Patents

Literature

338results about How to "Improve gluing quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

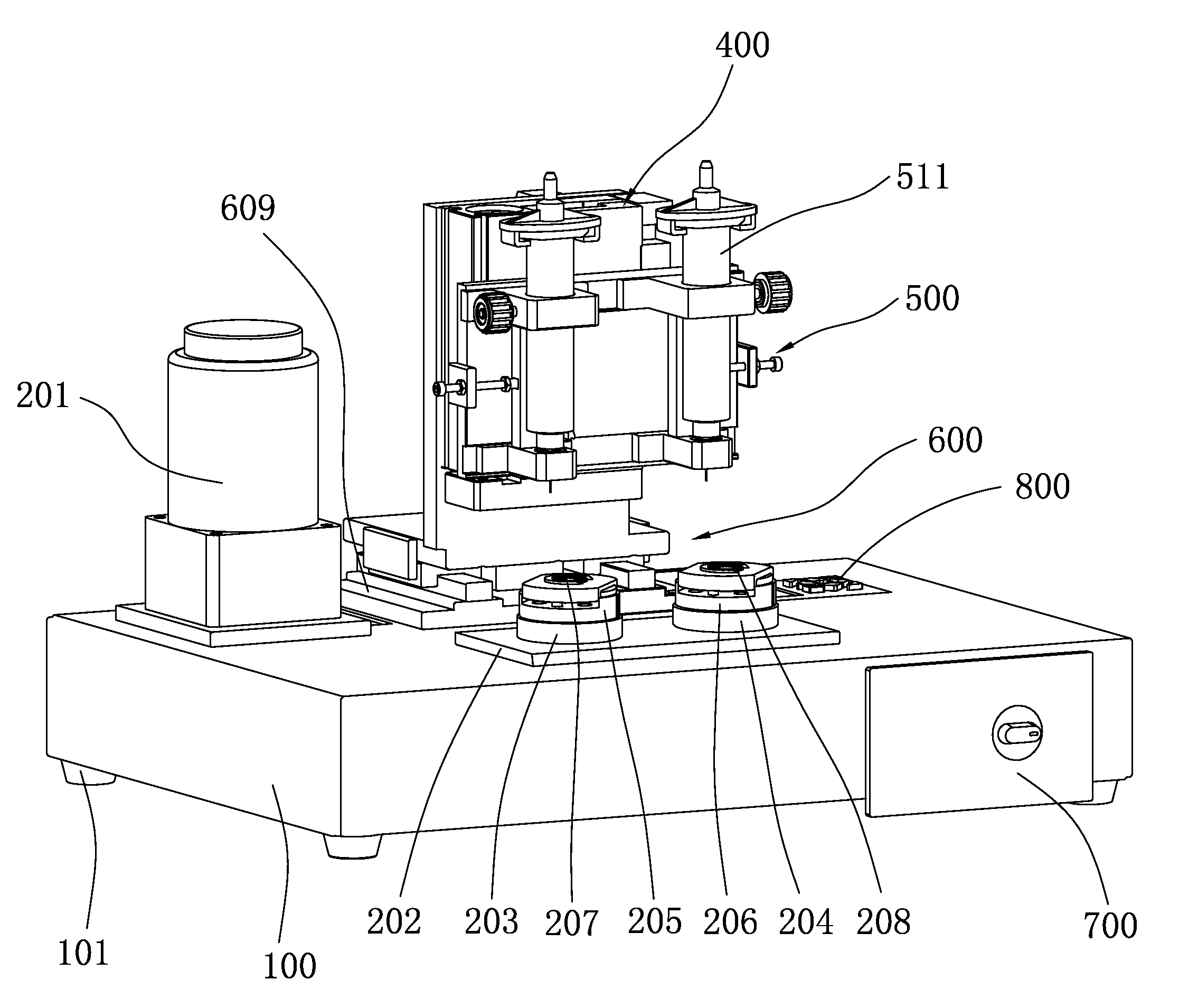

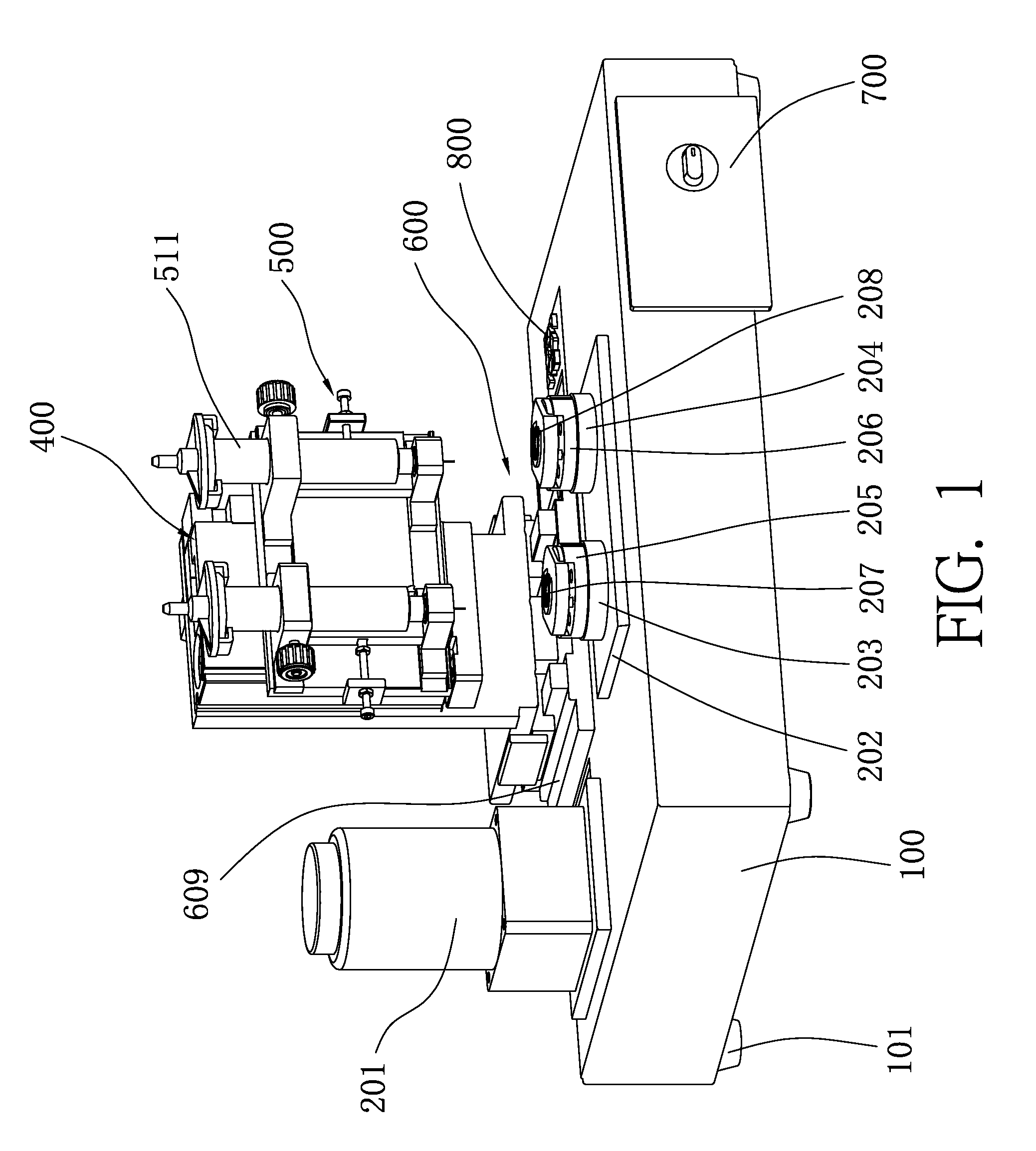

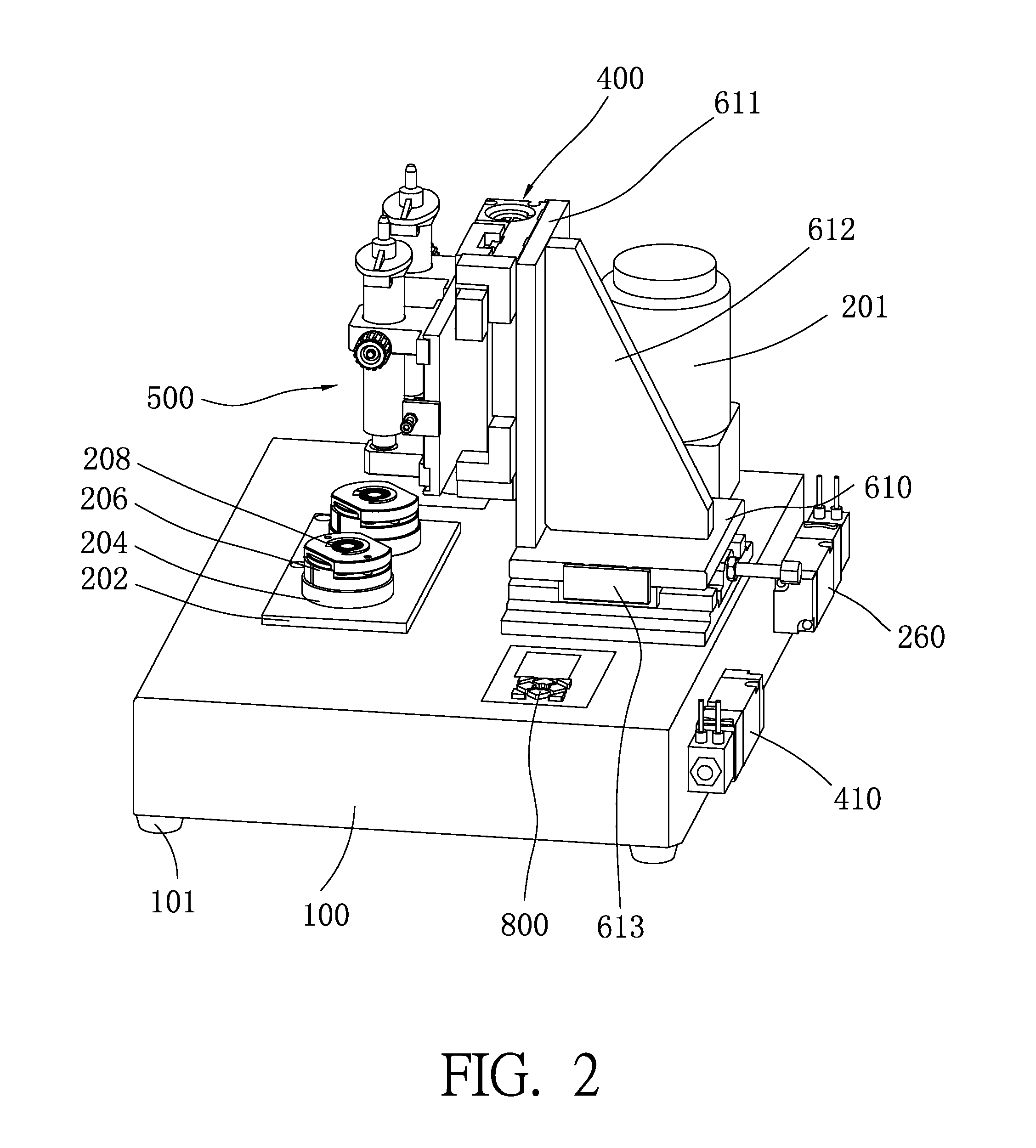

Gluing mechanism

InactiveUS20120031326A1Improve working efficiencyImprove gluing qualityLiquid surface applicatorsManual label dispensersMotor driveEngineering

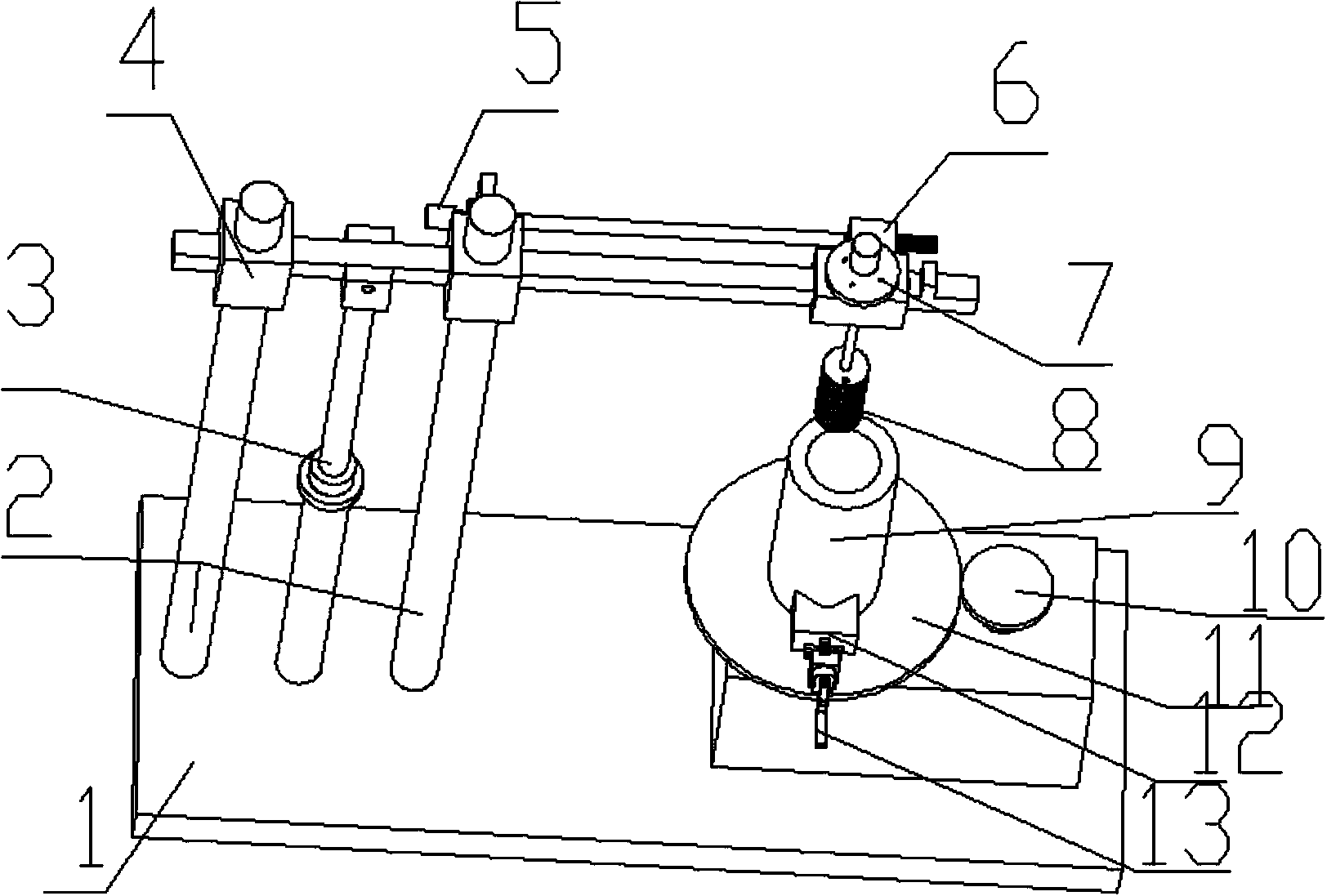

A gluing mechanism comprising a platform, a plurality of turn tables set on the platform for workpieces, a motor for driving the turn tables and a gluing device firmly set up on the platform. The gluing device comprises a forward assembly, an elevator, a panning assembly and a plurality of glue applicators. The forward assembly is set on the platform and moves along a shorter side of the platform. The elevator is set on the forward assembly and moves relative to the platform vertically. The panning assembly is set on the elevator and moves along a longer side of the platform. The glue applicators are installed on the panning assembly. The motor drives the turn tables simultaneously. The gluing mechanism of the present invention has benefits of simple structure, a high working efficiency and proceeds a precise rotary gluing process to workpieces. Therefore, an excellent gluing quality can be realized.

Owner:CHENG UEI PRECISION IND CO LTD

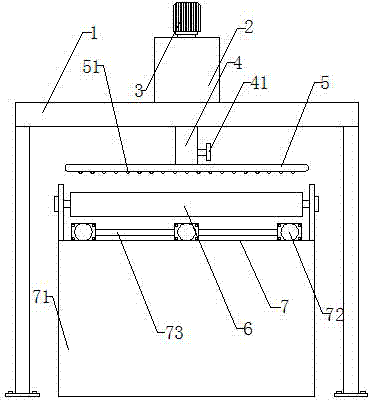

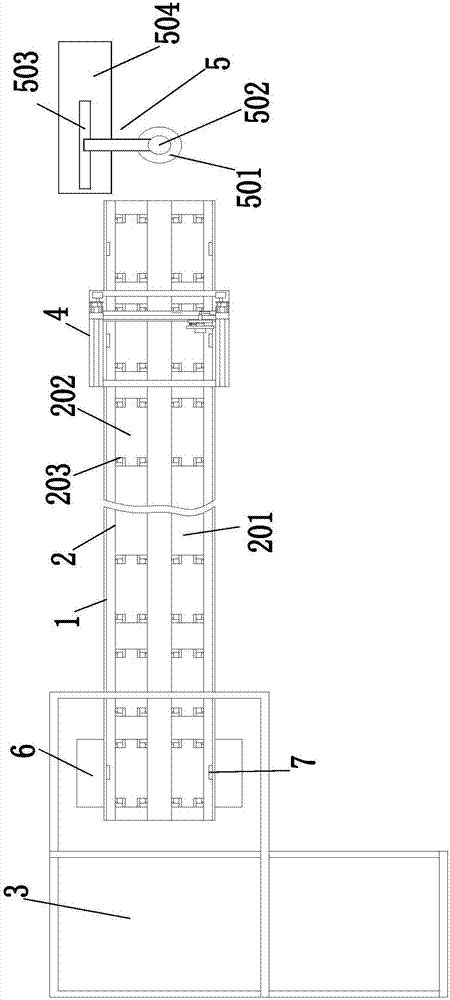

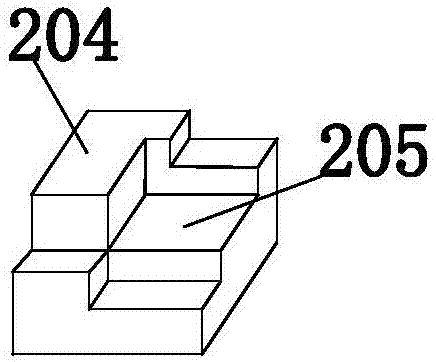

Layer-by-layer automatic feeding, marking and gluing integrated equipment for sheet materials

ActiveCN104708689AFast processingSpread evenlyOther plywood/veneer working apparatusAdhesive application devicesProduction lineEngineering

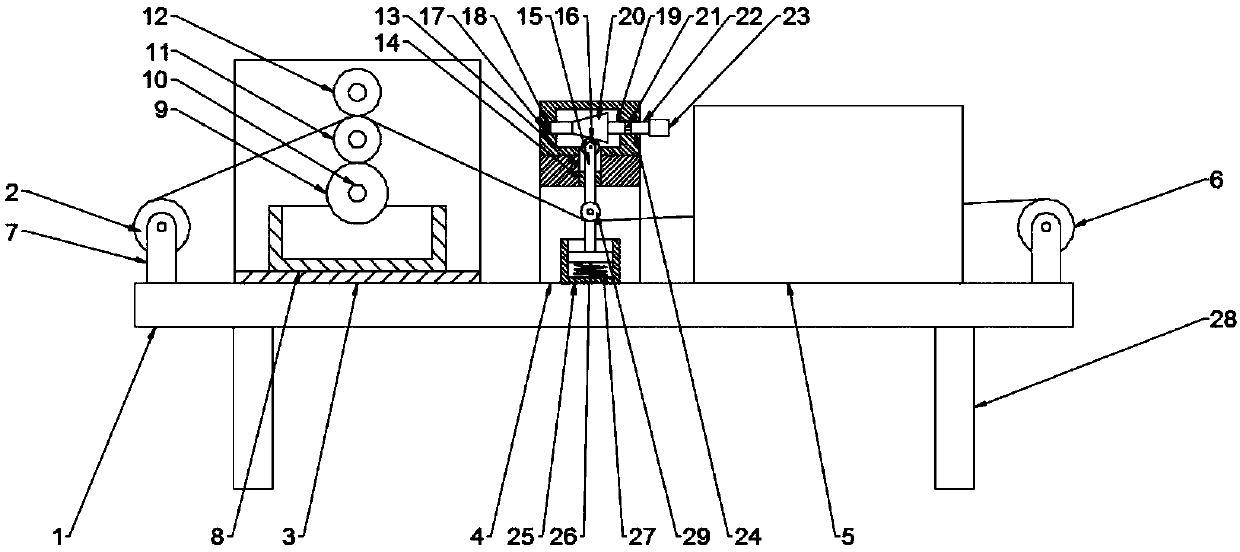

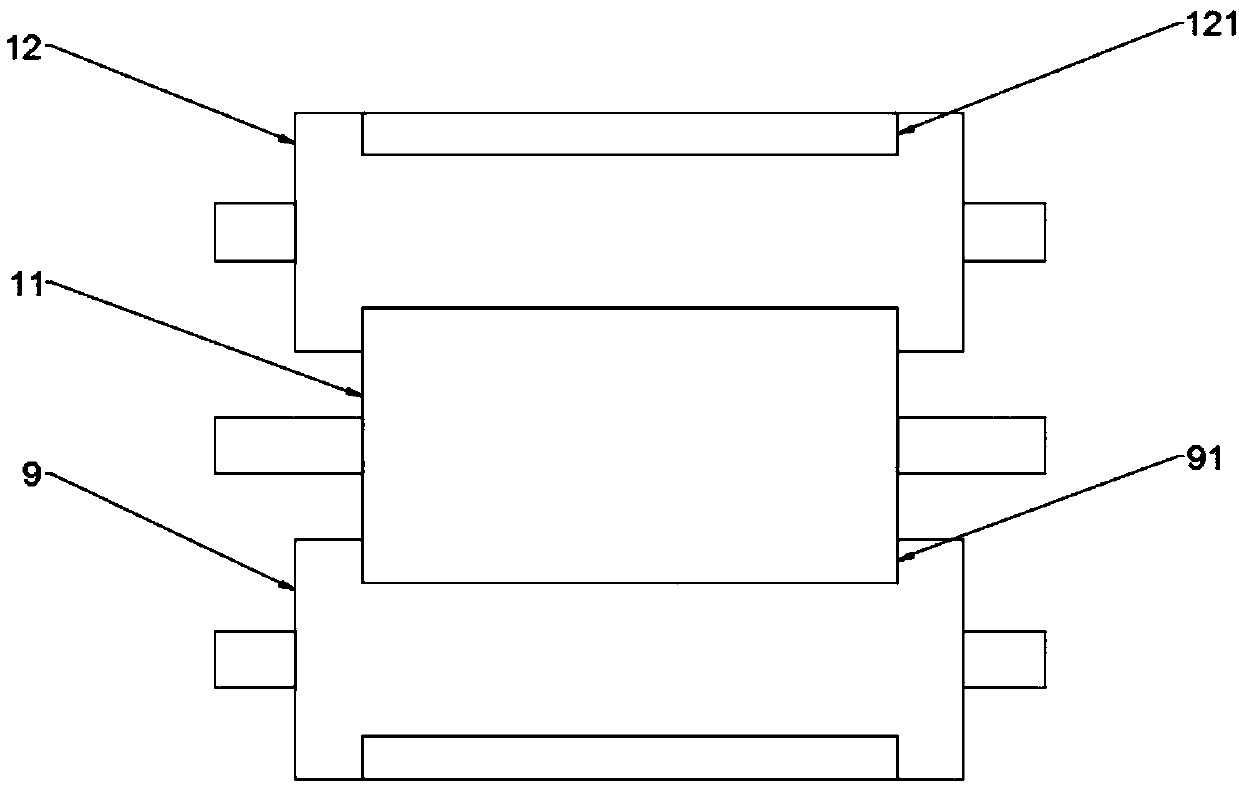

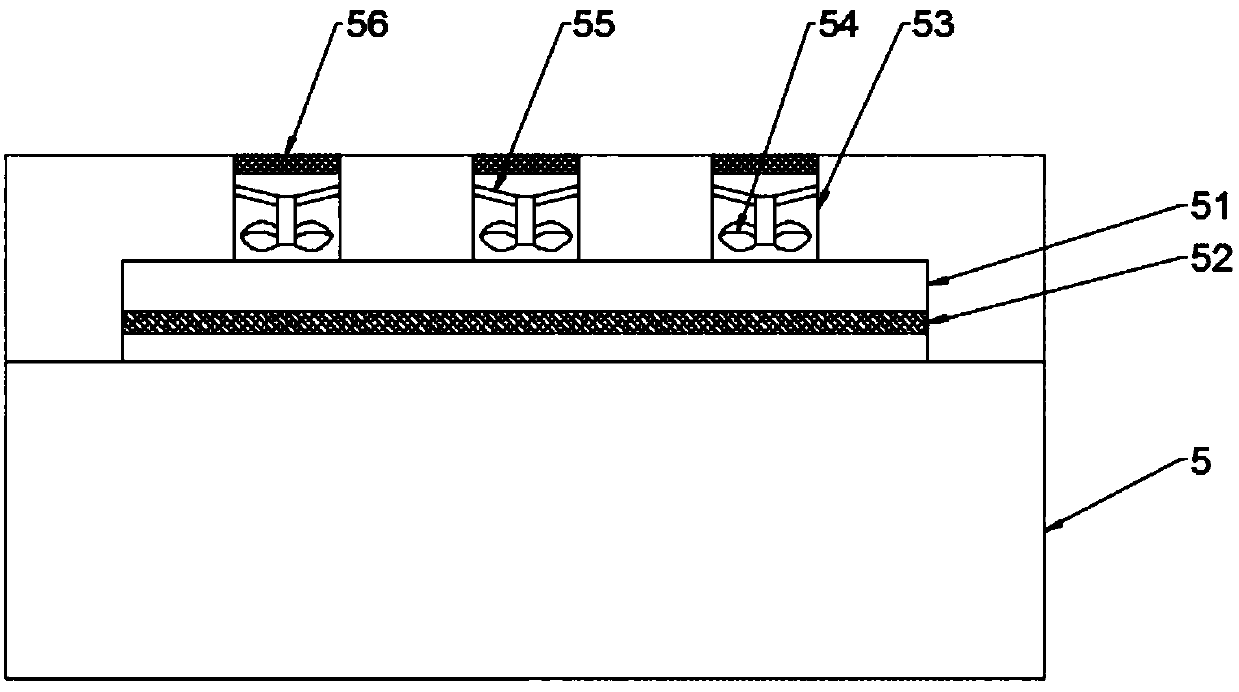

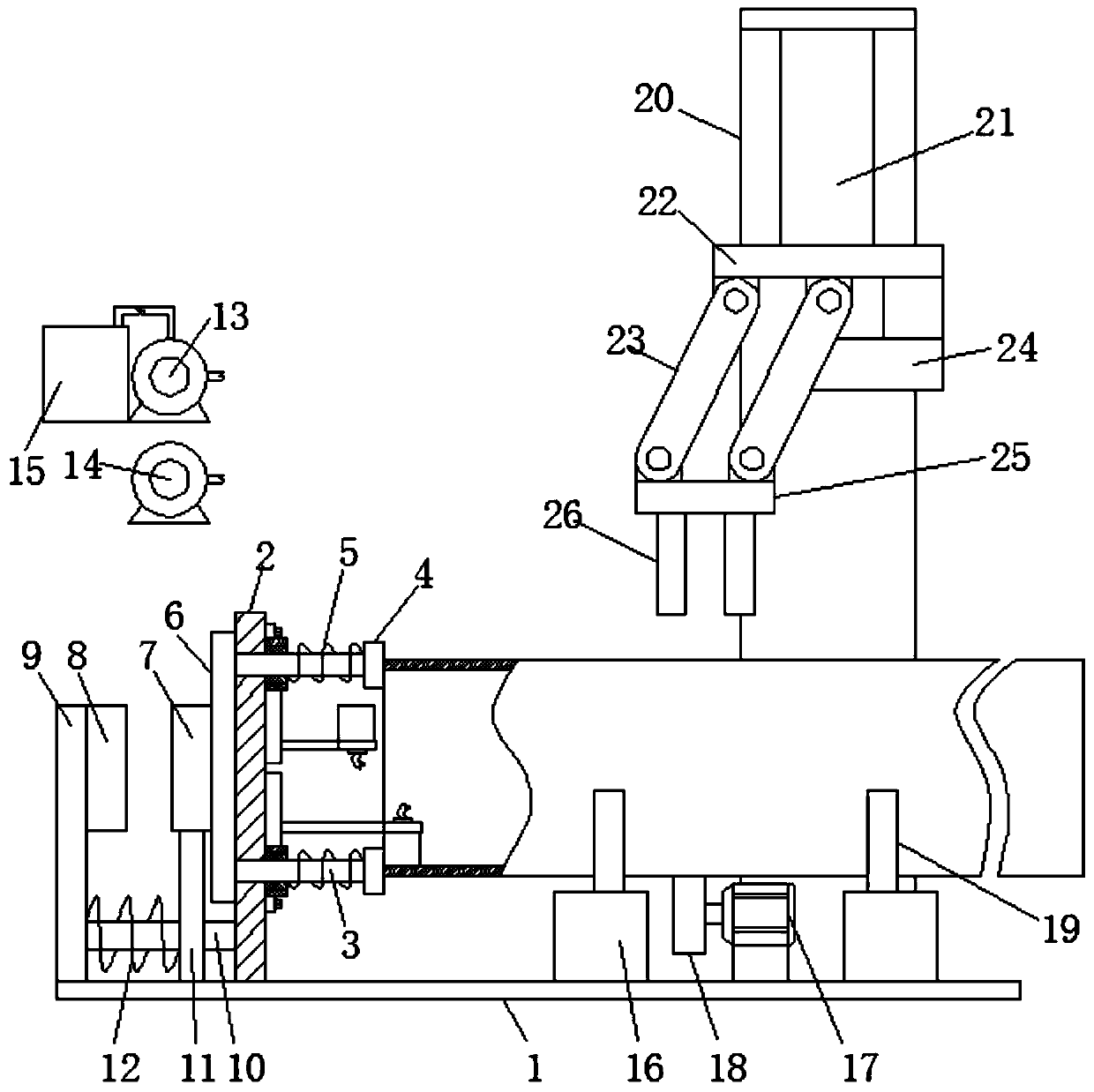

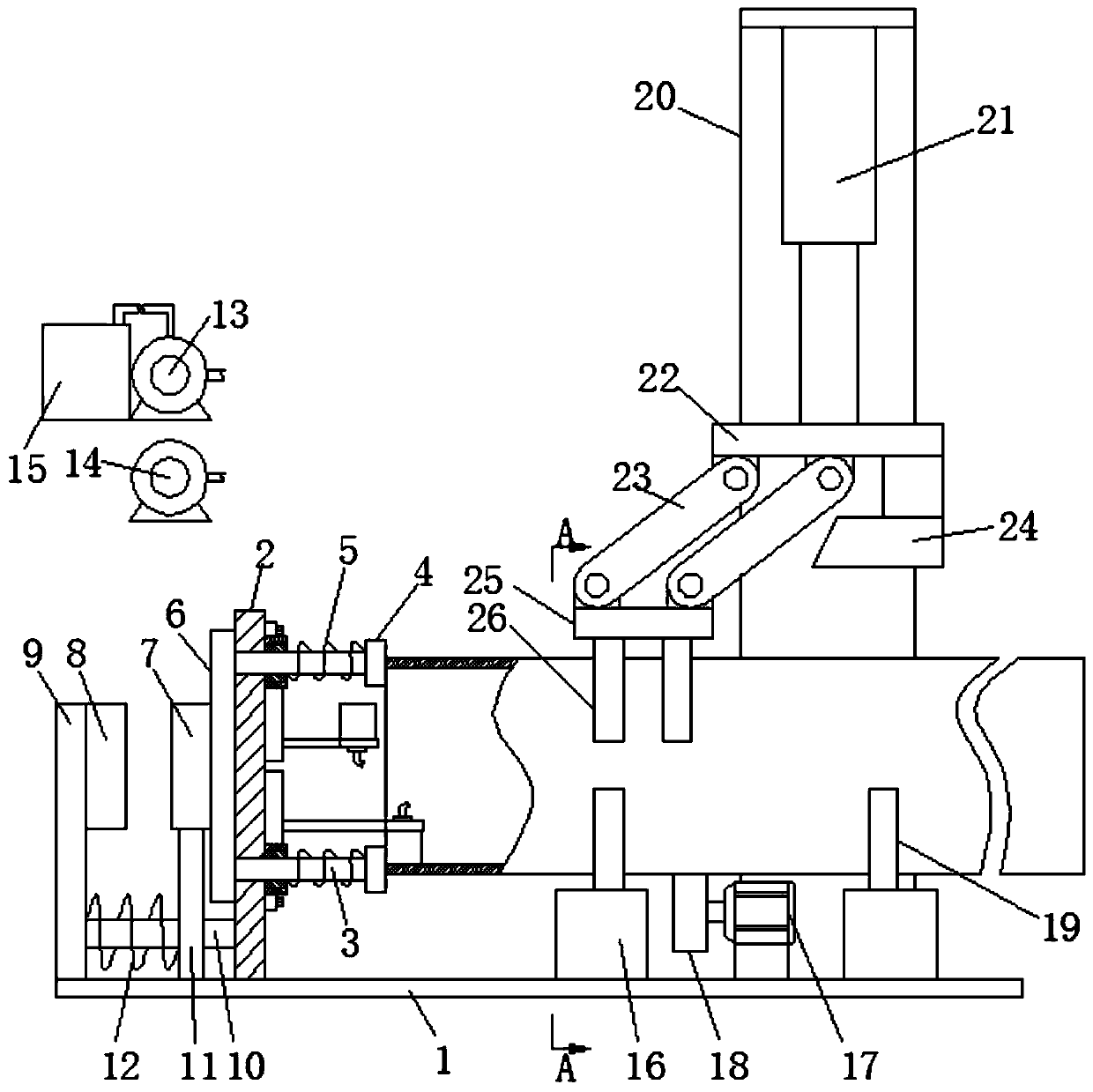

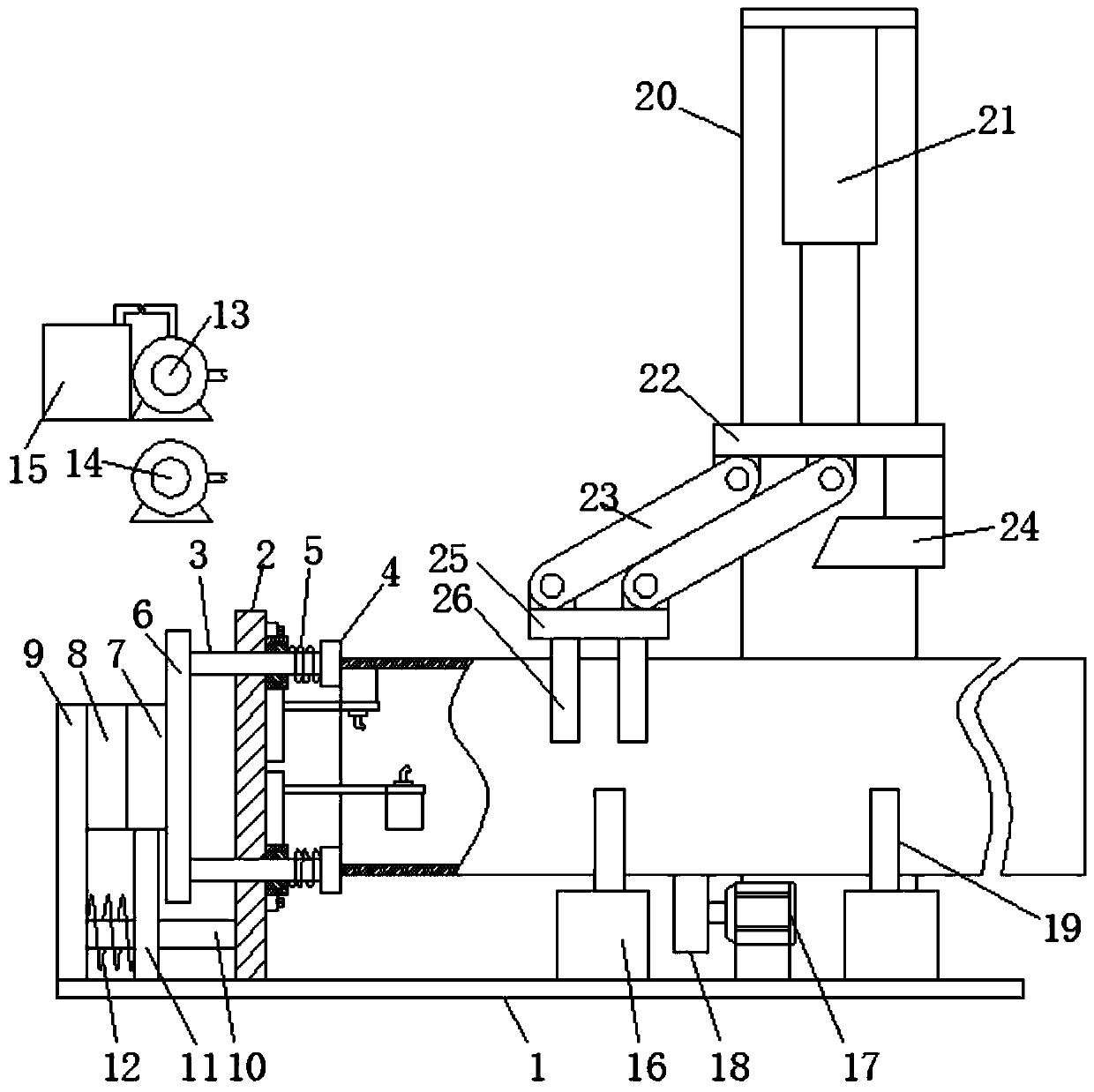

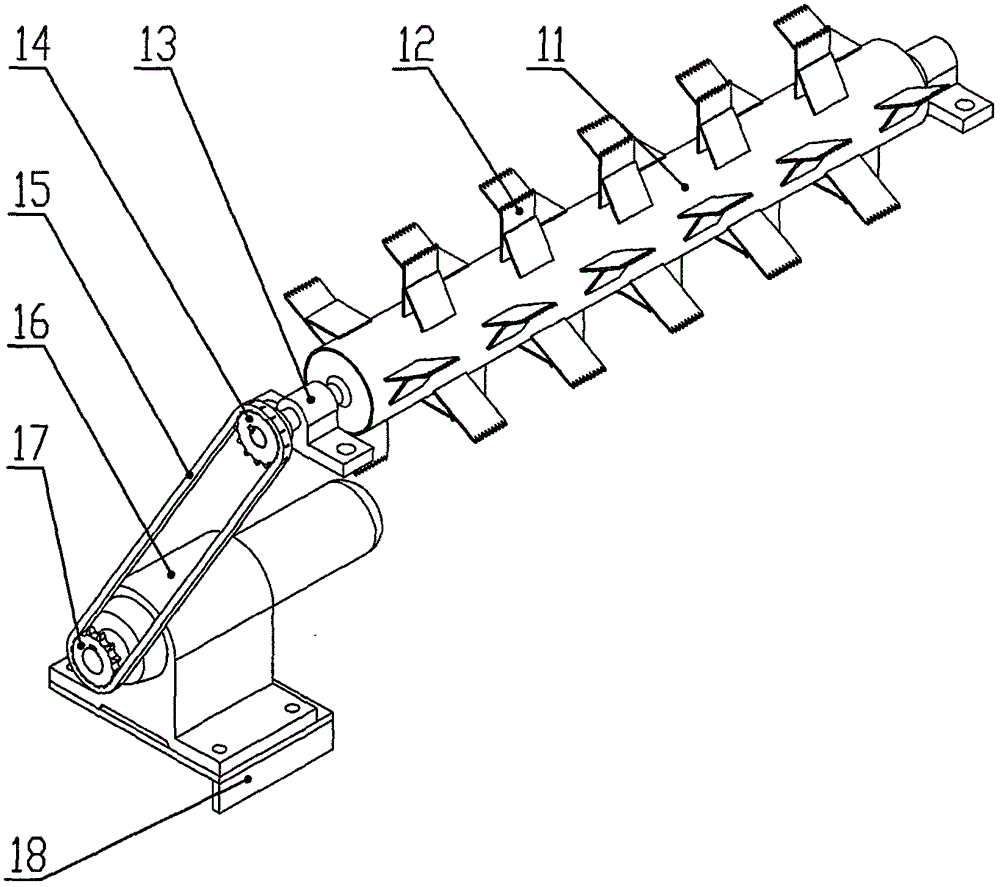

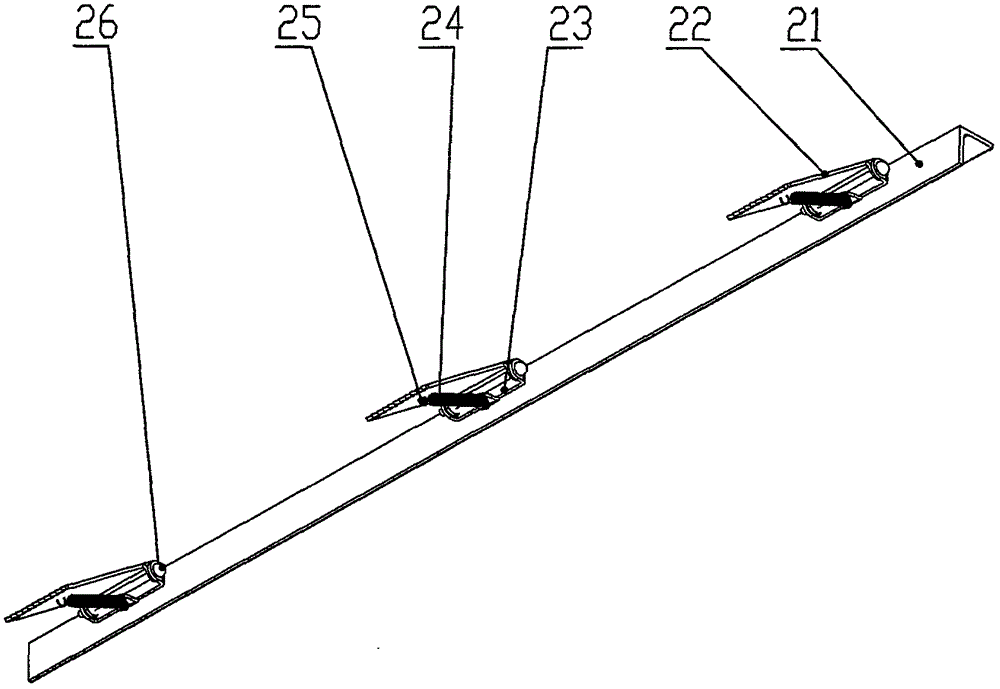

The invention discloses layer-by-layer automatic feeding, marking and gluing integrated equipment for sheet materials. The layer-by-layer automatic feeding, marking and gluing integrated equipment for the sheet materials comprises a marking device and a gluing device; the gluing device is arranged on one side of the marking device and a layer-by-layer automatic feeding device is arranged on the other side of the marking device; the layer-by-layer automatic feeding device comprises a pushing mechanism, a hoisting mechanism and a sliding mechanism in sequence; and the gluing device comprises a supporting framework, a stirring mechanism arranged at the upper end of the supporting framework, a material scattering mechanism arranged at the bottom of a transverse beam of the supporting framework, and a compression roller gluing mechanism arranged under the supporting framework. According to the layer-by-layer automatic feeding, marking and gluing integrated equipment, marking and gluing are integrated, transmission and interruption of machines are reduced in the process and the consistency of a production line is improved; and the machining time of the whole sheet material is shortened, materials can be automatically fed layer by layer, the transmission is buffered, the gluing can be automatically realized and the gluing is uniform.

Owner:JIANGSU KENTIER WOOD

Plate press machine with glue coating function

ActiveCN106738100AAccelerate solidificationLighten the laborPlywood pressesMulti-purpose machinesWood machiningPulp and paper industry

The invention belongs to the technical field of wood working equipment, and particularly discloses a plate press machine with glue coating function. The plate press machine comprises a first horizontal push hydrocylinder, a glue coating device, a plate presser and a feeder from left to right, wherein the glue coating device comprises a bracket, a glue tank, an air cylinder and a glue supply tank; the glue supply tank is a tank body with an opening on the lower end; the glue supply tank is fixed to the bracket; a piston is arranged in the glue supply tank, and driven by the air cylinder; the air cylinder is positioned above the glue supply tank; the side wall of the glue supply tank communicates with a glue suction pipe; one end of the glue suction pipe is positioned in the glue tank; the joint between the glue suction pipe and glue supply tank is provided with a first one-way valve; the piston is provided with a through hole, and the through hole is provided with a one-way valve; the lower surface of the piston is provided with a sponge layer; the feeder comprises an elevating table and a second horizontal push hydrocylinder; and the second horizontal push hydrocylinder is positioned on the elevating table. By adopting the technical scheme, the wood plate can be pressed immediately after finishing glue coating, and the glue coating and pressing processes are continuous, so the production efficiency is high.

Owner:重庆汇升套装门有限公司

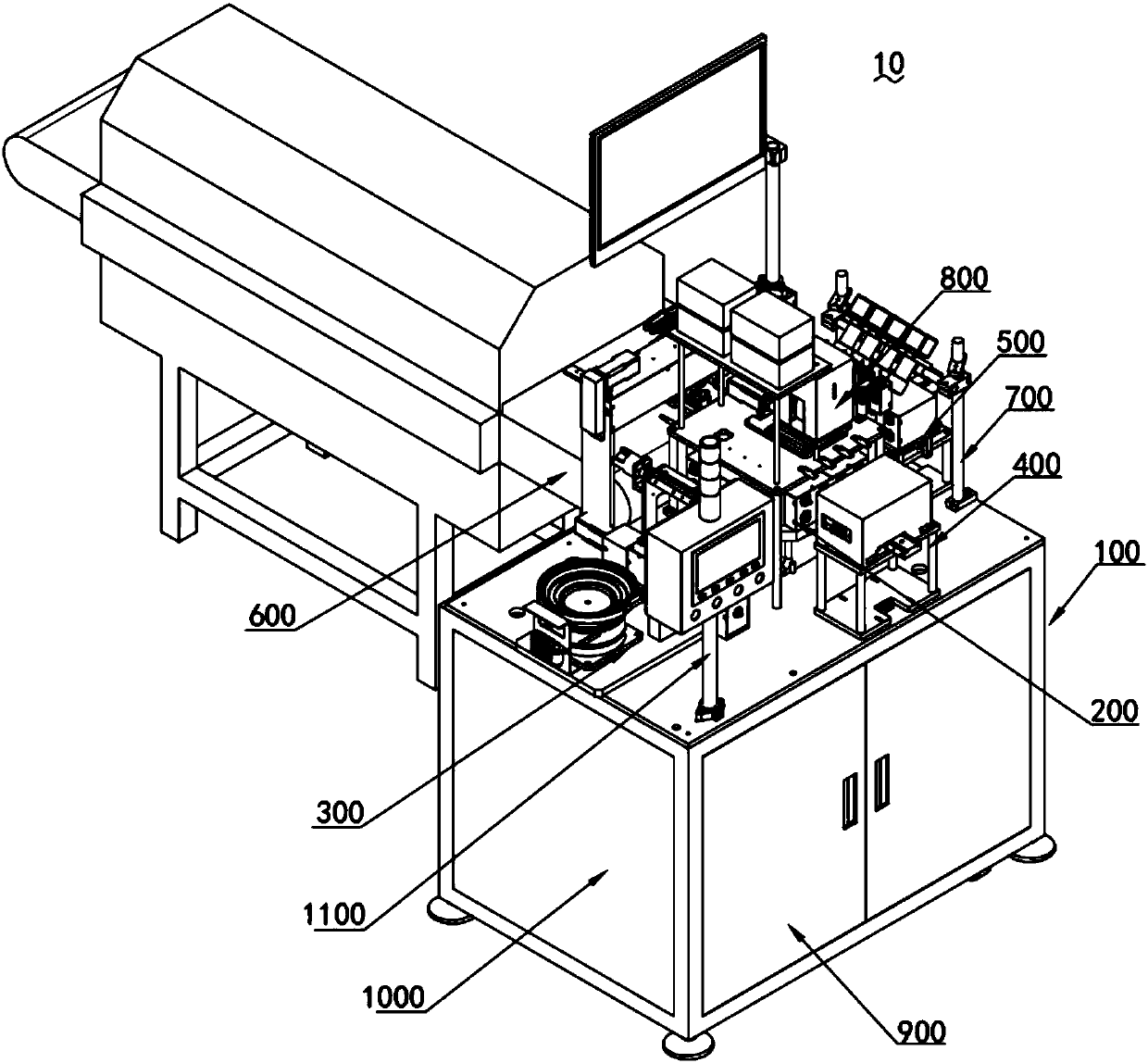

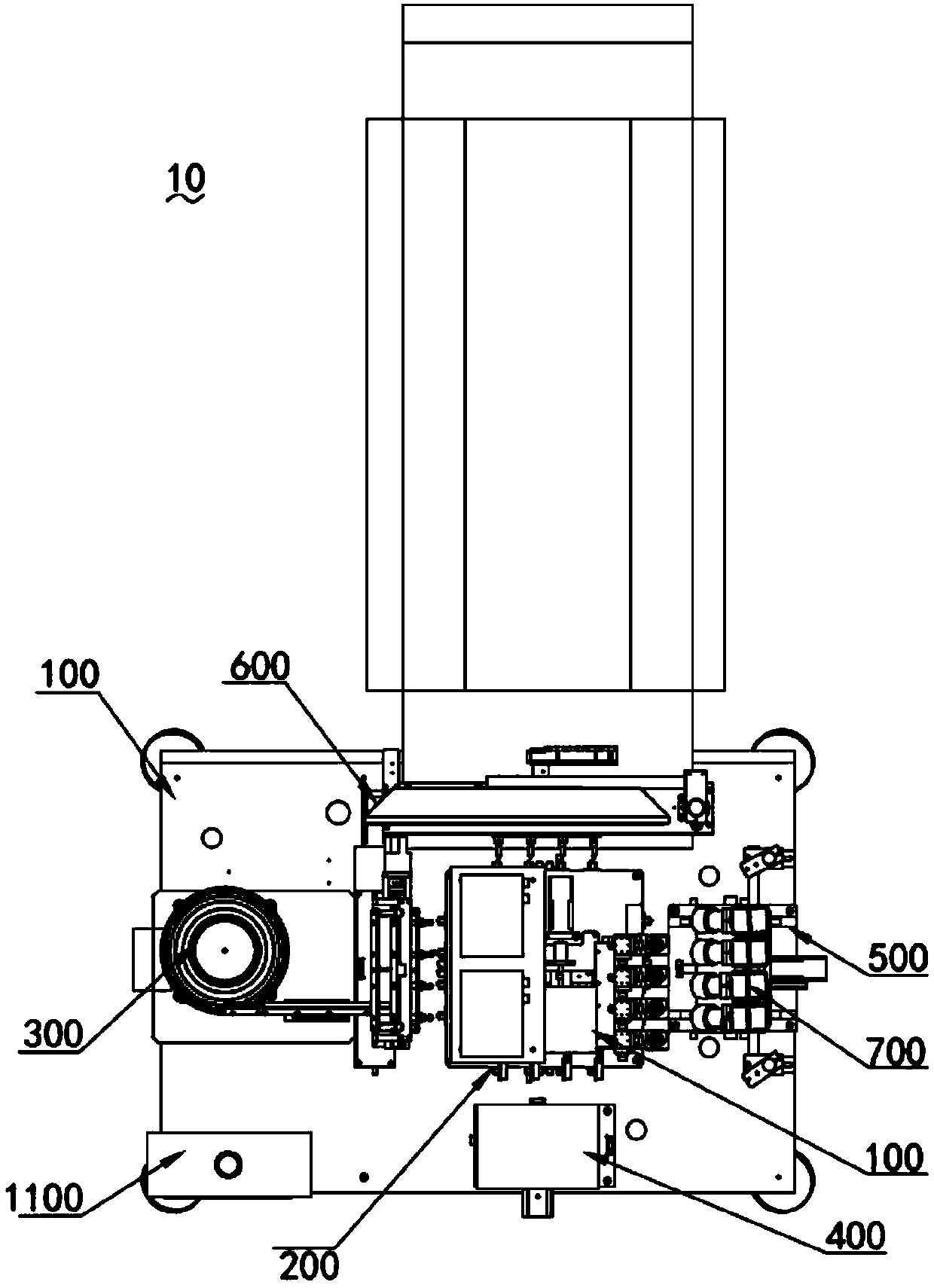

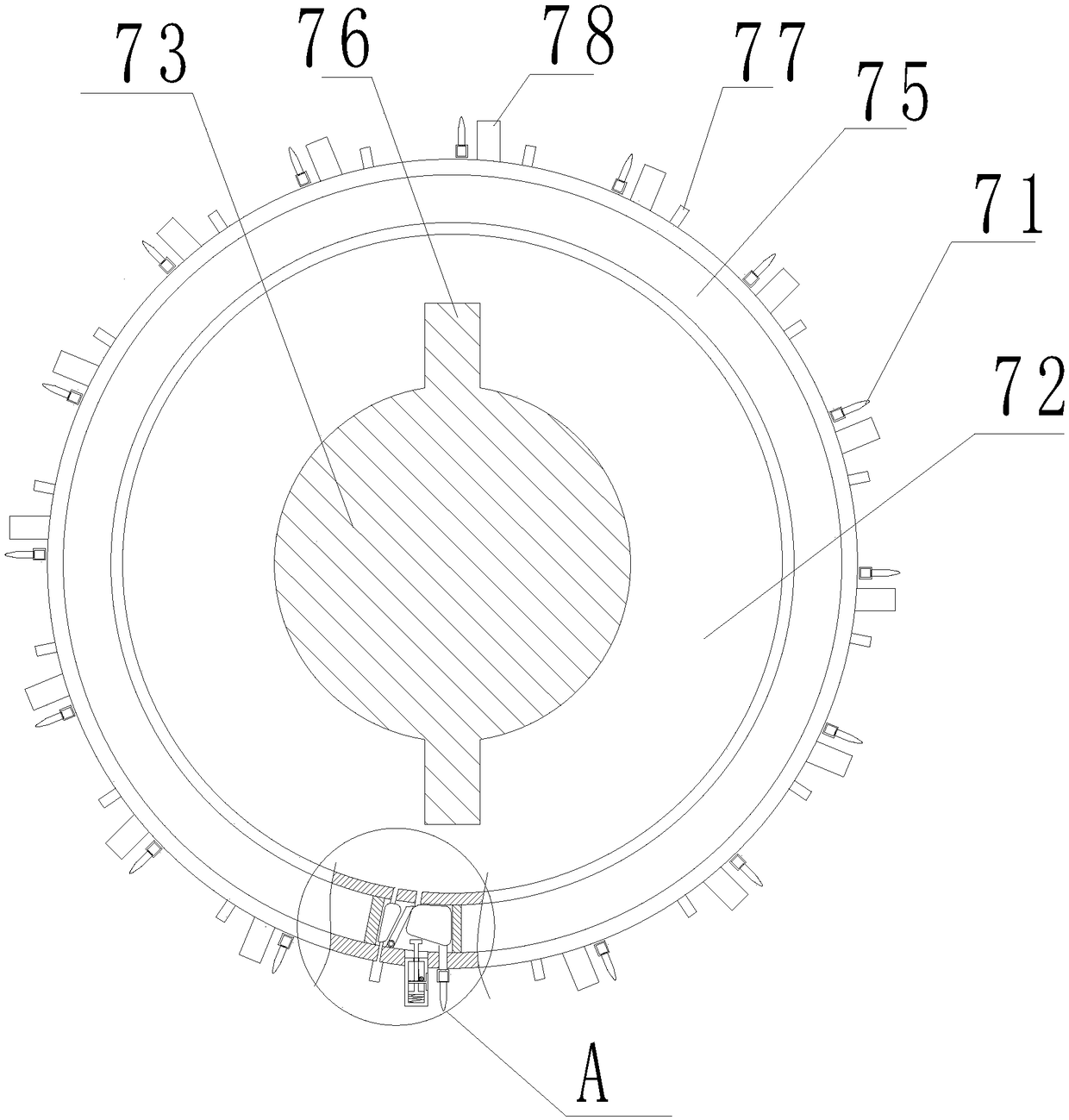

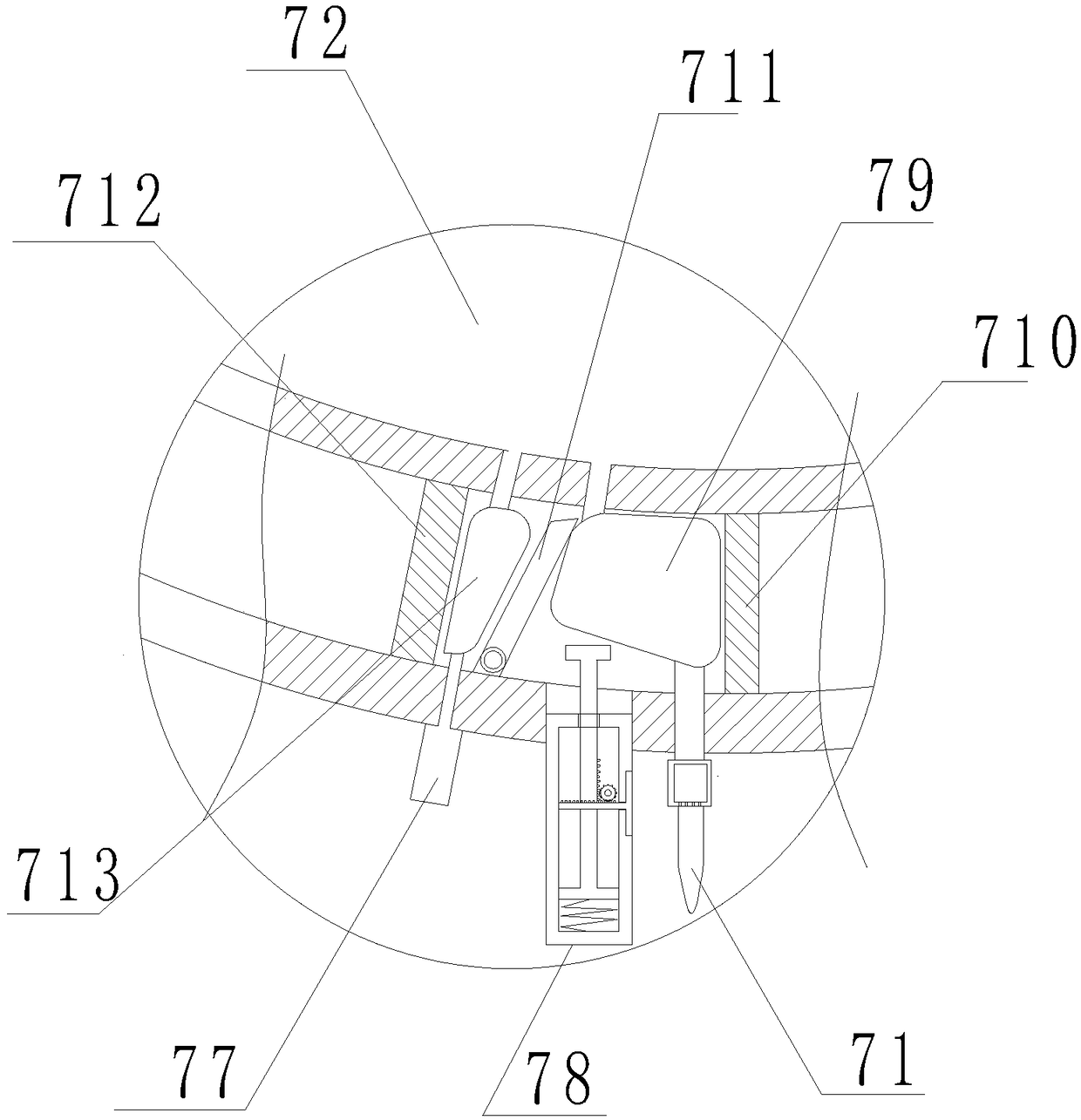

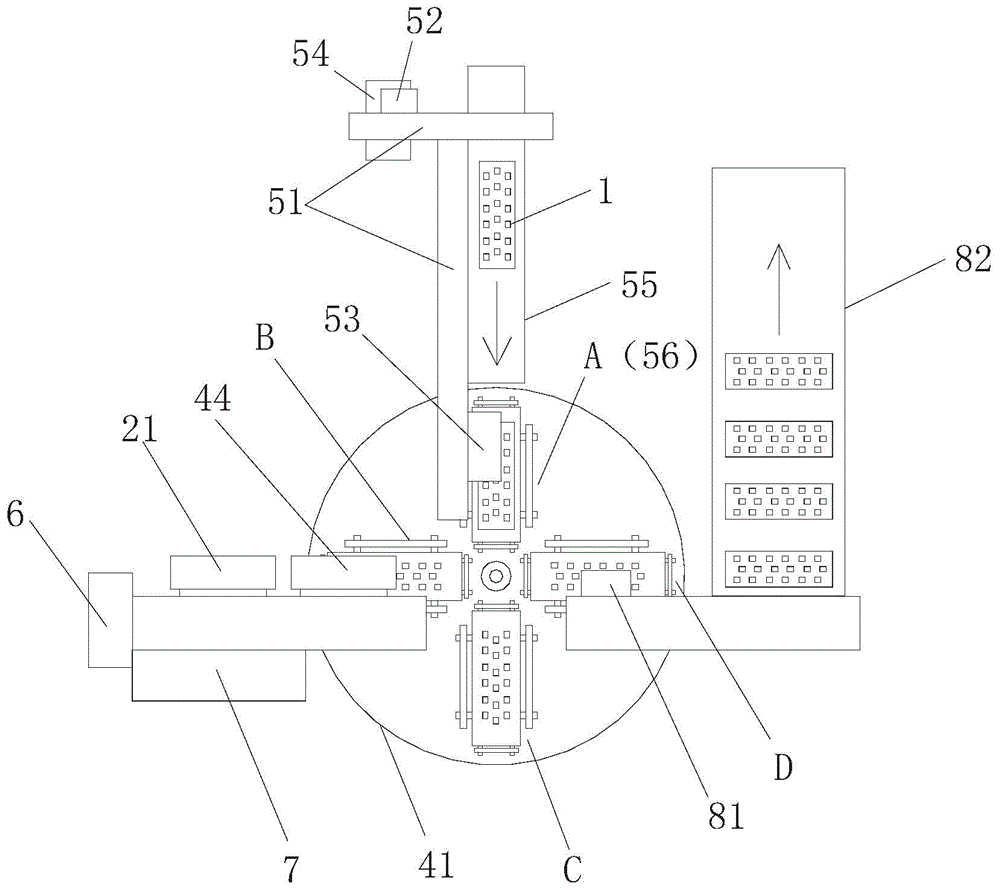

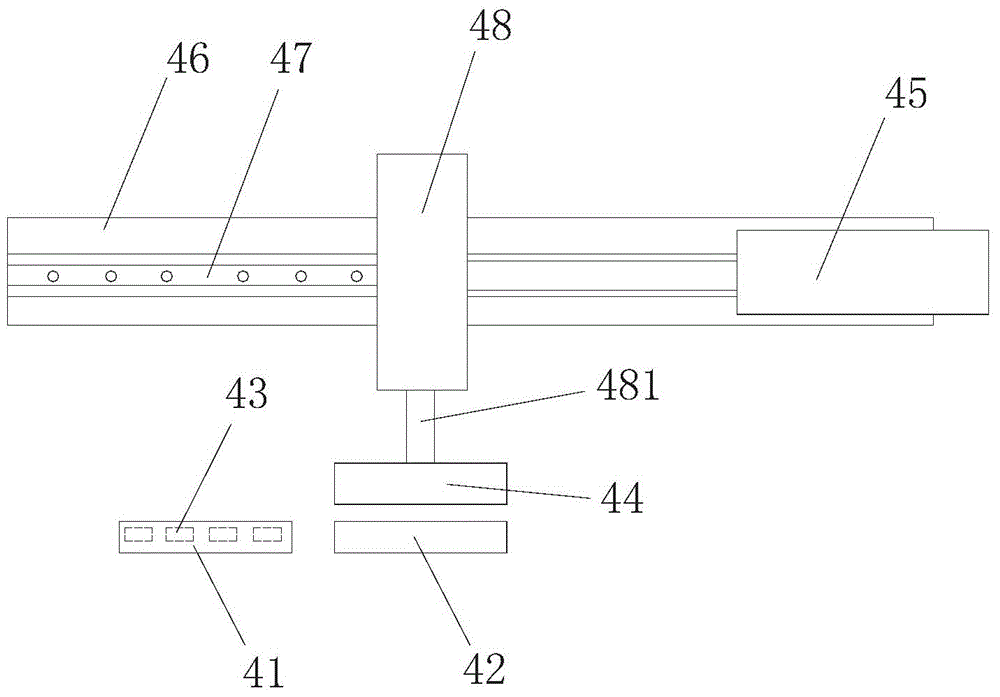

Electronic element high-efficiency vacuum gluing equipment

PendingCN107742573AImprove gluing qualityEasy to absorb and grabEncapsulation/impregnationElectricityEngineering

The invention relates to the technical field of electronic element gluing, and particularly relates to electronic element high-efficiency vacuum gluing equipment, which comprises a rack, a turntable mechanism, a loading mechanism, a positioning mechanism, a rotating mechanism, an unloading mechanism, a detecting mechanism, a gluing mechanism, a vacuum mechanism, an electric control mechanism and acontrol mechanism, wherein the turntable mechanism is arranged on the rack; the loading mechanism, the positioning mechanism, the rotating mechanism and the unloading mechanism are arranged on the rack and around the turntable mechanism; the detecting mechanism is fixed on the rack and above the rotating mechanism; the gluing mechanism is mounted on the rack and above the turntable mechanism; thevacuum mechanism and the electric control mechanism are arranged in the rack; the control mechanism is connected with the electric control mechanism and is fixed on the rack; the vacuum mechanism isconnected with the loading mechanism, the unloading mechanism and the turntable mechanism; the electric control mechanism is electrically connected with the turntable mechanism, the loading mechanism,the positioning mechanism, the rotating mechanism, the unloading mechanism, the vacuum mechanism and the control mechanism. The equipment provided by the invention has the advantages of full-automatic overall operation, high gluing quality of electronic elements, high gluing efficiency and high automation degree.

Owner:DONGGUAN TB ELECTRONICS TECH CO LTD

Coater scraper apparatus

ActiveCN103350055AMake sure the thicknessEnsure flatnessLiquid surface applicatorsCoatingsEngineeringMechanical engineering

The invention relates to a coater scraper apparatus. The apparatus comprises a scraper rack connected to a coater frame, a scarper having a cutting edge corresponding the coating roller of a coater is press-fitted on the scraper rack through a scraper press plate, a scraper rack adjusting shaft paralleling to the scraper rack is movably arranged on the coater frame in a penetrating mode, the scraper rack is connected with the scraper rack adjusting shaft and rotate around the scraper rack adjusting shaft, an adjusting worm gear is fixedly connected with the scraper rack adjusting shaft in a penetrating mode, the coater frame supports an adjusting worm having a driving cooperation with the adjusting worm gear, and the adjusting worm is connected with a hand wheel. The coater scraper apparatus accurately controls the adjustment between the scraper and the coating roller by adopting the scraper rack rotatablely far from or close to the coating roller and combining the scraper adjusting seat and a trimming cylinder, so the apparatus has the advantages of simple and compact structure, convenient and accurate adjustment, and effective ensure of the thickness of a glue solution on the coating roller for the uniform adjustment, and is suitable for the use of various different specification coating rollers and coating thicknesses.

Owner:泰兴联创绝缘材料有限公司

Full-automatic double-hollow glass gluing machine

ActiveCN102671816BImprove gluing efficiencyHigh degree of automationLiquid surface applicatorsCoatingsEngineeringAutomation

The invention discloses a full-automatic double-hollow glass gluing machine, comprising a single-glue nozzle dual-outlet mechanism and a double-measurement mechanism, wherein the single-glue nozzle dual-outlet mechanism comprises a glue nozzle main body and a glue nozzle front end; two glue outlets are formed at the glue nozzle front end; the two glue outlets are respectively communicated with a glue outlet channel in the glue nozzle main body; the double-measurement mechanism comprises two independent depth measurers; and the two depth measurers are respectively located in front of the two glue outlets at the glue nozzle front end. The full-automatic double-hollow glass gluing machine can be used for gluing the double-hollow glass twice in a sealed manner in one gluing process, so that the gluing efficiency is high, the gluing quality is good, and the automation degree is high.

Owner:北京昌益和自动化设备制造有限公司

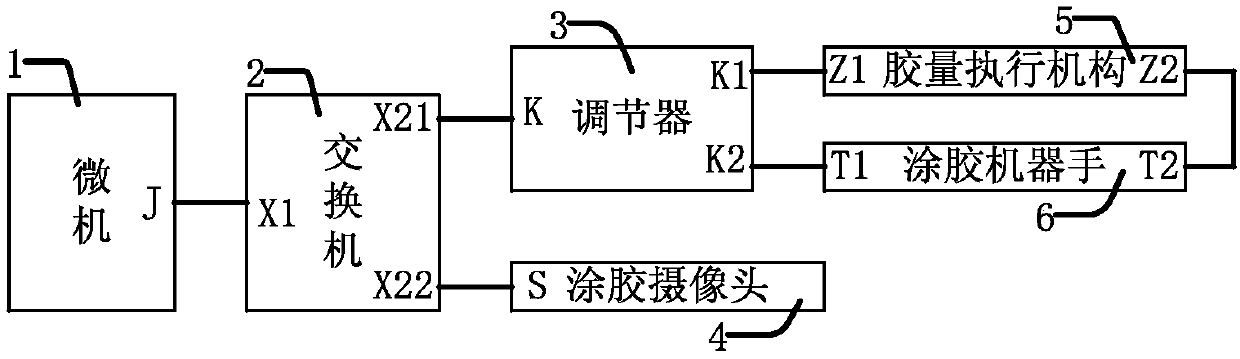

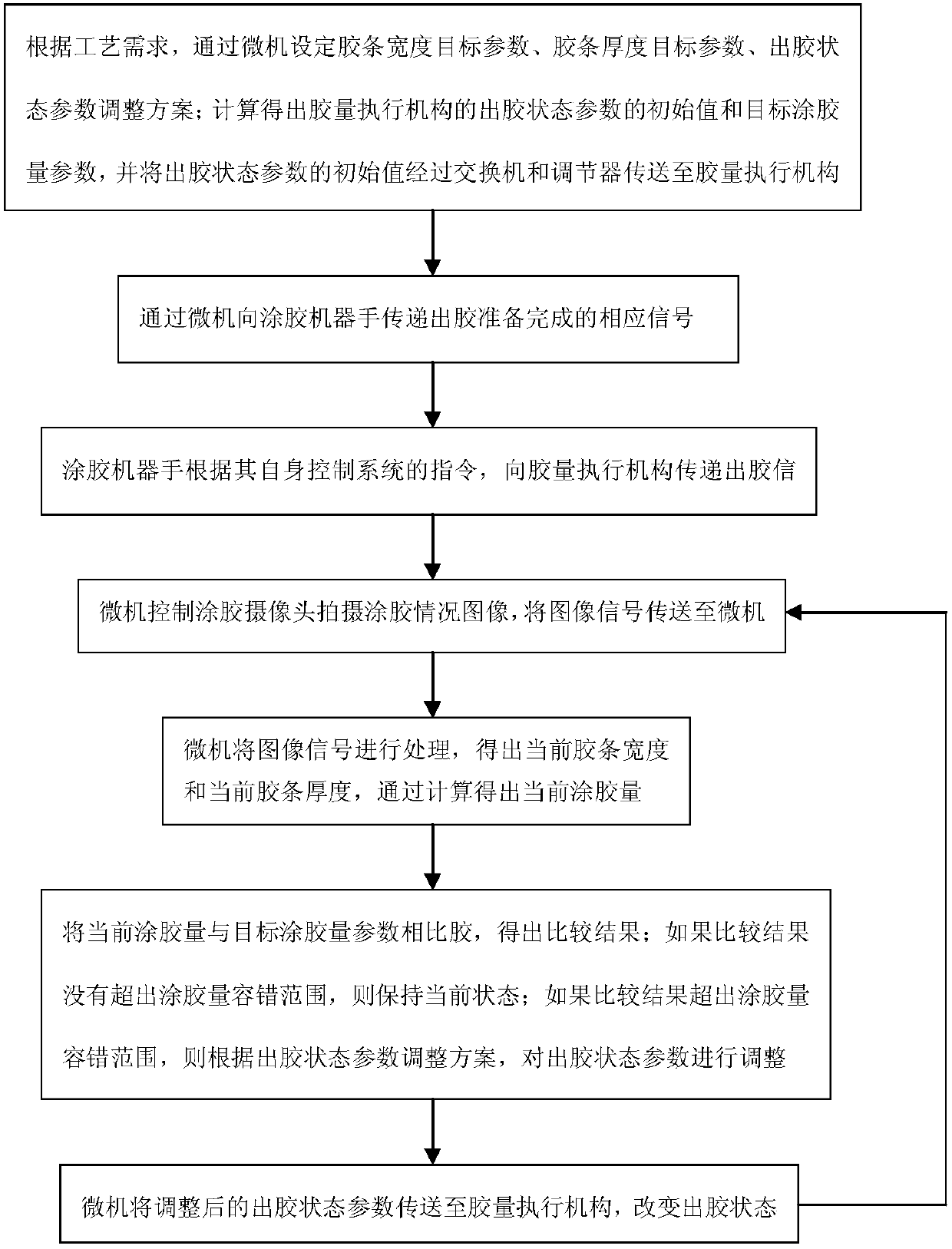

Automatic control device for glue coating amount of automatic part and control method

PendingCN107812674AAutomatic control is reliableRapid responseLiquid surface applicatorsCoatingsMicrocomputerAutomatic control

The invention belongs to the technical field of control over the glue coating quality and glue coating amount of automatic parts and particularly relates to an automatic control device for the glue coating amount of an automatic part and a control method. The automatic control device for the glue coating amount of the automatic part comprises a microcomputer, an exchanger, an adjuster, a glue coating camera, a glue amount executing mechanism and a glue coating manipulator. The control method of the automatic control device for the glue coating amount of the automatic part comprises the steps that firstly, a target parameter of the glue tape width, a target parameter of the glue tape thickness and a glue outlet state parameter adjusting scheme are set, and an initial value of a glue outletstate parameter and a target glue coating amount parameter of the glue amount executing mechanism are obtained; secondly, a corresponding signal of glue outlet preparation completion is transmitted tothe glue coating manipulator; thirdly, the glue amount executing mechanism starts glue outlet; fourthly, an image signal is sent to the microcomputer; fifthly, the current glue coating amount is obtained; sixthly, the glue outlet state parameter is adjusted; and seventhly, the glue outlet state is changed. The circulating time of the working process is smaller than 500 microseconds, the responseis rapid, and it is ensured that automatic control over the glue coating amount is stable and reliable.

Owner:SHENYANG LIGONG UNIV

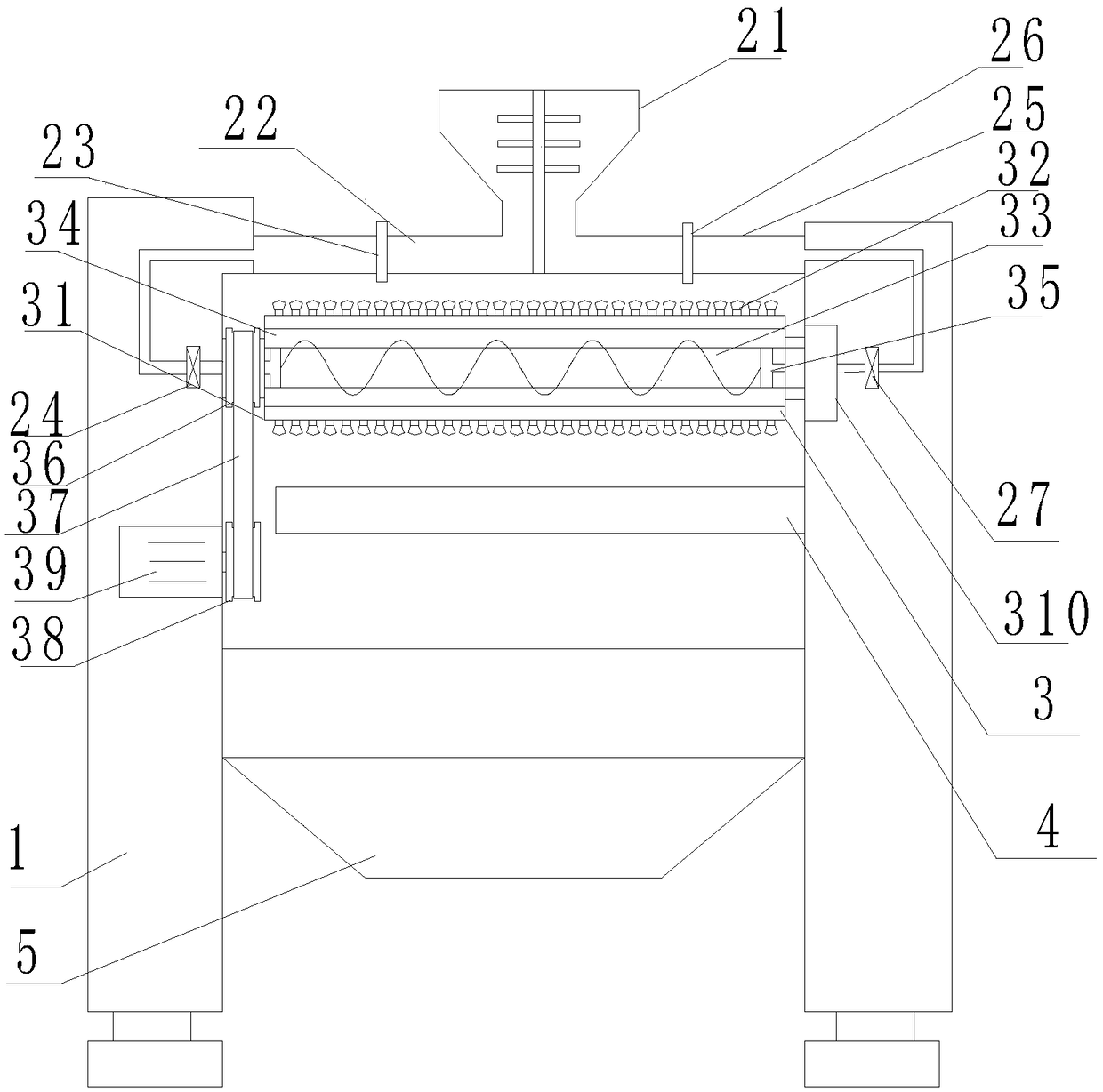

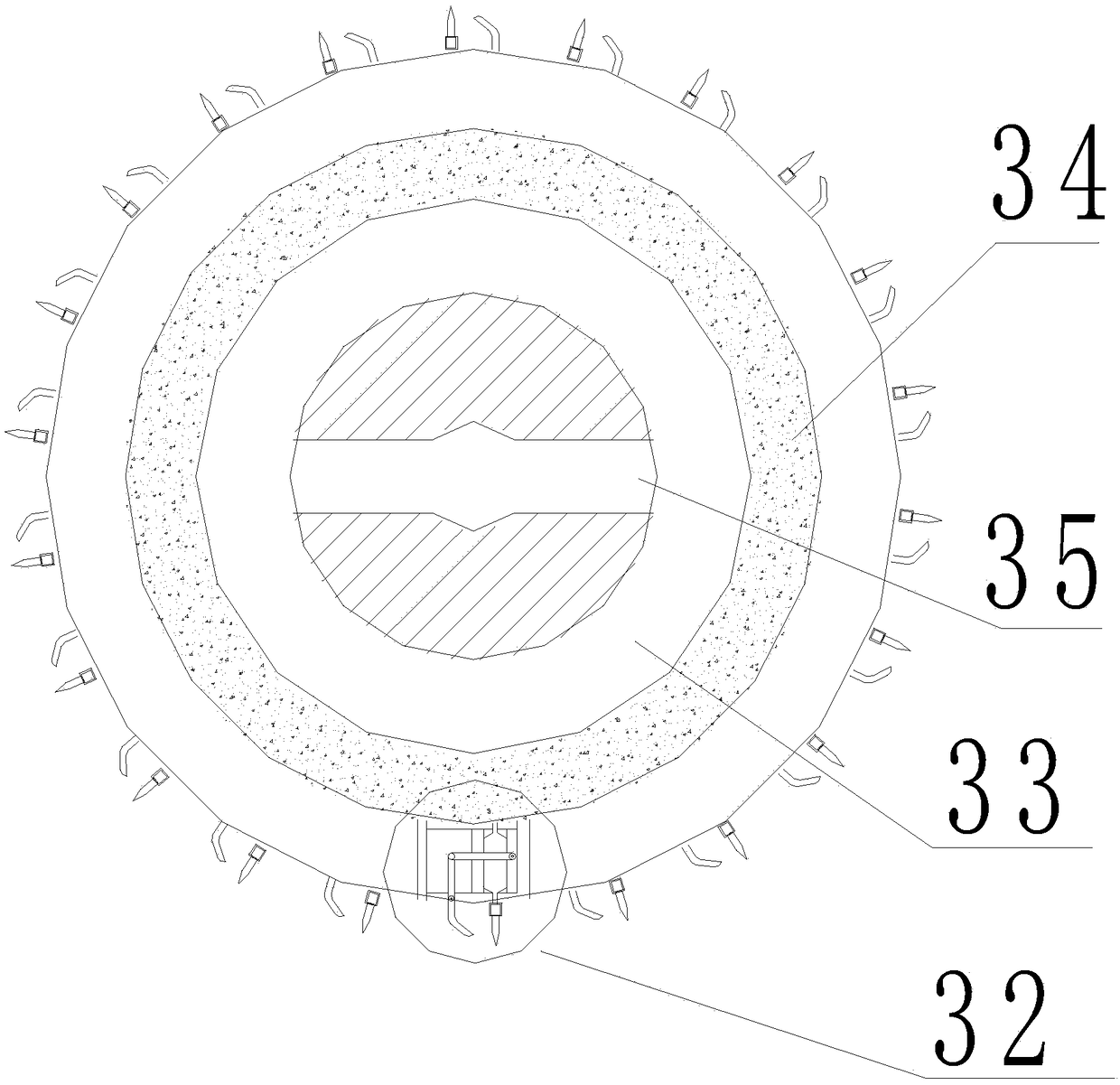

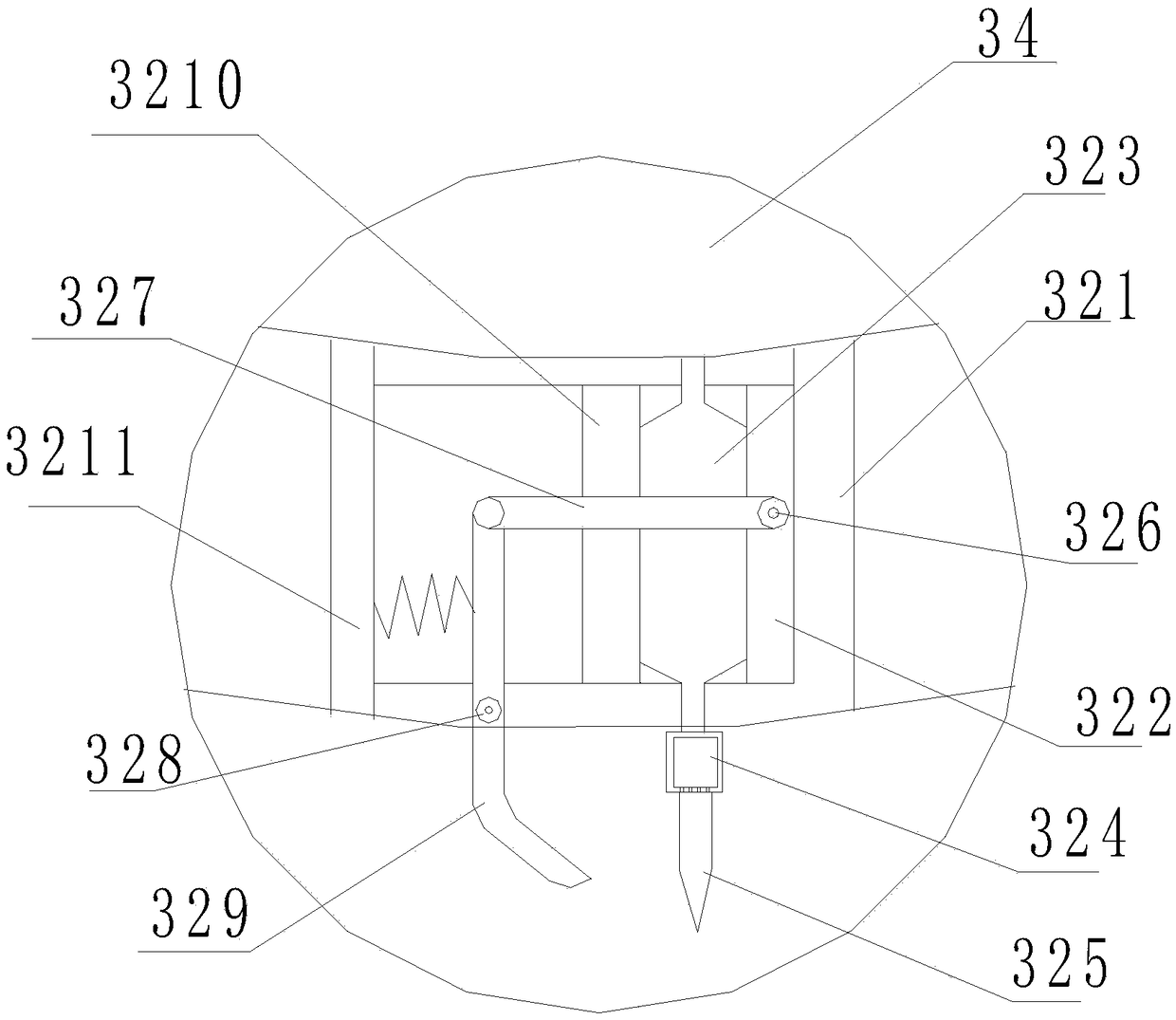

High-efficiency glue spreader

ActiveCN109382261AApply evenlyImprove gluing qualityLiquid surface applicatorsSpraying apparatusEngineeringMechanical engineering

The invention provides a high-efficiency glue spreader which comprises a rack, wherein a hopper is arranged at the top of the rack and communicates with blanking pipelines; a rotatable gluing roller is mounted below the hopper; a plate conveying belt is arranged below the gluing roller in a matched manner; a glue containing cavity is arranged in the gluing roller; the glue containing cavity communicates with the hopper through the blanking pipelines; a mechanism containing cavity is further arranged at the periphery of the glue containing cavity; a plurality of gluing partition plates and gluespraying partition plates are mounted in the mechanism containing cavity; the mechanism containing cavity is divide into a plurality of triggering cavities by the gluing partition plates and the gluespraying partition plates; the triggering cavities are internally provided with glue spraying air bags and gluing air bags; the gluing air bags and the glue spraying air bags communicate with the glue containing cavity respectively; the gluing air bags further communicate with gluing brushes mounted outside the gluing roller; the glue spraying air bags communicate with spraying heads mounted outside the gluing roller; and triggers are further elastically mounted outside the gluing roller. When the glue spreader works, the triggers are extruded to trigger the spraying heads to spray a plate; the gluing brushes glue the plate; the gluing quality is high; no secondary processing is required; and the working efficiency is high.

Owner:临泉县荣兴木业有限公司

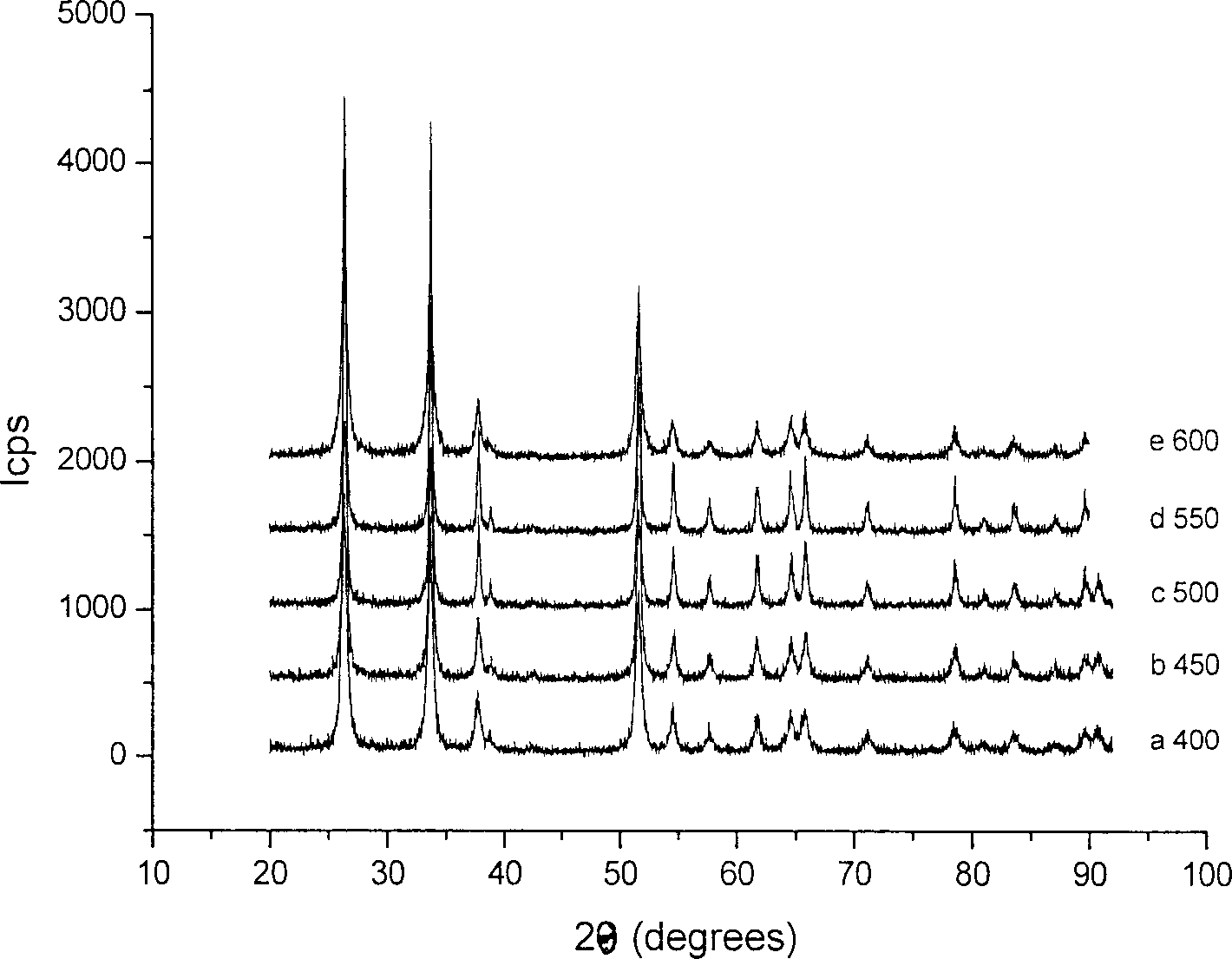

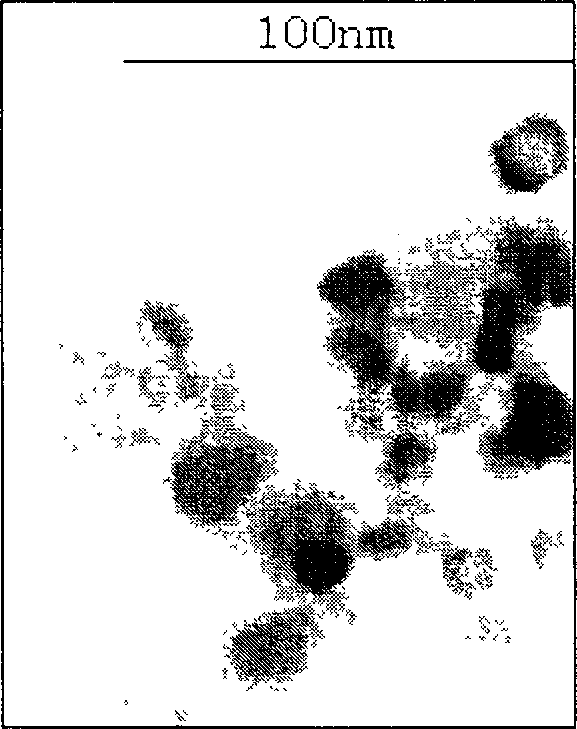

Method for preparing Nano granules of stannic oxide

InactiveCN1796287AThe preparation method is simple and easySmall particle sizeTin oxidesPolyethylene glycolMuffle furnace

This invention discloses a method to prepare a nano particle of tin oxide. In this method, the salt of tin, citric acid and poly (ethylene glycol) are used as raw materials. After dissolving in DIW, the solution is heated by microwave to form the precursor of gel, which is then baked in muffle furnace to prepare nano particle of tin oxide with good distribution and low aggregation. The average size of the particle is about 17.0 nanometers. The method has the characteristics of simple process, short cycle time of production.

Owner:GUANGDONG YESER IND CO LTD

Heat treatment process of agricultural straw

A process for thermally processing the straw and stalk of agricultural crops in order to use them for other purposes includes cutting short, removing dust, treating by steam under 0.1-0.3 MPa for 5-8 min or by microwave for 0.5-2.0 min, and pulverizing. Said powder of straw or stalk features its high binding power to adhesive, resulting in less consumption of adhesive.

Owner:NANJING FORESTRY UNIV

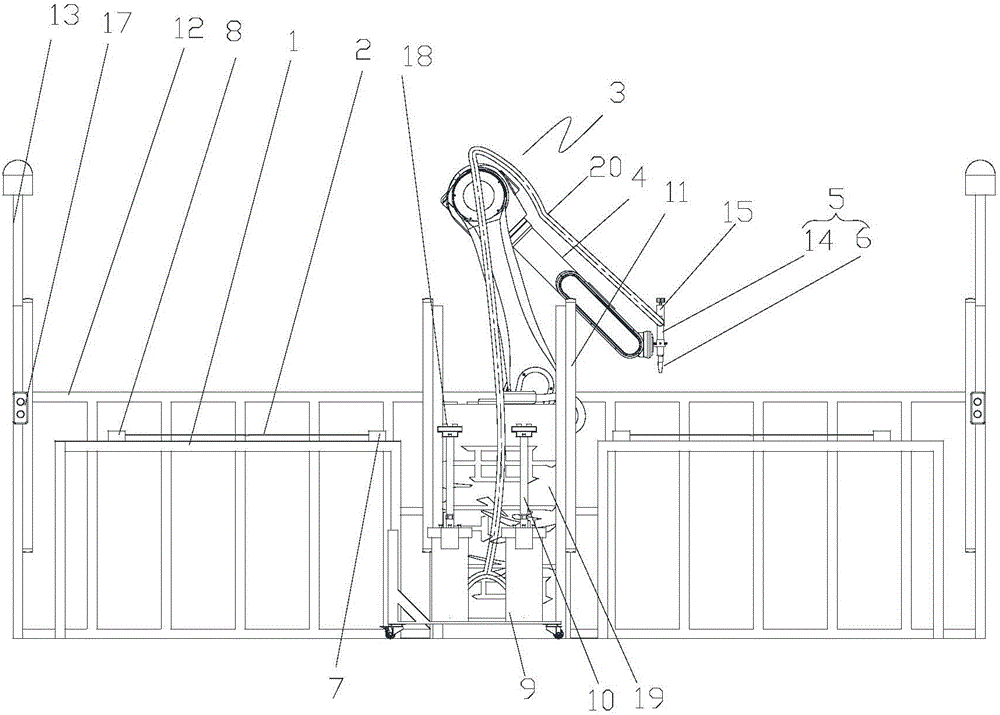

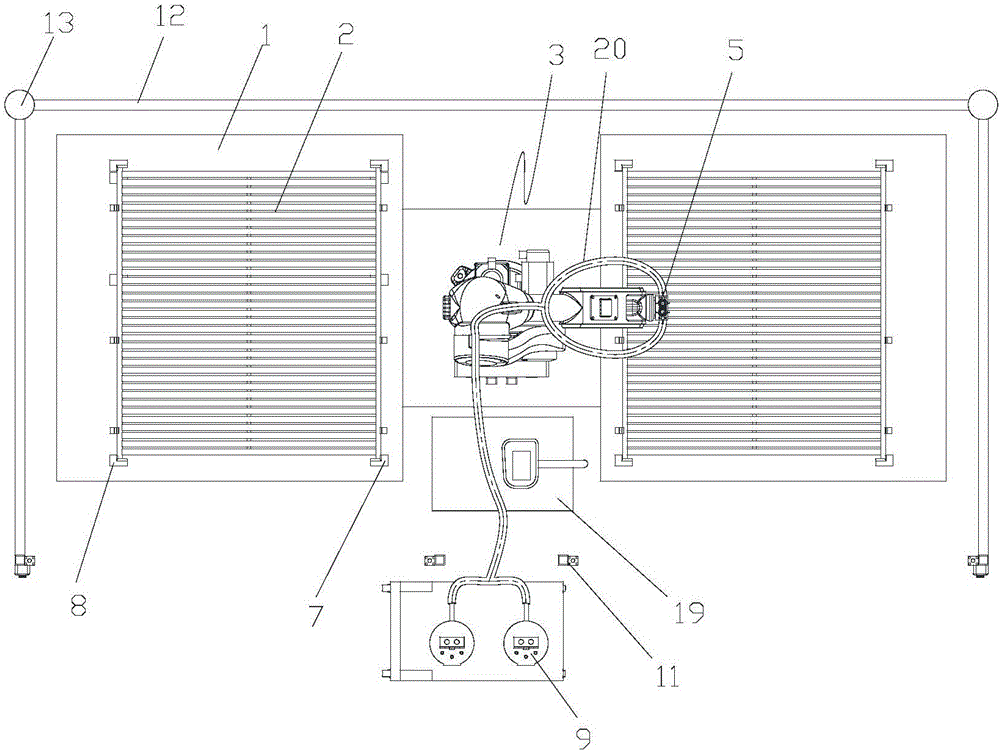

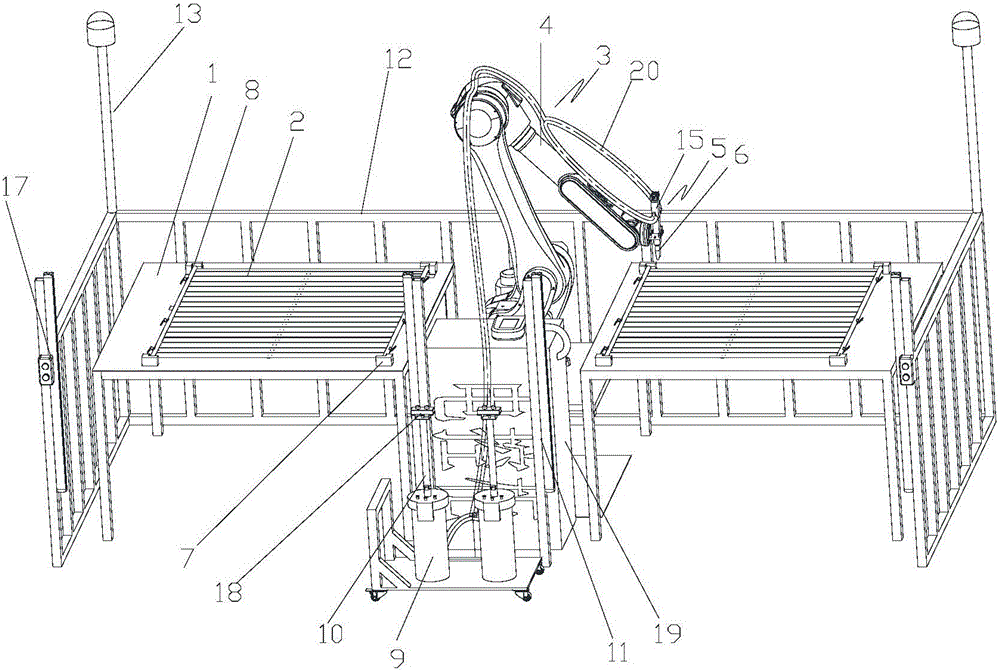

Automatic gluing device

ActiveCN105817392AAutomatic glue applicationReduce the difficulty of gluingLiquid surface applicatorsCoatingsEngineeringElectric control

The invention discloses an automatic gluing device. The automatic gluing device comprises a gluing worktable (1), a robot (3), a glue gun (5) and an electric control device (19), wherein a positioning structure for positioning a to-be-glued product (2) is arranged on the gluing worktable (1); the robot (3) comprises a first mechanical arm (4) which can move in the gluing direction of the to-be-glued product (2); the glue gun (5) is arranged on the first mechanical arm (4) and comprises a gun head (6) arranged corresponding to the to-be-glued product (2); and the electric control device (19) is electrically connected with the robot (3) and the glue gun (5), and controls the robot (3) and the glue gun (5) to be linked. According to the automatic gluing device disclosed by the invention, the problems of high labor intensity of manual gluing and poor gluing consistency in the prior art can be solved.

Owner:GREE ELECTRIC APPLIANCES INC

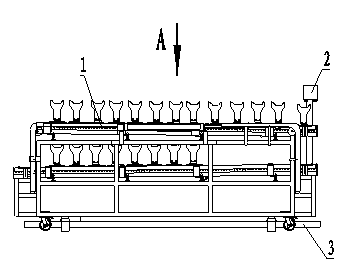

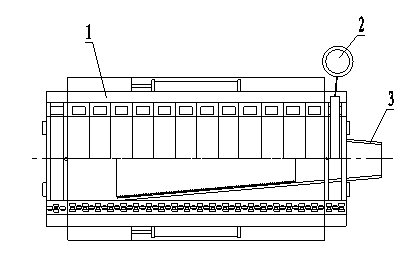

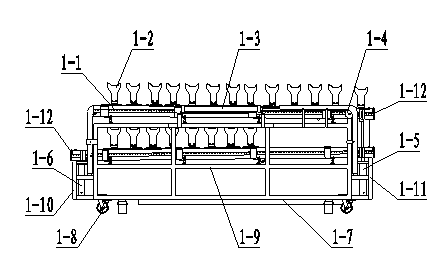

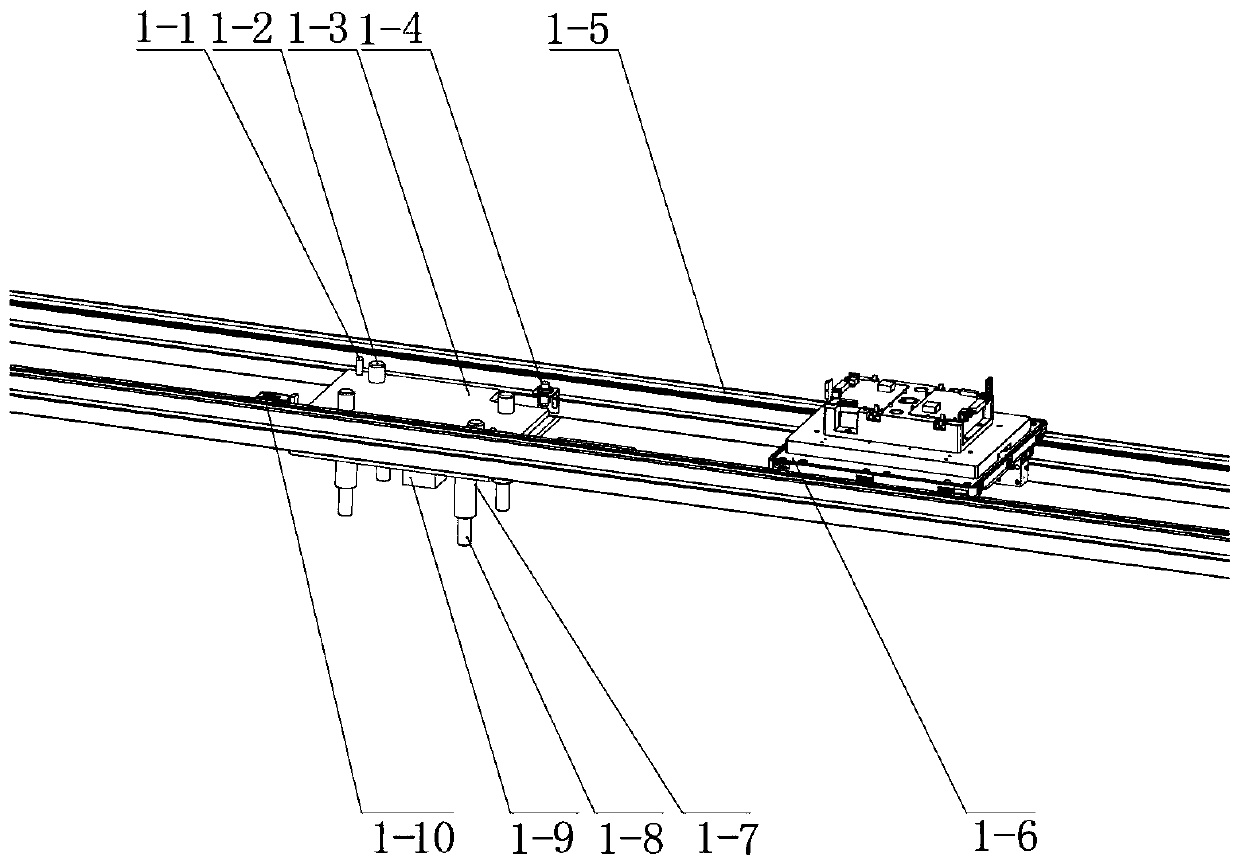

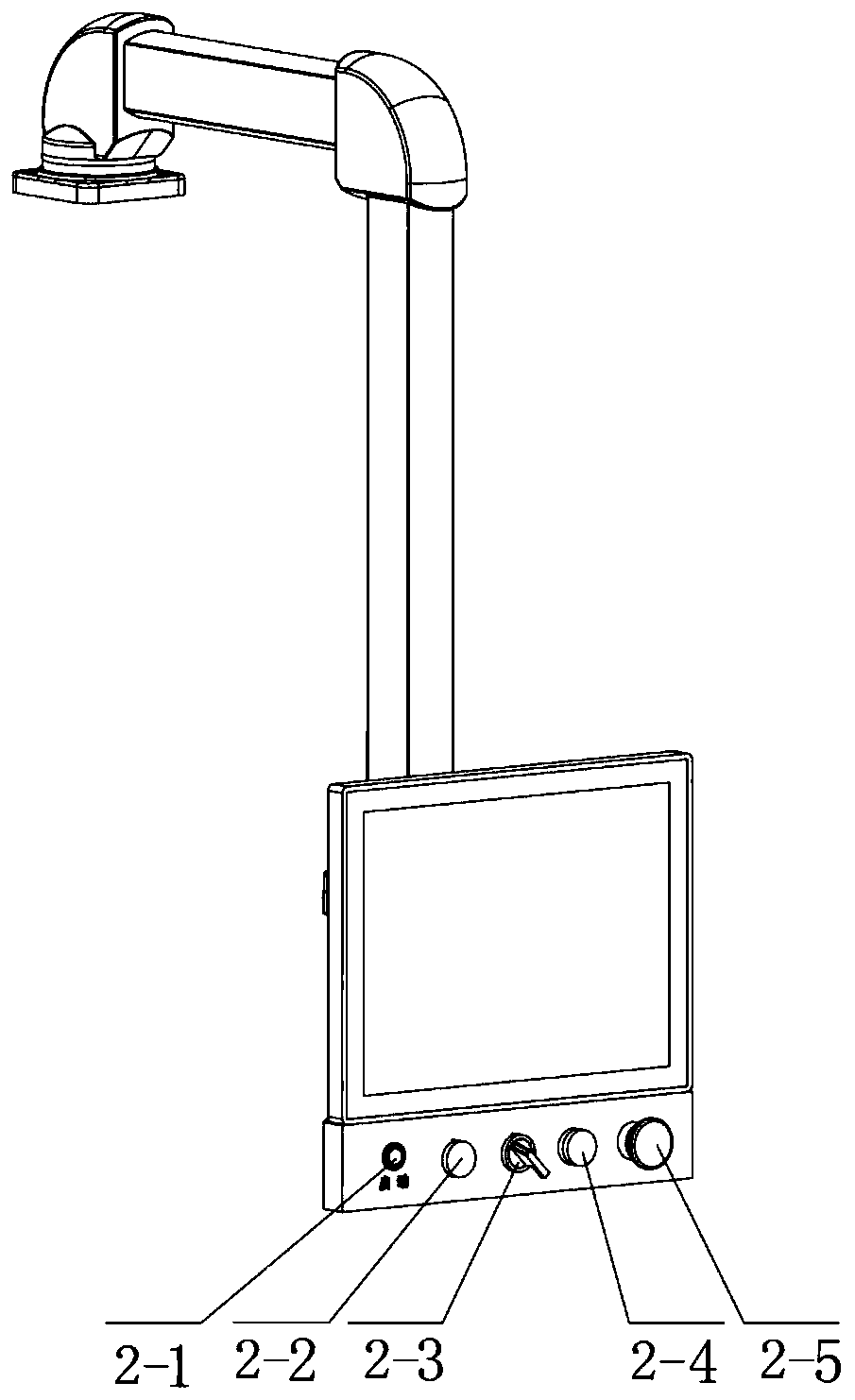

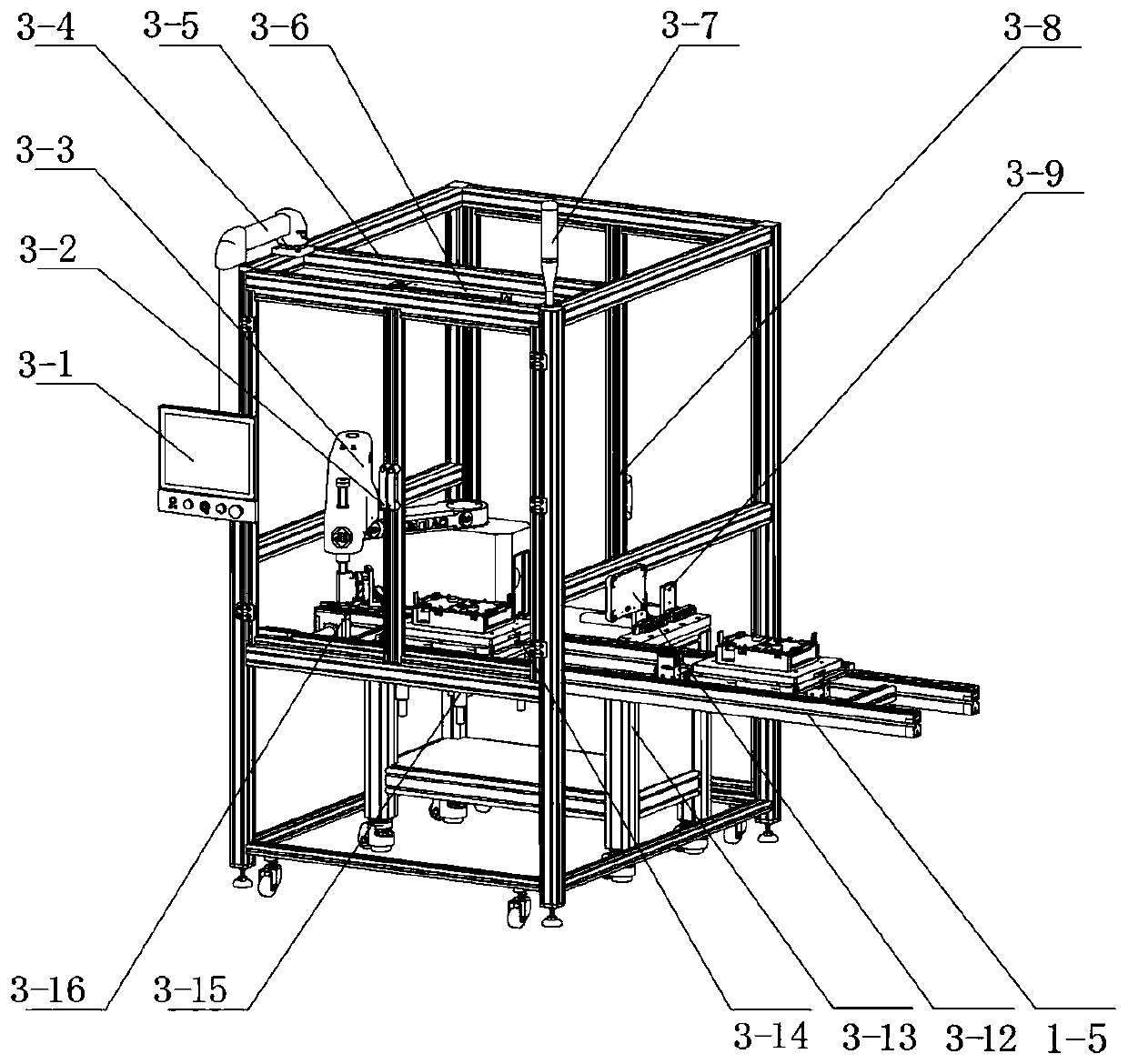

Automatic conveying and gluing equipment for welding workpieces

ActiveCN102700911AImprove gluing qualityImprove quality and efficiencySpraying apparatusWelding/cutting auxillary devicesProgrammable logic controllerEngineering

Automatic conveying and gluing equipment for welding workpieces is used for conveying parts of automotive bodies on an automatic welding production line and comprises a sliding circulating conveying device, a gluing mechanism, a positioning connecting track and a programmable logic controller (PLC) system. The sliding circulating conveying device can move between a secondary assembly welding station and a robot welding station; the robot welding station is provided with the positioning connecting track for the sliding circulating conveying device and the gluing mechanism, the gluing mechanism is arranged on the side of the positioning connecting track, and the sliding circulating conveying device and the gluing mechanism are controlled by the PLC system to circularly feed in workpieces and spray vibration reduction glue on the workpieces. The automatic conveying and gluing equipment has the advantages of high automation degree and reliability in operation, gluing quality is increased, collision of the workpieces is avoided when the workpieces are conveyed, and potential safety hazards caused by cross operation of manual operation and robot operation are eliminated.

Owner:长城汽车股份有限公司平湖分公司

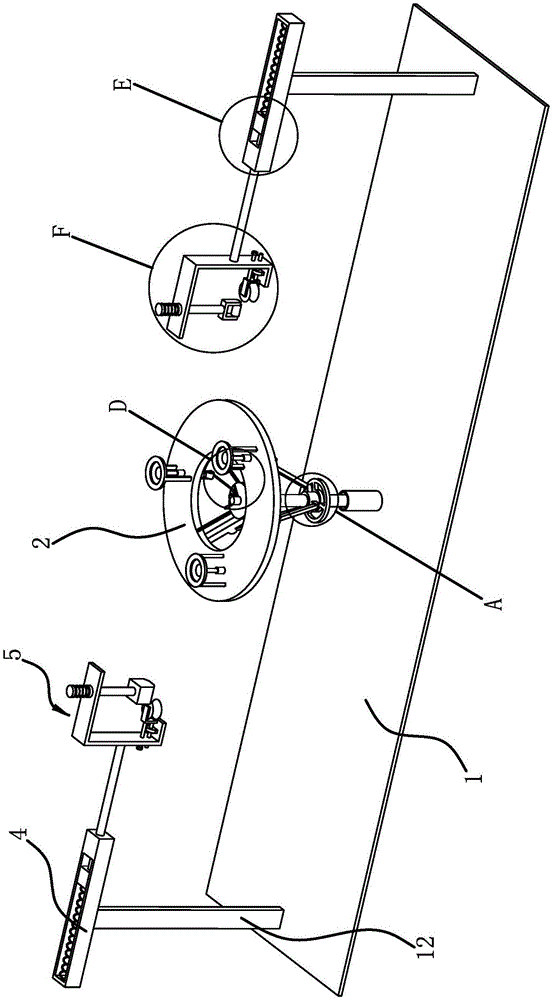

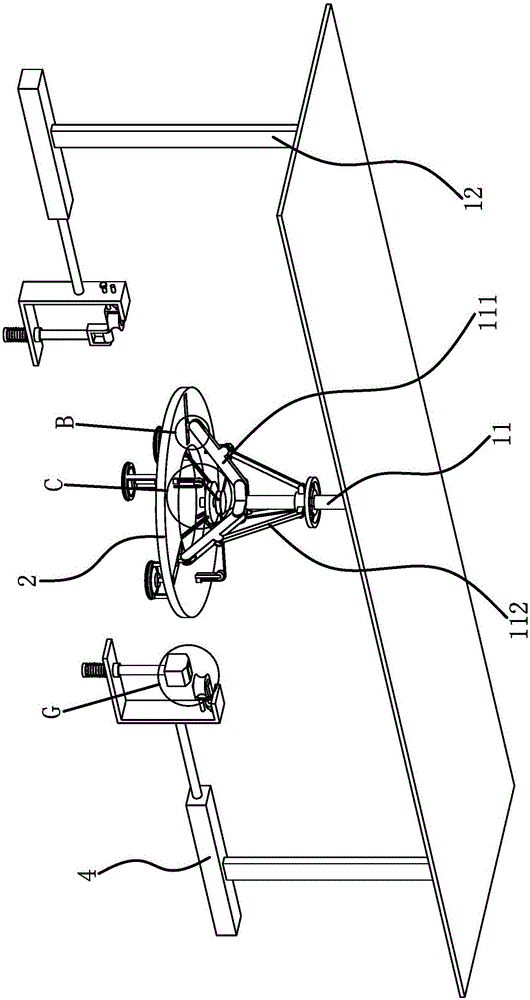

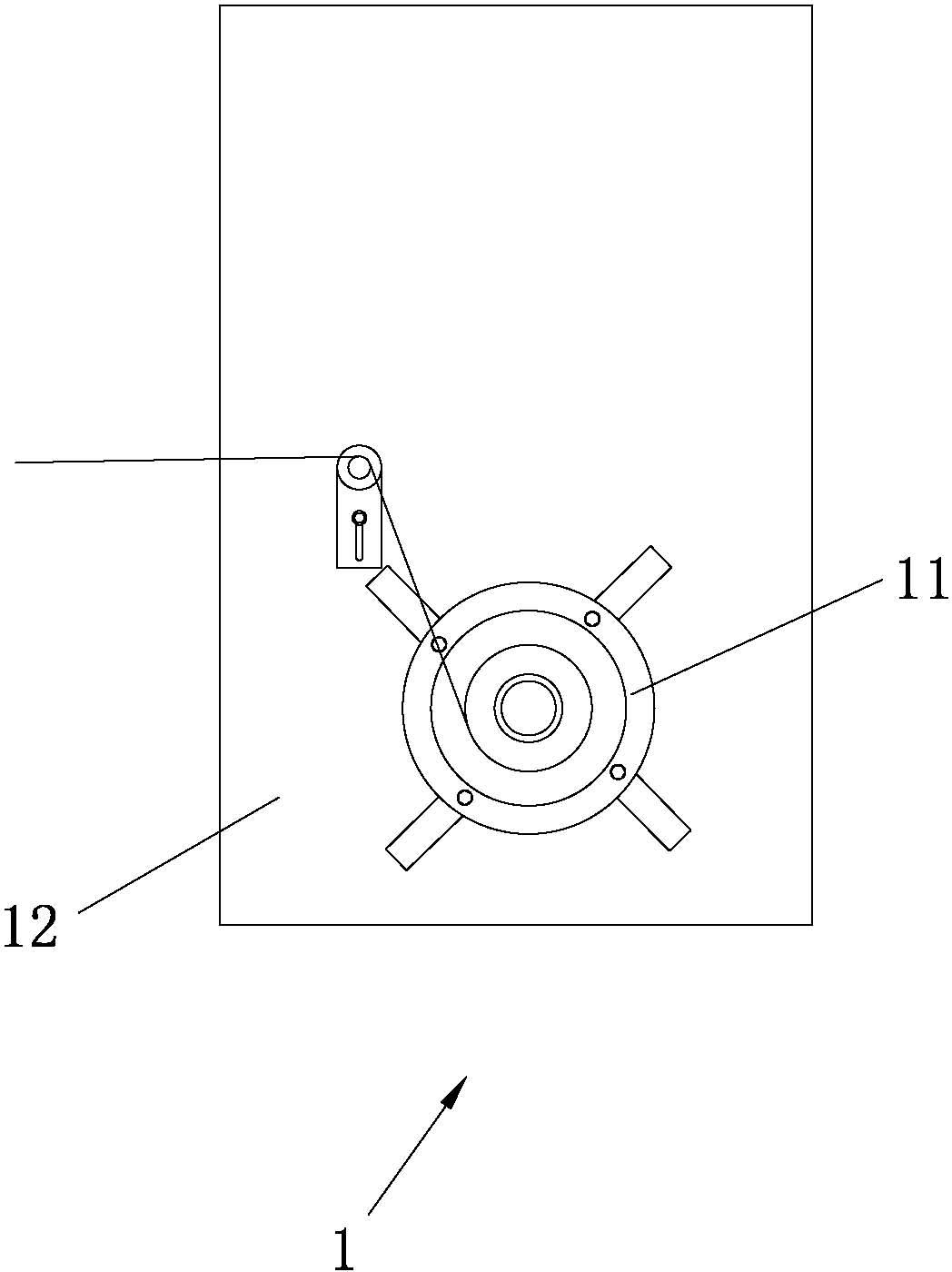

Automobile windscreen side face edge gluing device

InactiveCN106583142AThe glue layer is uniform and orderlyGood glue qualityLiquid surface applicatorsCoatingsEngineeringMechanical engineering

The invention provides an automobile windscreen side face edge gluing device, and belongs to the technical field of automobile mounting equipment. The problem that in the prior art, the automobile windscreen gluing quality is poor is solved. The automobile windscreen side face edge gluing device comprises a base, a main shaft is rotatably connected to the base, and a supporting plate is connected to the main shaft; a plurality of fixing rings are fixedly connected to the supporting plate in the circumferential direction; fixing discs are slidably connected to the supporting plate, and a rubber membrane is arranged between each fixing disc and the corresponding fixing ring; supporting rods are fixedly connected to the base and fixedly connected with substrates, a mounting frame is slidably connected to each substrate, a gluing wheel is connected to one mounting frame, and a balancing wheel is hinged to the other mounting frame; and each mounting frame is fixedly connected with a glue shell, and each glue shell is provided with a glue outlet. By means of the automobile windscreen side face edge gluing device, windscreen side face edges can be glued, the gluing quality is good, and the automobile windscreen side face edge gluing device is applicable to windscreens of vehicles of different types.

Owner:ZHEJIANG OCEAN UNIV

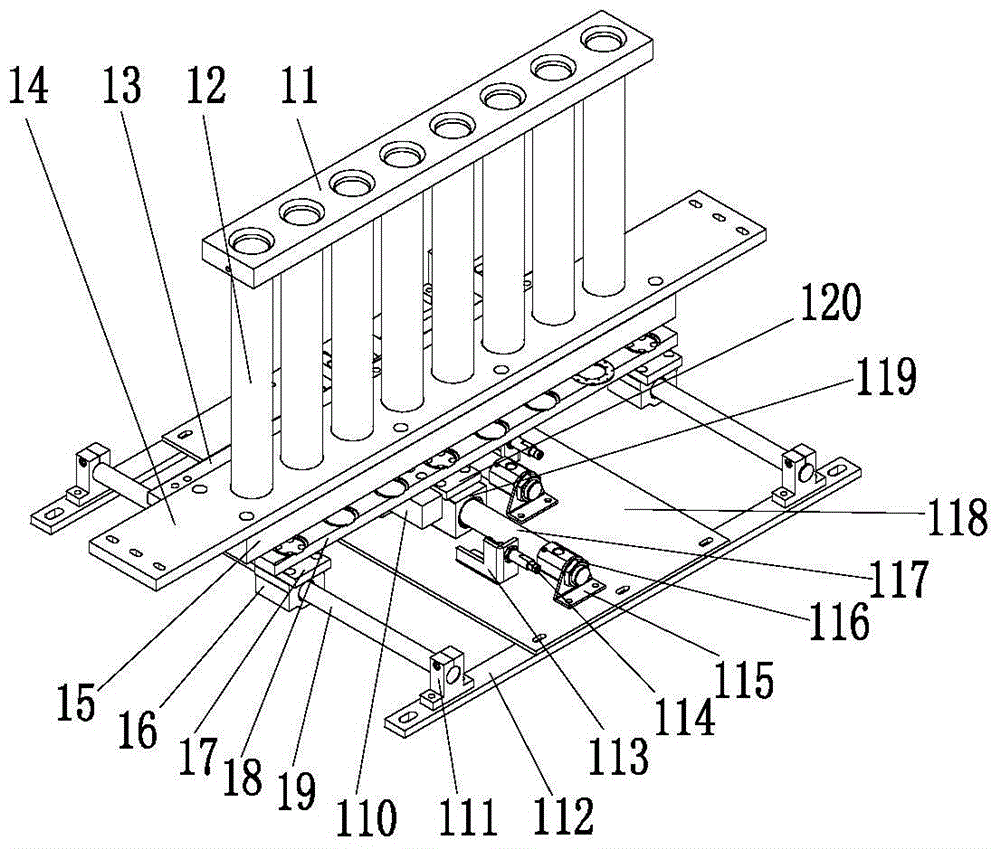

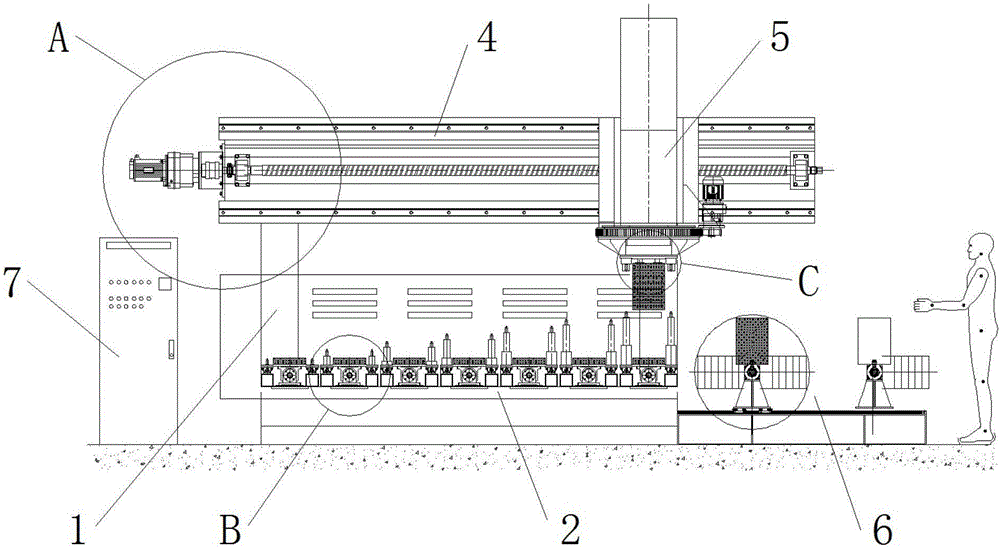

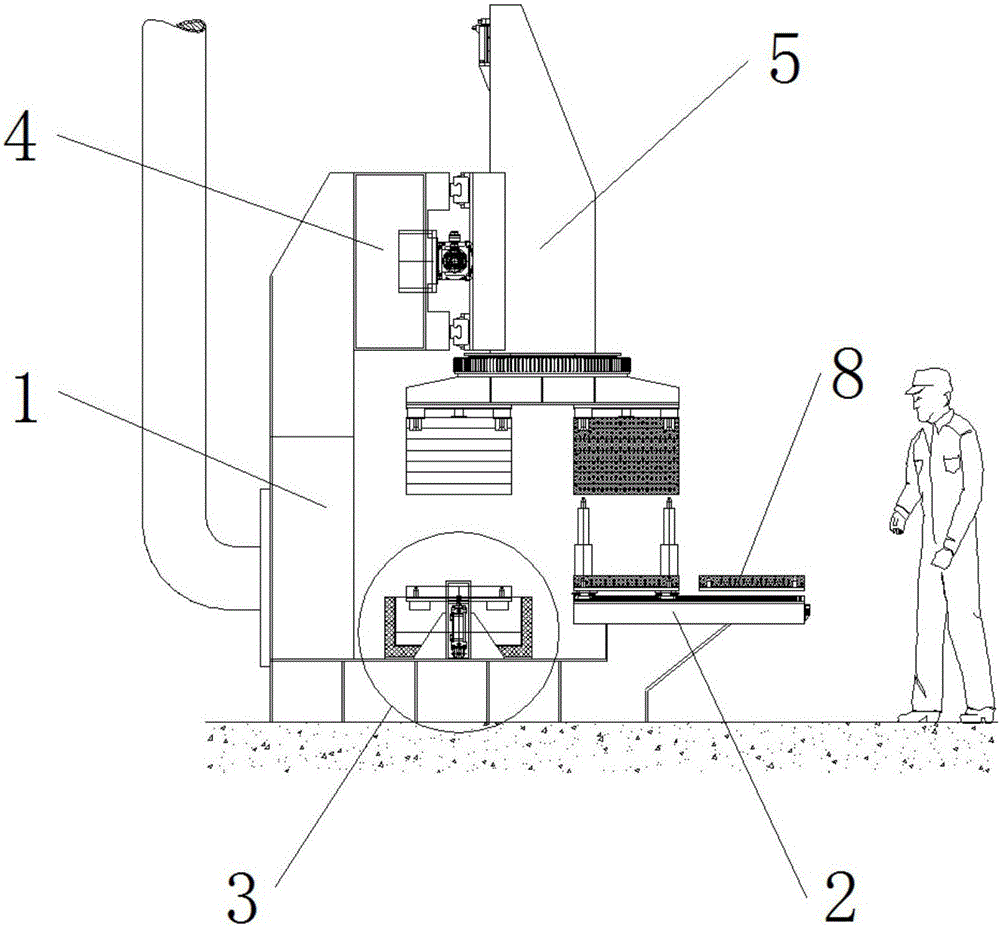

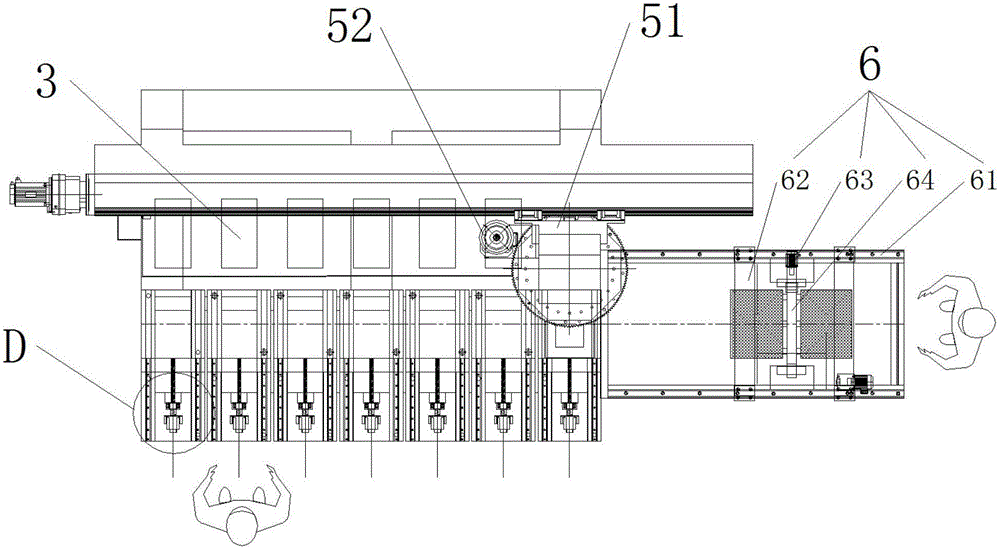

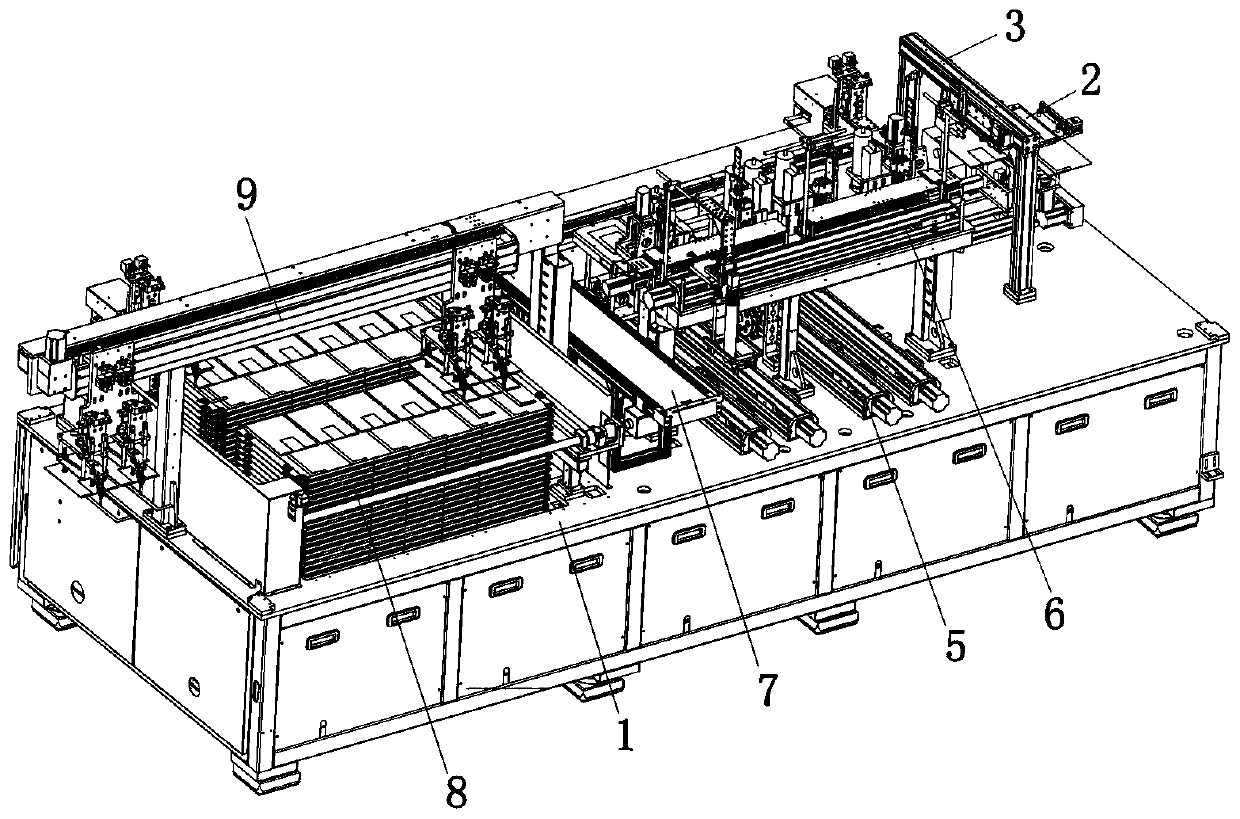

Automatic equipment for coating surfaces of iron rings by glue

InactiveCN104525431AIncrease productivityImprove quality and safetyLiquid surface applicatorsCoatingsAutomatic test equipmentEngineering

The invention discloses automatic equipment for coating the surfaces of iron rings by glue. The automatic equipment comprises a rack, a feeding module, a coating module, a discharging module, a platform movement module and a controller, wherein the rack is used as a support base; the feeding module is used for conveying a plurality of workpieces at the same time; the coating module is used for coating glue, the discharging module is used for unloading the workpieces; the platform movement module is used for overturning and carrying the workpieces at each station; the feeding module, the coating module and the discharging module are arranged on the rack in sequence along the length direction of the rack; the platform movement module is fixed at two sides of the rack in a stretching manner; the movable part of the platform movement module is capable of overturning and clamping the workpieces to sequentially convey the workpieces from the feeding module to the coating module and the discharging module along the length direction of the rack; the controller is in circuit connection with the feeding module, the coating module, the discharging module and the platform movement module. The automatic equipment for coating surfaces of iron rings by glue has the advantages of saving the human cost, being high in efficiency, high in accuracy, stable in quality and high in automation degree, greatly improving the production efficiency and satisfying the demand of industrial production.

Owner:SOUTH CHINA UNIV OF TECH

Environmental-friendly energy-saving veneer plywood glue coating device

InactiveCN108855768AReduce pollutionPlay a stirring roleLiquid surface applicatorsTransportation and packagingTransmission beltPulp and paper industry

The invention provides an environmental-friendly energy-saving veneer plywood glue coating device, which comprises a machine frame, wherein the top of the machine frame is fixedly provided with a feeding mechanism; a glue coating mechanism is connected under the feeding mechanism; a plate transmission belt is arranged under the glue coating mechanism; a waste glue collector is also fixedly arranged under the plate transmission belt; a glue accommodating air bag is arranged inside the glue coating mechanism; through the contraction and expansion of a glue accommodating air bag, the spraying andsuction on glue water is realized, so that the condition that residue glue water is thrown away by centrifugal force is effectively reduced; the glue material is effectively saved; meanwhile, the glue material pollution is reduced; meanwhile, the circulation spray suction of the material accumulation air bag also achieves the stirring effects on the glue materials in a material storage cavity, sothat the glue materials are more uniform; the glue coating quality is higher; during the cleaning, cleaning liquid is injected into the device; when a glue coating round tube rotates, the inside gluematerials can be cleanly cleaned through the spray washing by the glue accommodating air bag; convenience and high speed are realized; the waste glue collector recovers and treats the waste glue; green and environmental-friendly effects are achieved.

Owner:临泉县荣兴木业有限公司

Automatic gluing device

InactiveCN103639093AImprove efficiencyApply glue evenlyLiquid surface applicatorsCoatingsHydraulic cylinderEngineering

The invention discloses an automatic gluing device. The automatic gluing device comprises a gluing drum, a hydraulic cylinder and a to-be-glued vessel, wherein the wall of the gluing drum is provided with a rubber outlet pore, the gluing drum is connected with a first driving mechanism and driven by the first driving mechanism to rotate so as to throw out the rubber in the gluing drum from the rubber outlet pore; a piston rod of the hydraulic cylinder is connected with the gluing drum, and the gluing drum can be driven to move up and down by the hydraulic cylinder; the glued vessel is arranged below the gluing drum, the gluing drum moves downwards to be arranged in the glued vessel, and the gluing drum rotates and moves up and down so as to spread the rubber in the gluing drum onto the inner wall of the glued vessel. By adopting the automatic gluing device, the rubber can be uniformly coated on the inner wall of the vessel, the gluing quality is good, the efficiency is high, and the manual gluing can be substituted.

Owner:GUANGXI UNIV

Coating machine with tension degree regulating function

ActiveCN107685002AAvoid problemsImprove gluing qualityLiquid surface applicatorsCoatingsEngineeringMechanical engineering

The invention discloses a coating machine with a tension degree regulating function. The coating function comprises a workbench. An unreeling roll, a gluing box, a tension regulating box, a drying boxand a reeling roll are arranged at the top end of the workbench sequentially from left to right. A glue storage box is arranged at the bottom wall of an inner cavity of the gluing box. A gluing rollmatched with the glue storage box is rotationally connected to the bottom of the inner cavity of the gluing box through a rotating shaft. A guide roll is connected with the top of the inner cavity ofthe gluing box rotationally through a rotating shaft. A communicating hole is formed in the top end of the tension regulating box. A guide sleeve is arranged at the bottom of the communicating hole. Alifting rod is arranged in the guide sleeve. A support seat box corresponding to the tension regulating box is fixedly connected to the top end face of the workbench. A plurality of support legs areevenly arranged at the bottom end of the workbench. The coating machine has the advantages that through interworking among the gluing roll, a scraping roll and the guide roll with special structures,trimmings can be prevented effectively, so that gluing quality is improved; through the tension regulating box, regulation can be made timely according to tension degrees of adhesive tapes, and accordingly, production stability and continuity are guaranteed.

Owner:江苏蓝创新材料有限公司

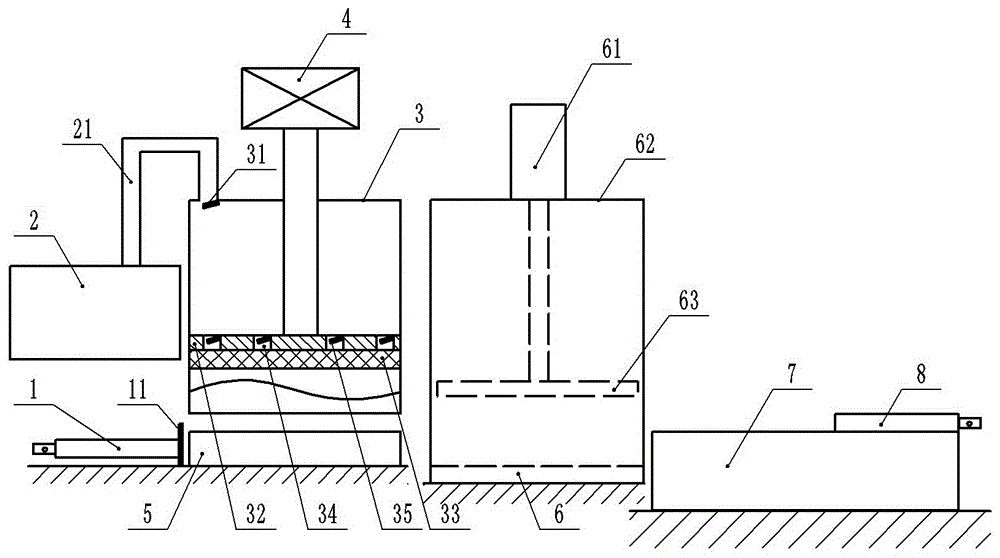

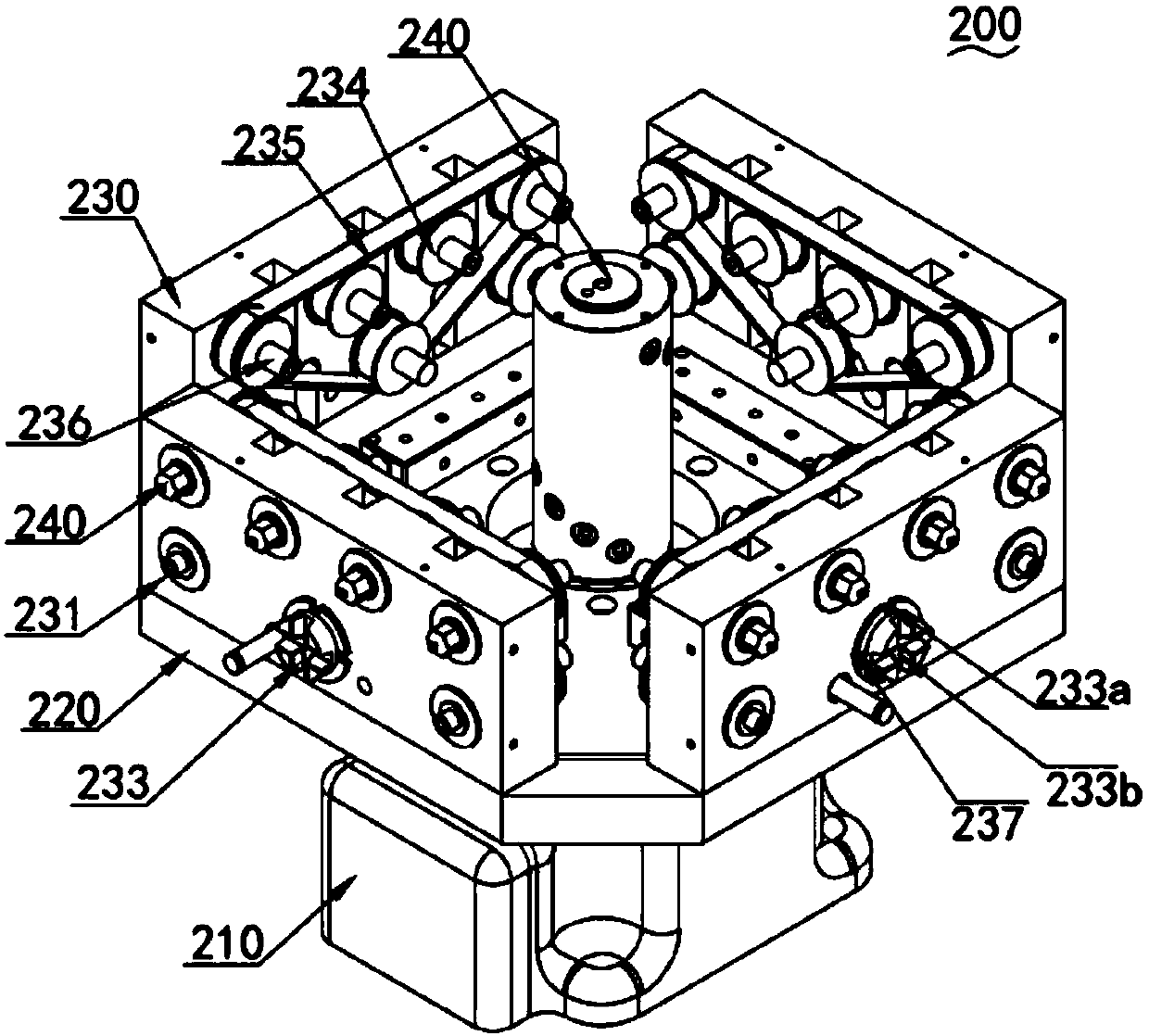

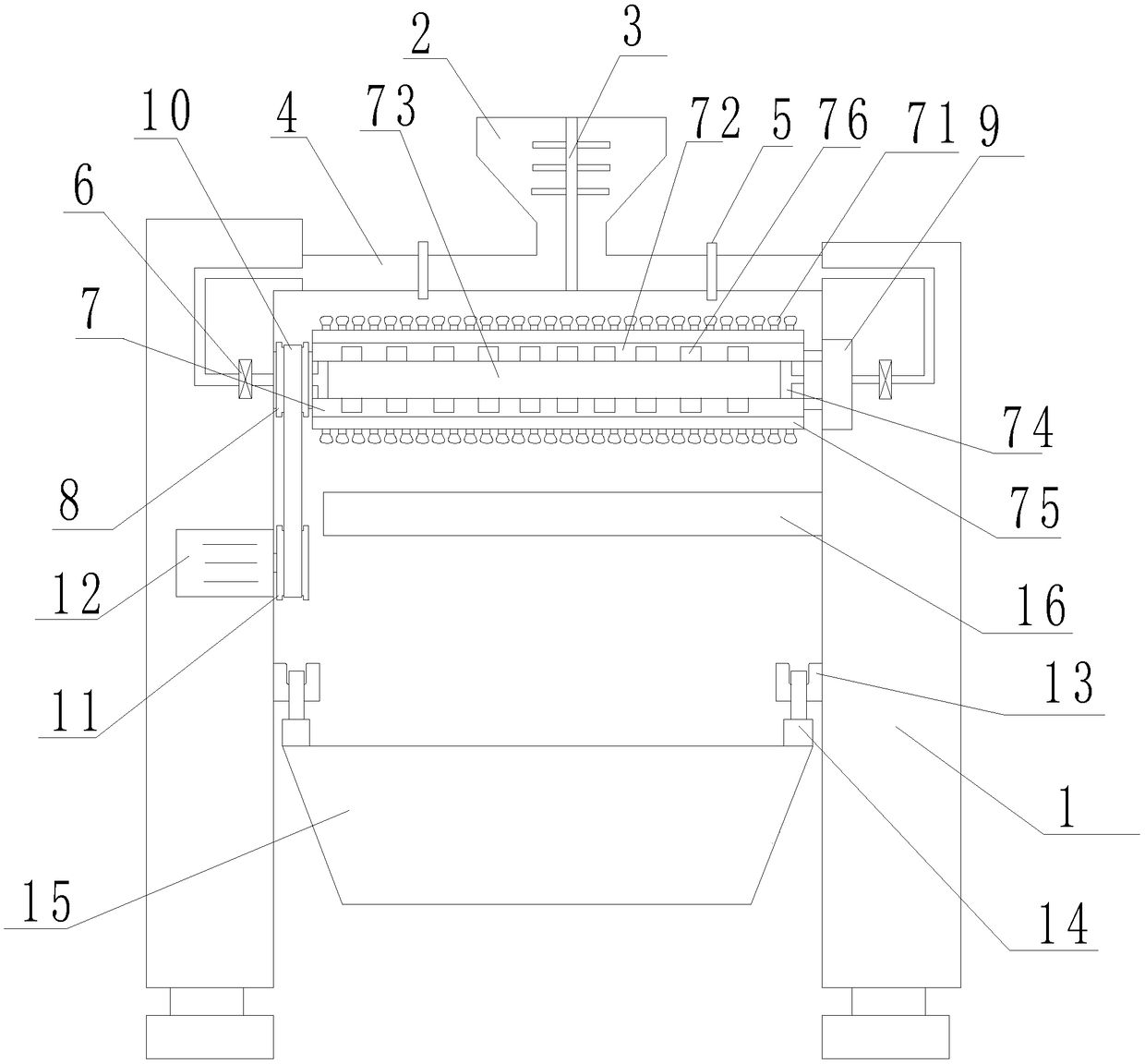

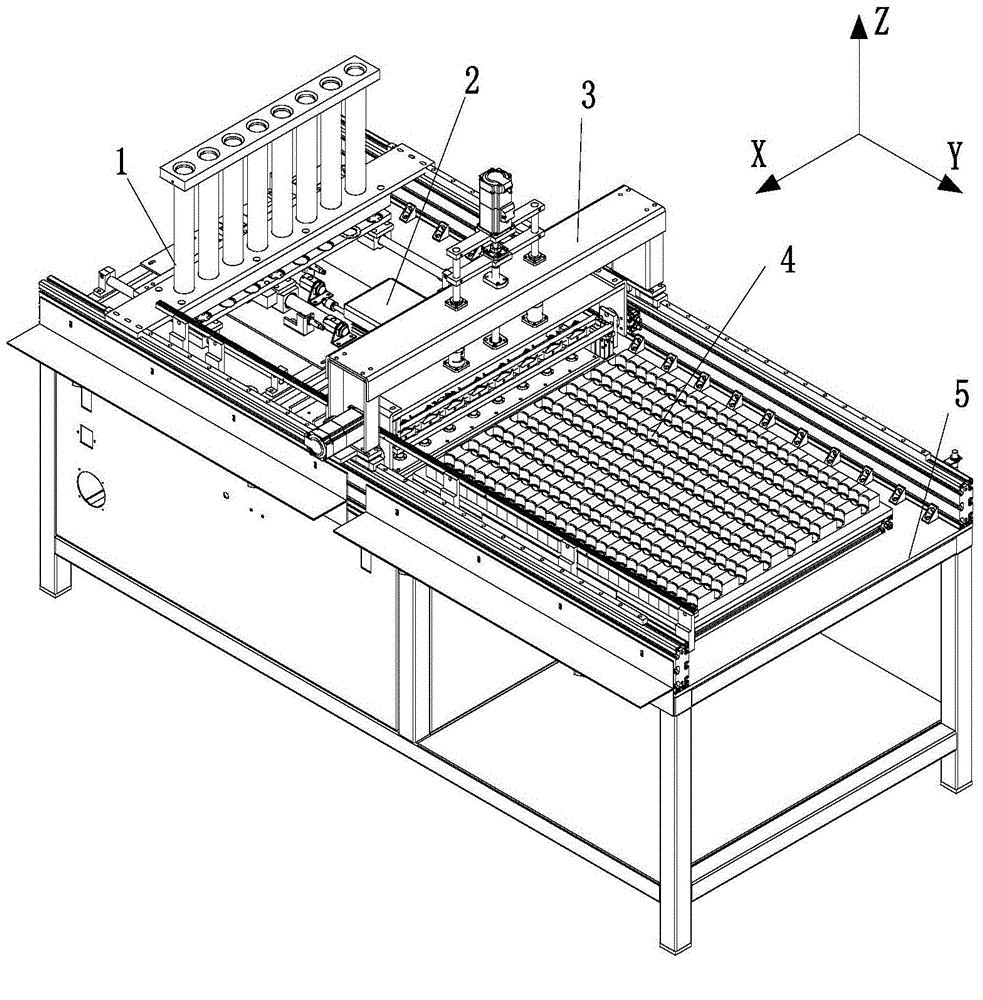

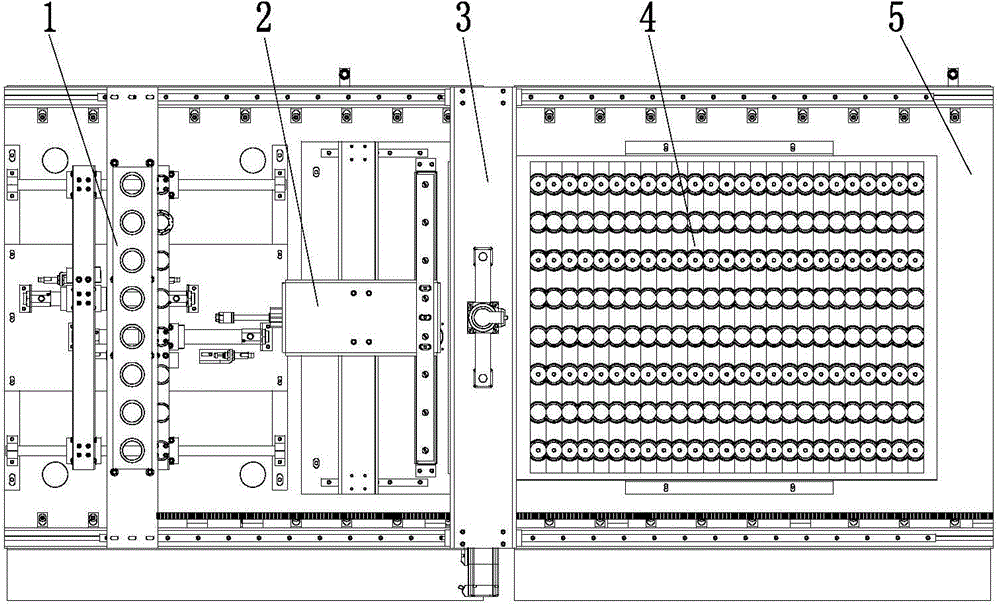

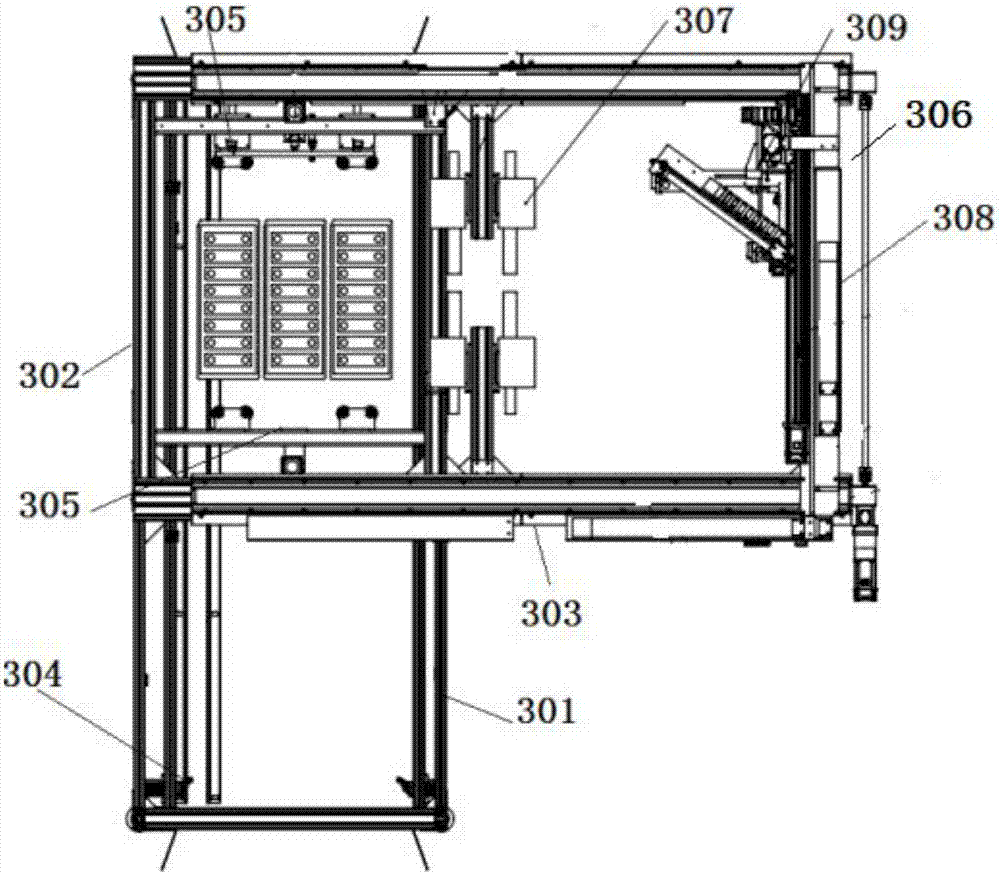

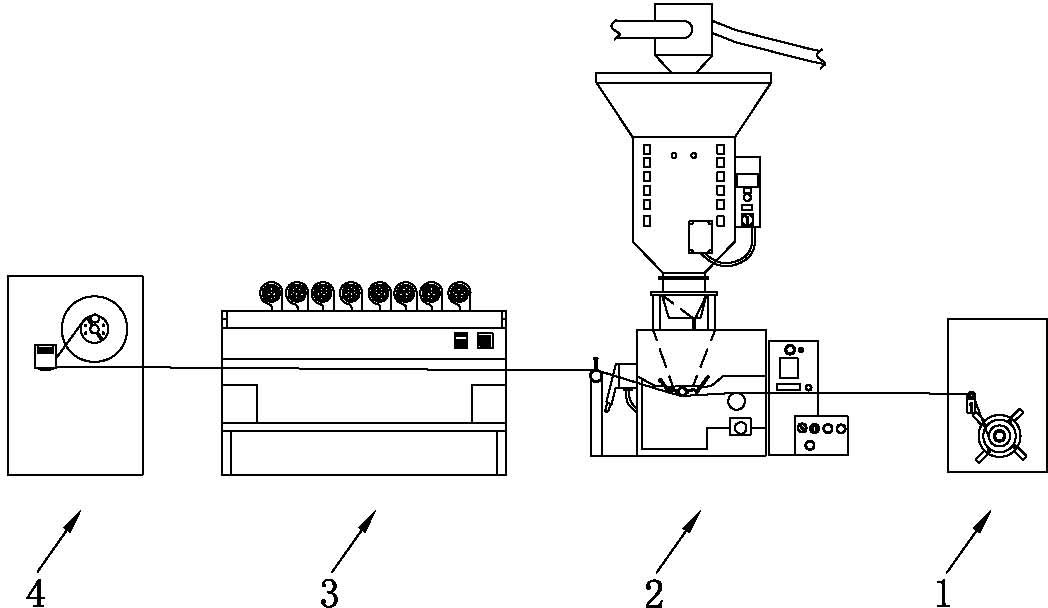

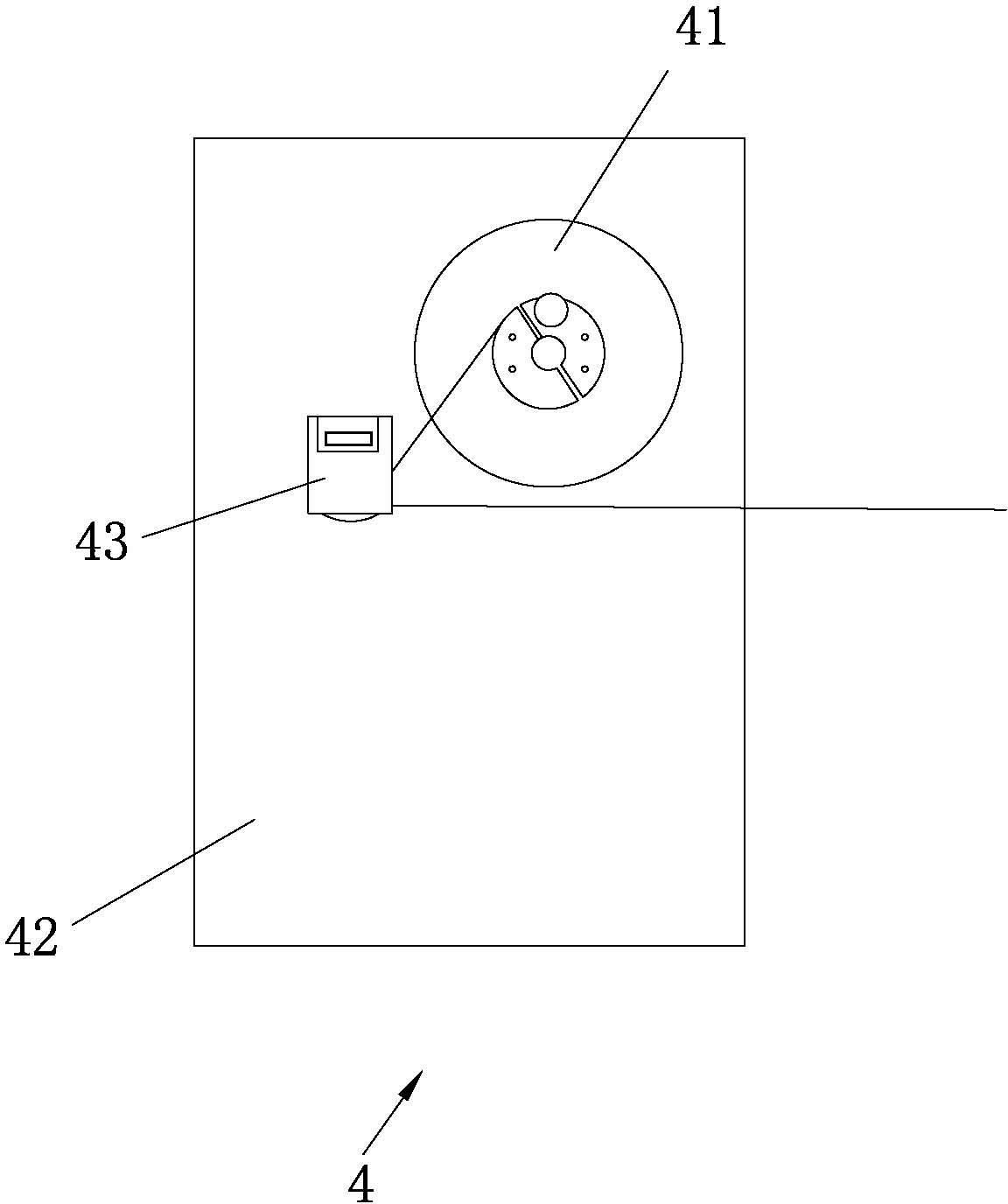

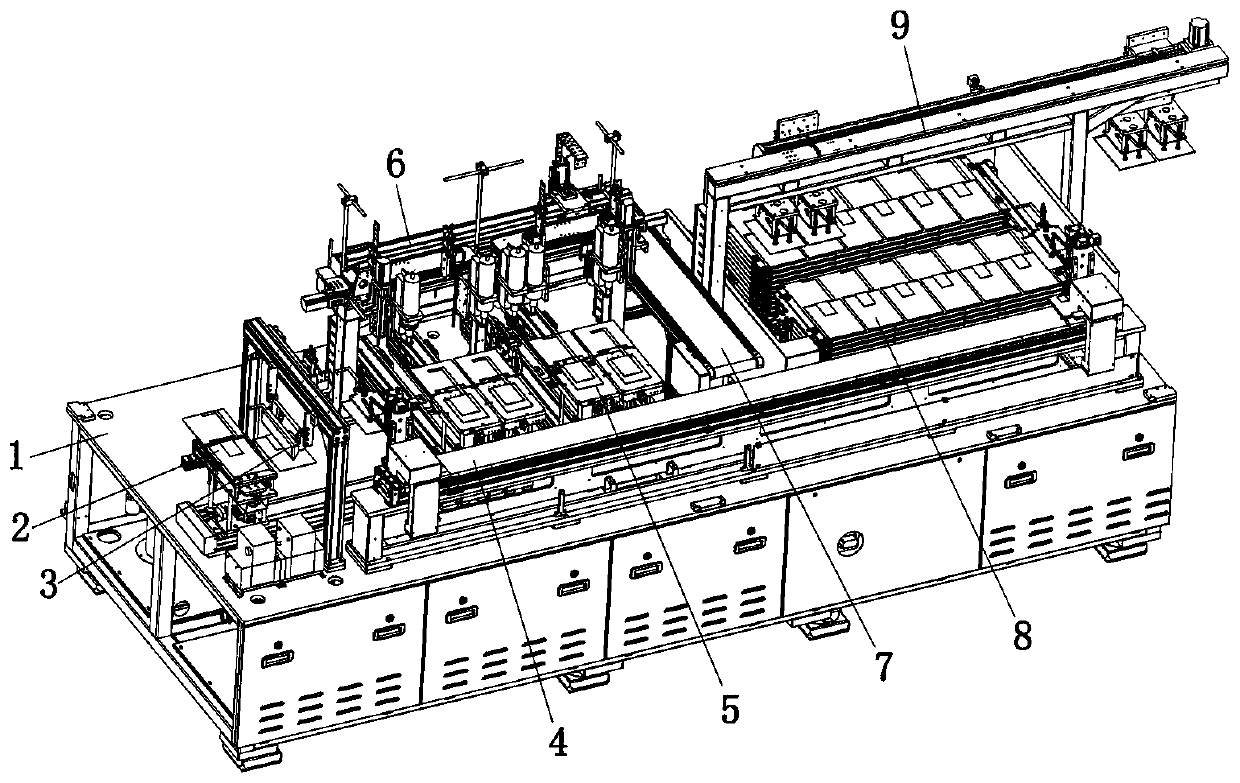

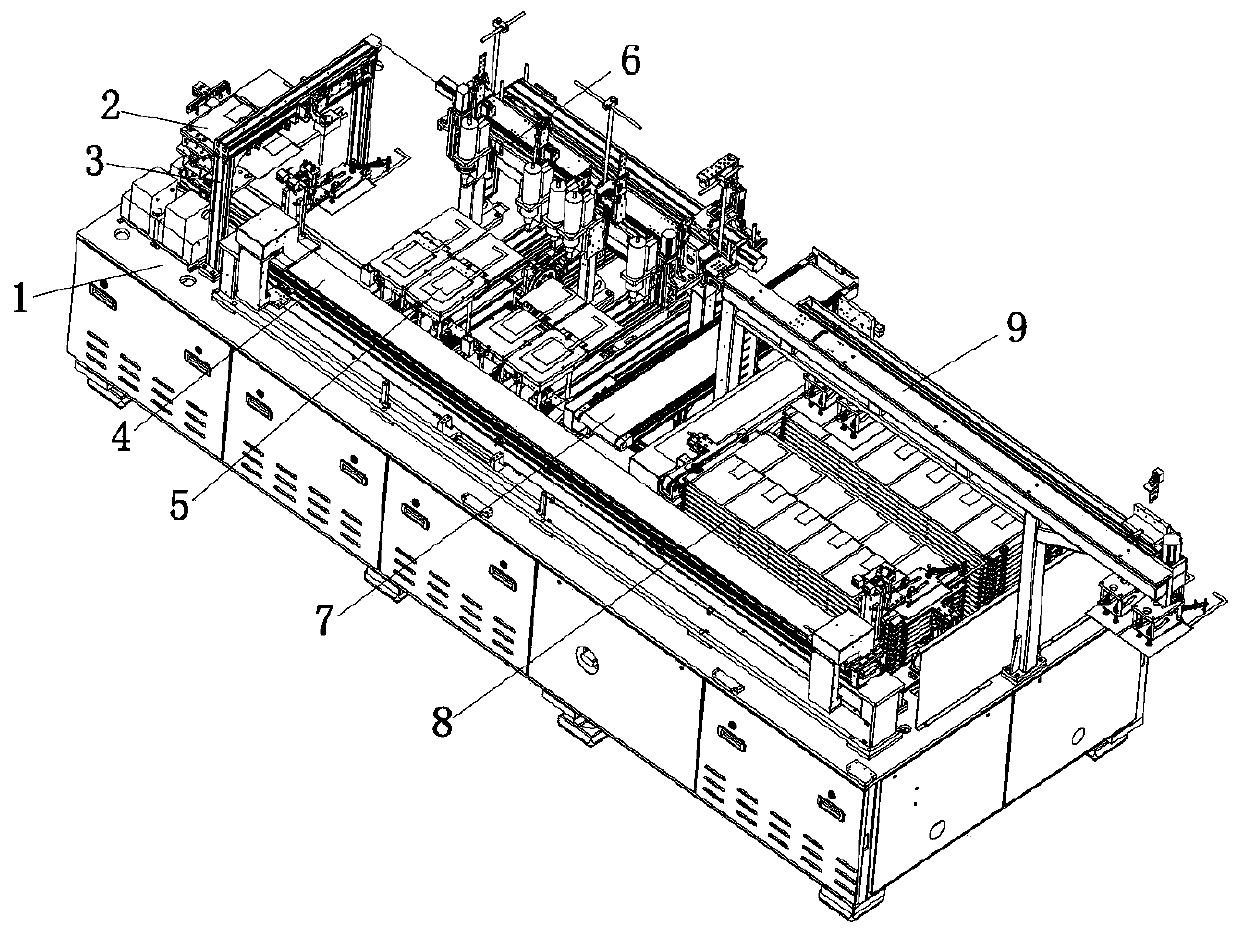

Complete gluing apparatus and gluing technology of new energy automobile assembled battery

ActiveCN107046147AReduce labor intensityReduce secondary pollutionAssembling battery machinesFinal product manufactureNew energyEngineering

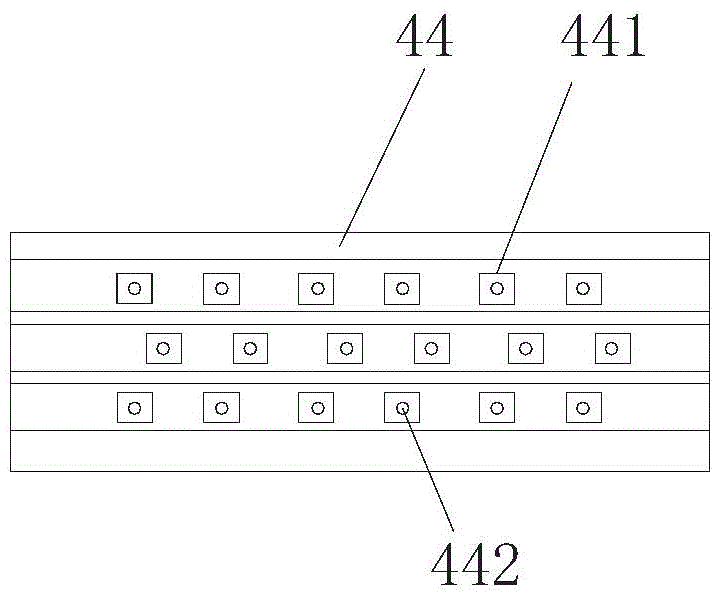

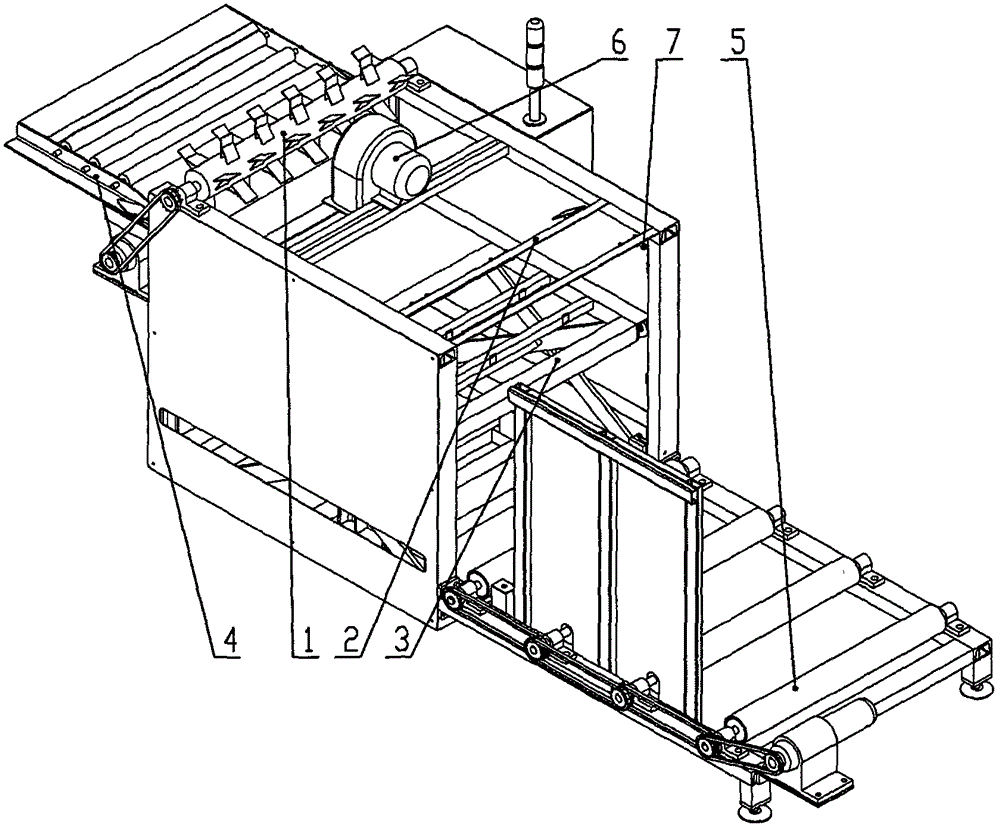

The invention relates to a complete gluing apparatus and a gluing technology of a new energy automobile assembled battery. The apparatus comprises a main frame (1), the main frame (1) is provided with a conveying device (2), a feeding device (3), a gluing device (4) and a cell grasping and stacking device (5) are sequentially arranged above the conveying device (2), the main frame (1) is provided with a cell overturning device (6), the conveying device (2) is provided with a positioning sensor (7), and the positioning sensor (7) is connected with a controller (8); the cell grasping and stacking device grasps cells to the cell overturning device; and the cell overturning device overturns the cells to a cell fixing and clamping assembly, the cells are conveyed to the gluing device through a conveying track and are glued, and the cell grasping and stacking device grasps and stacks the cells. The apparatus and the technology have the characteristics of improvement of the gluing quality, reduction of the labor intensity of workers, increase of the working efficiency, improvement of the surface cleanliness of the cells, and improvement of the labor safety.

Owner:湖州鑫远电池系统技术有限公司

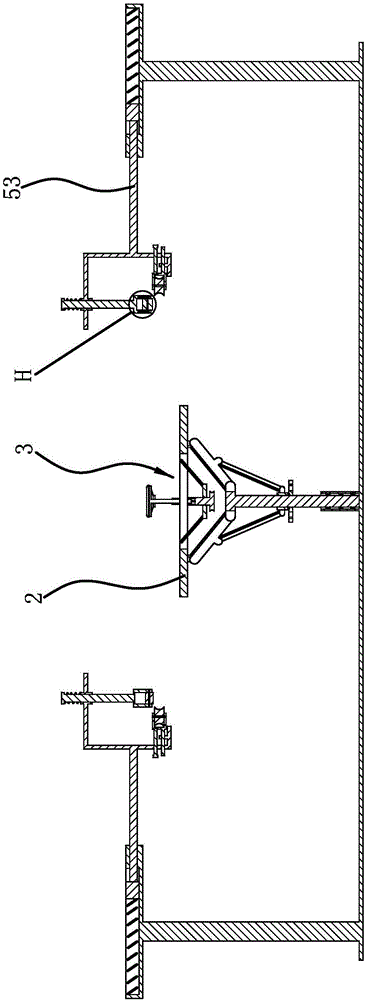

Multi-station digital pasting system for lost foam and pasting method of multi-station digital pasting system

ActiveCN105909639ASimplify equipment structureSimplify the installation processLiquid surface applicatorsMaterial gluingNumerical controlState of art

The invention discloses a multi-station digital pasting system for a lost foam and a pasting method of the multi-station digital pasting system. The multi-station digital pasting system mainly comprises a main rack, numerical control sliding table devices, a pasting system, a transverse movement driving system, a lifting rotating table, a main pouring gate pasting position changing device and an electric system connected with all the parts; by using the system, continuous pasting of a plurality of stations and automatic pouring gate pasting can be realized at one time, and corresponding moulds can be automatically switched according to the combination demand of templates to mount different templates; and compared with the prior art, the pasting system and method are high in automation degree and are used for reducing the cost while reducing the labor intensity of workers, and not only improving the pasting quality of the templates of the lost foam, but also remarkably increasing the pasting efficiency of the templates so as to have a considerable promotional value in the current trend of enterprise technological innovation transformation.

Owner:CMCU ENG

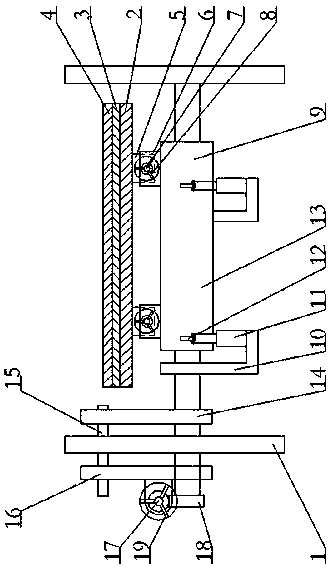

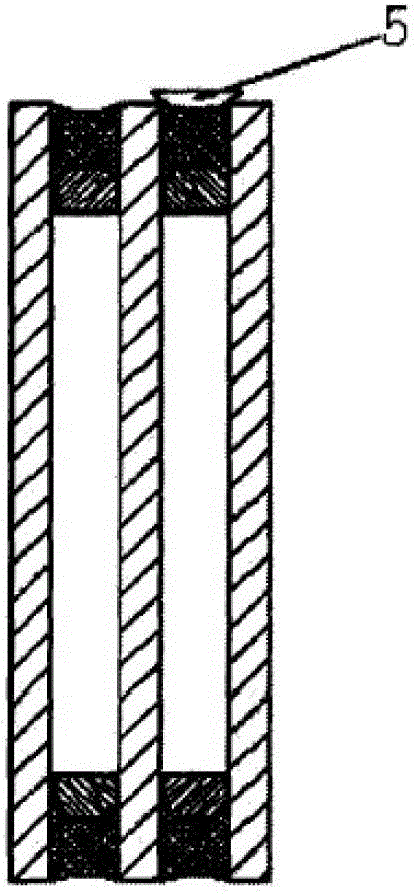

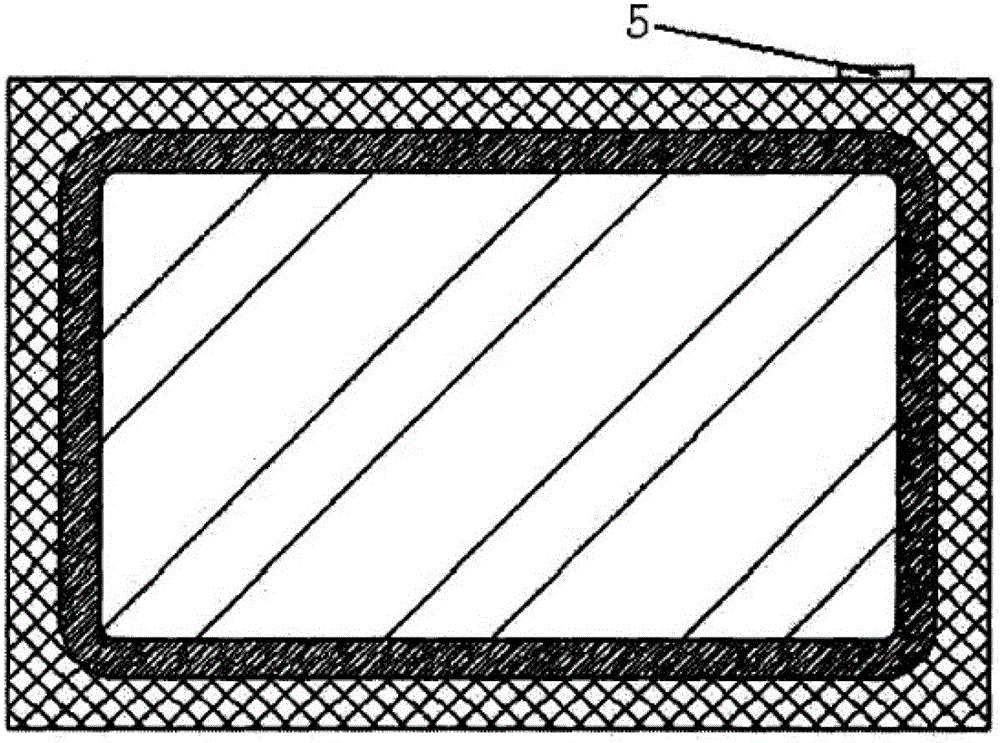

Edge banding back-coating hot melt adhesive device

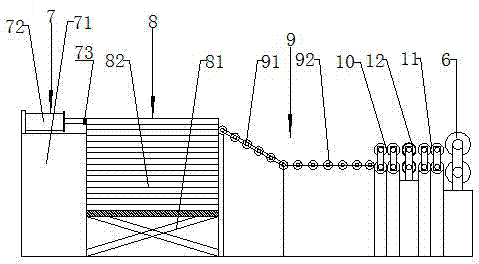

ActiveCN102671829AEasy to processIncrease productivityLiquid surface applicatorsCoatingsCoatingEdge banding

The invention relates to the technical field of production equipment of edge bandings, in particular to an edge banding back-coating hot melt adhesive device, which comprises an unreeling device for giving off edge bandings, a melt adhesive coating device, a cooling device and a rolling device, wherein the back surfaces of the edge bandings are coated with hot melt adhesive through the melt adhesive coating device to made gummed edge bandings, the gummed edge bandings are cooled and solidified by the cooling device, the gummed edge bandings after being cooled and solidified are rolled by the rolling device, and the unreeling device, the melt adhesive coating device, the cooling device and the rolling device are orderly arranged. The edge banding back-coating hot melt adhesive device is an automatic device integrated with unreeling, melt adhesive coating, cooling, solidifying and rolling, is particularly suitable for thin edge bandings, the thickness of the thin edge bandings is between 0.2mm and 0.8mm, and is convenient to process the made gummed edge bandings. The coating speed is between 20m / s and 30m / s, the coating amount is from 130g / square meter to 140g / square meter, more than two edge bandings can be coated for one time, and the production efficiency is high.

Owner:东莞市华富立装饰建材有限公司

Adhesive composition and method

ActiveUS20070004829A1Excellent Adhesive PropertiesPromote resultsPaper coatingCoatingsPolymerChemistry

Owner:AKZO NOBEL COATINGS INT BV

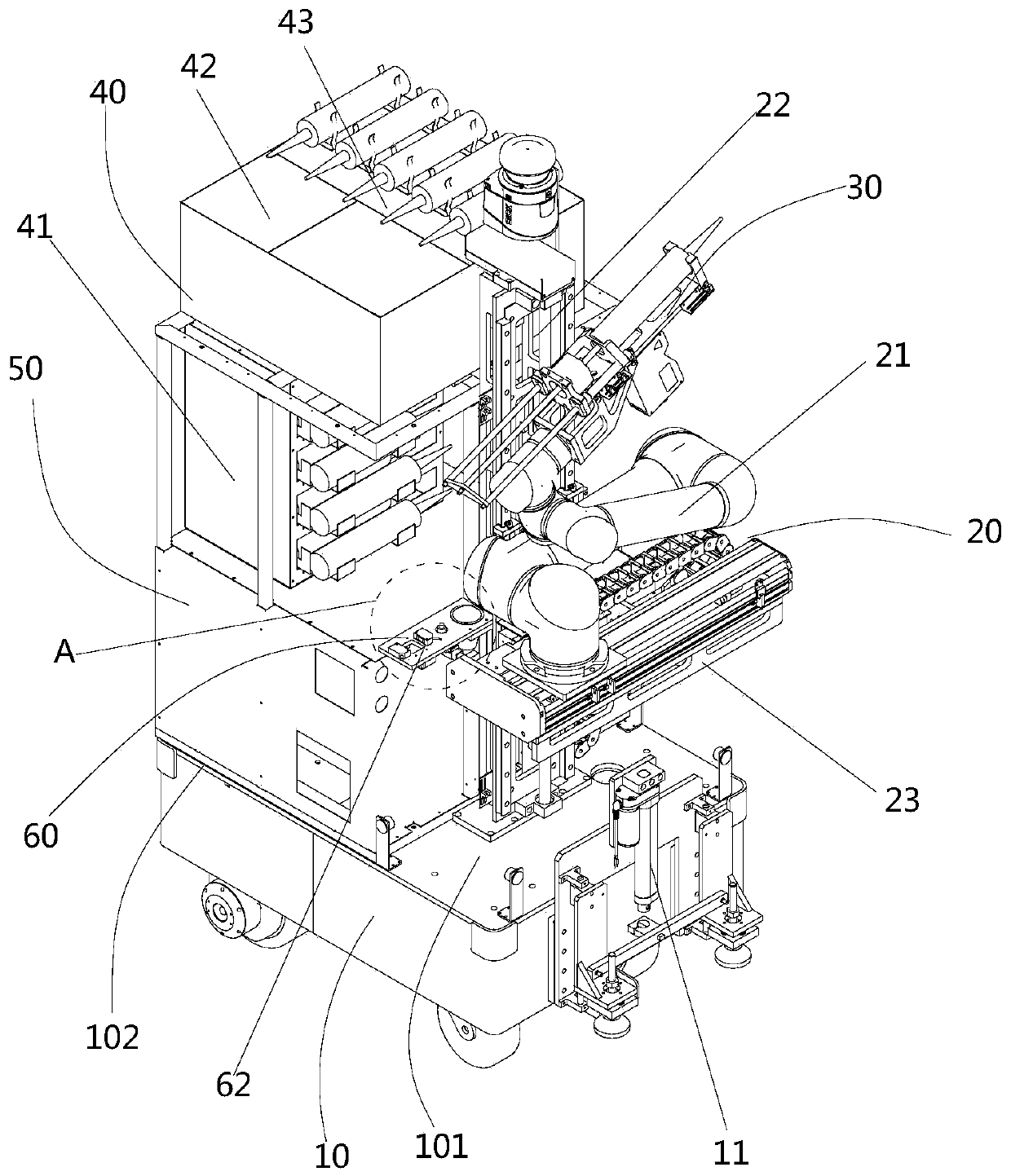

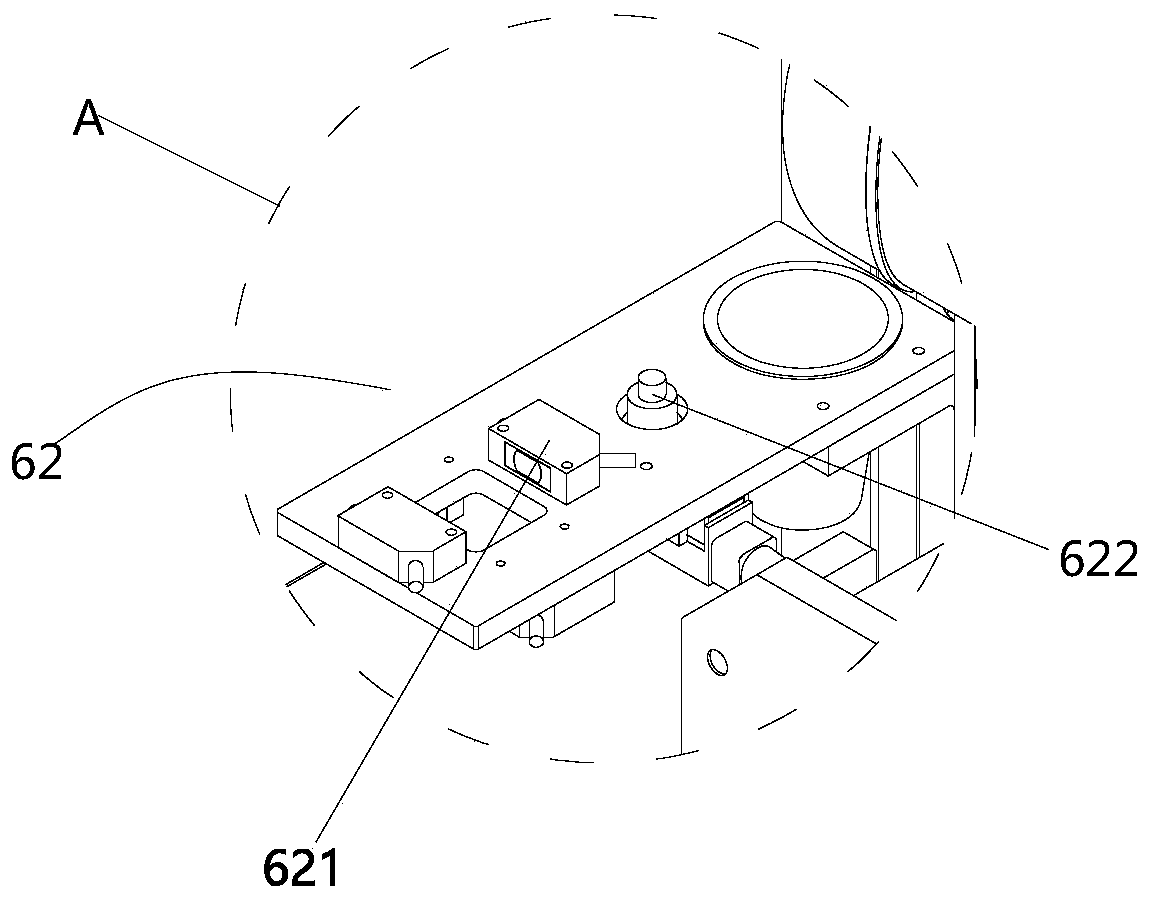

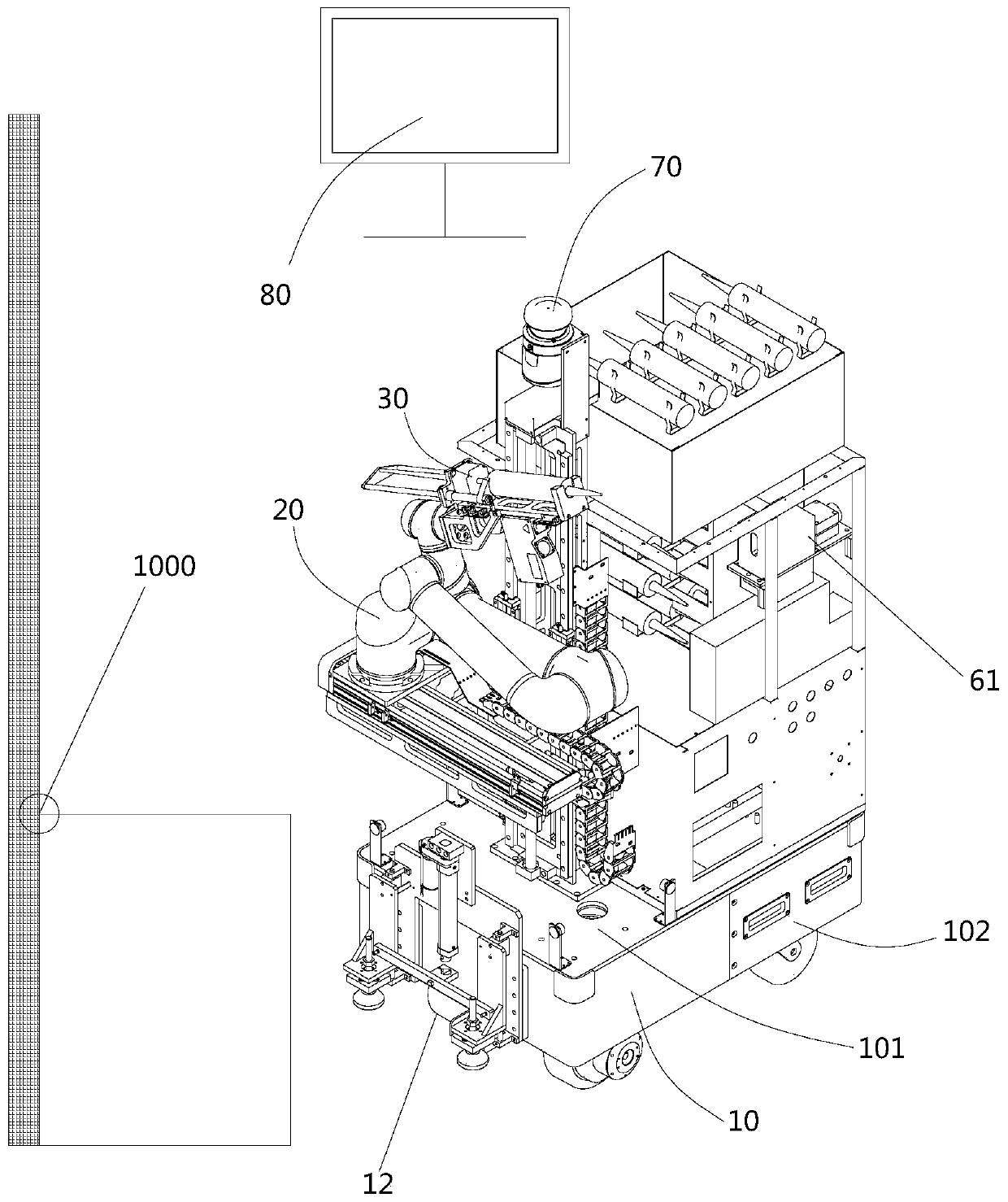

Gluing robot

ActiveCN110962144AImprove stabilityConvenient glue workLiquid surface applicatorsCoatingsLarge rangeRolling chassis

The invention provides a gluing robot. The gluing robot comprises a movable chassis, a gluing moving device, a gluing device and a stock bin; the movable chassis is used for providing walking power, and is provided with a gluing implementation area and a glue barrel supply area in the front end and the rear end respectively; the gluing device and the gluing moving device are both arranged in the gluing implementation area, the gluing moving device is connected to the movable chassis, and the gluing device is arranged on the gluing moving device and used for automatically clamping a glue barrelto conduct gluing or loosening the glue barrel to replace the glue barrel; and the stock bin is arranged in the rubber barrel supply area. The movable chassis, the gluing device, the gluing moving device and the stock bin are arranged, the stock bin is arranged at the rear end of the movable chassis, and the gluing device and the gluing moving device are arranged at the front end of the movable chassis, so that the space above the chassis is reasonably utilized, gluing in a larger range is conveniently completed, the weight of the gluing implementation area is matched with that of the glue barrel supply area, and the stability of the gluing robot is improved.

Owner:GUANGDONG BOZHILIN ROBOT CO LTD

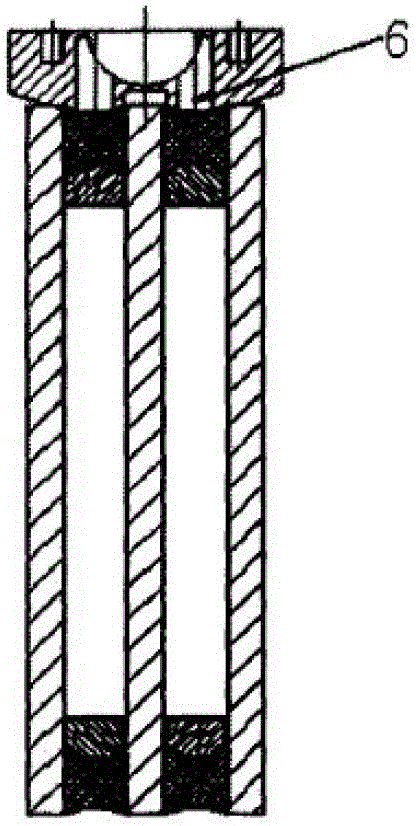

Port gluing device for pipeline connection and using method thereof

ActiveCN111318423AReduce human involvementReduce labor intensityLiquid surface applicatorsHollow article cleaningEngineeringElectrical connection

The invention relates to the field of pipeline connection equipment, in particular to a port gluing device for pipeline connection and a using method thereof. The port gluing device comprises a base,a vertical plate is fixed to the left end of the upper surface of the base, and a brushing mechanism used for cleaning and gluing a pipeline connection end is arranged on the vertical plate; and a pushing mechanism used for driving the pipeline to get close to the brushing mechanism is arranged on the right side of the upper surface of the base, a touch mechanism is arranged on the left side of the vertical plate, the pushing mechanism can be in transmission connection with the touch mechanism, and the touch mechanism is electrically connected with the brushing mechanism. According to the portgluing device for pipeline connection and the using method thereof, the pushing mechanism drives the touch mechanism to control the brushing mechanism to perform dust removal and glue coating treatment on a pipeline, dust removal and glue coating operation on the pipeline is achieved, the human participation degree is greatly reduced, then the labor intensity and the phenomenon of uneven angle coating caused by human factors are reduced, and the pipeline gluing uniformity is improved, so that the pipeline gluing quality is improved, and the connection strength and the connection sealing performance of a pipeline joint are uniform and consistent.

Owner:施索

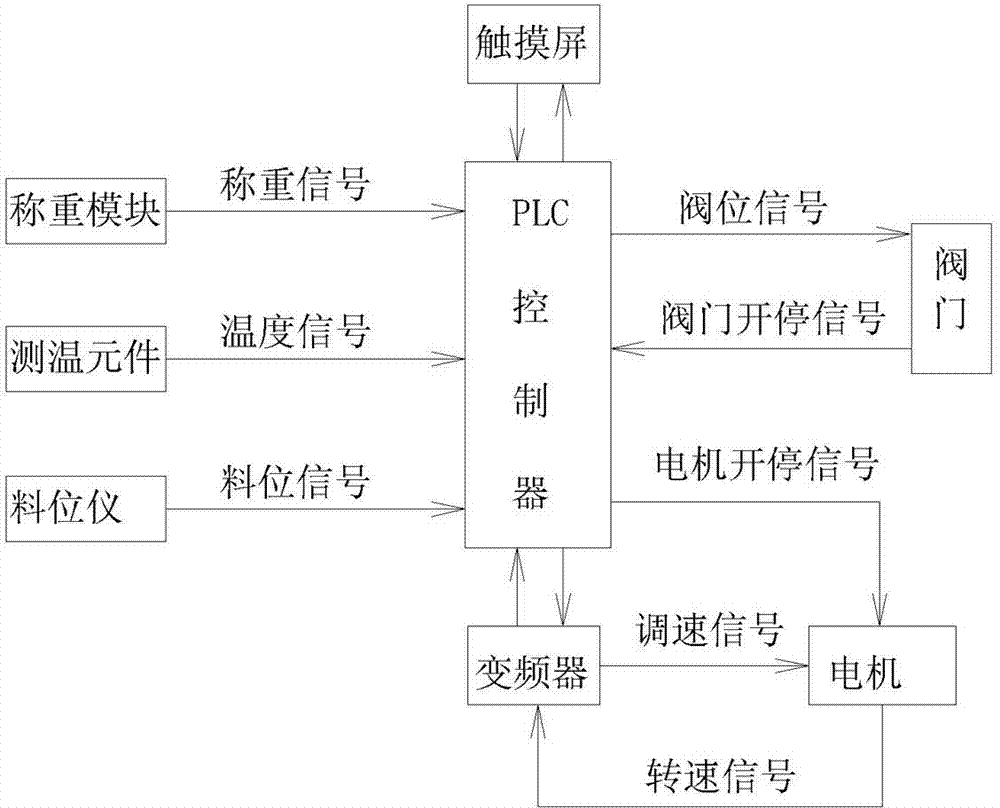

Powder charging system and powder charging method for producing polyurethane sealant

ActiveCN103897647AControl contentReduce moisture contentPolyureas/polyurethane adhesivesEngineeringSealant

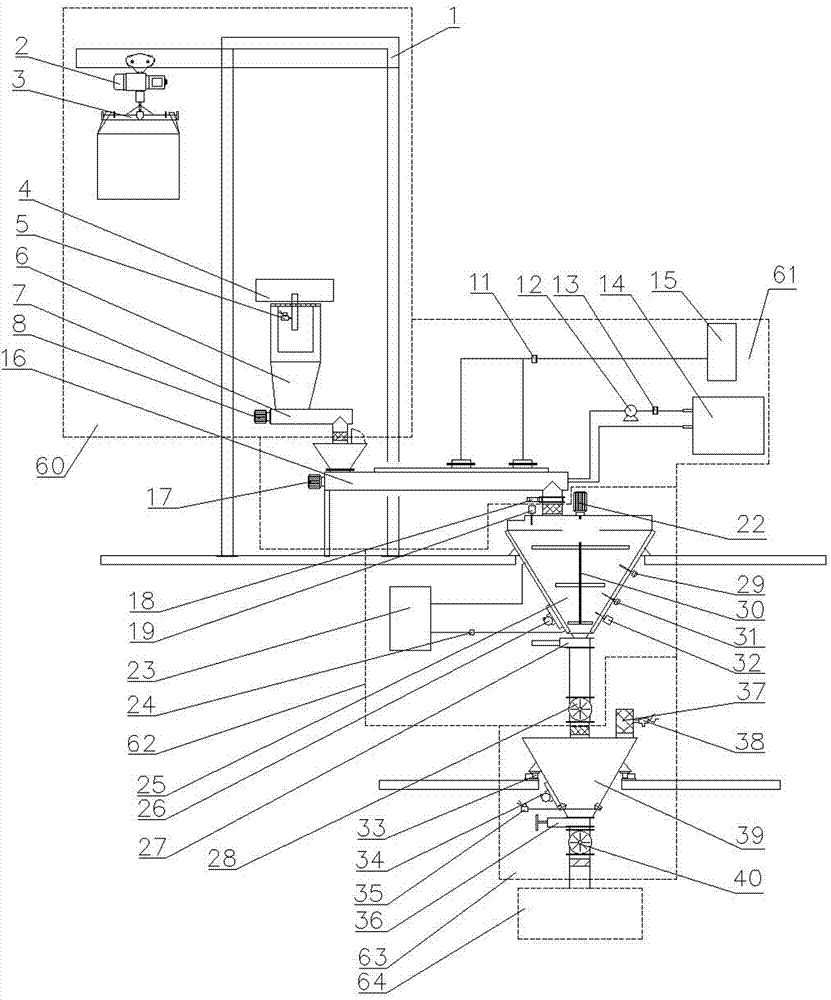

The invention discloses a powder charging system and a powder charging method for producing a polyurethane sealant. The charging system comprises a loading system, a drying system, a cooling system and a weighing system, wherein the loading system, the drying system, the cooling system and the weighing system are orderly connected into a closed powder delivery channel. The charging method comprises the steps of loading, drying, cooling and weighting, wherein when the weight of powder in a measuring bin is weighed by a weighing module to be 90% of a set value A, a second conveyor is controlled to add the powder at a dripping speed, and when the weight of the powder in the measuring bin is weighed by the weighing module to be less than the set value A by a value B, the powder is stopped from being fed into the weighing system. The powder charging system and the powder charging method have the advantages that the procedures of loading, drying, cooling and weighing are enabled to be continuous and all completed in the closed channel, the content of moisture of the powder can be well controlled, and therefore, the moisture content of the powder is kept at a low value. The quality of the sealant produced is improved.

Owner:SHANDONG NORTH MODERN CHEM IND

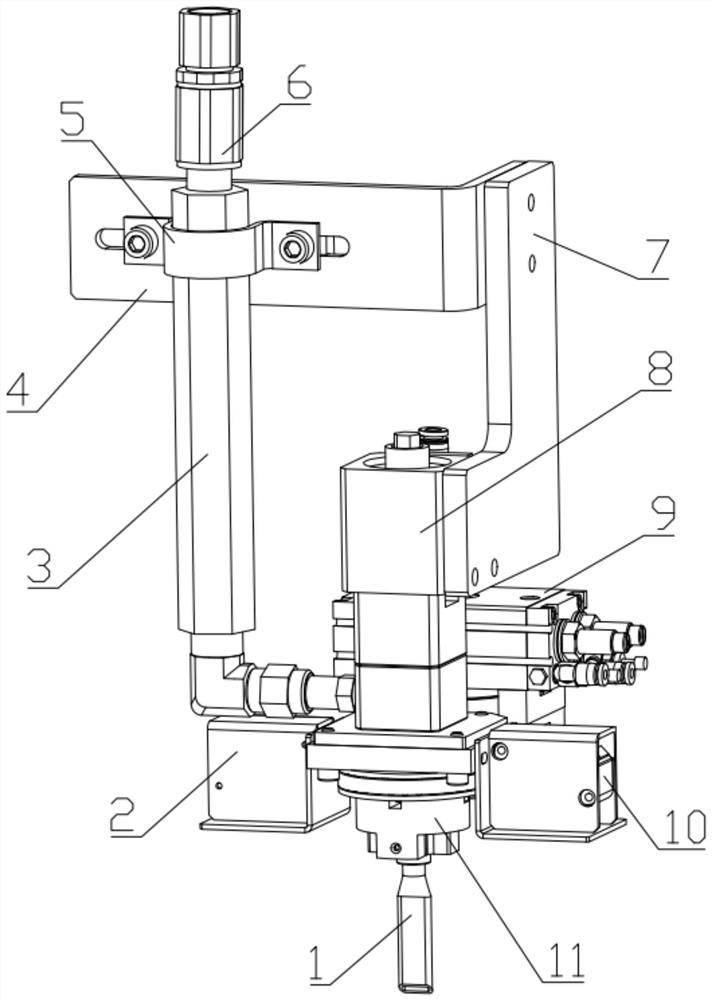

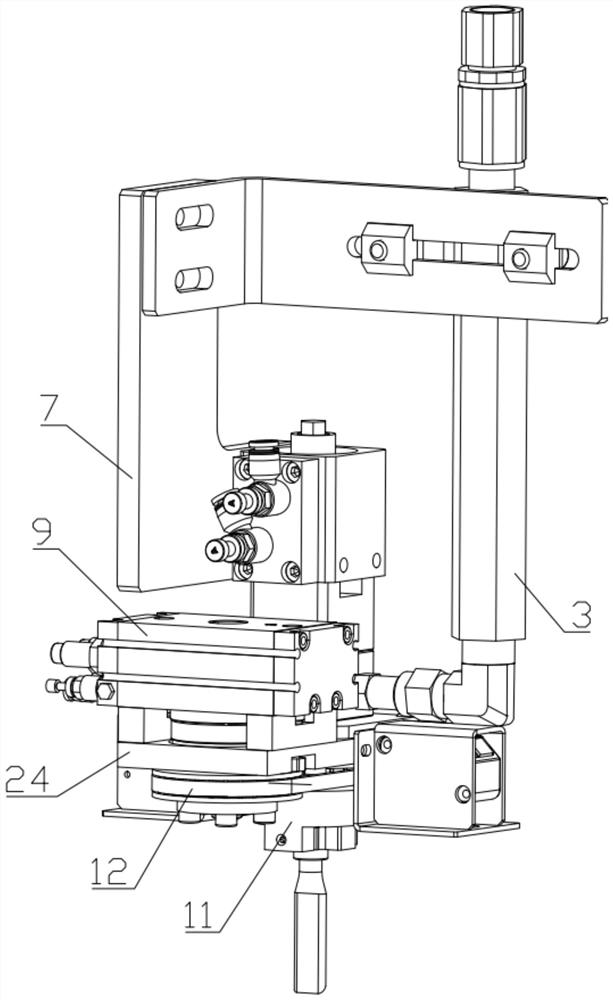

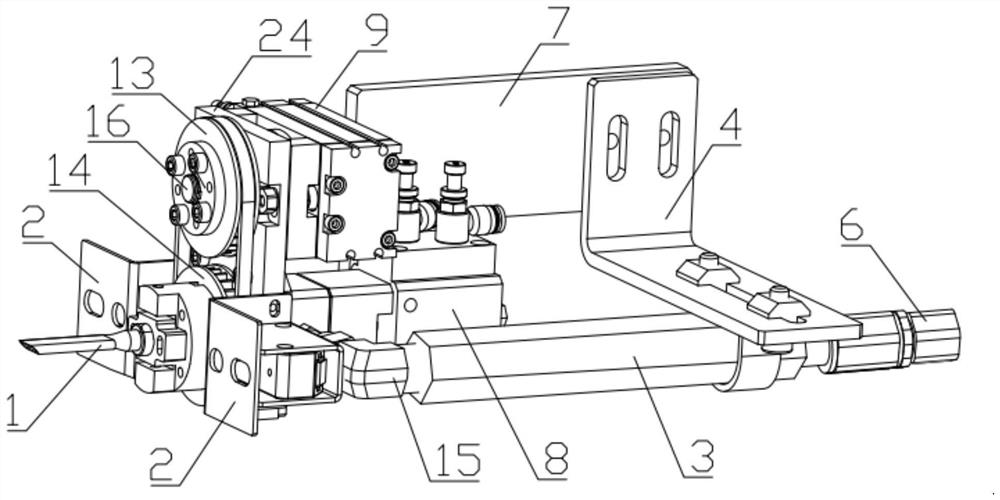

Independent rotary nozzle type compact gluing head capable of being detected online and gluing method thereof

ActiveCN112958375ACompact structureAccurate transmission ratioLiquid surface applicatorsCoatingsEngineeringMechanical engineering

The invention discloses an independent rotary nozzle type compact gluing head capable of being detected online and a gluing method thereof. An existing frame gluing machine realizes change of a nozzle angle by rotating a gluing valve integrally, and is complex in structure and large in power consumption. The gluing head comprises a glue supply assembly of the gluing valve, a nozzle rotating mechanism and an online bilateral detection device, wherein a rotating air cylinder of the nozzle rotating mechanism drives a flat needle nozzle to rotate and the flat needle nozzle rotates directly to glue photovoltaic frames arranged inside and outside with different orientations by a single gluing head, such that the power consumption is reduced. The online bilateral detection detects whether the flat needle nozzle is aligned with a gluing groove of a to-be-glued frame or not online and whether the height of the gluing groove meets a gluing demand or not, the glue surface height after gluing changes, such that it is ensured that the system finds the quality problem of the gluing groove in time to replace the gluing frame as well as finds and corrects a gluing error caused by deviation of the gesture of the flat needle nozzle, unsmooth glue discharge or too quick glue discharge, thereby improving the gluing quality to the maximum extent.

Owner:上海盛普流体设备股份有限公司 +1

PCB component automatic detection and assembling device and method

ActiveCN111482794AAutomatic gluing realizationAchieve clampingLiquid surface applicatorsElectronic circuit testingEngineeringPersonal computer

The invention discloses a PCB component automatic detection and assembling device and method. According to the PCB component automatic detection and assembling device and method, a PCB component automatic detection device, a PCB component automatic gluing device and a PCB component automatic screw-locking device are sequentially arranged on a basic line body unit, a pneumatic stopper, a secondarylocating mechanism and a tray-and-tool are sequentially arranged on an assembly line body, locating pins and locating columns are arranged at one side, close to the pneumatic stopper, of the upper portion of the secondary locating mechanism, a guide shaft is arranged at the lower end of each locating column, and a linear bearing is arranged in each guide shaft; and a proximity switch is arranged at one side close to the tray-and-tool, an air cylinder is arranged on the lower portion of the secondary locating mechanism, and the PCB component automatic detection device, the PCB component automatic gluing device and the PCB component automatic screw-locking device are connected with an industrial personal computer respectively and are used for realizing automatic detection, gluing and screw-locking operation on a PCB component. Through the PCB component automatic detection and assembling device and method, the automatic degree is high in the whole detection process, manpower is saved, efficiency is high, an error cannot be easily made, detection reliability is high, and replacement of a man with a machine is completely realized.

Owner:西安精雕精密机械工程有限公司

Full-automatic LCD glue dispenser

PendingCN110756395AHigh precisionImprove gluing qualityPretreated surfacesCleaning using gasesManufacturing engineeringElectrical and Electronics engineering

The invention discloses a full-automatic LCD glue dispenser. The full-automatic LCD glue dispenser comprises a feeding and cleaning mechanism, a feeding and carrying arm, a glue dispensing mechanism,a waste material belt, a curing and blanking mechanism and a blanking and carrying arm, wherein the feeding and cleaning mechanism is arranged on a machine table; the glue dispensing mechanism and thecuring and blanking mechanism are respectively arranged behind the feeding and cleaning mechanism at intervals in sequence; the waste material belt is arranged between the glue dispensing mechanism and the curing and blanking mechanism; the feeding and carrying arm is arranged on one side of the glue dispensing mechanism and the curing and blanking mechanism; and the blanking and carrying arm armis arranged above the curing and blanking mechanism in a spanning mode. The full-automatic LCD glue dispenser has the functions of feeding, correcting and cleaning, effectively improves the accuracyof glue dispensing positions and the glue dispensing quality, adopts a multi-station design, can simultaneously complete automatic glue dispensing of a plurality of LCDs, effectively improves the gluedispensing capacity, adopts a material plate with a rectangular path for transferring and blanking, and effectively utilizes the time consumed by transferring and blanking to realize glue layer curing while realizing the centralized high-speed blanking of the LCDs, and the position for blanking can be directly used for subsequent laminating assembly.

Owner:SHENZHEN ETMADE AUTOMATION EQUIP

Glue peeling and sticking device

ActiveCN104553234AImprove surface qualityAvoid getting onLamination ancillary operationsLaminationMechanical engineeringEngineering

Owner:YIHE PRECISION IND SUZHOU

Automatic conveying device for gluing of veneers

ActiveCN104477594AImprove veneer gluing qualityImprove labor productivityDe-stacking articlesConveyor partsEngineeringWaste material

The invention discloses an automatic conveying device for the gluing of veneers. The veneer material pile conveying outlet of a prepared-material shaping and conveying mechanism with moisture content detection is communicated with the inlet of an automatic material pile lifting platform; after being lifted by the automatic material pile lifting platform, veneer material piles enter an automatic veneer conveying mechanism; after being separated by the automatic veneer conveying mechanism, the first veneer of the veneer material pile enters a foldable directional conveying mechanism with a waste material recycling function; a reverse separation limiting mechanism is arranged in the veneer material pile conveying direction of the automatic veneer conveying mechanism; the reverse separation limiting mechanism limits the conveying direction of the veneer material pile of which the first veneer is separated; an automatic veneer material pile impurity recycling mechanism cooperates with the foldable directional conveying mechanism with the waste material recycling function to recycle the chips and the impurities of the veneer material pile. According to the automatic conveying device, the veneer gluing quality is improved, and the labour production efficiency is increased.

Owner:XIAMEN ZHONGSAI ELECTROMECHANICAL TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com