Mould for manufacturing fissure surface of rock like test block

A rock test block and fracture surface technology is applied in the field of molds for making rock test block fracture surfaces, which can solve the problems of low work efficiency, waste of mold materials, long processing cycle, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

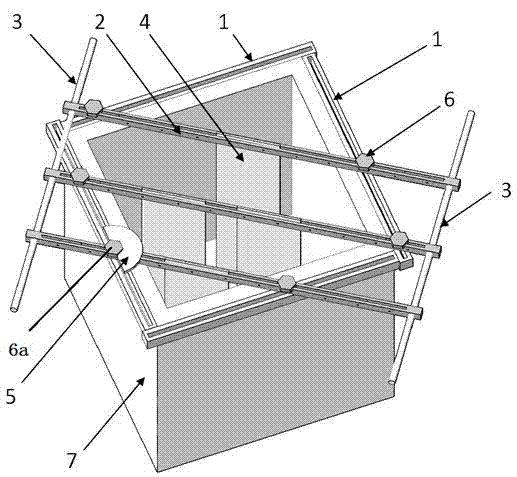

[0034] Such as figure 1 As shown, the present embodiment includes 4 chutes 1, 3 steel sheet positioning bars 2, 2 sliding bars 3, 4 steel sheets 4, 1 protractor 5, bolts 6, and 4 steel sheet fixing sheets 8.

[0035] The test block mold 7 used in this embodiment is a steel mold with a size of 150×150×150 mm (length×width×height), that is, the length of the side wall of the test block mold 7 is 150 mm. The size of chute 1 is 170×20×10mm (length×width×height), and the size of its straight slot hole is 150×6×10mm (length×width×height). On the top of the 4 side walls of the test block mold 7, and the slotted side faces up. The size of the steel sheet positioning rod 2 is 310×15×15mm (length×width×height), the size of the through groove is 250×3×15mm (length×width×height), and there are round holes with a diameter of 8mm at both ends. The axial direction of the circular hole is perpendicular to the axial direction of the steel sheet positioning rod 2, that is, when the sliding ro...

Embodiment 2

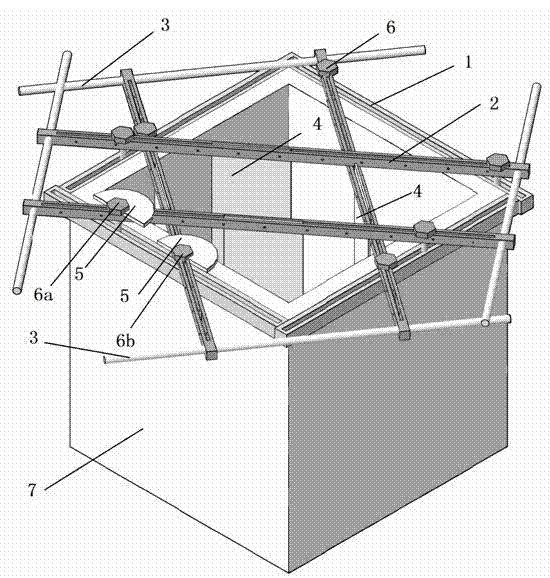

[0038] Such as image 3As shown, the present embodiment can process 2 groups of crack surfaces, including 4 slide grooves 1, 4 steel sheet positioning rods 2, 4 sliding rods 3, 4 steel sheets 4, 2 protractors 5, bolts 6, 4 steel sheet fixing sheets 8.

[0039] The test block mold 7 used in this embodiment is a steel mold with a size of 150×150×150 mm (length×width×height), that is, the length of the side wall of the test block mold 7 is 150 mm. The size of chute 1 is 170×20×10mm (length×width×height), and the size of its straight slot hole is 150×6×10mm (length×width×height). On the top of the 4 side walls of the test block mold 7, and the slotted side faces up. The size of the steel sheet positioning rod 2 is 310×15×15mm (length×width×height), the size of the through groove is 250×3×15mm (length×width×height), and there are round holes with a diameter of 8mm at both ends. The axial direction of the circular hole is perpendicular to the axial direction of the steel sheet po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com