Patents

Literature

135 results about "Dioctyl maleate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Dioctyl Maleate is a maleic acid that can act as a plasticizer and is used in resins to provide elasticity and flexibility. Dioctyl Maleate is a co-monomer which can be polymerized with vinyl acetate, vinyl chloride (PVC), acrylates as well as stearates.

Modified polylactic acid material and preparation method and application thereof

The invention provides a modified polylactic acid material and a preparation method and application thereof. The modified polylactic acid material comprises the following raw materials in part by weight: 40 to 70 parts of polylactic acid, 10 to 20 parts of thermoplastic polyester elastomer, 10 to 20 parts of plasticizer and 10 to 20 parts of organic or inorganic filler, wherein the thermoplastic polyester elastomer is polyester thermoplastic polyurethane; the plasticizer is one or two of tributyl acetocitrate, epoxidized soybean oil, propylene glycol polyester adipate or dioctyl maleate; and the organic or inorganic filler is one or more of starch, talcum powder, calcium carbonate, mica, montmorillonite, clay or titanium dioxide. The modified polylactic acid material has the advantages of improving the flexibility of a polylactic acid material and reducing the cost of a biodegradable material. A mechanical performance test shows that in the modified polylactic acid material, the tensile strength is 15 to 70 MPa and the fracture tensile rate is 20 to 38 percent.

Owner:江苏天仁生物材料有限公司

Plant fiber starch fully-biodegradable material and preparation method thereof

The invention discloses a plant fiber starch fully-biodegradable material and a preparation method thereof. The material is a product prepared by melting, blending and extruding thermoplastic corn starch, 50 to 60 mesh needlebush fibers, polylactic acid, inorganic stuffing, a crosslinking agent and a solubilizer in a twin-screw extruder. The thermoplastic corn starch is a product prepared by extruding the corn starch and the solubilizer which are blended according to a ratio of 40 to 70: 2 to 5 in a single screw extruder. In the invention, dioctyl maleate (MOD) is grafted onto the polylactic acid to perform a hydroxylation reaction of MOD-functionalized polylactic acid and thermoplastic starch, so that PLA and TPS interfaces are soluble mutually and the binding force of the interfaces is improved. The product has high water resistance and high mechanical properties. Compared with the conventional thermoplastic corn starch composition packing material, the stretching strength of the material of the invention is improved by 30 to 60 percent, the rigidity is increased by 15 to 35 percent, the water absorption is reduced by 13 to 40 percent, and the material is nontoxic and low in cost.

Owner:HUNAN UNIV OF TECH

Capacitor film containing modified attapulgite and preparation method thereof

ActiveCN102964664AImprove barrier propertiesImprove air tightnessFixed capacitor dielectricLow-density polyethylenePolyvinyl alcohol

The invention discloses a capacitor film containing modified attapulgite and a preparation method thereof. The capacitor film comprises the following raw materials, by weight: 30-40 parts of homogeneous ethylene / alpha olefin copolymer, 25-30 parts of metallocene linear low-density polyethylene resin, 13-18 parts of LDPE low-density polyethylene, 10-15 parts of homo-polypropylene, 3-5 parts of epoxy linseed oil, 2-3 parts of polyvinyl alcohol, 1-2 parts of aluminum hydroxide, 1-2 parts of polyisobutylene, 8-12 parts of diatomite, 1-2 parts of ferrocene, 1.2-1.5 parts of poly-4-methyl-1-pentene, 7-9 parts of modified attapulgite, 0.8-1.2 parts of an antioxidant DLTP, 0.6-0.8 part of tributyl citrate, 1.4-1.8 parts of dioctyl maleate, 4-6 parts of calcium stearate, 1.4-1.8 parts of vinyl tri (beta-methoxy ethyoxyl) silane and 0.8-1.2 parts of modified wood ash. The preparation method provided by the invention is simple; addition of diatomite, modified attapulgite and modified wood ash enhances resistance and air tightness of the film; besides, the capacitor film has characteristics of good pressure resistance, impact resistance, high heat sealing strength and good heat sealing performance.

Owner:ANHUI YIDA ELECTRONICS

High-temperature-resistant cable sheath material and preparation method thereof

ActiveCN103524844AExtended service lifeImprove high temperature resistanceInsulated cablesInsulatorsPolymer sciencePhosphate

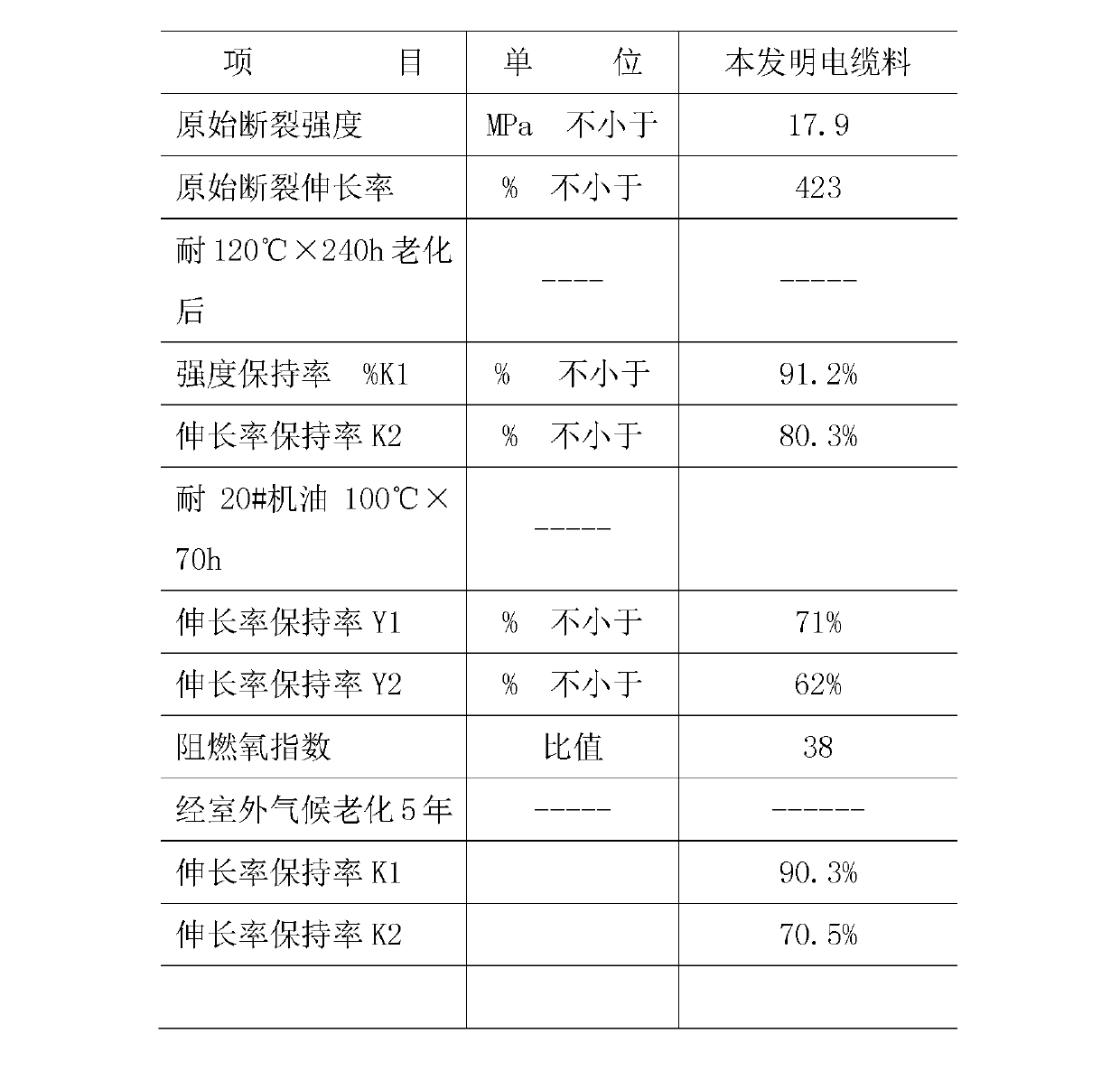

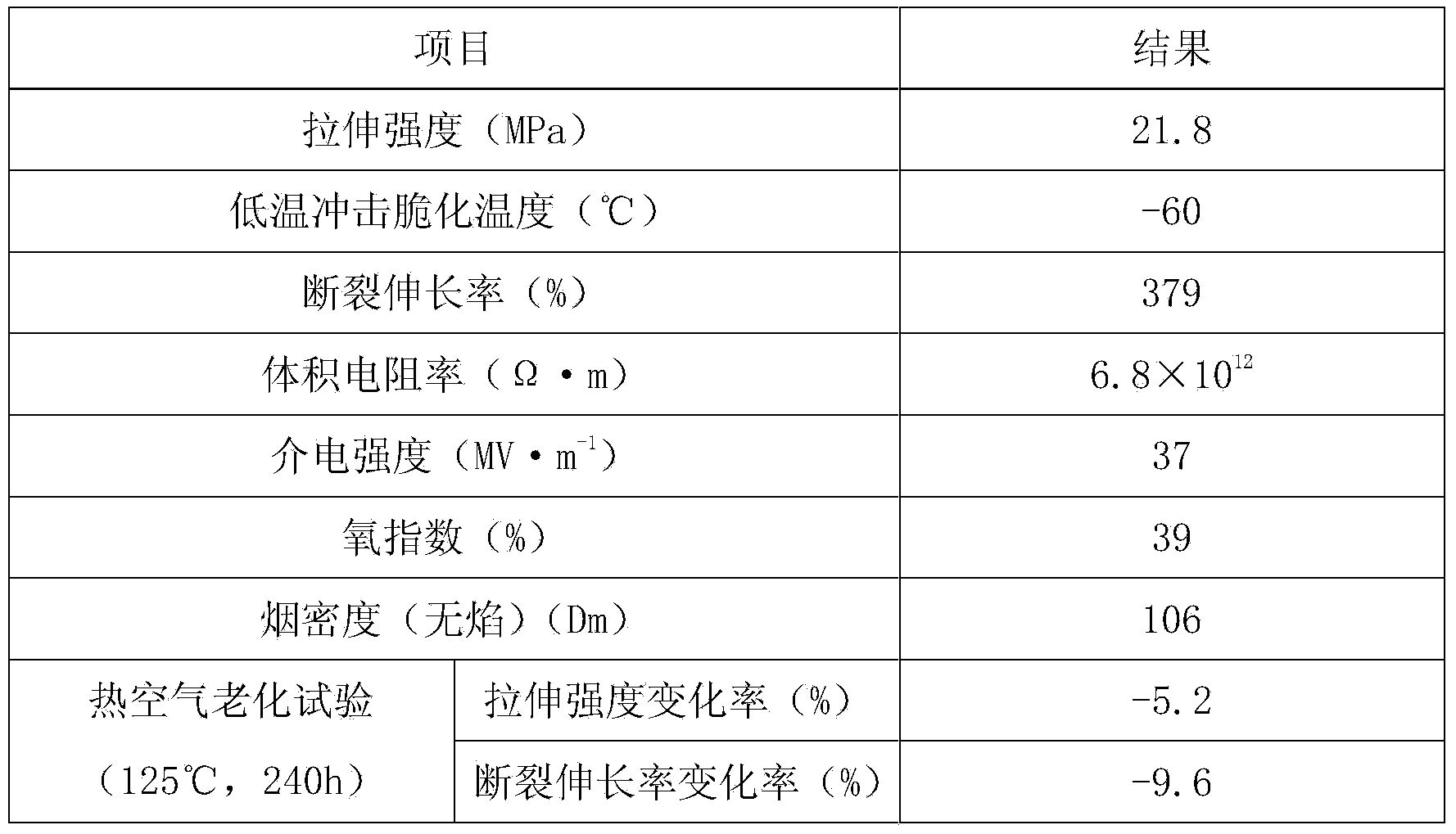

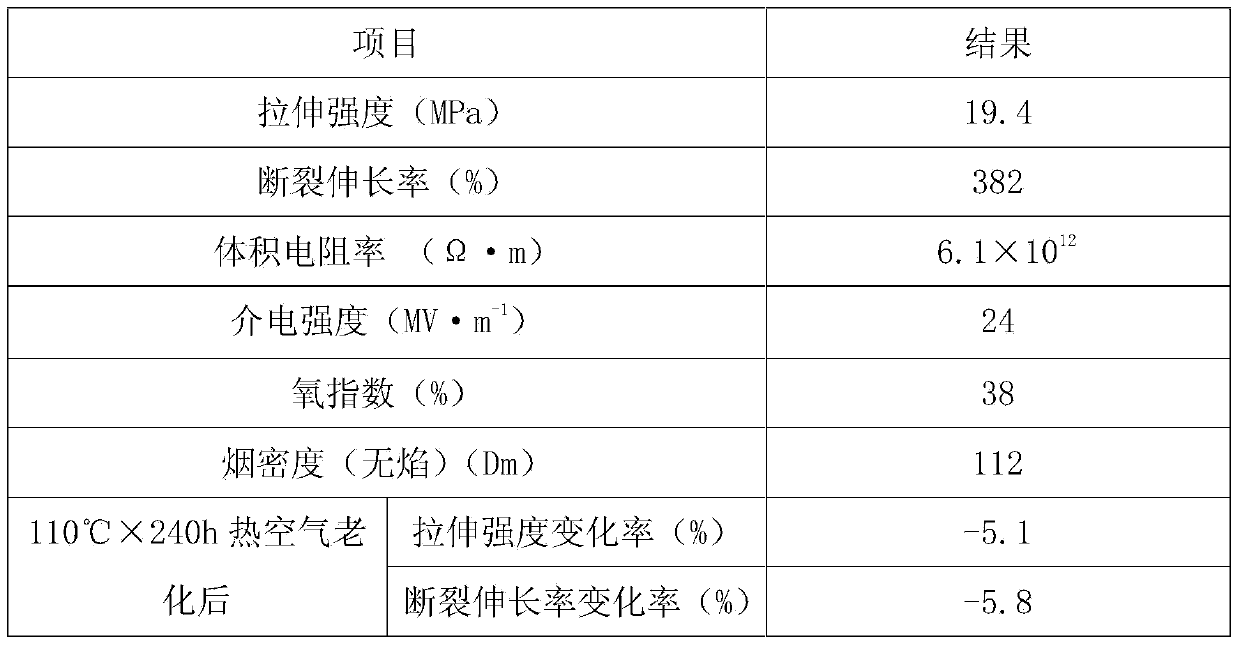

The invention discloses a high-temperature-resistant cable sheath material and a preparation method thereof. The sheath material comprises the following raw materials in parts by weight: 70-80 of high density polyethylene, 20-30 of ethylene-propylene-diene monomer, 10-15 of maleic anhydride grafted polyethylene, 5-10 of bisphenol A novolac epoxy resin, 8-12 of diphenyl tolyl phosphate, 4-8 of dioctyl maleate, 0.5-1 of di(tert-butylperoxyisopropyl)benzene, 2-3 of p-benzoquinone dioxime, 1-2 of triallyl isocyanurate, 3-5 of paraffin oil, 2-3 of active zinc oxide, 10-15 of magnesium hydroxide, 5-10 of aluminum hydroxide, 4-6 of talcum powder, 8-12 of fly ash, 5-10 of nano bauxite, 2-3 of dibutyltin dilaurate, 1-2 of an anti-aging agent MB, 1-2 of an anti-aging agent TPPD, and 4-6 of a composite filler. The sheath material prepared by the invention not only has good high temperature resistance and can be used in a 125 DEG C working environment for a long time, but also has good flame retardant effect, has the oxygen index of more than 35%, has non halogen and low smoke, and solves the problem of poor heat resistance of a high-flame-retardant sheath material.

Owner:滁州三界外信息科技有限公司

Stretch-proof cable sheath insulation material and preparation method thereof

InactiveCN102993518AGood physical propertiesDimensionally stableRubber insulatorsPlastic/resin/waxes insulatorsLead phosphateEthylene thiourea

The invention discloses a stretch-proof cable sheath insulation material and a preparation method thereof. The stretch-proof cable sheath insulation material comprises the following raw materials in parts by weight: 90-100 parts of neoprene CR121, 18-20 parts of chlorinated polyethylene, 15-25 parts of semi-reinforcing carbon black N774, 2-3 parts of magnesium oxide, 1-2 parts of ferrocene, 30-35 parts of mica powder, MB1-2 of antiager MB, 1-2 parts of 2-thiol group benzimidazole, 5-8 parts of dioctyl maleate, 1-2 parts of promoter DM1, 0.8-1 part of dibasic lead phosphate, 12 to 18 parts of nanometer silicon dioxide, 1-3 parts of 4, 4'- oxylbisbenzenesulfonyl hydrazide, 2-4 parts of antioxidant DSTP, 4-6 parts of glass powder, 0.8-1 part of zinc oxide, 2-3 parts of modified calcium carbonate, 5-6 parts of antimony oxide and 4-6 parts of ethylene thiourea. The stretch-proof cable sheath insulation material prepared by the method has the advantages of excellent physical properties, stable size, low percentage of contraction and greatly increased tensile strength, tearing strength resistance and resilience force performance.

Owner:安徽文峰电子科技集团有限公司

Halogen-free low-smoke flame-retardant TPE cable material

ActiveCN103525076AImprove flame retardant performanceImprove mechanical propertiesPlastic/resin/waxes insulatorsElastomerCarbon fibers

A provided halogen-free low-smoke flame-retardant TPE cable material is prepared from the following raw materials in parts by weight: 40-50 parts of polyurethane thermoplastic elastomer, 10-20 parts of POE elastomer, 30-40 parts of polypropylene resin resin, 5-10 parts of PE wax, 15-20 parts of aluminum hypophosphite, 8-10 parts of zinc borate, 10-12 parts of ammonium molybdate, 5-10 parts of ethylene-octene copolymer grafted maleic anhydride copolymer, 0.2-0.3 part of antioxidant 1024, 0.3-0.5 part of antioxidant 1035, 10-12 parts of epoxy butyl oleate, 10-12 parts of dicapryl phthalate, 5-10 parts of dioctyl maleate, 5-6 parts of carbon black N220, 5-10 parts of light calcium carbonate, 1-2 parts of zinc oxide, 5-10 parts of wollastonite powder, 10-12 parts of carbon fiber, 8-10 parts of nanometer boron carbide and 15-18 parts of a modified filling material. Cable conductors prepared from the cable material have the characteristics of being retardant in flame, environment friendly, good in flexibility and the like.

Owner:广东佰佳电线电缆实业有限公司

Preparation method of package-purposed plastic-based film containing modified calcined fluorite powder

ActiveCN103044756AImprove barrier propertiesImprove air tightnessFlexible coversWrappersLow-density polyethylenePolyvinyl chloride

The invention discloses a preparation method of a package-purposed plastic-based film containing modified calcined fluorite powder. The package-purposed plastic-based film is prepared from the following raw materials in parts by weight:10-15 parts of SG-1 type polyvinyl chloride, 3-5 parts of epoxidized linseed oil, 2-3 parts of oxidized polyethlene wax powder, 1-2 parts of distearoyl isopropoxy aluminate, 8-12 parts of kieselguhr, 35-40 parts of mLLDPE (metallocene Linear Low-Density Polyethylene), 38-42 parts of ethylene / alpha olefin copolymer, 8-12 parts of LDPE, 1-2 parts of polyisobutene, 1.2-2.5 parts of poly-4-methyl-1-amylene, 0.8-1.6 parts of nano potassium feldspar powder, 4-6 parts of modified calcined fluorite powder, 1-2 parts of crosslinking agent TAIC (triallyl isocyanurate), 1.5-3 parts of dibutyl maleate, 0.5-1 part of dioctyl maleate, 0.8-1.6 parts of calcium stearate and 1-2 parts of modified sepiolite powder. The package-purposed plastic-based film has good barrier property, gas tightness, pressure resistance and impact resistance and has the characteristics of high heat seal strength and good heat seal property.

Owner:平湖市泓博科技有限公司

Environmental-friendly termite-resistant cable sheath insulating material and method for preparing same

InactiveCN102993521AMeet the use requirementsGood physical propertiesRubber insulatorsPlastic/resin/waxes insulatorsPolyesterEnvironmental resistance

The invention discloses an environmentally-friendly termite-resistant cable sheath insulating material and a preparation method thereof. The material is prepared from the following raw materials in parts by weight: 90-97 parts of chloroprene rubber (CR) 121, 15-21 parts of chlorinated polyethylene, 15-22 parts of semi-reinforcing purpose furnace black N774, 2-3 parts of magnesium oxide, 2-5 parts of glass powder, 30-35 parts of barite powder, 1-2 of anti-aging agent MB, 1-2 of N-(beta-aminoethyl)-gamma-3-aminopropyltrimethoxysilane, 0.9-1.4 of poly(1, 2-propylene glycol adipate, 5-77 parts of dioctyl maleate, 1-2 parts of accelerator DM, 0.8-1 part of dibasic lead phosphite, 12-18.4 parts of hydrotalcite, 1-3 parts of 4, 4'-oxybis(benzenesulfonyl hydrazide), 2-4 parts of antioxidant DSTP, 4-6 parts of glass powder, 0.8-1 part of zinc oxide, 2-3 parts of modified calcium carbonate, 5-6 parts of antimony oxide, 3-5 parts of ethylene thiourea and 0.8-1 part of modified bentonite. The produced environmentally-friendly termite-resistant cable sheath insulating material has excellent physical performance, stable dimensions and low shrinkage factor, and the tensile strength, tear resistance and elastic force performance of a product are all greatly improved.

Owner:安徽文峰电子科技集团有限公司

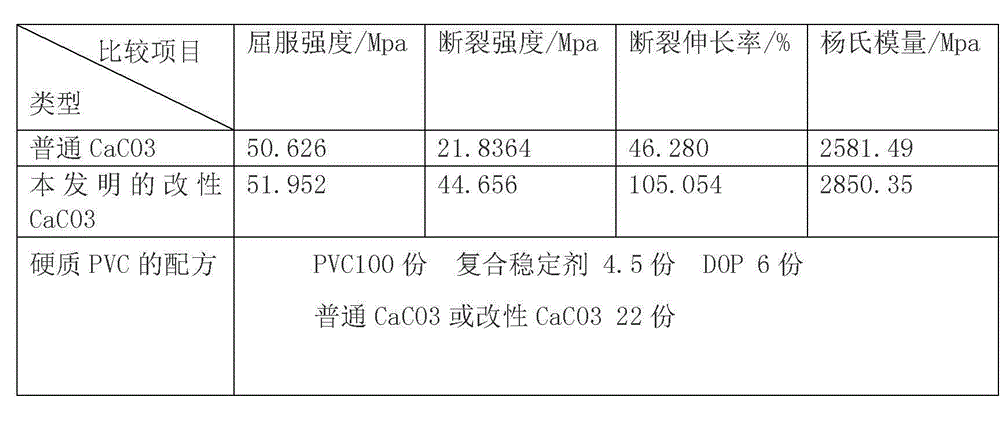

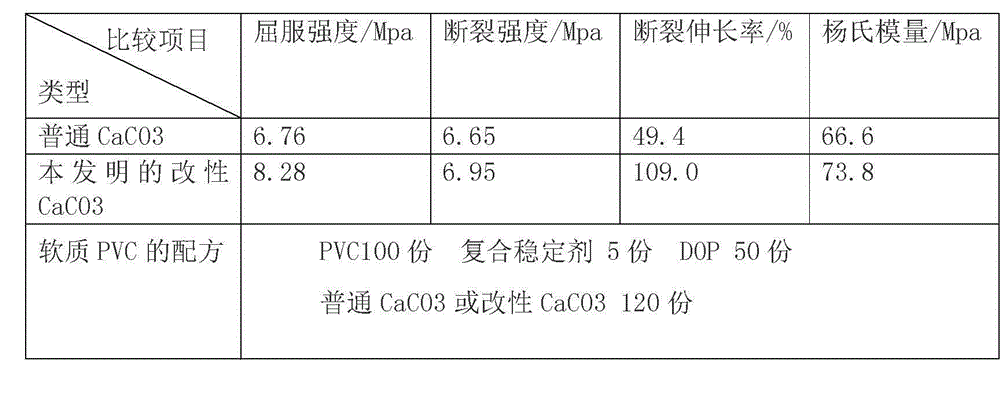

Modified calcium carbonate for anti-ultraviolet electric cable material, and preparation method thereof

InactiveCN103554704AUniform particle sizeLarge specific surface areaPlastic/resin/waxes insulatorsDispersityUltraviolet

The present invention provides modified heavy calcium carbonate for a fire retardation electric cable material. The modified heavy calcium carbonate is prepared from the following raw material components, by weight: 95-100 parts of calcium carbonate, 1-2 parts of octylphenol polyoxyethylene ether, 0.2-0.3 part of peregal O, 1-1.5 parts of dioctyl maleate, 0.2-0.4 part of zinc stearate, 0.1-0.2 part of magnesium oxide, 0.1-0.3 part of polyethylene wax, 0.1-0.4 part of an ultraviolet absorber UV-P, 1-2 parts of chitosan, 1-1.5 parts of polyphosphoric acid, and 2-3 parts of methyltriethoxysilane. The preparation method comprises: drying calcium carbonate, adding other raw materials according to the ratio, completely mixing in a high speed stirrer, and carrying out drying and grinding to obtain the finished product. The obtained modified calcium carbonate has characteristics of good dispersity and good ultraviolet resistance, and can be used for fire retardation electric cable materials so as to reduce cost and improve various processing performances of the electric cable material.

Owner:安徽金阳电器科技发展有限责任公司

High and low temperature-resistant insulating sheath material for transformer and preparation method thereof

ActiveCN103509353AGood high and low temperature resistanceImprove insulation performanceRubber insulatorsInsulated cablesTransformerBrucite

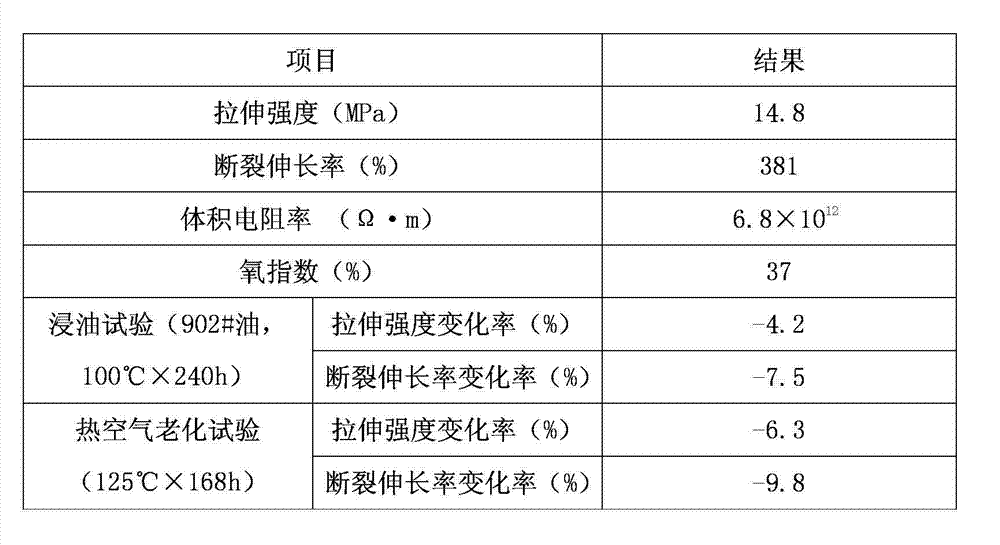

The invention discloses a high and low temperature-resistant insulating sheath material for a transformer and a preparation method thereof. The high and low temperature-resistant insulating sheath material is prepared from 70-90 weight parts of fluorosilicone rubber, 20-30 weight parts of SG-3-type PVC, 10-15 weight parts of dioctyl maleate, 5-10 weight parts of nylon acid diisobutyl ester, 15-20 weight parts of magnesium hydroxide, 10-15 weight parts of ammonium polyphosphate, 4-8 weight parts of molybdenum trioxide, 30-40 weight parts of fumed silica, 4-6 weight parts of zinc oxide, 2-3 weight parts of stearic acid, 1-2 weight parts of nano-cerium oxide, 1-2 weight parts of bis(P,P-bis-ethylhexyl diphosphato)ethanediolato titanate, 3-6 weight parts of oxidized polyethylene wax, 10-15 weight parts of brucite powder, 15-20 weight parts of nano-barite, 8-12 weight parts of nano-wollastonite and 4-6 weight parts of a composite filling material. The high and low temperature-resistant insulating sheath material has excellent high and low temperature resistance, good insulating properties, good physical and mechanical properties, good weathering aging resistance, acid and alkali resistance, radiation resistance and oil resistance, can be used in a temperature range of -60-180 DEG C for a long time, does not deform, embrittle and crack, and is durable.

Owner:ANHUI KELIN ELECTRONICS

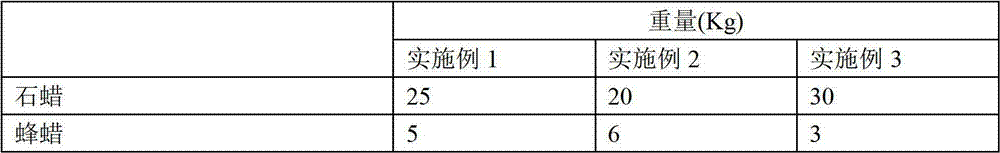

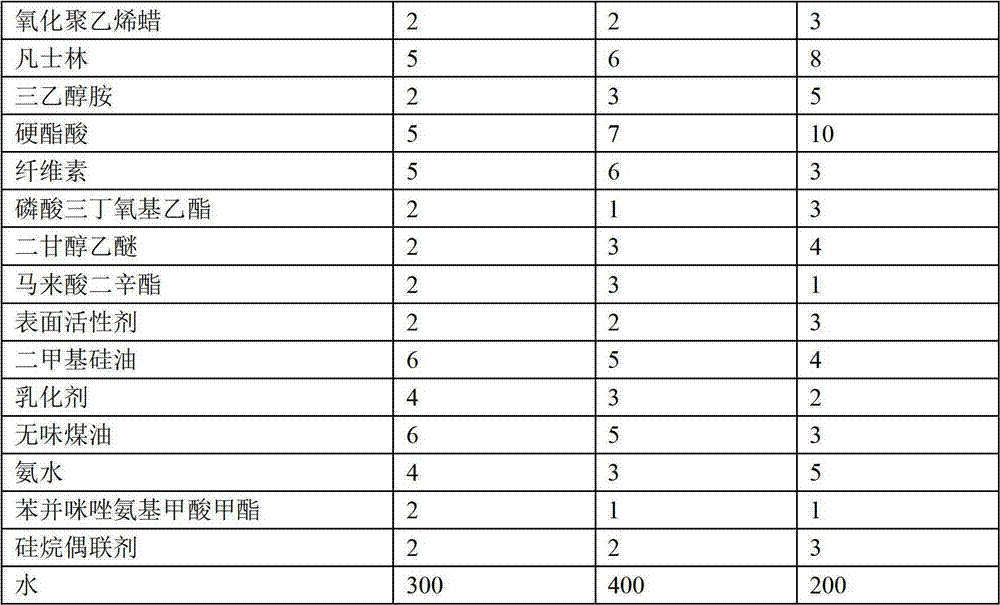

High-durability floor wax

The invention provides high-durability floor wax, and belongs to the technical field of a furniture cleaning agent. The high-durability floor wax comprises the following raw materials by weight: 20 to 30 parts of wax, 3 to 6 parts of beewax, 2 to 3 parts of oxidized polyethlene wax, 5 to 8 parts of Vaseline, 2 to 5 parts of triethanolamine, 5 to 10 parts of stearic acid, 3 to 7 parts of cellulose, 1 to 3 parts of butoxy triethyl phosphate, 2 to 4 parts of diglycol diethyl ether, 1 to 3 parts of dioctyl maleate, 2 to 3 parts of surface active agent, 4 to 6 parts of simethicone, 2 to 4 parts of emulsifying agent, 3 to 6 parts of odorless kerosene, 3 to 5 parts of ammonia water, 1 to 2 parts of benzimidazole methyl carbamate, 2 to 3 parts of silane coupling agent and 200 to 400 parts of water. With the adoption of the floor wax provided by the invention, the glossiness of the surface of a floor can be effectively improved, scratches can be shielded, and the damage of the friction on the floor surface to the floor can be effectively prevented; and after being subjected to a friction test, the floor wax also has high brightness and has no scratch.

Owner:盐城创咏新能源投资有限公司

Modified nylon polyamide 6 (PA6) material for automobile oil pipe and preparation method of modified nylon PA6 material

The invention discloses a modified nylon polyamide 6 (PA6) material for an automobile oil pipe, which is prepared from the following raw materials based on parts by weight: 100-110 parts of nylon PA6, 5-10 parts of ethylene propylene diene monomer 4903, 10-12 parts of polybutylece terephthalate (PBT), 3-5 parts of polycaprolactone, 10-15 parts of active calcium, 5-10 parts of nano argil, 1-2 parts of anti-aging agent NBC, 1-2 parts of anti-aging agent MB, 3-5 parts of N-(beta-aminoethyl)-gamma-aminopropyl trimethyl (ethyl) oxysilane, 1-2 parts of dicumyl peroxide (DCP), 1-2 parts of isopropyl bistearoyloxy aluminate, 1-2 parts of modified antioxidant 168, 15-20 parts of modified tree ash, 1-2 parts of antioxidant DLTP, 1-2 parts of adipic acid propylene glycol polyester, 1-2 parts of dioctyl maleate and 3-5 parts of zinc stearate. The antioxidant 168 and the tree ash are added into the modified nylon PA6 material for modification, so that the impact resistance, the toughness and the tensile strength of the nylon material are improved, and the material cost is reduced; and the modified nylon PA6 material has the advantages of good chemical resistance, permeability resistance and wear resistance, excellent size stability, high impact resistance and tensile strength and the like, and is hard to break, thus meeting the demand of the automobile oil pipe.

Owner:芜湖市鑫海橡塑制品有限责任公司

Organic ester sodium silicate self-hardening sand and preparation method thereof

The invention discloses organic ester sodium silicate self-hardening sand and a preparation method thereof. The organic ester sodium silicate self-hardening sand is prepared from the following raw materials in parts by weight: 65-85 parts of forsterite sand, 20-30 parts of iron ore sand, 3-5 parts of modified sodium silicate, 0.2-0.3 parts of diglycol acetate, 0.1-0.2 parts of fungacetin, 5-10 parts of slag, 4-8 parts of dicalcium silicate, 3-6 parts of medical stone, 2-4 parts of sawdust, 1.5-2.5 parts of polyethylene glycol, 2-3 parts of dioctyl maleate and 0.5-1.5 parts of sodium laurylsulfate. Compared with traditional CO2 blowing hardened sodium silicate sand, the organic ester sodium silicate self-hardening sand has the advantages that the amount of sodium silicate is reduced, and the water wave scattering property and used sand recycling property are greatly improved. Moreover, the liquidity of the molding sand is improved, the molding sand is easily compacted, the strength of the hardened sand is high, the refractoriness of the molding sand is improved, and the surface quality of a casting is obviously improved.

Owner:TONGLING JINGWEI FLUID SCI & TECH

PET (polyethylene glycol terephthalate) fiber/aluminum silicate fiber composite sound absorbing cotton and preparation method of PET fiber/aluminum silicate fiber composite sound absorbing cotton

InactiveCN102965845AHigh tensile strengthImprove impact resistanceConjugated synthetic polymer artificial filamentsSound producing devicesFiberPolymer science

The invention discloses PET (polyethylene glycol terephthalate) fiber / aluminum silicate fiber composite sound absorbing cotton, which is prepared from the following ingredients in parts by weight: 70 to 80 parts of PET fibers, 40 to 50 parts of aluminum silicate fibers, 10 to 15 parts of emulsifying agents OP-10, 5 to 10 parts of peregal O-35, 80 to 100 parts of PP (propene polymer), 30 to 40 parts of CPE (chlorinated polyethylene), 15 to 20 parts of nanometer celestite powder, 10 to 15 parts of modified kieselguhr, 2 to 3 parts of stearic acid, 5 to 8 parts of dioctyl maleate, 4 to 6 parts of zinc borate, 2 to 3 parts of ethylene bis stearamide, 1 to 2 parts of isopropyl dioleic(dioctylphosphate) titanate, 2 to 3 parts of calcium stearate, 1 to 2 parts of bi-sulfydryl isooctyl acetate di-n-octyl tin, 0.5 to 1.5 parts of anti-aging agents NBC and 1 to 2 parts of antioxidants DSTP. The sound absorbing cotton prepared by the invention has the advantages that the appearance evenness is good, the thickness is uniform, the hand feeling is soft, the product bonding degree is good, the tensile performance is high, the sound absorbing performance is excellent, the flame retardant effect is good, and the like.

Owner:芜湖跃飞新型吸音材料股份有限公司

Capacitor thin film containing modified bauxite and preparation method thereof

InactiveCN103102580AImprove barrier propertiesImprove air tightnessFixed capacitor dielectricLow-density polyethyleneCross-link

The invention discloses a capacitor thin film containing modified bauxite and a preparation method thereof. The capacitor thin film containing modified bauxite comprises the following raw materials in parts by weight: 50-60 of metallocene polypropylene resin, 27-33 of nylon 6, 13-16 of LDPE (Linear low density polyethylene), 10-15 of homo-polypropylene, 3-5 of epoxy linseed oil, 2-3 of polyvinyl alcohol, 1-2 of aluminum hydroxide, 1-2 of polyisobutylene, 8-12 of diatomite, 1-2 of ferrocene, 0.7-0.9 of poly-4-methyl-1-amylene, 5-7 of modified bauxite, 1.4-1.6 of cross-linking agent TAIC, 0.5-0.7 of polytetrafluoetylene, 1.6-2.0 of dioctyl maleate, 8-10 of calcium stearate and 1.1-1.3 of modified trees ash. The preparation method disclosed by the invention is simple; and simultaneously, the diatomite, the modified bauxite and the modified trees ash are added to the raw materials so that the barrier property and air tightness of the thin film are improved, and the thin film has good resistance to pressure and impact resistance and simultaneously has the characteristics of high heat-seal strength and good heat sealing property.

Owner:TONGLING YIHENGDA ELECTRONICS

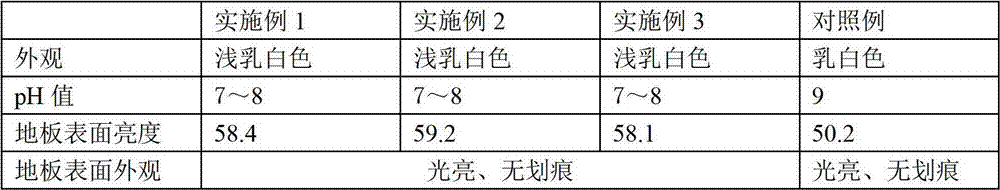

Oil-resistant acrylic rubber sealing pad for transformer and preparation method thereof

InactiveCN103360708AImprove cold resistanceImprove high temperature resistancePolymer scienceSodium Bentonite

The invention discloses an oil-resistant acrylic rubber sealing pad for a transformer and a preparation method thereof. The oil-resistant acrylic rubber sealing pad is prepared by the following raw materials in parts by weight: 45-55 parts of acrylic rubber, 15-20 parts of epichlorohydrin rubber, 8-12 parts of fluorine rubber, 5-10 parts of modified sepiolite powder, 3-6 parts of zinc borate, 2-4 parts of antimonous oxide, 2-3 parts of 2-hydroxy imidazoline, 3-4 parts of chlorinated paraffin, 0.5-1.5 parts of magnesium oxide, 8-12 parts of organic bentonite, 3-5 parts of calcined loess, 1-2 parts of ethylene bis oleamide, 1-2 parts of calcium zinc stabilizer, 2-4 parts of sulfur, 3-4 parts of dioctyl maleate, 2-3 parts of trioctyl trimellitate, 1-2 parts of anti-aging agent ODA, 1-2 parts of anti-aging agent TPPD, 1-2 parts of accelerator CZ and 2-3 parts of accelerator ZDC (zinc diethyl dithiocarbamate). Acrylic rubber with excellent thermo-oxidative ageing resistance and oil resistance is used as main material and is mixed with epichlorohydrin rubber and fluorine rubber to improve such properties of the acrylic rubber as cold resistance, high temperature resistance, water resistance, tensile strength, and the like.

Owner:ANHUI CHUNHUI INSTR CABLE GROUP

Production method of graphene modified polyaspartic acid-polyurea waterproof and anticorrosion coating

InactiveCN107793901AIncreased dispersionGood compatibilityAnti-corrosive paintsPolyurea/polyurethane coatingsEthylene diaminePolyaspartic acid

The invention relates to a production method of graphene modified polyaspartic acid-polyurea waterproof and anticorrosion coating. The production method is characterized by including: preparing graphene oxide; using isophorone diisocyanate to modify the graphene oxide, and using phenylhydrazine to reduce the graphene oxide to obtain isocyanate modified graphene; subjecting dioctyl maleate and ethylene diamine to Michael addition reaction to obtain aspartate; mixing the aspartate serving as the raw material, HDI serving as the curing agent, the isocyanate modified graphene serving as the modifier, and other auxiliaries to prepare the coating, and coating, curing and maintaining to obtain the graphene modified polyaspartic acid-polyurea waterproof and anticorrosion coating. The waterproof and anticorrosion coating keeps the excellent performance of traditional polyurea coating and also overcomes the defects that traditional polyurea is excessively fast in gelation and needs special equipment to perform construction.

Owner:ANHUI KUAILAI WATERPROOFING & ANTI CORROSION

High-toughness and high-shock-resistance polyvinyl chloride cable material and preparation method thereof

The invention discloses a high-toughness and high-shock-resistance polyvinyl chloride (PVC) cable material and a preparation method thereof. The cable material is prepared by the following raw materials in parts by weight: 40-60 parts of SG-3 PVC resin, 15-25 parts of ABS (acrylonitrile-butadiene-styrene) resin, 10-15 parts of PPS (poly phenylene snlfide) resin, 4-8 parts of flexibilizer HP4051, 5-10 parts of dibutyl sebacate, 3-6 parts of dioctyl maleate, 4-8 parts of mica powder, 5-10 parts of antimony trioxide, 10-15 parts of activated calcium carbonate, 15-20 parts of carbon black N339, 4-8 parts of composite packing, 2-3 parts of stearoyl-rac-glycerol, 2-3 parts of calcium-zinc composite stabilizer, 0.5-1 part of antioxidant 1010, 1-2 parts of dicumyl peroxide, and 0.5-1 part of trimethylolpropane triacrylate. The cable material has very high shock resistance and toughness under severe conditions such as high temperature, high humidity, high cold and high voltage, solves the problems of poor shock resistance and toughness of the existing PVC cable material, and has good heat resistance, flame retardancy and dimensional stability.

Owner:JING FENG GRP

Degradable packing material for food

The invention discloses a degradable packing material for food. The packing material comprises the following components in parts by weight: 100 parts of vegetable starch, 20-24 parts of konjak sol, 12-14 parts of bamboo fiber, 8-10 parts of ethylene-acrylic acid plastic, 6-8 parts of silicon oxide powder, 6-8 parts of dioctyl maleate, 3-5 parts of castor oil, 2-4 parts of glycerol, and 2-4 parts of a silane coupling agent, wherein length of the bamboo fiber is 4-6 mm; a preparation method of the konjak sol comprises the following steps: respectively weighing konjac glucomannan, carrageenan and soybean protein isolate; adding 10-12 g / L of konjac glucomannan, 18-22 g / L of carrageenan and 20-22 g / L of soybean protein isolate in water to be dissolved, stirring the mixture uniformly, standing and swelling for 3.5-4.5 hours to obtain the konjak sol.

Owner:WUXI HUANGSHENG PACKING PROD

Oil-resistant level PVC (Poly Vinyl Chloride) sheath material for power wire and preparation method thereof

InactiveCN103540054AExcellent Corrosion PropertiesIncrease elasticityPlastic/resin/waxes insulatorsInsulated cablesSodium BentonitePolyvinyl chloride

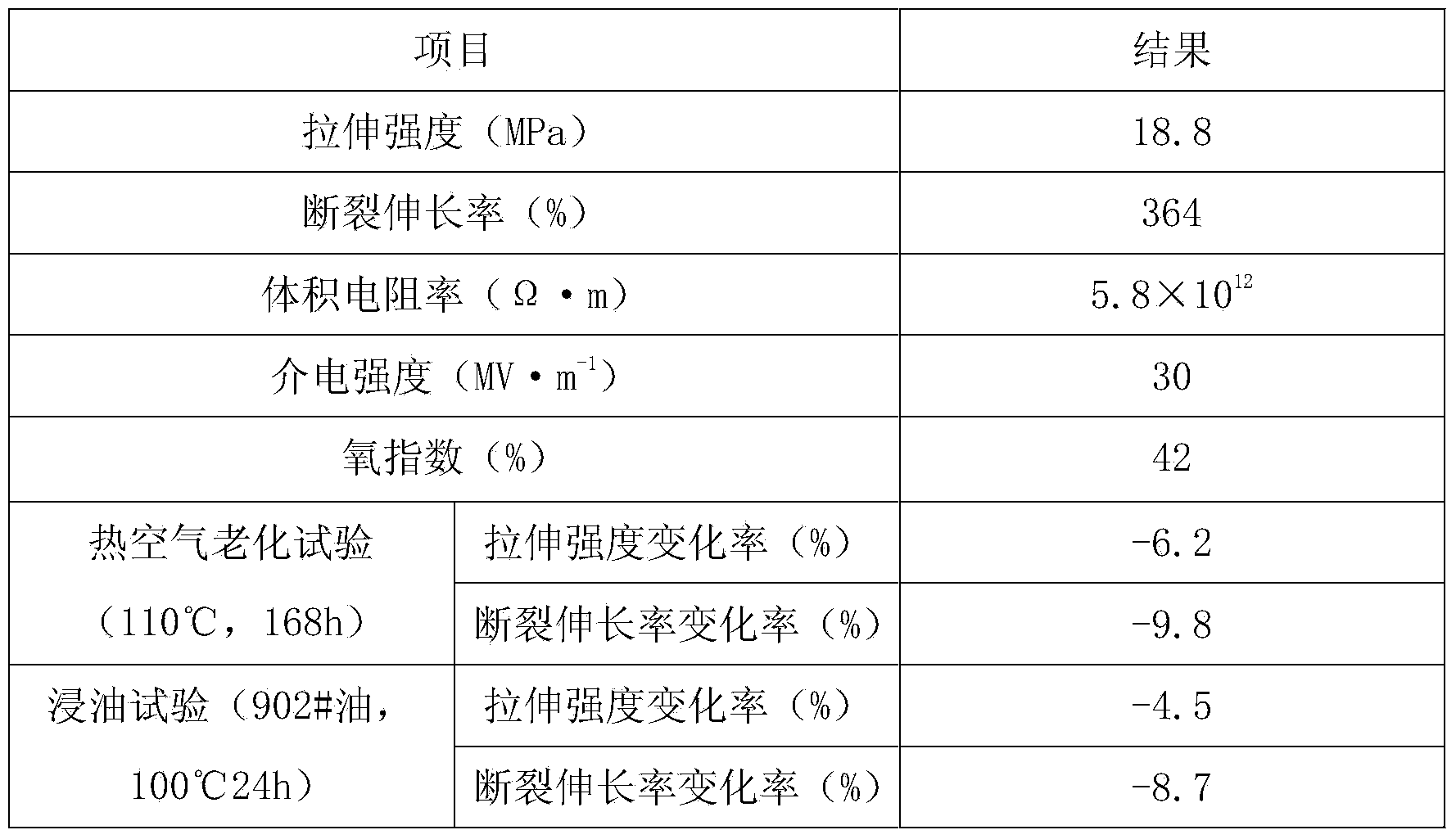

The invention discloses an oil-resistant level PVC (Poly Vinyl Chloride) sheath material for a power wire and a preparation method thereof. The oil-resistant level PVC sheath material is prepared from the following substances in parts by weight: 65-75 parts of polyvinyl chloride resin, 25-35 parts of nitrile rubber, 20-30 parts of carbon black N660, 10-15 parts of dioctyl maleate, 3-6 parts of light magnesium oxide, 2-4 parts of zinc oxide, 2-3 parts of dibenzothiazyl disulfide, 1-2 parts of tetrasulfide dipentylidene thiuram, 0.4-0.6 parts of 1,4-bistertiary butyl peroxy isopropyl benzene, 1.5-2.5 parts of triallyl isocyanuric acid ester, 0.5-1 part of insoluble sulfur, 4-8 parts of coumarone resin, 1-3 parts of stearic acid, 2-3 parts of palm wax, 1-2 parts of 2-thiol benzothiazole, 0.5-1.5 parts of methyl tin mercaptide, 10-15 parts of nano wollastonite, 5-10 parts of organic bentonite and 3-6 parts of composite filler. The sheath material is excellent in corrosion property of oil-resistant product organic solvents, maintains good flexibility, softness and mechanical strength after being immersed by oleophylic product organic solvents, is non-deformable and non-cracking in long-term use, and is long in service life.

Owner:天长市富达电子科技股份有限公司

High strength, anti-aging natural rubber/nitrile rubber cable material

The invention discloses a high strength, anti-aging natural rubber / nitrile rubber cable material. The raw material comprises the following components: natural rubber, nitrile rubber, precipitated silica, nano calcium carbonate, calcium sulfate whisker, zinc oxide, stearate, sulfur, 1,3-phenylene-di(1H-2,5-pyrrole-dione), 2-mercaptobenzothiazole thiazole parts, N-oxydisuccinic ethylenebis-2-benzothiazole sulfenamide, phthalate, di-n-octyl phthalate, dioctyl maleate, silane coupling agent and an antioxidant. The high strength, anti-aging natural rubber / nitrile rubber cable material disclosed by the invention is high in strength, and high in aging resistance, and the cable made from the material has good property and is long in service life, so that the cost is reduced.

Owner:繁昌县菲德通讯材料设计有限公司

Non-flame spread CPE rubber sheath material and preparation method thereof

ActiveCN103509261AImprove flame retardant performanceImprove high temperature resistanceRubber insulatorsPlastic/resin/waxes insulatorsCalcium silicateEpoxy

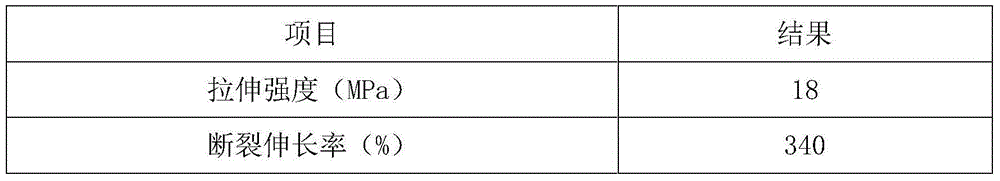

The invention discloses a non-flame spread CPE rubber sheath material and a preparation method thereof. The sheath material is prepared from the following raw materials in parts by weight: 60-80 parts of chlorinated polyethylene, 15-20 parts of Teflon, 10-15 parts of dimethyl silicone rubber, 12-18 parts of chlorinated paraffin, 30-40 parts of precipitated white carbon black, 20-30 parts of gas-mixture carbon black, 5-10 parts of calcium silicate, 10-15 parts of nanometer wollastonite, 4-6 parts of octyl epoxy stearate, 10-15 parts of dioctyl maleate, 3-4 parts of dicumyl peroxide, 4-6 parts of diallyl phthalatem, 10-15 parts of ammonium polyphosphate, 5-10 parts of encapsulated red phosphorus, 3-5 parts of calcium hydrate, 1-2 parts of zine stearate, 0.5-1 part of antiager 4020, 0.5-1 part of antioxidant DLTP and 3-6 parts of a composite filling material. The sheath material of the invention is good in flame retardation effect, is not combusted when contacting with naked fire, can be quickly extinguished automatically, has non-flame spread performance and excellent fireproofness and high-temperature resistance, overcomes the defects that conventional flame-retardant cable sheath materials still can be combusted and has flame spread performance, and helps to substantially improve the usage security of cables.

Owner:安徽天民电气科技有限公司

Polypropylene cable material and preparation method thereof

InactiveCN104231401AImprove protectionImprove mechanical propertiesPlastic/resin/waxes insulatorsOrganosolvEthylic acid

The invention discloses a polypropylene cable material. The polypropylene cable material is prepared by the following raw materials in parts by weight: 40 to 57 parts of metallocene linear polyethylene, 25 to 30 parts of atactic polypropylene, 3 to 4 parts of red phosphorus, 8 to 10 parts of magnesium hydroxide, 7 to 9 parts of gas-phase white carbon black, 50 to 57 parts of a composite filler, 2 to 4 parts of nano-calcium carbonate, 0.4 to 0.6 part of capsaicine, 3 to 6 parts of cashew nut shell oil, 5 to 8 parts of isophthalic acid ester, 1 to 2 parts of glycerol triacetate, 0.5 to 1 part of dioctyl maleate, 1 to 2 parts of ferrocene, and 1 to 3 parts of a colored glaze mixed material coloring agent. In addition, the invention also discloses a preparation method for the polypropylene cable material; the polypropylene cable material obtained by the preparation method has the advantages of high mechanical and machining properties, high temperature resistance grade, high impact resistance, high mechanical properties, high resistance to corrosion of a plurality of organic solvents, acids and alkalis, high cracking resistance and the like, is suitable for a cable, and can better protect the cable.

Owner:JIANGSU YUANFANG CABLE FACTORY

LDPE (Low-density polyethylene)/EVA (ethylene-vinyl acetate copolymer)/SBR (styrene butadiene rubber) composite foam material and preparation method thereof

InactiveCN103102559AImprove interfacial bond strengthHigh tensile strengthLow-density polyethyleneBenzoyl peroxide

The invention discloses an LDPE (low-density polyethylene) / EVA (ethylene-vinyl acetate copolymer) / SBR (styrene butadiene rubber) composite foam material. The foam material is prepared from the following raw materials in parts by weight: 80-100 parts of LDPE, 30-40 parts of EVA, 20-30 parts of SBR, 10-20 parts of talcum powder, 10-15 parts of nanometer celestite powder, 2-3 parts of bis(dioctyl pyrophosphate) ethylene titanate, 1-2 parts of anilino-methyl-triethoxysilane, 5-10 parts of magnesium hydroxide, 5-8 parts of azodicarbonamide, 5-8 parts of dioctyl maleate, 1-1.5 parts of benzoyl peroxide, 2-3 parts of zinc oxide, 1-2 parts of stearic acid, 1-2 parts of dioctyltin bis(isooctylmercaptoacetate), 2-3 parts of chlorinated polyethylene, 3-5 parts of modified wood ash, 1-2 parts of ultraviolet light absorber UV-360 and 2-3 parts of antioxidant 246. The produced LDPE foam material is light and soft, has high strength, good resilience, an ideal foaming effect, uniform, fine and dense pores and good flame retardance, is resistant to chemical corrosion and aging and is durable in use.

Owner:HEFEI LANGSHENG NOVEL MATERIAL CO LTD

Solar cell conductive slurry containing ethyl orthosilicate

ActiveCN103117103AImprove photoelectric conversion efficiencyImprove conductivityNon-conductive material with dispersed conductive materialCable/conductor manufactureSlurryCopper

The invention discloses solar cell conductive slurry containing ethyl orthosilicate. The solar cell conductive slurry is made of, by weight, 60-65 of material A, 15-20 of material B, 0.3-0.6 of ethyl orthosilicate, 0.5-0.8 of dioctyl maleate, and 1-2 of castor oil. The solar cell conductive slurry does not contain plumbum, completely meets environment-friendly requirements, is applied to production of solar cells, can form strong adhesive force on the surfaces of the solar cells, enables photovoltaic conversion efficiency of the cells to be high, meanwhile, utilizes silver powder, aluminum powder and copper powder which are different in grain diameter, increases contacting areas among grains, and therefore improves conductivity of silver slurry.

Owner:重庆新锐科技服务有限公司

Low-temperature-resistant high-density polyethylene power cable protective tube

InactiveCN105131406AImprove toughnessImprove wear resistancePlastic/resin/waxes insulatorsSilanesEngineering

The invention discloses a low-temperature-resistant high-density polyethylene power cable protective tube. The low-temperature-resistant high-density polyethylene power cable protective tube is composed of high-density polyethylene, flexibilizer, filler, coupling agents, plasticizer and bridging agents, the flexibilizer adopts liquid acrylate rubber, the filler adopts mica powder, the coupling gents adopt gamma-thiopropyl triethoxy silane, the plasticizer adopts dioctyl maleate, and the bridging agents adopt trimethyl hexamethylene diamine. The low-temperature-resistant high-density polyethylene power cable protective tube is composed of the high-density polyethylene, the flexibilizer, the filler, the coupling agents, the plasticizer and the bridging agents, and the low-temperature-resistant high-density polyethylene power cable protective tube has the advantages of being high in toughness, good in abrasive resistance, high in strength, stable in quality, convenient to process and produce, good in low temperature resistance and long in service life.

Owner:TAICANG CHENZHOU PLASTIC

Polyvinyl chloride cable material

ActiveCN103554630AReasonable formulaGood weather resistancePlastic/resin/waxes insulatorsInsulated cablesSilanesPolyvinyl chloride

The invention provides a polyvinyl chloride cable material, which is prepared from the following raw materials by weight: 50-60 parts of an ethylene-vinyl acetate copolymer EVA, 10-15 parts of HDPE (high density polyethylene), 10-12 parts of epoxy acrylate, 5-10 parts of ABS resin, 5-8 parts of a compatibilizer, 1-2 parts of a 3-aminopropyl trimethoxy silane, 1-2 parts of an aluminate coupling agent DL-411, 4-6 parts of dolomite, 4-6 parts of sepiolite, 1-2 parts of beryllium oxide, 2-3 parts of zinc oxide, 6-8 parts of dibutyl phthalate, 6-8 parts of tributyl citrate, 3-4 parts of dioctyl maleate, 0.1-0.2 part of oleamide, 10-12 parts of heavy calcium, 1-2 parts of barium stearate, 0.1-0.3 part of oxidized polyethylene wax, 10-15 parts of zinc borate, 4-6 parts of molybdenum trioxide, 1-2 parts of iron oxide and 10-15 parts of a modified filler. The invention has the advantages of simple preparation method, convenient operation and reasonable formula for raw materials. The prepared cable material has the characteristics of good weathering resistance, low smoke, aging resistance and good flame retardant performance.

Owner:ZHEJIANG XINYUANHONG MACROMOLECULE MATERIAL

Diatomite-containing nonwoven material for sound absorbing cotton

InactiveCN103710878AImprove mechanical propertiesImprove fire and water resistanceSound producing devicesNon-woven fabricsMedicinal herbsNonwoven fabric

The invention relates to a nonwoven material, in particular to a diatomite-containing nonwoven material for sound absorbing cotton. The nonwoven material is made from, by weight, 100 parts of isotactic polypropylene, 12-15 parts of diatomite powder, 5-8 parts of texanol, 12-15 parts of dimethyl isophthalate, 7-9 parts of chlorcosane, 3-4 parts of dioctyl maleate, 1-2 parts of quartz powder, 10-12 parts of rice hulls, 5-7 parts of bamboo charcoal powder, 2-3 parts of dandelion, 1-2 parts of agrimonia pilosa, 1-2 parts of rheum officinale, 2-3 parts of seeds of Job's tears, 1-2 parts of honeysuckle stems and 4-5 parts of auxiliaries. The nonwoven material contains the diatomite powder, the quartz powder and the like, thereby being improved in mechanical properties and durable in use; due to the raw materials such as the rice hulls, the bamboo charcoal powder and Chinese medicinal herbs, the material is low in cost and has good sound absorption effect; flame retardation and water resistance of the material are improved due to the chlorcosane; after being subjected to multi-layer superposition, the nonwoven material can be made into the sound absorbing cotton, and the nonwoven material is simple in process and broad in application prospect.

Owner:芜湖跃飞新型吸音材料股份有限公司

Halogen-free flame-retardant nylon composite material

The invention relates to a halogen-free flame-retardant nylon composite material, and belongs to the technical field of high polymer materials. The halogen-free flame-retardant nylon composite material is prepared from, by weight, 5-10 parts of caprolactam, 70-90 parts of PA66 resin, 5-15 parts of PA6 resin, 5-8 parts of silicon carbide, 6-11 parts of melamine pyrophosphate, 10-15 parts of acrylonitrile-butadiene-styrene copolymers, 5-10 parts of dioctyl maleate, 5-10 parts of di-n-hexyl azelate, 0.2-3 parts of modified nanometer rare earth oxides, 1-5 parts of microencapsulated halogen-free flame retardant, 0.1-0.6 part of accelerator, 0.1-0.5 part of activator, 0.1-0.5 part of stabilizer and 2-3 parts of lead fumarate. The halogen-free flame-retardant nylon composite material has the following performance indexes that the tensile strength is larger than 140 MPa, the bending strength is larger than 220 MPa, the impact strength of a cantilever beam notch is larger than 24 kj / m<2>, the melt flow index is larger than 16 g / 10 min, and the flame retardance reaches V-0(UL-94-1.6 mm). The high-temperature-resistant halogen-free flame-retardant nylon composite material not only has the barrier property, the dimensional stability, chemical resistance and high temperature resistance of high-temperature-resistant nylon, but also has the excellent impact resistance, flowability and flame retardant property.

Owner:TONGCHENG ZHONGHUI PLASTIC IND CO LTD

Adhesive with strong adhering property

InactiveCN102993988AImprove performanceAvoid damageNon-macromolecular adhesive additivesOrganic non-macromolecular adhesive(Hydroxyethyl)methacrylateAdhesive

The invention discloses an adhesive with strong adhering property. The adhesive with strong adhering property comprises the following raw materials: dioctyl maleate, nanometer smectite powder, styrene, hydroxyethyl methylacrylate, acrylate, crylic acid, sodium persulfate, allyloxy sodium, hydroxyalkyl sulphonate, pure benzene emulsion, sodium tripolyphosphate, sodium hypochlorite, argil, brown sugar, sodium laurate, starch, sodium hydroxide, borax, modified wood dust and water. The adhesive disclosed by the invention is stable in quality, strong in adhering property, excellent in connecting property, quick to dry and free from bubbling, and comprehensively improves various performances of corrugated cases; the modified wood dust is added, so that the damage of the water molecule to the adhesive can be reduced, and as a result, the water resistance of the adhesive is greatly improved; and the hydrophily is reduced, so that the adhesive has the characteristic of quick drying, and benefit is provided for using the adhesive in a high-speed tile line.

Owner:TONGLING GUOFANG PLUMBING TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com