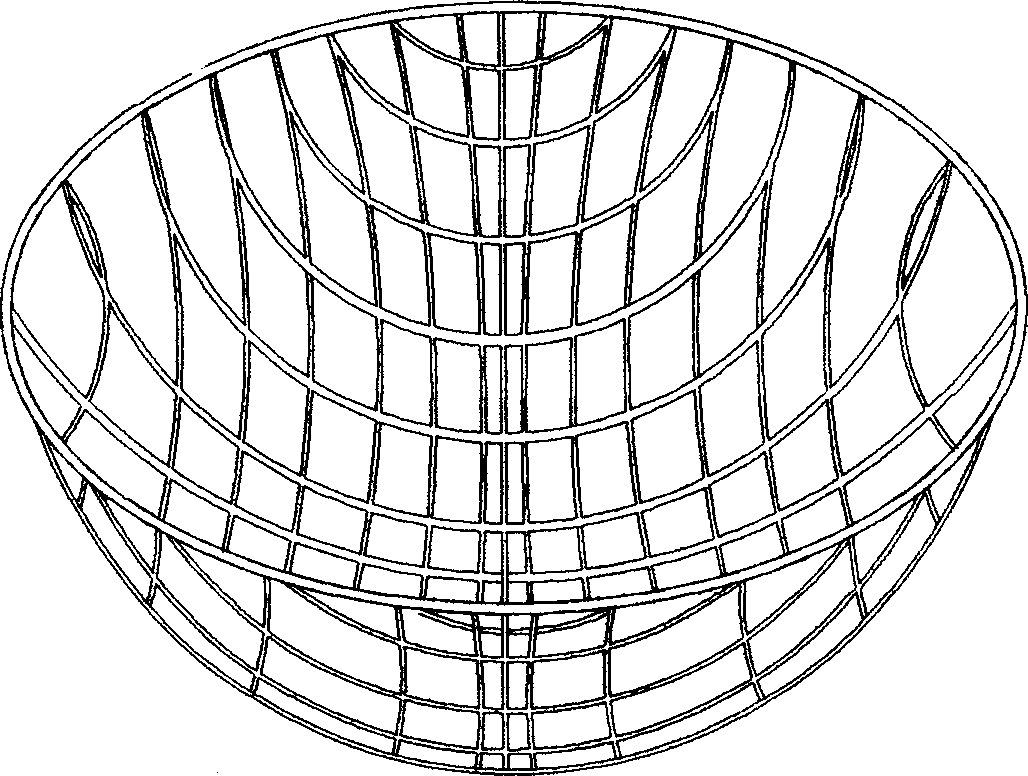

Fiber reinforced resin base composite material manhole cover

A fiber-reinforced resin and composite material technology, which is used in infrastructure engineering, water conservancy engineering, artificial islands, etc., and can solve the problems of material brittleness, cracks, knocked-off corners, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] Manhole cover is made according to formula of the present invention, operating procedure:

[0048] 16% unsaturated resin A, 5% prepreg FRP reinforcement B, 70% aggregate C, 6% filler D, 3% wear-resistant material E.

[0049] ① Unsaturated polyester resin A consists of 80 parts of unsaturated dibasic acid and anhydride

[0050] 1.5 parts methyl ethyl ketone peroxide

[0051] 1.0 parts cobalt naphthenate

[0052] 1.0 part flame retardant hexabromobenzene

[0053] 0.1 part of inorganic pigment mixed;

[0054] ②Prepreg FRP bar B consists of 10-20 parts of unsaturated resin

[0055] 8-20 parts glass fiber

[0056] ③ Aggregate C consists of 120 parts of 40-60 mesh sand

[0057] 120 parts of 20-40 mesh sand

[0058] 80 parts of 10-20 mesh sand

[0059] 30 pieces of 2-4mm stones

[0060] 30 pieces of 4-6mm stones

[0061] ④Fil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com