Patents

Literature

431 results about "Glue line" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

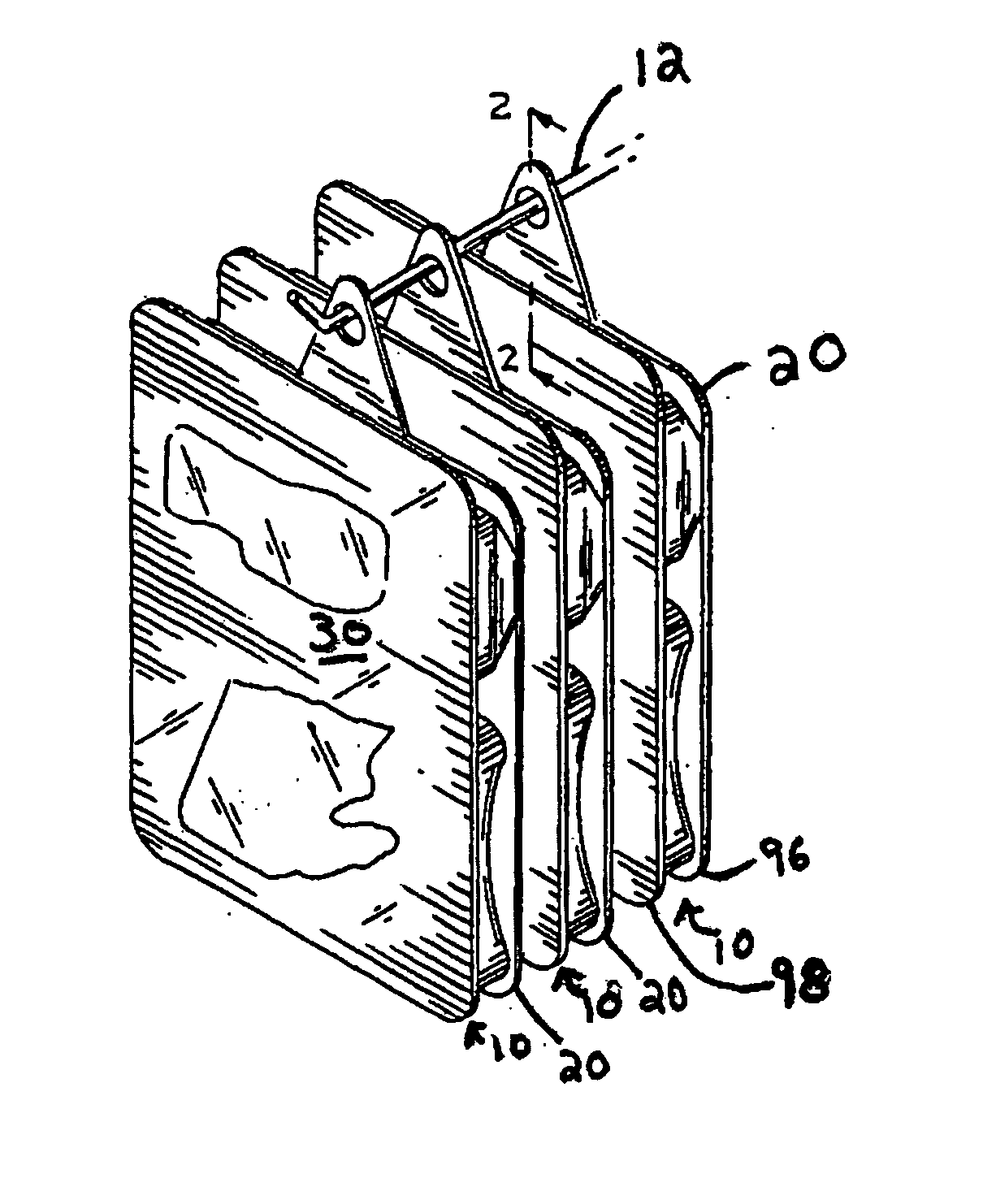

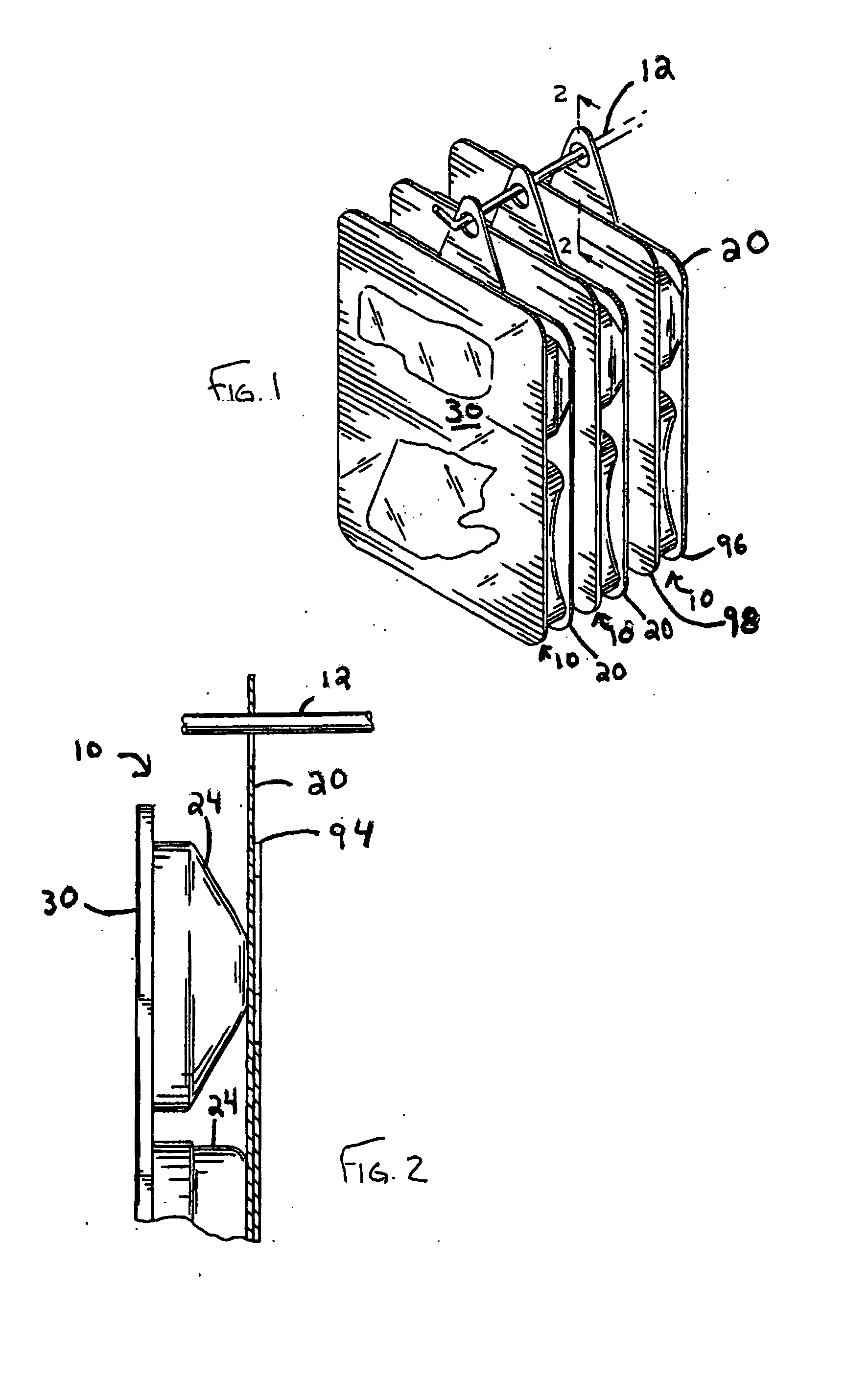

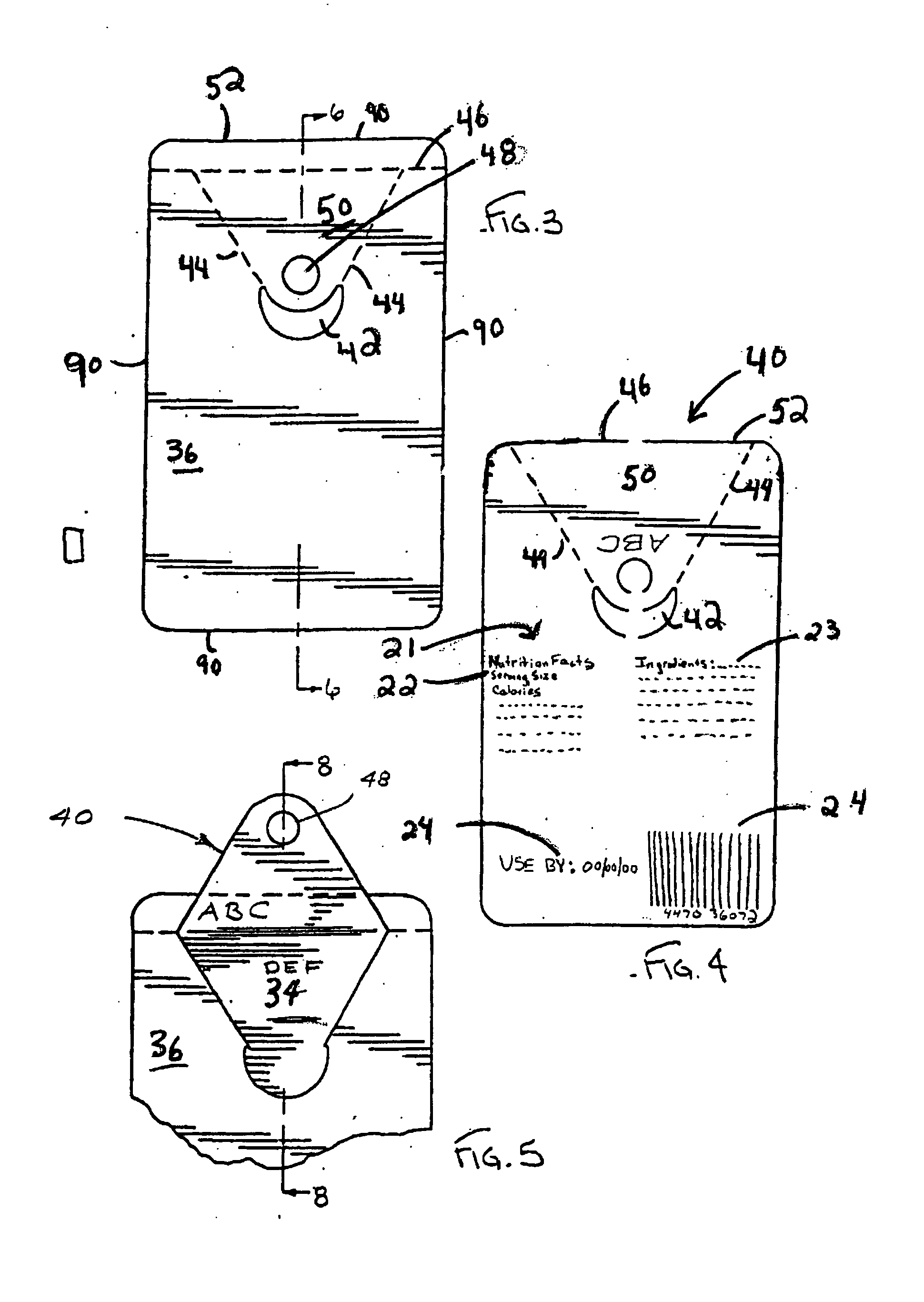

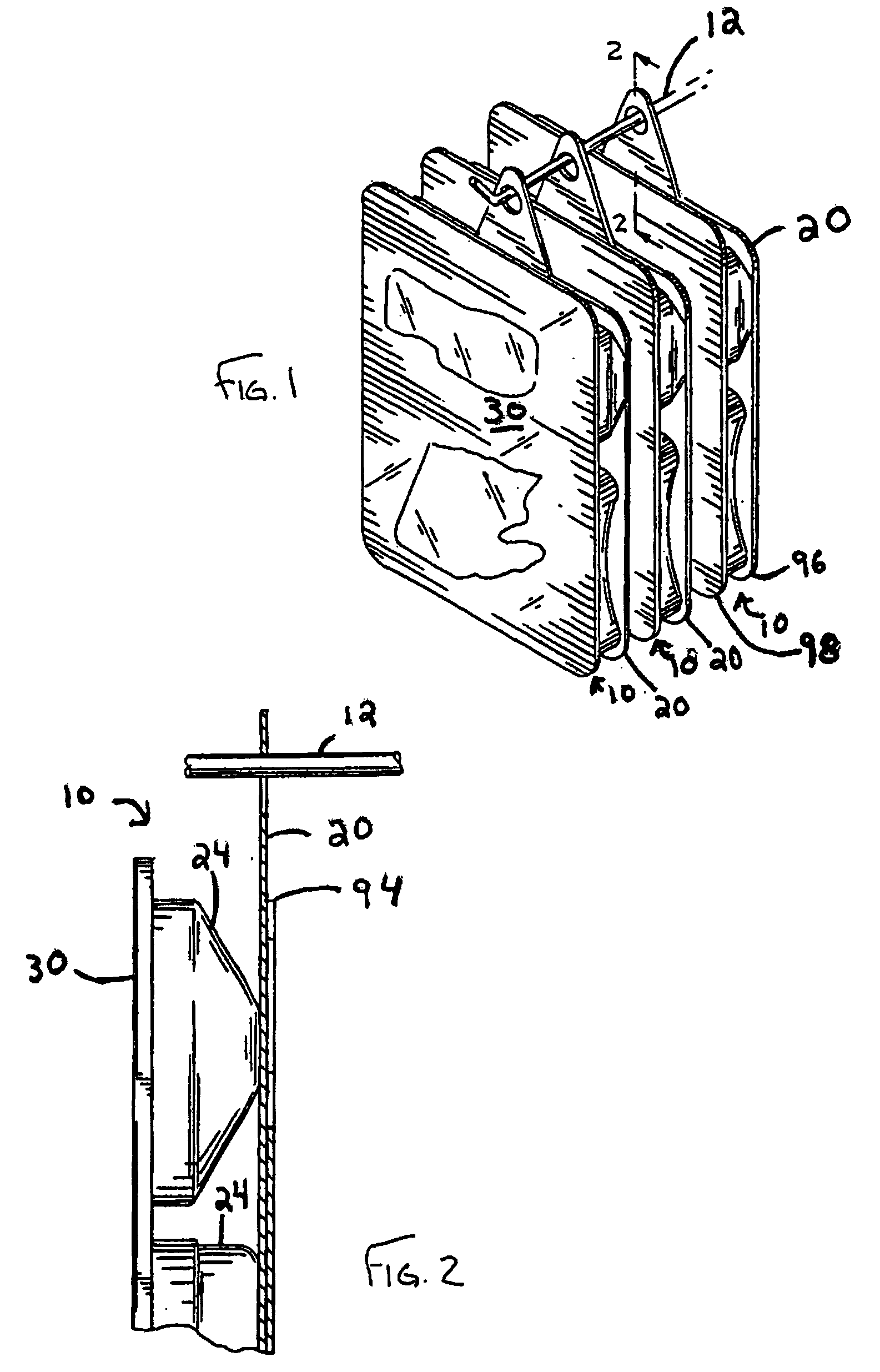

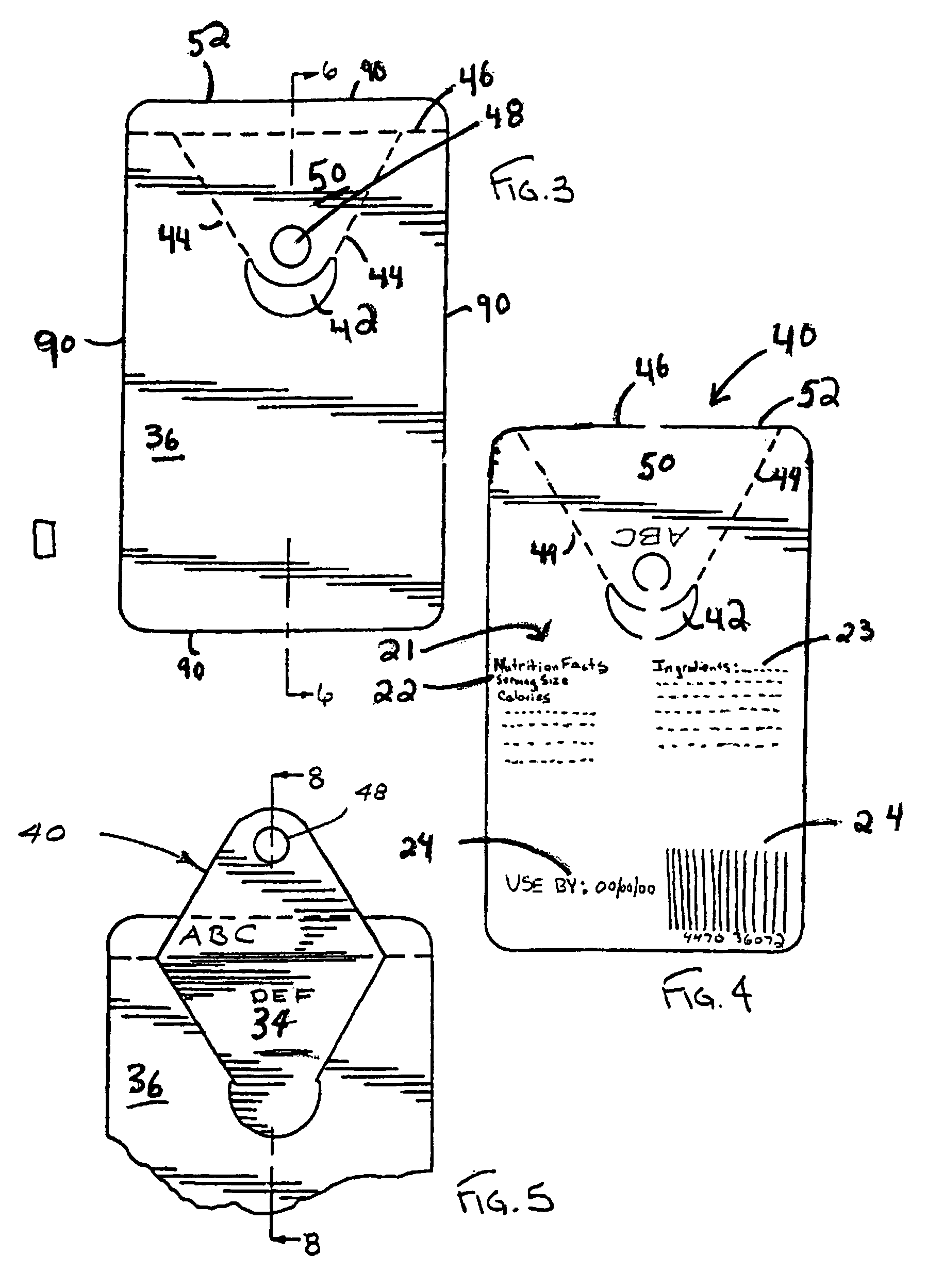

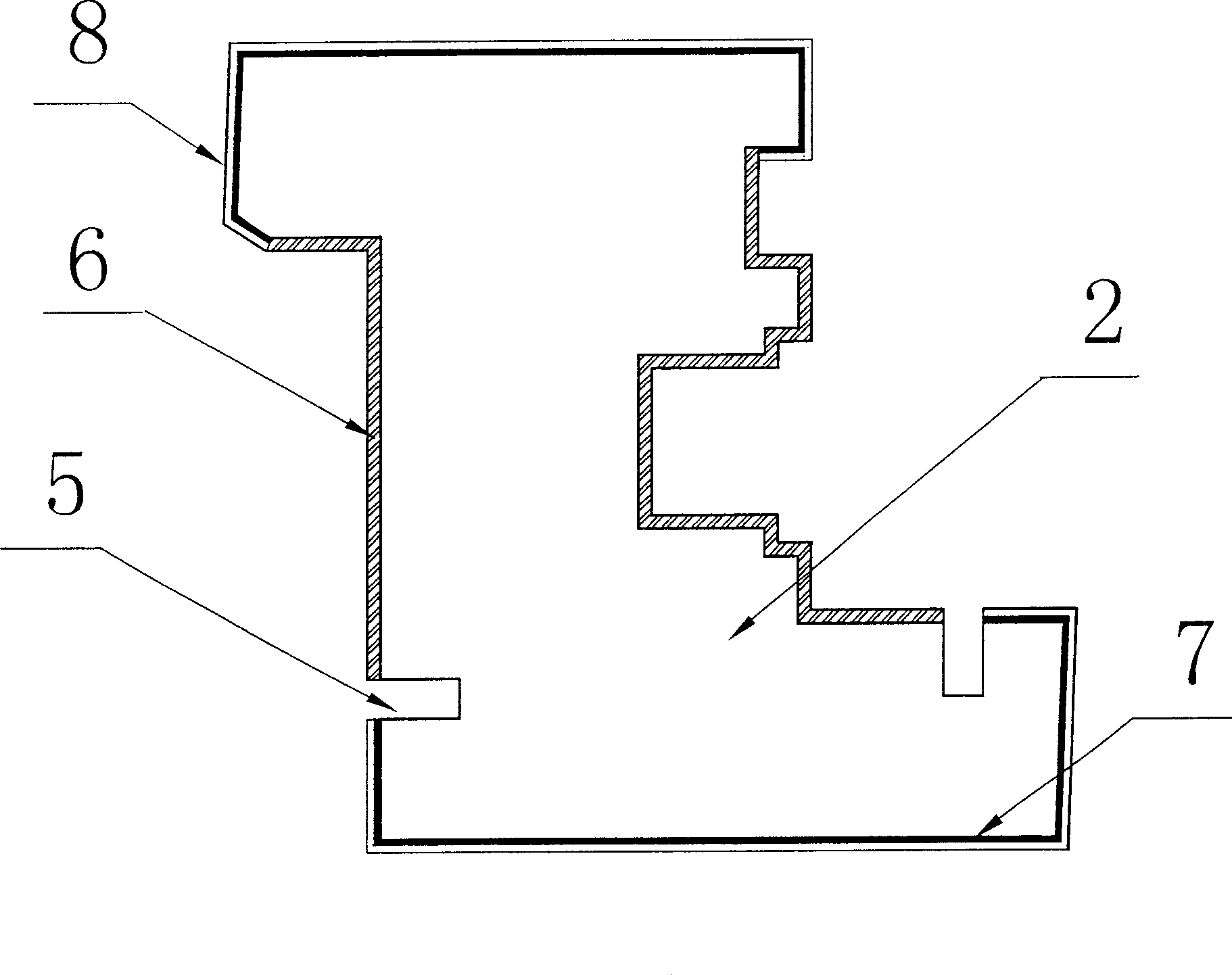

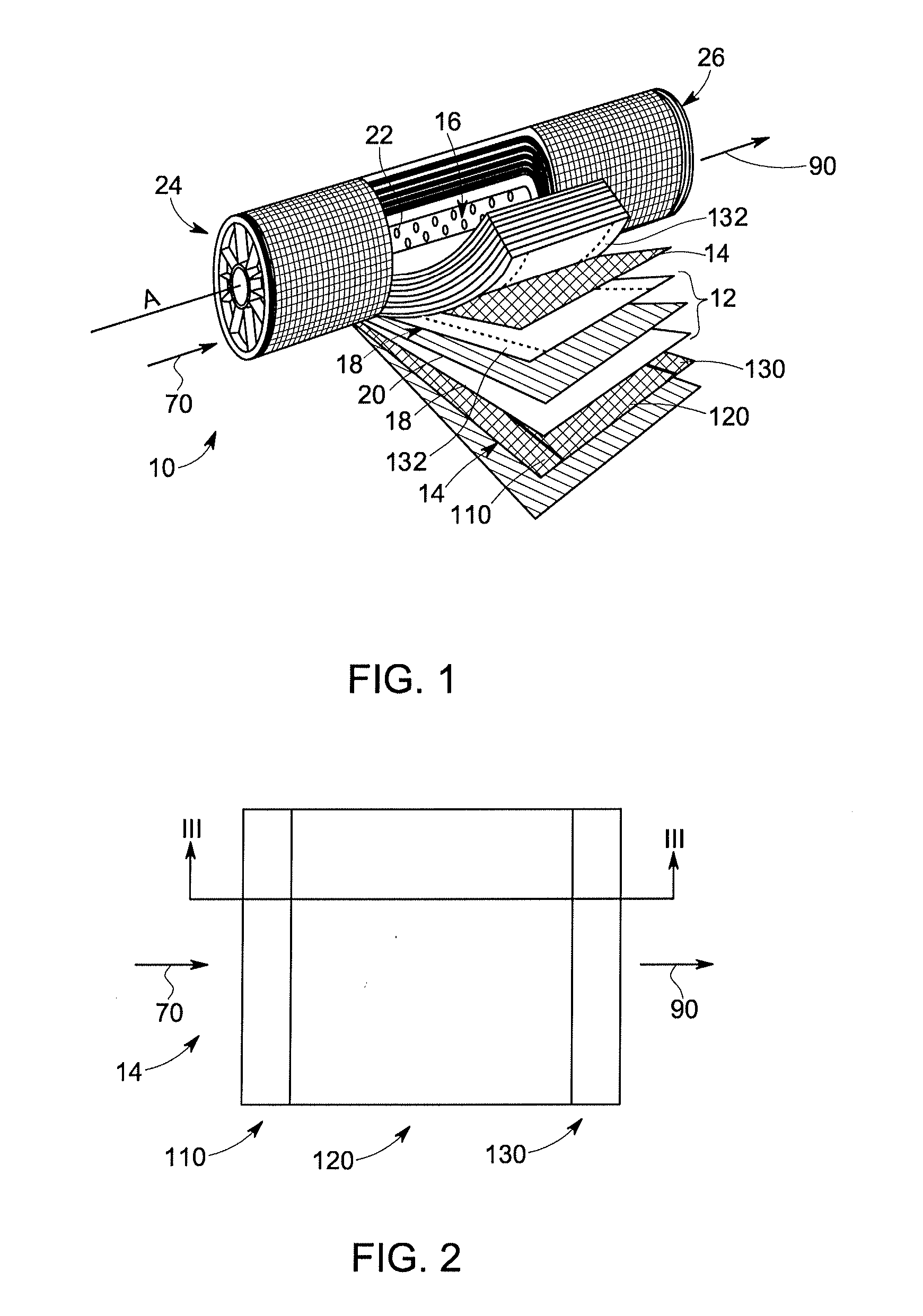

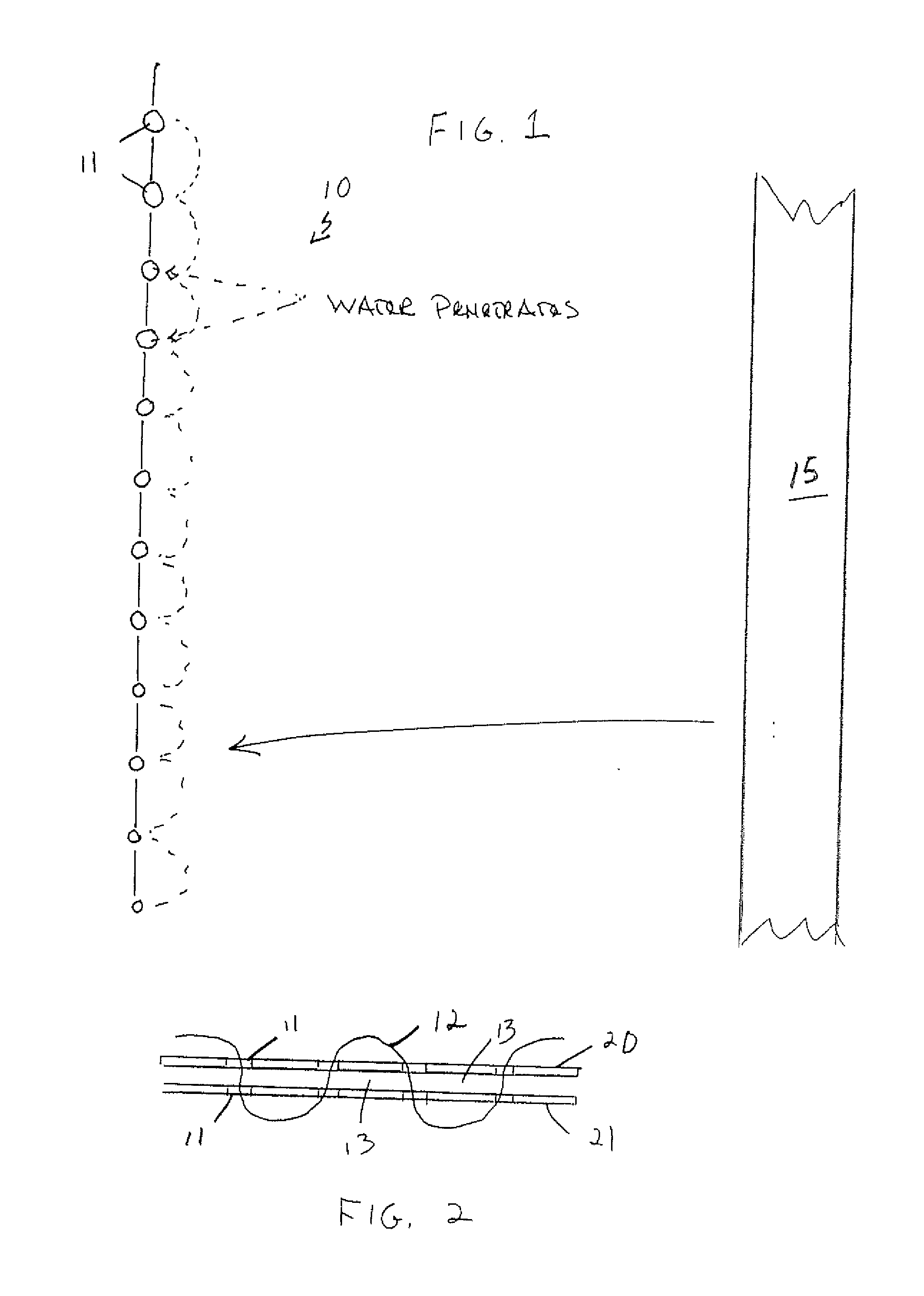

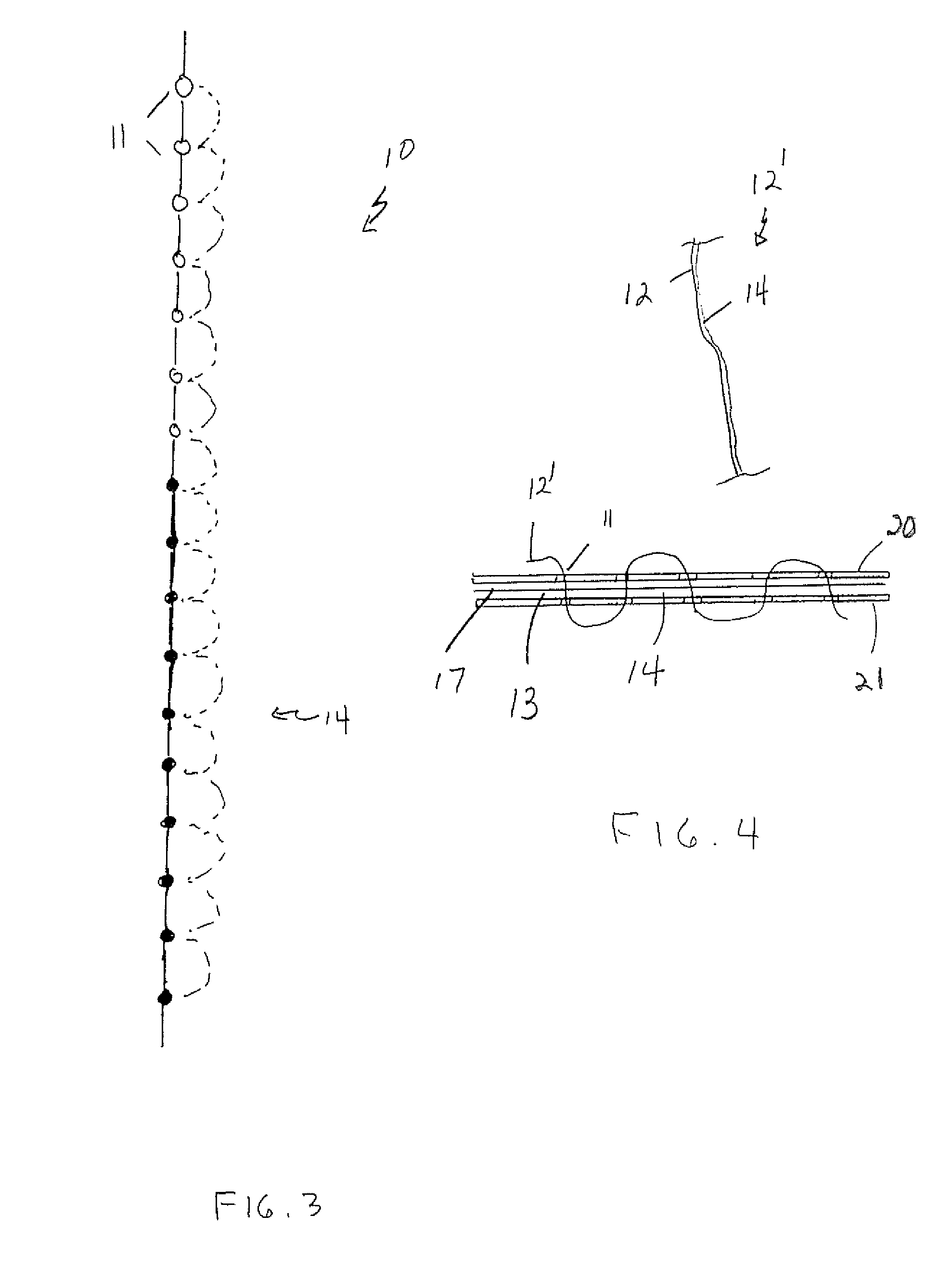

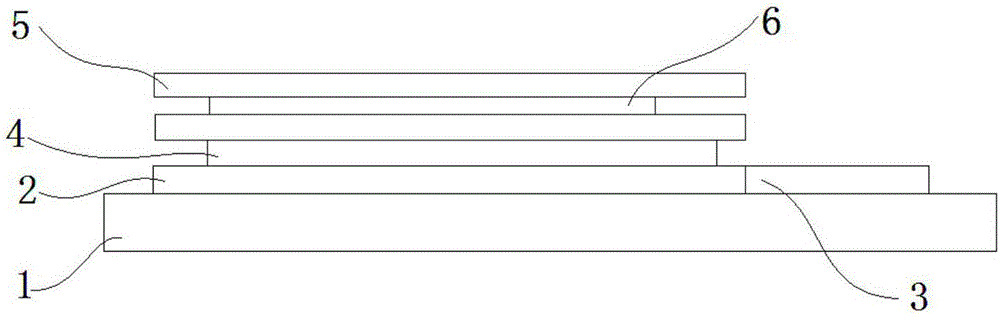

Hanger and backcard for packages

InactiveUS20050061759A1Increase the areaOther accessoriesContainer/bottle contructionGlue lineMechanical engineering

A backcard for use with compartmentalized containers, particularly food containers, that provides a hanging feature and an information feature is provided. The backcard may be secured to the container or package with glue lines properly placed on the package, or glue placed on the backcard. The hanging feature is formed by moving a tab located in an outermost sheet or layer from a non-extended position to an extended position. The backcard is provided with a substantial area, e.g., 50% or more of the backcard area, for printing information such as a list of nutritional facts, a list of food ingredients and the like for presentation to a consumer. In addition, a portion of the backcard may be removable or foldable to expose a portion of the outer layer or a substrate layer, thereby allowing each to display additional information.

Owner:KRAFT FOODS GRP BRANDS LLC

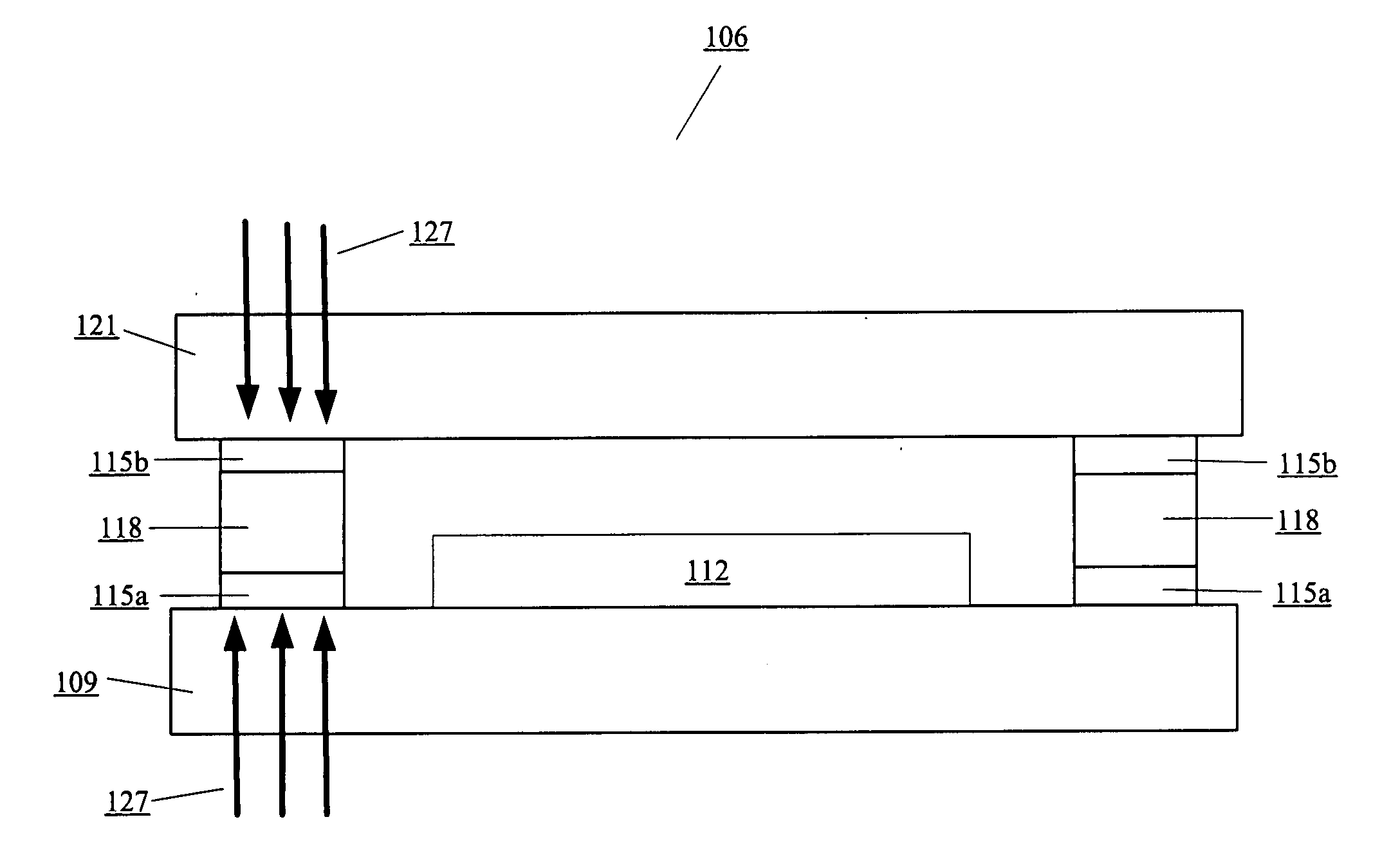

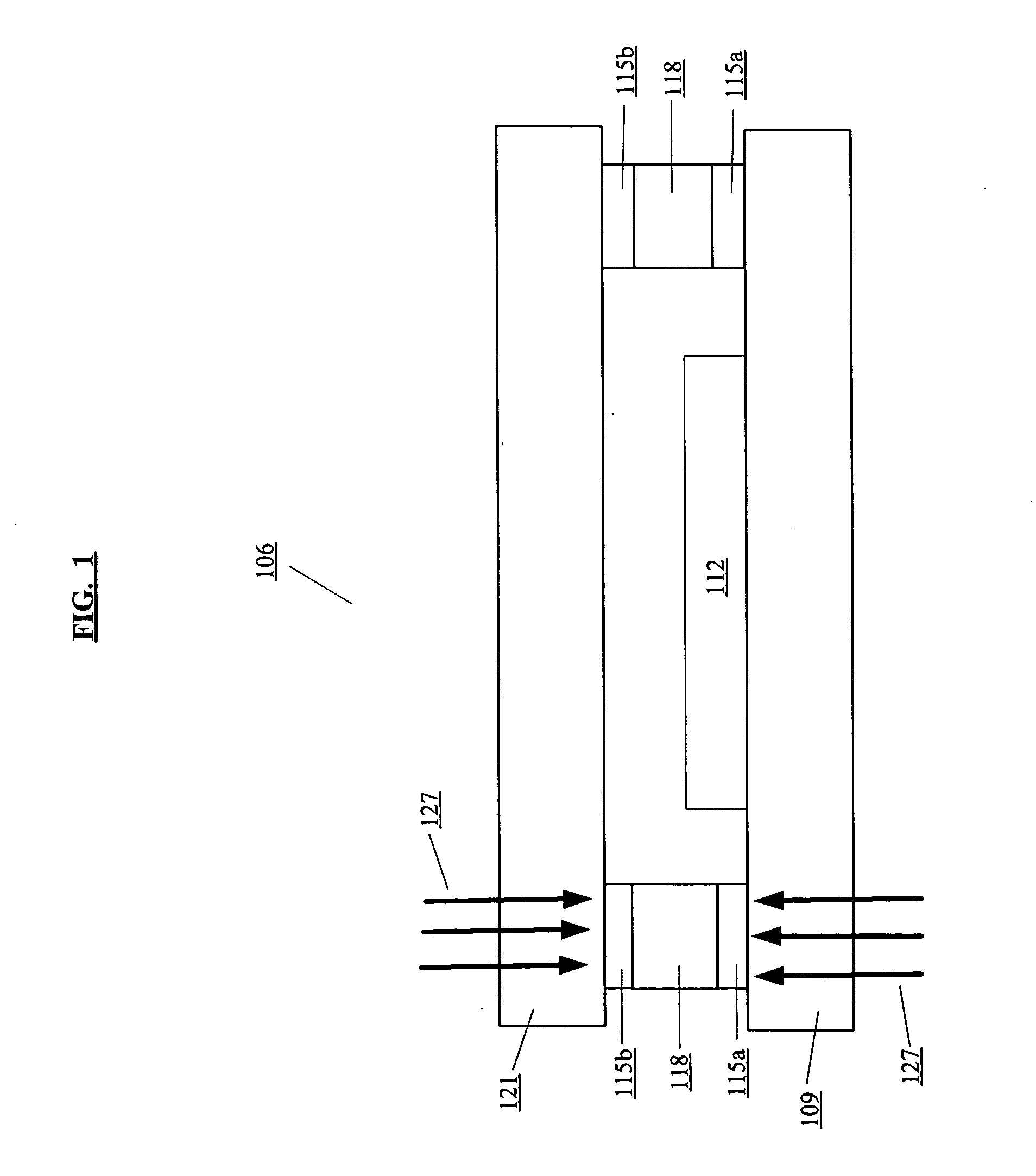

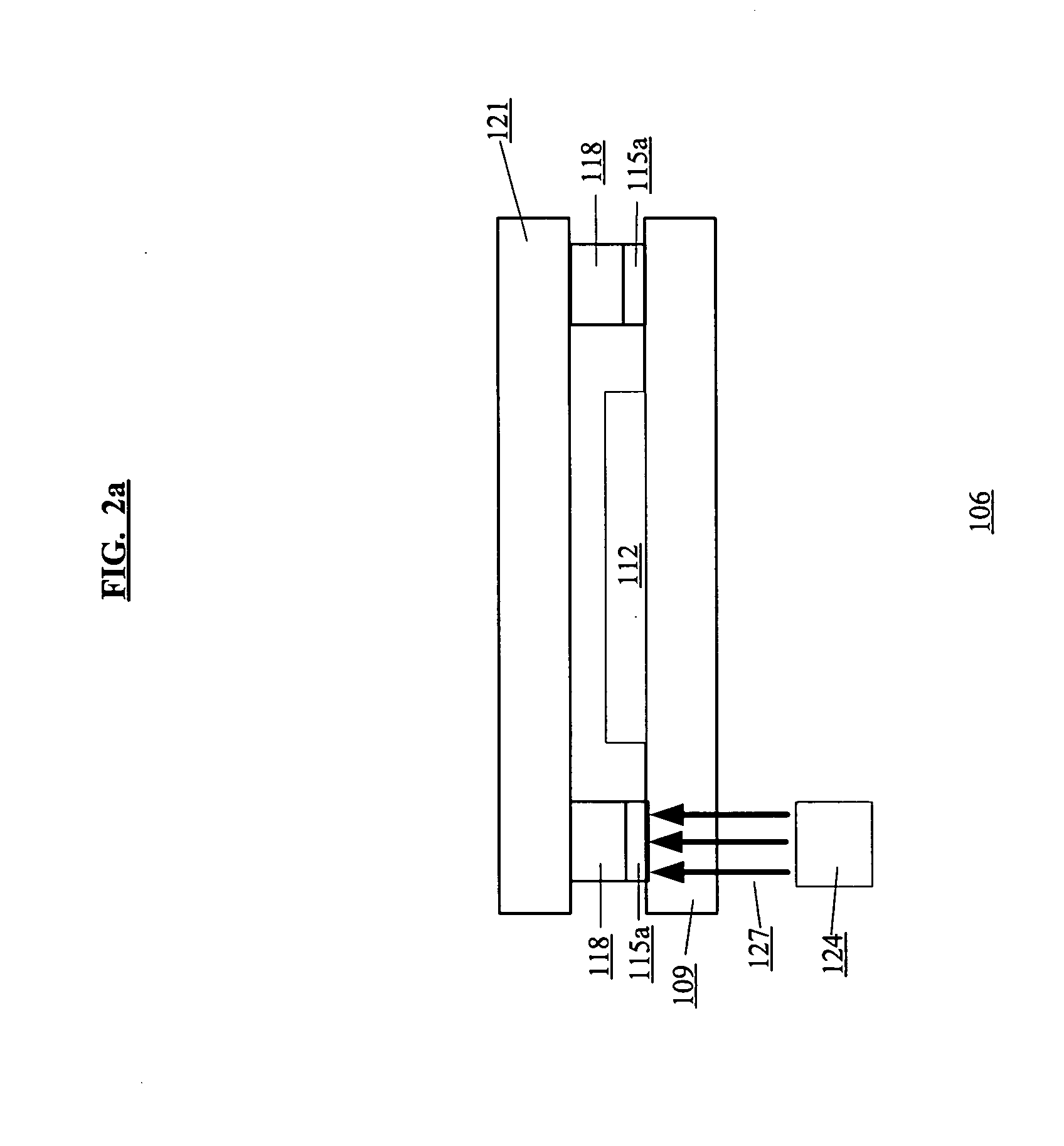

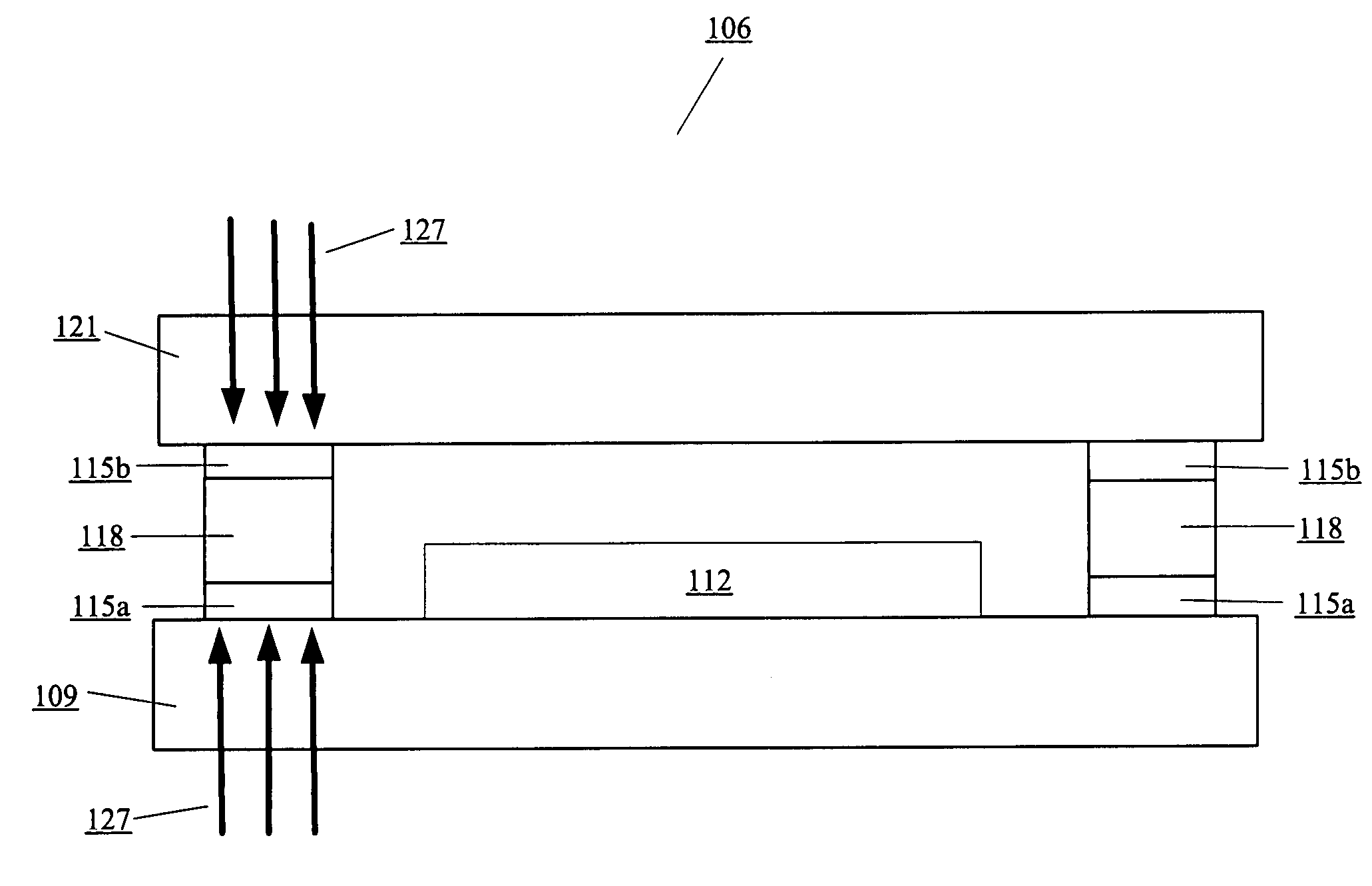

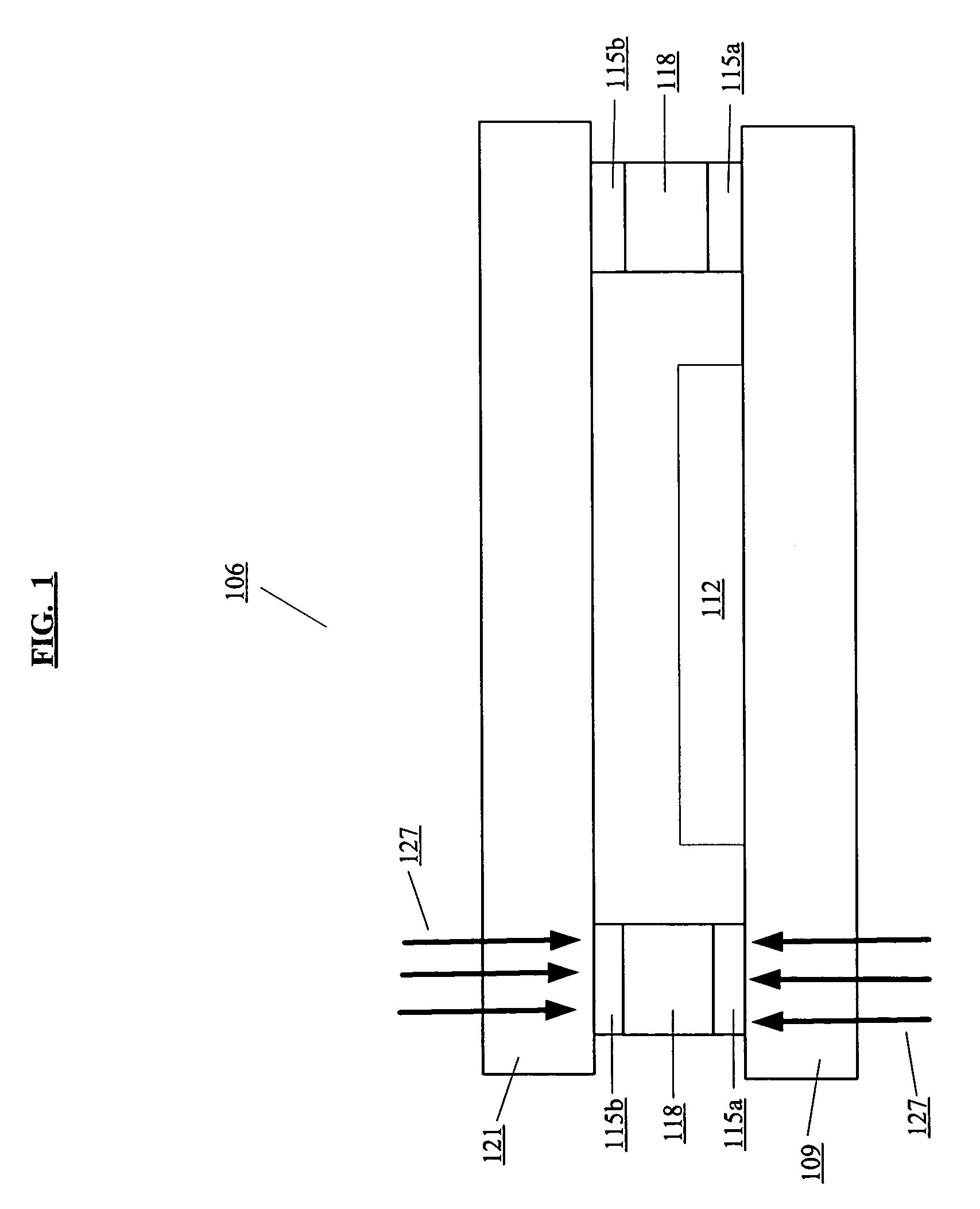

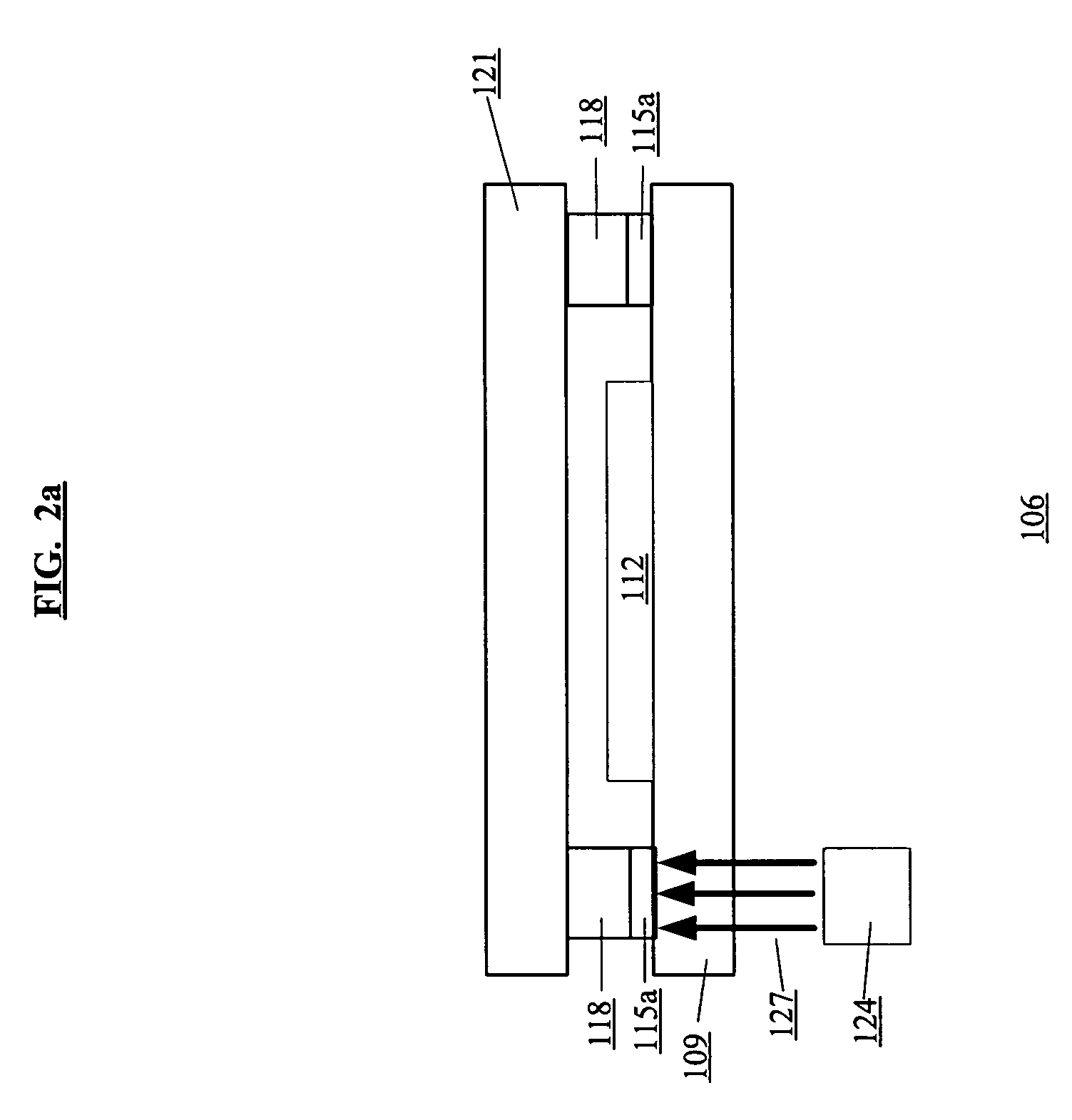

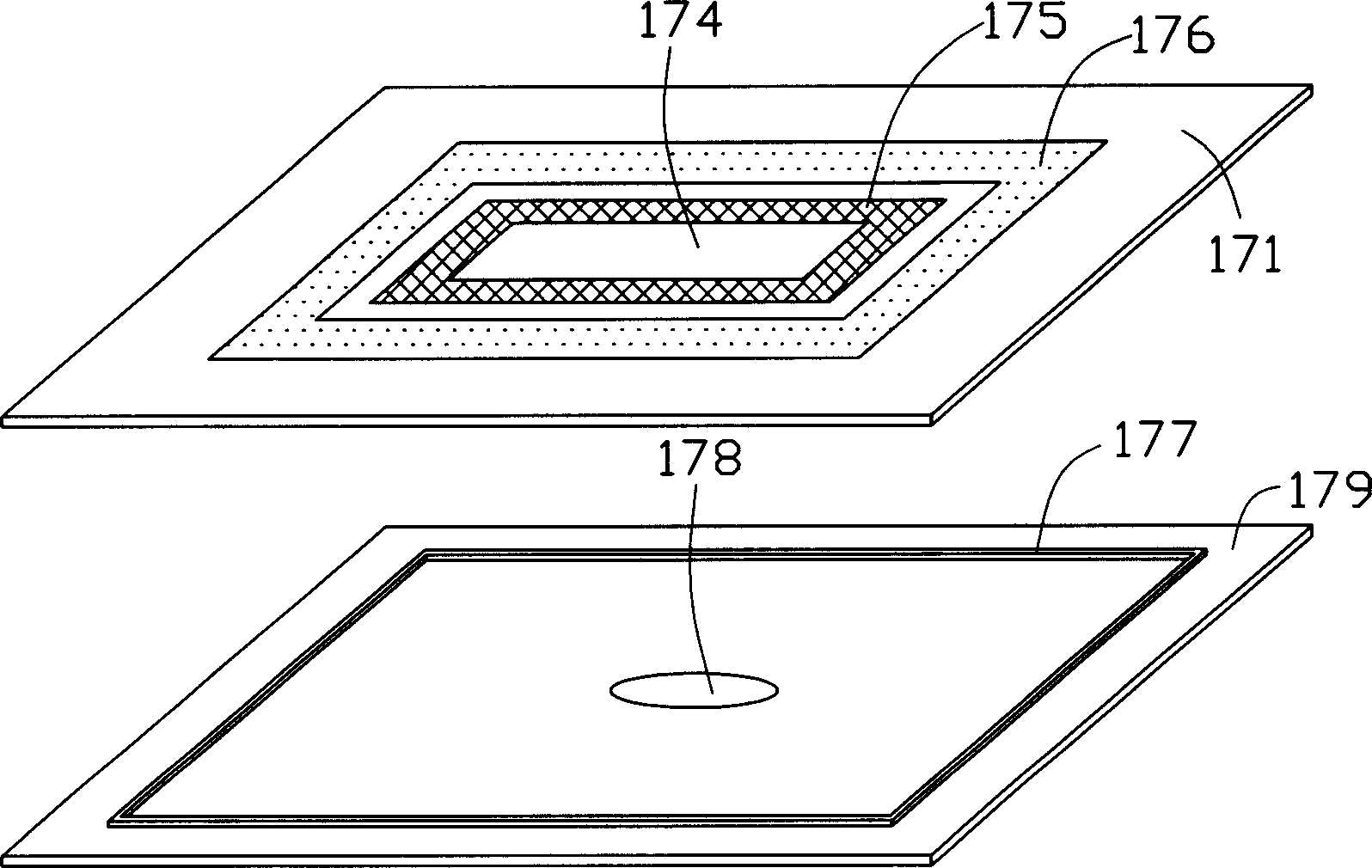

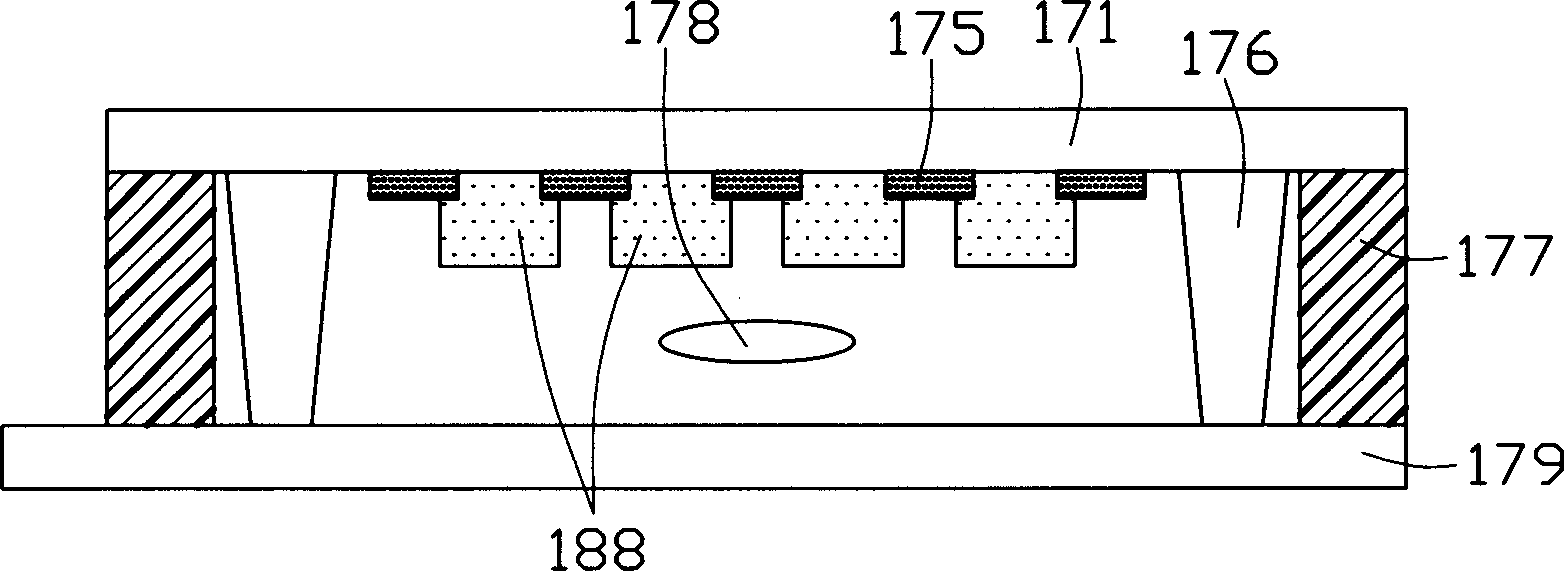

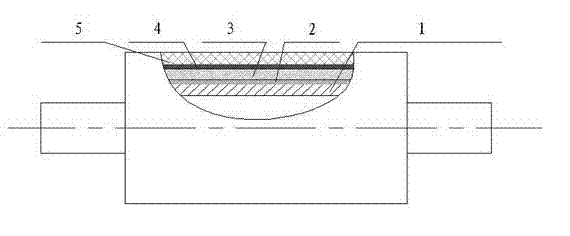

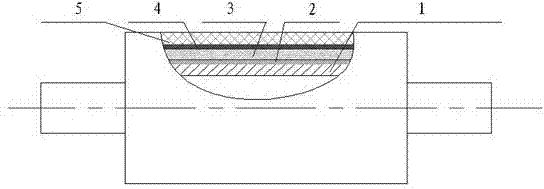

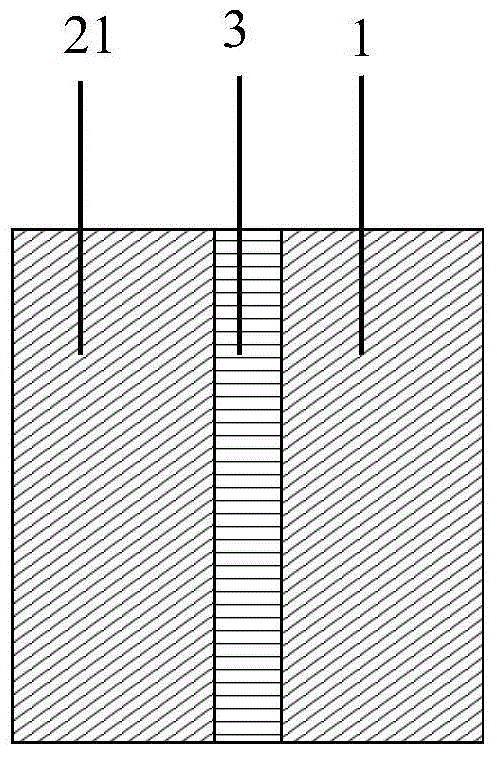

Sealing of electronic device using absorbing layer for glue line

ActiveUS20060049396A1Semiconductor/solid-state device detailsSolid-state devicesGlue lineEngineering

In one embodiment of the invention, a first absorbing layer is on a substrate and / or a second absorbing layer is on a heat-activated adhesive. If the IR source that supplies IR radiation is present on the substrate-side, then the absorption percentage of the substrate is less than the absorption percentage of the first absorbing layer if present and less than the absorption percentage of the second absorbing layer if present. If the IR source that supplies IR radiation is present on the “encapsulation cover”-side, then the absorption percentage of the encapsulation cover is less than the absorption percentage of the first absorbing layer if present and less than an absorption percentage of the second absorbing layer if present. The substrate and the encapsulation cover have a low thermal conductivity.

Owner:DOLYA HOLDCO 5 LTD

Sealing of electronic device using absorbing layer for glue line

ActiveUS7078726B2Semiconductor/solid-state device detailsSolid-state devicesPhysical chemistryGlue line

In one embodiment of the invention, a first absorbing layer is on a substrate and / or a second absorbing layer is on a heat-activated adhesive. If the IR source that supplies IR radiation is present on the substrate-side, then the absorption percentage of the substrate is less than the absorption percentage of the first absorbing layer if present and less than the absorption percentage of the second absorbing layer if present. If the IR source that supplies IR radiation is present on the “encapsulation cover”-side, then the absorption percentage of the encapsulation cover is less than the absorption percentage of the first absorbing layer if present and less than an absorption percentage of the second absorbing layer if present. The substrate and the encapsulation cover have a low thermal conductivity.

Owner:DOLYA HOLDCO 5 LTD

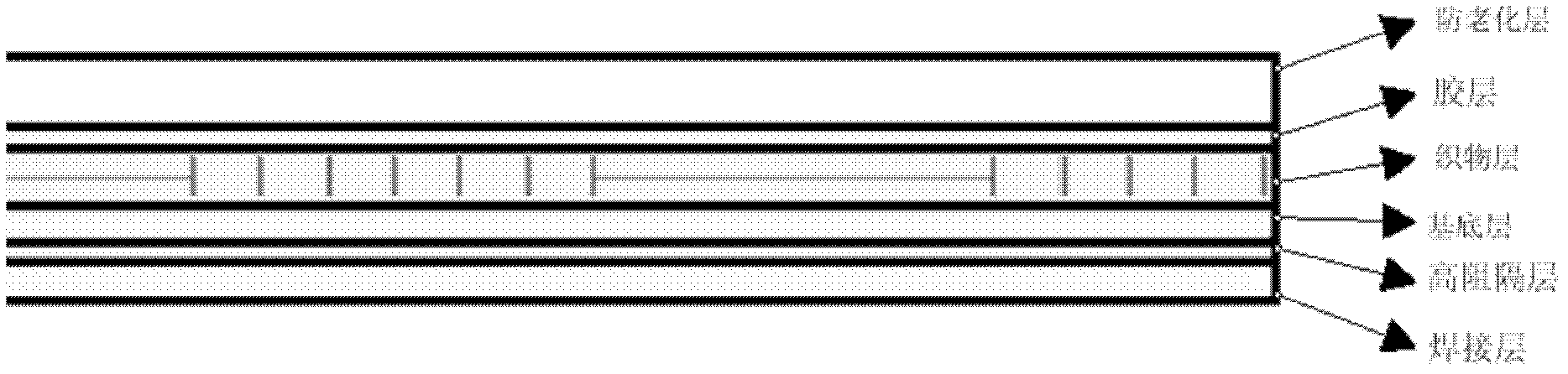

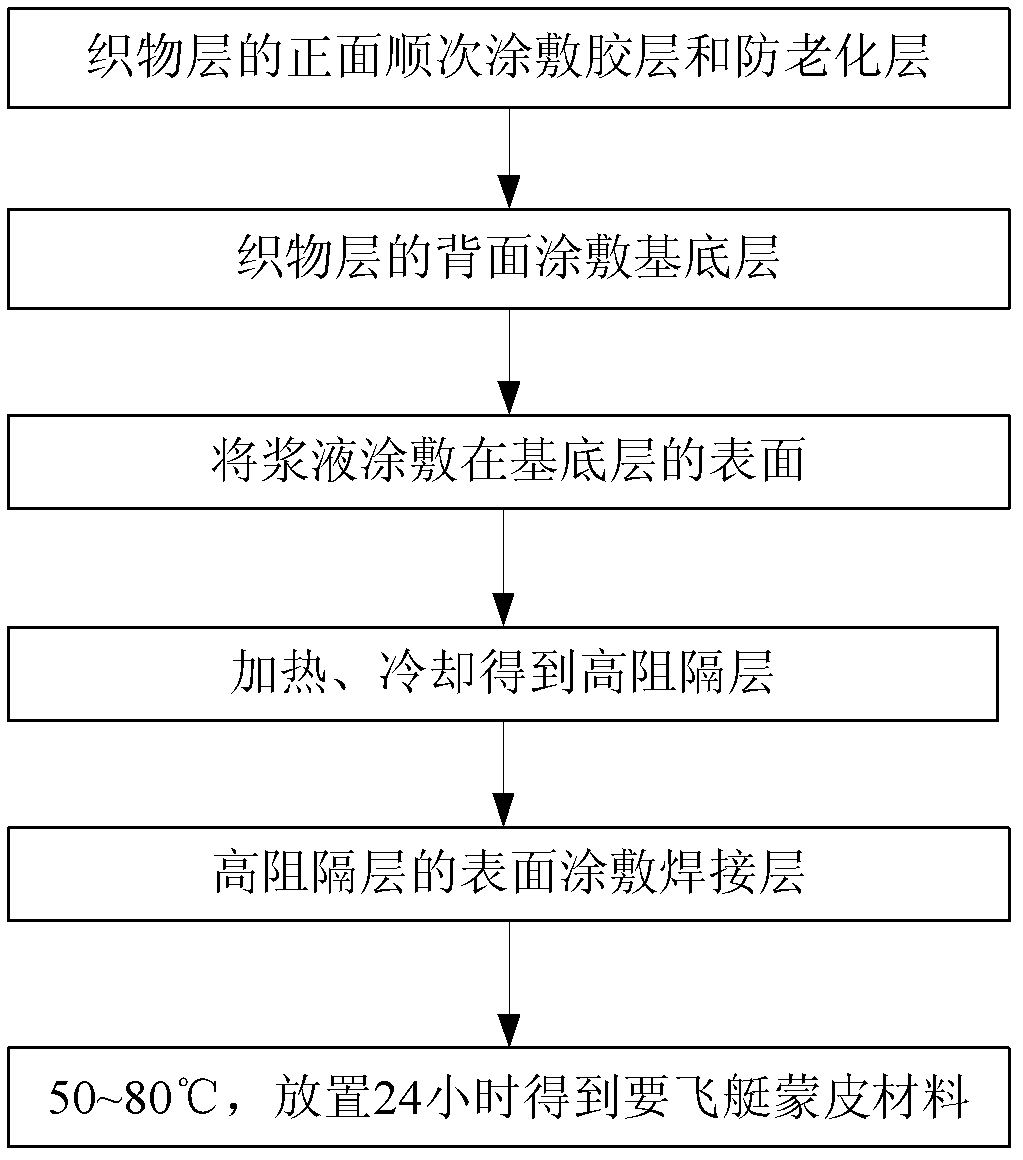

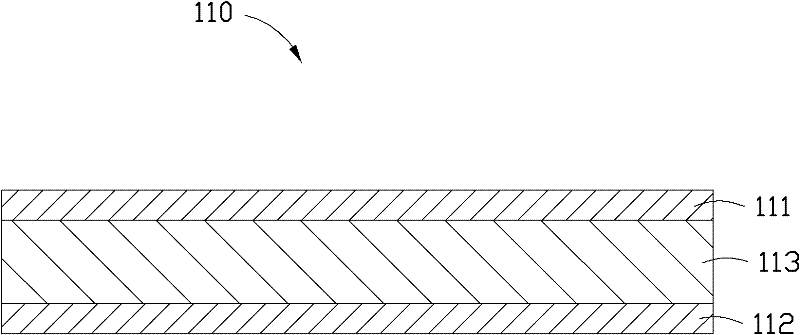

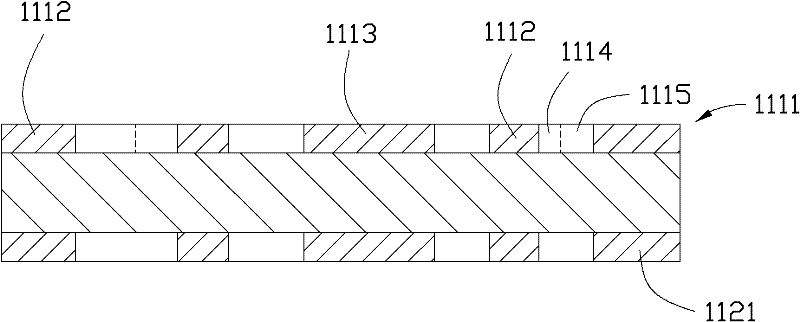

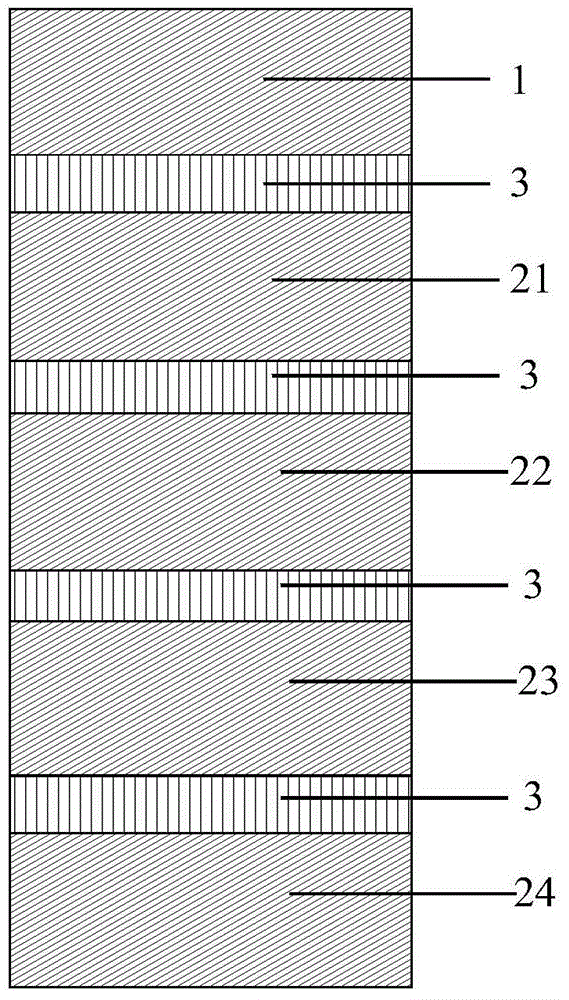

Airship sheath material and preparation method thereof

InactiveCN102416739AImprove barrier propertiesImprove rub resistanceSynthetic resin layered productsGas-bag arrangementsPolyvinyl alcoholNanoparticle

The invention provides an airship sheath material and a preparation method thereof. The sheath material comprises successively an anti-aging layer, a glue-line, a fabric layer, a basal layer, a high barrier layer and a weld layer. A material of the anti-aging layer is a thermoplastic polyurethane containing ZnO with a mass fraction of 1-3% and TiO2 with a mass fraction of 2.5-4% and having a thickness of 25-35 mum; a material of the high barrier layer is polyvinyl alcohol containing SiO2 nano particles with a mass fraction of 1.5-2.5%, a particle size of 20-70nm and a thickness of 1-3 mum. a material of the weld layer is thermoplastic polyurethane with a thickness of 20-30 mum. The high barrier layer of the airship sheath material is added with nano particles to gain a substantially enhanced obstruction effect and a helium permeation of 5-20ml / (m<2>.atm.24h). The preparation technology of the invention is simple; a coating technology and a simple applying technology are employed to realize a high obstruction effect.

Owner:BEIHANG UNIV

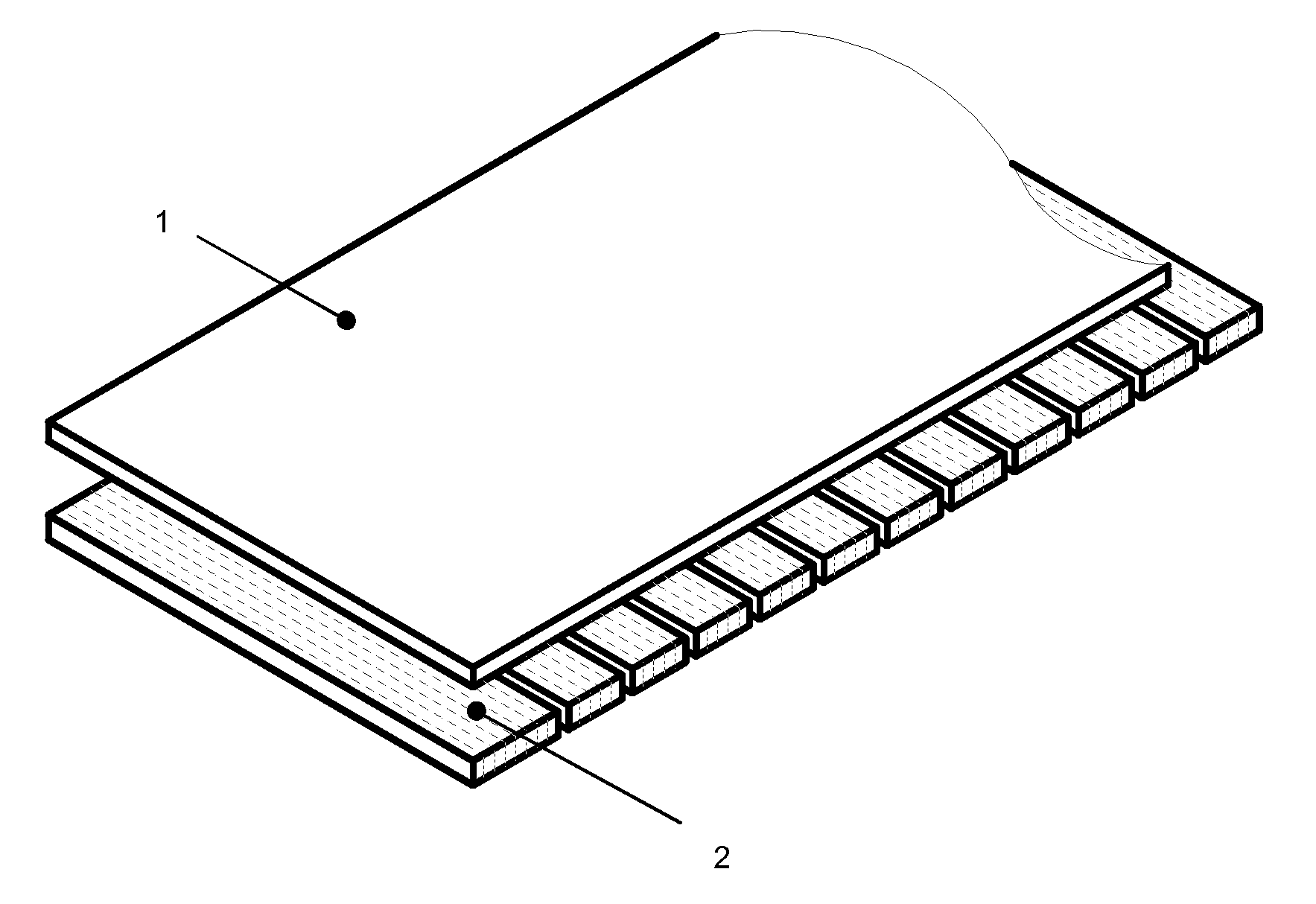

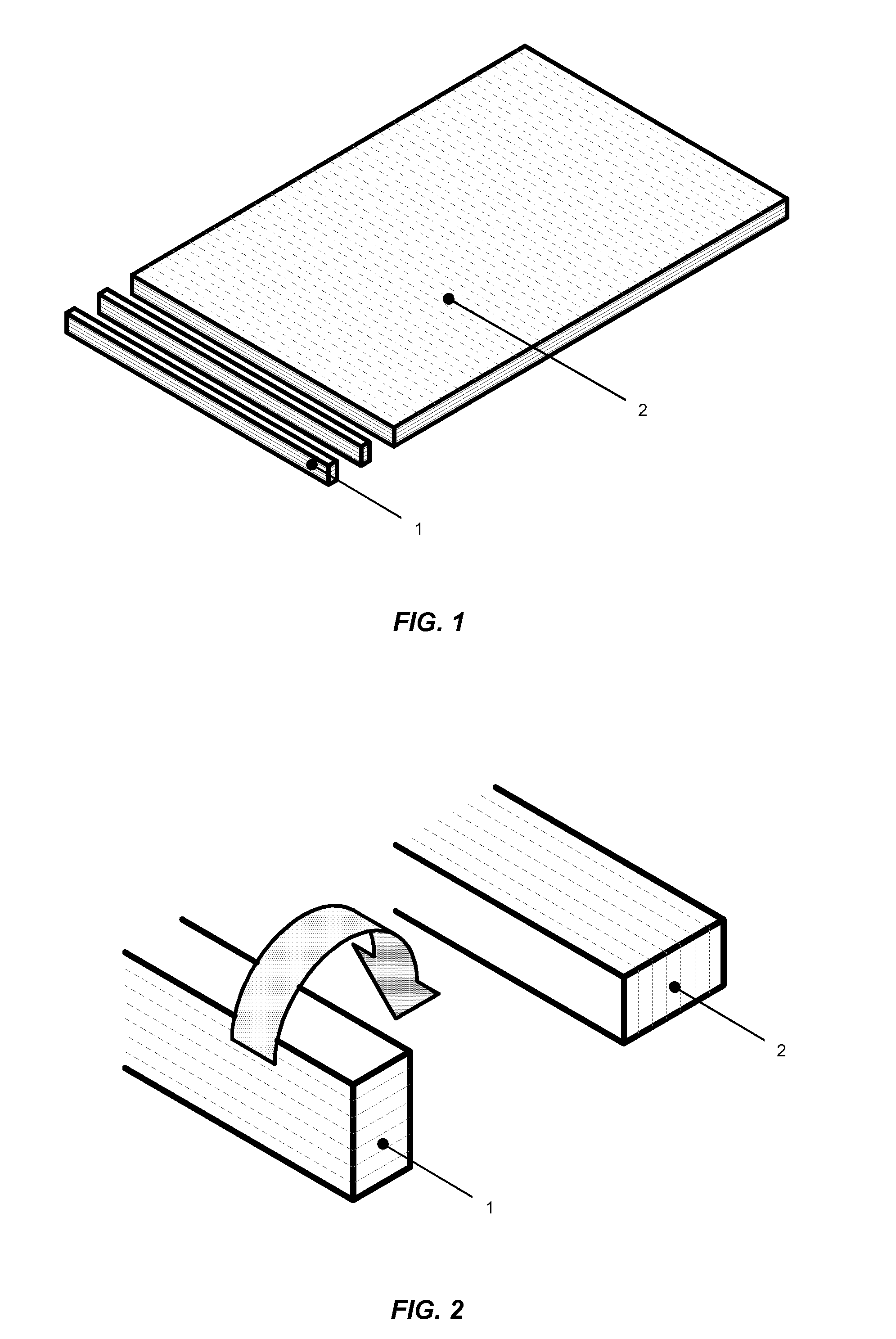

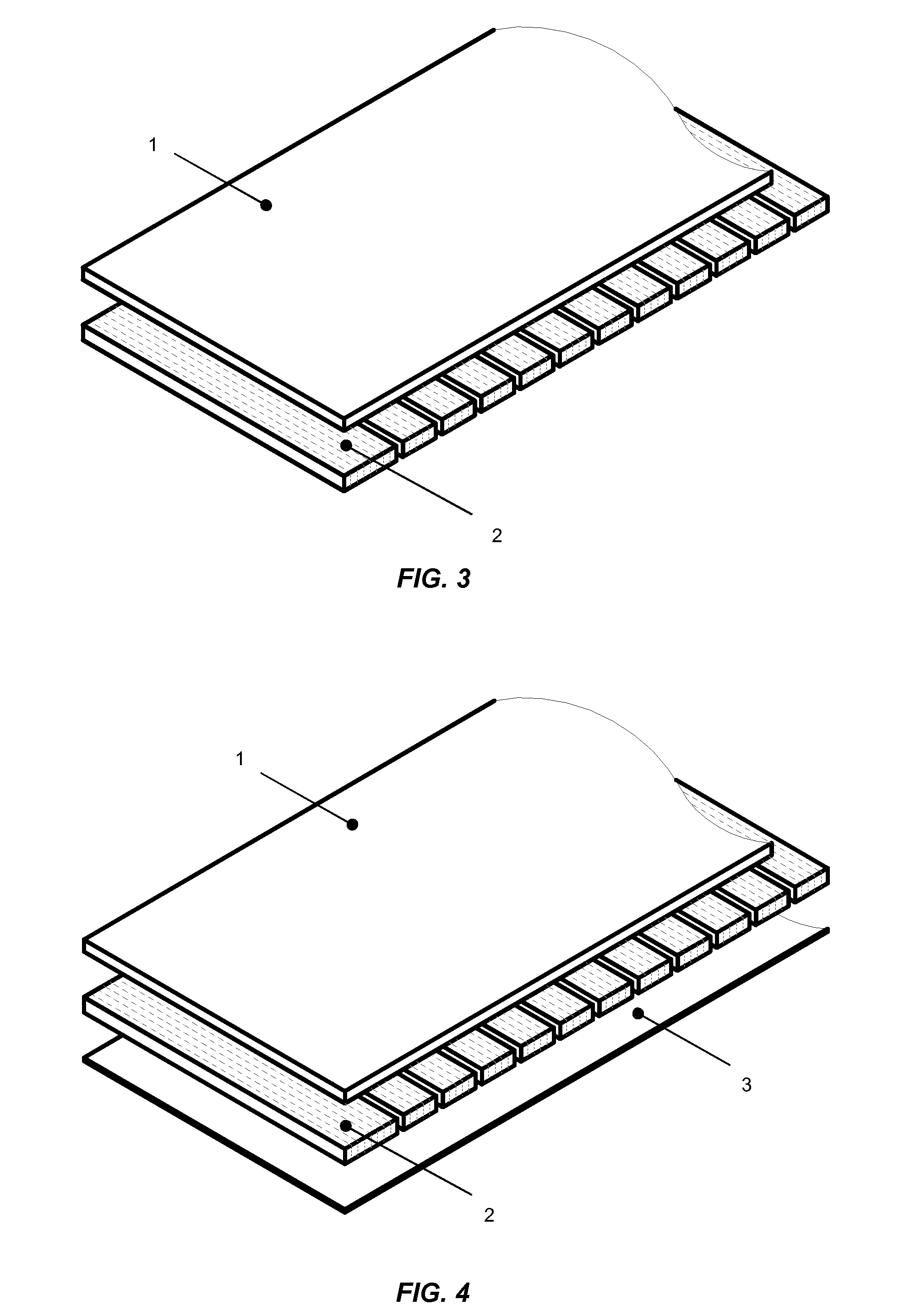

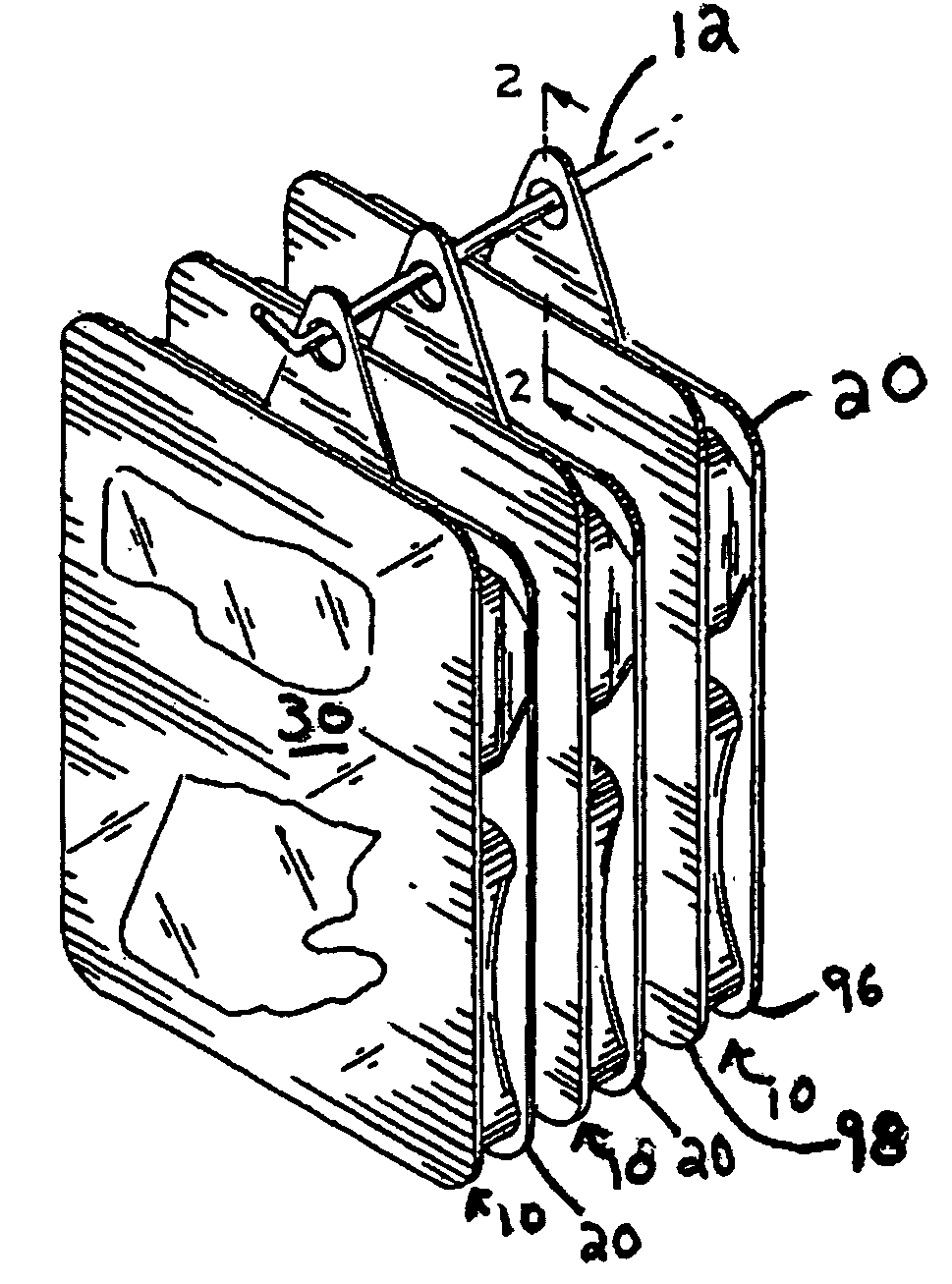

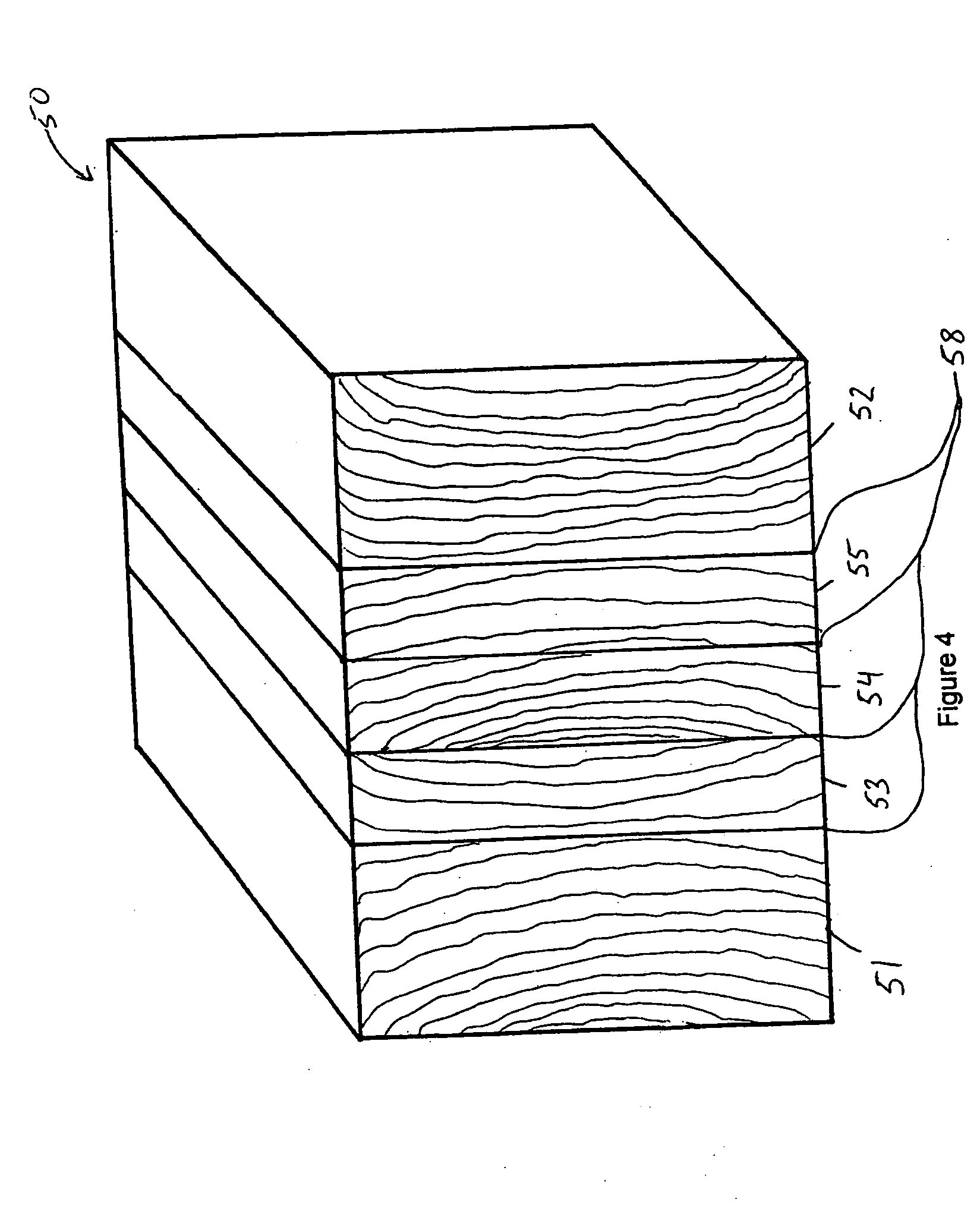

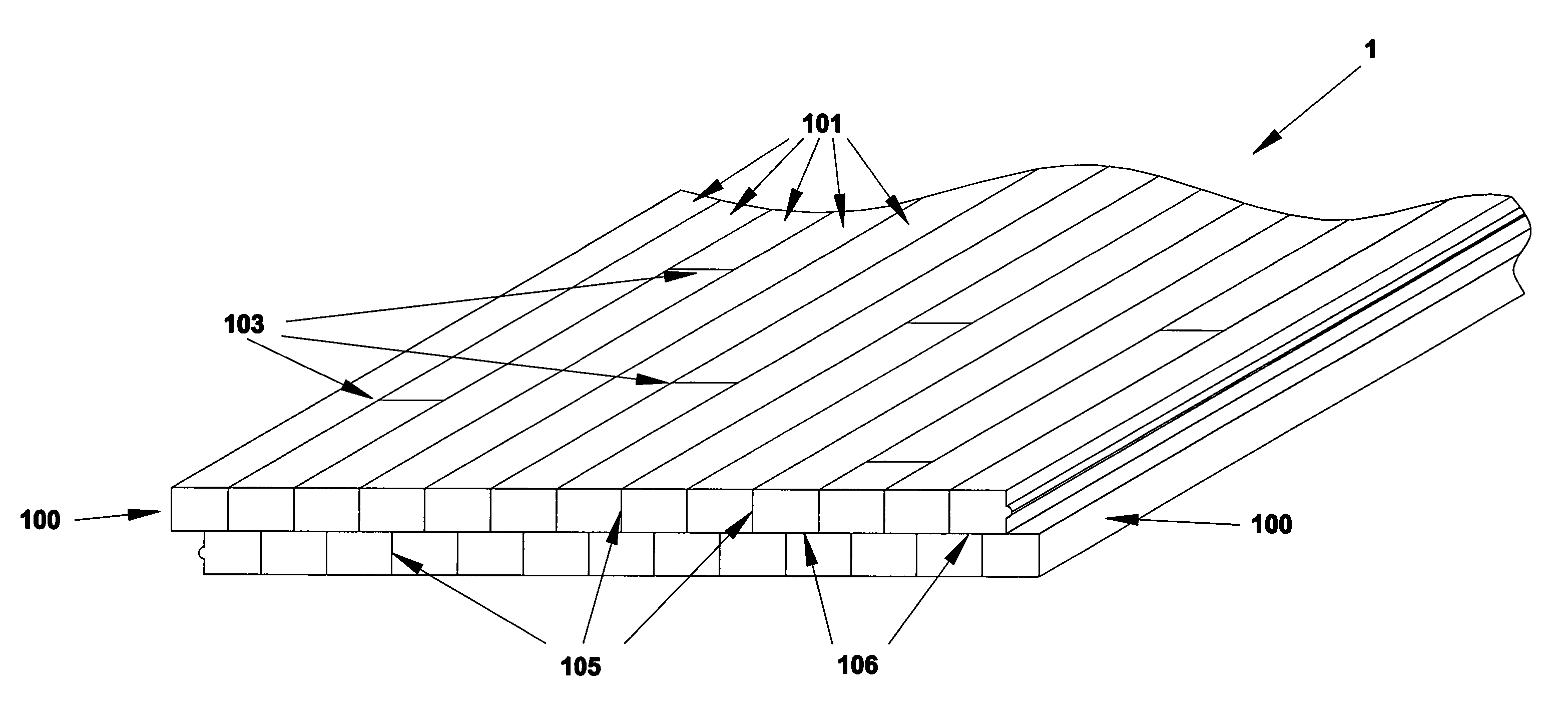

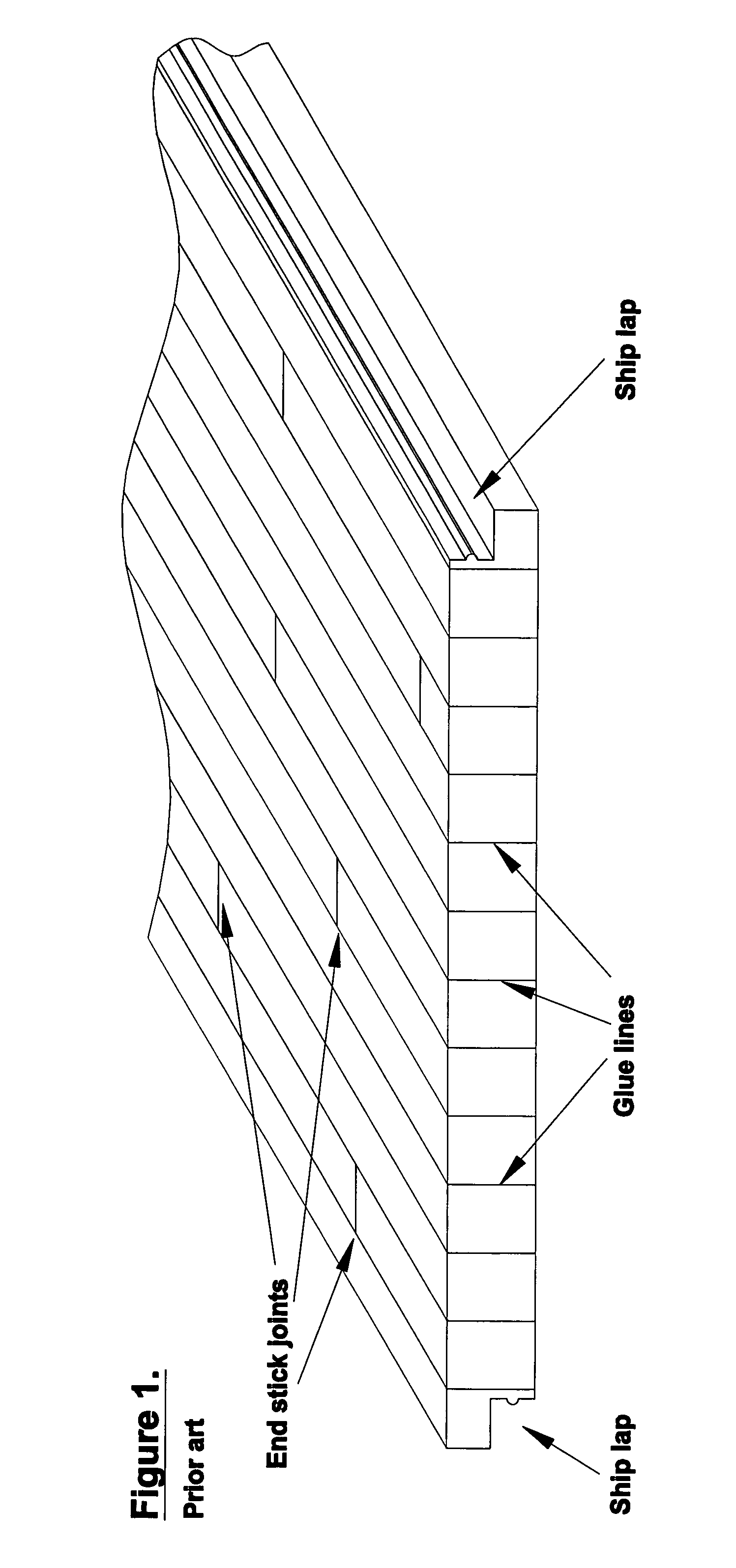

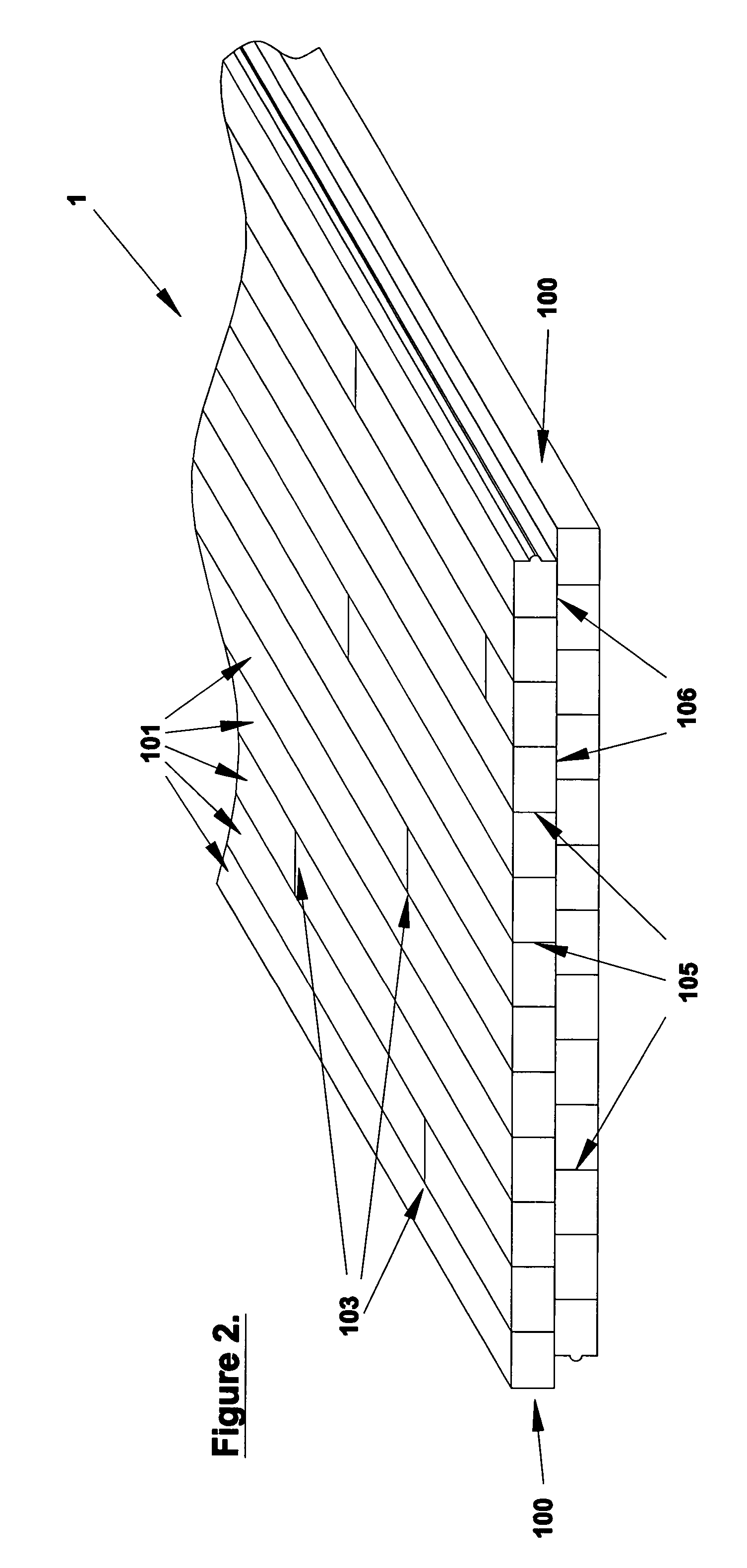

Engineered wood floor using core material with vertical glue-line position

ActiveUS20070292656A1Reduce and eliminate drawbackReduce and eliminate and problemLamination ancillary operationsLaminationEngineeringGlue line

Owner:TANJUNG KREASI PARQUET IND

Hanger and backcard for packages

A backcard for use with compartmentalized containers, particularly food containers, that provides a hanging feature and an information feature. The backcard may be secured to the container or package with glue lines properly placed on the package, or glue placed on the backcard. The hanging feature is formed by moving a tab located in an outermost sheet or layer from a non-extended position to an extended position. The backcard is provided with a substantial area, e.g., 50% or more of the backcard area, for printing information such as a list of nutritional facts, a list of food ingredients and the like for presentation to a consumer. In addition, a portion of the backcard may be removable or foldable to expose a portion of the outer layer or a substrate layer, thereby allowing each to display additional information.

Owner:KRAFT FOODS GRP BRANDS LLC

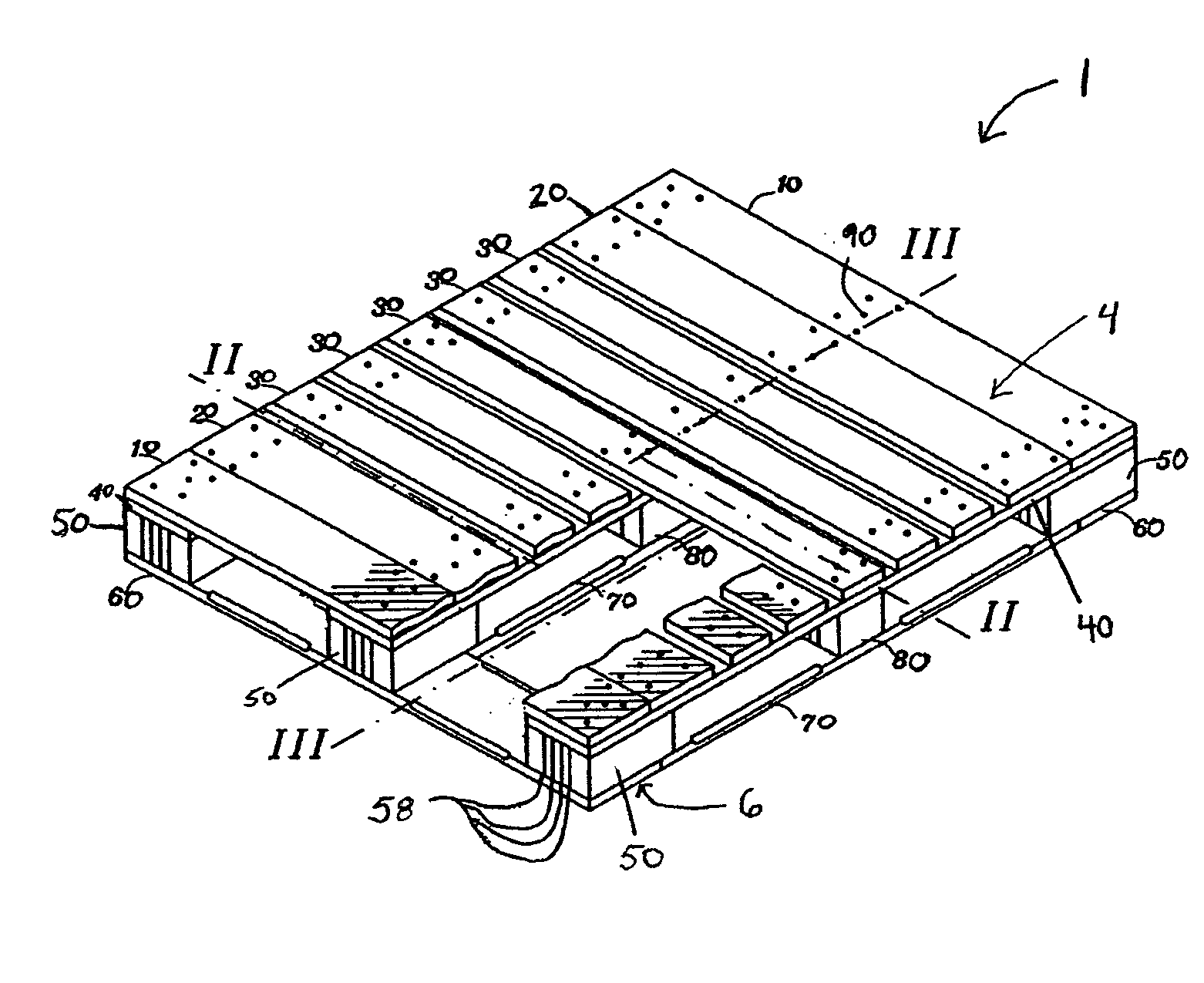

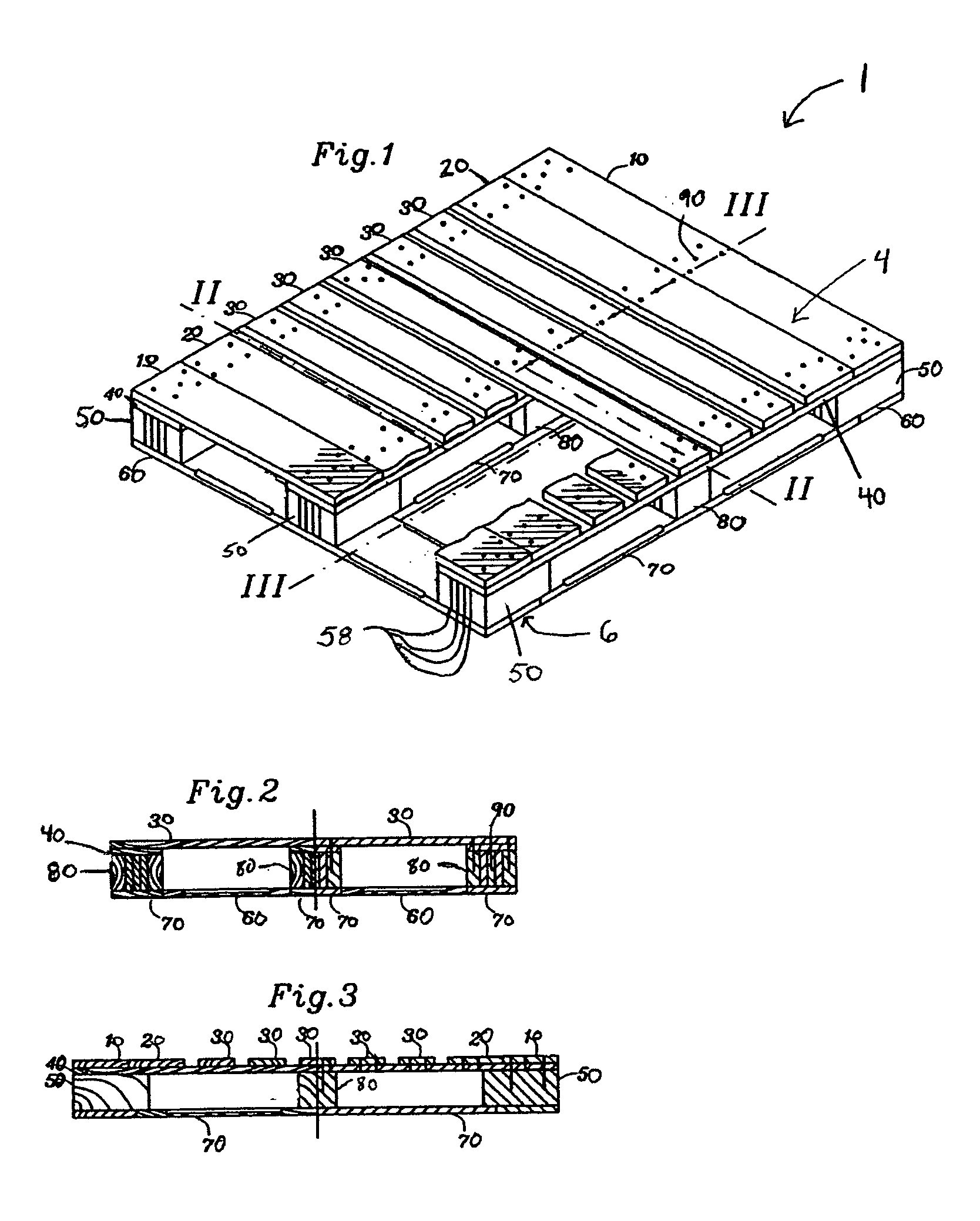

Pallet with laminate blocks

A wood pallet is disclosed. The pallet includes a top deck for receiving a load, a bottom deck, at least two spaced-apart stringers extending longitudinally between the ends of the pallet, and a plurality of spacer blocks attached to the stringers. The stringers and the spacer blocks are situated between the top deck and the bottom deck to maintain the decks in a spaced relationship. The plurality of spacer blocks comprise laminate blocks of glued wood components. The glue lines of the laminate spacer blocks are substantially perpendicular to the stringers and the grain of each of the wood components runs in the same direction as one another and against the width dimension of the spacer block.

Owner:POTOMAC SUPPLY CORP

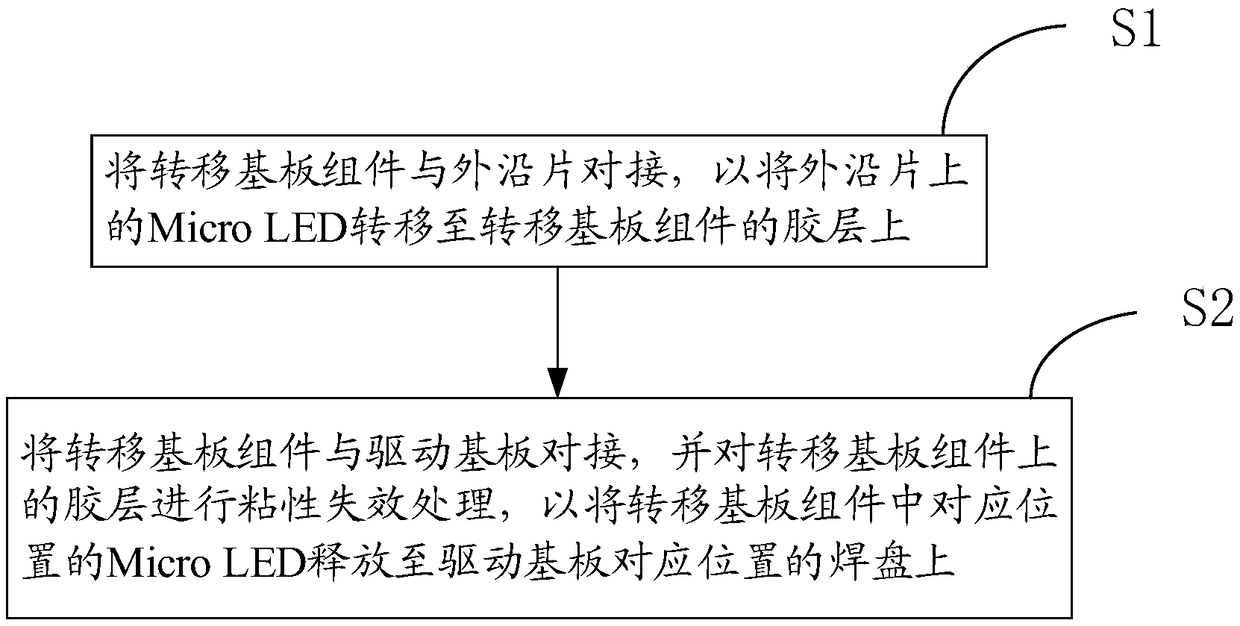

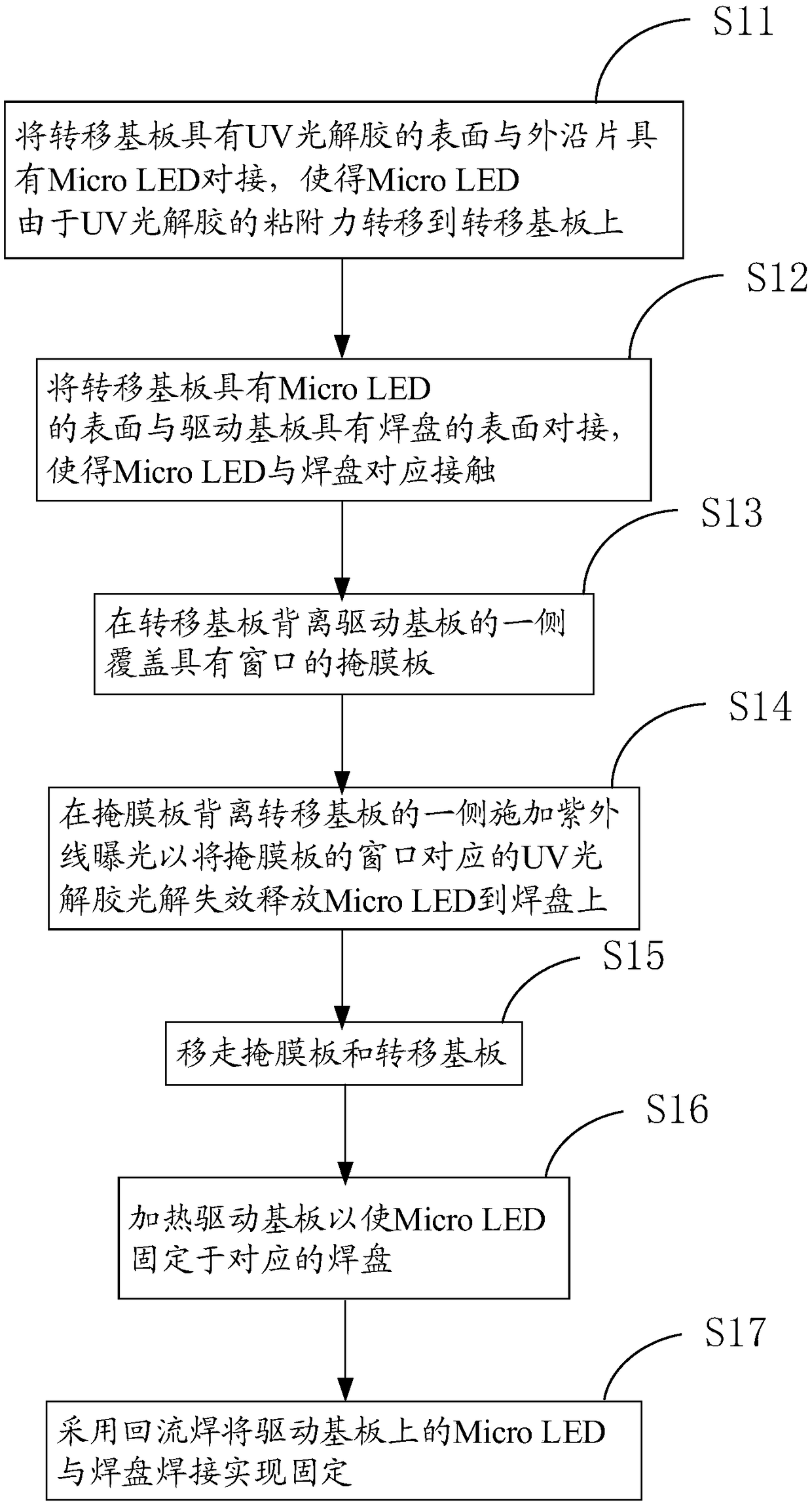

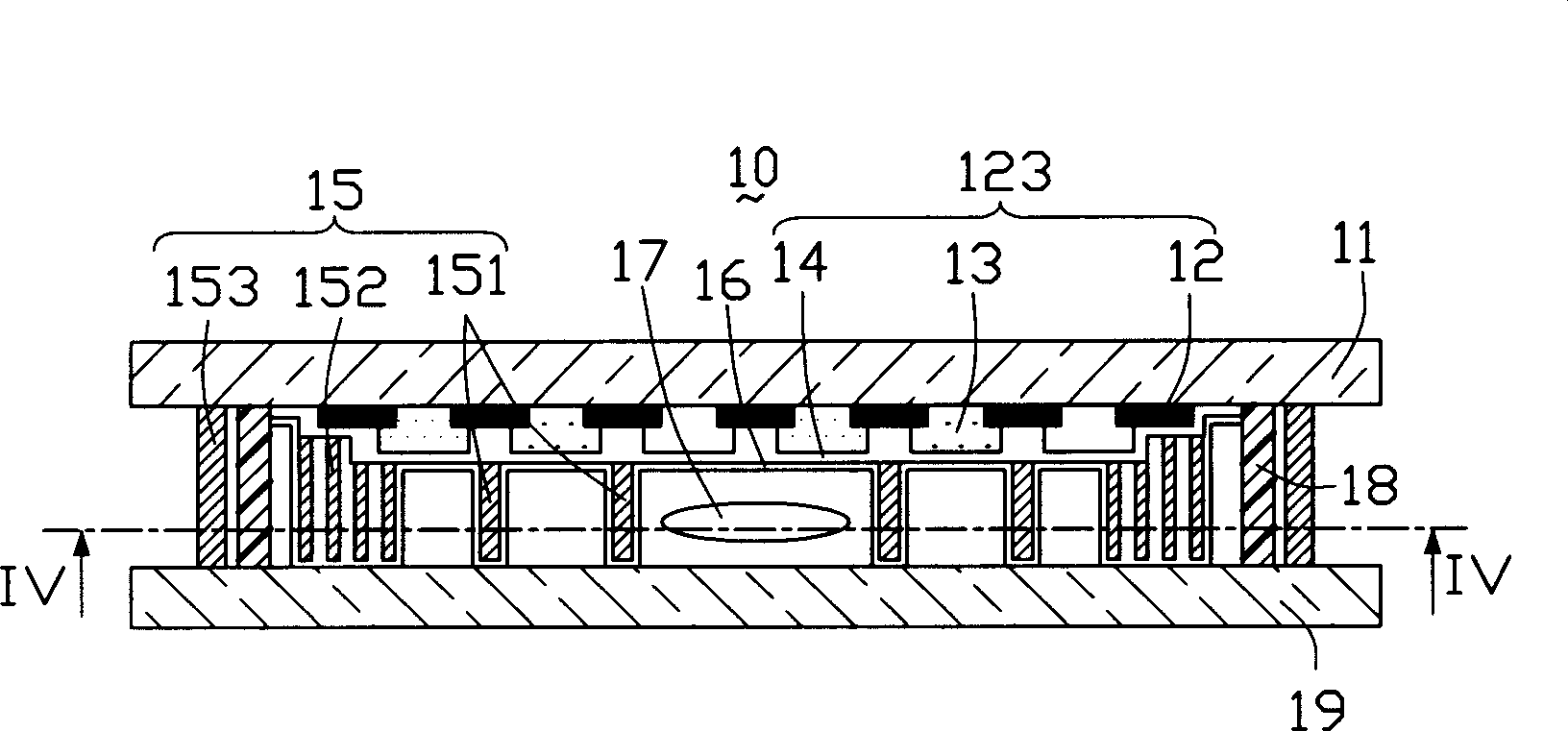

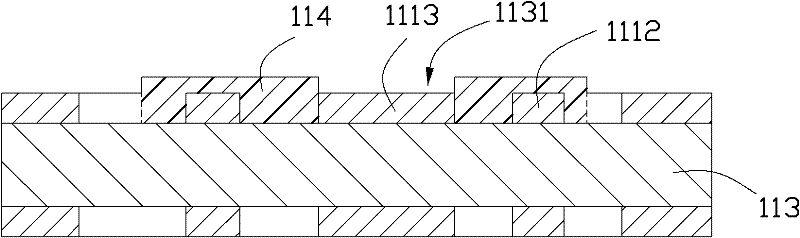

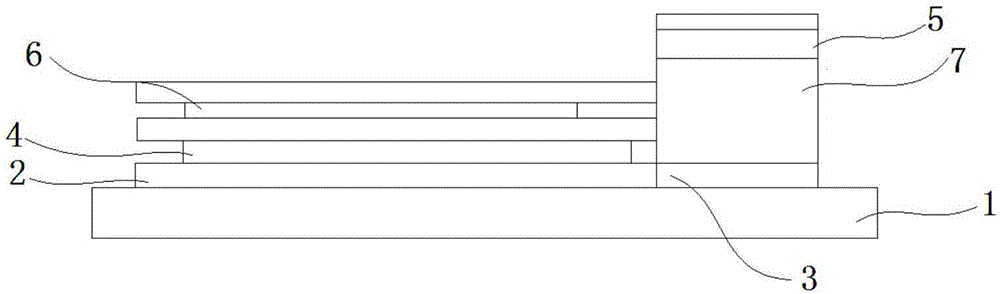

Manufacture method for Micro LED (Light Emitting Diode) display substrate

ActiveCN109473532ASolid-state devicesSemiconductor/solid-state device manufacturingButt jointEngineering

The invention relates to the technical field of display, in particular to a manufacture method for a Micro LED (Light Emitting Diode) display substrate. The manufacture method comprises the followingstep of transferring Micro LEDs in array distribution according to set gaps on an epitaxial wafer to a bonding pad corresponding to a driving substrate through a transfer substrate component. The stepof transferring comprises the following steps that: carrying out butt joint on the transfer substrate component and the epitaxial wafer to transfer the Micro LEDs on the epitaxial wafer to the glue line of the transfer substrate component, carrying out butt joint on the transfer substrate component and the driving substrate, and carrying out stickiness failure processing on the glue line on the transfer substrate component to release the Micro LED on the corresponding position in the transfer substrate component to the bonding pad on the corresponding position of the driving substrate. By useof the manufacture method, transfer equipment and assorted facilities do not need to be specially designed, batch fetching and transfer of the Micro LEDs can be realized to manufacture the Micro LEDdisplay substrate, and therefore, the manufacture method has the advantages of low cost, high transfer efficiency and the like.

Owner:HEFEI BOE OPTOELECTRONICS TECH +1

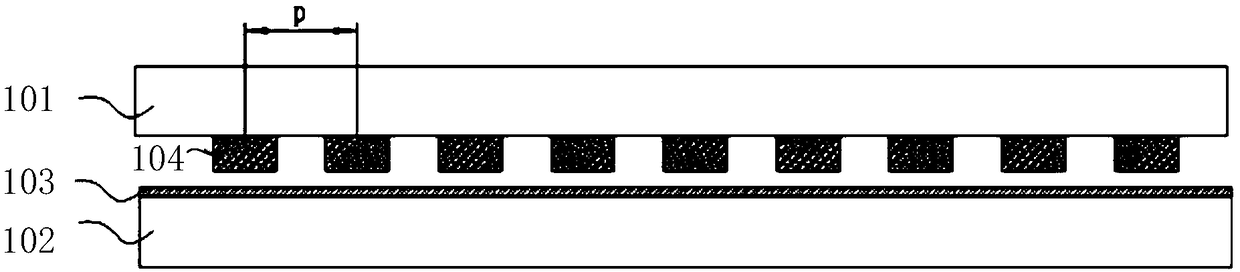

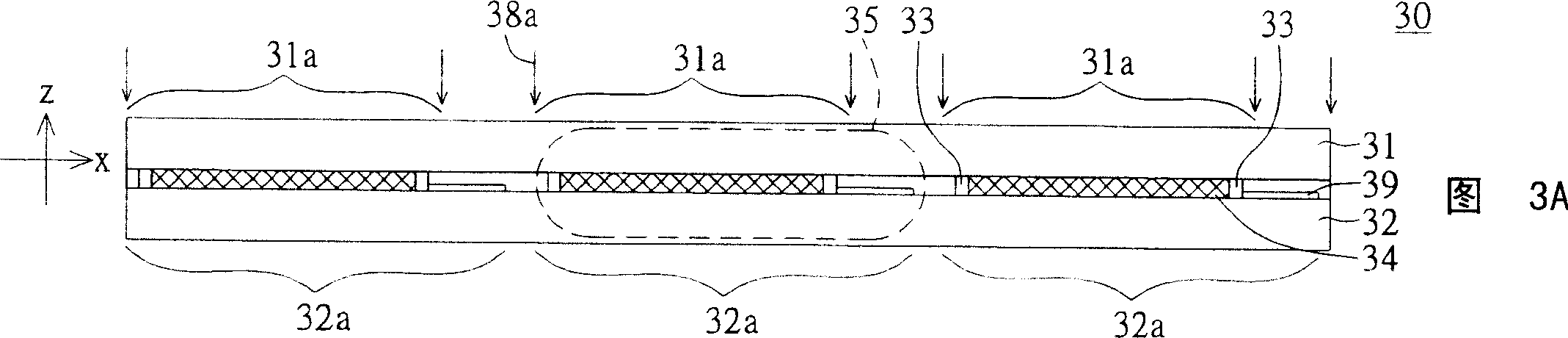

Faceplate of liquid crystal display

InactiveCN1696776AUniform thicknessAvoid light leakageStatic indicating devicesNon-linear opticsLiquid-crystal displayGlue line

A liquid crystal display panel is prepared as setting the first baseplate opposite to the second one and placing liquid crystal layer between said two baseplates, using glue line to bind said two baseplates, dividing each of said two baseplates to be a central portion and peripherical portion, scattering light interval objects in either central portion or peripherical portion of the two baseplates and confirming that its distribution density in central portion line near to glue line is greater than distribution in central portion far from glue line.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

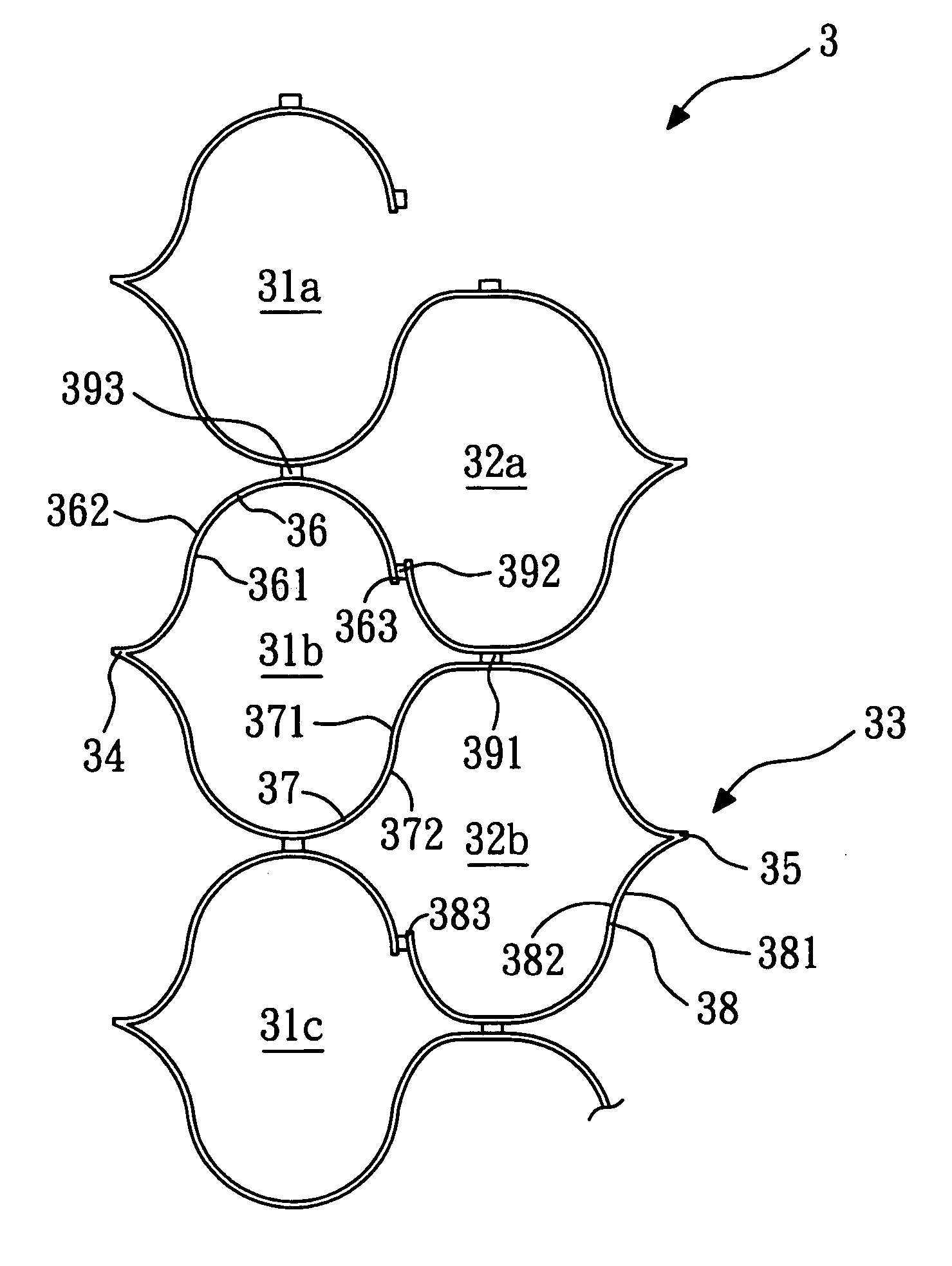

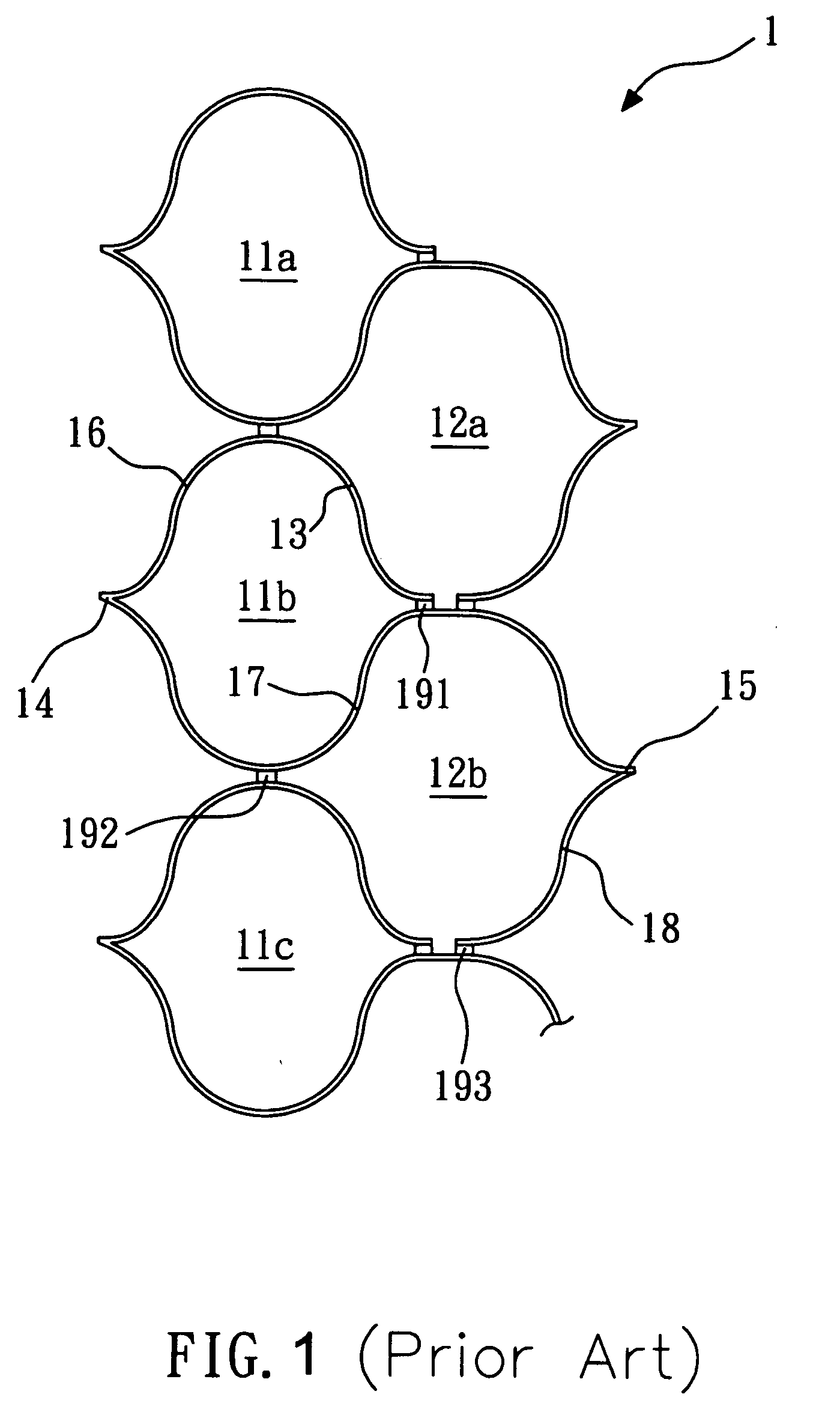

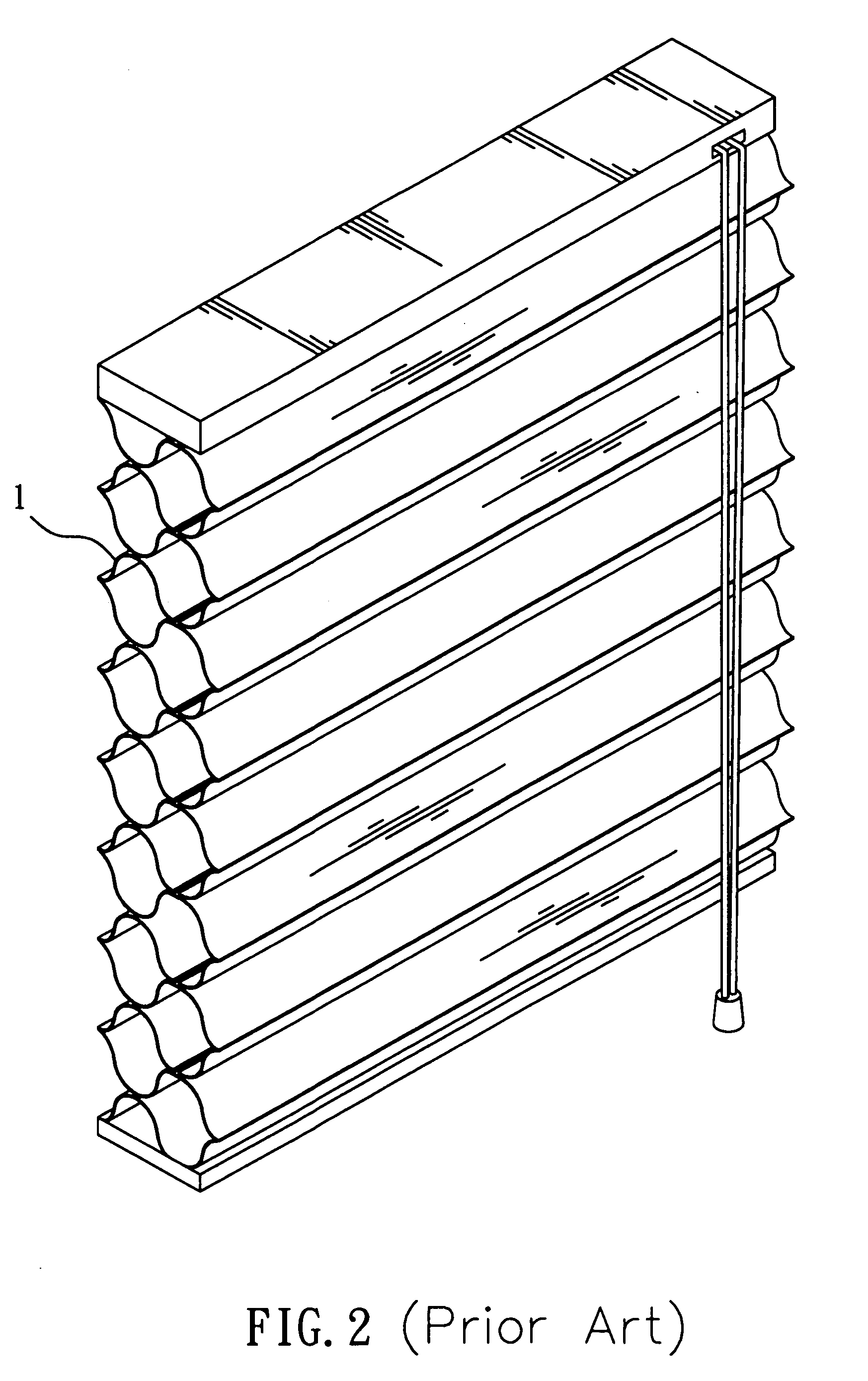

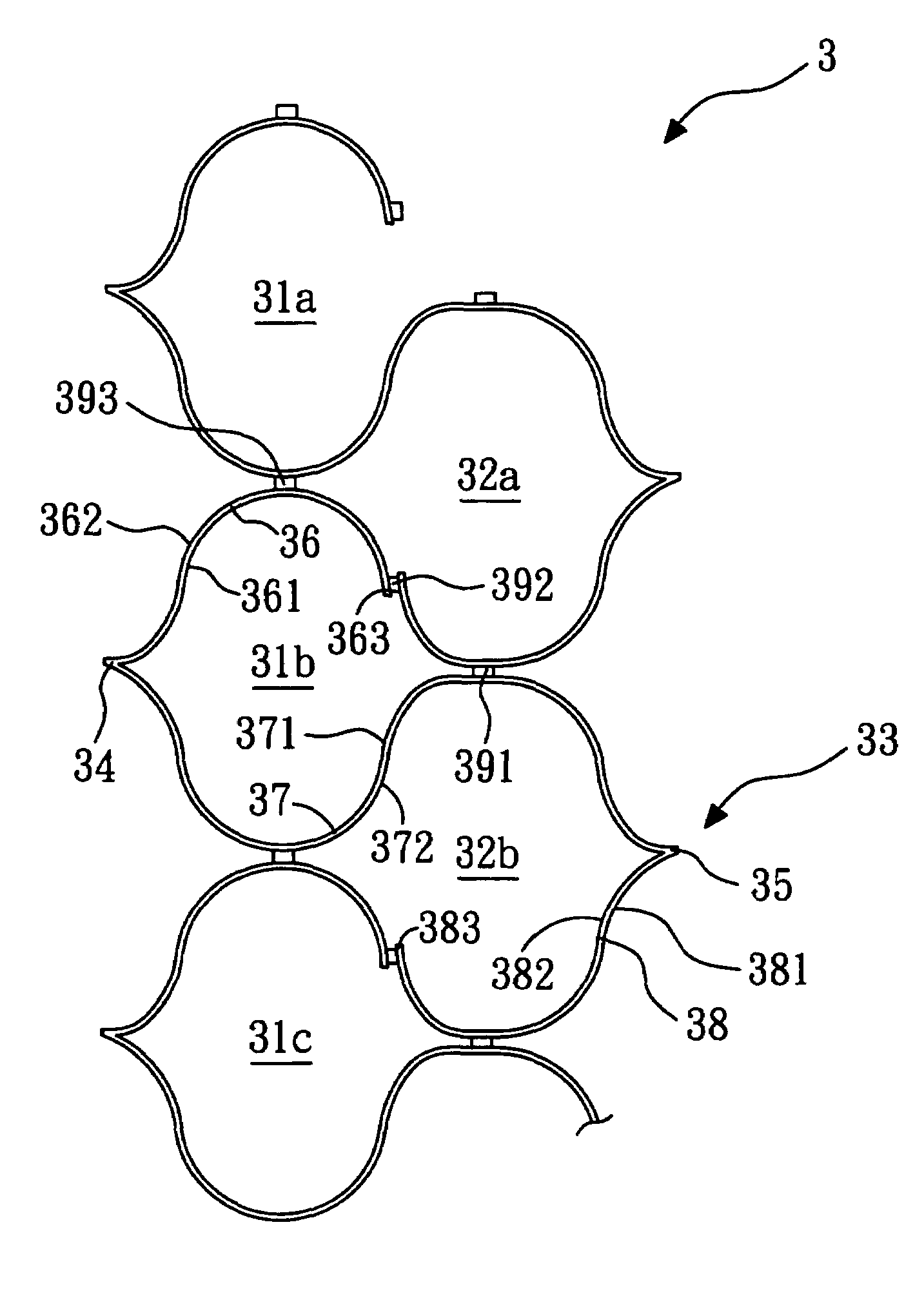

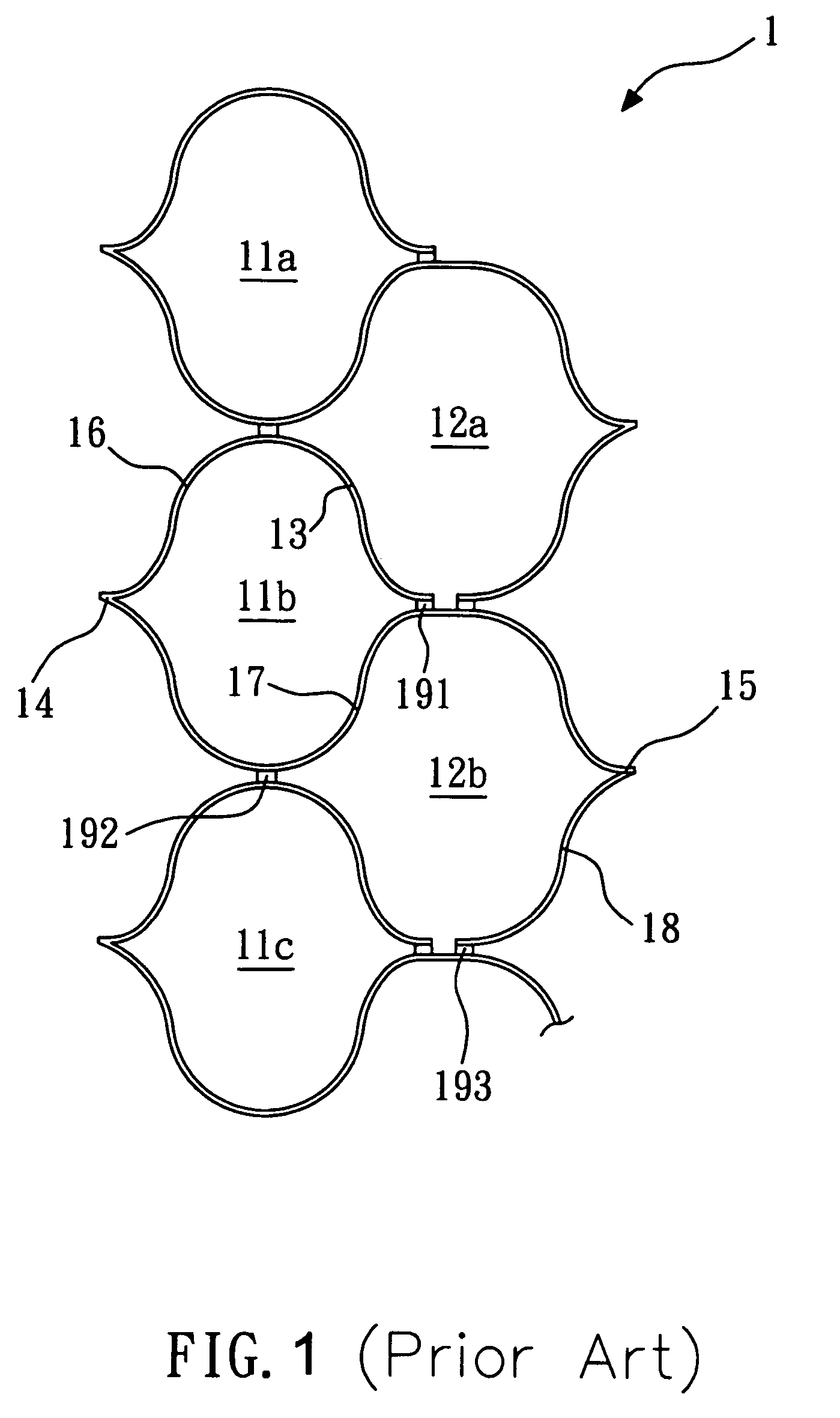

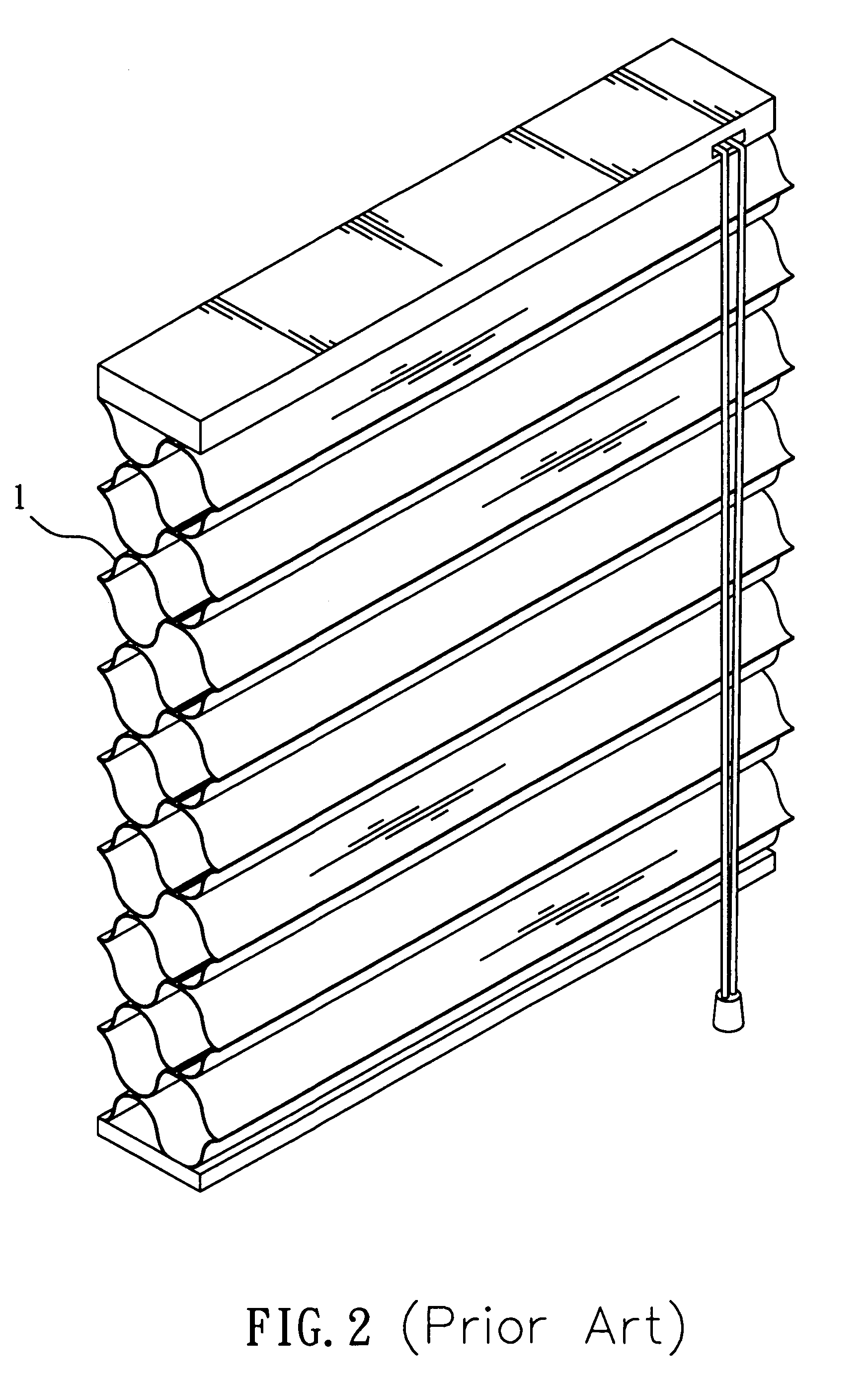

Foldable honeycomb structure and method for making the same

InactiveUS20070039697A1Glue position is accurateReduces cost timeExtensible doors/windowsCurtain accessoriesGlue lineMechanical engineering

The present invention relates to a foldable honeycomb structure and method for making the same. The method comprises (a) providing a plurality of flat strips; (b) forming a pair of longitudinal creases in each strip thereby defining the first two longitudinal margins of each strip and a central portion of each strip between the creases; (c) folding each strip along said creases so that each folded strip has two exposed outside surfaces; (d) applying at least three longitudinal glue lines to the exposed outside surface of each folded strip; and (e) stacking the glued strips. As a result, it need not open the longitudinal margins during the process of applying the longitudinal glue lines, which can avoid the deformation of the strip and have a precise gluing position.

Owner:METAL INDS RES & DEV CENT +1

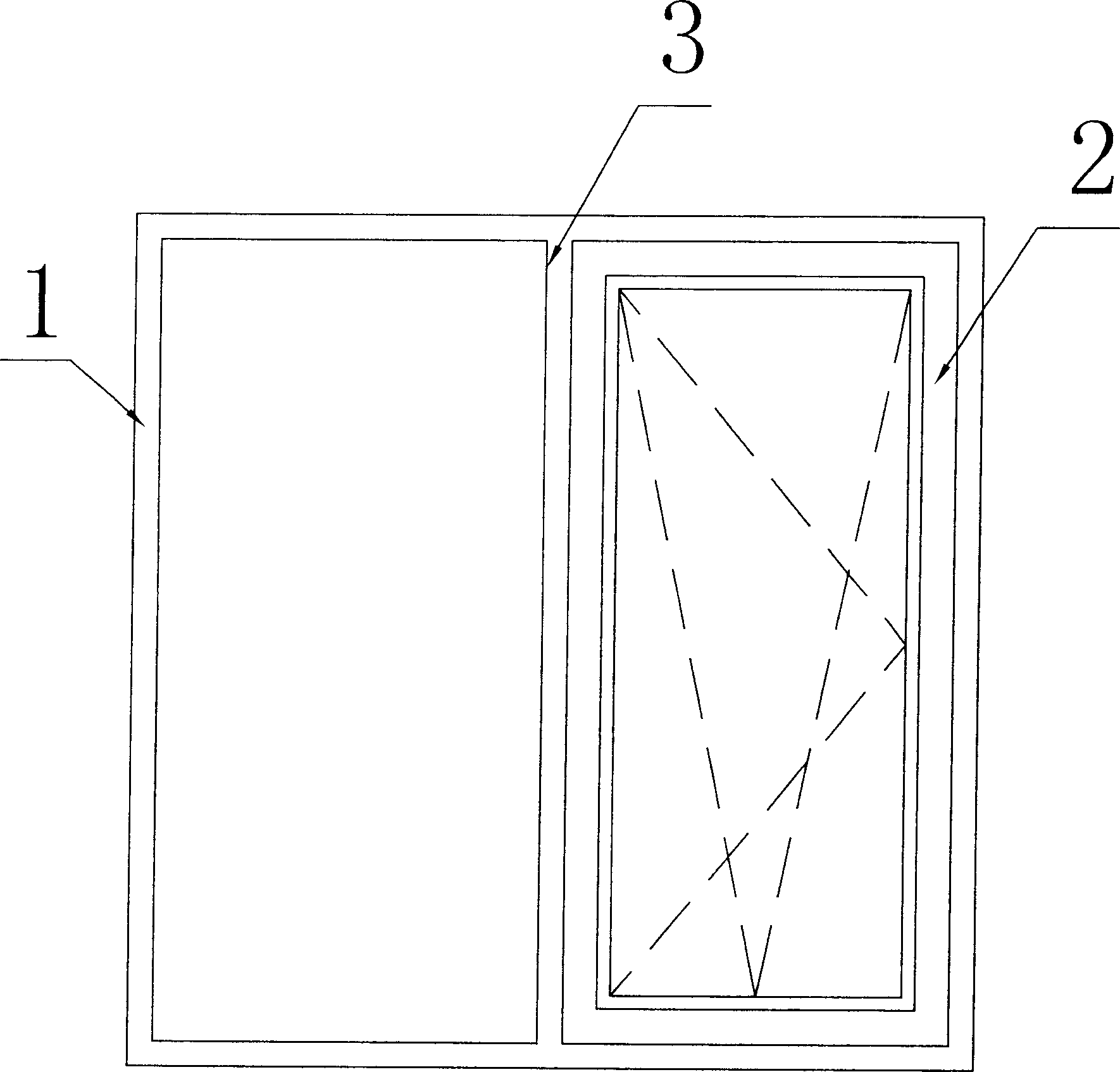

Environmental-protective and regenerative solid wooden plastic door and window and its production

This invention is a kind of regenerative environmental protecting type solid core wooden door and window. It is combined with frame structural section, sector structural section, middle frame structural section and sealing strips. The structural sections are solid core structural section. Their side faces are coated with plastic layer. The indoor face and outdoor face are coated with aluminum-coated layer through glue line. The main raw materials of the said solid core structural sections are regenerative polyolefine resin, plant fiber filler and auxiliary agent. The said regenerative polyolefine resin is the mixture of regenerative polypropylene and regenerative polyethylene. The plant fiber filler is wood fiber powder, hemp fiber powder, bamboo fiber powder, grass fiber powder, chaff powder or straw fiber powder. This invention decreases environmental pollution. It will not generate harmful gas when being heated. It also increases the anti-ultraviolet radiation, aging resistance and heat insulating performances.

Owner:北京大龙东升门窗幕墙工程有限公司

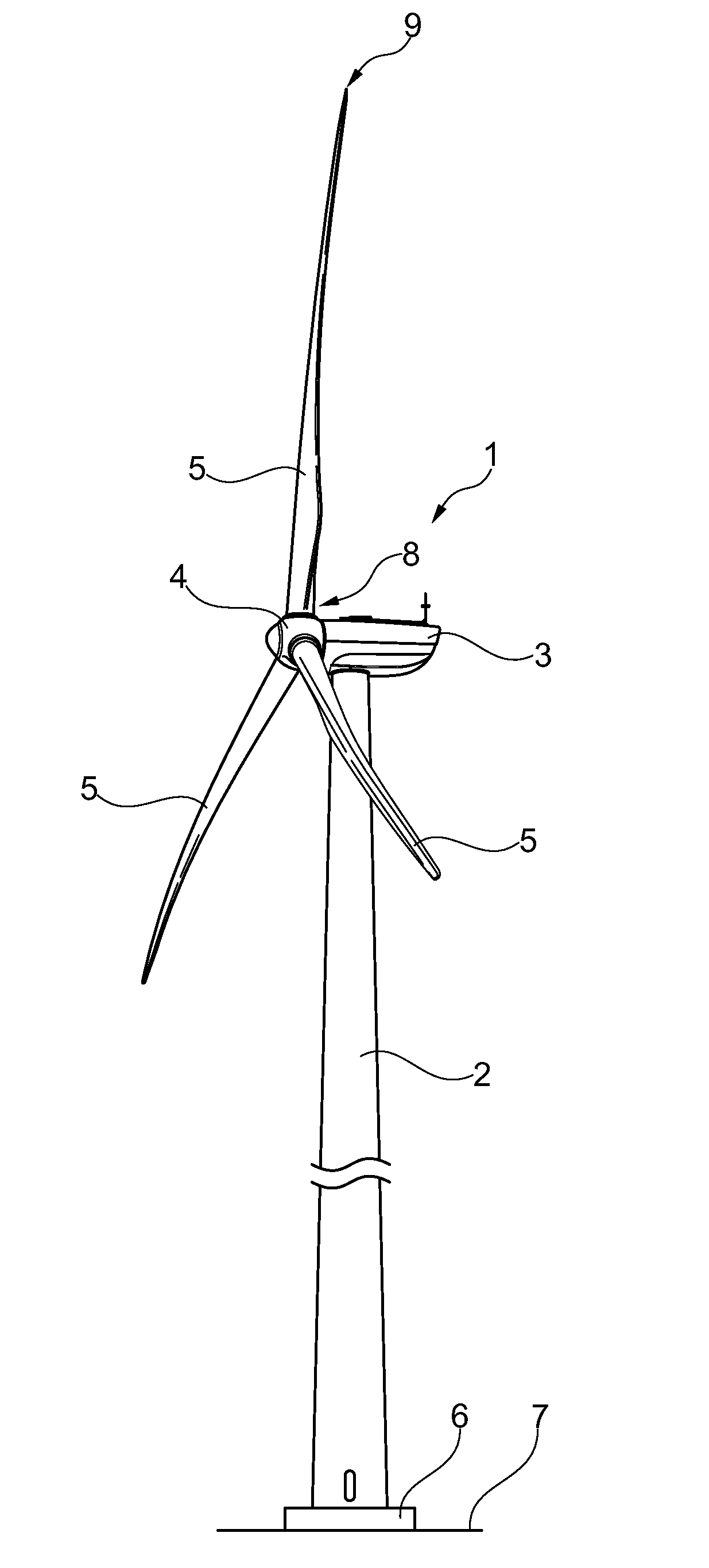

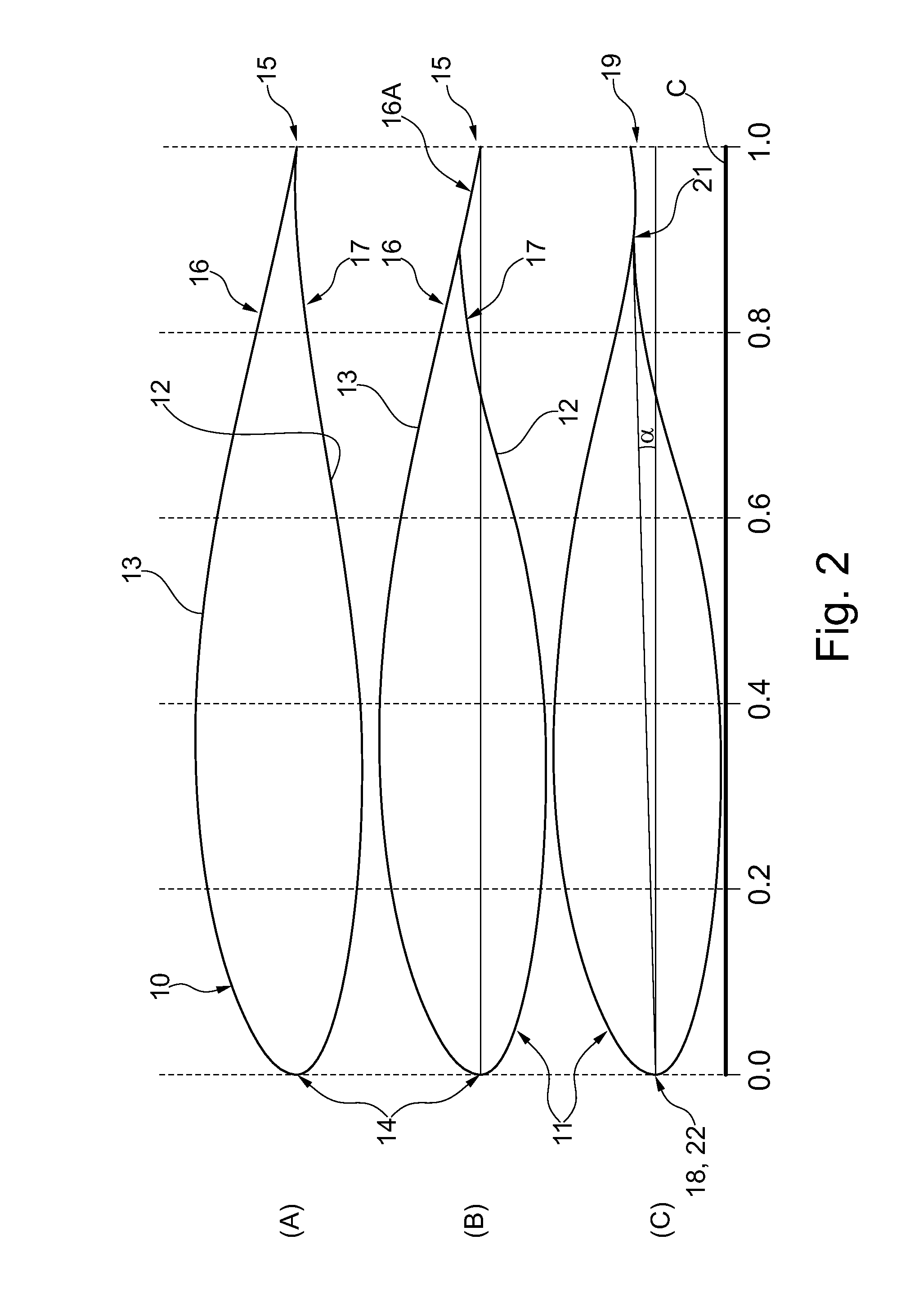

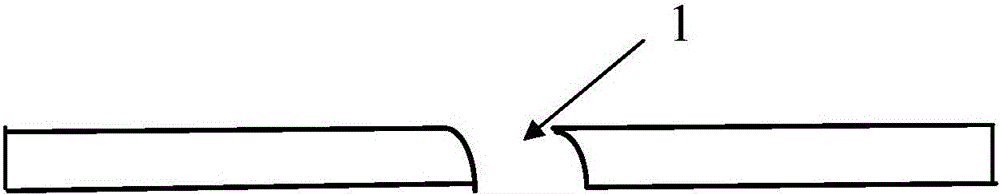

Wind turbine blade with extended shell section

InactiveUS20140369845A1Improved blade profile characteristicFinal product manufactureBlade accessoriesLeading edgeTurbine blade

The present invention relates to a manufacturing method for wind turbine blade and a wind turbine manufactured according to that method. The wind turbine blade comprises two shell parts wherein each shell part has a leading edge connected to a trailing edge via an inner surface. One of the two shell parts comprises an extended shell section which is configured as a flexible shell section. The shell section is configured to flex in a radial direction from a first position to a second position relative to the leading edge when an incoming wind is acting on the pressure side of the wind turbine blade. The wind turbine blade may be manufactured using a non-bonding layer removable arranged adjacent to the glue line between the two shell parts which reduces the amount of manual grinding or polishing of the glue region. This provides a wind turbine blade with an improved blade characteristic where the extended flexible shell section is specifically designed to have significant flexibility. The configuration provides a method for passively controlling the lift of the wind turbine blade.

Owner:ENVISION ENERGY DENMARK

Gum dipping liquid

The invention relates to a gum dipping liquid, and in particular relates to a polyester cord thread gum dipping liquid. The gum dipping liquid comprises the following components in parts by weight: 24.8-27.6 parts of phenolic resin mixture, 33.0-34.0 parts of butadiene-vinylpyridine copolymer latex, 15.5-16.5 parts of butadiene latex, 22.1-24.8 parts of water, 0.17-0.20 part of ammonia water, 0.03-0.05 part of peregal and 0.4-0.5 part of modified carbon black, wherein the phenolic resin mixture comprises 5.4-6.1wt% of resorcinol, 4.1-5.14wt% of formaldehyde, 0.1-0.16wt% of sodium hydroxide and the balance of water. According to the gum dipping liquid, the technical problems of complex gum dipping process, week glue line and rubber substrate adhesive force, severe environmental pollution and the like in the prior art can be solved, and a gum dipping liquid formula with a simple gum dipping process and good gum dipping liquid performance is provided.

Owner:JUNMA TIRE CORD

Feed spacers for spiral wound membrane element

InactiveUS20130146531A1Reduce the overall heightIncreasing active membrane area of elementMembranesSemi-permeable membranesMembrane surfaceEngineering

A feed channel spacer for a spiral wound membrane element has inlet and outlet edges that are thinner than the rest of the spacer material. The edges may be made thinner, for example, by passing the edges of a sheet of feed spacer material through a pair of hot rollers or by compressing the edges of the sheet in a heated press. The thinned edges of the feed spacer material are located in the element between glue lines applied to the permeate spacers of the element. The thin edges allow a greater membrane surface area to be provided in a given element diameter. A feed channel spacer may also have an area with obstructions to create micro-mixing effects. These obstructions may be provided on a feed spacer sheet of constant thickness, or one with thin edges.

Owner:GENERAL ELECTRIC CO

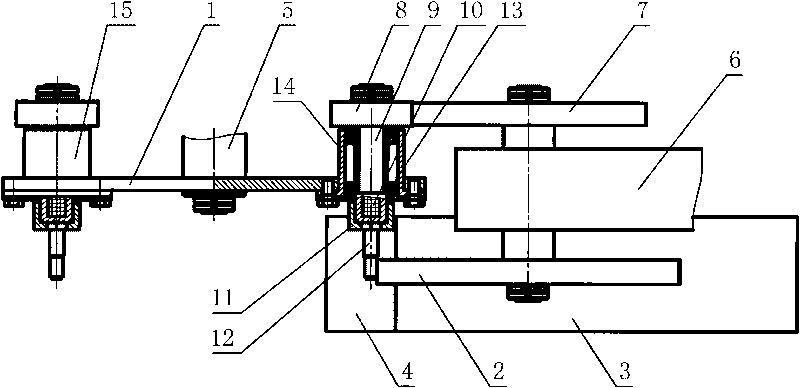

Automatic bolt spreading machine

InactiveCN101757999AEasy accessIncrease productivityLiquid surface applicatorsCoatingsDrive wheelStructural engineering

The invention relates to an automatic bolt spreading machine, which comprises a frame, a gluing wheel and a transmission device, wherein the gluing wheel and the transmission device are arranged on the frame; an output shaft of the transmission device is jointed with the gluing wheel; the lower part of the gluing wheel stretches into a glue-storing plate; an automatic outer-bolt spreading machine also comprises a rotating plate, wherein the periphery of the rotating plate is distributed with at least two electromagnetic chucks for clamping an outer bolt to be processed; driven wheels are fixedly arranged at the upper ends of the electromagnetic chucks; the driven wheels and driving wheels are ganged; the driving wheels are connected with the tail end of the output shaft of the transmission device; and the position to be glued of the outer bolt is contacted with the gluing wheel. The invention provides an automatic outer-bolt spreading machine which has high production efficiency and uniform glued glue line.

Owner:ZHEJIANG ZHAPU IND

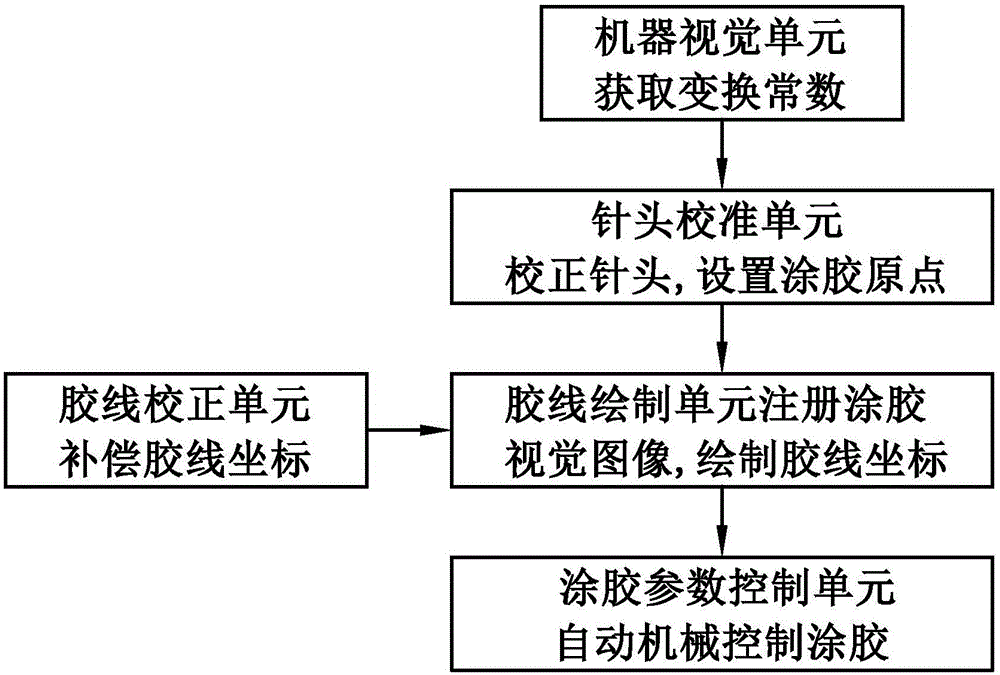

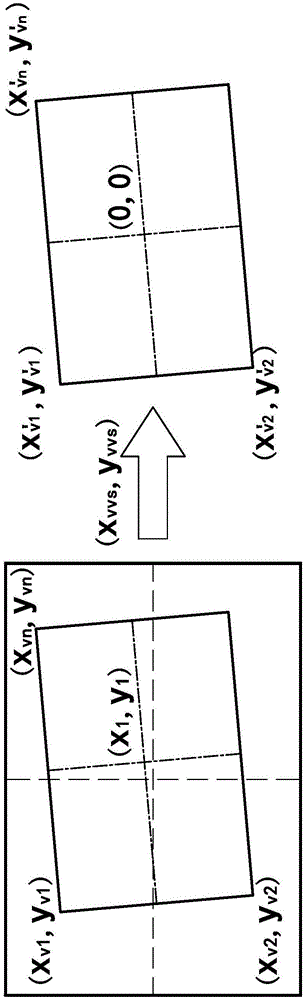

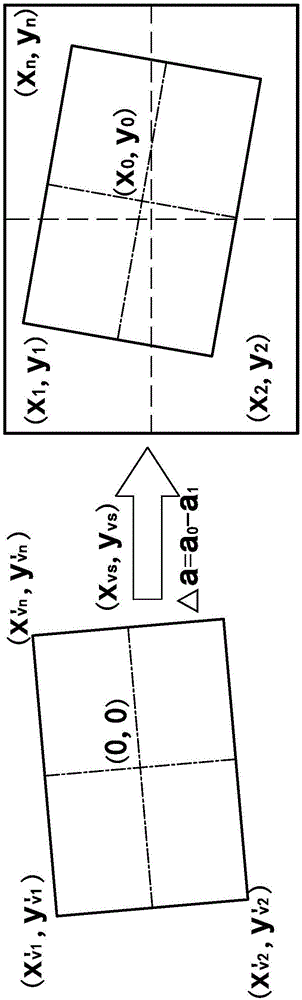

Automatic gluing system and gluing method thereof

The invention relates to an automatic gluing system and a gluing method thereof. The automatic gluing method comprises the following steps: S100) transformation constants of pixel coordinates and machinery coordinates of a target object can be obtained by a machinery vision unit; S200) a pin position is corrected by a pin calibration unit, a pin gluing original point is set; and S300) gluing visual image is registered by a glue line drafting unit for drafting the coordinate of the glue line path.

Owner:NINGBO SUNNY OPOTECH CO LTD

Wooden laminated floor product to improve strength, water protection and fatigue resistance

InactiveUS20070193179A1High strengthImprove fatigue resistanceWallsSuperstructure subunitsCouplingEngineering

A vehicular surface floor has a length and a width, made from a plurality of planks. Each plank has a length substantially equal to the length of the floor and a width that is less than the width of the floor. Each plank has first and second side surfaces and are arranged side by side so that a first side surface of one plank faces a second side surface of an adjacent plank, a joint region being formed at an area where the first side surface meets the second side surface. Each plank consists of at least two rows of boards, and each board consists of a plurality of segments joined end-to-end to one another by shaped coupling portions and side by side along a glue line; so that each of the at least two rows are longitudinally offset from an adjacent row, and a glue line of one row is offset from a glue line from an adjacent row.

Owner:PROLAM SOC & COMMANDITE

Polyurethane composite rubber roll and manufacture method thereof

ActiveCN102401004AEasy to useExtended service lifeShaft and bearingsRubber layered productsGlass fiberPolymer science

The invention discloses a polyurethane rubber roll and a manufacture method thereof, and belongs to the technical field of rubber roll. The polyurethane composite rubber roll comprises bonding layers and a polyurethane rubber layer. A five-layer structure comprises a core layer, a first bonding layer, a glass fiber reinforced plastic layer, a second bonding layer and a polyurethane rubber layer from inside to outside. The core layer and the glass fiber reinforced plastic layer are connected through a bonding layer; the glass fiber reinforced plastic layer and the polyurethane rubber layer are connected by the second bonding layer. A manufacture method comprises steps of: (1) cladding the first interface bonding layer; (2) cladding the glass fiber reinforced plastic layer; (3) cladding the second interface bonding layer; (4) cladding the polyurethane rubber layer. The polyurethane composite rubber roll with a five-layer structure of the invention can eliminate influences on the interface bonding layers caused by surface dark fringes on a cast iron core, sand holes and graphite migration, avoid reduction of core external diameter caused by reprocessing and preclude integral disengaging of a glue line. The invention enhances usefulness of the polyurethane rubber roll and prolongs usage life of the core.

Owner:南京金三力橡塑有限公司

Foldable honeycomb structure and method for making the same

InactiveUS7404428B2Precise positioningManufacture equipment can be moreExtensible doors/windowsCurtain accessoriesGlue lineEngineering

The present invention relates to a foldable honeycomb structure and method for making the same. The method comprises (a) providing a plurality of flat strips; (b) forming a pair of longitudinal creases in each strip thereby defining the first two longitudinal margins of each strip and a central portion of each strip between the creases; (c) folding each strip along said creases so that each folded strip has two exposed outside surfaces; (d) applying at least three longitudinal glue lines to the exposed outside surface of each folded strip; and (e) stacking the glued strips. As a result, it need not open the longitudinal margins during the process of applying the longitudinal glue lines, which can avoid the deformation of the strip and have a precise gluing position.

Owner:METAL INDS RES & DEV CENT +1

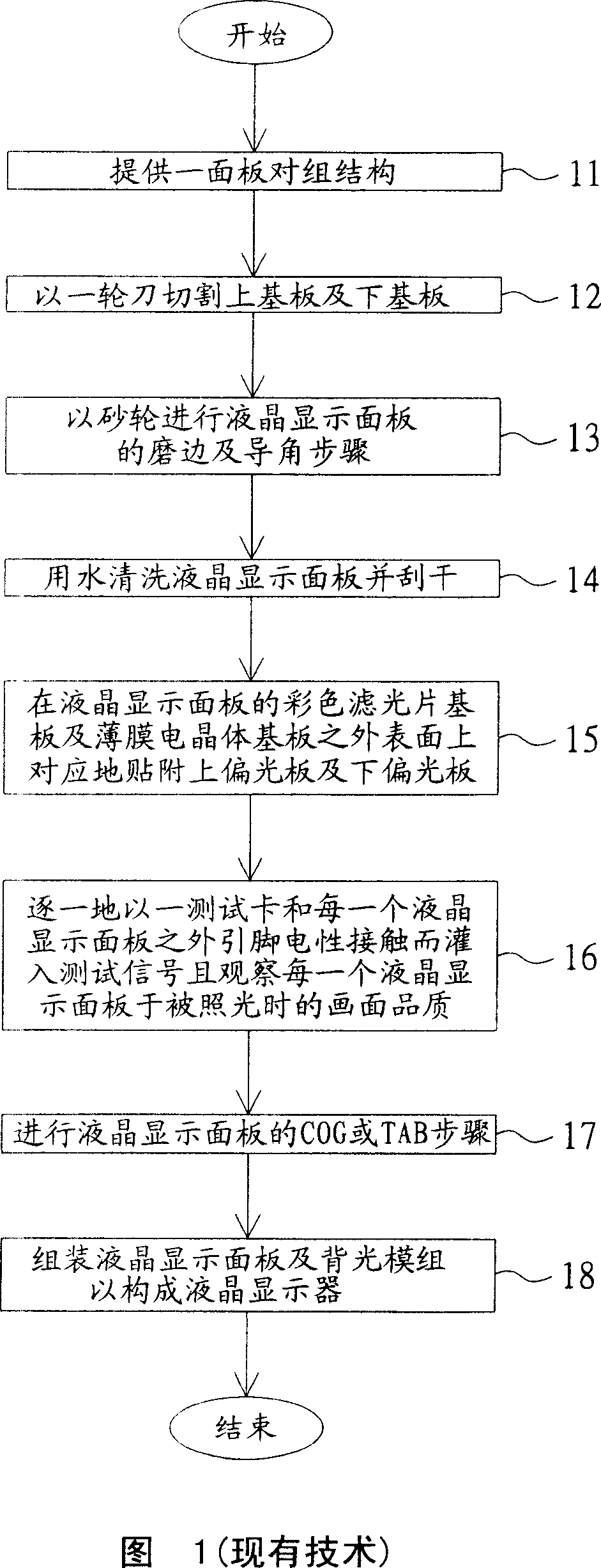

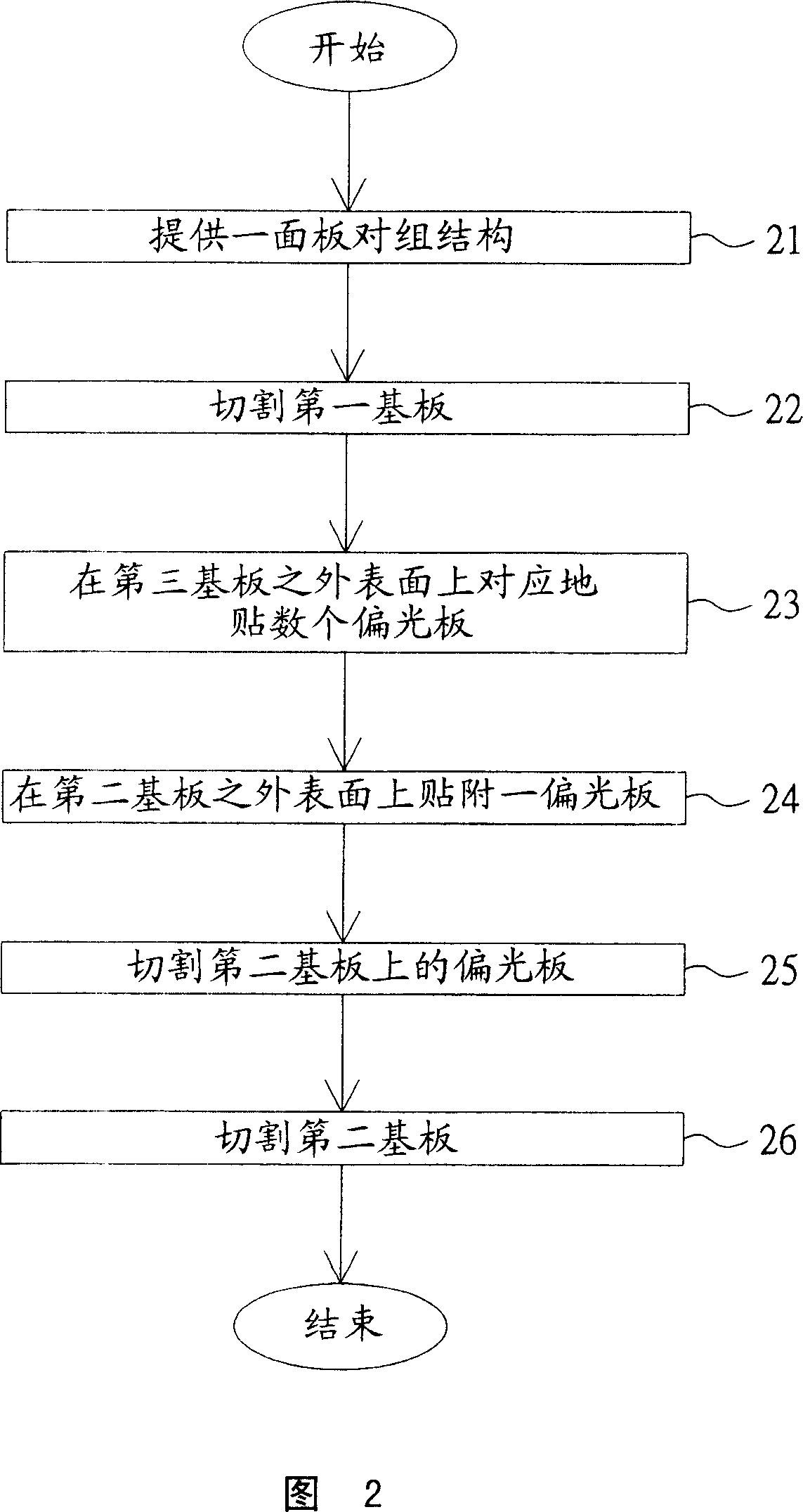

Method for producing liquid crystal display

A method for preparing liquid crystal display includes providing a face plate pair-set structure including the first base plate with a numbers of the third base plates, the second base plate with a numbers of the fourth base plates corresponding to the third ones and a numbers of glue lines for connecting internal surfaces of the first and second base plates, forming a liquid crystal display face plate by said third and fourth base plates as well as glue line, cutting the first base plate by the first laser, sticking the first and the second polarization plates separately on third and the second base plates then the second laser and the third laser to cut relevant plates.

Owner:INNOLUX CORP

Adhesive Thread System

InactiveUS20130048219A1Improve waterproof performanceEliminate needLamination ancillary operationsGarmentsNeedle punctureGlue line

A system for forming a waterproof seam between to sewn materials. The seam is formed using an adhesive coated thread. A thin strip of adhesive is placed between the two materials at the seam line. As the coated thread is sewn into the seam heat and pressure are simultaneously applied, melting the adhesive coating thereby filling the needle punctures. The melted adhesive coating will also flow into the areas between the needles punctures and between the materials. The heat and pressure applied to the coated thread will also melt the adhesive strip, causing additional adhesive to flow into the needle punctures and the areas between needle punctures.

Owner:FERREIRO ROXANNE

Circuit board manufacturing method

ActiveCN102271463AThe production process is simpleAvoid contactPrinted circuit aspectsMultilayer circuit manufactureEngineeringGlue line

The invention relates to a manufacturing method for a circuit board. The method comprises the following steps that: an internal layer substrate containing a first internal layer conducting layer is provided; the first internal layer conducting layer is formed into a first internal layer line graph that comprises a groove area and a non-groove area that is beyond the groove area; liquid ink material that covers the whole groove area is printed on an area of the first internal layer line graph, wherein the area of the first internal layer line graph is corresponded to the groove area, and the liquid ink material is solified and a protection layer is formed; a first glue line and a first external layer conducting layer are compressed successively on a surface of an area of the first internallayer line graph and a surface of the protection layer, wherein the area of the first internal layer line graph is corresponded to the non-groove area, and a first external layer conducting layer that the non-groove area corresponding to is manufactured to form a first external layer line graph; the first external layer conducting layer and the first glue line are cut along frontiers of the groove area so as to form an opening; and then areas of the first external layer conducting layer, the first glue line and the protection layer are removed to obtain a groove structure, wherein the areas of the first external layer conducting layer, the first glue line and the protection layer are corresponding to the groove area. According to the manufacturing method provided in the invention, line graphs in the groove can be effectively protected.

Owner:HONGQISHENG PRECISION ELECTRONICS (QINHUANGDAO) CO LTD +1

Environment-friendly type urea-formaldehyde resin adhesive and production method thereof

InactiveCN102229791AGood adhesionImprove performanceAldehyde/ketone condensation polymer adhesivesAdhesive cementPolymer science

An environment-friendly type urea-formaldehyde resin adhesive and a production method thereof. The method comprises the following steps: mixing glyoxal with urea in a container according to a certain mol ratio; adding a 10% polyvinyl alcoholic solution prepared in advance and urea under agitation, adjusting the pH value of the solution to be 7.5 to 8.5, and heating the solution to a temperature of 80 to 90 DEG C for reaction; adding a proper amount of urea for reaction for 40 minutes, adjusting the pH value of the solution to be 5 to 6, subjecting the solution to reaction at a temperature of 70 to 80 DEG C, and stopping the reaction when opacified sticky liquid appears or when cloudy sticky liquid appears under the condition that a droplet of the reaction solution is added into a glass with water at a temperature of 40 DEG C; cooling the solution to a temperature less than 40 DEG C and packaging the discharged products so as to obtain finished products. The adhesive provided in the invention belongs to excellent environment-friendly decoration materials, has remarkable adhesive properties, little smell, great initial adhesion, high final strength, good endurance and appropriate viscosity, is easy to paint and stable to store, and enables a glue film to be tough and tensile. Woodwork glued by the adhesive has no obvious glue lines, has excellent water tolerance, and produces no cracking in long-term usage.

Owner:王喆

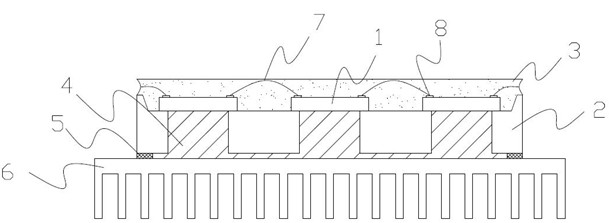

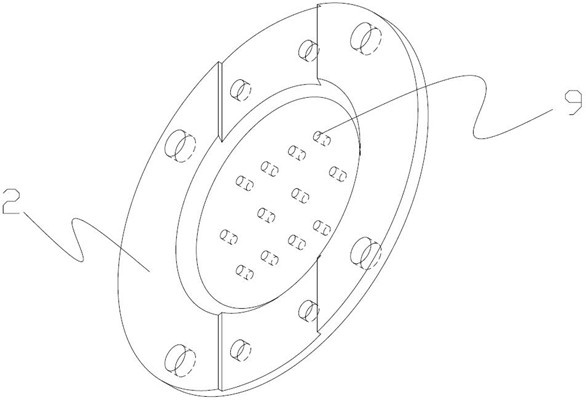

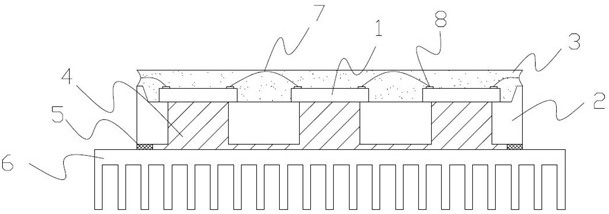

Liquid metal heat dissipation-based high-power LED (Light Emitting Diode) light source with threaded connection structure

InactiveCN102135248AReduce the die bonding processImprove reflectivityPoint-like light sourceLighting heating/cooling arrangementsFluorescenceEngineering

The invention discloses a high-power LED (Light Emitting Diode) light source based on room-temperature liquid metal micropore heat conduction, comprising LED chips, a microporous packaging base plate, a fluorescent glue line, room-temperature liquid metal, a sealing layer, a heat radiator, gold threads, LED chip electrodes and micro pores, wherein the sealing layer and the microporous packaging base plate are arranged on the heat radiator in sequence; the LED chips are arranged on the micro pores of the microporous packaging base plate; the room-temperature liquid metal is filled in the micro pores of the microporous packaging base plate; the LED chips are provided with the LED chip electrodes which are connected with the gold threads; and the fluorescent glue line covers on the LED chips. In the invention, the bottoms of the LED chips are directly contacted with the liquid meal with excellent heat conductivity; the liquid metal is closely contacted with the microporous base plate; as the LED chips are directly and closely contacted with the heat radiator through the liquid metal, the heat generated by the LED chips during working can be effectively radiated; therefore, the heat radiation effect of the high-power LED is better; the die bond processes of the LED packaging is reduced; the reflectivity of the bottoms of the LED chips is increased; and the light efficiency is greatly promoted.

Owner:符建

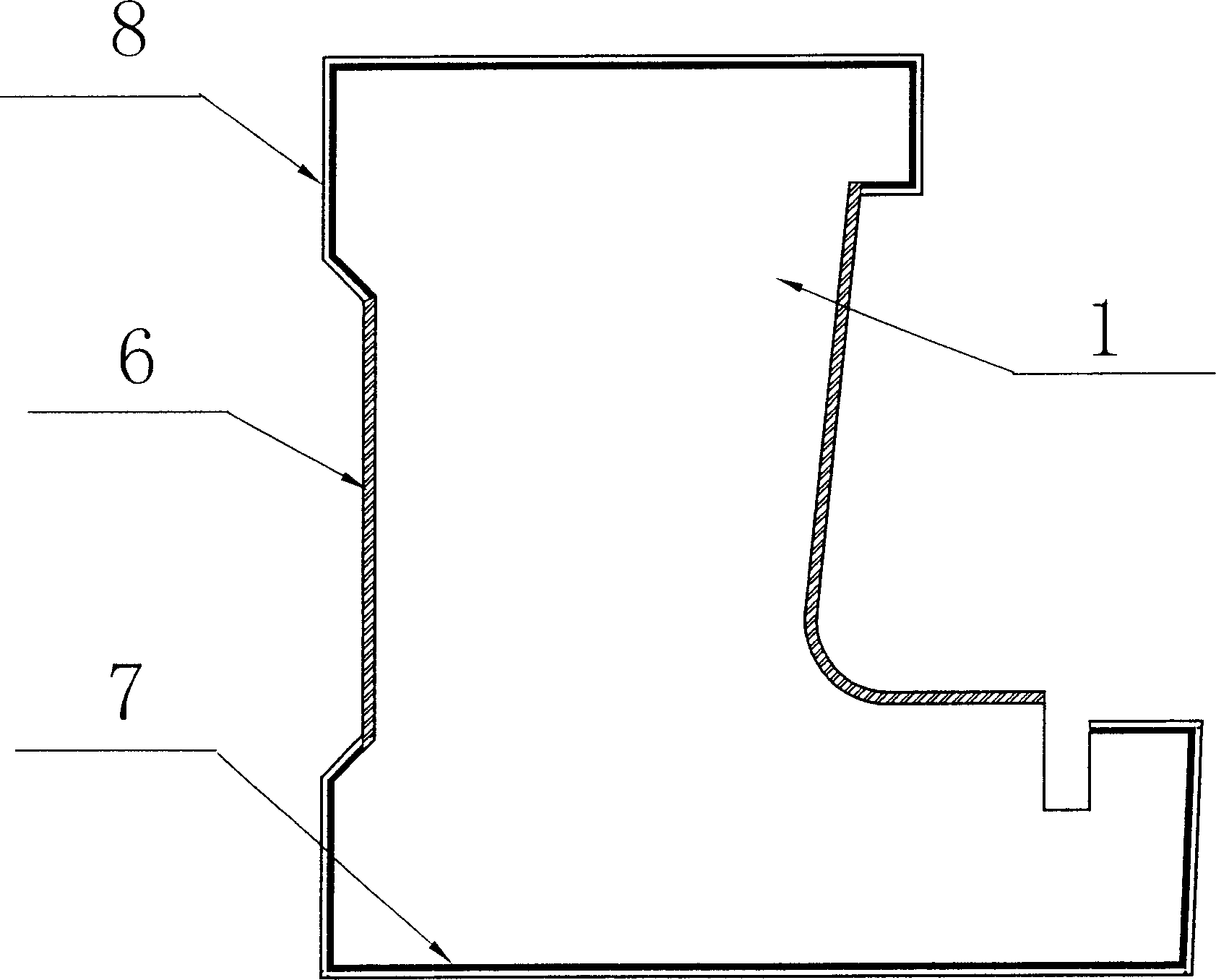

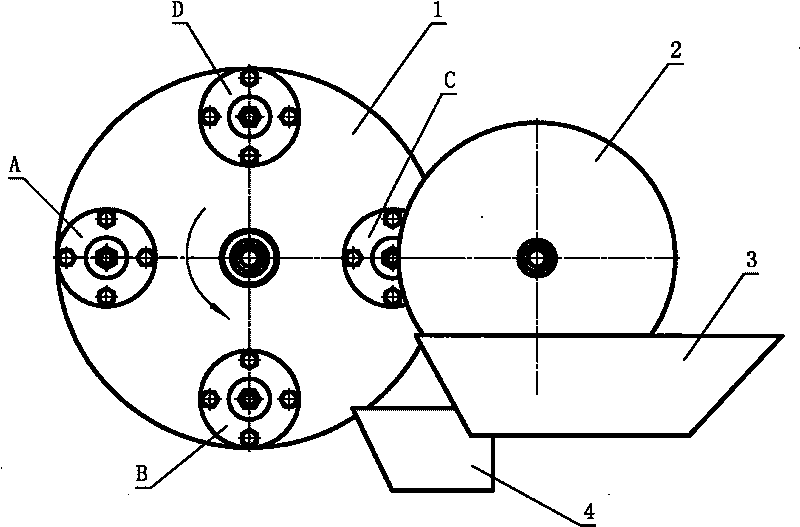

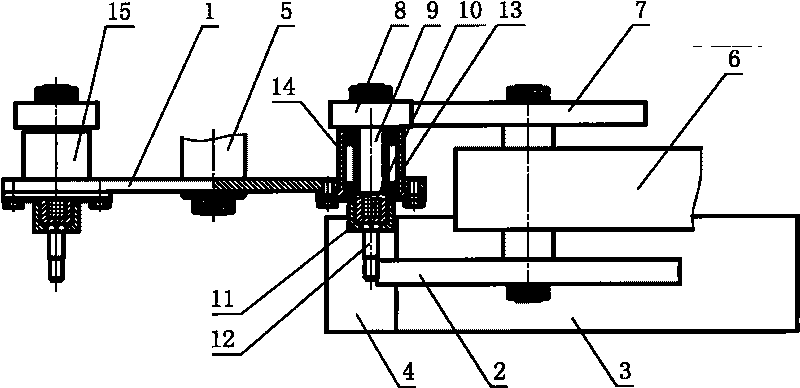

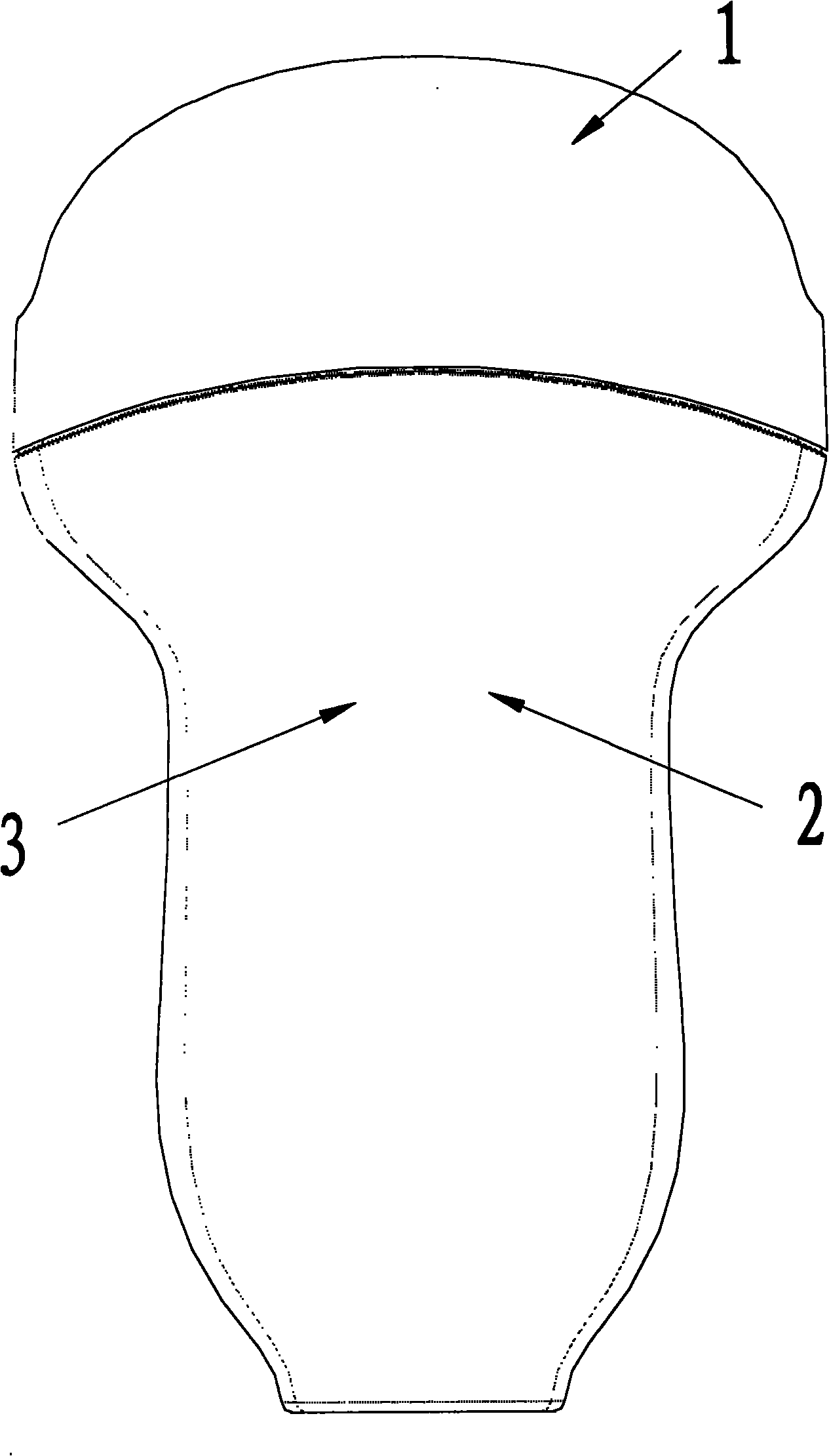

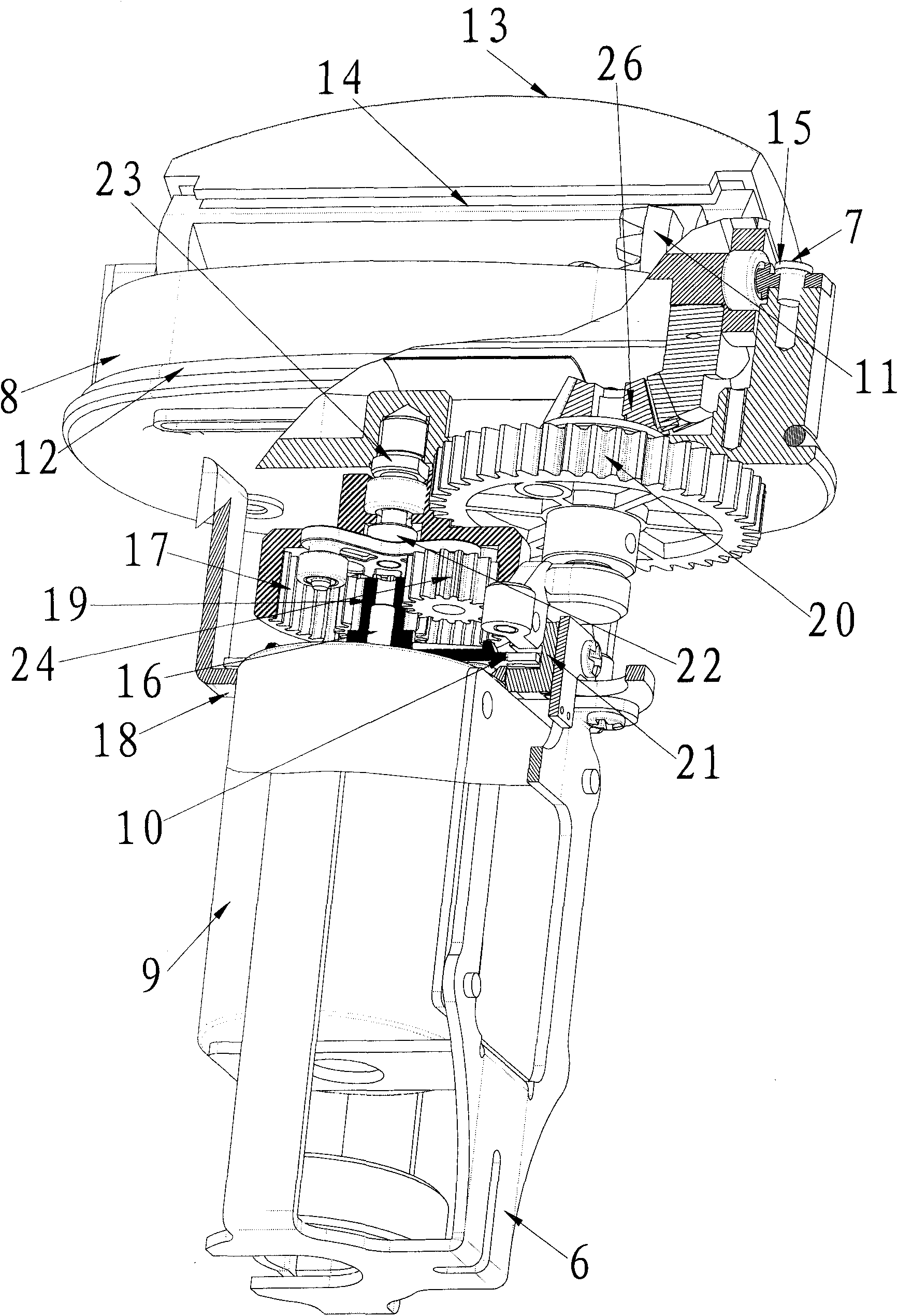

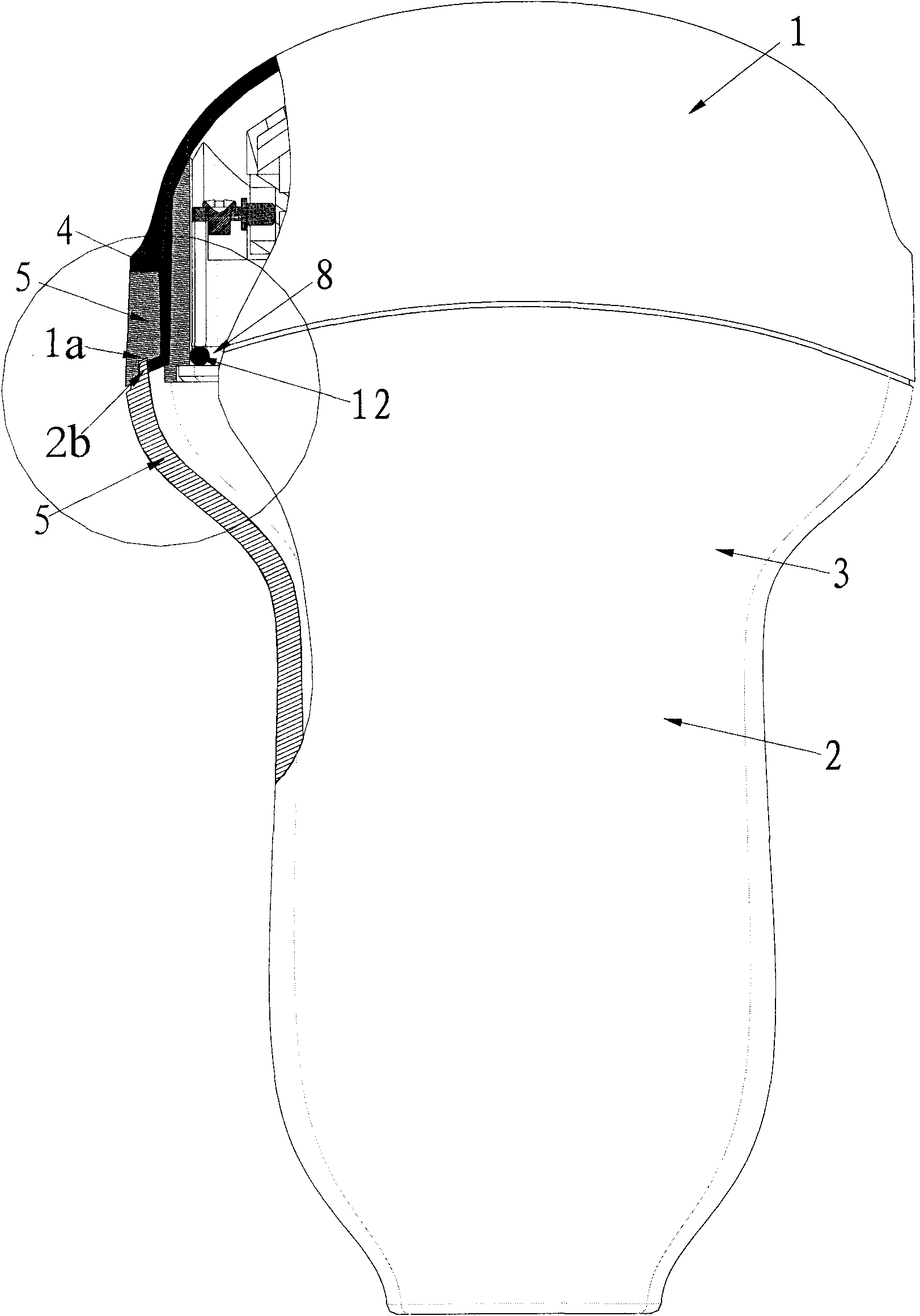

Ultrasonic scanning probe

ActiveCN102068279AEasy and flexible controlGuaranteed feasibilityUltrasonic/sonic/infrasonic diagnosticsInfrasonic diagnosticsTransducerDrive motor

The invention provides an ultrasonic scanning probe, which comprises a shell (3), a transducer (13), a transducer support (14), a probe body (8), a half bevel gear (11), a shaft bevel gear (26), a spur gear (20), a dual internal gear (17), a planetary gear train, a motor gear (19) and a drive motor (9). In the ultrasonic scanning probe , the defects of forceless inducer swing and ununiform scanning process can be solved, required high torque in a limited space can be obtained, the weight of the probe can be reduced, meanwhile, in terms of a sealing scheme, the ultrasonic scanning probe is strictly sealed, and therefore can meet waterproof and dustproof requirements, the shell is made of soft rubber and hard rubber by rubber-coating injection molding, an upper shell and a lower shells of the probe are solidified by adopting epoxy glue, a glue groove for containing the glue and a glue line are designed between the upper and the lower shells of the probe, consequently, the firmness and reliability of the structure can be guaranteed, and tightness and safety can be sufficiently ensured as well.

Owner:SONOSCAPE MEDICAL CORP

Thin film packaging method

ActiveCN106328827ASolid-state devicesSemiconductor/solid-state device manufacturingGlue lineEngineering

The application relates to a thin film packaging method, and the devices to be packaged comprises the lead area, wherein the packaging method comprises the steps of (1) coating organic glue line on the lead area of the devices to be packaged, to form the first intermediate; (2) packaging for the first intermediate is implemented by the upward side of the intermediate, so that to form the second intermediate after covering the packaging film on the upward side of the first intermediate; (3) removing the the packaging film and organic glue line covered at the upward side of the lead area of the second intermediate, to reveal the lead are. The thin film packaging method offered by the application implements the method of installing organic glue line in the lead area and removing organic glue line after thin film packaging to reveal the lead area, which can be used in the operations such as binding drive chip / flexible printed circuit board, point screen etc.

Owner:KUNSHAN NEW FLAT PANEL DISPLAY TECH CENT

Fireproof liquid of composite fireproof glass and preparation method thereof and composite fireproof glass

ActiveCN105131868AResolve microbubblesSolve fire resistanceNon-macromolecular adhesive additivesEster polymer adhesivesCross-linkFunctional monomer

The invention discloses a fireproof liquid of composite fireproof glass and a preparation method thereof and a composite fireproof glass, relates to a field of safety glass, and solves the problems that a fireproof glue-line has micro bubbles and bad flame resistance. The main method of the invention is as follows: polyol, a functional monomer, deionized water and an auxiliary agent are mixed for obtaining a first mixed emulsion, silica is added, and a silica dispension emulsion is obtained; styrene, methyl methacrylate and butyl acrylate monomer are mixed, a second mixed monomer emulsion is obtained, a cross-linking agent, deionized water, the silica dispersion emulsion and an initiator are added, and a soap-free seeded emulsion is obtained after reaction; acrylic acid, styrene, methyl methacrylate and butyl acrylate monomer are mixed, a third mixed monomer emulsion is obtained, deionized water, the initiator, the cross-linking agent and the soap-free seeded emulsion are added, and a soap-free emulsion with core-shell structure is obtained after reaction; a potassium hydroxide solution and an auxiliary agent are added, after mixing, standing and refiltering, an obtained filtrate is the fireproof liquid of composite fireproof glass. The fireproof liquid provided by the invention can be solidified into a fireproof glue, which has good fireproof performance without micro bubbles.

Owner:CHINA BUILDING MATERIALS ACAD

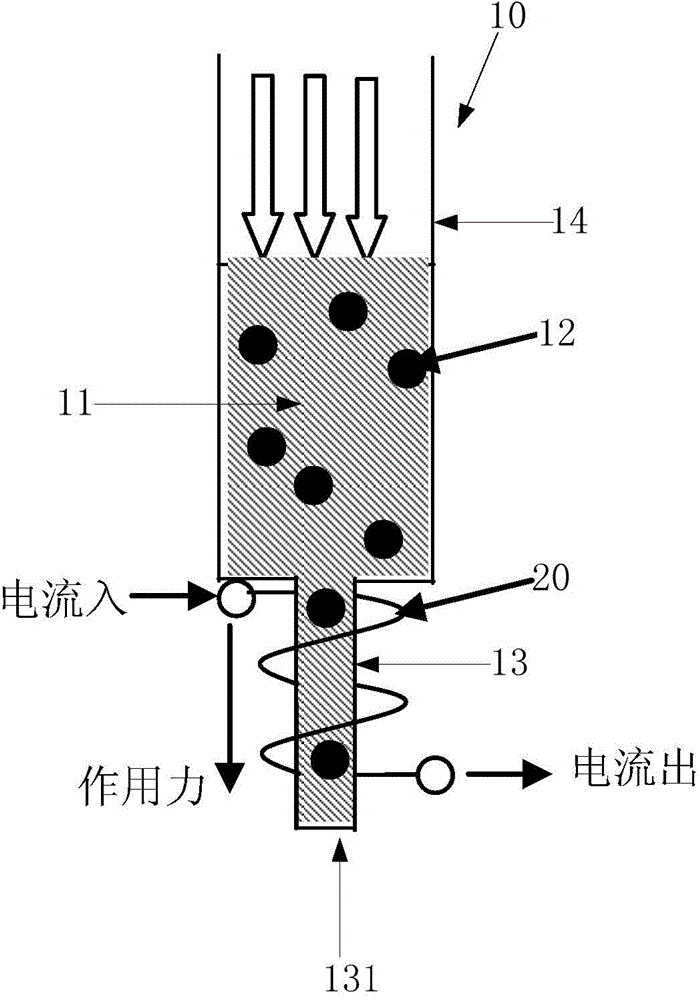

Gluing device and method

ActiveCN103909040AControl flow speedUniform flow velocityNon-macromolecular adhesive additivesPretreated surfacesEngineeringGlue line

The invention provides a gluing device and method. The gluing device comprises an instilling head and a magnetic field generation structure, wherein the instilling head is used for guiding adhesives along the instilling direction, and magnetic materials are added in the adhesives; the magnetic field generation structure is used for applying an induction magnetic field to the instilling head, and the same or opposite acting force is applied to the instilling direction to the magnetic materials by the induction magnetic field. According to the invention, the acting force same with or opposite to the instilling direction is applied to the magnetic materials by adding the magnetic materials into to-be-instilled adhesives and applying the induction magnetic field into the instilling head, so that aim of controlling the flowing speed of the adhesives toward the instilling direction is achieved by the acting force to the adhesives by the magnetic materials; the adhesives in the gluing device can be instilled successfully; the flowing speed is more uniform; the problem that glue breaking or glue line thinning which is caused by insufficient air pressure or pressure in gluing in the prior art is solved.

Owner:BOE TECH GRP CO LTD +1

Solvent-free monocomponent organosilicon conducting resin used in LEDs and preparation method thereof

InactiveCN102191012AEasy to prepareProcess stabilityNon-macromolecular adhesive additivesSemiconductor devicesDecompositionSilanes

The invention discloses a solvent-free monocomponent organosilicon conducting resin used in LEDs and a preparation method of the conducting resin, comprising the following steps of heating 1 to 10 parts by weight of curing accelerator to a temperature of 60 to 80 DEG C, stirring and adding 0.1 to 5 parts of polymerization inhibitor, uniformly mixing and cooling the solution to a room temperature, adding 10 to 30 parts by weight of ethene silicone oil, 1 to 10 parts by weight of curing agent silicone oil with hydrogen, 0.5 to 5 parts by weight of interface strengthening agent silane coupling agent, 0.5 to 10 parts by weight of silane reinforcing filling material silica, uniformly mixing the solution and adding 60 to 80 parts by weight of silver powder conductive filling material, uniformly mixing the solution and grinding the solution with a three-stick grinder. The conducting resin provided in the invention can be stored for more than 6 months at the temperature of 0 DEG C. The resin can be stored for more than two weeks at the room temperature and the viscosity of the resin increases 25%. The resin does not have solvent volatilization in a solidification process and does not generate pores in the glue-line. The heat decomposition temperature of the resin after solidification is 300 DEG C with 2% heat weight loss. At solidification, the heat weight loss (1%, room temperature small particle thrust) is 5Kgf / die (2*2mm); the volume resistivity is equal or less than 2.0*10-4w.cm; the glass-transition temperature is less than 10 DEG C and the pencil hardness is 7B.

Owner:上海本诺电子材料有限公司

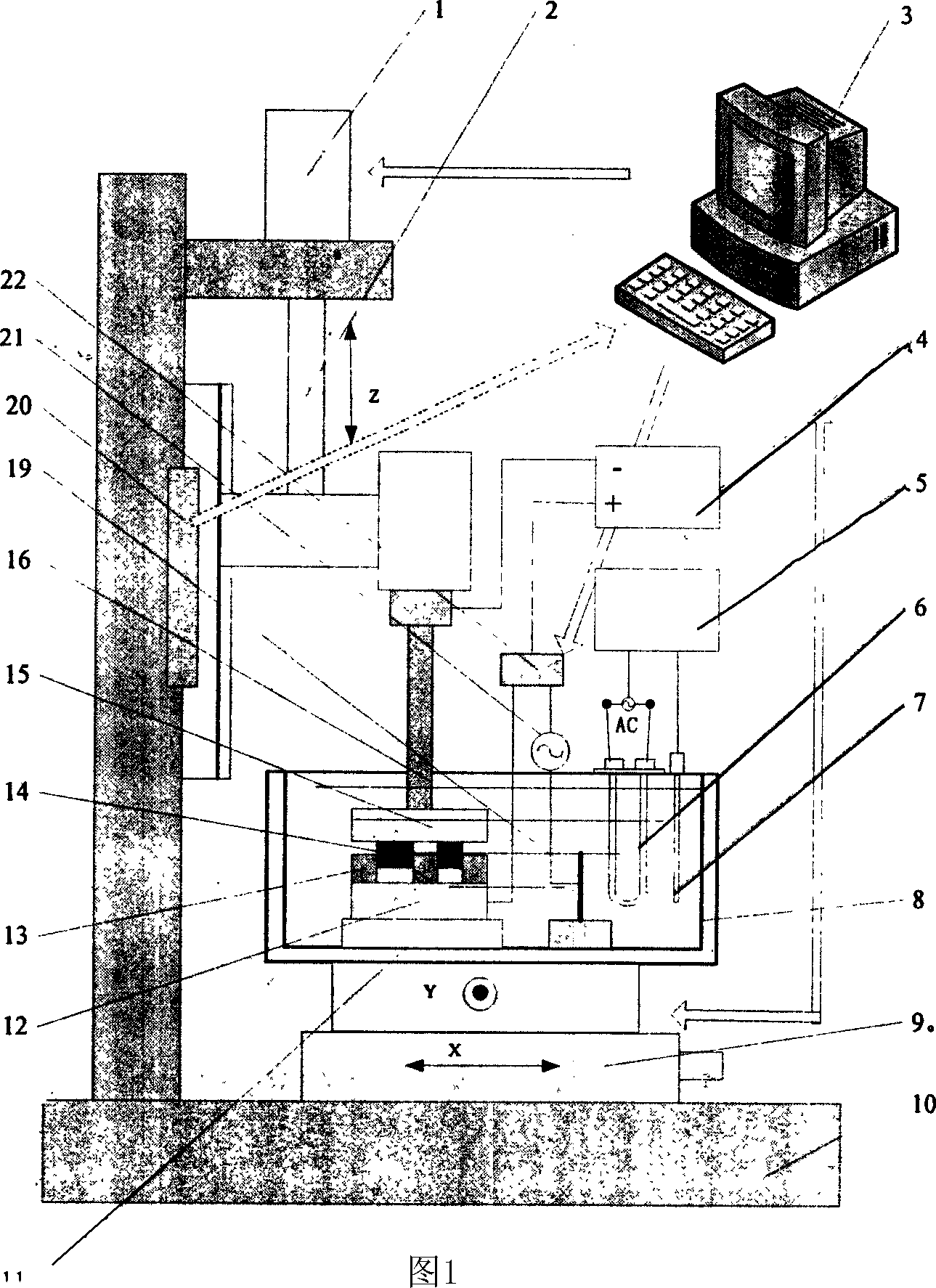

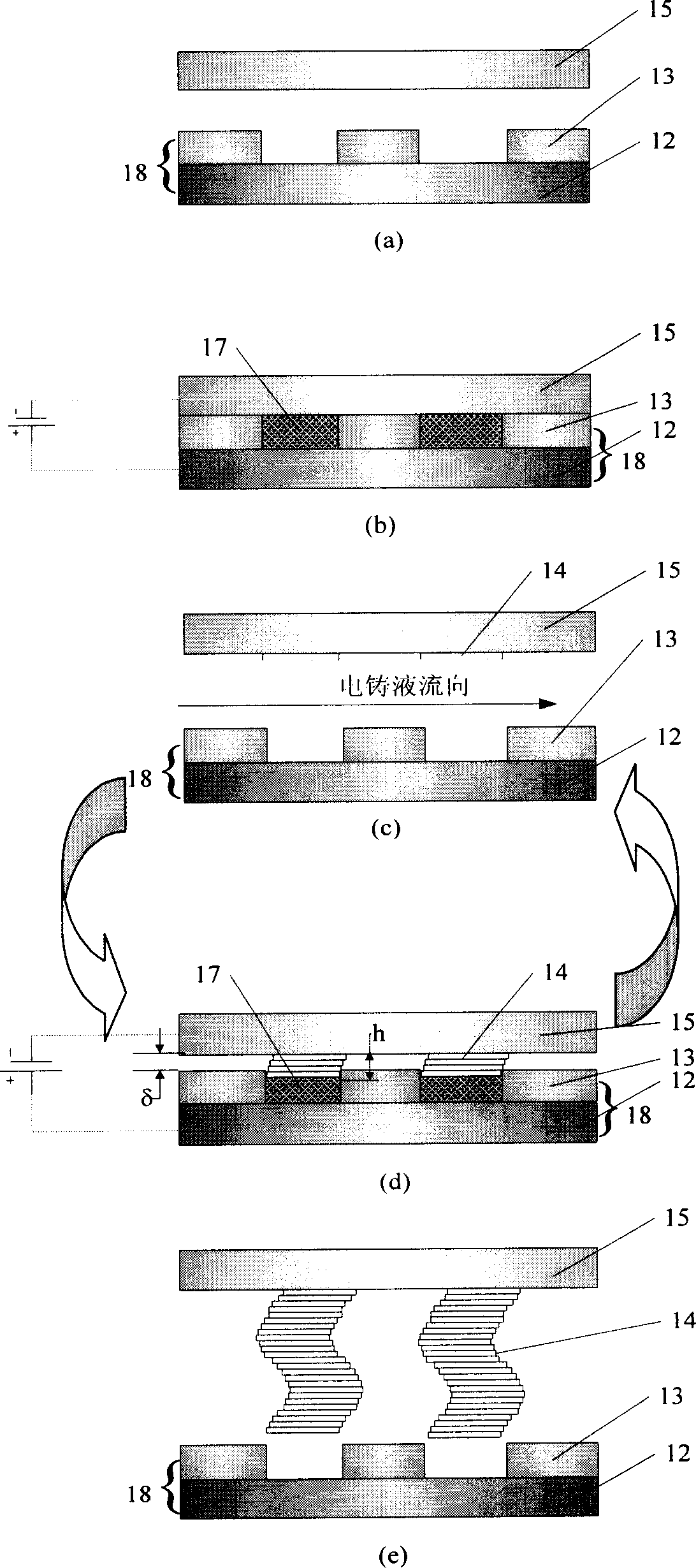

Three-dimensional microstructure electroforming method and apparatus

InactiveCN1827861ADense tissueSteep side wallsElectroforming by electrophoresisElectricityFine structure

The invention relates the three-dimensional fine structure electrocasting and device, belonging to micro handling field. The method uses barrier anode film plate to limit electrodeposition. Computer controls electrical source to make the electrodeposition progress at intervals. At non-electrical deposition, the barrier anode film plate and cathode relative move, define the relative dislocation according to element configuration shape. At every beginning of deposition cycle, define the relative dislocation at Z direction to guarantee that sedimentary deposit surface is lower than glue line surface. The apparatus key is the connection of electroforming device and digital controller, the relative dislocation of barrier anode film plate and cathode anode film and the on-line measurement of the deposit height. The invention has the advantages of fine and close structure, straight side panel and low cost.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com