Patents

Literature

33results about How to "Glue position is accurate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

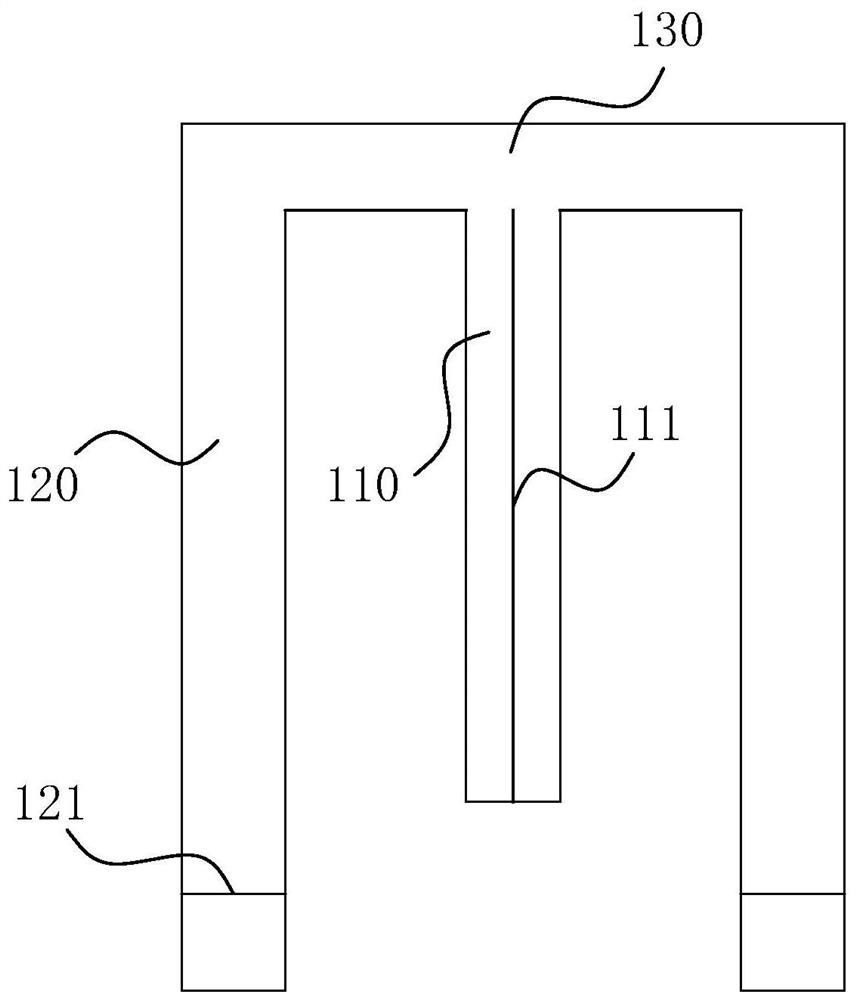

Foldable honeycomb structure and method for making the same

InactiveUS20070039697A1Glue position is accurateReduces cost timeExtensible doors/windowsCurtain accessoriesGlue lineMechanical engineering

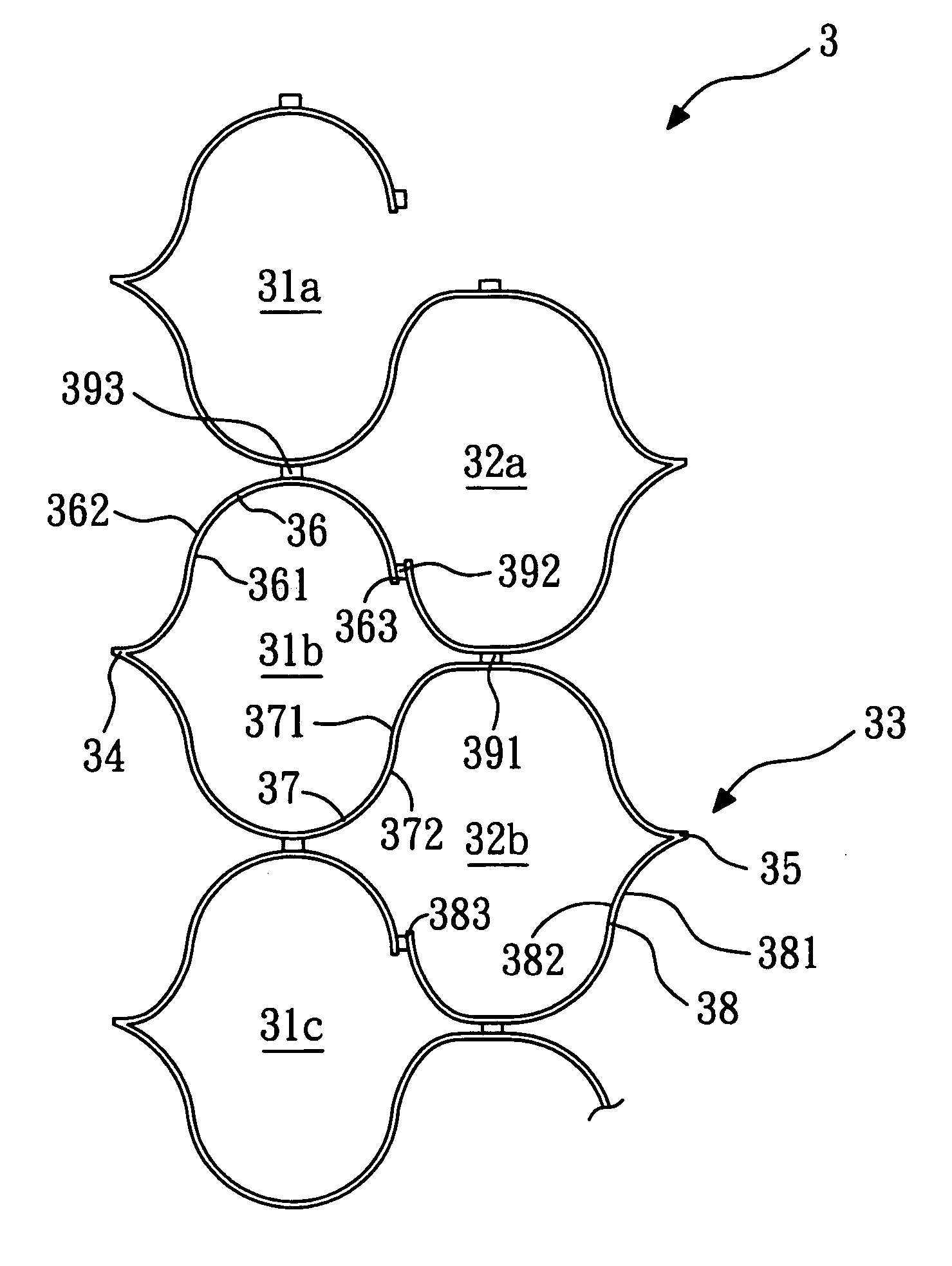

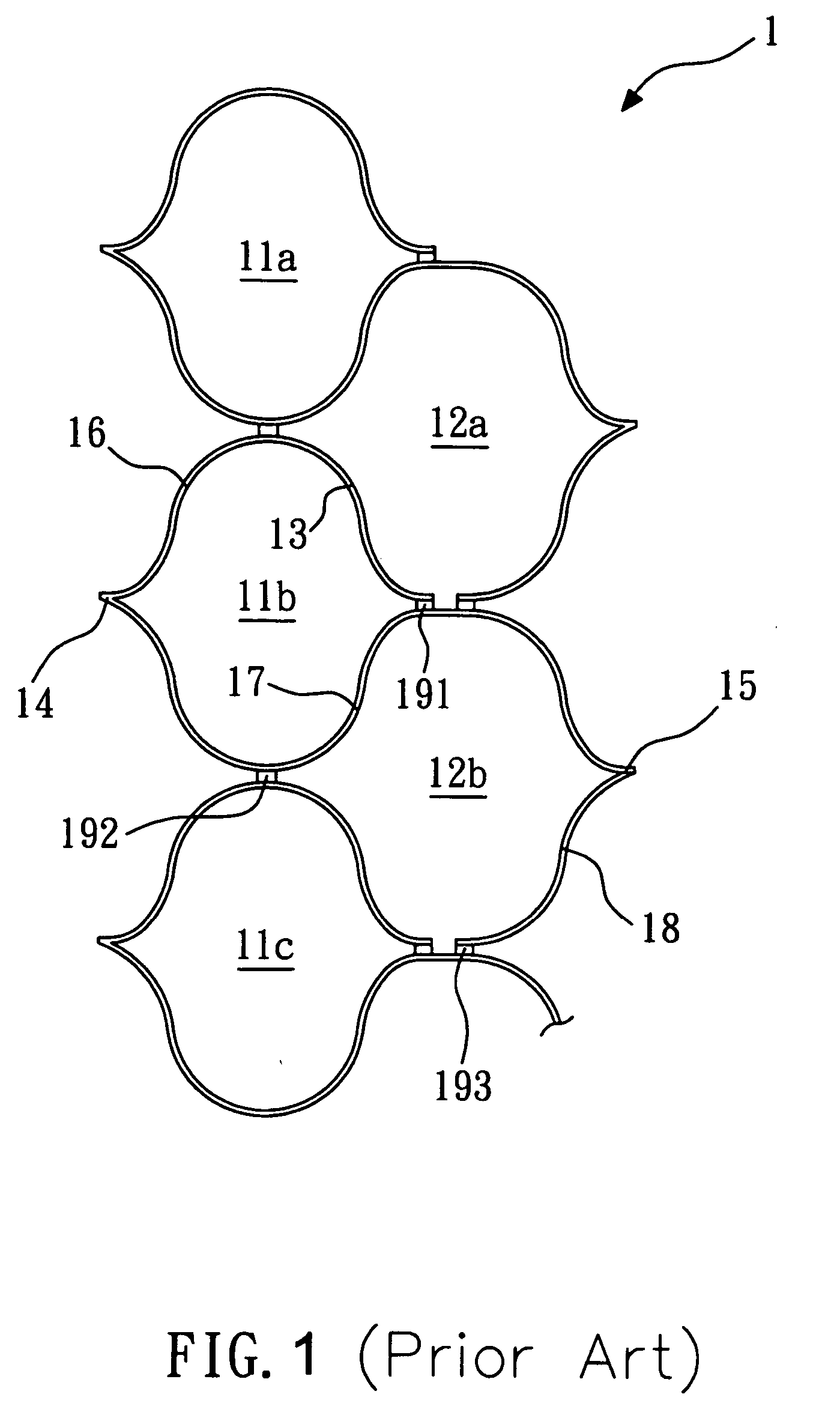

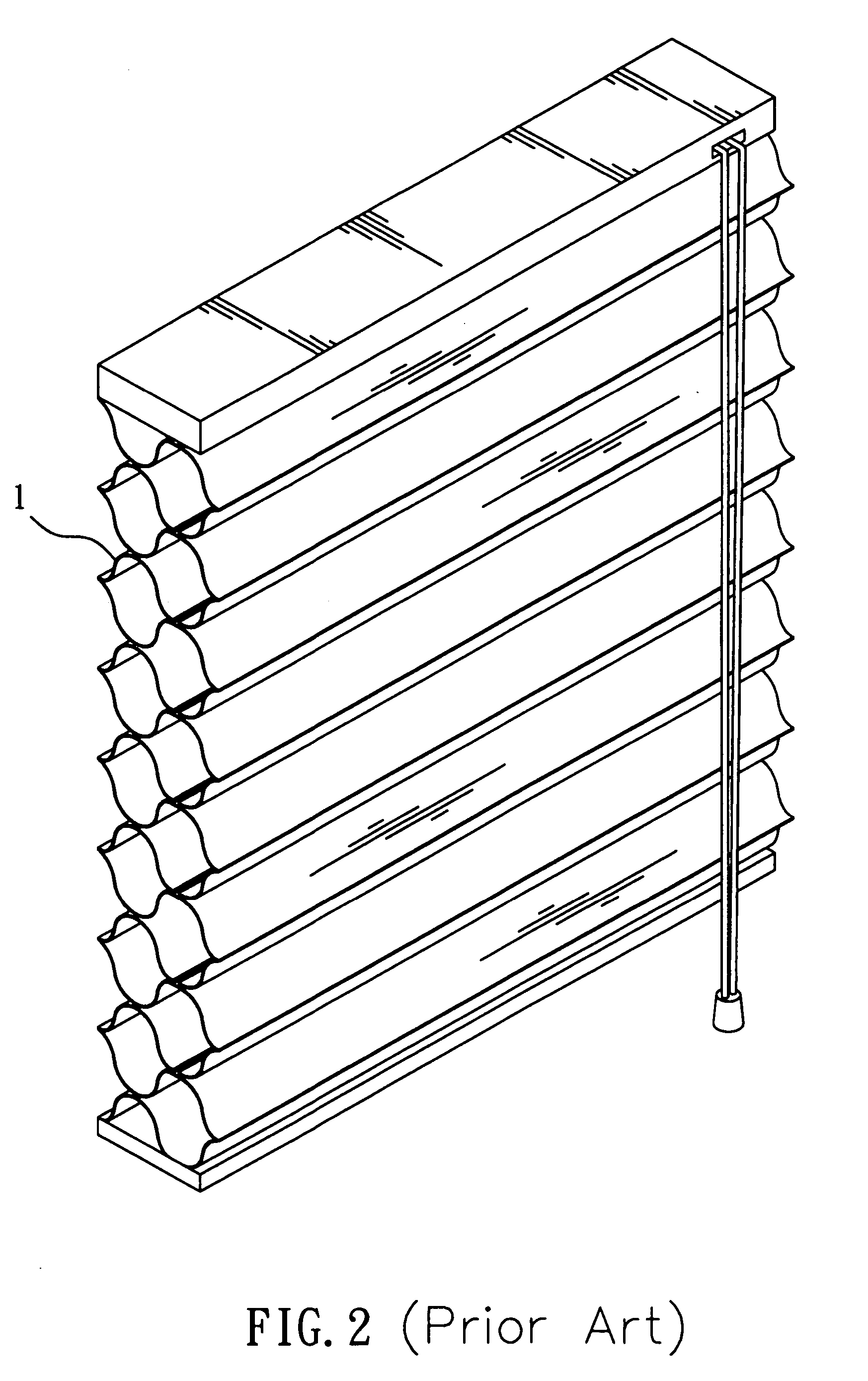

The present invention relates to a foldable honeycomb structure and method for making the same. The method comprises (a) providing a plurality of flat strips; (b) forming a pair of longitudinal creases in each strip thereby defining the first two longitudinal margins of each strip and a central portion of each strip between the creases; (c) folding each strip along said creases so that each folded strip has two exposed outside surfaces; (d) applying at least three longitudinal glue lines to the exposed outside surface of each folded strip; and (e) stacking the glued strips. As a result, it need not open the longitudinal margins during the process of applying the longitudinal glue lines, which can avoid the deformation of the strip and have a precise gluing position.

Owner:METAL INDS RES & DEV CENT +1

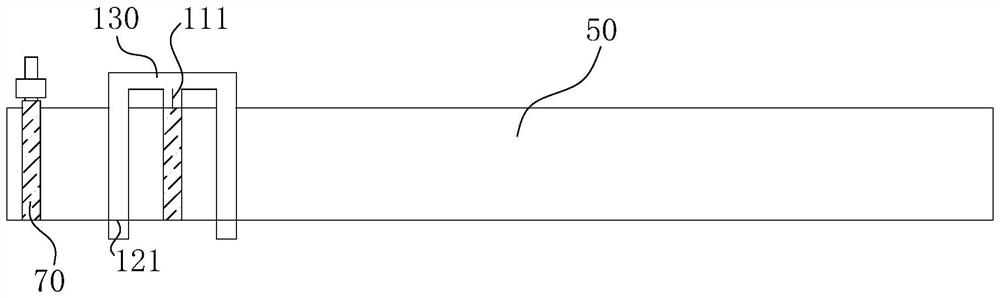

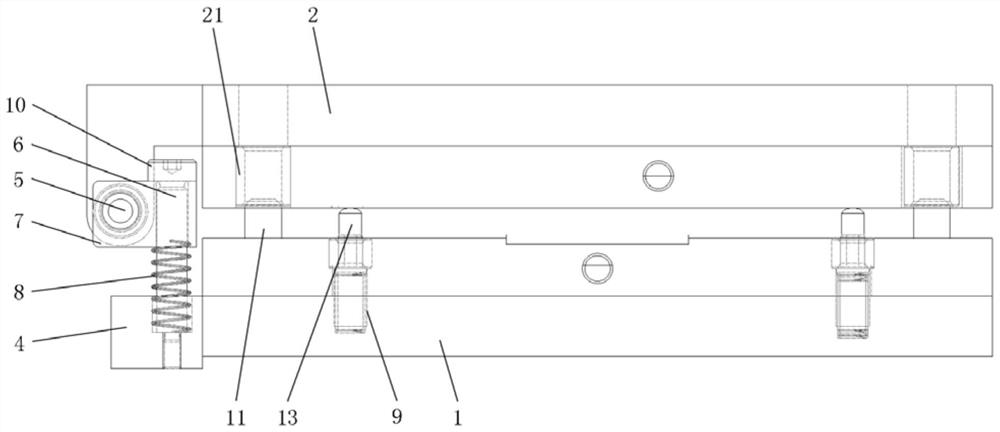

Gluing device and gluing method

ActiveCN103579577ANo bubblesWrinkle freeElectrode manufacturing processesElectrical and Electronics engineering

The invention discloses a gluing device. The gluing device comprises a gluing mechanism. The gluing mechanism comprises gluing rollers and movable gluing plates opposite to the gluing rollers. The movable gluing plates are used for transferring a glue tape towards a pole piece. The gluing rollers cooperate with the movable gluing plates and evenly rolling-paste the glue tape on the pole piece. The invention also discloses a gluing method utilizing the gluing device. The gluing rollers are used for gluing and can evenly rolling-paste the glue tape on the pole piece along with pole piece feeding without bubble and fold production.

Owner:SHENZHEN YINGHE TECH

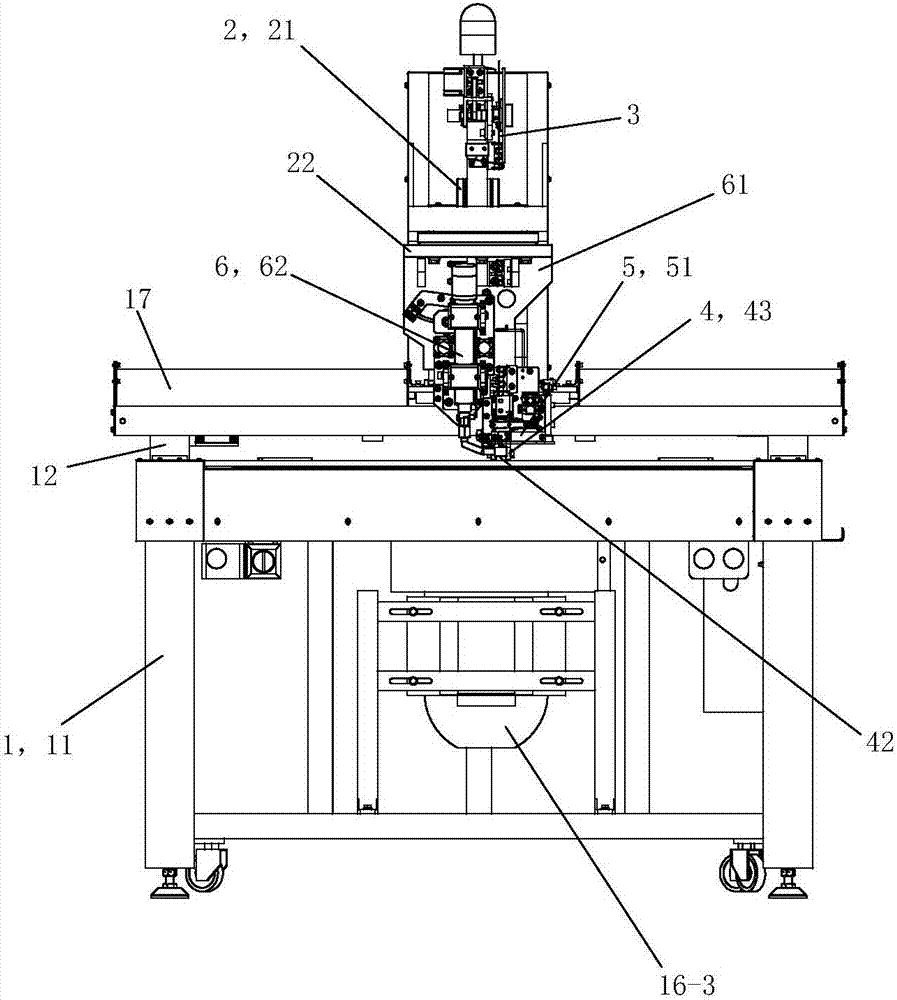

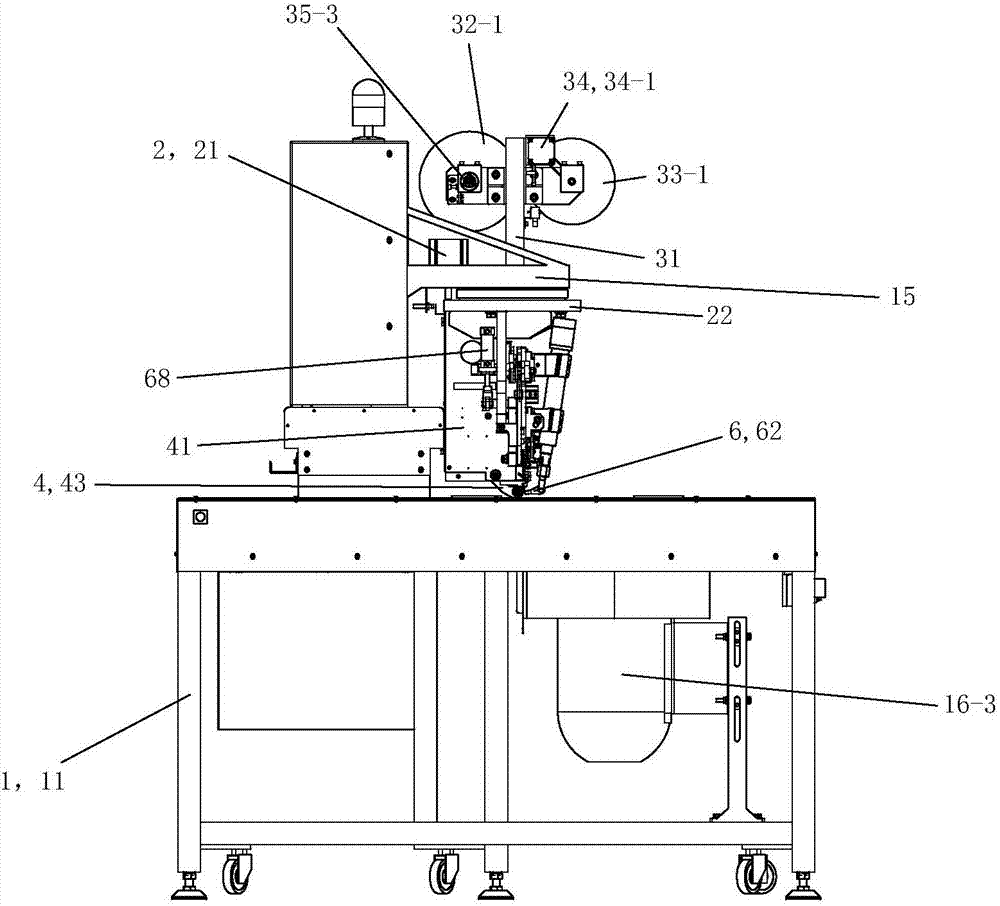

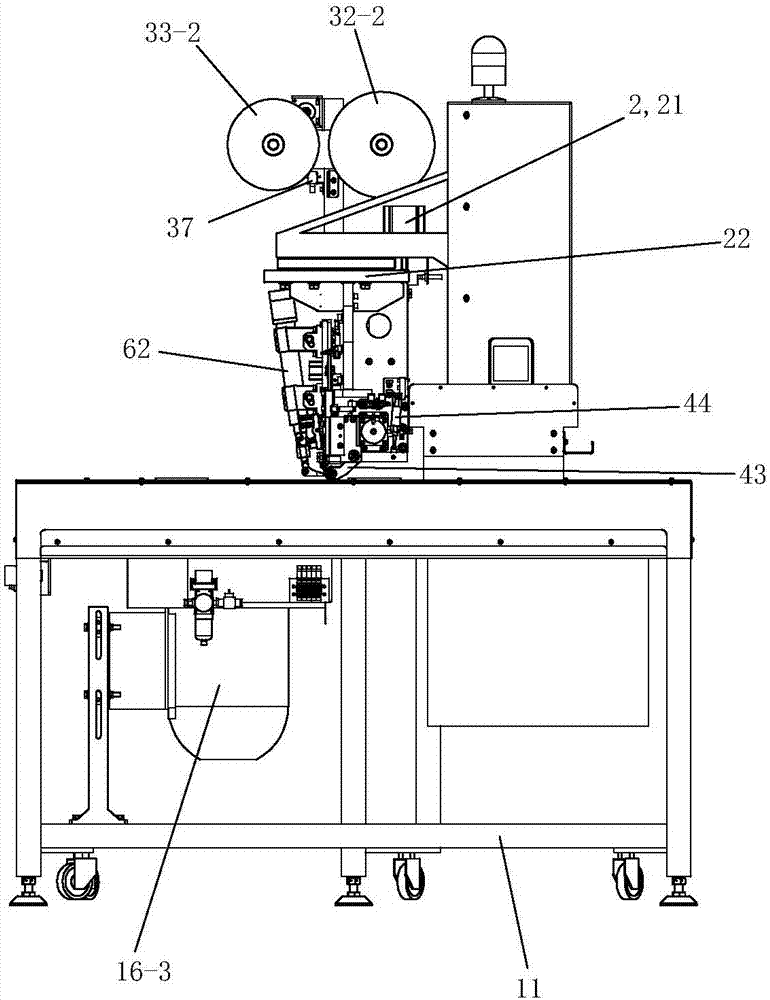

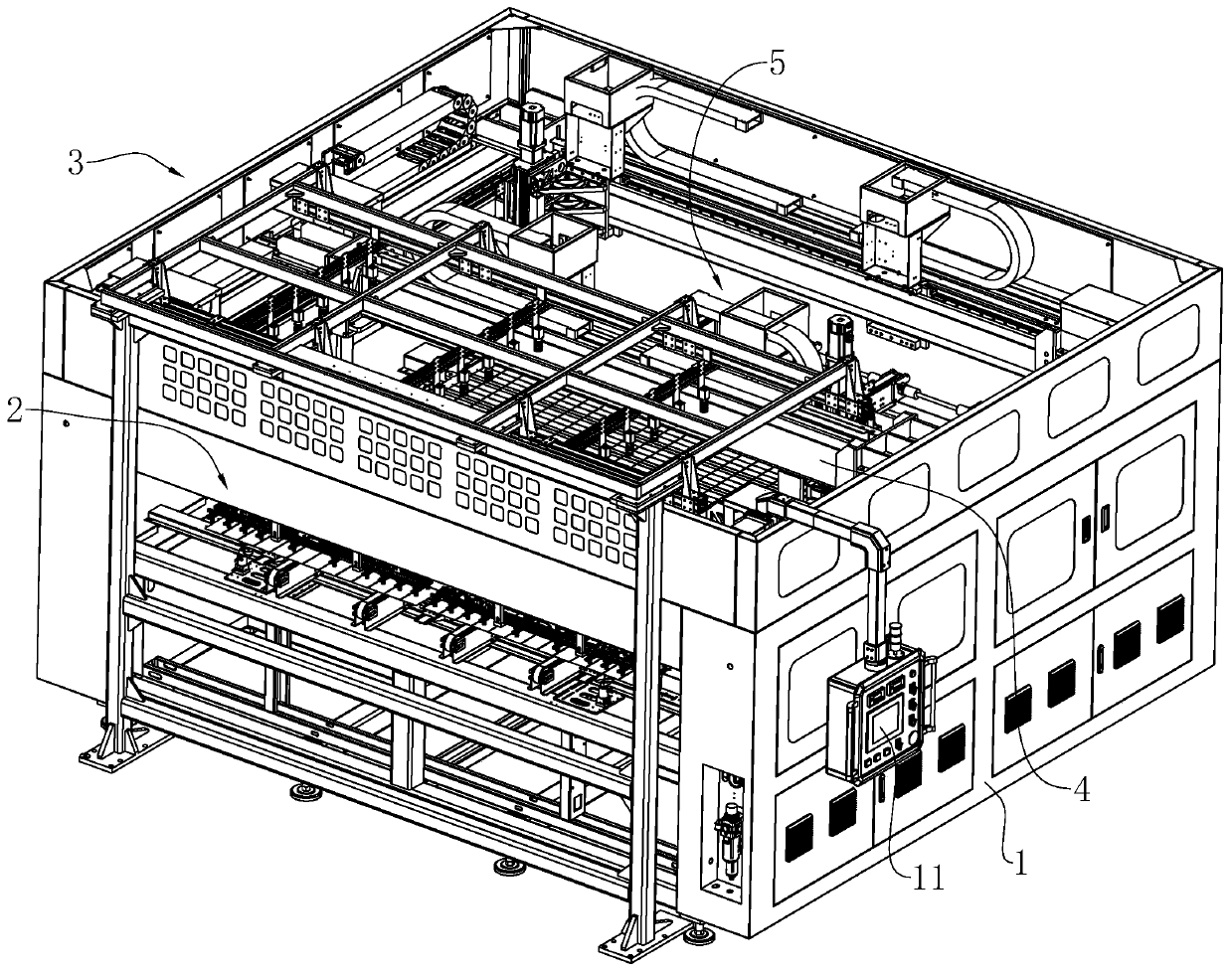

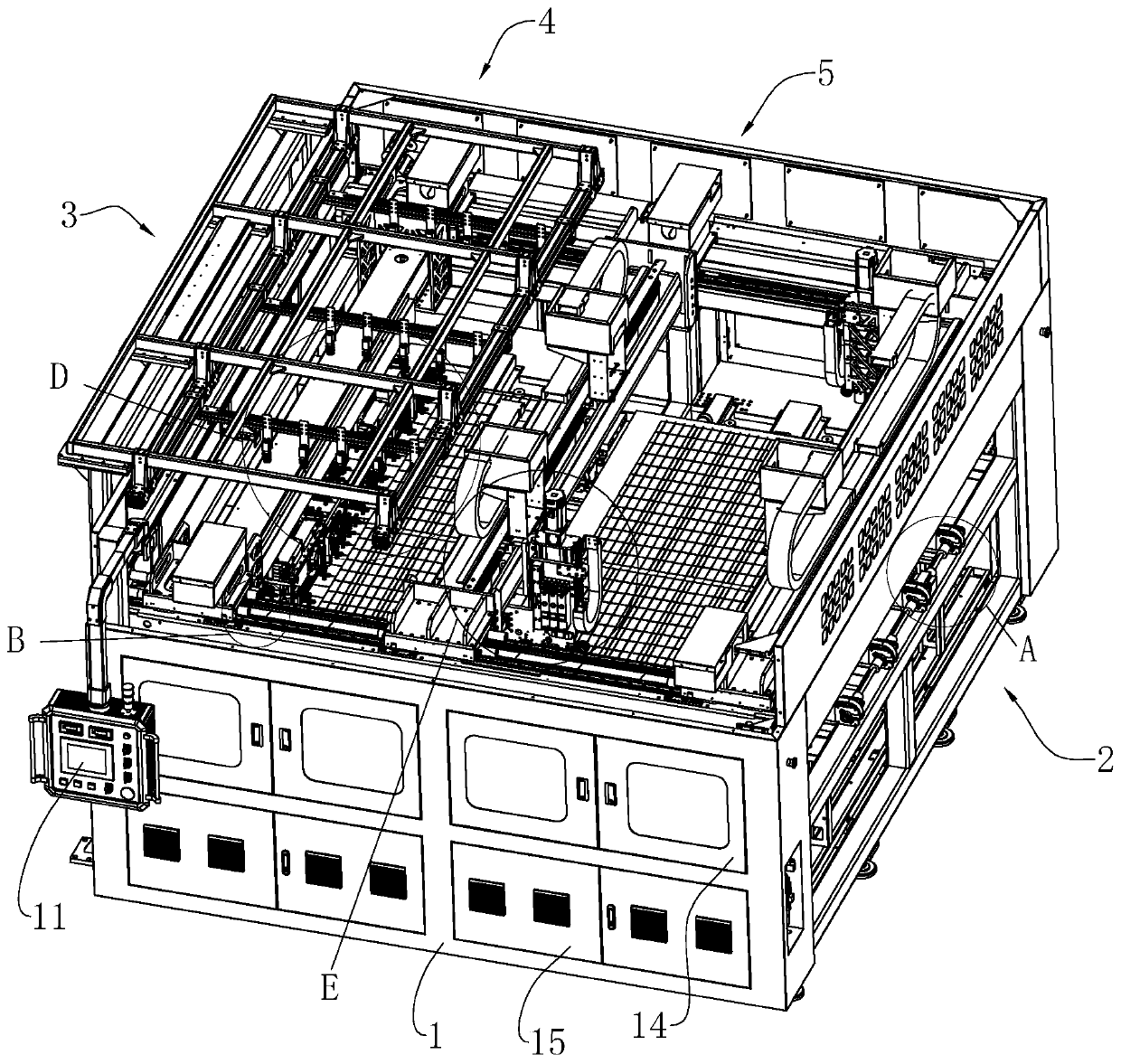

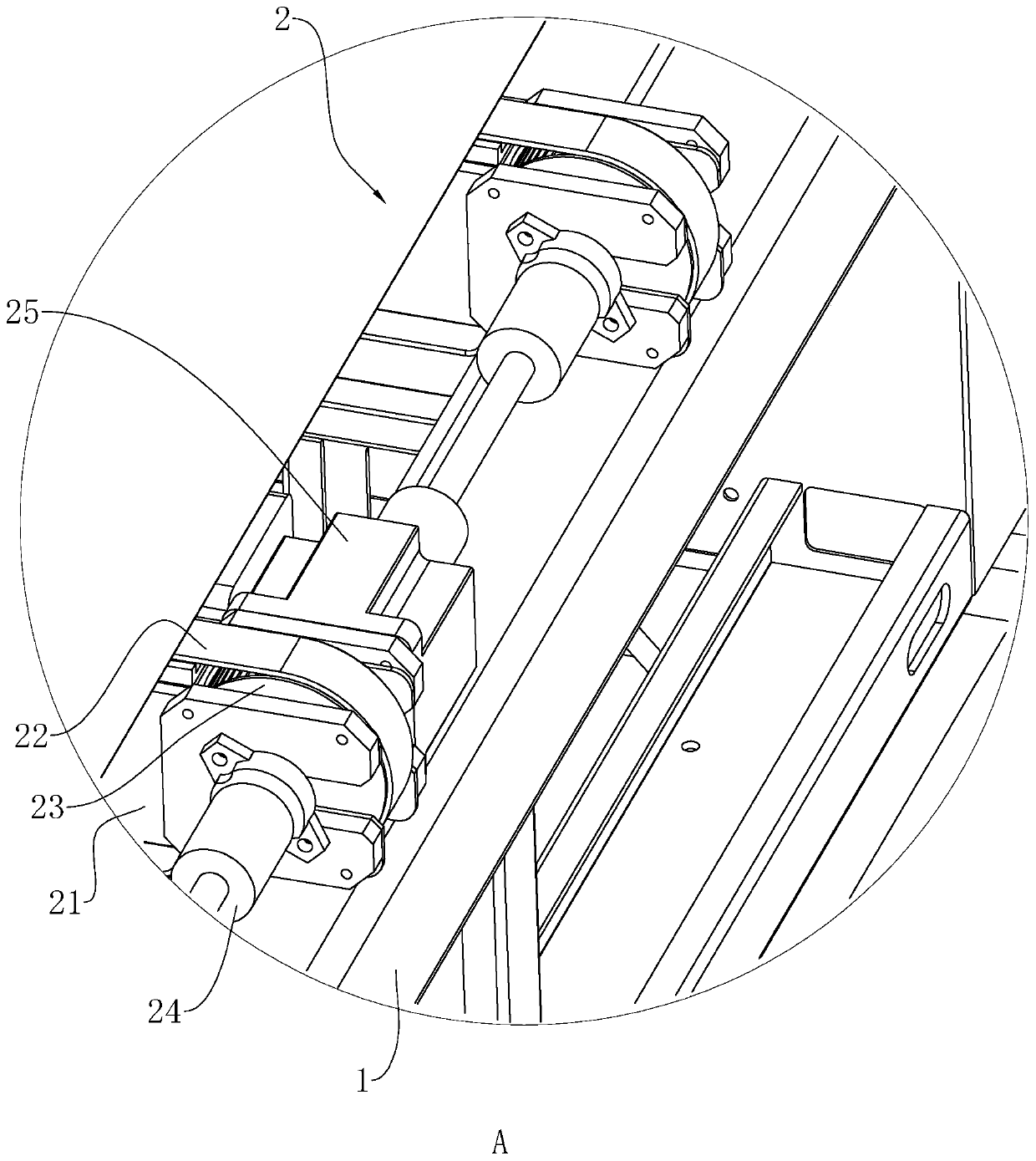

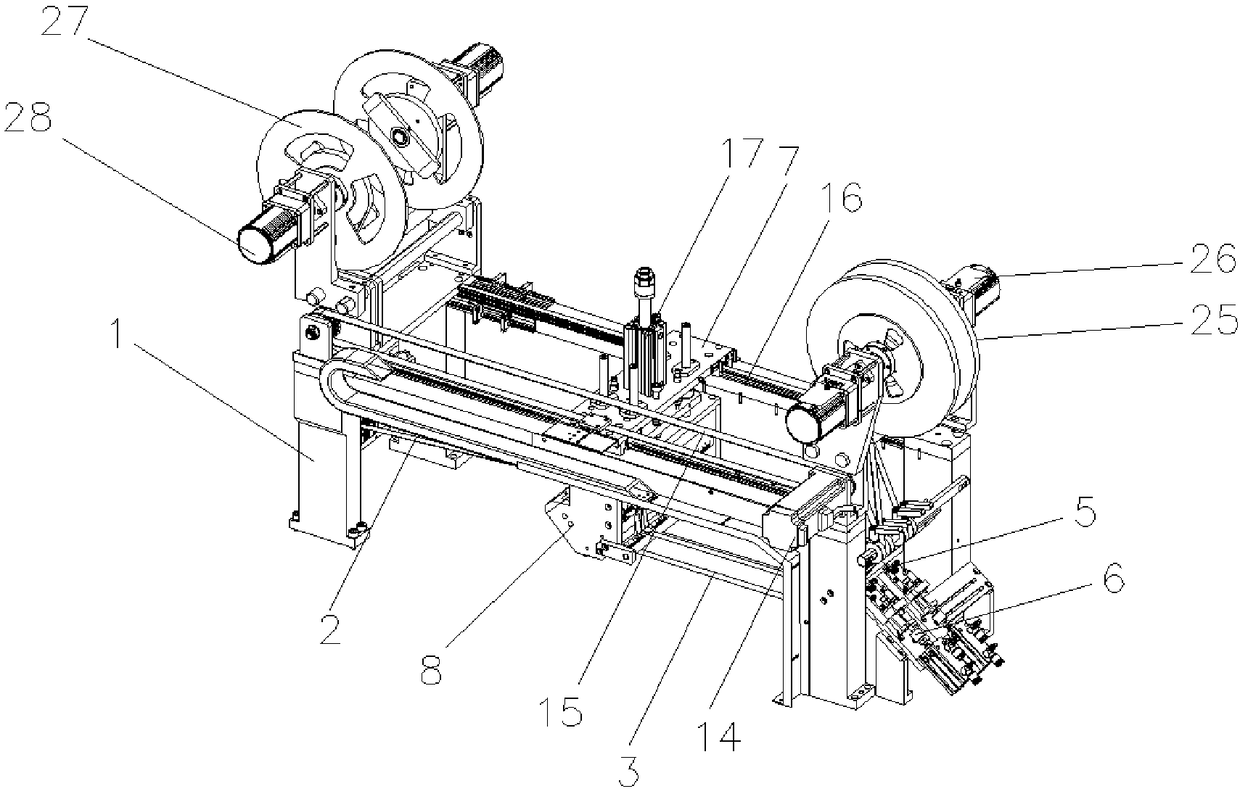

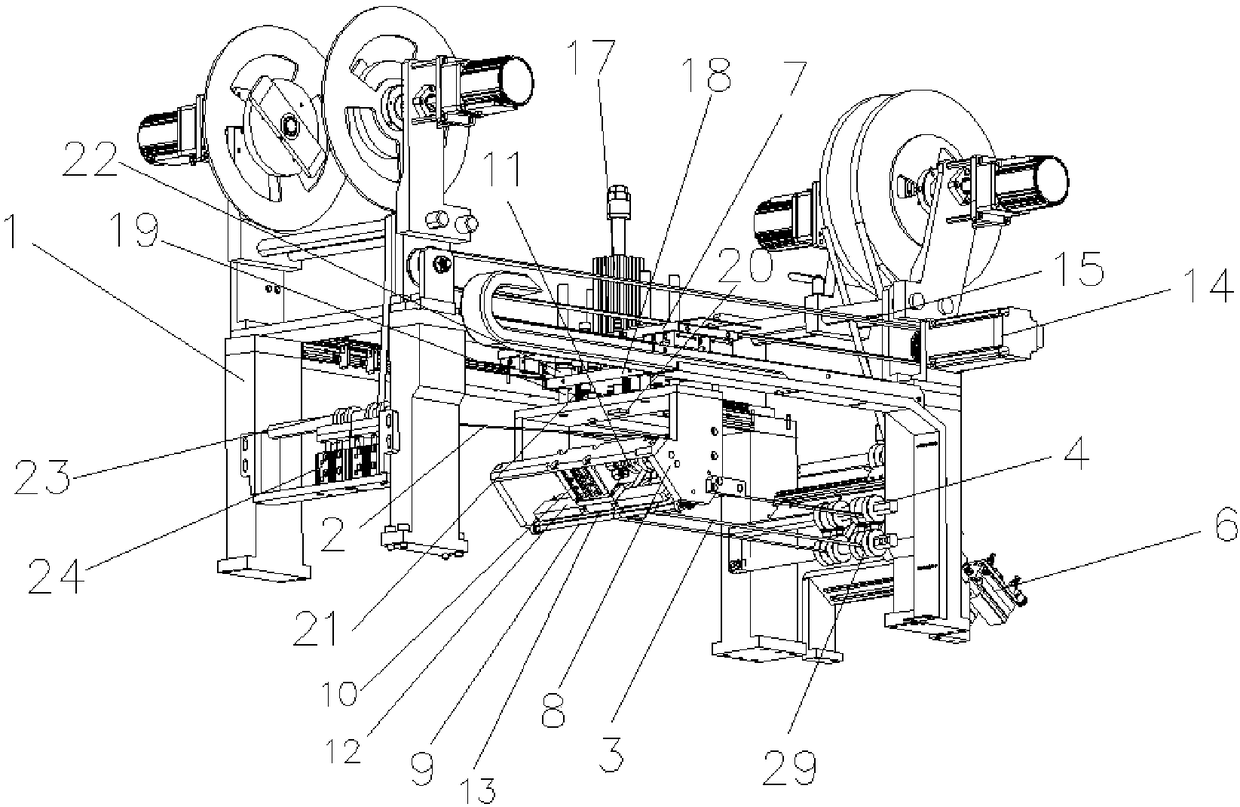

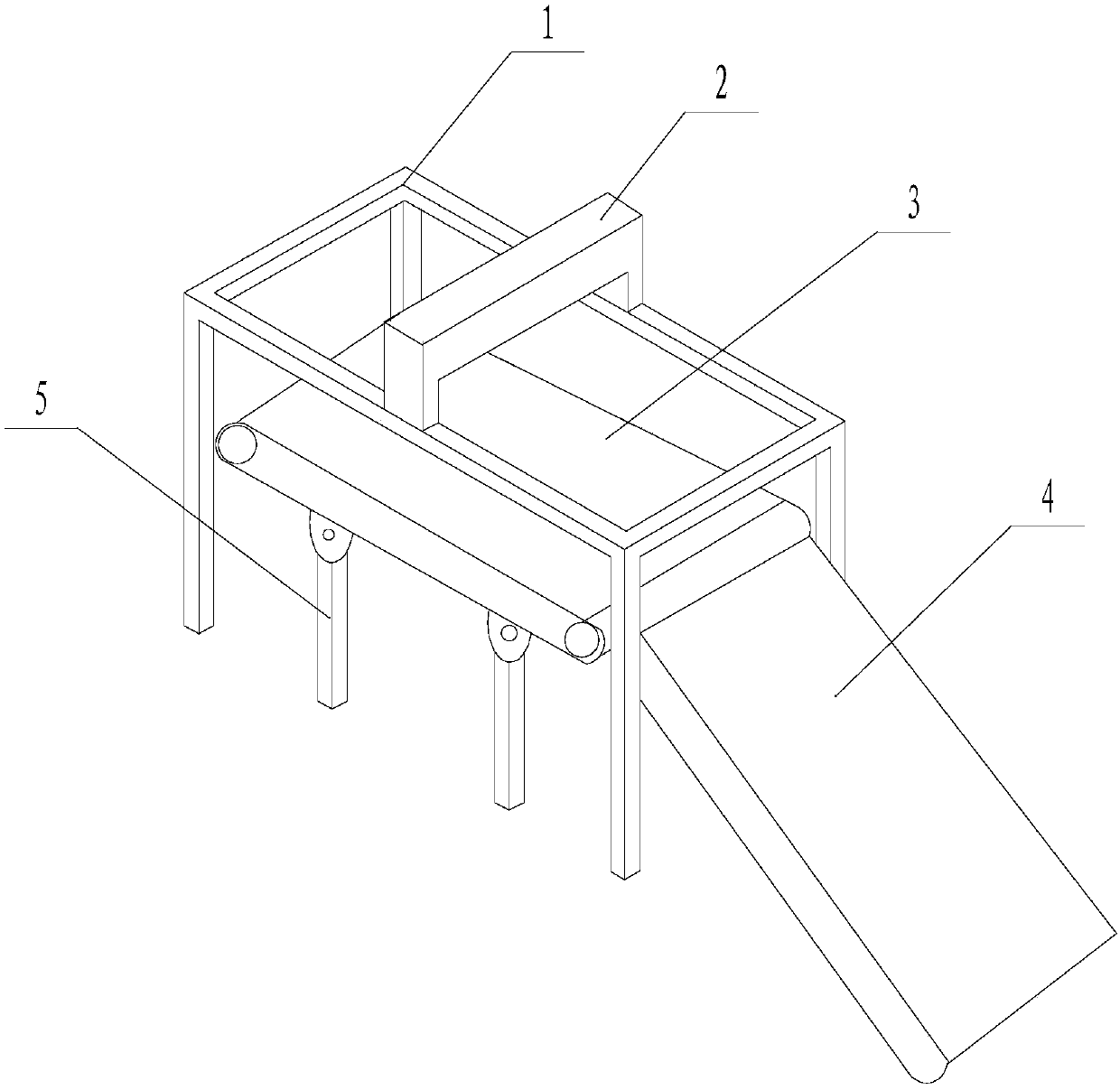

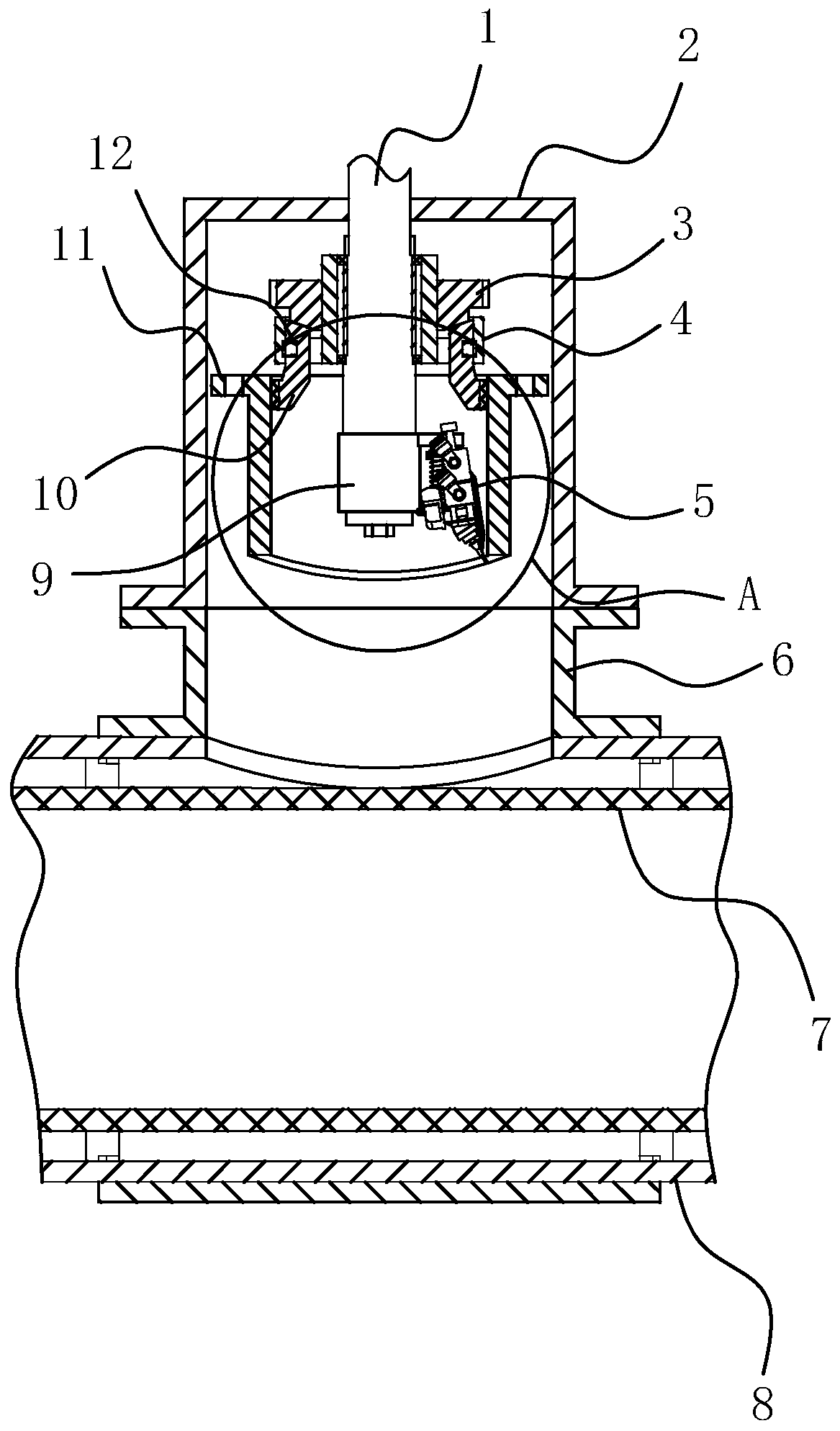

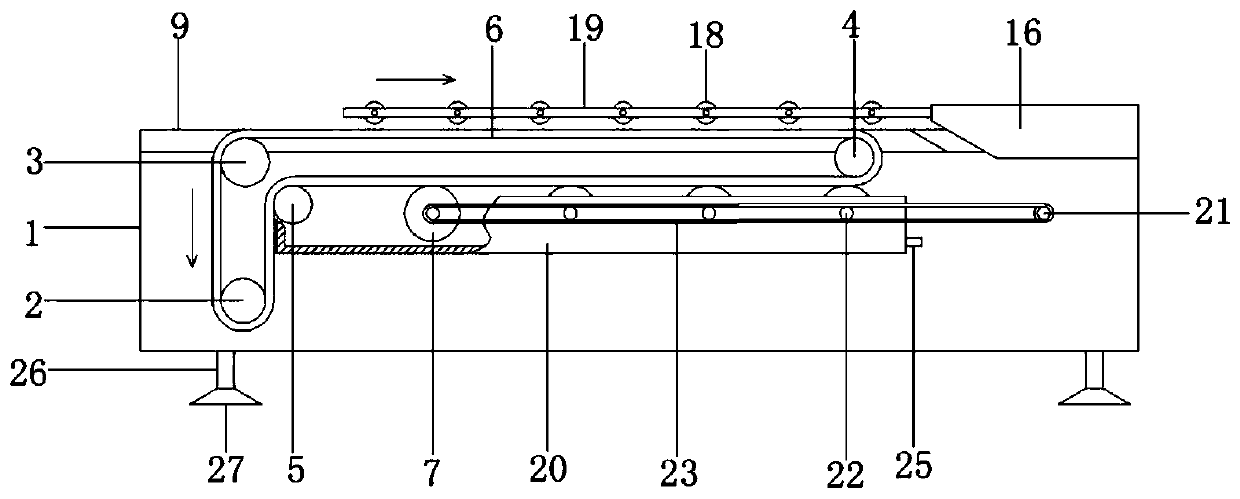

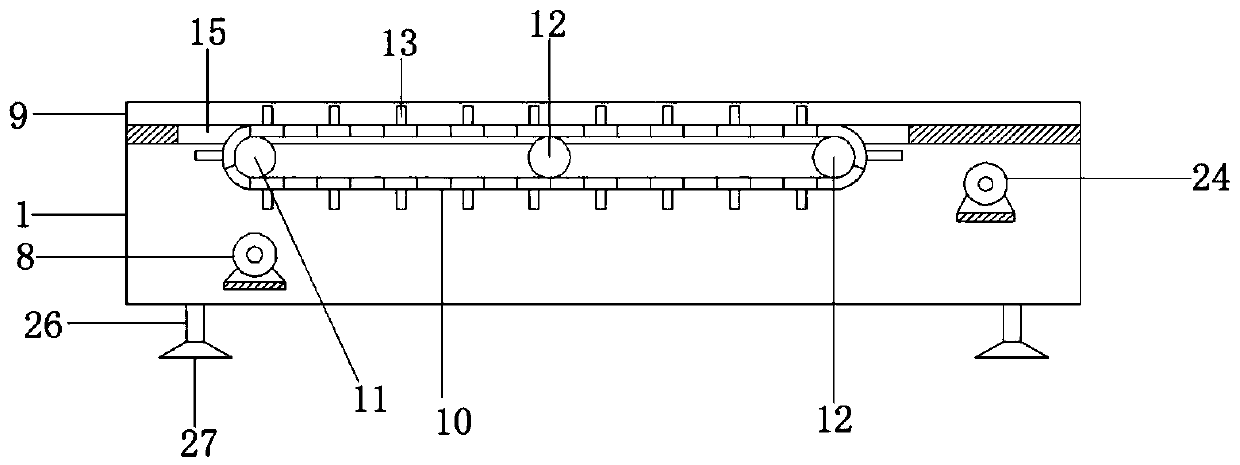

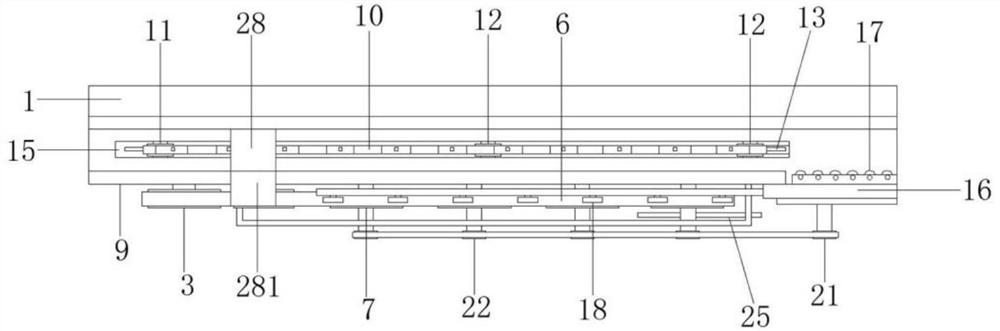

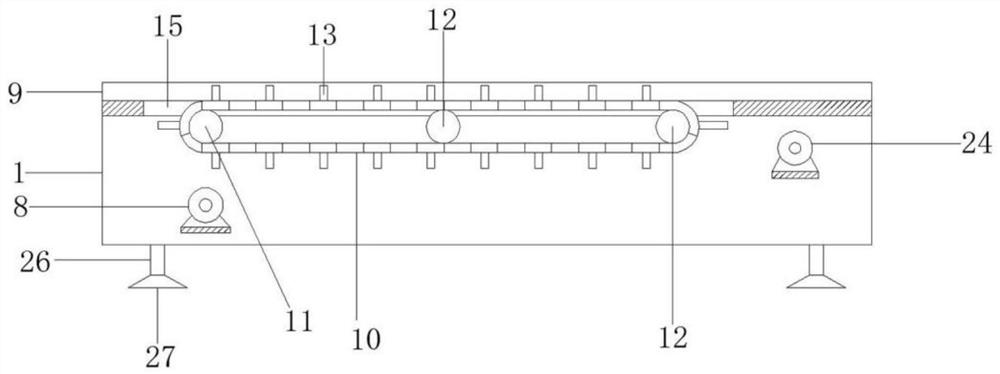

Hot-melting strip pasting machine

The invention discloses a hot-melting strip pasting machine which is characterized by comprising a working table, an adjustment assembly, a conveying device, a pressing roller device, a shearing device and a hot wind device, wherein the working table comprises a rack, a first movable portal frame, a front-rear walking mechanism, a left-right walking mechanism and a second installation hanging bracket; the first movable portal frame is disposed on the rack by the front-rear walking mechanism and can be moved back and forth; the second installation hanging bracket is disposed on the first movable portal frame by the left-right walking mechanism and can be moved horizontally; the conveying device, the pressing roller device and the hot wind device are disposed on the second installation hanging bracket of the working table in a rotatable manner by the adjustment assembly; the conveying device is used to install corresponding hot-melting adhesive films and recycle corresponding release paper; the pressing roller device is used to press and paste the hot-melting adhesive films on corresponding fabrics; the shear device is disposed on the pressing roller device and used to cut off the hot-melting adhesive films; and the hot wind device is used to heat the holt-melting films.

Owner:CHANGZHOU ZHIGU ELECTROMECHANICAL TECH CO LTD

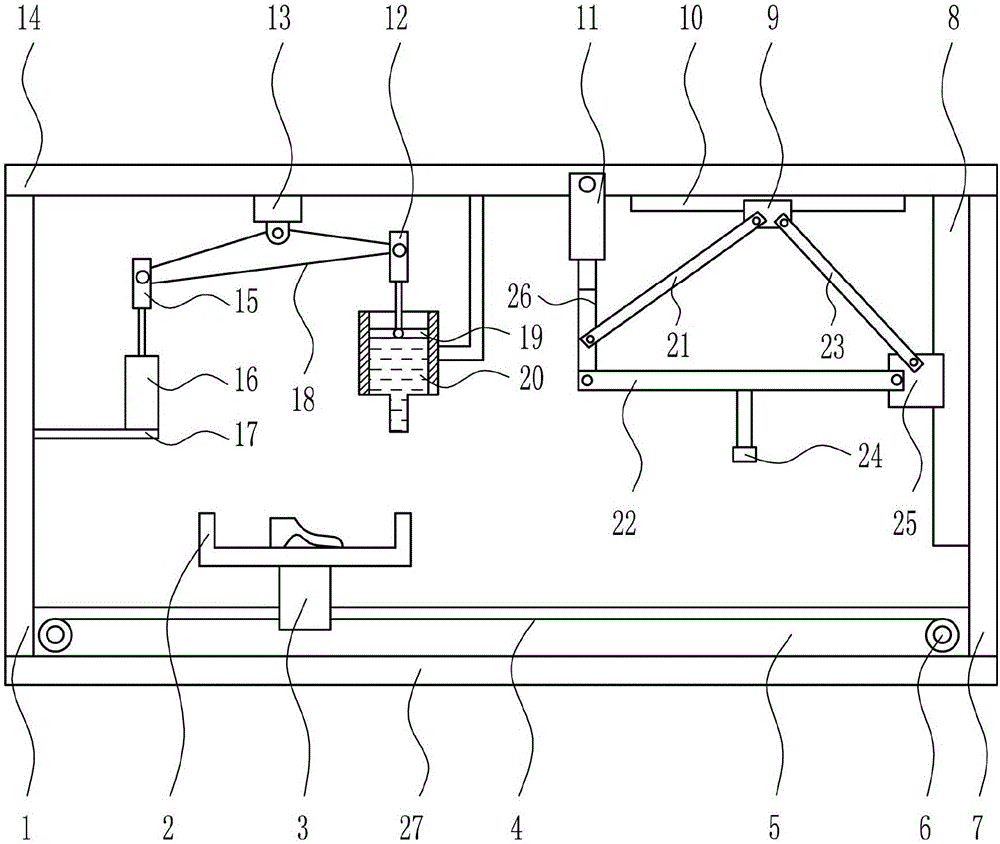

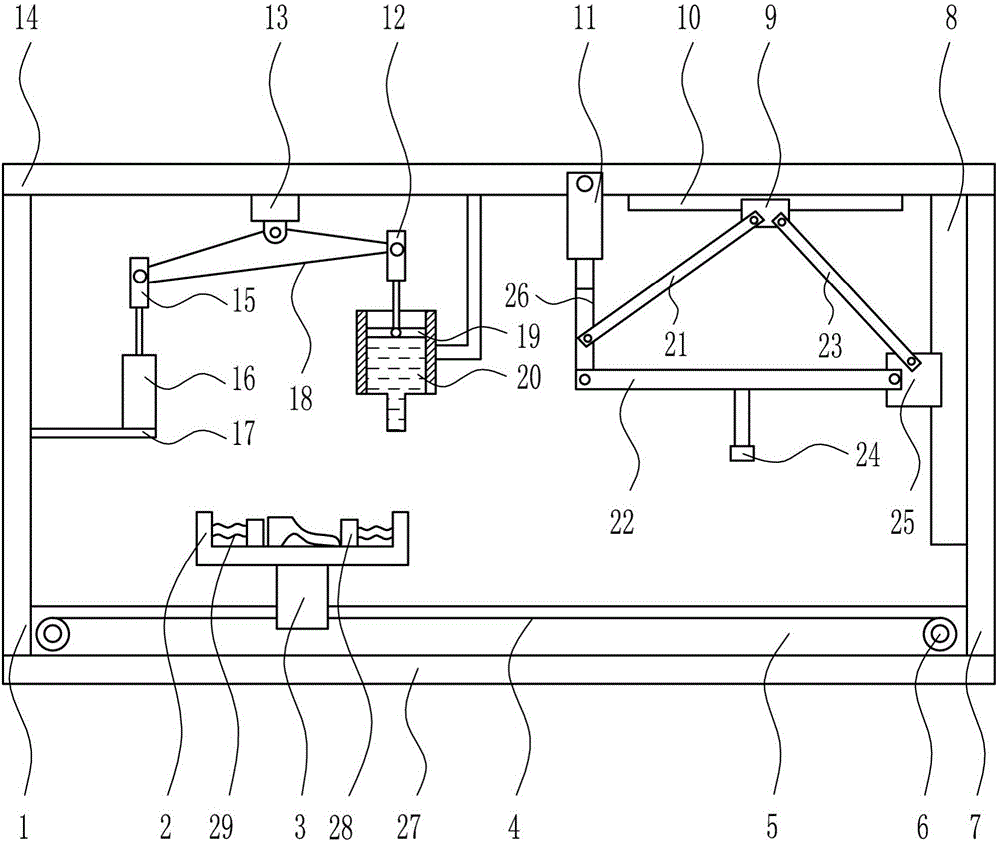

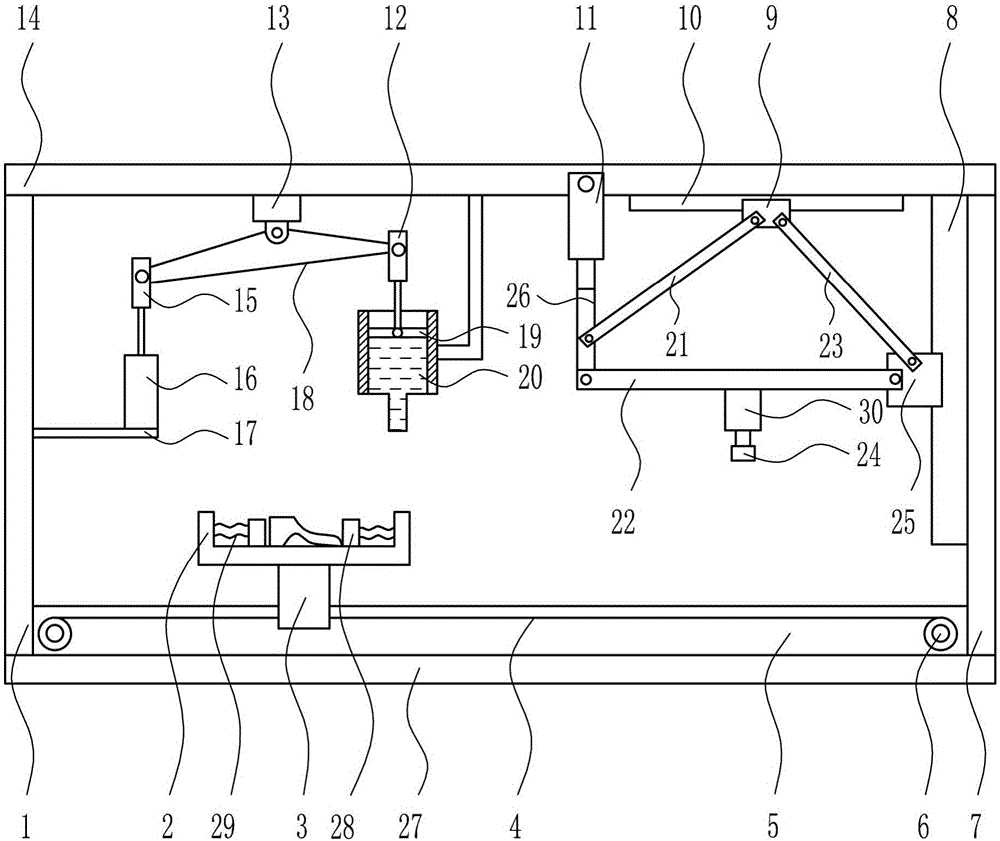

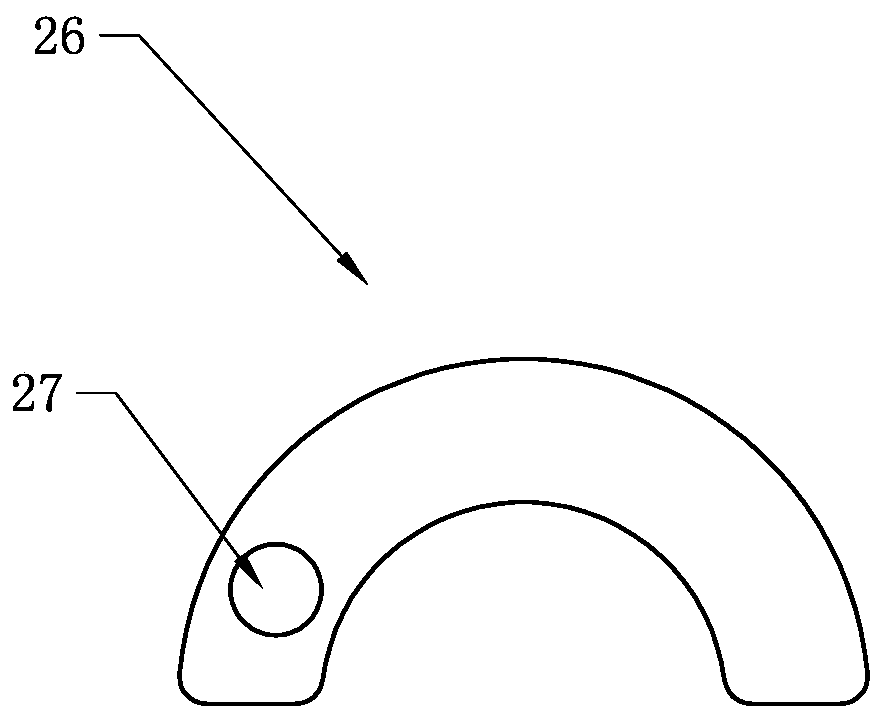

Shoemaking gumming device

InactiveCN106108264APrevent sliding left and rightFully gluedShoe gluingMechanical engineeringPiston

The invention relates to a gumming device, in particular to a shoemaking gumming device, and aims to provide the shoemaking gumming device being accurate in gumming position, comprehensive in gumming, and visual enough for observation. The shoemaking gumming device comprises a left bracket, an accommodating rack, a first slider, a stay wire, a first slide rail, an electric reel, a right bracket, a second slide rail, a third slider, a third slide rail, a first electric push rod, a fifth connecting rod, a supporting seat, a top plate, a fourth connecting rod, a cylinder, a fixing plate, a swing rod, a piston, a cylinder body, a third connecting rod, a second connecting rod, a first connecting rod, a pressing block, a second slider, a lifting rod and a bottom plate. The shoemaking gumming device has the effects of being accurate in gumming position, comprehensive in gumming, and visual enough for observation; being fast in gumming speed, reasonable in design, and convenient to use, the shoemaking gumming device is highly practical.

Owner:ZHEJIANG KAJIALI SHOES CO LTD

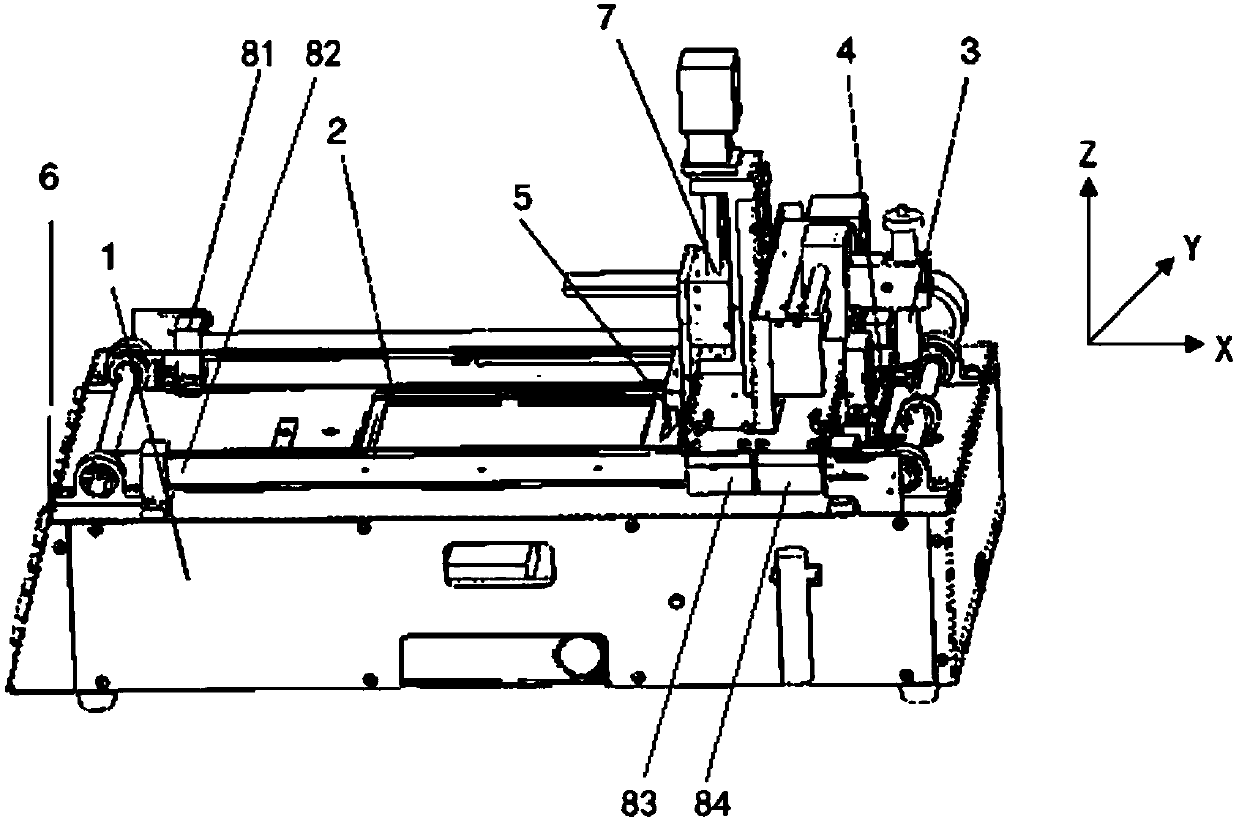

Automatic gluing device

InactiveCN109604113AGuaranteed movement speedConsistent amount of glueLiquid surface applicatorsCoatingsEngineeringCoating

The invention discloses an automatic gluing device. A vacuum adsorption table, a glue discharging needle tube, a glue scraping scraper plate and a control device are included. The upper end face of the vacuum adsorption table serves as a work plane for adsorbing a to-be-glued workpiece. The glue discharging needle tube horizontally moves along a horizontal control guide rail arranged on the work plane and is used for spot coating of an adhesion agent to the to-be-glued workpiece adsorbed to the work plane. The glue scraping scraper plate horizontally moves along the horizontal control guide rail and is used for scraping the adhesion agent arranged on the surface of the to-be-glued workpiece in a spot coating manner to be even and flat. The control device is connected with the vacuum adsorption table, the glue discharging needle tube, the glue scraping scraper plate and the horizontal control guide rail and controls the motions of the vacuum adsorption table, the glue discharging needletube, the glue scraping scraper plate and the horizontal control guide rail. According to the device, adsorption is utilized for achieving to-be-glued workpiece fixing, the to-be-glued surface is completely in the flat work plane, a machine is used for replacing manual work to finish spot coating and slicking, the position and the glue amount of each-time spot coating can be guaranteed, it can beguaranteed that the pressure and the speed of the glue scraping scraper plate relative to the to-be-glued workpiece are fixed, uniform gluing is finally achieved, and the gluing quality is improved.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

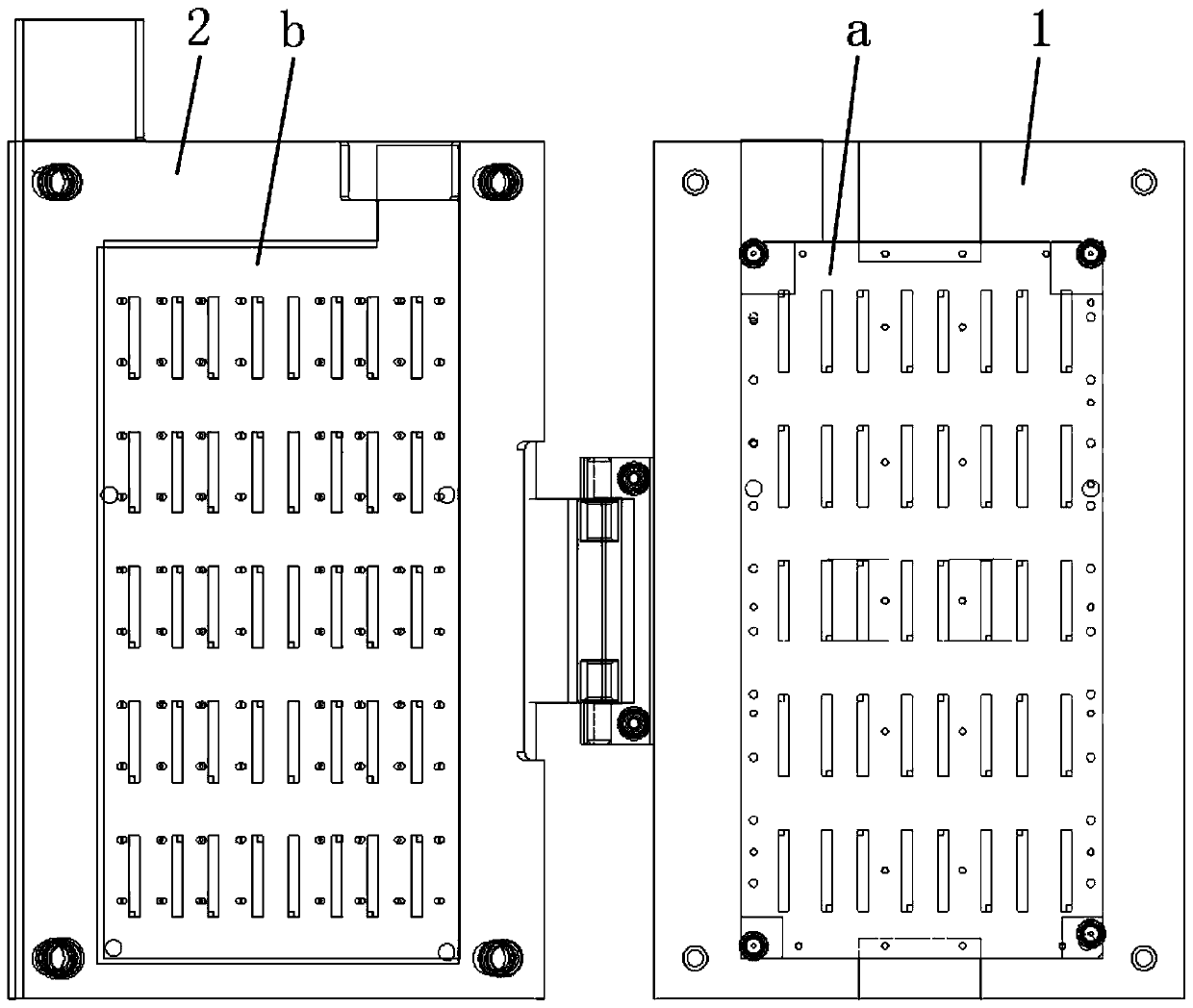

Tool for pressing conductive adhesive

The invention discloses a tool for pressing a conductive adhesive. The tool comprises a platform, a plurality of conductive adhesive carriers and a pressure plate, wherein the conductive adhesive carriers are arranged on the platform; a groove for accommodating a conductive adhesive attached object is formed on each conductive adhesive carrier; the pressure plate is arranged at a position above the conductive adhesive carriers, and can perpendicularly move; a plurality of clamping grooves without bottom surfaces are formed on the lower surface of the pressure plate, and are in one-to-one correspondence with the conductive adhesive carriers; and each clamping groove comprises a lateral jack into which a workpiece can be inserted. According to the tool for pressing the conductive adhesive, the conductive adhesive can be pressed on a semi-finished product with foam. The semi-finished product is the foam, and a glass fiber board is arranged on one side of the foam, and can be clamped by the clamping grooves on the tool and a rotary chuck, so that the other side of the foam can move towards the conductive adhesive carriers, and then the conductive adhesive is adhered to the foam. The tool is accurate in adhesive pressing position and higher in efficiency.

Owner:KUSN MAIZHI FIXTURE TECH

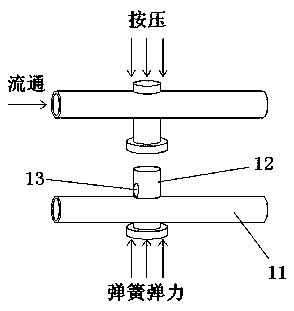

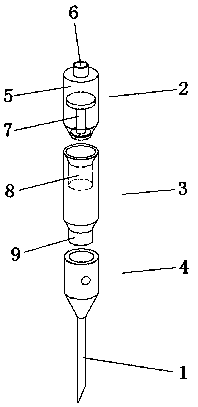

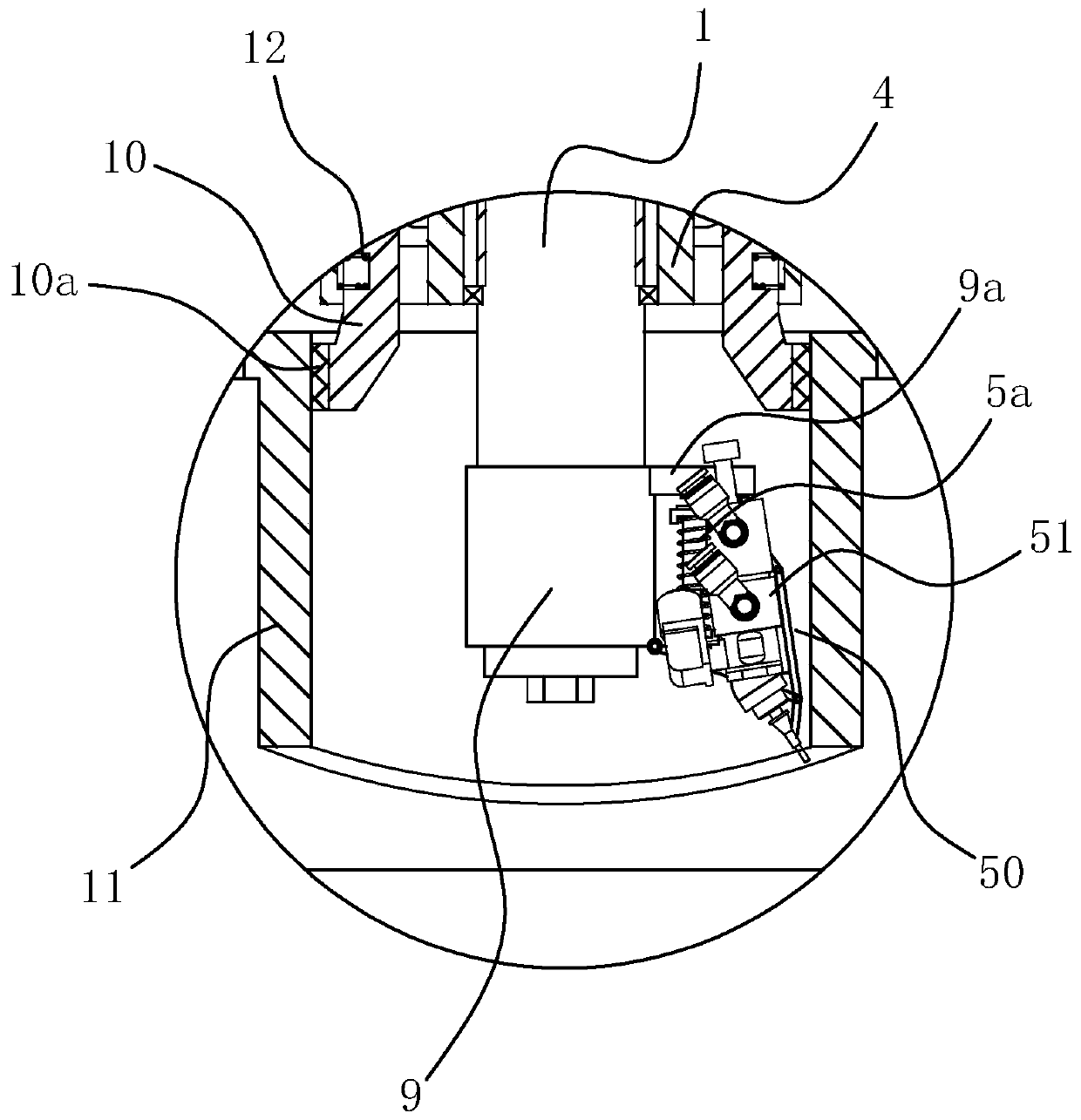

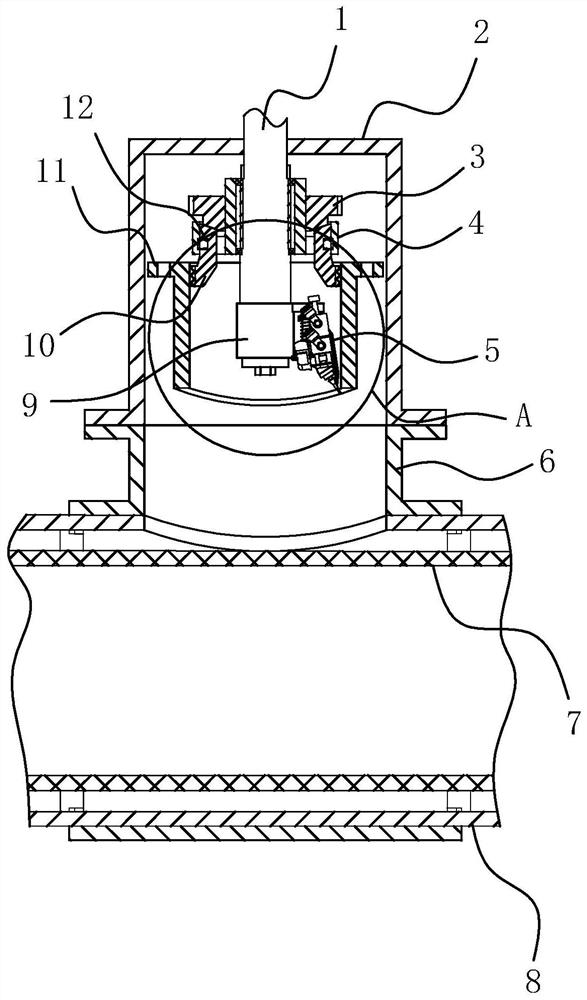

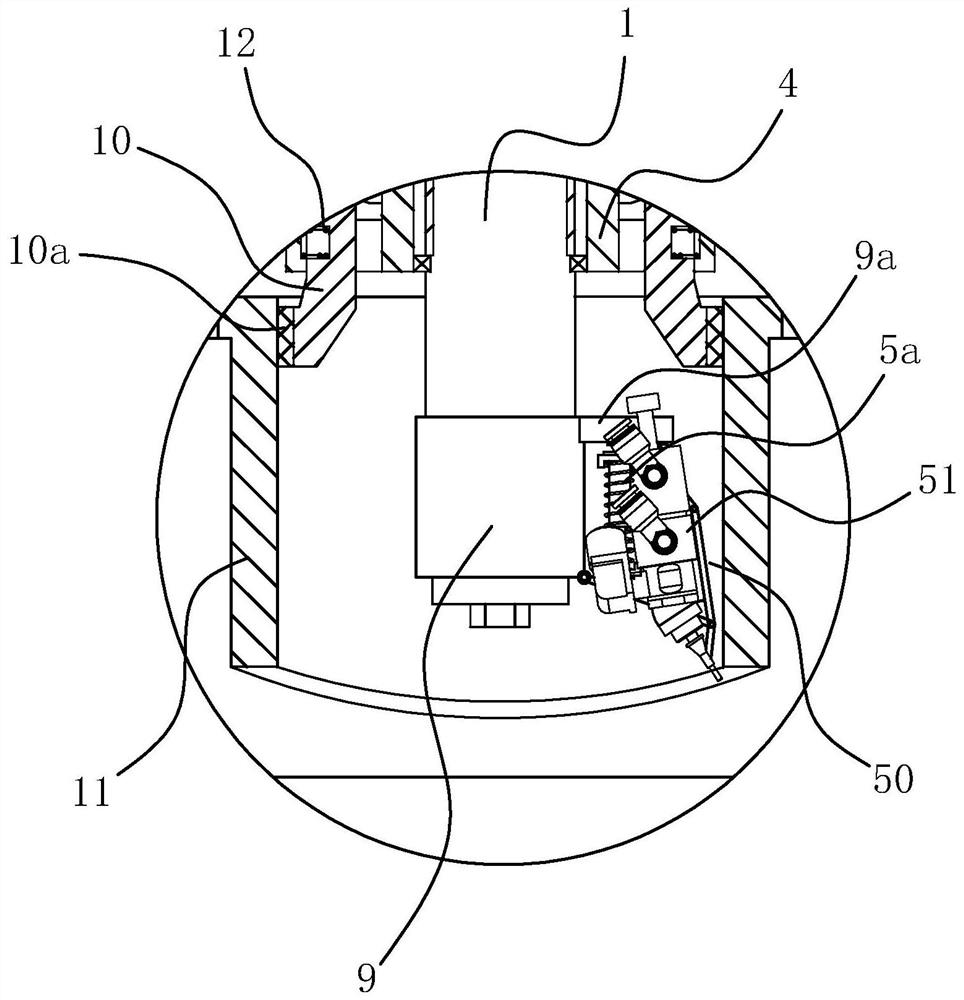

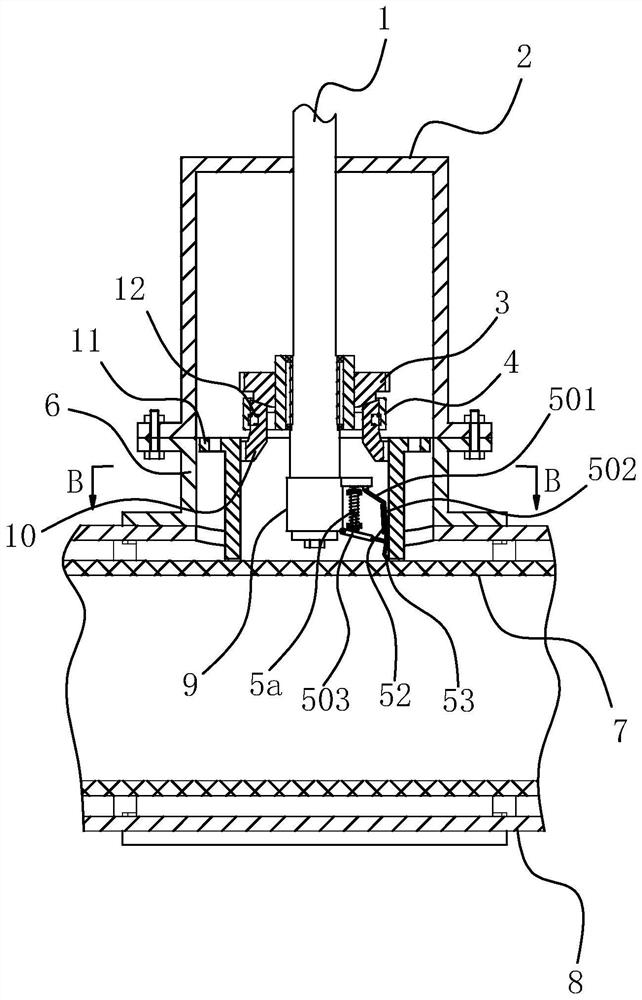

Manual air inflation and glue injection device for guitar processing

InactiveCN108970926ASimple structureEasy to holdLiquid surface applicatorsCoatingsAir compressionEngineering

The invention discloses a manual air inflation and glue injection device for guitar processing. The manual air inflation and glue injection device comprises an air compression section and a glue storage and injection section, and the air compression section and the glue storage and injection section are connected through a compressed air hose; the air compression section comprises a compression bin; an inflator pump is arranged on one side of the compression bin; the glue storage and injection section comprises a glue storage bin and a glue injection needle head; the glue injection needle headis arranged below the glue storage bin; and a glue injection switch is arranged on the glue storage bin; and a one-way valve is arranged at the joint of the air compression section and the compressedair hose as well as the joint of the glue storage and injection section and the compressed air hose. The manual air inflation and glue injection device has the advantages of being simple in structure, convenient to hold, convenient to use, capable of easily controlling the gluing amount, uniform in gluing, accurate in gluing position, capable of facilitating the gluing use at the corners and capable of improving the gluing quality of a guitar.

Owner:正安索尔乐器文化发展有限公司

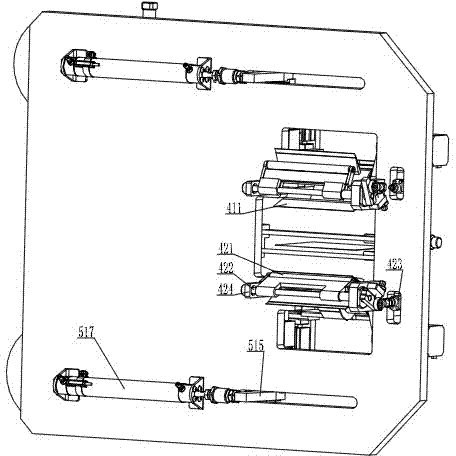

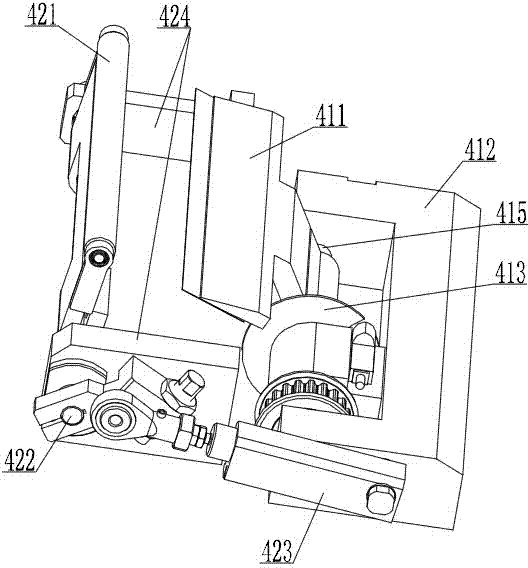

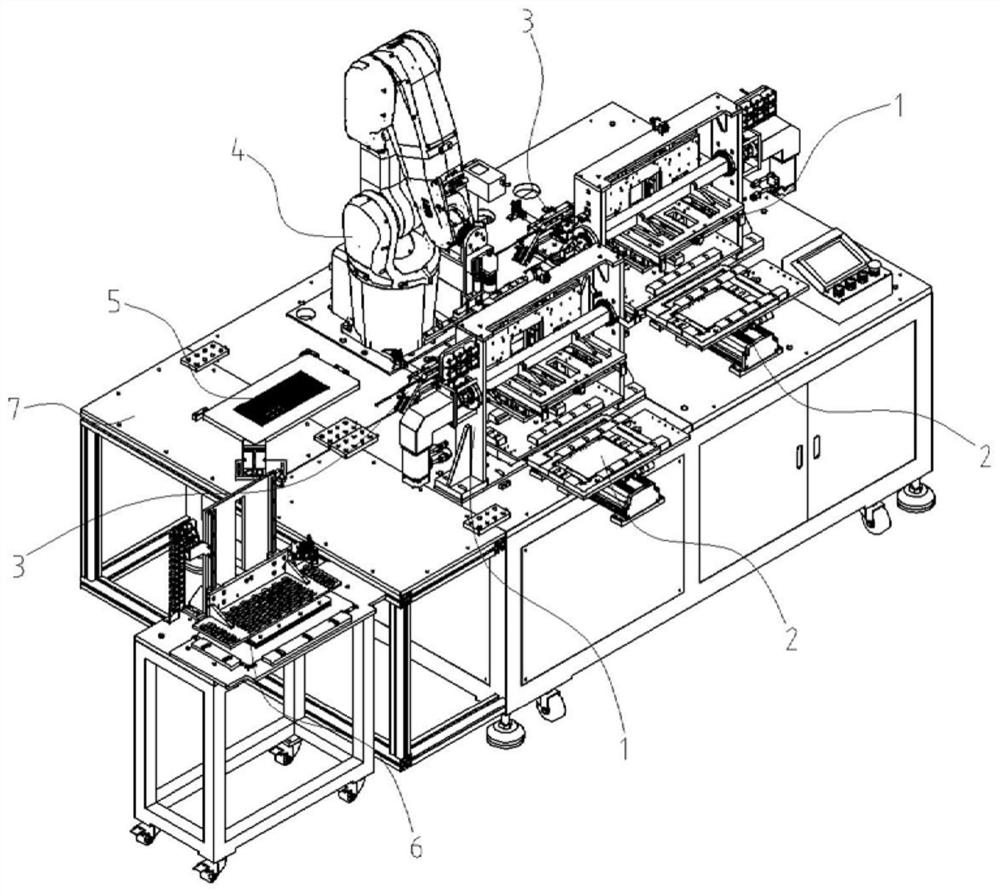

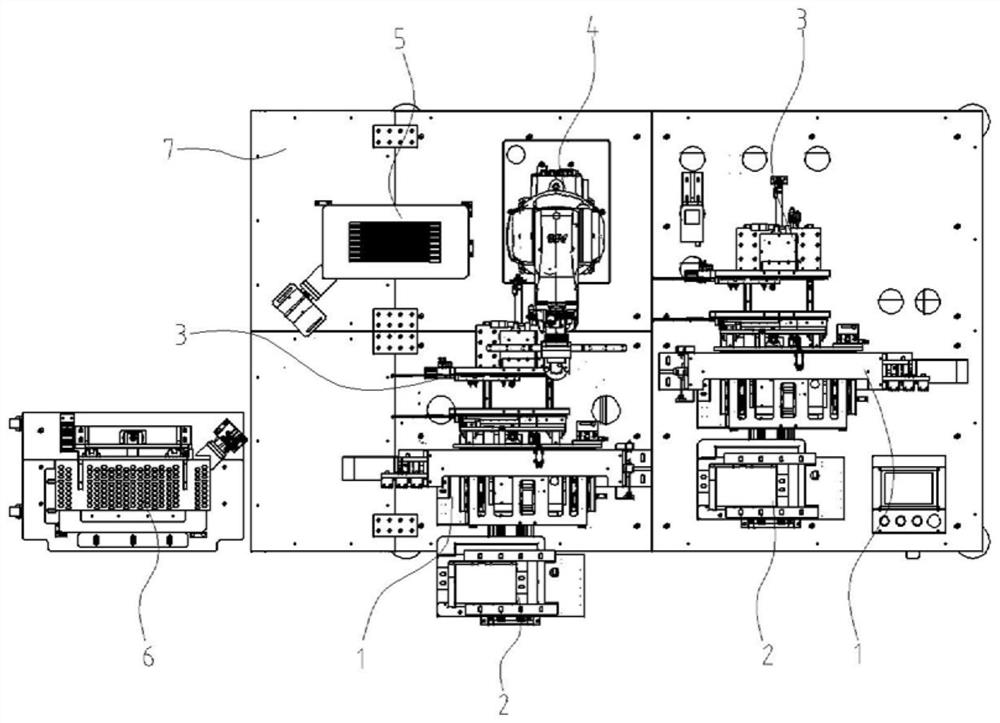

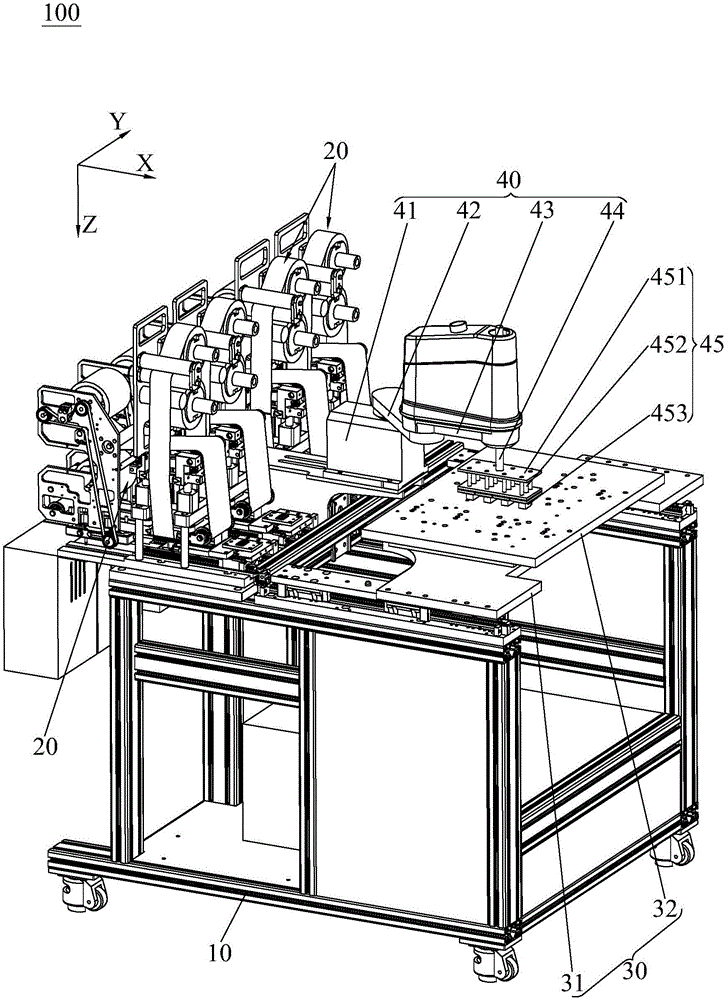

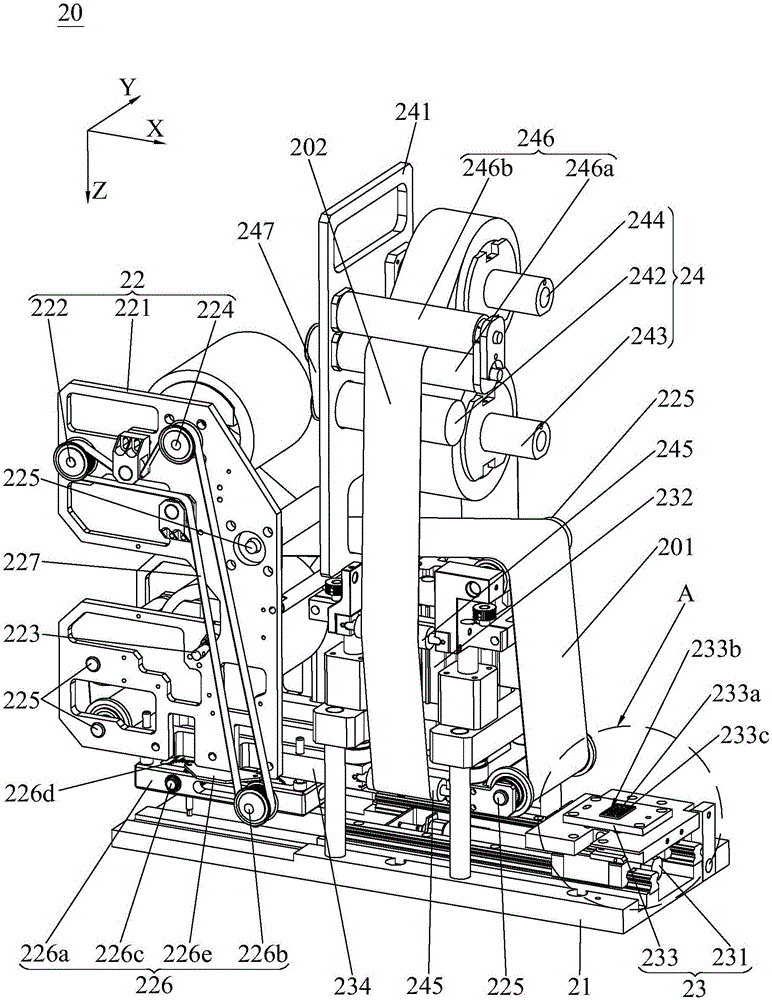

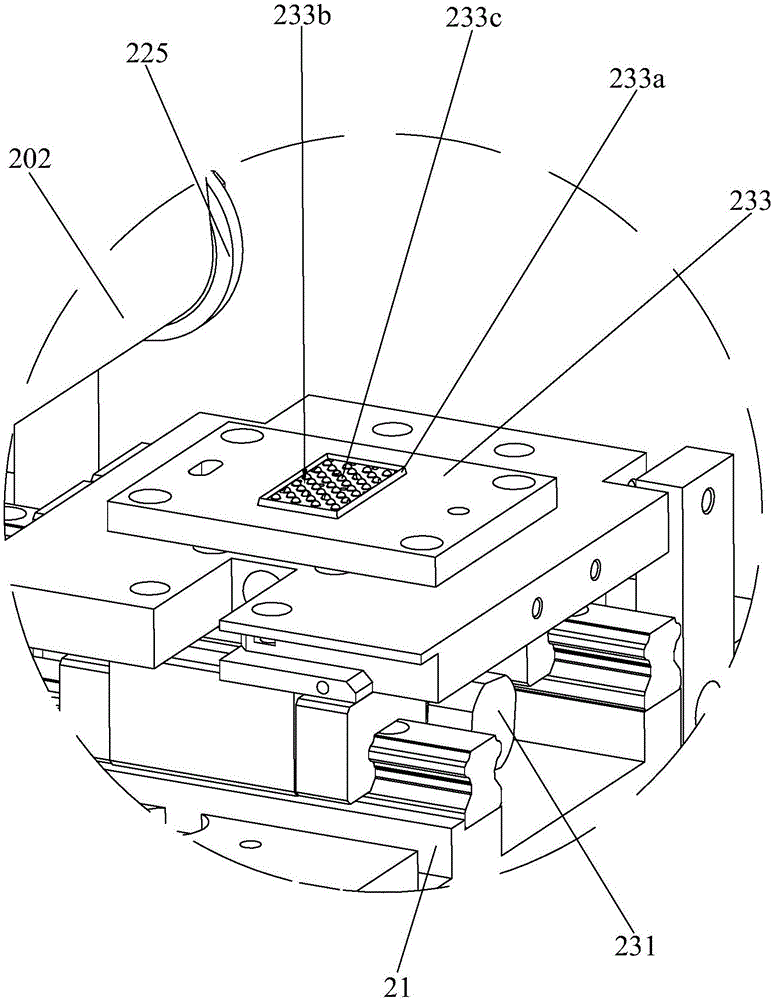

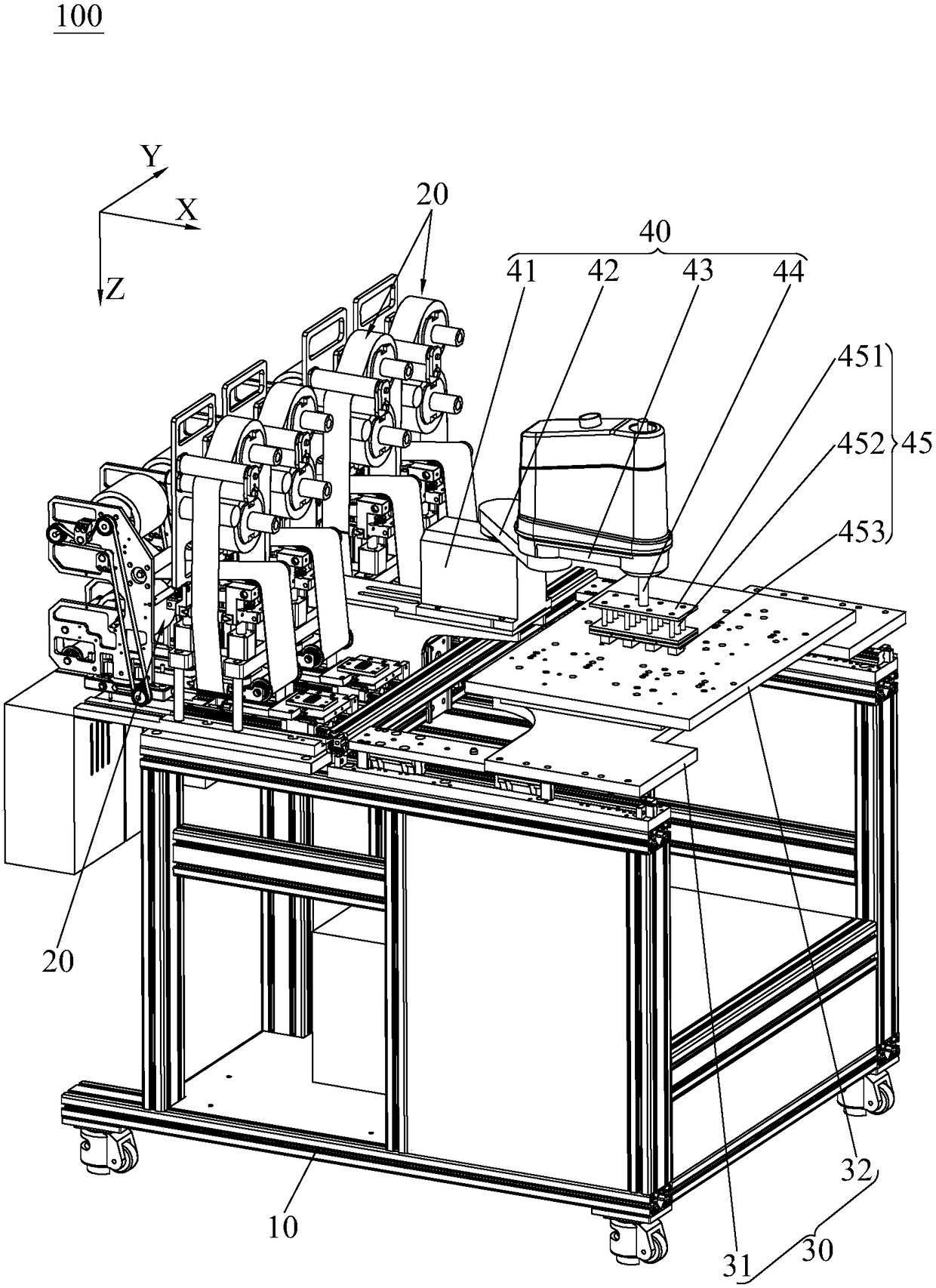

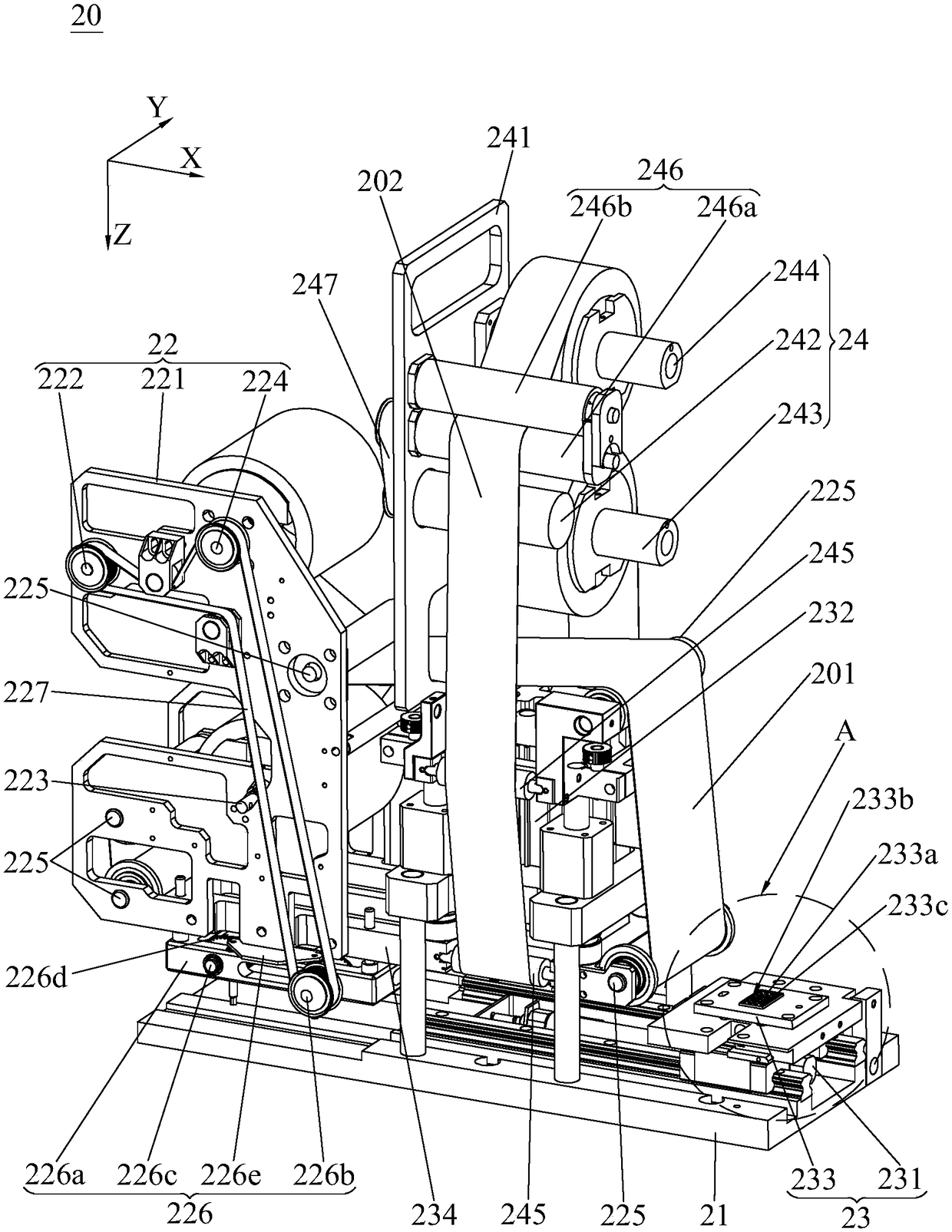

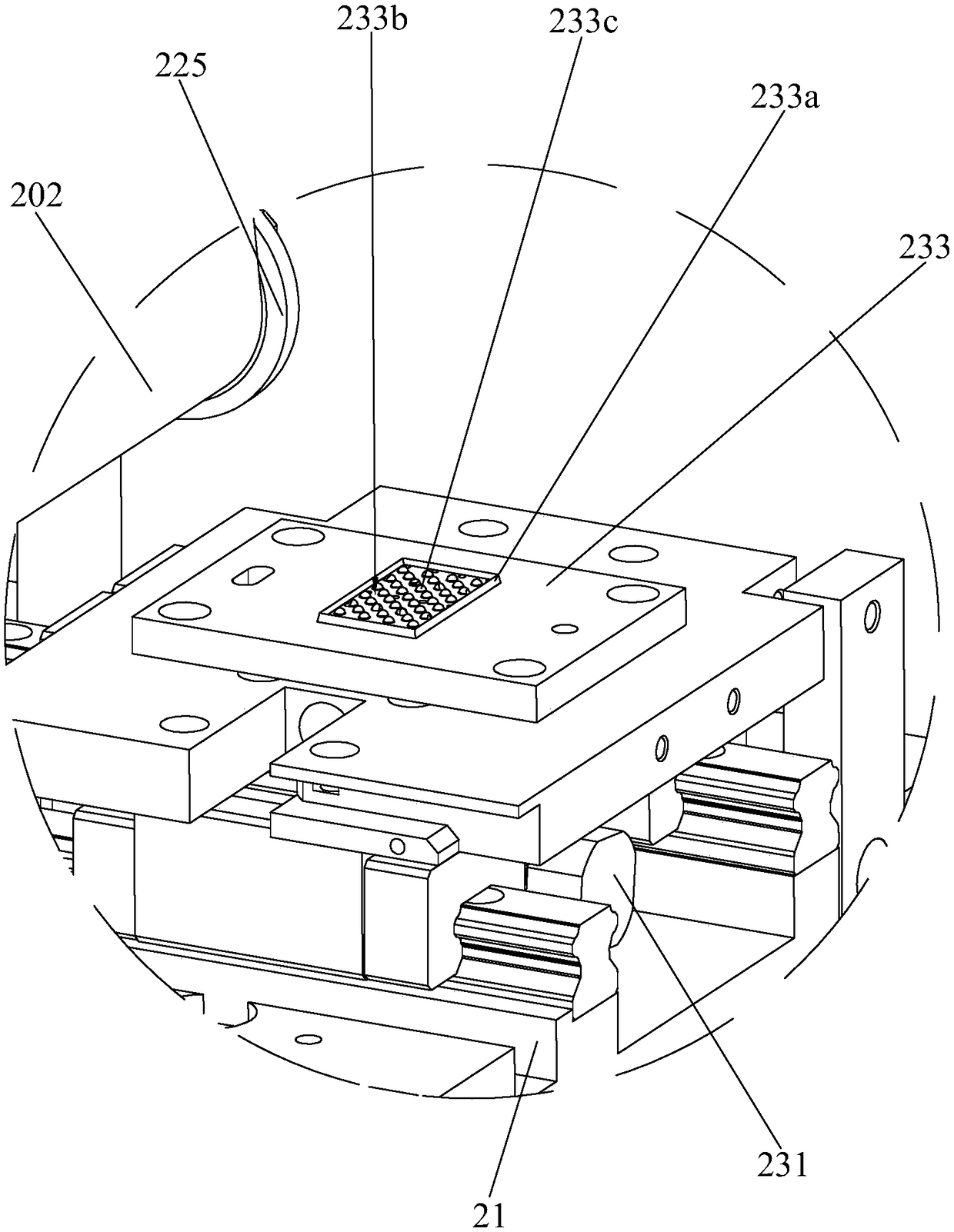

Automatic assembling equipment of FPC light bars

InactiveCN112355603AAvoid human contactAvoid damageMaterial gluingMetal working apparatusStructural engineeringMaterial transfer

The invention discloses automatic assembling equipment of FPC light bars. The automatic assembling equipment comprises a material placing mechanism used for placing FPC light bars, a material transferring mechanism, a material taking robot, a material taking and attaching mechanism and a positioning jig used for loading iron frames, wherein the material taking robot is used for transferring the FPC light bars from the material placing mechanism to the material transferring mechanism; the material transferring mechanism is used for transferring the FPC light bars to the material taking and attaching mechanism; and the material taking and attaching mechanism is used for attaching the FPC light bars to the iron frames. According to the automatic assembling equipment of FPC light bars, the material placing mechanism, the material transferring mechanism, the material taking robot, the material taking and attaching mechanism and the positioning jig cooperate with each other to automaticallyload and attach the FPC light bars; the manual contact with the FPC light bars is avoided; the risks of damage of LED lights and breakage of the FPC light bars are reduced; the problems that the FPC light bars cannot be tightly attached manually and the falling risks exist are solved; the gluing positions of the FPC light bars are more accurate; and the assembly accuracy of the products can be better met.

Owner:HUIZHOU WAI CHI ELECTRONICS CO LTD

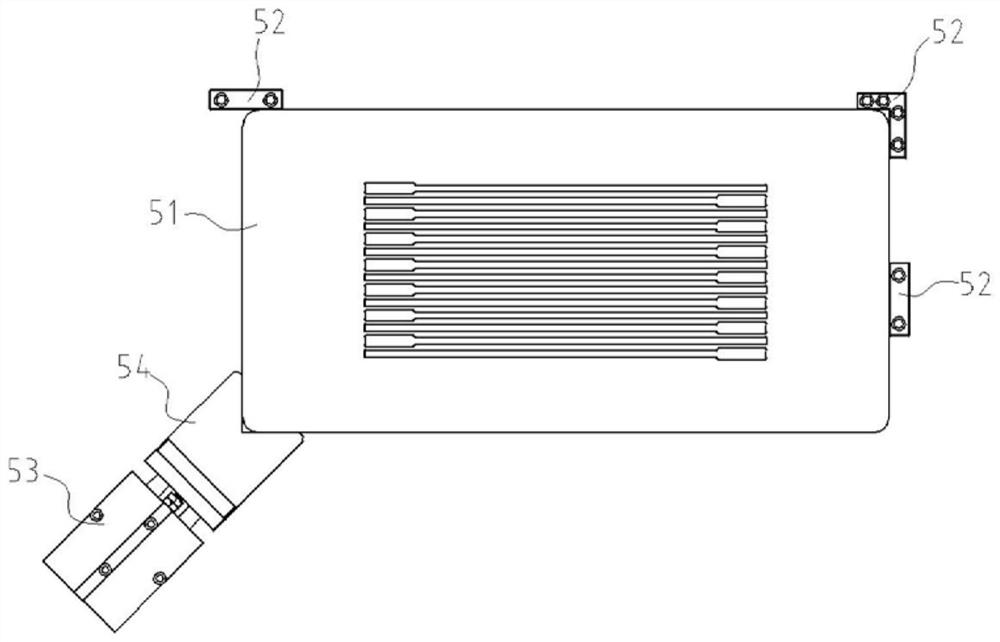

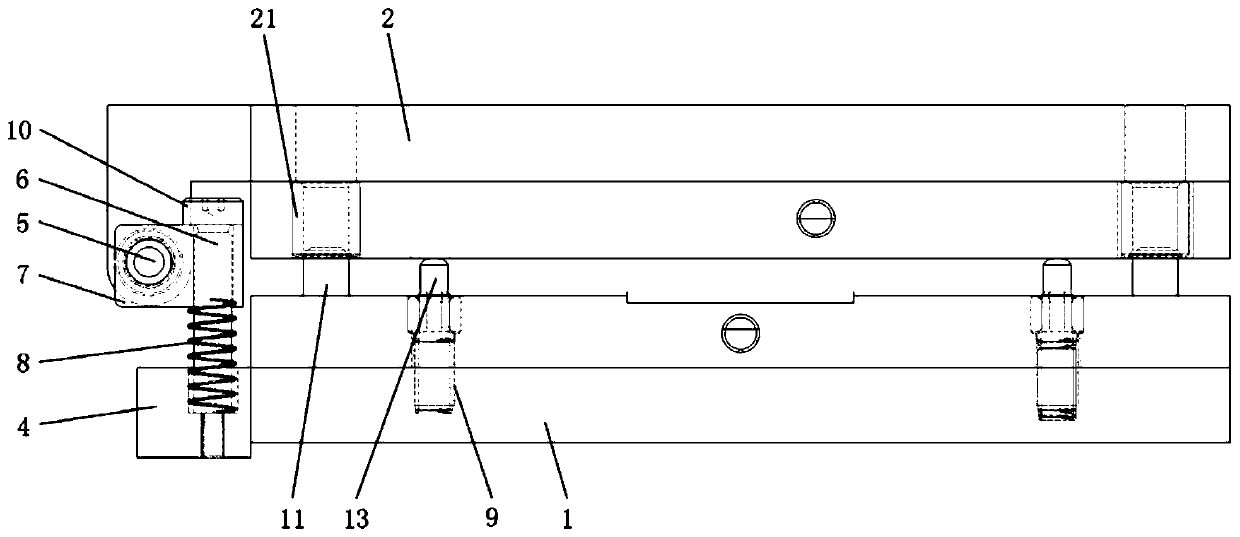

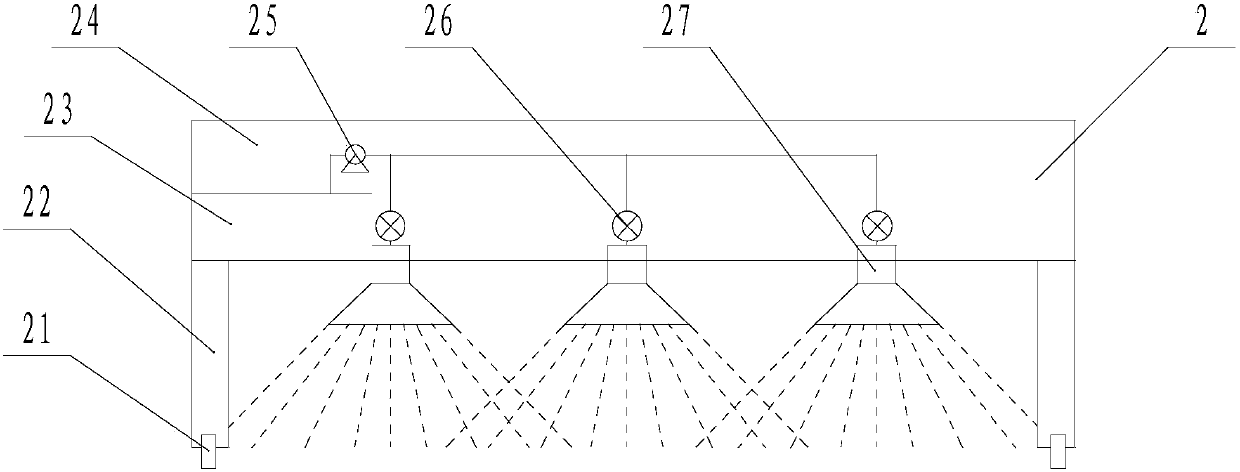

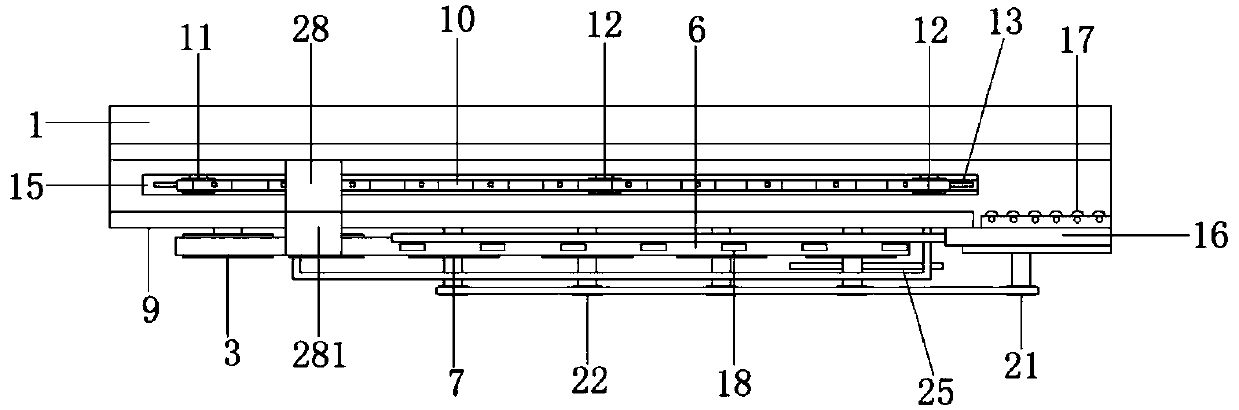

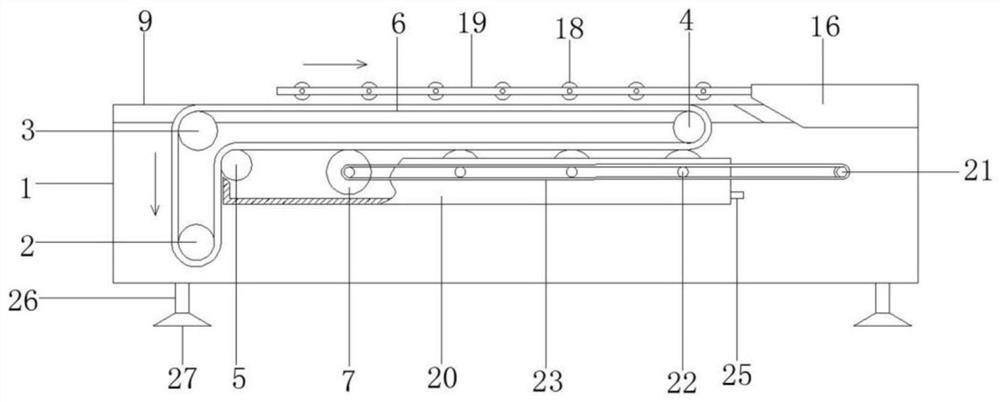

Typesetting and glue pasting device for solar battery strings

ActiveCN111086916ASmall footprintHigh adjustment accuracyElectrical componentsArticle deliveryAdhesive beltEngineering

The invention relates to a typesetting and glue pasting device for solar battery strings. The device comprises a rack, wherein a conveying mechanism for driving the battery strings to move, a detection mechanism for detecting position information of the battery strings, a deviation rectifying mechanism for placing the battery strings, a glue pasting mechanism for fixing the position of the adjacent battery strings and a controller for controlling each mechanism in the rack to act are arranged on the rack, the glue pasting mechanism comprises a glue pasting cross beam, a plurality of sets of glue pasting assemblies are arranged on the glue pasting cross beam, each glue pasting assembly comprises a material containing plate for placing high-temperature adhesive tape reels, comprises a material pasting block for finishing pasting adhesive taps and finishing pressing the adhesive tapes simultaneously, and comprises a transmission shaft for driving the material pasting block to rotate and amaterial cutting assembly for cutting the high-temperature adhesive tapes, the glue pasting mechanism simultaneously finishes the three actions of pasting the adhesive tapes, pressing the adhesive tapes and cutting the adhesive tapes, and in the rotating process of the transmission shaft, the two actions of pulling the adhesive tapes and adjusting the position of the material pasting block are finished. The typesetting and glue pasting device has the effects of being low in battery string re-typesetting rate, high in deviation rectifying and glue pasting processing efficiency of the battery strings.

Owner:SUZHOU HUIBANG AUTOMATION SYST

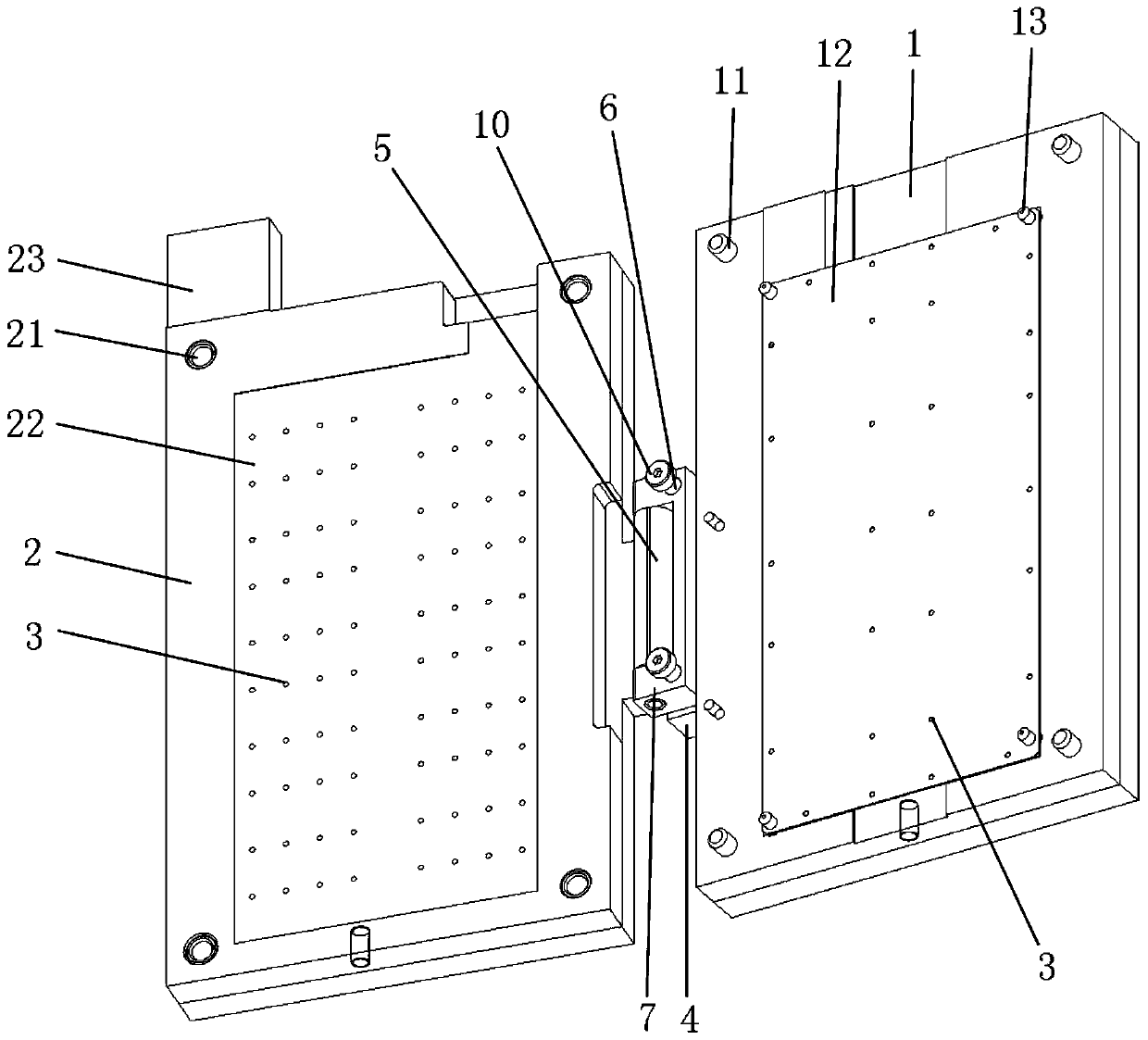

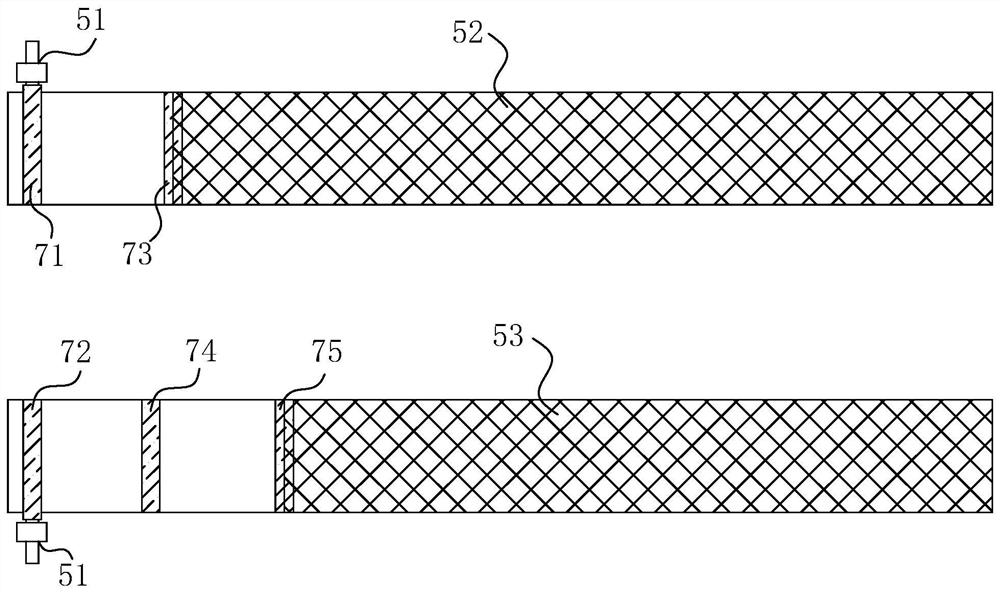

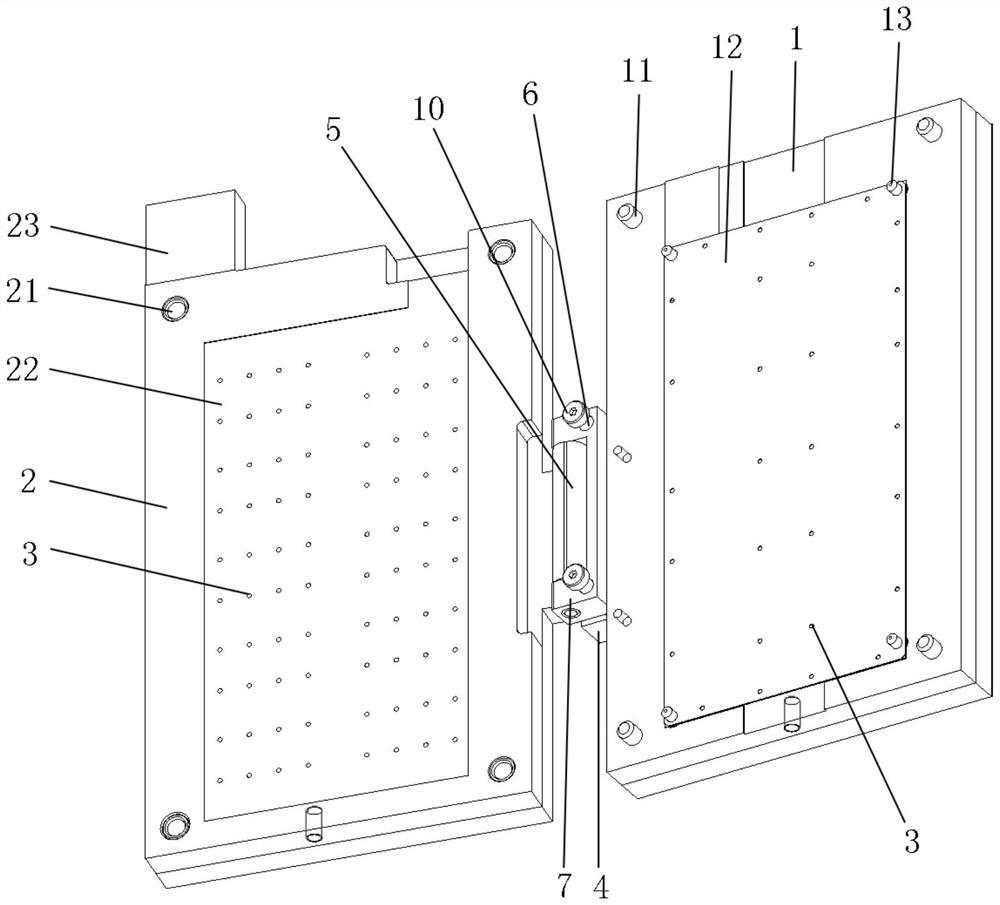

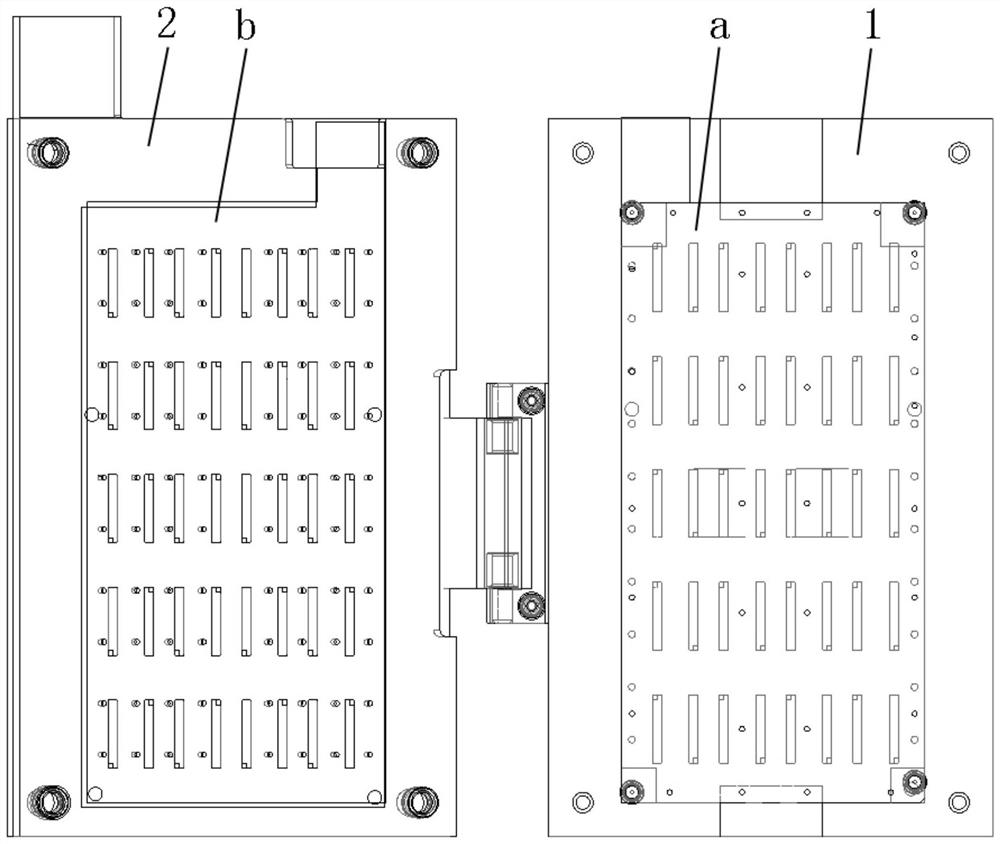

FPC surface rubberizing device

ActiveCN111356293AImprove glue application efficiencyImprove efficiencyInsulating substrate metal adhesion improvementPrinted circuit secondary treatmentEngineeringMechanical engineering

The invention discloses an FPC surface rubberizing device. The device comprises a mounting plate for positioning and mounting a whole FPC board, and a turnover plate which is connected to the mountingplate in a turnover manner and is used for positioning and mounting a PSA board; the surface of the mounting plate and the surface of the turnover plate are each provided with a plurality of suctionholes used for generating negative pressure suction effects on the FPC board and the PSA board, and the turnover plate enables the PSA board to be attached to the FPC board when being turned over to be attached to the surface of the mounting plate. Thus, under the action of the suction holes, when the FPC board is mounted on a surface of the mounting plate, the FPC board can be kept completely stretched under the action of negative pressure suction, and the phenomenon of curling and bending is avoided; and meanwhile, when the PSA board is mounted on the surface of the turnover plate, all partsof the surface of the PSA board can be kept flat under the action of negative pressure attraction, and the phenomenon of bending and wrinkling is prevented. Therefore, the FPC surface rubberizing efficiency can be improved, meanwhile, the PSA is prevented from bending and wrinkling in the attaching process, and it is guaranteed that the rubberizing position is accurate.

Owner:GEER TECH CO LTD

Paperboard adhesive adhering mechanism

ActiveCN108943851AAvoid wrinklesFacilitate precise moldingBox making operationsPaper-makingCardboardAdhesive

The invention discloses a paperboard adhesive adhering mechanism. A double-sided adhesive tape feeding module can provide double-sided adhesive tape for a double-sided adhesive tape attaching module;a release paper receiving module can receive no-adhesive release paper led out of the double-sided adhesive tape attaching module; a turning roller is rotationally installed on a rack; double-sided adhesive tape led out of a face adhesive feeding module is turned through the turning roller; one side of double-sided adhesive tape release paper tightly adheres to the surface of the turning roller; aknife edge of a cutting knife installed on the rack in a linear sliding manner can cut off the adhesive face of the double-sided adhesive tape on the surface of the turning roller; a horizontal slider slides along a straight line and is positioned on the rack; a head portion is installed on the lower side of the horizontal slider in a rising and falling manner; an attaching roller is installed onthe head portion; the double-sided adhesive tape led out of the position of an adhesive face cutting device is turned through the attaching roller and then is led out of the head portion; and a clamping mechanism can lamp the release paper turned through the attaching roller. The paperboard adhesive adhering mechanism achieves that the double-sided adhesive tape is pulled at fixed length and is subjected to adhesive adhering at fixed length, the adhesive adhering speed is high, the adhesive adhering position is accurate, and subsequent paper box accurate forming is facilitated.

Owner:昆山谛镨科自动化科技有限公司

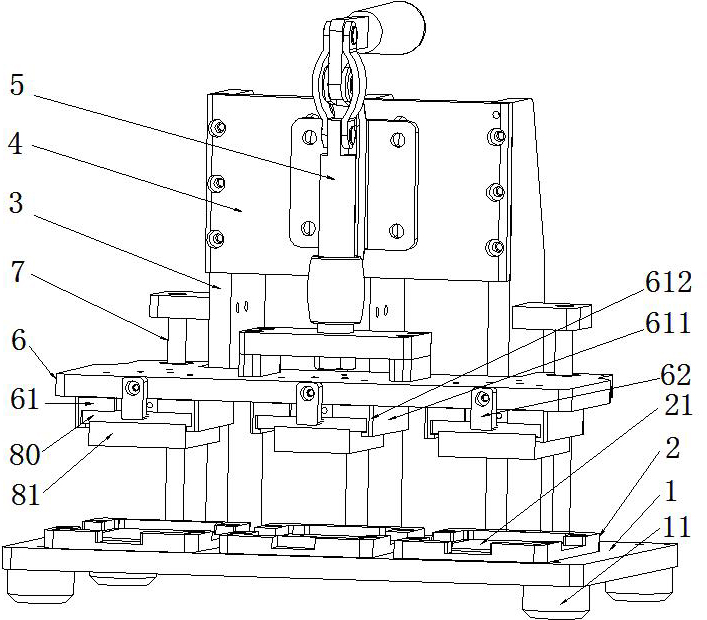

Evaporator gluing locating tool and evaporator carrying device

PendingCN111842055AImprove consistencyAvoid churnLiquid surface applicatorsCoatingsAdhesive glueMechanical engineering

The invention relates to an evaporator gluing locating tool and an evaporator carrying device, belongs to the technical field of air conditioner manufacturing and solves a technical problem that the existing evaporator has deviation in gluing and glue loses when a product is moved and the glue is not solidified. The evaporator gluing locating tool comprises a support component and a fixed component, the fixed component can be connected on a board carrying the evaporator, and the support component is connected on the fixed component and used for supporting and locating the evaporator; and the evaporator carrying device comprises a board body, a block body and the evaporator gluing locating tool, the evaporator gluing locating tool and the block body both are mounted on the board body, and the block body is located at a lateral of the evaporator gluing locating tool so as to limit the carried evaporator. The evaporator gluing locating tool can locate the evaporator thereon and fix position of the evaporator while gluing, thus, accurate locating gluing is realized, and without manual movement, gluing can be completed directly on a carrying line, so, loss of glue during movement can beavoided.

Owner:GREE ELECTRIC APPLIANCES WUHAN +1

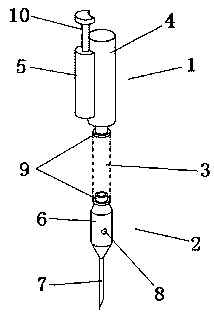

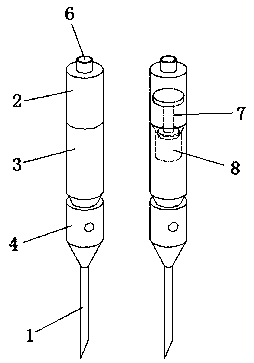

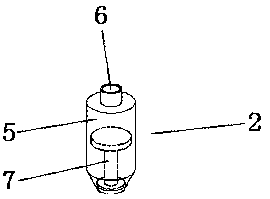

Pneumatic glue injecting pen for guitar machining

InactiveCN108906520ASimple structureEasy to holdLiquid surface applicatorsCoatingsAir compressionEngineering

The invention discloses a pneumatic glue injecting pen for guitar machining. The pneumatic glue injecting pen for guitar machining comprises a pen body and a glue injecting needle; the pen body comprises an air compression section, a glue storage section and a switch section connected in sequence; the glue injecting needle is connected with the switch section; the air compression section comprisesa compression bin; an inflation port is formed in the upper end of the compression bin; an air pressure piston is arranged in the compression bin; the air pressure piston consists of an upper end piston head, a connecting rod and a lower end piston head; a funnel pipe is arranged in the glue storage section; the funnel pipe corresponds to the lower end piston head of the air pressure piston in size; the lower end of the glue storage section is connected with the switch section through the connecting pipe; and a glue injecting switch is arranged on the switch section. The pneumatic glue injecting pen for guitar machining is simple in structure, convenient to hold by a hand, convenient to use, easy to control the gluing quantity, uniform in gluing and accurate in gluing position, and improves the guitar gluing quality.

Owner:正安索尔乐器文化发展有限公司

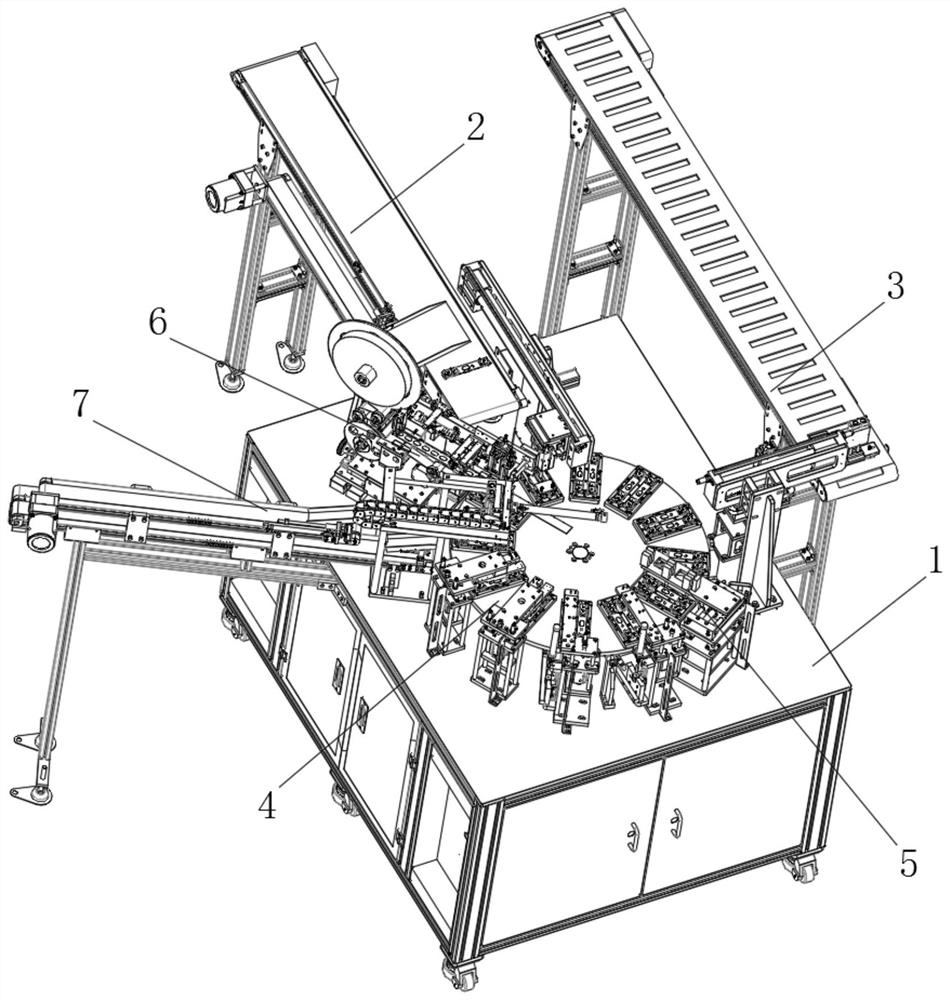

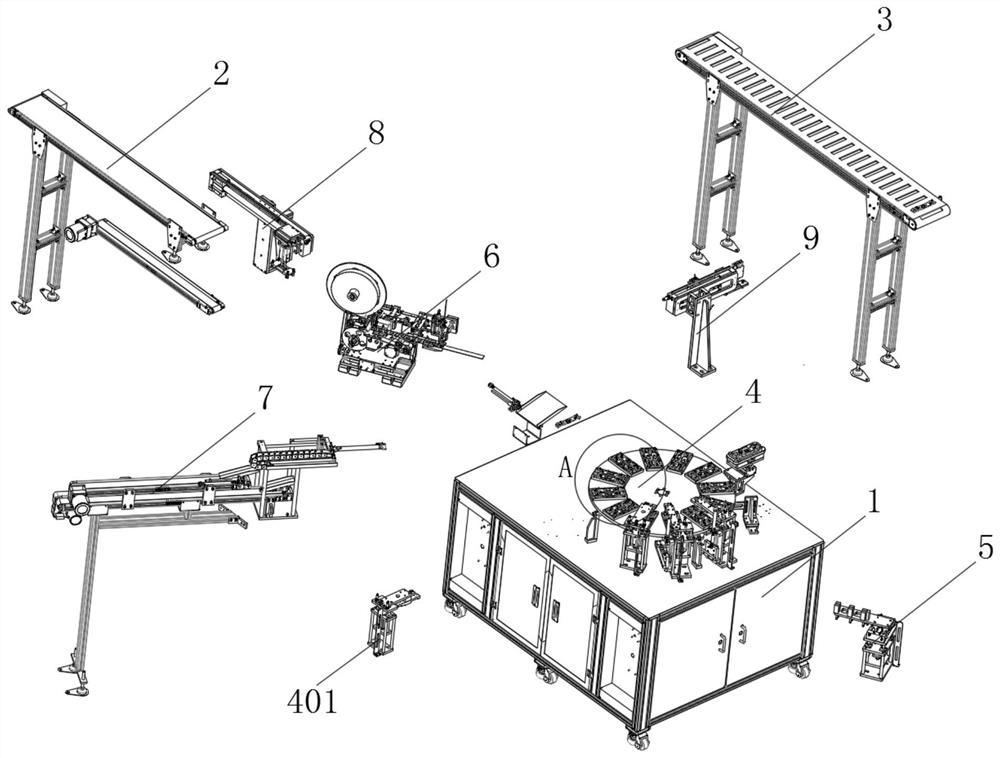

A self-feeding high-efficiency environmental protection paper bag pasting and pulling machine

ActiveCN110328895BIncrease capacityEasy to fixBag making operationsPaper-makingElectric machineryProcess engineering

The invention discloses an efficient and environment-friendly paper bag handle-adhering machine capable of automatically feeding. The machine comprises a supporting table, a bag feeding disc, a handlefeeding platform, a working disc, a glue coating plate and a pressing seat, wherein the upper end face of the supporting table is horizontally provided with the working disc, and the working disc isof a circular structure. The invention has the beneficial effects that a first conveying belt of the bag feeding disc can be used for synchronously placing multiple paper bags for delivery, and is matched with a plurality of falling and mounting seats of identical radians on the edge of the working disc to load the paper bags, thus improving accommodating capability of the handle-adhering machineto simultaneously perform handle-adhering processing on the paper bags; and meanwhile, the paper bags are clamped in a clamping groove for handle-adhering processing, two baffle blocks at the two endsof the clamping groove are matched to clamp the paper bags, so that the paper bags can be stably and firmly fixed, thus ensuring that the positions during paper bag gluing, handle adhering and flattening are more accurate so as to improve the paper bag processing quality of the handle-adhering machine; and finally, a fifth motor sleeves on three second sleeve columns to drive a glue box to move front and back for adjustment, thus ensuring the gluing position to the paper bags is more accurate.

Owner:NINGBO FEIHONG STATIONERY

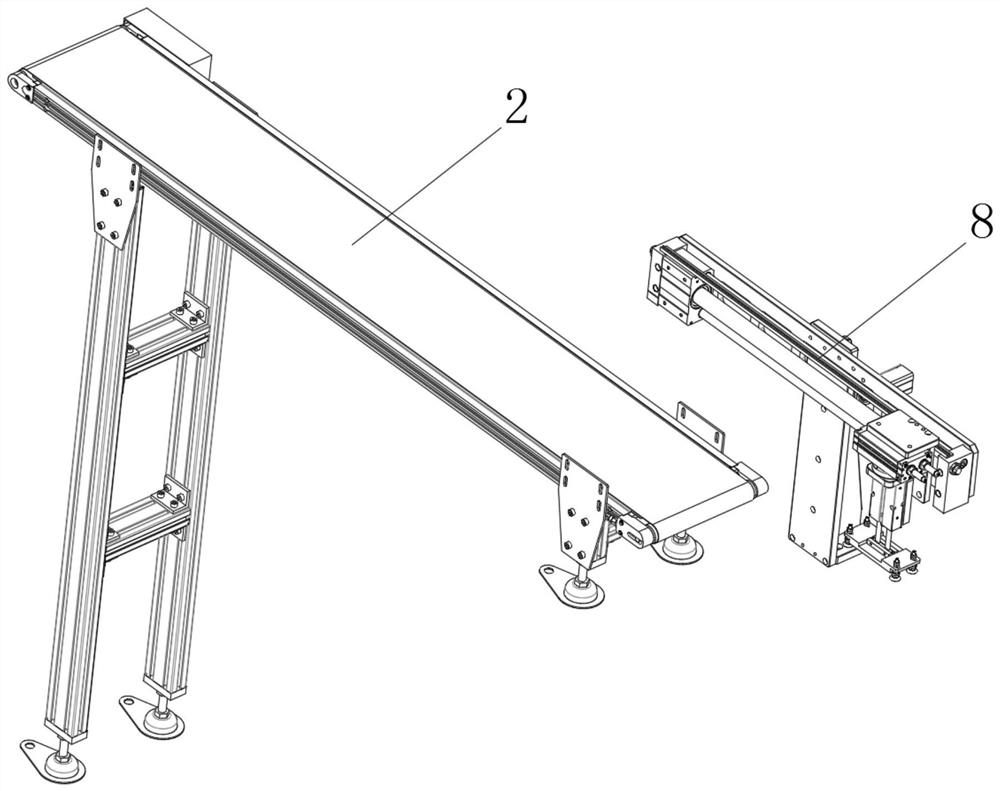

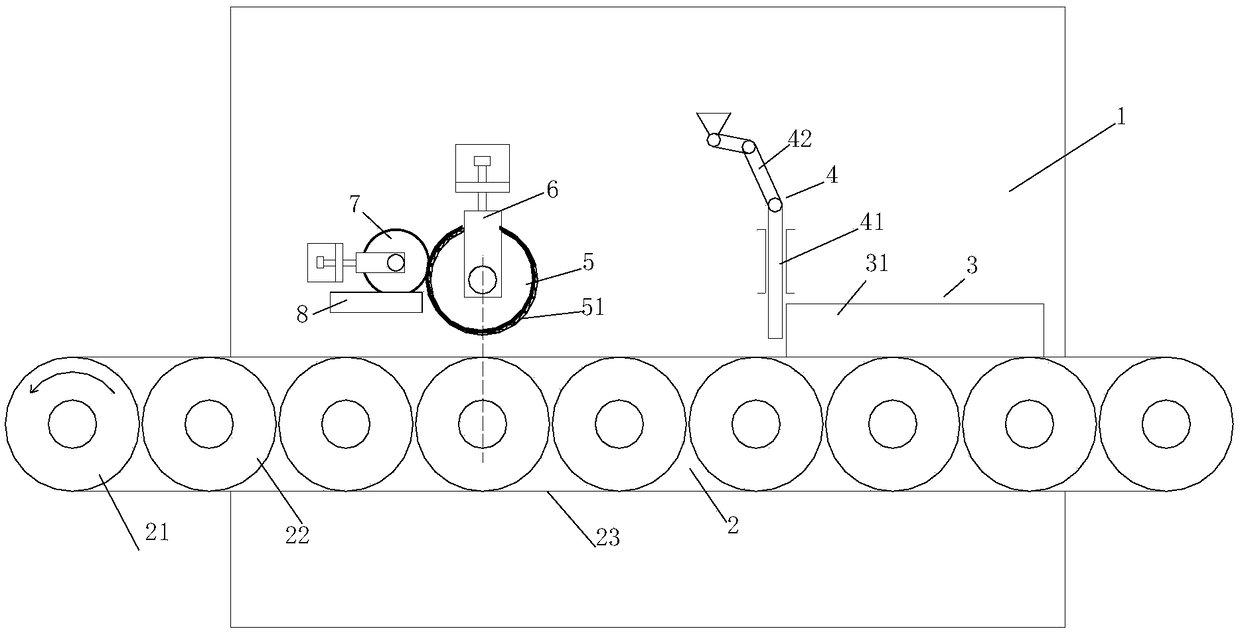

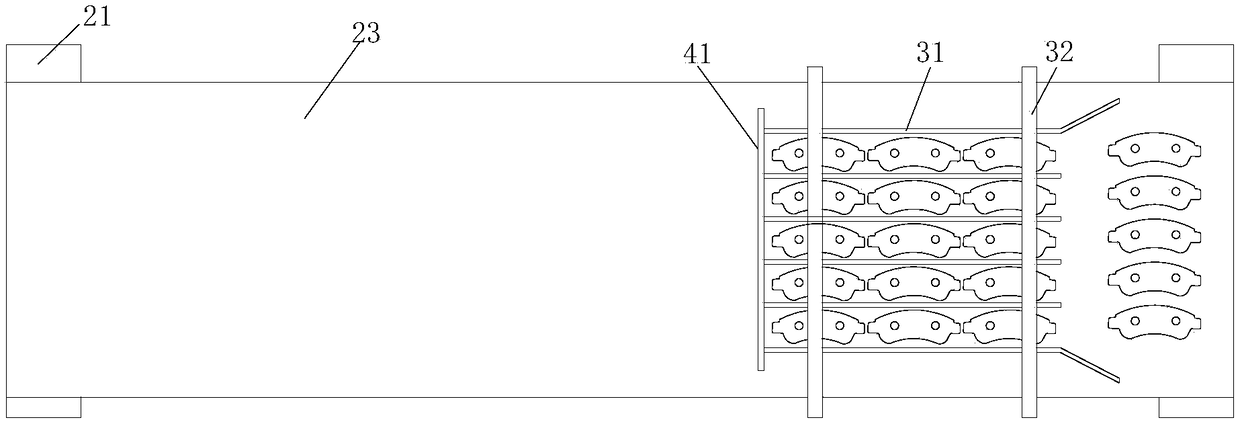

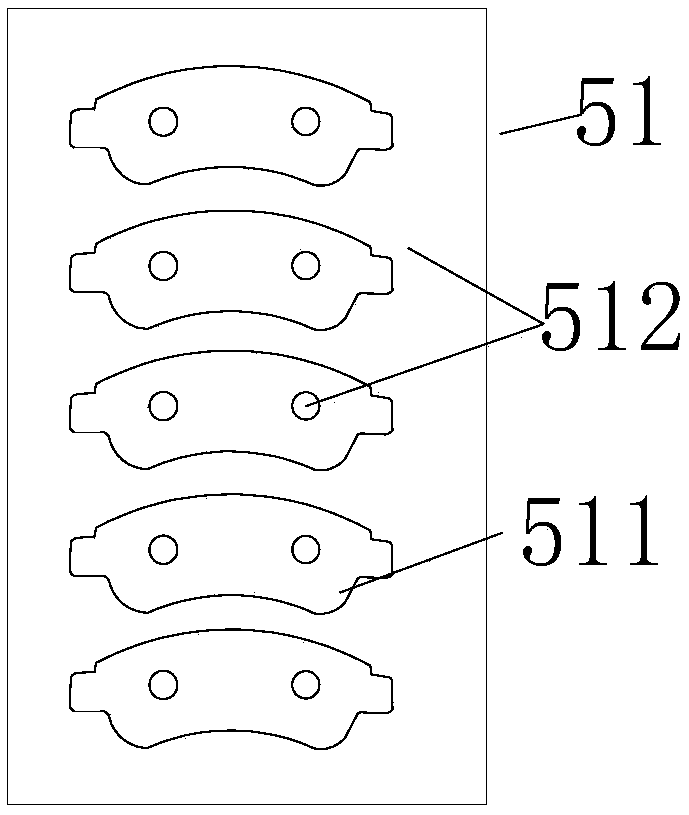

Steel back gluing device for brake clutch plate production

InactiveCN108745763AAchieve productionIncrease productivityLiquid surface applicatorsCoatingsEngineeringTransfer mechanism

The invention discloses a steel back gluing device for brake clutch plate production. The steel back gluing device comprises a rack, a transfer mechanism, a guide plate mechanism, a first rubber roller, a second rubber roller and a glue storage hopper, wherein the guide plate mechanism can be used for clearing up steel backs which are arranged disorderly on a conveyor belt, so that the steel backsare linearly and regularly arranged; a printing area and a non-printing area are arranged on first roller silica gel on the first rubber roller; after the first roller silica gel plane is expanded, the shape of the printing area is matched with glued surfaces of the steel backs; when the printing area glues the steel backs, only the printing area of the first rubber roller is in contact with theupper surfaces of the steel backs, and connecting through holes which do not need to glue in the steel backs are not in contact with the printing area on the first roller silica gel, so that product scrap due to the fact that the connecting through holes which do not need to glue in the steel backs are stained with glue can be prevented, and glue also can be saved. Therefore, the invention provides the steel back gluing device for the brake clutch plate production, and the steel back gluing device is uniform in gluing, is accurate in gluing position, saves glue usage amount and is convenient to use.

Owner:ANHUI GUIDA AUTO PARTS

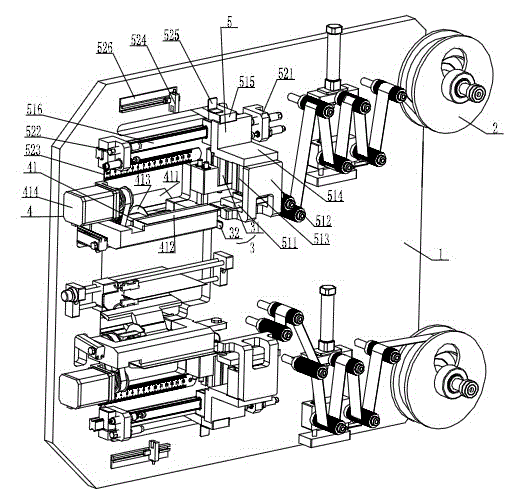

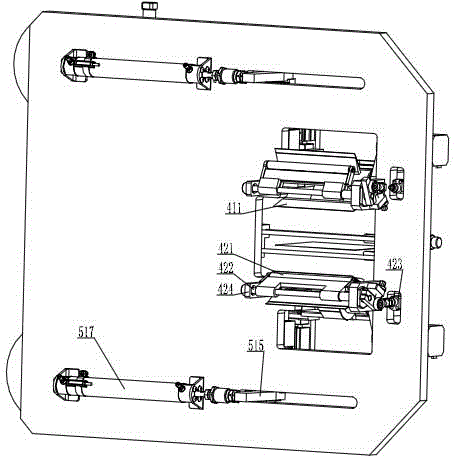

Automatic cutting and rubberizing machine

ActiveCN106626686AReduce usage requirementsRealize the way of workingLamination ancillary operationsLaminationEngineeringManipulator

The invention discloses an automatic cutting and rubberizing machine, which comprises a rack, a bearing platform, a rubberizing manipulator, and at least one cutter, wherein the cutter comprises a fixed base plate, an adhesive film-conveying mechanism, and an adhesive film-cutting mechanism, the fixed base plate is arranged on the rack, the adhesive film-conveying mechanism and the adhesive film-cutting mechanism are both arranged on the fixed base plate, the adhesive film-conveying mechanism conveys a to-be-cut strip-shaped adhesive film into the adhesive film-cutting mechanism, the adhesive film-cutting mechanism cuts out sheet adhesive films from the strip-shaped adhesive film, and the adhesive film-conveying mechanism rolls the strip-shaped adhesive film cut by the adhesive film-cutting mechanism; the bearing platform is arranged on the rack, to-be-rubberized products are borne by the bearing platform, and the bearing platform can drive the borne products to move; and the rubberizing manipulator attaches the sheet adhesive films at preset positions on the products. The automatic cutting and rubberizing machine disclosed by the invention can implement automatic cutting and rubberizing, and has the advantages of high rubberizing speed, manual operation replacement, production cost reduction and accurate rubberizing position.

Owner:SHENZHEN ZHENQIN ELECTRONICS TECH

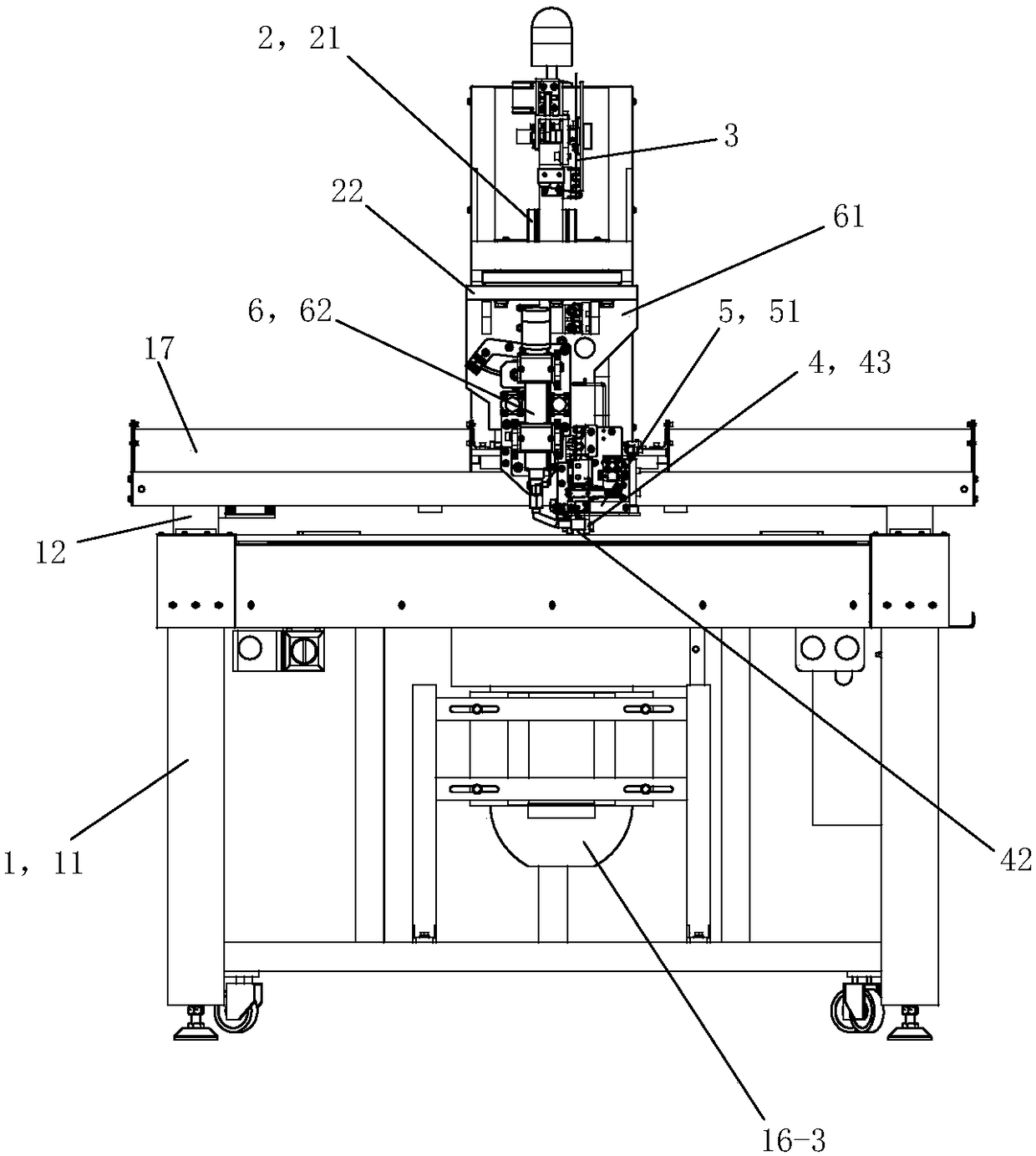

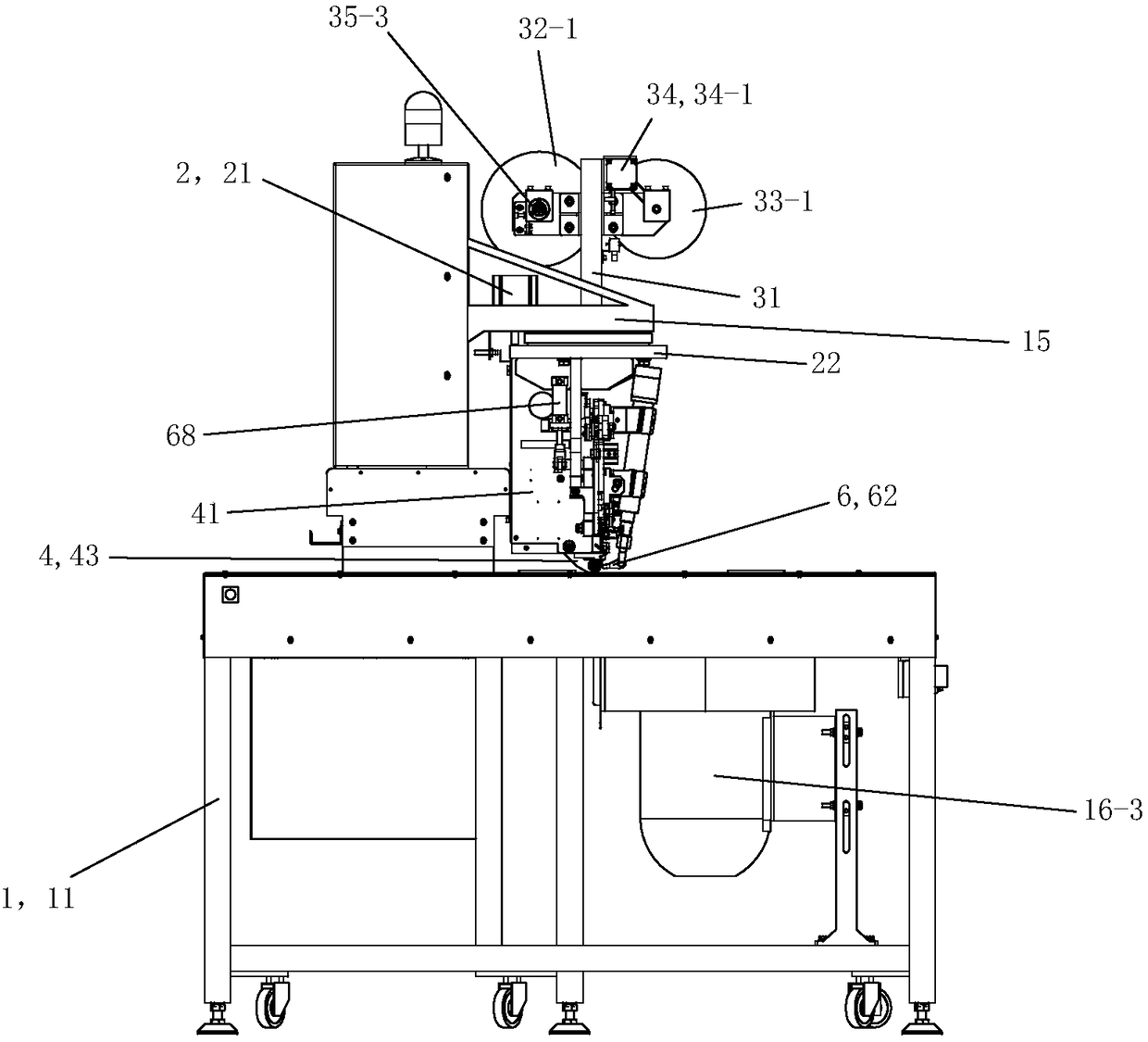

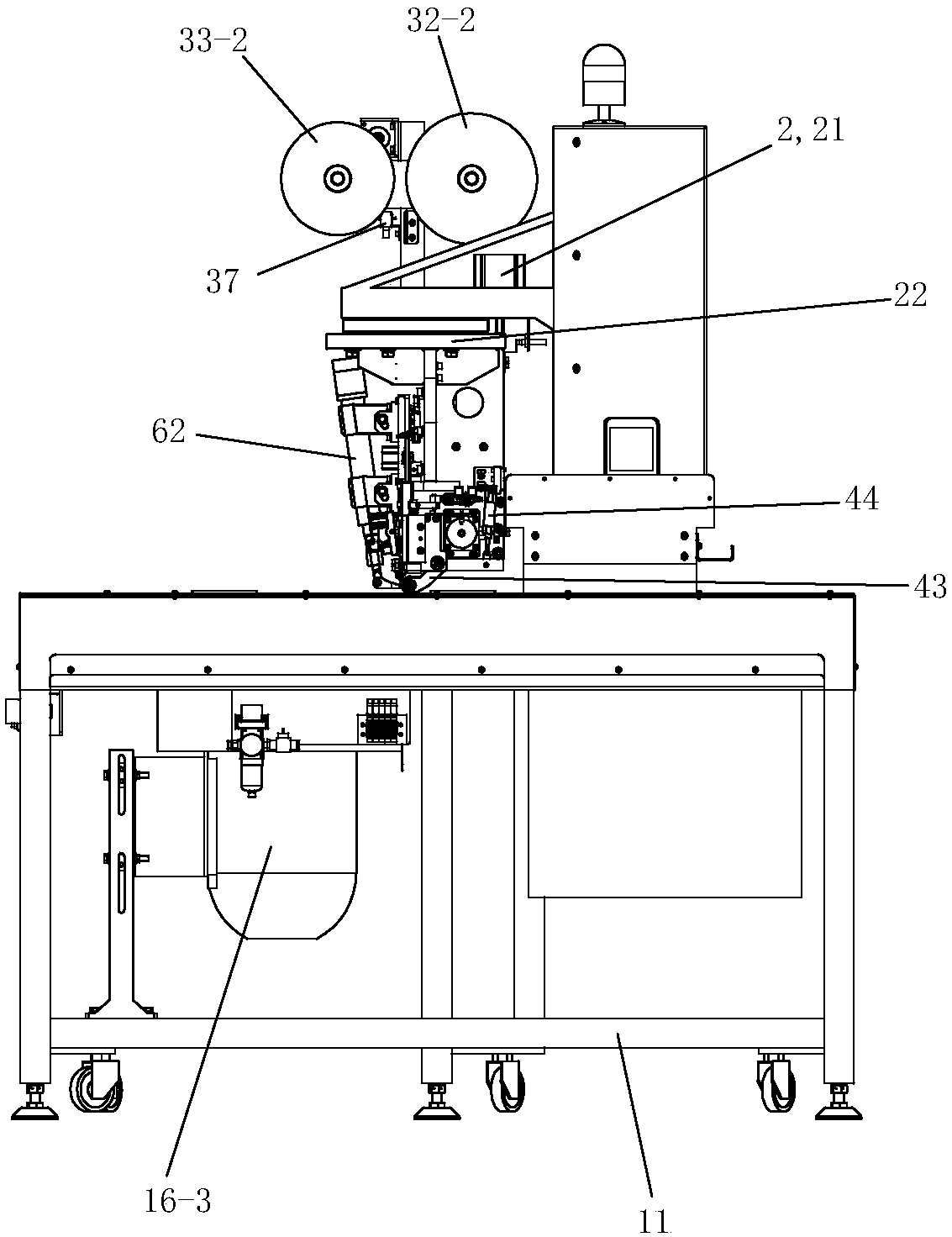

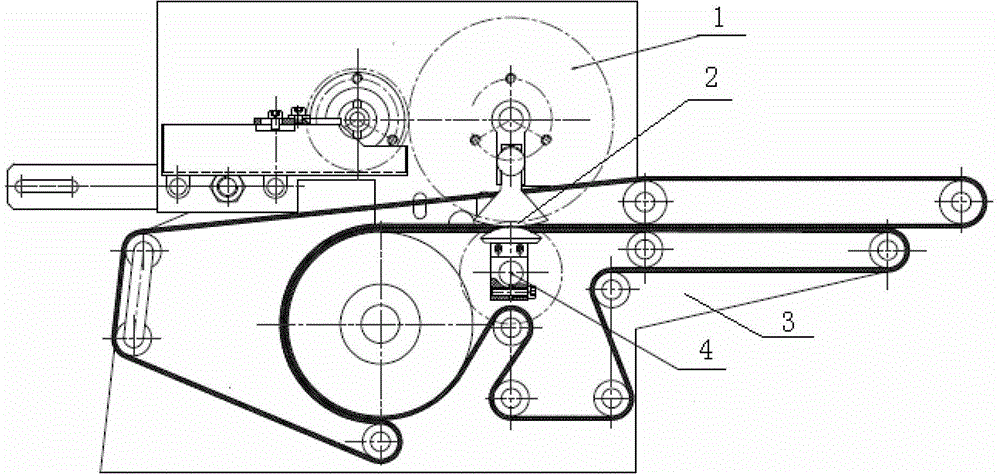

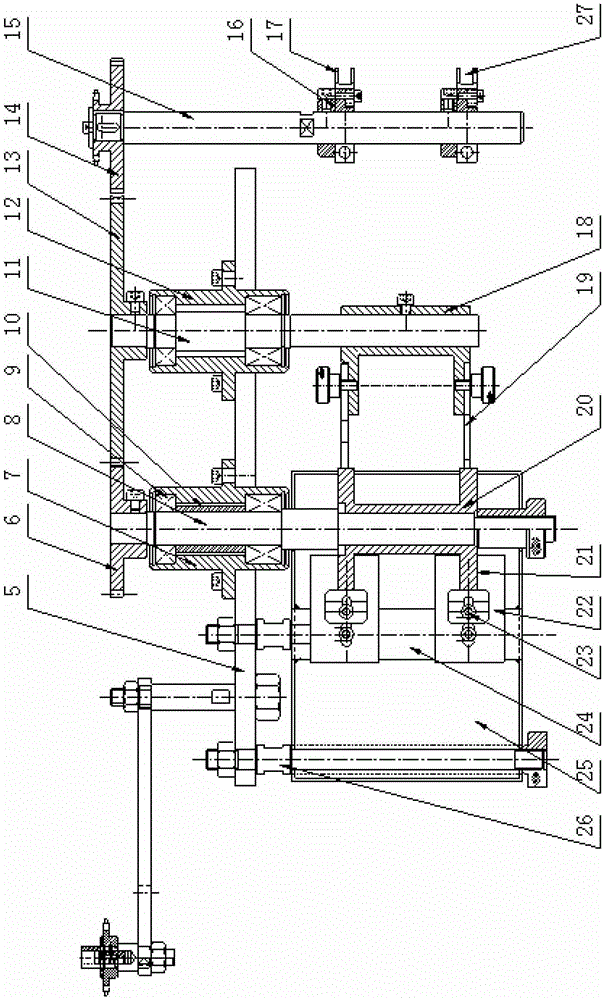

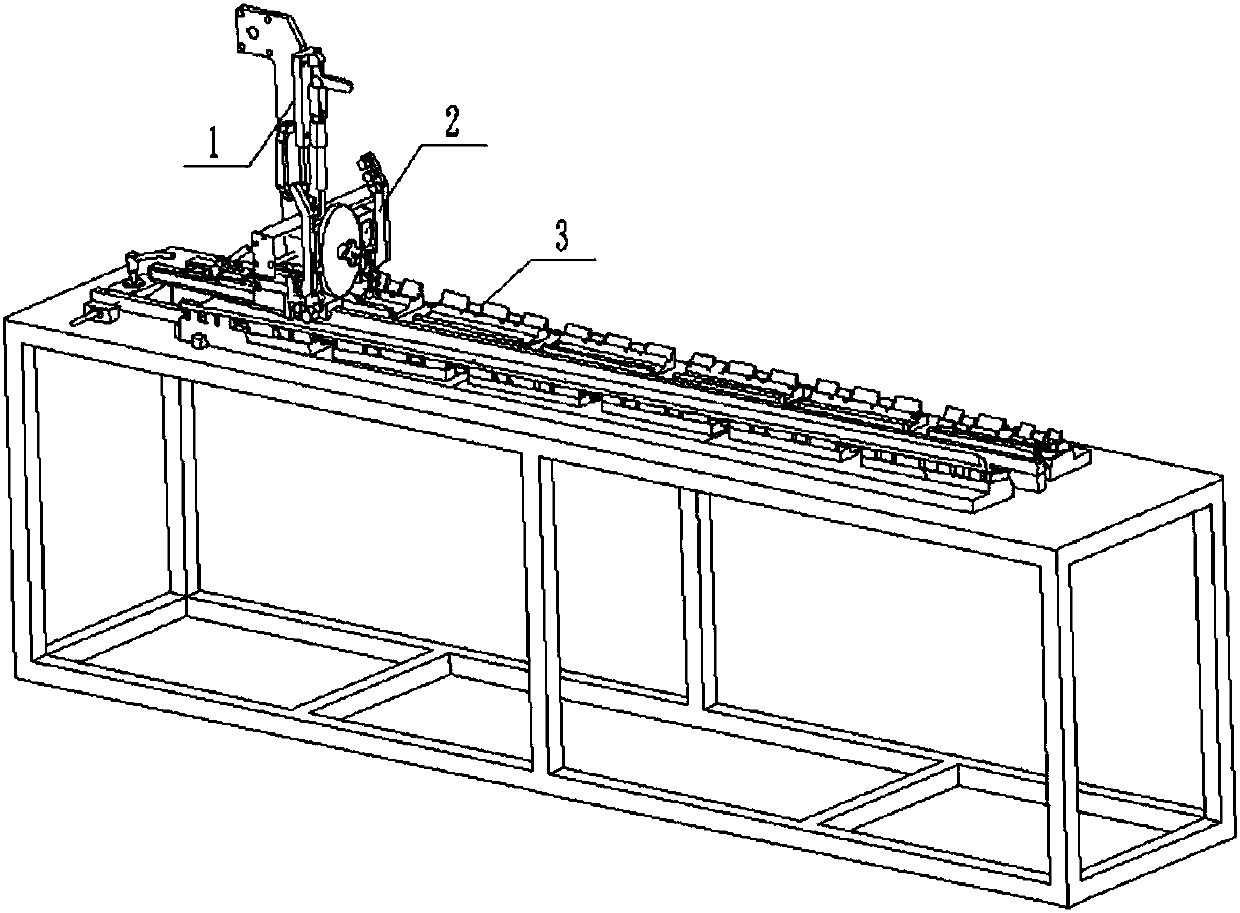

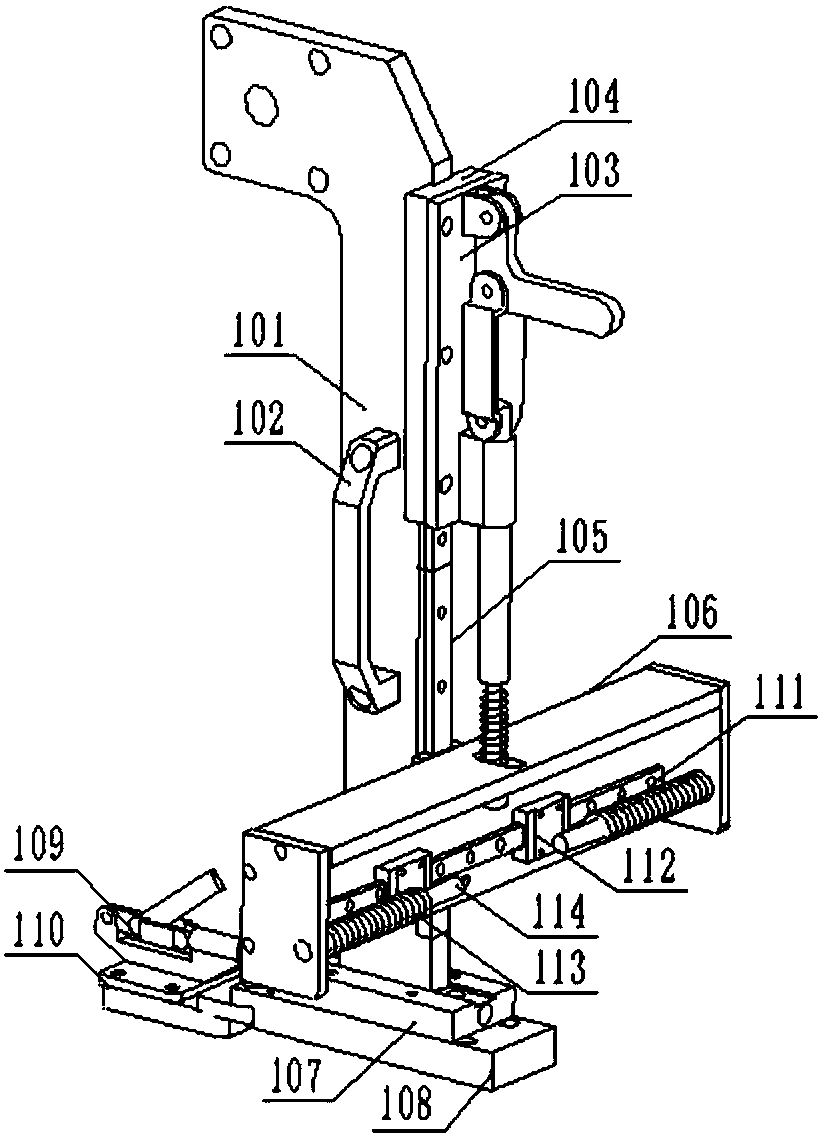

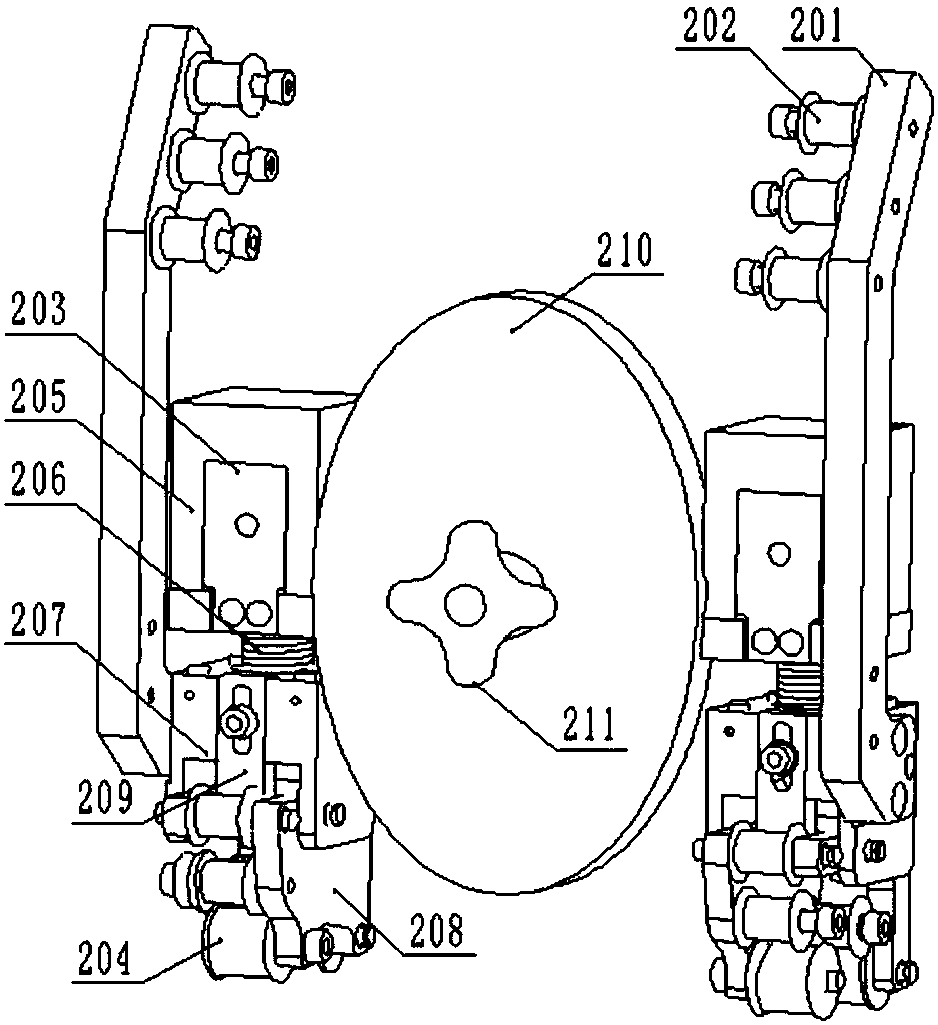

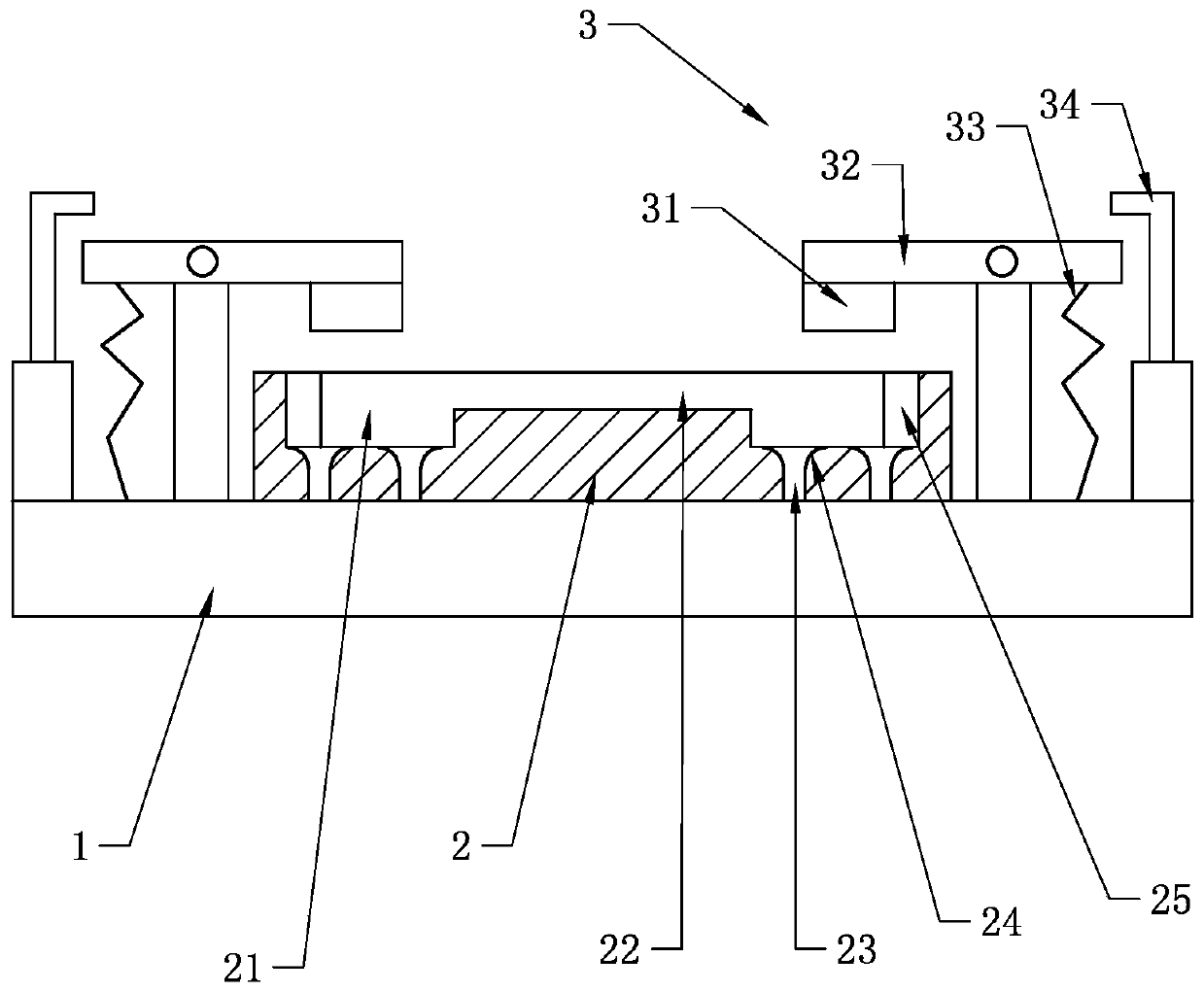

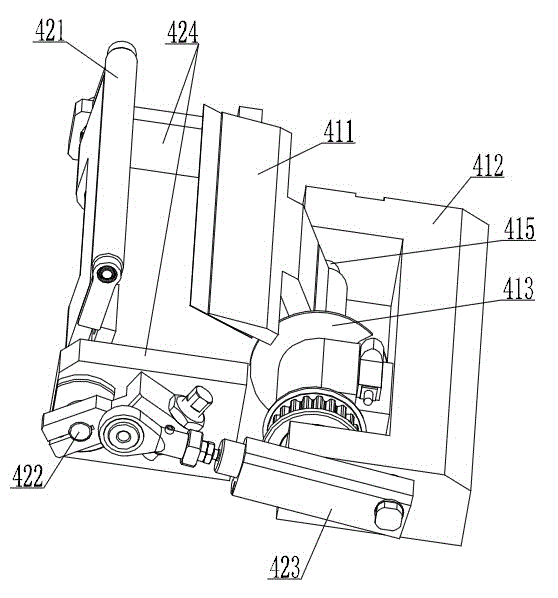

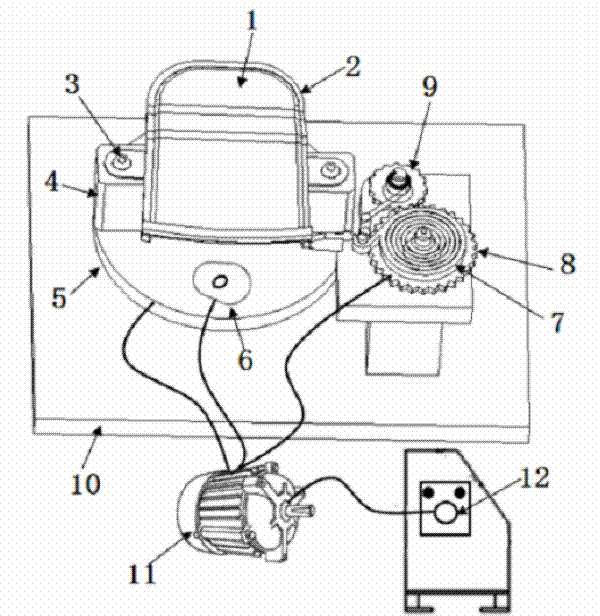

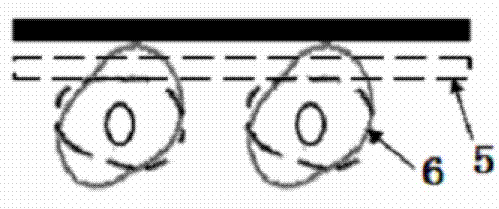

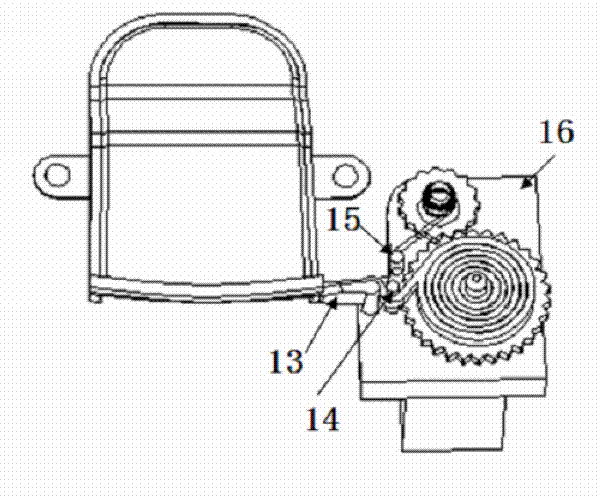

Hot melt sticking machine

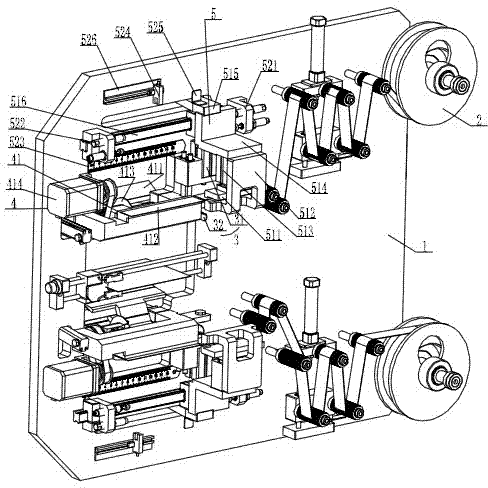

A hot-melt tape affixing machine, comprising a workbench (1), an adjustment component (2), a feeder apparatus (3), a press roller apparatus (4), a shearing apparatus (5), and an air heating apparatus (6). The workbench comprises a machine frame (11), a first movable gantry (12), a forward / rearward traveling mechanism (13), a leftward / rightward traveling mechanism (14), and a second mounting hanger (15). The movable gantry is arranged on the machine frame via the forward / rearward traveling mechanism. The second mounting hanger is arranged on the first movable gantry via the leftward / rightward traveling mechanism. The feeder apparatus, the press roller apparatus, and the air heating apparatus are rotatably arranged on the second mounting hanger via the adjustment component. The hot-melt tape affixing machine increases the degree of automation and increases production efficiency.

Owner:CHANGZHOU ZHIGU ELECTROMECHANICAL TECH CO LTD

Glue rolling device of cigarette hard case packaging machine

InactiveCN102886921BThe position of the glue line is accurateEasy to addBox making operationsPaper-makingEngineeringCoating

The invention relates to a glue rolling device of a cigarette hard case packaging machine. The glue rolling device is characterized by comprising a glue rolling mechanism; the glue rolling mechanism mainly consists of a wall board, a glue box, a first shaft rack, a gluing shaft, a gluing wheel, a small gear, a second shaft rack, a glue rolling shaft, a glue rolling sheet and a large gear; the first shaft rack and the second shaft rack are fixedly mounted on the wall board in parallel; the gluing shaft is rotatably mounted on the first shaft rack; a small shaft gear is coaxially and fixedly mounted at the back part of the coating shaft; the gluing wheel is fixedly mounted at the front part of the gluing shaft; the glue rolling shaft is rotatably mounted on the second shaft rack; the large gear engaged with the small gear is coaxially and fixedly mounted at the back part of the glue rolling shaft; the front part of the glue rolling shaft is fixedly connected with the glue rolling sheet corresponding to the gluing wheel in position; and the glue box at the lower part of the coating wheel is fixedly mounted on a nesting board. The glue rolling device of the cigarette hard case packaging machine provided by the invention has the advantages that the structure is compact, the transmission is stable and reliable, the glue coating position is accurate, simplicity and the glue can be added simply and conveniently, the installation is simple, the glue can be effectively prevented from leakage, and glued glue films are can be consistent in thickness.

Owner:天津市茂林烟机配件开发有限公司

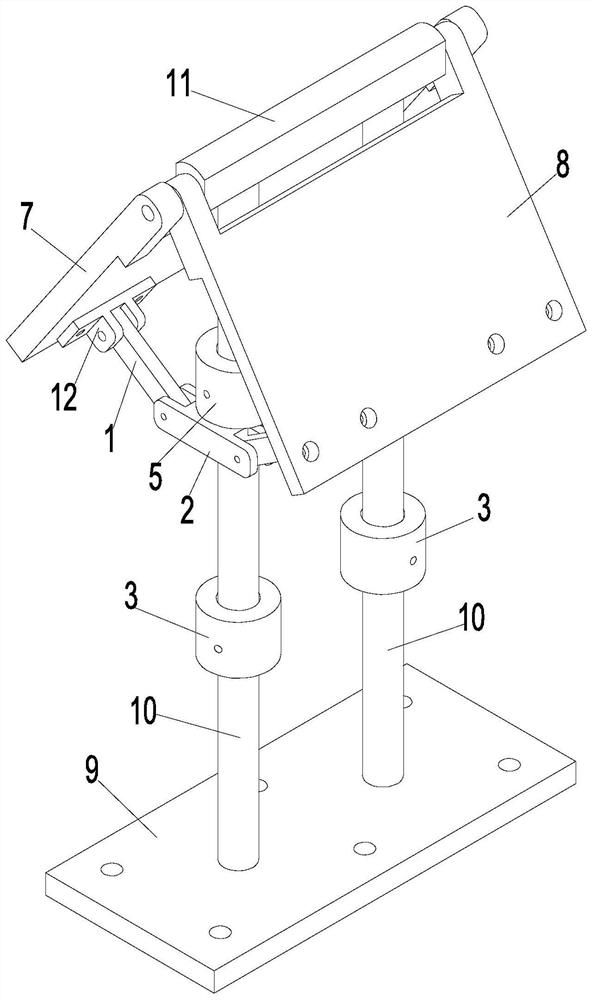

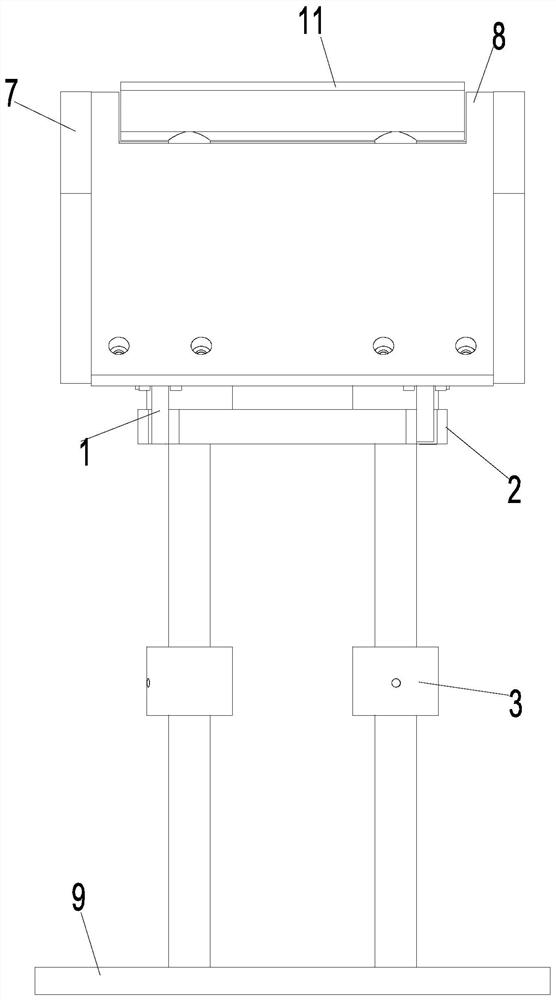

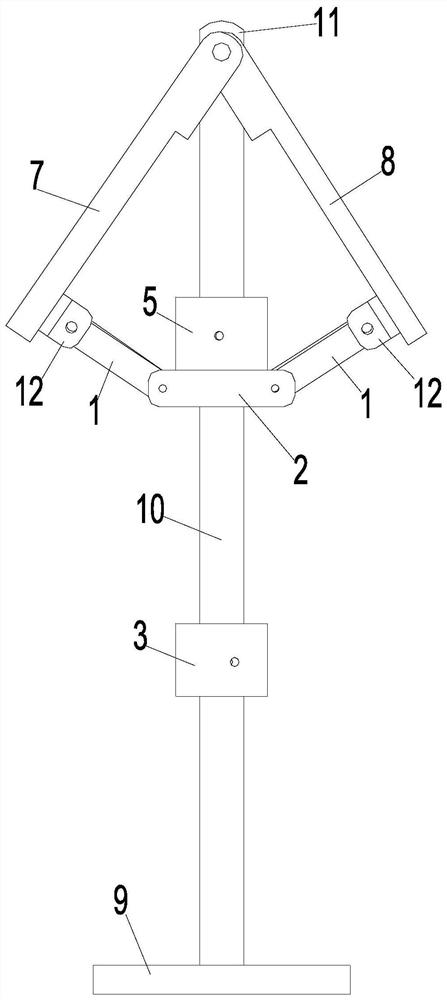

Automatic gluing jig for automobile side skirt inner plate

InactiveCN110578739AReduce equipmentGlue position is accurateMaterial gluingEngineeringPosition error

Owner:CHANGCHUN BORU ELECTRIC EQUIP CO LTD

Bonding tooling for a bread machine

Owner:JIANGMEN KANGBAISHI ELECTRICALS CO LTD

Automatic cutting and gluing machine

ActiveCN106626686BReduce usage requirementsRealize the way of workingLamination ancillary operationsLaminationEngineeringManipulator

The invention discloses an automatic cutting and rubberizing machine, which comprises a rack, a bearing platform, a rubberizing manipulator, and at least one cutter, wherein the cutter comprises a fixed base plate, an adhesive film-conveying mechanism, and an adhesive film-cutting mechanism, the fixed base plate is arranged on the rack, the adhesive film-conveying mechanism and the adhesive film-cutting mechanism are both arranged on the fixed base plate, the adhesive film-conveying mechanism conveys a to-be-cut strip-shaped adhesive film into the adhesive film-cutting mechanism, the adhesive film-cutting mechanism cuts out sheet adhesive films from the strip-shaped adhesive film, and the adhesive film-conveying mechanism rolls the strip-shaped adhesive film cut by the adhesive film-cutting mechanism; the bearing platform is arranged on the rack, to-be-rubberized products are borne by the bearing platform, and the bearing platform can drive the borne products to move; and the rubberizing manipulator attaches the sheet adhesive films at preset positions on the products. The automatic cutting and rubberizing machine disclosed by the invention can implement automatic cutting and rubberizing, and has the advantages of high rubberizing speed, manual operation replacement, production cost reduction and accurate rubberizing position.

Owner:SHENZHEN ZHENQIN ELECTRONICS TECH

Plywood glue coating device

The invention discloses a plywood glue coating device and belongs to the technical field of plywood glue coating. The problems that glue coating in the prior art is not uniform, and the glue coating amount cannot be controlled are solved. The plywood glue coating device comprises a support, a glue coating machine and a supporting table; the glue coating machine is composed of a glue coating support and a glue coating box; the glue coating box is provided with an atomizer which is connected with a glue storing box in the glue coating box through a pipeline; and a water pump is arranged betweenthe atomizer and the glue storing box. The plywood glue coating device can be used for plywood glue coating.

Owner:连云港森福木业有限公司

Glue sticking device and sticking method

The invention discloses a gluing device. The gluing device comprises a gluing mechanism. The gluing mechanism comprises gluing rollers and movable gluing plates opposite to the gluing rollers. The movable gluing plates are used for transferring a glue tape towards a pole piece. The gluing rollers cooperate with the movable gluing plates and evenly rolling-paste the glue tape on the pole piece. The invention also discloses a gluing method utilizing the gluing device. The gluing rollers are used for gluing and can evenly rolling-paste the glue tape on the pole piece along with pole piece feeding without bubble and fold production.

Owner:SHENZHEN YINGHE TECH

Automatic gluing machine

InactiveCN104742483AImprove efficiencyHigh precisionLamination ancillary operationsLaminationBall bearingPaper tape

The invention relates to an automatic gluing machine for automatically gluing products. A base is connected with a rotating disk, a magnetic benchmark base is arranged on the rotating disk, the rotating disk is connected with a motor, a cam at the lower part of the rotating disk is connected with the motor, an adhesive tape is arranged on an adhesive tape roll gear plate which is connected with the motor, an isolation paper tape roll gear plate is meshed with the adhesive tape roll gear plate, two guiding posts are respectively closely matched with a ball bearing guide bushing, the ball bearing guide bushing is arranged on a support block, the two guiding posts and the isolation paper tape roll gear plate are driven by the adhesive tape roll gear plate, the guiding post I and the guiding post II are connected with the adhesive tape and isolation paper, respectively, the adhesive tape roll gear plate and the isolation paper tape roll gear plate are fixed on the support block on the base, a gluing contact is connected with the support block, the adhesive tape is connected onto the gluing contact, the adhesive tape is glued on a product by the gluing contact, and a controller is connected with the motor. The automatic gluing machine is quick and stable in location, saves time for locating a product artificially, can ensure accurate gluing positions, and can effectively ensure the gluing precision and stability of products and improve the gluing efficiency.

Owner:XIANGYANG SUNRISE MACHINERY

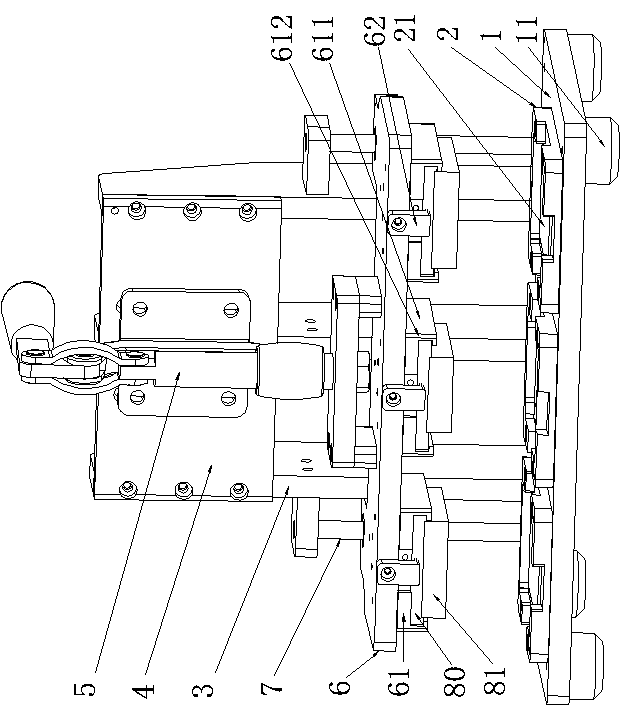

Lithium battery pole piece rubberizing tool

ActiveCN113422099ASure easyGlue position is accurateAssembling battery machinesFinal product manufactureEngineeringPole piece

The invention relates to a lithium battery rubberizing tool which comprises a rubberizing part, a reference part and a connecting part, and the rubberizing part is connected with the reference part through the connecting part. The length of the reference part is larger than the width of the pole piece, a horizontal reference line is arranged on the surface of one end, away from the connecting part, of the reference part, a vertical reference line is arranged on the surface of the rubberizing part in the length direction, and the horizontal reference line is perpendicular to the vertical reference line. After the lithium battery pole piece rubberizing tool is clamped into the pole piece, the lithium battery pole piece rubberizing tool moves to the position needing rubberizing along the pole piece, observation purely depends on naked eyes, the rubberizing position is easy to determine, deviation is avoided, the rubberizing position is accurate, the horizontal reference line and the vertical reference line serve as rubberizing references, rubberizing is not prone to inclination and the rubberizing precision is high compared with purely manual rubberizing, and meanwhile the rubberizing operation is simpler, and the rubberizing efficiency is improved.

Owner:SHANGHAI YUYUAN POWER TECH CO LTD

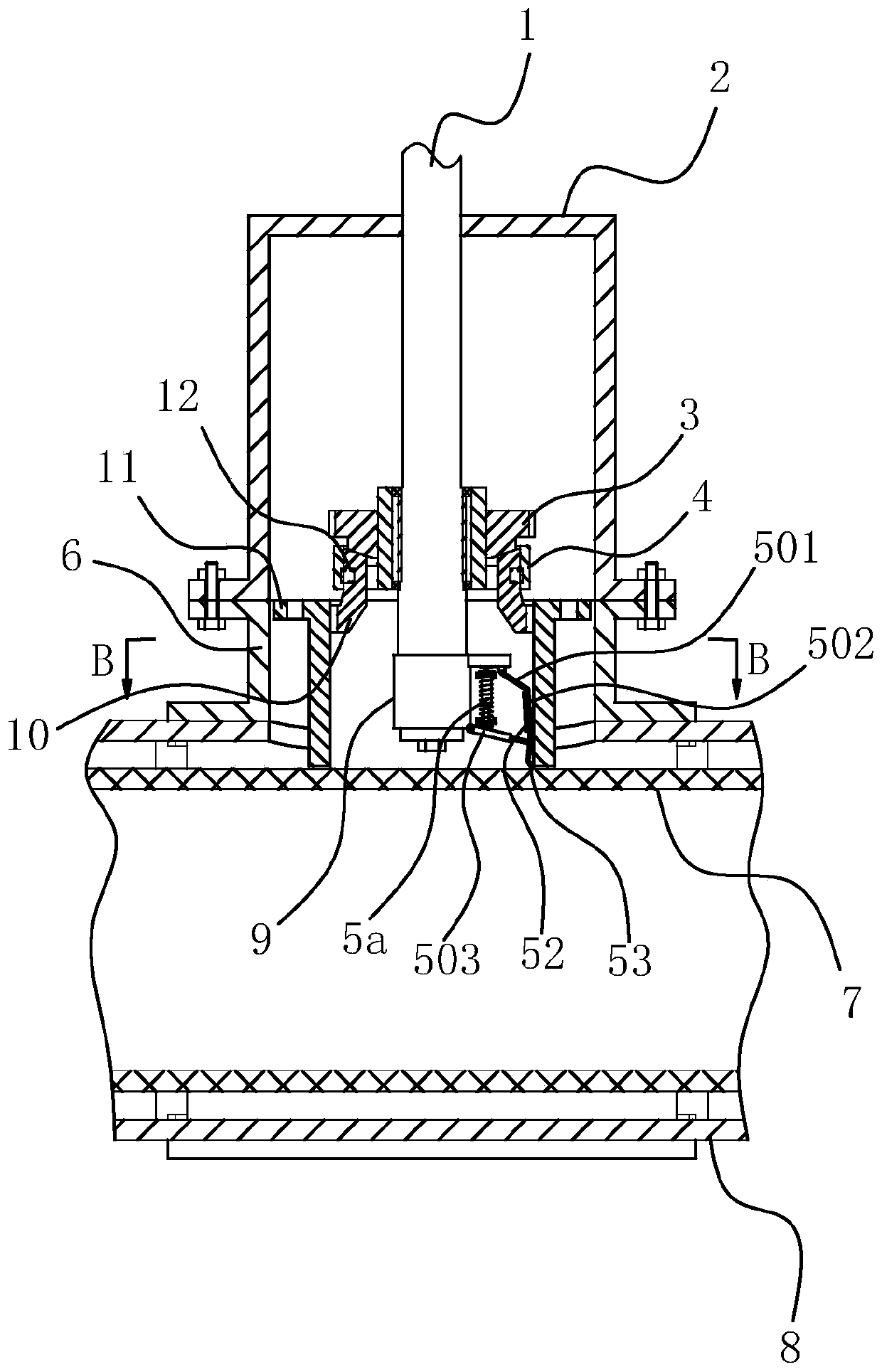

PE pipe fitting machining equipment

ActiveCN111545412AStable positionGuaranteed bonding effectLiquid surface applicatorsMaterial gluingPipe fittingDetent

The invention discloses PE pipe fitting machining equipment. The PE pipe fitting machining equipment comprises a locating seat used for locating an inner-layer flange and a rod body in axial running fit with the locating seat. The rod body penetrates through the locating seat and drives the locating seat to move in the radial direction of an inner-layer pipe of a dual-layer pipe fitting together with the inner-layer flange. A gluing locator is arranged at the lower end of the rod body and comprises a gluing gun and a connecting portion enabling the gluing gun to be in movable fit with the rodbody. The connecting portion comprises a middle connecting rod fixed with the gluing gun, an upper connecting rod rotationally connected with the upper end of the middle connecting rod and a lower connecting rod rotationally connected with the lower end of the middle connecting rod. The connecting portion locates the gluing gun to be in an inclined state, and when the rod body rotates relative tothe locating seat, the connecting portion drives the gluing gun to move up and down, so that a glue outlet of the gluing gun is aligned to the intersection of the inner-layer flange and the inner-layer pipe of the dual-layer pipe fitting. By means of the PE pipe fitting machining equipment, the mounting difficulty of the inner-layer flange is reduced, and the fixing effect of the inner-layer pipeand the inner-layer flange is guaranteed.

Owner:HUNAN HENGYUAN NEW MATERIAL TECH DEV CO LTD

Paper box rapid gluing and forming machine

ActiveCN111452427AReduce labor intensityHigh speedBox making operationsPaper-makingDrive wheelAdhesive belt

The invention relates to a paper box rapid gluing and forming machine. The paper box rapid gluing and forming machine comprises a machine shell, a gluing mechanism and a caterpillar track conveying mechanism, wherein the gluing mechanism comprises a driving wheel, a first track transfer wheel, a second track transfer wheel, a third track transfer wheel, a gluing belt and a plurality of gluing wheels, the driving wheel is connected with a transmission shaft of a first motor arranged in the machine shell, the first track transfer wheel, the second track transfer wheel, the third track transfer wheel and the gluing wheels are arranged on the outer wall of the machine shell, the first track transfer wheel is located over the driving wheel, the second track transfer wheel and the first track transfer wheel are located at the same horizontal position, the third track transfer wheel is located below the first track transfer wheel and the second track transfer wheel, and the gluing belt is connected with the driving wheel, the first track transfer wheel and the second track transfer wheel in a wrapping manner and bypasses the third track transfer wheel from top. The provided paper box rapid gluing and forming machine can replace manual gluing of paper boxes, the gluing speed is higher, and the labor intensity of workers can be reduced.

Owner:湖南中南金叶印务有限责任公司

PE pipe fitting processing equipment

ActiveCN111545412BStable positionGuaranteed bonding effectLiquid surface applicatorsMaterial gluingPipe fittingDouble-walled pipe

The invention discloses a PE pipe fitting processing equipment, which includes a positioning seat for positioning the inner flange and a rod body axially rotatable with the positioning seat. The rod body penetrates the positioning seat and drives the positioning seat together with the inner flange The radial movement of the inner tube of the double-layer pipe fitting, the lower end of the rod body is provided with a glue-coating locator, and the glue-coating locator includes a glue gun and a connecting part that movably cooperates the glue gun with the rod body, and the connecting part It includes a middle connecting rod fixed to the glue gun, an upper connecting rod rotatably connected to the upper end of the middle connecting rod, and a lower connecting rod rotatably connected to the lower end of the middle connecting rod. The connecting part positions the glue gun in an inclined state, so When the rod body rotates relative to the positioning seat, the connecting part drives the glue gun to move up and down so that the glue outlet of the glue gun is aligned with the junction of the inner flange and the inner pipe of the double-layer pipe fitting. The invention aims to provide a processing equipment for PE pipe fittings, which can reduce the installation difficulty of the inner flange and ensure the fixing effect of the inner pipe and the inner flange.

Owner:HUNAN HENGYUAN NEW MATERIAL TECH DEV CO LTD

A fpc surface glue device

ActiveCN111356293BImprove glue application efficiencyImprove efficiencyInsulating substrate metal adhesion improvementPrinted circuit secondary treatmentEngineeringGelatin

The invention discloses an FPC surface gluing device, comprising a mounting plate for positioning and installing a whole FPC board, and a flipping plate that is reversibly connected to the mounting plate and used for positioning and installing a PSA board, the mounting plate and The surface of the flipping plate is provided with a number of suction holes for negative pressure adsorption on the FPC board and the PSA board respectively, and the flipping plate is turned over until it is attached to the surface of the mounting plate. When making described PSA board and described FPC board stick. In this way, through the function of each suction hole, when the FPC board is installed on the surface of the installation board, the FPC board can be fully extended through the negative pressure suction to avoid curling and bending; at the same time, when the PSA board is installed on the surface of the flip board When it is on the surface, the surface of the PSA board can be kept flat by negative pressure suction to prevent bending and wrinkling. Therefore, the efficiency of gluing on the surface of the FPC can be improved, and at the same time, the bending and wrinkling of the PSA during the attaching process can be avoided to ensure that the gluing position is accurate.

Owner:GEER TECH CO LTD

A carton fast gluing forming machine

ActiveCN111452427BReduce labor intensityHigh speedBox making operationsPaper-makingAdhesive beltMolding machine

The invention relates to a carton rapid gluing forming machine, which includes a machine casing, a gluing mechanism and a chain rail transmission mechanism. The gluing mechanism includes a driving wheel, a first track changing wheel, a second track changing wheel, a third changing track track wheel, rubberized belt and several glued wheels, the driving wheel is connected with the drive shaft of the first motor arranged in the casing, the first track changing wheel, the second track changing wheel, the third track changing wheel The wheels and the gluing wheel are arranged on the outer wall of the casing, the first track changing wheel is located directly above the driving wheel, the second track changing wheel is at the same horizontal position as the first track changing wheel, and the third track changing wheel is located at the same level as the first track changing wheel Below the first track-changing wheel and the second track-changing wheel, the coated belt encloses the driving wheel, the first track-changing wheel, and the second track-changing wheel, and bypasses the third track-changing wheel from above. The invention provides a carton rapid gluing forming machine which can replace the manual gluing of the carton, has faster gluing speed and can reduce the labor intensity of workers.

Owner:湖南中南金叶印务有限责任公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com