Patents

Literature

459results about How to "Improve gluing efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

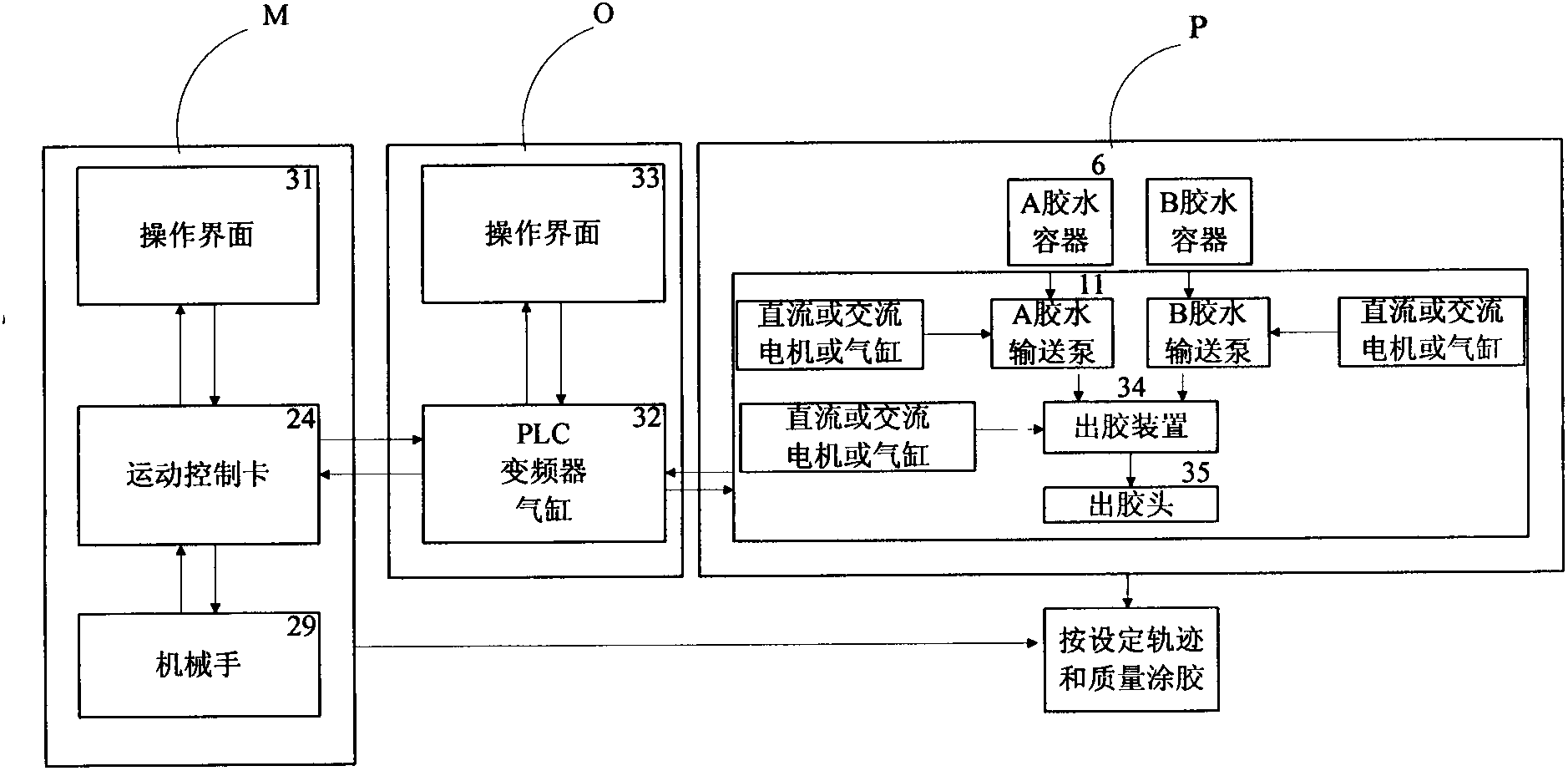

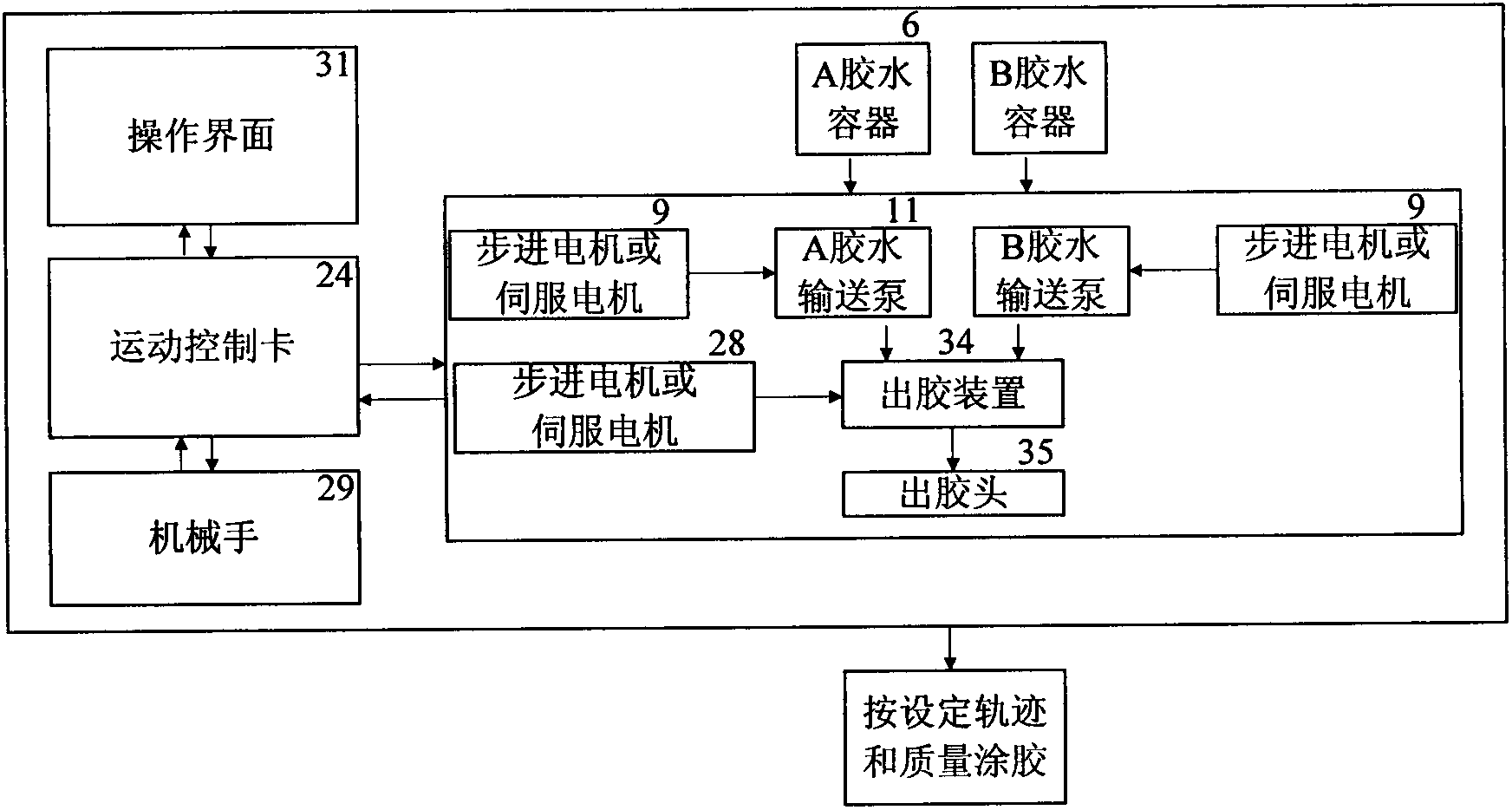

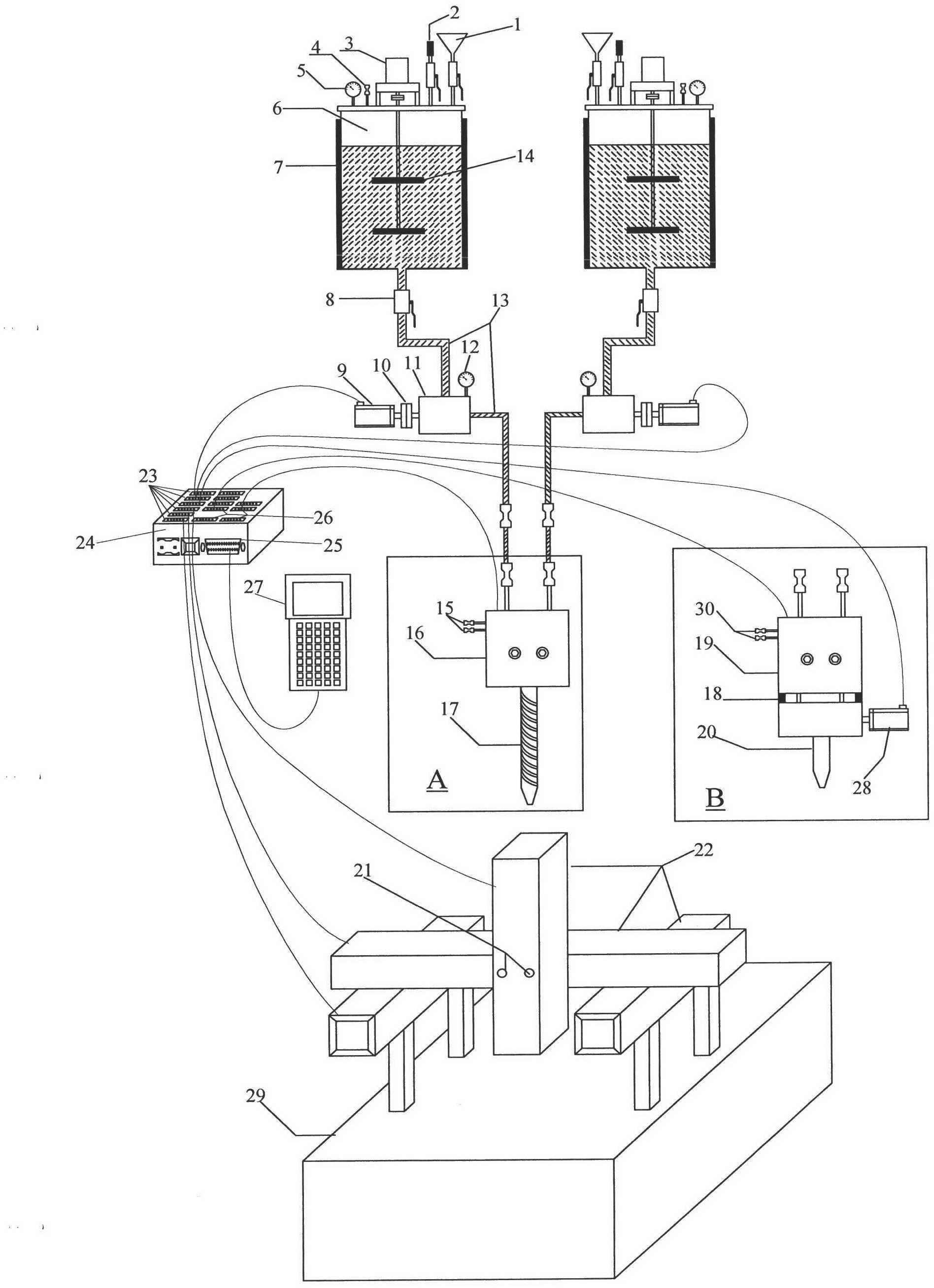

Glue-pouring integrated machine and coating method thereof

InactiveCN102513265AAdjust the mix in real timeSynchronous controlLiquid surface applicatorsCoatingsControl systemSynchronous control

The invention discloses a glue-pouring integrated machine, which comprises a coating control system and a glue-pouring machine, the glue-pouring machine is sequentially connected to at least two raw material containers, a material conveying pump and a glue output device through a catheter, the coating control system comprises a motion control card, an operation display box which is connected with the motion control card and a manipulator, the motion control card controls the material conveying pump, the glue output device and the manipulator simultaneously. The invention also discloses a coating method, which comprises the following steps step 1, setting control parameters of the motion control card; step 2, control the material conveying pump by the motion control card for conveying the material to a mixing module of the glue-pouring machine; step 3, controlling the glue output device by the motion control card under the stirring and mixing processes are finished; and step 4, controlling the trajectory of the manipulator by the motion control card for realizing the coating. The glue-pouring integrated machine and the coating method can realize the regulation of mixing the different raw materials, can realize fully synchronous control for all motors, eliminate the redundant equipment, improve the coating efficiency, and meet the demand of high precision treatment.

Owner:上海义信自动化科技有限公司

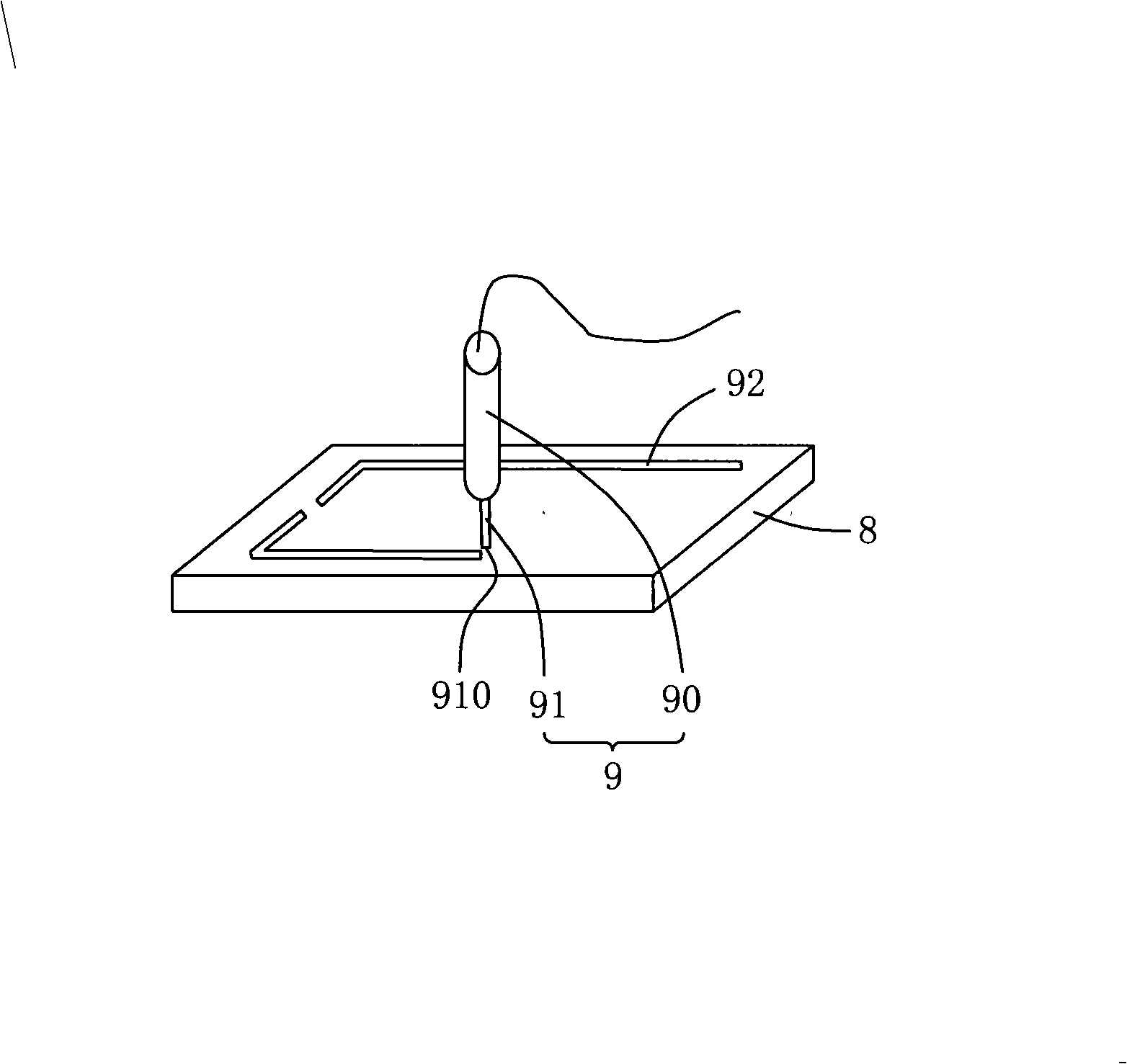

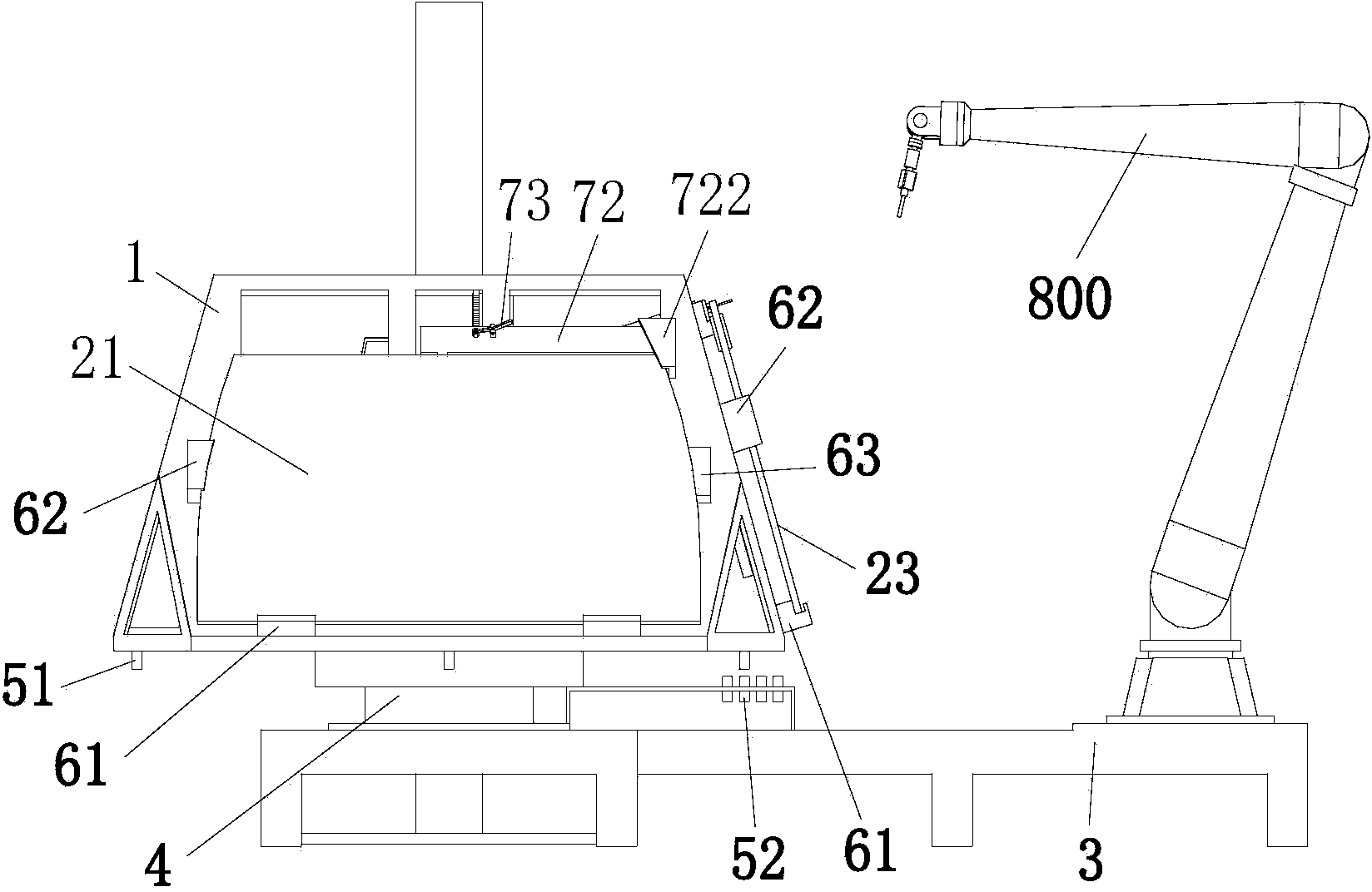

Car windshield glue coating system

ActiveCN109954627AAddressing inhomogeneitySolve efficiency problemsPretreated surfacesCoatingsCoating systemEngineering

The invention provides a car windshield glue coating system. The car windshield glue coating system comprises a pre-coating robot and a pre-coating device; the pre-coating device is used for providinga pre-coating agent during pre-coating, the pre-coating robot is used for grabbing glass at the corresponding position, them moving to the lower part of the pre-coating device and driving the glass to move according to the specified trajectory, and thus the glass is coated with the pre-coating agent. Manual operation is replaced by the pre-coating robot and the pre-coating device, the problems ofuneven coating, low efficiency and health damage caused by manual operation are solved, the car windshield glue coating system further comprises a first feeding device, a feeding robot, a centering device, a second feeding device and a glue coating robot, the manual operation is completely replaced by the robot, workers only need to place material frames onto the first feeding device, the automatic degree is high, and the glue coating quality can be ensured.

Owner:GUANGQI HONDA

Shoe-making gluing device

The invention discloses a shoe-making gluing device which comprises a mounting cover. A plurality of slide rods are fixedly connected to the upper side of a moving plate which is arranged in the mounting cover, the upper end of each slide rod is fixedly connected with a slider, and the inner top of the mounting cover is provided with a strip slide groove corresponding to the sliders. A driving mechanism is arranged on the outer side of the moving plate, two symmetrical supporting rods are fixedly connected to the lower side of the moving plate, a gluing roller sleeves a rotating shaft which isin rotational connection between the two supporting rods, and a liquid outlet pipe is connected to one side of a glue box which is fixedly connected to one side of the mounting cover. By arrangementof a regulation mechanism for driving a piston to move, glue in the glue box can be extruded out of the liquid outlet pipe and sprayed to soles through a nozzle, then the gluing roller is driven to shake bilaterally by the driving mechanism to uniformly apply the glue, and accordingly gluing efficiency and gluing uniformity are improved.

Owner:YANCHENG JINRUI PETROLEUM MACHINERY CO LTD

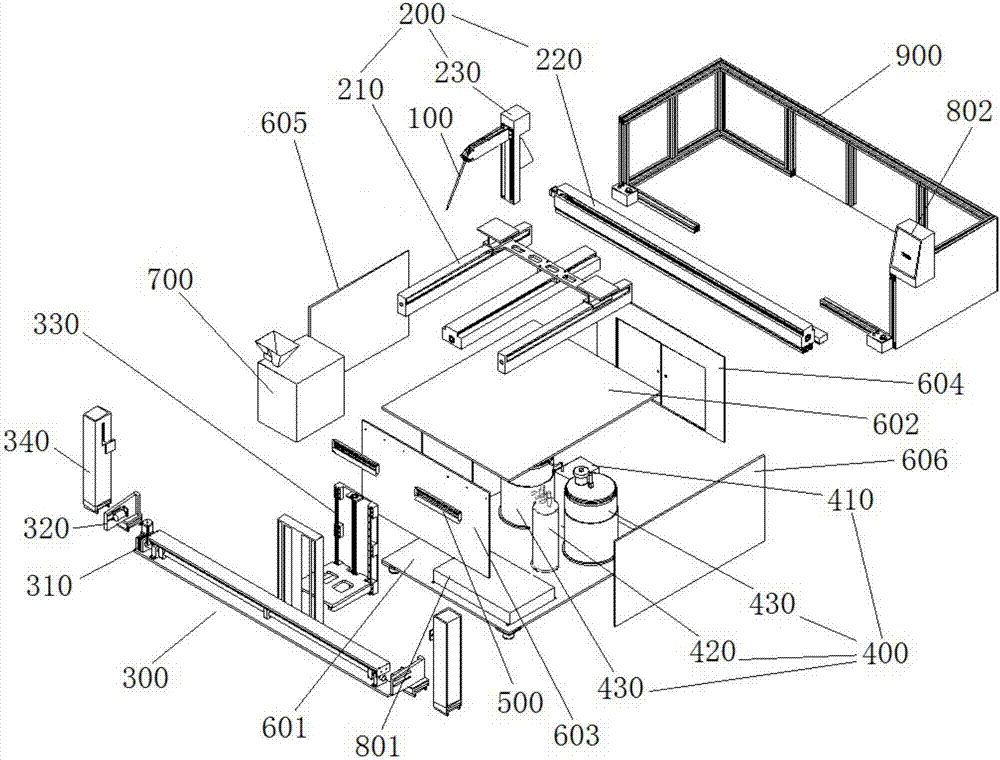

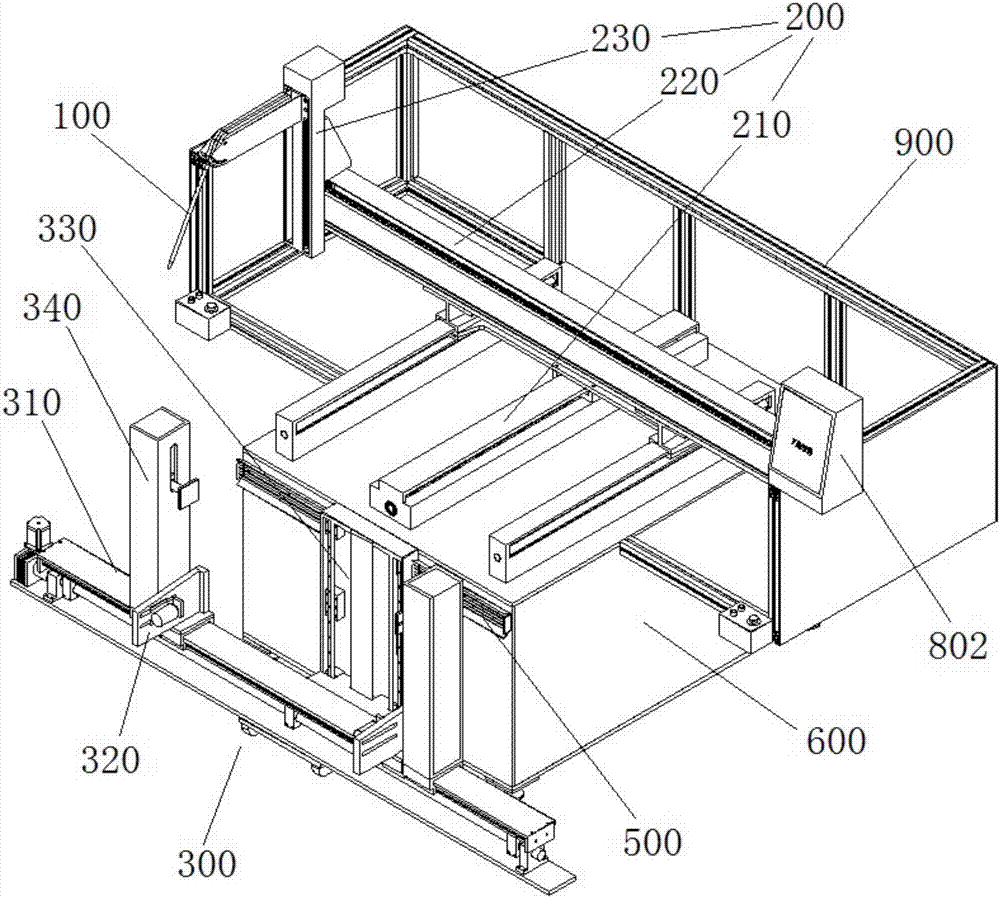

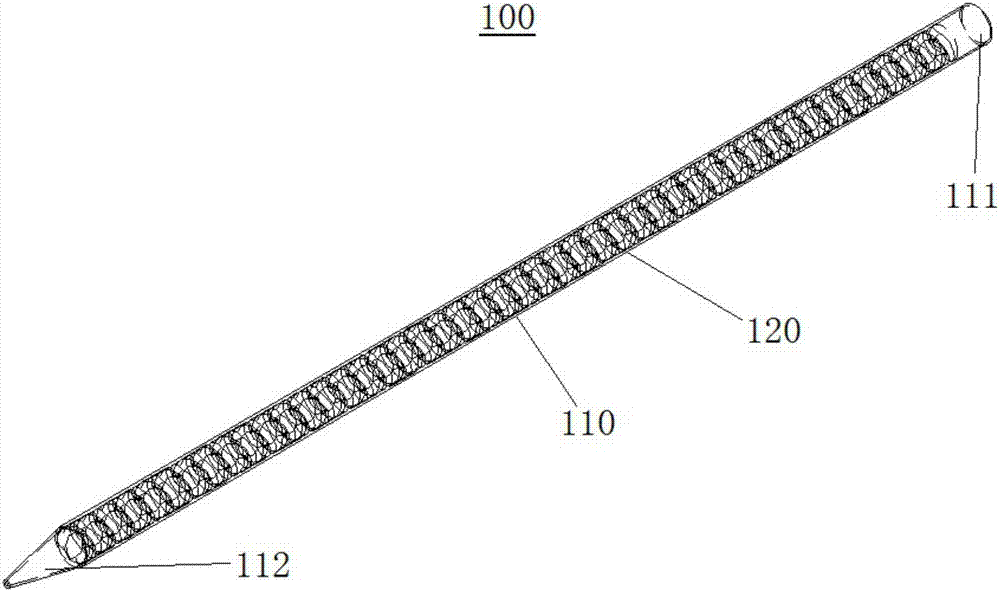

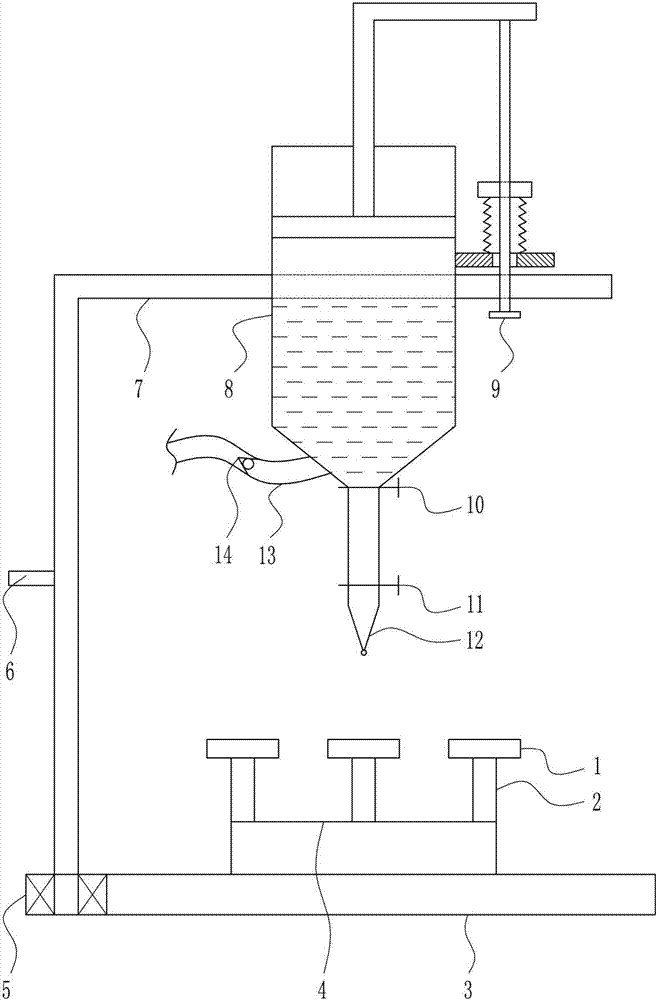

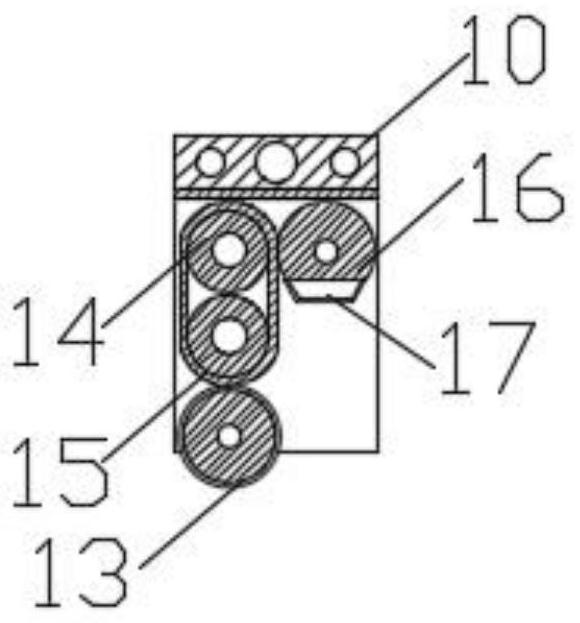

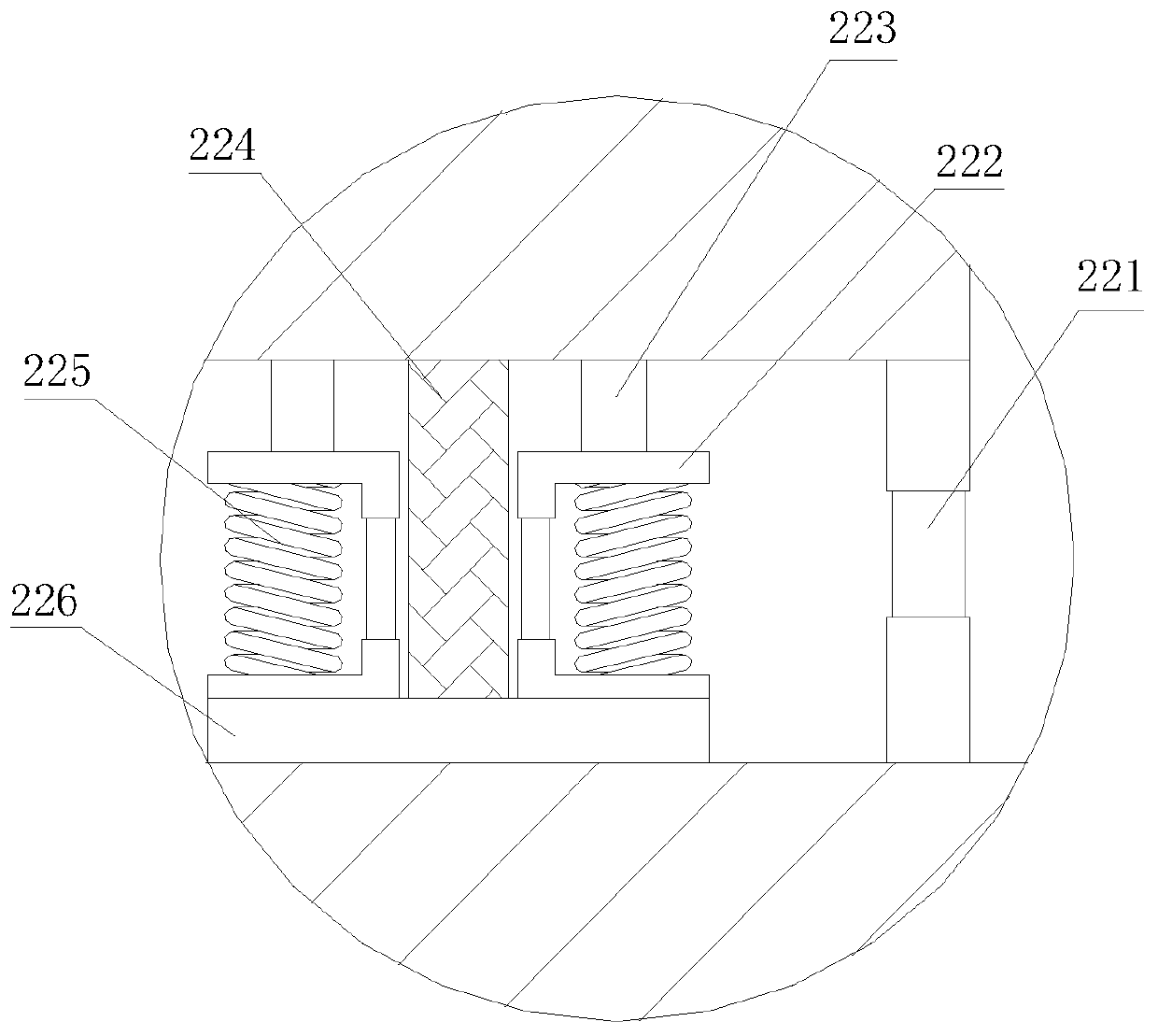

Full-automatic double-hollow glass gluing machine

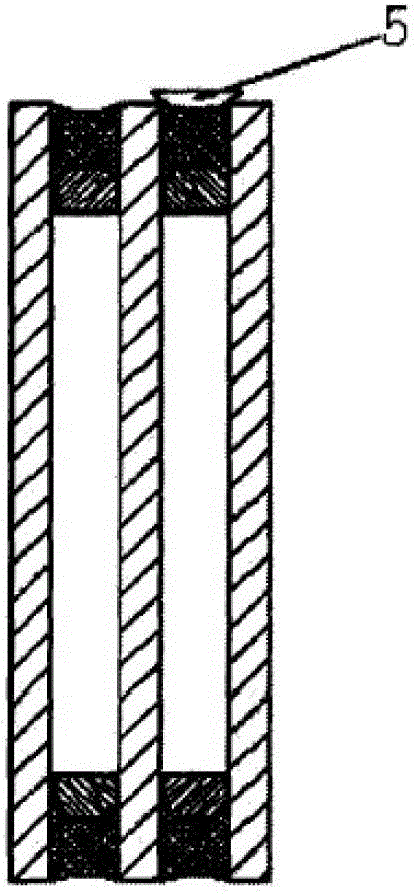

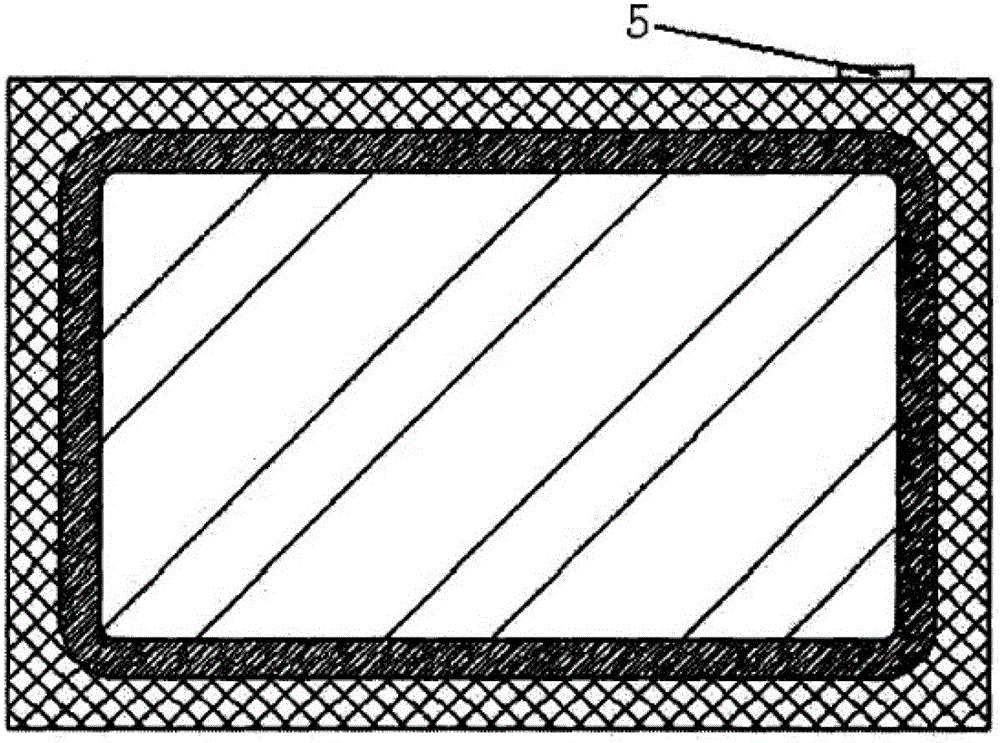

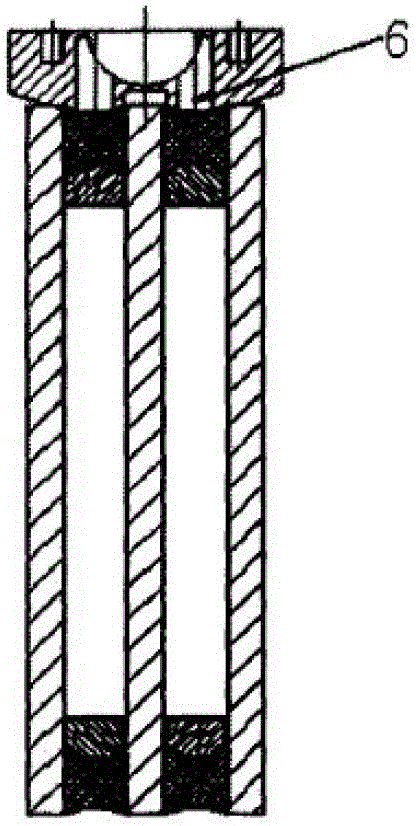

ActiveCN102671816BImprove gluing efficiencyHigh degree of automationLiquid surface applicatorsCoatingsEngineeringAutomation

The invention discloses a full-automatic double-hollow glass gluing machine, comprising a single-glue nozzle dual-outlet mechanism and a double-measurement mechanism, wherein the single-glue nozzle dual-outlet mechanism comprises a glue nozzle main body and a glue nozzle front end; two glue outlets are formed at the glue nozzle front end; the two glue outlets are respectively communicated with a glue outlet channel in the glue nozzle main body; the double-measurement mechanism comprises two independent depth measurers; and the two depth measurers are respectively located in front of the two glue outlets at the glue nozzle front end. The full-automatic double-hollow glass gluing machine can be used for gluing the double-hollow glass twice in a sealed manner in one gluing process, so that the gluing efficiency is high, the gluing quality is good, and the automation degree is high.

Owner:北京昌益和自动化设备制造有限公司

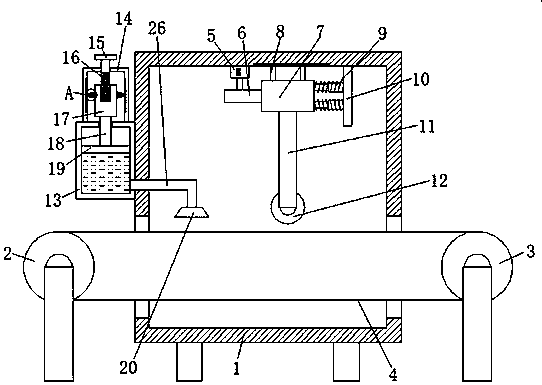

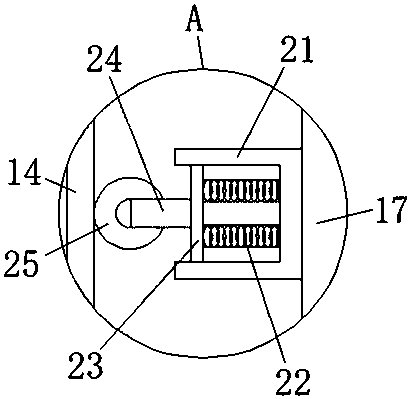

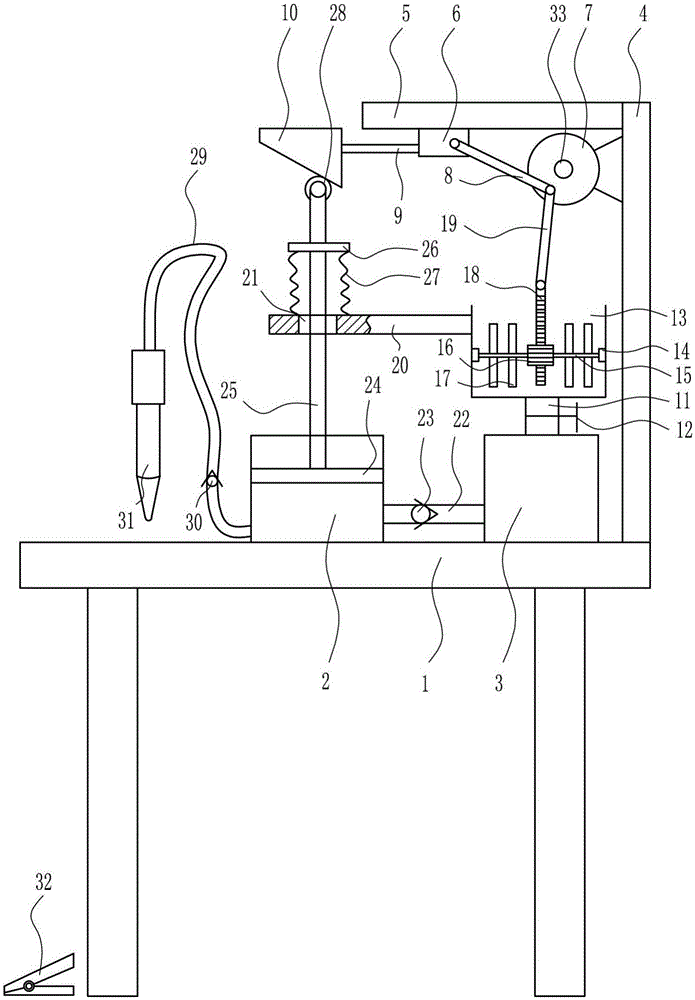

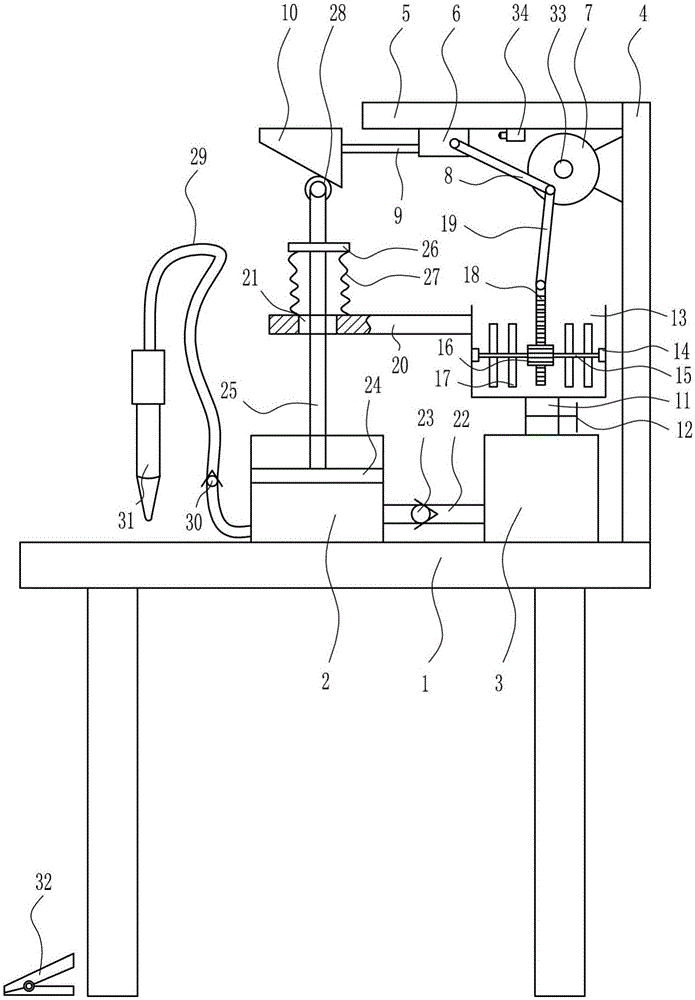

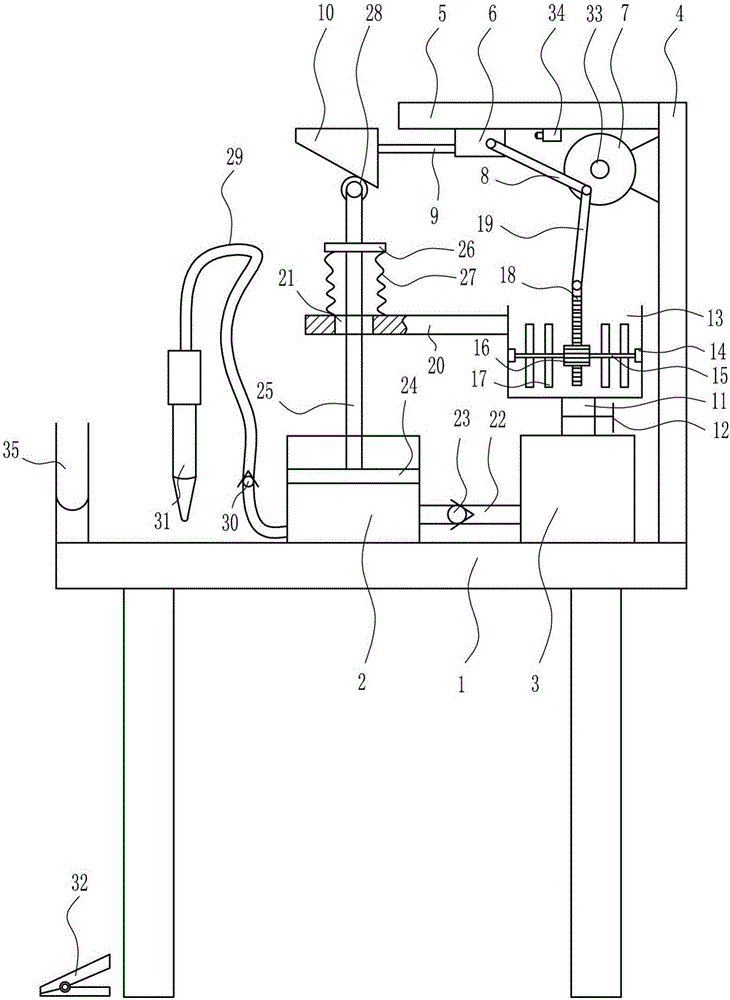

A highly-efficient sole glue applying device used in shoe factories

The invention relates to a sole glue applying device used in shoe factories, in particular to a highly-efficient sole glue applying device used in shoe factories. The highly-efficient sole glue applying device used in shoe factories has the advantages of uniform glue applying, high glue applying speed and glue saving. The highly-efficient sole glue applying device comprises a support frame, a compression cylinder, a transfer box, a support, a slide rail, a slider, a disc, a first connecting rod, a strut, a wedge-shaped block, a connecting pipe, an electronic control valve, a stirring tank, bearing bases, a rotating shaft, a gear, stirring rods, a rack, a guide rod, a liquid outlet pipe, a first check valve, a piston, a push rod, a fixing plate, a spring, a contact wheel, a hose, a glue gun, a pedal and a motor. The motor rotates to drive the stirring rods to rotate, so that glue is stirred; by using the push rod and the piston, glue enters the glue gun; the highly-efficient sole glue applying device achieves the effects of uniform glue applying, high glue applying speed and glue saving.

Owner:张浩杰

Glue gun

InactiveCN103406241AReduce wasteGlue evenlyLiquid surface applicatorsCoatingsPulp and paper industryFlange

The invention discloses a glue gun which comprises a glue nozzle, wherein a glue feeding hole is formed in the glue nozzle; a scraper blade is arranged at the head of the glue nozzle; a glue body accommodating cavity is formed in the lower end of the scraper blade; two sides of the glue body accommodating cavity extend towards the head of a nozzle body to form cambered flanges; a through hole is formed in the scraper blade; the lower end of the through hole is communicated with the glue body accommodating cavity; the upper end of the through hole is communicated with the end face of the upper end of the scraper blade; the through hole in the upper end of the scraper blade is connected with a hollow hose; the other end of the hollow hose is connected with a glue body collection device. When the glue gun is used for dispensing glue, redundant glue bodies in a slit can be scraped to another slit with a small amount of glue bodies under the action of the scraper blade, and the residual glue bodies are sucked into the glue body collection device. Therefore, the glue gun has the beneficial effects that the glue dispension is uniform, the redundant glue bodies can be recycled, the waste of glue bodies is effectively reduced, and the cost is reduced.

Owner:ZHEJIANG HAOQING AUTOMOBILE MFG CO LTD +1

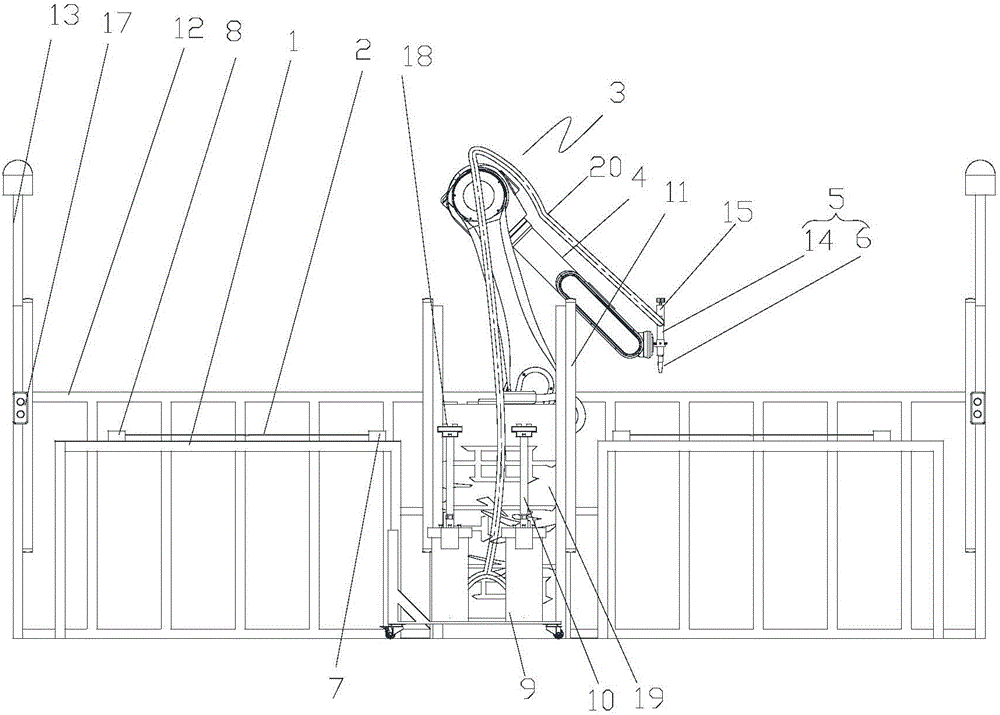

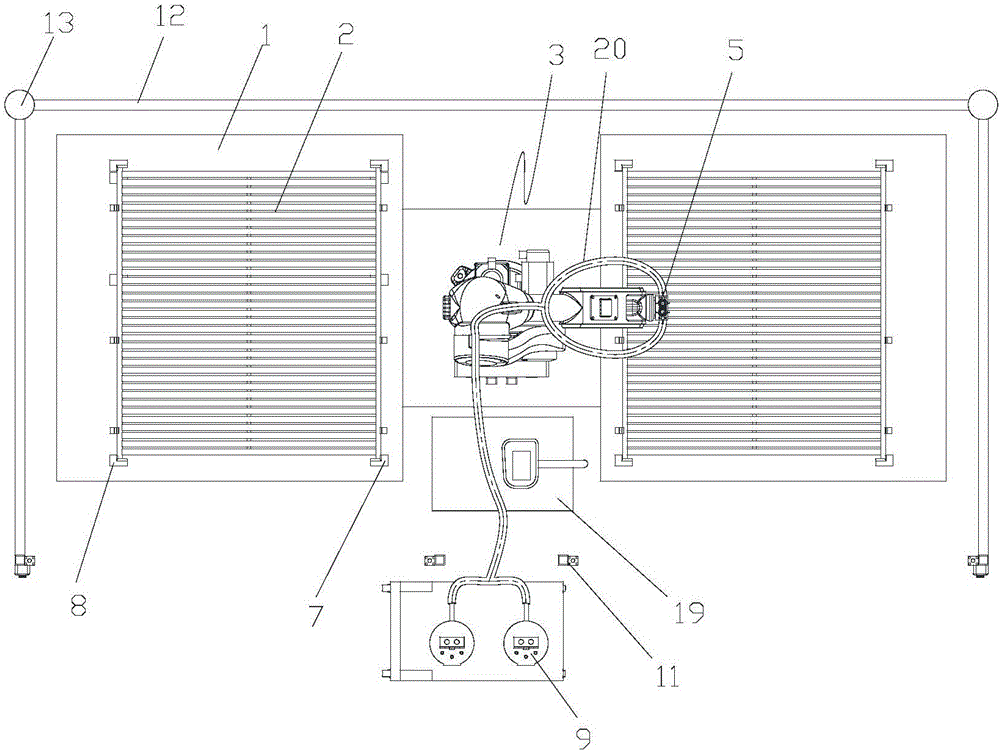

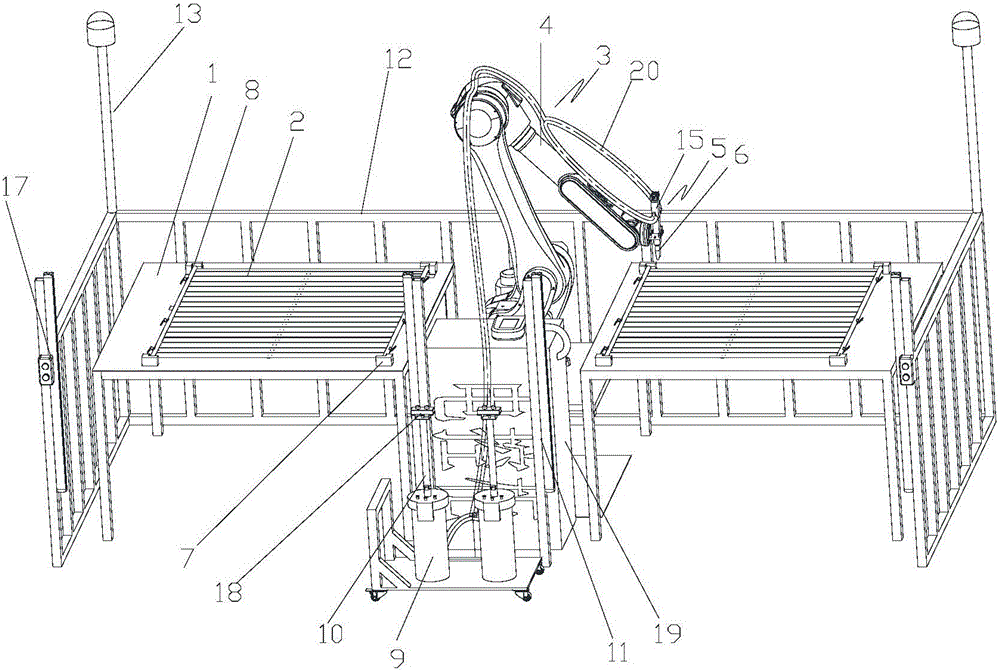

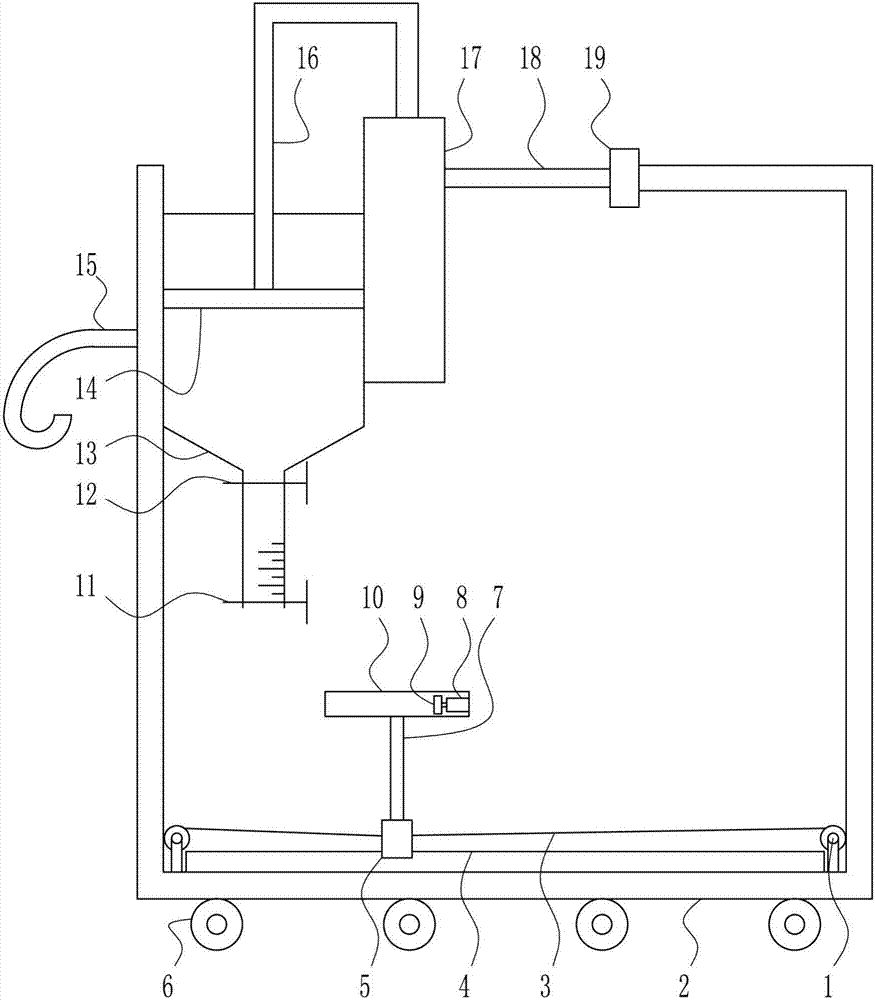

Automatic gluing device

ActiveCN105817392AAutomatic glue applicationReduce the difficulty of gluingLiquid surface applicatorsCoatingsEngineeringElectric control

The invention discloses an automatic gluing device. The automatic gluing device comprises a gluing worktable (1), a robot (3), a glue gun (5) and an electric control device (19), wherein a positioning structure for positioning a to-be-glued product (2) is arranged on the gluing worktable (1); the robot (3) comprises a first mechanical arm (4) which can move in the gluing direction of the to-be-glued product (2); the glue gun (5) is arranged on the first mechanical arm (4) and comprises a gun head (6) arranged corresponding to the to-be-glued product (2); and the electric control device (19) is electrically connected with the robot (3) and the glue gun (5), and controls the robot (3) and the glue gun (5) to be linked. According to the automatic gluing device disclosed by the invention, the problems of high labor intensity of manual gluing and poor gluing consistency in the prior art can be solved.

Owner:GREE ELECTRIC APPLIANCES INC

Novel automatic gluing device for plate

InactiveCN105903630AImprove gluing efficiencyReasonable structureLiquid surface applicatorsCoatingsEngineeringMechanical engineering

Owner:ANHUI DONGPING WOOD GRP

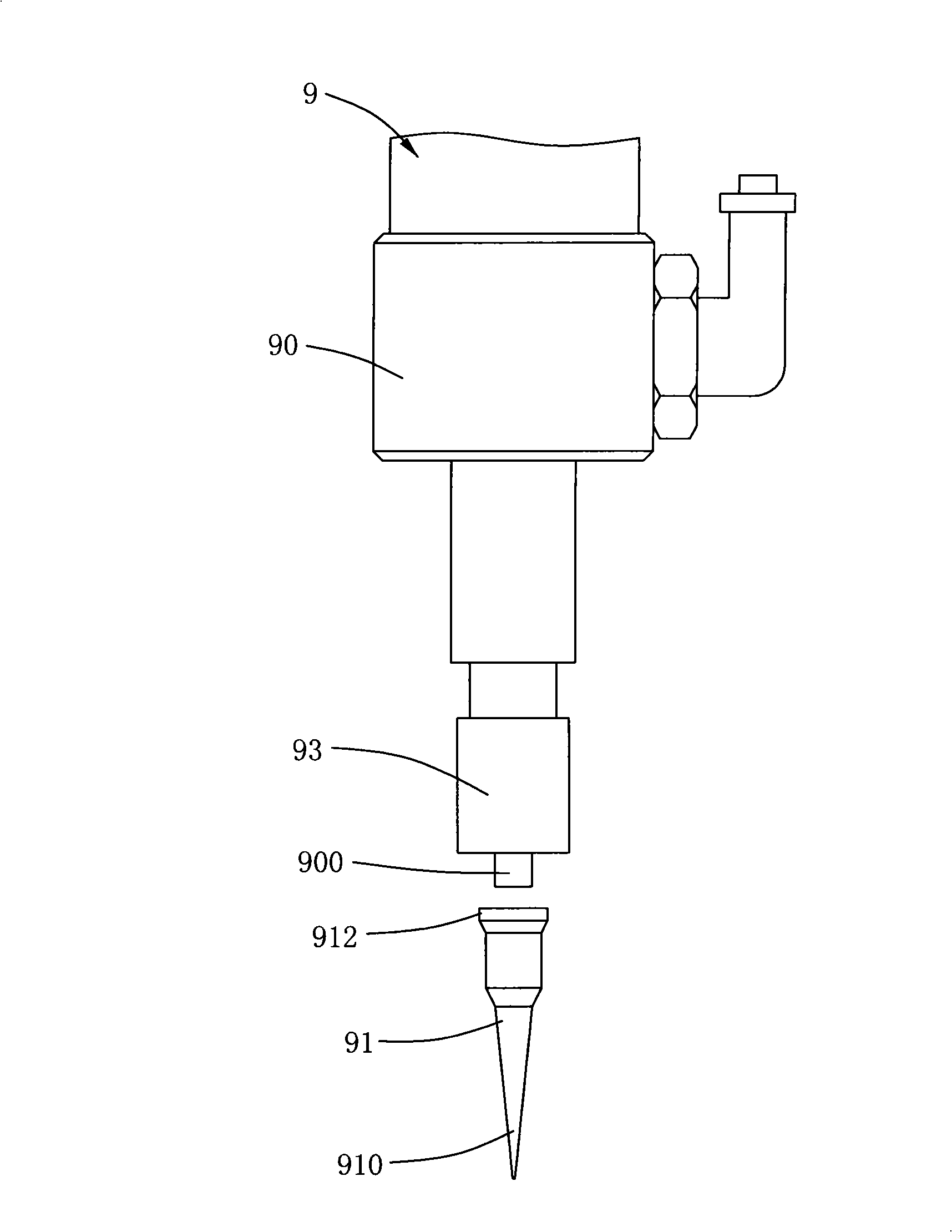

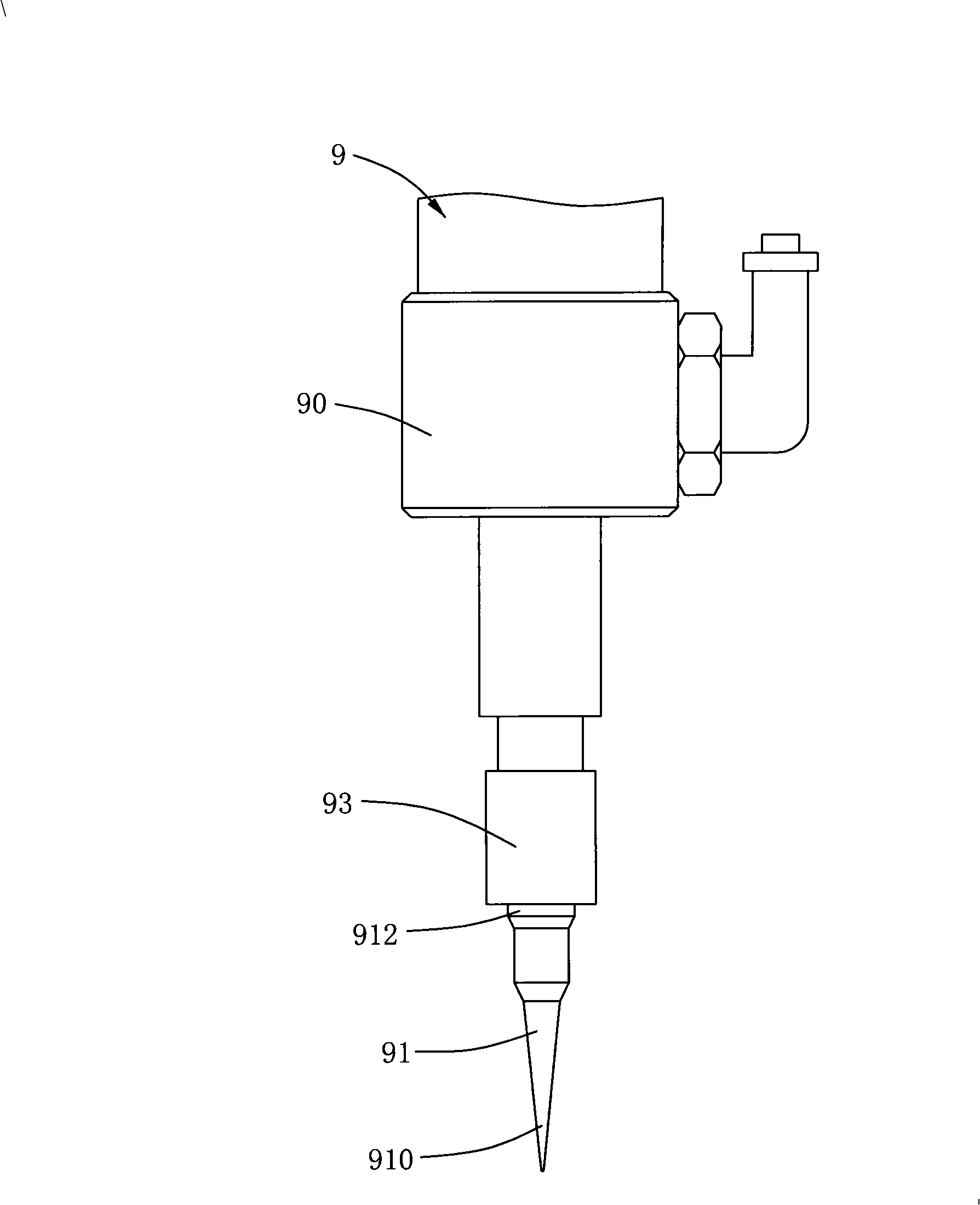

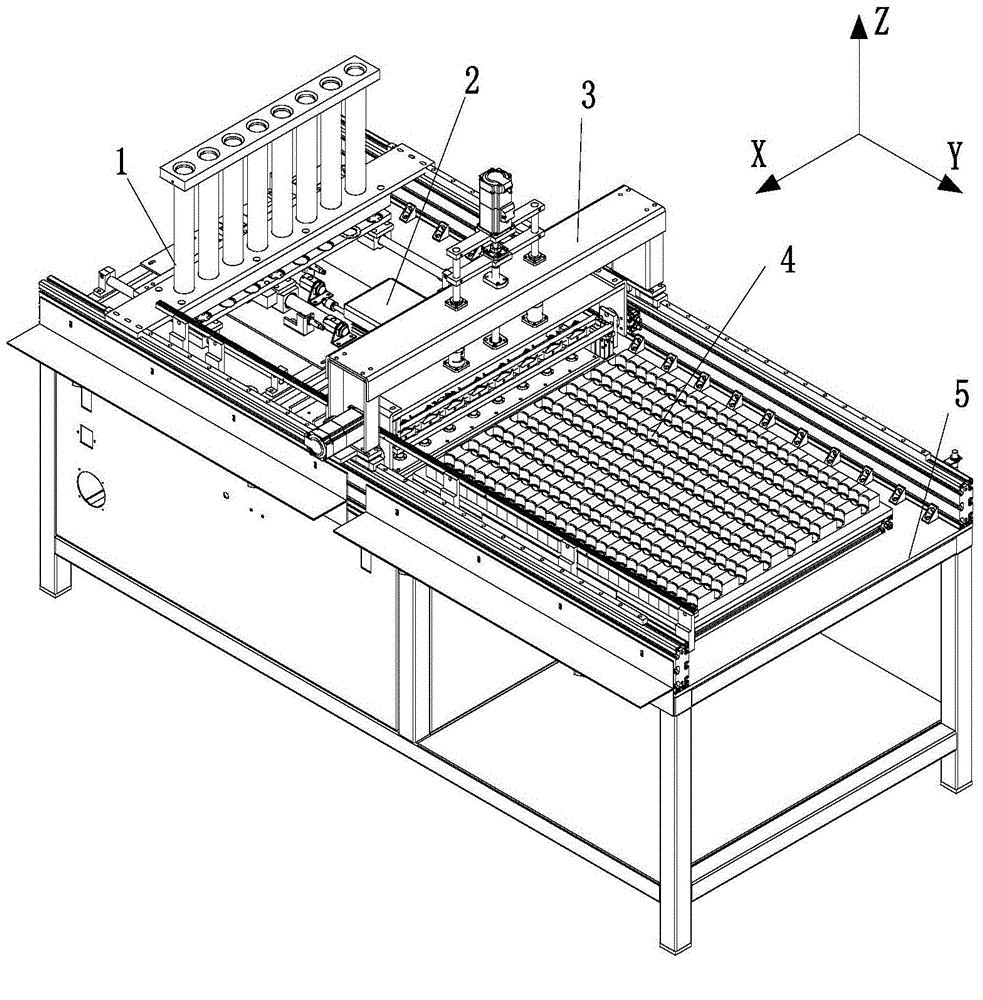

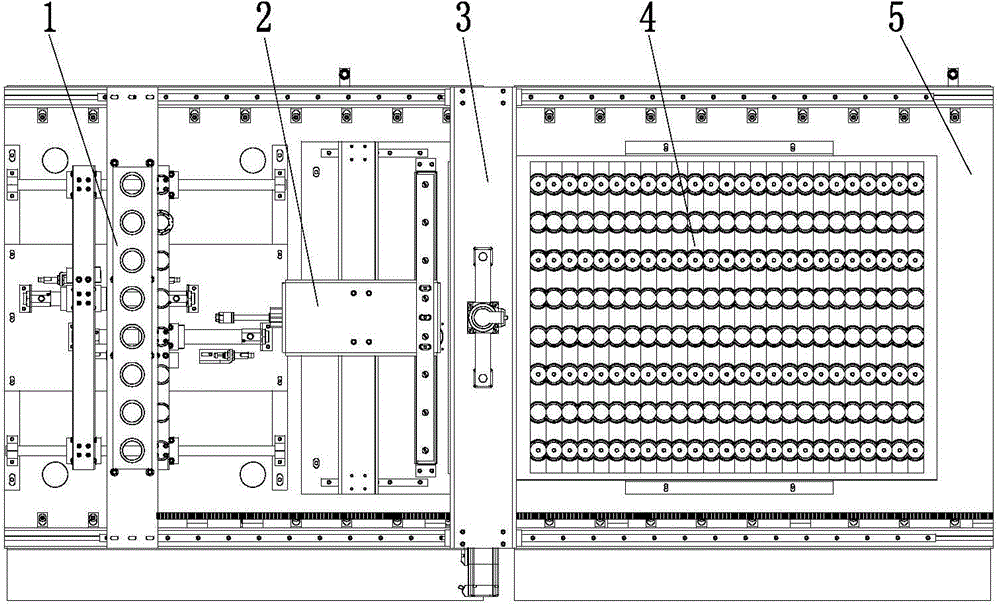

Glue spreading apparatus, using and maintaining method for the glue spreading apparatus

InactiveCN101318169AHigh strengthNo bending deformationLiquid surface applicatorsSpraying apparatusConical tubeMechanical engineering

The invention discloses a rubberizing device, comprising a base, a pin base, a rubberizing pin on the pin base, a fixing mechanism and a pin protecting mechanism. In an embodiment of the invention, the fixing mechanism comprises a slide block and a clamp; wherein the slide block can be arranged on a guide rail of the base in a sliding way, and drives the pin base and the rubberizing pin to lift up and down to adjust the distance between the fixing mechanism and the pin protecting mechanism; the clamp is connected with the slide block to clamp the pin base. The pin protecting mechanism comprises a conical tube; the conical tube can be separately sheathed on the outside of the rubberizing pin. During the use and maintenance of the rubberizing device, when the distance between the fixing mechanism and the pin protecting mechanism is increased, the rubberizing pin can be moved out of the pin protecting mechanism thus realizing quick replacement and improving the operation efficiency.

Owner:AU OPTRONICS (XIAMEN) CORP +1

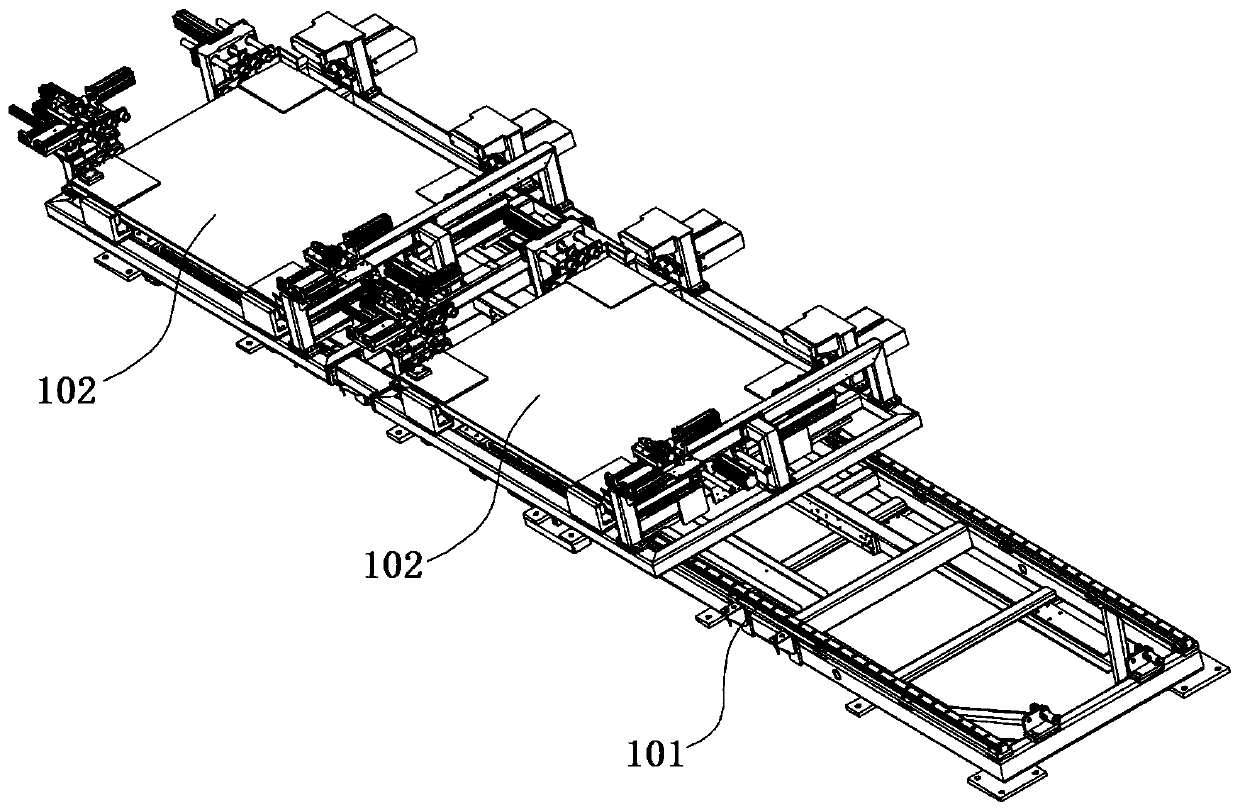

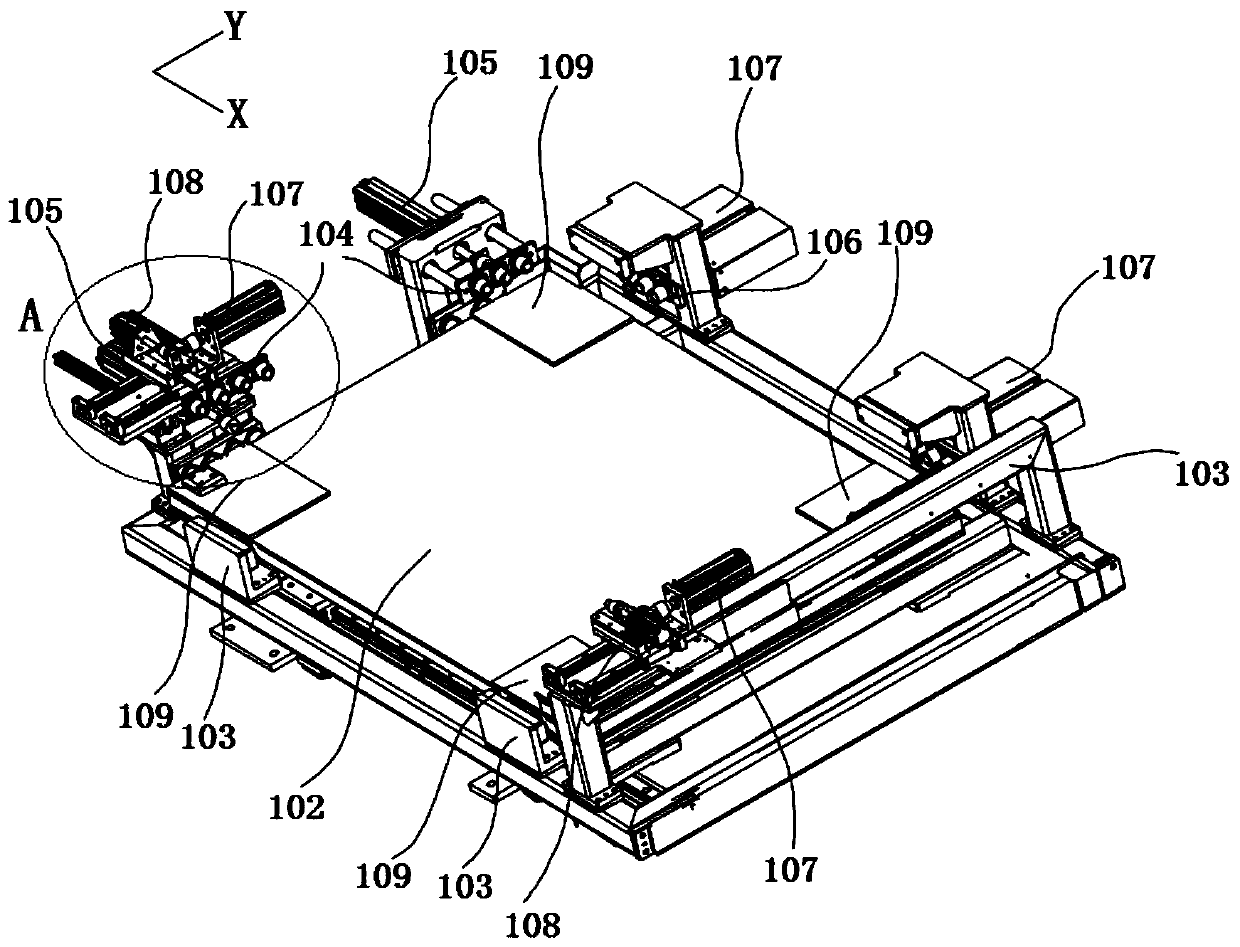

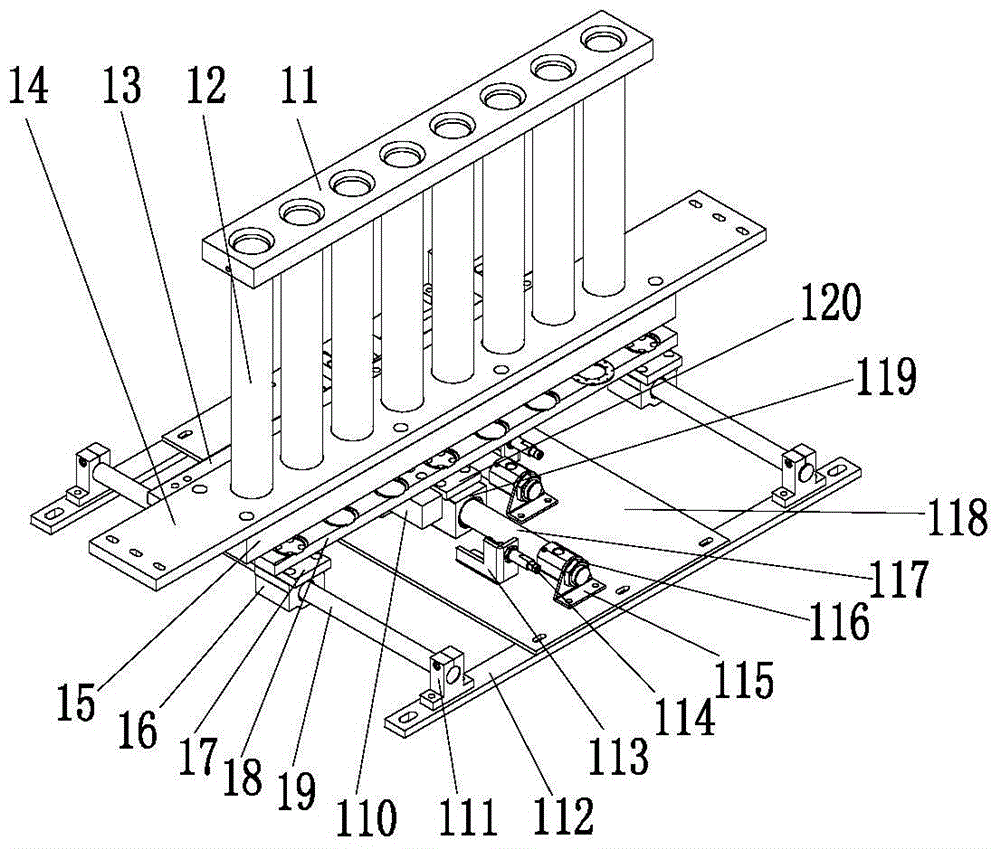

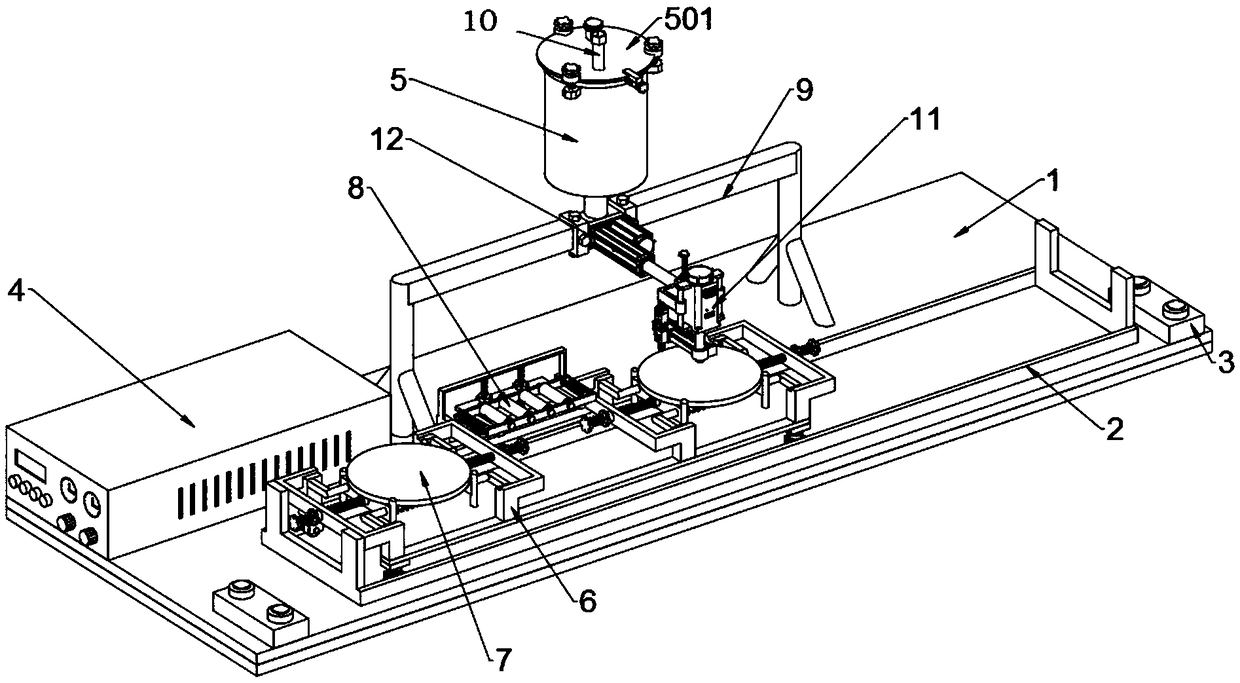

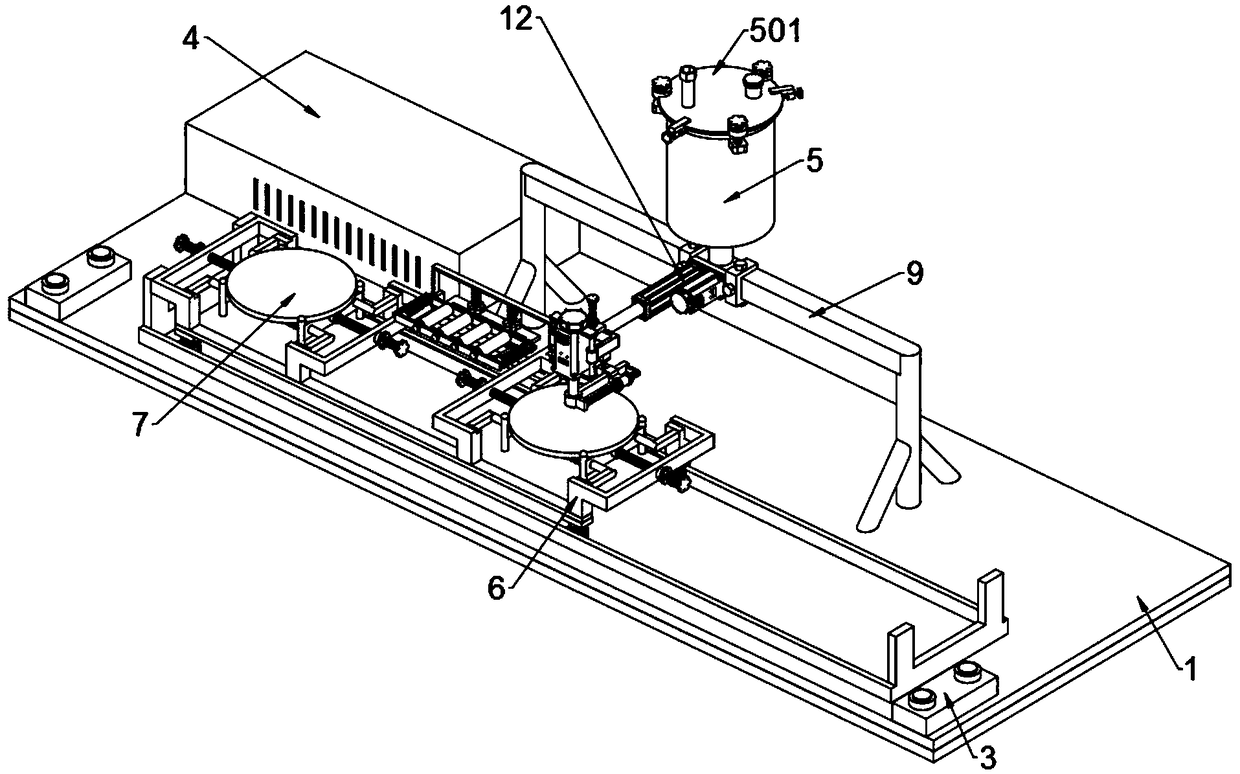

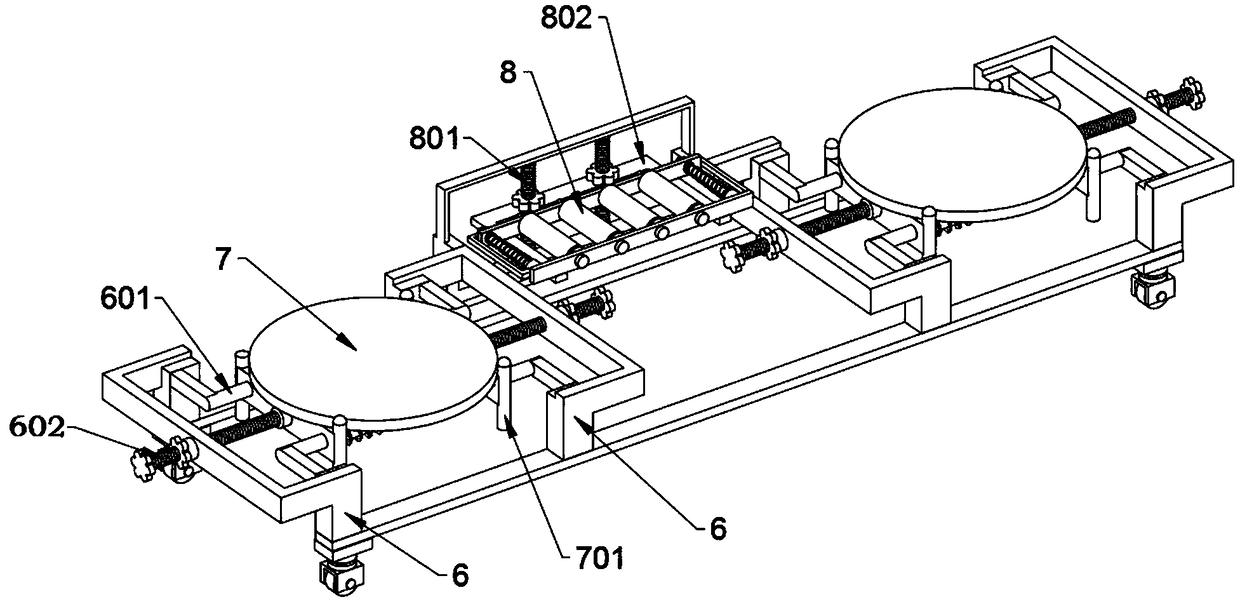

Automatic equipment for coating surfaces of iron rings by glue

InactiveCN104525431AIncrease productivityImprove quality and safetyLiquid surface applicatorsCoatingsAutomatic test equipmentEngineering

The invention discloses automatic equipment for coating the surfaces of iron rings by glue. The automatic equipment comprises a rack, a feeding module, a coating module, a discharging module, a platform movement module and a controller, wherein the rack is used as a support base; the feeding module is used for conveying a plurality of workpieces at the same time; the coating module is used for coating glue, the discharging module is used for unloading the workpieces; the platform movement module is used for overturning and carrying the workpieces at each station; the feeding module, the coating module and the discharging module are arranged on the rack in sequence along the length direction of the rack; the platform movement module is fixed at two sides of the rack in a stretching manner; the movable part of the platform movement module is capable of overturning and clamping the workpieces to sequentially convey the workpieces from the feeding module to the coating module and the discharging module along the length direction of the rack; the controller is in circuit connection with the feeding module, the coating module, the discharging module and the platform movement module. The automatic equipment for coating surfaces of iron rings by glue has the advantages of saving the human cost, being high in efficiency, high in accuracy, stable in quality and high in automation degree, greatly improving the production efficiency and satisfying the demand of industrial production.

Owner:SOUTH CHINA UNIV OF TECH

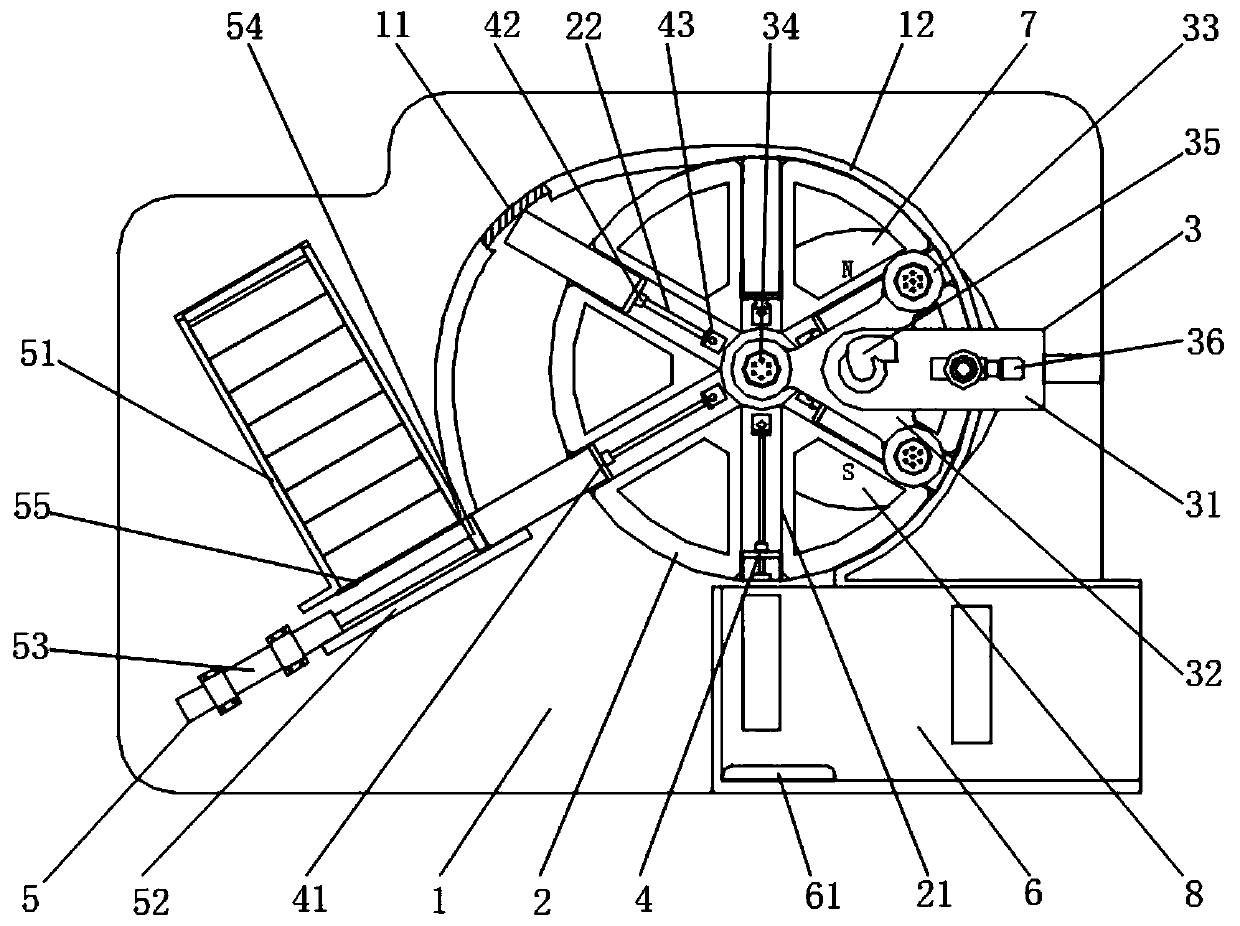

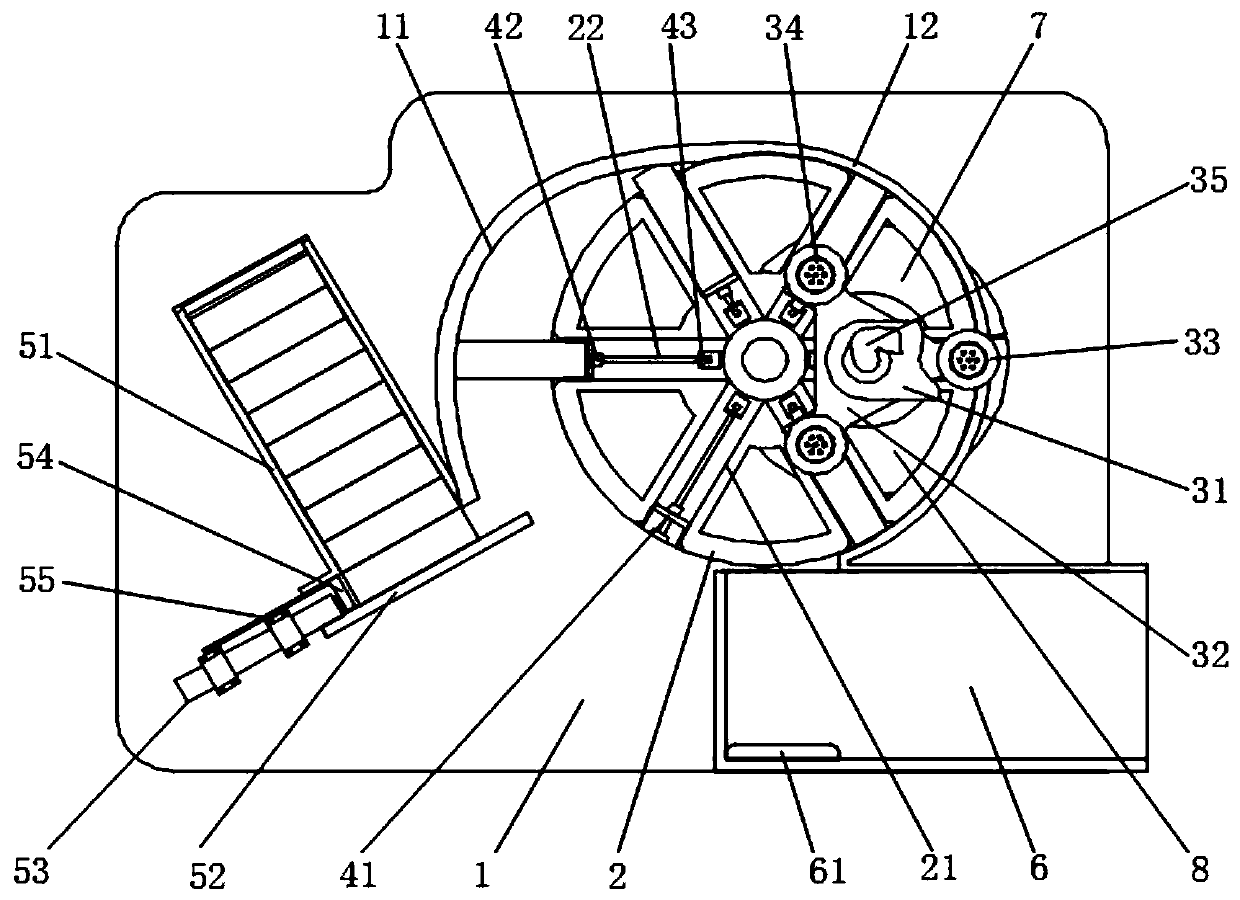

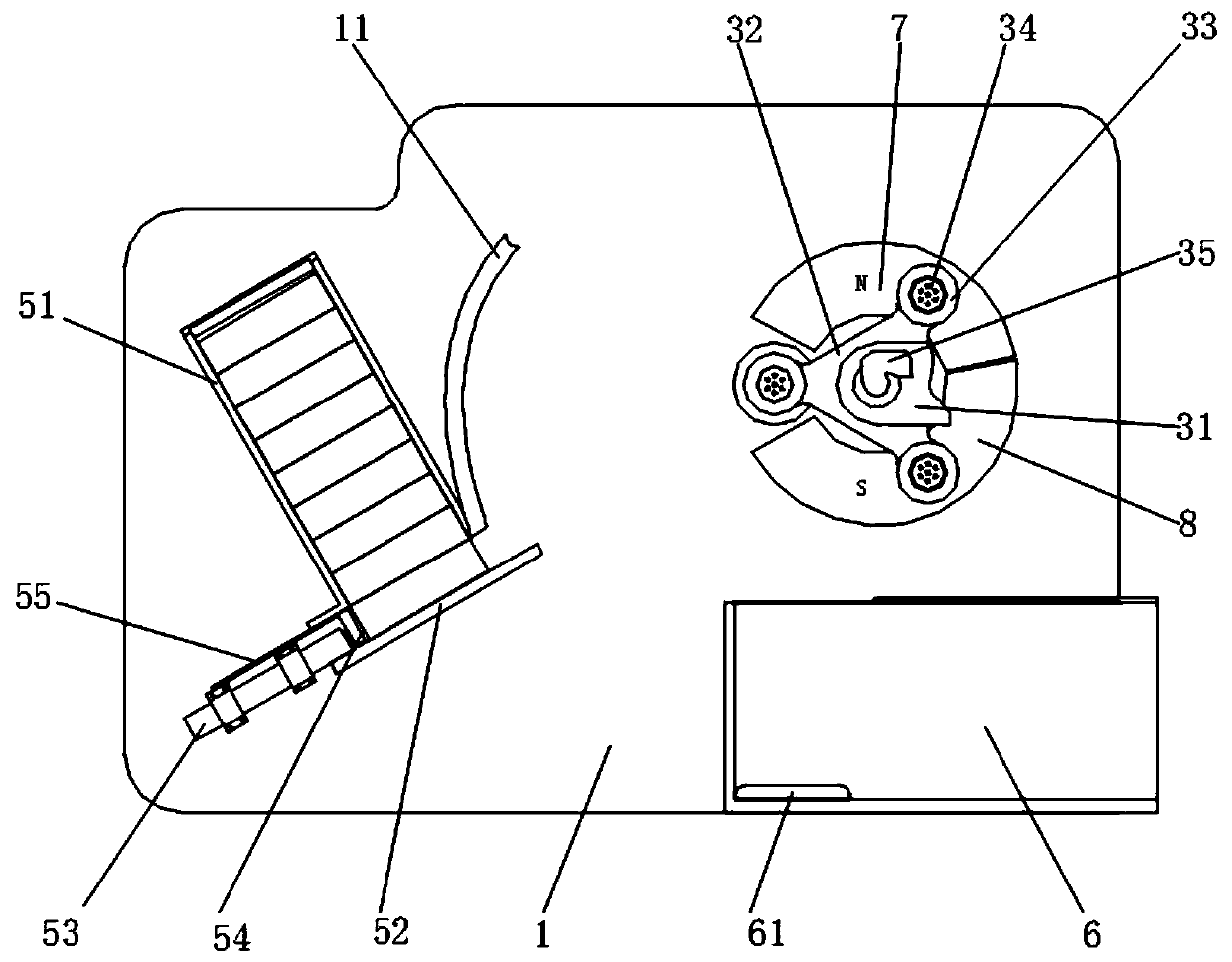

Nanometer material surface glue spreading device

ActiveCN111451077AEasy glue applicationImprove functionality and convenienceLiquid surface applicatorsCoatingsElectric machineryPiston

The invention discloses a nanometer material surface glue spreading device comprising a workbench. A rotating disk is arranged on the top of the workbench. Six T-shaped sliding grooves are evenly formed on the top of the rotating disk and distributed on the top of the rotating disk in the radial direction. A rotating shaft is fixedly connected to the bottom of the rotating disk. The bottom end ofthe rotating shaft penetrates through the workbench and is rotationally connected with the workbench. The outer portion of the bottom end of the rotating shaft is fixedly provided with a gear ring. Adrive motor is fixedly installed at the bottom of the workbench and in transmission connection with the gear ring through a gear. According to the nanometer material surface glue spreading device, therotating disk is arranged and in linkage with an equilateral triangle rotating disk, when the rotating disk rotates, three glue spraying barrels can move back and forth in a reciprocating manner on two plate grooves in the same radial direction, through cooperation of vertical position change of magnetic pistons, the glue spreading function on nanometer plates is achieved, cleaning of the nanometer plates before glue spreading is also achieved, and the filling efficiency for glue spreading by equipment is greatly improved.

Owner:山东恒信科技服务有限公司

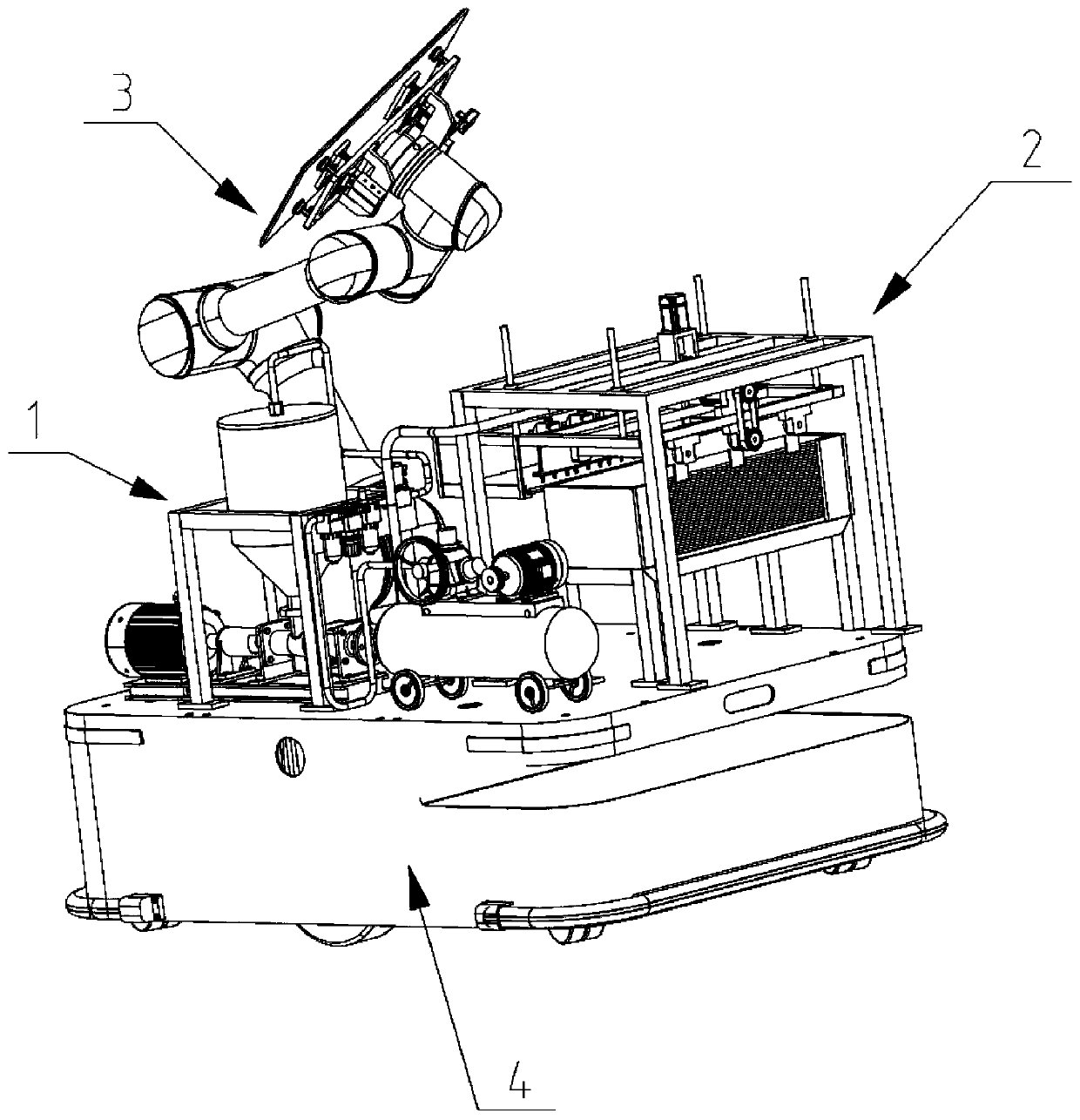

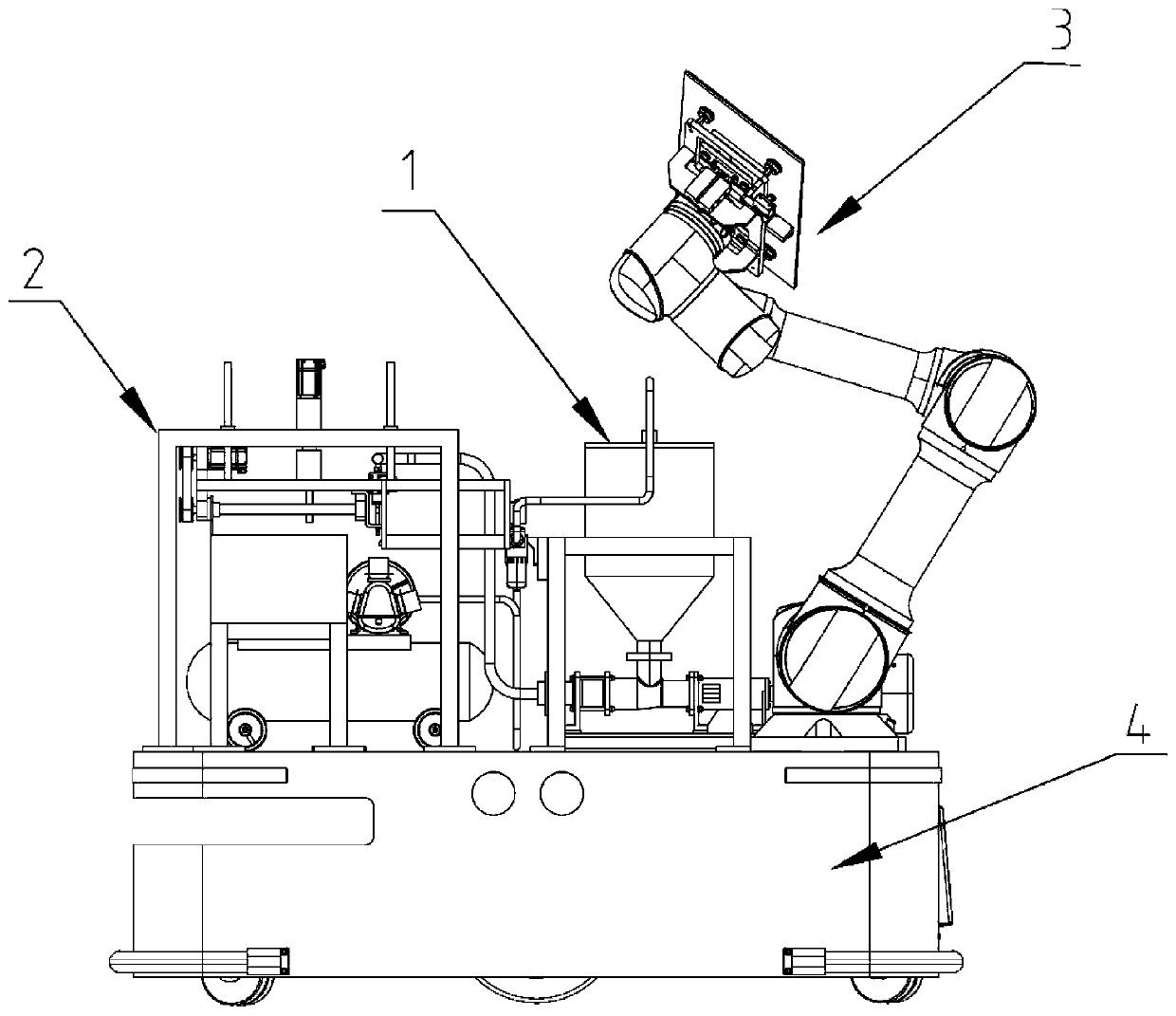

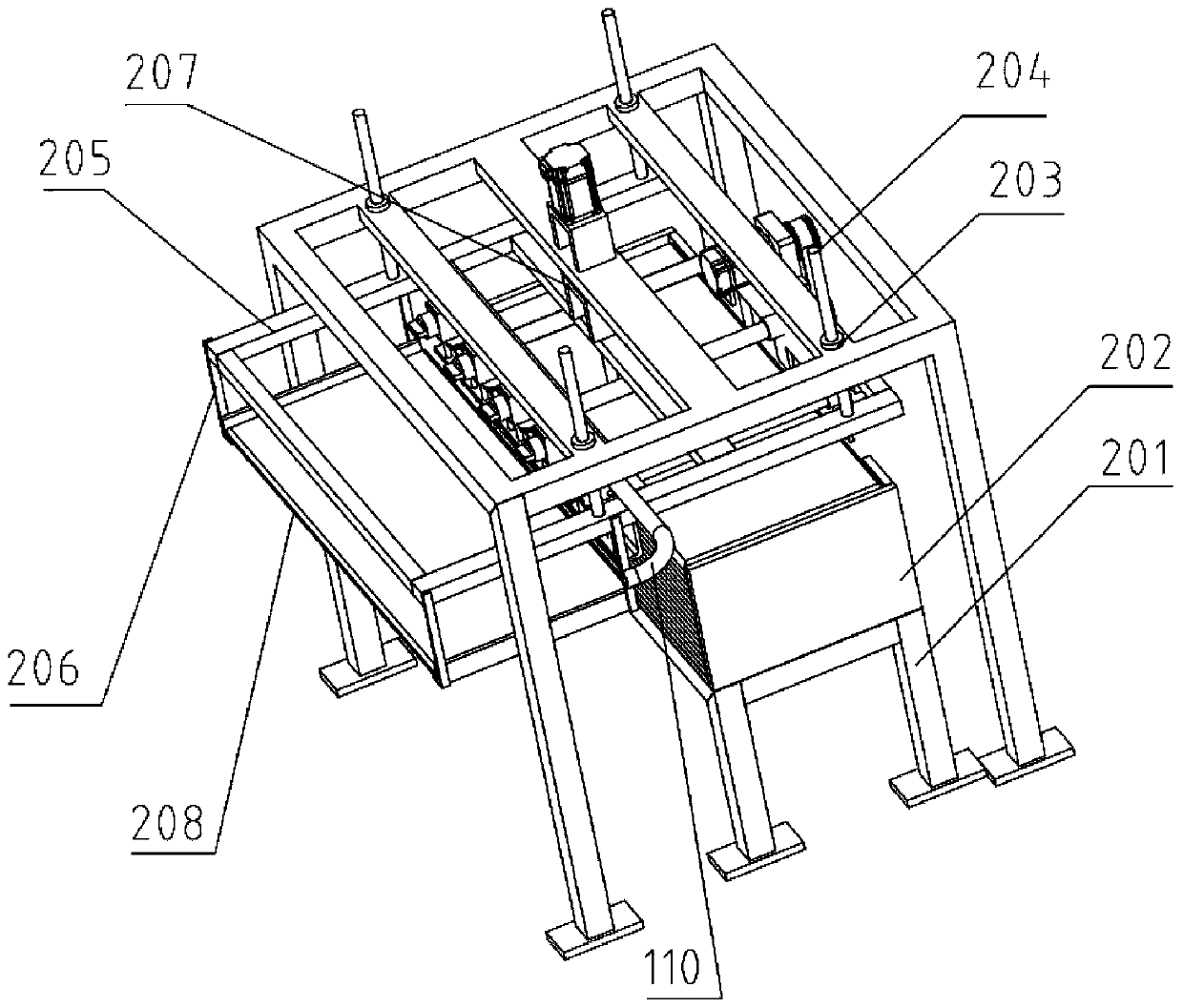

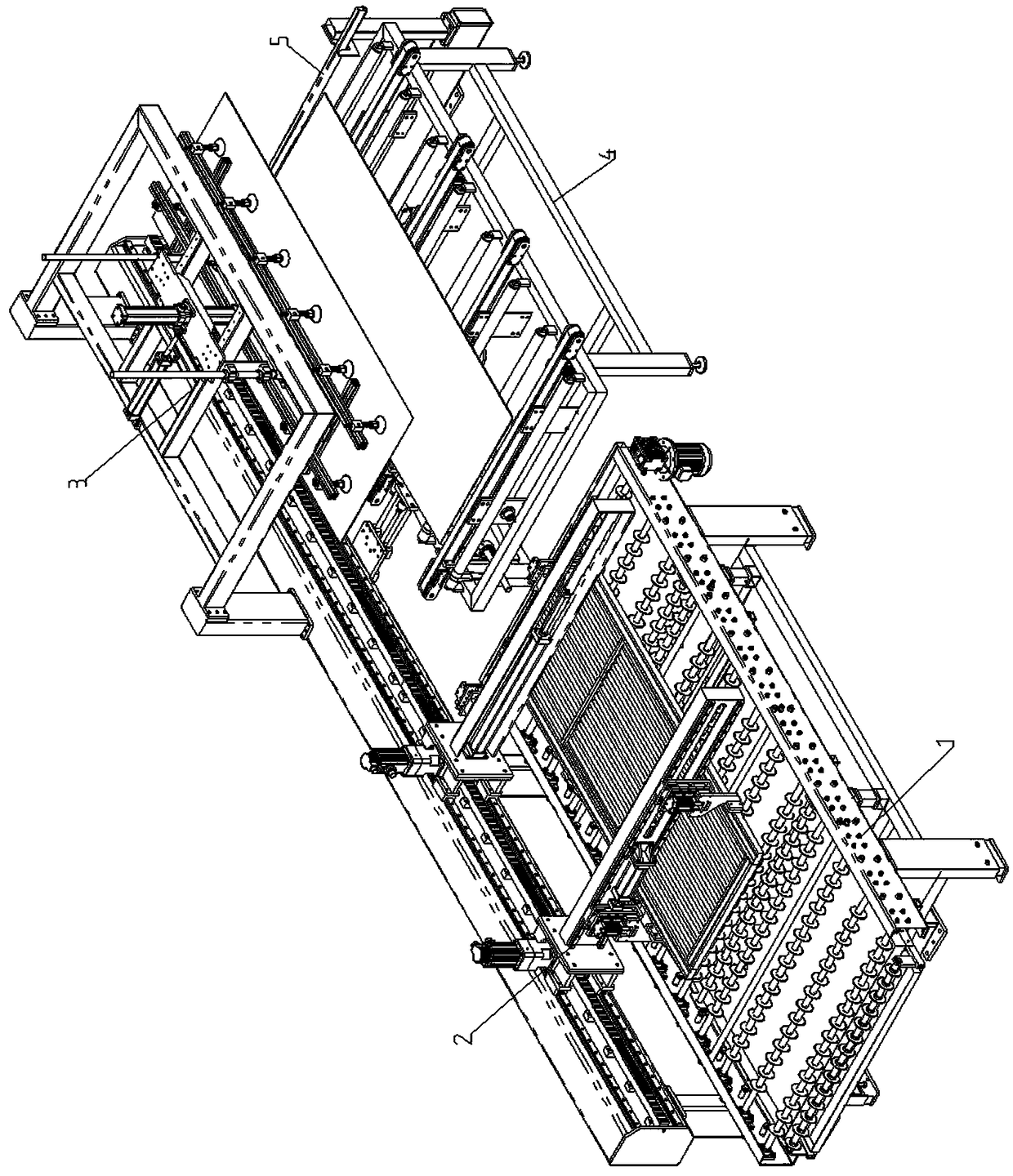

Wall tile gluing device and wall tile gluing and laying robot

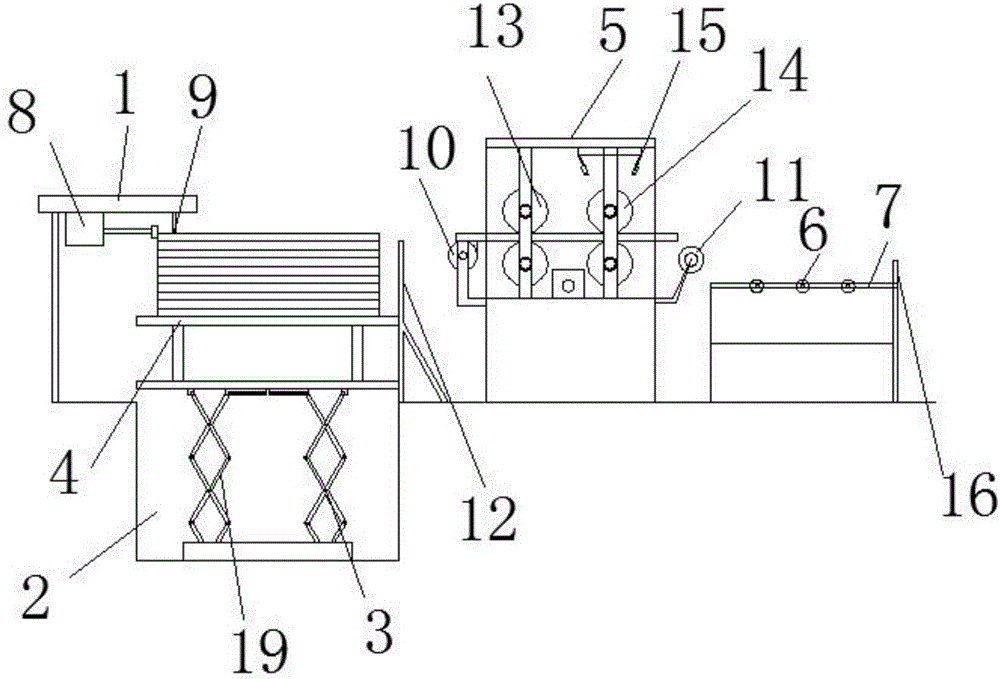

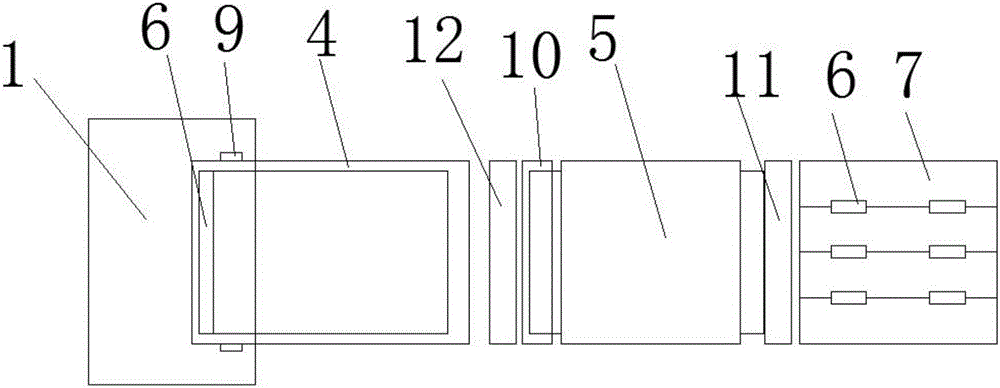

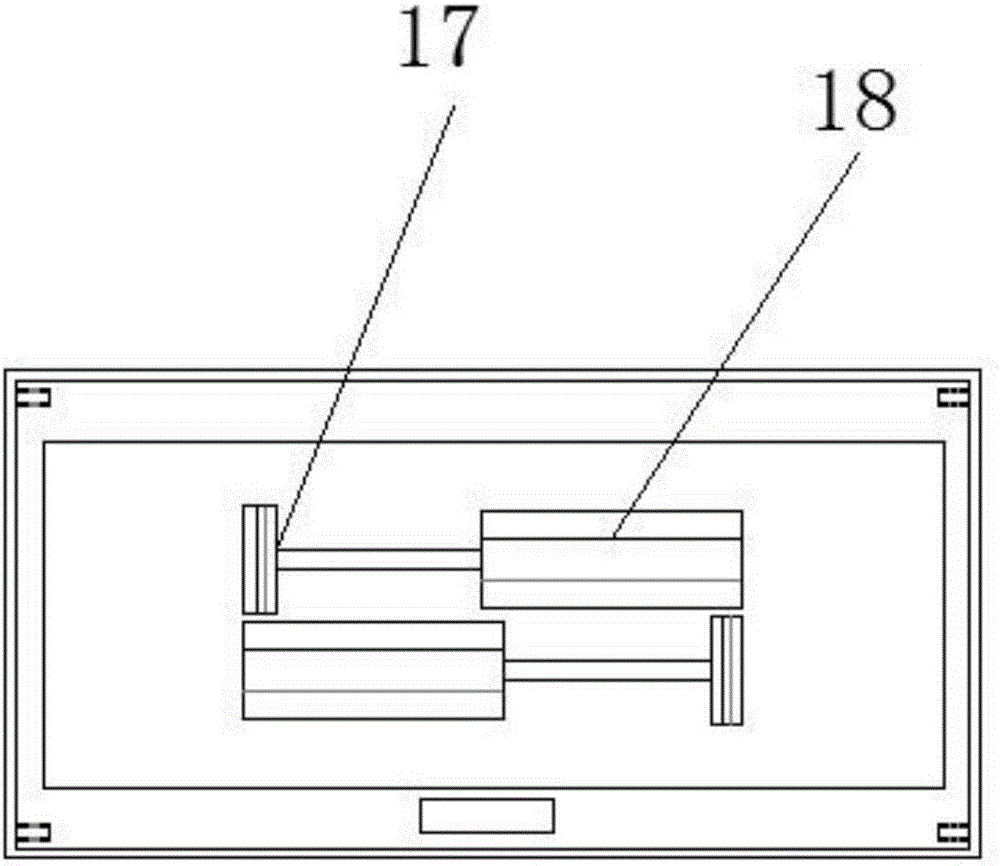

ActiveCN110607896AImprove gluing efficiencySmall footprintBuilding constructionsEngineeringMechanical engineering

The invention discloses a wall tile gluing device and a wall tile gluing and laying robot. The wall tile gluing device comprises a tile discharging box for storing to-be-glued tiles, a tile receivingbox for receiving the glued tiles, a gluing mechanism, a tile conveying mechanism and a lifting driving mechanism, wherein the gluing mechanism is used for coating the back surface of the tiles with tile glue; the tile conveying mechanism is used for conveying the to-be-glued tiles from the tile discharging box to the gluing mechanism and conveying the glued tiles to the tile receiving box; the lifting driving mechanism is configured to drive the tile receiving box, the tile conveying mechanism and the gluing mechanism to lift together. The wall tile gluing device achieves automatic gluing andgreatly improves gluing efficiency of the wall tiles, the tile receiving box, the tile conveying mechanism and the gluing mechanism can be driven to descend together by distance of one tile after gluing of one tile, the next tile is glued continuously, and space can be saved by the structural design.

Owner:GUANGDONG BOZHILIN ROBOT CO LTD

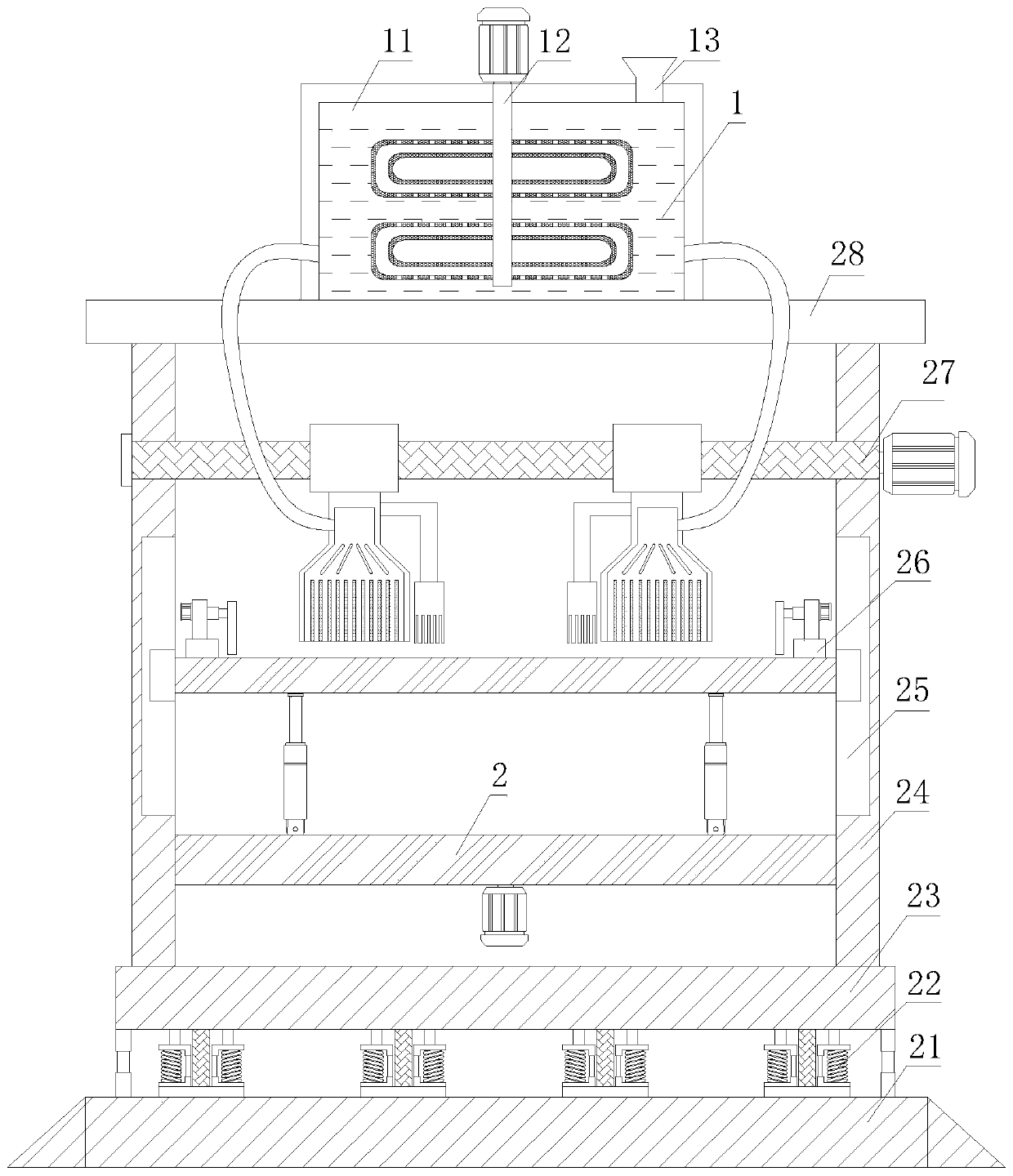

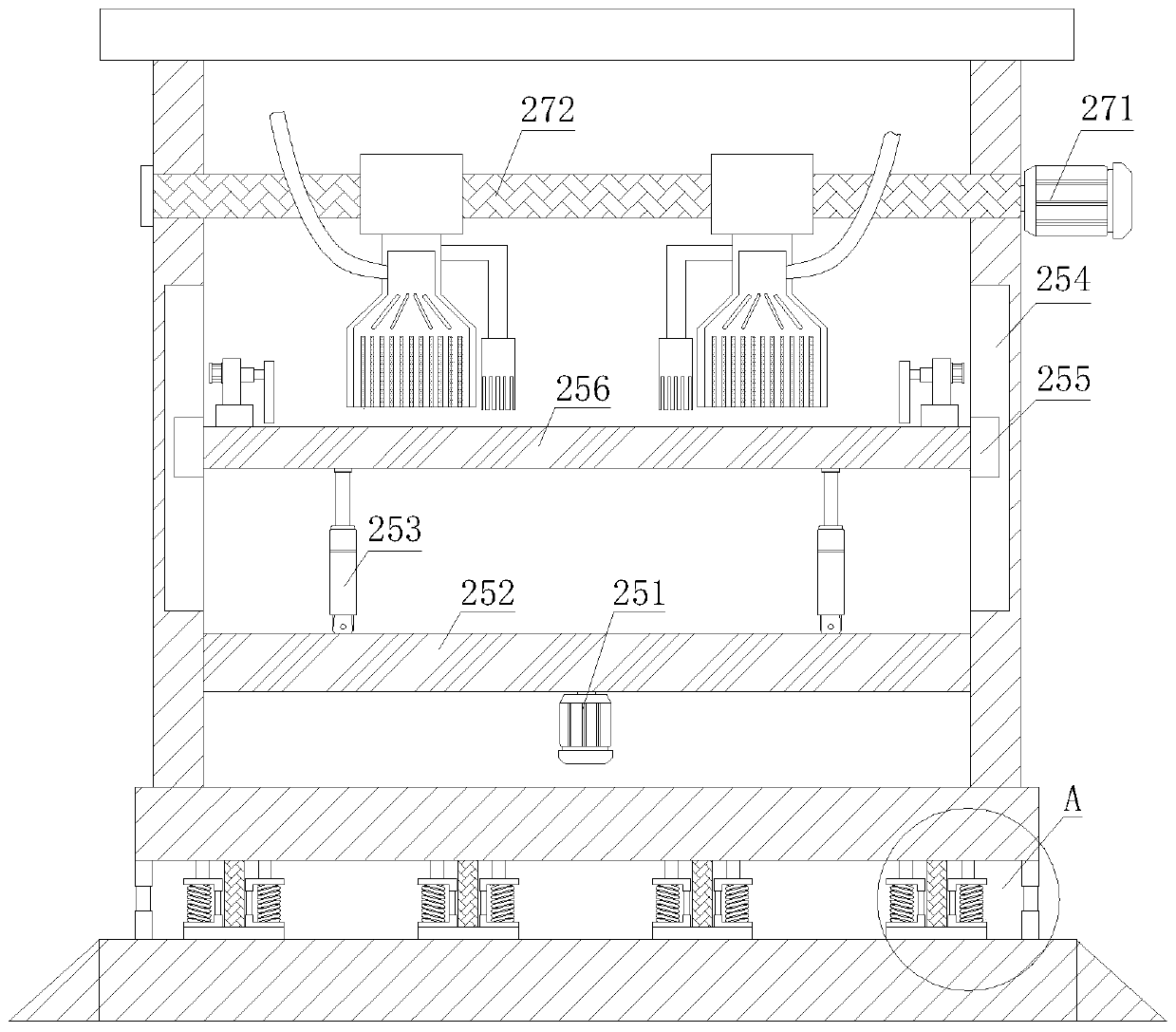

Full-automatic hot-pressing gluing equipment

ActiveCN106113169ANo manual operation requiredImprove gluing efficiencyPlywood pressesVeneer pressesMechanical engineeringHeating energy

The invention relates to a hot-pressing gluing machine, and particularly relates to full-automatic hot-pressing gluing equipment. According to the technical scheme, the full-automatic hot-pressing gluing equipment comprises a gluing device, wherein the gluing device comprises a machine body, laminating plates and a driving mechanism; laminating space exists between the laminating plates; a heat energy generator is arranged on the machine body; a device for inputting objects to be glued and a device for completing output of the glued objects are respectively and symmetrically arranged at the two sides of the machine body; the device for inputting the objects to be glued comprises a rack, a conveying platform erected on the rack, a feeding mechanism erected on the conveying platform and a lifting mechanism a capable of lifting the conveying platform; and the device for completing output of the glued objects comprises a rack, an output platform erected on the rack, a discharging mechanism erected on the output platform and a lifting mechanism b erected on the rack. According to the technical scheme, the full-automatic hot-pressing gluing equipment has the advantages of improving gluing efficiency, saving labor cost and eliminating safety hazards.

Owner:ZHEJIANG NEW CENTURY MACHINERY MFG

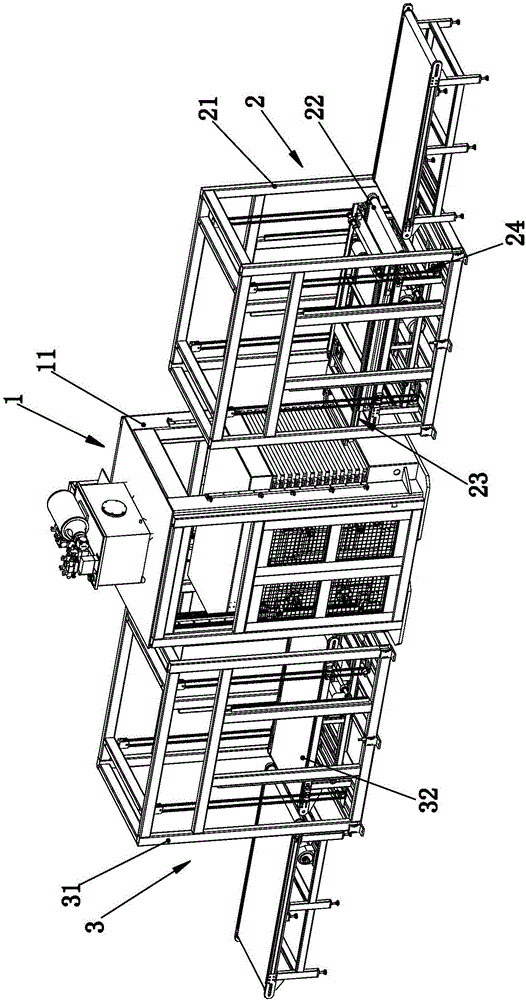

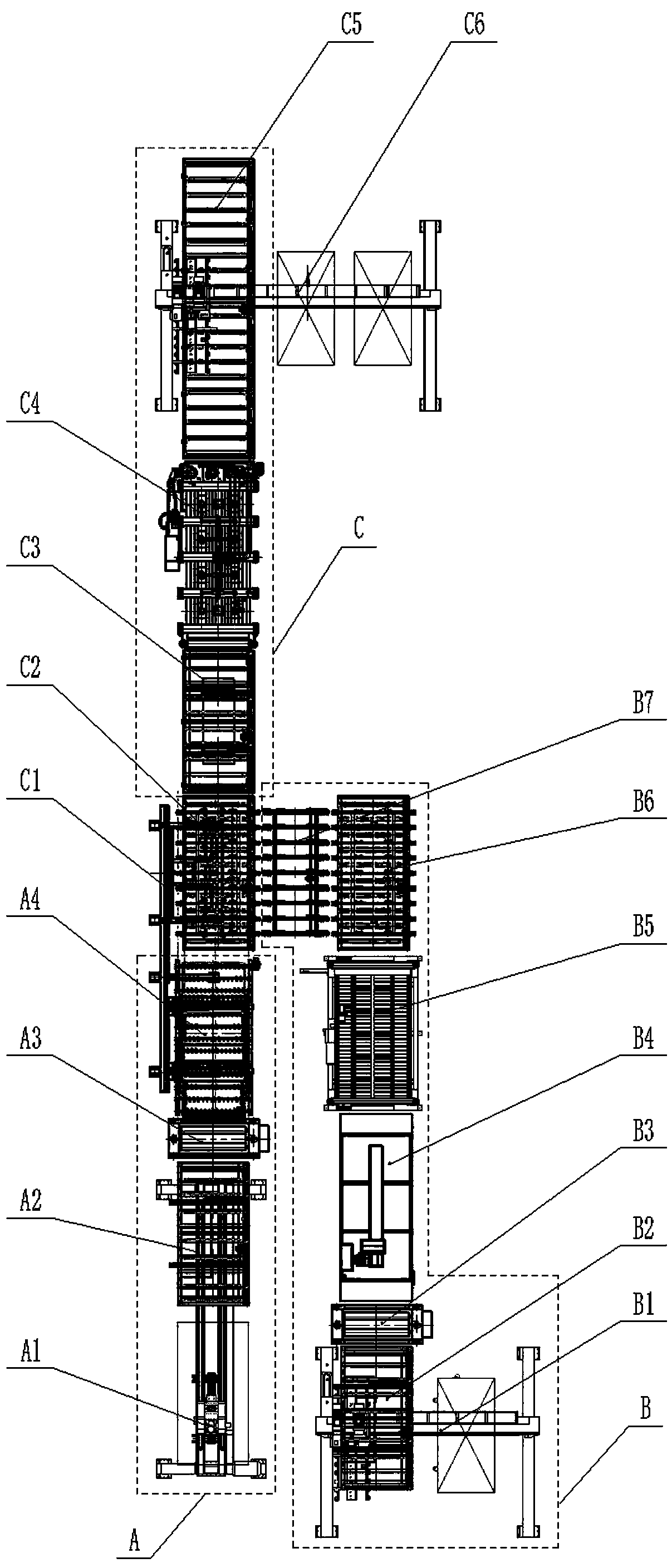

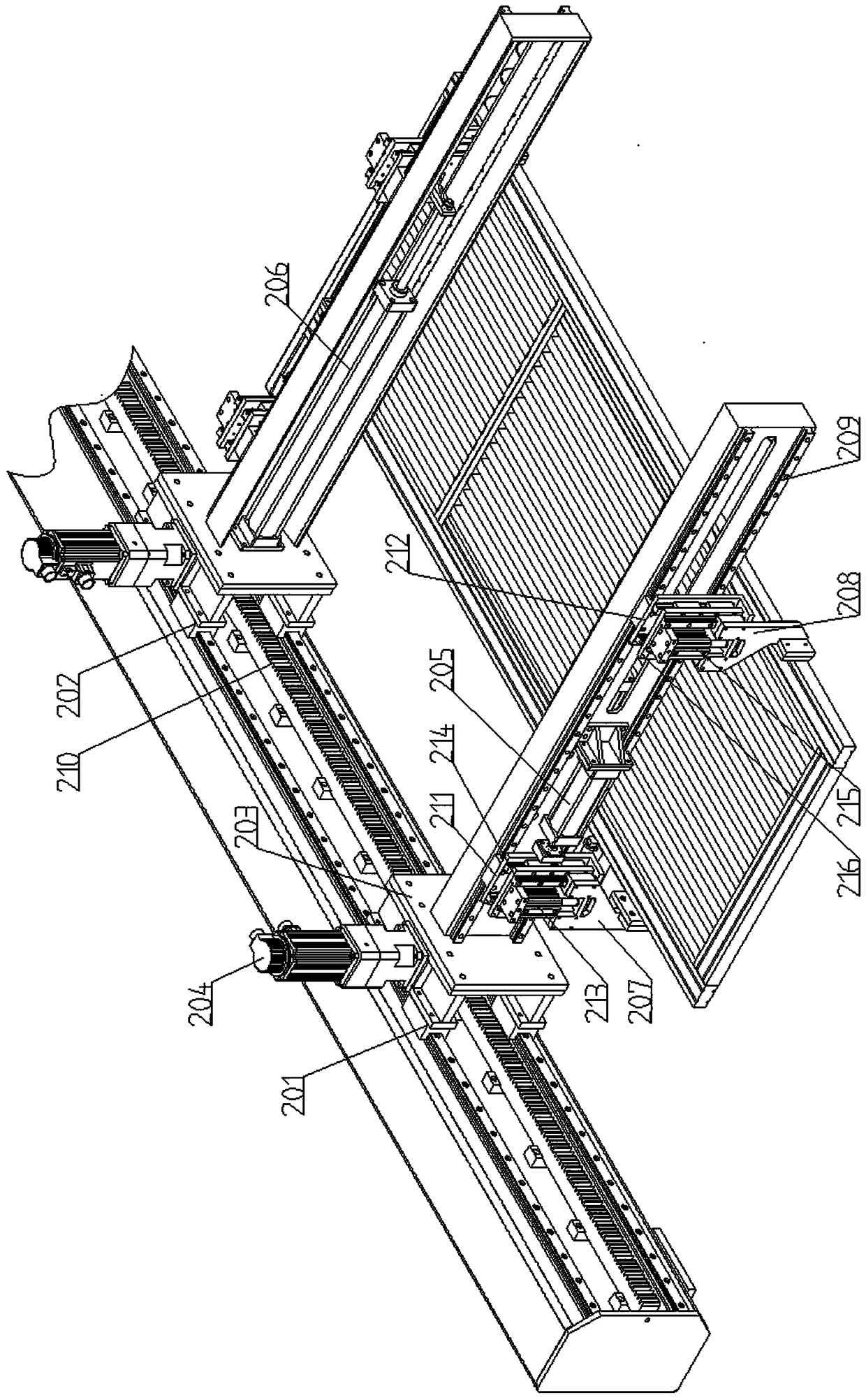

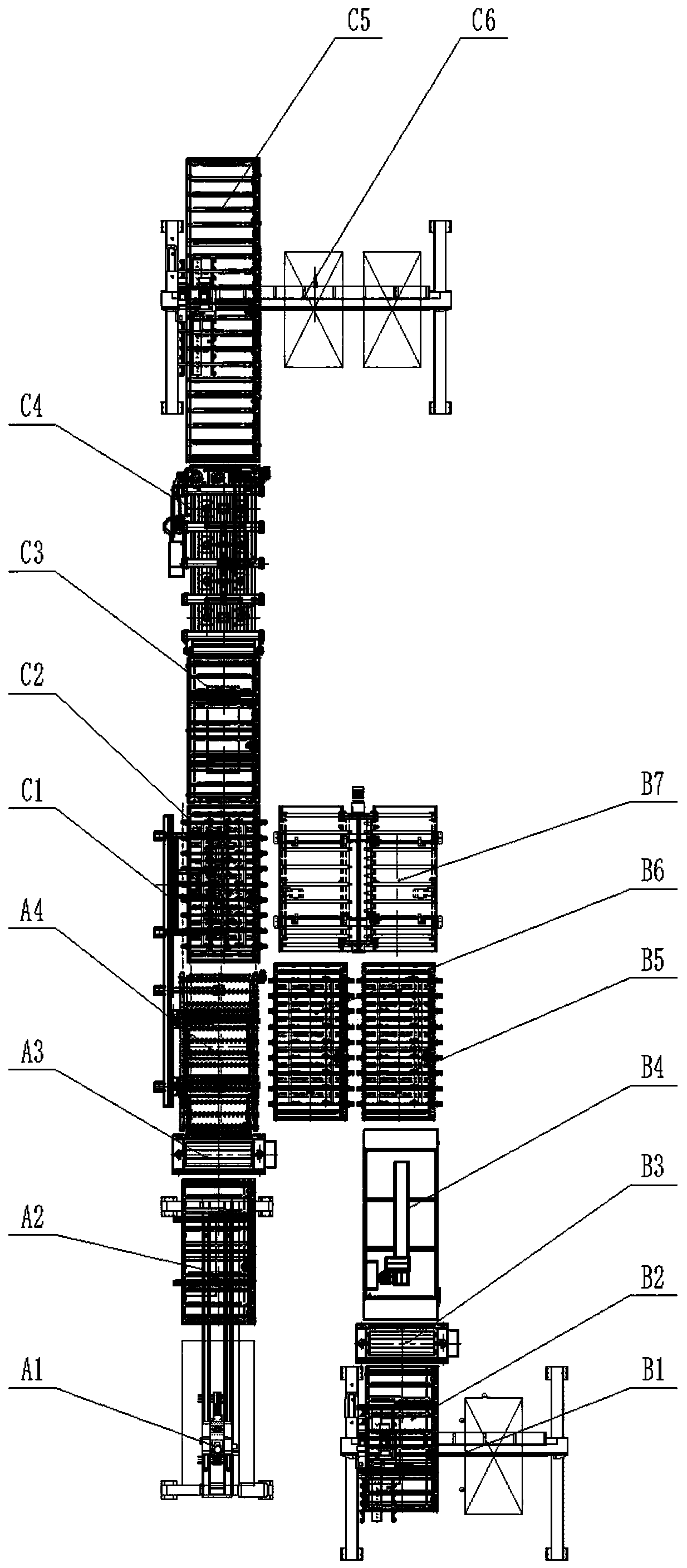

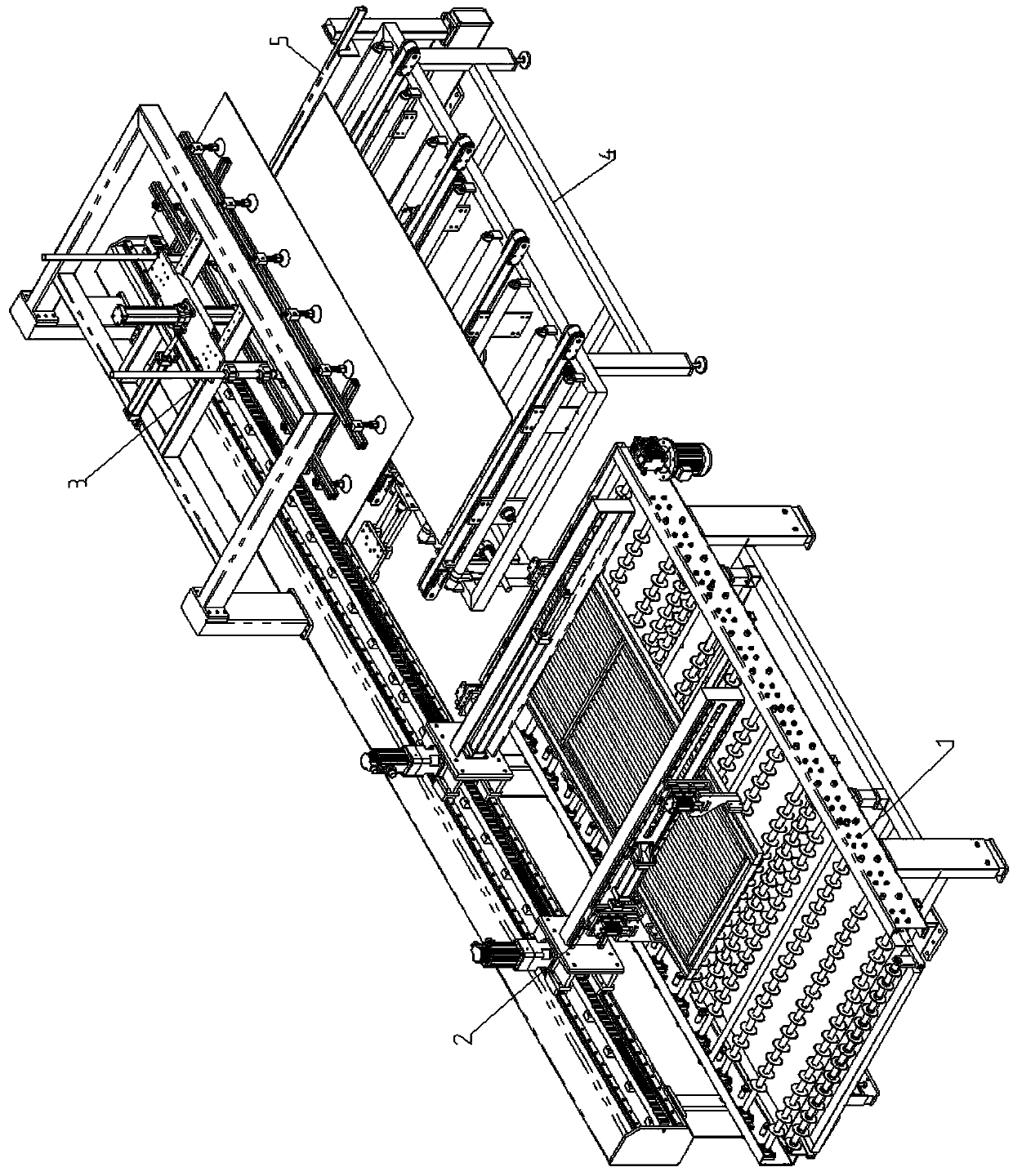

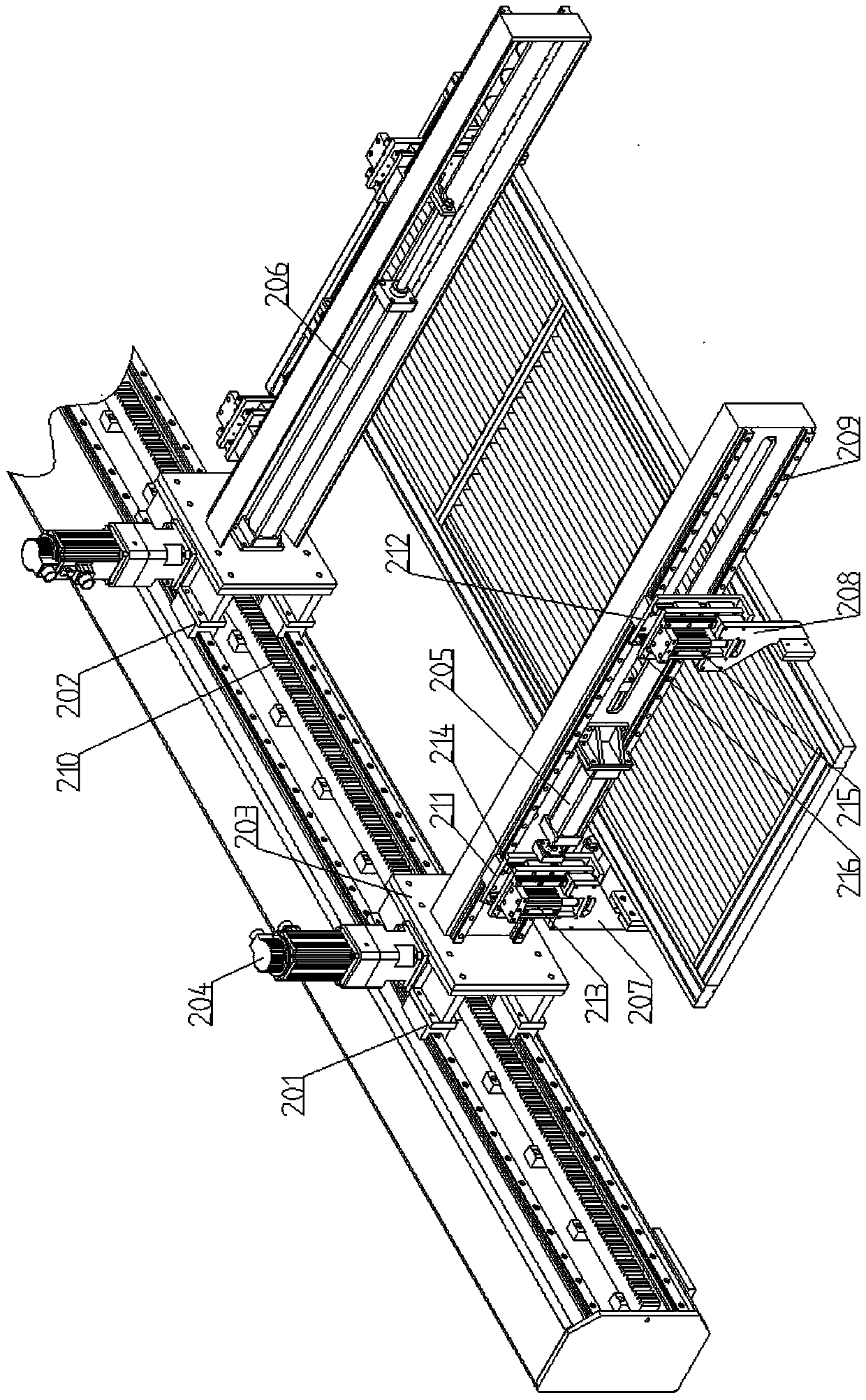

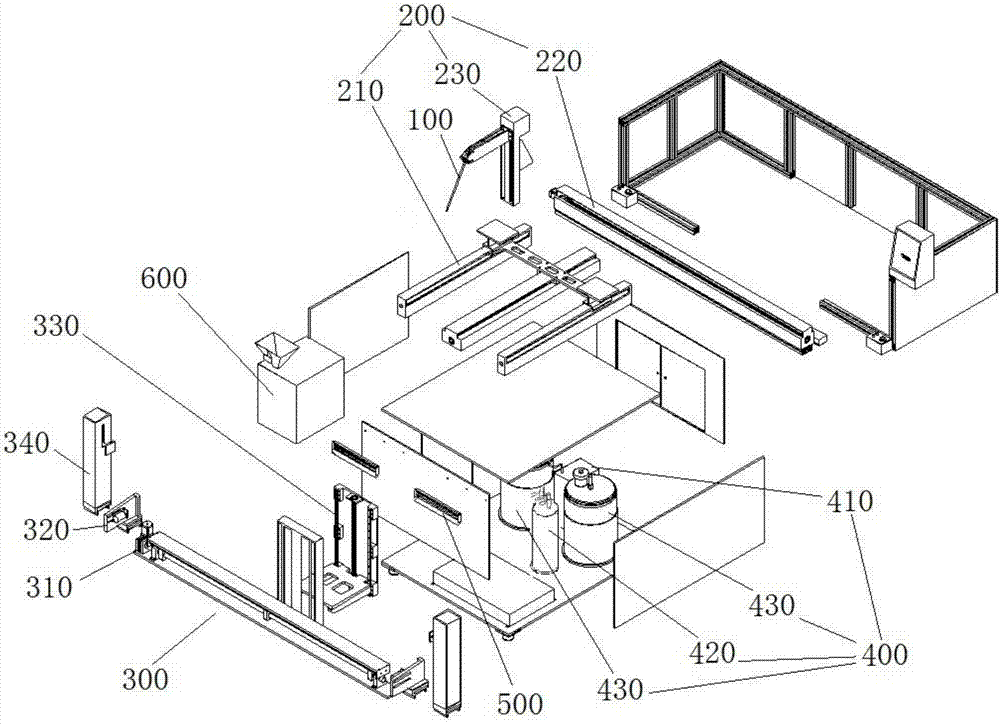

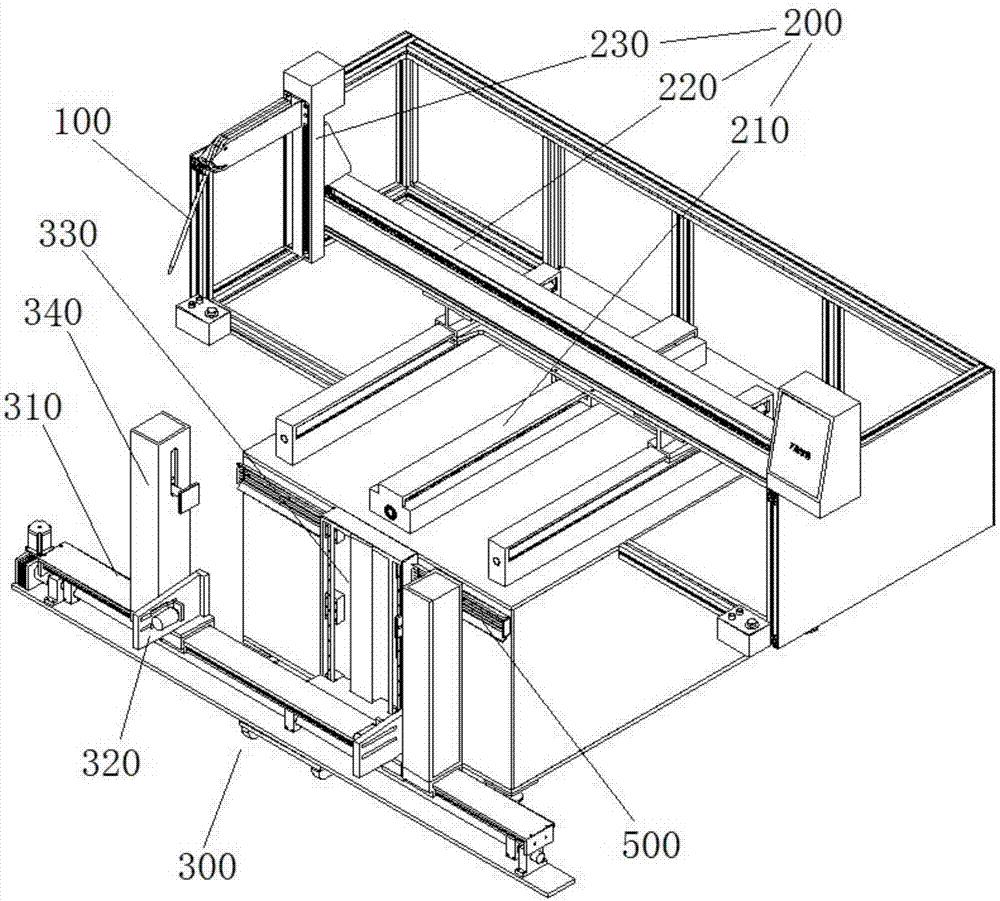

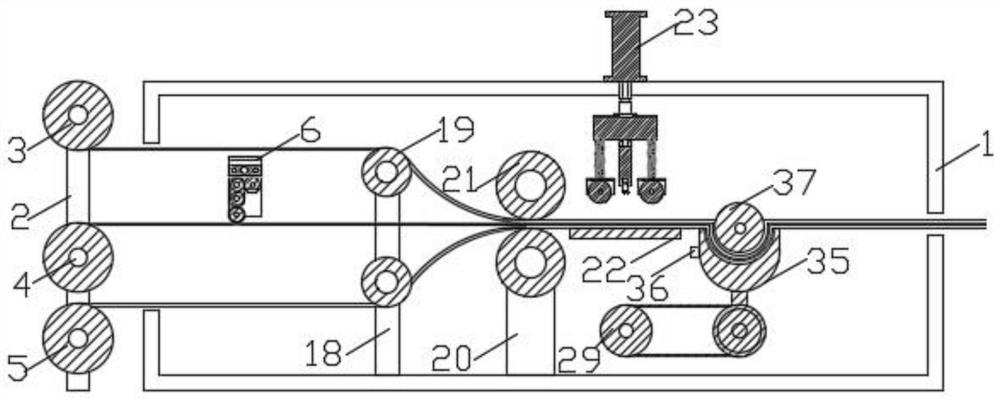

Production line and method for wooden door veneering

ActiveCN109454741AImprove gluing efficiencyReduce waiting timeWood veneer joiningProduction lineGlue line

The invention discloses an automatic production line for wooden door veneering. The automatic production line for wooden door veneering comprises a core plate gluing line, a panel and bottom plate glue line and a plate combining line, wherein the core plate gluing line and the plate combining line are arranged in sequence according to the feeding direction, and the panel and the bottom plate gluing line are arranged in parallel with the above two. According to the automatic production line for wooden door veneering, the core plate, the plate and the bottom plate are respectively and synchronously coated with two gluing lines, the gluing efficiency is greatly improved, the improved cantilever assembling machine is adopted, so that the core plate is coated with the glue line, and the plate and the bottom plate gluing line are fed in two different directions, so that the waiting time of queuing and the like is reduced.

Owner:山西万锐液压机械有限公司

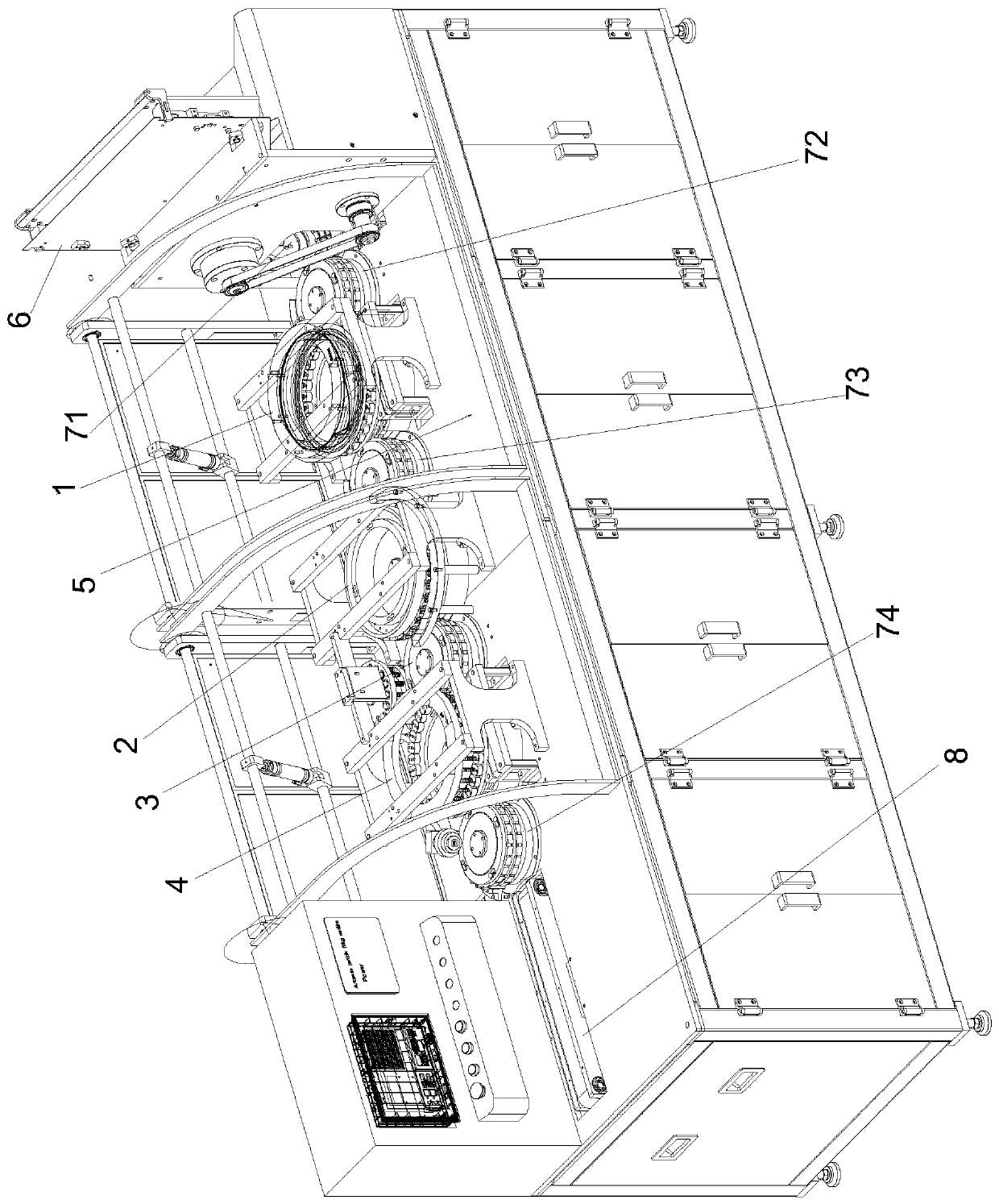

Improved particle continuous filling equipment

PendingCN110419768AGuaranteed uptimeEfficiencyCigarette manufactureTobacco devicesPunchingBurn cigarette

The invention provides improved particle continuous filling equipment, wherein in a priming section, a priming drum is utilized to drive cigarette blank pipes and an edge layer at the top end to synchronously rotate, a compound cam and compound punching needles above are matched, and by up-and-down movement of the compound punching needles, priming on the cigarette blank pipes is implemented; in afilling section, a filling drum is utilized to drive a feeding disk at the top end to rotate, a filling cam is matched with a plurality of moving pistons on the feeding disk, opening / closing of eachfilling through hole on a ring-shaped groove of the feeding disk is implemented, and filling is carried out in a filling working region where a separator is positioned; in a gluing section, glue dispensing rods and the cigarette pipes can be in contact at a meshing point under the press-against action of a gluing cam, a gluing wheel in a glue pool glues the glue dispensing rod; and in a sealing section, rotation of a sealing drum is utilized to drive sealing punching needles to be matched with a sealing cam above so as to implement up-and-down movement of the sealing punching needles and complete sealing on the glued cigarette pipes. According to the invention, higher efficient and high quality preparation of a particle heating non-burning cigarette product can be implemented, and cost isreduced.

Owner:CHINA TOBACCO ANHUI IND CO LTD

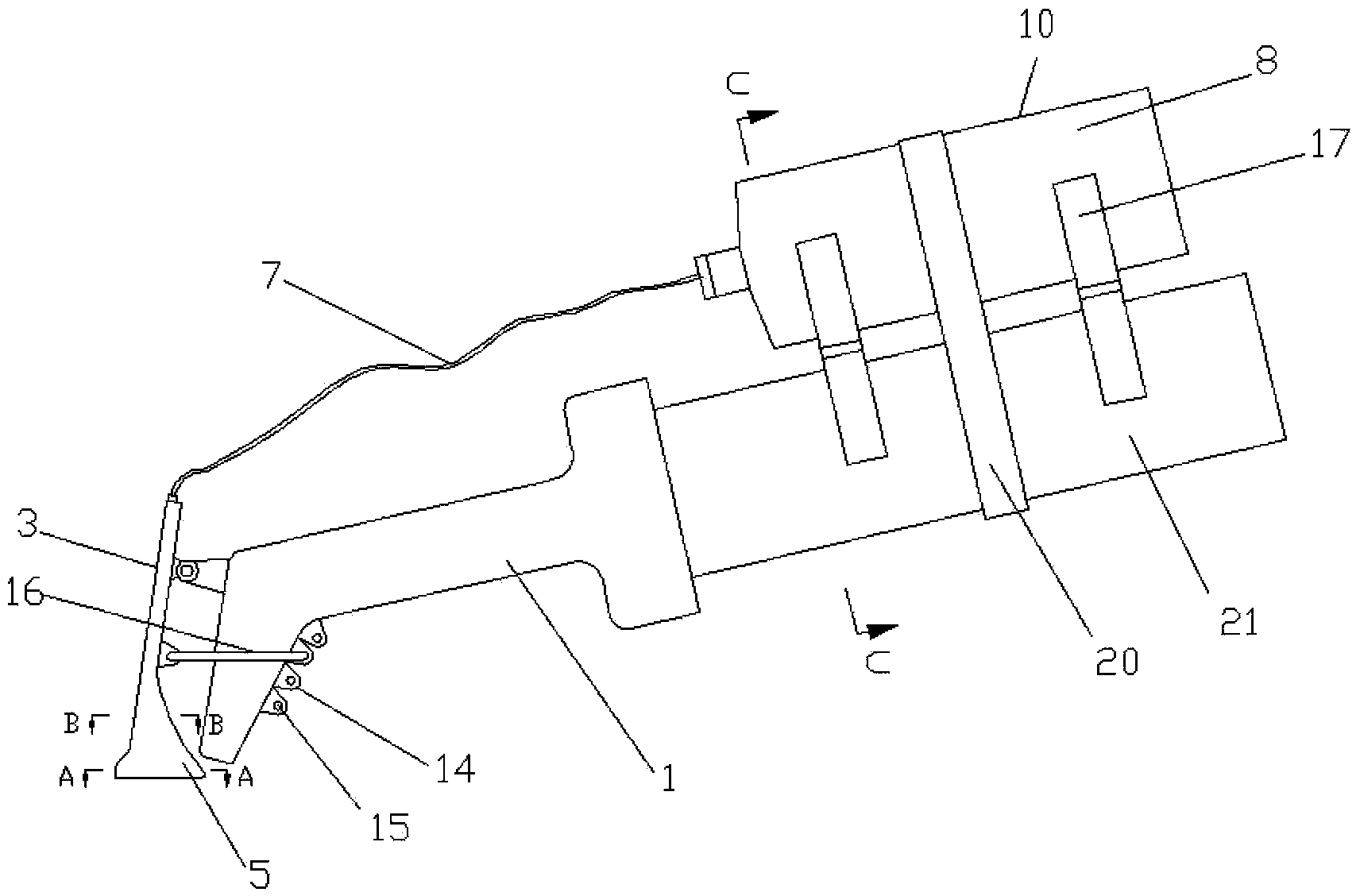

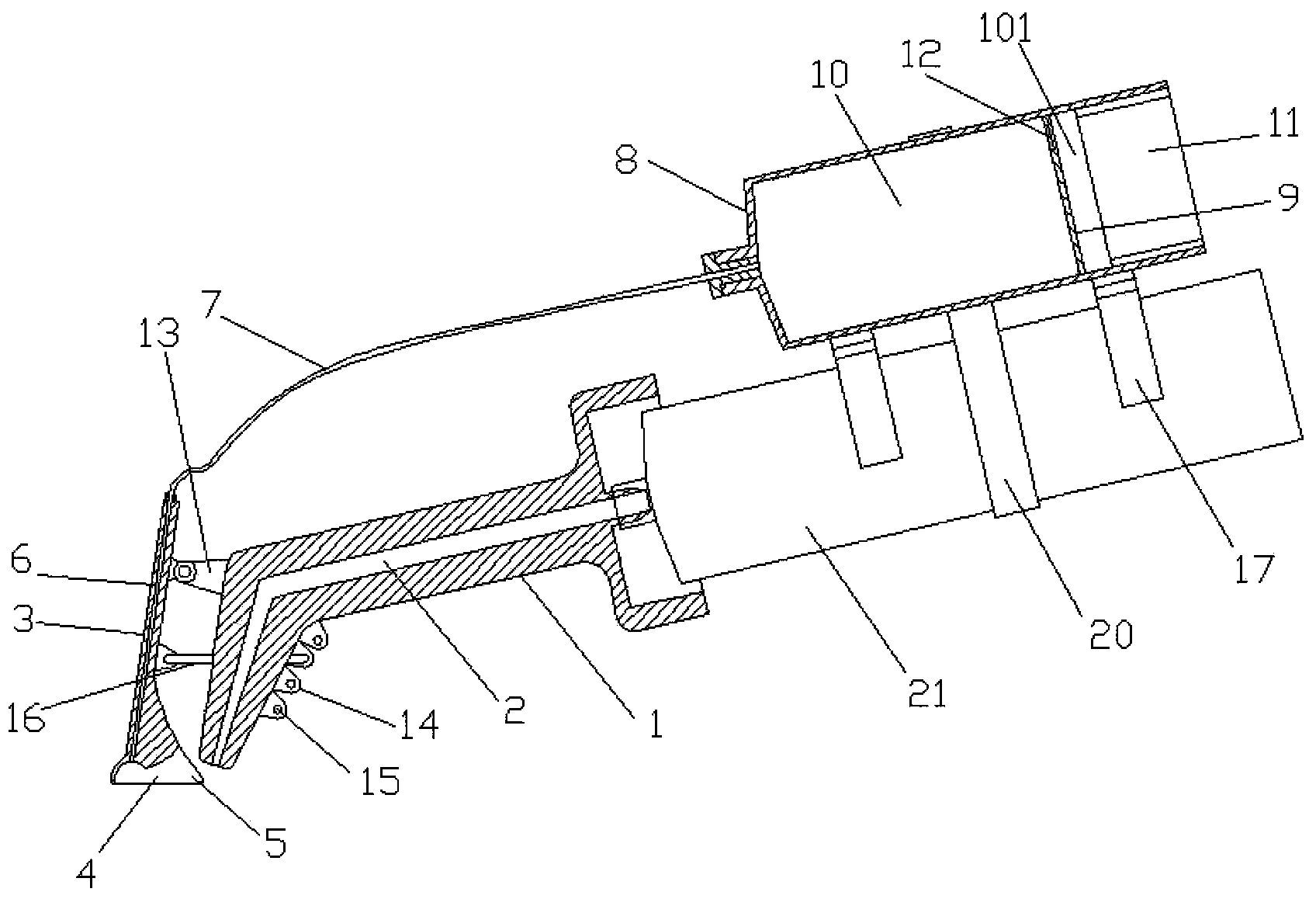

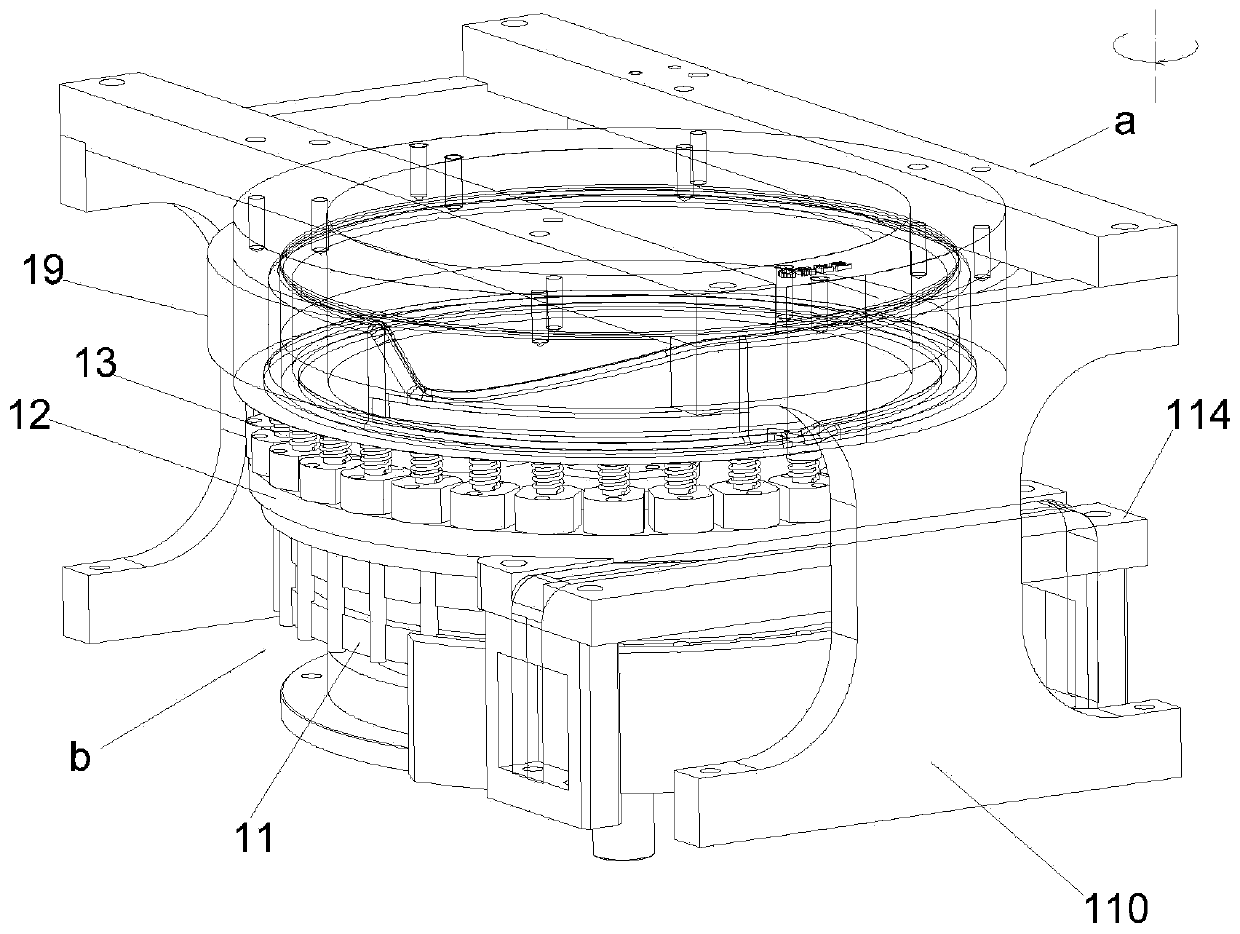

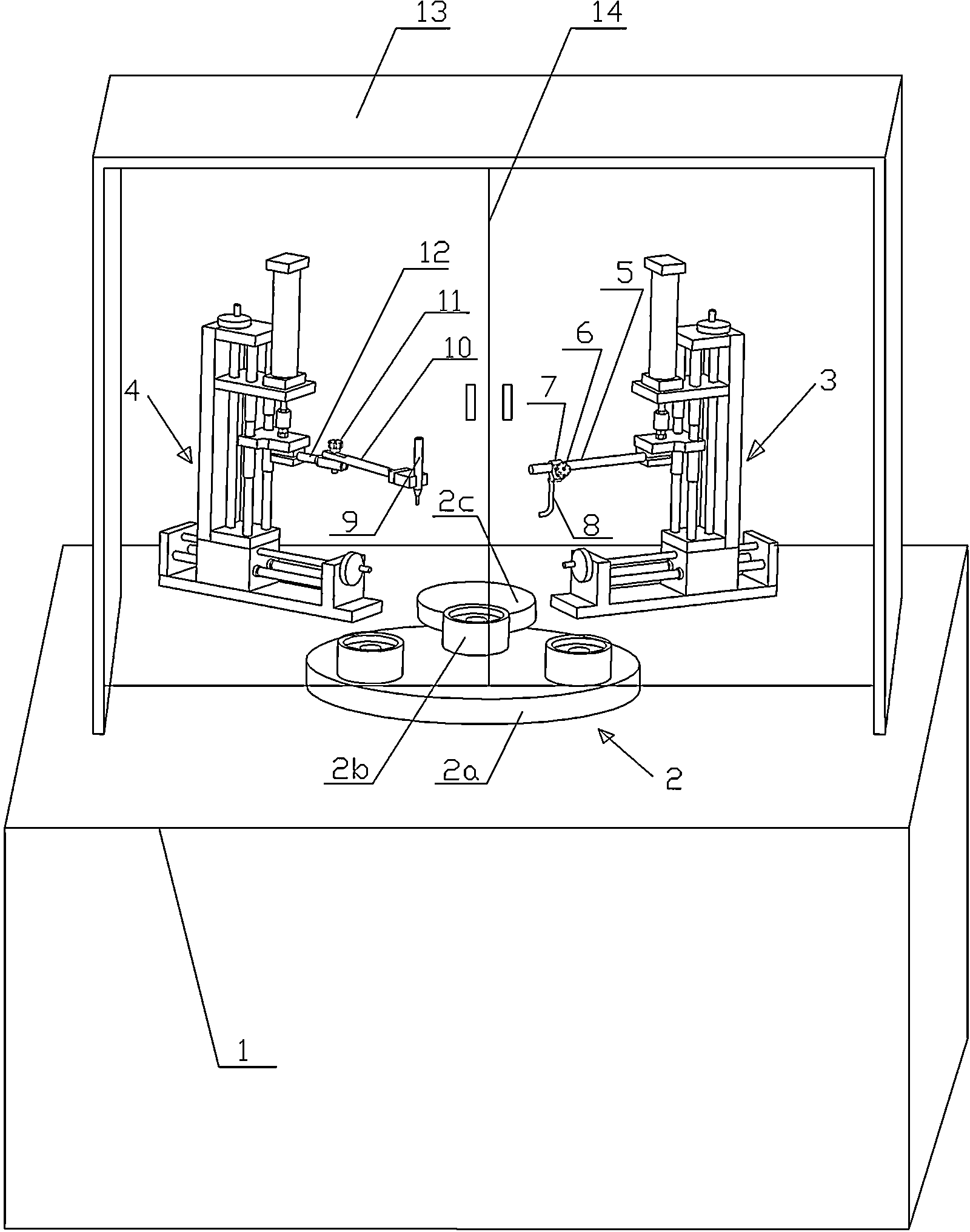

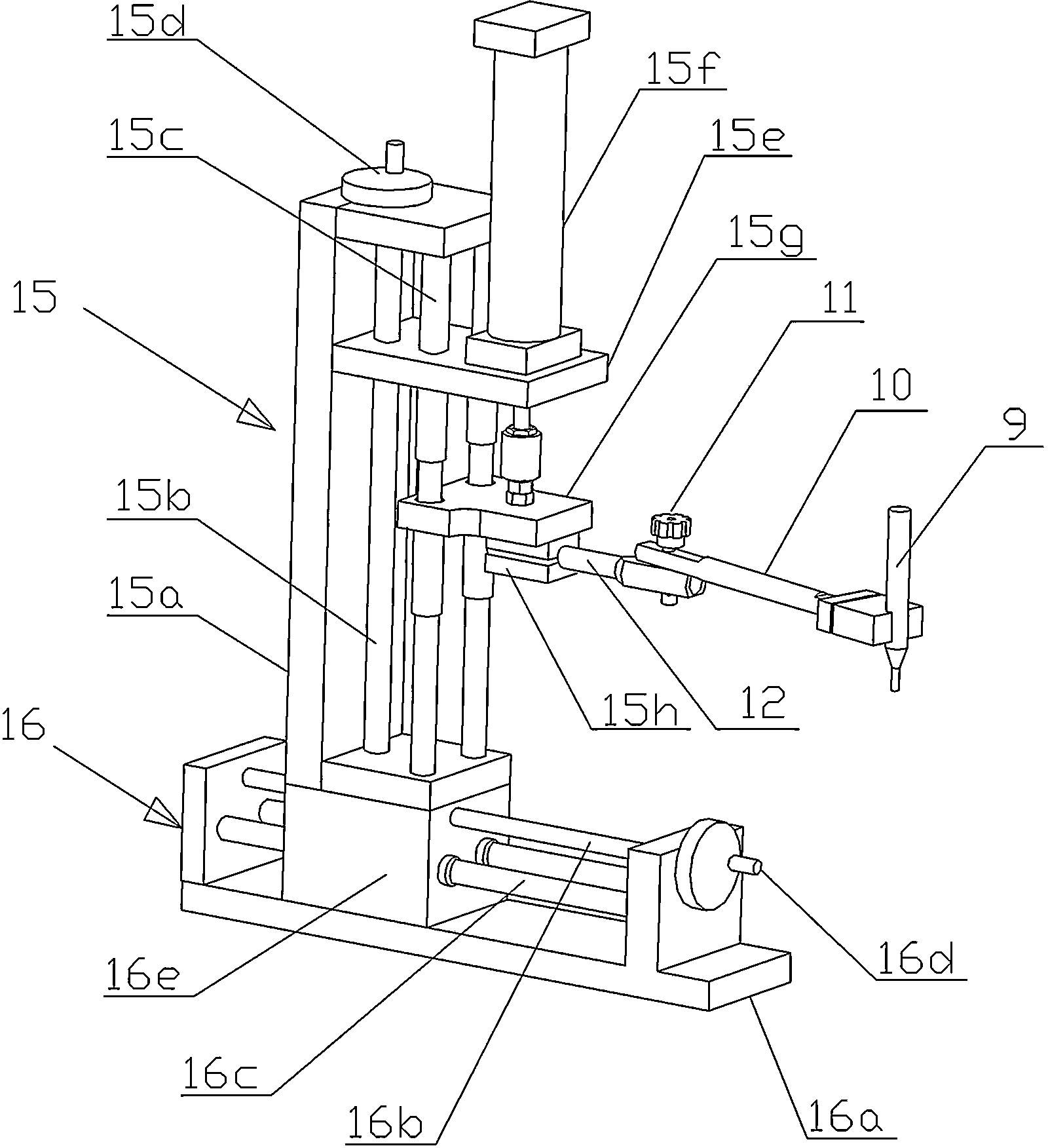

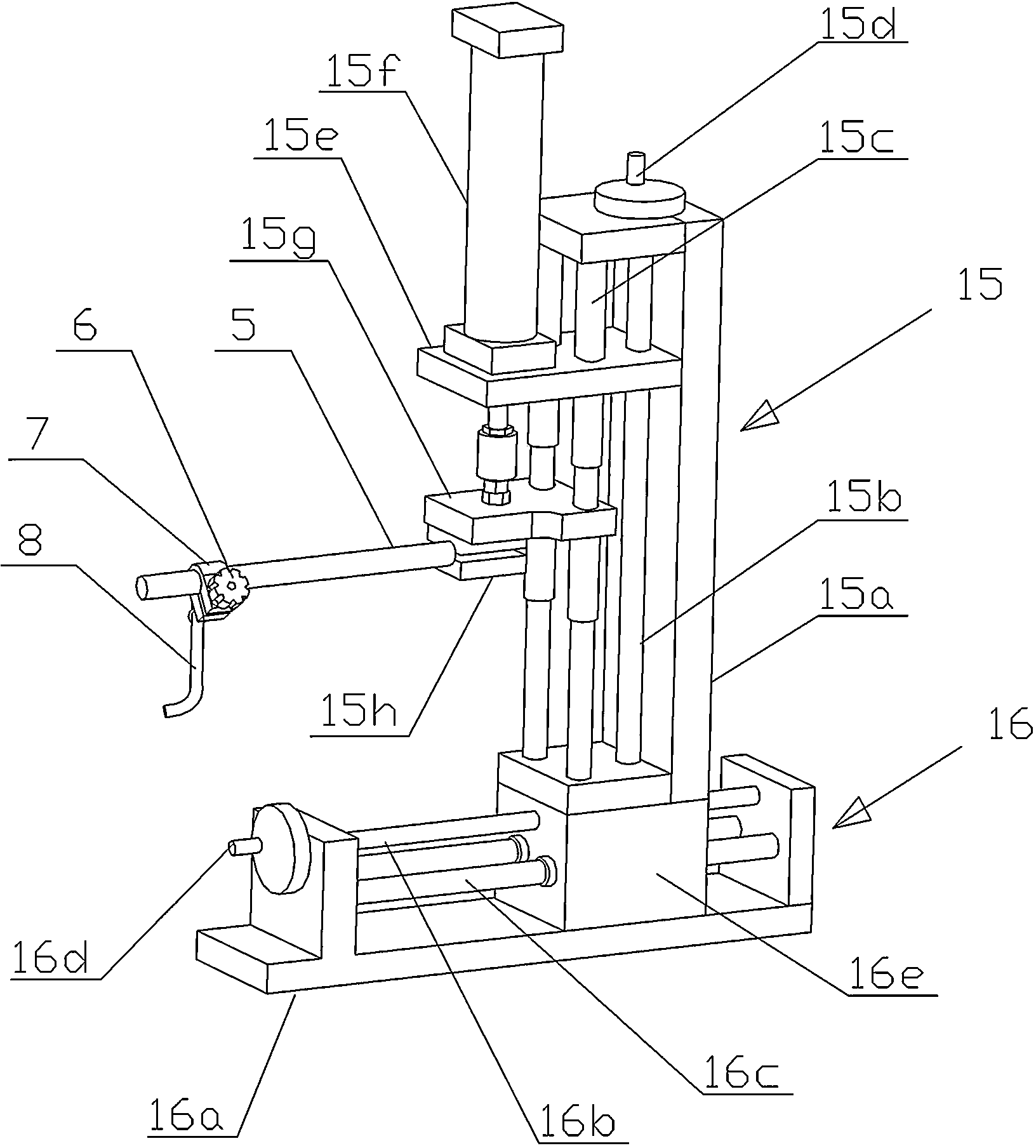

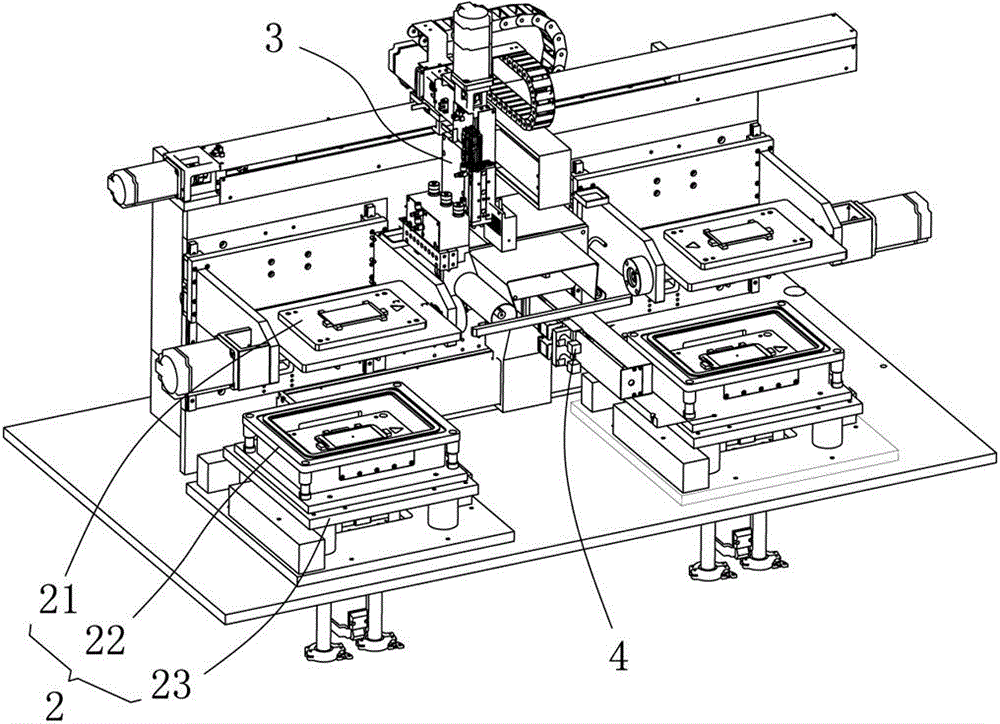

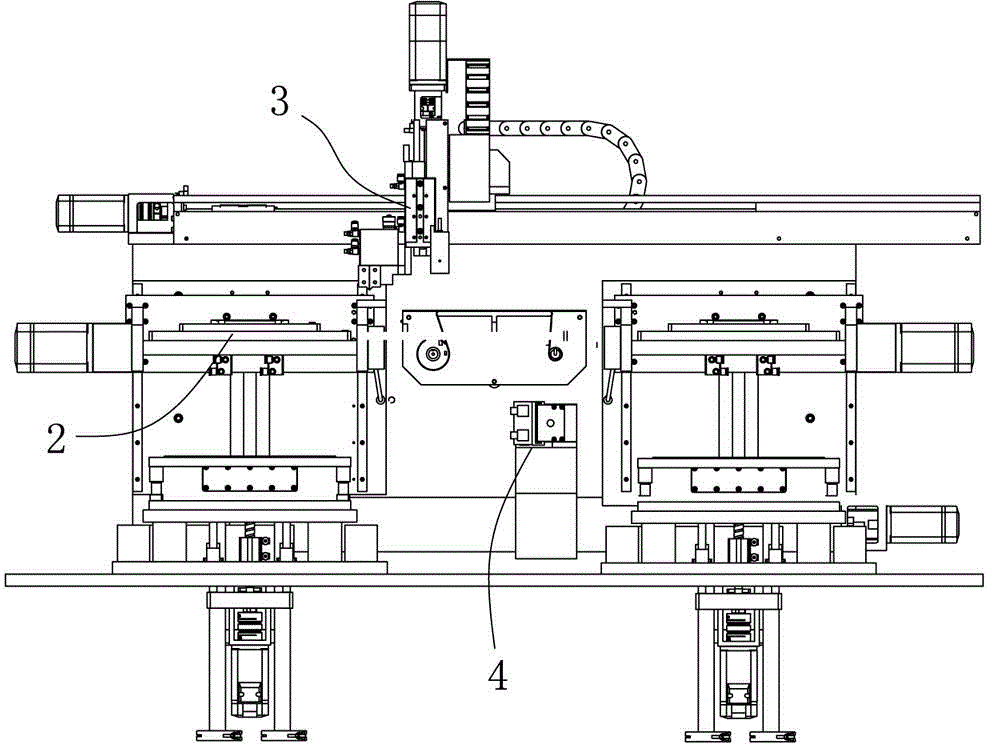

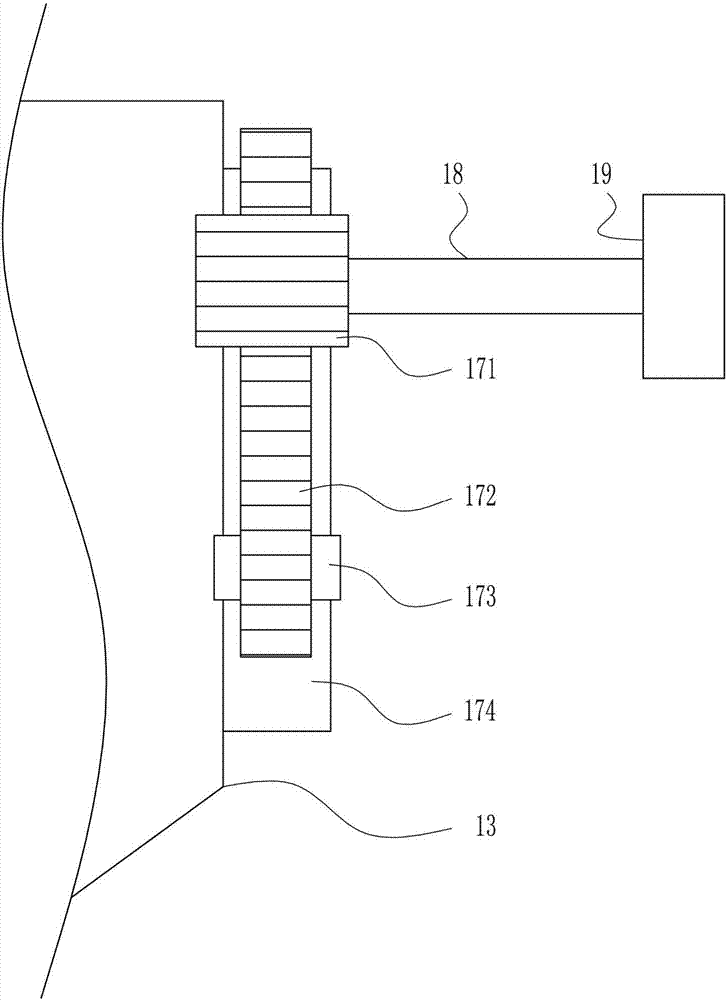

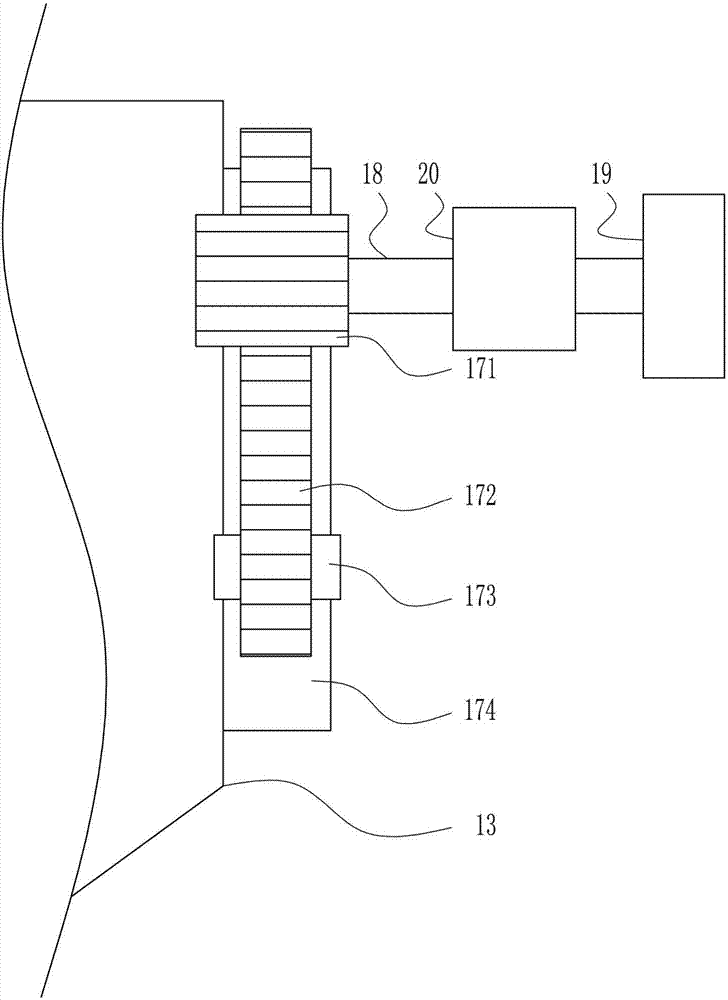

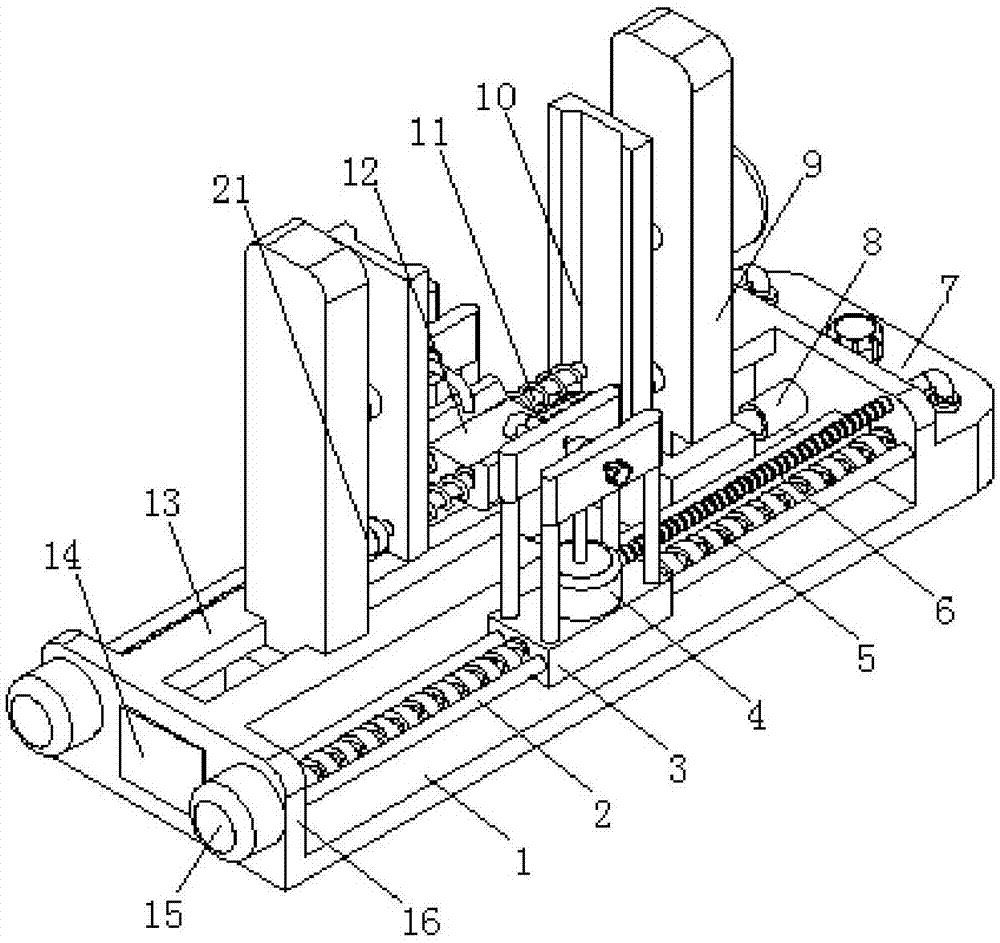

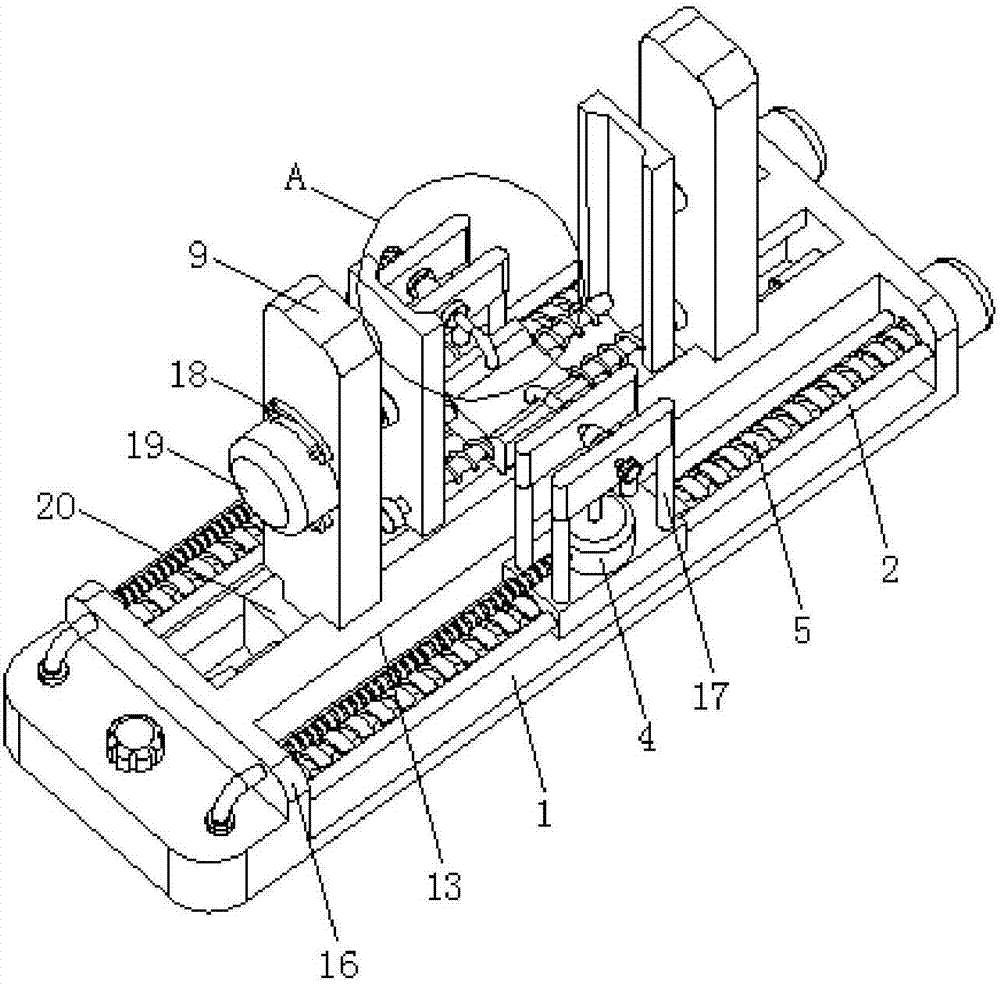

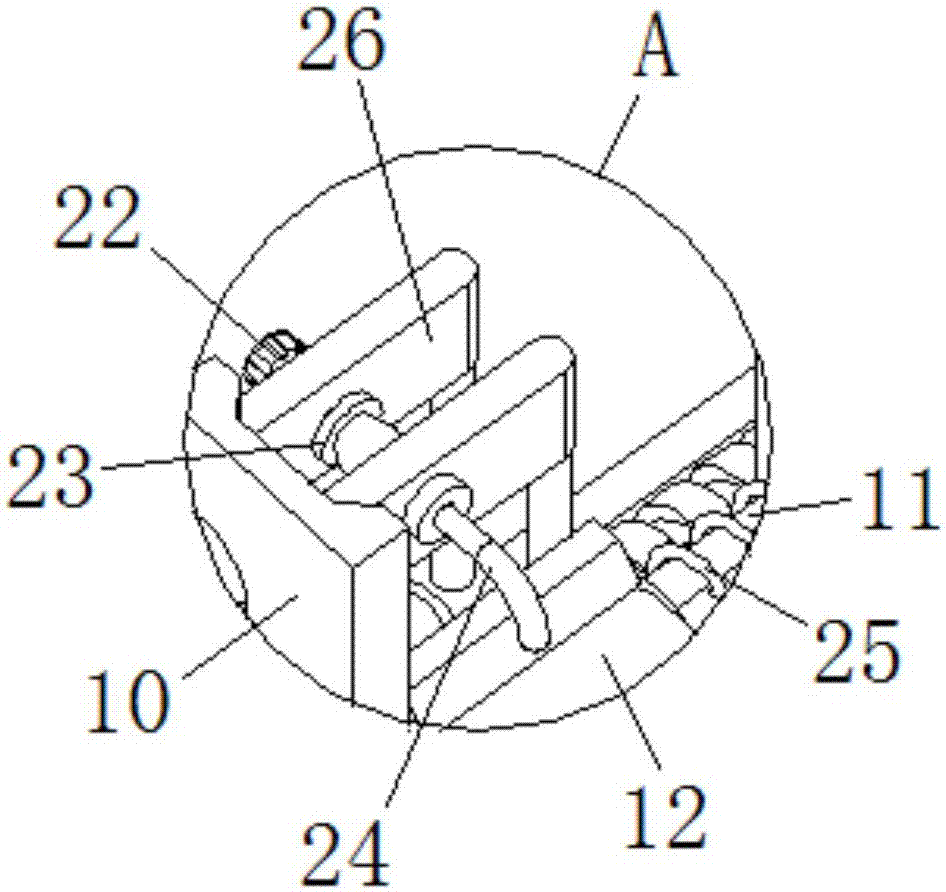

Automatic double-station gluing machine

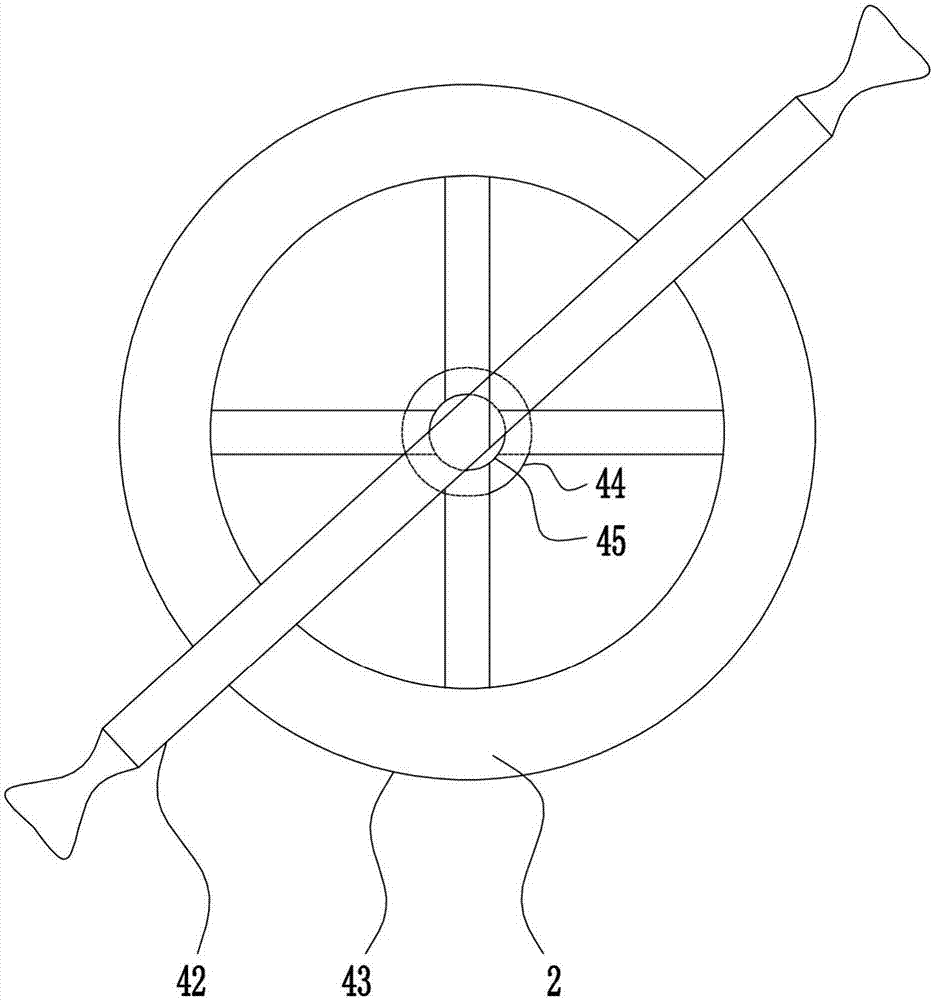

ActiveCN104028412ASimple structureEasy to adjustLiquid surface applicatorsCoatingsEngineeringMechanical engineering

The invention relates to an automatic double-station gluing machine. The automatic double-station gluing machine comprises a working table (1), and a revolving device (2) provided with a workpiece, wherein the working table is provided with a first connecting rod (12) controlled by a first transmission mechanism (4) to lift and translationally moved; a horizontal swinging rod (10) is arranged at one end of the first connecting rod; one end of the horizontal swinging rod is fitted and connected with the first connecting rod through a first locking bolt (11), and the other end of the horizontal swinging rod is connected with an end surface gluing brush (9); the working table is further provided with a second connecting rod (5) controlled by a second transmission mechanism (3) to lift and translationally moved; a U-shaped clamping base (7) is arranged on the second connecting rod; one side of the U-shaped clamping base is connected with a circumferential surface gluing brush (8); a second locking bolt (6) is arranged at the other side of the U-shaped clamping base; and the U-shaped clamping base is locked through the second locking bolt. The automatic double-station gluing machine has the advantages of simple structure and convenience for operation and adjustment, can synchronously coat adhesive on the end surface and circumferential surface of the workpiece, and has higher gluing efficiency and applicability.

Owner:ANHUI HAOFANG ELECTROMECHANICS

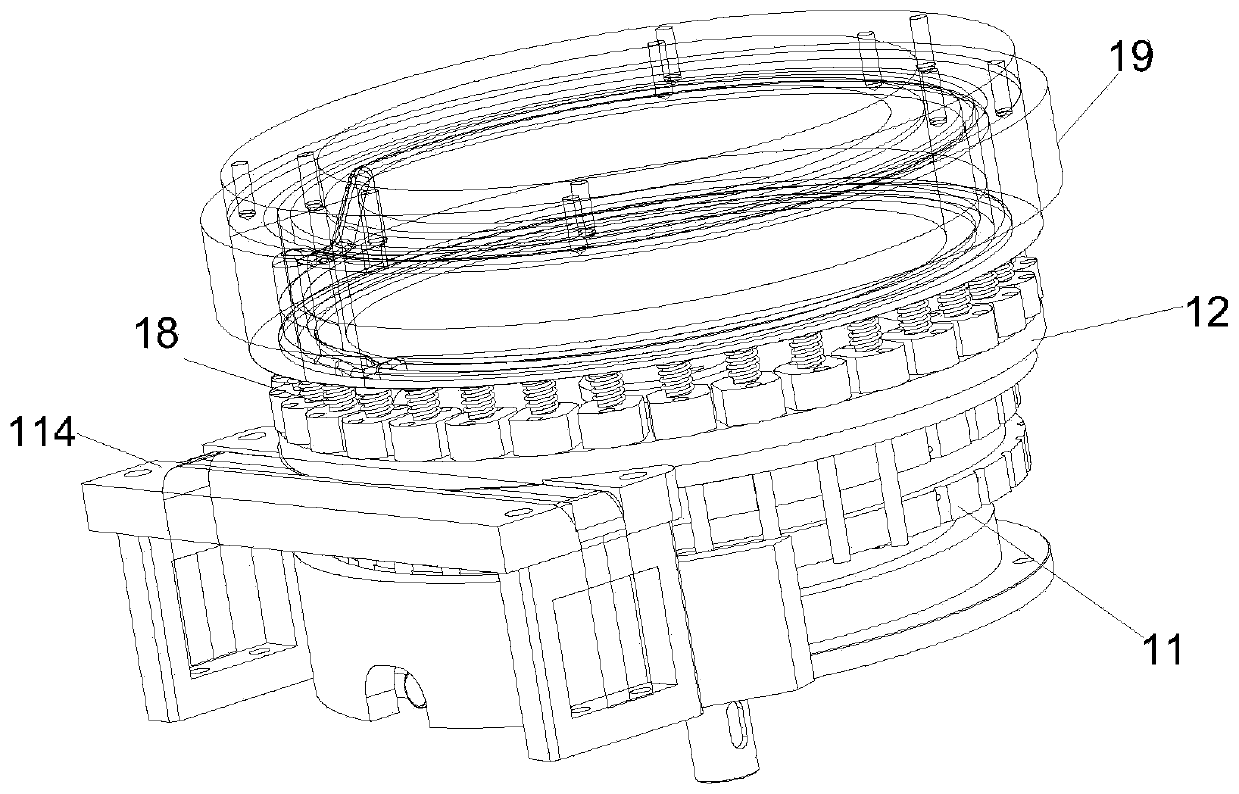

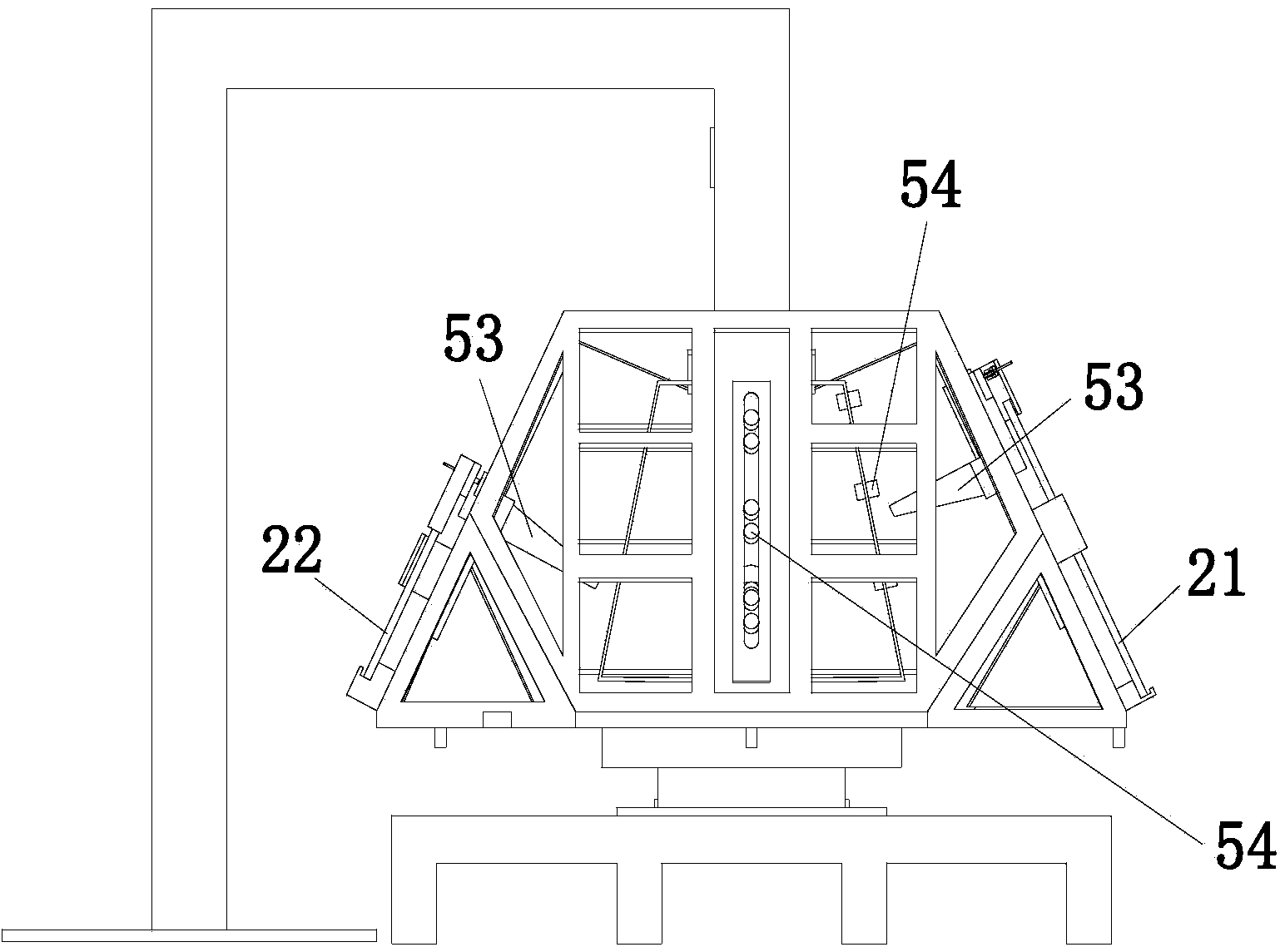

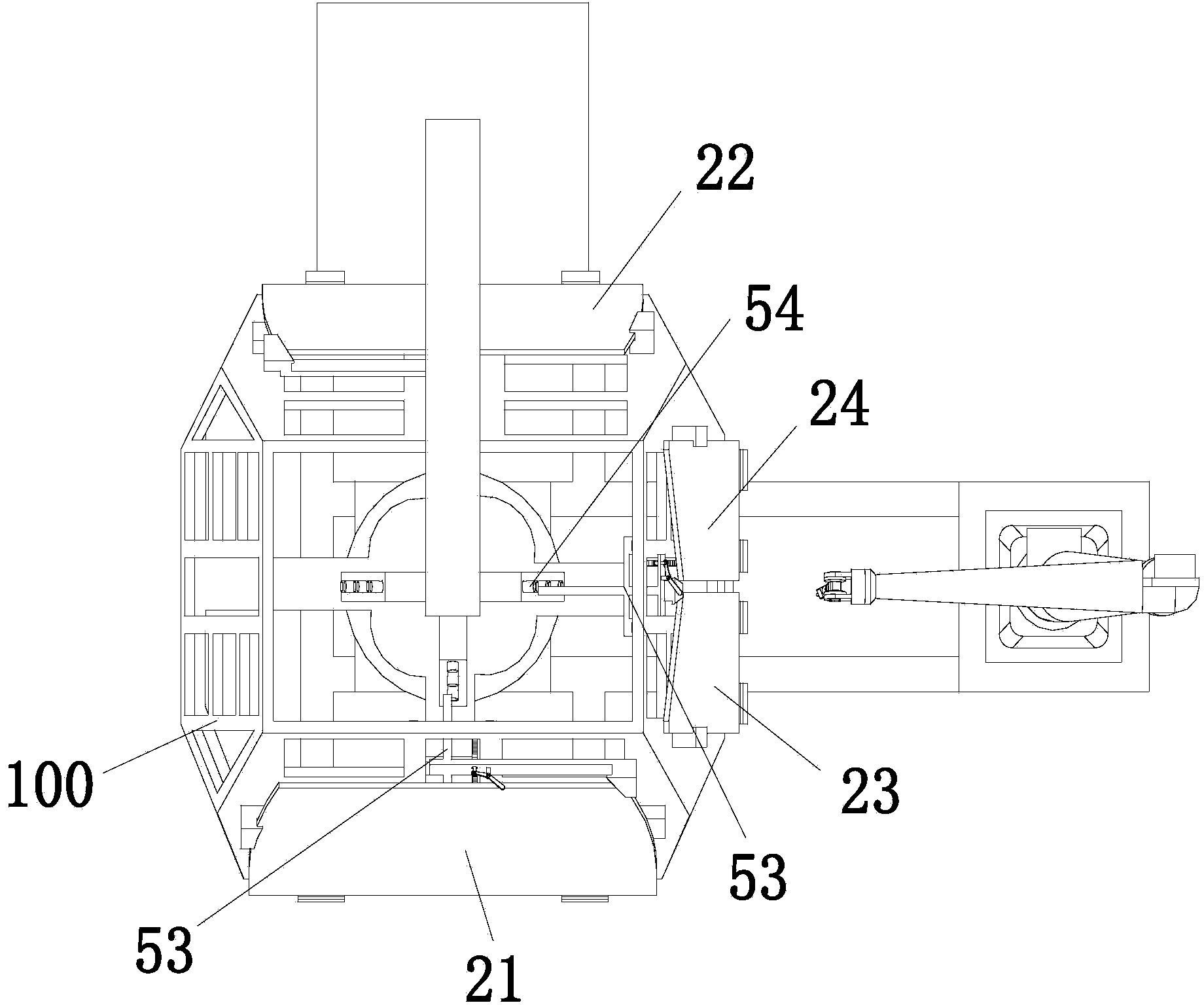

Glass gluing device

InactiveCN103977938AImprove gluing efficiencySmall footprintLiquid surface applicatorsCoatingsEngineeringWindshield

The invention discloses a glass gluing device. The glass gluing device comprises a polyhedral rotating table (1), a fixed assembly and a clamp, wherein the polyhedral rotating table (1) comprises a plurality of working table surfaces; the fixed assembly is arranged on the polyhedral rotating table (1) and is used for fixing each windscreen of a whole vehicle to the working table surfaces; the clamp is arranged on the polyhedral rotating table (1) and is used for clamping the windscreen on the working table surfaces. According to the glass gluing device, the floor space of the glass gluing device can be reduced, the application range of the glass gluing device is extended, and the working efficiency of the glass gluing device is increased.

Owner:TIANJIN BOXIN AUTOMOBILE PARTS

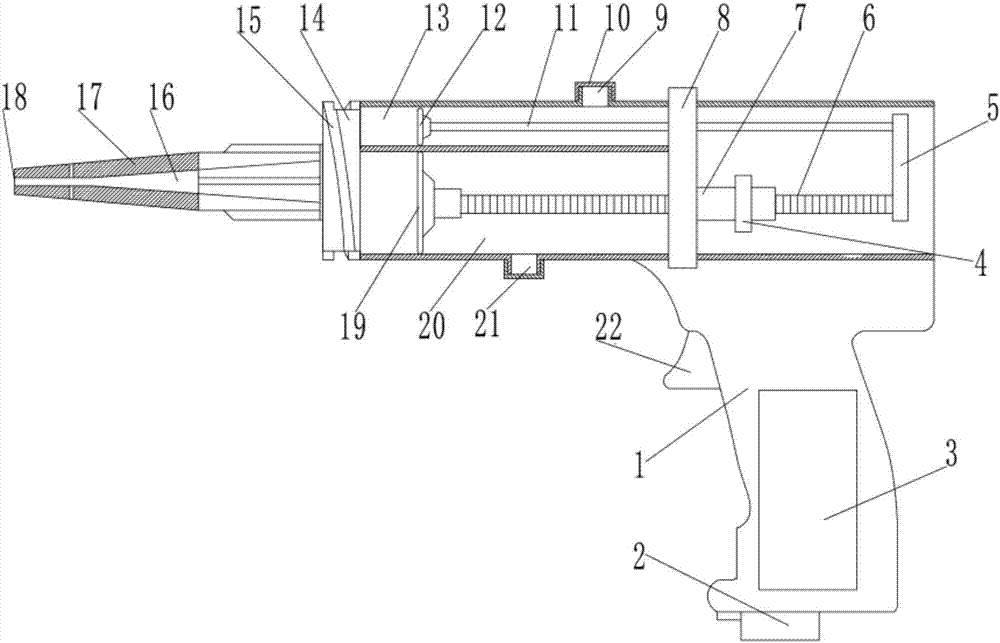

Two-pack electric glue gun for building

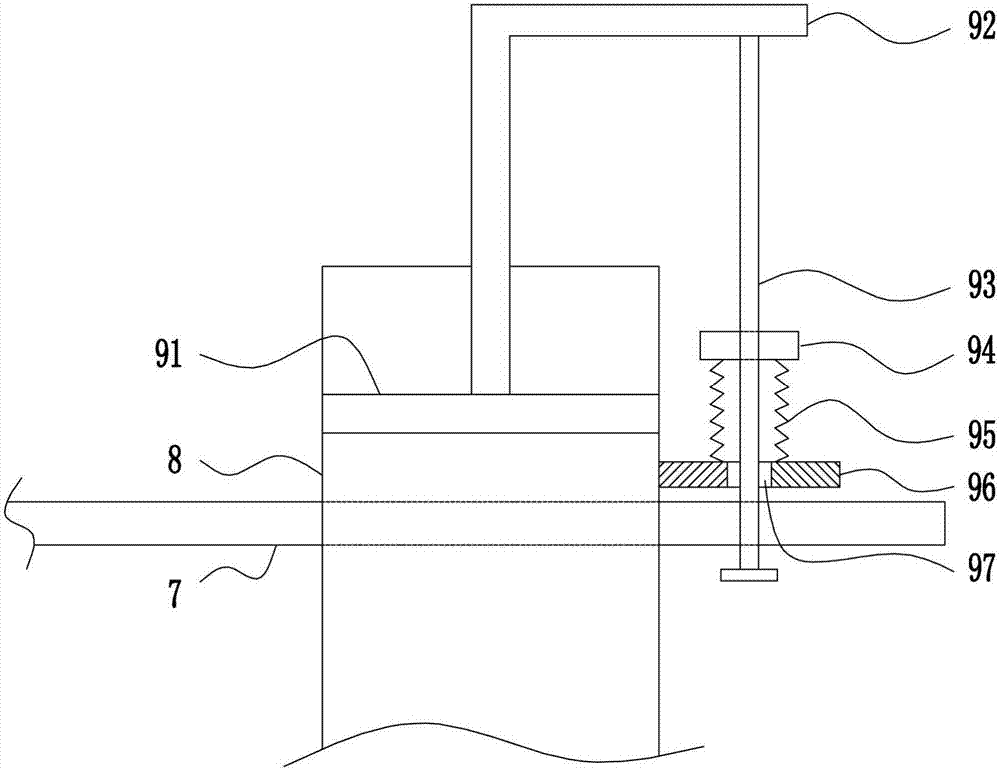

PendingCN107461035AEasy to operateImprove gluing efficiencyBuilding repairsBuilding material handlingThreaded rodPiston

The invention discloses a two-pack electric glue gun for a building. The two-pack electric glue gun for the building comprises a gun body, a primary cylinder body and a secondary cylinder body which do not communicate with each other are fixed to the gun body, glue gum and a curing agent are stored in each of the primary cylinder body and the secondary cylinder body, a second glue pushing piston and a first glue pushing piston slidably matched with the primary cylinder body and the secondary cylinder body correspondingly are mounted in the primary cylinder body and the secondary cylinder body correspondingly, a threaded rod and a pushing rod are fixed to the ends of the second glue pushing piston and the first glue pushing piston correspondingly, and the right ends of the primary cylinder body and the secondary cylinder body are sealed through end covers. The two-pack electric glue gun for the building has the beneficial effects that the glue gum and the curing agent extruded out by the second glue pushing piston and the first glue pushing piston flow out from an extruding head after entering a mixer to be fully mixed, the extruded glue can be more plump and rich through the design of a V-shaped glue out channel, operation of the two-pack electric glue gun for the building is convenient, and the gluing efficiency can be improved greatly.

Owner:ZHENGZHOU UNIV

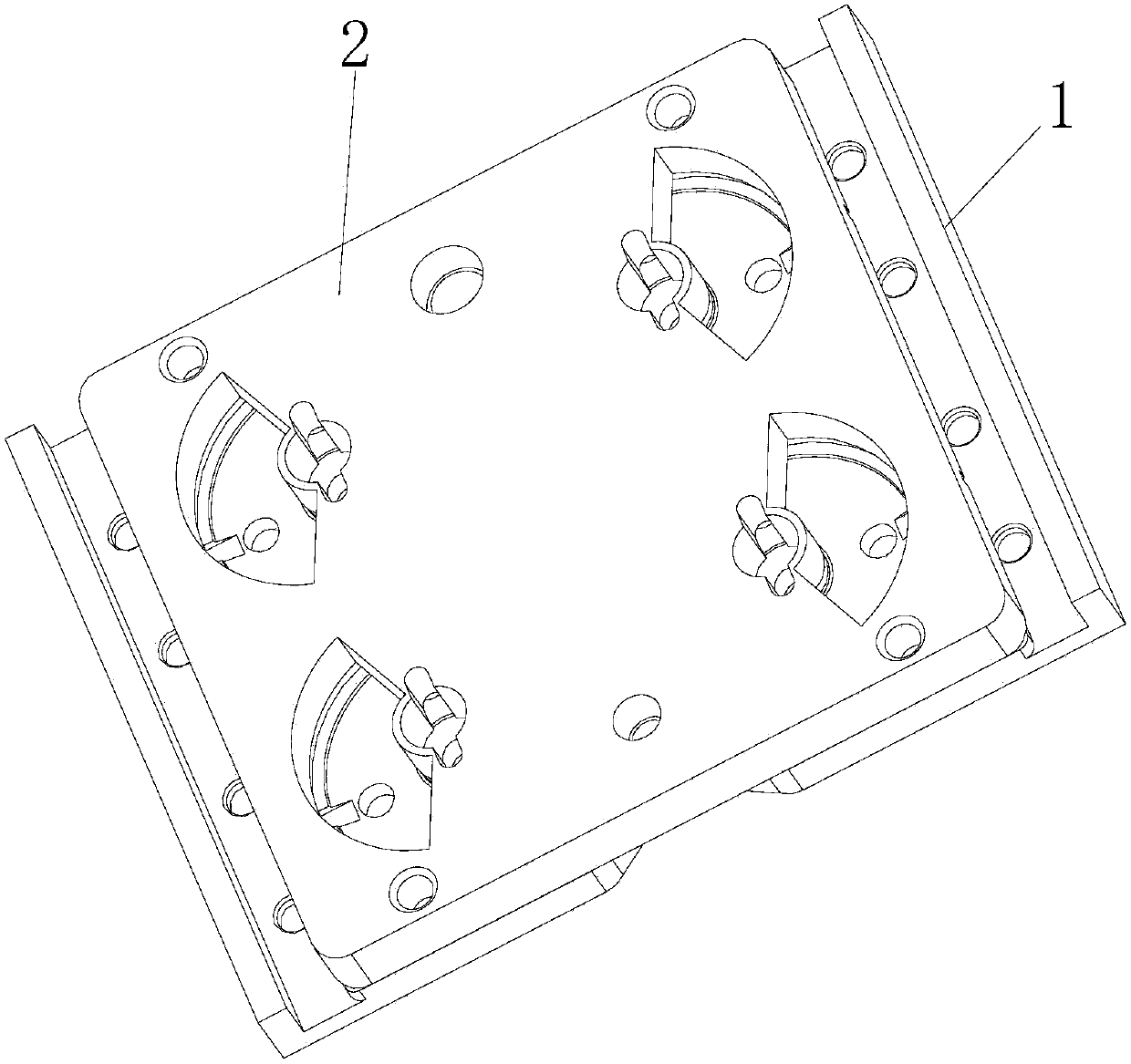

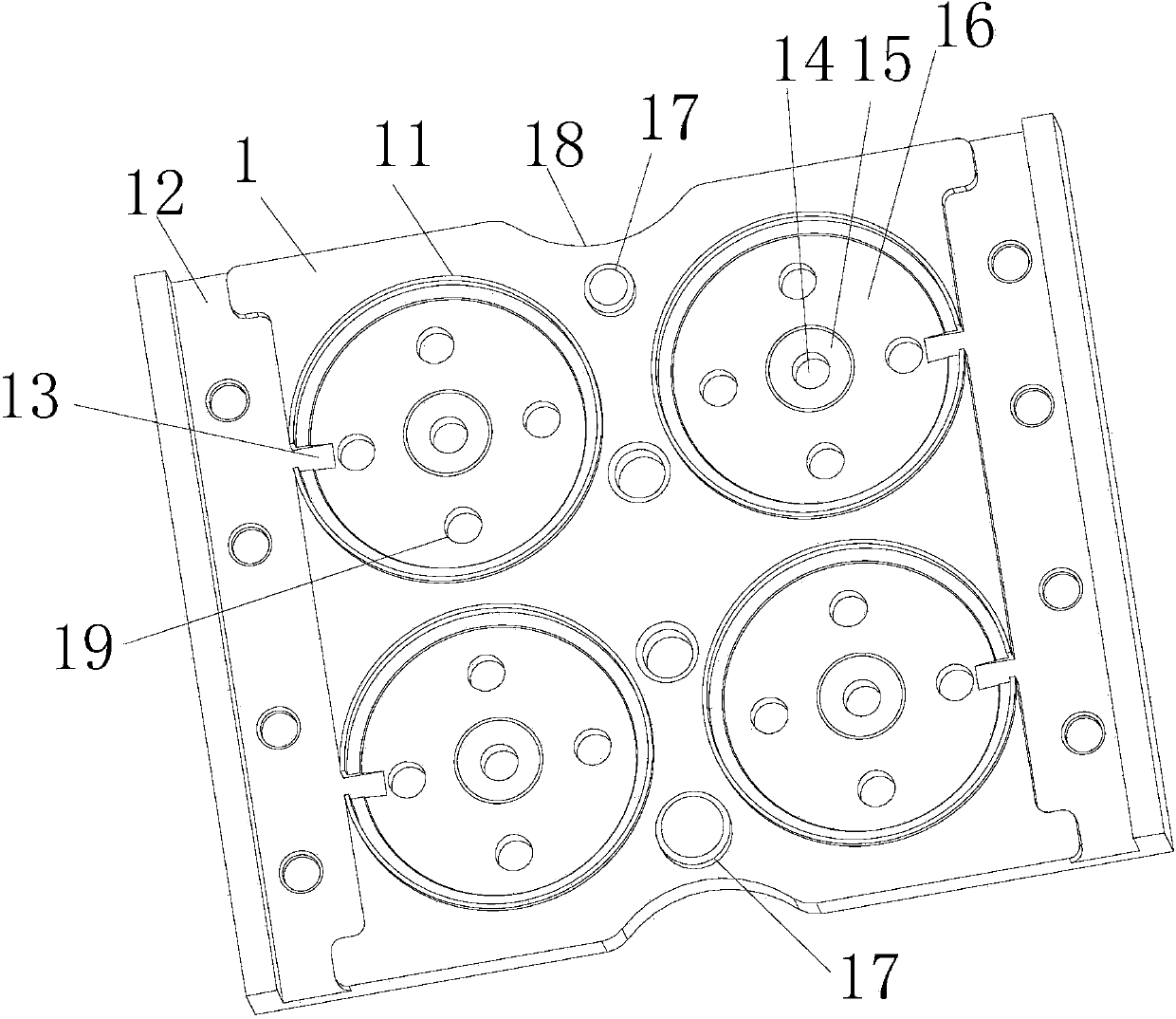

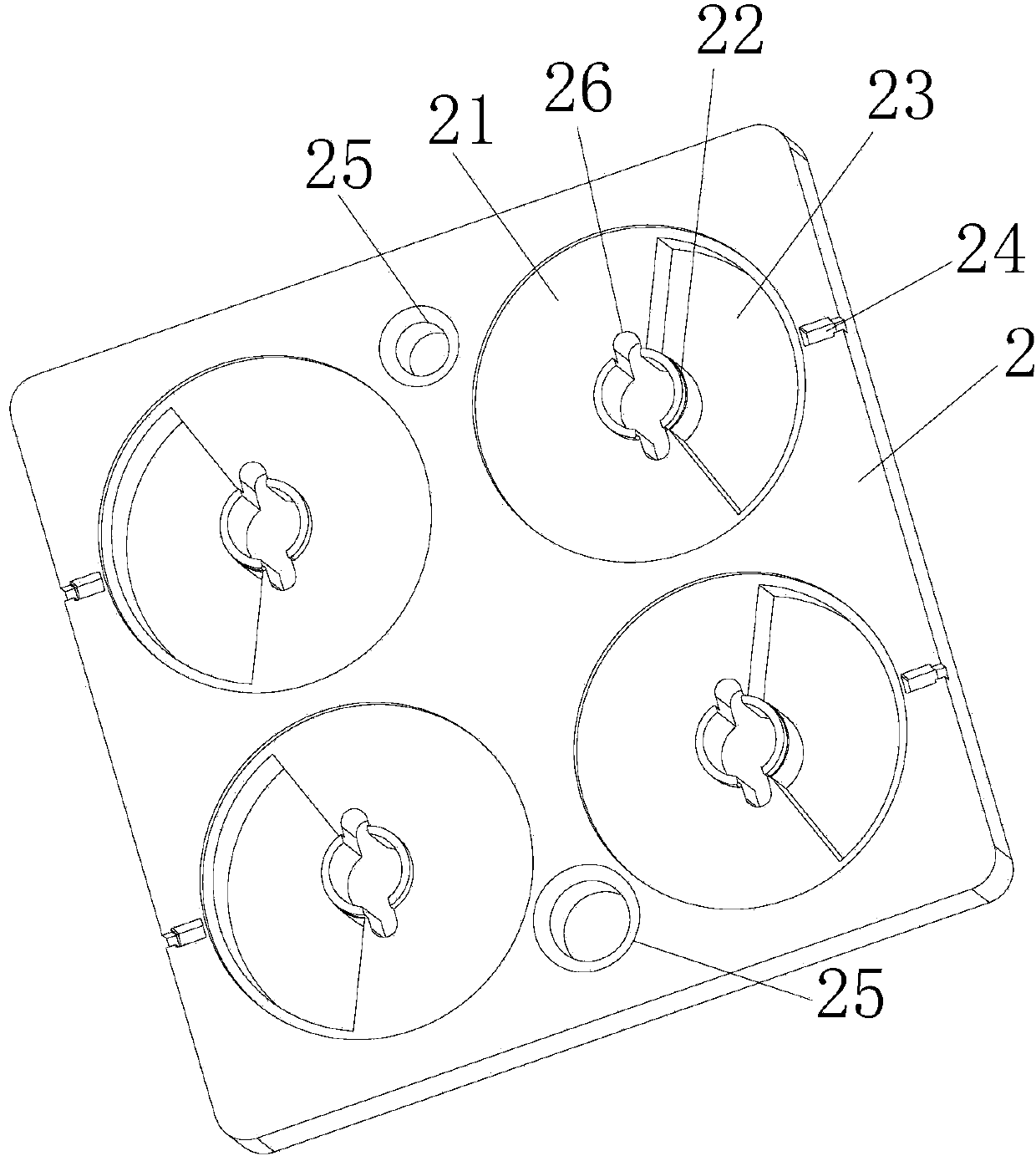

Tool and process for producing diaphragm of loudspeaker

The invention relates to a tool for producing a diaphragm of a loudspeaker. The tool comprises a substrate and a seat cover, wherein a plurality of round locating slots are formed in the surface of the substrate, a first ring groove and a second ring groove are formed in each locating slot, each first ring groove and the corresponding second ring groove are concentric, each second ring groove is arranged at the outer side of the corresponding first ring groove, a central hole is arranged in each first ring groove, line pressing grooves and lead grooves communicated with the locating slots and the line pressing grooves are arranged in positions, which are arranged at two sides of the locating slots, on the substrate, each lead groove is arranged on the central line of the corresponding locating slot and is vertical to the corresponding line pressing groove, and the substrate is further provided with limited posts; compressing grooves matched with the locating slots are arranged in the substrate, a round locating column and an arc-shaped hole concentric to the locating column are arranged at the center of each compressing groove, line clip grooves corresponding to the lead grooves are arranged in the seat cover, and a line clip structure is formed by each lead groove and the corresponding line clip groove. The tool has the characteristics of automatic operation and capabilities of avoiding inconsistent line stack effect of a voice coil, which is caused by manual operation, and effectively controlling line stack force of a lead and the like.

Owner:BESTAR HLDG

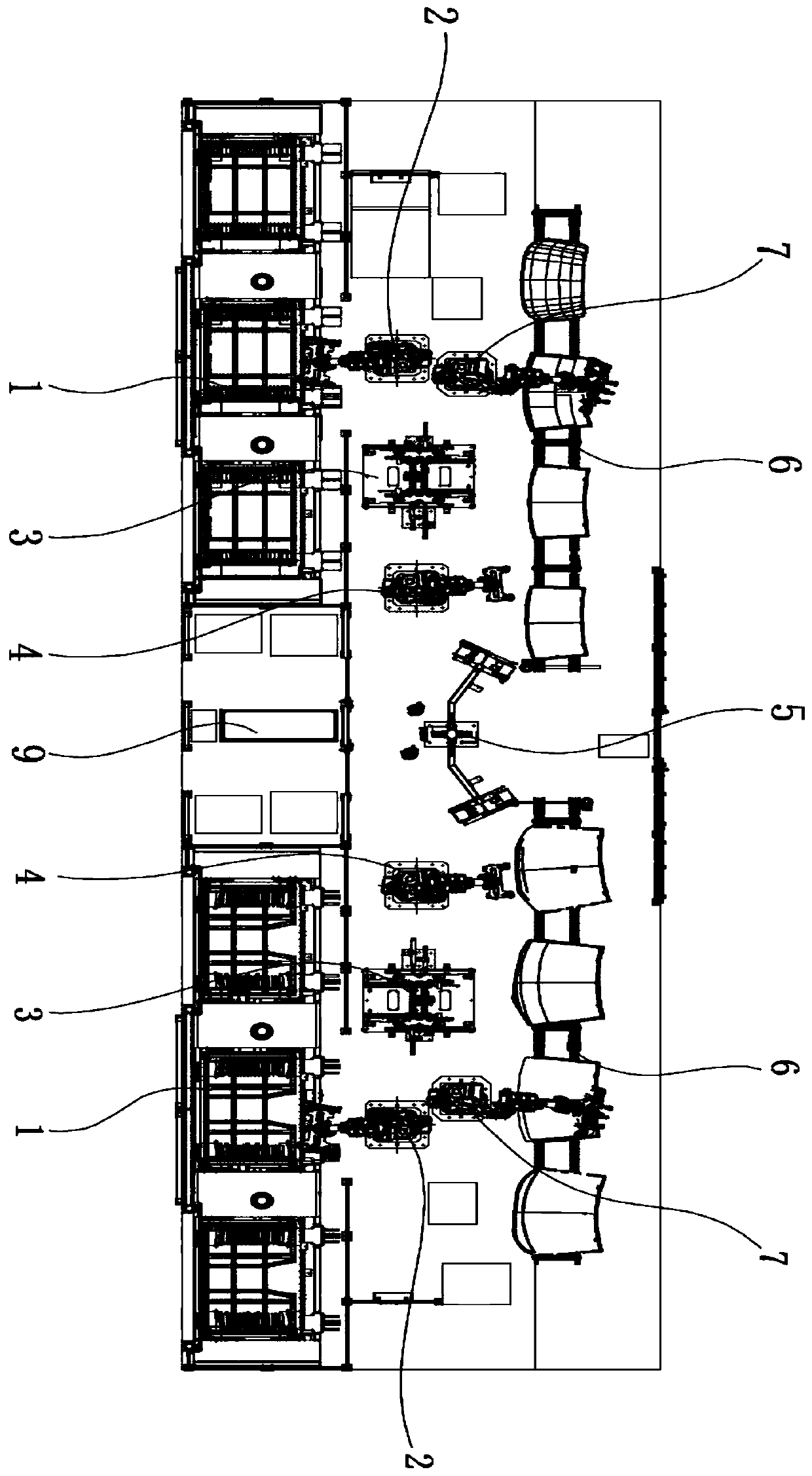

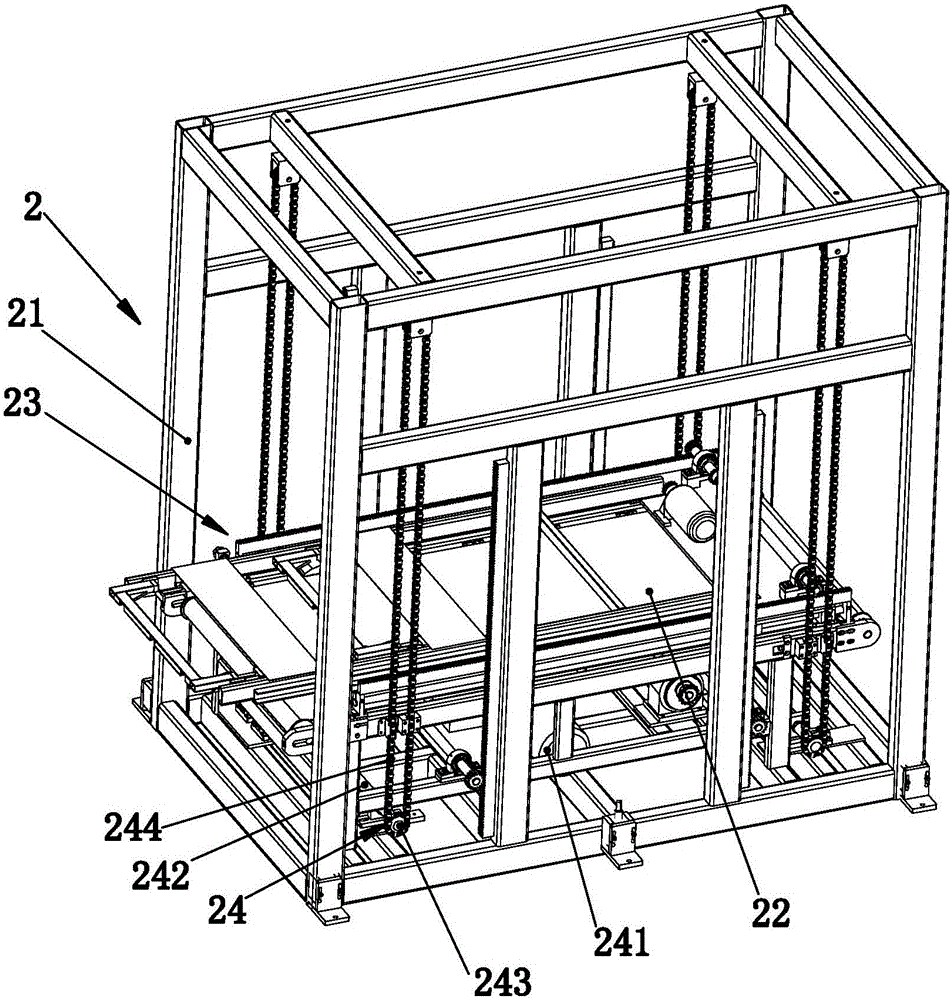

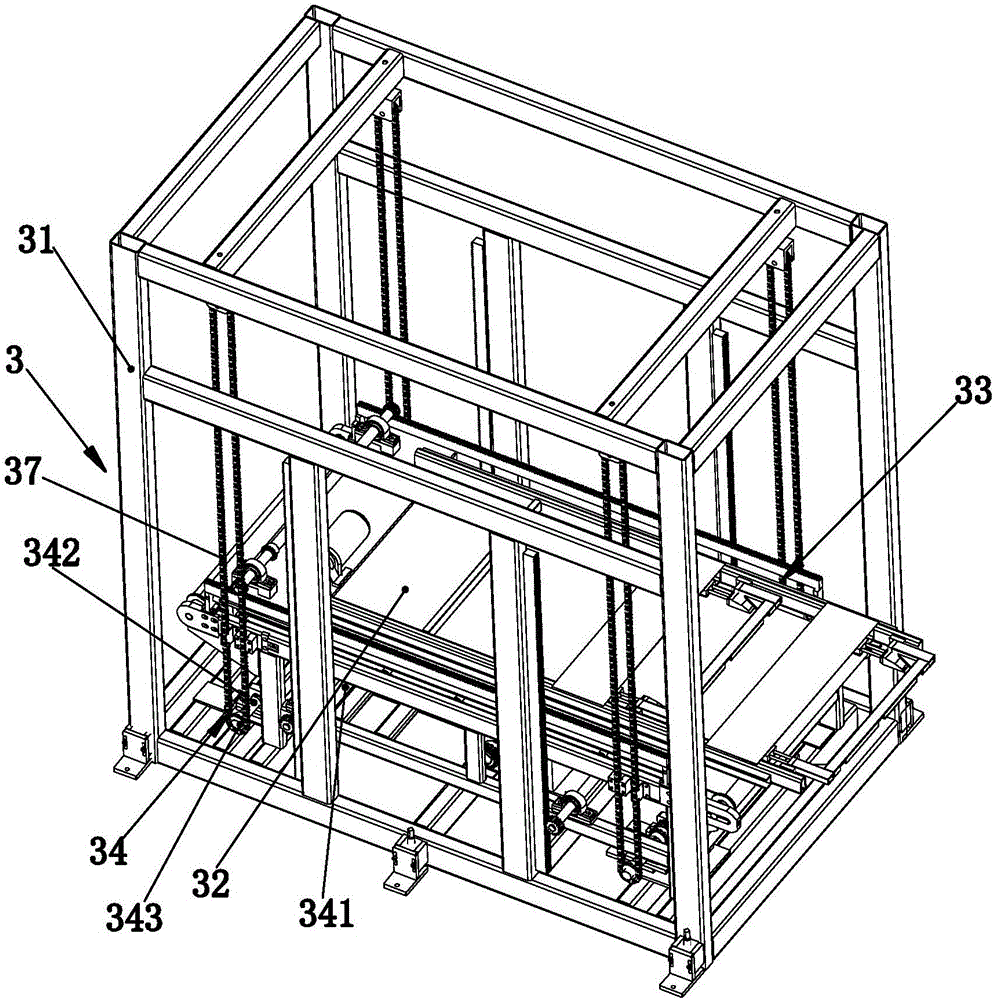

Automatic production line for wooden door veneering

PendingCN109551578AImprove gluing efficiencyReduce waiting timeOther plywood/veneer working apparatusWood veneer joiningProduction lineGlue line

The invention discloses an automatic production line for wooden door veneering. The automatic production line comprises a core plate glue coating line, a panel and bottom plate glue coating line and aplate combining line, wherein the core plate glue coating line and the plate combining line are arranged in sequence according to the feeding direction, and the panel and bottom plate glue coating line is arranged in parallel with the above two glue coating lines. According to the automatic production line, a core plate, a panel and a bottom plate are correspondingly and synchronously coated by the two glue coating lines, the glue coating efficiency is greatly improved, an improved cantilever assembling machine is adopted, so that the core plate glue coating line and the panel and bottom plate glue coating line are fed in two different directions, and the waiting time for mutual queuing is reduced.

Owner:山西万锐液压机械有限公司

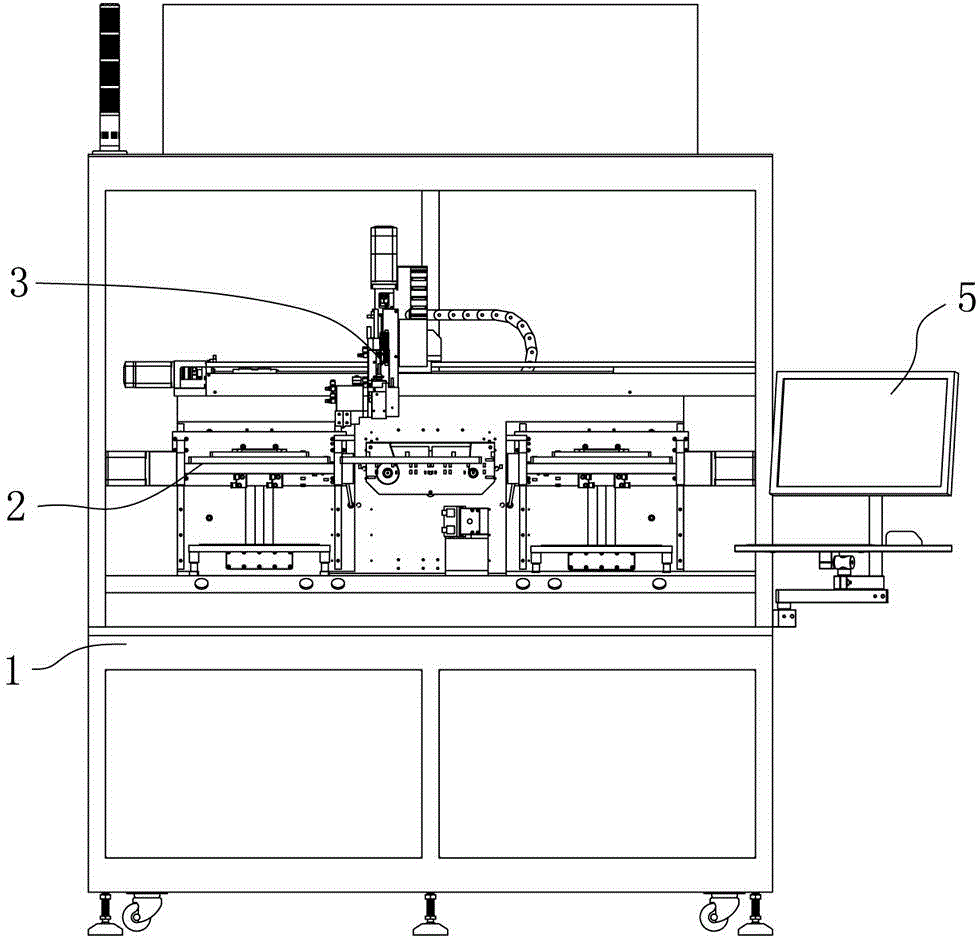

Automatic alignment laminating machine of double-station CCD

ActiveCN104476901AImprove gluing efficiencyAvoid glue overflow and air bubble productionControlling laminationLaminationCcd cameraCamera lens

The invention discloses an automatic alignment laminating machine of a double-station CCD. The automatic alignment laminating machine comprises a machine table, an overturning and vacuum laminating system, a UV glue slit coating system and an automatic CCD alignment system, wherein the overturning and vacuum laminating system, the UV glue slit coating system and the automatic CCD alignment system are mounted on the machine table. The UV glue slit coating system is arranged above the overturning and vacuum laminating system and can allow two laminating stations to be coated. The coating system comprises a glue coating three-shaft mechanical arm and a slit coating head connected with the glue coating three-shaft mechanical arm, and the slit coating head can evenly coat glue on touch screen glass at a time. The automatic CCD alignment system comprises a CCD camera which slides in the horizontal direction and a lens, and the CCD camera and the lens climb to the position of a product to enable an automatic XXY calibration table to move so that alignment can be achieved. According to the automatic alignment laminating machine, the slit coating head can be used for evenly coating glue on the touch screen glass at a time, and the automatic alignment laminating machine has the advantages of being high in glue coating efficiency, capable of avoiding glue overflowing and bubble generating through the linear glue coating and vacuum laminating modes, high in CCD alignment precision and the like.

Owner:XIAMEN LIJU AUTOMATION TECH

Glue coating equipment

ActiveCN107042188AControl the amount of glue injectedControl movement speedPretreated surfacesCoatingsEngineeringMaterial resources

The invention provides glue coating equipment. The glue coating equipment comprises a glue gun, a three-dimensional moving device, a frame adjusting device, a feeding device and a drying device. The glue gun is mounted on the three-dimensional moving device. The three-dimensional moving device can drive the glue gun to move front and back, left and right, and up and down. The frame adjusting device is mounted on the front side of the three-dimensional moving device and can fix a frame and adjust the relative angle of the frame and the glue gun. The feeding device is connected with the glue gun through a pipeline. The feeding device can convey glue to the glue gun to coat the frame with the glue. The drying device is mounted on one side of a frame glue coating position. The drying device can dry the glue on the frame. By adopting the glue coating equipment, glue coating can be completed rapidly and efficiently; mechanization is realized in the glue coating process of frame filters; manpower and material resources are greatly reduced; the product quality is guaranteed; and the glue coating efficiency of the frame filters is improved.

Owner:广州金田瑞麟环境科技有限公司

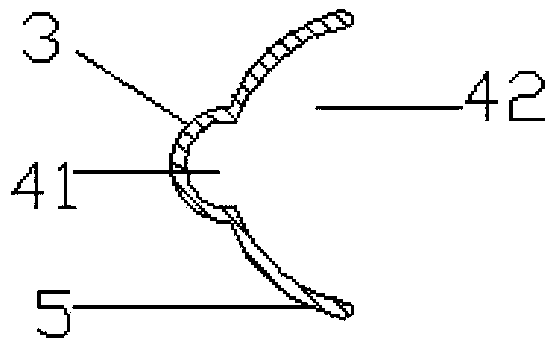

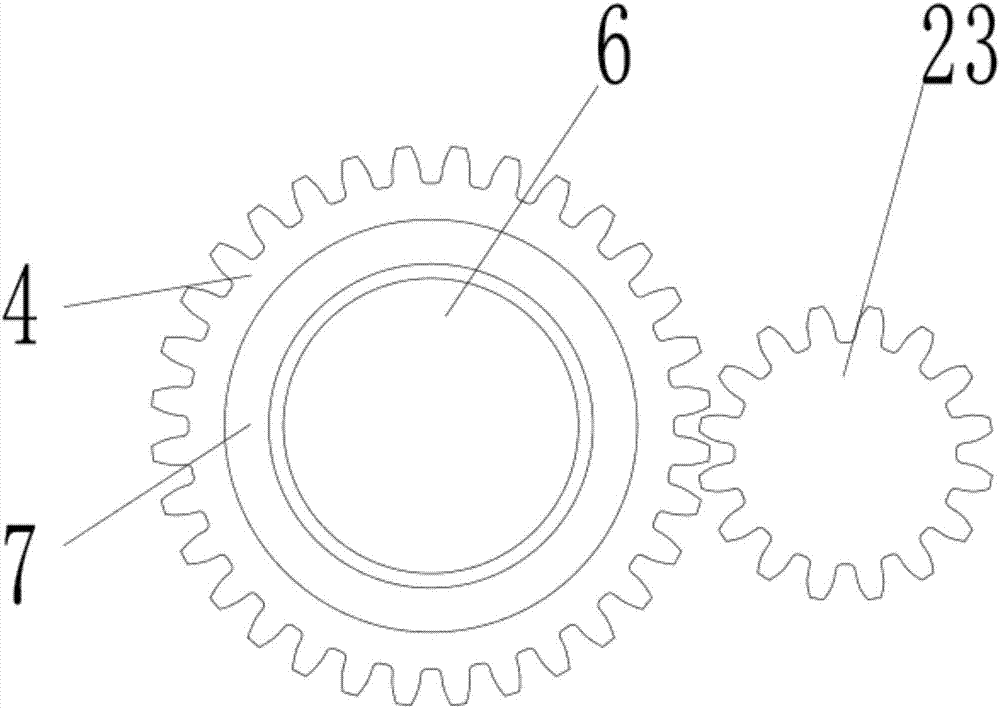

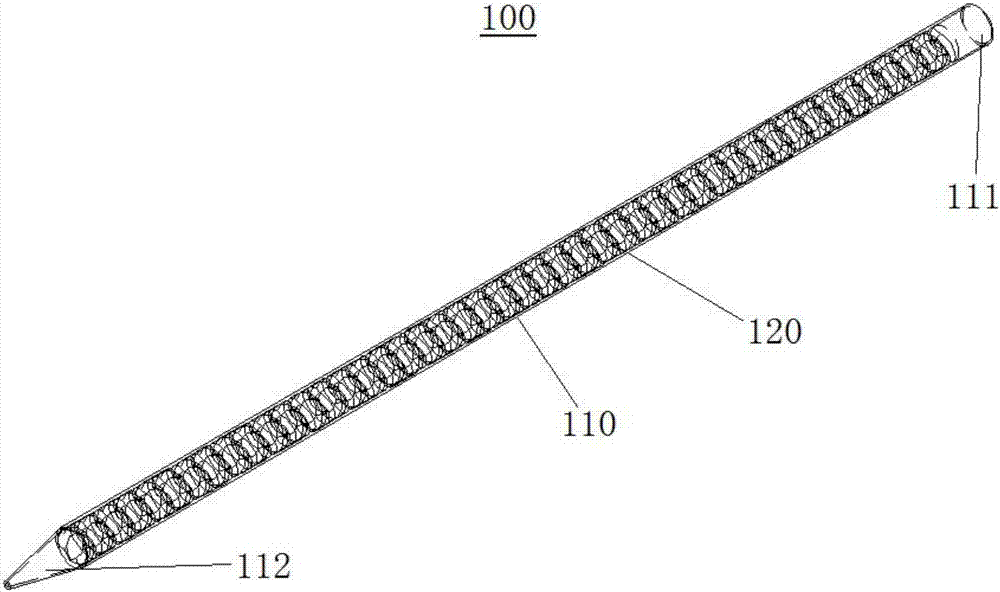

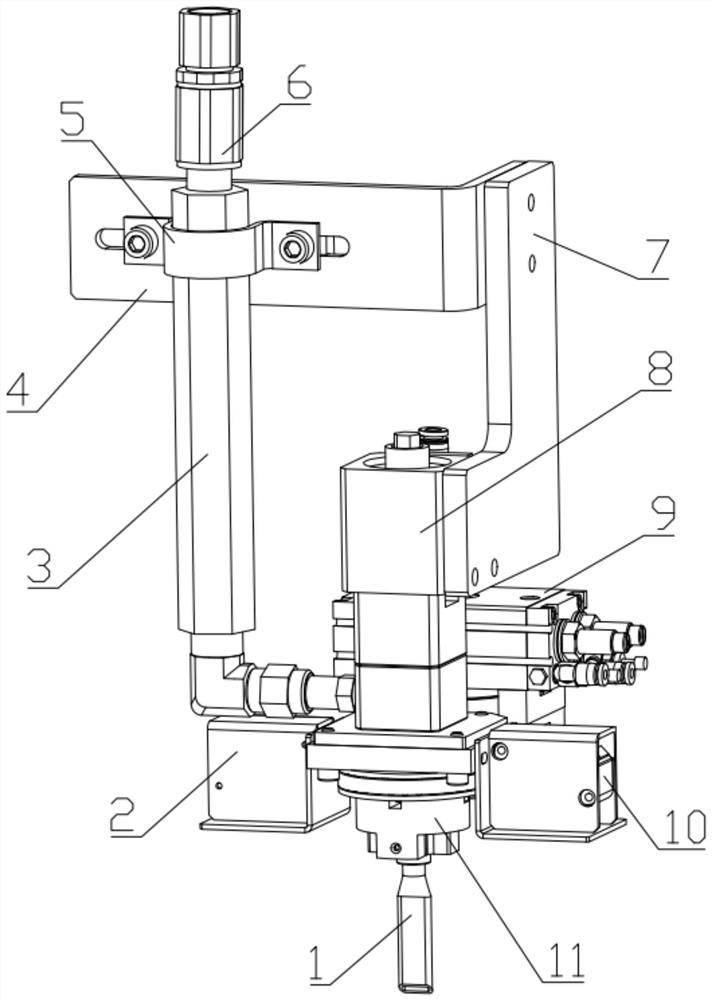

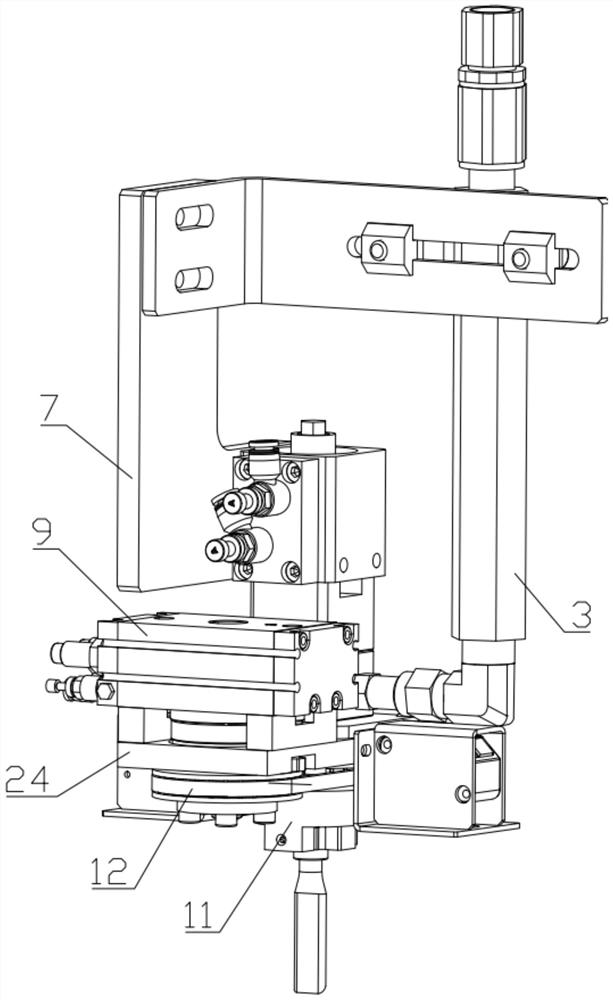

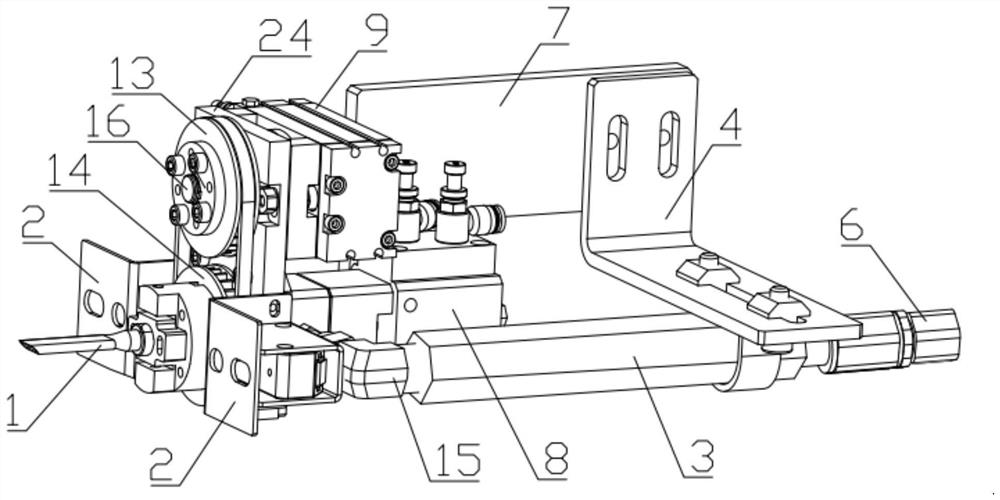

Independent rotary nozzle type compact gluing head capable of being detected online and gluing method thereof

ActiveCN112958375ACompact structureAccurate transmission ratioLiquid surface applicatorsCoatingsEngineeringMechanical engineering

The invention discloses an independent rotary nozzle type compact gluing head capable of being detected online and a gluing method thereof. An existing frame gluing machine realizes change of a nozzle angle by rotating a gluing valve integrally, and is complex in structure and large in power consumption. The gluing head comprises a glue supply assembly of the gluing valve, a nozzle rotating mechanism and an online bilateral detection device, wherein a rotating air cylinder of the nozzle rotating mechanism drives a flat needle nozzle to rotate and the flat needle nozzle rotates directly to glue photovoltaic frames arranged inside and outside with different orientations by a single gluing head, such that the power consumption is reduced. The online bilateral detection detects whether the flat needle nozzle is aligned with a gluing groove of a to-be-glued frame or not online and whether the height of the gluing groove meets a gluing demand or not, the glue surface height after gluing changes, such that it is ensured that the system finds the quality problem of the gluing groove in time to replace the gluing frame as well as finds and corrects a gluing error caused by deviation of the gesture of the flat needle nozzle, unsmooth glue discharge or too quick glue discharge, thereby improving the gluing quality to the maximum extent.

Owner:上海盛普流体设备股份有限公司 +1

Gluing equipment for frame filter gluing

ActiveCN106862013AImprove gluing efficiencyAccelerate solidificationLiquid surface applicatorsCoatingsFixed frameEngineering

The invention provides gluing equipment for frame filter gluing. The gluing equipment comprises a gluing gun, a three-dimensional movement device, a frame adjustment device, a material feeding device and a drying device. The gluing gun is installed on the three-dimensional movement device, and the three-dimensional movement device can drive the gluing gun to move forwards and backwards, leftwards and rightwards and up and down; the frame adjustment device is installed on the front side of the three-dimensional movement device, and the frame adjustment device can fix a frame and adjust the angle of the frame relative to the gluing gun; the material feeding device is connected with the gluing gun through a pipe and can convey glue to the gluing gun to perform gluing on the frame; and the drying device is installed on one side of the frame gluing position and can dry glue on the frame. By the adoption of the gluing equipment, gluing action can be completed rapidly and efficiently, the gluing process of a frame filter can be mechanized, manpower and materials are greatly reduced, product quality is guaranteed, and gluing efficiency of the frame filter is improved.

Owner:广州金田瑞麟环境科技有限公司

Gluing device for leather shoe manufacturing

The invention relates to a gluing device, in particular to the gluing device for leather shoe manufacturing. The gluing device for leather shoe manufacturing aims at achieving the technical purpose of providing the gluing device for leather shoe manufacturing. To achieve the technical purpose, the gluing device for leather shoe manufacturing comprises shoe molds, support rods, a base plate, rotation equipment, a second bearing base, a handle, an L-shaped rotation rod, a glue box, an extruding device, a first valve, a second valve and the like; the base plate is provided with the rotation equipment, the rotation equipment is evenly connected with the support rods, the upper ends of the support rods are connected with the shoe molds, the left side of the rotation equipment is provided with the second bearing base, the second bearing base is provided with the L-shaped rotation rod, and the middle of the left side of the L-shaped rotation rod is connected with the handle. According to the gluing device for leather shoe manufacturing, leather shoe gluing achieves quantitative control over glue, the waste of glue is prevented, the gluing efficiency of the leather shoe is improved, the gluing precision is high, and the device is stable, safe to operate and suitable for gluing of leather shoes with different sizes.

Owner:平邑仁安中医药产业发展有限公司

Antibacterial environment-friendly diaper with high hygroscopicity

InactiveCN112155860AMulti-expansionRapid expansionLaminationLamination apparatusReverse osmosisEngineering

The invention discloses an antibacterial environment-friendly diaper with high hygroscopicity. According to the diaper, by utilizing physicochemical properties of konjac glucomannan, including high viscosity, high hygroscopicity, rapid expansion and the like, a nanofiber membrane is prepared through electrostatic spinning, so that the bioavailability and the water binding capacity of the konjac glucomannan are improved; the konjac glucomannan nanofiber membrane / base anti-reverse osmosis layer has a sufficient space structure, and is breathable and antibacterial, and meanwhile, is also cool, and has a prickly heat removal effect and breathability. The konjac glucomannan has stable performance, and the prepared konjac glucomannan environment-friendly diaper has high bioavailability, good antibacterial performance and high hydroscopicity. According to the konjac glucomannan environment-friendly diaper disclosed by the invention, menthol therein acts on the skin or mucous membranes, and has the effects of being cool and relieving itching; cortex phellodendri and flos lonicerae can enhance immunity, diminish inflammation, relieve internal heat, stop bleeding and the like; and musk is anti-inflammatory and bacteriostatic. The diaper has the advantages of being convenient in material taking and low in cost, having a good antibacterial property, a simple preparation process, being poisonless and harmless, having biodegradability and good bioavailability.

Owner:陈孝庆

Shoe gluing device

The invention relates to a gluing device, and in particular relates to a shoe gluing device. A technical problem to be solved by the invention is to provide the shoe gluing device. In order to solve the technical problem, the invention provides the shoe gluing device comprising electrical reels, a support, pull wires a first sliding rail, a first sliding block, pulleys, a strut, an electrical push rod, an arc-shape stop dog, a shoe-shaped groove and a first valve, wherein the pulleys are uniformly arranged at the bottom outside the support, a handle is arranged on the left side wall outside the support, the first siding rail is arranged at the bottom in the support, the electrical reels are arranged at the bottom in the support on left and right sides of the first sliding rail, the pull wires are wound on the electrical reels, and the tail ends of the pull wires are connected with the first sliding block. It should be noted that abovementioned embodiments with specific and detailed description are only preferred embodiments of the invention, but should not be considered as limiting the scope of the invention.

Owner:林永贵

Glass gluing equipment capable of improving use stability

PendingCN107952624AImprove stabilityImprove gluing efficiencyLiquid surface applicatorsCoatingsMotor driveCoupling

The invention discloses a glass gluing equipment that can improve the stability of use. It includes a base. A slide rail is provided at the middle position of the upper side of the base. Two sets of symmetrically distributed fixed plates are provided on both sides of the base. There are two sets of sliding rods on the side of the fixed plate close to the screw, and a first sliding platform is provided in the middle of the sliding rod and the screw. One set of fixed plates is provided with a liquid storage tank on the side away from the slide rail. The side of the fixed plate close to the PLC controller is provided with two sets of symmetrically distributed first servo motors. The output shaft of the first servo motor is connected to one end of the rotating shaft through a coupling, and is connected through the side clamping plate and the bottom clamping plate. Used together, the stability of the glass gluing equipment can be improved. The output shaft of the second servo motor rotates to drive the side splints to rotate, thereby improving the gluing efficiency. The sliding shafts and springs provided between the side splints can be used for glass frames of different sizes. Gluing makes it easy to use.

Owner:胡振宇

Automatic dispersing device for machining process of electronic product workpieces

PendingCN109304278AAvoid flatness effectsEasy to take outLiquid surface applicatorsSpraying apparatusEngineeringAtmospheric pressure

The invention provides an automatic dispersing device for a machining process of electronic product workpieces. The automatic dispersing device comprises a pneumatic glue valve and a positioning screw, wherein a support is supported and welded in the middle of the rear side of a substrate; a glue barrel is supported and welded at the center of a cross bar at the top end of the support, and a barrel cover is locked and sealed at an opening in the top end of the glue barrel; a glue outlet pipe arranged on a bottom plate of the glue barrel is locked and communicated with the pneumatic glue valvethrough a hose; two switch panels are symmetrically arranged on substrate surfaces on the left side and the right side of a track frame, are electrically connected with electric parts in an air pressure case and control opening and closing of the pneumatic glue valve. Four support frames are arranged and combined to form a product piece placement trolley, and by means of the product piece placement trolley, two finished products can conveniently slide left and right for performing windless switch gluing, and the gluing efficiency is effectively improved.

Owner:SICHUAN INFORMATION TECH COLLEGE

Gluing device for multi-layer solid wood composite floor machining

InactiveCN110871151AQuality improvementImprove gluing efficiencyLiquid surface applicatorsCoatingsSolid woodAdhesive glue

The invention discloses a gluing device for multi-layer solid wood composite floor machining. The gluing device comprises a glue storage device and the gluing device, floors are clamped and fixed through a clamping structure, then, the floors are driven to ascend and descend under the action of a lifting sliding structure, the lifting sliding structure until the upper ends of the floors is in contact with the gluing structure, then the gluing structure slides back and forth along a sliding rod under the action of a motor II to perform gluing work on the floors, the gluing efficiency of the device is improved, manpower and material resources are reduced, the arrangement of brushes improves the uniformity of the gluing of the device, the practicability of the device is improved, the qualityof the gluing is improved, by arranging a stretchable rod II and the lifting sliding structure, the floors of different sizes can be clamped and glued, the practicability of the device is improved, the production cost is saved, the buffering effect is improved through arrangement of a damping structure, the service life of the device is prolonged, by arranging a stirring structure, the problem that glue in the glue storage box is solidified due to long-term nonuse can be prevented, resources are saved, and the production cost is reduced.

Owner:洪江区华兴木业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com