Light and pressure-proof fast-decomposed cast magnesium alloy

A technology for casting magnesium alloys and magnesium-aluminum alloys, which is applied in the field of casting magnesium alloys, can solve the problems of high activity, prolonging the construction period, and inability to carry out safe preparation, and achieves reasonable component distribution ratio, simple production process, and improved overall strength and reliability. The effect of decomposition performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

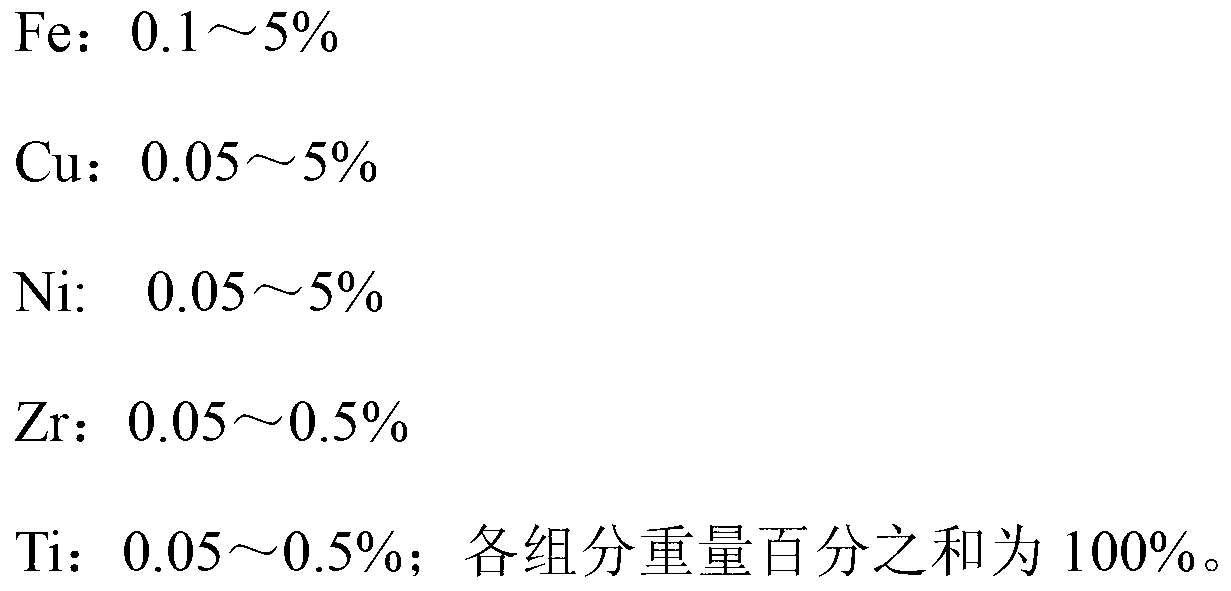

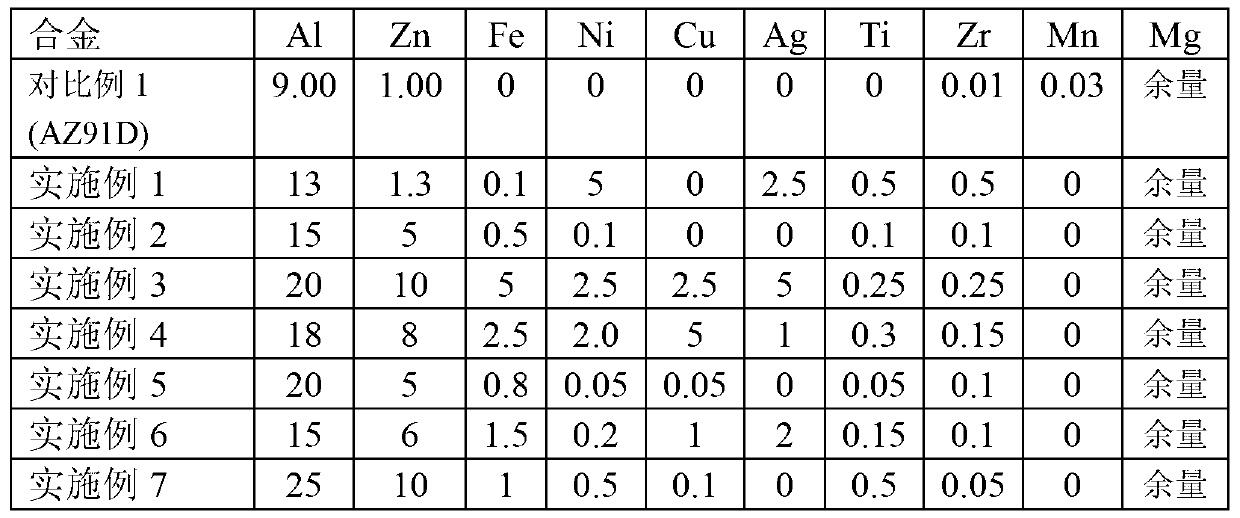

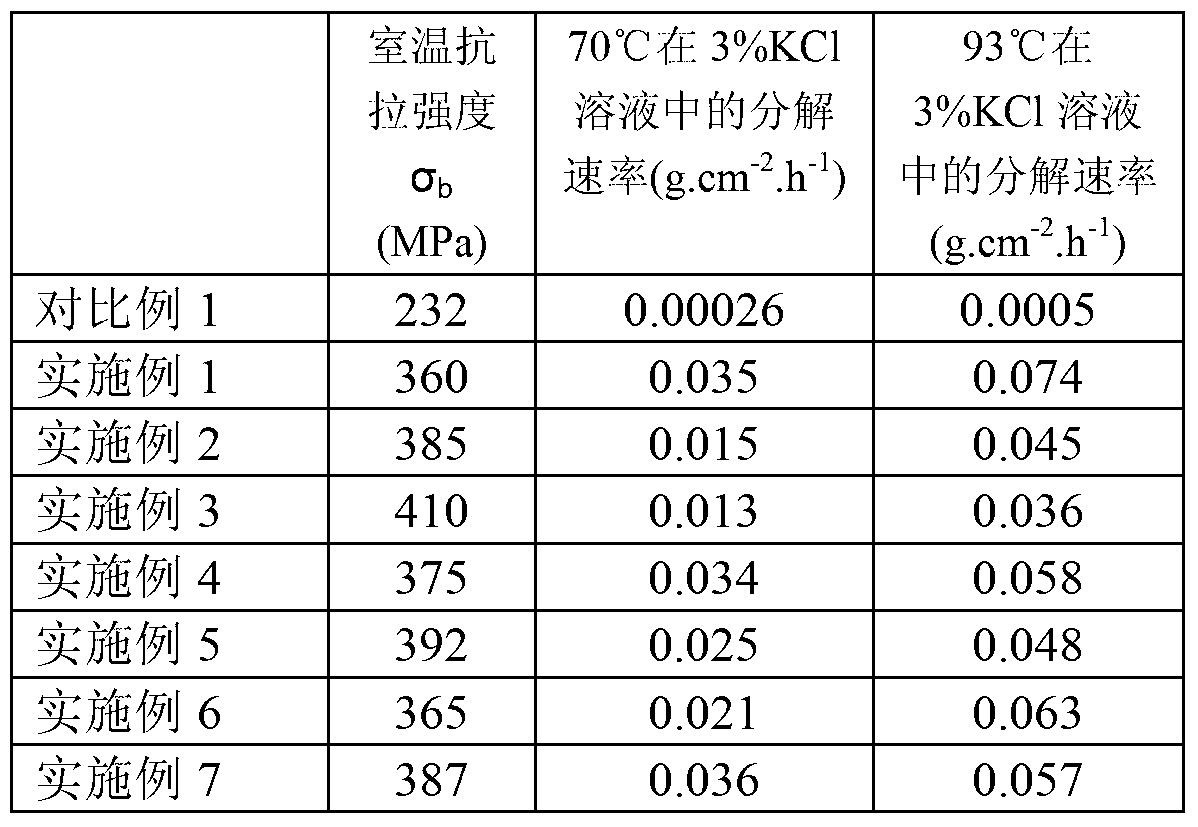

[0034] The composition and weight percentage of the alloy are:

[0035] 13%Al-2%Zn-0.1%Fe-5%Ni-2.5%Ag-0.5%Ti-0.5%Zr, the rest is Mg.

[0036] The preparation method is: first put pure magnesium and pure aluminum into the smelting furnace and raise the temperature to 700°C; after melting, bake the Al-Fe master alloy, Al-Ni master alloy, Al-Ag master alloy, Al- Put the Zr master alloy, Al-Ti master alloy and pure zinc into the magnesium-aluminum alloy melt, and raise the temperature to 740°C at the same time; after melting, when the temperature drops to 720°C, pass in argon gas for degassing treatment; cool down to 700°C, Stand still, cast under the protection of argon, and cool down.

Embodiment 2

[0038] The composition and weight percentage of the alloy are:

[0039] 15%Al-5%Zn-0.5%Fe-0.1%Ni-0.1%Ti-0.1%Zr, the rest is Mg.

[0040] The preparation method is: first put pure magnesium and pure aluminum into the smelting furnace, heat up to 730 ° C; after melting, bake the Al-Fe master alloy, Al-Ni master alloy, Al-Zr master alloy, Al- Put the Ti master alloy and pure zinc into the magnesium-aluminum alloy melt, and raise the temperature to 760°C at the same time; 6 Cast under the protection of mixed gas with air, and cool down.

Embodiment 3

[0042] The composition and weight percentage of the alloy are:

[0043] 20%Al-10%Zn-5%Fe-2.5%Ni-2.5%Cu-5%Ag-0.25%Ti-0.25%Zr, the rest is Mg.

[0044] The preparation method is: first put pure magnesium and pure aluminum into the smelting furnace and raise the temperature to 715°C; after melting, bake the Al-Fe master alloy, Al-Ni master alloy, Al-Cu master alloy, Al- Put the Ag master alloy, Al-Zr master alloy, Al-Ti master alloy and pure zinc into the magnesium-aluminum alloy melt, and raise the temperature to 780°C at the same time; 2 Cl 6 The refining agent is degassed; the temperature is lowered to 700°C, left standing, cast under the protection of argon, and cooled.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com