Electronic control system for dust blowing and sucking equipment rotary frame

An electronic control system and equipment technology, applied in general control systems, control/regulation systems, electrical program control, etc., can solve the problems of scratches on the surface and unsatisfactory effect of steel pipe dust removal.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

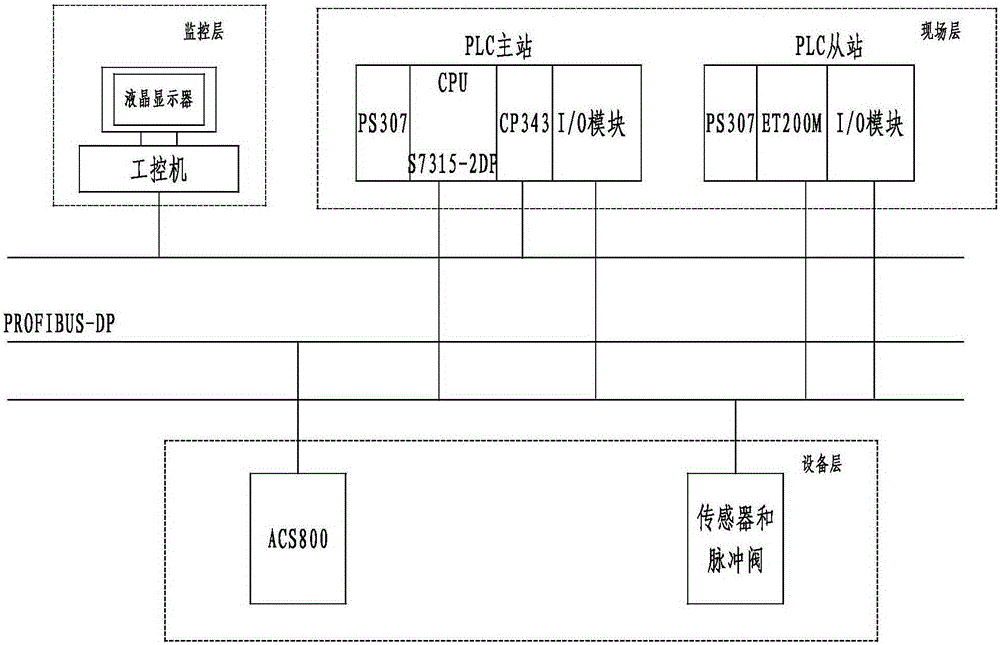

[0016] see figure 1 , an electric control system for a soot blowing and suction equipment turret, at least including:

[0017] Equipment layer; the equipment layer includes a speed sensor for collecting the rotation speed of the turret, a frequency converter for controlling the rotation of the turret, and an absolute encoder is installed on the frequency converter;

[0018] On-site layer; the on-site layer includes Siemens S7300 series PLC; the Siemens S7300 series PLC includes two parts, PLC master station and PLC slave station; wherein: the PLC master station includes S7315-2DP controller, CP343-1 Ethernet communication module; And master station I / O module; Described PLC slave station comprises Siemens ET200M and slave station I / O module;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com