Patents

Literature

683results about "Frames" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

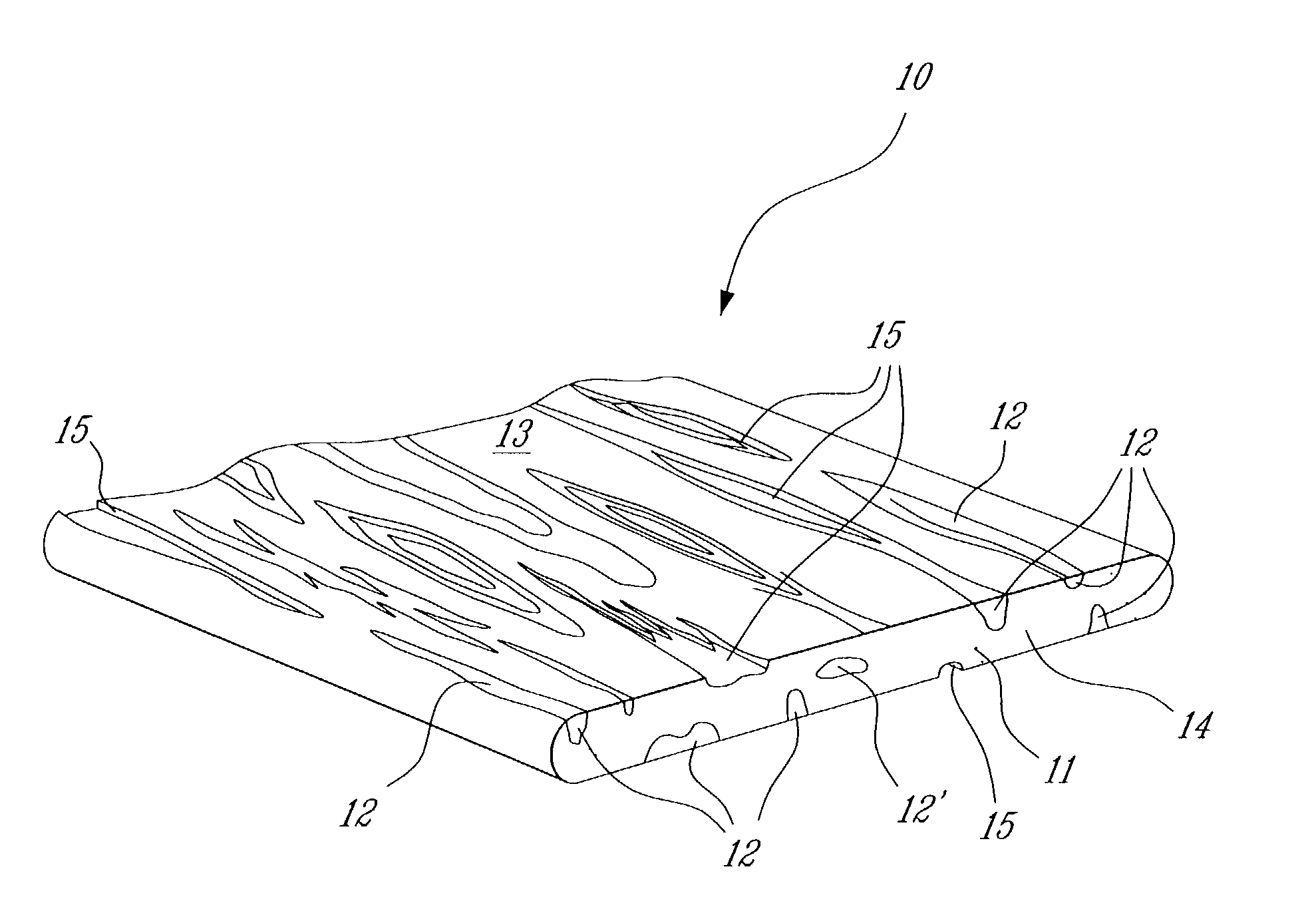

Compositions and methods for use in three dimensional model printing

InactiveUS7300619B2Similar elasticitySimilar strengthButtonsLiquid surface applicatorsOrganic compoundPolymer chemistry

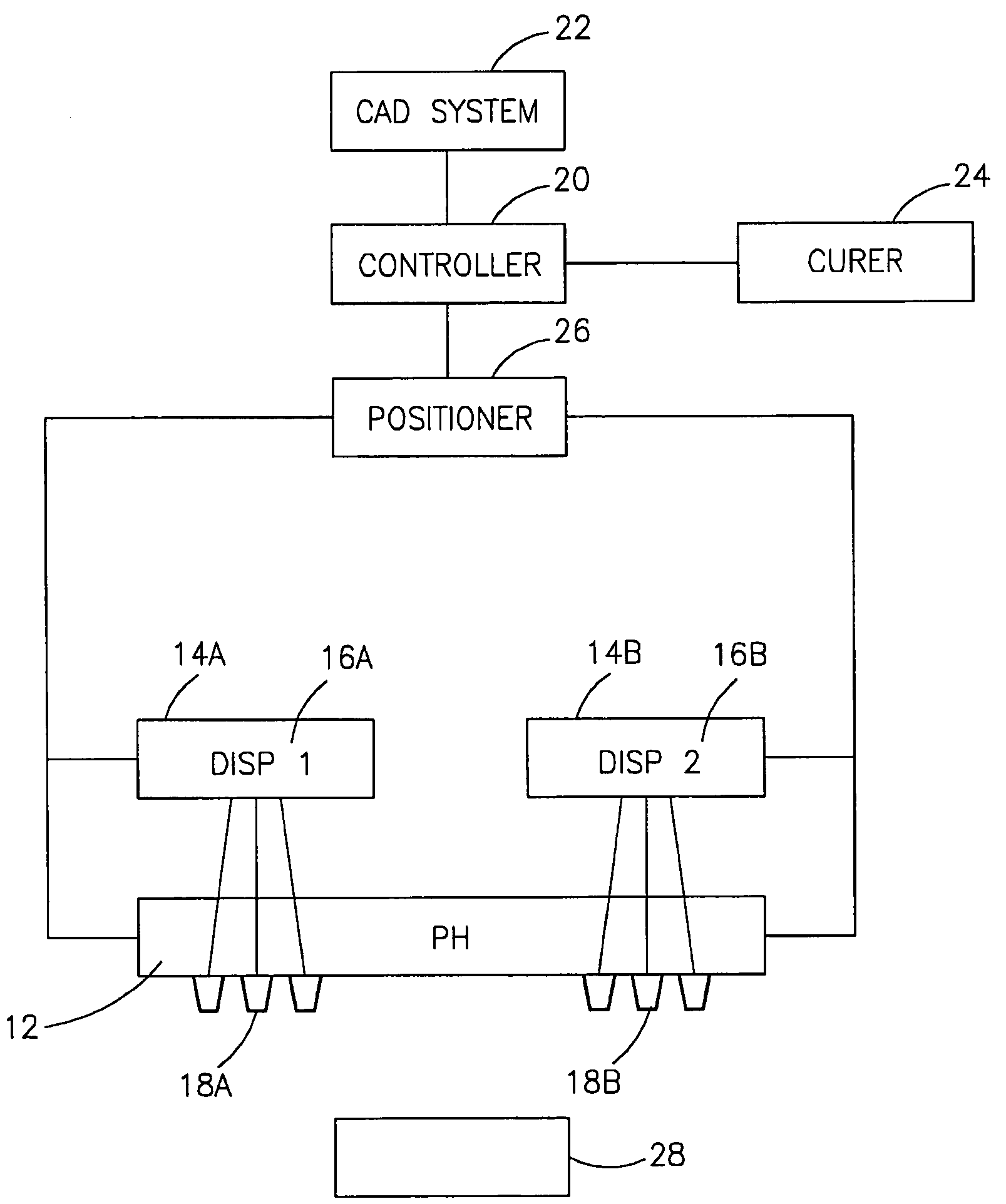

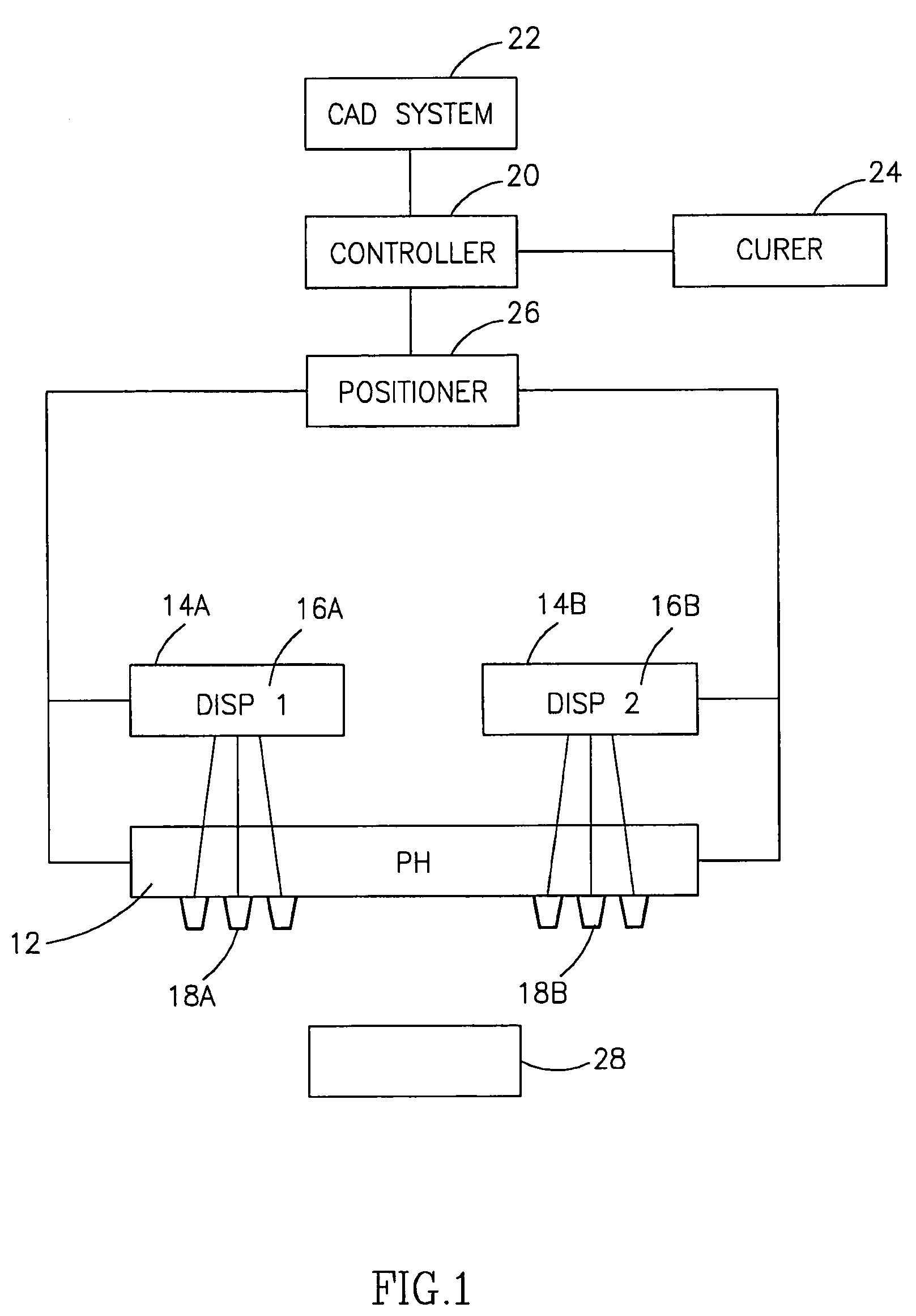

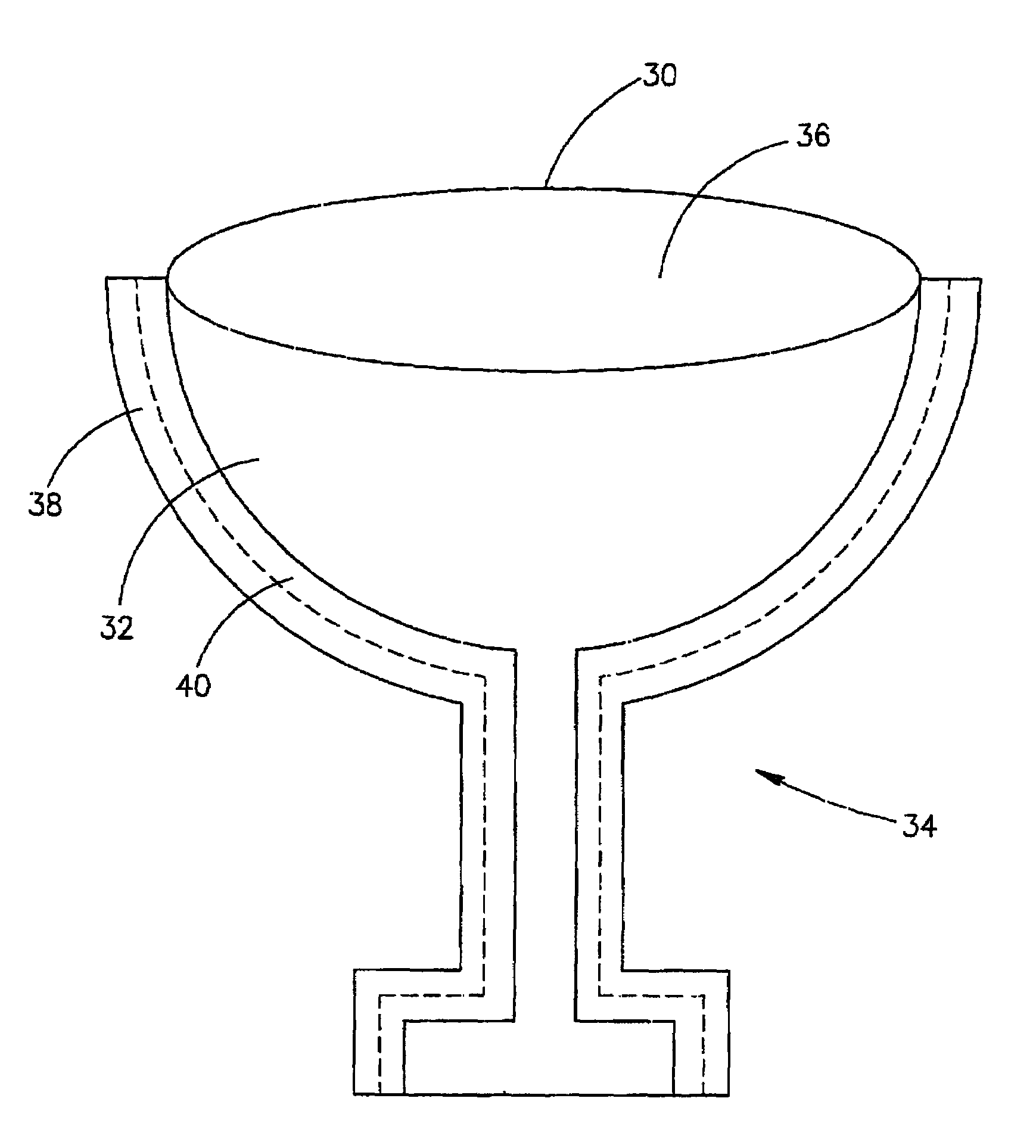

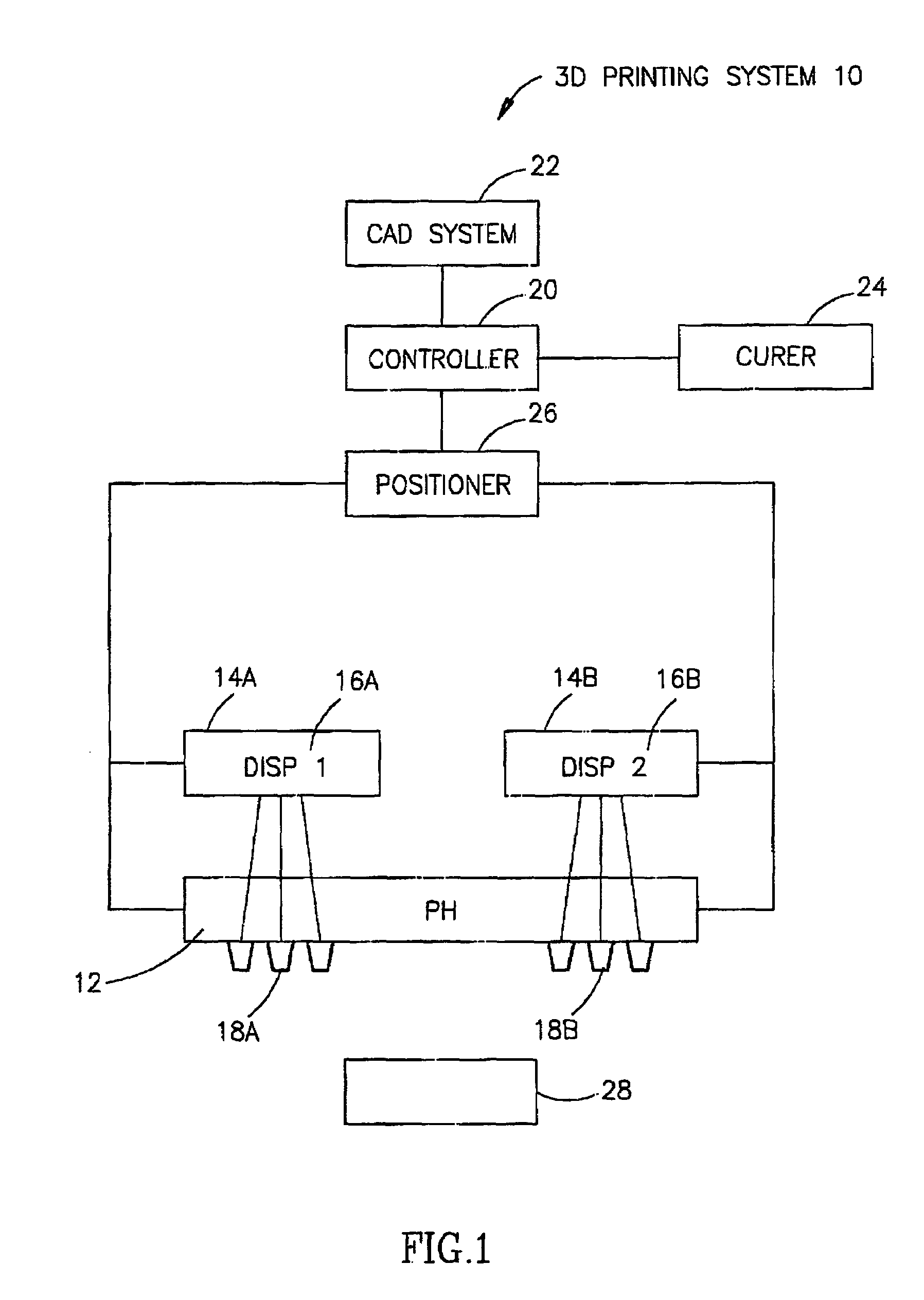

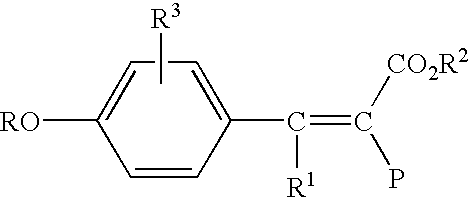

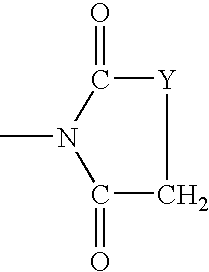

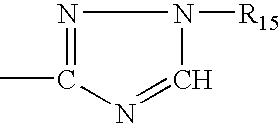

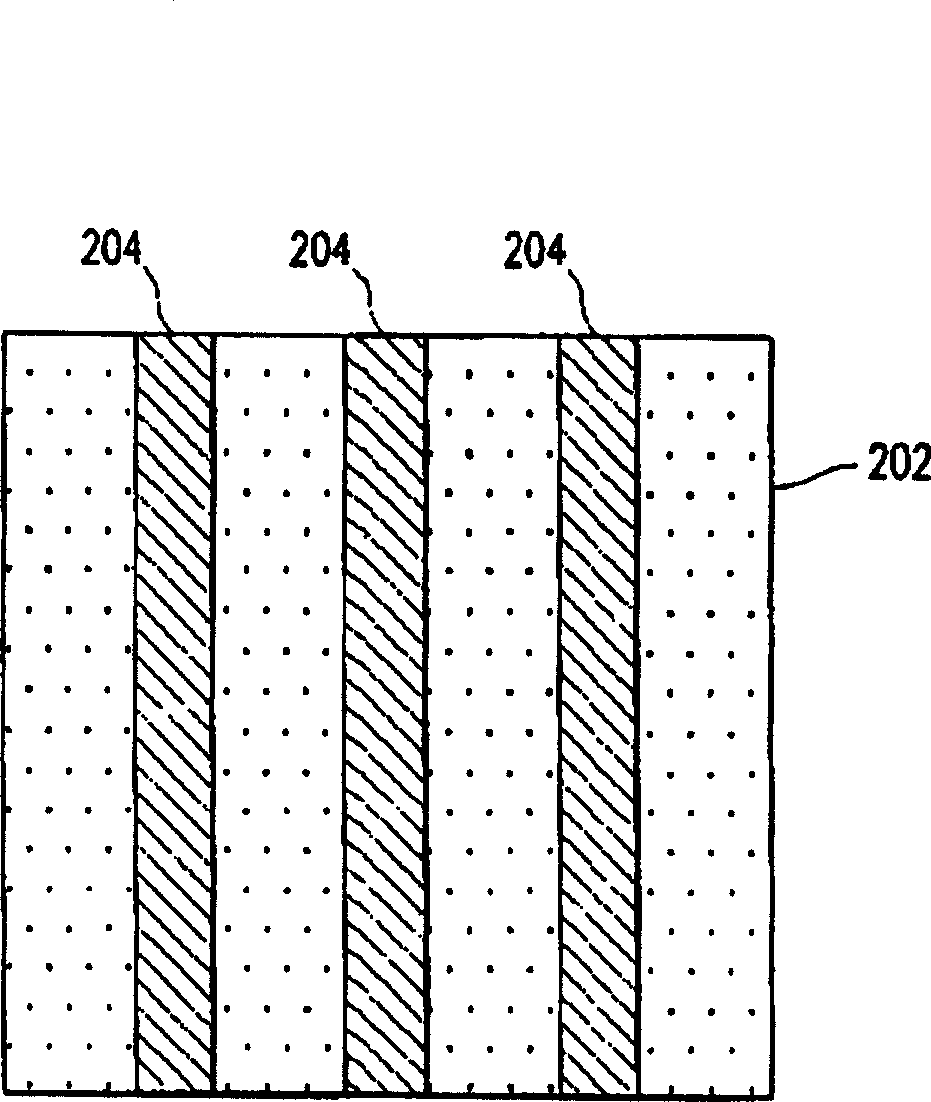

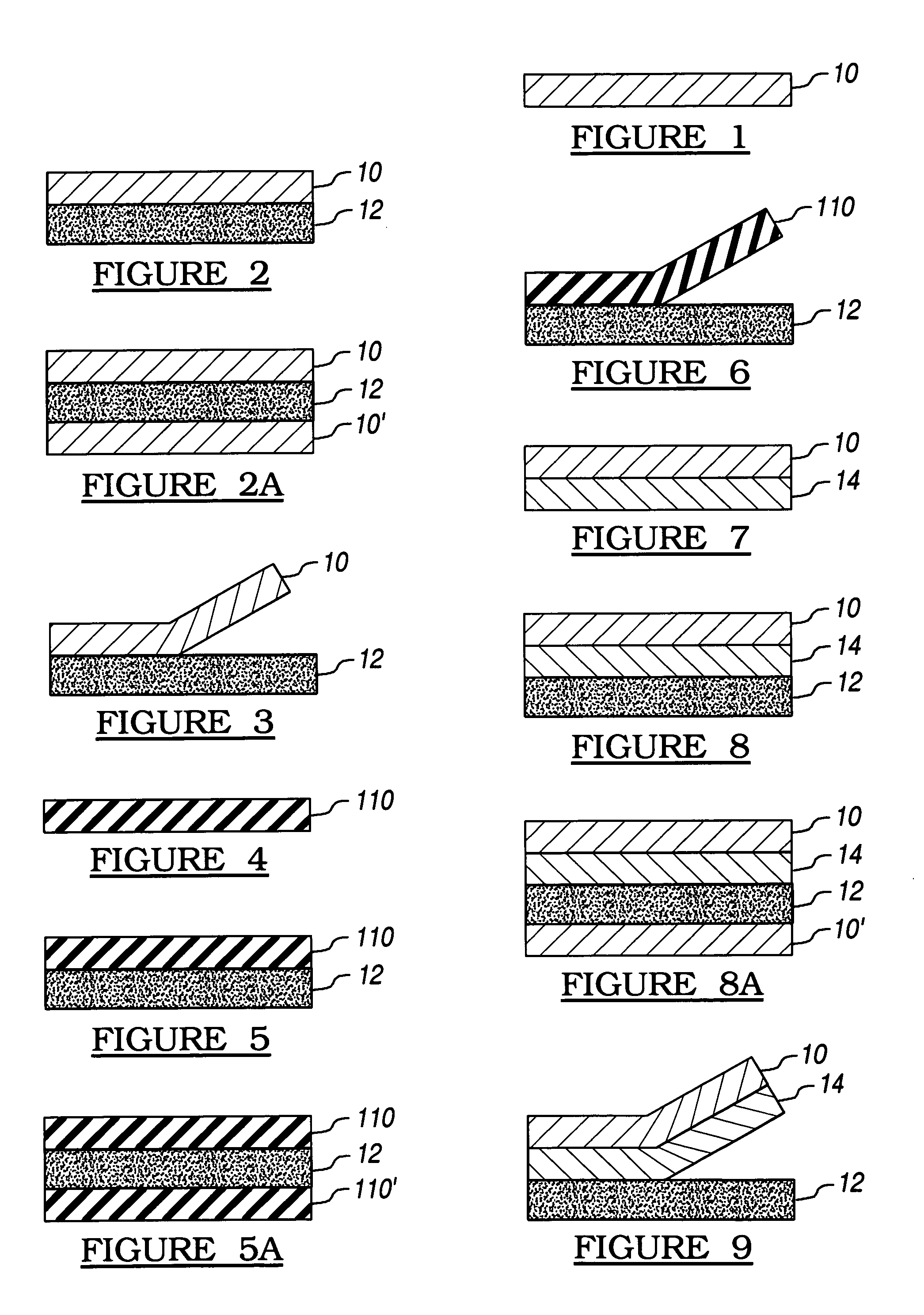

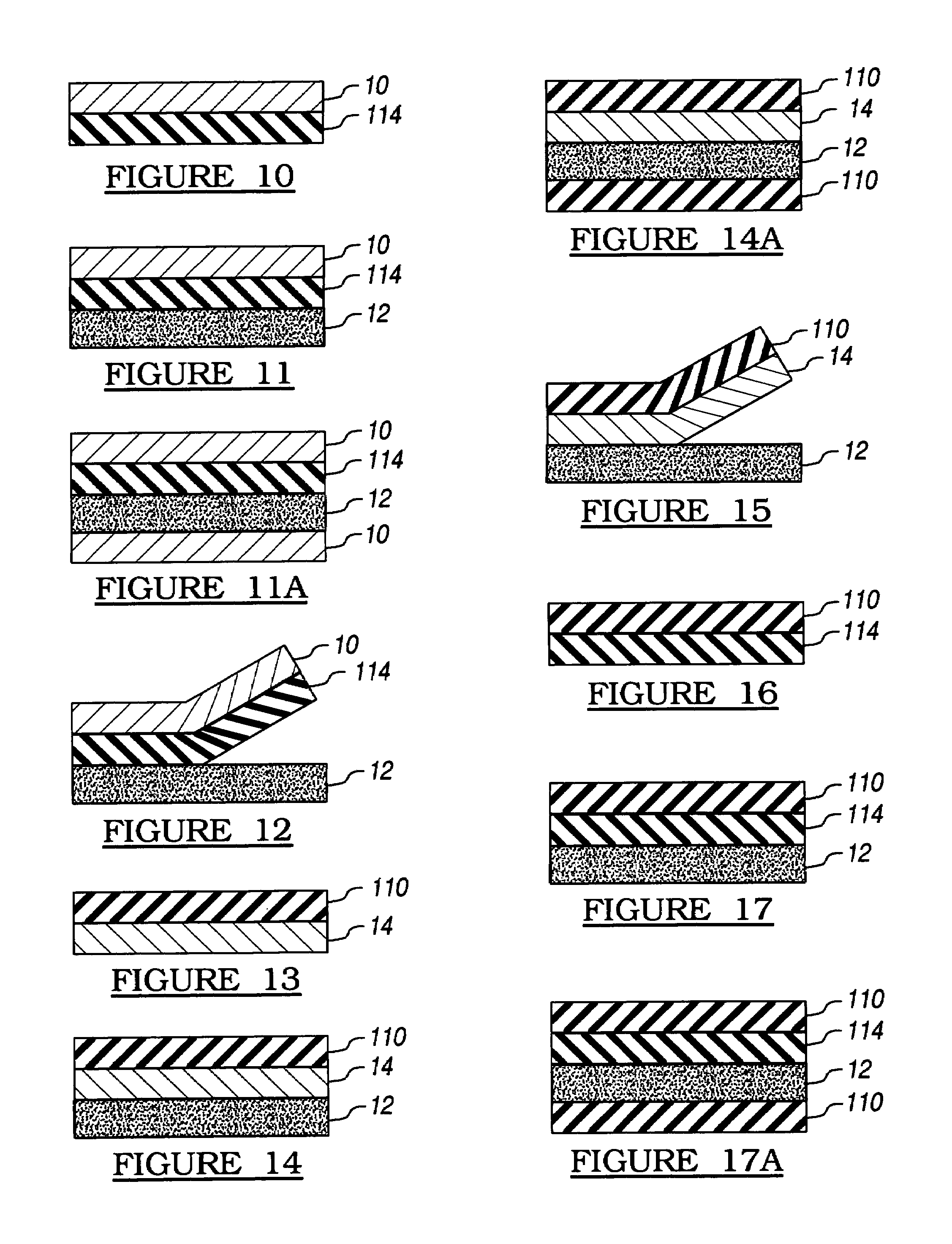

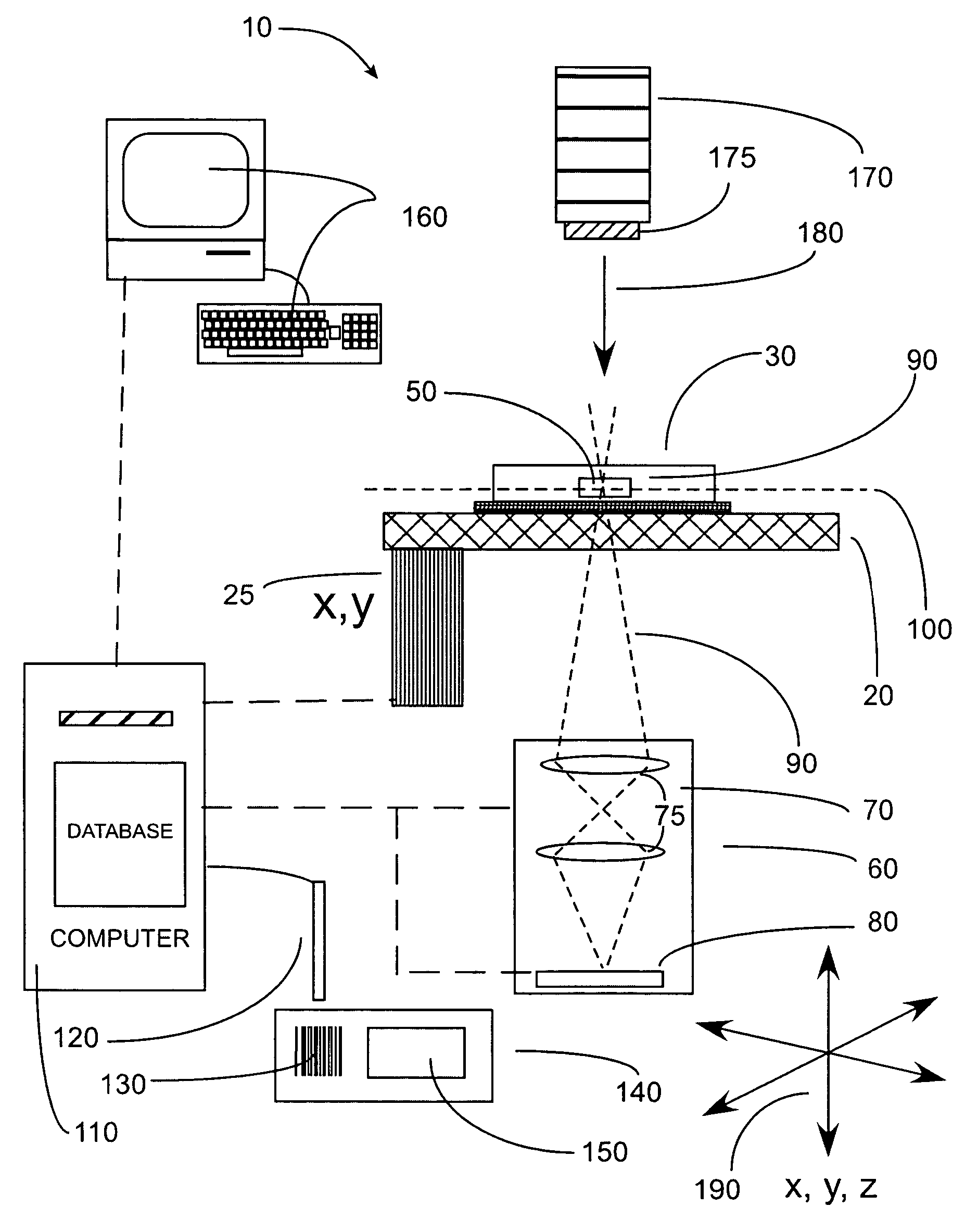

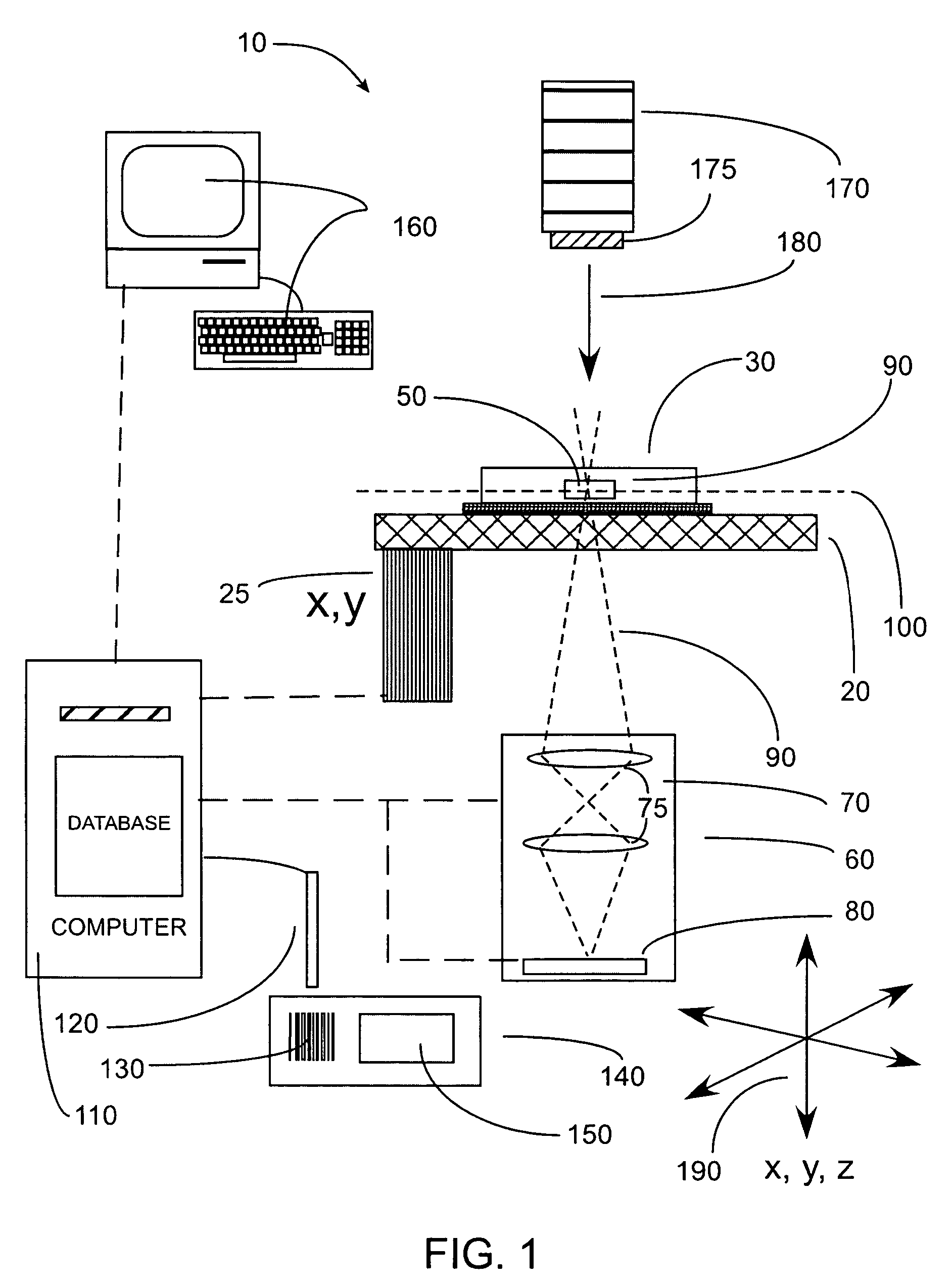

A pseudo composite material, may include, inter alia, a first phase and a second phase, wherein each phase may include, inter alia, an organic compound, wherein each phase comprising a multiplicity of construction layers, wherein the layers were deposited by ink-jet printing, wherein the pseudo composite material exhibits non-homogeneous three-dimensional structure. A method is disclosed for the preparation of a pseudo composite material. An apparatus is disclosed for printing a pseudo composite material. Furthermore, there is disclosed a method for printing a three-dimensional object using various suitable materials.

Owner:STRATASYS LTD

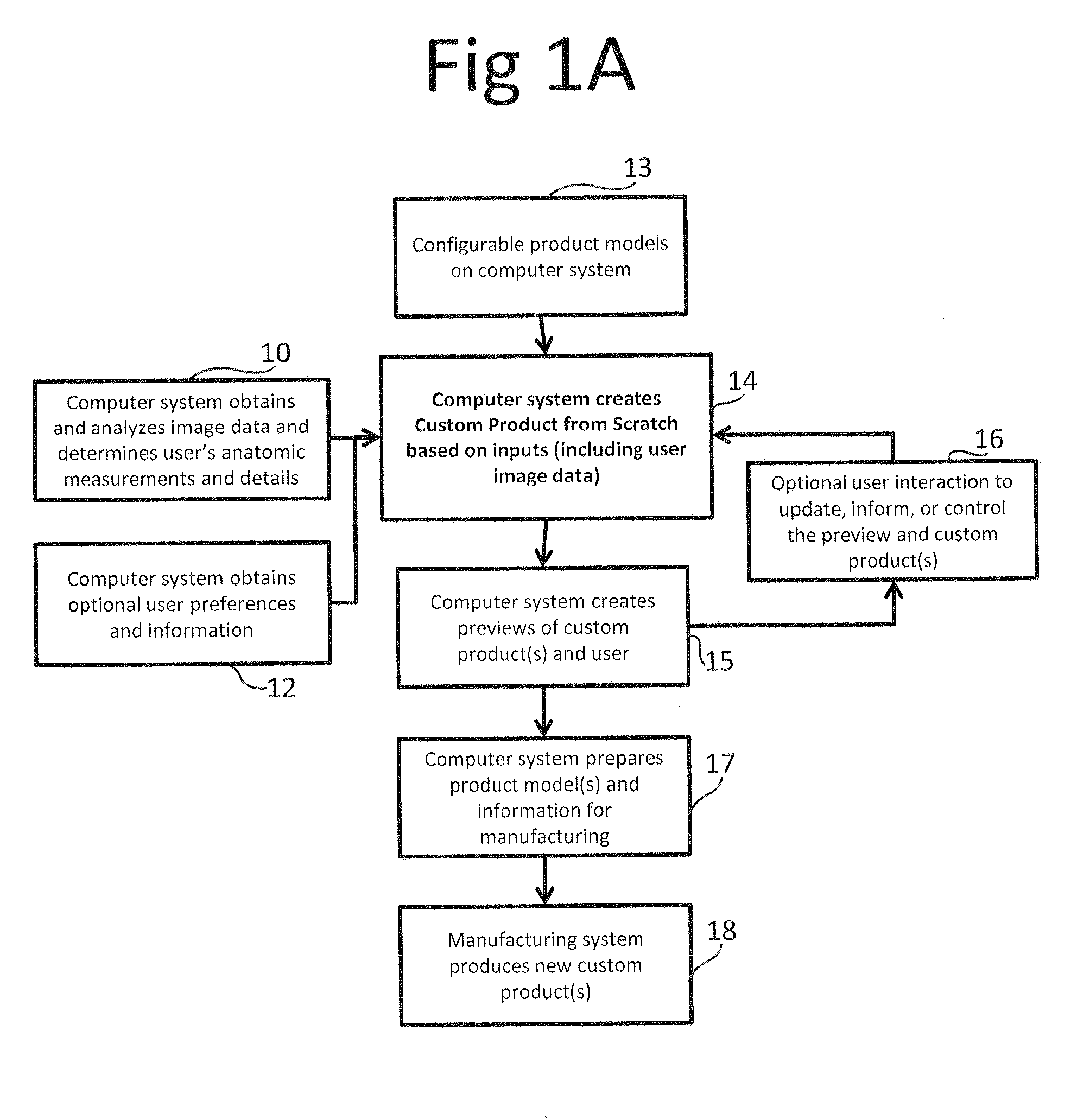

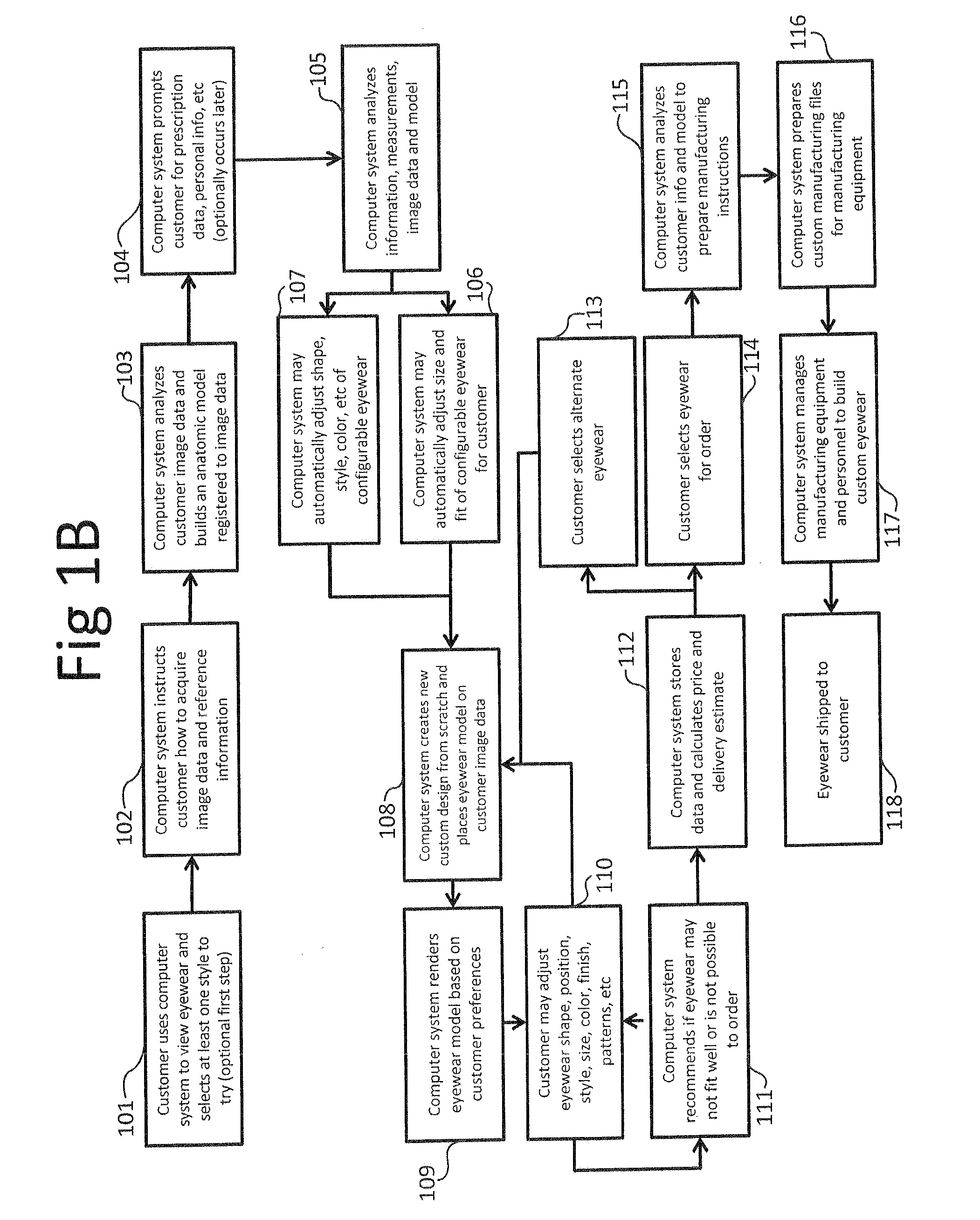

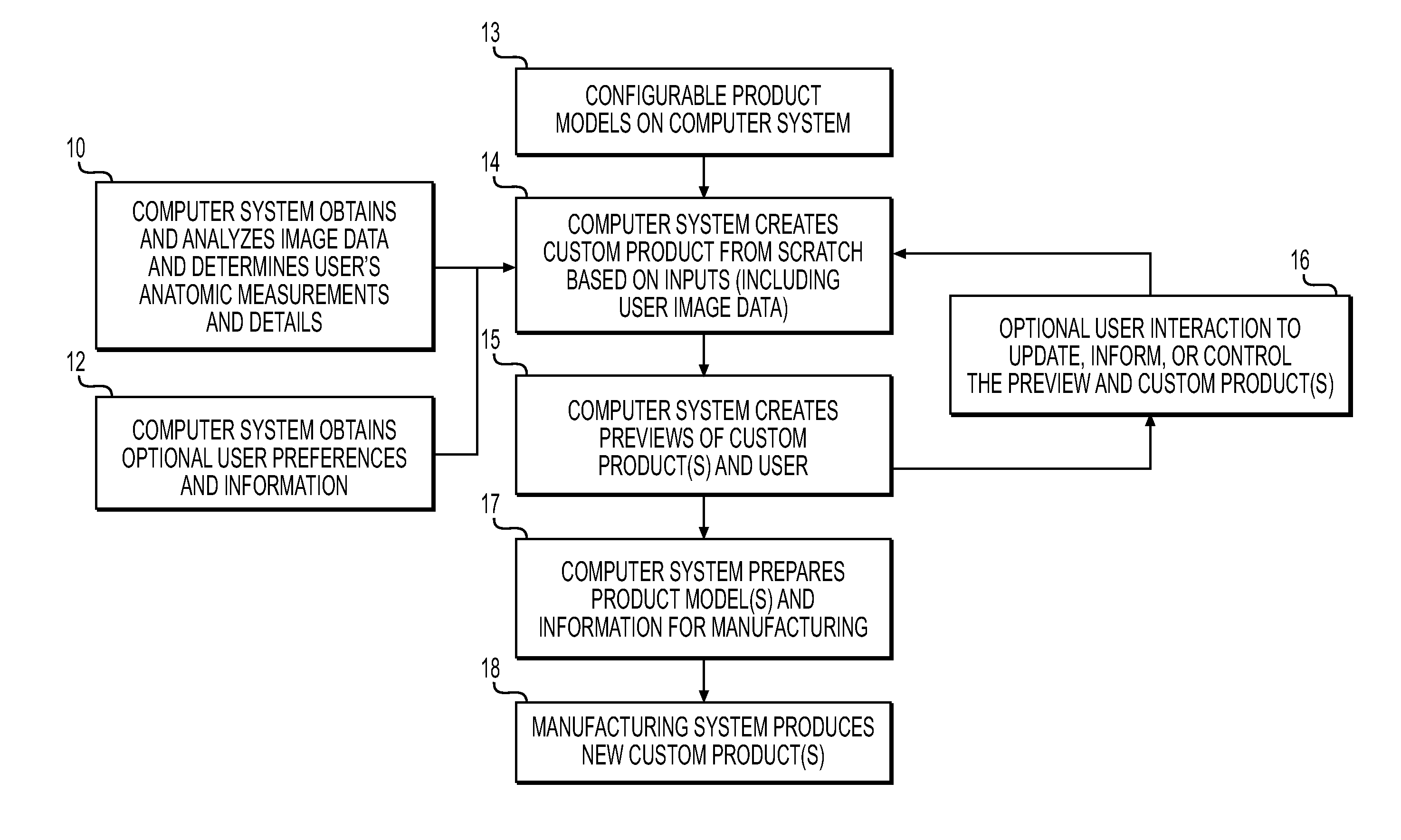

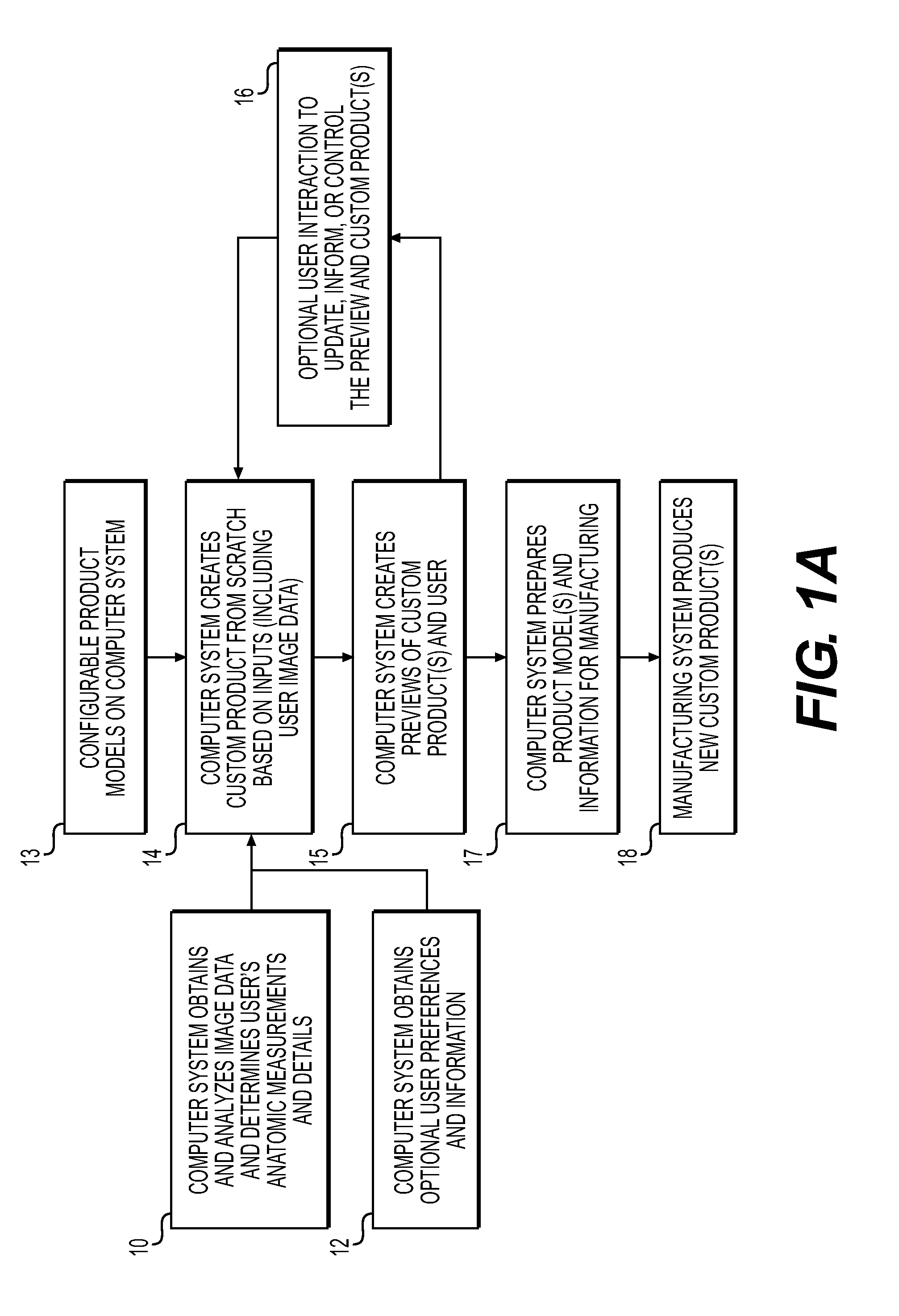

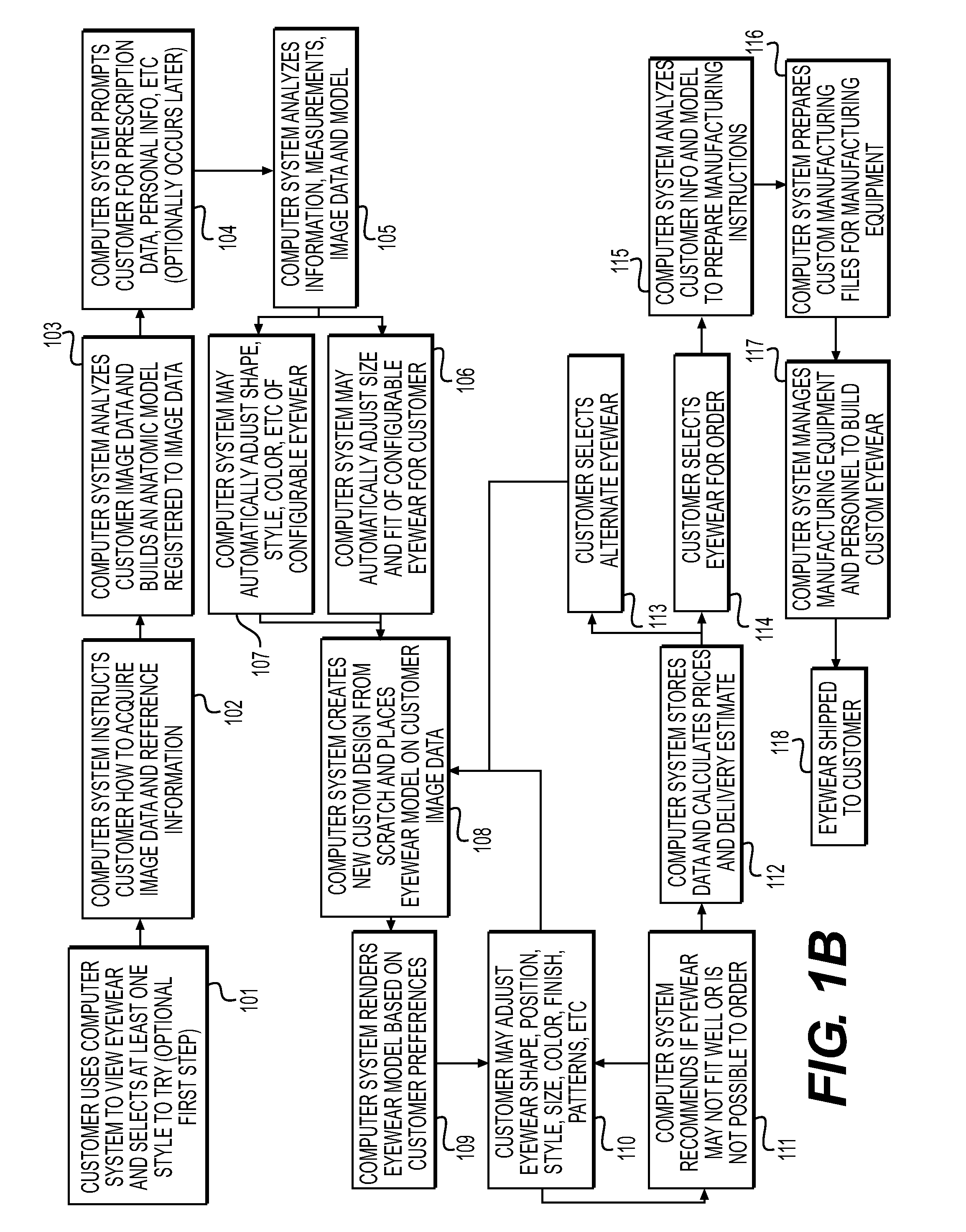

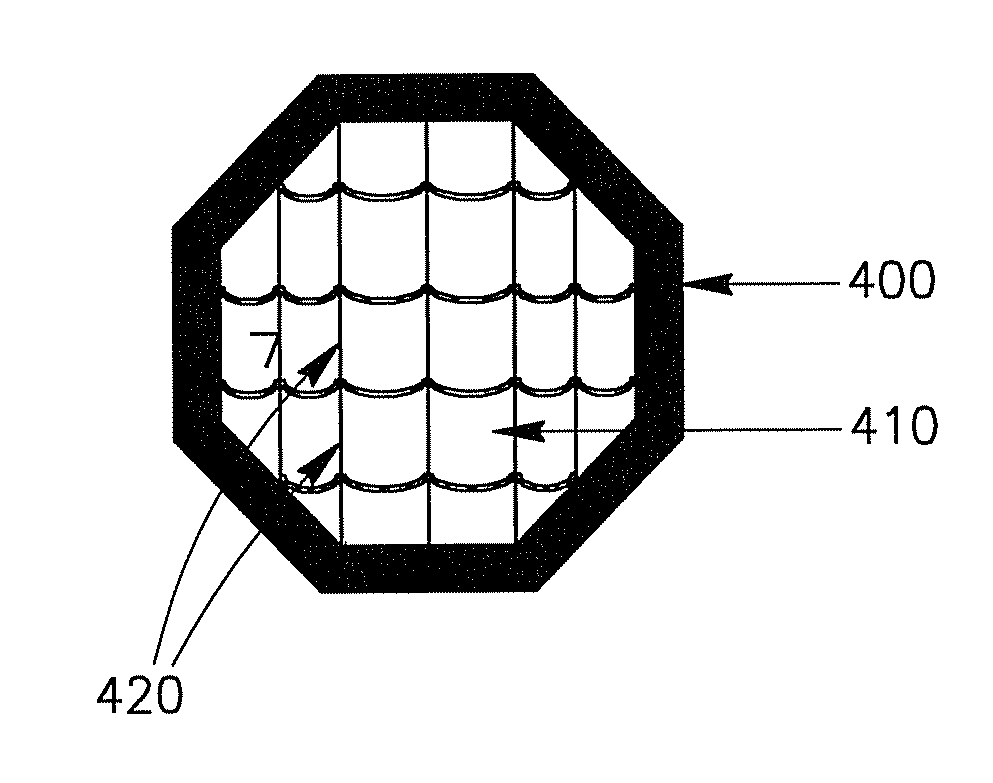

Method and system to create products

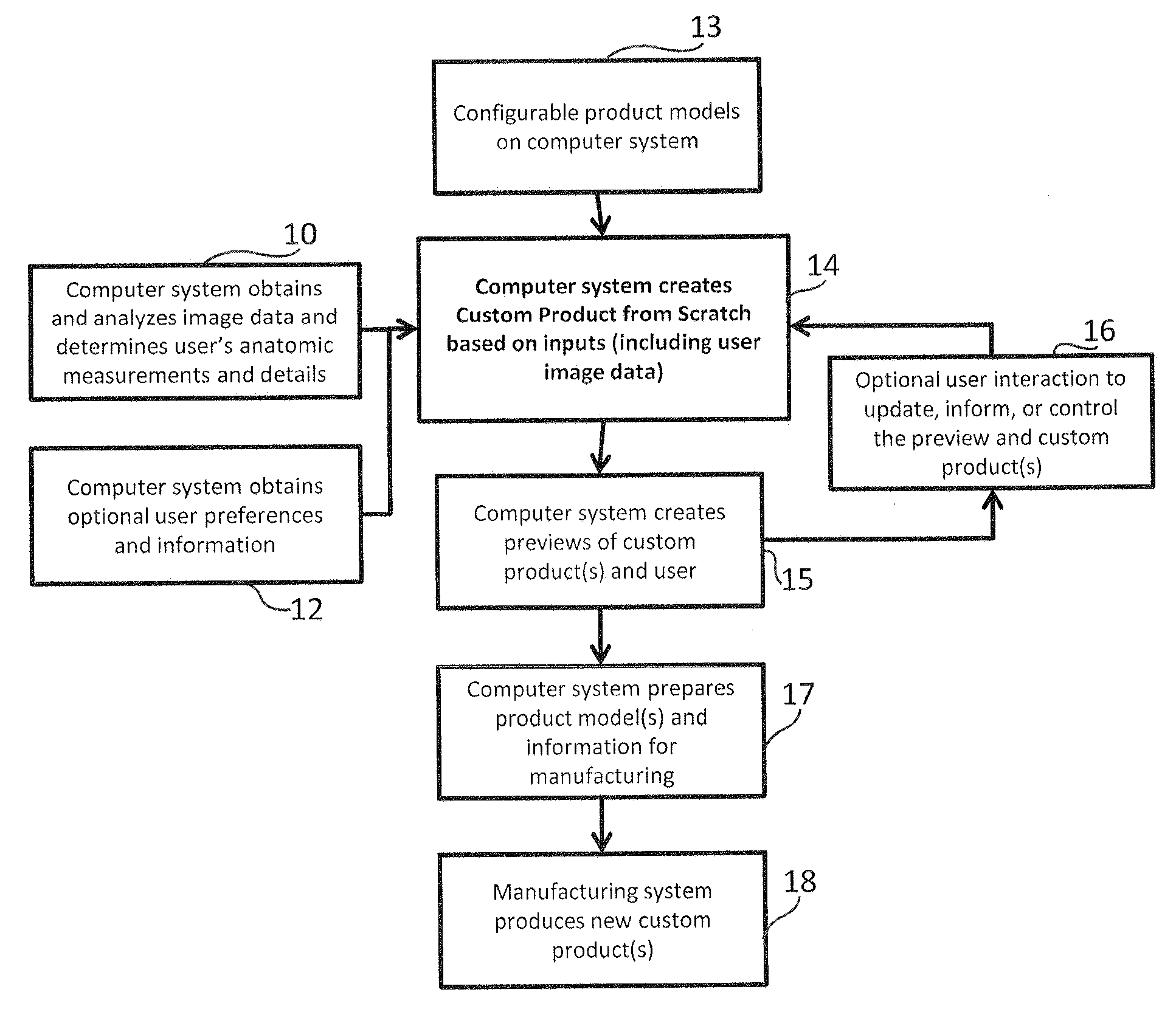

Systems and methods for creating fully custom products from scratch without exclusive use of off-the-shelf or pre-specified components. A system for creating custom products includes an image capture device for capturing image data and / or measurement data of a user. A computer is communicatively coupled with the image capture device and configured to construct an anatomic model of the user based on the captured image data and / or measurement data. The computer provides a configurable product model and enables preview and automatic or user-guided customization of the product model. A display is communicatively coupled with the computer and displays the custom product model superimposed on the anatomic model or image data of the user. The computer is further configured to provide the customized product model to a manufacturer for manufacturing eyewear for the user in accordance with the customized product model. The manufacturing system is configured to interpret the product model and prepare instructions and control equipment for the manufacturing of the customized product.

Owner:BIS

Compositions and methods for use in three dimensional model printing

Compositions for use in the manufacture of three-dimensional objects including compositions for use as a support and / or release material in the manufacture of the three-dimensional objects are provided. There is thus provided, in accordance with an embodiment of the present invention, a composition suitable for building a three-dimensional object. The compositions may include, inter alia, a curable component, having a functional group, wherein if the functional group is a polymerizable reactive functional group, then the functional group is a (meth)acrylic functional group, a photo-initiator, a surface-active agent and a stabilizer; wherein said composition has a first viscosity of about 50–500 cps at a first temperature, wherein said first temperature is ambient temperature, and a second viscosity lower than 20 cps at a second temperature wherein said second temperature is higher than said first temperature, wherein, after curing, the composition results in a solid form. There is thus provided, in accordance with another embodiment of the present invention, a composition suitable for support in building a three-dimensional object. The compositions may include, inter alia: a non-curable component, a curable component, wherein the non-curable component is not reactive with said curable component, a surface-active agent and a stabilizer; wherein said composition has a first viscosity of about 20–500 cps at a first temperature, wherein said first temperature is ambient temperature, and a second viscosity lower than 20 cps at a second temperature wherein said second temperature is higher than said first temperature, wherein, after irradiation, the composition results in a solid, a semi-solid or liquid material. A method for the preparation of a three-dimensional object by three-dimensional printing is provided in accordance with embodiments of the present invention. Embodiments of the present invention further provide a three-dimensional object prepared according to the methods of the invention.

Owner:STRATASYS LTD

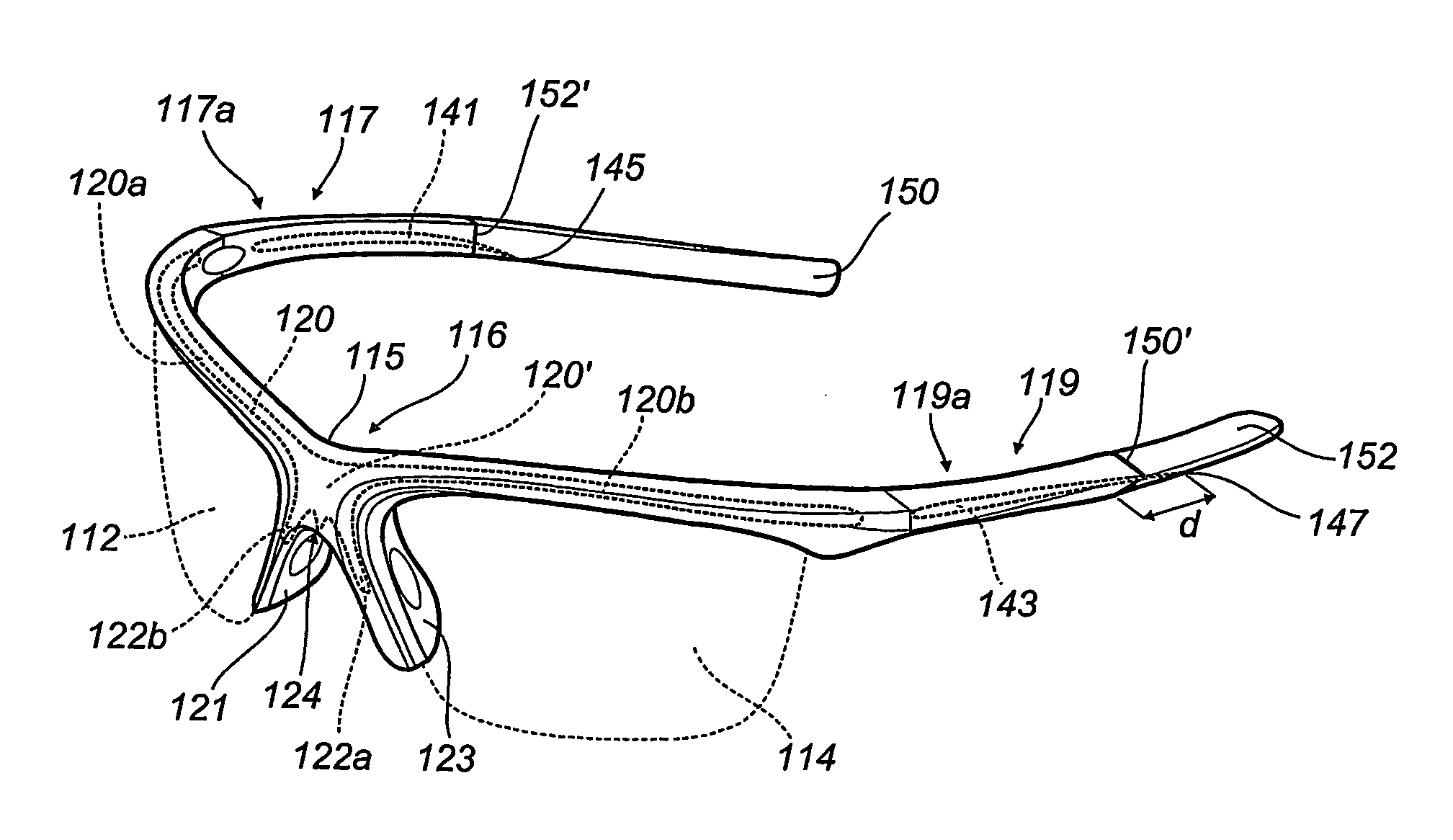

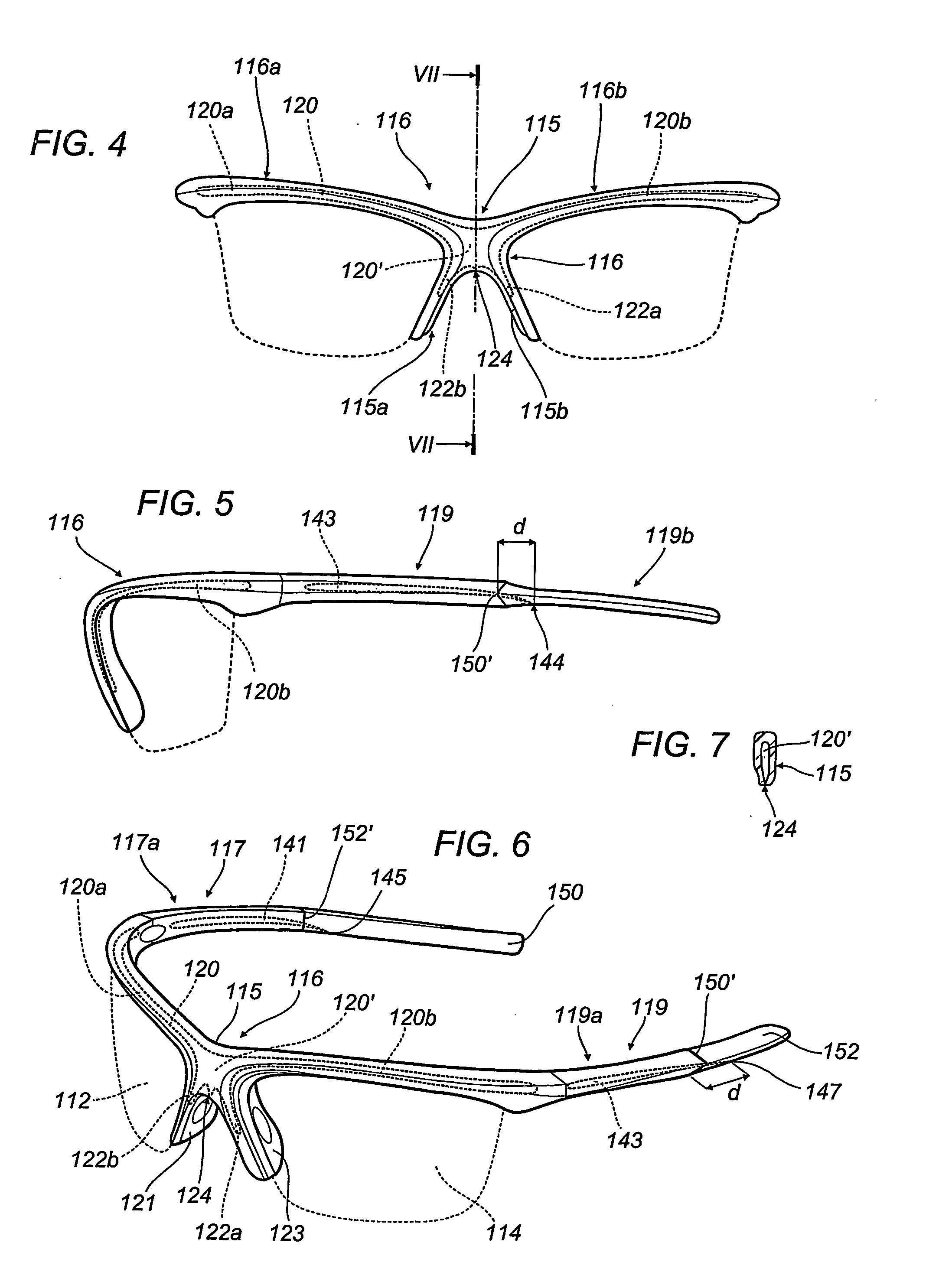

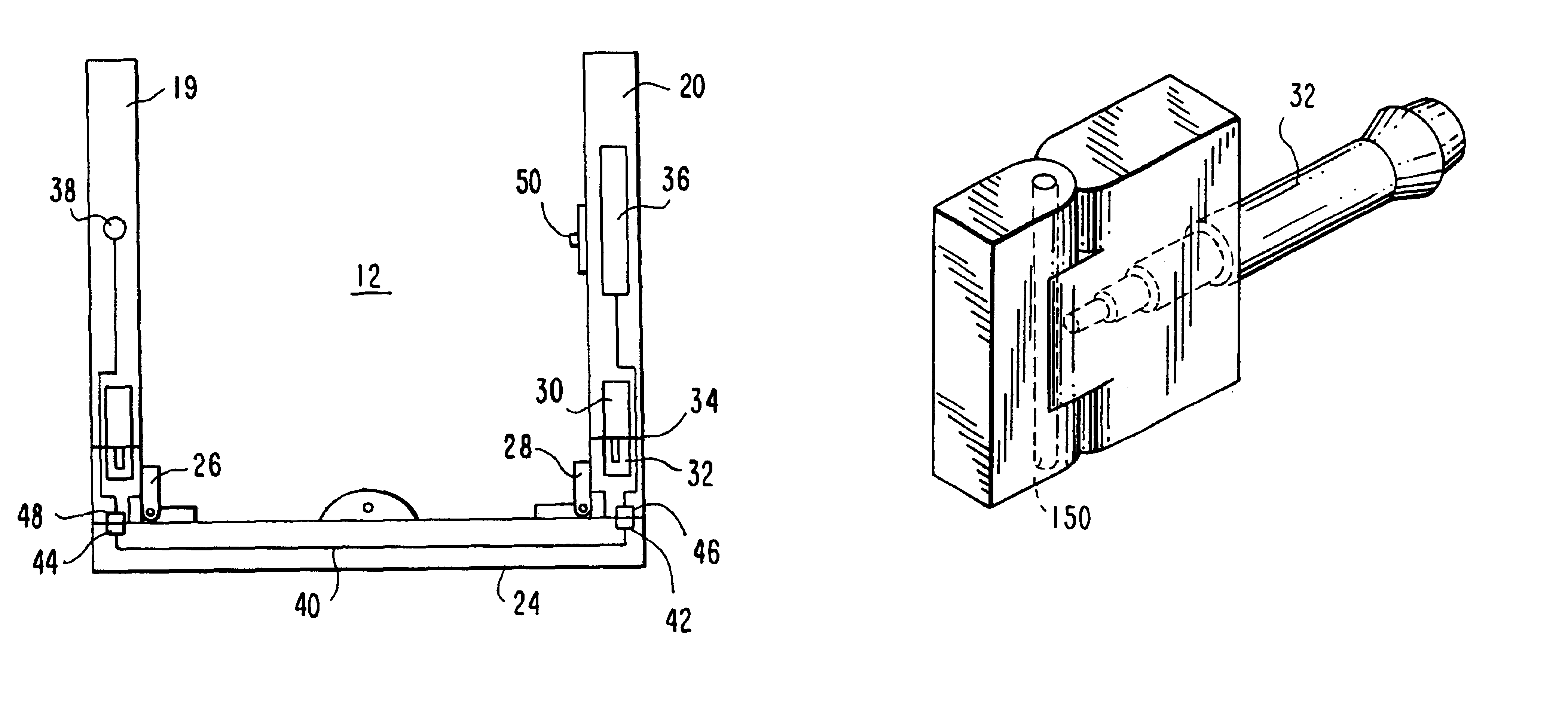

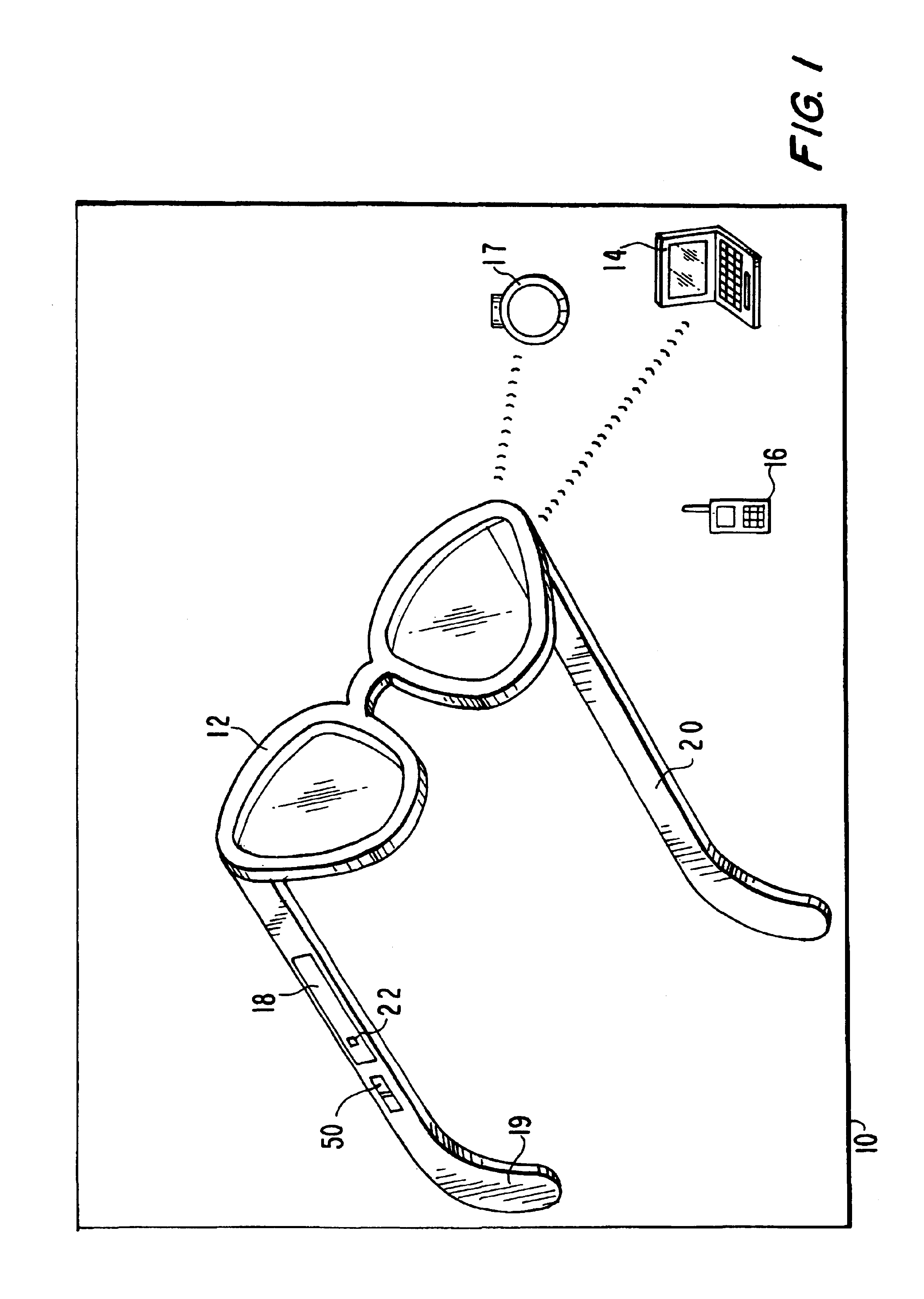

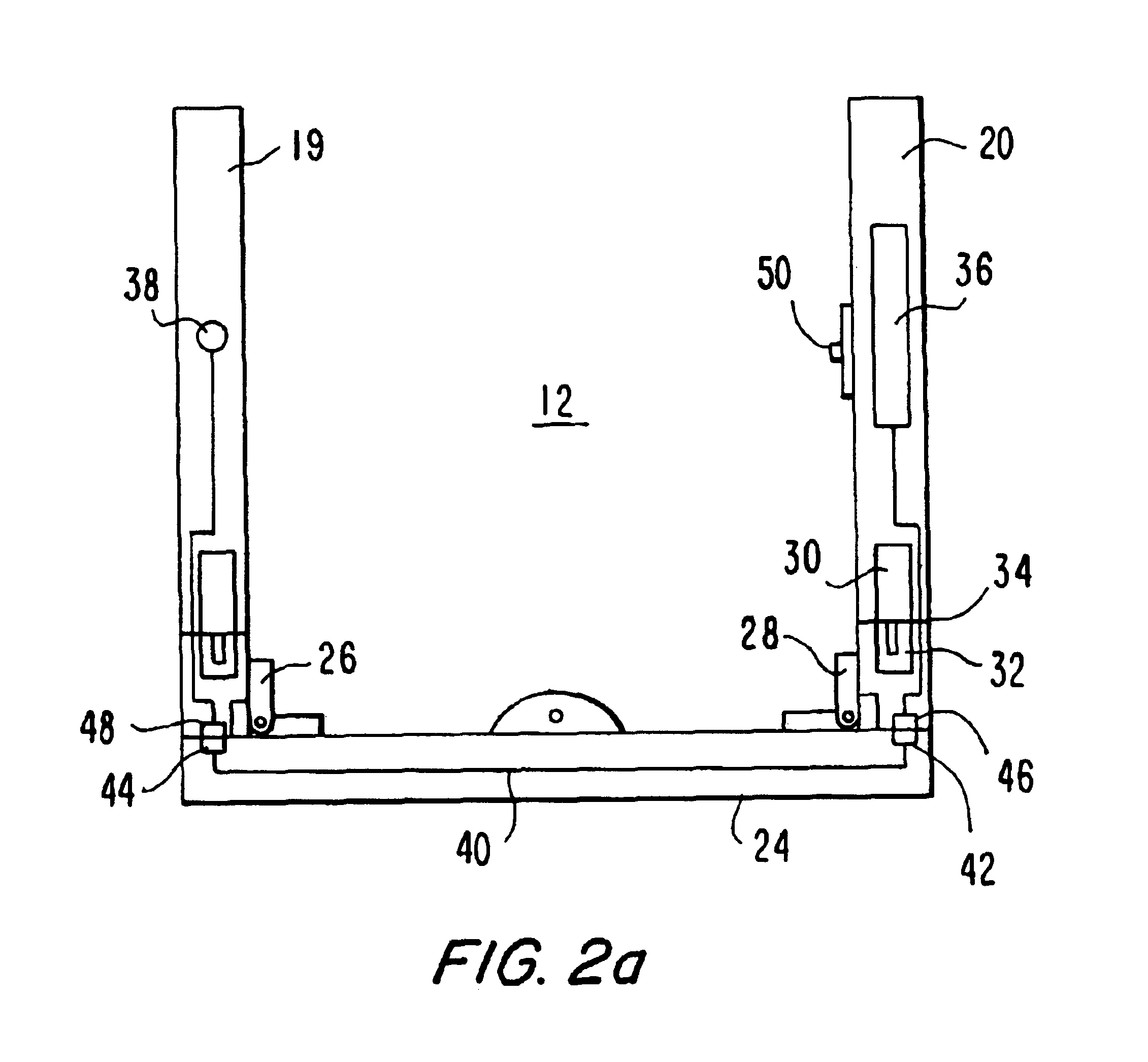

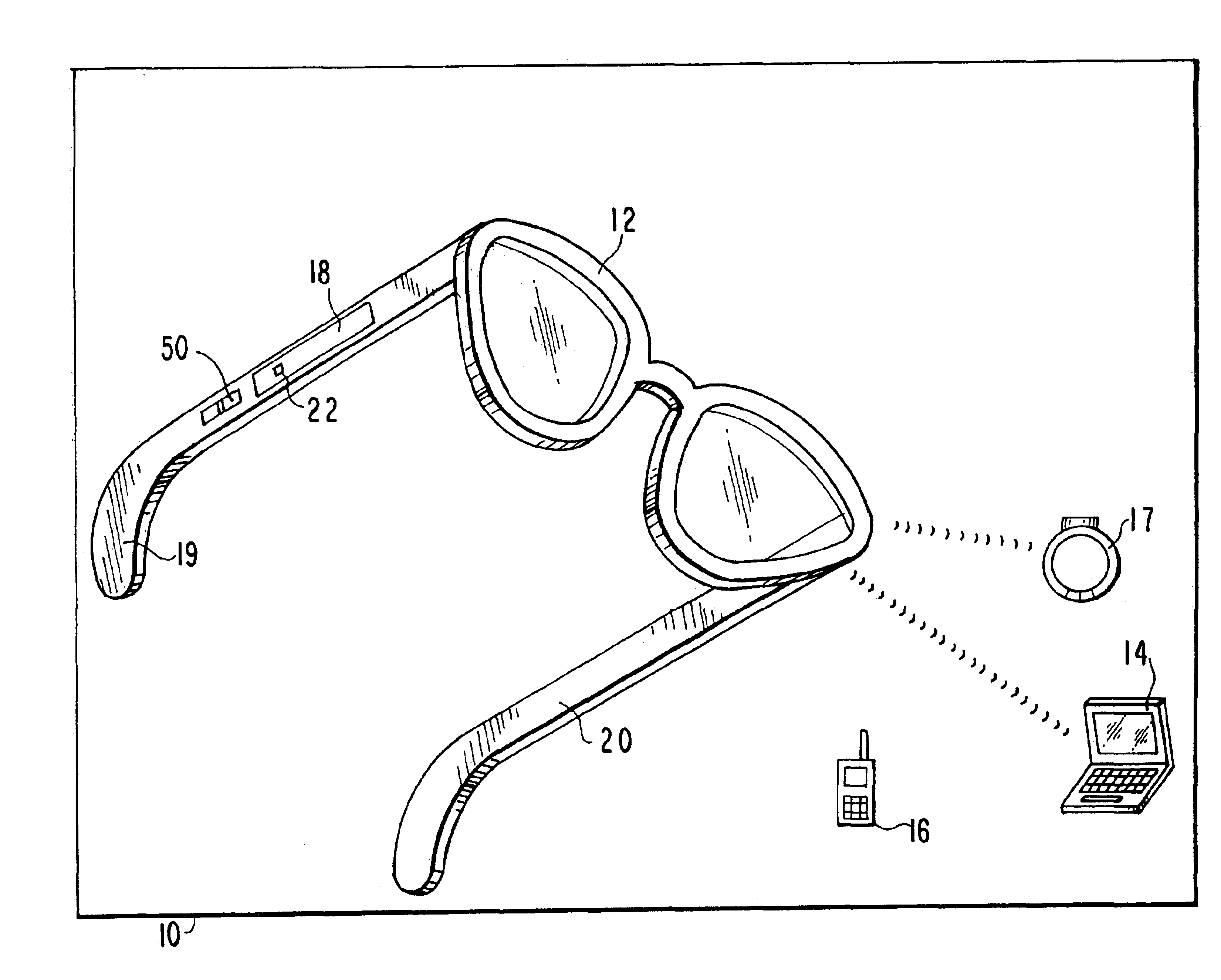

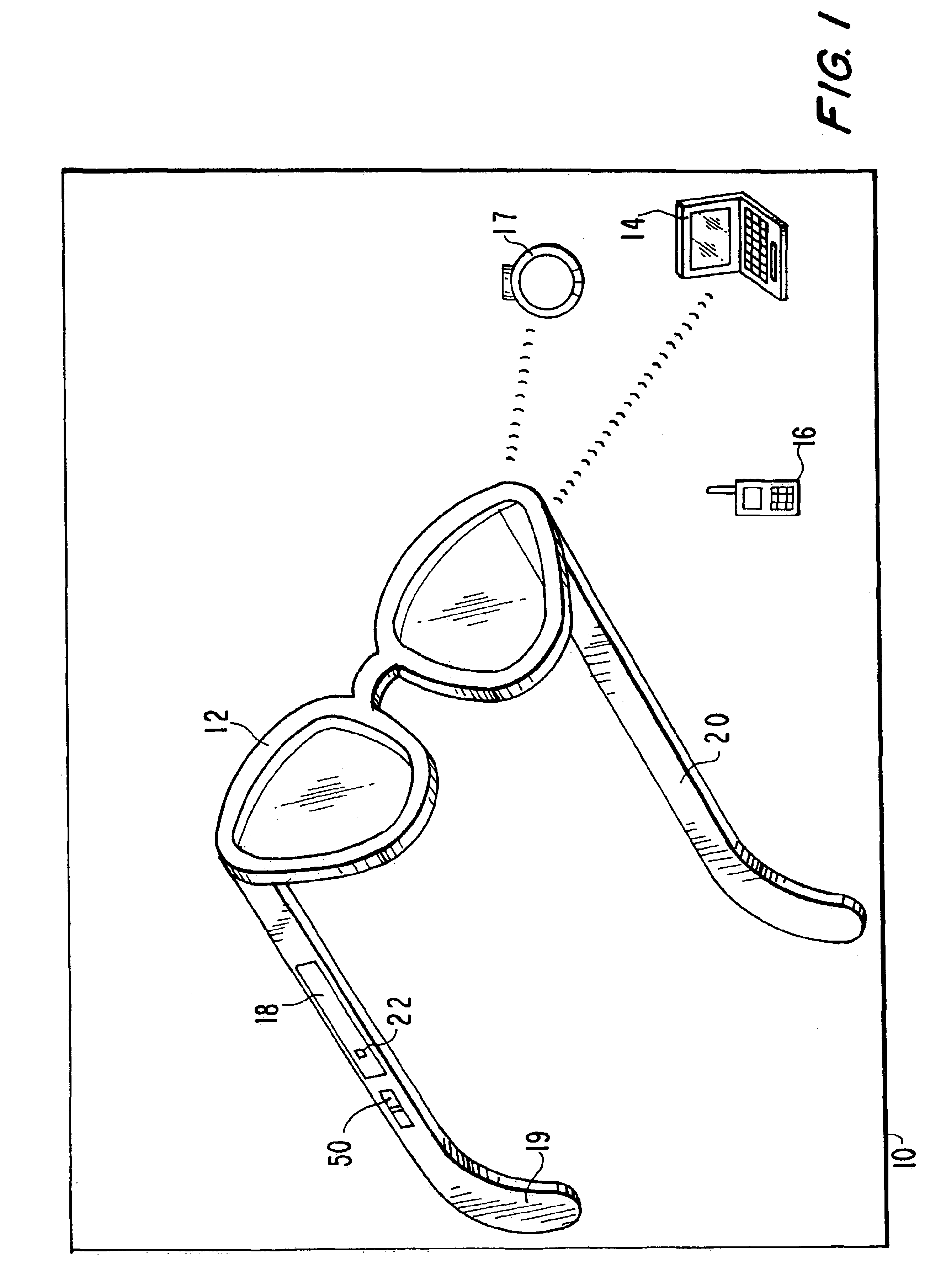

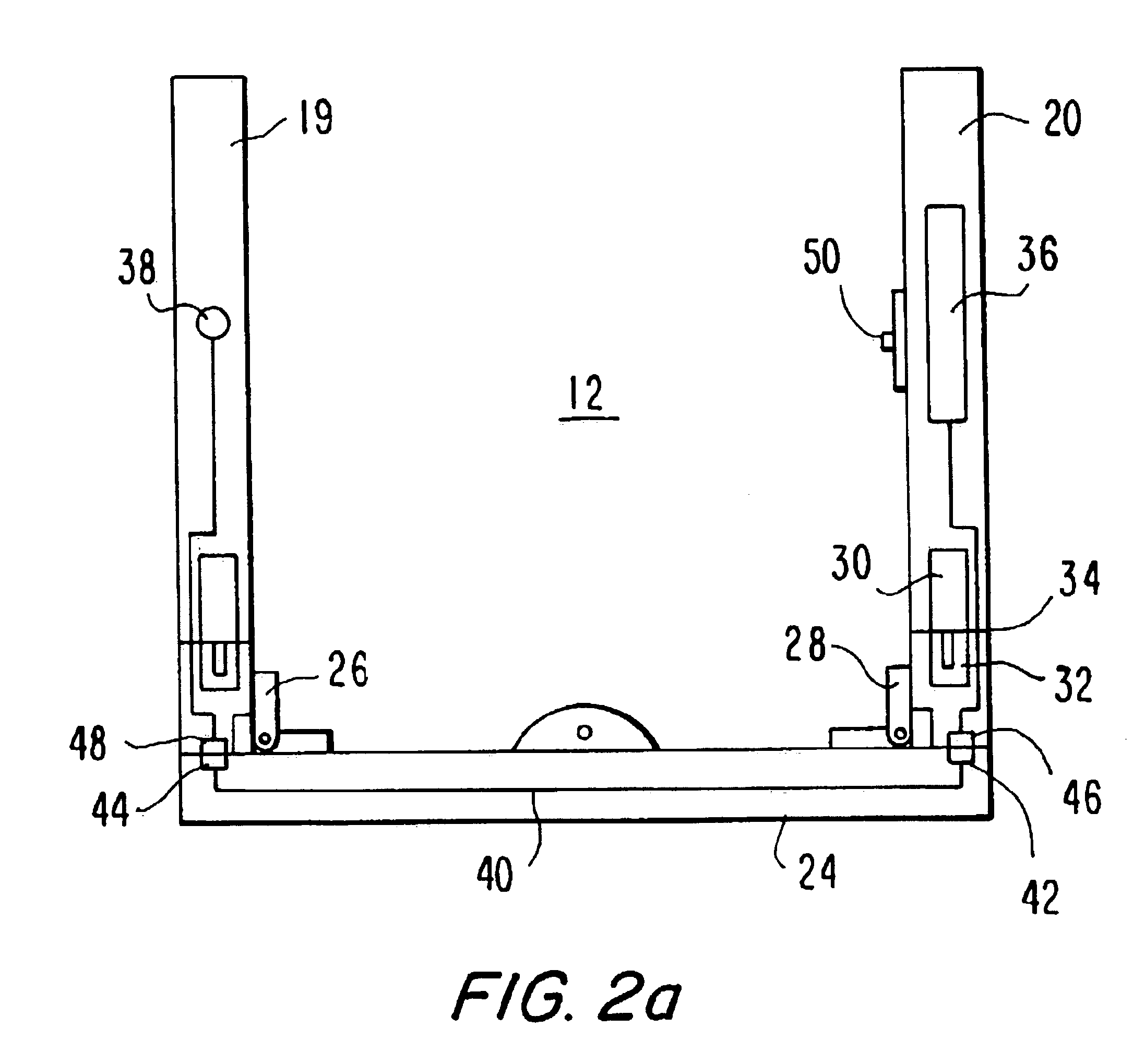

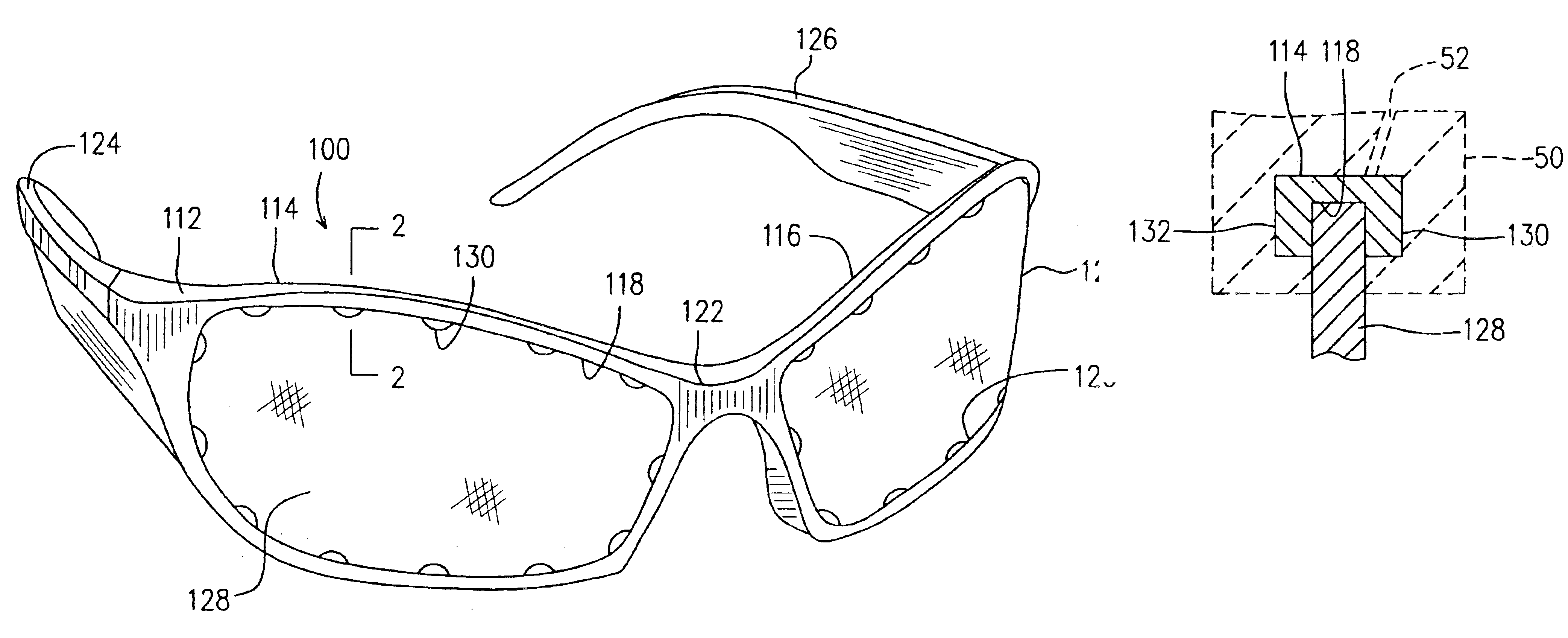

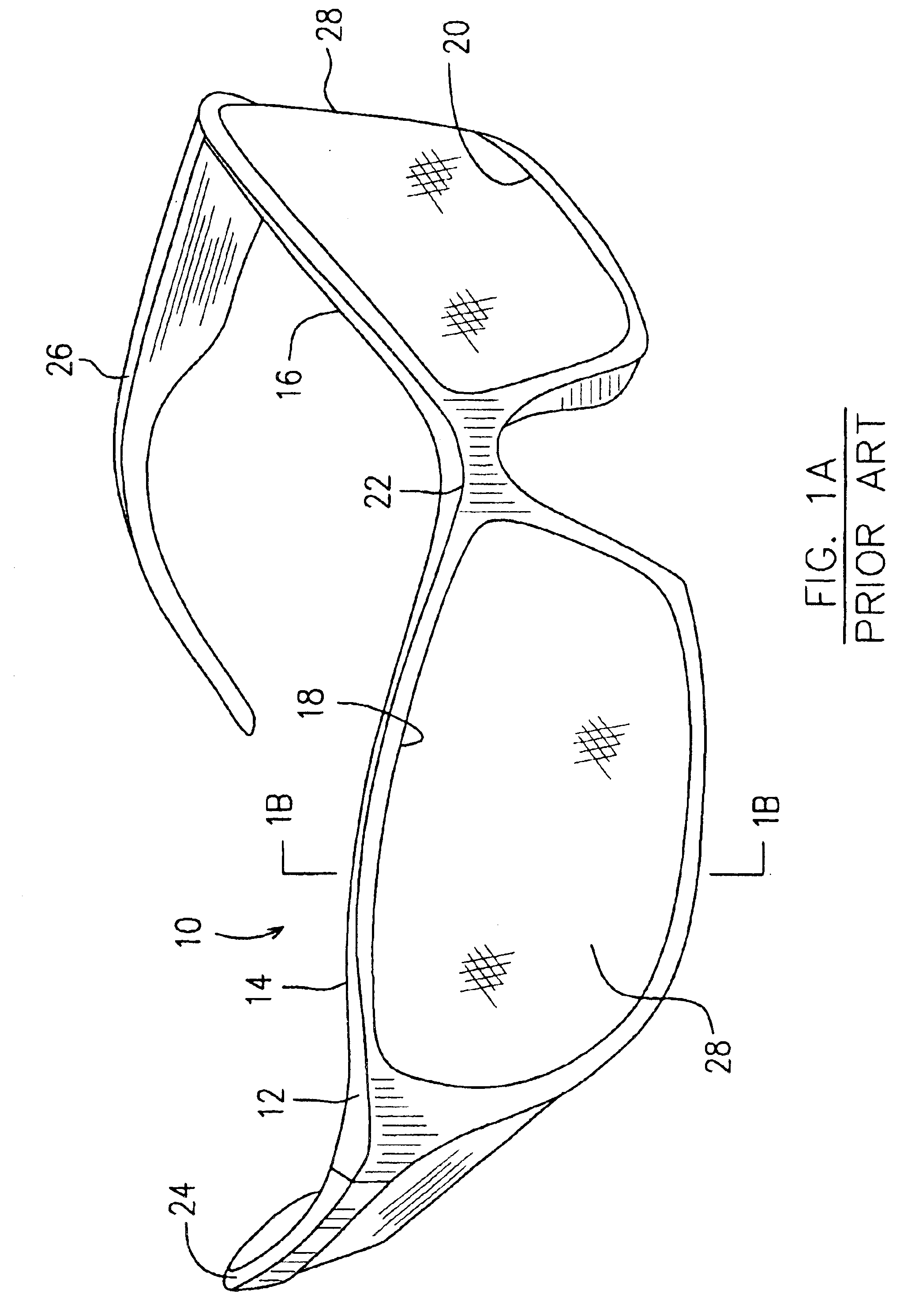

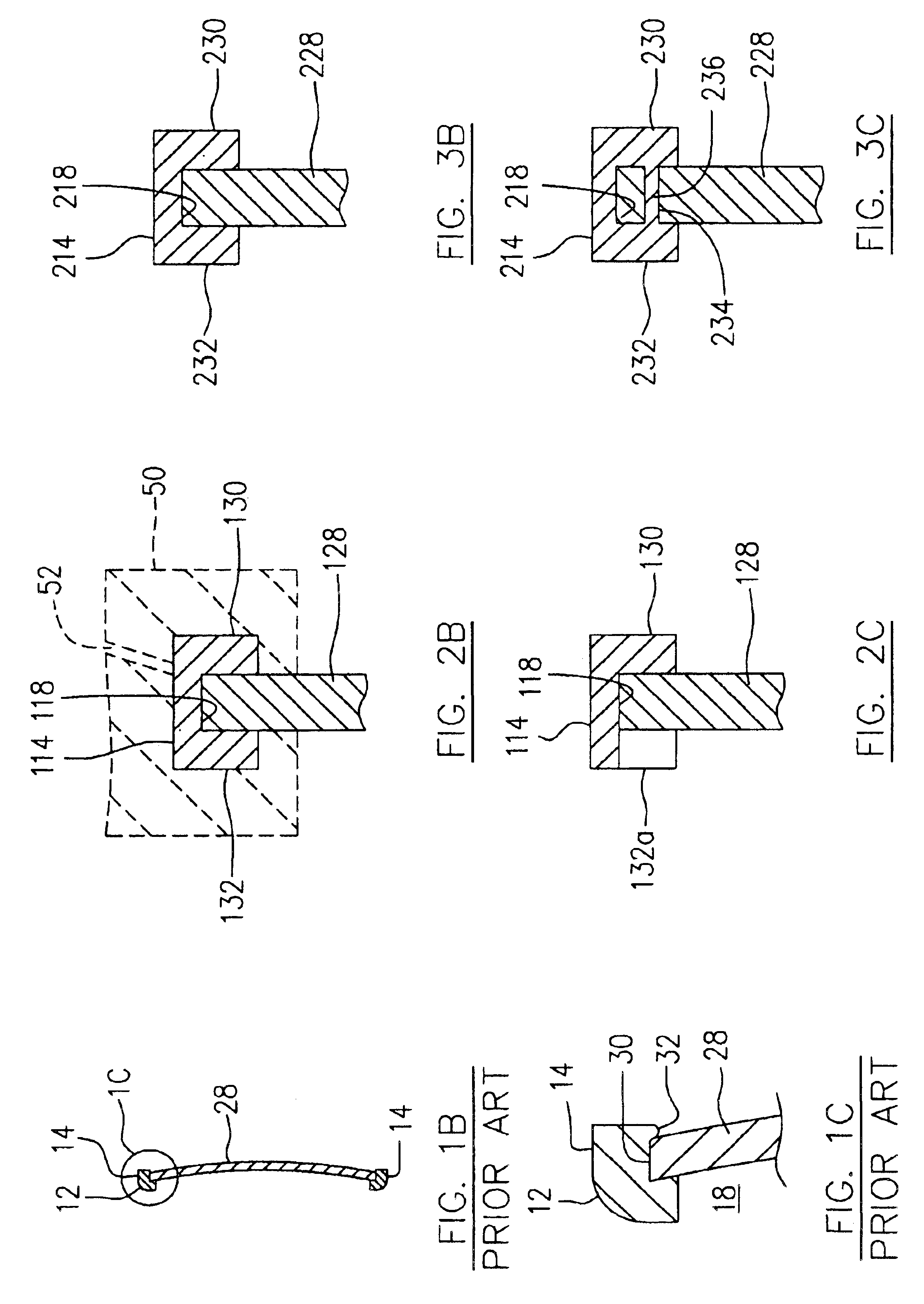

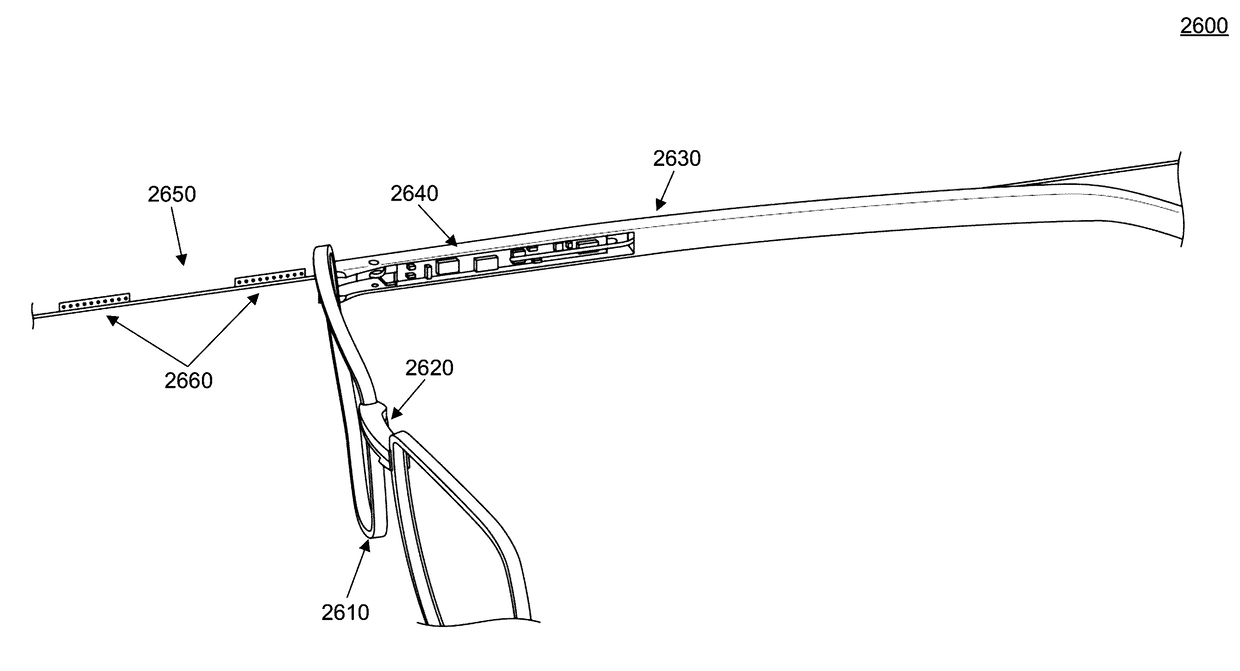

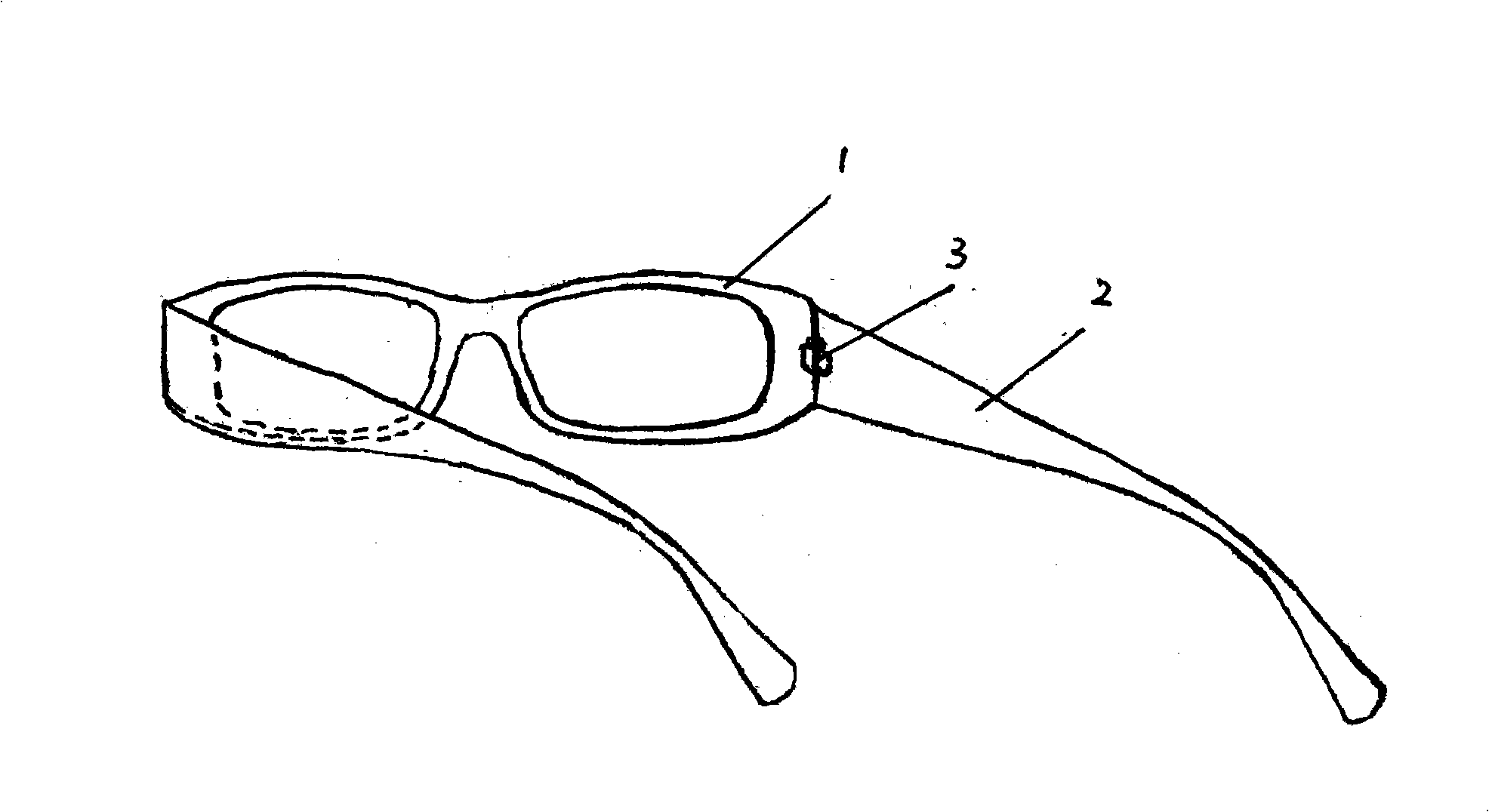

Eyewear with exchangeable temples housing bluetooth enable apparatus

InactiveUS6929365B2Increase power consumptionSmall sizeComponent separationFramesTransceiverHand held

A wireless ad hoc pico network is formed by eyewear and other devices such as a computer, a bracelet and a telephone having similar transceivers mounted on them. Master slave relationships are configurable. Other devices, such as a radio, a CD player, a hand held global positioning satellite system and a heart rate monitor, having similar transceivers, can also be connected with the transceiver of the eyewear. The transceivers operate on globally available, unlicensed radio band, 2.45 gigahertz (GHz) and conforms to the Bluetooth standard. The power consumption of Bluetooth enabled devices is less than three percent of the power consumption of a mobile phone. The eyewear includes a frame and connected to the frame are two temples. Temples are connected to frame via hinges. Temples have a male portion of a connector incorporated in them. Female portion of the connector is made integral with the hinges. When the male portion is inserted in the female portion the temple is attached to the frame. The temples can be removed by pulling the connector apart, and a temple with different apparatus within it can be inserted in place of the removed temples. The temple may have co-molded within its body, an apparatus such as an audio device, a camera, a speaker, and a microphone, and a display device such as liquid crystal or an alarm. In another embodiment, eyewear constitutes a distance alarm to monitor the movement of, for example, a child. A device in form of, for example, a bracelet is worn by the child. The transceivers in the eyewear and the bracelet form a small-range wireless network, i.e., piconet, wherein the eyewear and the bracelet communicate using signals conforming to the Bluetooth technology. The transceiver in the eyewear is configured to generate an alarm when the bracelet exceeds a predetermined distance from eyewear.

Owner:III HLDG 4

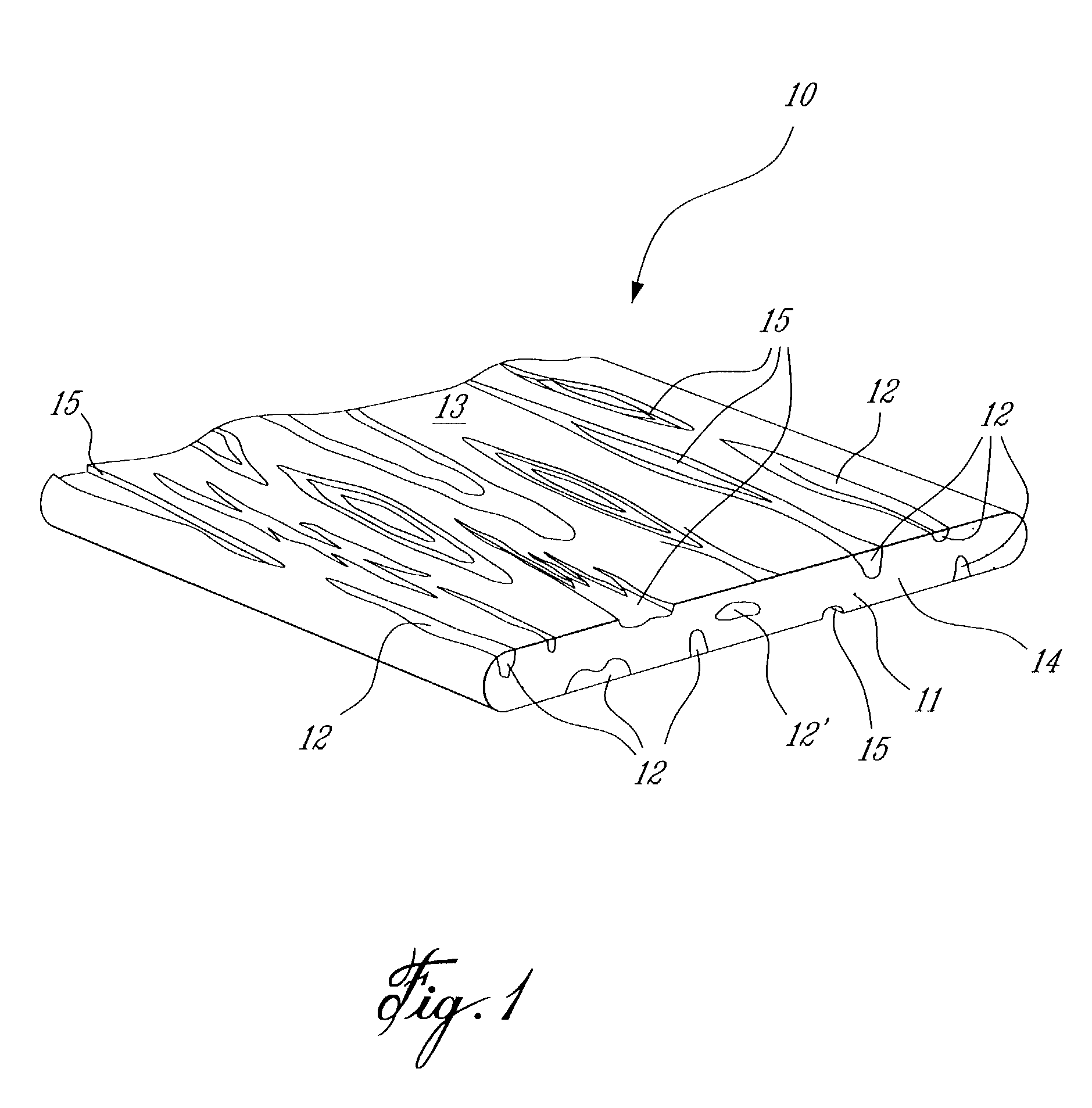

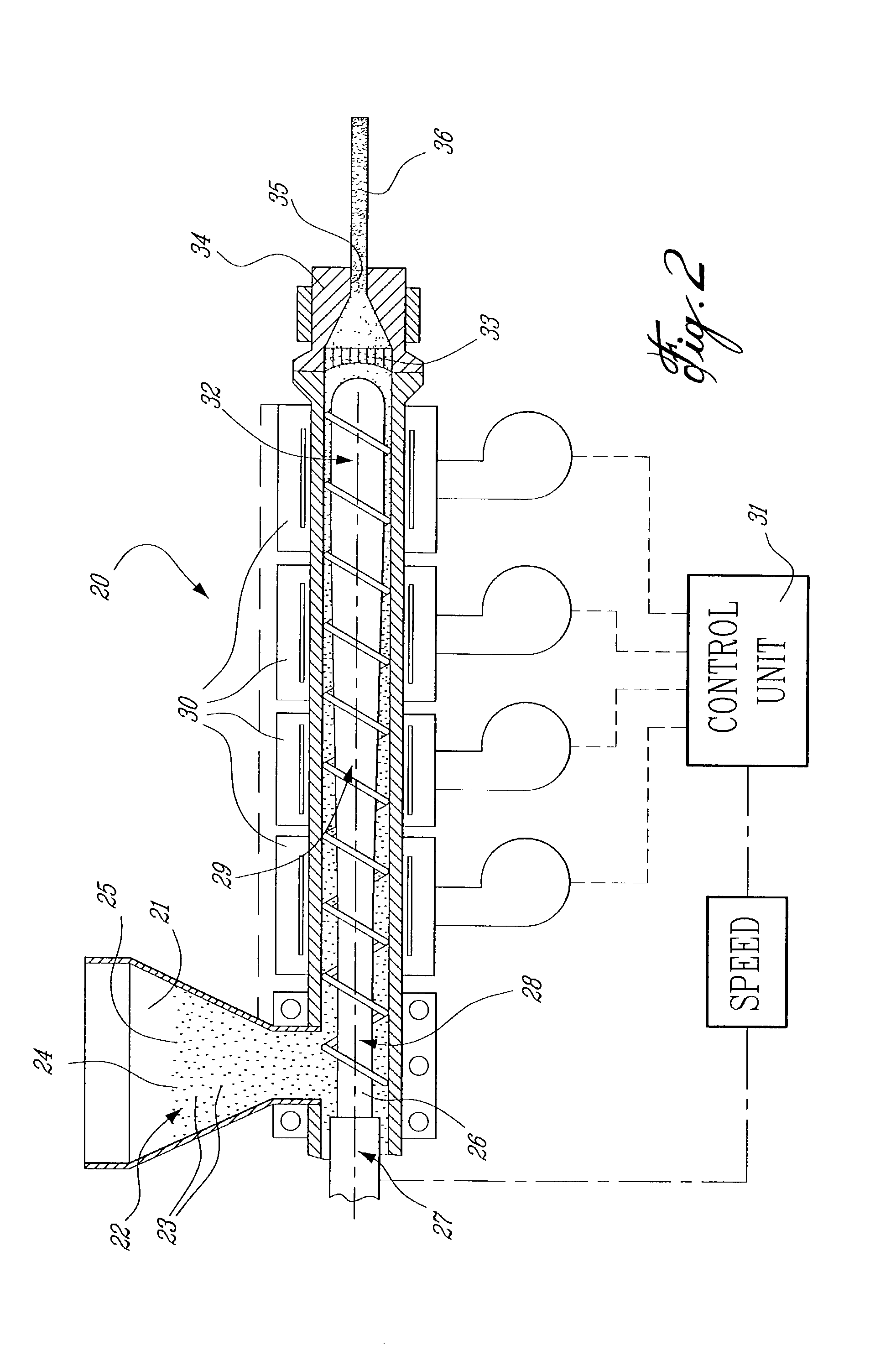

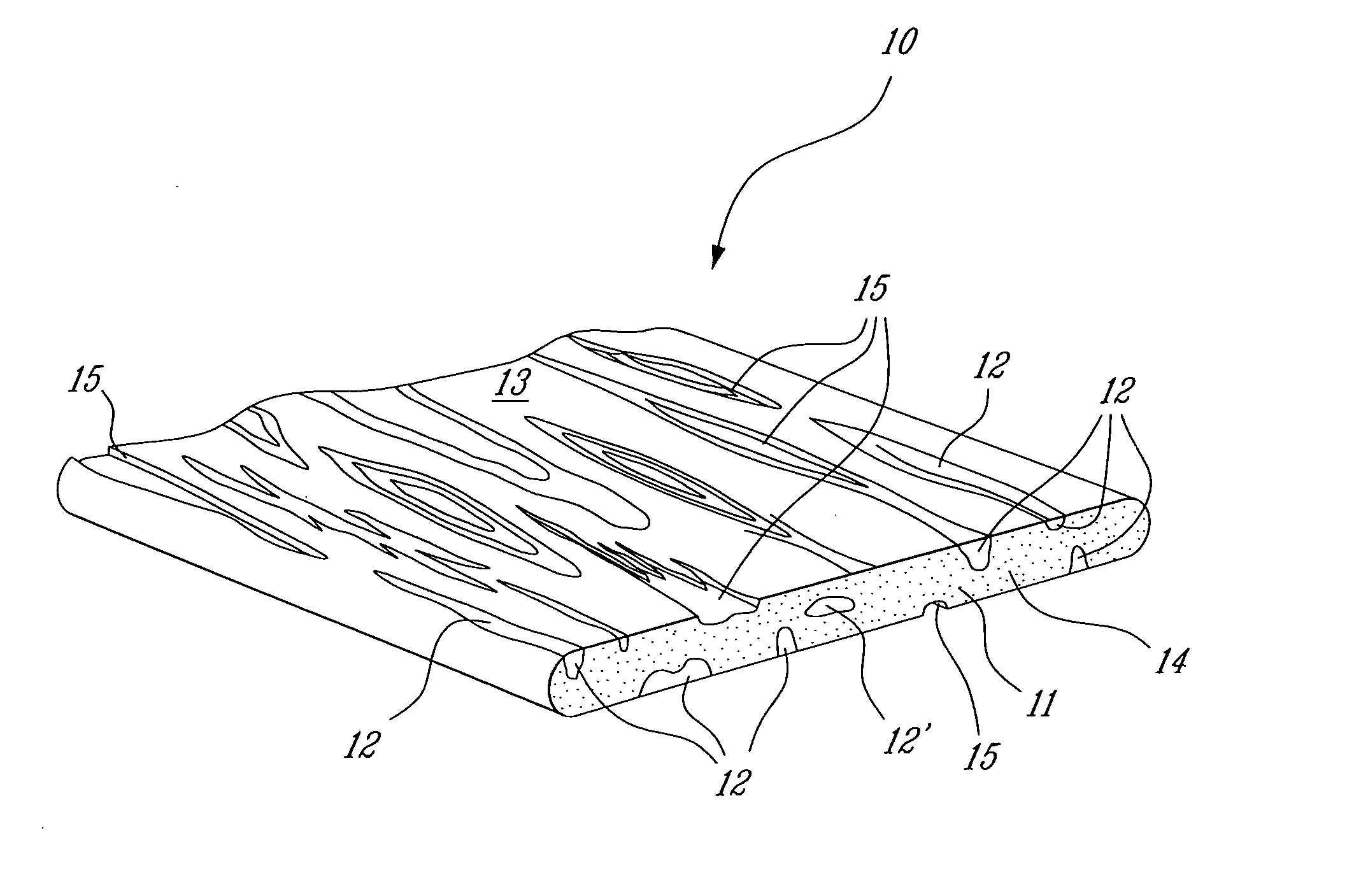

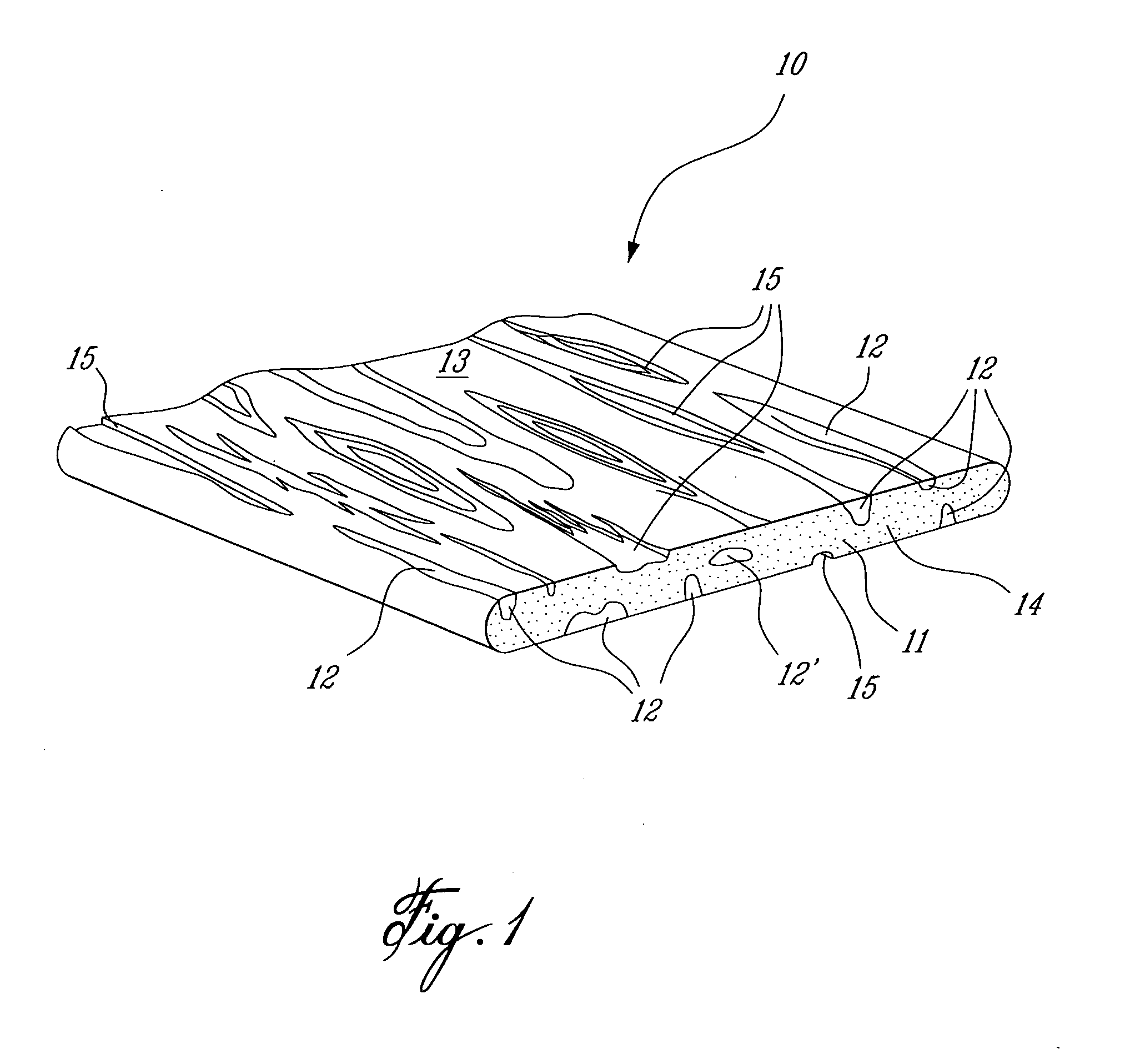

Extruded wood imitation component and process

An extruded wood imitation component and process is described. The component has a solid core containing coloured polymer material formed from a mix of coloured thermoplastic polymer with veins of contrasting coloured polymer throughout the core and on outer surfaces of the component simulating natural wood. In the extrusion process the mixture includes coloured polymer pellets of different colours and sizes which are mixed and melted in an extruder under controlled conditions to provide contrasting streaks of molten polymer throughout a molten extruded core and on outer surfaces of the core of the extrudate which exits the land of the die.

Owner:STAR PLAST HLDG

Method and system to create products

Systems and methods for creating fully custom products from scratch without exclusive use of off-the-shelf or pre-specified components. A system for creating custom products includes an image capture device for capturing image data and / or measurement data of a user. A computer is communicatively coupled with the image capture device and configured to construct an anatomic model of the user based on the captured image data and / or measurement data. The computer provides a configurable product model and enables preview and automatic or user-guided customization of the product model. A display is communicatively coupled with the computer and displays the custom product model superimposed on the anatomic model or image data of the user. The computer is further configured to provide the customized product model to a manufacturer for manufacturing eyewear for the user in accordance with the customized product model. The manufacturing system is configured to interpret the product model and prepare instructions and control equipment for the manufacturing of the customized product.

Owner:BIS

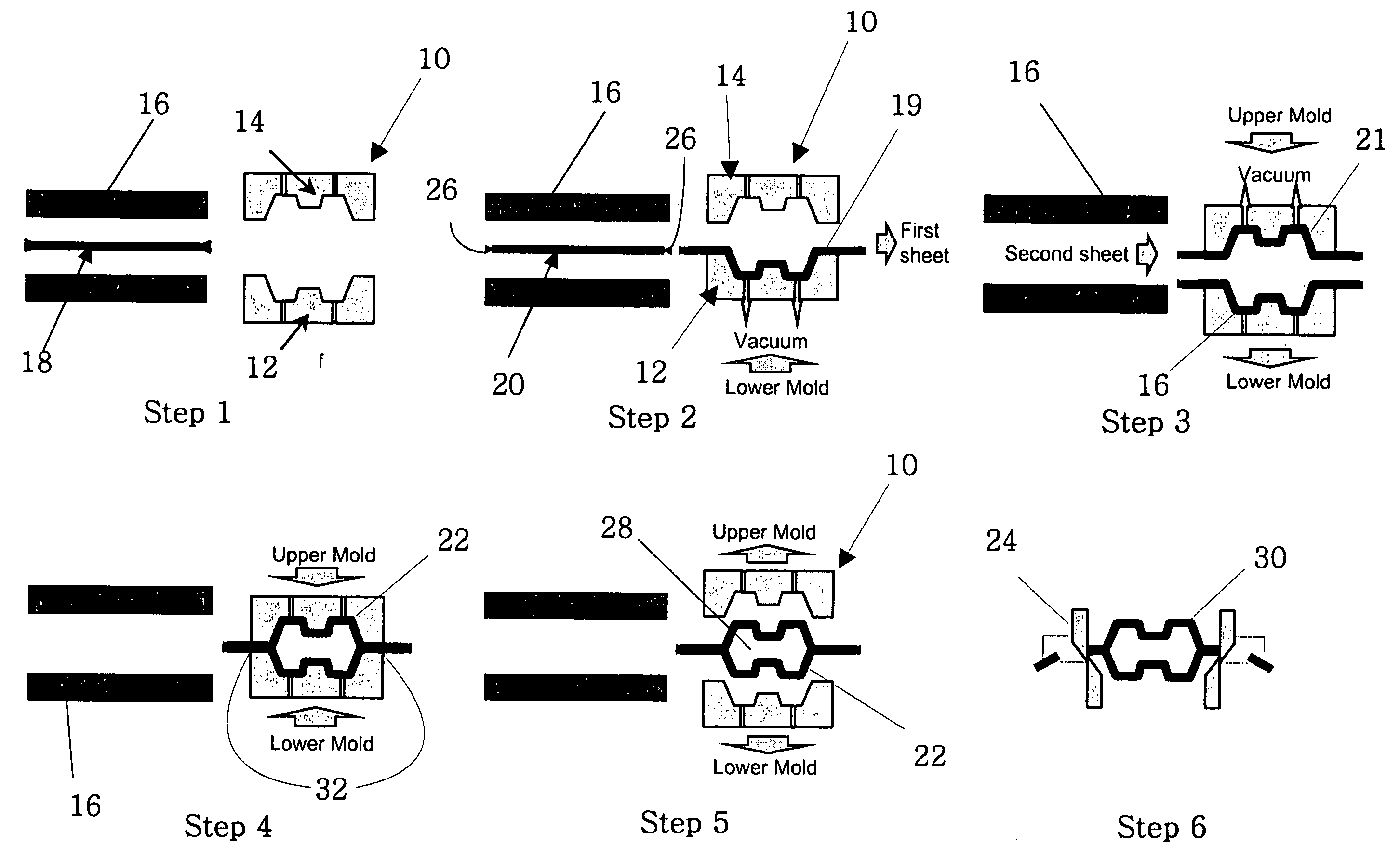

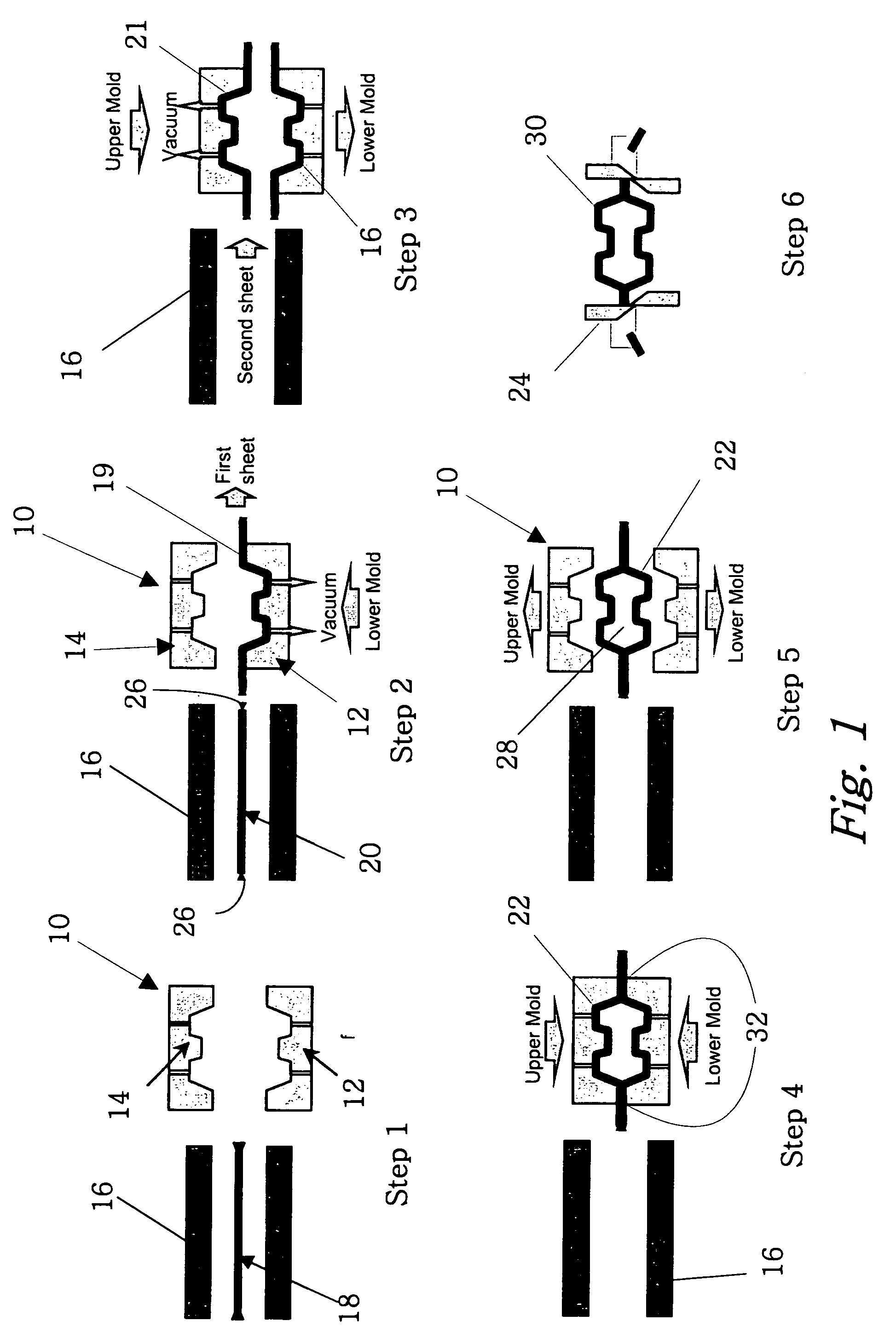

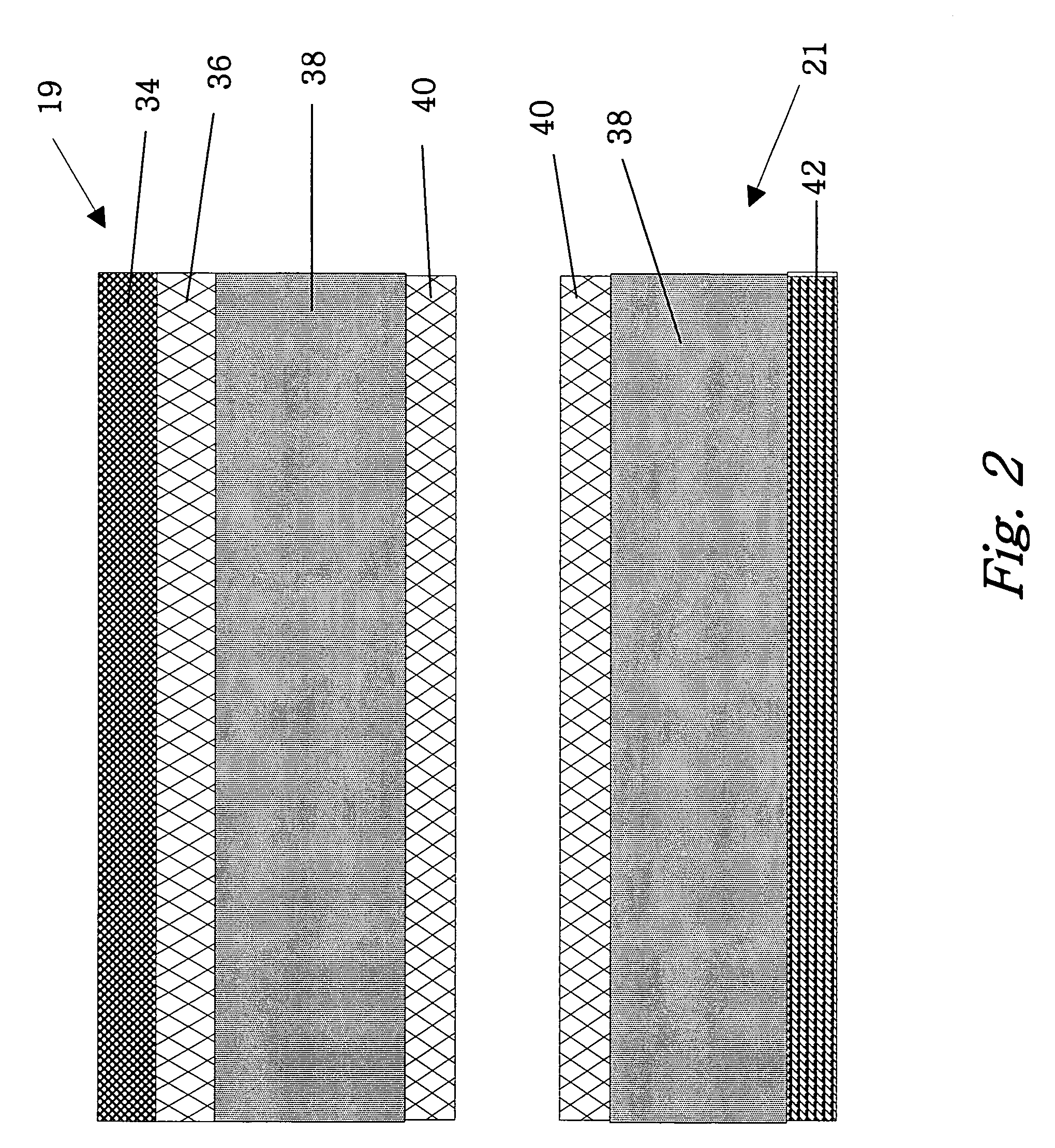

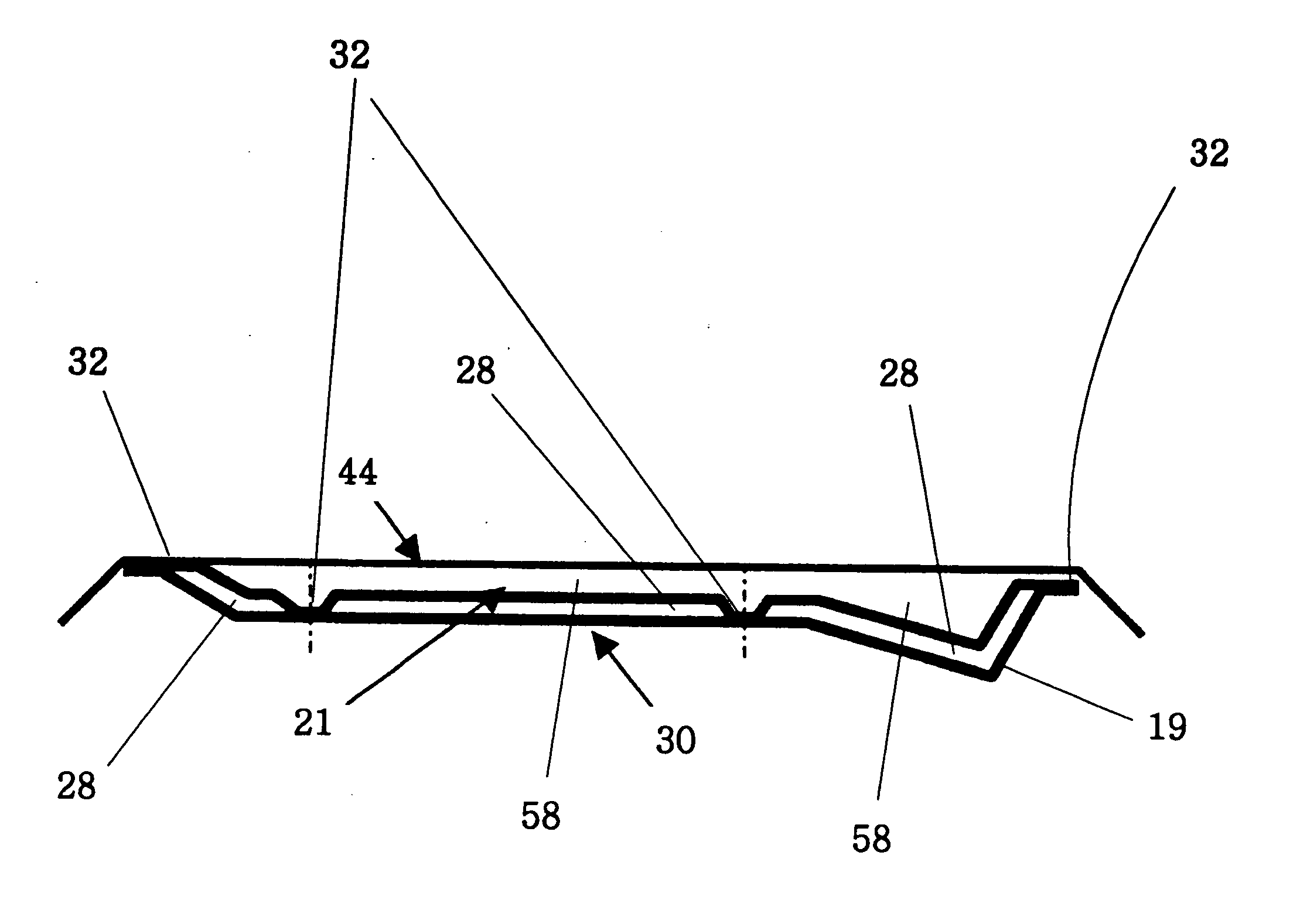

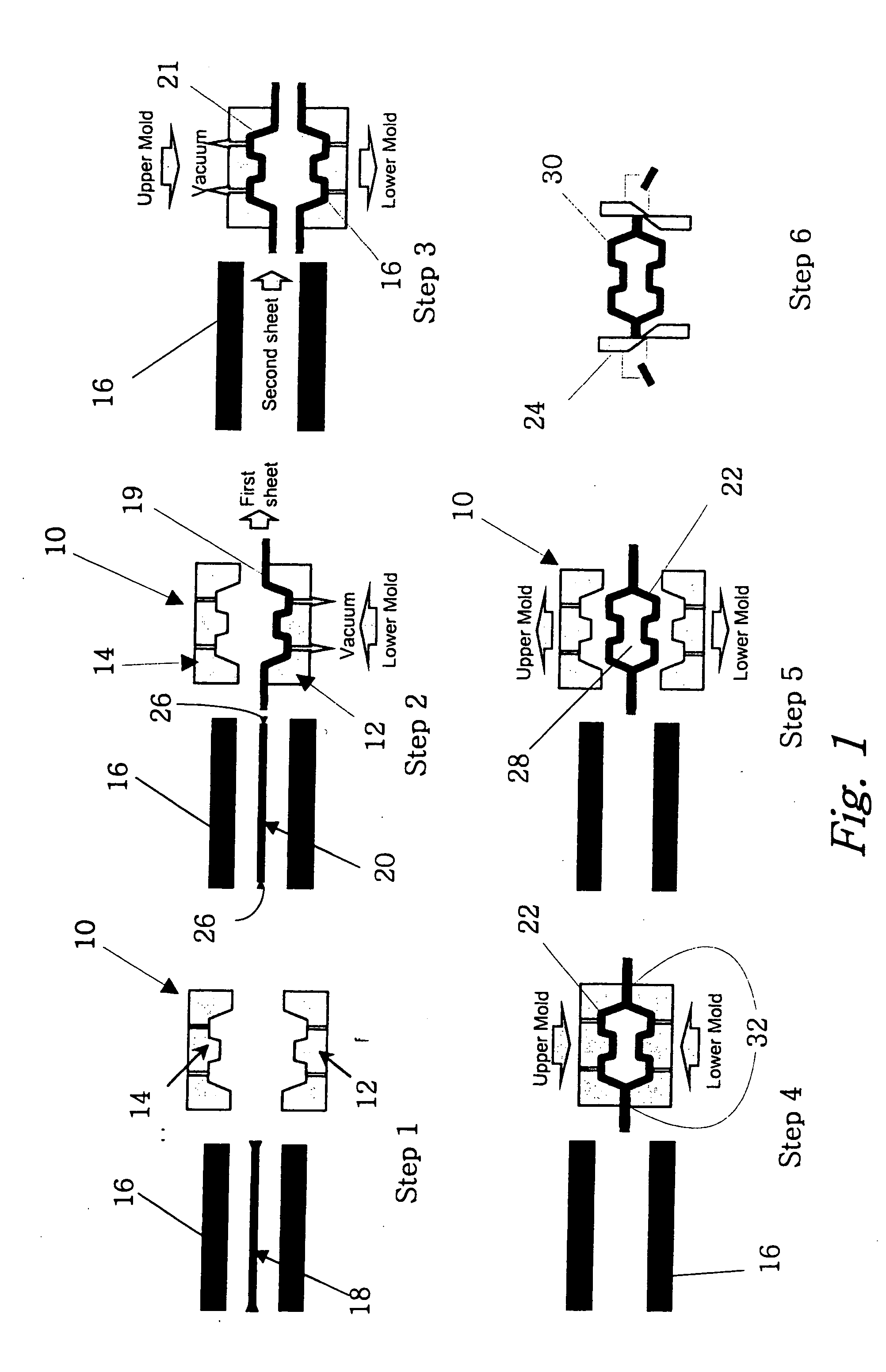

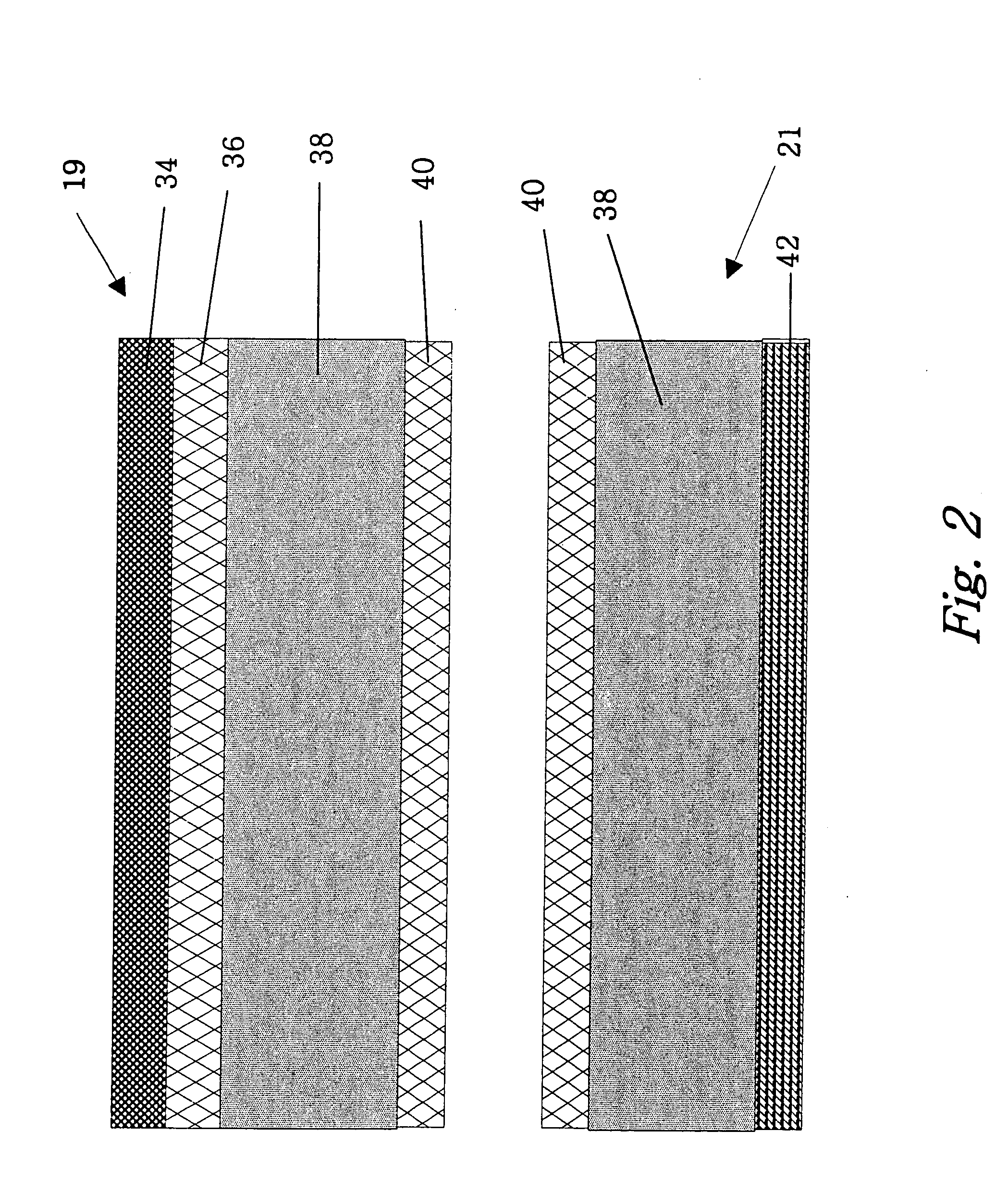

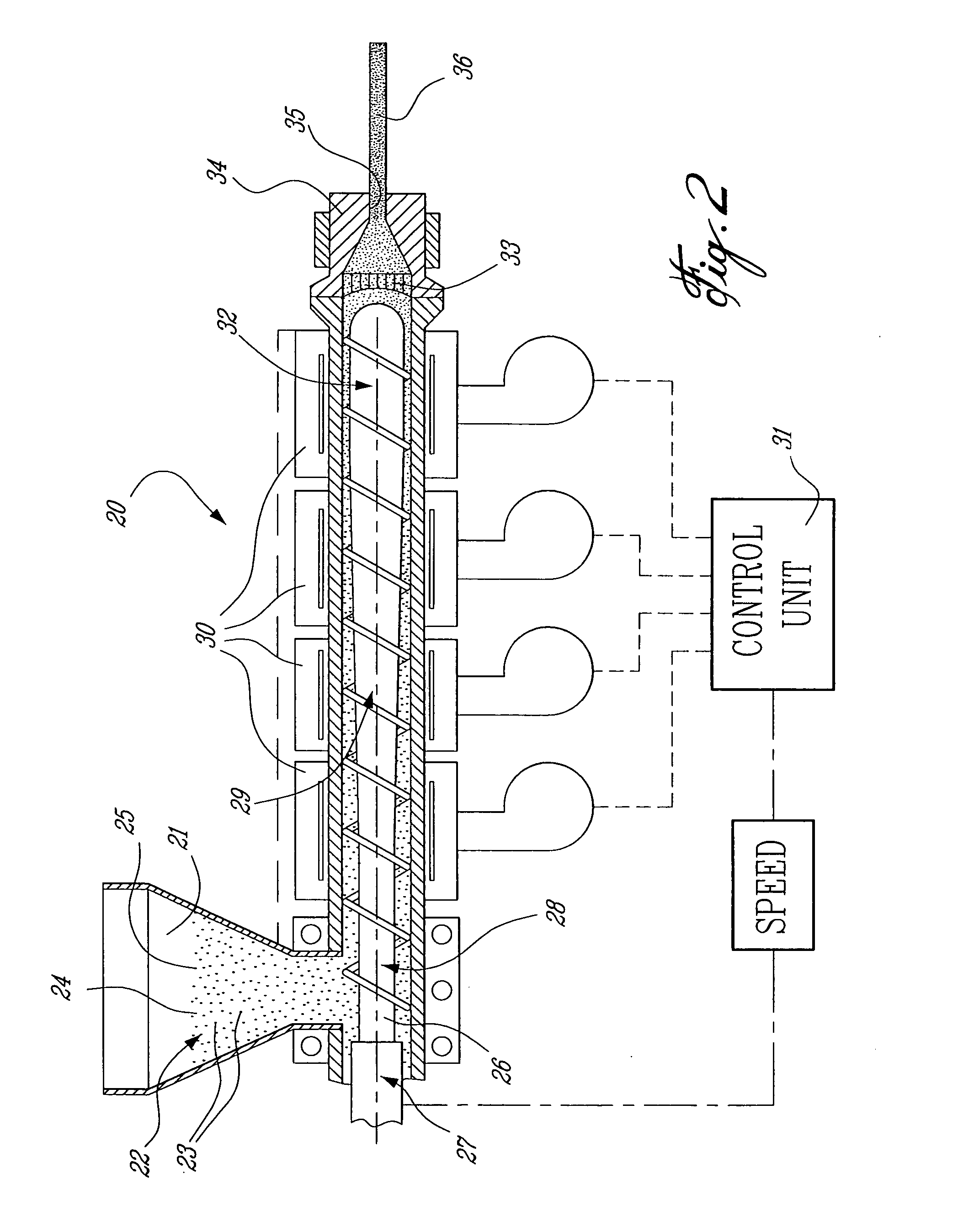

Twin-sheet thermoforming process

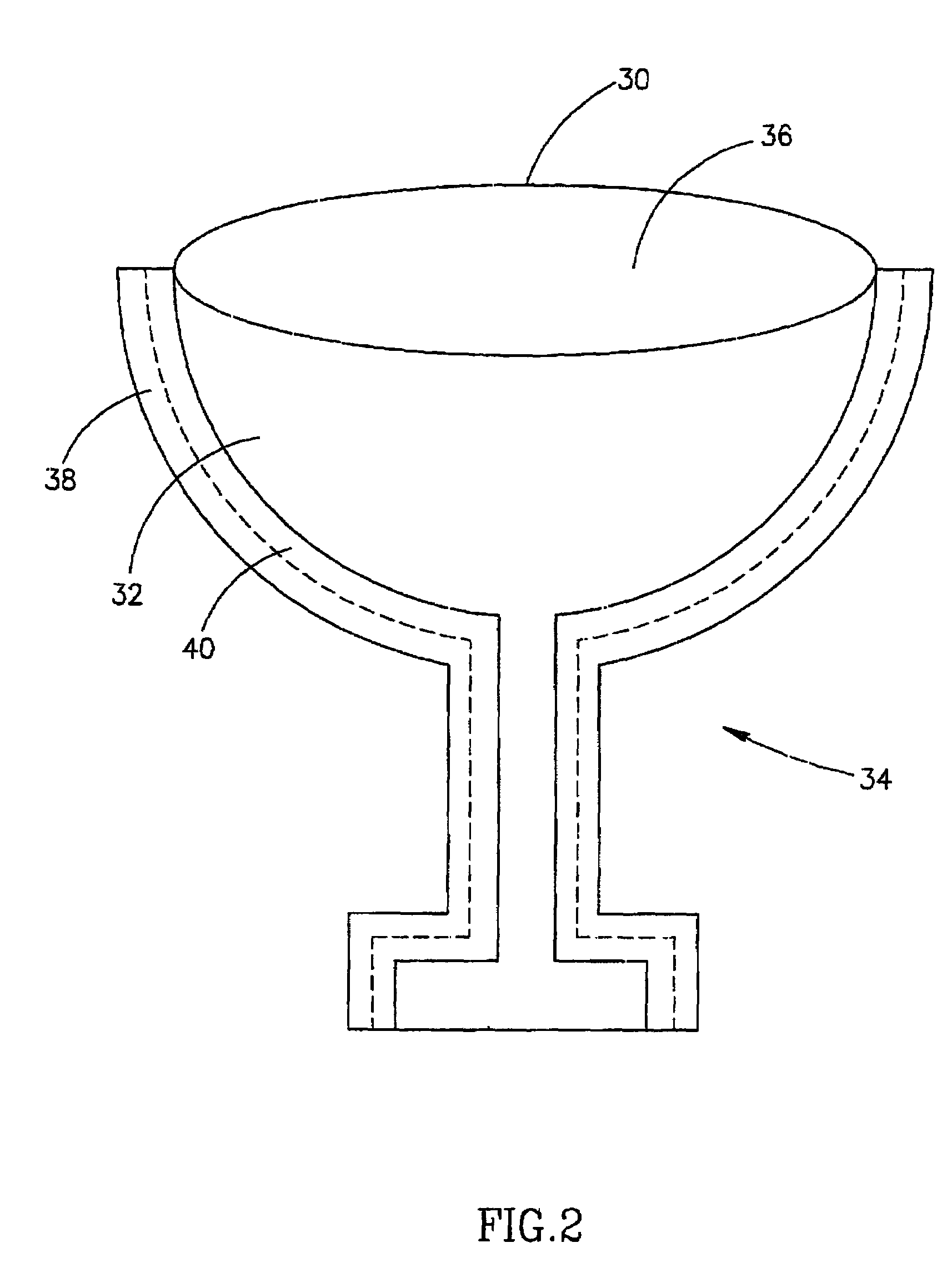

A twin-sheet thermoforming process for the manufacture of vehicle headliners. In the process a first sheet and second sheet of SuperLite material are mounted onto respective frames. The frames transfer the sheets into an oven, where they are heated to a desired temperature using IR. The first sheet is combined with a cover-stock material using compression molding forming a covered first headliner part. The covered first headliner part is then transferred to a second mold station. The second sheet is heated and then transferred from the oven to the second mold station where it is vacuum-formed on the upper half mold, forming a second headliner part. The upper and lower mold halves are pressed together fusing and sealing the first and second headliner parts into a unified part. The unified part is then unloaded and trimmed as necessary forming a headliner. The SuperLite material used to form the headliner is a sheet of low pressure, thermoformable, thermoplastic composite comprised of polypropylene and long chopped glass fibers.

Owner:AZDEL INC

Twin-sheet thermoformed products

A twin-sheet thermoforming process for the manufacture of vehicle headliners. In the process a first sheet and second sheet of SuperLite material are mounted onto respective frames. The frames transfer the sheets into an oven, where they are heated to a desired temperature using IR. The first sheet is combined with a cover-stock material using compression molding forming a covered first headliner part. The covered first headliner part is then transferred to a second mold station. The second sheet is heated and then transferred from the oven to the second mold station where it is vacuum-formed on the upper half mold, forming a second headliner part. The upper and lower mold halves are pressed together fusing and sealing the first and second headliner parts into a unified part. The unified part is then unloaded and trimmed as necessary forming a headliner. The SuperLite material used to form the headliner is a sheet of low pressure, thermoformable, thermoplastic composite comprised of polypropylene and long chopped glass fibers.

Owner:AZDEL INC

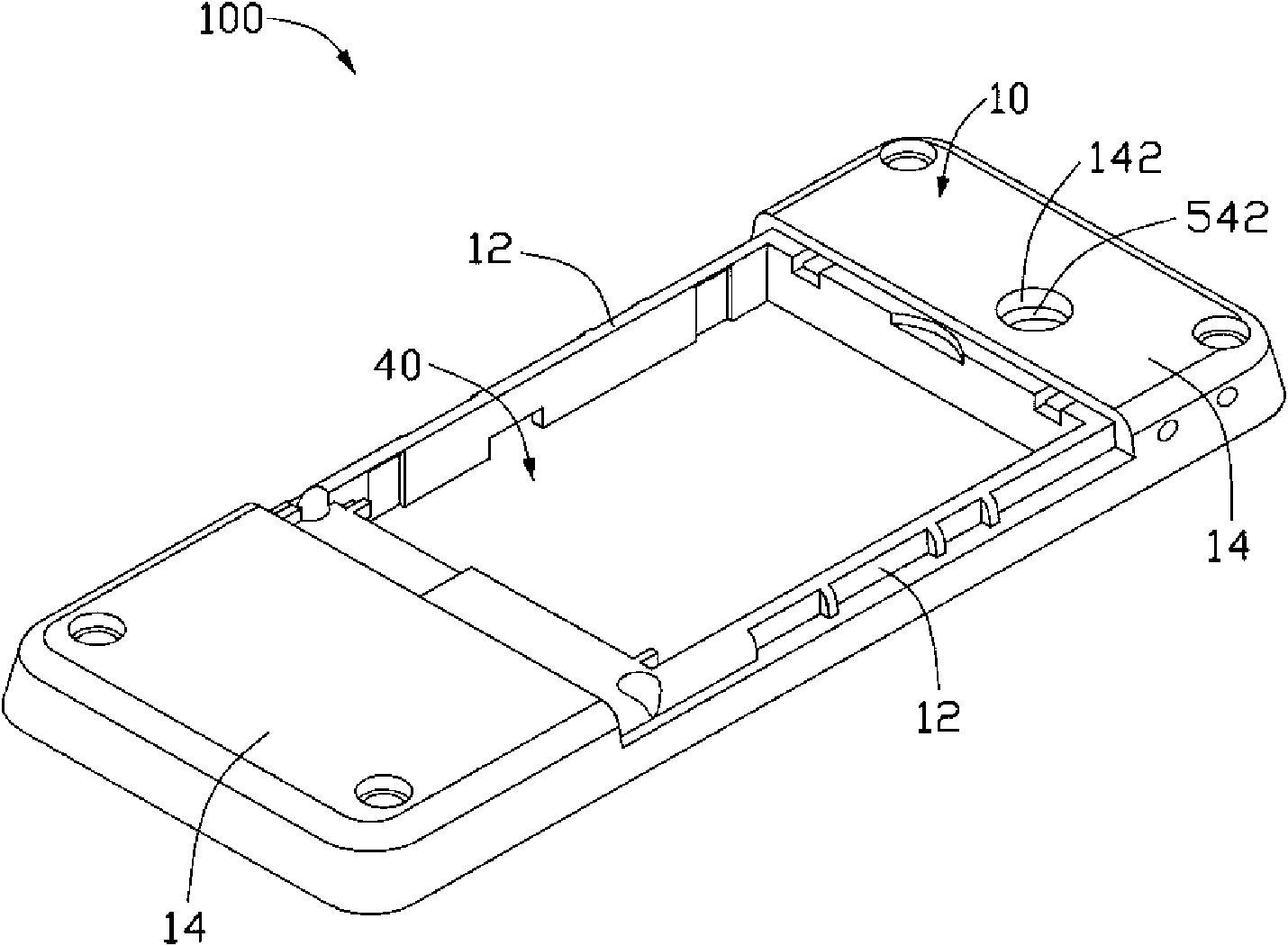

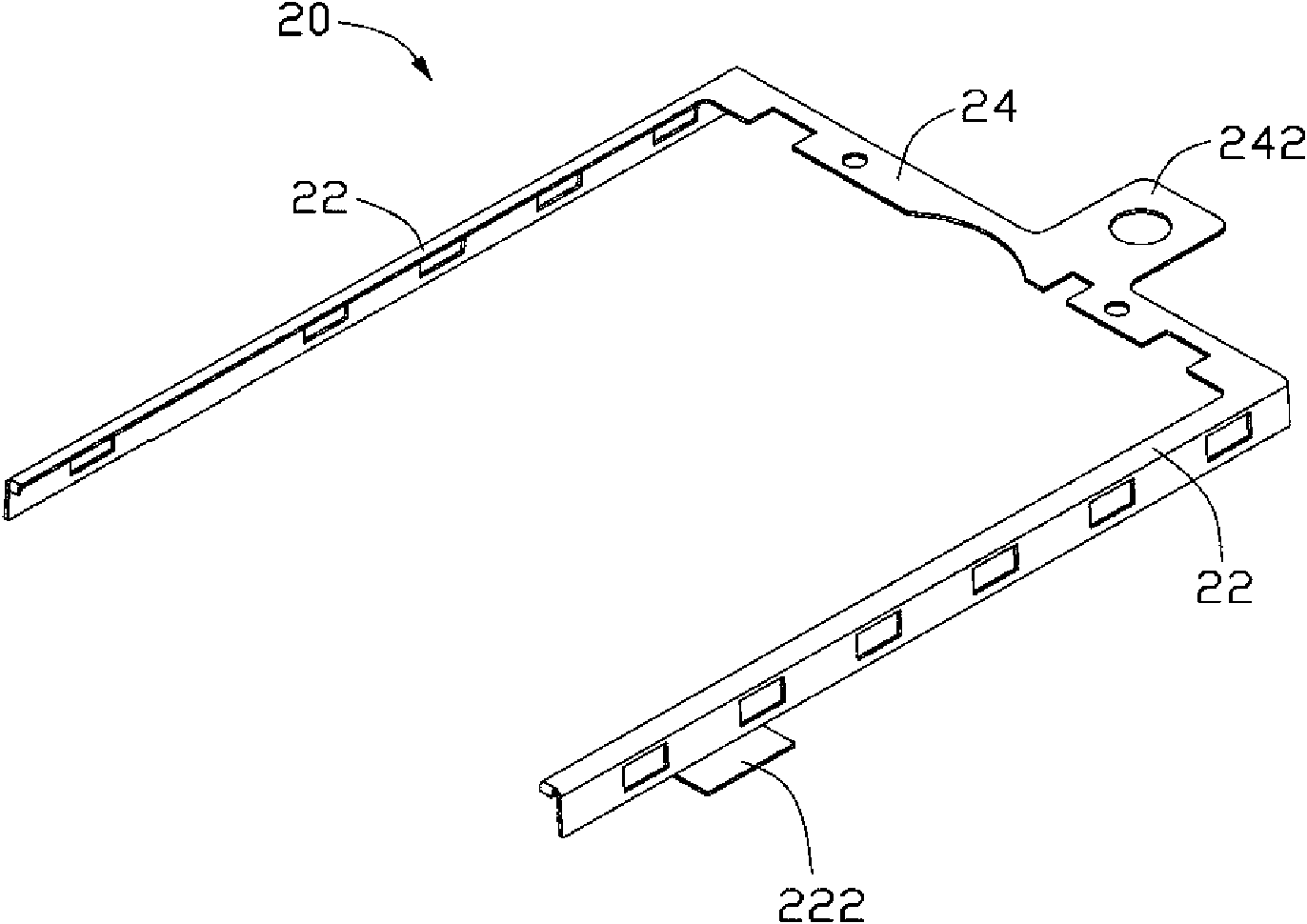

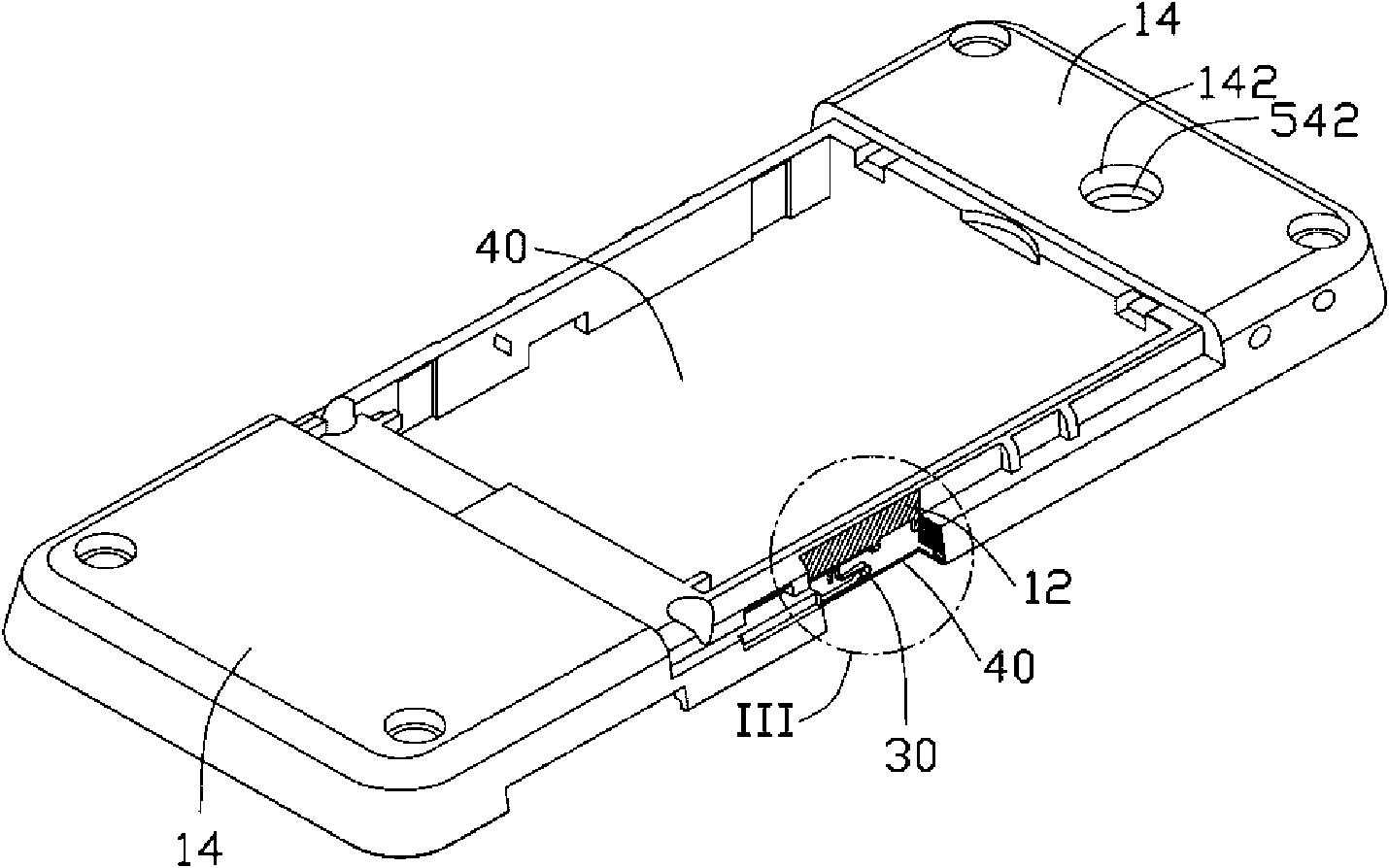

Casing component embedded with antenna and manufacturing method thereof

InactiveCN101652040AHigh strengthSave layout spaceAntenna supports/mountingsFramesElectricityElectrical connection

Owner:SHENZHEN FUTAIHONG PRECISION IND CO LTD +1

Transparent polyamide molding materials having improved transparency, resistance to chemicals and high permanent fatigue strength

ActiveUS6943231B2High transparencyHigh permanent fatigue strengthNon-fibrous pulp additionFramesPolyamideCarboxylic acid

Transparent polyamide molding materials are provided which are characterized in that they have a melting enthalpy between 0 and 12 J / g and the polyamides are constituted of100 mole-% of a diamine mixture having 10-70 mole-% of PACM [bis-(4-amino-cyclohexyl)-methane] with less than 50 wt.-% of trans,trans-isomer and 90-30 mole-% of MACM [bis-(4-amino-3-methyl-cyclohexyl)-methane], wherein, optionally, 0-10 mole-% can be replaced by other aliphatic diamines having 6 to 12 C atoms, cycloaliphatic, alkyl-substituted cycloaliphatic, branched aliphatic diamines or multiamines having 3 to 12 amino groups or mixtures thereof, and100 mole-% of long-chain aliphatic dicarboxylic acids having 8 to 14 C atoms or mixtures of these dicarboxylic acids, wherein 0-10 mole-% can be replaced by other aromatic or cycloaliphatic dicarboxylic acids having 8 to 16 C atoms, which are especially selected from the group consisting of isophthalic acid, terephthalic acid, naphthalenedicarboxylic acid, cyclohexanedicarboxylic acid or mixtures thereof, andwherein, optionally, 0-10 mole-% of the other long-chain aliphatic diamines and 0-10 mole-% of the other long-chain aliphatic dicarboxylic acids can be added as 0-20 mole-% of ω-aminocarboxylic acids having 6 to 12 C atoms or lactams having 6 to 12 C atoms.Further, methods for producing the polyamide moulding materials and methods for producing and further treating moulded articles from the polyamide moulding materials are provided. Especially, the present invention relates to glasses and lenses which are obtainable from the polyamide moulding materials.

Owner:EMS CHEM AG

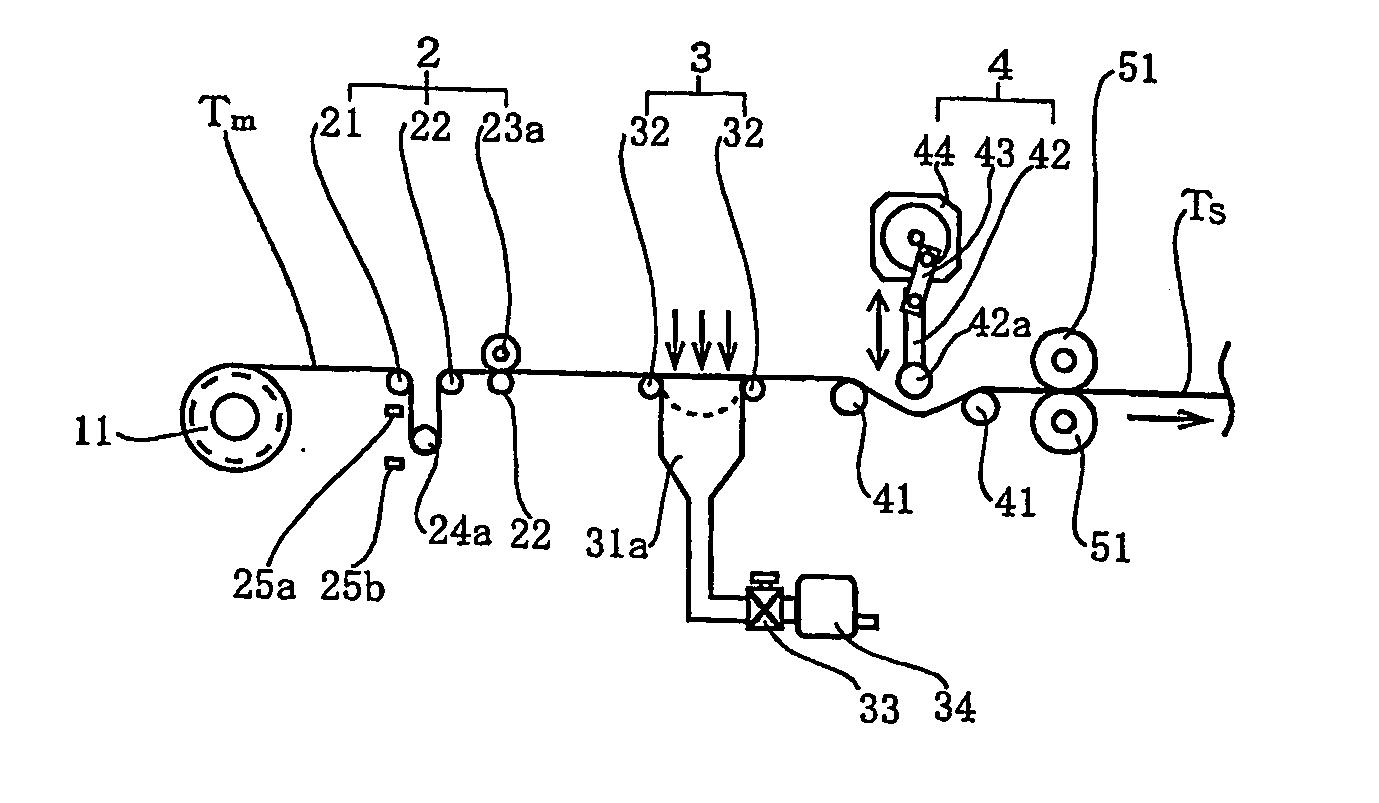

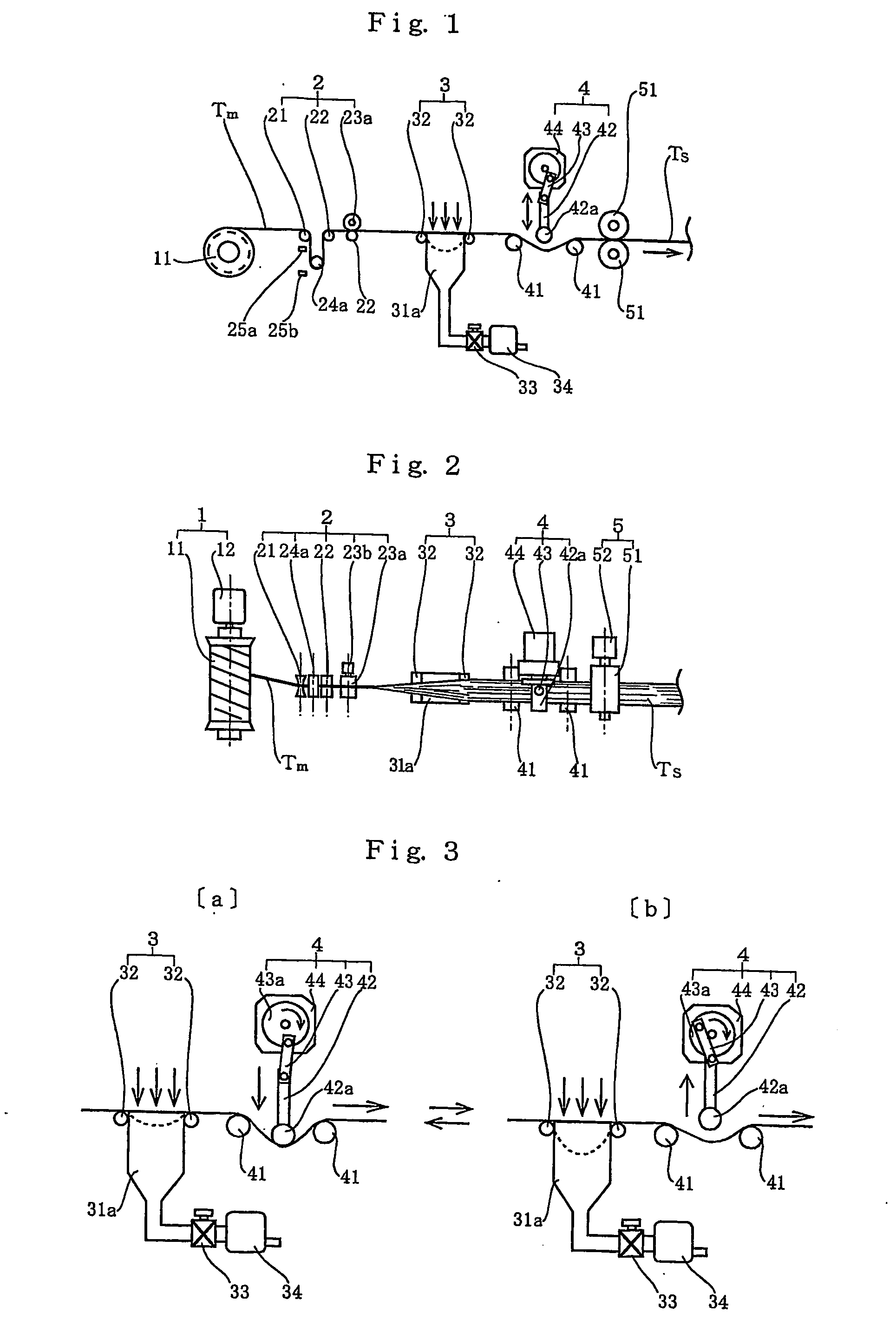

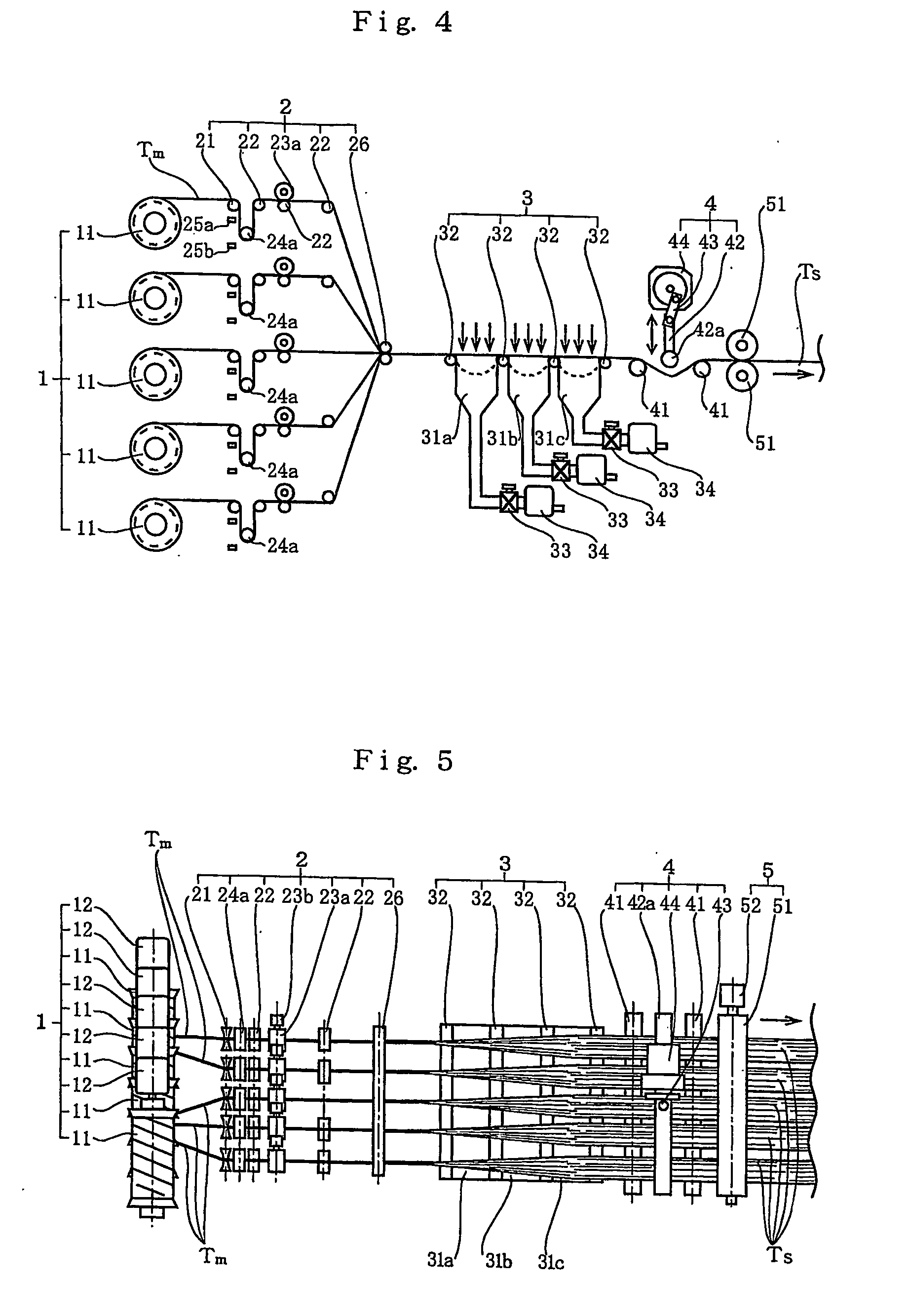

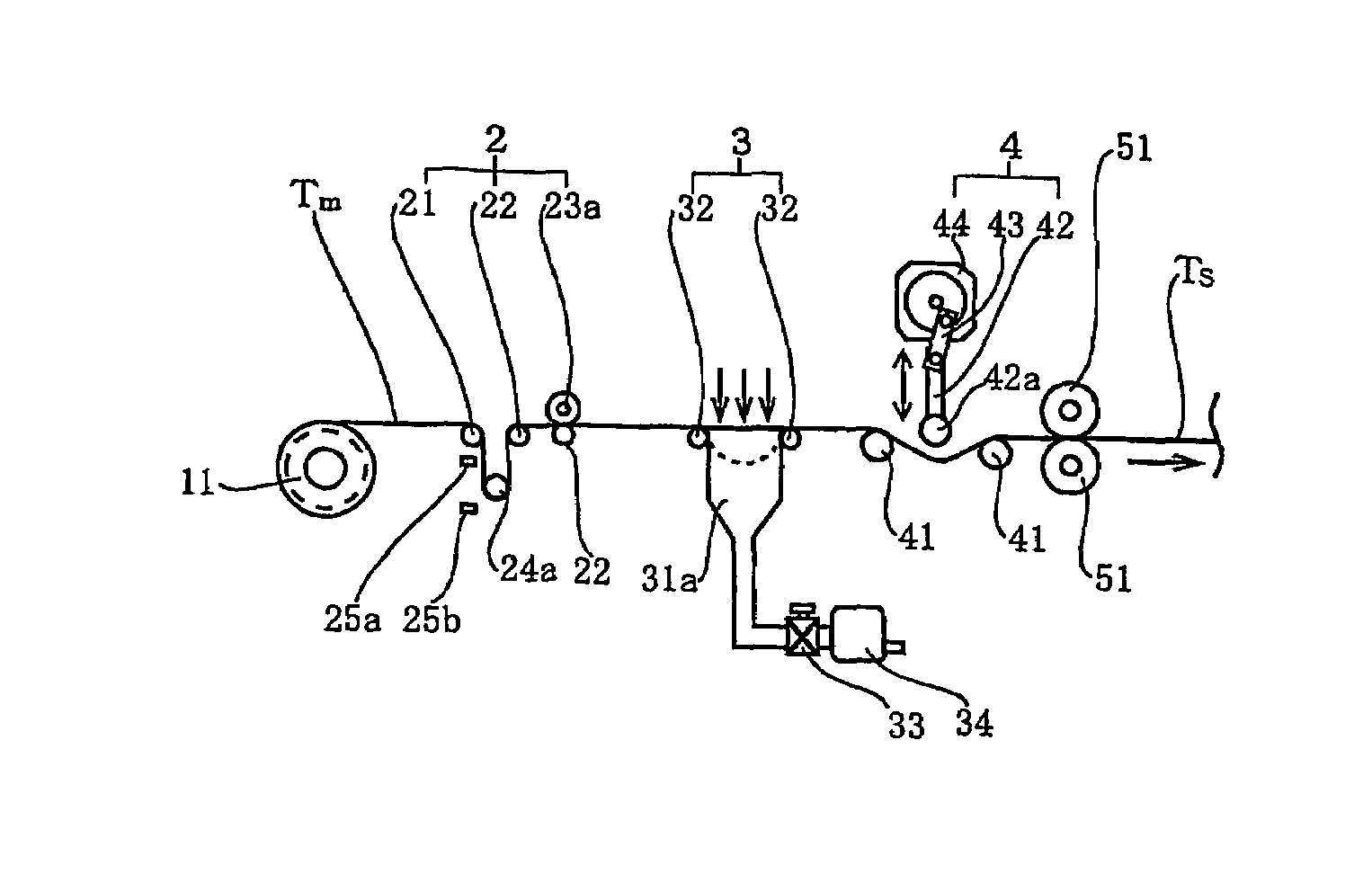

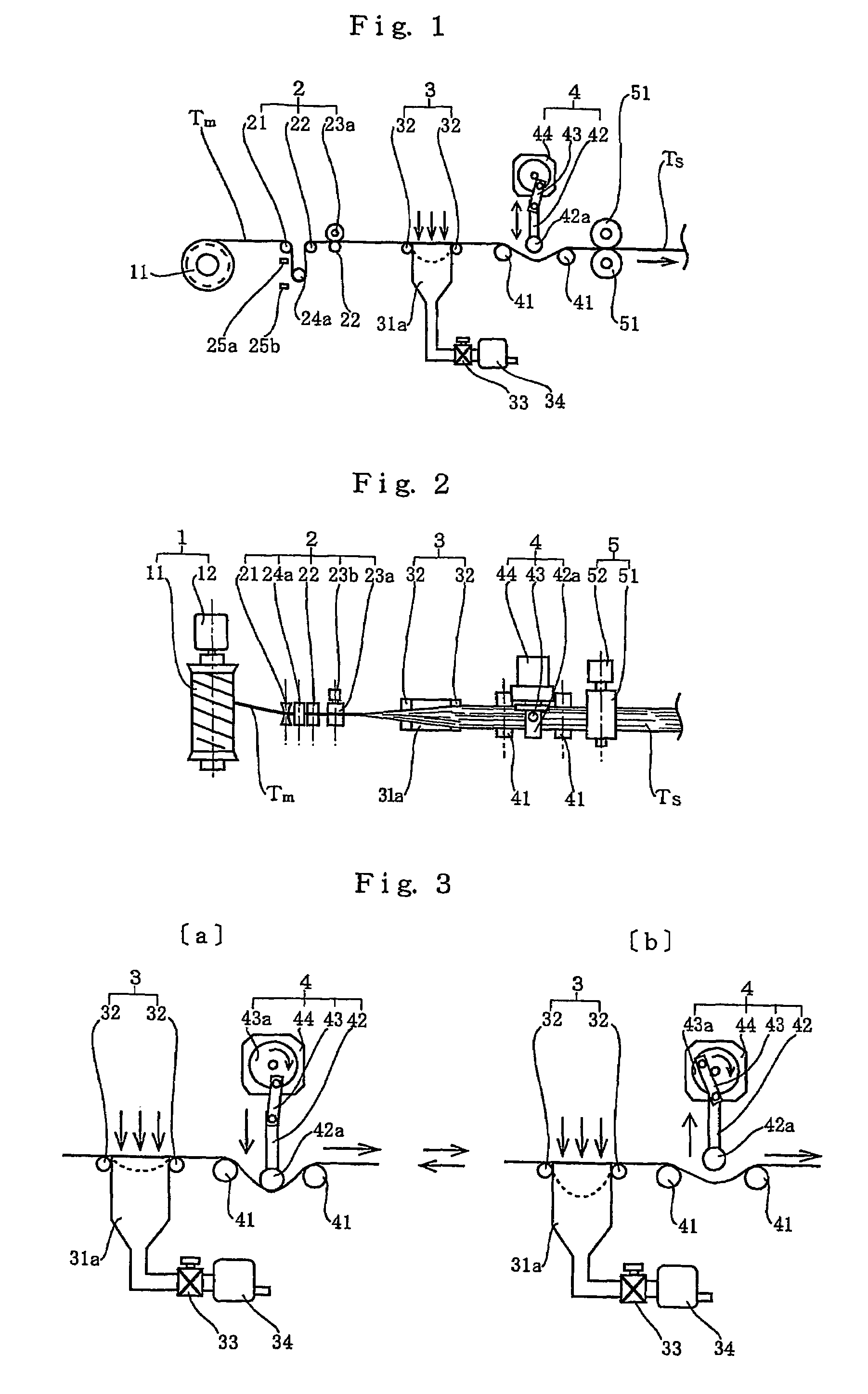

Method of producing a spread multi-filament bundle and an apparatus used in the same

ActiveUS20060137156A1Efficient mass productionImprove efficiencyButtonsRecord carriersEngineeringVolumetric Mass Density

A method of producing a spread multi-filament bundle and an apparatus is used in which an arbitrary number of multi-filament bundles of higher strength are simultaneously spread with high speed and a high-quality. A spread multi-filament bundle or sheet with the component monofilaments thereof aligned in parallel widthwise and uniformly distributed in density is produced. The respective multi-filament bundles fed from a yarn supplier or a creel are subjected to fluctuation of the tensile force applied thereto alternatively between tension and relaxation and the respective bundles as subjected to such fluctuation are passed in succession through a fluid flowing spreader.

Owner:FUKUI PREFECTURE

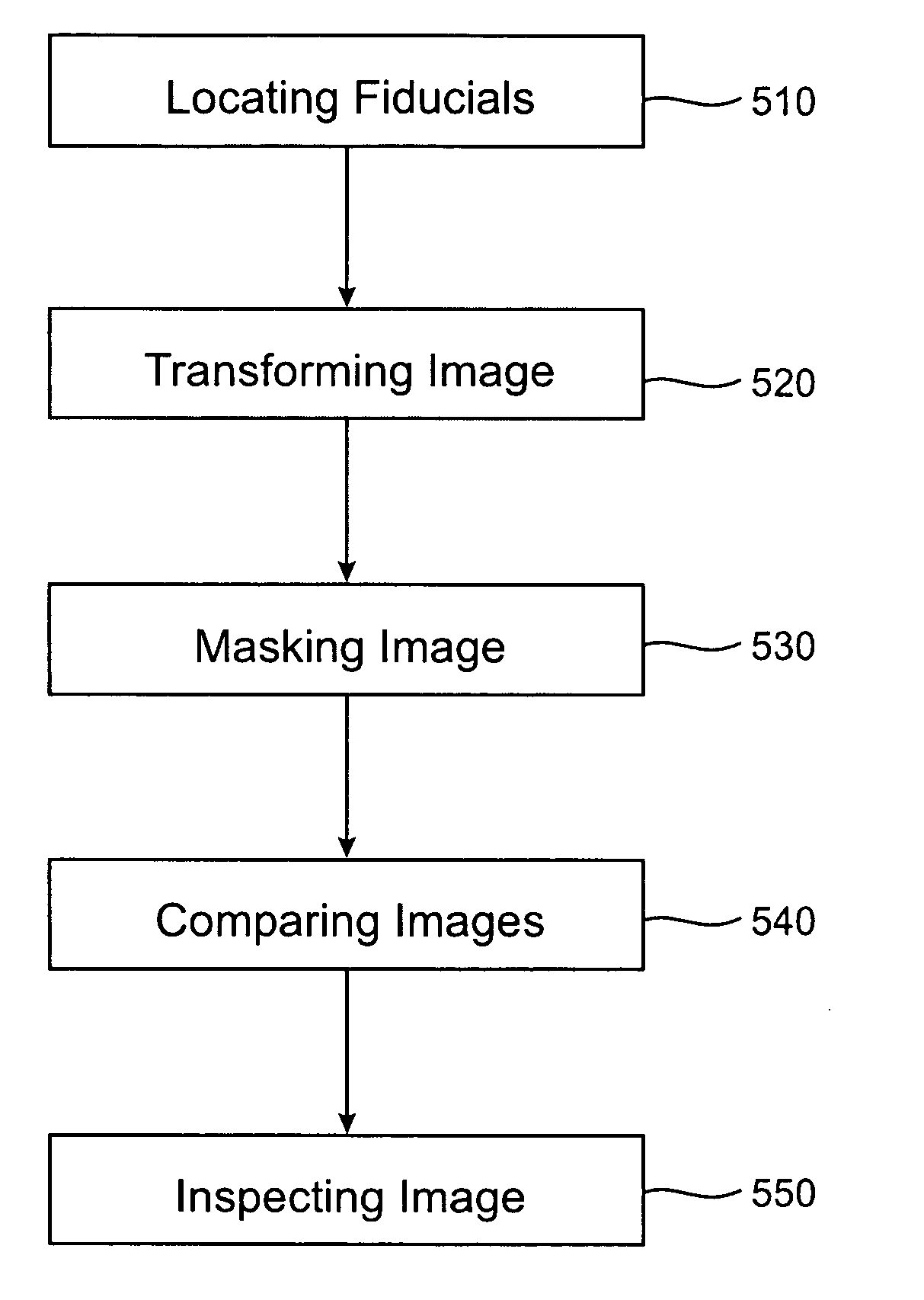

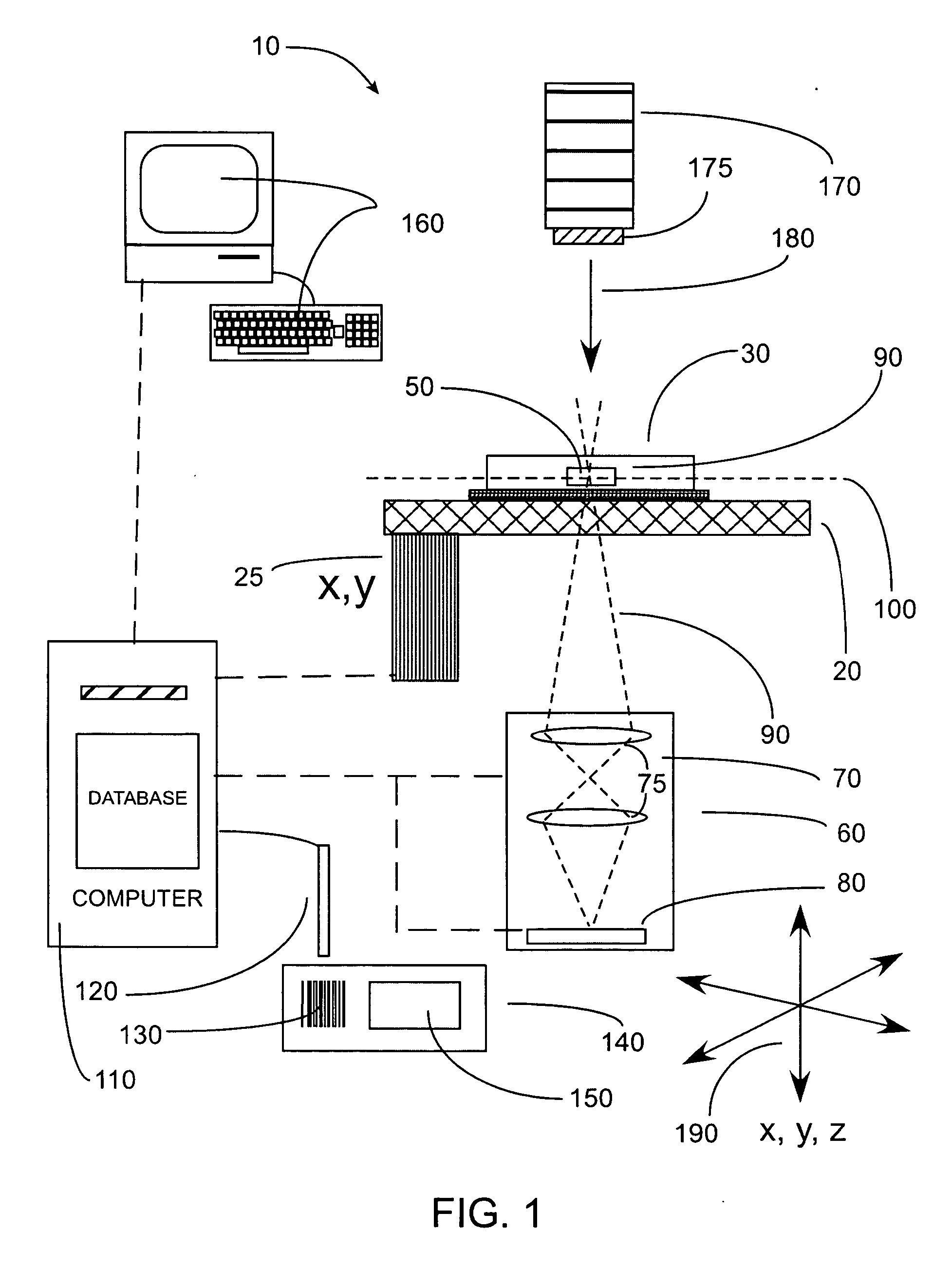

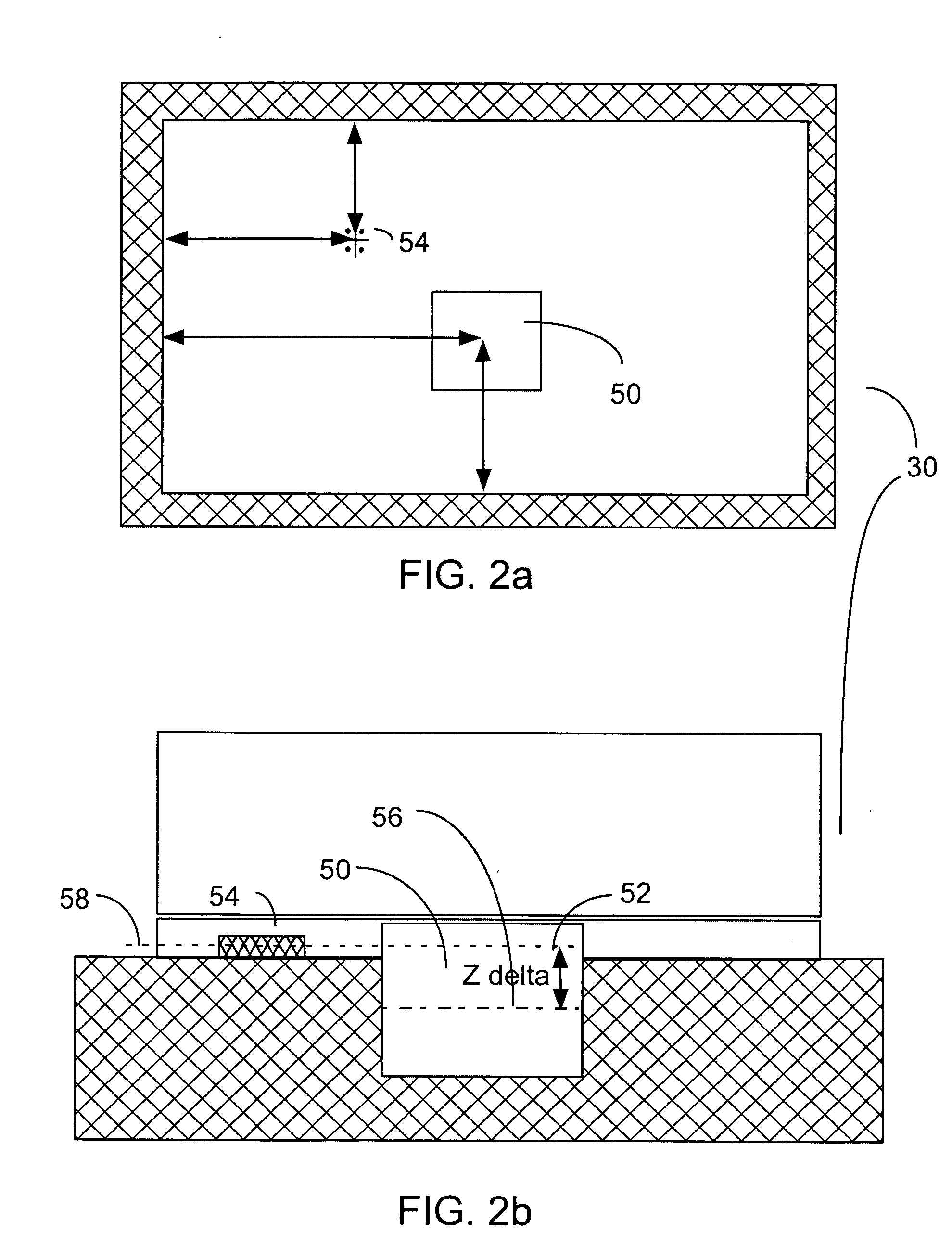

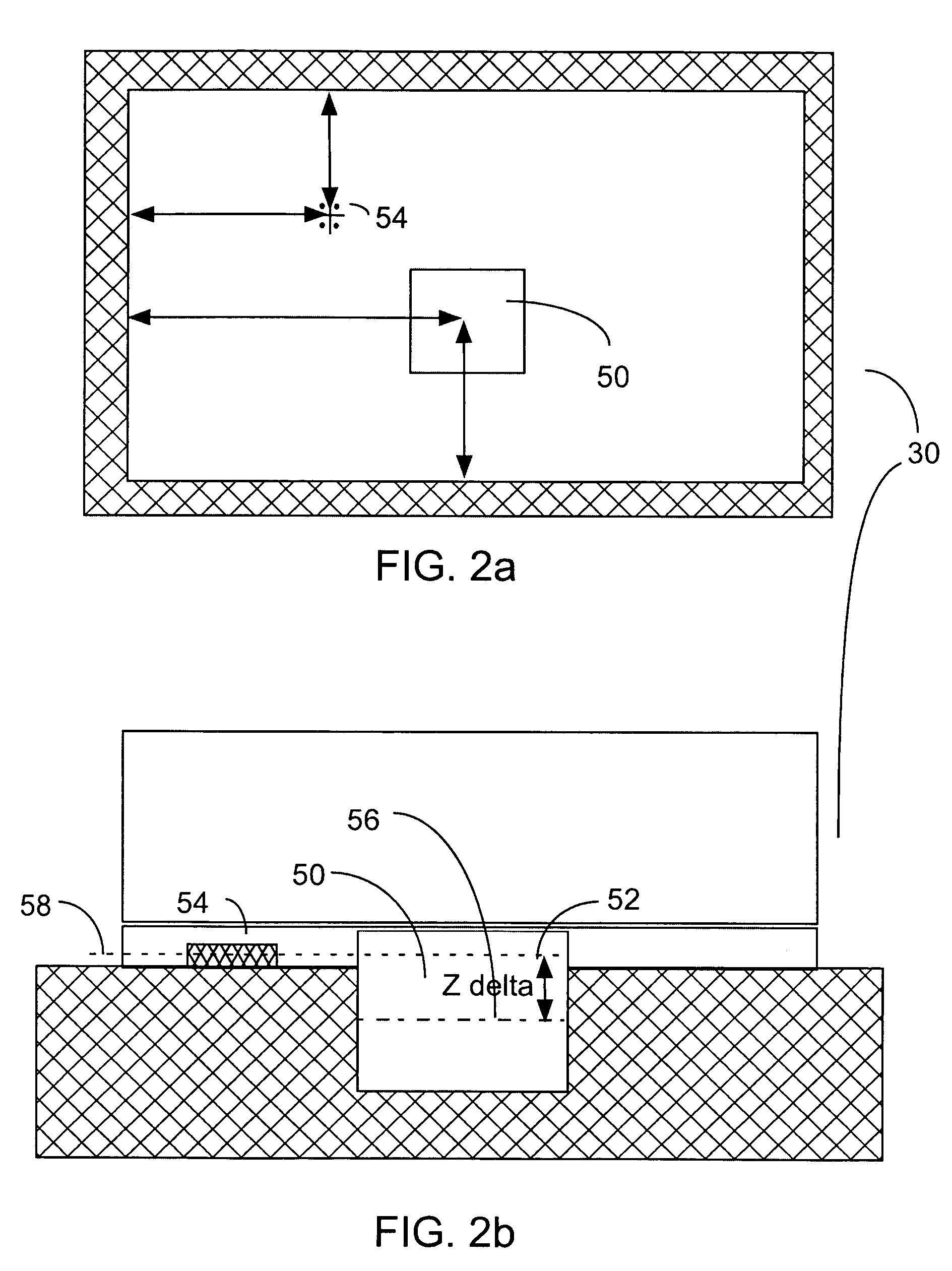

Image processing method and system for microfluidic devices

InactiveUS20050282175A1Increase speedSimple processImage enhancementButtonsImaging processingState dependent

A method for processing an image of a microfluidic device. The method includes receiving a first image of a microfluidic device. The first image corresponds to a first state. Additionally, the method includes receiving a second image of the microfluidic device. The second image corresponds to a second state. Moreover, the method includes transforming the first image and the second image into a third coordinate space. Also, the method includes obtaining a third image based on at least information associated with the transformed first image and the transformed second image, and processing the third image to obtain information associated with the first state and the second state.

Owner:FLUIDIGM CORP

Method of manufacturing eyewear

InactiveUS6911172B2Increase power consumptionSmall sizeComponent separationFramesTransceiverDisplay device

A wireless ad hoc pico network is formed by eyewear and other devices such as a computer, a bracelet and a telephone having similar transceivers mounted on them. The eyewear includes a frame and connected to the frame are two temples. Temples are connected to frame via hinges. Temples have a male portion of a connector incorporated in them. Female portion of the connector is made integral with the hinges. When the male portion is inserted in the female portion the temple is attached to the frame. The temples can be removed by pulling the connector apart, and a temple with different apparatus within it can be inserted in place of the removed temples. The temple may have co-molded within its body, an apparatus such as an audio device, a camera, a speaker, and a microphone, and a display device such as liquid crystal or an alarm.

Owner:III HLDG 4

Method of producing a spread multi-filament bundle and an apparatus used in the same

ActiveUS7571524B2Efficient mass productionImprove efficiencyButtonsRecord carriersYarnVolumetric Mass Density

A method of producing a spread multi-filament bundle and an apparatus is used in which an arbitrary number of multi-filament bundles of higher strength are simultaneously spread with high speed and a high-quality. A spread multi-filament bundle or sheet with the component monofilaments thereof aligned in parallel widthwise and uniformly distributed in density is produced. The respective multi-filament bundles fed from a yarn supplier or a creel are subjected to fluctuation of the tensile force applied thereto alternatively between tension and relaxation and the respective bundles as subjected to such fluctuation are passed in succession through a fluid flowing spreader.

Owner:FUKUI PREFECTURE

Compositions and methods for use in three dimensional model printing

InactiveUS20080105818A1Similar elasticitySimilar strengthButtonsRecord carriersInvestment castingMaterials science

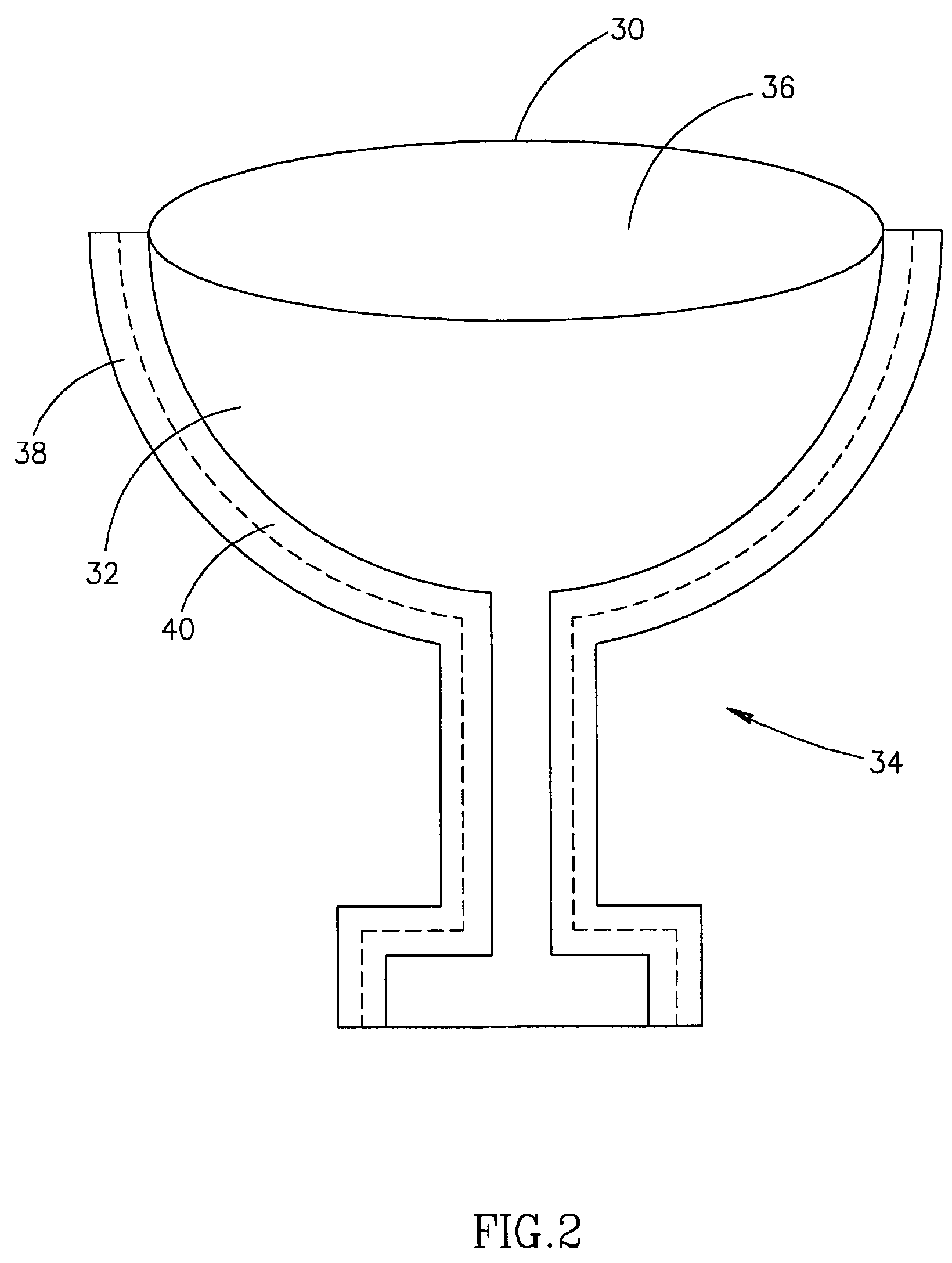

Embodiments of the invention are directed to a method of producing three-dimensional prototype molds for use in investment casting. The method includes dispensing modeling material and support material in a predetermined arrangement, in layers, to produce a three-dimensional mold having an outer shell. Generally, the out shell includes modeling material and the interior of the mold includes support material. Then the mold is cured.

Owner:OBJET GEOMETRIES

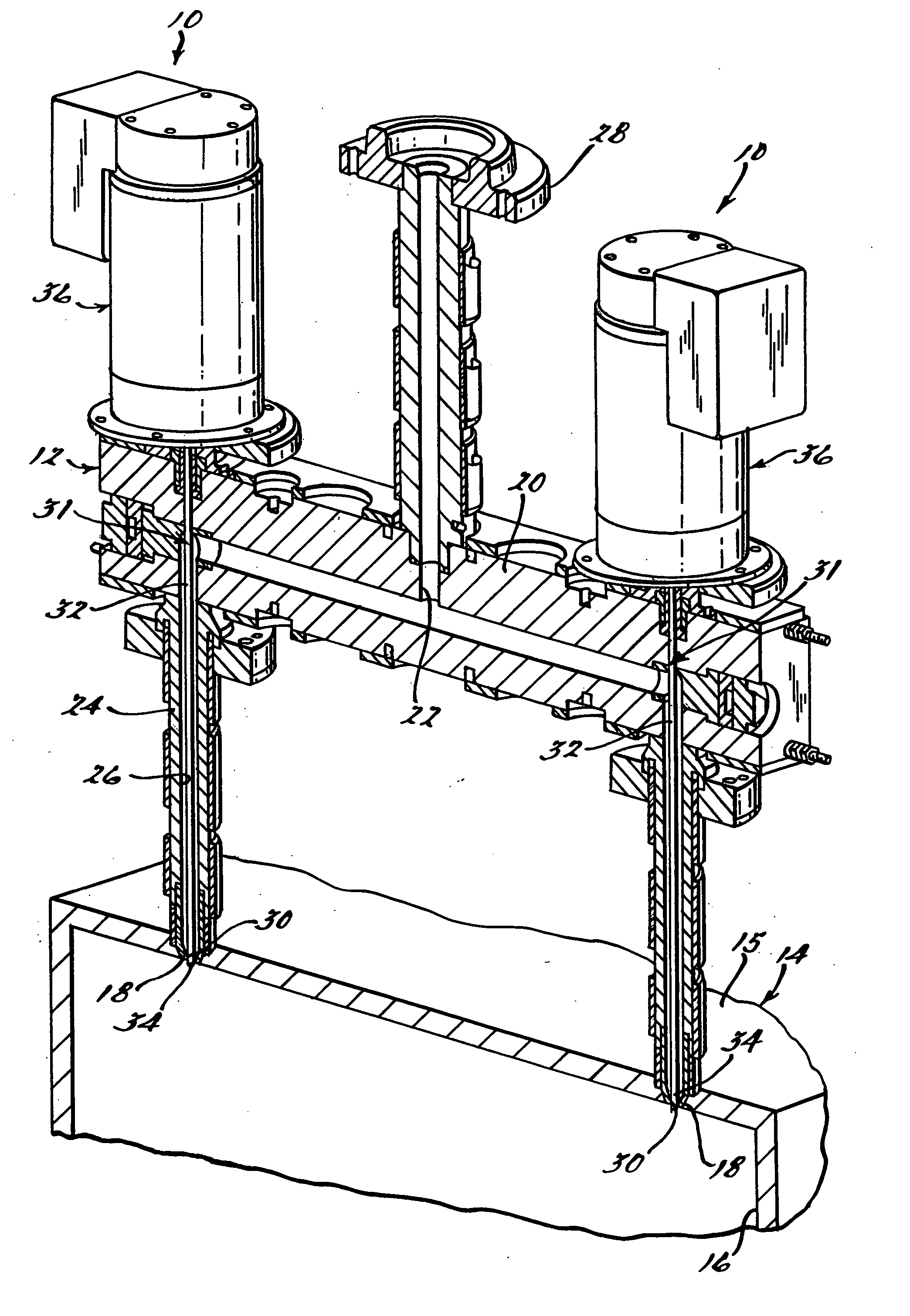

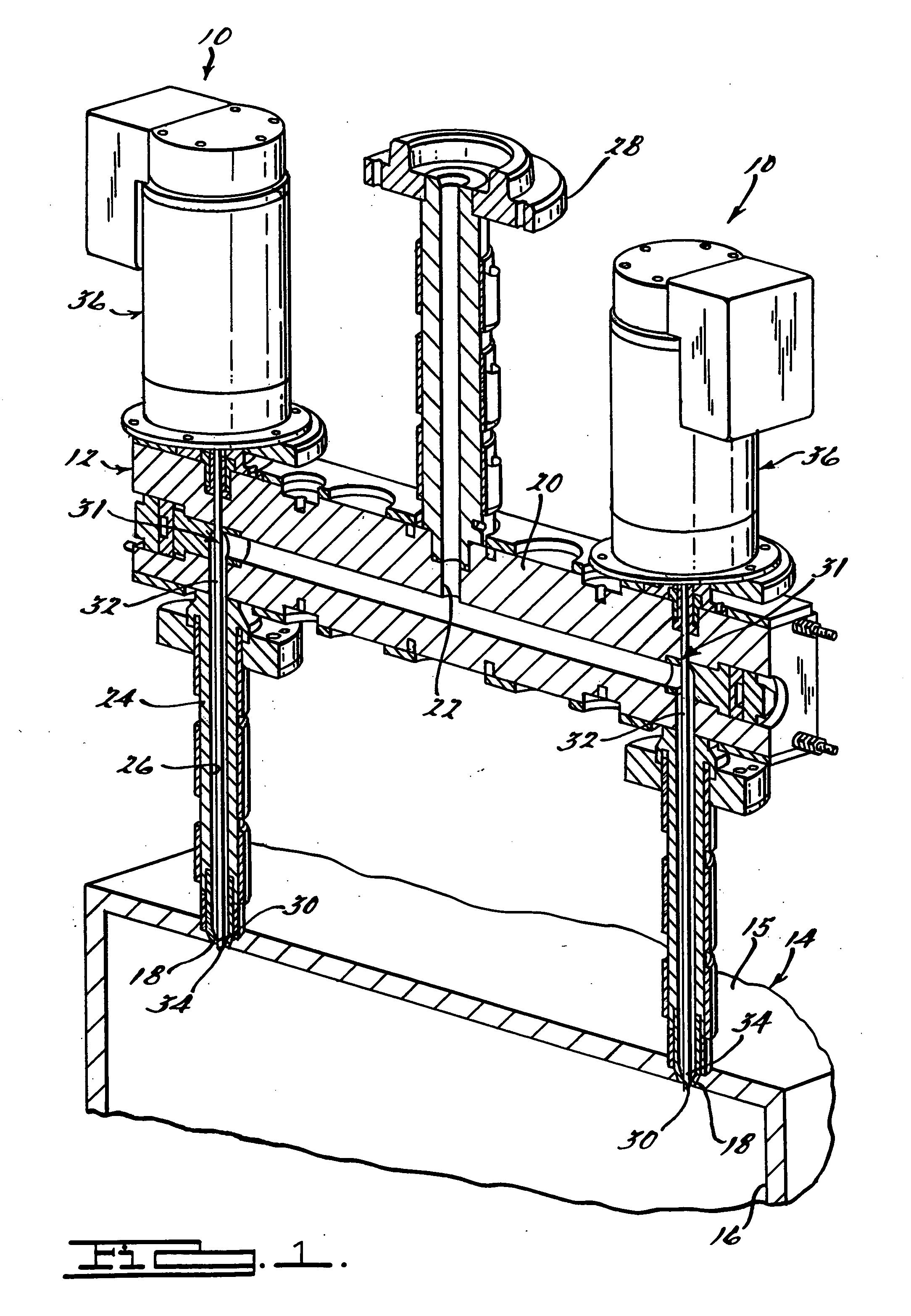

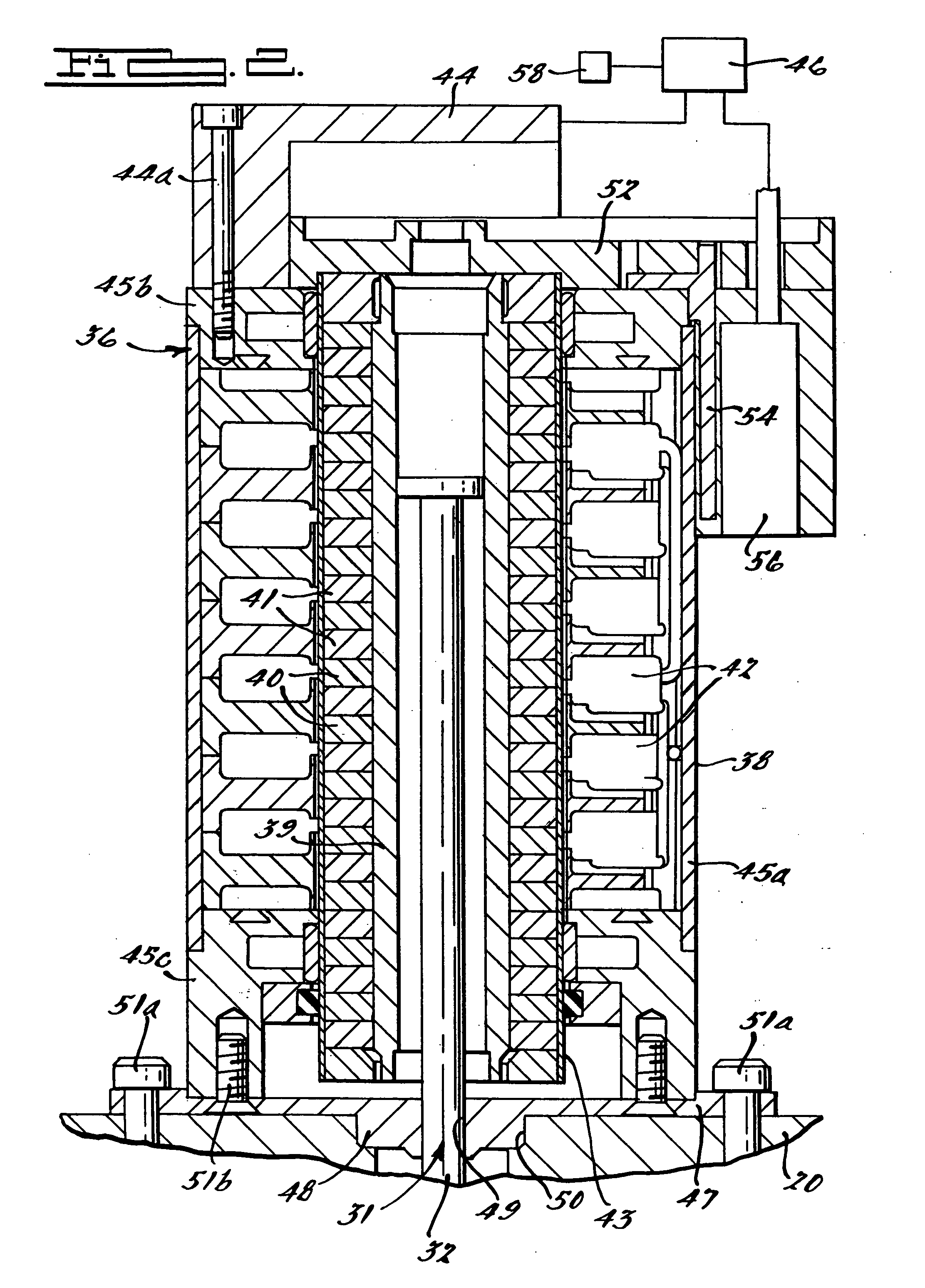

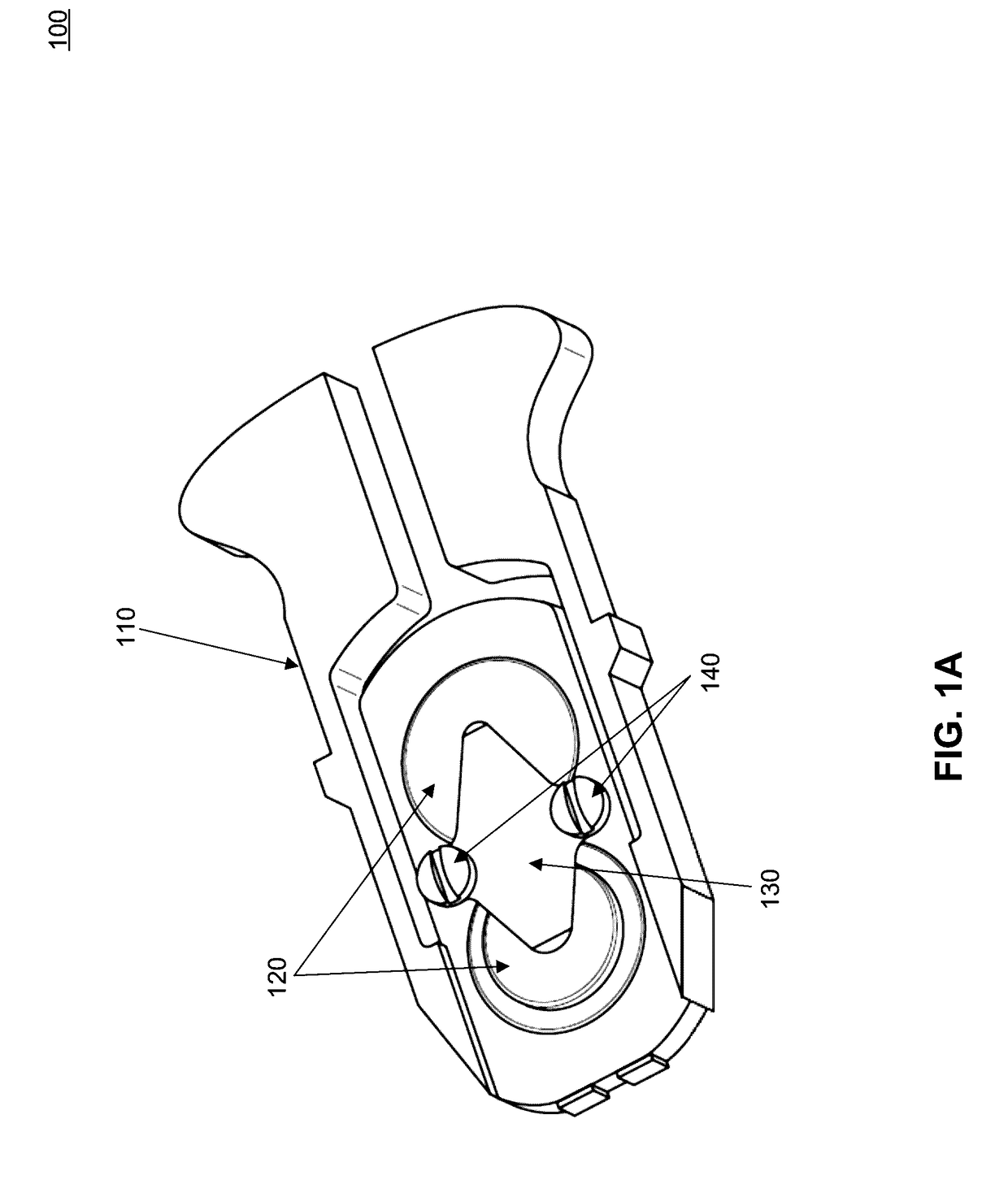

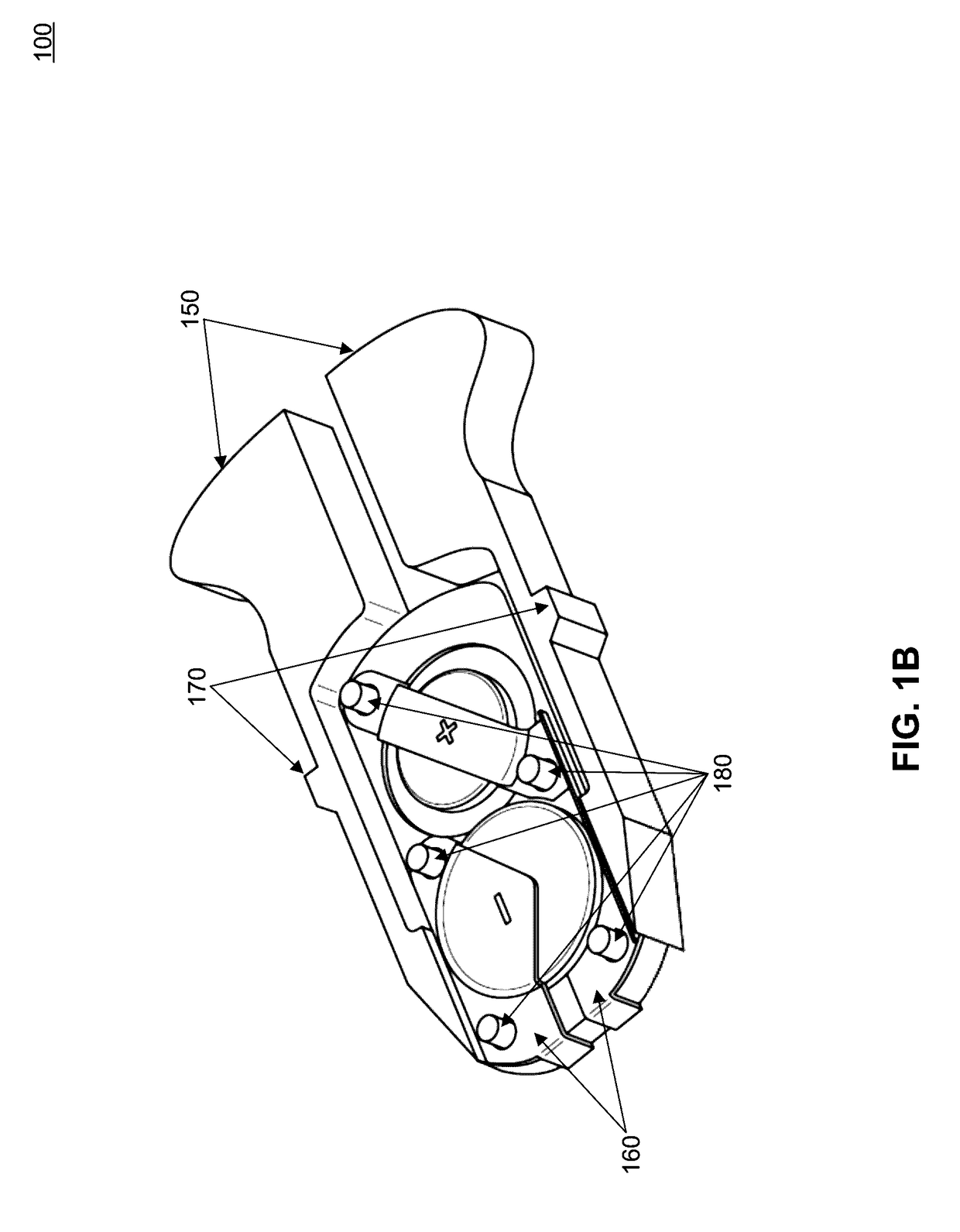

Valve gate assembly

ActiveUS20050100625A1Process controlEasy to adjustButtonsRecord carriersEngineeringMechanical engineering

A valve gate assembly for regulating a flow of molten material into a mold. The valve gate assembly includes a movable valve that can move between a fully closed position and a fully open position. The valve gate assembly further includes an actuating system operatively cooperating with the valve to move the valve and infinitely position the valve between the fully closed position and the fully open position.

Owner:PLASTIC ENG & TECHN SERVICES

Compositions and method for improving reheat rate of PET using activated carbon

ActiveUS20040249113A1Improving reheat rateMinimize impactEnvelopes/bags making machineryButtonsActivated carbonPolyester

A polyester composition, a preform, and a bottle, containing a polyester such as polyethylene terephthalate or polyethylene naphthalate and activated carbon to enhance the rate for reheating the composition is provided. Activated carbon may be added in the presence of active phosphorus containing compounds, or at any stage in the melt phase after prepolymerization and after the polyester polymer is solidified. Polyester concentrates containing activated carbon may be added to bulk polyesters to make preforms suitable for blowing into bottles.

Owner:ALPEK POLYESTER SA DE CV

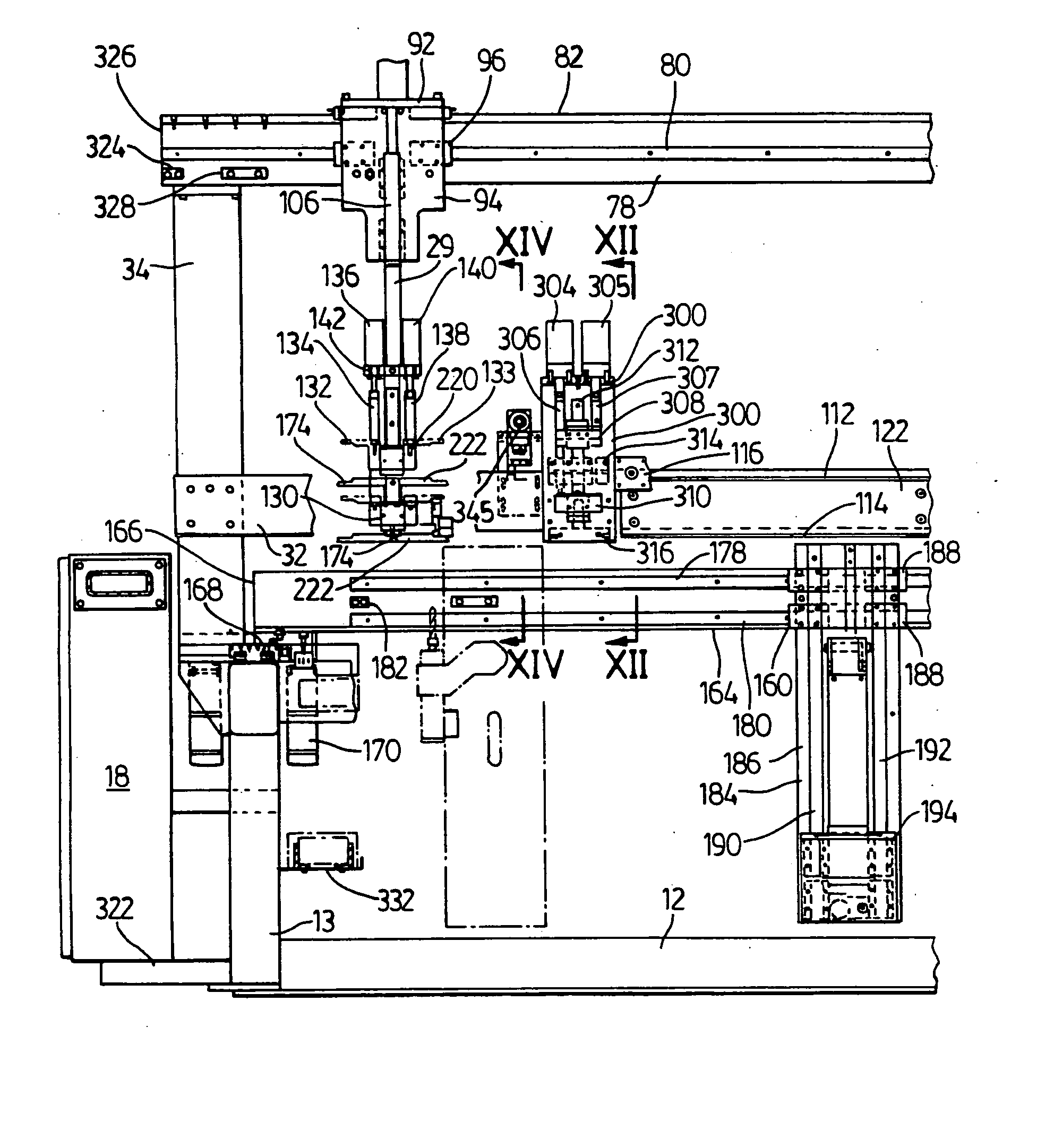

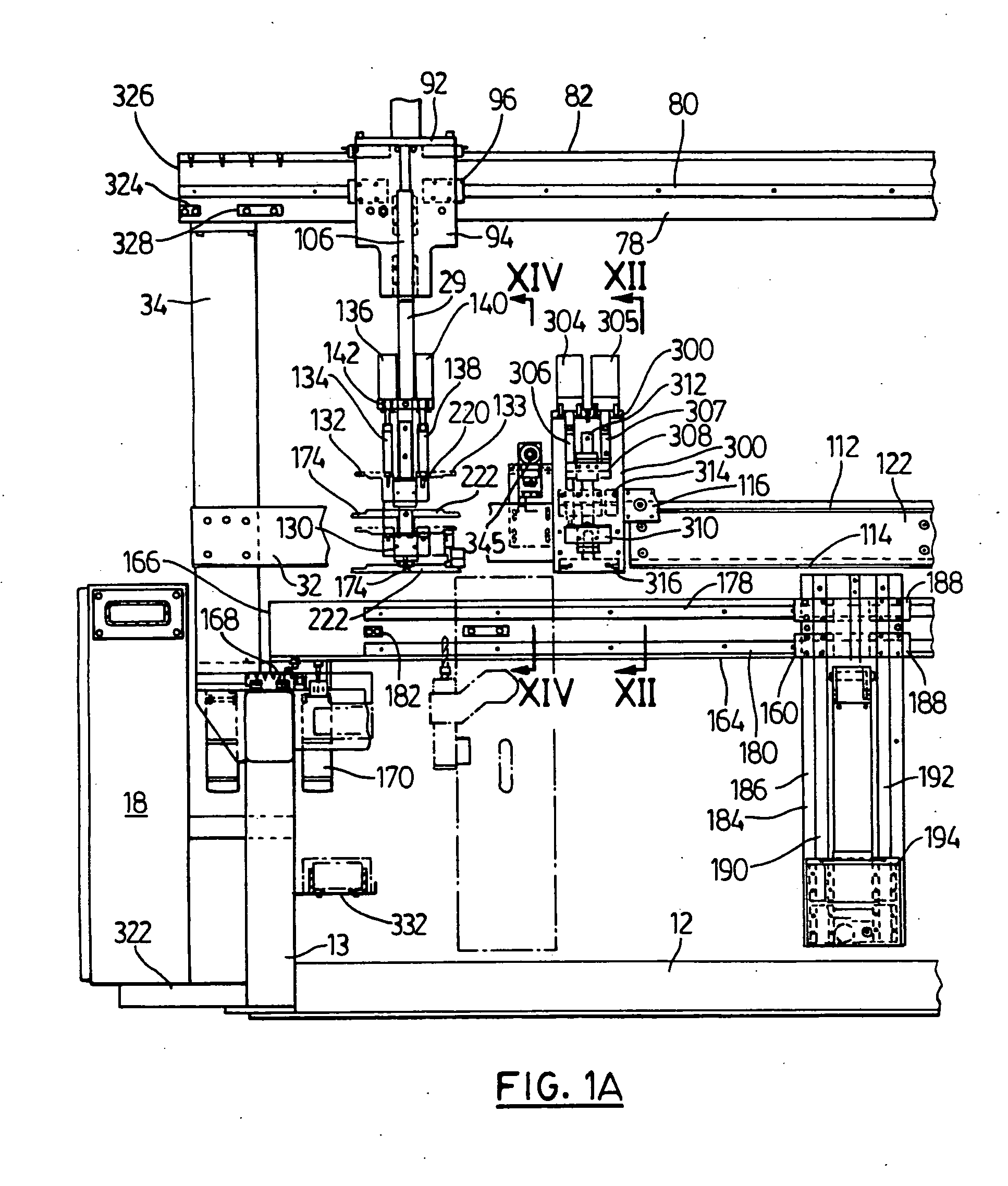

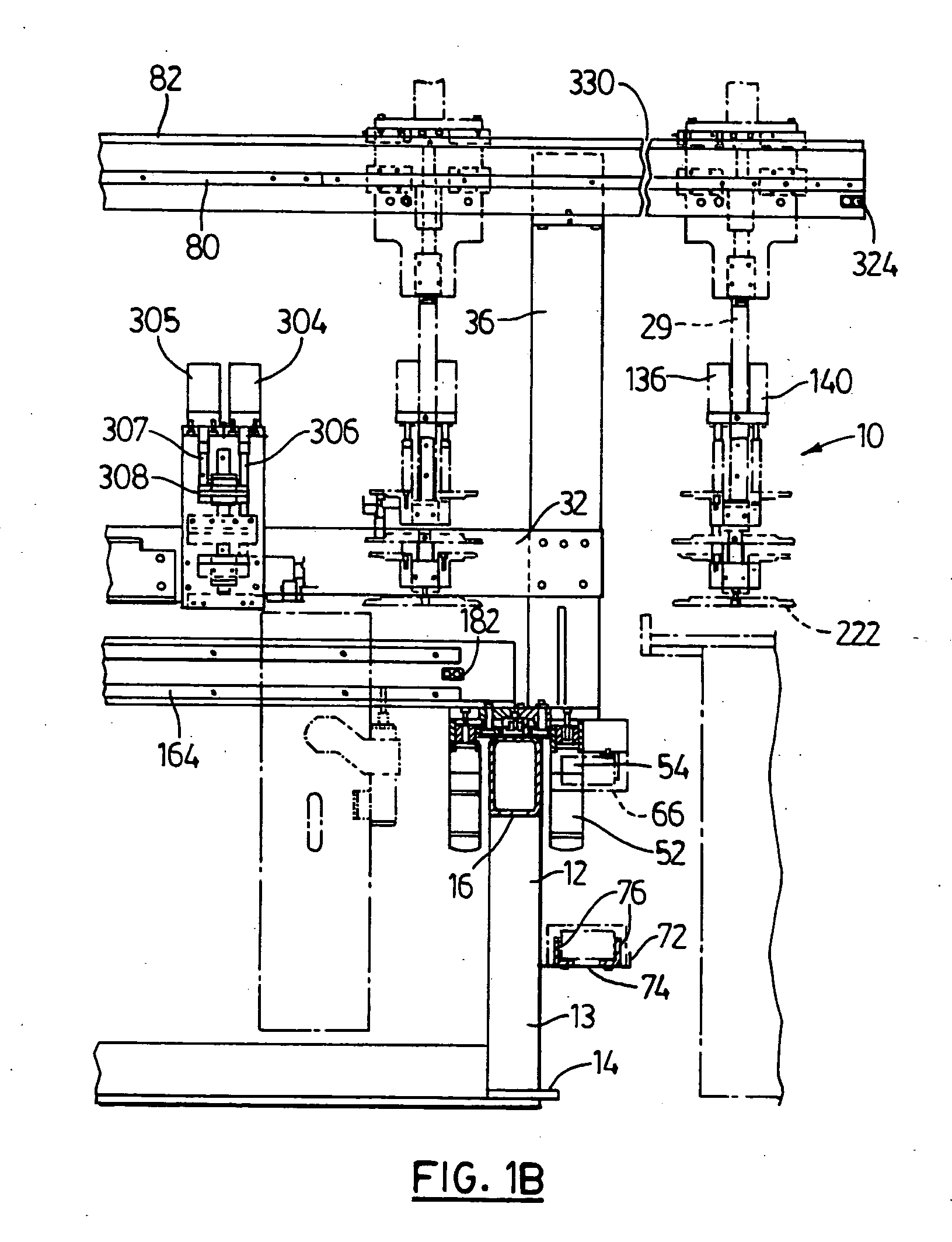

Apparatus and method for manufacturing plastic frameworks such as window frames

InactiveUS20050257361A1Reduce manufacturing costEfficient and flexibleAutomatic control devicesThread cutting feeding devicesProduction lineEngineering

A production line and a method for carrying out machining and cleaning operations on rectangular framework, such as window frames, is provided. Initially, elongate plastic frame members are welded together in a plastic frame welding machine, thereby forming two rectangular frameworks located one above the other. These are moved to a framework processing machine along separate predetermined paths where the first path being located above the second path. The paths are provided by horizontally extending guide arrangements on the machine which has at least one power tool for carrying out machining operations, this tool being supported by a transporting mechanism capable of moving the tool both horizontally and vertically. Machining steps are carried out on the two frame works while they are held one above the other in the processing machine. The frameworks are then moved to a weld cleaning machine along respective upper and lower paths and further processing operations including weld cleaning steps are carried out in this machine.

Owner:PRO LINE AUTOMATION SYST

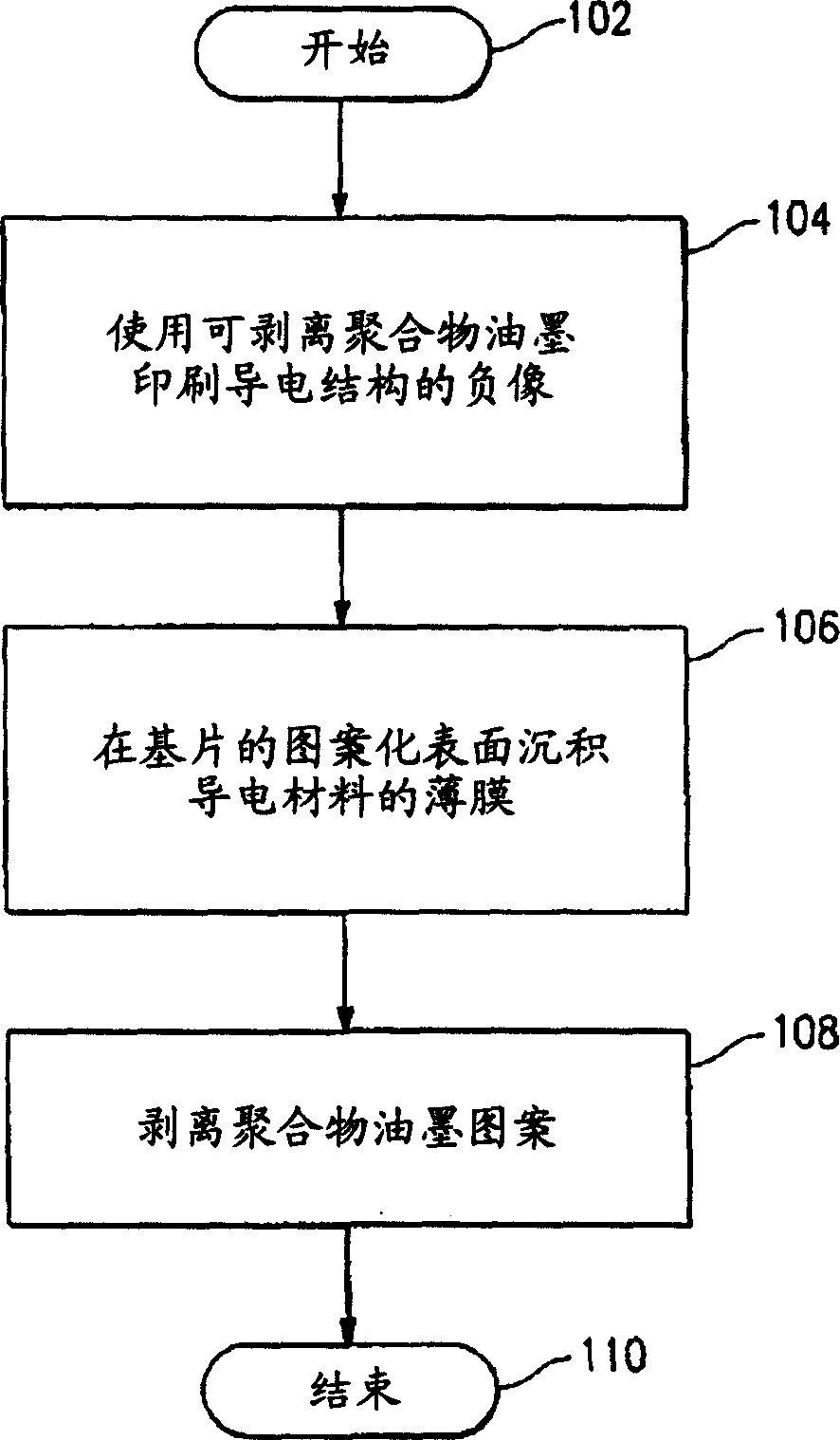

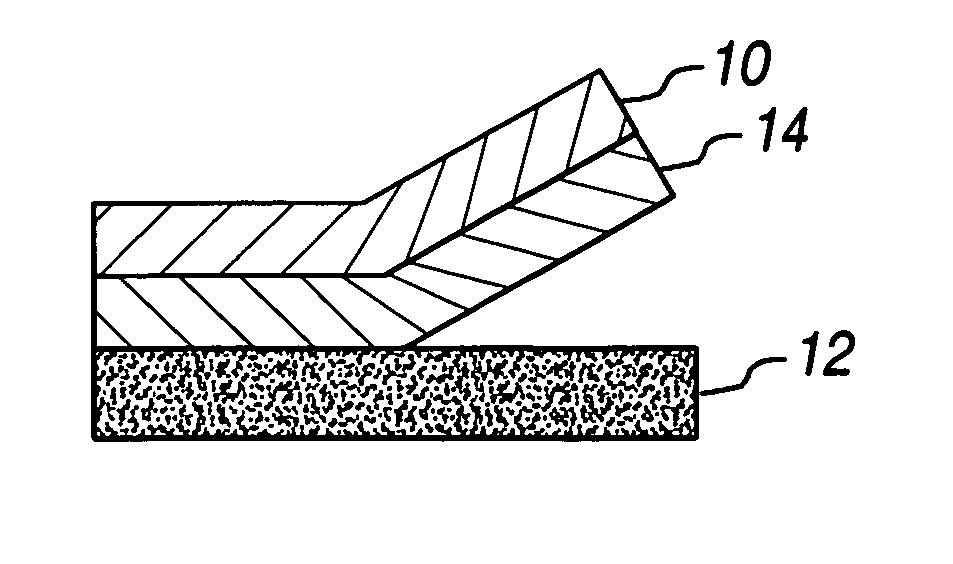

Process for forming a patterned thin film structure for in-mold decoration

A process for forming a patterned thin film structure on a substrate or in-mold decoration film is disclosed. A pattern is printed with a material, such as a masking coating or ink, on the substrate, the pattern being such that, in one embodiment, the desired structures will be formed in the areas where the printed material is not present, i.e., a negative image of thin film structure to be formed is printed. In another embodiment, the pattern is printed with a material that is difficult to strip from the substrate, and the desired thin film structures will be formed in the areas where the printed material is present, i.e., a positive image of the thin film structure is printed. The thin film material is deposited on the patterned substrate, and the undesired area is stripped, leaving behind the patterned thin film structure.

Owner:SIPIX CHEM

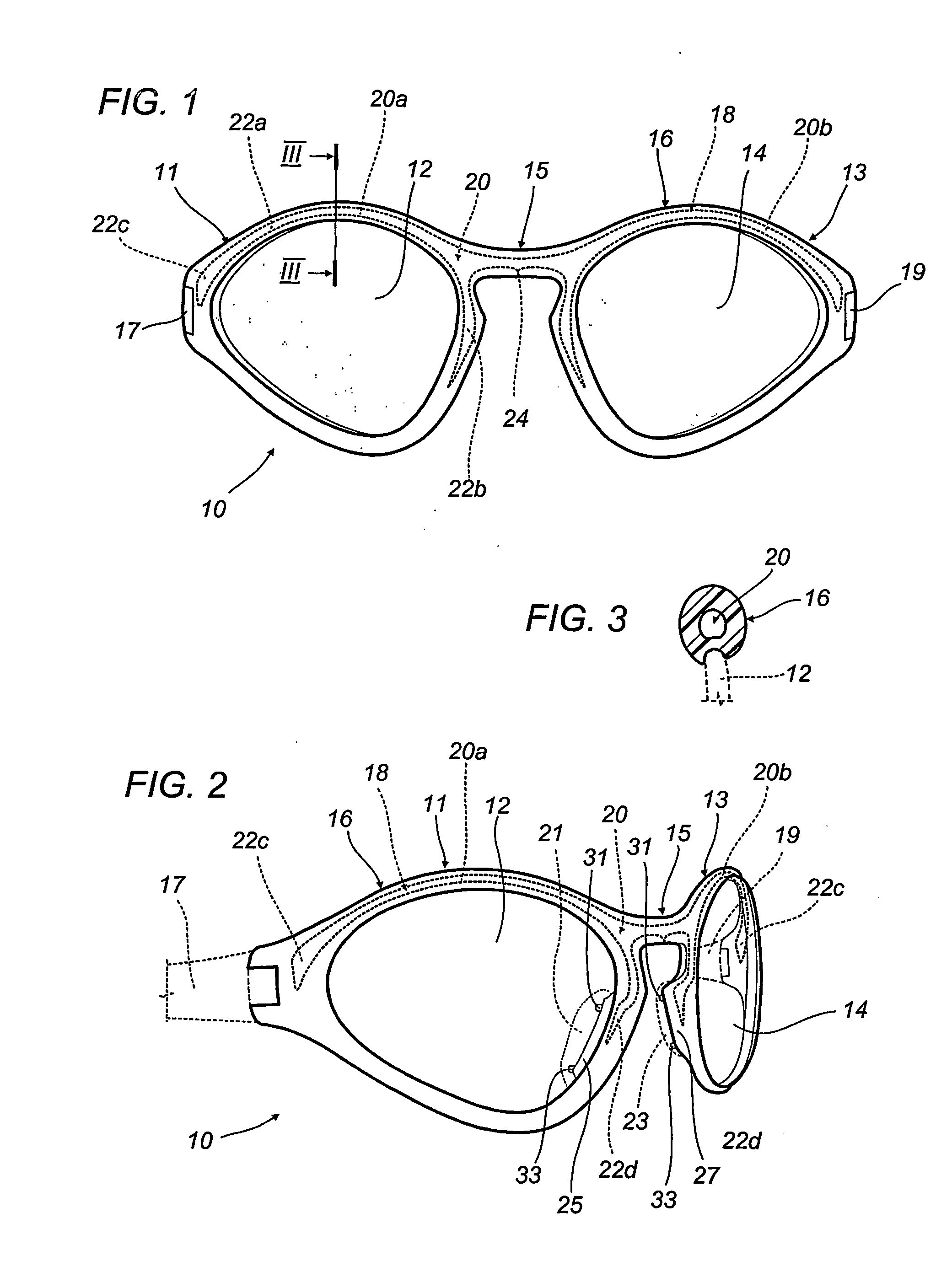

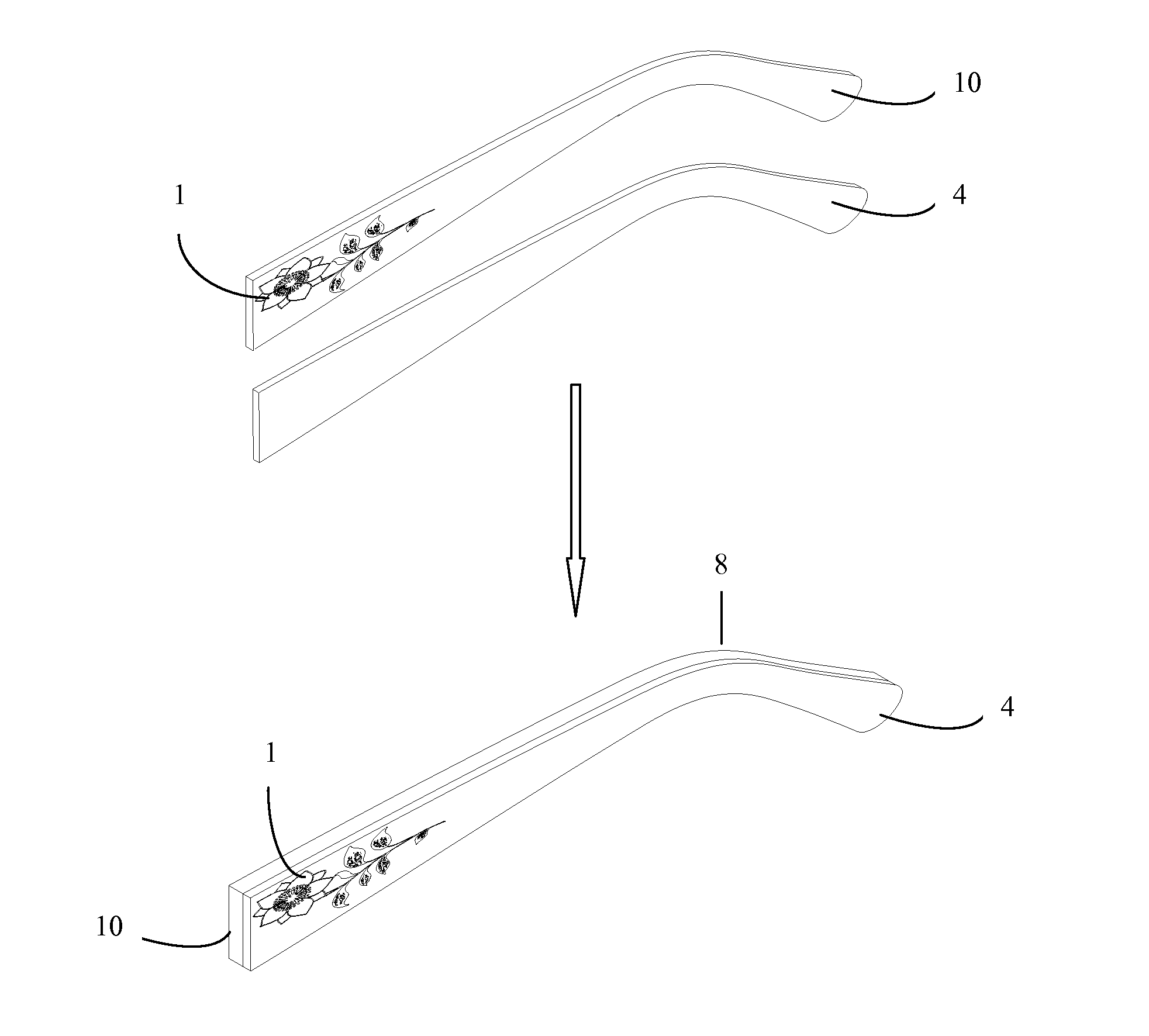

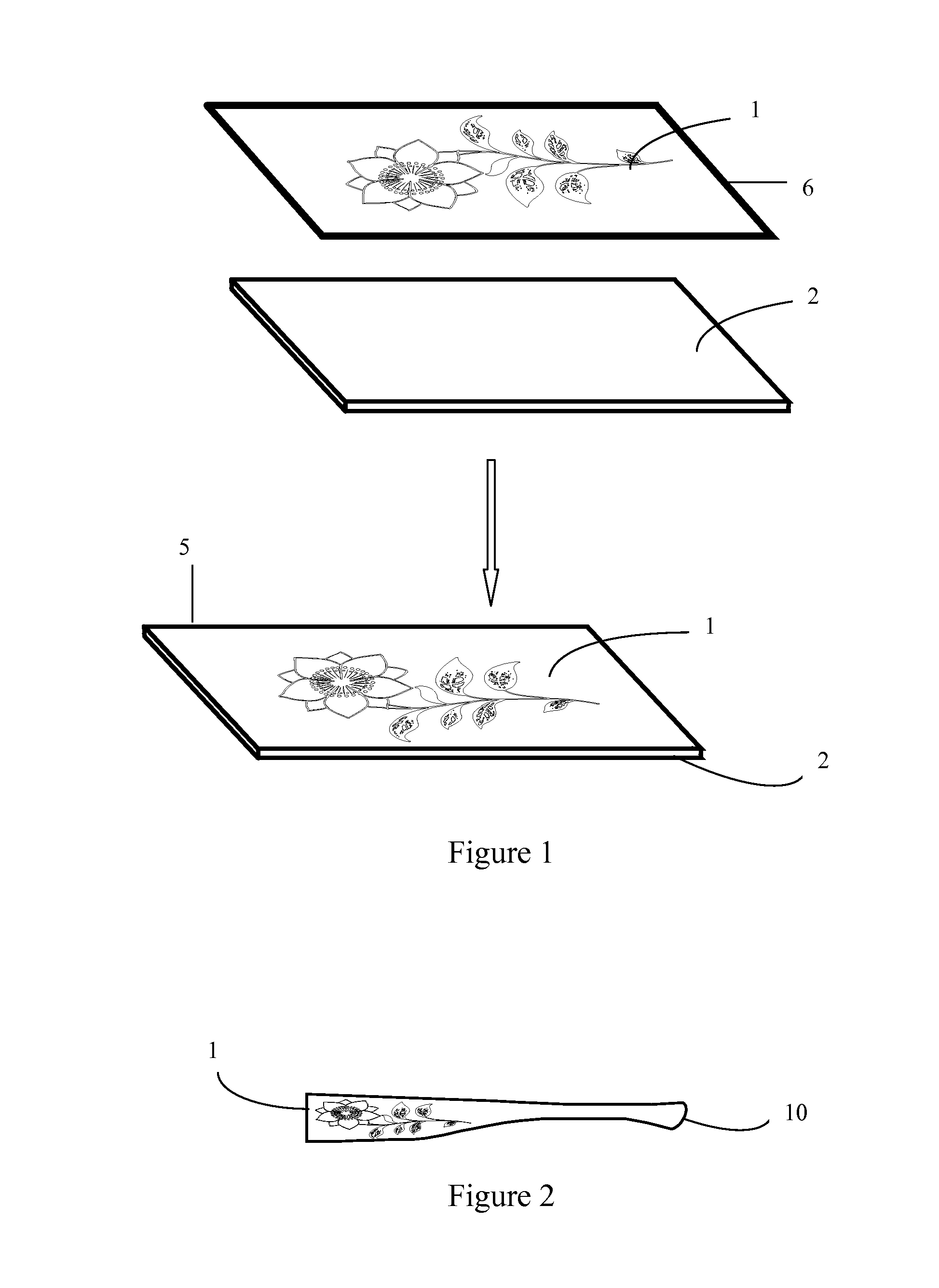

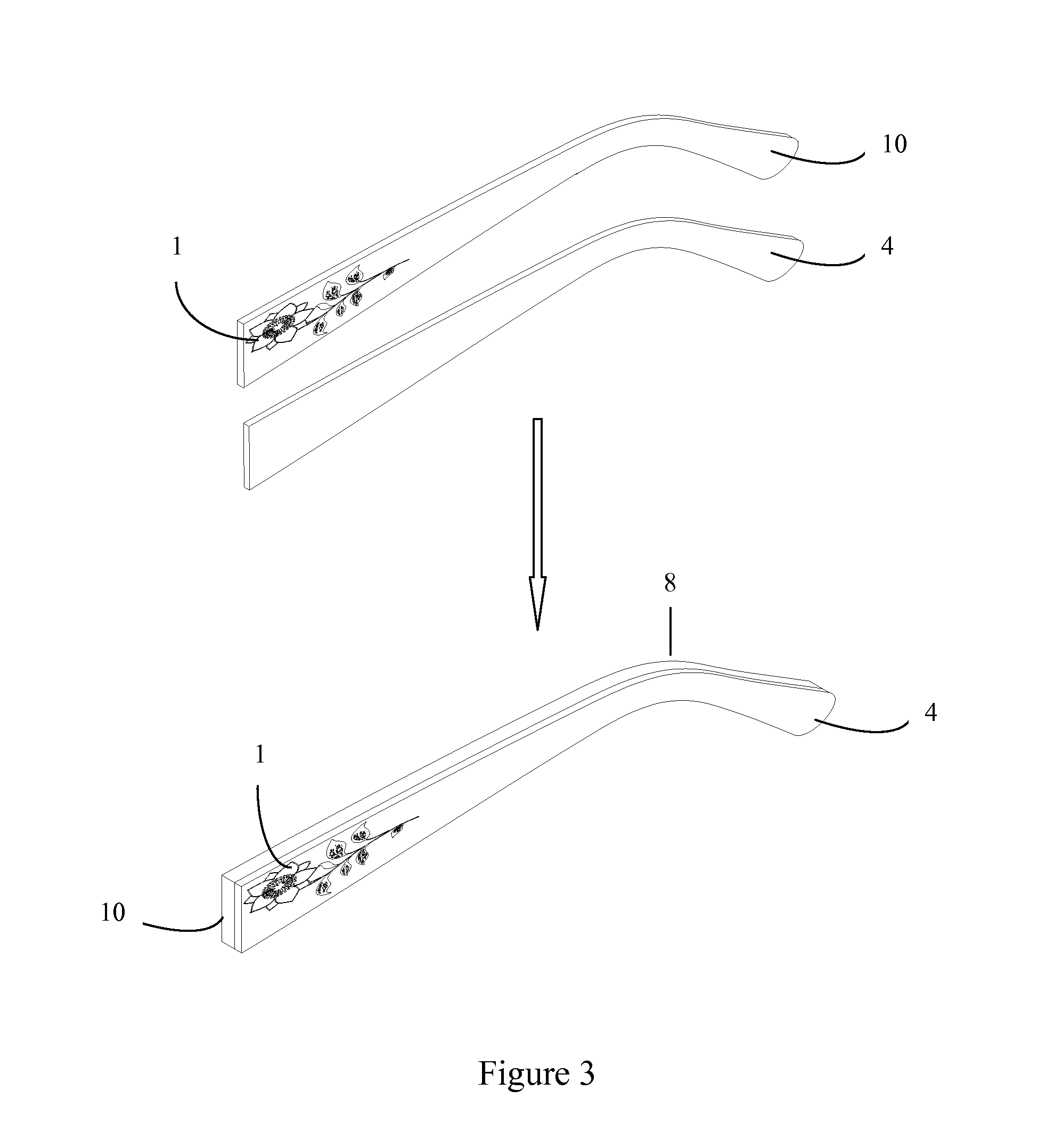

Method of making eyeglass frame by injection molding

InactiveUS20130069274A1Reduce decreaseReduce wasteFramesCoatingsEngineeringInjection molding machine

Disclosed herein are methods of making an eyeglass frame comprising a frame front and / or a pair of temples, wherein each of the frame front and temples independently comprises a top layer and a patterned layer having the shape of a frame front and / or a pair of temples, and wherein the patterned layer comprises a laminate and a design pattern on a surface of the laminate, the method comprising the steps of: a) providing a mold having a cavity, wherein the shape of the cavity corresponds to the shape of the frame front and / or the temples; b) setting the patterned layer for the frame front and / or the temples in the mold; and c) injecting a melt of a first polymer composition into the cavity to form the top layer. In some embodiments, at least one of the frame front and temples further comprises a bottom layer.

Owner:OKIA OPTICAL

Lens attachment combined with formation of eye glasses frame

ActiveUS6899427B1Rule out the possibilitySpectales/gogglesNon-optical adjunctsUses eyeglassesPlastic materials

Owner:SHELDON BRENT

Lens, lens blank, and eyewear

ActiveUS20170108713A1View field is obstructedSpectales/gogglesCoupling device connectionsCamera lensEyewear

A lens includes a lens body, and an electro-active section (liquid crystals and a diffraction section) that is provided to a region of part of the lens body. The lens includes a pair of electrodes that are embedded in the lens body, that are electrically connected to a focal length modification section, that extend downward from an upper side end of the lens body, and that are disposed substantially parallel to each other spaced apart in a width direction orthogonal to an up-down direction of the lens body. Lower ends of the pair of electrodes are disposed spaced apart from the electro-active section in the up-down direction of the lens body.

Owner:MITSUI CHEM INC

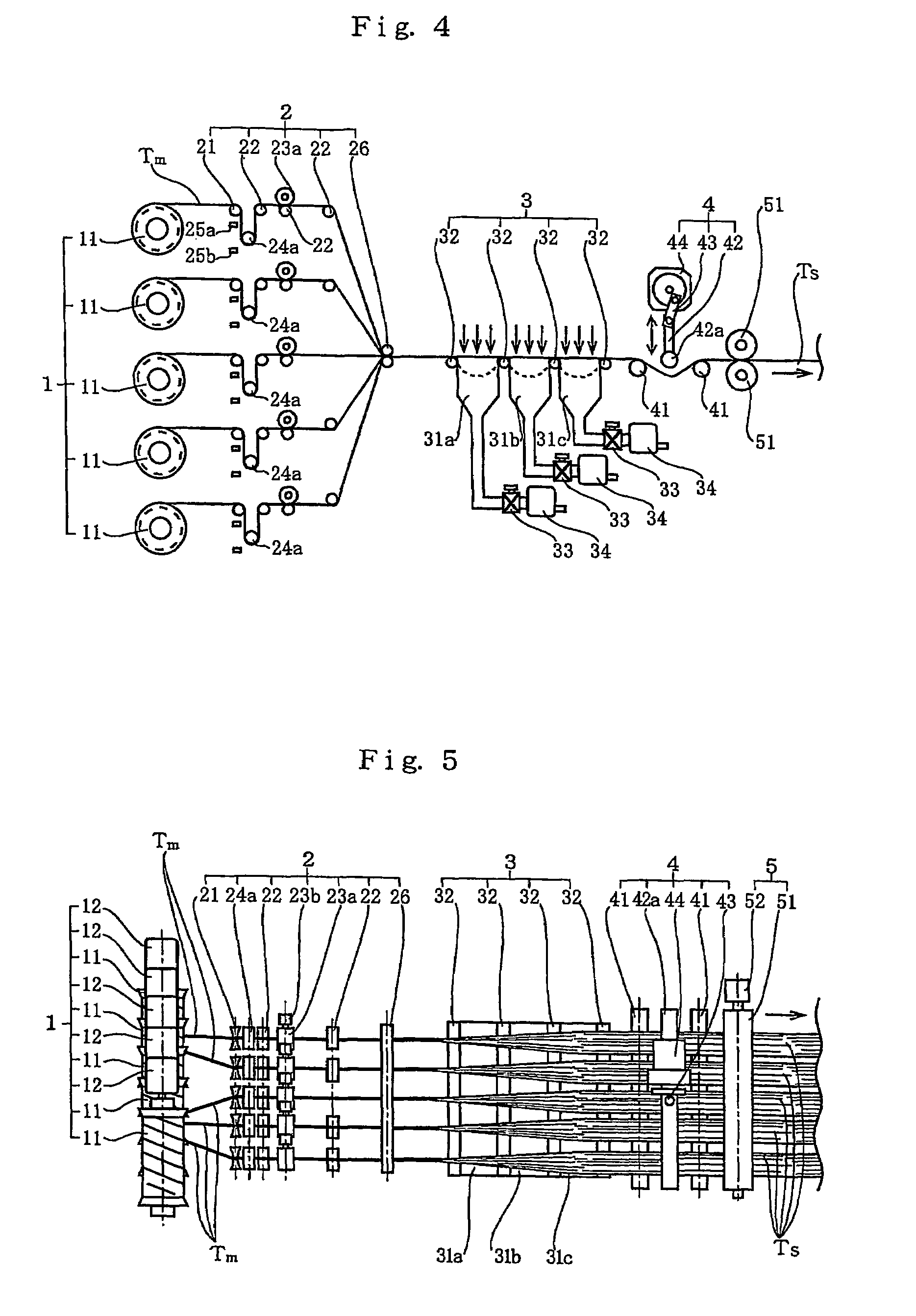

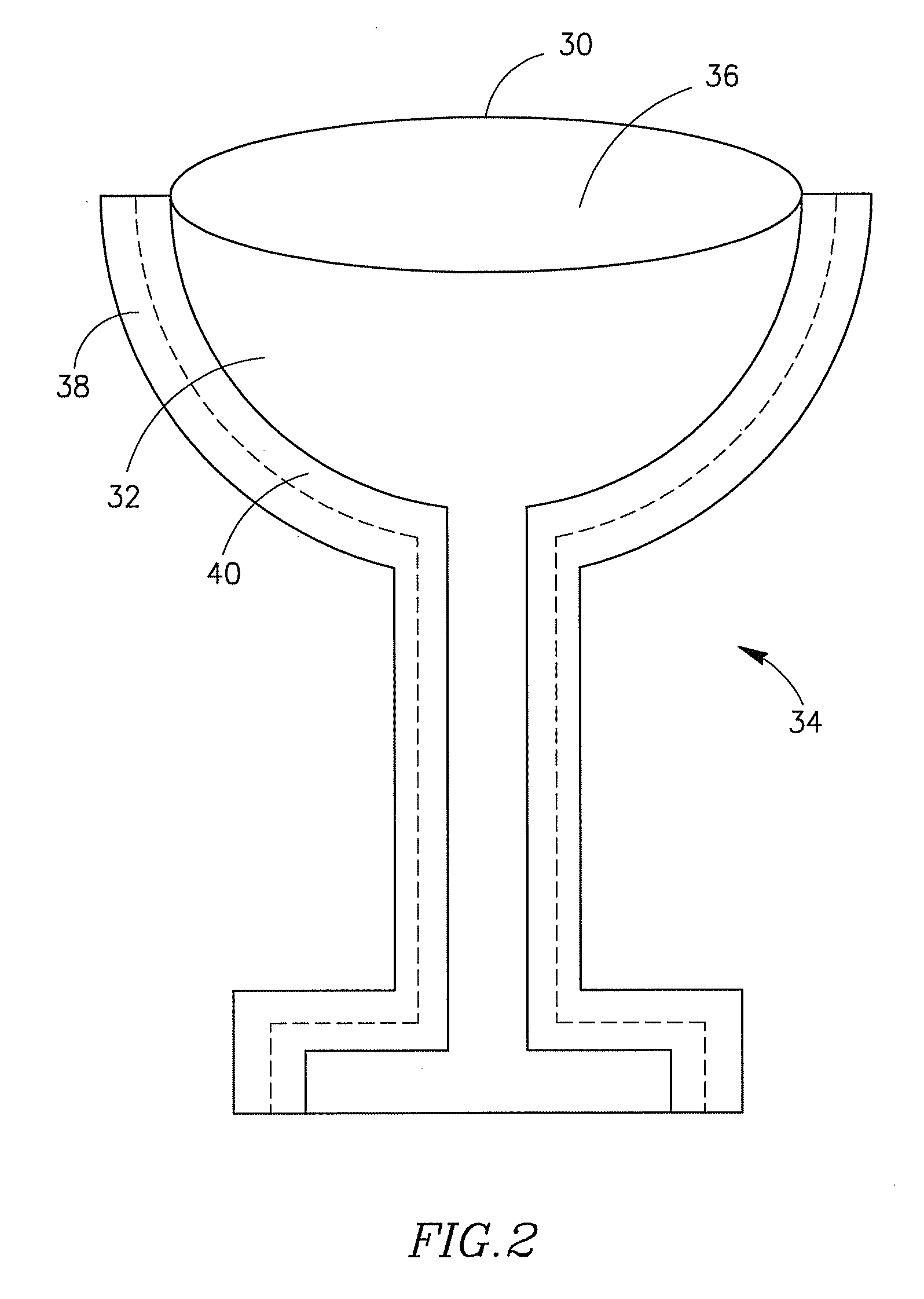

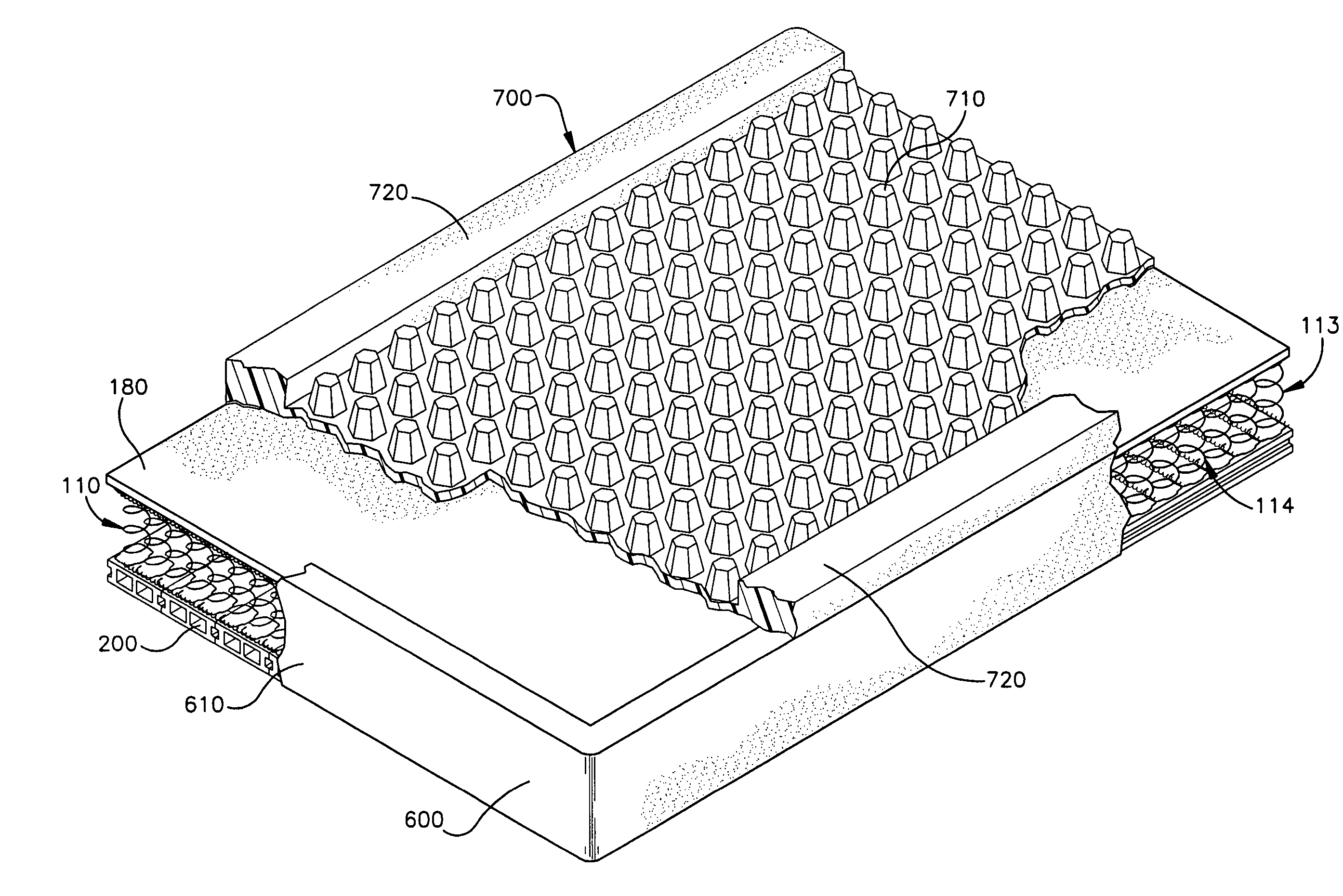

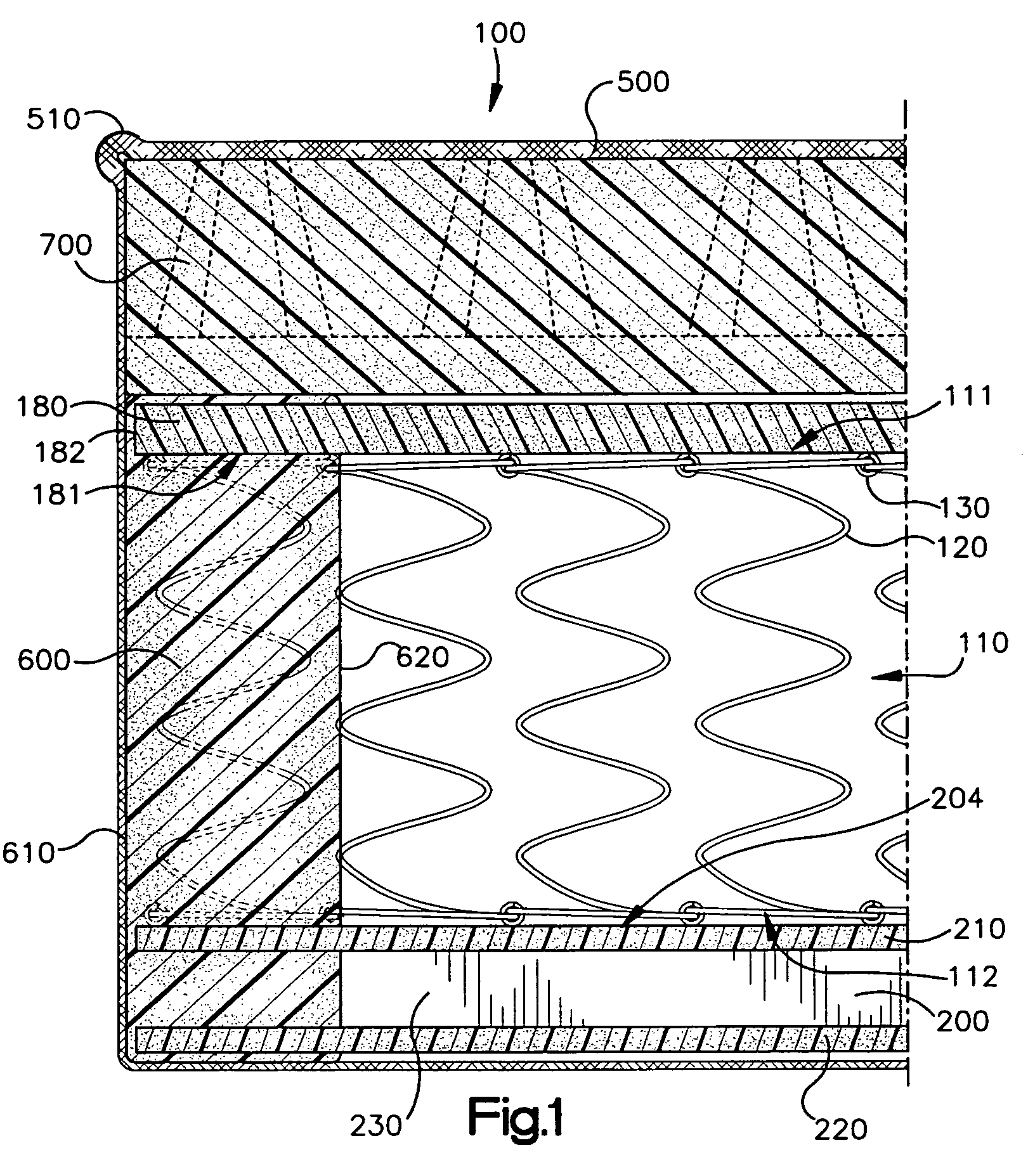

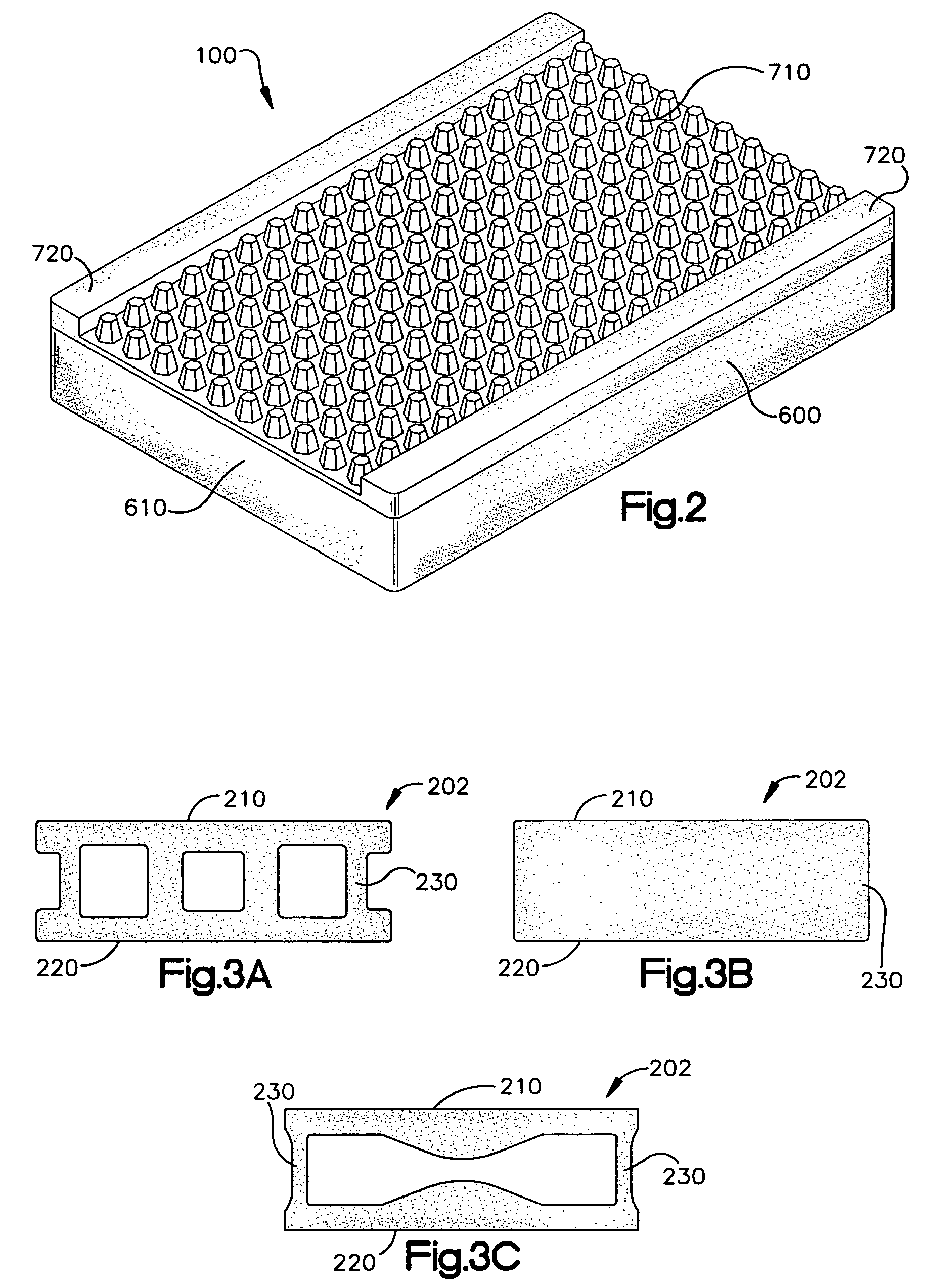

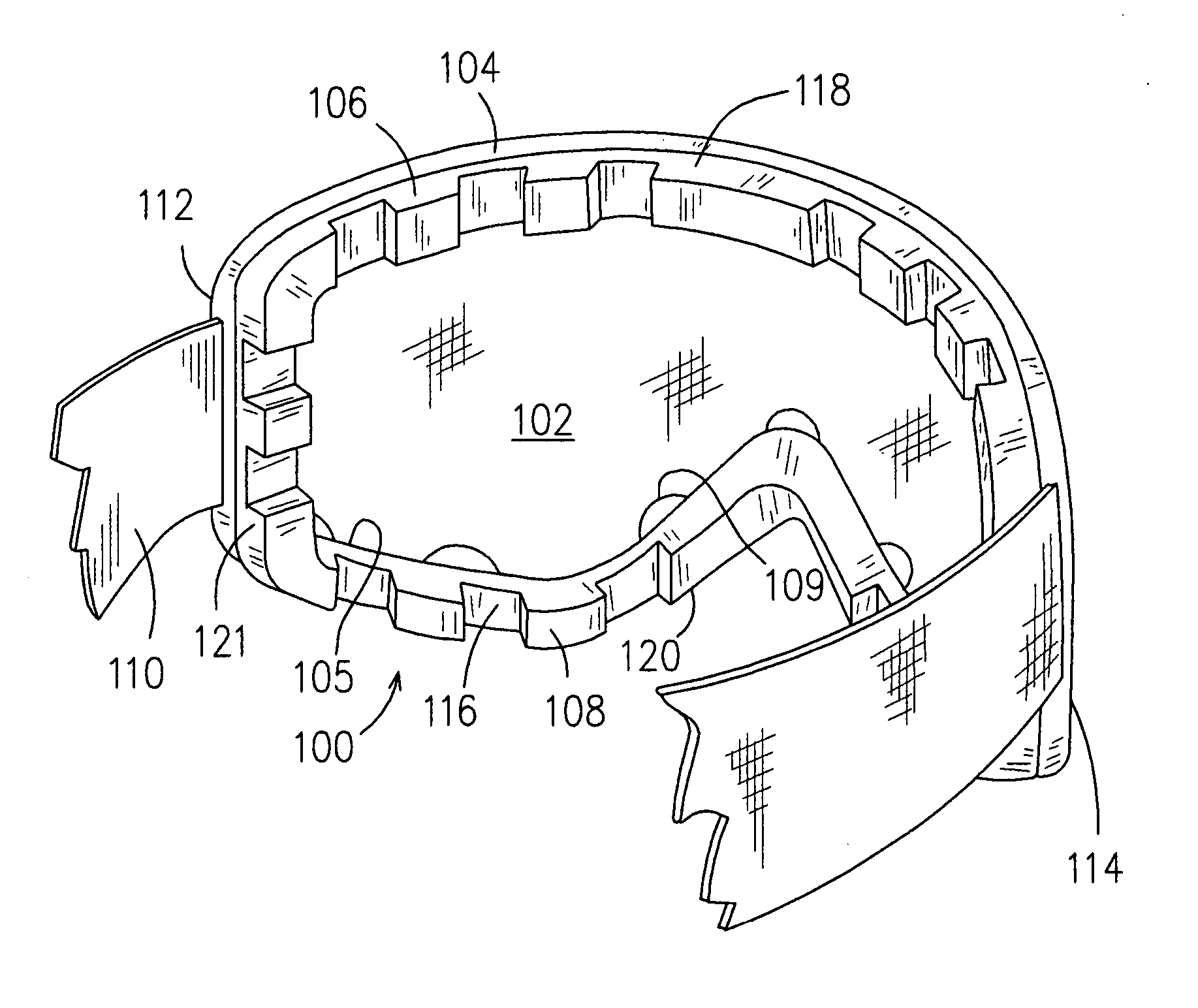

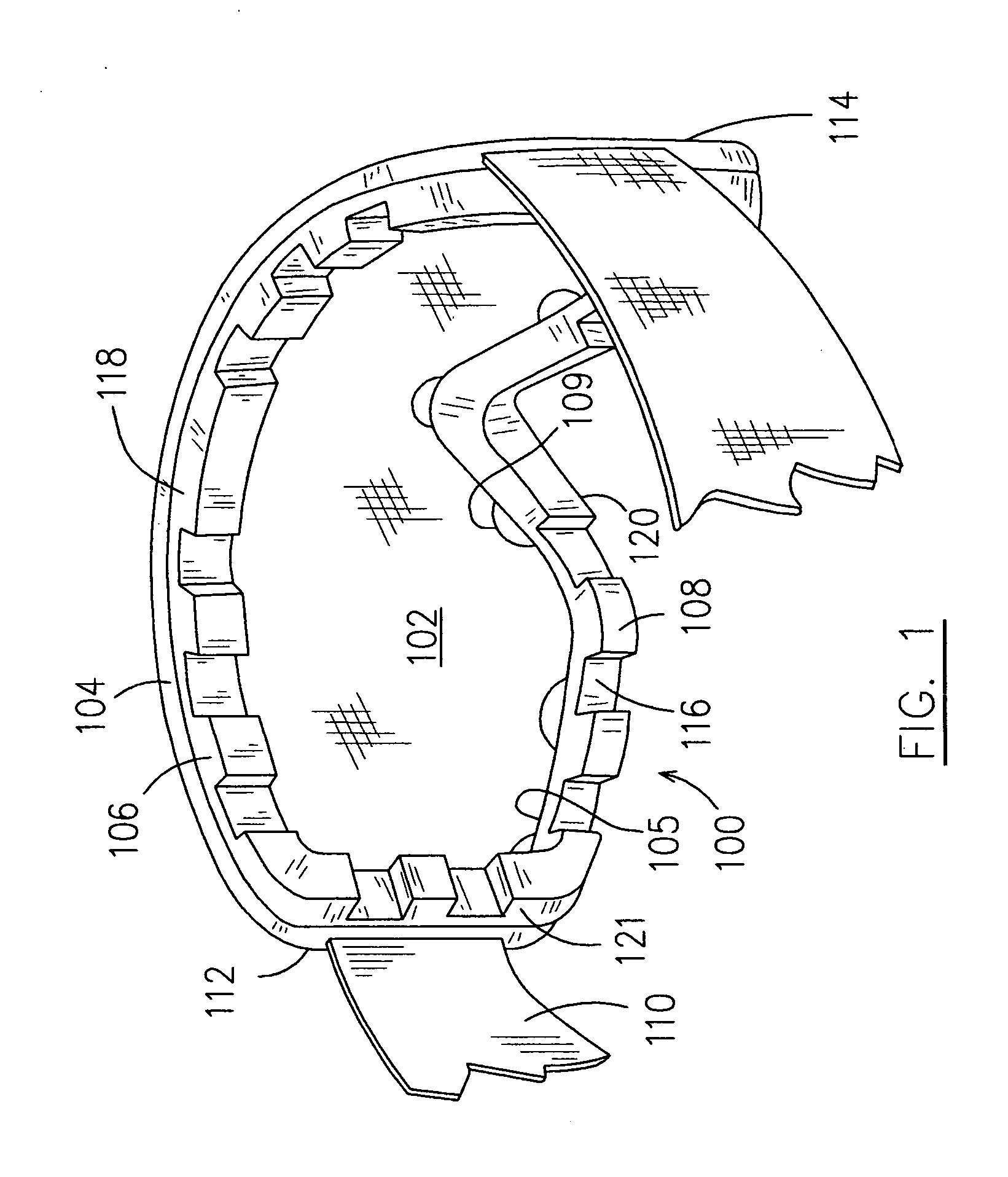

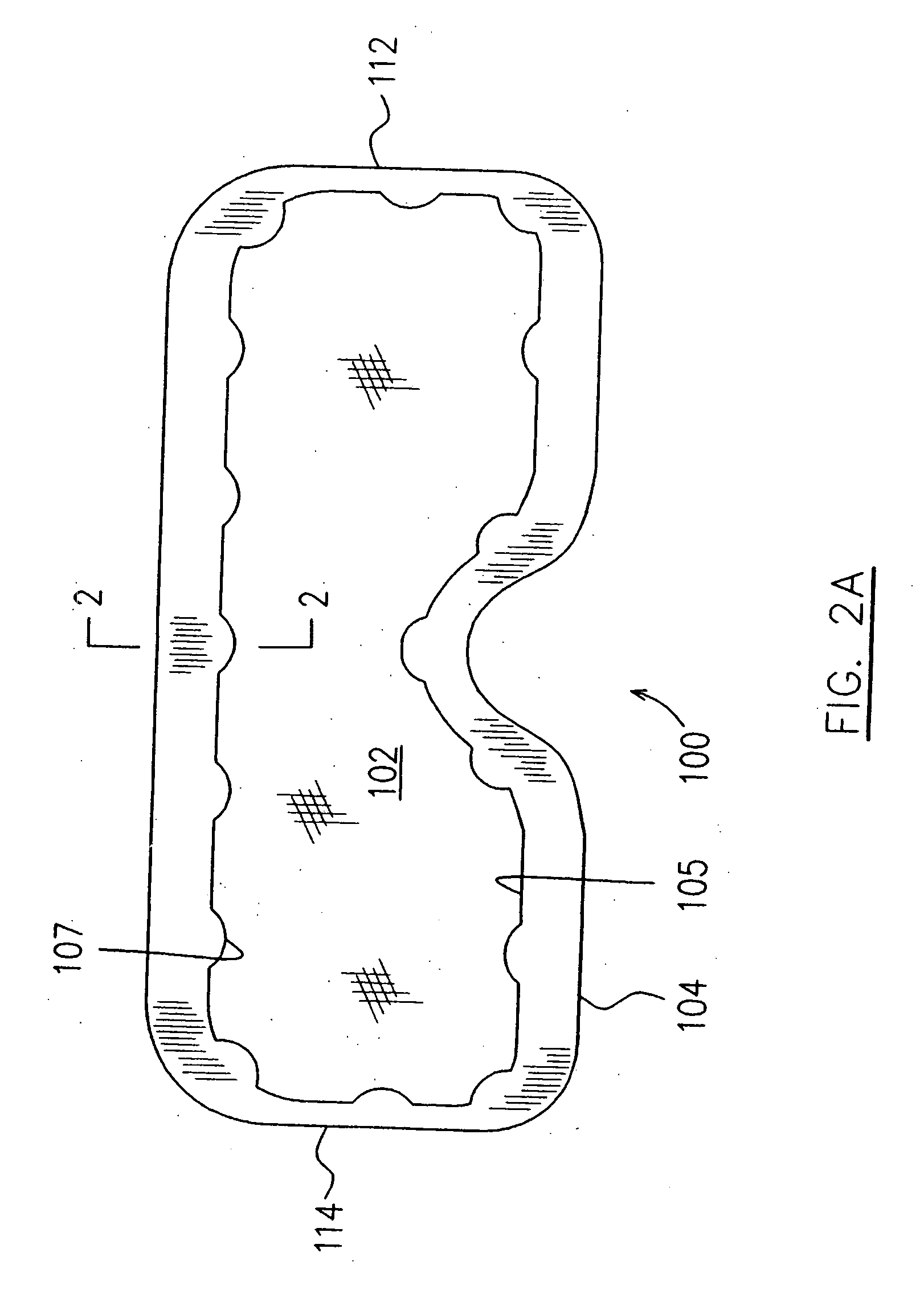

Foam encased innerspring with internal foam components (triple case)

InactiveUS7185379B2Highly variable and tunable support systemIncrease support densityButtonsRecord carriersEngineeringVolumetric Mass Density

A molded foam-encased integrated flexible support device includes an innerspring positioned upon a three-dimensional thermoplastic foam deck as a flexible foundation, and a molded foam encasement which structurally integrates the foam deck with the innerspring by attachment to perimeter coils of the innerspring. A sculpted foam topper is adhesively bonded to a support surface of the foam-encased innerspring, forming a unitized mattress or support structure with fully integrated innerspring and internal and external foam components. The sculpted foam topper is designed with varying contours and densities to provide the desired support and feel characteristics for different comfort profiles. The foam encased innerspring with internal three-dimensional foam structures is upholstered for use as a mattress, seating, or other flexible support structure.

Owner:SEALY TECH LLC

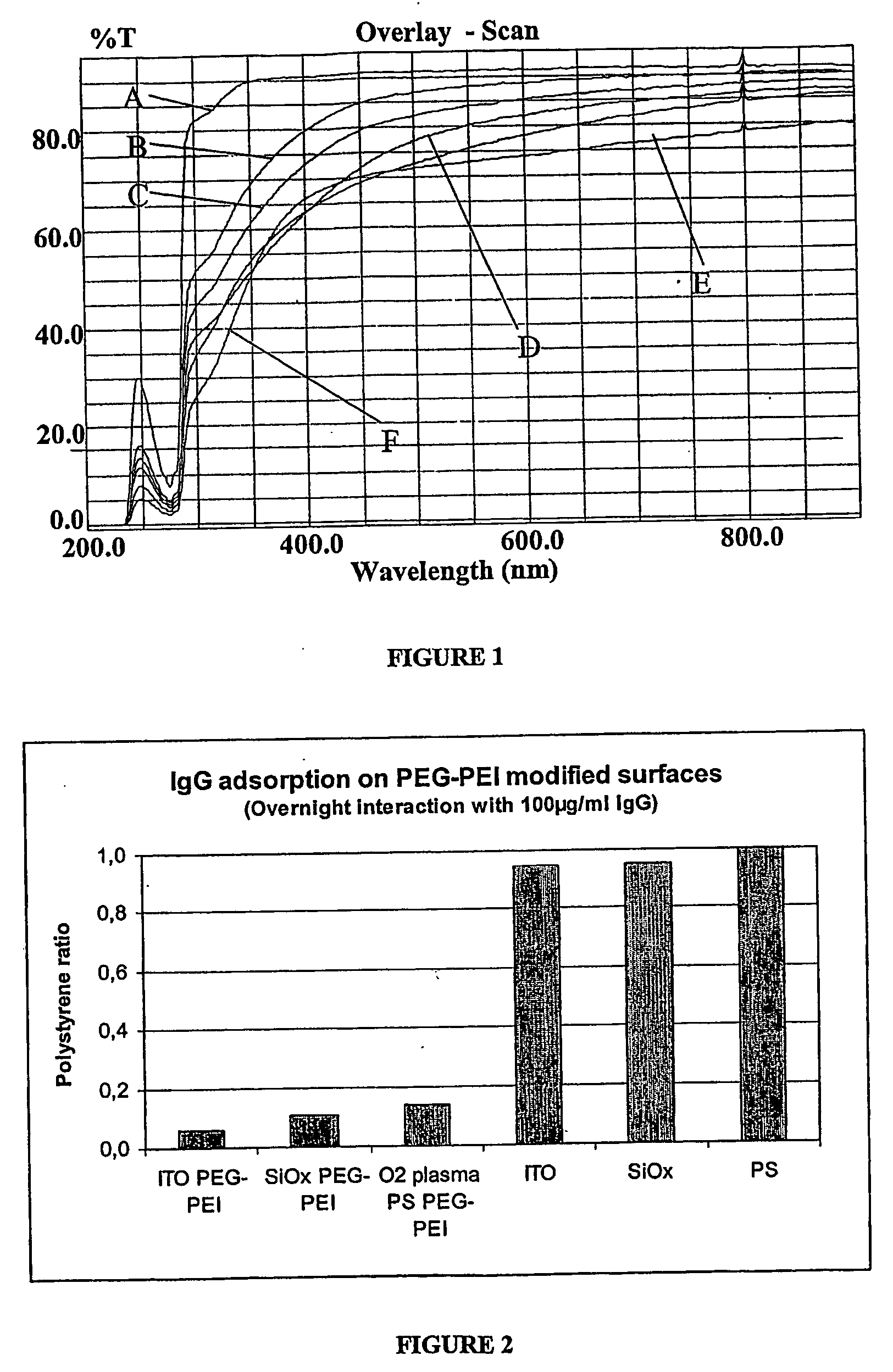

Inner walls of microfluidic devices

A microfluidic device comprising one, two, three or more enclosed microchannel structures, each of which comprises a) an inlet arrangement with an inlet opening for liquid, b)a reaction microcavity (RM1) downstream to the inlet opening, and c) an upstream section that is located between the inlet opening and the reaction microcavity (RM1) and is defined between two planar substrates made of plastic material which substrates are common for said microchannel structures. The characteristic feature is that the inner wall in said upstream section exposes a hydrophilic surface area with an underlying base layer comprising metal oxide. In one aspect the microfluidic device as such is covered.

Owner:GYROS

Preparation method of memory sheet glasses frame

InactiveCN101284424AReduce weightAvoid deformationFramesNon-optical partsCellulose acetateEngineering

The invention relates to a method for producing a spectacle frame, in particular to a method for producing a spectacle frame made of memory sheets. The method comprises the following steps: a spectacle rim takes memory plastic (TR090) as the raw material and adopts the injection process, at the same time a metal connecting piece is arranged in an injection mold and is directly injected into the frame face material; earpieces adopt cellulose acetate sheets as the raw material and are formed by jointing materials in more than two different colors; and the spectacle rim is connected with the earpieces via connecting pieces.

Owner:周国新

Decorative system composite and method

InactiveUS7144612B2High tensile strengthAvoid feature lossButtonsRecord carriersThermoformingCombined use

Owner:BOBS HLDG

Image processing method and system for microfluidic devices

InactiveUS7583853B2Increase speedHigh sensitivityImage enhancementButtonsImaging processingState dependent

A method for processing an image of a microfluidic device. The method includes receiving a first image of a microfluidic device. The first image corresponds to a first state. Additionally, the method includes receiving a second image of the microfluidic device. The second image corresponds to a second state. Moreover, the method includes transforming the first image and the second image into a third coordinate space. Also, the method includes obtaining a third image based on at least information associated with the transformed first image and the transformed second image, and processing the third image to obtain information associated with the first state and the second state.

Owner:FLUIDIGM CORP

Extruded wood imitation component and process

Owner:STAR PLAST HLDG

Lens attachment combined with formation of goggles frame

Owner:SHELDON BRENT

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com