Patents

Literature

304 results about "Winding function" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

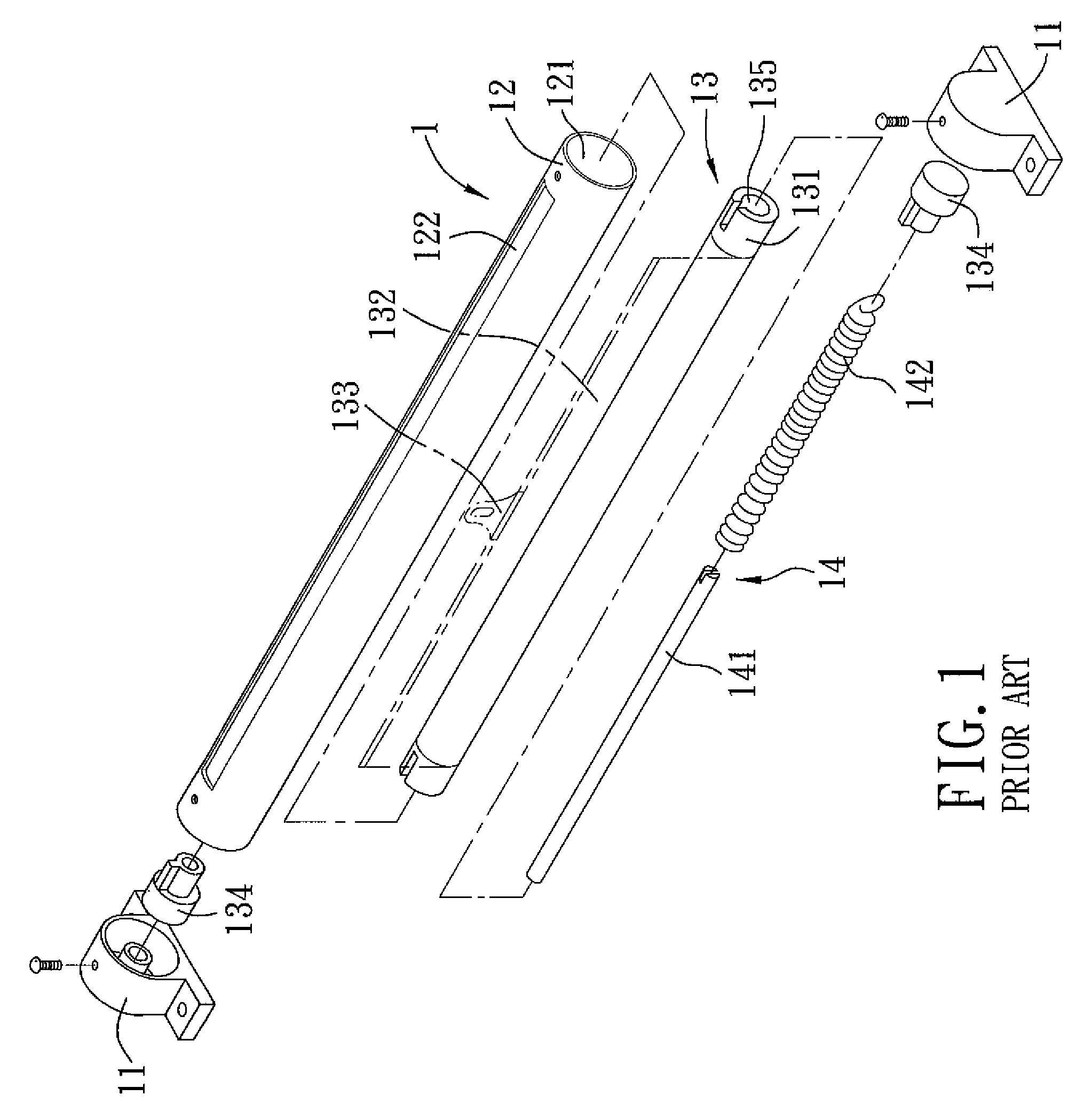

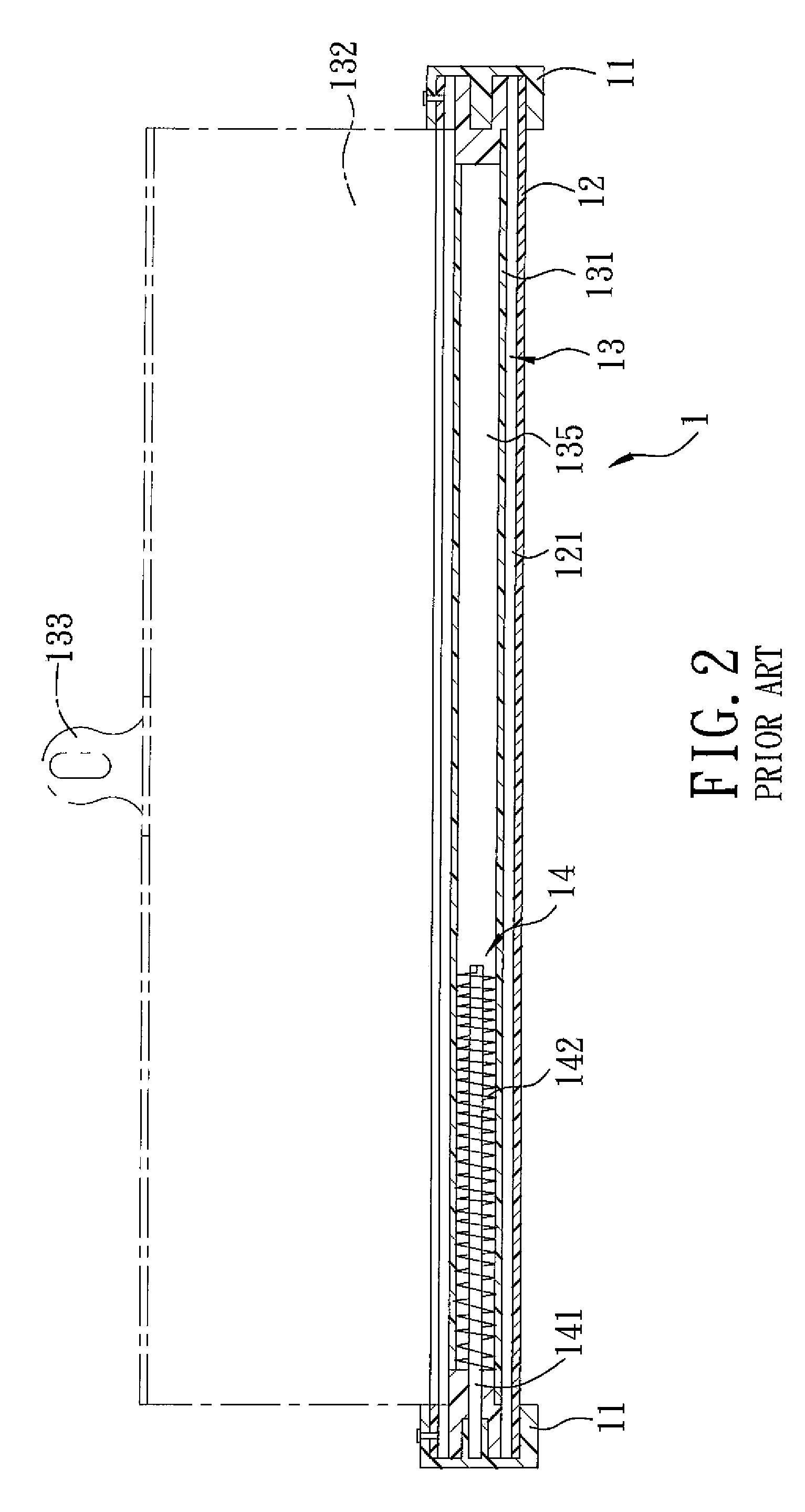

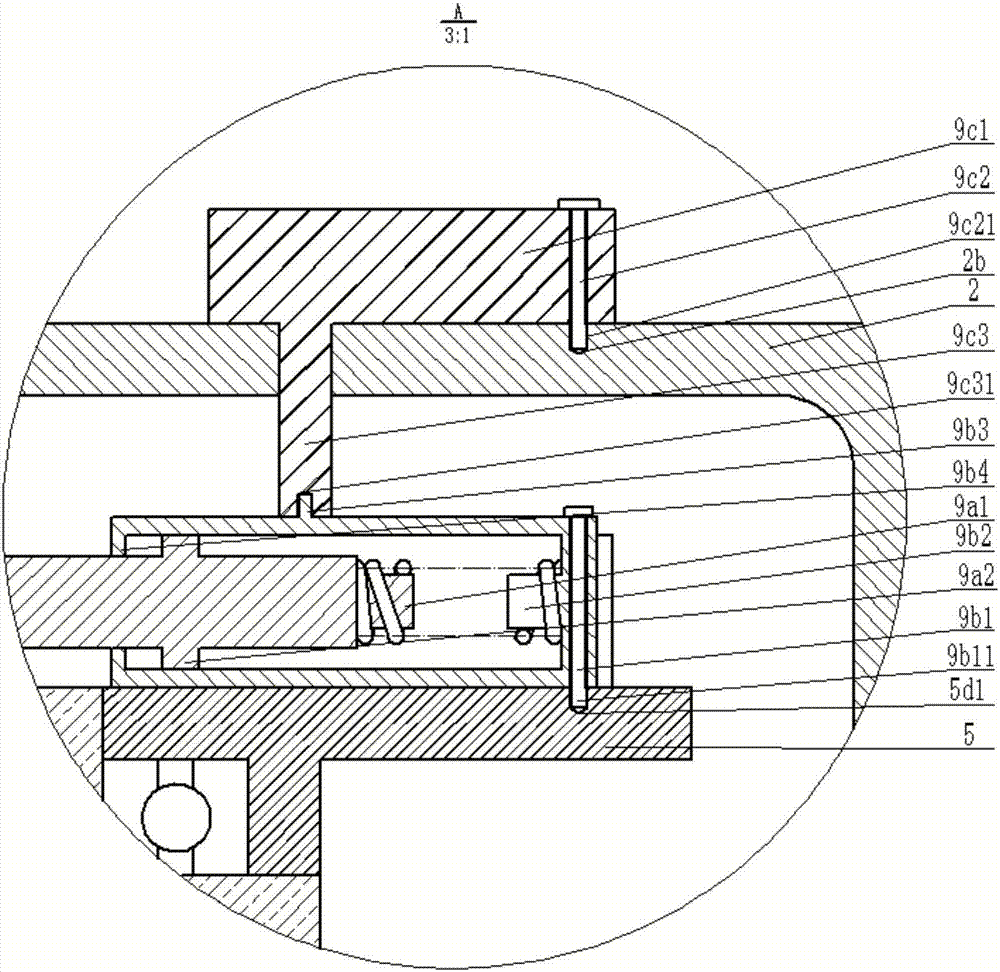

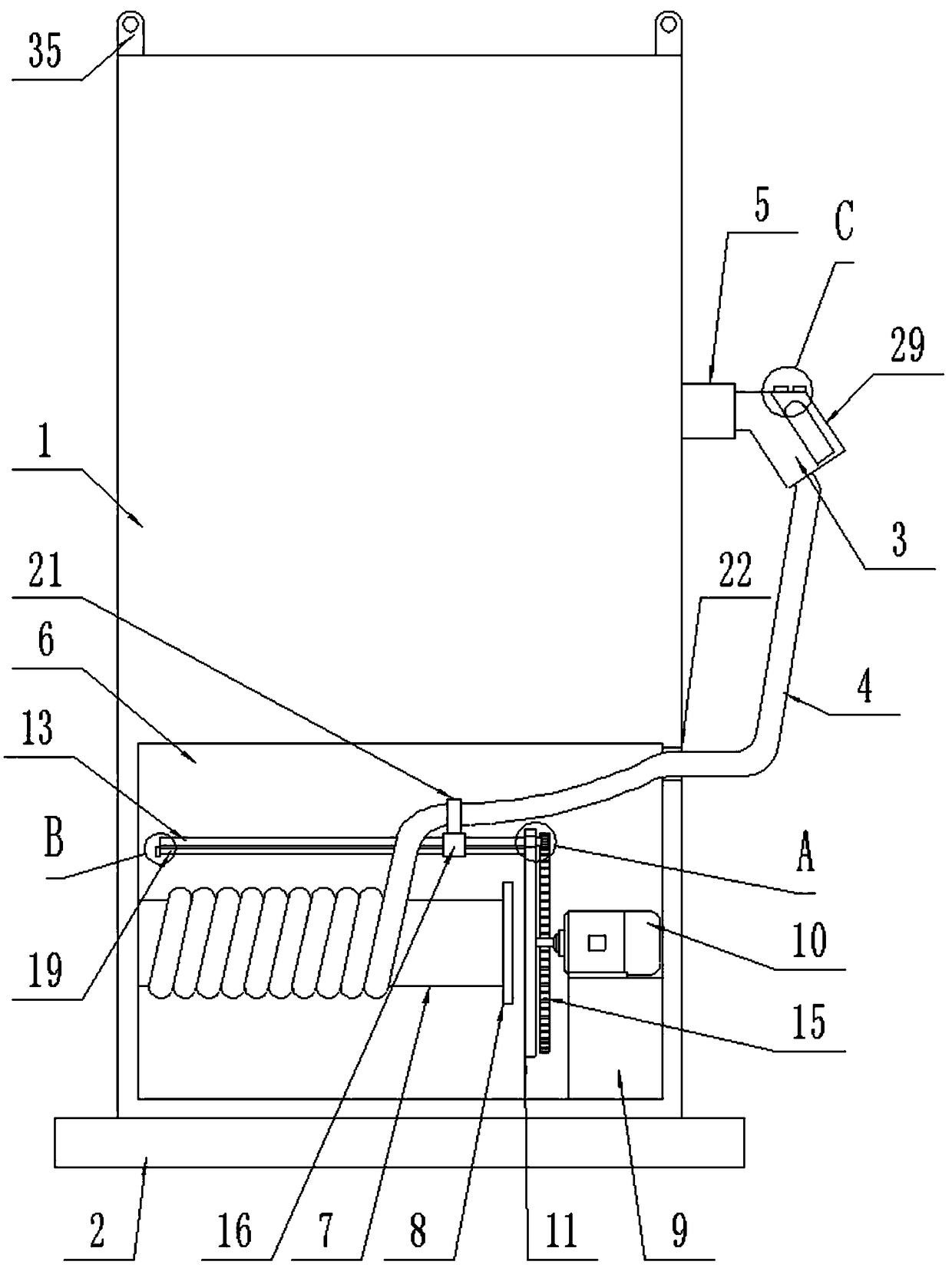

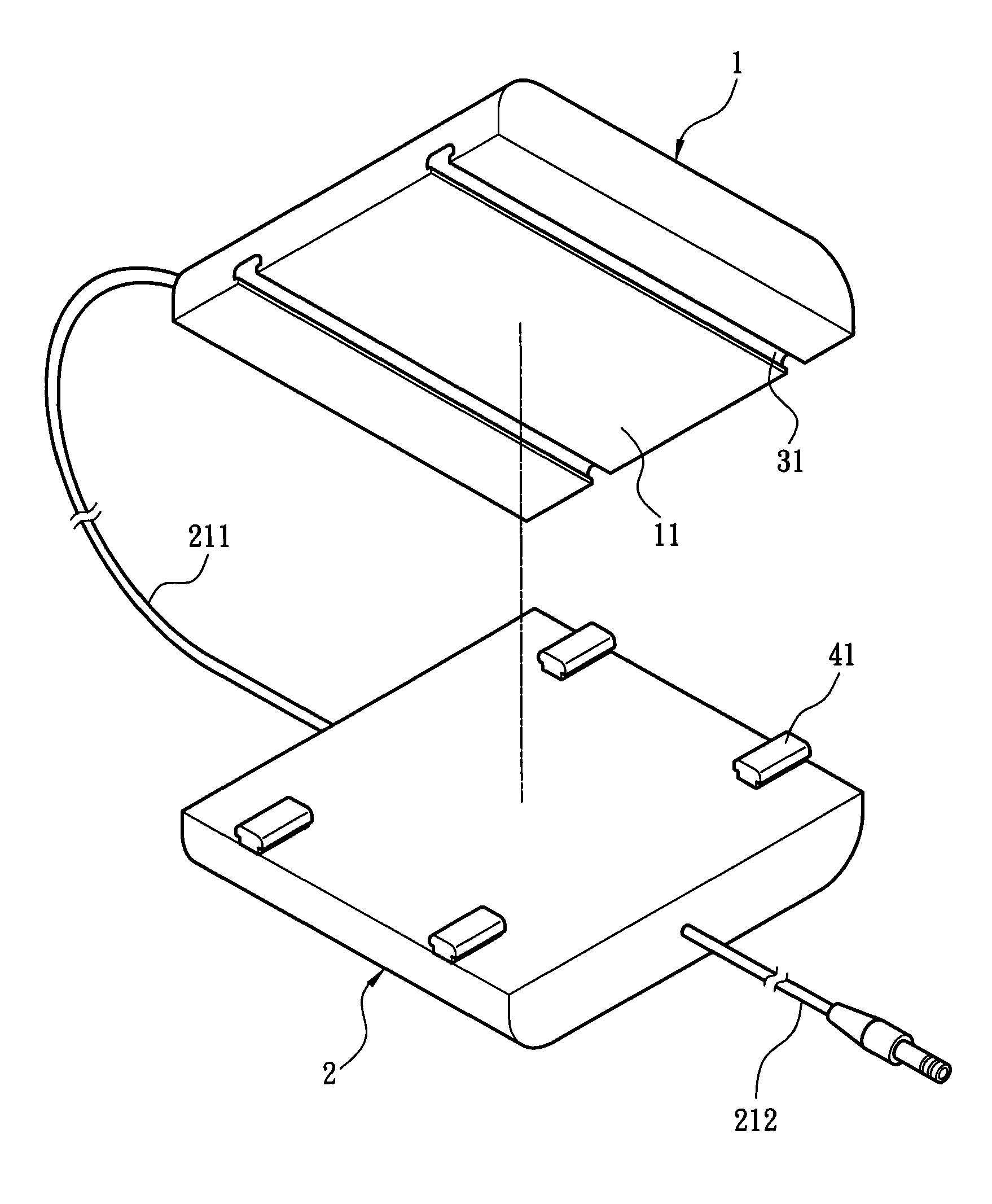

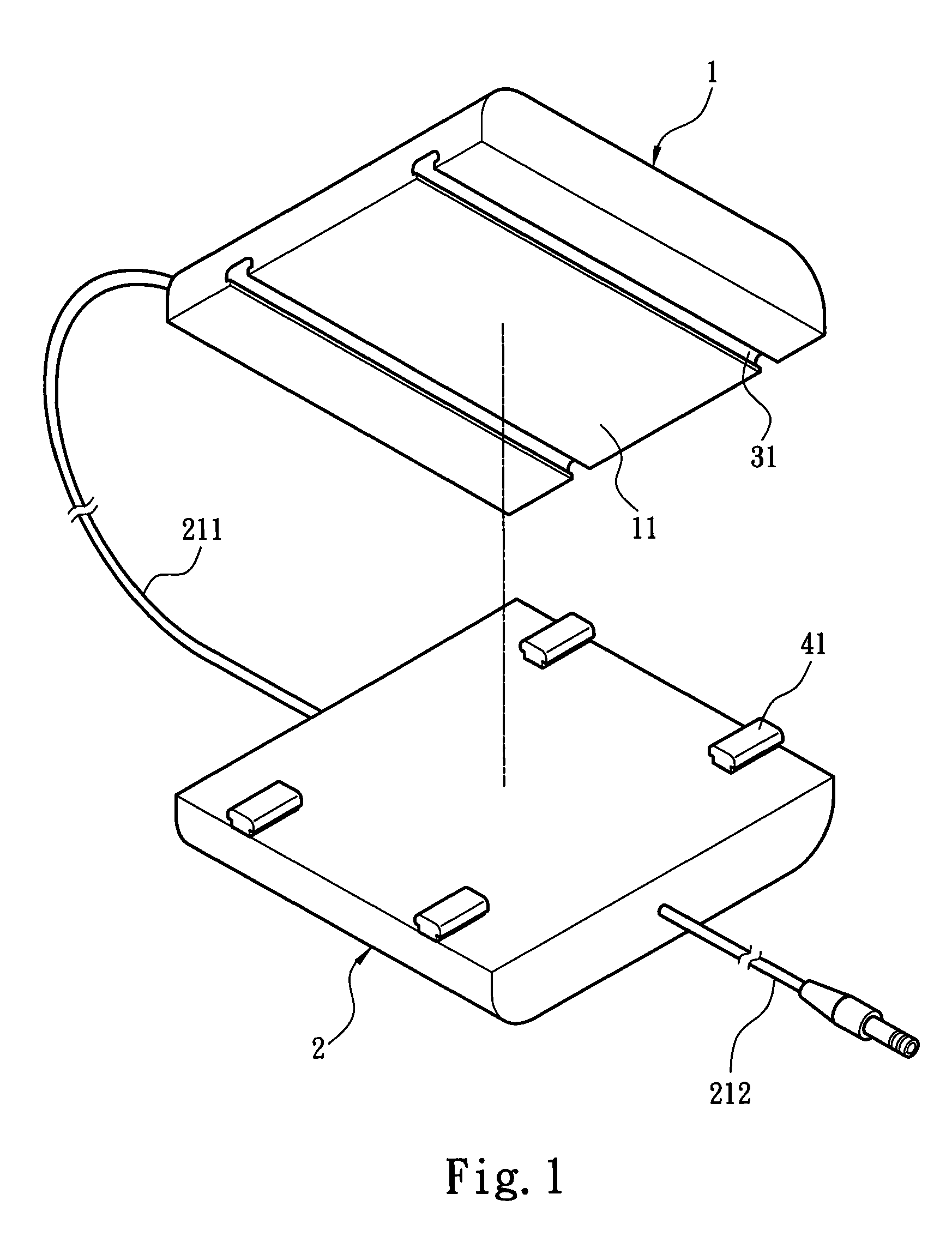

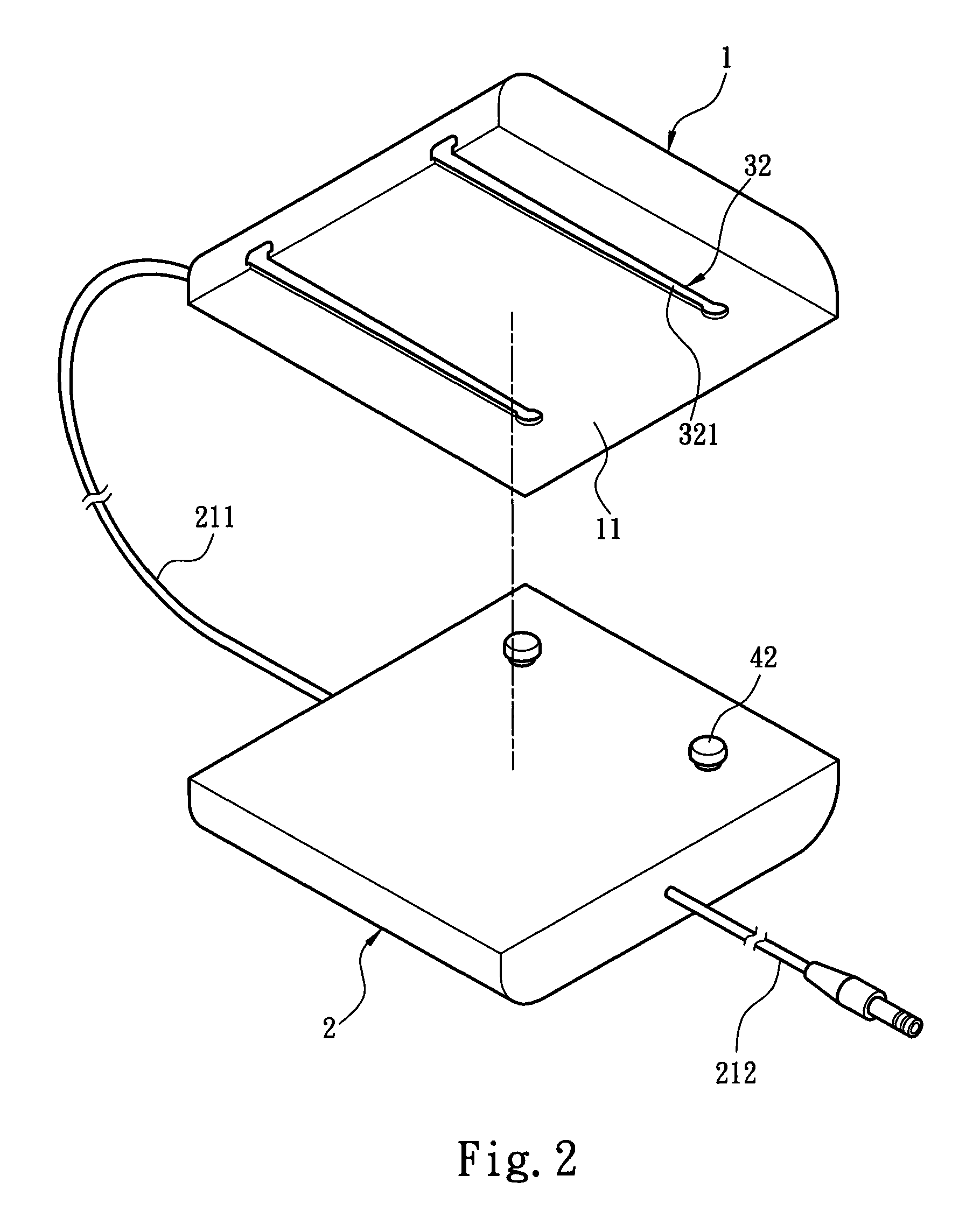

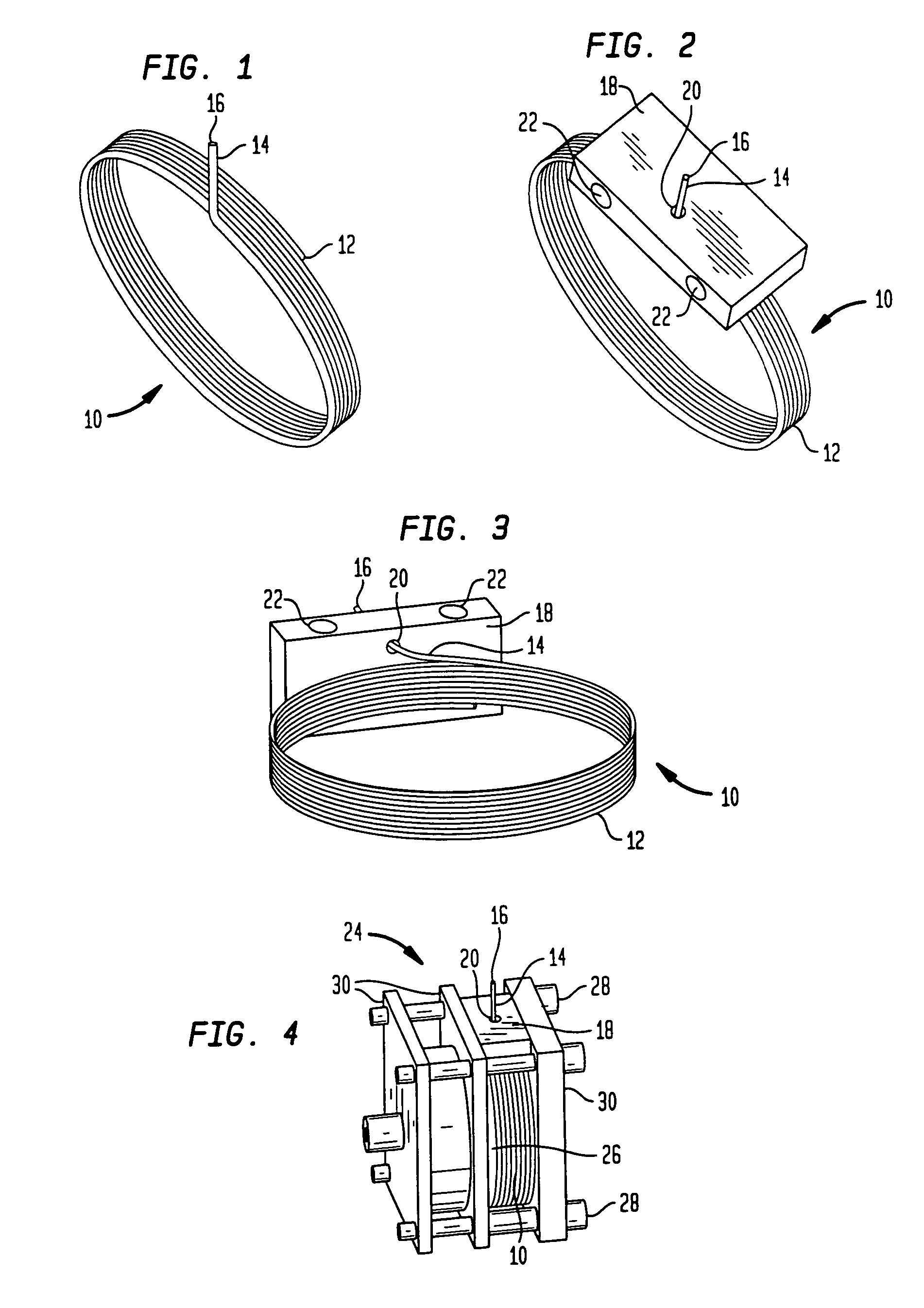

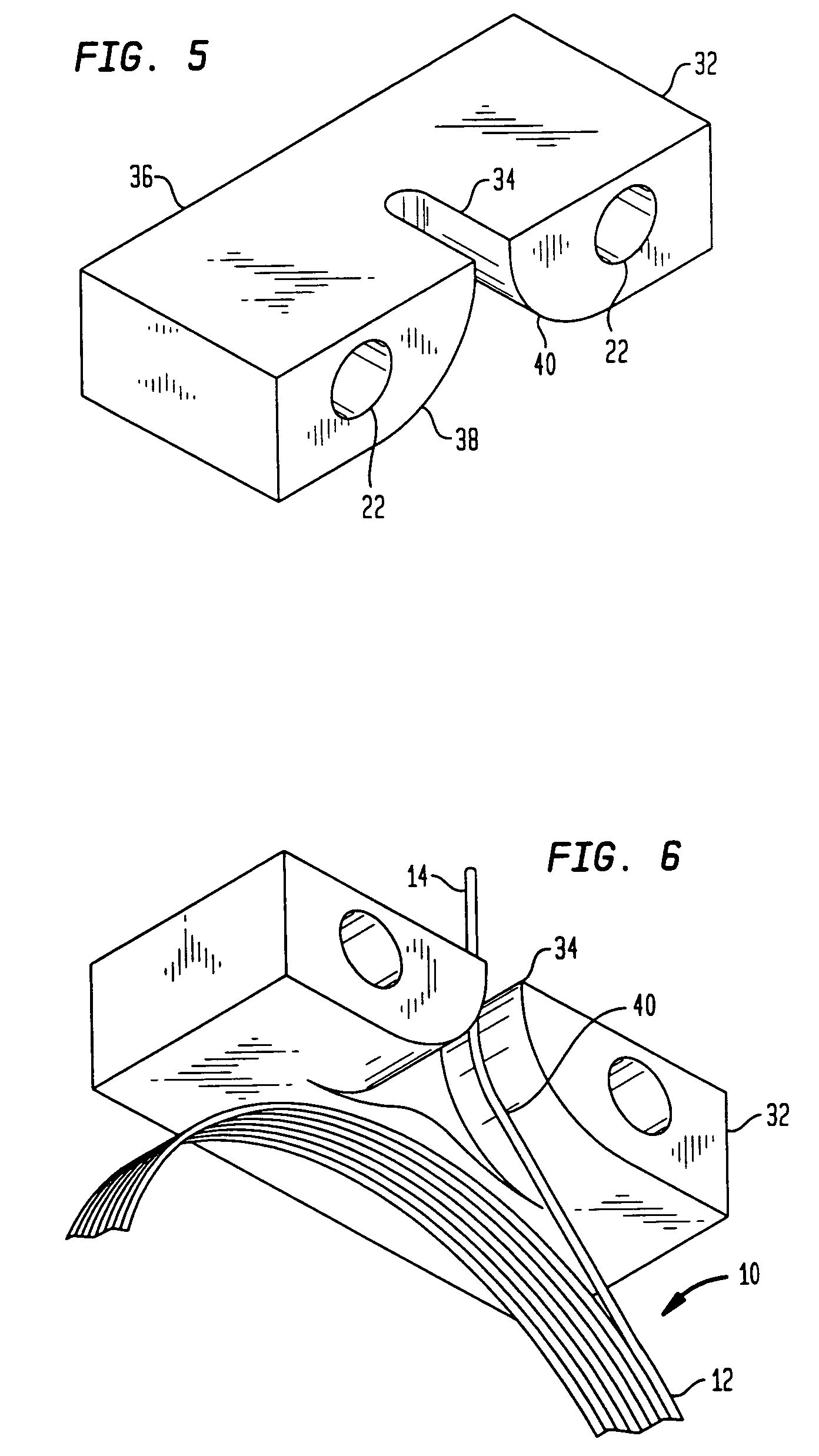

Window covering having a winding function

InactiveUS8307879B2Easy to assembleEasy to replaceScreensCurtain suspension devicesWinding functionWindow covering

A window covering includes a mounting unit, a shading unit, and a winding unit. The mounting unit includes a first fixing member and a second fixing member. The shading unit includes a rotating axle, a curtain member fixed at one end to the rotating axle and which is wound on and unwound from the rotating axle, a first rotating member, and a second rotating member. The first rotating member and the second rotating member are fixed to the rotating axle and extend respectively through the first fixing member and the second fixing member to support rotation of the rotating axle therebetween. The winding unit is mounted to the first fixing member and includes a spring reel secured to the first rotating member to rotate therewith, an auxiliary wheel, and a spring wound around the auxiliary wheel and which is fixed at one end to the spring reel.

Owner:MACAUTO IND CO LTD

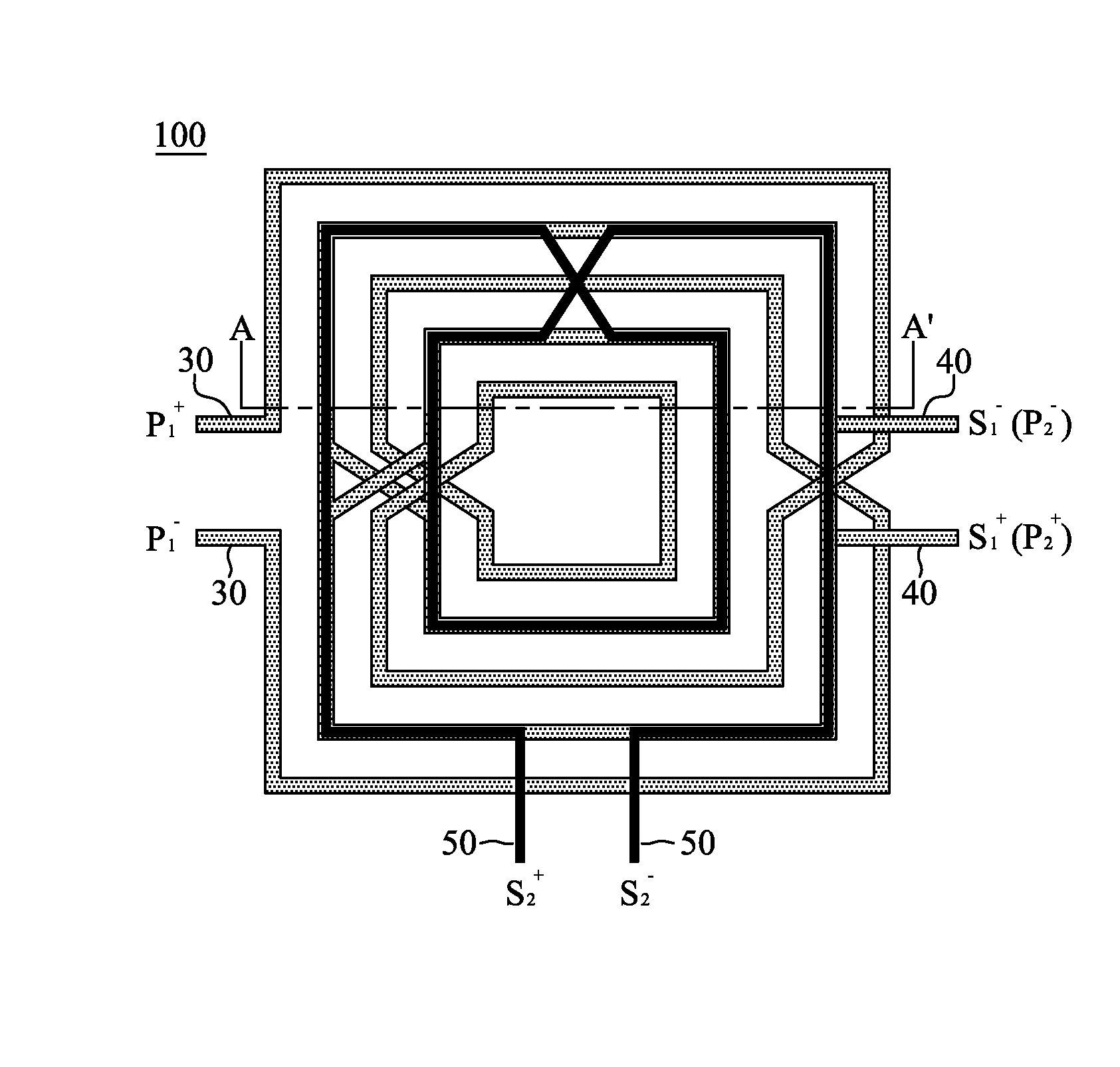

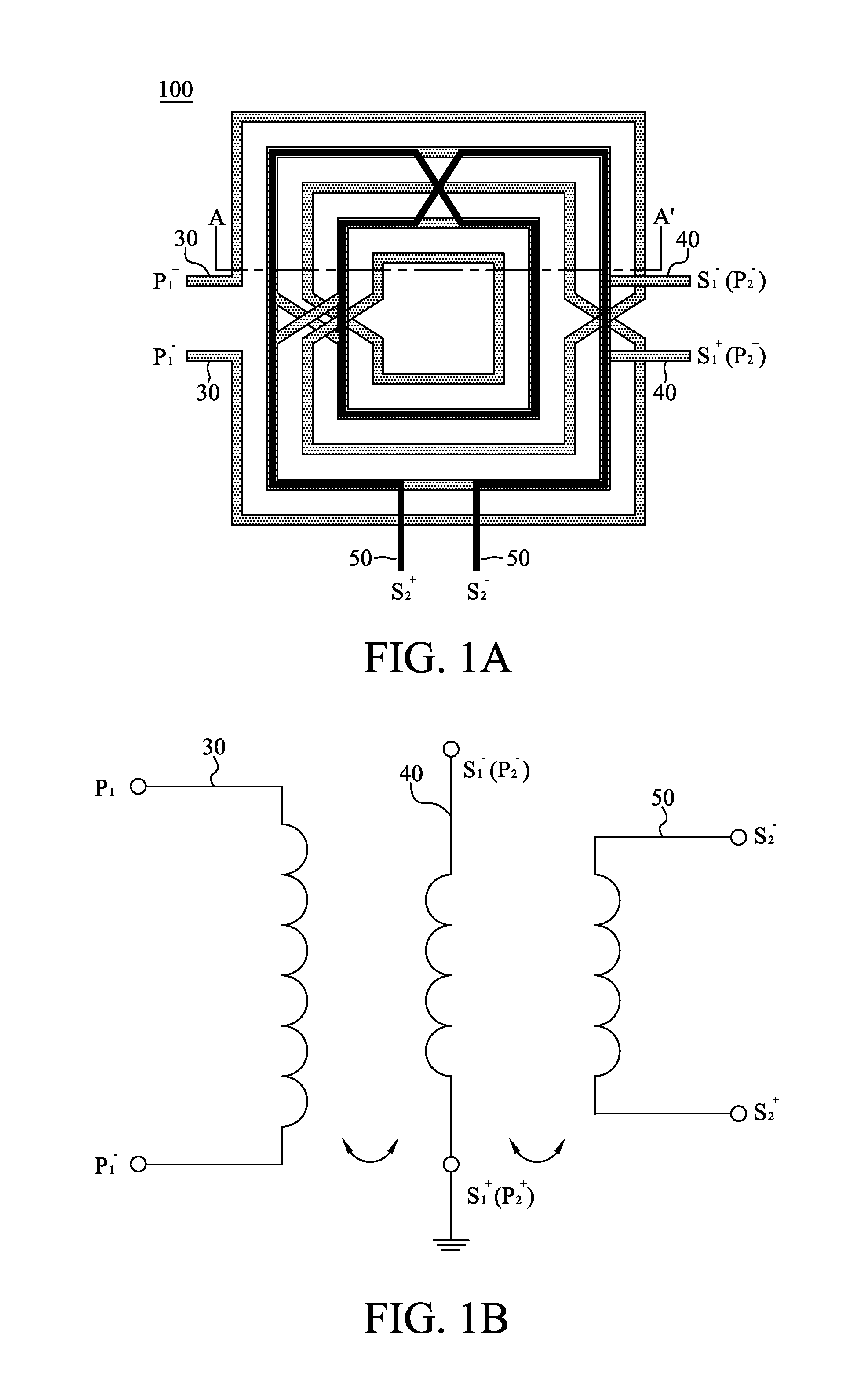

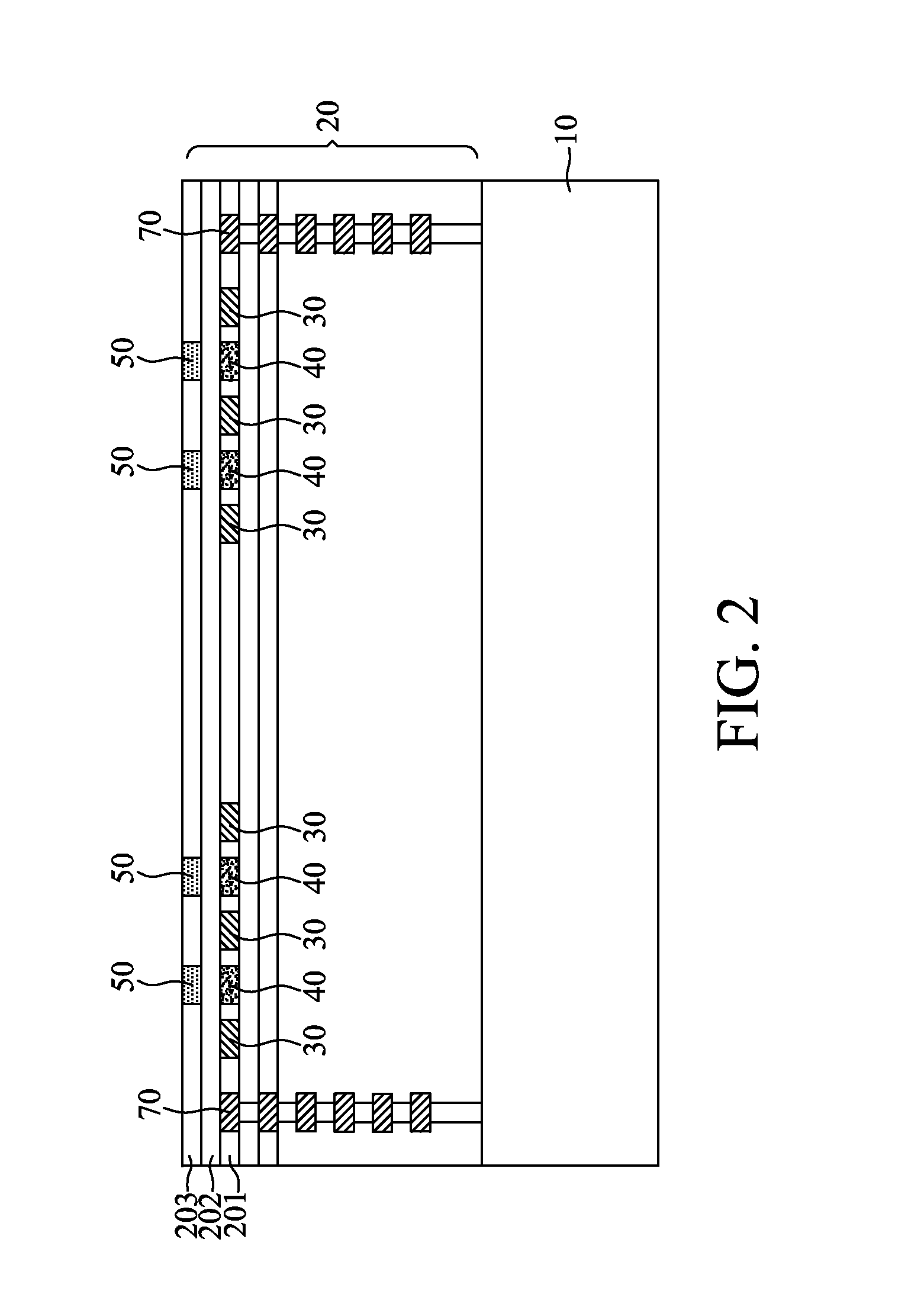

On-chip transformer having multiple windings

InactiveUS20130265132A1Transformers/inductances coils/windings/connectionsFixed transformers or mutual inductancesTransformerEngineering

An on-chip transformer formed on an integrated-circuit substrate is disclosed. The on-chip transformer includes: a multi-winding structure comprising first, second and third windings which are spatially separated from each other; and a guard ring surrounding the multi-winding structure; wherein the first and second windings function as a first transformer, and the second and third windings function as a second transformer.

Owner:REALTEK SEMICON CORP

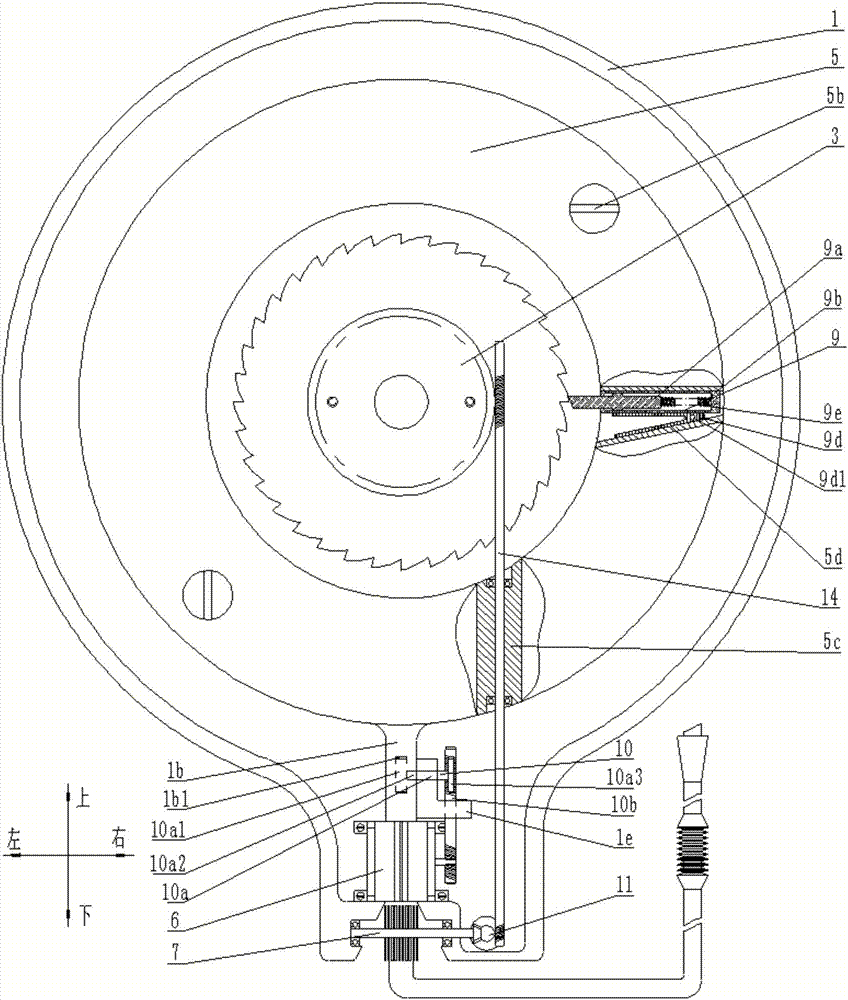

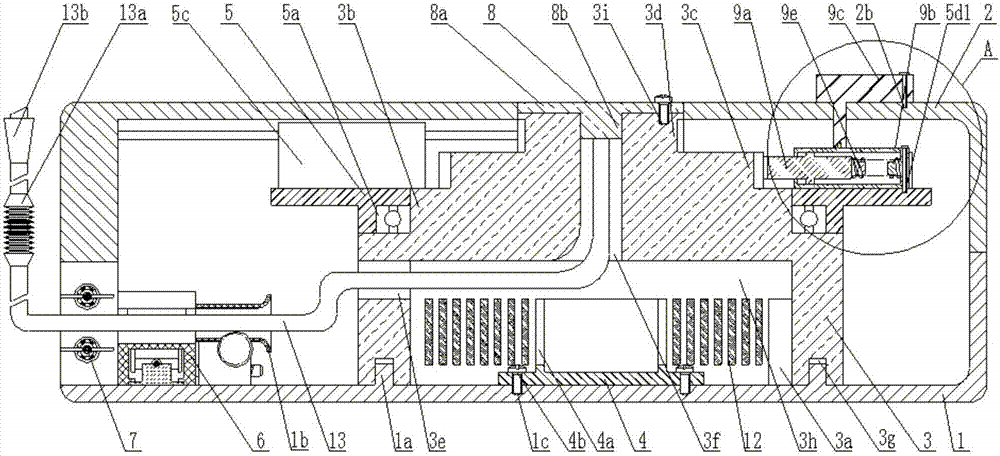

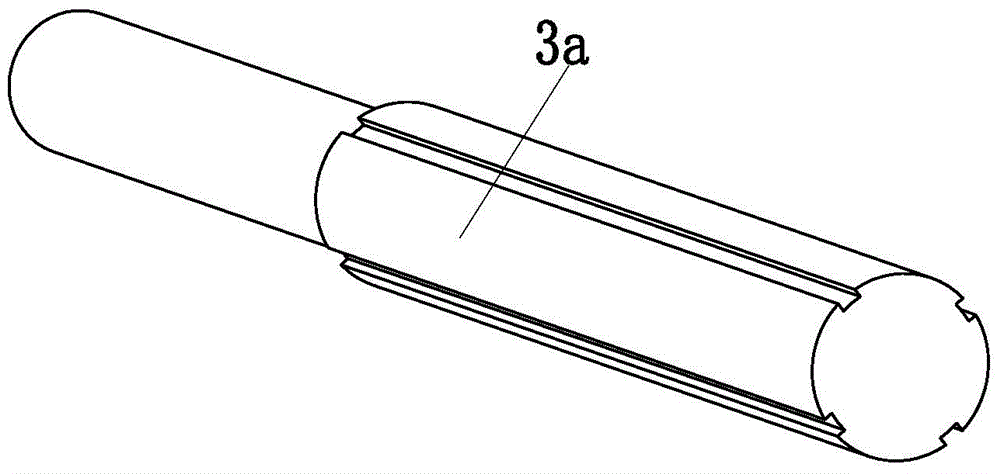

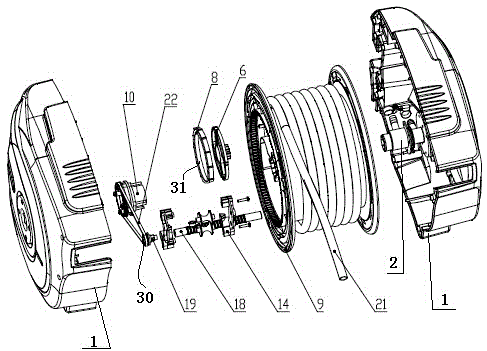

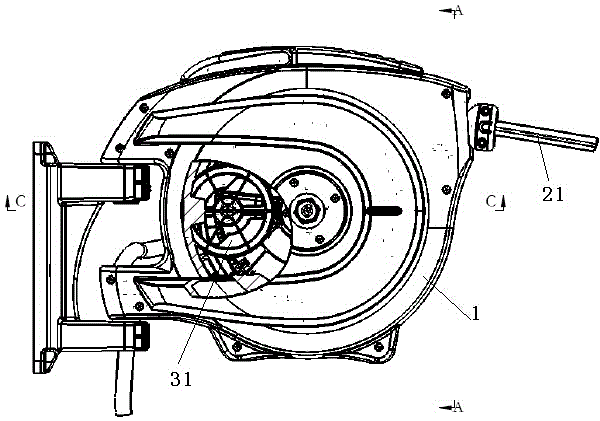

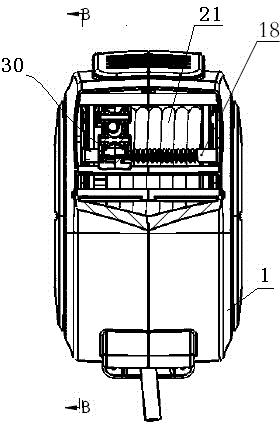

Wire coil with automatic wire winding function for electrical test

The invention relates to a wire coil with an automatic wire winding function for an electrical test. The wire coil comprises a lower end cover, an upper end cover, a coil spring winding device, a winding wheel, an upper wire winding disc, a coil spring, a wire cable connector device, an automatic emergency stop device, a wire cable dust removing device, a wire cable and the like. The winding wheel is arranged on the lower end cover. The coil spring winding device is arranged inside the winding wheel. The coil spring is arranged between the coil spring winding device and the winding wheel. The upper wire winding disc is arranged on the winding wheel. The wire cable connector device is arranged in the position, located above the upper wire winding disc, of the winding wheel. The wire cable penetrates through the winding wheel to be connected with the wire cable connector device. The wire cable dust removing device and the automatic emergency stop device are sequentially arranged at a wire cable inlet of the wire disc. When the wire coil winds the wire cable, the winding speed of the wire cable is decreased before the wire cable reaches the winding tail end, the phenomenon that the winding speed is excessively large, so that the tail end of the wire cable hurts a human body is avoided. Meanwhile the wire cable dust removing device sweeps the recycled wire cable to keep the wire cable clean. The wire coil totally adopts the mechanical structure, so that energy is saved, and the using range is enlarged.

Owner:LIANGSHAN POWER SUPPLY CO OF STATE GRID SHANDONG ELECTRIC POWER CO +1

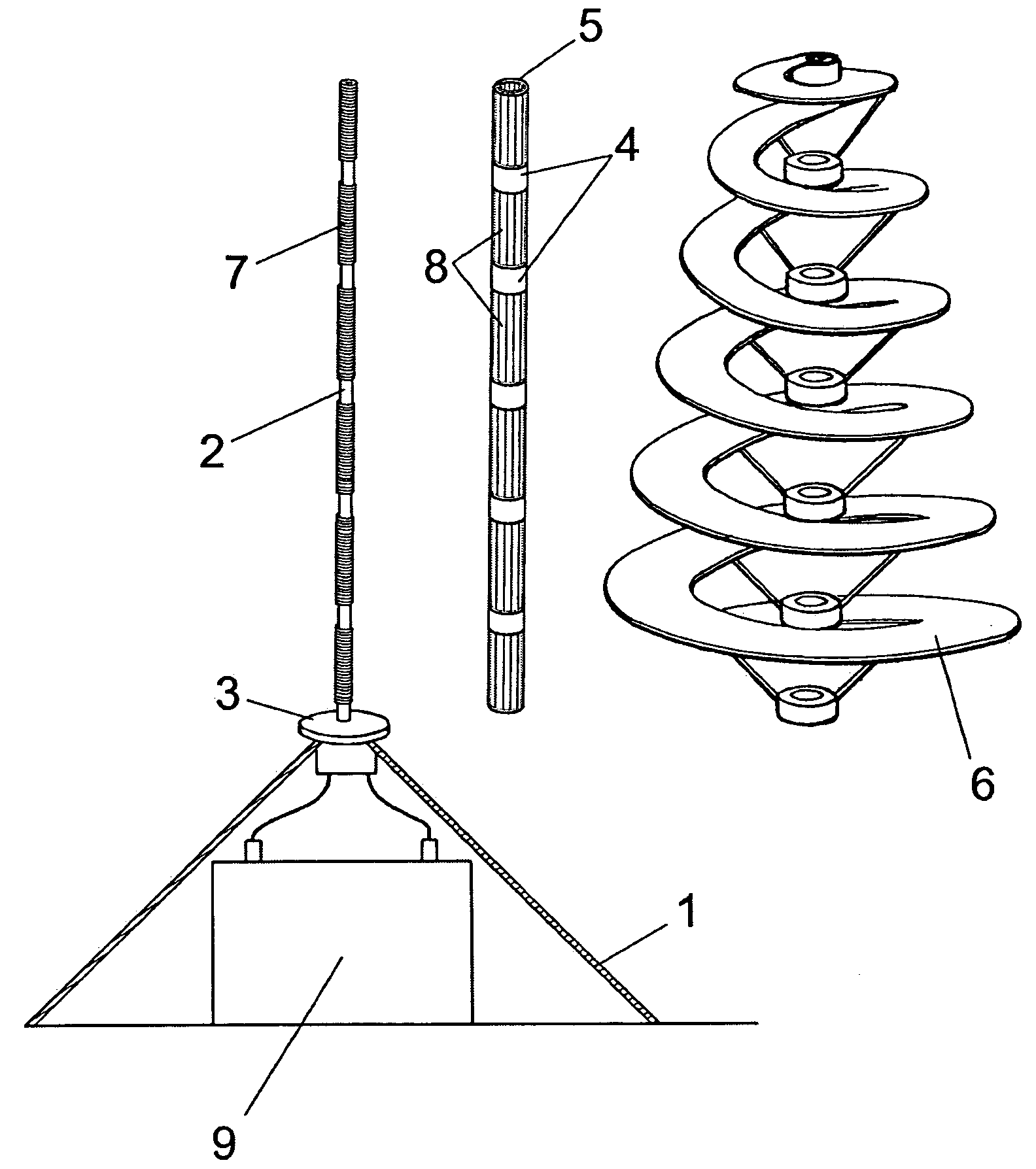

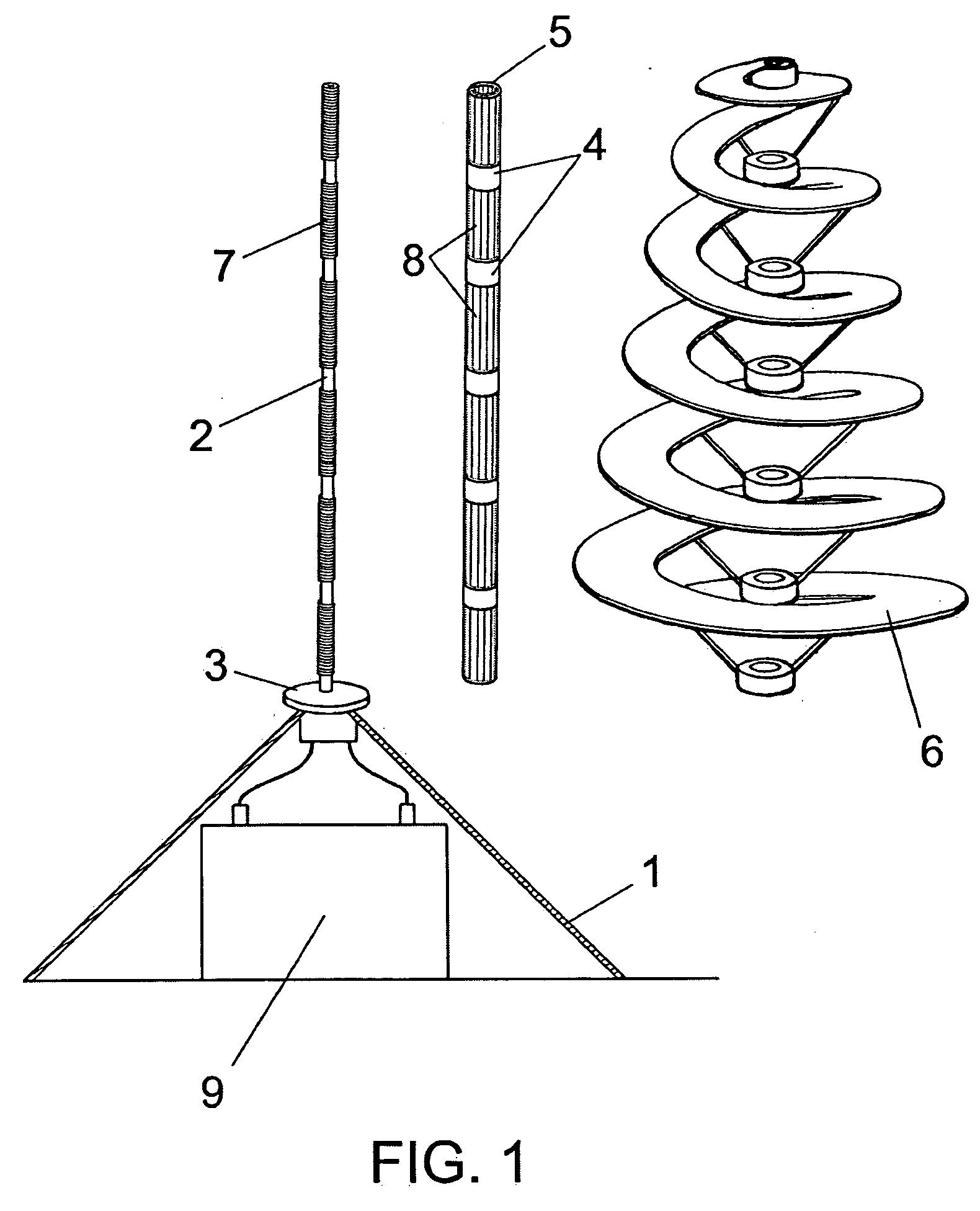

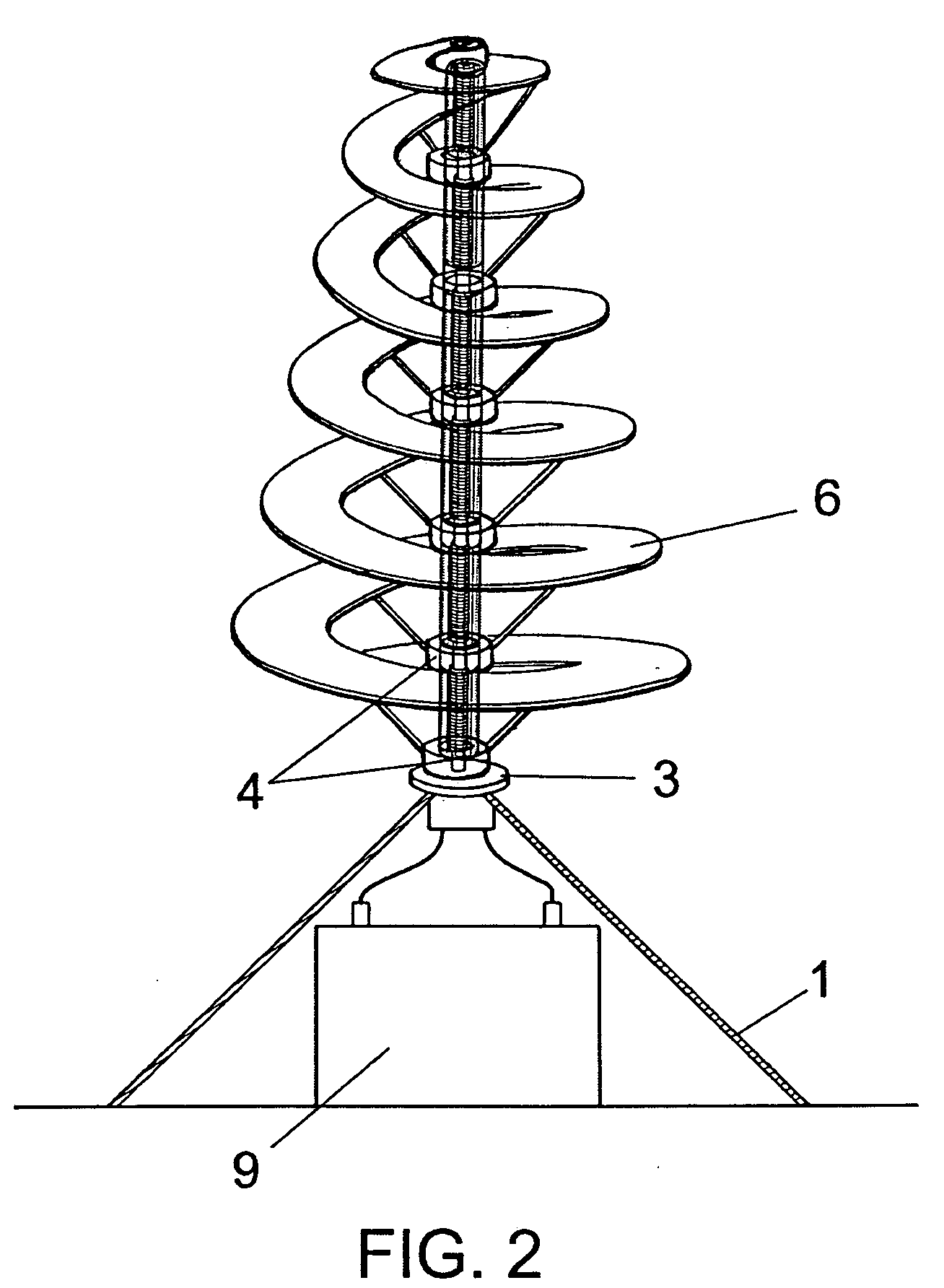

Electrical-Energy Generator

Electrical-energy generator of the type that incorporate a plinth or pedestal from which emerges a vertical, fixed shaft on which is mounted, via bearings, a second shaft to which a blade of conical, helicoidal shape is secured, which imparts a rotary movement to the movable shaft through the effect of the wind, characterized in that said fixed shaft is tubular and incorporates within it an electrical winding functioning as stator, whilst the movable shaft, which is also tubular, incorporates within it a plurality of permanent magnets that convert it into a rotor, all the aforesaid in such a manner that the actual shaft of the generator simultaneously constitutes the dynamo or the alternator that converts the mechanical energy into electrical energy.

Owner:M ARIZA GARCIA SAN MIGUEL JOSE +1

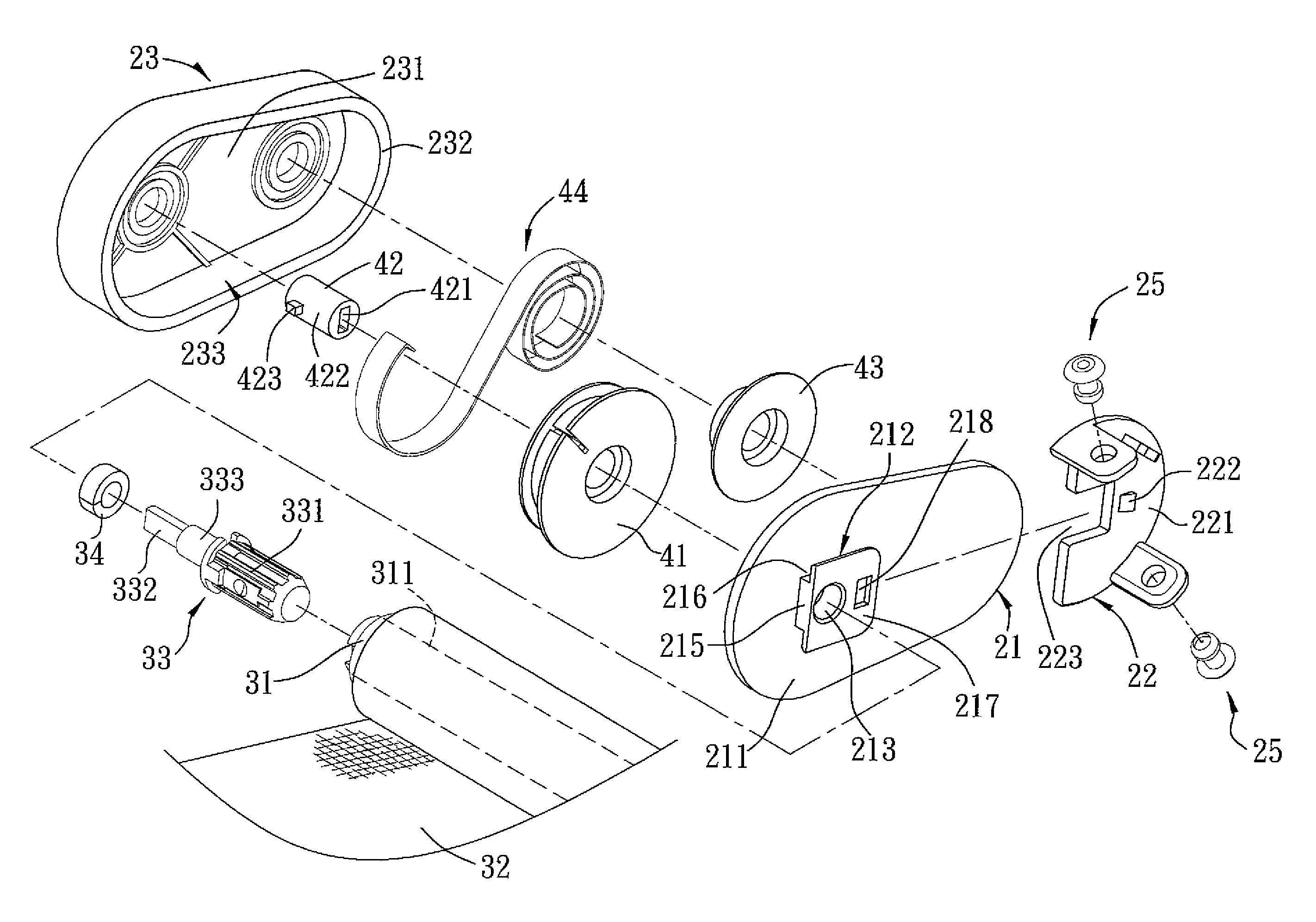

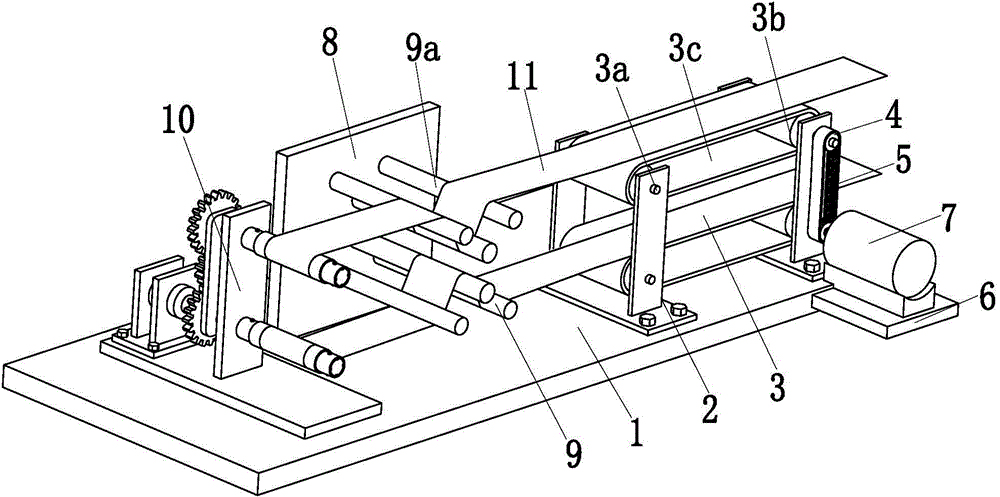

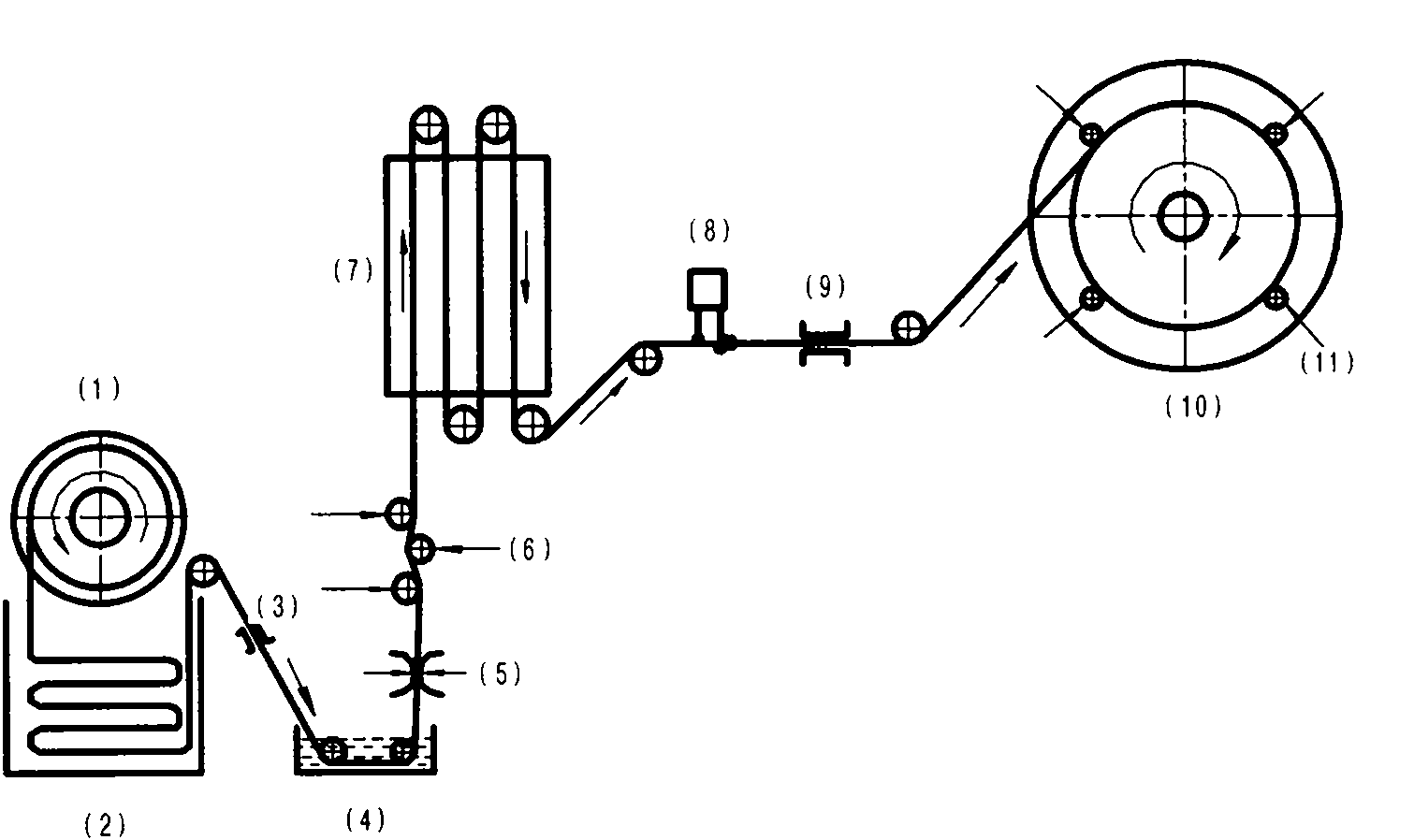

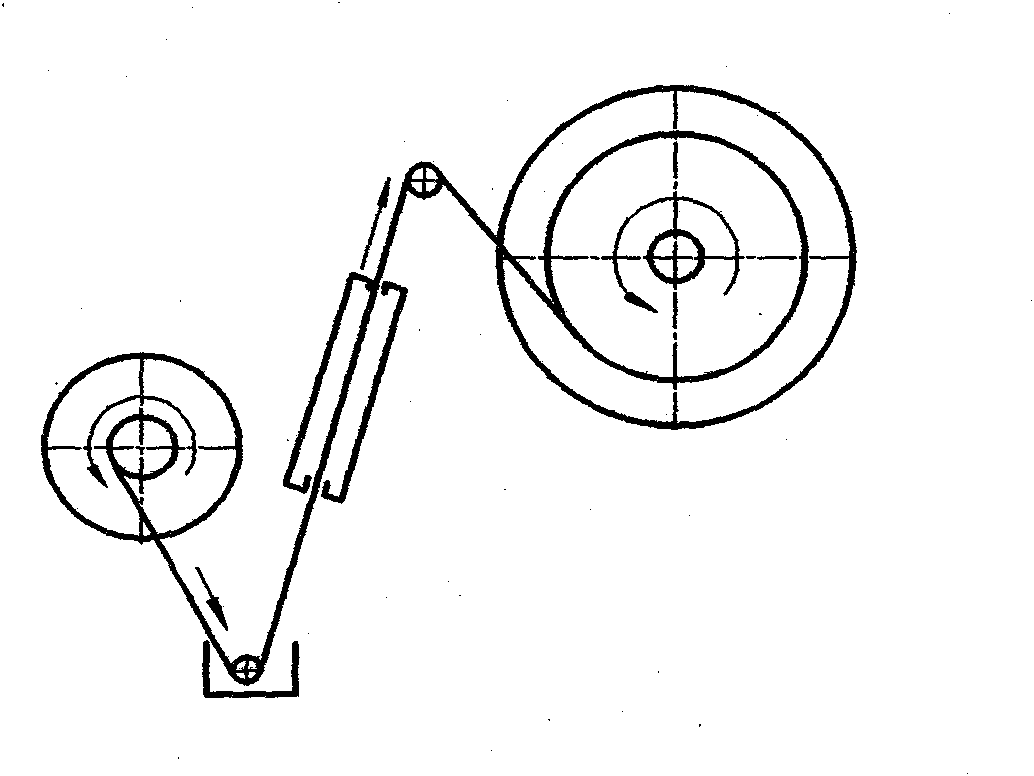

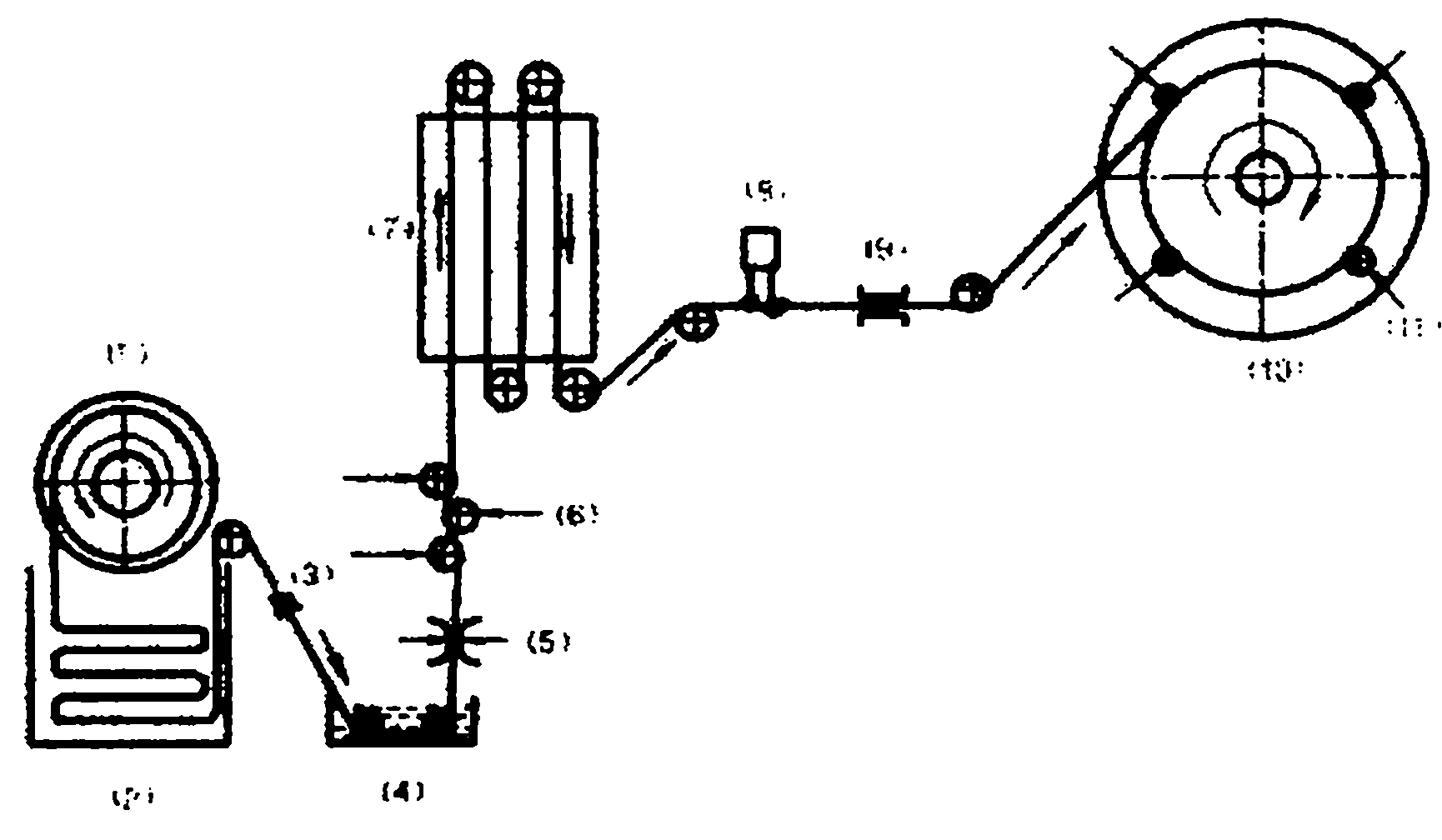

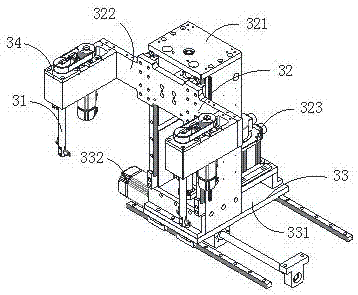

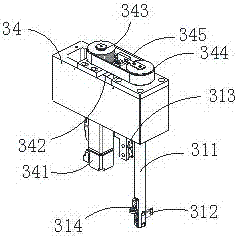

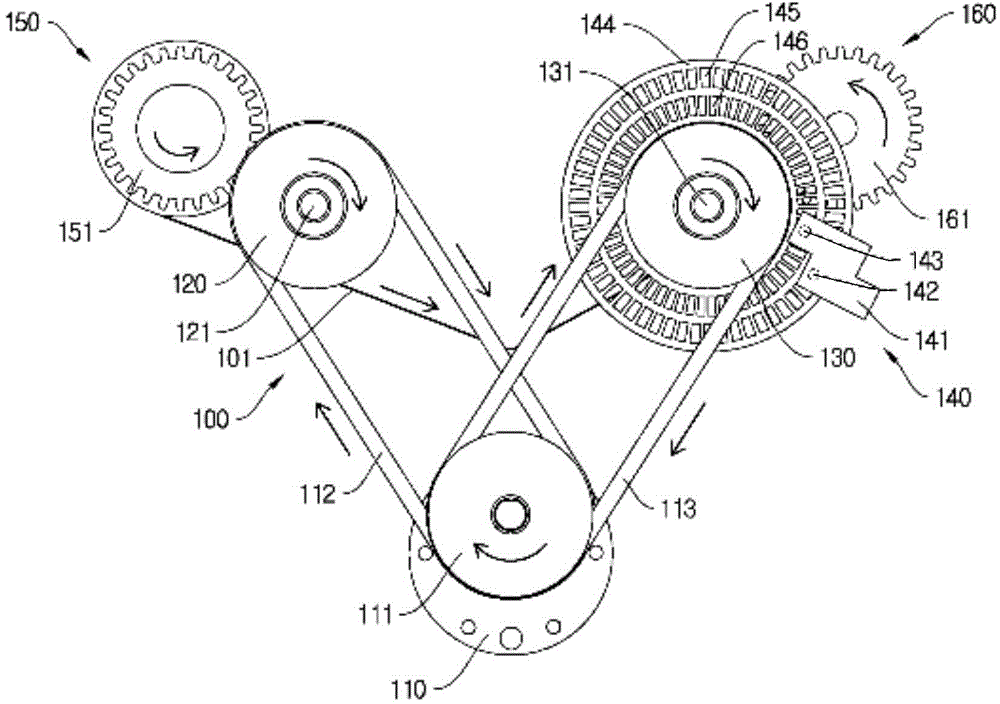

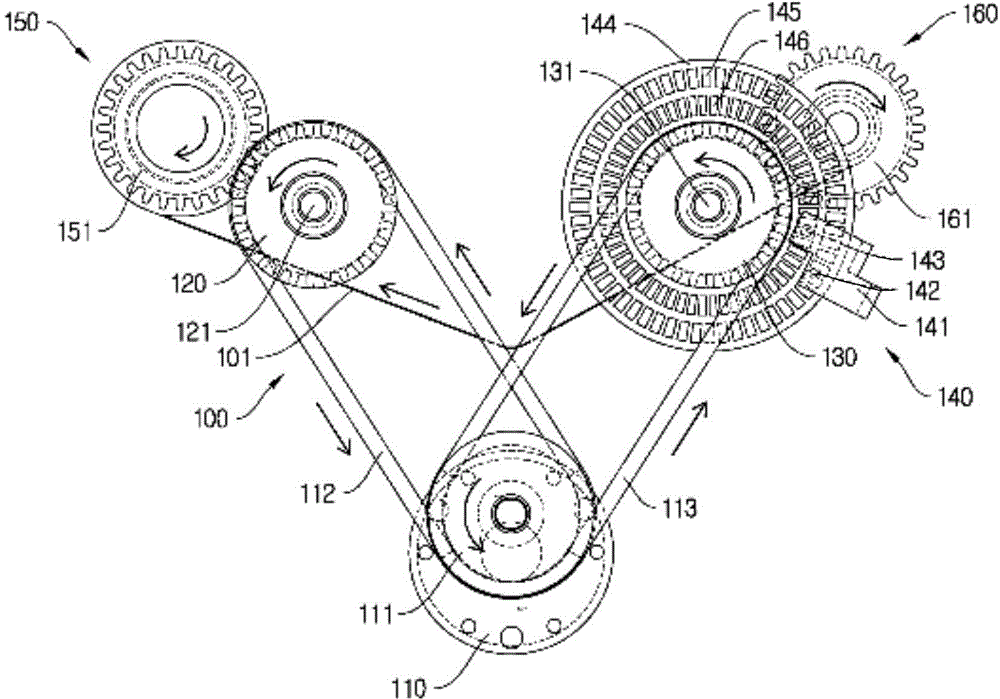

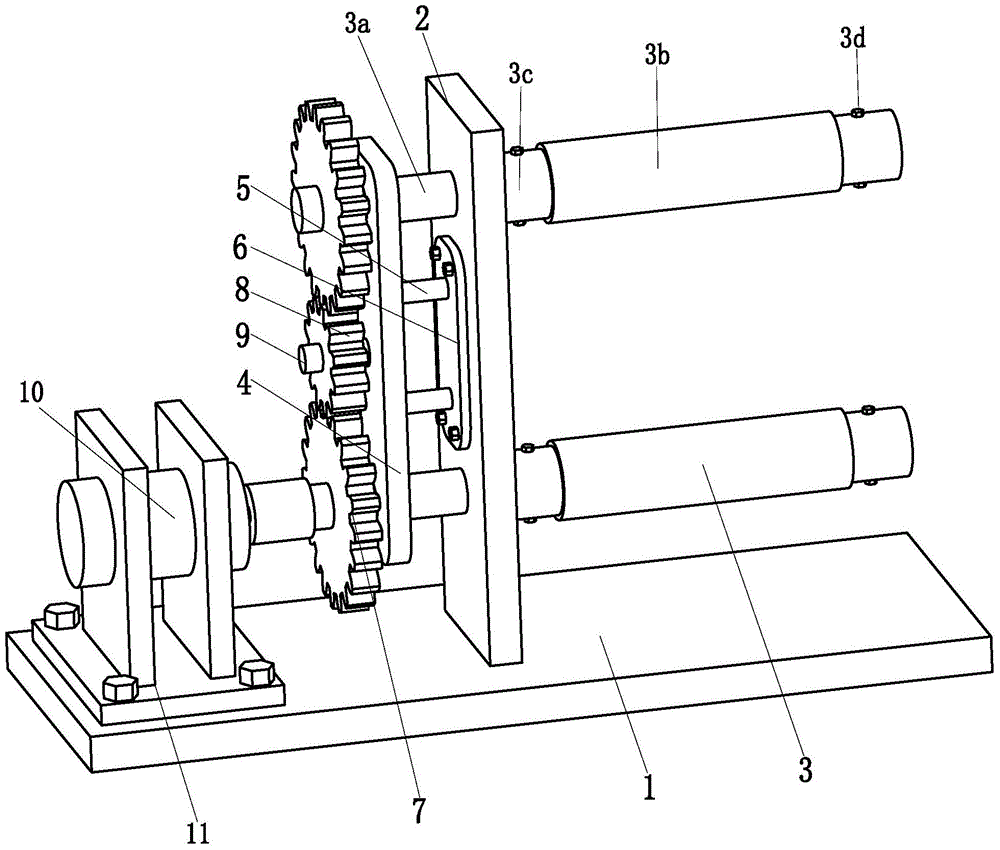

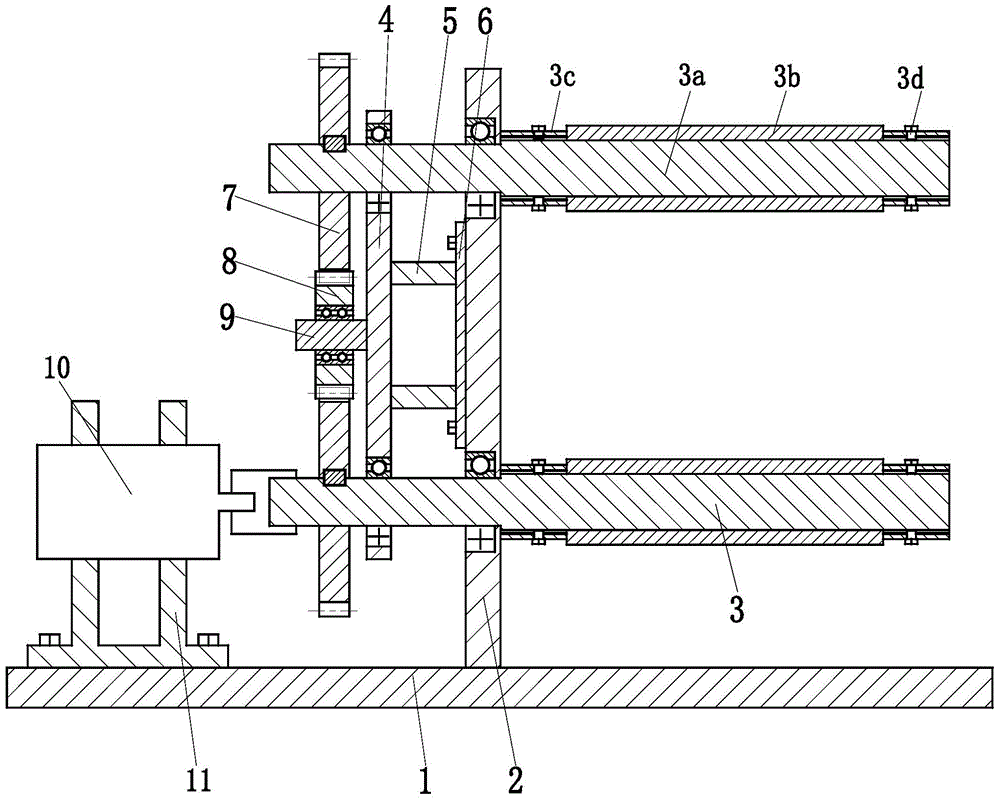

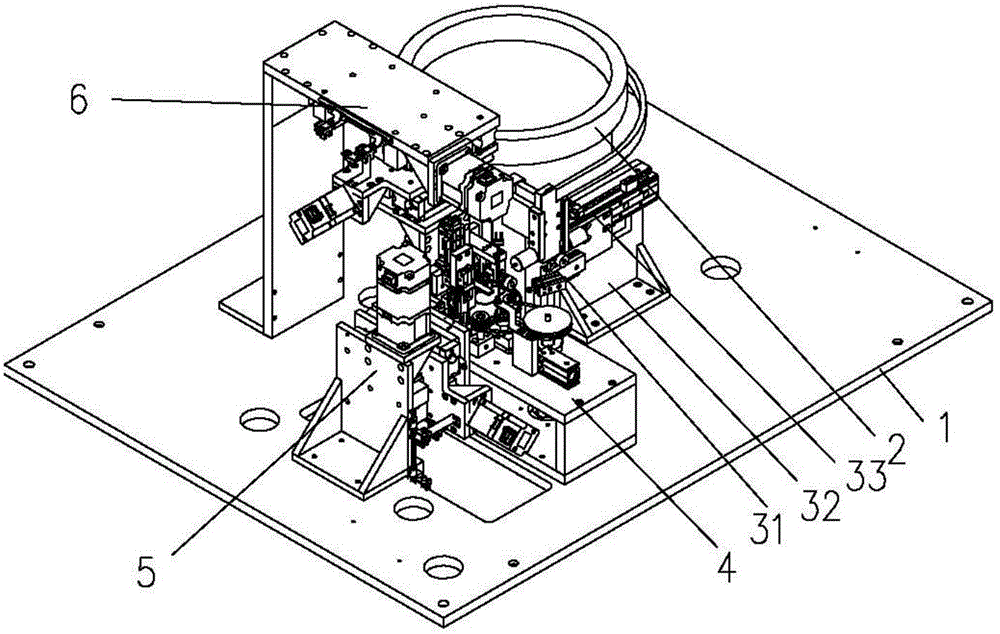

Dialyzing paper winding equipment

InactiveCN104891229ARealize bidirectional winding functionAddressing Structural ComplexityWebs handlingEngineeringConductor Coil

The invention relates to dialyzing paper winding equipment which comprises a bottom plate. Two mounting supports are arranged on the right side of the bottom plate; the two mounting supports are connected with the bottom plate; two transmission mechanisms are mounted between the two mounting supports; the transmission mechanisms comprise driven rotary drums and driving rotary drums, and the driven rotary drums are connected with the driving rotary drums by conveyor belts; two V-shaped belt pulleys are respectively mounted at the front ends of the two driving rotary drums; the two V-shaped belt pulleys connected with each other by a V belt; a support plate is welded on the right side of the bottom plate; a first driving motor is mounted on the support plate; the first driving motor is connected with the driving rotary drums; a first fixing plate is welded on the bottom plate; two V-shaped tension mechanisms are symmetrically welded on the first fixing plate; each V-shaped tension mechanism comprises three tension shafts; a double-winding device is welded on the left side of the upper end surface of the bottom plate. The dialyzing paper winding equipment has a bidirectional dialyzing paper winding function on the premise of low cost, and has the advantages of low cost, easiness and convenience in operation, high work efficiency, wide application range and the like.

Owner:ANQING TIANRUN PAPER PACKAGING

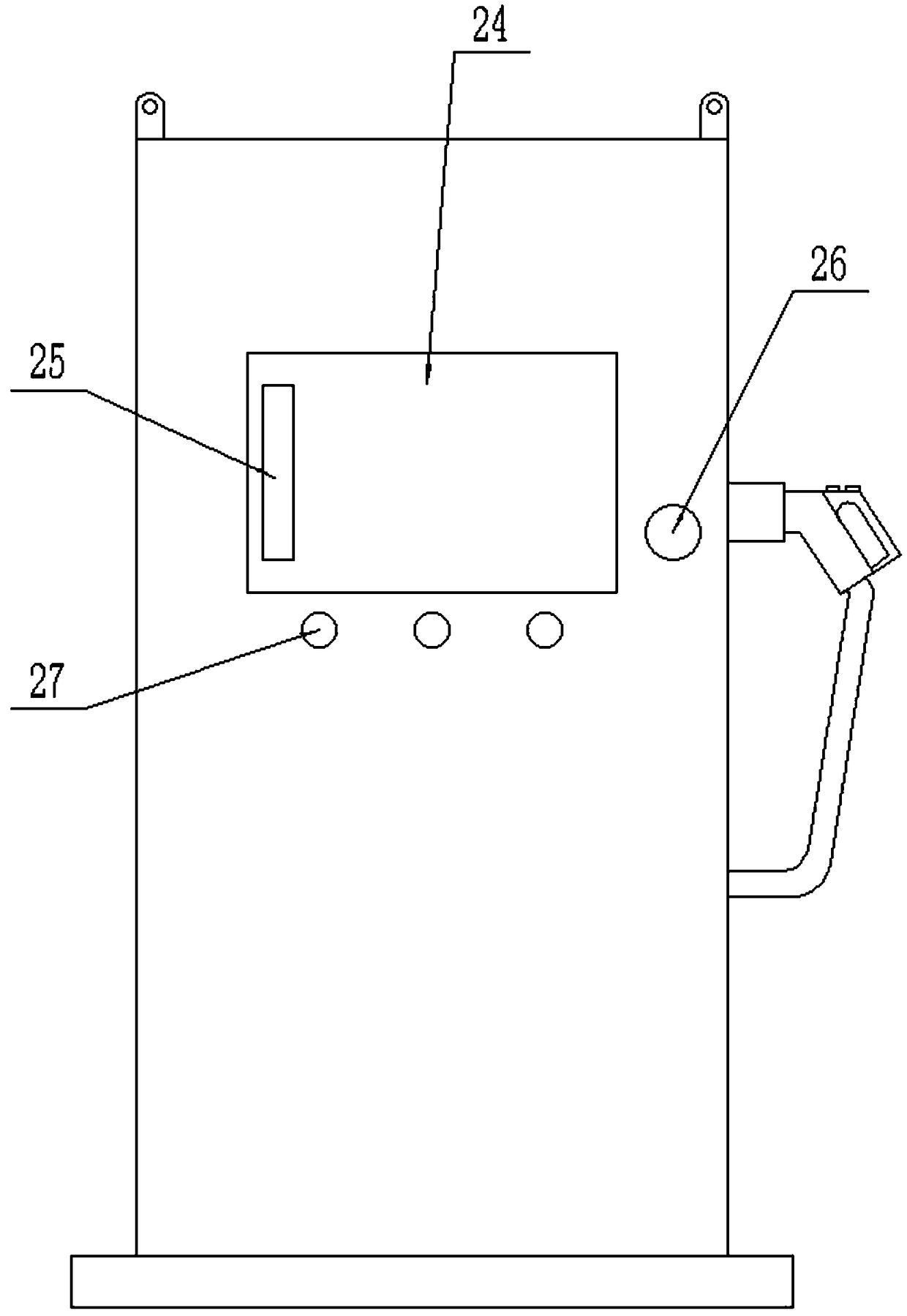

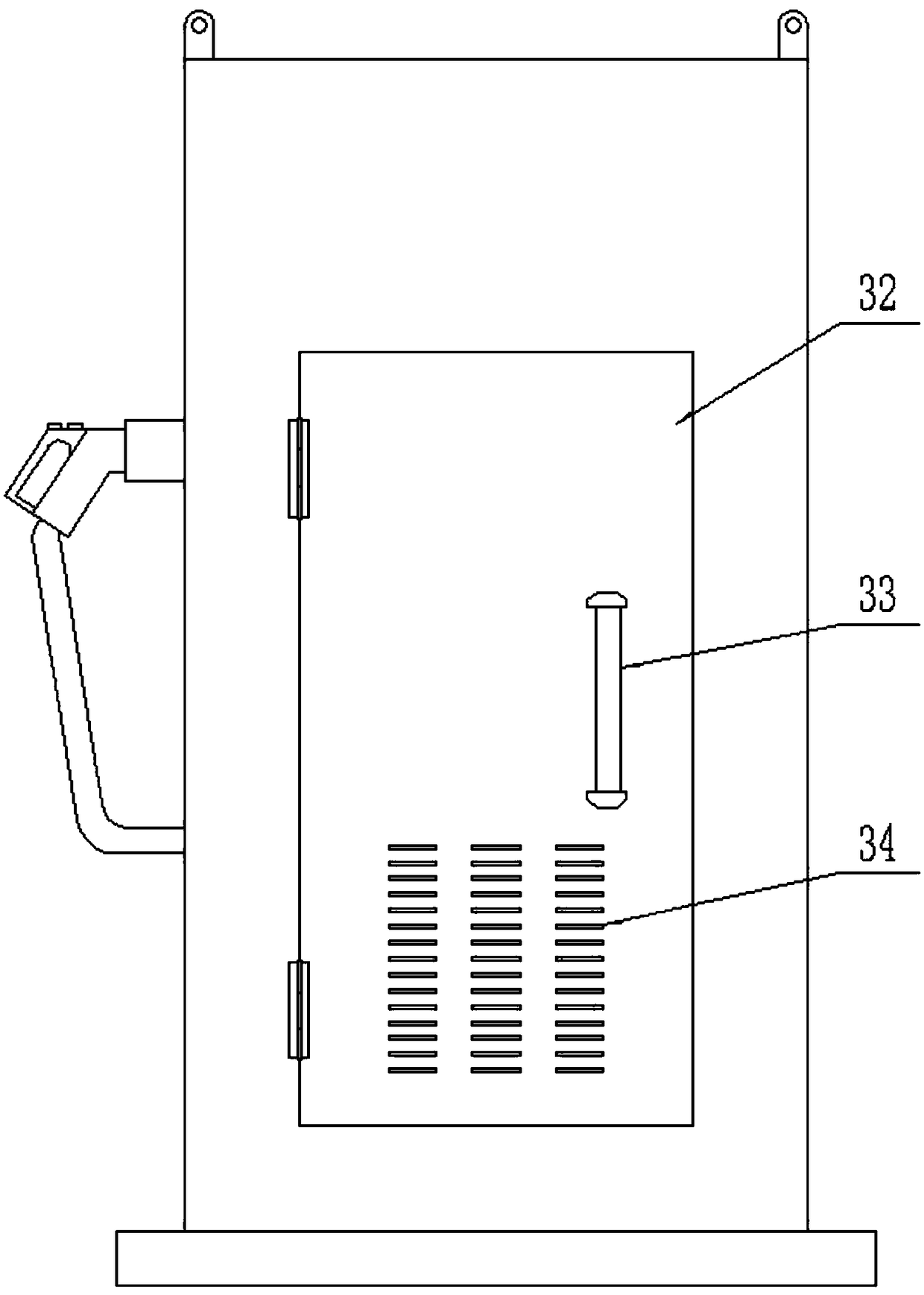

Electric automobile charging pile with automatic winding function

InactiveCN108909521AReduce wearExtended service lifeElectric propulsionFlexible lead accommodationEngineeringConductor Coil

The invention discloses an electric automobile charging pile with an automatic winding function. The electric automobile charging pile with the automatic winding function comprises a charging pile body, a base, a charging gun, a cable and a charging gun fixing seat; the base is fixedly mounted on the ground; the charging pile body is fixed on the base; a winding chamber is formed in the charging pile body; a winding cylinder is fixed at the left end of the winding chamber; a boss is arranged on the right side of the winding chamber; a reduction motor is mounted on the boss; a turntable is fixed at a rotating end of the reduction motor; a screw rod and a cross rod are arranged on the turntable; a circular gear is mounted at the right end of the screw rod; a gear ring in engaged connection with the circular gear is fixed on the winding chamber; a nut seat is arranged on the screw rod; the cross rod penetrates through the nut seat; a cable arranging ring is fixed at one end of the nut seat; a cable penetrates through a cable inlet and outlet port and the cable arranging ring to extend out of the charging pile body to be connected with the charging gun. The electric automobile chargingpile with the automatic winding function has the beneficial effects of simple structure and high practicability.

Owner:杨树楠

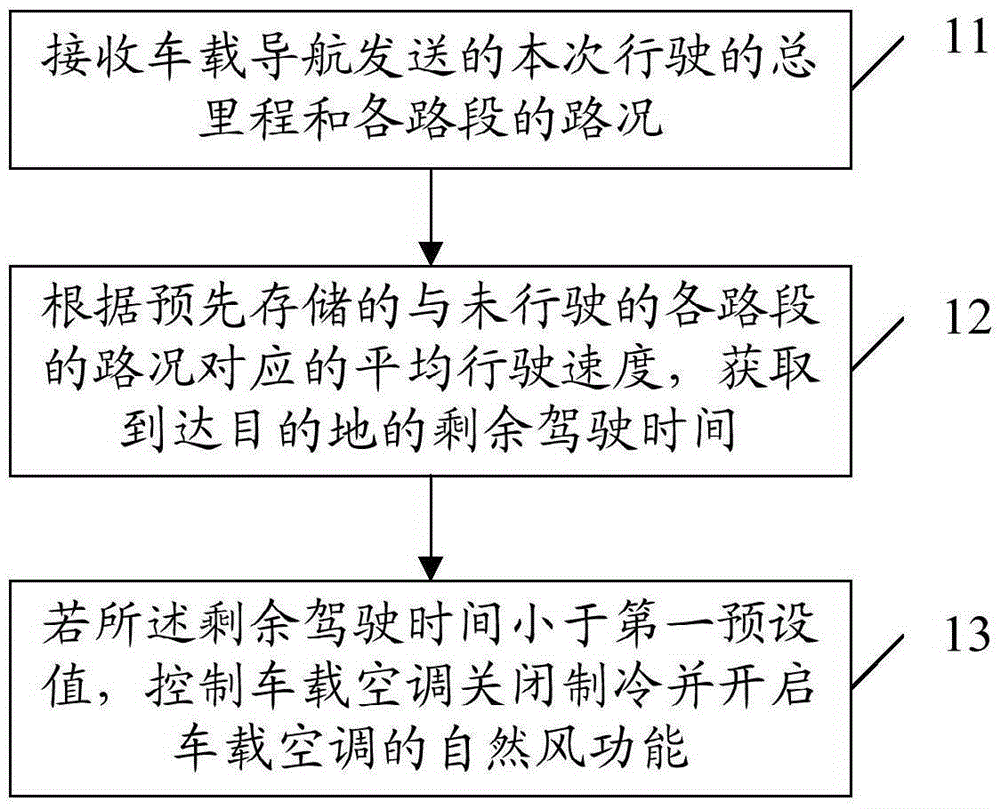

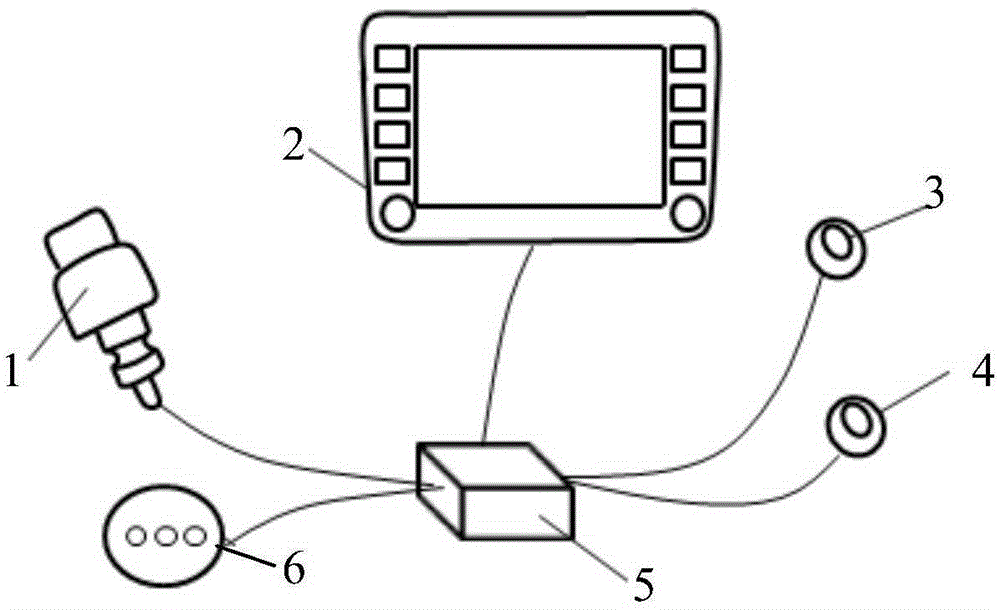

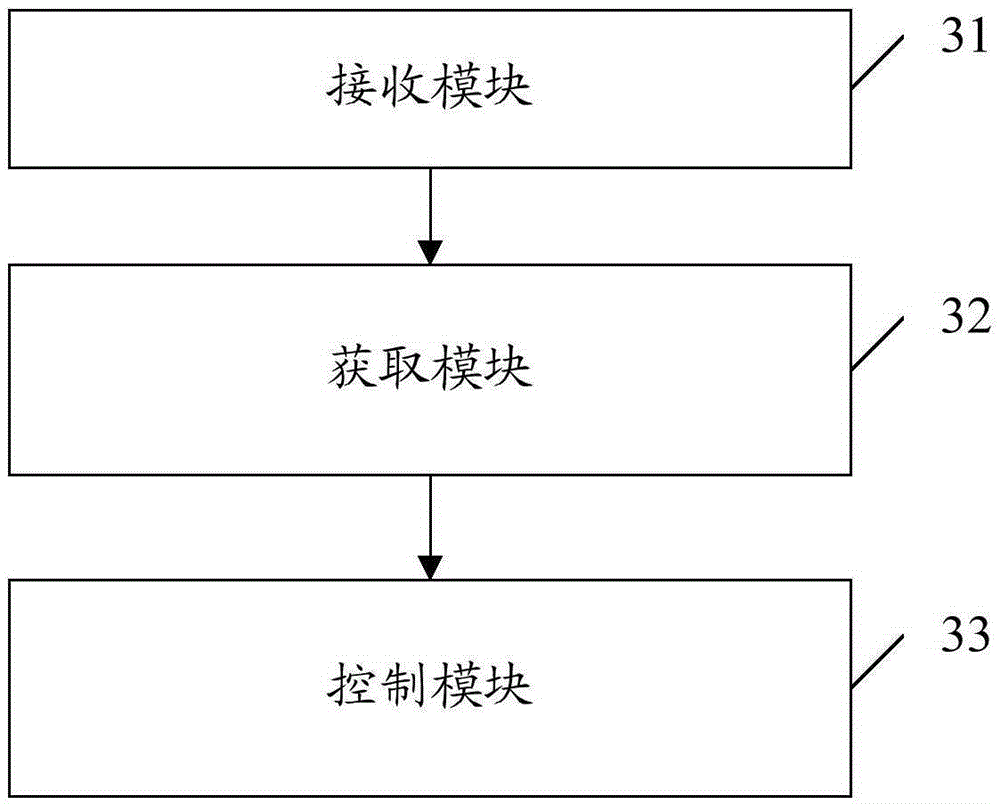

Control method, device and system for vehicle-mounted air conditioner

ActiveCN105291760ASmall temperature changeIncrease temperatureAir-treating devicesVehicle heating/cooling devicesIn vehicleTemperature difference

The invention provides a control method, device and system for a vehicle-mounted air conditioner. The control method comprises the steps that the total mileage and the road section road conditions, sent by a vehicle-mounted navigation, of this-time driving are received; the retained driving time reaching a destination is acquired according to a pre-stored average driving speed corresponding to the road conditions of road sections which are not driven on; if the retained driving time is smaller than a first preset value, the vehicle-mounted air conditioner is controlled to stop refrigerating, and a natural wind function of the vehicle-mounted air conditioner is started. According to the control method, device and system for the vehicle-mounted air conditioner, the retained driving time reaching the destination is acquired according to the pre-stored average driving speed corresponding to the road conditions of the road sections, refrigerating of the air conditioner is stopped and the natural wind function of the air conditioner is started a few minutes before reaching the destination, therefore, the temperature change in a vehicle is small, and the taking comfort is not influenced; the temperature in pipelines of the air conditioner rises back to eliminate the temperature difference with the outside, and therefore relative dryness of an air conditioning system is kept to prevent mold from reproducing; meanwhile, ventilating can save more energy resources than refrigerating.

Owner:BAIC GRP ORV CO LTD

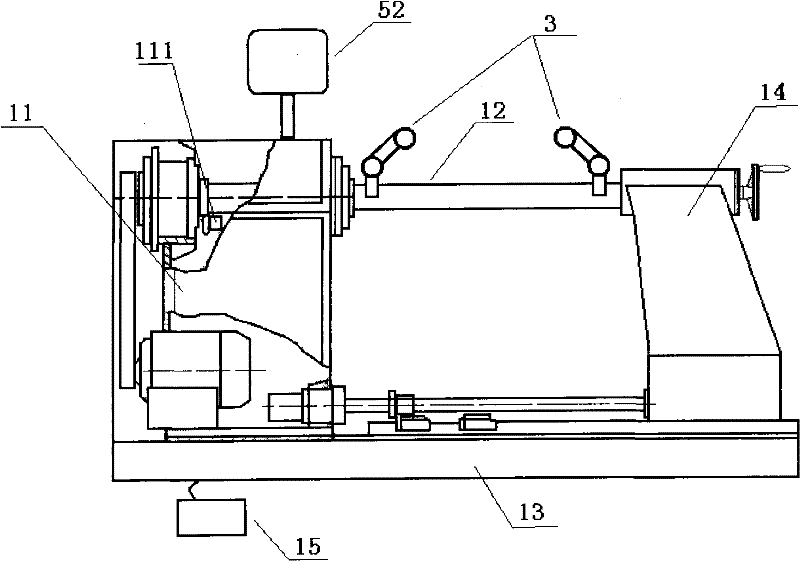

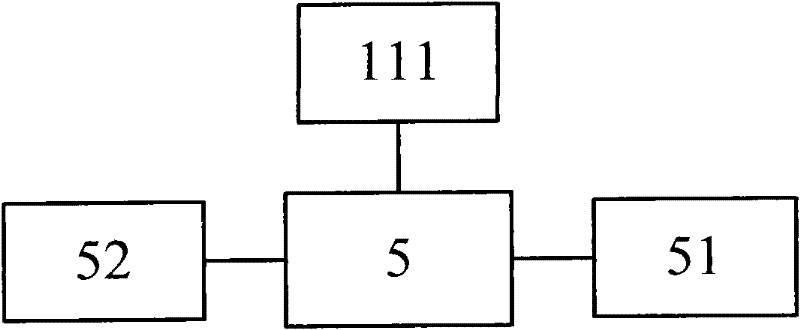

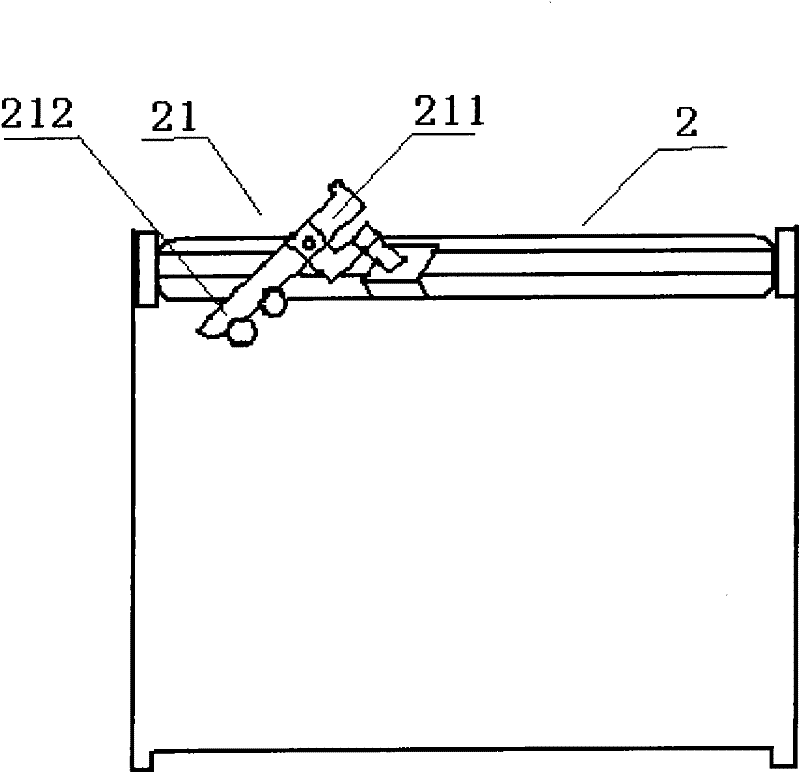

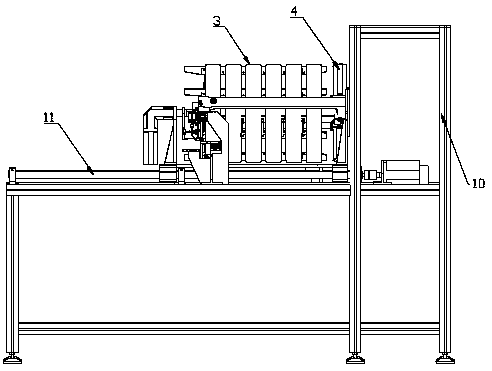

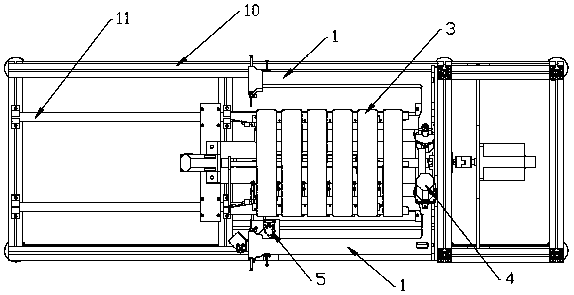

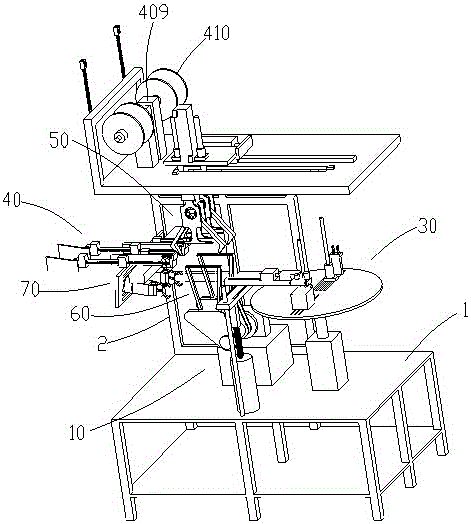

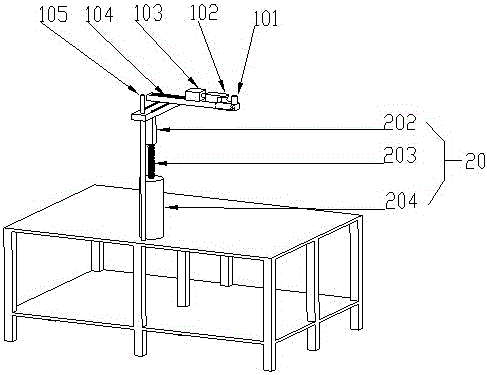

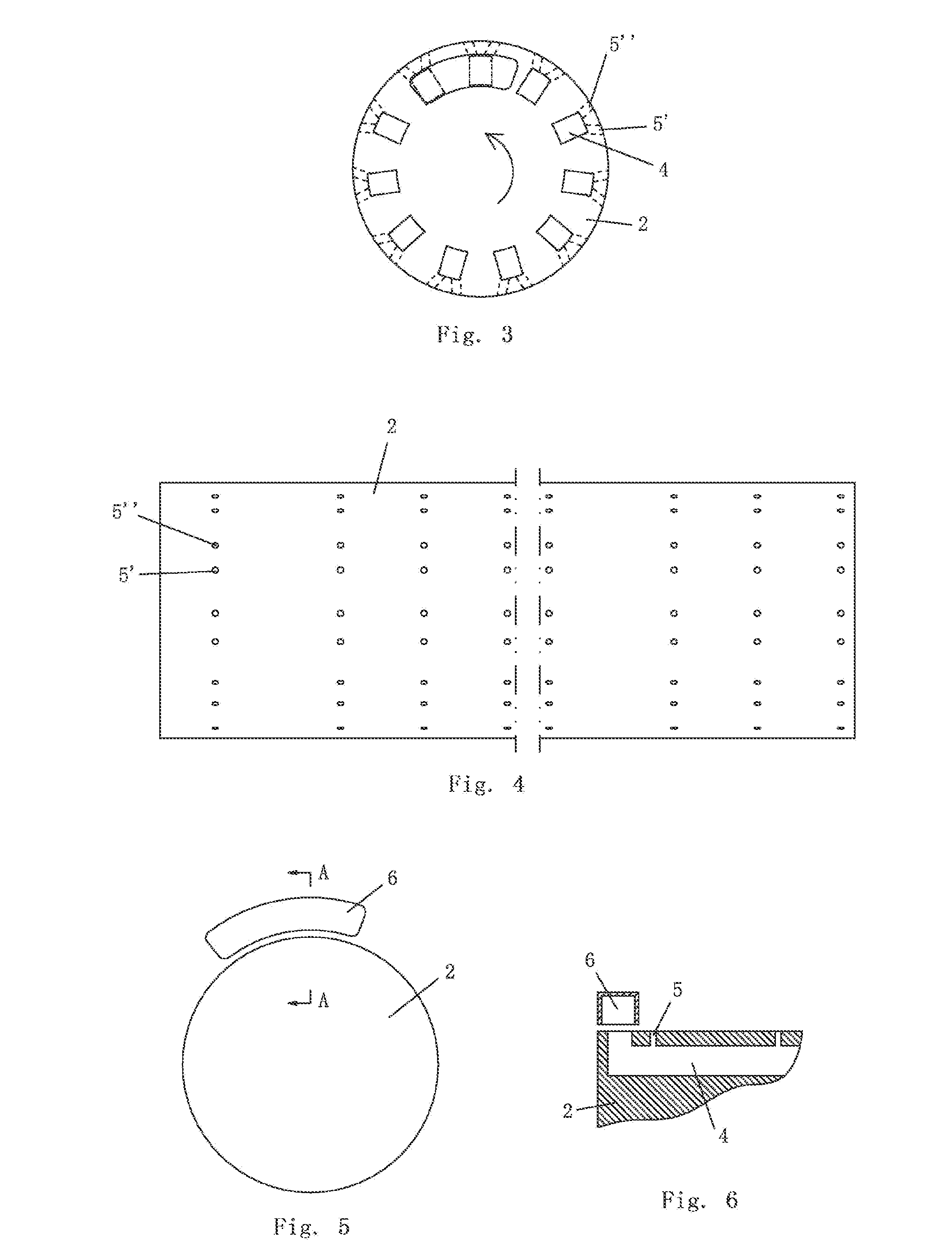

Automatic wire arranging and winding machine

InactiveCN102237195AImprove insulation performanceSmooth transmissionFilament handlingCoils manufactureWinding machinePulp and paper industry

The invention relates to the field of machining, in particular to an automatic wire arranging and winding machine. The automatic wire arranging and winding machine comprises a main machine, a wire arranging mechanism, a paying-off mechanism, an insulated paper winding system and a motor set for providing power, wherein the insulated paper winding system comprises a layer insulating paper winding system and an end insulating paper winding system; the layer insulating paper winding system comprises a bracket and a layer winding power system; the layer winding power system comprises a layer paper feeding system and a layer paper shearing system; the end insulating paper winding system comprises a paper tray and an end winding action system; the end winding action system comprises an end paper feeding system and an end paper shearing system; the end paper feeding system is provided with a paper pressing roller; the motor controlled input end of the paper pressing roller is connected with a micro controller system; and the circumferential surface of the paper pressing roller is provided with a concave cavity capable of accommodating a coil lead. Because the technical scheme is adopted, the automatic wire arranging and winding machine realizes the automatic wire winding function, the transmission of the whole machine is stable, and a coil manufactured by the automatic wire arranging and winding machine has a good insulating effect.

Owner:上海通力电工设备厂

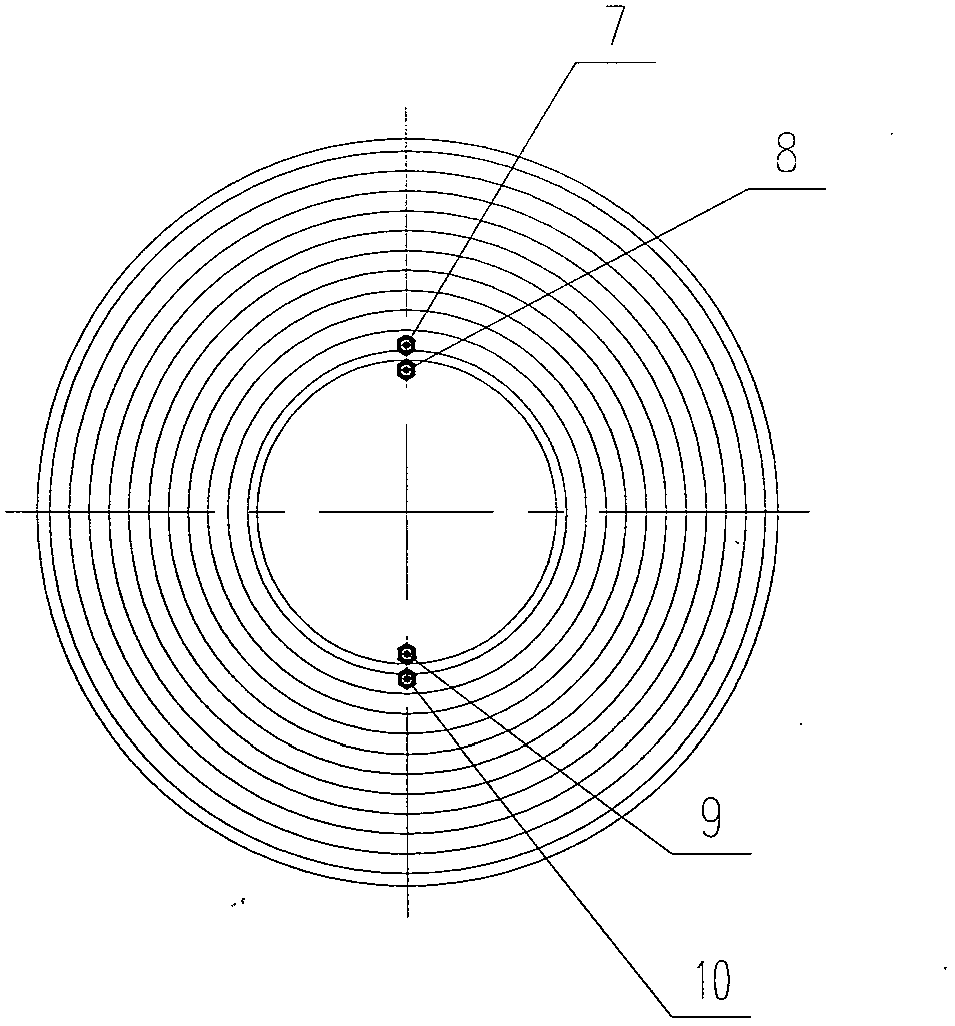

Amorphous soft magnetic alloy magnetic core winding machine

InactiveCN102254674AControlled thicknessHigh dielectric strengthTransformers/inductances magnetic coresInductances/transformers/magnets manufactureEngineeringDielectric strength

The invention provides an amorphous soft magnetic alloy magnetic core winding machine, which comprises a material discharging mechanism having a driving device, a storage box for preventing distortion and tensile force change of belt material, a front and back tension control mechanism for adjusting pressing force, a temperature-adjustable constant temperature liquid coating tank, a coat thickness control device, an electrothermal constant temperature coat drying device, a coat insulation property detecting device, a winding main shaft and a material rewinding plate, a magnetic ring pressing mechanism, a base and an electrical control system and the like. The equipment integrates coating and winding functions; the thickness of the coat is controlled (the thickness of an SiO2 coat is controlled to be between 0.6 to 1 mu m; the dielectric strength of the coat is excellent (interlayer pressure resistance can be 20V); the coating and winding speed is high (the speed can be 1m / s); the winding quality is uniform; the winding duty ratio can be more than 0.8; and the winding machine is suitable for winding the amorphous magnetic core and nanocrystalline magnetic core which have the thickness of 0.01 to 0.05mm, the width of 10 to 150mm and the diameter of 100mm to 1,200 mm and are required by a high-pressure narrow-pulse high-power device.

Owner:零八一电子集团四川力源电子有限公司

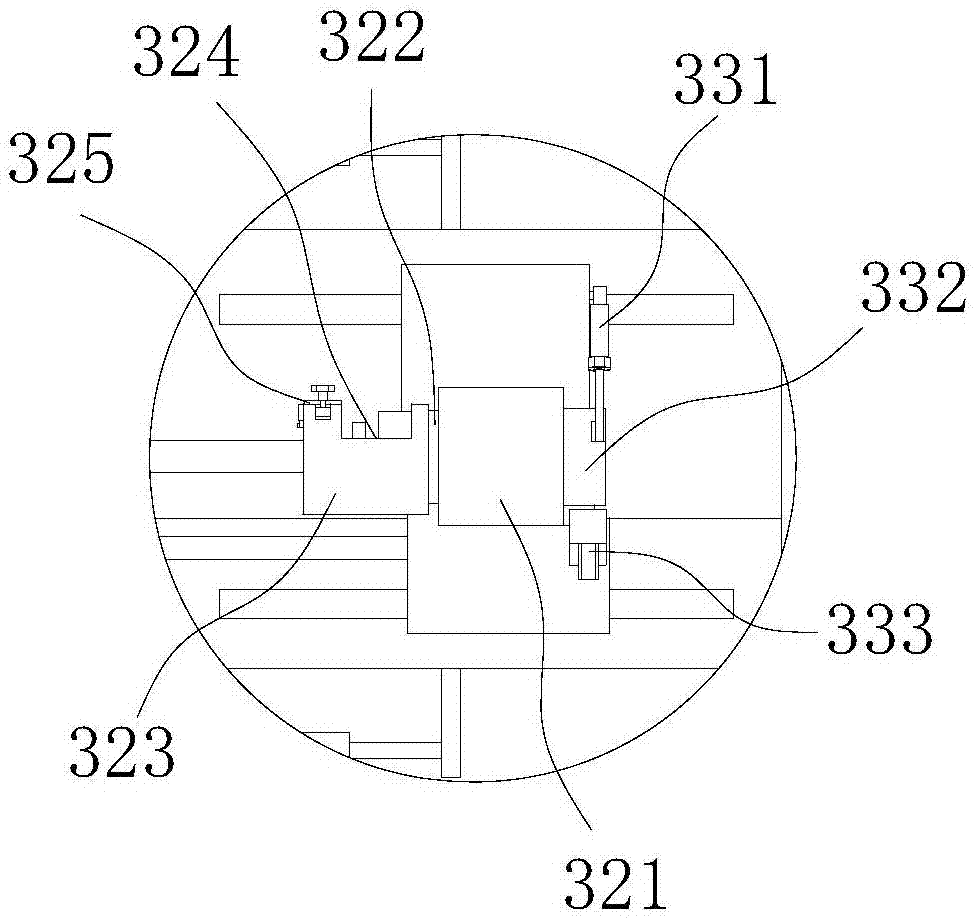

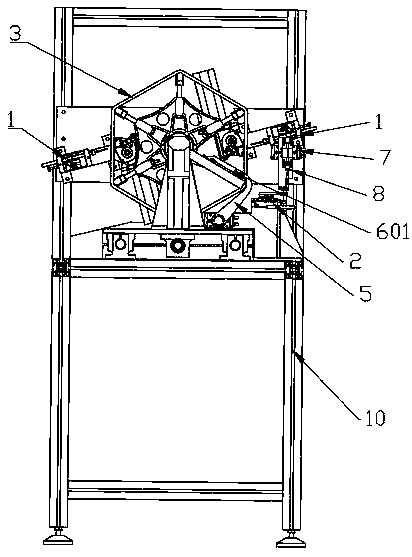

Vertical winding machine and winding method thereof

InactiveCN107546934AAvoid tanglesImprove stabilityManufacturing dynamo-electric machinesWinding machineWire tension

The invention discloses a vertical winding machine and a winding method of the vertical winding machine, which mainly include a frame and a tension control mechanism installed on the frame for controlling the tension of the enameled wire, and for embedding the enameled wire into the stator wire groove. The vertical winding mechanism, the product rotation mechanism used to fix the stator and drive the stator to rotate, the clamping and arranging mechanism used to limit the position of the enameled wire in the stator wire slot, and the cross-slot mechanism used to hook the enameled wire when the enameled wire crosses the slot And control components for controlling all power sources on the inner winding machine. The multi-strand wire vertical inner winding machine provided by the invention can automatically wind the inner winding stator in the whole process, and the winding is uniform, and the enameled wire will not be scratched during the winding process.

Owner:东莞拓蓝自动化科技有限公司

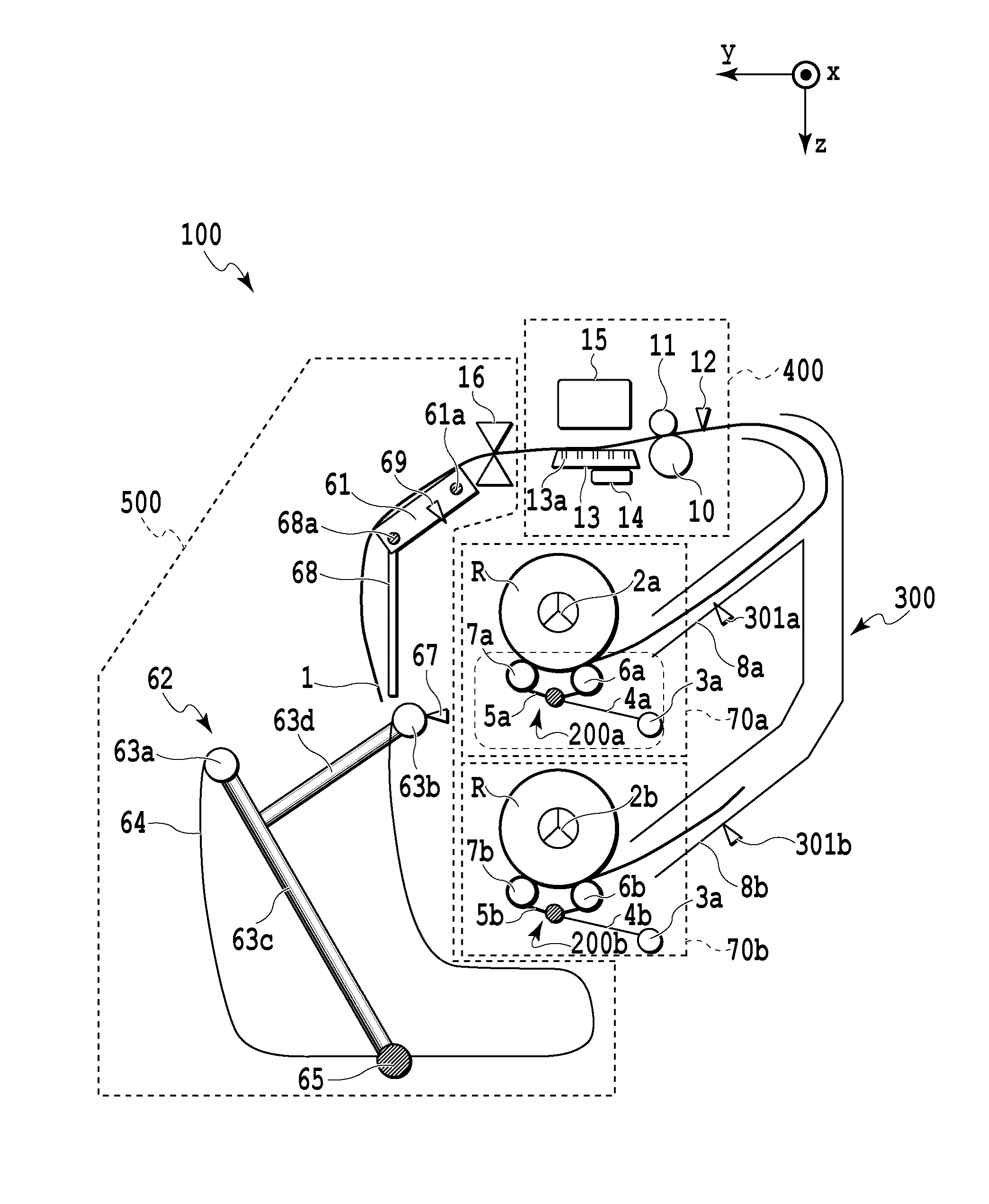

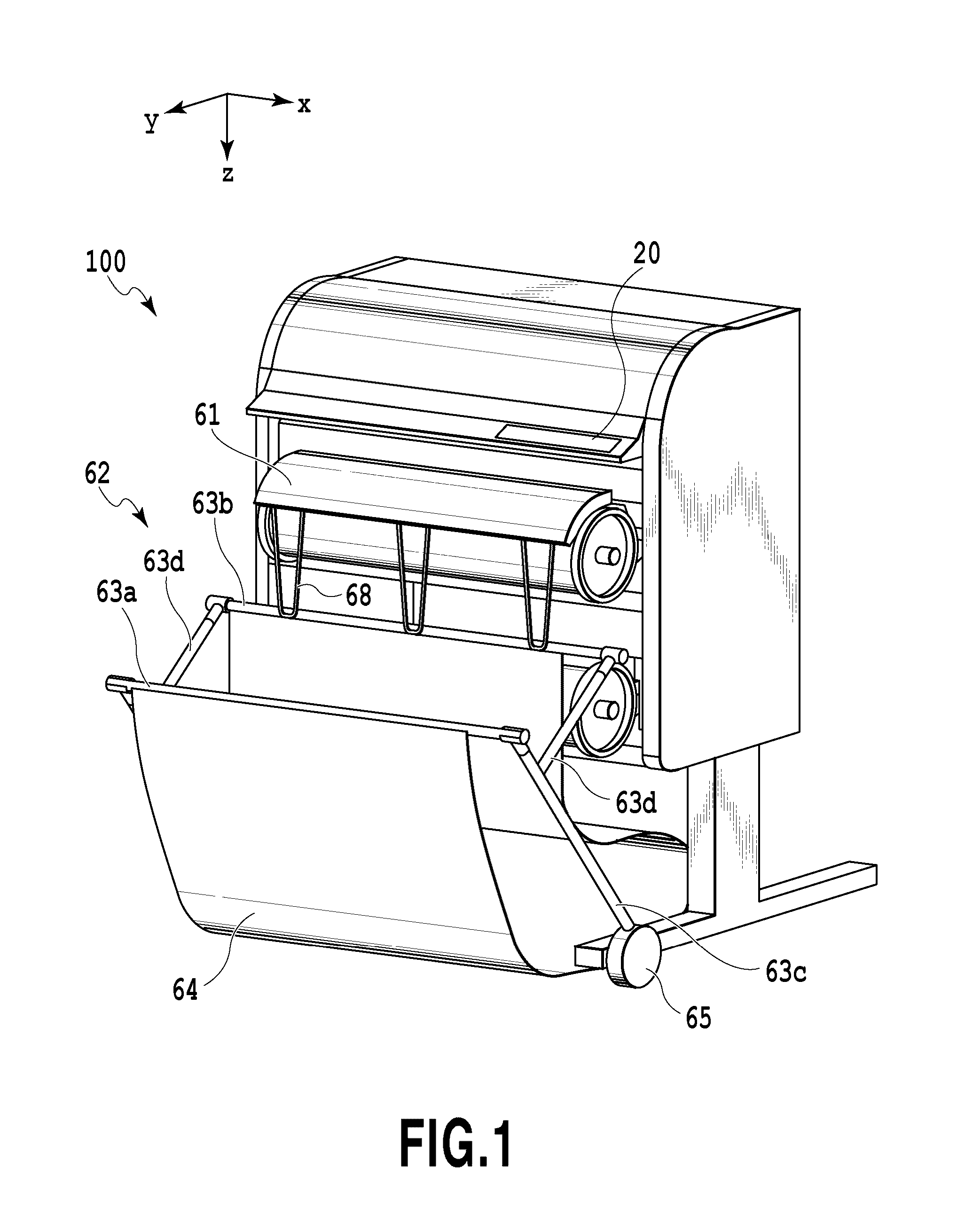

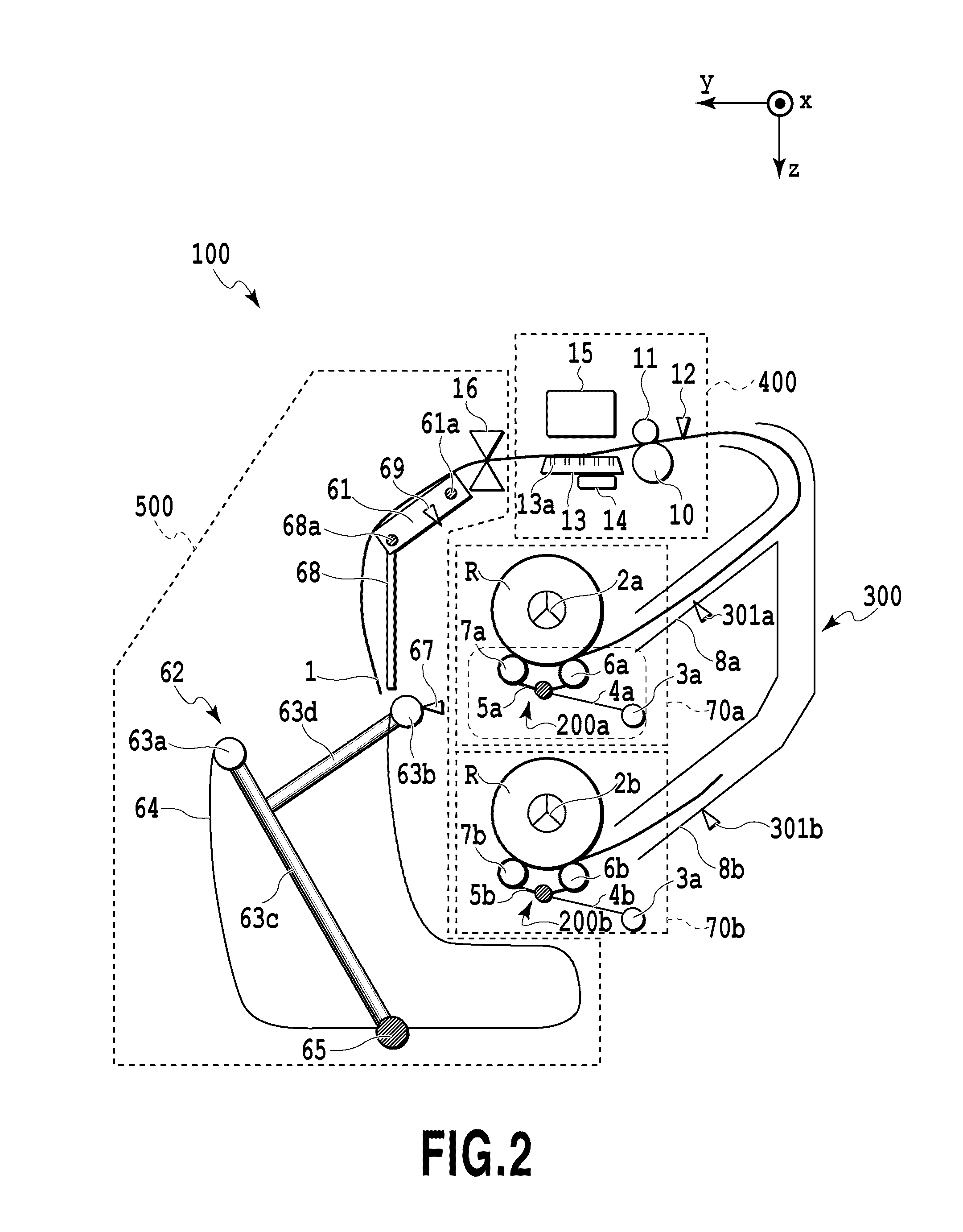

Printing apparatus

There is provided a printing apparatus having a supply function and a winding function, in which a sheet is guided to a desirable position. To achieve this, the apparatus includes: a supply unit configured to hold a plurality of rolls of a wound continuous sheet; a printing unit configured to print an image on a sheet drawn from one of the rolls held by the supply unit; a storage unit configured to store a sheet printed in the printing unit; and a guiding unit configured to guide a sheet discharged from the printing unit to the storage unit, wherein the guiding unit is capable of switching between guiding the sheet discharged from the printing unit to the storage unit and guiding the sheet discharged from the printing unit to the supply unit so that the sheet is wound.

Owner:CANON KK

Dust removal apparatus having automatic winding function

InactiveCN105506947AEasy to cleanTake it away in timeMechanical cleaningPressure cleaningArchitectural engineeringConductor Coil

The invention discloses a dust removal apparatus having an automatic winding function. The dust removal apparatus comprises a box body. The top of the box body is provided with a de-ionizing fan. The bottom of the box body is provided with an exhaust fan. The bottom at one side of the box body is provided with a cloth inlet, and the top at the other side of the box body is provided with a cloth outlet. The outside of the cloth outlet is provided with a cloth winding device. The box body is provided with a vertically symmetrical shaping roller. The inside of the shaping roller is provided with a steam generator. The surface of the shaping roller is provided uniformly with a steam distributing holes. The inside of the box body is provided with a first drive roller and a second drive roller. The inner side of the side wall of the box body is provided with a first transverse brush and a second vertical brush. The inner side of the side wall of the box body is provided with a second transverse brush and a second vertical brush. The width of the first vertical brush and the width of the second vertical brush are the same as the width of the textile cloth. The invention can not only effectively clean the dust on the surface of the textile cloth to prevent the dust from sticking onto the textile cloth or scattering in the environment, but also automatically wind up the textile cloth after the dust is removed.

Owner:WUXI HONGFEN MACHINERY FACTORY

Printing ribbon driving device

The invention discloses a printing ribbon driving device, which comprises a ribbon supplying shaft, a ribbon winding shaft, a ribbon and a drive, wherein the ribbon is wound on the ribbon supplying shaft and the ribbon winding shaft, the drive can positively and reversely rotate, when the drive drives the ribbon winding shaft to clockwise rotate, transmission does not exist between the drive and the ribbon supplying shaft, the ribbon supplying shaft rotates through being pulled by the ribbon, when the drive drives the ribbon supplying shaft to anticlockwise rotate, transmission does not exist between the drive and the ribbon winding shaft, and the ribbon winding shaft rotates through be pulled by the ribbon. The printing ribbon driving device has the advantages that the simultaneous execution of the identification card printer printing function and the ribbon winding function is realized through adopting one drive, and the ribbon control precision and the printer stability of products are greatly improved.

Owner:王晨

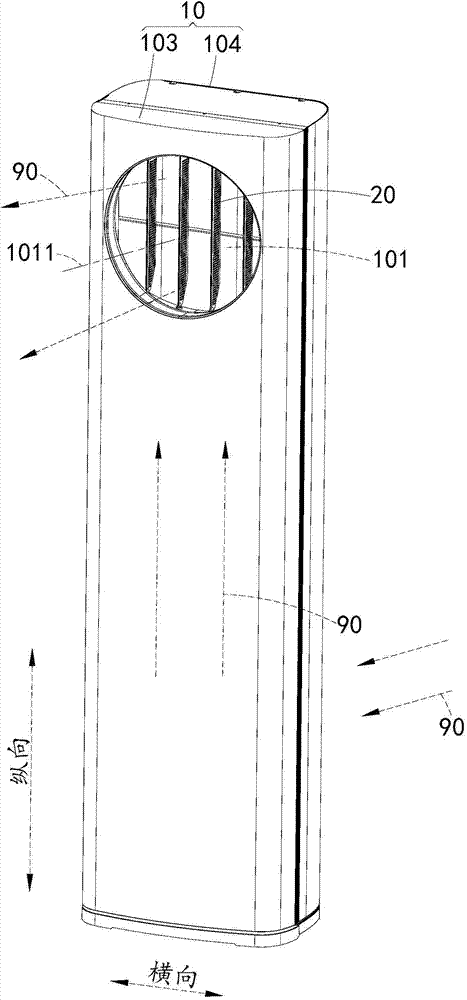

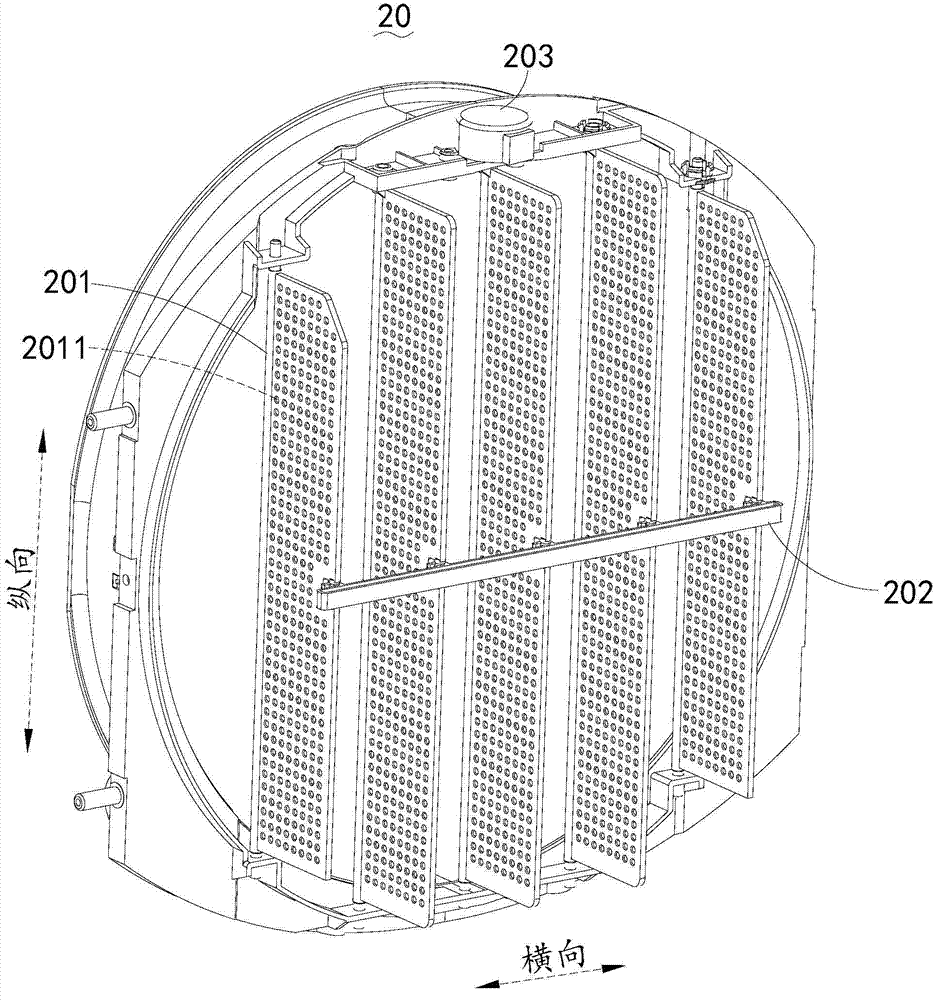

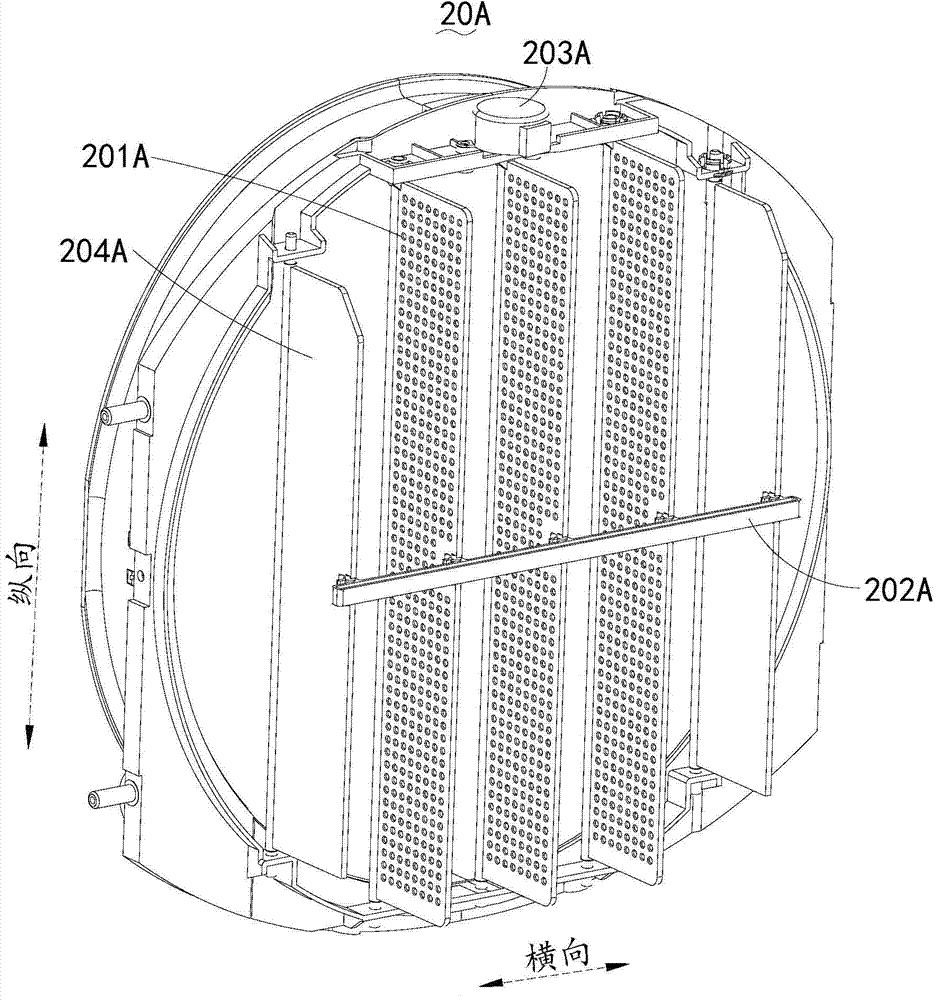

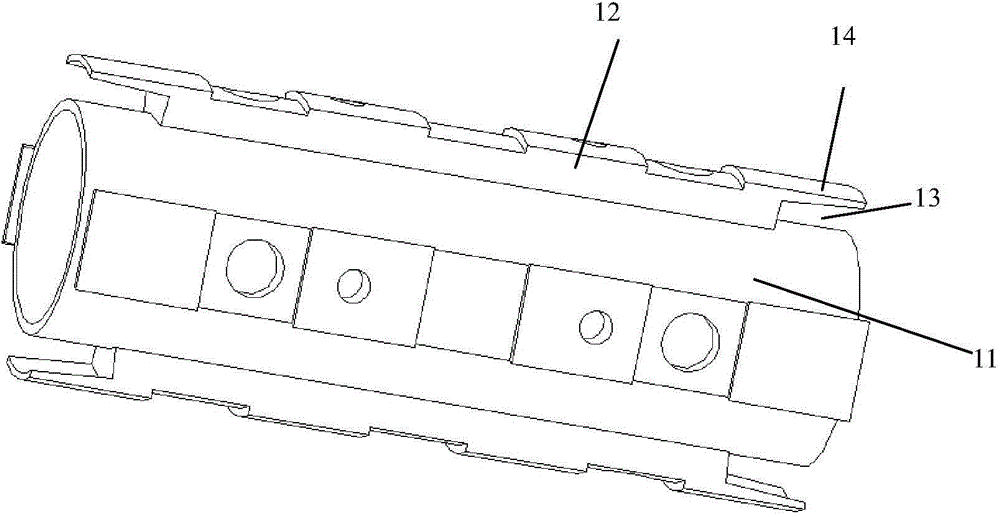

Plate-shaped guide vane, wind guide device and air conditioner indoor unit

ActiveCN104748341ATo achieve the effect of soft windThe effect of soft wind is strongLighting and heating apparatusAir conditioning systemsEngineeringWinding function

Owner:GD MIDEA AIR-CONDITIONING EQUIP CO LTD +1

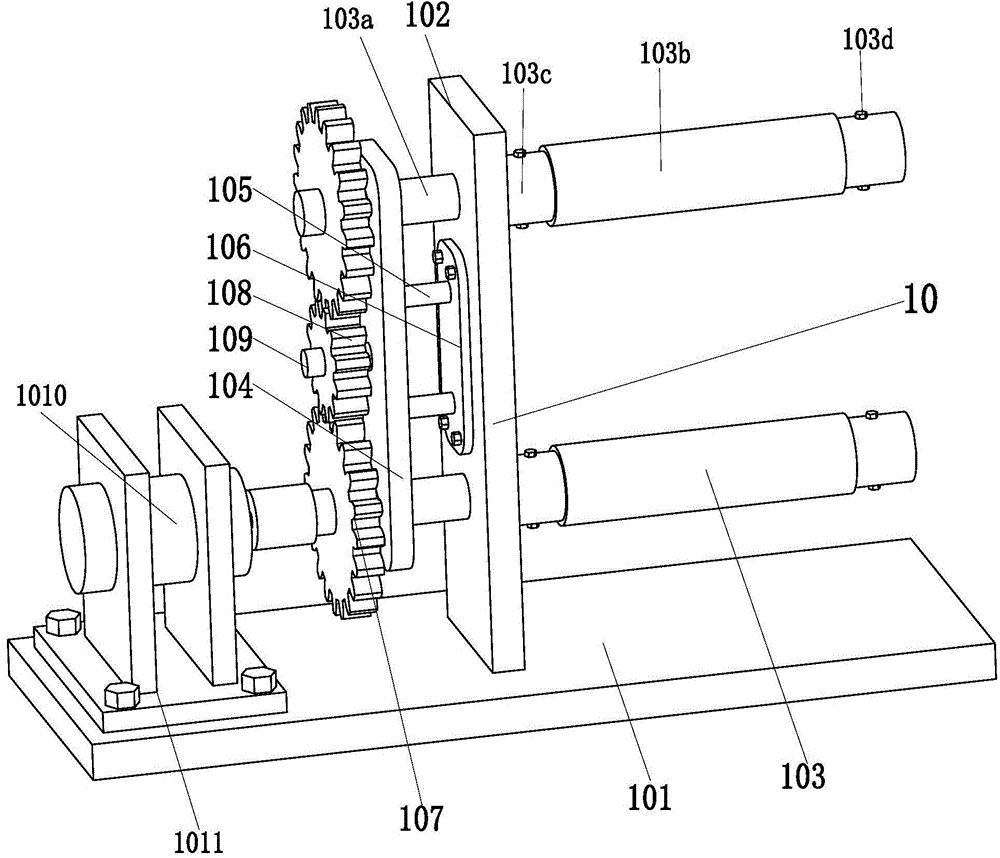

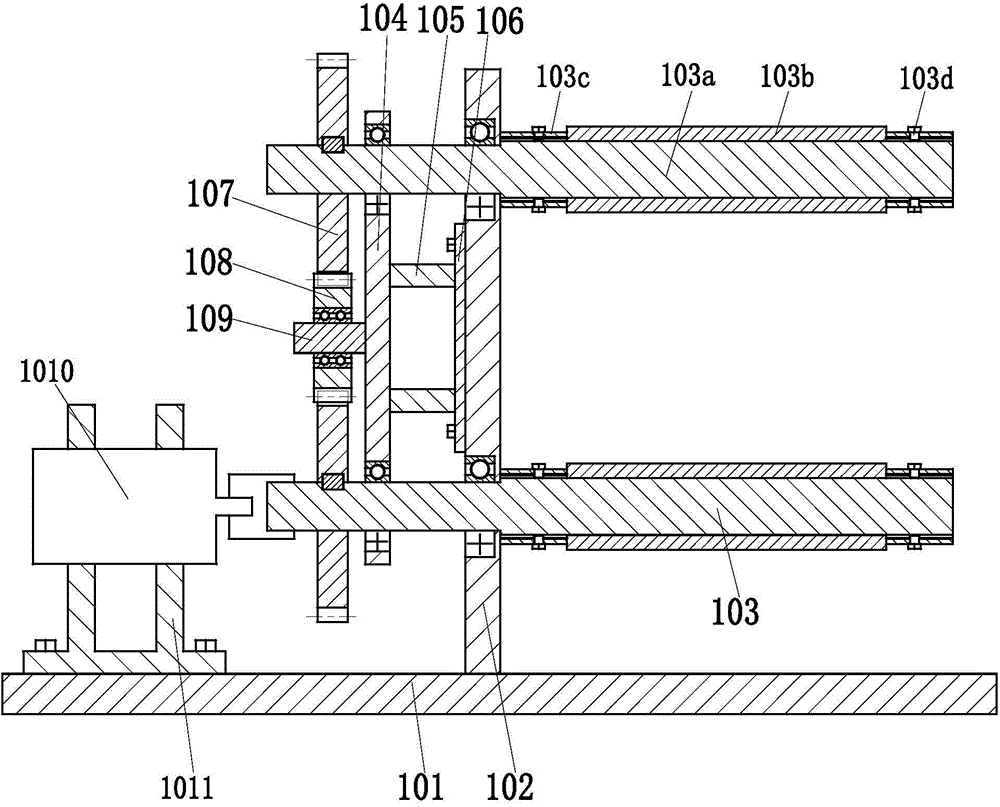

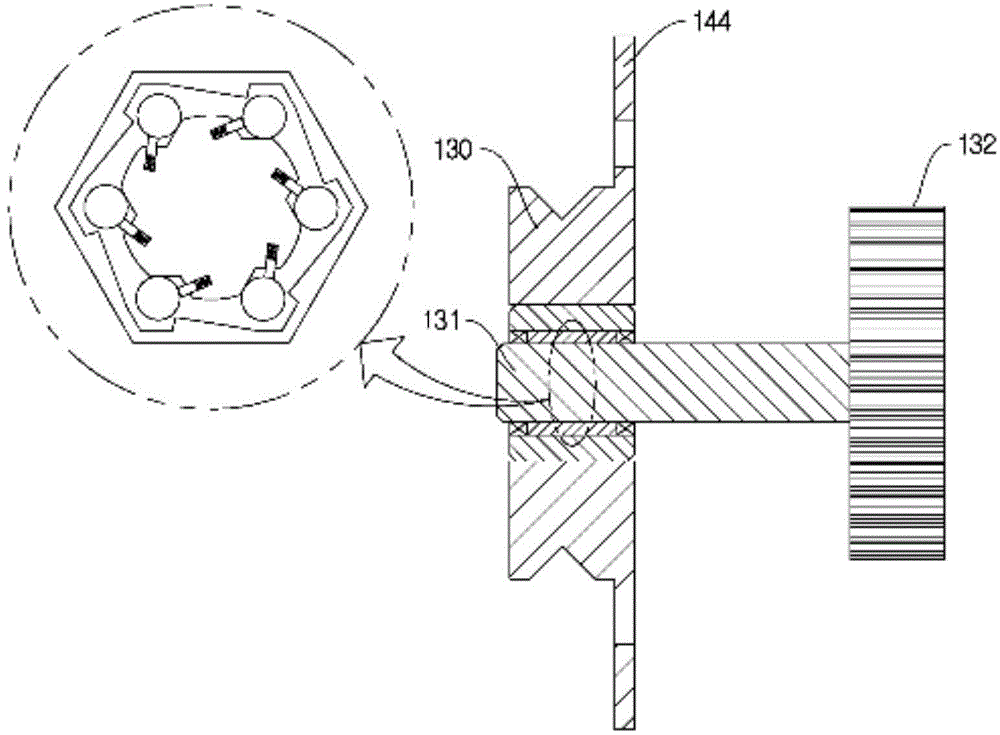

Double-winding device for dialyzing paper winding device

InactiveCN104944185ALimited axial movement functionRealize bidirectional winding functionWebs handlingBall bearingCoupling

The invention relates to a double-winding device for a dialyzing paper winding device. The double-winding device comprises a base plate. A fixing plate is welded to the base plate. Two winding branched chains are installed on the upper side and the lower side of the fixing plate through bearings. The winding branched chains comprise step shafts, installing sleeves are arranged on the outer sides of the middles of the step shafts, two sides of the step shafts are sleeved with two limiting shaft barrels respectively, and the upper end and the lower end of each limiting shaft barrel are connected with an upper strip-shaped groove and a lower strip-shaped groove of the corresponding step shaft through two limiting screws respectively. A supporting disc is arranged on the two step shafts through bearings respectively. Two transmission gears are arranged at the tail ends of the two step shafts through keys respectively. An idle pulley is meshed between the two transmission gears and installed on a fixing shaft through a ball bearing. The fixing shaft is welded to the middle of the supporting disc. A drive motor is installed at the left ends of the step shafts through a coupler. The two-direction winding function of dialyzing paper can be achieved on the premise that cost is low, and the double-winding device has the advantages of being low in cost, easy and convenient to operate, high in working efficiency, wide in application range and the like.

Owner:ANQING TIANRUN PAPER PACKAGING

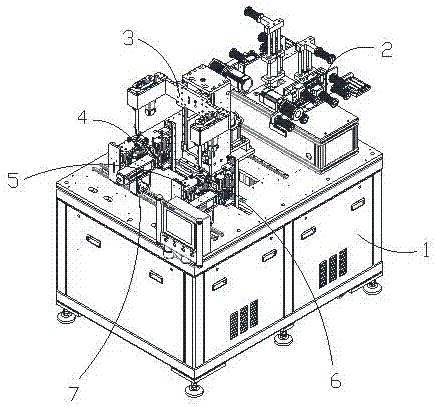

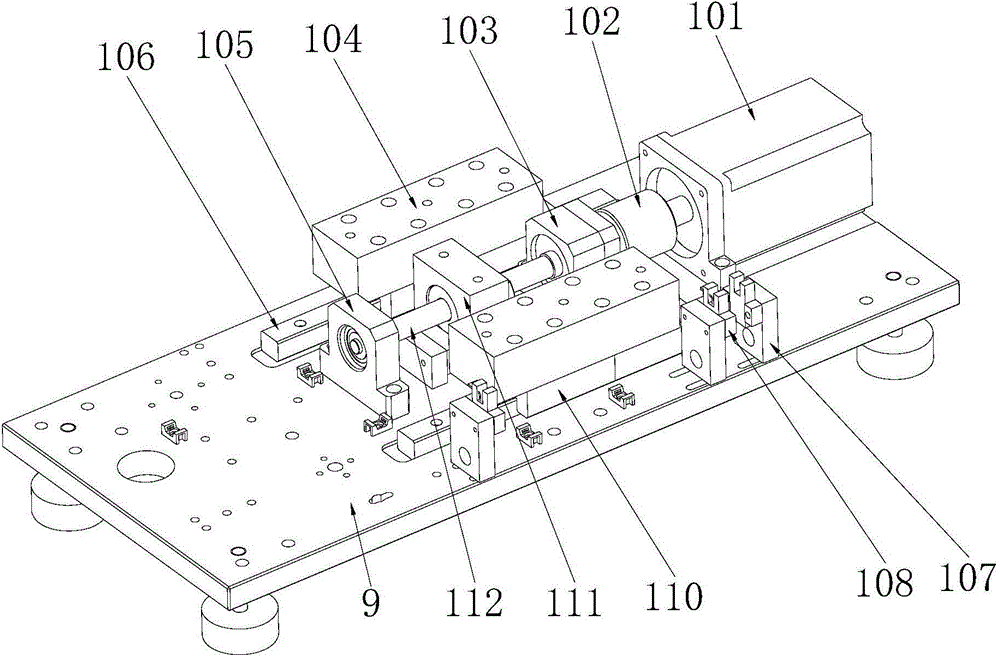

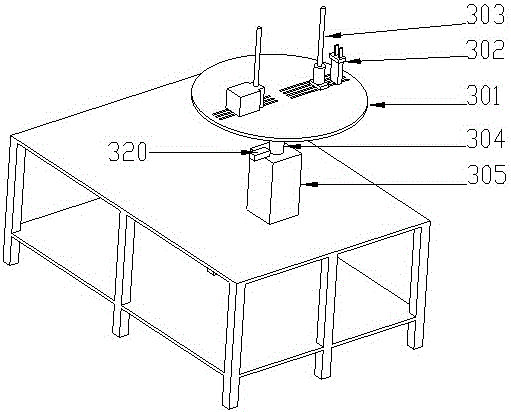

Automatic winding machine

InactiveCN104916425AFully automatedReasonable structureFilament handlingCoils manufactureWinding machineProgrammable logic controller

The invention discloses an automatic winding machine which comprises a base plate, a winding mechanism, a traction mechanism, a loading mechanism, a vibrating disk, a feeding mechanism and a PLC (Programmable Logic Controller), wherein the vibrating disk and the mechanisms are mounted on the base plate, and connected with the PLC. The automatic winding machine realizes a precise and full-automatic winding function, is simple to operate and rapid and accurate in winding and feeding, increases the yield of a coil, and lowers the maintenance cost and the labor input.

Owner:XIAMEN RONGBO AUTOMATION TECH CO LTD

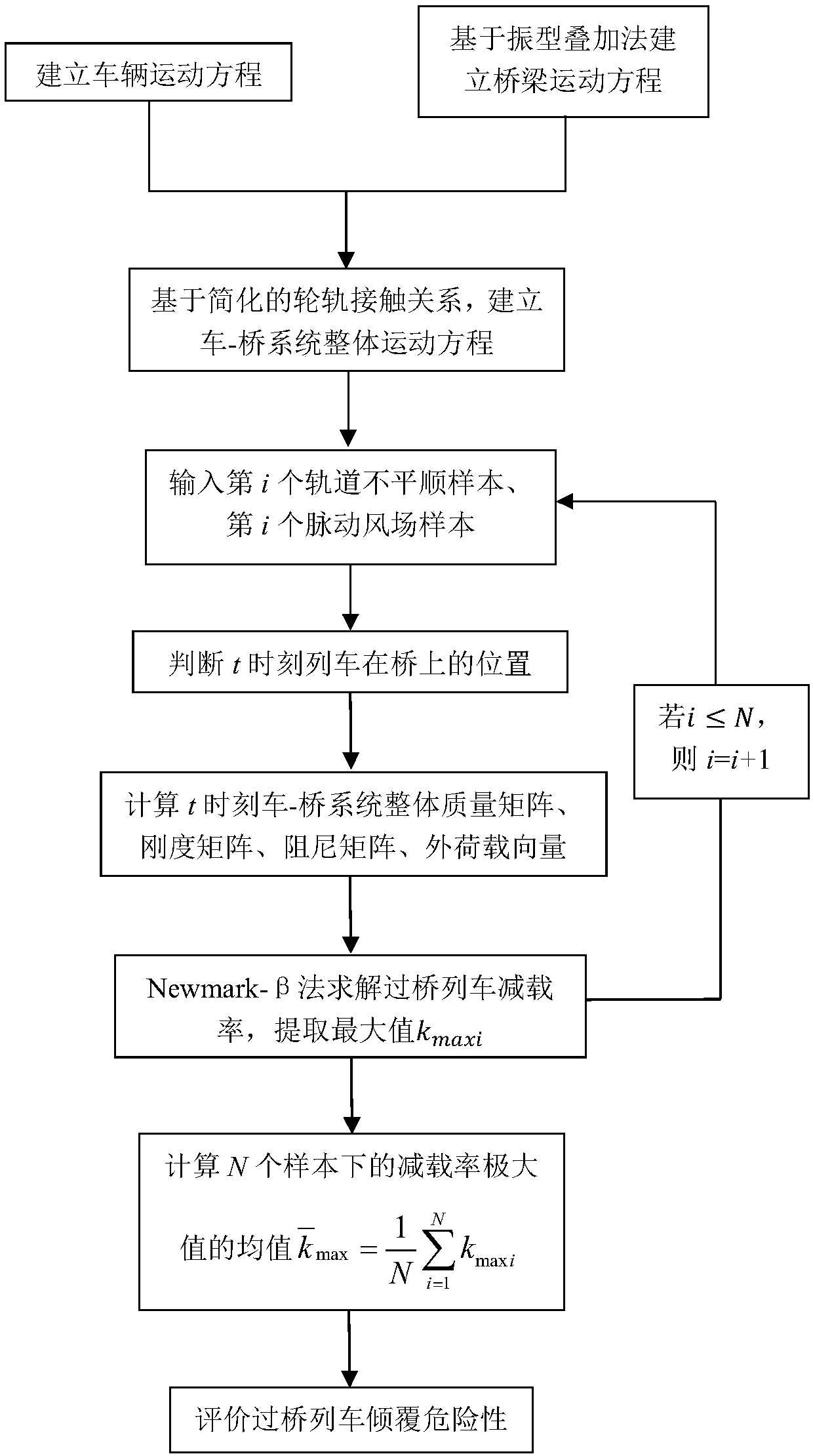

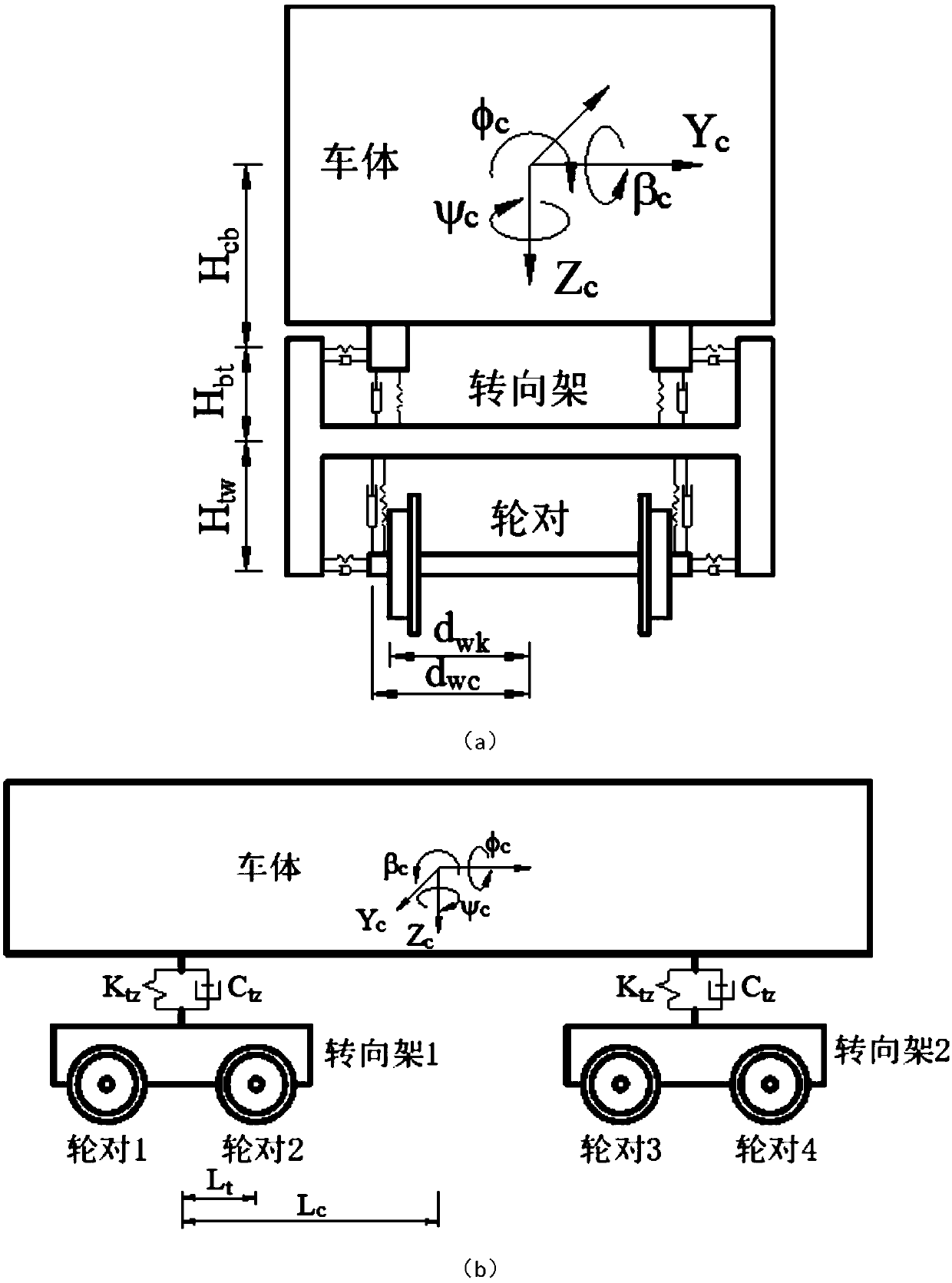

Bridge crossing train overturning risk assessment method based on mode superposition method

InactiveCN108763716ALess freedomSmall amount of calculationDesign optimisation/simulationResourcesContact modelEngineering

Owner:SOUTHWEST JIAOTONG UNIV +1

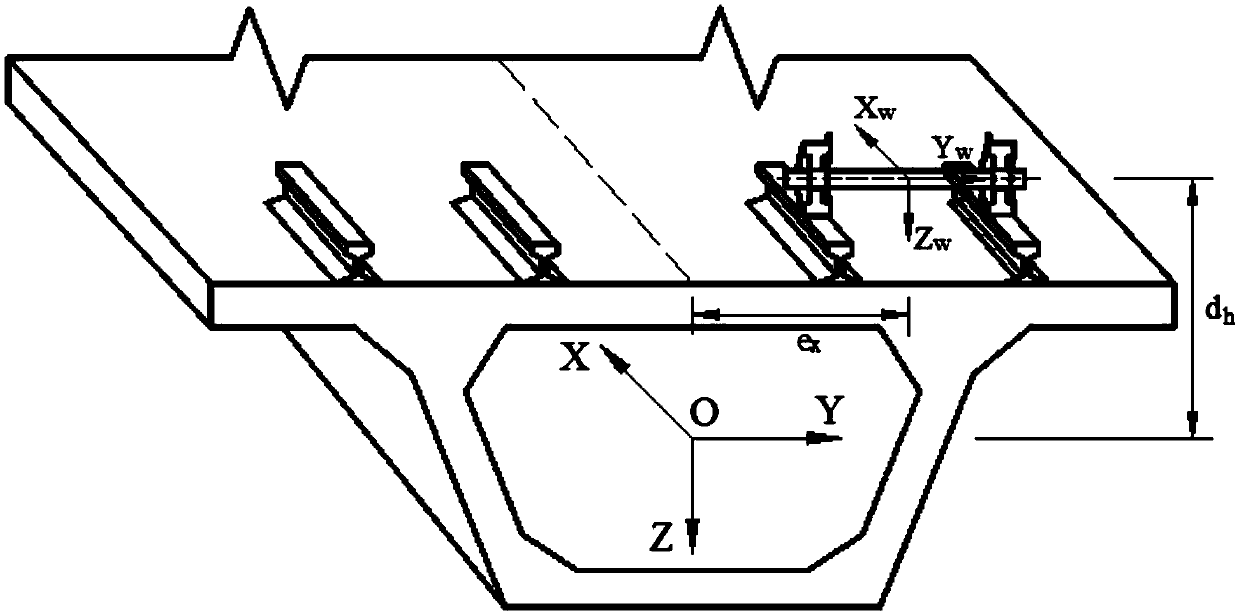

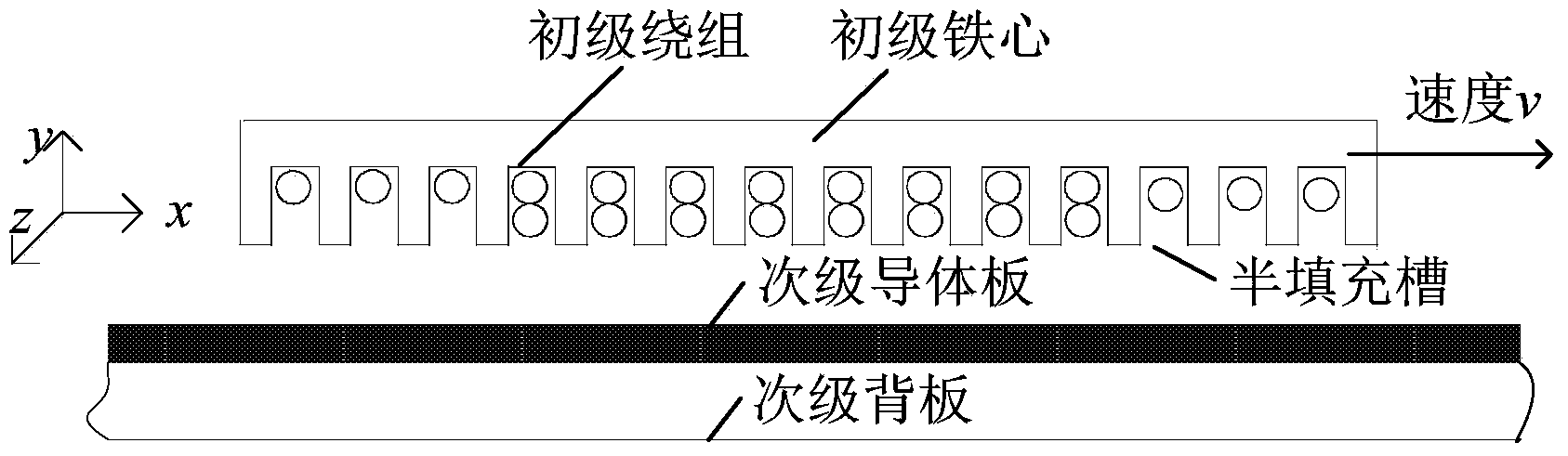

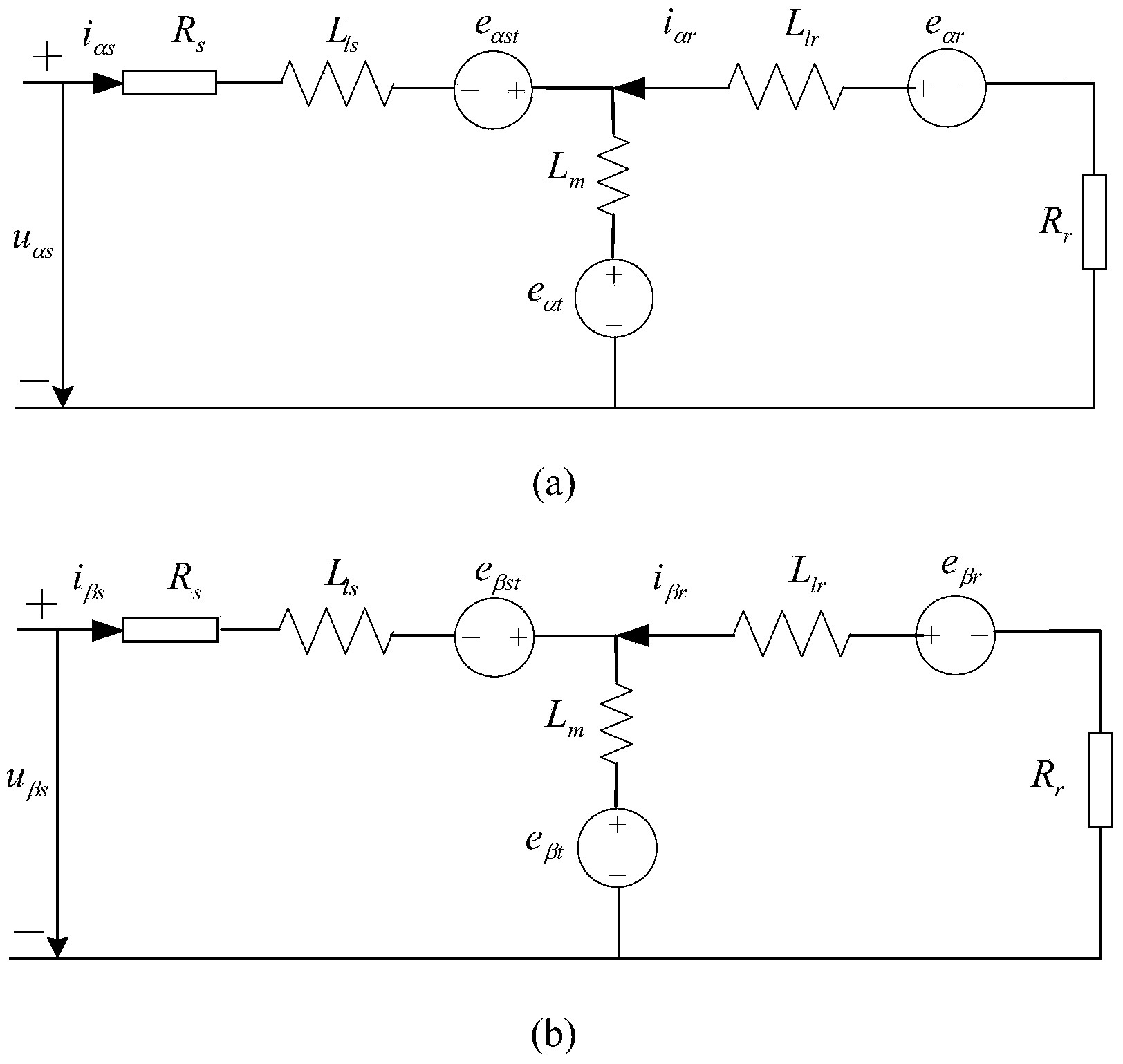

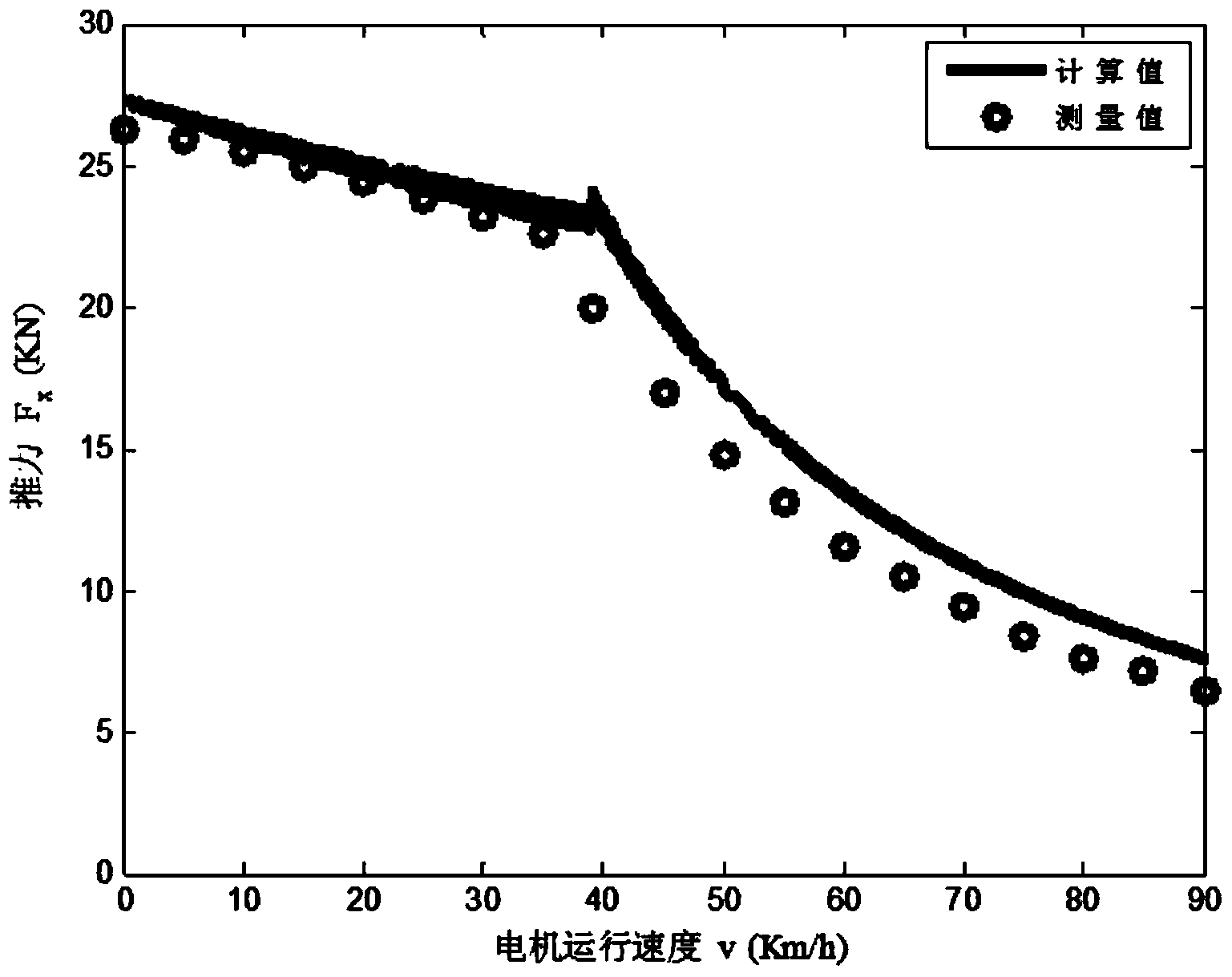

Linear induction motor drive characteristic analysis equivalent circuit and analysis method

ActiveCN103904978AAccurate and effective analysisSimple methodAC motor controlElectrical resistance and conductanceElectric machine

The invention discloses a linear induction motor drive characteristic analysis equivalent circuit and an analysis method. A Maxwell equation is combined with a winding function method, and a primary winding function, a secondary fundamental wave winding function and a secondary end effect wave winding function of a linear induction motor are obtained in terms of distribution of an actual primary winding of the linear induction motor. According to a winding function basic theory, equivalent inductance and the motion potential coefficient of the linear induction motor are analyzed and calculated, a voltage and flux linkage equation of the linear induction motor is built, and further, a novel equivalent circuit model of the linear induction motor is built. By means of the novel equivalent circuit mode, steady-mode and dynamic characteristics of the linear induction motor are analyzed. On the basis of the distribution situation of actual windings of the motor, influences of a transverse edge effect, a longitudinal edge effect and a primary semi-filled groove of the linear inductance motor on motor inductance and secondary resistance are reasonably considered, and drive characteristics of the linear induction motor are accurately and effectively analyzed.

Owner:HUAZHONG UNIV OF SCI & TECH

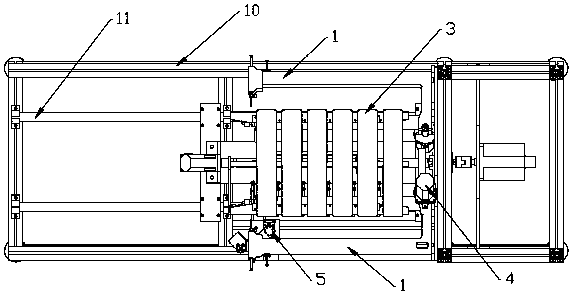

After-treatment production line having automatic roll changing and winding function

ActiveCN107381161ATension balanceReduce scrap rateWebs handlingElectric machineryStructural engineering

The invention discloses an after-treatment production line having an automatic roll changing and winding function and belongs to the technical field of copper foil after-treatment equipment. The after-treatment production line is characterized by comprising a first rack, a first rotating seat is movably on the first rack along the horizontal direction, and unwinding units are arranged on two sides of the first rotating seat respectively; the first rotating seat is connected with a first rotation driving motor, and one unwinding unit after being rotated by 180 degrees by taking the first rotating seat as a rotating shaft is coincident with the other unwinding unit; the first rack is sequentially provided with an unwinding connection device, an unwinding foil storage device, a copper foil after-treatment device, a winding foil storage device, a winding connection device and a winding and roll changing device along the copper foil advancing direction. The after-treatment production line is convenient to use and good in effect and used for copper foil production.

Owner:MEIZHOU WEILIBANG ELECTRONICS TECH CO LTD

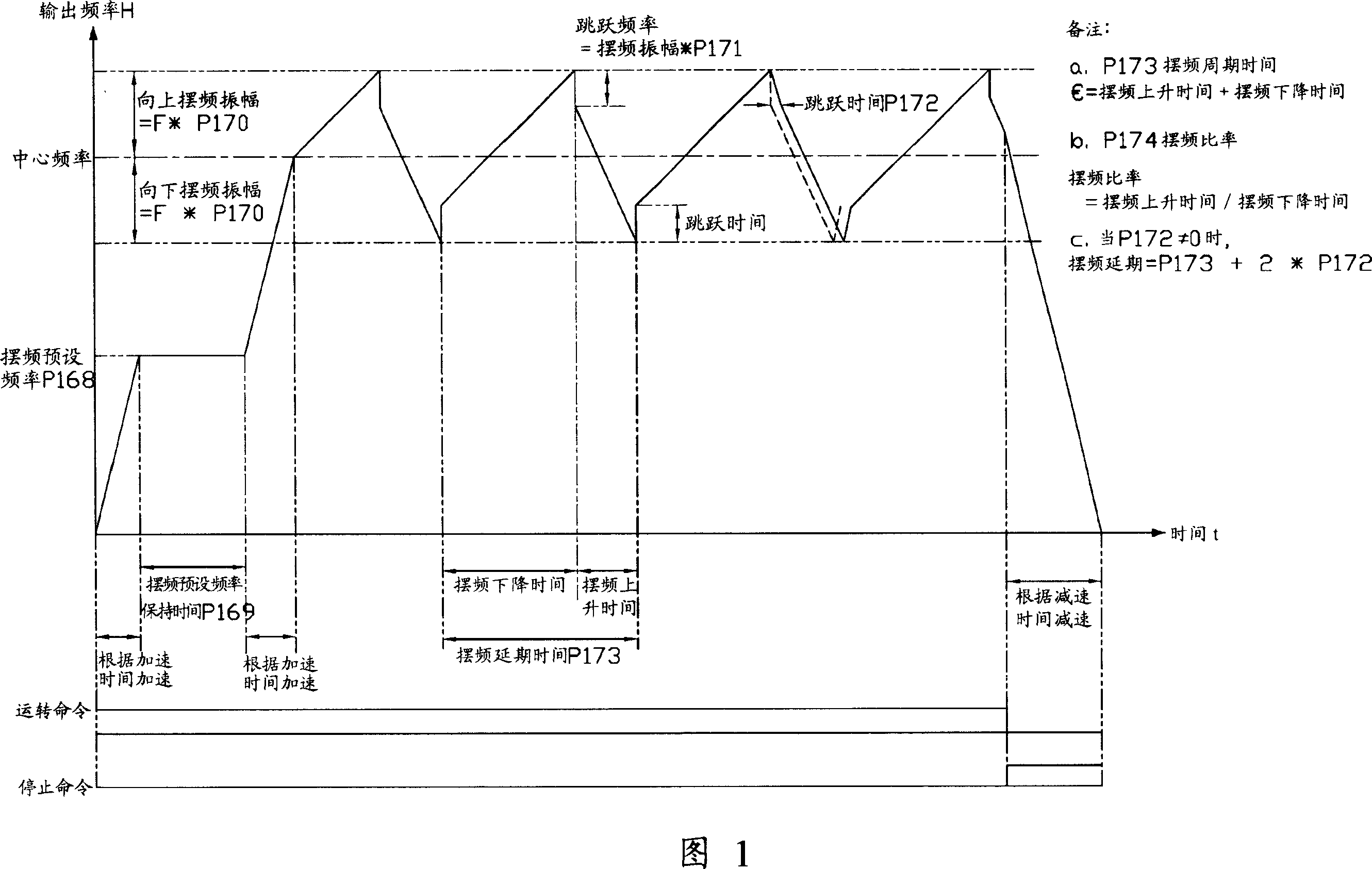

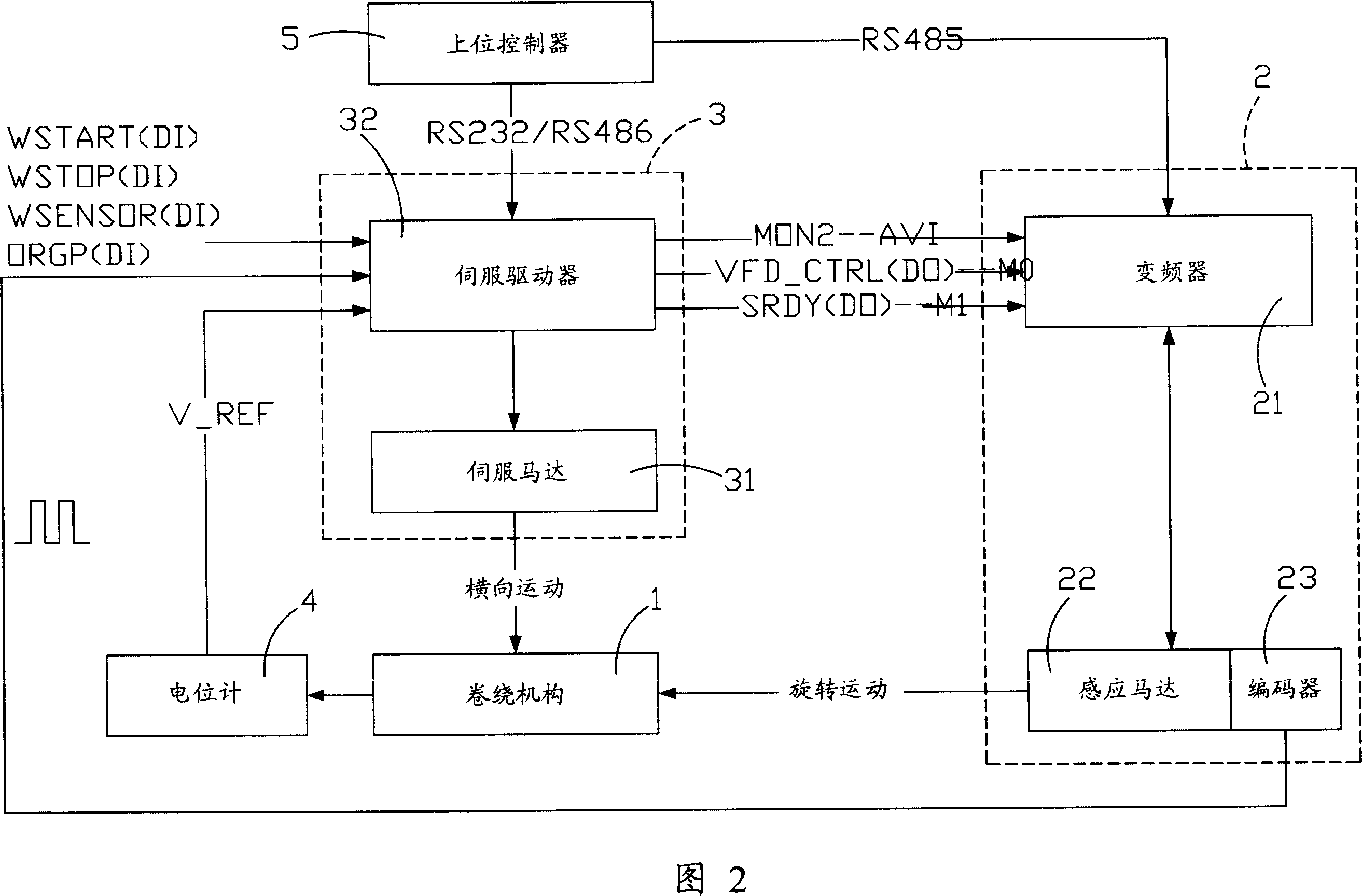

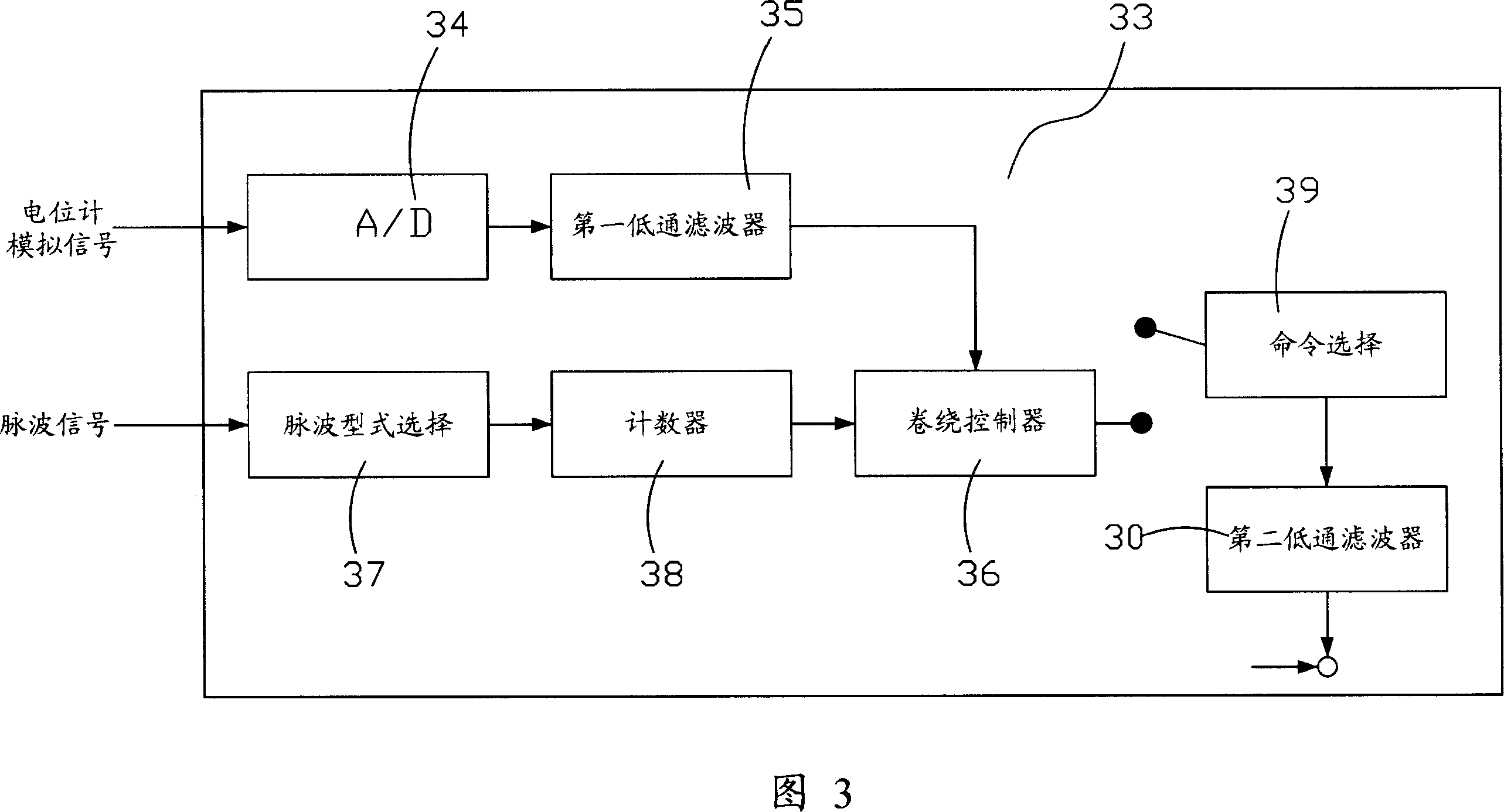

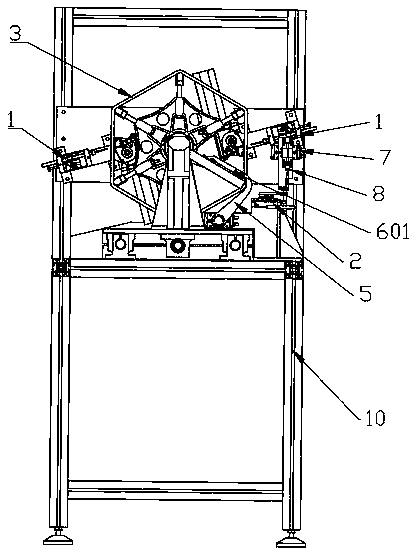

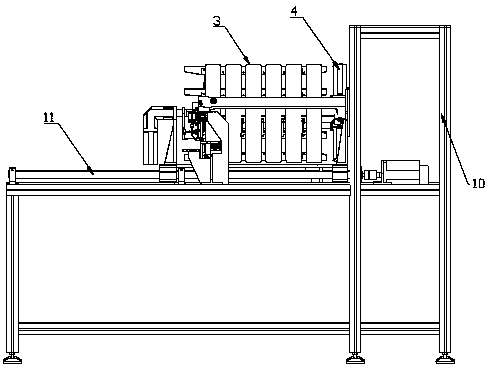

Servo driving special machine with high-speed winding function

This invention relates to a servo drive special machine with a high speed winding function including: a winding unit, a rotation control unit controlling the rotation of the winding unit, a traverse action control unit controlling the traverse action of the winding unit, a potentiometer and a host controller, in which, the servo drive of the traverse action control unit and its internal winding order process unit and the start-up signals set by the winding parameter and input from outside are utilized to match with the potentiometer to test potential of the signals, compute the frequency conversion instruction of a converter to start up the induced motor to drive rotation of the winding unit, and a coder connected by the induced motor generates and outputs pulse signals, the winding order process unit computes the pulse order of the servo motor to output it to drive the servo motor to drive the winding unit to act horizontally to guide wires to be winded between two ends of a drum.

Owner:DELTA ELECTRONICS INC

Automatic plaiting method

ActiveCN108251961ARealize the function of automatic windingSolve the problem of difficult knotsBraidWinding functionCable harness

The invention discloses an automatic plaiting method and belongs to the field of mechanical and electrical integration. The device provided by the invention comprises a winding mechanism, an automaticknotting device, a thread frame and a power system, wherein the winding mechanism is used for winding threads into bundles; the automatic knotting device is used for knotting wound thread heads, inner thread heads and outer thread heads. The method comprises the following steps: driving the thread frame to make an axial progressive movement under the action of the winding mechanism by the power system and enabling the thread frame to rotate around a shaft; winding wiring harnesses separately by the winding mechanism; knotting the wound thread heads, inner thread heads and outer thread heads by the automatic knotting device after winding completion. According to the method disclosed by the invention, an operation of completing separated winding by one thread by the winding mechanism is provided, a single-thread chain stitch manner is adopted for winding, the automatic winding function is completely realized, and one-shear thread opening of the formed strands can be realized in the subsequent procedure. The wound thread heads, the inner thread heads and the outer thread heads can be knotted by the automatic knotting device, a bionic hand knotting manner is realized, and the problemof knotting difficulty is effectively solved.

Owner:YIBIN HIEST FIBER +1

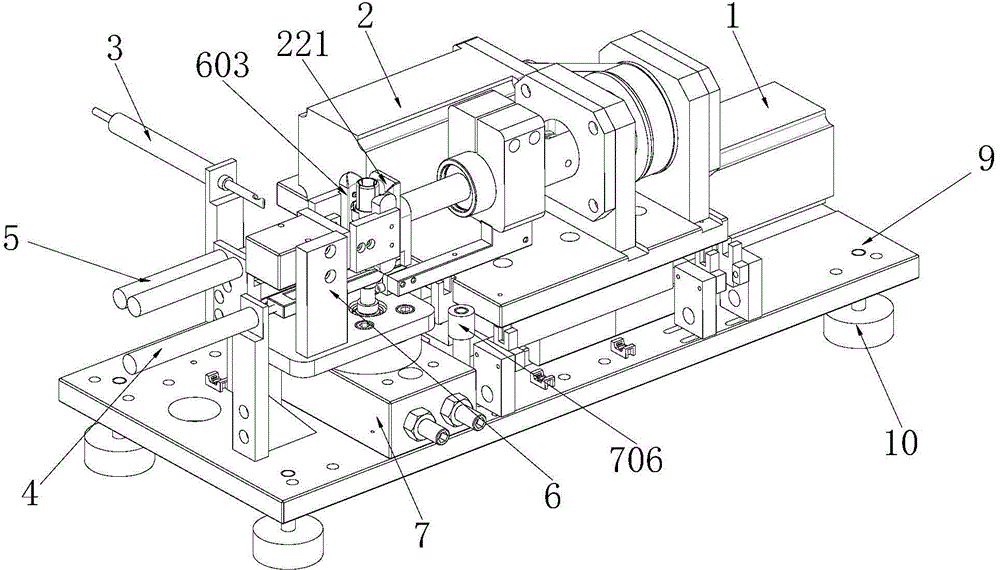

Coil holder used to wind coil and automatic coil winding machine

ActiveCN105845428AEliminate the effects ofSimple structureCoils manufactureWinding machineSingle stage

The invention relates to the technical field of automatic equipment, and discloses a coil holder used to wind a coil. Two ends of a winding portion on the coil holder respectively extend outward to form resisting portions. A winding space is formed between each resisting portion and a coil holder main body. Also disclosed is an automatic coil winding machine, comprising a feeding assembly, a winding rotating assembly, and a coil holder clamping assembly. The feeding assembly drives the winding rotating assembly to realize movement on a horizontal direction. The winding rotating assembly compresses a winding portion of a to-be-winded coil holder, and realizes winding on the to-be-winded coil holder. The coil holder clamping assembly realizes clamping of the to-be-winded coil holder. The automatic coil winding machine realizes an automatic winding function on the to-be-winded coil holder, and the machine is simple in structure, reliable in functions, and easy in realization. The machine can realize multistage winding, and improves winding efficiency, installing on a common coil holder after single-stage winding is not needed, and a large quantity of winding fixtures are removed, so as to save large amount of time for dismounting the fixtures, optimize production process, and greatly improve production efficiency.

Owner:HANS LASER TECH IND GRP CO LTD +1

Automatic recovery speed-limiting sorting tube or wire winder

The invention relates to an automatic recovery speed-limiting sorting tube or wire winder. The middle of a shell is connected with a disc body in a rotating mode through a wheel shaft, a volute spiral spring is arranged in the disc body, one end of the volute spiral spring is connected with the wheel shaft, and the other end of the volute spiral spring is connected with the disc body. Tubes or electric wires are wound on the disc body. A sorting device used for the tubes or the wires is arranged on a tube or wire outlet of the front end of the shell. A speed limiting device used for slowly recovering the tubes or the wires is arranged between the side face of the disc body and the shell. Compared with the prior art, due to the fact that the sorting device and the speed limiting device for slow recovering are arranged on the automatic recovery tube or wire winder at the same time, the ordered arrangement of the tubes or the electric wires on the disc body can be achieved, the purpose for controlling and limiting the rotating speed of the disc body can also be achieved, hence, on the premise that the automatic recovery tube or wire winding function is not changed, the safety of a user can be protected, and the tube or wire winder, connected tools and the like cannot be damaged. The sorting device and the speed limiting device are simple in structure and can be mounted and used in an existing automatic recovery tube or wire winder.

Owner:士商(湖州)精密技术有限公司

Power adapter provided line winding

A power adapter equipped with line winding function comprises an adapter body and a line winding means. The adapter body includes a housing and a conversion circuit held in the housing. The housing has a coupling side substantially in parallel with the conversion circuit. The coupling side includes at least one first coupling portion. The line winding means includes a first conducting line end and a second conducting line end that are extensible or retractable and electrically connected. The first conducting line end is extended into the housing to form electric connection with the conversion circuit. Hence the first conducting line end can transfer electric power from the conversion circuit to the second conducting line end. The line winding means further has at least one second coupling portion which is separable or latchable with the first coupling portion through forces. By coupling of the first and second coupling portions the line winding means can be coupled on the coupling side so that the adapter body and the line winding means are coupled to become a portable power adapter.

Owner:INNOTRANS TECH

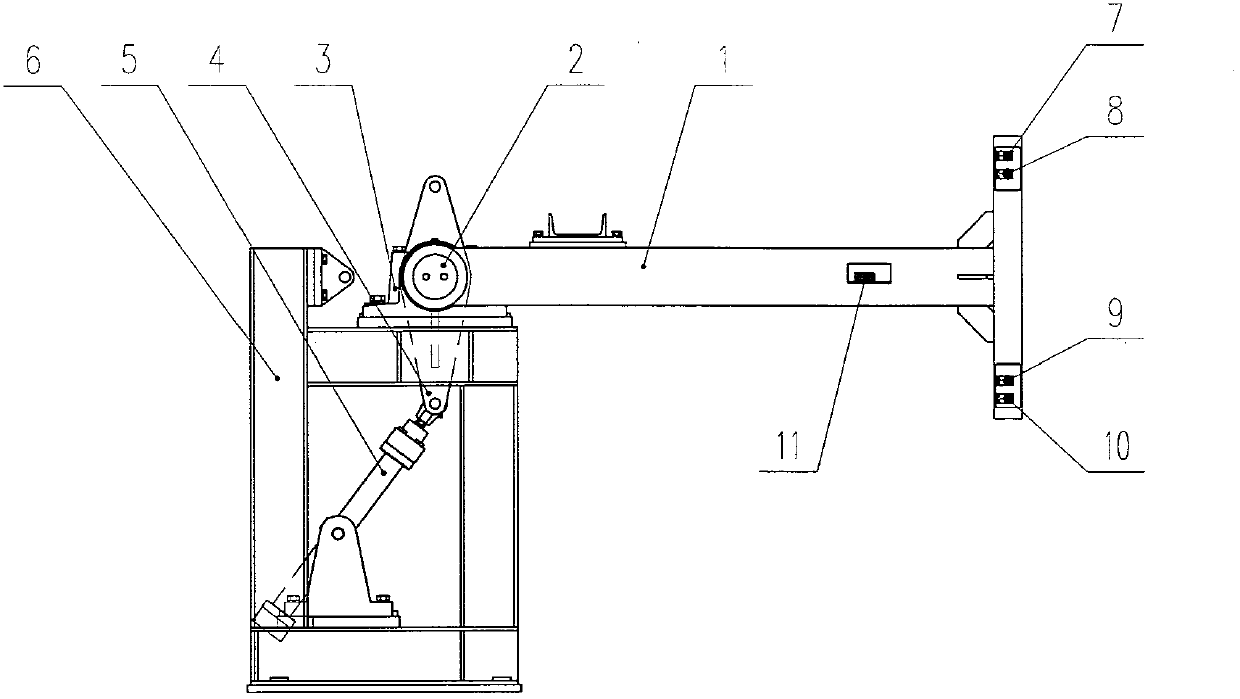

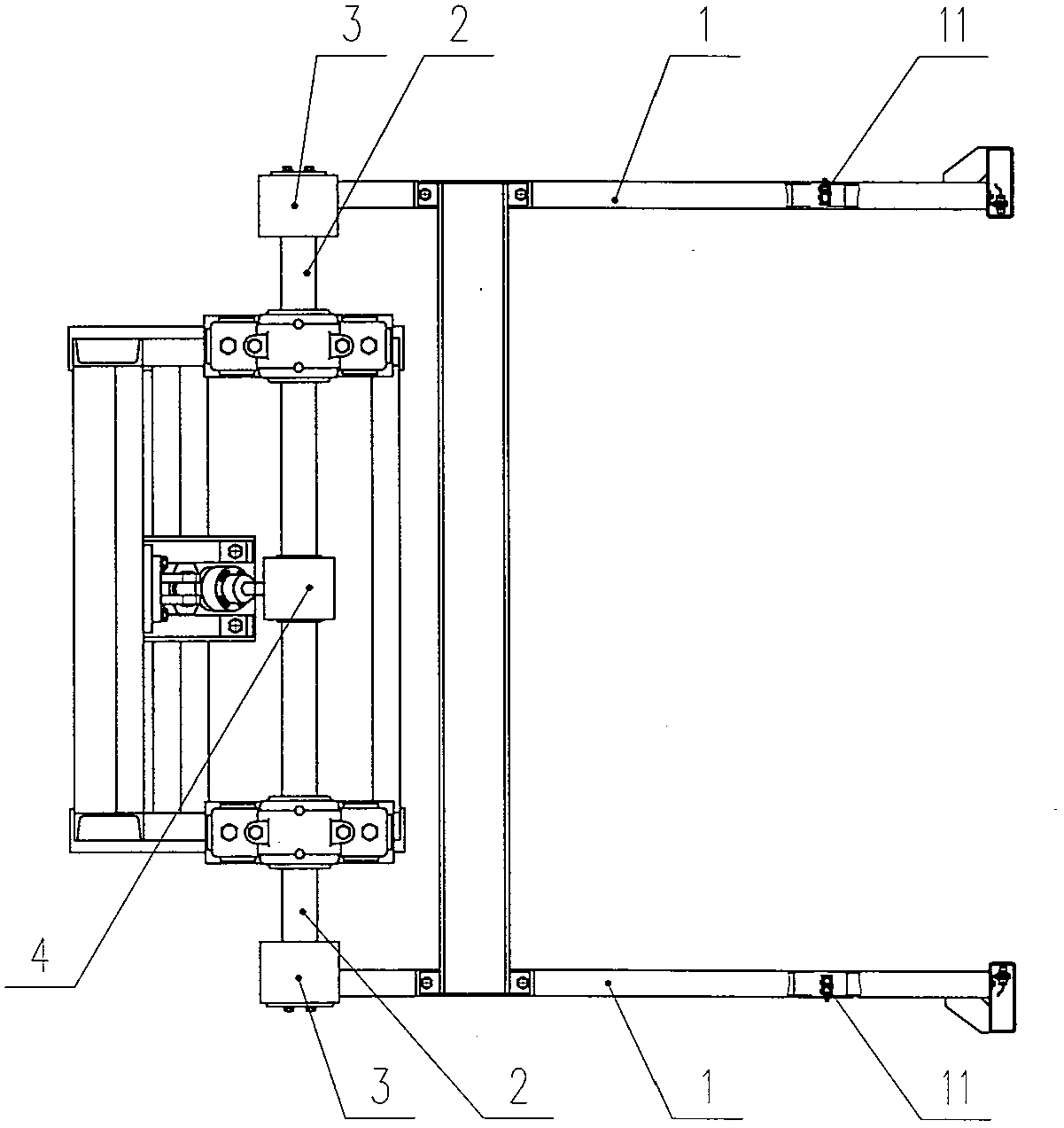

Swing-arm-type automatic winding and centering device

The invention discloses a swing-arm-type automatic winding and centering device which comprises a pair of swing arms, wherein the swing arms are linked together through a shaft; bearing seats of two support shafts are fixed on a support; a swing rod which forms an angle being 90 degrees with the swing arms is fixed in the middle of the shaft; a swing oil cylinder pushes the swing rod to rotate so as to drive the shafts to rotate, so that the swing arms are driven to swing up and fall off; four groups of correlation-type photoelectric switches and a group of laser ranging sensors are installed on the swing arms, and the height centering and width centering of steel coil winding can be realized at the same time, so that the automatic winding function of steel coils is realized. The swing-arm-type automatic winding and centering device has the characteristics of simple structure, low cost, high accuracy, high reliability and the like.

Owner:CHINA NAT HEAVY MACHINERY RES INSTCO

Automatic weaving and twisting machine

ActiveCN108049019ARealize the function of automatic windingSolve the problem of difficult knotsBraidElectronic waste recyclingEngineeringWinding function

The invention discloses an automatic weaving and twisting machine. The automatic weaving and twisting machine comprises a winding mechanism for winding a thread into a beam, an automatic knotter for knotting a winding thread residue, an inner-layer thread residue and an outer-layer thread residue, a thread frame and a power system, wherein the powder system drives the thread frame to perform axialprogressive movement below the winding mechanism and to perform rotary movement along an axis; the winding mechanism separately winds a thread beam; and after finish of winding, the winding thread residue, the inner-layer thread residue and the outer-layer thread residue are knotted by the automatic knotter. As the winding mechanism is provided, separated winding can be finished through one thread; a single thread chain stitch is adopted for winding, so that the automatic winding function is fully achieved; meanwhile, a formed twisted thread can be set out by one cut in the follow-up procedure; and as the outer-layer thread residue, the inner-layer thread residue and the winding thread residue are knotted by the automatic knotter, a bionic manual knotting mode is realized, and the problemof difficult knotting is effectively solved.

Owner:YIBIN HIEST FIBER +1

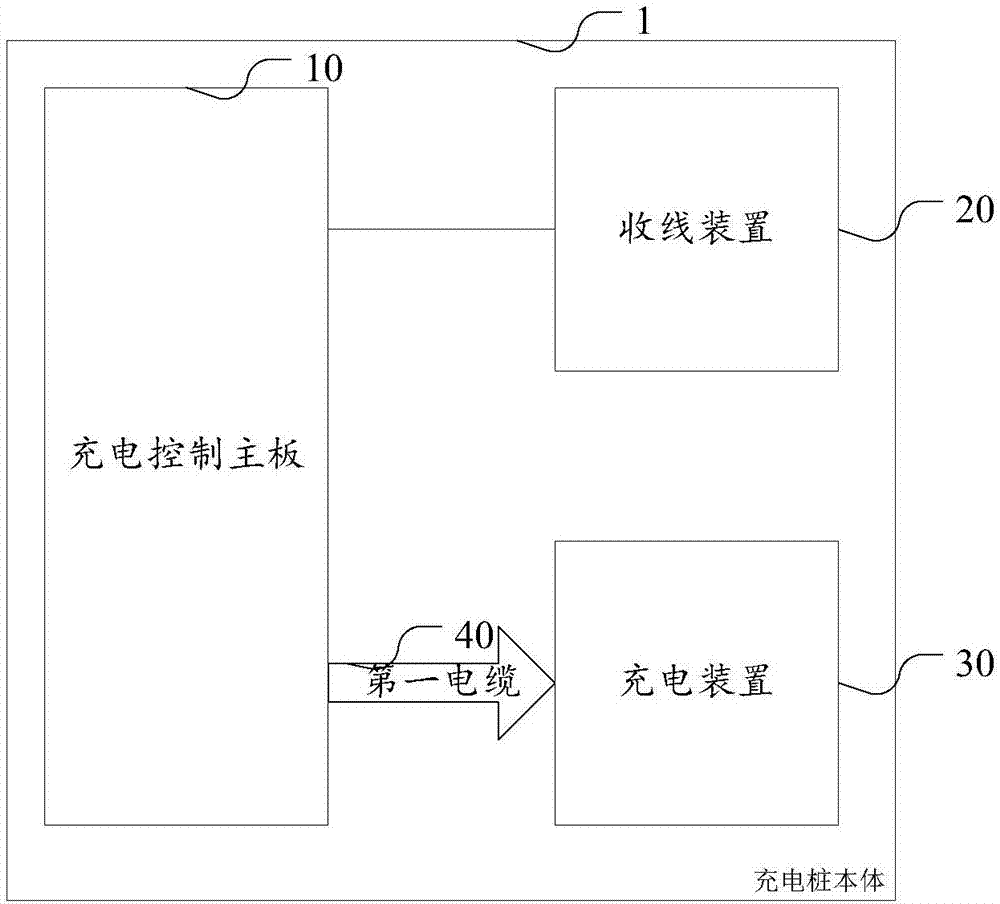

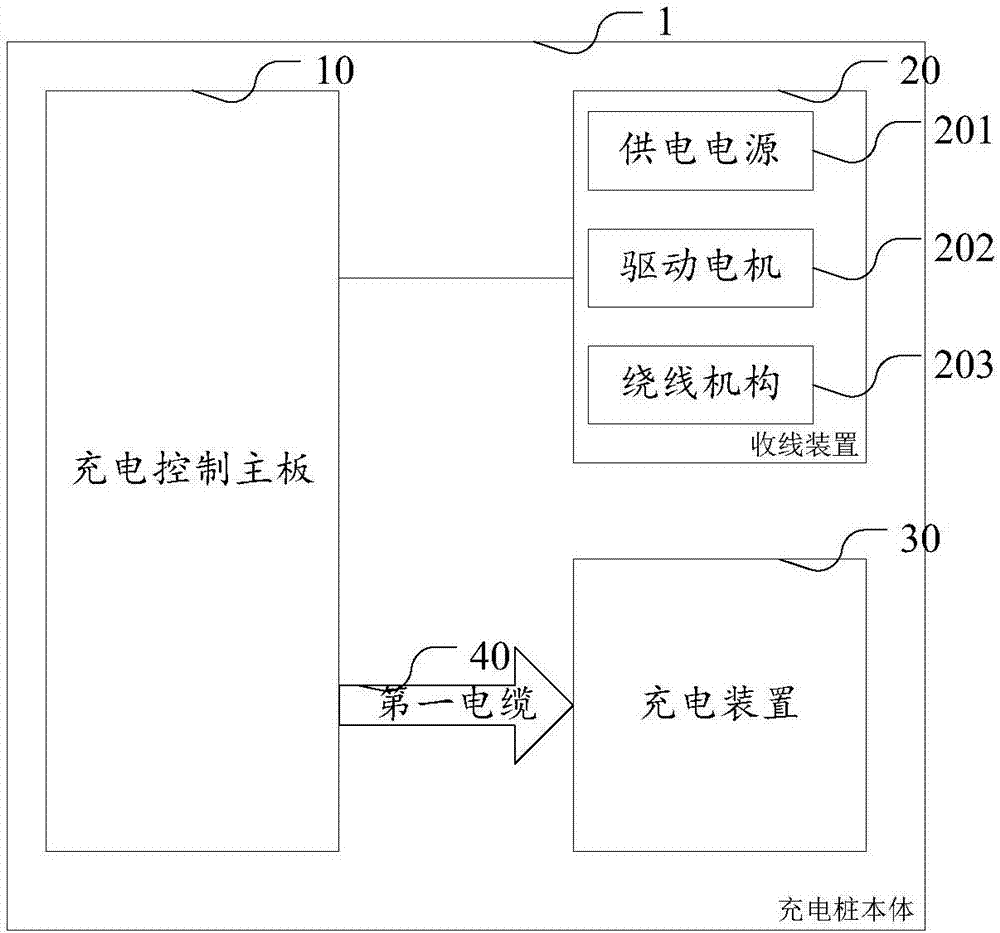

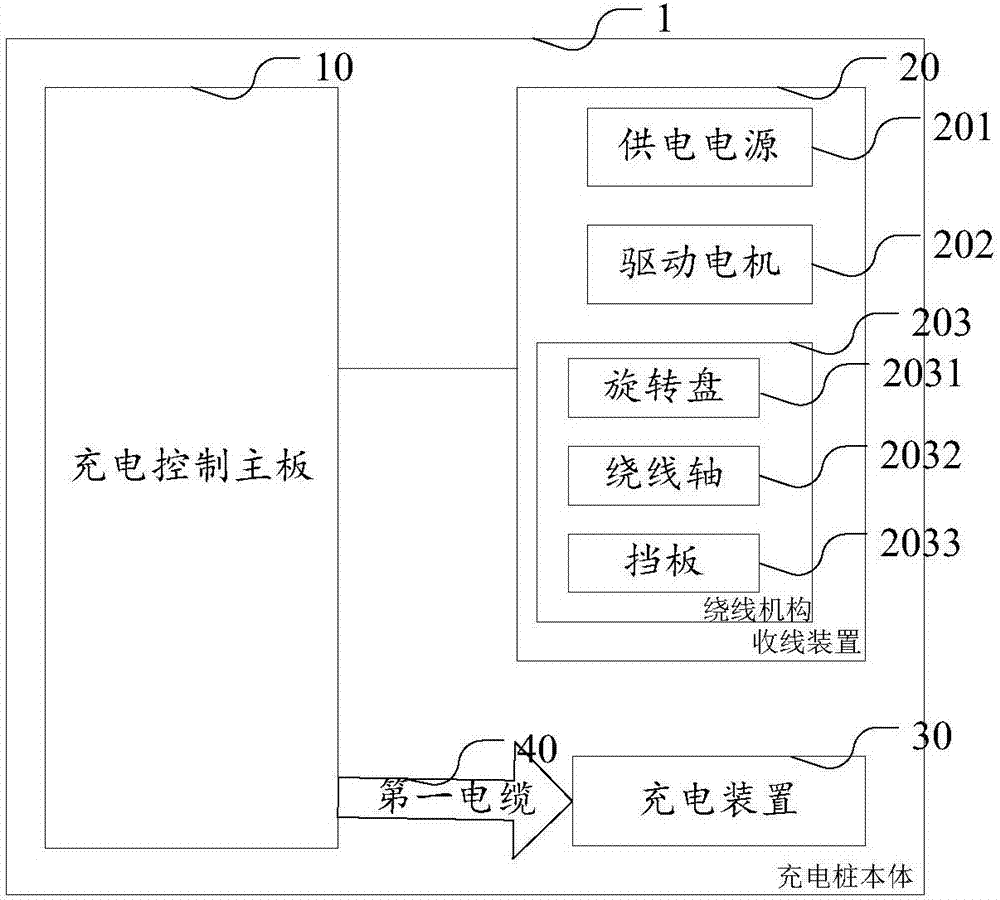

Charging pile with automatic winding function and charging pile management system

PendingCN107415753AEliminate potential safety hazardsPrevent agingPropulsion by batteries/cellsElectric vehicle charging technologyCredit cardCharge control

The invention discloses a charging pile with an automatic winding function and a charging pile management system. A charging pile body is divided into an upper layer and a lower layer and comprises a charging control mainboard on the upper layer, a winding device on the lower layer and a charging device on the lower layer. Through cooperation of the charging control mainboard and the winding device, first cable automatic winding and unwinding are achieved, and the intellectualization level is improved; a control instruction is generated through external operation, the function does not need to be integrated, and the size is decreased; and a first cable can be stored, and thus the potential safety hazard that the first cable is suspended outside is avoided. The management system comprises the charging pile body and a management end. Mutual networking of the multiple charging piles through the management end is further achieved while the beneficial effects of the charging piles are achieved, identity authentication information can be united to be managed, thus identity authentication is achieved, and the phenomena of prevention of theft of credit cards and the like are achieved; and multiple payment modes are expanded, and fee payment can be conducted through media, such as bank cards and identity cards, with the unique identification functions.

Owner:浙江智充电力科技有限公司

Automatic wire winding equipment

InactiveCN106218994ARealize automatic winding functionIncrease productivityFilament handlingBinding material applicationEngineeringConductor Coil

The invention relates to automatic wire winding equipment. The automatic wire winding equipment comprises a panel; a guide device is arranged on the panel and provided with a lifting device; and one side of the guide device is provided with a wire winding device. The automatic wire winding equipment has an automatic wire winding function, thus, manual wire winding is replaced by designing an optimized structure, the production efficiency is high, and the quality can be ensured.

Owner:江西森鸿科技股份有限公司

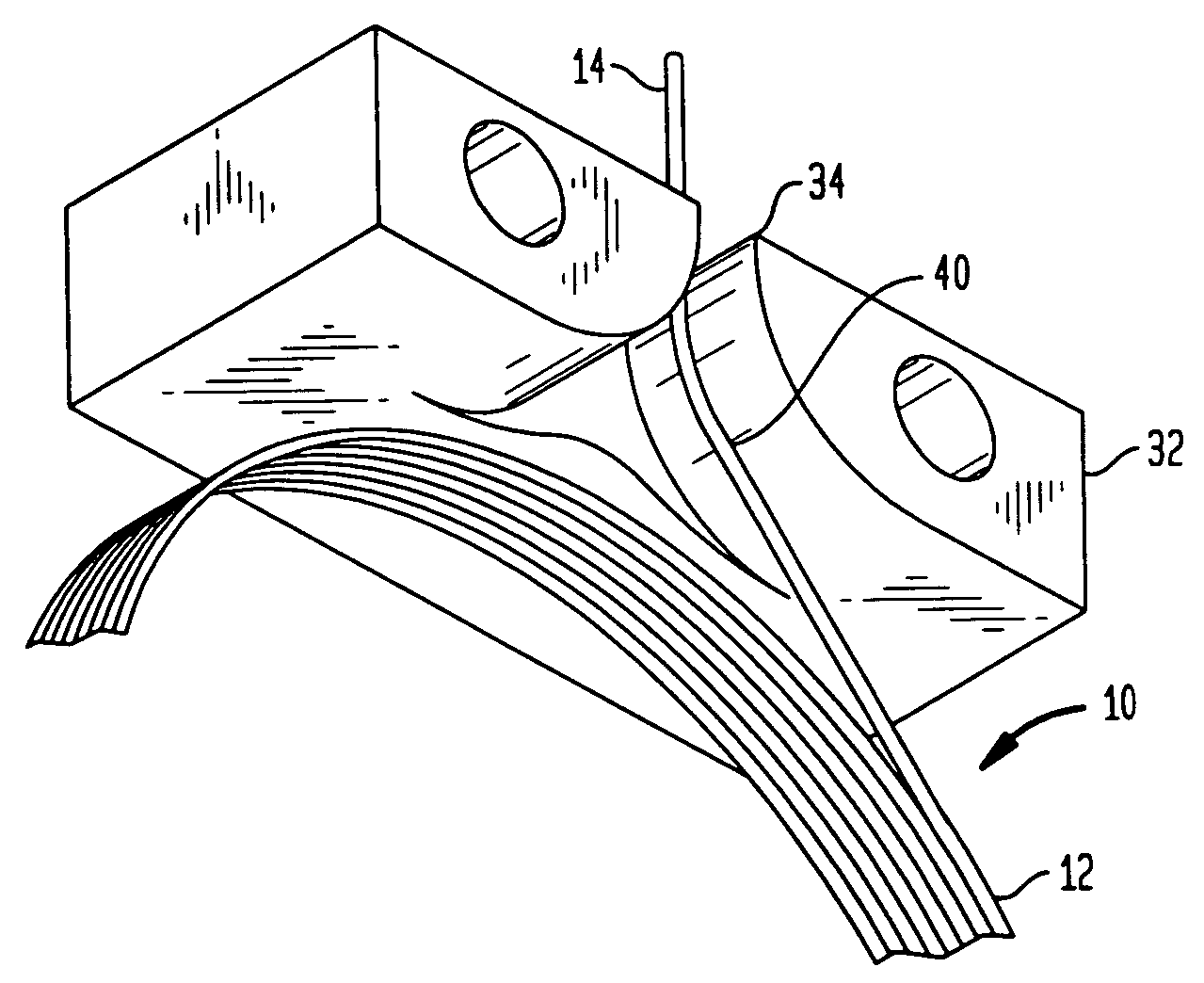

Lead guide for cable extension type position sensors

InactiveUS7100861B2Increase rangePrecise processMeasurement devicesProjector film strip handlingConductor CoilPosition sensor

Owner:CONTROL PRODS

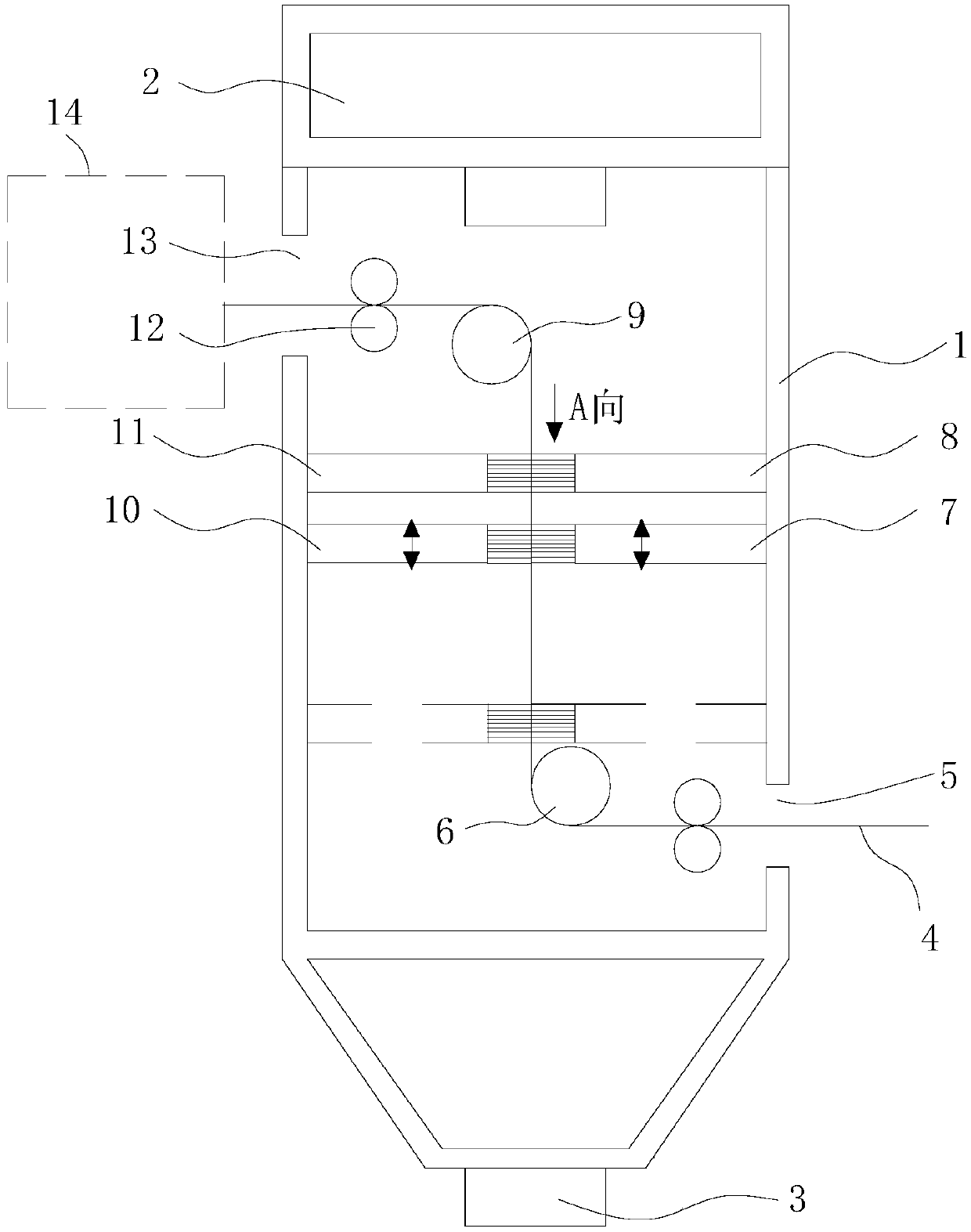

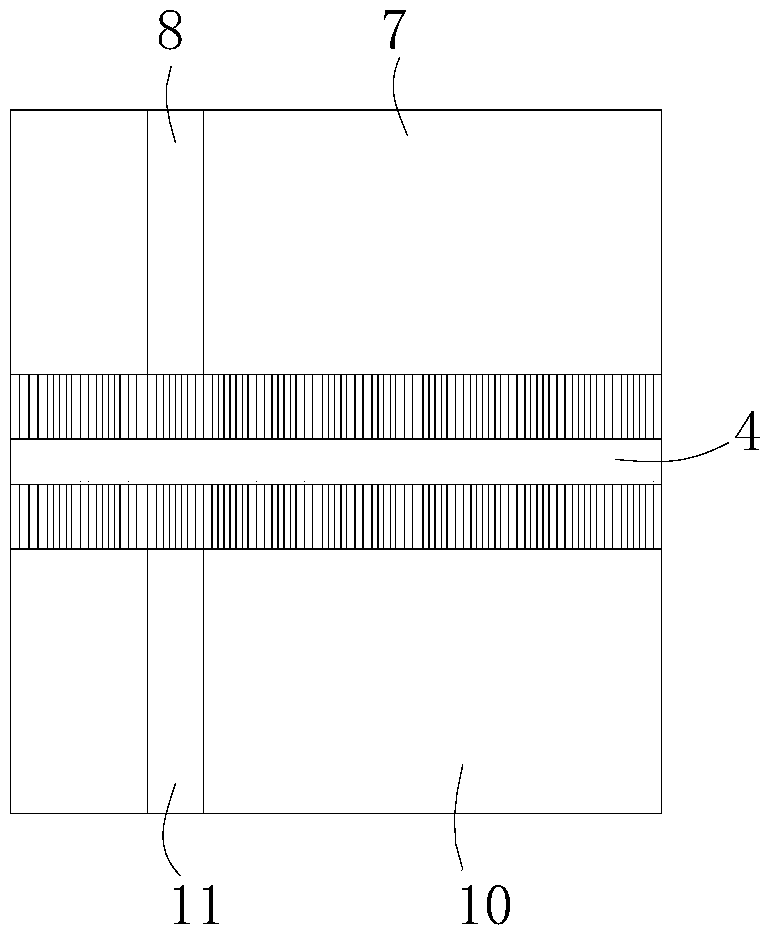

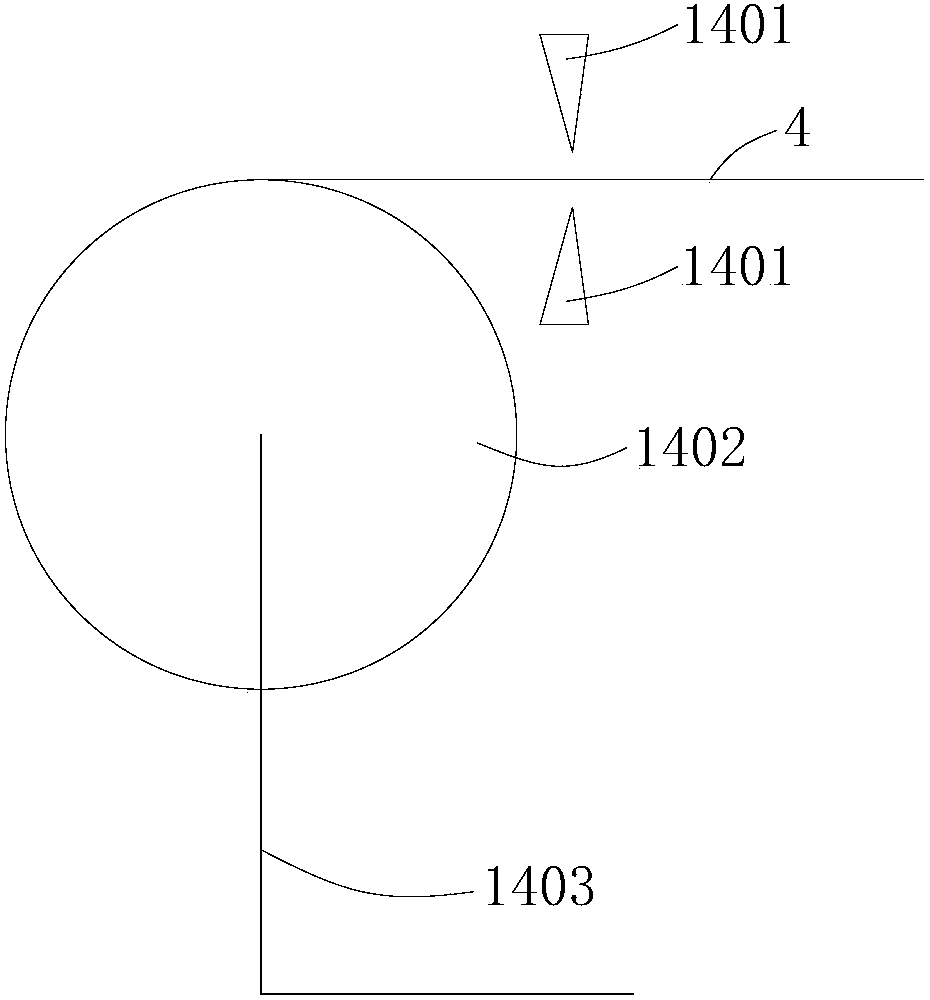

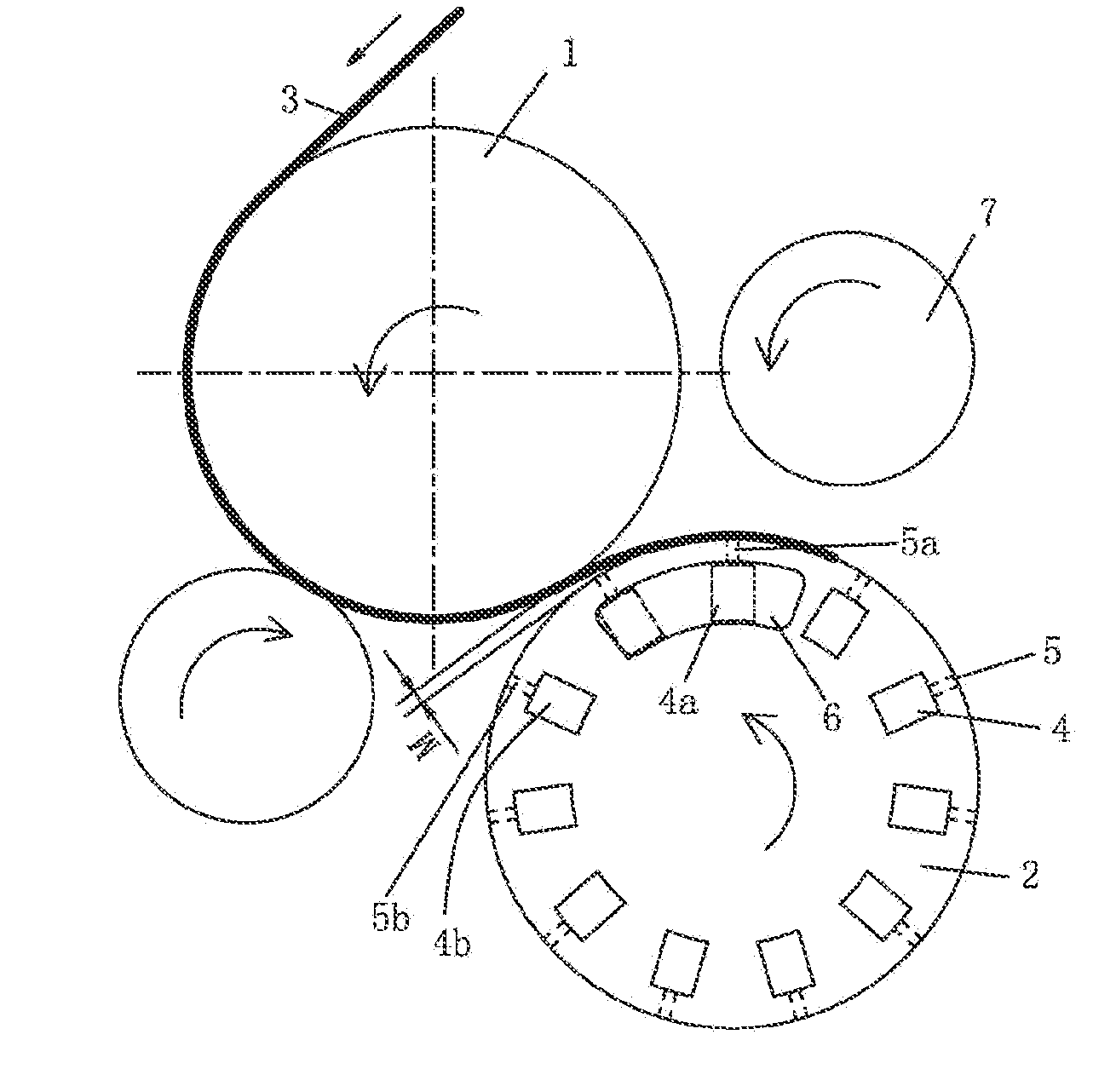

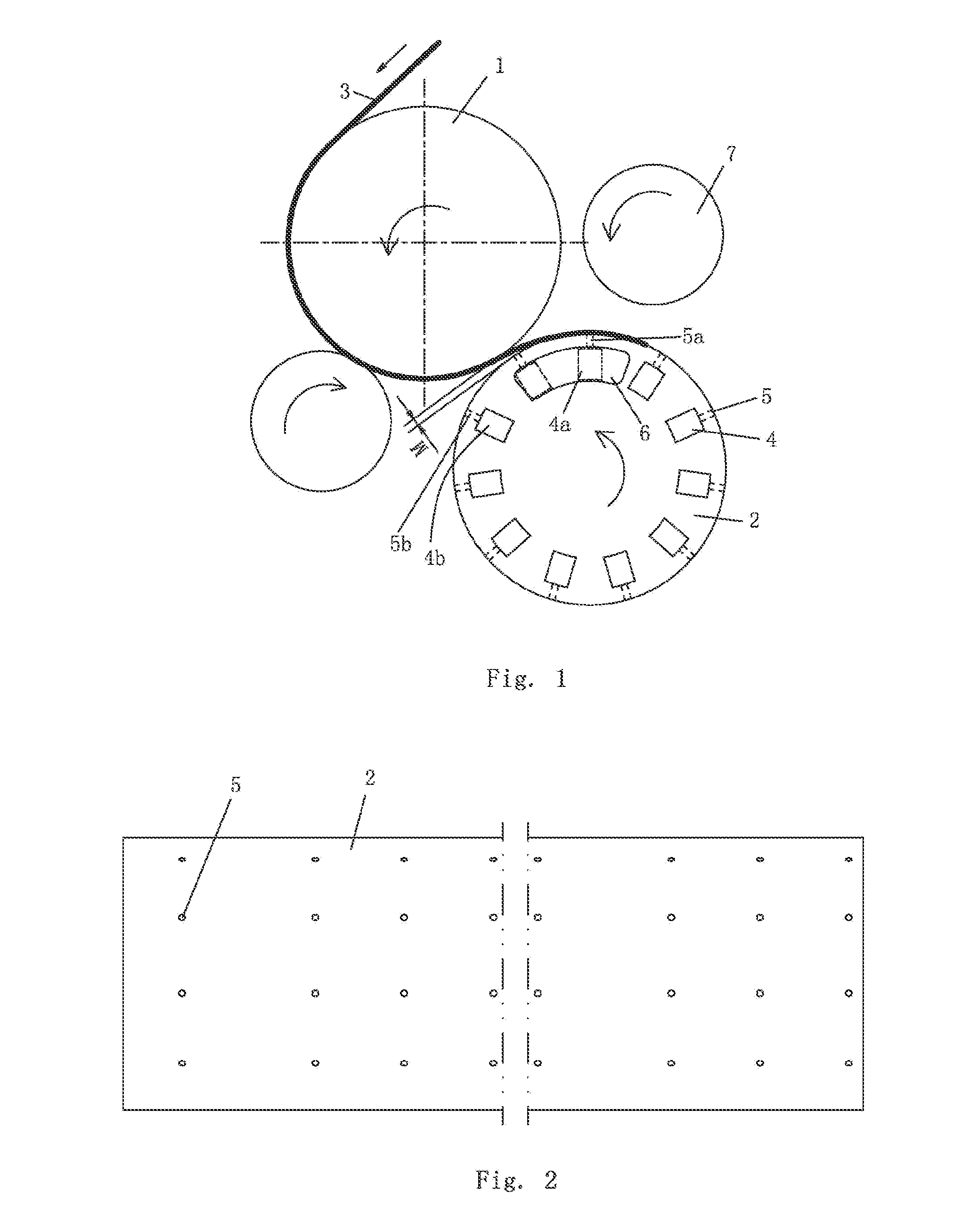

Coreless paper roll rewinding machine without a winding assisting plate

ActiveUS20130026280A1Improve reliabilityReduce the complexity of the structureWebs handlingPulp and paper industryConductor Coil

A coreless paper roll rewinding machine without a winding assisting plate comprises rewinding upper roller (1) and a rewinding lower roller (2) that are parallel with each other. Paper (3) is wound on the rewinding upper roller (1) and passes through a roller gap between the rewinding upper roller (1) and the rewinding lower roller (2). A plurality of airflow channels (4) are formed in a roller body of the rewinding lower roller (2), and each of the air flow channel (4) is interconnected with a set of air suction holes (5) on the surface of the roller body. An air suction cover (6) provided with an exhaust opening is arranged close to the end of the rewinding roller (2). When one set of air suction holes (5) on the surface of the rewinding lower roller (2) is close to the roller gap, the air flow channel (4) interconnected with the set of air suction holes is rotated to an region interconnected with the exhaust opening of the air suction cover (6). When the set of air suction holes (5) on the surface of the rewinding lower roller (2) is far away the roller gap, the corresponding air flow channel (4) is rotated to region where it deviates from the exhaust opening. This coreless paper roll rewinding machine has high winding reliability, stable rewinding function and uniform roll compactness, and can prevent the indentation on the surface of the paper roll.

Owner:FOSHAN BAOSUO PAPER MASCH MFG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com