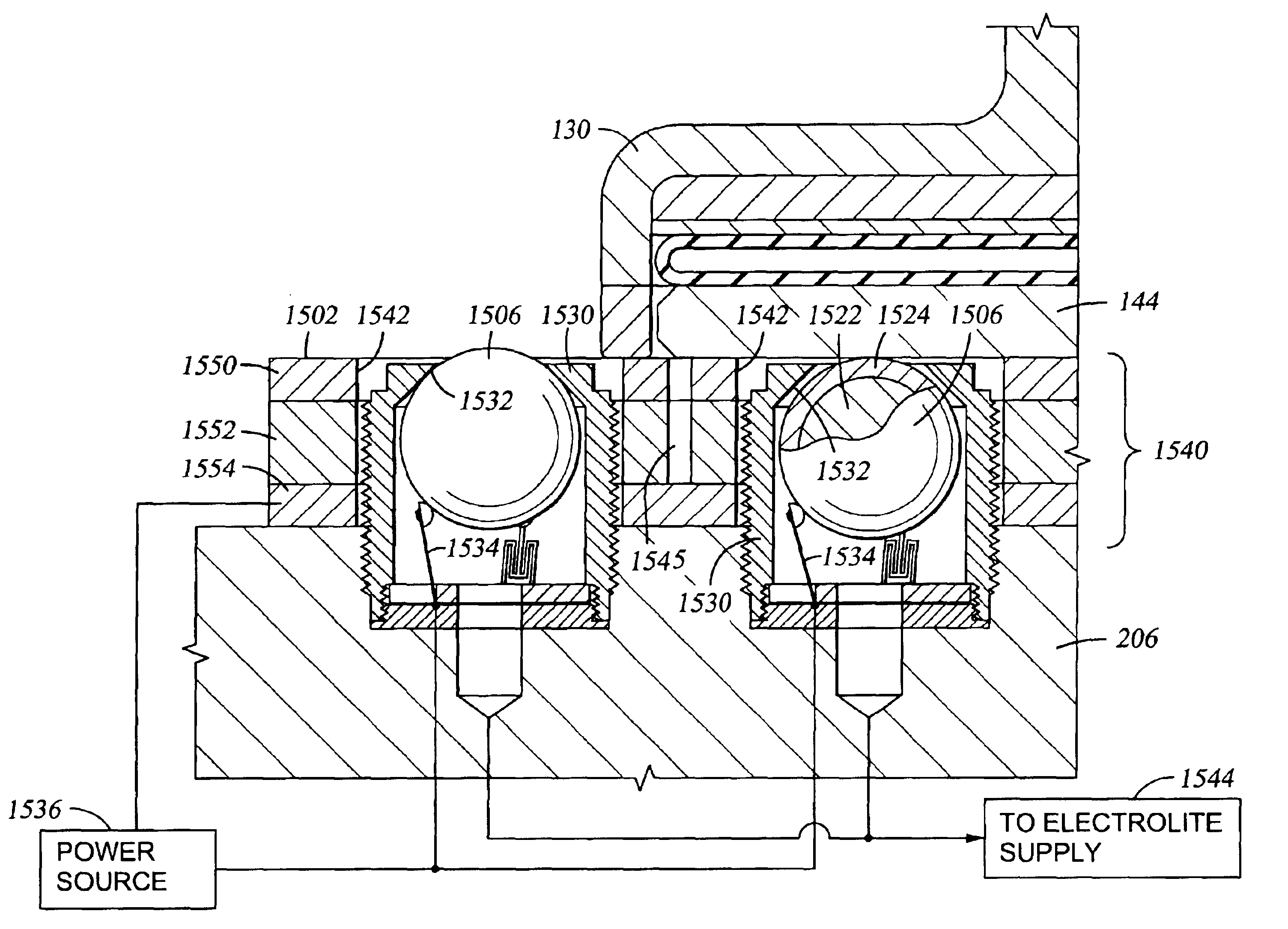

Conductive polishing article for electrochemical mechanical polishing

InactiveUS6962524B2Easy to moveSemiconductor/solid-state device manufacturingFlexible-parts wheelsEngineeringContact element

Embodiments of a ball assembly are provided. In one embodiment, a ball assembly includes a housing, a ball, a conductive adapter and a contact element. The housing has an annular seat extending into a first end of an interior passage. The conductive adapter is coupled to a second end of the housing. The contact element electrically couples the adapter and the ball with is retained in the housing between seat and the adapter.

Owner:APPLIED MATERIALS INC

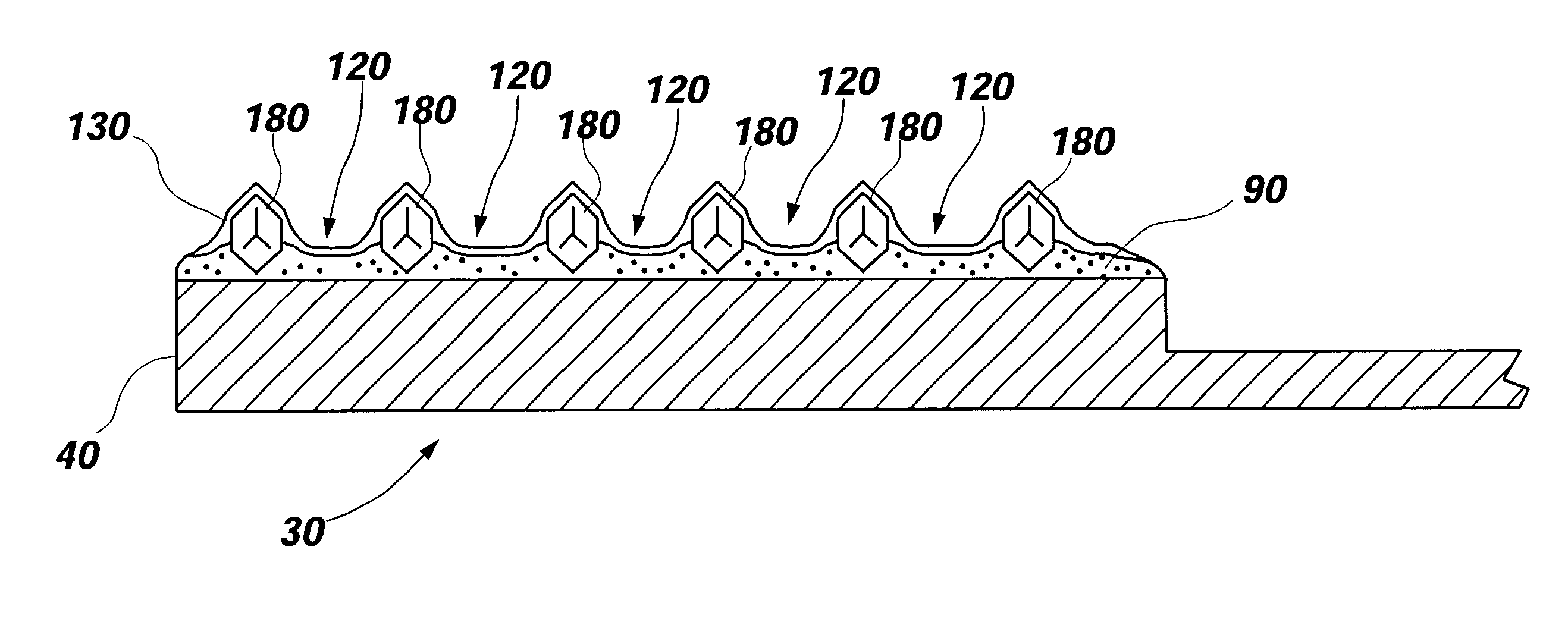

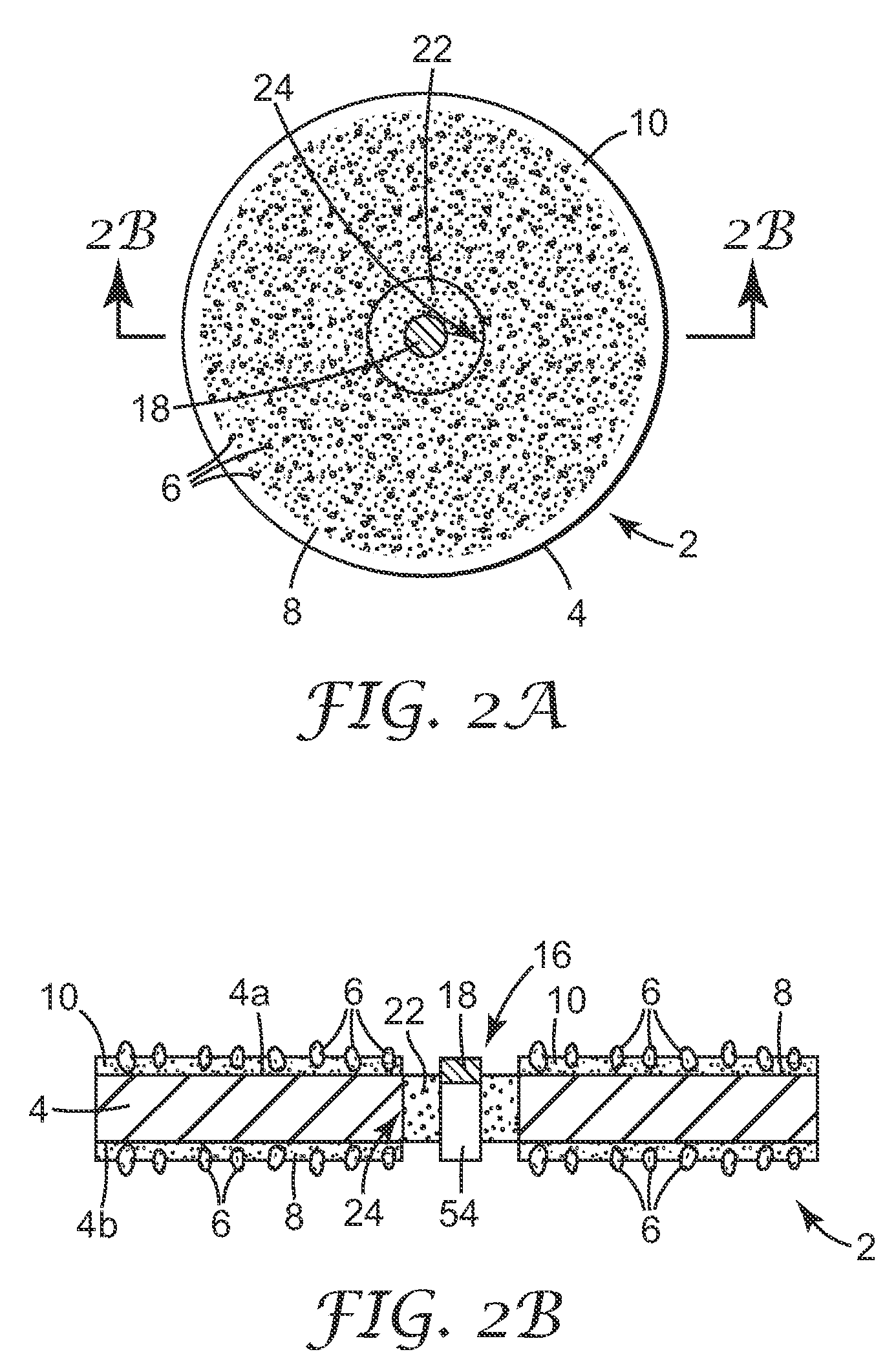

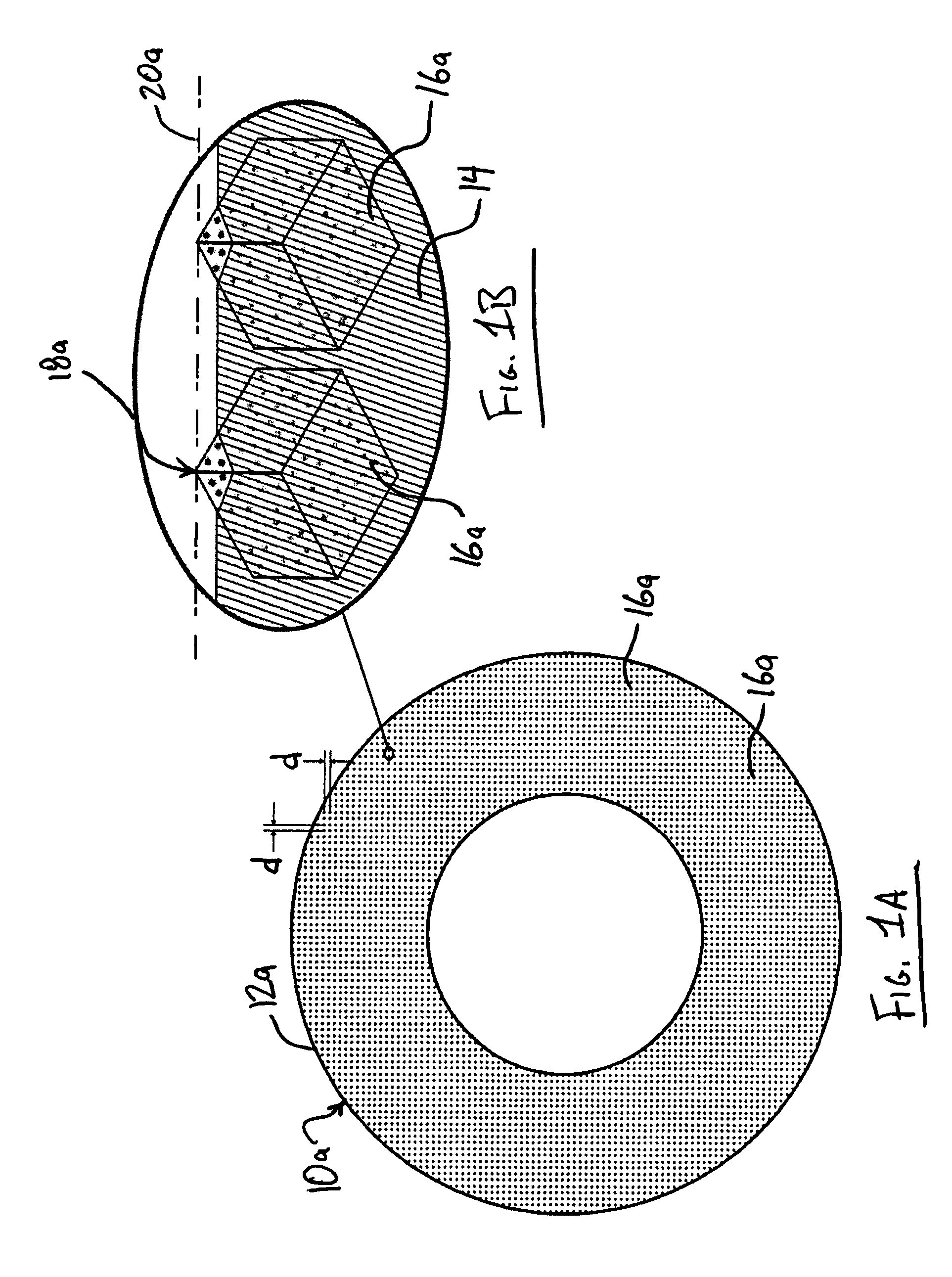

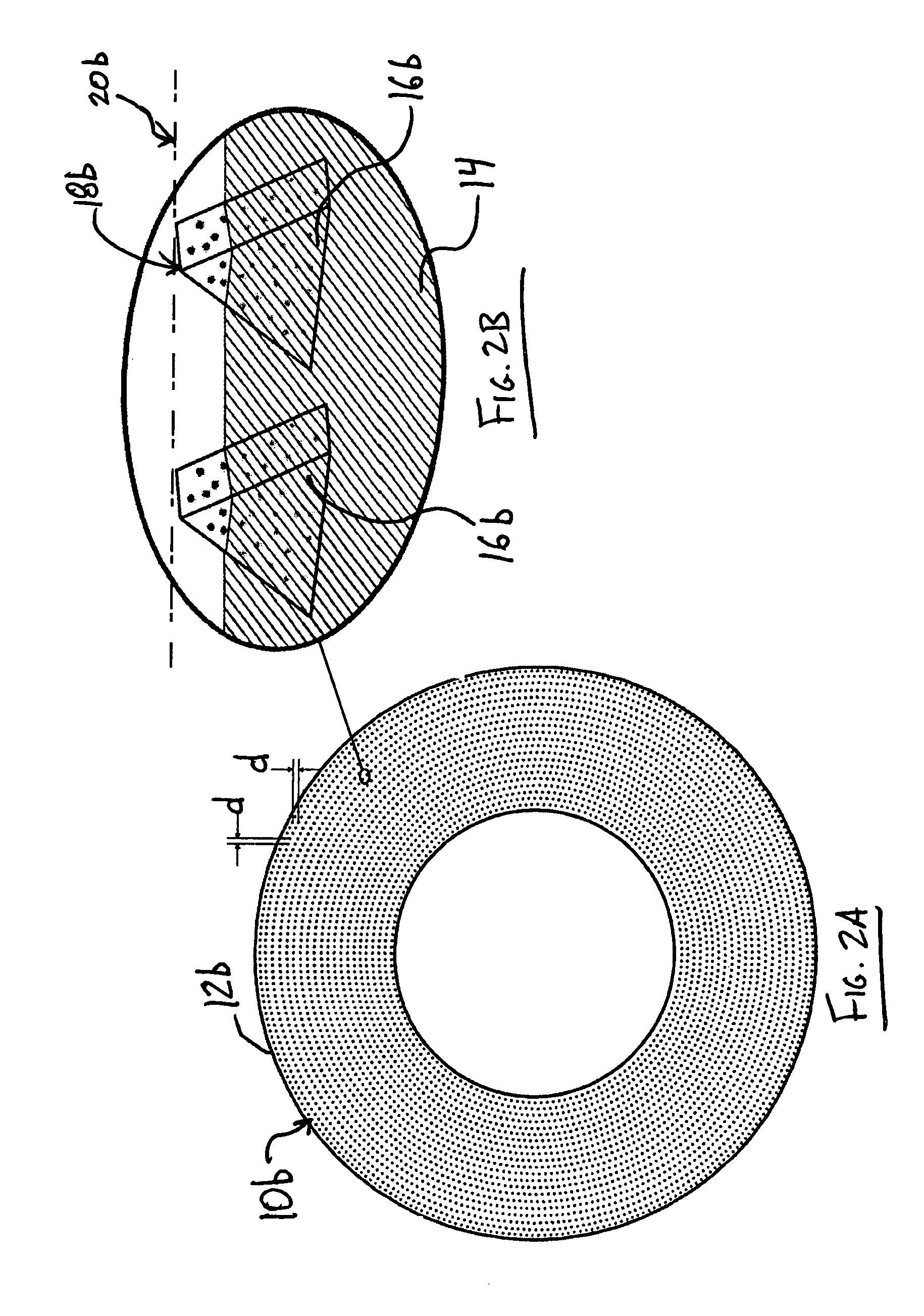

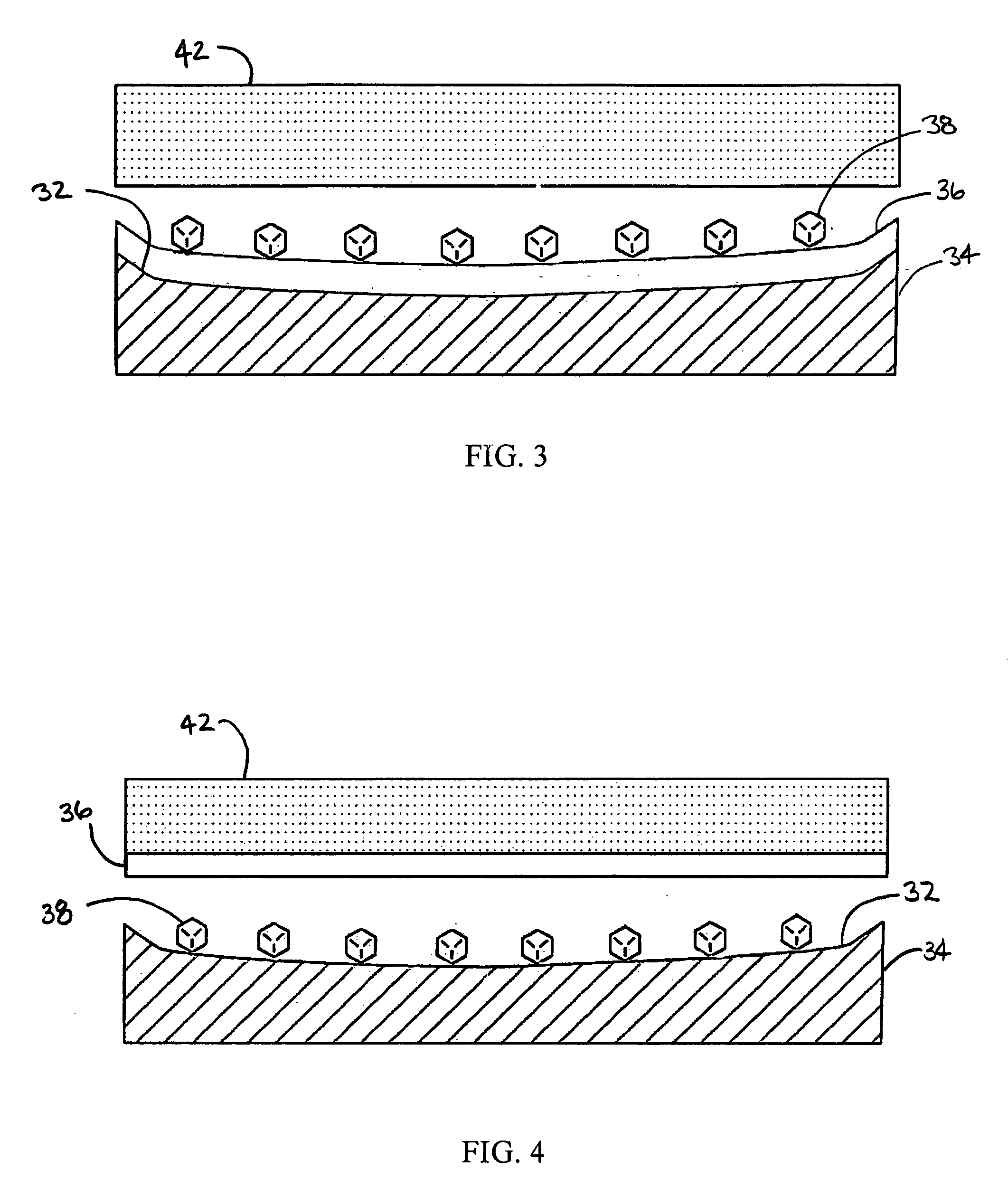

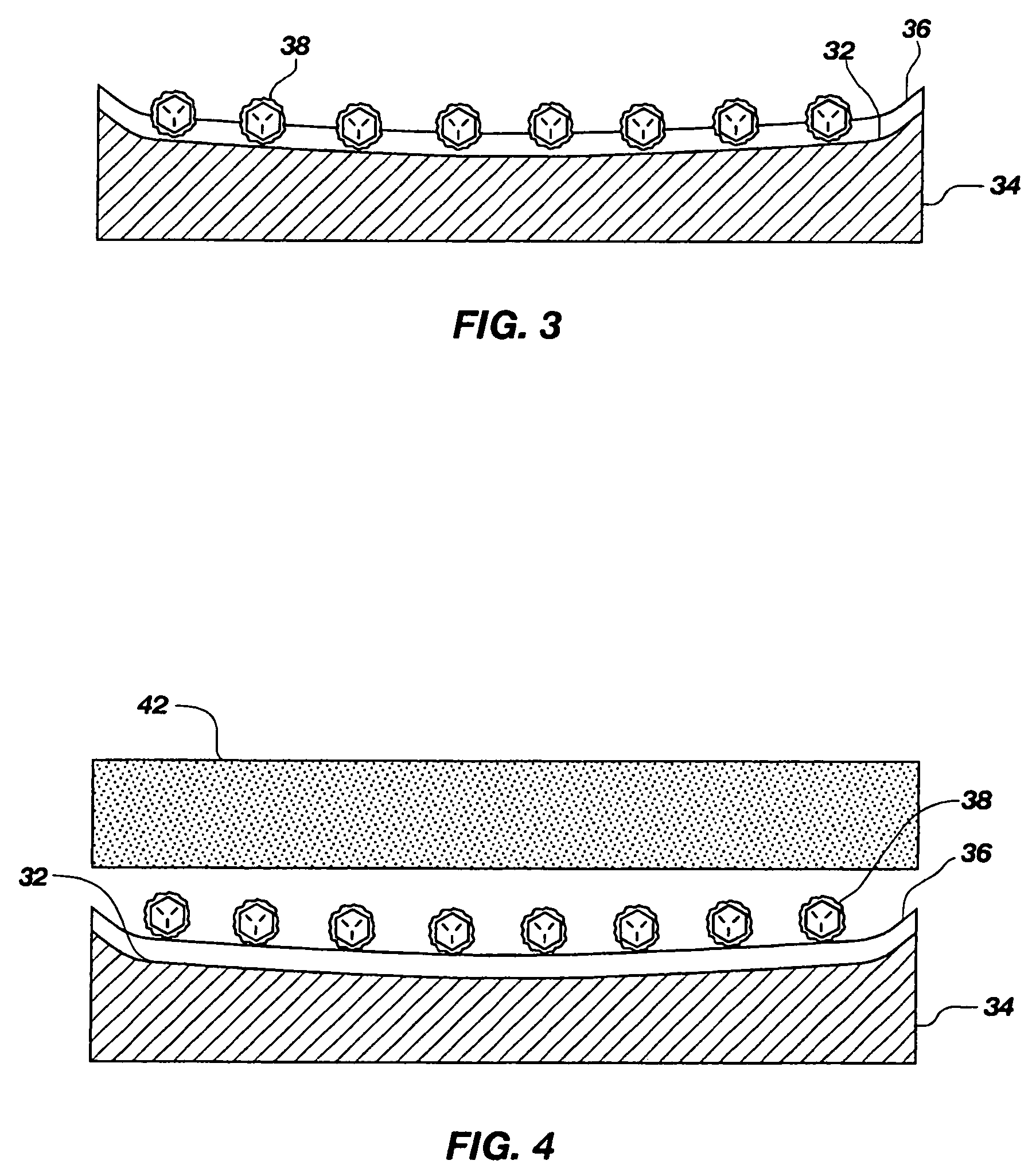

Contoured CMP pad dresser and associated methods

InactiveUS7201645B2Increase loadImprove permeabilityPolishing machinesRevolution surface grinding machinesEngineeringMechanical engineering

Owner:KINIK

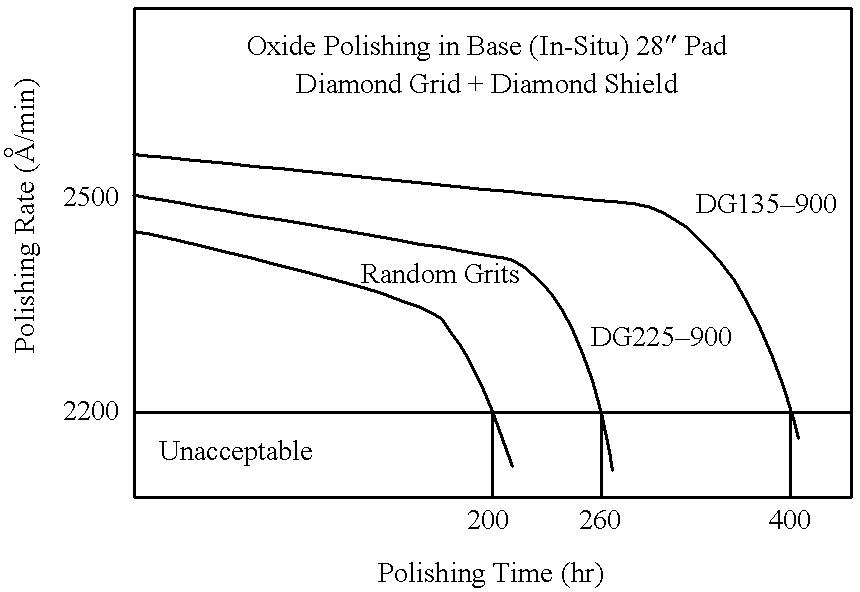

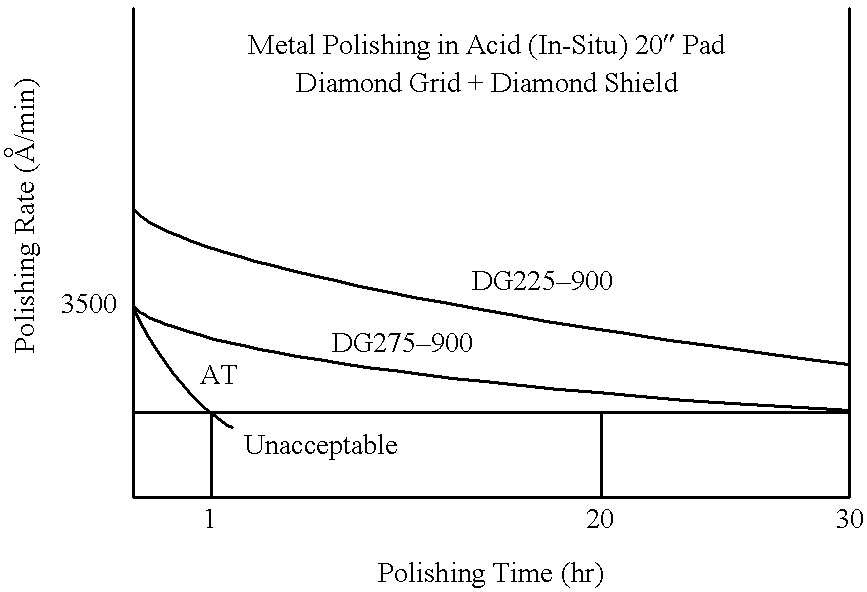

Diamond grid CMP pad dresser

InactiveUS6884155B2Easy to monitorUniform sizePolishing machinesRevolution surface grinding machinesSuperhard materialDiamond-like carbon

The present invention discloses a CMP pad dresser which has a plurality of uniformly spaced abrasive particles protruding therefrom. The abrasive particles are super hard materials, and are typically diamond, polycrystalline diamond (PCD), cubic boron nitride (cBN), or polycrystalline cubic boron nitride(PcBN). The abrasive particles are brazed to a substrate which may be then coated with an additional anti-corrosive layer. The anti-corrosive layer is usually a diamond or diamond-like carbon which is coated over the surface of the disk to prevent erosion of the brazing alloy by the chemical slurry used in conjunction with the CMP pad. This immunity to chemical attack allows the CMP pad dresser to dress the pad while it is polishing a workpiece. In addition to even spacing on the substrate, the abrasive particles extend for a uniform distance away from the substrate, allowing for even grooming or dressing of a CMP pad both in vertical and horizontal directions. A method of producing such a CMP pad dresser is also disclosed.

Owner:KINIK

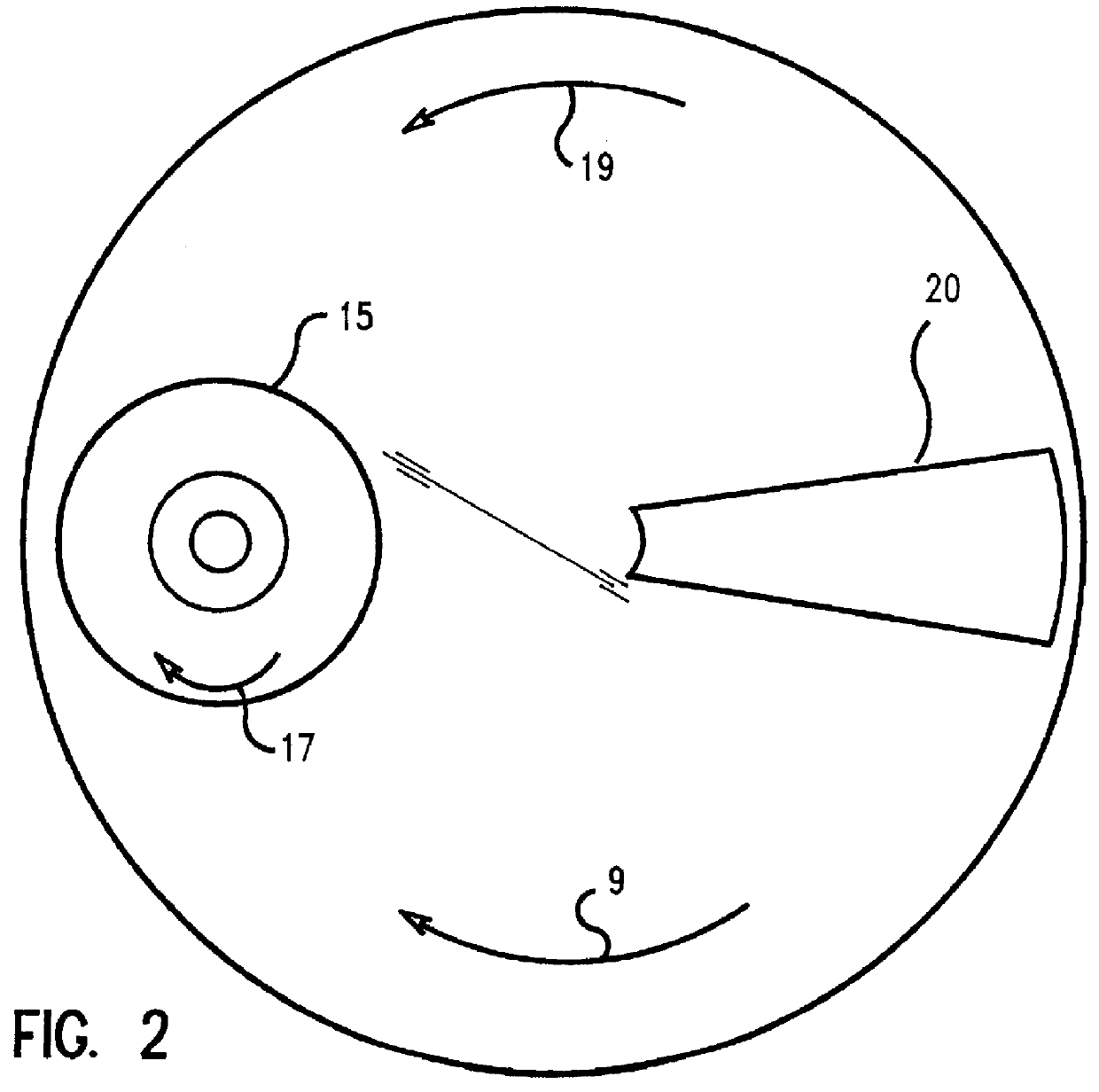

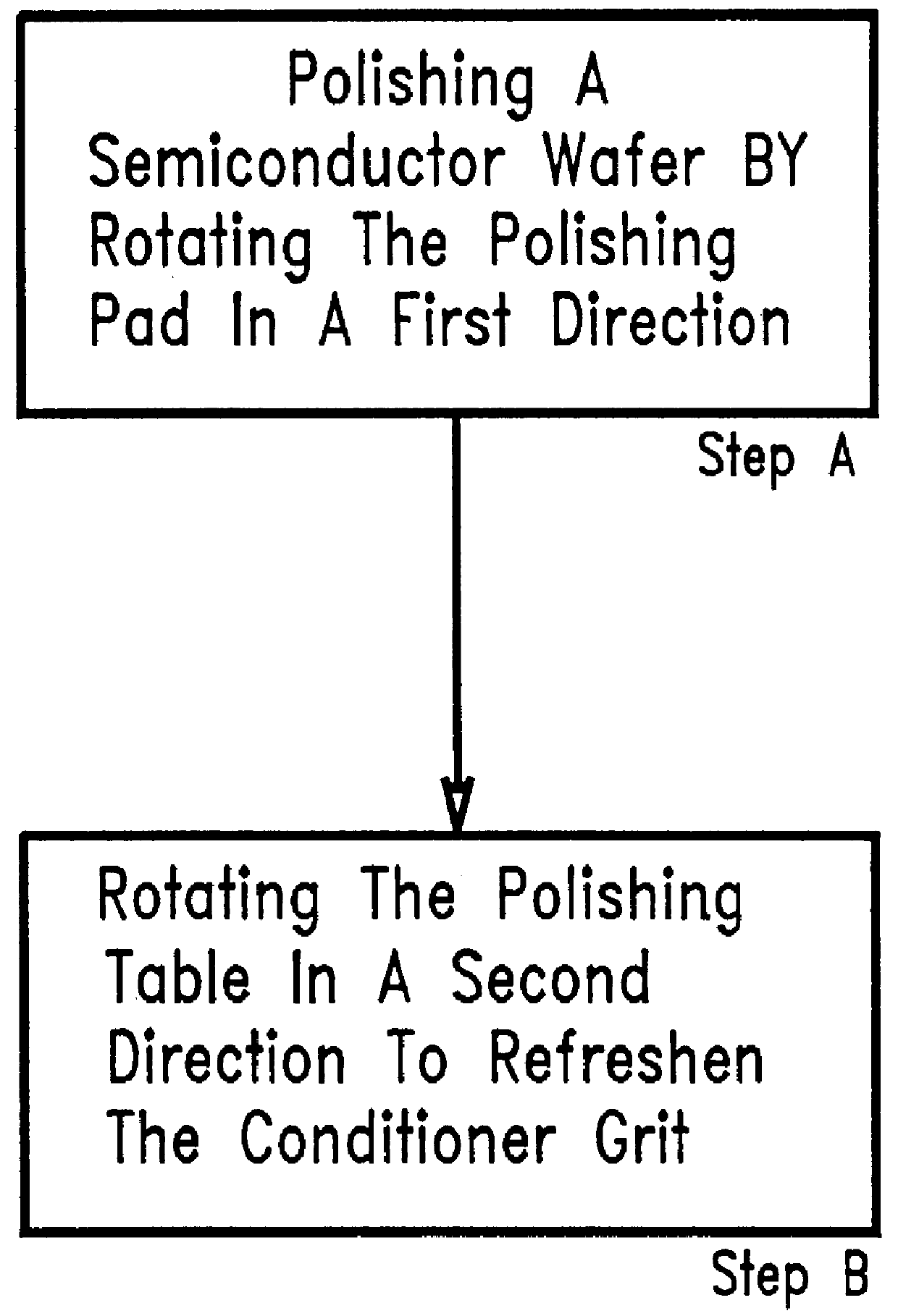

In-situ pad conditioning process for CMP

InactiveUS6022266AGood conditioning effectGrinding drivesBelt grinding machinesSlurryImproved method

Owner:GOOGLE LLC

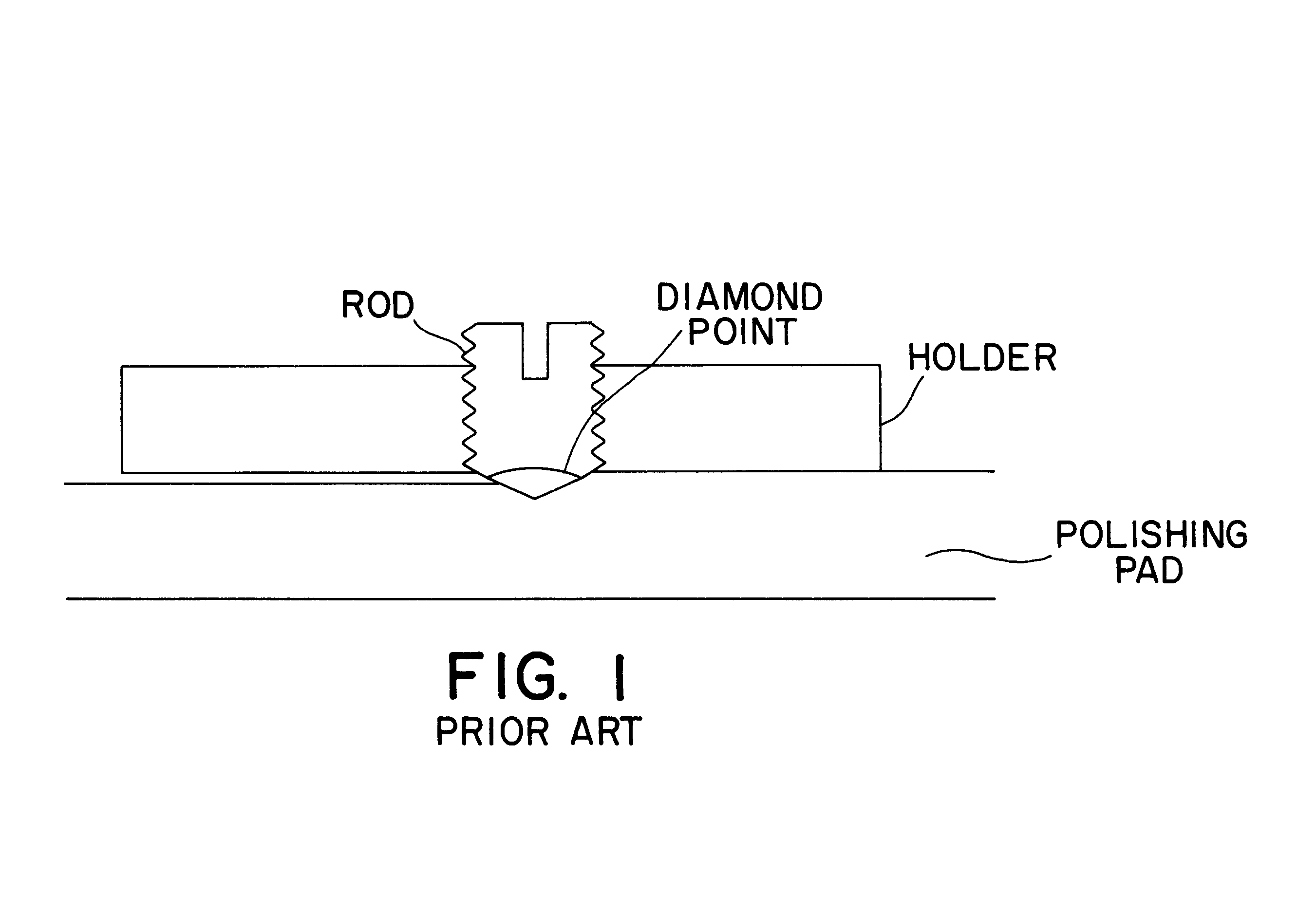

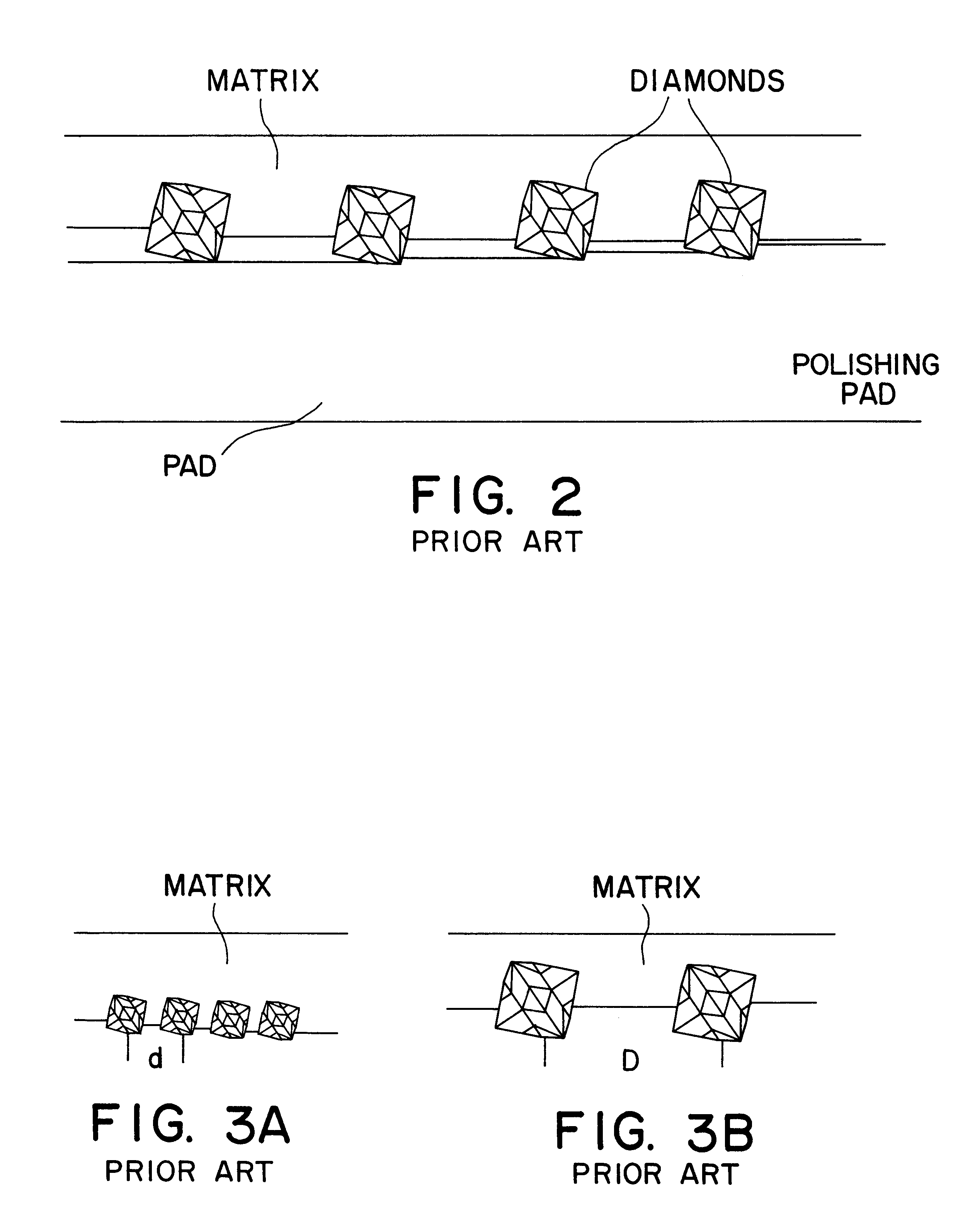

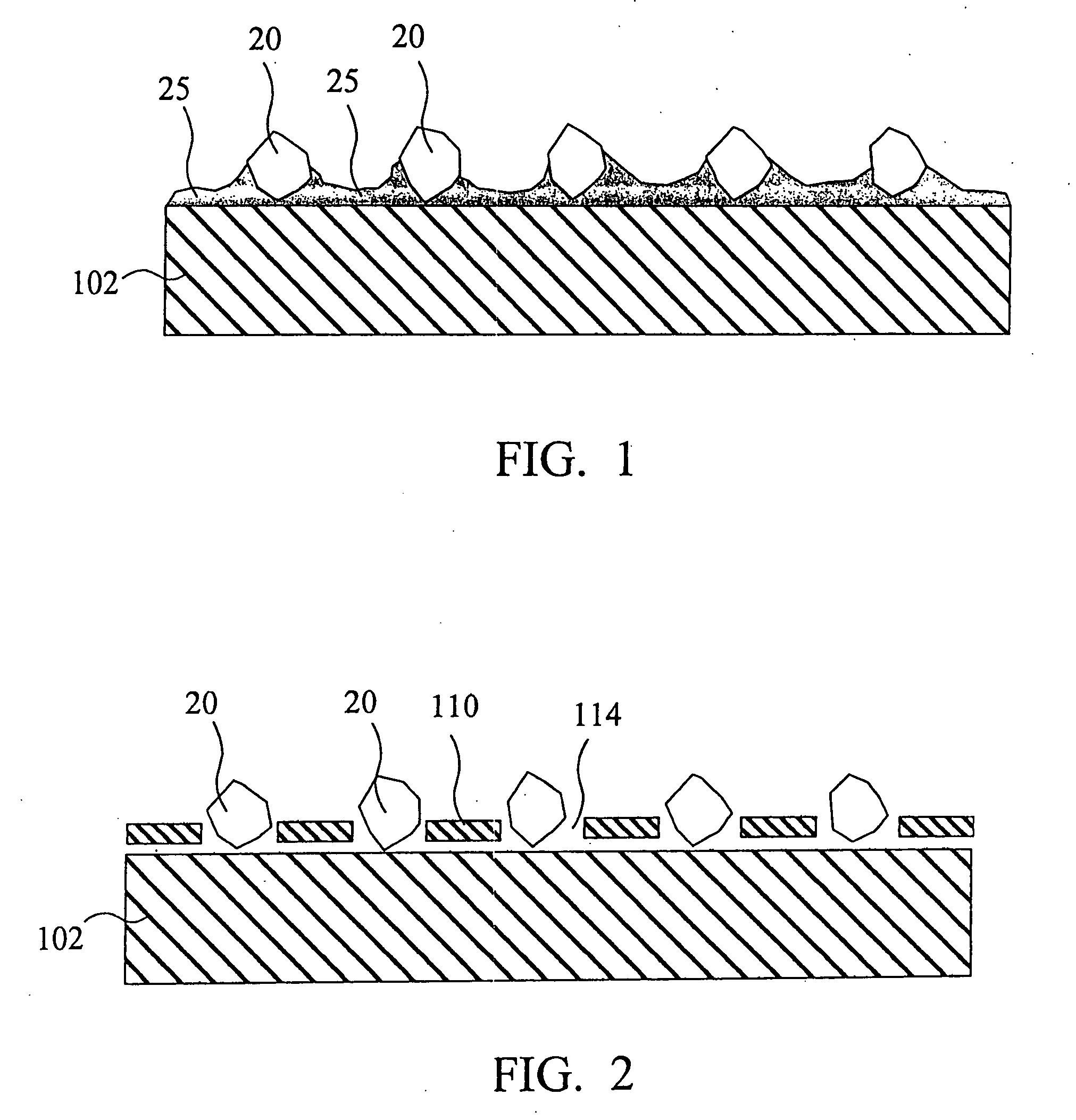

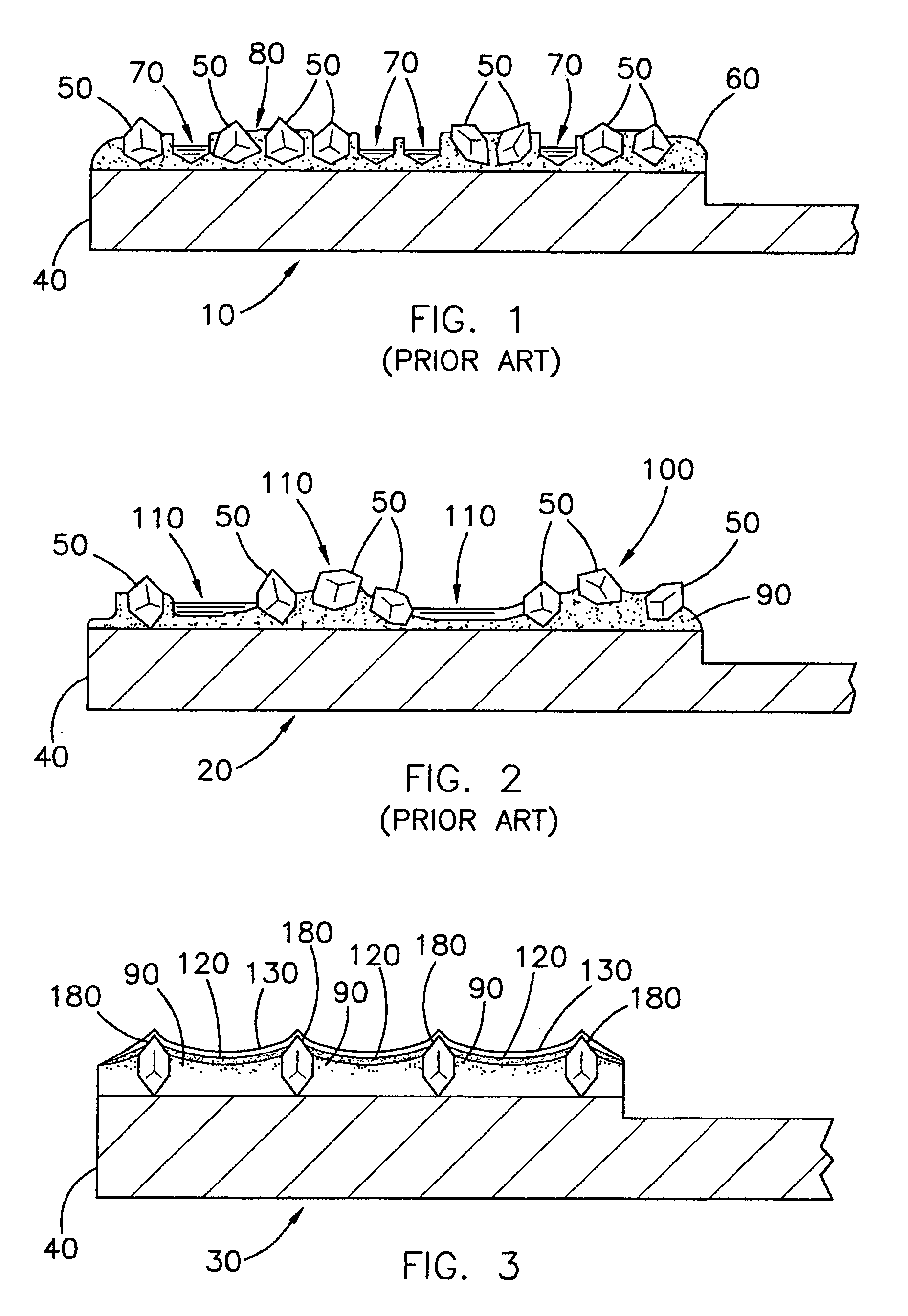

Conditioning tools and techniques for chemical mechanical planarization

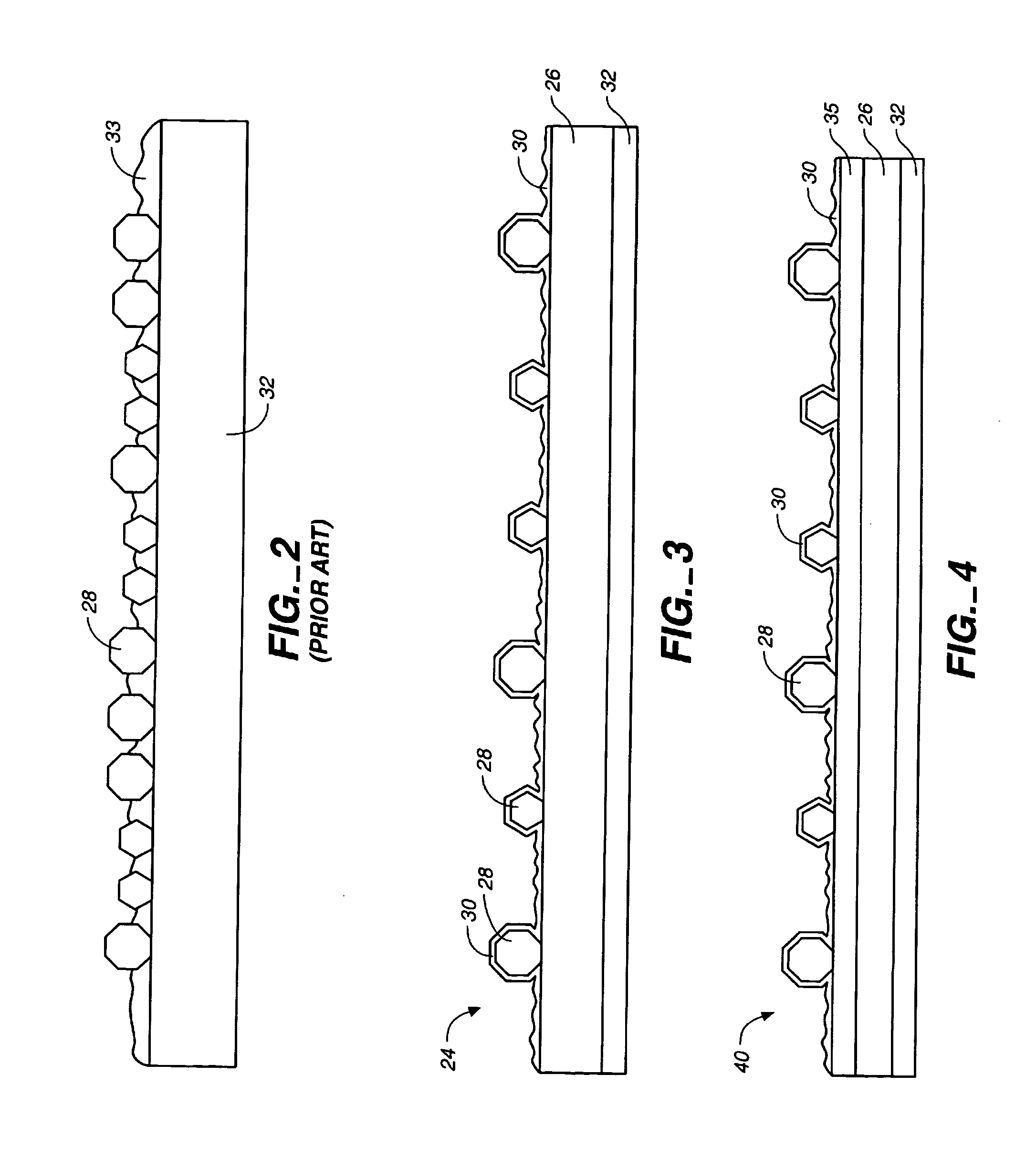

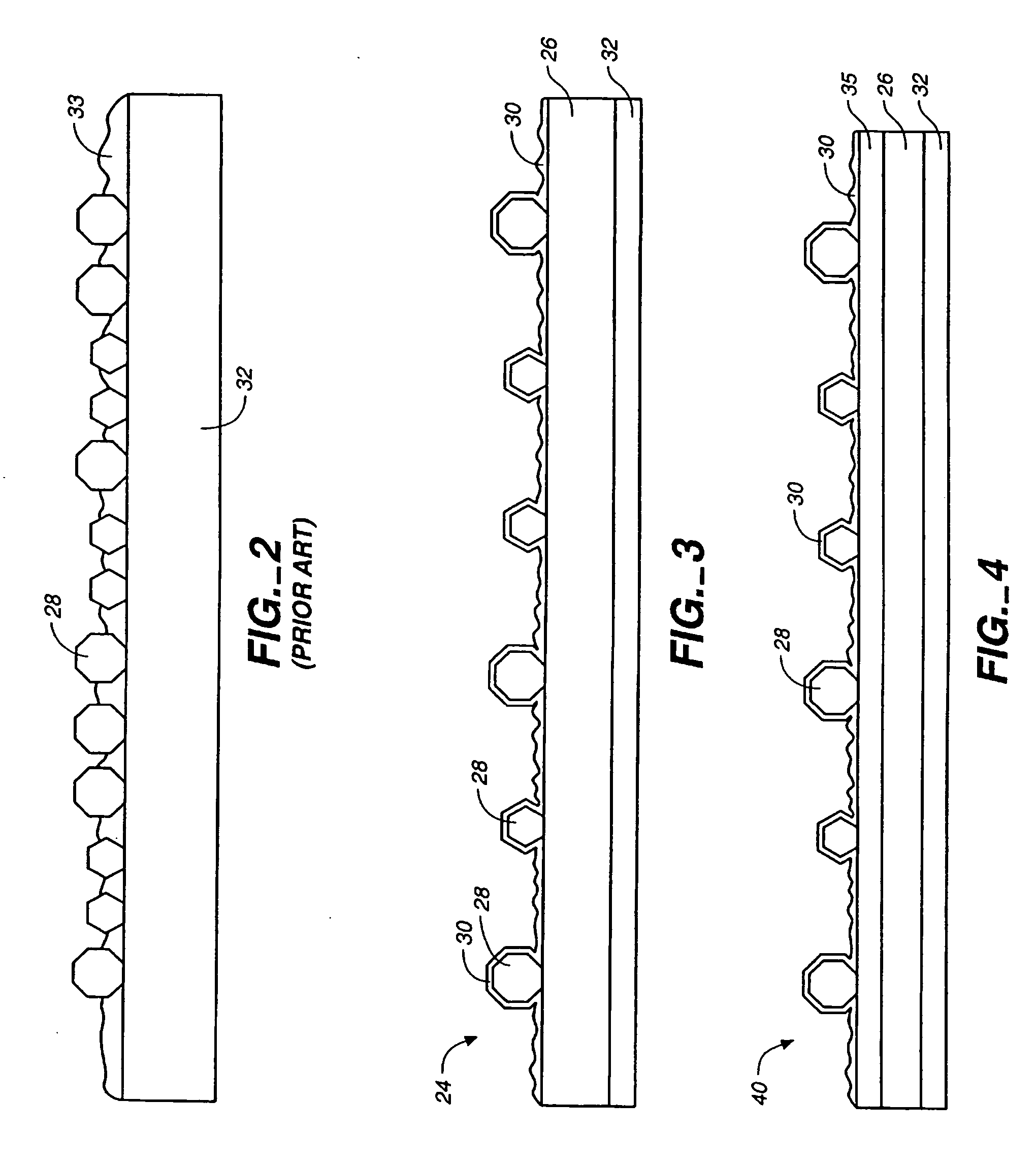

InactiveUS20080271384A1Reduce the overall heightPigmenting treatmentOther chemical processesCopperMetal

Tools for conditioning chemical mechanical planarization (CMP) pads comprise a substrate with abrasive particles coupled to at least one surface. The tools can have various particle and bond configurations. For instance, abrasive particles may be bonded (e.g., brazed or other metal bond technique) to one side, or to front and back sides. Alternatively, abrasive particles are bonded to a front side, and filler particles coupled to a back side. The abrasive particles can form a pattern (e.g., hexagonal) and have particle sizes that are sufficiently small to penetrate pores of a CMP pad during conditioning, leading to fewer defects on wafers polished with the conditioned CMP pad. Grain bonding can be accomplished using brazing films, although other metal bonds may be used as well. Also, balanced bond material (e.g., braze on both sides) allows for low out-of-flatness value.

Owner:SAINT GOBAIN ABRASIFS INC +1

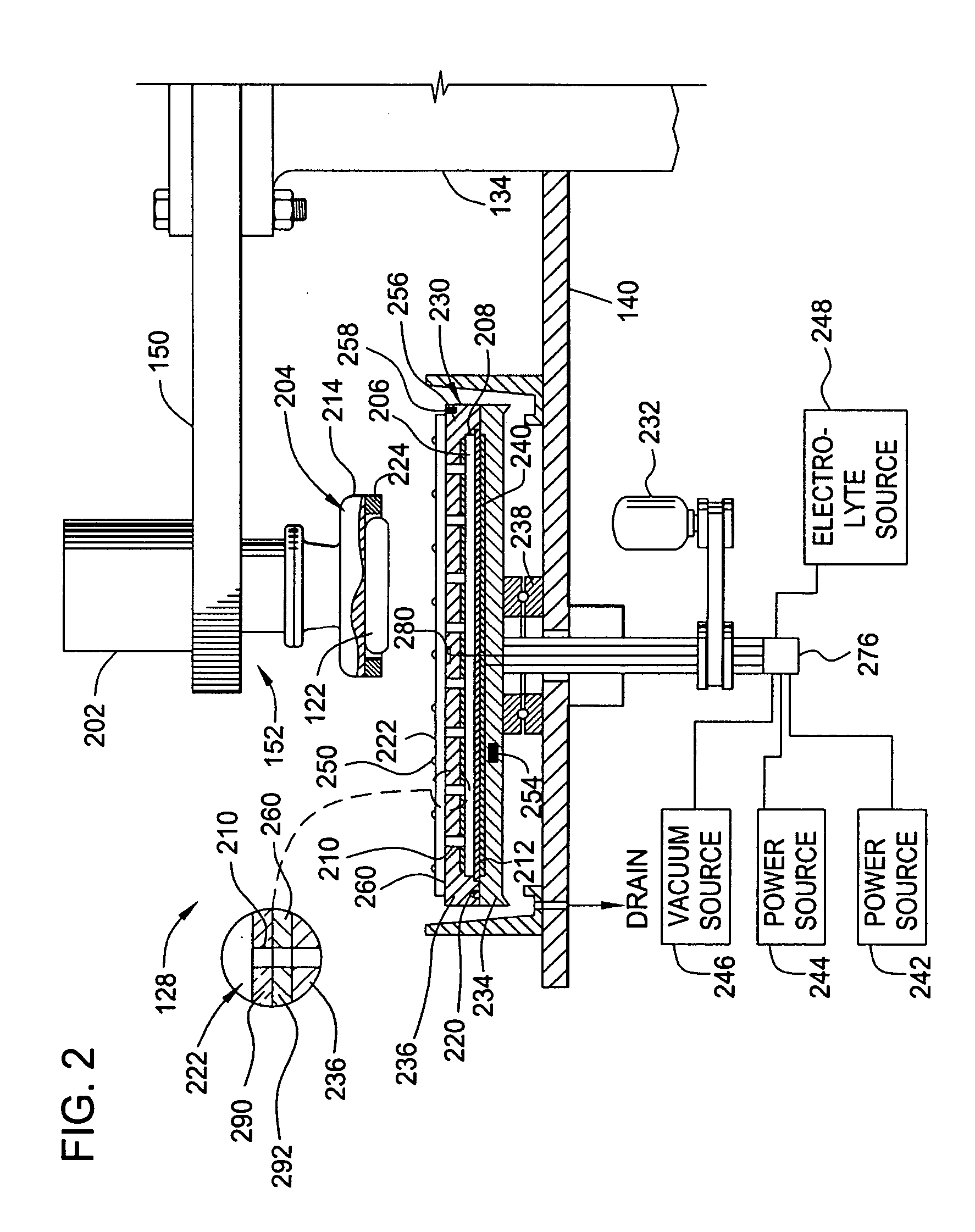

Method and apparatus for electrochemical mechanical processing

InactiveUS20050000801A1CellsSemiconductor/solid-state device manufacturingProcess chemistryEngineering

Embodiments of the invention generally provide a method and apparatus for processing a substrate in an electrochemical mechanical planarizing system. In one embodiment, a cell for polishing a substrate includes a processing pad disposed on a top surface of a platen assembly. A plurality of conductive elements are arranged in a spaced-apart relation across the upper planarizing surface and adapted to bias the substrate relative to an electrode disposed between the pad and the platen assembly. A plurality of passages are formed through the platen assembly between the top surface and a plenum defined within the platen assembly. In another embodiment, a system is provided having a bulk processing cell and a residual processing cell. The residual processing cell includes a biased conductive planarizing surface. In further embodiments, the conductive element is protected from attack by process chemistries.

Owner:APPLIED MATERIALS INC

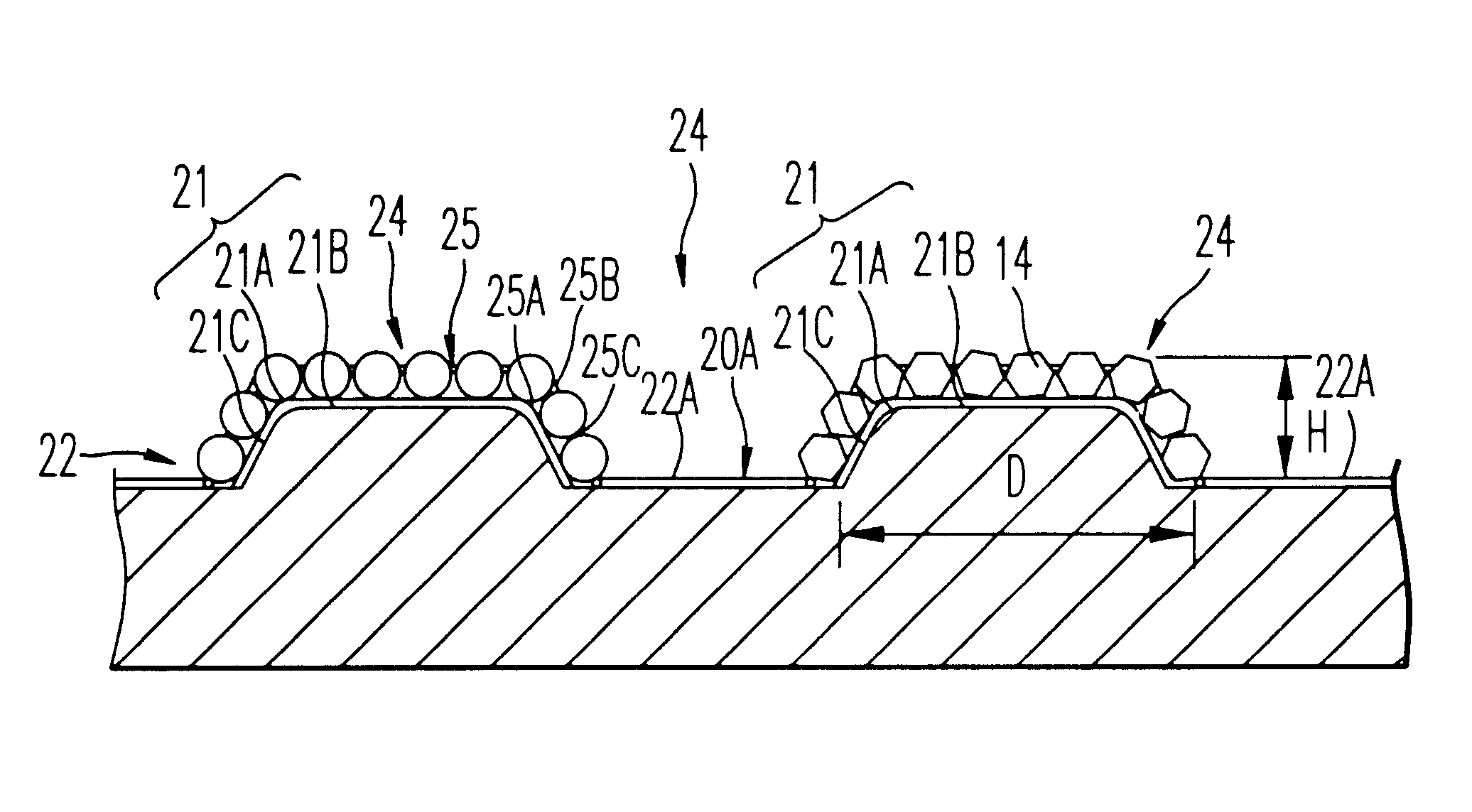

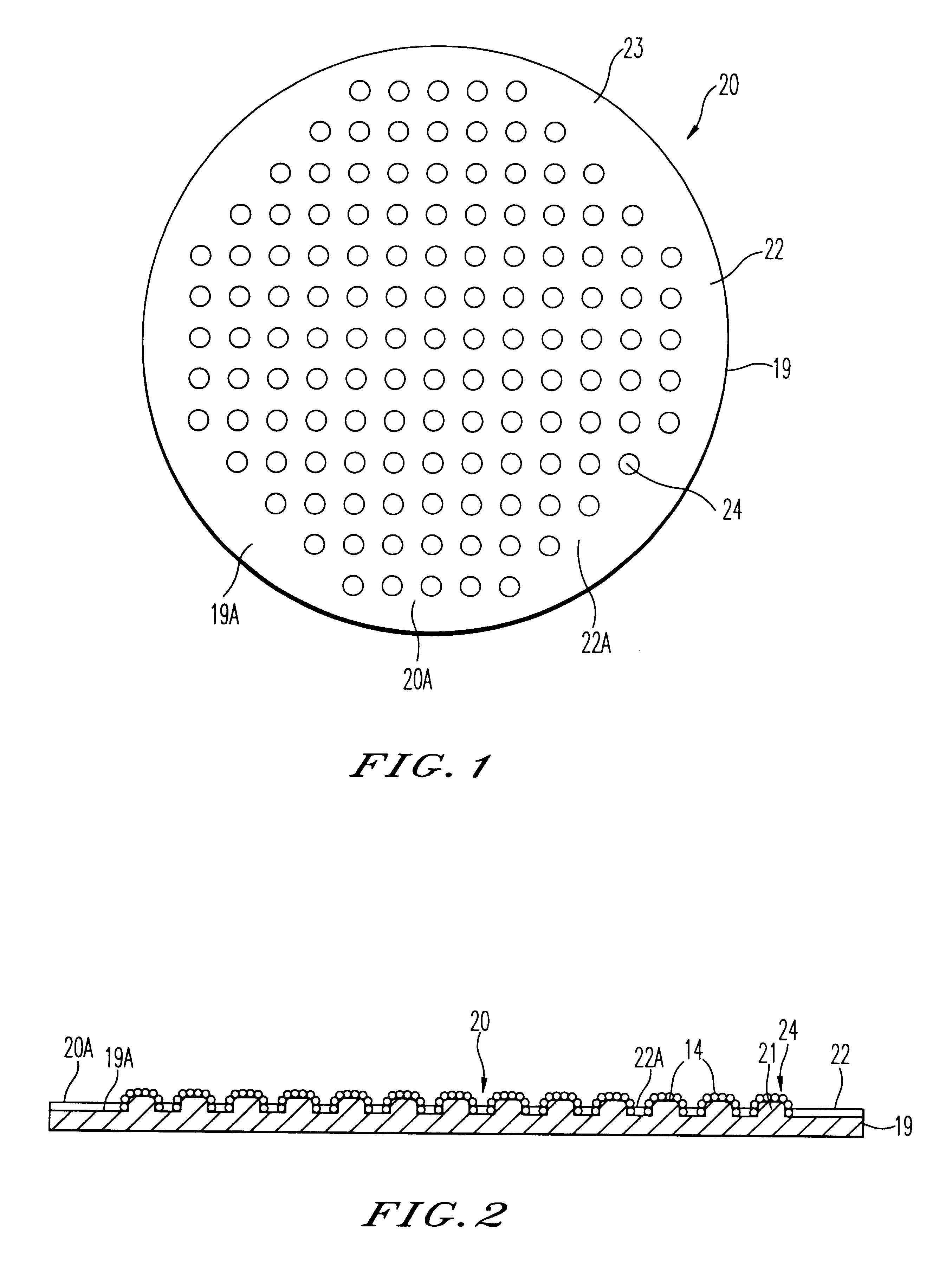

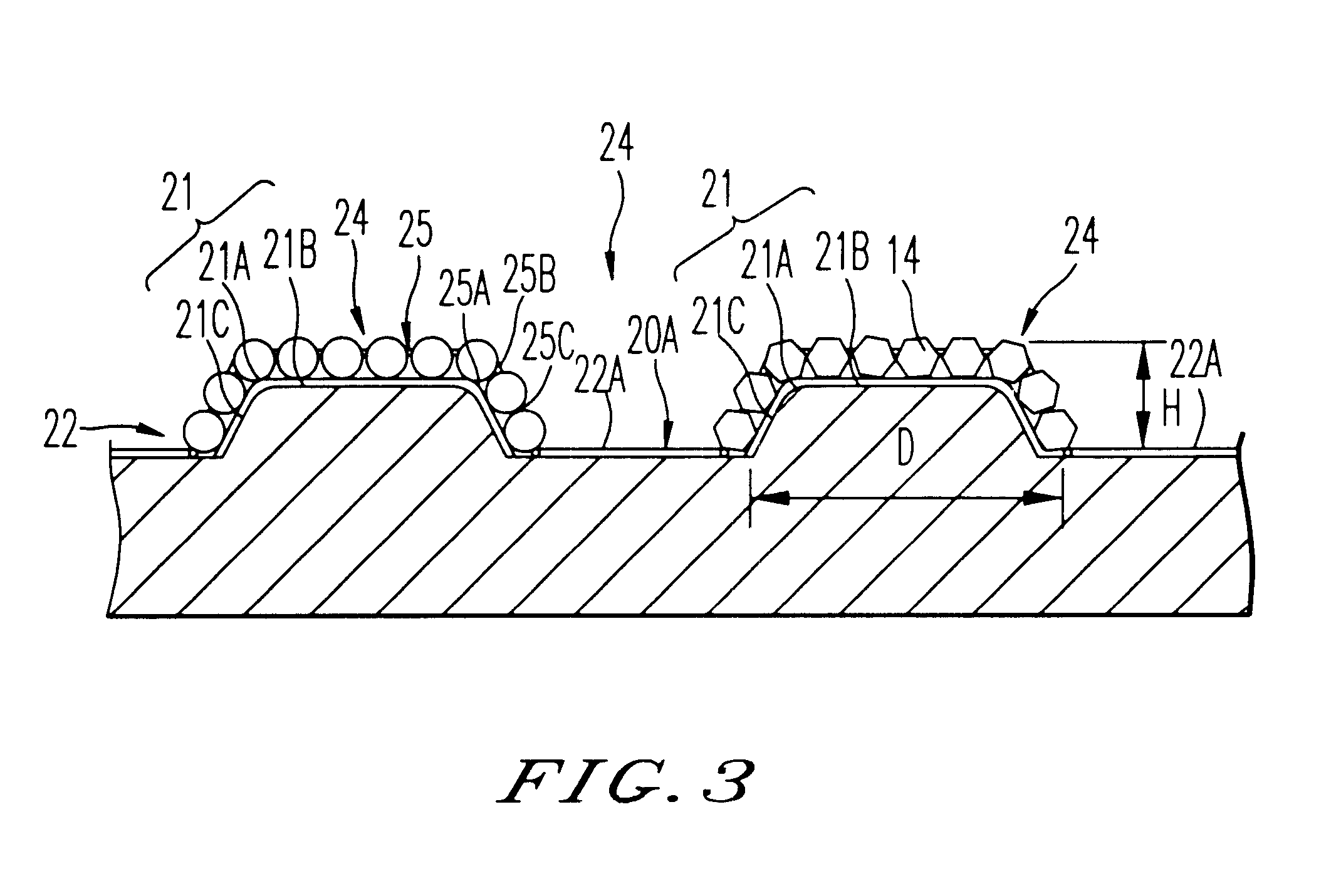

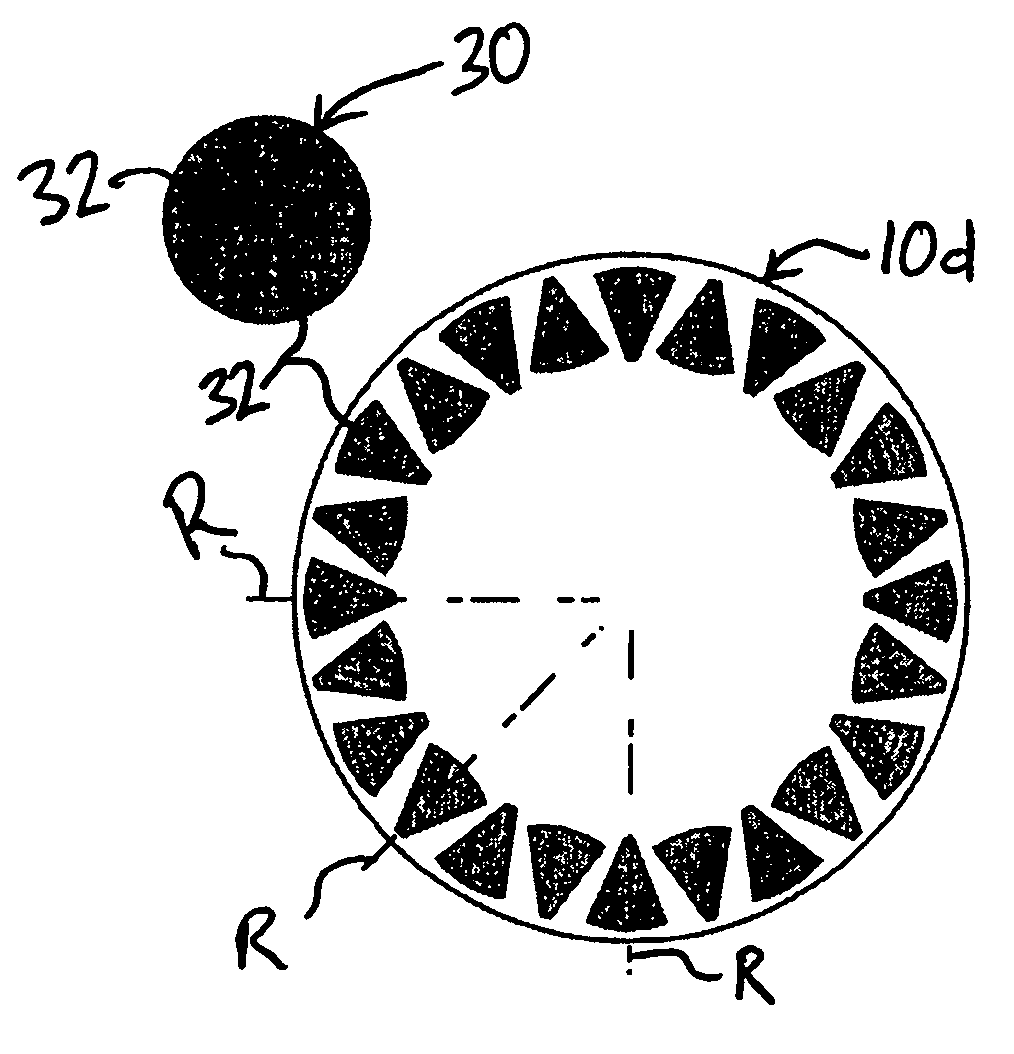

Abrasive tool with metal binder phase

InactiveUS6419574B1Sufficient sharpnessImprove discharge performanceRevolution surface grinding machinesGrinding drivesWear particleMetal

In the electrodeposited abrasive wheel 20 of the abrasive tool according to the present invention, plural mound parts 21, which are upheaved at the central domain of base metal 19 in almost columnar shape, are arranged mostly in the shape of lattice. An abrasive grain layer 22 is formed on a base metal 19, and plural ultra abrasive grains 14 are adhered only to each mound parts 21 by electrodeposited metal phase 25, and referred as the small abrasive-grain-layer parts 24, respectively. Ultra abrasive grains are laid out at corner R part 21a and top 21b of the mound parts 21 at the small abrasive-grain-layer parts 24. Ultra abrasive grains at each small abrasive-grain-layer parts are set as 11-500 pieces, and the rate which ultra abrasive grains occupy to the whole area of abrasive grain layer accounted by plane projection is set as 20%-80% of the range. At the time of grinding, only ultra abrasive grains contact to grinding work piece, then high abutment pressure is maintained, and sharpness and the discharge performance of ground wastes are good.

Owner:MITSUBISHI MATERIALS CORP

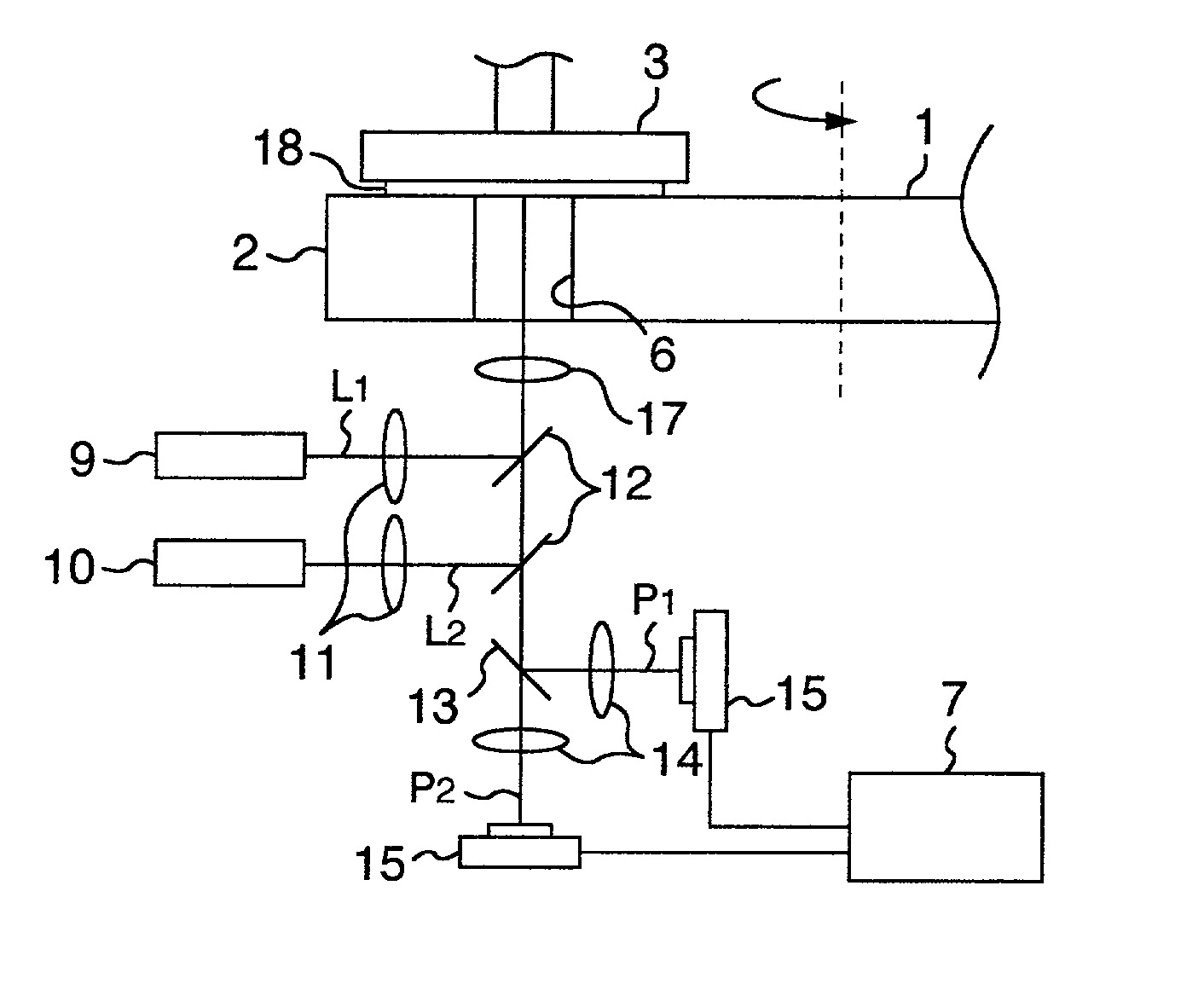

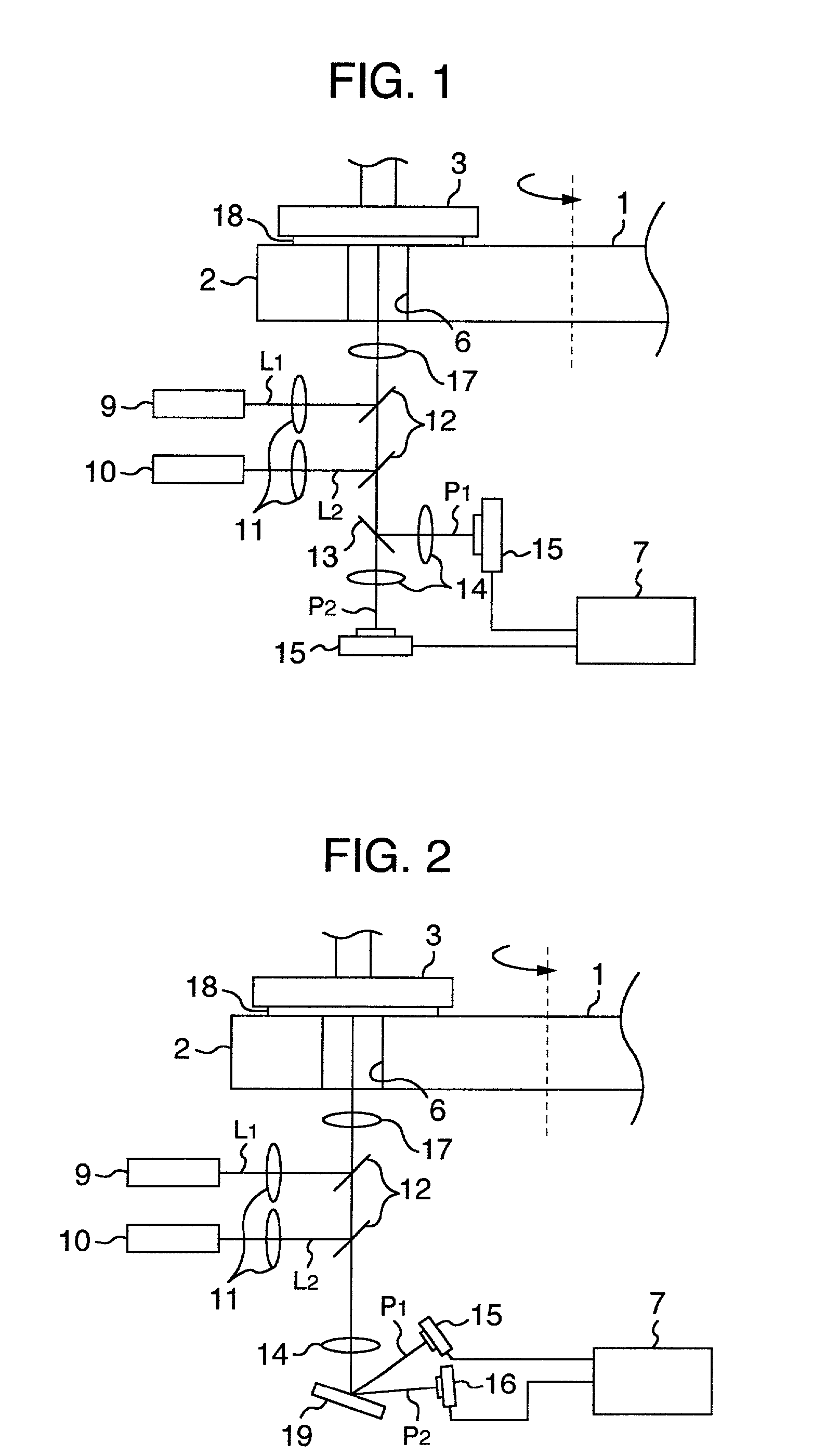

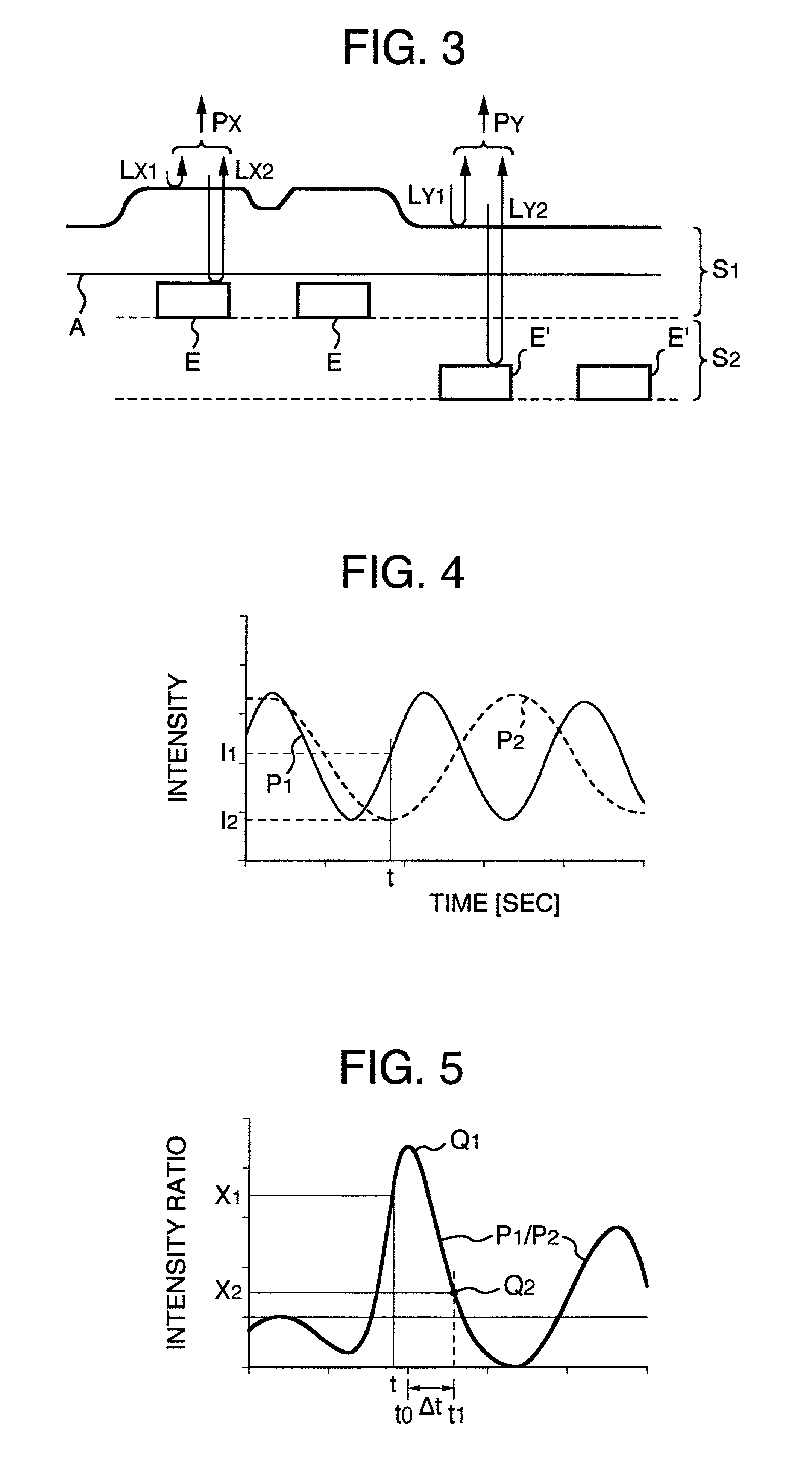

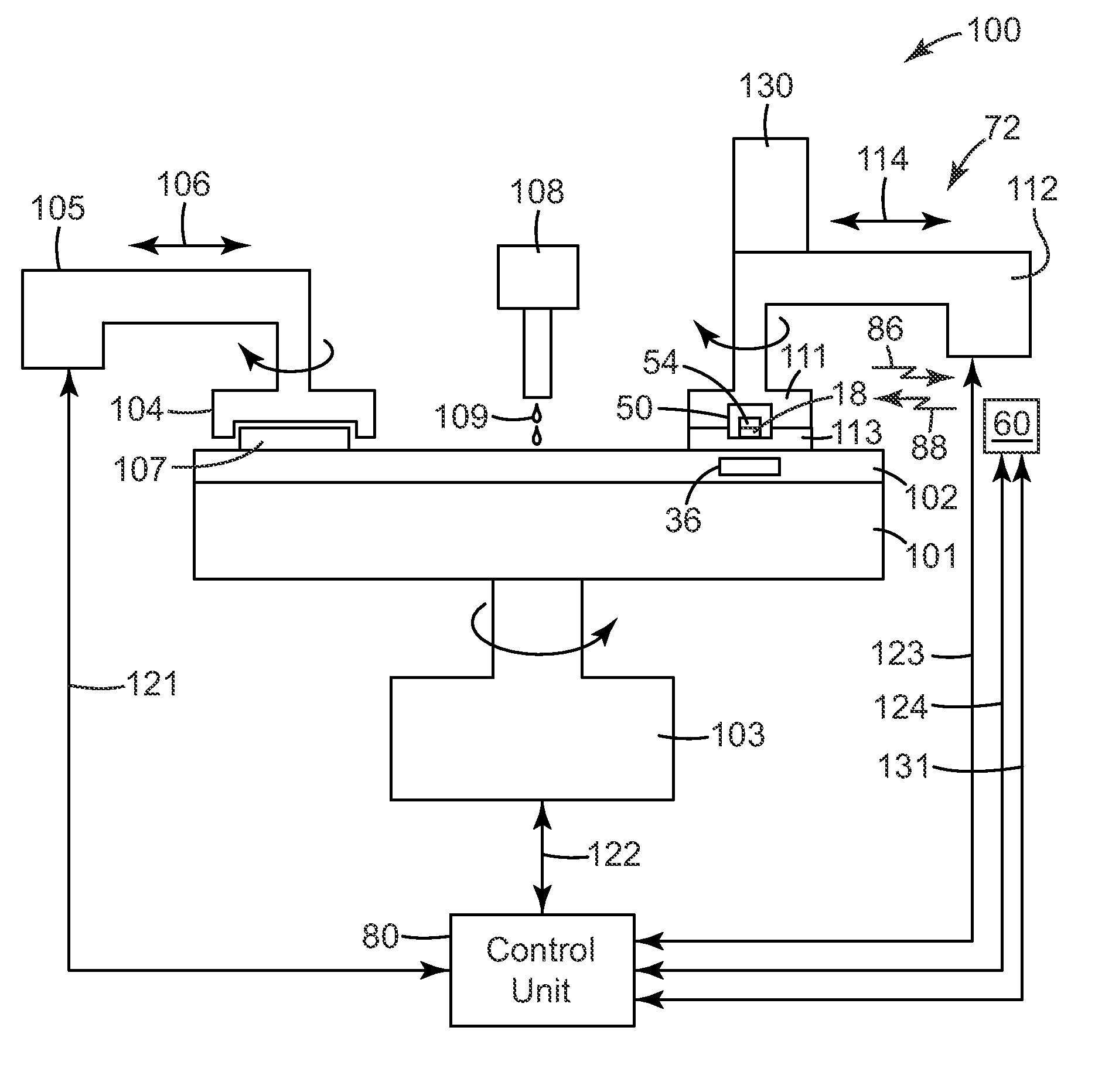

Method of detecting and measuring endpoint of polishing processing and its apparatus and method of manufacturing semiconductor device using the same

InactiveUS20020127950A1Improve accuracyImprove throughputSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device manufacturingBeam splitterLaser light

Laser sources output laser lights L.sub.1 and L.sub.2 having different wavelengths so as to increase an accuracy of an endpoint detection of polishing processing by enabling an accurate detection of a film thickness of a layer insulating film on a surface of a wafer to be polished by the CMP processing, the lights are emitted from a detection window via a beam splitter to the layer insulating film formed on the surface of the wafer to be polished by a pad, different optical detectors detect interference lights corresponding to the laser lights L.sub.1 and L.sub.2 reflected and generated from a surface of the layer insulating film and a pattern under the surface via the detection window, the beam splitter, and a dichroic mirror, the detection results are supplied to a film thickness evaluation unit 7, a film thickness of the layer insulation film is detected on the basis of a relationship between intensities of the reflected interference lights to the laser lights L.sub.1 and L.sub.2 or the intensity ratio, and an endpoint of polishing processing is determined when the film thickness is equal to a predetermined value.

Owner:HITACHI LTD

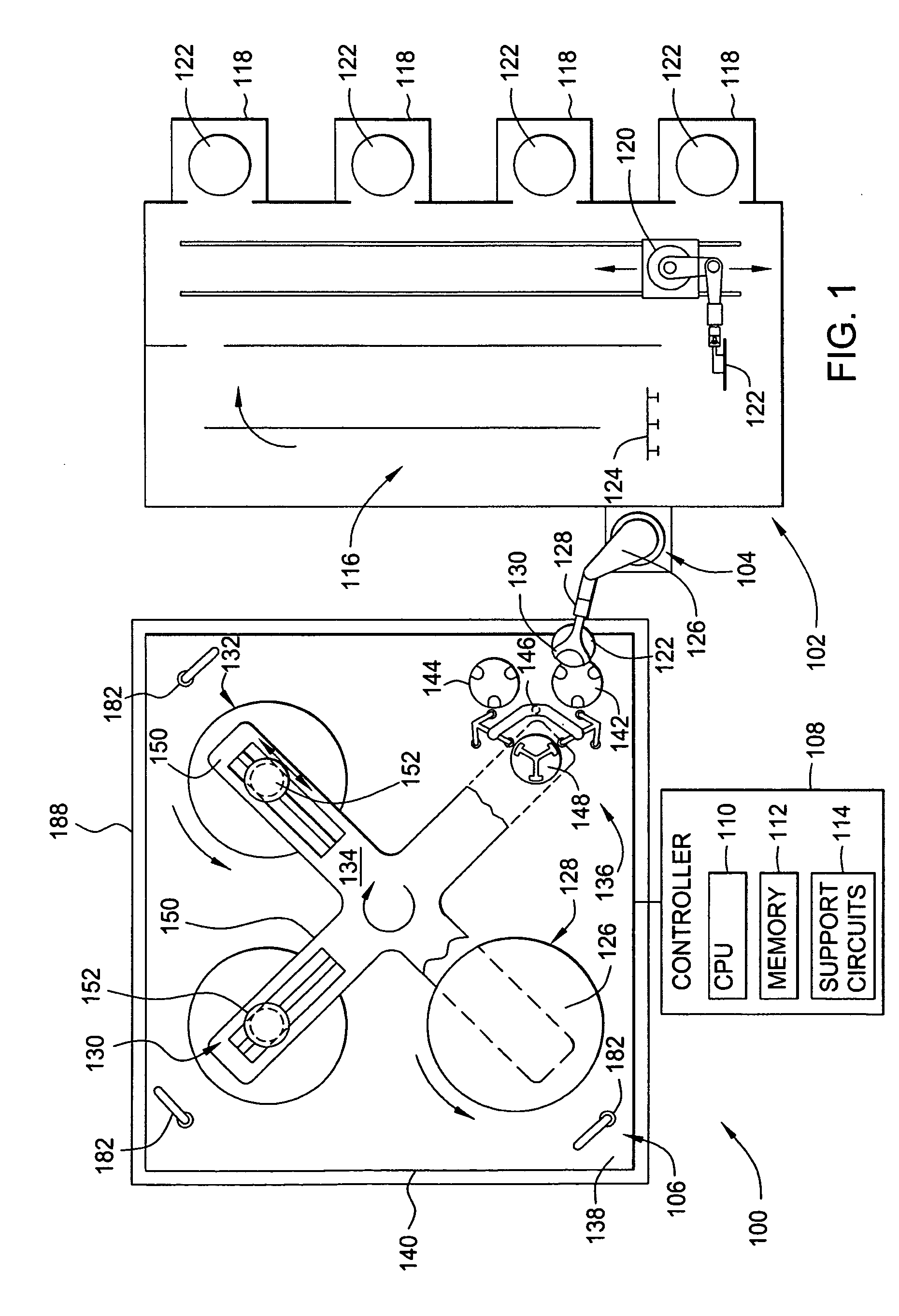

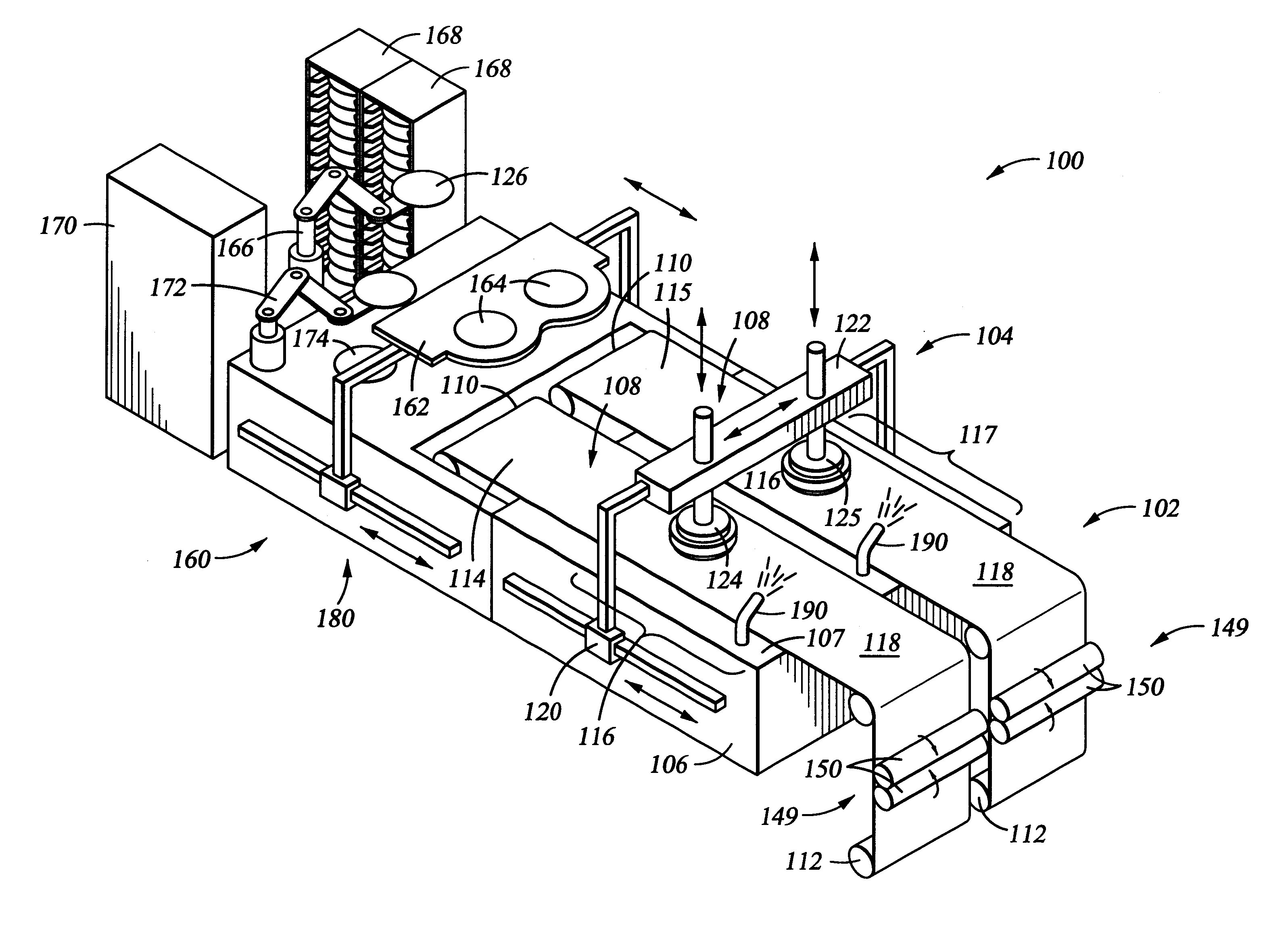

Planarization system with multiple polishing pads

InactiveUS6626744B1Edge grinding machinesPolishing machinesElectrical and Electronics engineeringHead position

An apparatus for simultaneously polishing wafers including at least a first and a second web of polishing media. At least two polishing heads are provided on a carrier coupled to a drive system such that one polishing head positions a wafer against the first web and a second polishing head positions a second wafer against the second web. The drive system imparts a programmed polishing motion or pattern to the polishing heads.

Owner:APPLIED MATERIALS INC

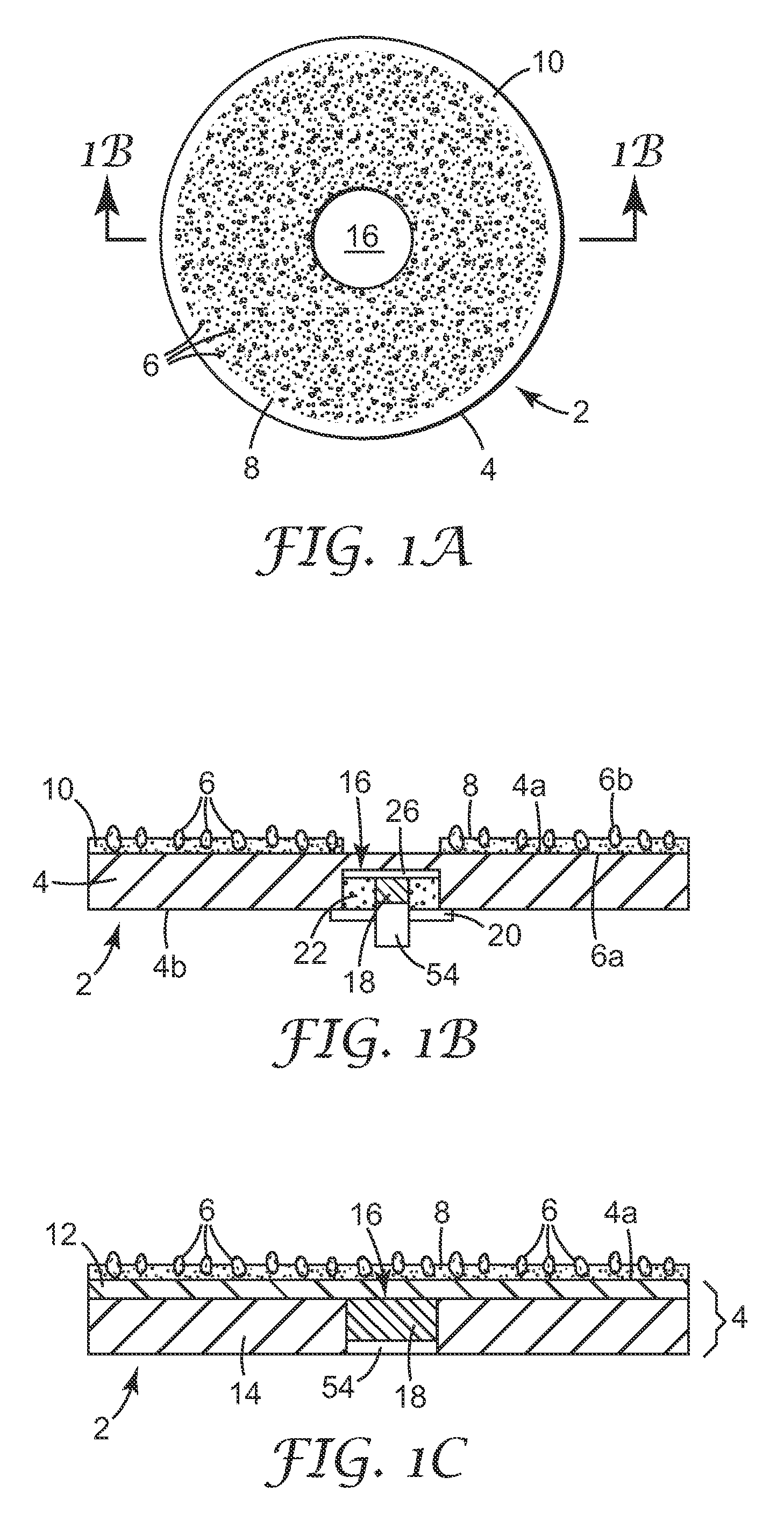

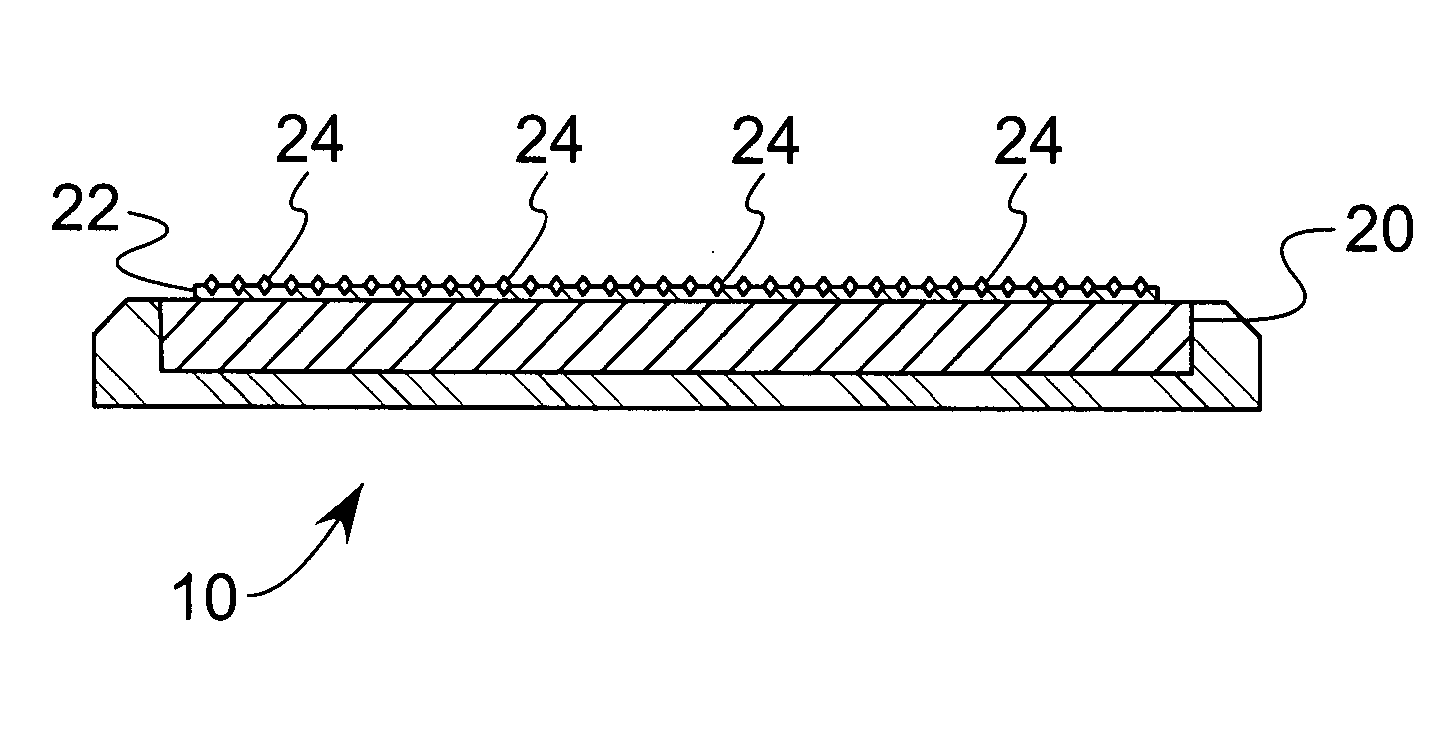

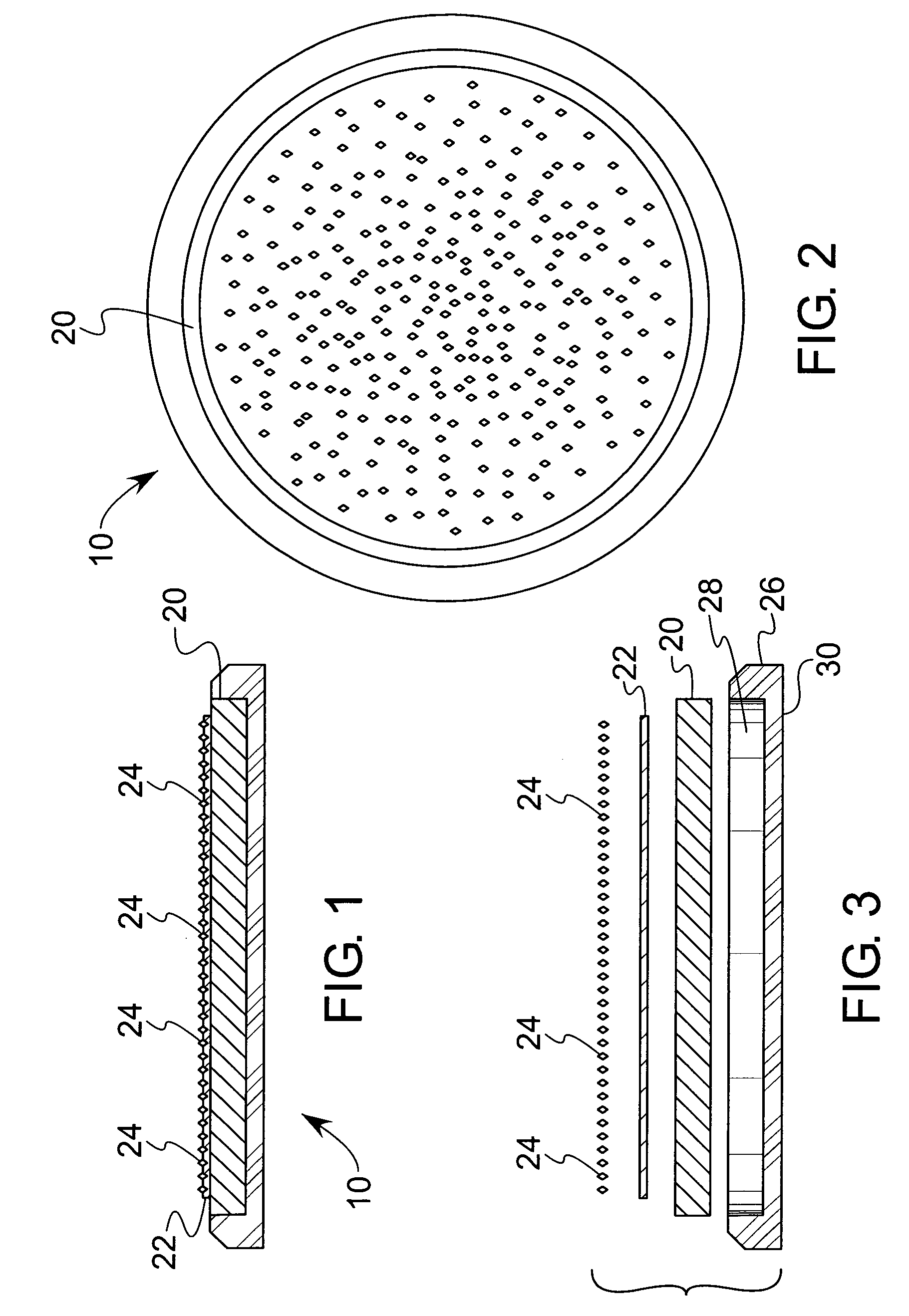

Abrasive articles, CMP monitoring system and method

ActiveUS7840305B2Easy to operate the machineAvoid damageGrinding drivesBelt grinding machinesMonitoring systemEngineering

The disclosure relates to abrasive articles useful in chemical-mechanical polishing (CMP), the articles including a substrate with opposite major surfaces, an abrasive material overlaying at least a portion of at least one of the major surfaces, and at least one of a radio frequency identification (RFID) tag, a RFID tag reader, or a sensor for providing CMP information to a transmitter positioned near the substrate, the transmitter positioned near the substrate and adapted to wirelessly receive CMP information and wirelessly transmit the CMP information to a remote receiver. The disclosure also relates to a CMP pad conditioner for wirelessly communicating CMP information to a remote receiver, a CMP process monitoring system for wirelessly communicating CMP information to a remote receiver, and a method for conditioning a CMP pad using a CMP process monitoring system for wireless communicating CMP information to a remote receiver.

Owner:3M INNOVATIVE PROPERTIES CO

CMP diamond conditioning disk

A method of making and the resulting non-metallic CMP conditioning pad comprising a non-metallic substrate and a single layer of abrasive particles bonded to the substrate by a non-metallic bonding medium. Preferred substrates include aluminum oxide and graphite. A bonding system employing finely powdered aluminum oxide particles mixed with a suitable adhesive is employed to bond the abrasive layer to the aluminum oxide substrate. Silicon carbide particles mixed into a compatible adhesive carrier including a polymer composition is preferred for bonding the abrasive particle layer to a graphite or carbide substrate.

Owner:ABRASIVE TECH

CVD diamond-coated composite substrate containing a carbide-forming material and ceramic phases and method for making same

InactiveUS20050276979A1Improve adhesionLow costLiquid surface applicatorsEngine sealsReaction bonded silicon carbideComposite substrate

The present invention relates to a composite material and the method of making same ,which comprises a CVD diamond coating applied to a composite substrate of ceramic material and an unreacted carbide-forming material of various configurations and for a variety of applications. One example of the composite material is a composite of SiC and free silicon metal known as Reaction-Bonded Silicon Carbide. Several examples of applications of the invention include: 1) heads or disks for conditioning polishing pads, including pads used in Cheniical-Mechanical-Planarization, 2) cutting and dressing tool inserts and tips, 3) heat spreaders for electronic devices, and 4) wear components including mechanical seals and pump seals.

Owner:BEST ENGINEERED SURFACE TECH LLC

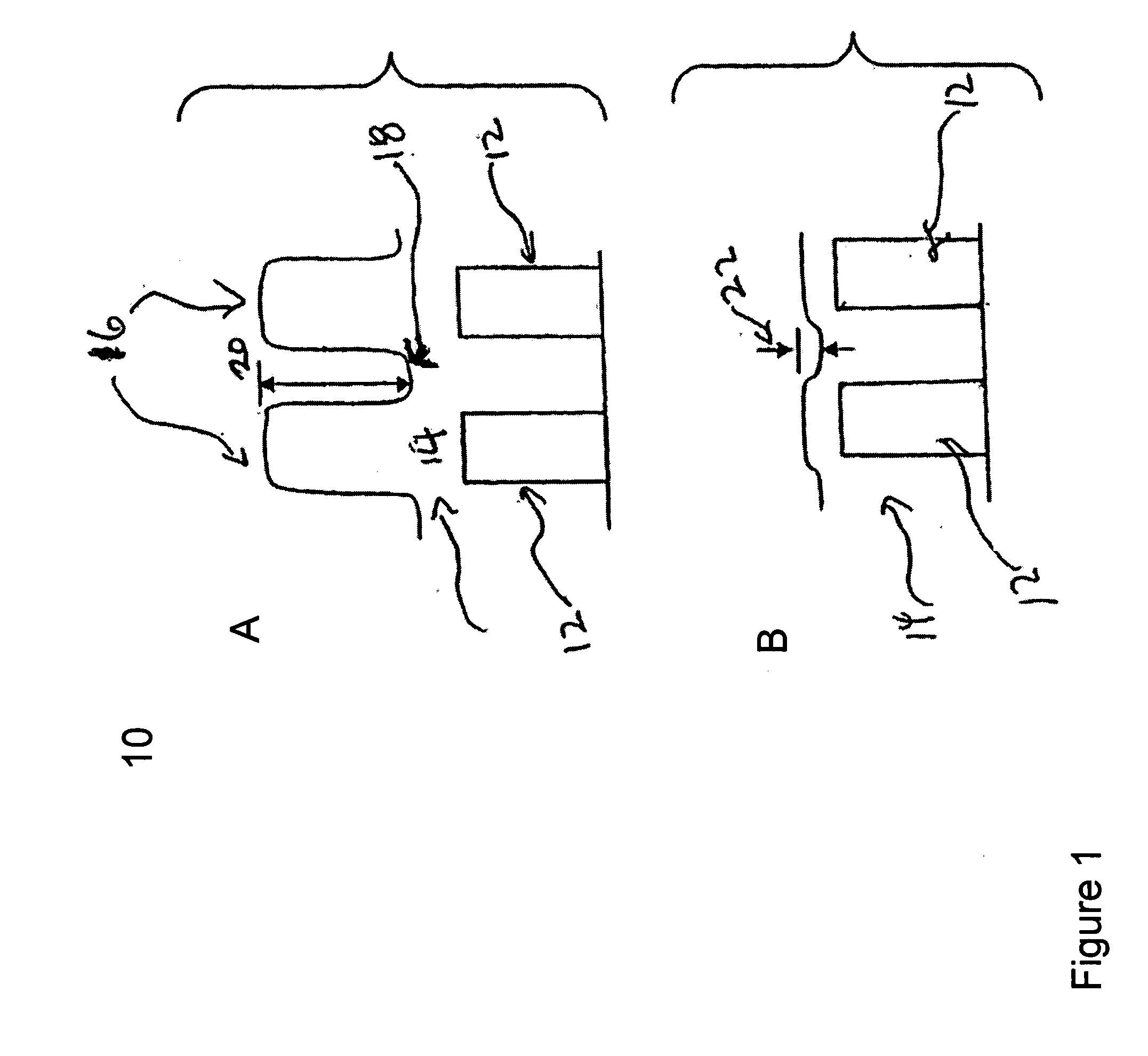

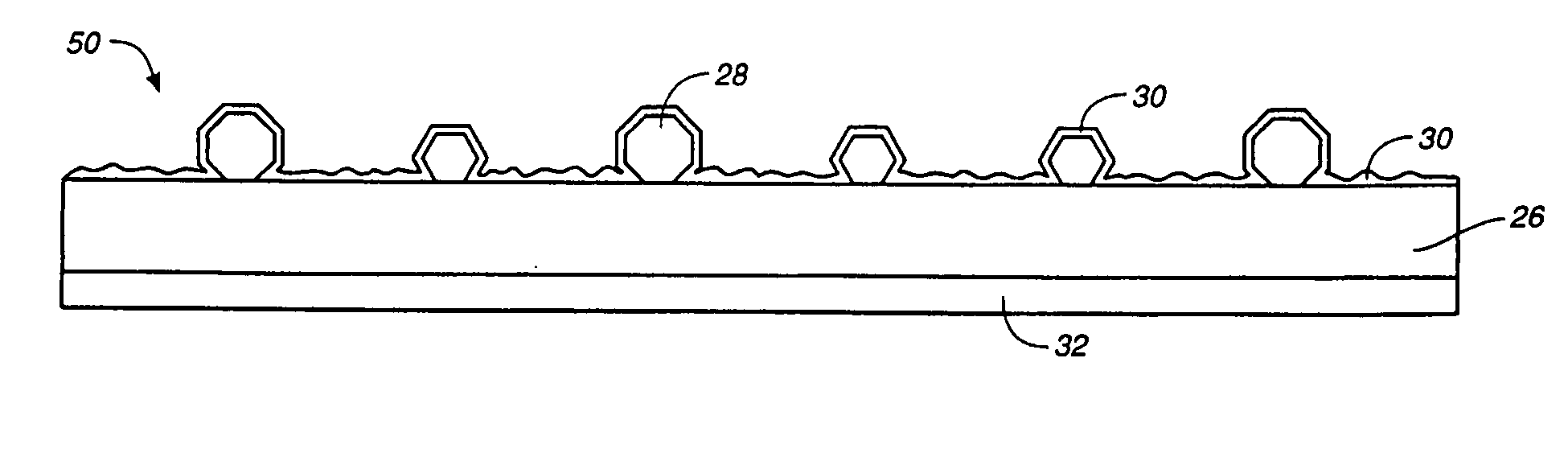

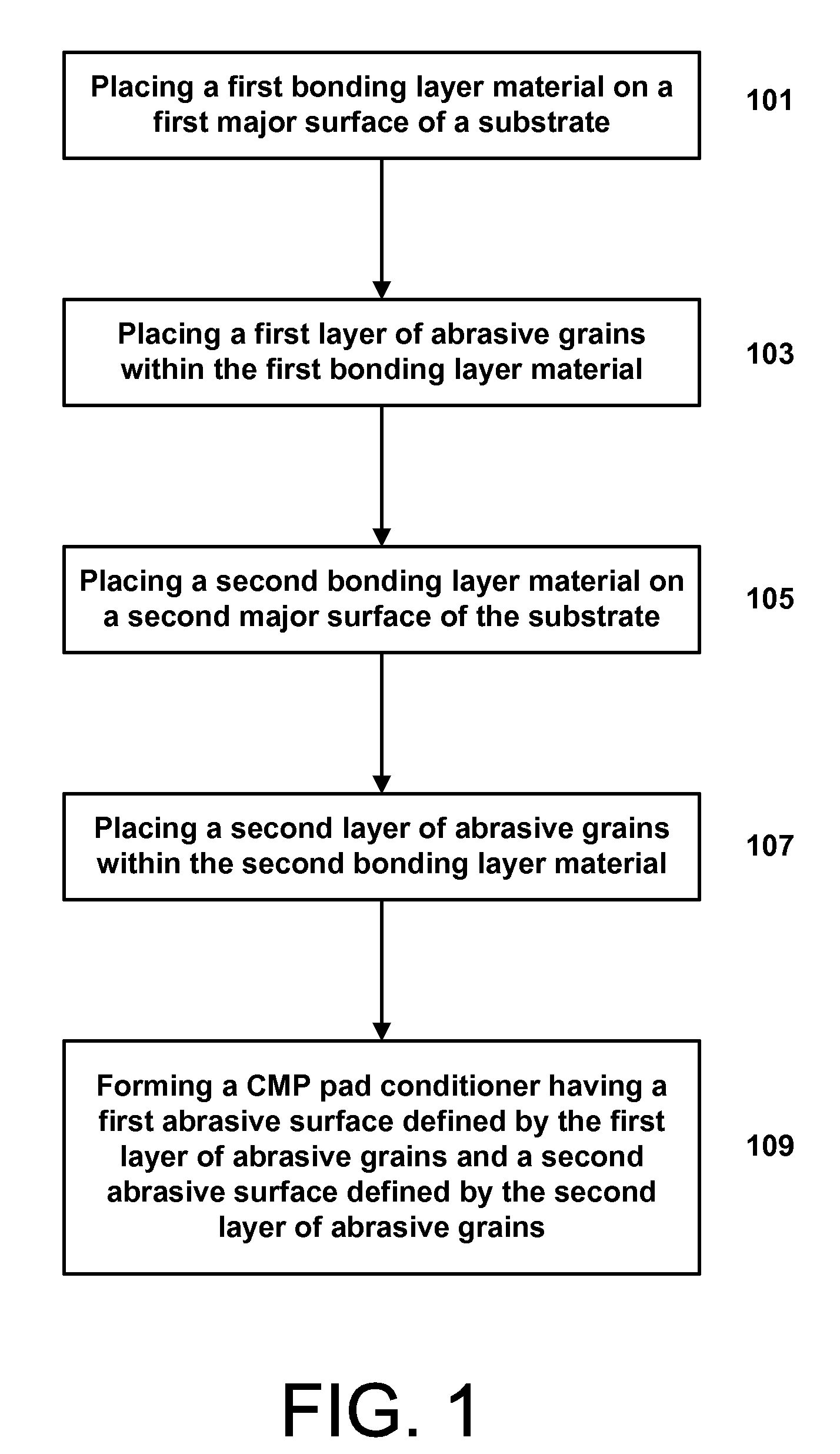

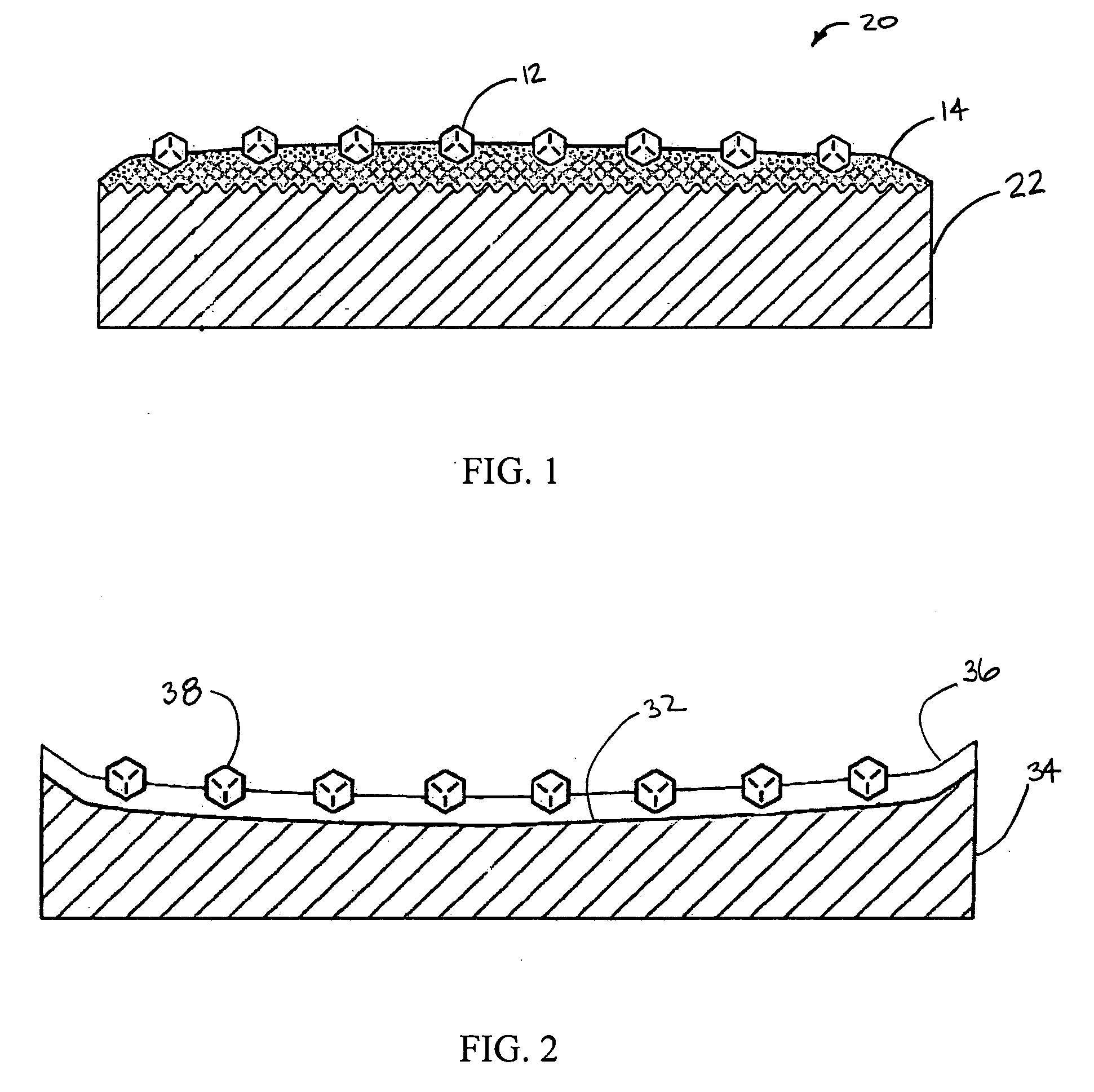

Abrasive tool for use as a chemical mechanical planarization pad conditioner

An abrasive tool including a CMP pad conditioner having a substrate including a first major surface, a second major surface opposite the first major surface, and a side surface extending between the first major surface and the second major, wherein a first layer of abrasive grains is attached to the first major surface and a second layer of abrasive grains is attached to the second major surface. The conditioner further includes a first sealing member extending in a peripheral direction along a portion of the side surface of the substrate.

Owner:SAINT GOBAIN ABRASIVES INC +1

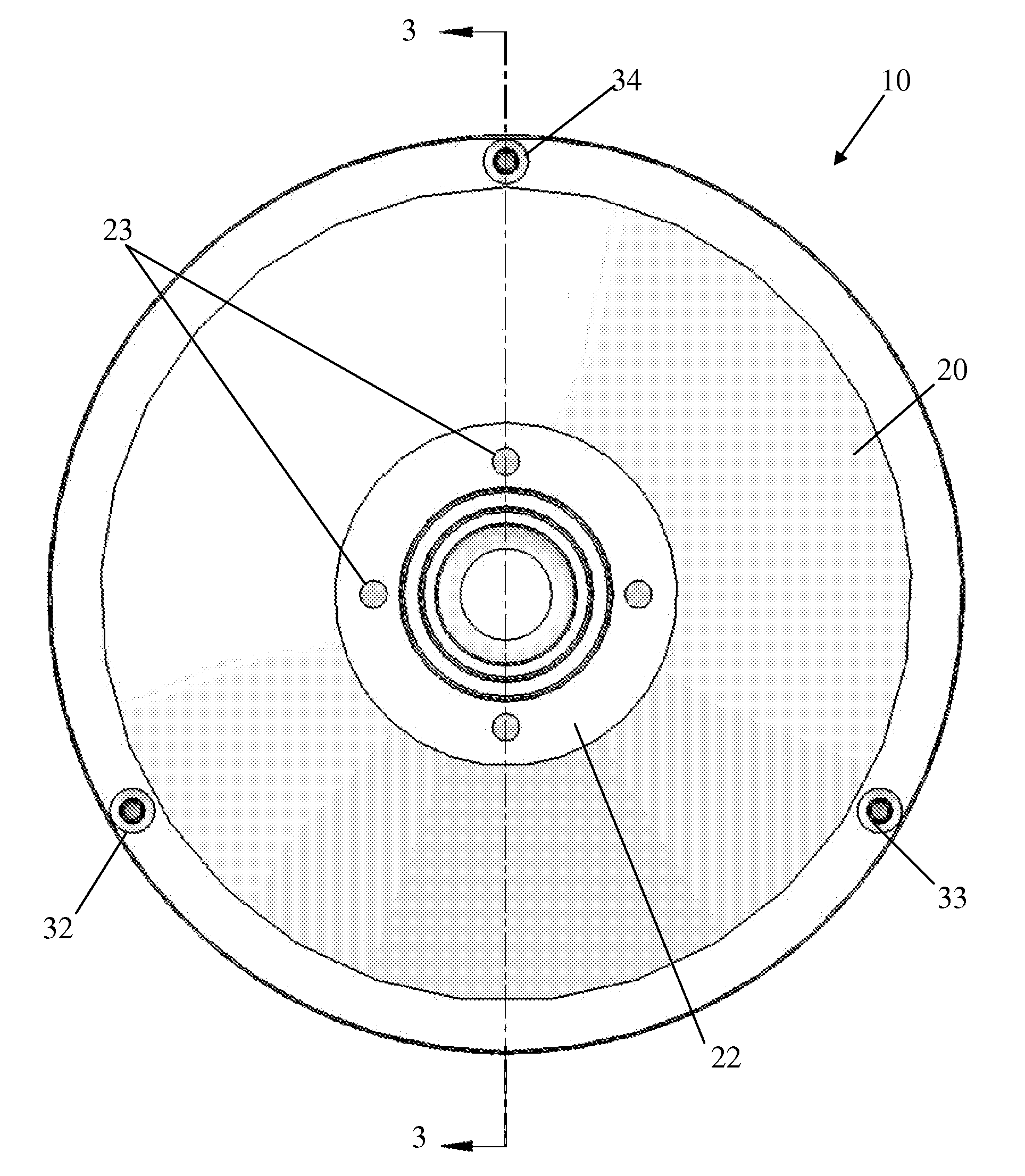

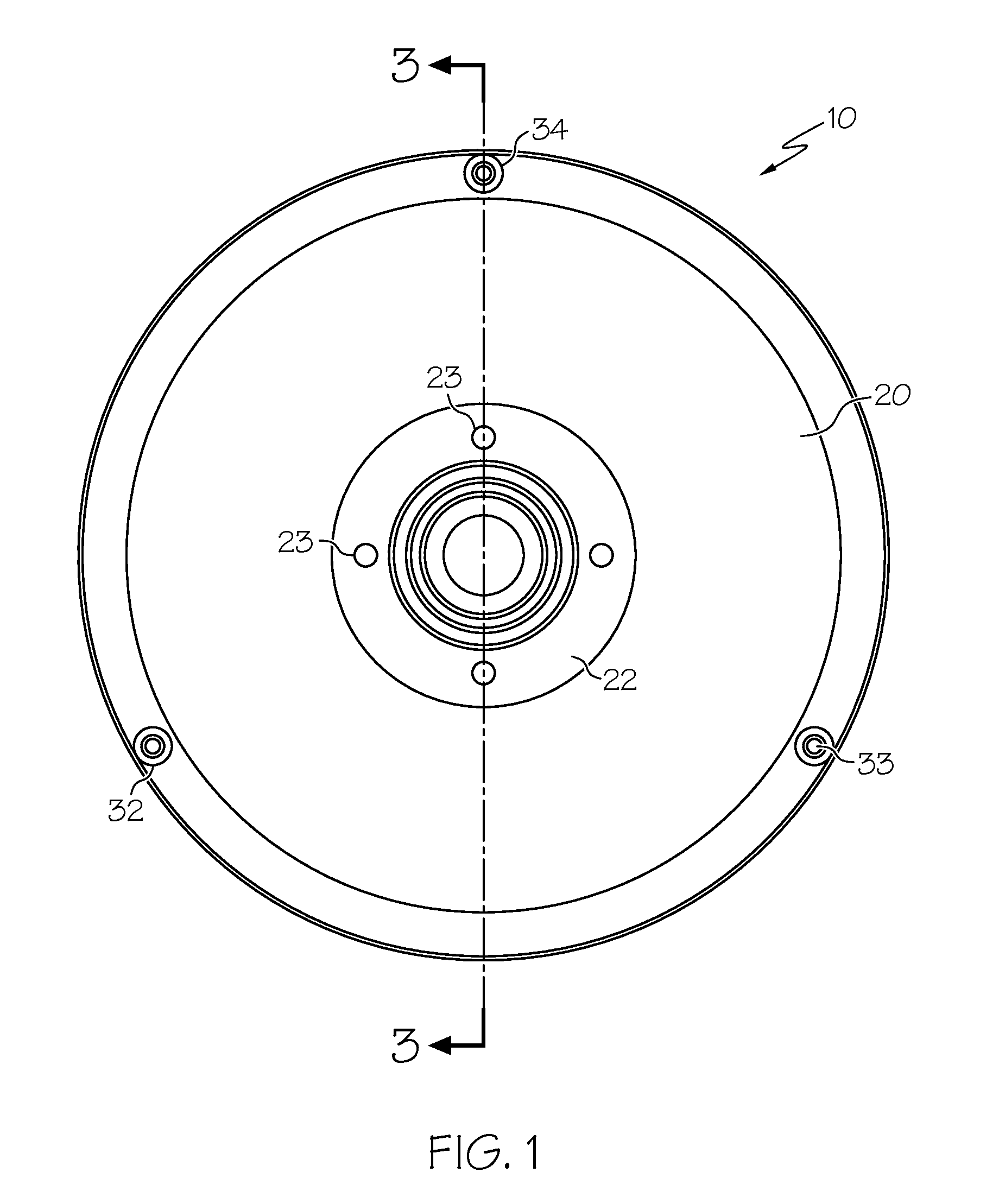

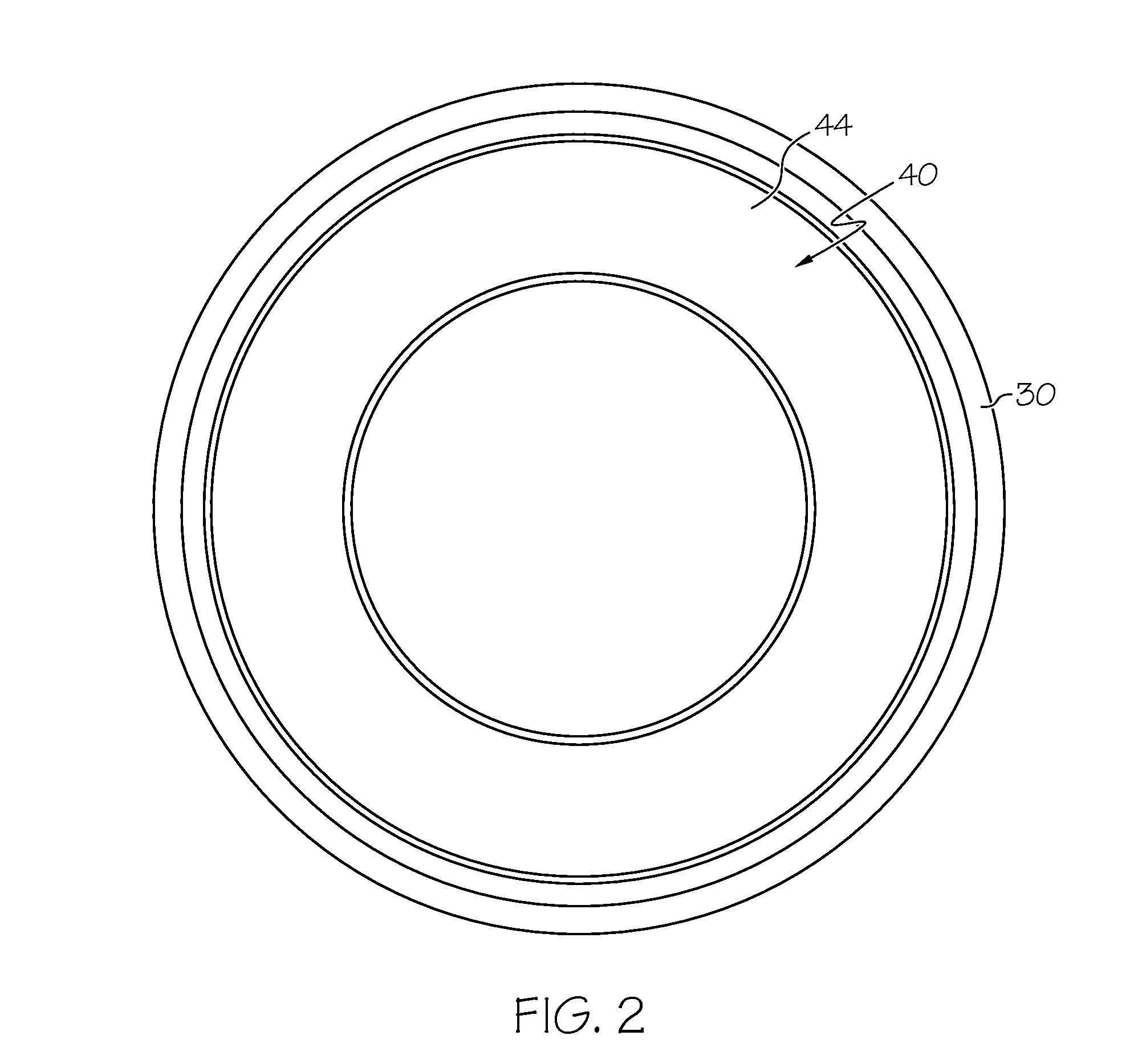

Multiple-sided cmp pad conditioning disk

InactiveUS20110097977A1Efficiently provideGrinding drivesBelt grinding machinesEngineeringMechanical engineering

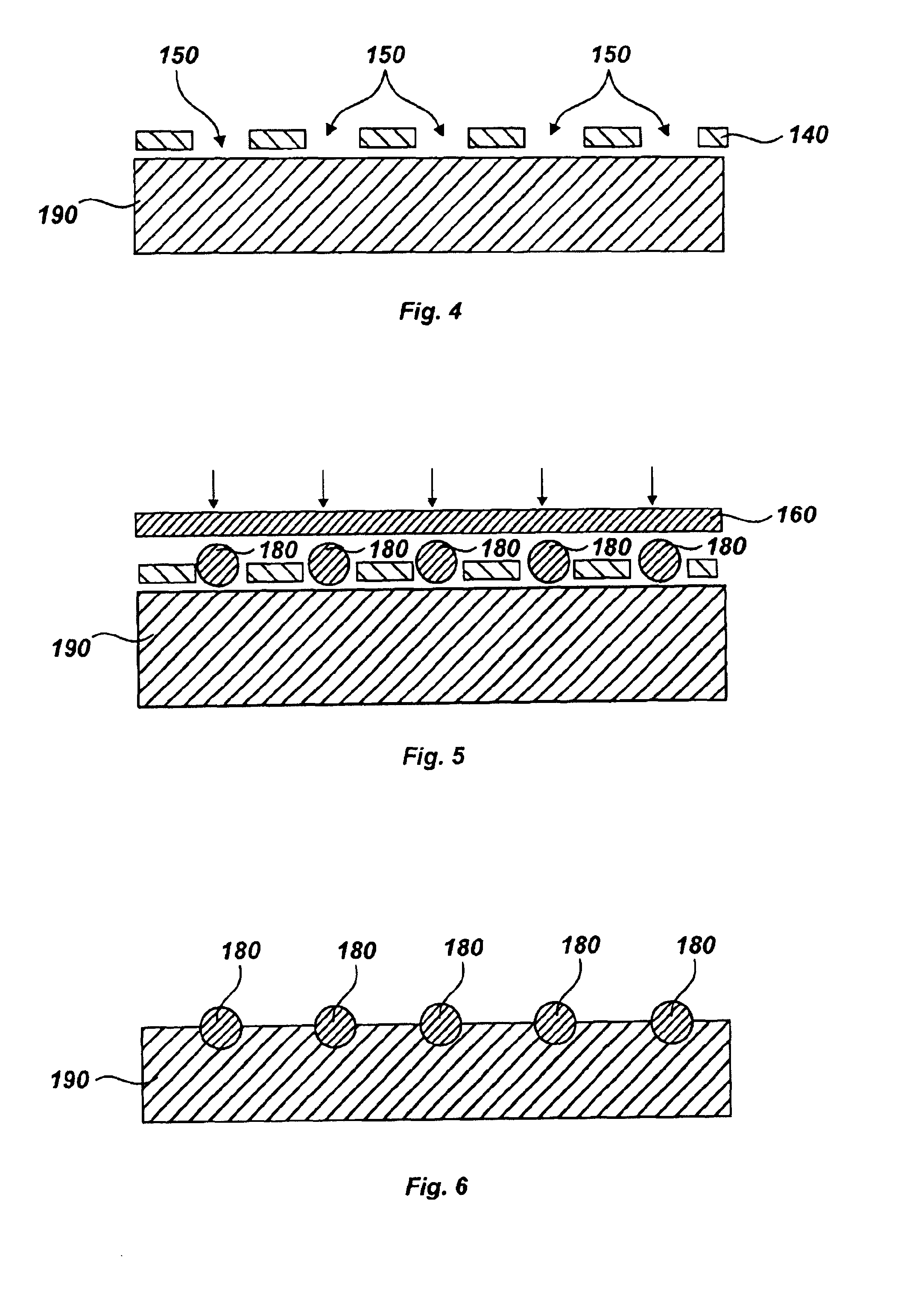

A conditioning tool for restoring a used CMP polishing pad to an operable condition. The tool includes a base that attaches to a driven machine and has a surface from which a shoulder protrudes that receives a peripheral edge of a disk. The disk has two opposing surfaces, each of which is substantially planar and has abrasive mounted thereon. The disk's peripheral edge is held in place between the base shoulder and a ring that has a shoulder that is complementary to the disk's peripheral edge. The ring is fastened to the base with the abrasive of the first disk surface protruding through an aperture in the ring, and the opposing disk surface spaced from the base's surface. After the disk's first surface is worn, the disk can be turned around to expose the opposite surface's abrasive to a CMP pad.

Owner:ABRASIVE TECH

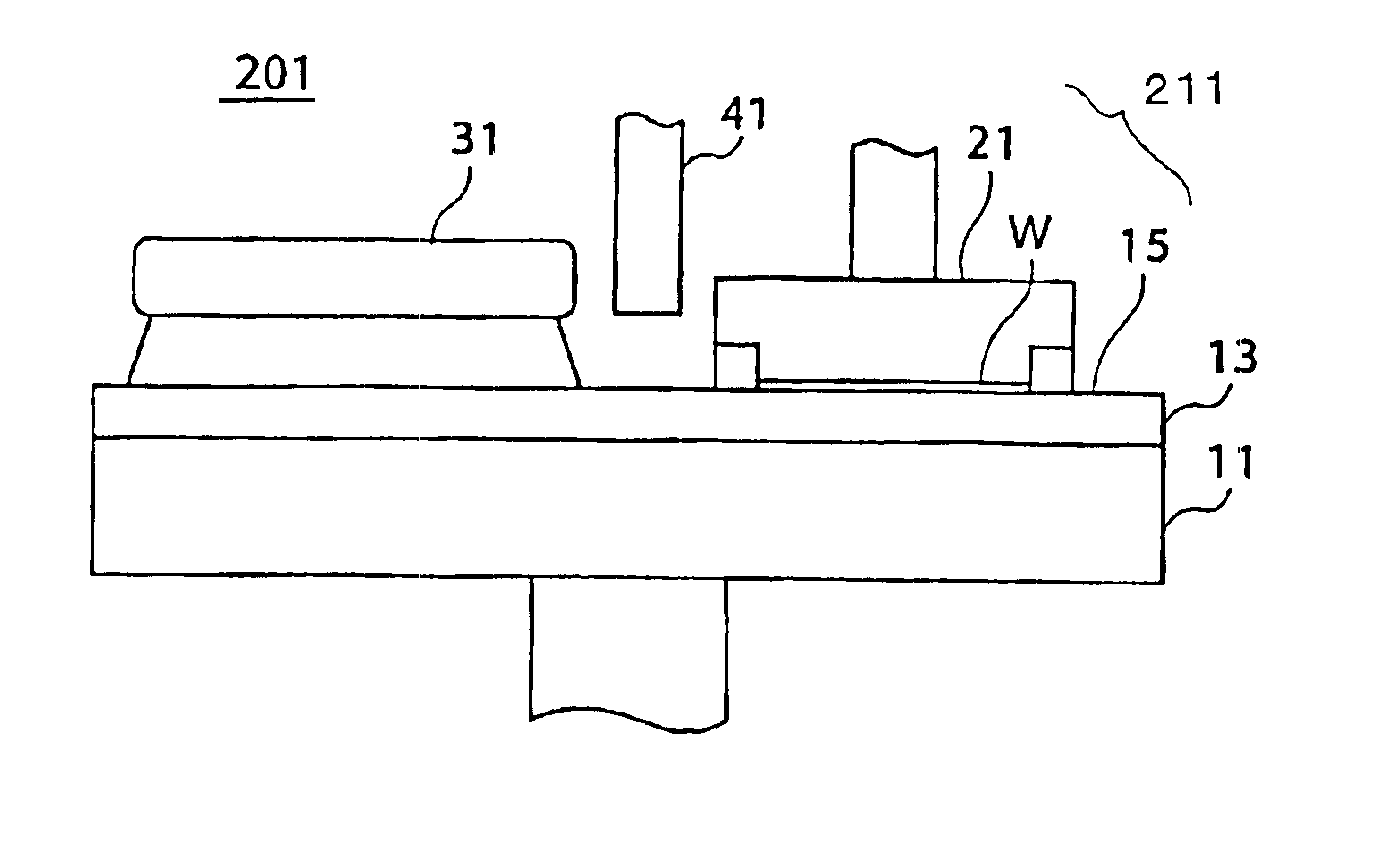

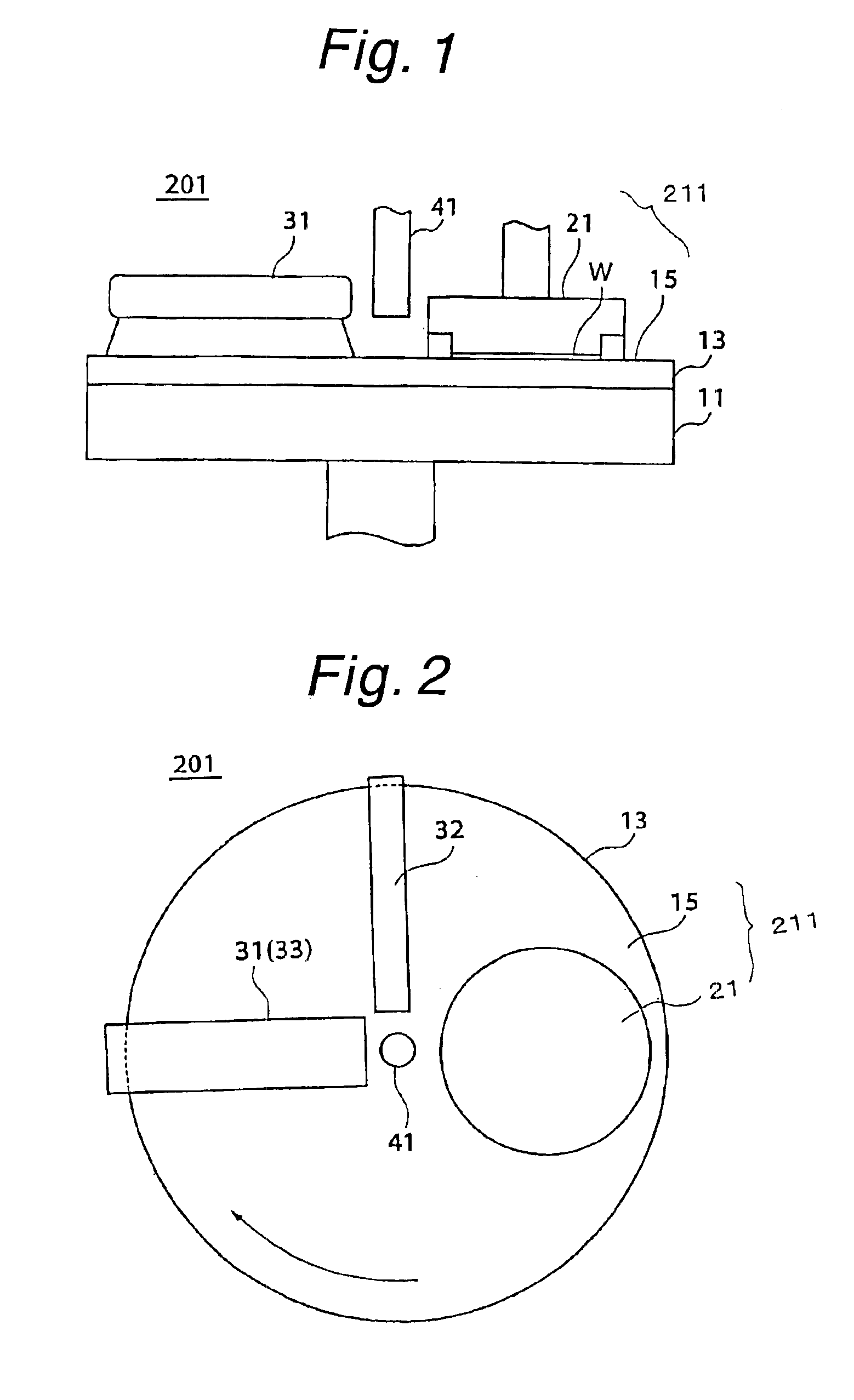

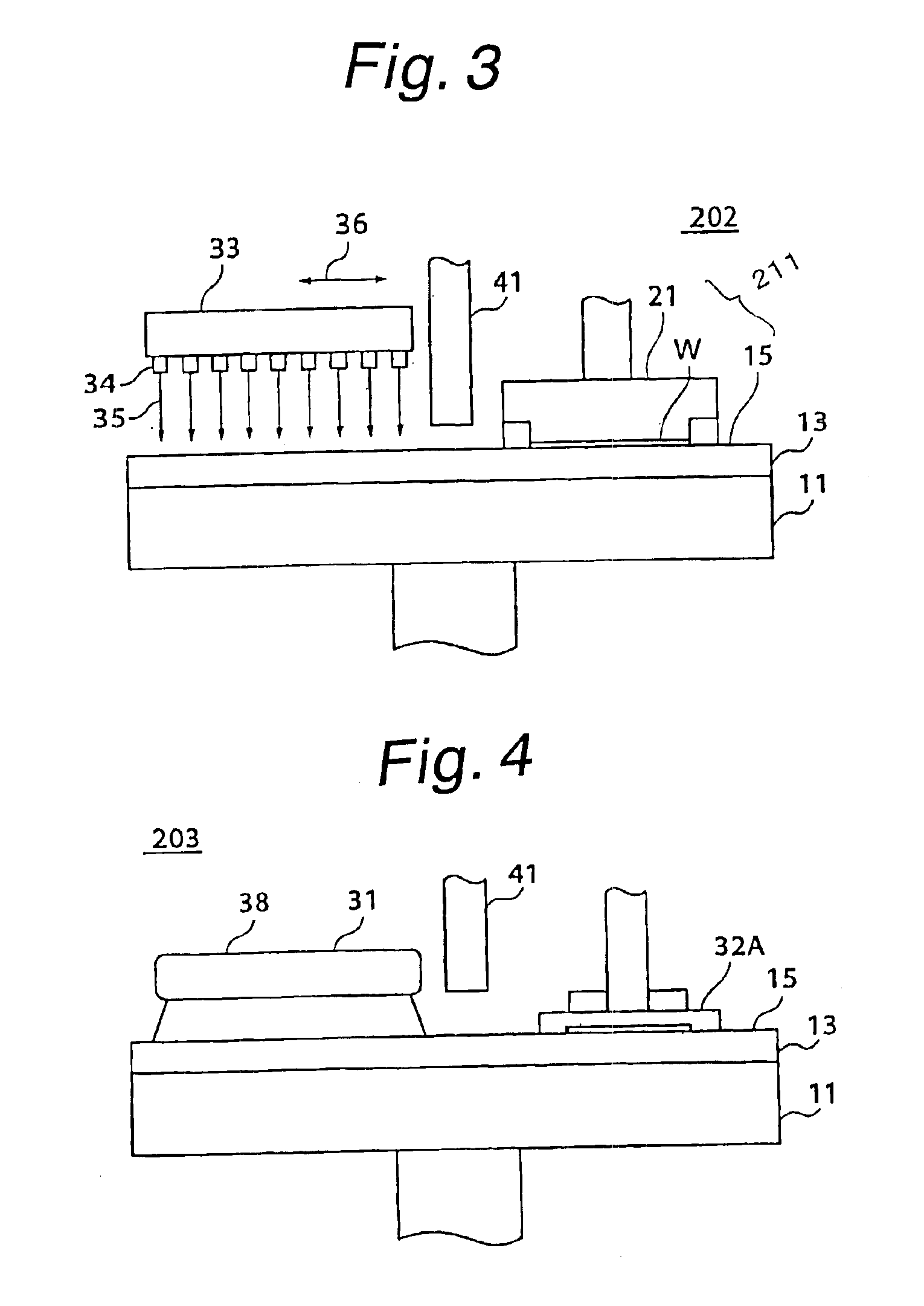

Polishing apparatus and dressing method for polishing tool

InactiveUS6899592B1Easy to dressReduce the binding forceGrinding drivesAbrasive surface conditioning devicesIrradiationBond Force

In a polishing apparatus, a polishing tool including abrasive particles and a binder for bonding together the abrasive particles is pressed against a substrate to polish the substrate. The polishing apparatus has a light source for irradiating a polishing surface with light rays for weakening a bond force of the binder for bonding together the abrasive particles, and a waste matter removing mechanism for forcefully removing waste matter produced by polishing or waste matter produced by irradiation. By irradiating the polishing surface with the light rays, dressing of the polishing surface is performed, and products resulting from dressing and the like are removed. The polishing apparatus supplies abrasive particles to the polishing surface stably by dressing and allows high-speed polishing of the substrate.

Owner:EBARA CORP

Superhard cutters and associated methods

A cutting device comprises a plurality of individual polycrystalline cutting elements secured in a solidified organic material layer. Each of the plurality of individual polycrystalline cutting elements has a substantially matching geometric configuration.

Owner:KINIK

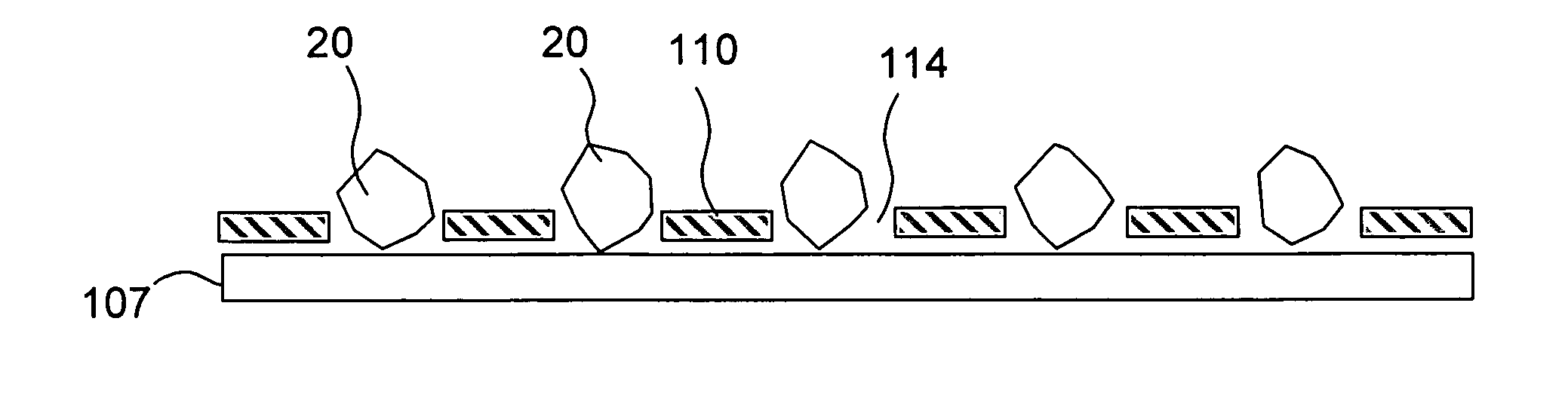

Methods of bonding superabrasive particles in an organic matrix

InactiveUS20070060026A1High retention rateMinimizes mechanical stressRevolution surface grinding machinesAbrasion apparatusFriction forceMaterials science

Owner:KINIK

Chemical mechanical polishing pad dresser

ActiveUS7258708B2Enhance layeringHigh retention ratePigmenting treatmentOther chemical processesMetal coatingMetallic coating

CMP pad dressers and their methods of manufacture are disclosed. One aspect of the present invention provides a CMP pad dresser having improved superabrasive grit retention in a resin layer. The CMP pad includes a resin layer, superabrasive grit held in the resin layer such that an exposed portion of each superabrasive grit protrudes from the resin layer, and a metal coating layer disposed between each superabrasive grit and the resin layer, where the exposed portions are substantially free of the metal coating layer. The metal coating layer acts to increase the retention of the superabrasive grit in the resin layer as compared to superabrasive grit absent the metal coating layer.

Owner:KINIK

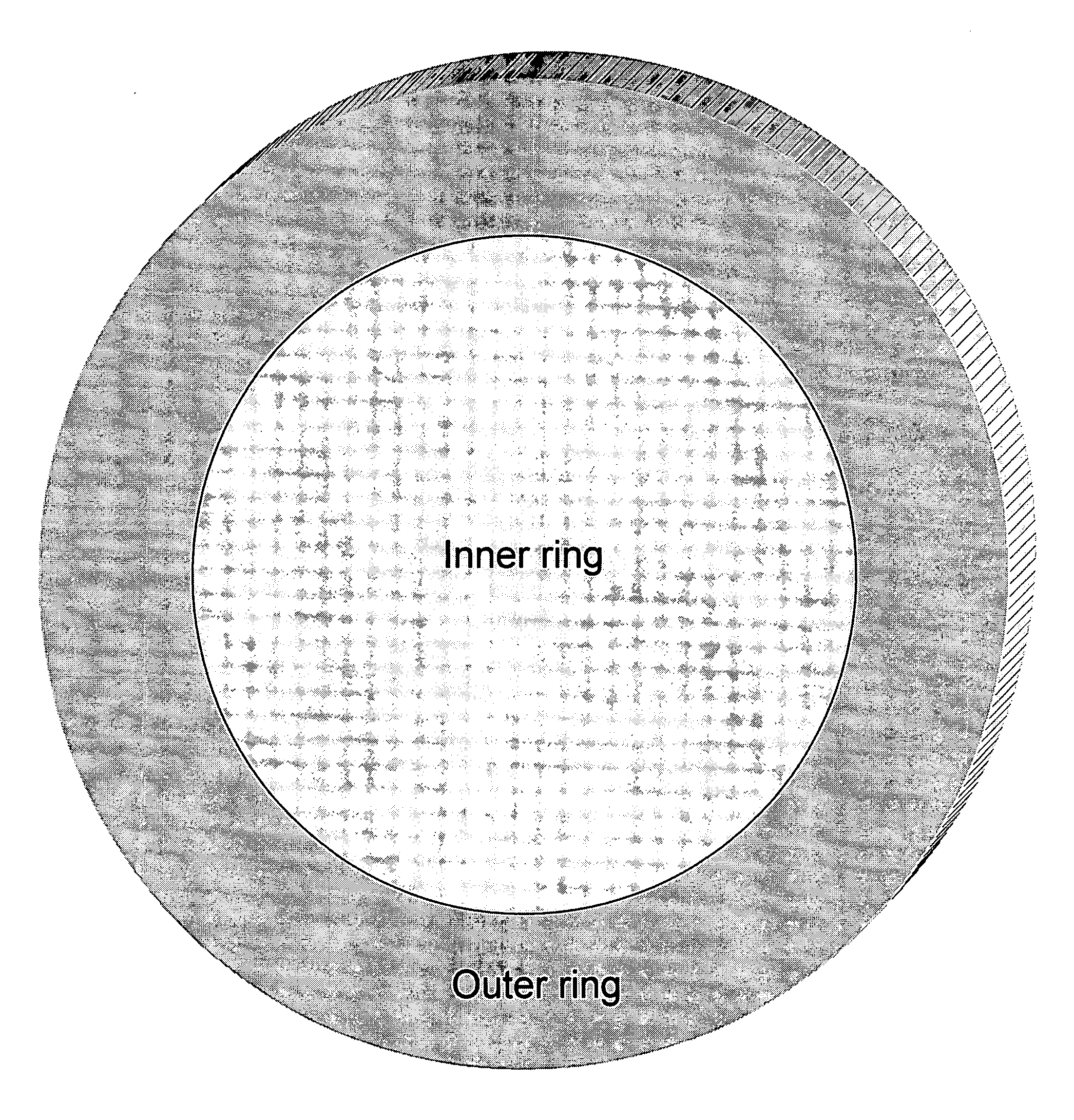

Conditioner and conditioning disk for a CMP pad, and method of fabricating, reworking, and cleaning conditioning disk

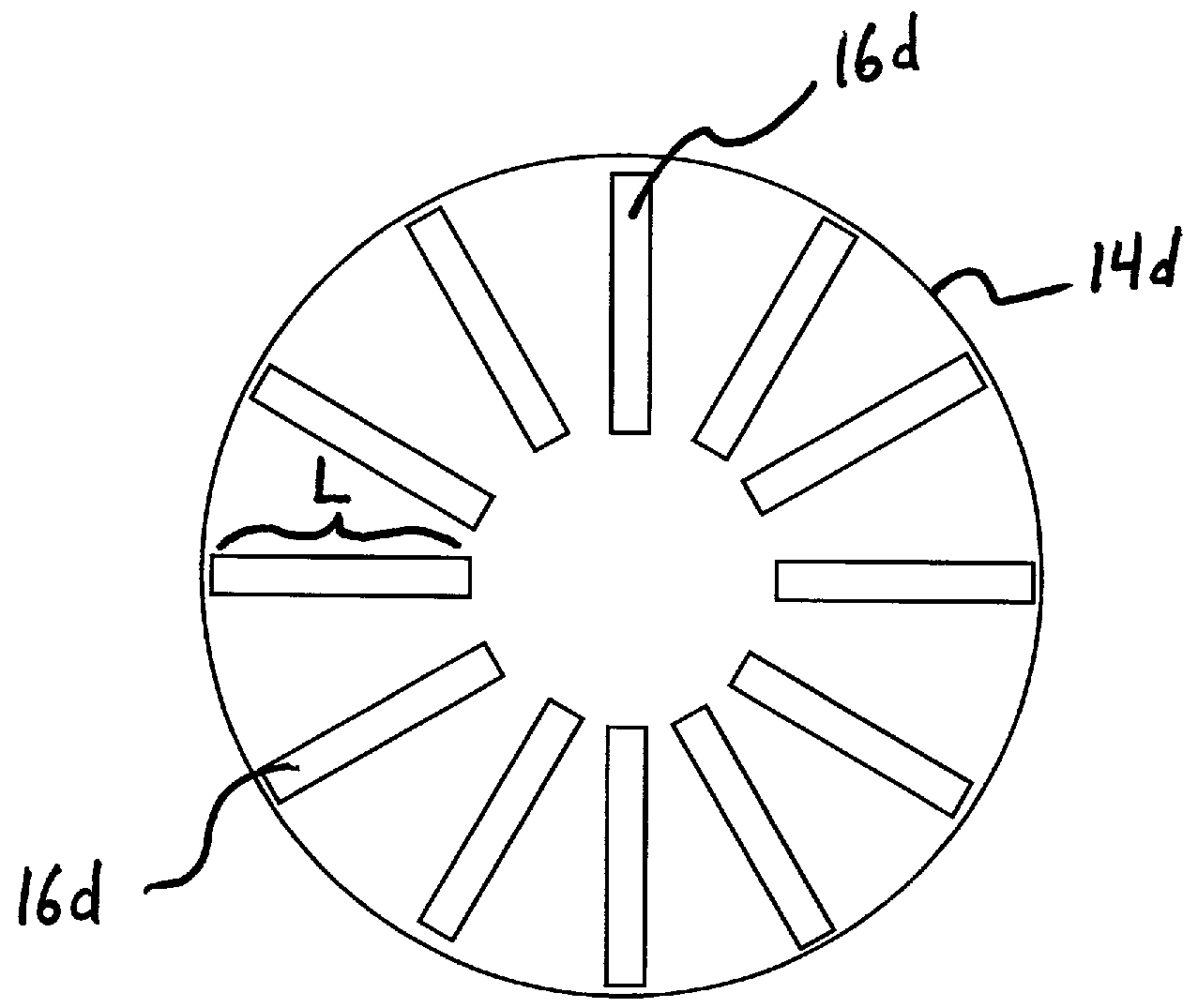

InactiveUS20020127962A1Effective conditioningProlong lifeGrinding drivesBelt grinding machinesSize differenceCleaning methods

A conditioning disk and a conditioner for a chemical mechanical polishing (CMP) pad, and a method of fabricating, reworking, and cleaning the conditioning disk, are utilized to improve conditioning efficiency, and to reduce production expenses. The conditioning disk for a CMP pad is divided into regions defined by a size difference of abrasive grains formed on the body surface in each region of the conditioning disk. The method of fabricating the conditioning disk is performed by forming adhesive films for attaching the abrasive grains onto the body surface multiple times. In addition, a used conditioning disk may be reworked by detaching the abrasive grains from the body, and attaching new abrasive grains. A used conditioning disk can also be cleaned of by-products of the conditioning process by a cleaning method using a HF solution or BOE (buffered oxide etch) solution.

Owner:SAMSUNG ELECTRONICS CO LTD

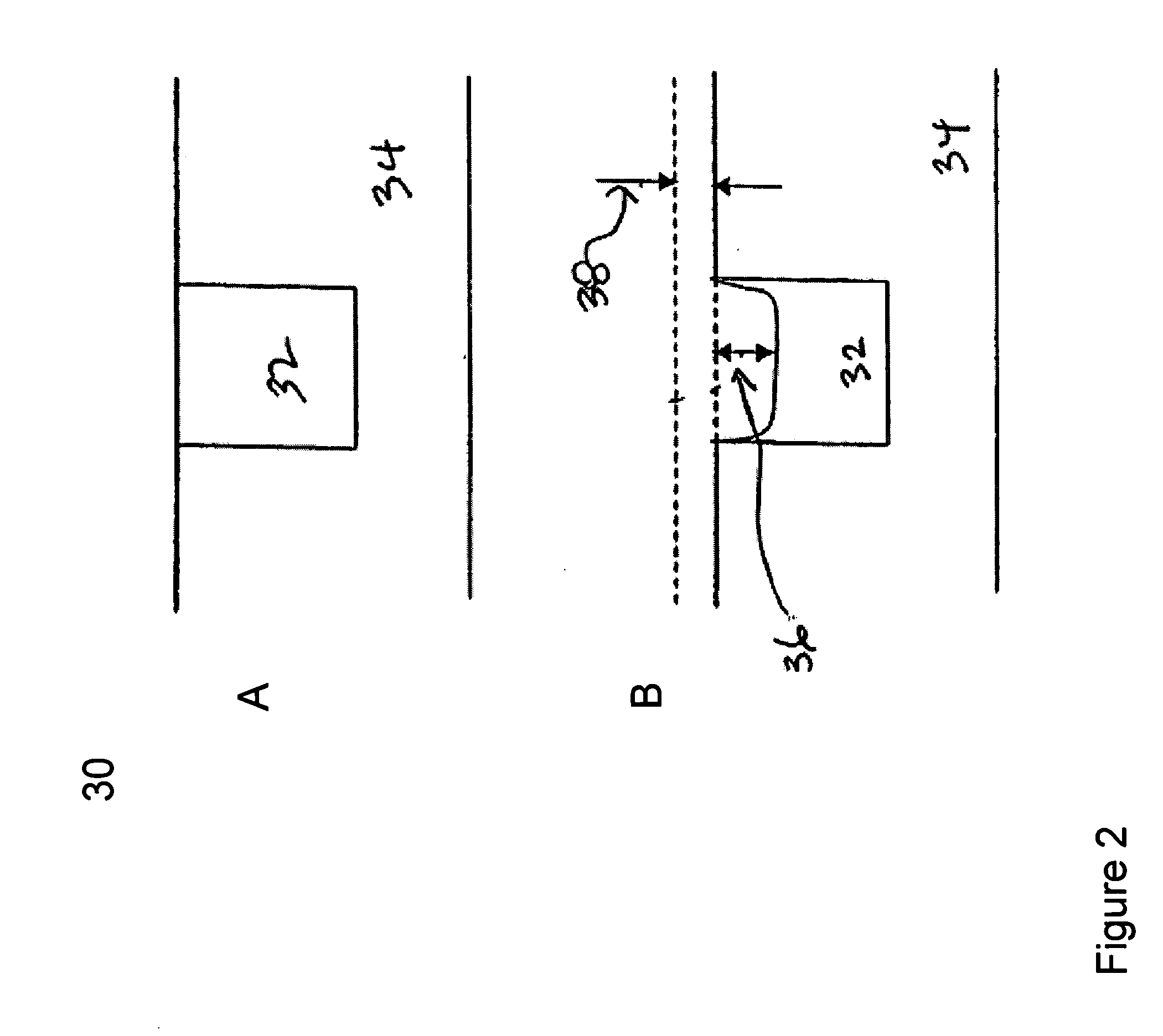

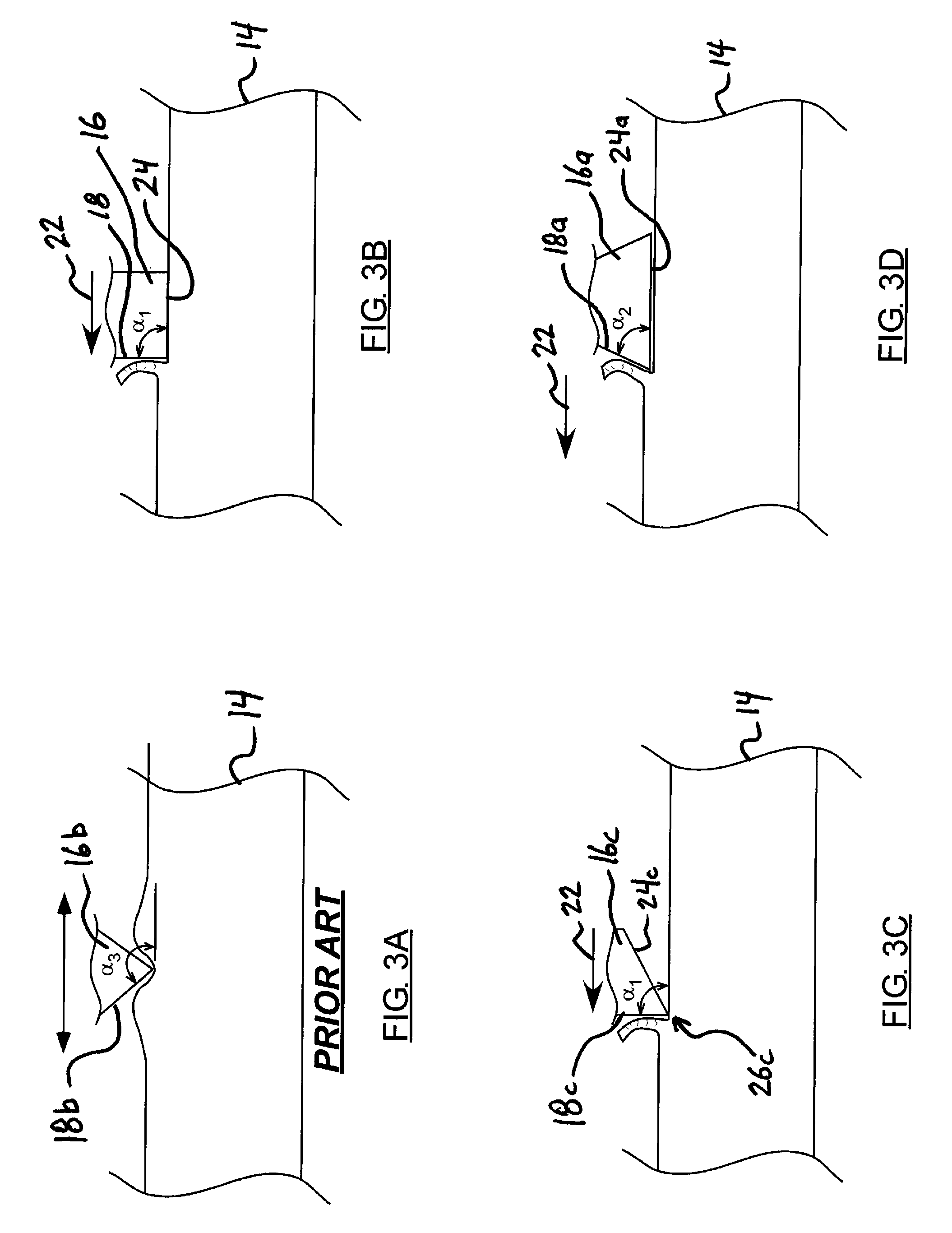

Cmp pad conditioners and associated methods

InactiveUS20080153398A1Reduce degree of compressionMinimize compressionGrinding drivesBelt grinding machinesBiomedical engineering

A method of reducing a degree of compression of a CMP pad during conditioning of the CMP pad comprises engaging the CMP pad with at least one superhard cutting element, the cutting element including a cutting face, the cutting face being angled at 90 degrees or less relative to a finished surface of the CMP pad; and moving the CMP pad and the cutting element relative to one another in a direction resulting in removal of material from the CMP pad with the cutting face to thereby condition the CMP pad.

Owner:SUNG CHIEN MIN

Brazed diamond tools and methods for making the same

Superabrasive tools and methods for the making thereof are disclosed and described. In one aspect, superabrasive particles are chemically bonded to a matrix support material according to a predetermined pattern by a braze alloy. The brazing alloy may be provided as a powder, thin sheet, or sheet of amorphous alloy. A template having a plurality of apertures arranged in a predetermined pattern may be used to place the superabrasive particles on a given substrate or matrix support material.

Owner:SUNG CHIEN MIN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com