Patents

Literature

146results about How to "Easy to operate the machine" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

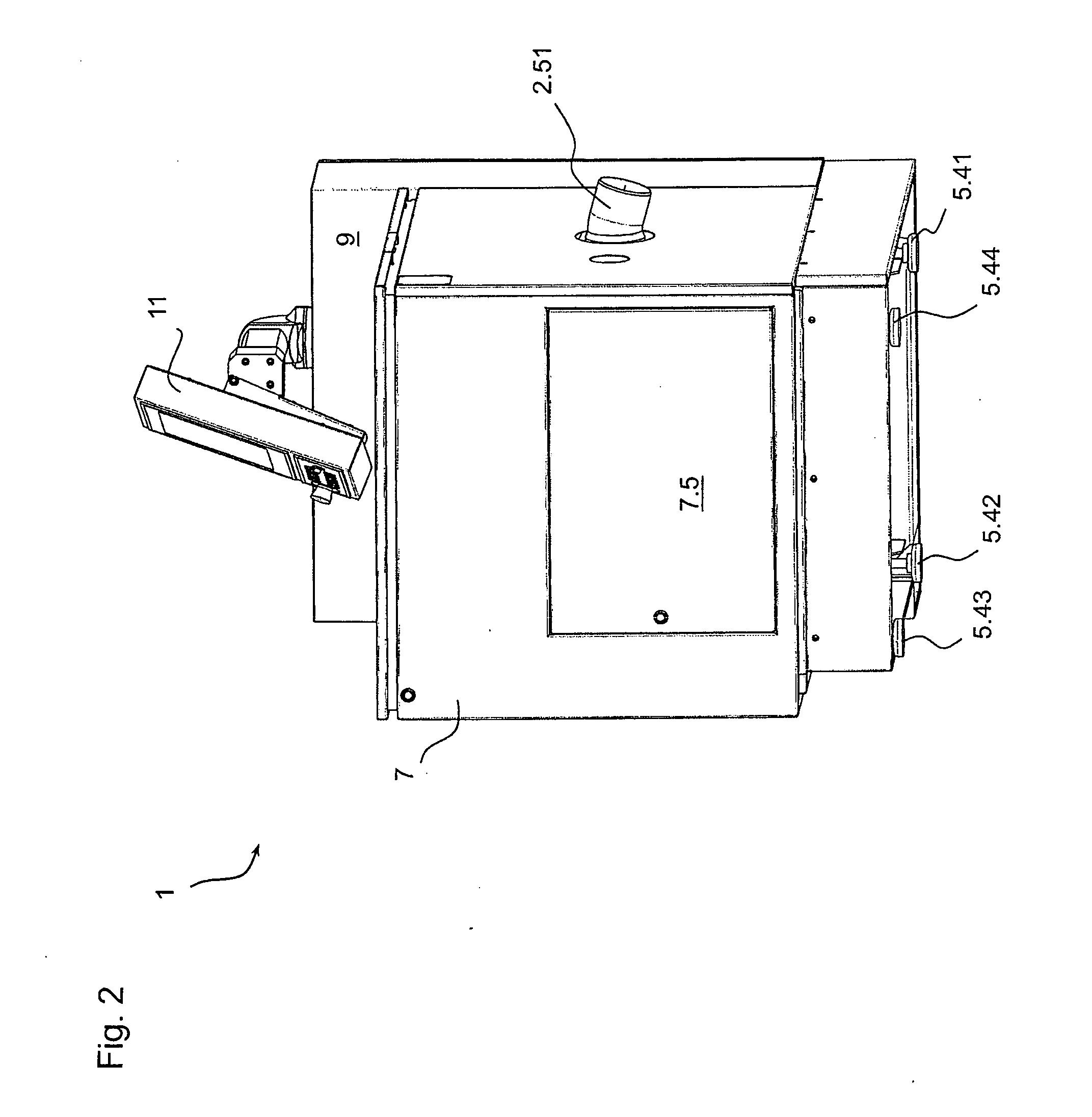

Intelligent molding environment and method of configuring a molding system

ActiveUS20060082009A1Easy to operate and controlReduce complexityAuxillary shaping apparatusMolding machineEngineering

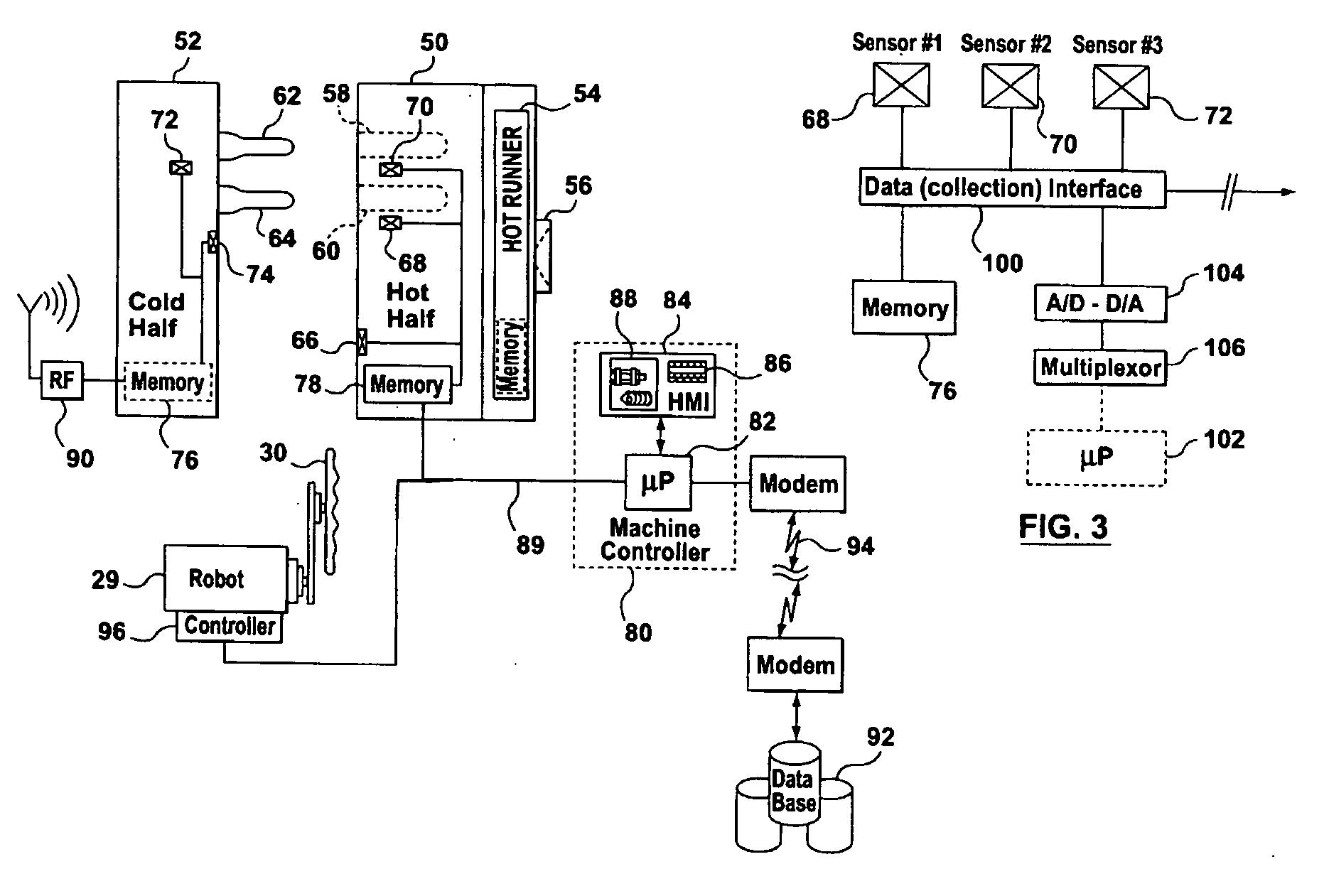

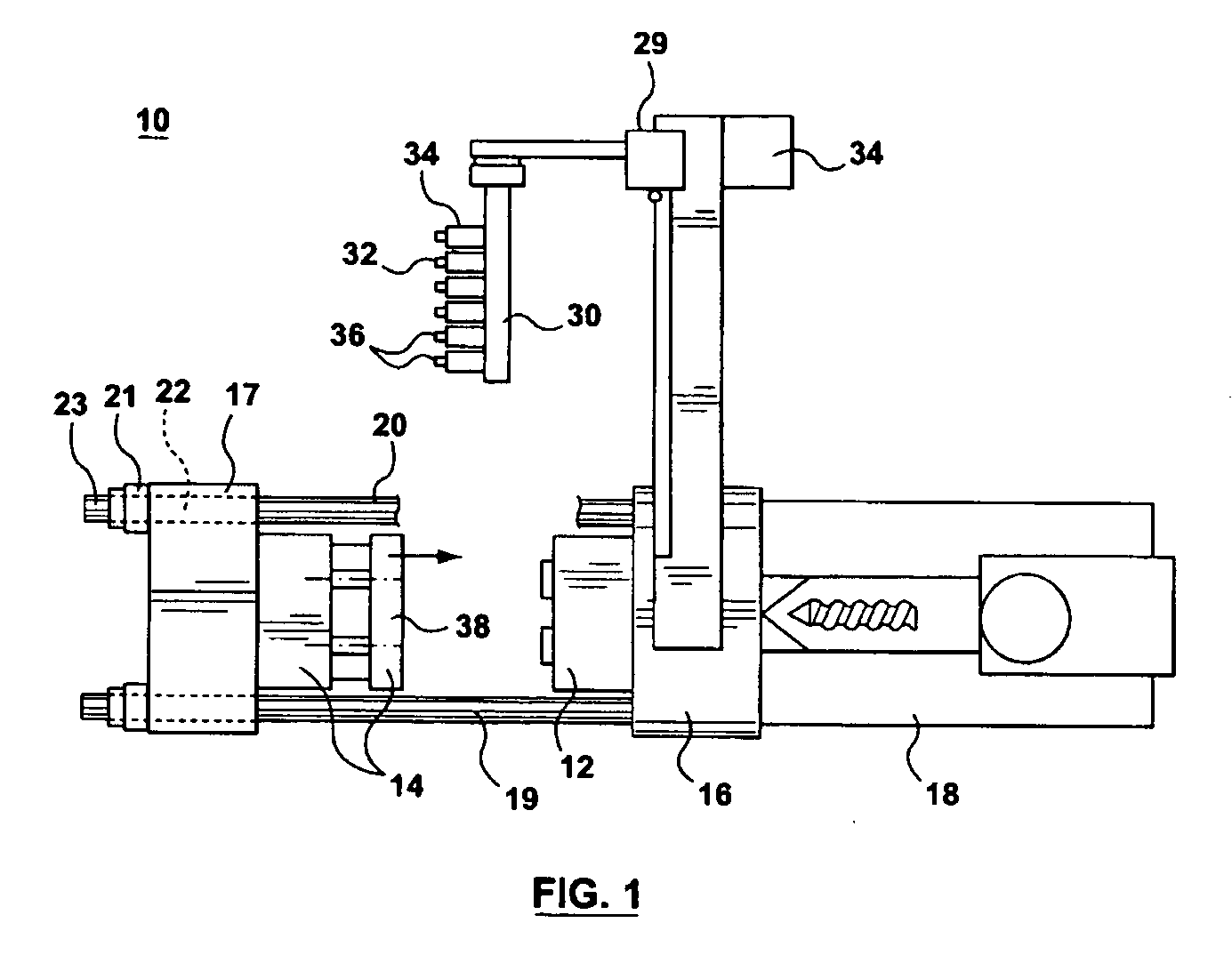

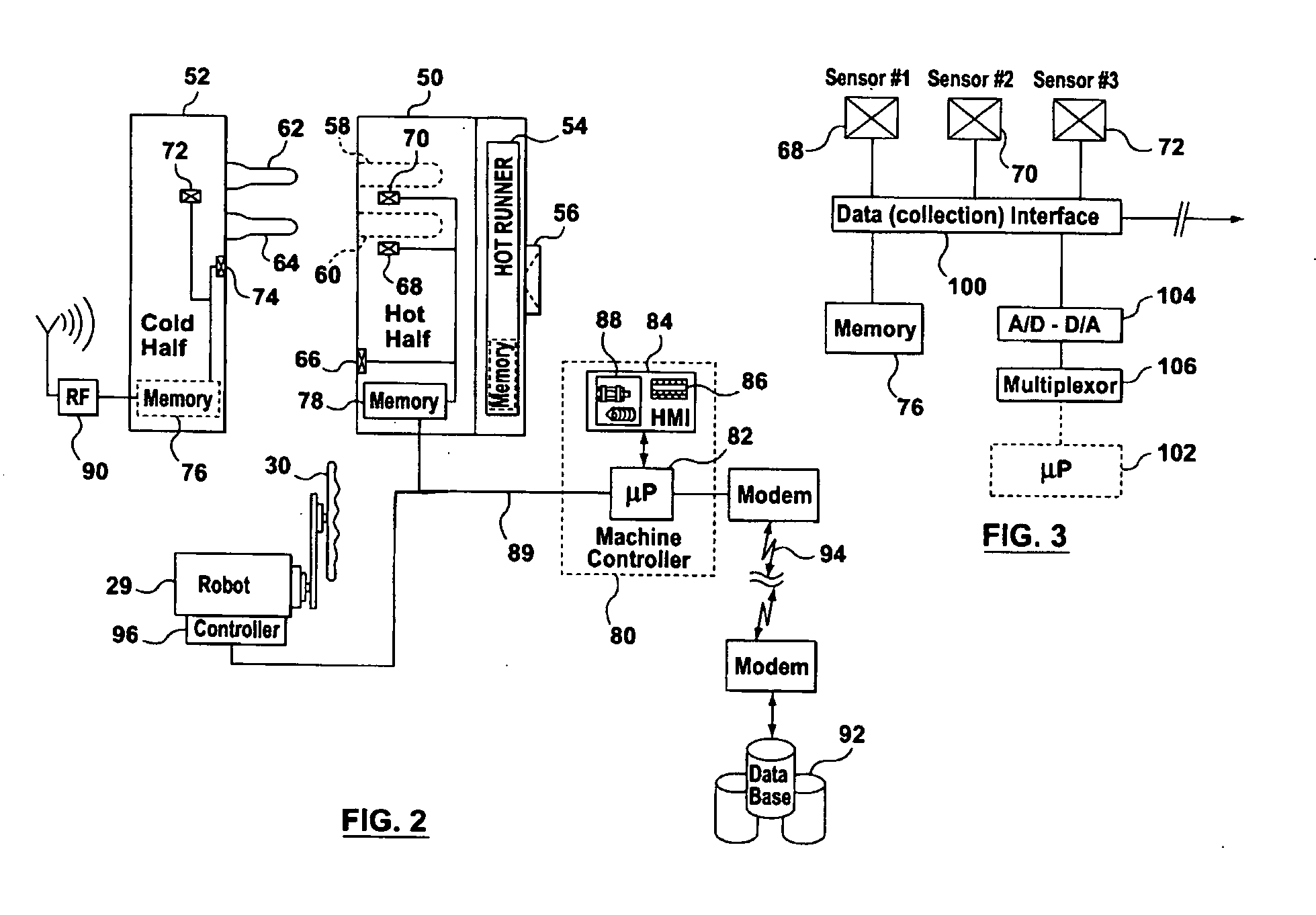

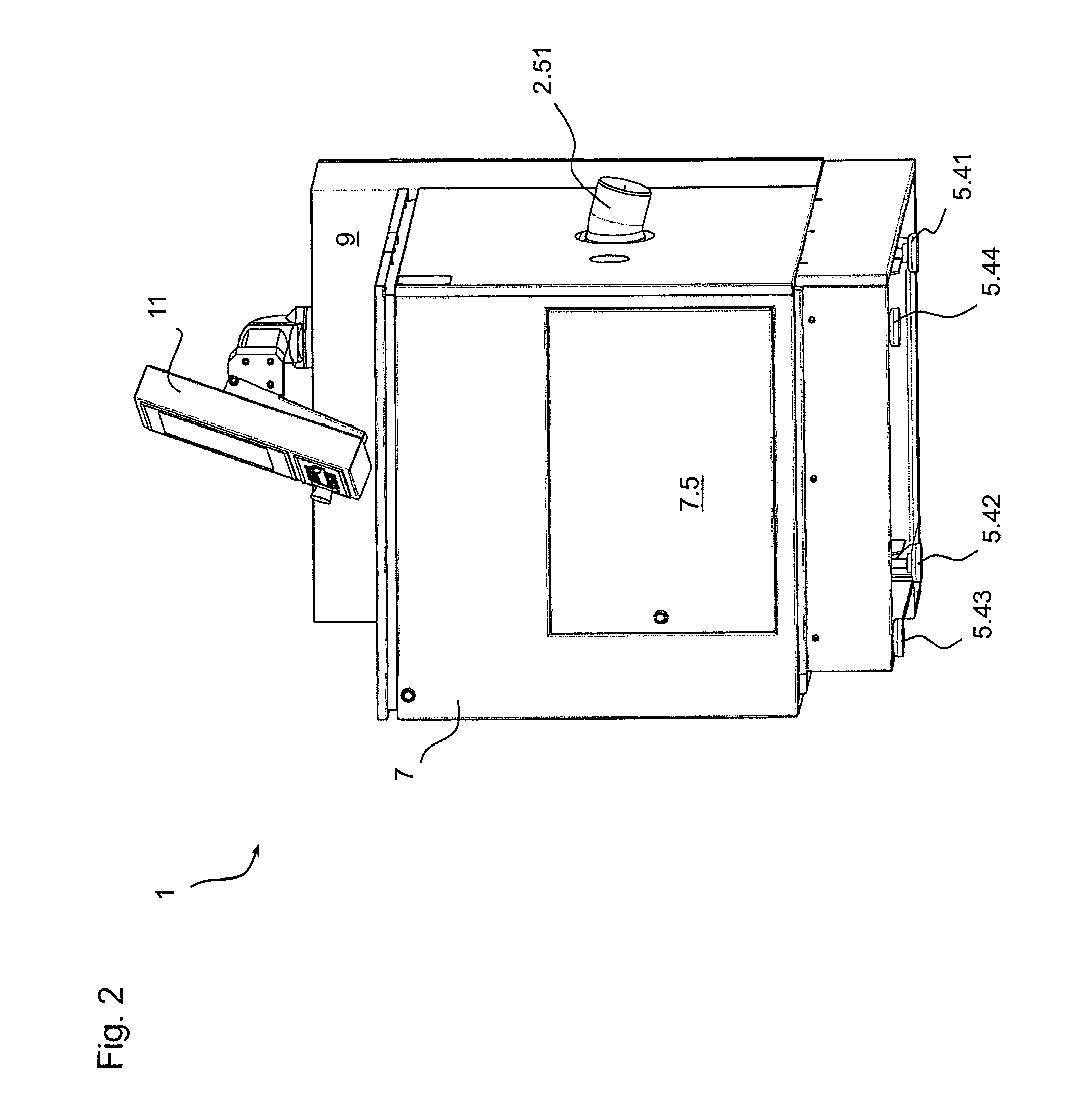

An intelligent molding system (FIG. 2) is provided that makes use of data directly associated with a molding environment or particular mold (50, 52). Accessible data, typically stored locally in an in-mold memory device (76, 78) or input via an HMI (86), identifies parameters germane to mold set-up and machine operation. Upon receiving such data, a machine controller (80) operates to configure a molding machine (10) to an initial set-up defined by the data considered close to an optimal operating condition for the mold. Mold set-up data can include information relating to a fill profile for a molded article that is partitioned into different zones having different thicknesses and geometries. Weighting factors for the various zones compensate for differing cooling and flow characteristics. The memory (76, 78) can also be used to store historical data pertaining to mold operation, settings and alarms.

Owner:HUSKY INJECTION MOLDING SYST LTD

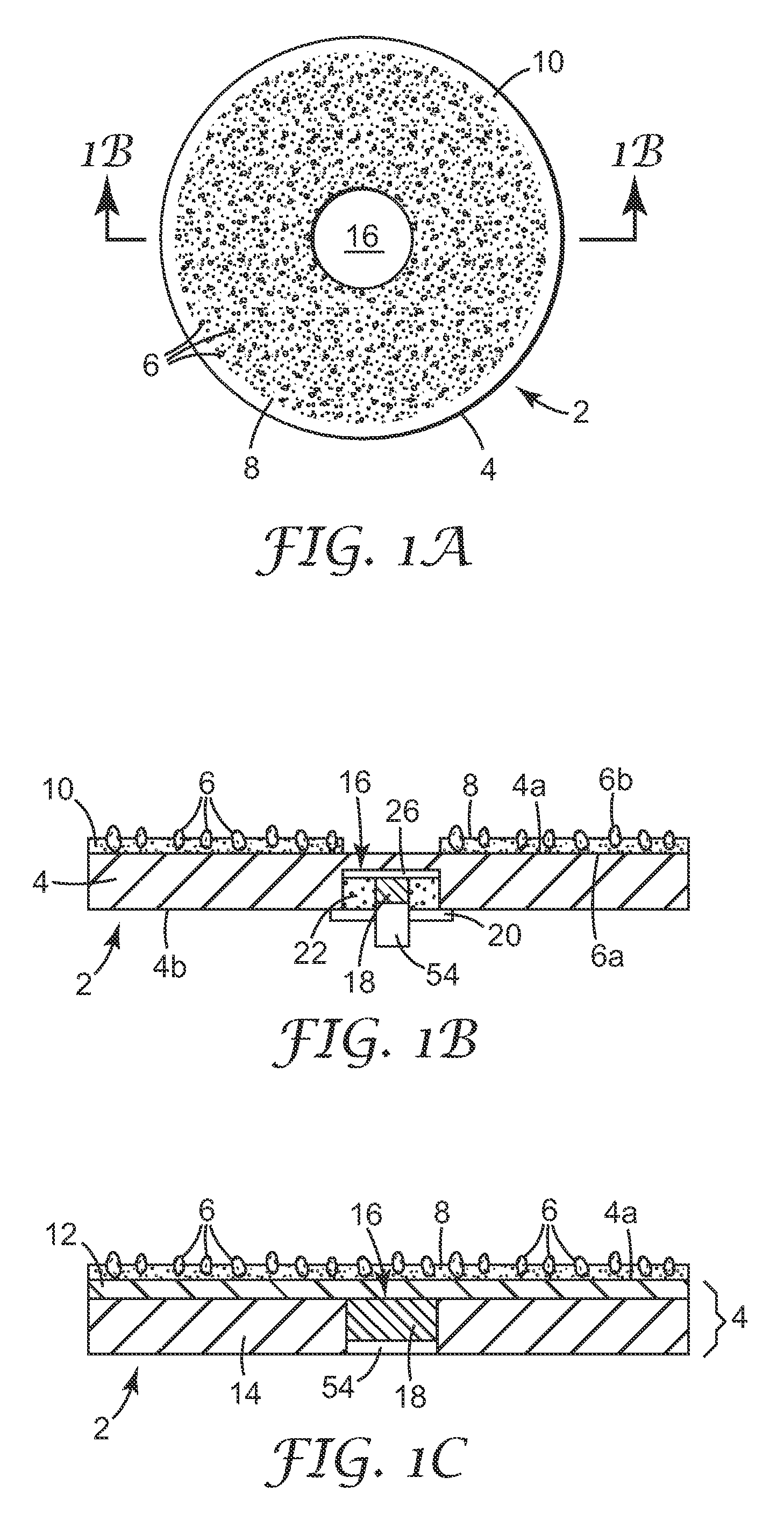

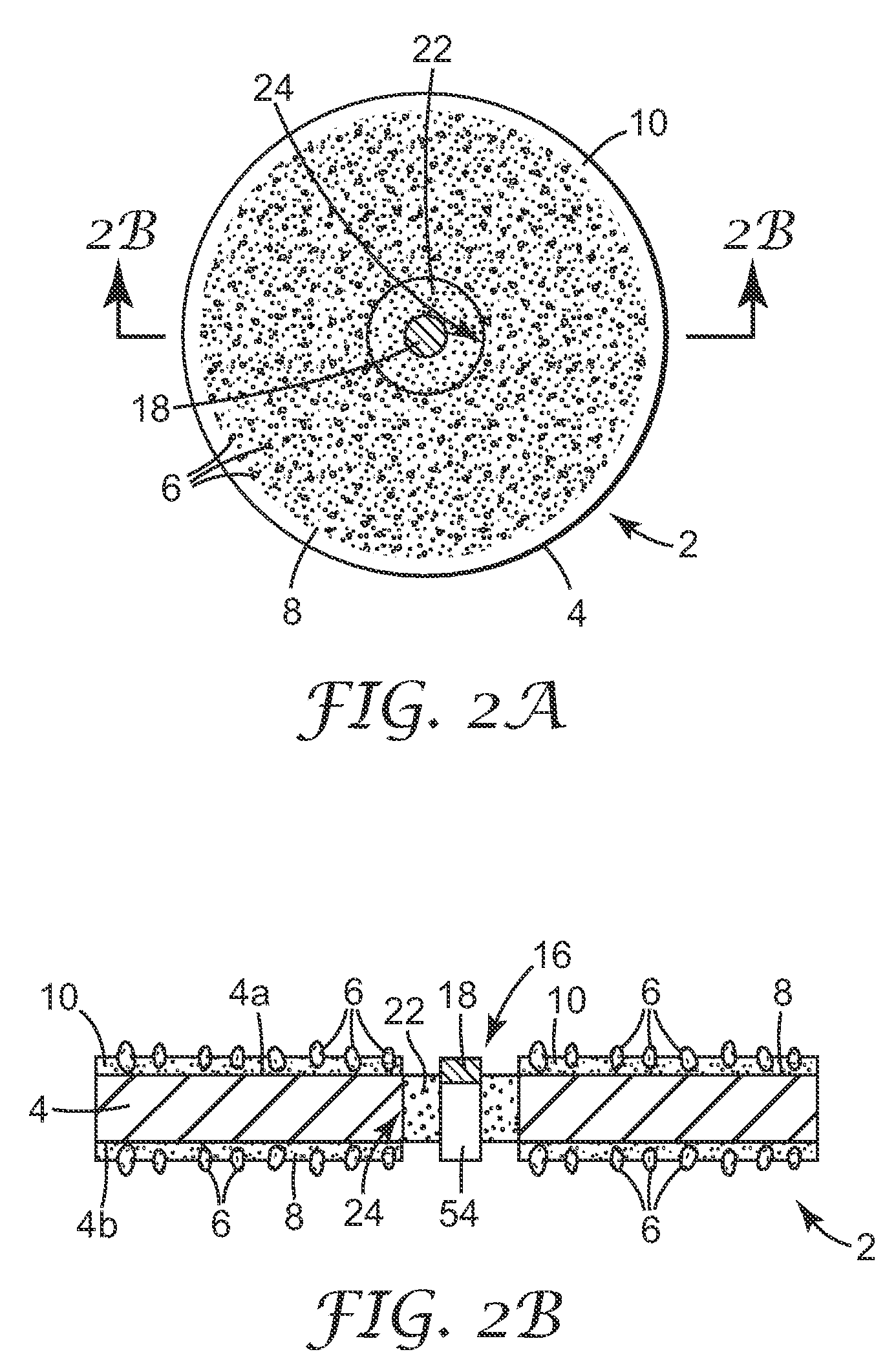

Abrasive articles, CMP monitoring system and method

ActiveUS7840305B2Easy to operate the machineAvoid damageGrinding drivesBelt grinding machinesMonitoring systemEngineering

The disclosure relates to abrasive articles useful in chemical-mechanical polishing (CMP), the articles including a substrate with opposite major surfaces, an abrasive material overlaying at least a portion of at least one of the major surfaces, and at least one of a radio frequency identification (RFID) tag, a RFID tag reader, or a sensor for providing CMP information to a transmitter positioned near the substrate, the transmitter positioned near the substrate and adapted to wirelessly receive CMP information and wirelessly transmit the CMP information to a remote receiver. The disclosure also relates to a CMP pad conditioner for wirelessly communicating CMP information to a remote receiver, a CMP process monitoring system for wirelessly communicating CMP information to a remote receiver, and a method for conditioning a CMP pad using a CMP process monitoring system for wireless communicating CMP information to a remote receiver.

Owner:3M INNOVATIVE PROPERTIES CO

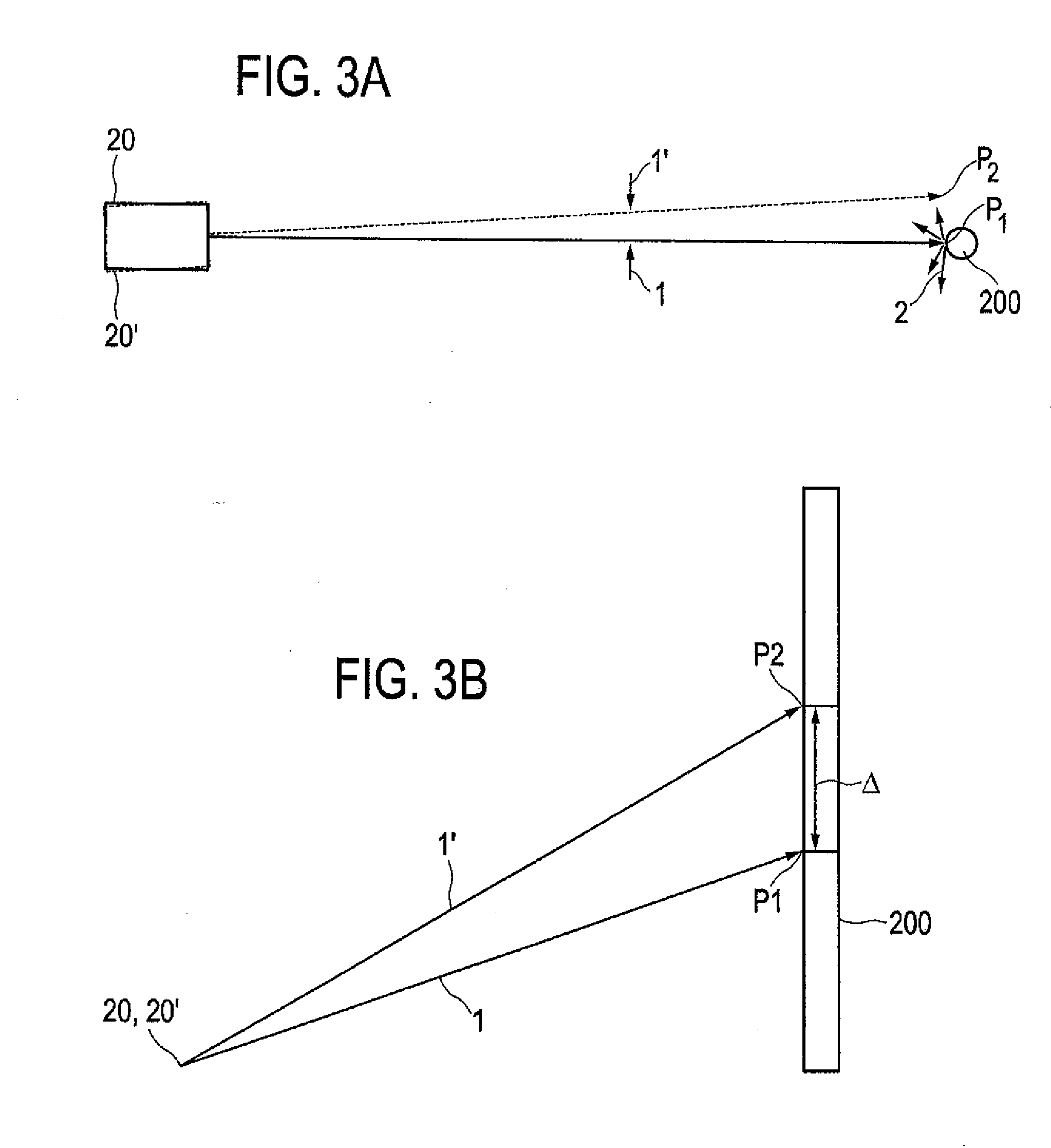

Measuring device for noncontact measurement of distances to a target object

InactiveUS20120105825A1Improve visualizationEasy to handleOptical rangefindersActive open surveying meansCamera lensImaging processing

A measuring device, having: a housing; a distance measuring unit situated in the housing uses an optical measuring beam, with the aid of which the distance between a reference point and at least one measuring point on a target object is measurable without contact; a photoelectric image acquisition unit situated in the housing having a viewfinder and camera lens situated in the housing as well as an image path connecting them for detecting target points of the target object, an image processing unit and a control and computation unit with the aid of which the image of the image processing unit is displayable. The image processing unit defines target points pixels in exactly one single photoelectric image, the control and computation unit allocating the distance of the reference point to the measuring point to at least one of the pixels, the allocation available for further processing.

Owner:HILTI AG

Method for recovering valuable metals from waste lithium iron phosphate battery cathode material

ActiveCN108110357AReduce usageRealize high-grade optimal recoveryWaste accumulators reclaimingProcess efficiency improvementAfter treatmentLithium iron phosphate

The invention discloses a method for recovering valuable metals from a waste lithium iron phosphate battery cathode material. The method specifically comprises the following steps: (1) fully roastingand oxidizing the disassembled, broken and ground lithium iron phosphate battery cathode material, so that Fe and Li metal elements in the battery cathode material are generated into Fe2O3, FePO4 andLi3PO4 through being roasted and oxidized; (2) placing a roasted material that is fully-roasted and oxidized in the step (1) in a dilute acid solution for soaking, so that Li3PO4 in the roasted material is fully dissolved and filtered to realize the separation of the Li3PO4 in the roasted material from the Fe2O3 and the FePO4; (3) taking a filtrate after treatment in the step (3) and regulating the filtrate to be alkaline, so that Li3PO4 in the filtrate is directly separated out into a precipitate. Therefore, the recovery of the solid Li3PO4 is realized. The method disclosed by the invention is short in technical process, simple to operate, low in cost and environmentally-friendly and can preferentially select and recycle the high-grade lithium metals in the lithium iron phosphate batterycathode material, thereby having a wide industrial application prospect.

Owner:MEISHAN SHUNYING POWER BATTERY MATERIALS CO LTD

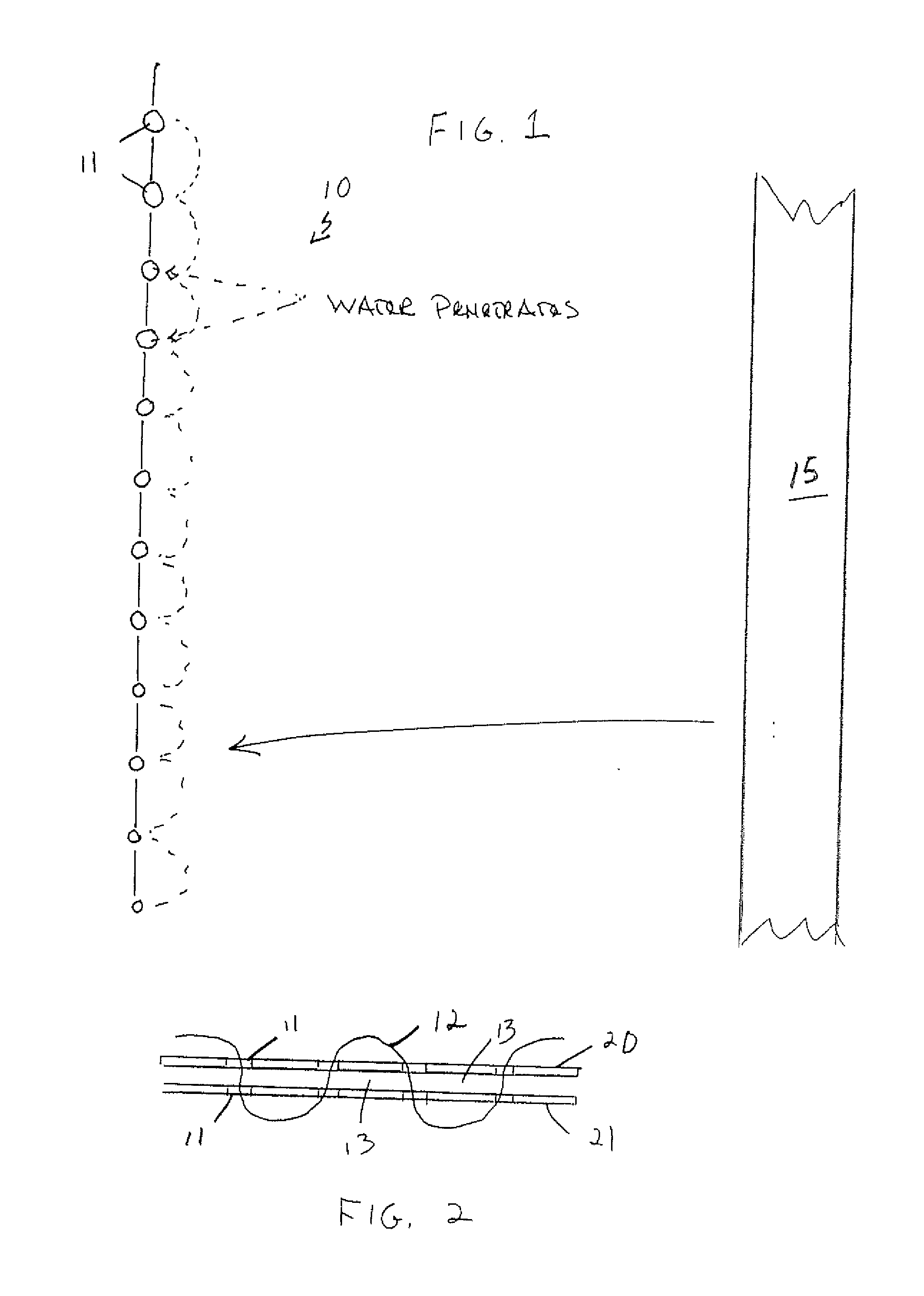

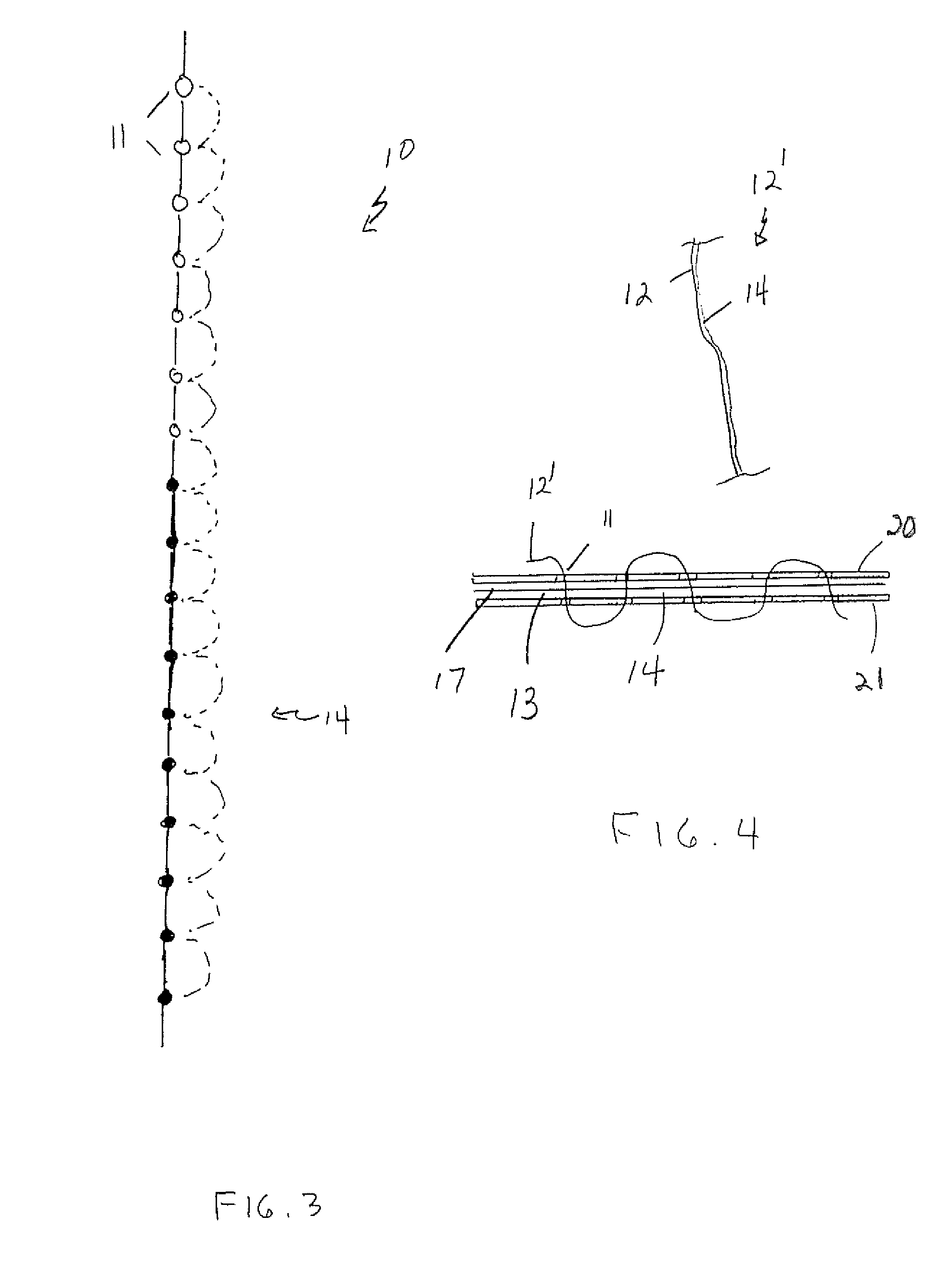

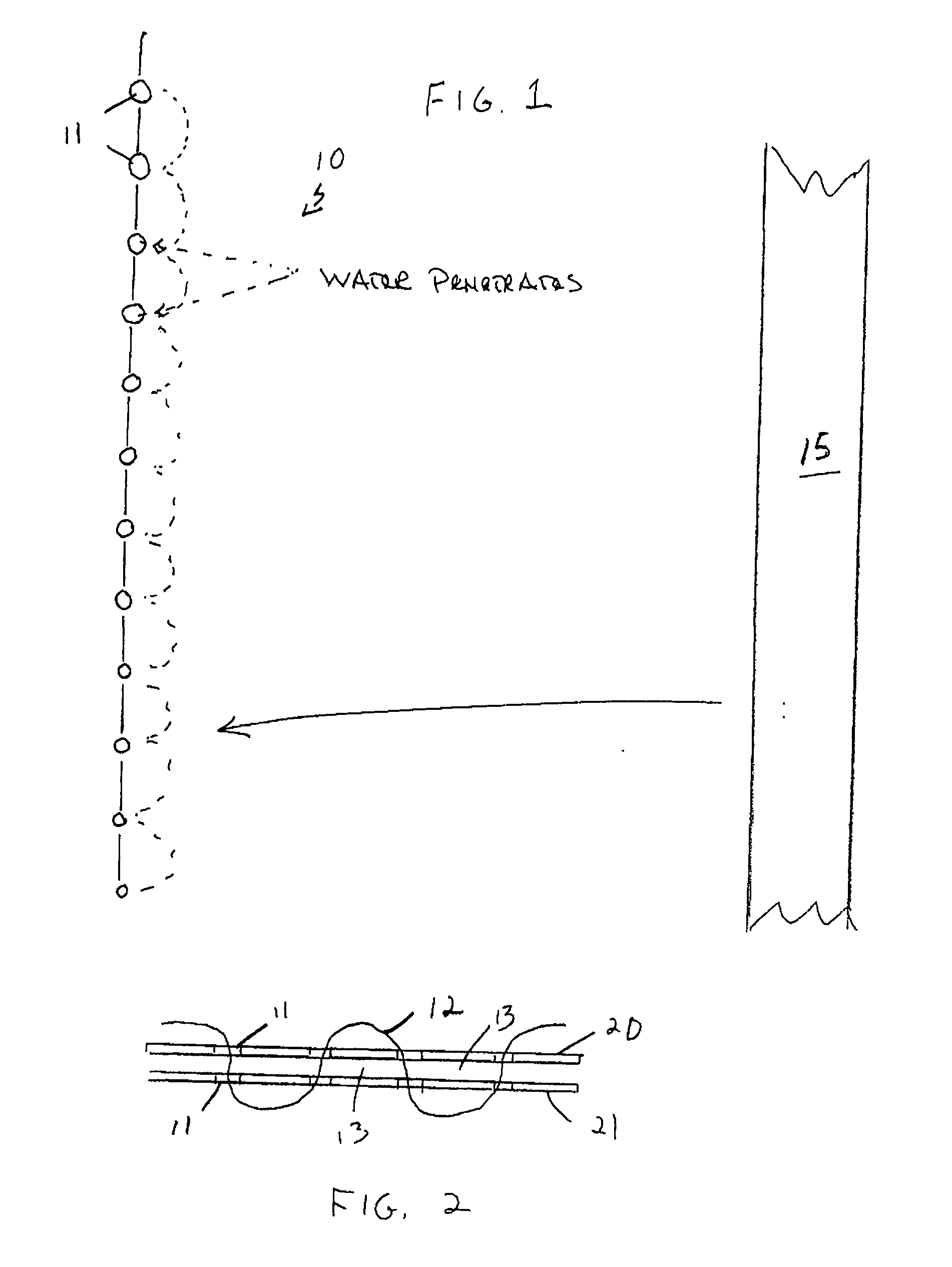

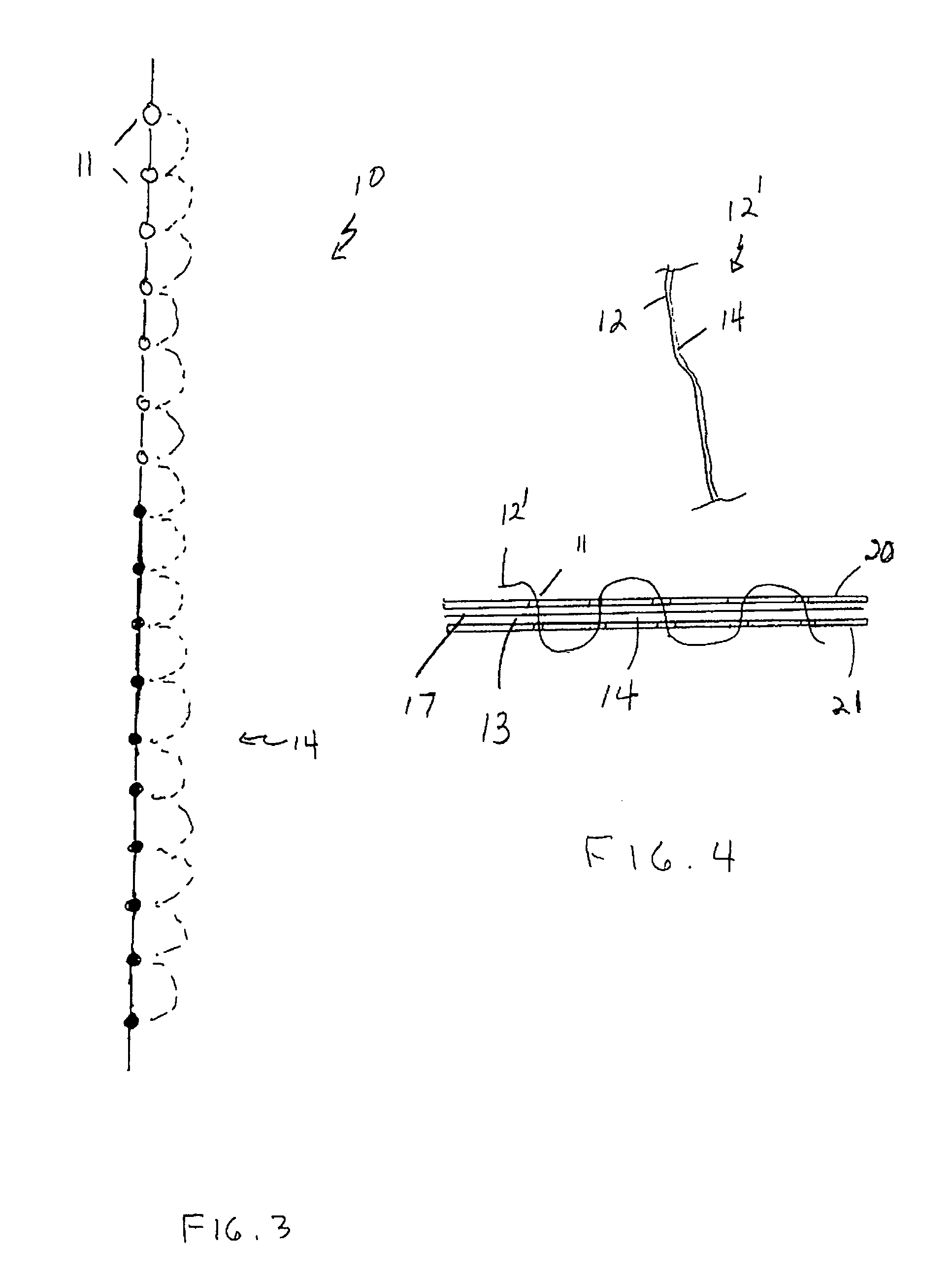

Adhesive Thread System

InactiveUS20130048219A1Improve waterproof performanceEliminate needLamination ancillary operationsGarmentsNeedle punctureGlue line

A system for forming a waterproof seam between to sewn materials. The seam is formed using an adhesive coated thread. A thin strip of adhesive is placed between the two materials at the seam line. As the coated thread is sewn into the seam heat and pressure are simultaneously applied, melting the adhesive coating thereby filling the needle punctures. The melted adhesive coating will also flow into the areas between the needles punctures and between the materials. The heat and pressure applied to the coated thread will also melt the adhesive strip, causing additional adhesive to flow into the needle punctures and the areas between needle punctures.

Owner:FERREIRO ROXANNE

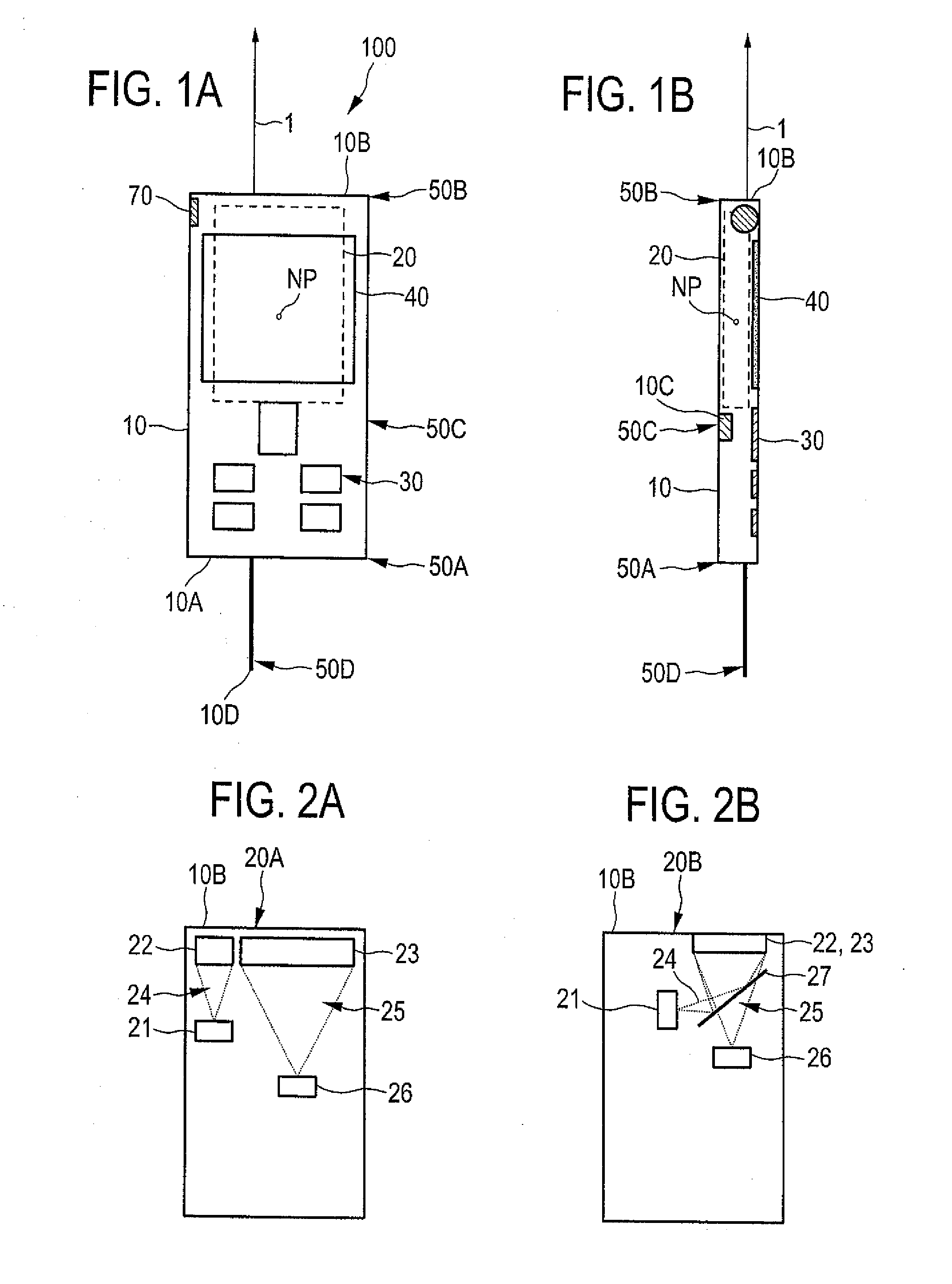

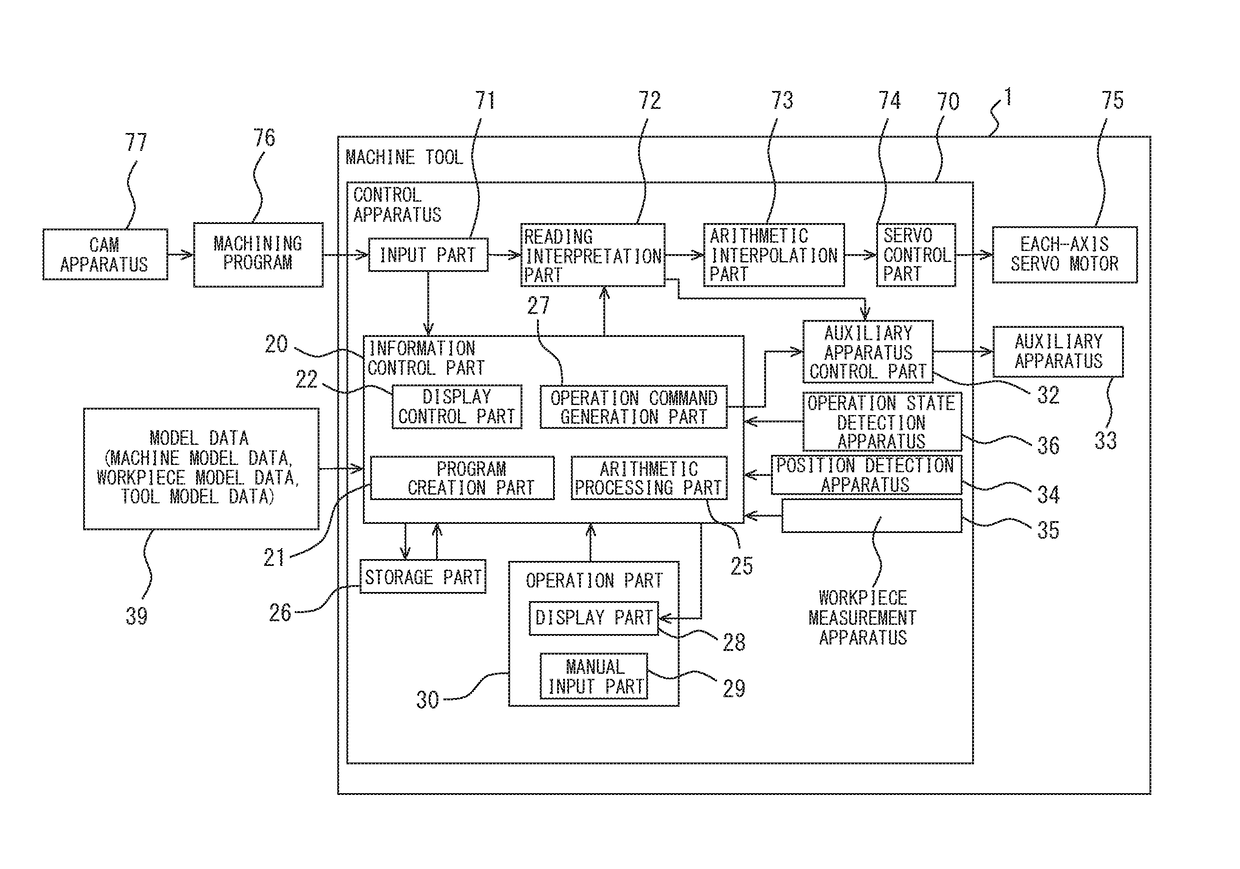

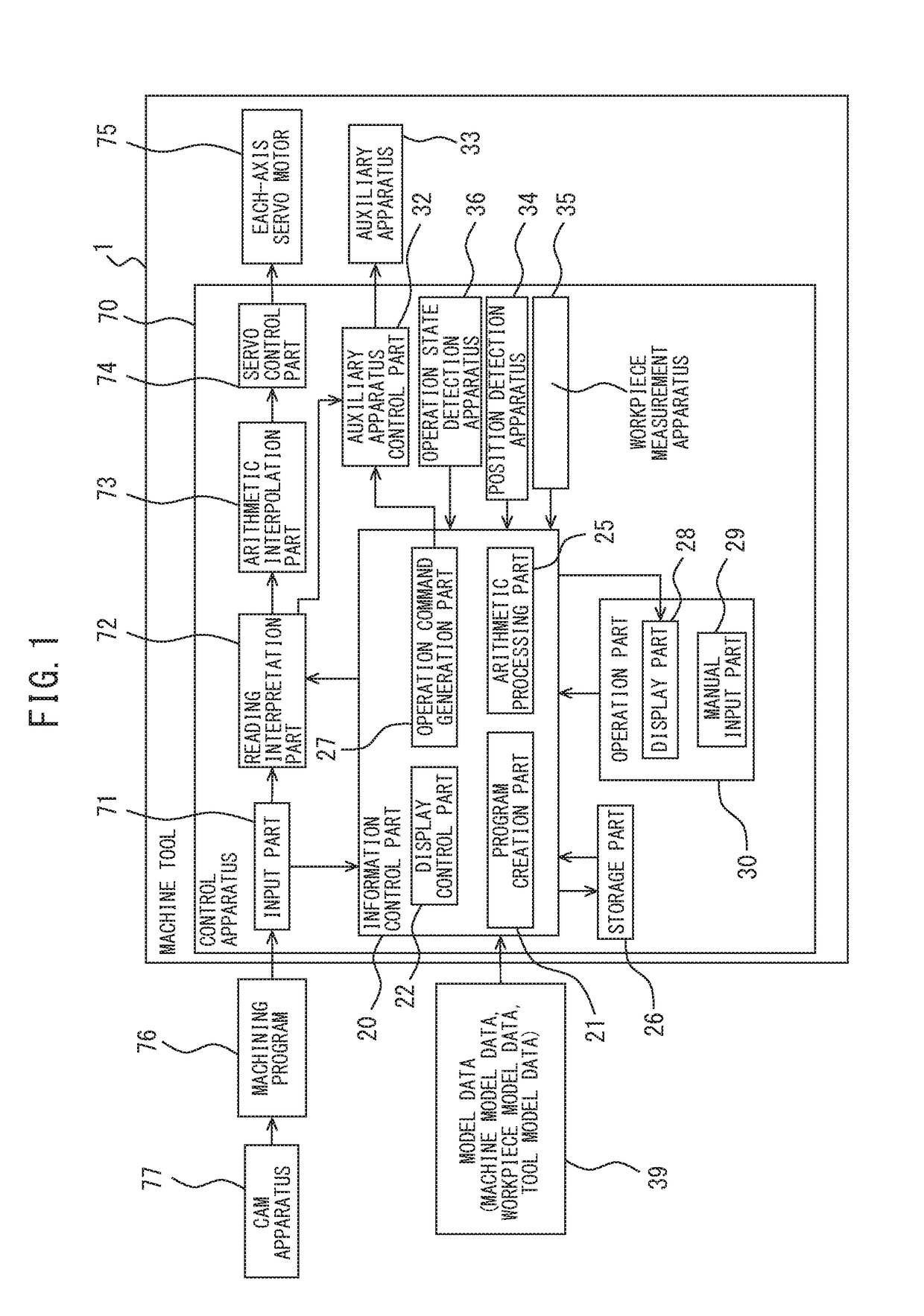

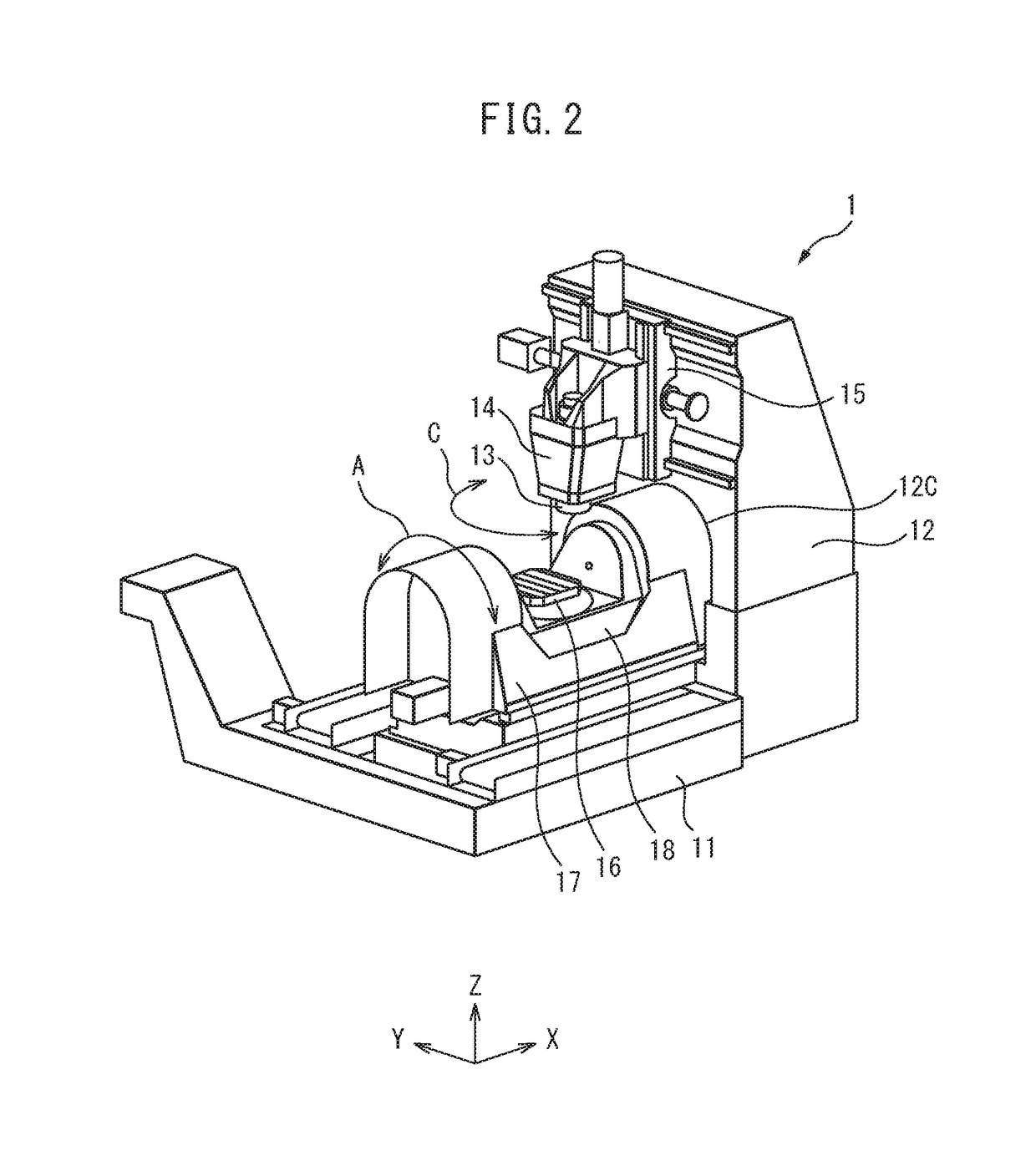

Machine tool control method and machine tool control device

InactiveUS20170308055A1Easy to operateErroneous operation can be suppressedProgramme controlComputer controlMachine tool controlComputer science

This method of controlling machine tool for machining a workpiece by moving a tool and the workpiece relatively to each other comprises: displaying an image of the machine tool on a display unit, pre-storing a motion of the machine tool corresponding to an operation by an operator with respect to the image of the machine tool; obtaining a content of the operation by the operator with respect to the image of the machine tool; generating an operation command for causing the machine tool to operate according to the operation content; and activating the machine tool on the basis of the operation command.

Owner:MAKINO MILLING MASCH CO LTD

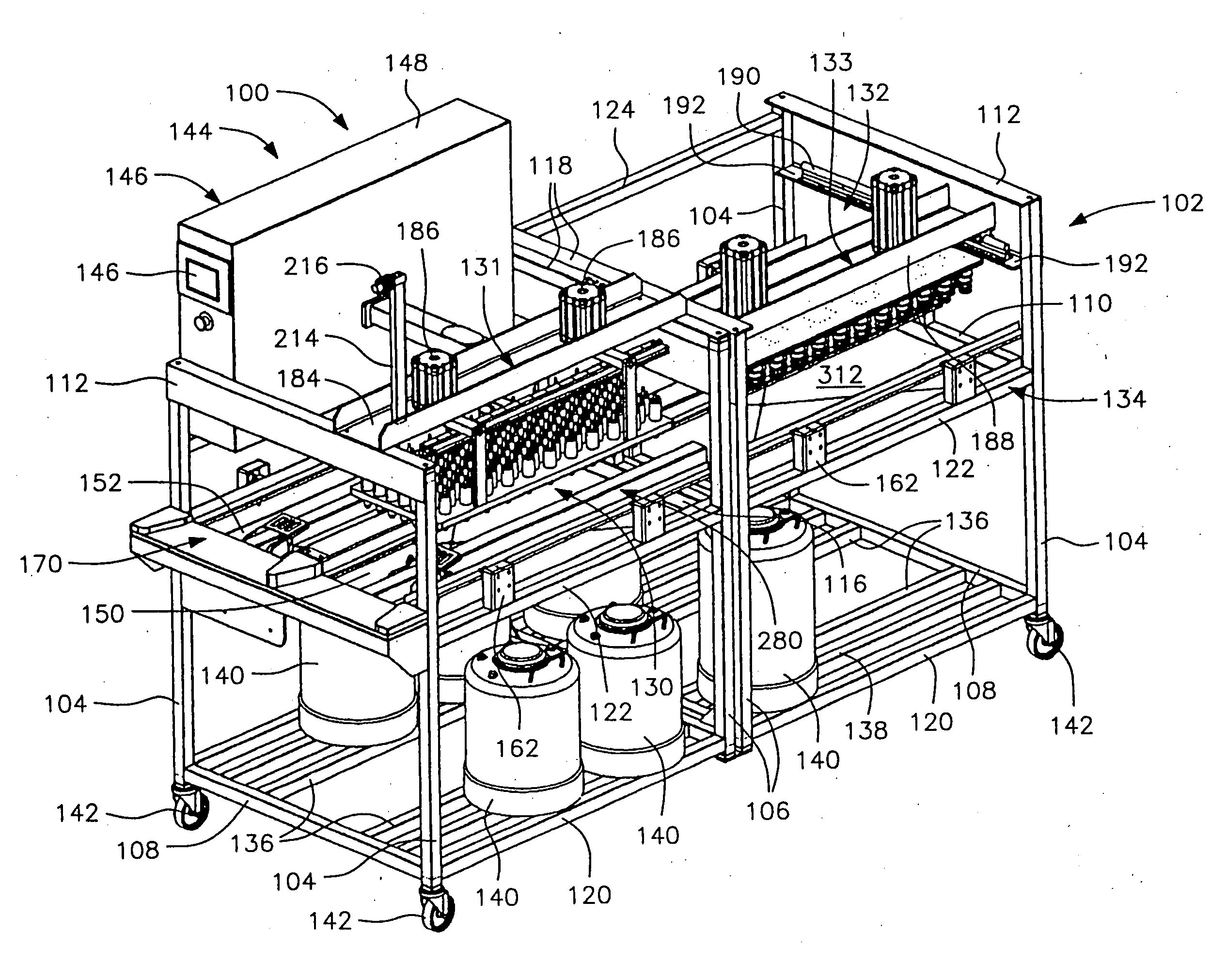

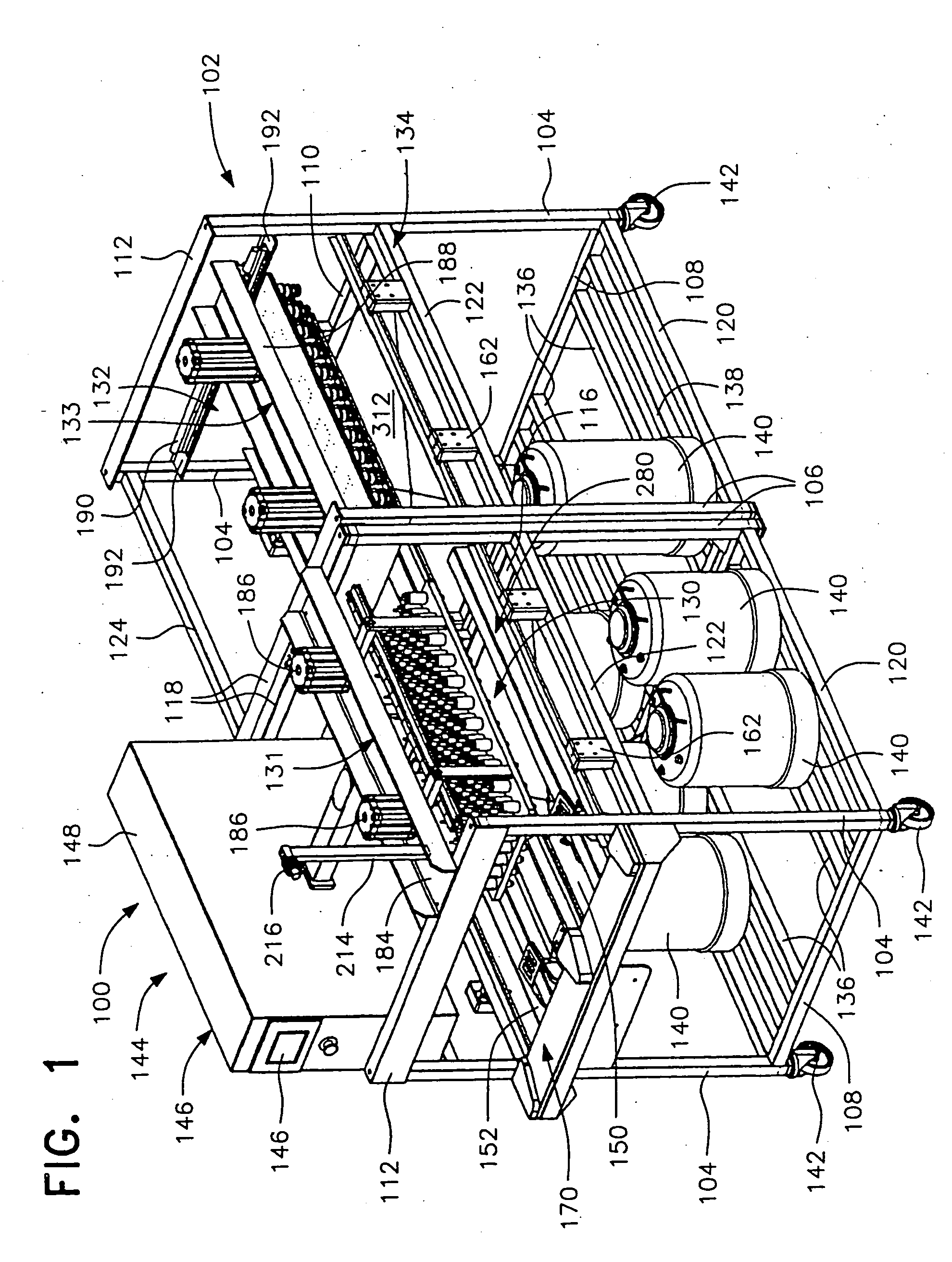

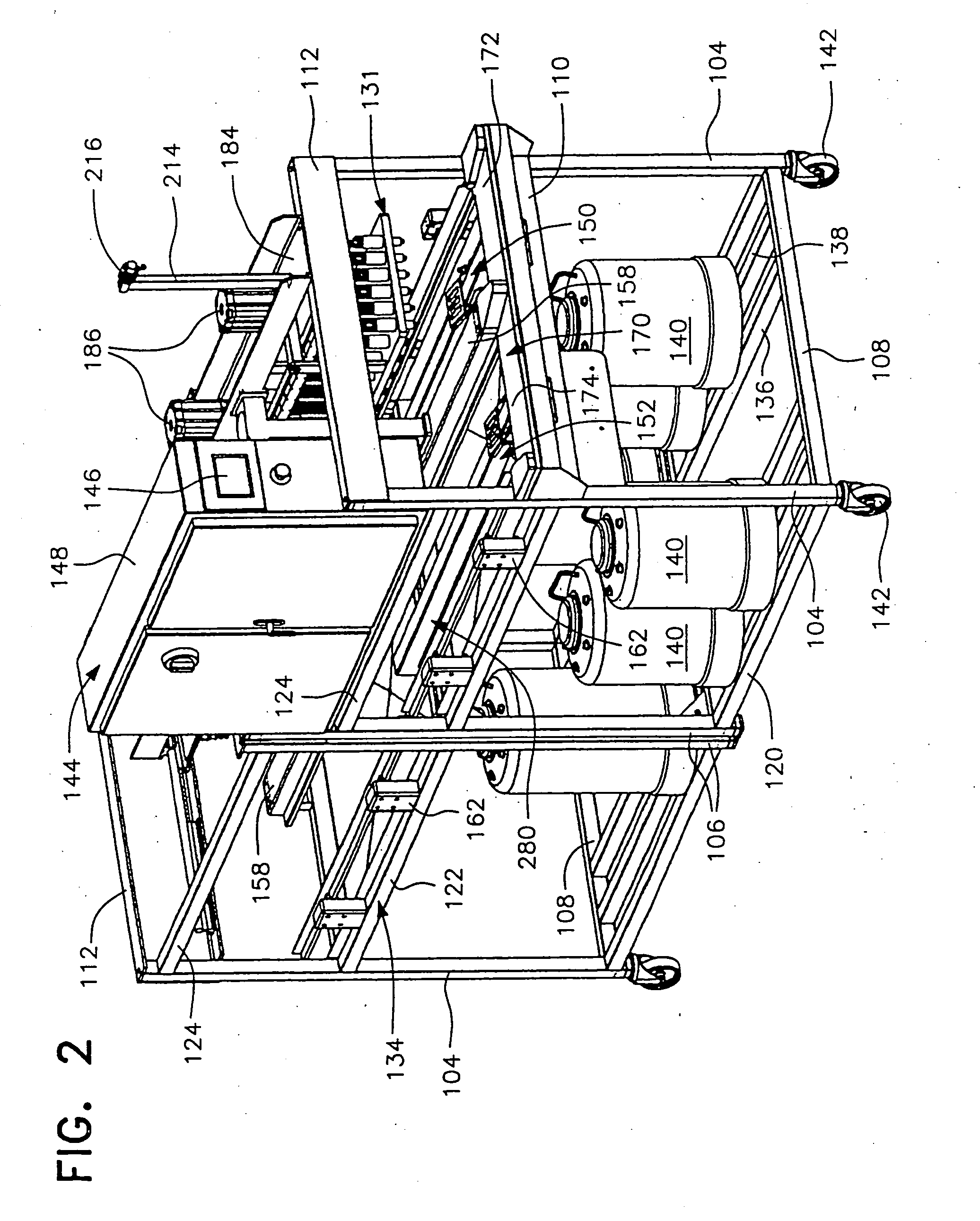

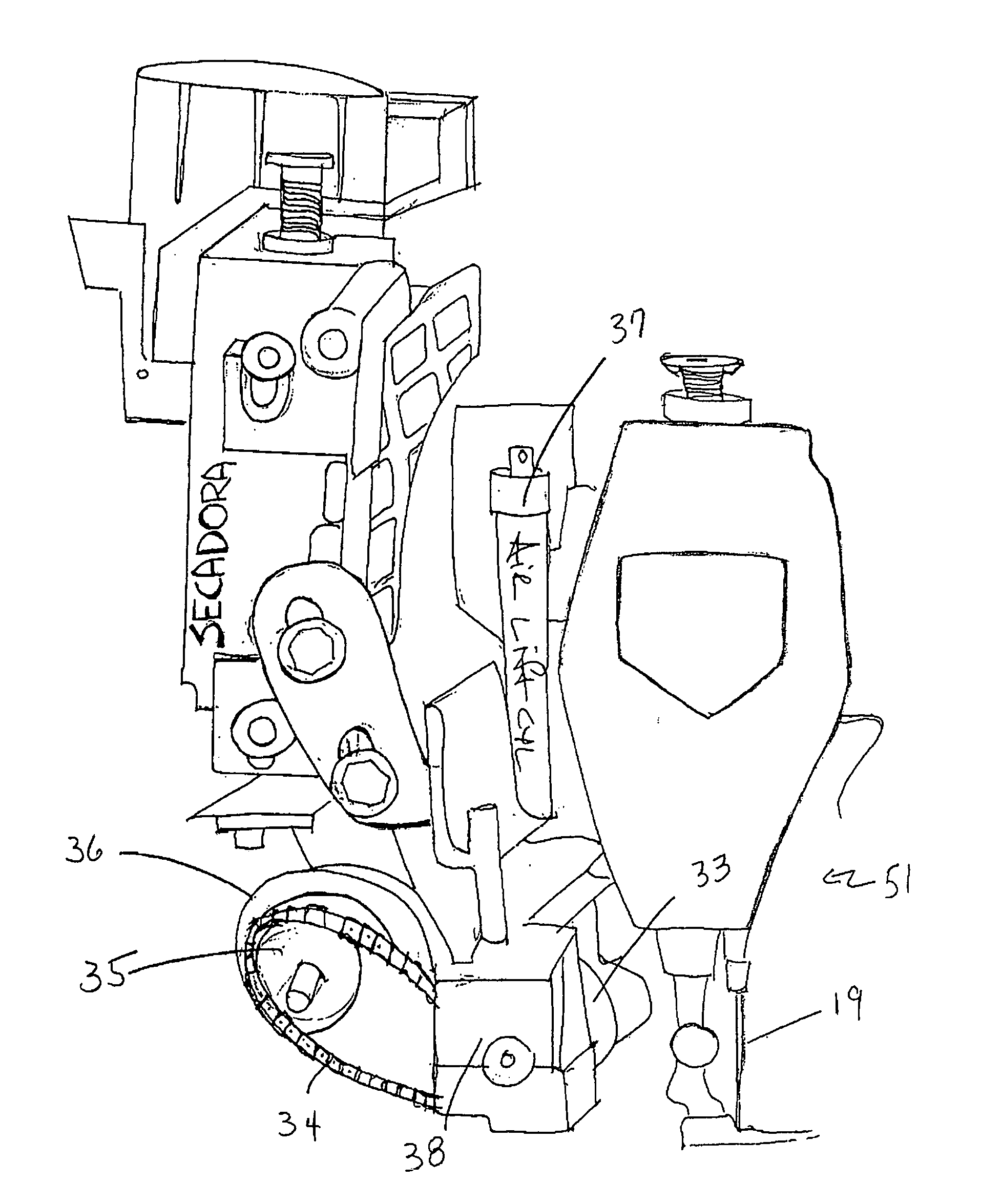

Automated egg injection machine and method

A pneumatically operated egg injection machine includes a sealed frame structure with a pair of in line parallel tracks through an injection section and a transfer section in series. An injection assembly over one parallel track includes a plurality of injectors gripped in a support plate to simultaneously inject vaccine into the same injection region irrespective of egg height and orientation. Fluid delivery systems meter prescribed vaccine dosages to the injecting needles with reduced turbulence, friction, heat and residence time to increase the delivered titer to the injected eggs. A transfer assembly includes a plurality of transfer suction cups which lift the injected eggs by causing a reduced pressure in a ring around the injection hole while maintaining the injection hole at atmospheric pressure, thus avoiding negative pressure in the egg. Once the eggs are lifted, the plate and suction cups move horizontally across the machine over to the other parallel track to deposit the injected eggs. All of the eggs are injected and transferred as a single group. The injection assembly is sprayed with a sanitizing solution at the same time that the injected eggs are moved from the injection section to the transfer section and the transfer assembly can transfer the eggs from the incubating tray to the hatching tray while the eggs in the next incubating tray are injected by the injecting assembly, thus increasing machine speed. The operation of the machine is controlled and monitored by a controller or computer with appropriate visual display monitor.

Owner:SANOVO CAPITAL

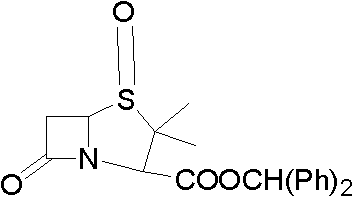

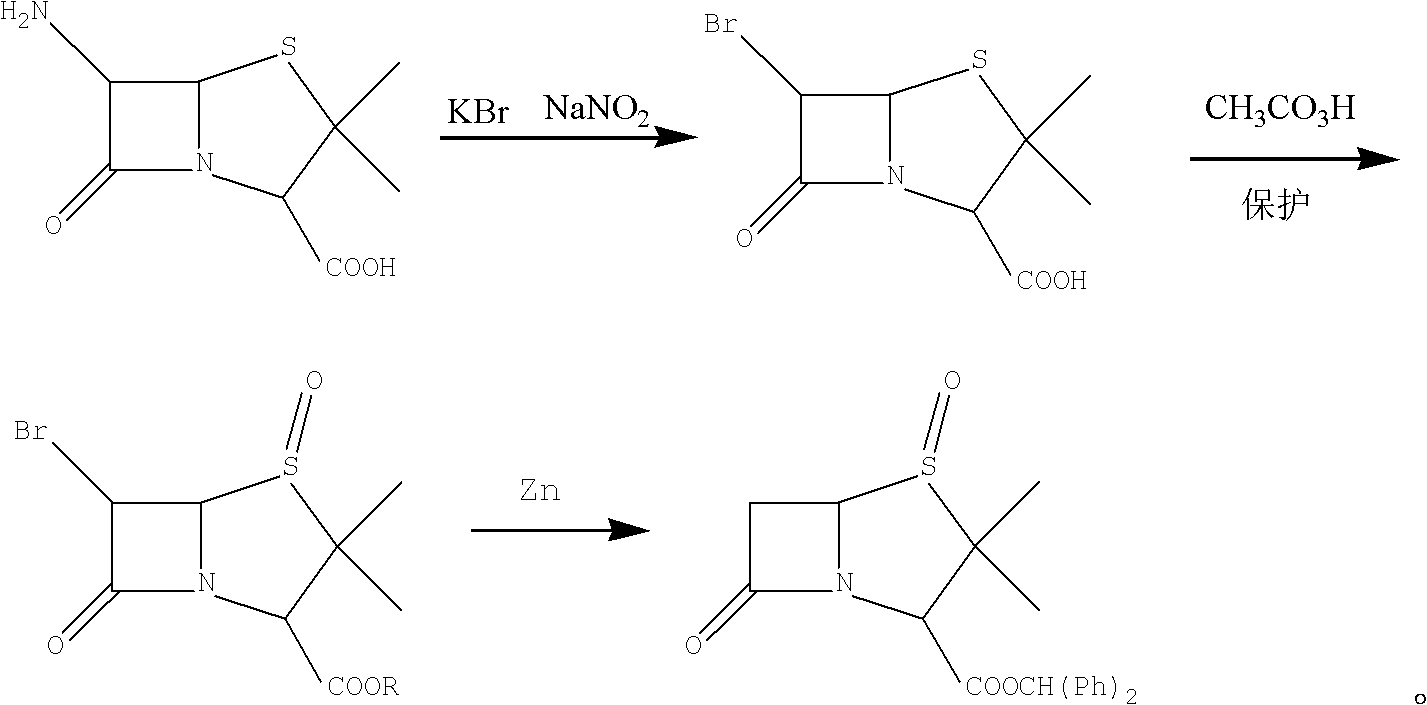

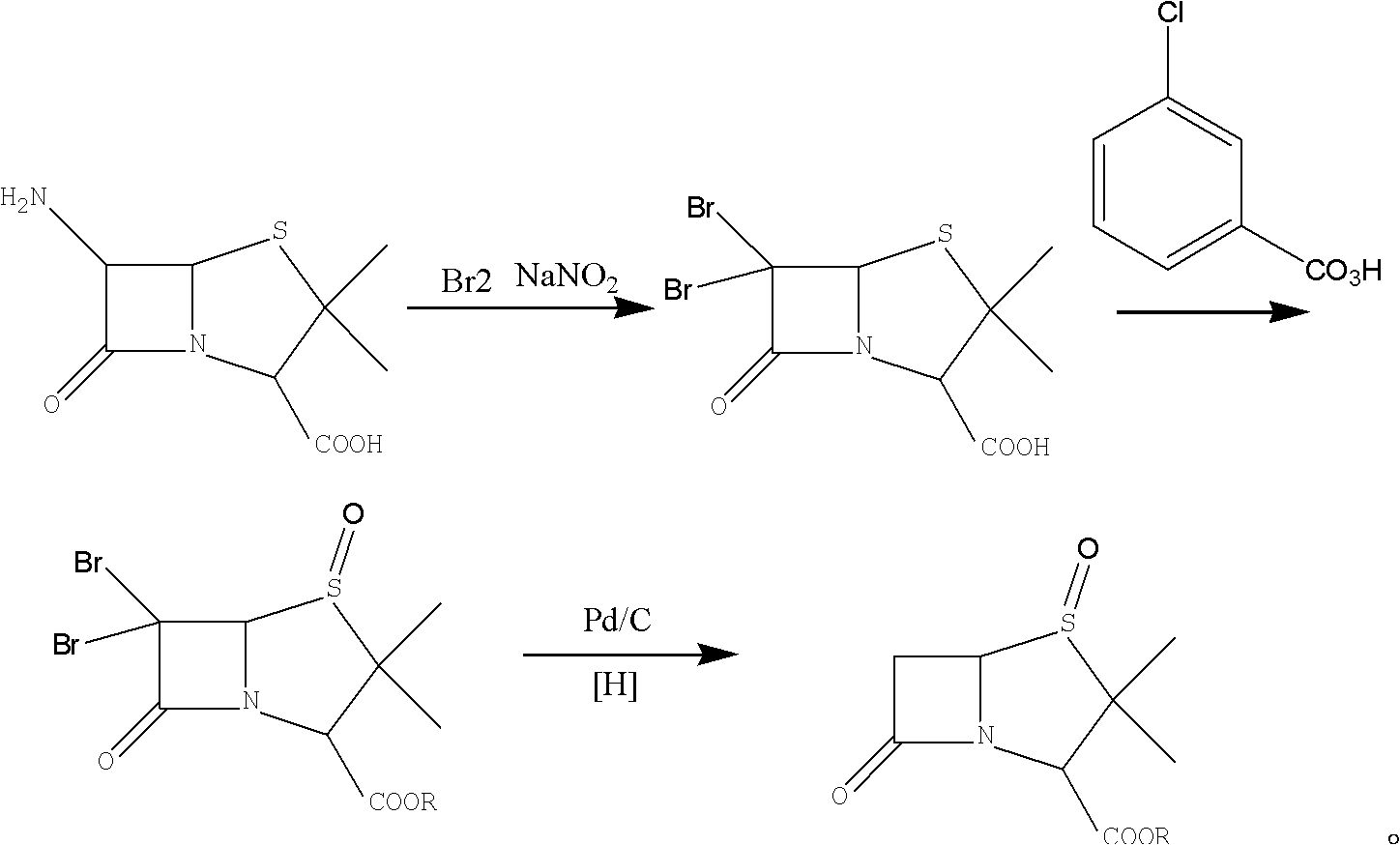

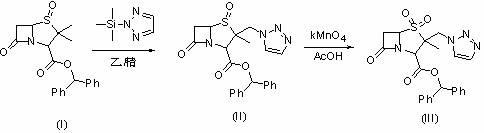

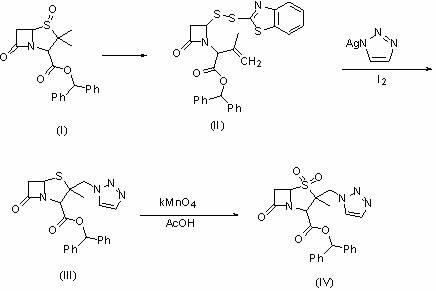

Method for preparing penicillanic acid sulfoxide diphenyl methyl ester

ActiveCN101935324AQuality improvementIncrease profitOrganic chemistryHigh pressureMeta-Chloroperoxybenzoic acid

The invention provides a method for preparing penicillanic acid sulfoxide diphenyl methyl ester. Penicillanic acid sulfoxide is prepared by the following four-step reaction. Hydrobromic acid is used as a brominating agent for substituting potassium bromide and bromine, and hydrogen peroxide is used as an oxidant for substituting peracetic acid and chloroperoxybenzoic acid, so the preparation method is safe and environment-friendly; in addition, the hydrogen peroxide is reacted with a compound (iii) under the catalysis action of acetyl molybdenum pyruvate so that the reaction mole yield can be obviously improved and reaches 90 percent; zinc powder which substitutes palladium and carbon is used as a reducing agent, so high-pressure equipment is not needed in the reaction; and the preparation method simplifies the process operation step, is easy for industrialized production, and reduces the production cost.

Owner:江西祥太生命科学有限公司

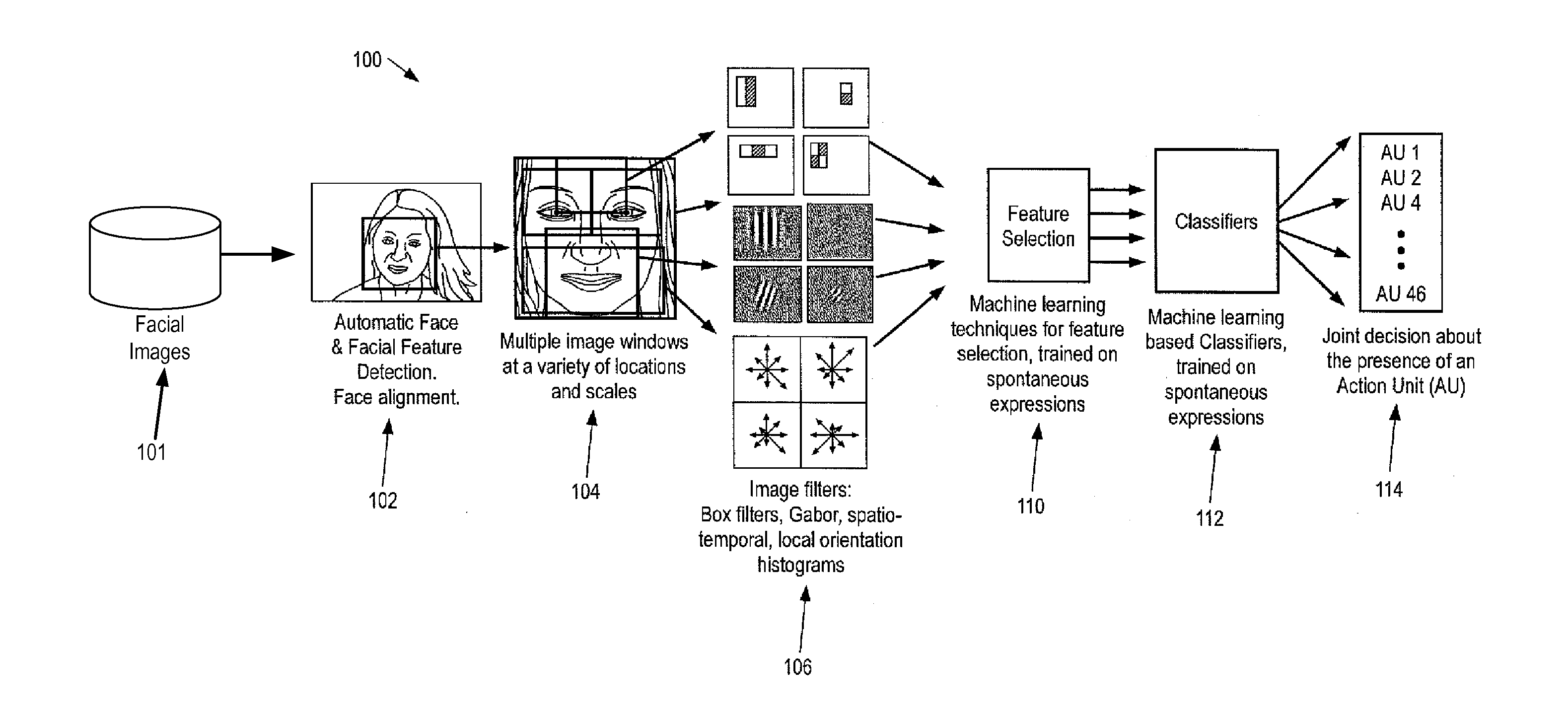

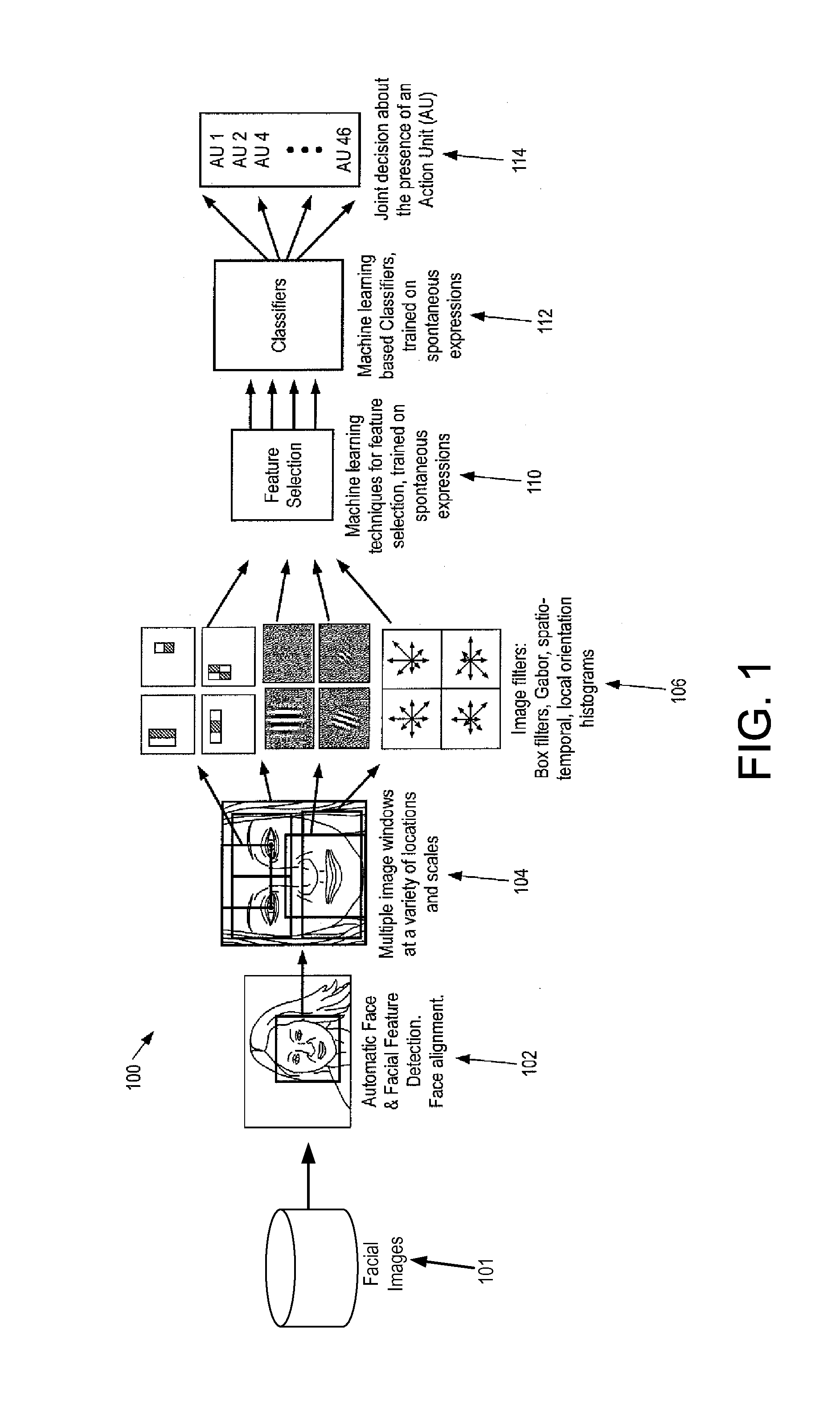

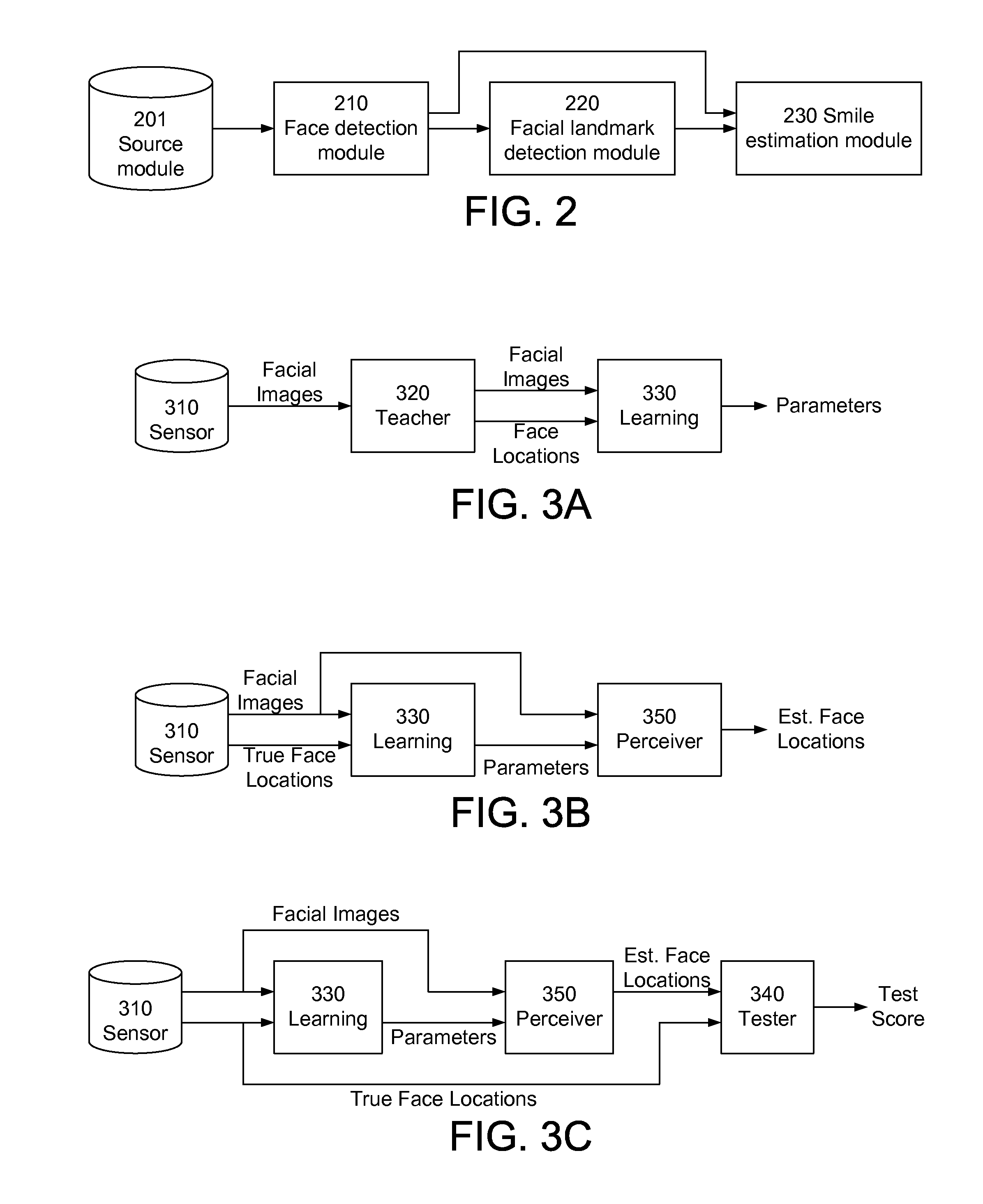

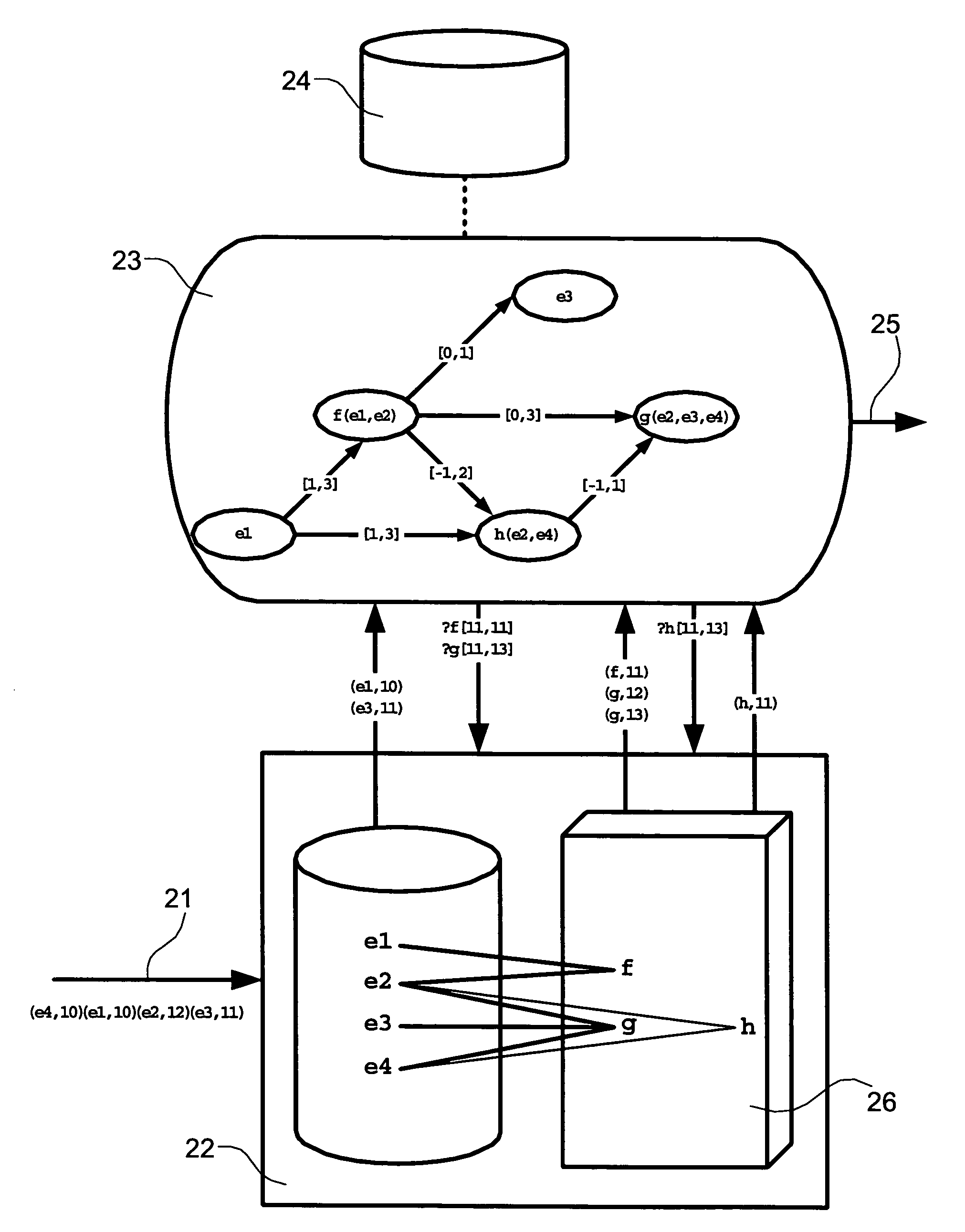

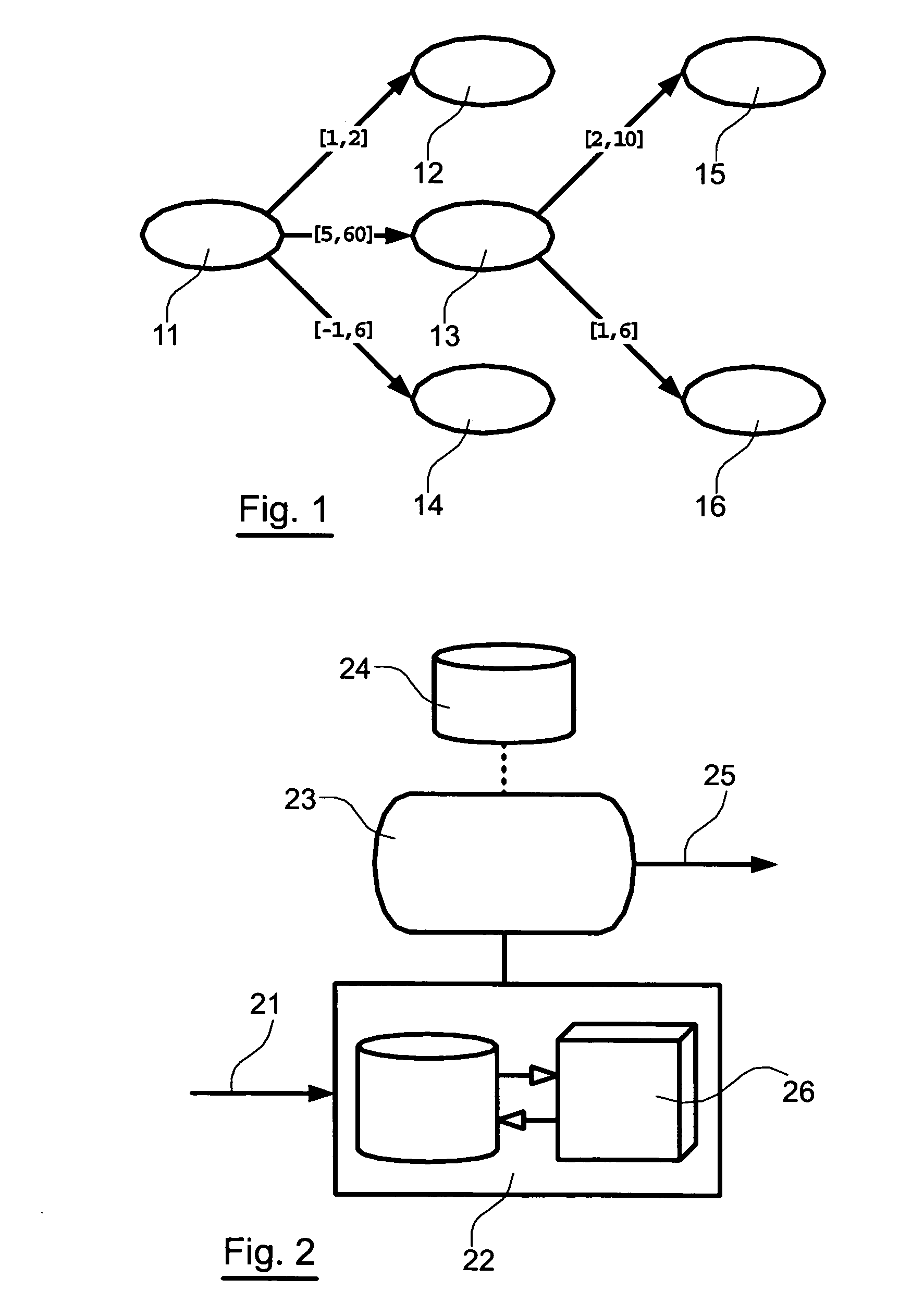

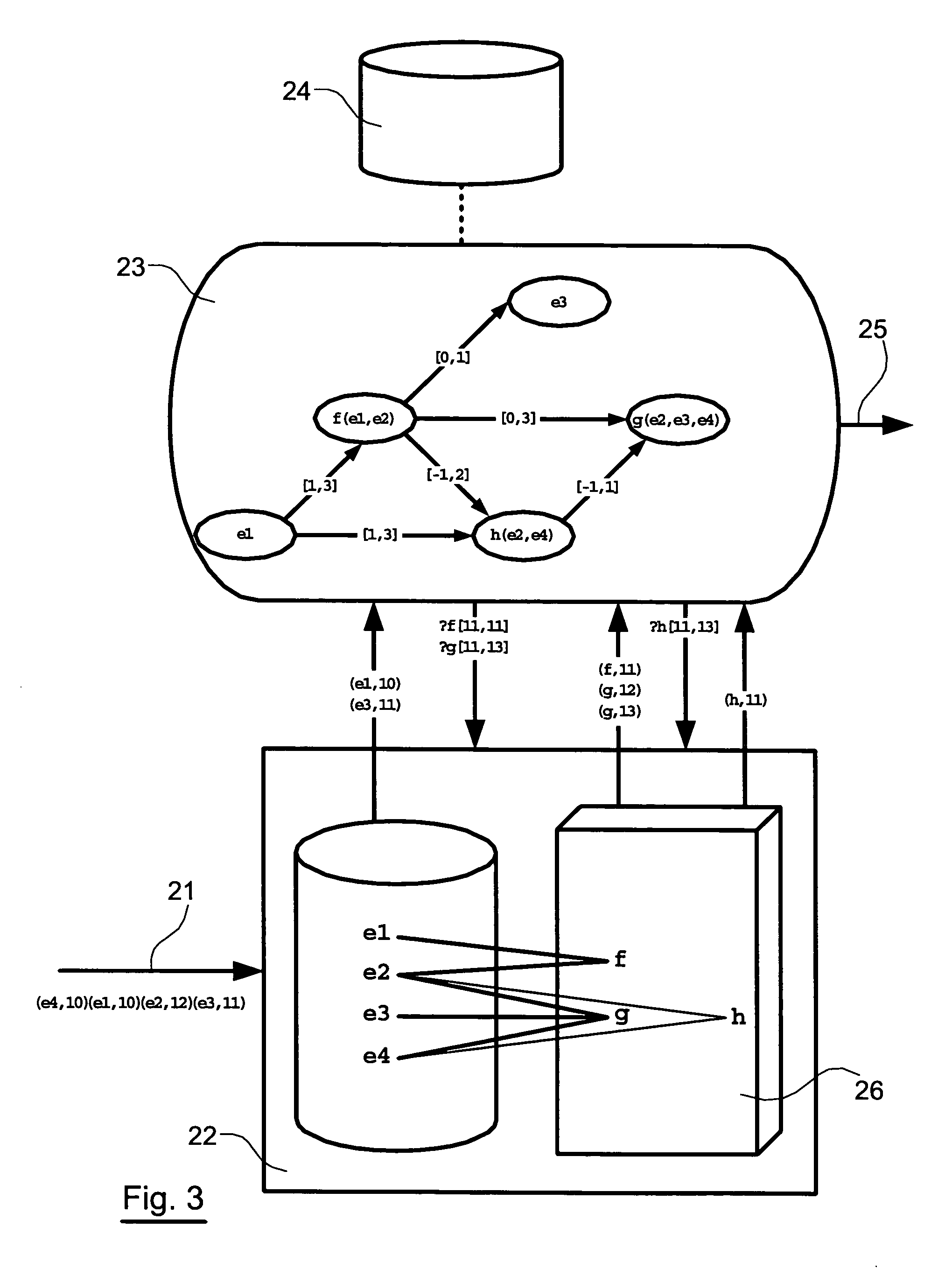

Facilitating Operation of a Machine Learning Environment

InactiveUS20140310208A1Easy to operate the machineDigital computer detailsMachine learningAs DirectedAlgorithm

Machine learning systems are represented as directed acyclic graphs, where the nodes represent functional modules in the system and edges represent input / output relations between the functional modules. A machine learning environment can then be created to facilitate the training and operation of these machine learning systems.

Owner:EMOTIENT

High temperature scarlet ceramic pigment and production method thereof

The invention provides a high temperature scarlet ceramic pigment and its preparing process, wherein the raw materials comprise (by weight percent) yttrium oxide 63.50-66.50, aluminum oxide 30.50-34.50, chromium hemitrioxide 0.90-1.90, and mineralization agent 1-5. The preparing process consists of weighing raw materials and batching, grinding the batches and sieving, drying and dewatering, synthesizing in a high-temperature electric resistance furnace, thermal insulating and naturally cooling, grinding, rinsing and sieving.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY

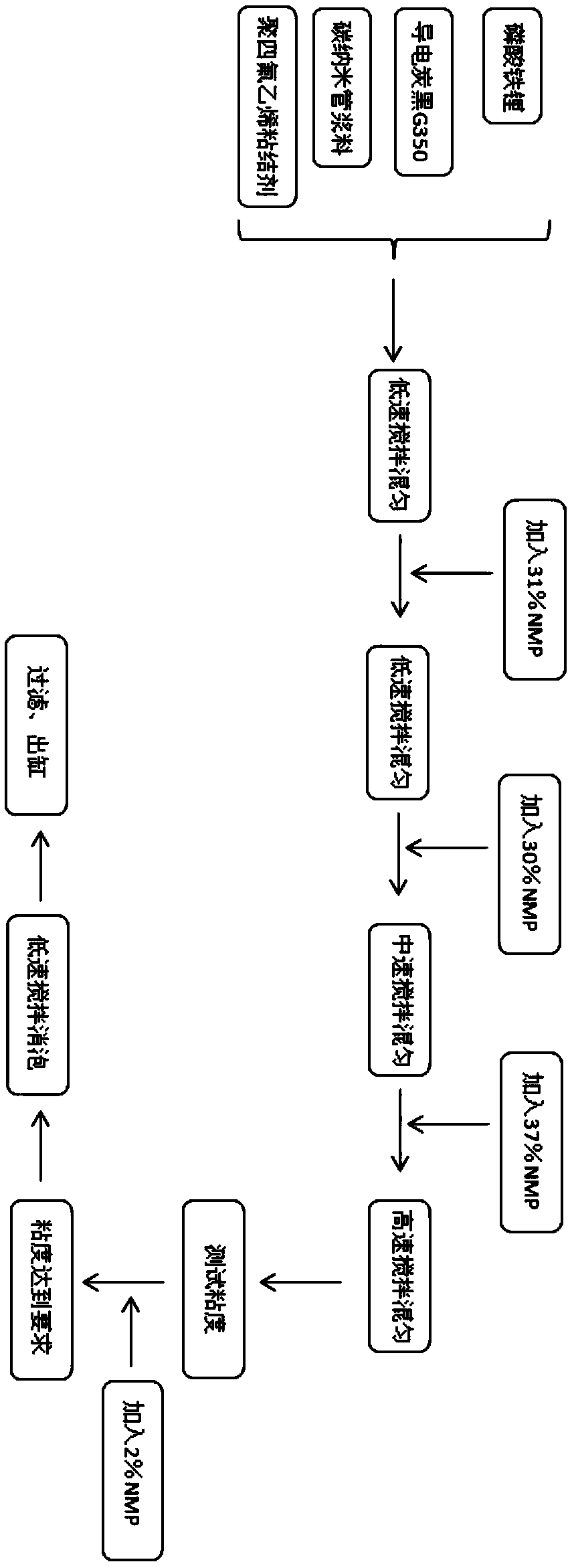

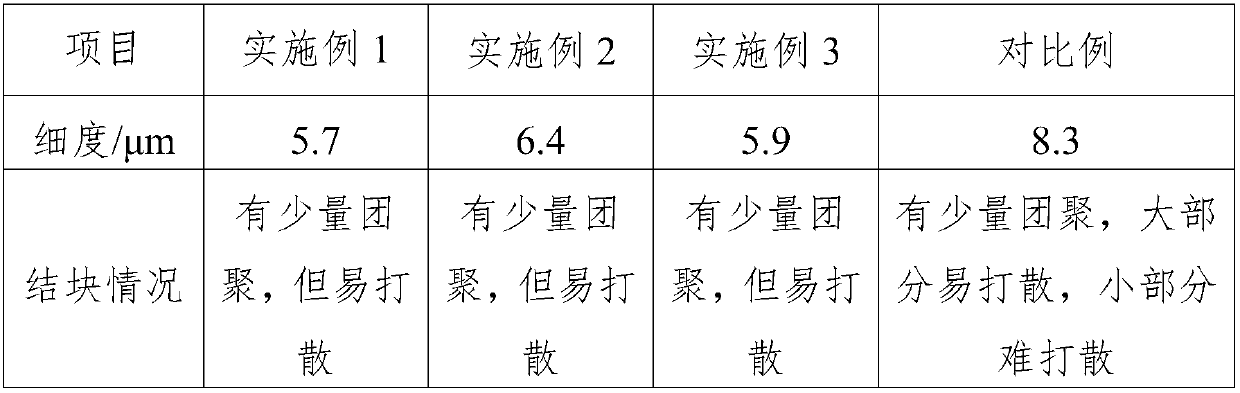

Preparation method of lithium ion battery sizing agent

InactiveCN109560264ASimplify process stepsShorten process timeCell electrodesSecondary cellsSizingLithium electrode

The invention relates to the field of lithium ion batteries, and specifically relates to a preparation method of a lithium ion battery sizing agent. The preparation method of the lithium ion battery sizing agent disclosed by the invention comprises the following five steps: dry material blending, low-speed high-viscidity stirring, medium-speed medium-viscidity stirring, high-speed low-viscidity stirring, viscidity modification and sizing agent discharge. The preparation method can be used for preparing an oily positive electrode sizing agent, an oily negative electrode sizing agent and an aqueous negative electrode sizing agent, the special working procedure of prefabricating a glue solution can be saved, the technological operating steps of the blending working procedure are simplified, the technological time is shortened, the utilization rate and capacity of the equipment are improved, gluing equipment, glue solution storage equipment or transfer equipment does not need to be purchased, the automation degree of blending is improved, and the uniformity and stability of the sizing agent are improved.

Owner:福建冠城瑞闽新能源科技有限公司

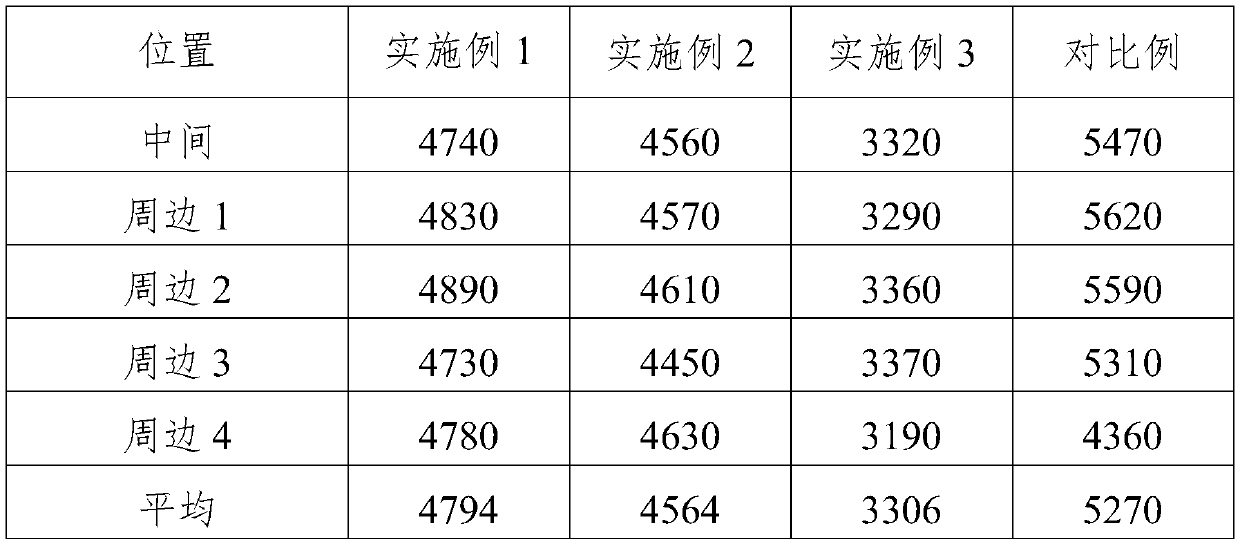

Method for preparing 2 beta-methyl penicillanate benzhydryl dioxide

ActiveCN102304139AIncreased nucleophilic reactivityReduce pollutionOrganic chemistryAcetic acidCupric bromide

The invention provides a method for preparing a 2 beta-methyl penicillanate benzhydryl dioxide, which is to prepare the 2 beta-methyl penicillanate benzhydryl dioxide by four-step reactions. In the method, hydrobromic acid and sodium nitrite or cupric bromide serving as a brominating agent and other methods are adopted, especially bromide is generated by using adsorption of anionic resin, and water is a side product, so that the method is safe and environmentally friendly; the resin can be used repeatedly; the reaction molar yield can be remarkably improved, reaching over 75 percent; and dichloromethane, water, little glacial acetic acid, particularly as well as a catalytic amount of concentrated sulfuric acid are used to replace massive glacial acetic acid serving as a solvent, so that massive glacial acetic acid is removed. The method has unique process, stable product quality, mild process condition and easy control, the traditional azidation reaction and ethynylation reaction are eliminated, the production cost is reduced, the environmental pollution is greatly reduced, and no special equipment is required. The method is suitable for industrial generation in scale.

Owner:JIANGXI FUSHINE PHARMA CO LTD

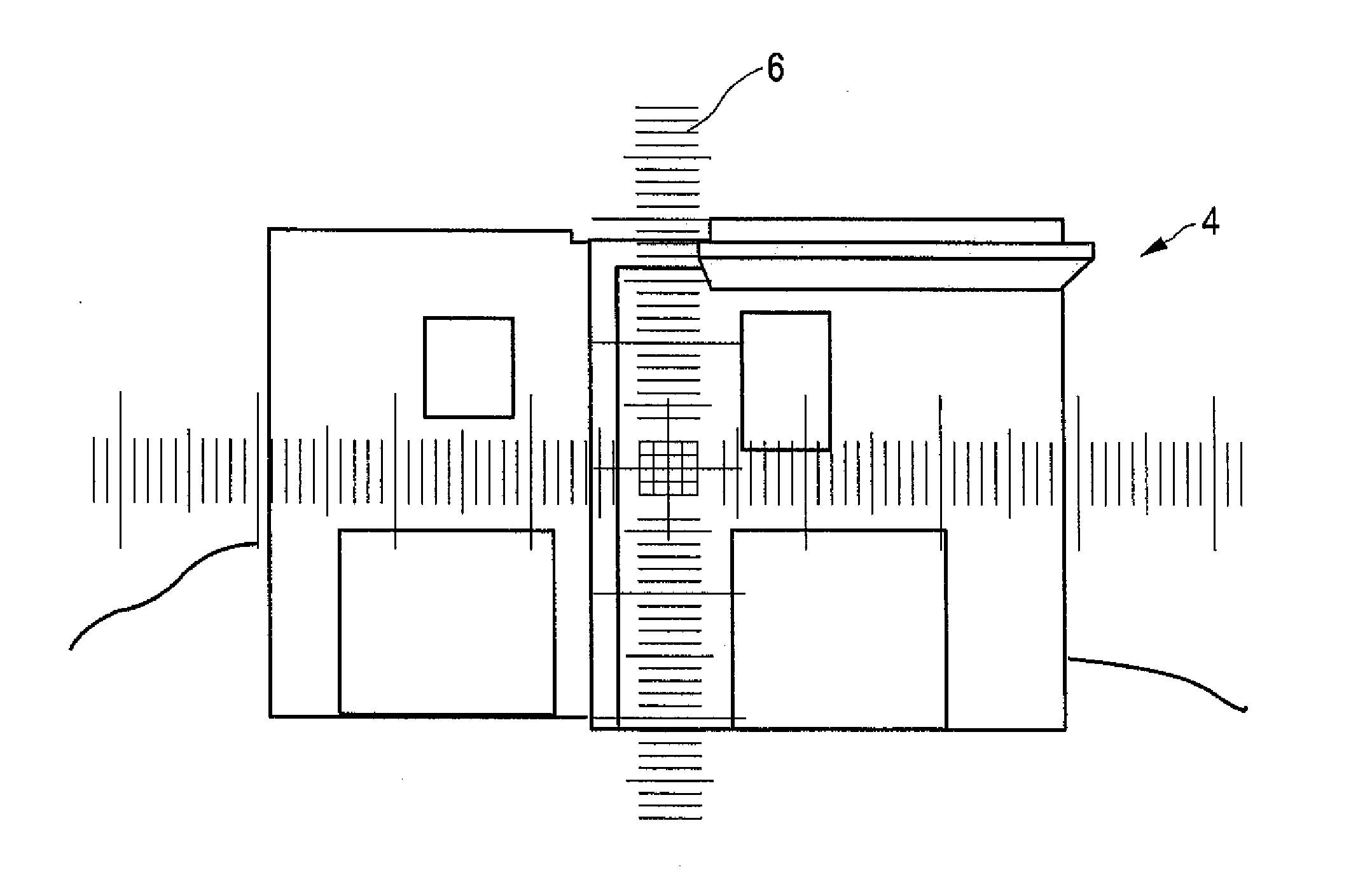

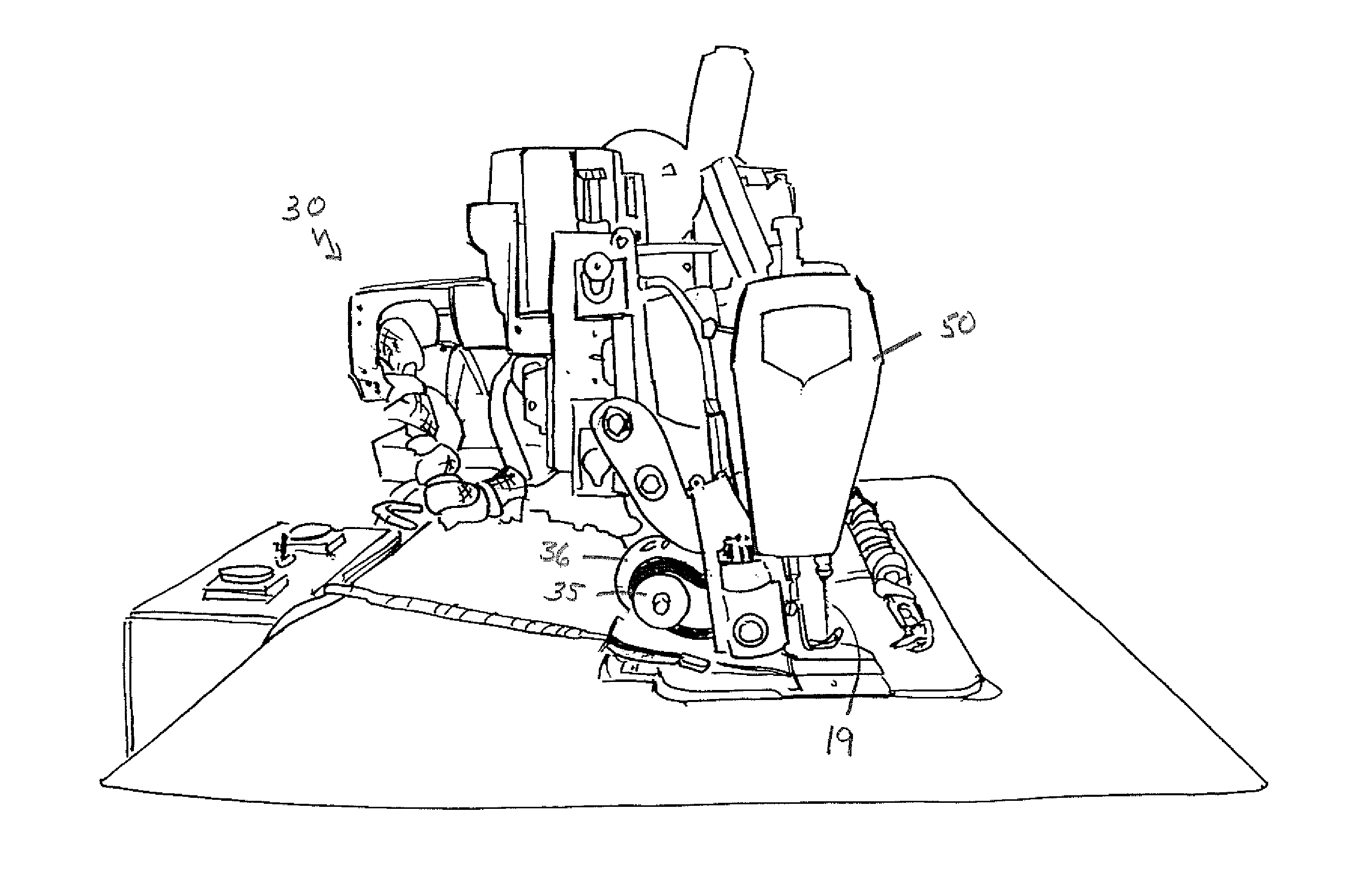

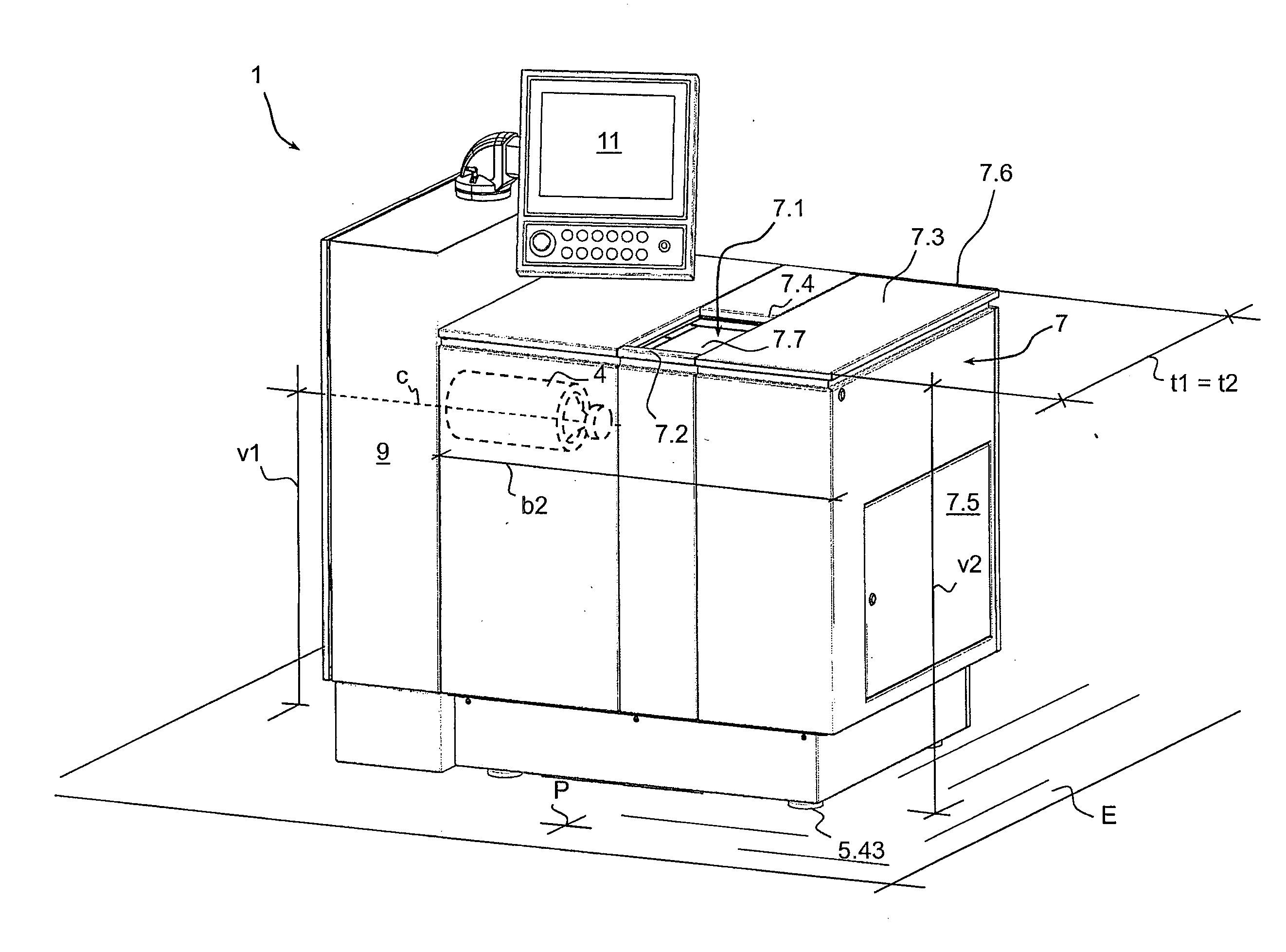

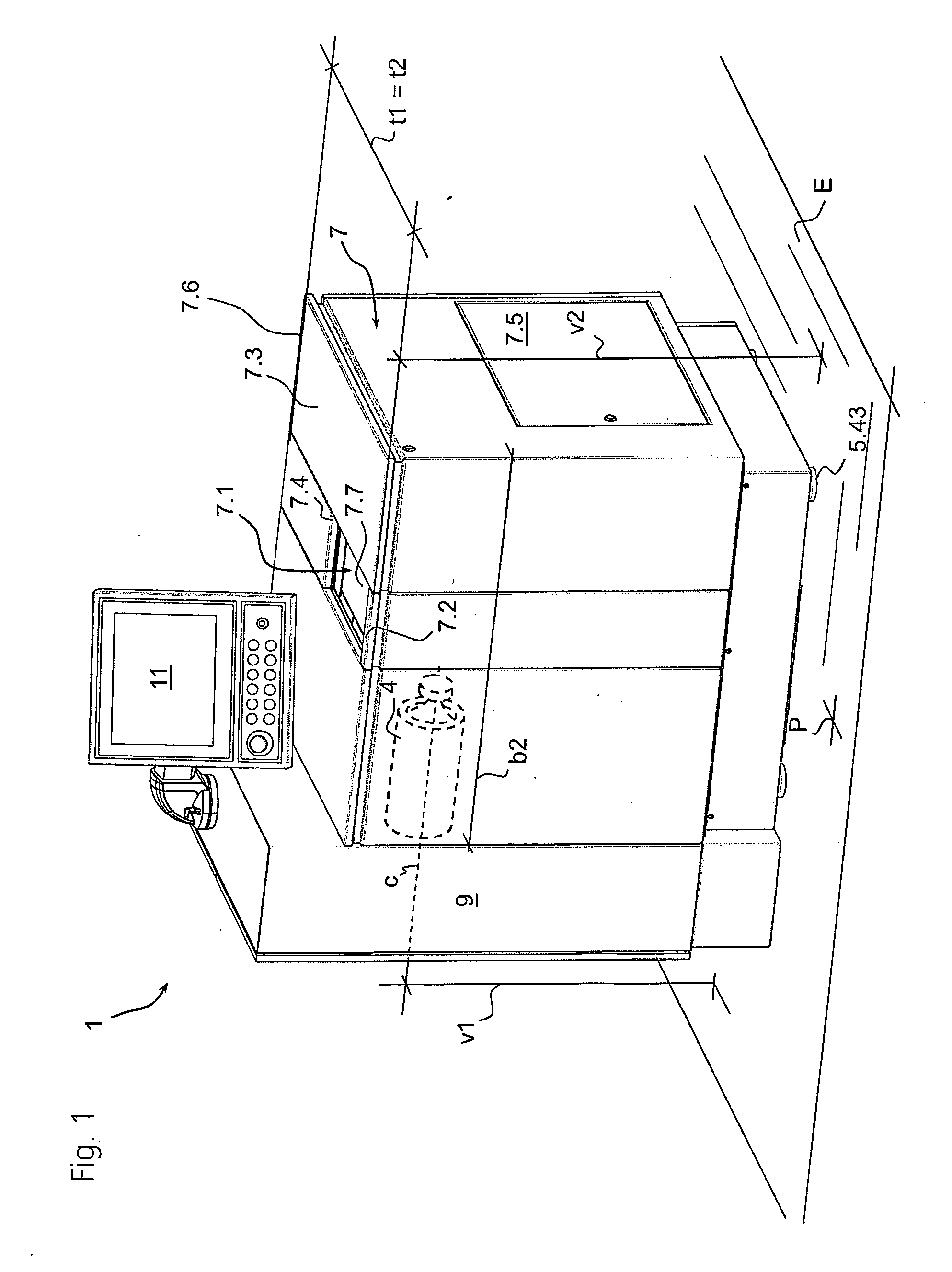

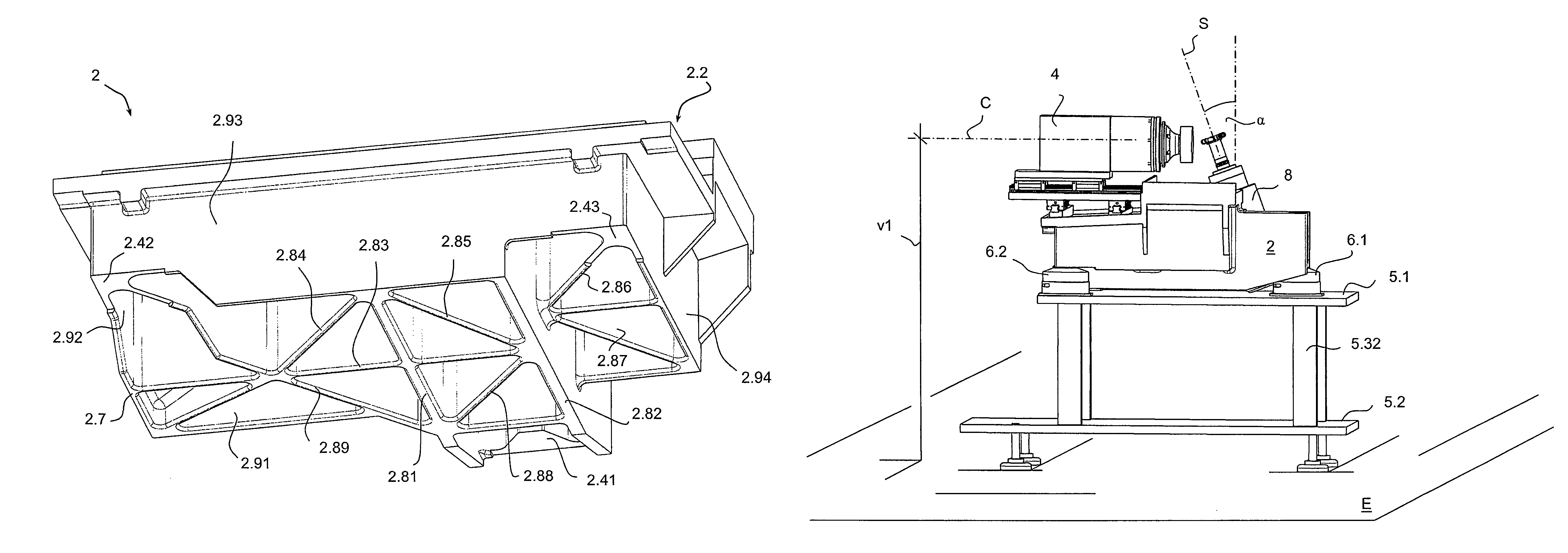

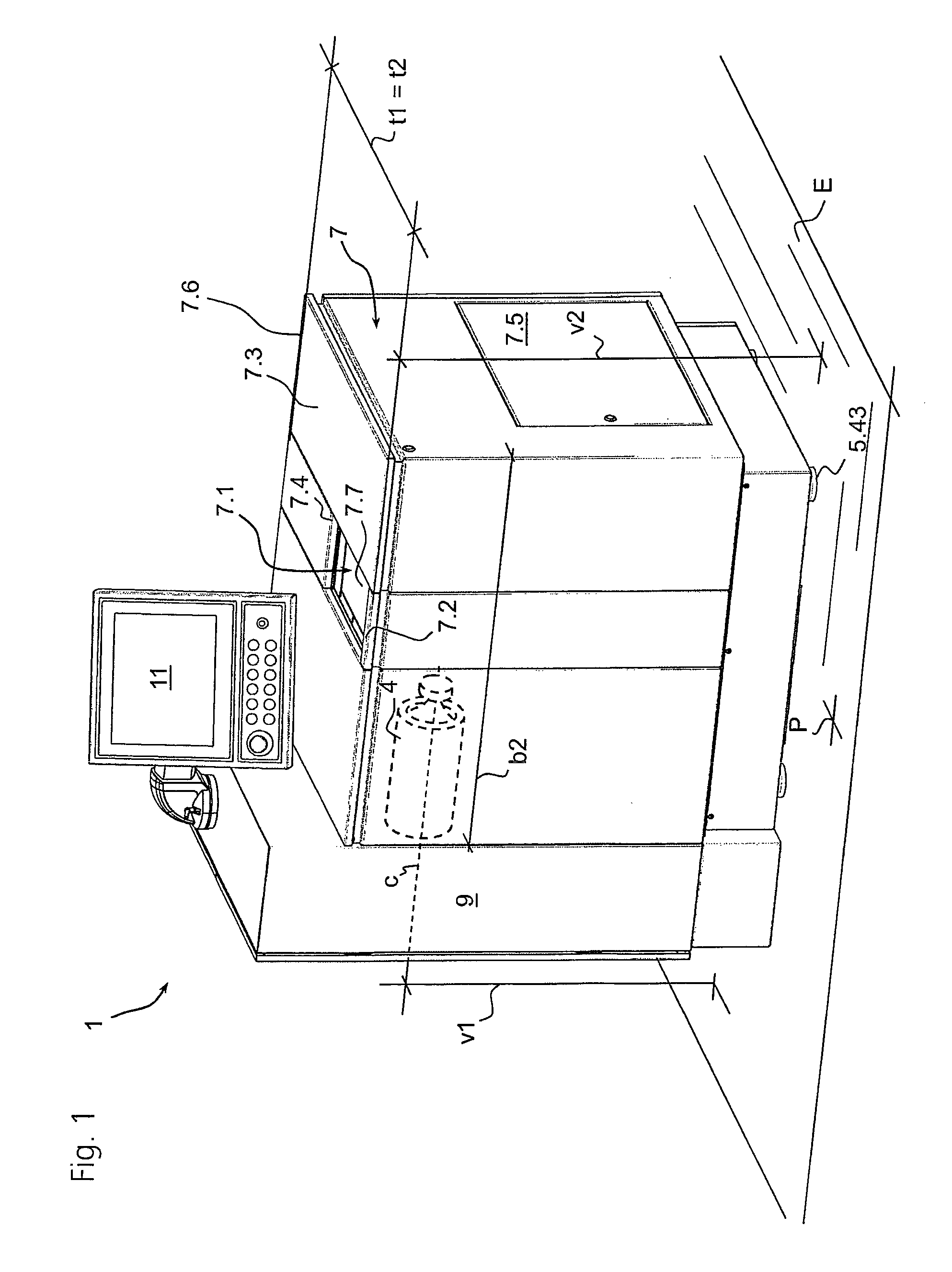

Lathe for manufacturing ophthalmic lenses made of plastic

ActiveUS20100224039A1Reduce quality problemsReduce loadLathesTurning machine accessoriesRotational axisEngineering

A turning machine for producing non rotationally symmetric surfaces of synthetic spectacle lenses, having a support plane E, a machine bed made of cast iron with a width b1 and a mass m1, a linear motor with an actuator comprising a turning tool holder and an oscillation axis Z, a workpiece spindle with a rotational axis C and a movement axis X, wherein the machine bed has at least two bearing surfaces arranged at a distance for the linear motor and for the workpiece spindle, and between the two bearing surfaces, a chip space is provided which is limited at least partially by the machine bed, wherein the linear motor is supported on the first bearing surface and the workpiece spindle is supported on the second bearing surface in relation to the chip space opposite the linear motor, wherein the mass of the machine bed has the maximum value m1, and the value m1 lies between 100 kg and 500 kg, between 150 kg and 300 kg, between 170 kg and 200 kg or 180 kg. A turning machine, in which the ratio of the mass m1 of the machine bed to a moved mass m2 of the linear motor 3 is greater than a quotient Q, wherein the quotient Q is between 1:500 and 1:20, between 1:60 and 1:30 or between 1:140 and 1:100, or 1:40 or 1:120.

Owner:SCHNEIDER GMBH & CO KG

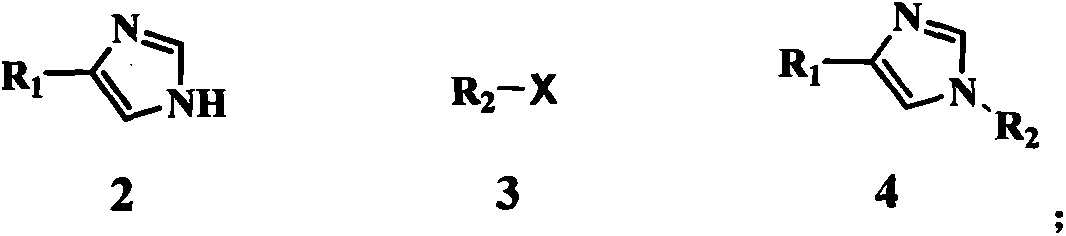

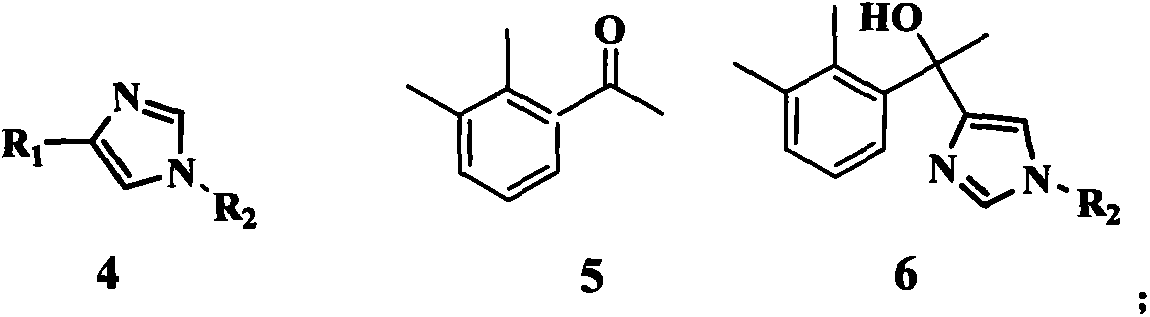

Method for preparing medetomidine

ActiveCN103664788AEfficient preparationSimple process conditionsOrganic chemistryMedetomidineChemistry

The invention discloses a method for preparing medetomidine. Medetomidine can be effectively prepared according to the method for preparing medetomidine, and by adopting a cheap 4-imidazole derivative and cheap 1-(2,3-dimethylphenyl)ethanone as raw materials, the medetomidine product is prepared only through three-step reactions. The method has simple process conditions, is easy to control, and is conducive to industrialized mass production; and the yield of medetomidine prepared by the method for preparing medetomidine can reach 76%, and the product purity can reach 99.5%.

Owner:YICHANG HUMANWELL PHARMA +1

Fat-soluble potassium ferrate slow releaser and preparation method thereof

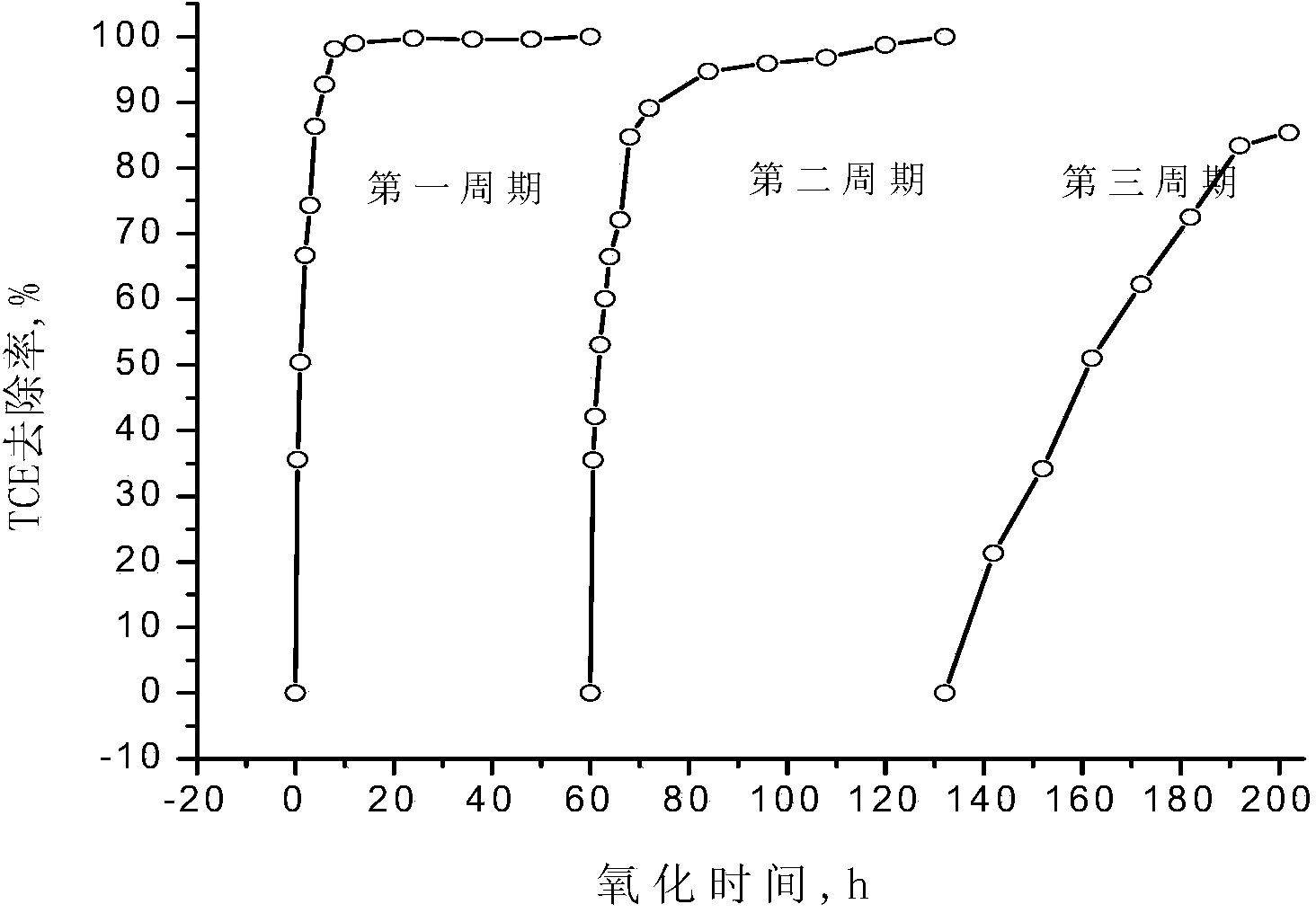

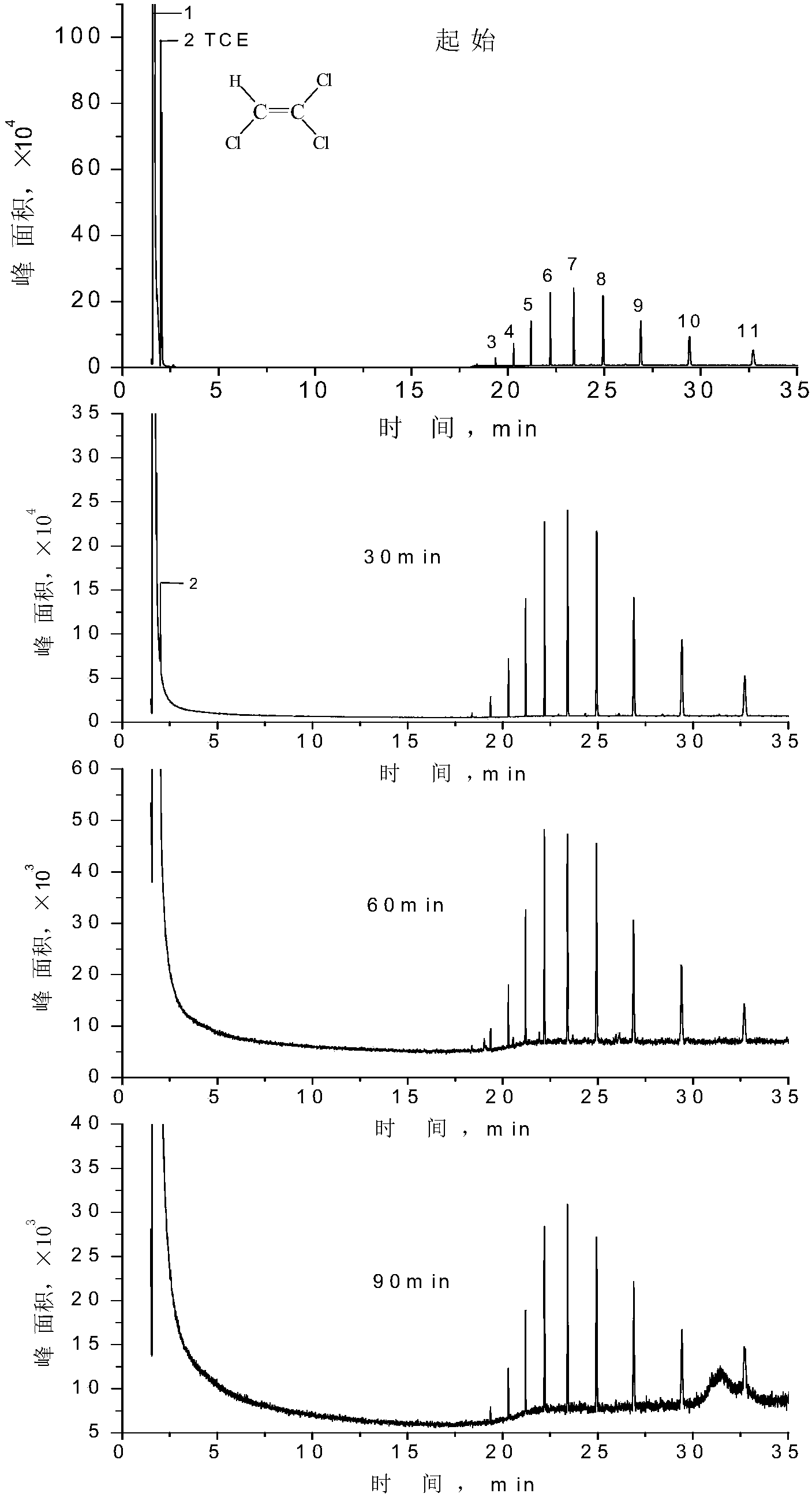

ActiveCN104071885AAvoid secondary pollutionReduce releaseContaminated groundwater/leachate treatmentWater/sewage treatment by oxidationRoom temperaturePolyethylene glycol

The invention provides a fat-soluble potassium ferrate slow releaser and a preparation method thereof. The fat-soluble potassium ferrate slow releaser comprises an outer wall and an inner core, wherein the outer wall which is sliced paraffin wraps the inner core, and the inner core is potassium ferrate powder. The preparation method comprises the following steps: adding the sliced paraffin into an ethanol solution containing polyethylene glycol, and heating and stirring; after the sliced paraffin is fully dissolved, adding an emulsifier and continuously stirring; and finally, adding the potassium ferrate powder and stirring till cooling to room temperature, thus obtaining the fat-soluble potassium ferrate slow releaser with the outer wall being sliced paraffin and the inner core being potassium ferrate. The slow releaser provided by the invention can solve the problem that the oxidizing agent is not selectively consumed when chloridized organic pollutants in underground water are treated by potassium ferrate, can improve the utilization ratio of the potassium ferrate oxidizing agent and is simple in operating step of the process and short in period.

Owner:HUAQIAO UNIVERSITY

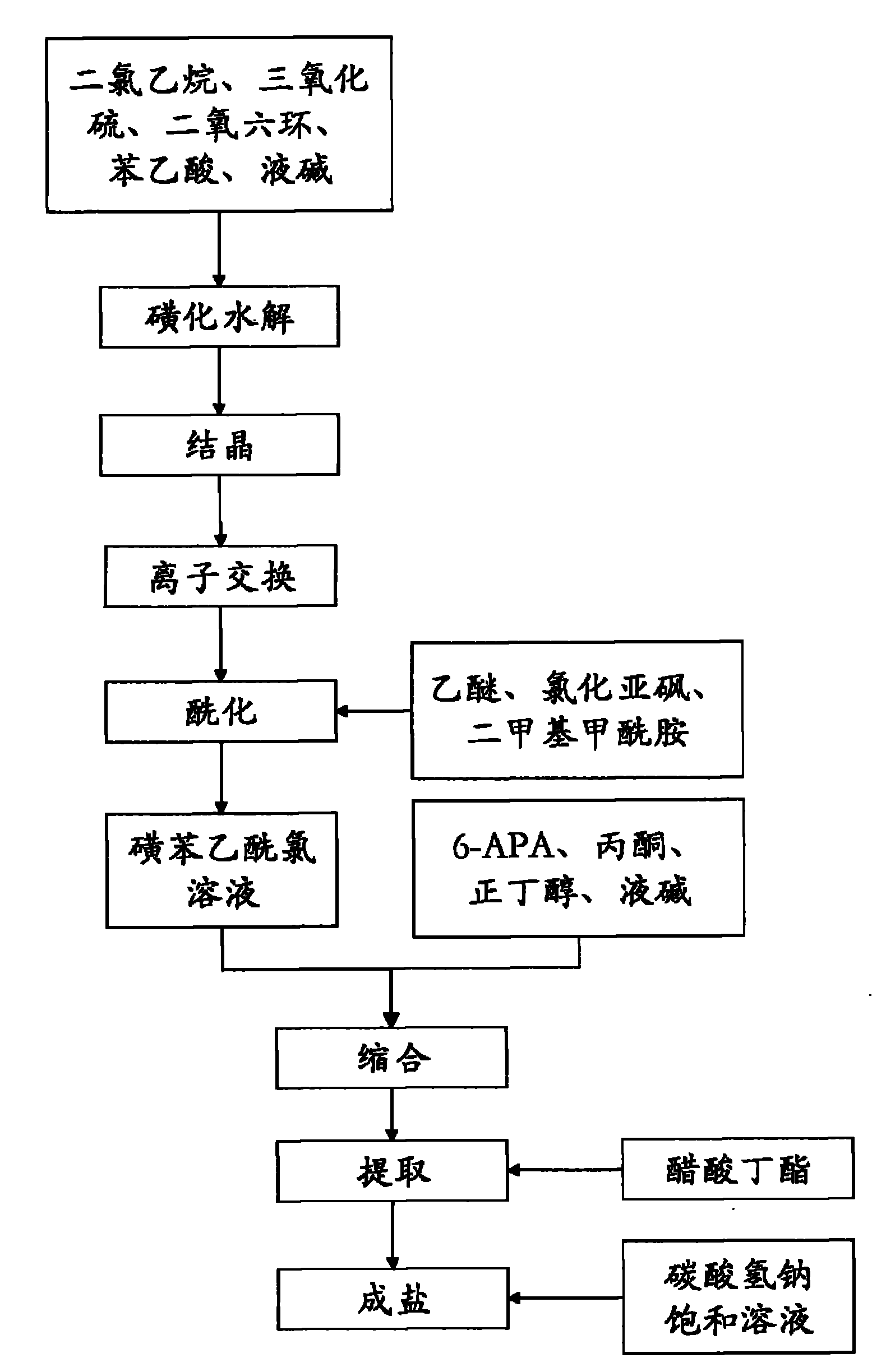

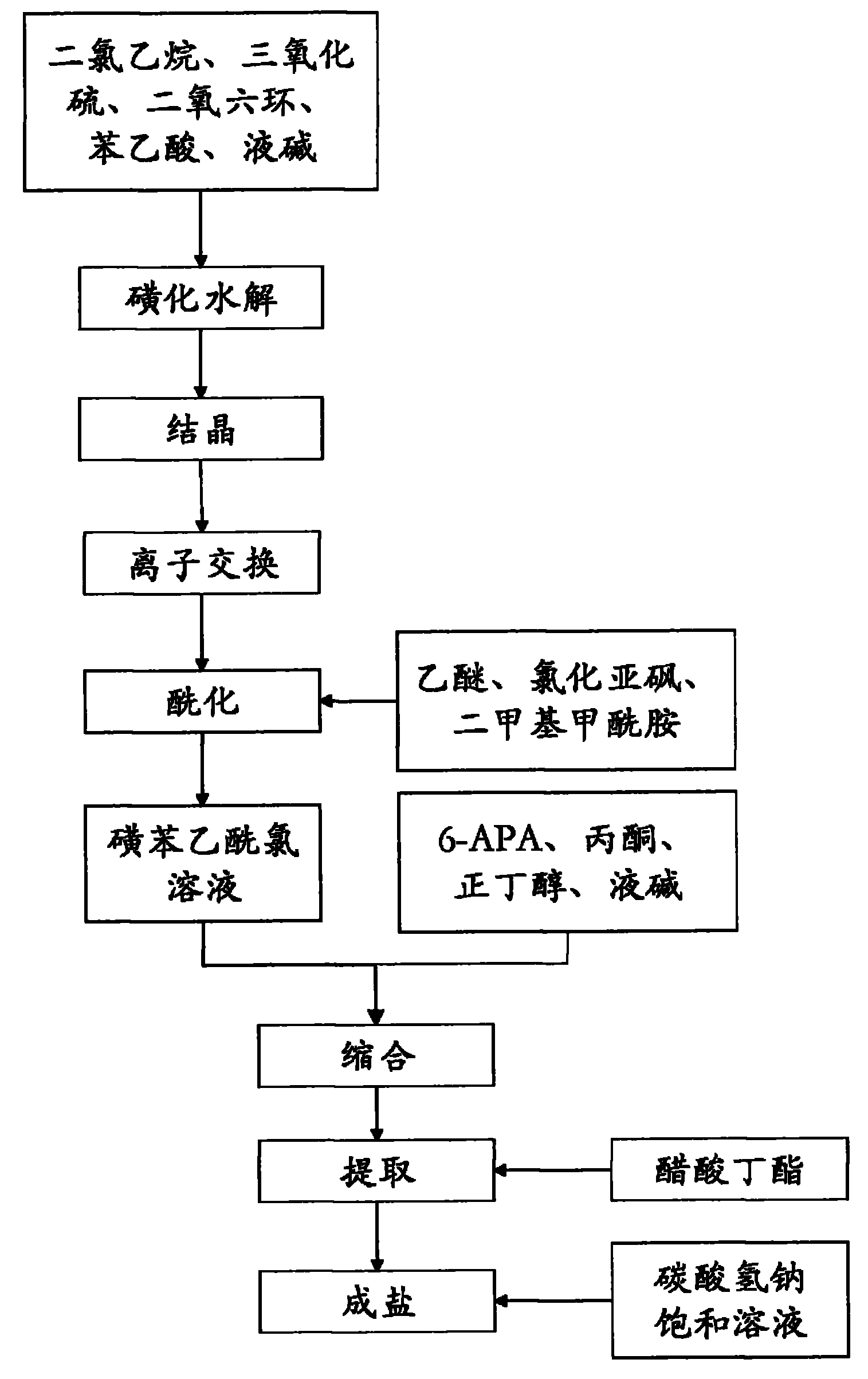

Preparation methods of sulbenicillin sodium and injection thereof

InactiveCN101805356ASimple stepsLess impurities in the reactionAntibacterial agentsOrganic chemistryIonIon exchange

The invention discloses a preparation method of sulbenicillin sodium, which comprises the following steps of: sulfonating, hydrolyzing, crystallizing, ion-exchanging, acidylating, condensing, extracting and salifying to obtain sulbenicillin sodium. The method has the advantages of simple technological steps, fewer reaction impurities and high product purity, and the yield is higher than 50%. Meanwhile, the invention also relates to a preparation method of a sulbenicillin sodium injection.

Owner:HUNAN ERKANG XIANGYAO PHARMA

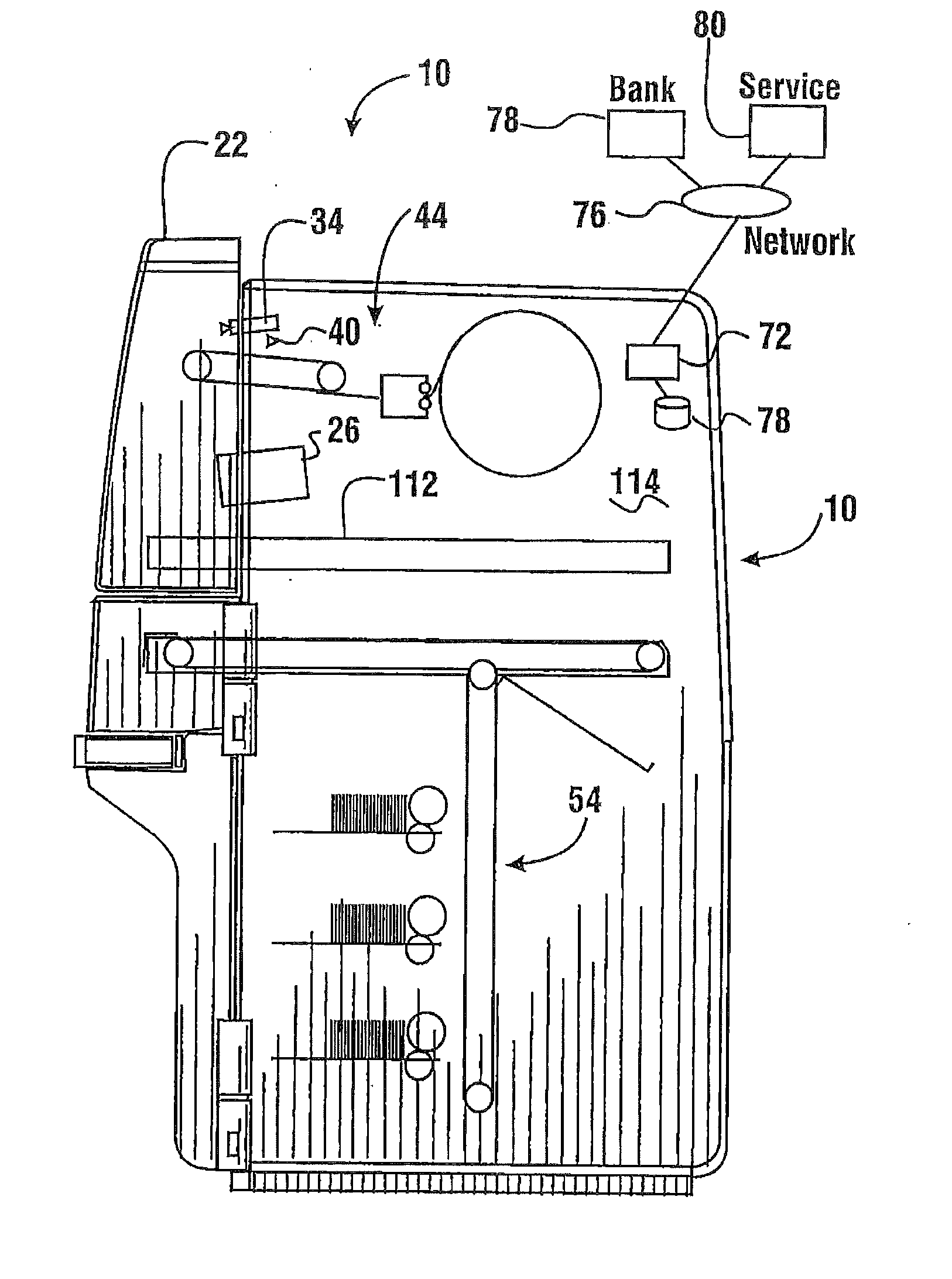

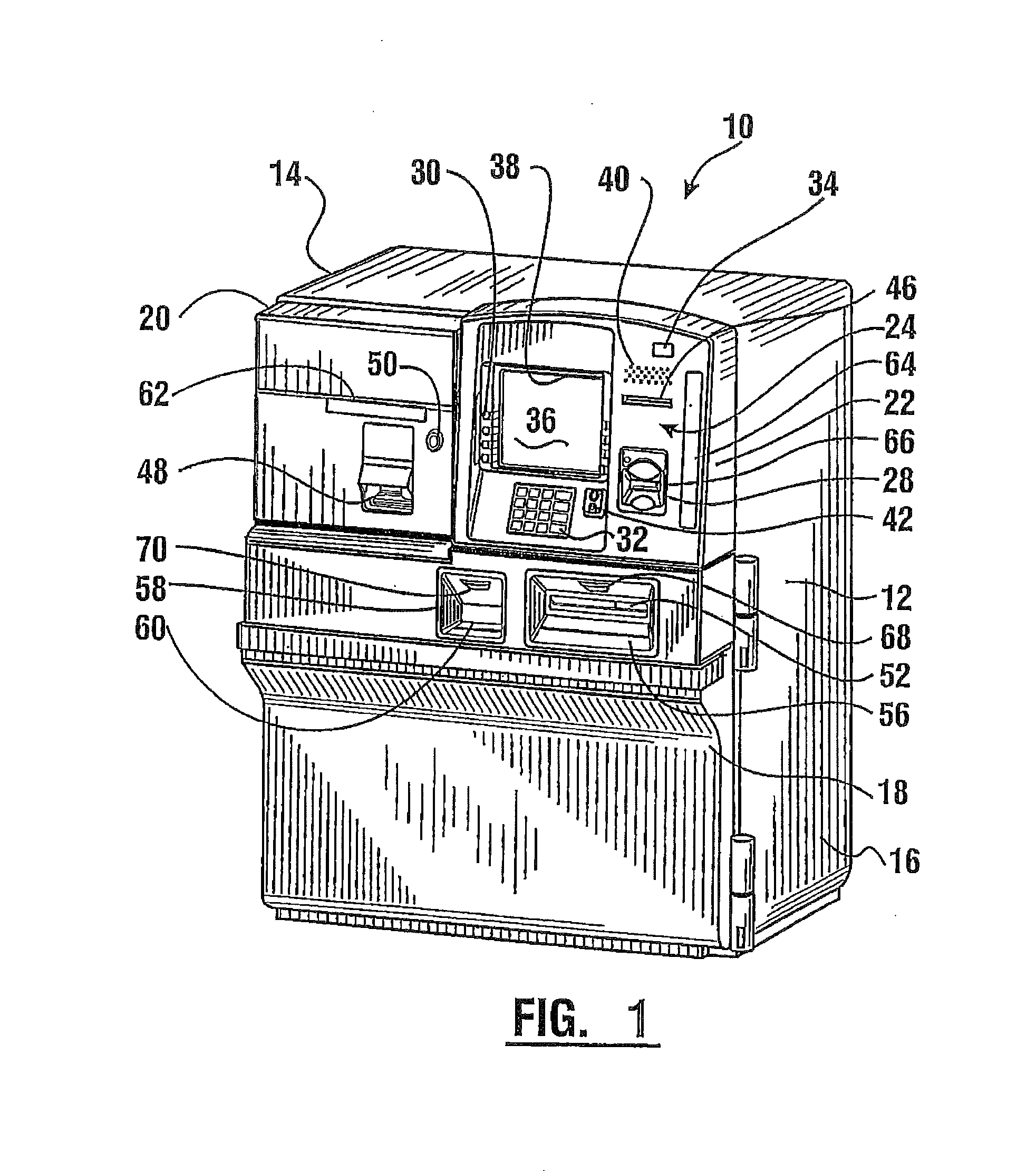

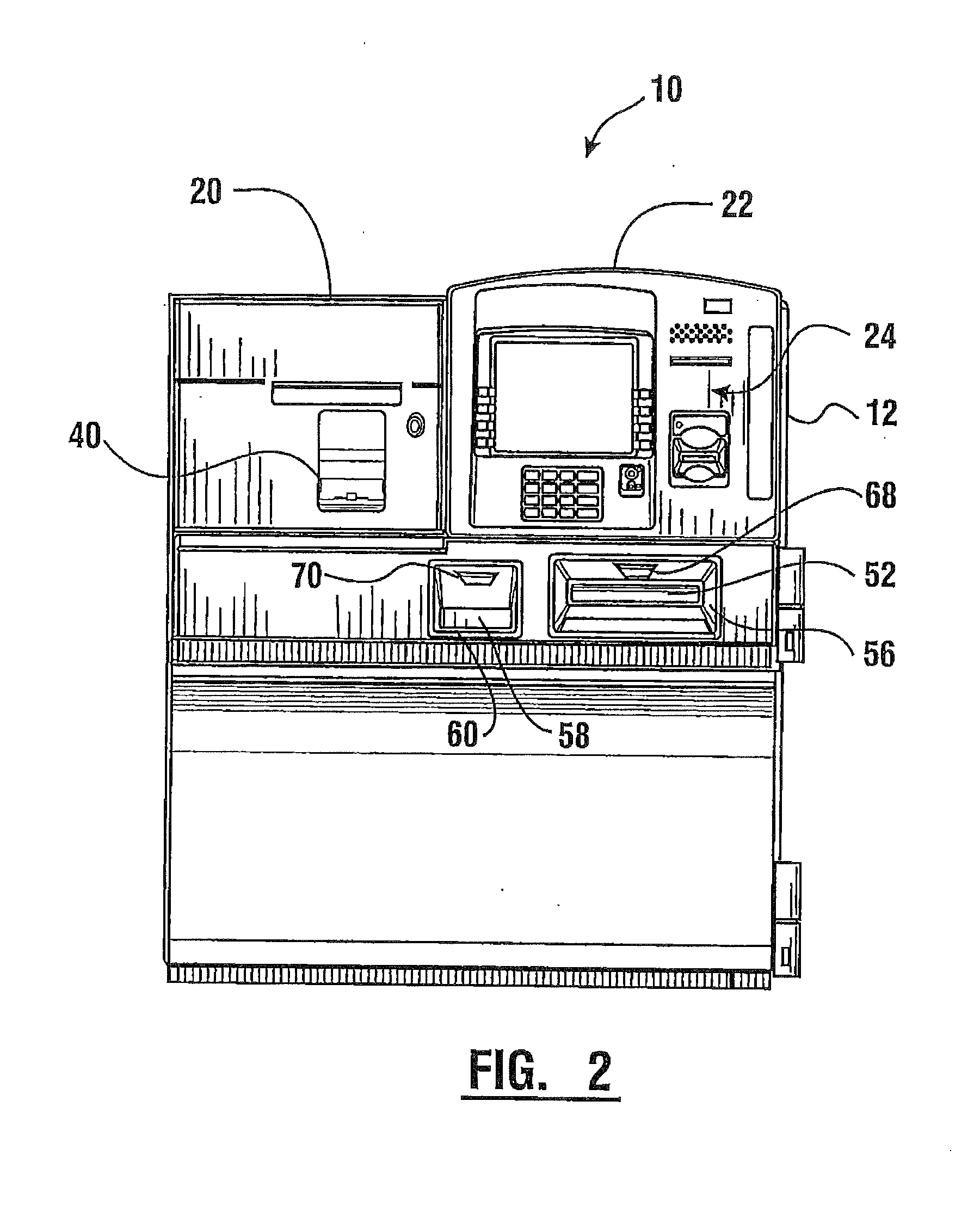

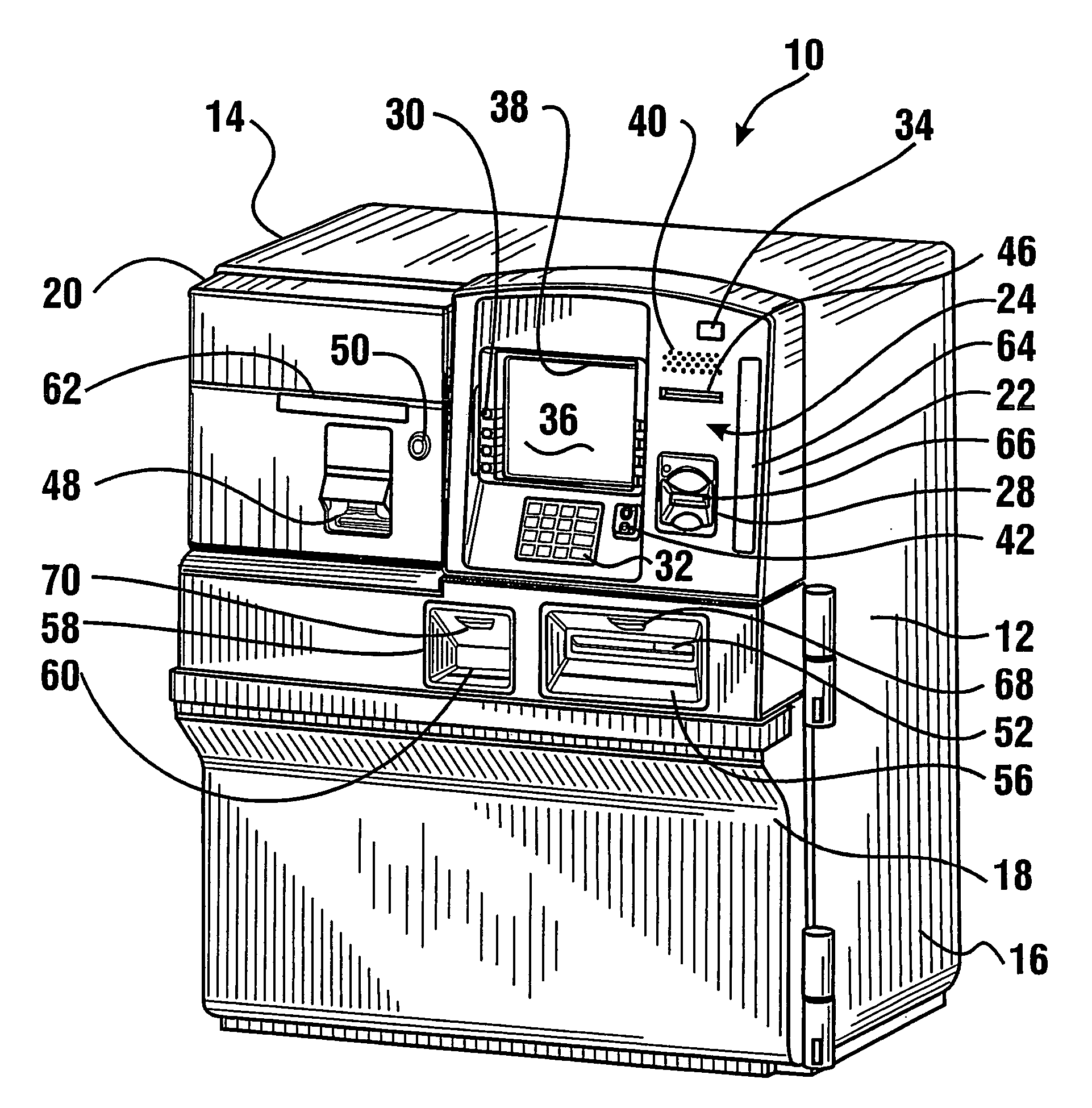

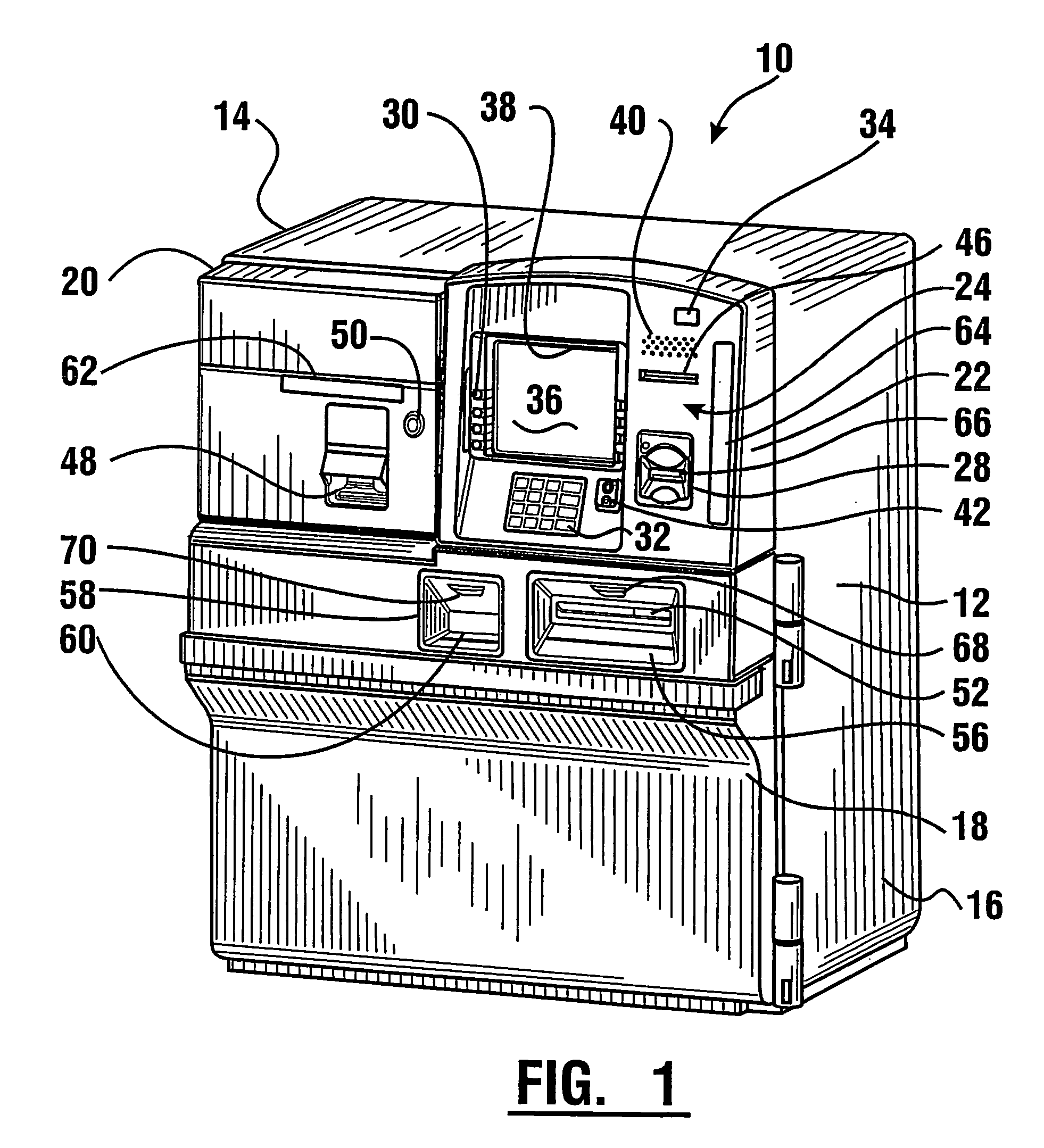

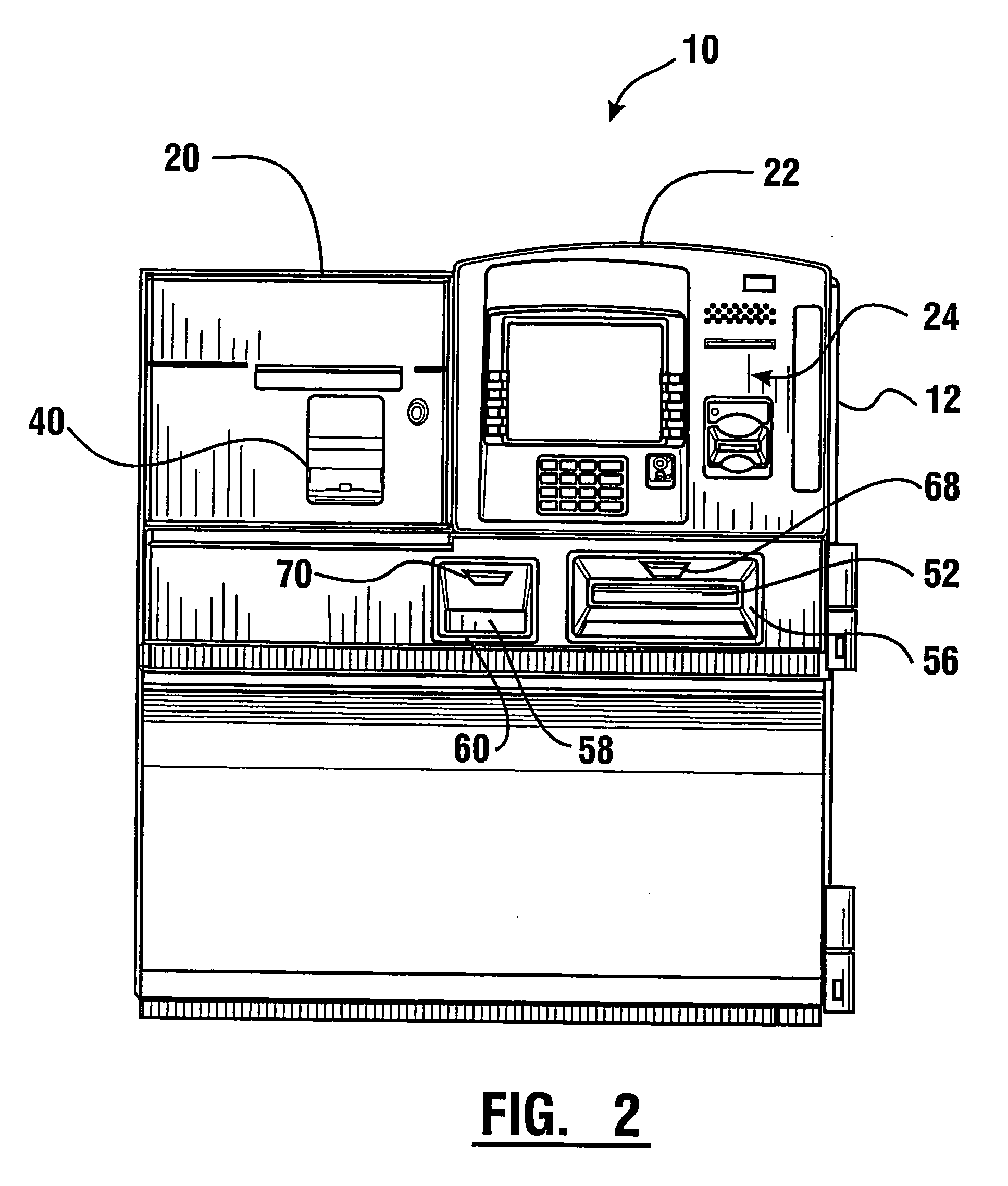

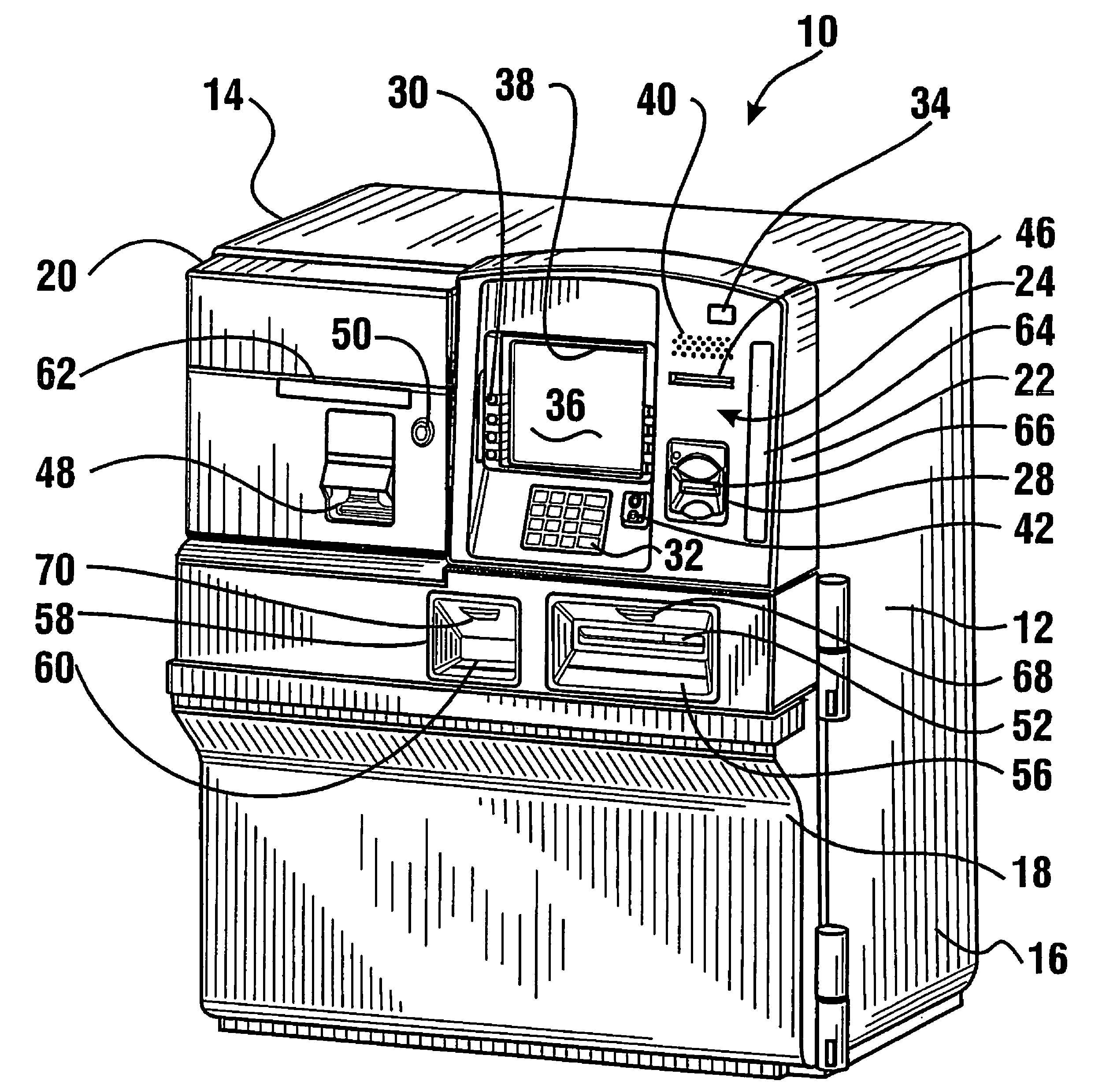

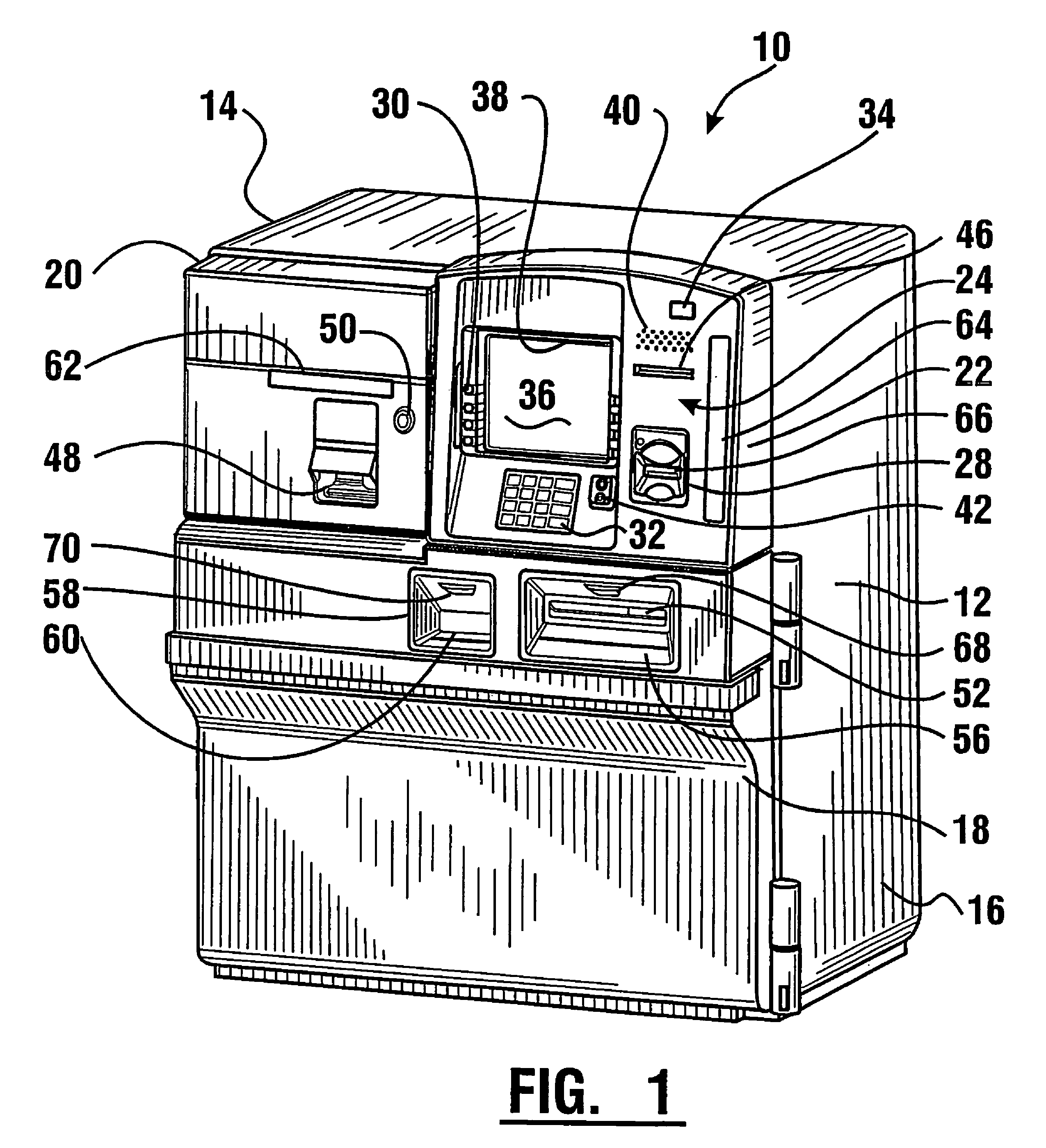

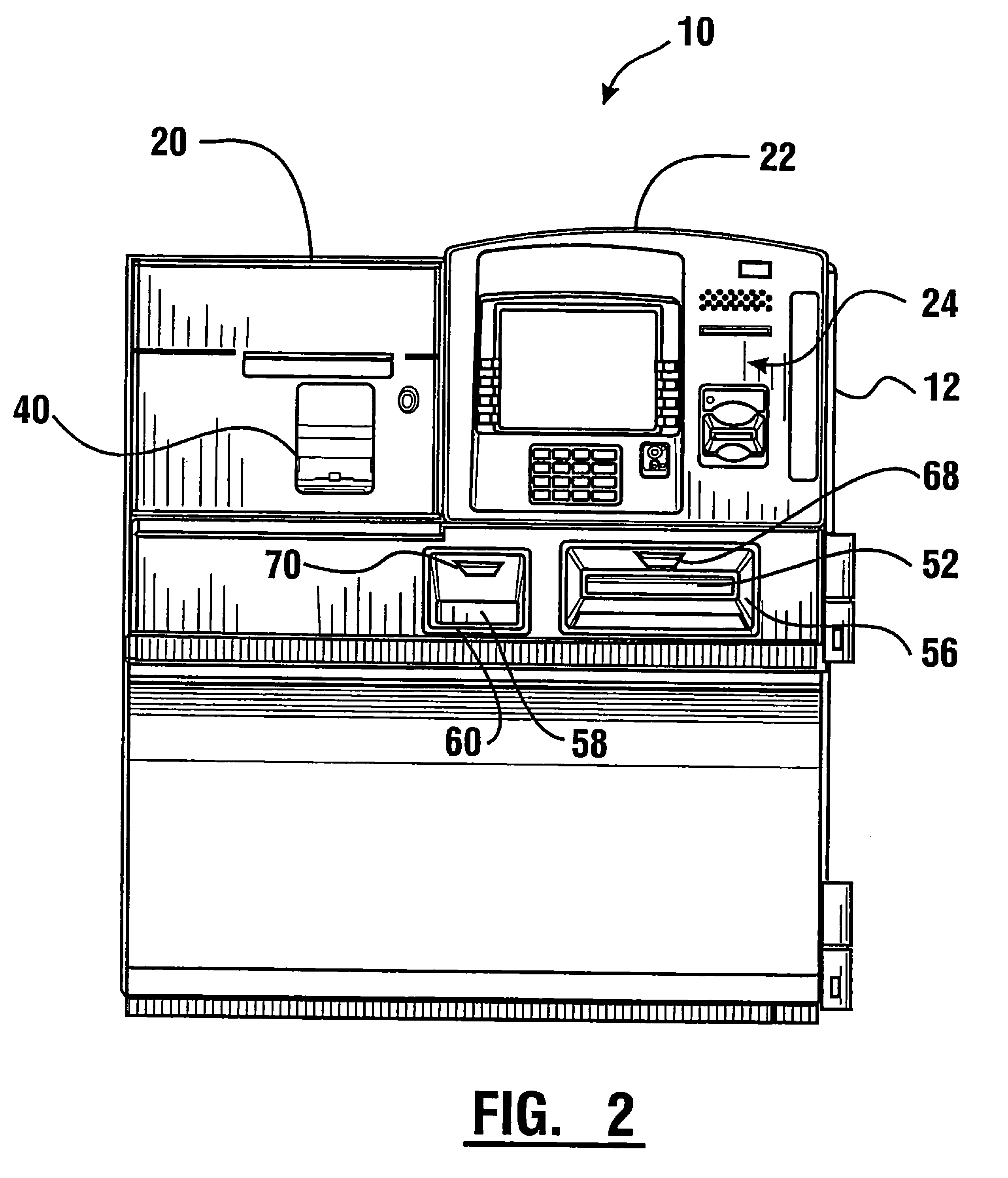

Automated banking machine operated responsive to data bearing records with improved resistance to fraud

InactiveUS20140151449A1Easy to detectIncrease capacityComplete banking machinesFinanceEngineeringCard reader

A banking system machine is controlled responsive to data read from data bearing records. The machine includes a card reader, a keypad, a cash dispenser, a cash outlet, a deposit accepting opening, and other transaction locations that may be susceptible to the installation of fraud devices. An anti-fraud sensing system is associated with the machine to sense the probable installation of unauthorized devices on the machine. Such unauthorized devices may include fraudulent card reading devices, fraudulent keypad input intercepting devices, cash outlet trap devices, and deposit input diversion devices.

Owner:DIEBOLD SELF SERVICE SYST DIV OF DIEBOLD NIXDORF INC

Automated banking machine operated responsive to data bearing records with improved resistance to fraud

ActiveUS20090101705A1Easy to detectIncrease capacityComplete banking machinesFinanceEngineeringCard reader

An automated banking machine is controlled responsive to data read from data bearing records. The automated banking machine includes a card reader, a keypad, a cash dispenser, a cash outlet, a deposit accepting opening and other transaction locations that may be susceptible to the installation of fraud devices. An anti-fraud sensing system is operative in the machine to sense the probable installation of unauthorized devices on the machine. Such unauthorized devices may include for example, fraudulent card reading devices, fraudulent keypad input intercepting devices, cash outlet trap devices, deposit input diversion devices or other fraud devices.

Owner:DIEBOLD SELF SERVICE SYST DIV OF DIEBOLD NIXDORF INC

Automated banking machine operated responsive to data bearing records with improved resistance to fraud

ActiveUS8002176B2Easy to detectIncrease capacityComplete banking machinesFinanceEngineeringCard reader

An automated banking machine is controlled responsive to data read from data bearing records. The automated banking machine includes a card reader, a keypad, a cash dispenser, a cash outlet, a deposit accepting opening and other transaction locations that may be susceptible to the installation of fraud devices. An anti-fraud sensing system is operative in the machine to sense the probable installation of unauthorized devices on the machine. Such unauthorized devices may include for example, fraudulent card reading devices, fraudulent keypad input intercepting devices, cash outlet trap devices, deposit input diversion devices or other fraud devices.

Owner:DIEBOLD SELF SERVICE SYST DIV OF DIEBOLD NIXDORF INC

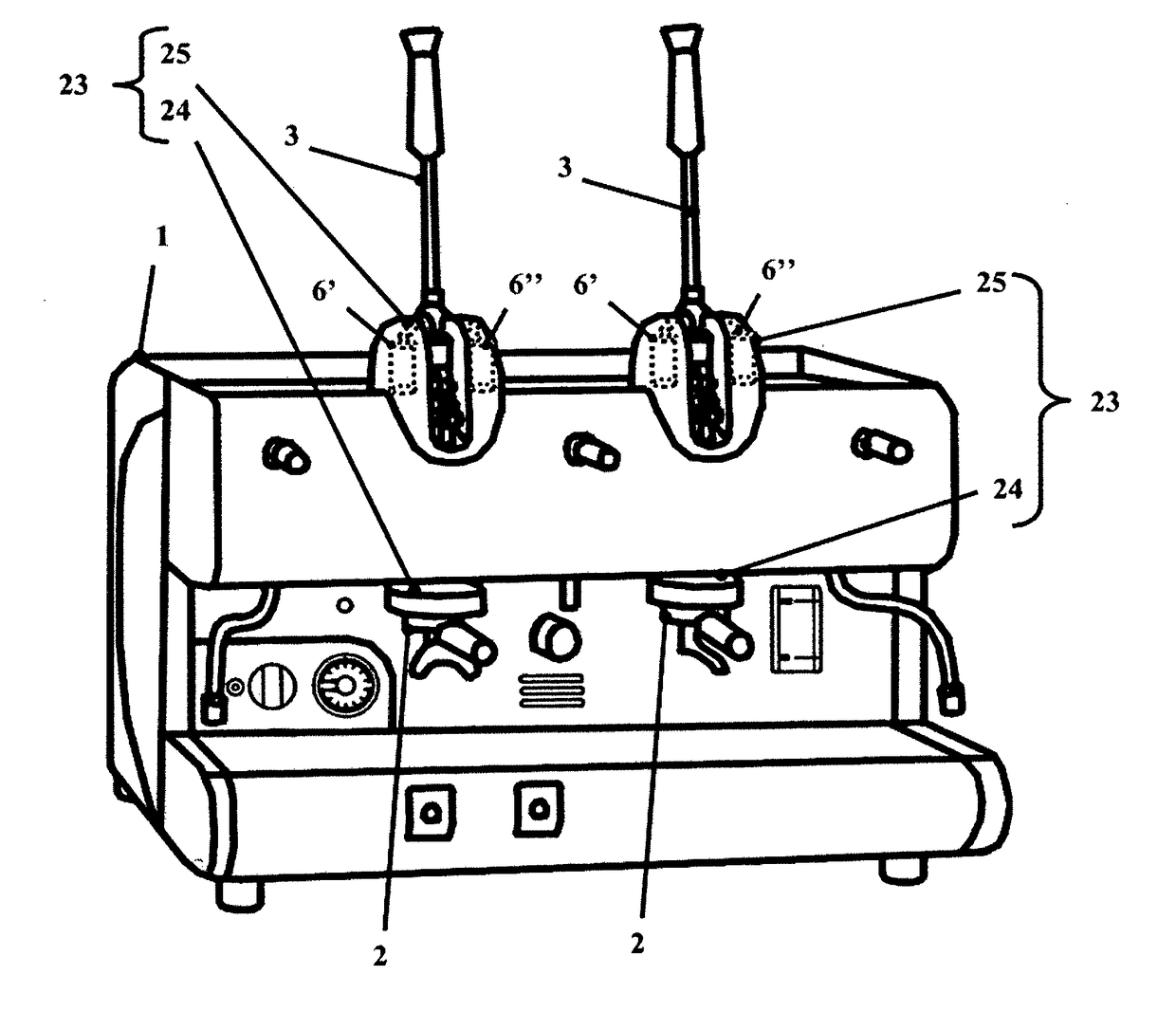

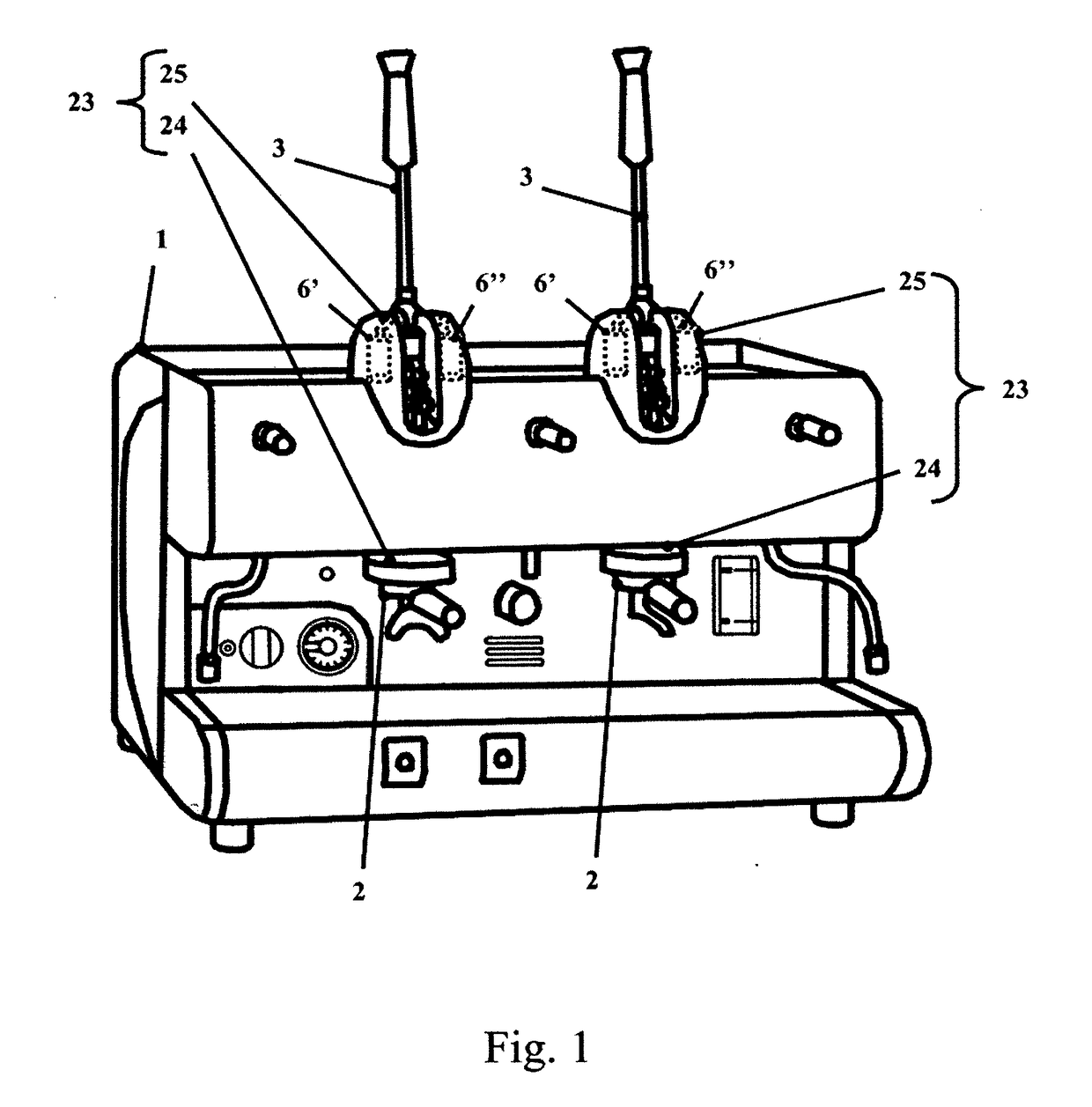

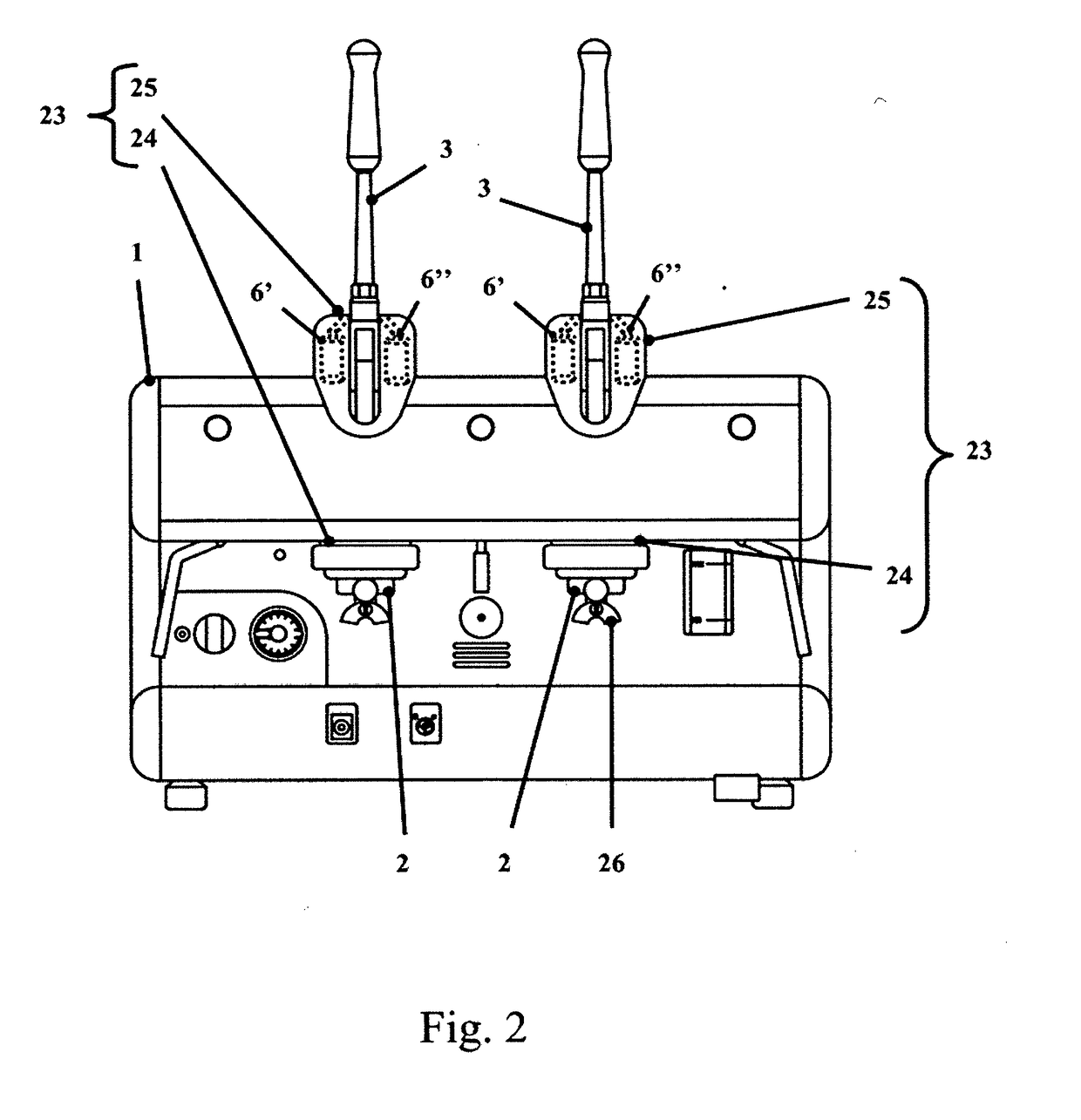

Coffee machine

ActiveUS20170332828A1Improve the safety of useEliminate riskBeverage vesselsEspresso coffeeEngineering

Owner:LA SAN MARCO

Method for the recognition of a chronicle, device and corresponding computer program

InactiveUS20060215025A1Guaranteed usageEasy to operate the machineError detection/correctionColor television detailsData miningComputer program

Owner:FRANCE TELECOM SA

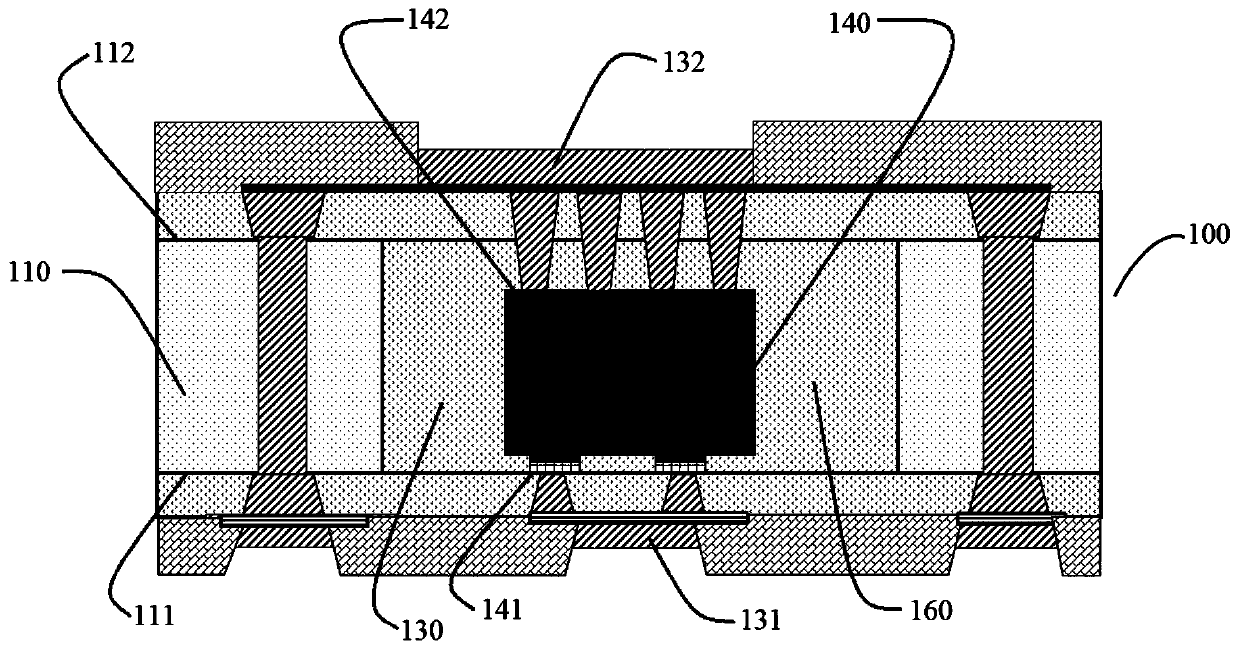

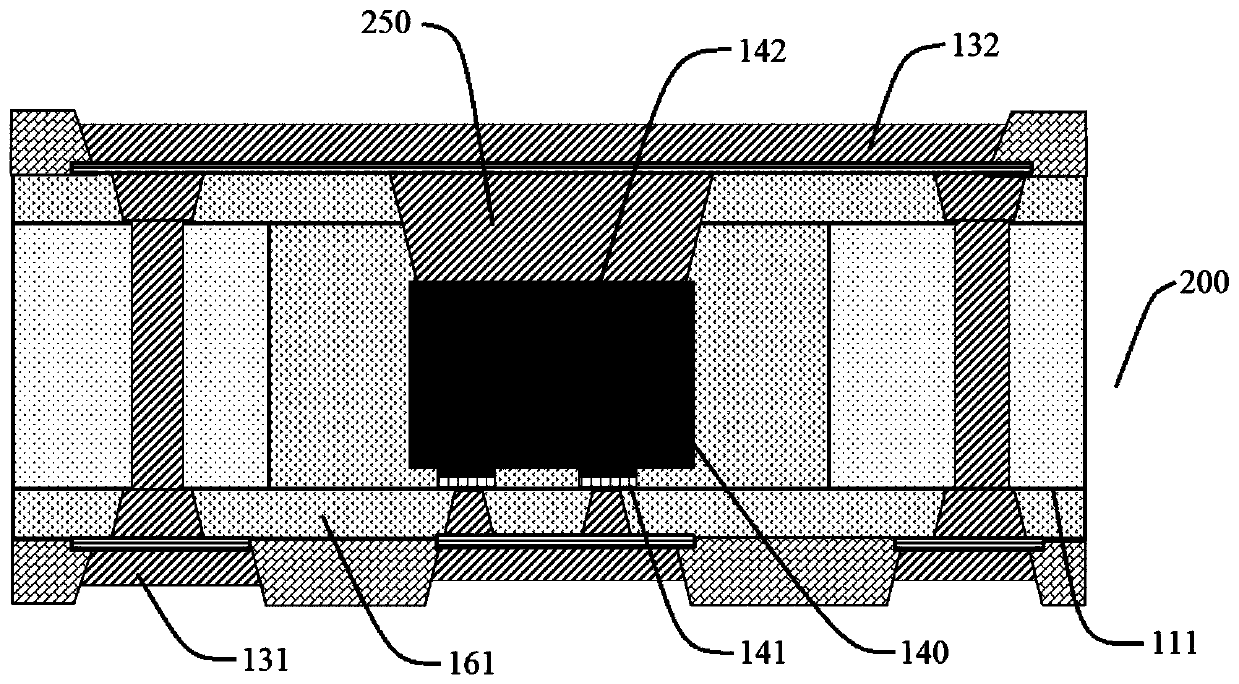

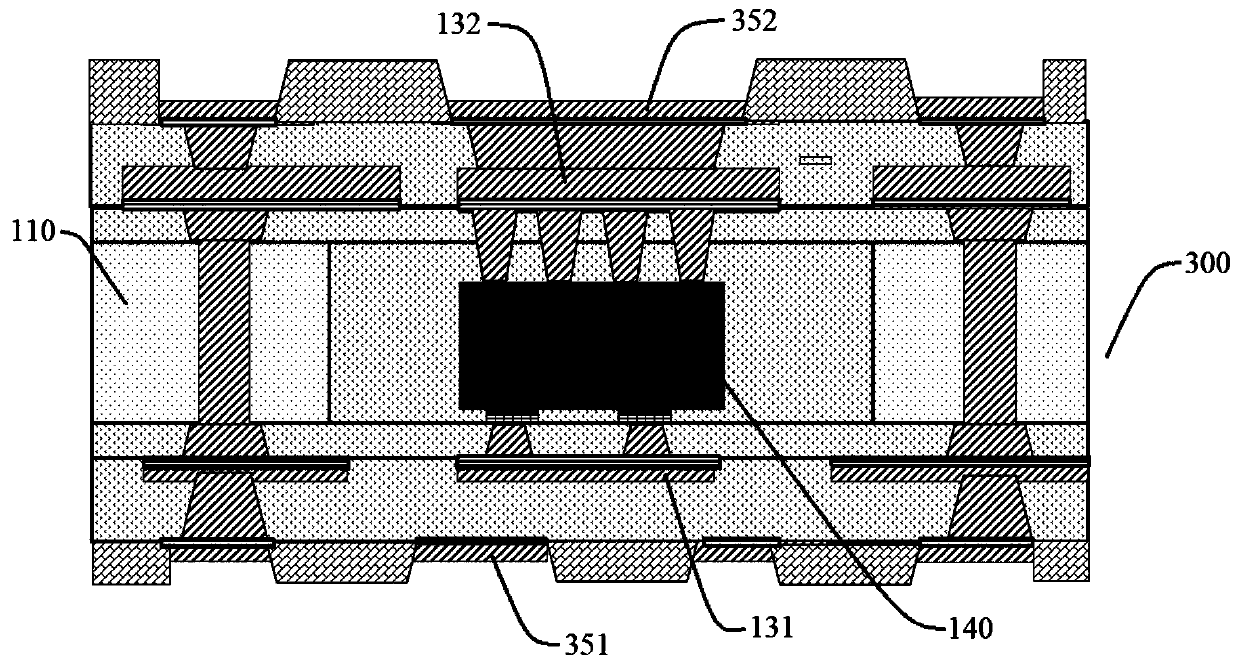

Embedded chip package and manufacturing method thereof

InactiveCN111554639AAvoid risk of damageSimplify process stepsSemiconductor/solid-state device detailsSolid-state devicesComputer hardwareDielectric

The invention discloses an embedded chip package and a manufacturing method thereof. The chip package includes at least one chip and a frame surrounding the at least one chip, the chip is provided with a terminal surface and a back surface which are separated by the height of the chip, and the height of the frame is equal to or larger than the height of the chip, wherein a gap between the chip andthe frame is completely filled with a photosensitive polymer dielectric material, a terminal surface of the chip is coplanar with the frame, a first wiring layer is arranged on the terminal surface of the chip, and a second wiring layer is arranged on the back surface of the chip. The invention further discloses a manufacturing method of the embedded chip package.

Owner:ZHUHAI ADVANCED CHIP CARRIERS & ELECTRONICS SUBSTRATE SOLUTIONS TECH

Lathe for manufacturing ophthalmic lenses made of plastic

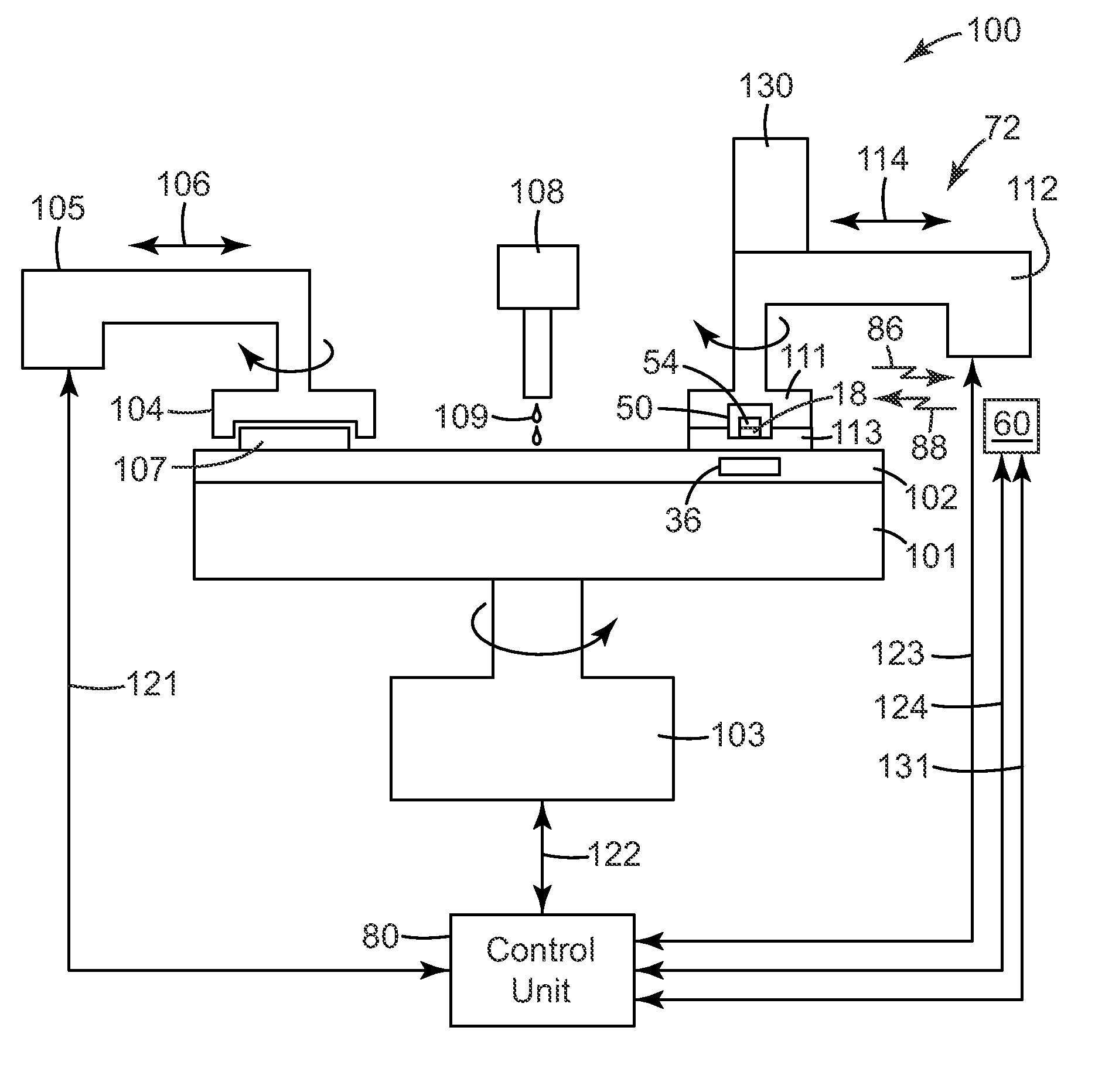

ActiveUS8683897B2Easy to operate the machineRigid structureLathesMachine tool componentsRotational axisEngineering

A turning machine for producing non rotationally symmetric surfaces of synthetic spectacle lenses, having a support plane E, a machine bed made of cast iron with a width b1 and a mass m1, a linear motor with an actuator comprising a turning tool holder and an oscillation axis Z, a workpiece spindle with a rotational axis C and a movement axis X, wherein the machine bed has at least two bearing surfaces arranged at a distance for the linear motor and for the workpiece spindle, and between the two bearing surfaces, a chip space is provided which is limited at least partially by the machine bed, wherein the linear motor is supported on the first bearing surface and the workpiece spindle is supported on the second bearing surface in relation to the chip space opposite the linear motor, wherein the mass of the machine bed has the maximum value m1, and the value m1 lies between 100 kg and 500 kg, between 150 kg and 300 kg, between 170 kg and 200 kg or 180 kg. A turning machine, in which the ratio of the mass m1 of the machine bed to a moved mass m2 of the linear motor 3 is greater than a quotient Q, wherein the quotient Q is between 1:500 and 1:20, between 1:60 and 1:30 or between 1:140 and 1:100, or 1:40 or 1:120.

Owner:SCHNEIDER GMBH & CO KG

Adhesive thread system

ActiveUS20160243755A1Improve waterproof performanceEliminate needGarmentsSewing apparatusNeedle punctureGlue line

A system for forming a waterproof seam between to sewn materials. The seam is formed using an adhesive coated thread. A thin strip of adhesive is placed between the two materials at the seam line. As the coated thread is sewn into the seam heat and pressure are simultaneously applied, melting the adhesive coating thereby filling the needle punctures. The melted adhesive coating will also flow into the areas between the needle punctures and between the materials. The heat and pressure applied to the coated thread will also melt the adhesive strip, causing additional adhesive to flow into the needle punctures and the areas between needle punctures.

Owner:SECO SYST LLC

Synthetic method of semaglutide

PendingCN111944039ASimplify process stepsReduced racemic impuritiesPeptide preparation methodsBulk chemical productionSide chainPeptide sequence

The invention discloses a solid-phase synthesis method of semaglutide. The method comprises the following steps of carrying out solid-phase synthesis on semaglutide S1-S4 fragment resin, and performing cracking and purifying to obtain a first fragment; synthesizing lysine, with a side chain group, of the semaglutide S20 as a second fragment; and sequentially coupling amino acids or peptide fragments according to a peptide sequence of the semaglutide to obtain semaglutide resin, and then performing cracking and purifying to obtain the semaglutide. According to the method, a solid-phase synthesis process combining fragmentation and gradual synthesis is adopted, so that technological process steps are simplified, and industrial large-scale production is facilitated; and full-protection 1-4 fragments of the semaglutide are prepared and applied to solid-phase synthesis of the semaglutide as key starting materials, so that the generation of D-His racemization impurities and +Gly impurities is reduced, the purification difficulty of a crude product is obviously reduced, the purity and yield of the semaglutide are greatly improved, and the production cost is reduced.

Owner:SHENZHEN JYMED TECH

Method for preparing high-purity chlorogenic acid by aluminum salt precipitation

InactiveCN102675106AHigh purityHigh yieldCarboxylic acid esters separation/purificationChlorogenic acidOrganic solvent

The invention discloses a method for preparing high-purity chlorogenic acid by aluminum salt precipitation, which comprises the following steps: (1) impurity removal: mixing a chlorogenic acid extract and water in a material / liquid ratio of 1:10-1:150, and adding an aluminum salt precipitant to precipitate impurities while controlling the pH value at 1-4.5, wherein the unit of the material / liquid ratio is g / ml; (2) precipitation: washing the impurities, merging the washing liquid with the supernatant, and selectvively precipitating chlorogenic acid while controlling the pH value at 4.5-7; (3) dissociation: suspending the precipitate in a cosolvent of which the material / liquid ratio is 1:2-1:50, and adding acid to dissolve the precipitate; and (4) crystallization: concentrating the organic layer solution to 1 / 5-1 / 30 of the original volume, cooling and standing to crystallize, washing the crystals, and drying to obtain the high-purity chlorogenic acid. The method disclosed by the invention is suitable for purifying low-purity chlorogenic acid extract, lowers the production cost, reduces the consumption of the organic solvent, relieves the environmental pollution, and satisfies the requirements for green chemical technology.

Owner:SOUTHWEAT UNIV OF SCI & TECH

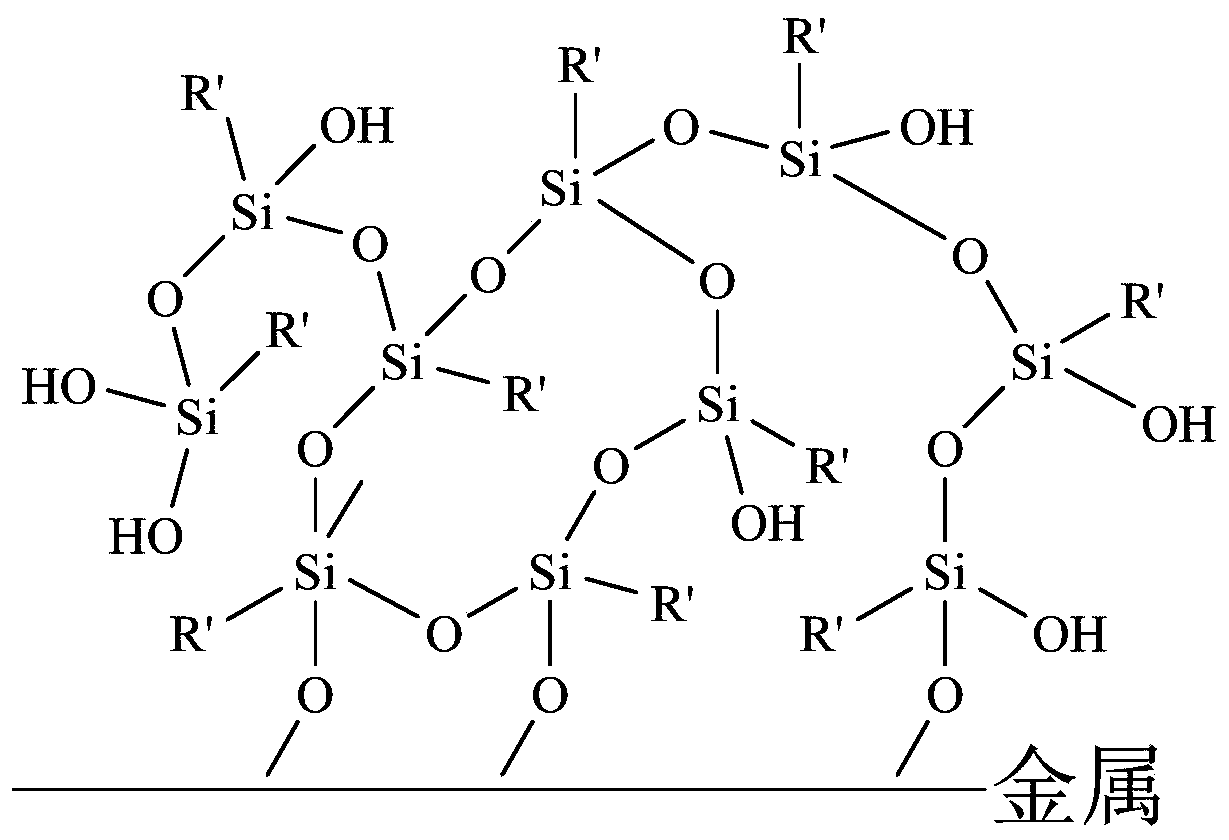

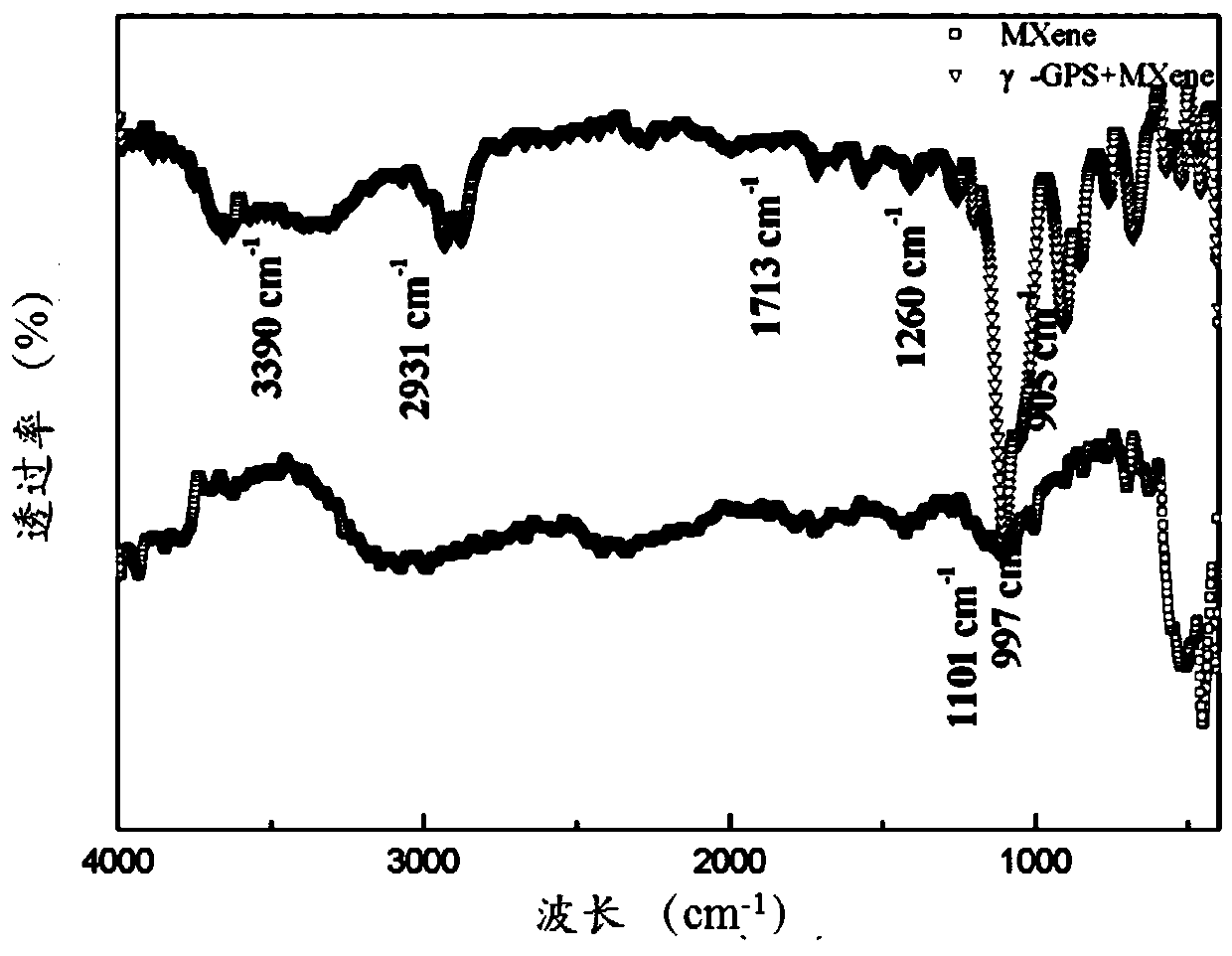

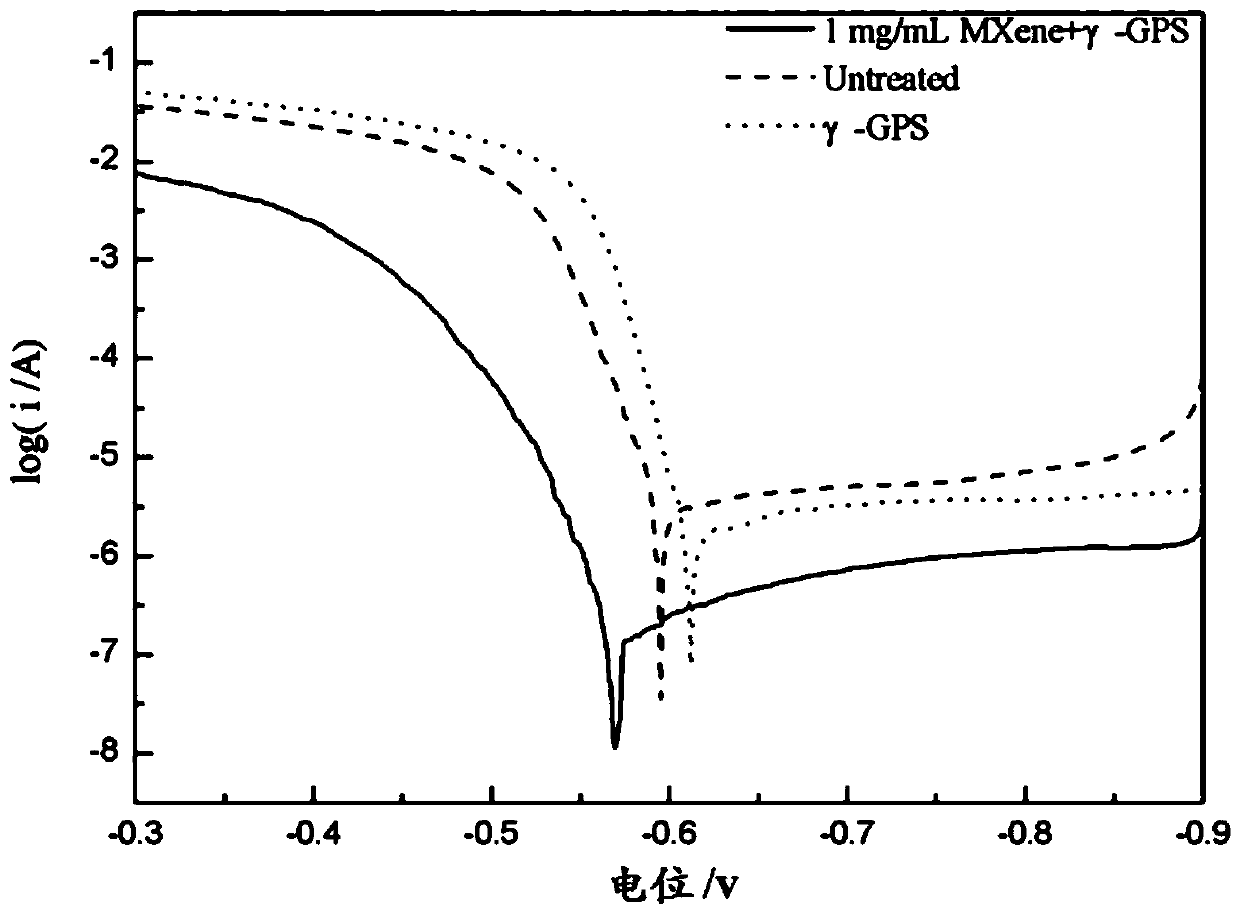

Application of MXene/silane surface composite silane film in metal corrosion protection

ActiveCN110527995ASimplify process stepsShort hydrolysis timeMetallic material coating processesCorrosion resistantSurface finishing

The invention belongs to the field of metal corrosion protection, and particularly relates to application of an MXene / silane surface composite silane film in metal corrosion protection. The method comprises the following steps: preparing and hydrolyzing an MXene / silane mixed solution, carrying out surface treatment on a metal sample, dipping the metal sample in a mixed silane hydrolysate, and curing to form a film. The MXene / silane surface composite silane film protective surface treatment technology is adopted, the defect that a single silane film is not compact is overcome, the operation iseasy, safety and environmental protection are achieved, diffusion of a corrosive medium can be effectively hindered by doping the MXene, and the corrosion resistance of the silane film is improved.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Thermoplastic polymer film composite linerless aluminum foil tape

InactiveCN102634294AReduce weightHigh tensile strengthFilm/foil adhesivesLaminationUltimate tensile strengthAluminum foil

The invention provides a thermoplastic polymer film composite linerless aluminum foil tape. According to the thermoplastic polymer film composite linerless aluminum foil tape provided by the invention, lining paper is not used; and as the lining paper is thrown away as garbage during the using process, resources can be greatly saved, the production cost can be reduced, and the weight of a finished product aluminum foil layer tape is also greatly reduced. According to the thermoplastic polymer film composite linerless aluminum foil tape provided by the invention, a thermoplastic polymer film and one side of an aluminum foil layer are adhered and stuck together by heating through a heating roller so as to realize the release effect, and the manufacturing process is simple; furthermore, the finished product is high in tensile strength, easy to break and easy to uncoil and tear off from a tape coil, and can avoid the phenomenon that the tape is stretched; and the finished product is very convenient to operate by a machine or by hands.

Owner:佛山市亿达胶粘制品有限公司

Method for roll-press dyeing through twisting

InactiveCN101929046AReduce labor intensityLow costTextile treatment machine partsDyeing processWarm waterEngineering

The invention relates to a method for roll-press dyeing through twisting. The method comprises the following steps of: (1) putting unprocessed fabrics into warm water for soap boiling and desizing or adding a detergent and a bleaching agent for impurity removal and bleaching; (2) putting the processed long fabrics together freely or folding and putting the processed long fabrics together by using an accordion to form a long fine rope, after the fabrics are put together, fixing one end of the fabrics on a stainless steel circular tube by threads, rolling and tying the fabrics put together on the stainless steel circular tube until the end of the fabrics is reached when twisting the fabrics put together, and fixing the end of the fabrics by the threads; and (3) performing spot brushing of dyes on the fixed fabrics, dyeing bottom colors, washing to remove surface dyeing, and fixing the colors. The method has the advantages of simplicity, low cost and high efficiency; and the obtained fabric patterns are full of the beauty of rhythm, have a unique style and enrich the expression forms of tie-dye patterns.

Owner:DONGHUA UNIV

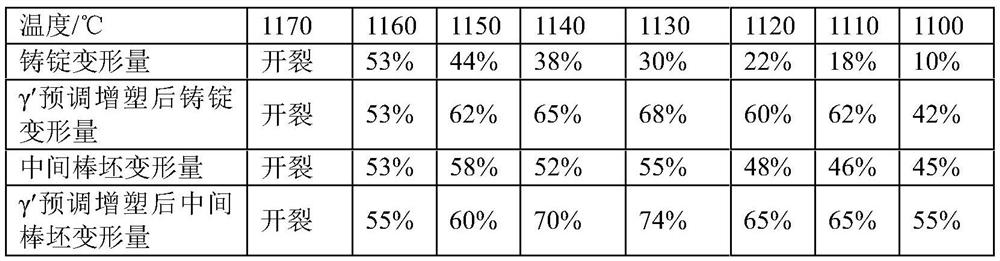

Gamma'phase pre-adjusting plasticizing production process of high-performance high-temperature alloy

ActiveCN112746231AImprove high temperature plasticityReduce deformation resistanceMetal-working apparatusIngotHeat conservation

The invention discloses a gamma'phase pre-adjusting plasticizing production process of a high-performance high-temperature alloy, and belongs to the technical field of material processing. The gamma 'phase pre-adjusting plasticizing production process comprises the following preparation steps: 1, smelting is performed to prepare a cast ingot to form a fine-grain homogeneous bar after multi-heating forging; 2, before the bar is forged in a two-phase region, when the heating number forging deformation is higher than the critical cracking deformation, the bar is treated through the gamma'phase pre-adjusting plasticizing technology so as to improve the critical cracking deformation, gamma 'phase pre-adjusting plasticizing adjusts the temperature of the bar subjected to two-phase region forging to be the forging temperature Td, heat preservation is conducted for 2-12 h, then the temperature is reduced to 800-1000 DEG C at the speed of 5-50 DEG C / min, and heat preservation is conducted for 3-12 hours; and 3, the cast ingot or the bar billet obtained in the second step is heated to the forging temperature Td again, heat preservation is conducted, the cast ingot or the bar billet is taken out of a furnace and forged, and a homogeneous bar billet is obtained after multiple times of forging. The hot working high-temperature plasticity of the high-temperature alloy is improved.

Owner:BEIJING CISRI GAONA TECH +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com