Servo driving special machine with high-speed winding function

A servo drive, servo drive technology, applied in AC motor control, general control system, non-electric variable control and other directions, can solve the problem that the rotating shaft does not provide linear speed control, the winding length is limited, the winding form is fixed, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The technical content of the present invention will be described in detail below with reference to the accompanying drawings.

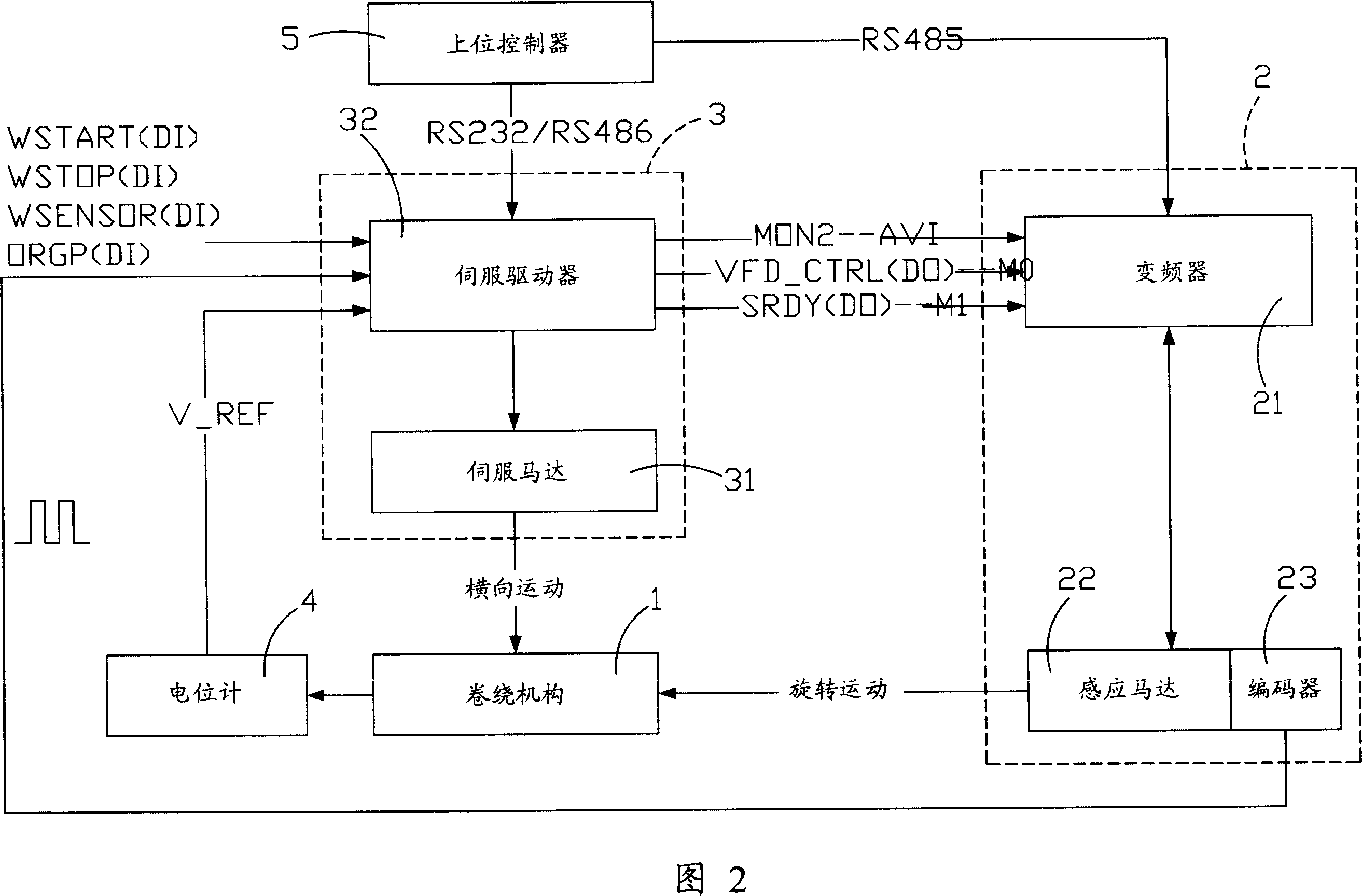

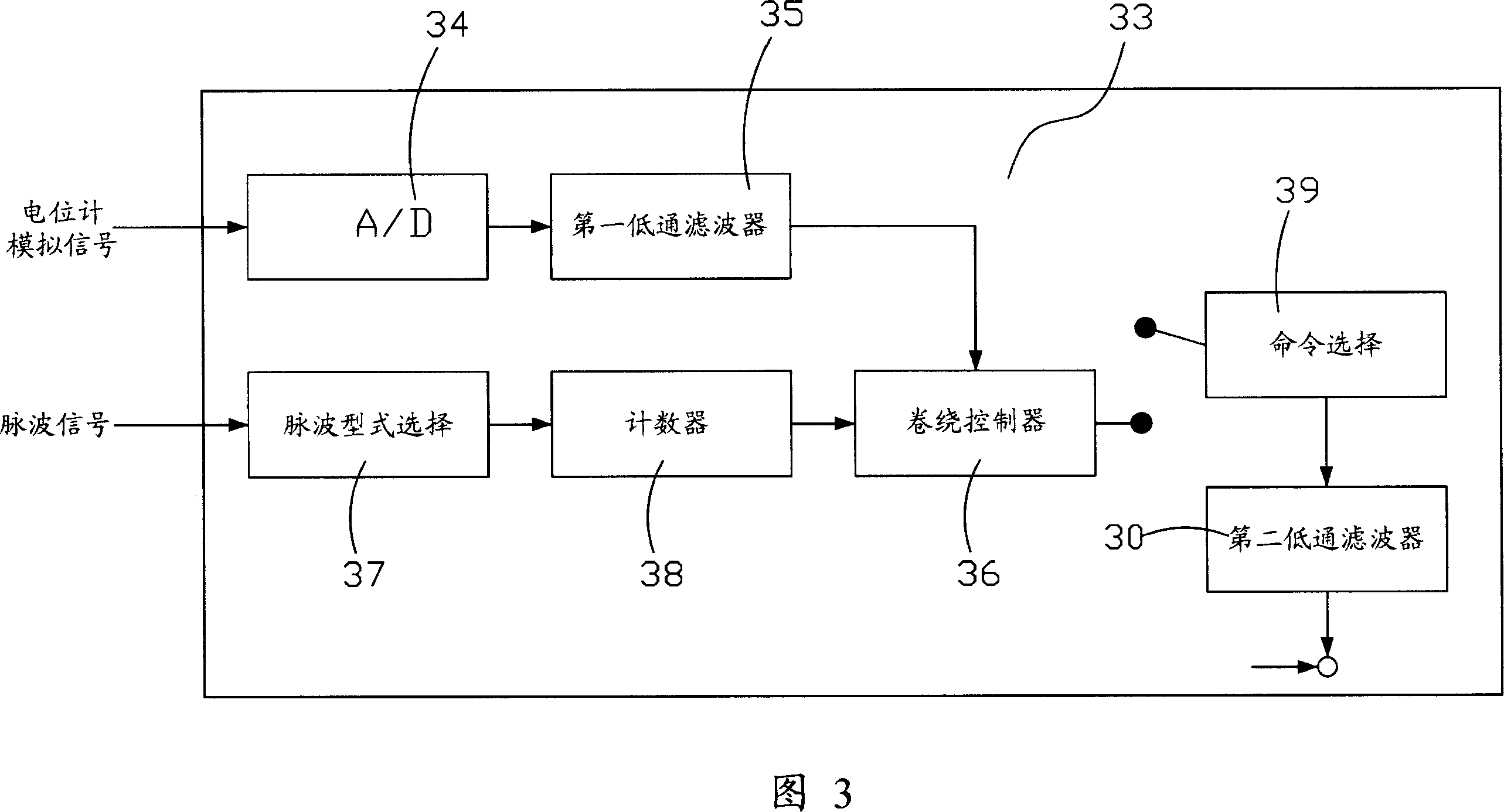

[0046] Figures 2 and 3 are schematic diagrams of the special frame for servo drive with high-speed winding function of the present invention. As shown in the figure, the servo-driven special machine with high-speed winding function of the present invention includes: a winding mechanism 1, a rotation control mechanism 2 that controls the rotation of the winding mechanism 1, and a lateral movement that controls the horizontal reciprocating movement of the winding mechanism 1. Control mechanism 3, potentiometer 4 and host controller 5. The above-mentioned device constitutes a special machine for servo winding control with high-speed winding, multi-winding mode and line speed control planned by parameter setting.

[0047] Winding mechanism 1 includes at least one winder mechanism, a rotary movement mechanism that performs a rotating winding action...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com