Automatic gluing machine

A gluing machine and automatic technology, applied in the field of gluing of mechanical parts, can solve the problems of inaccurate gluing position, low efficiency of manual gluing, and affecting the stickiness of adhesive strips, so as to improve gluing efficiency and reduce human error factors , the effect of saving time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

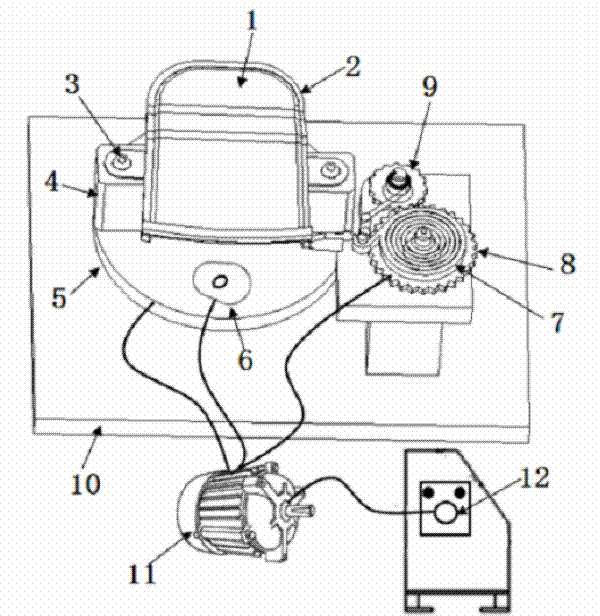

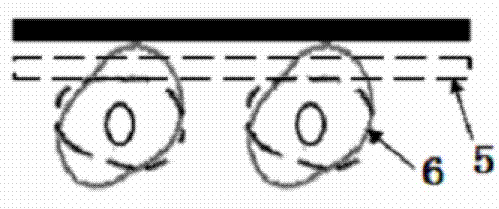

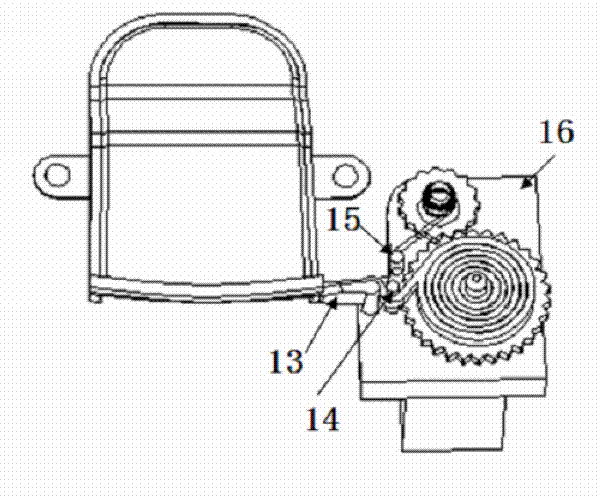

[0014] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, the base 10 is connected to the rotating disk 5, and the magnetic reference base 4 is installed on the rotating disk 5. The positioning pin 3 and the magnetic reference block 4 are interference fit, and the tapered part on the upper part of the positioning pin 3 is inserted into the hole of the product 1. The product 1 is adsorbed on the magnetic reference block 4 to ensure that the product 1 is accurately positioned on the positioning pin 3 . The rotating disk 5 is connected with the motor 11, and the motor 11 drives the rotating disk 5 to rotate 180 degrees. The cam 6 used to move the rotating disc 5 up and down is mounted on the lower part of the rotating disc 5. The cam 6 is connected to the motor 11. There can be three or more cams. The cam 6 can be replaced according to the shape of the rubber strip 7 to achieve sticking. The versatility of the rubber shape; the rubber strip 7 is installed on the ru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com