Disc loading substrate surface coating device

A technology of substrate surface and coating device, which is applied to the device for coating liquid on the surface, pretreatment surface, coating, etc., can solve the problems of damage to the surface sprayed with glue, difficult to adhere to, and difficult to collect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

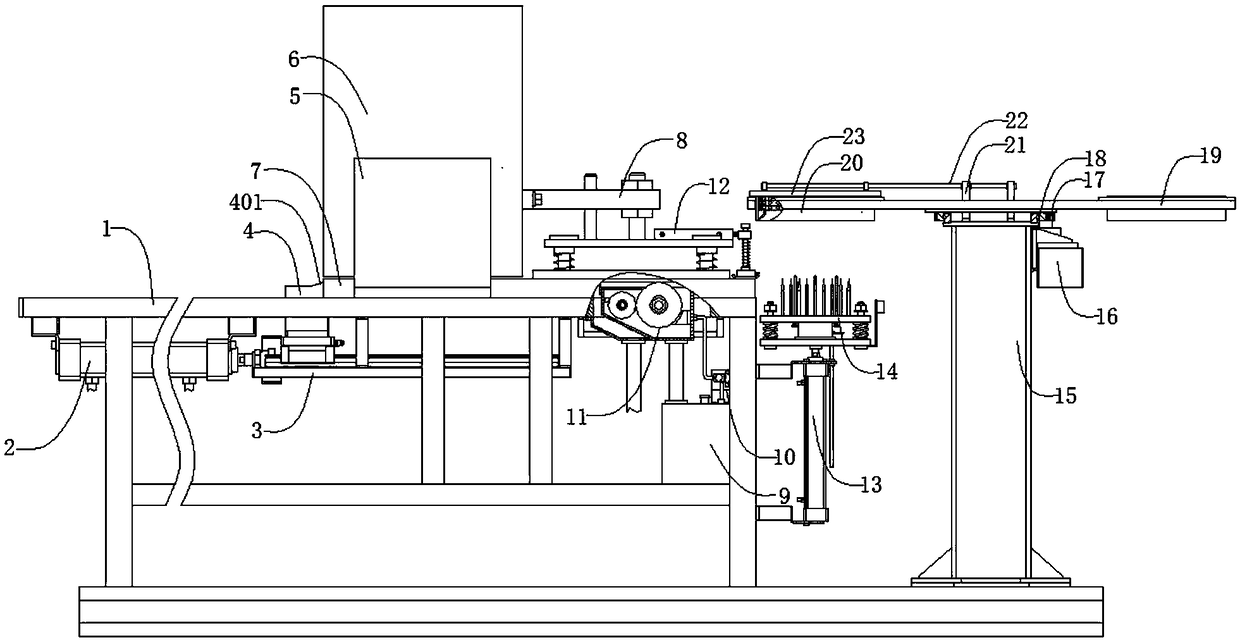

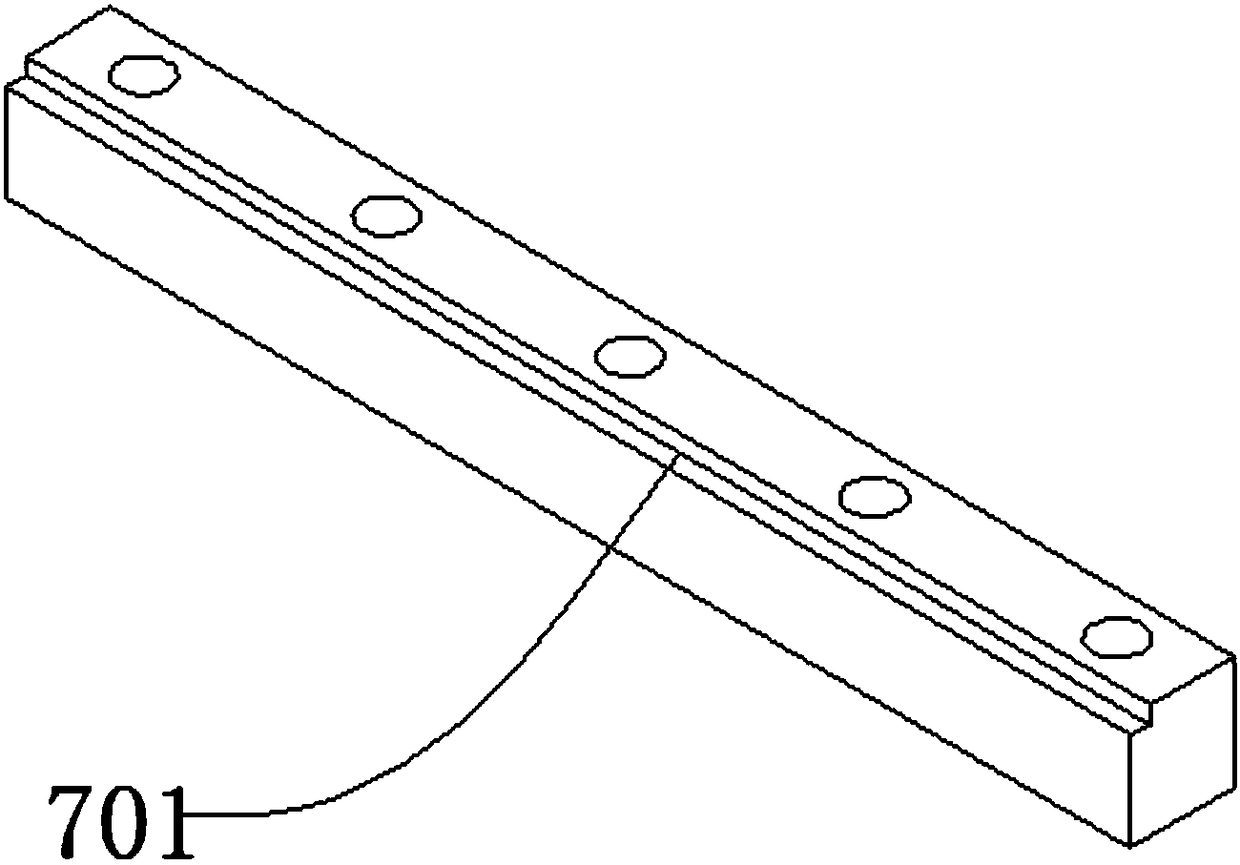

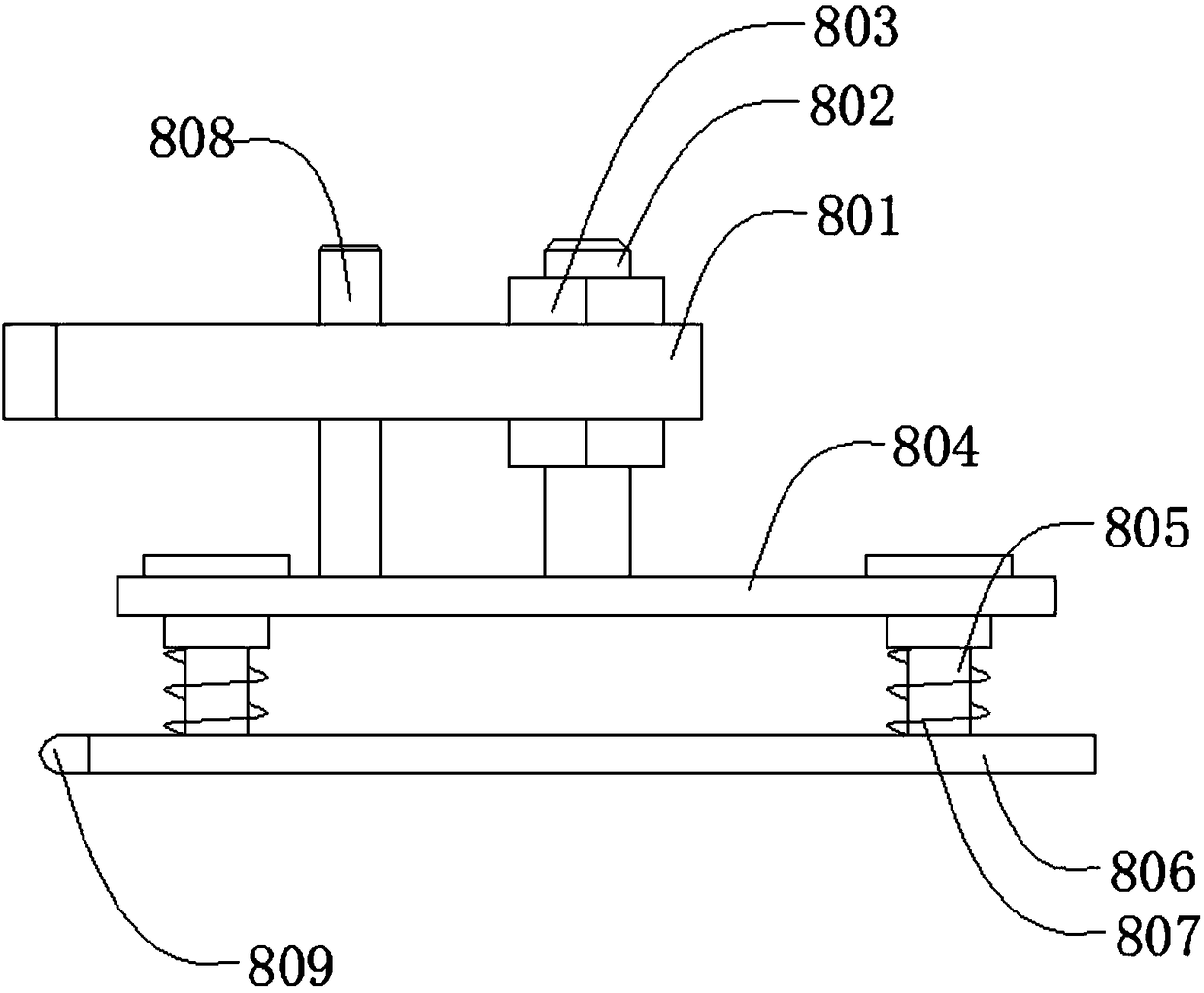

[0028] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 , Figure 11As shown, a disk-loading substrate surface coating device includes a frame 1, a pushing cylinder 2, a lower supporting plate 3, a pushing head 4, a bracket 5, a board box 6, a carrier strip 7, and a pre-pressing mechanism 8. Glue tank 9, peristaltic pump 10, coating mechanism 11, reclaiming mechanism 12, jacking cylinder 13, carrier mechanism 14, column 15, servo motor 16, gear 17, slewing bearing 18, disc 19, aggregate Mechanism 20, support 21, support rod 22, baffle plate 23, described pushing material cylinder 2 is positioned at the left lower end of frame 1, and described pushing material cylinder 2 is connected with frame 1 by bolt, and described lower supporting plate 3 is located at the lower end of the frame 1, the lower supporting plate 3 is connected with the frame 1 by bolts, the pushing head 4 is located at the up...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com