Casing component embedded with antenna and manufacturing method thereof

The technology of a shell component and manufacturing method is applied to antenna parts, antennas, resonant antennas, etc., which can solve the problems of large internal space and low production efficiency of electronic devices, and achieve the goals of saving layout space, improving production efficiency, and enhancing strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

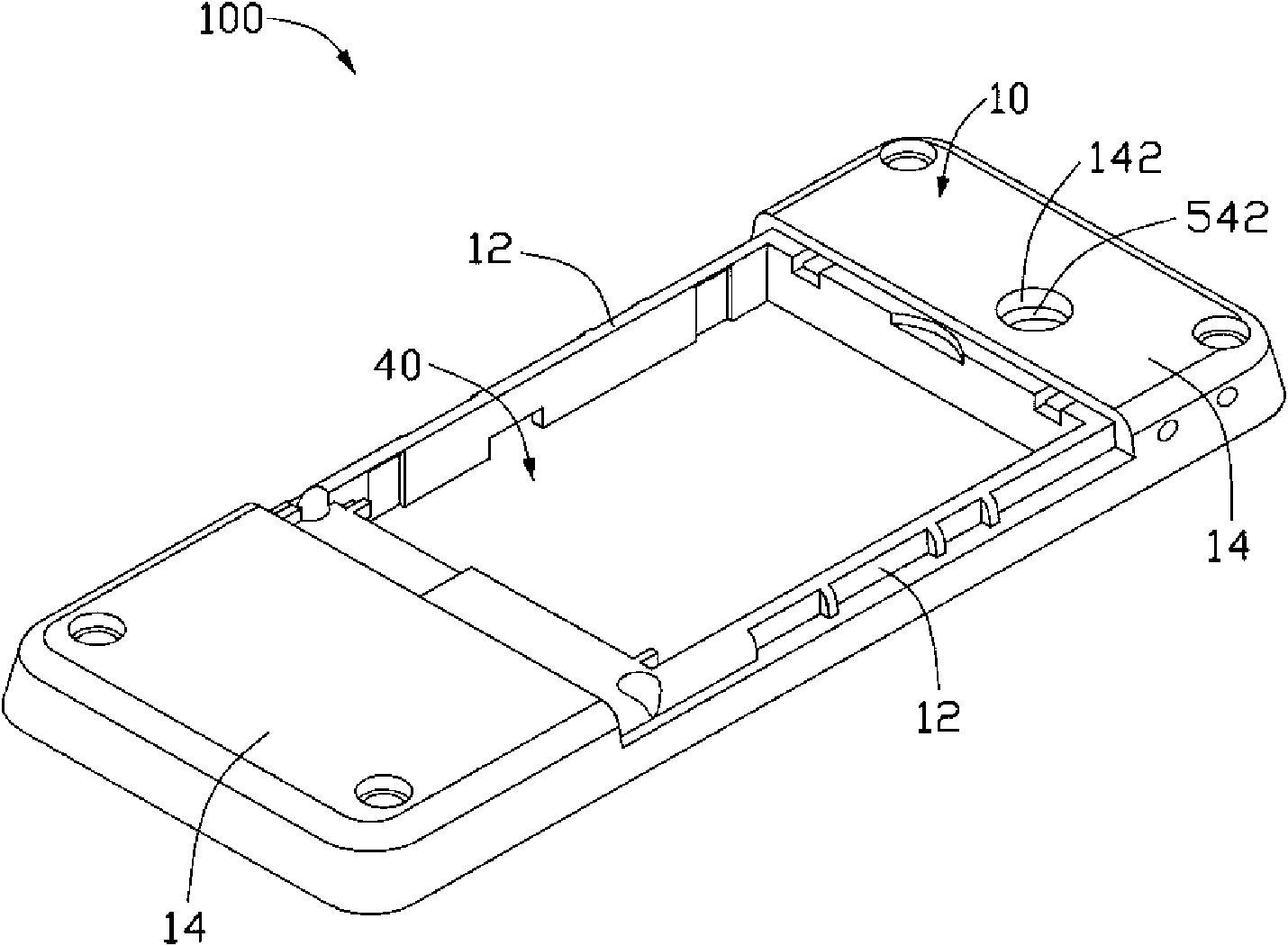

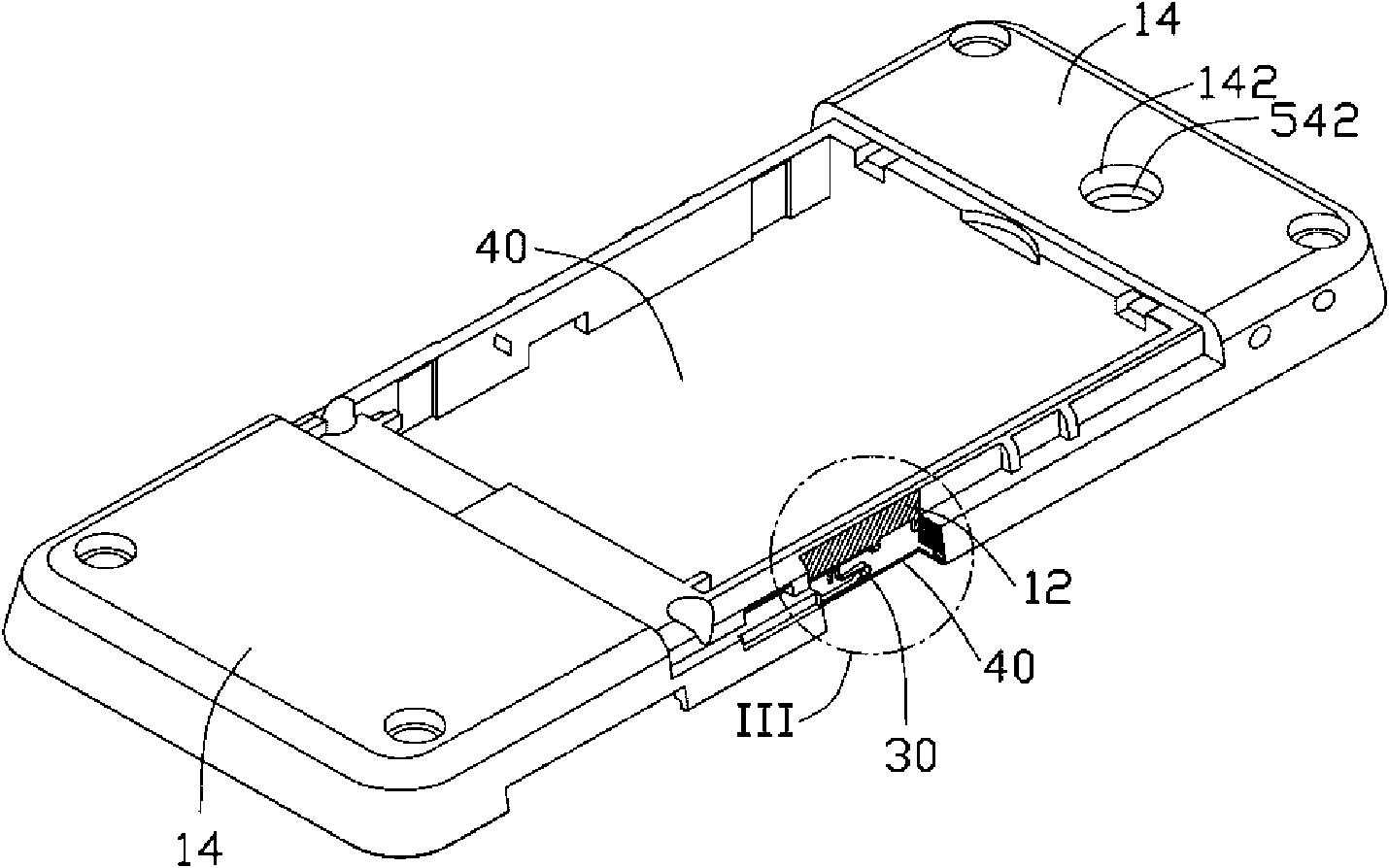

[0018] see figure 1 , figure 2 and image 3 , the housing assembly 100 of the built-in antenna in the preferred embodiment of the present invention includes a housing 10 , an antenna body 20 , a connecting body 30 and a circuit board 40 . The antenna body 20 is embedded in the casing 10 and is electrically connected to the circuit board 40 through the connecting body 30 .

[0019] The housing 10 is a frame made of plastic material, which includes two opposite first side walls 12 and two opposite end portions 14 . A blind hole 142 is formed on one end portion 14, and the blind hole 142 is a round hole.

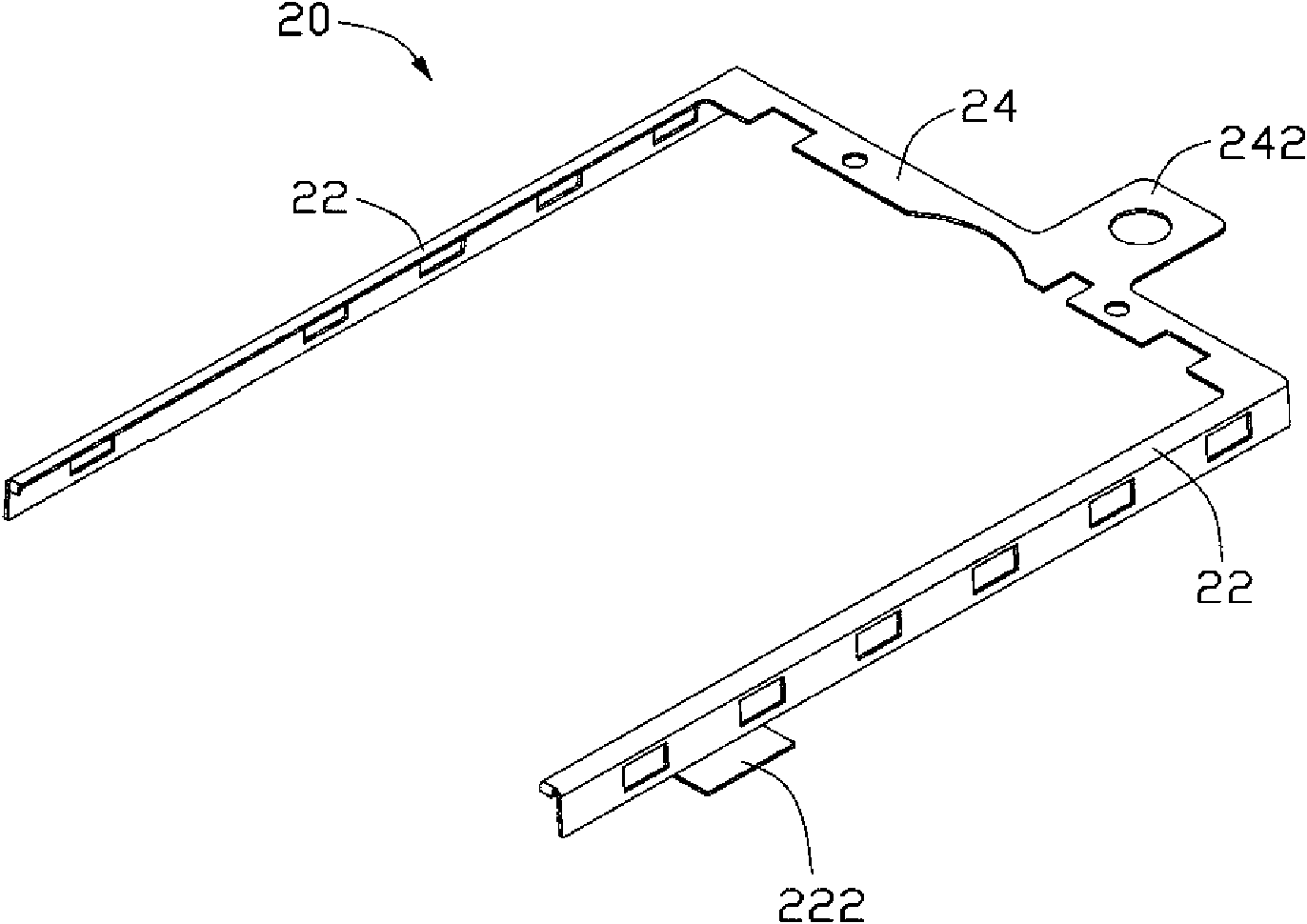

[0020] The antenna body 20 is substantially a “U”-shaped frame, which includes two opposite antenna arms 22 and a connecting arm 24 connecting the two antenna arms 22 . The outer side of each antenna arm 22 is formed with an electrical connection portion 222 electrically connected to the circuit board 40 through the connecting body 30. One side of the connecting arm 24 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com