Patents

Literature

972 results about "Protractor" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A protractor is a measuring instrument, typically made of transparent plastic or glass, for measuring angles. Most protractors measure angles in degrees (°). Radian-scale protractors measure angles in radians. Most protractors are divided into 180 equal parts. Some precision protractors further divide degrees into arcminutes.

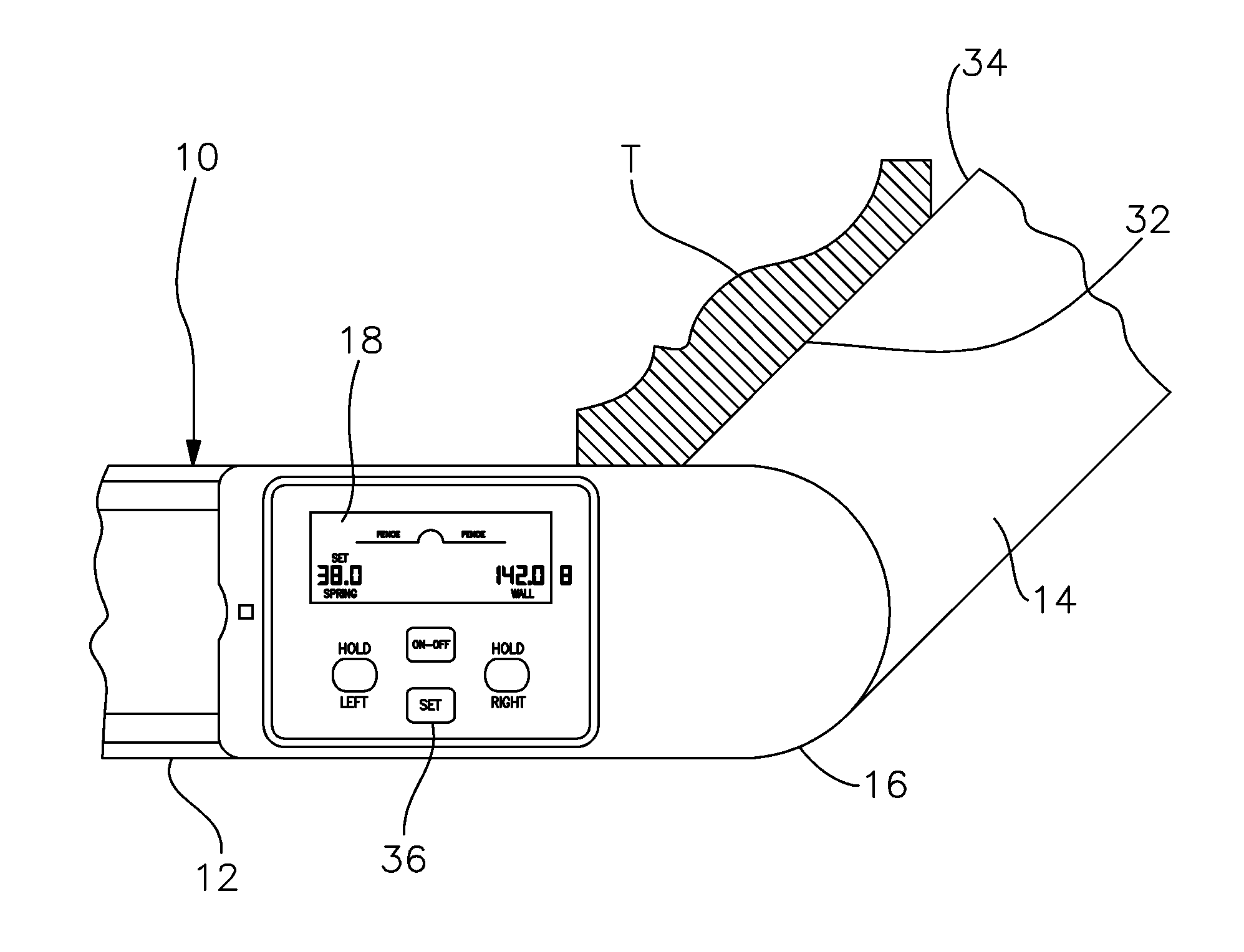

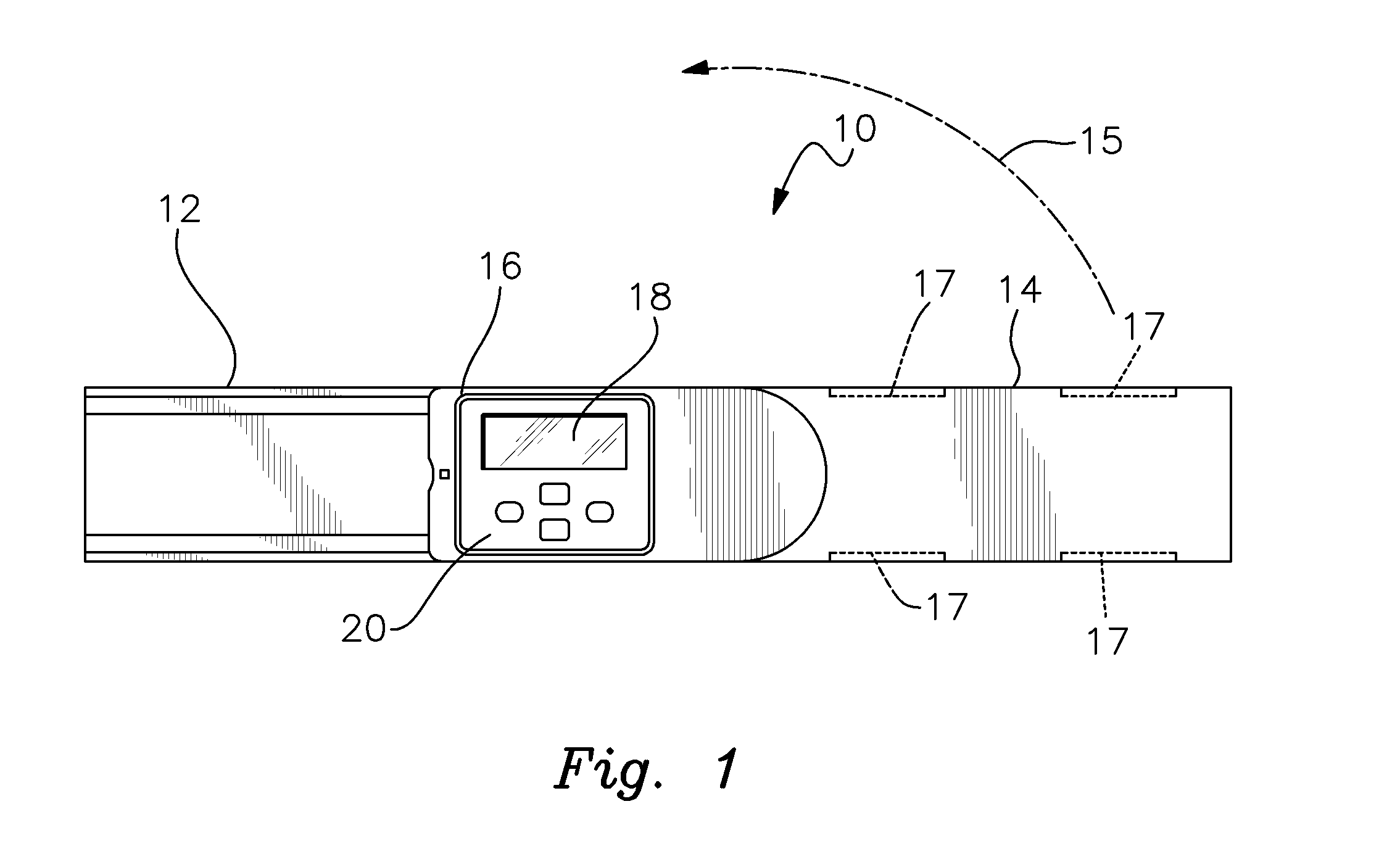

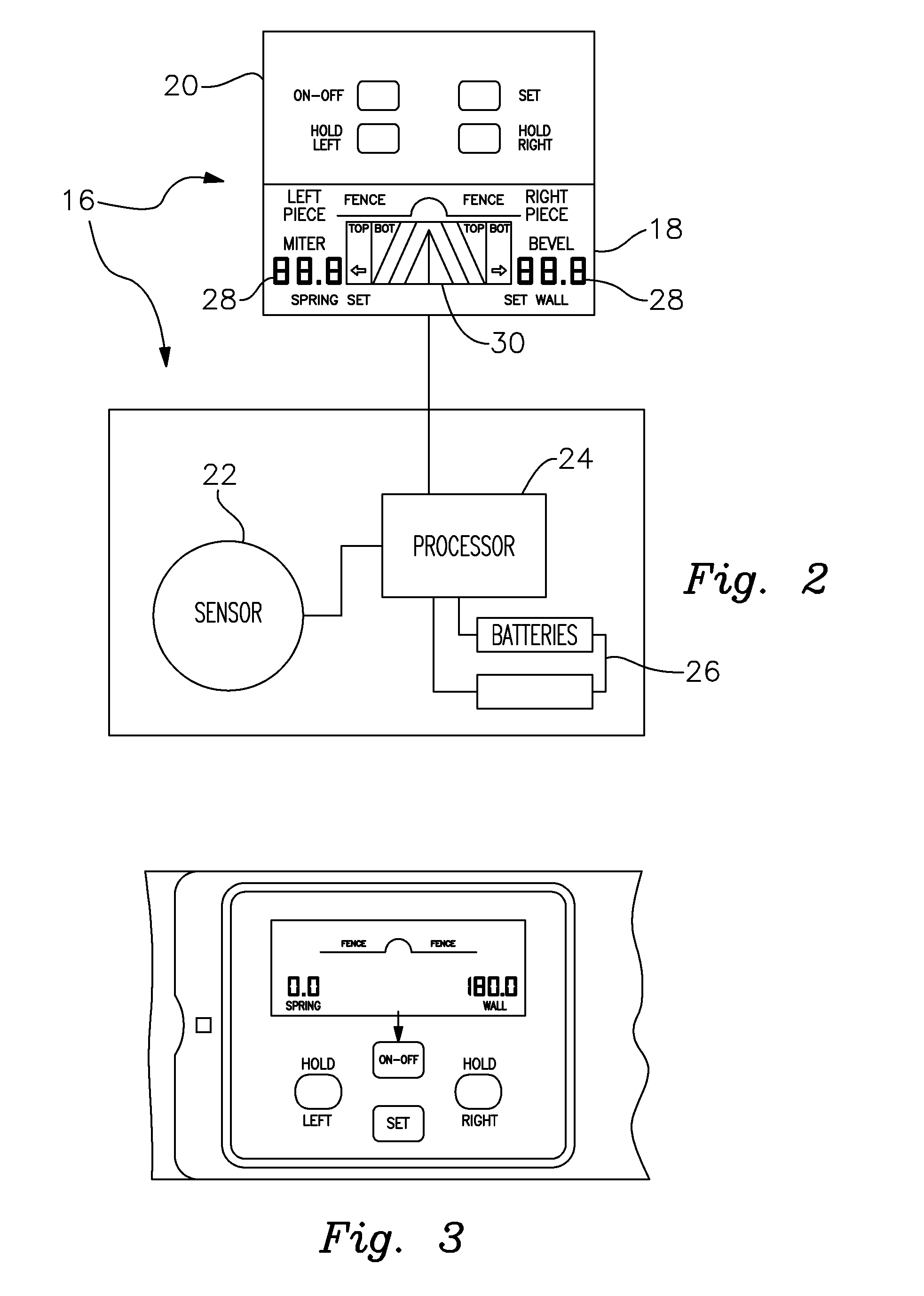

Crown Molding Protractor

InactiveUS20160238365A1Calculated quickly and accuratelyFacilitates and guides adjustmentBuilding constructionsAngles/tapers measurement gaugesProtractorCrown molding

A digital protractor is provided for measuring spring and wall angles and determining and effecting bevel and miter angle adjustments of a miter saw to adjoining pieces of trim in accordance with the measured spring and wall angles. The protractor includes a pair of pivotally interconnected arms. At least one sensor is attached to one of the arms and a digital readout is secured to the other arm. The readout includes means for determining the bevel and miter angles such that the protractor can be set to those angles to properly adjust the miter saw in accordance with the calculated angles.

Owner:WIXEY BARRY DOUGLAS +2

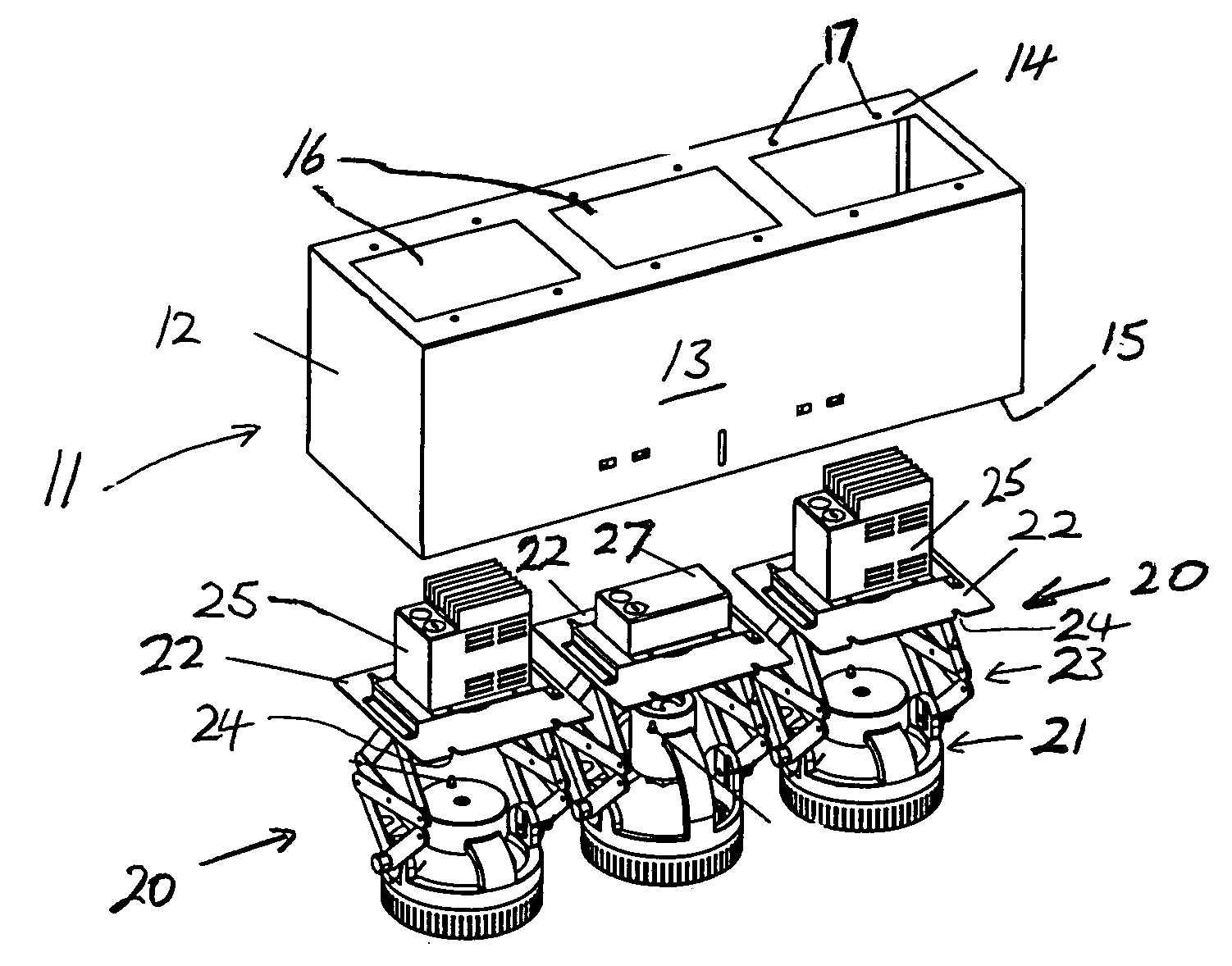

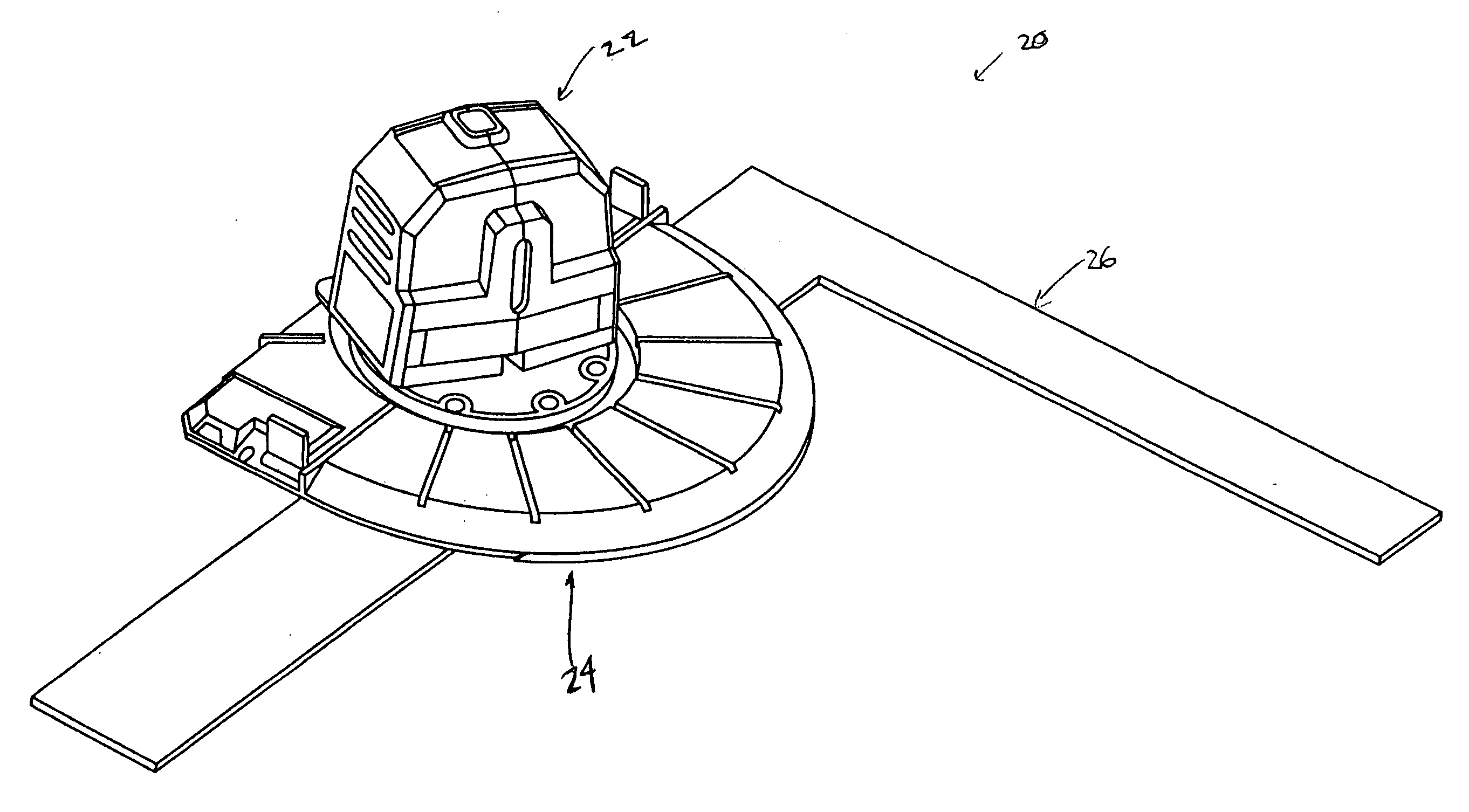

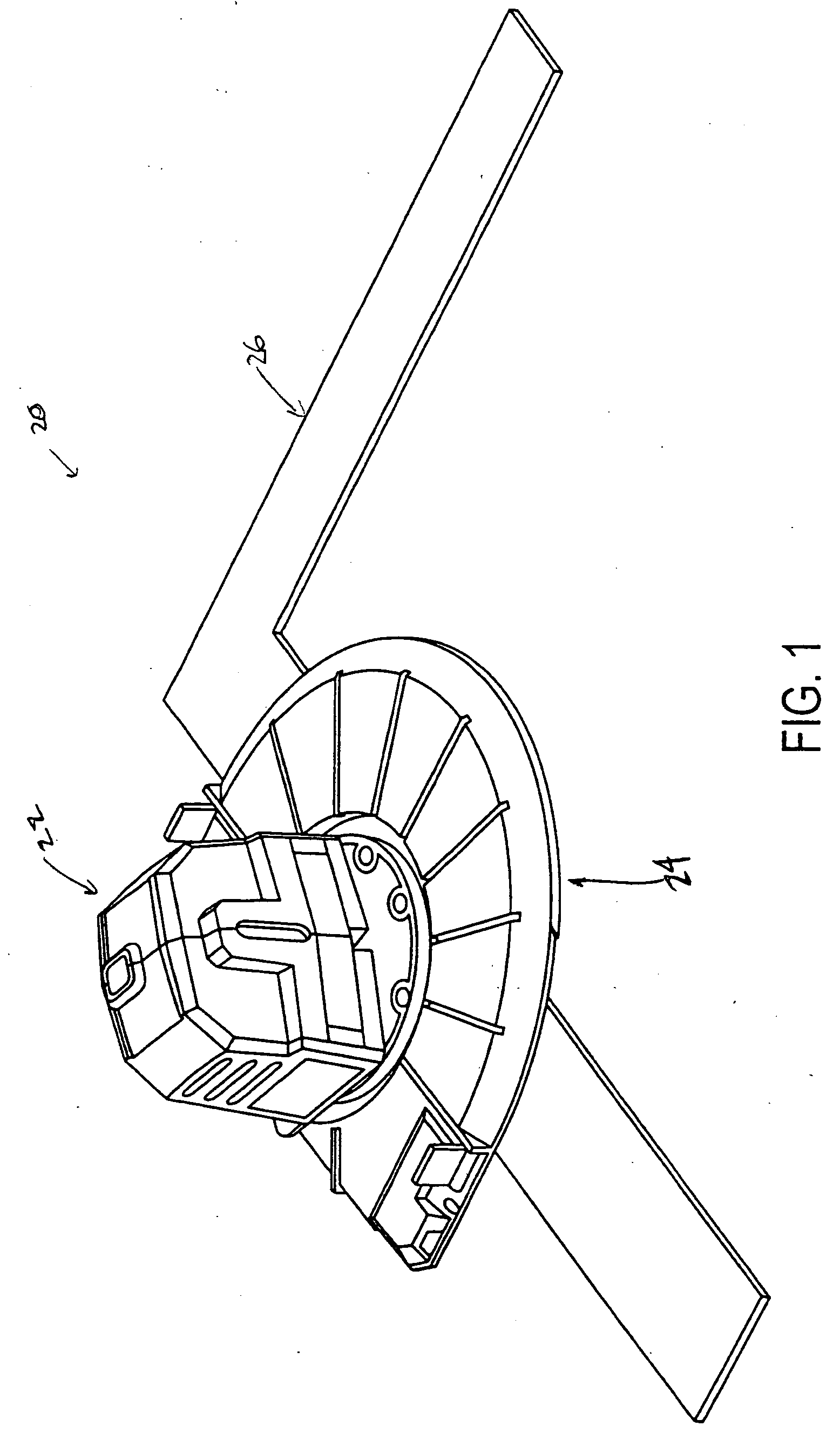

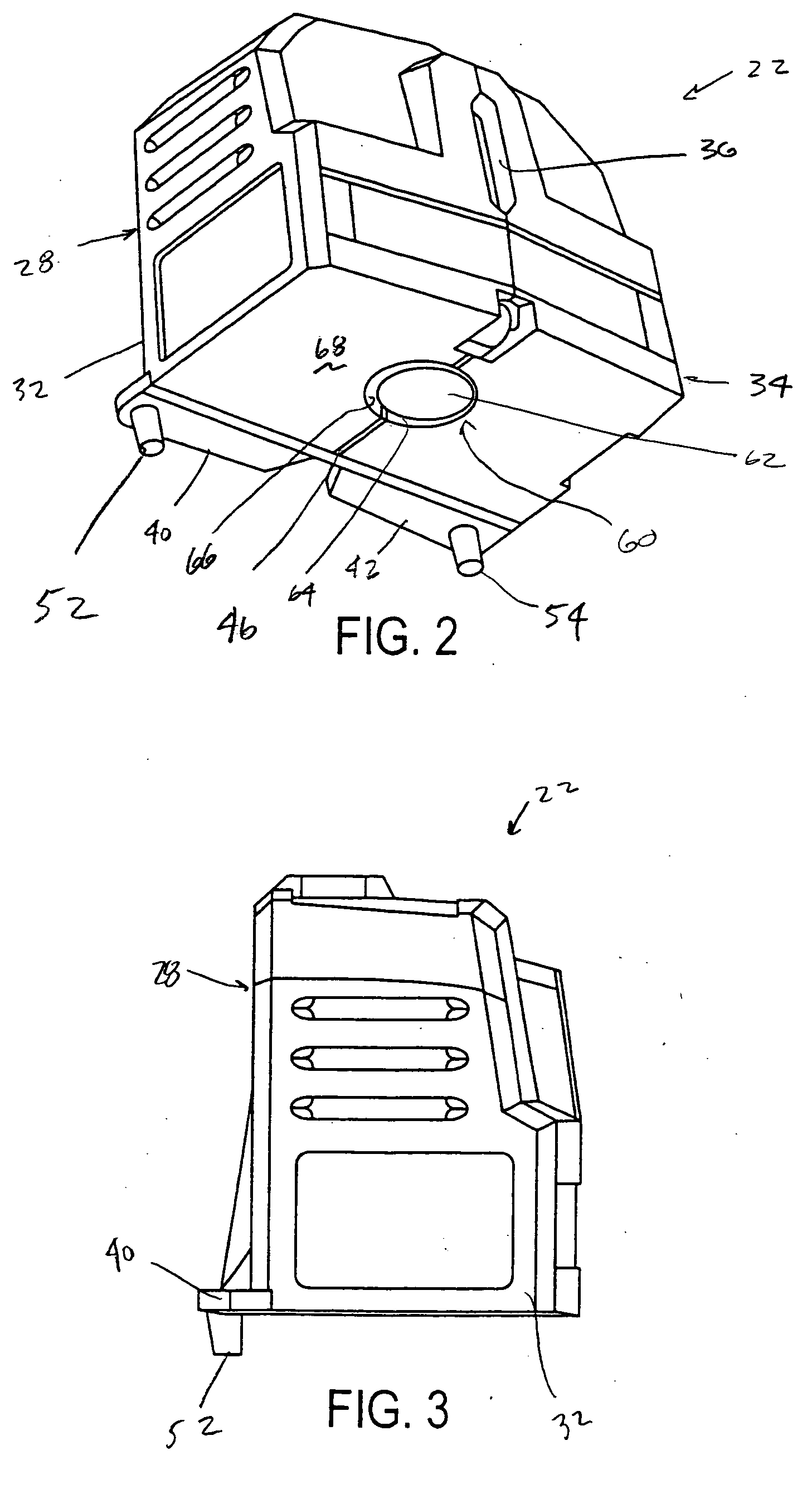

Modular downlight assembly

ActiveUS7431482B1Avoid difficult choicesLimiting pivotal movementLighting support devicesElectric circuit arrangementsProtractorModularity

A modular downlight assembly having a channel shaped back housing for mounting in a ceiling cavity and formed with a series of identical apertures receiving, respectively, when mounted in the cavity, selected similar individual downlight modules. Each module has a mounting plate with a power supply mounted on an upper back face received, concealed from view, in an aperture and a lamp housing pivotally suspended from a turnable on a lower face by a scissor linkage for extension and retraction out of and into the housing channel. A protractor for indicating rotational direction is marked on the lower face of the mounting plate. Meshed gear teeth are provided on endmost links of the two linkages of each scissor link, synchronizing their movement. Selected links have movement limiting flanges extending into paths of movement of adjacent links and of the lamp housing limiting extension, pivotal movement and rotation.

Owner:WAC LIGHTING

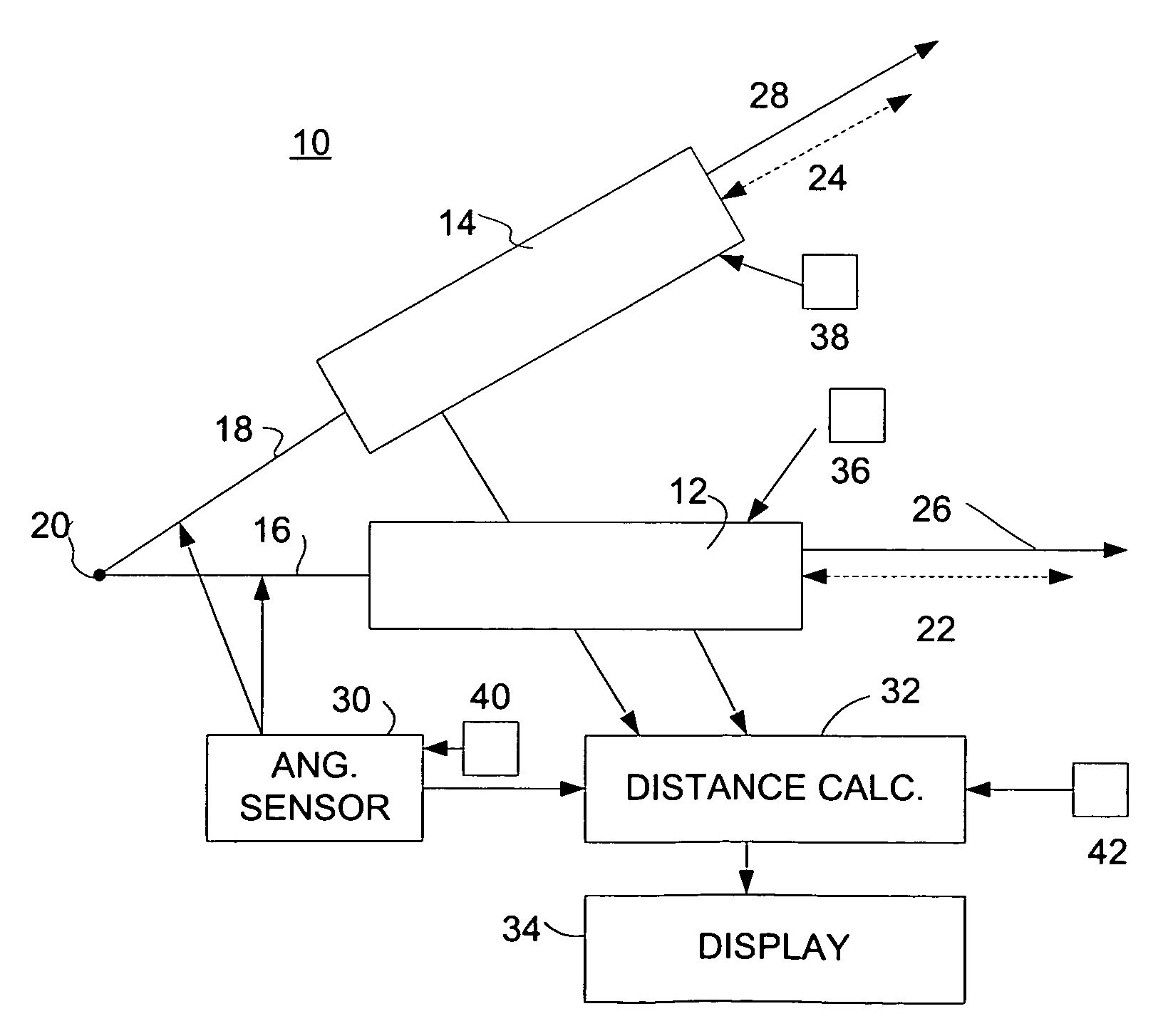

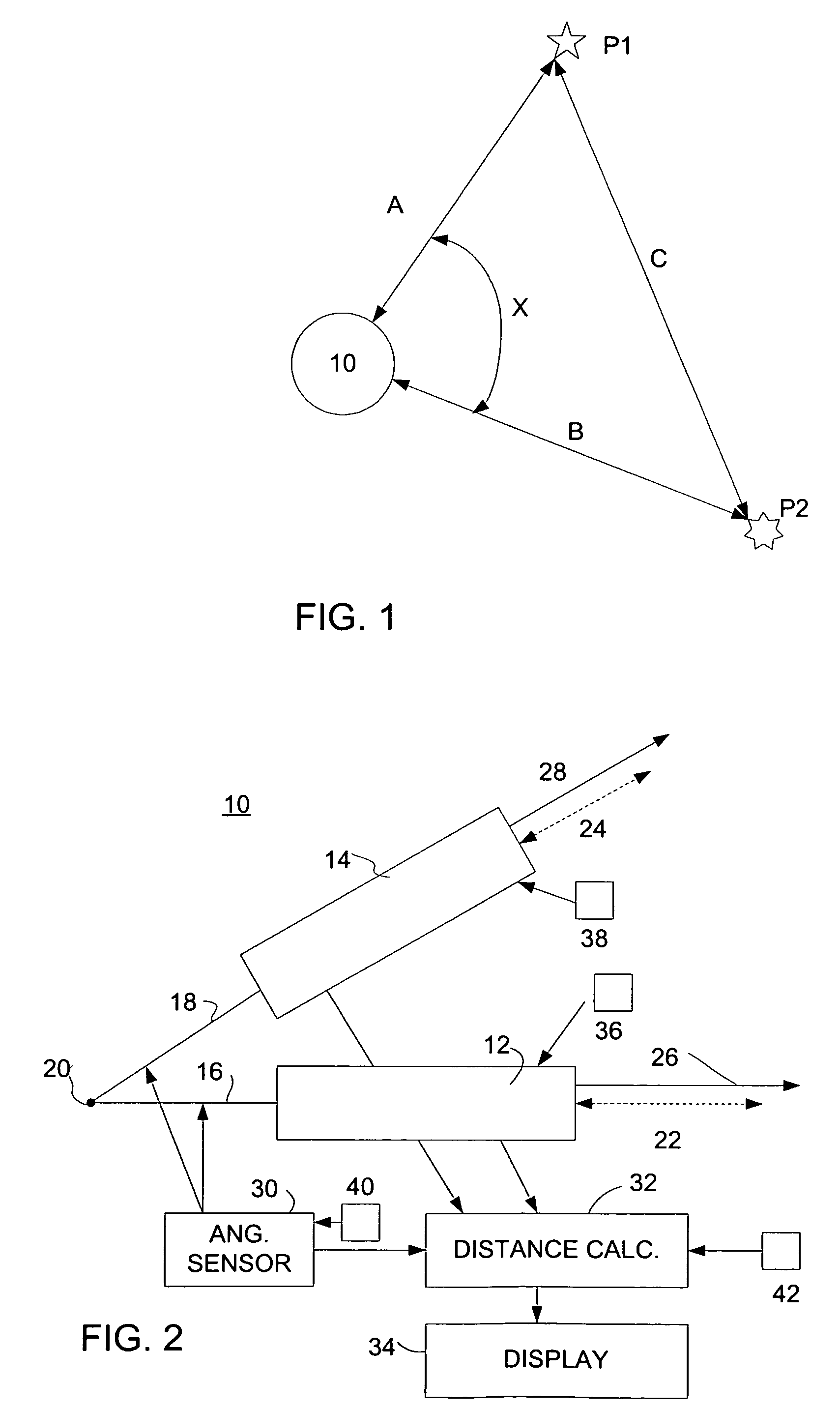

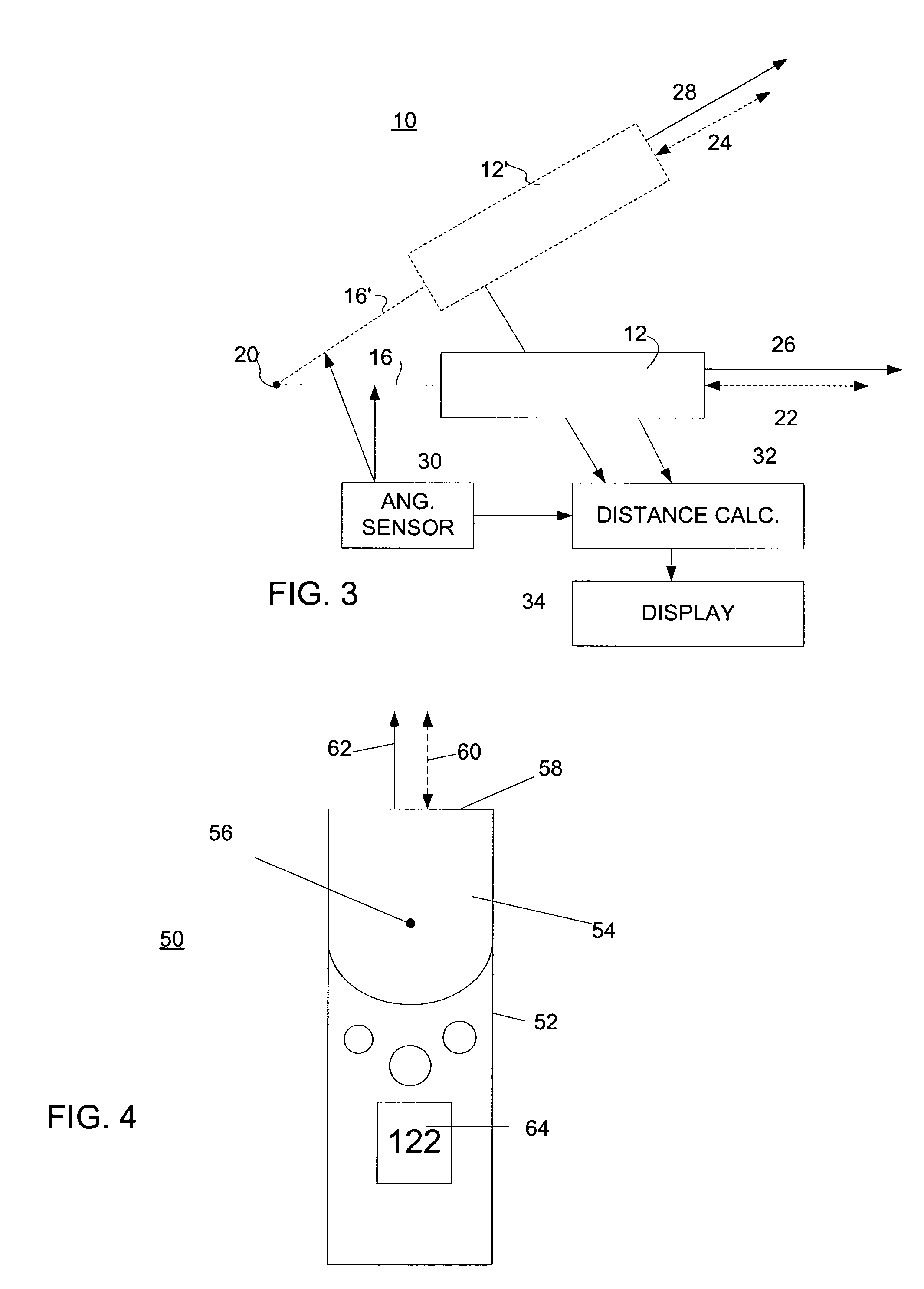

Method and apparatus for distance measurement

A device for measuring physical characteristics includes a beam generator component generating first and second beams at two points. The device further includes a protractor that measures the angle between the beams. The device measures the distances to the two points and with the angle between the two beams, determines a predetermined characteristic, such as the distance between the two points.

Owner:TYROLER DAN

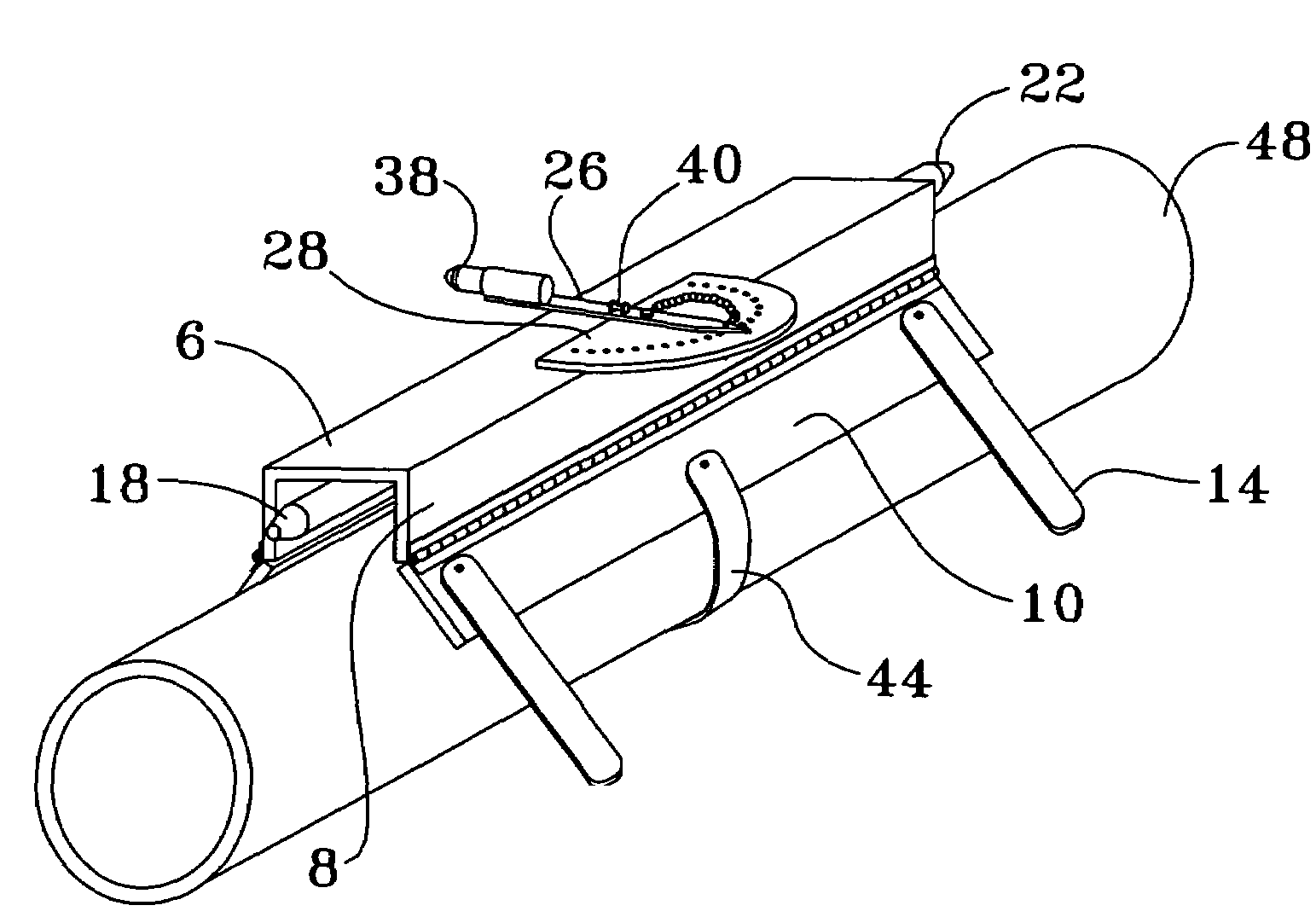

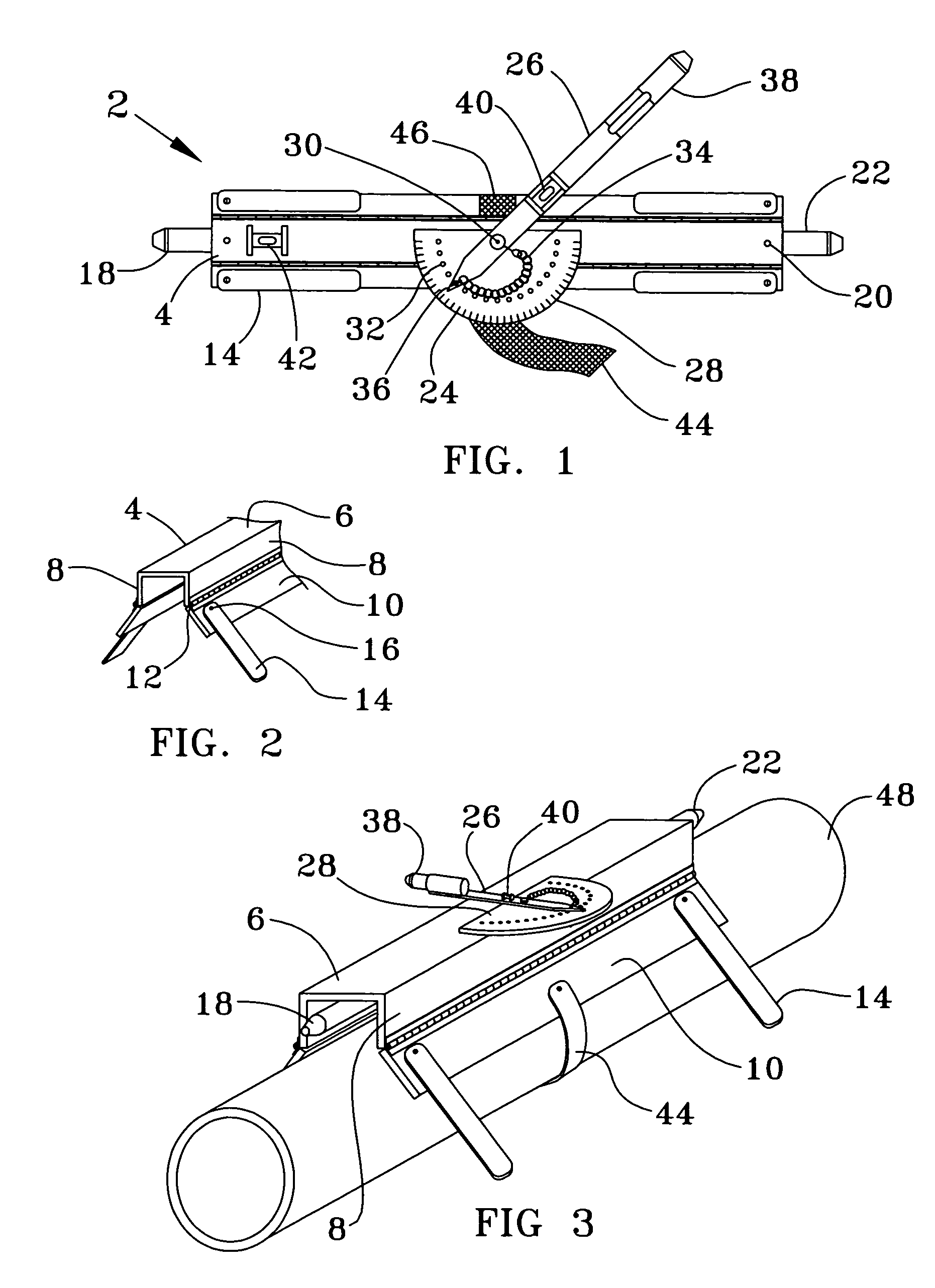

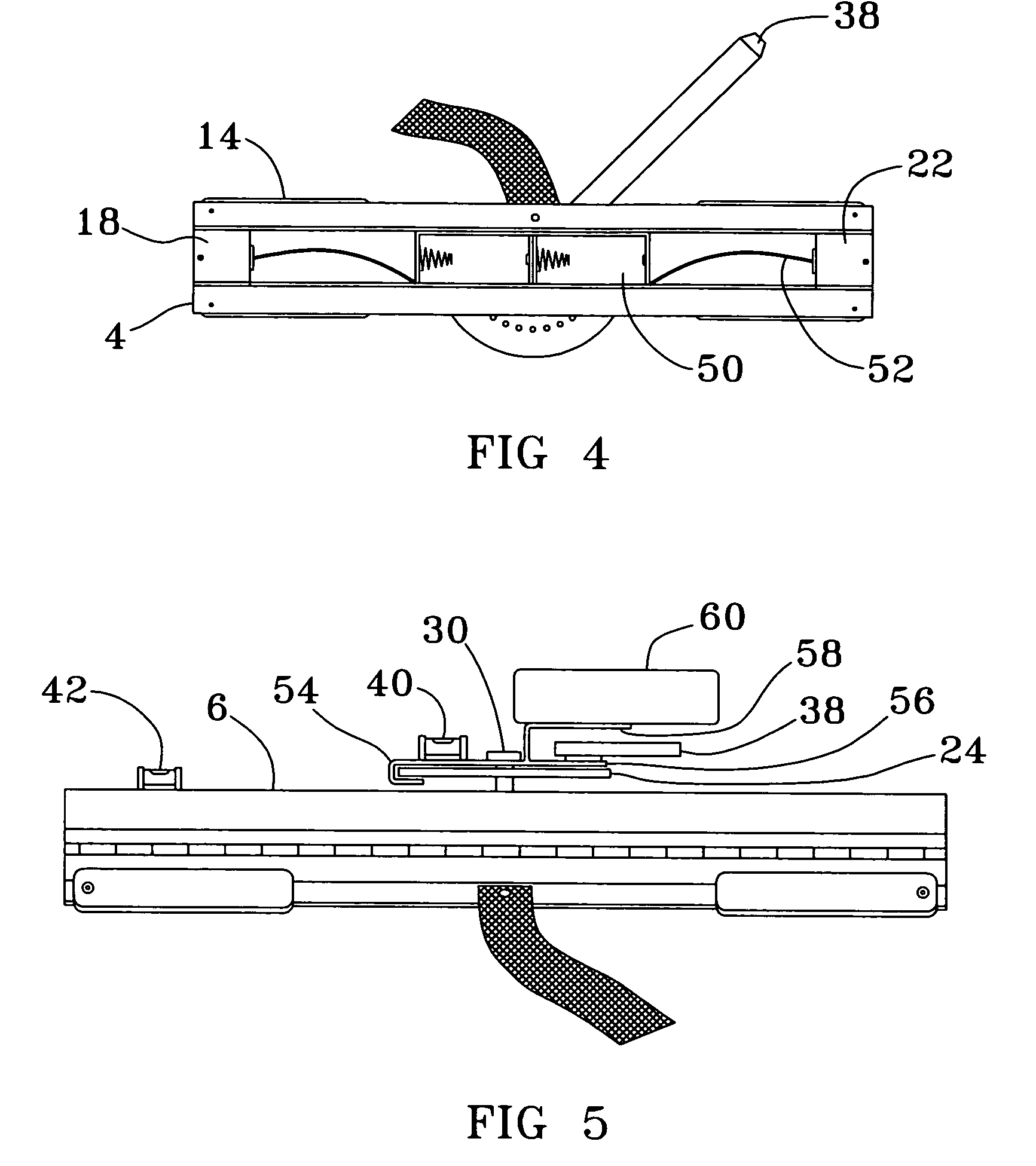

Multi-function layout square with laser

InactiveUS6839974B1Easy constructionReduce manufacturing costSlippage preventionActive open surveying meansEngineeringSupport surface

A multi-function layout square of modular construction having a laser that is capable of performing multiple functions is disclosed. The multi-function square has a metallic outer casing with magnetic properties, with a protractor plate slidably, pivotally, and removably attached by thumbscrews to the casing that can be moved and rotated with respect to the casing and slid linearly along a portion of the length of the casing. When the protractor plate is removed the casing may be used as a level, a plumb bob, a ruler, and a compass. When the protractor plate is attached the tool may be used as a framing square, roofing framing square or rafter square, and a gauge or scribe for straight lines, arcs, or circles. The laser, a switch, and a pair of bubble level vials are contained in a module installed at one end of the casing, and a second module containing batteries is removably installed at the other end of the casing. Each module has electrical contacts that engage the interior surface of the casing and contacts that engage the batteries when the modules are installed and abutted. When the switch is on, a circuit is completed through the metallic casing, which electrically connects the batteries to the laser. The casing may be suspended vertically from a support surface by passing a string or wire through a bore in one of the thumbscrews, may be mounted on a tripod, or may be magnetically attached to metal objects.

Owner:HITCHCOCK JAMES N

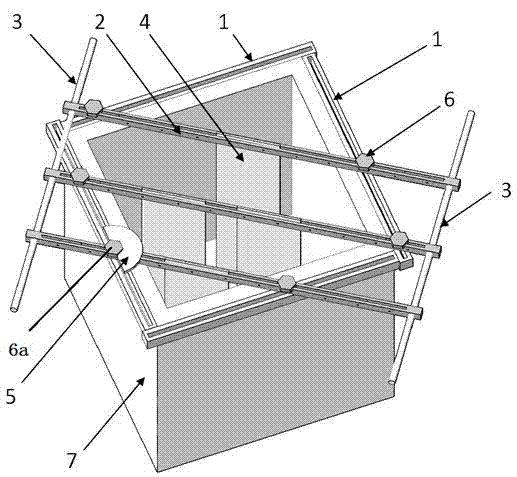

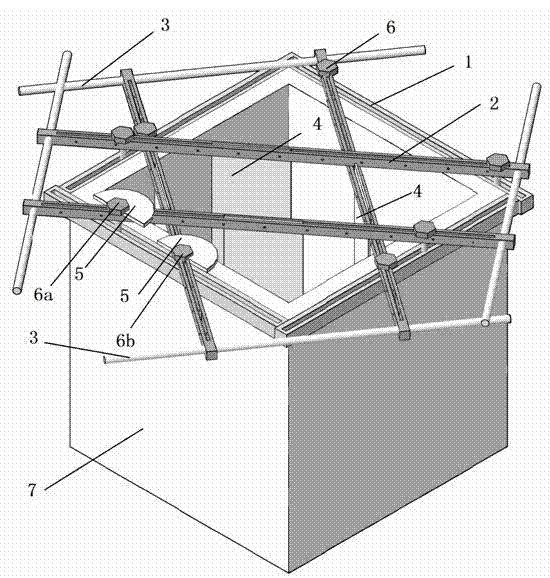

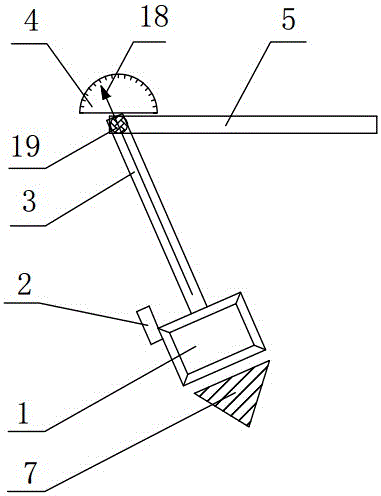

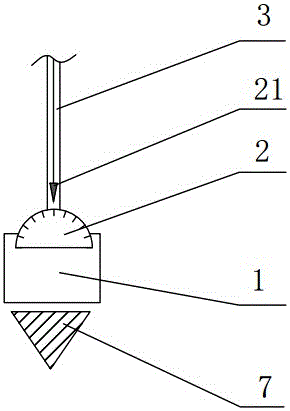

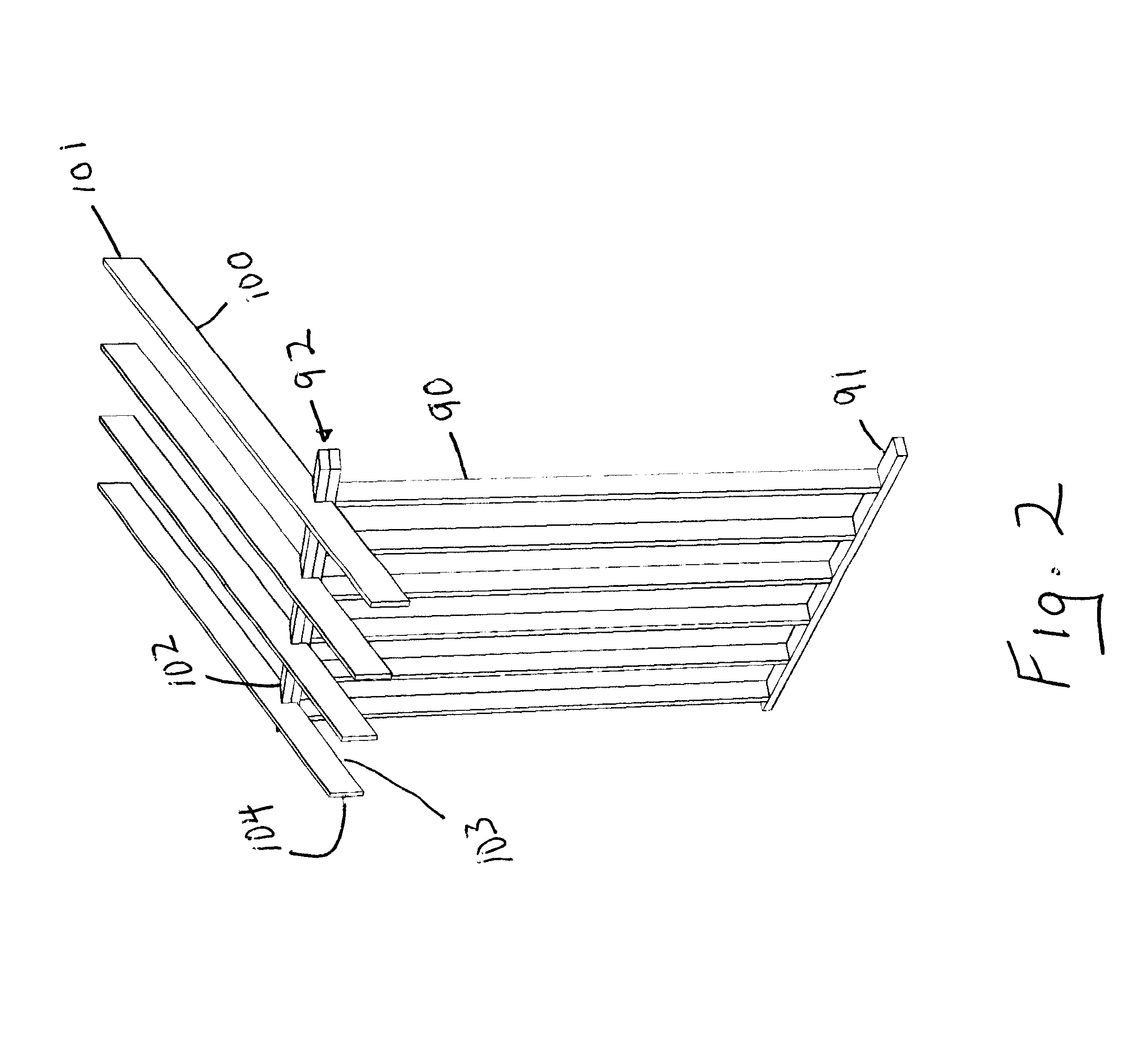

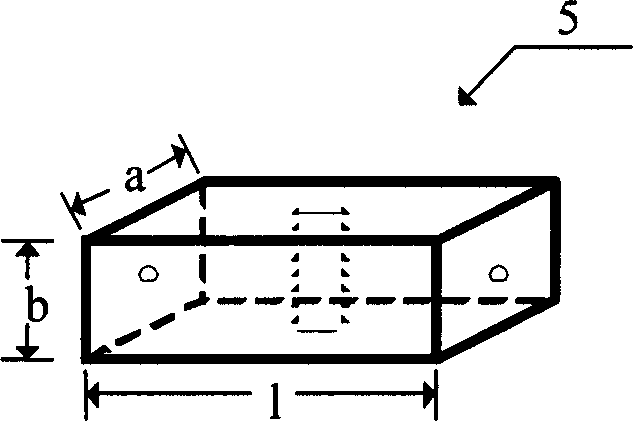

Mould for manufacturing fissure surface of rock like test block

InactiveCN102519767APrevent movementEasy to transformPreparing sample for investigationCeramic shaping apparatusProtractorSheet steel

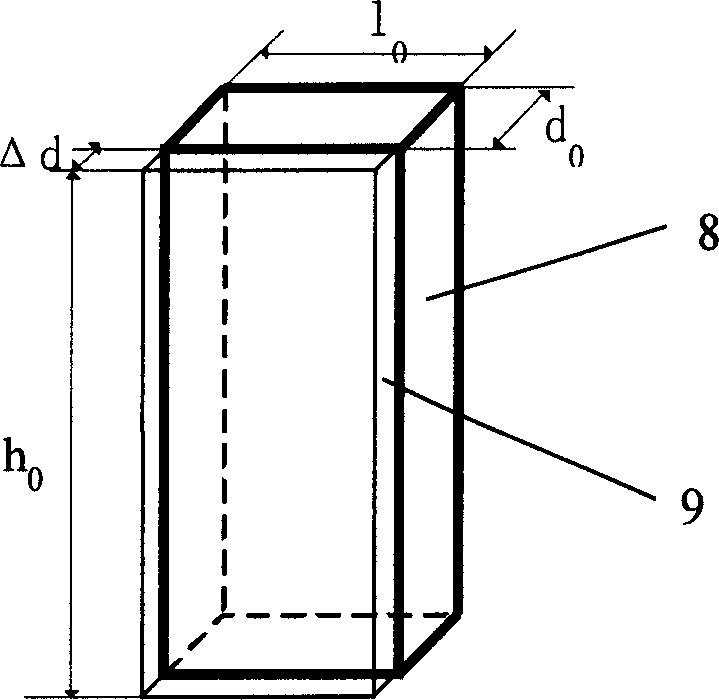

The invention discloses a mould for manufacturing a fissure surface of a rock like test block. The mould comprises a sliding groove, a sheet steel locating rod, a protractor, a sliding rod and a sheet steel, wherein the sliding groove is a long strip type metal component provided with a straight groove hole; the sheet steel locating rod is a metal rod; the sliding rod is a metal rod marked with ascale; a sheet steel fixing sheet is a hard sheet provided with a notch and stuck on the bottom surface of the test block mould; the sliding groove is fixed on the top of the side wall of the test block mould; the sheet steel locating rod is fixed above the sliding groove; the circle centre of the protractor passes through any bolt and is fixed above the sheet steel locating rod; the sliding rod passes through holes at two ends of the sheet steel locating rod and is vertical to the sheet steel locating rod; one end of the sheet steel is fixed in a through groove of the sheet steel locating rod; and the other end of the sheet steel is clamped in the notch of the sheet steel fixing sheet. The mould disclosed by the invention is capable of conveniently and rapidly adjusting parameters of thefissure surface of the test block, such as an inclination angle, an interval, a communication rate and the like. The mould is easy to process and can be repetitively utilized, thus, the manufacture efficiency and the precision of the test block are increased.

Owner:WUHAN UNIV

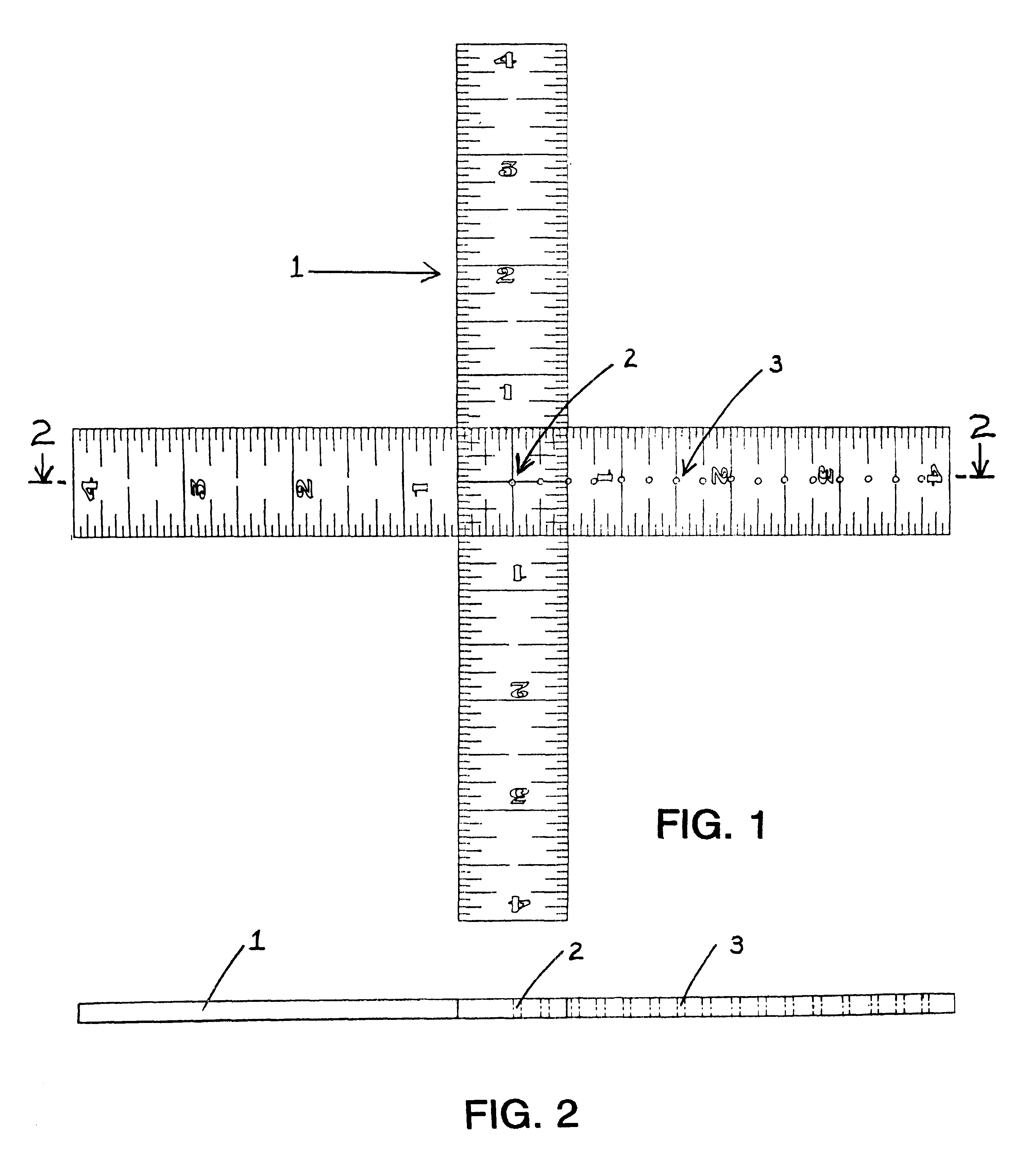

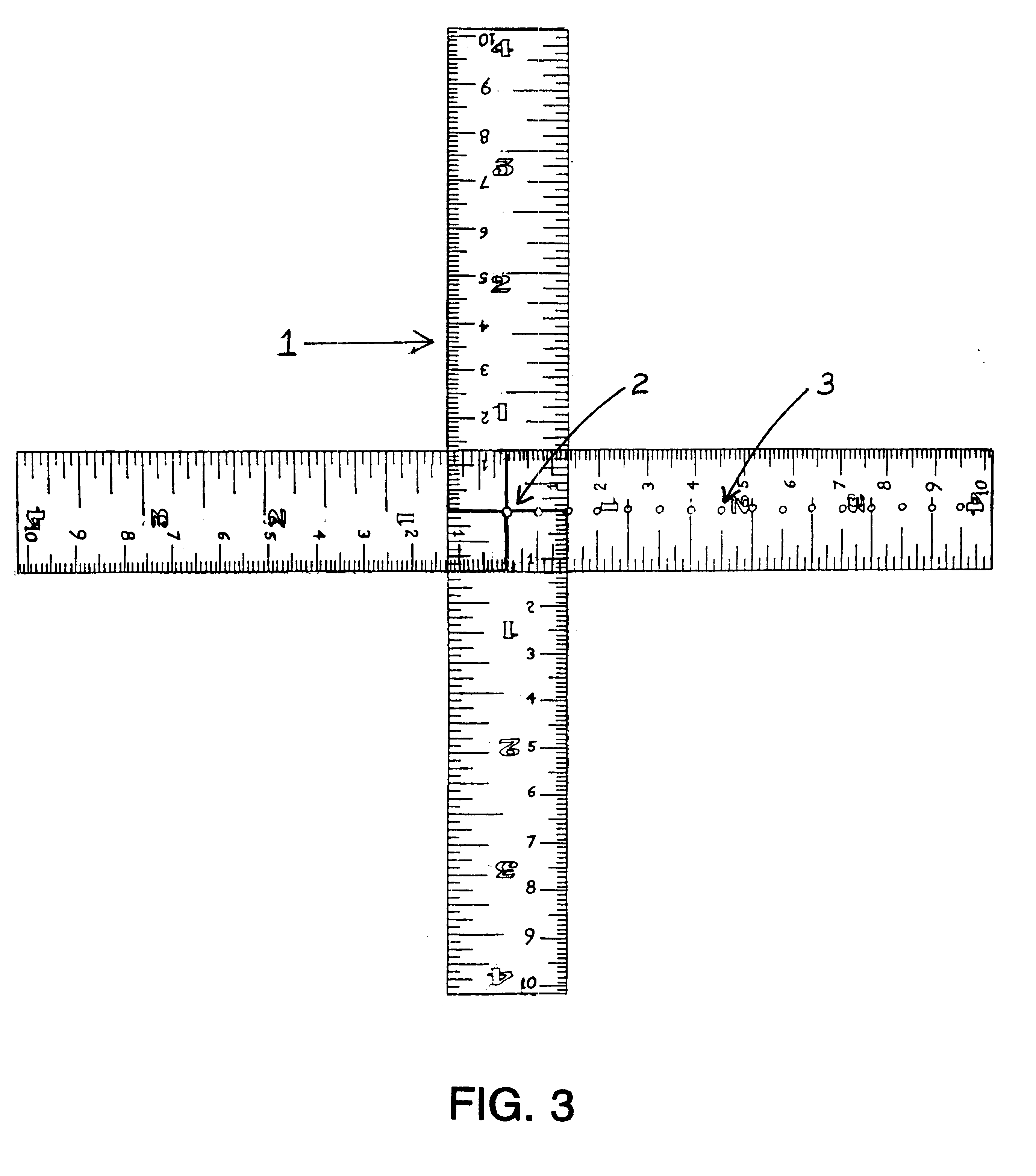

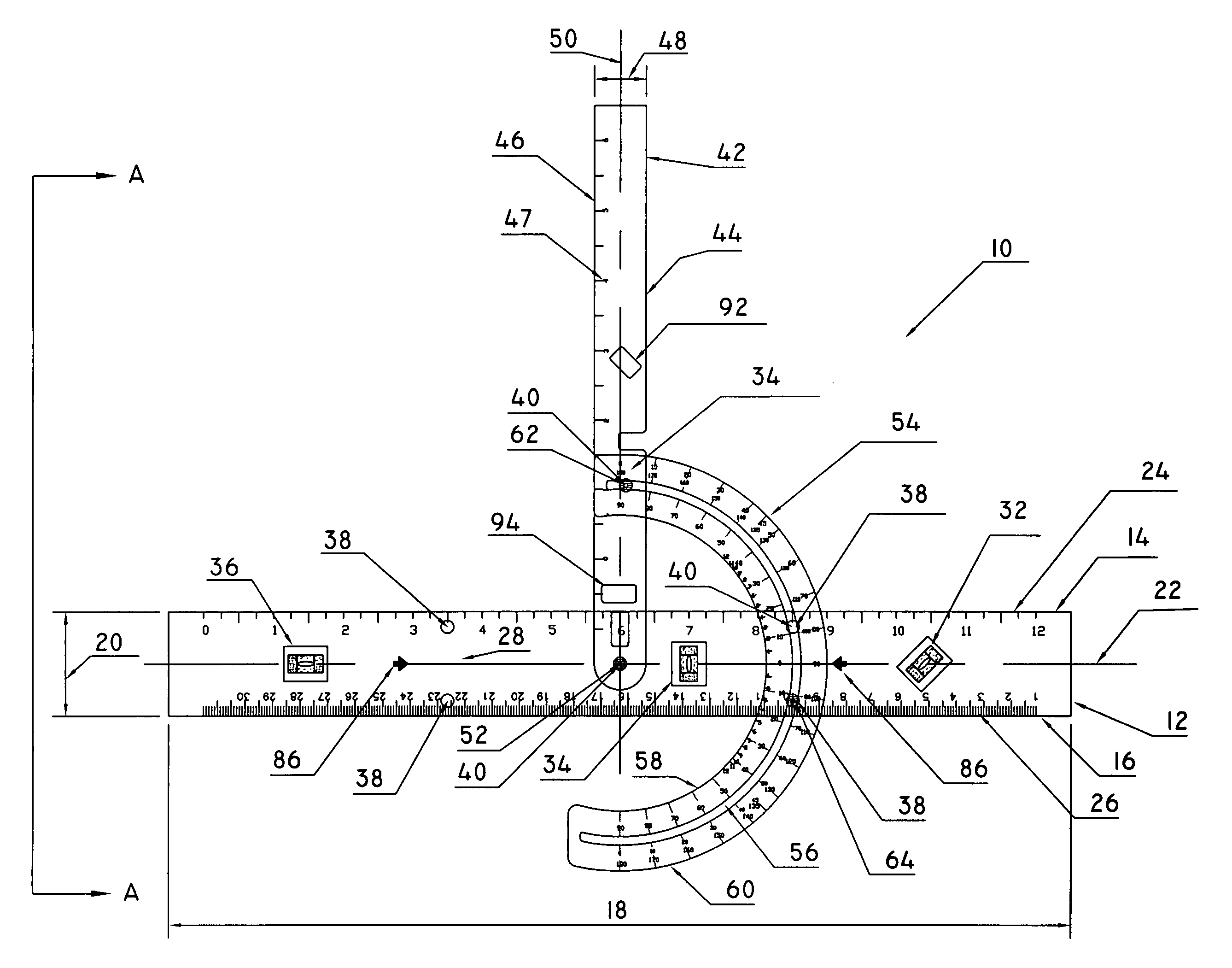

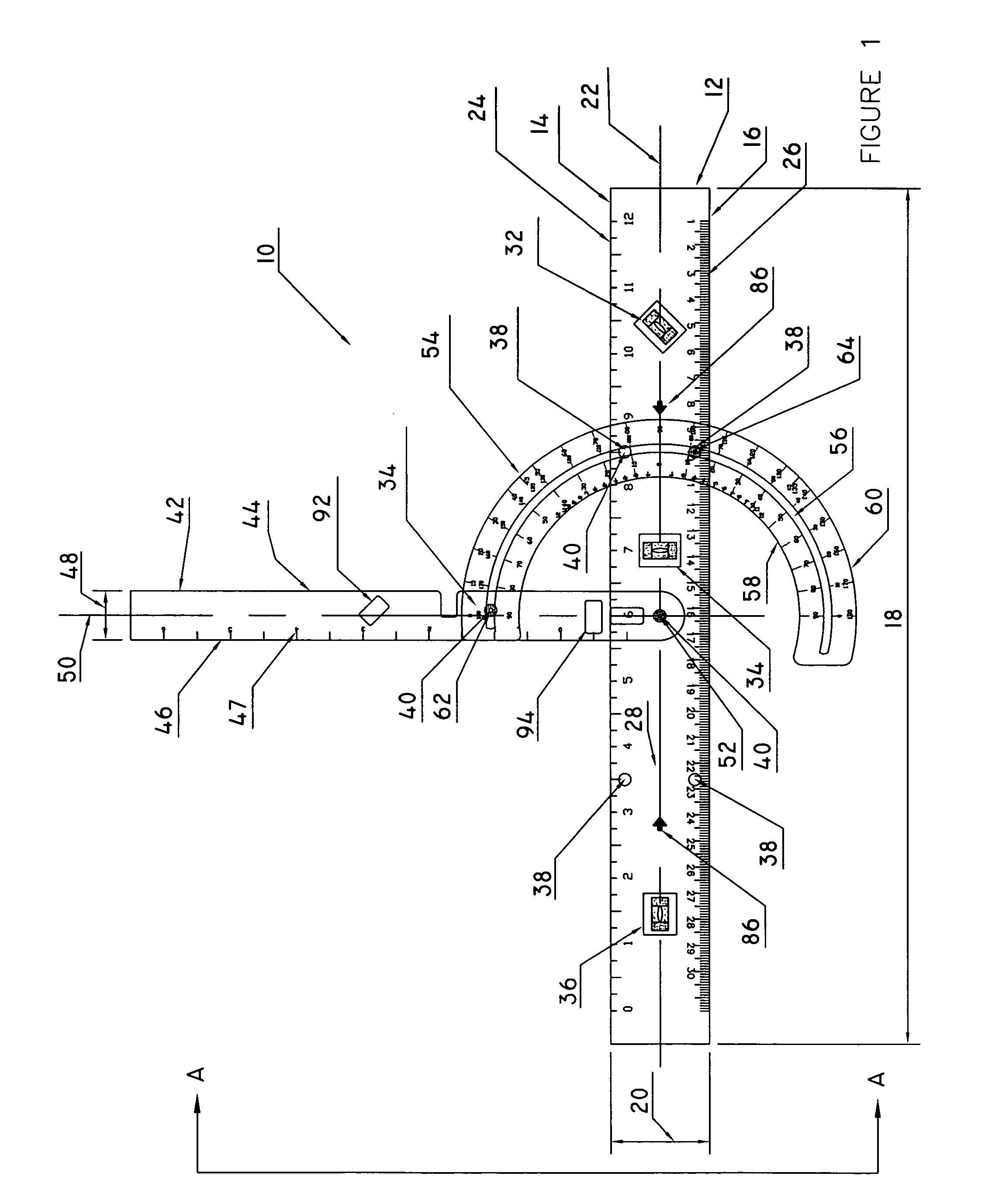

Measuring and drafting tool

This Measuring and Drafting Tool relates to a new and useful type of measuring and drafting tool that may be used to accomplish a plurality of functions using a singular tool. These functions include application as a ruler, straight edge, T-square, square or squaring tool, center gage, an edge transcribing and duplicating tool, and as a tool for striking circles and circle arcs. Some modified embodiments of the Measuring and Drafting Tool are also capable of angle measurement and protractor functions, and may also include one or more bubble levels incorporated into the ruler segments, thereby allowing the user to check if a horizontal surface is level.

Owner:WOLF SIGRID HAMMER

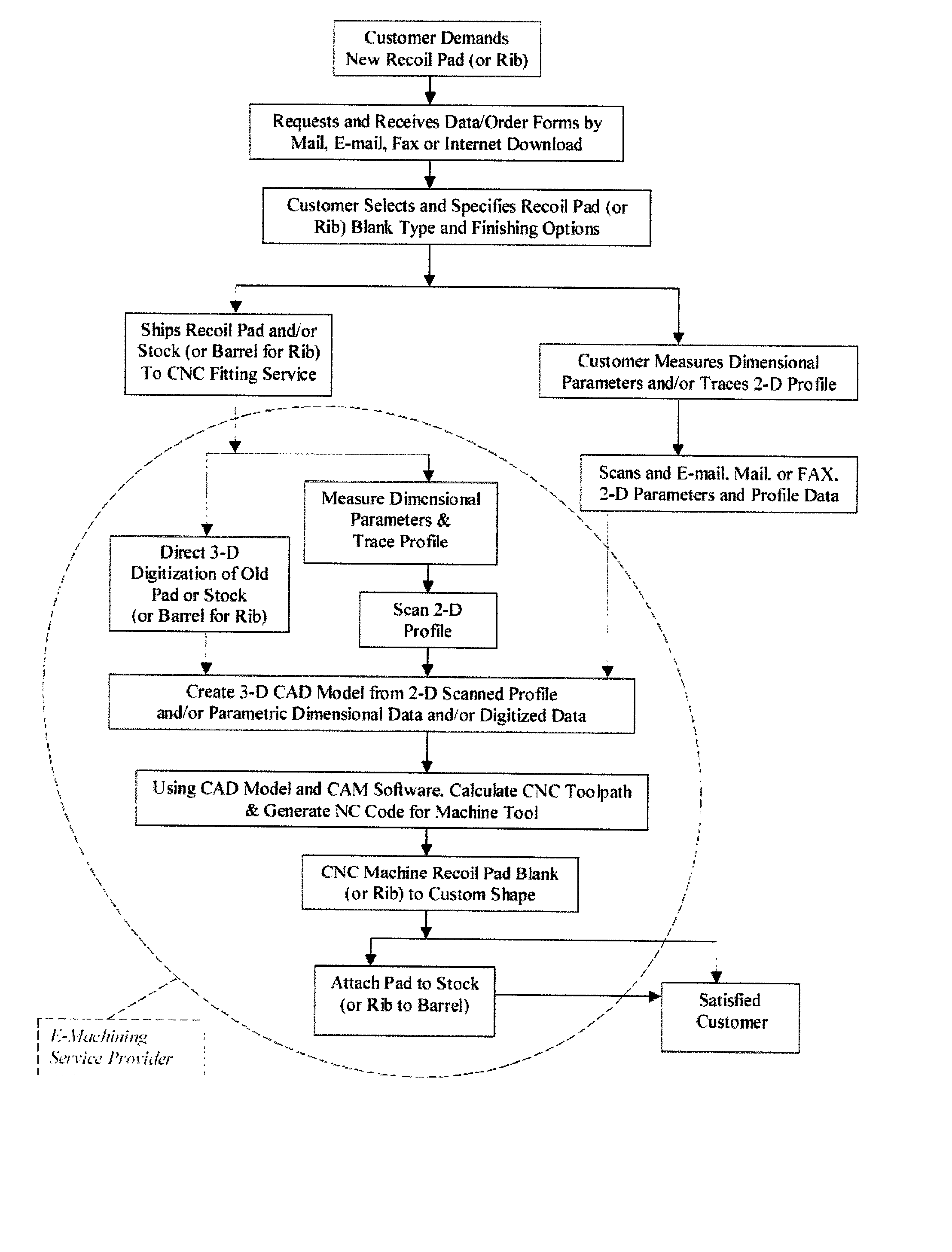

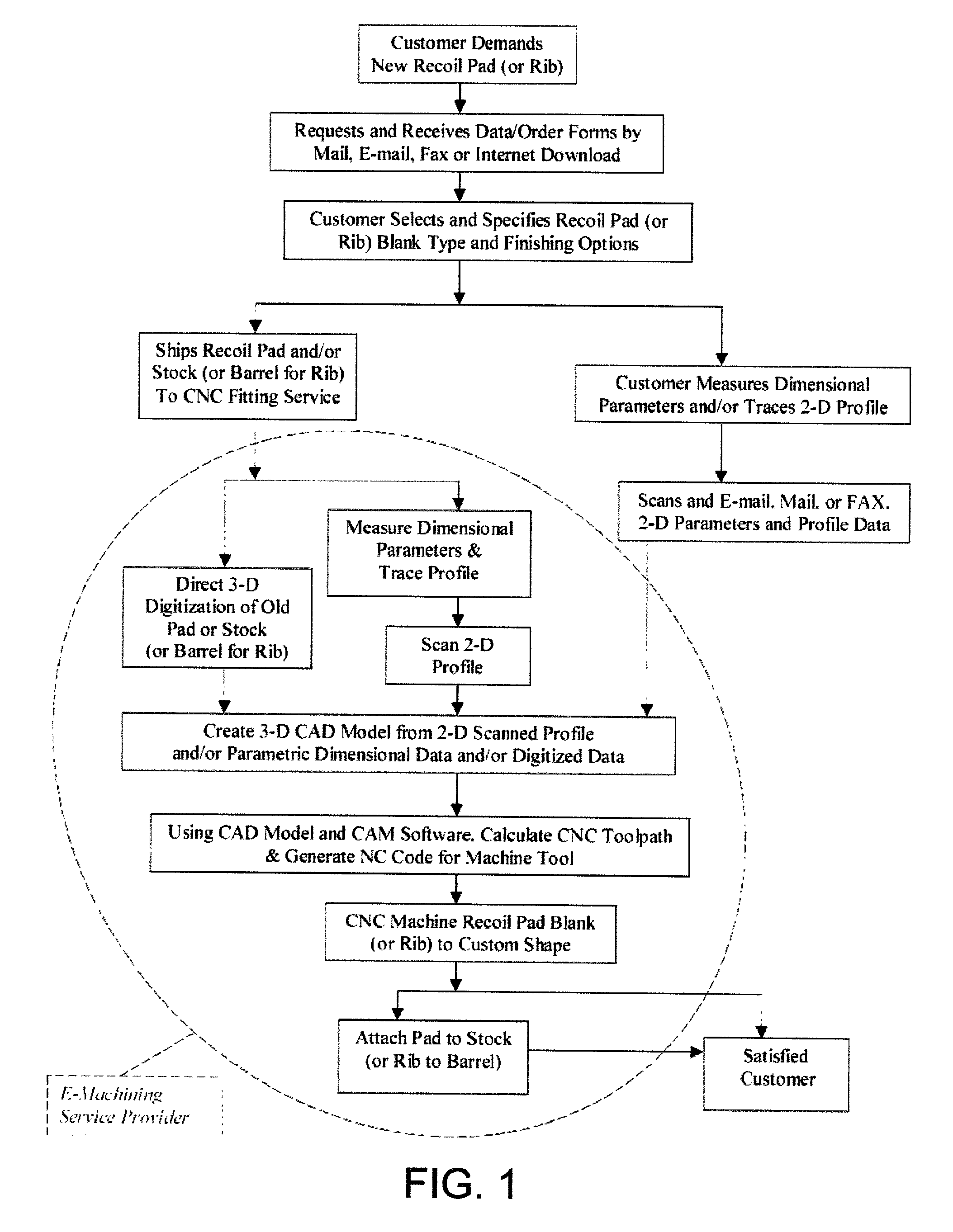

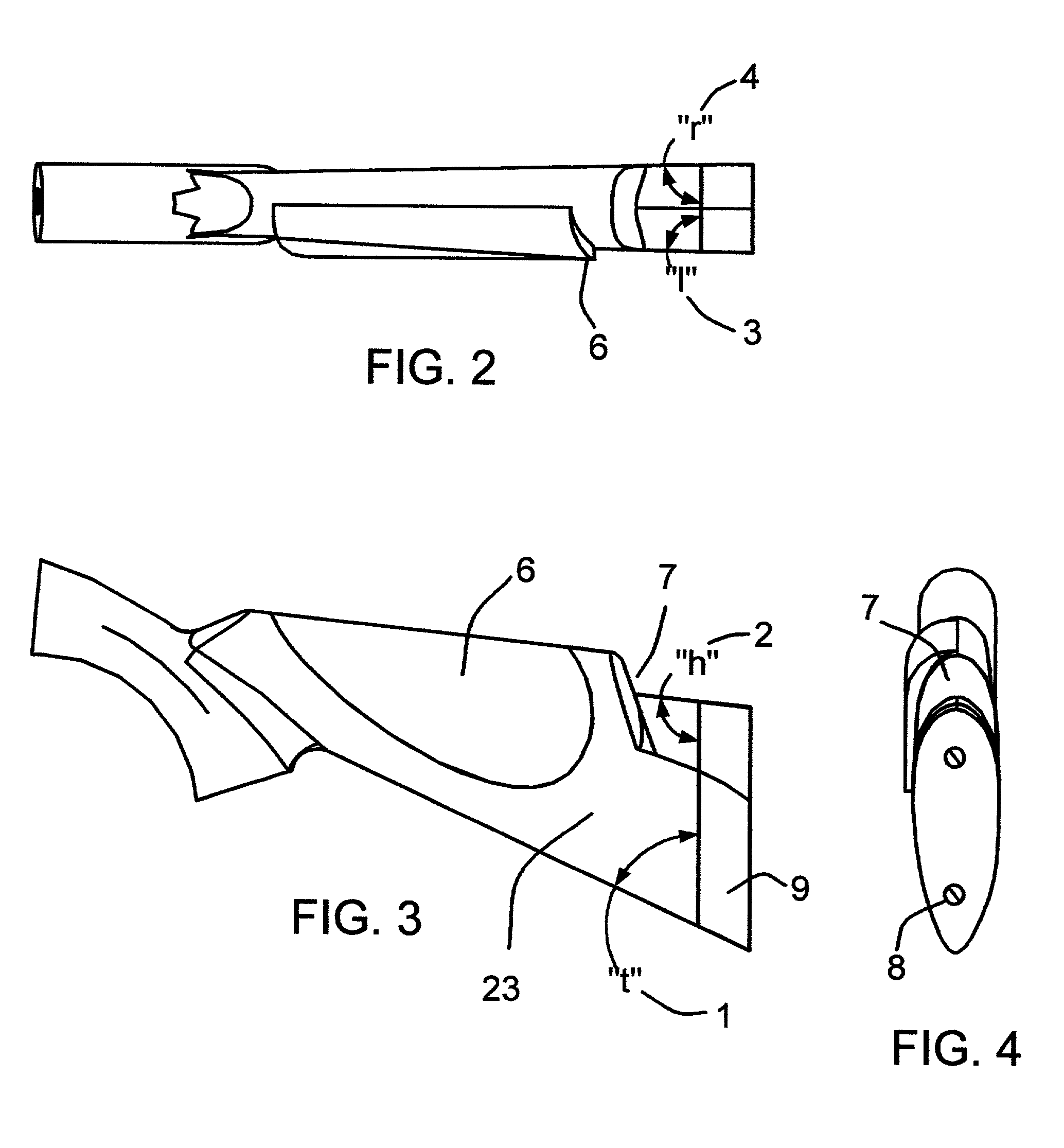

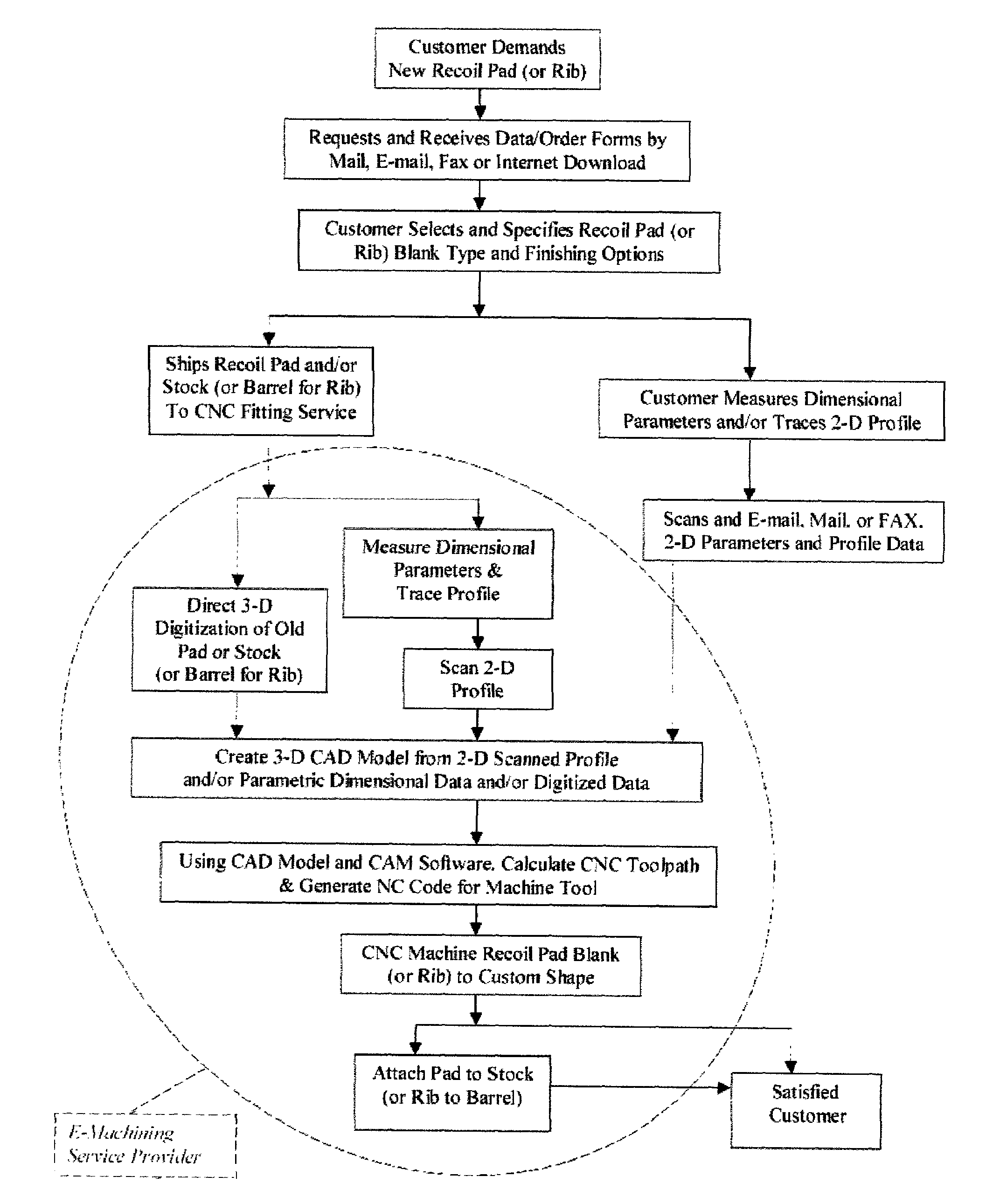

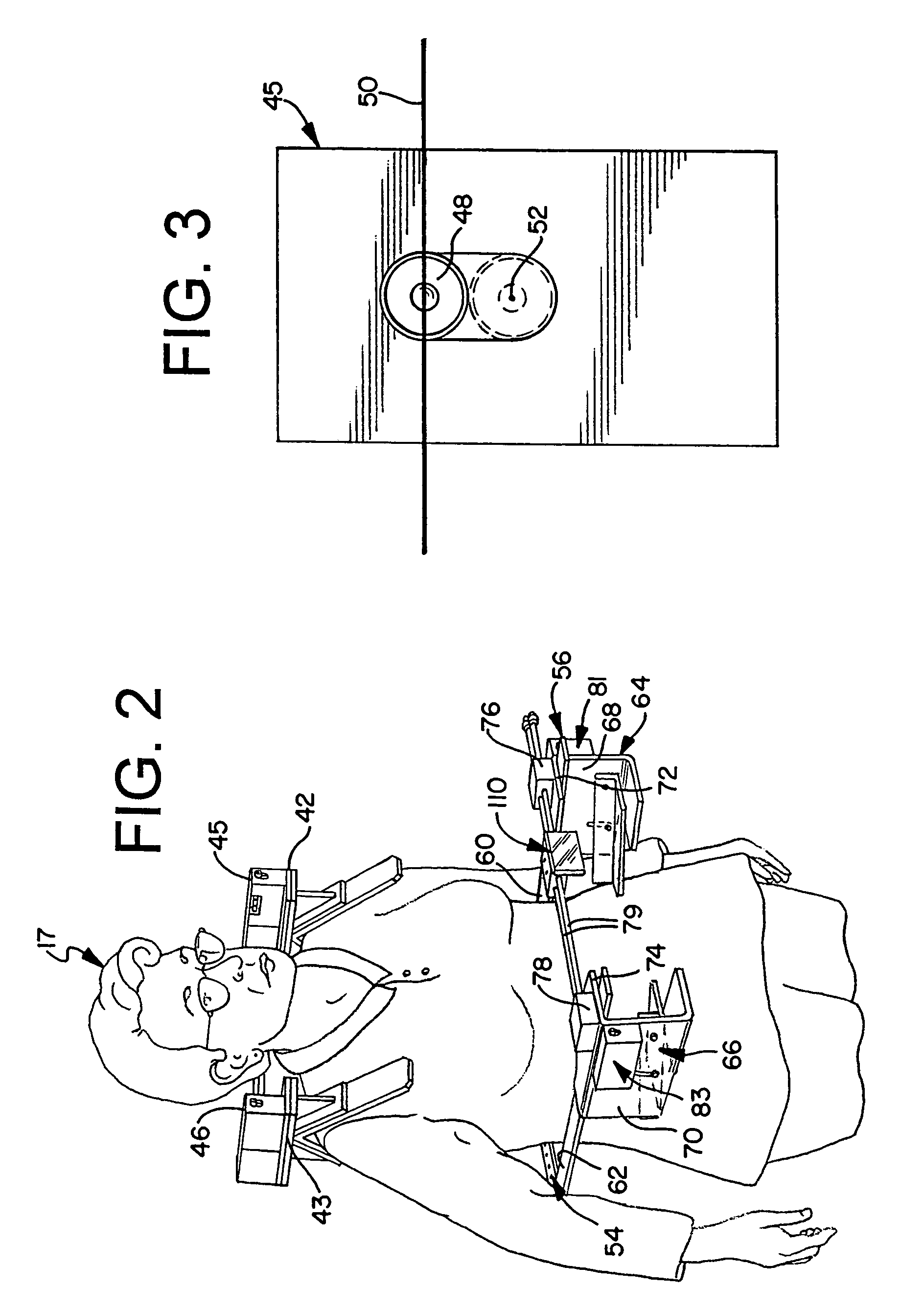

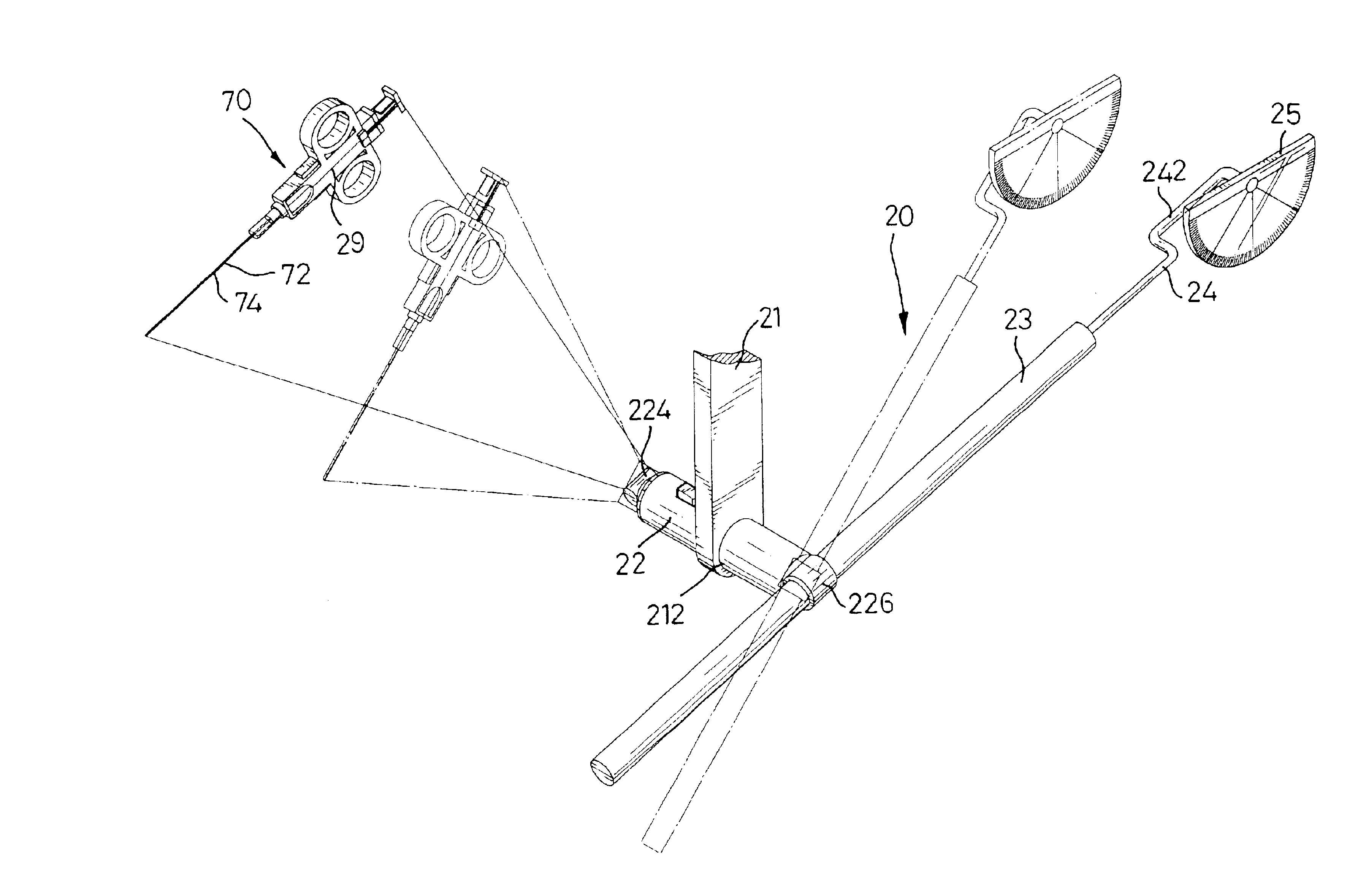

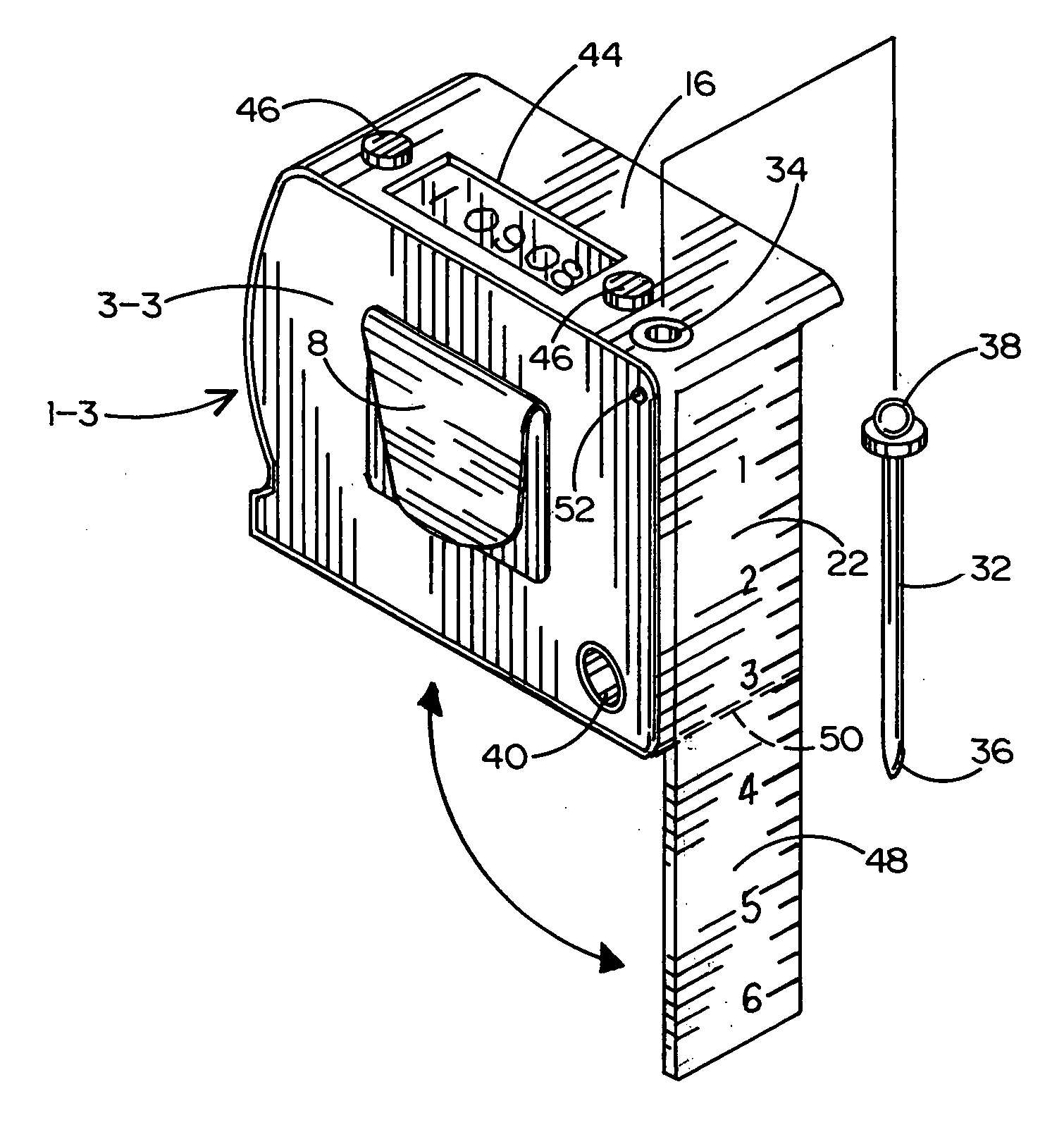

Method and apparatus for precisely fitting, reproducing, and creating 3-dimensional objects from digitized and/or parametric data inputs using computer aided design and manufacturing technology

InactiveUS20020114537A1Computer controlSimulator controlComputational scienceManufacturing technology

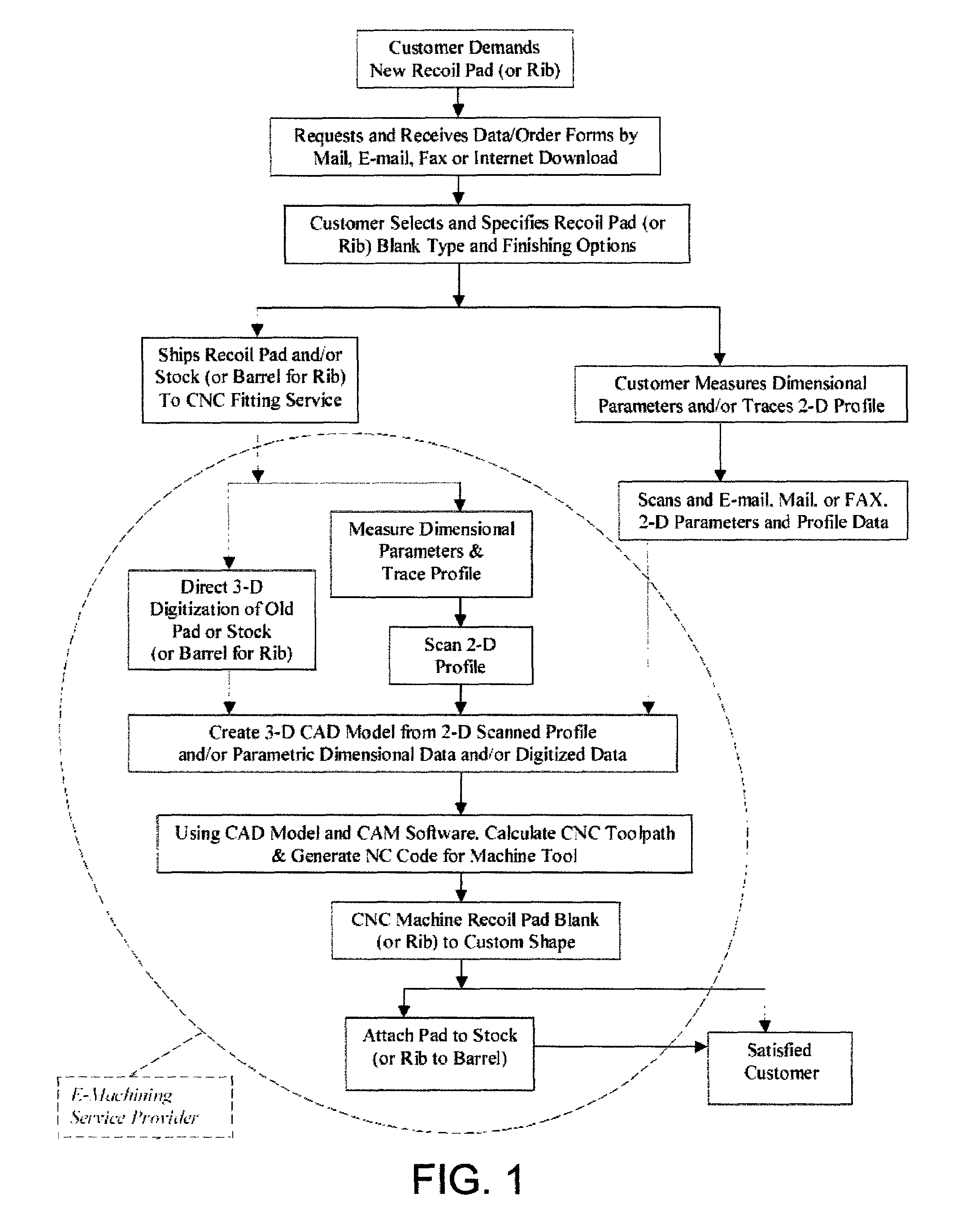

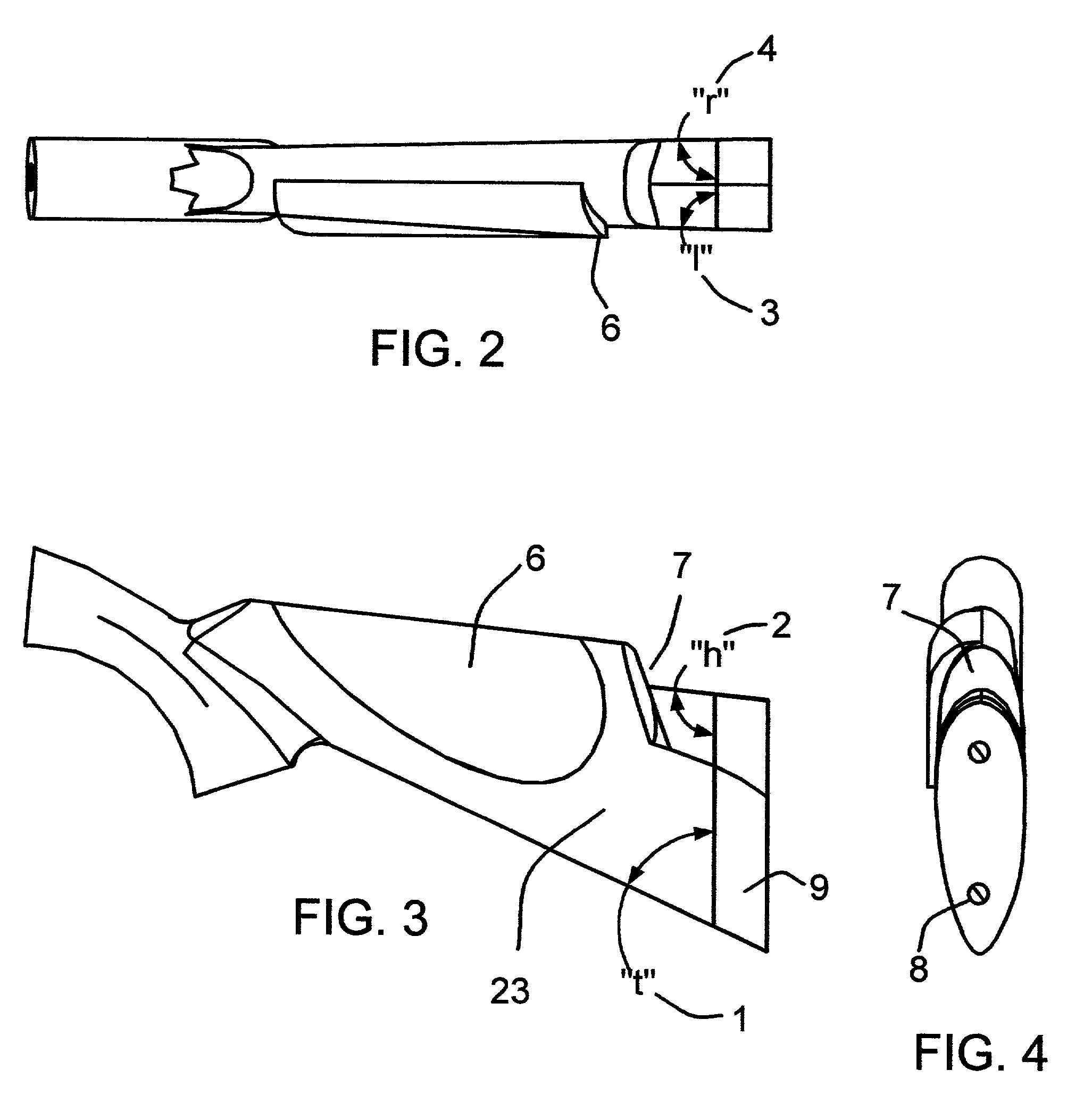

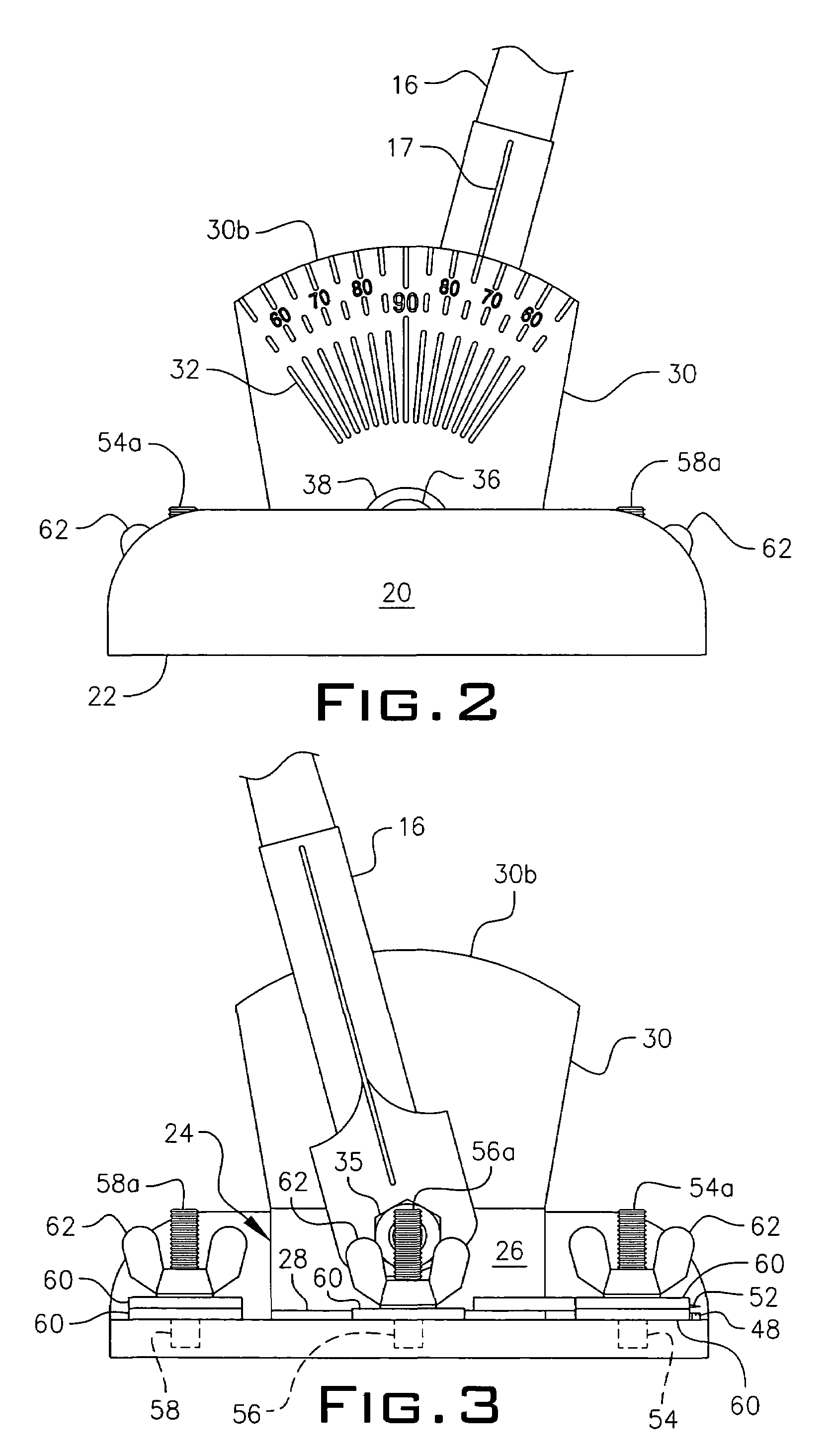

A high-technology method for creating, reproducing, and or precisely fitting custom appendages to topographically complex structures. The method comprises a combination of novel measurement techniques in conjunction with computerized modeling and machining processes applied to achieve a virtually perfect tailored fit with mating structures. The method does not require the physical presence of the mating structure so the modeling and machining operations may be conducted at a separate location based solely on parametric dimensional and / or graphical data inputs and a customized data form Said data may be transmitted conventionally or electronically as by fax or the internet. The invention includes a printed virtual protractor tool (16) for accurately measuring angles. A means for direct digitization of the required topological data input is also provided. The novel aspects of this invention can be combined with conventional fitting equipment and processes. The scope of this invention is exceedingly broad with a variety of potential applications cited. Two examples are presented to illustrate utility in the context of complex operations routinely encounter by gunsmiths in fitting recoil pads (9) to gunstocks (23) and fitting sighting ribs (37) to gun barrels (42).

Owner:SUTULA JR DANIEL P

Method and apparatus for precisely fitting, reproducing, and creating 3-dimensional objects from digitized and/or parametric data inputs using computer aided design and manufacturing technology

InactiveUS7225050B2Effective and economicalFacilitate efficient removal of materialComputer controlSimulator controlManufacturing technologyThe Internet

A high-technology method for creating, reproducing, and or precisely fitting custom appendages to topographically complex structures. The method comprises a combination of novel measurement techniques in conjunction with computerized modeling and machining processes applied to achieve a virtually perfect tailored fit with mating structures. The method does not require the physical presence of the mating structure so the modeling and machining operations may be conducted at a separate location based solely on parametric dimensional and / or graphical data inputs and a customized data form. Said data may be transmitted conventionally or electronically as by fax or the internet. The invention includes a printed virtual protractor tool (16) for accurately measuring angles. A means for direct digitization of the required topological data input is also provided. The novel aspects of this invention can be combined with conventional fitting equipment and processes. The scope of this invention is exceedingly broad with a variety of potential applications cited. Two examples are presented to illustrate utility in the context of complex operations routinely encounter by gunsmiths in fitting recoil pads (9) to gunstocks (23) and fitting sighting ribs (37) to gun barrels (42).

Owner:SUTULA JR DANIEL P

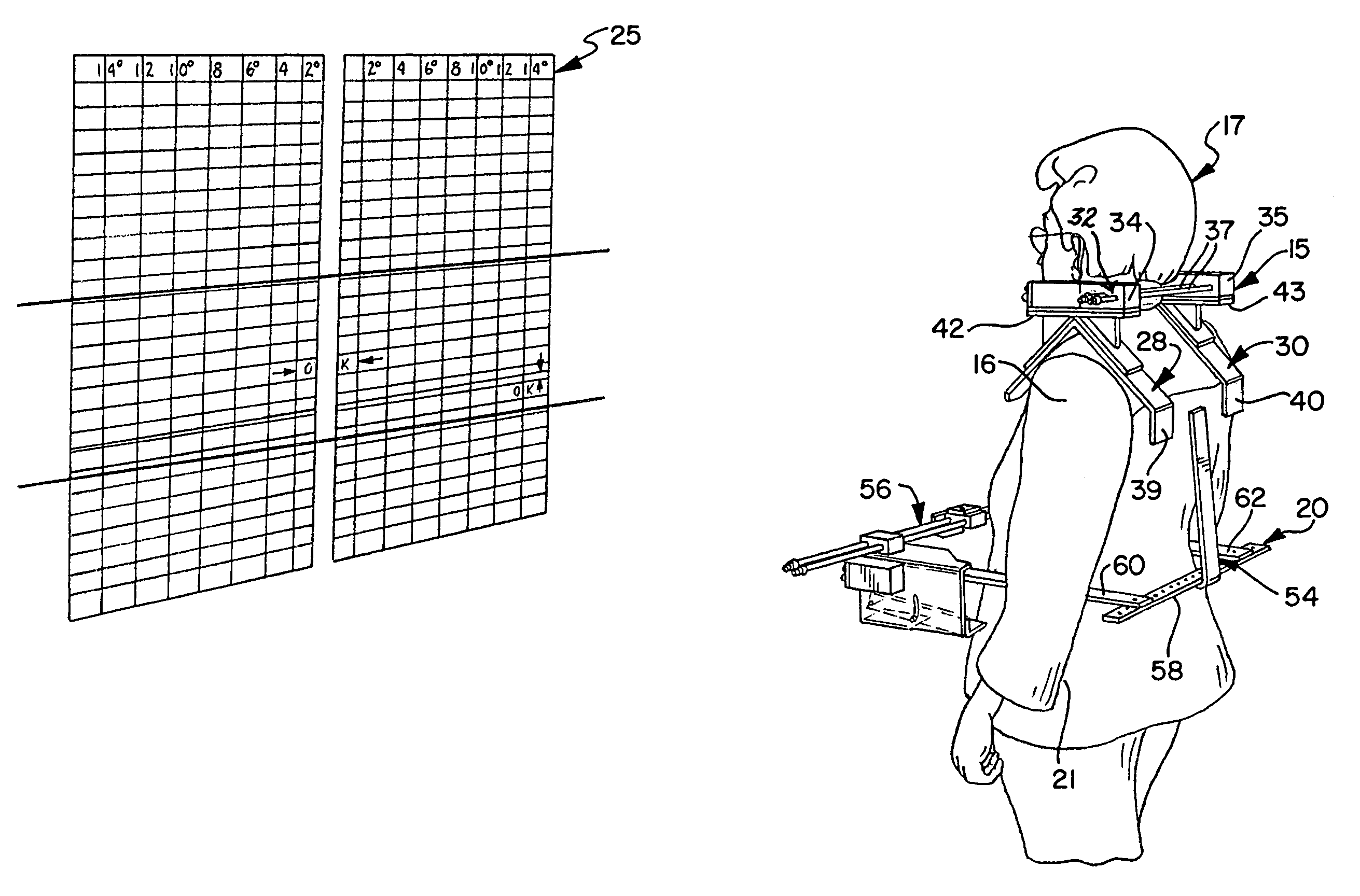

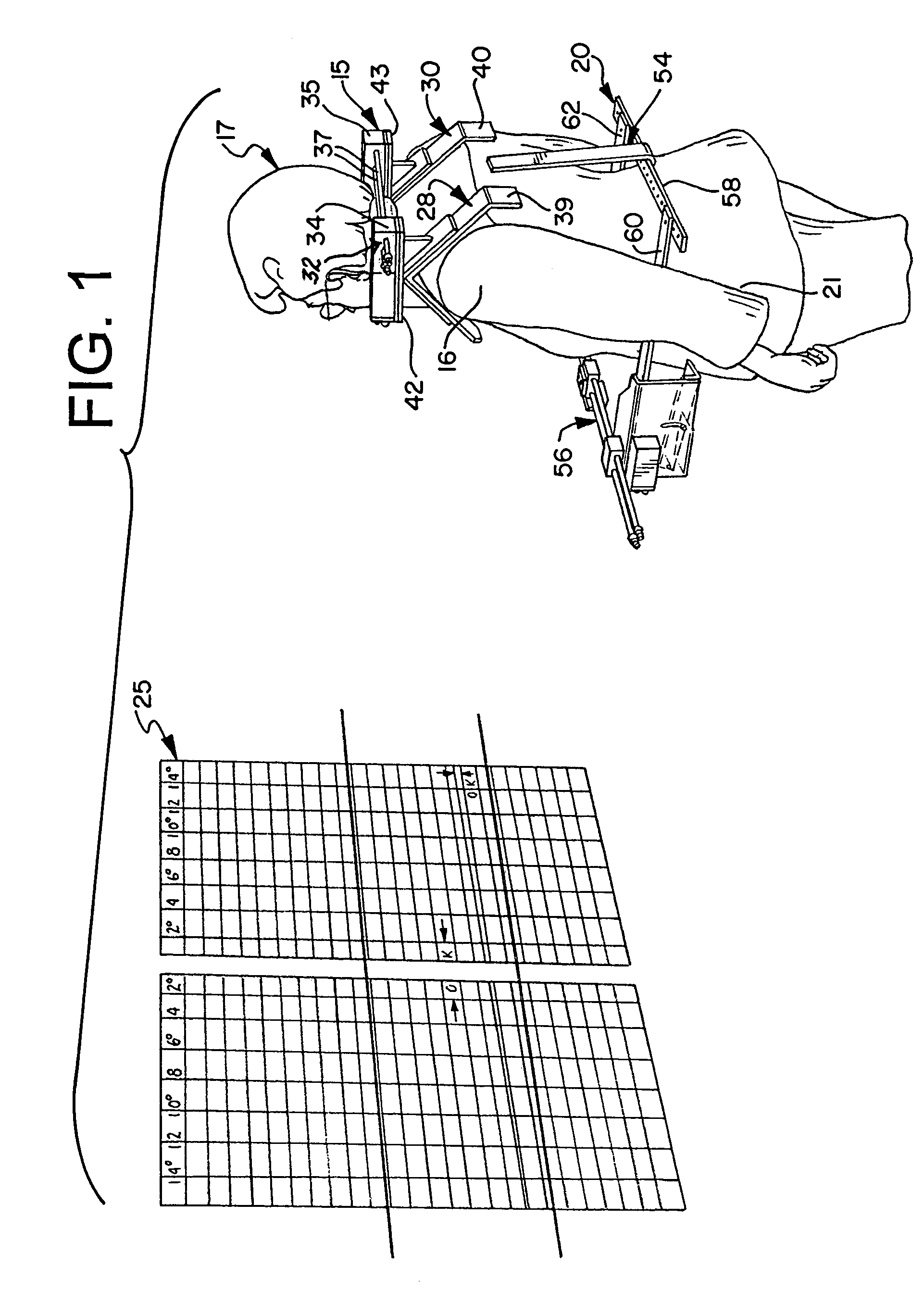

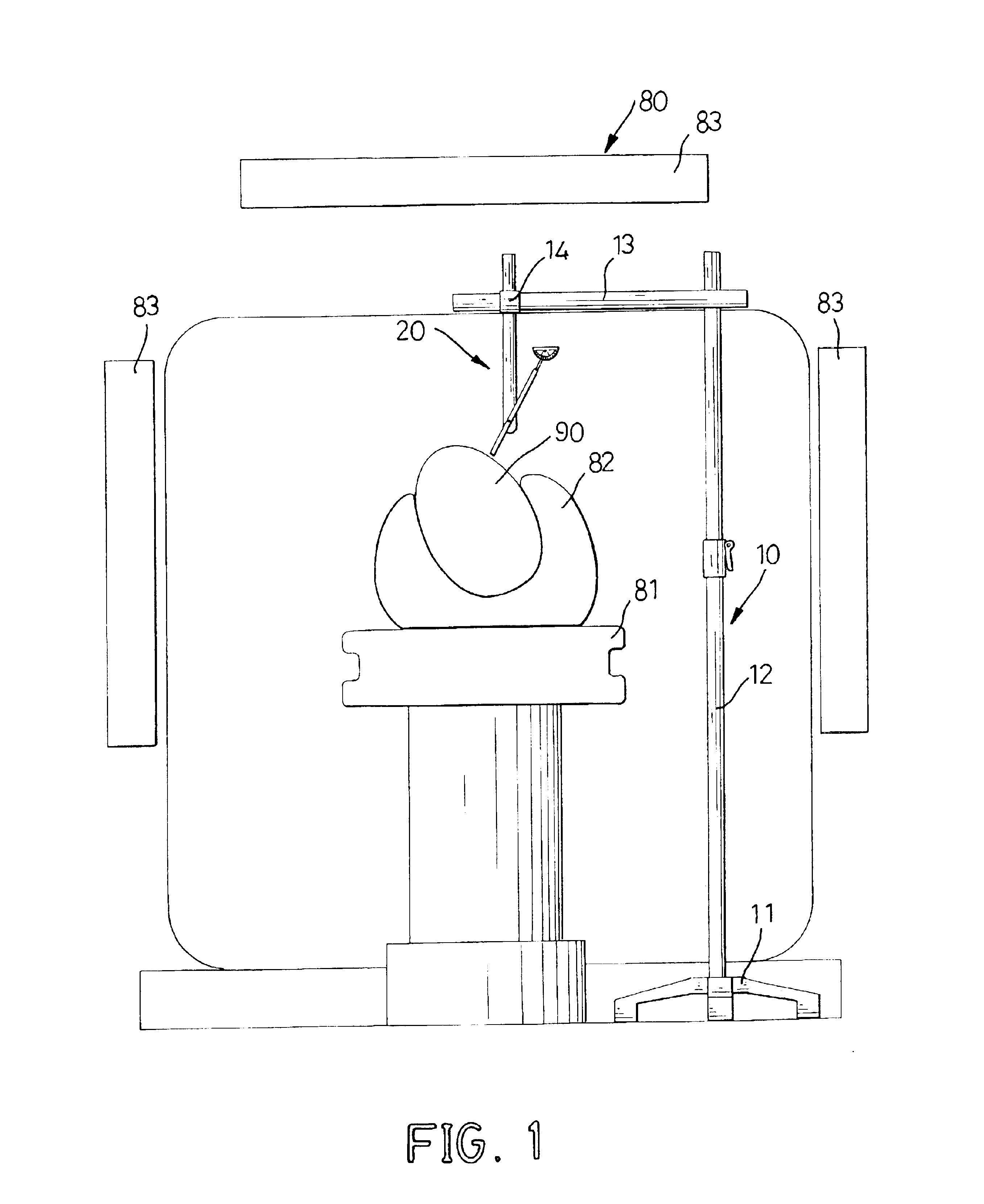

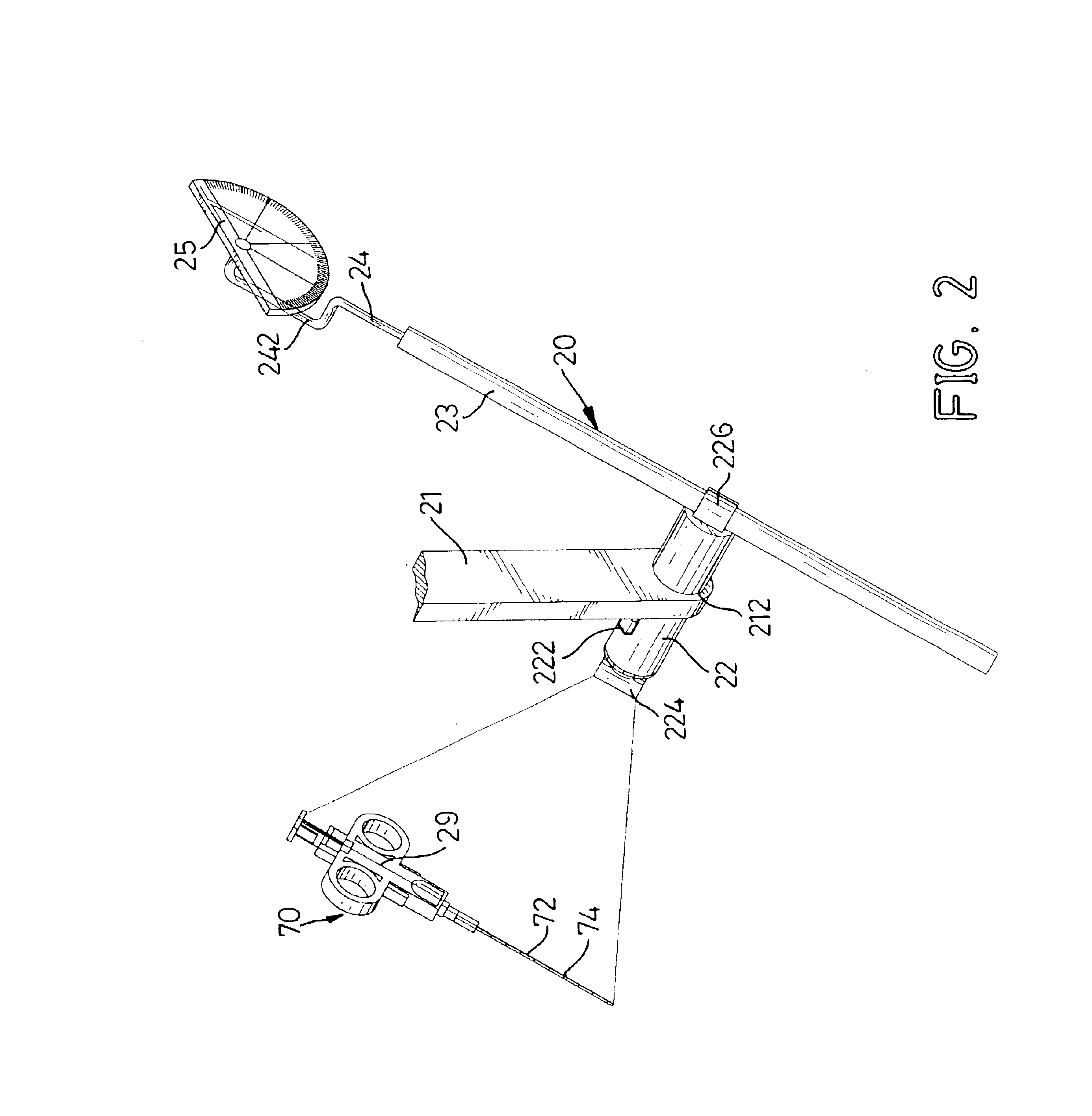

Method and apparatus for measuring spinal distortions

InactiveUS7131952B1Accurately and inexpensively overcomesReduce usageMeasurement devicesSurgeryProtractorPelvic girdle

A method and apparatus for measuring the spinal distortions of a person with laser sources prior to and after chiropractic treatment of a patient to differentiate between spinal distortions prior to and subsequent to any treatment. The apparatus includes a wall chart having measurement indicia, shoulder and / or pelvic girdle harnesses or frames mounted on a patient and each having means for projecting laser line and / or dot beams onto the wall chart for measuring spinal tilt and torque. A unique protractor is provided to coact with the wall chart and the laser line beam to measure spinal tilt. A laser source for projecting a vertical line beam measures abnormalities in posture by projecting the beam to a side of a patient.

Owner:DICKHOLTZ SR MARSHALL +1

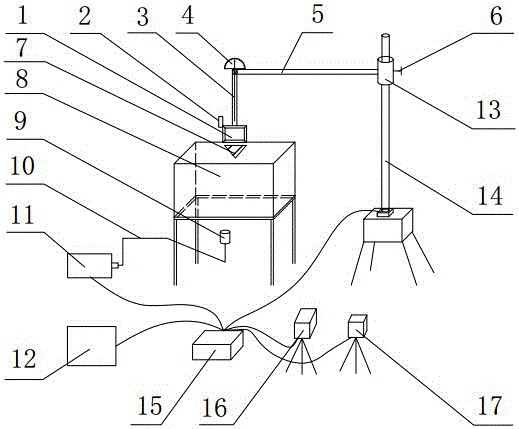

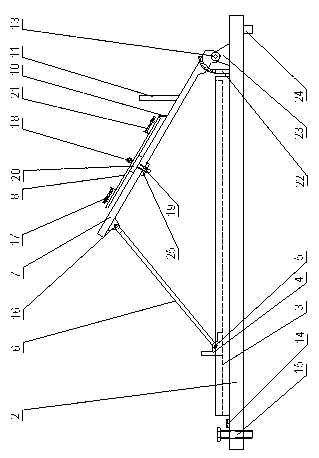

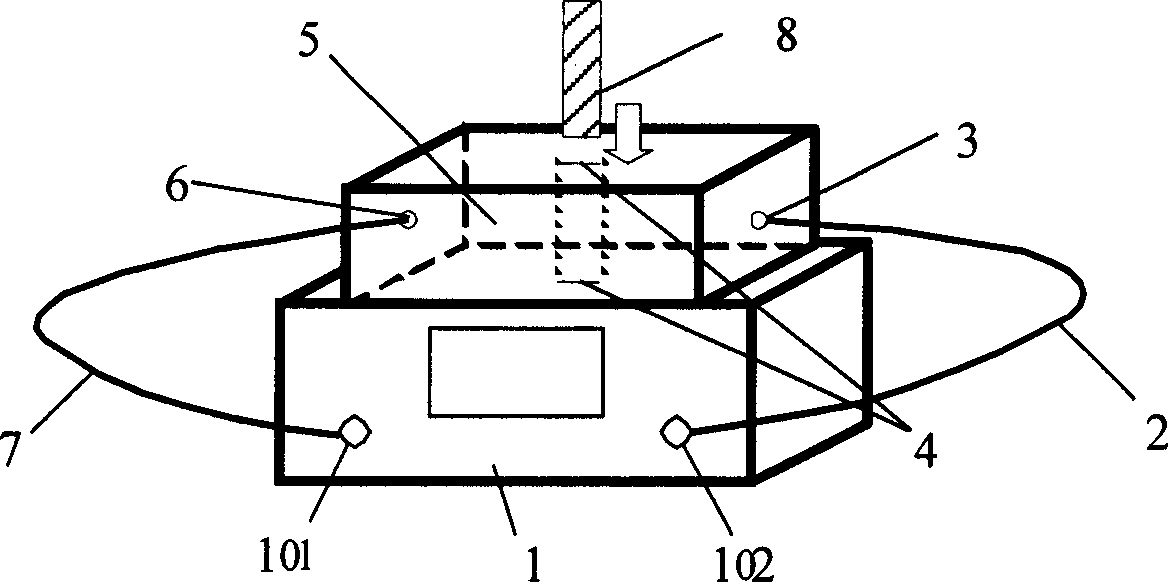

Experiment device for stable multi-angle entering-into-water of object

The invention belongs to hydraulic experiment model facilities, and particularly relates to an experiment device for stable multi-angle entering-into-water of an object. The experiment device comprises a transparent water tank, an electromagnetic releasing device and a data acquisition system. The electromagnetic releasing device comprises supporting columns and a vertical rod. One end of the vertical rod is hinged with a transverse supporting rod through a first hinge joint, and the other end is hinged with an electromagnet block through a second hinge joint, wherein a water entering object is attracted with the bottom of the electromagnet block. A transverse water entering angle adjusting pointer and a longitudinal water entering angle adjusting pointer are vertically fixed on different sides of the vertical rod. A transverse water entering angle protractor is fixedly arranged on the transverse supporting rod. A longitudinal water entering angle protractor is fixedly arranged on the electromagnet block. The electromagnetic releasing device is connected with an industrial control computer through a cable. The data acquisition system comprises a synchronization instrument, a laser transmitter, a high-speed image photographing instrument and a high-speed camera, wherein the synchronization instrument is controlled by the industrial control computer. The experiment device can stably release water entering objects with different shapes and furthermore can accurately control the water entering angles of the objects.

Owner:ZHEJIANG UNIV

Tool for determining optimal putter characteristics

A tool has an adjustable lie angle, face angle, weight, and shaft length and is used by a golfer to adjust a putter to the optimal lie angle, face angle, weight and shaft length for that golfer. The tool head has a face plate and a sole disposed normal to one another. An angle member has a vertical wall disposed parallel to the face plate and a horizontal wall that overlies the sole. A hosel is pivotally mounted to the vertical wall and a first protractor is fixedly secured to the vertical wall. A marker on the hosel indicates the lie angle on the first protractor. A second protractor secured to the sole indicates a face angle when the shaft of the club is rotated about its axis. Weights are selectively added to the toe, heel, or mid-point of the putter head to determine an optimal weight and weight distribution.

Owner:RINKER JAMES

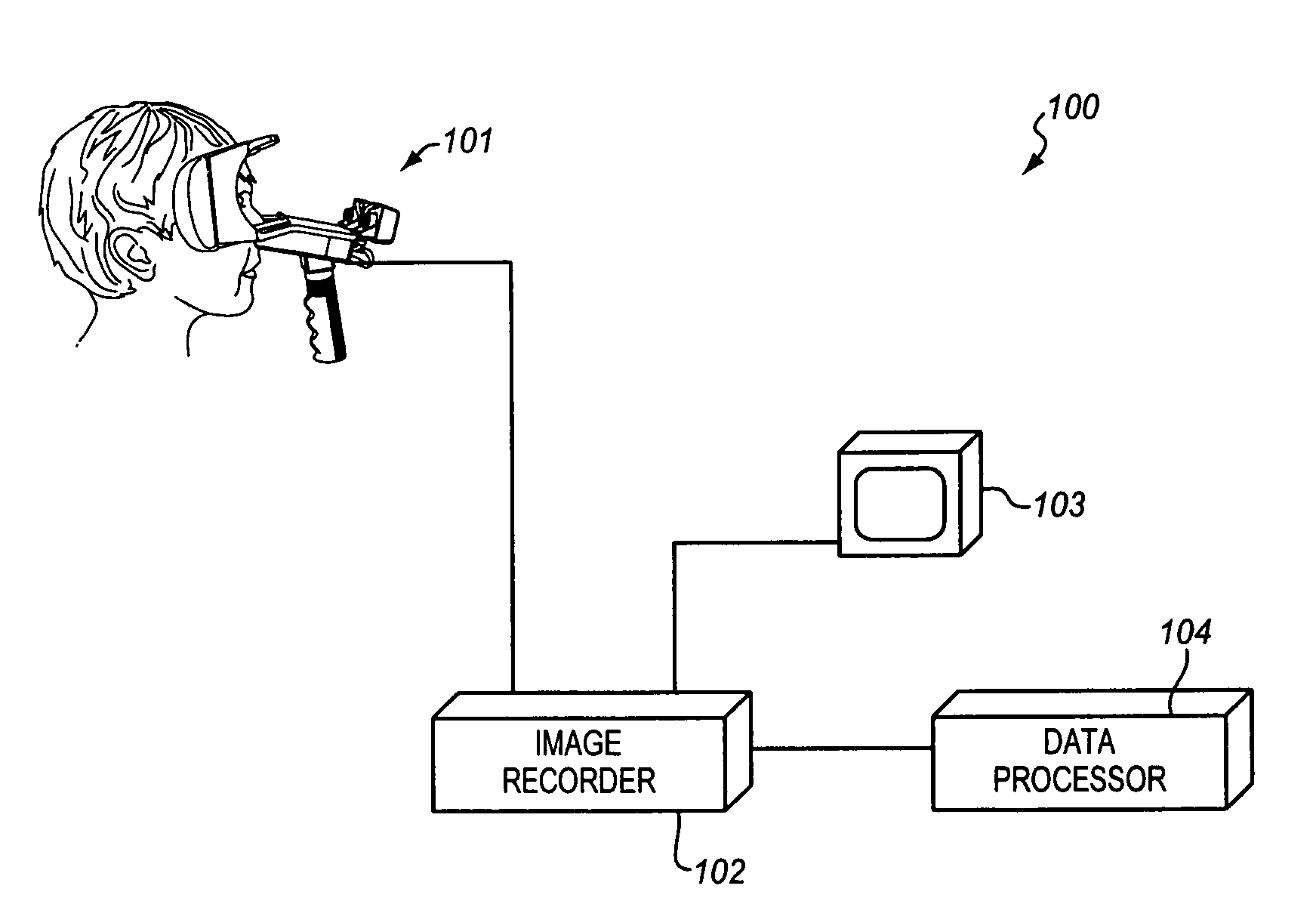

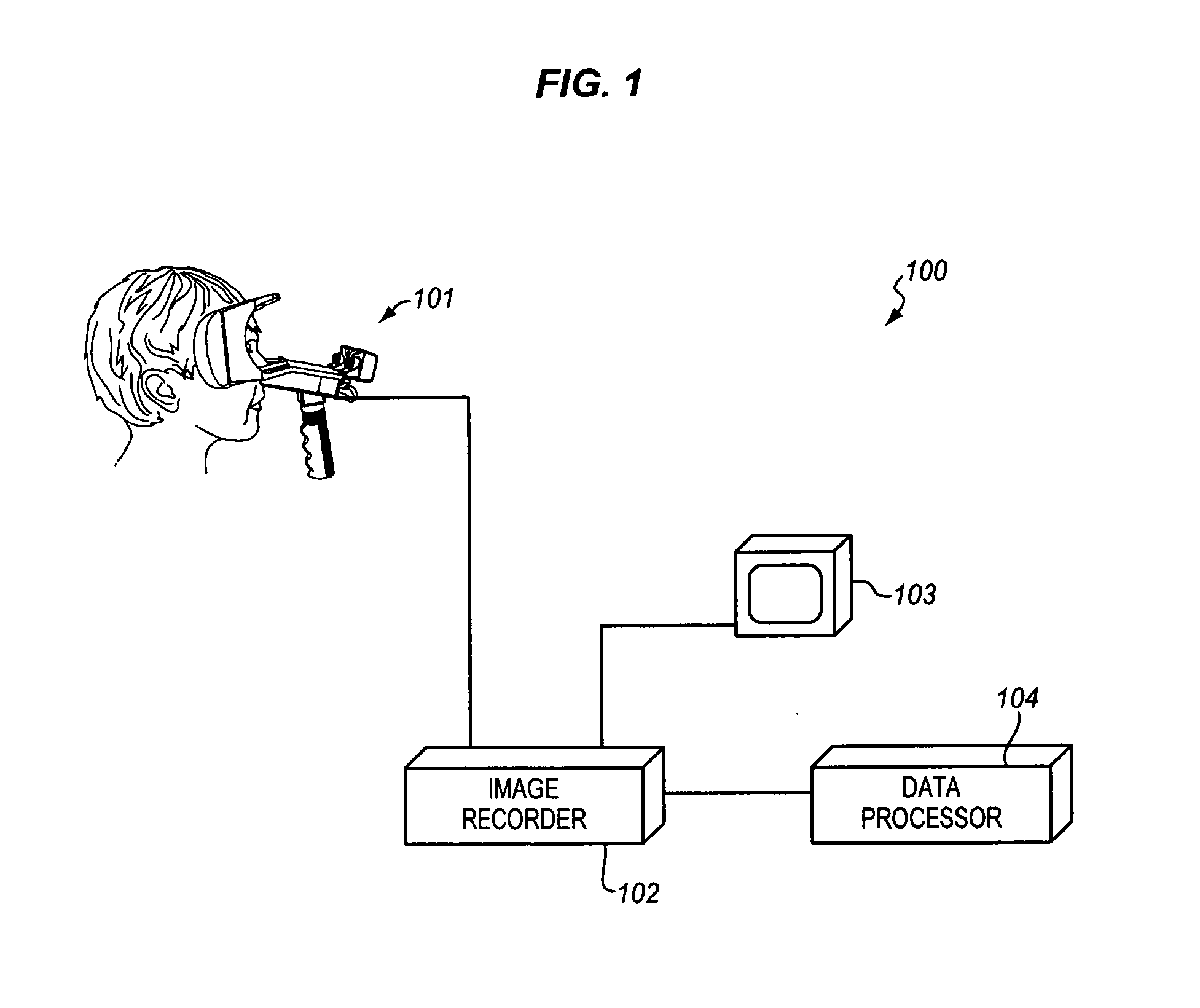

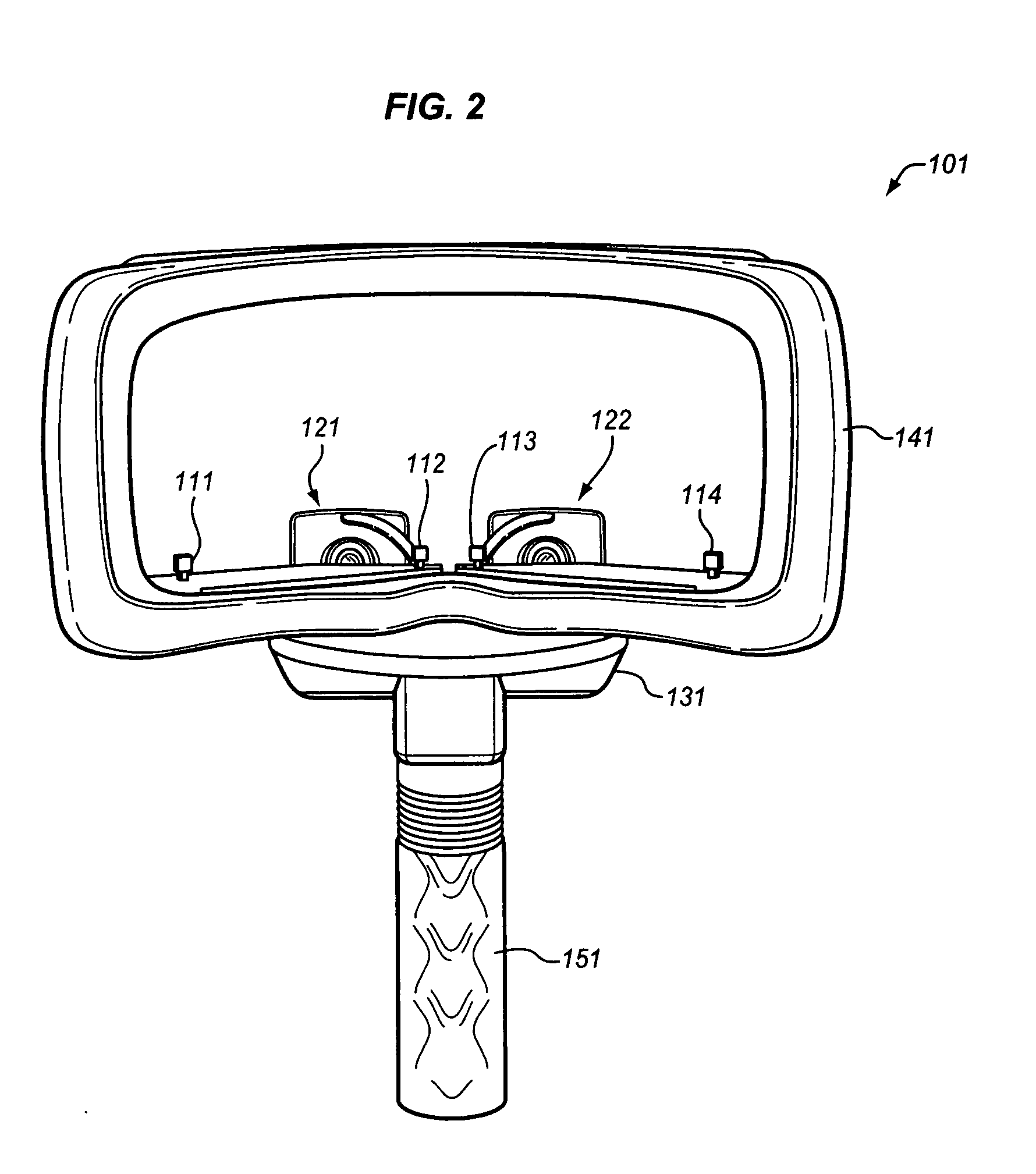

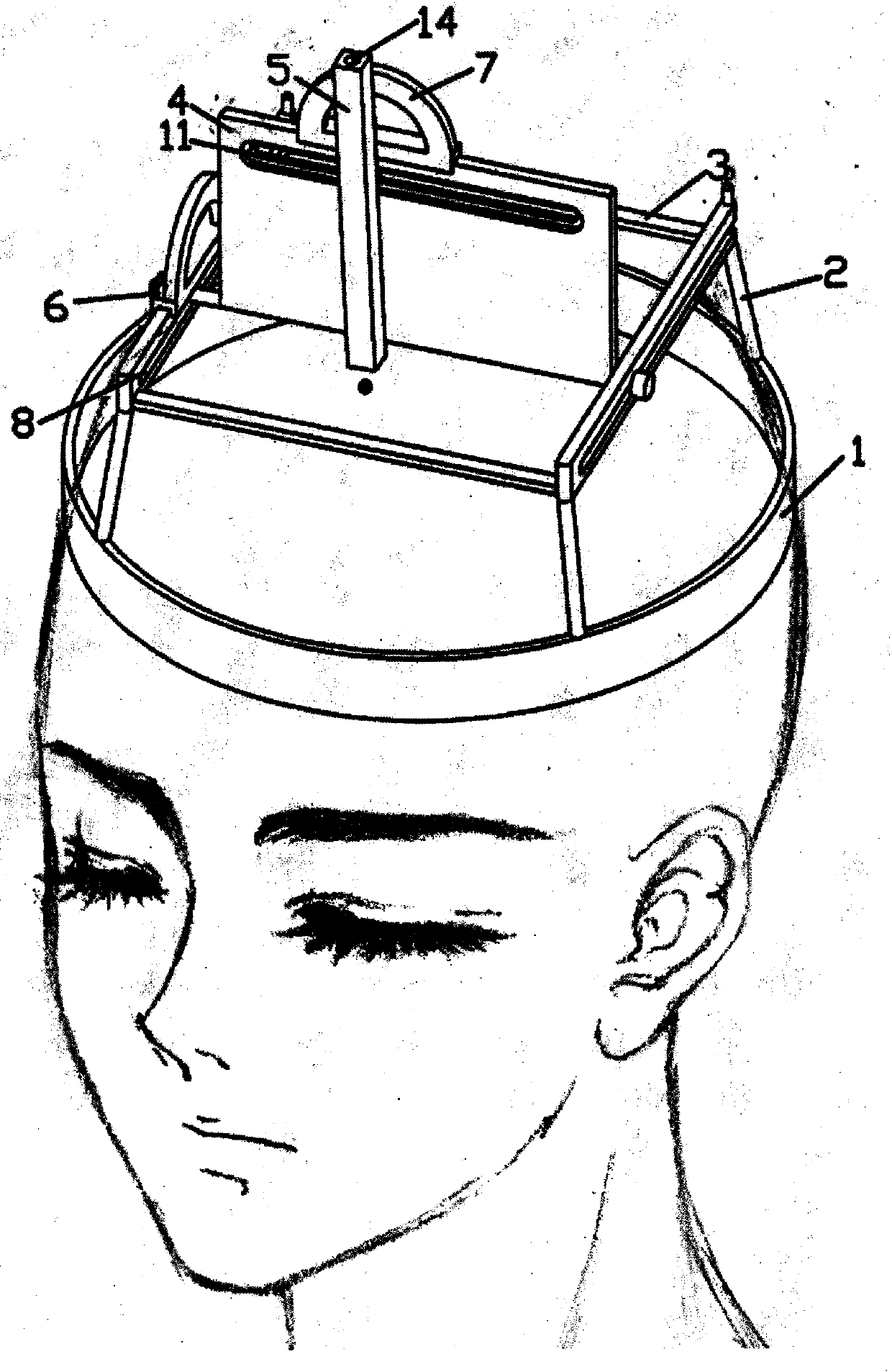

Image-based system to observe and document eye responses having a reflective protractor for measurement of stimulus position

ActiveUS20070236663A1Good for observationImprove responseHealth-index calculationEye diagnosticsFace sheetHeadphones

The image-based system is used to observe and document eye responses which can be used to implement the procedures defined in the Standardized Field Sobriety Test as well as the Drug Recognition Expert Program. These eye responses include pupil movement, as well as pupil size and responses, for either one or both eyes simultaneously. The system includes a headset against which the subject places their face. The faceplate has an opening through which illumination devices transmit beams of infrared light to illuminate the subject's eyes. A reflective protractor, having a scale imprinted thereon, is mounted on the headset above the eye opening and facing the test administrator to provide an image of the stimulus target that is used by the test administrator. Two imaging devices are mounted on the headset opposite the eye opening to generate images of the subject's illuminated eyes. The generated images are transmitted to an image recording device for storage and an image display device for display to a test administrator.

Owner:VISIONETX

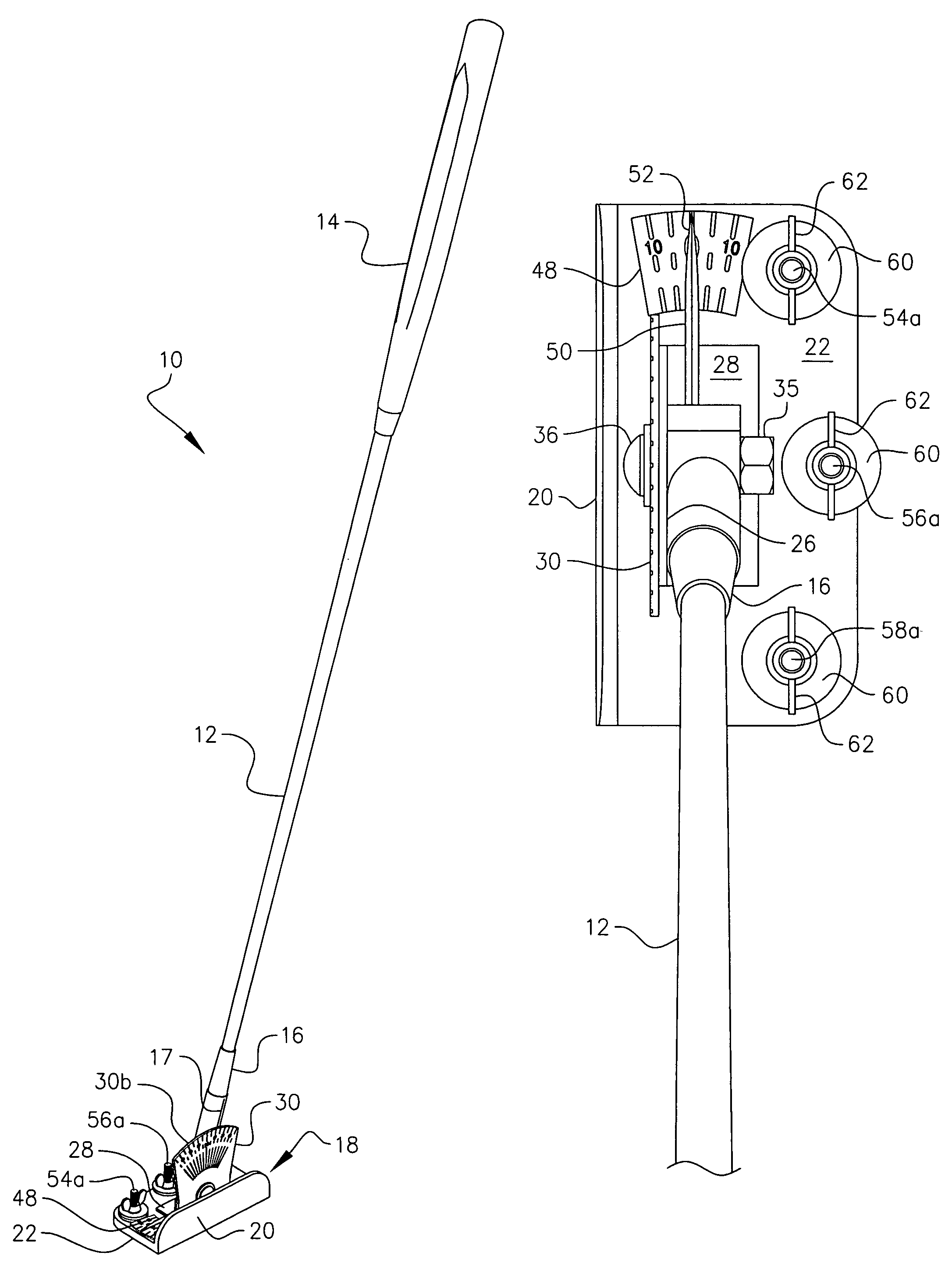

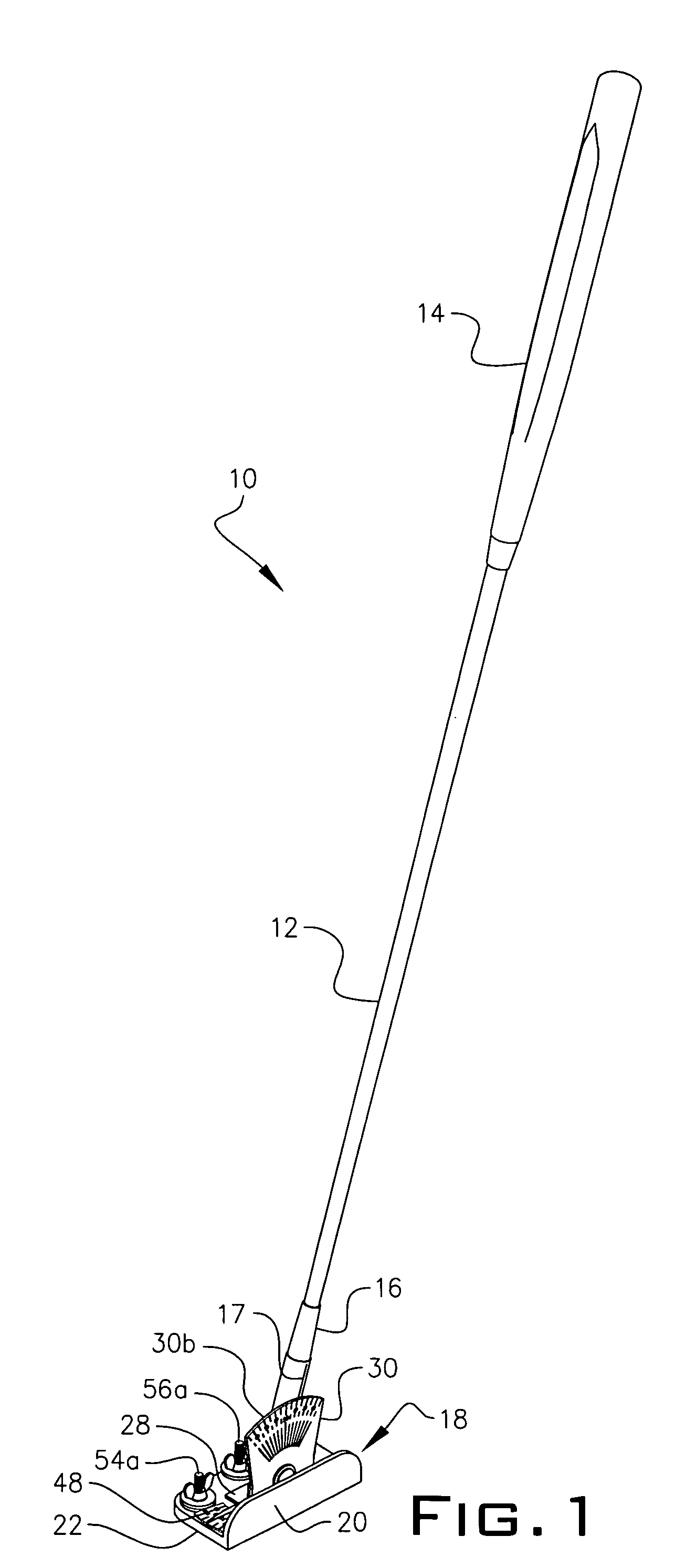

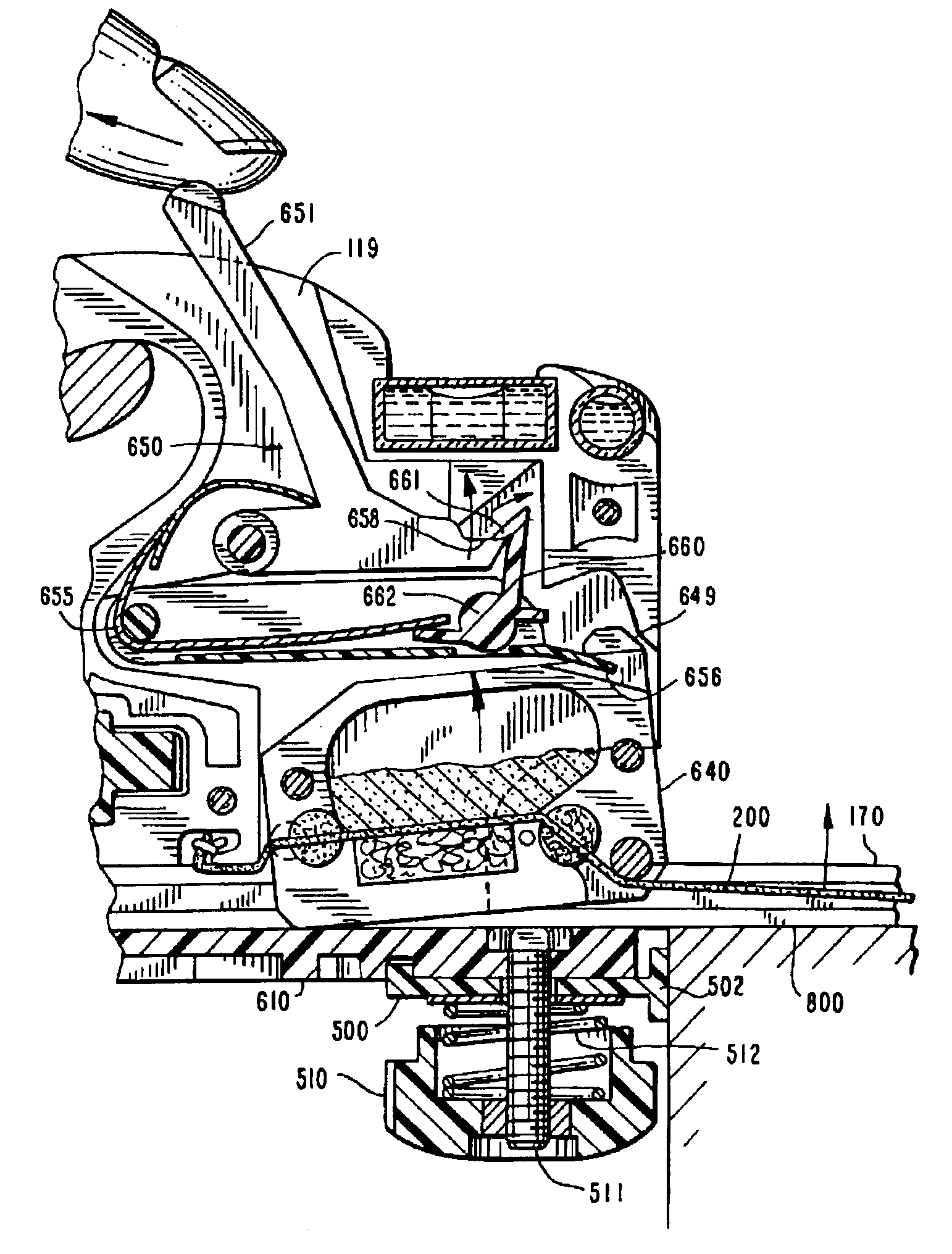

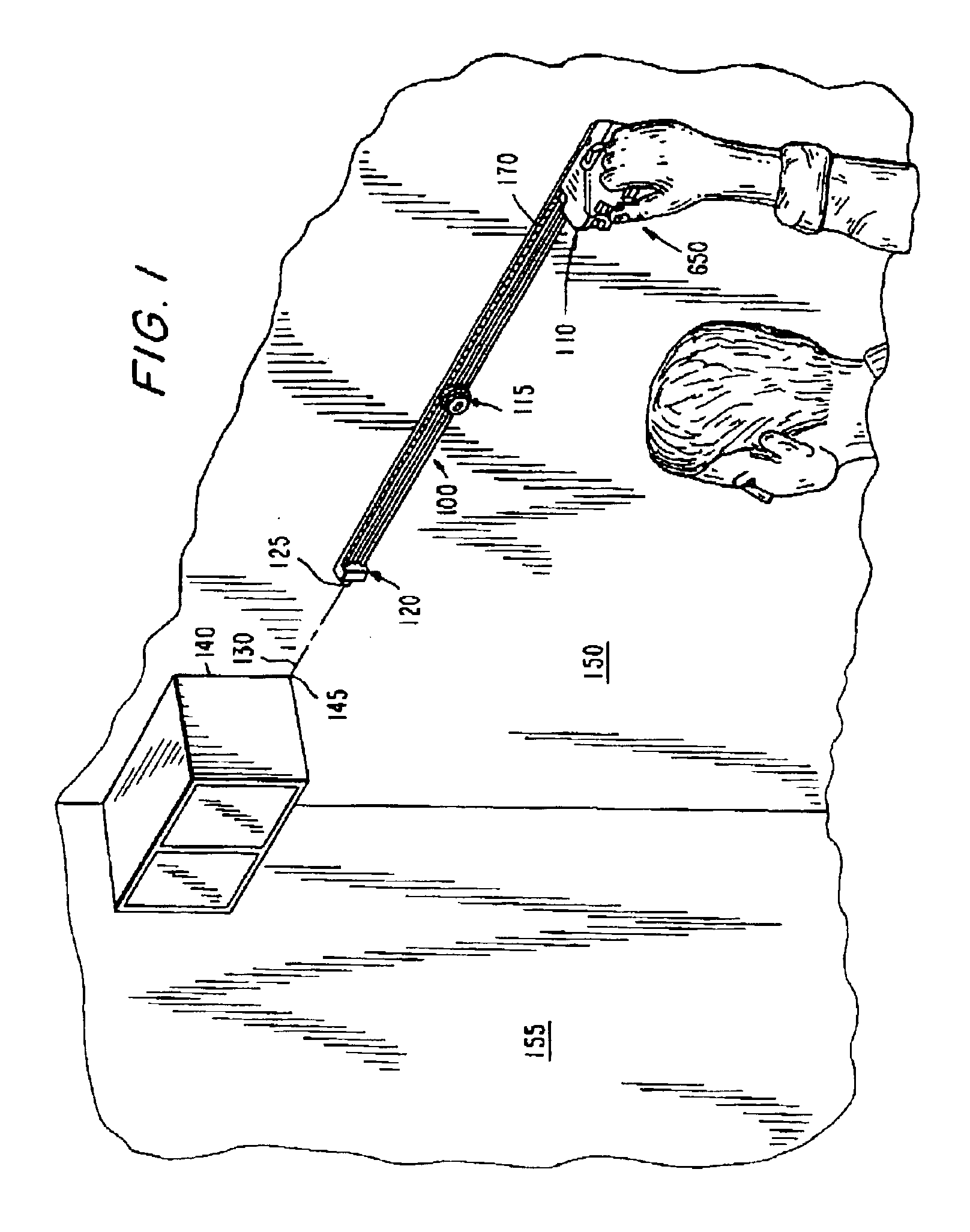

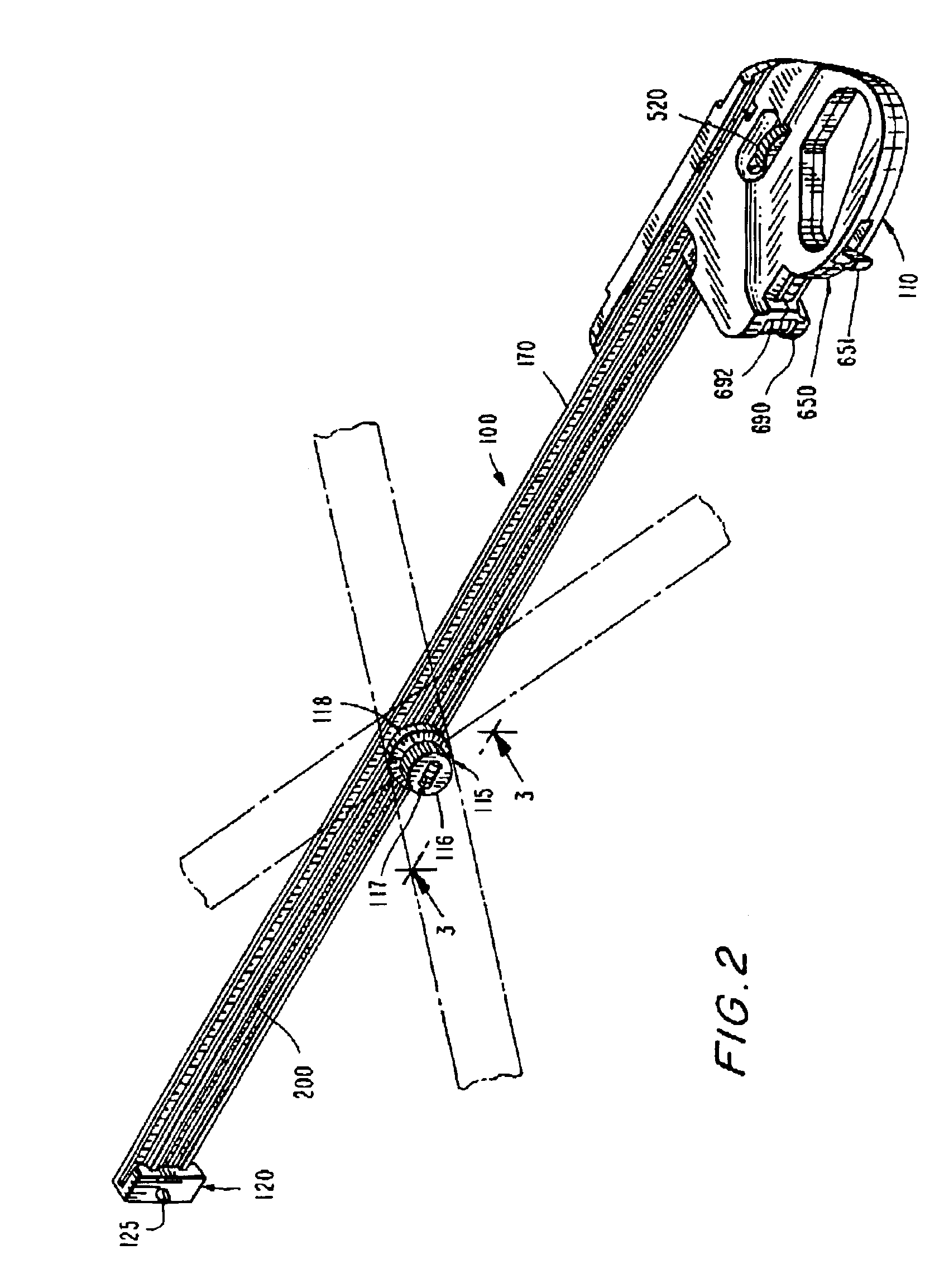

Line-marking device with positioning devices and trigger activator

InactiveUS6944962B2Easily and accurately positionEasily and accurately and markOther artistic work equipmentsProtractorEngineering

A line-marking device (100) includes a chalk line (200) that is held in an elongated frame (170). A worker can position and align the device, then snap the line (200) using a manually operated trigger (650) to leave a mark on a surface (530), such as a wall or floor. An adjustable level device (115) on the frame (170) can be rotated to dial a desired angle for the line. The adjustable level device (115) may be provided in an angle setting device independently of the line-marking device. A laser device (125) may be carried at the tip (120) of (or elsewhere on) the frame (170) to allow the chalk line to be aligned with a reference mark (145). Respective markings (176, 177) on edge regions of rails (171, 174) of the frame (170) may indicate an angular setting of a guide bar (500), or, a protractor (810, 810a) may indicate the angular setting. The guide bar (500) may be relocated facing away from the filament (200) and used as an angle finding device. A retractable tape measure (1500) carried by the device enables a worker to measure distances from the chalk line.

Owner:UMBRO LLC

Laser angle guide assembly for computed tomography and method for the same

A laser angle guide assembly has a stand and a laser guide. The laser guide is rotatably attached to the stand and has a laser pointer, a transparent column, a guiding rod, an index stick and a protractor. The laser pointer has a head for emitting a laser. The transparent column is attached to the laser pointer to transfer the laser to an index line with an inclination. The guiding bar is attached to the laser pointer. The index stick is attached to the guiding bar and has an index section with an inclination parallel to the inclination of the index line. The protractor with graduations is rotatably attached to the index stick and corresponds to the index section. Accordingly, the laser pointer will generate an index line to provide a guide to the doctor to insert the needle into the patient body at a desired angle.

Owner:CHAN WING SHEUNG

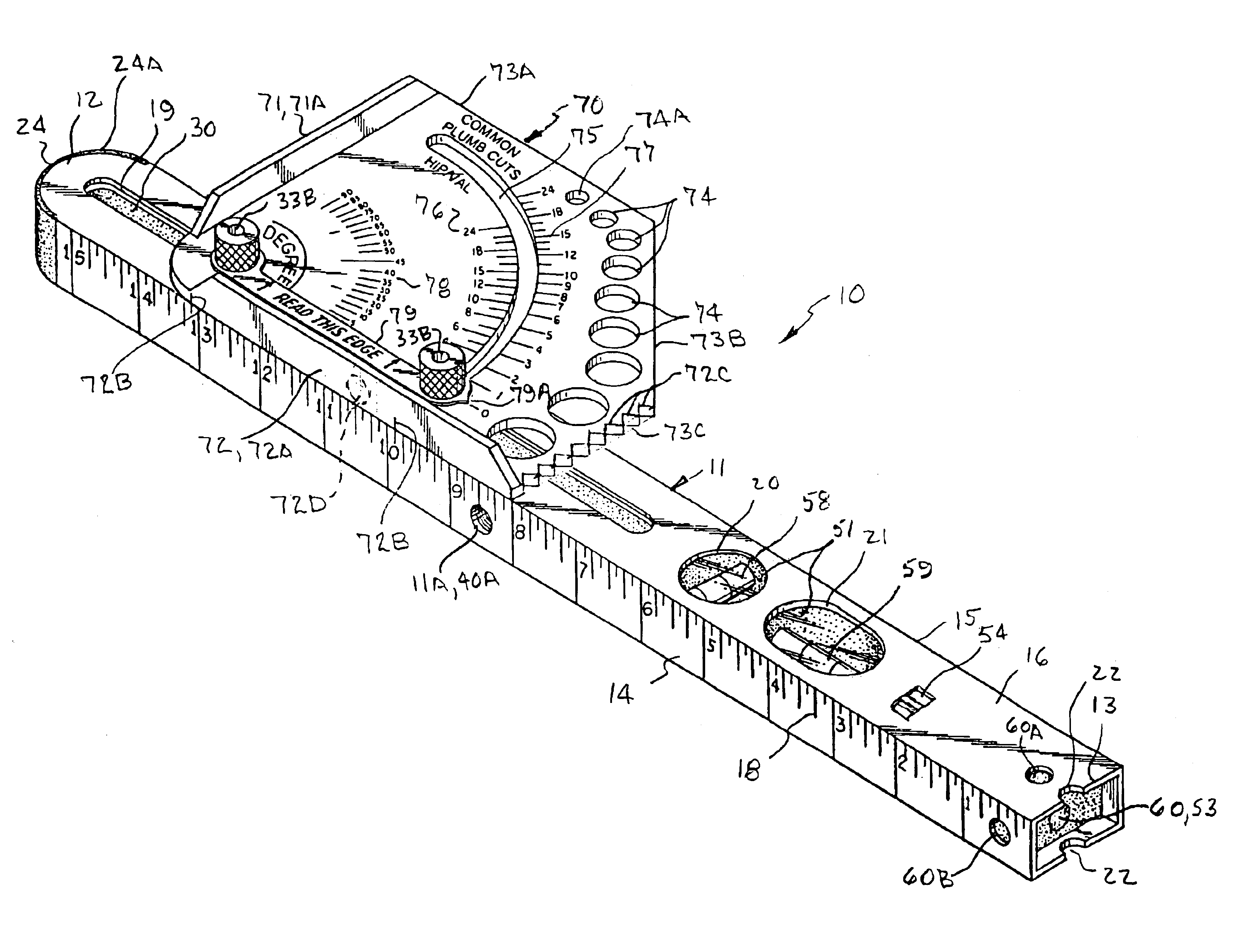

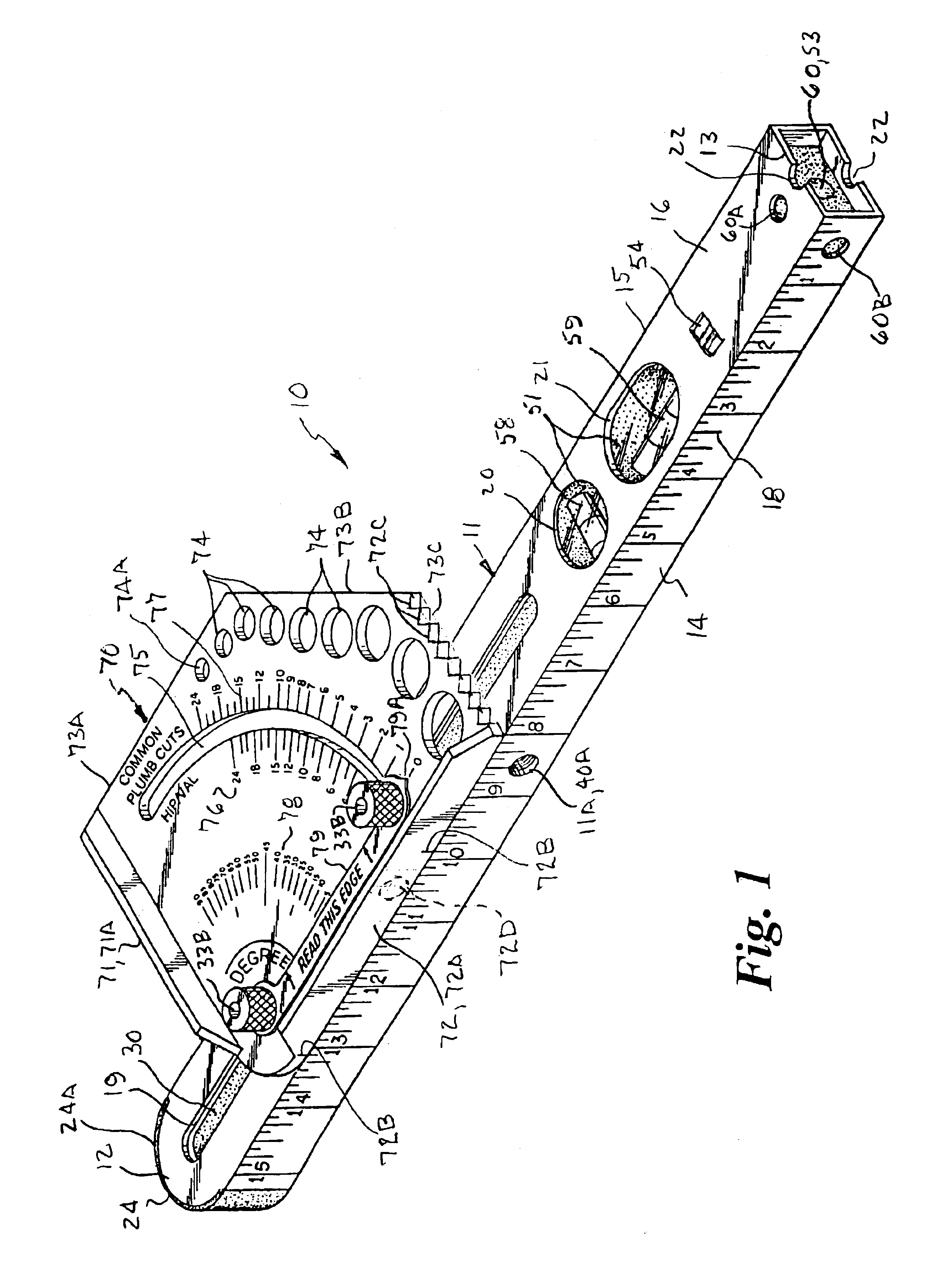

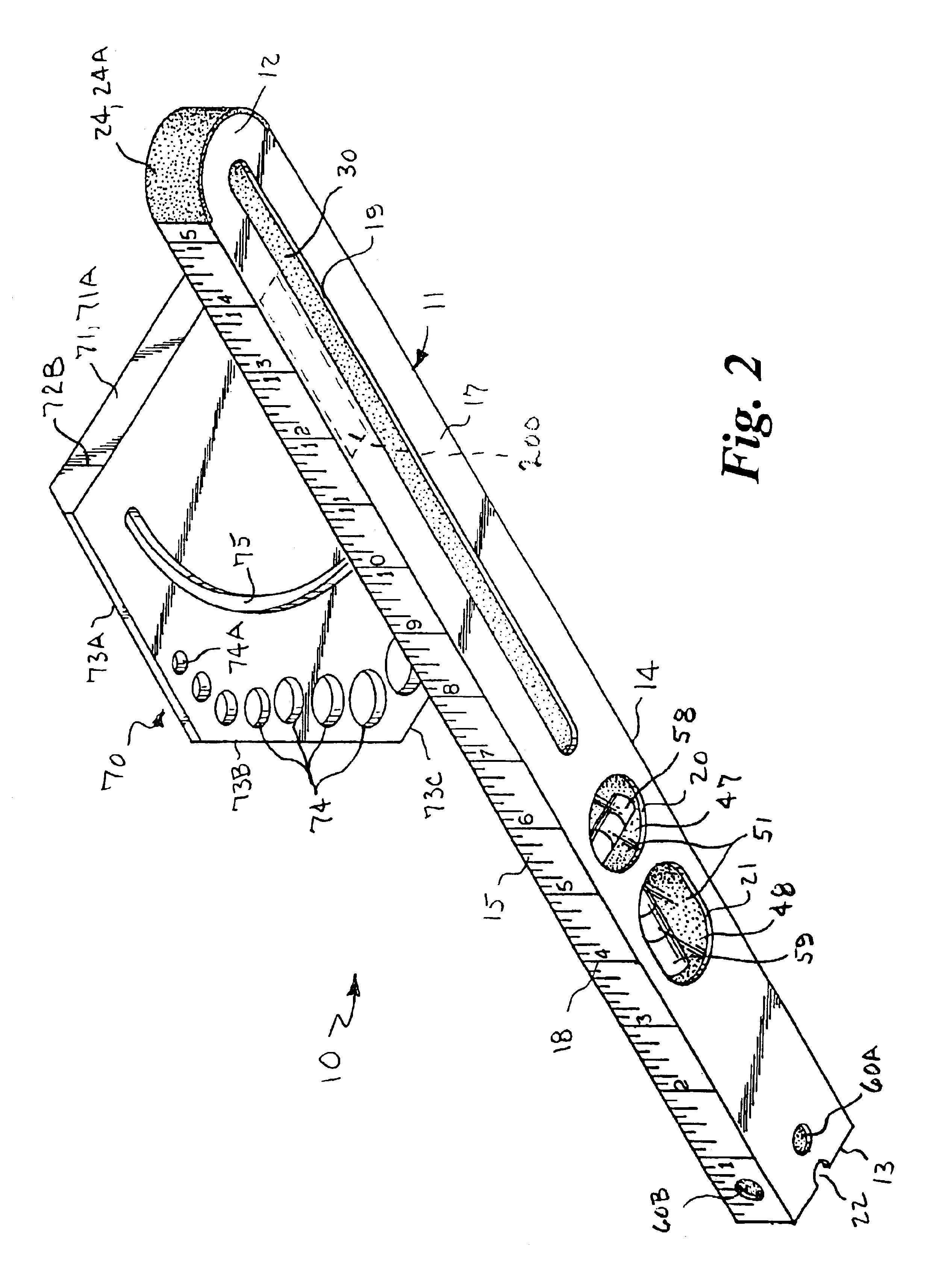

Common rafter and hip layout tool

A common rafter and hip layout tool which provides a protractor portion, a common cut marking edge, a common cut marking edge pantograph arm to which is connected a bird's mouth marking arm, a seat cut marking arm connected at a right angle to the bird's mouth marking arm and a tail length marking arm. The pantograph arm and connected bird's mouth marking arm facilitates the marking of the bird's mouth cut and the seat cut. Movement of the common cut marking edge to the location indicated by the tail length marking arm facilitates the making of parallel cuts for the common rafter ridge cut and the tail cut.

Owner:NYQUIST SHELBY M

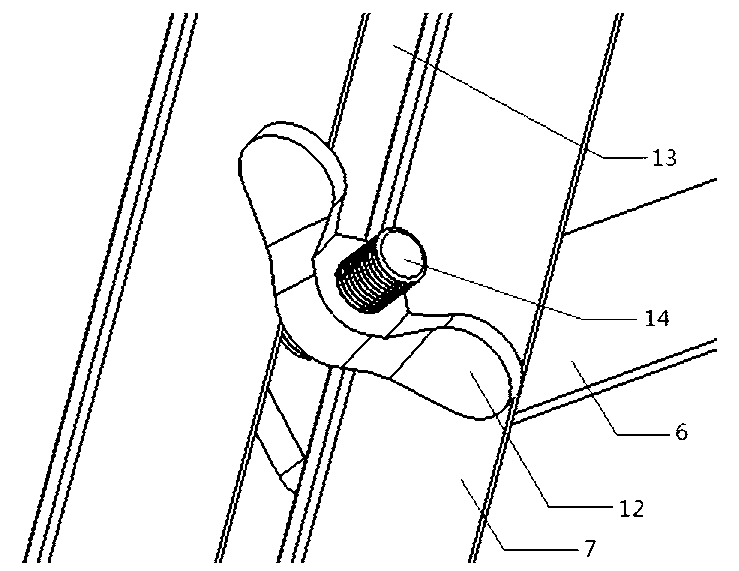

Tilting testing device for measuring anisotropy of sliding friction angle of rock joint surface

InactiveCN103307959AReforming the Insufficiency of Sliding Friction Angle MeasurementRealize continuous measurementAngles/taper measurementsMaterial analysisProtractorTest sample

The invention relates to a tilting testing device for measuring the anisotropy of a sliding friction angle of a rock joint surface. The testing device consists of a base, a sliding rail, a hinge frame and a compass. According to the device, the shortcomings of the conventional sliding friction angle measurement of the rock joint surface are overcome; a lower disc of a rock joint surface test sample is fixedly arranged on the compass through a clamping threaded rod, and the compass is rotated in a testing process to continuously measure the anisotropic sliding friction angle of the disc-shaped rock joint surface test sample which consists of an upper disc and the lower disc along any sliding direction and reutilize the test sample; and the upper and lower discs of the rock joint surface slide relative to each other by slowly enlarging a tilting angle of a flat plate, and the tilting angle of the flat plate is read through an angulometer in real time, so that a value of the sliding friction angle of the rock joint surface can be directly obtained.

Owner:INST OF ROCK AND SOIL MECHANICS - CHINESE ACAD OF SCI

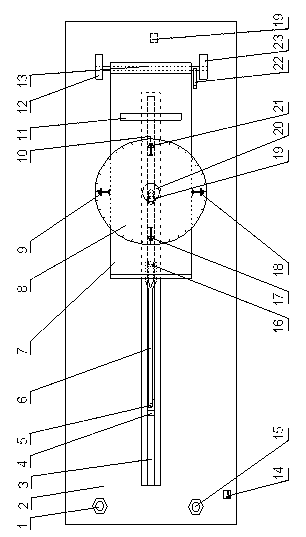

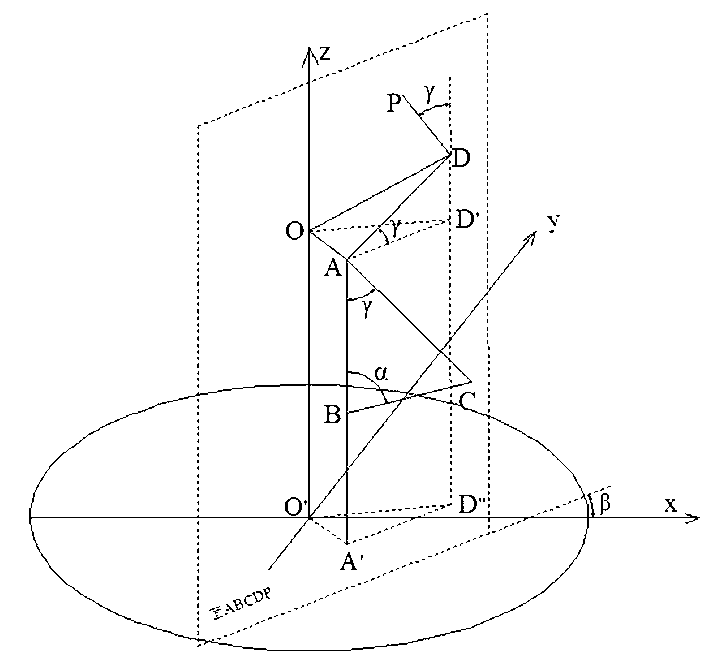

Simple laser scanning device

The invention discloses a simple laser scanning device. The device comprises a circular tabulate base with 360-degree circumferential azimuth scales, a universal level, a column, an azimuth pointer, a sliding bar, a guide bar, a guide groove, a protractor and a laser range finder. Azimuths and dip angles of measuring lines are changed by rotating the column and moving the sliding bard, distances between different positions of an object to be measured and a laser point can be scanned and determined, and three-dimensional coordinates of the measurement points can be determined according to geometrical relationships to obtain surface spatial form coordinates of the object to be measured, accordingly, a three-dimensional form model of the object to be measured is established, and spatial form three-dimensional laser scanning and engineering deformation measurement, monitoring and scanning are performed on chambers, tunnels, cavities, goafs and the like in all directions without contacting with or disturbance to structure or engineering entities. The device is simple to operate, low in cost, convenient to carry and capable of being popularized, greatly optimizing and reducing data acquisition density and preventing later cumbersome processing of mass data.

Owner:HEFEI UNIV OF TECH

Measurer of dielectric film microwave complex dielectric permittivity

This invention relates to testing equipment of nm order thickness medium thin film microwave complex dielectric permittivity. It includes resonant cavity, net analyzer and medium substrate. Radiofrequency interconnection devices are set on both ends of the cavity, through hole is set in middle part, the substrate is used to burdening medium thin film, the through hole can be through in it and its two ends are out of the cavity. The input and output ends of the analyzer are connected to the two couplers of the cavity. Substrate coated and uncoated can be separately inserted into the through holes of the cavity to get two groups of resonance frequency and quality factor value. Then the medium thin film complex dielectric permittivity can be got by the two data combined with the cavity, substrate and rectangular protractor of the film. The permittivity includes real part and loss angle tangent. So this invention is a general, precision testing device of medium thin film microwave complex dielectric permittivity.

Owner:ZHEJIANG UNIV

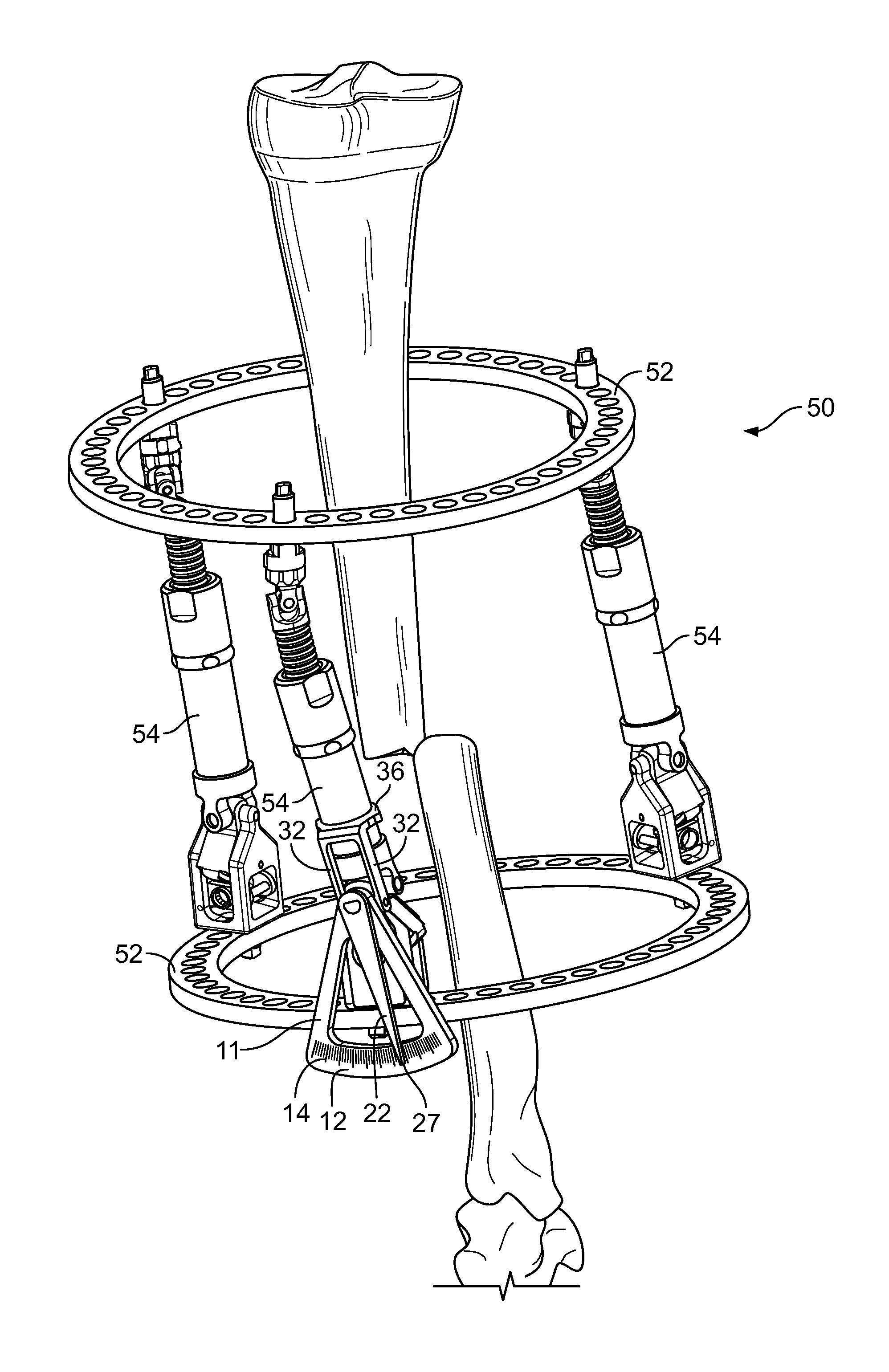

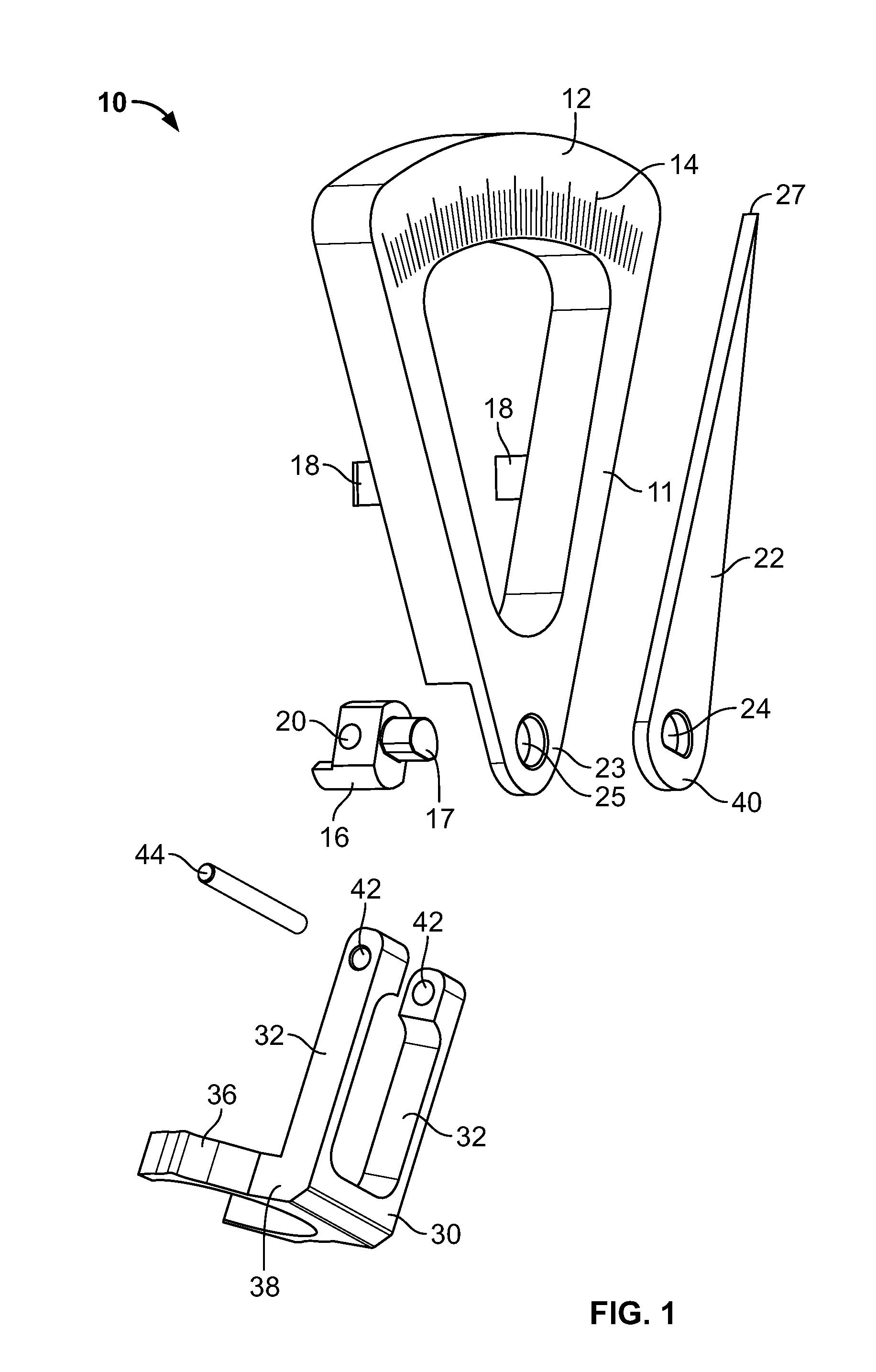

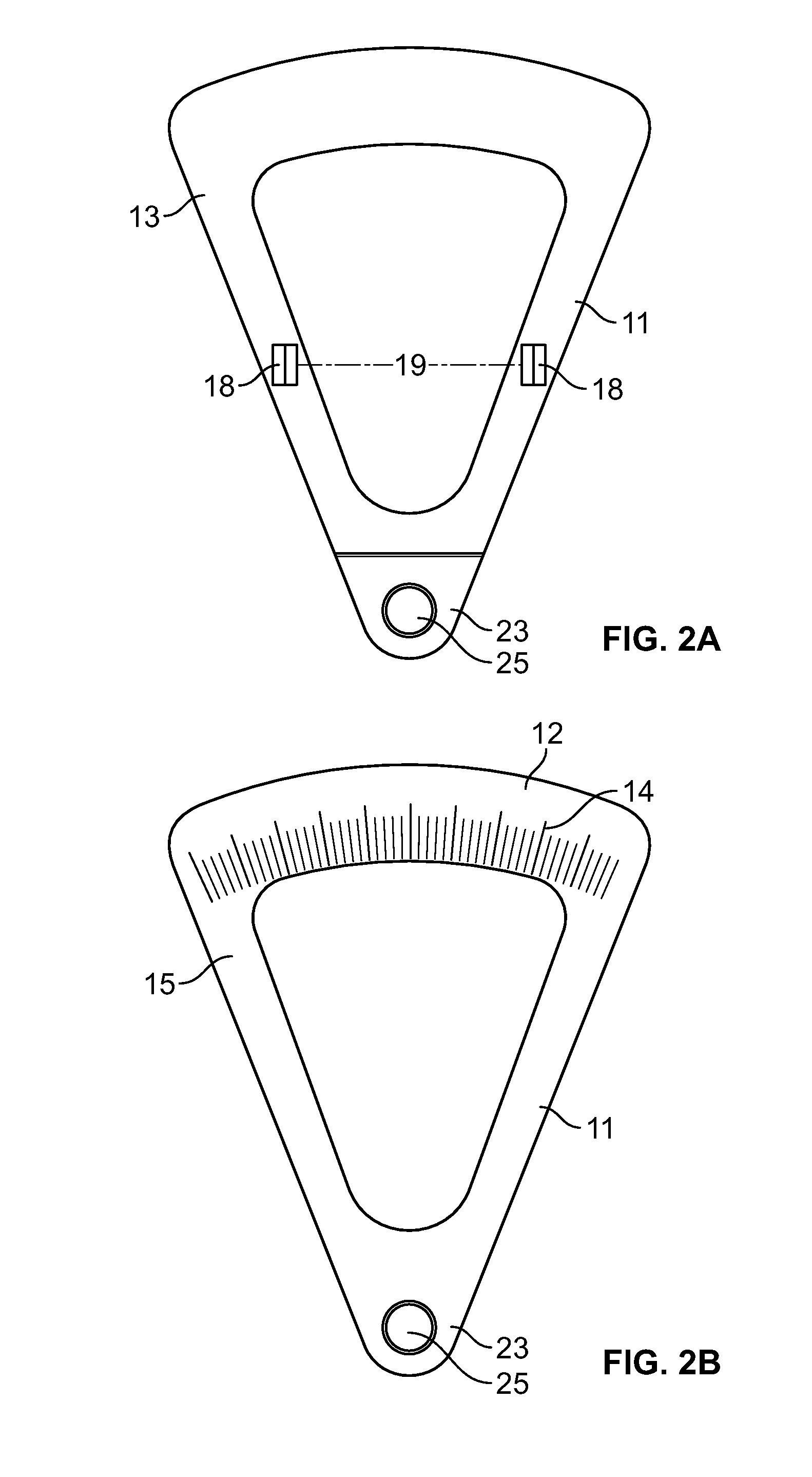

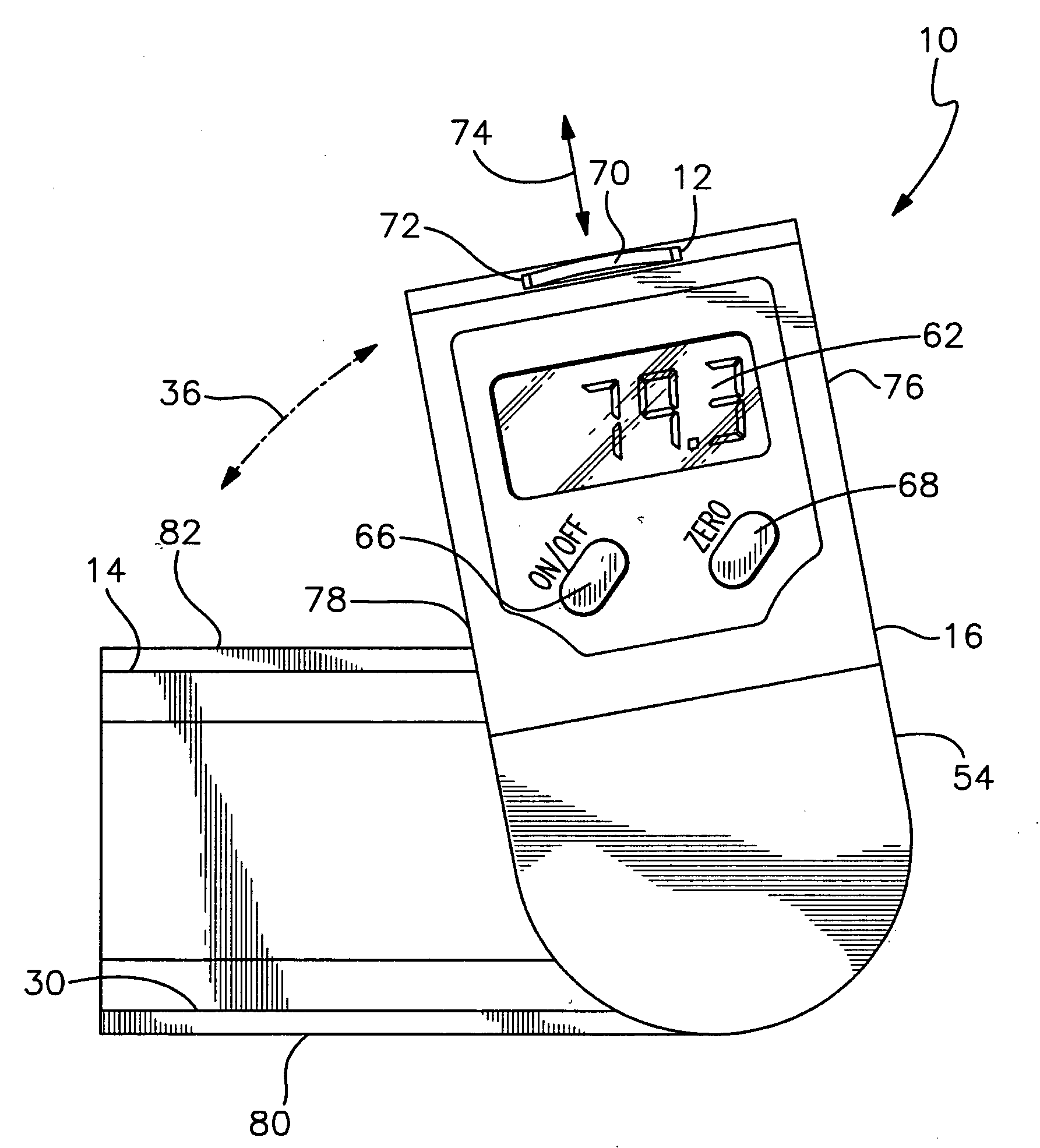

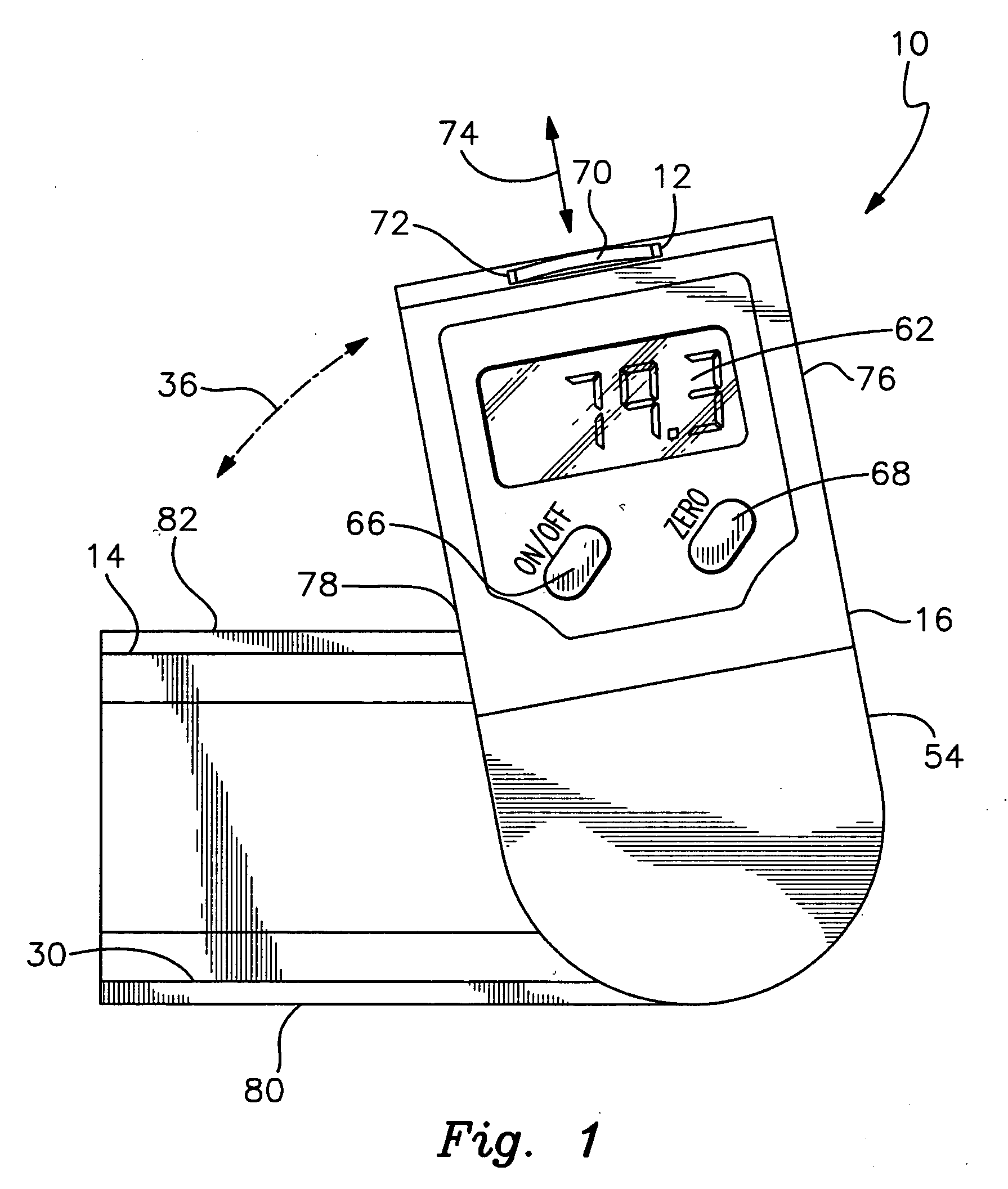

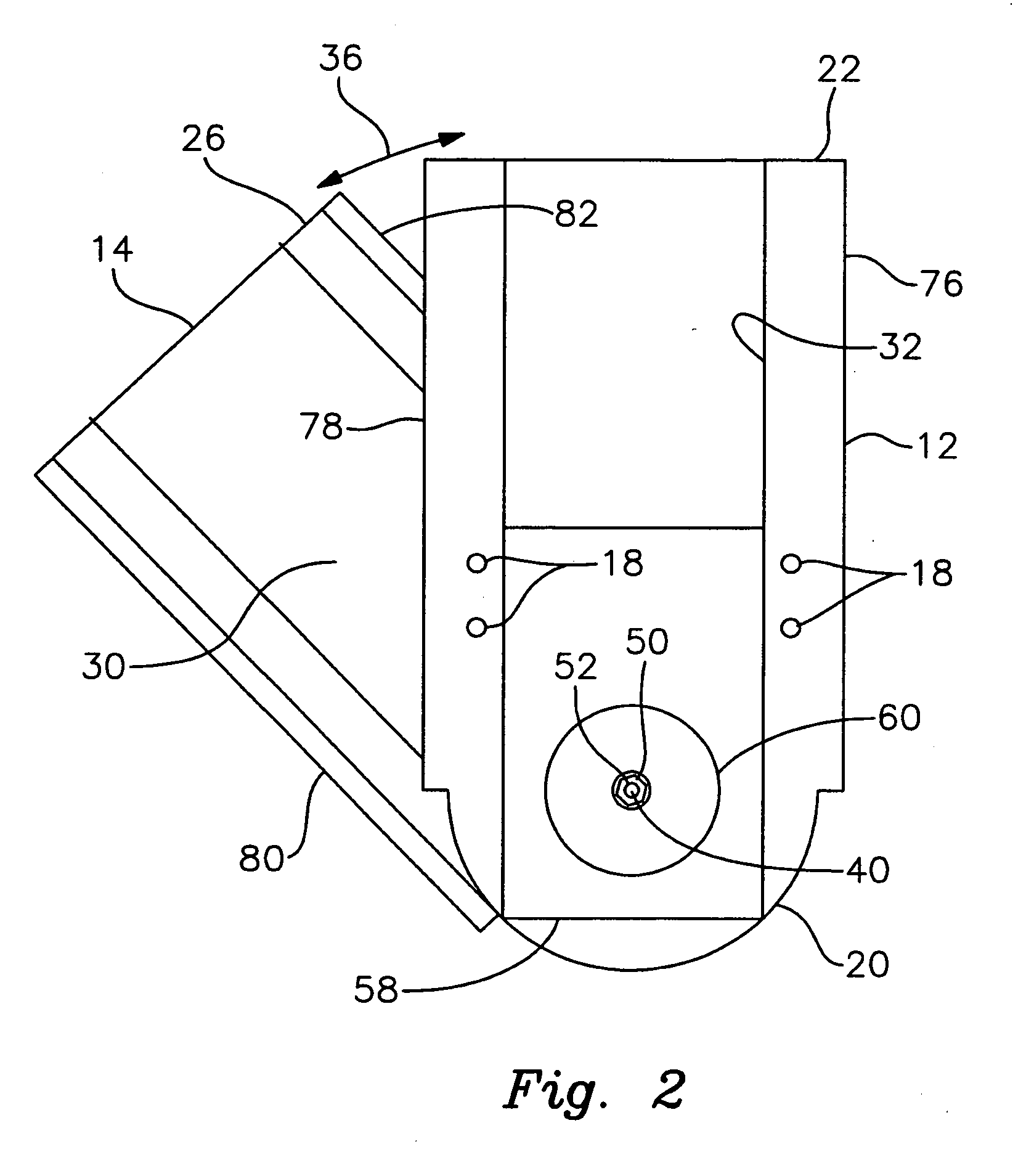

Measurement device for external fixation frame

A protractor for use with an external fixation frame is provided. The protractor may include a face having angle designations thereon and a set of opposed and extending flanges projecting from said face. The flanges may connect to a portion of an external fixation frame, such as a ring (or other component) of the frame. The face may also include a post member to which a rotatable dial is mounted. An elongate member may be pivotally connected to a portion of the post member and may include a clamp. The clamp may be used to connect to an alternate portion of an external fixation frame, such as a strut of the frame. Thus, the protractor may be connected to two points on an external fixation frame so as to measure the angle between such points. Related methods of using the aforementioned protractor are also disclosed.

Owner:STRYKER EURO OPERATIONS HLDG LLC

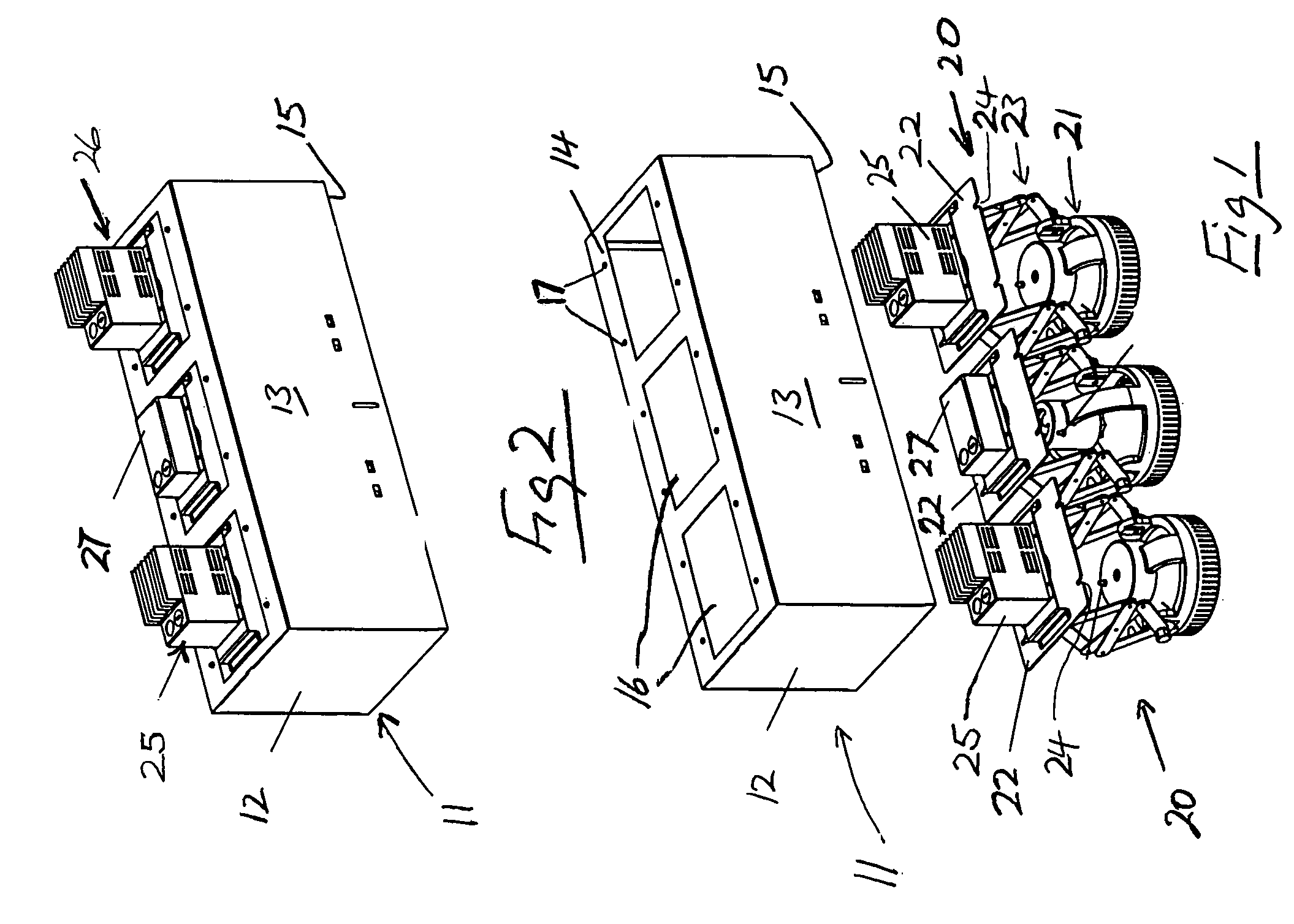

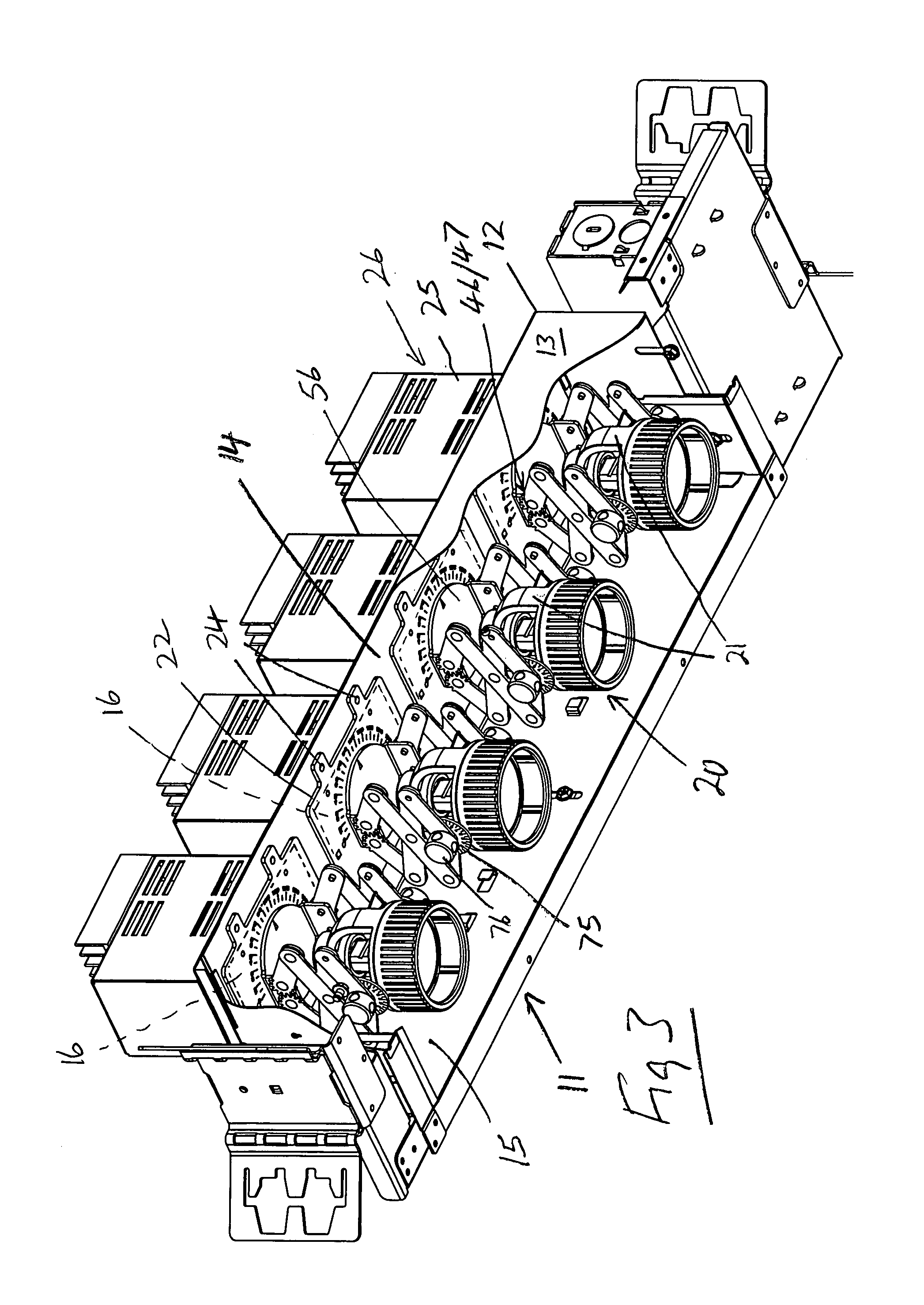

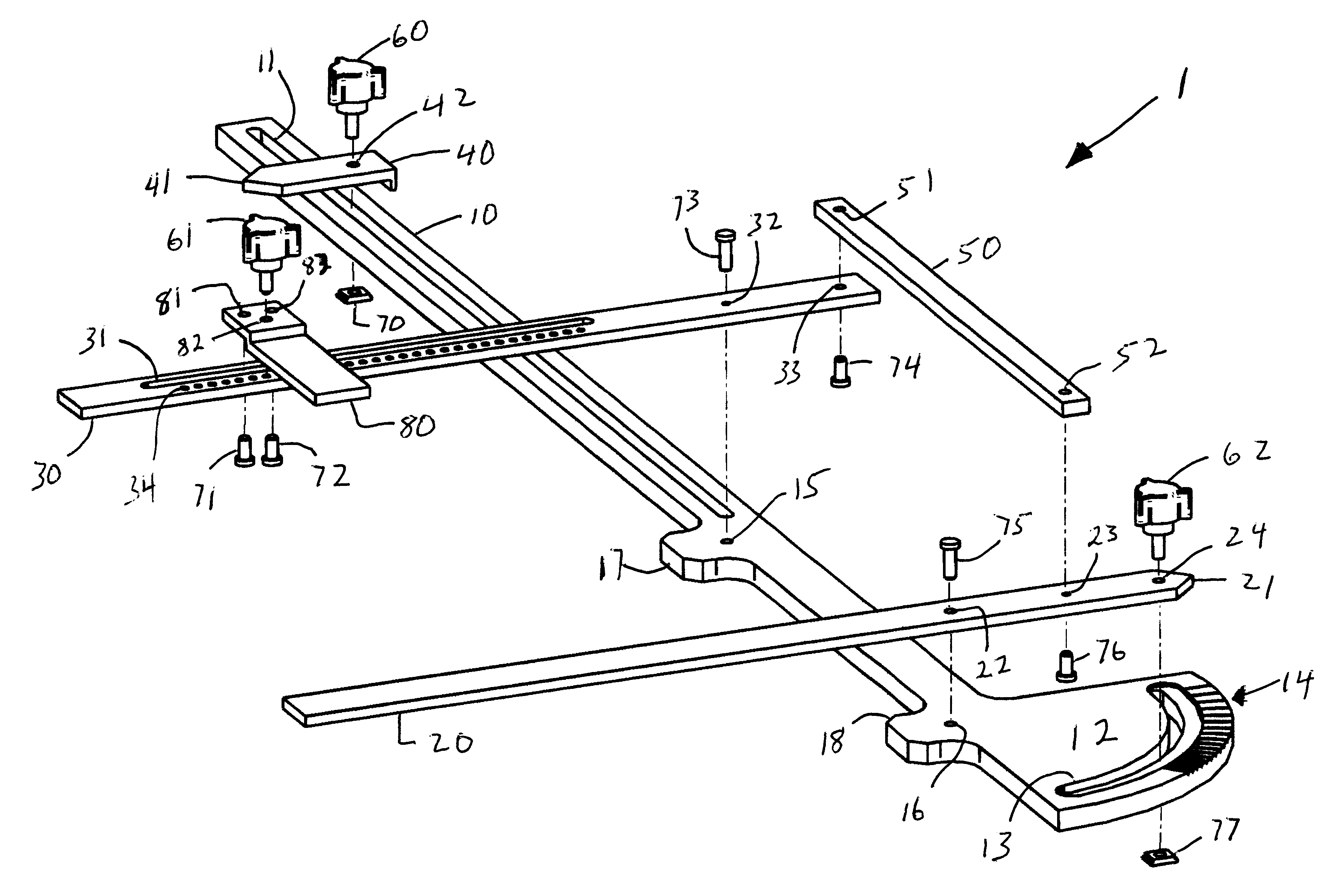

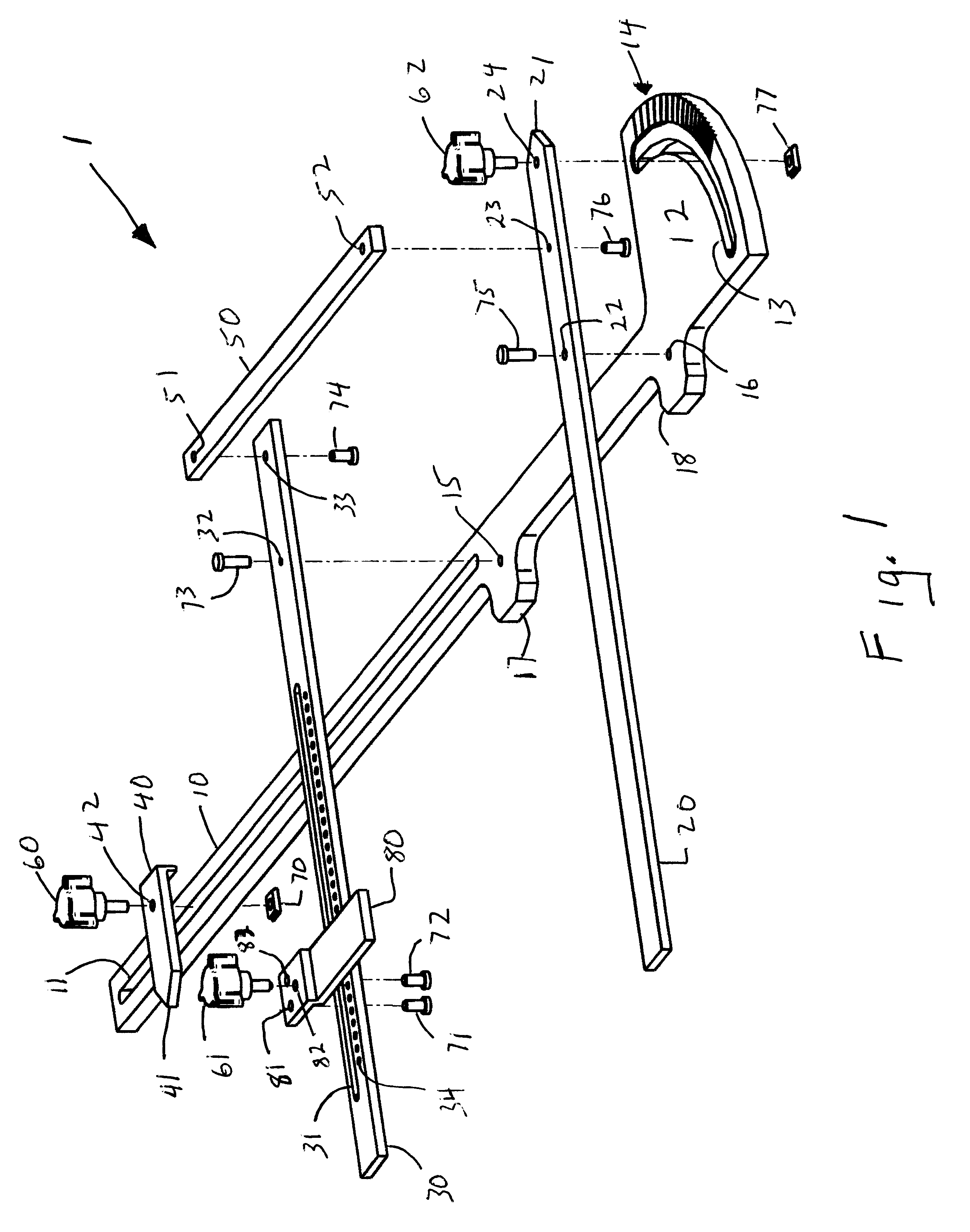

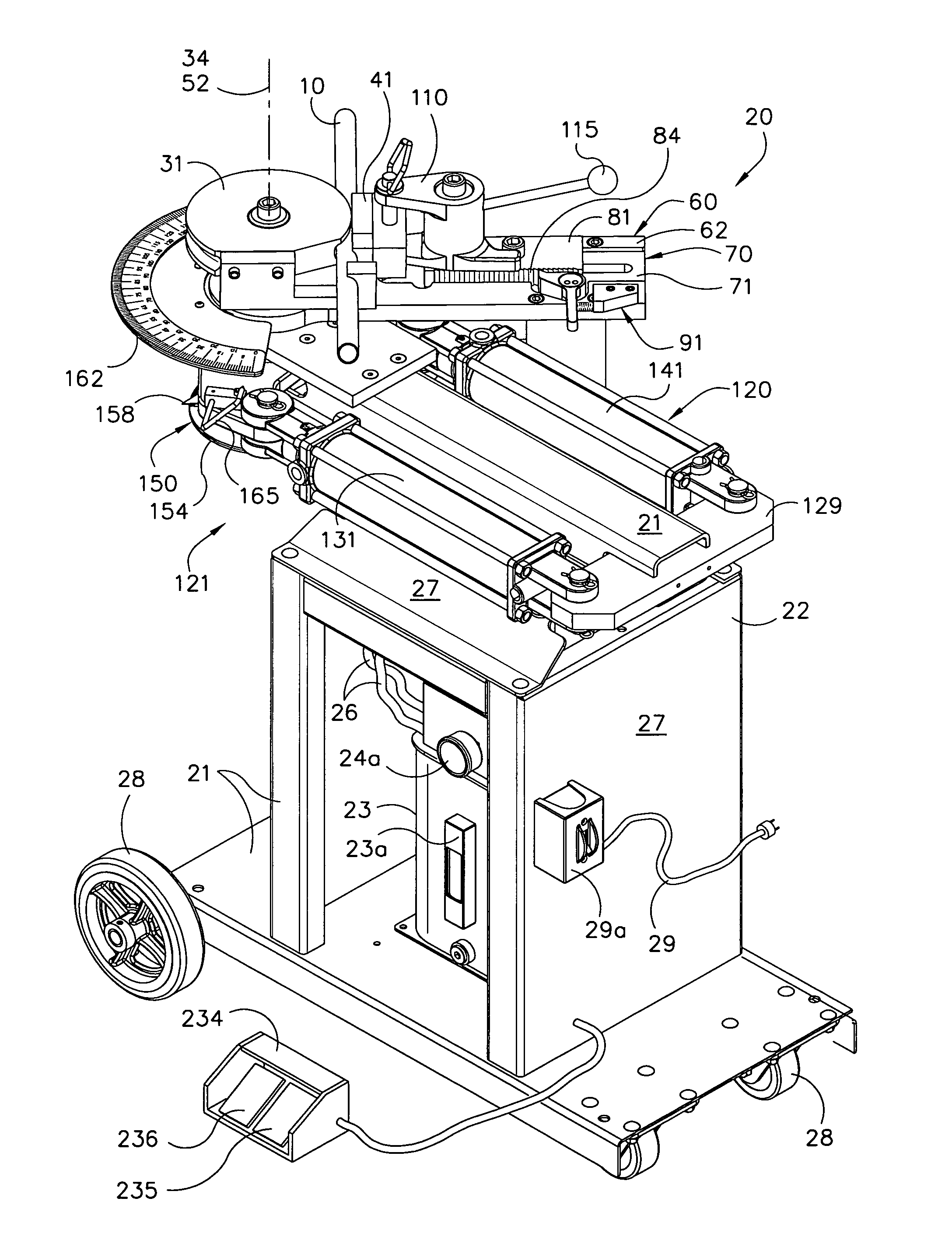

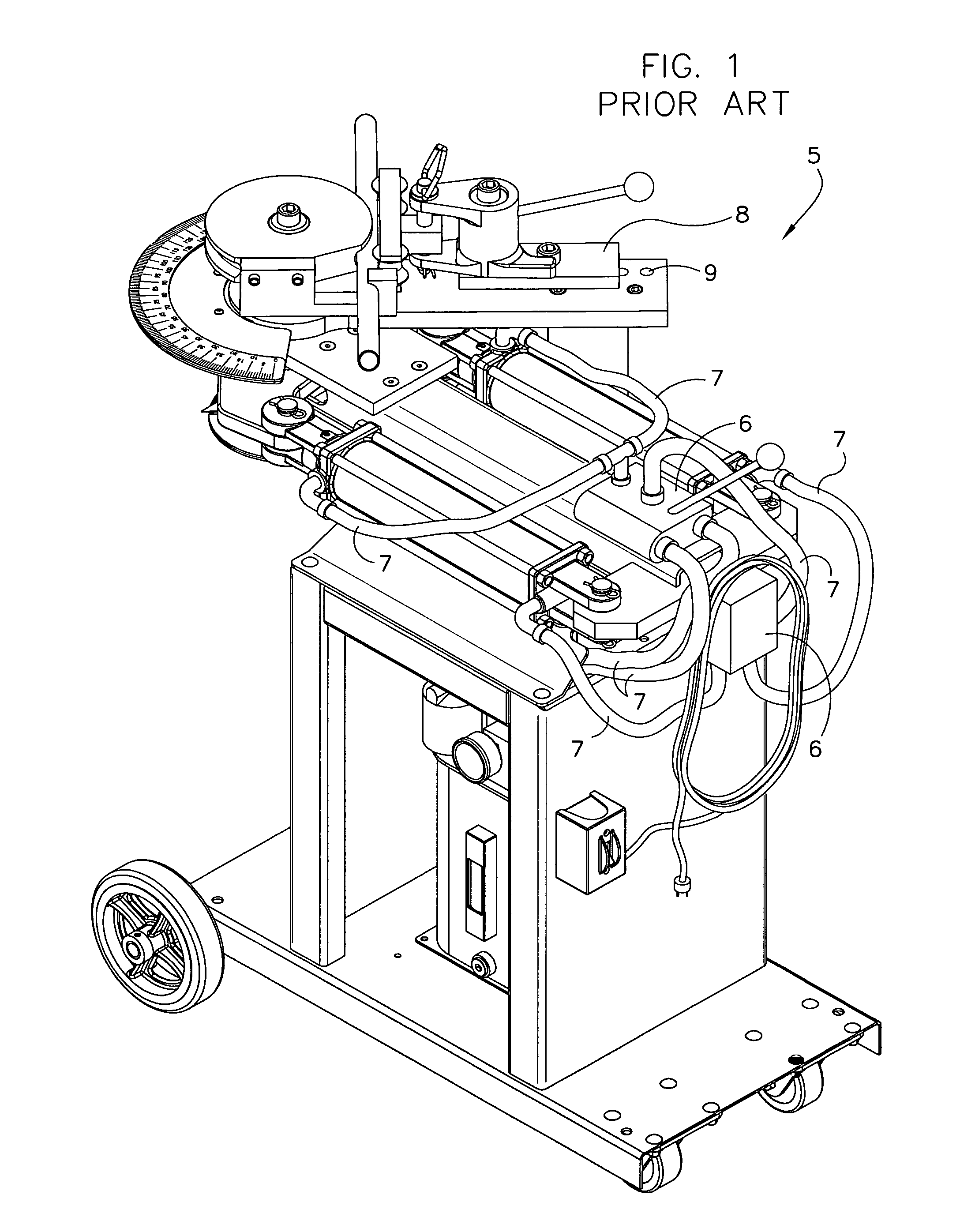

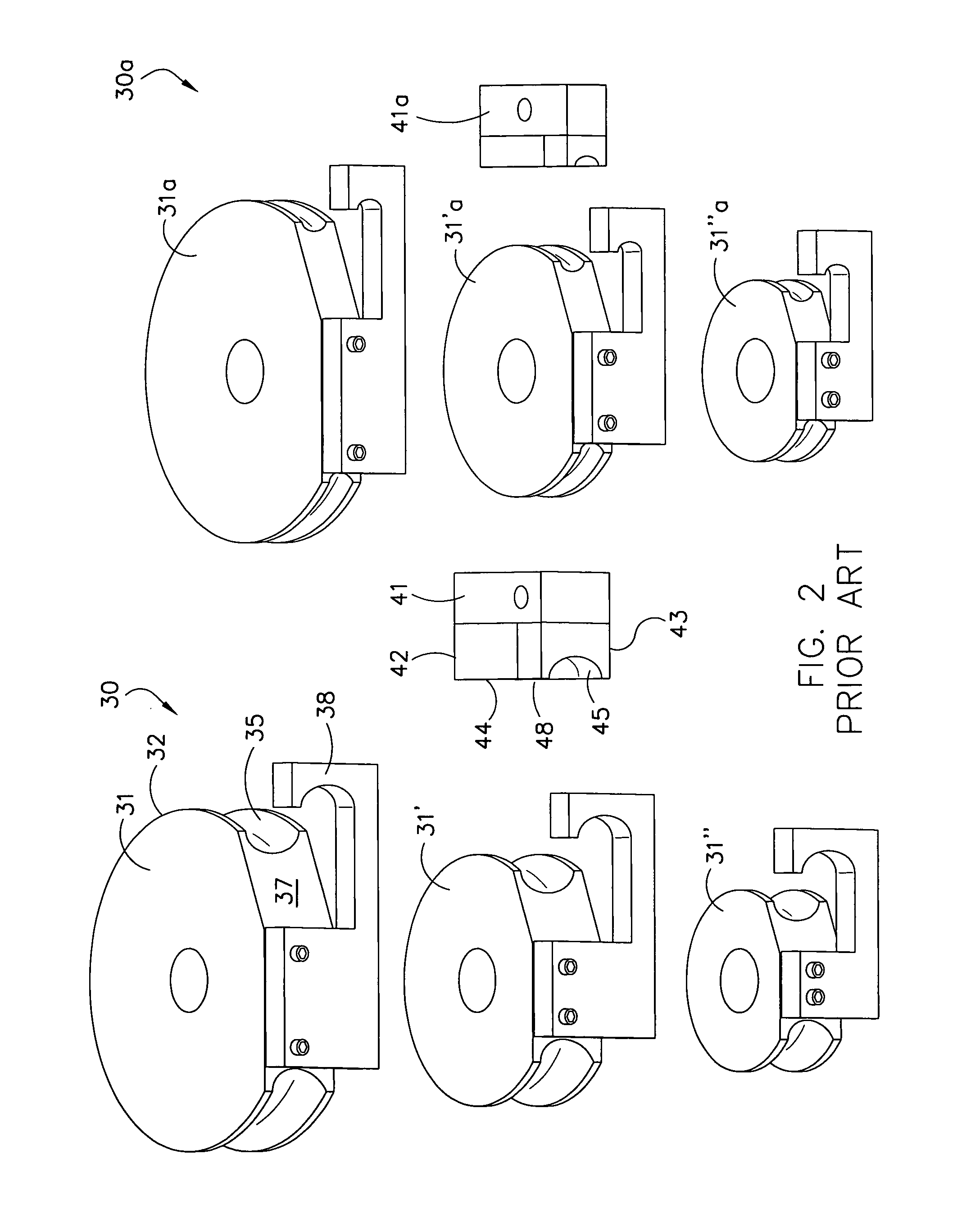

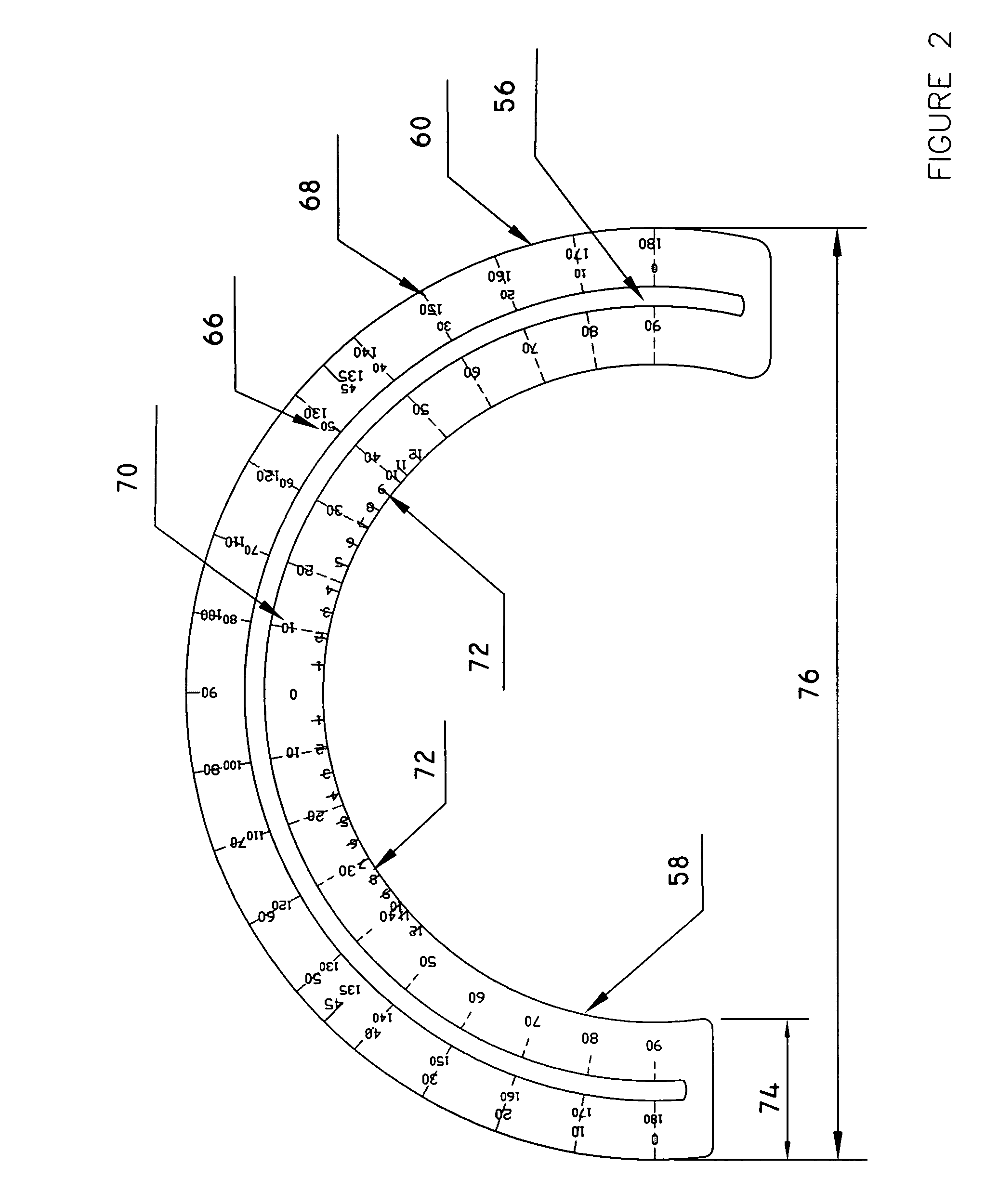

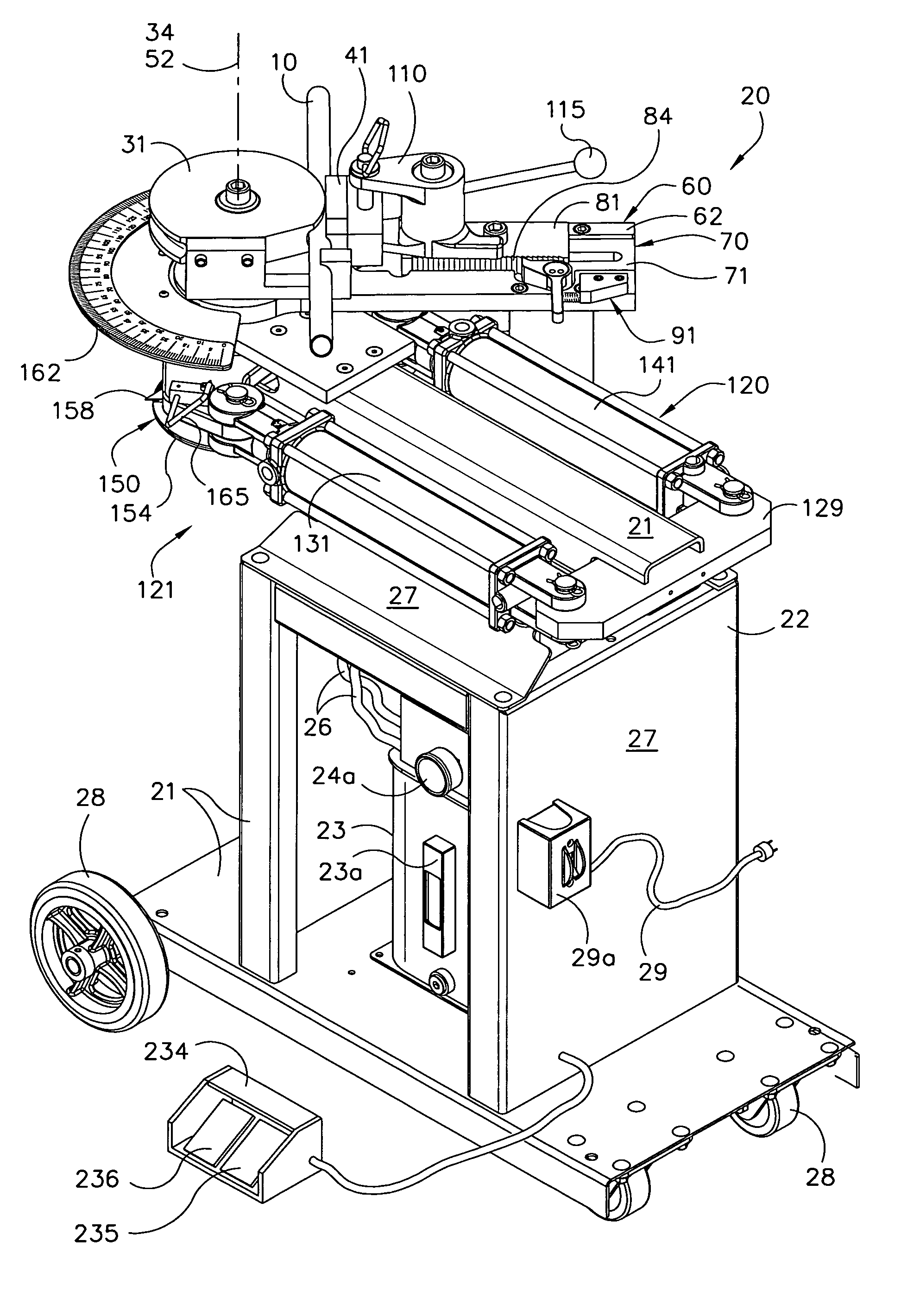

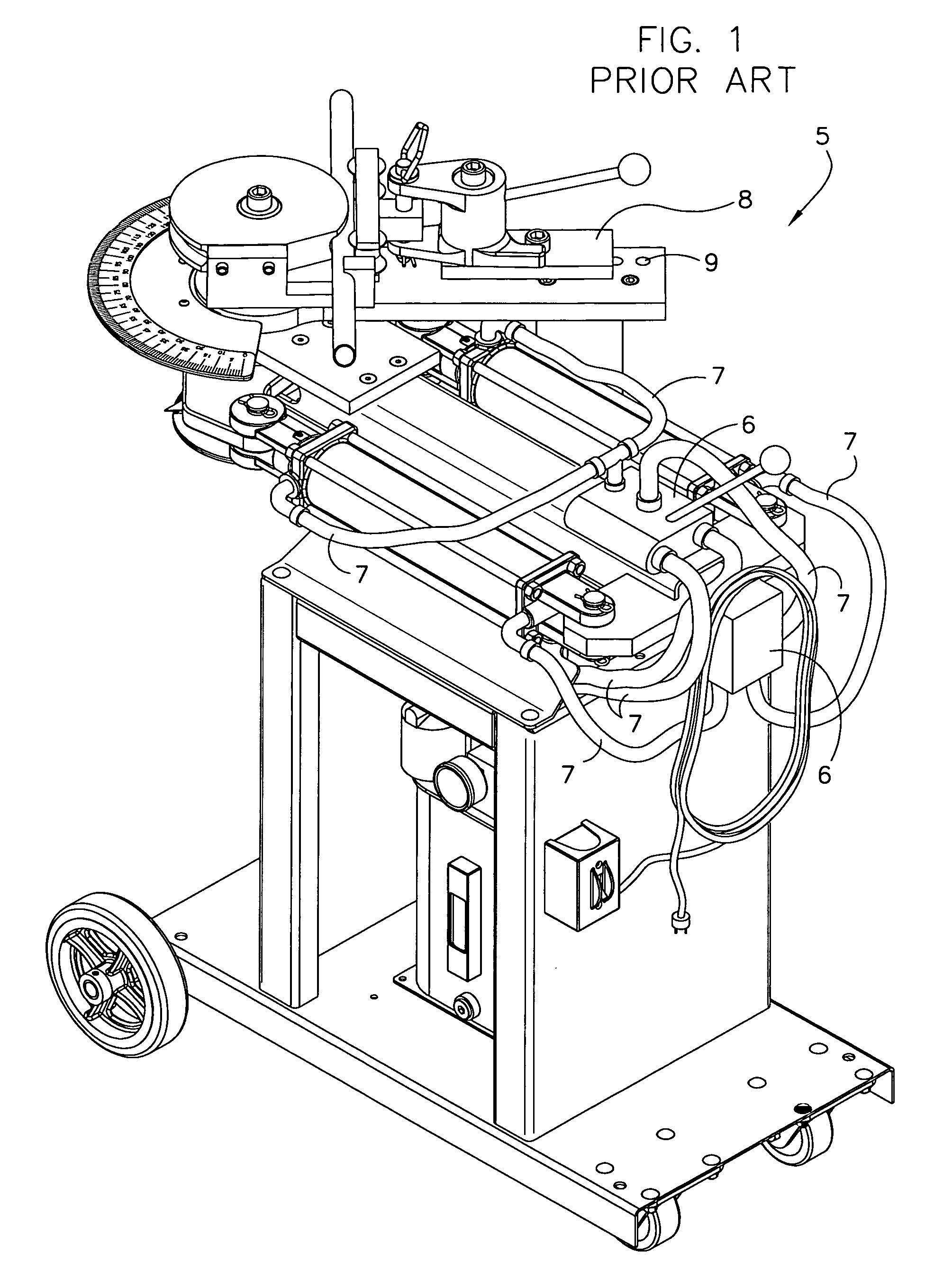

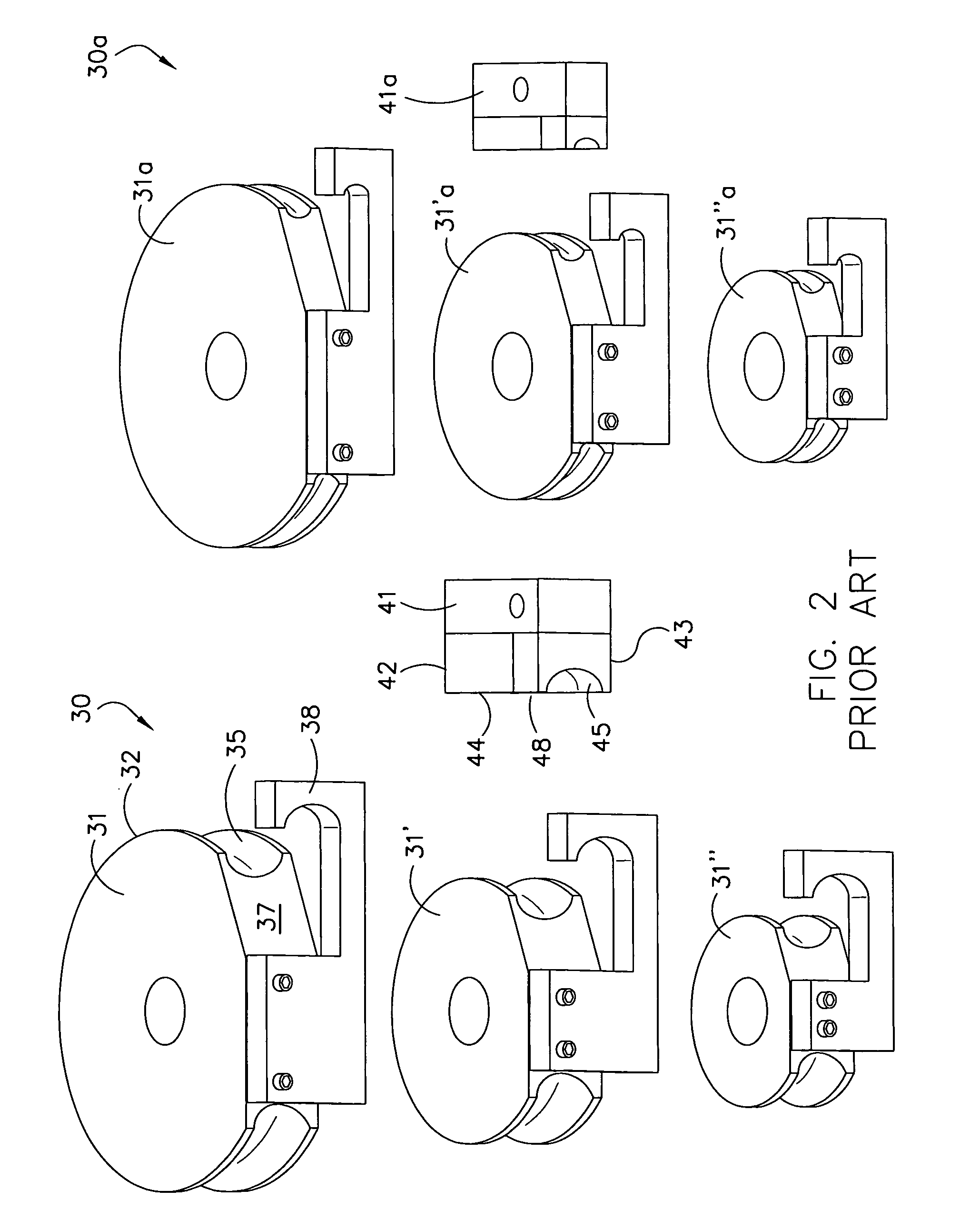

Rotary draw tube bender

ActiveUS7380430B1Precise bendingAccurate settingShaping toolsForging/hammering/pressing machinesProtractorControl system

The invention is a rotary draw bending machine and process for bending materials such as tubes or pipes into precise bends. A spindle holds a bending die, and a radial arm holds a counter-die. The spindle and arm are simultaneously rotated in opposite directions by a dual hydraulic drive controlled by an electro-hydraulic control system with foot pedal controls. The bend angle is preset by a protractor-like dial and limit switch mechanism. The radial arm has a slide track to align the counter-die with the bending die. The ratchet mechanism has teeth to allow incremental advancement of the counter-die when aligning it with its bending die to accurately set the gap between the dies. The machine is used with a wide variety of dies to bend a wide variety of workpiece diameters. The ratchet mechanism preferably includes a fine tuning device to provide an infinite range of alignment positions.

Owner:JPW IND

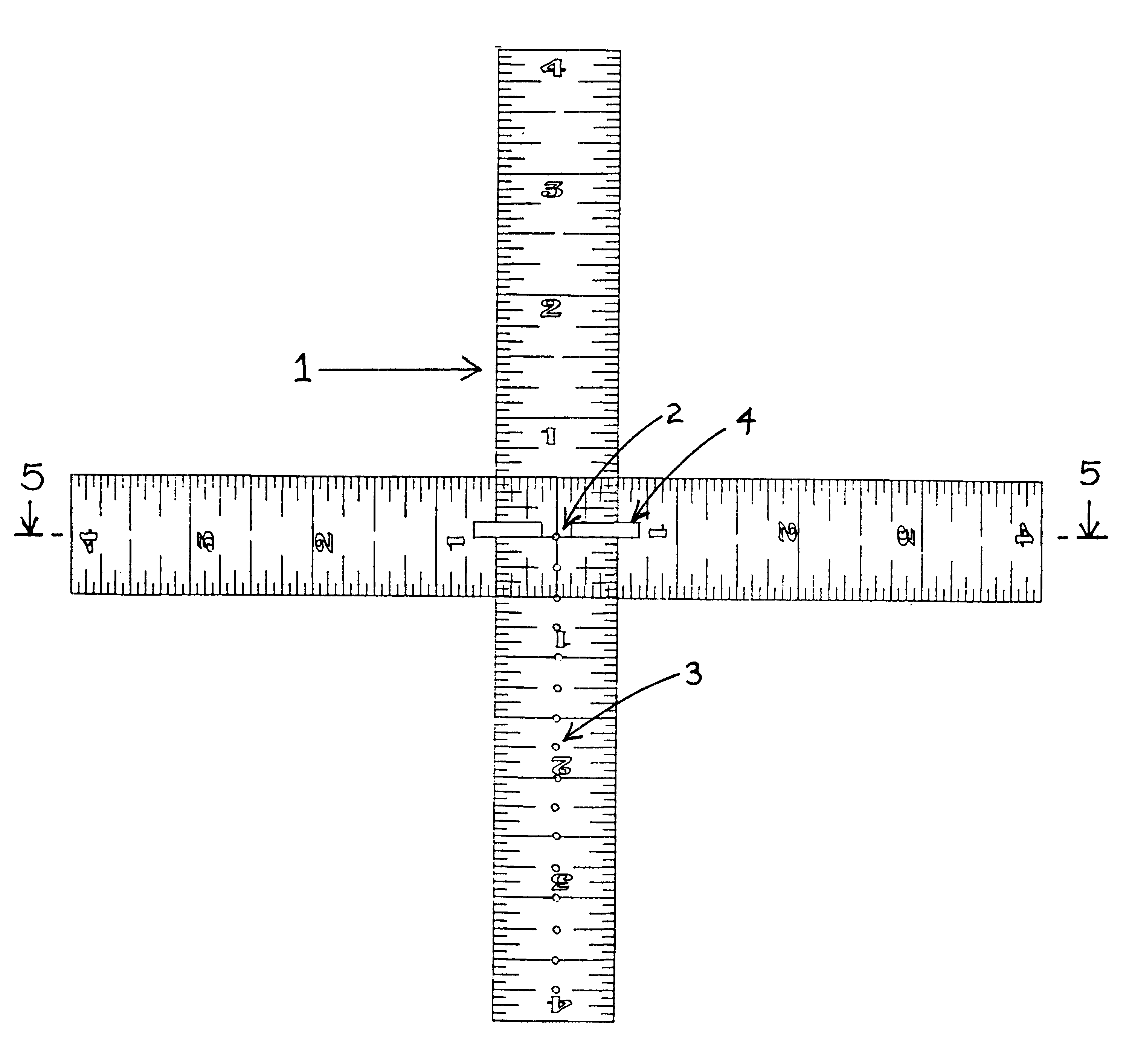

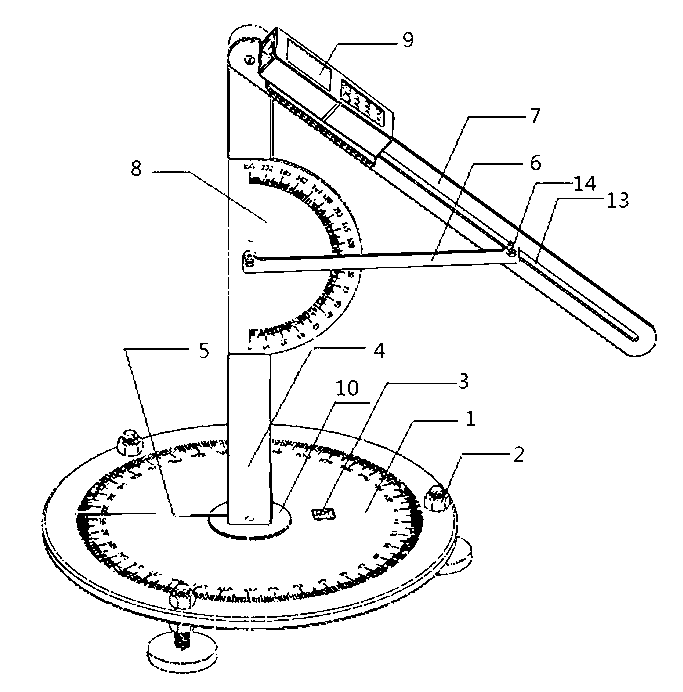

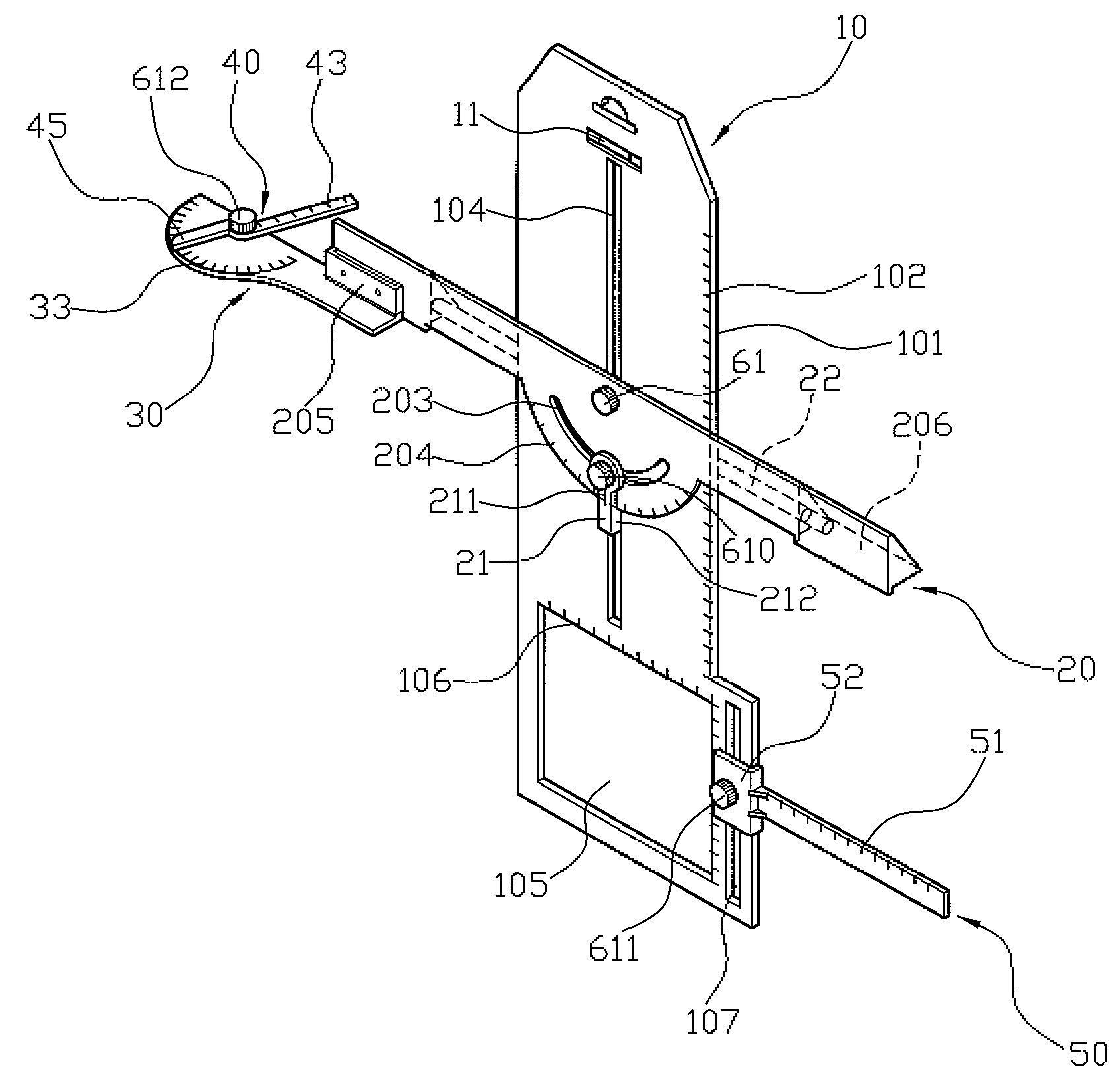

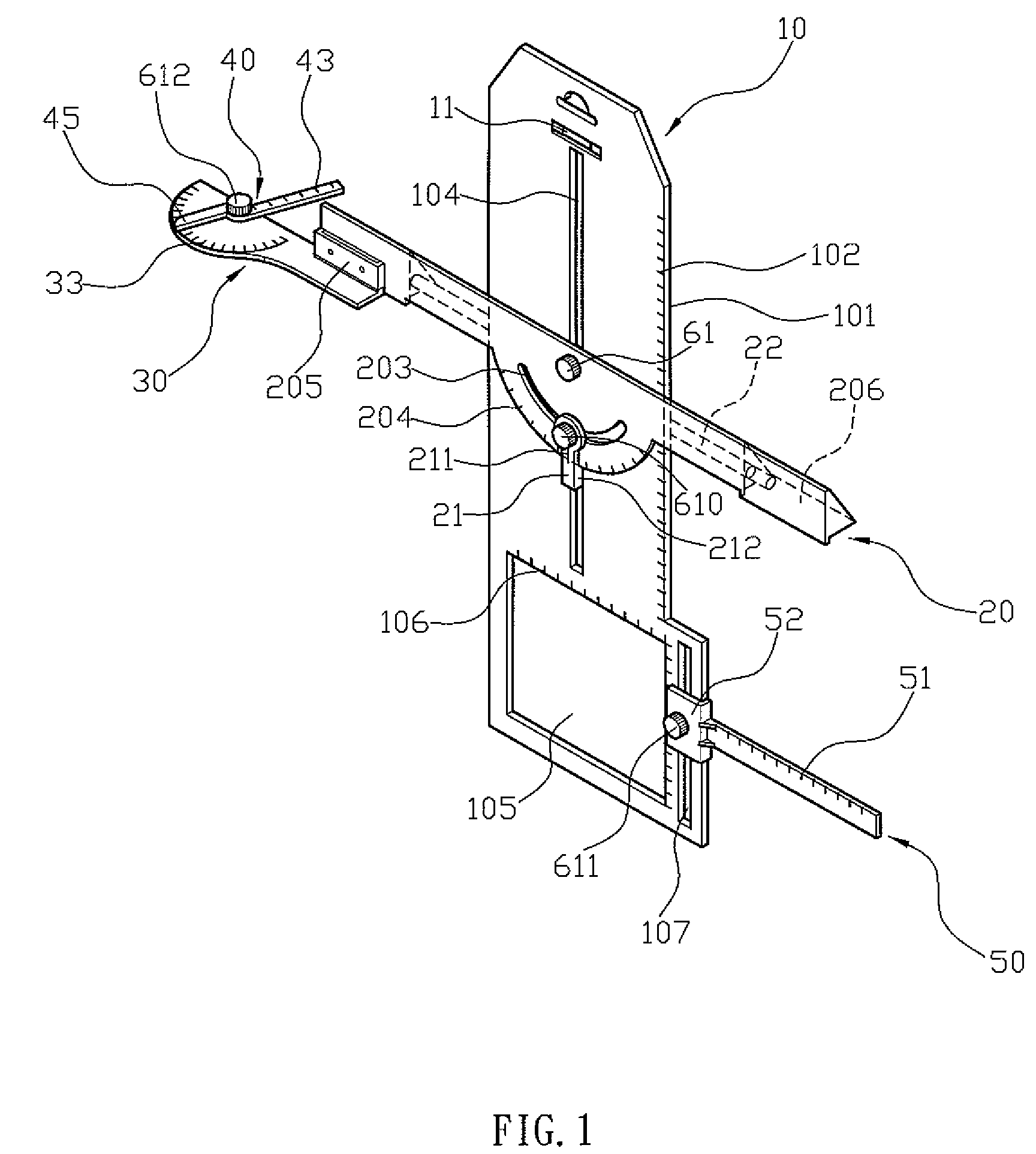

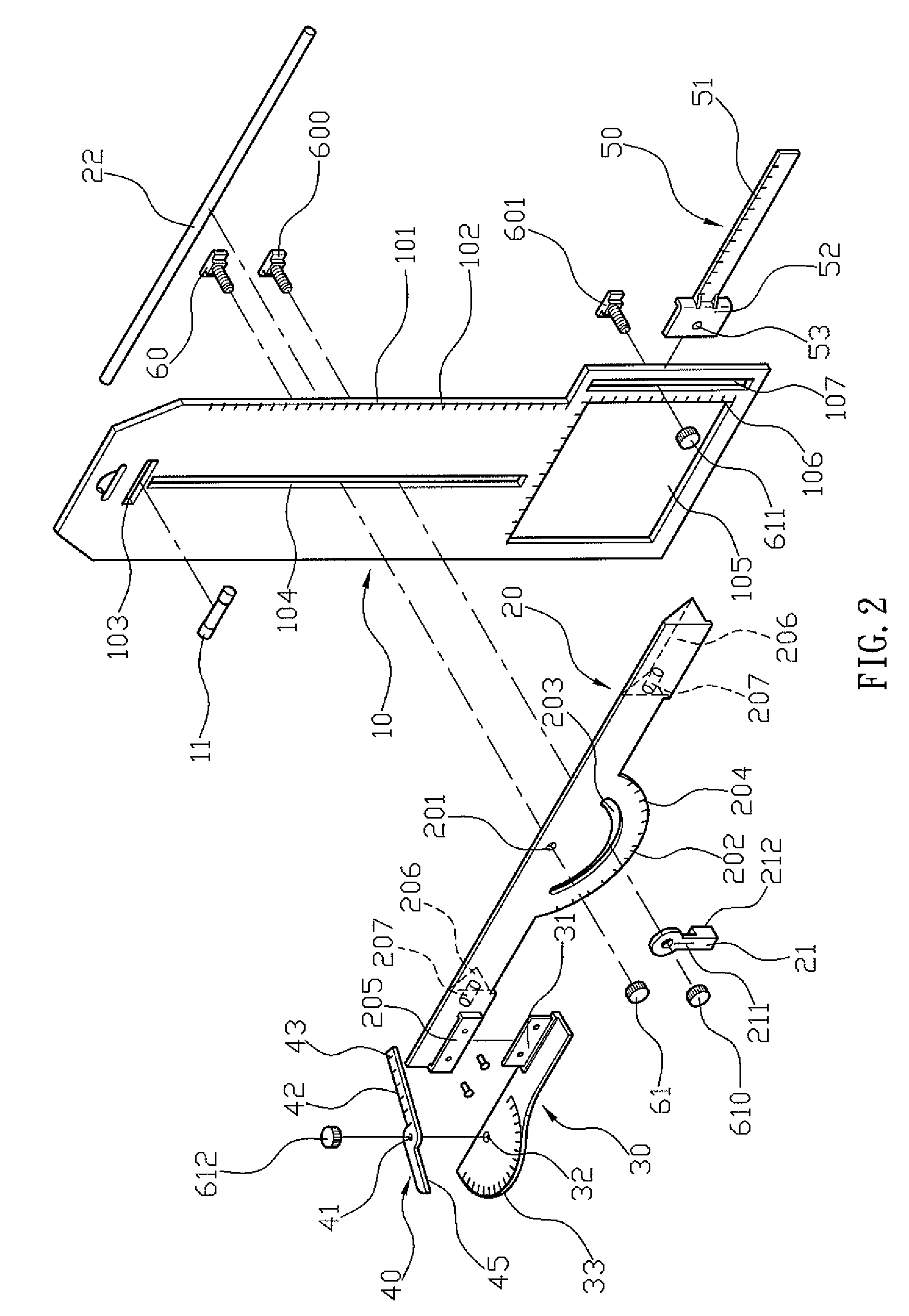

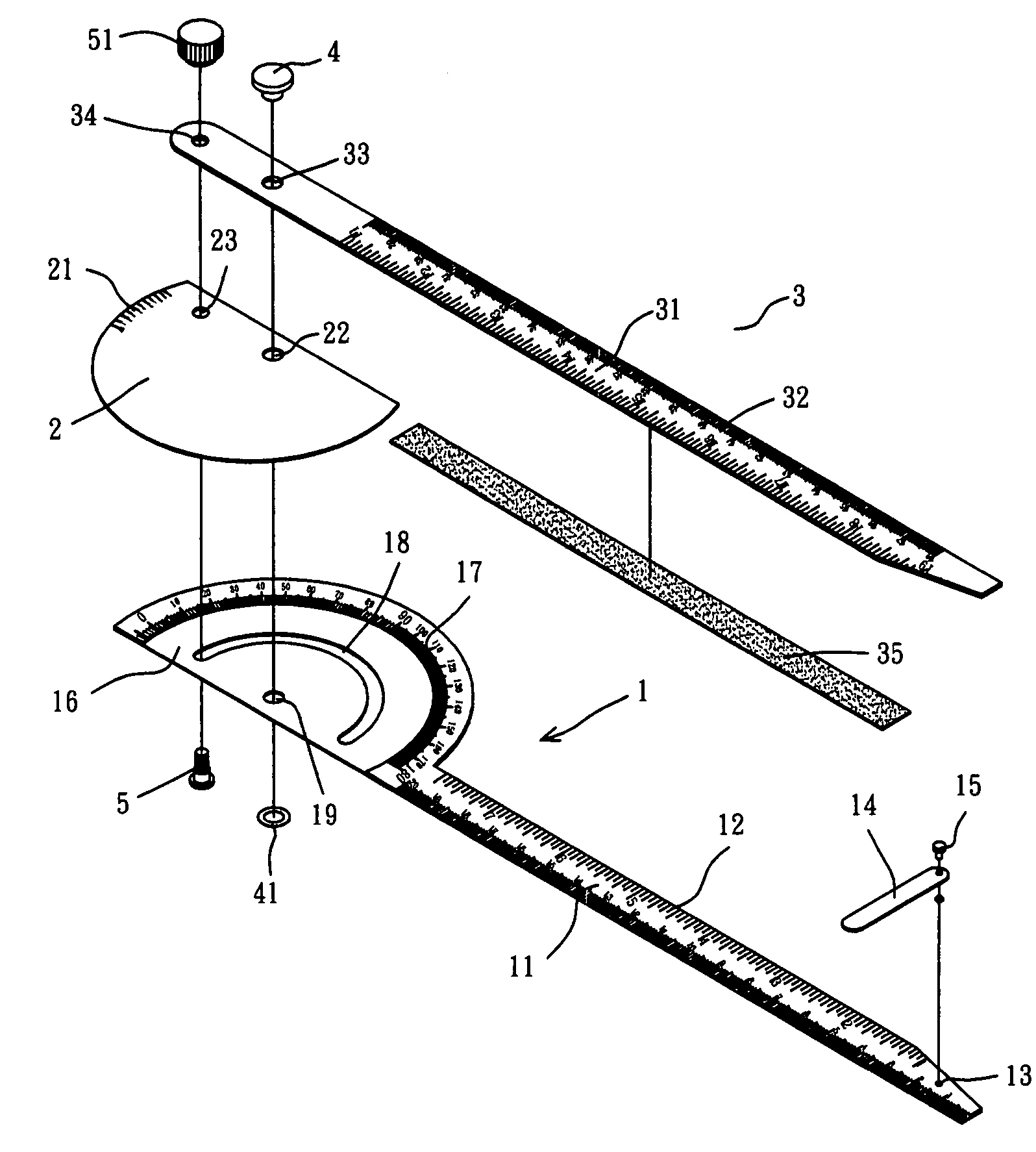

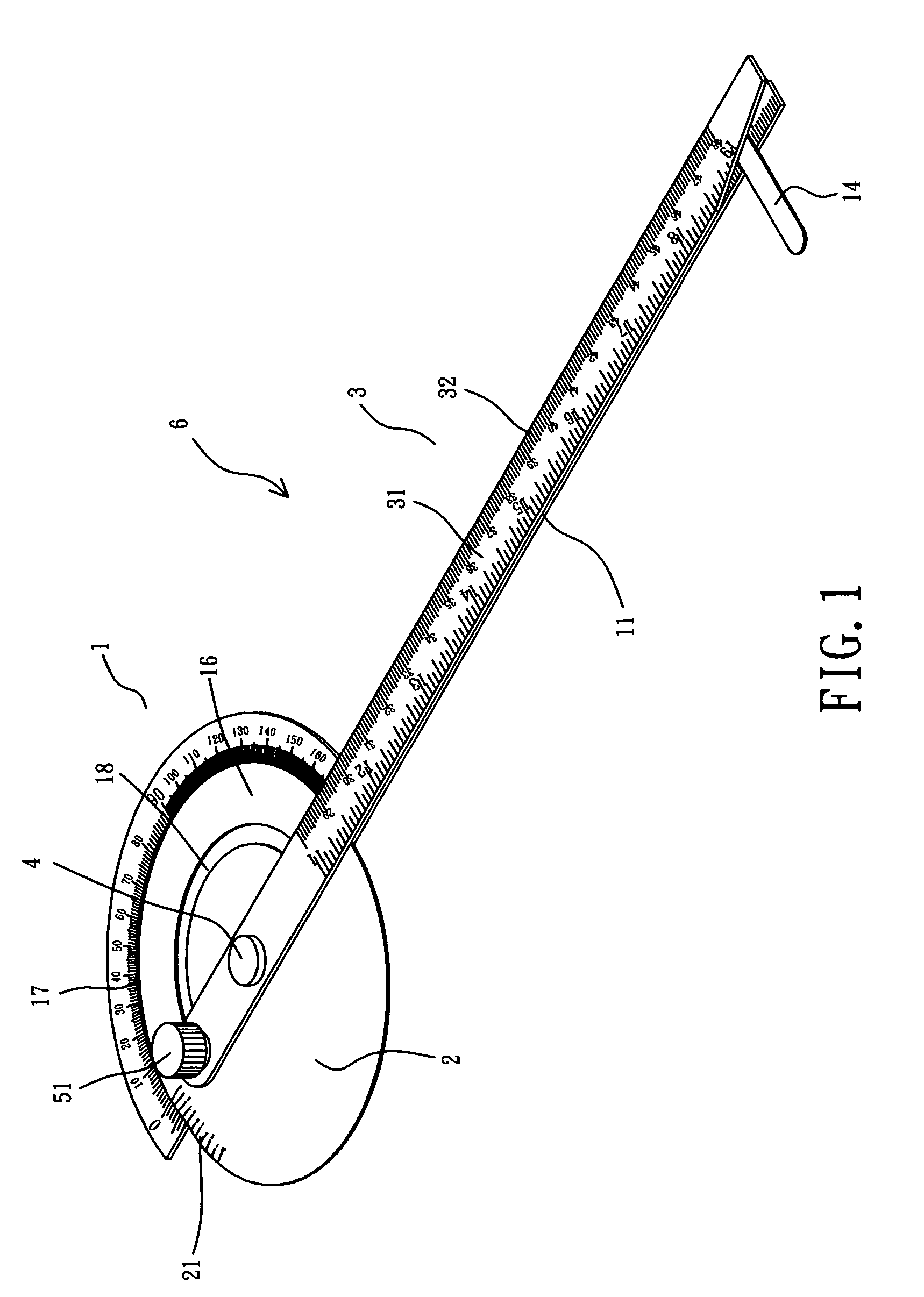

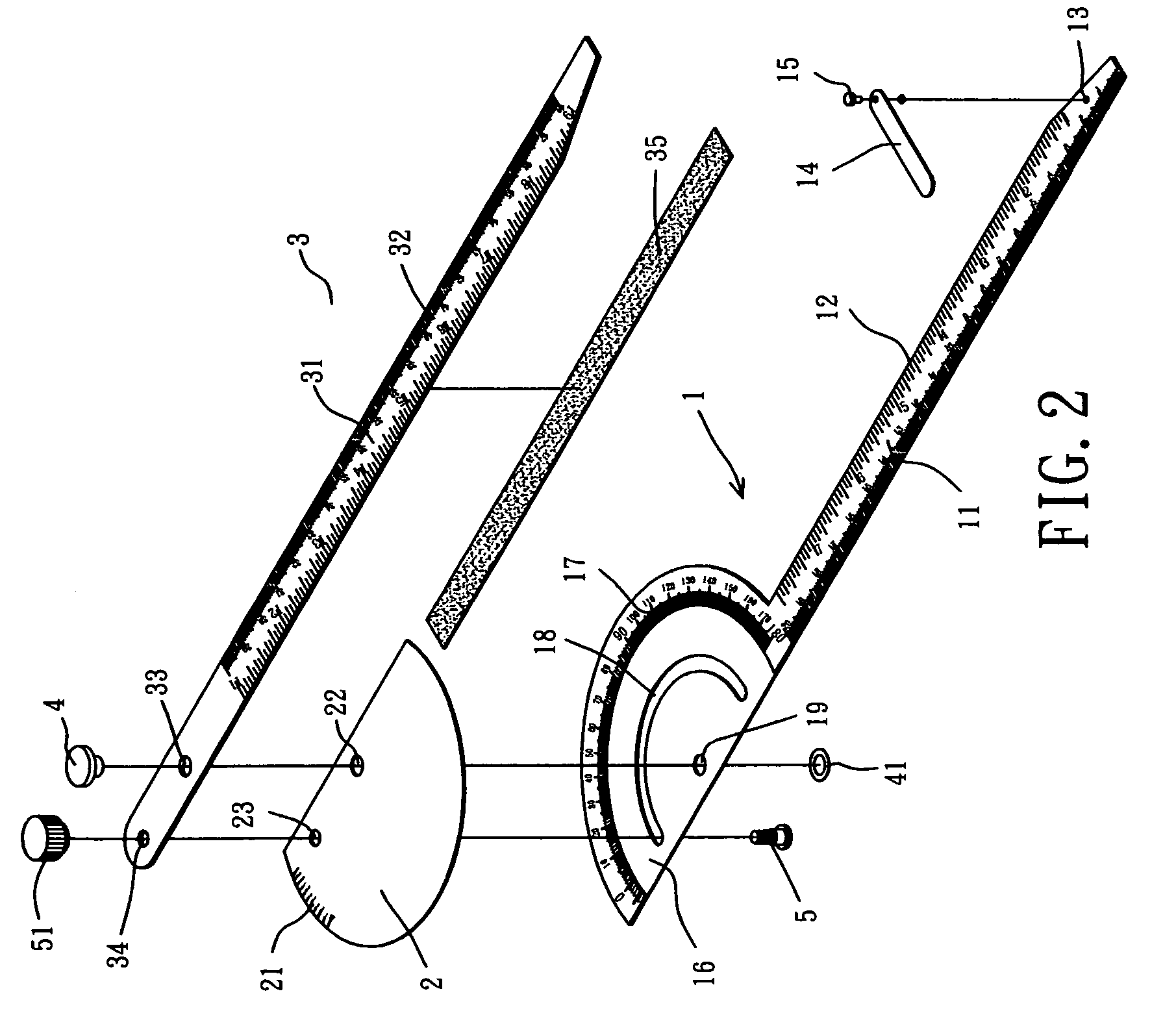

Three-dimensional combination measuring tool

InactiveUS7739806B1Easy to adjustEasy to operateBuilding material handlingStraightedgesProtractorEngineering

A combination measuring tool includes a main body having a first portion having a plurality of first graduations and a second portion having a plurality of second graduations, a transverse bar movably and rotatably mounted on the main body and having a semi-circular protrusion having a plurality of angle scales, a protractor secured to the transverse bar and having a plurality of angle scales, a pivot plate pivotally mounted on the protractor, and a ruler movably mounted on the main body and having a plurality of graduations. Thus, the measuring and drawing angle of the combination measuring tool can be adjusted easily and freely, thereby facilitating a user operating the combination measuring tool to draw marking lines.

Owner:NEDFUL PROD +1

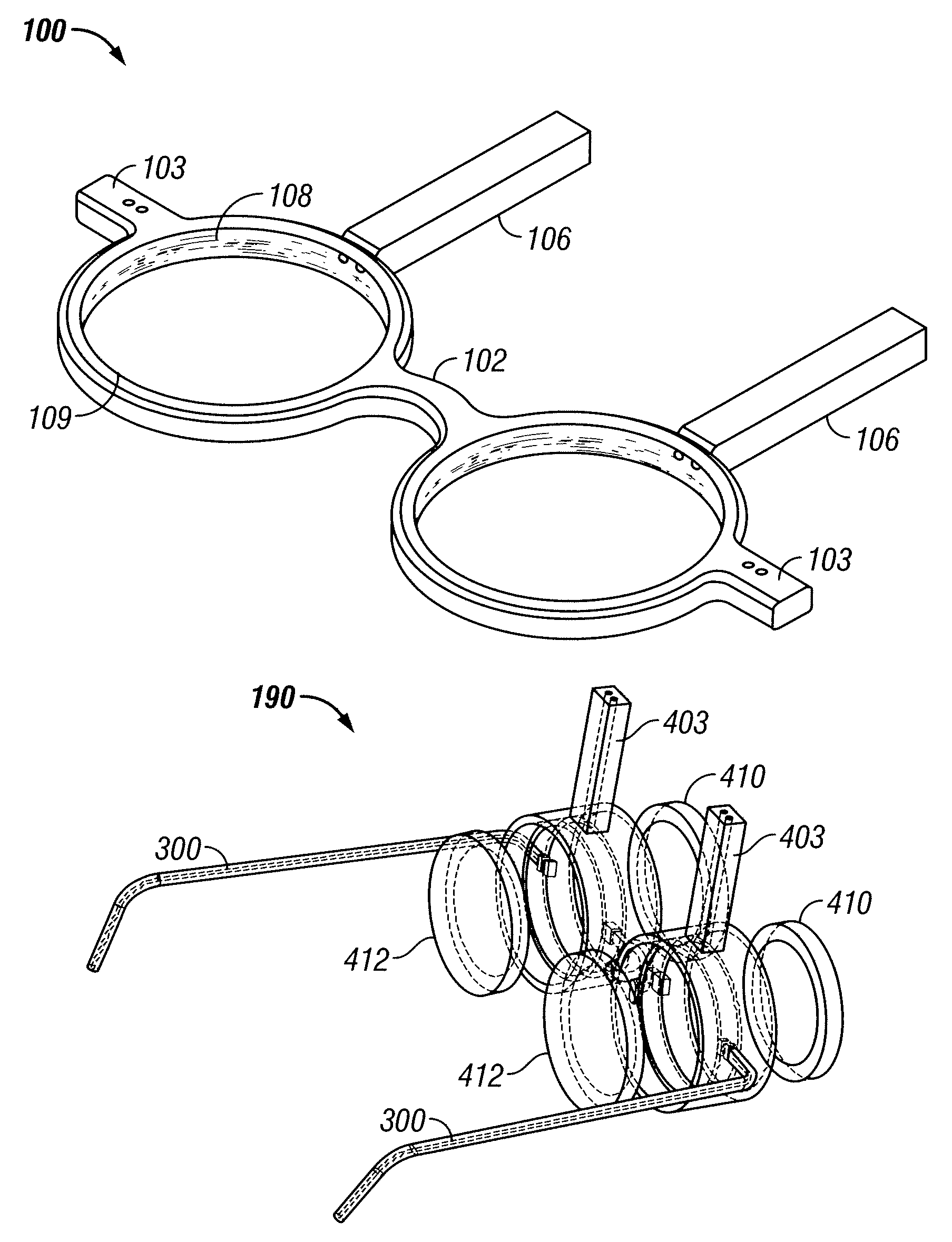

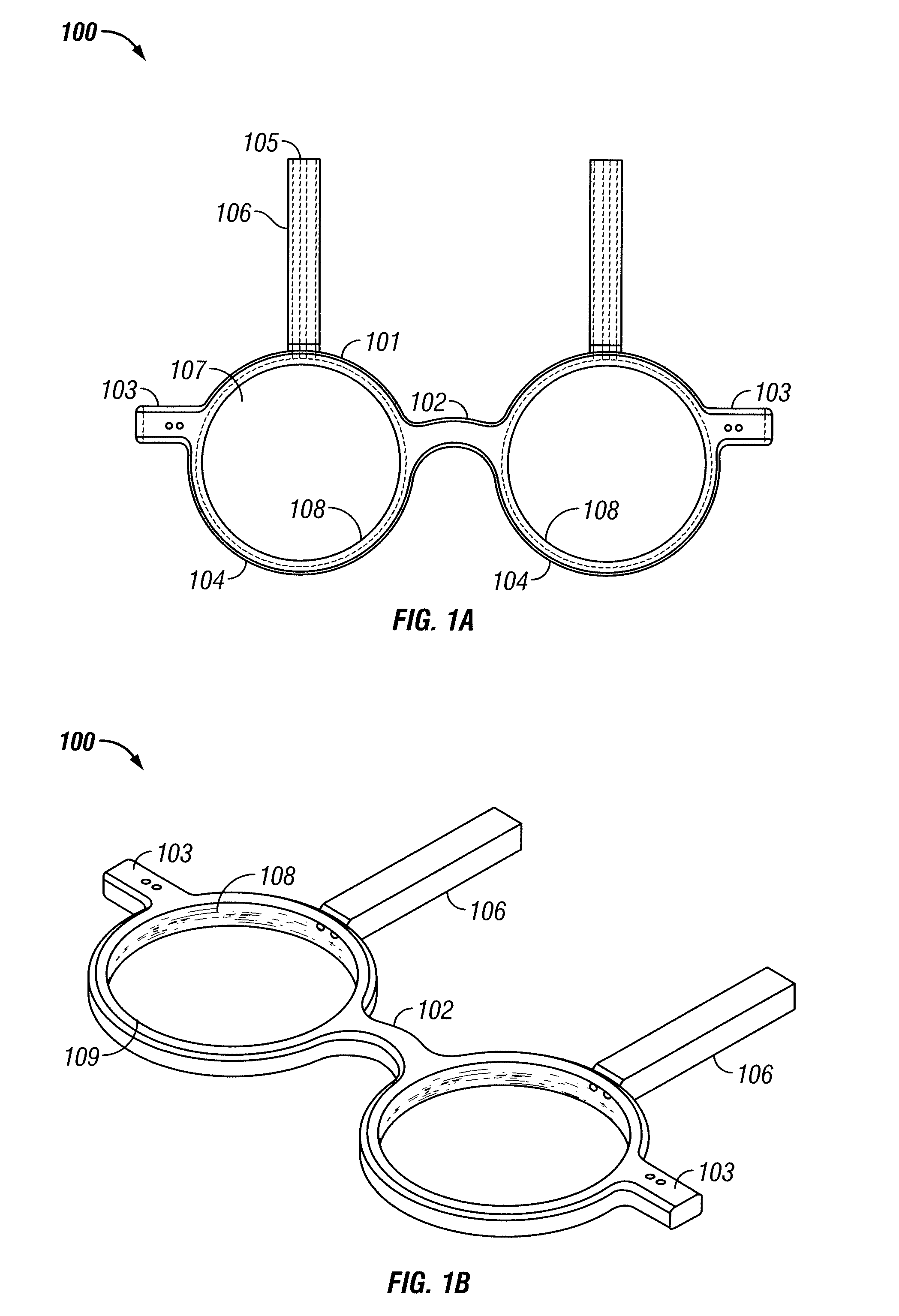

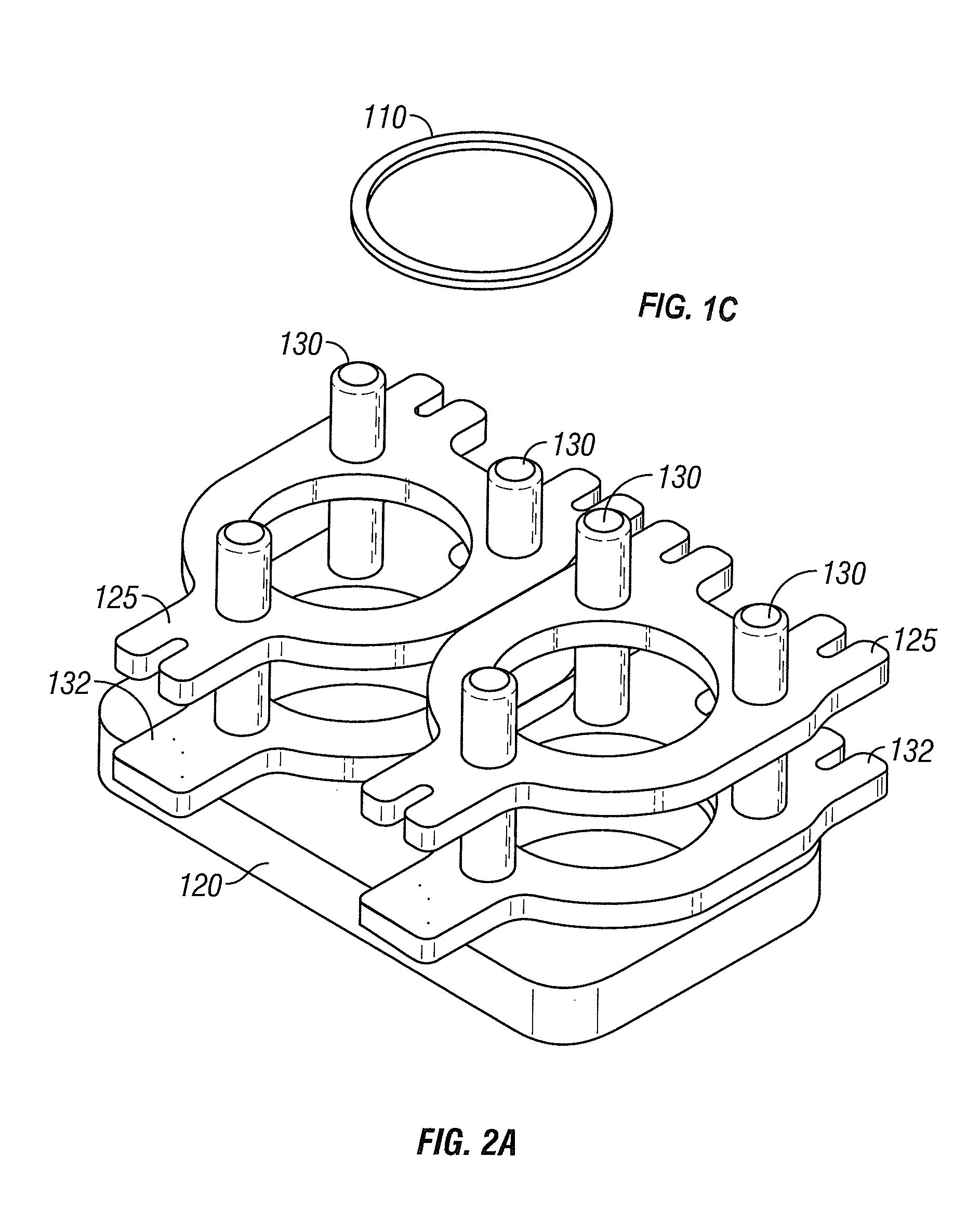

Ophthalmic eyewear with lenses cast into a frame and methods of fabrication

The present invention is directed to a method of manufacturing spectacle lens eyewear using a block mold, front and back optical inserts, front and back optical insert gaskets, a protractor insert, a closing mechanism and a preformed frame, the method comprising the steps of: selecting a front optical insert from a look up table or computer program product and assembling the insert into the block mold; selecting a front optical insert gasket and assembling the gasket onto the front optical insert; assembling the frame front onto the front optical insert gasket; selecting a back optical insert gasket and assembling the gasket onto the back side of the frame front; selecting a back optical insert from a look up table or computer program product and assembling the insert onto the back optical insert gasket; assembling the protractor insert and adjusting the position of the back optical insert to the axis indicated on a look up table or computer program product; assembling the mold closing mechanism and securing the mold; filling the cavity through a first capillary tube; curing the closed mold to polymerize the lenses; removing the ophthalmic eyewear from the block mold and releasing the front and back optical inserts and insert gaskets; and removing the capillary tube housing and attaching earpieces.

Owner:OCULAR SURFACE INNOVATIONS INC +1

Digital protractor

ActiveUS20090038168A1Easy to useLow costSlippage preventionUsing mechanical meansProtractorControl theory

A digital protractor for measuring angular displacement from a referenced surface includes a substantially congruent pair of pivotally interconnected upper and lower arms, which arms are superposable upon one another. Each arm has a pair of substantially parallel engagement edges extending longitudinally of the arm. One of the arms is engagable along an engagement edge thereof with the reference surface. A capacitive sensor is secured to the lower arm and a digital readout device is secured to the upper arm for operatively cooperating with the capacitive sensor to measure and display the angular displacement from the arm engaging the reference surface to the other arm.

Owner:WIXEY BARRY DOUGLAS

Protractor and ruler combination

InactiveUS6978550B2Facilitating operating protractorAvoid scratchesCircular curve drawing instrumentsStraightedgesProtractorEngineering management

A protractor and ruler combination includes a main ruler having a side formed with a protractor, a secondary ruler rotatably mounted on the main ruler, and an auxiliary ruler having a side secured on the secondary ruler, so that the secondary ruler is moved in concert with the auxiliary ruler on the protractor of the main ruler. Thus, the auxiliary ruler is moved relative to the main ruler, and the secondary ruler is moved in concert with the auxiliary ruler on the protractor of the main ruler, so that the included angle between the ruler section of the main ruler and the ruler section of the auxiliary ruler is measured exactly.

Owner:XIEH KUN LI

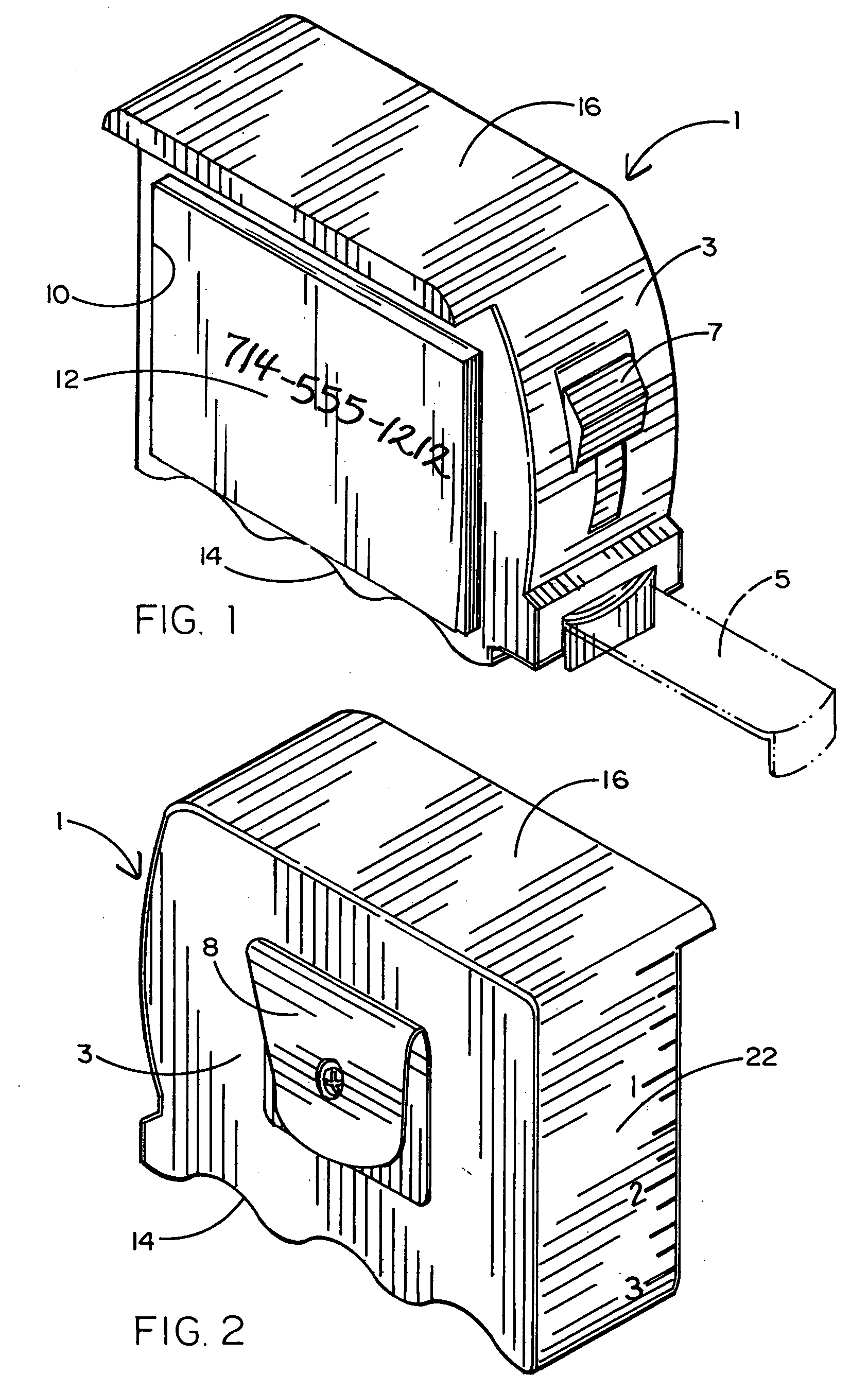

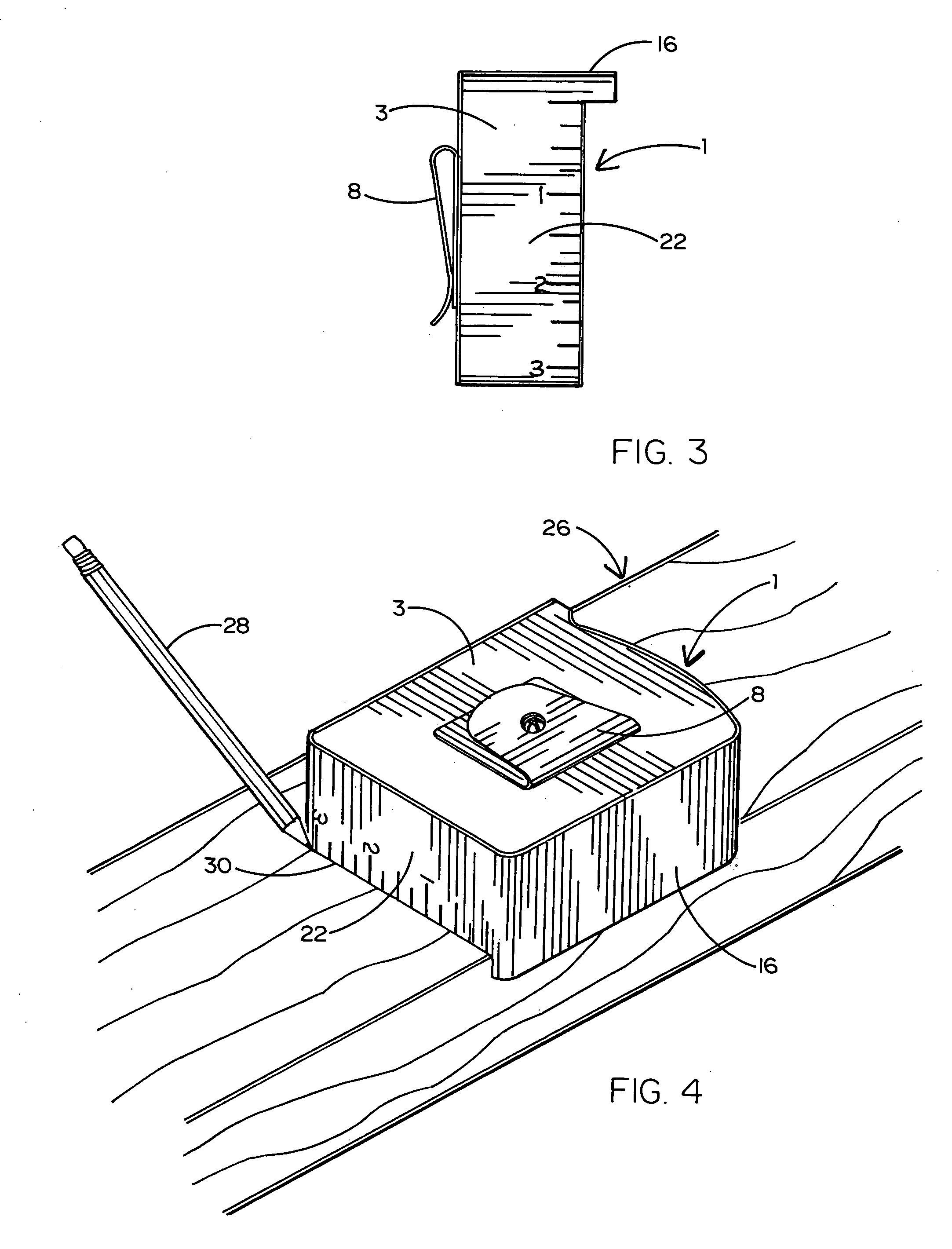

Multi-function tape measure

A compact, easy-to-carry multi-function tape measure to perform a variety of different jobs at home or in the field and ideally suited for use by carpenters, contractors, do-it-yourselfers, and the like. The tape measure includes a housing in which the usual pull-out measuring tape is carried. A retaining lip projects outwardly from the top of the housing. The housing has a graduated straight edge that is aligned perpendicular with the retaining lip. In use, the housing is laid on its side such that the outwardly projecting retaining lip overhangs and moves into interlocking engagement with a work surface to be cut. At the same time, the straight edge of the housing lies against the work surface to create a guide along which a marking instrument is moved for marking a cutting line on the work surface. The housing may also include the additional features of a graduated straight edge extension pivotally coupled to the straight edge, a recess for receiving a stack of peel-off note sheets on which messages are written, a finger grip, a removable scribe for marking the work surface with the cutting line, a slide-out protractor attached to and movable with the straight edge, a digital display, and a level.

Owner:ALKER GRIFFIN C

Multi-task protractor

A multi-task protractor apparatus having the capabilities of a rotating protractor, adjustable triangle, ruler, miniature leveler, framing square and roof angle finder is disclosed. The multi-task protractor accurately measures angles and slopes and provides two straight edges for constructing angles and triangles.

Owner:JOHNSON MARION

Pipe sizing and alignment device

InactiveUS7240437B1Quick and accurate judgmentEconomical and simpleAngles/taper measurementsSurveying instrumentsProtractorLight beam

The present invention relates to an improved pipe sizing and alignment device that can quickly and precisely attach it's concave base to, and align itself with the horizontal axis of a circular, main pipe. Through the use of multiple lasers, one of which is mounted to an adjustable arm that pivots about the center of a graduated protractor mounted on the concave base, the device can be located along the main pipe and the collimated beam of light from the laser directed at a distant plumbing component. This shows the specific fitting location for a tie in between the main pipe and plumbing component that will allow the horizontal axis of the main pipe to remain true to it's original spatial position with respect to the building structure. An electronic distance measuring device, also mounted to the adjustable arm, precisely indicates distance.

Owner:MOLDOVAN EMILIAN

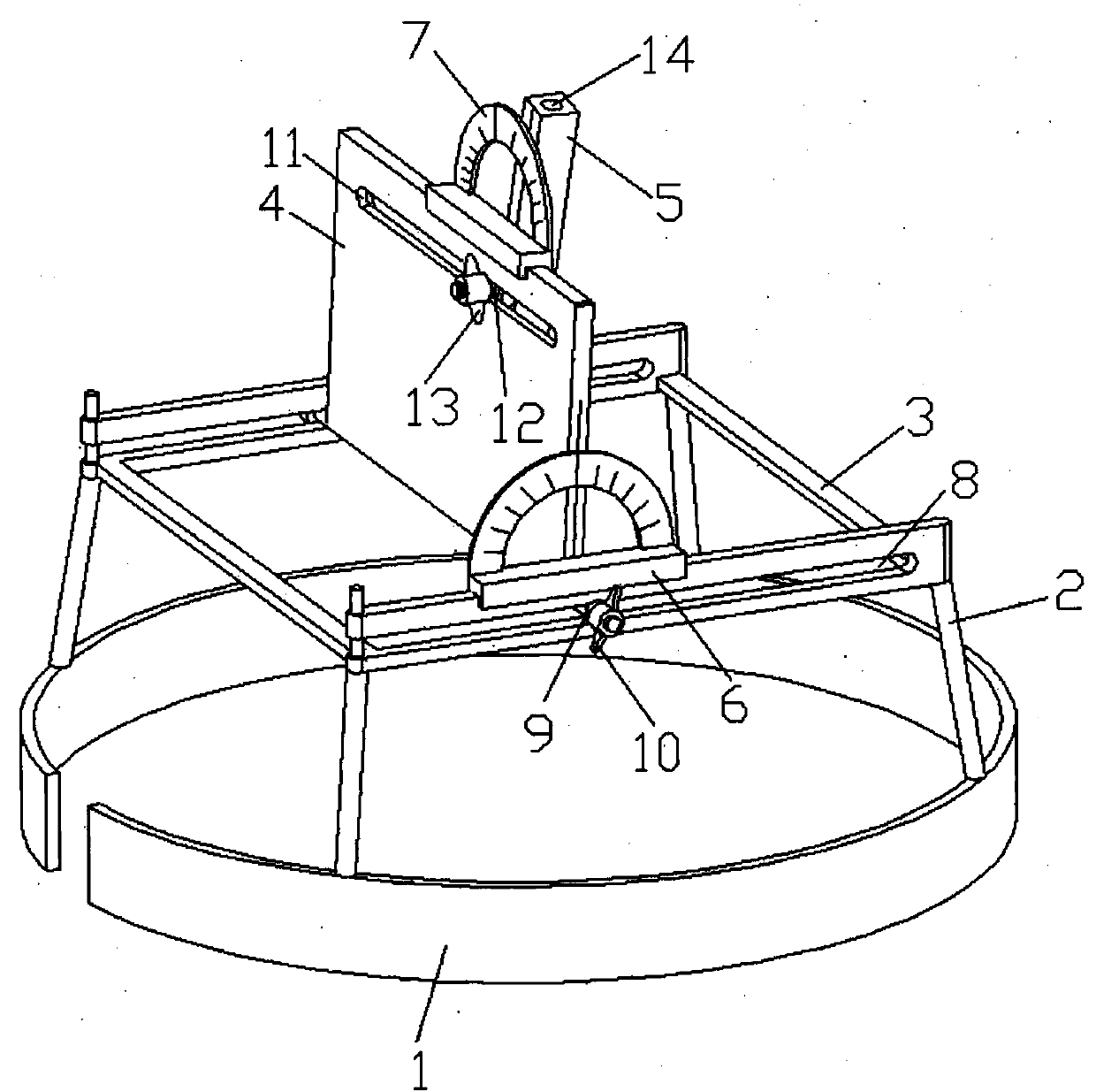

Lateral ventricle puncture location guiding device

The invention relates to a lateral ventricle puncture location guiding device. The lateral ventricle puncture location guiding device is characterized by comprising a head band, wherein the head band is used for being arranged on the head in a sleeved mode, a guide plate which can horizontally move is arranged on a support, the guide plate is vertically arranged and can swing in a front-and-back mode, the swing angle of the guide plate is set through a first protractor, a guide tube which can horizontally move is arranged on the guide plate, the moving direction of the guide tube is perpendicular to the moving direction of the guide plate, the guide tube is vertically arranged and can swing in a left-and-right mode, and when the guide tube swings to be in place, the position of the guide tube is locked through a second locking mechanism, a through hole is formed in the guide tube, and a puncture needle can be guided to penetrate into the brain through the through hole. The lateral ventricle puncture location guiding device has the advantages of being simple in structure, convenient to use, capable of providing a location guiding device for lateral ventricle puncture and capable of being used for lateral ventricle puncture operations to guide cerebrospinal fluid out.

Owner:上海中山医疗科技发展有限公司 +1

Rotary draw tube bender

The invention is a rotary draw bending machine and process for bending materials such as tubes or pipes into precise bends. A spindle holds a bending die, and a radial arm holds a counter-die. The spindle and arm are simultaneously rotated in opposite directions by a dual hydraulic drive controlled by an electro-hydraulic control system with foot pedal controls. The bend angle is preset by a protractor-like dial and limit switch mechanism. The radial arm has a slide track to align the counter-die with the bending die. The ratchet mechanism has teeth to allow incremental advancement of the counter-die when aligning it with its bending die to accurately set the gap between the dies. The machine is used with a wide variety of dies to bend a wide variety of workpiece diameters. The ratchet mechanism preferably includes a fine tuning device to provide an infinite range of alignment positions.

Owner:JPW IND

Laser square protractor kit

A laser, square, protractor kit has a laser marker with a housing. The housing has a first positioning member. The protractor has a base with a second positioning member which cooperates with the first positioning member to position the housing on the protractor base. The protractor base also includes a third positioning member. A framing square is coupled with the third positioning member enabling the protractor to be positioned on the framing square.

Owner:BLACK & DECKER INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com