Patents

Literature

127results about "Frameless domes" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

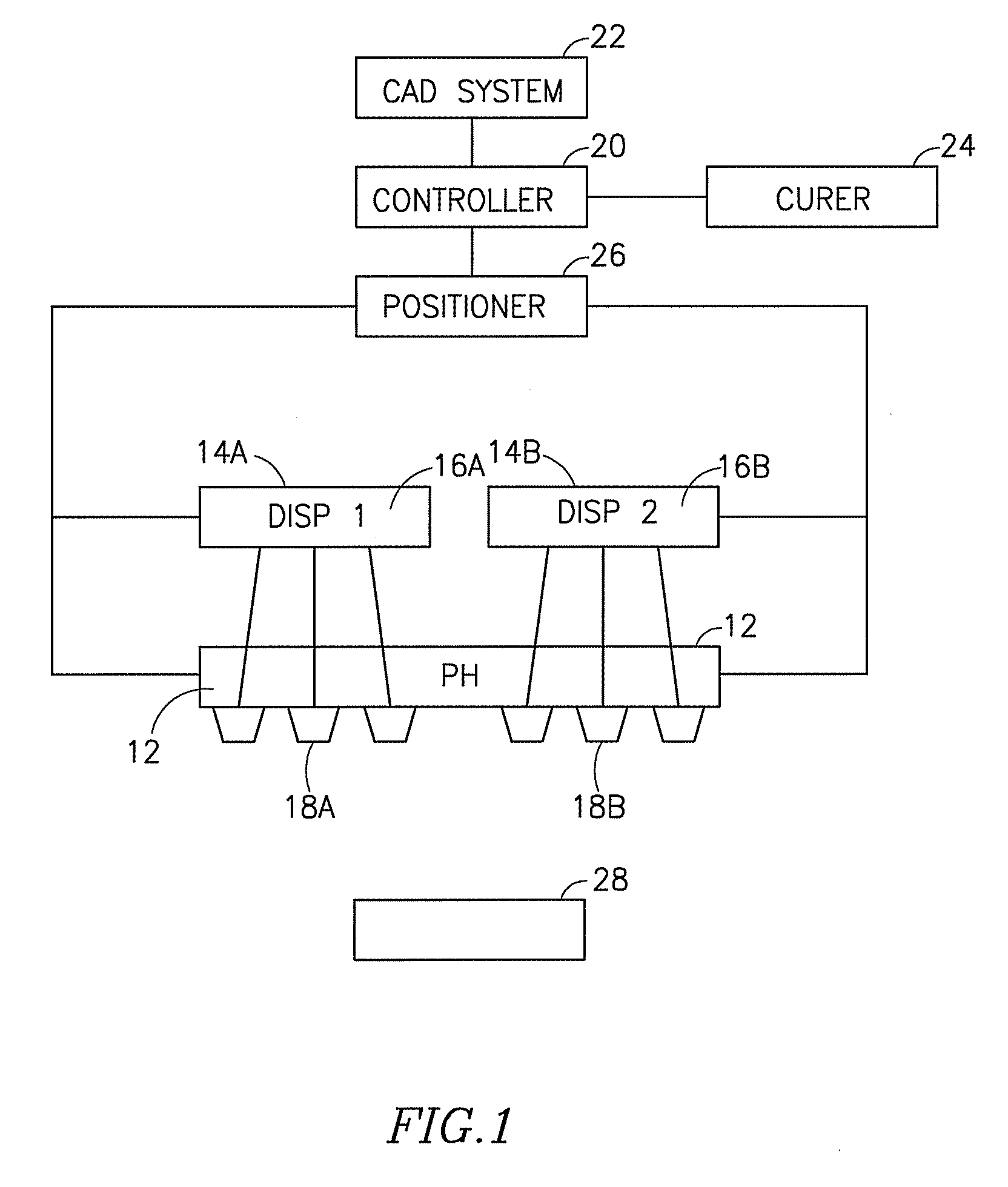

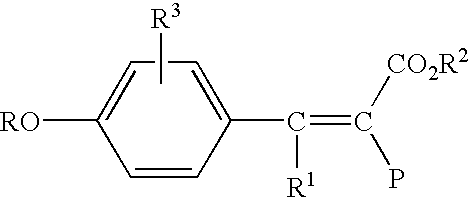

Compositions and methods for use in three dimensional model printing

InactiveUS7300619B2Similar elasticitySimilar strengthButtonsLiquid surface applicatorsOrganic compoundPolymer chemistry

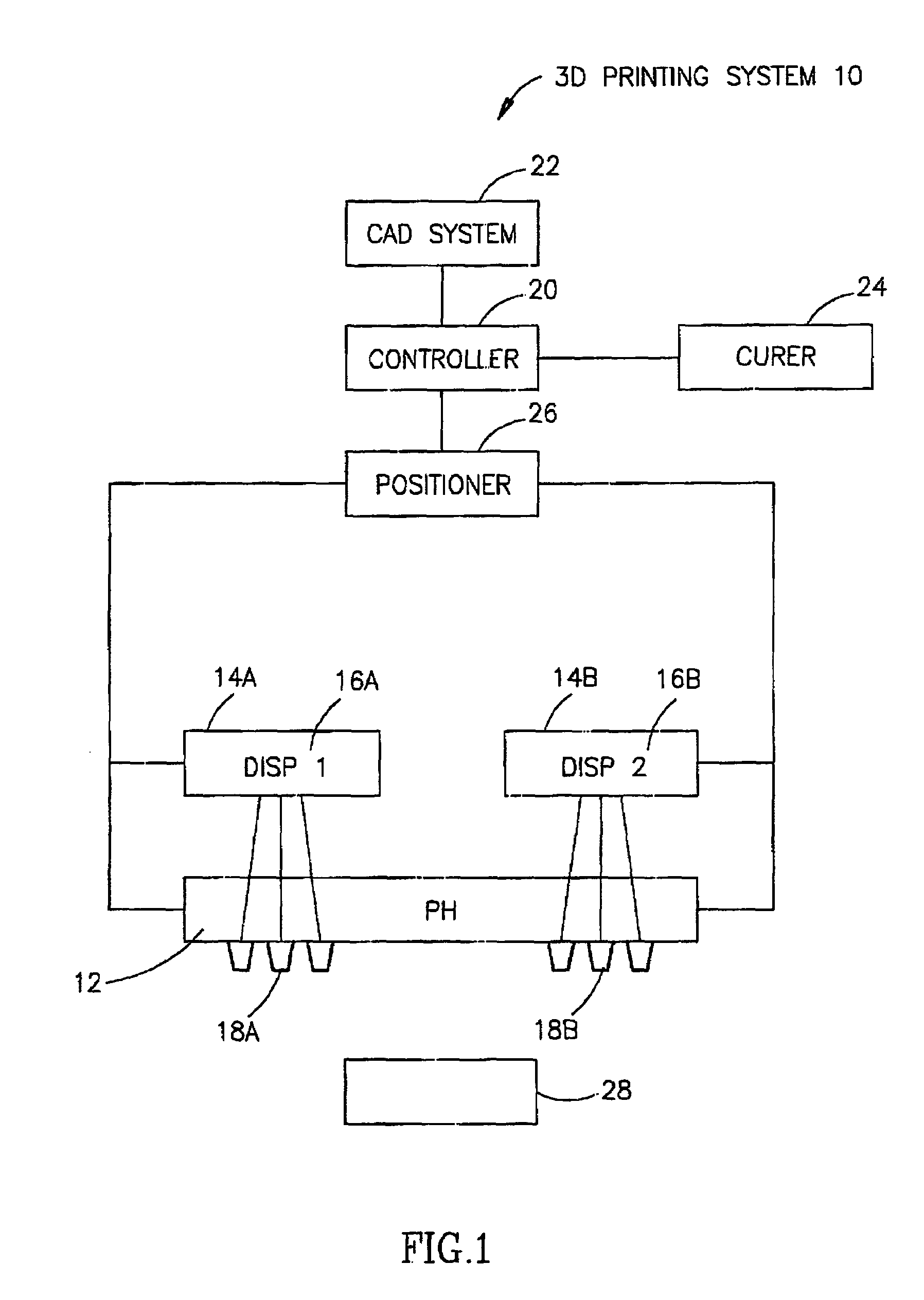

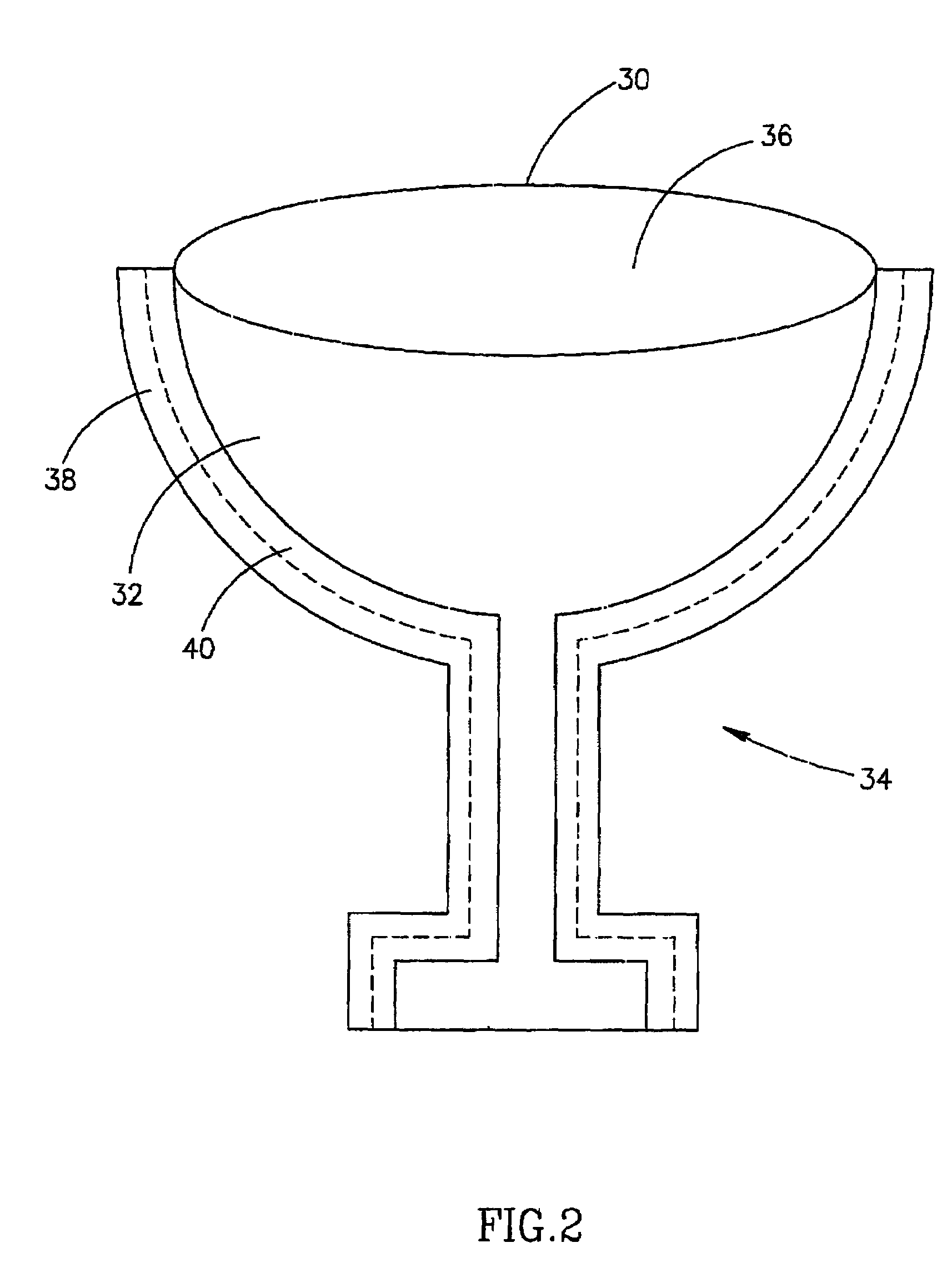

A pseudo composite material, may include, inter alia, a first phase and a second phase, wherein each phase may include, inter alia, an organic compound, wherein each phase comprising a multiplicity of construction layers, wherein the layers were deposited by ink-jet printing, wherein the pseudo composite material exhibits non-homogeneous three-dimensional structure. A method is disclosed for the preparation of a pseudo composite material. An apparatus is disclosed for printing a pseudo composite material. Furthermore, there is disclosed a method for printing a three-dimensional object using various suitable materials.

Owner:STRATASYS LTD

Compositions and methods for use in three dimensional model printing

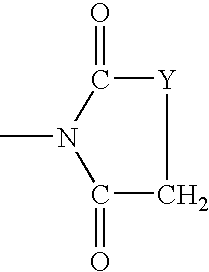

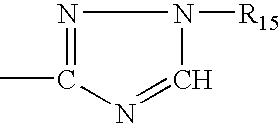

Compositions for use in the manufacture of three-dimensional objects including compositions for use as a support and / or release material in the manufacture of the three-dimensional objects are provided. There is thus provided, in accordance with an embodiment of the present invention, a composition suitable for building a three-dimensional object. The compositions may include, inter alia, a curable component, having a functional group, wherein if the functional group is a polymerizable reactive functional group, then the functional group is a (meth)acrylic functional group, a photo-initiator, a surface-active agent and a stabilizer; wherein said composition has a first viscosity of about 50–500 cps at a first temperature, wherein said first temperature is ambient temperature, and a second viscosity lower than 20 cps at a second temperature wherein said second temperature is higher than said first temperature, wherein, after curing, the composition results in a solid form. There is thus provided, in accordance with another embodiment of the present invention, a composition suitable for support in building a three-dimensional object. The compositions may include, inter alia: a non-curable component, a curable component, wherein the non-curable component is not reactive with said curable component, a surface-active agent and a stabilizer; wherein said composition has a first viscosity of about 20–500 cps at a first temperature, wherein said first temperature is ambient temperature, and a second viscosity lower than 20 cps at a second temperature wherein said second temperature is higher than said first temperature, wherein, after irradiation, the composition results in a solid, a semi-solid or liquid material. A method for the preparation of a three-dimensional object by three-dimensional printing is provided in accordance with embodiments of the present invention. Embodiments of the present invention further provide a three-dimensional object prepared according to the methods of the invention.

Owner:STRATASYS LTD

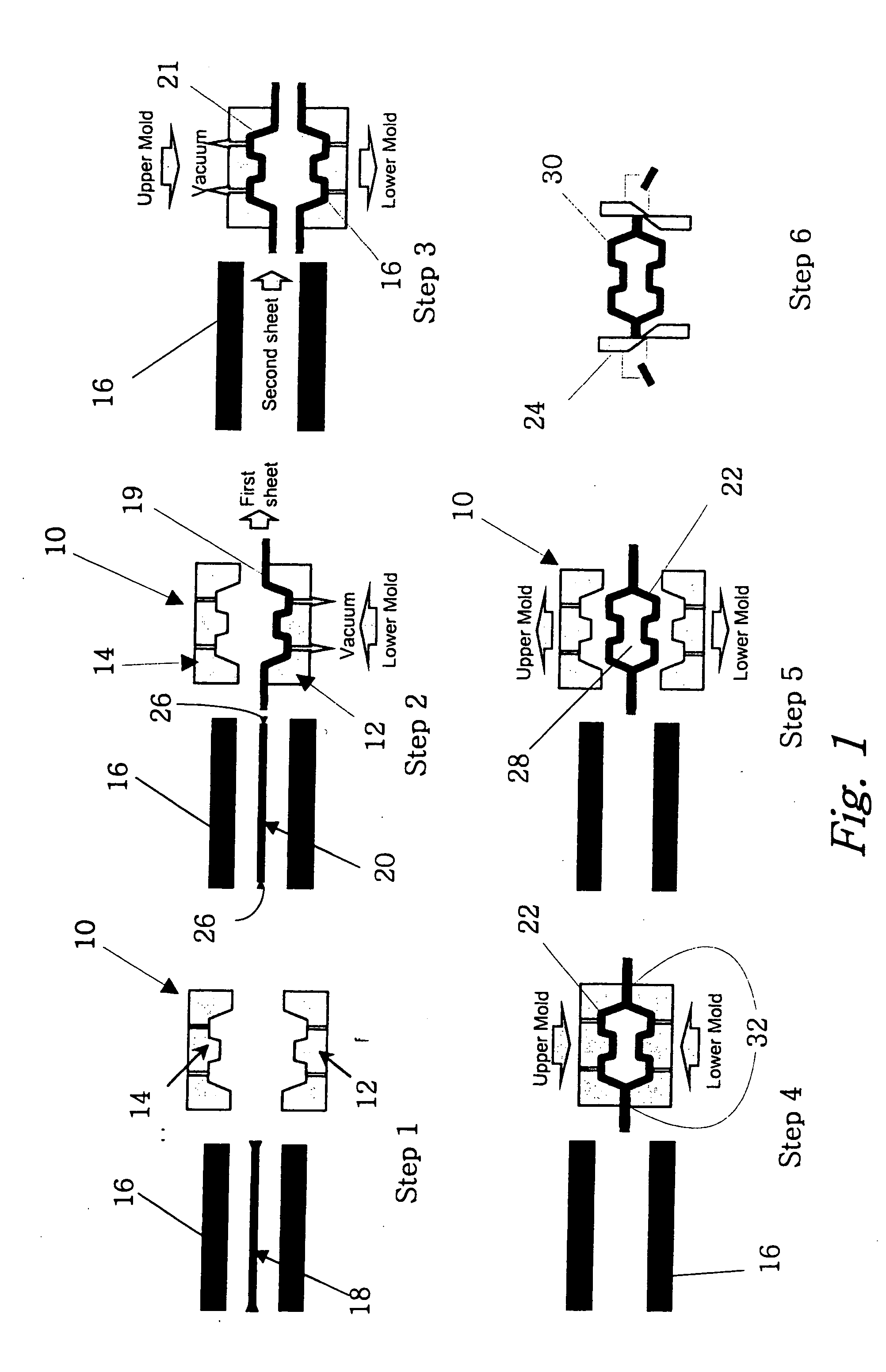

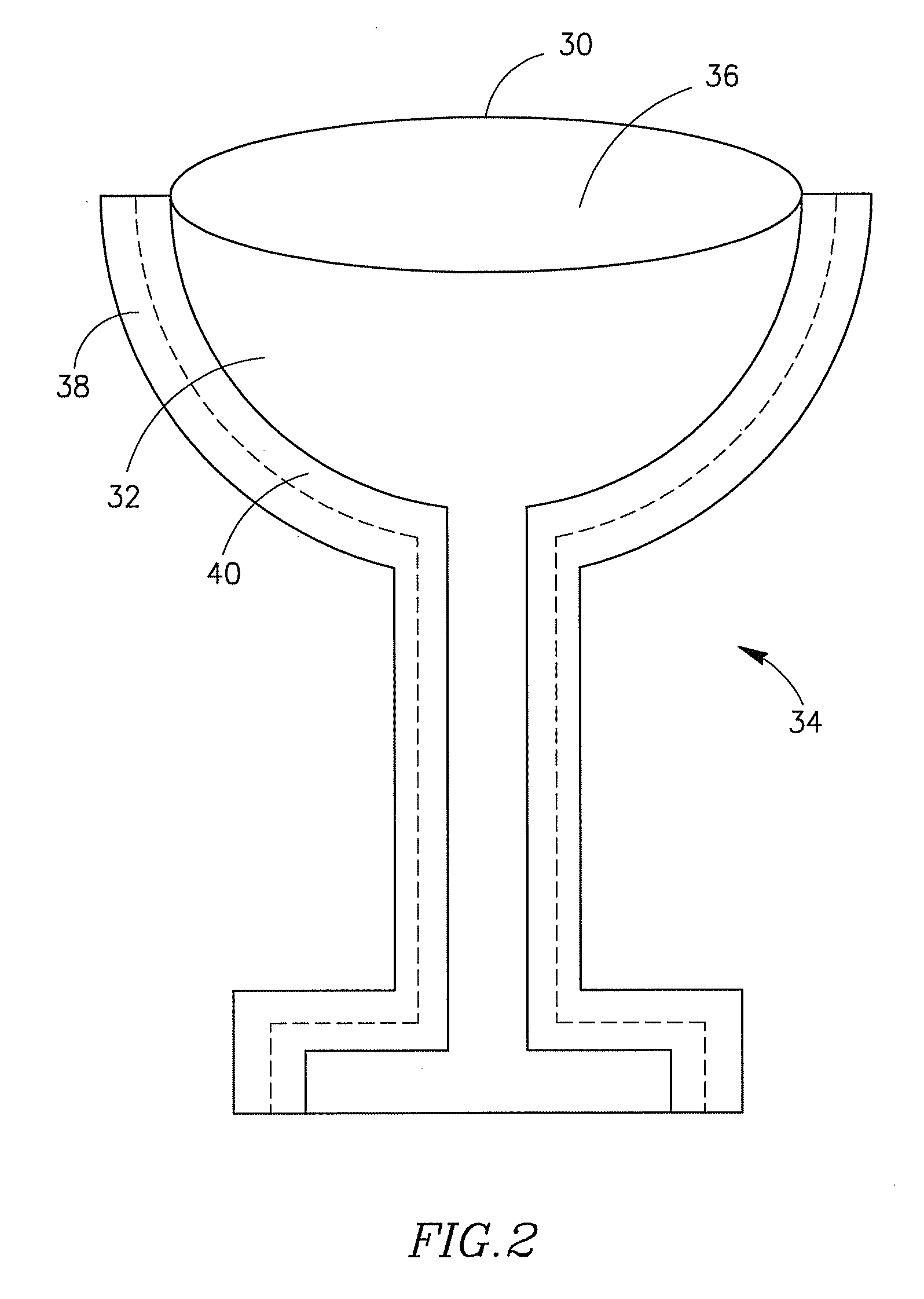

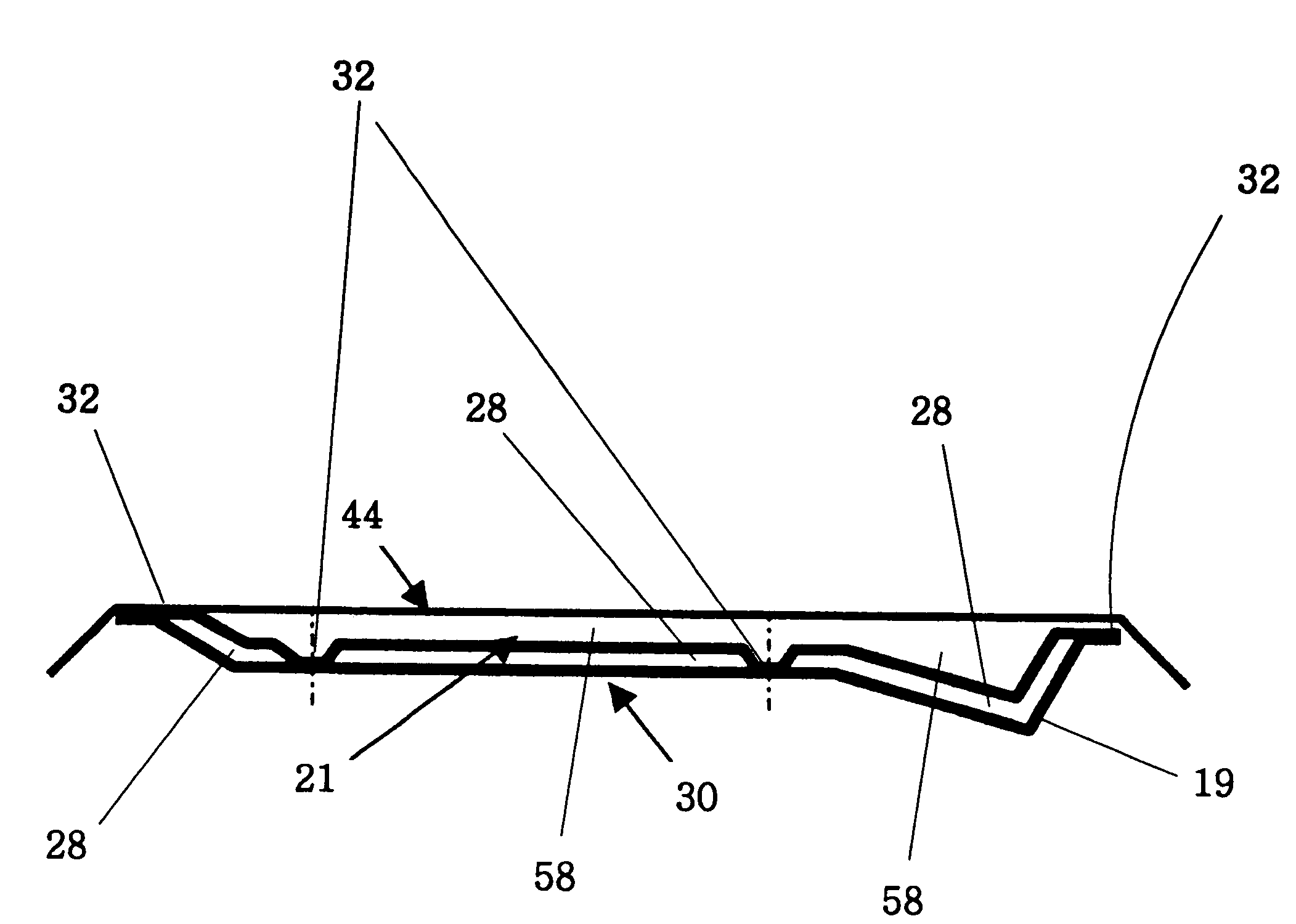

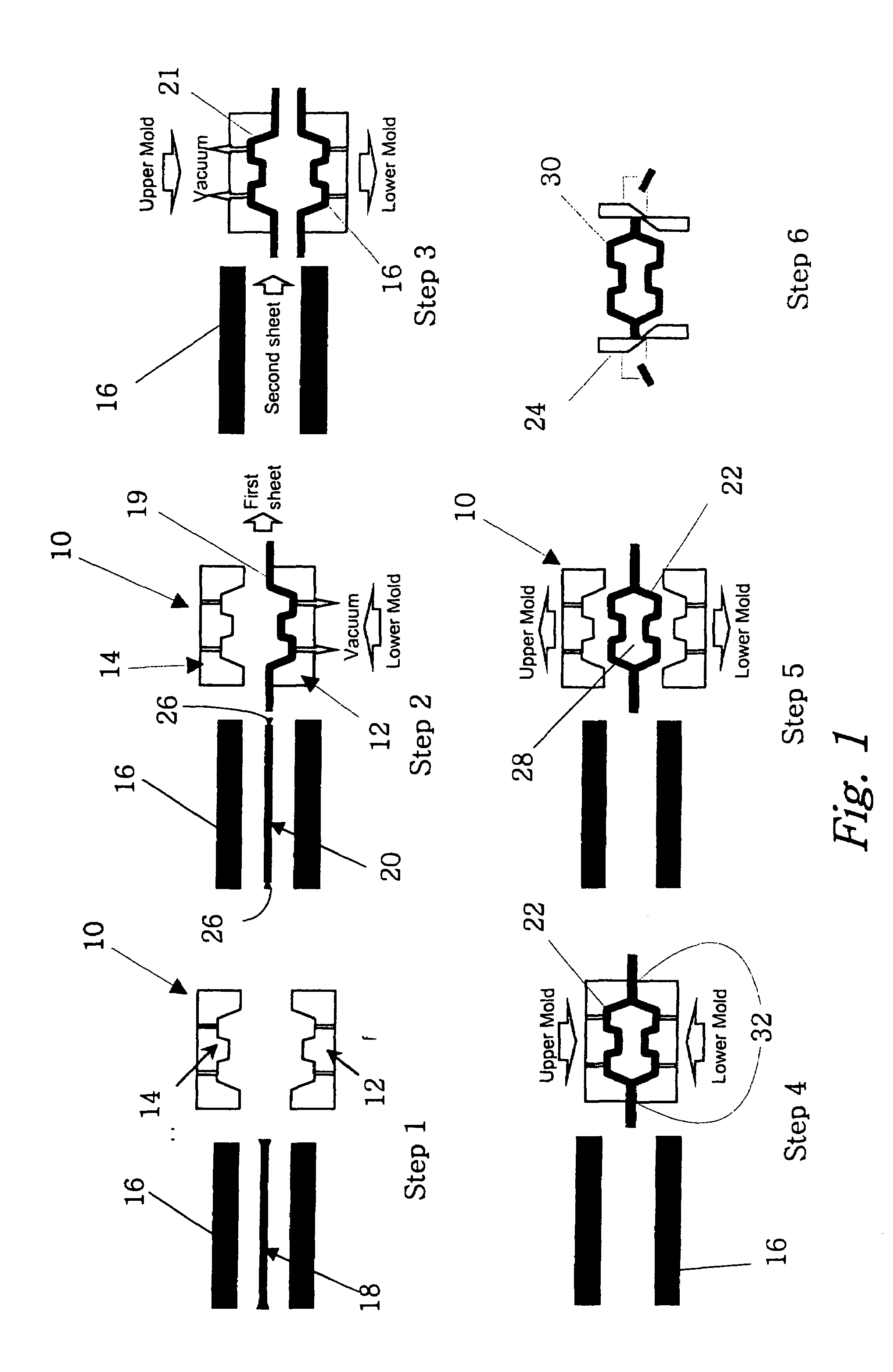

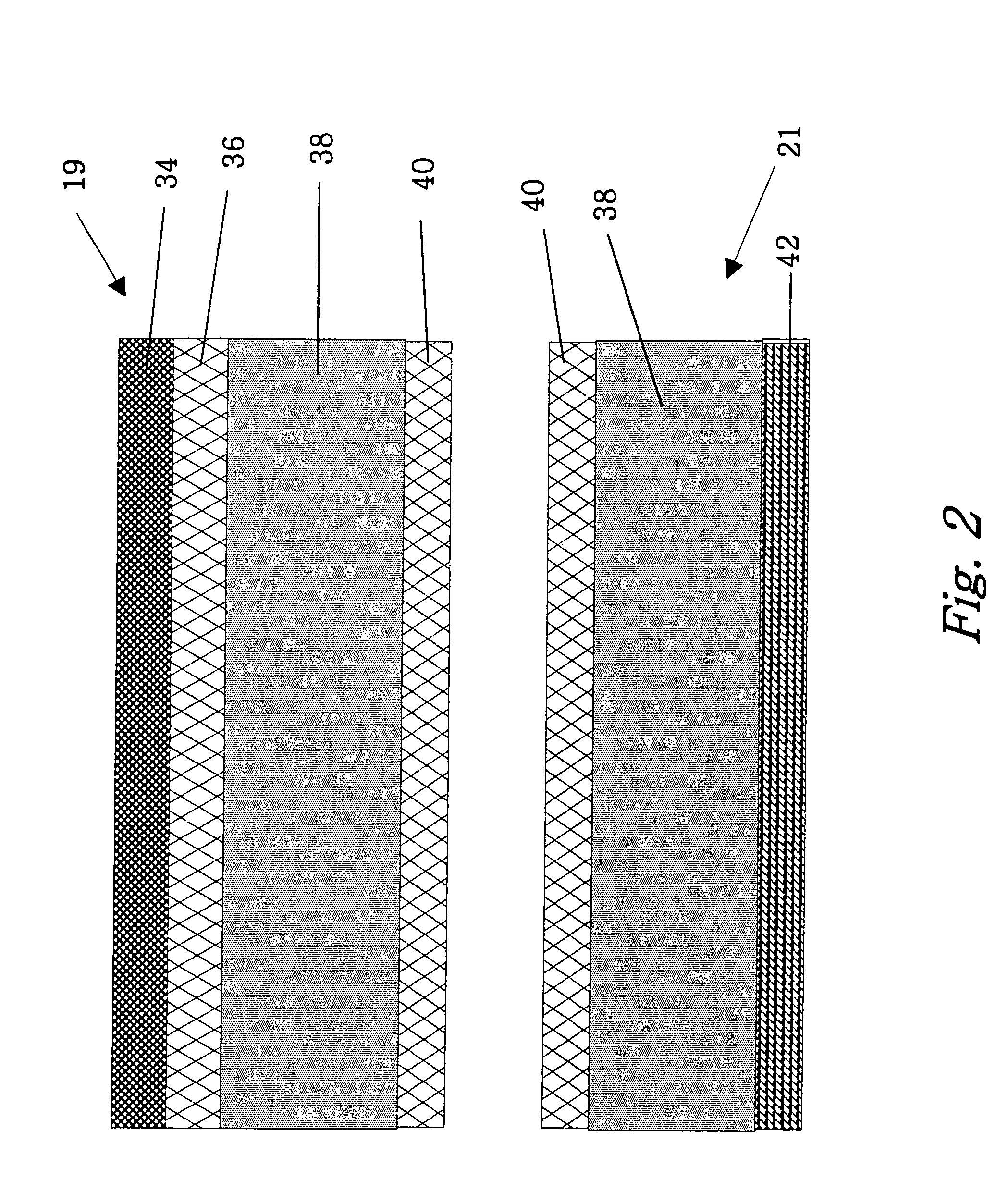

Twin-sheet thermoforming process

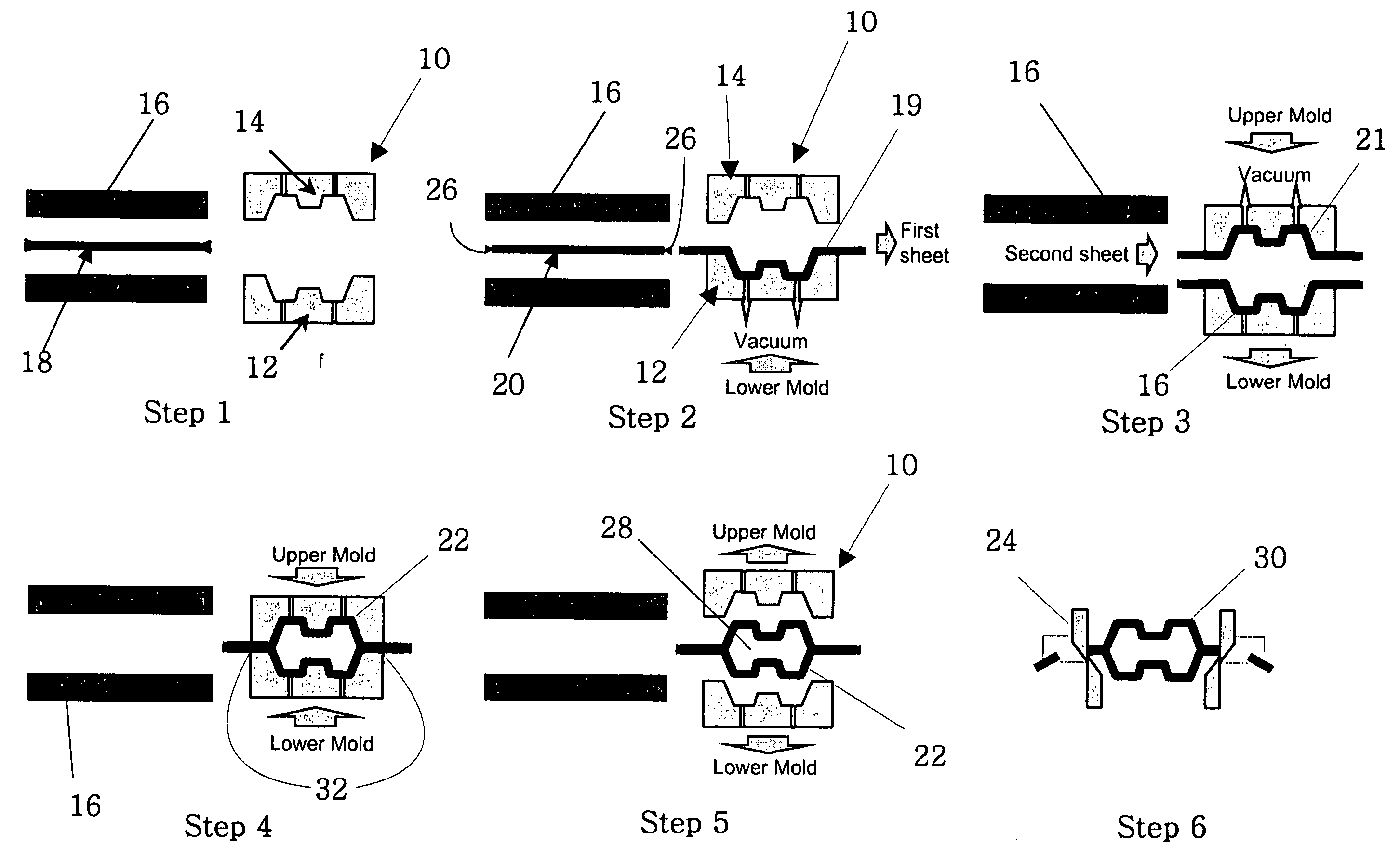

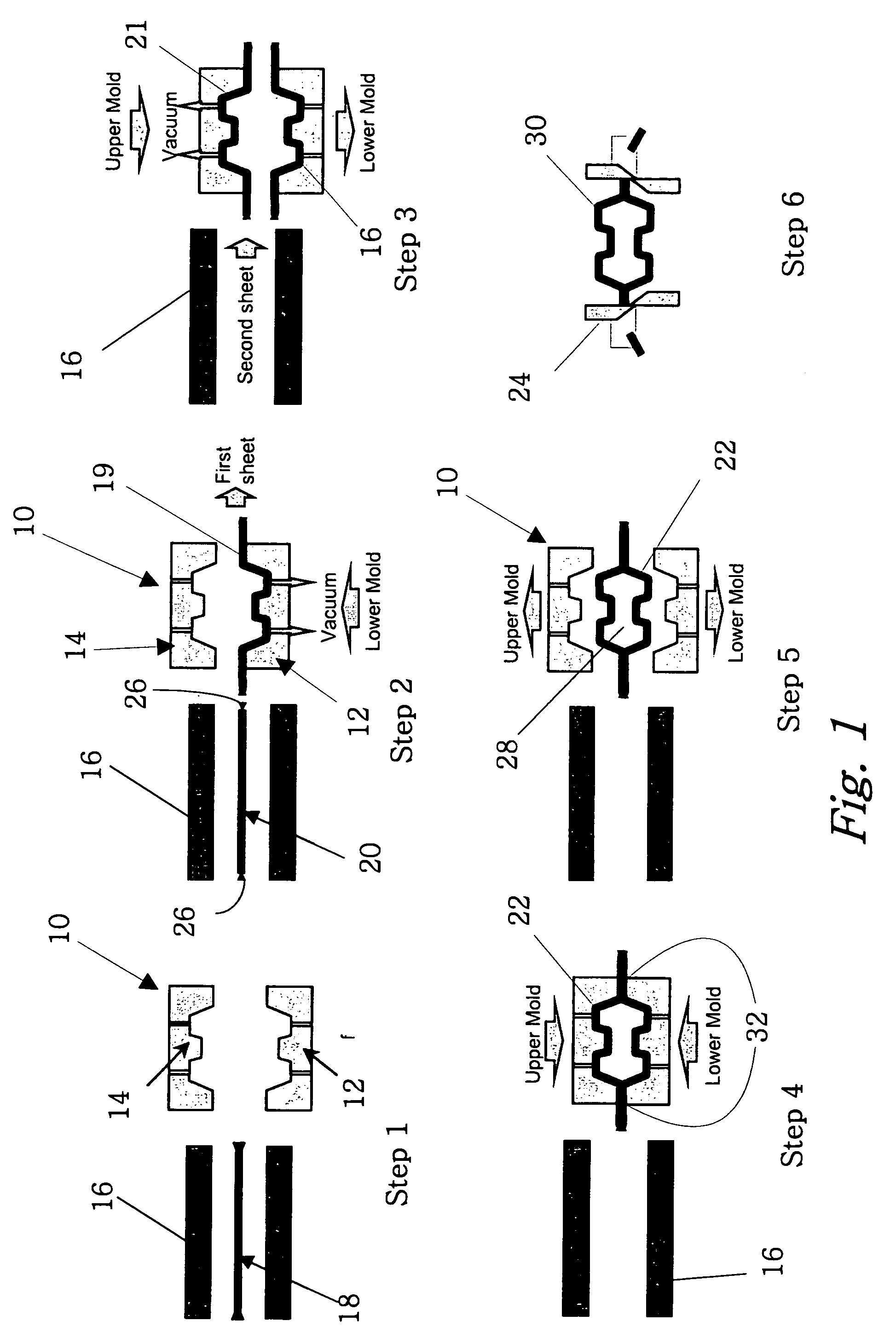

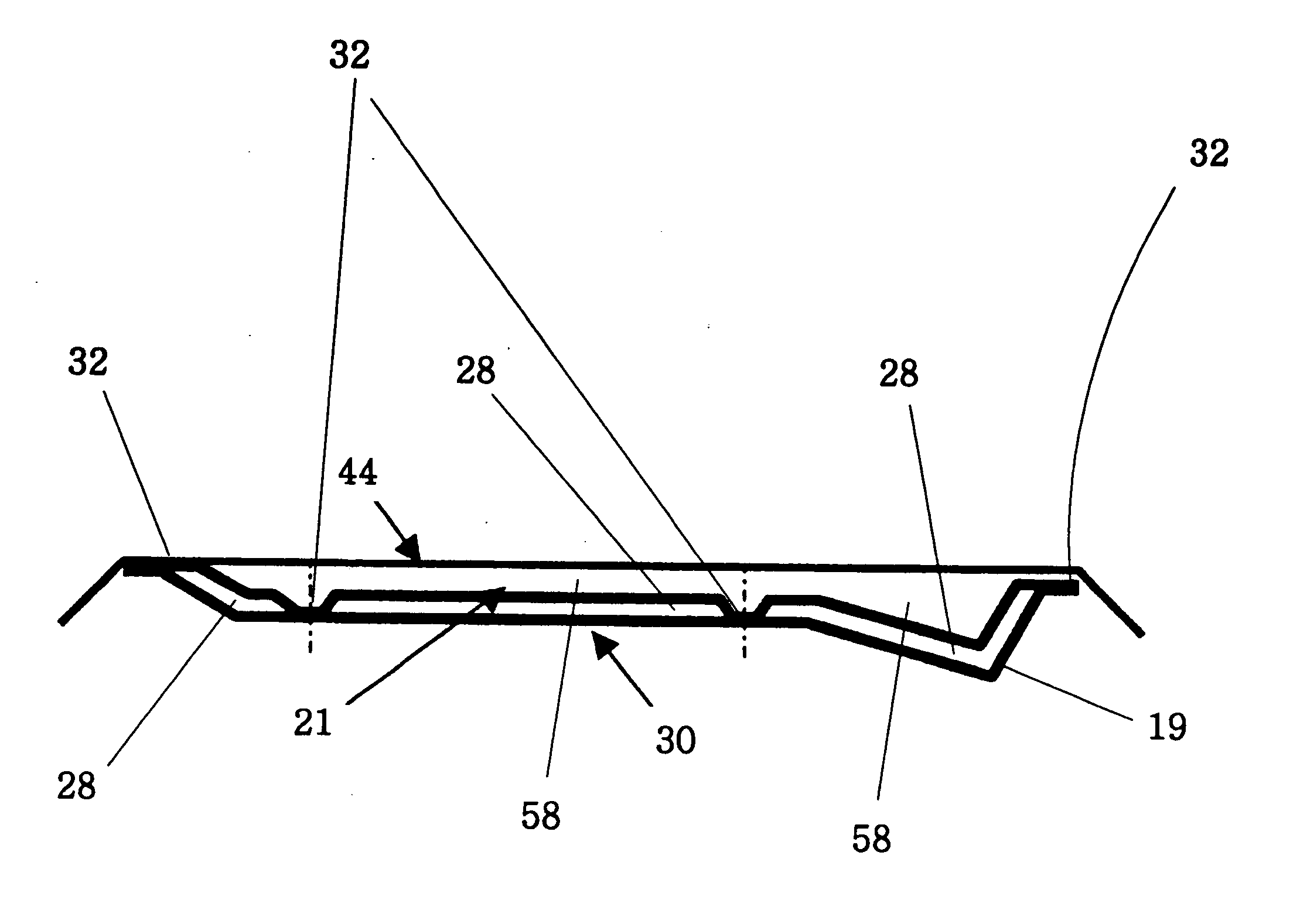

A twin-sheet thermoforming process for the manufacture of vehicle headliners. In the process a first sheet and second sheet of SuperLite material are mounted onto respective frames. The frames transfer the sheets into an oven, where they are heated to a desired temperature using IR. The first sheet is combined with a cover-stock material using compression molding forming a covered first headliner part. The covered first headliner part is then transferred to a second mold station. The second sheet is heated and then transferred from the oven to the second mold station where it is vacuum-formed on the upper half mold, forming a second headliner part. The upper and lower mold halves are pressed together fusing and sealing the first and second headliner parts into a unified part. The unified part is then unloaded and trimmed as necessary forming a headliner. The SuperLite material used to form the headliner is a sheet of low pressure, thermoformable, thermoplastic composite comprised of polypropylene and long chopped glass fibers.

Owner:AZDEL INC

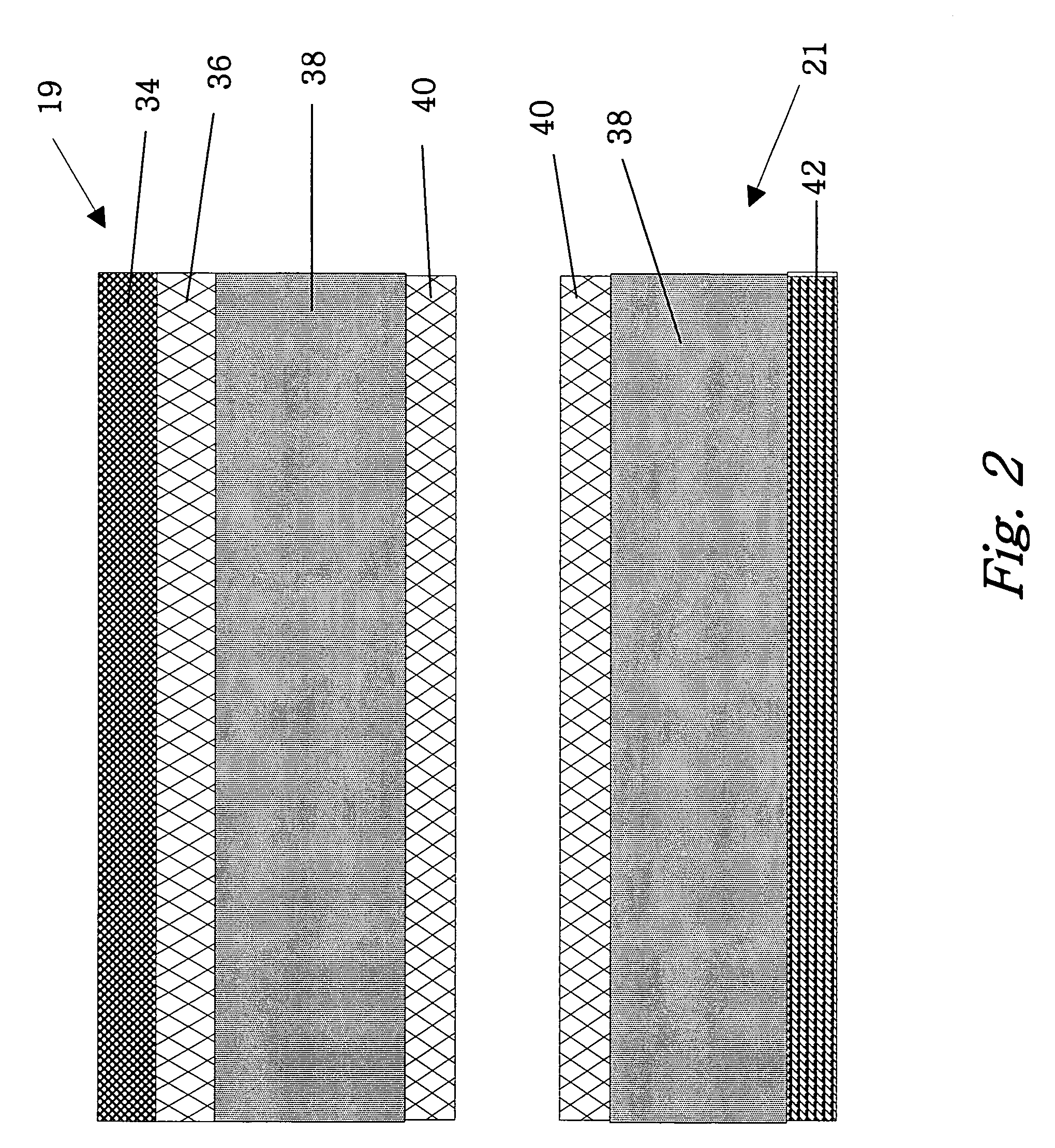

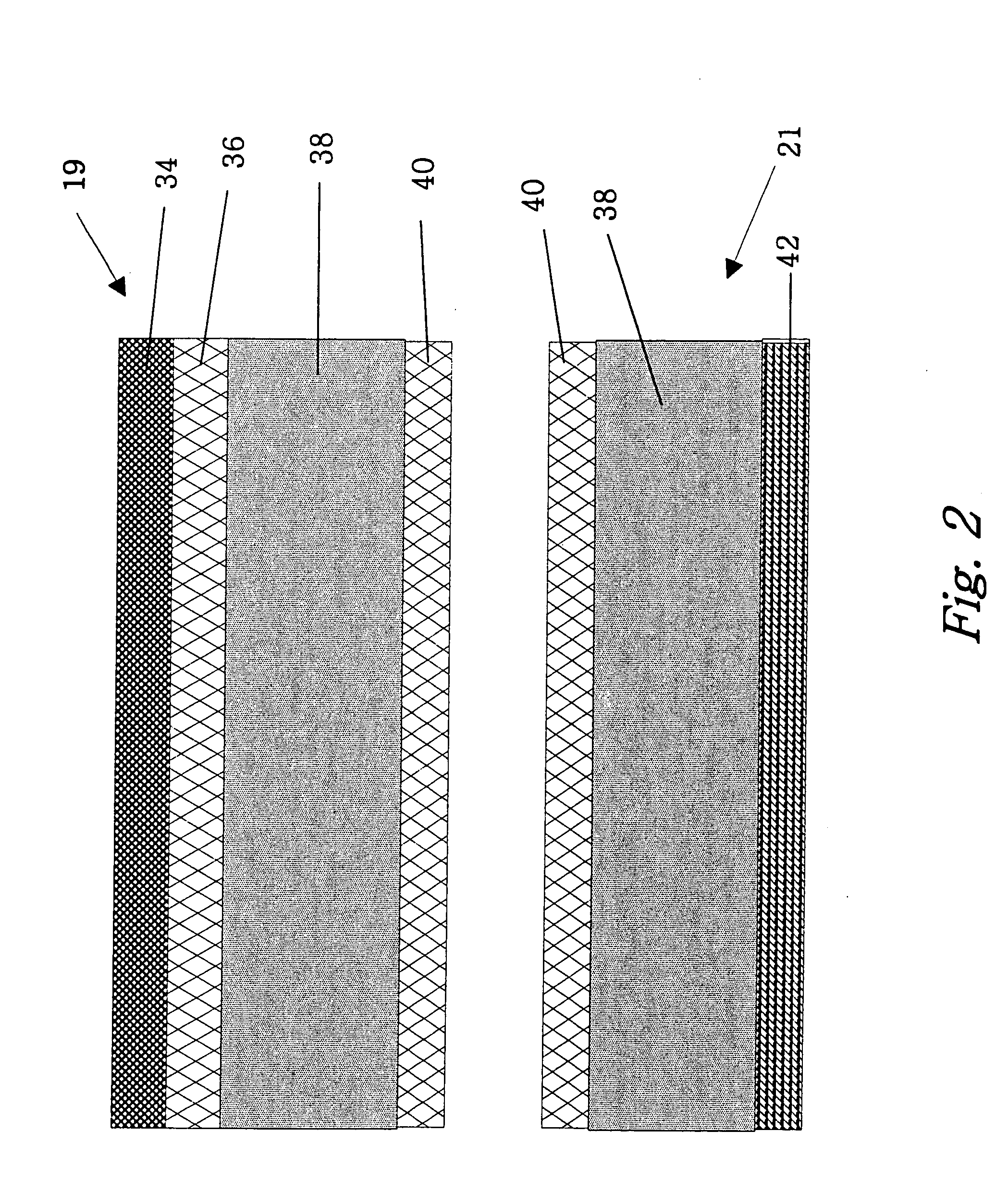

Twin-sheet thermoformed products

A twin-sheet thermoforming process for the manufacture of vehicle headliners. In the process a first sheet and second sheet of SuperLite material are mounted onto respective frames. The frames transfer the sheets into an oven, where they are heated to a desired temperature using IR. The first sheet is combined with a cover-stock material using compression molding forming a covered first headliner part. The covered first headliner part is then transferred to a second mold station. The second sheet is heated and then transferred from the oven to the second mold station where it is vacuum-formed on the upper half mold, forming a second headliner part. The upper and lower mold halves are pressed together fusing and sealing the first and second headliner parts into a unified part. The unified part is then unloaded and trimmed as necessary forming a headliner. The SuperLite material used to form the headliner is a sheet of low pressure, thermoformable, thermoplastic composite comprised of polypropylene and long chopped glass fibers.

Owner:AZDEL INC

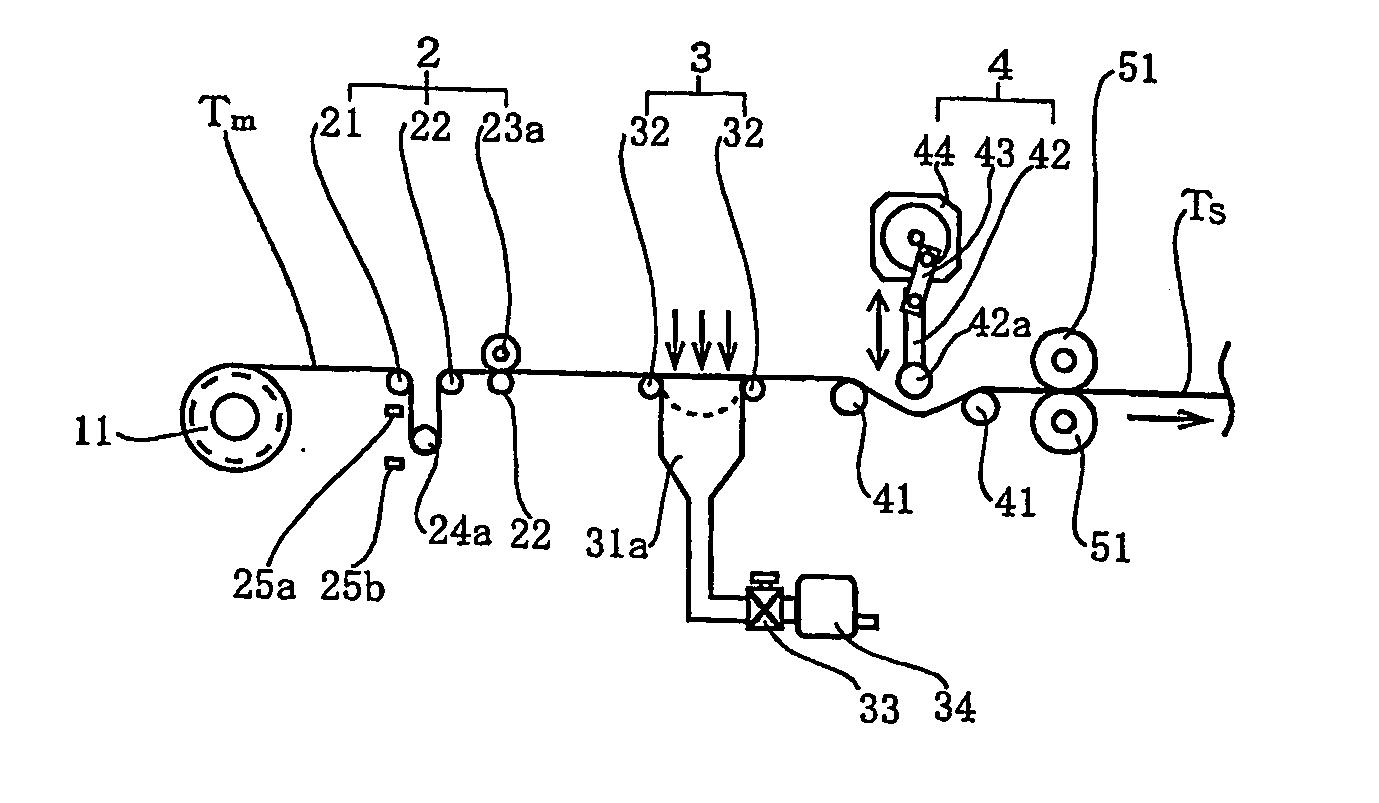

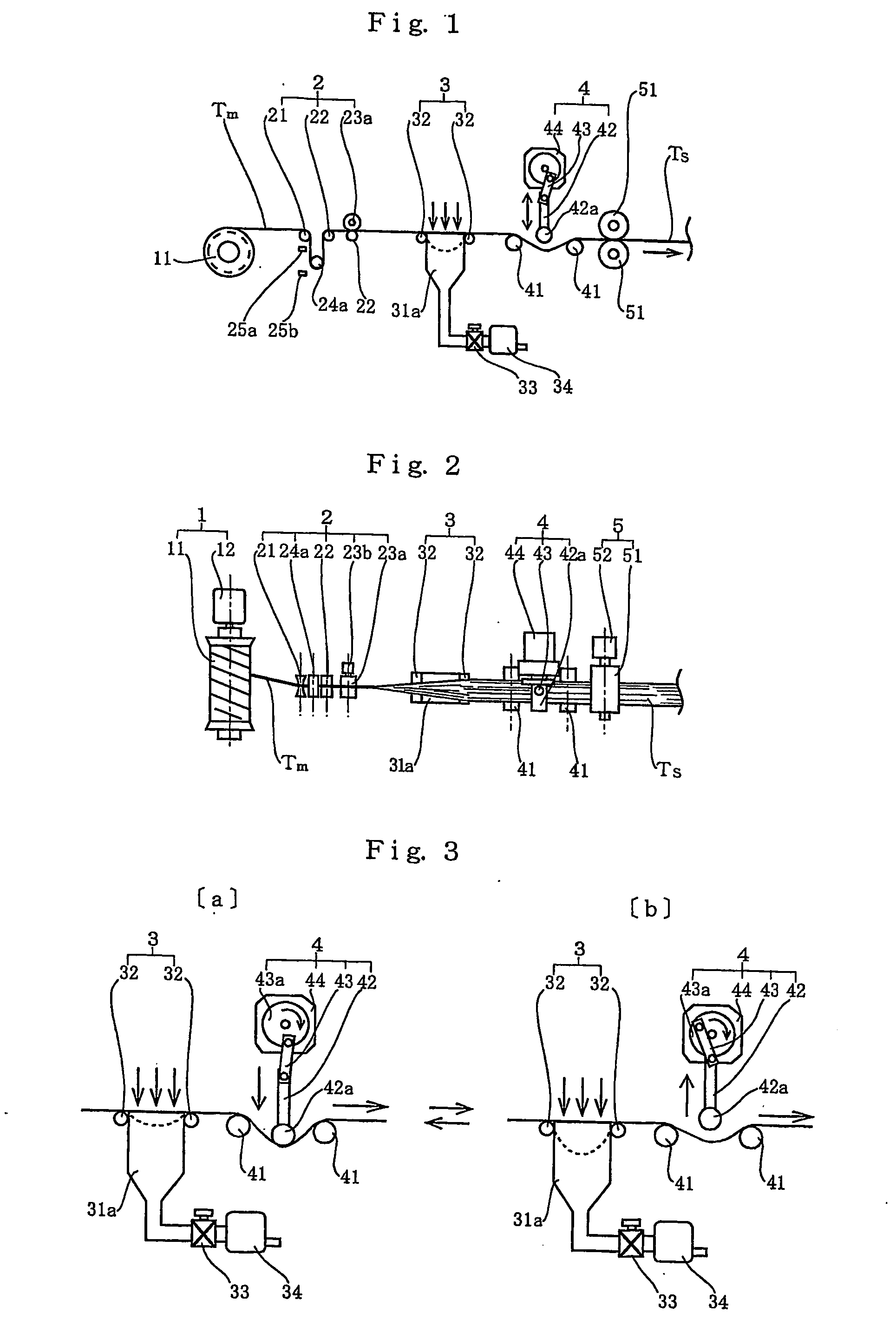

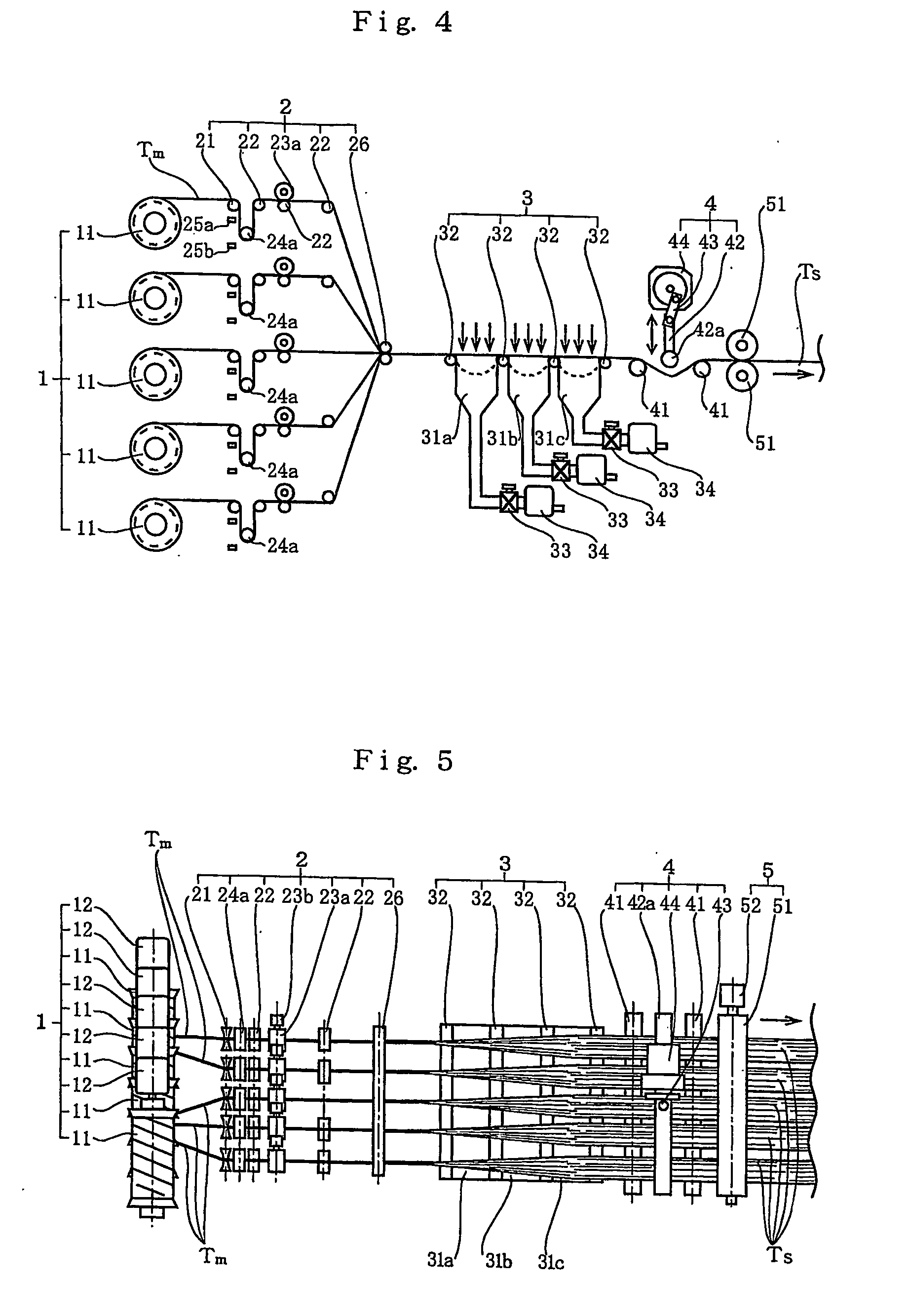

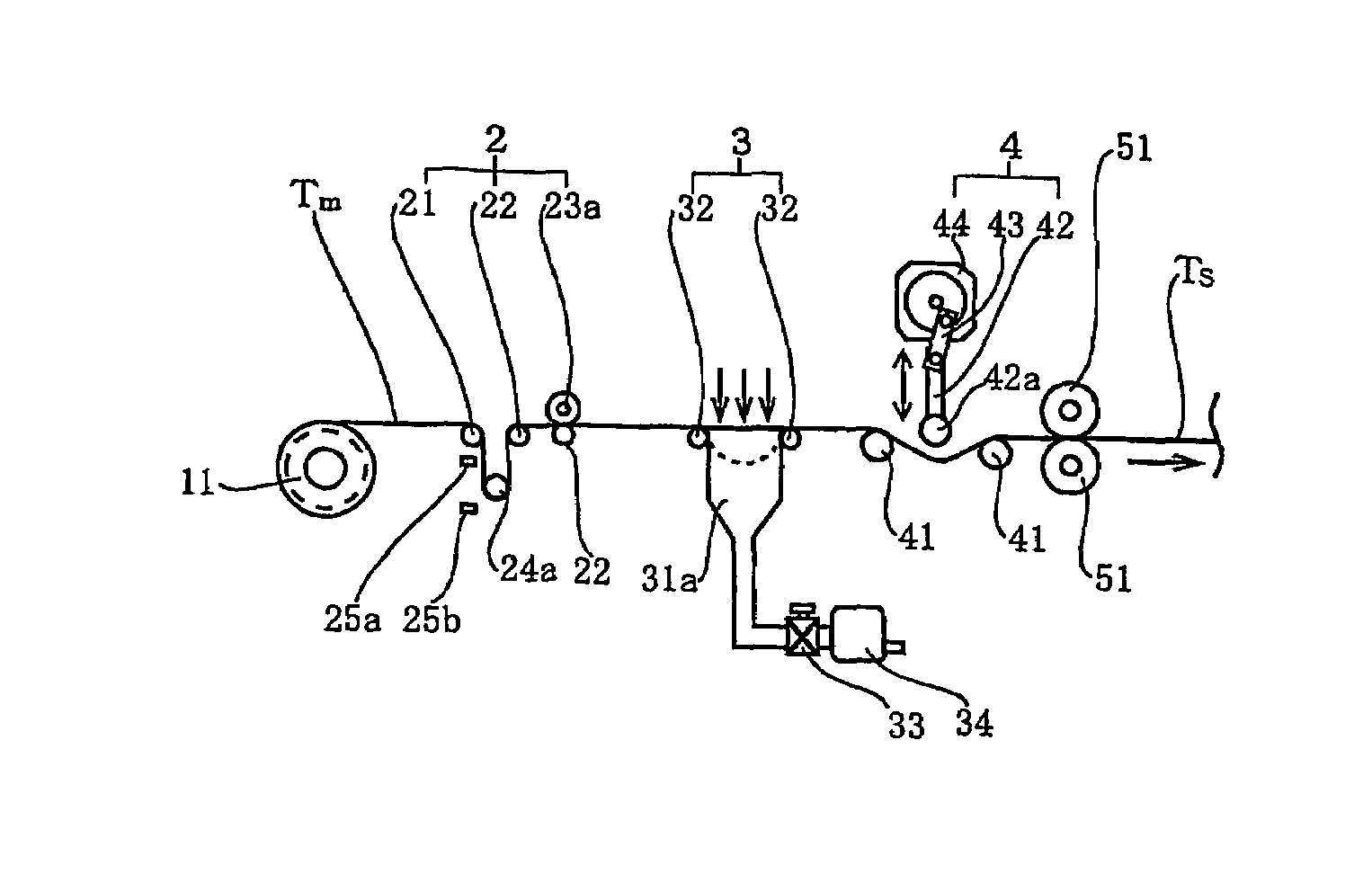

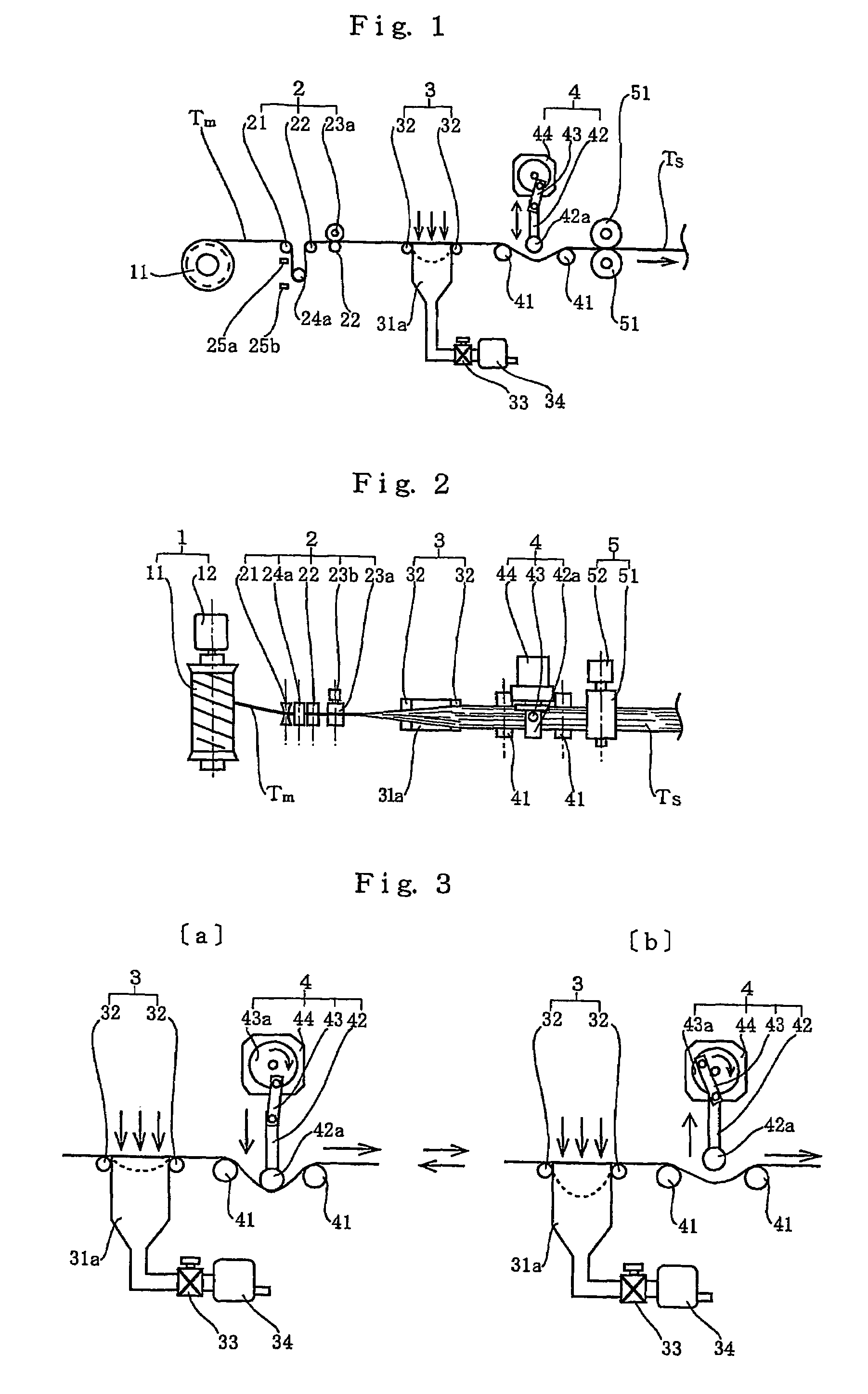

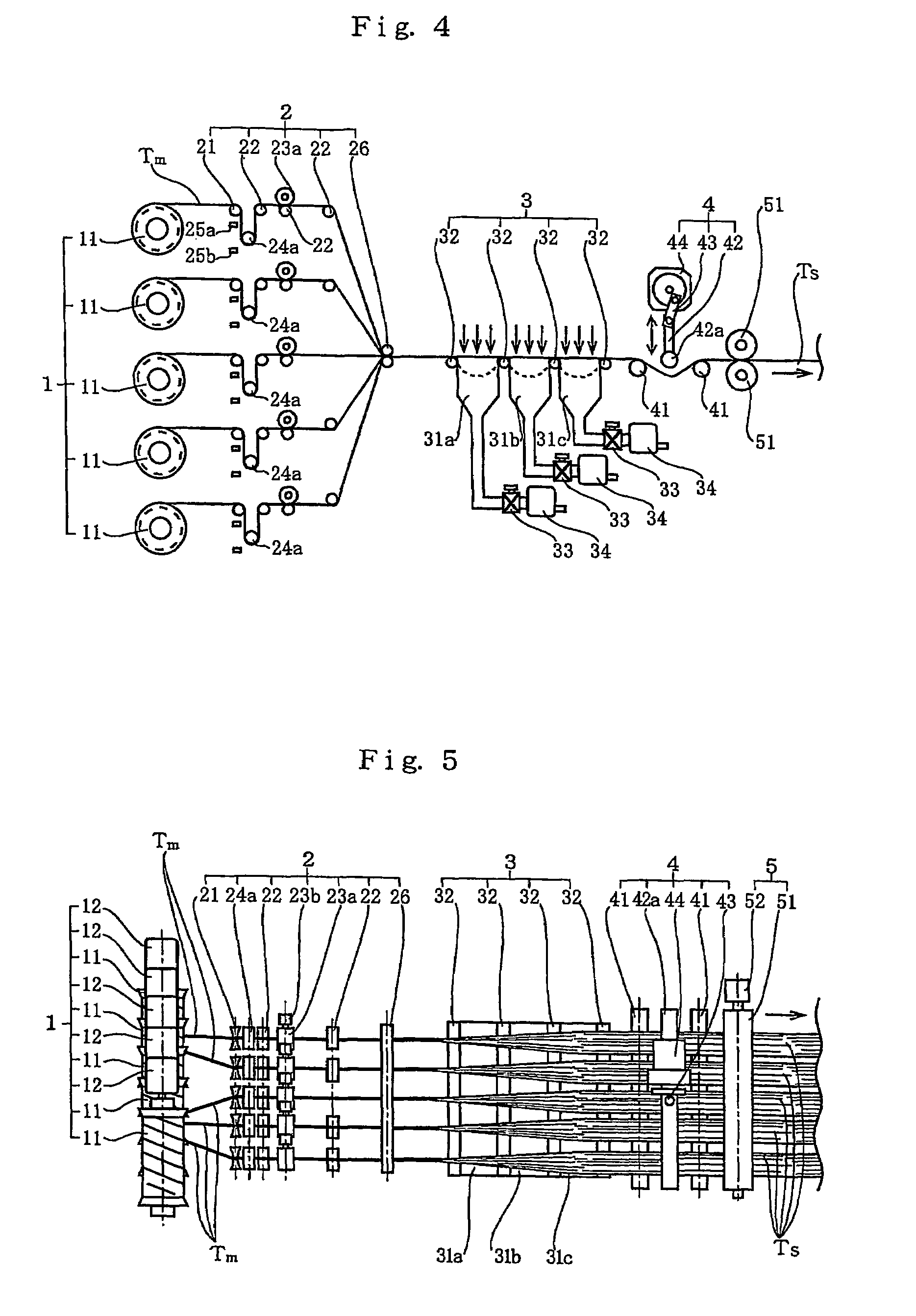

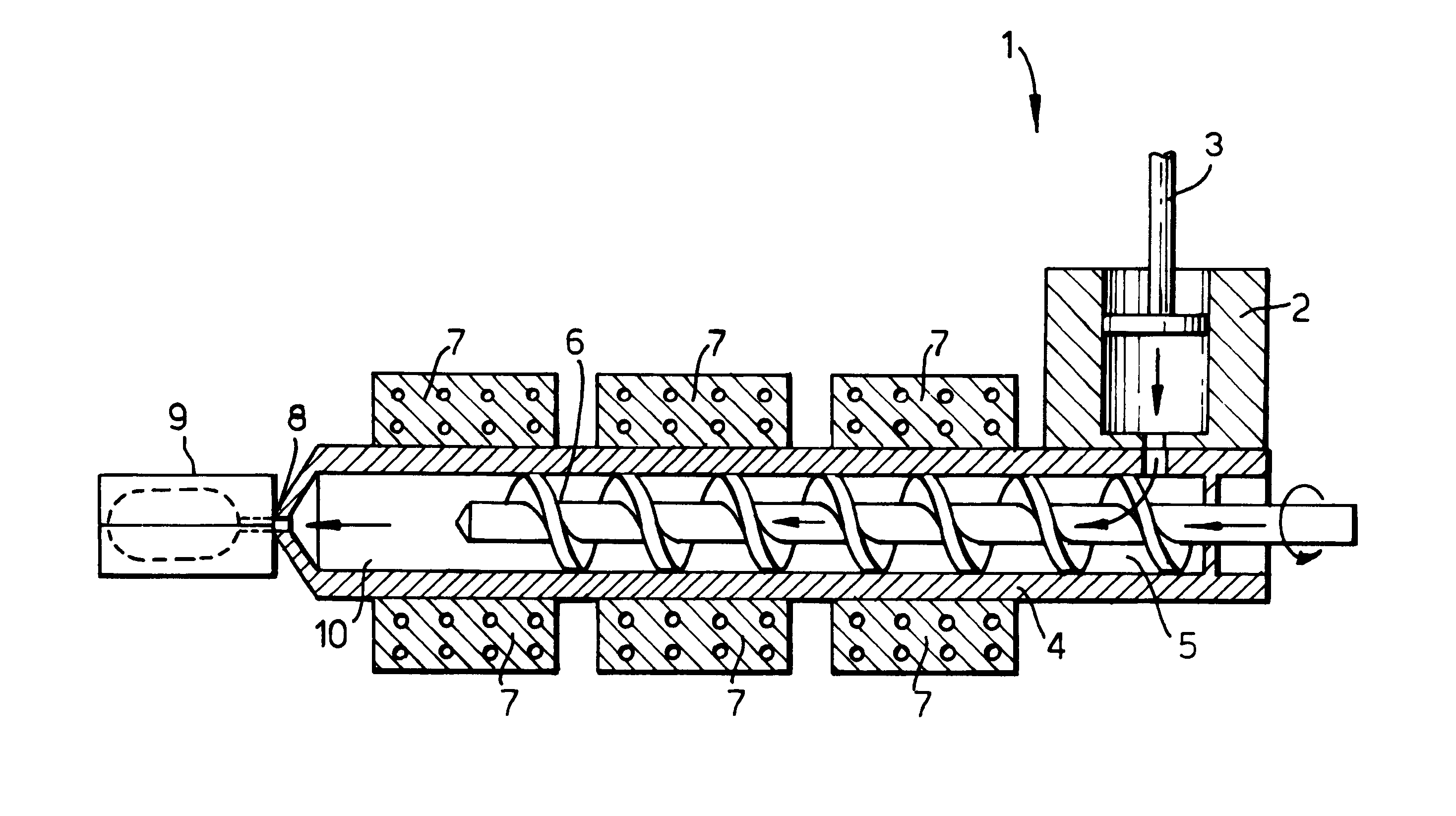

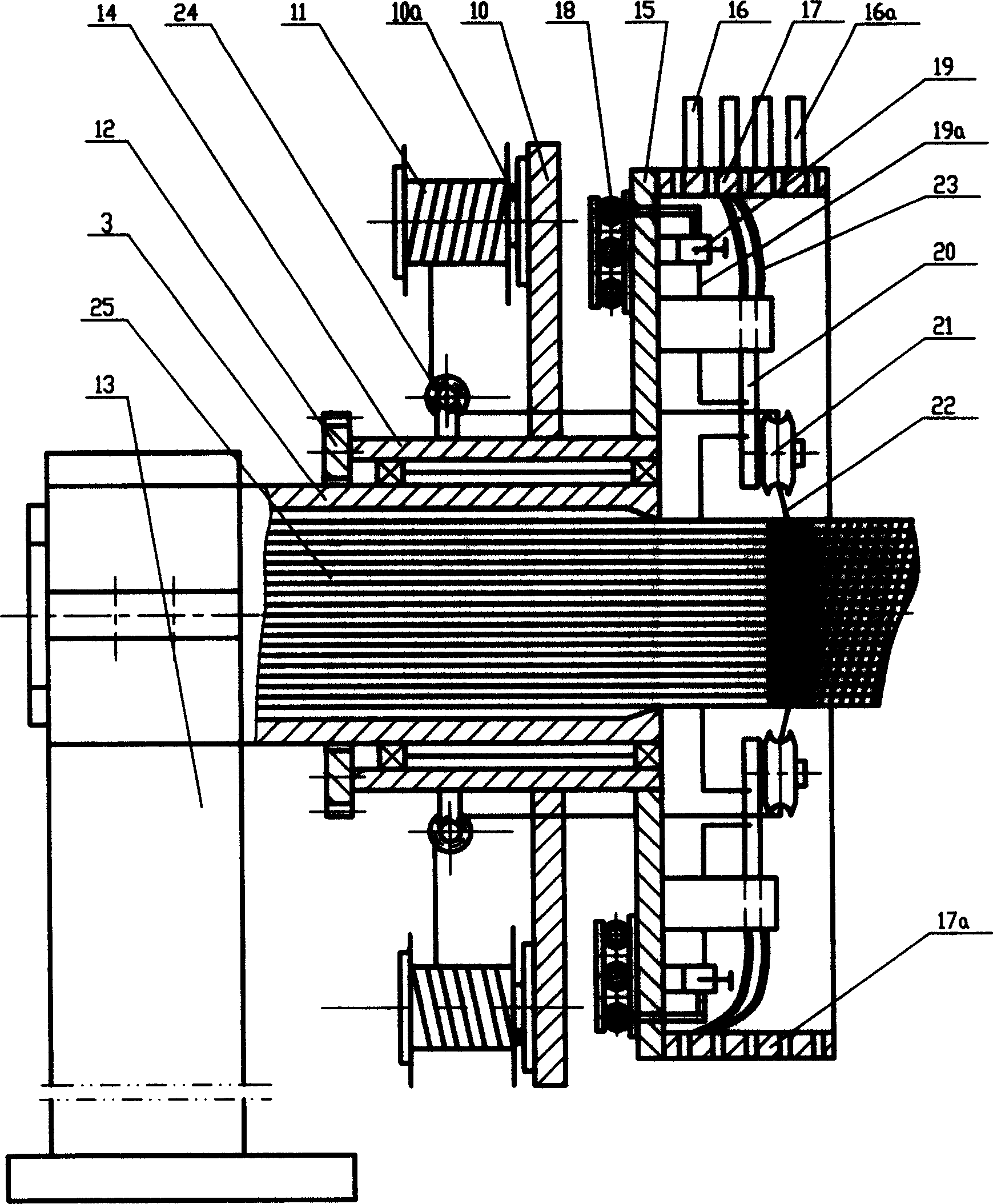

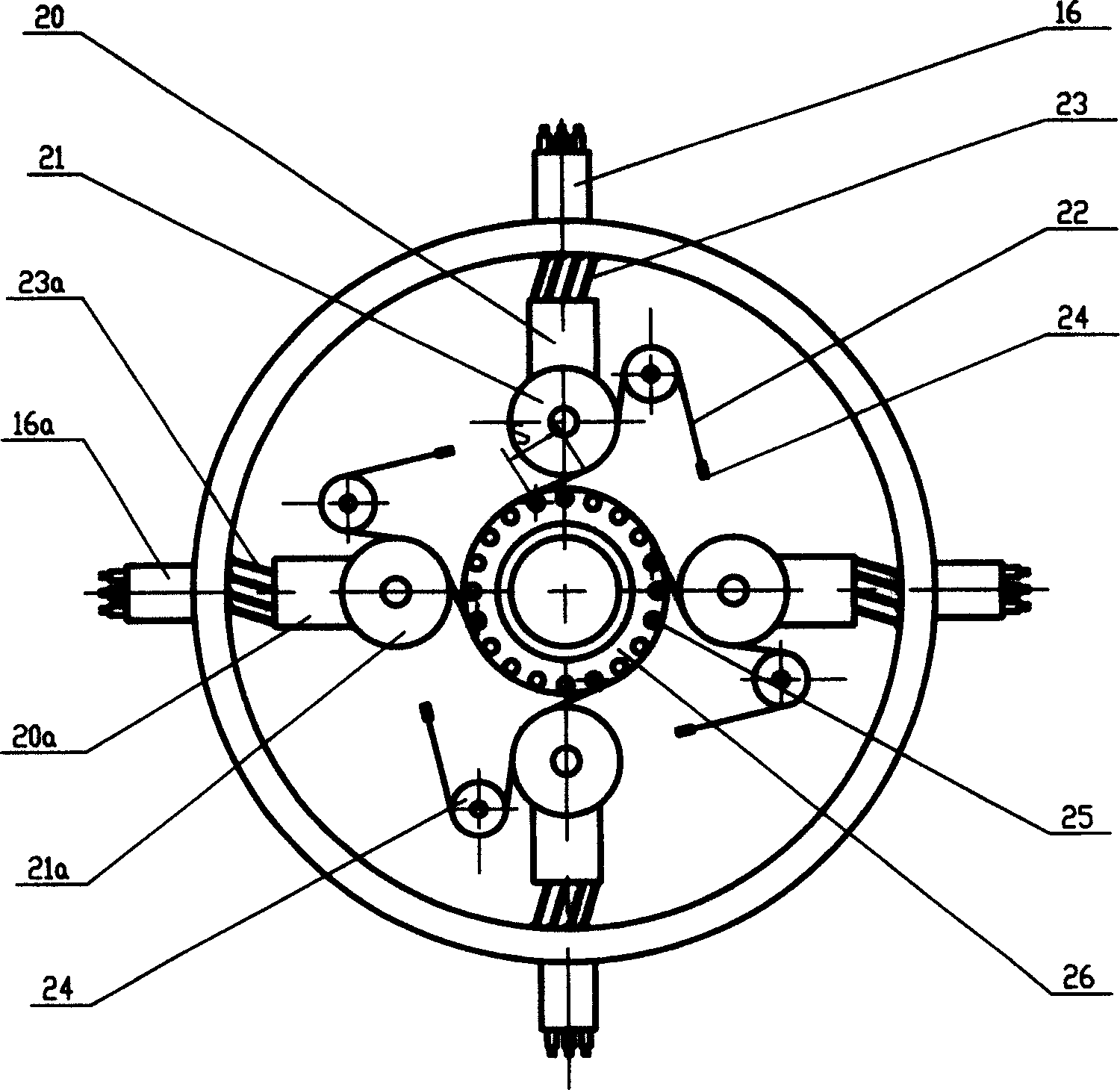

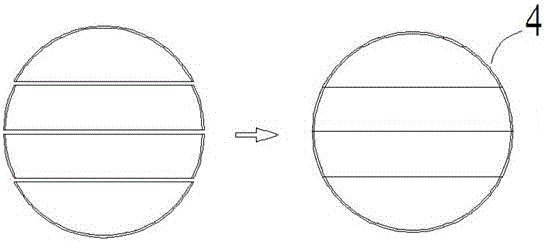

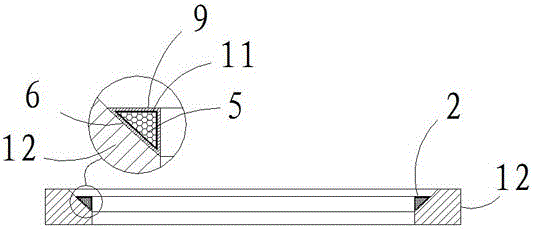

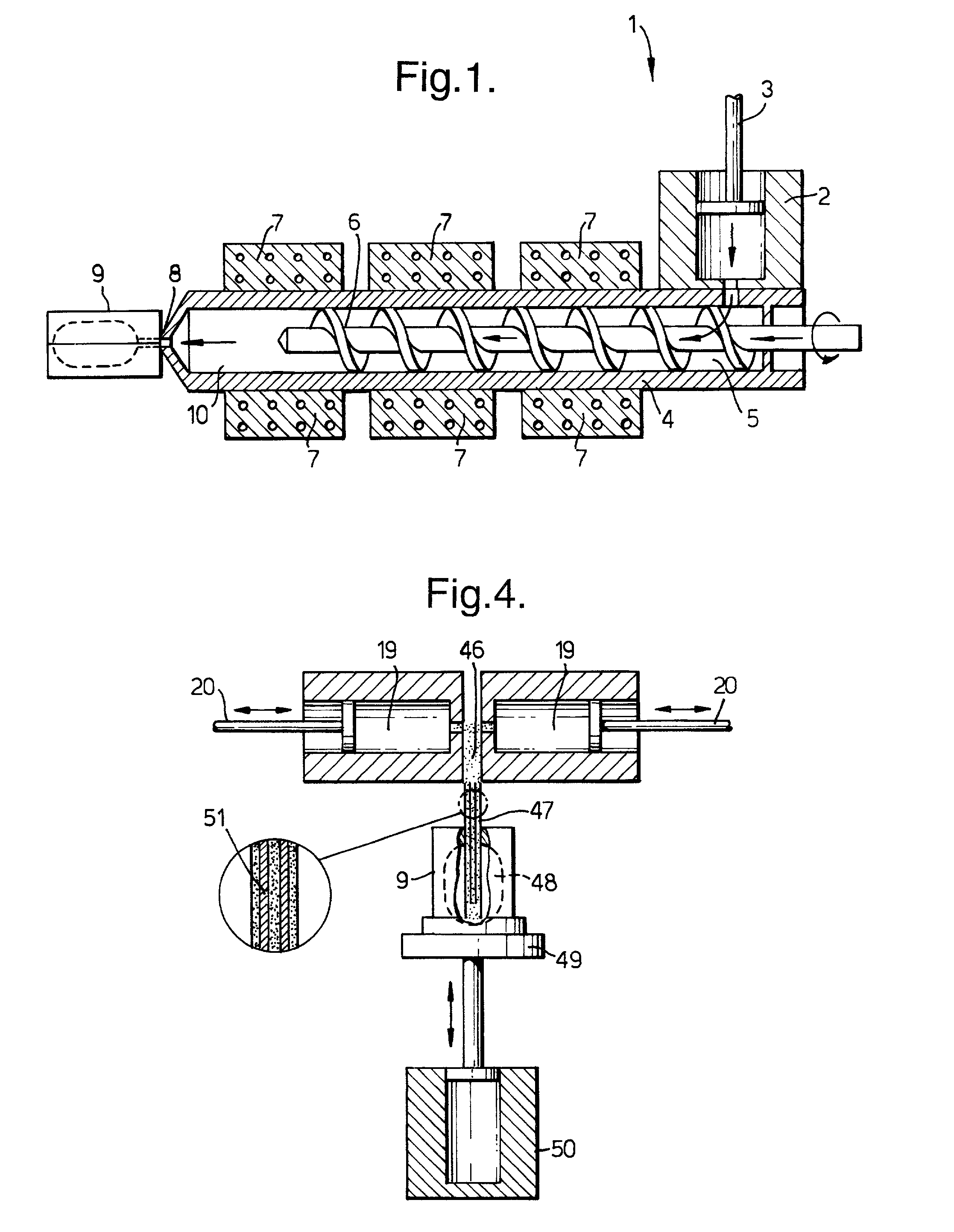

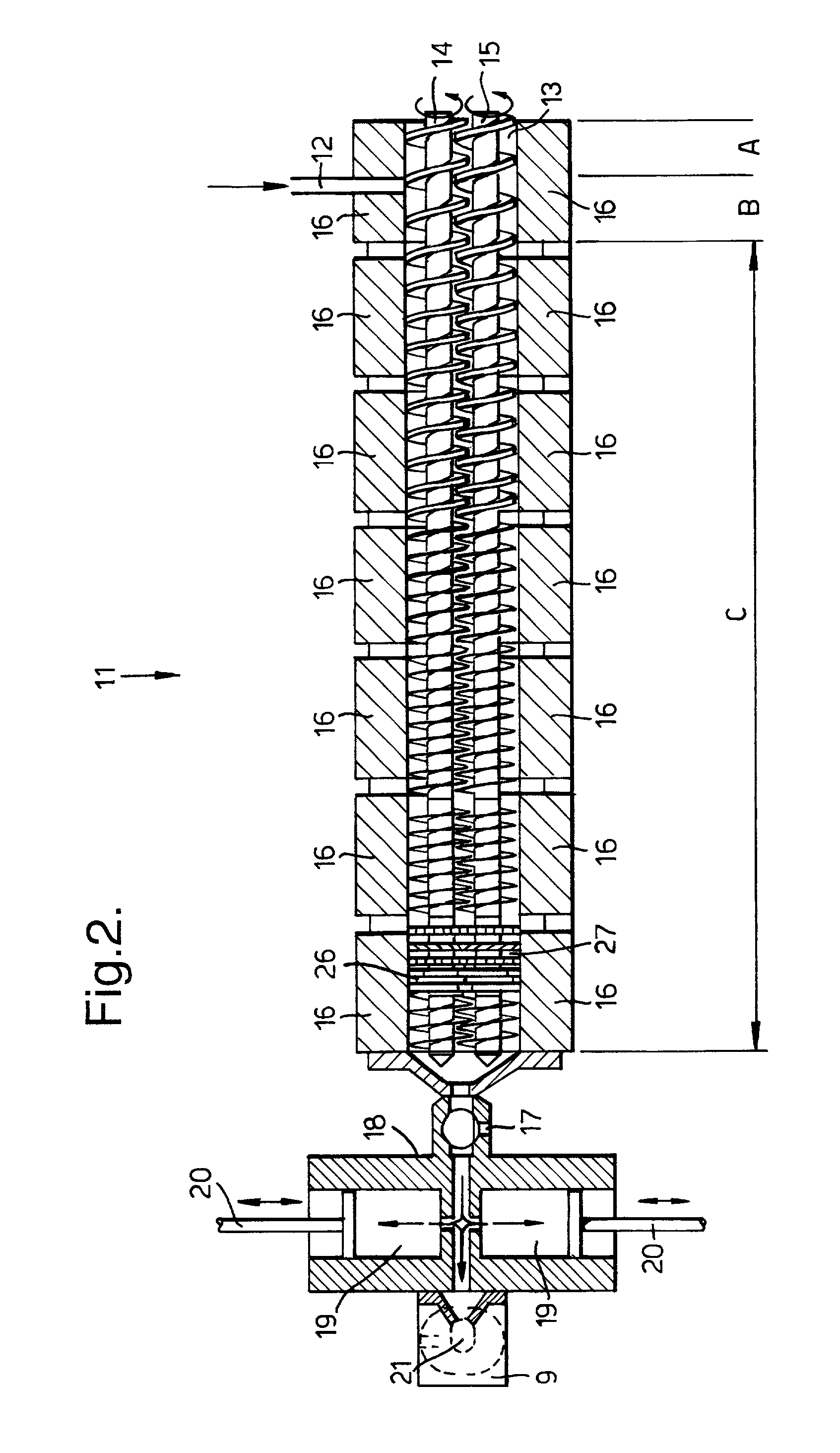

Method of producing a spread multi-filament bundle and an apparatus used in the same

ActiveUS20060137156A1Efficient mass productionImprove efficiencyButtonsRecord carriersEngineeringVolumetric Mass Density

A method of producing a spread multi-filament bundle and an apparatus is used in which an arbitrary number of multi-filament bundles of higher strength are simultaneously spread with high speed and a high-quality. A spread multi-filament bundle or sheet with the component monofilaments thereof aligned in parallel widthwise and uniformly distributed in density is produced. The respective multi-filament bundles fed from a yarn supplier or a creel are subjected to fluctuation of the tensile force applied thereto alternatively between tension and relaxation and the respective bundles as subjected to such fluctuation are passed in succession through a fluid flowing spreader.

Owner:FUKUI PREFECTURE

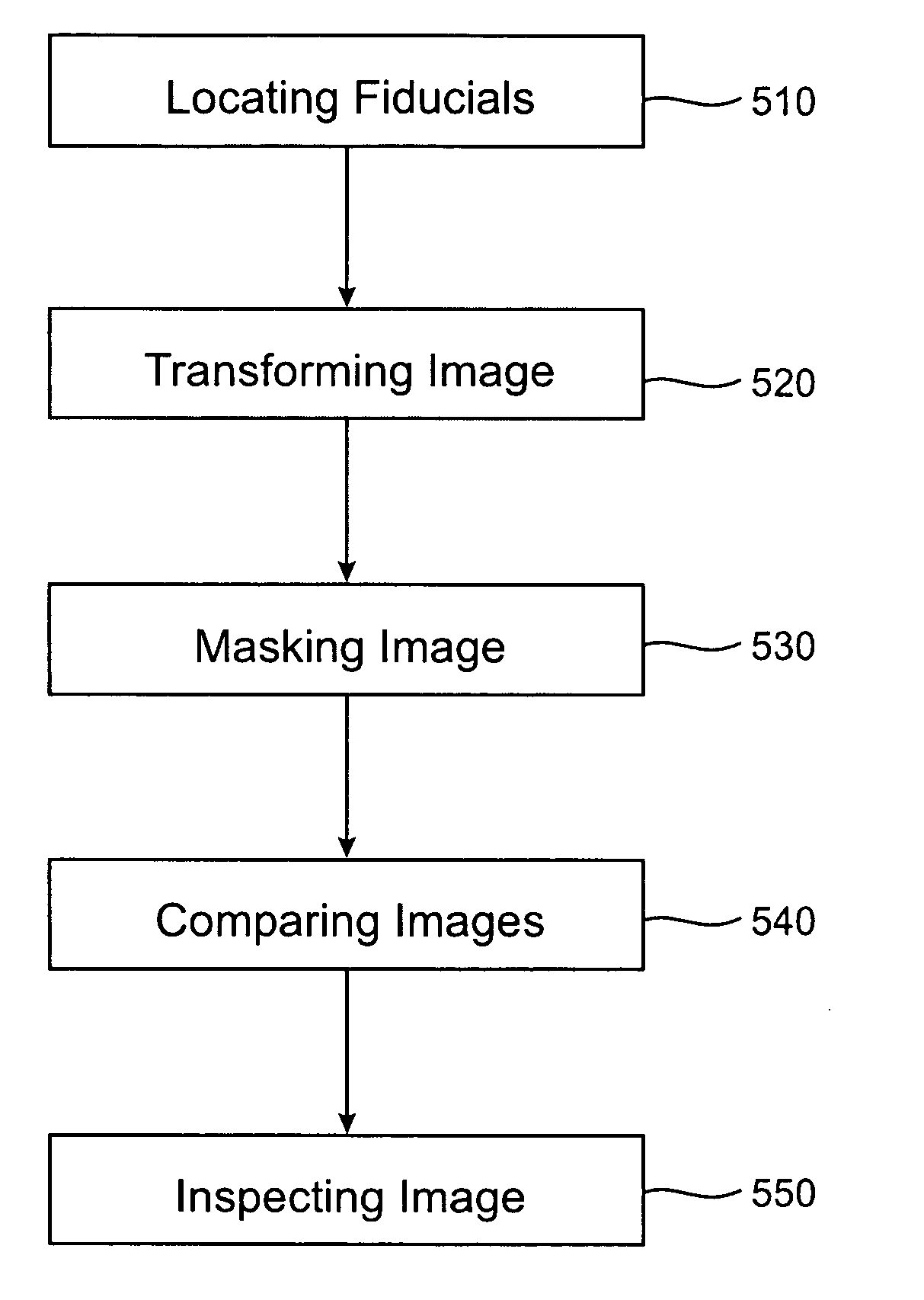

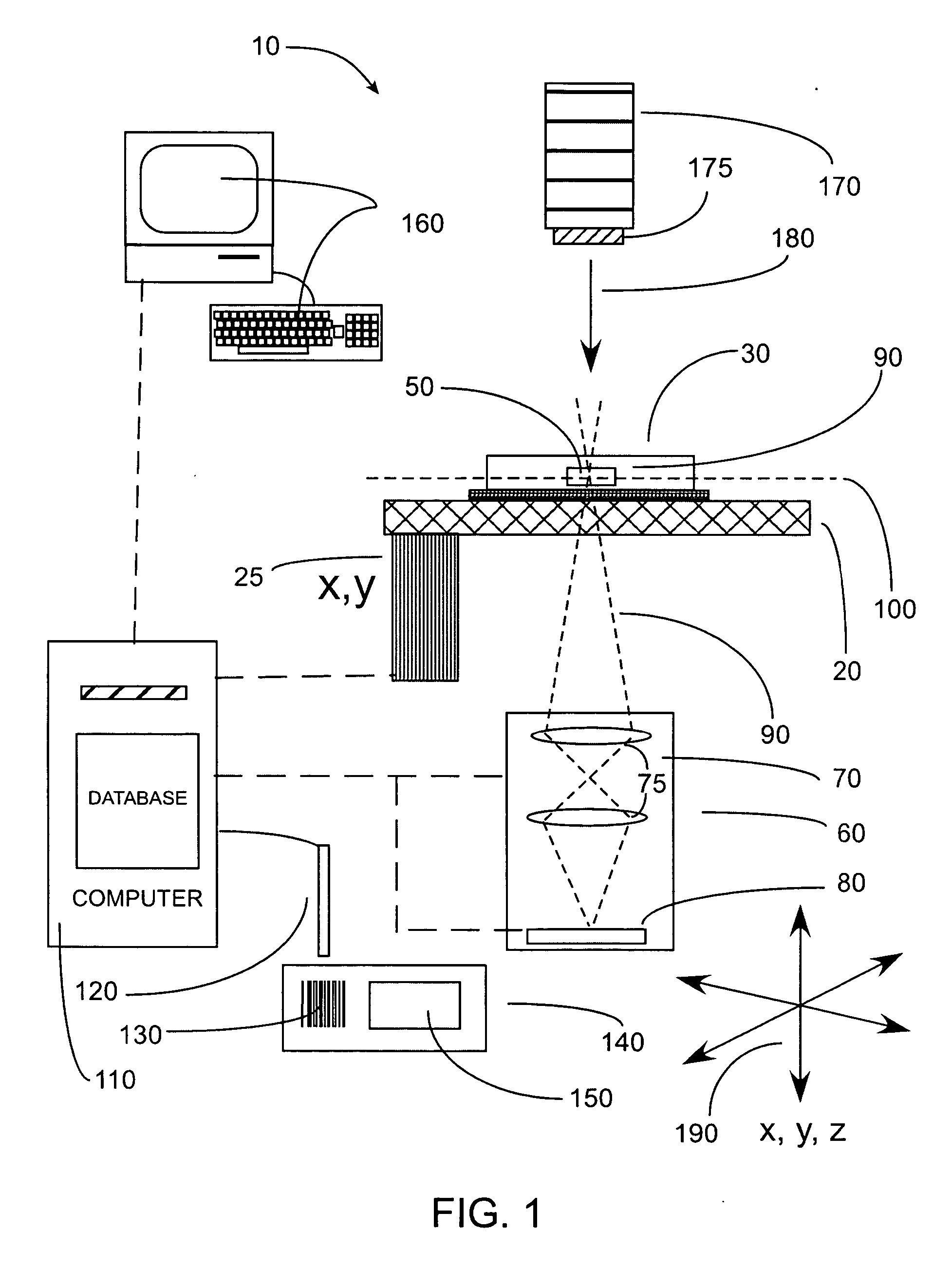

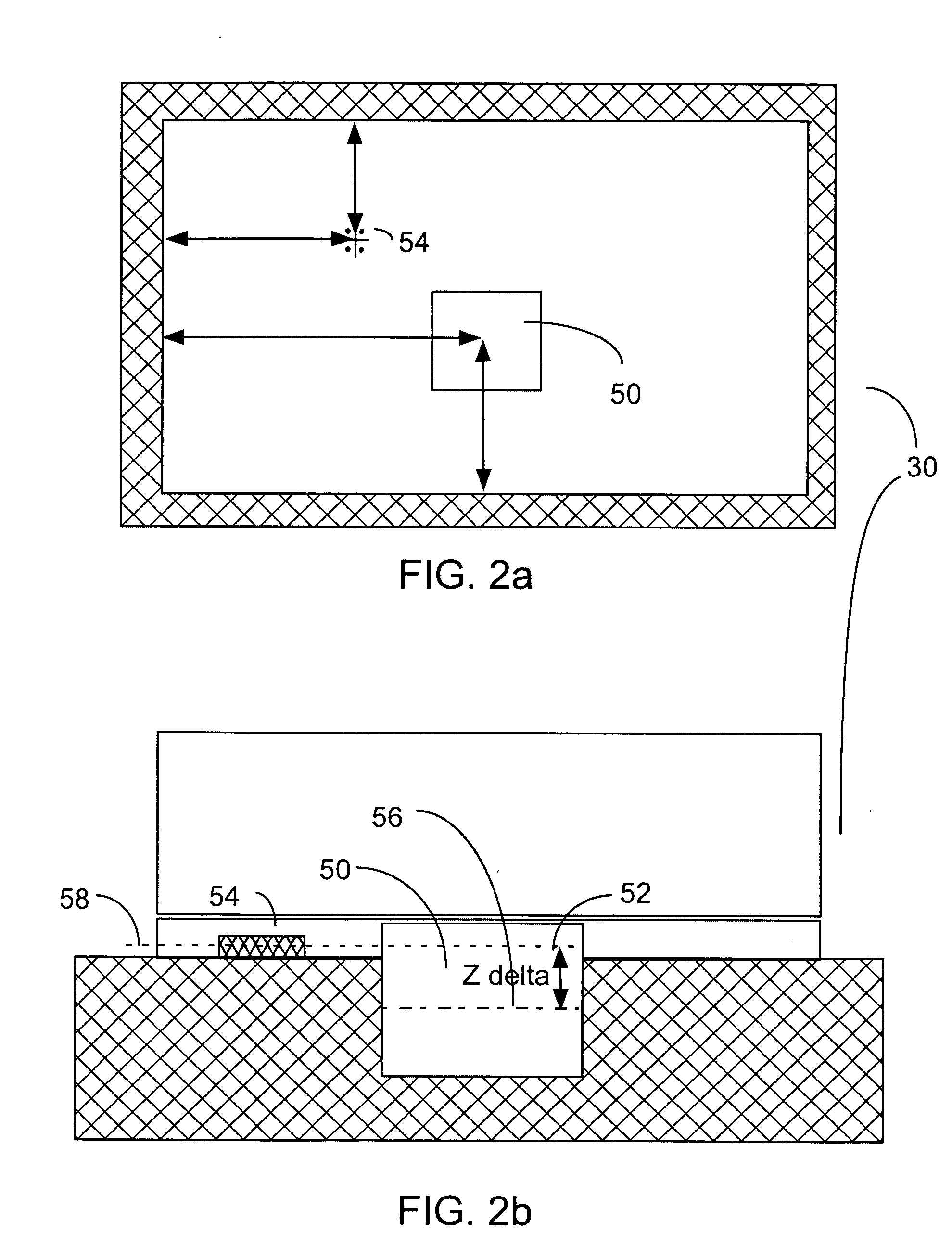

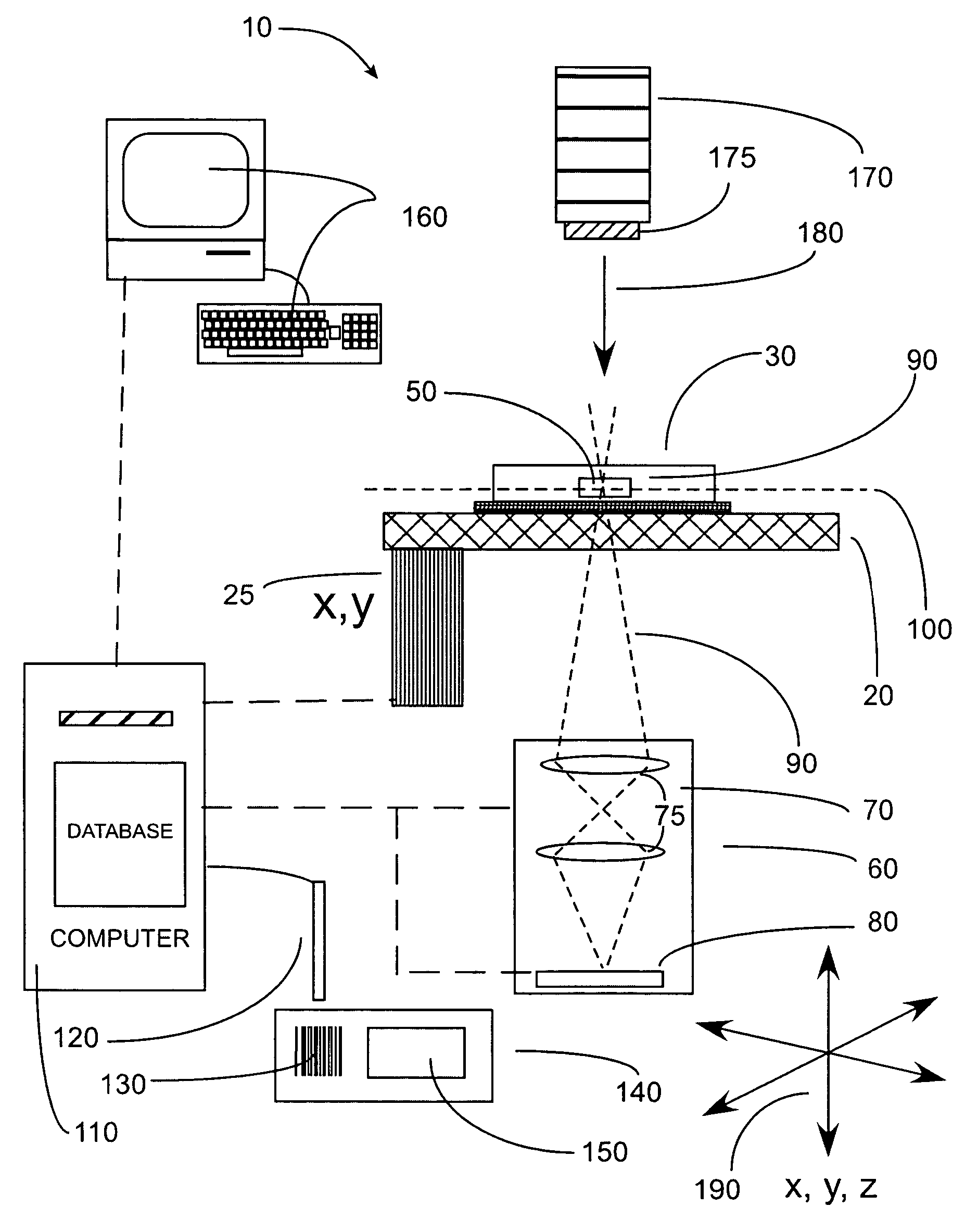

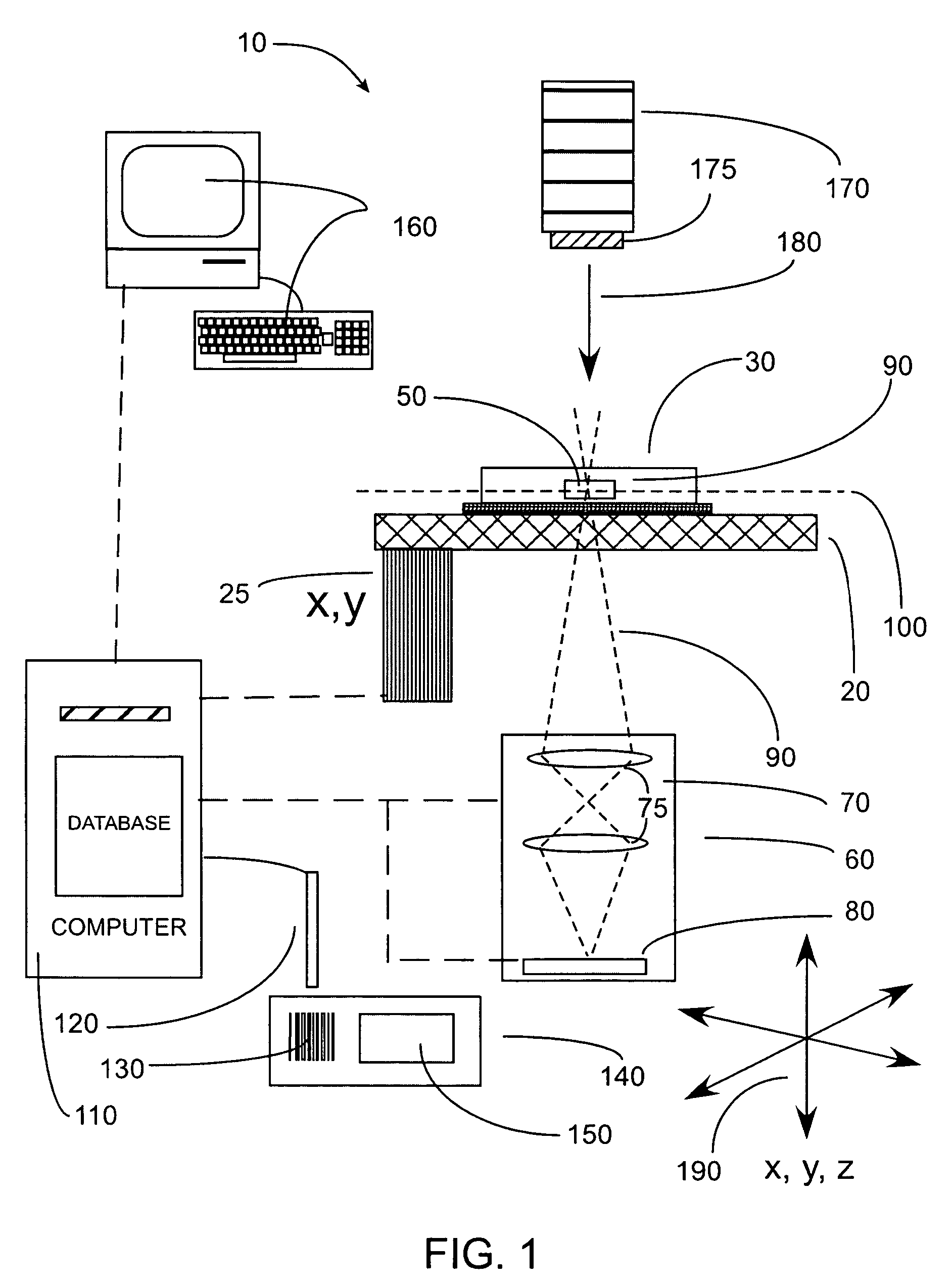

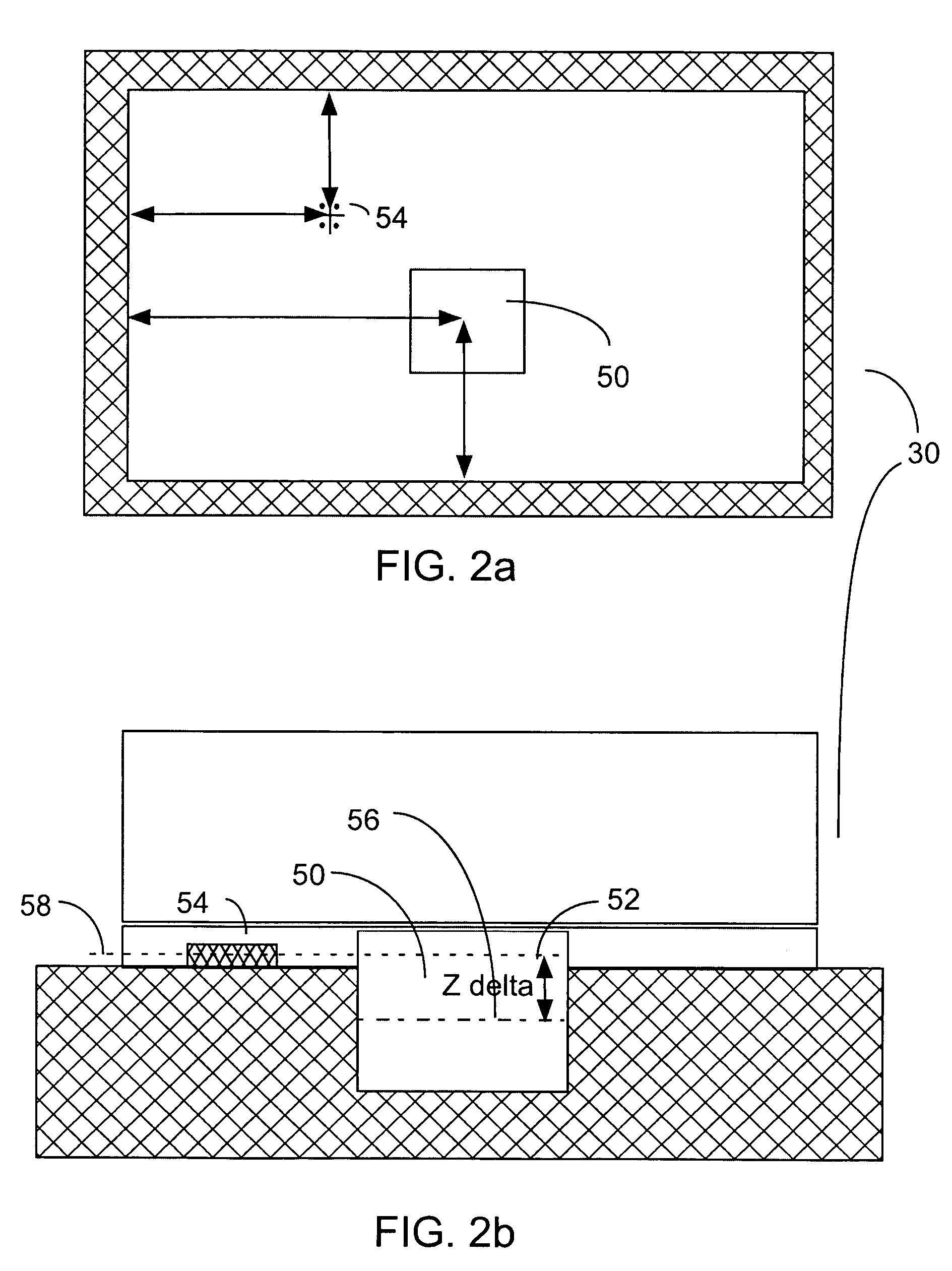

Image processing method and system for microfluidic devices

InactiveUS20050282175A1Increase speedSimple processImage enhancementButtonsImaging processingState dependent

A method for processing an image of a microfluidic device. The method includes receiving a first image of a microfluidic device. The first image corresponds to a first state. Additionally, the method includes receiving a second image of the microfluidic device. The second image corresponds to a second state. Moreover, the method includes transforming the first image and the second image into a third coordinate space. Also, the method includes obtaining a third image based on at least information associated with the transformed first image and the transformed second image, and processing the third image to obtain information associated with the first state and the second state.

Owner:FLUIDIGM CORP

Method of producing a spread multi-filament bundle and an apparatus used in the same

ActiveUS7571524B2Efficient mass productionImprove efficiencyButtonsRecord carriersYarnVolumetric Mass Density

A method of producing a spread multi-filament bundle and an apparatus is used in which an arbitrary number of multi-filament bundles of higher strength are simultaneously spread with high speed and a high-quality. A spread multi-filament bundle or sheet with the component monofilaments thereof aligned in parallel widthwise and uniformly distributed in density is produced. The respective multi-filament bundles fed from a yarn supplier or a creel are subjected to fluctuation of the tensile force applied thereto alternatively between tension and relaxation and the respective bundles as subjected to such fluctuation are passed in succession through a fluid flowing spreader.

Owner:FUKUI PREFECTURE

Compositions and methods for use in three dimensional model printing

InactiveUS20080105818A1Similar elasticitySimilar strengthButtonsRecord carriersInvestment castingMaterials science

Embodiments of the invention are directed to a method of producing three-dimensional prototype molds for use in investment casting. The method includes dispensing modeling material and support material in a predetermined arrangement, in layers, to produce a three-dimensional mold having an outer shell. Generally, the out shell includes modeling material and the interior of the mold includes support material. Then the mold is cured.

Owner:OBJET GEOMETRIES

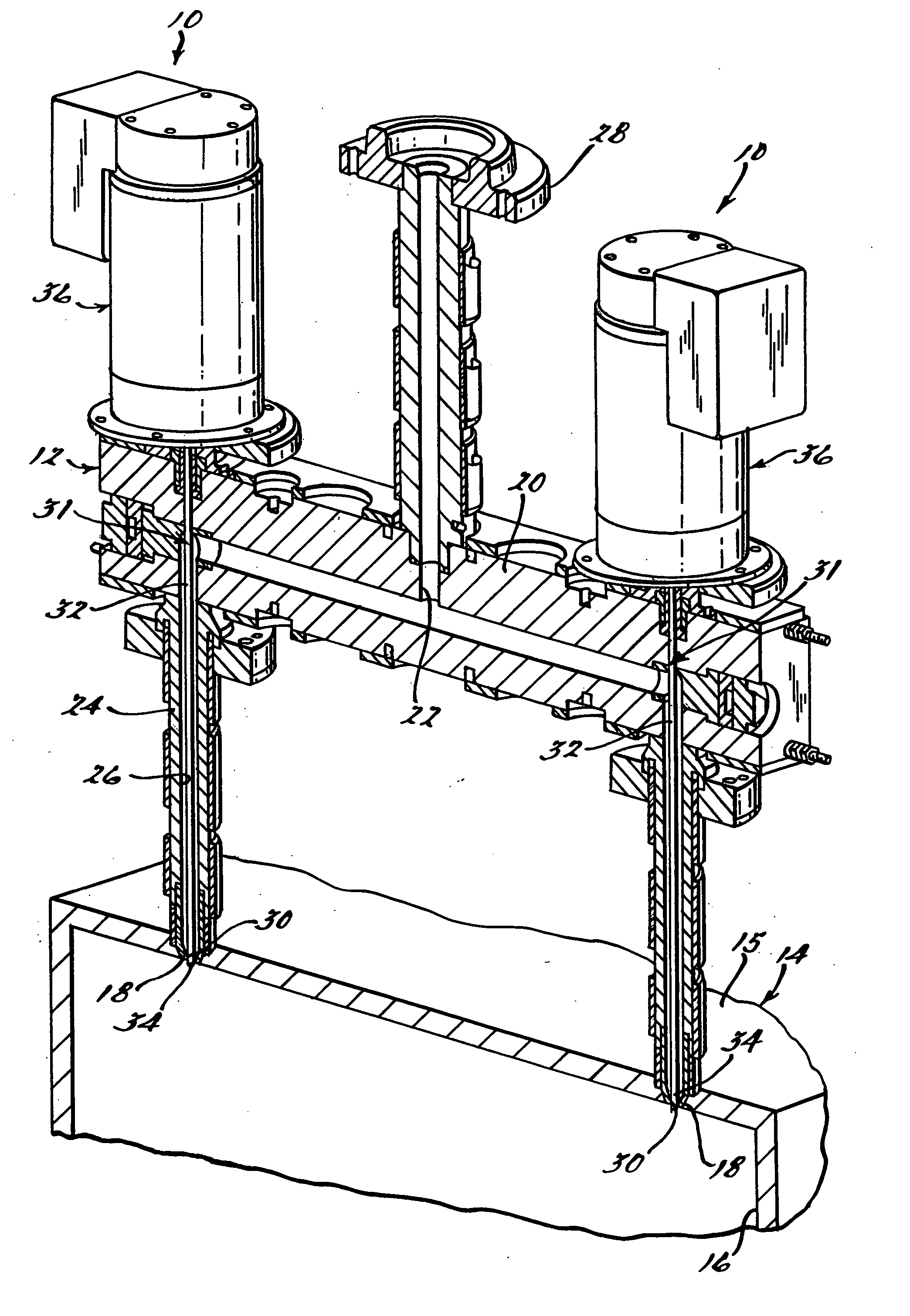

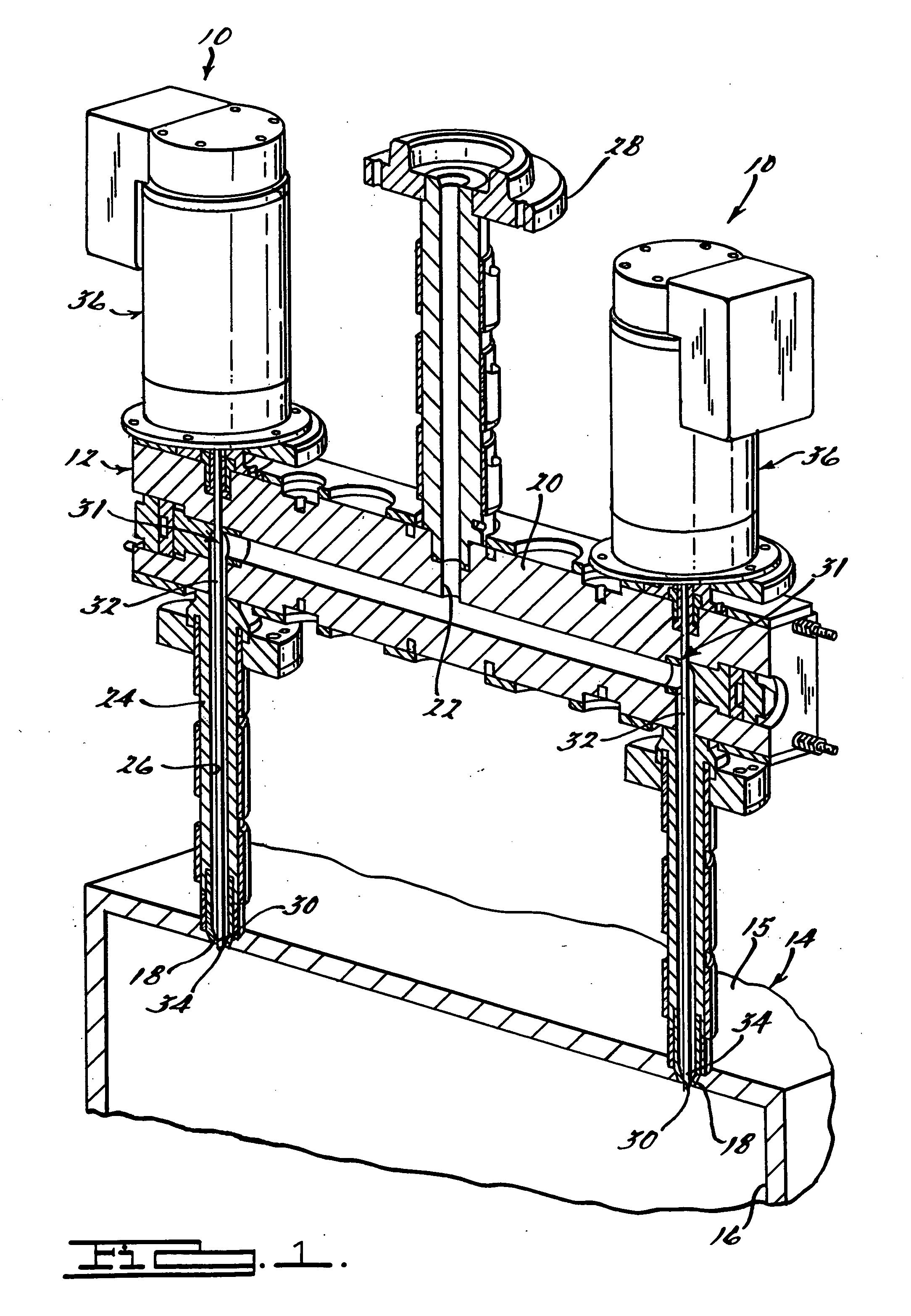

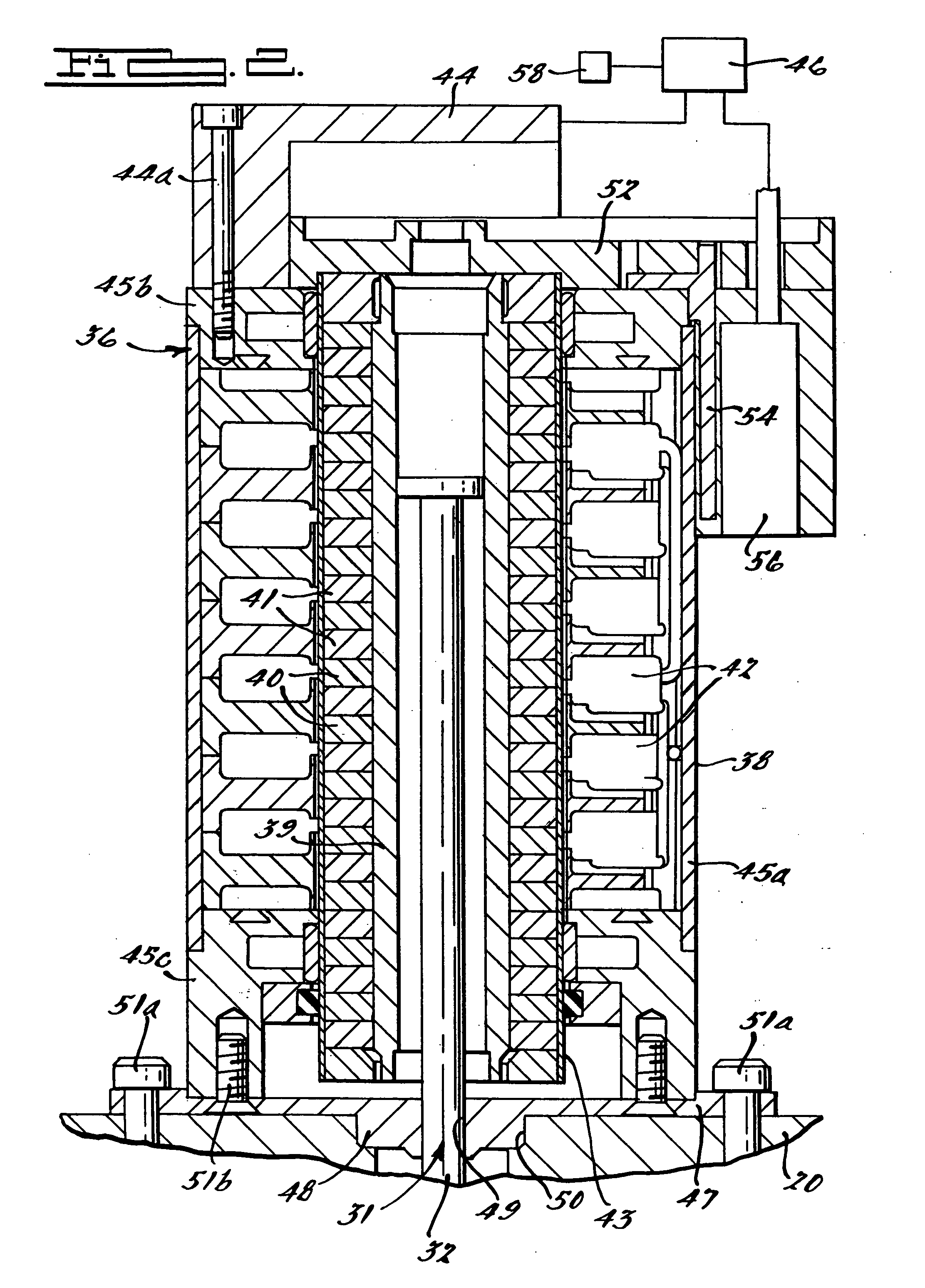

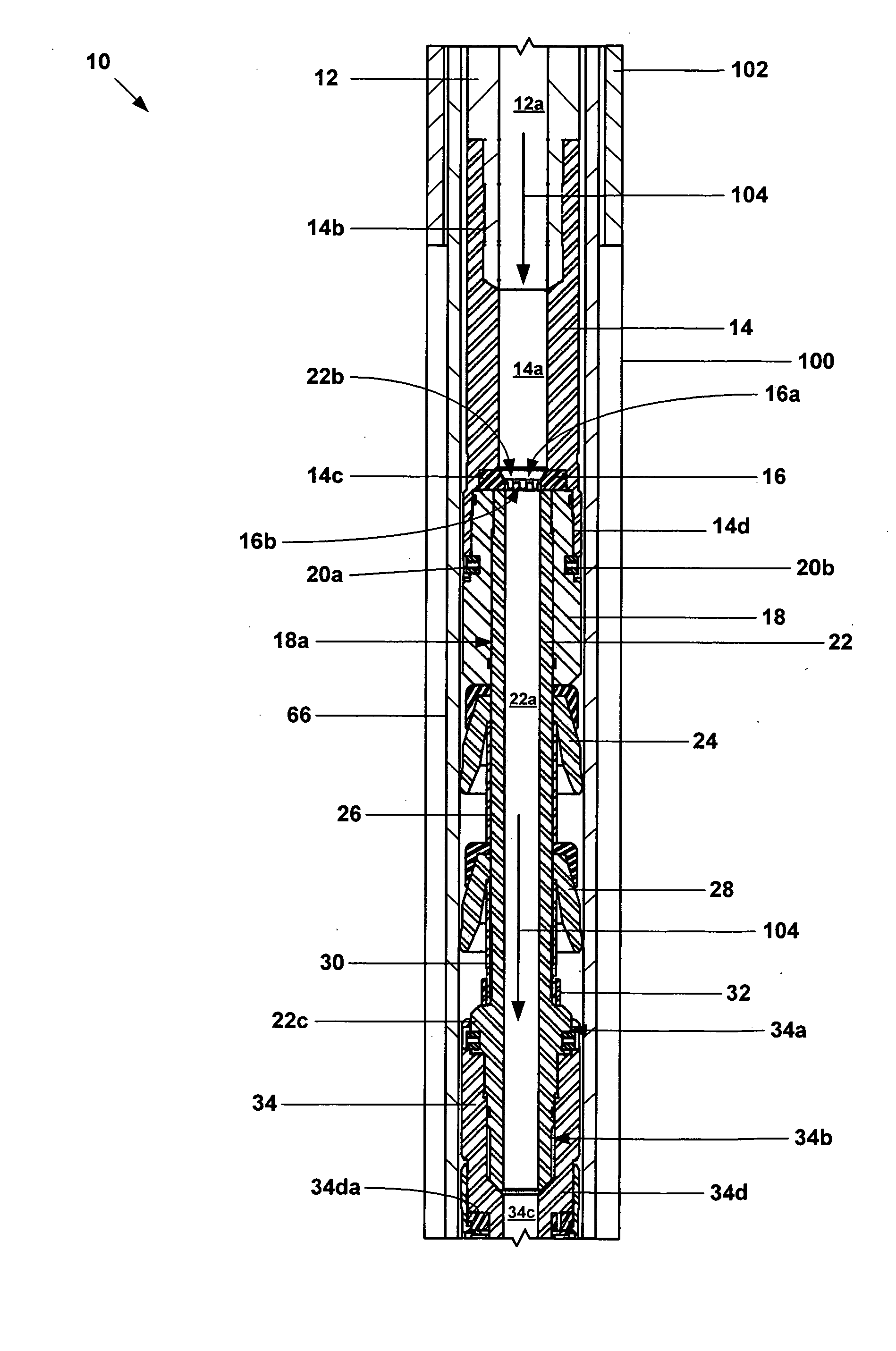

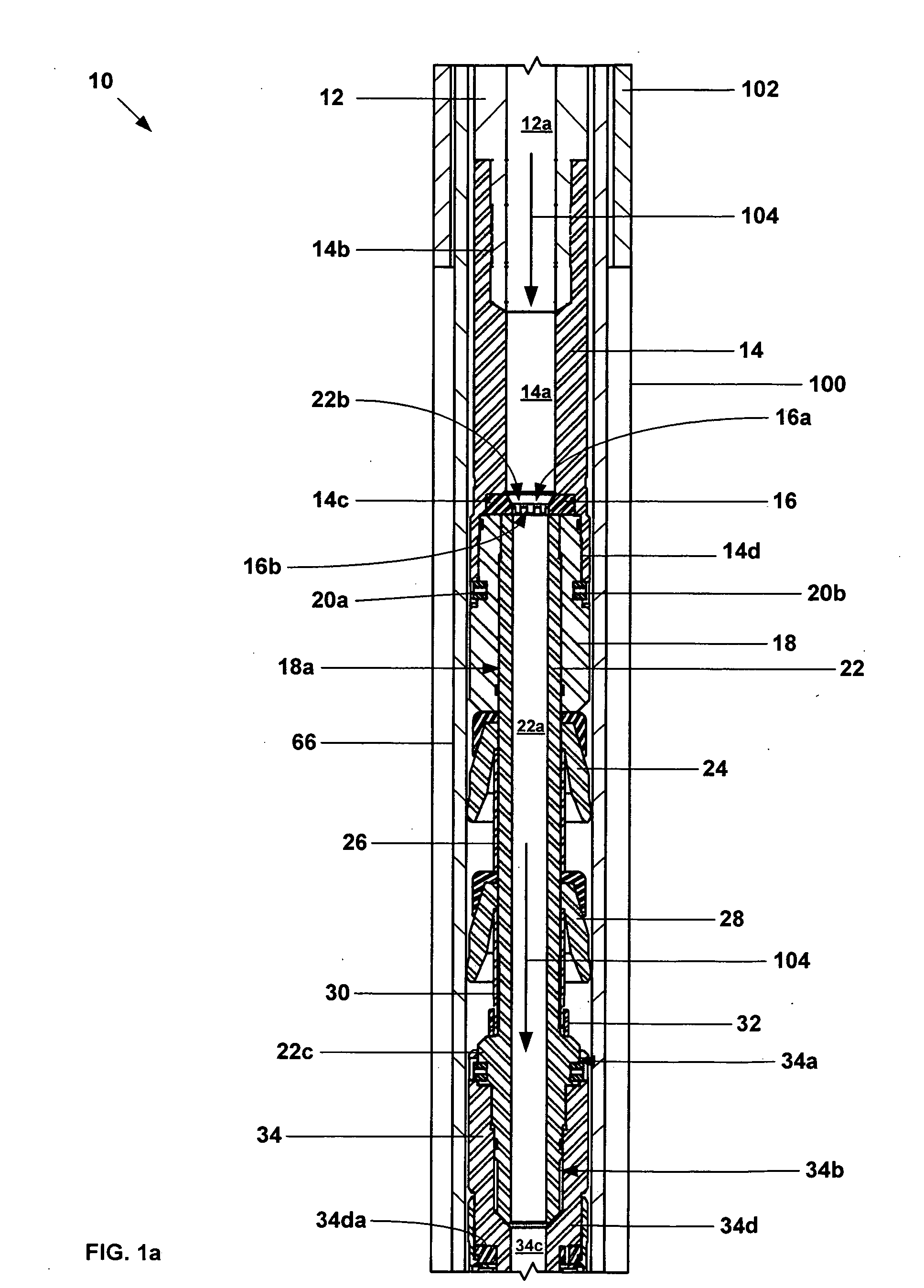

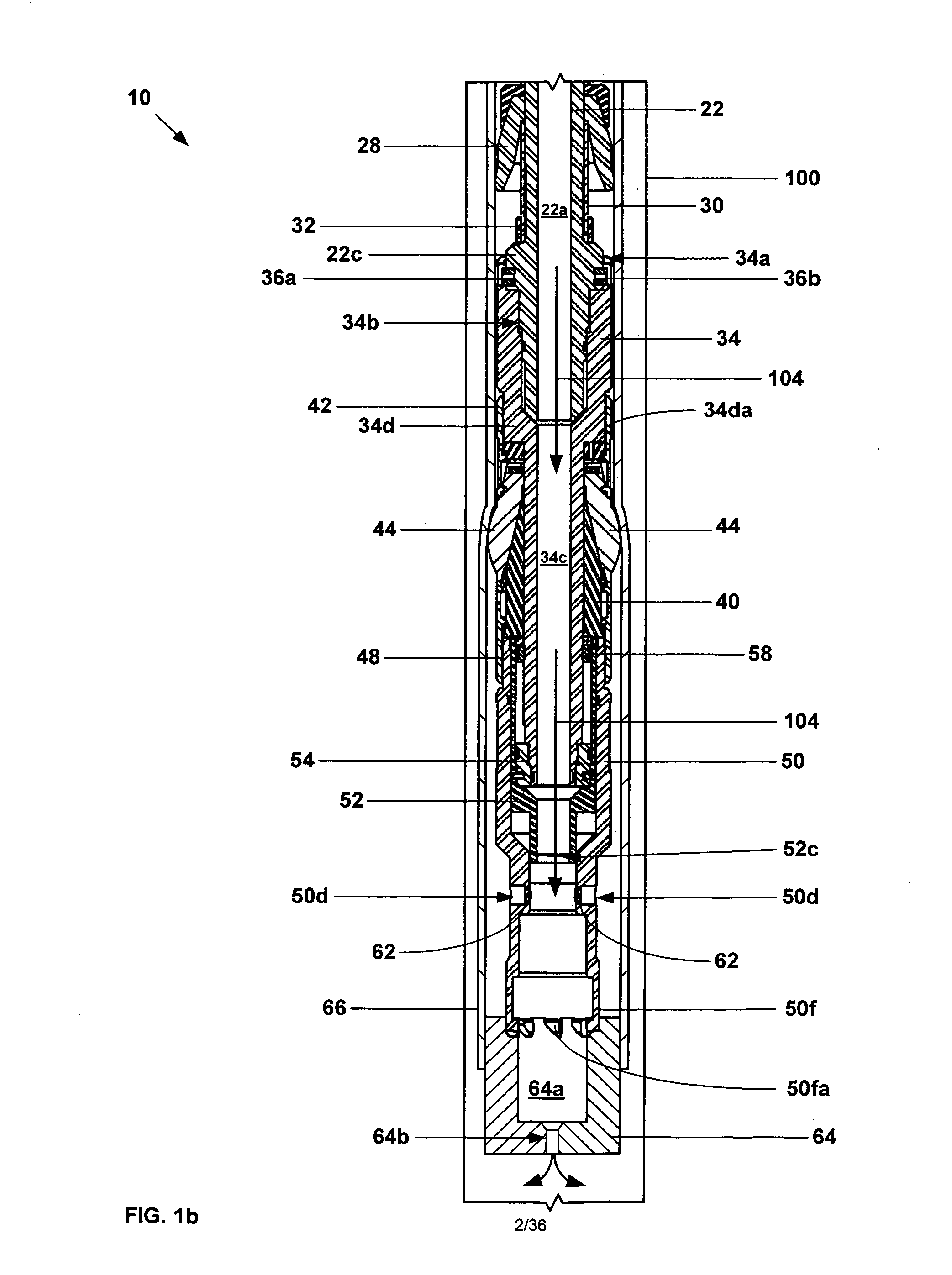

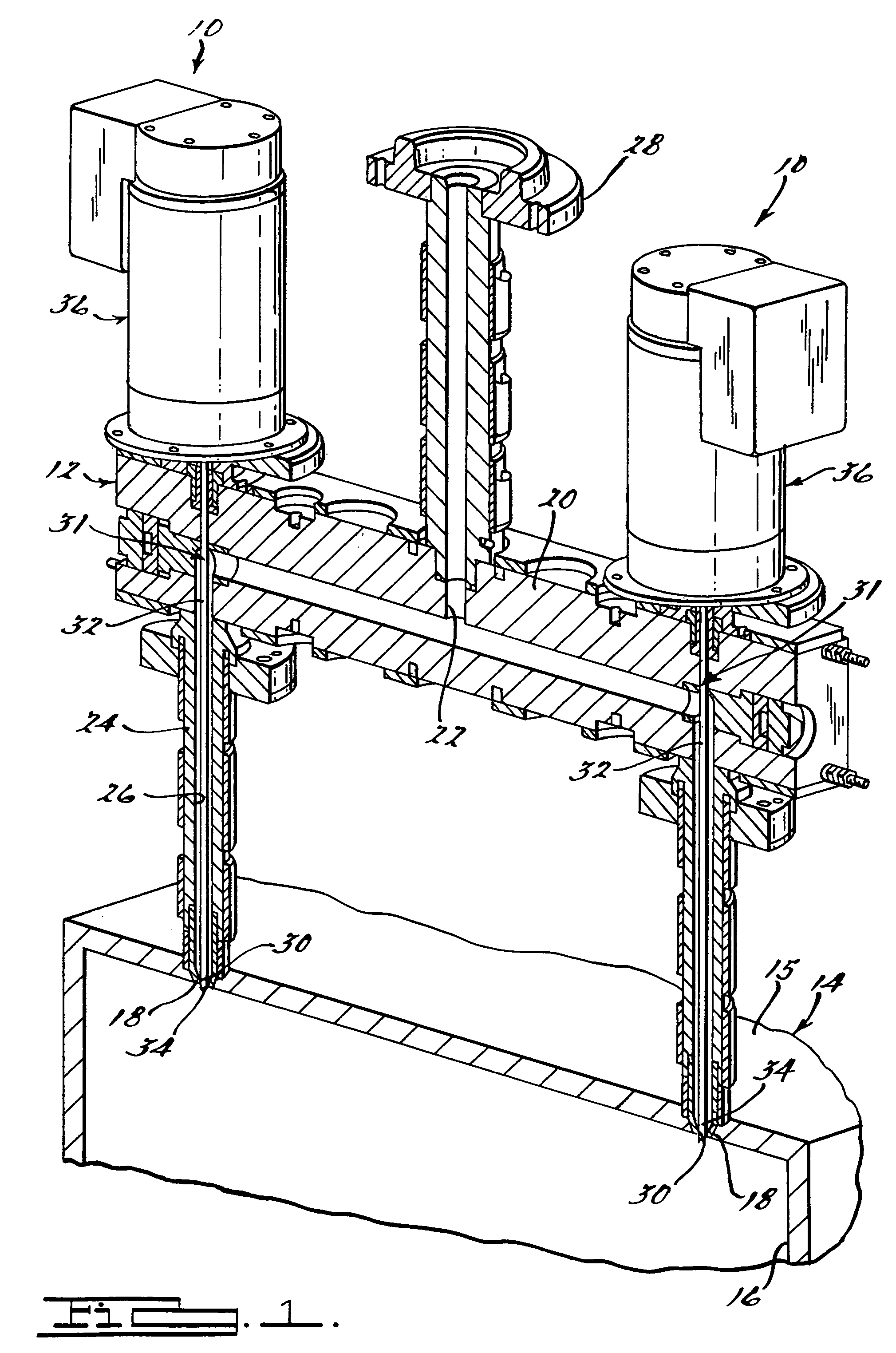

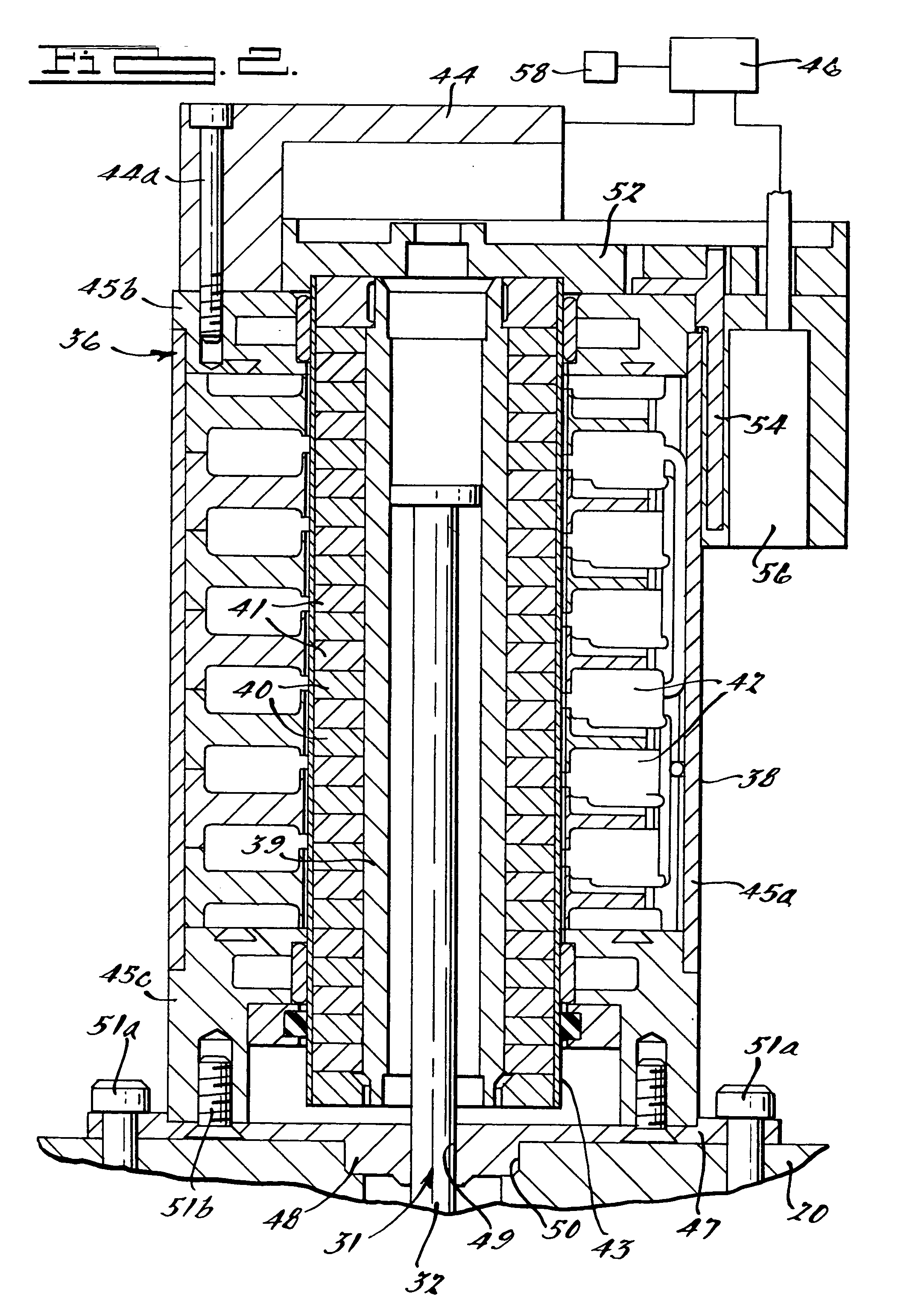

Valve gate assembly

ActiveUS20050100625A1Process controlEasy to adjustButtonsRecord carriersEngineeringMechanical engineering

A valve gate assembly for regulating a flow of molten material into a mold. The valve gate assembly includes a movable valve that can move between a fully closed position and a fully open position. The valve gate assembly further includes an actuating system operatively cooperating with the valve to move the valve and infinitely position the valve between the fully closed position and the fully open position.

Owner:PLASTIC ENG & TECHN SERVICES

Compositions and method for improving reheat rate of PET using activated carbon

ActiveUS20040249113A1Improving reheat rateMinimize impactEnvelopes/bags making machineryButtonsActivated carbonPolyester

A polyester composition, a preform, and a bottle, containing a polyester such as polyethylene terephthalate or polyethylene naphthalate and activated carbon to enhance the rate for reheating the composition is provided. Activated carbon may be added in the presence of active phosphorus containing compounds, or at any stage in the melt phase after prepolymerization and after the polyester polymer is solidified. Polyester concentrates containing activated carbon may be added to bulk polyesters to make preforms suitable for blowing into bottles.

Owner:ALPEK POLYESTER SA DE CV

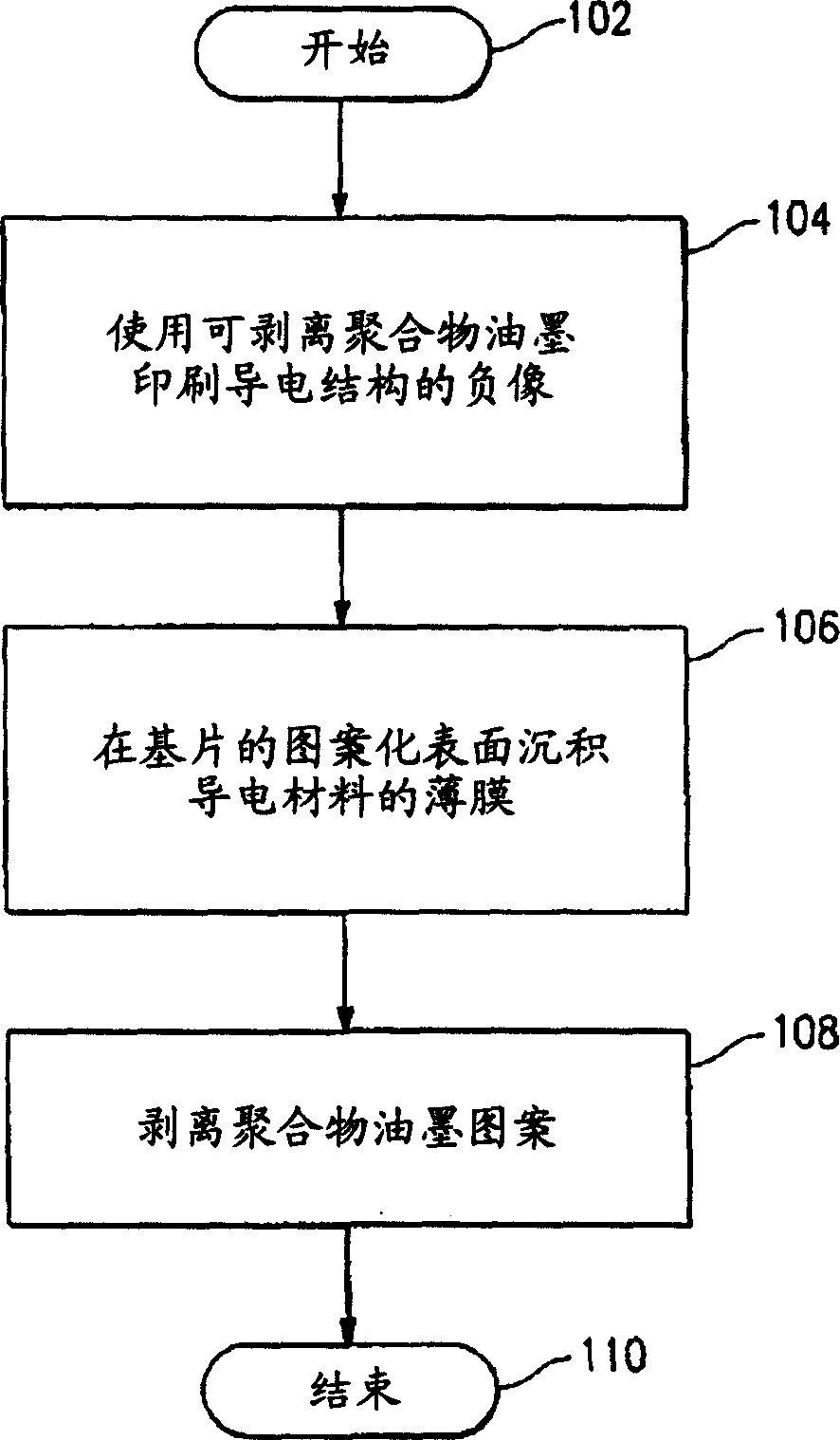

Process for forming a patterned thin film structure for in-mold decoration

A process for forming a patterned thin film structure on a substrate or in-mold decoration film is disclosed. A pattern is printed with a material, such as a masking coating or ink, on the substrate, the pattern being such that, in one embodiment, the desired structures will be formed in the areas where the printed material is not present, i.e., a negative image of thin film structure to be formed is printed. In another embodiment, the pattern is printed with a material that is difficult to strip from the substrate, and the desired thin film structures will be formed in the areas where the printed material is present, i.e., a positive image of the thin film structure is printed. The thin film material is deposited on the patterned substrate, and the undesired area is stripped, leaving behind the patterned thin film structure.

Owner:SIPIX CHEM

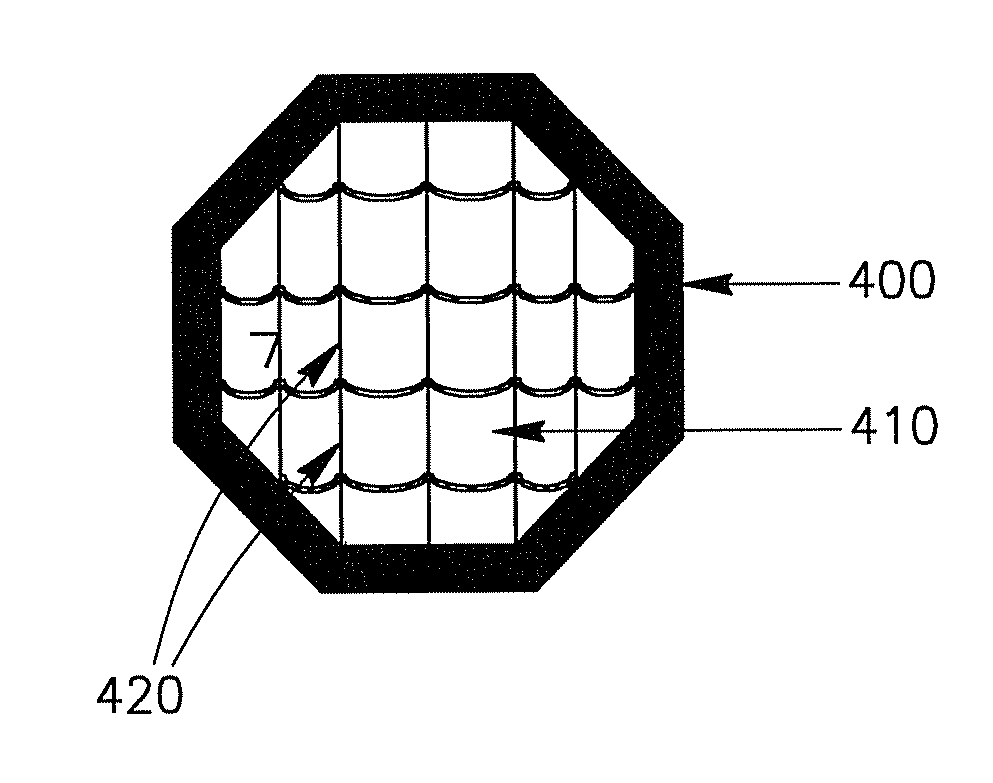

Foam encased innerspring with internal foam components (triple case)

InactiveUS7185379B2Highly variable and tunable support systemIncrease support densityButtonsRecord carriersEngineeringVolumetric Mass Density

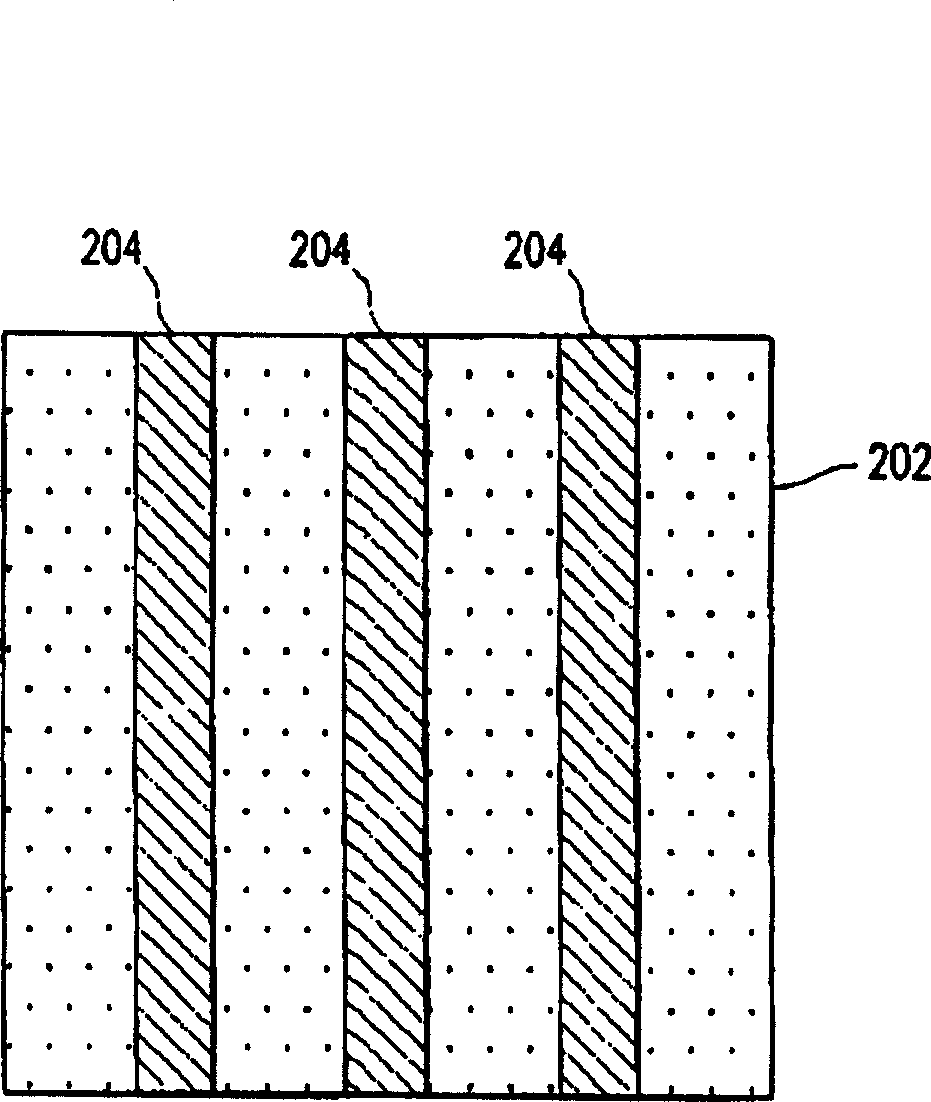

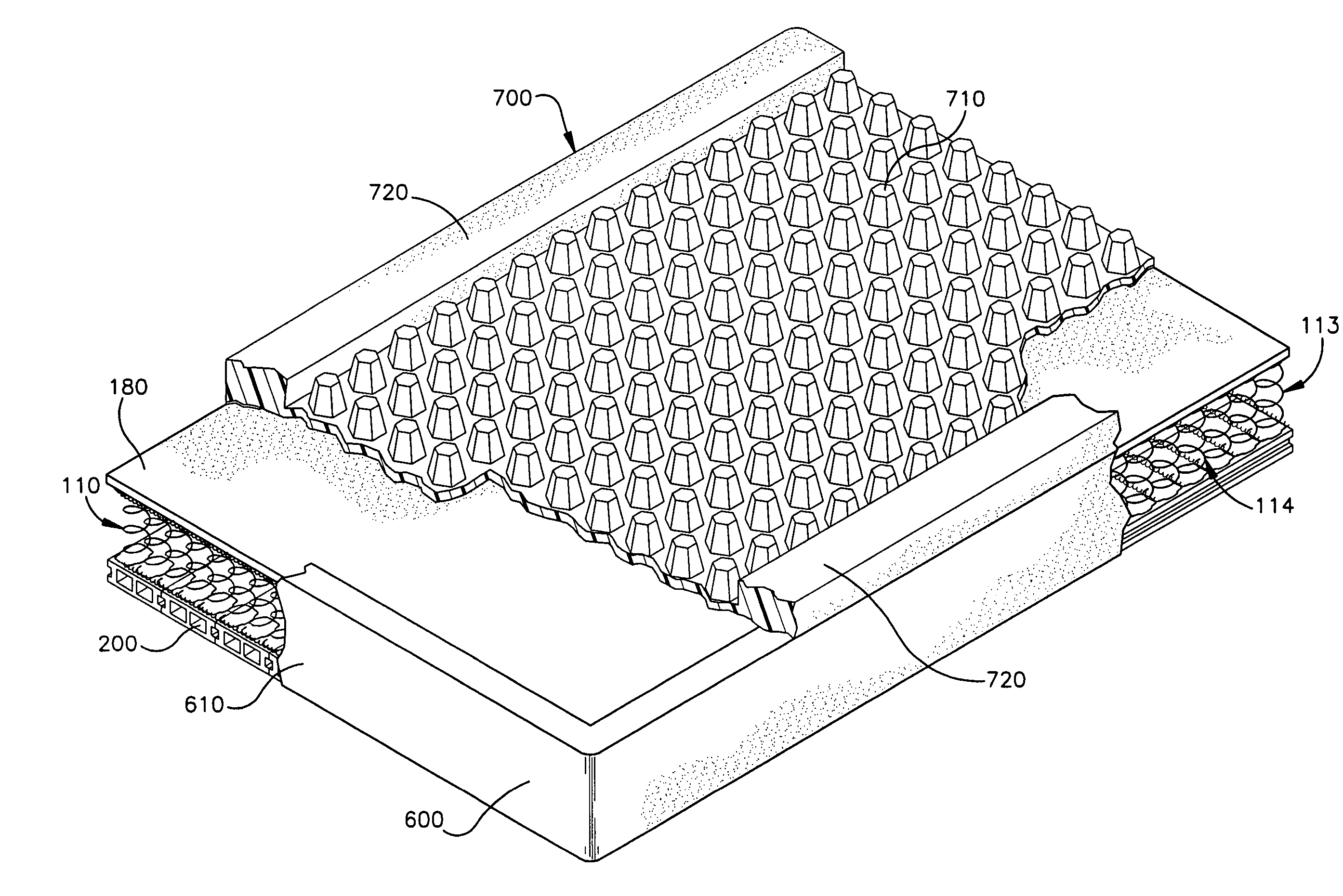

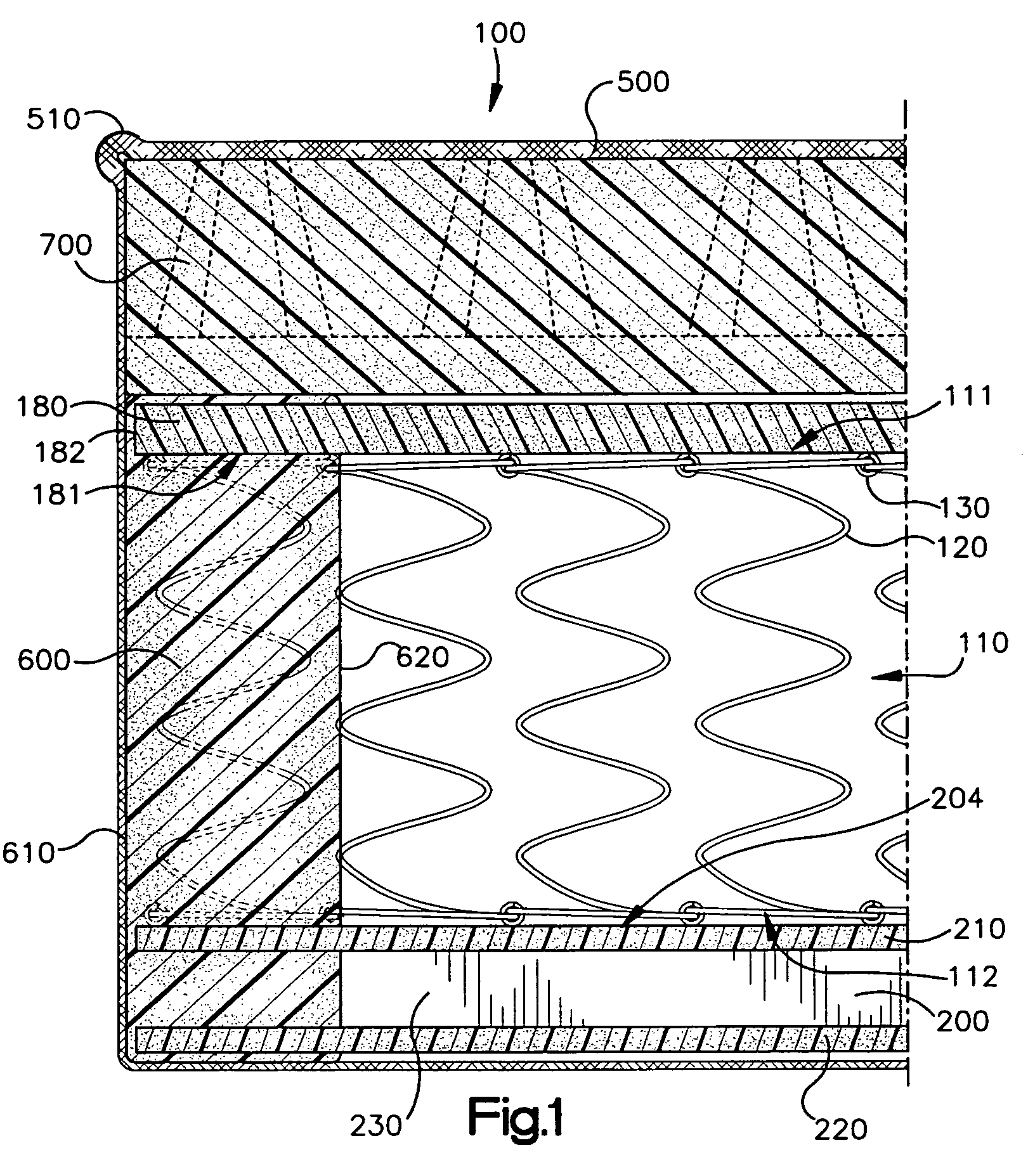

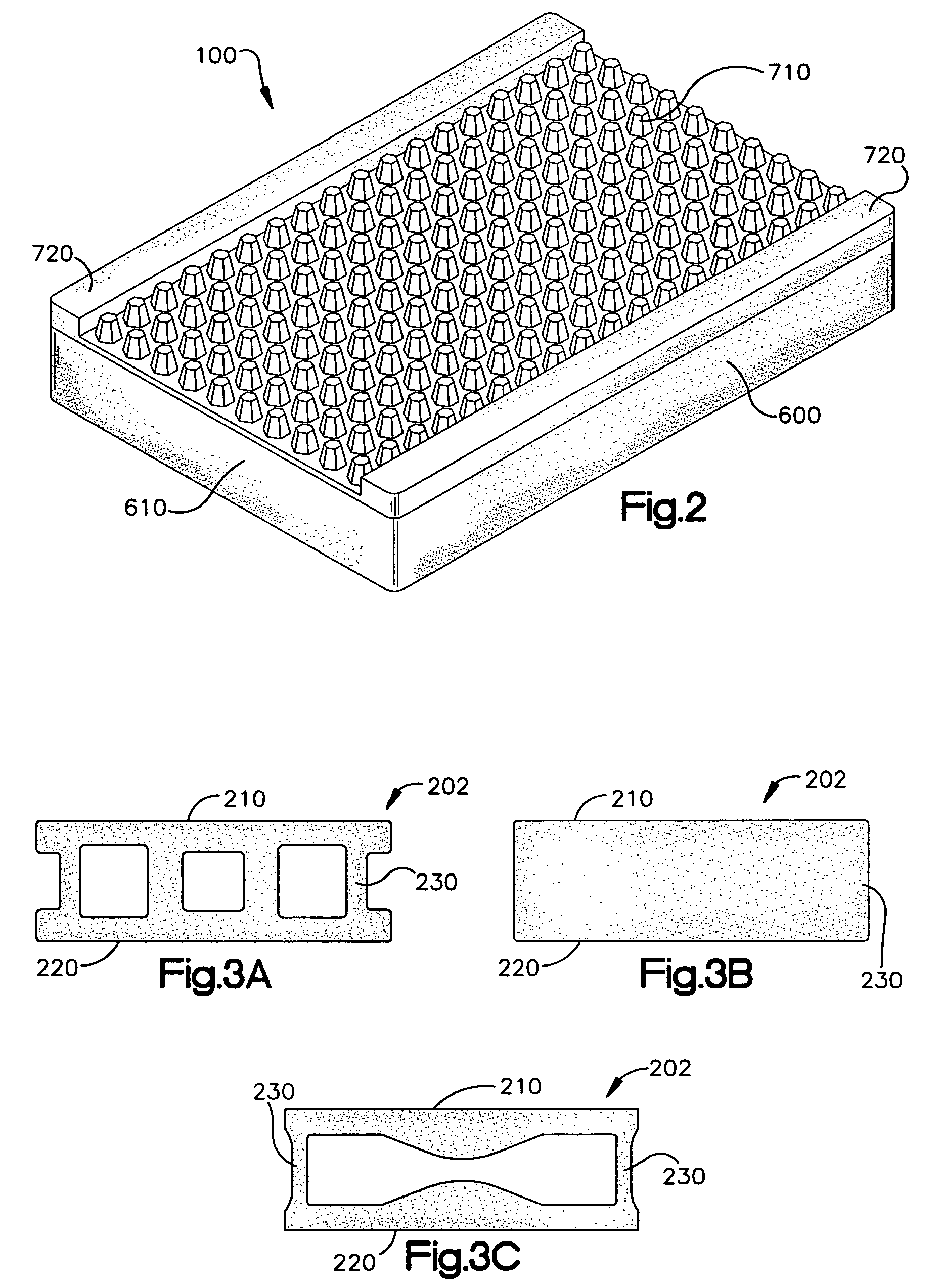

A molded foam-encased integrated flexible support device includes an innerspring positioned upon a three-dimensional thermoplastic foam deck as a flexible foundation, and a molded foam encasement which structurally integrates the foam deck with the innerspring by attachment to perimeter coils of the innerspring. A sculpted foam topper is adhesively bonded to a support surface of the foam-encased innerspring, forming a unitized mattress or support structure with fully integrated innerspring and internal and external foam components. The sculpted foam topper is designed with varying contours and densities to provide the desired support and feel characteristics for different comfort profiles. The foam encased innerspring with internal three-dimensional foam structures is upholstered for use as a mattress, seating, or other flexible support structure.

Owner:SEALY TECH LLC

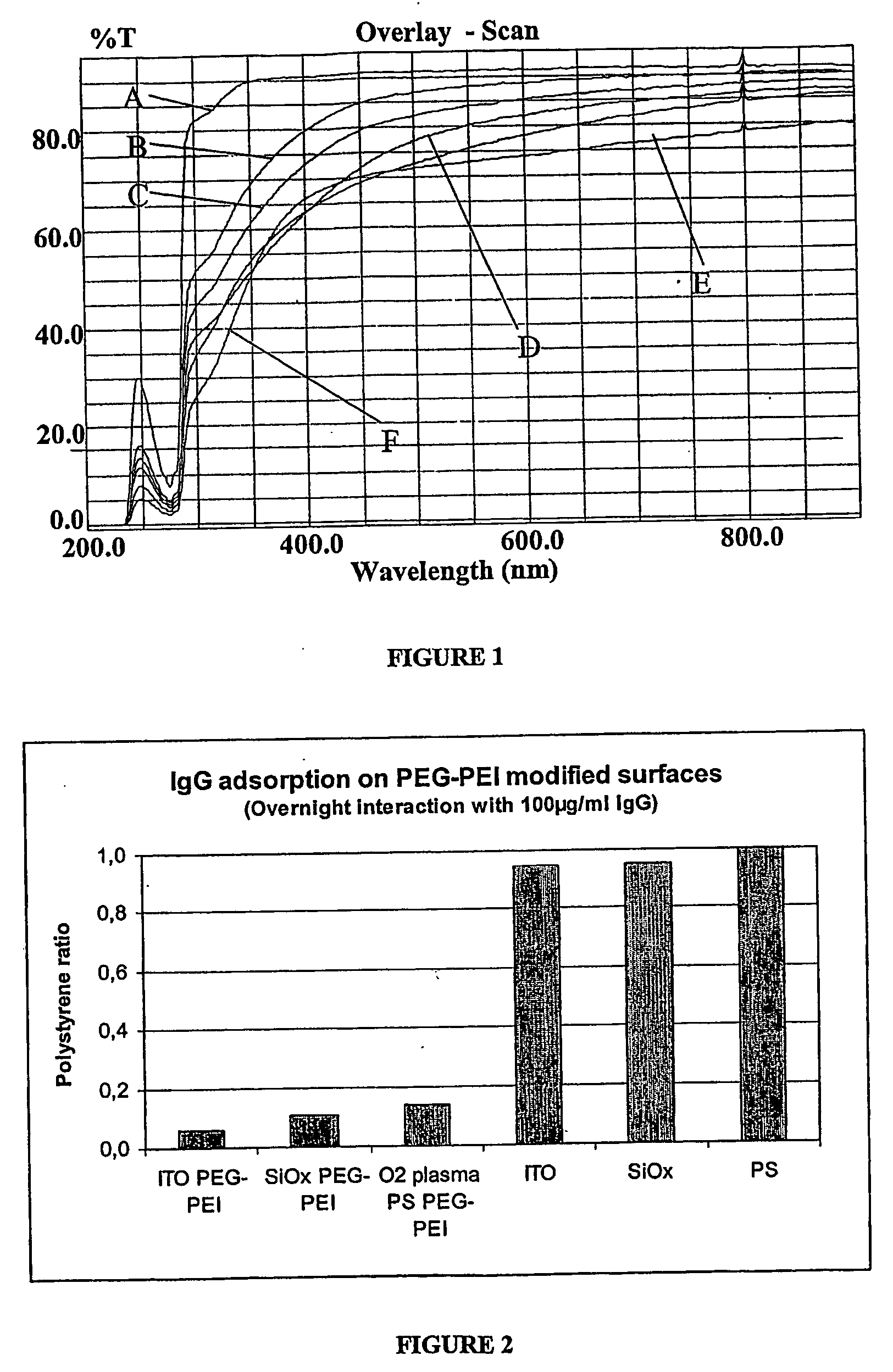

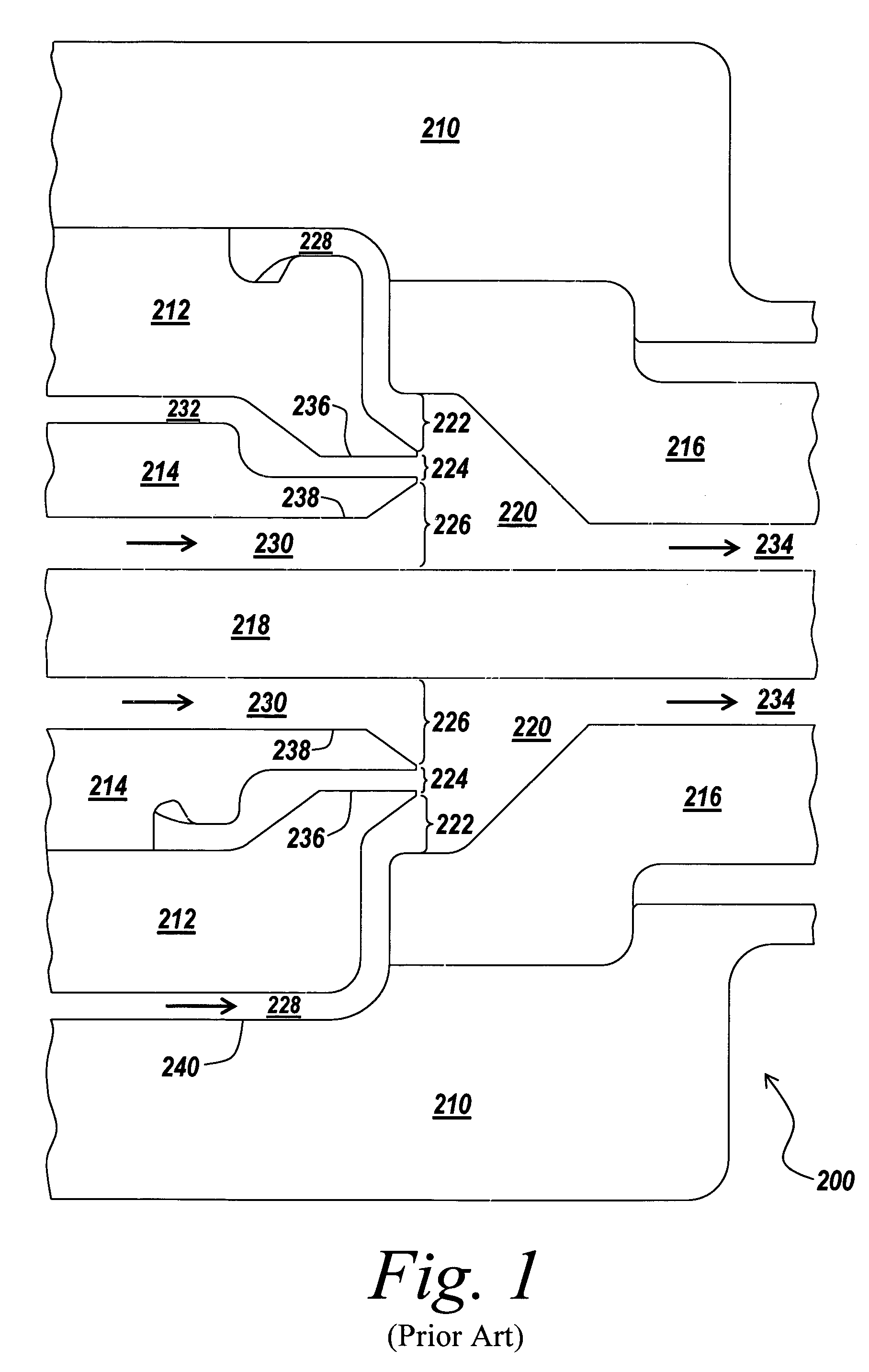

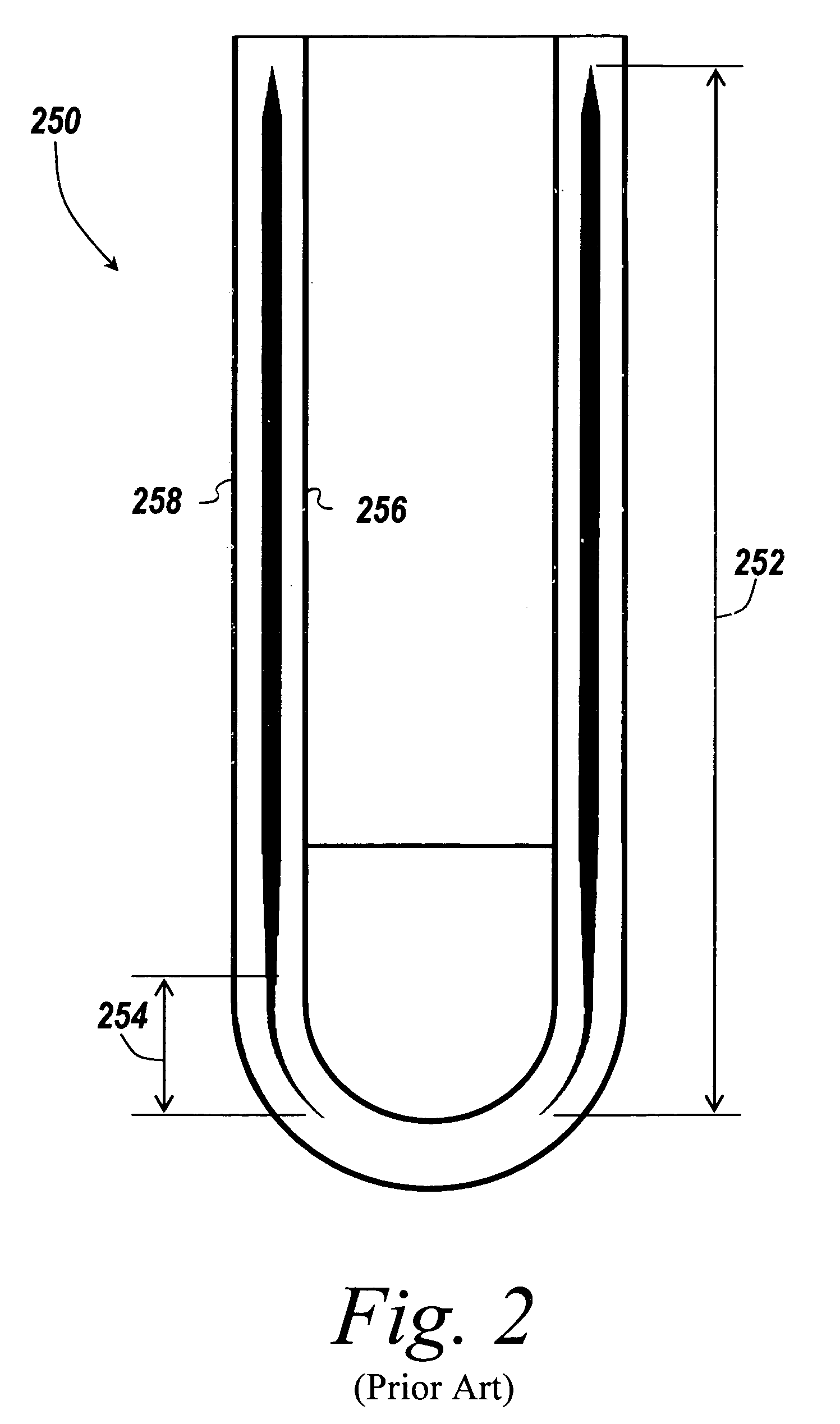

Inner walls of microfluidic devices

A microfluidic device comprising one, two, three or more enclosed microchannel structures, each of which comprises a) an inlet arrangement with an inlet opening for liquid, b)a reaction microcavity (RM1) downstream to the inlet opening, and c) an upstream section that is located between the inlet opening and the reaction microcavity (RM1) and is defined between two planar substrates made of plastic material which substrates are common for said microchannel structures. The characteristic feature is that the inner wall in said upstream section exposes a hydrophilic surface area with an underlying base layer comprising metal oxide. In one aspect the microfluidic device as such is covered.

Owner:GYROS

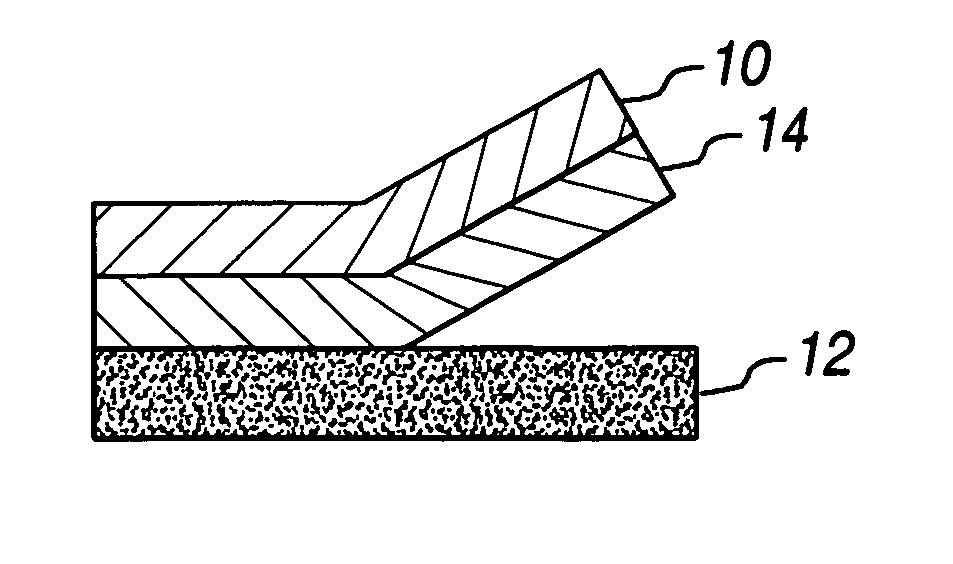

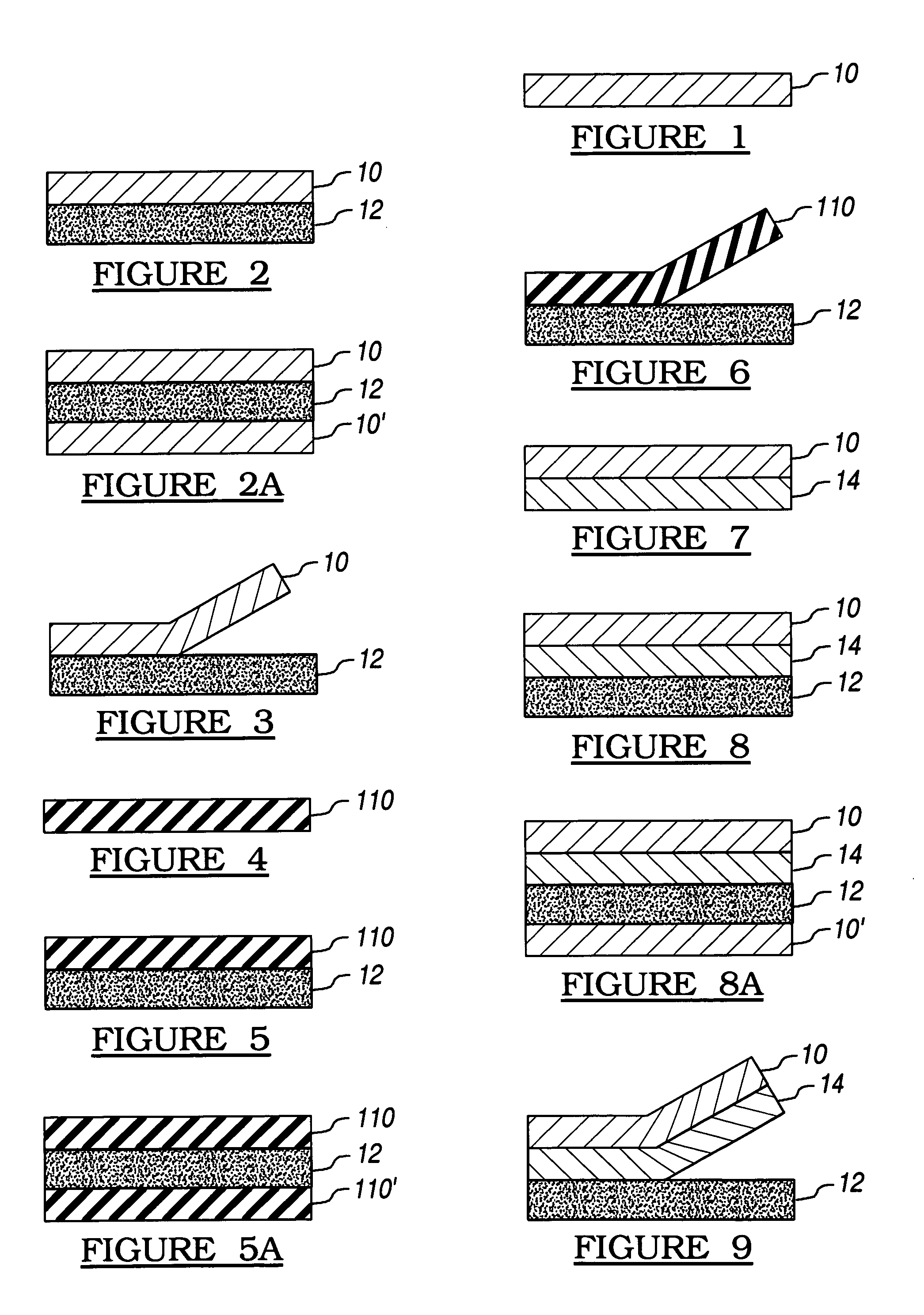

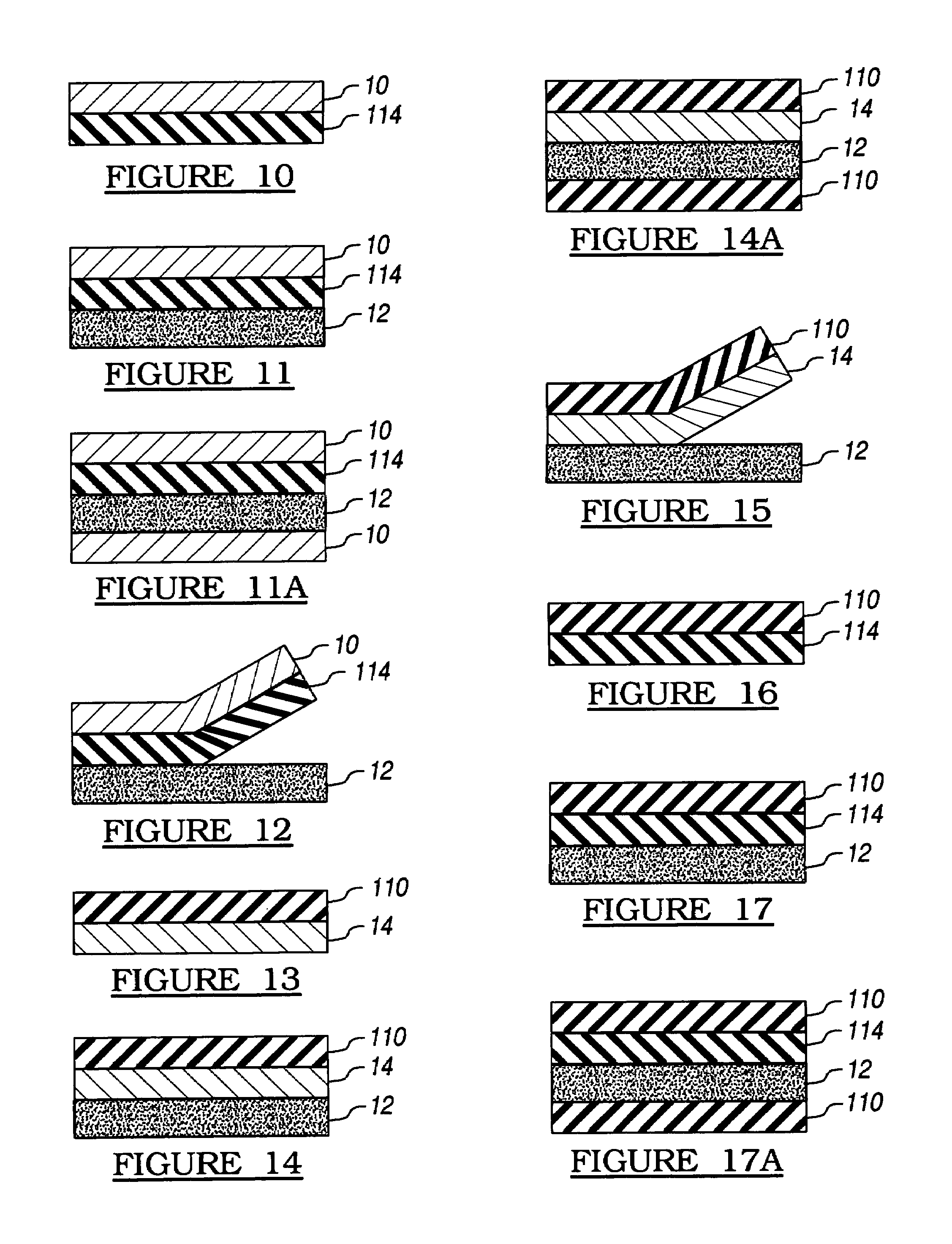

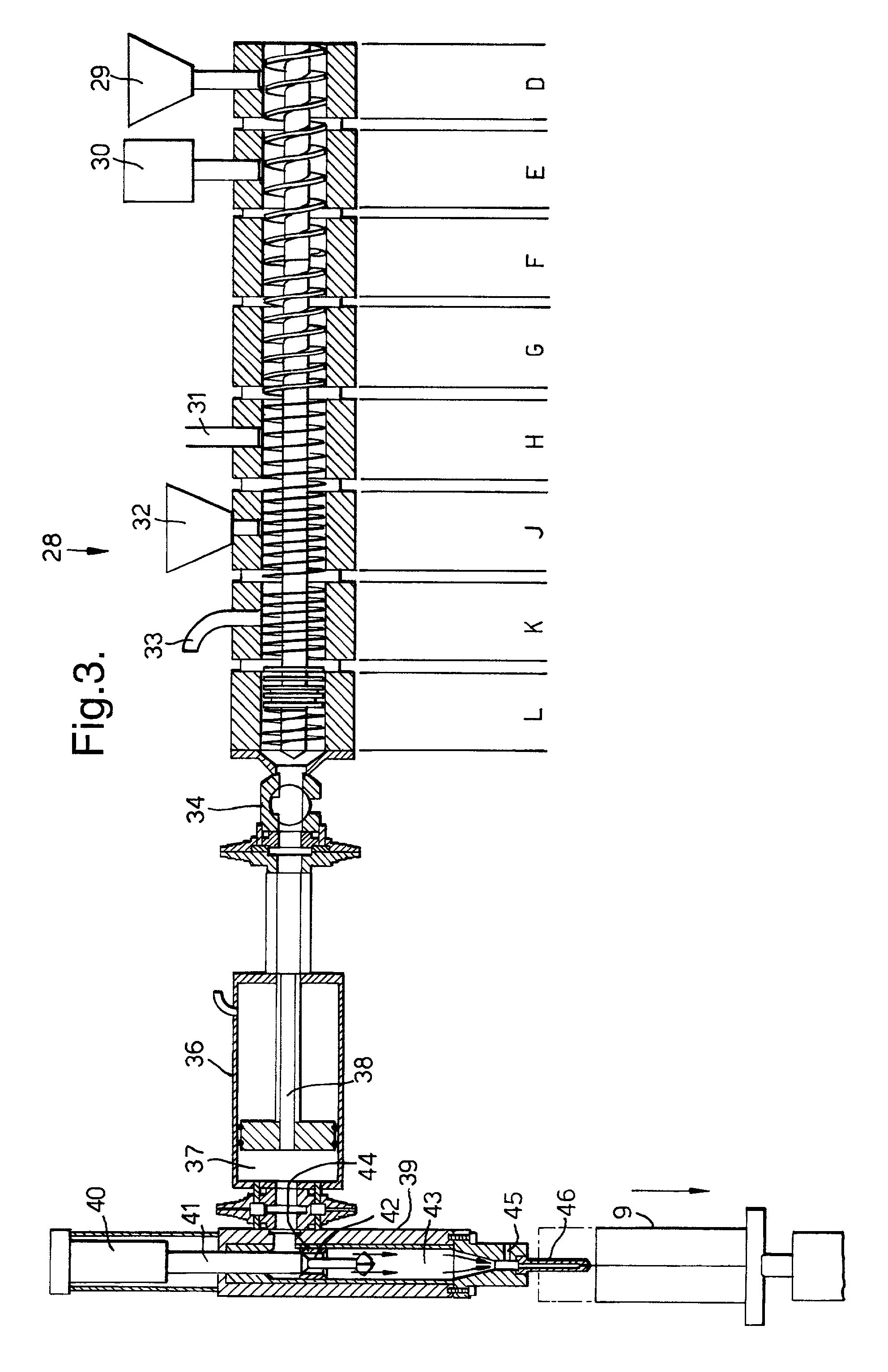

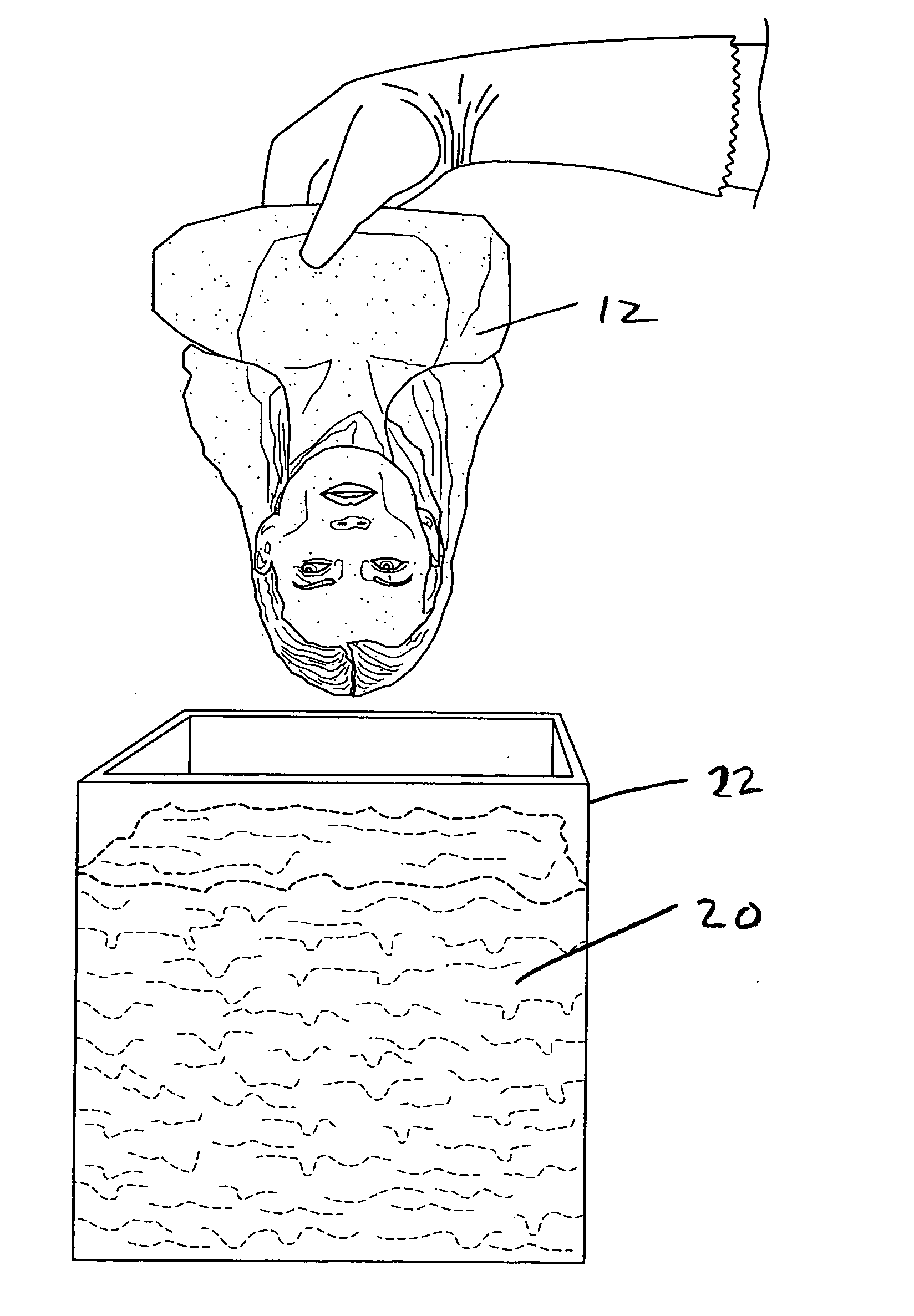

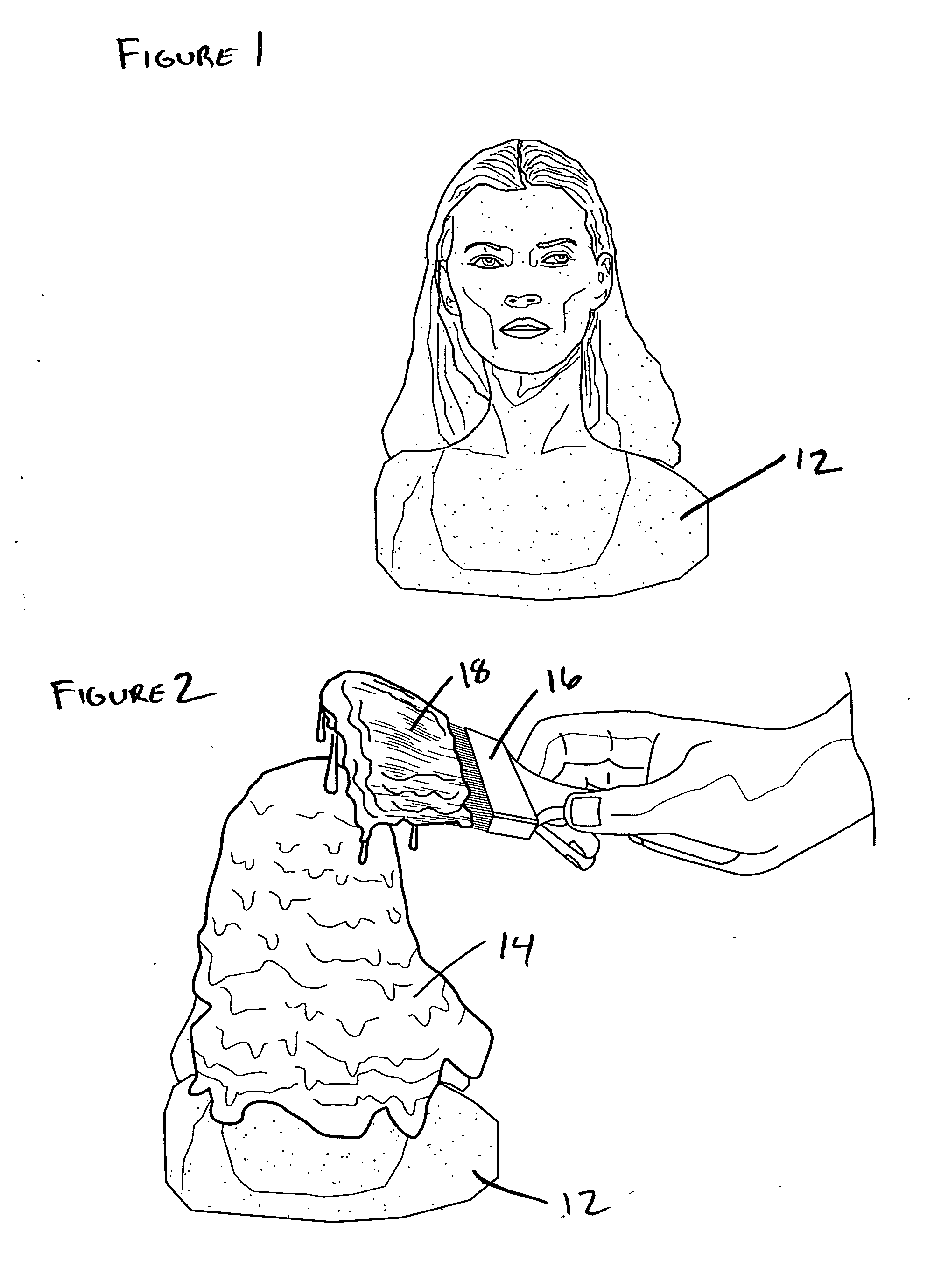

Decorative system composite and method

InactiveUS7144612B2High tensile strengthAvoid feature lossButtonsRecord carriersThermoformingCombined use

Owner:BOBS HLDG

Image processing method and system for microfluidic devices

InactiveUS7583853B2Increase speedHigh sensitivityImage enhancementButtonsImaging processingState dependent

A method for processing an image of a microfluidic device. The method includes receiving a first image of a microfluidic device. The first image corresponds to a first state. Additionally, the method includes receiving a second image of the microfluidic device. The second image corresponds to a second state. Moreover, the method includes transforming the first image and the second image into a third coordinate space. Also, the method includes obtaining a third image based on at least information associated with the transformed first image and the transformed second image, and processing the third image to obtain information associated with the first state and the second state.

Owner:FLUIDIGM CORP

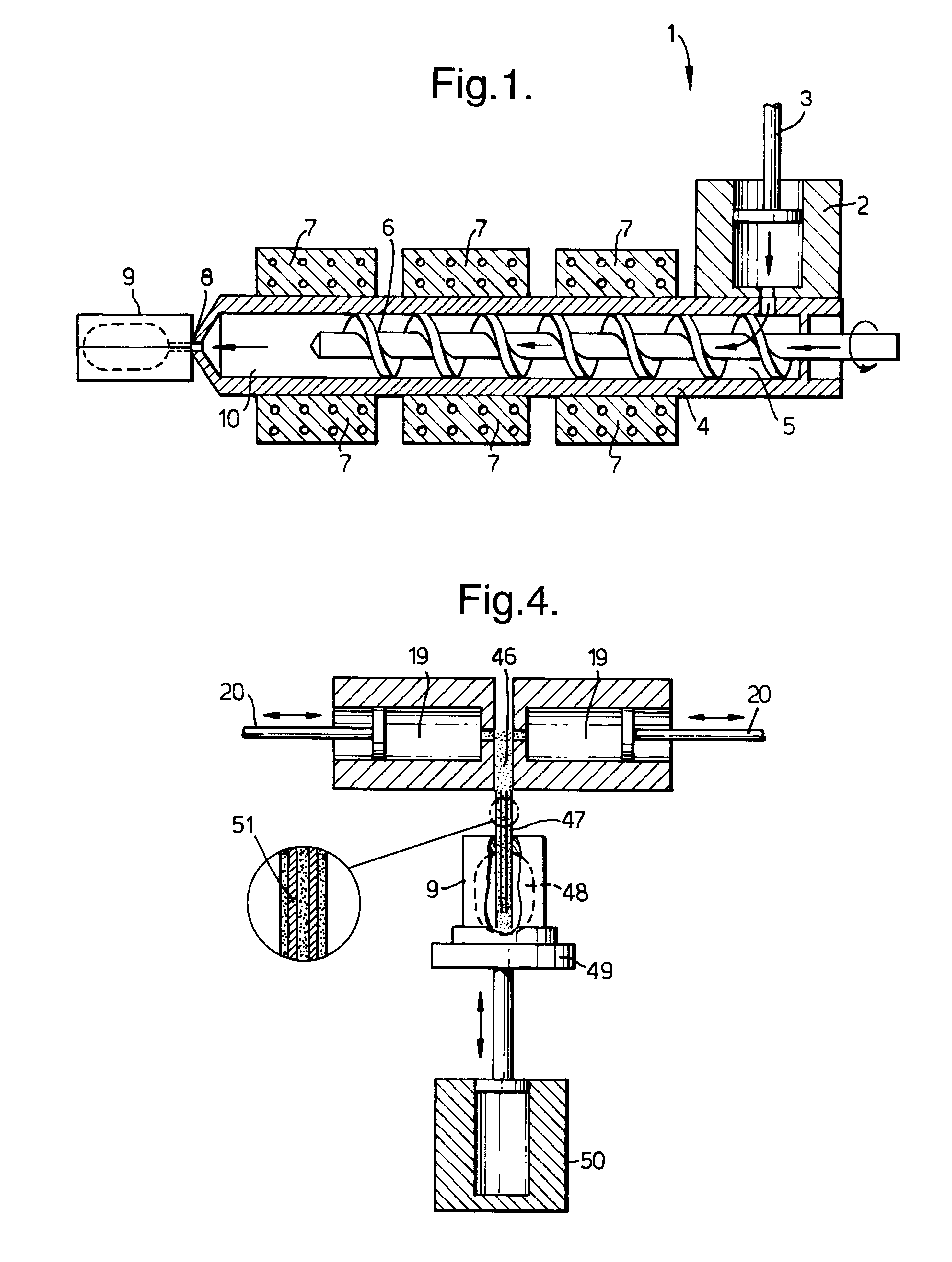

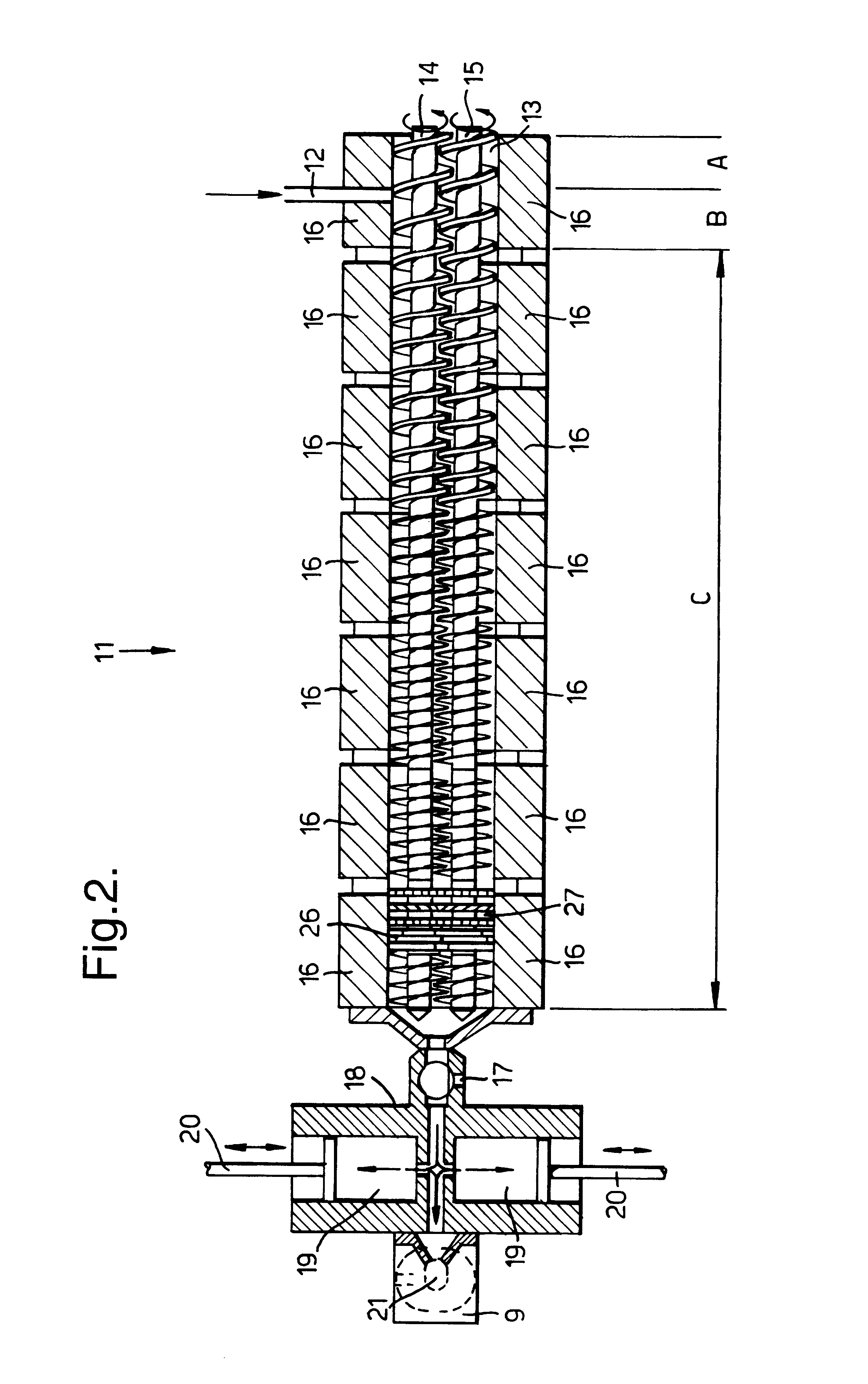

Process for molding of a detergent composition

InactiveUS6224812B1Reduce operating costsLower operating temperatureButtonsRecord carriersShell moldingSemi solid

A process for forming detergent bars by injection moulding in which a pressure is applied to a partially structured detergent composition to deliver it to a mould. The detergent composition can be delivered to the mould in a substantially semi-solid state, at a temperature below 70° C. and at a pressure at the point of injection of greater than 20 psi. Apparatus for forming detergent bars according the invention are also described

Owner:LEVER BROTHERS

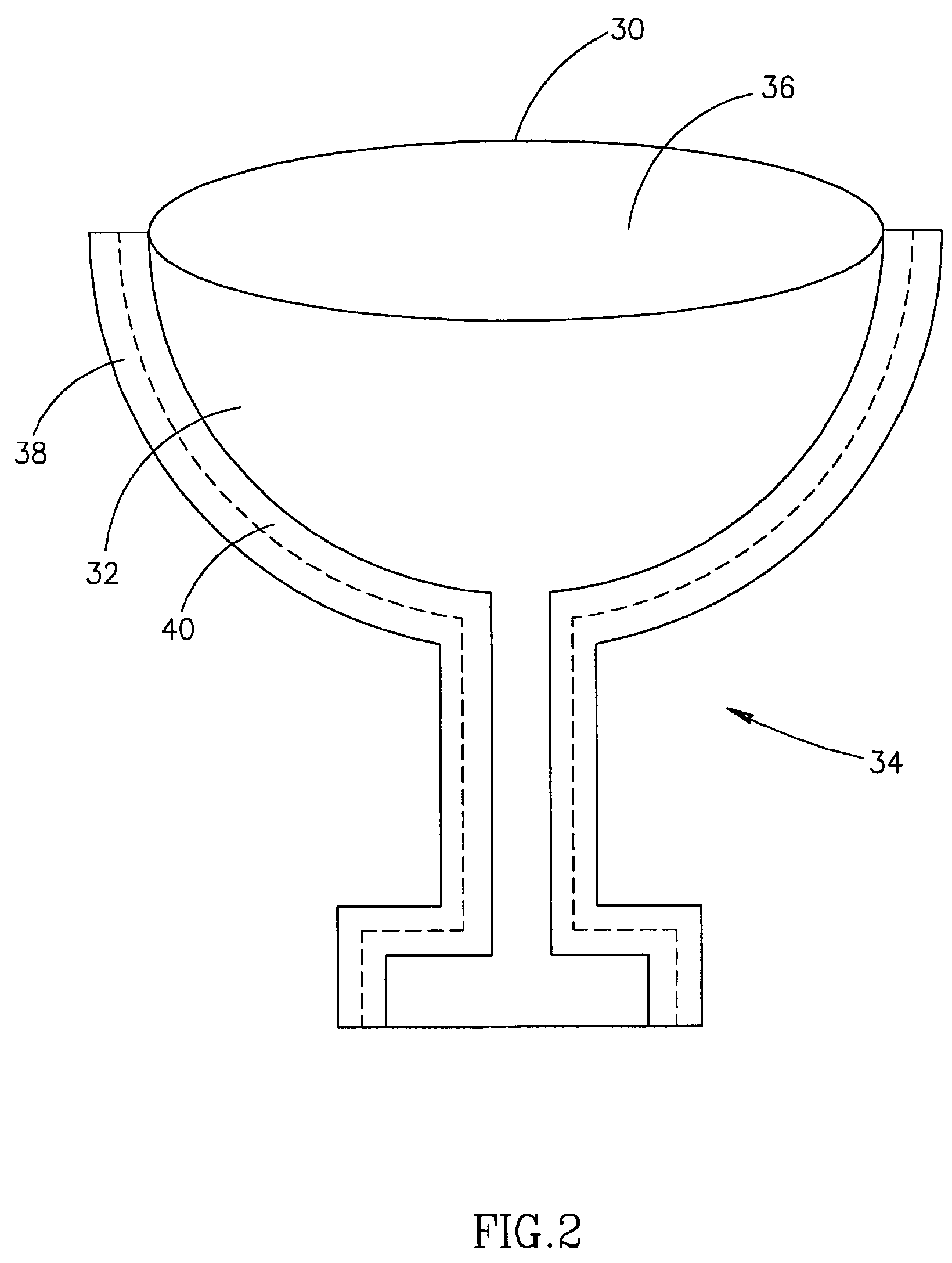

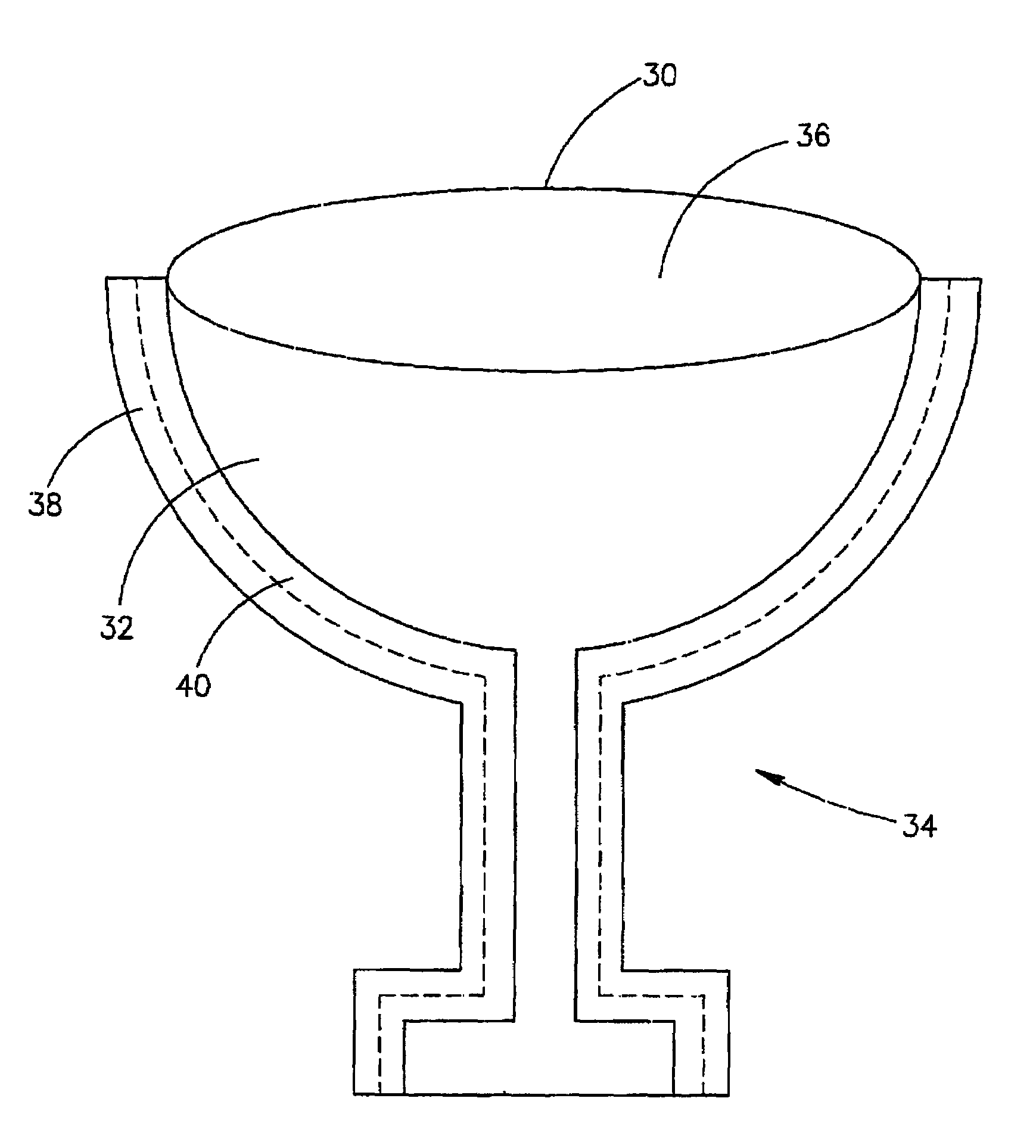

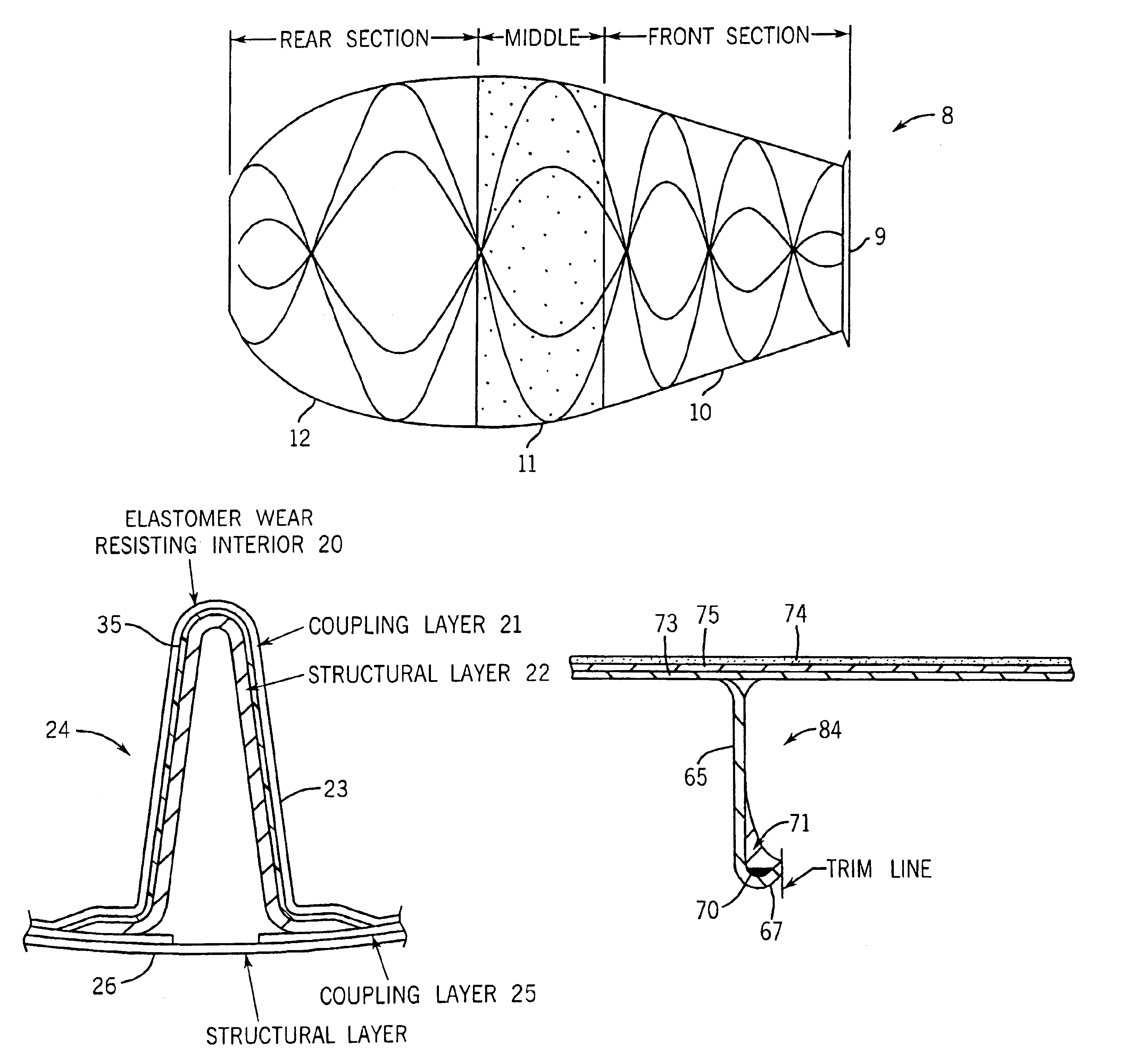

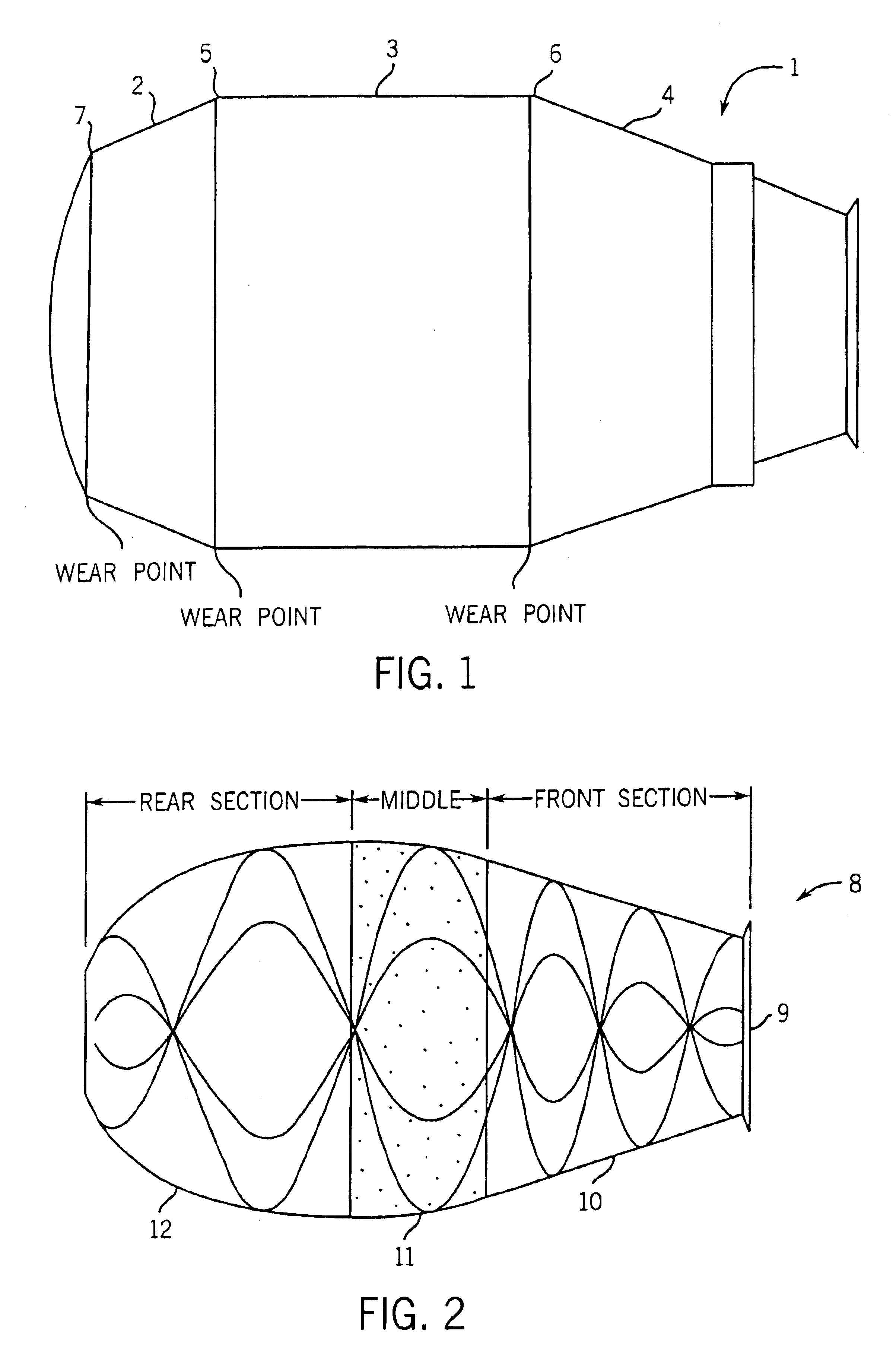

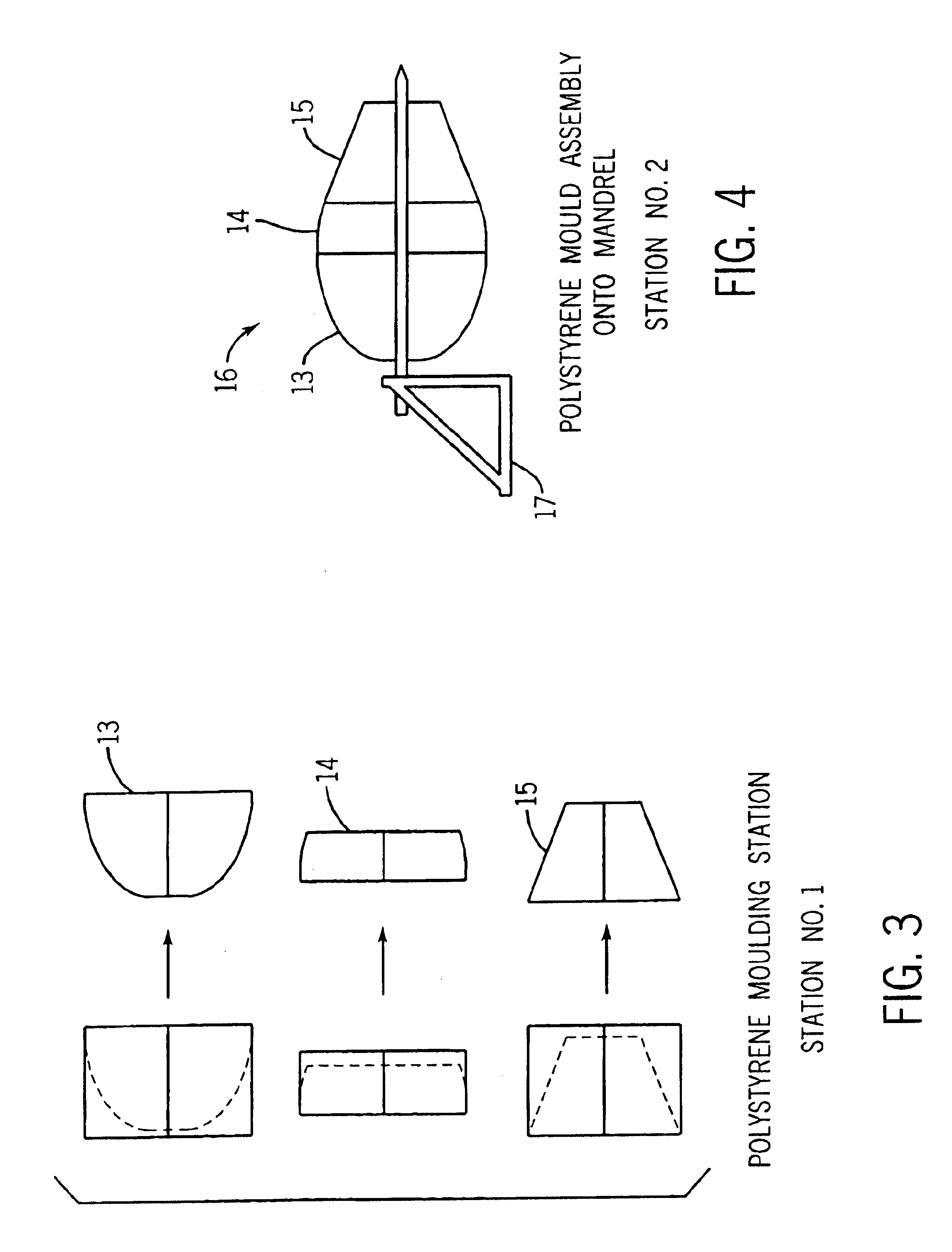

Plastics drum for concrete mixing and methods of manufacture thereof

InactiveUS6902311B1Prolong lifeGood mixing propertiesRotating receptacle mixersButtonsHeavy dutyCivil engineering

A heavy duty rotary concrete mixing drum capable of attachment to a vehicle. The drum comprises a first end which engages a vehicle powered drive assembly which rotates the drum for mixing of said concrete and a second end from which mixed concrete is discharged. The drum is manufactured from at least one layer of plastics material; wherein the drum includes a wall having integral internal formations which promote mixing and discharge of said concrete and an inner surface which promotes mixing of the concrete.

Owner:KHOURI ANTHONY

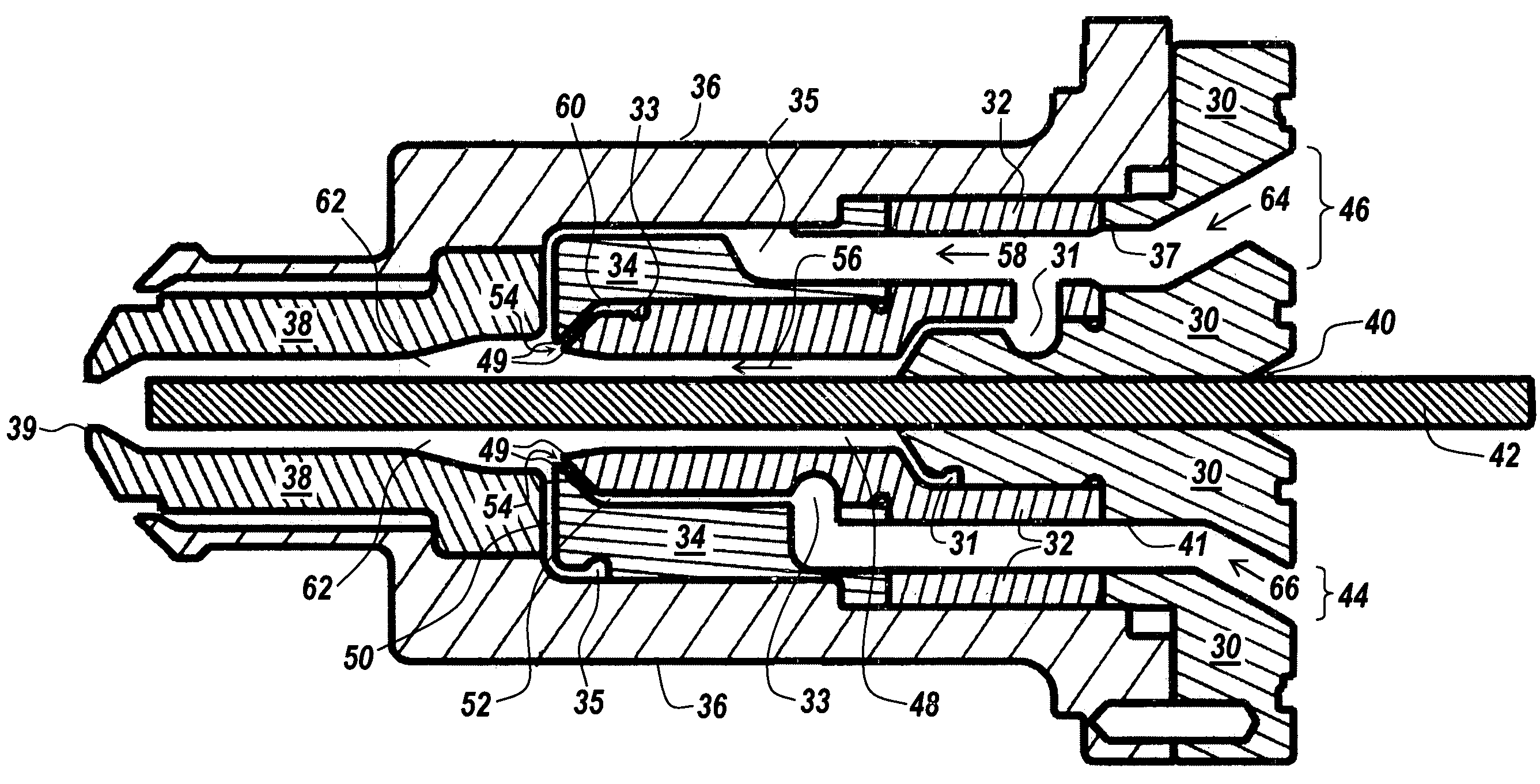

Co-injection nozzle with improved interior layer termination

ActiveUS7306446B2Easy to controlImproved barrier layer protectionButtonsRecord carriersEngineeringCo injection

Disclosed herein are a method and apparatus for combining two or more streams of a polymeric material to form a plastic object. The method and apparatus are capable of ending an interior layer of the plastic object at a desired length to avoid the need to clean selected surfaces of components used to form the plastic object. The method and apparatus increase the velocity of the polymeric material used to form the plastic object in certain components used to form the plastic object. The increase in the velocity of the polymeric material facilitates the ending of the interior layer of the plastic object.

Owner:CINCINNATI MILACRON INC

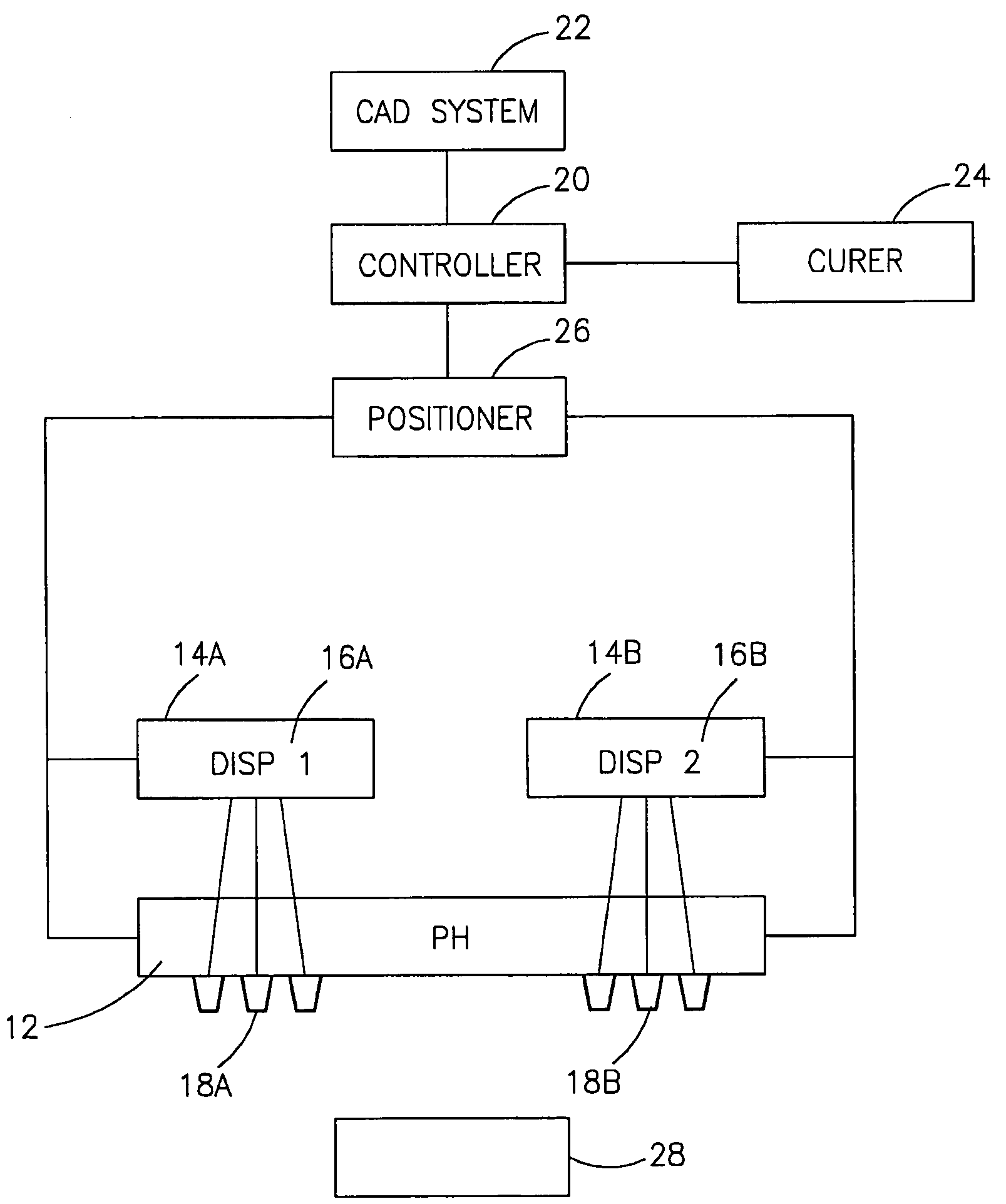

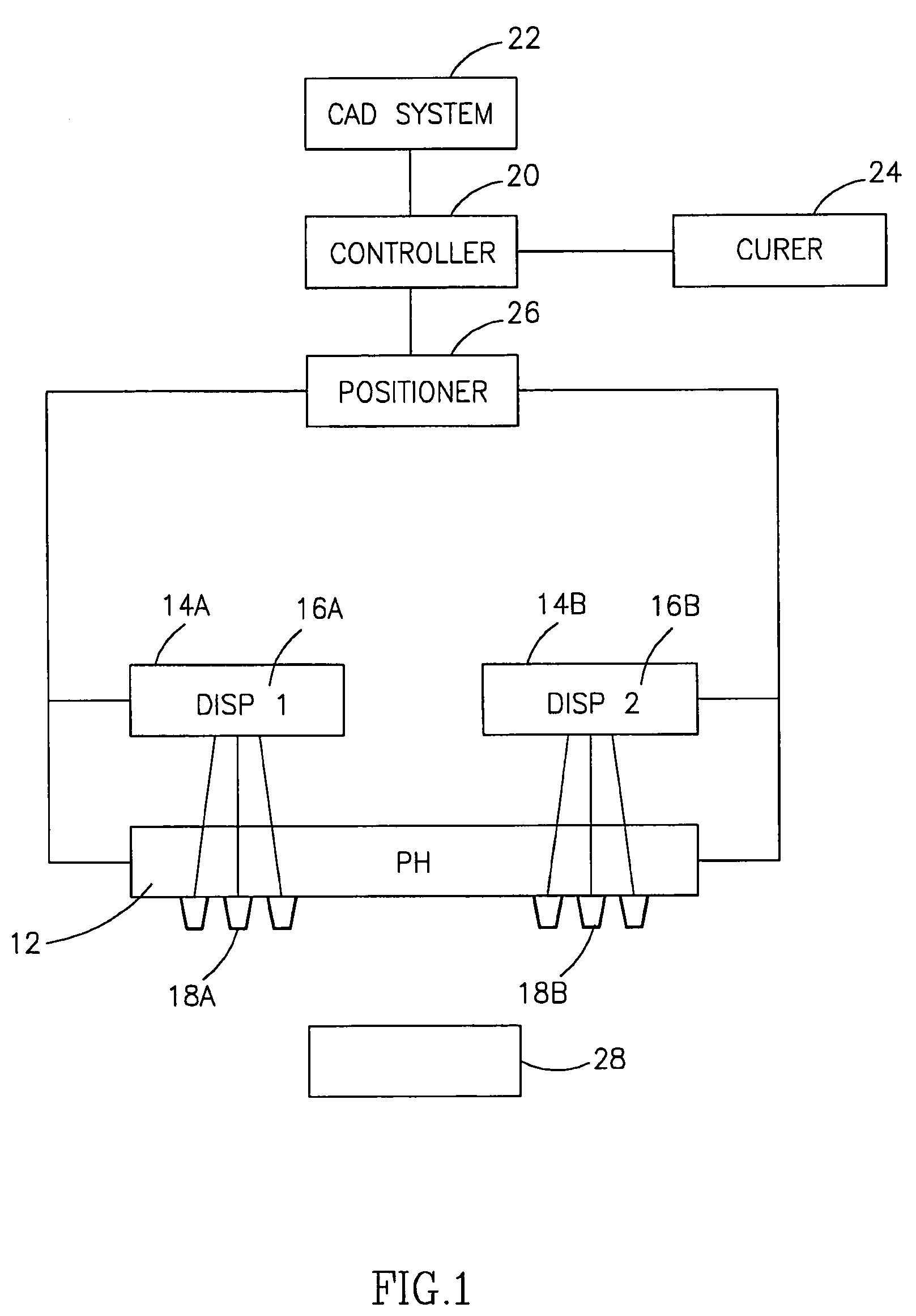

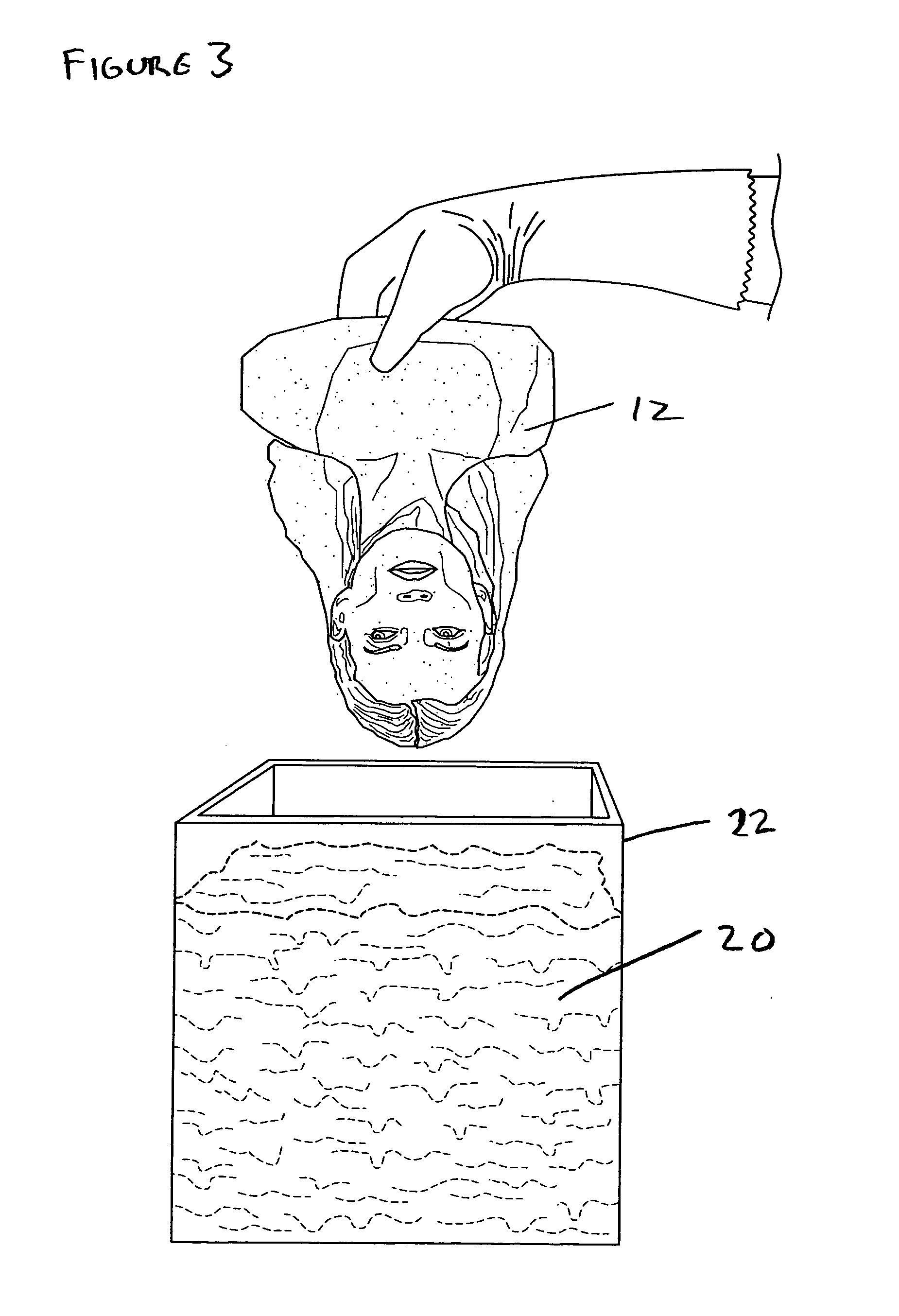

Apparatus and method for making preforms in mold

Apparatus and a method of preparing fiber preforms disperses fibers and binder on a forming support surface such that the materials are conditioned and then applied to the surface where the composite material solidifies. Reinforcing material, such as fiber, is mixed with binder, such as thermoplastic or thermoset materials, so that the materials adhere. Then, the adhesive mixture is dispersed in a controlled pre-determined weight ratio on the support surface where the mixture sticks to the support surface, cools and solidifies. The deposited mixture can be an open mat having interstices between fibers. The deposited mixture can also be shaped further into a final desired shape before complete solidification. This method eliminates the need for solvents and their associated problems. The process does not require a vacuum or plenum system to hold the reinforcing material in place. The preform can be made in any shape, including sections or asymmetric configurations and remain in mold while being processed to a composite molded article.

Owner:BRUNSWICK CORPORATION

Propane diol-based polyester resin and shrink film

ActiveUS7008698B2Improve shrinkageReadily adjustable shrink propertyWrappers shrinkageButtonsWater bathsPolymer thin films

A shrinkable polymer film including a modified polyester resin polymerized from monomers including a dicarboxylic acid and a glycol, wherein the glycol includes 2-methyl-1,3-propanediol, and wherein the polymer film shrinks at least about 50% in a main shrinkage direction after ten seconds in an 80 degree Celsius hot water bath.

Owner:MITSUBISHI POLYESTER FILM

Treated rubber and products made therefrom

InactiveUS6896964B2High tensile strengthHigh elongationButtonsRecord carriersPolymer scienceUltimate tensile strength

Treated rubber is made from ground rubber and a polyurethane resin. Products made by mixing treated rubber with additional polyurethane resin, molding and curing the polyurethane have higher tensile strengths and / or elongations than similar products made from untreated rubber. The method using treated rubber uses less polyurethane binder to produce products of equivalent strengths. The molding time is also reduced because of the reduced amount of polyurethane binder used.

Owner:RYVEC

Collapsible expansion cone

Owner:WATSON BROCK WAYNE +1

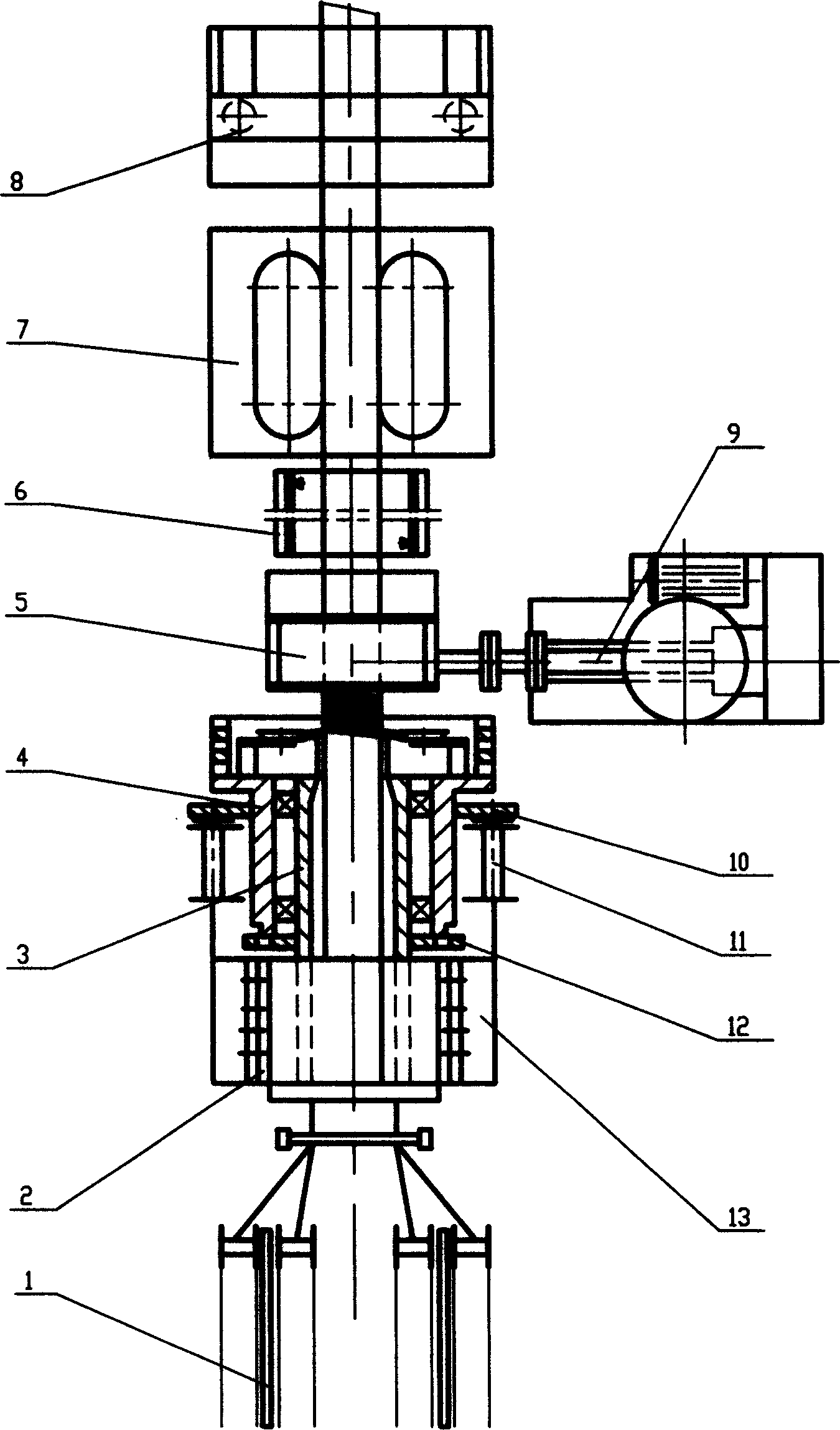

Pipeline containing compound pipe of steel skeleton-plastic, and manufacture of compound pipe

InactiveCN1562617AFirmly connectedConsistent corrosion resistanceButtonsRecord carriersThermoplasticMetallurgy

A composite steel skeleton-plastic pipe is prepared through welding the warp steel wires with the weft steel wires by net shaper and fuzzy resistance welding technology to form a netted steel skeleton, feeding it in a pipe shaping unit while extruding the fused plastics in it for combining the steel skeleton with the fused plastic, and cooling. Its making machine and the pipeline of said pipe are also disclosed.

Owner:ハルビンスターウェイマシーナリーマニュファクチャリングカンパニーリミテッド

Twin-sheet thermoformed products

A twin-sheet thermoforming process for the manufacture of vehicle headliners. In the process a first sheet and second sheet of SuperLite material are mounted onto respective frames. The frames transfer the sheets into an oven, where they are heated to a desired temperature using IR. The first sheet is combined with a cover-stock material using compression molding forming a covered first headliner part. The covered first headliner part is then transferred to a second mold station. The second sheet is heated and then transferred from the oven to the second mold station where it is vacuum-formed on the upper half mold, forming a second headliner part. The upper and lower mold halves are pressed together fusing and sealing the first and second headliner parts into a unified part. The unified part is then unloaded and trimmed as necessary forming a headliner. The SuperLite material used to form the headliner is a sheet of low pressure, thermoformable, thermoplastic composite comprised of polypropylene and long chopped glass fibers.

Owner:AZDEL INC

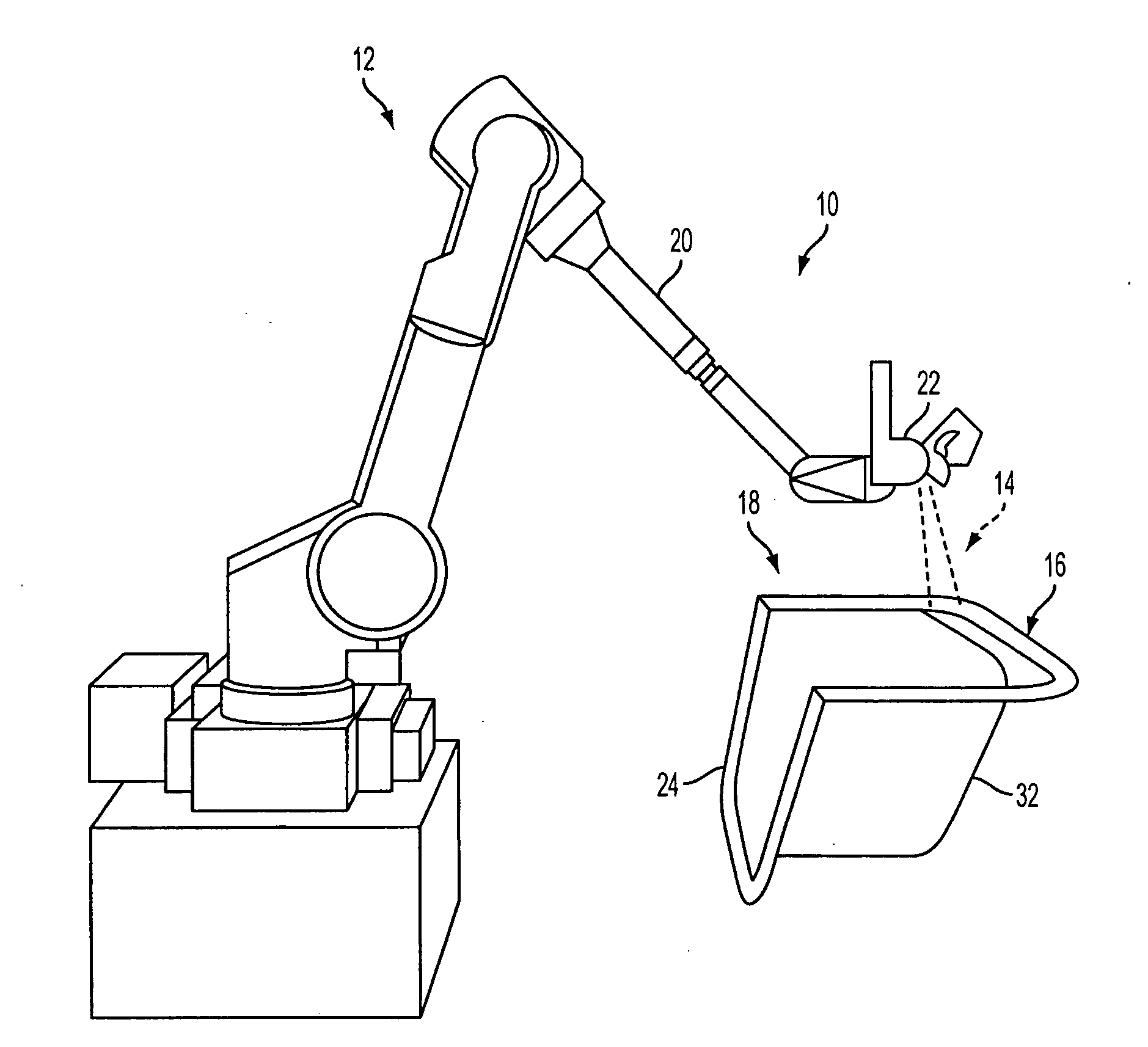

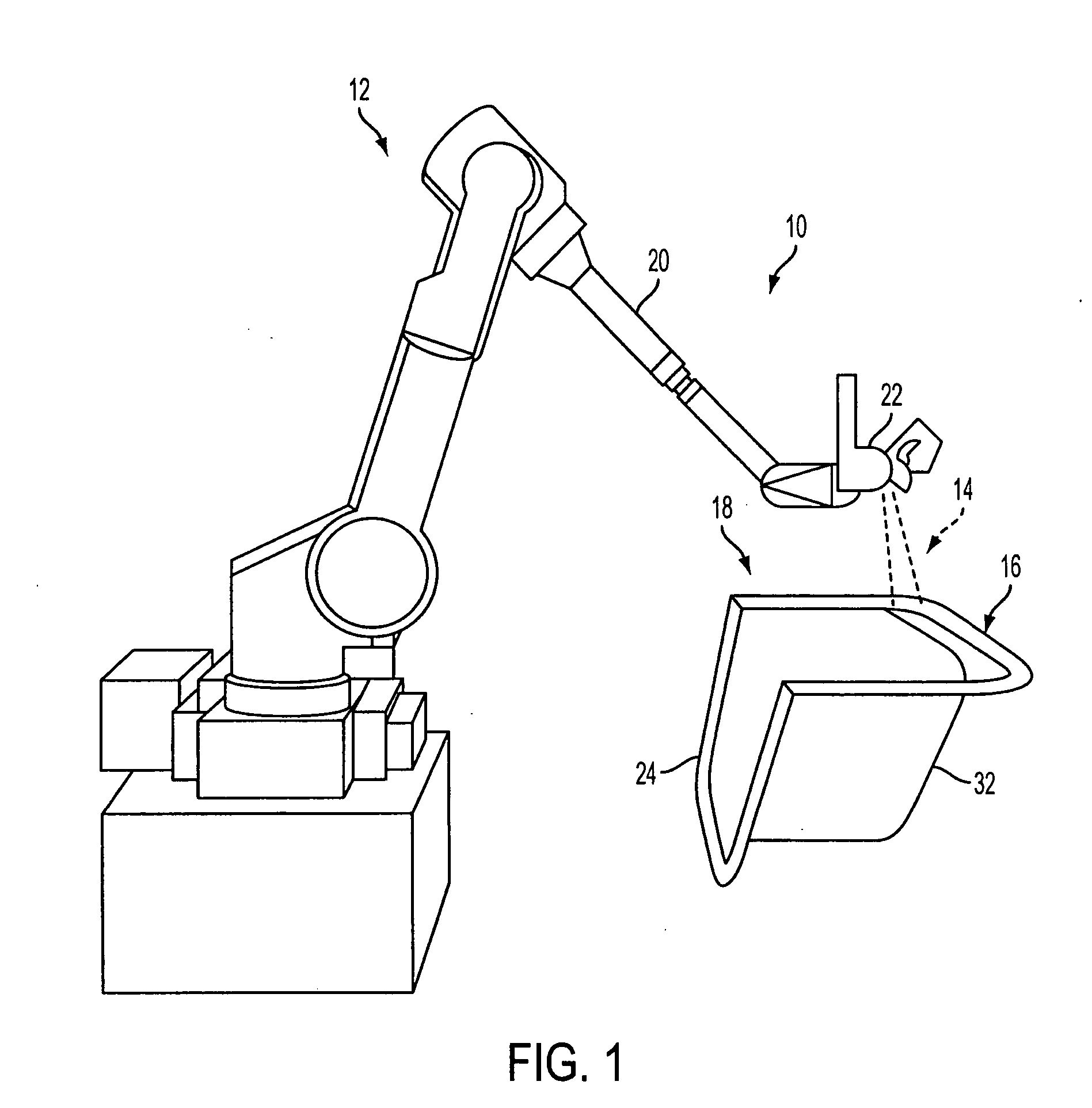

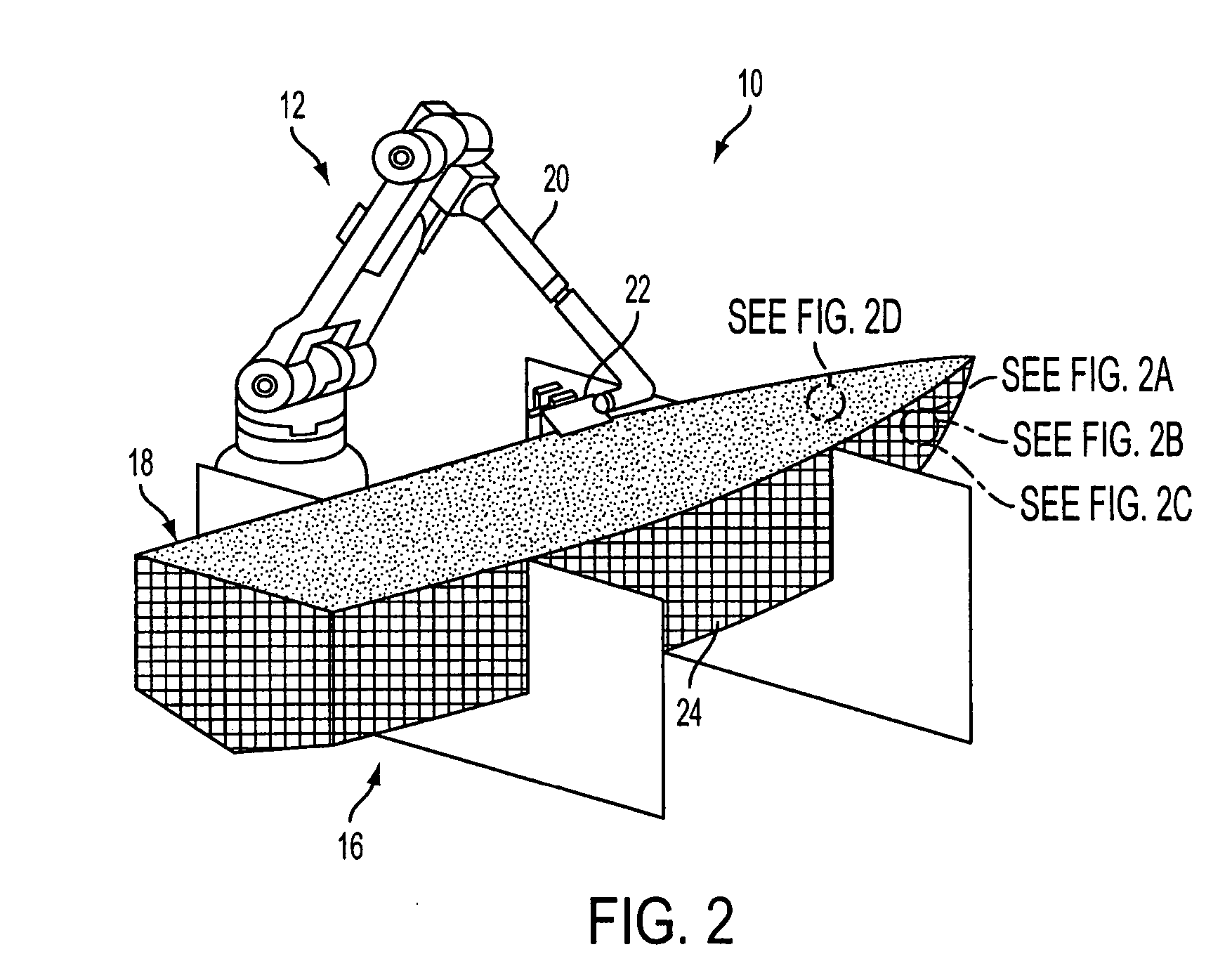

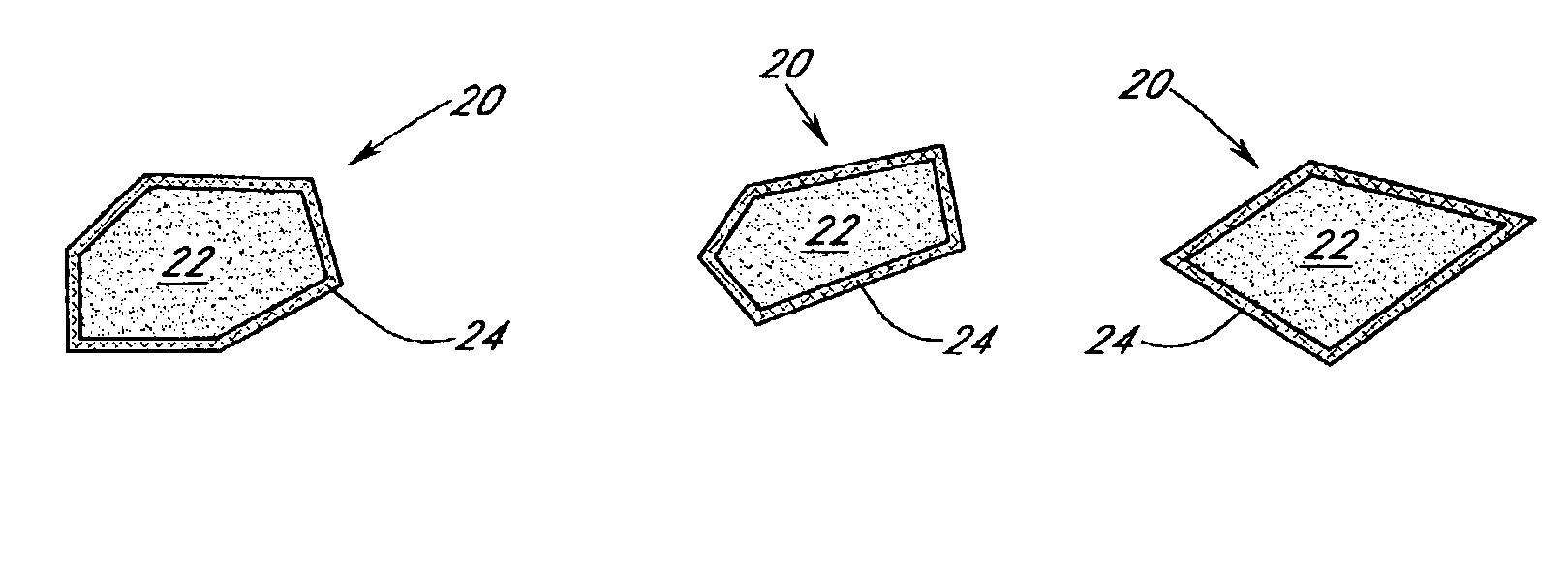

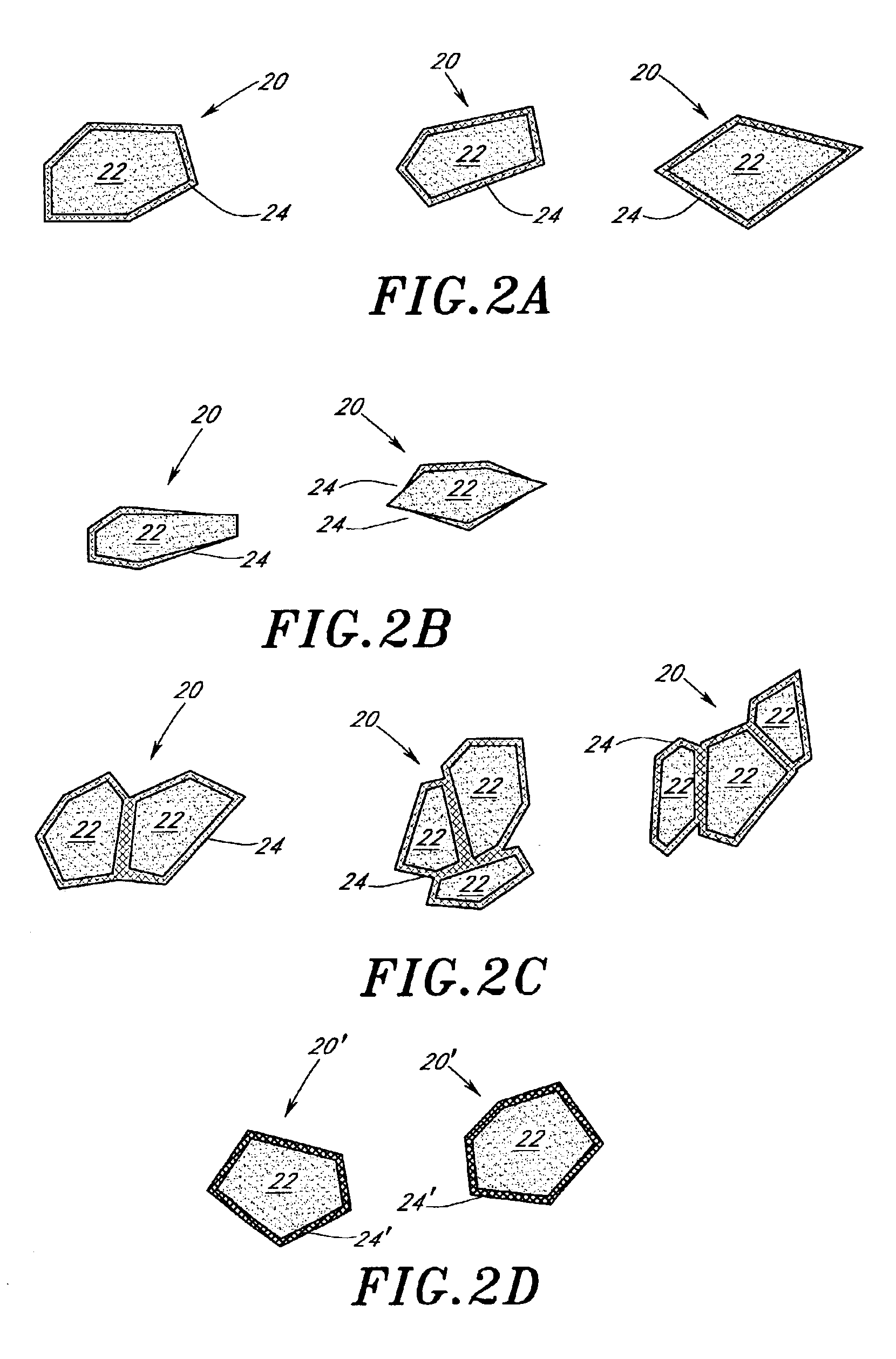

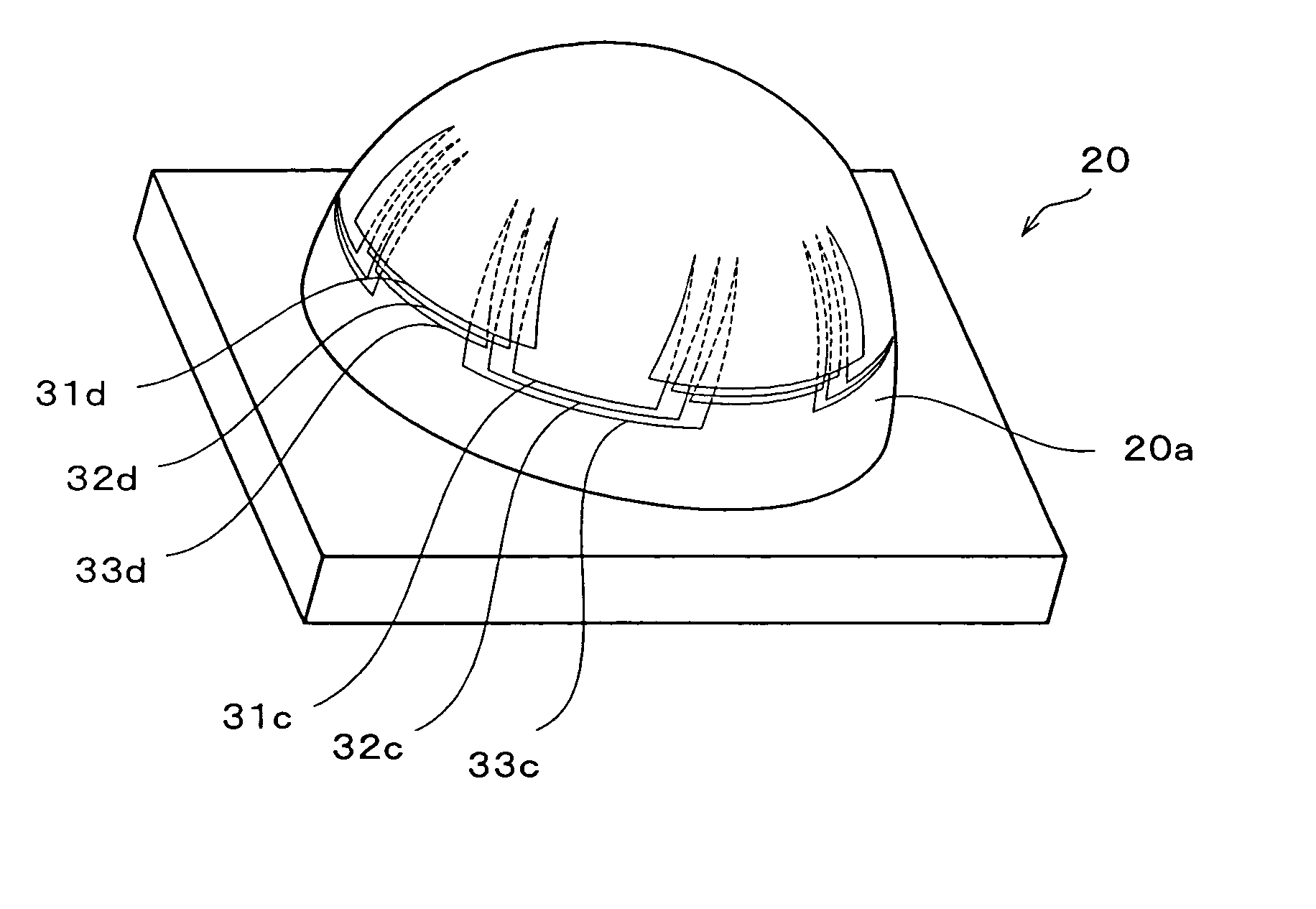

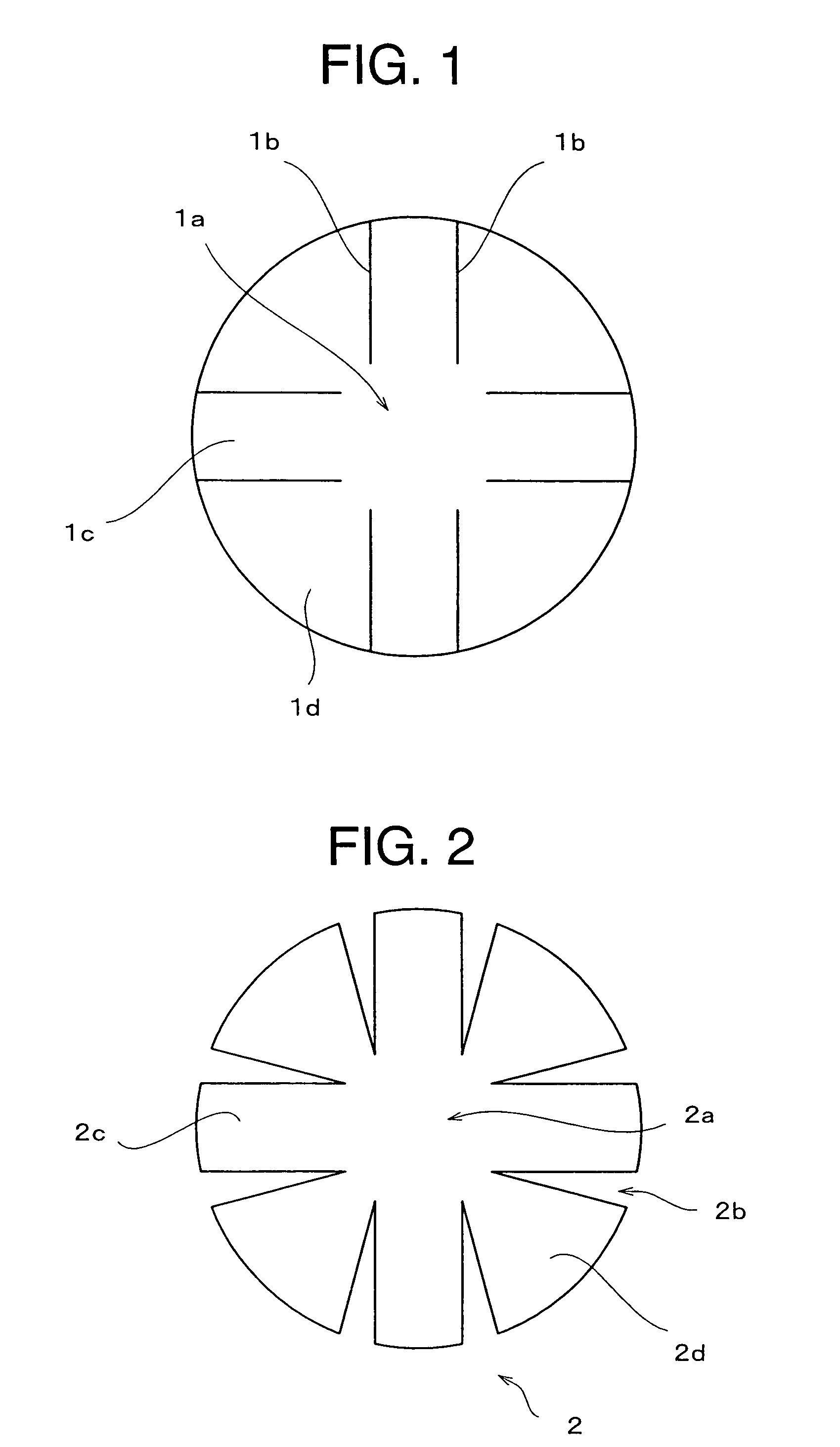

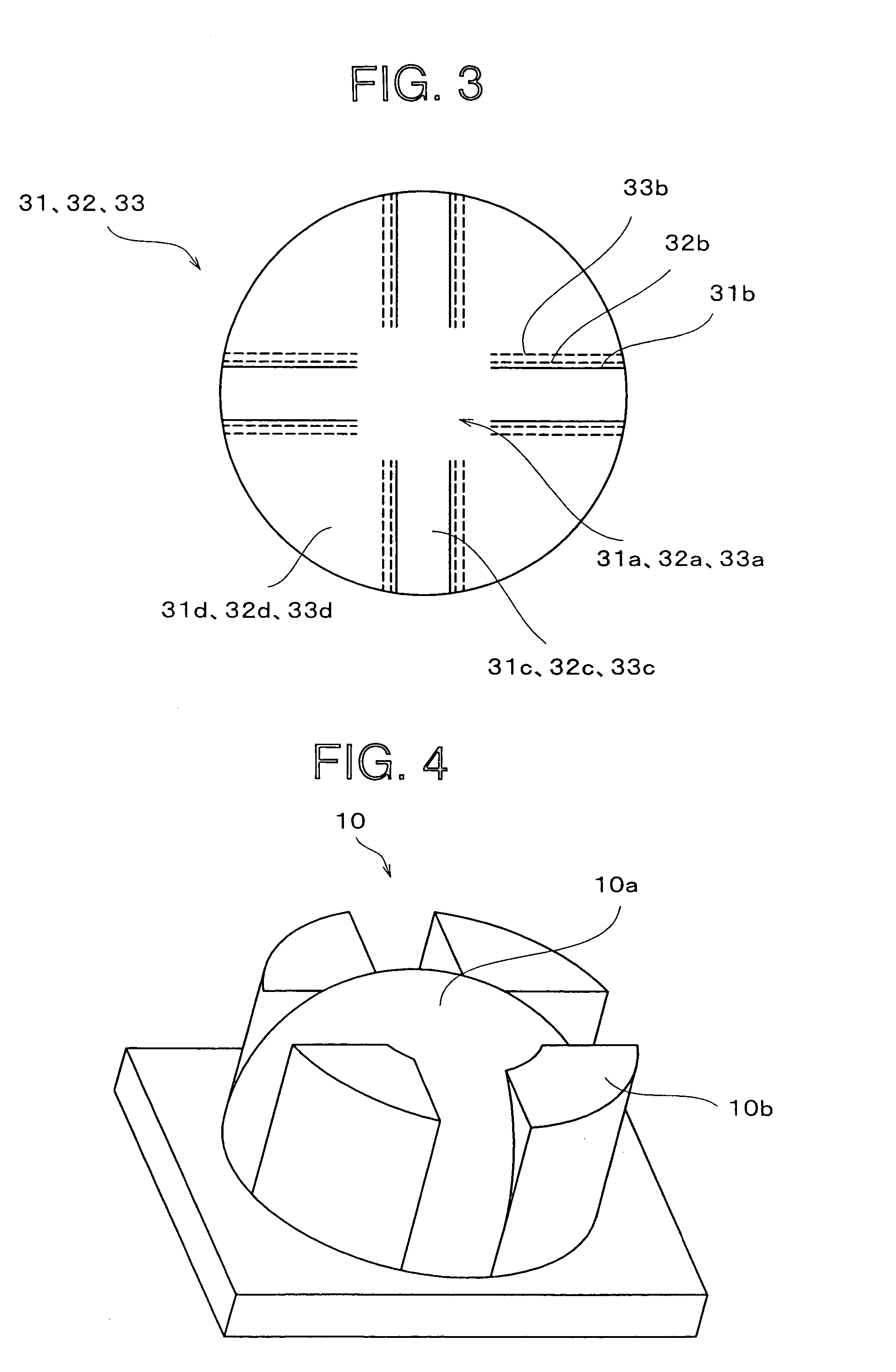

Method of producing formed product of fiber-reinforced composite material and the formed product

ActiveUS20050253294A1Reduce dispersionShort timeFrameless domesDomestic articlesFiber-reinforced compositeThree dimensional shape

A method is presented for stably, highly, and efficiently producing a three-dimensional molded article of a fiber-reinforced composite material having a three-dimensional shape, uniform quality, and free from wrinkles by press molding a plurality of prepregs cut out in a predetermined shape and also to a molded article.

Owner:MITSUBISHI CHEM CORP

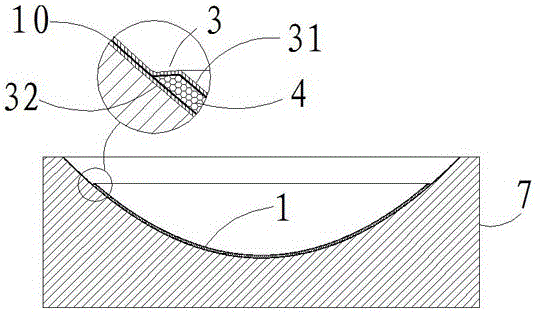

PMI (polymethacrylimide) foam sandwich aircraft radar cover and manufacturing method thereof

A PMI (polymethacrylimide) foam sandwich aircraft radar cover comprises a concave cover body and a flange ring, wherein the concave cover body and the flange ring consist of a skin layer, a cover body adhering layer and a PMI sandwich layer. A manufacturing method of the PMI foam sandwich aircraft radar cover comprises the process steps of flange foam blank milling molding, cover body PMI foam blank block molding and skin adhering molding and curing. The product provided by the invention has the advantages of light weight, high rigidity and signal stability, and completely can meet electrical property, mechanical property and environment-resistant property test index requirements required by design. According to the PMI foam sandwich block molding process, the variable quantity of foam thickness is small after thermal molding and bending of flat foam, so the electrical property requirement of the radar cover is met to the greatest extent, and the wave transmission property becomes poor due to large variable quantity of foam density and thickness after molding by the integral molding process is effectively avoided.

Owner:SICHUAN TIANYUAN MACHINERY CO LTD OF 081 ELECTRONICS GRP

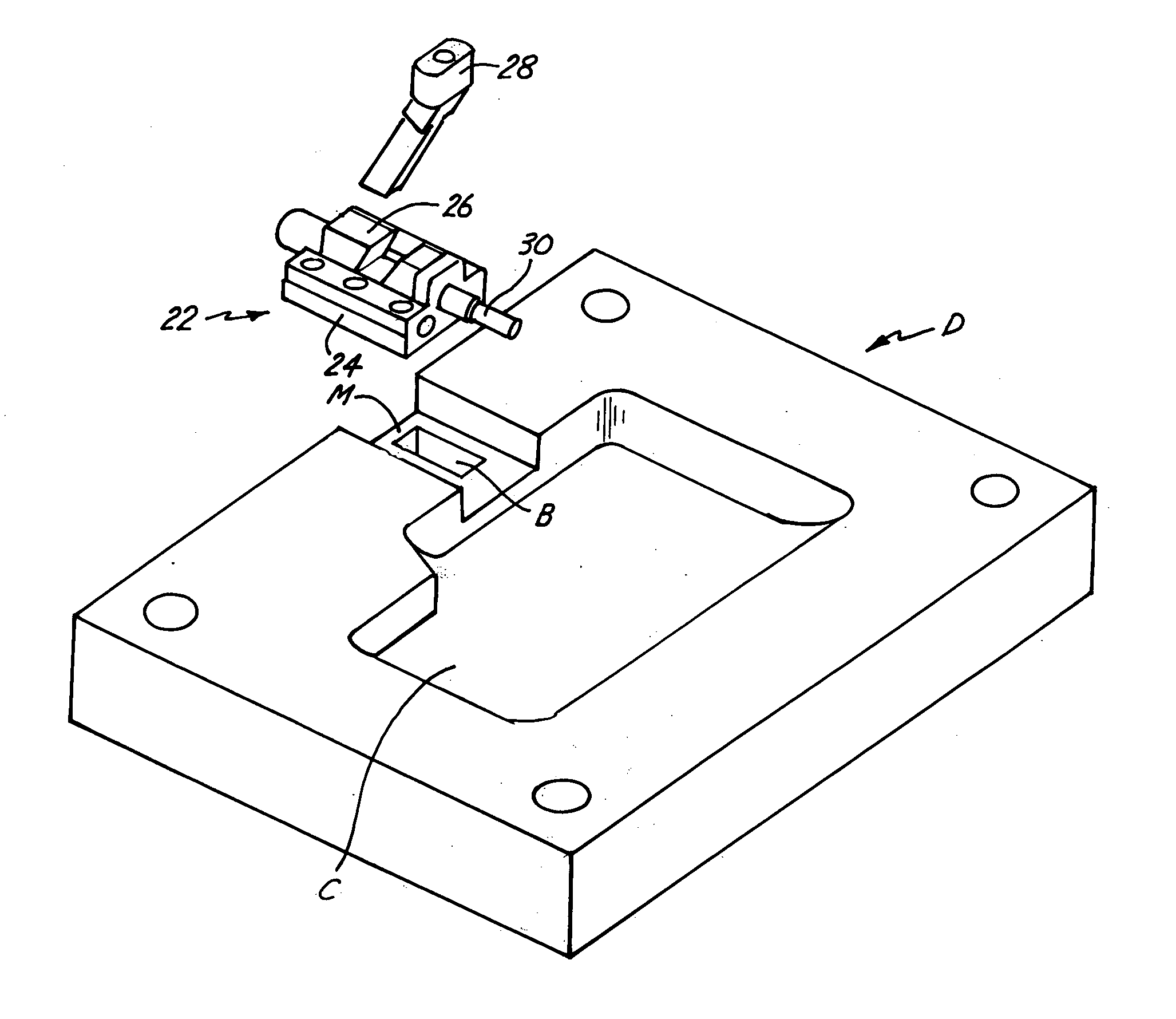

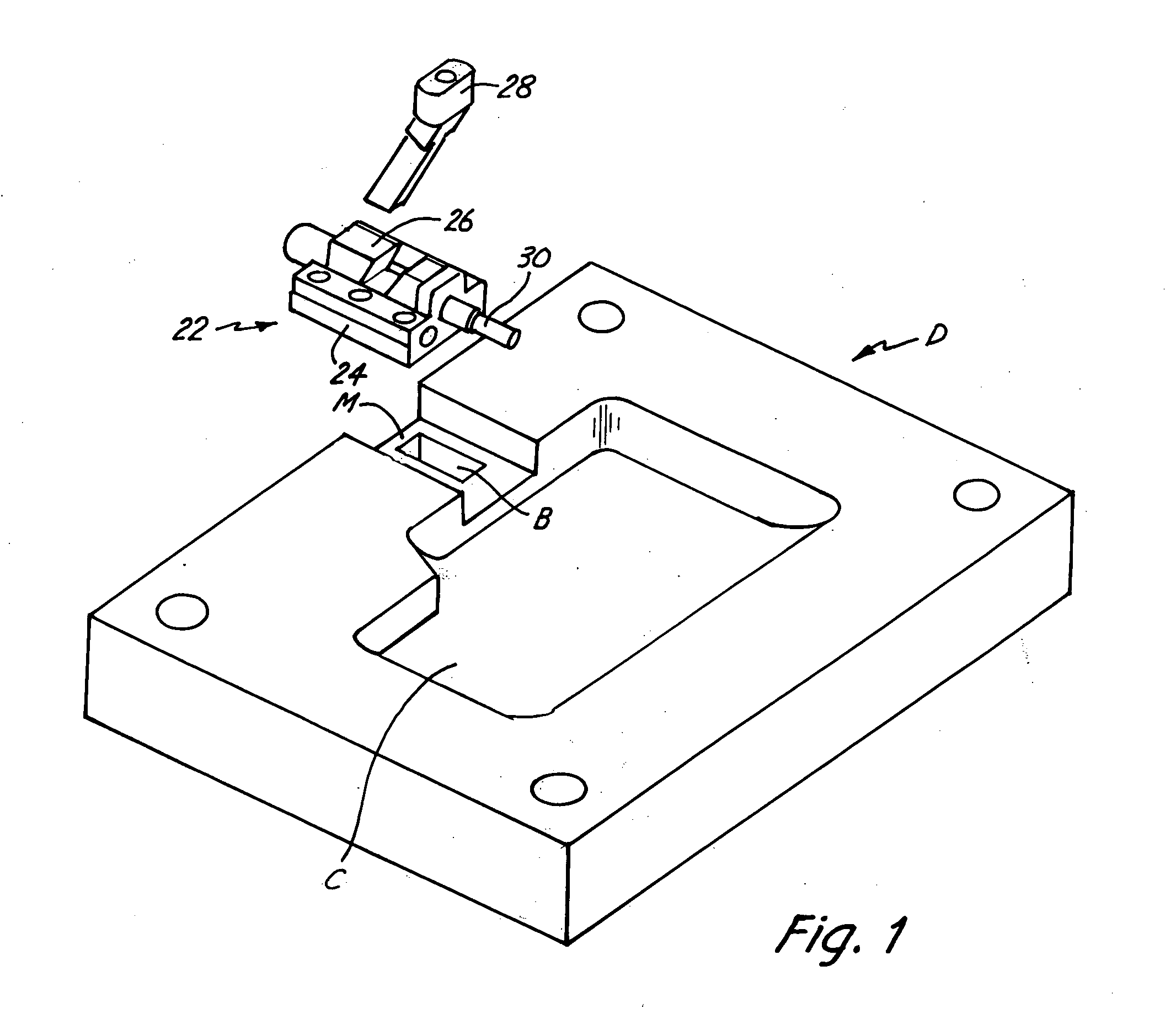

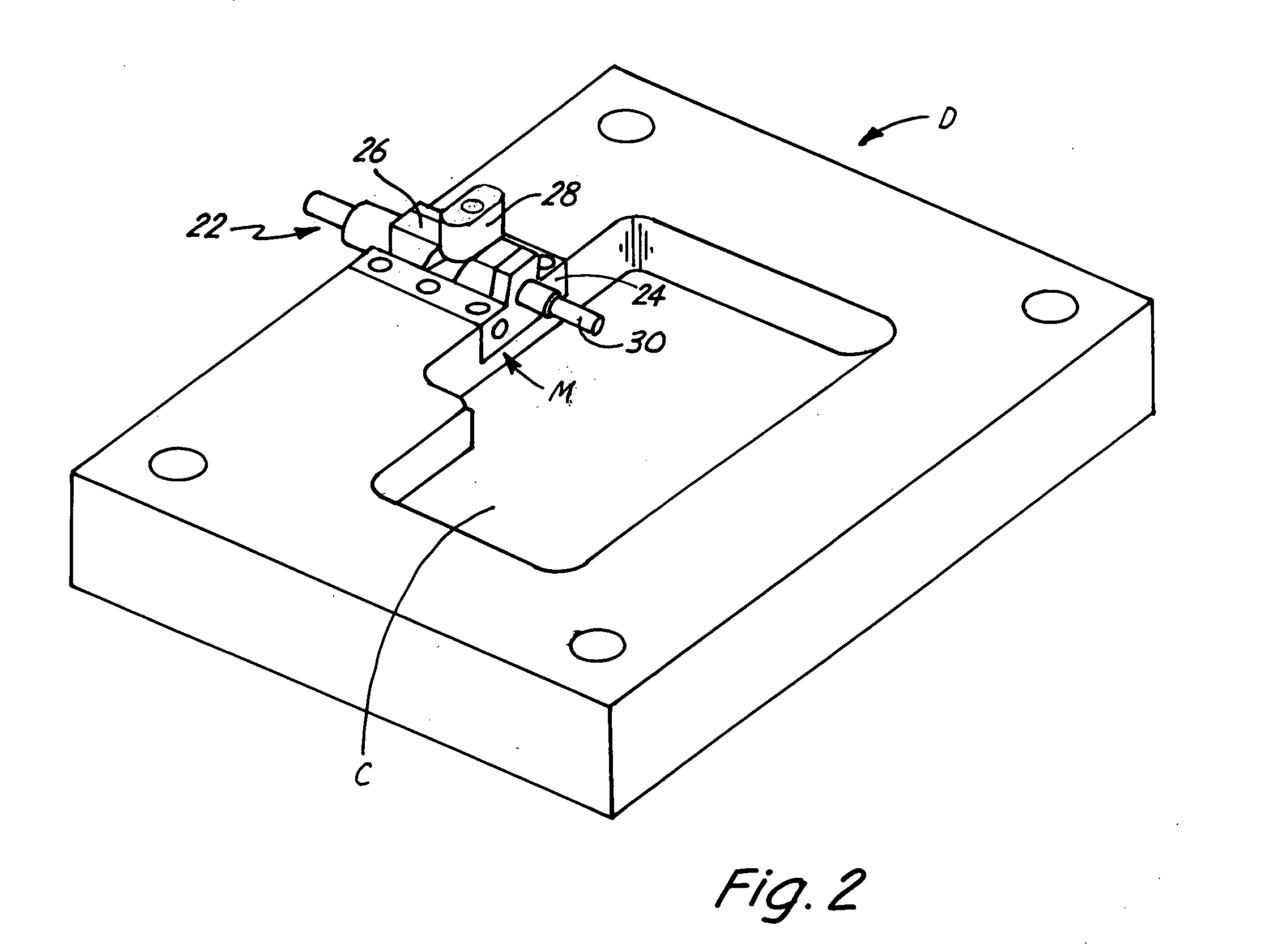

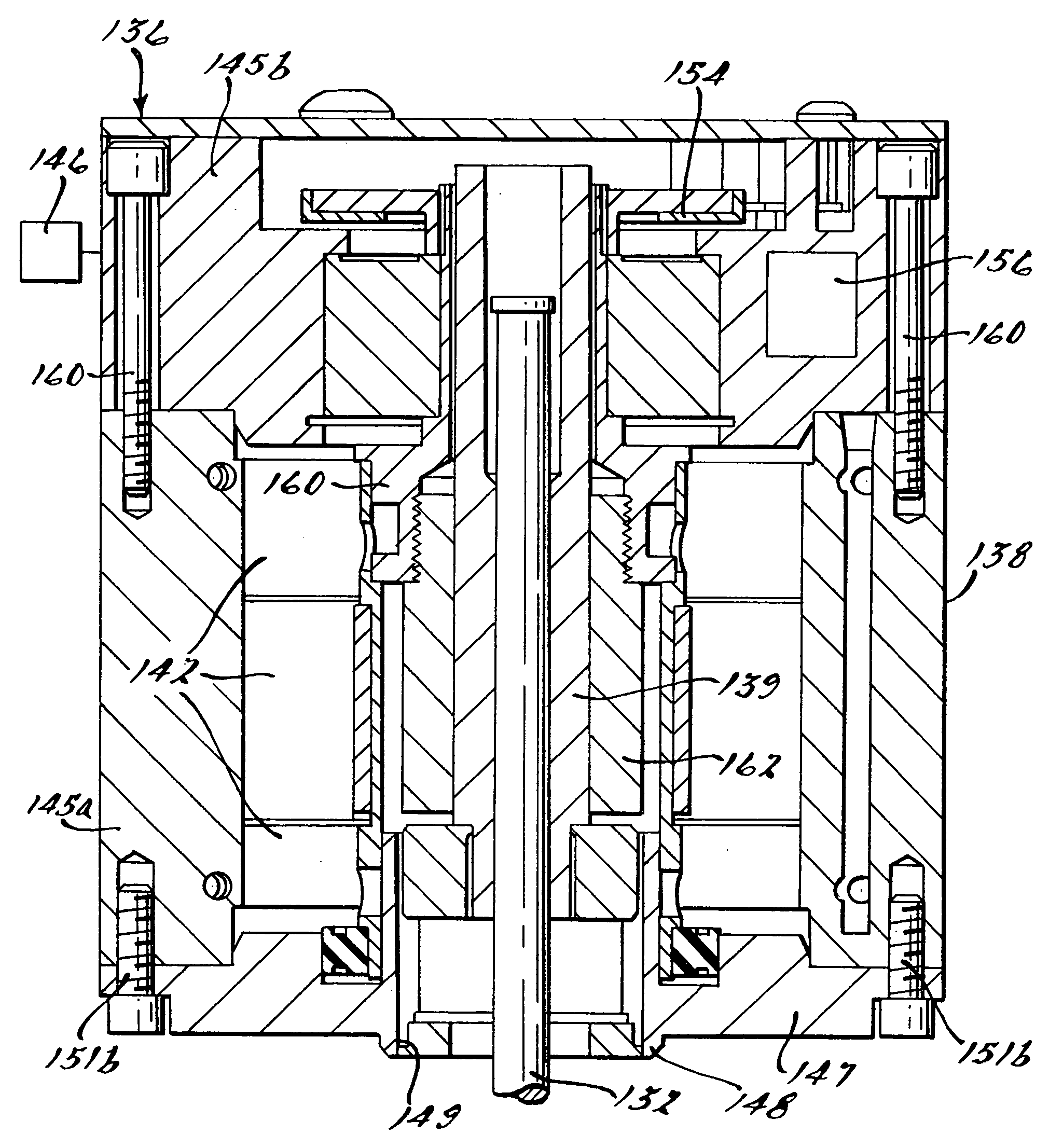

Universal slide assembly for molding and casting systems

InactiveUS20050098295A1Easy to installEasy to operateButtonsRecord carriersCost effectivenessEngineering

The present invention is a universal slide assembly for molding or casting systems used to introduce complex designs to moldings and castings, which is cost effective, easy to install, and easy to operate, and includes a base, a slide, and a cam lever. The base is directly insertable into a movable-die half for immediate use without requiring the slide to be individually designed or adapted to a particular movable-die half. The cam lever is capable of moving the slide towards and away from a core without the use of hydraulic power, through cam action.

Owner:DUBAY RICHARD L

Valve gate assembly

A valve gate assembly for regulating a flow of molten material into a mold. The valve gate assembly includes a movable valve that can move between a fully closed position and a fully open position. The valve gate assembly further includes an actuating system operatively cooperating with the valve to move the valve and infinitely position the valve between the fully closed position and the fully open position.

Owner:PLASTIC ENG & TECHN SERVICES

Process and apparatus for the production of a detergent composition

InactiveUS20010011067A1Lower operating temperatureReduce operating costsCosmetic preparationsButtonsSemi solidInjection moulding

A process for forming detergent bars by injection molding in which a pressure is applied to a partially structured detergent composition to deliver it to a mold. The detergent composition can be delivered to the mold in a substantially semi-solid state, at a temperature below 70° C. and at a pressure at the point of injection of greater than 20 psi. Apparatus for forming detergent bars according the invention are also described.

Owner:LEVER BROTHERS

Molding composition and method of use

ActiveUS20050061471A1Reducing necessary finishing workFaster turn around timeButtonsRecord carriersColloidal silicaSlurry

A slurry composition for a mold and method of use thereof. The slurry composition includes about 45-80% by weight alumina, about 10-30% by weight silicon carbide, and about 10-50% by weight colloidal silica. In one aspect, the alumina component comprises a material selected from the group consisting of brown fused alumina, white fused alumina, tabular alumina, calcined alumina, and mixtures thereof. In another aspect, the composition includes fumed silica at 2-5% by weight. The composition may also include a setting agent at 0.05-2% by weight.

Owner:MAGNECOMETREL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com