Glue coating automatic turnover machine

A technology of automatic turning and turning mechanism, which is applied in the direction of coating, non-electric variable control, and device for coating liquid on the surface, etc. It can solve the problems of difficult guarantee of glue coating quality, low efficiency, and high labor intensity of operators. The effect of simple structure and fast rotation and positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be described in detail below in conjunction with the following embodiments and accompanying drawings.

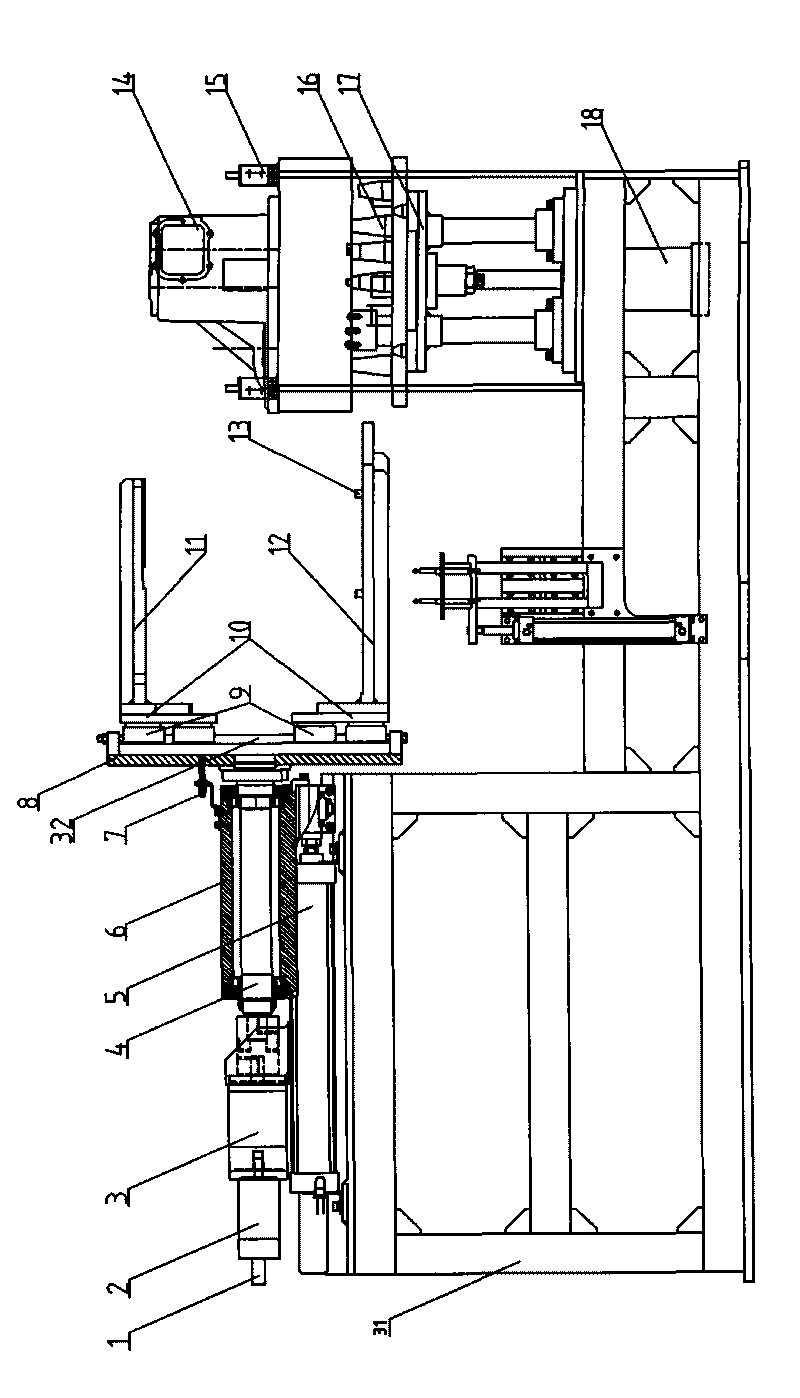

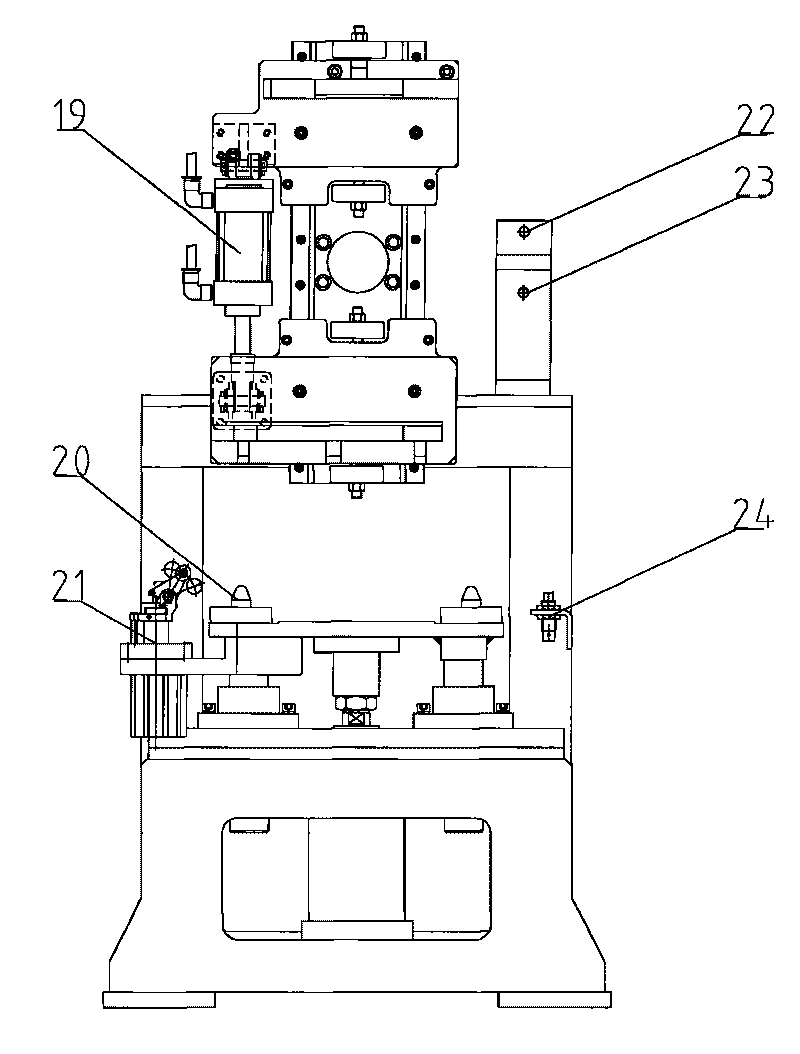

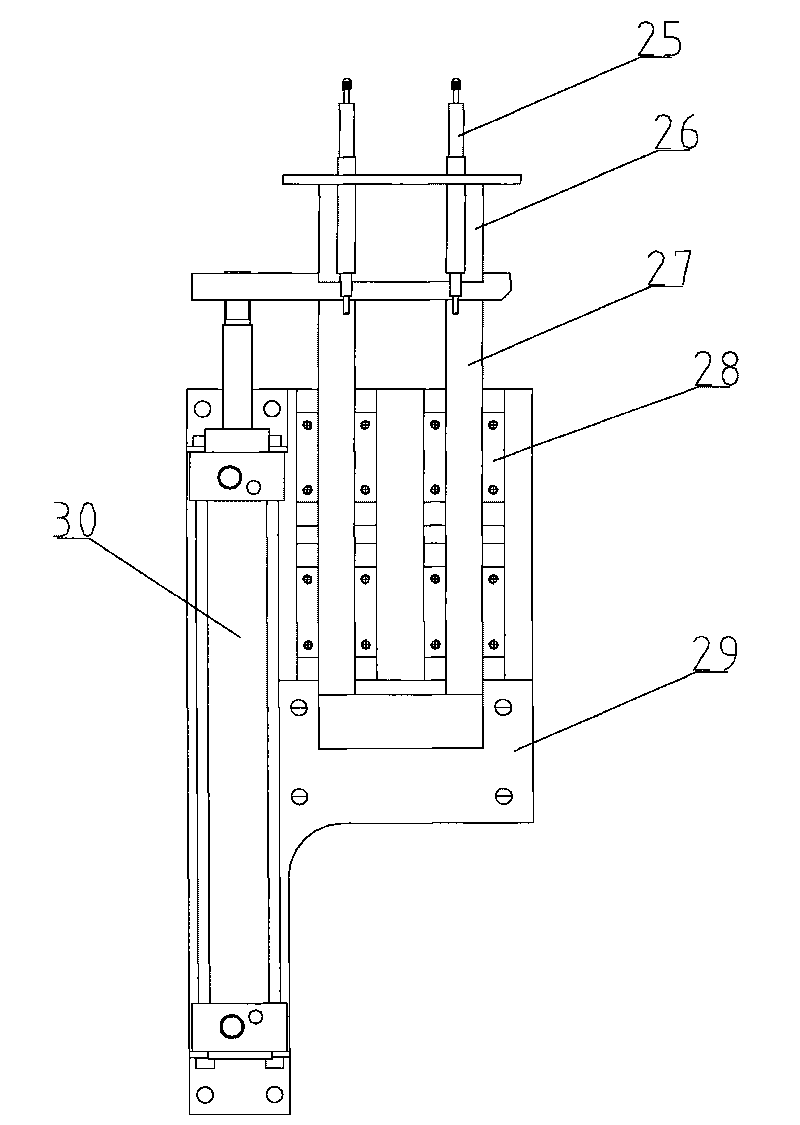

[0044] Such as figure 1 As shown, the gluing automatic turning machine of the present invention includes a turning mechanism, a manipulator mechanism, a lifting mechanism, a distance measuring mechanism, and a control device.

[0045] The control device consists of an industrial computer, a motion control card, an interface expansion card, a digital input module D / I, a digital output module D / O, an analog input module A / I, an electric gas valve, a proximity switch, a displacement sensor, Composed of servo drive, servo motor, and encoder. The motion control card is a PCI bus structure, which is inserted into the industrial computer; it is equipped with a touch screen, connected to the industrial computer through the USB bus, and its function is to display various parameters and equipment status, fault alarm, formula download, accept operatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com