Dual-wavelength binocular vision seam tracking method and tracking system

A binocular vision and tracking system technology, applied in welding equipment, arc welding equipment, manufacturing tools, etc., can solve the problems of inability to accurately judge the left and right deviation of the welding seam, limit the application of ultrasonic sensors, etc., to improve fault tolerance and reliability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Embodiment 1: Dual-wavelength binocular vision welding seam tracking method.

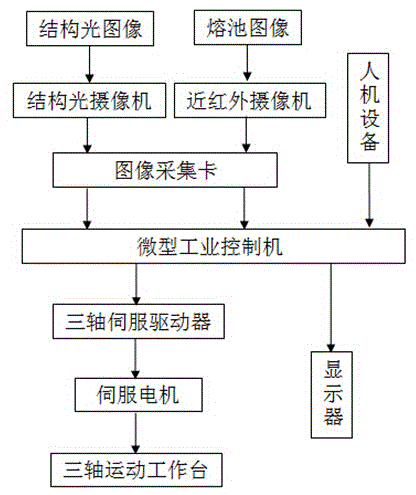

[0028] refer to image 3 as shown, image 3 It is a working diagram of the dual-wavelength binocular vision welding seam tracking method of the present invention. The method comprises the steps of:

[0029] a. Image acquisition: The micro-industrial control computer issues instructions to make the structured light laser emit structured light across the weld seam, and at the same time issue instructions to start the near-infrared camera and the structured light camera to work, and coordinate the near-infrared camera and the structured light camera through the welding process synchronously The image acquisition card collects the infrared image of the molten pool area and the structured light image of the welding seam at the front of the molten pool, and transmits the obtained dual-wavelength image to the micro industrial control computer;

[0030] b. Data processing: apply the multi-informat...

Embodiment 2

[0035] Embodiment 2: A dual-wavelength binocular visual seam tracking system.

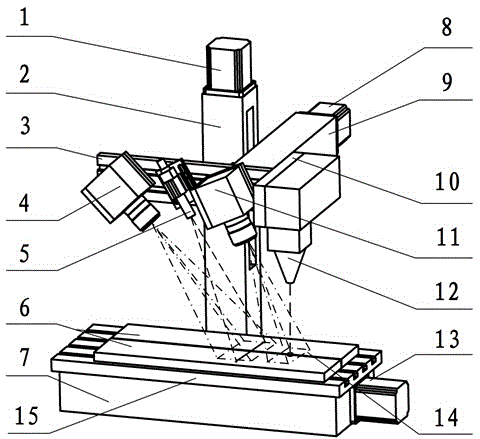

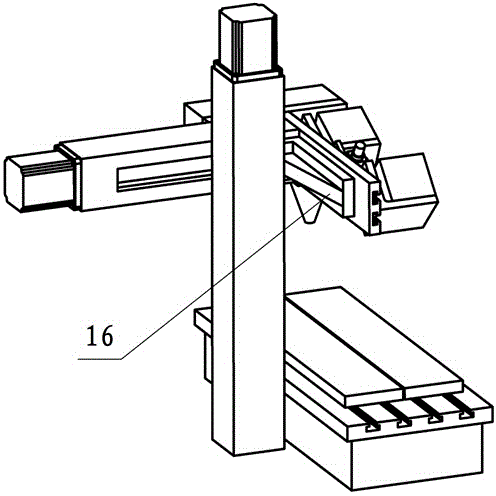

[0036] refer to figure 1 and figure 2 As shown, a dual-wavelength binocular visual seam tracking system includes a dual-wavelength binocular visual inspection system, a three-axis servo-driven seam tracking system and a miniature industrial control computer. The dual-wavelength binocular visual inspection system includes a near-infrared camera 11. A structured light camera 4, a structured light laser 5 and a sensor mounting plate 3, the structured light camera 4 is mounted on the left front end of the sensor mounting plate 3, the near-infrared camera 11 is mounted on the right front end of the sensor mounting plate 3, the structure The optical laser 5 is located between the structured light camera 4 and the near-infrared camera 11, and is installed on the middle end of the sensor mounting plate 3; Frame 2, the upper surface of the X-axis fixed frame 7 is equipped with a welding table 15, the wel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com