Patents

Literature

119 results about "Benzenesulfonyl hydrazide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

BENZENESULFONYL HYDRAZIDE is a white to light-colored crystalline solid. Insoluble in water and denser than water.Contact may irritate skin, eyes and mucous membranes. May be toxic by ingestion.

Ethylene propylene diene terpolymer sponge rubber and preparation method thereof

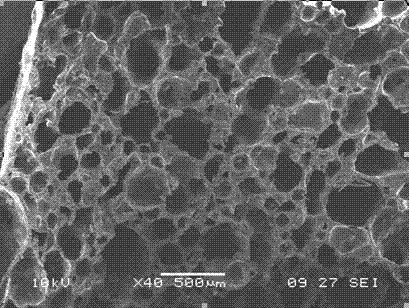

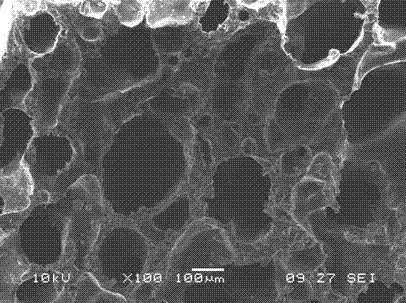

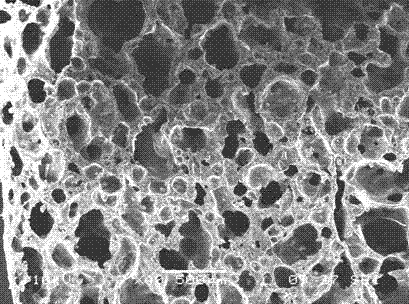

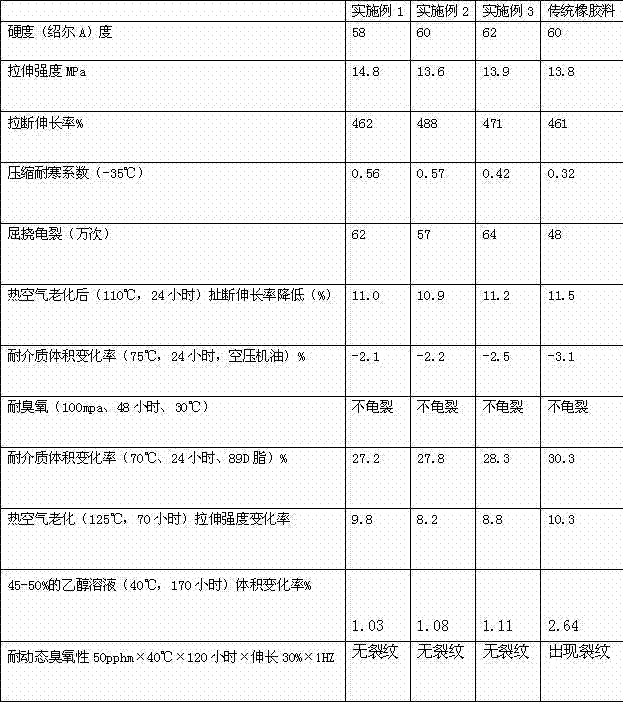

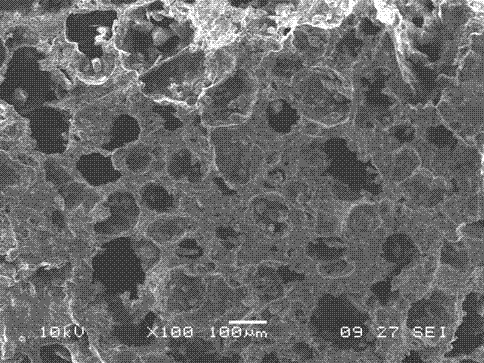

The invention provides an ethylene propylene diene terpolymer sponge rubber and a preparation method thereof, relating to a rubber and a preparation method thereof. The ethylene propylene diene terpolymer sponge rubber is prepared from ethylene propylene diene terpolymer, a foaming agent, a filling enhancer, a plasticizer, molecular sieve powder with a hygroscopic effect, a vulcanizing agent and a vulcanizing aid. The ethylene propylene diene terpolymer sponge rubber is characterized in that the molecular sieve powder is used for replacing traditional talc powder or calcium carbonate to be used as a filling agent, a foaming agent azobisformamide (AC) and a foaming agent 4,4'-oxy bis(benzenesulfonyl hydrazide) (OBSH) are combined and matched with an accelerant, and the decomposing rate of the foaming agent and the vulcanizing rate of the ethylene propylene diene terpolymer are matched, thus a microporous sponge rubber sealing product with a hygroscopic function is prepared under die pressing vulcanization conditions. The tensile strength, elongation percentage, stress at definite elongation, compression set and other indexes of the ethylene propylene diene terpolymer sponge rubber can meet the use performance requirements of sponge sealing strips; and at the same time, the sponge rubber has uniform foam pores, small density and hygroscopic function.

Owner:JINGDONG RUBBER

Butyl rubber for wrapping capacitor case

The invention discloses a butyl rubber for wrapping a capacitor case, which is prepared from the following raw materials: butyl rubber (BBK232), LANXESS Deutschland 9650 ethylene propylene diene monomer, poly-4-methyl-1-pentylene, zinc oxide, nano fluorite powder, nano bentonite, attapulgite, anti-aging agent NBC, anti-aging agent OD, polyamide wax micropowder, accelerator TMTD, accelerator CZ, N-2-(aminoethyl)-3-aminopropyltrimethoxysilane, isopropyl tri(dioctylpyrophosphate)titanate, antioxidant 1035, carbon black N339, N660 carbon black 15-25, dibasic lead phosphite, tributyl citrate, stearic acid, coumarone, propanediol sebacate polyester, benzenesulfonyl hydrazide, ferrocene and modified kieselguhr. According to the reasonable raw material formula, the produced rubber has favorable comprehensive properties and strong binding property with metal; and the rubber has high mechanical properties, fatigue resistance, dynamic ozone resistance, aging resistance and the like, thereby providing a high-intensity protective function for the capacitor.

Owner:江苏南翔橡胶制品有限公司

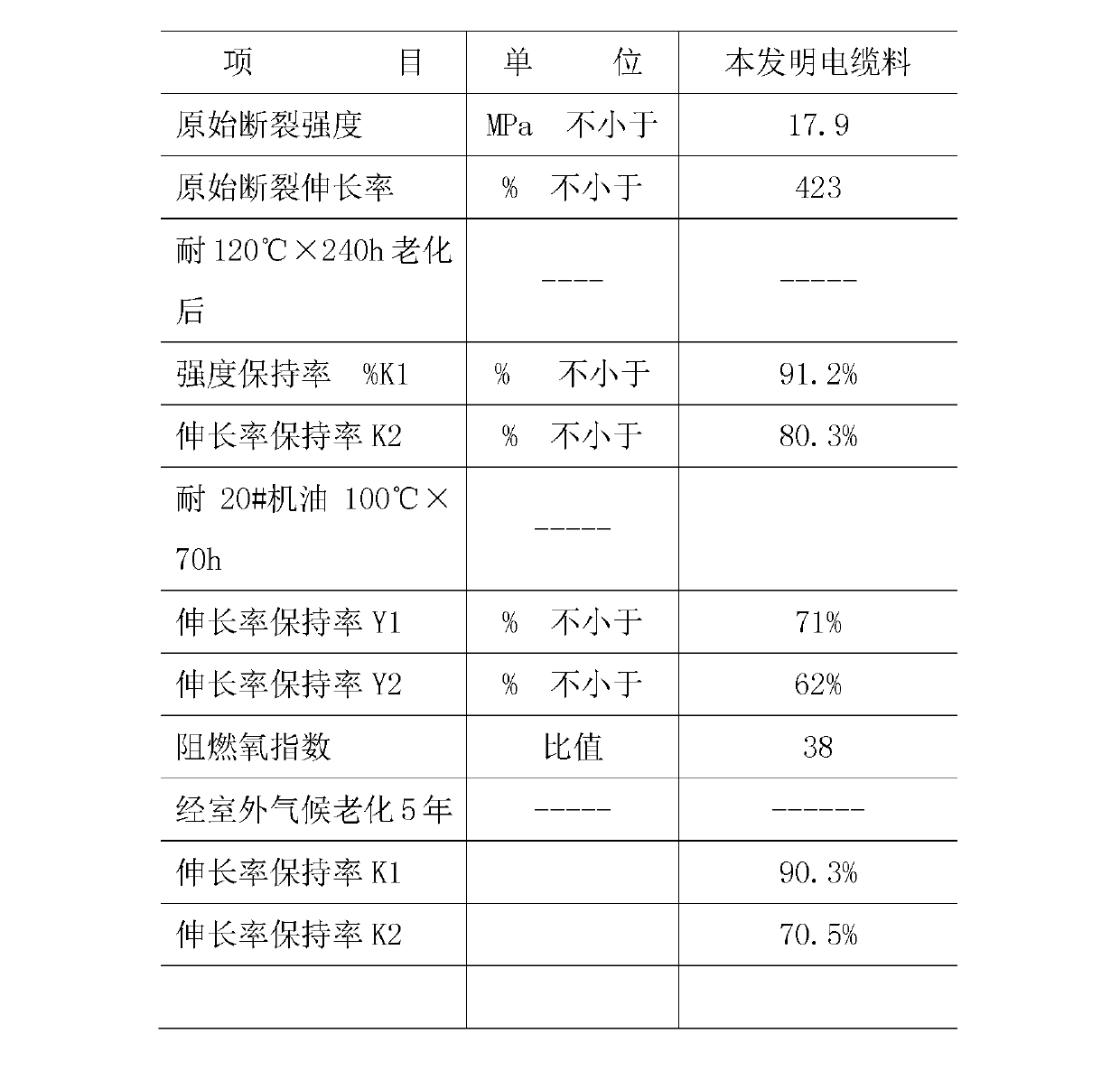

Environmental-friendly termite-resistant cable sheath insulating material and method for preparing same

InactiveCN102993521AMeet the use requirementsGood physical propertiesRubber insulatorsPlastic/resin/waxes insulatorsPolyesterEnvironmental resistance

The invention discloses an environmentally-friendly termite-resistant cable sheath insulating material and a preparation method thereof. The material is prepared from the following raw materials in parts by weight: 90-97 parts of chloroprene rubber (CR) 121, 15-21 parts of chlorinated polyethylene, 15-22 parts of semi-reinforcing purpose furnace black N774, 2-3 parts of magnesium oxide, 2-5 parts of glass powder, 30-35 parts of barite powder, 1-2 of anti-aging agent MB, 1-2 of N-(beta-aminoethyl)-gamma-3-aminopropyltrimethoxysilane, 0.9-1.4 of poly(1, 2-propylene glycol adipate, 5-77 parts of dioctyl maleate, 1-2 parts of accelerator DM, 0.8-1 part of dibasic lead phosphite, 12-18.4 parts of hydrotalcite, 1-3 parts of 4, 4'-oxybis(benzenesulfonyl hydrazide), 2-4 parts of antioxidant DSTP, 4-6 parts of glass powder, 0.8-1 part of zinc oxide, 2-3 parts of modified calcium carbonate, 5-6 parts of antimony oxide, 3-5 parts of ethylene thiourea and 0.8-1 part of modified bentonite. The produced environmentally-friendly termite-resistant cable sheath insulating material has excellent physical performance, stable dimensions and low shrinkage factor, and the tensile strength, tear resistance and elastic force performance of a product are all greatly improved.

Owner:安徽文峰电子科技集团有限公司

Method for eliminating peculiar smell of EVA (ethylene-vinyl acetate) foamed material

The invention relates to a method for eliminating peculiar smell of an EVA (ethylene-vinyl acetate) foamed material. The foamed system comprises the following core components in parts by weight: 70-100 parts of EVA, 1-20 parts of foaming agent, 0.5-10 parts of foaming crosslinking agent, 1-25 parts of peculiar smell eliminator, 0.5-5 parts of zinc oxide and 0.5-5 parts of stearic acid. The foaming agent is one or more of azobisformamide, azodiisobutyronitrile, dinitrosopentamethylene tetramine and 4,4'-oxo-bis-benzenesulfonyl hydrazide. The foaming crosslinking agent is one or more of dicumyl peroxide and bis tert-butyl peroxycumene. The peculiar smell eliminator is one or more of aluminum tripolyphosphate, aluminum dihydrogen tripolyphosphate, aluminum dihydrogen phosphate, aluminum monohydrogen phosphate and aluminum phosphate. The method effectively eliminates peculiar smell generated in the foaming process to obtain an EVA foamed product, which is environment-friendly and smellless and has favorable foaming effect; and the method has the advantages of simple preparation technique, low price, high stability and favorable repetitiveness.

Owner:义乌市大胜橡塑制品有限公司

Blowing agent

InactiveUS20150267024A1Easy to processEasy to prepareOther chemical processesMixing methodsSodium bicarbonateHydrogen

The present invention relates to a new composition comprising 4,4′-oxybis(benzenesulfonylhydrazide) (OBSH) and sodium hydrogen carbonate (SBC), a process for the manufacturing thereof, and its use as blowing agent for the manufacturing of expanded thermoplastic materials and rubber compounds.

Owner:LANXESS LTD

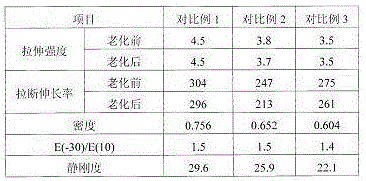

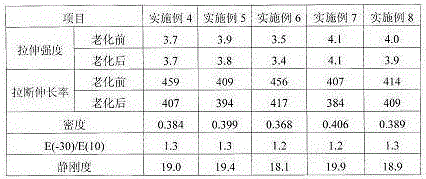

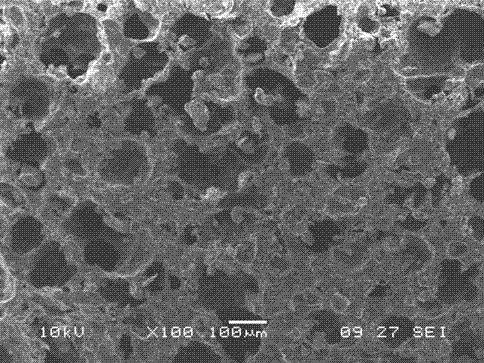

Microporous rubber base plate and preparation process thereof

The invention belongs to the technical field of microporous rubber and discloses a microporous rubber base plate and a preparation process thereof. The microporous rubber base plate has the major technical characteristic that the microporous rubber base plate body is prepared from the following components in parts by weight: 100 parts of ethylene-propylene-diene rubber, 6-18 parts of polyethylene glycol mixture, 60-100 parts of a filling material, 30-60 parts of alkane oil, 6-12 parts of a foaming agent, 2.5-5.5 parts of a vulcanizing agent and 2-5.5 parts of an accelerant. According to the microporous rubber base plate, an evenly diffused multi-phase structure is formed by mechanically blending low-Mooney EPDM and high-Mooney EPDM, and in combination with benzenesulfonic acid formed in the reaction process of neutralizing the foaming agent 4,4-oxodibenzenesulfonyl hydrazide by use of the polyethylene glycol mixture, the foaming ratio can be increased. In addition, accessories carbon black excellent in reinforcement property and porous diatomite filler excellent in aging property and light in weight are adopted, and consequently, the microporous rubber base plate has such properties as high strength, low rigidity and low temperature dependency.

Owner:HENGSHUI ZHONGTIEJIAN ENG RUBBER

Light-colored microporous EPDM sponge rubber and preparation method thereof

The invention relates to rubber and a preparation method thereof, and provides a light-colored microporous EPDM sponge rubber which is advantageous in uniform pore, large expansion ratio and less compression permanent deformation and is suitable for producing sealing strip products, and a simple and feasible preparation method thereof. The light-colored microporous EPDM sponge rubber is made from EPDM sponge rubber, foaming agents, reinforcing fillers, plasticizers, anti-aging agents, colorants, vulcanizers and other vulcanizing additives. The colorants may be rutile titanium dioxide, fluorescent whiteners and ultramarines; the foaming agents, such as azobisformamide (AC), 4,4'-oxydibenzenesulfonyl hydrazide (OBSH) and urea, are heated to decompose to release gases; the types and consumptions of vulcanizers and vulcanizing additives can be changed. The light-colored microporous EPDM sponge rubber can be used in combination with white building materials, and the application range of rubber materials is increased.

Owner:SHENYANG INSTITUTE OF CHEMICAL TECHNOLOGY

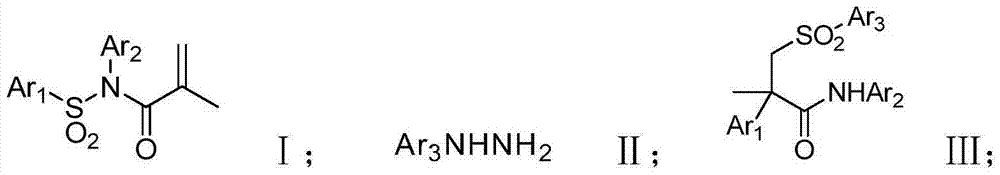

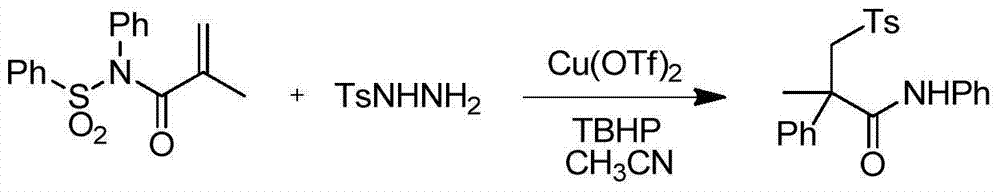

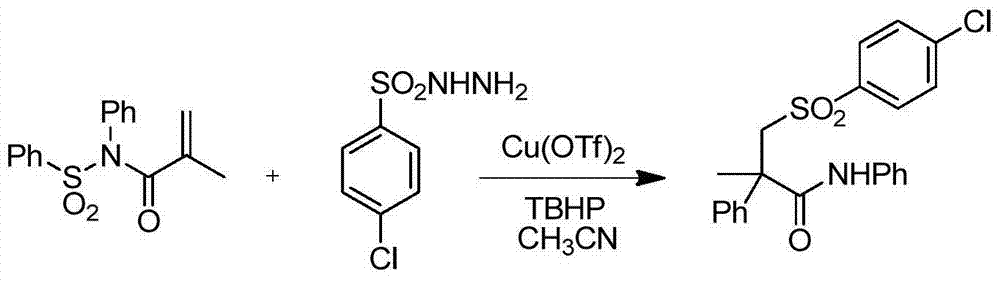

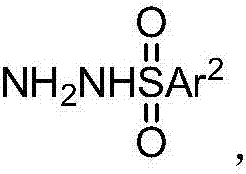

Method for synthesizing alpha-aryl-beta-sulfonyl amide

InactiveCN104262213AThe synthesis process is simpleEasy to operateOrganic chemistryOrganic compound preparationCarbon numberHydrazine compound

The invention discloses a method for synthesizing alpha-aryl-beta-sulfonyl amide. The method comprises the following steps: mixing N-phenyl N-sulfonyl acrylamide compounds with p-methyl benzenesulfonyl hydrazide to obtain a mixture; then, adding a catalyst into the mixture, adding an oxidant into the mixture after dissolving the catalyst with a solvent, and reacting for 1-10 hours at 0-150 DEG C; and after the reaction is completed, separating and purifying the mixture to obtain alpha-aryl-beta-sulfonyl amide, wherein a structural formula of the N-phenyl N-sulfonyl acrylamide compounds is as shown in formula (I) described in the specification, a structural formula of the alkyl sulfonyl hydrazine is as shown in formula (II) described in the specification and a structural formula of the alpha-aryl-beta-sulfonyl amide compound is as shown in formula (III) described in the specification, wherein Ar1, Ar2 and Ar3 are independently selected from alkyl or substituted alkyl; a substituent group on substituted alkyl is alkyl with a carbon number of 5-6, alkoxy with a carbon number of 3-6 or halogen.

Owner:ZHEJIANG UNIV OF TECH

Multilayer plastic-wood composite board and preparation method thereof

InactiveCN103818072AImprove surface strengthRigidity is smallSynthetic resin layered productsSodium bicarbonatePolymer science

A multilayer plastic-wood composite board includes a solid plastic-wood surface layer, a porous plastic-wood sandwich layer, and a solid plastic-wood core layer, wherein the sandwich layer is located between the surface layer and the core layer; the surface layer is formed through the melt blending and extrusion of polyethylene, modified wood powder, maleic anhydride grafted polyethylene, an ultraviolet light absorber, nano-silica and glyceryl stearate; the sandwich layer is formed through the melt blending and extrusion of polyethylene, modified wood powder, maleic anhydride grafted polyethylene, 4, 4'-oxybis (benzenesulfonyl hydrazide), citric acid, sodium bicarbonate and talcum powder; the core layer is formed through the melt blending and extrusion of polyethylene, modified wood powder, maleic anhydride grafted polyethylene, calcium carbonate powder, stearic acid and chlorinated polyethylene. The multilayer plastic-wood composite board provided by the invention has a reasonable design and a simple structure, and is convenient to manufacture; compared with other plastic-wood boards, the multilayer plastic-wood composite board has the advantages of larger surface strength, high hardness and rigidity, light weight, low costs for production, transportation and installation, as well as strong bolt anchoring force, and is applicable for the manufacture of indoor and outdoor floors, guardrails, decorative boards, and the like.

Owner:G&S HUZHOU ENTERPRISES

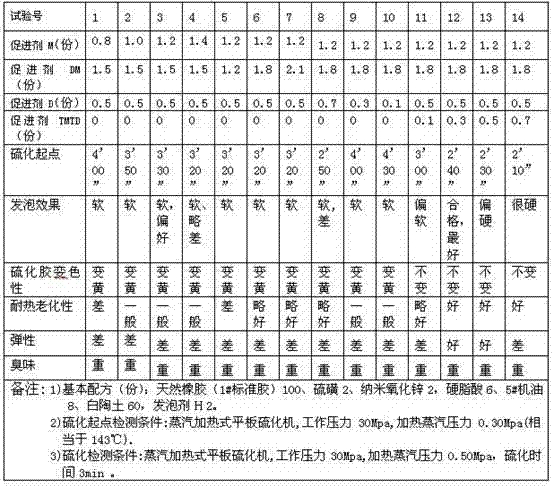

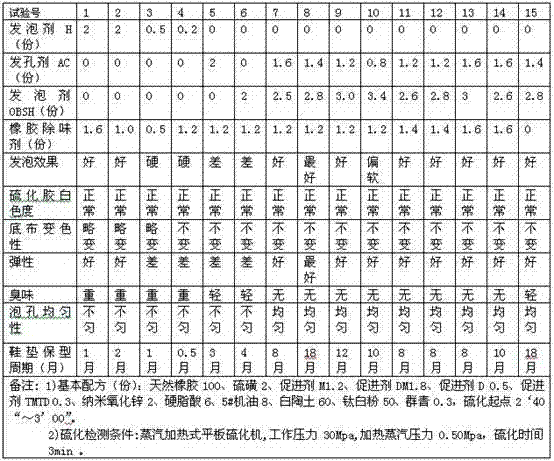

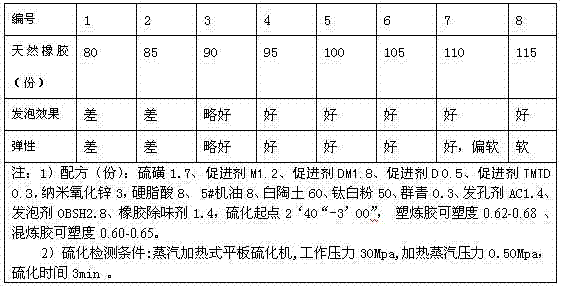

Natural rubber white odorless spongy cushion for in situ color-protecting shoes and preparation method thereof

ActiveCN102391550APrevent high temperature agingShort vulcanization timeInsolesLaminationActivated carbonPolymer science

The invention discloses a natural rubber white odorless spongy cushion for in situ color-protecting shoes and a preparation method thereof. The raw materials of the spongy cushion comprises natural rubber, sulfur, an accelerating agent, a vulcanizing active agent, a hole-forming agent AC (activated carbon), titanium white, 5# engine oil, kaolin, a rubber odor-removing agent and a foaming agent OBSH (oxybis(benzenesulfonyl hydrazide)). In the invention, the odorless spongy for shoes is prepared by utilizing the natural rubber as a main body; vulcanization is promoted by using a thiuram accelerating agent TMTD (tetramethyl thiuram disulfide) to inhibit the high-temperature ageing of the natural rubber, thereby ensuring that titanium white and kaolin filled white spongy rubber do not generate high yellowing to discolor the bottom surfaces in the shoes; the foaming agent AC and OBSH are jointly used, so as to achieve the shape keeping property and even bubbles and low odor of the inner bottoms of the spongy shoes; because no water gas is generated in the foaming process of spongy, heterochromatic substances are not dissolved and transported to cause the yellowing and discoloring of white soft goods of the inner bottoms of the shoes, thus the spongy cushion has abundant white keeping capacity; and the odor generated in the process of vulcanizing the spongy rubber can be effectively removed through the rubber odor-removing agent.

Owner:际华制鞋工业有限公司

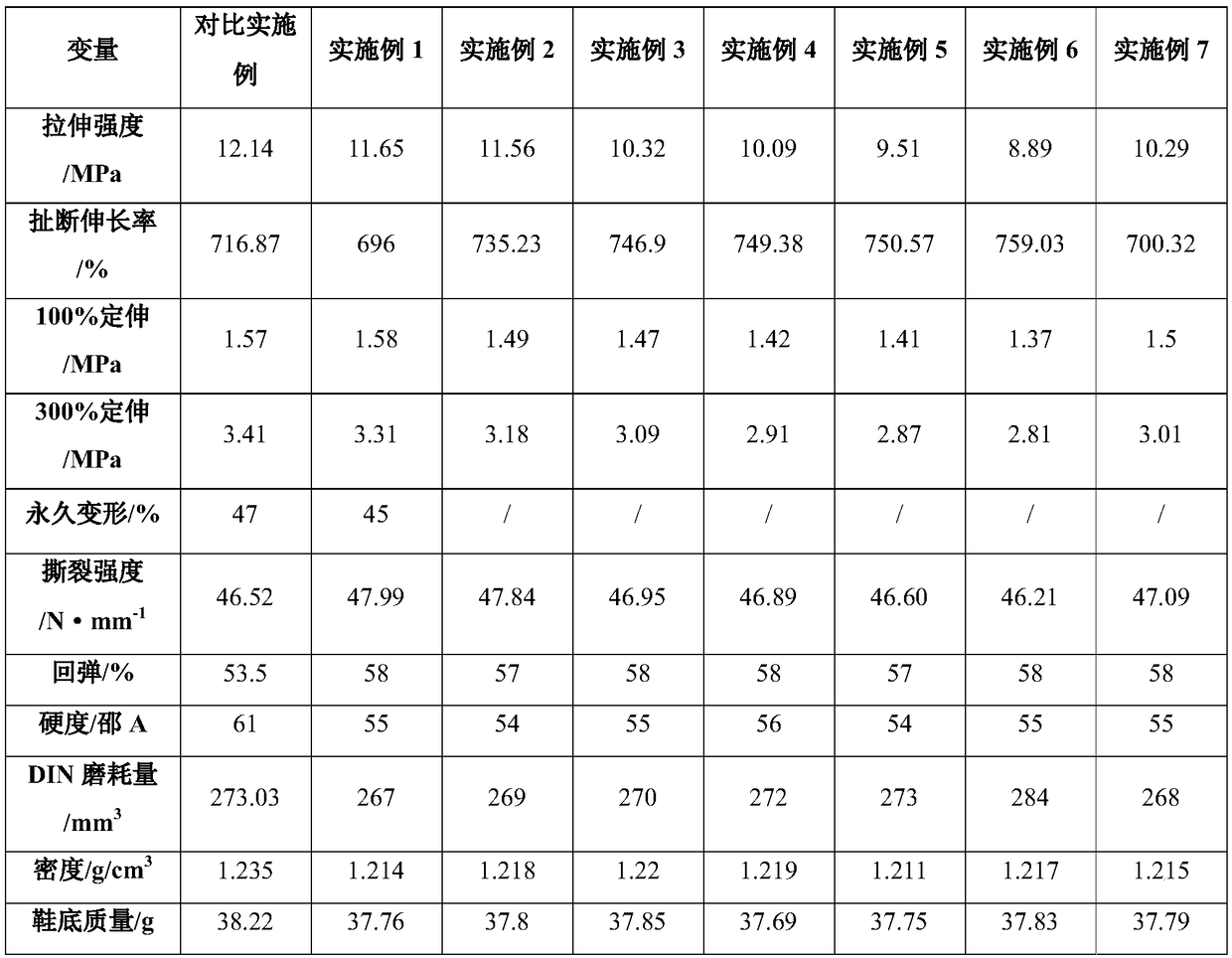

Foamed shoe sole material and preparation method thereof

The invention relates to a foamed shoe sole material and a preparation method thereof. The shoe sole material comprises, by weight, 100 parts of rubber body, 35-45 parts of filler, 25-35 parts of operating oil, 1-4 parts of accelerant, 0.5-1 part of stearic acid, 3-7 parts of zinc oxide, 25-50 parts of white carbon black, 20-30 parts of modified kaolin, 2-5 parts of silane coupling agent, 1-5 parts of inorganic nano crystal whisker, 0.5-3 parts of 4,4-oxybis(benzenesulfonyl hydrazide), 0.3-1.5 parts of paraffin, 5-8 parts of polyethylene glycol, 1-3 parts of styrenated phenol, 1-3 parts of phenolic resin and 1.5-4 parts of sulfur. The foamed shoe sole material has more uniform foaming holes, the weight of a shoe sole is reduced, and meanwhile, the shoe sole material has relatively high wear resistance. The foamed shoe sole material is high in abrasion and light, and can be conveniently used for preparing mountaineering shoe soles and tennis shoe soles.

Owner:GUANGZHOU WEIZHEN CHEM TECH CO LTD

Low-density polyethylene-modified polyvinyl chloride (PVC) synthetic leather and manufacturing method thereof

InactiveCN102995447AGood flexibilityHas a natural and comfortable feelSynthetic resin layered productsLaminationLow-density polyethylenePolyester

The invention discloses low-density polyethylene-modified polyvinyl chloride (PVC) synthetic leather. The low-density polyethylene-modified PVC synthetic leather comprises a surface layer, a foamed layer, a bonding layer and a brushing fabric, and is characterized in that the surface layer is prepared by mixing the following raw materials in parts by weight to form slurry: 30 to 40 parts of SG-1 type PVC resin, 70 to 80 parts of SG-6 type PVC resin, 45 to 50 parts of propanediol sebacate polyester, 20 to 25 parts of n-butyl methacrylate, 5 to 6 parts of PVC color paste, 1 to 2 parts of di-hydrosulfo isooctyl chloroacetate di-n-octyl tin, 1 to 2 parts of zinc stearate, 5 to 10 parts of light calcium carbonate, 2 to 3 parts of 4,4'-oxo bi-benzenesulfonyl hydrazide, 40 to 45 parts of nano- barite powder and 50 to 60 parts of modified bentonite. Through the improvements of the formula and the process, the flexibility of the synthetic leather is improved, and the synthetic leather has a natural comfortable hand feeling similar to that of natural leather and is difficult to damage or tear after being used for 3 to 5 years.

Owner:HEFEI ANSHAN COATING FABRICS

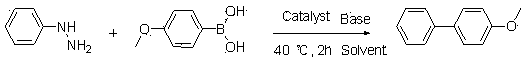

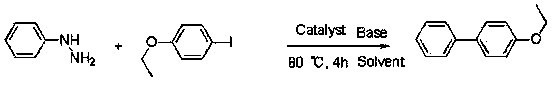

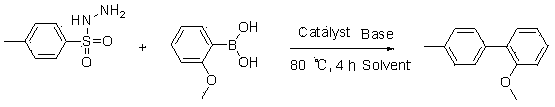

Synthetic method of biphenyl compounds

InactiveCN103553856ASimple and fast operationImprove reaction efficiencyOrganic compound preparationOrganic substitutionSulfohydrazideHalogen

The invention relates to a synthetic method of biphenyl compounds. Based on novel coupling reaction of phenylhydrazine or benzenesulfonyl hydrazide, the phenylhydrazine or benzenesulfonyl hydrazide is used as a substrate, and coupled after being acted by transition metal in a catalytic manner, so that the biphenyl compounds can be conveniently and effectively combined. Compared with the existing method, the synthetic method disclosed by the invention is extensive in applicable substrate range, mild in reaction condition, simple and convenient to operate and high in reaction efficiency, and is a method with important application value. The method disclosed by the invention is further used for synthesizing biphenyl compounds containing halogens. The invention provides a simple, novel and efficient method.

Owner:TONGJI UNIV

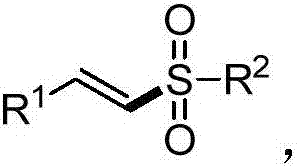

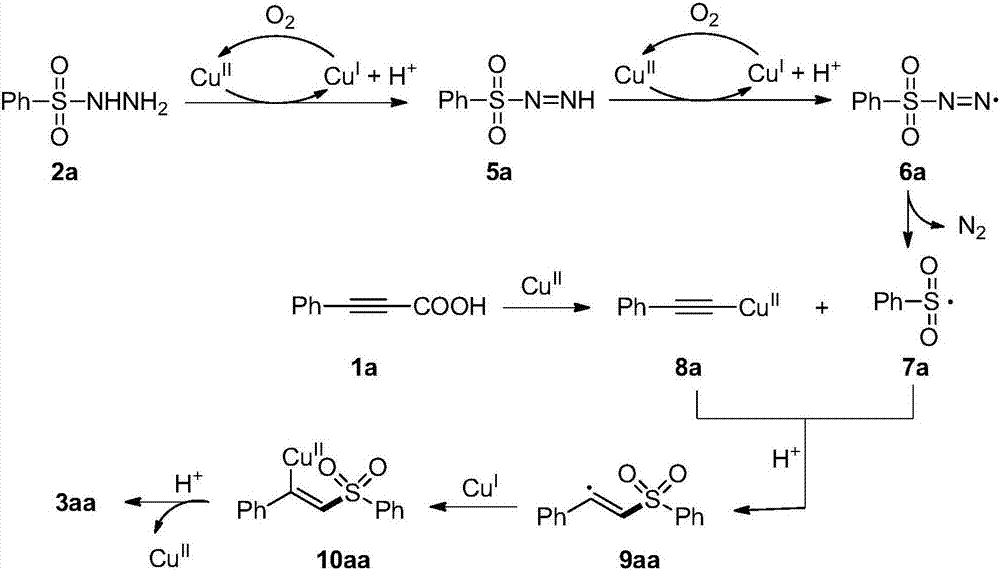

(E)-alkenyl sulfone compound and preparation method thereof

InactiveCN107162943AGood substrate compatibilityHigh yieldOrganic compound preparationOrganic chemistry methodsOrganic solventCopper

The present invention relates to a (E)-alkenyl sulfone compound and a preparation method thereof. The preparation method comprises: dissolving a benzenesulfonyl hydrazide-based substrate and a phenylpropiolic acid substrate in an organic solvent, adding a copper catalyst, and carrying out a reaction by using oxygen in air as an oxidizing agent so as to obtain the (E)-alkenyl sulfone compound, wherein the chemical formula is defined in the specification. Compared to the method in the prior art, the method of the present invention has the following characteristics that the finally required (E)-alkenyl sulfone compound can be obtained with the inexpensive catalyst Cu2O and the green oxidant O2 without the additional additives, and the method provides good compatibility for the substrates having different electronic effects and steric hindrance on the aromatic ring, and has high yield.

Owner:TONGJI UNIV

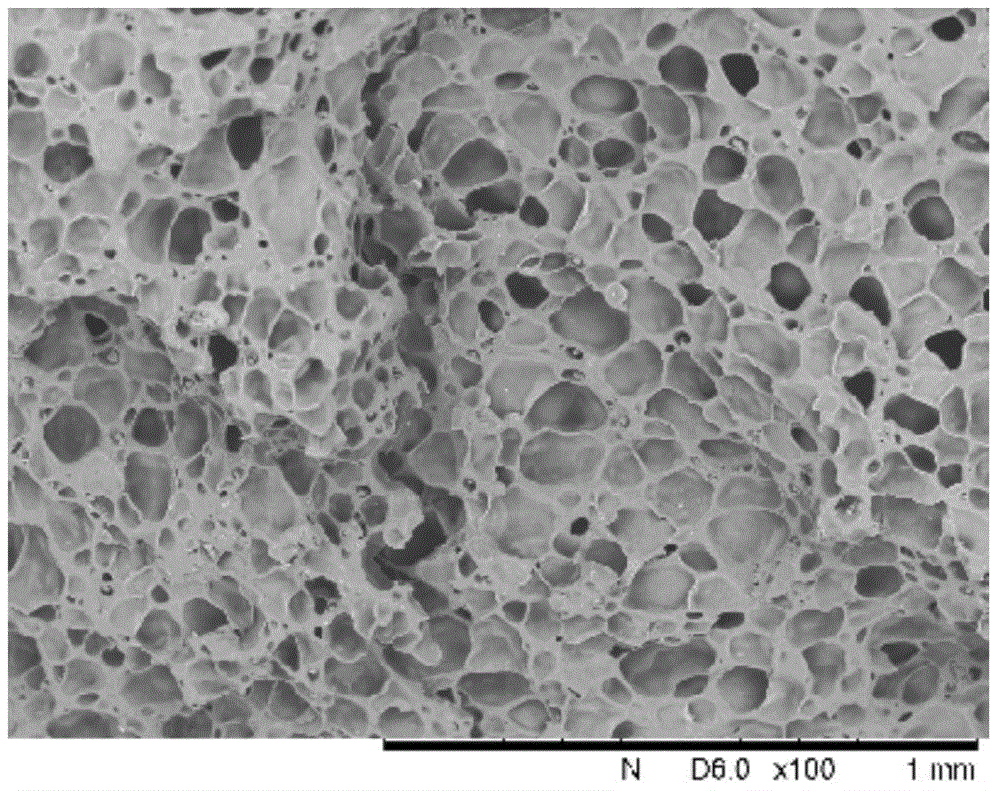

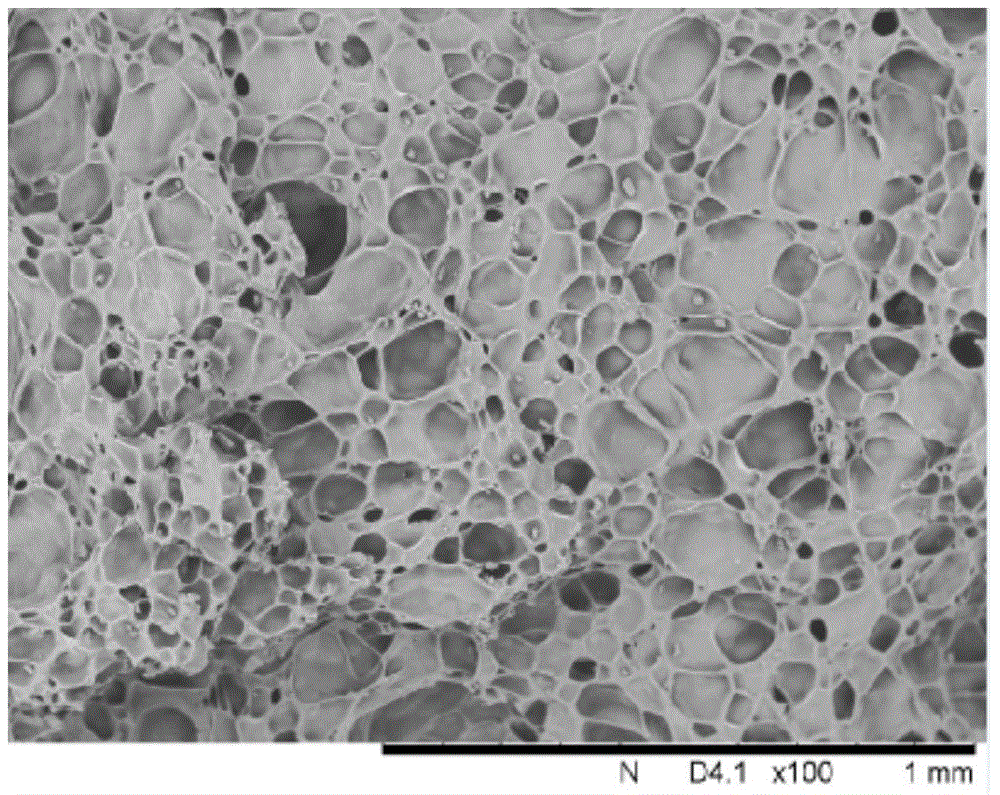

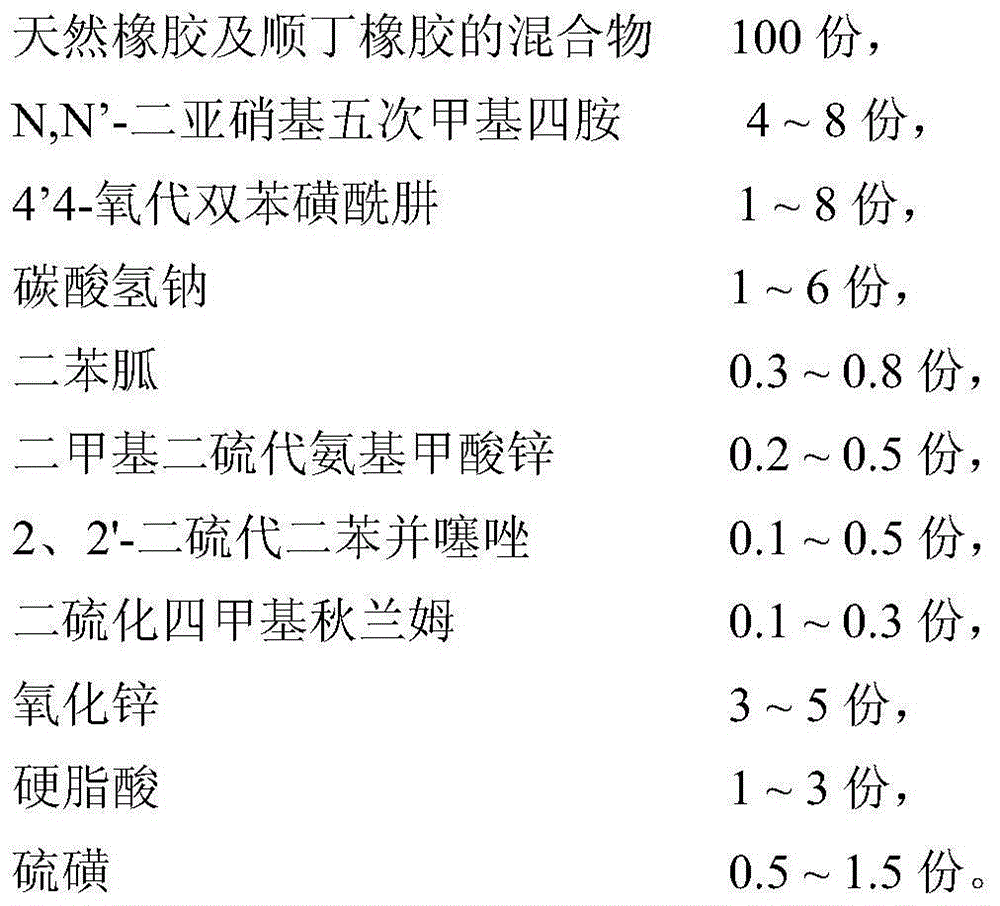

A rubber foaming oil-adsorbing material and a preparing method thereof

InactiveCN105585745AGood oil retentionImprove adsorption capacityOther chemical processesOxygenStearic acid

The invention relates to a rubber foaming oil-adsorbing material and a preparing method thereof. The material comprises 100 parts by weight of a mixture comprising natural rubber and polybutadiene, 4-8 parts by weight of N,N'-dinitrosopentamethylenetetramine, 1-8 parts by weight of 4,4'-oxybis(benzenesulfonyl hydrazide), 1-6 parts by weight of sodium hydrogen carbonate, 0.3-0.8 part by weight of diphenylguanidine, 0.2-0.5 part by weight of zinc dimethyldithiocarbamate, 0.1-0.5 part by weight of 2,2'-dithiobis(benzothiazole), 0.1-0.3 part by weight of tetramethylthiuram disulfide, 3-5 parts by weight of zinc oxide, 1-3 parts by weight of stearic acid and 0.5-1.5 parts by weight of sulfur. The material adopts the mixture comprising the natural rubber and the polybutadiene as a substrate and is lower in cost and higher in oil adsorbing rate. The oil adsorbing rate of the material for xylene is 48.6 g / g, and the oil adsorbing rate of the material for gasoline is 30 g / g or above. The method is simple in process and prone to industrial production.

Owner:NINGBO UNIV

Vehicle-used oil resistant insulated rubber pipe

InactiveCN103724826AGood oil resistanceGood non-conductive performanceFlexible pipesHydration reactionButanedioic acid

The invention discloses a vehicle-used oil resistant insulated rubber pipe, which comprises the following raw materials in parts by weight: 81-90 parts of ternary ethylenepropylene EP35, 25-30 parts of butyronitrile rubber, 1-2 parts of sulfosuccinate sodium salt, 4-6 parts of brucite, 2-3 parts of beta-diketone, 2-3 parts of calcium phosphate, 30-35 parts of carbon-white, 2-4 parts of hydrate zinc borate, 1-3 parts of 4,4'-oxybis benzenesulfonyl hydrazide, 2-4 parts of calcium fluoride, 2-3 parts of triglycol, 1-2 parts of an accelerant CA, 1-2 parts of an antiager KY405, 0.8-1 part of sulphur and 14-25 parts of composite filler. The vehicle-used oil resistant insulated rubber pipe, disclosed by the invention, has the characteristics of good oil and flex resistant and anti-crack performance, good utilization of electric insulation performance of carbon-white and high insulation performance, and meanwhile has excellent insulation performance and improved security.

Owner:WUHU JIACHENG ELECTRONICS TECH

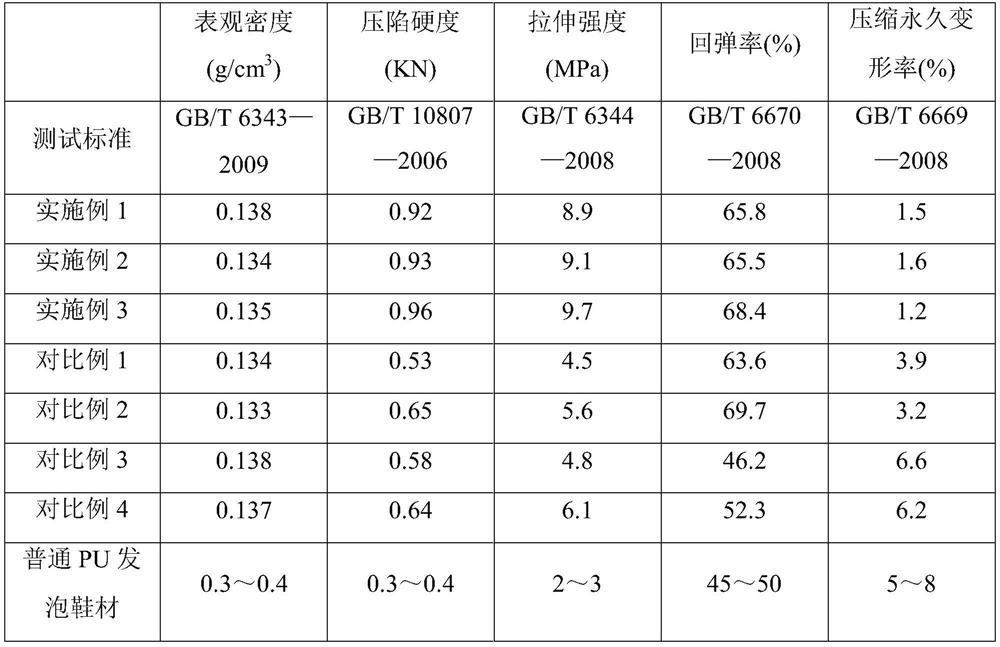

PU foaming shoe material capable of releasing negative ions and preparation method thereof

The invention discloses a PU foaming shoe material capable of releasing negative ions and a preparation method thereof. The PU foaming shoe material is prepared from the following raw materials in parts by weight: 70-80 parts of polyester polyurethane, 12-16 parts of ethylene-vinyl acetate copolymer, 5-7 parts of styrene-ethylene-butadiene-styrene block copolymer, 4-6 parts of a negative ion additive, 1.2-1.7 parts of 4-methylbenzenesulfonyl hydrazine, 0.45-0.55 parts of triethylene diamine, 0.08-0.12 parts of triallyl isocyanurate, 2-3 parts of talcum powder, 2-4 parts of titanium dioxide, 1-2 parts of zinc oxide, 2-4 parts of stearic acid and 1.5-2.7 parts of zinc stearate, wherein the negative ion additive is a mixture of opal powder and medical stone powder, and the mass ratio of opalpowder to medical stone powder is 1: (0.6-0.8). The PU foaming shoe material capable of releasing negative ions is small in density and light in weight; the indentation hardness is high, the tensile strength is high, and the mechanical property is good; the rebound rate is high, the compression set rate is low, the elasticity is good, and permanent deformation is not likely to happen in the usingprocess; and the overall performance is excellent.

Owner:ZHEJIANG SEMIR GARMENT CO LTD +1

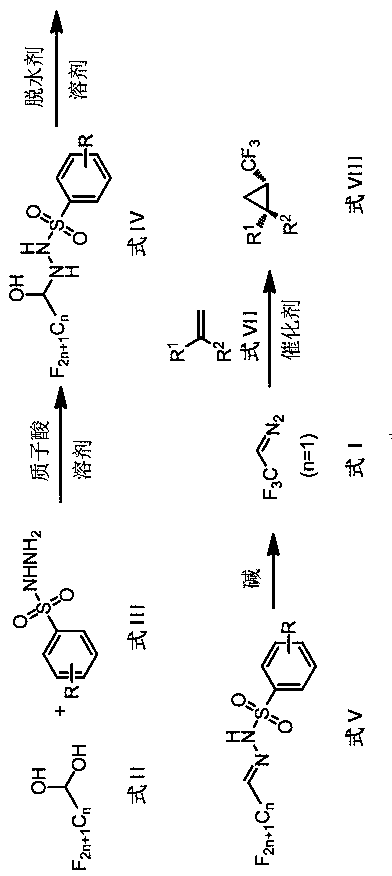

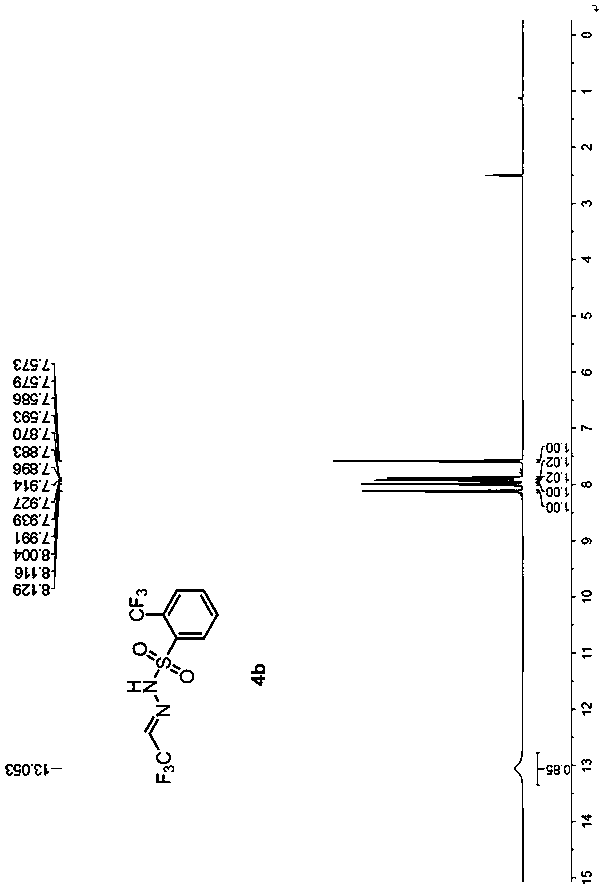

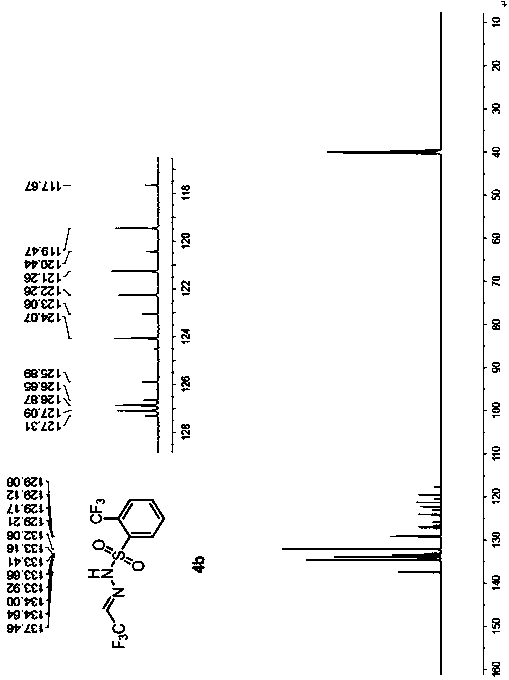

Preparation method and application of perfluoroalkyl diazomethane

ActiveCN107739317AAvoid separationSafe and efficient separationSulfonic acid amide preparationHalogenated hydrocarbon preparationPhotochemistryChemistry

The invention discloses a method for mildly generating perfluoroalkyl diazomethane in situ. By utilizing the method, through starting with perfluoroalkyl aldehyde or a hydrate thereof, which is low inprice and is easily obtained, a substitution reaction is generated with a derivative of benzenesulfonyl hydrazide under the catalysis of protonic acid; the dehydration is carried out in the presenceof a dehydrating agent to obtain a perfluoroalkyl diazomethane precursor; the perfluoroalkyl diazomethane is slowly released in an alkaline condition. Further, by utilizing the preparation method of the perfluoroalkyl diazomethane, a novel method for synthesizing trifluoromethyl cyclopropane in a two-phase system through a one-pot method without carrying out separation is invented. By using the method, the separation of trifluoromethyl diazomethane which has toxicity and explosion danger is avoided; the method has the advantages of mild reaction condition, wide substrate range and good functional-group tolerance, and meanwhile, the method has the advantages of being simple and convenient to operate and needing no special equipment to slowly dropwise add, can be used for safely and efficiently synthesizing the trifluoromethyl cyclopropane, whose order of magnitude is 1 to 100 grams, in a laboratory and has further industrialized application potential.

Owner:NORTHEAST NORMAL UNIVERSITY

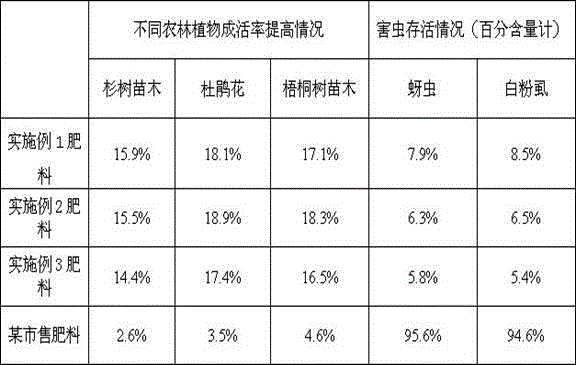

Antimicrobial pesticidal slow-release fertilizer for agriculture and forestry

InactiveCN105061102AThe preparation process is simpleImprove survival rateFertilizer mixturesDecabromodiphenyl etherPolystyrene

The invention relates to an antimicrobial pesticidal slow-release fertilizer for agriculture and forestry, which is composed of the following components in parts by mass: 40-44 parts of polystyrene foamed granule, 42-46 parts of ultrafine fiber, 38-42 parts of fly ash aluminum oxide, 42-46 parts of 4,4-oxo-bis benzenesulfonyl hydrazide, 38-42 parts of nano hollow sphere particle, 42-46 parts of dibutyltin dilaurate, 38-42 parts of halogenated butyl rubber, 44-48 parts of azobisformamide, 38-42 parts of polymethylene polyphenyl polyisocyanate, 42-46 parts of artificial mica, 38-42 parts of polyvinyl fluoride, 42-46 parts of polyaryl oxadiazole fiber, 38-42 parts of melamine cyanurate, 42-46 parts of antimony trioxide, 38-42 parts of decabromodiphenyl oxide, 42-46 parts of calcium carbonate, 38-42 parts of polyamide wax micropowder, 42-46 parts of polydimethylsiloxane, 38-42 parts of diaminodiphenylmethane and 1000-2000 parts of water. The product has excellent antimicrobial and pesticidal properties, and enhances the survival percent of plants in agriculture and forestry.

Owner:龚灿锋

Environment-friendly PVC sealing strip and preparation method thereof

The invention provides an environment-friendly low-shrinkage PVC sealing strip. The sealing strip comprises 100 parts of PVC, 15-30 parts of EPDM rubber, 80-100 parts of a plasticizer, 8-18 parts of calcium carbonate, 8-16 parts of zinc oxide, 15-25 parts of carbon black, 6-10 parts of chlorinated paraffin, 5-8 parts of a calcium-zinc stabilizer, 0.5-2 parts of a bis(benzenesulfonyl hydrazide) ether foaming agent and 1-5 parts of a flame retardant. By unique process control in the preparation process of the sealing strip, the VOC content is reduced, and the mechanical property and the shrinkage resistance of the sealing strip are improved.

Owner:温州包鹿新材料有限公司

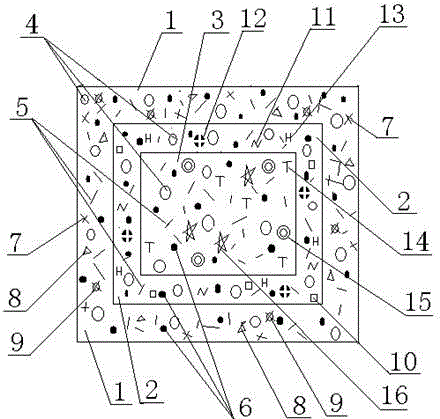

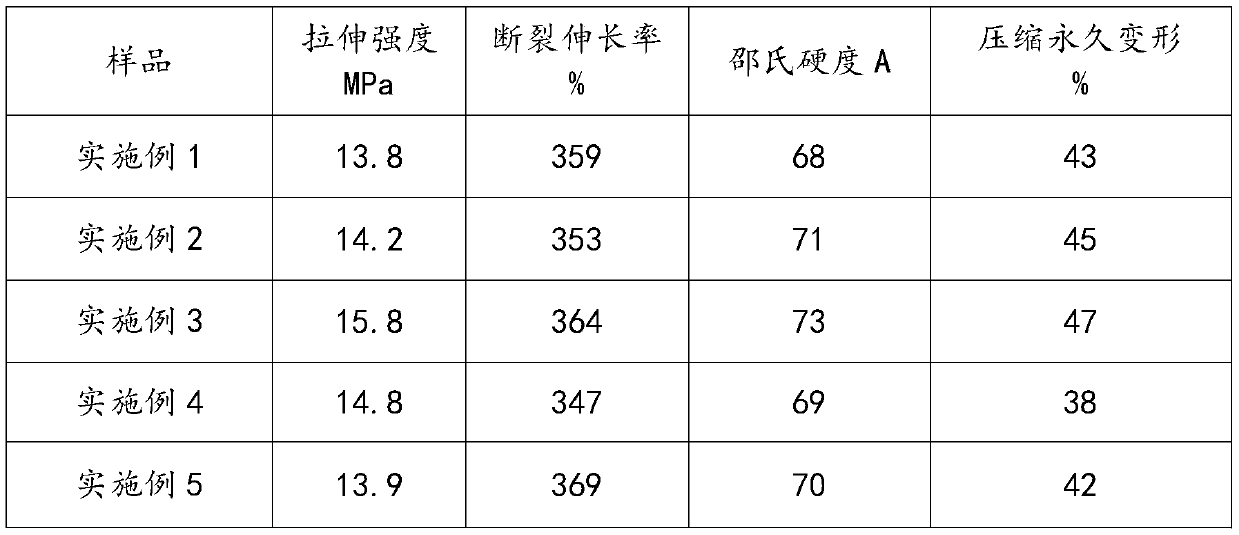

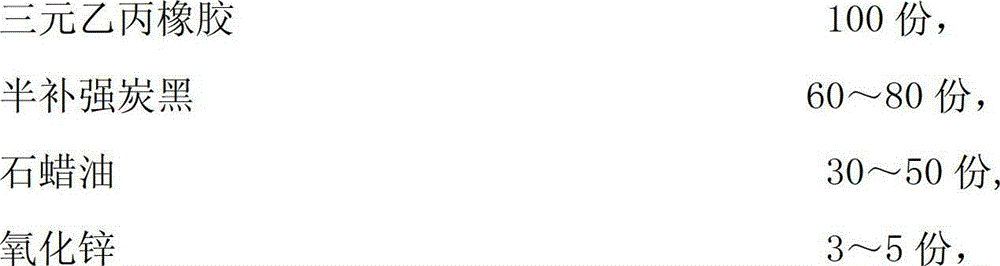

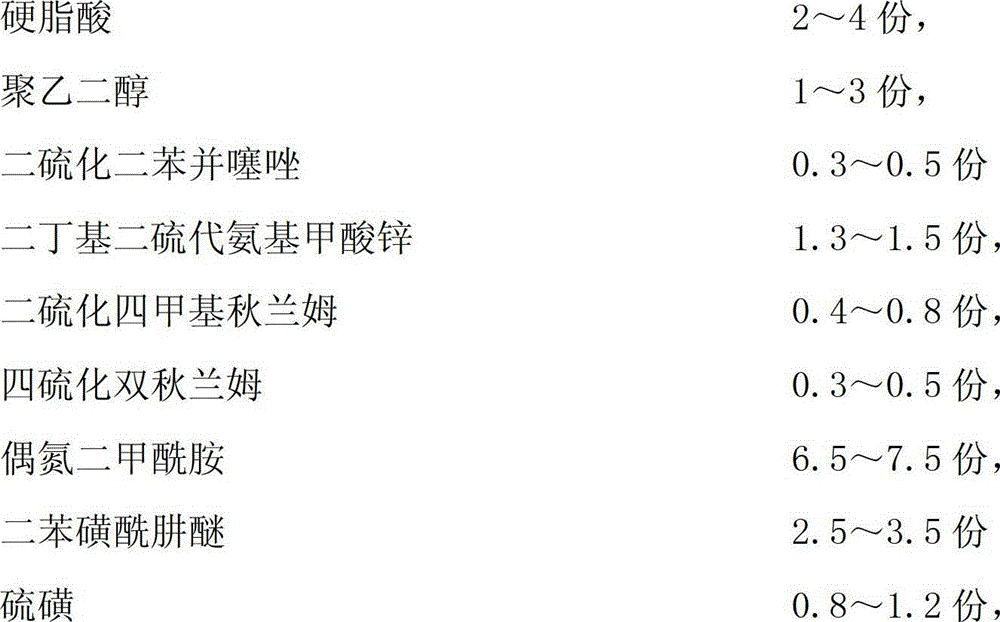

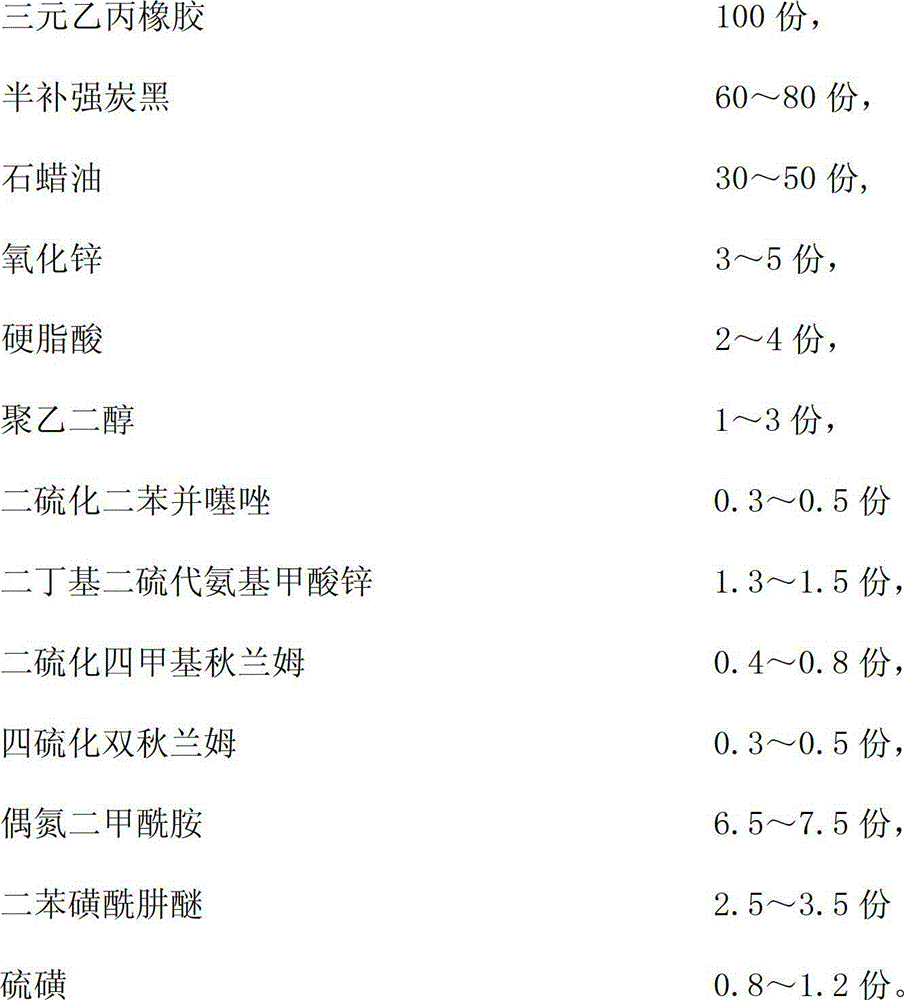

Ethylene-propylene-diene monomer mould pressing abnormal shape sponge sheath rubber composition

The invention relates to an ethylene-propylene-diene monomer (EPDM) mould pressing abnormal shape sponge sheath rubber composition. The composition includes the components by weight: 100 parts of EPDM rubber, 60-80 parts of semi-reinforcing carbon black, 30-50 parts of paraffin oil, 3-5 parts of zinc oxide, 2-4 parts of stearic acid, 1-3 parts of polyethylene glycol, 0.3-0.5 parts of dibenzothiazole disulfide, 1.3-1.5 parts of zinc dibutyldithiocarbamate, 0.5-0.8 parts of tetramethylthiuram disulfide, 0.3-0.5 parts of dithiuram tetrasulfide, 6.5-7.5 parts of azodicarbonamide, 2.5-3.5 parts of 4,4'-oxybis(benzenesulfonyl hydrazide), and 0.8-1.2 parts of sulfur. The EPDM rubber is used in the invention. By adjusting the ratio of various components in the recipe and process conditions, the abnormal shape sponge sheath with excellent heat aging resistance, small density, stable dimension and smooth and exquisite surface can be prepared.

Owner:TIANJIN PENGYI GRP CO LTD

Silicon foaming adhesive composition and its preparation method, silicon foaming adhesive and ultrasonic sensor

ActiveCN102408718APorosity is easy to controlReduce aftershocksWave based measurement systemsPorosityUltrasonic sensor

The invention provides a silicon foaming adhesive composition, by taking the total mass of the silicon foaming adhesive composition as a reference, the silicon foaming adhesive composition has the following ingredients: 50-75% of polydimethylsiloxane, 15-40% of dimethicone, 5-20% of silica micropowder, 0.5-2% of silicone resin, 1-10% of coupling agent, 0.5-3% of 4,4'-oxydibenzenesulfonyl hydrazide, 0.5-3% of crystalline hydrate. The invention also provides a preparation method of the silicon foaming adhesive composition, a silicon foaming adhesive prepared by the silicon foaming adhesive composition and an ultrasonic sensor containing the silicon foaming adhesive. The silicon foaming adhesive has large porosity and uniform aperture distribution, the ultrasonic sensor by using the silicon foaming adhesive has the advantages of small aftershock and low impedance.

Owner:BYD CO LTD

A light-weight attapulgite binder for building partition walls

The invention discloses a light board attapulgite binder for building partition walls. The binder is composed of the following raw materials: by weight, 120-150 parts of 32.5 rapid hardening aluminum sulfate salt cement, 40-50 parts of pure acrylic emulsion, 4-6 parts of polyvinyl alcohol, 3-4 parts of diethylene glycol, 2-3 parts of hydroxyethyl methyl cellulose, 100-150 parts of silica sand, 4-6 parts of plant fiber, 3-5 parts of alunite powder, 4-8 parts of benzenesulfonyl hydrazide, 5-10 parts of dolomite powder, 10-15 parts of attapulgite, 4-8 parts of furnace slag powder, 1-2 parts of sodium borate, 5-8 parts of triethanolamine, 0.5-1 parts of 3-aminopropyl trimethoxy silane. The light board attapulgite binder for building partition walls has strong adhesion, reduces chances of delamination and spalling, guarantees engineering quality, avoids the problems of hollowing and cracking after long-term usage, and therefore raises the durability.

Owner:ANHUI GUODIAN ENERGY EQUIP ENG

Dual-curing UV (Ultraviolet Rays) glue based on acrylic-modified hyperbranched waterborne polyurethane and preparation method thereof

ActiveCN107189730AImprove wear resistanceImprove mechanical propertiesNon-macromolecular adhesive additivesModified epoxy resin adhesives(Hydroxyethyl)methacrylatePropanoic acid

The invention provides a dual-curing UV (Ultraviolet Rays) glue based on acrylic-modified hyperbranched waterborne polyurethane and a preparation method thereof. The specific preparation method comprises the following steps: putting isophorone diisocyanate and dibutyltin dilaurate into a four-opening flask, and stirring at room temperature; firstly, adding polycarbonate diols to react, then, adding hydroxyl terminated polyether modified silicone oil, and carrying out temperature reaction; then, adding dimethylol propionic acid to react, and finally, adding hydroxyethyl methylacrylate and 4-metoxyphenol to react; finally, adding Di-PE to react to prepare hyperbranched waterborne polyurethane; adding hydroxyl-containing acrylic monomer and initiator into hyperbranched waterborne polyurethane to react to obtain acrylic-modified hyperbranched waterborne polyurethane; mixing with epoxy acrylate, and adding acrylic acid, benzenesulfonyl hydrazide, saccharin, photoinitiator and stabilizer; stirring in a planetary mixer, adding isopropyl benzene hydroperoxide initiator, and carrying out vacuum stirring and light-proof packaging to obtain the dual-curing UV glue based on the acrylic-modified hyperbranched waterborne polyurethane.

Owner:福建纳川水务有限公司

Light board attapulgite binder for building partition walls

The invention discloses a light board attapulgite binder for building partition walls. The binder is composed of the following raw materials: by weight, 120-150 parts of 32.5 rapid hardening aluminum sulfate salt cement, 40-50 parts of pure acrylic emulsion, 4-6 parts of polyvinyl alcohol, 3-4 parts of diethylene glycol, 2-3 parts of hydroxyethyl methyl cellulose, 100-150 parts of silica sand, 4-6 parts of plant fiber, 3-5 parts of alunite powder, 4-8 parts of benzenesulfonyl hydrazide, 5-10 parts of dolomite powder, 10-15 parts of attapulgite, 4-8 parts of furnace slag powder, 1-2 parts of sodium borate, 5-8 parts of triethanolamine, 0.5-1 parts of 3-aminopropyl trimethoxy silane. The light board attapulgite binder for building partition walls has strong adhesion, reduces chances of delamination and spalling, guarantees engineering quality, avoids the problems of hollowing and cracking after long-term usage, and therefore raises the durability.

Owner:ANHUI GUODIAN ENERGY EQUIP ENG

Method for improving dispersity of photovoltaic panel electronic paste

InactiveCN112642316AEvenly dispersedGood dispersionMixing methodsTransportation and packagingSulfohydrazideSodium-p-toluenesulfinate

The invention relates to the technical field of electronic paste, and discloses a method for improving dispersity of photovoltaic panel electronic paste. The method comprises the following steps: preparing nano-copper powder from copper acetate and hydrazine hydrate under proper conditions, treating the nano-copper powder with toluenesulfonyl hydrazine, and aggregating toluenesulfonyl hydrazine on nano-copper tiny agglomerates; countless tiny bubbles are generated by decomposing in hot water, the bubbles burst and gas driving force generated by the bubbles promote tiny agglomerates formed by agglomeration of the nano-copper particles to be dispersed and fully infiltrated, and the sodium p-toluenesulfonate generated after the p-toluenesulfonylhydrazine is decomposed can promote effective infiltration of paste to the nano-copper particles. P-toluenesulfonyl hydrazide can hydrolyze on the surfaces of the nano-copper tiny agglomerates to generate countless small bubbles to crush the tiny agglomerates to be fully dispersed, and the generated sodium p-toluenesulfonate can also promote the slurry to fully infiltrate the nano-copper particles, so that the problem of agglomeration of the filler tiny agglomerates, which is difficult to solve by traditional mechanical stirring and ball milling, is effectively solved; therefore, uniform and stable dispersion of the conductive phase in the electronic paste is realized.

Owner:CHENDU NEW KELI CHEM SCI CO LTD

LDPE (Low-density polyethylene)/EPDM (ethylene-propylene-diene monomer)/POM (polyoxymethylene) composite foam material and preparation method thereof

ActiveCN103102561AImprove interfacial bond strengthHigh tensile strengthLow-density polyethylenePhosphorous acid

The invention discloses an LDPE (low-density polyethylene) / EPDM (ethylene-propylene-diene monomer) / POM (polyoxymethylene) composite foam material. The foam material is prepared from the following raw materials in parts by weight: 80-100 parts of LDPE, 30-40 parts of EPDM, 20-30 parts of POM, 10-20 parts of activated calcium carbonate, 10-15 parts of nanometer argil, 2-3 parts of aluminate coupling agent DL-411, 1-2 parts of phenylisopropyl tri(dioctyl acyloxy pyrophosphate) titanate, 5-10 parts of decabromobibenzyl, 5-8 parts of 4,4'-oxybis benzenesulfonyl hydrazide, 5-8 parts of phthalate, 1-1.5 parts of biperoxide carbamate, 2-3 parts of zinc stearate, 1-2 parts of calcium stearate, 1-2 parts of dibasic lead phosphite, 2-3 parts of microcrystalline wax, 3-5 parts of modified wood ash, 1-2 parts of ultraviolet light absorber UV-329 and 2-3 parts of antioxidant 1076. The produced LDPE foam material is light and soft, has high strength, good resilience, an ideal foaming effect, uniform, fine and dense pores and good flame retardance, is resistant to chemical corrosion and aging and is durable in use.

Owner:重庆锋胜包装材料有限公司

Anti-ageing salt elimination underground pipe used for saline-alkali soil and preparation method of anti-ageing salt elimination underground pipe

The invention provides an anti-ageing salt elimination underground pipe used for saline-alkali soil. The underground pipe comprises, by weight, 55-68 parts of polyethylene, 15-26 parts of polyether sulfone, 5-11 parts of itaconate, 0.9-1.8 parts of 4,4'-oxy-bis(benzenesulfonylhydrazide), 0.7-2.4 parts of zinc stearate, 5-16 parts of C9-based aromatic base crude oil resin, 7-13 parts of modified organosilicon-based polymer, 3-6 parts of nanometer sodium zirconium phosphate, 8-14 parts of silicone rubber, 4-8 parts of cyclic olefin copolymer and 0.8-2.5 parts of isothiazolinone. The invention further provides a preparation method of the underground pipe. The inner wall and the outer wall of the prepared underground pipe are each in a corrugated shape; the nominal outside diameter is 10.5 cm, and the average wall thickness is 0.72 mm; the effective water absorption area of the pipe is 70 cm<2> / m; the anti-ageing salt elimination underground pipe has the beneficial effects of being resistant to ageing and long in service life.

Owner:WEIFANG YOURONG IND

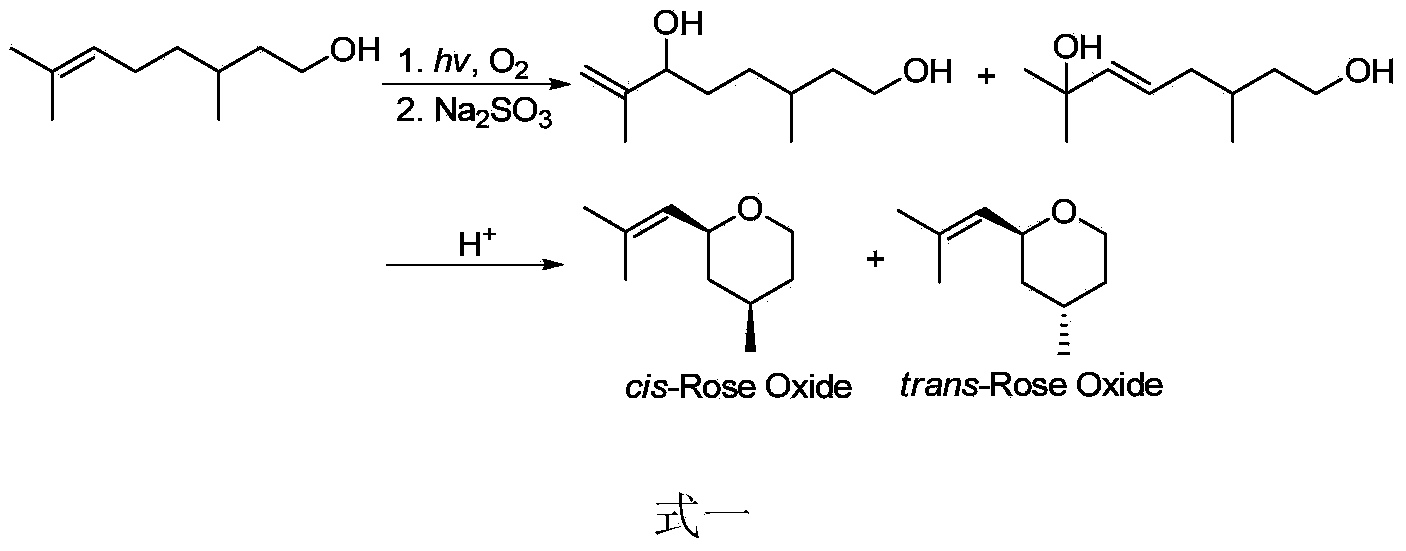

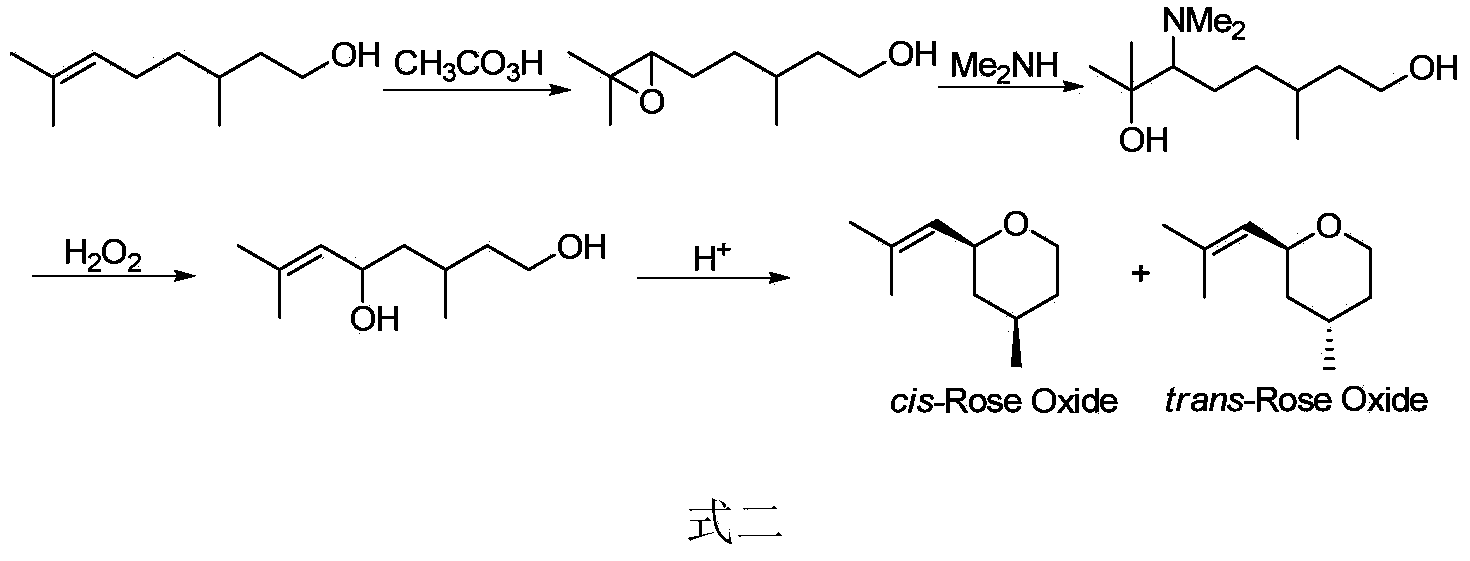

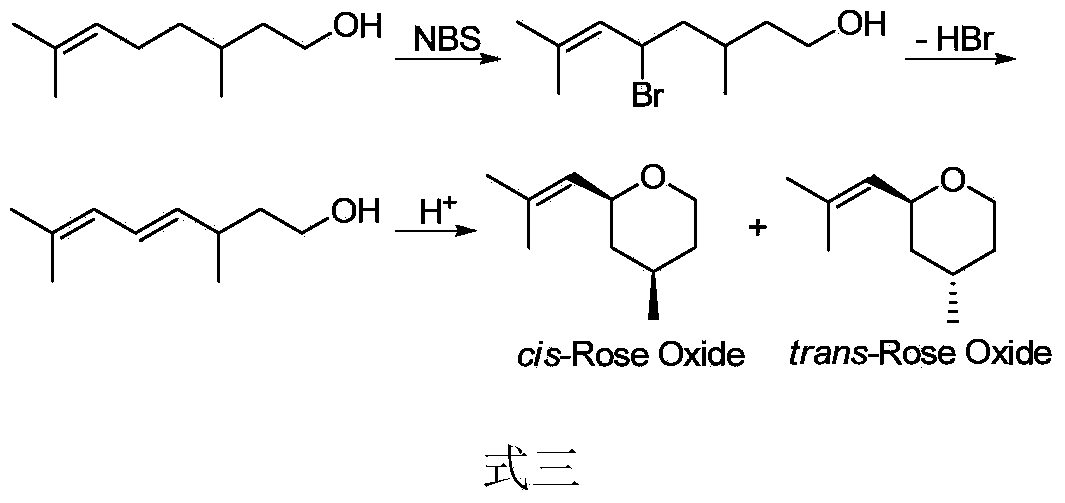

Preparation method of rose ether

The invention discloses a preparation method of rose ether. The preparation method of the rose ether comprises the following steps: firstly, with geraniol as a starting raw material, performing epoxidation, epoxy rearrangement and selective oxidation to obtain corresponding alpha, beta-unsatisfied ketone; secondly, combining with phenylsulfonyl hydrazine or a derivative thereof to form a phenylsulfonyl hydrazone intermediate, and obtaining a corresponding olefinic compound through amine catalysis; finally, cyclizing the olefinic compound to obtain the rose ether. In the whole process of the preparation method, no toxic reagent and no expensive metal reagent are used, so that the reaction posttreatment is convenient and the production cost is relatively low; three-dimensional selectivity of the reaction can be controlled by changing reaction conditions, so that synthesis of cis-rose ether or a mixture of cis-rose ether and trans-rose ether is realized; the reaction yield is relatively high.

Owner:LANZHOU UNIVERSITY

Nano composite foaming agent for preparing polyurethane and preparation method thereof

The invention discloses a nano composite foaming agent for preparing polyurethane, and particularly relates to the technical field of foaming agents, and the nano composite foaming agent comprises the following raw materials: 4, 4-oxo-bis (benzenesulfonyl) hydrazine, modified nano silicon dioxide and layered montmorillonite. The mesoporous silica is subjected to polymer grafting reaction after pore expansion treatment, so that the mesoporous silica has super-large mesoporous channels, the mesoporous silica has excellent dispersity and good interfacial compatibility, and then n-octyl alcohol is added to modify the mesoporous silica and acetone. The nano composite foaming agent can be more uniformly dispersed into polyurethane to reduce the local foaming agent amount, and the nano composite foaming agent provided by the invention not only has small particle size, but also has high loading capacity on a chemical foaming agent, so that microporous foamed plastic with better foaming quality can be obtained.

Owner:江苏威久科技发展有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com