Patents

Literature

3372results about How to "Meet performance requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

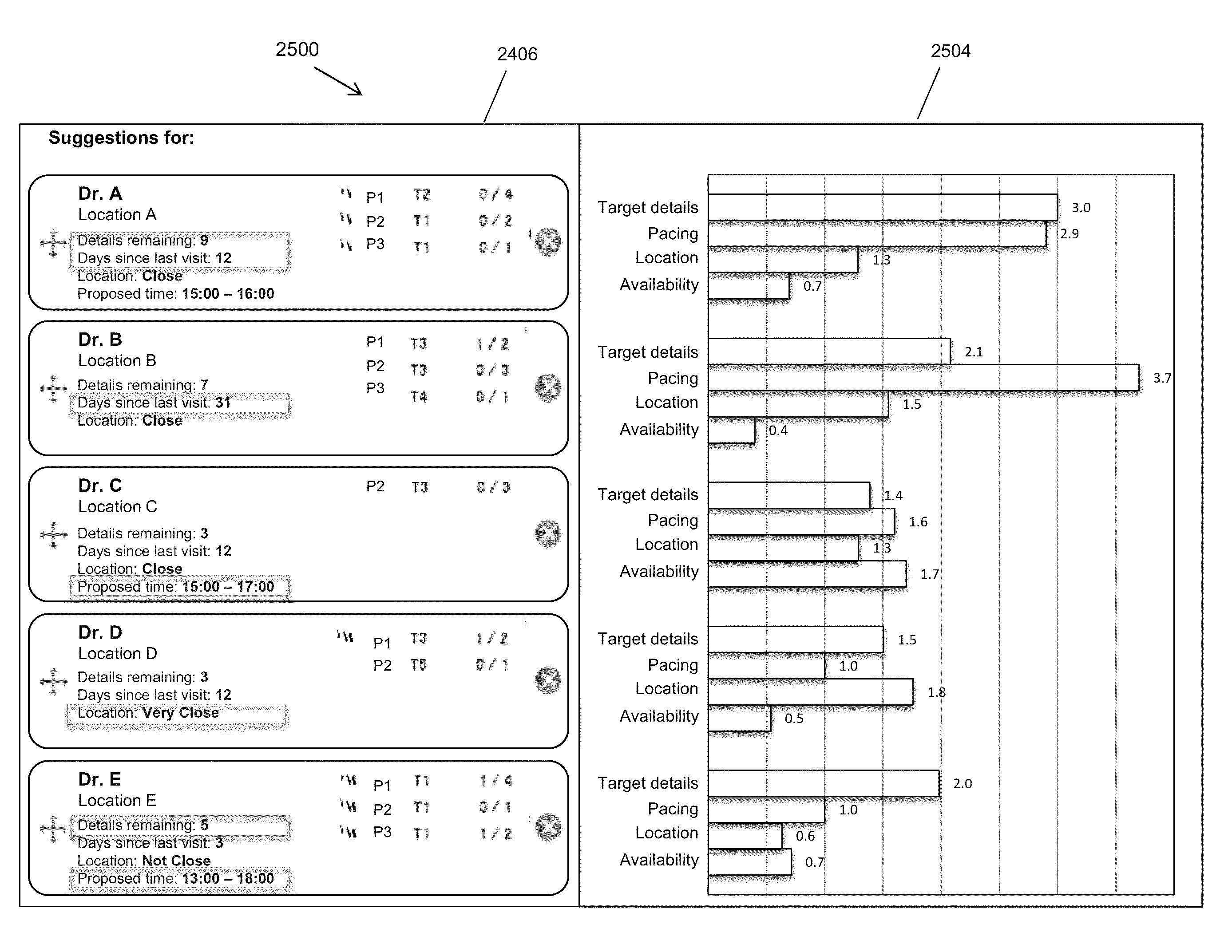

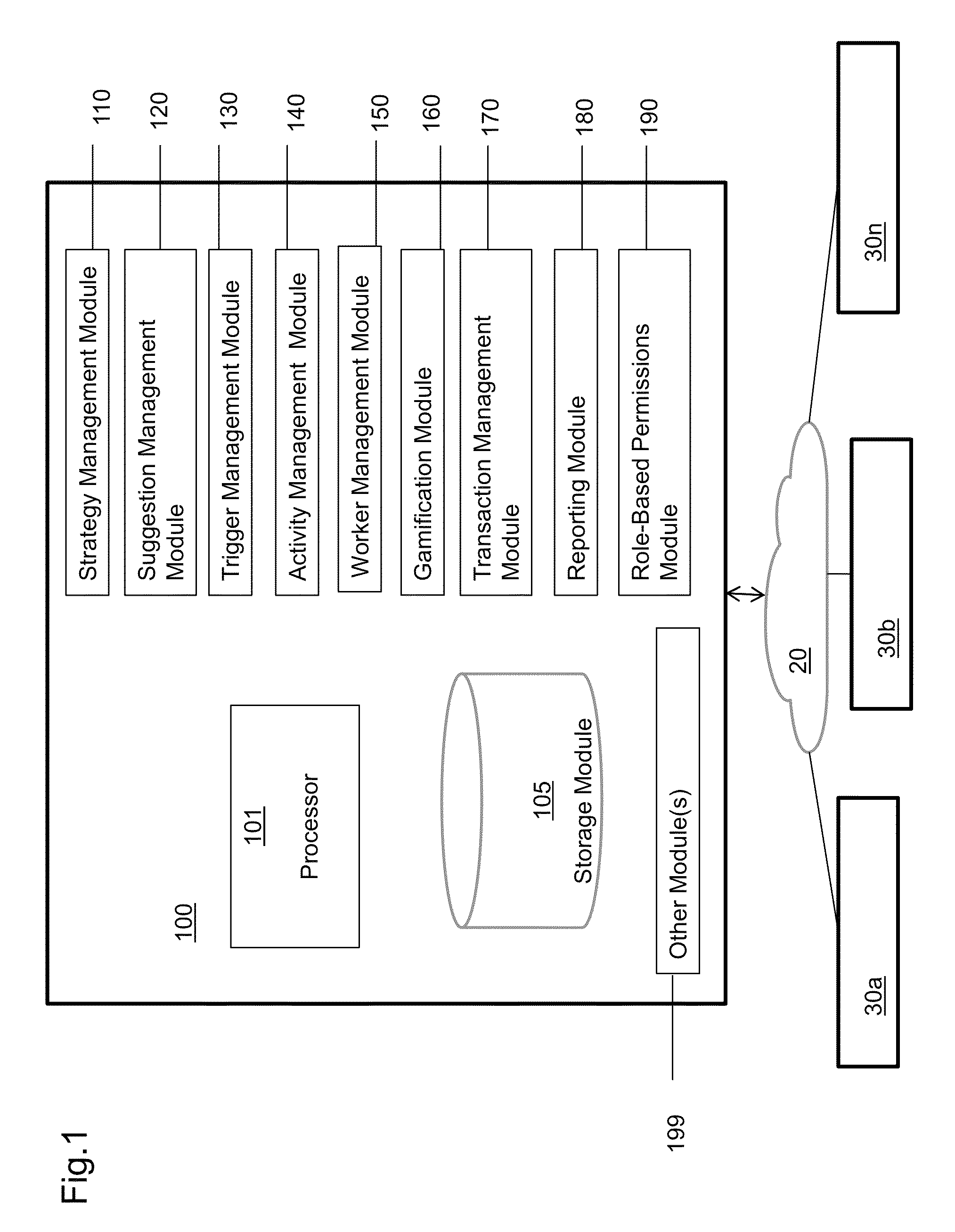

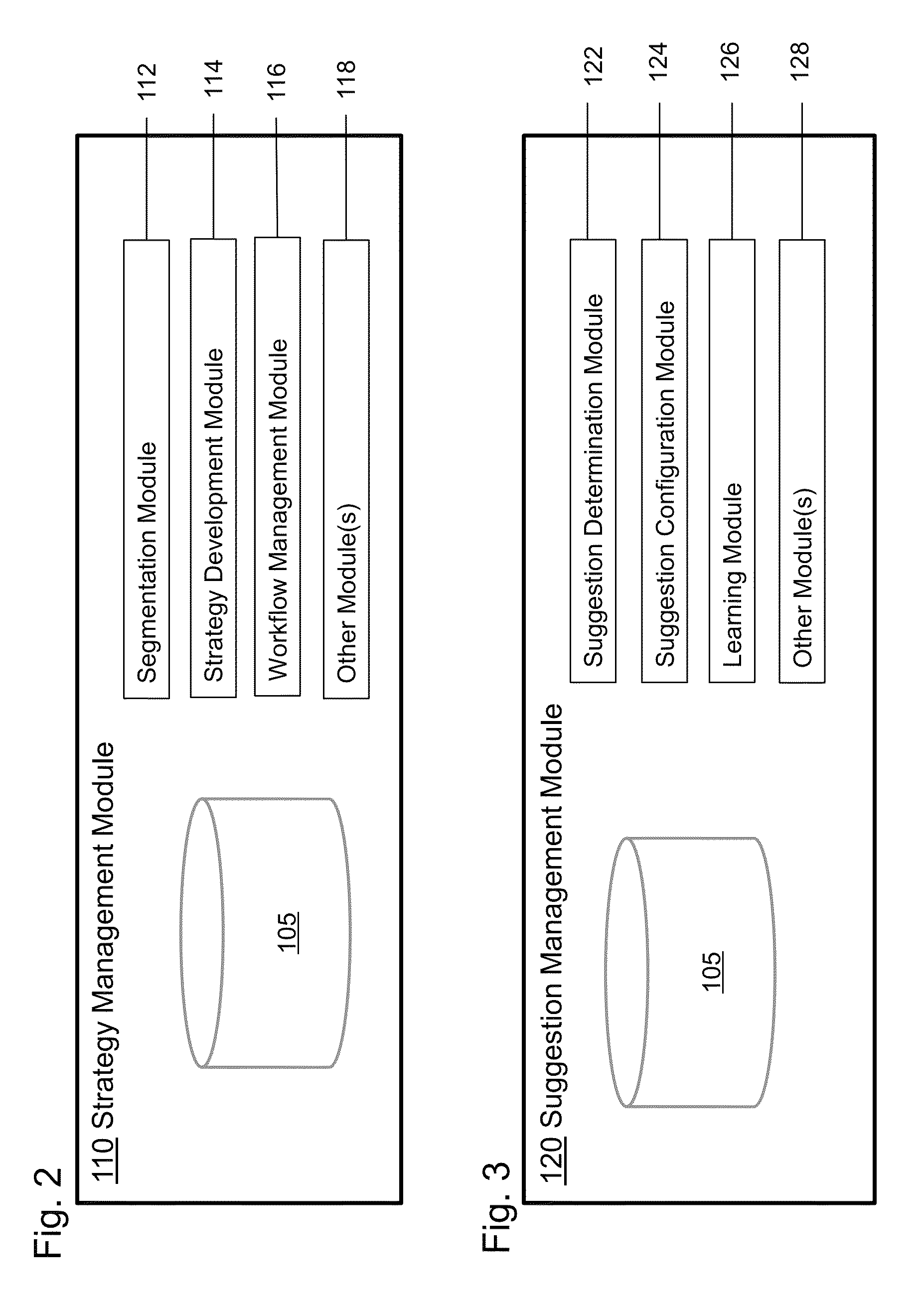

System and method for managing system-level workflow strategy and individual workflow activity

ActiveUS8744890B1Facilitate of suggestionImprove efficiencyInstrumentsTechnical standardKnowledge management

A system and method for managing workflow including the ability to manage system-level workflow strategy, manage individual workflow activity, and provide suggestions to optimize individual workflow activity, is provided. The system may provide suggestions to workers based on their schedules and activities that the workers have to perform. Users of the system may configure the criteria used in determining which suggestions to provide to workers. The system may refine the suggestions provided to workers based on feedback received regarding the suggestions previously provided.

Owner:AKTANA INC

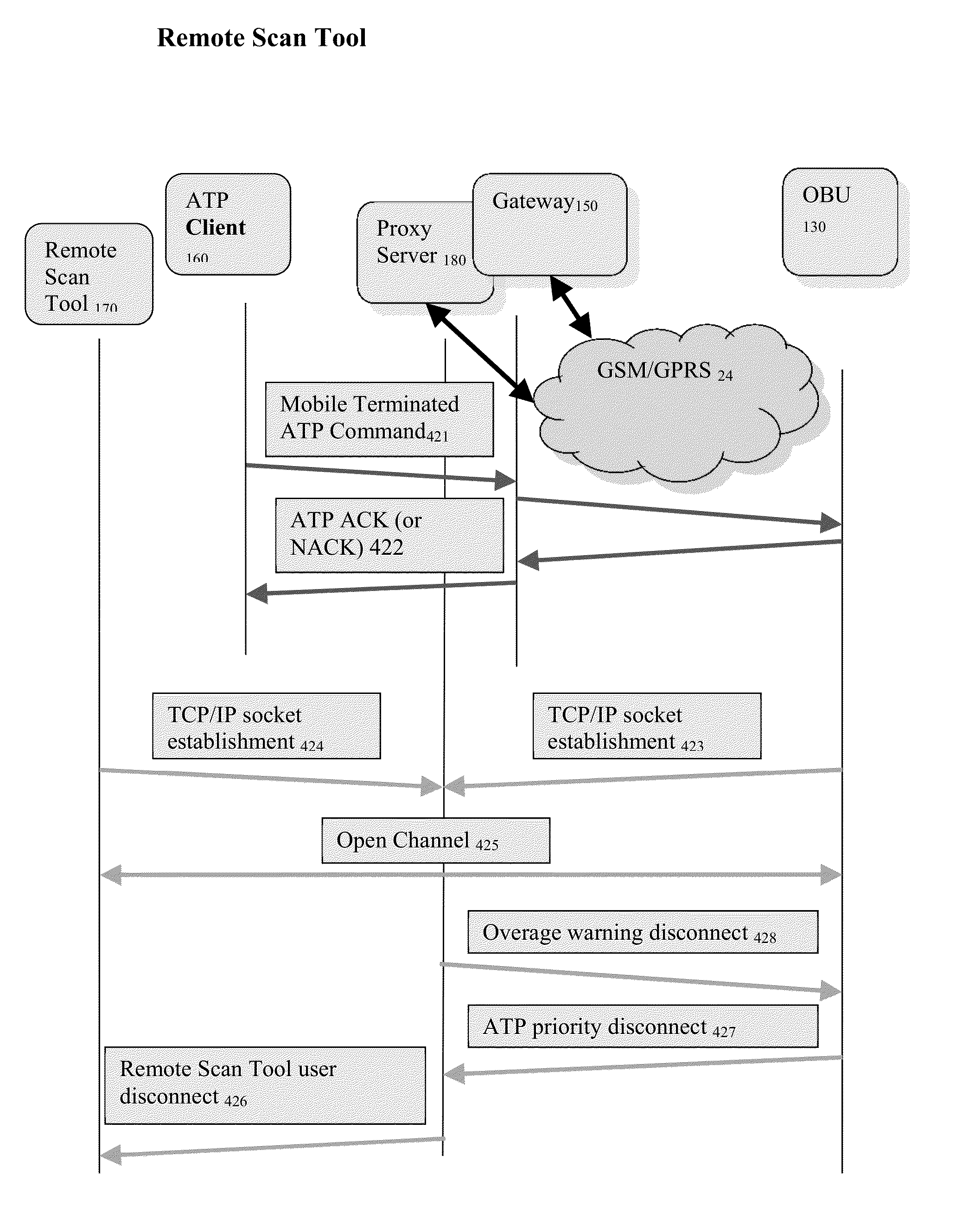

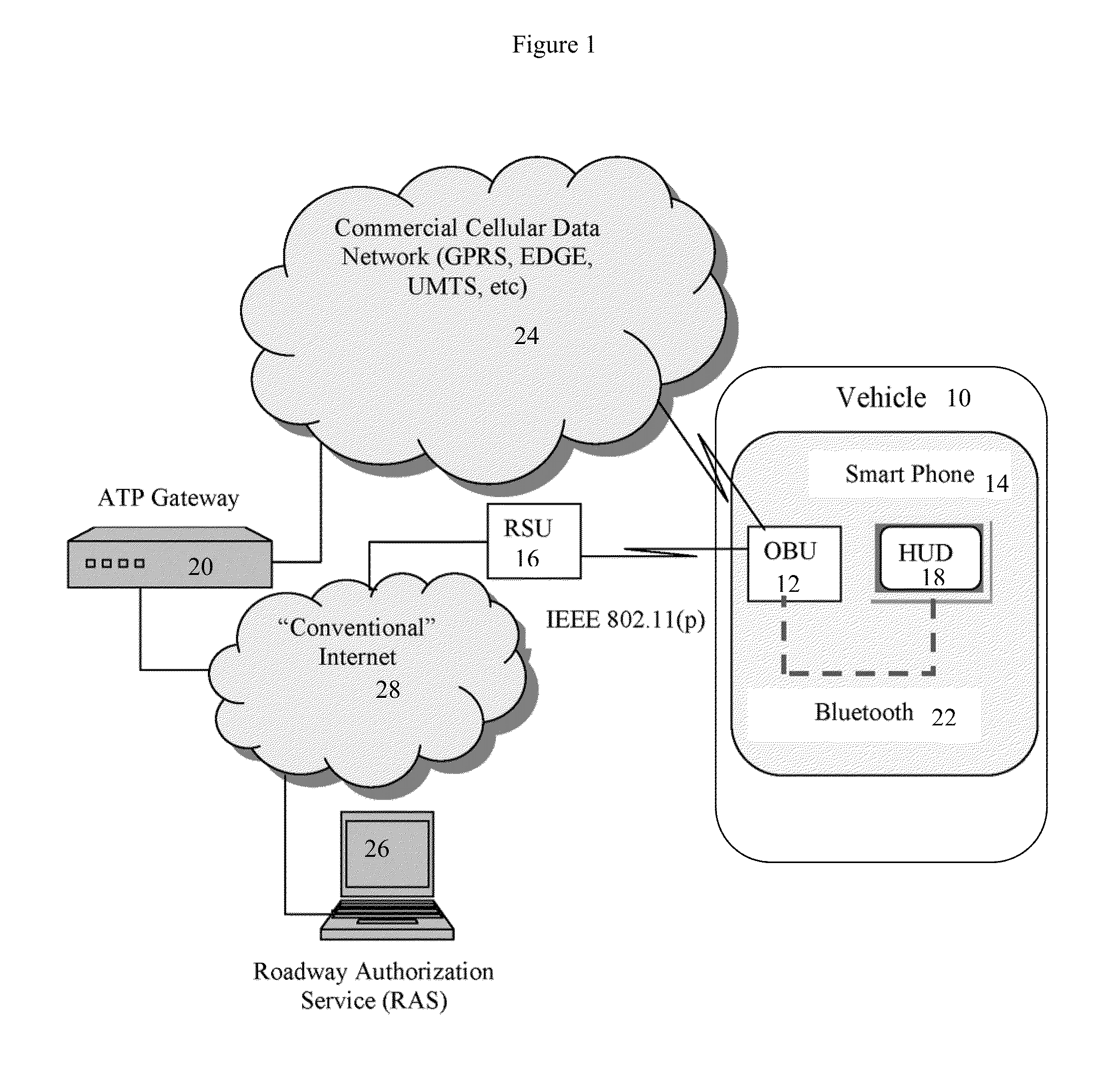

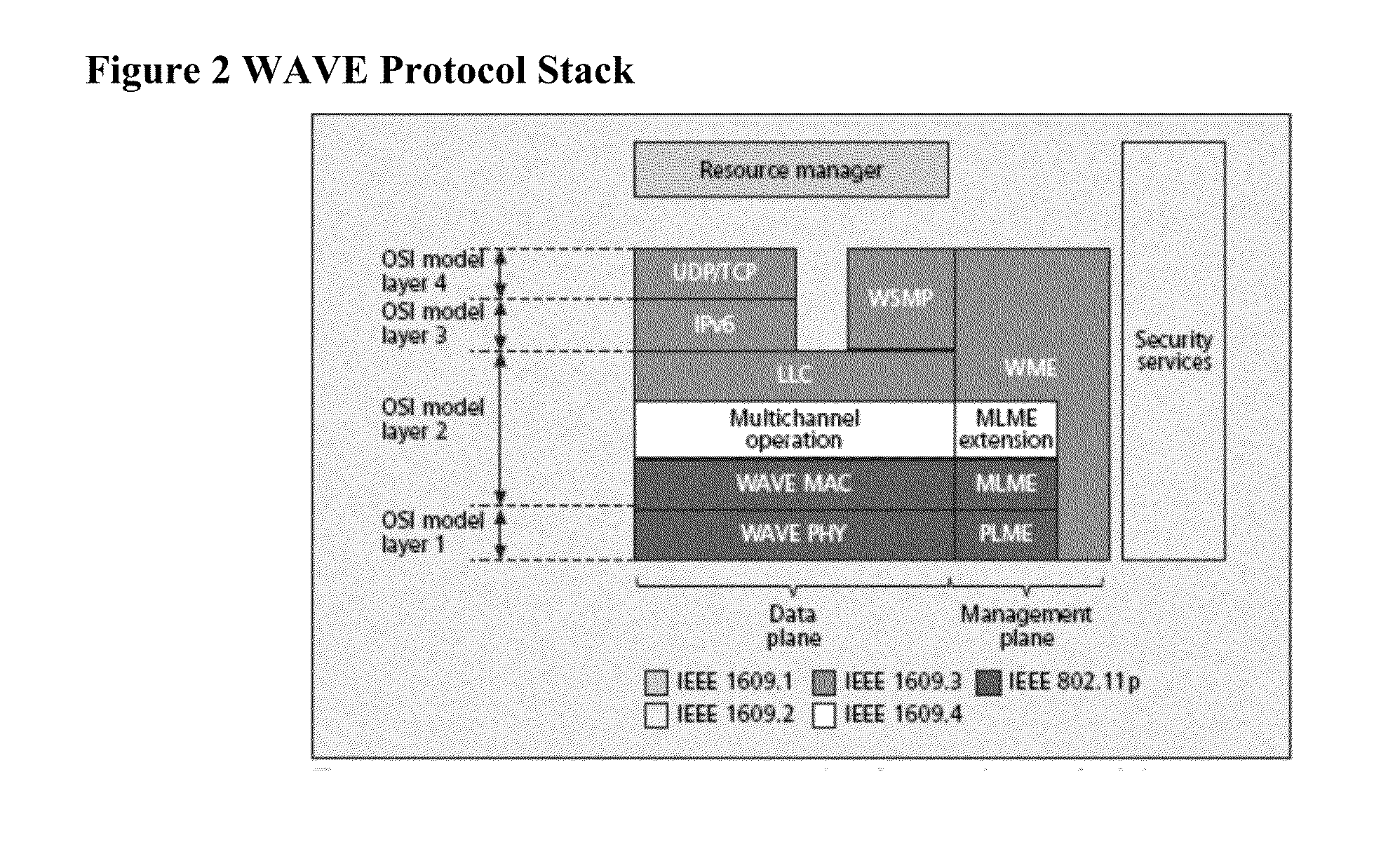

Vehicle communications via wireless access vehicle environment

InactiveUS20140195102A1Little and no hardware costImprove road safetyVehicle testingRegistering/indicating working of vehiclesControl signalStream data

Vehicle Communications using IEEE 802.11p WAVE functionality includes structure and method whereby a smart phone (SP) linked to an On Board Unit (OBU) having WAVE functionality, and incorporating Automotive Telemetry Protocol (ATP), has at least one processor to configure the SP as a GUI for the OBU, and to enable WAVE authentication of the SP through a networked Road Side Unit. Preferably, the OBU opens, after a command from an ATP Client, a virtual connection for streaming data between the vehicle data bus and a remote server providing an automotive scan tool. Also preferably, the SP may use either cellular or IEEE 802.11 control signals to trialaterate its geographic position with greater accuracy than GPS, and to hand off the geo-position fixes to the OBU. Accumulated geo-location information may be reported to a remote server, providing a centralized geographic trend analysis of plural SPs operating with OBUs.

Owner:PAXGRID TELEMETRIC SYST

Anti-sulfur well mouth valve body welding repair method

ActiveCN107520526AImprove carrying capacityAvoid softening problemsArc welding apparatusWelding/cutting media/materialsCarbon alloyTungsten

The invention belongs to the welding industry, and particularly relates to an anti-sulfur well mouth valve body welding repair method, and in particular to a welding repair method of 4130 medium-carbon alloy steel in an anti-sulfur valve body with the hardness being 197 HBW -237 HBW. The anti-sulfur well mouth valve body welding repair method is characterized by comprising the following steps that a product to be repaired is cleaned to determine a damage position; a pit badly eroded needs to be polished; a workpiece is totally preheated to 130 DEG C before welding; filling of the pit is firstly achieved by adopting the argon tungsten-arc welding; then, the machined surface is subject to repair welding; the local or total heat treatment insulation is performed for 3 hours at 640 DEG C; in the welding repair method, preheating is performed to reach 130 DEG C before welding; the local or total heat treatment insulation is performed for 3 hours at 640 DEG C after welding; and the Ar+CO2 mixed gas arc welding is adopted in the method, and the method greatly increases the product utilization rate and improves the comprehensive efficiency.

Owner:YANTAI JEREH PETROLEUM EQUIP & TECH

A welding repair method for anti-sulfur wellhead valve body

ActiveCN107520526BMeet the requirements of low temperature impact absorption energy greater than 27JAvoid softeningArc welding apparatusWelding/cutting media/materialsMachined surfaceMixed gas

The invention belongs to the welding industry, and particularly relates to an anti-sulfur well mouth valve body welding repair method, and in particular to a welding repair method of 4130 medium-carbon alloy steel in an anti-sulfur valve body with the hardness being 197 HBW -237 HBW. The anti-sulfur well mouth valve body welding repair method is characterized by comprising the following steps that a product to be repaired is cleaned to determine a damage position; a pit badly eroded needs to be polished; a workpiece is totally preheated to 130 DEG C before welding; filling of the pit is firstly achieved by adopting the argon tungsten-arc welding; then, the machined surface is subject to repair welding; the local or total heat treatment insulation is performed for 3 hours at 640 DEG C; in the welding repair method, preheating is performed to reach 130 DEG C before welding; the local or total heat treatment insulation is performed for 3 hours at 640 DEG C after welding; and the Ar+CO2 mixed gas arc welding is adopted in the method, and the method greatly increases the product utilization rate and improves the comprehensive efficiency.

Owner:YANTAI JEREH PETROLEUM EQUIP & TECH CO LTD

Flame-retardant polyester material with high glow wire ignition temperature and preparation method thereof

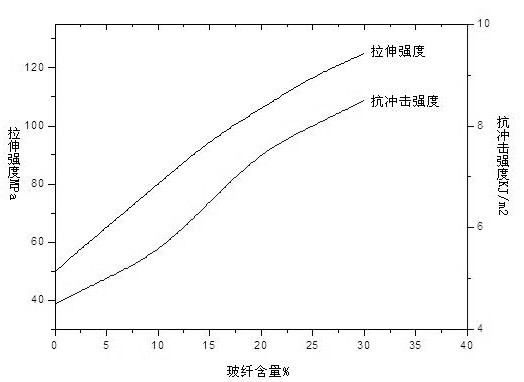

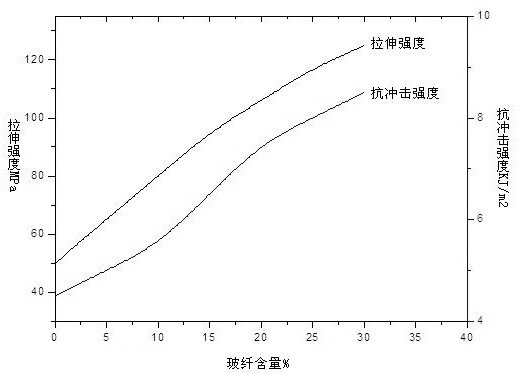

ActiveCN102250450AGWIT performance improvementsMeet performance requirementsPolyester resinUltimate tensile strength

The invention discloses a fame-retardant polyester material with a high glow wire ignition temperature and a preparation method thereof. The flame-retardant polyester material with a high glow wire ignition temperature is composed of the following components in parts by weight: 100 parts of polyester resins, 15-50 parts of bromine-series flame retardant, 5-20 parts of synergistic flame retardant, 0-20 parts of toughening agent, 0-80 parts of carbon forming agent, 5-40 parts of hot oxygen barrier agent, 0-120 parts of fibrous reinforcing agent and 0-10 parts of processing aid. The preparation method of the flame-retardant polyester material with a high glow wire ignition temperature comprises: drying the polyester resins, mixing with other components to obtain a premixed material, then feeding the premixed material into a twin-screw extruder, melting and plasticizing, kneading and mixing, extruding, drawing, cooling, pelletizing, drying and finally packaging. The flame-retardant polyester material with a high glow wire ignition temperature has the advantages of low cost, high glow wire ignition temperature, similar mechanical strength to ordinary flame-retardant polyester and wide application range.

Owner:KINGFA SCI & TECH CO LTD +1

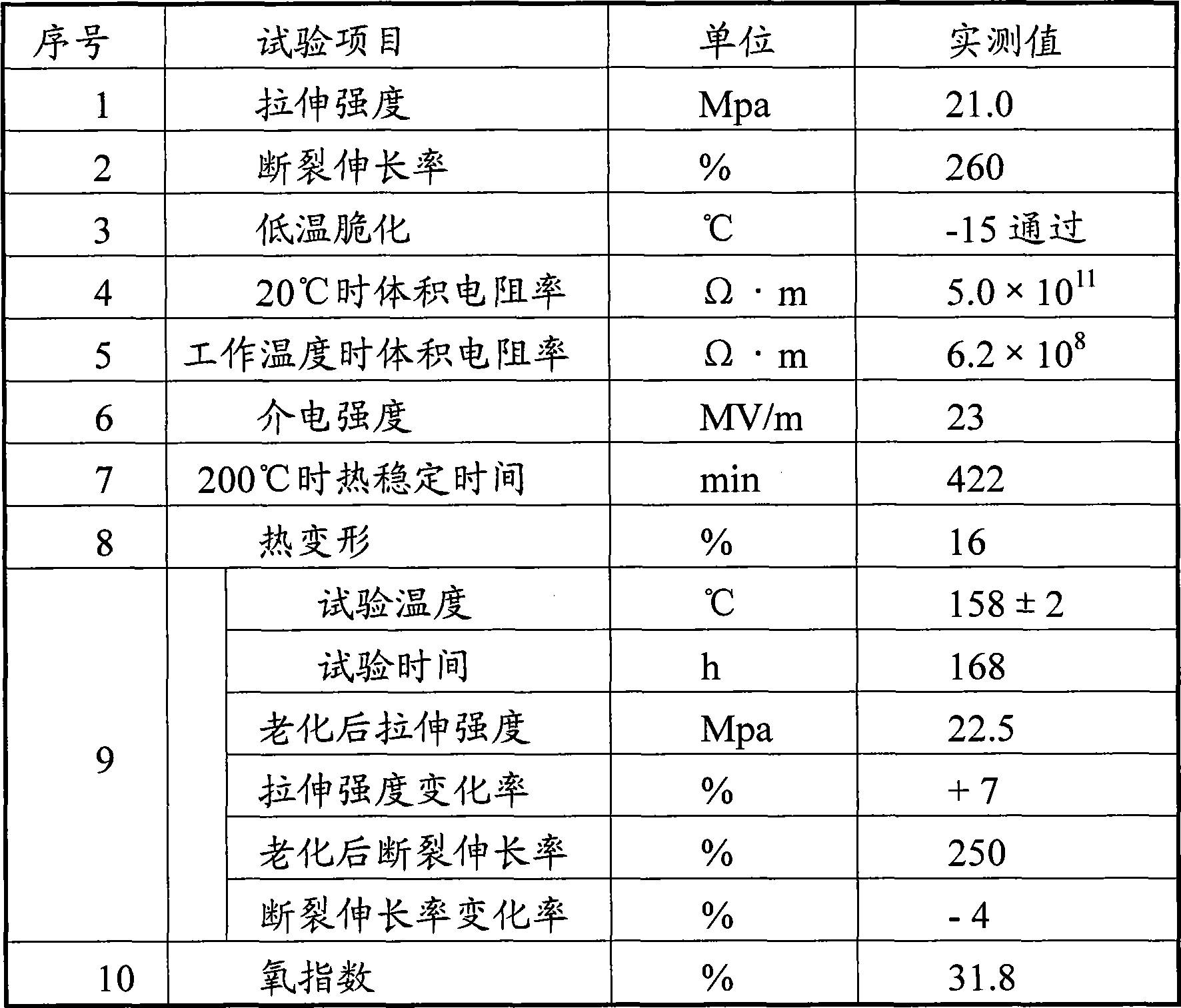

High temperature resistant environment-protective polychloroethylene material for electric wire and cable

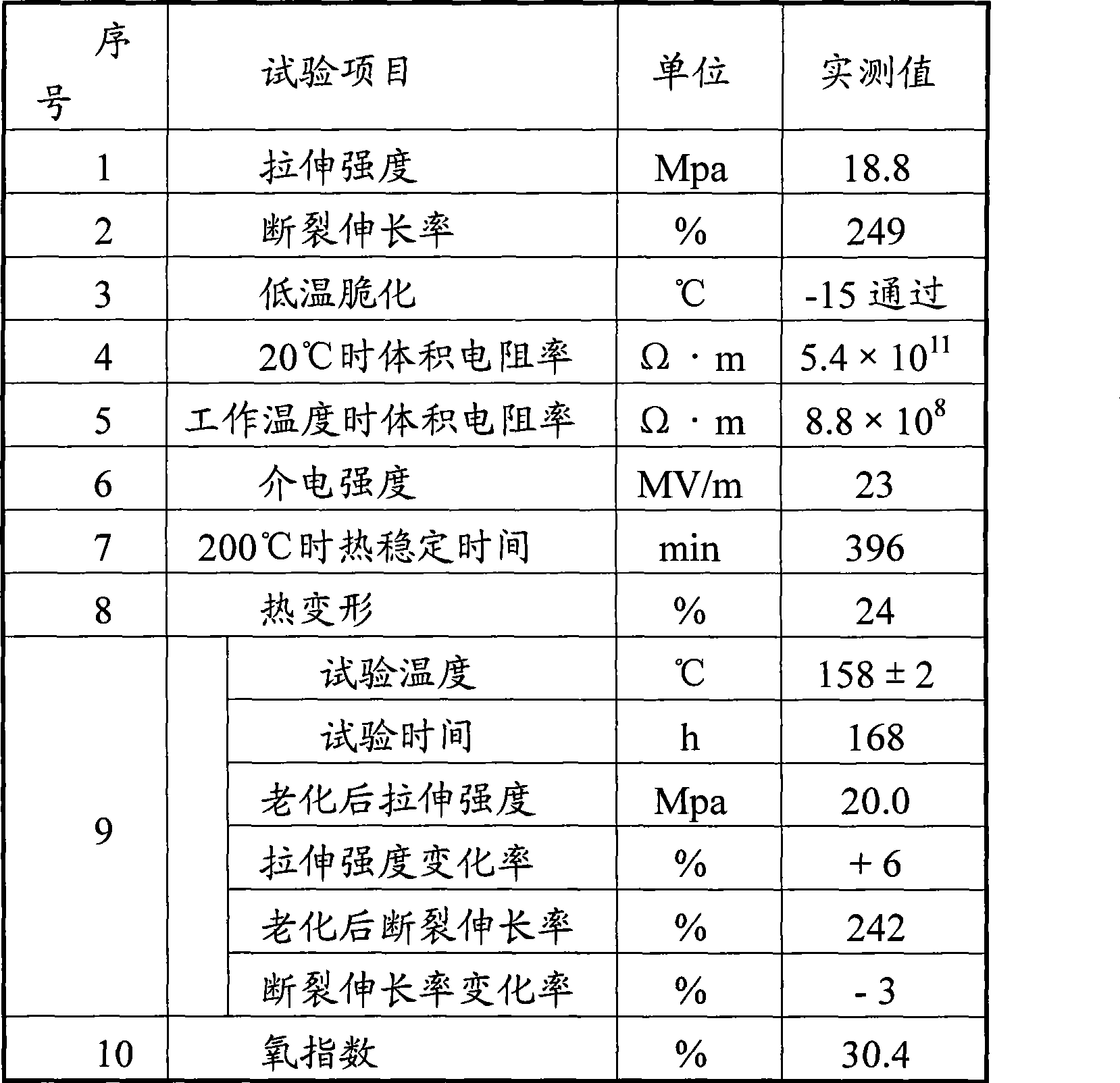

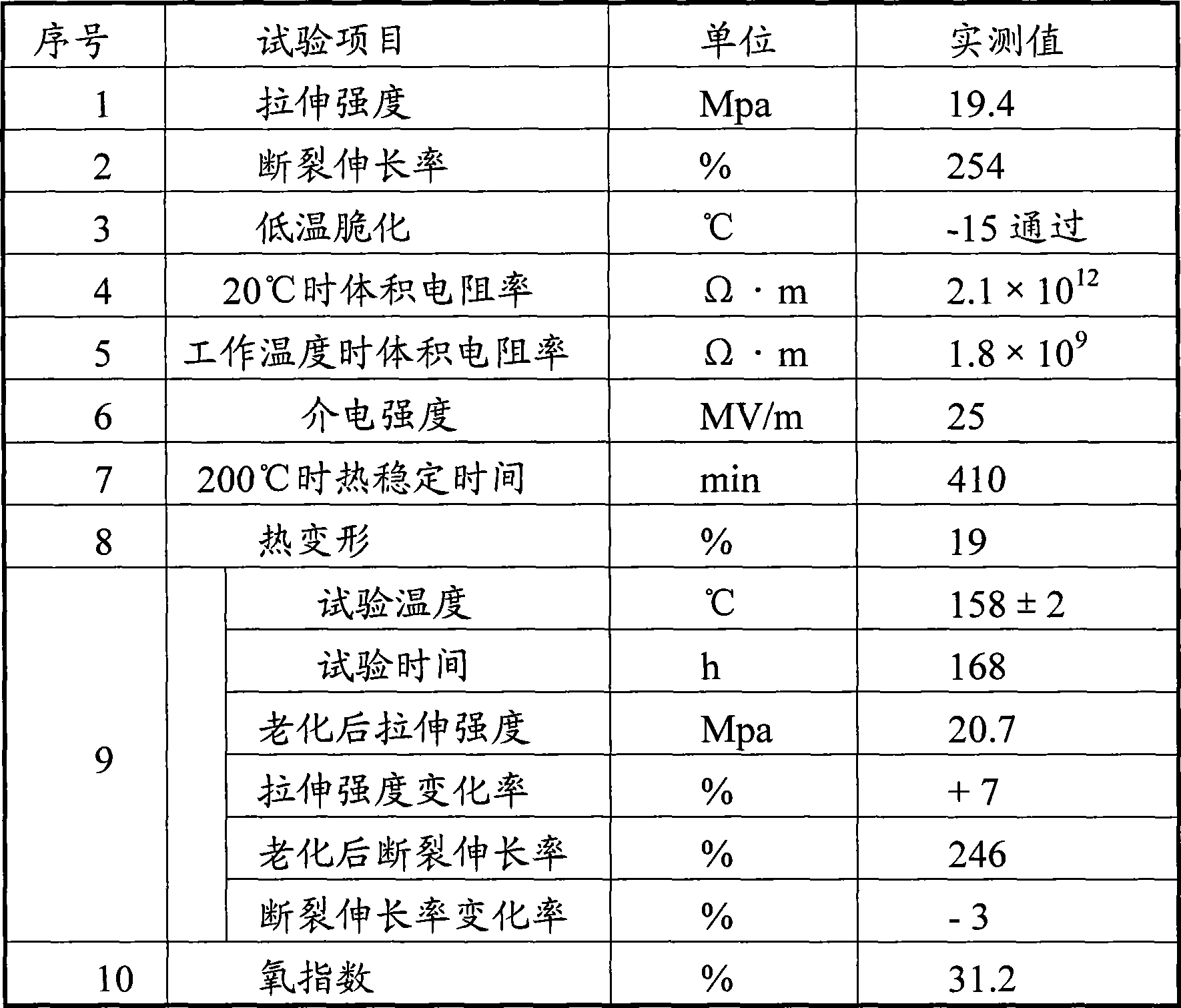

InactiveCN101412834AImprove mechanical propertiesImprove insulation performancePlastic/resin/waxes insulatorsInsulated cablesPolyesterPolyvinyl chloride

The invention provides a high-temperature resistant environment-friendly polyvinyl chloride material for wires and cables. A raw material formulation mainly comprises the following materials in weight portion: 80 to 120 portions of loose-type polyvinyl chloride resin, 20 to 55 portions of tetraoctyl pyromellitate, 5 to 35 portions of polyester plasticizer and 12 to 18 portions of calcium-zinc stabilizer, wherein the polymerization degree of the loose-type polyvinyl chloride resin is between 2,000 and 3,000; in the calcium-zinc stabilizer, the total content of lead, cadmium, mercury and hexavalent chromium is less than or equal to 10 ppm of the total weight of the calcium-zinc stabilizer; the polyester plasticizer is polypropylene-1, 2-glycol adipate or polypropylene-1, 3-butylene terephthalate; and the molecular weight of the polyester plasticizer is between 3,000 and 4,000. After the material is aged in a hot-air oven for 168 hours at 158 DEG C, the retention rate of tensile strength is up to 106 percent; the retention rate of elongation at break is 97 percent; and the material is good in mechanical physical properties and insulating property. Therefore, the material meets the temperature-resistant requirement on long-term operating temperature at 125 DEG C in UL1581.

Owner:中广核三角洲(江苏)塑化有限公司

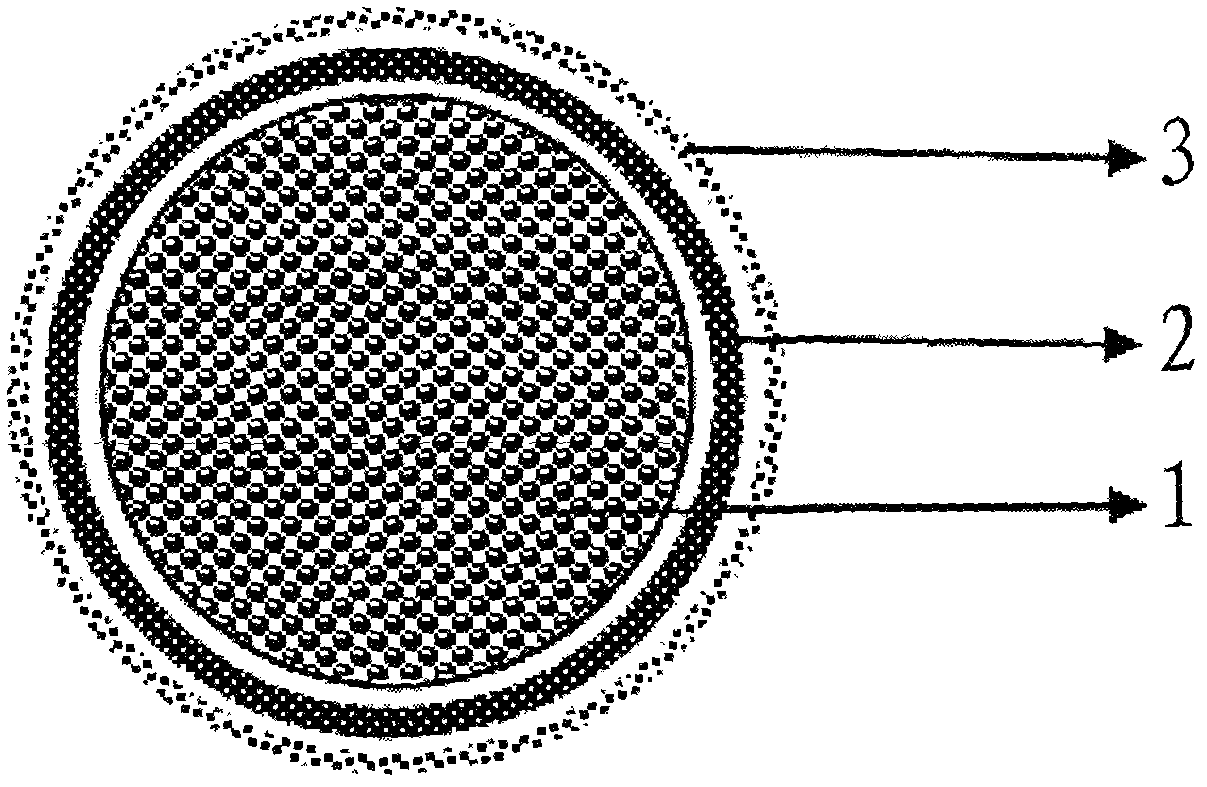

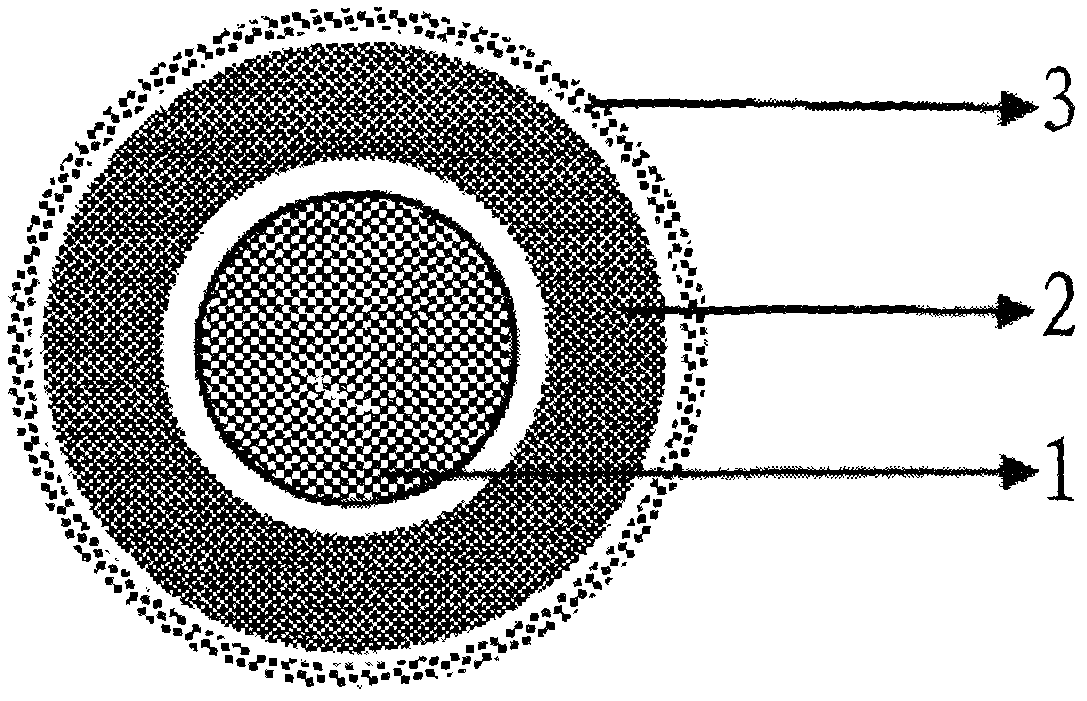

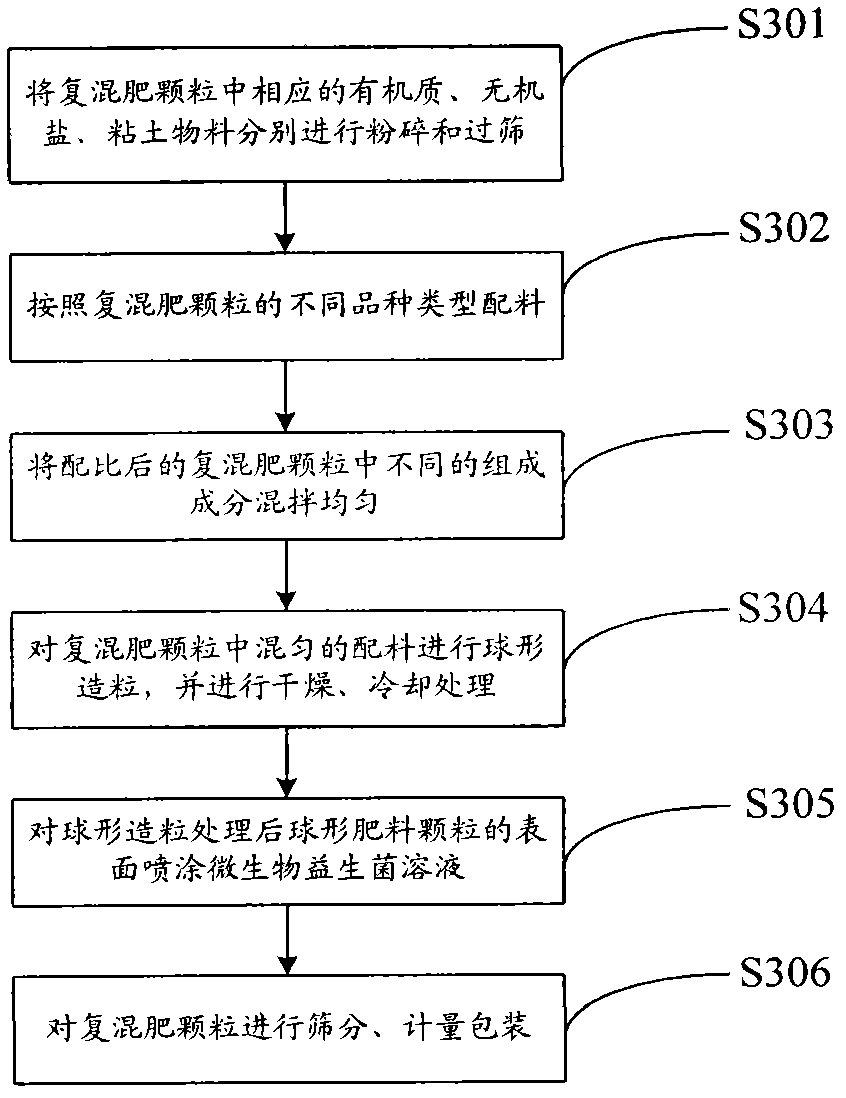

Slowly-releasing water conservation biological organic and inorganic compound fertilizer particles and production method thereof

InactiveCN102584477AGuaranteed nutrient supplyPromote conversionEnergy inputFertiliser formsContinuous croppingHigh concentration

The invention belongs to the technical field of bio-organic fertilizer production, and provides slowly-releasing water conservation biological organic and inorganic compound fertilizer particles and a production method thereof. The fertilizer has the advantages of reasonable structure, unique processing technique, scientific formulation, high fertilizer effect, improved soil physical condition, convenience application, and wide application scope; high-grade bio-organic fertilizer meeting the requirements of organic agricultural vegetable, fruits or food production, or fertilizer having special functions of drought resisting, saline and alkaline resisting and continuous cropping resisting and capable of specially meeting fertilizer requirement rules of various crops can be further designed and developed. The fertilizer effect playing way in the invention is unique, and component parts such as probiotics, inorganic nutrients, regulatory factors, organic matter and the like can be respectively played in time and space. Through the design to fertilizer particle structure and formula, the advantages of organic matter, high concentration of inorganic fertilizer, slowly-releasing efficiency and the special effects of beneficial microorganisms are integrated and slowly-releasing water conservation biological organic and inorganic compound fertilizer particles can be the first choice in replacing organic and inorganic compound fertilizers, compound fertilizers and inorganic slow release fertilizers.

Owner:贾洪涛

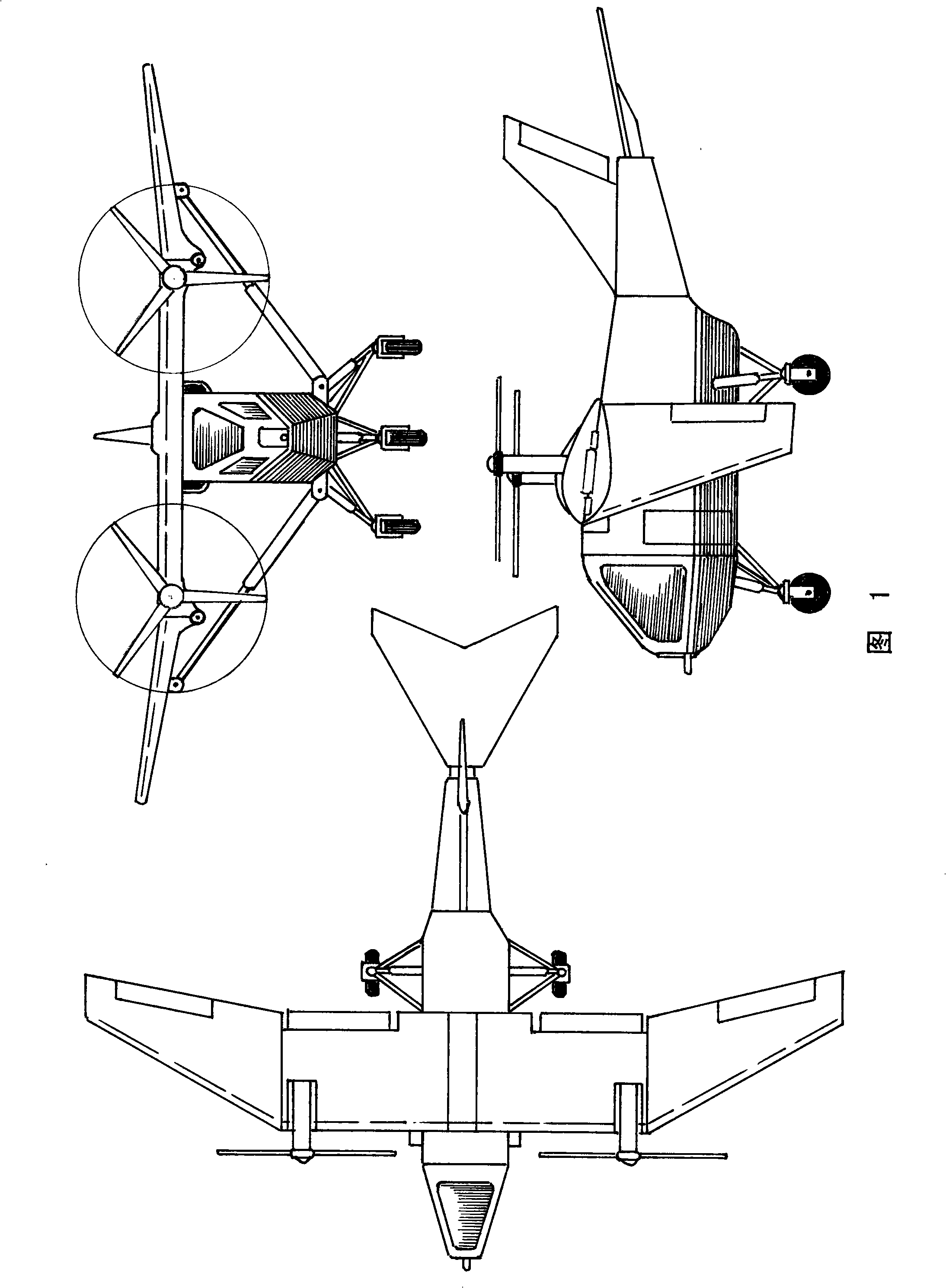

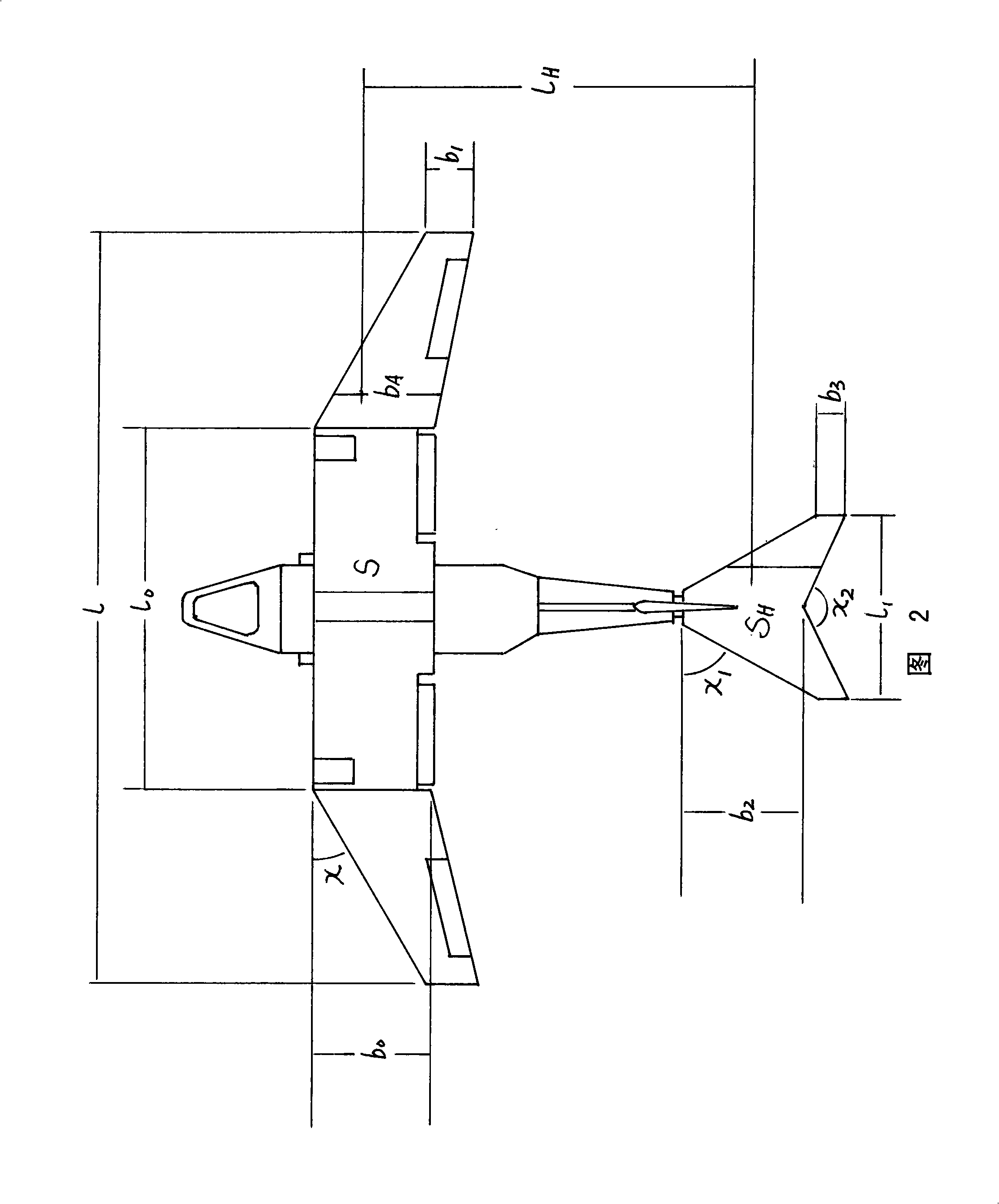

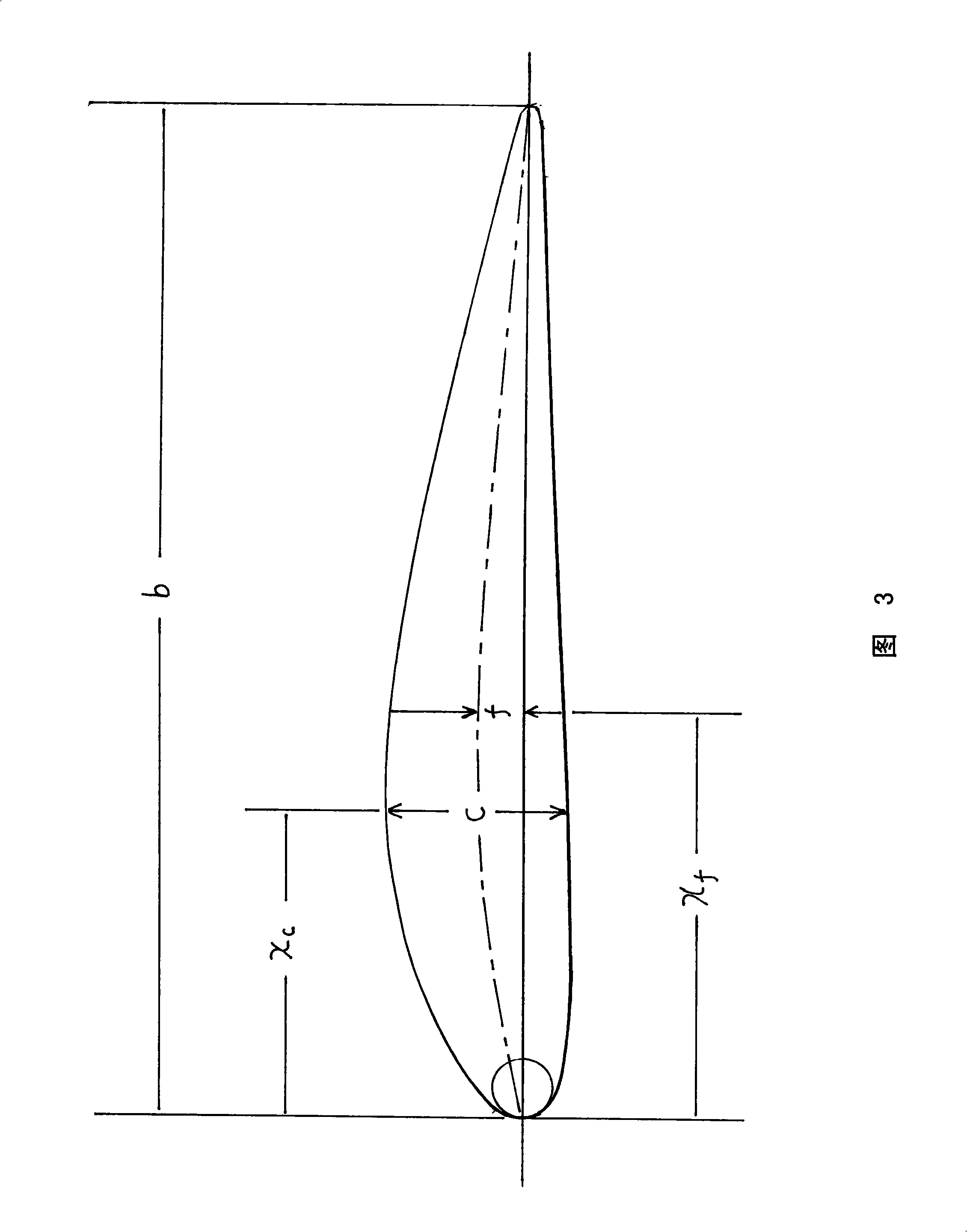

Swallow type inclined rotation rotorcraft

ActiveCN101314409AMeet performance requirementsGive full play to the advantagesRotocraftRotary wingHinge angle

The invention relates to a swallow-type tilt-rotor aircraft, which integrates a helicopter with a fixed-wing aircraft. With external shapes changed, three aircraft types, namely the helicopter, the fixed-wing aircraft and the tilt-rotor aircraft, can be used for flying independently. The aircraft adopts a swallow-type aerodynamic configuration and has a geometrical shape similar to a swallow among flyers. The aircraft is provided with a hydraulic staypole folding wing; an outer segment wing and a middle segment wing are in hinged connection and can be folded downwards and stretched upwards; a coaxial tilt-rotor system is arranged on a wing beam structure of the middle segment wing, forming a horizontal-type double-rotor configuration; two pairs of rotors can rotate to and fro between a vertical position and a horizontal position; when the rotors are positioned in the vertical position and the outer segment wing is folded downwards, the aircraft is a helicopter; when the rotors are positioned in the horizontal position and the outer segment wing is stretched upwards, the aircraft becomes a fixed-wing aircraft. The aircraft is provided with a combined-type engine system consisting of a plurality of engines and a common axis, thereby having reliable safety performance. The aircraft is simple in structure, good in performance and wide in practical range.

Owner:周武双

Low alloy high-strength steel plate capable of being welded in large energy input and method of producing the same

ActiveCN101153370AImprove toughnessSimple designRoll mill control devicesHeat treatment process controlHeat-affected zoneSheet steel

The invention provides a high strength low alloy steel plate suitable for high heat input welding and is characterized in that the chemical composition (wt percent) of steel comprises 0.04 percent to 0.16 percent of C, 0.10 percent to 0.50 percent of Si, 0.40 percent to 1.8 percent of Mn, 0.020 percent to 0.050 percent of Nb, 0.006 percent to 0.030 percent of Ti, 0.0030 percent to 0.010 percent of N, 0.015 percent to 0.060 percent of Al and the rest, Fe and other inevitable impurities; meanwhile, C+Mn / 6+Si / 24+Ni / 40+Cr / 5+Mo / 4+V / 14 is less than or equal to 0.45 percent and the total amount of Ti and the total amount of N are that [Ti percent]T is more than or equal to 2.667[N percent]T-0.004667 percent; moreover, Ti microalloying is adopted to ensure that the Ti / N ratio in the second sort of particle generated ranges between 2.4 and 3.2. The manufacture method of the steel plate adopts austenite recrystallization zone and austenite non-recrystallization zone rolling and forced water cooling after rolling; moreover, when the steel plate is under 50 KJ / cm to 150 KJ / cm high heat input welding, the welding heat affected zone has excellent toughness. The invention has the advantages of simple production process, low cost and wide applicability.

Owner:ANGANG STEEL CO LTD

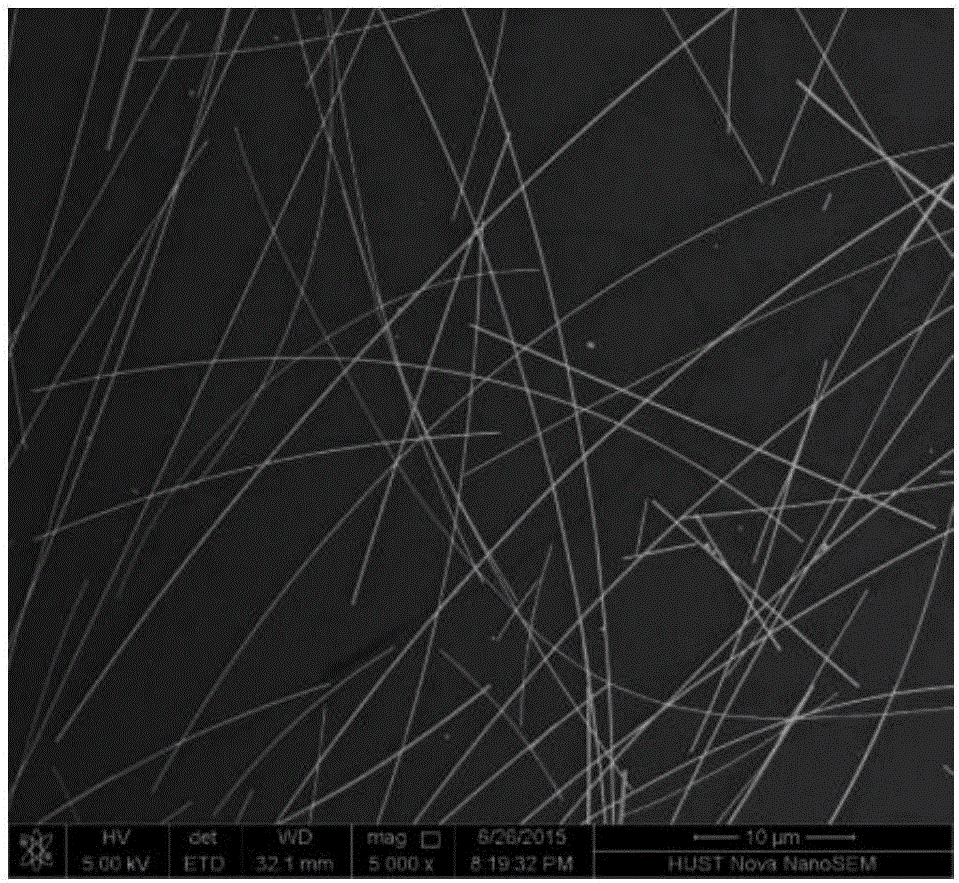

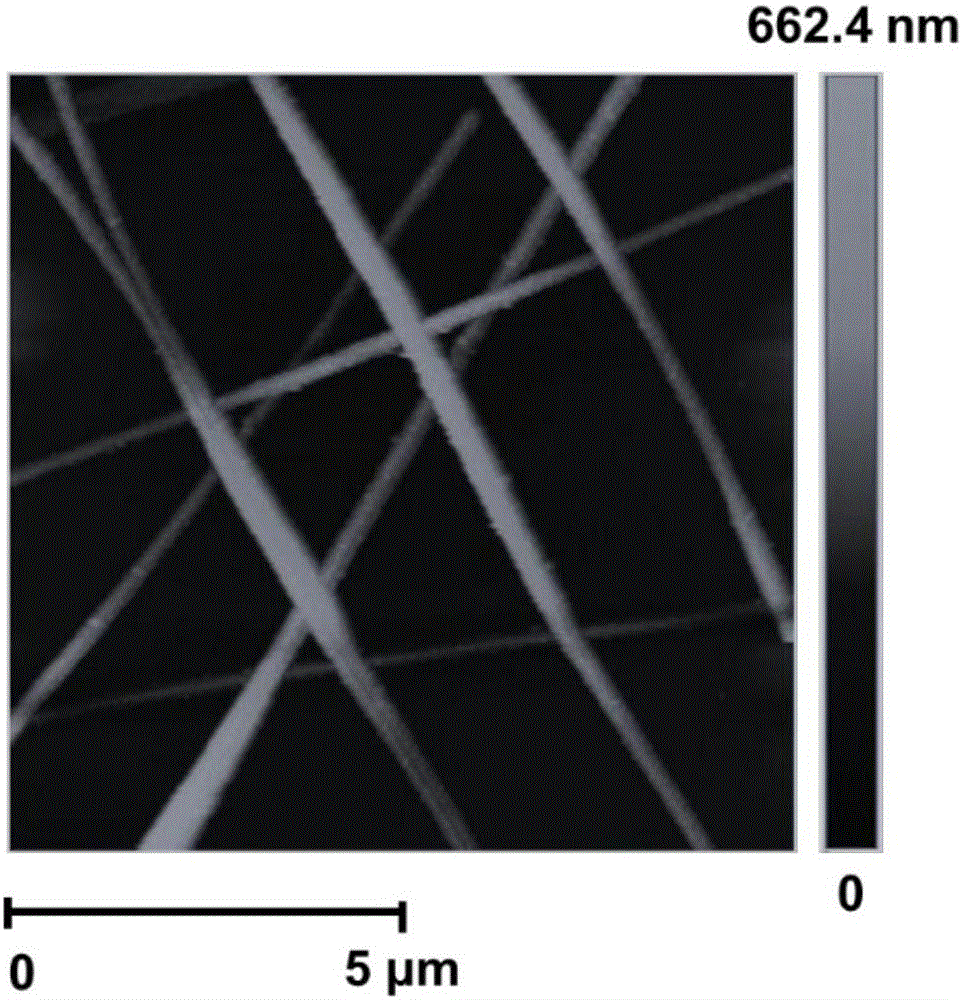

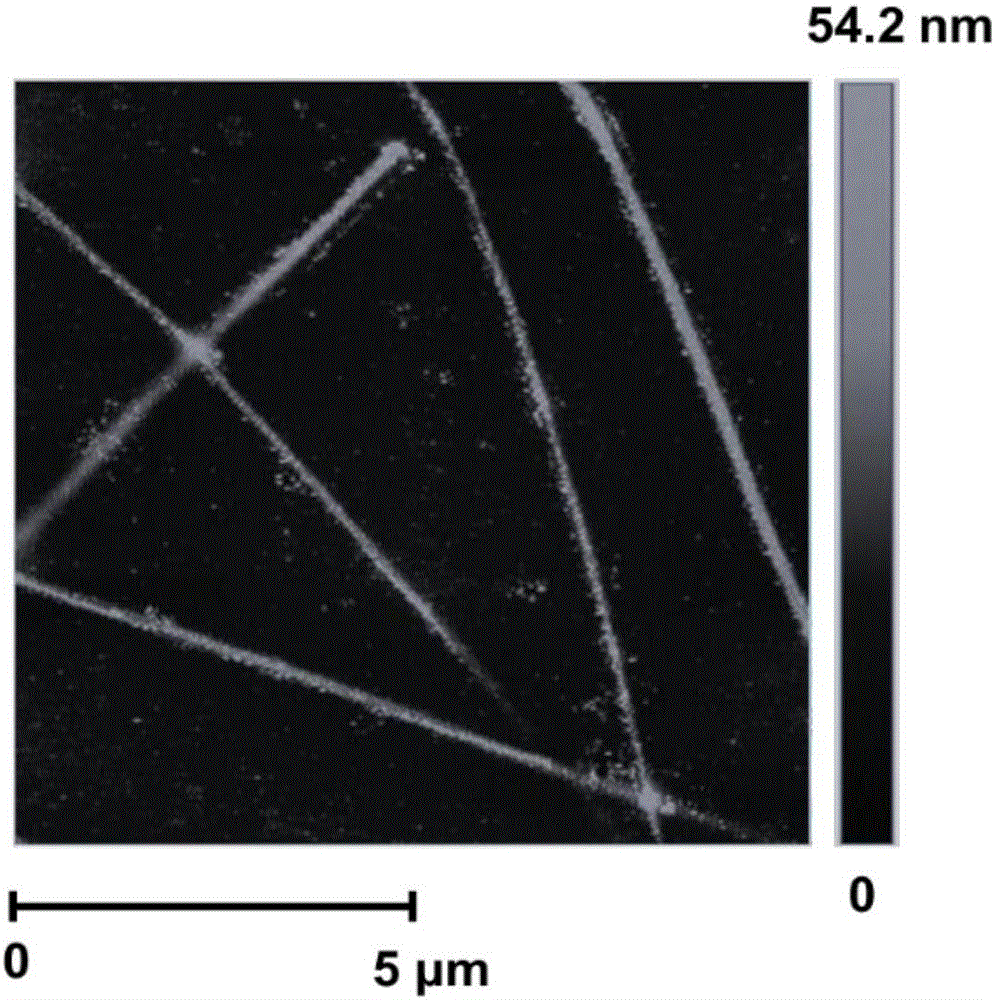

Low-roughness and low-square-resistance flexible transparent conductive composite thin film and preparation method therefor

ActiveCN106782769AReduce roughnessImprove conductivityConductive layers on insulating-supportsApparatus for manufacturing conducting/semi-conducting layersPolymer thin filmsSolar battery

The invention belongs to the technical field of photo-electronics, and more specifically relates to a low-roughness and low-square-resistance flexible transparent conductive composite thin film, wherein the thin film adopts a three-layer composite structure; the lowest bottom layer is provided with a transparent polymer thin film; the middle layer is provided with a conductive network formed by metal nanowires; the topmost layer is a provided with a transparent conductive layer which uniformly covers the transparent polymer thin film and the conductive network; the flexible transparent conductive composite thin film is less than 20-nanometer in average roughness, less than 30-ohm / square meter in square resistance, and greater than 80% of light transmittance within a visible light range; and the transparent conductive thin film can bear bending with radius of curvature of 2mm. The invention also discloses a preparation method for the flexible transparent conductive composite thin film. The flexible transparent conductive composite thin film provided by the invention has low roughness, high conductivity, high light transmittance, simple preparation method and low cost, and is particularly suitable for flexible display and illumination, a flexible solar battery and flexible touch equipment.

Owner:HUAZHONG UNIV OF SCI & TECH

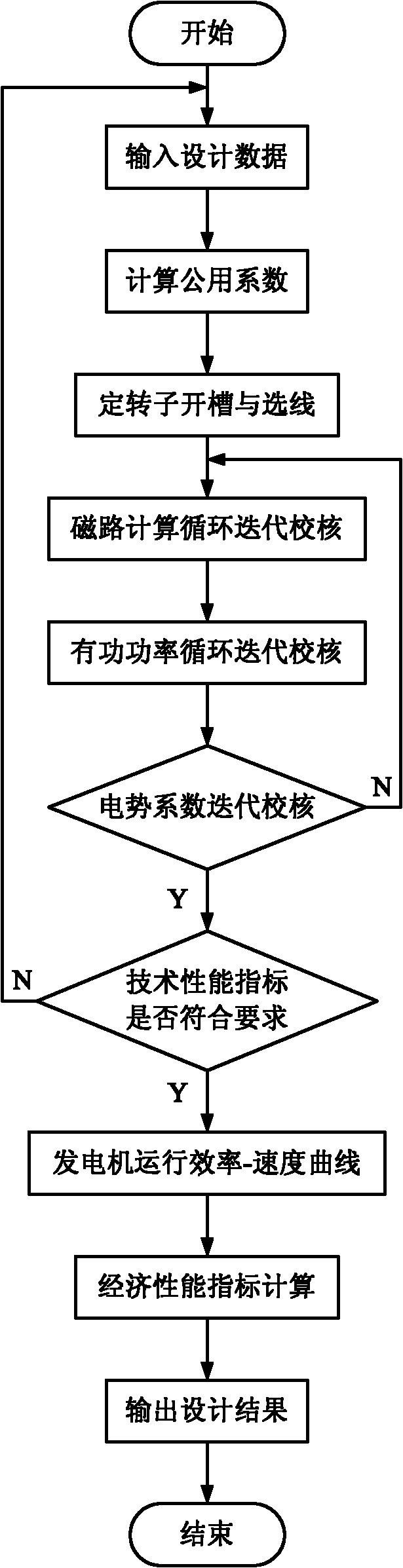

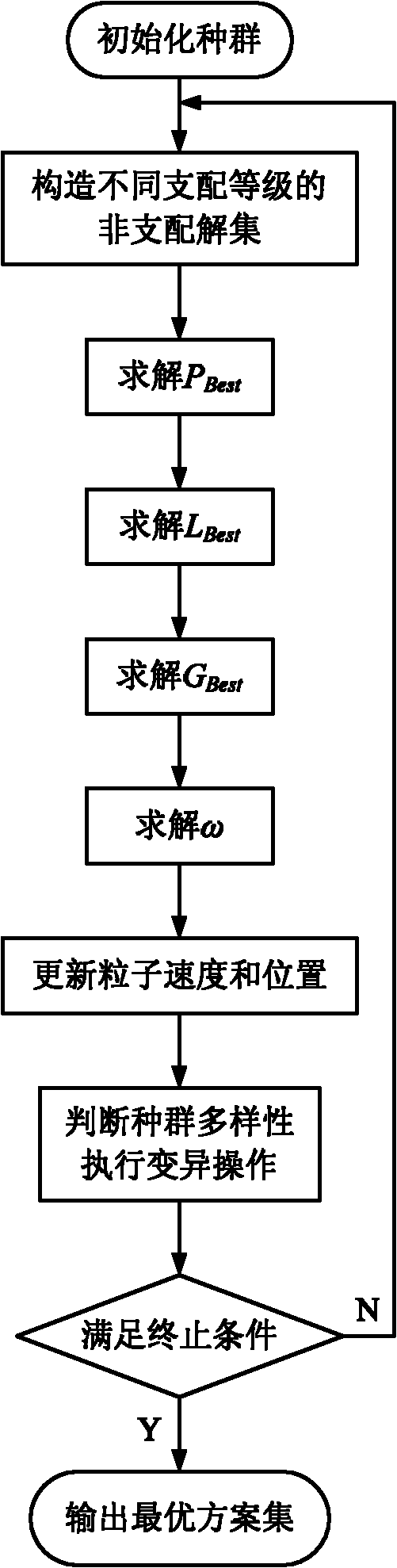

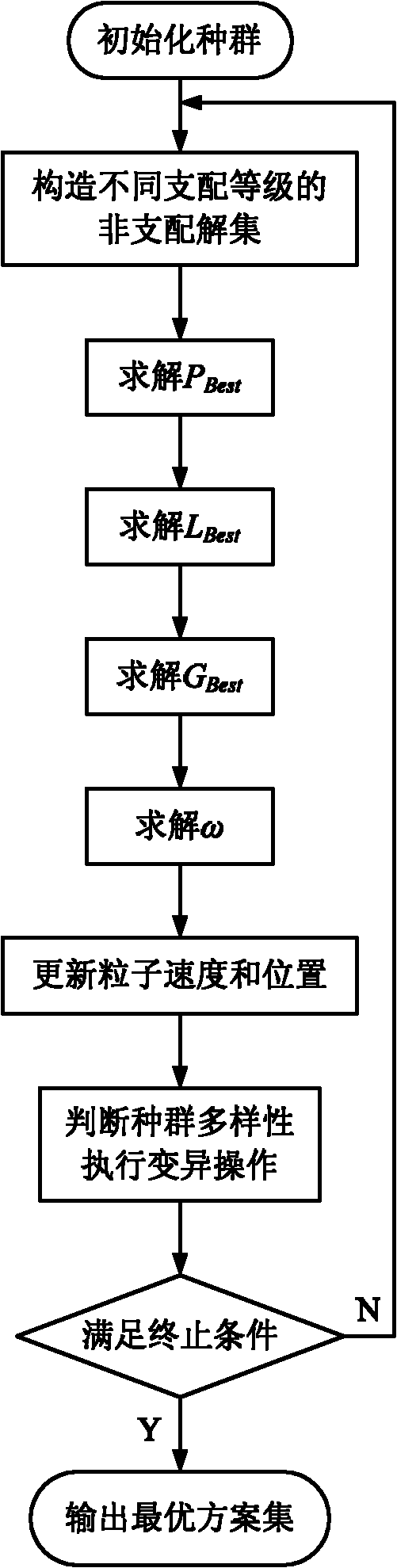

Multi-objective hybrid particle swam optimization design method for double-fed wind power generator

InactiveCN101833607AMeet performance requirementsIncrease cost benefitAC motor controlSpecial data processing applicationsSimulationWind power generation

The invention belongs to the field of motor optimization designs, and relates to a multi-objective hybrid particle swam optimization design method for a double-fed wind power generator. The method comprises the following steps of: (1) determining a constraint condition and a to-be-optimized design variable of the double-fed wind power generator, and establishing sub-objective function equations to form a multi-objective function; (2) constructing variable space by using the to-be-optimized design variable, and constructing non-dominated solution sets of population according to the quality of an objective value; (3) ordering the non-dominated solution sets according a Pareto domination mechanism, determining a population niche by taking a non-dominated solution as a core, establishing a particle speed updating mechanism and finally obtaining an optimal design scheme; manufacturing a mode machine according to the optimal design scheme, inspecting an actual operation index of a motor, and comparing the actual operation index with an index given by the design scheme; and if the actual operation index exceeds a requirement range of operation indexes, adjusting a performance design scheme. Due to the adoption of the motor optimization design method provided by the invention, overall economic benefit and wind energy utilization rate of a wind power generating system can be improved.

Owner:TIANJIN UNIV

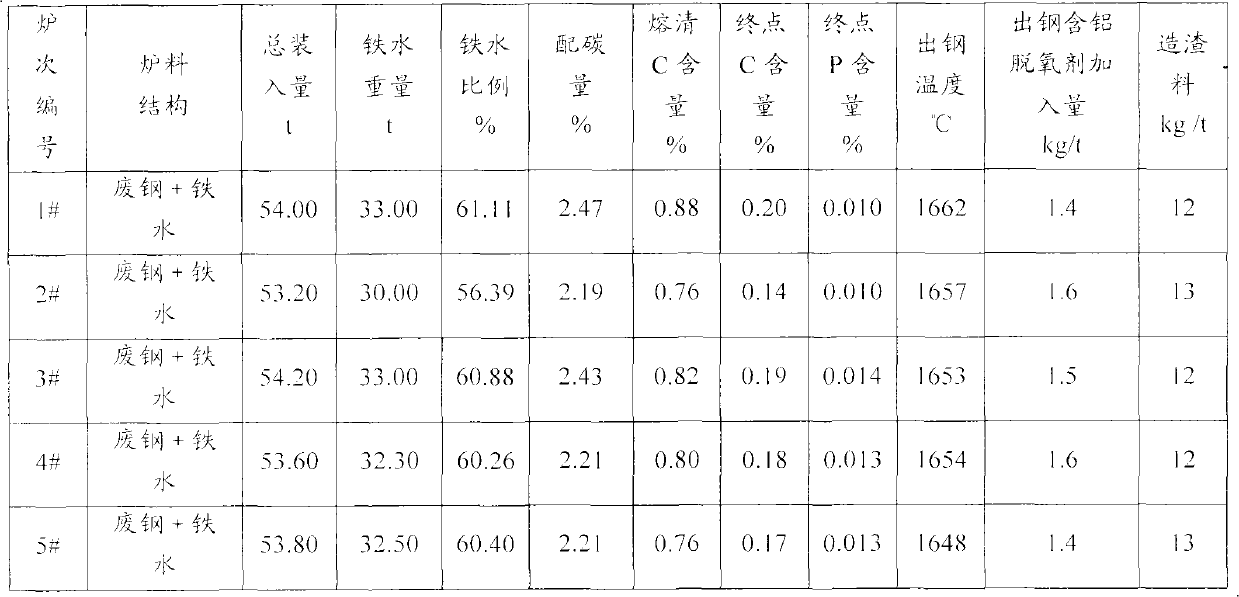

Ultrahigh-malleability tunnel supporting anchor rod steel of converter continuous cast billet and production method

The invention relates to ultrahigh-malleability tunnel supporting anchor pile steel of converter continuous cast billet and a production method, which belongs to the technical field of a mine anchor rod. The anchor rod steel comprises the following components by weight percent: 0.5 to 0.70 percent of carbon, 0.15 to 1.20 percent of silicon, 0.5 to 2.5 percent of manganese, less than or equal to 0.045 percent of phosphorus, less than or equal to 0.045 percent of sulfur, 0 to 1.00 percent of chrome, 0 to 1.00 percent of nickel, 0 to 1.00 percent of molybdenum, 0 to 0.30 percent of copper, 0.03 to 0.40 percent of vanadium, 0.01 to 0.2 percent of aluminum, 0 to 0.10 percent of titanium, 0 to 0.10 percent of boron, 0.001 to 0.0 percent of niobium, 0.004 to 0.020 percent of nitrogen, and iron for the surplus; the yield strength Rel is larger than or equal to 600 MPa, the percentage elongation delta 5 is larger than or equal to 20 percent, the impact strength is 20 DEG C, Akv is larger than or equal to 27 J, and the breaking load is larger than or equal to 300 KN. By adopting the production process flow of converter crude metallurgy, LF furnace fine metallurgy and full protection continuous casting, the steel grade has the advantages that the purity is high, the structure is dense, the grain is fine, the physical chemistry properties of the steel are stable, the over-all mechanical property is good, the production operation and process flow are simple, and the rolled metal finished product can be directly used without heat treatment to the rear part.

Owner:SHOUGANG CORPORATION

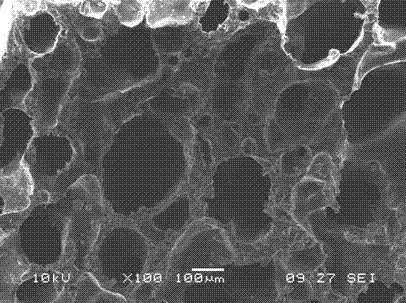

Process for preparing sludge autoclaved aerated concrete building block

InactiveCN101850574AHigh porosityMeet production requirementsSludge treatment by de-watering/drying/thickeningSolid waste managementBrickSludge

The invention belongs to the technical field of environmental engineering, and particularly relates to a process for preparing a sludge autoclaved aerated concrete building block. The process mainly comprises the following steps of: (1) quickly stirring and mixing spare dried sludge, water and lime, coal ash, cement, gypsum and aluminum powder with physical and chemical properties meeting the brick making requirements in a certain ratio and in turn; (2) feeding the mixture obtained in the step (1) into a die, and putting the die into a thermostatic curing box of 40 DEG C or 60 DEG C to perform foaming and curing for 4 hours; (3) putting the blank foamed and cured in the step (2) into an autoclave, and curing the blank for over 8 hours by adopting a stepwise buck-boost curing mode; and (4) piling the product discharged from the autoclave outdoors for over 2 days. The process can reach hazard-free and recycling treatment of urban sludge, save clay resources and save the brick making cost, and has remarkable economic, social and environmental benefits.

Owner:HUNAN UNIV OF SCI & TECH

High-strength high-toughness low temperature steel for ship and manufacture method thereof

ActiveCN102851591AAchieve sex changeImprove purityRoll mill control devicesProcess efficiency improvementCrack resistanceHeat-affected zone

The invention discloses high-strength high-toughness low temperature steel for ship and manufacture method thereof. The steel is composed of (by wt%) C 0.04-0.12, Si 0.20-0.55, Mn 0.8-1.4, P 0.005-0.015, S less than or equal to 0.005, Als 0.02-0.07, N less than or equal to 0.005, Cu 0.05-0.40, Ni 0.05-0.50, and Fe and unavoidable impurity in balance, with Ni / Cu of 1.2-1.5; and one or more than two of Nb 0.005-0.03, Ti 0.005-0.02, Ca 0.001-0.006, and Mg 0.0005-0.002. The steel has advantages of low compression ratio, high strength, good low temperature impact energy, good texture uniformity, and good elongation, to ensure low hardenability and cold crack resistance of repair welding heat-affected zone even if under polar climate condition.

Owner:ANGANG STEEL CO LTD

Heat resisting low expansion silumin and preparation thereof

The invention belongs to the field of non-ferrous materials and preparation and formation thereof, and relates to heat-resisting low-expansion high-silicon cast aluminum alloy. The alloy comprises the following compositions in percentage by mass: 18 to 25 percent of silicon, 1.0 to 2.5 percent of copper, 0.2 to 0.8 percent of magnesium, 0.5 to 2.5 percent of nickel, 0.3 to 0.6 percent of manganese, 0.3 to 1.0 percent of misch metal RE (the content of cerium is more than 40 percent), 0.006 to 0.04 percent of phosphorus, and the balance of aluminum. The production method comprises: firstly, melting raw materials of copper, nickel, silicon and aluminum into an aluminum silicon alloy fused mass; secondly, re-superheating the aluminum silicon alloy fused mass to the temperature of between 850 and 870 DEG C, adding manganese raw materials, and obtaining a mixed fused mass after uniform melting; thirdly, adjusting the temperature of the mixed fused mass to between 780 and 800 DEG C and adding the magnesium into the mixed fused mass; fourthly, adding rare earth raw materials into the mixed fused mass, maintaining at the temperature for 10 to 15 minutes, and raising the temperature to between 820 and 840 DEG C; fifthly, performing refining; and sixthly, raising the temperature of the refined mixed fused mass to between 830 and 850 DEG C, adding phosphorus raw materials into the mixed fused mass for modification, maintaining at the temperature for 15 to 20 minutes after modification, and performing casting, wherein the casting temperature is between 790 and 830 DEG C. Castings can well meet the performance requirements of peripheral materials of automobile engines after T6 heat treatment.

Owner:HUAZHONG UNIV OF SCI & TECH

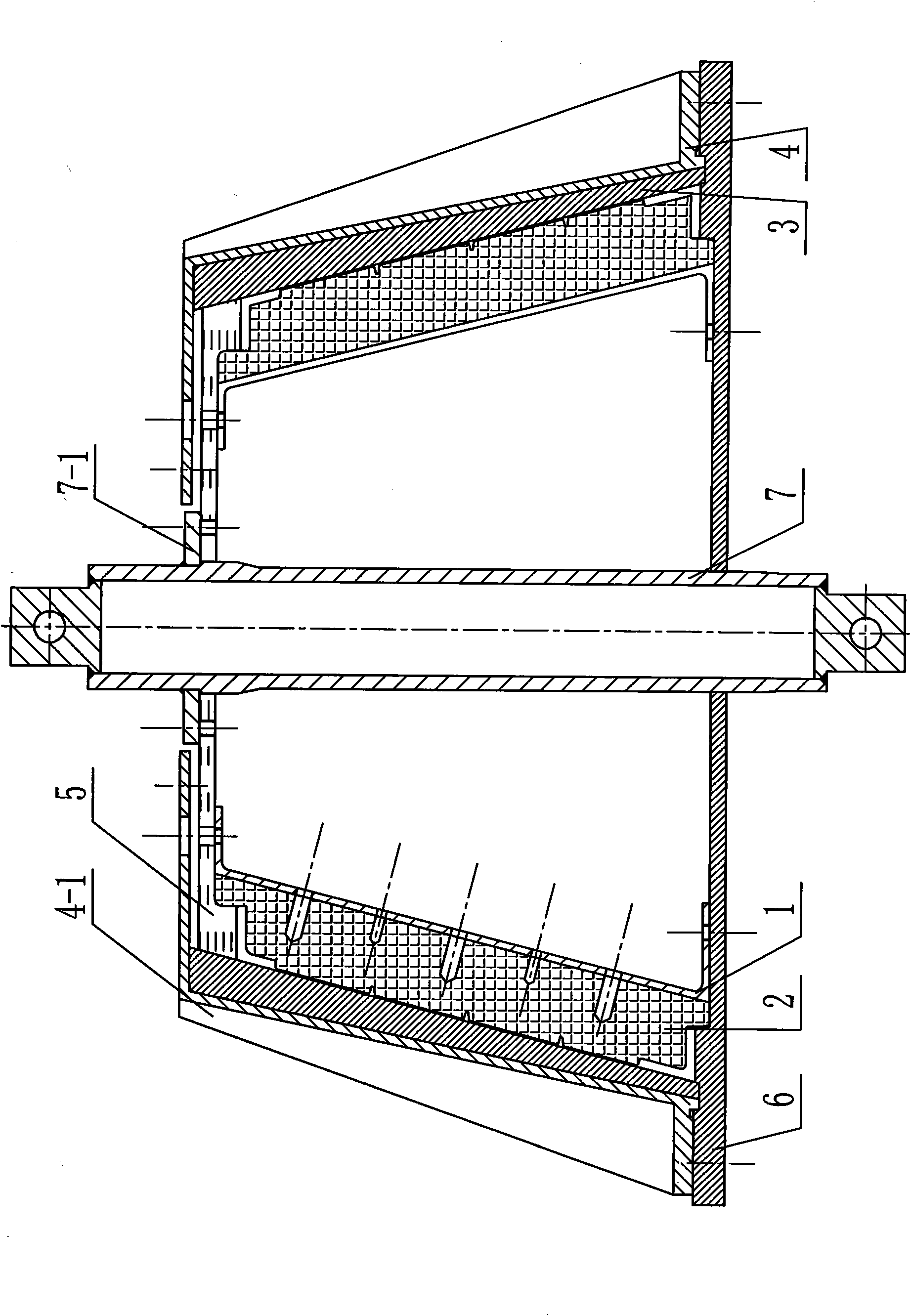

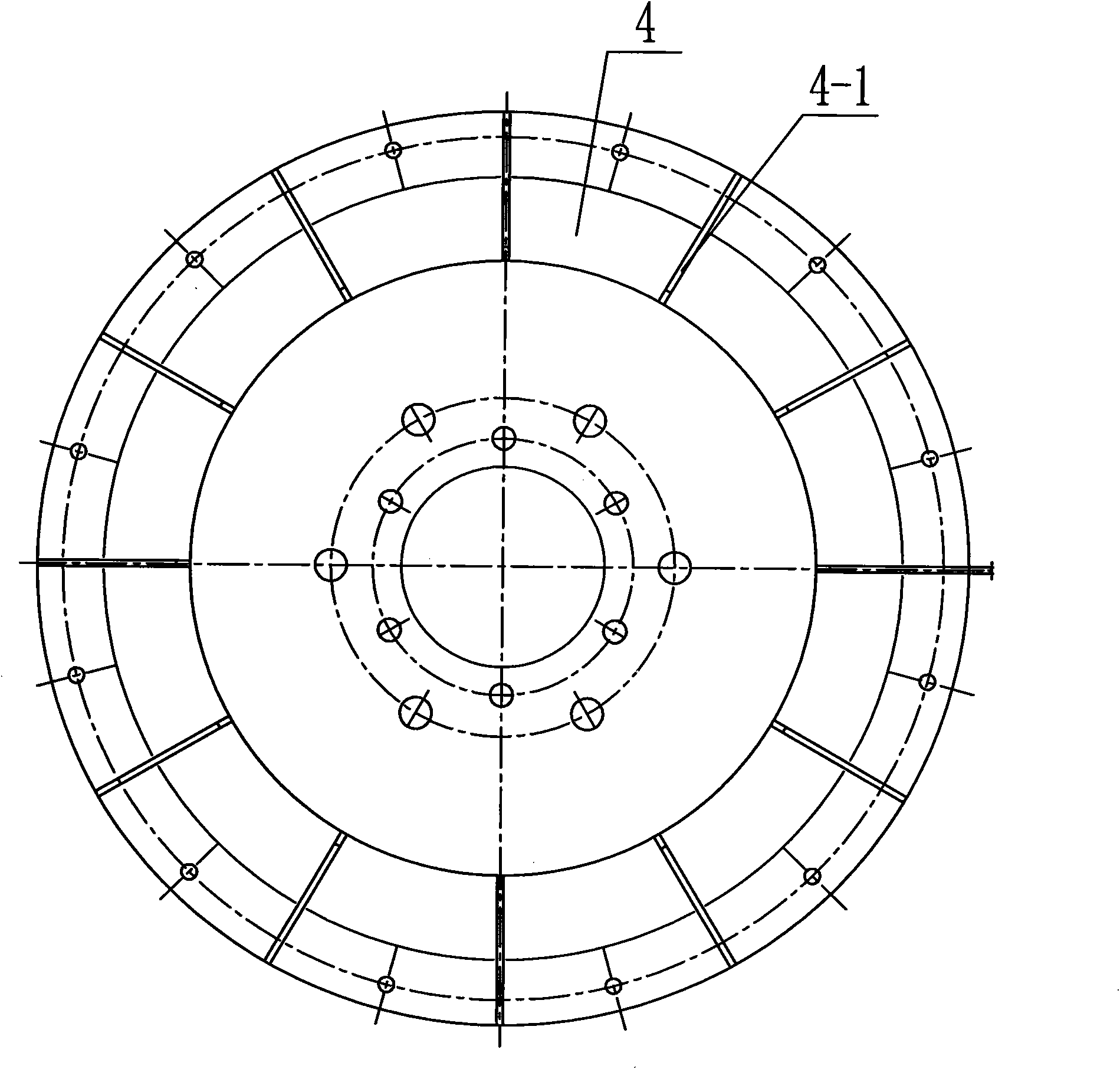

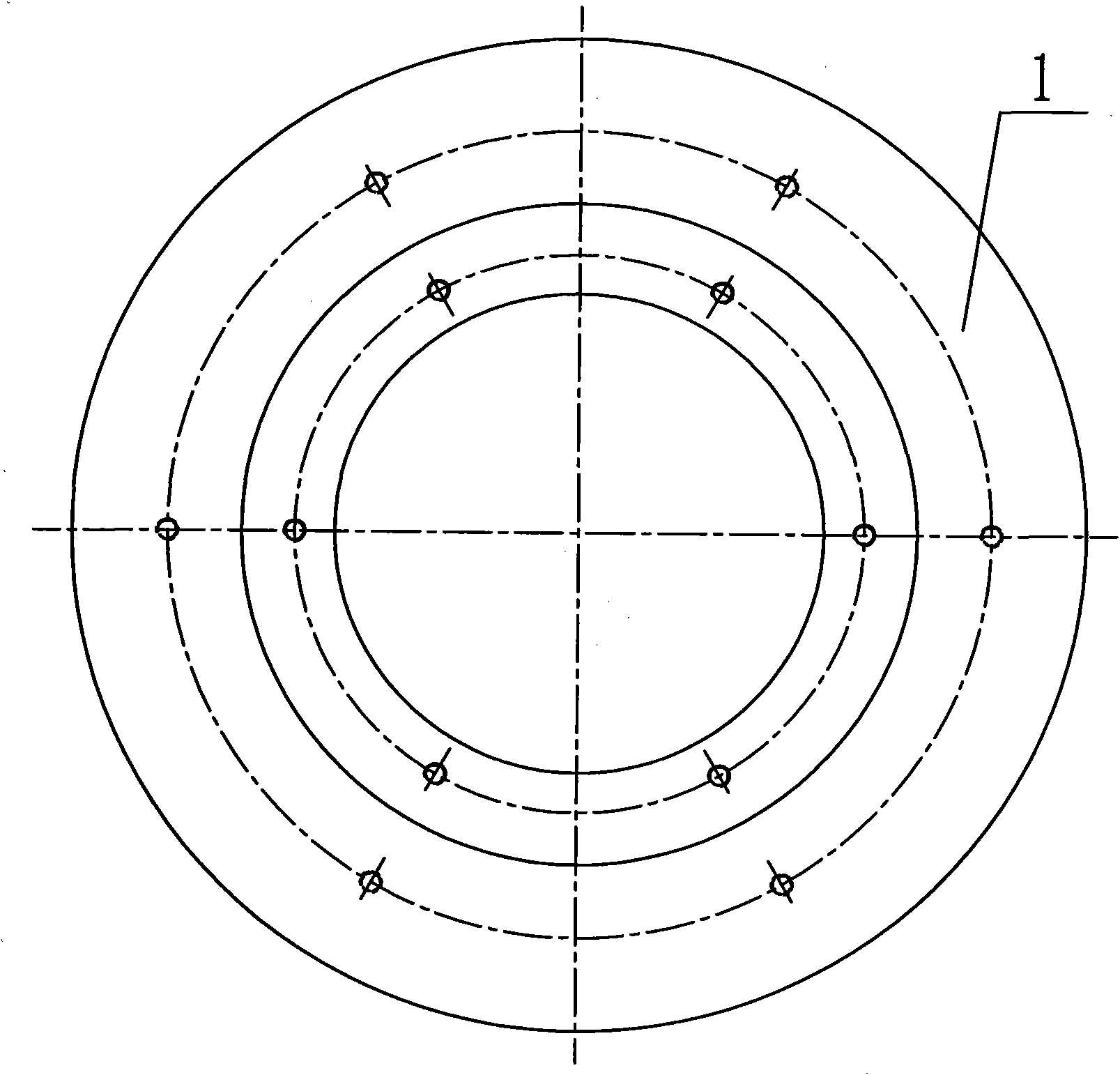

Preparation mould of carbon fiber composite material casing of airplane and aircraft and forming method thereof

The invention discloses a preparation mould of a carbon fiber composite material casing of an airplane and an aircraft and a forming method thereof, belonging to the field of winding carbon fiber composite material preparation and solving the problem that the traditional airplane and aircraft casing formed by winding a continuous fiber is provided with process holes after formed, so that the fiber is fractured to influence the performance of the casing. In the preparation mould, a mould core is fixed with an inner mould; a plurality of annular clamping grooves are arranged on the outer ring surface of the inner mould; an outer mould is coaxial with the inner mould; a pressurizing sleeve is sleeved outside the outer mould; an upper cover plate is fixed with the mould core and the inner mould; a lower cover plate is fixed with the mould core, the inner mould and the pressurizing sleeve; a shaft passes through center holes of the upper cover plate and the lower cover plate and is fixed with the upper cover plate; the space among the outer mould, the upper cover plate, the lower cover plate and the inner mould is a forming space; and the forming process of the casing comprises the following steps of: winding a longitudinal rib and an annular rib on the mould, flattening, reinforcing and flattening; longitudinally, annularly and spirally winding the casing; and pressurizing and then curing by adopting a curing furnace. The invention is used for casings of formed airplanes and aircrafts.

Owner:HARBIN INST OF TECH +1

Aluminum alloy and preparation method thereof

The invention discloses aluminum alloy and a preparation method thereof. The aluminum alloy comprises, by weight, 4.0%-11.0% of Zn, 2.0%-3.0% of Mg, 0-0.3% of Si, 0-0.4% of Ti, 0-0.2% of Cu, 0-0.01% of Zr, 0-0.01% of Cr, 0-0.01% of Mn, less than 0.1% of Fe and the balance Al and accessory impurities. The weight ratio of Zn to Mg is 2-6. According to the aluminum alloy, the surface appearance defects such as fibrous structure stripes and surface yellowing in the anodic oxidation treatment process of commercial 7xxx-series (such as 7075, 7050 and 7055) high-strength aluminum alloy are overcome, high strength and good anodic oxidation treatment surface appearance of the aluminum alloy are integrated, the strength of the aluminum alloy for existing electronic equipment body shells is further improved, and the requirement of electronic equipment lighting and thinning development for aluminum alloy materials for the equipment body shells is effectively met; meanwhile, the application field of the 7xxx-series high-strength aluminum alloy also can be expanded.

Owner:AAC MICROTECH CHANGZHOU

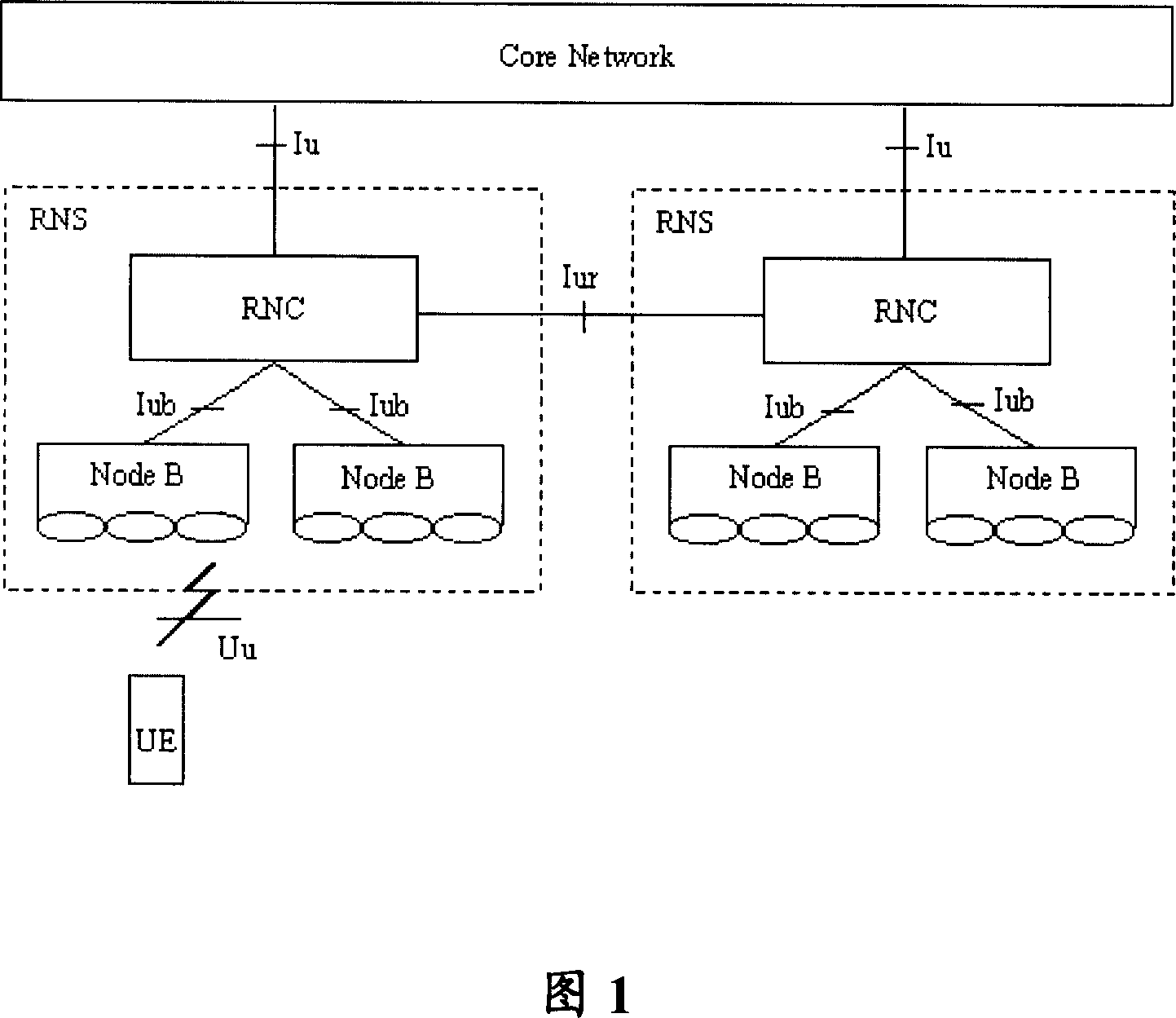

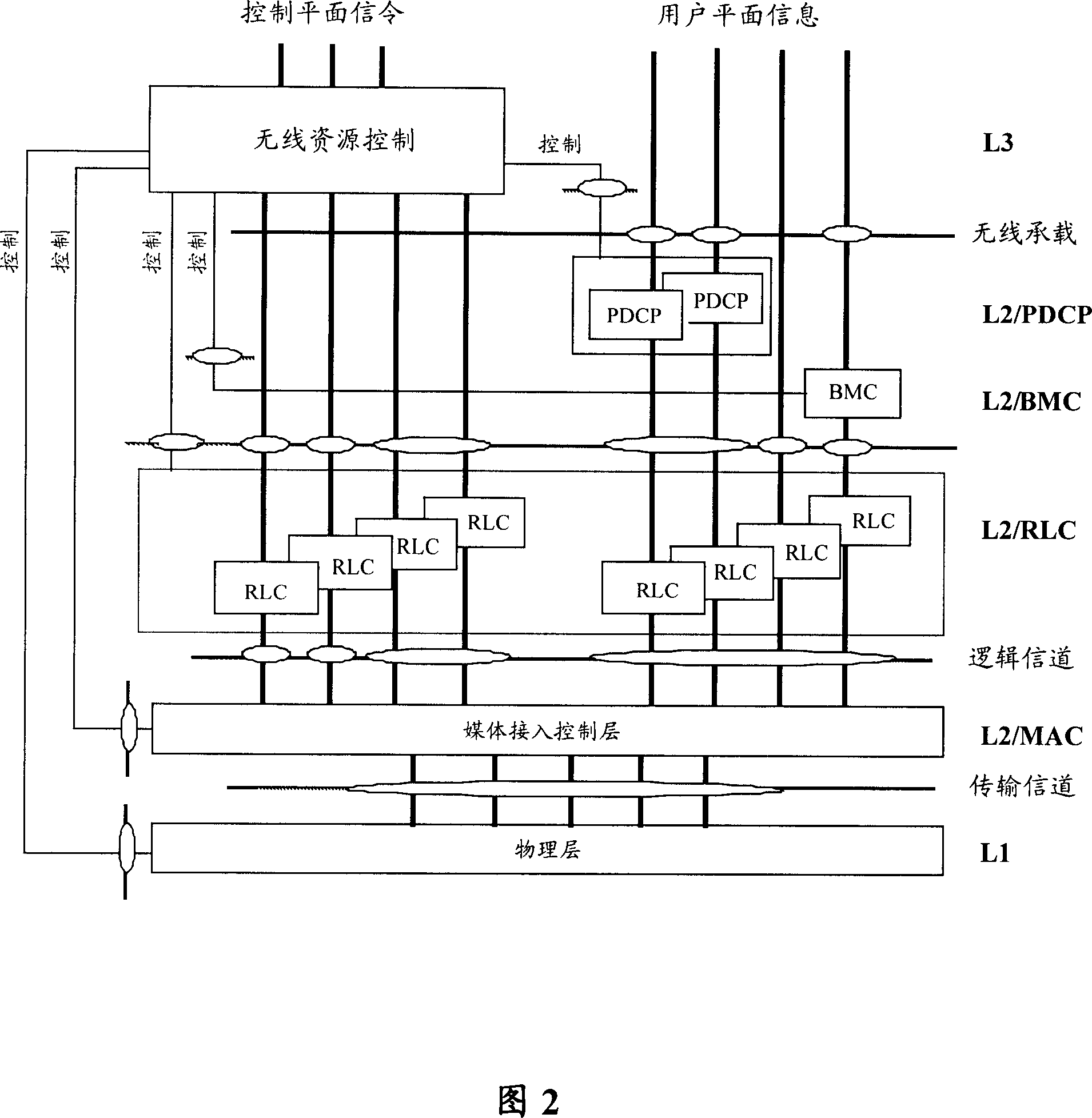

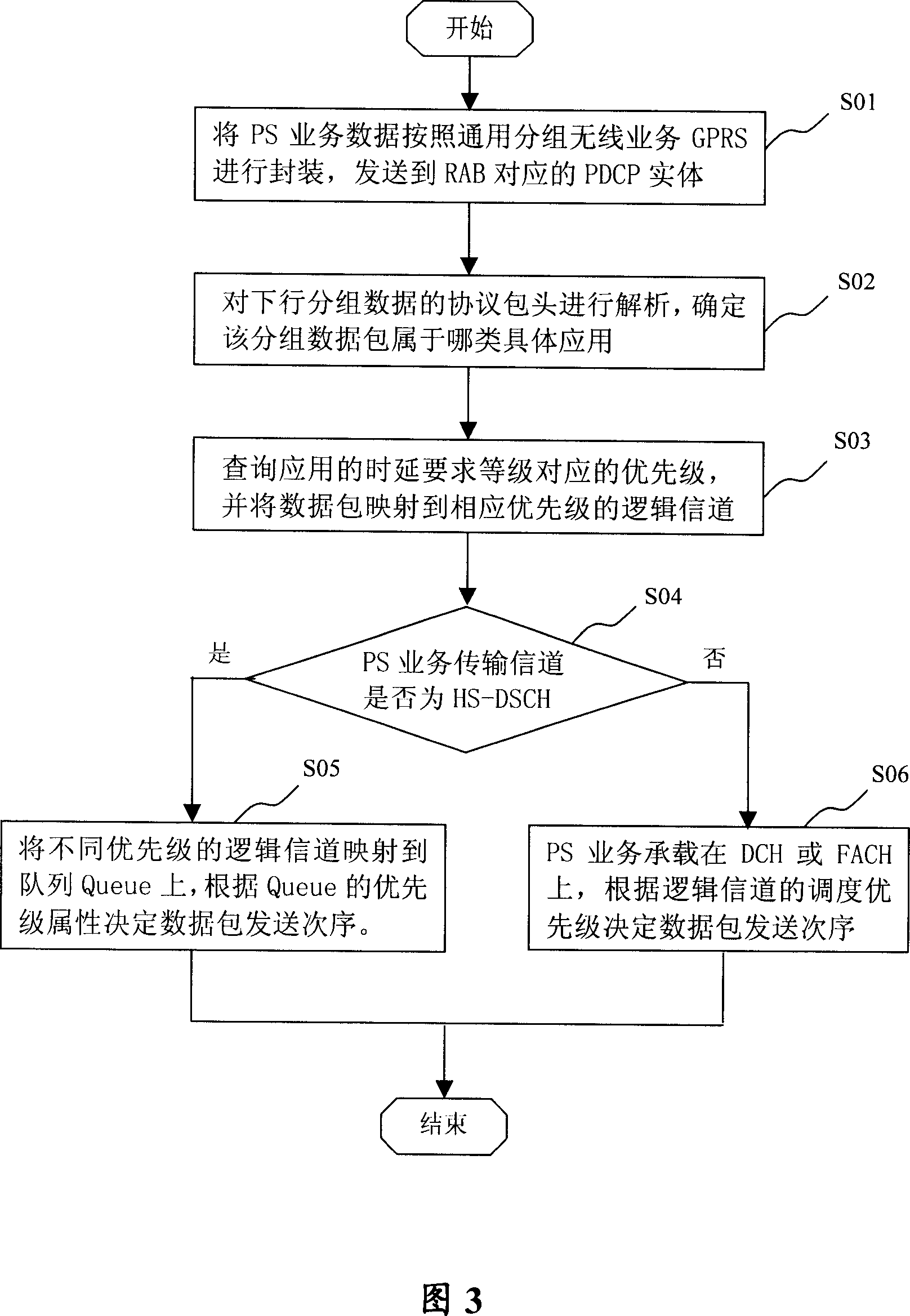

Wireless access loaded packet data service QoS management method.

InactiveCN1968198ASend quicklyMeet performance requirementsRadio/inductive link selection arrangementsData switching networksTraffic capacitySupport group

The invention relates to a QoS manage method of wireless access support group data service, wherein it comprises that: judging the service type of data supported by wireless access; based on said type, finding the sending priority of data pack; projecting the data pack with high priority to the channel with high priority, to be sent out. When the time delay demand of application service, based on the data flux of target address, classifying the priorities; projecting the data pack with low data flux to the logic channel with high priority, to confirm the application data pack with high time delay demand to be sent quickly, to meet the service quality QoS of different application services.

Owner:HUAWEI TECH CO LTD

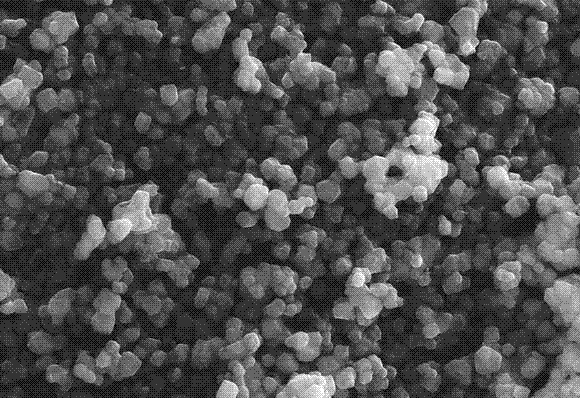

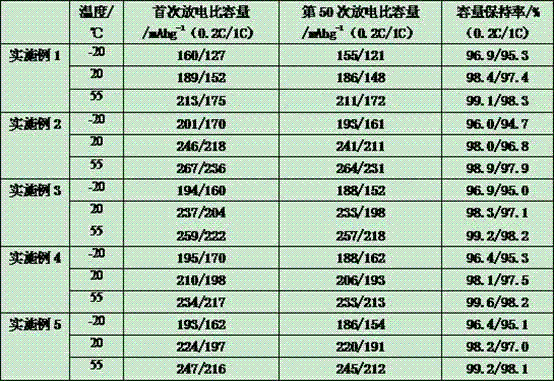

Cathode material for fast lithium ion conductor phase-modified lithium ion battery and preparation method thereof

InactiveCN102760884AImprove transmission characteristicsImprove surface propertiesCell electrodesRare-earth elementElectrical conductor

The invention discloses a cathode material for a fast lithium ion conductor phase-modified lithium ion battery and a preparation method thereof. The key points of the technical scheme are as follows: the cathode material for the fast lithium ion conductor phase-modified lithium ion battery is a composite material consisting of a rare-earth element doped composite layered lithium ion battery cathode material xLi2MO3 (1-x) LiN(1-y)RyO2 (M is Mn, Ti or Sn, N is Mn, Ni, Co, Fe, Cr, V or Mo, R is one or more than one of Sc, Y, Pr, Nd, La, Ce, Sm, Yb, Eu and Gd, x is larger than 0 and smaller than 1, and y is larger than 0 and smaller than 0.2) and a fast lithium ion conductor, wherein the molar ratio of the fast lithium ion conductor to the rare-earth element doped composite layered lithium ion battery cathode material is n:1, and n is larger than 0 and smaller than or equal to 0.15. The invention also discloses a preparation method of the cathode material for the fast lithium ion conductor phase-modified lithium ion battery. The cathode material for a fast lithium ion conductor phase-modified lithium ion battery has the advantages of high specific capacity, good rate capacity, stability in recycling and strong temperature adaptation.

Owner:HENAN NORMAL UNIV

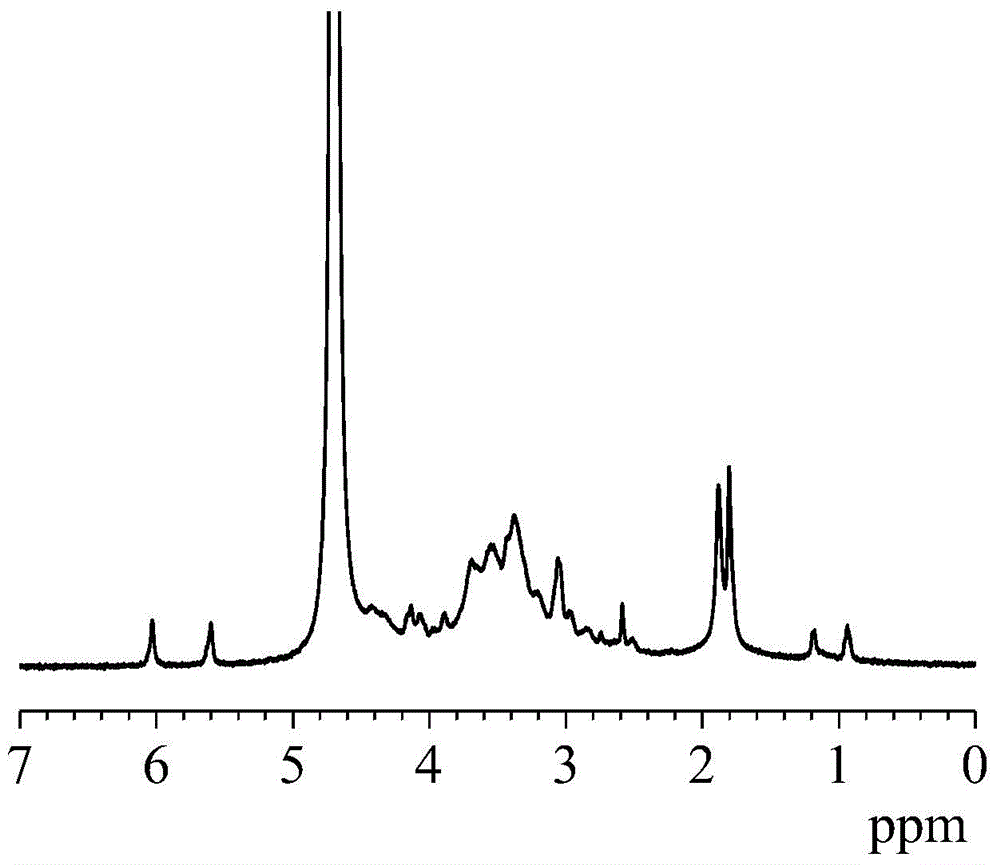

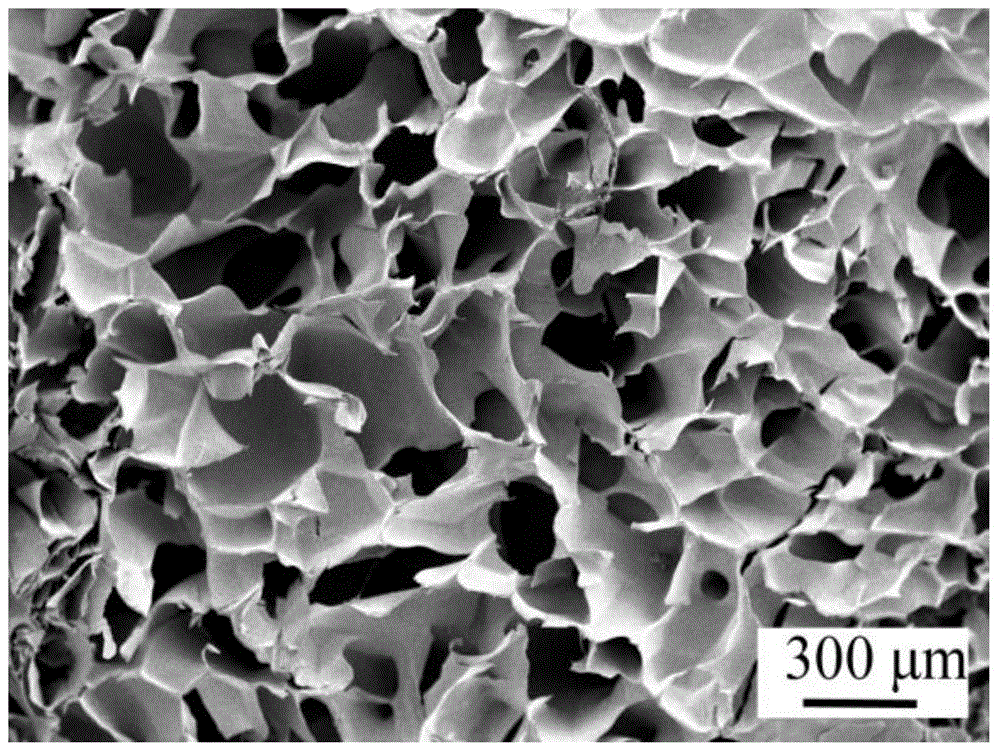

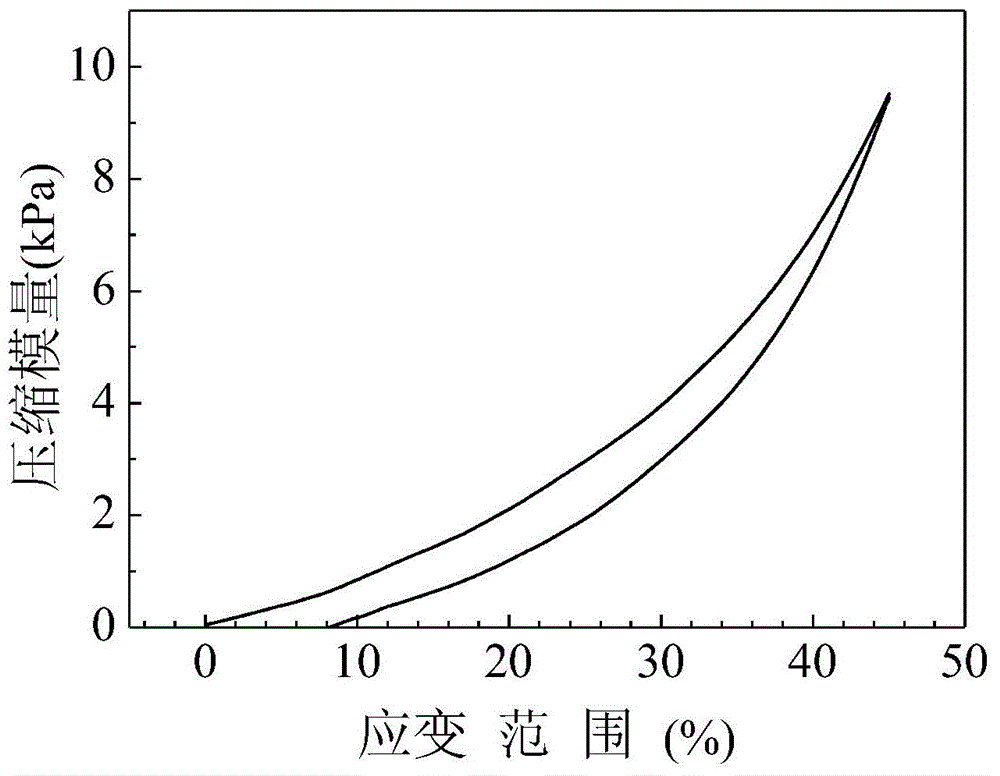

Injectable double-crosslinked hyaluronic acid aquagel and preparation method thereof

ActiveCN104910396ARaw materials are easy to getMild reaction conditionsAnimal cellsPharmaceutical non-active ingredientsTissue engineeringPhotoinitiator

The invention discloses an injectable double-crosslinked hyaluronic acid aquagel and a preparation method thereof. The preparation method comprises the following steps: synthesizing formylated hyaluronic acid and amino / methylacryloyl bifunctional hyaluronic acid containing disulfide bond in the side chain, uniformly mixing the formylated hyaluronic acid and amino / methylacryloyl bifunctional hyaluronic acid containing disulfide bond in the side chain with a water-soluble photoinitiator, and carrying out photochemical polymerization to obtain the injectable double-crosslinked hyaluronic acid aquagel. The method has the advantages of accessible raw materials, mild reaction conditions, short reaction time, simple technique and the like. The prepared aquagel is formed by a Schiff base crosslinking mechanism and a photocrosslinking mechanism, and the two crosslinking networks are connected together. The crosslinking network chain of the aquagel contains the disulfide bond and Schiff base, and thus, the aquagel has dual sensitivities for reduction and pH. The hyaluronic acid aquagel has flexible and adjustable mechanical properties, microstructure, degradation property, swelling capacity and the like, is injectable, and has application prospects in the aspects of cell transfer, tissue engineering, three-dimensional cell culture and the like.

Owner:WUXI JIANGNAN CABLE

Steel for medium/heavy duty vehicle gear shaft blank in cross wedge rolling process and preparation method thereof

The invention provides steel for a medium / heavy duty vehicle gear shaft blank in the cross wedge rolling process and a preparation method thereof. The steel comprises the following chemical compositions by weight percent: 0.37%-0.44% of C, 0.15%-0.35% of Si, 0.55%-0.90% of Mn, less than or equal to 0.030%of P, less than or equal to 0.035% of S, 0.85%-1.25% of Cr, 0.15%-0.35% of Mo, 0.02%-0.05% of Ti, 0.020%-0.050% of Alt, less than or equal to 2.5*10<-4>% of H, 30*10<-4>%-70*10<-4>% of N, less than or equal to 15*10<-4>% of T.O and the balance of Fe and inevitable impurities.

Owner:LAIWU IRON & STEEL GRP

High-pressure self-packing leather cup rubber for packer and preparation method thereof

The invention discloses high-pressure self-packing leather cup rubber for a packer. The high-pressure self-packing leather cup rubber is prepared from the following raw materials in parts by weight: 30-40 parts of nitrile rubber, 20-30 parts of isoprene rubber, 20-40 parts of ethylene propylene terpolymer 5962 (LANXESS Deutschland), 10-15 parts of fluorosilicone rubber, 3-5 parts of natural rubber, 30-40 parts of high abrasion furnace black N330, 10-15 parts of modified white carbon black, 3-4 parts of antimony trioxide, 8-10 parts of modified wood ash, 4-6 parts of attapulgite, 4-6 parts of meerschaum, 9-11 parts of modified iron tailing slag powder, 0.5-1 part of stearic acid, 0.5-1 part of isocyanate, 0.2-0.4 part of accelerant DM, 0.3-0.6 part of accelerant BZ, 1-2 parts of calcium stearate, 2-4 parts of zinc oxide, 0.2-0.4 part of ferrocene, 1-2 parts of polyethylene wax, 1-2 parts of antioxidant DSTP, 1-2 parts of anti-aging agent, 2-3 parts of coupling agent DL-151 and 16-18 parts of epoxy linseed oil. The rubber disclosed by the invention has excellent ozone resistance, excellent low temperature resistance and heat resistance and is large in operating temperature range and environment-friendly in process, so that the rubber can be used for preparing various packing materials.

Owner:WUHU HENGKUN AUTO PARTS

Nano doping dielectric material for preparing base-metal inner-electrode multi-layer ceramic sheet type capacitor

ActiveCN101182201AImprove performanceMeet performance requirementsFixed capacitor dielectricStacked capacitorsBarium titanateCeramic capacitor

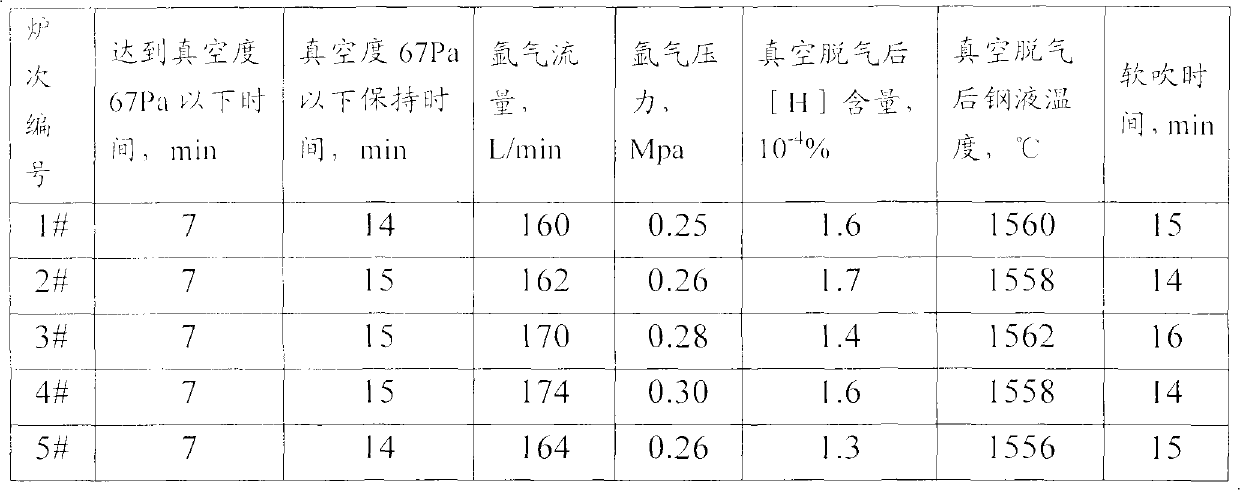

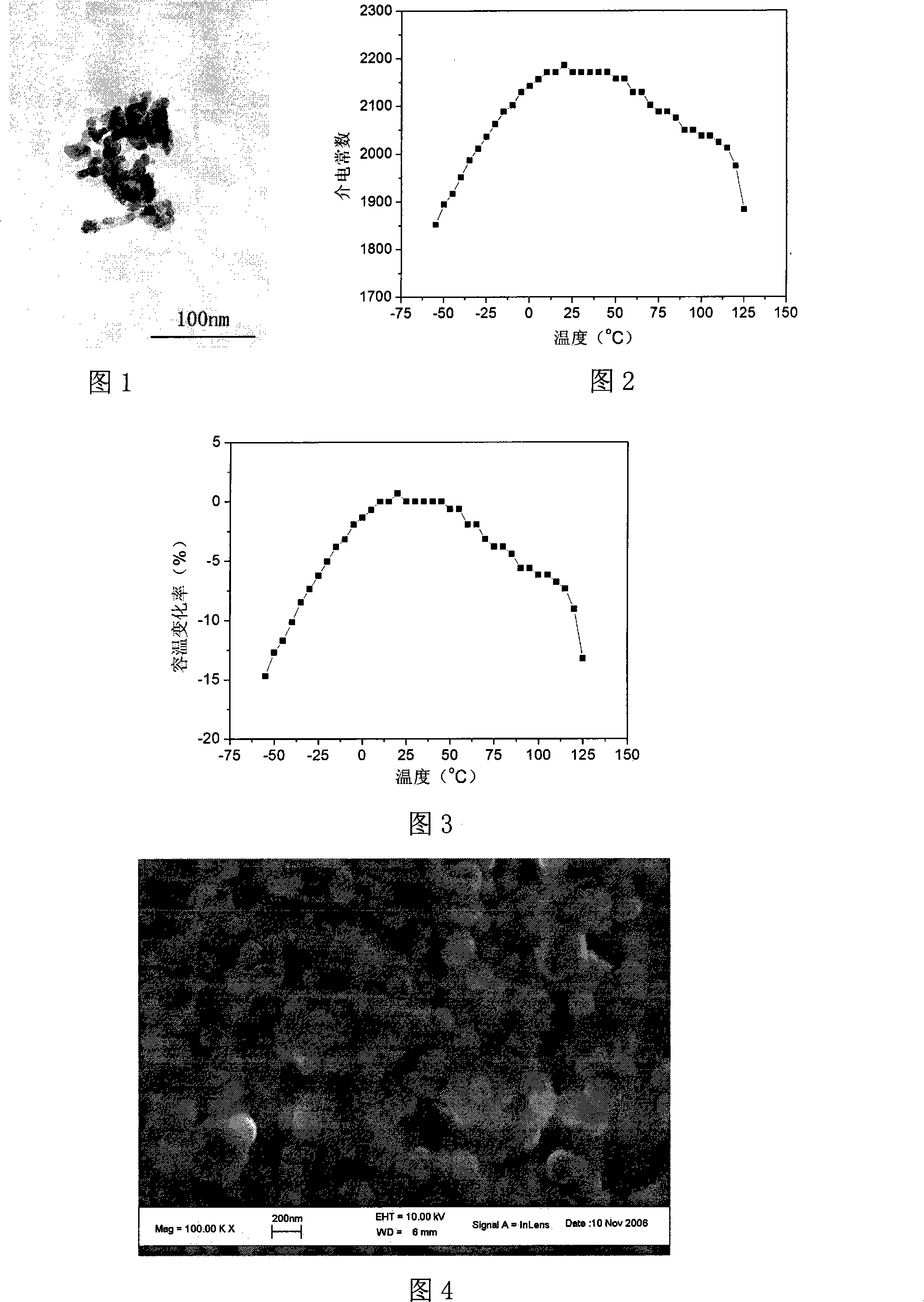

The invention discloses a base metal internal electrode multilayer ceramic chip capacitor dielectric material prepared by nano-doping, which belongs to the technical scope of capacitor material preparation. The ceramic material is composed of barium titanate BaTiO3 as the main material with a mole fraction of 90-98 mol% in the formula and nano dopant accounting for 2-10 mol% of the total material. In a reducing atmosphere, "two-stage" sintering or conventional sintering at a temperature range of 950 ° C to 1250 ° C can obtain X7R / X5R type MLCC materials with excellent performance. The room temperature dielectric constant of the material (wafer sample) can be Controlled at 2000-2600, capacity temperature change rate ≤ ± 15%, dielectric loss at room temperature ≤ 1.5%, ceramic grain size can be controlled at 100-200nm, good uniformity, suitable for production of large capacity, dielectric layer thickness less than Multilayer ceramic capacitors with an ultra-thin dielectric layer of 3 μm, high insulation resistivity, and stable performance.

Owner:TSINGHUA UNIV

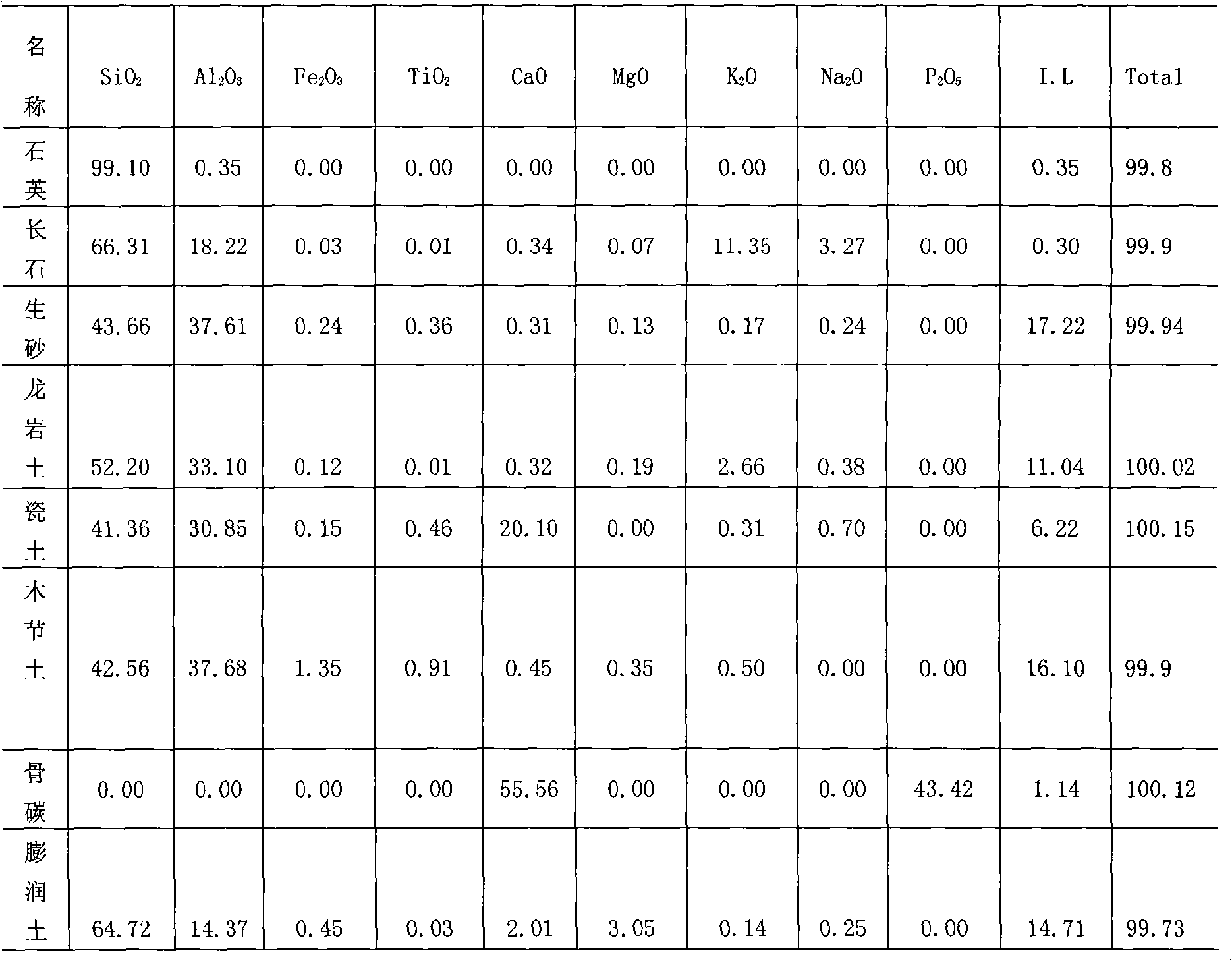

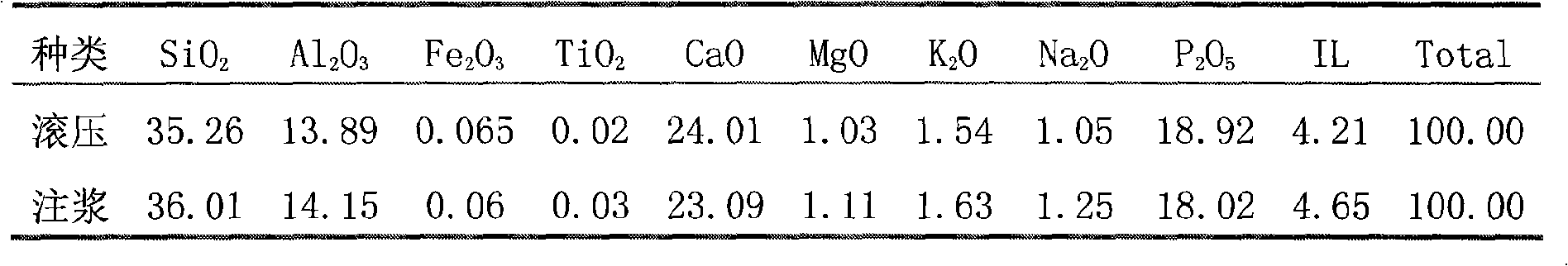

Bone porcelain with high resistance of heat shocks and production method thereof

InactiveCN101289307AReduce contentSmall coefficient of thermal expansionClaywaresHigh resistanceSodium Bentonite

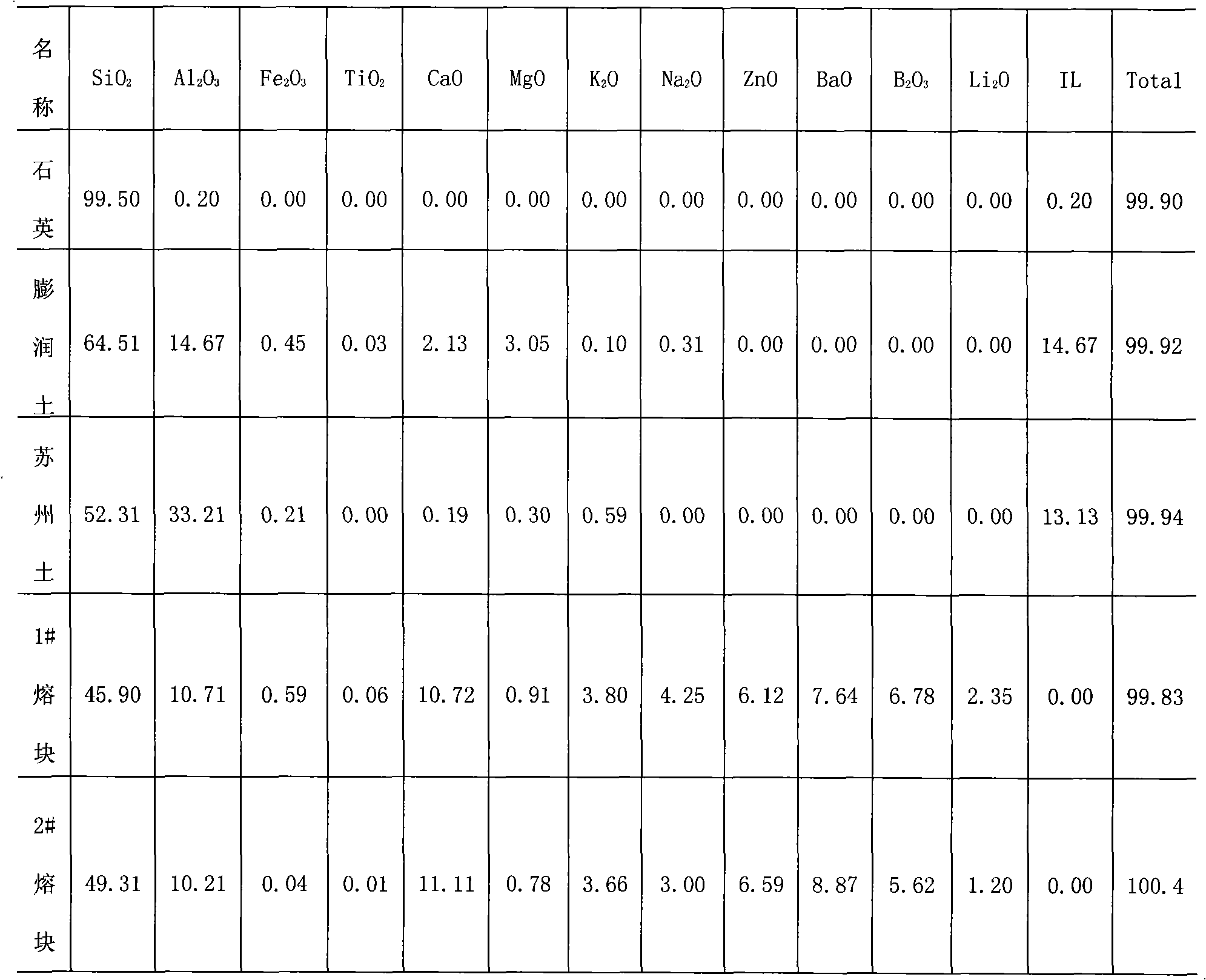

The invention relates to a bone china with high resistance to heat shocks and a manufacture method thereof. The raw material components of the bone china stock and the weight percentages are: 9 to 12 of quartz, 7 to 10 of feldspar, 11 to 14 of greensand, 4 to 7 of Longyan clay, 5 to 8 of china clay, 4 to 7 of kibushi clay, 42 to 46 of bone coal and 7 to 10 of bentonite; the raw material components and the weight percentages of glaze material are: 5 to 8 of the quartz, 2 to 5 of the bentonite, 3 to 6 of Suzhou clay, 50 to 53 of model one fused block and 34 to 37 of model two fused block; the bone china has the resistance to heat shocks that no crack occurs during the heat change in the water with the temperature of 200 to 20 DEG C for once. The manufacture steps are as follows: preparing stock paste, preparing glaze paste, roller forming, grouting and forming, biscuit firing, glazing, glaze firing and decorating firing. The enamel layer of the invention has the advantages of large elasticity, good toughness and mechanical property. The raw material ingredients have no lead and zero radioactivity, which are green. The manufacture method is scientific and reasonable, and the product has the resistance to heat shocks that no crack occurs during the heat change in the water with the temperature of 200 to 20 DEG C at one time.

Owner:唐山隆达骨质瓷有限公司

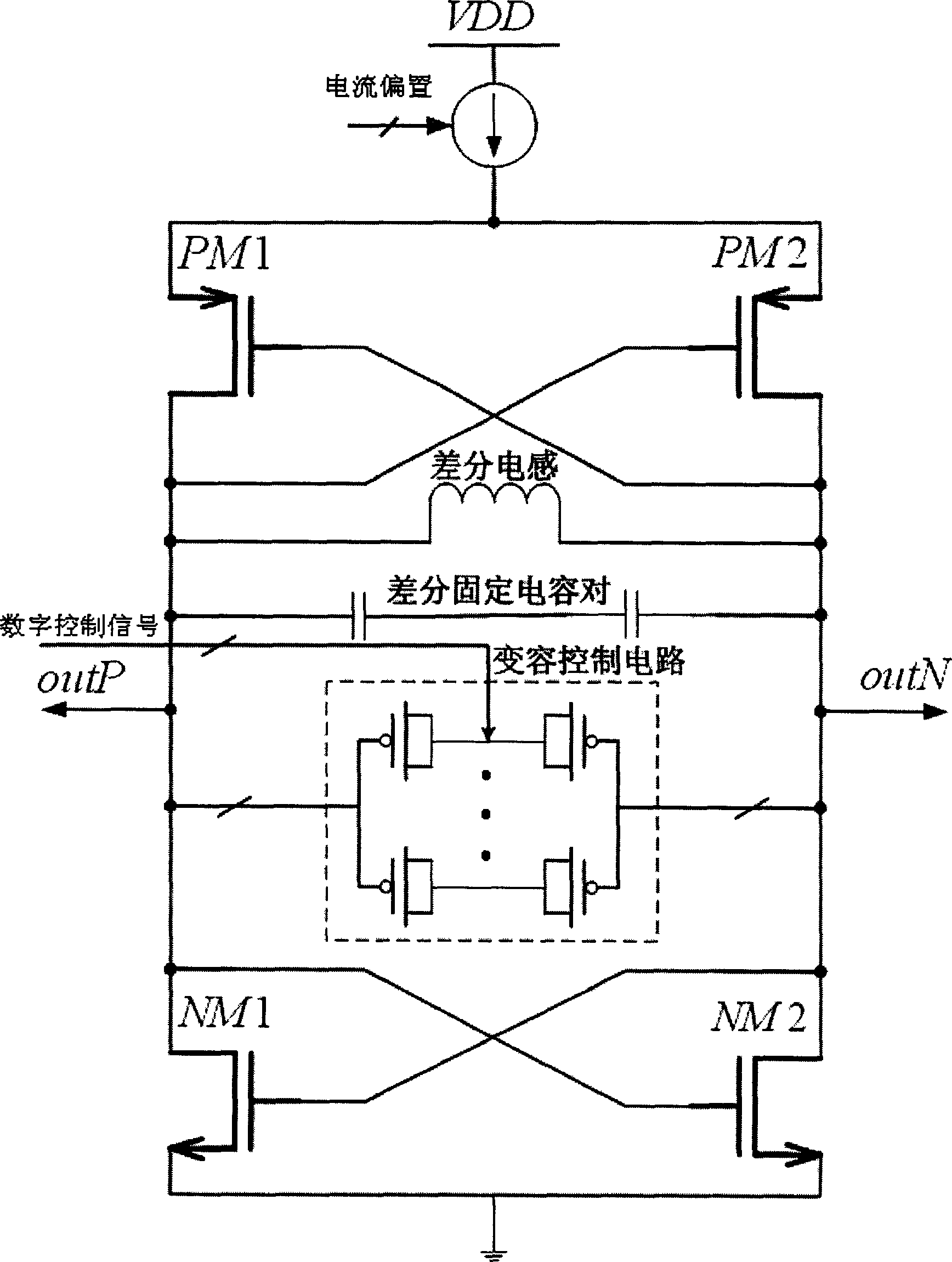

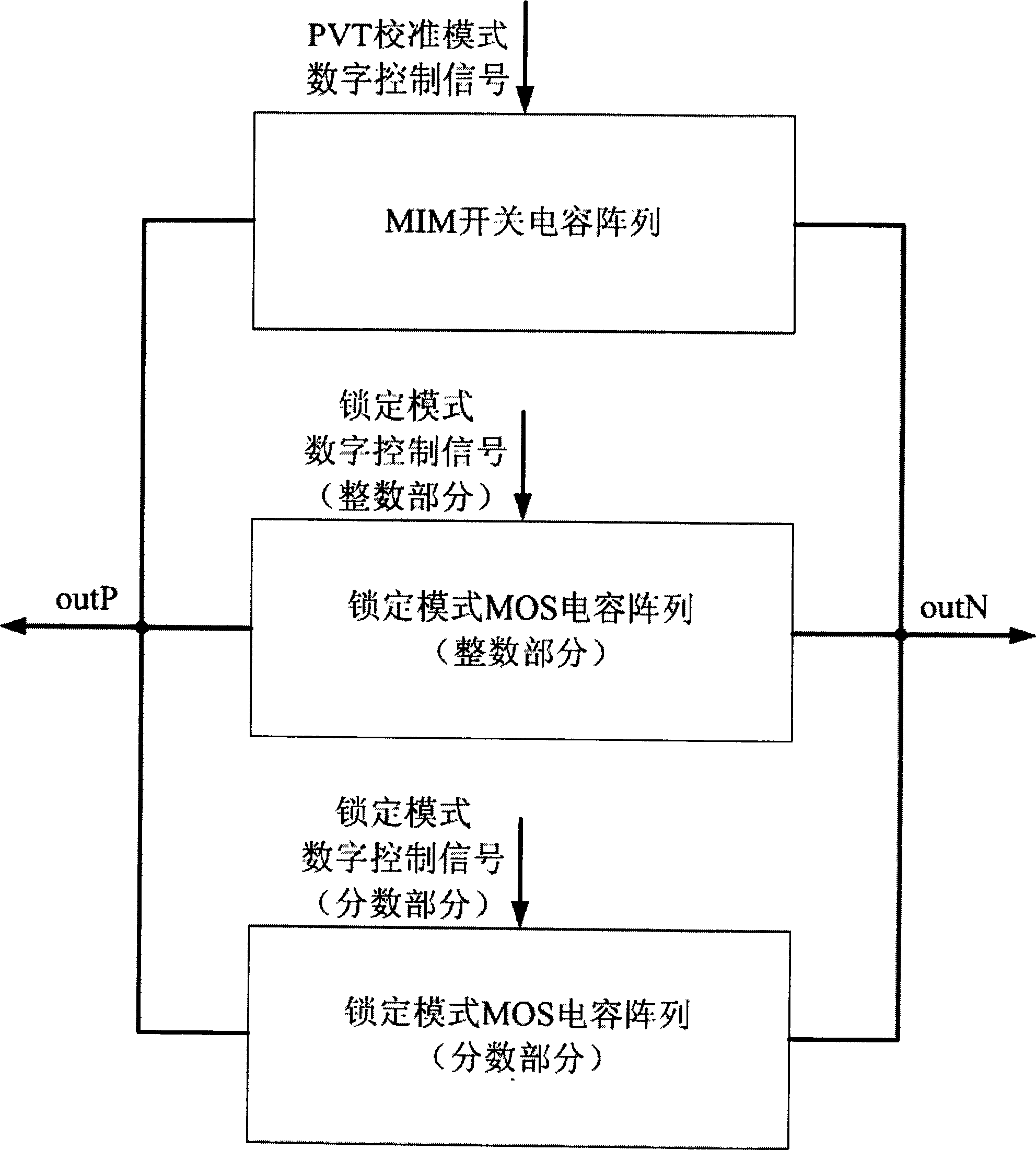

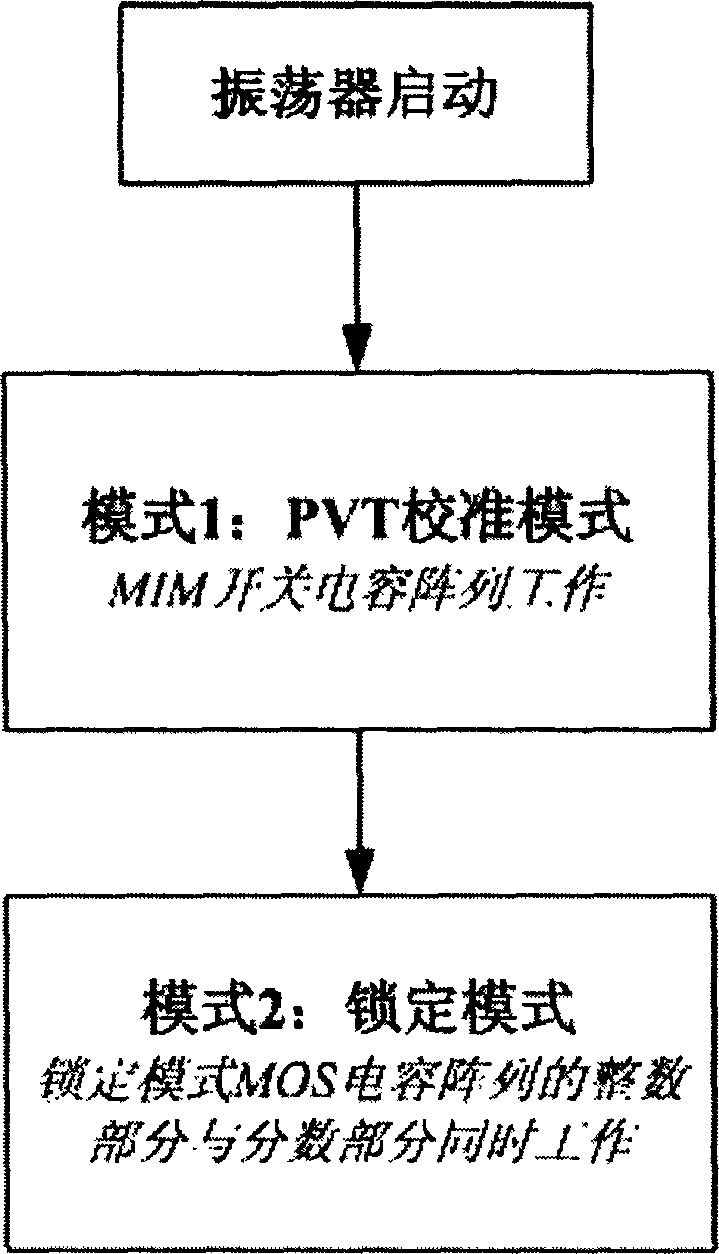

CMOS digital control LC oscillator on chip

InactiveCN1832333AReduce phase noiseLow spuriousPulse automatic controlOscillations generatorsCMOSCapacitance

This invention relates to a design technology for chips of T-R devices of the wireless communication system characterizing in applying a double-mode step-forward method composed of an technology-voltage-temperature calibration mode and a locking mode to get the assigned output oscillation frequency step by step, in which, in the calibration mode, a MIM switch condenser array controlled by digital signals is applied for frequency rough calibration in a rather wide sphere and in the locking mode, a MOS condenser matrix combining with a modulation mode of high speed digit sigma delta controlled by digital signals is applied to get an accurate output oscillation frequency in a rather wide sphere, especially a coupling mode of an improved MOS variable-capacitance diode is applied to reduce the sensitivity of oscillators to noises, at the same time, a sigma delta modulator of a single-step three-stages feedforward structure is applied to reduce the stray in output signals and a fixed differential capacitor of certain capacitance values is parallel to both ends of the variable-capacitance control circuit to reduce the phase noise of the oscillator and improve the linearity of frequency adjustment.

Owner:TSINGHUA UNIV

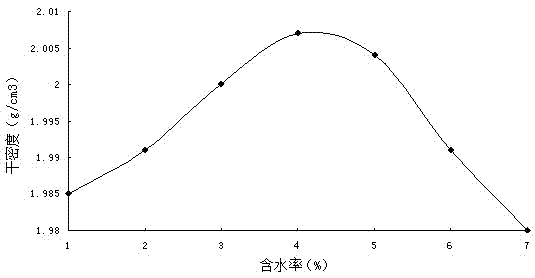

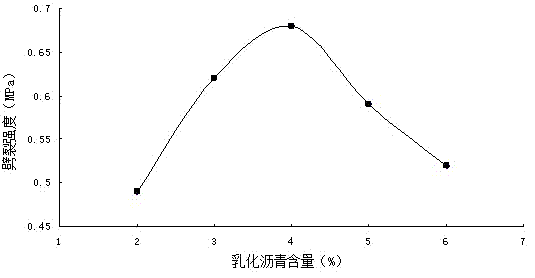

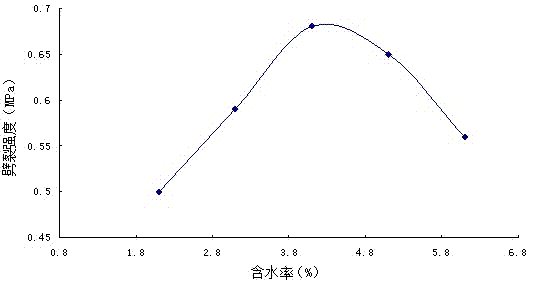

Preparation method of emulsified asphalt cold recycling asphalt mixture

InactiveCN102765902AGood dosageBest moisture contentSolid waste managementRoad engineeringBitumen emulsion

The invention provides a preparation method of an emulsified asphalt cold recycling asphalt mixture. The preparation method relates to the field of road engineering and includes the following steps: obtaining milling samples of old asphalt pavement, determining grading of filler, determining weight percentage of rough milling materials, fine milling materials, cement and mineral powder in raw materials, determining optimum moisture content a, determining optimum dosage of emulsified asphalt, determining optimum moisture content b, conducting checking and stirring the emulsified asphalt cold recycling asphalt mixture. The preparation method is rigor. Determination of optimum usage and optimum moisture content of emulsified asphalt gives consideration to the lubrication effect of water and asphalt in the molding process. The optimum moisture content and the optimum dosage of the emulsified asphalt are determined through checking. The preparation method adopts the processes of rotating, compacting, once molding and nourishment, accords with reality, and is reasonable and capable of meeting requirements for actual engineering.

Owner:JIANGSU TRANSPORTATION RES INST CO LTD +2

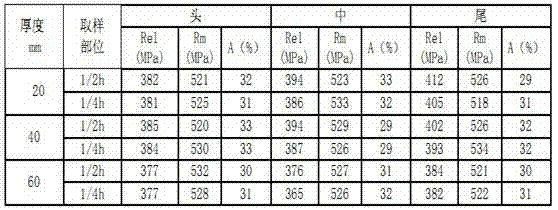

Production method for low-alloy medium-thick steel plate

The invention discloses a production method for a low-alloy medium-thick steel plate. The process route comprises the following stages in turn: converter steelmaking, external refining, continuous casting, heating, rolling, and accelerated cooling. Steel comprises the following components by weight percent: 0.15-0.17% of C, 0.20-0.40% of Si, 0.55-0.65% of Mn, less than or equal to 0.020% of P, less than or equal to 0.020% of S, 0.020-0.040% of Al, 0.014-0.016% of Nb, and less than or equal to 0.30% of CEV. The (P+F) micro-structural feature of the traditional Q345D steel plate is maintained by the steel plate; according to the design of the components of the steel plate, the Mn is reduced by 0.9%, no Ni is added and 0.015% of Nb is increased, so that the cost per ton of steel alloy is reduced; the Nb micro-alloying treatment is supplemented with TMCP (Thermo Mechanical Control Process) technology, so that the demand on the performance of the steel plate is met, the percentage elongation is increased by 2%-3% and the impact toughness is increased by about 90J; the CEV of the steel plate is reduced to below 0.30% and the welding property of the steel plate is greatly improved; and the measures, such as, the great reduction of the alloy, the eliminating of ladle furnace process route, the Direct Hot Charging Rolling (DHCR) of hot casting blank, and the like, are taken, so that the production cost of the steel plate is greatly lowered.

Owner:HUNAN VALIN XIANGTAN IRON & STEEL CO LTD

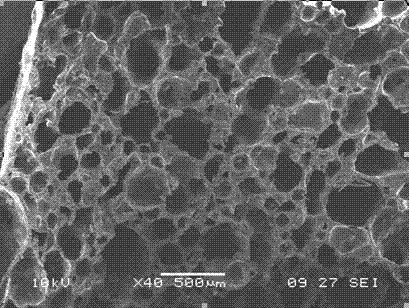

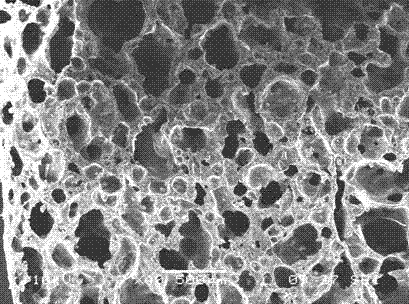

Ethylene propylene diene terpolymer sponge rubber and preparation method thereof

The invention provides an ethylene propylene diene terpolymer sponge rubber and a preparation method thereof, relating to a rubber and a preparation method thereof. The ethylene propylene diene terpolymer sponge rubber is prepared from ethylene propylene diene terpolymer, a foaming agent, a filling enhancer, a plasticizer, molecular sieve powder with a hygroscopic effect, a vulcanizing agent and a vulcanizing aid. The ethylene propylene diene terpolymer sponge rubber is characterized in that the molecular sieve powder is used for replacing traditional talc powder or calcium carbonate to be used as a filling agent, a foaming agent azobisformamide (AC) and a foaming agent 4,4'-oxy bis(benzenesulfonyl hydrazide) (OBSH) are combined and matched with an accelerant, and the decomposing rate of the foaming agent and the vulcanizing rate of the ethylene propylene diene terpolymer are matched, thus a microporous sponge rubber sealing product with a hygroscopic function is prepared under die pressing vulcanization conditions. The tensile strength, elongation percentage, stress at definite elongation, compression set and other indexes of the ethylene propylene diene terpolymer sponge rubber can meet the use performance requirements of sponge sealing strips; and at the same time, the sponge rubber has uniform foam pores, small density and hygroscopic function.

Owner:JINGDONG RUBBER

Thermosetting fluorine-carbon resin for metal coiled material and coating thereof

The invention relates to a thermosetting fluorocarbon resin and the coating thereof. The copolymerization chain segment of the resin comprises chlorotrifluoroethylene of 45.0-55.0mol percent, vinyl-acetic ester of 28.0-37.0mol percent, vinyl versatate of 4.0-10.0mol percent, hydroxyl vinyl ether of 10.0-14.0mol percent and aliphatic olefine acid of 0-0.6mol percent. The fluorocarbon coating mainly comprises the following components with certain weight percentage, thermosetting fluorocarbon resin of 20.0-40.0 percent, cross-linking agent of 0-15.0 percent, paint of 0-35.0 percent, promoter of 0.15-1.5 percent and mixed solvent of 30.0-60.0 percent. The fluorocarbon coating adopts no acid catalyst, has stable properties in storage, has excellent softness, methyl ethyl ketone wiping resistance and aging resistance, etc., and is applicable for rolling coating of metal rolling material.

Owner:万博新材料科技(南通)有限公司

Method for preparing self-emulsifying aqueous epoxy resin curing agent

ActiveCN101649041AImprove performanceMeet performance requirementsAnti-corrosive paintsEpoxy resin coatingsOrganic acidTetramine

The invention relates to a method for preparing a self-emulsifying aqueous epoxy resin curing agent. The method comprises the following steps: taking triethylene tetramine and liquid-state epoxy resinCYD128 as raw materials and obtaining an epoxy resin CYD128-TETA addition compound by a synthetic reaction, wherein the mole ratio of the materials of the triethylene tetramine and the epoxy resin CYD128 is (1-2.2):1; then, dripping a mixed end sealing agent to the epoxy resin CYD128-TETA addition compound, neutralizing the secondary amine hydrogen salification of a generated product after end sealing by organic acid, and finally, diluting with water so as to obtain the self-emulsifying aqueous epoxy resin curing agent, wherein the chemical metering ratio of epoxy radicals in the mixed end sealing agent and primary amine hydrogen in the epoxy resin CYD128-TETA addition compound is 1:1. The invention adopts the common end sealing agent to carry out mixed end sealing, thereby enhancing theproperty of a condensate greatly, meeting the performance requirement of aqueous epoxy land lawn paint, and being widely applied to aqueous epoxy land lawns, steel product preservatives and woodenwarelacquer.

Owner:湖北山虎涂料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com