Patents

Literature

5183 results about "Servo drive" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A servo drive is a special electronic amplifier used to power electric servomechanisms. A servo drive monitors the feedback signal from the servomechanism and continually adjusts for deviation from expected behavior.

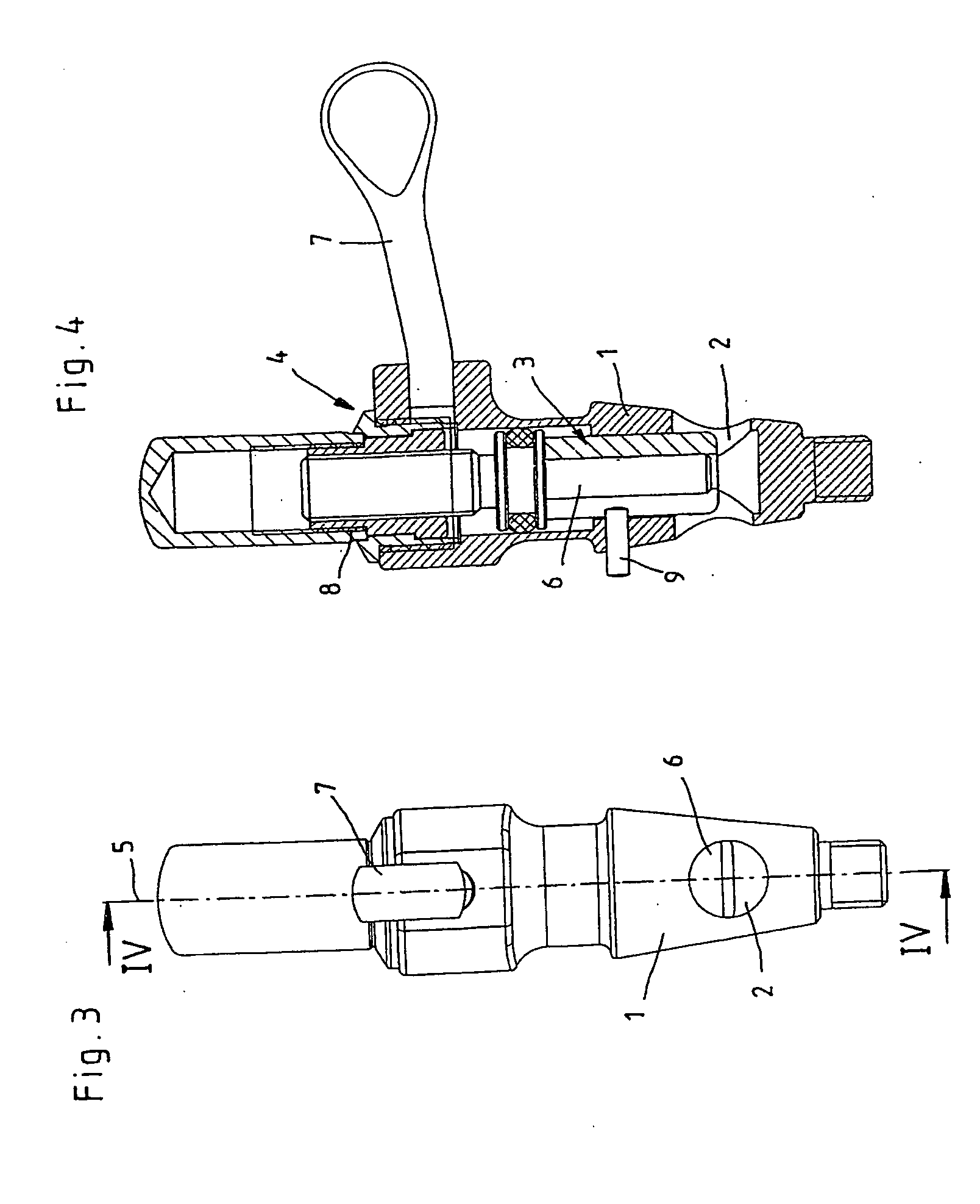

Surgical coupling device

InactiveUS20070179477A1Simple structureSimple and safe operationDiagnosticsSpannersCouplingEngineering

A surgical coupling device detachably connects a tool holder to a surgical instrument, wherein the tool holder is provided with a recess into which a coupling portion of the instrument can be inserted detachably, wherein a locking recess is provided in an inner wall of the recess, with which a locking member can be engaged detachably, the locking member being supported at the instrument, wherein the locking member is selectively movable into a locking position and a release position by a servo drive.

Owner:GEBR BRASSELER GMBH & CO KG

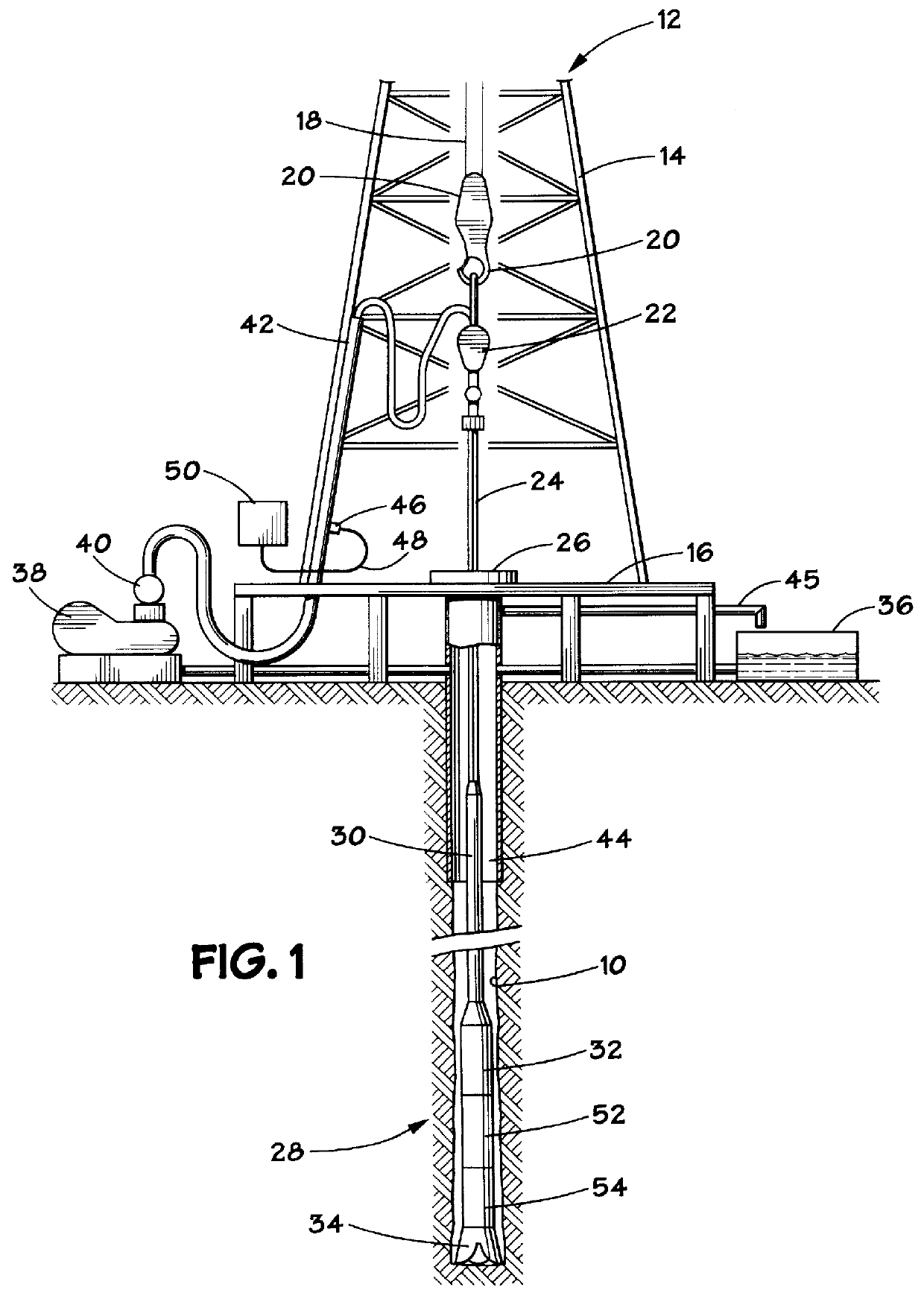

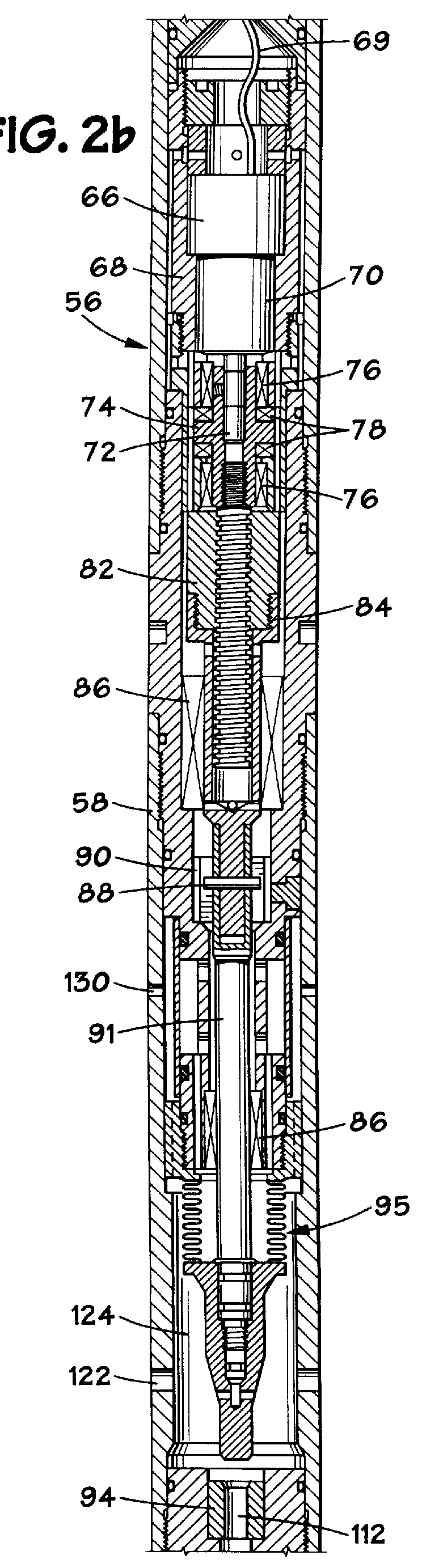

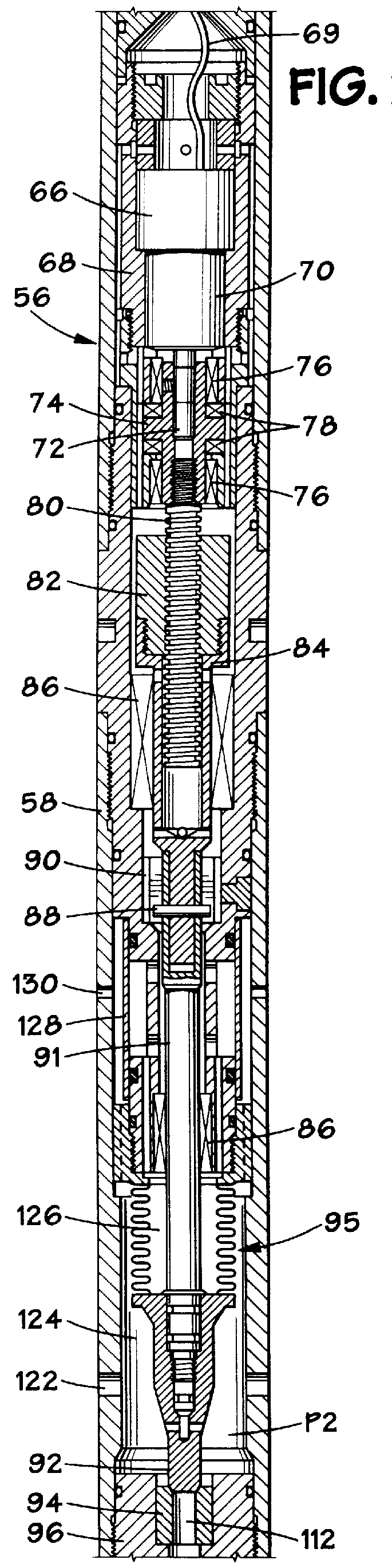

Servo-driven mud pulser

An improved servo-driven pulser is disclosed, for use in measurement while drilling applications. In the pulser, a battery powered on-board DC electric motor is used to operate a servo-valve, which in turn adjusts internal tool fluid pressures to cause operation of a main valve to substantially reduce mud flow to a drill bit, thereby creating a positive pressure pulse detectable at the surface. De-energizing the motor driving the pilot valve results in re-adjustment of internal fluid pressures, causing the main valve to reopen, thereby terminating the pressure pulse.

Owner:SMITH INT INC +1

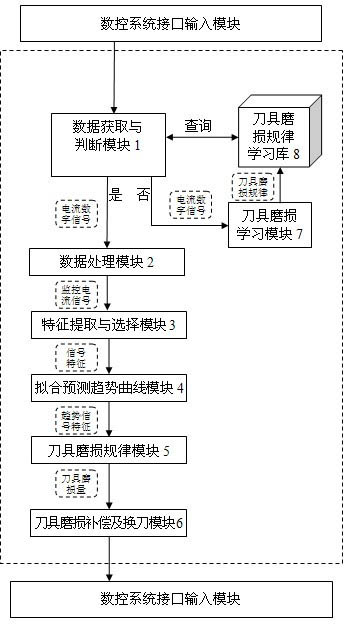

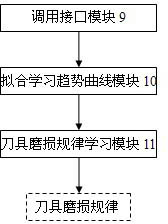

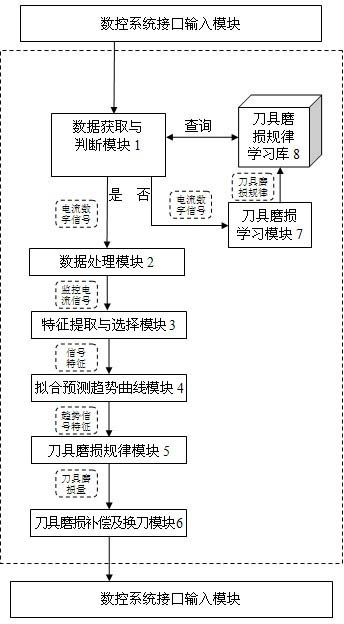

Tool wear monitoring system capable of realizing self-learning in numerical control machining state

InactiveCN102073300ACutting Condition MonitoringReal-time monitoring of cutting statusProgramme controlComputer controlData acquisitionEngineering

The invention discloses a tool wear monitoring system capable of realizing self-learning in a numerical control machining state. The structure of the system is that: a tool wear rule learning library stores learned tool wear rules; a data acquisition and judgment module provides a servo drive current digital signal for a data processing module to perform format conversion and store the signal as a monitoring current signal; a characteristic extraction and selection module selects signal characteristics strongly correlated with tool wear; a fitted predicted trend curve module establishes a signal characteristic-tool machining service life relationship curve; a tool wear rule module obtains the learned tool wear rules from the tool wear rule learning library, and substitutes the trend signal characteristics into the learned tool wear rules to obtain a tool wear extent; and a tool wear compensation and tool replacement module makes a tool wear compensation and tool replacement decision according to the tool wear extent, and provides the tool wear compensation and tool replacement decision for a numerical control system interface input module. The system is applied to the condition offluctuating cutting parameters in mass production, and can achieve relatively higher accuracy under the condition of constant cutting parameters.

Owner:HUAZHONG UNIV OF SCI & TECH +1

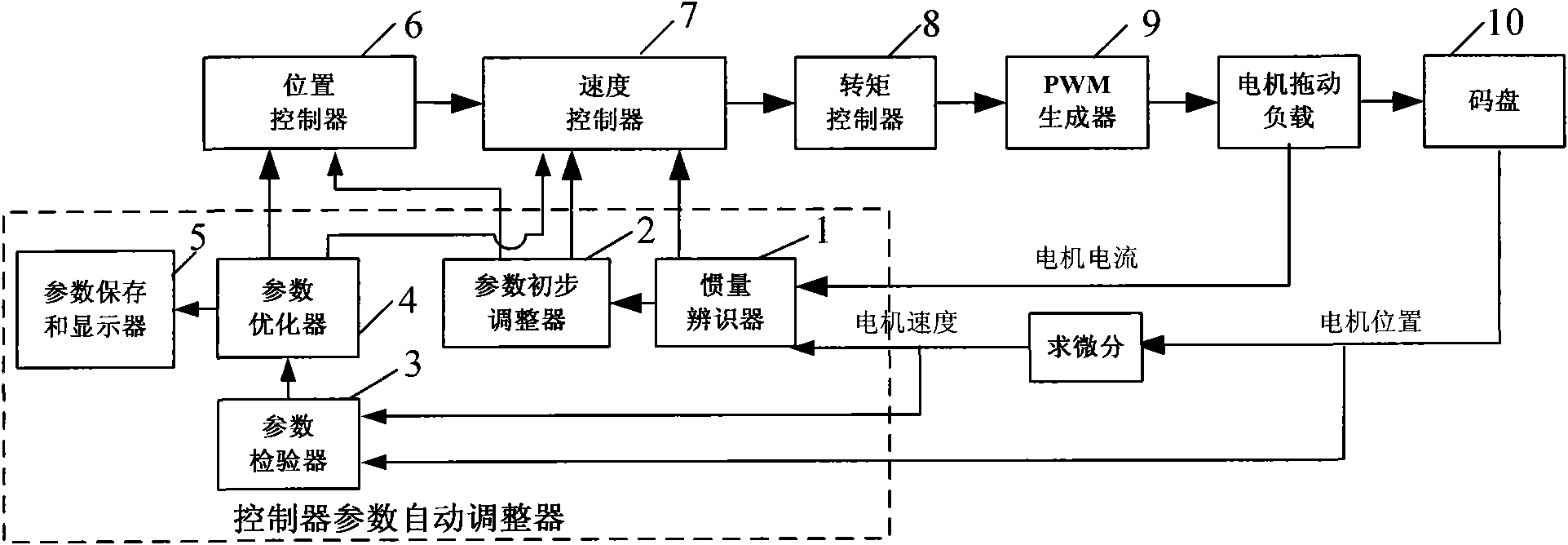

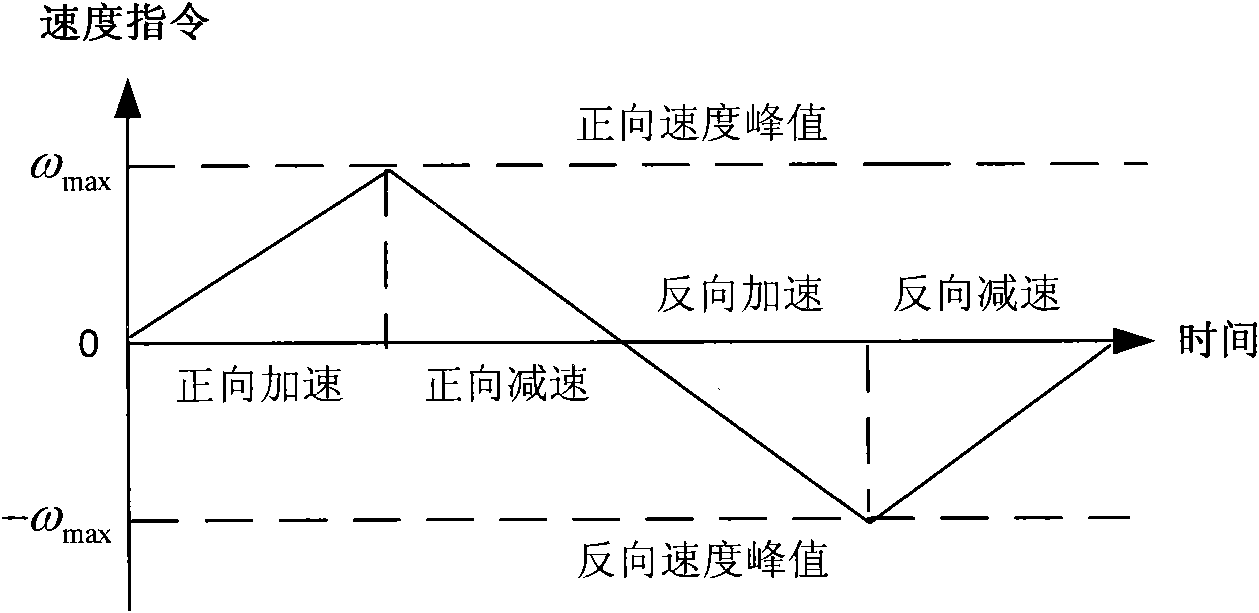

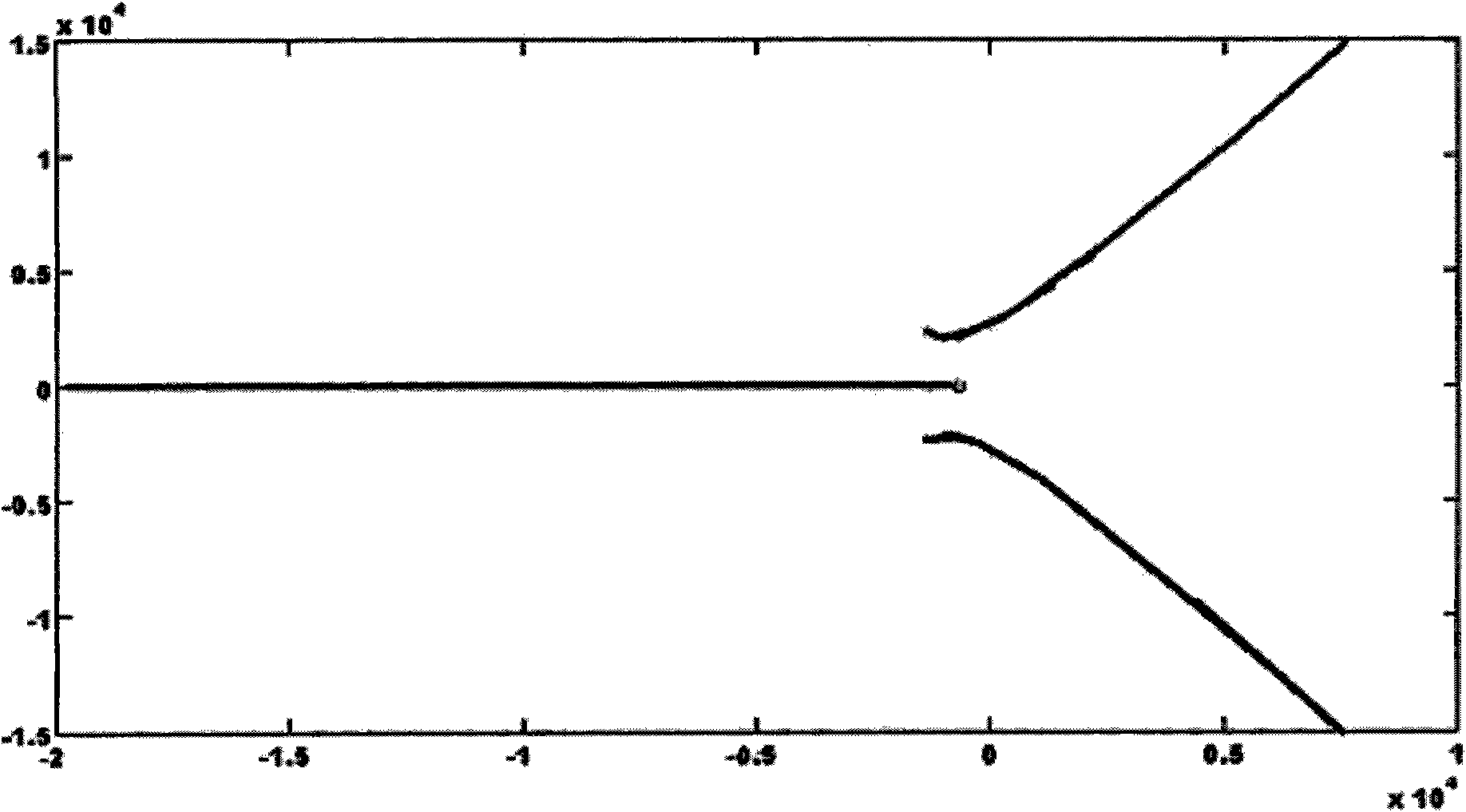

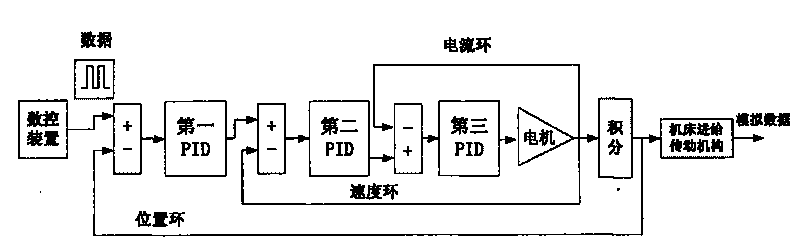

Automatic regulating apparatus for controller parameters of servo driver of motor and method thereof

ActiveCN101895252AGood control effectAvoid misalignmentMotor parameters estimation/adaptationPermanent magnet synchronous motorDisplay device

The invention discloses an automatic regulating apparatus for controller parameters of a servo driver of a motor and a method thereof. The apparatus comprises an inertia identifier, a parameter initial regulator, a parameter checker, a parameter optimizer, a parameter saving and displaying device, a speed controller, a position controller, a torque controller, a PWM (Pulse-Width Modulation) generator and a coded disc. In the invention, the servo driver of an alternating current permanent magnet motor automatically configures the parameters of the position controller and the speed controller according to different rotary inertias of mechanic load, checks and further optimizes the automatically configured parameters through the parameter checker and the parameter optimizer so that the position response and the speed response of the servo driver are relatively optimal. The servo driver of the alternating current permanent magnet synchronous motor automatically regulates the control parameters according to work occasions and achieves ideal control effect. The whole process is manual participation free and completed fully by the servo motor of the alternating current permanent magnet synchronous motor.

Owner:上海新时达线缆科技有限公司 +2

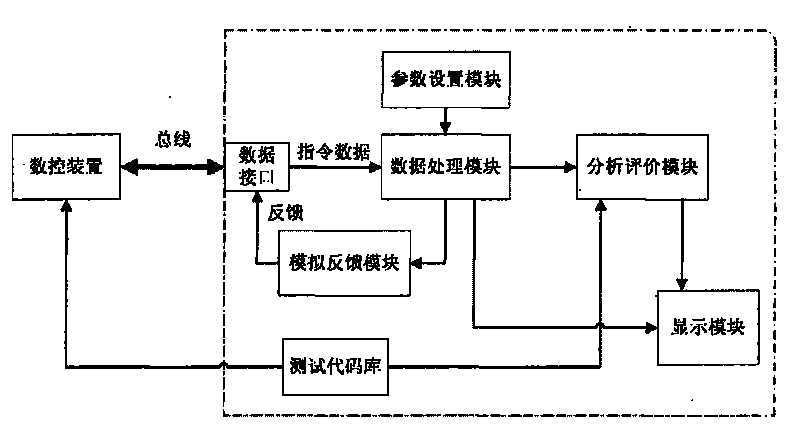

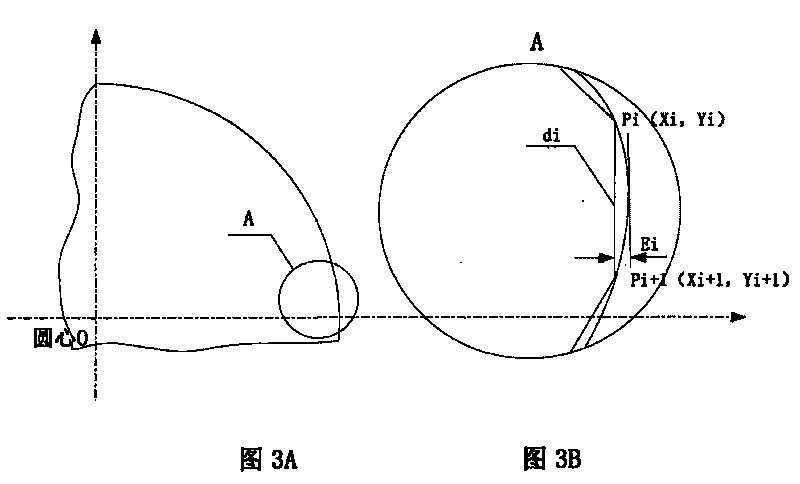

Detection analysis device for technical indexes of numerical control device

InactiveCN101758422AComprehensive detection effectComprehensive evaluationMeasurement/indication equipmentsAnalog feedbackTest fixture

The invention discloses a detection analysis device for technical indexes of a numerical control device, belongs to a test device for the numerical control device, and solves the problems that the conventional detection analysis devices for the technical indexes of the numerical control device are not universal for various numerical control devices and the detected and analyzed technical indexes are not comprehensive. The detection analysis device comprises a data interface, a parameter setting module, a data processing module, an analog feedback module, an analysis evaluation module, a display module and a test code library. The data processing module computes the indication data received by the data interface, and the test result is output to the analysis evaluation module and the display module. The parameter setting module sets parameters of the analog feedback module. The test code library provides standard test G codes for each item to be tested. The detection analysis device for the technical indexes of the numerical control device simulates characteristics of actual servo drive, motor and machine tool by using the analog feedback module, computes corresponding feedback data, removes the influence of uncertainty of an actual electromechanical system and inconsistent processing performance of the machine tool, and can accurately and objectively analyze and evaluate each important technical index of the numerical control device.

Owner:HUAZHONG UNIV OF SCI & TECH +1

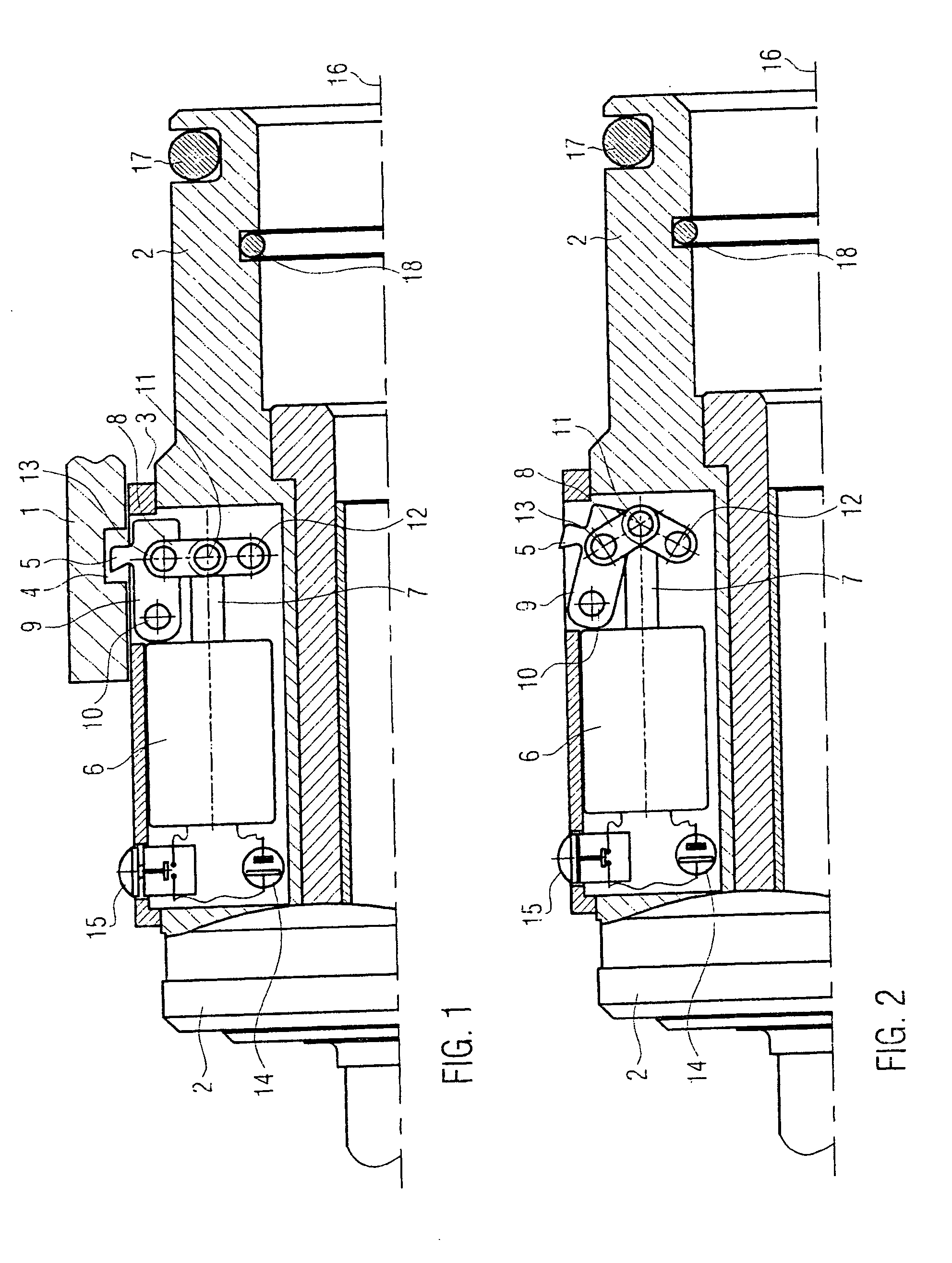

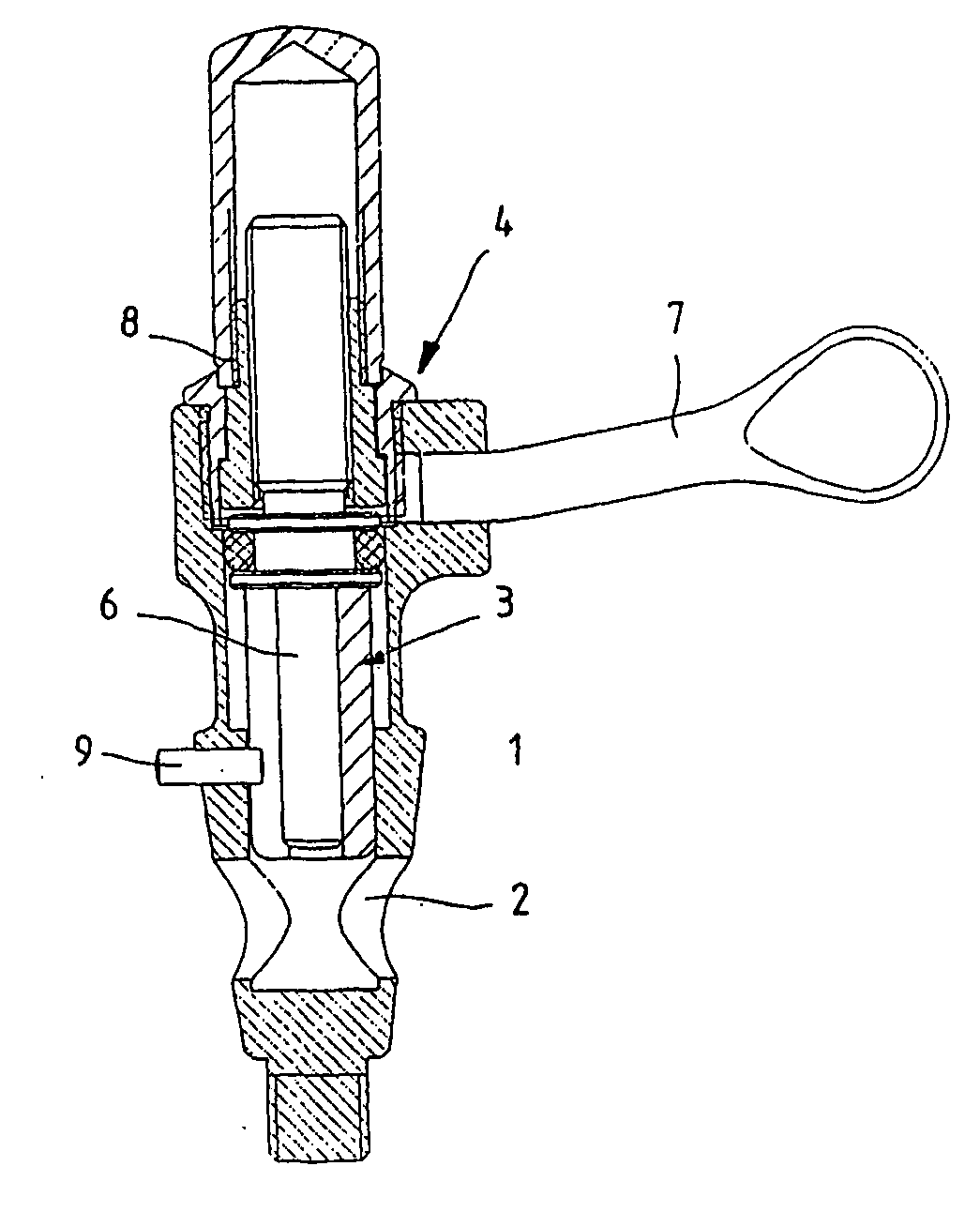

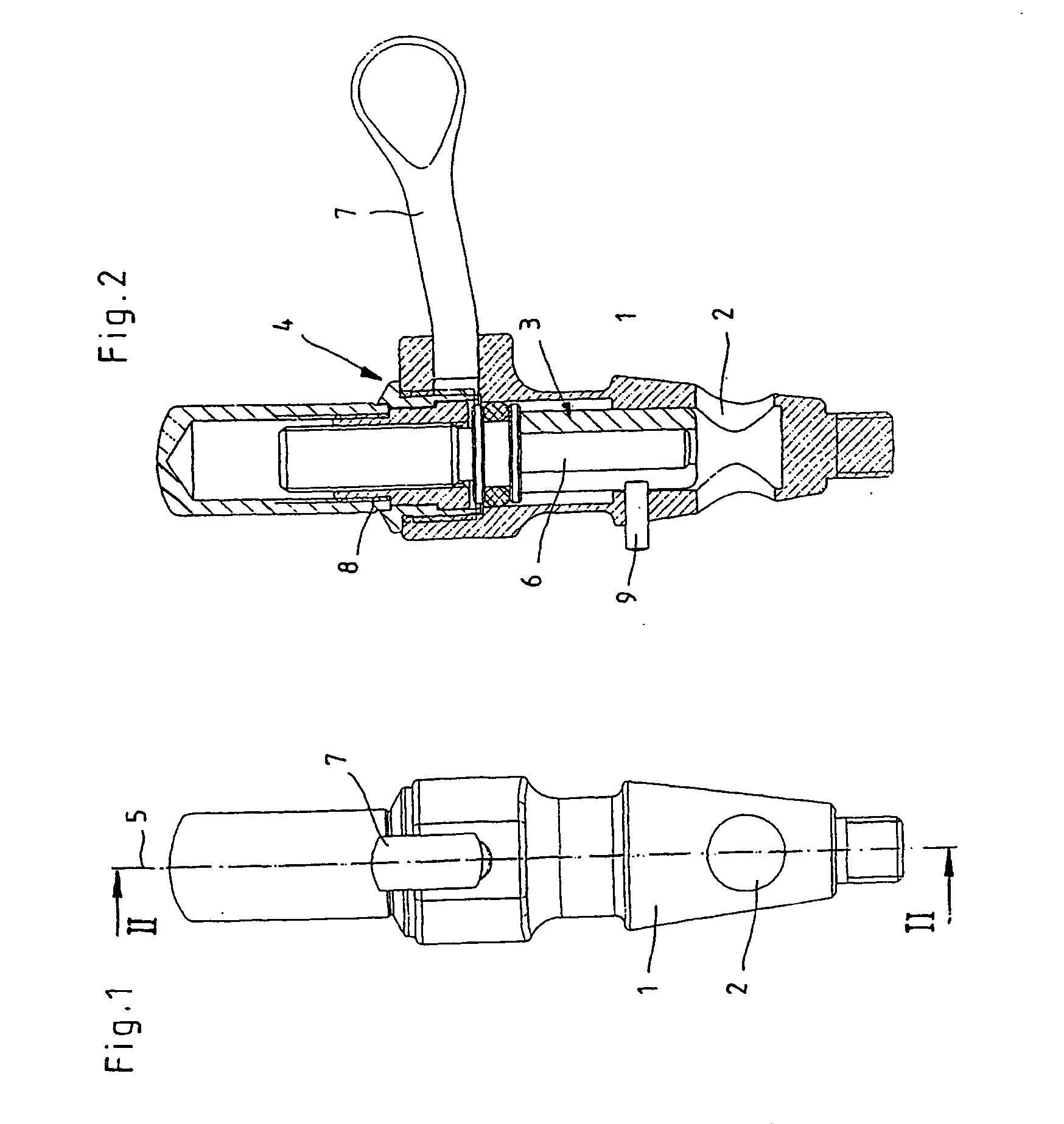

Medical-technology valve device for suction and/or flushing lines of medical instruments

InactiveUS20060229499A1Close fastOpen fastOperating means/releasing devices for valvesSurgeryEngineeringEndoscopic surgery

The invention relates to a medical-technology valve device for suction and / or flushing lines of medical instruments, particularly instruments for endoscopic surgery, having a valve housing equipped with a through bore-hole and having a valve body, movably positioned in the valve housing, by which valve body the through bore-hole can be locked and opened again, and where the valve body is configured as a piston that can be displaced essentially perpendicularly to the through bore-hole by means of a servo drive, so that a rotary movement of the servo drive can be transformed into an axial movement of the piston. To produce a medical-technology valve device that makes possible a reproducible adjustment of the flow volume that is to be regulated, while allowing a reduction of turbulence, it is proposed with the invention that the servo drive is configured as a hand lever that can rotate around the longitudinal axis of the piston and can be displaced to move the piston from the position that frees the through bore-hole into the position that closes the through bore-hole by an angle of 90 degrees with respect to the longitudinal axis of the piston.

Owner:KARL STORZ GMBH & CO KG

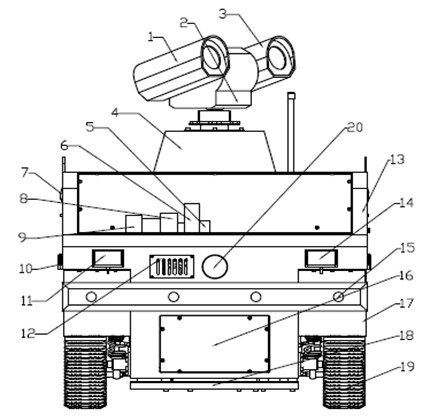

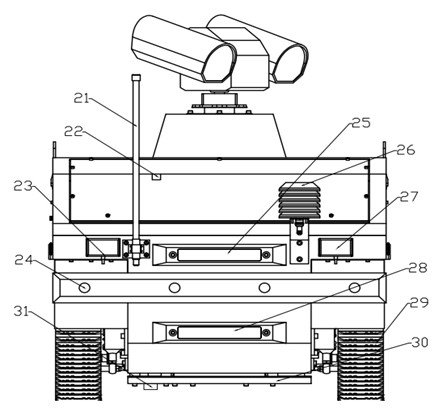

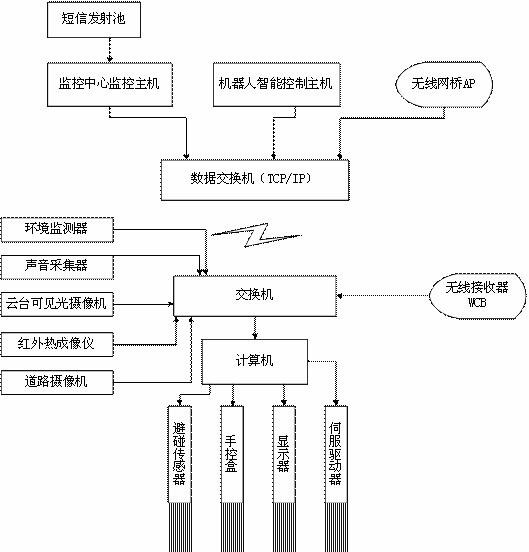

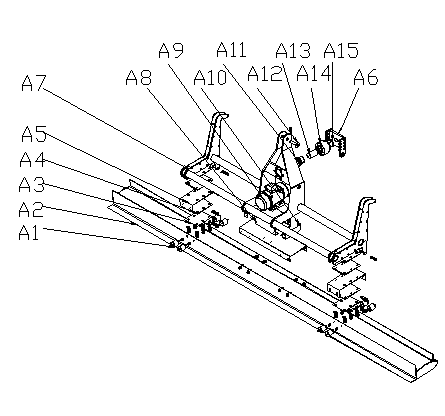

Magnetic navigation routing inspection robot

InactiveCN102541064AImprove stabilityExtended service lifePosition/course control in two dimensionsTransformerElectric power system

A magnetic navigation routing inspection robot relates to routing inspection equipment for a power system transformer substation. The robot can achieve automatic circulation detection by combination of a magnetic navigation portion, a caterpillar band walking structure portion, a control and collection portion and a wireless communication portion, wherein the magnetic navigation portion comprises a front navigation sensor and a rear navigation sensor which are used for receiving magnetic strip signals of walking tracks of the robot on the ground, the caterpillar band walking structure portion comprises a caterpillar band, a collision prevention sensor, a motor driver and a landmark sensor, the control and collection portion comprises a microprocessor and a plurality of sensors and is connected with a servo driver to control movement of a car body, the sensors are connected with a processor which is connected with a wireless network bridge to transmit processed data collected by the sensors to a remote personal computer (PC) through wireless transmission after treatment, and real-time monitoring of a far end on a spot is achieved.

Owner:沈阳中汇方元通信科技有限公司

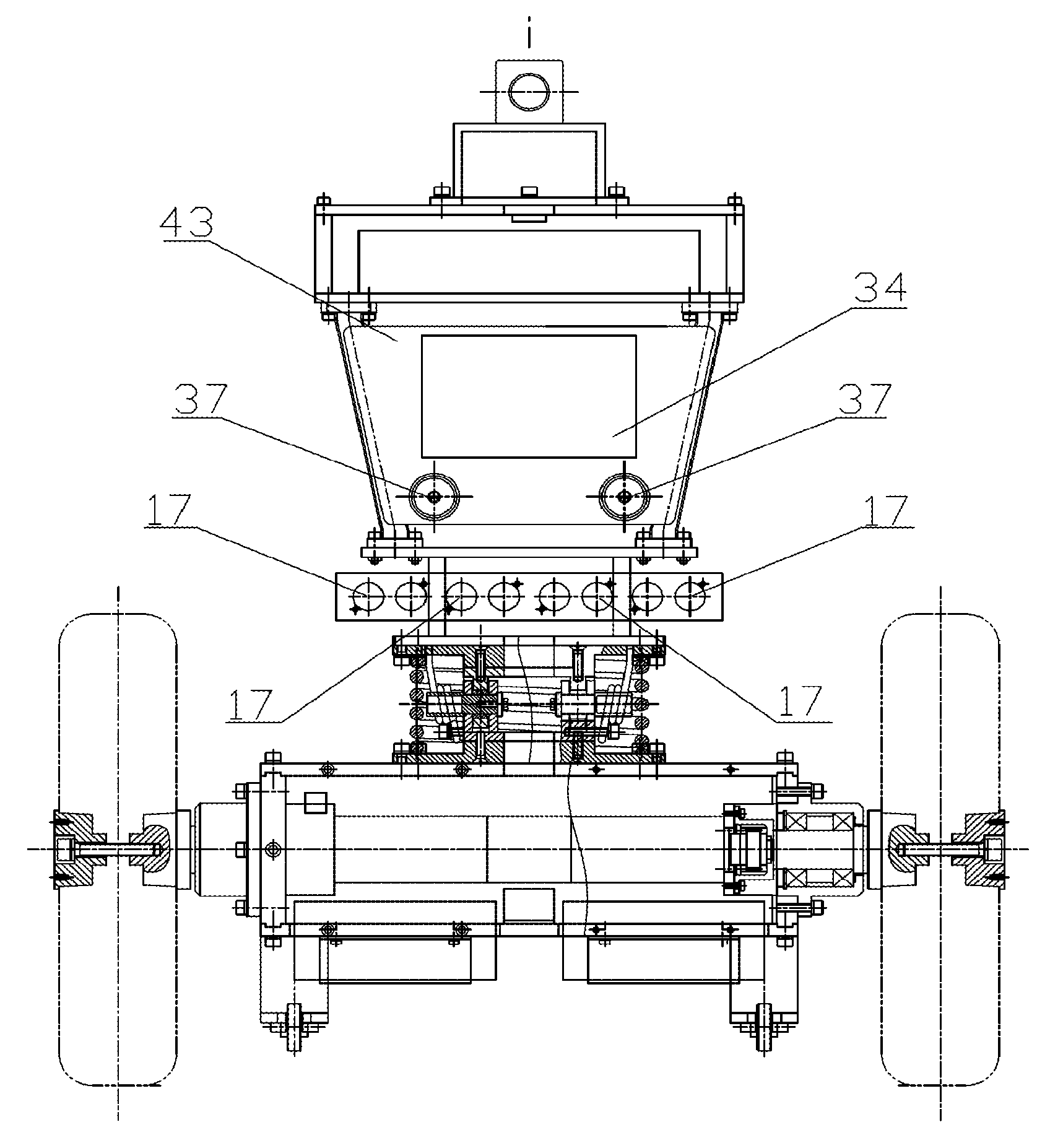

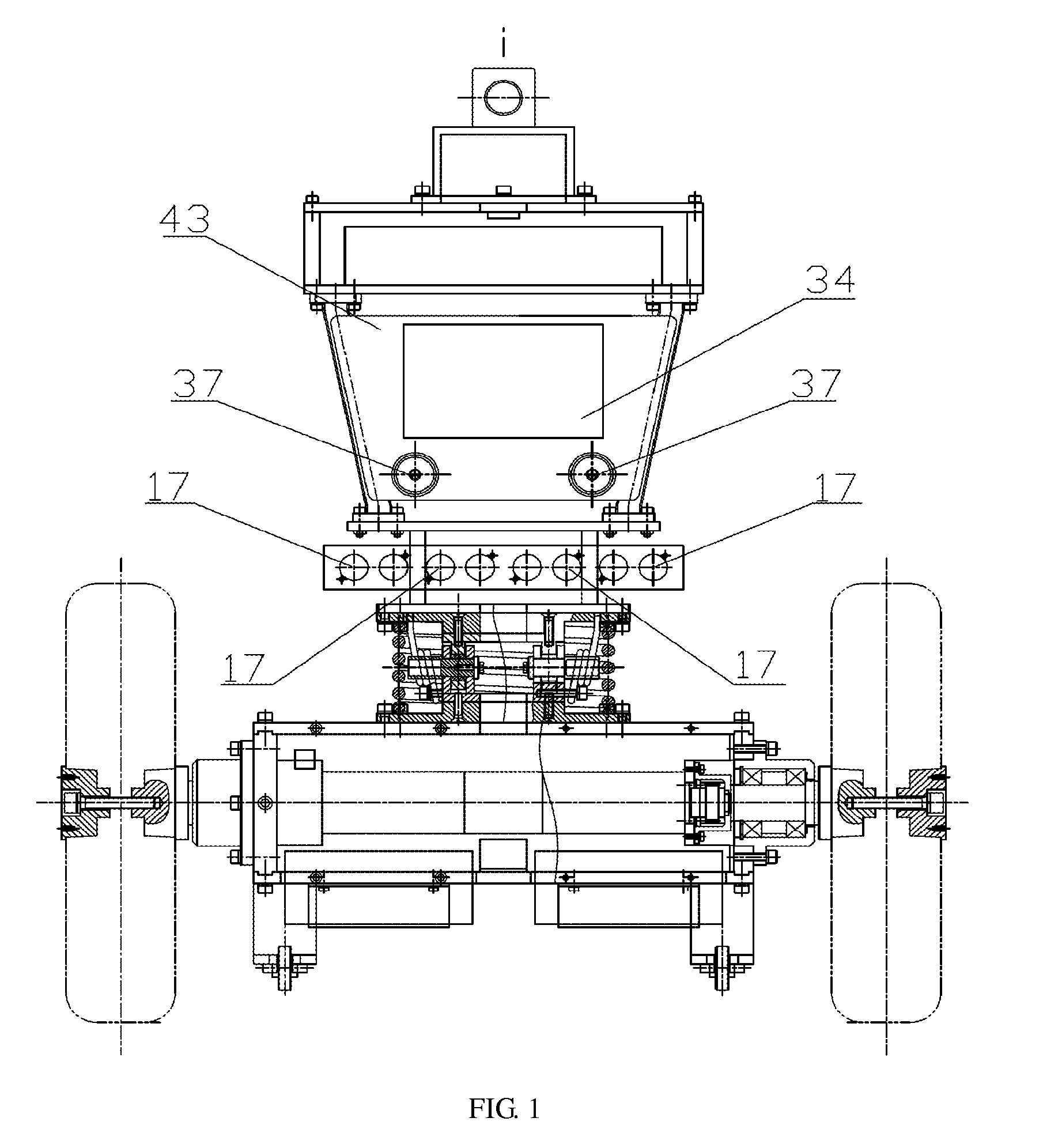

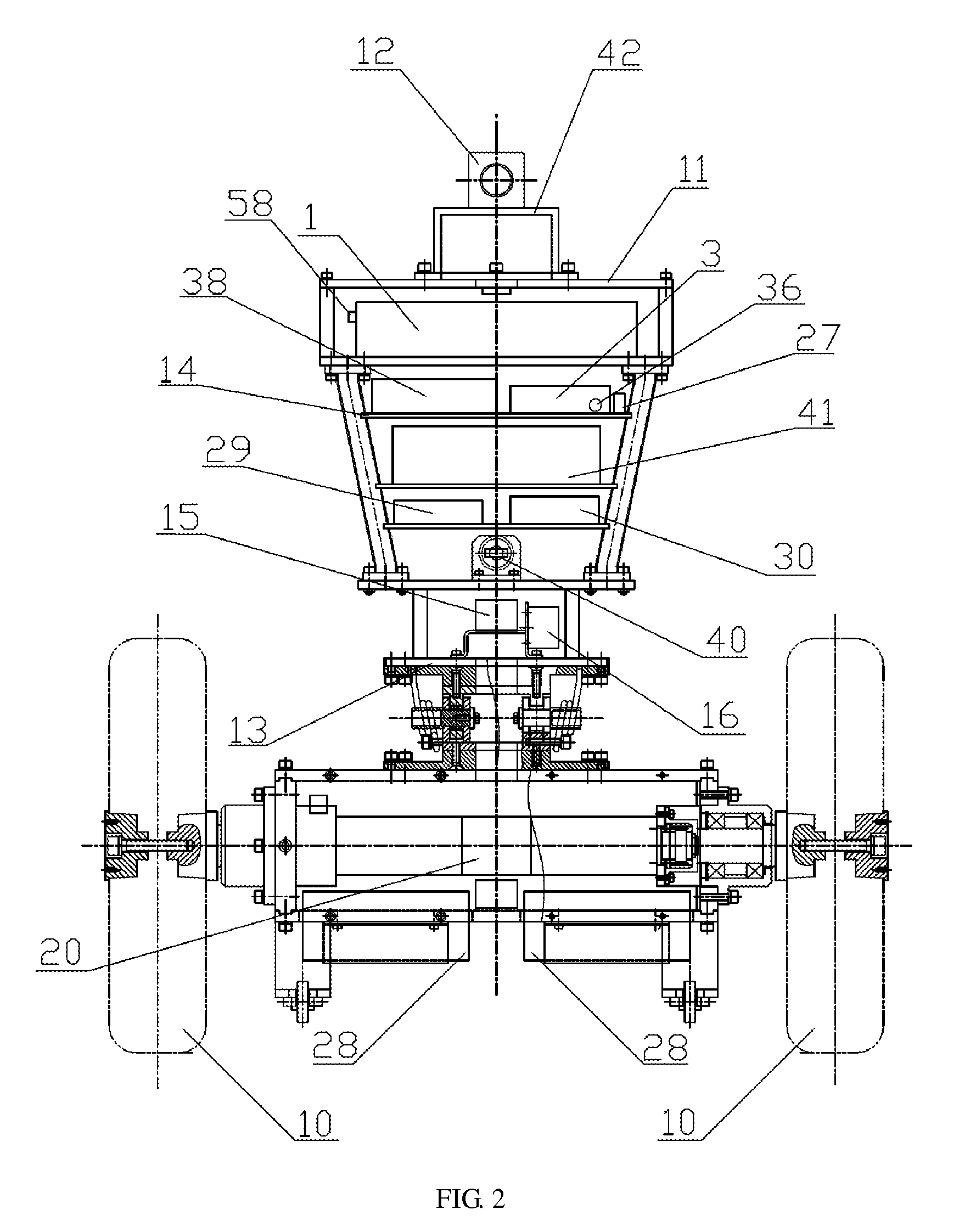

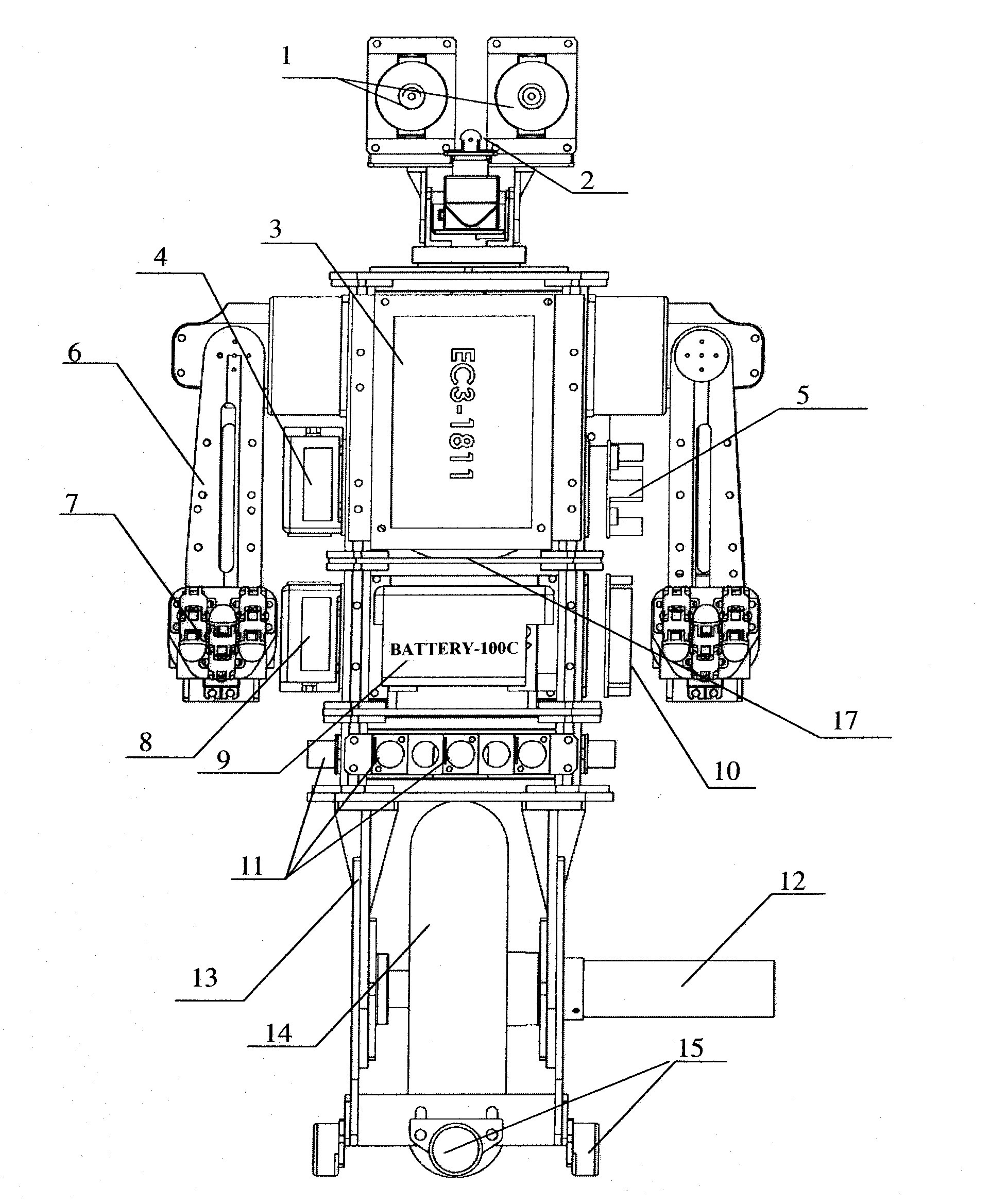

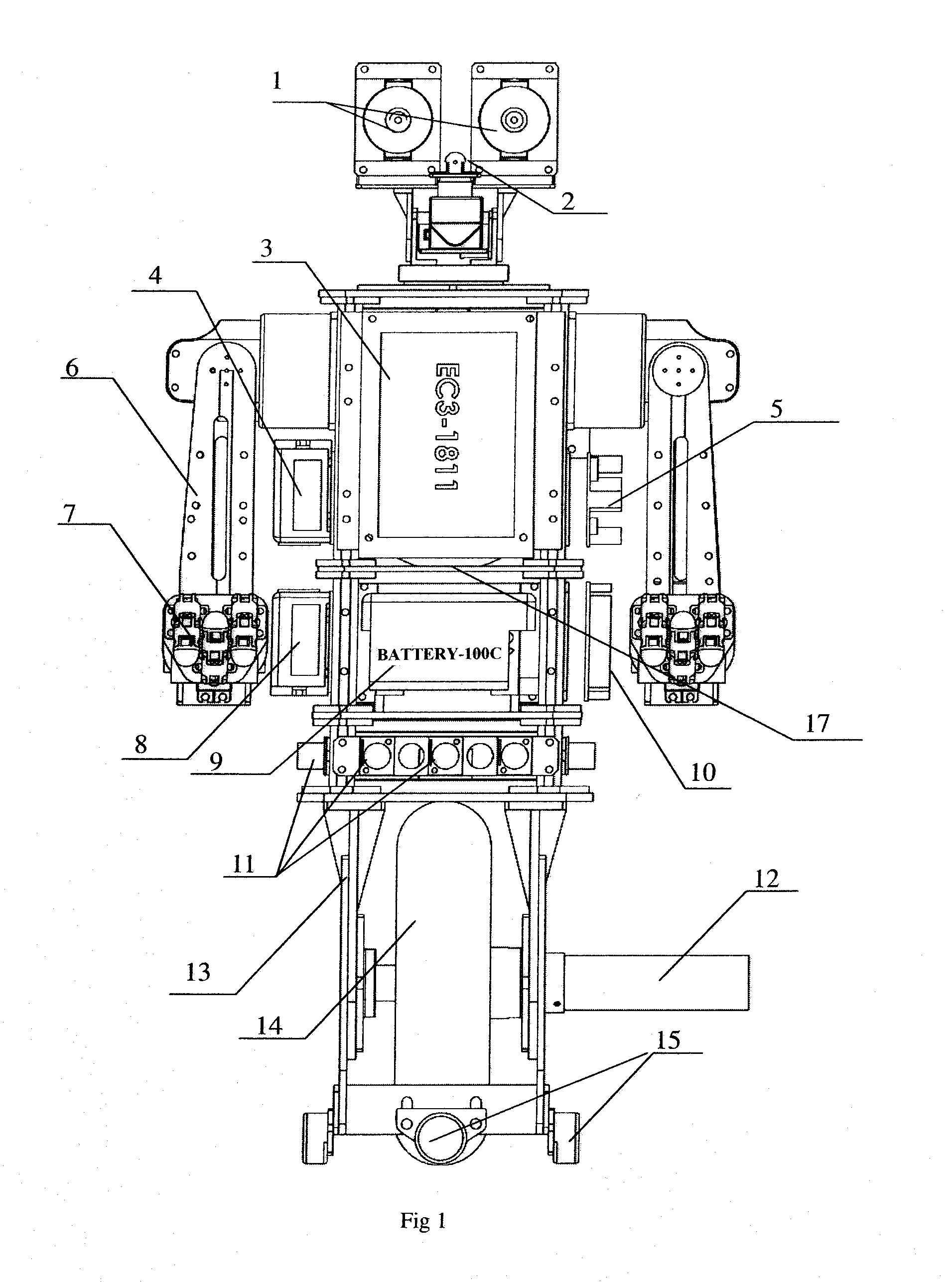

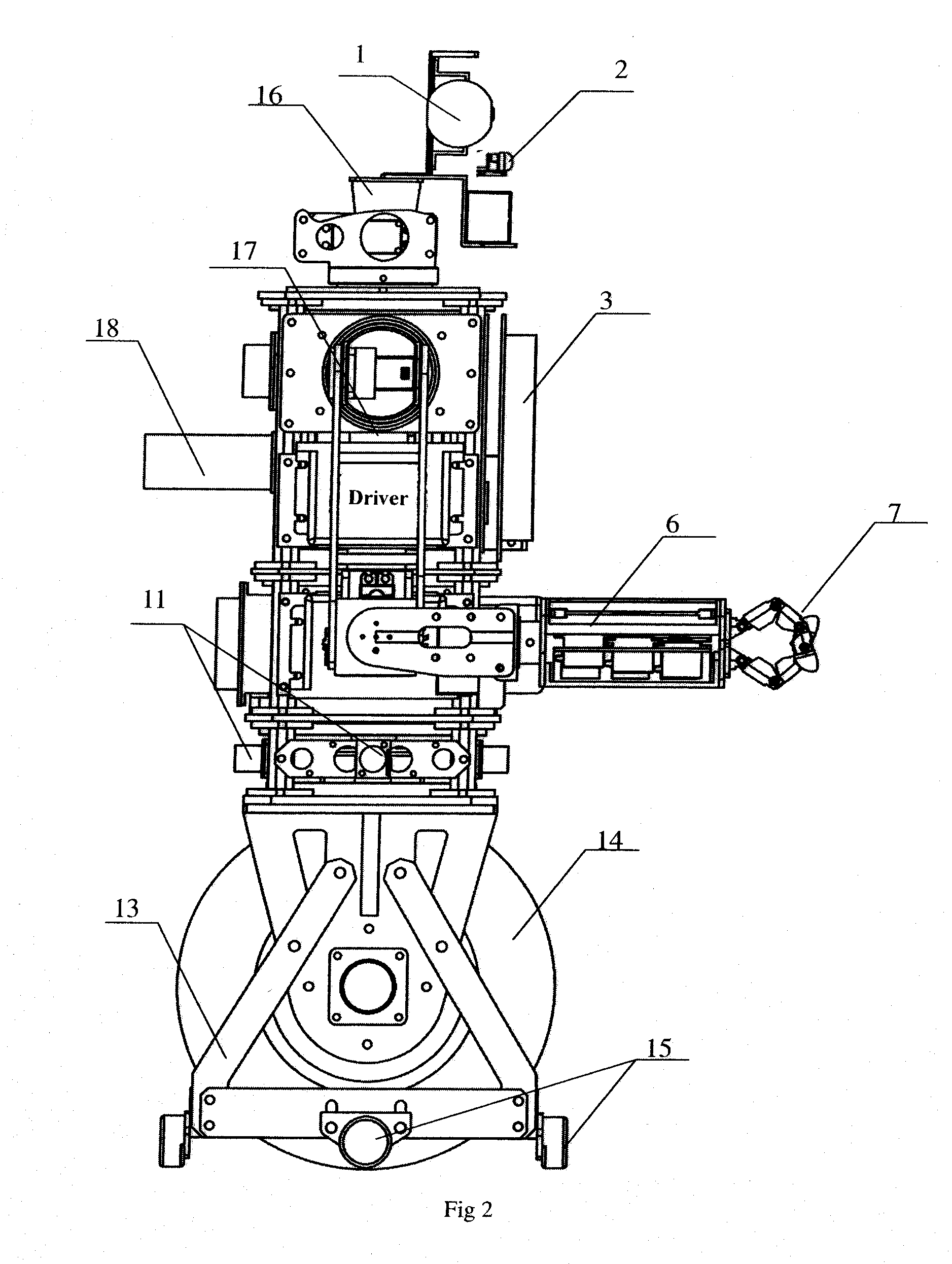

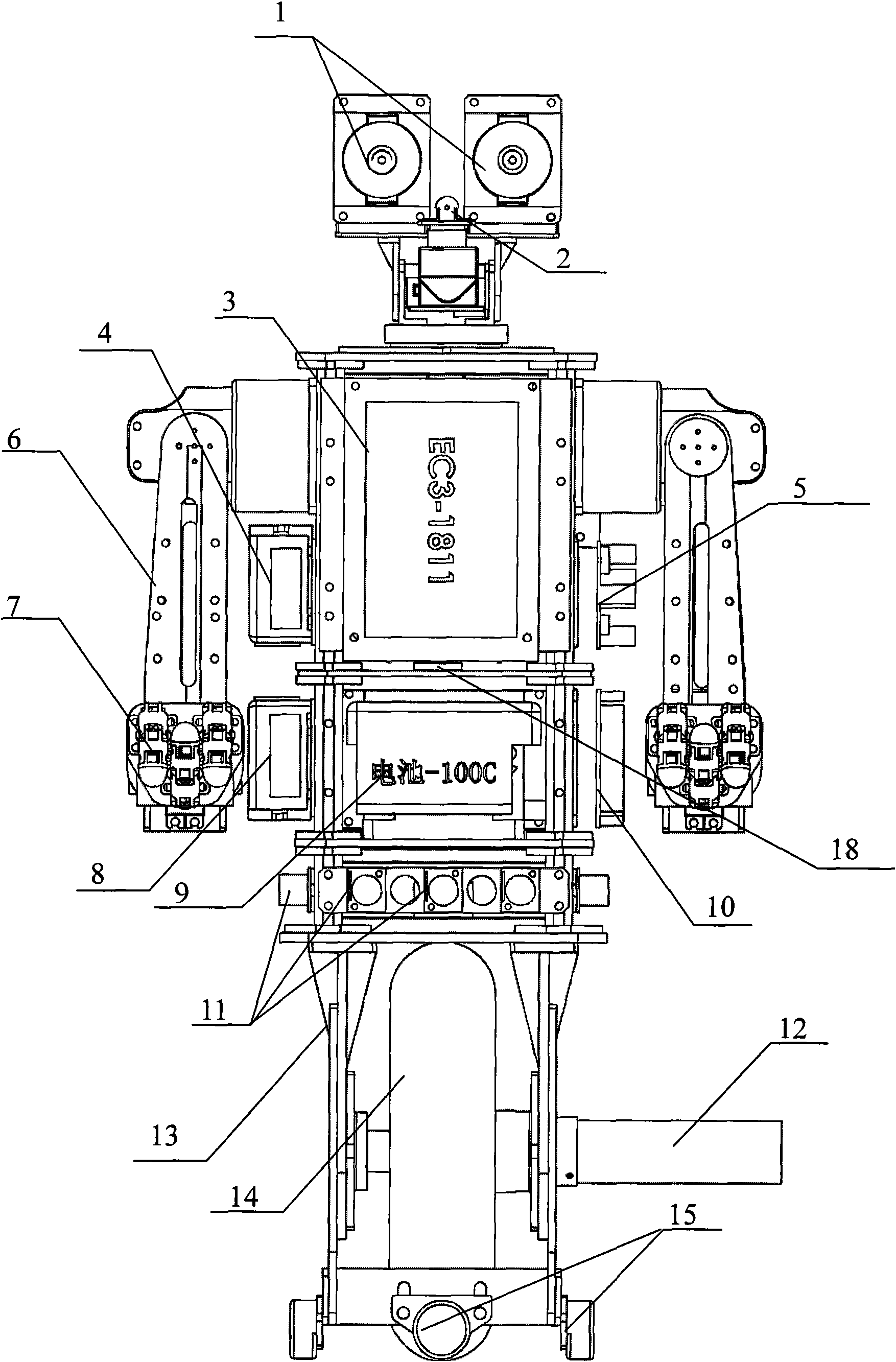

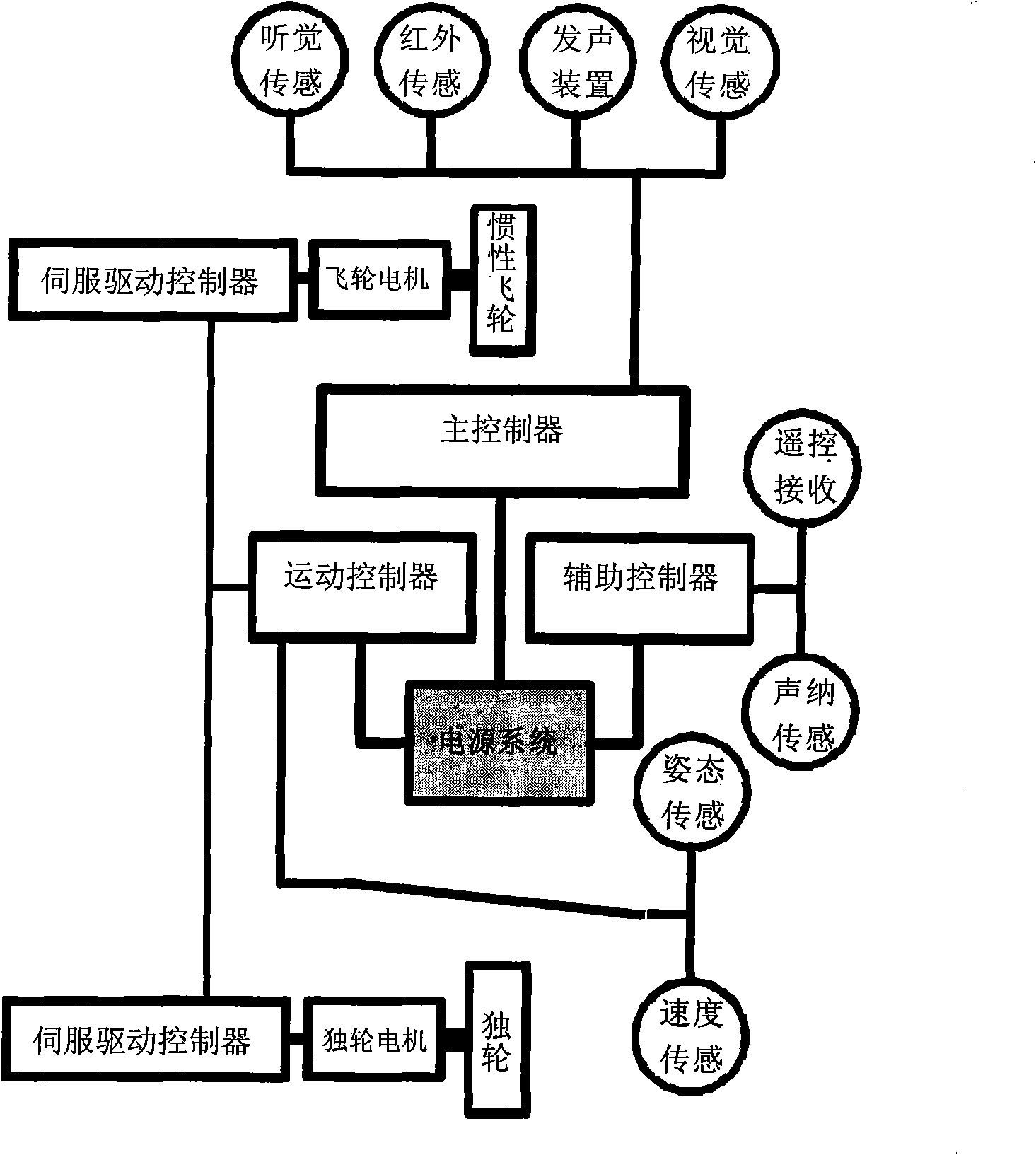

Flexible two-wheeled self-balancing robot system and its motion control method

ActiveUS20100292840A1Function increaseEasy to identifyProgramme controlComputer controlRemote controlOutput device

A flexible two-wheeled self-balancing robot system and its motion control method include a main controller 1, a motion controller 2, an assistant controller 3, two servo drivers 4, sensors, input / output devices, two DC motors 5 and a power supply system; a camera is installed on truck's top board 11, a tilt-meter and a gyro are installed both in truck 6 and chassis 8. Truck 6 and chassis 8 are connected with an elastic joint in which is installed a two-arm torsion spring and a cylindrical spring; the main controller 1 is connected to the motion controller 2, the assistant controller 3 and input / output devices. The user commands received by the main controller 1 are immediate commands or stored commands; through main controller 1 running the motion behavior decision algorithm, the motion controller 2 running the motion balancing control algorithm, and the servo drives 4 controlling the torques of the motors 5, locomotion on plane and remote control of the robot can be implemented.

Owner:BEIJING UNIV OF TECH

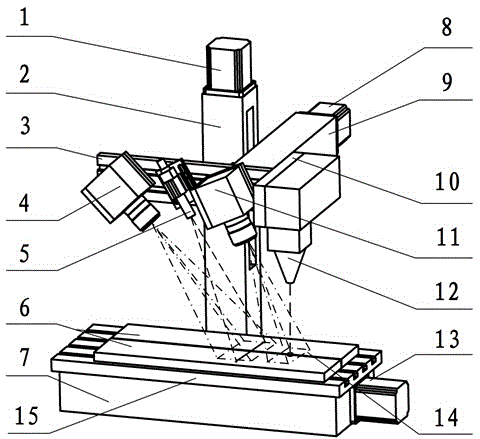

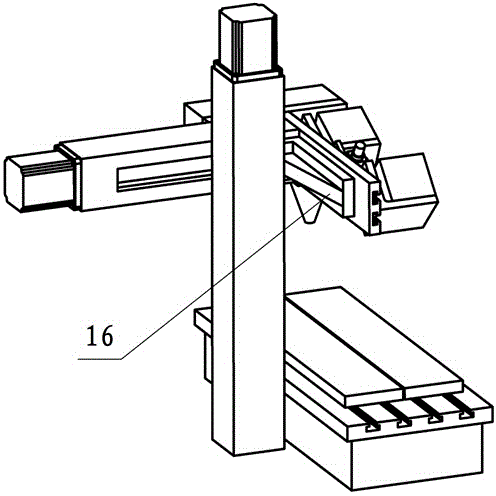

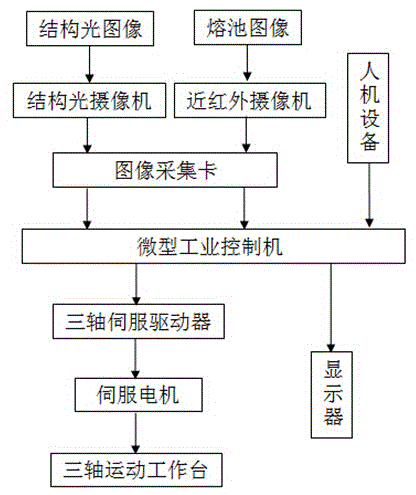

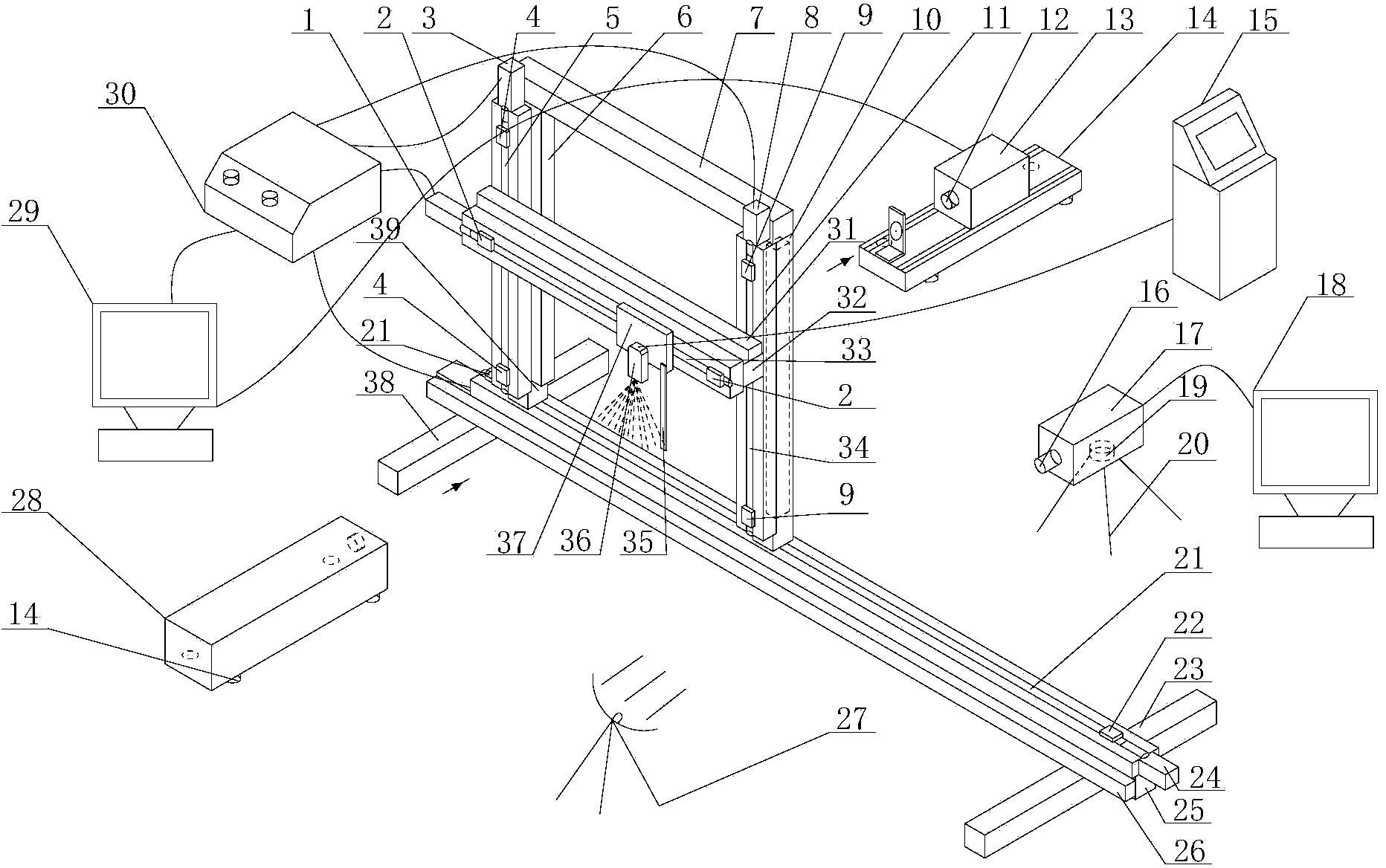

Dual-wavelength binocular vision seam tracking method and tracking system

ActiveCN104942404AAccurate measurementOvercoming strong arcArc welding apparatusReconstruction algorithmVisual perception

The invention discloses a dual-wavelength binocular vision seam tracking method. The method comprises the steps including image acquisition, data processing, seam tracking and the like. The invention further discloses a tracking system for implementing the method. The system adopts a near-infrared and structured light dual-wavelength binocular vision sensing system, images of a molten pool and different wavelengths of seam area images with of seams are measured simultaneously and transmitted to a miniature industrial control computer, and the seam positions are measured accurately with a multi-information fusion algorithm and a seam image three-dimensional reconstruction algorithm; the miniature industrial control computer adopts the Kalman filter algorithm to perform optimal estimation on the seam tracking deviation state according to a seam position detection result, a servo driver drives a servo motor to move so as to control a 3-axis motion workbench to generate corresponding motion, a welding torch or a laser head is controlled for deviation correction, and the seams are tracked accurately. The system can eliminate hard light, splashing and electromagnetic interference on a welding site and improve the seam tracking accuracy and reliability.

Owner:GUANGDONG UNIV OF TECH +1

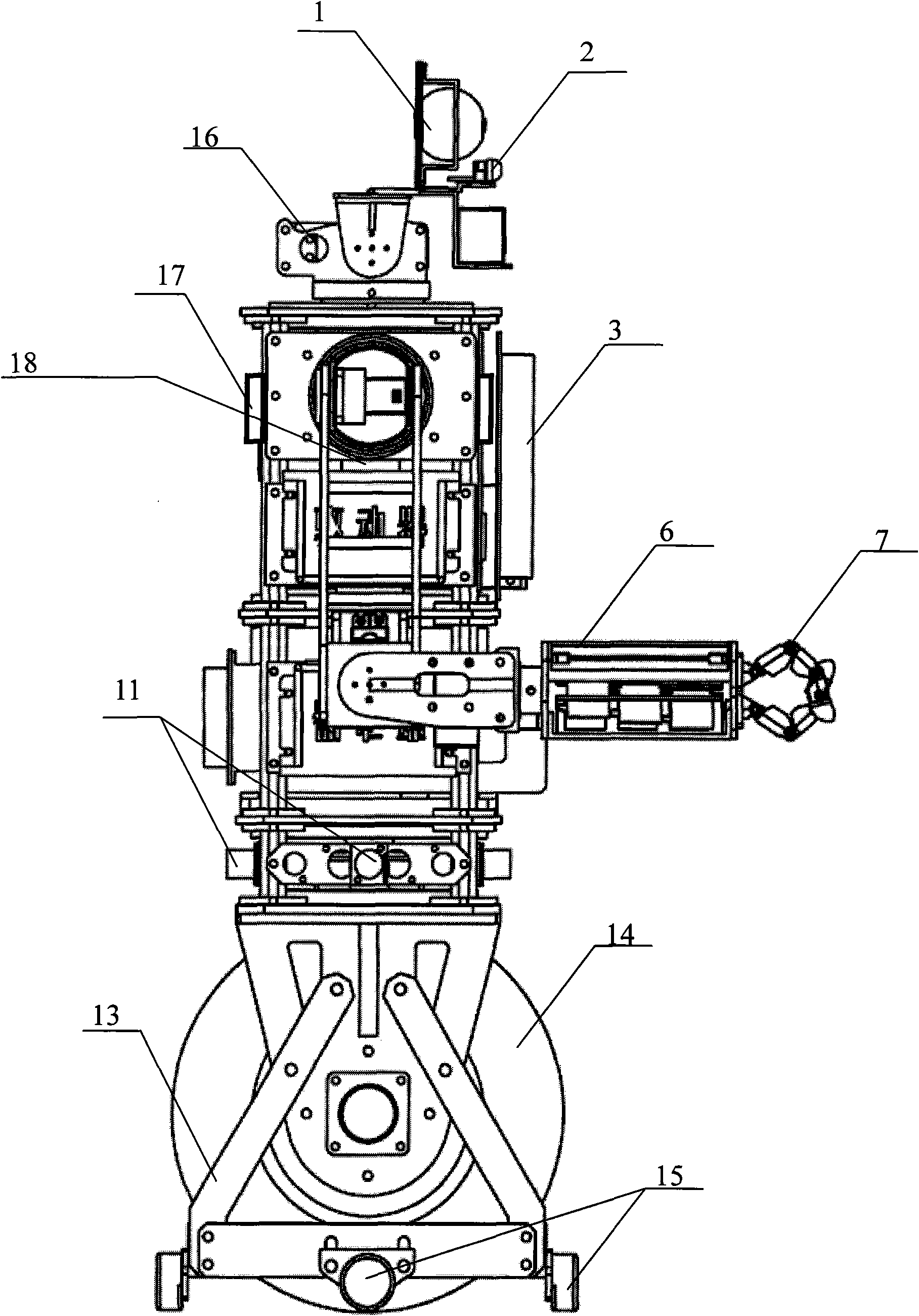

Single wheel robot system and its control method

ActiveUS20110010013A1Non-linearUncertainty of the system increaseProgramme controlComputer controlRobotic systemsControl system

This invention relates to a single wheel robot system and its control method. The robot is an intelligent self-control and thus self-balancing unicycle riding robot. The control method is the balance control method of the static imbalance unicycle robot. The single wheel robot includes mechanical body and control system; the body contains a single wheel in the substructure which can rotate around for balance; the control system comprises state sensors, motion controller, servo-driven controllers, and a power system. Among them, the motion controller receive signals from the state sensors, in accordance with control procedures for processing of the received signal, thereby issuing control instructions. The servo drive controller receives the control instructions and controls the motors of the robot to adjust posture to be balanced.

Owner:BEIJING UNIV OF TECH

Shuttling car walking along crossed track

InactiveCN103101737ASimple structureSmall footprintStorage devicesMechanical conveyorsTrackwayEngineering

The invention relates to logistics storage equipment, in particular to a shuttling car walking along a crossed track. The shuttling car comprises a car body, a longitudinal walking mechanism, lifting mechanisms, horizontal walking mechanisms, a carrier device and an electric system. The car body is a fundamental component which installs and fixes all components, and the longitudinal walking mechanism is arranged on the car body. The lifting mechanisms are respectively arranged on the car body and a longitudinal wheel axle of the longitudinal walking mechanism, the horizontal walking mechanisms are arranged on lifting supports of the lifting mechanisms, the carrier device is arranged on the car body, and the electric system is connected with servo motors of all mechanisms and arranged in spaces of interiors of the lifting supports. The shuttling car has the function of walking along the crossed track, simplifies a system structure applied in a storage logistics system, can save occupied area, and improves operation efficiency. Servo driving technology and digital control are adopted, and positioning is accurate. A charging battery is adopted as a power source to achieve wireless traveling, conveniently and flexibly move, and have wide application prospect.

Owner:QILU UNIV OF TECH

Antenna beam tracking device and method of moving communication satellite communication system

InactiveCN101916915ASimple designEasy wiringAntenna adaptation in movable bodiesRadio transmissionHardware structureGeolocation

The invention discloses antenna beam tracking device and method of a moving communication satellite communication system. The antenna beam tracking device comprises a geographical position detection device, a carrier gesture detection unit, a signal intensity detection unit, a signal conditioning circuit and a master control computer, wherein the master control computer controls a servo driver; and the servo driver controls an azimuth and pitching motor. The antenna beam tracking method comprises the following steps of: 1, initially capturing a target satellite; 2, tracking: setting initial parameters, storing and updating the initial parameters in real time, generating simultaneous disturbance random vectors, driving disturbance, measuring the intensity of received signals, estimating gradient, determining tracking error signals, regulating antenna beam pointing directions, and judging the received signals; and 3, recapturing. The invention has the advantages of simple design, low cost, system implementation without changing the hardware structure of an original tracking system, easy operation, high tracking accuracy and fast tracking speed and overcomes the defects of inconvenient operation, complex tracking step, lower tracking accuracy and tracking speed, and the like of the traditional method.

Owner:PLA SECOND ARTILLERY ENGINEERING UNIVERSITY

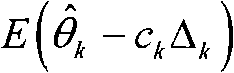

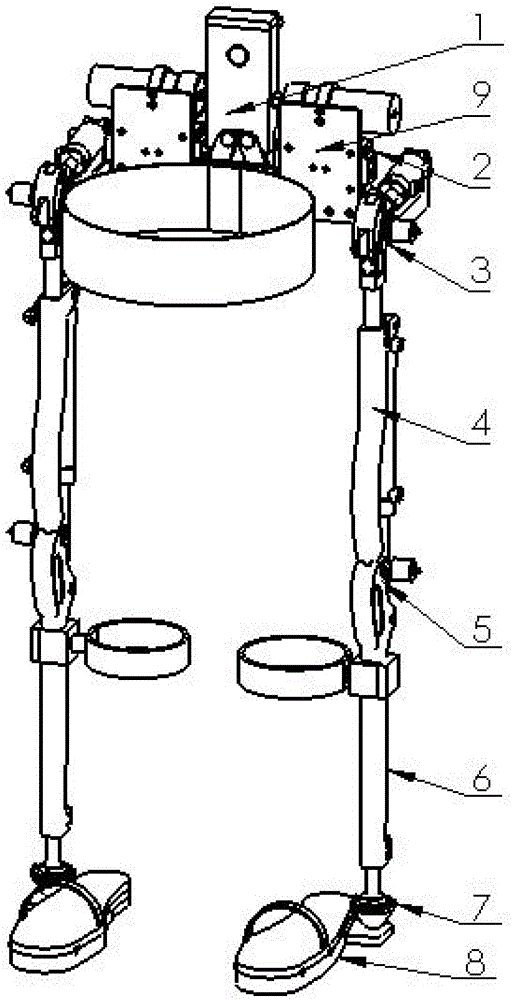

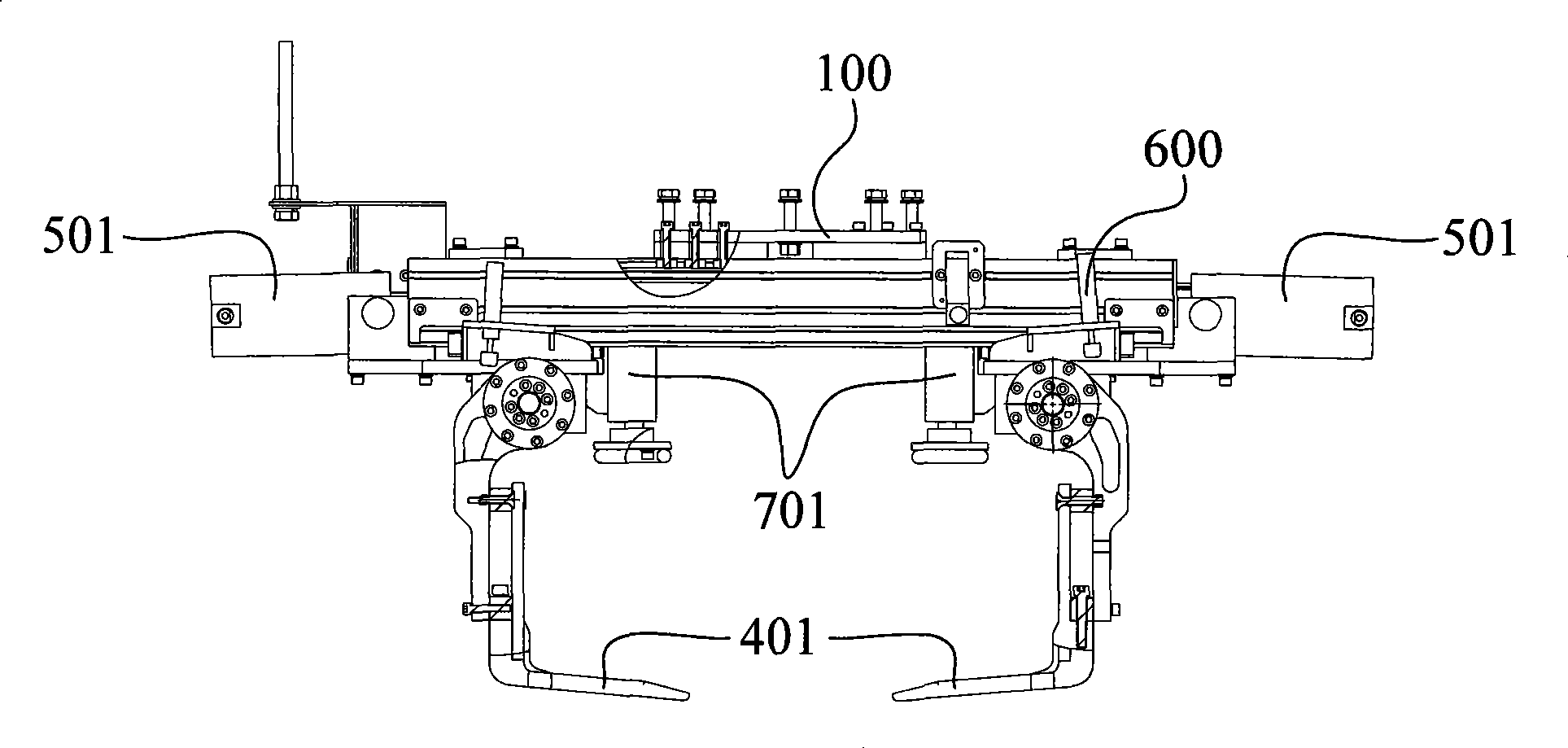

Wearable power-assisted exoskeleton lower limb mechanism

The invention discloses a wearable power-assisted exoskeleton lower limb mechanism which comprises a waist part, a left leg, a right leg, a hydraulic servo driving system, a real-time controller and a power supply module, wherein the right leg and the left leg have same structures and are respectively hinged to the waist part and symmetrically arranged on two sides of the waist part; the hydraulic servo driving system is connected with the left leg and the right leg respectively and controls the left leg and the right leg; the hydraulic servo driving system is connected with the real-time controller; the power supply module supplies power to the hydraulic servo driving system. Motions of hip joints, knee joints and ankle joints are cooperated to complete walking, and 7 degrees of freedom are totally realized; the hip joints and the ankle joints respectively have 3 degrees of freedom, which are respectively bending / stretching, external expanding / internal contraction and medial rotation / lateral rotation; the knee joints have one degree of freedom of bending / stretching. The wearable power-assisted exoskeleton lower limb mechanism is simple, convenient to wear and adjustable in length, and is suitable for being worn by people of different heights and weights and making all the joints of the exoskeleton move freely.

Owner:ZHEJIANG UNIV +1

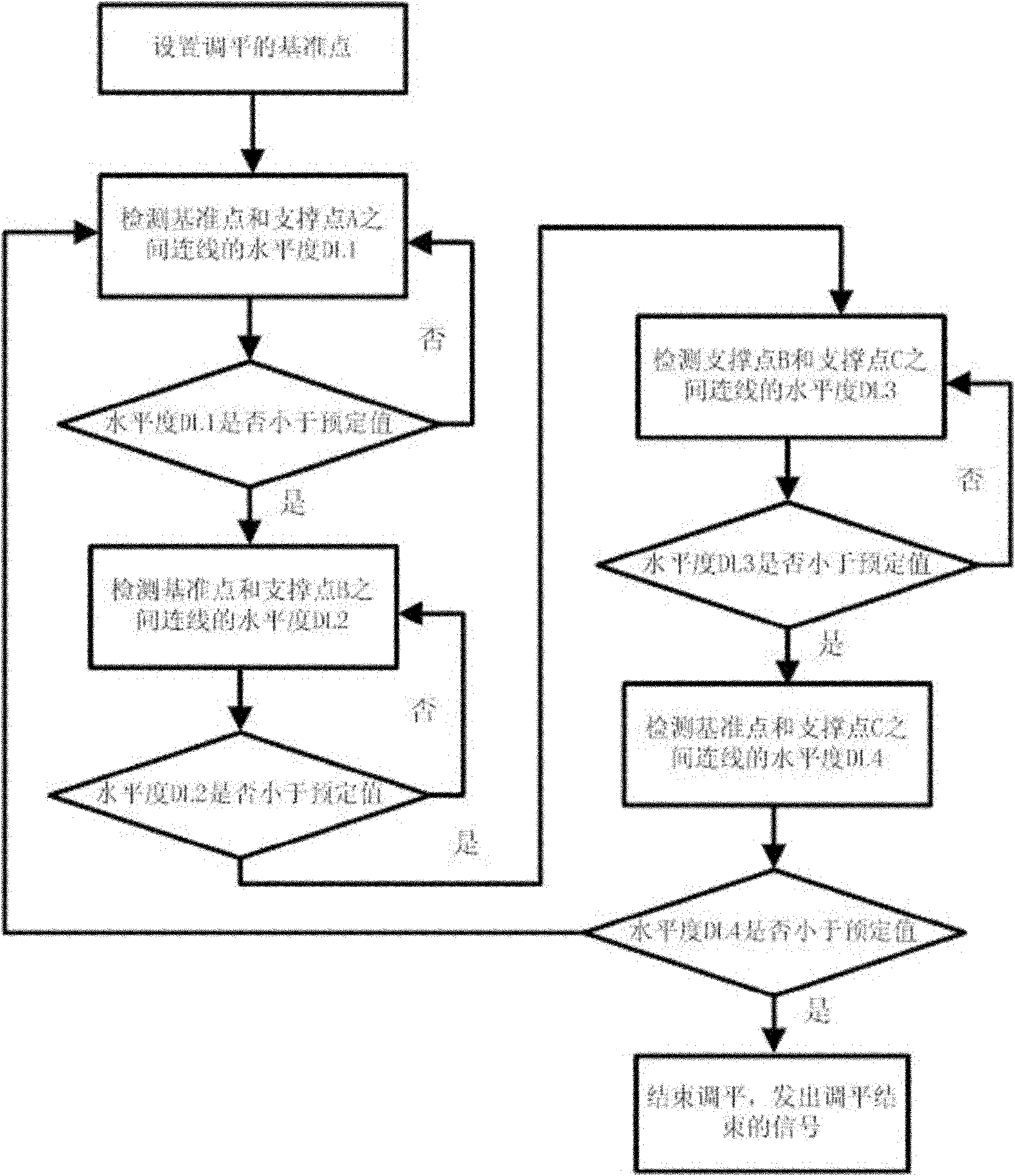

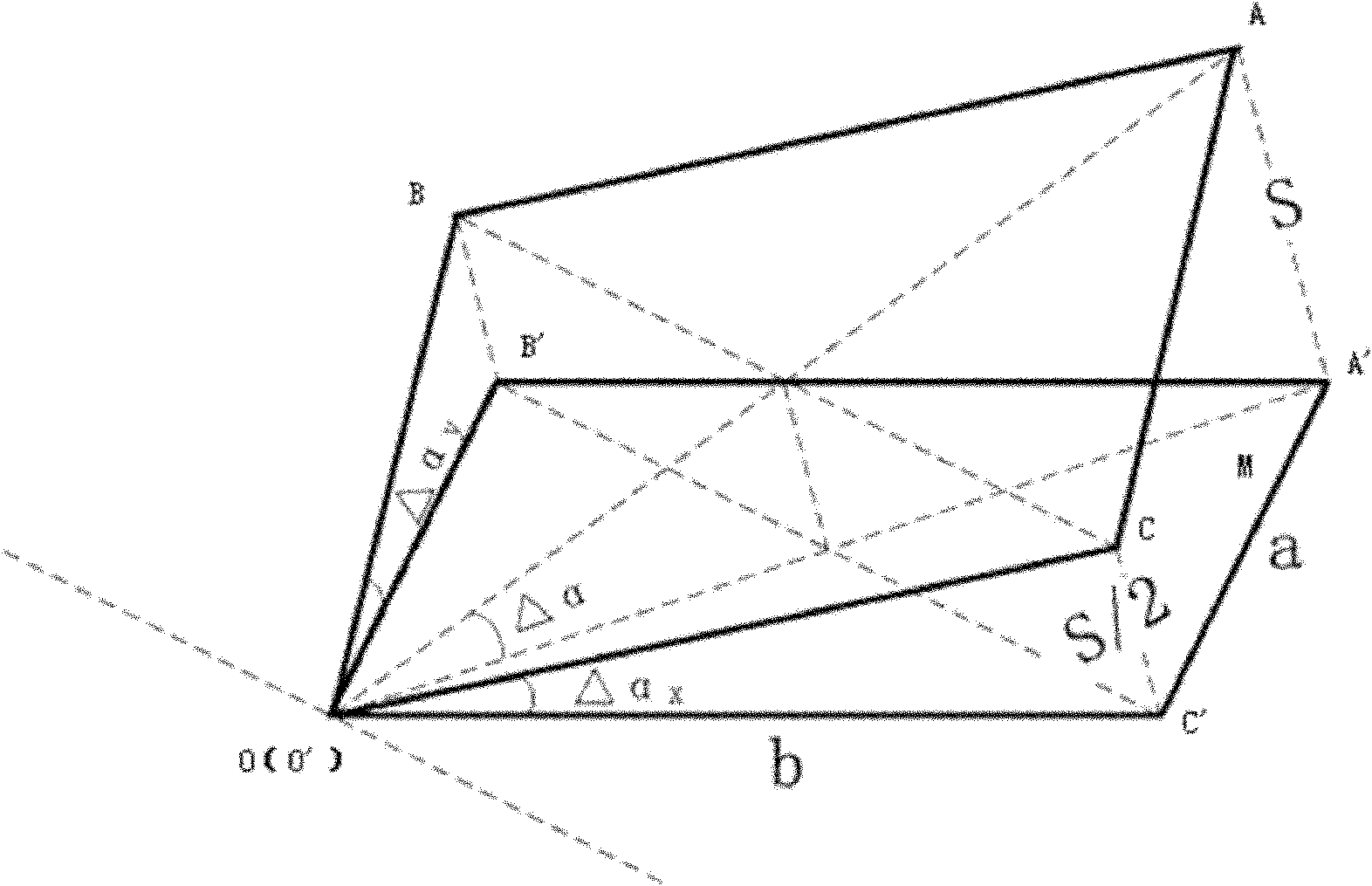

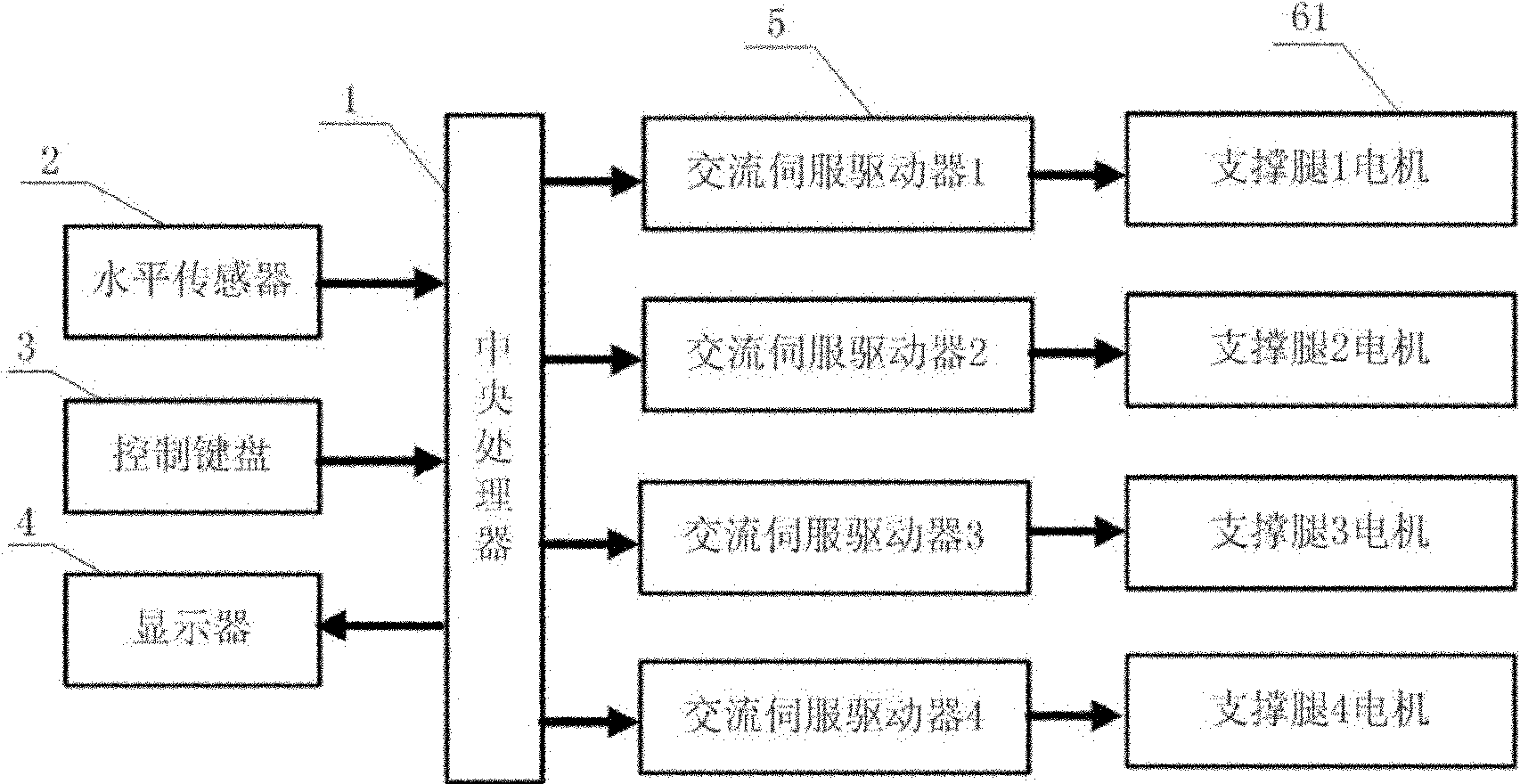

Leveling method based on four-point support and electromechanical automatic leveling system

InactiveCN102053624AImprove reliabilityStructural force change is reasonableAttitude controlDisplay deviceSimulation

The invention discloses a leveling method based on four-point support and an electromechanical automatic leveling system. In the leveling method, a symmetrical diagonal lifting and leveling strategy is adopted, and the leveling purpose is achieved mainly by regulating the levelness of the ligatures among supporting points on diagonal lines; and the leveling system comprises a central processor, a level sensor, a control keyboard, a display, four alternating-current servo drivers and four supporting legs; and each supporting leg comprises a motor, a speed reducer, a ball screw and a base. The invention is particularly suitable for large-medium-sized radar truck vehicle-mounted platforms, communication vehicles and various engineering vehicles for engineering machinery, the method has the advantages of high leveling efficiency, high leveling reliability and the like, and the leveling system has the advantages of high leveling precision, high intelligent degree, high speed, strong carrying capacity, good stability, high transmission efficiency, suitability for severe environments and the like.

Owner:ANHUI BOWEI CHANGAN ELECTRONICS

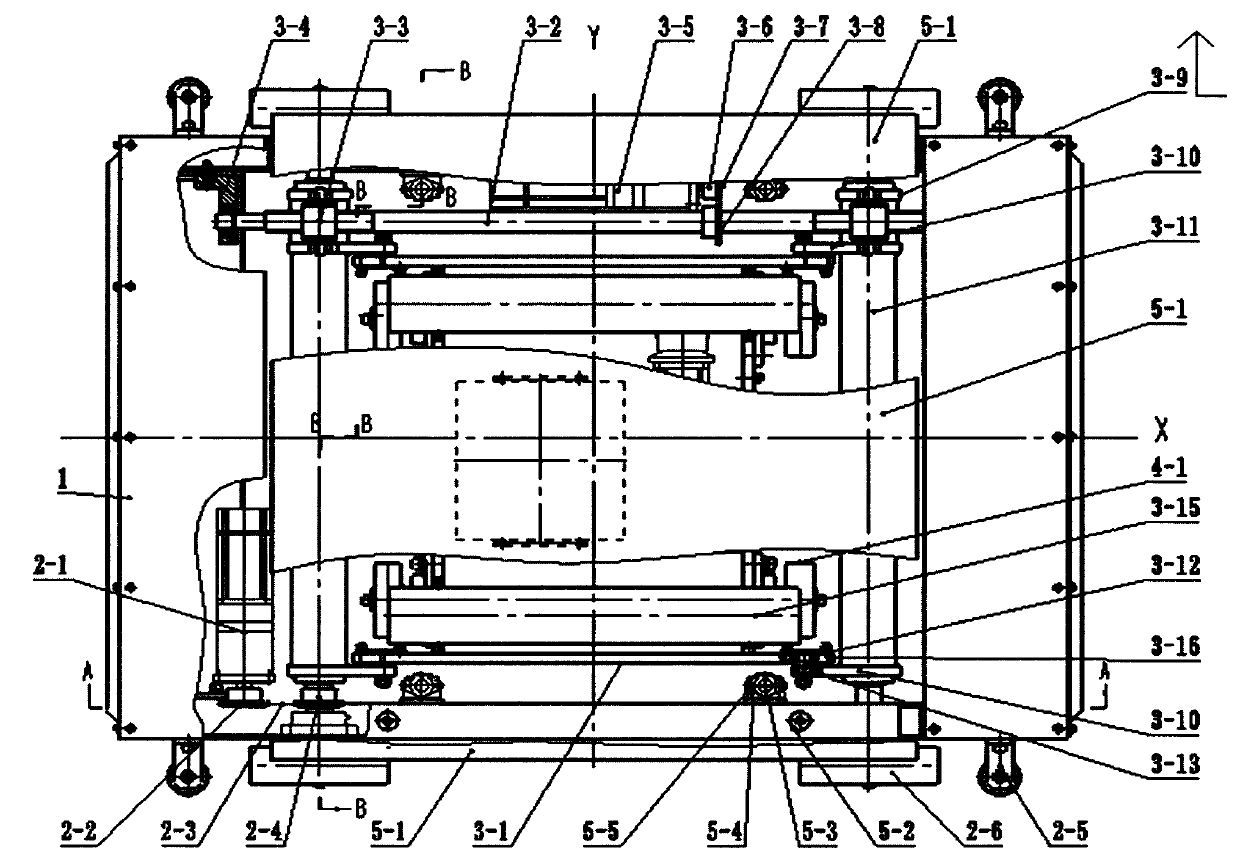

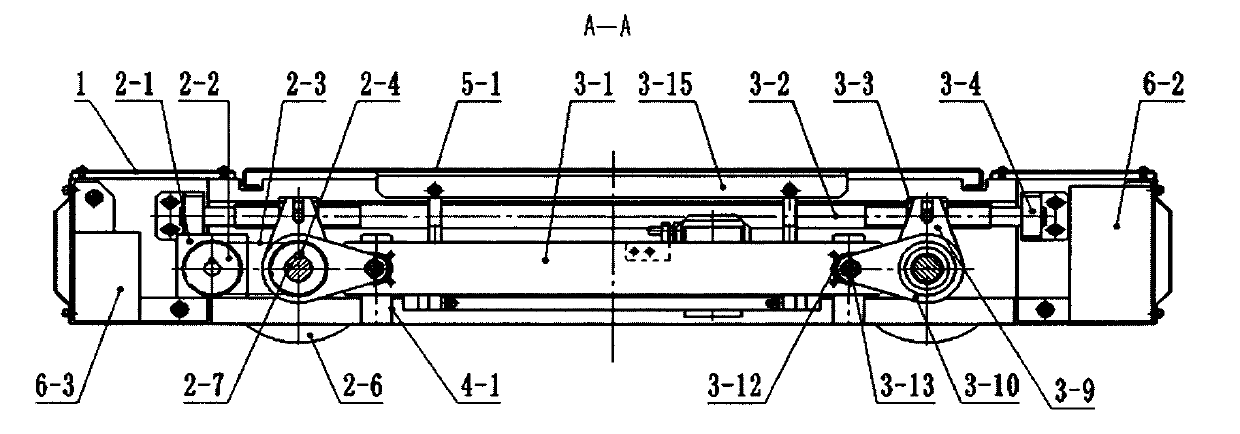

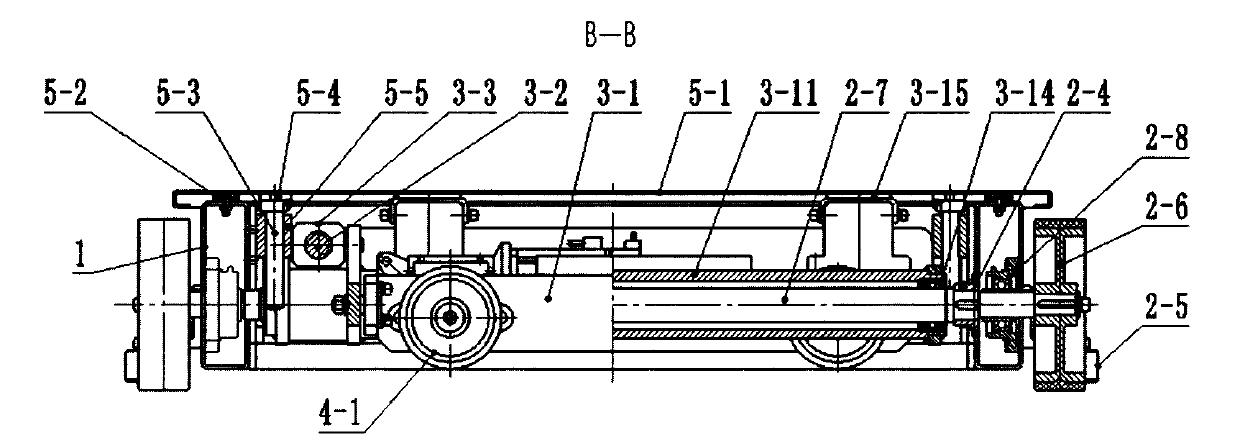

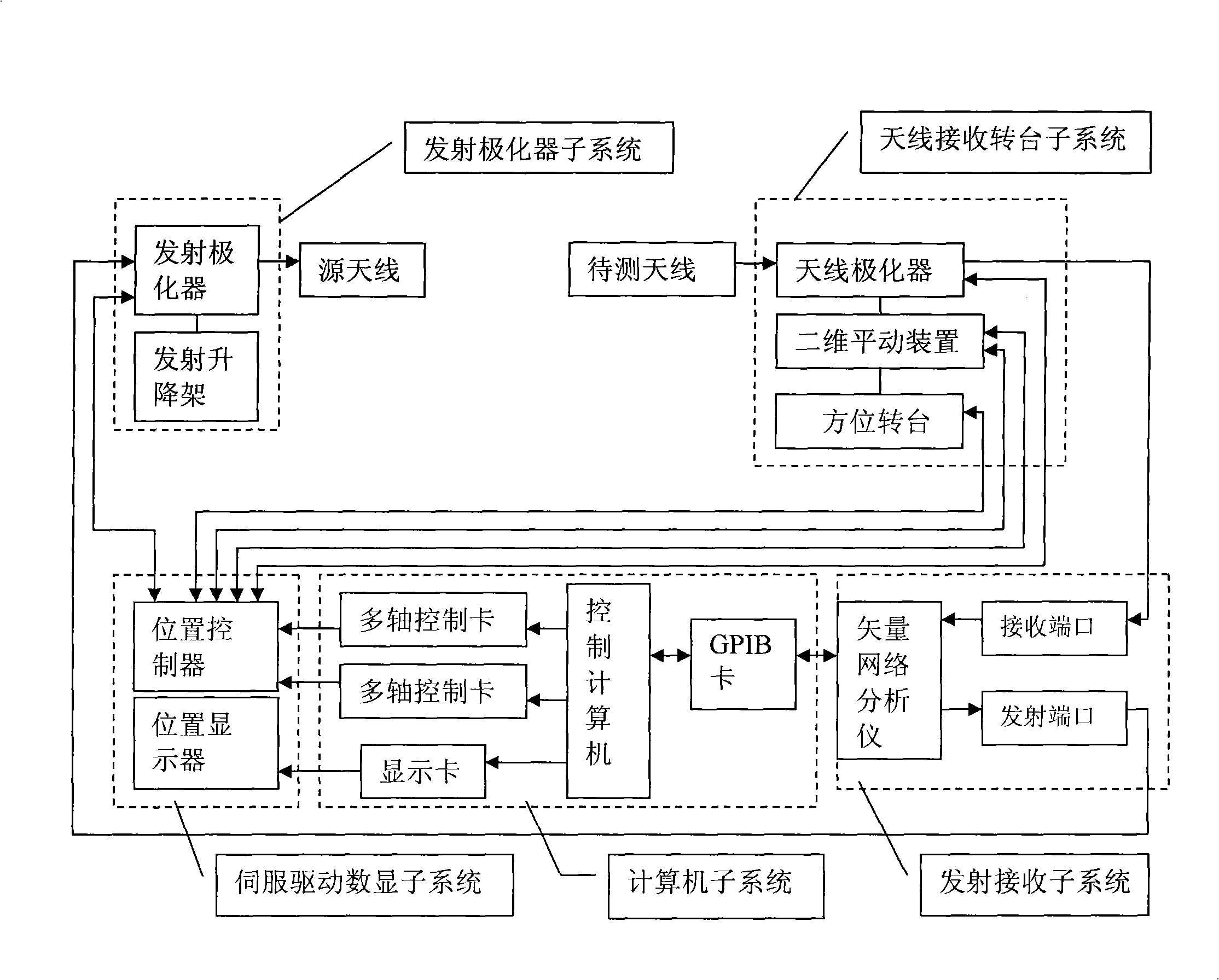

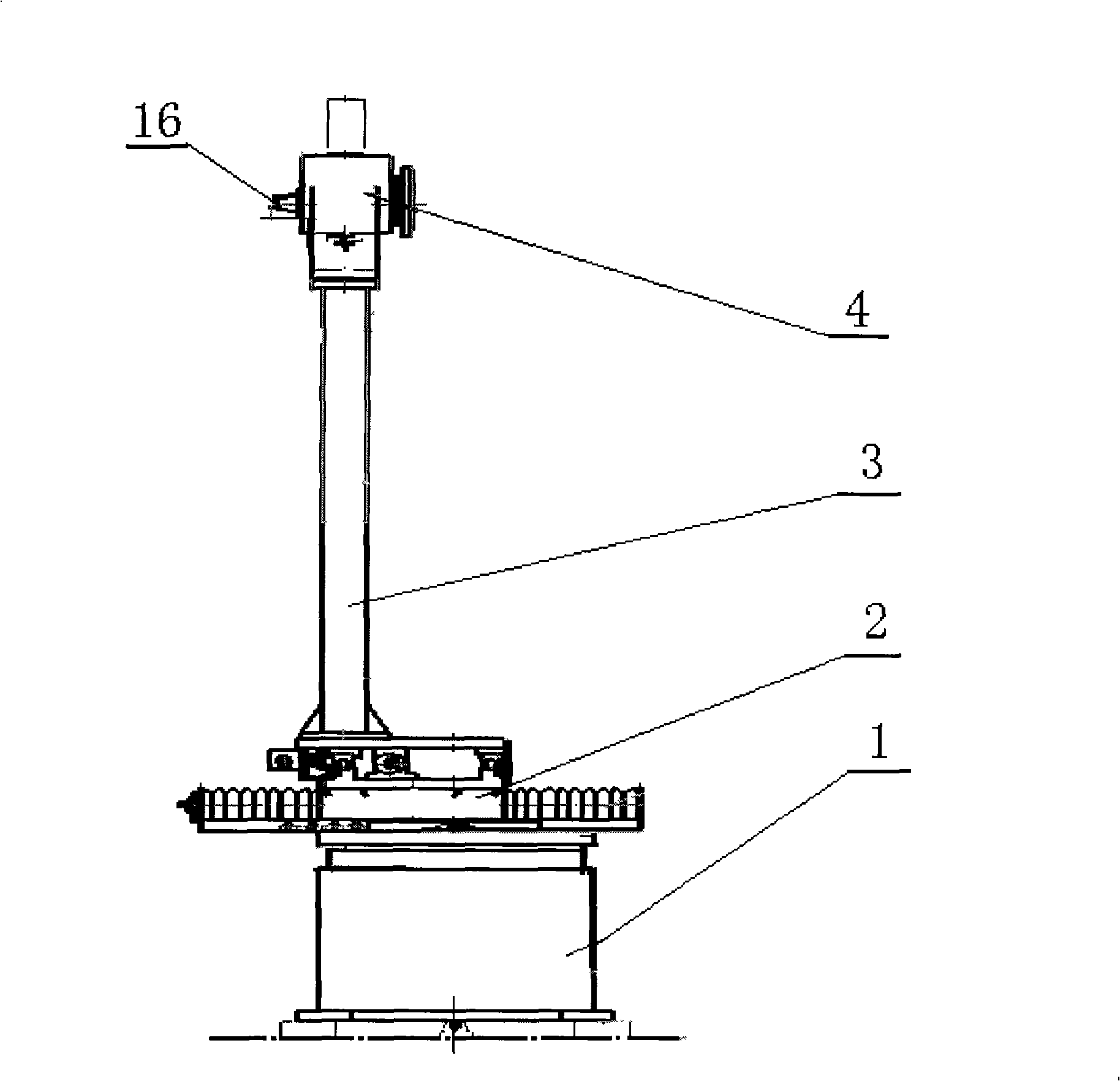

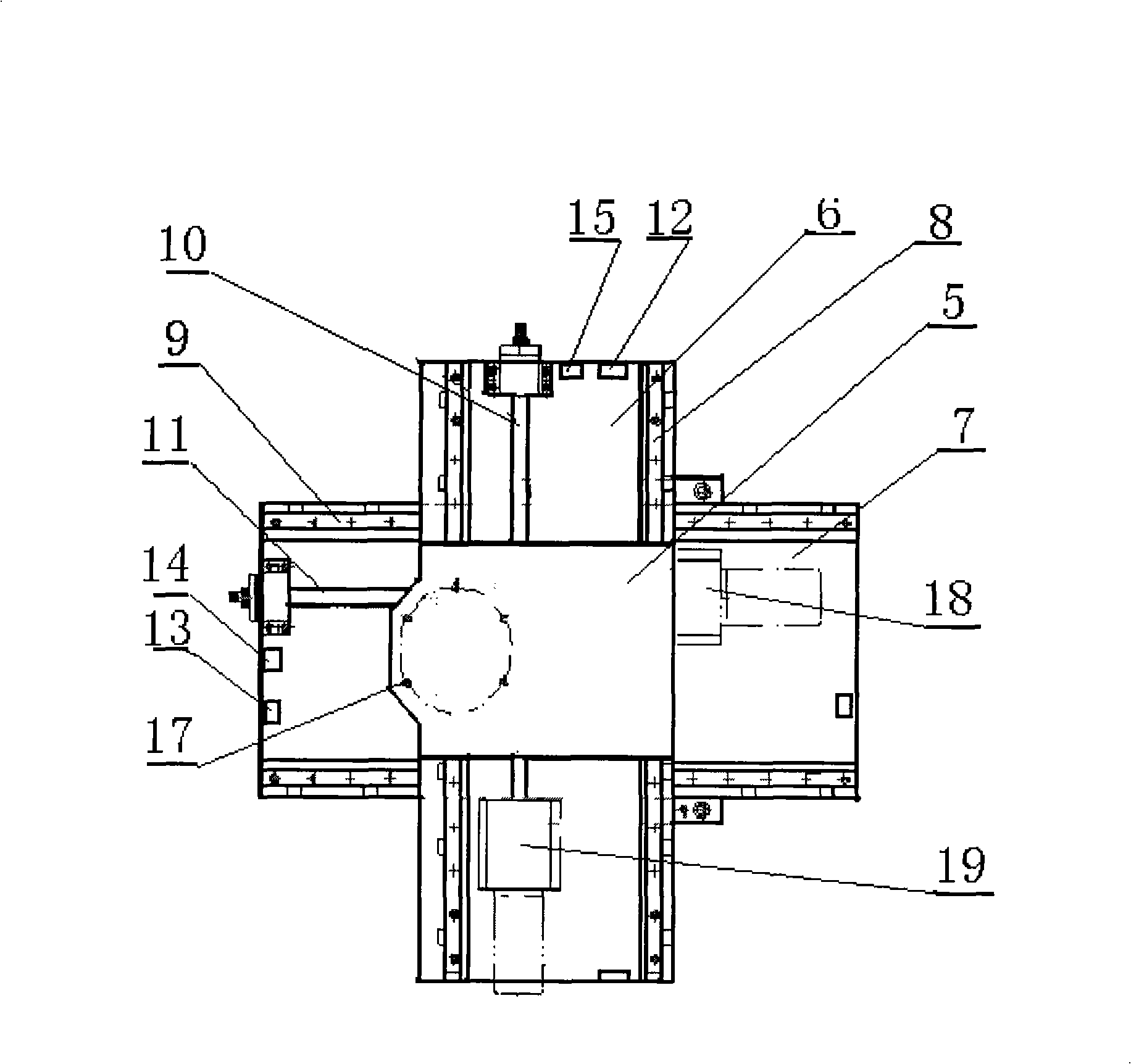

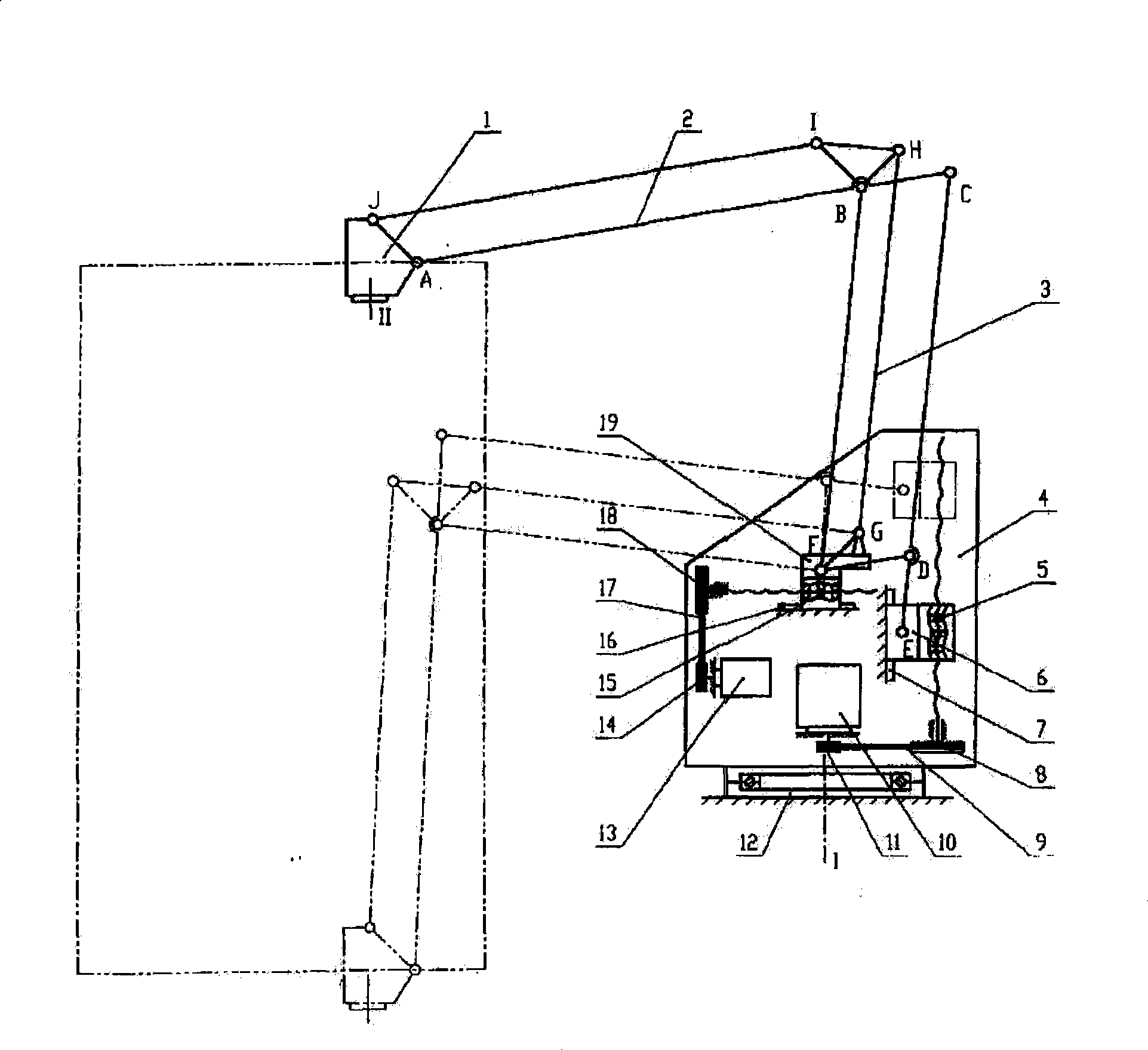

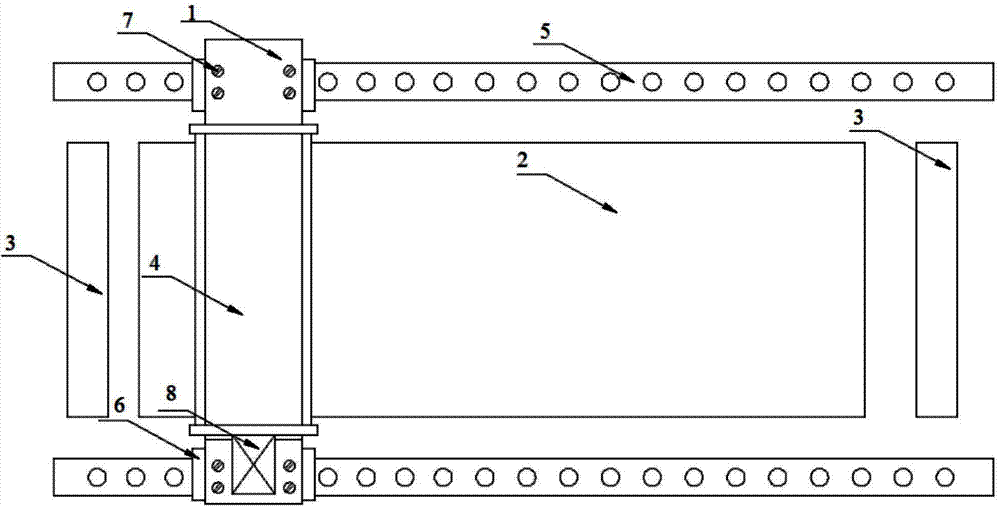

Automatic measuring system of antenna phase center

InactiveCN101320061AEnsure safetyStable positionAntenna radiation diagramsAntenna polarizationPolarizer

The invention discloses an automatic measuring system in the center of an antenna phase, which comprises an antenna receiving rotary table subsystem, an emission polarizer subsystem, an emission and reception subsystem, a servo drive digital display subsystem and a computer subsystem. The antenna receiving rotary table subsystem and the emission polarizer subsystem are both connected with the emission and reception subsystem, the servo drive digital display subsystem and the computer subsystem; wherein, the antenna receiving rotary table subsystem consists of a direction rotary table (1), a two-dimensional translation device (2), a bracket (3) and an antenna polarizer (4). The two-dimensional translation device (2) is positioned between the direction rotary table (1) and the antenna polarizer (4) and used for automatically adjusting the positions of an antenna and the rotating axis of the direction rotary table, thereby making the phase center of the antenna near the axle center of the rotary table and ensuring the stable positions of the rotating axis of the direction rotary table and the rotating axis of the antenna polarizer when the direction rotary table is rotating. The automatic measuring system provided by the invention has the advantage of high measuring automation and can be used to accurately mark the phase centers of antennas.

Owner:XIDIAN UNIV

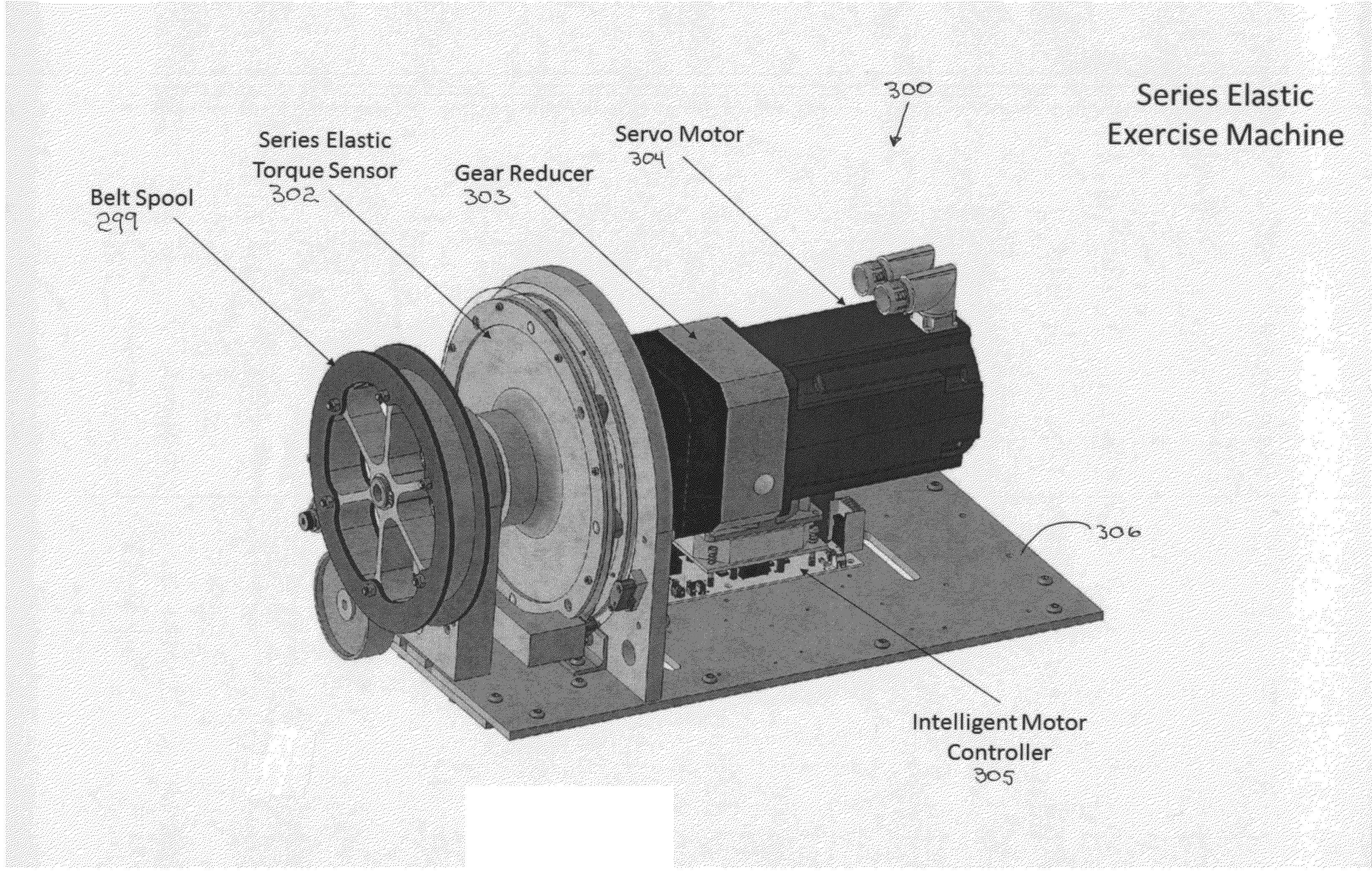

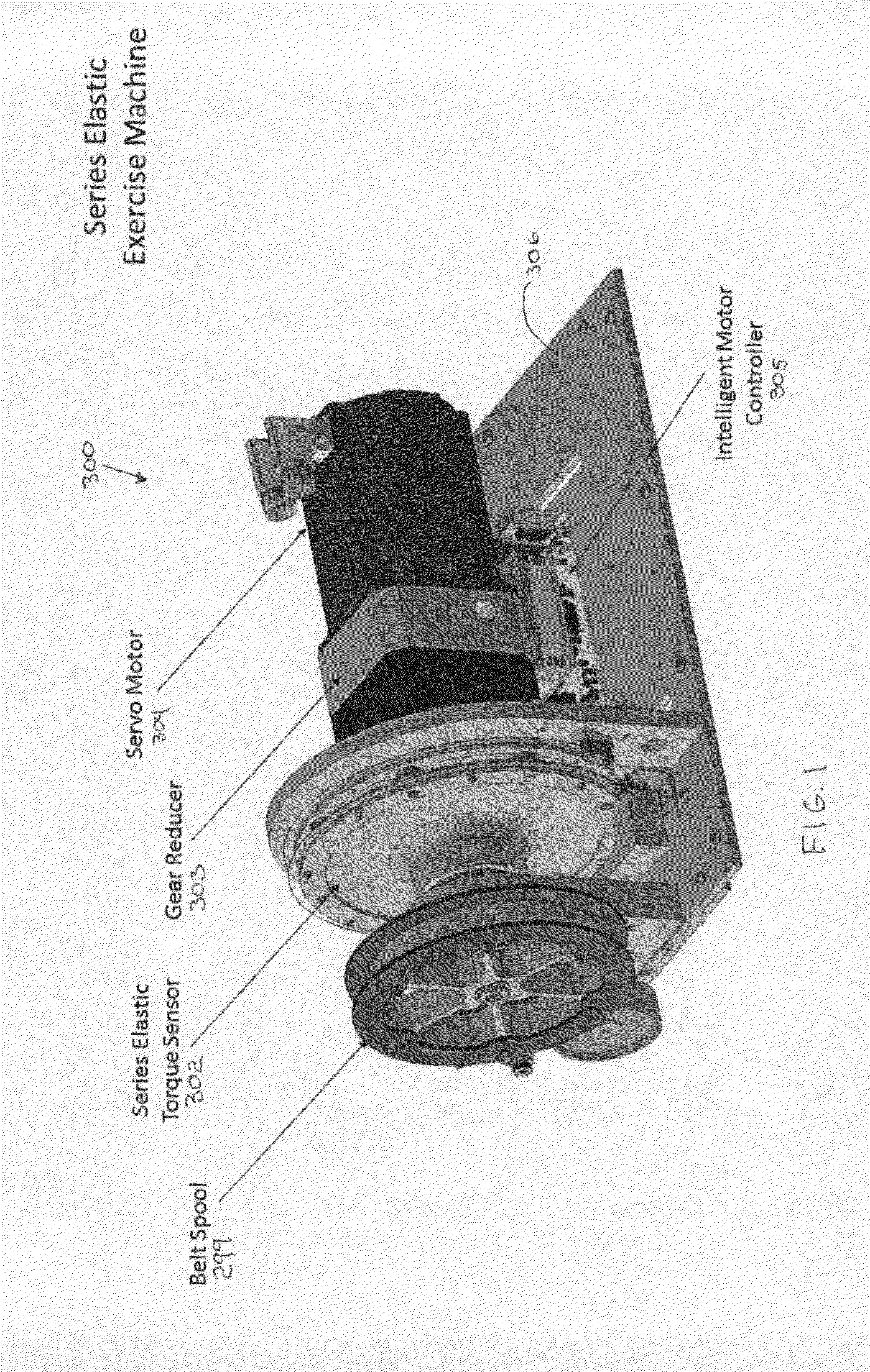

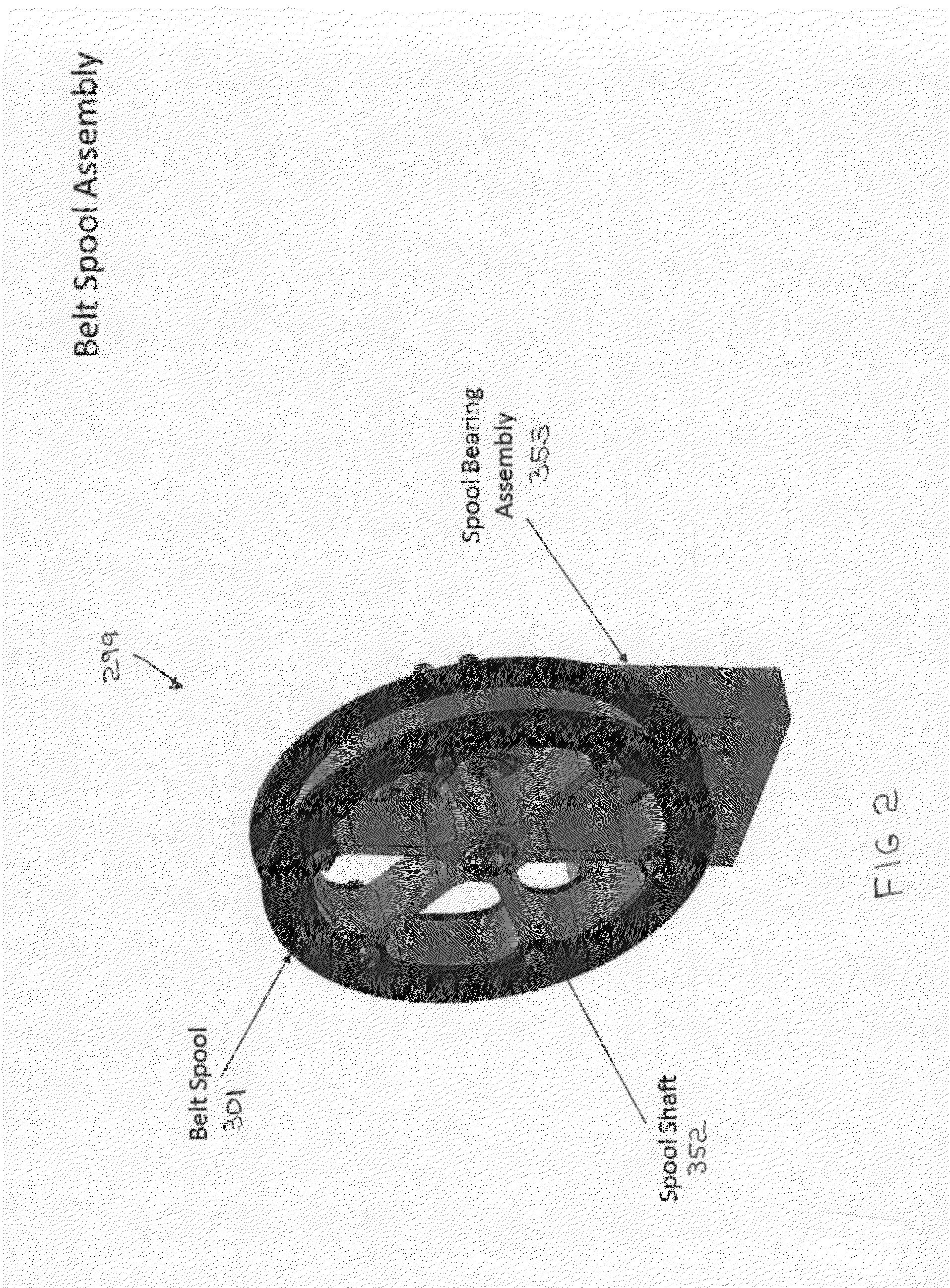

Series Elastic Motorized Exercise Machine

The disclosure teaches a novel exercise apparatus. This apparatus does not generate load momentum. The apparatus is based around a series elastic torque sensor and contains an intelligent servo drive with reduction gear to control a variable speed rotating motor shaft. The combination of the motor, gear reducer, spring, angle measurement sensors (position sensors), and intelligent motor controller is a series elastic actuator which is the basis for the exercise device. The exercise device also contains a load transfer mechanism adopted to provide an interface between an individual and the torque sensor. The apparatus allows for isokinetic, isometric, isotonic, and variable force modes of exercise without hardware configuration.

Owner:RETHINK MOTION INC

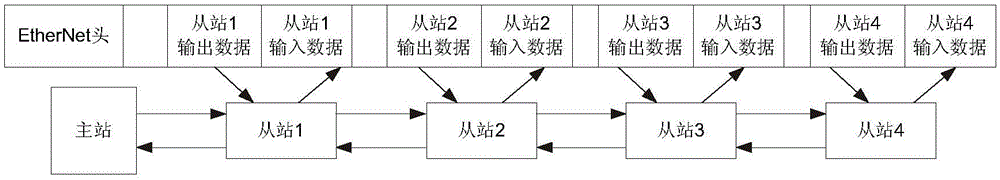

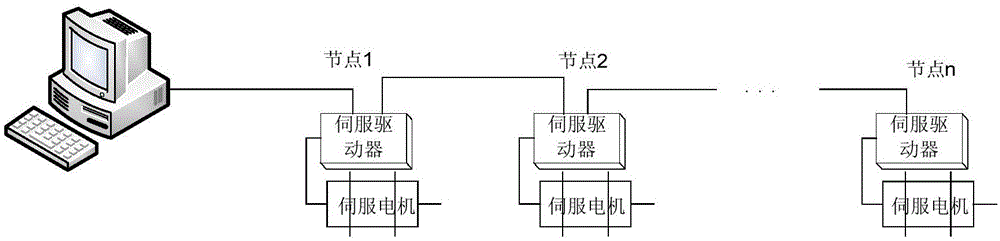

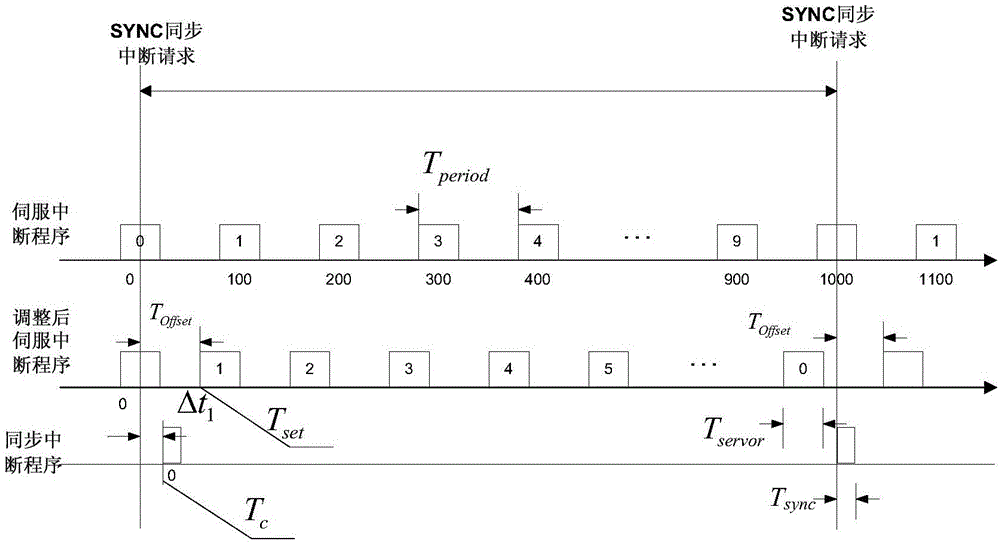

Servo driver synchronized method based on Ether CAT real-time Ethernet

ActiveCN105024777AAvoid confictUpdates will not be interruptedTime-division multiplexTime deviationEther

A servo driver synchronized method based on Ether CAT real-time Ethernet comprises the steps as follows: a slave station link layer control module requests a synchronous interruption to an application layer control module while a distribution clock is triggered; the application layer control module calculates interrupt response time delay delta t1 while entering into the synchronous interruption every time, calculates Tset = TOffset + (Tc-delta t1) while entering into the synchronous interruption for the first time, wherein Tset represents next time of initiating servo interruption after the application layer control module receives a synchronous interruption request for the first time, and TOffset represents time deviation between the next time of initiating servo interruption and time of receiving the synchronous interruption request after the application layer control module receives the synchronous interruption request, and the application layer control module adjusts timing cycle of a servo program which enters into the synchronous interruption for the first time and recovering the timing cycle of other servo programs to normal in a first communication period. The servo driver synchronized method of the invention avoids the conflicts between data updating and a servo application program, and synchronously updates and executes servo control data.

Owner:SHANGHAI STEP ELECTRIC +1

One-wheel robot system and control method thereof

The invention relates to a single-wheel robot system and a control method thereof, belonging to the field of intelligent robot, in particular to a static unbalanced robot which can autonomically control movement balance further to autonomically ride a monocycle and a movement balance control method thereof. The single-wheel robot comprises a robot body and a balance detection and control system and is characterized in that the lower part of the robot body is provided with a single wheel which can rotate front and back, and the middle of the robot is provided with an inertial flywheel which can rotate left and right and is horizontally placed; the balance detection and control system comprises a movement controller, a posture detector and a servo drive controller, wherein the posture detector and the servo drive controller are connected with the movement controller; and the movement controller 10 receives a signal of a posture sensor and processes the received signal according to a control procedure so as to send a control order to control a motor through the servo drive controller to regulate the posture balance of the single-wheel robot. The invention provides a control platform which not only belongs to robotics but also belongs to the field of control science and intelligent control, thereby meeting the needs of multi-subject scientific research and teaching.

Owner:BEIJING UNIV OF TECH

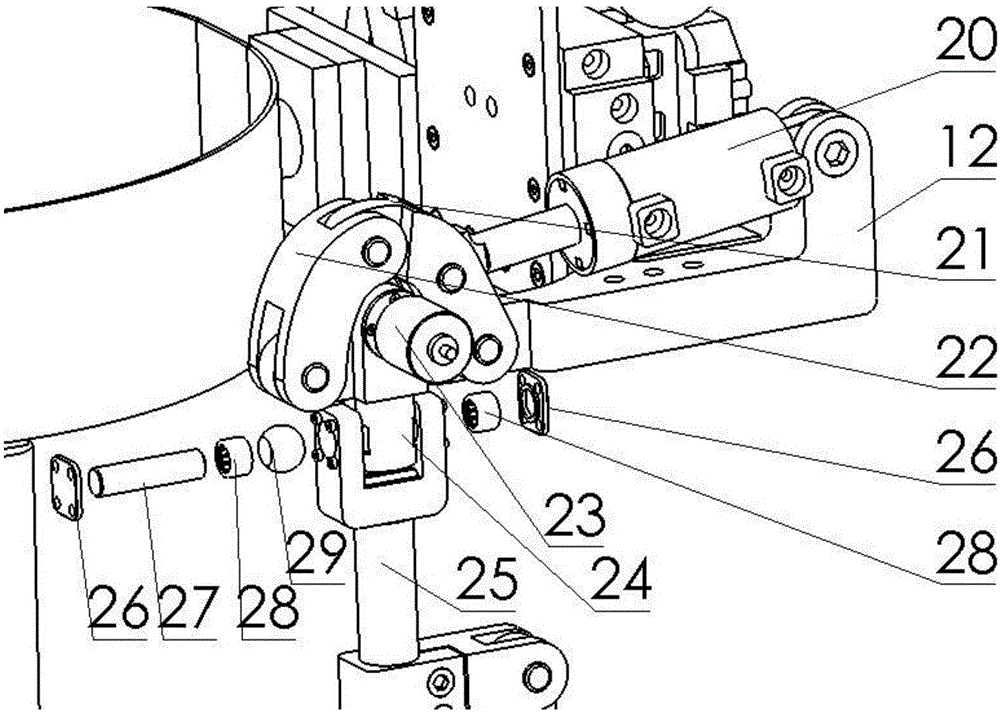

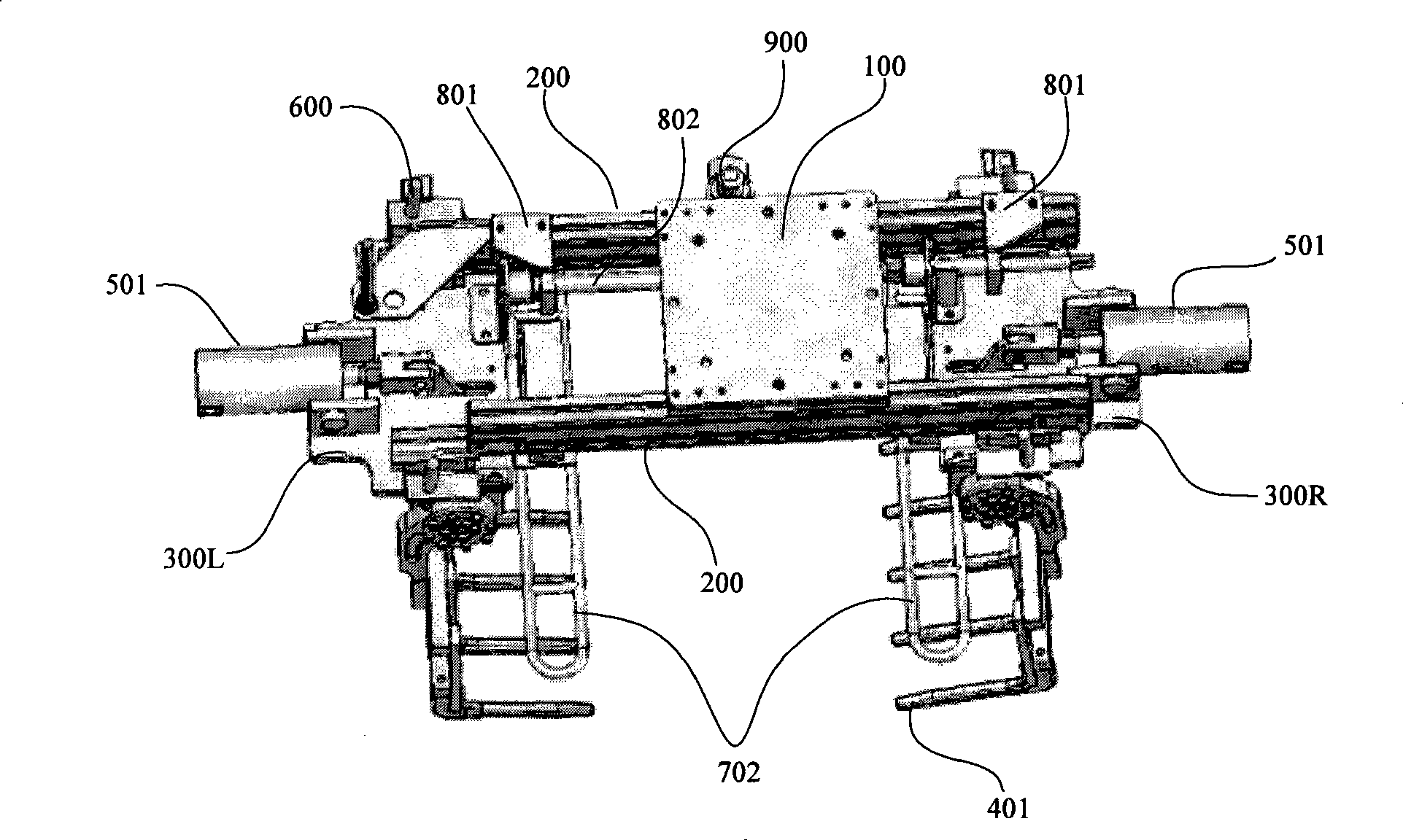

Stacking robot

The invention relates to a palletizing robot which is used for palletizing bag type packages. The palletizing robot comprises a wrist, an arm mechanism, a wrist posture adjusting mechanism, a machine frame, a servo drive system, a base seat and a bag grasper. The palletizing robot is characterized in that a bag grasper structure is provided, and the bag grasper comprises a top plate, a parallel guide rail, a left supporting plate, a right supporting plate, a finger mechanism and a clamping plate mechanism. A rectangular framework is formed by the parallel guide rail, the left supporting plate and the right supporting plate. The finger mechanism is composed of a left mechanism and a right mechanism which are mutually symmetrical, a plurality of L-shaped fingers, a plurality of connecting rods, a pair of bearing frames and a rotating shaft are arranged on one side. The L-shaped fingers are fixed on the connecting rods in parallel, a pair of bearing frames is fixed on the connecting rods, and the rotating shaft is arranged between the bearing frames. Two air cylinders are respectively fixed on the left and the right supporting plates, and the piston rod end is connected to the rotating shaft. The clamping plate mechanism is composed of a vertical air cylinder and a clamping plate. The palletizing robot can bear heavier weight, and can grasp the bag type packages on flat ground very easily.

Owner:SHANGHAI TRIOWIN INTELLIGENT MACHINERY CO LTD

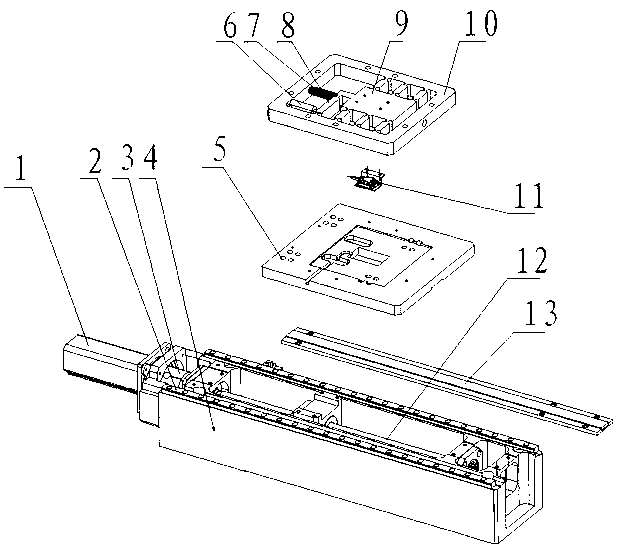

Coaxial macro-micro composite linear motion platform device and accuracy compensation method thereof

InactiveCN103170845AGuaranteed continuityNo lagMeasurement/indication equipmentsOther manufacturing equipments/toolsElectricityLocation detection

The invention discloses an accuracy compensation method of the coaxial macro-micro composite linear motion platform device. The linear motion platform device comprises a macro motion device, a micro motion device, a control device and a location detection device, wherein the macro motion device is composed of a servo driver, a straight line drive module, a straight line guide rail, a base and a macro moving working platform. The micro motion device is composed of a piezoelectric ceramic driver or a voice coil motor and a flexible hinge amplifying mechanism. The flexible hinge amplifying mechanism is composed of a flexible hinge, a micro motion working platform and a frame. The piezoelectric ceramic driver or the voice coil motor drives the flexible hinge amplifying mechanism to drive the micro motion working platform to generate displacement. The location detection device detects displacement information of a macro-micro motion working platform in real time and sends the displacement information to the control device. The control device drives the micro motion working platform to compensate motion of the macro motion device in real time according to detection information of a macro-micro motion displacement sensor, and thus high static accuracy and high dynamic accuracy of the coaxial macro-micro composite linear motion platform device are achieved.

Owner:SANYING MOTIONCONTORL TIANJIN INSTR CO LTD

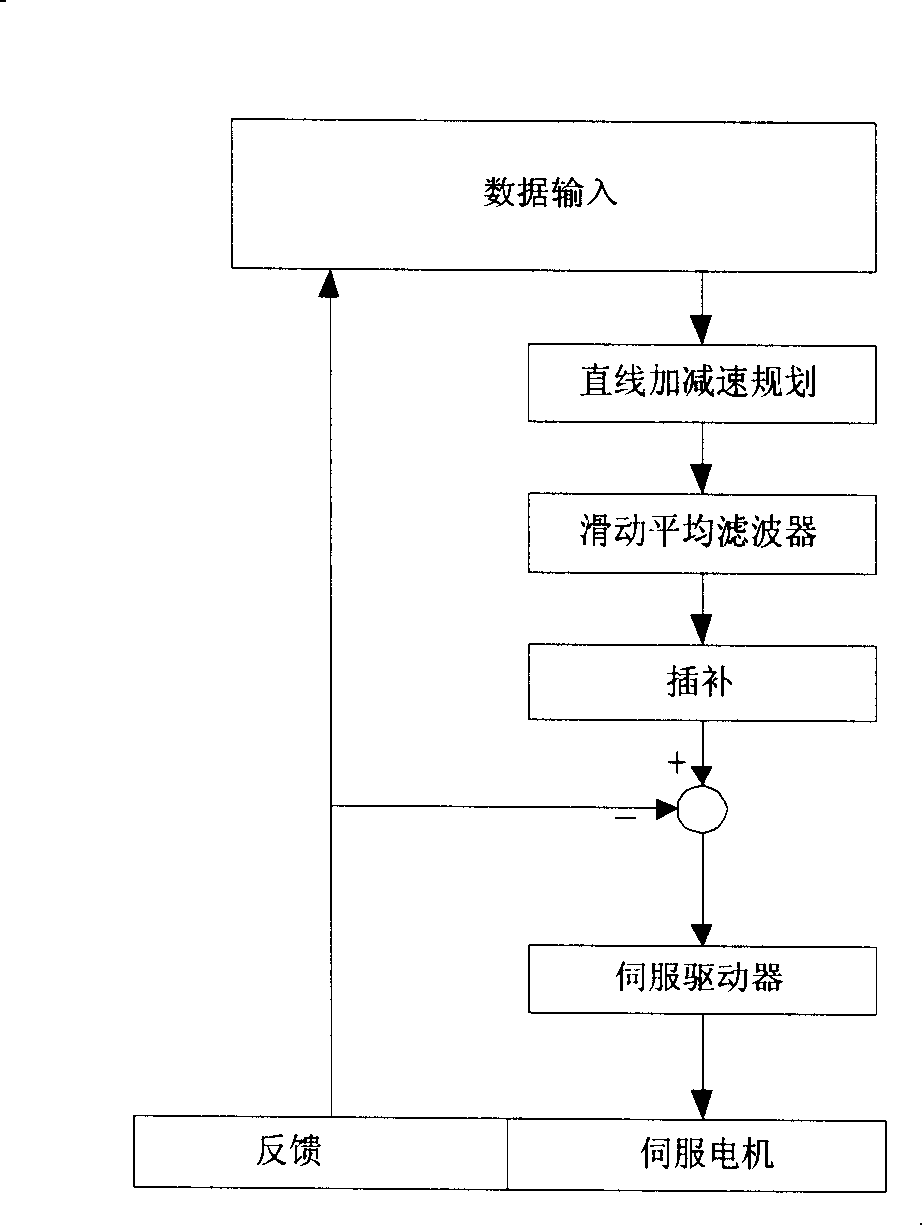

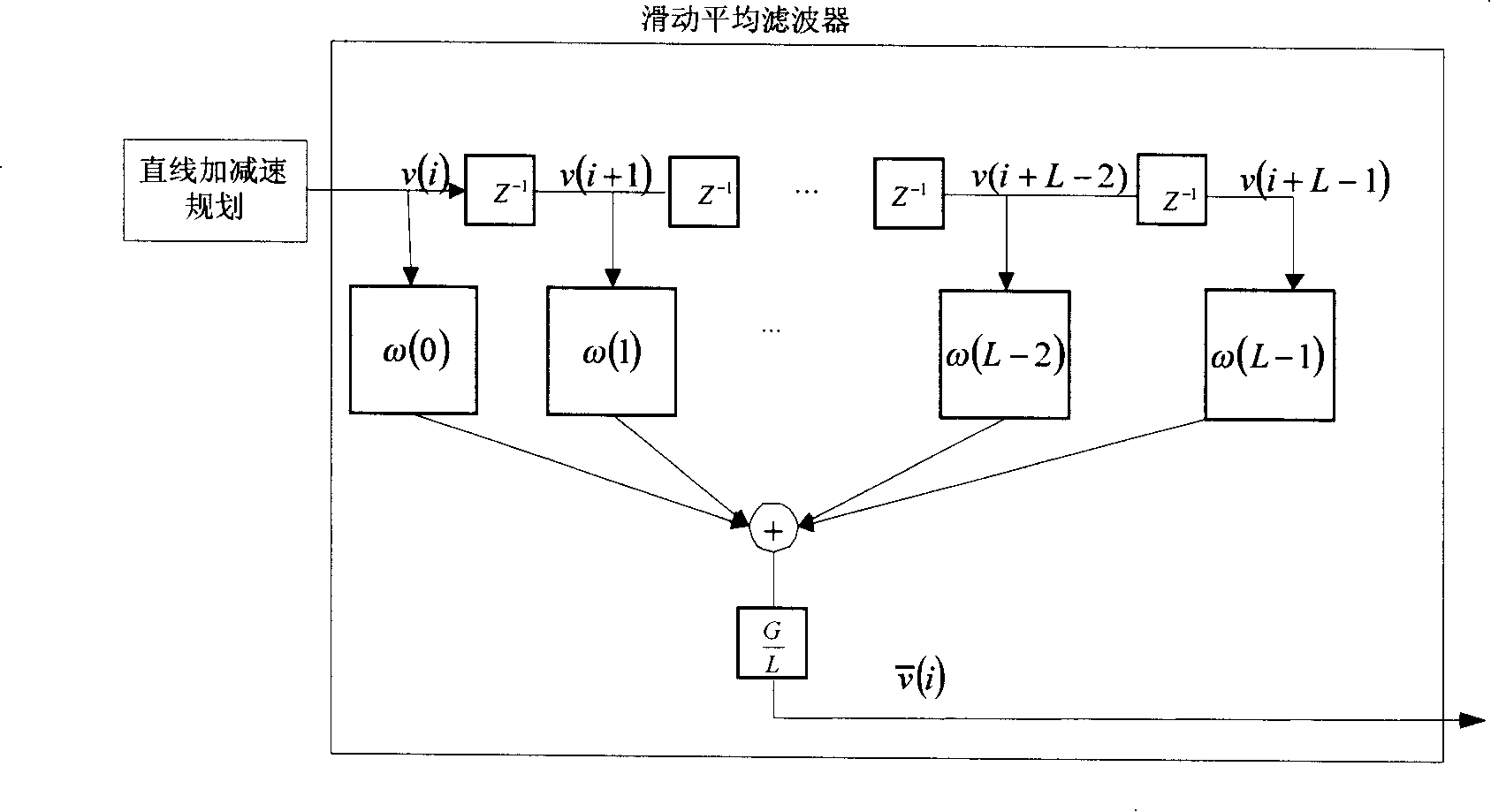

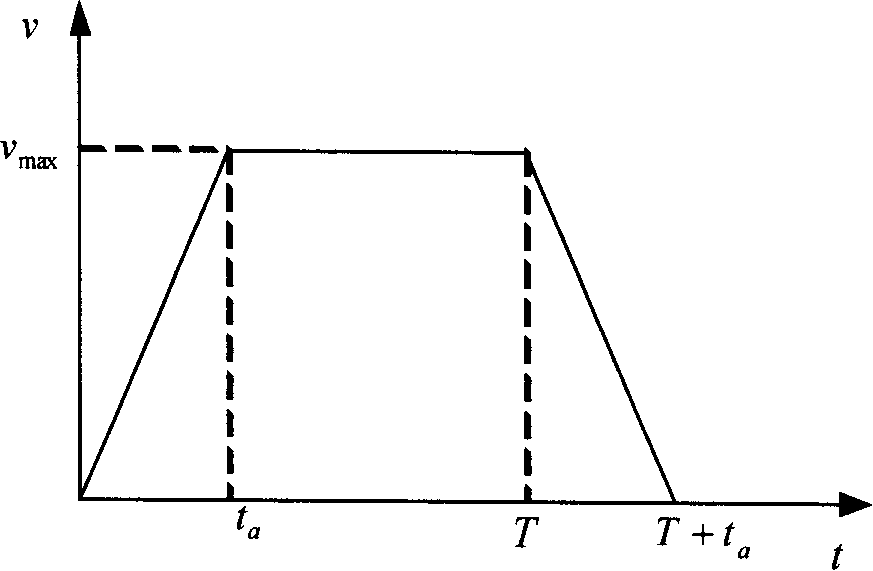

Filter technique based numerical control system acceleration and deceleration control method

ActiveCN101211177ASolve Vibration ProblemsReduce vibrationDigital technique networkNumerical controlMoving averageAverage filter

The invention relates to an acceleration or deceleration control method of numerical control system based on filter technique, which comprises the following steps: planning straight acceleration or deceleration by using the inputted workpiece program data; performing moving average filtering and filter compensation on the planned speed of the straight acceleration or deceleration to obtain a new planned speed value and a position value; performing interpolation on the position value; transmitting the interpolated position value to a servo driver in order to control a servomotor; wherein the moving average filtering of the planned speed of the straight acceleration or deceleration is implemented by adding a moving average filter after planning the straight acceleration or deceleration to control sudden changes of an accelerated speed, particularly comprising the following steps: calculating the speed with a method of planning the moving average filtering speed; changing the smooth degree of the straight acceleration or deceleration by selecting filter length (i.e. controlling the magnitude and the shape of the accelerated speed); and calculating a planned position according to the speed after filtering. The invention solves the vibration problem of a numerically-controlled machine tool during movement, and has the advantages of easy implementation, good compatibility and good flexibility.

Owner:SHENYANG GOLDING NC & INTELLIGENCE TECH CO LTD

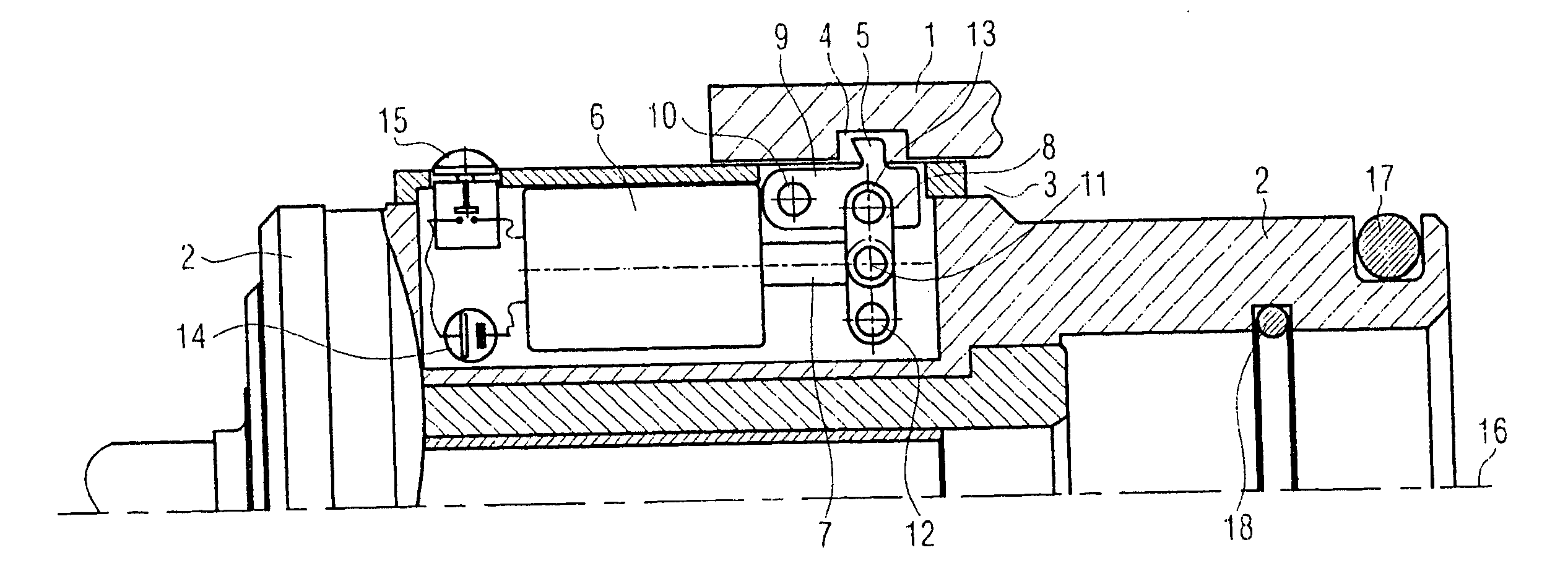

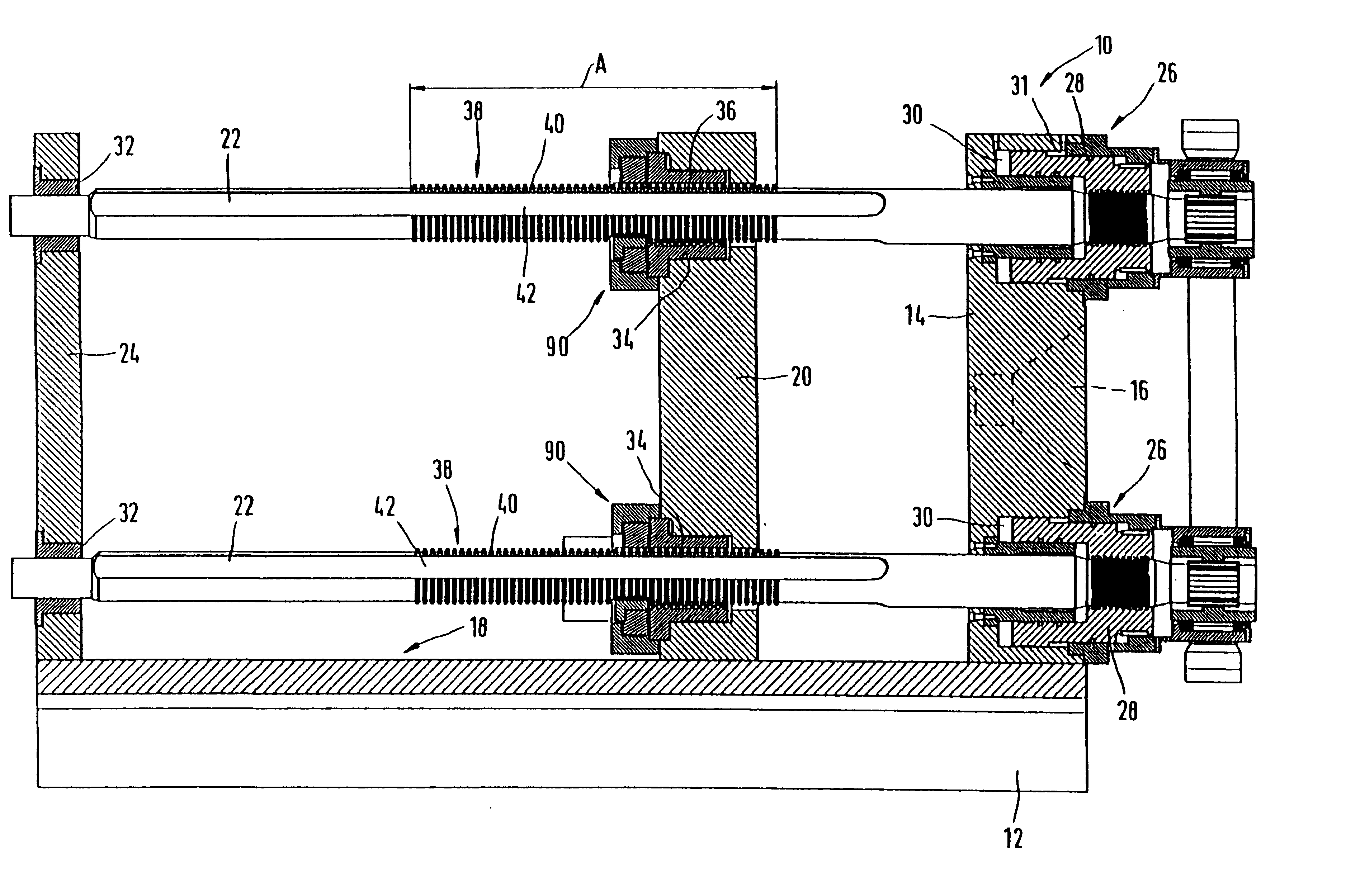

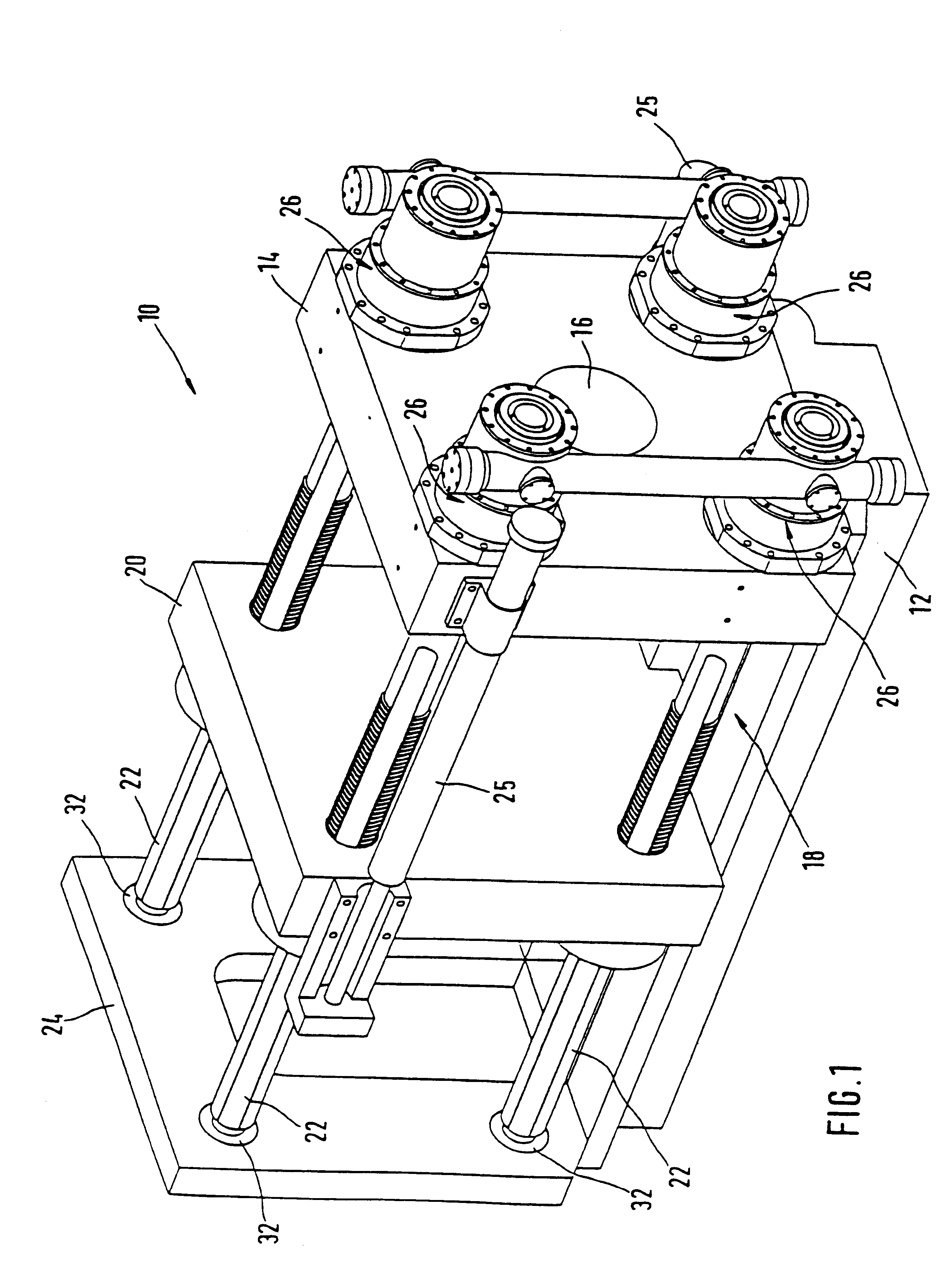

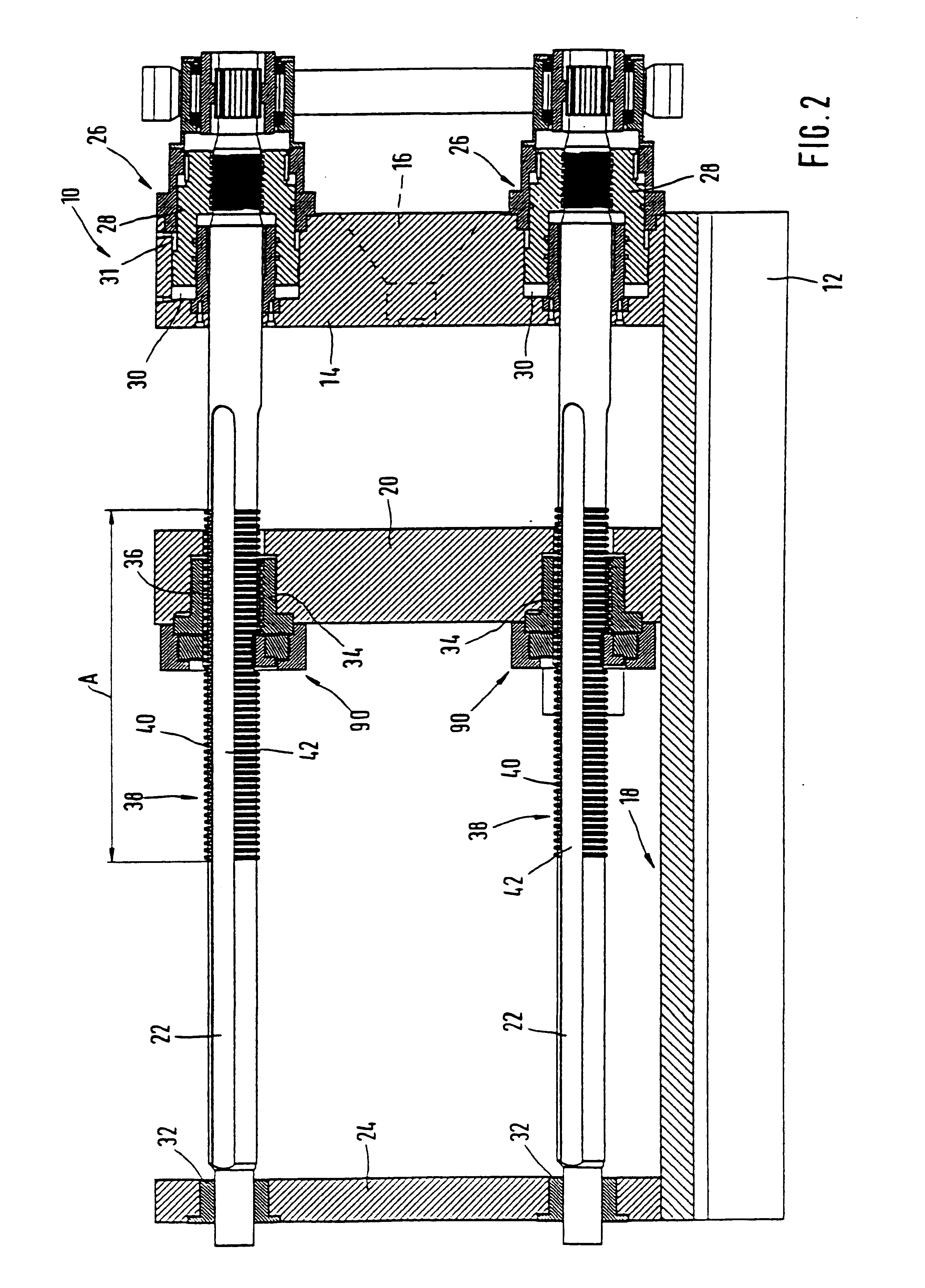

Closing unit for injection molding machine

A closing unit for an injection moulding machine has a movable closing die and a fixed matching die designed as clamping dies for an injection mould, as well as several hydraulic cylinders mounted on the fixed matching die to apply a closing force. A servo-drive allows the drawbars to swivel around their longitudinal axes up to a first and second angular position. A first locking device arranged on the drawbars along a first section A of the drawbars co-operates with second locking device arranged on the movable closing die. In the first angular position of the drawbars, the locking devices allow the movable closing die to move axially with respect to the drawbars, and in a second angular position of the drawbars they transmit the required closing force.

Owner:HUSKY INJECTION MOLDING SYST LTD

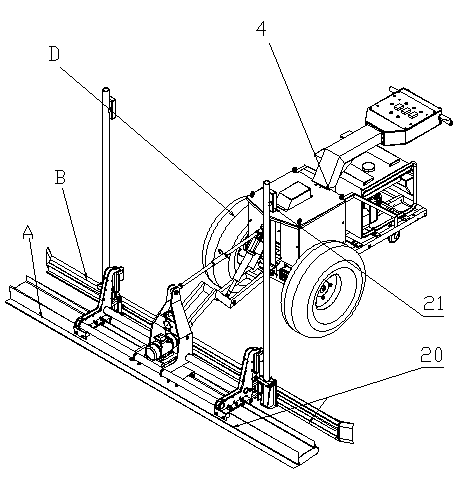

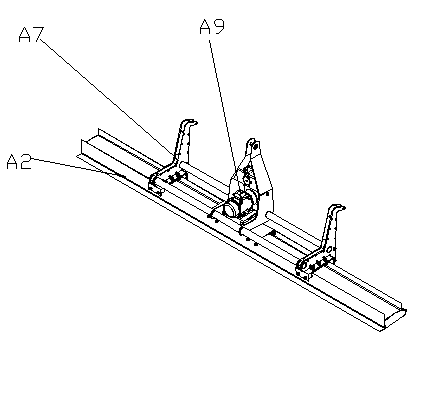

All-electric driven concrete laser leveler

InactiveCN102797214ASimple and lightweight structureReduce weightBuilding constructionsRoads maintainenceLaser transmitterEngineering

The invention discloses an all-electric driven concrete laser leveler. The all-electric driven concrete laser leveler comprises a vibrating plate module, a scraping plate module, a pull rod module, a walking mechanism, a central control box, a horizontal sensor, a protective shell, a frame, a control panel, a power generator unit, a caster, a power generator unit bottom plate, a pull rod pin, an electric cylinder pin, a motor protective plate, an electric cylinder, a first connecting rod pin, a second connecting rod pin, a connecting rod welding body, an electric push rod, a third connecting rod pin, an electric cylinder connecting rod, a laser transmitter, a vibrating scraping plate module, a laser receiver and other main parts. As an advanced laser control technology and a computer controlled servo driving technology are adopted in the whole machine and the original hydraulic driving system is replaced with an all-electric driving system, the all-electric driven concrete laser leveler disclosed by the invention has the advantages of high automation degree, high construction efficiency, high accuracy, light weight, simplicity in operation, less construction personnel, low construction cost and so on, and is suitable for places with comparatively small loads, such as terraces laid with double-layer reinforcing meshes, floor terraces and so on.

Owner:张晓军

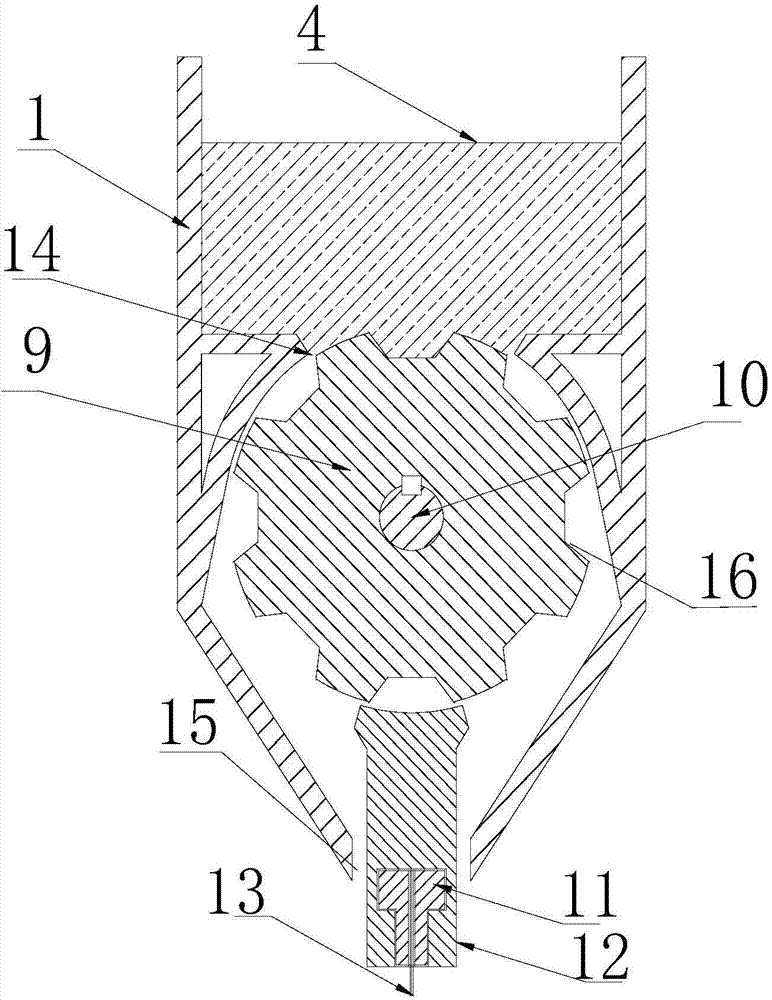

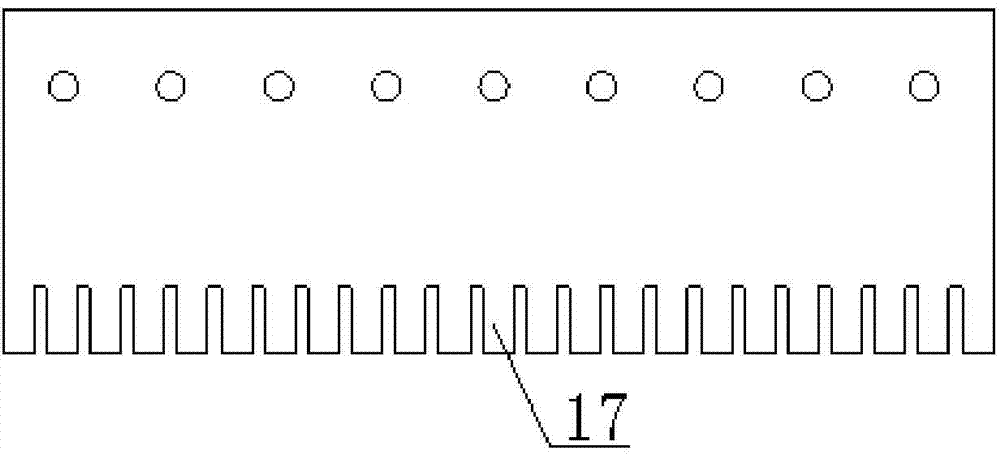

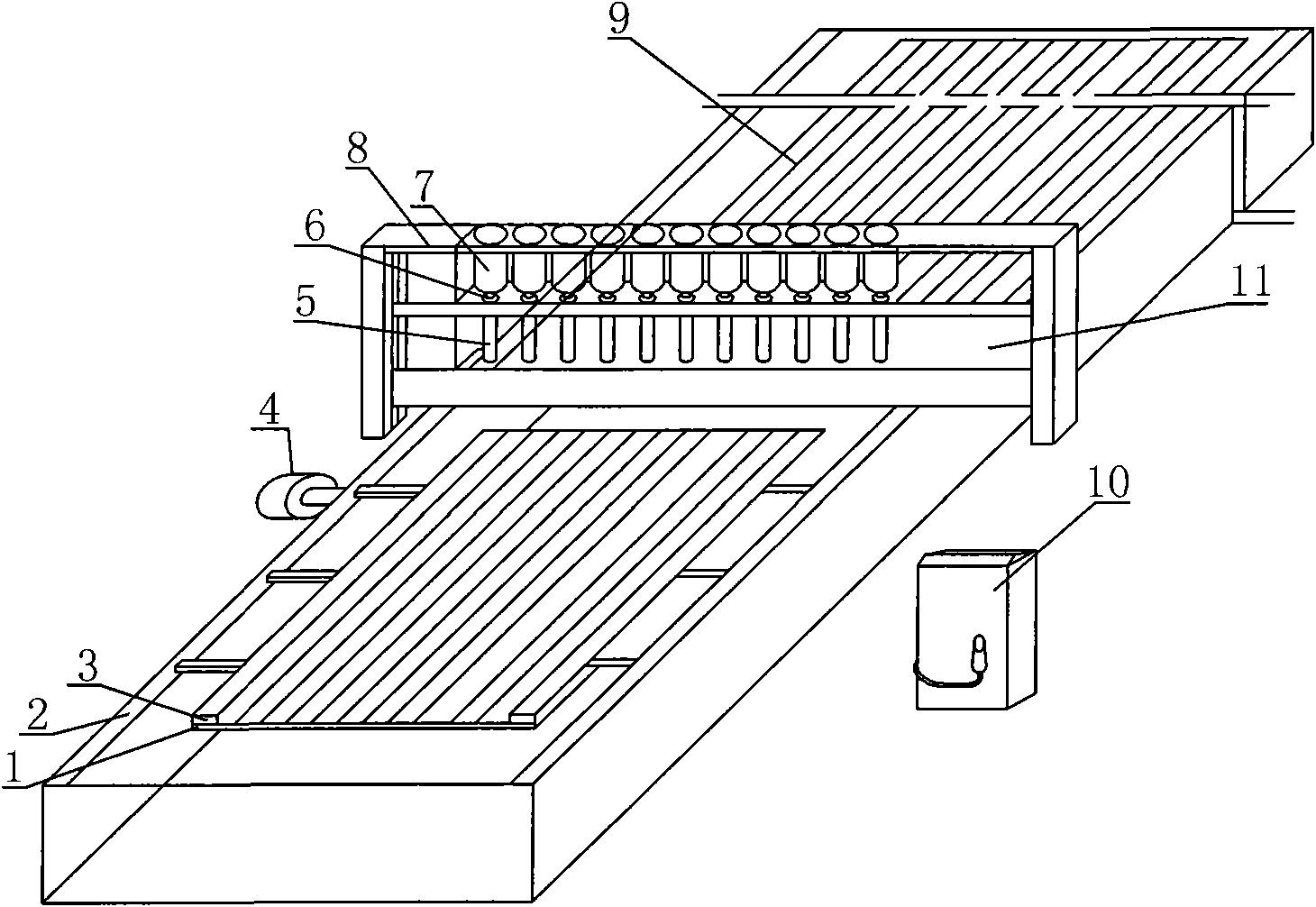

Powder spreading device and powder spreading method for selective laser melting (SLM) equipment

ActiveCN103691947AReduce wasteRealize quantitative powder supplyIncreasing energy efficiencySelective laser meltingSelective laser sintering

The invention discloses a powder spreading device and a powder spreading method for selective laser melting (SLM) equipment. The device comprises a powder spreading main body, an auxiliary guide rail linear motor and an auxiliary powder spreading guide motor, wherein the auxiliary guide rail linear motor is used for driving the powder spreading main body to slide on an auxiliary powder spreading guide rail; the inside of the powder spreading main body is partitioned into three segments, namely, a cylindrical segment, a circular arc segment and a conical segment from top to bottom respectively; the cylindrical segment is a powder carrying area; a powder feeding hole is formed between the cylindrical segment and the circular arc segment; the circular arc segment is provided with a powder supply roller; a plurality of dovetail grooves are uniformly formed on the powder supply roller; the excircle of the powder supply roller is tangential to a circular arc on the upper part of the circular arc segment; the powder supply roller is driven to rotate by a servo driving motor; the conical segment is provided with a powder scraping device; the bottom of the conical segment is provided with a powder outlet; the upper end of the powder scraping device is tangential to the excircle of the powder supply roller, and the lower end of the powder scraping device extends out of the powder outlet; gaps are reserved between the lower end of the powder scraping device and the two ends of the powder outlet; the powder scraping device comprises a flexible powder scraping brush. By adopting the powder spreading device and the powder spreading method, quantitative powder supply can be realized, waste of powder is reduced, bidirectional powder spreading can be performed, the SLM molding auxiliary process time is shortened, and the SLM molding efficiency is increased.

Owner:SOUTH CHINA UNIV OF TECH

Feedforward control method for flexible torque of robot based on flexible kinetic model

InactiveCN108714896AImprove accuracyIn line with the actual workProgramme-controlled manipulatorEstimation methodsRobot dynamic

The invention discloses a feedforward control method for a flexible torque of a robot based on a flexible kinetic model. The method comprises the following steps: S1, establishing a cognizable minimuminertial parameter model of a flexible joint of the robot; S2, carrying out data sampling and pretreatment on joint movement parameters in the moving process of the flexible joint of the robot in real time periodically; S3, substituting the pre-treated joint movement parameters into the cognizable minimum inertial parameter model, recognizing flexible kinetic parameters by means of the least square estimation method, and substituting the parameters back to calculate a torque value needed by the flexible joint; S4, sending the torque value as a feedforward amount to a bottom layer of a servo driver periodically; and S5, overlaying the feedforward amount and an output amount of an electric current loop in a form of compensation to achieve flexible control of the robot. By establishing the kinetic model of the flexible joint of the robot and recognizing the torque rigidity parameter of the flexible joint and the minimum inertial parameter to obtain the torque value as the feedforward amount, dynamic response and positioning precision of the robot are improved.

Owner:SOUTH CHINA UNIV OF TECH

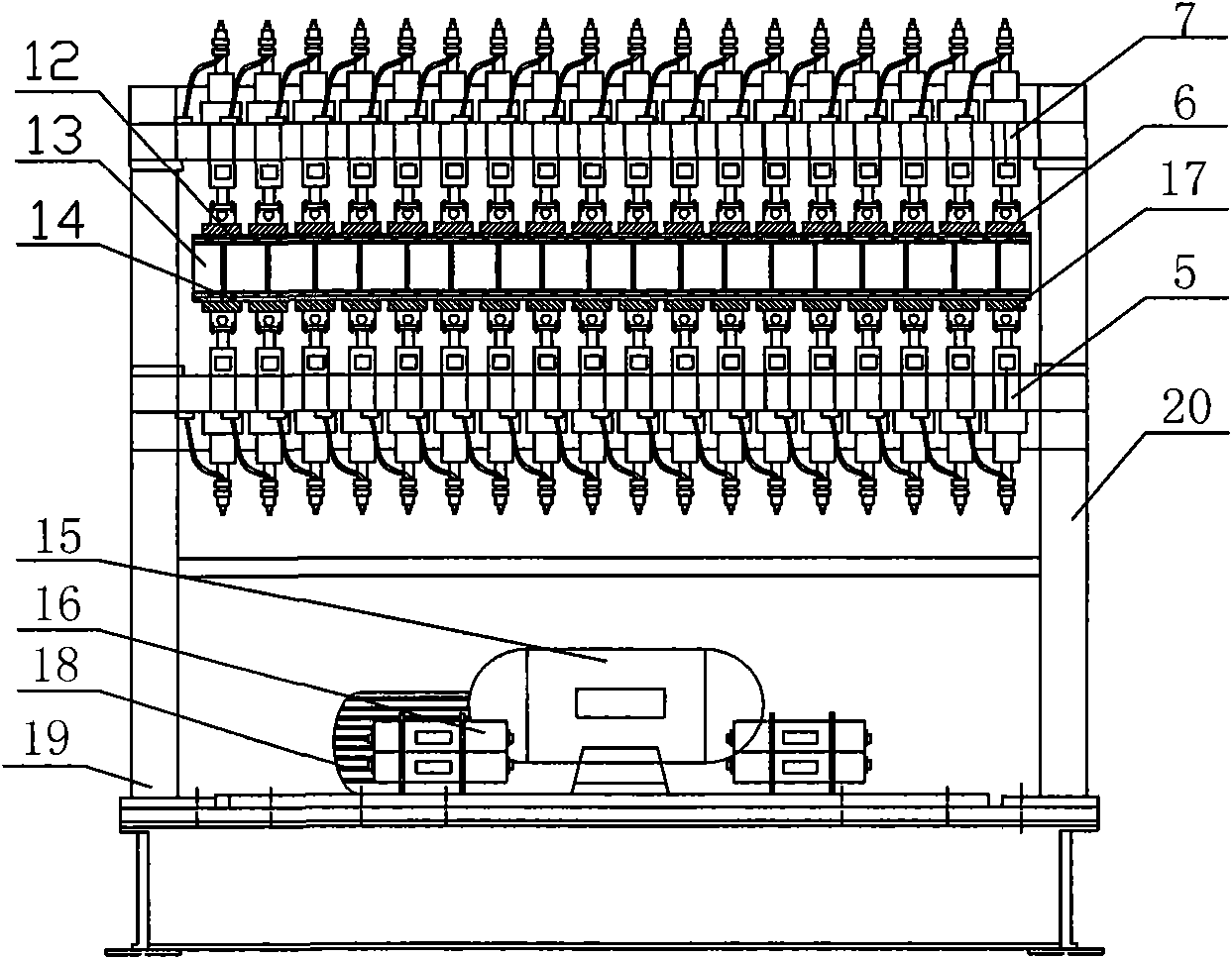

Spray characteristic parameter detection device and method

ActiveCN104181083AEasy to moveHigh degree of automationParticle size analysisControl systemEngineering

The invention discloses a spray characteristic parameter detection device and method. The spray characteristic parameter detection device comprises an integral support rack, a two-dimensional moving unit, a servo motor, a servo control unit, a spray control system, a pulse nozzle, a high-speed camera image acquisition system and a laser particle size analyzer system. On the basis of the device, the spray characteristic parameter detection method comprises the following steps: detecting an outline shape of spray, macroscopic two-dimensional distribution of spray and the flying speed of particles of spray by virtue of the high-speed camera image acquisition system; and detecting the particle size of spray with two-dimensional distribution in a spatial two-dimensional plane travel range by a two-dimensional precise servo driving system based on a laser particle size analyzer according to the outline and the macroscopic two-dimensional distribution of spray on the basis of a spray image acquisition result.

Owner:TIANJIN UNIV OF COMMERCE

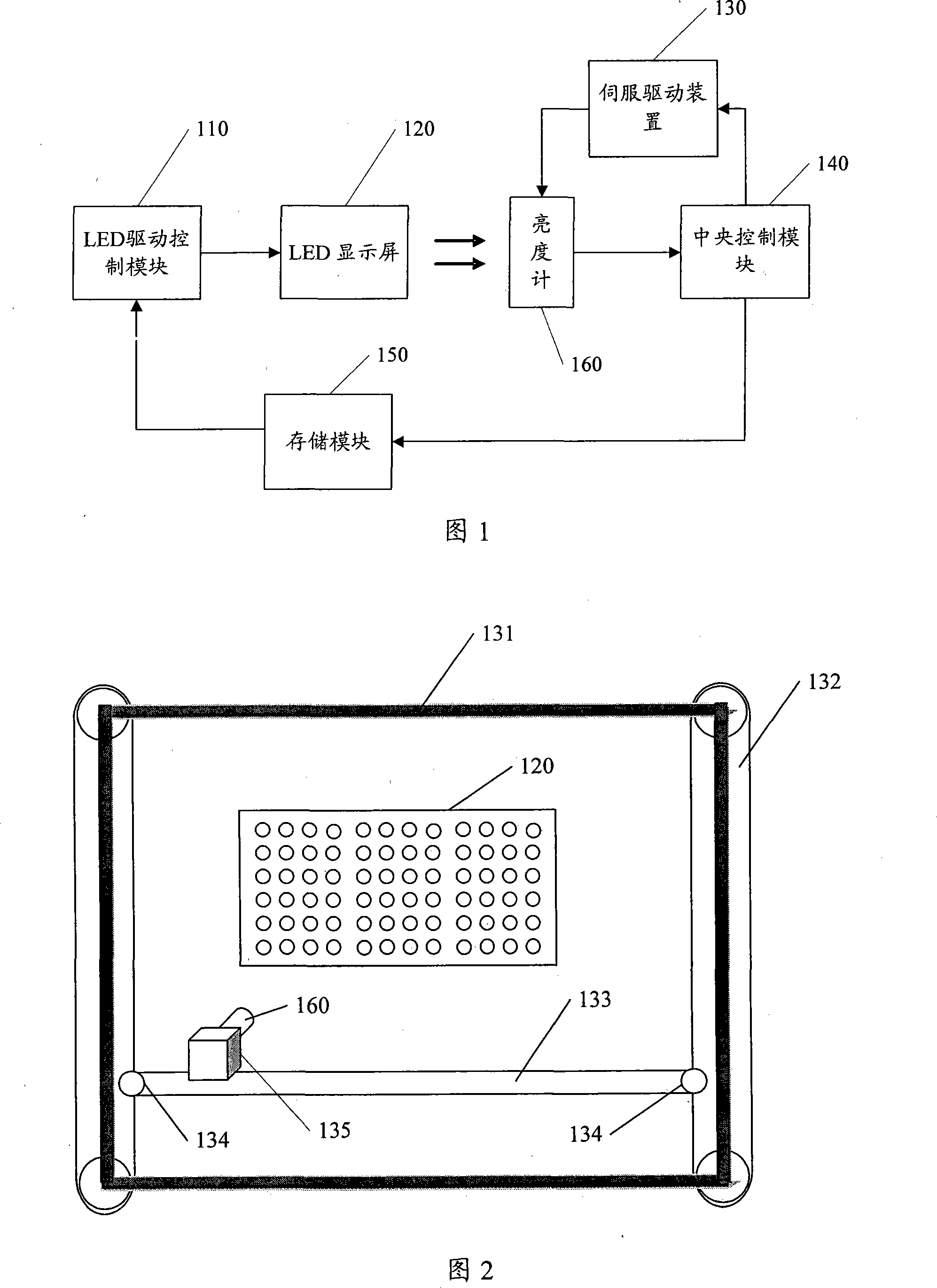

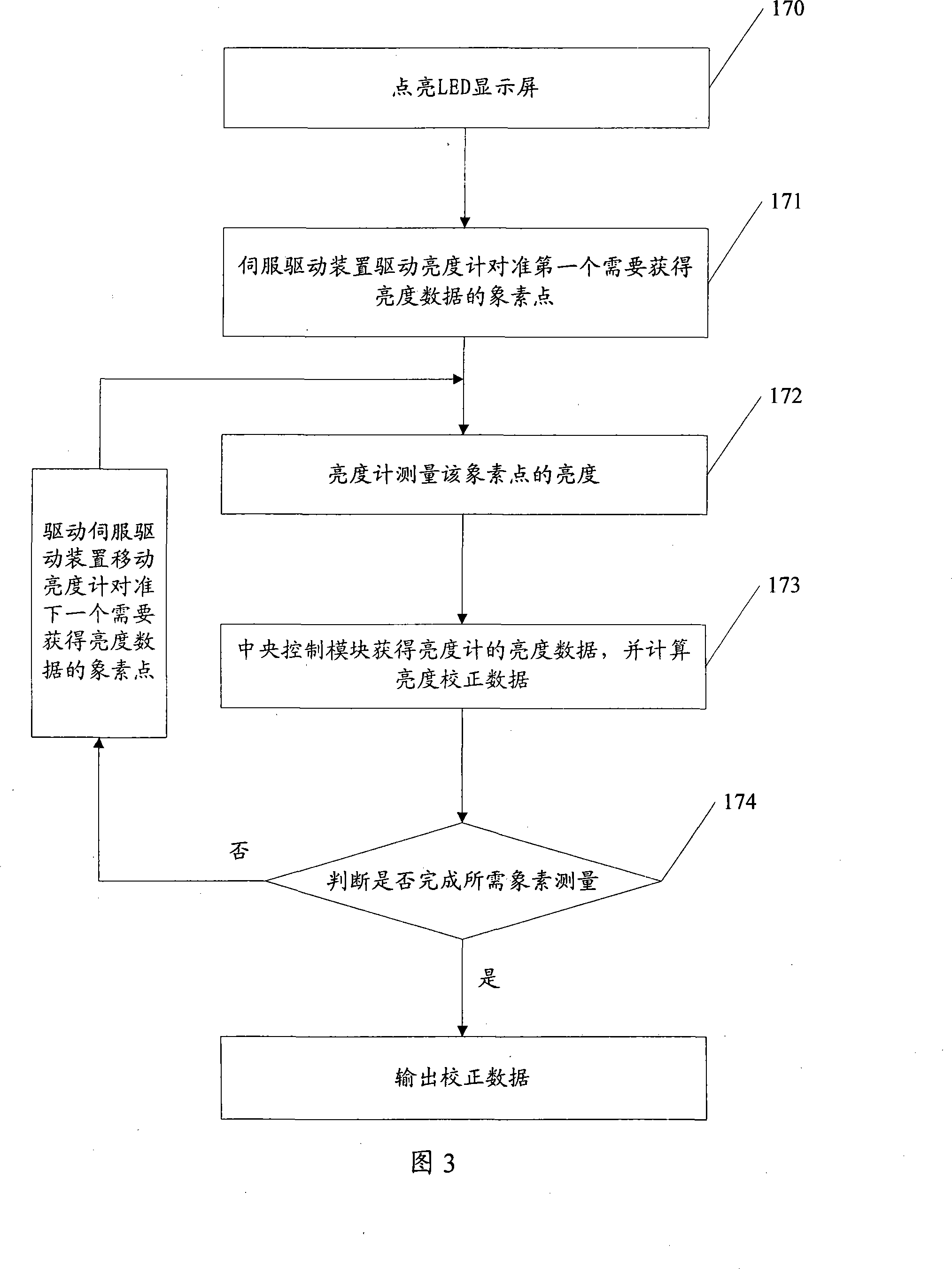

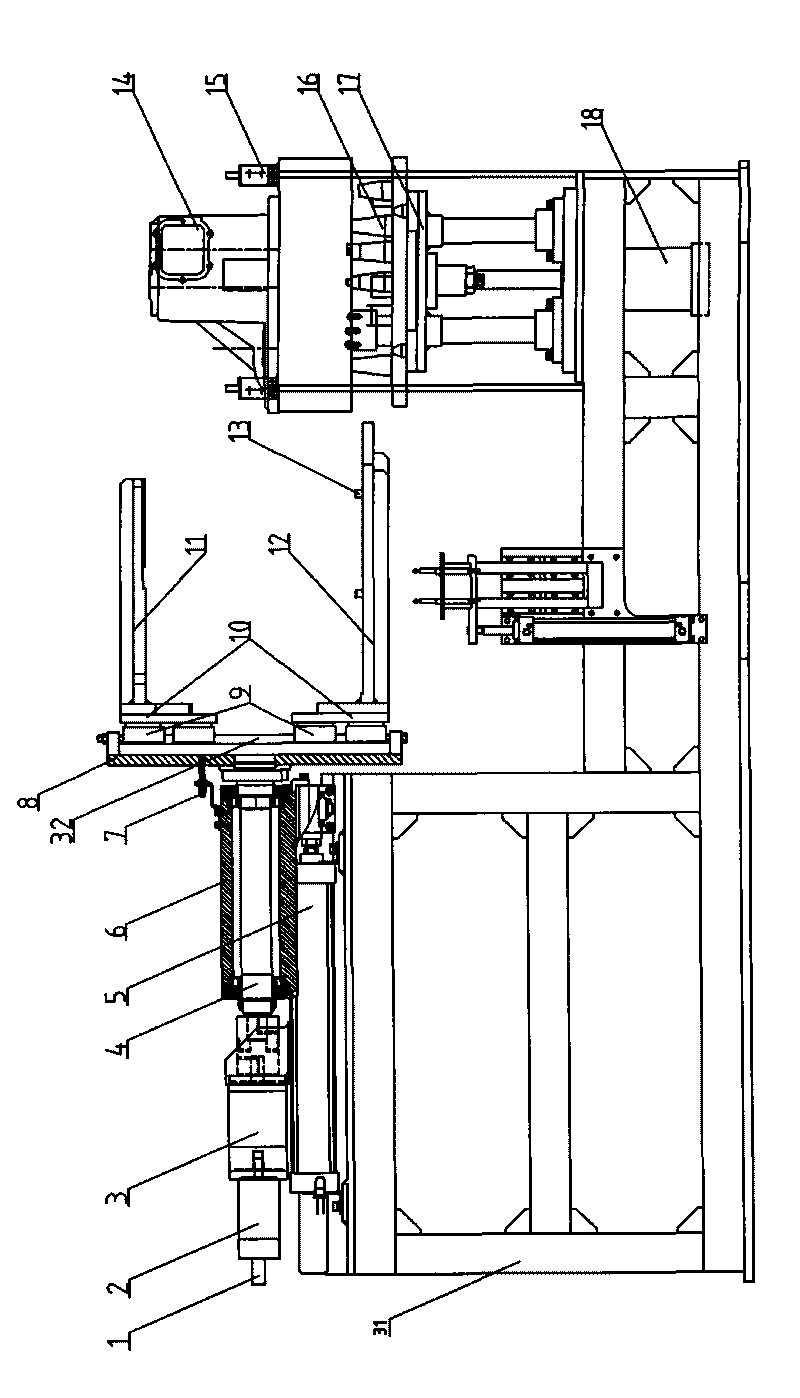

System and method for obtaining gamma correction data point-to-point as well as application system thereof

InactiveCN101206833AAcquisition speed is fastHigh data accuracyElectrical apparatusElectroluminescent light sourcesLED displayComputer module

The invention discloses a system and a method for obtaining brightness correction data point by point and the application system thereof. The system comprises a servo driving devicewhich is used for controlling a brightness meter to obtain the brightness of pixel points point by point; a central control module,which is used for controlling the motion of the servo driving device and receiving the brightness data of the pixel points on a LED display screen obtained by the brightness meter, and through which the brightness data is processed and the brightness correction data is calculated; a memory module, which is used for memorizing the brightness correction data obtained by the central control module. In the invention, the brightness meter is automatically moved through utilizing a two-dimensional servo system, to ensure the central control module to obtain the brightness data and obtain the correction data through calculation , to be provided for a LED driving chip. The invention has the advantages that the trouble and the inaccuracy of the manual operation are avoided, the collection speed and the data precision of the pixel brightness are greatly enhanced, and the invention realizes that the correction data is obtained quickly and accurately and used for adjusting the brightness of the LED display screen.

Owner:SHENZHEN DIANMING TECH

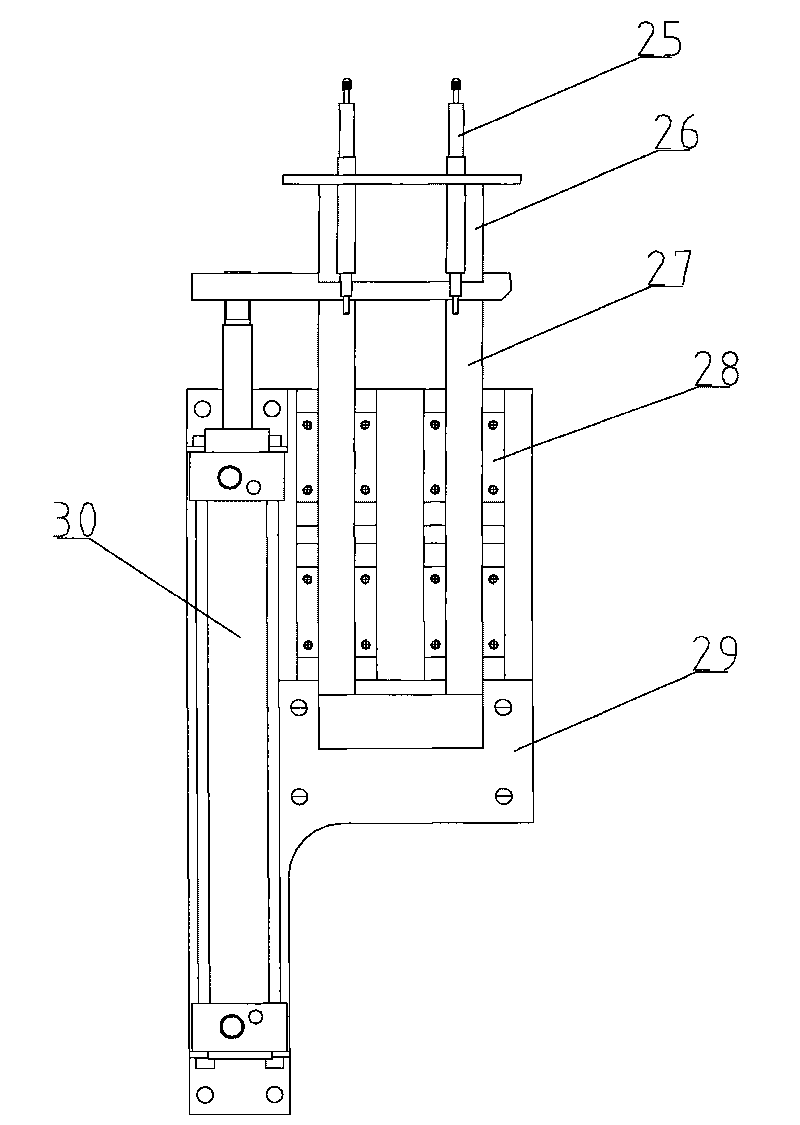

Glue coating automatic turnover machine

InactiveCN101745491AFast rotation positioningAccurate rotation positioningLiquid surface applicatorsCoatingsEngineeringAutomation

The invention discloses a glue coating automatic turnover machine, which comprises a turnover mechanism, a mechanical hand mechanism, a lifting mechanism, a distance measuring mechanism and a controller, wherein the turnover mechanism is arranged on a glue coating frame, the mechanical hand mechanism is connected with a rotating shaft and a bearing seat in the turnover mechanism through the glue coating frame, the lifting mechanism is arranged on the glue coating frame and is positioned in front of the mechanical hand mechanism, the distance measuring mechanism is arranged on the glue coating frame and is positioned under the mechanical hand mechanism, and the controller is connected with each mechanism. The invention adopts a mechanical hand for tightly clamping work pieces, the mechanical hand is provided with a clamp which consists of a clamp press plate and a clamp base, then, a servo driver is used for driving a servo motor to drive the rotating shaft for turning small combining surfaces of the work pieces to a position where the glue coating surface faces up, the distance measuring mechanism provided with a displacement sensor is used for detecting the positions of the work pieces, and the lifting mechanism provided with a tray positioning pin is used for lifting the work pieces to the glue coating positions. The invention has the characteristics of accurate turnover positioning and high automation degree.

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI

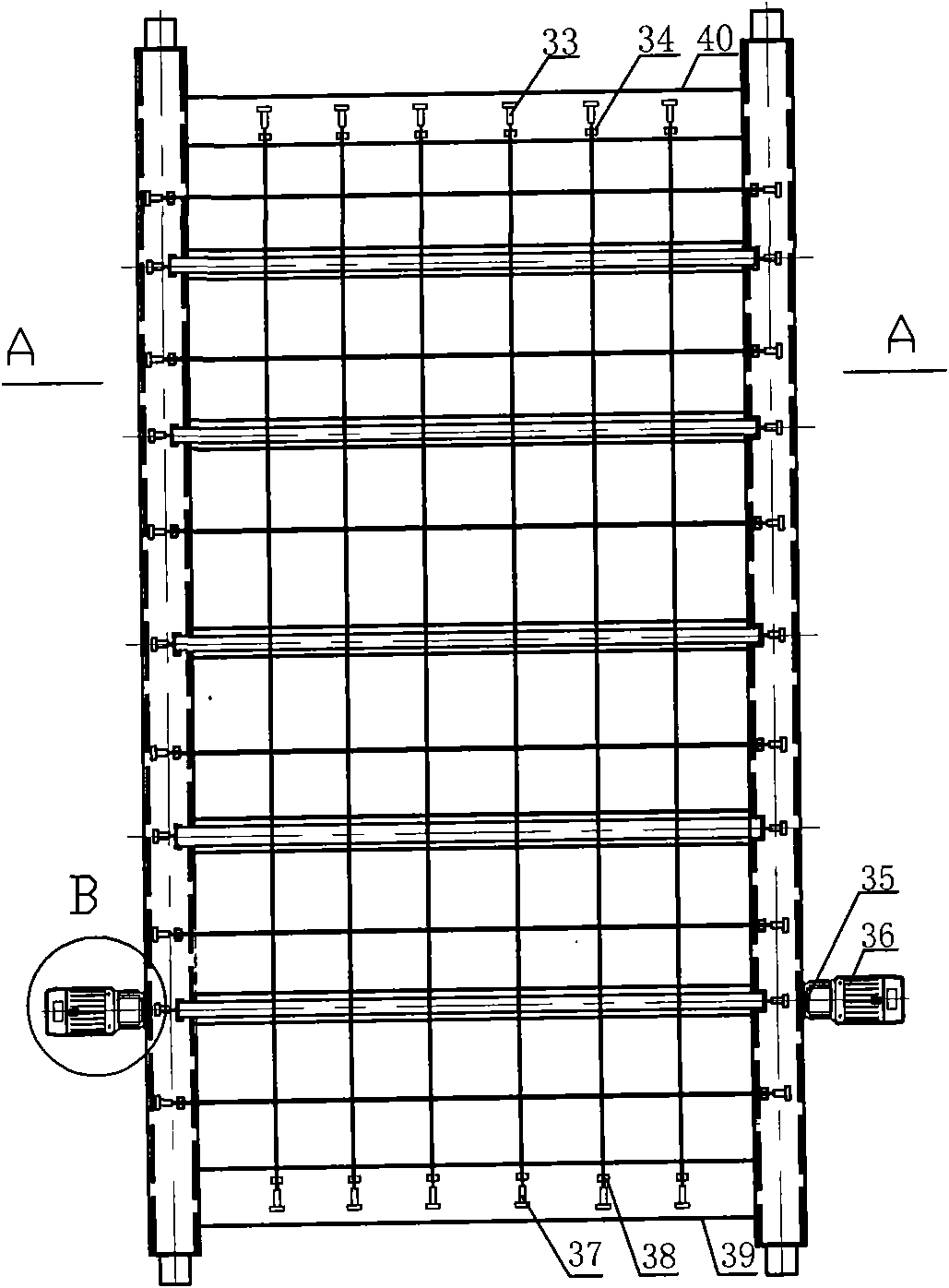

Steel meshwork automatic welding device and production technology thereof

InactiveCN101913020AMeet the work intensityMeet job requirementsWelding electric supplyProgramme control in sequence/logic controllersNumerical controlTransformer

The invention belongs to the technical field of mechanical-electrical integration and particularly relates to a steel meshwork automatic welding device and production technology thereof. The device of the invention comprises a gantry pressure welding frame, a numerical control pressure welder, a pressurizing mechanism, a resistance welding transformer, an electric control cabinet, a resistance welding controller, a trolley track, a mould base trolley, a step trolley, a demountable welding fixture and a servo drive device, wherein the mould base trolley contains a mould base cross beam, a mould base left end beam, a mould base right end beam, mould base trolley wheels, a left lateral overturning and positioning frame, a right lateral overturning and positioning frame, a left lateral overturning cylinder, a right lateral overturning cylinder, positioning frame pins, an upper positioning block, a lower positioning block, a mould base front end beam, a mould base back end beam, a front lateral overturning positioning frame, a back lateral overturning positioning frame, a front lateral overturning cylinder, a back lateral overturning cylinder, and positioning frame pins. The device of the invention and the welding technology thereof have high degree of automation, higher work efficiency, good consistency of the product and high quality of the product; and the device and technology are especially suitable for the engineering with short construction time and high demand on the construction period.

Owner:EAST STEEL STRUCTURE BRIDGE

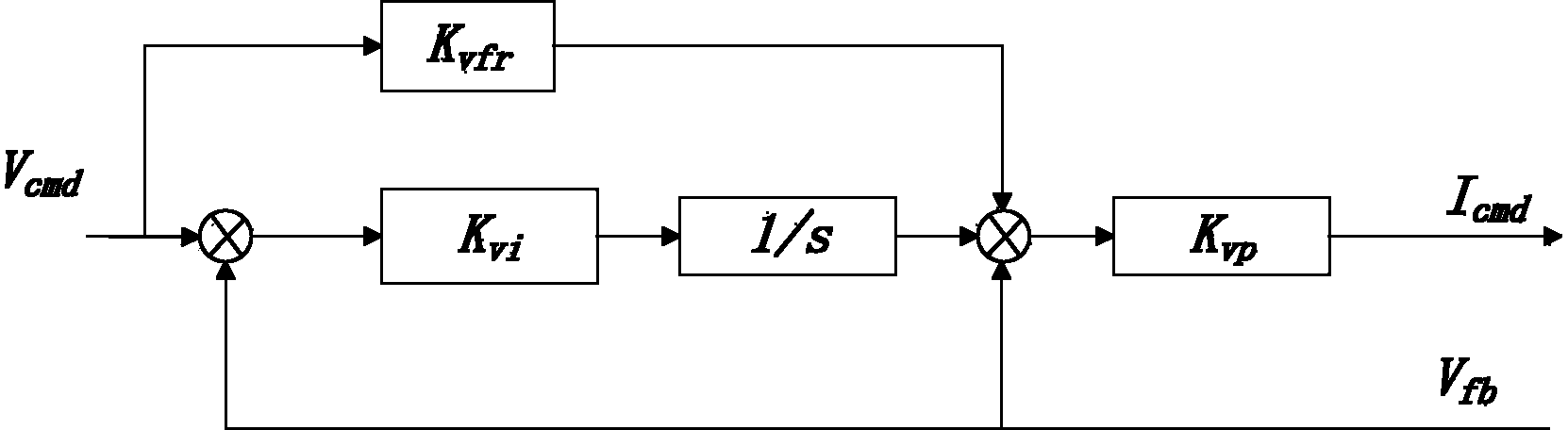

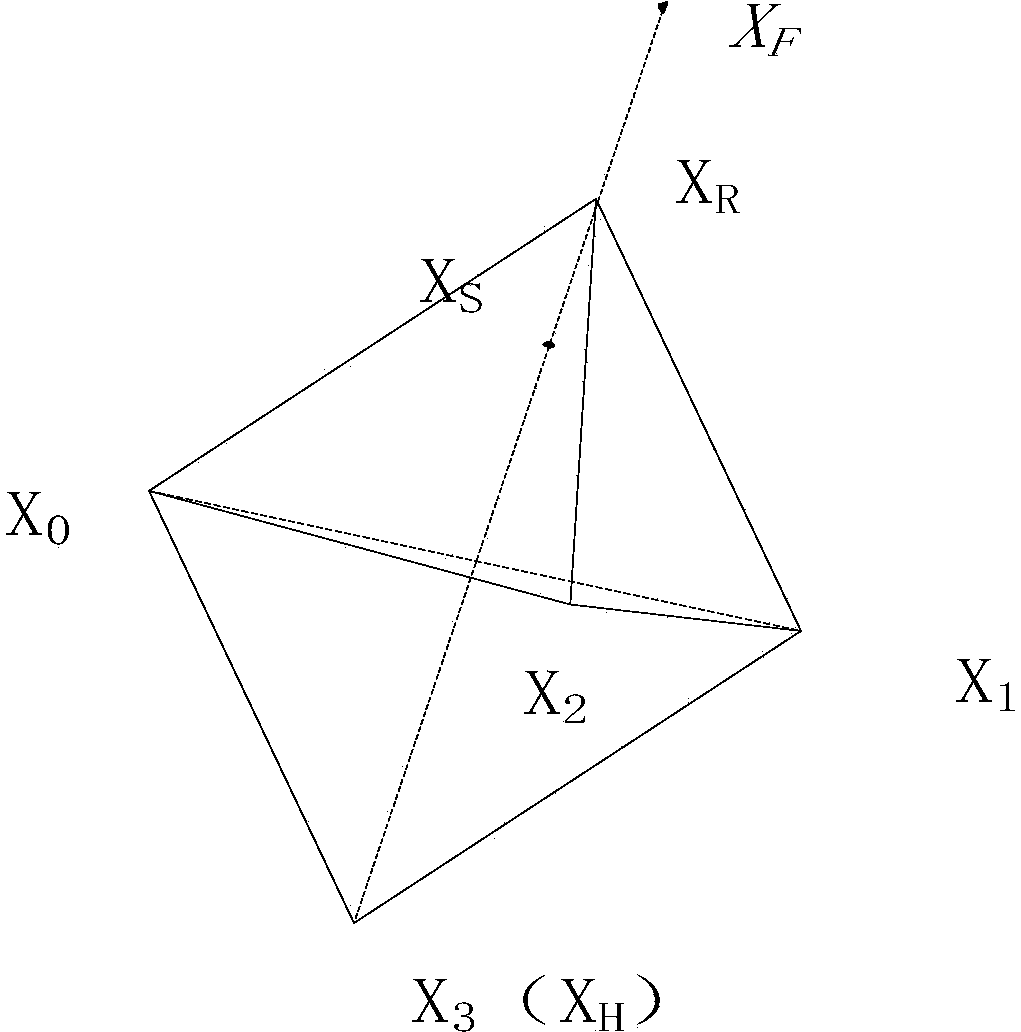

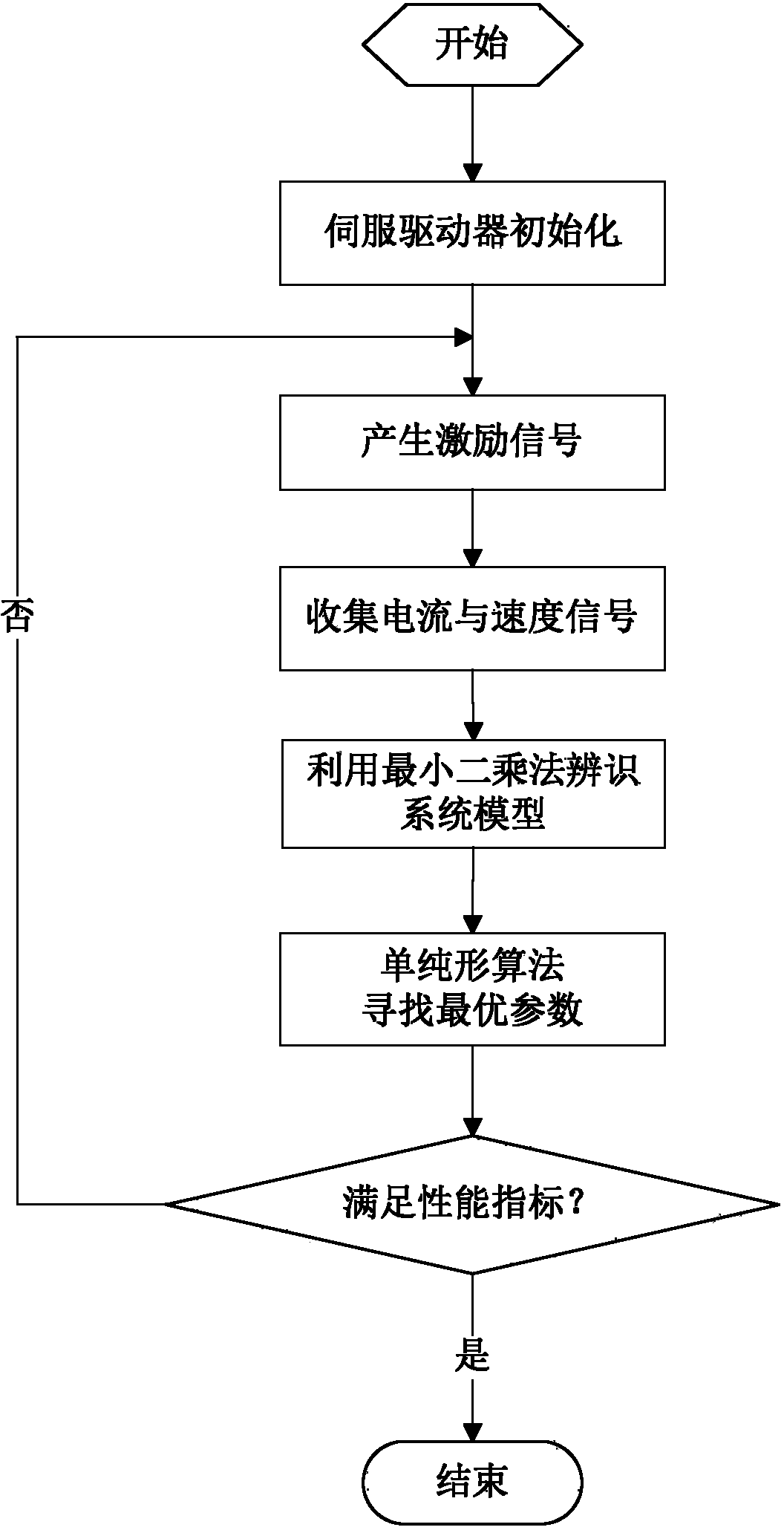

PDFF-based AC servo driver control parameter self-tuning method

ActiveCN103713516AImprove robustnessImprove controllabilityControllers with particular characteristicsPattern search algorithmPermanent magnet synchronous motor

The invention discloses a PDFF-based AC servo driver control parameter self-tuning method. Firstly, current and speed signals required for identifying an AC servo system model are acquired; secondly, according to the acquired signals, a speed loop controlled object model of a permanent magnet synchronous motor AC servo driving system is identified and parameters of the model are identified; and finally, according to the parameters and performance indexes of the model, searching optimization tuning is performed on control parameters of a servo driver so that the optimal control parameter is acquired. According to the self-tuning method, a PDFF controller is utilized to substitute a conventional PI controller on a speed loop of the servo driver and the parameters of the controller are automatically tuned. The model of the controlled object is identified by the self-tuning method by utilizing a recursion least square method. Then according to the feasible performance indexes, searching optimization is performed on the parameters of the controller by utilizing a mode searching algorithm, and the optimal control parameter is obtained so that the servo driving system can be great in anti-disturbance capability, control precision and robustness.

Owner:HUAZHONG UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com