Pipeline containing compound pipe of steel skeleton-plastic, and manufacture of compound pipe

A technology of steel skeleton and composite pipe, which is applied in the direction of pipes/pipe joints/fittings, threaded products, frameless domes, etc., which can solve the problem of affecting the service life of welding wheels, reducing work efficiency, and reducing the service life of equipment parts And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

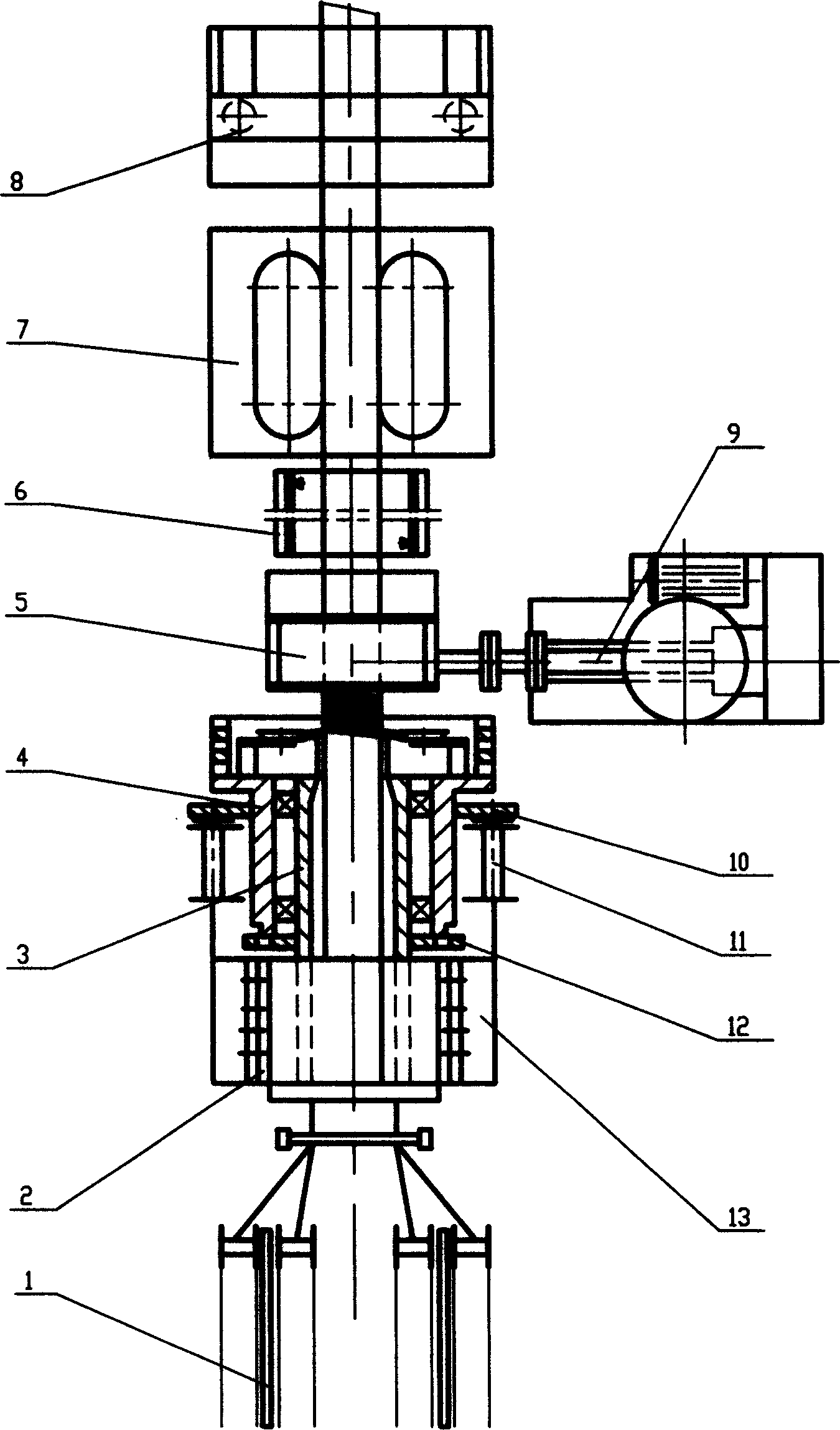

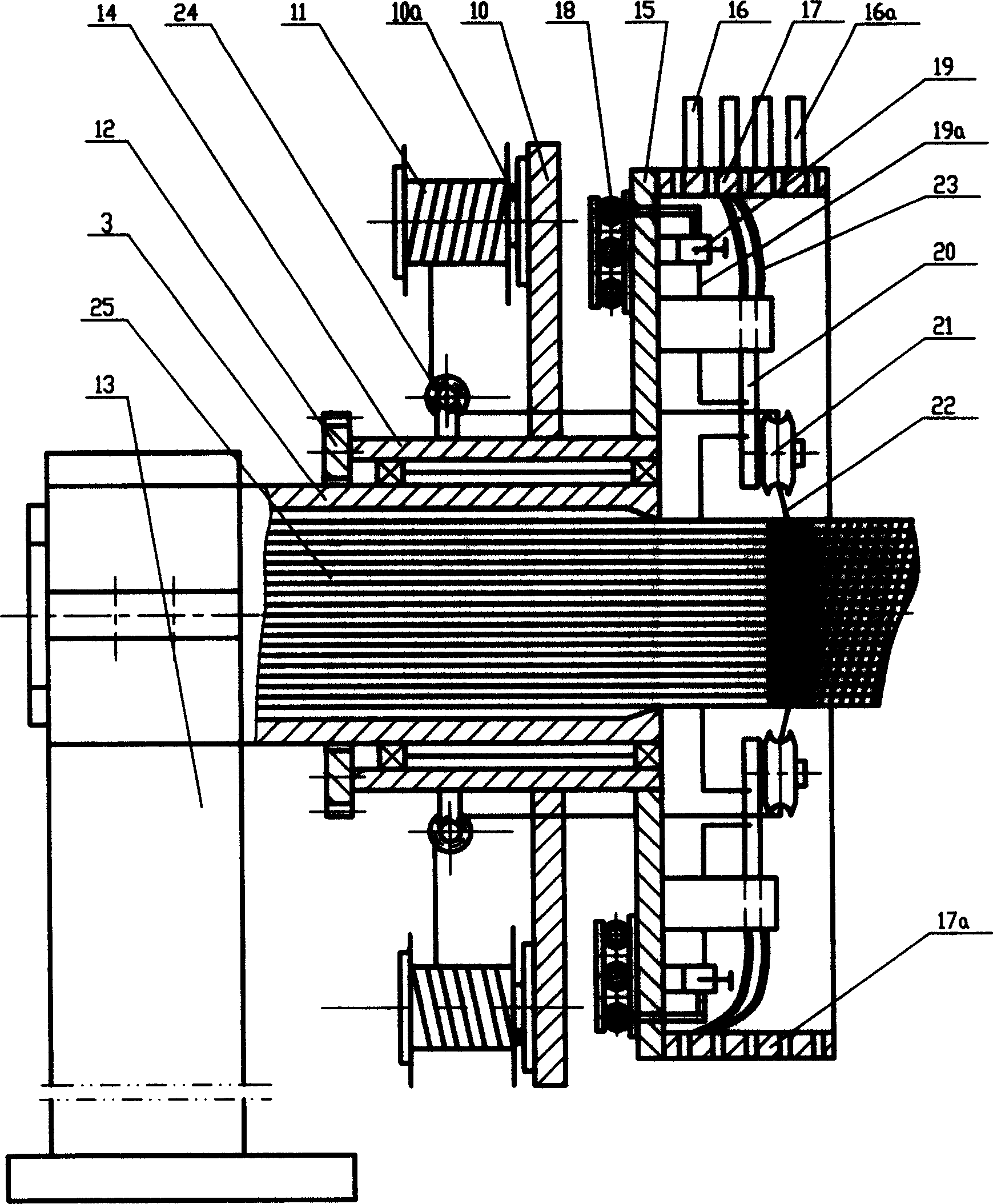

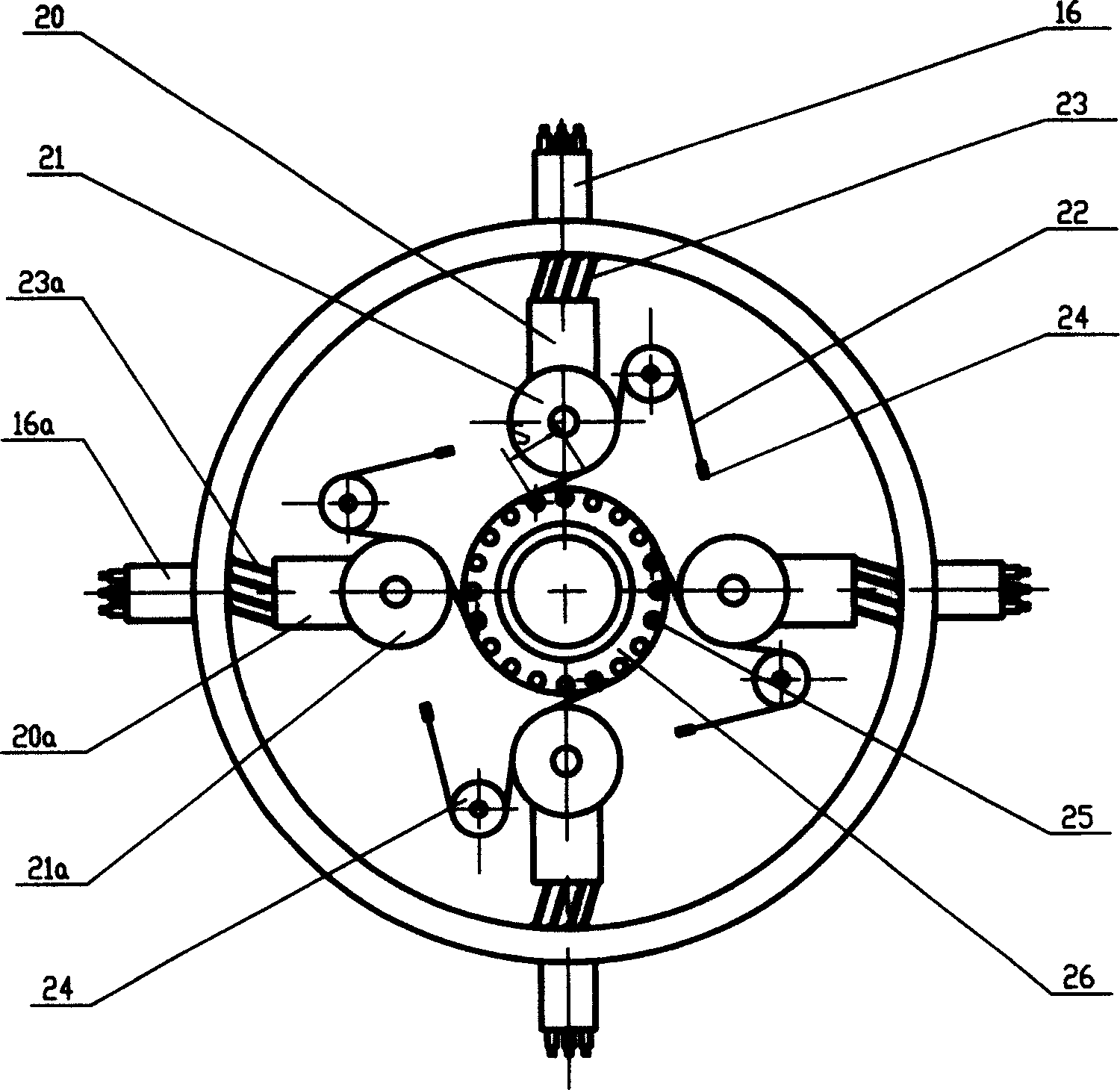

[0024] see figure 1 and 2 , the warp steel wires uniformly distributed along the circumferential axis are sent from the warp distribution device 1 through the warp channel to the welded mesh forming machine 2, and are connected to the traction head at the composite machine head 5. The welded mesh forming machine 2 is a cantilever structure, including a machine base 13, a cantilever support shaft 3 connected to the machine base 13, and a winding welding mechanism 4, wherein the machine base 13 and the cantilever support shaft 3 are fixed, and the winding welding mechanism 4 passes through the bearing Supported on the cantilever support shaft 3, the rotary winding function of the winding welding mechanism 4 is realized in this way: the motor drives the gear 12 meshed with the transmission mechanism through a conventional transmission mechanism (not shown), and the gear 12 is fixedly connected to the winding welding mechanism 4. on the connecting sleeve 14, so that the winding a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com