Patents

Literature

580results about How to "Apply glue evenly" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

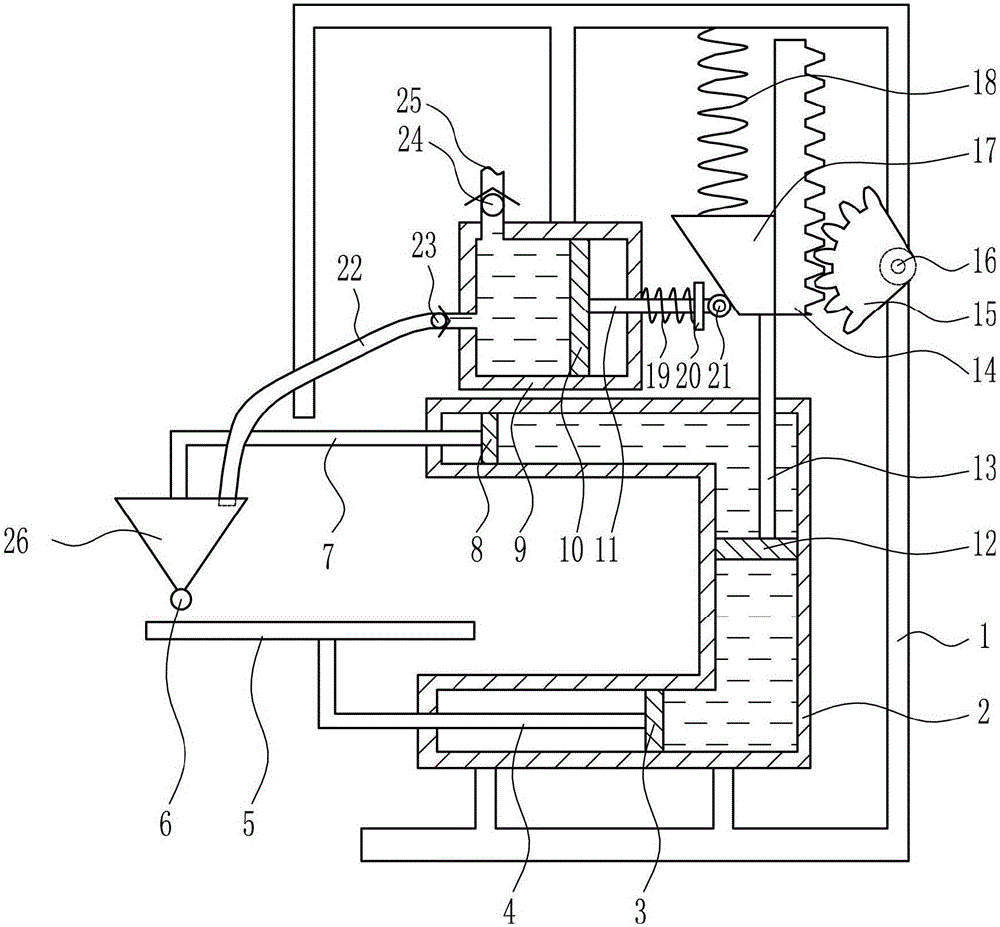

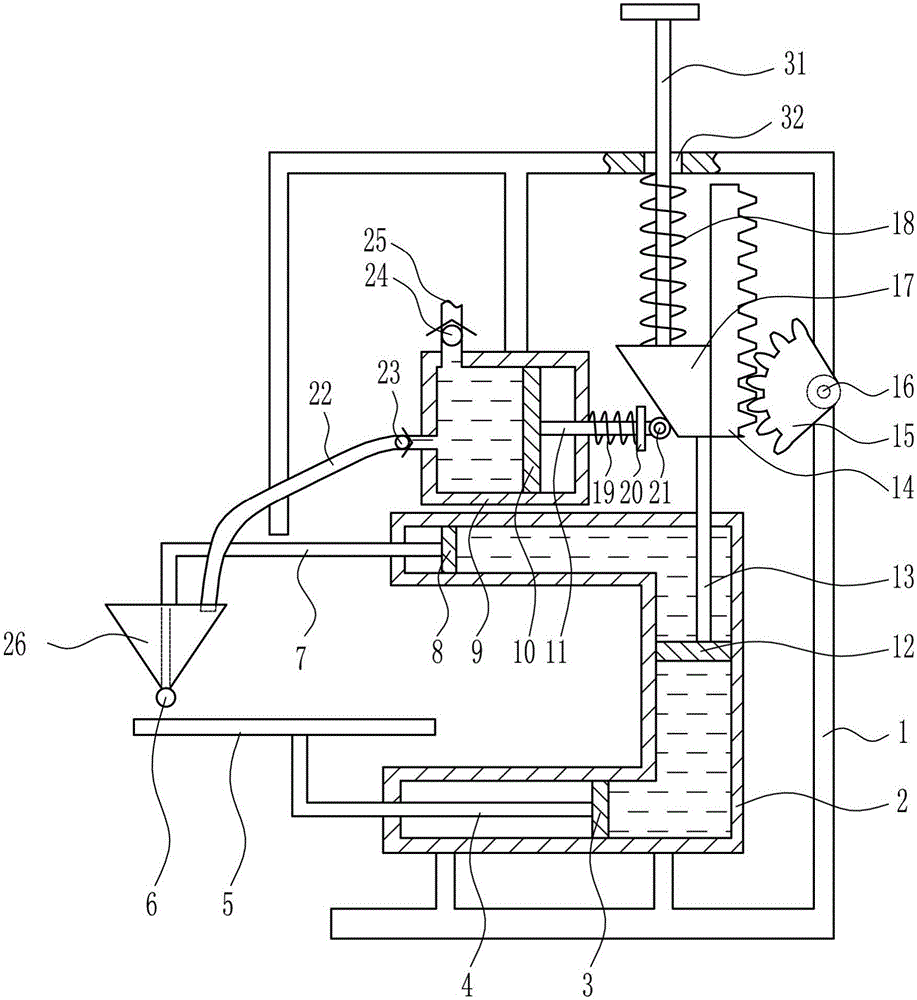

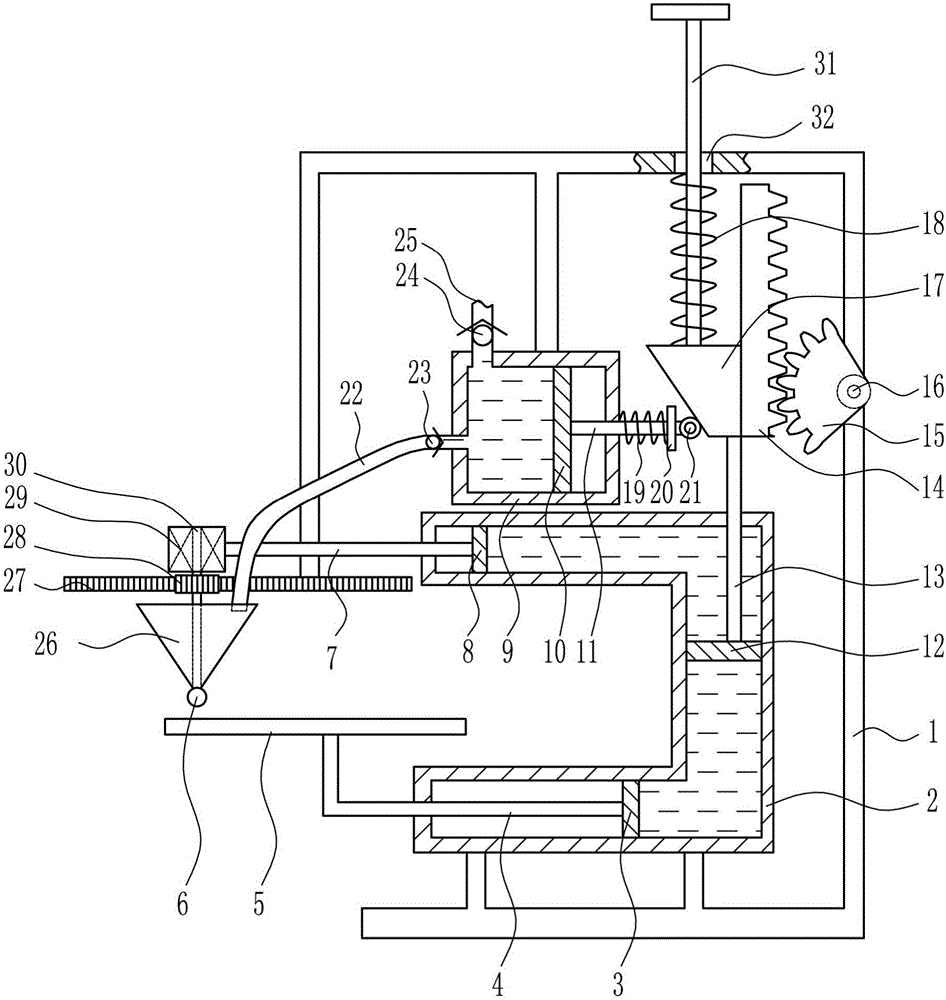

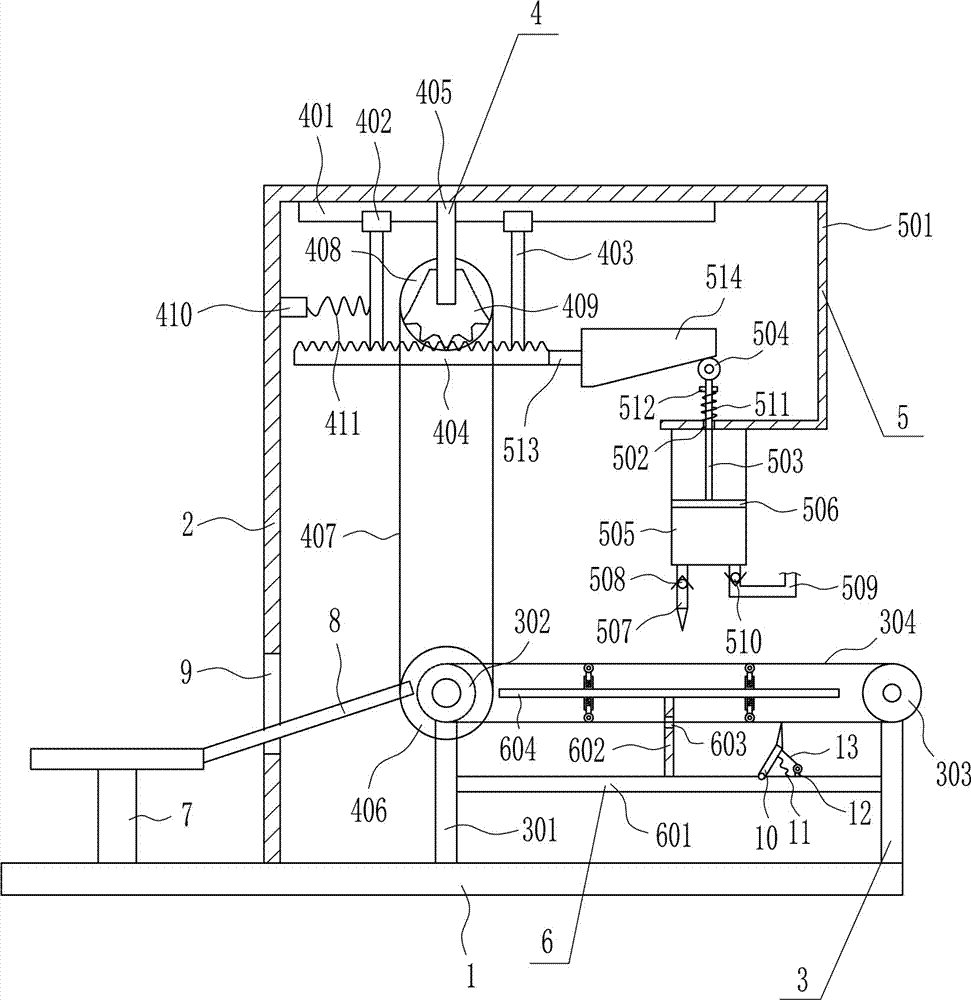

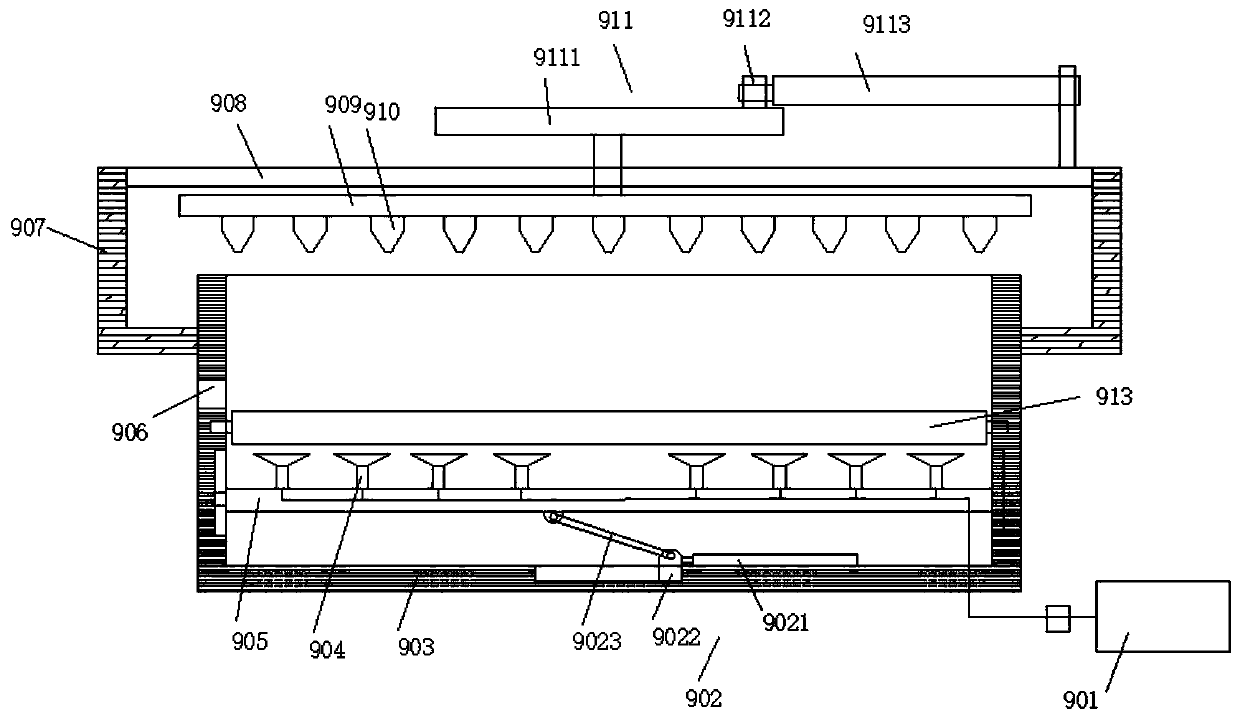

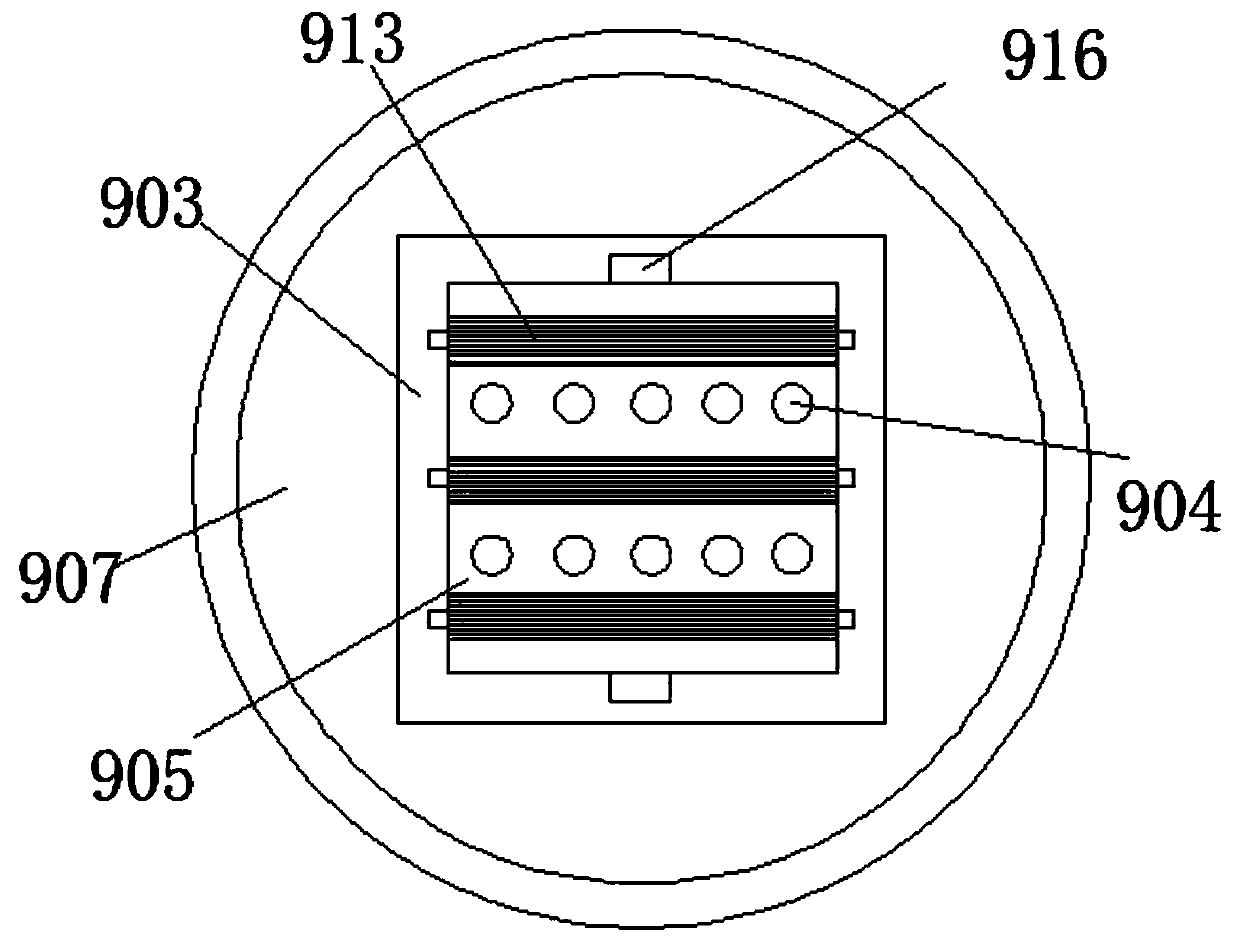

Efficient gluing equipment for shoemaking in shoe factories

InactiveCN106670056AApply glue evenlyDevice stableLiquid surface applicatorsCoatingsPistonFixed frame

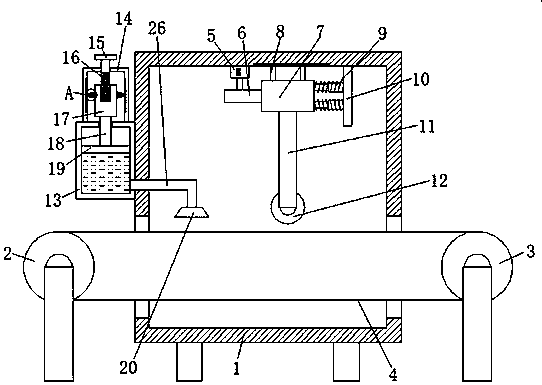

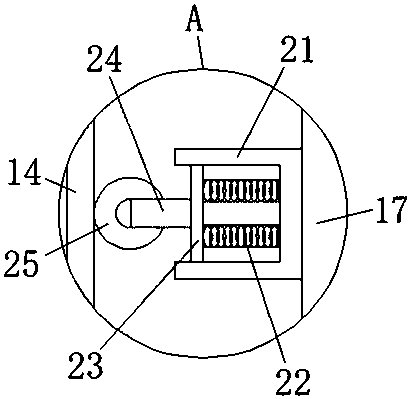

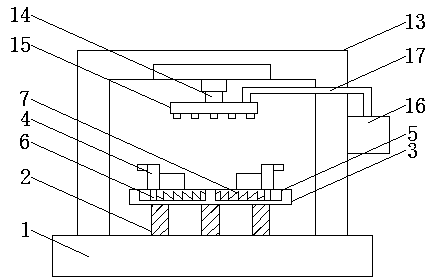

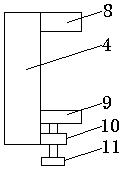

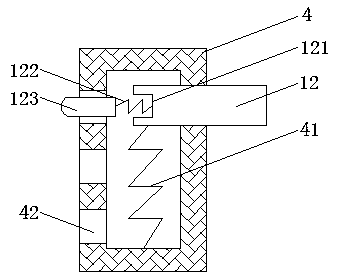

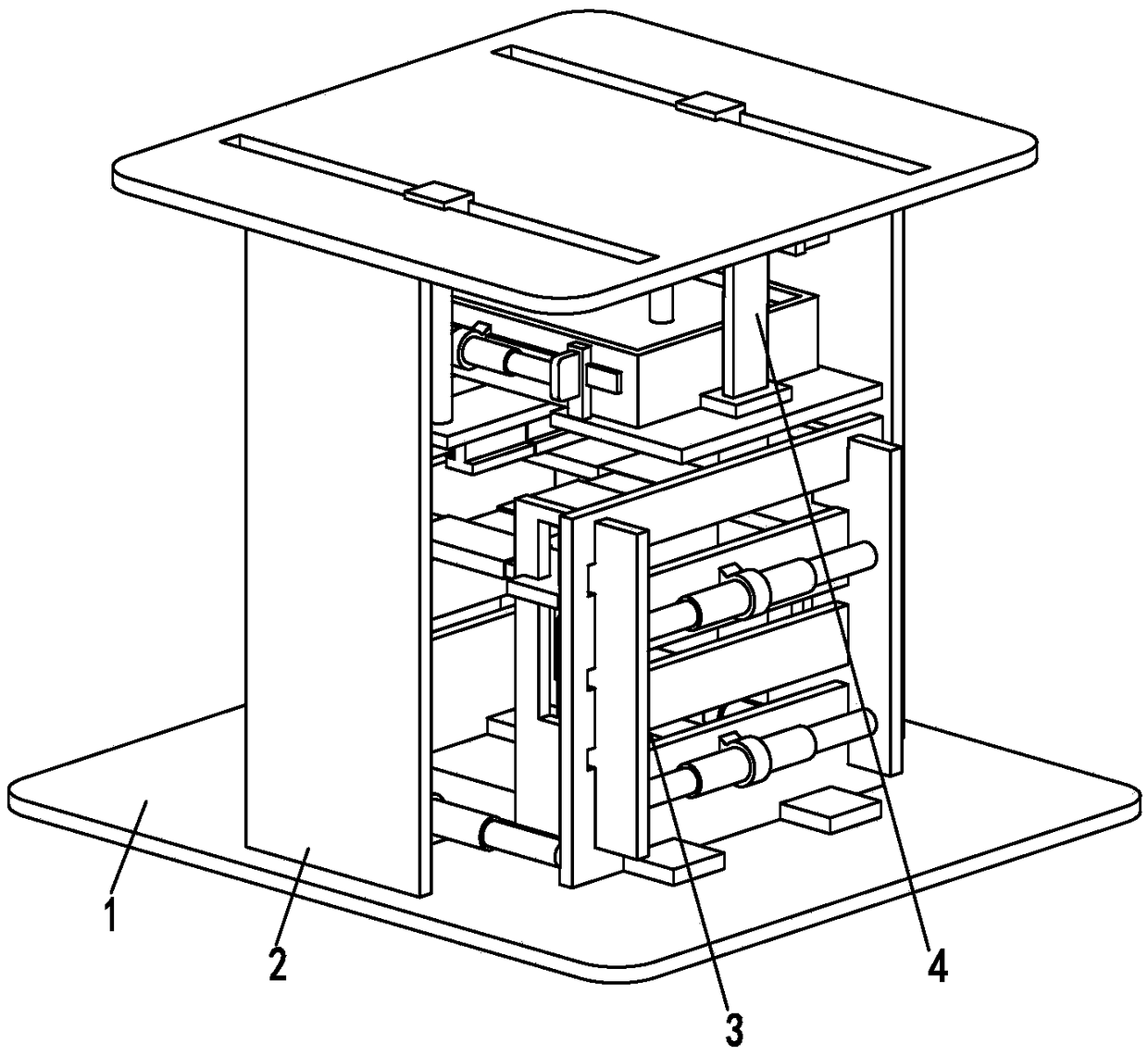

The invention relates to gluing equipment, in particular to efficient gluing equipment for shoemaking in shoe factories. According to the efficient gluing equipment for shoemaking in the shoe factories, rapid gluing can be conducted, the gluing effect is good, and the gluing efficiency is high. The efficient gluing equipment for shoemaking in the shoe factories comprises a fixed frame, a U-shaped cylinder body, a first piston, a first left-right movement rod, a placing plate, a gluing head, a second left-right movement rod, a second piston, a small cylinder body and the like. The small cylinder body, a motor and the U-shaped cylinder body are arranged on the fixed frame in sequence from top to bottom. The motor is provided with a fan-shaped gear. The first piston is arranged in the lower portion of the U-shaped cylinder body in a matched mode. The first left-right movement rod is arranged on the left portion of the first piston. The efficient gluing equipment for shoemaking in the shoe factories achieves the effects of being good in gluing effect and high in gluing efficiency; a large number of gluing tasks can be rapidly completed through the efficient gluing equipment; in addition, a large amount of labor force is not needed; and a glued finished product is beautiful.

Owner:林永远

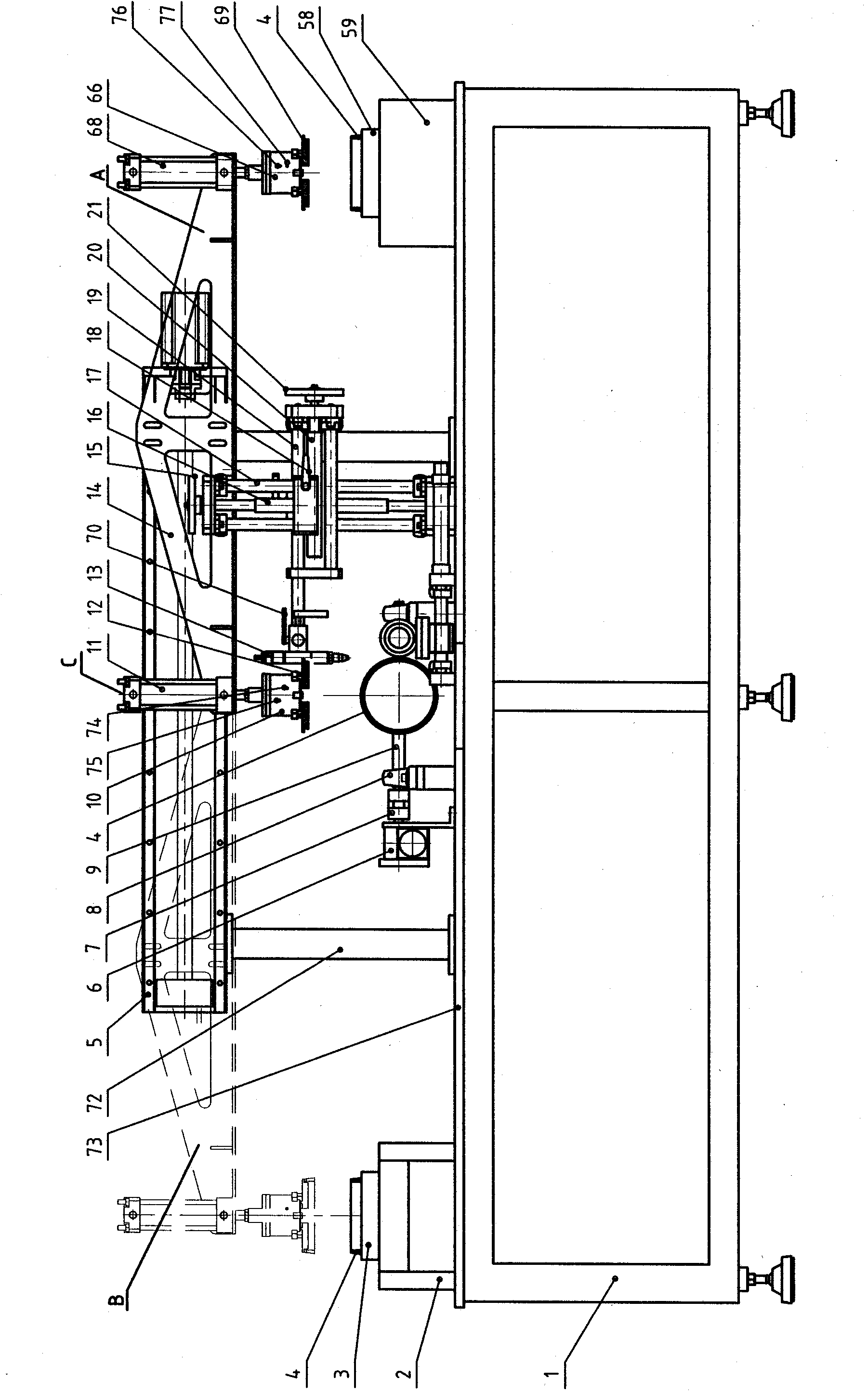

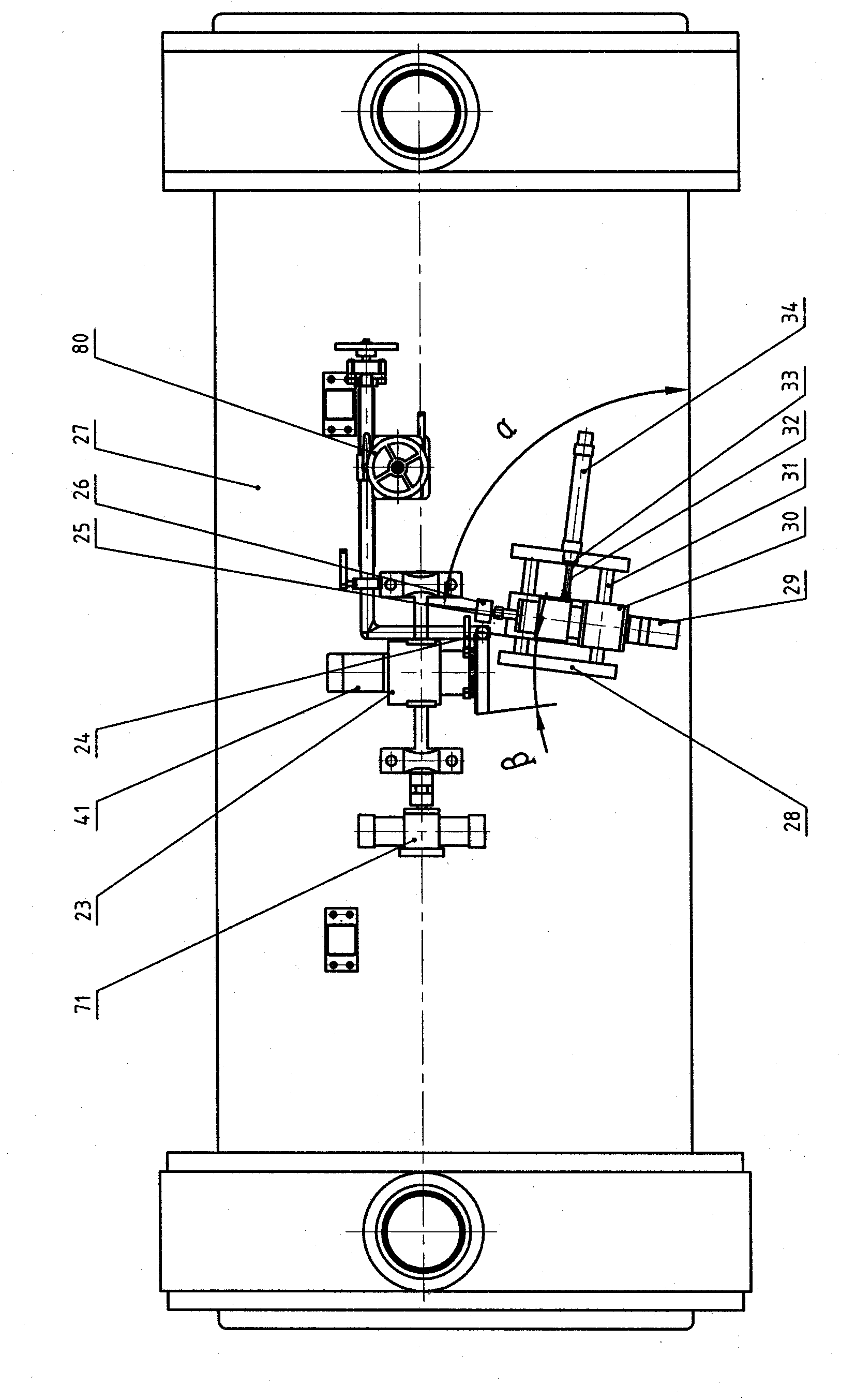

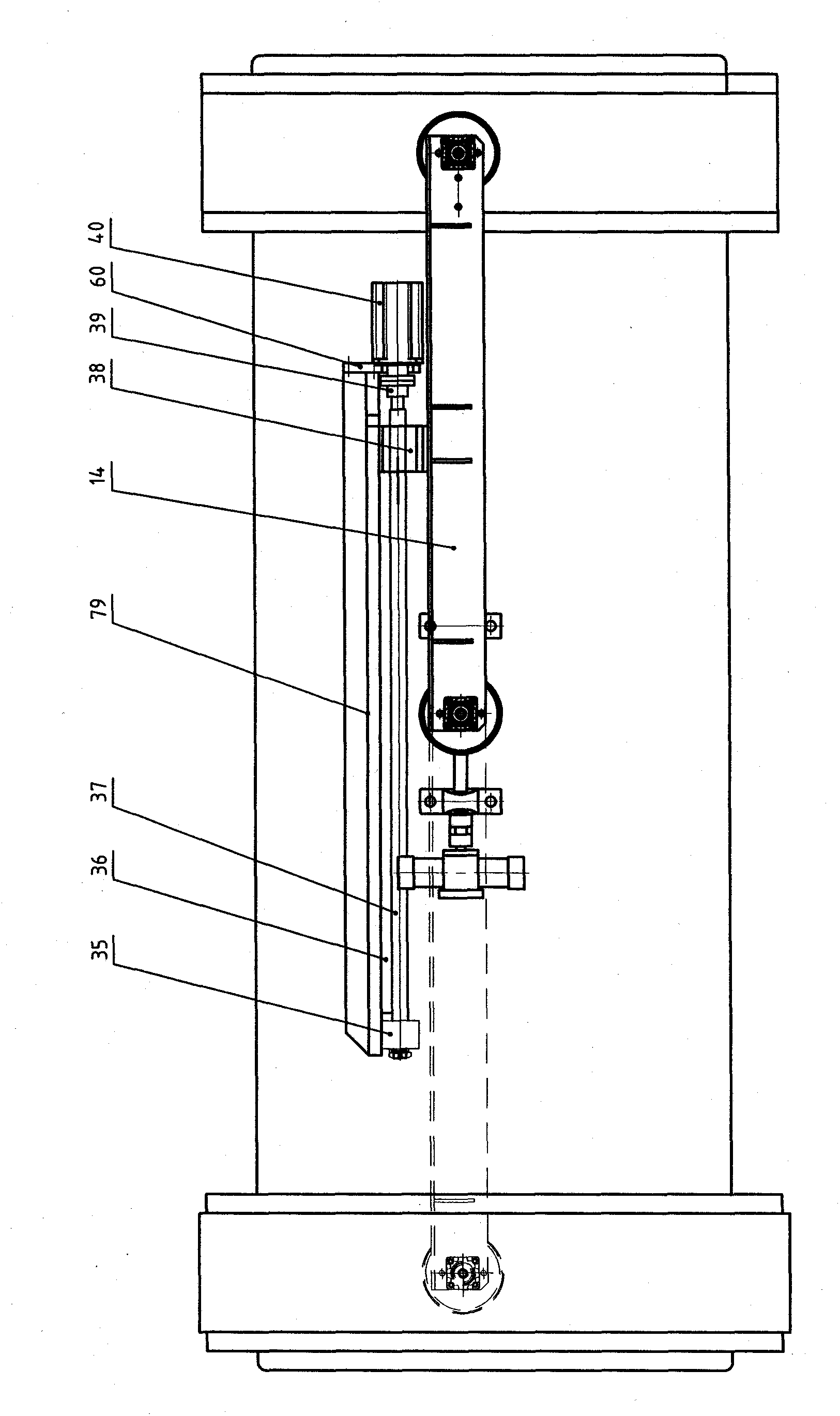

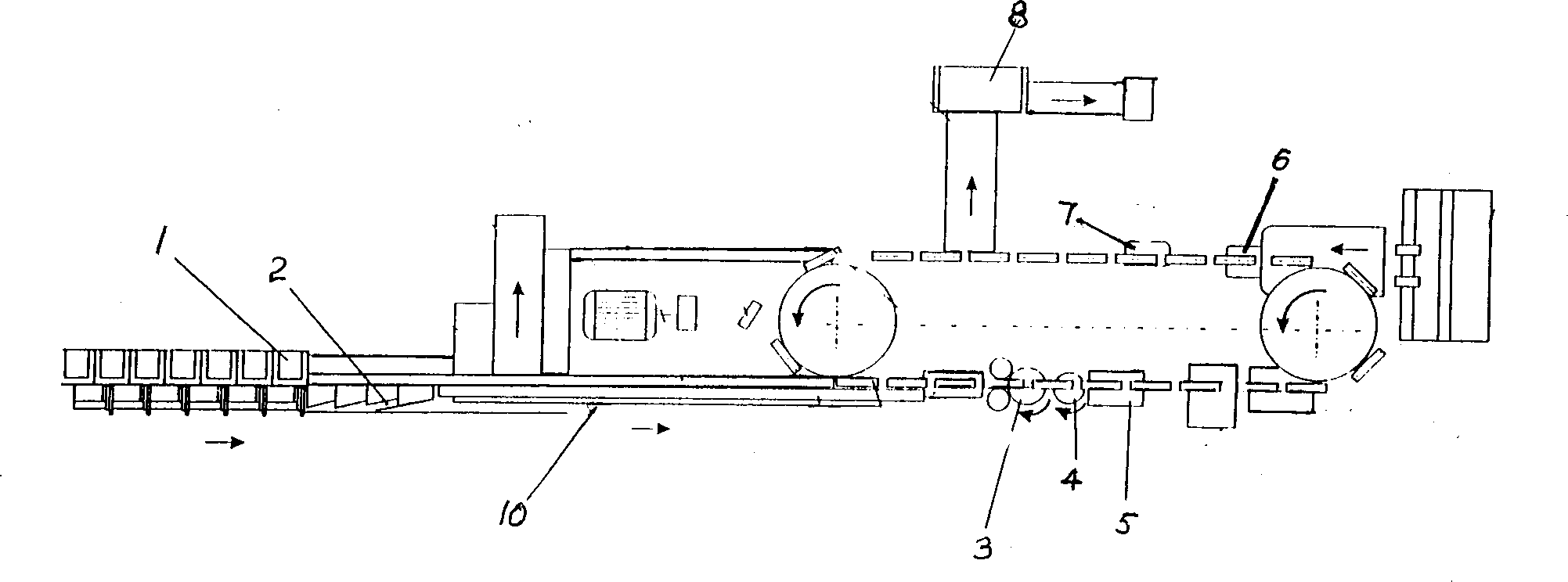

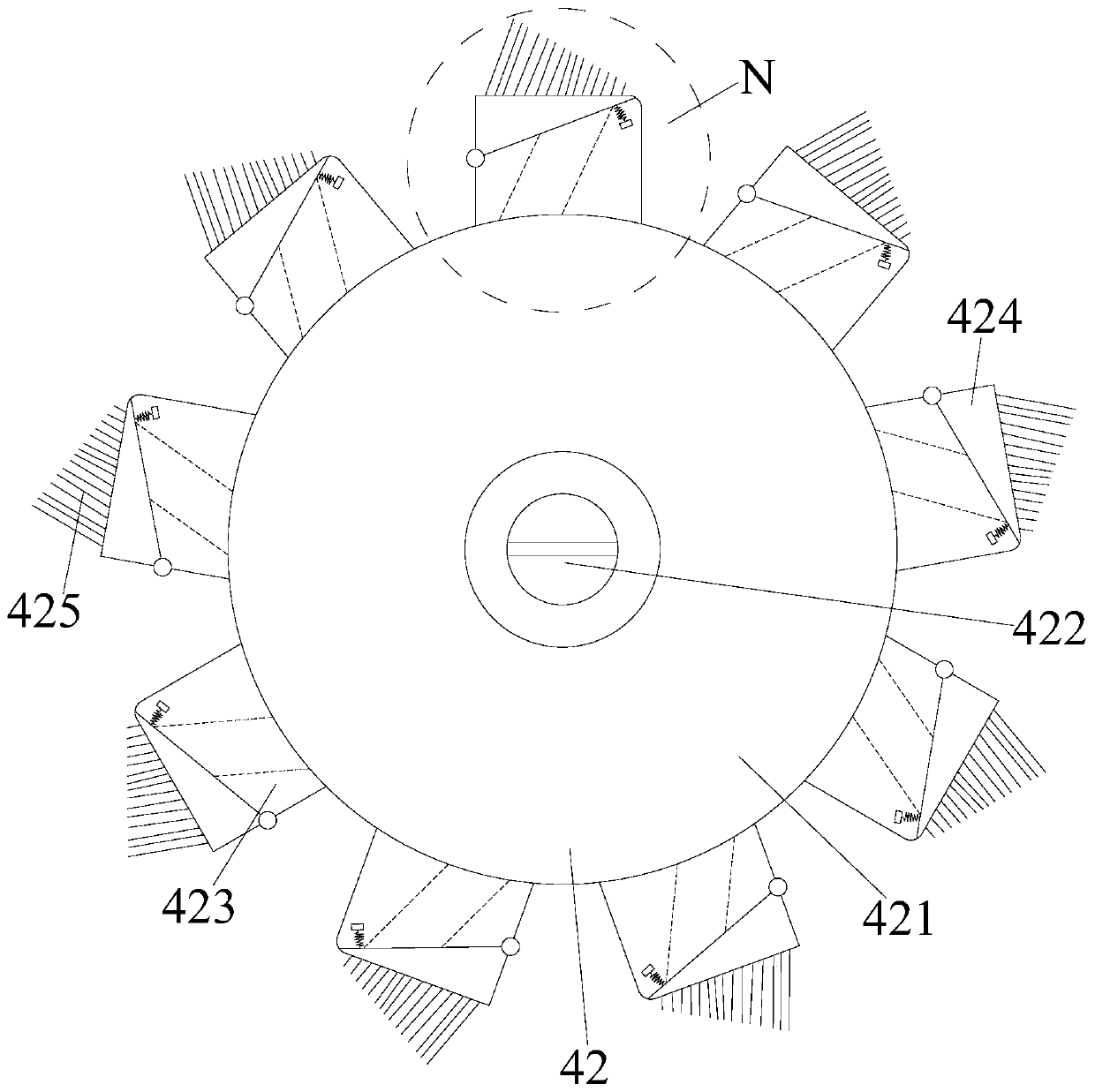

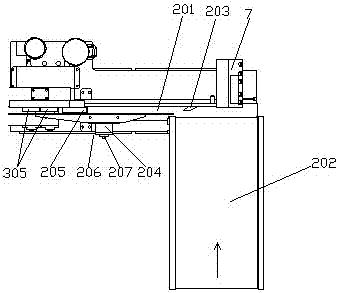

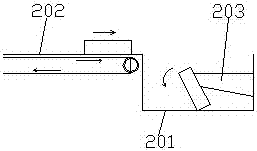

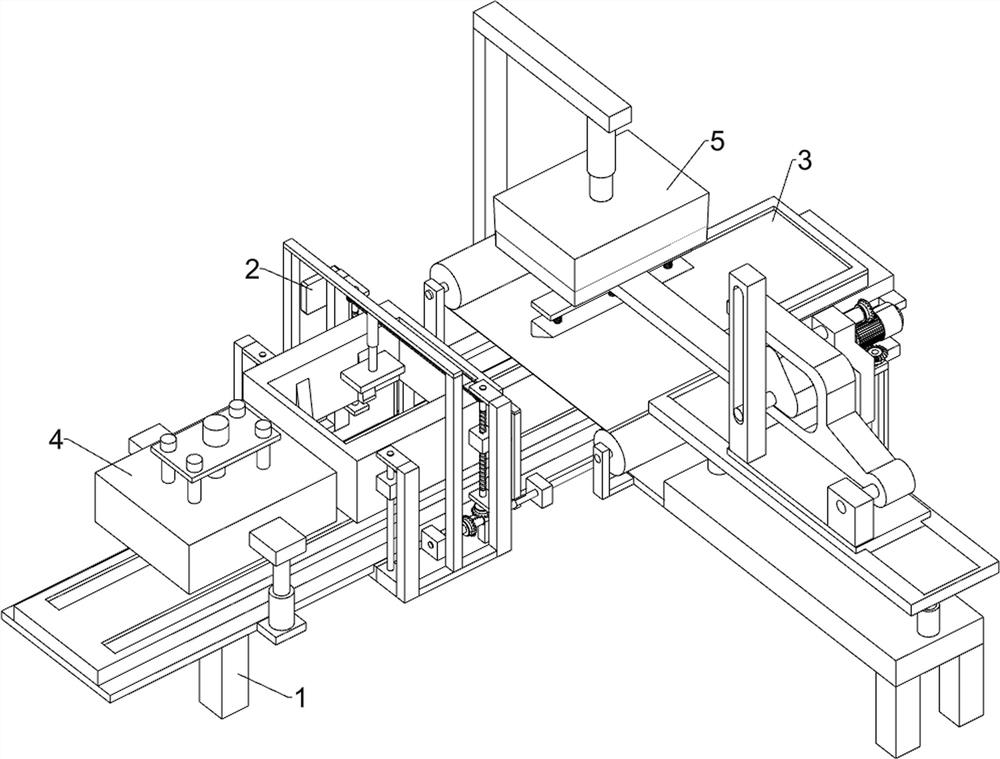

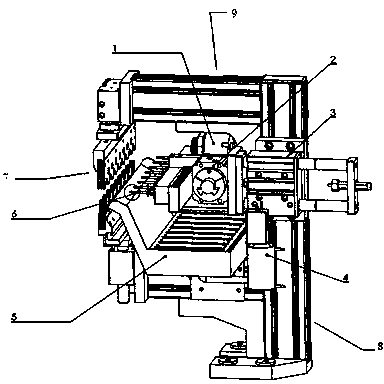

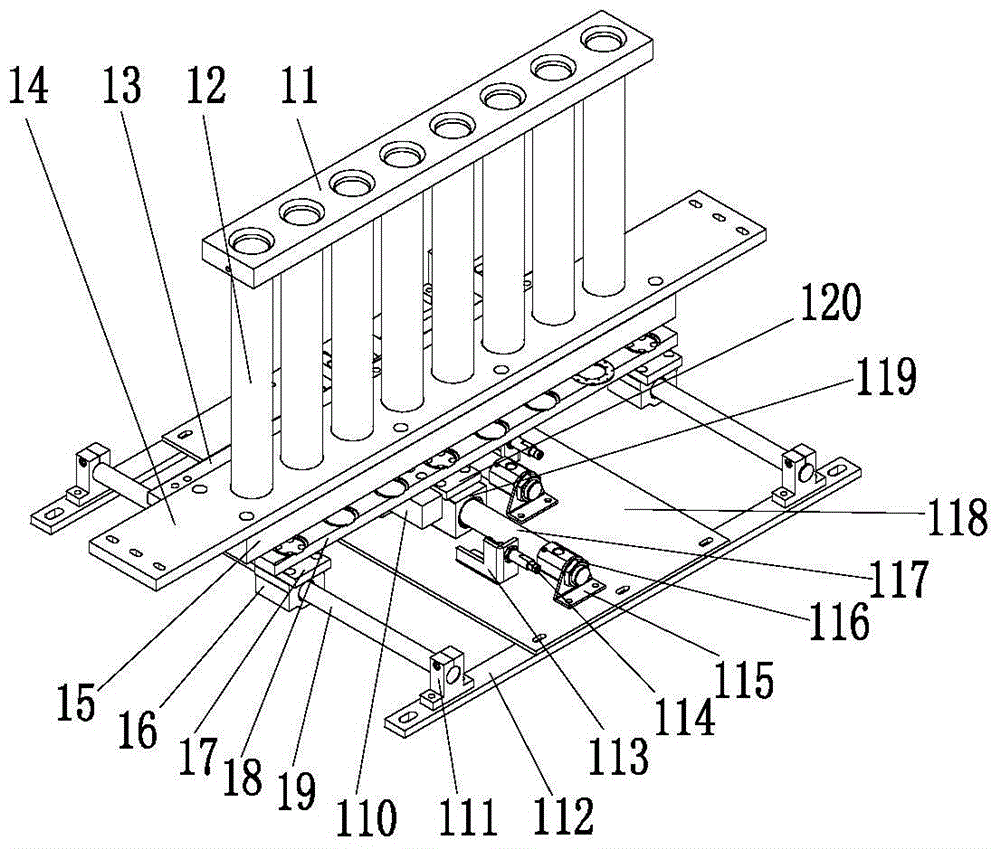

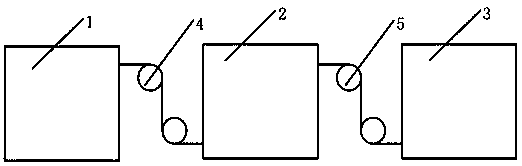

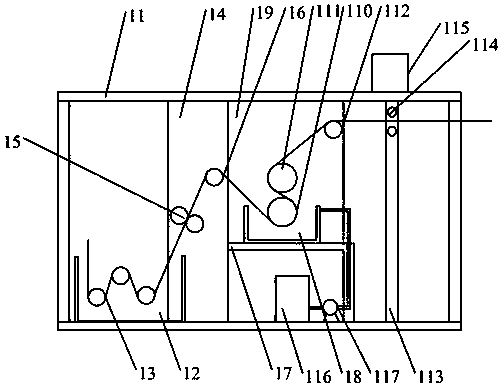

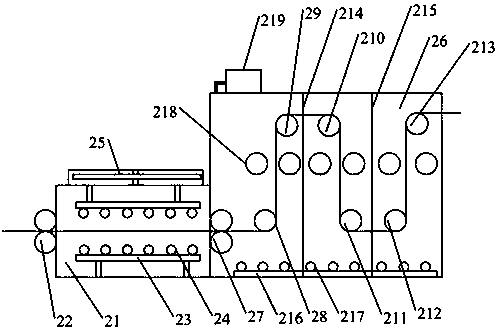

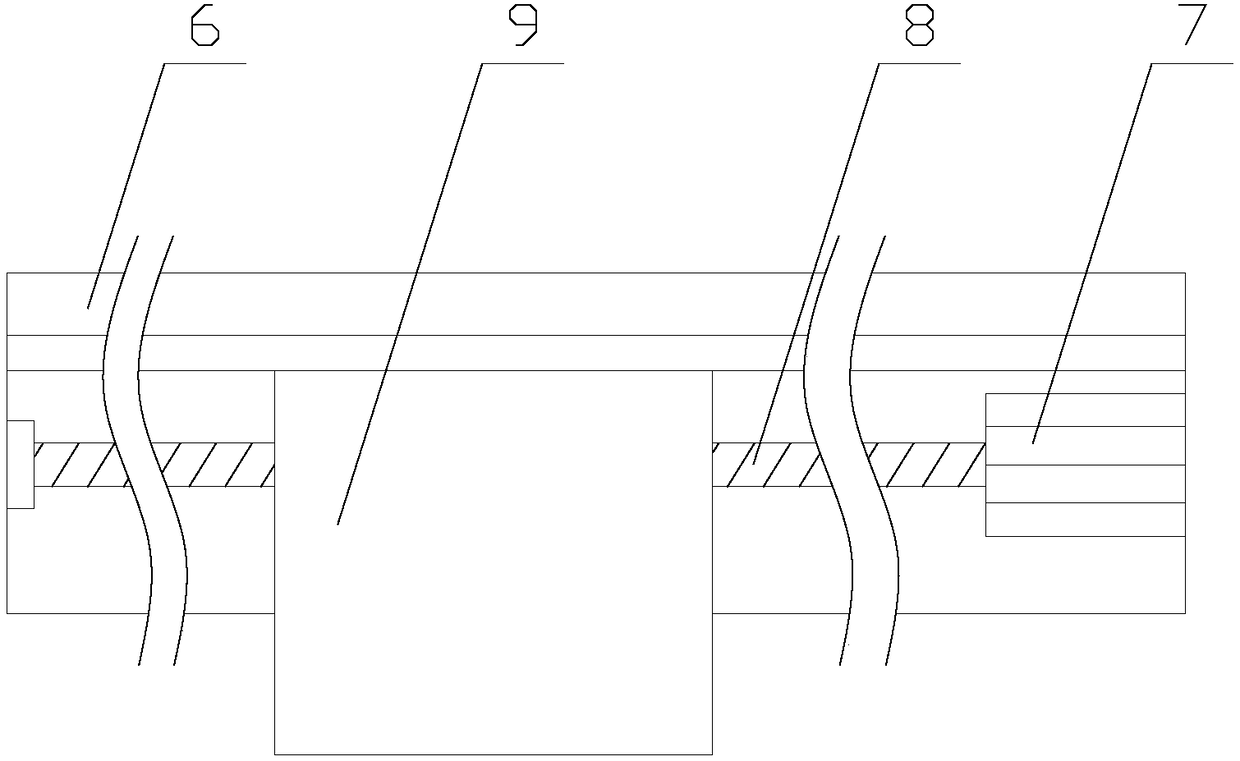

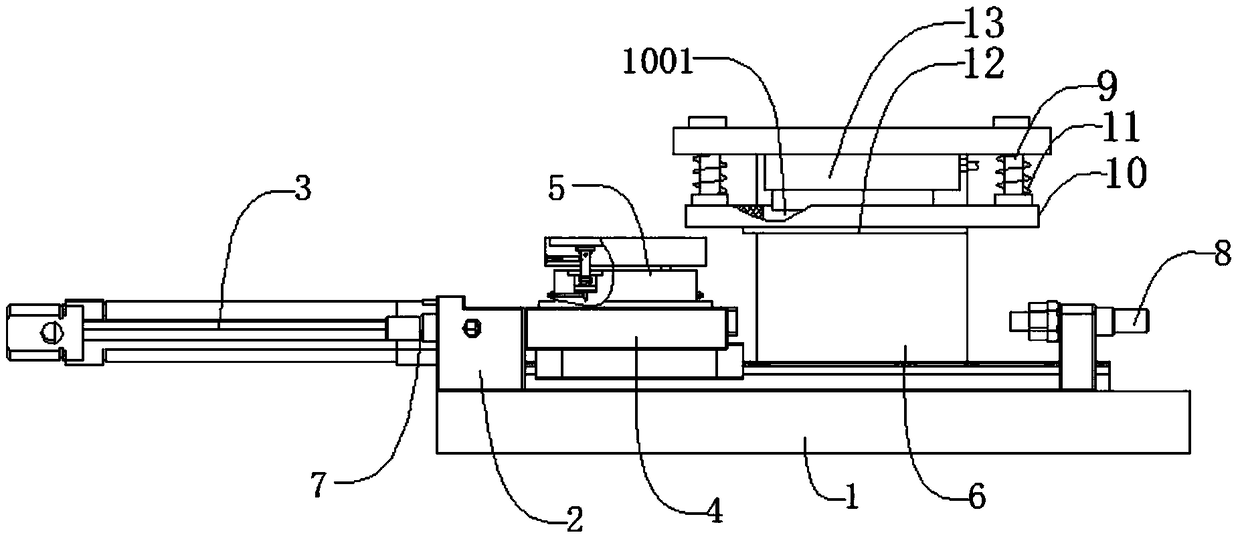

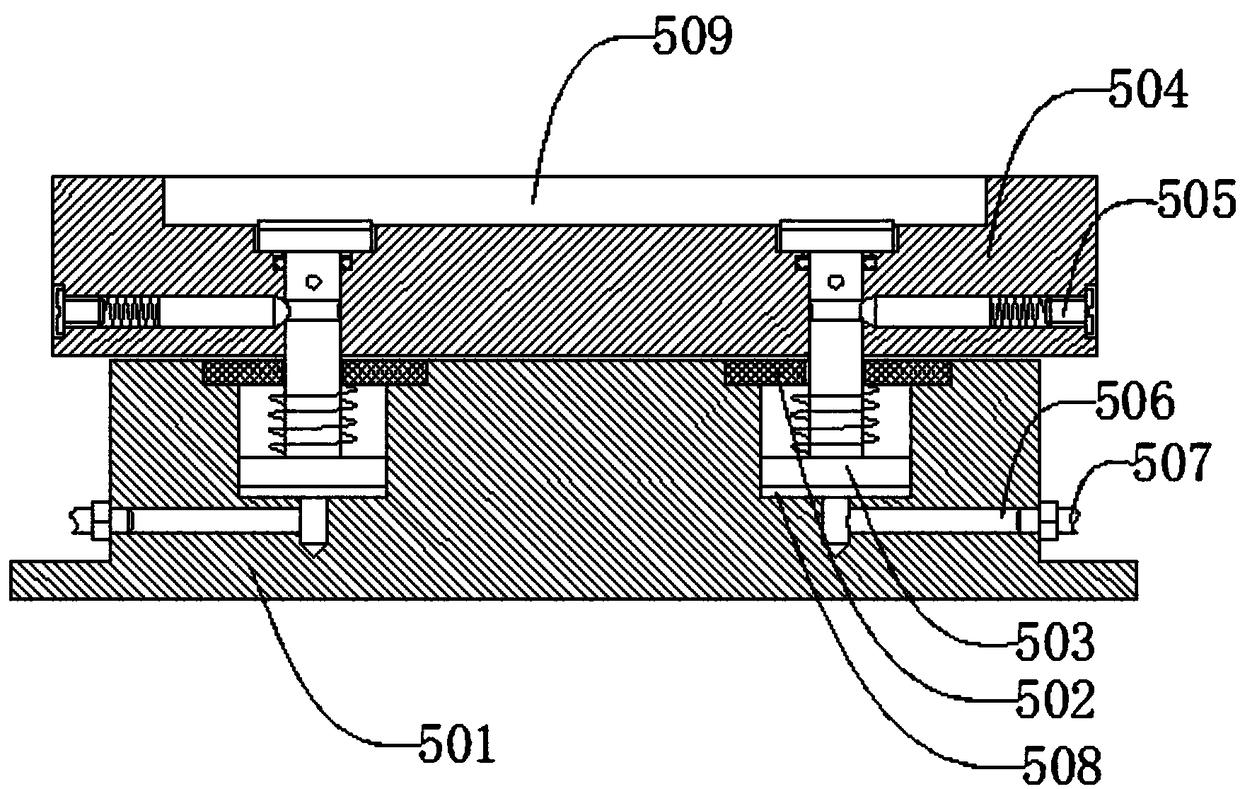

Fully-automatic gluing equipment suitable for various parts

ActiveCN102553774AApply glue evenlyMitigate threats to your healthLiquid surface applicatorsCoatingsEngineeringFully automatic

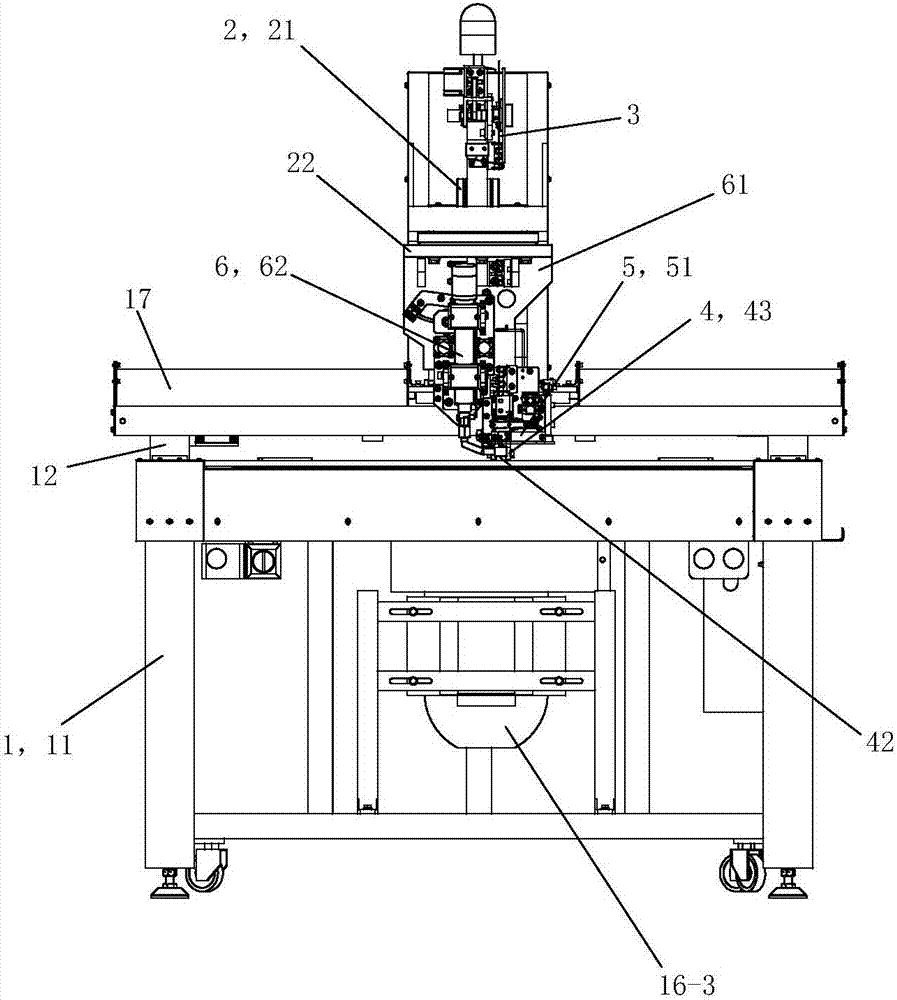

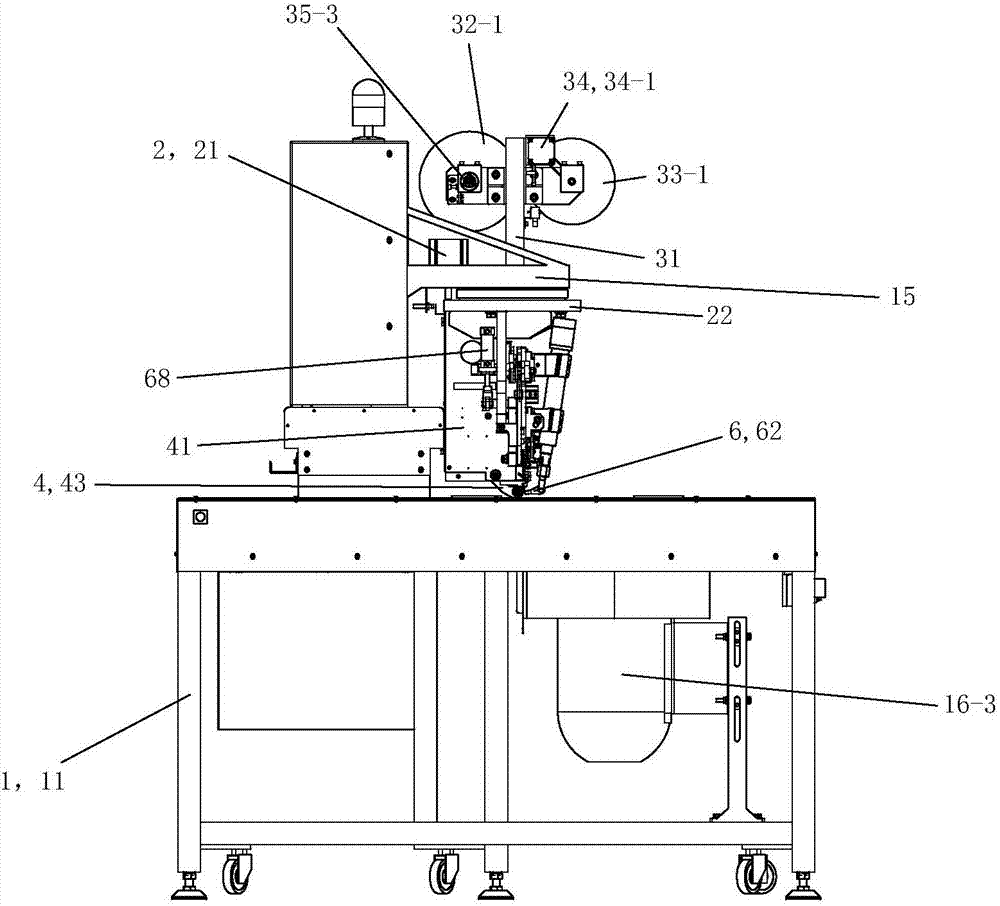

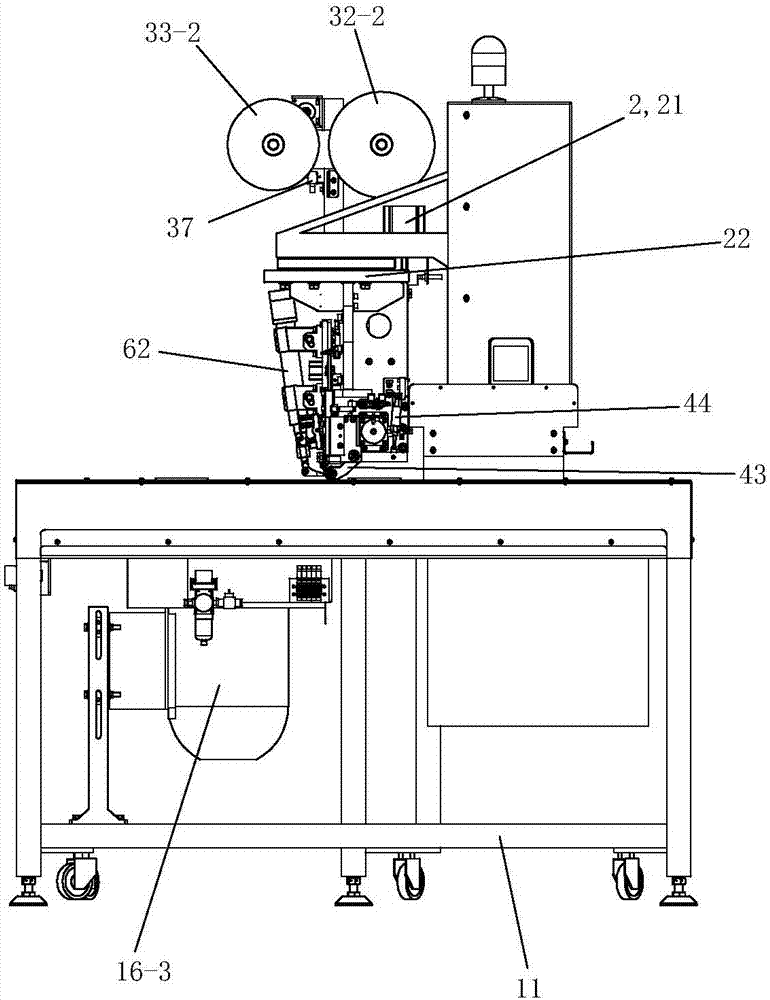

The invention provides fully-automatic gluing equipment suitable for various parts and relates to the fully-automatic gluing equipment. The fully-automatic gluing equipment solves the problem that the conventional cylindrical, ring-shaped, conical, circular truncated cone-shaped and circular truncated cone ring-shaped parts cannot be fully automatically glued on the same equipment. The fully-automatic gluing equipment comprises a machine frame, and a feeding workbench, a transmission platform, a part transverse transmission device, a tensioning collet A, a tensioning collet C, a rotary collet device, a swinging device, a glue head adjusting device and a glue scraping device which are fixed on the machine frame, wherein the feeding workbench comprises a feeding positioning die; the feeding positioning die is fixed on a feeding workbench panel; and the feeding positioning die is used for accurately positioning the parts and placing the parts in to the positioning die. The fully-automatic gluing equipment has high generality, can glue on the outer surfaces of the cylindrical, ring-shaped, conical, circular truncated cone-shaped and circular truncated cone ring-shaped parts and can glue on the inner surfaces of the cylindrical, ring-shaped, conical, circular truncated cone-shaped and circular truncated cone ring-shaped parts.

Owner:DALIAN HUAGONG INNOVATION TECH

Gluing and binding machine

InactiveCN1370689AThe whole machine is in stepSimple structureBook making processesBookbinding adhesiveSprayerEngineering

The present invention relates to the field of printing equipment technodlogy. The gluing and binding machine includes page distributing mechanism, cover page conveying mechanism, vibrating and tidying mechanism and gluing and binding formation mechanism combined by a conveying belt into an integral and controlled by a programmed controller. The page distributing mechanism comsists of one or more page distributing conveying belts and several paper suckers; the cover page conveying mechanism consists of paper sucking and impressing wheel; the vibrating and tidying mechanism consists of vibrating cylinder driven paper sucking disc; and the gluing and binding formation mechanism consists of chain driven by chain wheel, support board, paper preheater, glue sprayer and setter.

Owner:贾永康

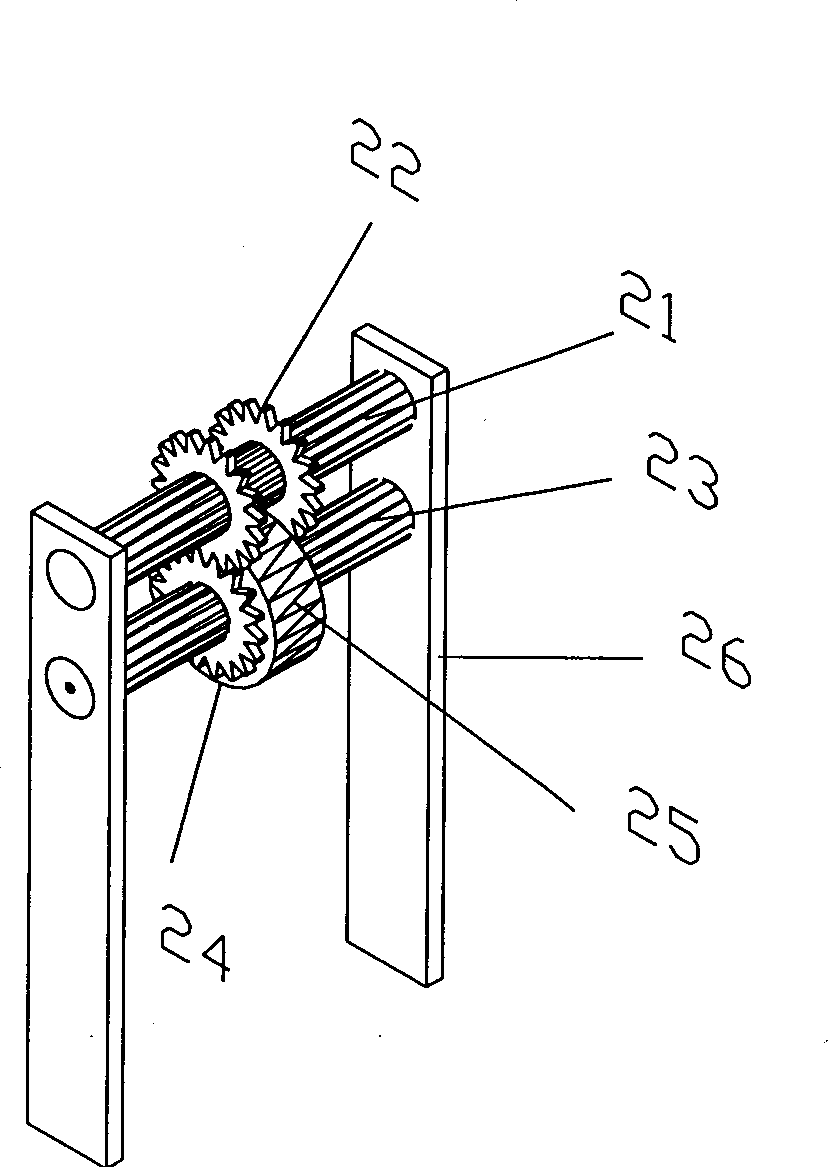

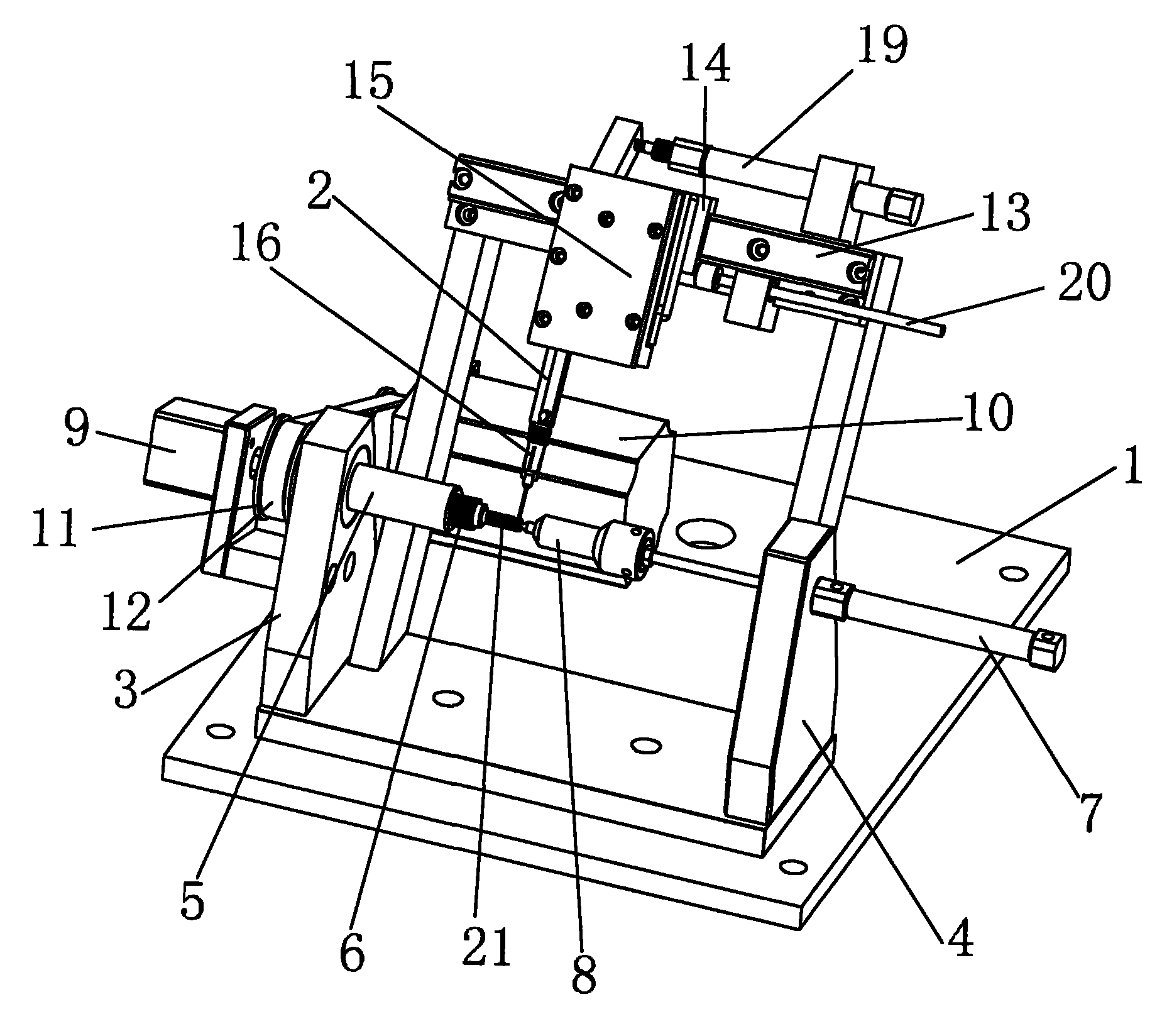

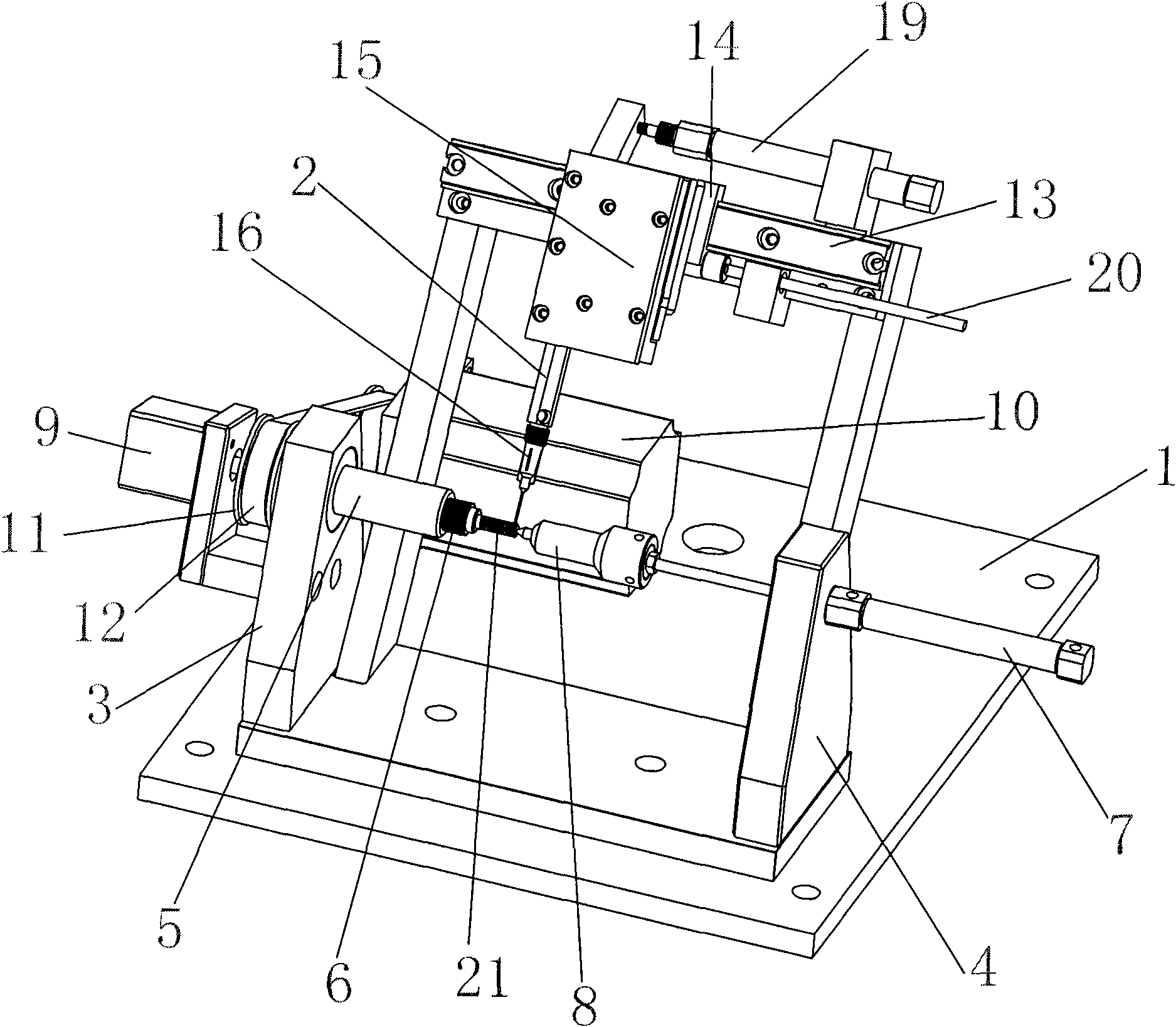

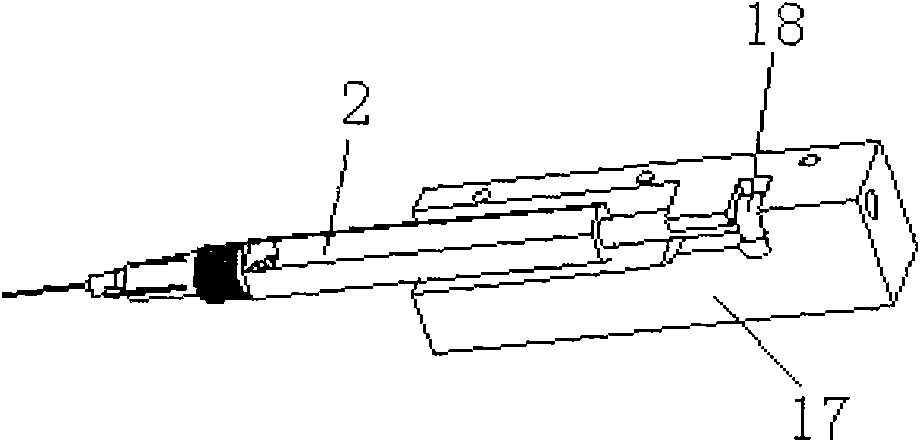

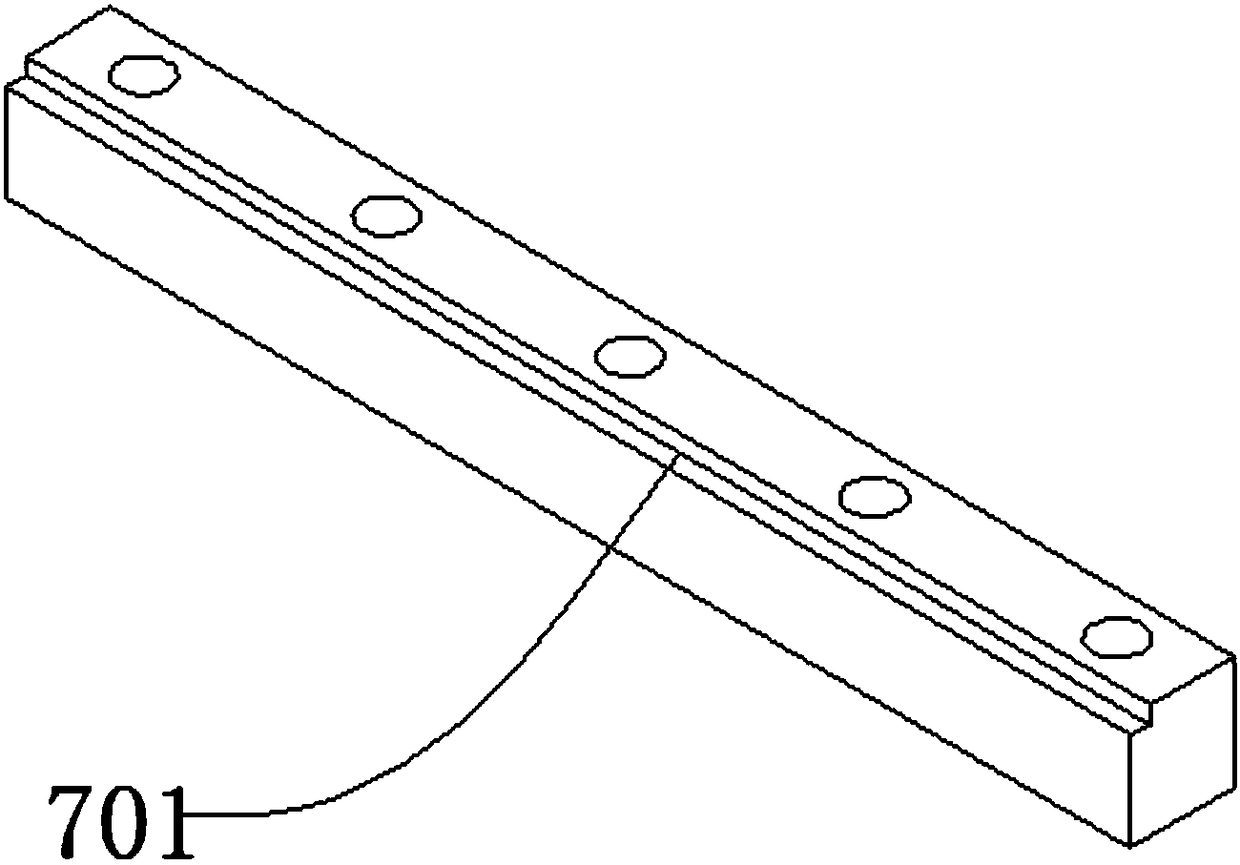

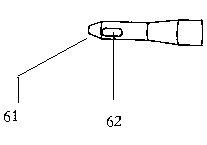

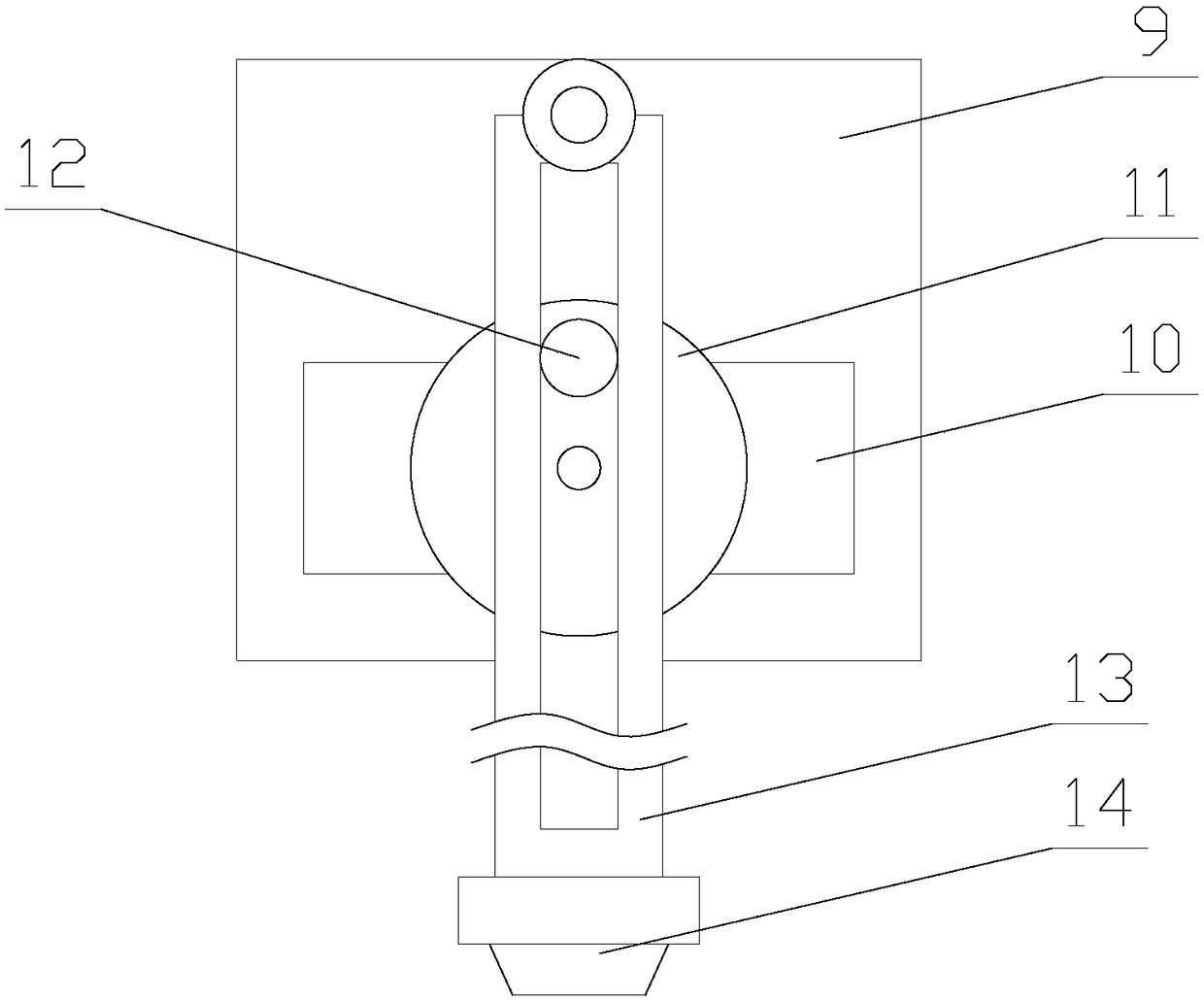

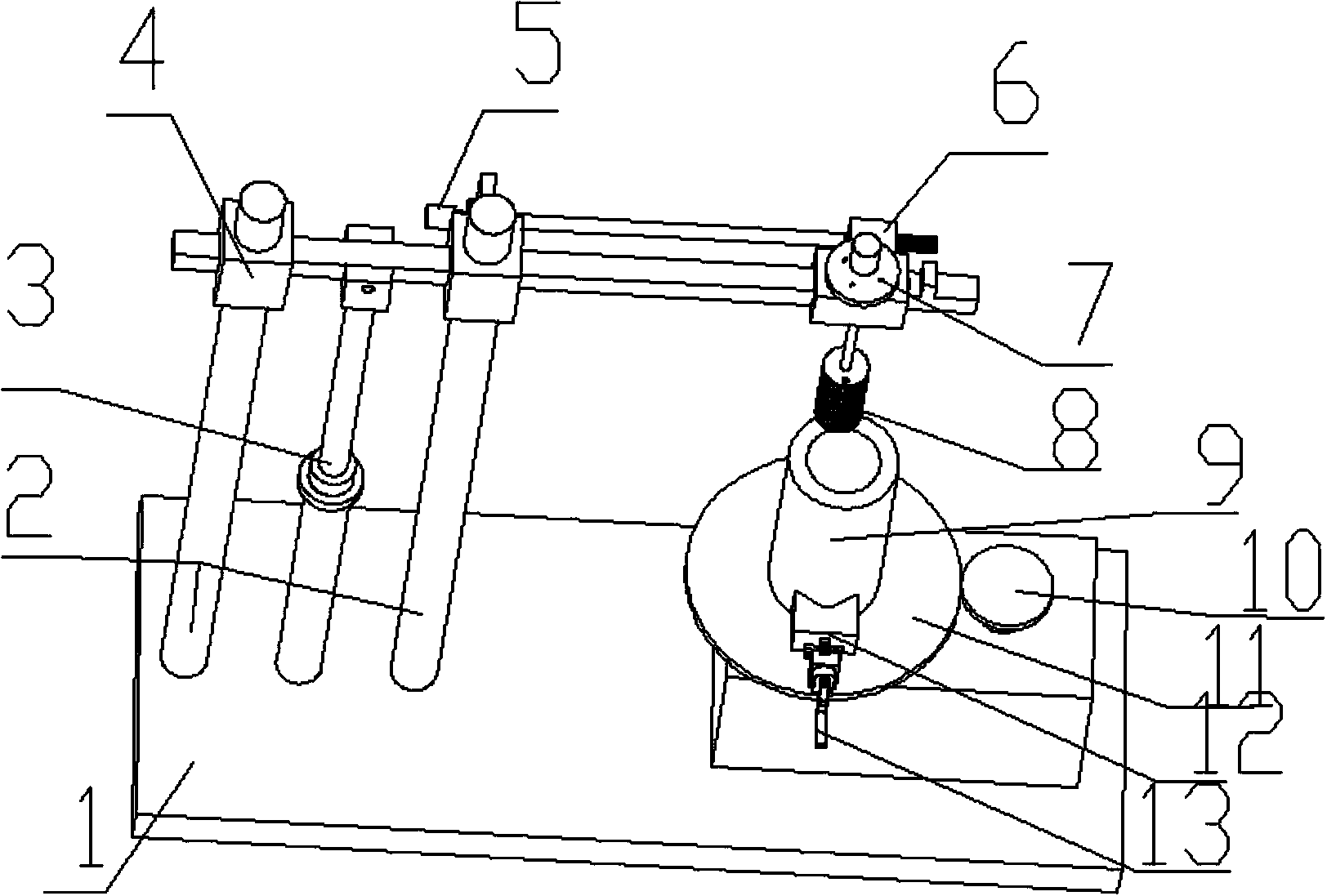

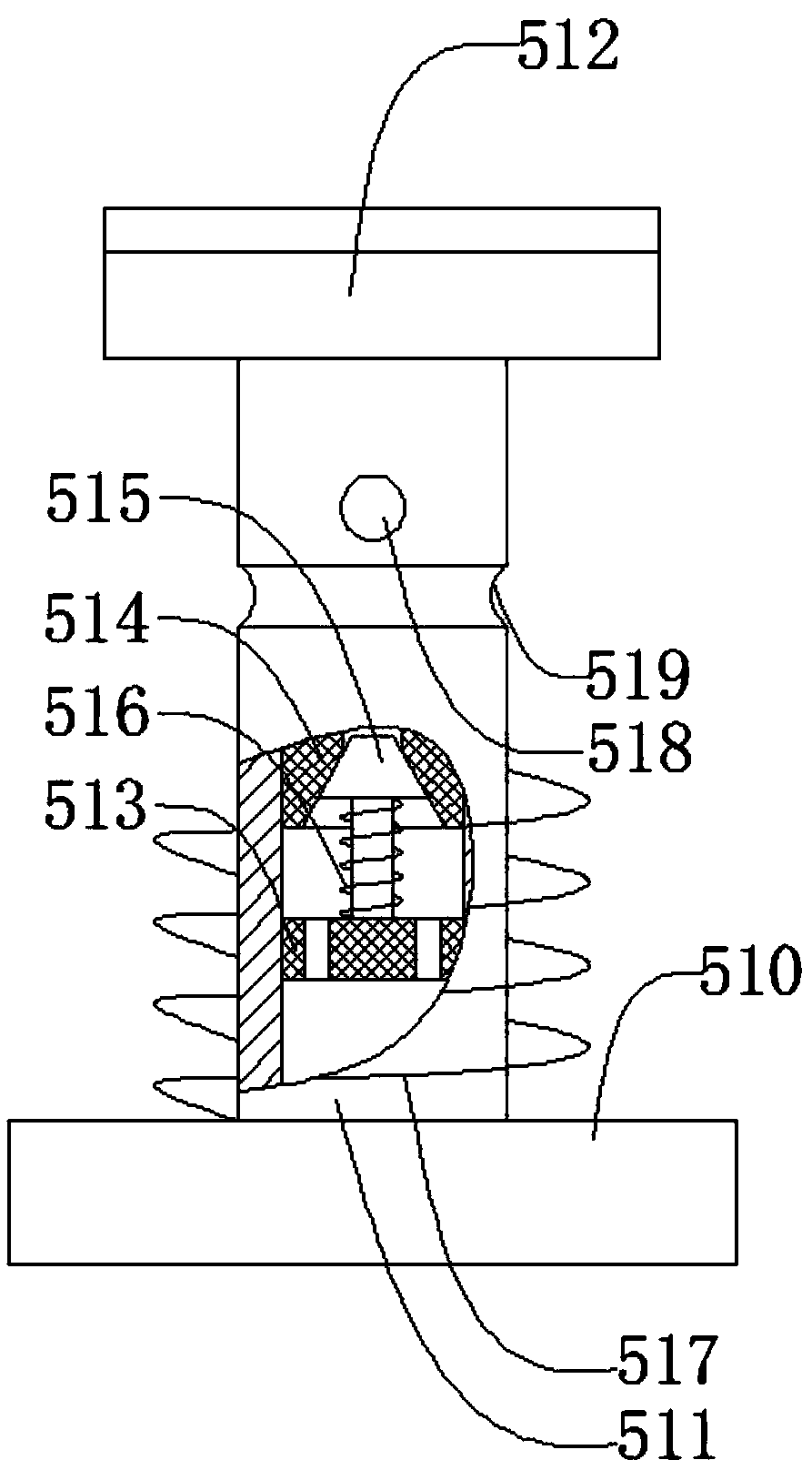

Screw adhesive supplier

ActiveCN101811110AImprove work efficiencyApply glue evenlyLiquid surface applicatorsCoatingsRotational axisEngineering

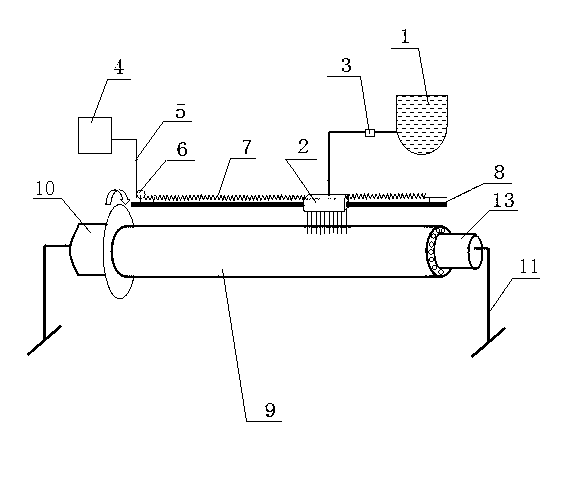

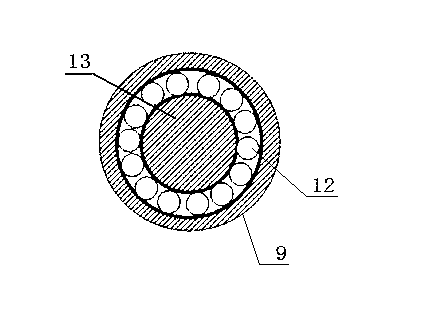

The invention discloses a screw adhesive supplier, which comprises a machine table and an adhesive gun. The machine table is provided with a first permanent seat and a second permanent seat, the first permanent seat is provided with a rotatable rotating shaft, and the tail end of the rotating shaft faces the second permanent seat and is provided with a clamp; the second permanent seat is provided with a jacking cylinder, the tail end of a piston rod of the jacking cylinder faces the first permanent seat and is connected with a jacking head, and the jacking head is opposite to the clamp; the rotating shaft is connected with a rotating drive mechanism for driving the rotating shaft to rotate; and a slide rail parallel to the rotating shaft is arranged above the rotating shaft and the jacking cylinder, the slide rail is glidingly provided with a slide block, the slide block is connected with a slipway cylinder arranged vertically, the slide block of the slipway cylinder is connected with the adhesive gun which is arranged vertically, an adhesive outlet head at the lower end of the adhesive gun is sleeved with an adhesive outlet needle communicated with the adhesive outlet head, and the adhesive outlet needle is aligned with the central axis of the rotating shaft. The screw adhesive supplier can perform 360-degree uniform adhesive coating on the periphery of a screw thread part, and has high work efficiency.

Owner:上海大花自动化科技股份有限公司

Shoe-making gluing device

The invention discloses a shoe-making gluing device which comprises a mounting cover. A plurality of slide rods are fixedly connected to the upper side of a moving plate which is arranged in the mounting cover, the upper end of each slide rod is fixedly connected with a slider, and the inner top of the mounting cover is provided with a strip slide groove corresponding to the sliders. A driving mechanism is arranged on the outer side of the moving plate, two symmetrical supporting rods are fixedly connected to the lower side of the moving plate, a gluing roller sleeves a rotating shaft which isin rotational connection between the two supporting rods, and a liquid outlet pipe is connected to one side of a glue box which is fixedly connected to one side of the mounting cover. By arrangementof a regulation mechanism for driving a piston to move, glue in the glue box can be extruded out of the liquid outlet pipe and sprayed to soles through a nozzle, then the gluing roller is driven to shake bilaterally by the driving mechanism to uniformly apply the glue, and accordingly gluing efficiency and gluing uniformity are improved.

Owner:YANCHENG JINRUI PETROLEUM MACHINERY CO LTD

Automatic adhesion device for outer surface of bushing

InactiveCN102836800AStrong standardApply glue evenlyLiquid surface applicatorsCoatingsEngineeringMechanical engineering

The invention relates to an automatic adhesion device for an outer surface of a bushing. An adhesive box of the automatic adhesion device for the outer surface of the bushing is connected with an adhesive brush through a pipeline; an adhesive injection control device is connected in series with the pipeline for connecting the adhesive box with the adhesive brush; a pedestal of the adhesive brush is arranged on a sliding polished rod in a penetrating way; a transmission lead screw of an adhesive rush feeding mechanism is in threaded connection with the pedestal of the adhesive brush; the bushing is arranged on a rotary bracket; one end of the bushing is in threaded connection with an electric rotary disc of the rotary bracket, and the other end of the bushing is arranged together with a bearing and a bearing fixing rod of the rotary bracket; and brush hair of the adhesive brush is just in contact with the bushing. According to the automatic adhesion device, automatic adhesive brushing of an oil field bushing is realized, the entire process is automatically realized, the adhesive brush does rectilinear motion during adhesive brushing, and the brushed bushing is driven by the electric rotary disc to rotate; since the adhesive brush only does rectilinear motion, adhesive brushing on the bushing with the same force by the brush hair of the adhesive brush in an entire adhesive brushing process can be guaranteed, the automatic adhesion device is highly standard, and uniform adhesive brushing can be realized.

Owner:NORTHEAST GASOLINEEUM UNIV

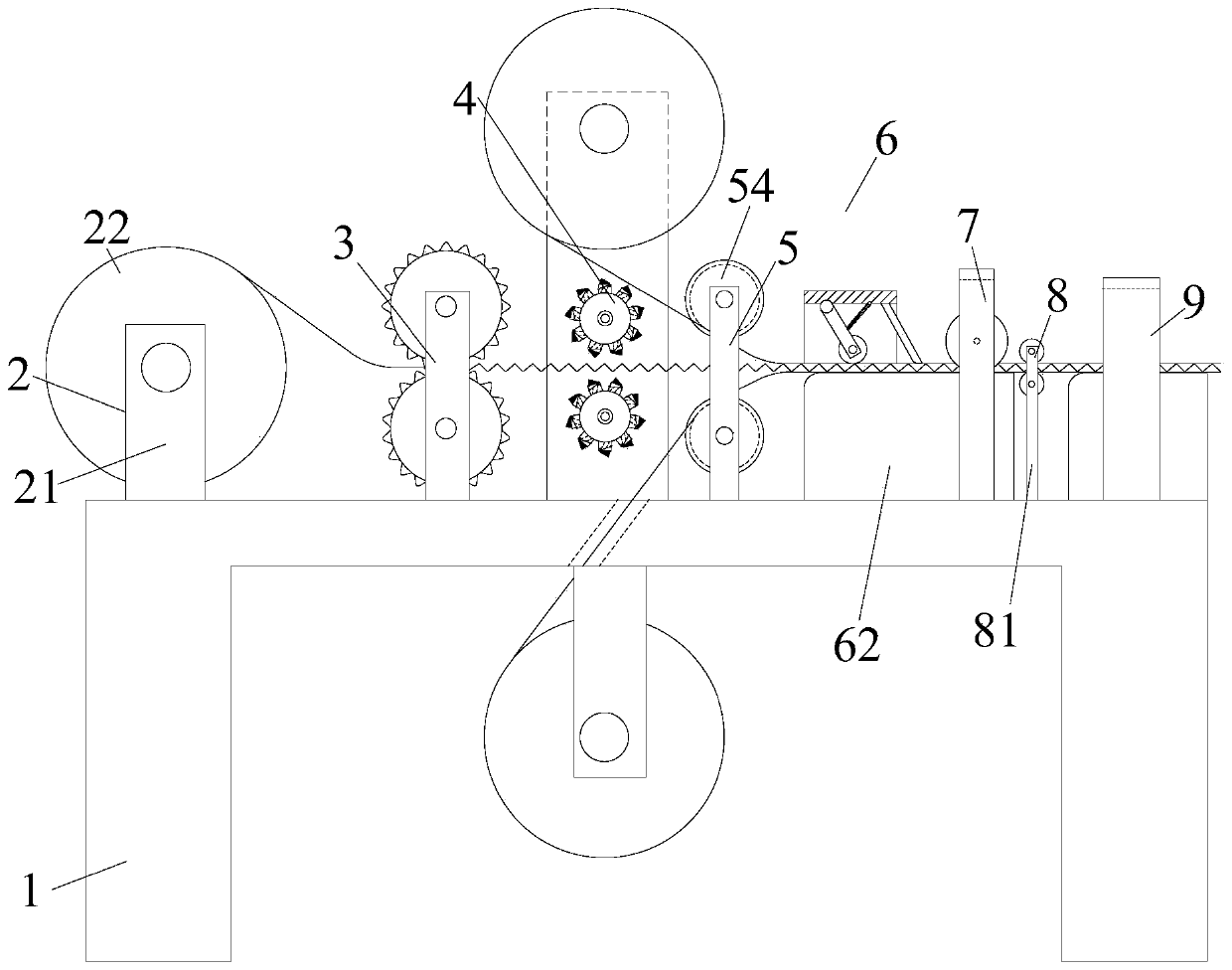

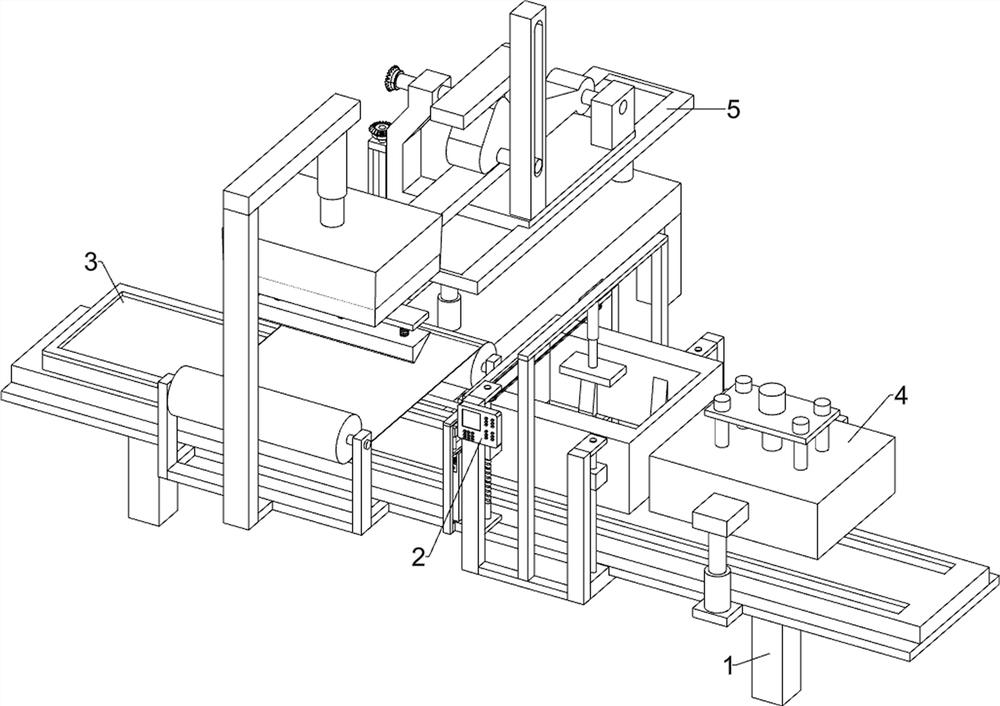

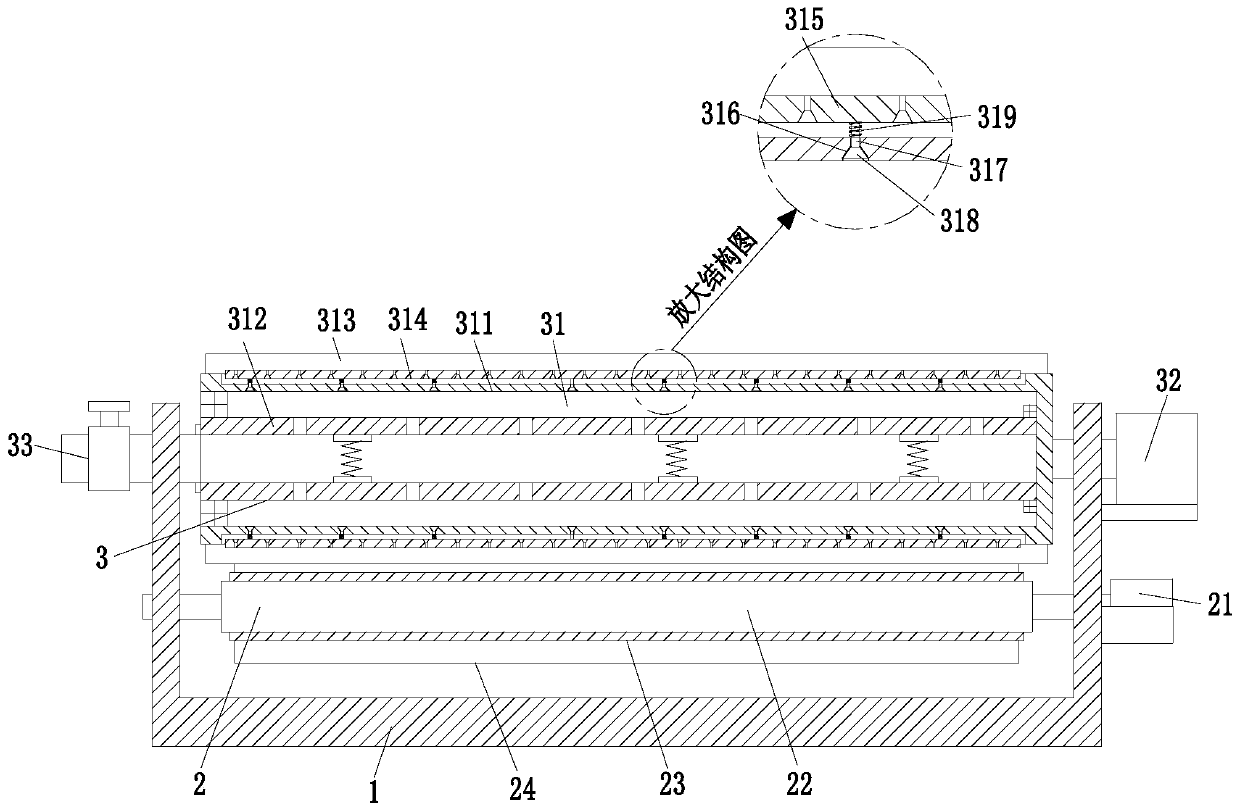

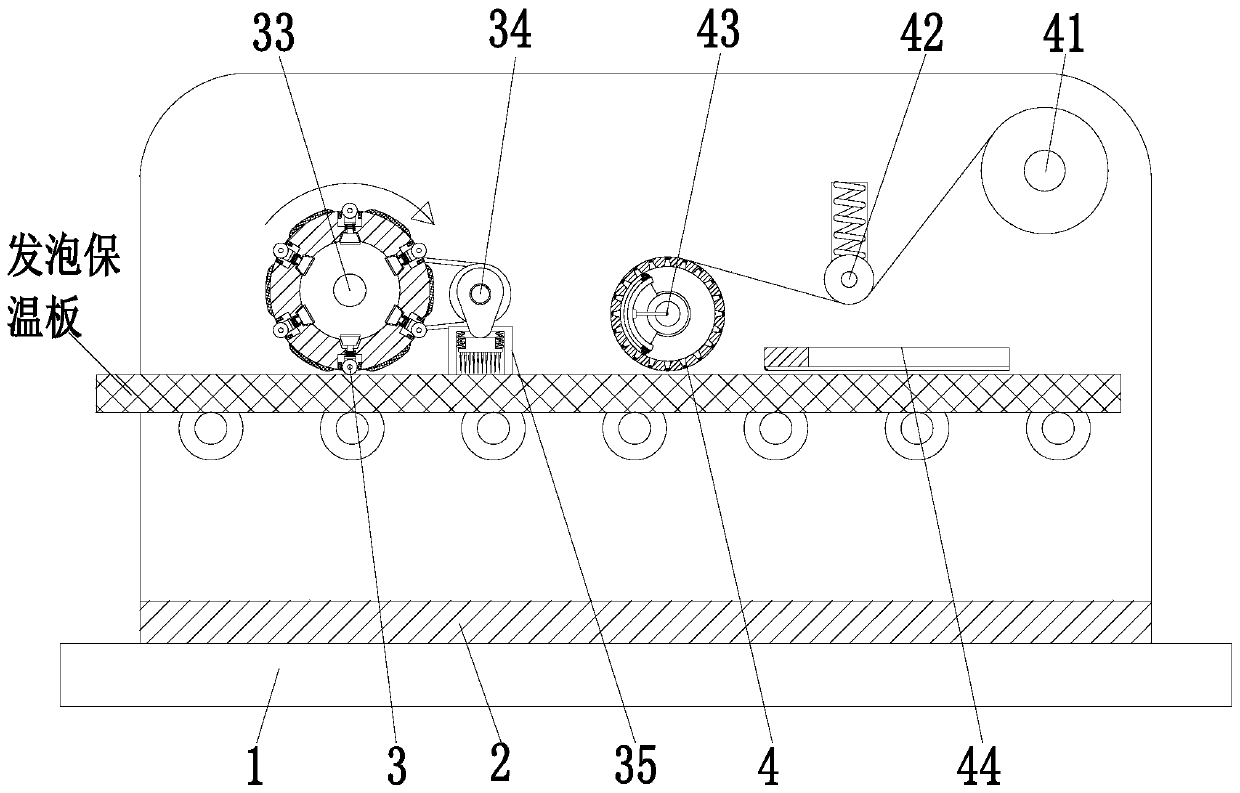

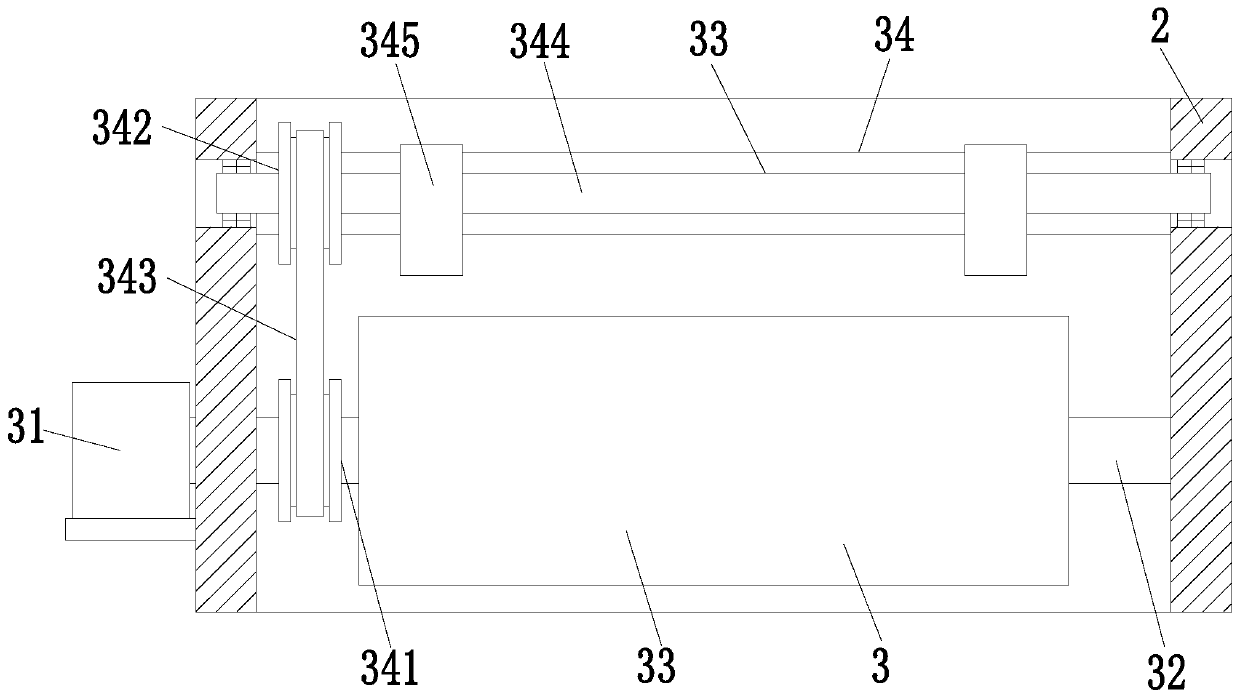

Corrugated paper forming and manufacturing system

ActiveCN110712394ASmooth paperUniform thicknessLiquid surface applicatorsMechanical working/deformationAdhesive glueMechanical engineering

The invention relates to a corrugated paper forming and manufacturing system which comprises a mounting table, a core paper bracket, an indentation device, a gluing device, a surface paper feeding device, a pressing device, two edge cutting devices, a traction device and a cutting device; and the mounting table is sequentially provided with the core paper bracket, the indentation device, the gluing device, the surface paper feeding device, the pressing device, the two edge cutting devices, the traction device and the cutting device from left to right. By adopting the corrugated paper forming and manufacturing system provided by the invention, the problems that the paper surface of corrugated paper processed by existing corrugated paper processing equipment is uneven, is inconsistent in thickness and has phenomena of wrinkles, cracks and holes as well as the problems that the processed corrugated paper is not closely attached to surface paper, a large quantity of glue is wasted, and themanufacturing cost is increased and the like are solved.

Owner:东莞市世昌智能制造科技有限公司

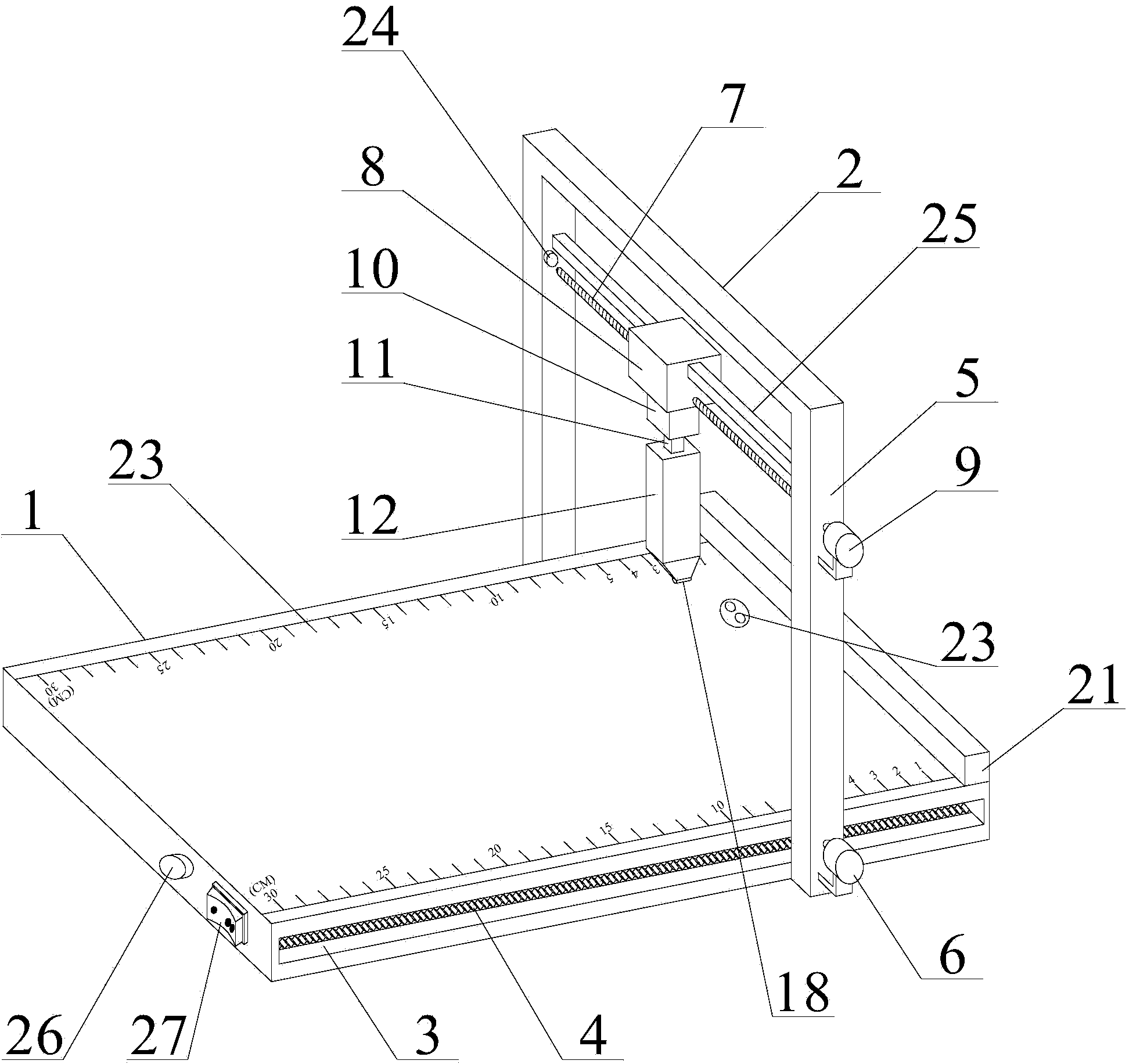

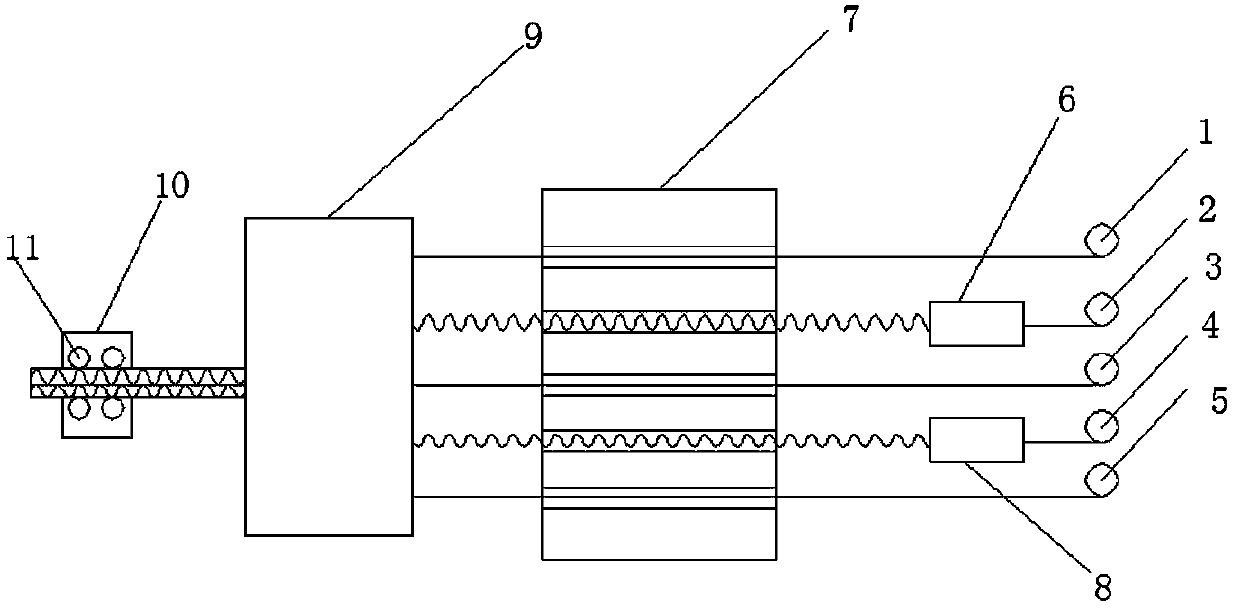

Small alternating current-direct current automatic glue spreader

InactiveCN103586163AAvoid stickingReduce cumbersome operationsLiquid surface applicatorsCoatingsElectric machinePush pull

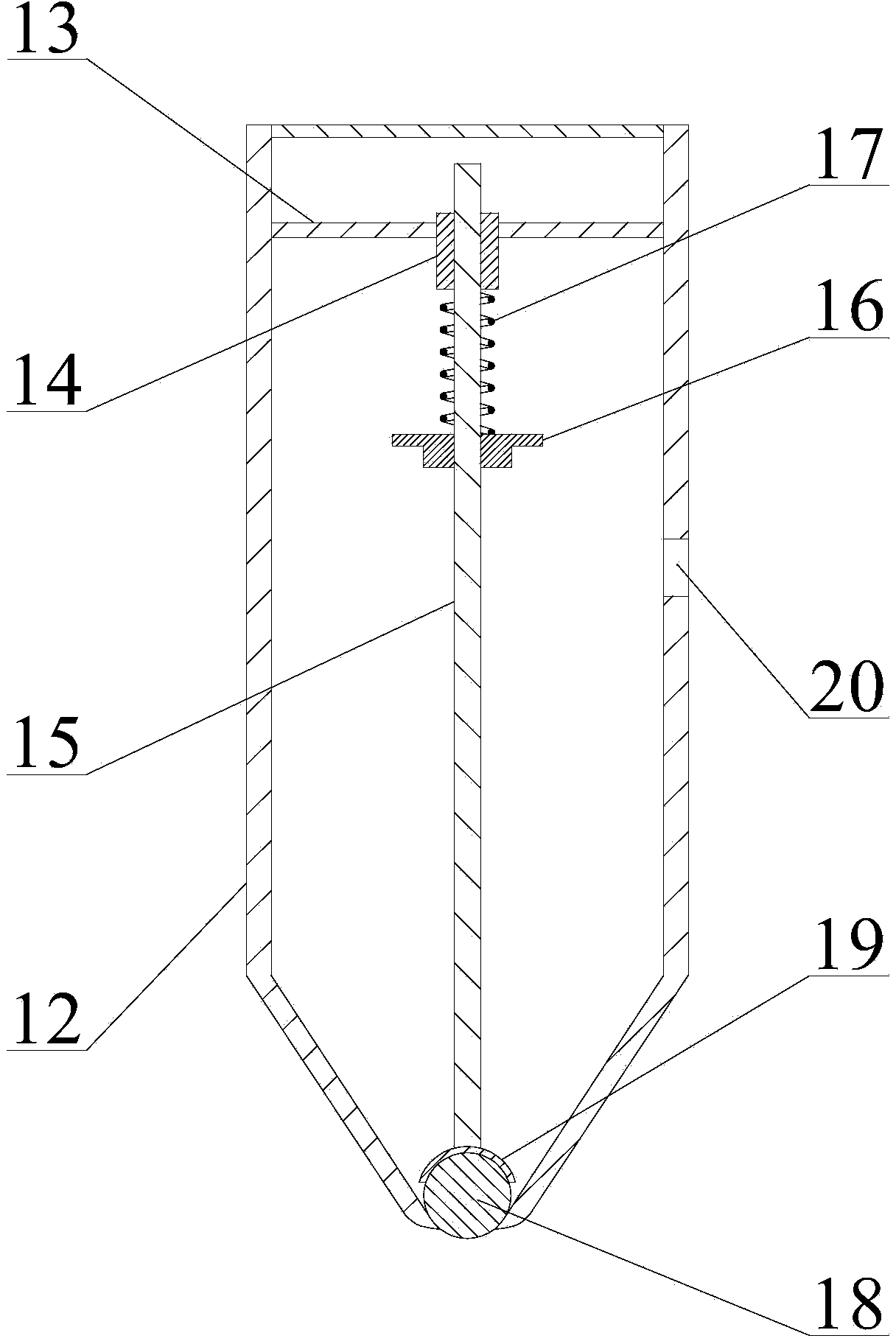

The invention discloses a small alternating current-direct current automatic glue spreader, and belongs to the field of office supplies. The glue spreader solves the problems that the manual glue spreading speed is low, the spreading is nonuniform, and adhesion is caused easily. Racks (4) are fixed in a cavity (3) of a bottom plate (1) of the glue spreader; gears meshed with the racks (4) are fixed on a cross rod of a gantry (2); a first motor (6) is fixed with one end of the cross rod; a screw rod (7) between two uprights (5) is sleeved with a slide block (8); a second motor (9) is fixed with one end of the screw rod (7); a push-pull electromagnet (10) is fixed below the slide block (8); a glue bottle (12) is fixed at the lower end of the push-pull electromagnet (10); the lower end of the glue bottle (12) is in an inverted trapezoid shape; a glue outlet is a strip-shaped port, and is closed by a cylindrical pressure head (18); and a pressure sheet (19) is fixed at the lower end of a threaded rod (15). The glue spreader has the advantages that the glue spreader is high in glue spreading speed, uniform in glue spreading, time-saving, labor-saving, and convenient to move and carry.

Owner:NORTHEAST GASOLINEEUM UNIV

Hot-melting strip pasting machine

The invention discloses a hot-melting strip pasting machine which is characterized by comprising a working table, an adjustment assembly, a conveying device, a pressing roller device, a shearing device and a hot wind device, wherein the working table comprises a rack, a first movable portal frame, a front-rear walking mechanism, a left-right walking mechanism and a second installation hanging bracket; the first movable portal frame is disposed on the rack by the front-rear walking mechanism and can be moved back and forth; the second installation hanging bracket is disposed on the first movable portal frame by the left-right walking mechanism and can be moved horizontally; the conveying device, the pressing roller device and the hot wind device are disposed on the second installation hanging bracket of the working table in a rotatable manner by the adjustment assembly; the conveying device is used to install corresponding hot-melting adhesive films and recycle corresponding release paper; the pressing roller device is used to press and paste the hot-melting adhesive films on corresponding fabrics; the shear device is disposed on the pressing roller device and used to cut off the hot-melting adhesive films; and the hot wind device is used to heat the holt-melting films.

Owner:CHANGZHOU ZHIGU ELECTROMECHANICAL TECH CO LTD

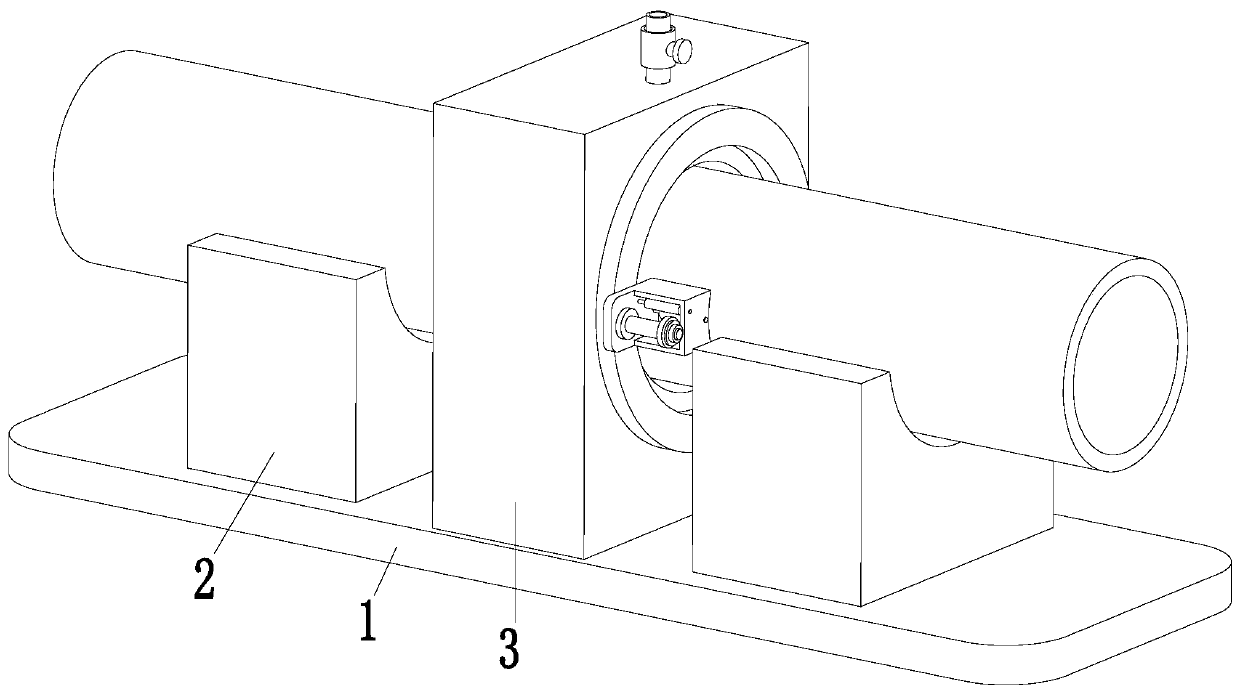

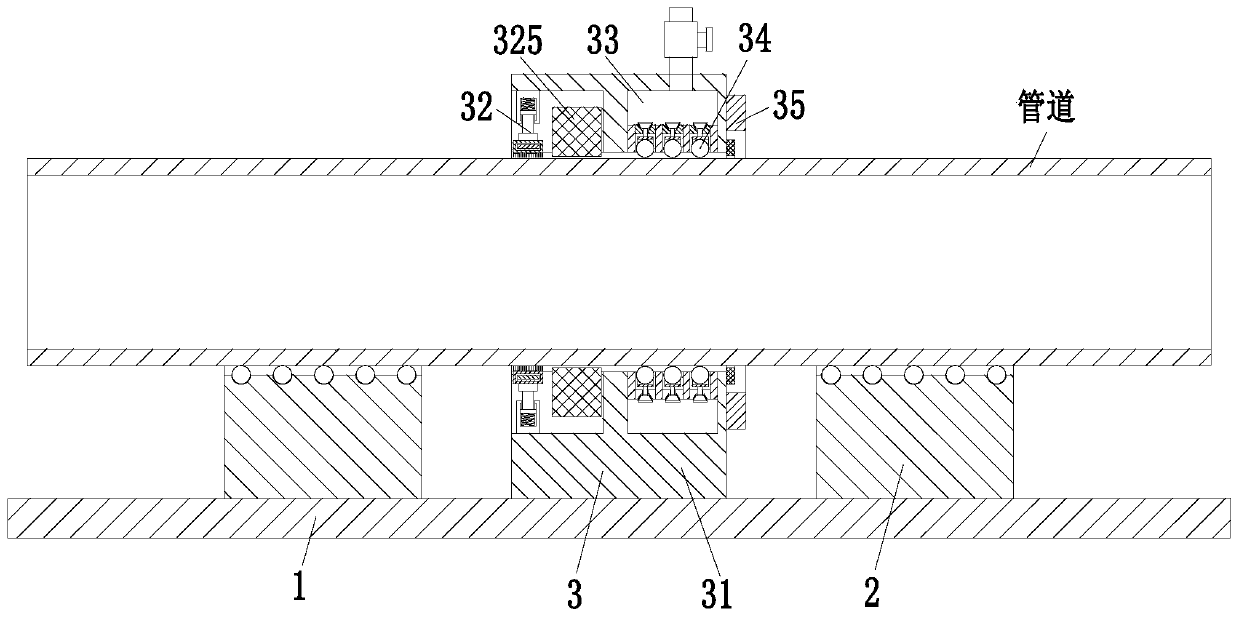

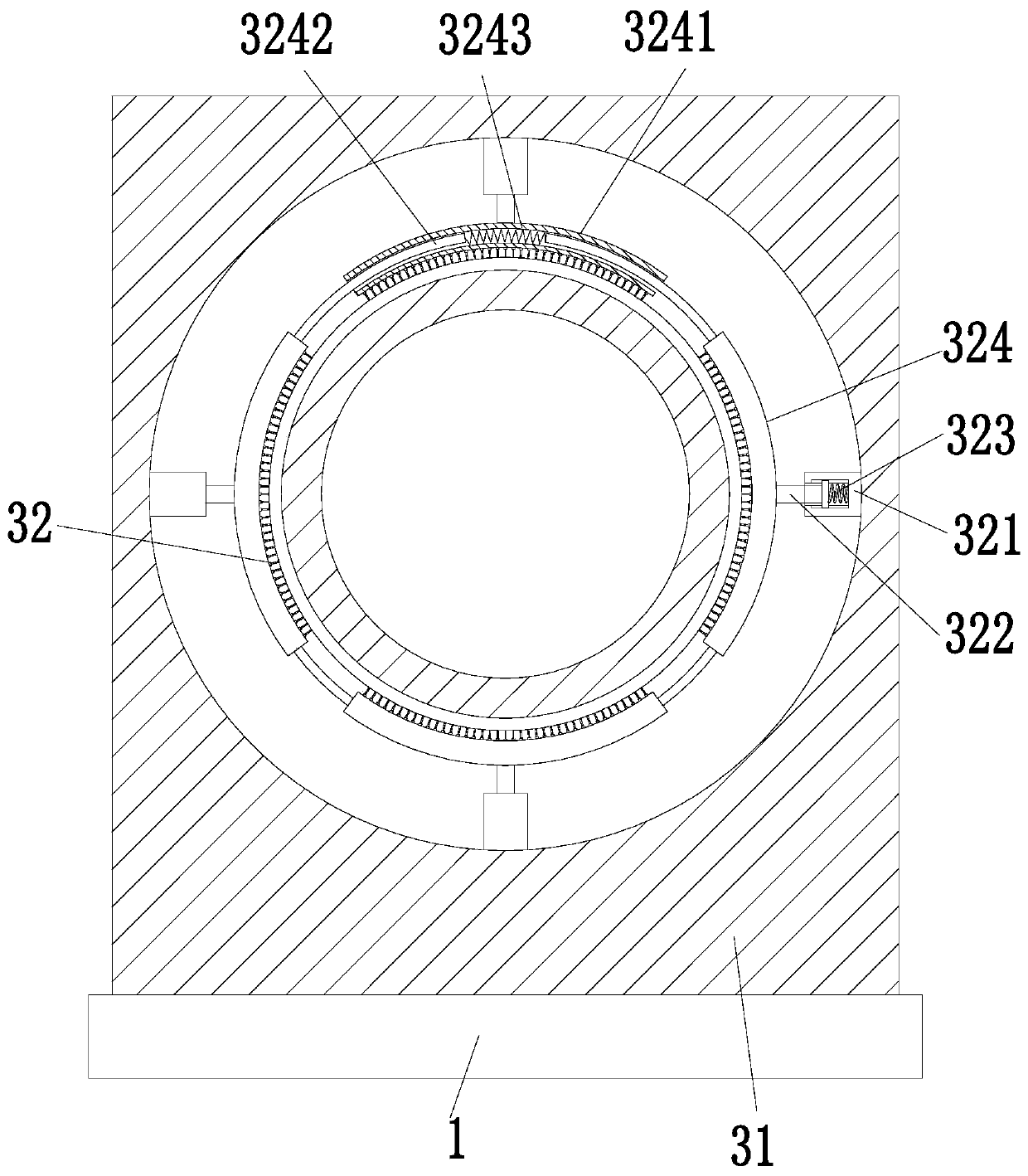

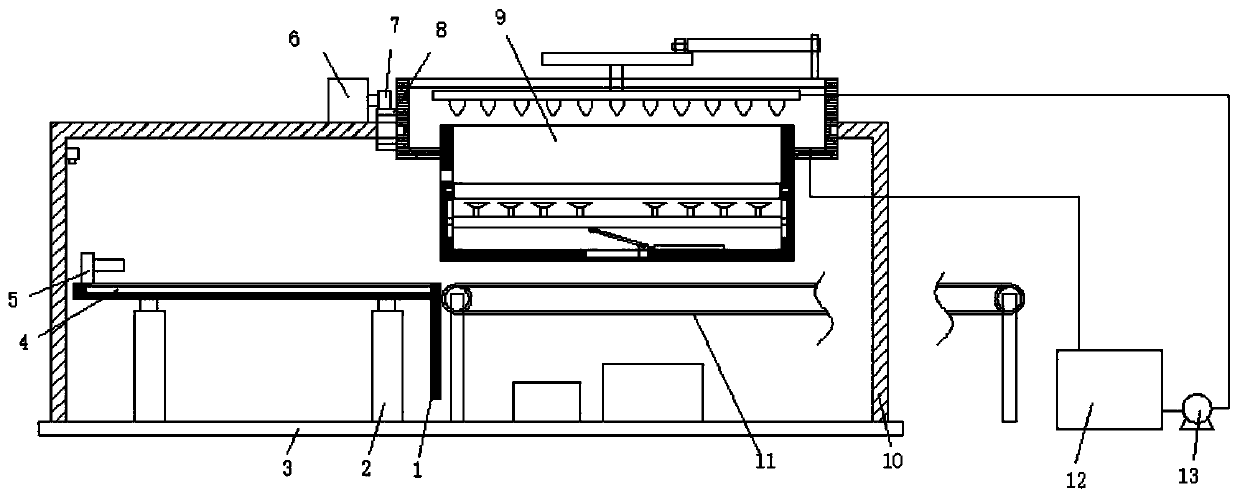

Insulation processing equipment of petroleum conveying pipeline and pipeline insulation processing technology

ActiveCN111318410AFacilitate subsequent processingEfficient removalLiquid surface applicatorsThermal insulationProcess engineeringPipe insulation

The invention relates to insulation processing equipment of a petroleum conveying pipeline and a pipeline insulation processing technology. The equipment comprises a bottom plate, locating frames anda processing device. The locating frames are symmetrically mounted at the upper end of the bottom plate. The processing device is arranged between the locating frames and is mounted in the middle of the upper end of the bottom plate. The problems that when existing equipment carries out gluing processing on the pipeline, generally, impurities adhering to the surface of the pipeline cannot be removed, the adhesion result of glue is influenced, meanwhile, generally, the glue smearing effect is poor, the glue is not smeared evenly, a gap is prone to being generated between an insulation band andthe pipeline, when the existing equipment winds the insulation band on the outer surface of the pipeline, the winding effect is poor, efficiency is low, the attachment result between the insulation band and the pipeline is poor, and the insulation effect of the pipeline is influenced can be solved.

Owner:荆州市恒基石油机械有限公司

Processing method for surface electrodes of three-dimensional quartz micro-mechanical structure

ActiveCN103058126AApply glue evenlyEliminate centrifugal forceDecorative surface effectsChemical vapor deposition coatingChemical corrosionWidth ratio

The invention relates to the technical field of micro-mechanical processing of quartz, and particularly relates to a processing method for surface electrodes of a three-dimensional quartz micro-mechanical structure. The processing method comprises the steps of cleaning the surface of a metal film of the three-dimensional quartz micro-mechanical structure, spraying glue on the cleaned surface of the metal film to obtain an photoetching adhesive layer, then exposing and developing the photoetching adhesive layer, and finally hardening the photoetching adhesive layer; and corroding the metal film with a chemical corrosion method by taking the photoetching adhesive layer as a mask, and then removing the photoetching adhesive layer to accomplish the processing of the surface electrodes of the three-dimensional micro-mechanical structure. According to the processing method, wafers of different sizes and shapes can be sprayed with glue, and meanwhile, the side wall with a large depth-to-width ratio of the three-dimensional quartz micro-mechanical structure can be uniformly coated with glue. Through an ultrasonic glue spray manner, the uniformity of the photoetching adhesive layer on the three-dimensional micro-mechanical structure can be improved. As an ultrasonic cleaning procedure is added to the developing step, the adhesion of the photoetching adhesive layer to substrate materials of the three-dimensional quartz micro-mechanical structure is lowered, and thus a short-circuit situation during the electrode processing is completely eradicated.

Owner:BEIJING RES INST OF TELEMETRY +1

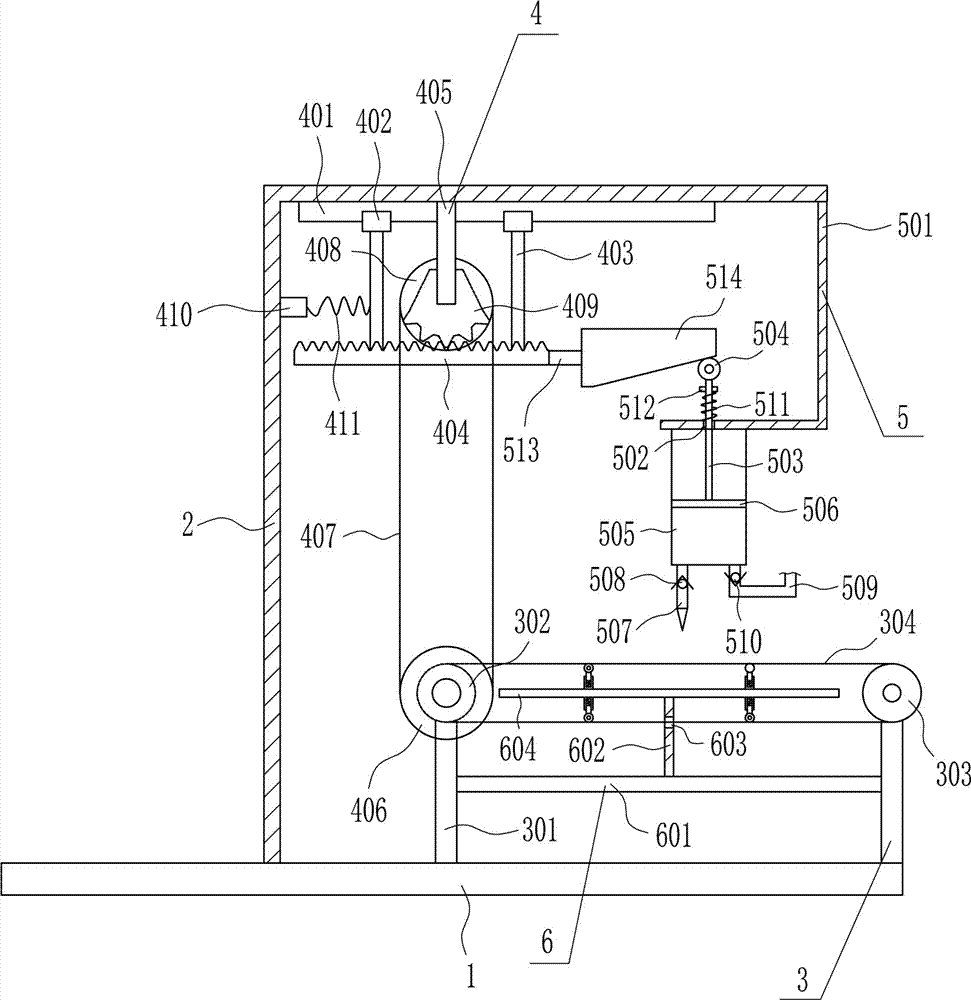

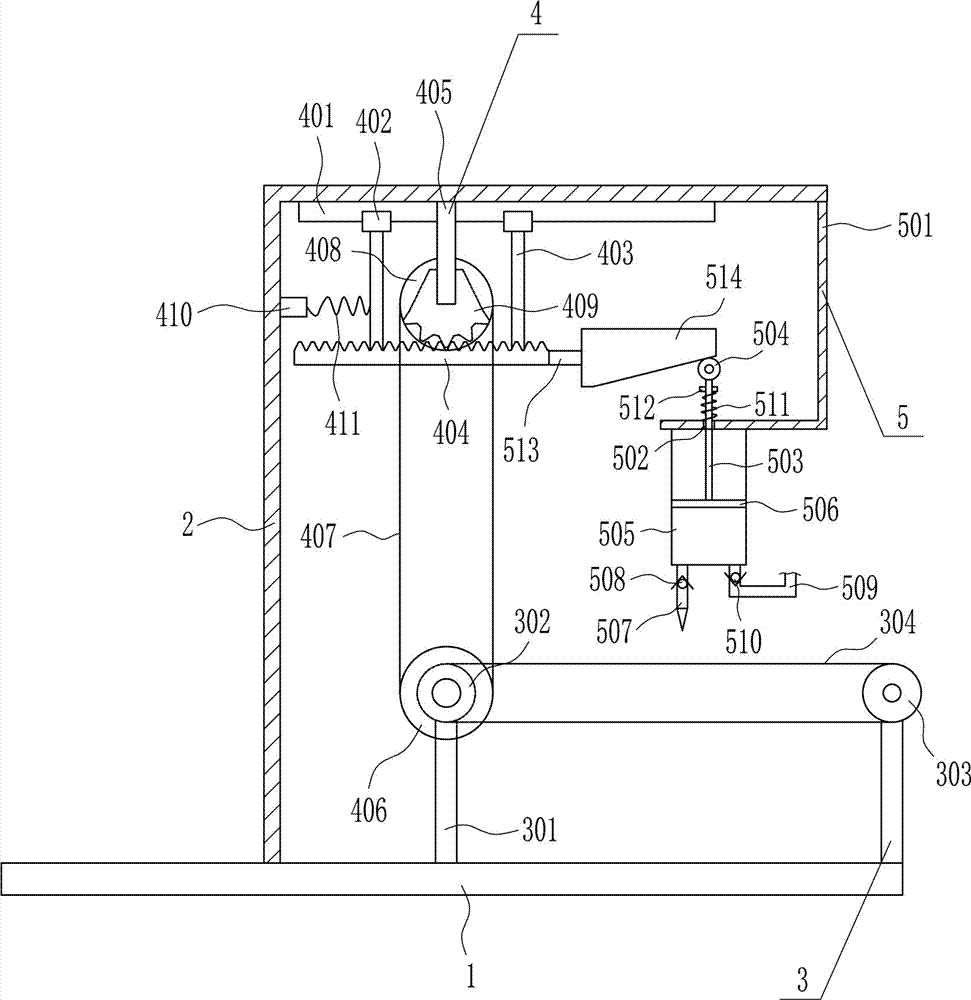

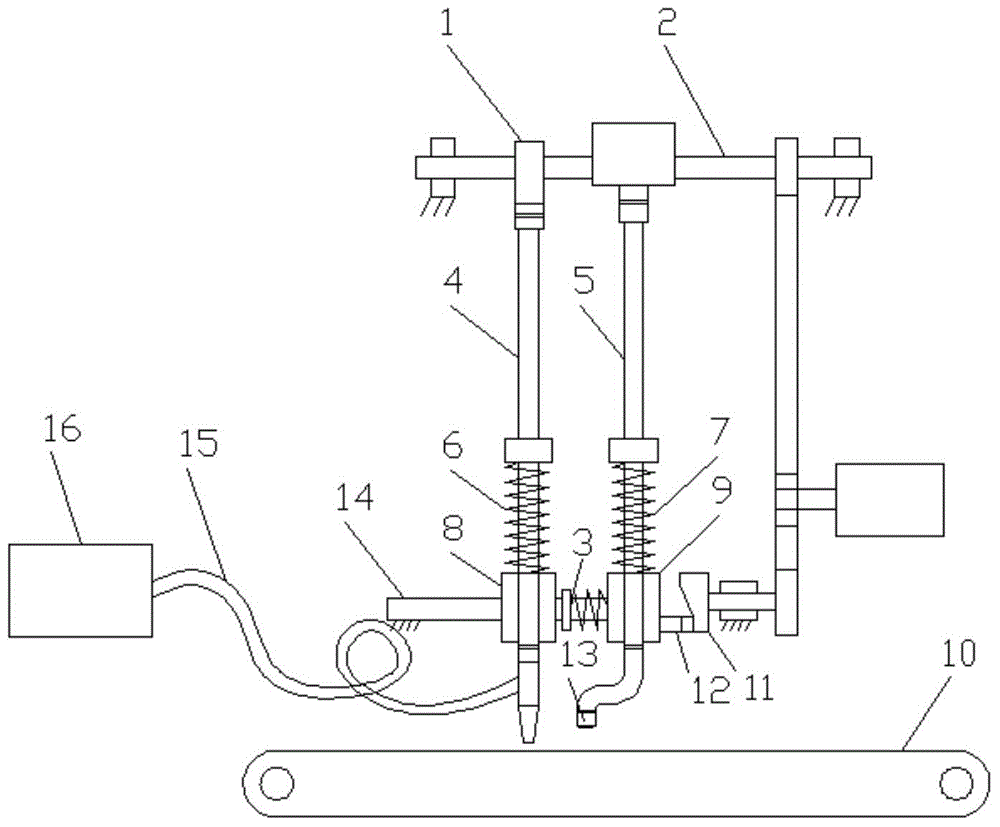

Gluing equipment for electronic component production

InactiveCN107999333AAvoid jitterApply glue evenlyLiquid surface applicatorsCleaning using toolsElectronic componentWaste management

The invention relates to gluing equipment, and particularly relates to gluing equipment for electronic component production. The invention aims to provide gluing equipment for electronic component production, which has the advantages of uniformity in gluing, manpower saving and simplicity in operation. In order to solve the technical problem, the invention provides the gluing equipment for electronic component production. The gluing equipment comprises a bottom plate and the like, wherein an inverted L-shaped plate is connected to the left side of the top of the bottom plate, a conveying device is installed on the right side of the top of the bottom plate, a driving device is installed in the top of the inverted L-shaped plate, the driving device is connected with the conveying device, a gluing device is installed on the rightmost side in the top of the inverted L-shaped plate, the gluing device is connected with the driving device, and a gluing component of the gluing device is located just above the conveying device. According to the gluing equipment, the conveying device is started to operate, so that the gluing device is driven to operate and glue an electronic component, and the electronic component can be prevented from shaking by a damping device, so that the effects of uniformity in gluing, manpower saving and simplicity in operation are achieved.

Owner:南昌安润科技有限公司

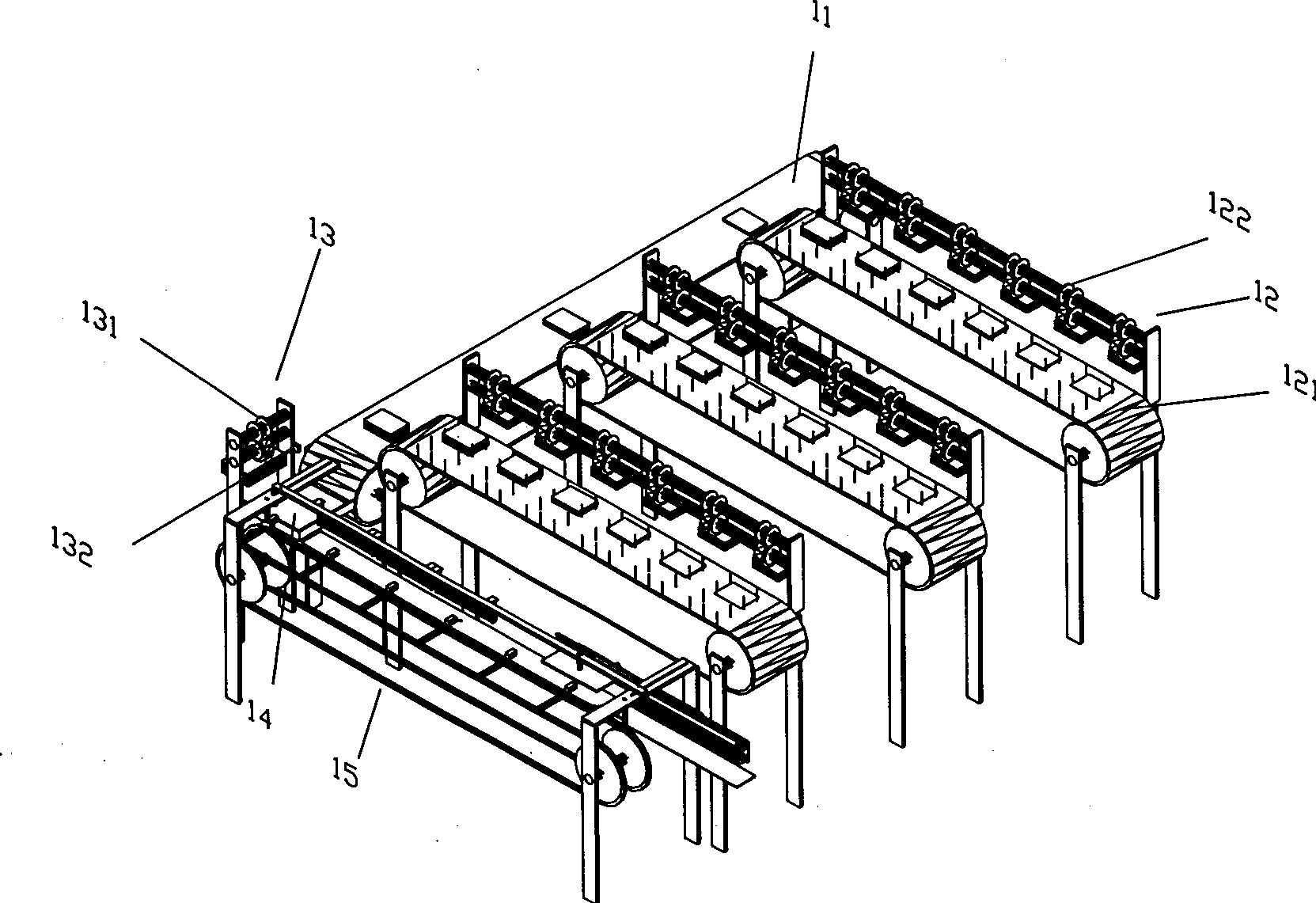

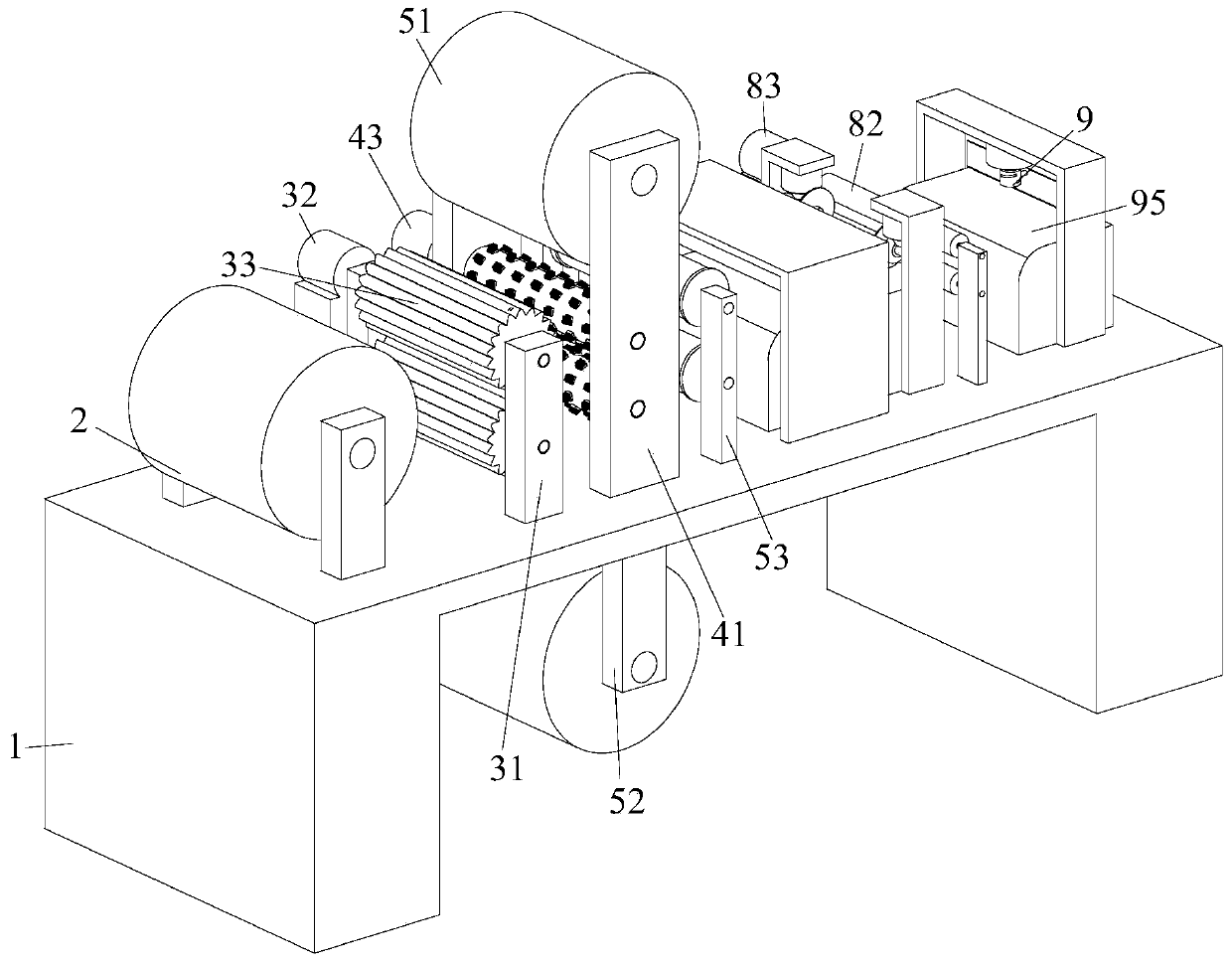

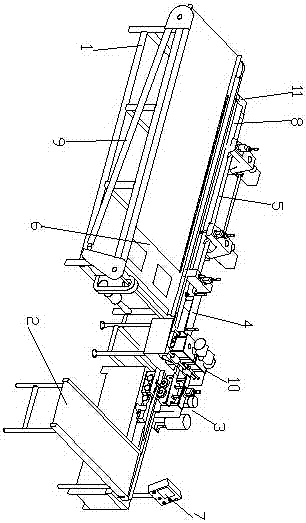

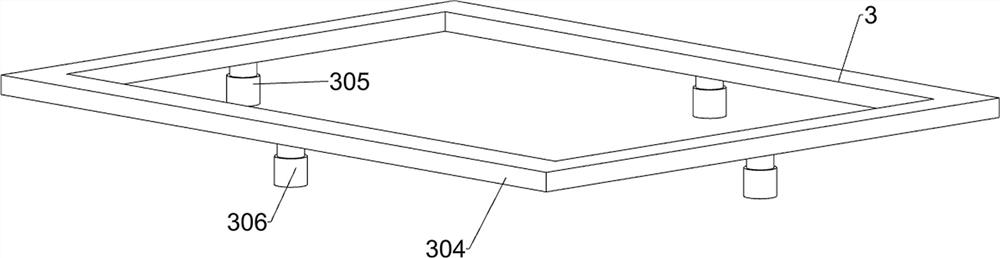

Automatic batten plate splicing machine

ActiveCN106863497AClear division of laborImprove efficiencyOther plywood/veneer working apparatusWood veneer joiningRotational axisAutomatic control

The invention relates to an automatic batten plate splicing machine which comprises a work frame, a feeding device, a pressing wheel buffering device, a gluing device, a sawing device, a one-way pushing device, a plate pushing device, an electrical automatic control system and a main conveying belt. The tail end of the main conveying belt is provided with a limiting mechanism. The pressing wheel buffering device comprises a power mechanism, a moving mechanism and a transmission mechanism. A buffer drives rotating shafts to move vertically through a connecting piece to buffer vertical displacement changes, brought by movement, of rolling pressing wheels. The automatic batten plate splicing machine is reasonable in structure, ingenious in design, capable of conducting discharging conveniently, high in conveying speed and stable; plate splicing and gluing are integrated; a buffering mechanism is arranged so that the service life can be effectively prolonged, and the technical problems that in an existing batten plate splicing machine, discharging is not stable, battens are likely to be stacked, the conveying speed is too low, noise is large, battens need to be glued in advance for standby use, manual work is wasted, and the service life is affected are solved; and the automatic batten plate splicing machine is an important technical innovation for the prior art and has very good market prospects and development space.

Owner:PINGDINGSHAN ANTAIHUA MINING SAFETY EQUIP MFG

Paperboard gumming machine

InactiveCN105728260AApply glue evenlyLiquid surface applicatorsCoatingsReciprocating motionPaperboard

The invention discloses a paperboard gumming machine. The paperboard gumming machine comprises a rack, a dispensing bar, a gumming bar, a cam shaft used for driving the dispensing bar and the gumming bar to do reciprocating motion in the vertical direction, an end face cam for driving the gumming bar to do reciprocating motion in the horizontal direction, a conveying belt arranged below the gumming bar and a driving device used for driving the cam shaft and the end face cam to rotate; a gum outlet is formed in the lower end of the dispensing bar, a gumming head for evenly smearing gum is arranged at the lower end of the gumming bar, and a first return spring for providing elasticity for resetting of the dispensing bar in the vertical direction is connected between the dispensing bar and the rack; and a second return spring for providing elasticity for resetting of the gumming bar in the vertical direction is connected between the gumming bar and the rack. By means of the paperboard gumming machine, two working procedures including dispensing and gumming can be automatically completed successively, and it is guaranteed that gum can be evenly smeared to a paperboard.

Owner:重庆市合川区华丰包装有限公司

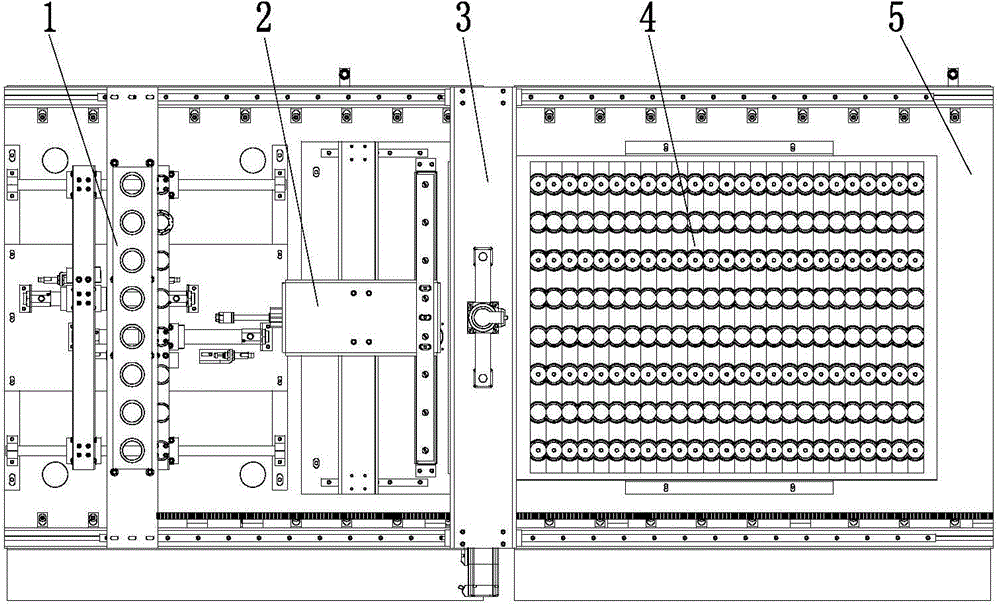

Automatic gluing and board pasting device for melamine impregnated paper composite board

PendingCN113103383AApply glue evenlyAvoid prone to bulgeWood veneer joiningAdhesive application devicesProcess engineeringFiberboard

The invention relates to the technical field of composite board machining, in particular to an automatic gluing and board pasting device for a melamine impregnated paper composite board, and aims to solve the technical problem about how to provide the automatic gluing and board pasting device for the melamine impregnated paper composite board. According to the technical scheme, the automatic gluing and board pasting device for the melamine impregnated paper composite board comprises a bottom frame, a controller, a conveying and gluing assembly, a board pasting and pressing assembly and a sticker trowelling assembly; and the board pasting and pressing assembly is connected with the sticker trowelling assembly. When the device is used, the surfaces of a base board and the composite board are automatically and uniformly glued, operation is easy, meanwhile, the manpower consumption is reduced, the production cost is reduced, the problem that swelling and layering are likely to be generated between boards is solved, then the fiberboard is accurately and automatically attached, follow-up trimming is facilitated, and the surface is flattened to avoid bubbles while covering with the impregnated paper is performed.

Owner:李广有

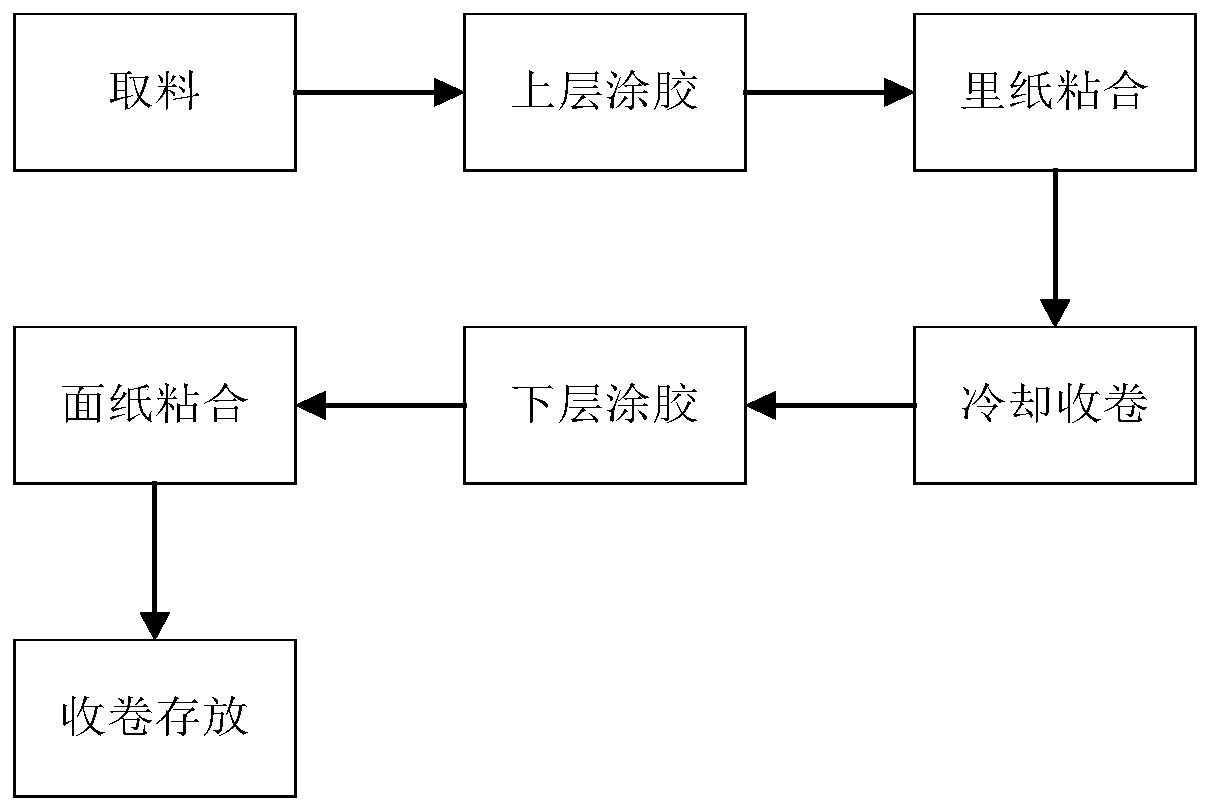

Printing packaging corrugated paper production method

ActiveCN110116519AImprove gluing effectIncrease productivityLiquid surface applicatorsMechanical working/deformationPaper productionPulp and paper industry

The invention relates to a printing packaging corrugated paper production method. A mounting frame, a conveying belt and a gluing device are included, the mounting frame is of a U structure, the conveying belt is arranged on the lower end in the mounting frame, the gluing device is arranged on the upper end in the mounting frame, the gluing device is located in the middle of the upper end of the conveying belt, the problems that when existing corrugated paper is produced, efficiency is low, quality is poor, existing market needs cannot be met, when a corrugated paper core is glued, when the corrugated paper core is stressed, deforming or damage is prone to happening, meanwhile, during gluing, glue coating is not uniform, and glue waste is easily caused are solved, and the advantages of being good in gluing effect, high in production efficiency, and capable of gluing the corrugated paper convex face evenly and effectively reducing the glue waste are achieved.

Owner:汕头市柏瑞纸品包装厂有限公司

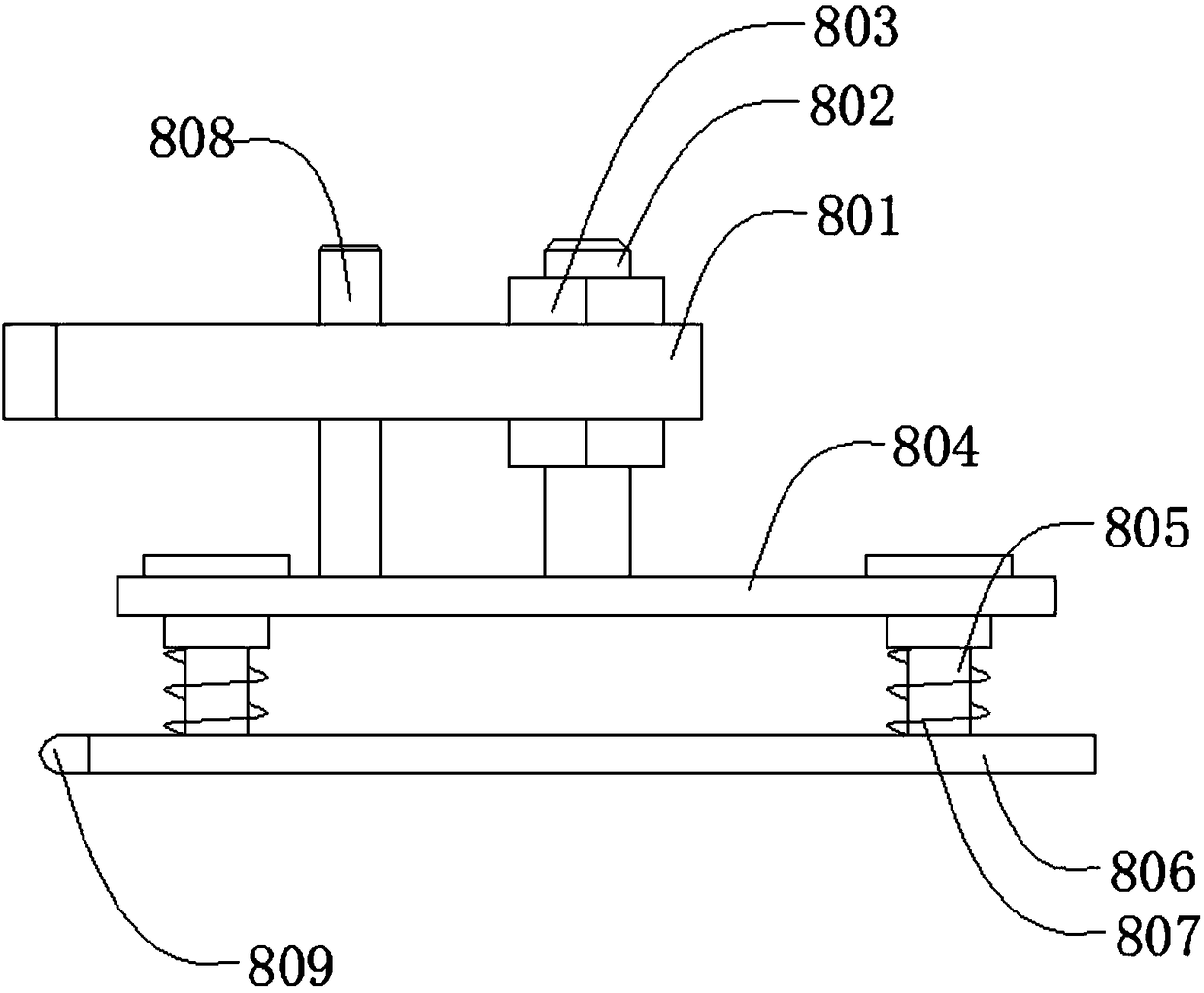

Wood board extruding device and method with positioning function

ActiveCN108908534APrevent movementImprove stabilityWood veneer joiningPulp and paper industryWood panel

The invention discloses a wood board extruding device with a positioning function in the technical field of wood board processing. The wood board extruding device comprises a base. A buffering deviceis arranged on the outer wall of the top of the base. The top end of the buffering device is movably connected with an extruding platform. Fixing plates are arranged on the left side and the right side of the top of the extruding platform. Moving grooves are formed in the left side and the right side of the top of the extruding platform. The adjacent ends of two adjusting springs are connected with the inner walls of the adjacent sides of the two moving grooves. In the device, through contraction of the adjusting springs, the two fixing plates fix a wood board from the left side and the rightside, and the wood board is prevented from moving during machining; meanwhile, supporting springs contract, limiting plates fix the wood board from the upper portion, the wood board fixing stability is further improved, and the wood board is prevented from moving during machining; and through changing of the distance between the two fixing plates and the distance between a baffle and a pressing device, the device can fix wood boards different in size.

Owner:XINCHANG LUHENG MASCH CO LTD

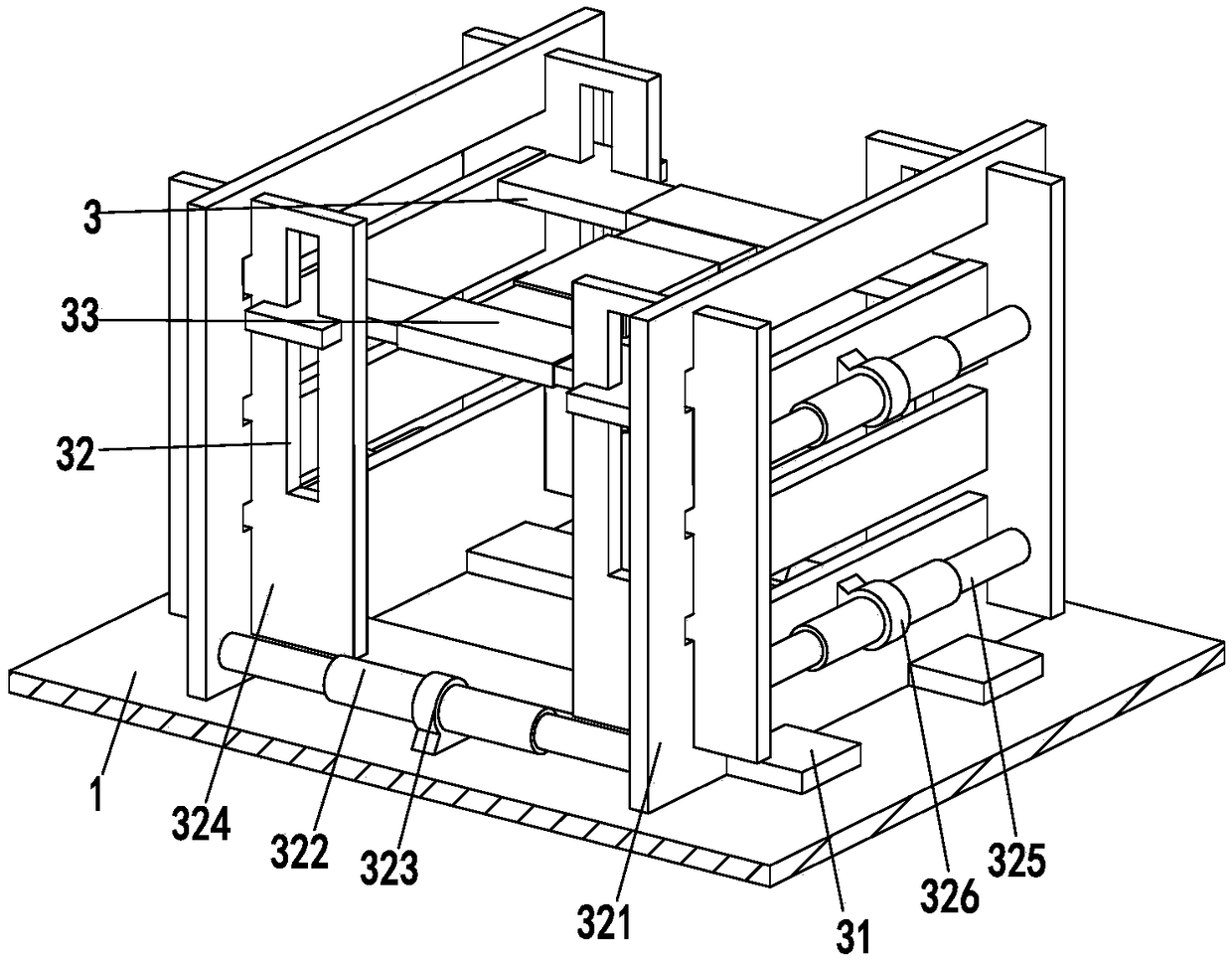

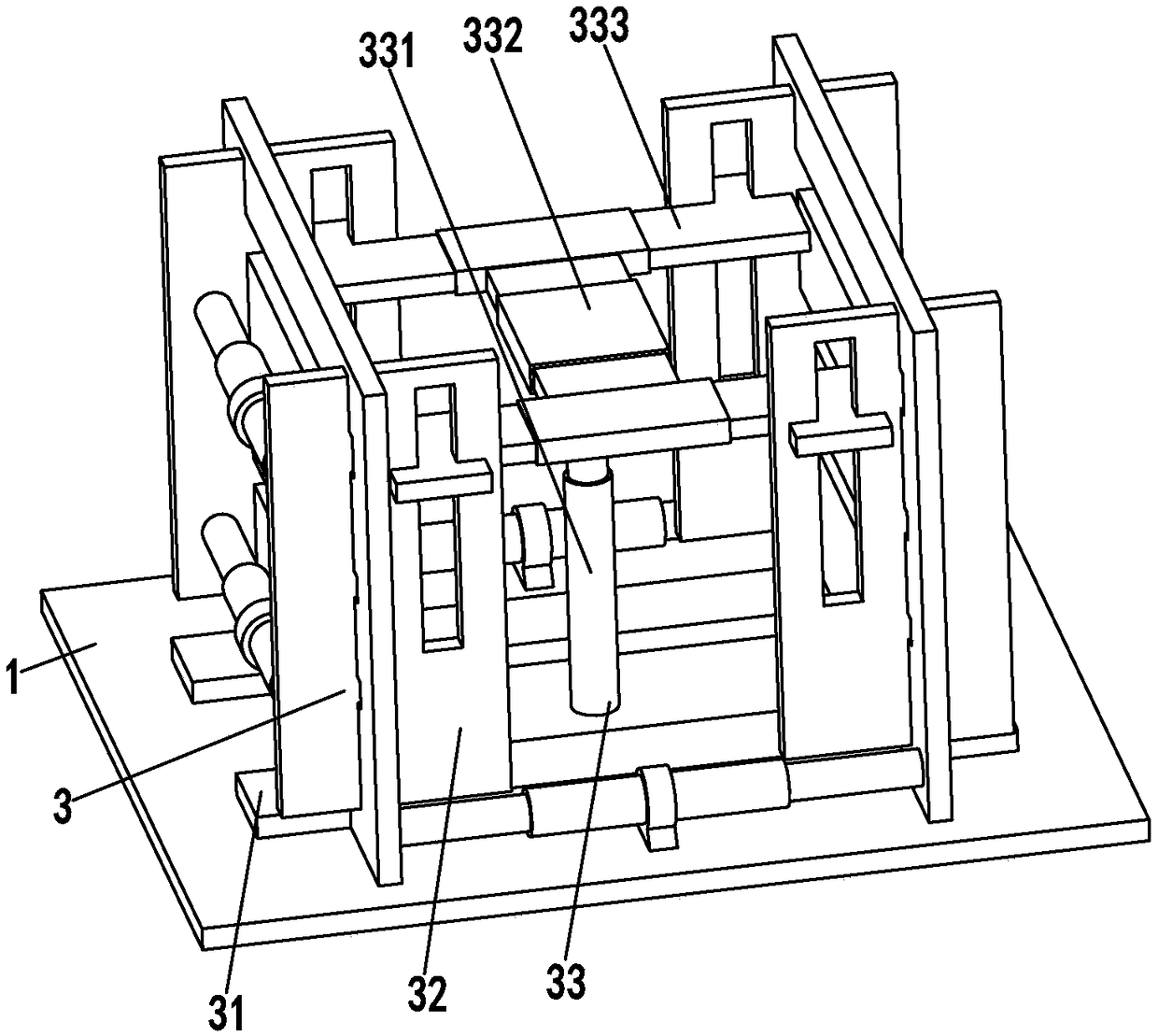

Composite board automatic gluing device

ActiveCN108656260AMeet work needsAvoid affecting work progressAdhesive application devicesEngineeringMechanical engineering

The invention relates to a composite board automatic gluing device. The device comprises a bottom plate, a mounting rack, a stacking device and a gluing device; the mounting rack is installed on the bottom plate, sliding chutes are formed in the mounting rack, the gluing device is installed in the sliding chutes, and the stacking device is installed at the lower end of the gluing device; the stacking device is installed on the bottom plate, and the stacking device comprises a linear guide rail, a limiting mechanism and a supporting mechanism; the gluing device comprises a glue discharging mechanism and a leveling mechanism; and the leveling mechanism comprises sliding blocks, sliding rods, a transverse plate, a telescopic leveling frame, a fixed supporting plate, an adjusting length air cylinder, a connecting ring and a driving branched chain. According to the composite board automatic gluing device, the problems that board codes are not even, gluing are non-uniform, glue is easy to waste, the adjustability is poor and the like in an existing composite board gluing process are solved; and the function of automatically gluing the composite board can be achieved, and the device has the advantages of being neat in stacking, uniform in gluing, not easy to waste glue, and flexible to adjust.

Owner:江苏林德曼新材料科技有限公司

Paper pulp for sized diaphragm paper of alkaline cell and preparation technique for applying paper pulp to prepare diaphragm paper

ActiveCN101581054AImprove compactnessImprove uniformityDefoamers additionWater-repelling agents additionFiberWater soluble

The invention discloses a paper pulp which is used for sized diaphragm paper of an alkaline cell and has the function of separating a positive electrode and a negative electrode in the alkaline cell and a preparation technique for applying the pulp material to prepare the diaphragm paper. The paper pulp consists of pulp materials and auxiliary materials; the pulp materials consist of ultrafine vinylon fiber, ultrafine viscose fiber, water soluble vinylon fiber and cotton pulp; and the auxiliary materials consist of an antifoaming agent and a dispersing agent. The sized diaphragm paper of the alkaline cell prepared by the paper pulp can greatly reduce the defects of lumps, air bubble holes and the like, thus improving the tube-making performance and discharge performance of the diaphragm paper in producing the alkaline cell and stability of the diaphragm paper product; and the technique for applying the paper pulp to produce the diaphragm paper not only has high production efficiency, but also has little environmental pollution.

Owner:WELBON SPECIAL MATERIALS CO LTD

Disc loading substrate surface coating device

The invention discloses a disc loading substrate surface coating device. The disc loading substrate surface coating device comprises a frame, a pushing cylinder, a lower support plate, a push head, abracket, a plate box, a plate carrying bar, a prepressing mechanism, a glue box, a peristaltic pump, a coating mechanism, a taking mechanism, a jacking cylinder, a plate carrying mechanism, a stand column, a servo motor, a gear, a revolving support, a disc, a collecting mechanism, a bracket, a support rod and a baffle plate. The device is simple in structure, can coat the surfaces of substrates with glue, can continuously stack the substrates coated with the glue into the collecting mechanism to achieve subsequent multilayer pressing, meanwhile, is uniform in coating to prevent the condition of bad glue adhesion caused by secondary pollution, is precise in gluing area, and effectively prevents wastes of the glue as the glue can be recycled.

Owner:MAANSHAN JULI SCI & TECH

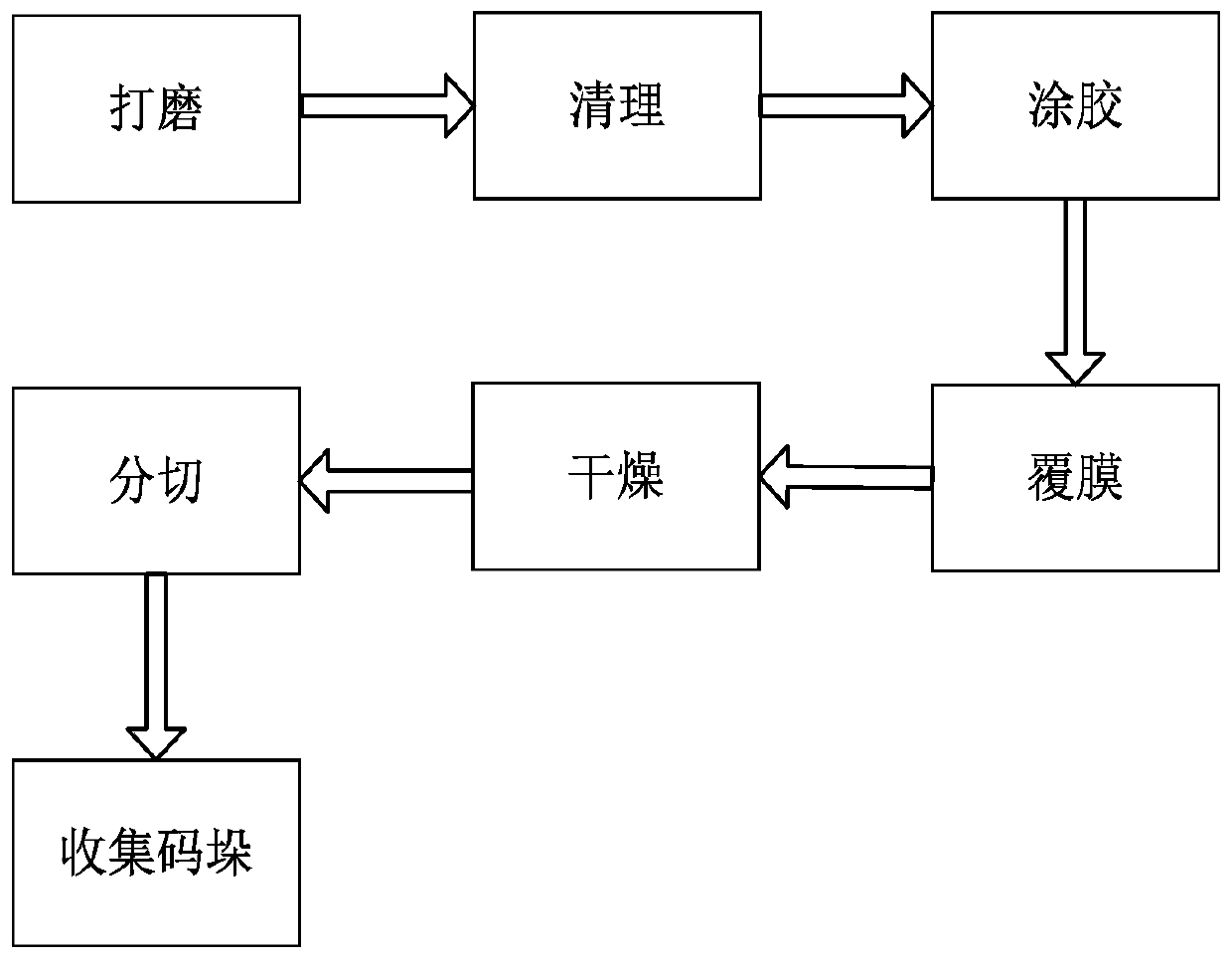

Surface treatment process for formed cement foaming insulation board

ActiveCN111391469AConducive to subsequent lamination processingEfficient coatingLamination ancillary operationsLaminationThin membraneFilm-coated tablet

The invention relates to a surface treatment process for a formed cement foaming insulation board, which comprises a bottom plate, a supporting frame, a gluing device and a laminating device, the supporting frame is installed at the upper end of the bottom plate, conveying rollers are evenly installed in the supporting frame through pin shafts, the gluing device is installed on the left side of the interior of the supporting frame, and the laminating device is installed on the right side of the interior of the supporting frame. According to the invention, the problems that the existing equipment is inconvenient to operate; the gluing effect is poor and the coating is not uniform; the foaming insulation board is of a porous structure; a glue solution cannot quickly permeate into the foaminginsulation board; a depression on the surface of the foam insulation board is generated after filming, which affects the surface quality; and meanwhile, when existing equipment is used for carrying out film coating processing on the foaming heat preservation plate, deviation usually occurs between a thin film and a plate, the phenomena of wrinkles and bubbles are likely to occur on the outer surface of the attached thin film, and the using effect is affected are solved.

Owner:深圳东诚装饰建筑集团有限公司

Gluing apparatus in medical-device automatic assembly equipment

InactiveCN104384071AEasy to transformEnter fullyLiquid surface applicatorsCoatingsEngineeringCatheter

At present, gluing assembling of a plurality of catheters and drip funnel assemblies is finished by means of machines, but most of automatic gluing apparatuses are unreasonable in design and easily cause nonuniform gluing phenomena. When an unevenly-gummed infusion apparatus is clinically used, a bonding position is easy to loose under a certain liquid pressure and brings great safety hidden trouble for a patient. When conventional automatic gluing equipment is designed, the assemblies are clamped only by a clamp, the soft assemblies, such as catheters, drip funnels and the like, are easy to deform, and when the to-be gummed assemblies only depend on the clamp for fixing, sometimes the purpose of enabling a gluing rod or a gluing column to completely fully enter the assemblies cannot be realized, and the gluing process is nonuniform. The invention aims at providing a gluing apparatus in medical-device automatic assembly equipment, and the gluing apparatus is characterized by comprising fixing teeth for fixing medical-device assemblies and a glue-dispensing rod with a glue storage groove. The gluing apparatus solves the problems that the flexible medical-device assemblies are easy to deform in the gluing process and gluing is nonuniform.

Owner:NANCHANG MINGFU AUTOMATION EQUIP

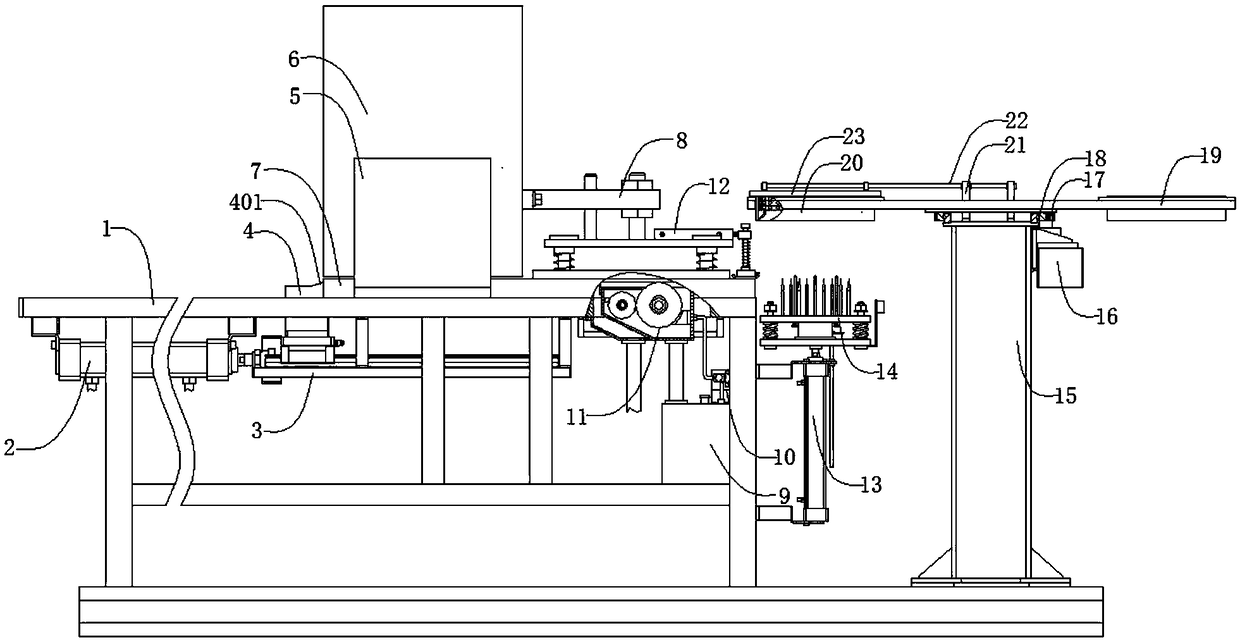

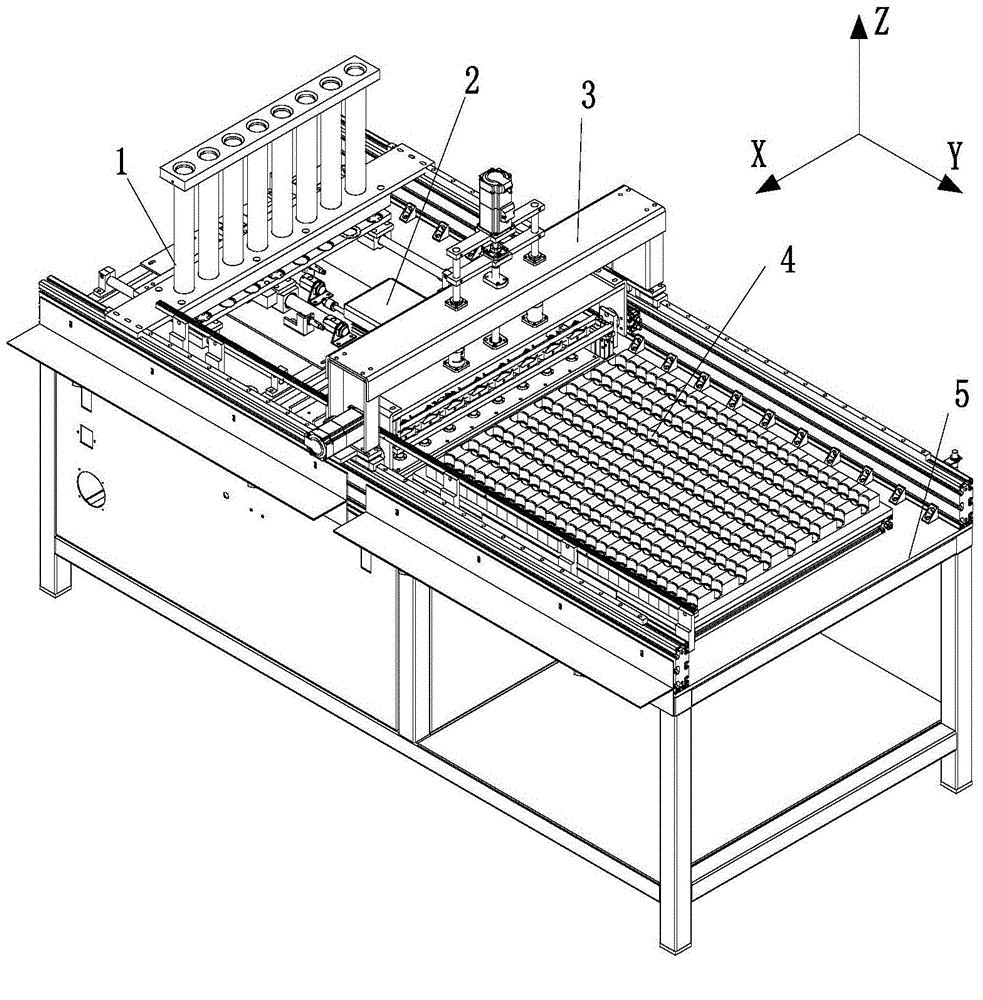

Automatic equipment for coating surfaces of iron rings by glue

InactiveCN104525431AIncrease productivityImprove quality and safetyLiquid surface applicatorsCoatingsAutomatic test equipmentEngineering

The invention discloses automatic equipment for coating the surfaces of iron rings by glue. The automatic equipment comprises a rack, a feeding module, a coating module, a discharging module, a platform movement module and a controller, wherein the rack is used as a support base; the feeding module is used for conveying a plurality of workpieces at the same time; the coating module is used for coating glue, the discharging module is used for unloading the workpieces; the platform movement module is used for overturning and carrying the workpieces at each station; the feeding module, the coating module and the discharging module are arranged on the rack in sequence along the length direction of the rack; the platform movement module is fixed at two sides of the rack in a stretching manner; the movable part of the platform movement module is capable of overturning and clamping the workpieces to sequentially convey the workpieces from the feeding module to the coating module and the discharging module along the length direction of the rack; the controller is in circuit connection with the feeding module, the coating module, the discharging module and the platform movement module. The automatic equipment for coating surfaces of iron rings by glue has the advantages of saving the human cost, being high in efficiency, high in accuracy, stable in quality and high in automation degree, greatly improving the production efficiency and satisfying the demand of industrial production.

Owner:SOUTH CHINA UNIV OF TECH

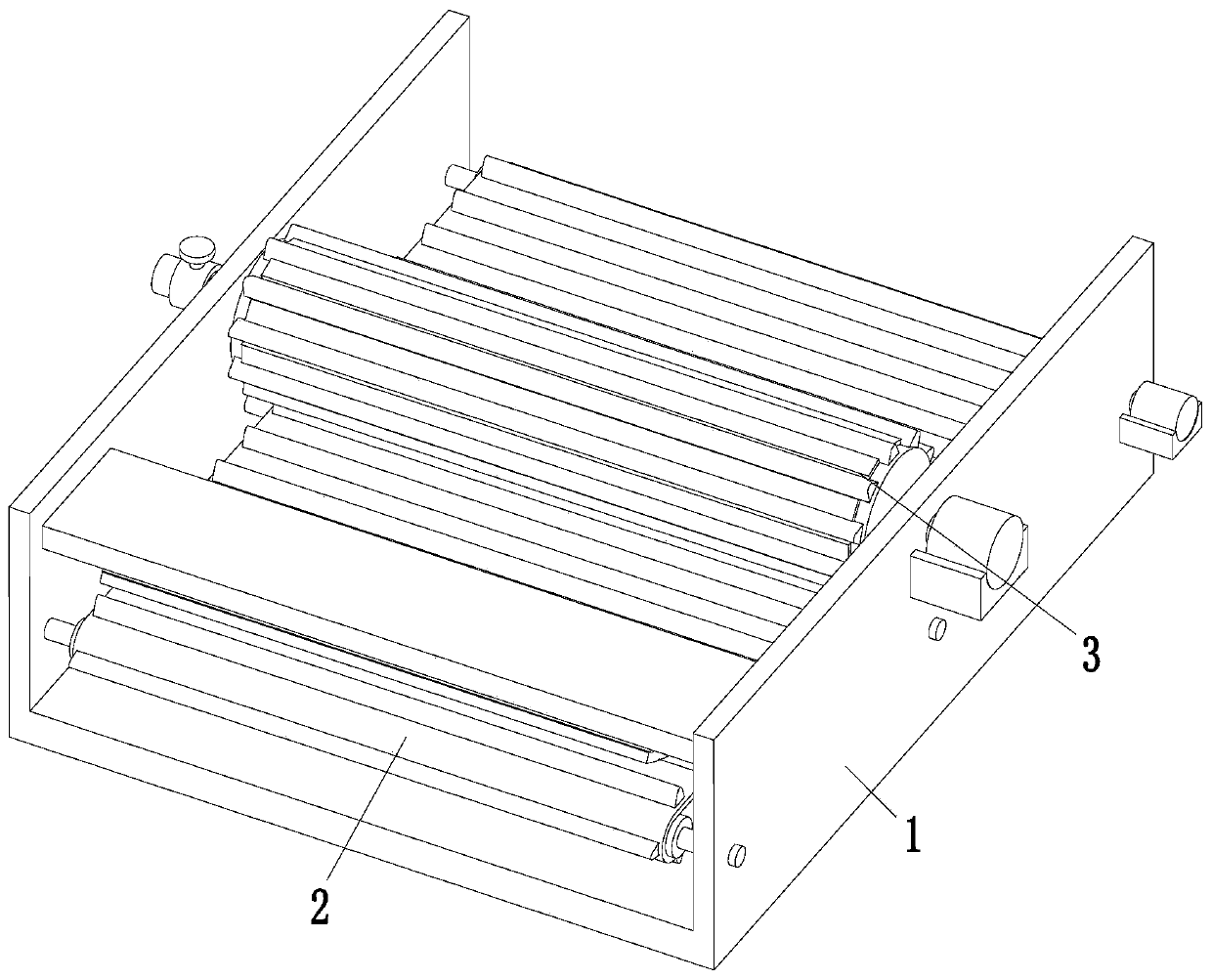

Coiling production device of glass fiber cloth

PendingCN107638998AImprove adhesionReasonable structural designPretreated surfacesCoatingsGlass fiberEngineering

The invention relates to the technical field of production of glass fiber cloth and in particular relates to a coiling production device of glass fiber cloth. The coiling production device comprises agluing device, wherein the gluing device comprises a gluing frame body; a wetting groove and a gluing groove are mounted on the gluing frame body respectively; a wetting roller is mounted in the wetting groove; a gluing roller and a glue homogenization roller are mounted at the upper end of the gluing groove; an outlet end of the gluing device is connected with a drying device through a first device connecting roller; the drying device comprises a pre-heating drying box and a multi-grade drying box; the outlet end of the drying device is connected with a coiling device through a second deviceconnecting roller. The coiling production device of the glass fiber cloth, provided by the invention, is reasonable in structural design and the glass fiber cloth and resin glue are easier to stick;the glue is uniformly coated and is more easily dried; in a drying process, a glue material is completely dried, so that a phenomenon that a white edge is generated in a coiling and cutting process isavoided; in a coiling process, the cloth can be cut and directly coiled according to production requirements; in a whole process, former equipment does preparation for next equipment, a production process is smooth and the working efficiency is improved.

Owner:SHANDONG TIANRUI FIBERGLASS COMPOSITES

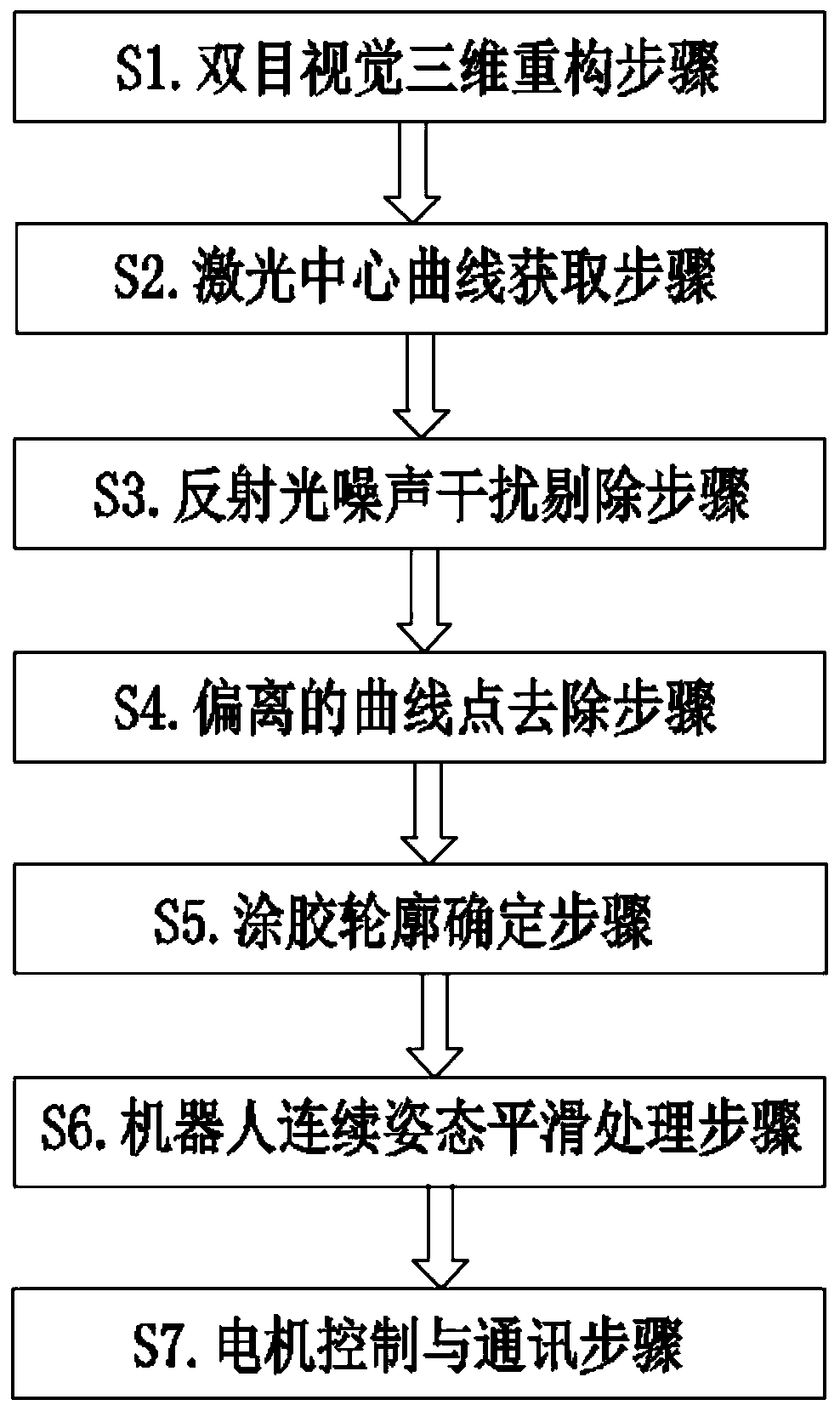

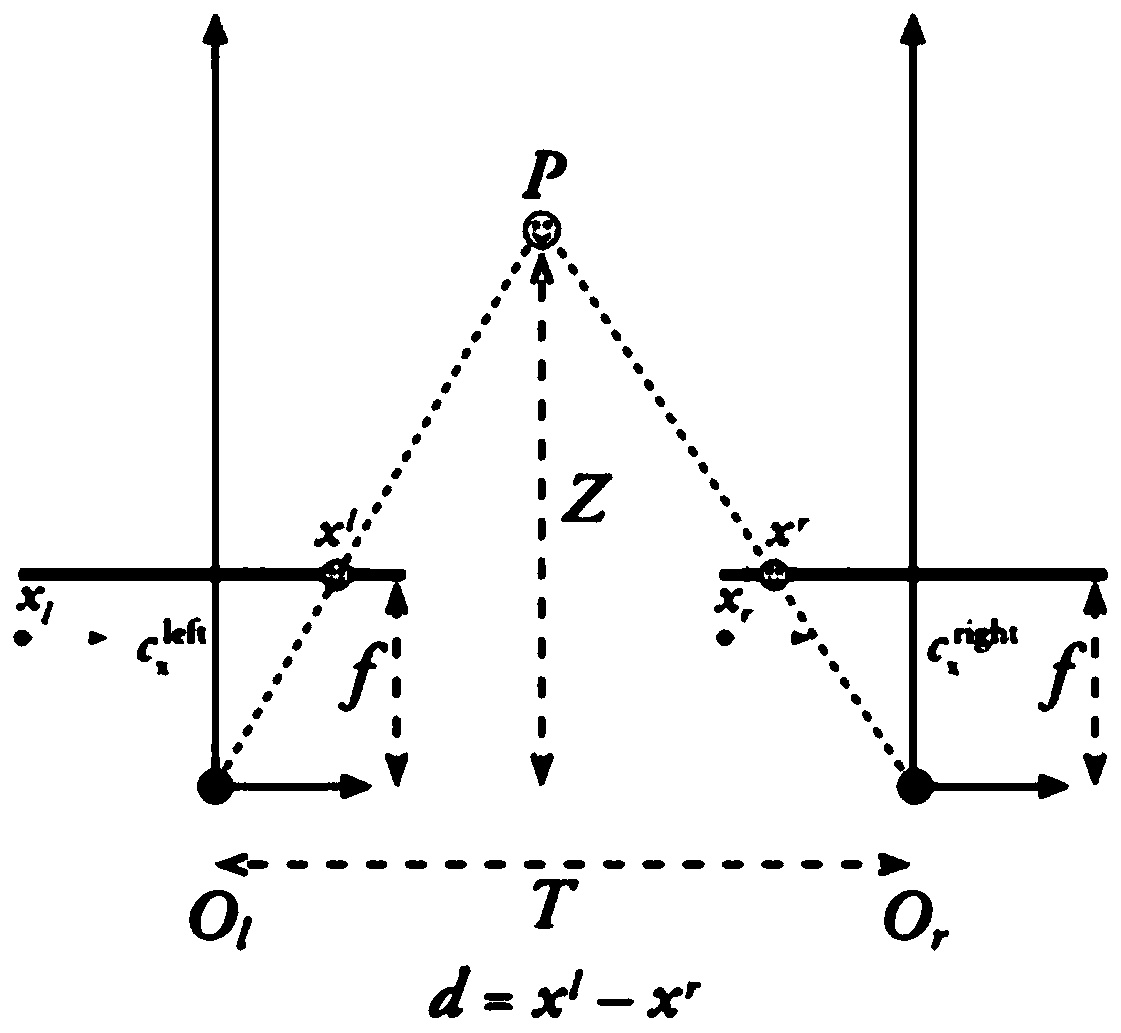

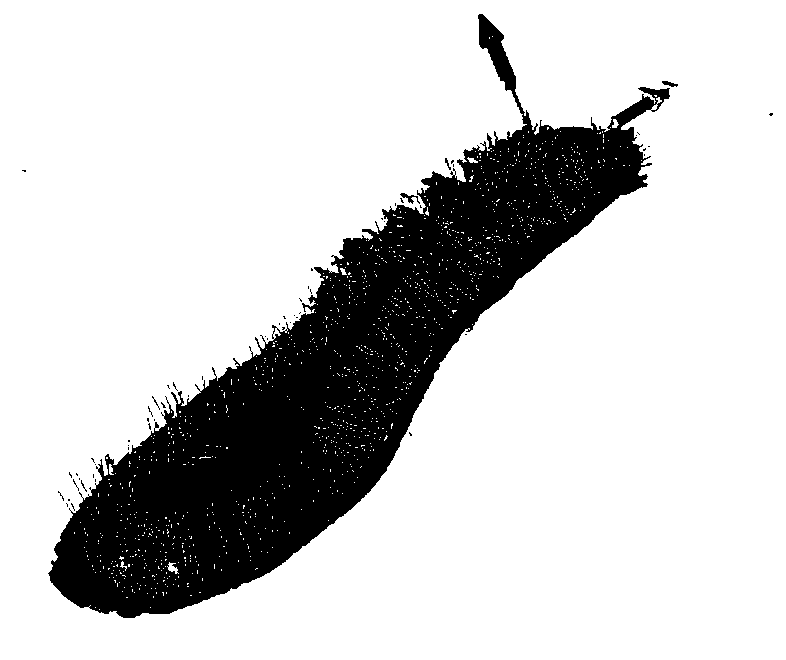

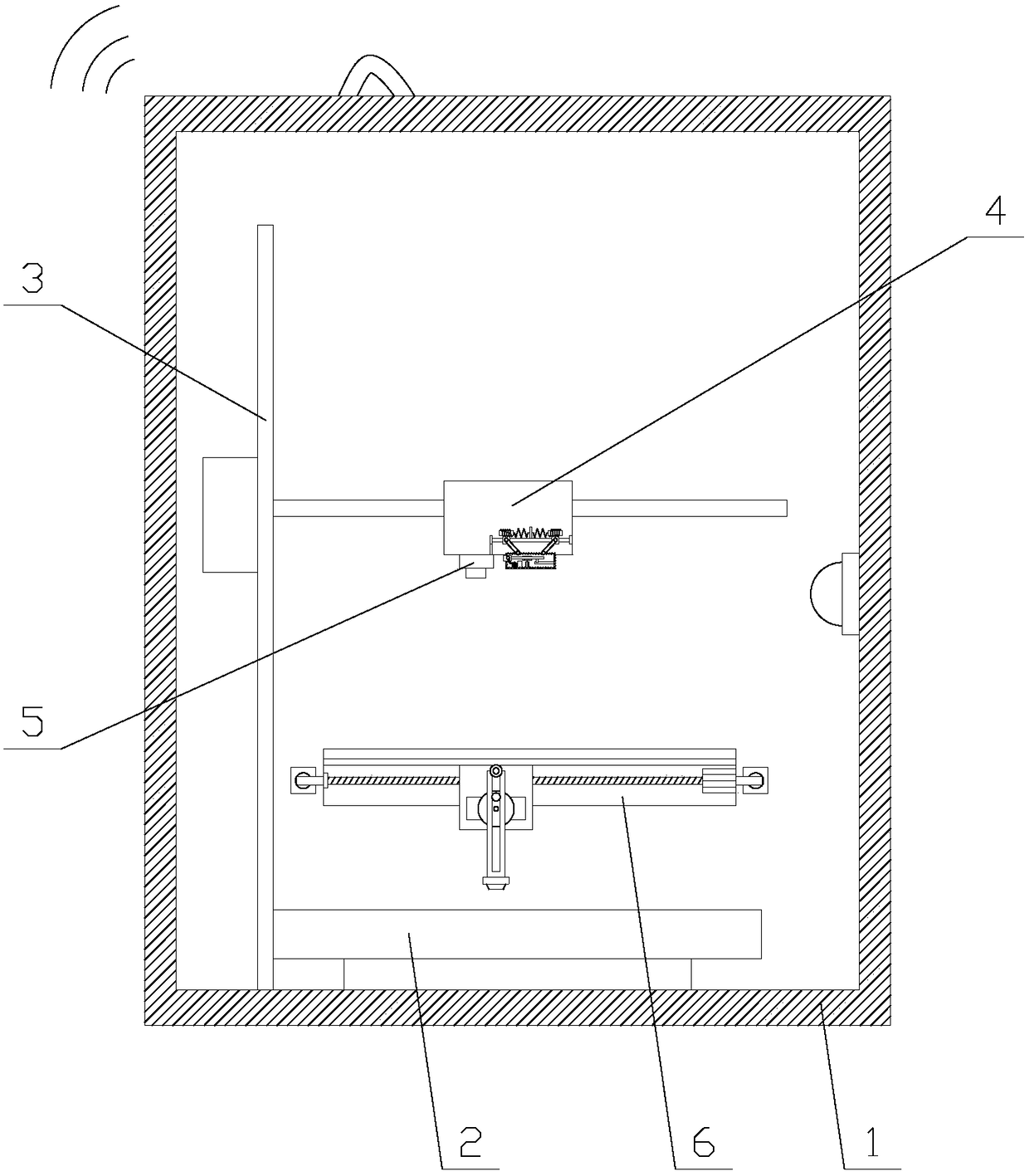

Control method of high-precision automatic sole gluing system

PendingCN110876512AAvoid the influence of gluing accuracyAutomatic and precise gluing operationShoe gluingElectric machineryEngineering

The invention provides a control method of a high-precision automatic shoe sole gluing system. The control method comprises a binocular vision three-dimensional reconstruction step, a laser center curve acquisition step, a reflected light noise interference elimination step, a deviated curve point removal step, a gluing contour determination step, a robot continuous posture smooth processing stepand a motor control and communication step. According to the shoe sole gluing device, the shoe sole can be automatically and accurately glued, the position deviation of the shoe sole in the clamping process is prevented from influencing the gluing precision, the robot is effectively prevented from shaking when moving on the gluing track, gluing is uniform, and automatic and accurate gluing can also be achieved for shoe material deep-color or light-reflecting shoe soles. The control method of the high-precision automatic shoe sole gluing system has the advantages of being high in intelligence,stable in imaging, high in universality, reliable in quality and the like.

Owner:GUANGDONG UNIV OF TECH +2

Internet-of-Things-based intelligent printing device with good printing effect

InactiveCN108215185AImprove adhesionAvoid destructionAdditive manufacturing apparatusSpraying apparatusEngineering3d printer

The invention relates to an Internet-of-Things-based intelligent printing device with a good printing effect. The device comprises a main body, a printing platform, a stroke rod, a stroke block and anozzle, and further comprises a gluing mechanism and a wire removal mechanism, the gluing mechanism comprises a moving assembly and a swinging assembly, and the wire removal mechanism includes a lifting assembly and a wiping assembly. The gluing mechanism can uniformly glue the printing platform to enhance the adhesion of the printing platform and a first layer material and prevent the bottom of amodel from upwarping, so lateral cracks in the top structure of the model are avoided, and the printing stability and the printing success rate are improved; and the wire removal mechanism can sweepand absorb plastic filaments and plastic coagulum residual on the nozzle to prevent the influences of wires caused by dripping of excess plastics from the nozzle on the printing effect, so the practicability and the reliability of a 3D printer are improved.

Owner:惠安县冠威机械设备有限公司

Automatic gluing device

InactiveCN103639093AImprove efficiencyApply glue evenlyLiquid surface applicatorsCoatingsHydraulic cylinderEngineering

The invention discloses an automatic gluing device. The automatic gluing device comprises a gluing drum, a hydraulic cylinder and a to-be-glued vessel, wherein the wall of the gluing drum is provided with a rubber outlet pore, the gluing drum is connected with a first driving mechanism and driven by the first driving mechanism to rotate so as to throw out the rubber in the gluing drum from the rubber outlet pore; a piston rod of the hydraulic cylinder is connected with the gluing drum, and the gluing drum can be driven to move up and down by the hydraulic cylinder; the glued vessel is arranged below the gluing drum, the gluing drum moves downwards to be arranged in the glued vessel, and the gluing drum rotates and moves up and down so as to spread the rubber in the gluing drum onto the inner wall of the glued vessel. By adopting the automatic gluing device, the rubber can be uniformly coated on the inner wall of the vessel, the gluing quality is good, the efficiency is high, and the manual gluing can be substituted.

Owner:GUANGXI UNIV

Production process of high-strength ultrathin composite corrugated boards

The invention discloses a production process of high-strength ultrathin composite corrugated boards. The process includes the steps of a, producing kraft, and winding the produced kraft to first, second, third, fourth and fifth paper rolls; b, allowing the first, third and fifth paper rolls to provide the kraft to a double facer, and allowing the kraft on the second and fourth paper rolls to be formed by a corrugating machine and be supplied to the double facer; c, after the double facer outputs, pressing the kraft and corrugated paper into composite boards by a laminating device; d, drying the composite boards in a drying device before outputting finished boards; e, cutting and storing the finished boards. The process has the advantages that the surface of the corrugated paper is evenly coated with glue by the double facer, long composite boards can be produced by the process and can be cut as required, and different composite boards of different corrugated types, such as DE type, can also be produced by the process.

Owner:ZHEJIANG GUANGHUI PACKAGING PRINTING

Card gluing mechanism

PendingCN108160414ASimple structureApply glue evenlyLiquid surface applicatorsCoatingsMechanical engineeringRaw material

The invention discloses a card gluing mechanism. The gluing mechanism comprises a base, a fixing base, a pushing air cylinder, a sliding base, a jacking and placing mechanism, a supporting frame, a first proximity switch, a second proximity switch, guide rods, a pressing frame, first springs, a glue uniformizing plate with a plurality of glue uniformizing holes and a gluing mechanism; and a raw material plate to be glued is placed in the jacking and placing mechanism, the pushing air cylinder pushes the sliding base to move rightwards in place, the jacking and placing mechanism drives the rawmaterial plate to move upwards to be in contact with the glue uniformizing plate, the first springs are compressed, the gluing mechanism penetrates through the pressing frame to be in contact with theglue uniformizing plate, then a glue solution coats the raw material plate due to the action of the surface tension, so that glue solution coating is completed. According to the card gluing mechanism, the structure is simple, gluing can be automatically carried out on the raw material plate, the jacking and placing mechanism can be used for carrying out positioning and fixing and exerting certainpressure on the raw material plate, so that gluing is uniform, the gluing process and the raw material plate ejection process are combined together, so that the action time is shortened, and the production efficiency is improved; and meanwhile, devices such as air cylinders do not need to be arranged, so that the production cost is effectively reduced.

Owner:BEAUTIFUL CARD TECH SUZHOU CO LTD

Efficient gluing device for plywood

InactiveCN110027066AApply glue evenlyGood gluing effectGlue gunsLoading/unloadingEngineeringAutomation

The invention belongs to the field of plywood processing, and particularly relates to an efficient gluing device for plywood. The efficient gluing device for the plywood aims to solve the problems that an existing gluing device is not uniform in gluing, and automatic feeding and discharging cannot be realized. The device comprises a base, a feeding conveying belt, a supporting frame and a gluing mechanism, wherein a plurality of first telescopic rods are fixed at one end of the base, and the output shaft of the first telescopic rods are connected with a feeding plate with an L-shaped verticalsection; a mounting groove is formed in the top end of the feeding plate, and a rodless air cylinder is arranged in the mounting groove; the output shaft of the rodless air cylinder is connected witha material pushing plate slidably connected to the top end of the feeding plate, one end of the feeding plate is provided with the feeding conveying belt, and one end of the feeding conveying belt isarranged on the base; the upper end face of the feeding conveying belt and the upper end face of the feeding plate are located on the same plane, and a gluing mechanism positioned on one side of the feeding plate is arranged above the feeding conveying belt; according to the device, the automation degree is high, the automatic feeding and discharging of plates can be realized, the gluing is uniform, and the gluing effect is good.

Owner:融安县华荣木业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com