Measurer of dielectric film microwave complex dielectric permittivity

A technology of complex permittivity and dielectric thin film, which is applied in measuring devices, measuring electrical variables, measuring resistance/reactance/impedance, etc., can solve the problems of large measurement errors and the inability to realize the dielectric thin film microwave complex permittivity, and achieve high Sensitivity, the effect of precise measuring devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

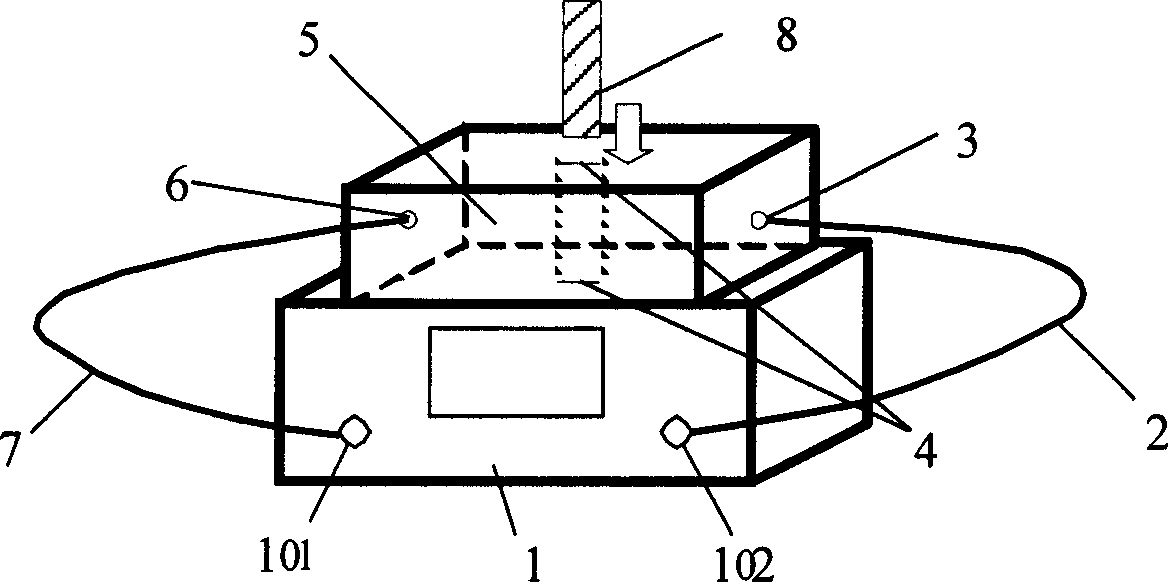

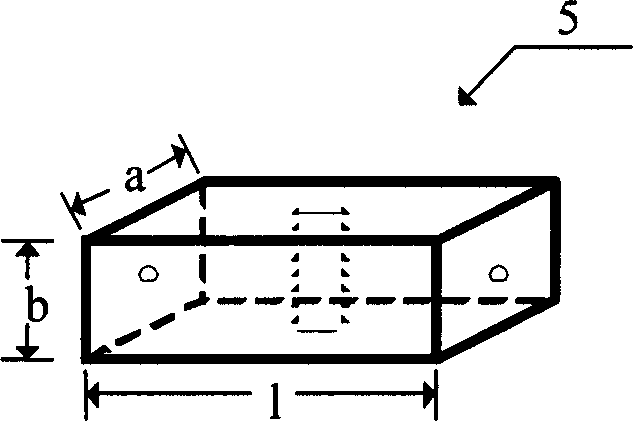

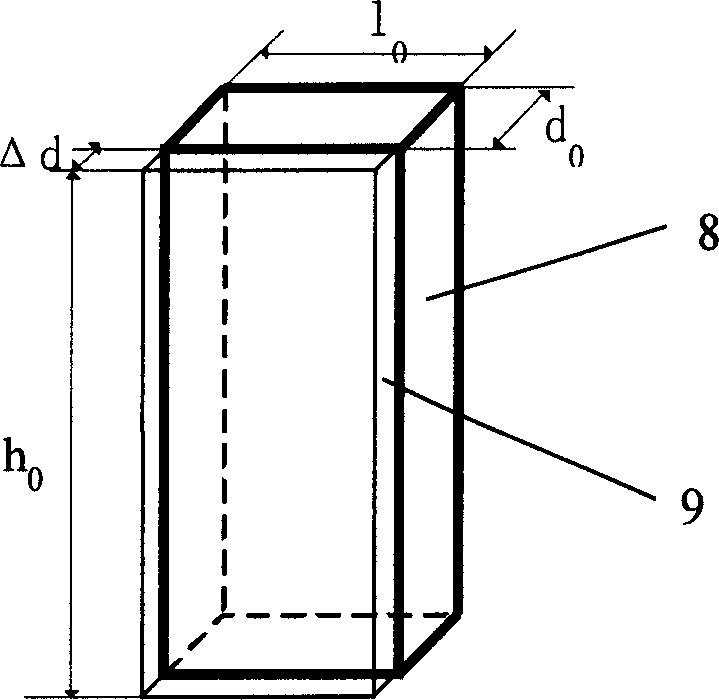

[0028] A device for measuring the microwave complex permittivity of dielectric thin films. The metal resonant cavity 5 is made of a standard rectangular waveguide model 153IEC-R32, and the width a, height b, and length l are 72.14mm, 34.04mm, and 138.52mm respectively. mm, there are 10mm long and 0.5mm wide thin grooves 4 in the middle of the upper and lower planes of the resonant cavity respectively; the dielectric substrate 8 is made of quartz material, and its thickness is d 0 and width l 0 0.46mm and 9.89mm respectively; the model of network analyzer 1 is Agilent 8714ET, which is connected to the rectangular metal resonator 5 through a ring coupler, and the measured dielectric film is MC-91[BaO-(SmNdLa) 2 o 3 -Bi 2 o 3 -TiO 2 ] dielectric ceramic thin film, its thickness Δd is measured by α step meter, and is 810nm, according to the steps of the present invention, adjust the frequency range and the amplitude scale of the network analyzer to an appropriate value, and ca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com