Patents

Literature

214 results about "Dibutyl sebacate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Dibutyl sebacate (DBS) is an organic chemical, a dibutyl ester of sebacic acid. Its main use is as a plasticizer in production of plastics, namely cellulose acetate butyrate, cellulose acetate propionate, ethyl cellulose, polyvinyl butyral, polyvinyl chloride, polystyrene, and many synthetic rubbers (especially nitrile rubber and neoprene) and other plastics. It can be used for plastics in use in the food packaging industry, in plastics used for medical devices, and for pharmaceutical applications, e.g. as a plasticizer for film coating of tablets, beads, and granules. It is also used as a lubricant in shaving lotions, and a flavoring additive in non-alcoholic beverages, ice cream, ices, candy, and baked goods. It provides excellent compatibility with a range of plastic materials, superior properties at low temperatures, and good oil resistivity. Its other names include Morflex, Kodaflex, polycizer, Proviplast 1944 and PX 404. Dibutyl sebacate is also used as a desensitizer in Otto fuel II, a torpedo monopropellant.

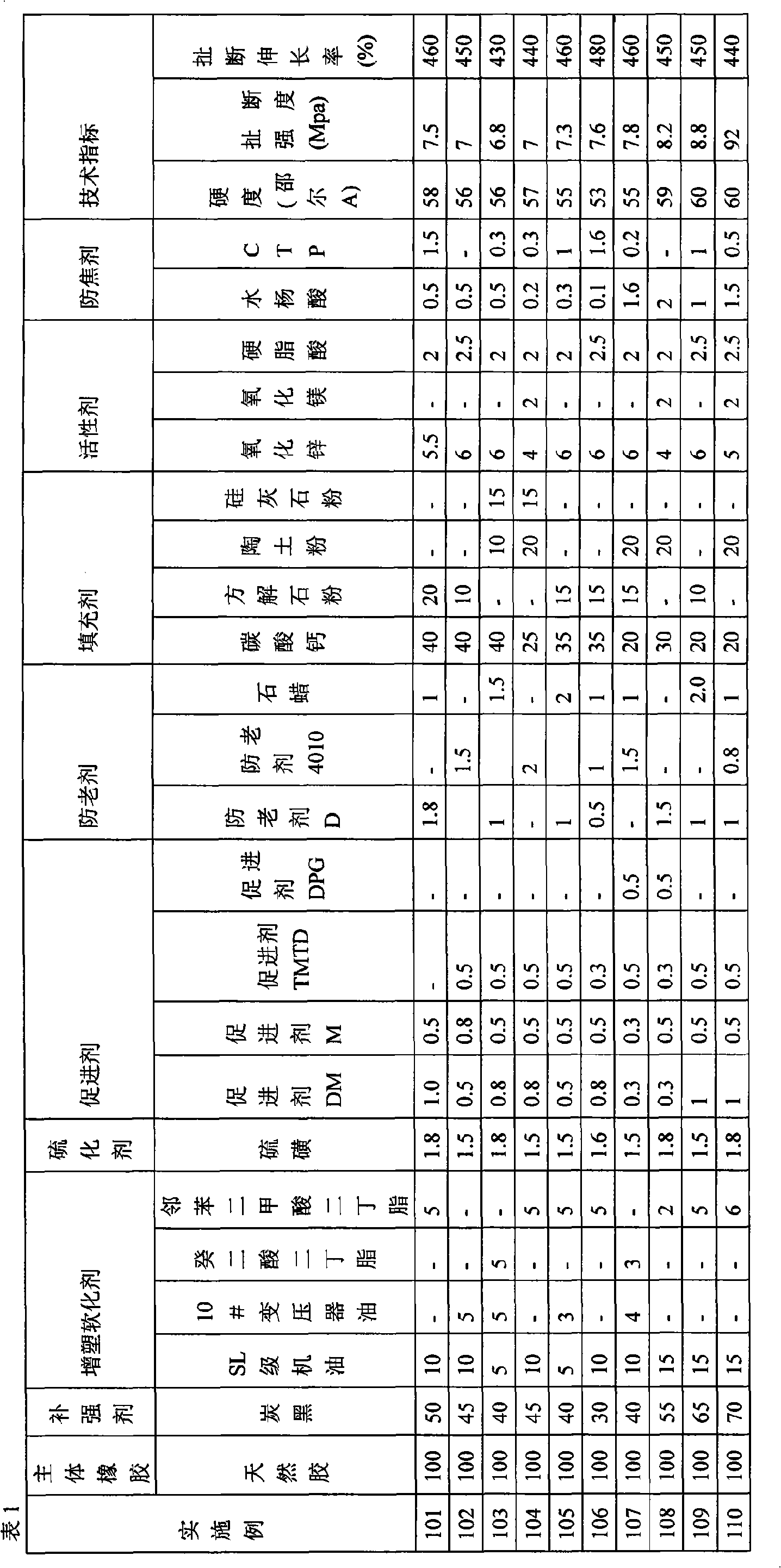

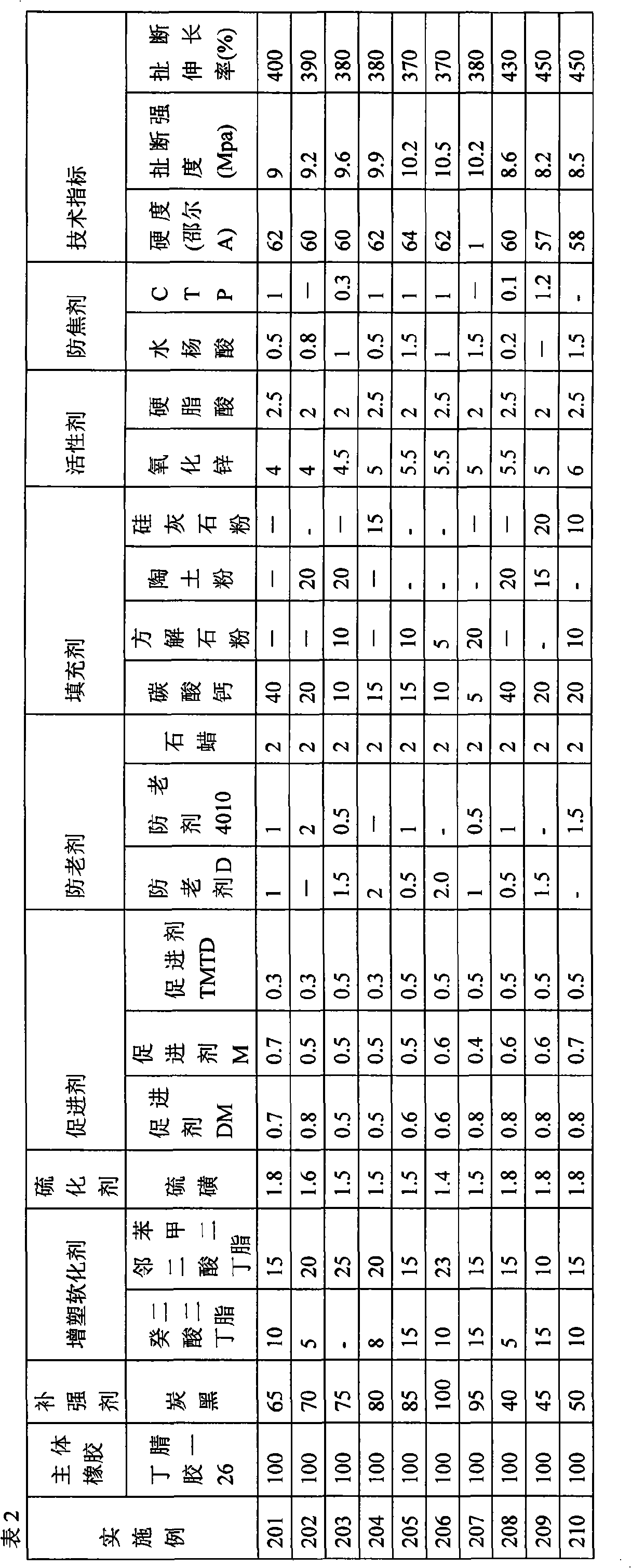

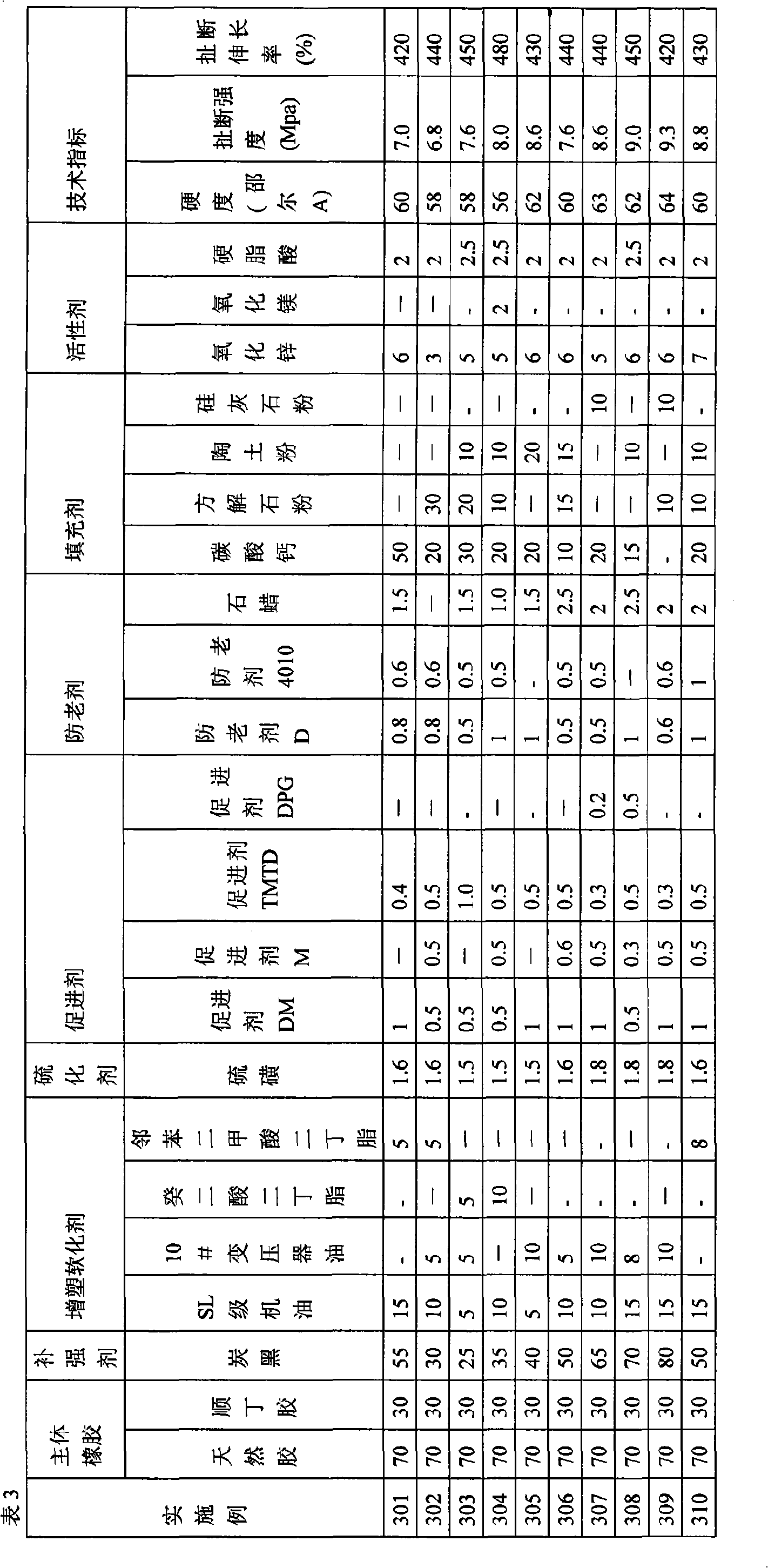

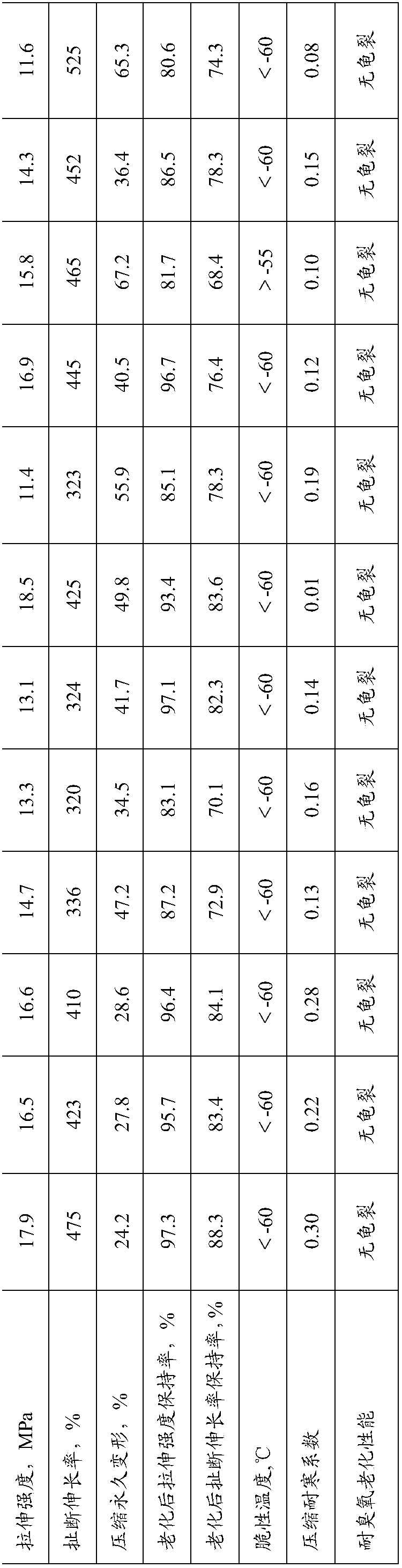

Cold resistant rubber

The invention aims at providing a low-temperature resistant rubber which can be used for a long time in low temperature and has almost the same tensile strength and elongation at break and the same hardness at low temperature as at normal temperature. The low-temperature resistant rubber contains main body rubber, strengthening agent, plasticization softener and curing ingredient, and the weight ratio of main body rubber : strengthening agent : plastifying softener : curing ingredient is 100:10-350:5-75:0.5-3; the main body rubber is natural gum, styrene-butadiene-rubber, cis-butadiene rubber, butyl rubber, ethylene propylene diene rubber, butadiene nitrile rubber or the combination of natural gum and cis-butadiene rubber; the strengthening agent is black carbon or white carbon; the plastifying softener is machine oil, transformer oil, dibutyl sebacate, dibutyl phthalate or silicon oil; the curing ingredient is 2,5-dimethyl curing ingredient or sulphur.

Owner:南京固柏橡塑制品有限公司

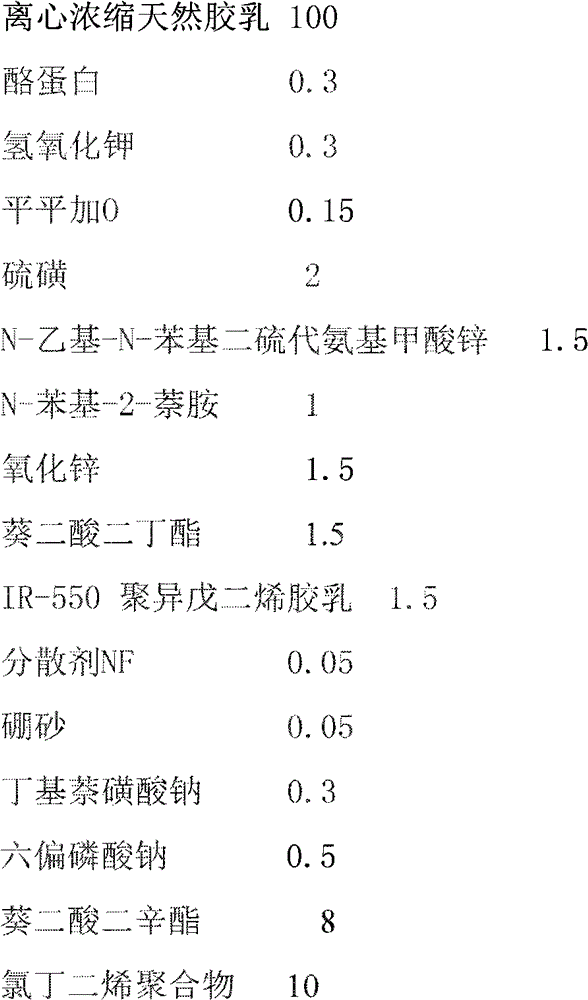

Weather monitoring device and application thereof

ActiveCN102718994AGood dispersionSame plasticizing effectBalloon aircraftsInstrumentsDibutyl sebacateDIETHYL SEBACATE

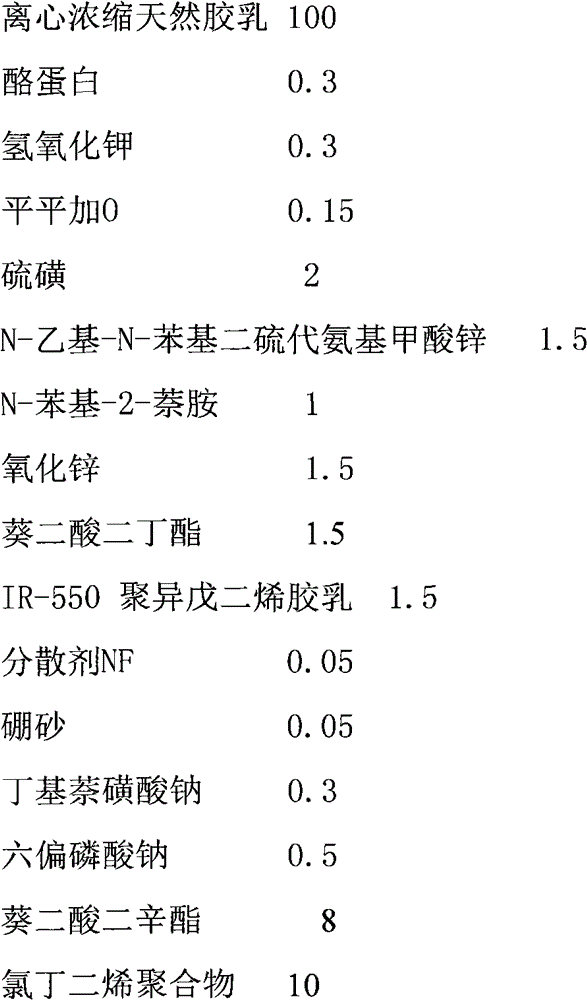

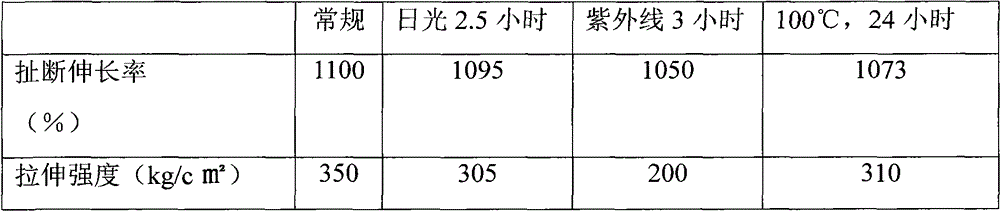

The invention relates to a weather monitoring device, in particular to a new weather balloon, which comprises the following components by weight percent: 100 of centrifugal concentrated natural latex, 0.3 of casein, 0.3 of potassium hydroxide, 0.15 of peregal 0, 2 of sulphur, 1.5 of N-ethyl-N-phenyl dithiocarbamate zinc, 1 of N-phenyl-2-naphthylamine, 1.5 of zinc oxide, 1.5 of dibutyl sebacate, 1.5 of IR-550 polyisoprene latex, 0.05 of dispersing agent NF, 0.05 of borax, 0.3 of sodium butylnaphthalenesulfonate, 0.5 of sodium hexametaphosphate, 8 of dioctyl sebacate and 10 of chloroprene polymer. The new weather balloon provided by the invention has the advantages of high sounding altitude, long sounding time and wide application prospect.

Owner:南通市通州区新志浩实业有限公司

Preparation method of wearproof and antibacterial blended fabric

ActiveCN103757914AImprove wear resistanceImprove antibacterial propertiesVegetal fibresDibutyl sebacatePolyvinyl alcohol

The invention provides a preparation method of a wearproof and antibacterial blended fabric. The preparation method comprises the following steps: (1) preparing fabric coating liquid from 5-9 parts of polyvinyl alcohol tert-butyraldehyde, 3-5 parts of dibutyl sebacate, 7-10 parts of dammar, 5-7 parts of ethyl acetate, 4-6 parts of magnesium oxide, 3-4 parts of zinc oxide and 15-19 parts of ethanol; (2) heating and then dissolving the components in the step (1), stirring the components uniformly after dissolving, and sealing and insulating the components at 80 DEG C after uniform stirring; (3) taking a cotton and polyvinyl chloride blended fabric; (4) blade-coating the coating liquid at the outer layer of the blended fabric with a scraper blade; (5) ventilating and drying the blended fabric, thus preparing the wearproof and antibacterial blended fabric.

Owner:吴江市先锋针织有限公司

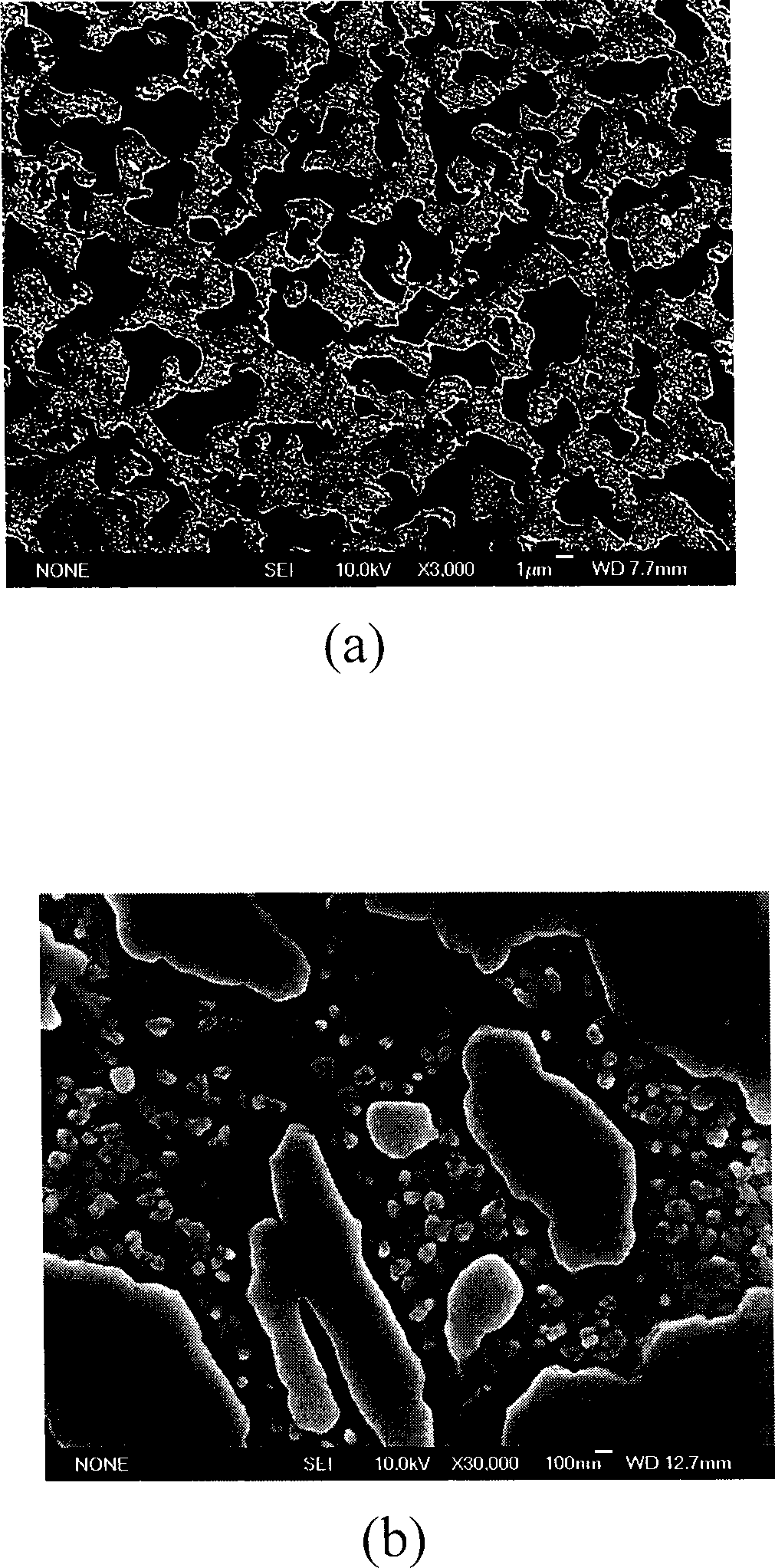

Method for preparing polyvinylidene fluoride micro-porous film with thermal induced phase separation method

InactiveCN102626594AStructure can be controlledCan control the sizeSemi-permeable membranesFiberDibutyl sebacate

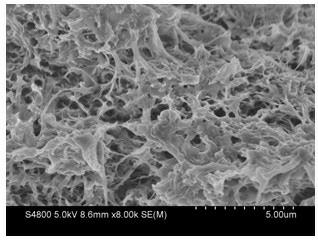

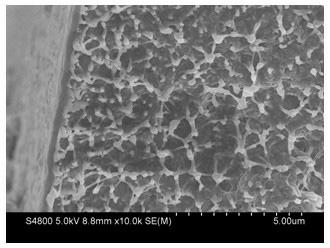

The invention discloses a method for preparing a polyvinylidene fluoride micro-porous film with a thermal induced phase separation method, belonging to the technical field of preparation of a polyvinylidene fluoride micro-porous film. The method comprises the following steps of: mixing a polyvinylidene fluoride resin with a cosolvent consisting of weak and strong action potential solvents, wherein the weak action potential solvent is benzyl benzoate or dibutyl sebacate, and the strong action potential solvent is dimethyl phthalate, monoglyceride or benzophenone; heating for dissolving into a homogeneous mixture; and cooling and scraping into a flat plate film or spinning into a hollow fiber film. The method has the advantages that: by adjusting the mixture ratio of the strong and weak action potential solvents in the cosolvent, the compatibility with PVDF (Polyvinylidene Fluoride) can be adjusted, and the microcellular structure and size of the film can be further controlled. Moreover, a PVDF film prepared with the method has high strength, which can be up to 9.5MPa; and the water flux is high, and can be up to 705 L / (m<2>.bar.h).

Owner:TIANJIN UNIV

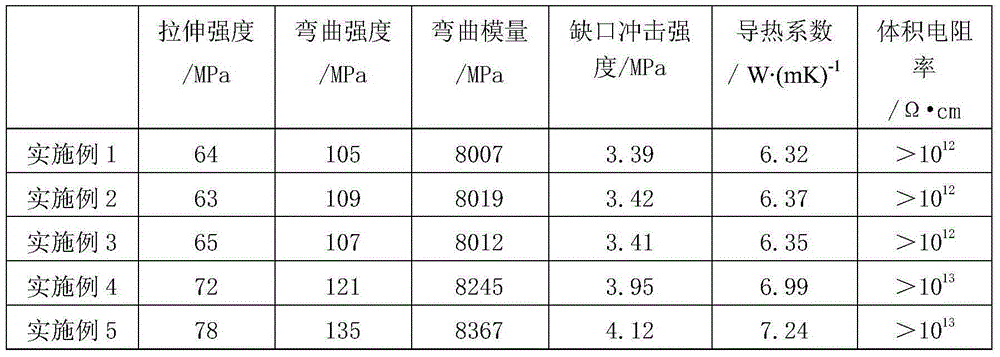

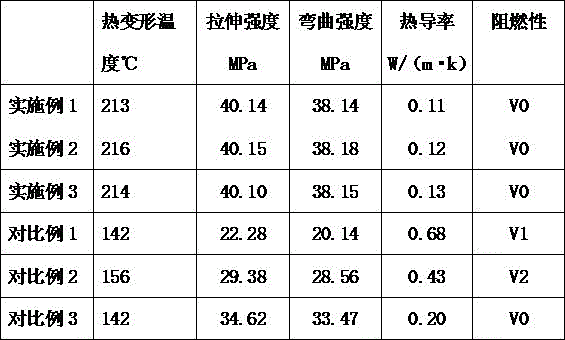

Preparation method of thermal conductive electrical insulating material

InactiveCN105061855AImprove mechanical propertiesImprove thermal conductivityPlastic/resin/waxes insulatorsLow-density polyethyleneLinear low-density polyethylene

The invention discloses a preparation method of a thermal conductive electrical insulating material. The preparation method comprises carrying out heating stirring mixing on high density polyethylene, linear low density polypropylene, nitrile rubber, dibutyl sebacate, ethyl acetoacetate, dimethylaminoethyl methacrylate, polyamide resin, polyvinyl acetate, hydroxyl silicone oil, powdered steatile, stearic acid, a filler and a coupling agent, carrying out ball milling and drying on the mixture, adding the dried mixture into a double screw extruder, carrying out extrusion, and carrying out granulation and cooling. The thermal conductive electrical insulating material has good mechanical properties and heat conduction performances.

Owner:ENG EQUIP CO LTD SUZHOU SAI SIDE

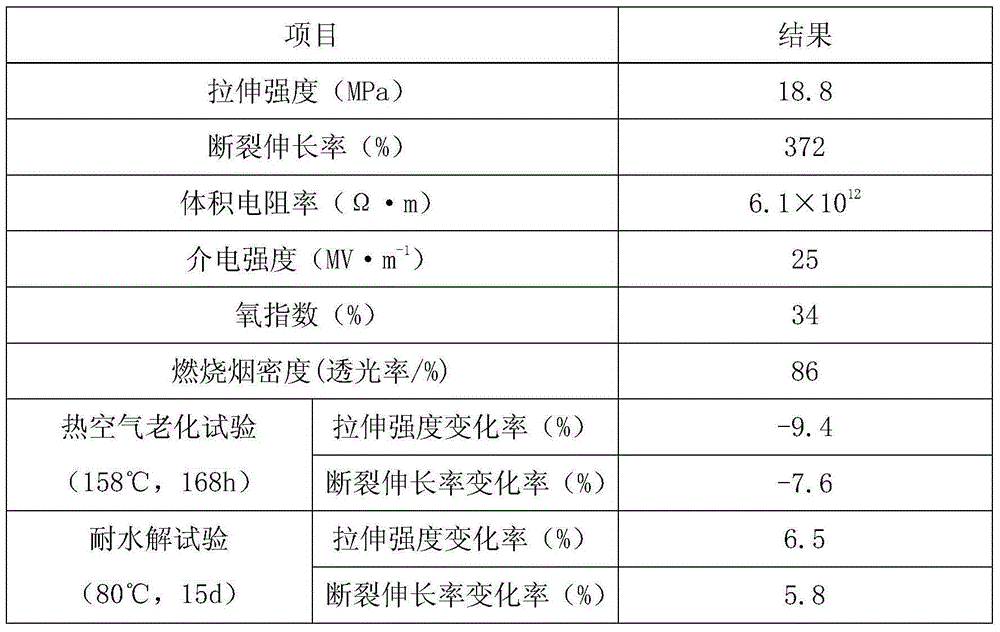

Hydrolysis-resistant cable material for automobile and preparation method of hydrolysis-resistant cable material

InactiveCN105037960AImprove hydrolysis resistanceAvoid hydrolysisRubber insulatorsFire retardantTert butyl

The invention discloses a hydrolysis-resistant cable material for an automobile and a preparation method of the hydrolysis-resistant cable material. The hydrolysis-resistant cable material is prepared from the following raw materials, by weight part: 45-60 of ethylene propylene diene monomer rubber, 22-34 of tetrafluoroethylene-propylene rubber, 9-14 of rectorite powder, 5-10 of C5 hydrogenated petroleum resin, 2-3 of tert-butyl-hydroperoxide, 1.5-2.5 of basic lead carbonate, 3-5 of polyparadinitrosobenzene, 4-8 of dibutyl sebacate, 2-3 of magnesium oxide, 1-2 of zinc stearate, 3-6 of disproportionated rosin, 2.5-4.5 of N-ethyl-p-toluenesulfonamide, 12-17 of a composite flame retardant agent, 5-10 of spherical silicon powder, 1-2 of an accelerant PPD, 1-2 of an accelerant ZBPD, and 1-2 of an antioxidant 2246. The prepared cable material has excellent hydrolysis resistance, so that the electric wires and cables of the automobile can be effectively prevented against hydrolysis. The cable material can maintain excellent properties after continuously used in high pressure and high temperature, and has good electrical insulation property, mechanical strength, corrosion resistance, abrasive resistance, and thermal resistance.

Owner:ANHUI CHUNHUI INSTR CABLE GROUP

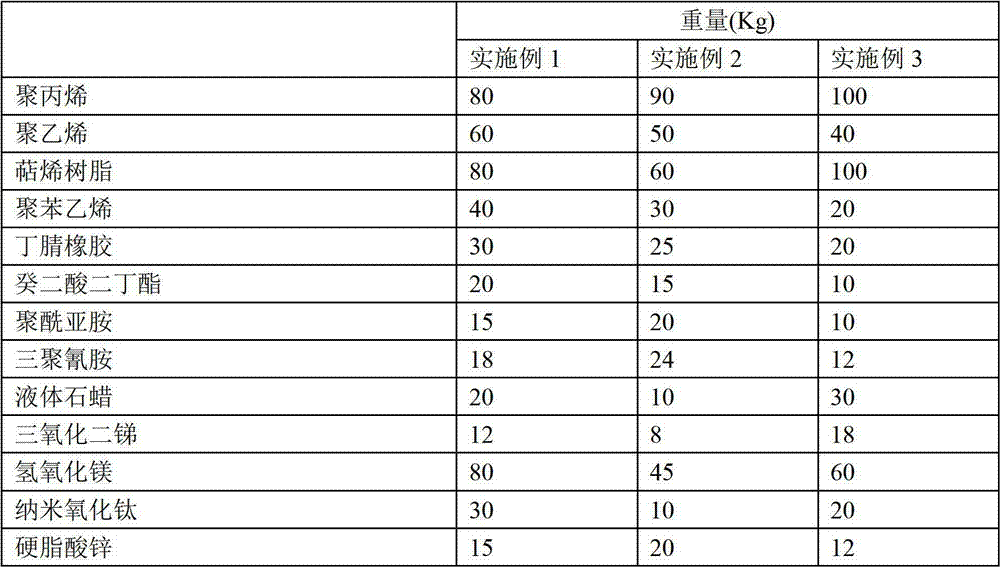

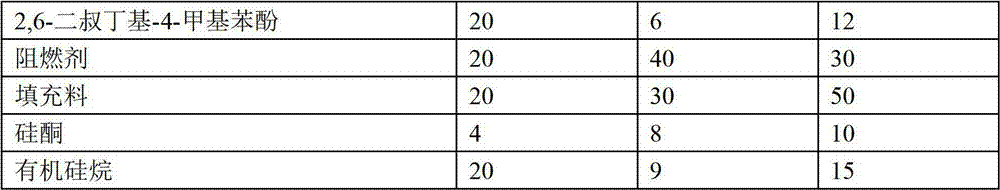

Thermoplastic fire retardant plastic

ActiveCN102875893AImprove flame retardant performanceLow smoke productionDibutyl sebacatePolystyrene

The invention provides a thermoplastic fire retardant plastic. The plastic is made from the following raw materials by weight: 80-100 parts of polypropylene, 40-60 parts of polyethylene, 60-100 parts of terpene resin, 20-40 parts of polystyrene, 20-30 parts of nitrile rubber, 10-20 parts of dibutyl sebacate, 10-20 parts of polyimide, 12-24 parts of melamine, 10-30 parts of liquid paraffin, 8-20 parts of antimonous trioxide, 40-80 parts of magnesium hydroxide, 10-30 parts of nanometre titanium oxide, 10-22 parts of zinc stearate, 5-20 parts of 2,6-tertiary butyl-4-methylphenol, 20-40 parts of fire retardant, 20-50 parts of filler, 4-10 parts of silicone and 5-20 parts of organosilane. The thermoplastic fire retardant plastic provided by the invention has a good fire retardant property.

Owner:广州亿成塑料制品有限公司

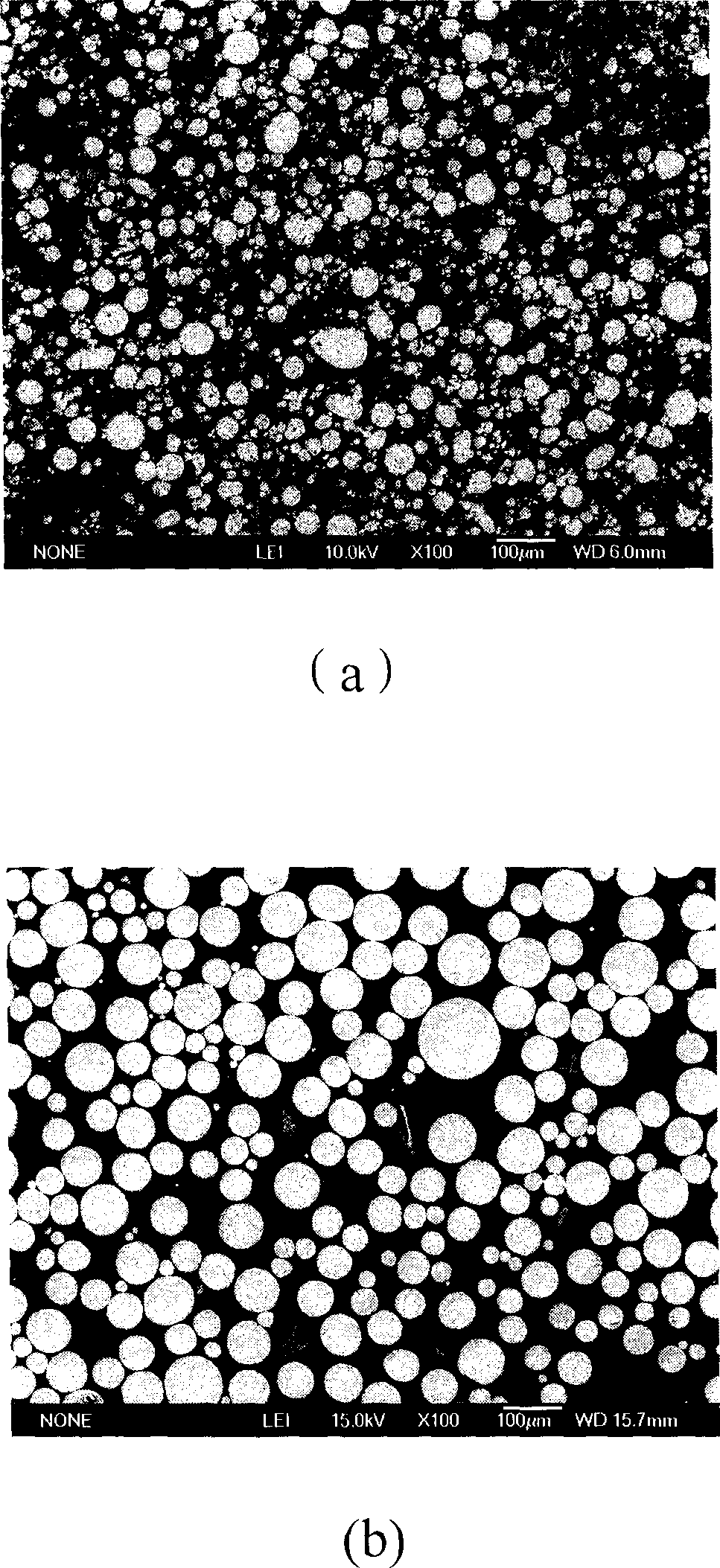

Low melting-point alloy powder spheroidizing and nano microcrystallizing process

The present invention relates to a low melting point lead-free welding flux alloy powder spheroidization and microcrystal nano formation process. Said invention is characterized by that said method utilizes the low melting point alloy powder with irregular forms which is obtained by high-pressure gas atomization and adopts the following steps: using organic spheroidizing afent dibutyl sebacate and organic dispersing agent polyoxyethylene actyl phenyl ether to prepare organic solvent mixture solution, uniformly mixing said alloy powder and organic solvent and making the alloy powder be dispersed in said organic solvent, heating and melting, then quickly extracting and cooling so as to obtain the spheroidized powder and microcrystal nano alloy microparticles.

Owner:SHANGHAI UNIV

Enteric coatings for orally ingestible compositions

A suspendible enteric coating composition for encasing orally ingestible articles wherein the enteric coating composition comprises a pH-dependent polymer selected from a group containing alginates and alginic acids, a pH-independent water insoluble polymer selected from the group comprising ethylcellulose and ethylcellulose-containing compositions, and a plasticizer selected from the group containing triethyl citrate, glycerin, propylene glycol, triacetin, acetylated monoglycerides, dibutyl sebacate, polyethylene glycols, sorbitals, middle chain triglycerides and combinations thereof. A three step method for providing a stable outer enteric coating on an ingestable item comprising a first step of encasing the item with a suspension comprising a mixture of at least a sugar and a microcrystalline cellulose, a second step of then encasing the item with a suspension comprising a mixture of a film-forming polymer and a plasticizer, and a third step of finally encasing the item with the enteric coating composition.

Owner:VIVA PHARMA

High-toughness low-temperature-resistant modified rubber sealing member and preparation method thereof

The invention discloses a high-toughness low-temperature-resistant modified rubber sealing member, prepared from the following raw materials in parts by weight: 35-45 parts of chlorosulfonated polyethylene rubber, 15-25 parts of a modified copolymer, 2-6 parts of butadiene-acrylonitrile rubber, 4-8 parts of fluororubber, 2-5 parts of vinylidene fluoride hexafluoropropylene rubber, 3-6 parts of polyvinyl chloride, 2-5 parts of carbon black N550, 3-6 parts of dibutyl phthalate, 2-5 parts of dibutyl sebacate, 3-4 parts of an anti-aging agent RD, 4-8 parts of modified glass fibers, 4-8 parts of magnesium oxide, 8-9 parts of zinc oxide, 3-6 parts of a silane coupling agent KH-570, 3-6 parts of bisphenol AF, 2-5 parts of stearic acid, and 4-6 parts of a vulcanization accelerator DCP. The invention also provides a preparation method of the high-toughness low-temperature-resistant modified rubber sealing member. The rubber sealing member prepared by the method provided by the invention has excellent toughness and low temperature resistance.

Owner:安徽亚兰密封件股份有限公司

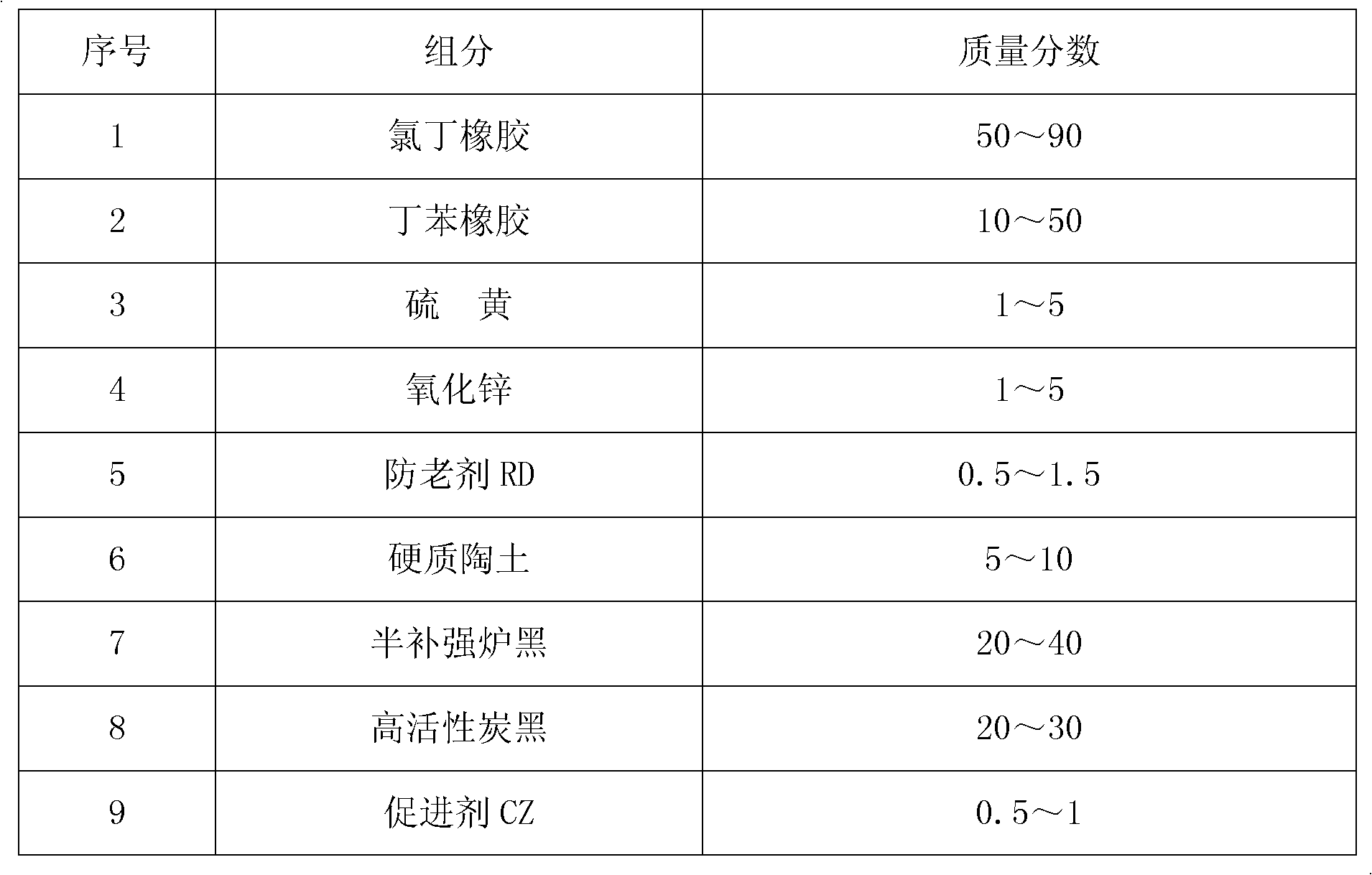

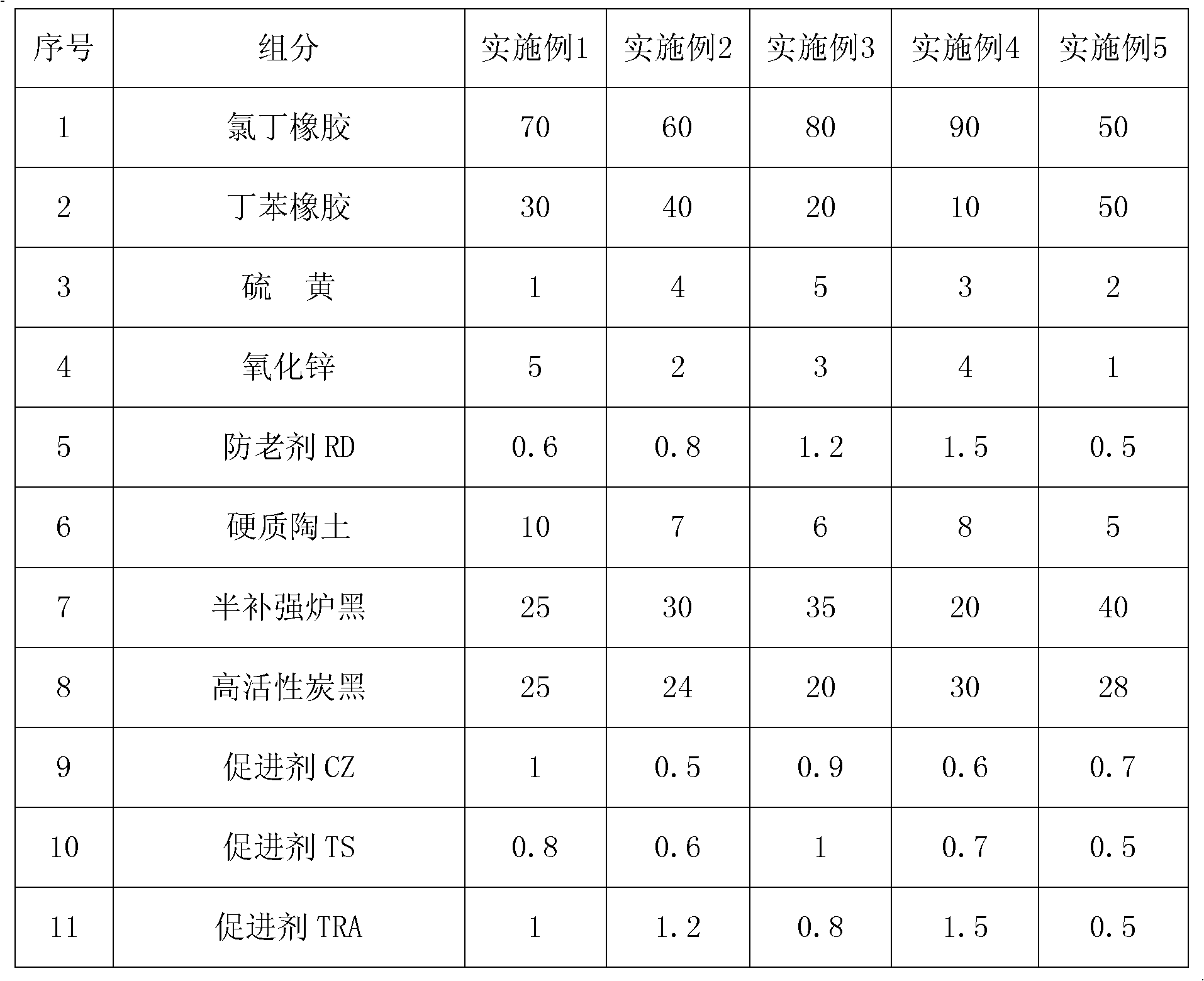

Chloroprene rubber composition

The invention relates to a chloroprene rubber composition. The chloroprene rubber composition comprises the following components of chloroprene rubber, butadiene styrene rubber, sulfur, zinc oxide, an anti-aging agent RD, hard china clay, semi-reinforcing furnace black, high-activity carbon black, an accelerant CZ, an accelerant TS, an accelerant TRA, dibutyl sebacate, diaryl para phenylene diamine, gamma-sulfydryl propyl trimethoxy silane, phenyl-beta and a mixture of naphthylamine and diphenyl para phenylene diamine. The butadiene styrene rubber and the chloroprene rubber are used in a combination way, and the coaction of auxiliary agents such as the diaryl para phenylene diamine, the dibutyl sebacate and the like is realized, so that the low-temperature cold resistance of the chloroprene rubber is further improved, the brittleness temperature of the chloroprene rubber can reach -56 DEG C without rubber fracture, and the chloroprene rubber has high oil resistance and other properties without obvious changes. The using value of the chloroprene rubber is improved while the cold resistance of the chloroprene rubber is improved, so that the chloroprene rubber composition has great significance of better exerting effects of a chloroprene rubber material and a chloroprene rubber material product in fields of automobiles, petrochemical industry and the like, the safety control of the product is improved, and the service life of the product is prolonged.

Owner:TIANJIN PENGYI GRP CO LTD

Dripping pill for treating coronary heart diseases and preparation method thereof

ActiveCN101711792AReflect high efficiency and quick effectImprove complianceHydroxy compound active ingredientsPill deliveryGlycerolCoronary heart disease

The invention relates to a dripping pill for treating coronary heart diseases, which comprises a medicinal active component, a substrate auxiliary material, a plastic component, propylene glycol and water, wherein the medicinal active component is prepared from radix salviae miltiorrhizae, radix notoginseng and borneol; the substrate auxiliary material is erythrol; the plastic component is selected from one or more of polyethylene glycol, xylitol, lactitol, manna sugar, glycerol, soluble starch, gelatin, methyl cellulose, sodium carboxymethylcellulose, hydroxypropyl methylcellulose, acacia, alginic acid, dextrin, schardinger dextrin, citric acid ester, acetoglyceride, dibutyl sebacate, refined coconut oil and castor oil; and relative to the total weight of the dripping pill, the dripping pill comprises the following components by weight percent: 1-40% of medicinal active component, 0-10% of plastic component, 1-10% of propylene glycol, 0-10% of water and the balance substrate auxiliary material. The dripping pill has safety, no toxicity, low moisture-absorption property and high dissolution and dispersion speed.

Owner:TIANJIN TASLY PHARMA CO LTD

Adhesive for chip multilayer ceramic capacitor and preparation method of adhesive

InactiveCN102433088AHigh strengthImprove reliabilityNon-macromolecular adhesive additivesPolymer scienceDibutyl sebacate

The invention relates to an adhesive for a chip multilayer ceramic capacitor and a preparation method of the adhesive. The adhesive consists of the following components by weight percent: 10-30 percent of polyvinyl butyral resin, 60-80 percent of solvent and 2-10 percent of plasticizer, wherein the molecular weight of the polyvinyl butyral resin is (8 to 12)*104; the solvent comprises aromatic solvent which takes a slightly soluble or swelling effect to resin powder and alcohol or lipid solvent which is used for dissolving the resin powder; and the plasticizer is one to two of phthalic acid ester and dibutyl sebacate. The adhesive can inhibit the poor dispersion of ceramic green diaphragms and can reduce resin particle insoluble substances in the ceramic green diaphragms. When the thickness of each ceramic green diaphragm is below 1-3mum and the number of the layers of the ceramic green diaphragms is increased to 150 to 300, the chip multilayer ceramic capacitor with a good performance can be formed and has the characteristics of small breakdown proportion, high reliability, fewer internal flaws and especially fewer voids in dielectric layers.

Owner:GUANGDONG FENGHUA ADVANCED TECH HLDG

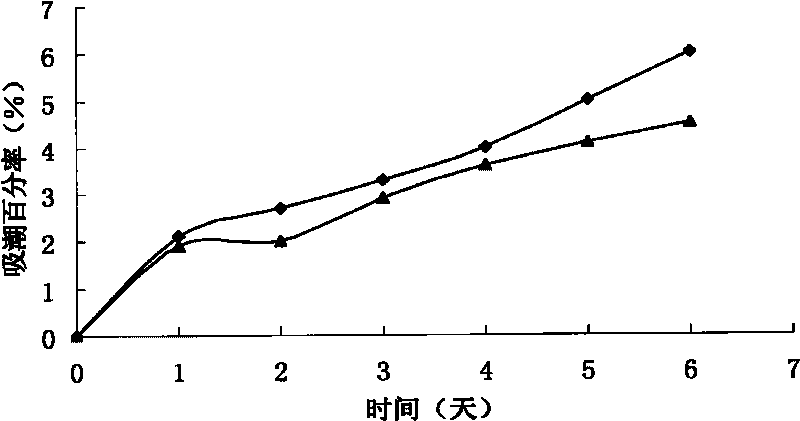

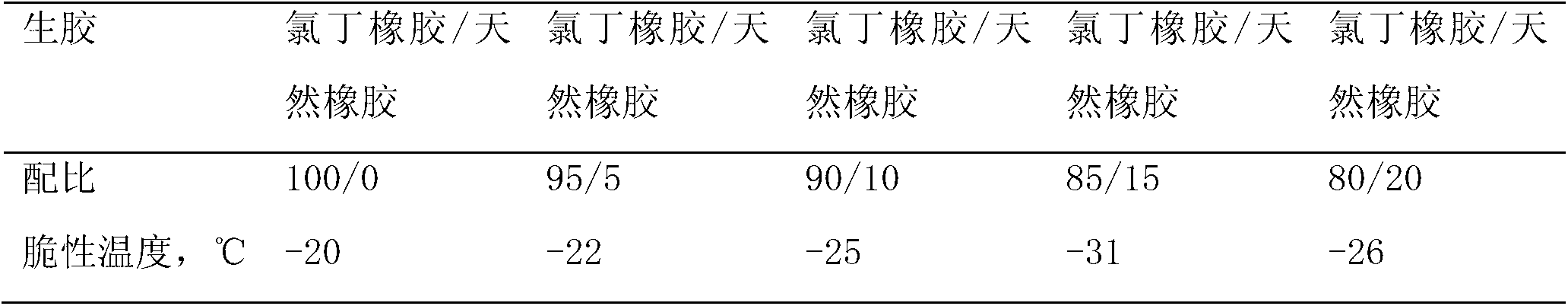

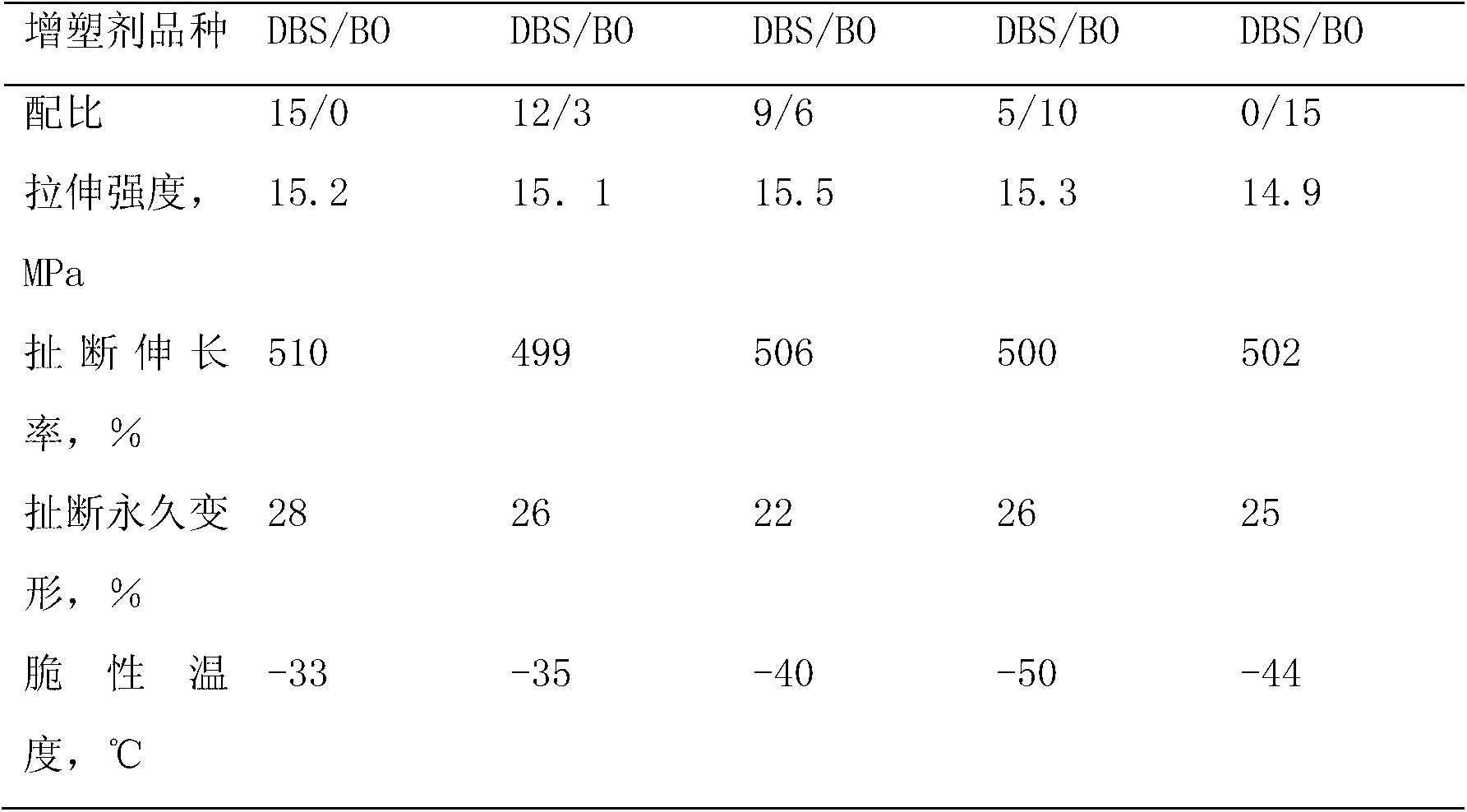

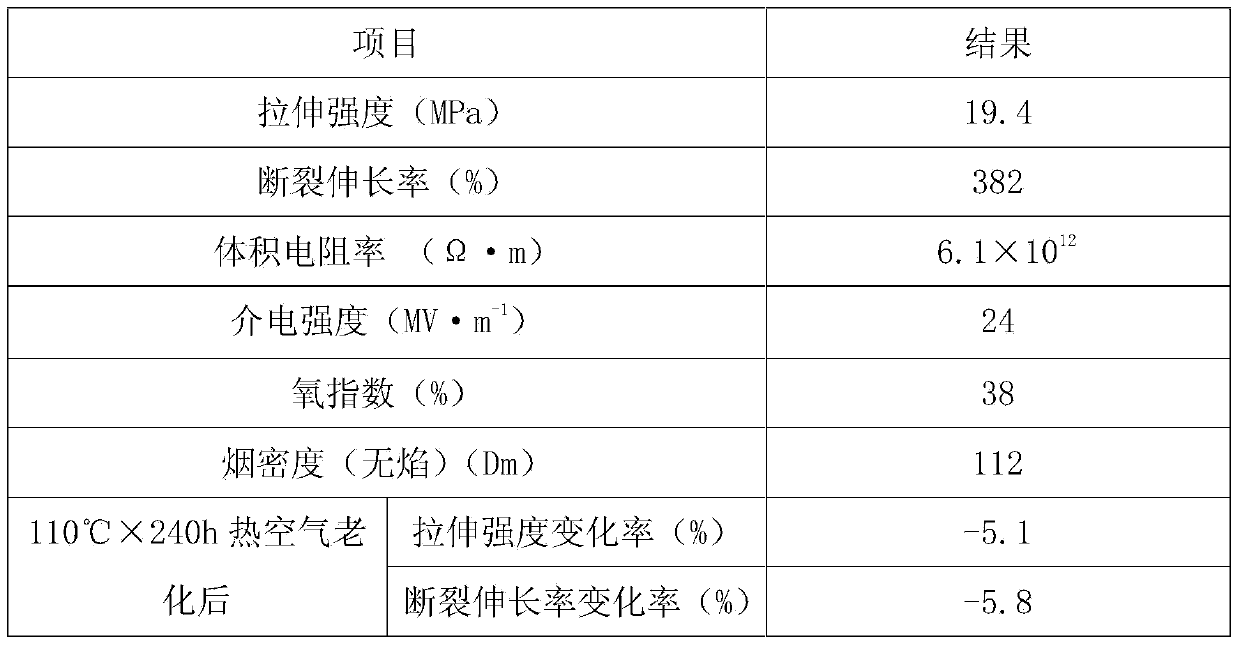

Highly cold-resistant rubber dam

ActiveCN103073765AImprove cold resistanceSatisfy low temperature resistanceDibutyl sebacatePolymer science

The invention discloses a highly cold-resistant rubber dam which is composed of materials as follows: raw rubber, a plasticizer, carbon black, an active agent and a vulcanizing agent; the weight ratio of the raw rubber to the plasticizer is 100 / 10-100 / 15; the raw rubber is composed of chloroprene rubber and natural rubber, and the weight ratio of the chloroprene rubber to the natural rubber is 90 / 10-80 / 20; and the plasticizer is butyl oleate, dibutyl sebacate, or a mixture of butyl oleate and dibutyl sebacate. Through tests, the brittleness temperature of the high cold-resistant rubber dam can achieve subzero 50 DEG C, the cold resistance is good, physical and mechanical properties of the tensile strength, the elongation at break and the like can also meet industrial standards, and requirements for the water conservancy industry on low temperature resistance and physical and mechanical properties of rubber dams in high cold temperature environments can be met.

Owner:青岛华海环保工业有限公司

High-toughness and high-shock-resistance polyvinyl chloride cable material and preparation method thereof

The invention discloses a high-toughness and high-shock-resistance polyvinyl chloride (PVC) cable material and a preparation method thereof. The cable material is prepared by the following raw materials in parts by weight: 40-60 parts of SG-3 PVC resin, 15-25 parts of ABS (acrylonitrile-butadiene-styrene) resin, 10-15 parts of PPS (poly phenylene snlfide) resin, 4-8 parts of flexibilizer HP4051, 5-10 parts of dibutyl sebacate, 3-6 parts of dioctyl maleate, 4-8 parts of mica powder, 5-10 parts of antimony trioxide, 10-15 parts of activated calcium carbonate, 15-20 parts of carbon black N339, 4-8 parts of composite packing, 2-3 parts of stearoyl-rac-glycerol, 2-3 parts of calcium-zinc composite stabilizer, 0.5-1 part of antioxidant 1010, 1-2 parts of dicumyl peroxide, and 0.5-1 part of trimethylolpropane triacrylate. The cable material has very high shock resistance and toughness under severe conditions such as high temperature, high humidity, high cold and high voltage, solves the problems of poor shock resistance and toughness of the existing PVC cable material, and has good heat resistance, flame retardancy and dimensional stability.

Owner:JING FENG GRP

Waterproof building-out cable

InactiveCN105860371AHigh temperature resistantOil resistantRubber insulatorsInsulated cablesCarvacryl acetateBisphenol AF

The invention discloses a waterproof building-out cable which comprises a cable core and a sheath. The sheath is made from a modified fluororubber composite material. The modified fluororubber composite material comprises fluororubber, methyl vinyl silicone rubber, ethylene-propylene-diene monomer rubber, epichloro-hydrin rubber, an ethylene-vinyl acetate copolymer, fluororubber graft vinyl triethoxy silane, alumina, stearic acid, bisphenol AF, benzyl triphenyl phosphorus chloride, ethylidene thiourea, modified nano-silica, carbon black N550, silica powder, rectorite powder, talcum powder, calcined kaolin, barium sulfate, an accelerant PPD, an accelerant ZBPD, an accelerant CZ, dioctyl phthalate, epoxy fatty acid butyl ester, dibutyl sebacate, erbium oxide, lanthanum stearate, an anti-aging agent 2246 and 2,2'-ethylidene bis(4,6-di-tert-pentylphenol). The waterproof building-out cable is high in strength, good in water resistance and excellent in aging resistance.

Owner:ANHUI HUAYU CABLE GRP

Drop pill for treating coronary heart disease and preparation thereof

InactiveUS20110195136A1Reduced stabilityDifficult to controlBiocideHydroxy compound active ingredientsAdditive ingredientCoronary heart disease

The present invention relates to a drop pill for treating coronary heart disease, comprising an active pharmaceutical ingredient (API), a matrix adjuvant, a plastifying adjuvant, propylene glycol and water. the API is prepared from Radix salvia miltiorrhira, Panax notoginseng and Borneol; the matrix adjuvant is erythritol; the plastifying adjuvant is one or more selected from the group consisting of polyethylene glycols, xylitol, lactitol, mannitol, glycerine, soluble amylum, gelatin, methyl cellulose, sodium carboxymethycellulose (CMC-Na), hydroxypropyl methylcellulose (HPMC), arabic gum, alginic acid, dextrin, cyclodextrin (CD), citrate, glycerol acetate, dibutyl sebacate, refined coconut oil and castor oil; Wherein, relative to the total weight of the drop pill, the API is 1˜40 wt %, the plastifying adjuvant 0˜10 wt %, the propylene glycol 1˜10 wt %, the water 0˜10 wt % and the balance is the matrix adjuvant. The drop pills of the present invention are safe and non-toxic, low moisture absorption and rapid dissolution.

Owner:TIANJIN TASLY PHARMA CO LTD

Anticorrosive and antirust powder coating for pipeline

InactiveCN105482648AImprove resistance to media penetrationImprove antibacterial propertiesAnti-corrosive paintsPowdery paintsDibutyl sebacatePolyvinyl alcohol

The invention discloses an anticorrosive and antirust powder coating for a pipeline. The powder coating is prepared from the following raw materials in parts by weight: 8 to 9 parts of palygorskite, 0.16 to 0.2 parts of an aluminum-zirconium coupling agent, 0.5 to 0.6 parts of an organic silicone leveling agent, 0.2 to 0.3 parts of polydimethyl siloxane, 8 to 10 parts of titanium dioxide, 5 to 6 parts of graphene, 1 to 2 parts of rubber powder, 0.2 to 0.3 parts of octadecenedioic acid, 2 to 3 parts of dibutyl sebacate, 4 to 5 parts of a dicyandiamide curing agent, 90 to 100 parts of bisphenol A type epoxy resin, 6 to 8 parts of phenol-formaldehyde resin, 0.1 to 0.2 parts of rare earth chloride, 15 to 18 parts of chitosan and 4 to 5 parts of polyvinyl alcohol. A preparation process is simple, the raw materials are easily obtained, a cured film is high in hardness and anticorrosive and antirust performance, and has remarkable economical and social benefits, and service life of the pipeline can be prolonged when the powder coating is used for the pipeline.

Owner:TONGLING SIDE TECH

Paint additive

The invention discloses a paint additive. The paint additive is prepared by, by weight, 8-12 parts of polysiloxane, 7-11 parts of hydroxyethyl cellulose, 2-4 parts of acrylate, 6-8 parts of epoxy resin anti-yellowing agent, 1-5 parts of ethyl acetate, 8-11 parts of lavender, 11-14 parts of triethanolamine, 3.2-8 parts of dispersant, 6-9 parts of dibutyl sebacate, 3.5-7 parts of eupatorium fortunei, 11-13 parts of borneol, 1.5-4 parts of clove, 1.3-3 parts of yelloweeed, 6.2-10 parts of rosemary, 2.3-6 parts of polysiloxane and 1.2-5 parts of paracresol. The paint additive has the advantages that the paint additive can improve adhesiveness and glossiness of paint; various traditional Chinese medicine ingredients are added, so that damage, to environment and human body, of the paint is reduced.

Owner:QINGDAO MAIKE 3D HI TECH CO LTD

Cold-resistant low-compression permanent deformation rubber composition and preparation method thereof

ActiveCN108546364AImprove low temperature performanceGood low temperaturePolymer scienceDibutyl sebacate

Owner:METALS & CHEM RES INST CHINA ACAD OF RAILWAY SCI +2

Antifreezing cooling liquid

InactiveCN104087258AGood storage stabilityCorrosion has a good inhibitory effectHeat-exchange elementsCalcium silicateDibutyl sebacate

The invention discloses an antifreezing cooling liquid which is composed of the following raw materials in parts by weight: 2-3 parts of ethylene glycol monoethyl ether acetate, 1-2 parts of 1,2-propanediol, 2-4 parts of polyethylene glycol, 2-3 parts of acrylic acid, 3-5 parts of ethylene glycol, 2-3 parts of azelaic acid, 3-4 parts of octanedioic acid, 4-5 parts of dibutyl sebacate, 2-4 parts of adipic acid, 3-4 parts of boric acid, 4-5 parts of sodium fluosilicate, 3-4 parts of calcium silicate, 3-5 parts of dimethicone, 2-5 parts of cinnamic acid, 4-6 parts of styrene, 2-4 parts of sorbitol and 100-120 parts of pure water. The antifreezing cooling liquid is good in storage stability and has a good inhibition effect on corrosion of aluminum and aluminum alloy.

Owner:司徒建辉

Preparation method of rubber plasticizer dioctyl sebacate

InactiveCN104592015AReduce dosageLight colorOrganic compound preparationCarboxylic acid esters preparationDibutyl sebacateDistillation

The invention discloses a preparation method of a rubber plasticizing agent dioctyl sebacate. The method includes the following steps: 1, adding sebacic acid, 2-ethyl hexanol and a catalyst stannous oxide into a four-neck flask equipped with a thermometer, a reflux distributor and an agitator, introducing nitrogen, and conducting esterification reaction under 200 DEG C-230 DEG C; 2, after the reaction, cooling to 90 DEG C, adding lye water for neutralization, washing, standing for layering, releasing lye water, conducting reduced pressure distillation, and finally add activated carbon for adsorption and filleting to obtain the dioctyl sebacate product. The preparation method provided by the invention employs a non-solid acid catalyst stannous oxide for catalytic synthesis of dioctyl sebacate, and has the advantages of high catalytic activity, short reaction time, small amount of catalyst, light color of the obtained product, simple post treatment process, no corrosion of the catalyst on the equipment, no waste liquid produced, green, and environment-friendliness.

Owner:QINGDAO WANGYU RUBBER

A high-performance capacitor plastic housing

ActiveCN106519600AImprove mechanical propertiesLow costPolytetramethylene terephthalateDibutyl sebacate

A high-performance capacitor plastic housing is disclosed. The plastic housing is prepared from polybutylene terephthalate, ABS plastic, a filler, a color concentrate, dibutyl sebacate, polyamide, a lubricant and an auxiliary agent. The auxiliary agent is prepared from, by weight, carboxyl cellulose, sorbitan trioleate, rosin, sodium hexametaphosphate, alkali lignin, acrylamide, diatomite, sodium tripolyphosphate, methyl salicylate, tea seed oil and mint oil. The plastic housing has characteristics of good mechanical properties, good processing performance, a low cost, a low melt viscosity, high impact strength, good thermal aging resistance and excellent thermal stability.

Owner:ANHUI FEIDA ELECTRICAL TECH CO LTD

High-strength high-toughness modified silicone rubber material

The invention discloses a high-strength high-toughness modified silicone rubber material, which comprises silicone rubber, ethylene-propylene-diene terpolymer rubber, hydrogenated butadiene-acrylonitrile rubber, chlorosulfonated polyethylene rubber, fluororubber, butyl rubber, hydroxyl-terminated polybutadiene, methacrylic acid, vinyltriethoxysilane, low density polyethylene, liquid paraffin, dibutyl sebacate, nanometer silica, silicon carbide, zinc oxide, magnesium oxide, nylon, graphite powder, zinc stearate, chlorinated paraffin, aluminum diethylphosphinate, tetraethoxysilane, dibutyltin dilaurate, a high strength modification auxiliary agent and a high-toughness modification filling material. The silicone rubber material is excellent in high-strength high-toughness performance.

Owner:天长市荣盛有机硅科技有限公司

Cover rubber for conveying belt in refrigeration industry

ActiveCN103665456AGuaranteed normal transmissionImprove low temperature resistanceConveyorsDibutyl sebacateAluminium hydroxide

The invention belongs to the technical field of rubber for conveying belts, and particularly discloses cover rubber for a conveying belt in the refrigeration industry. The cover rubber comprises components in parts by weight as follows: 25 parts of butadiene rubber, 8 parts of rubber and plastic alloy, 7 parts of phenolic resin, 1-2 parts of zinc borate, 2-4 parts of nano-zinc oxide, 1-3 parts of stearic acid, 1-3 parts of sulfur, 10-15 parts of high-abrasion-resistance furnace black, 5-10 parts of carbon black N550, 10-20 parts of intermediate super abrasion furnace black, 1-5 parts of tri-antimony trioxide, 0.5-3 parts of aluminum hydroxide, 1-3 parts of an anti-aging agent 4010, 0.5-1 part of an anti-aging agent A, 10-15 parts of 70% chlorinated paraffin, 1-2 parts of cobalt naphthenate, 5-10 parts of an organic silane coupling agent, 1-5 parts of montmorillonoid, 2-3 parts of an accelerator 6PPD, 3-5 parts of an accelerator TMTD, 5-10 parts of dibutyl sebacate, 1-3 parts of barium stearate and 2-5 parts of glass fiber powder. On the premise of excellent low temperature resistance, performance such as abrasion resistance, tear resistance and the like is also excellent, and the cover rubber fills in the blank of the refrigeration industry.

Owner:徐州淳康生物科技有限公司

High-elastic nanometer material

The invention discloses a high-elastic nanometer material. The high-elastic nanometer material is characterized by comprising the following substances in parts by weight: 27-34 parts of polyethylene, 11-24 parts of dichlorofluoroethane, 35-56 parts of dimethyl siloxane, 15-32 parts of epoxidized soybean oil, 11-16 parts of oleic acid, 5-10 parts of kieselguhr, 1-7 parts of molecular sieve, 10-21 parts of paraffin, 3-14 parts of chloroparaffin, 13-24 parts of calcium sulfonate, 45-72 parts of sulfuric acid, 3-11 parts of dibutyl sebacate, 5-13 parts of stearyl trimethyl ammonium chloride, 35-40 parts of polyurethane and 5-24 parts of activated aluminum nanometer function material. The nanometer modified material has the characteristics of good elasticity, sound absorption, thermal insulation, oil resistance, high temperature resistance, cold resistance, abrasion resistance and shock absorption.

Owner:QINGDAO HUA CHENG TIAN MACHINERY MFG

Method for manufacturing anti-wear antibacterial pillowcase

ActiveCN106263908AContinuous uninterrupted sewing operationIncrease productivityPillowsMechanical cleaningPolyvinyl butyralDibutyl sebacate

The invention provides a method for manufacturing an anti-wear antibacterial pillowcase. The method solves the technical problems that steps of an existing manufacturing method are too simple, and pillowcase fabric does not have anti-wear and antibacterial performance. The method for manufacturing the anti-wear antibacterial pillowcase includes the following steps that a, fabric coating liquid is prepared from, by weight, 20-30 parts of polyvinyl butyral, 12-15 parts of dibutyl sebacate, 5-8 parts of titanium dioxide, 6-12 parts of chitosan, 7-10 parts of magnesium oxide, 1-3 parts of zinc oxide, 10-14 parts of ammonium molybdate, 14-18 parts of sodium citrate, 3-5 parts of anti-ageing agent and 16-24 parts of ethyl alcohol; b, the components in the step a are poured into a stirring machine to be stirred and prepare the coating liquid; c, the coating liquid is smeared on the outer layer of fabric by means of a scraper; d, the coated fabric is placed in an oven to be dried; e, the dried fabric is cut by a cutting machine to be cut into a semi-finished product in a required size; f, the semi-finished product is sewn by a sewing device. The method has the advantage of being high in universality.

Owner:苏州红海家纺科技有限公司

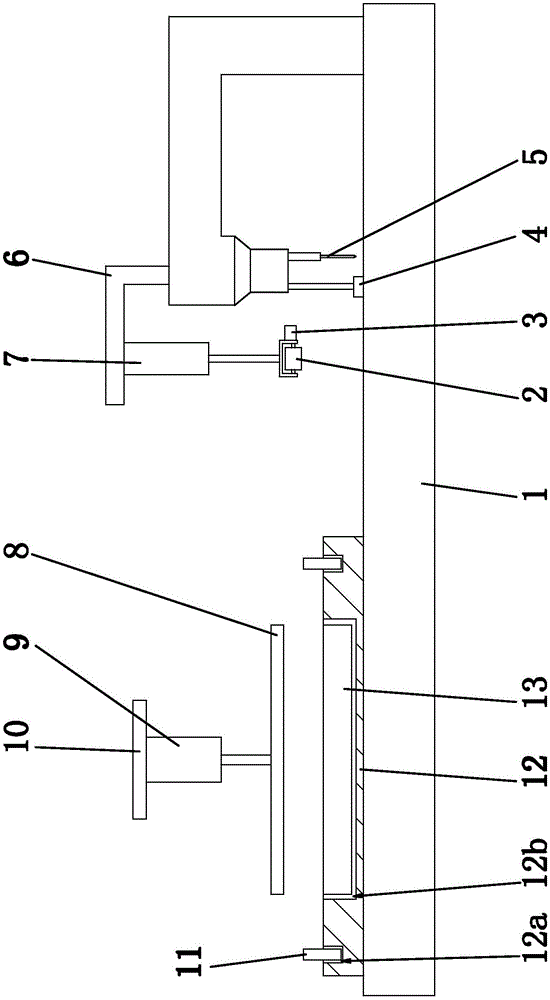

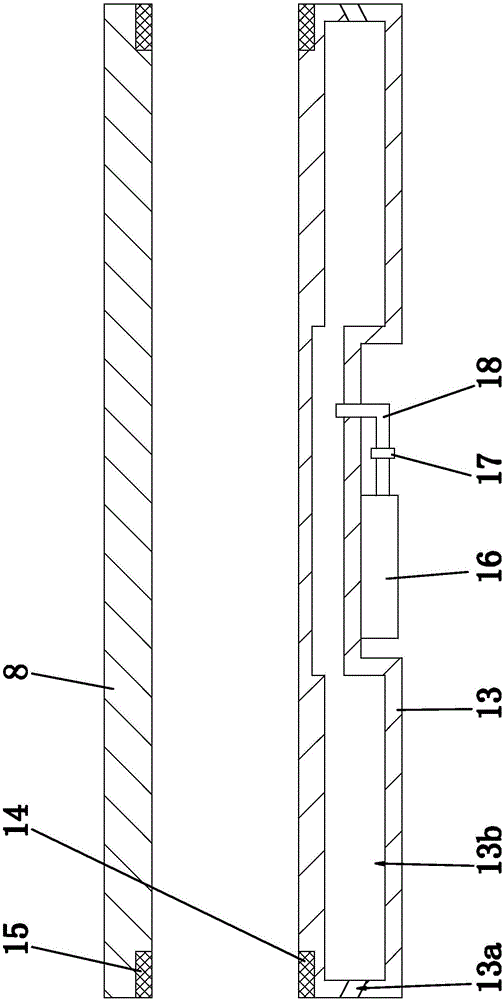

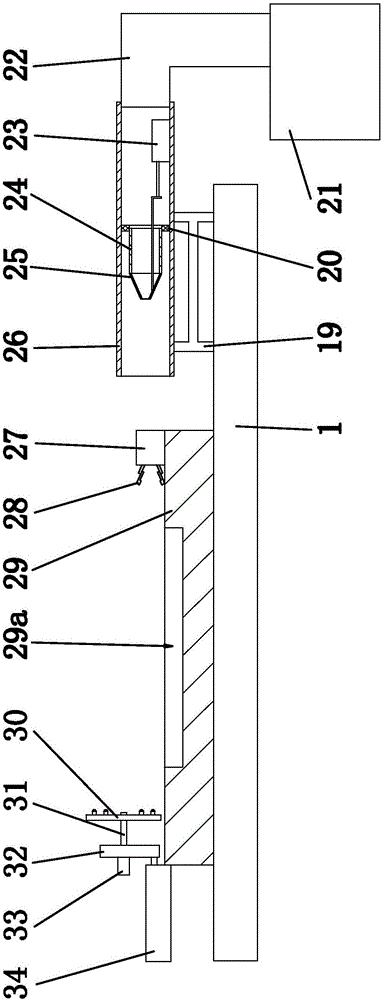

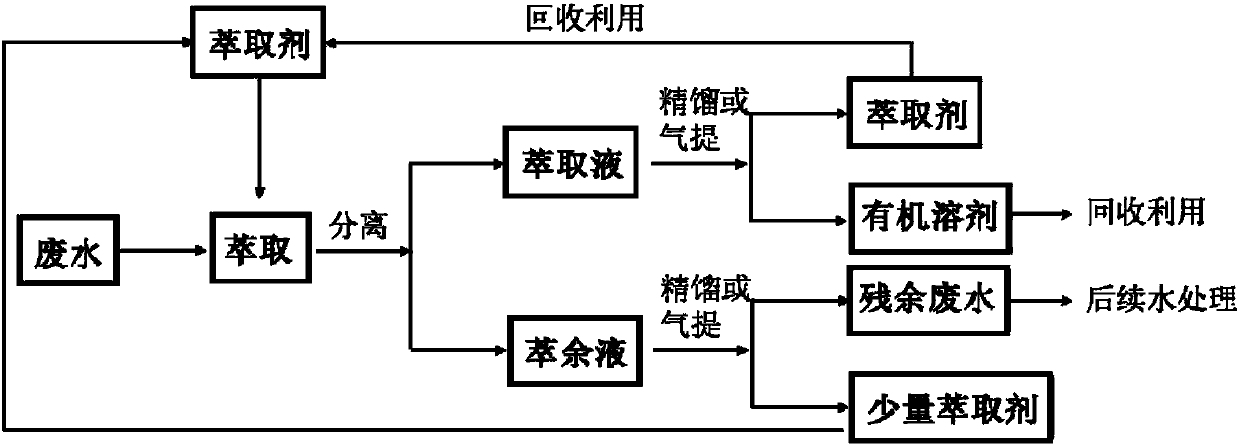

Method for recovering organic solvent from maleic anhydride wastewater

InactiveCN106698575AReduce consumptionReduce the difficulty of biochemistryWater contaminantsWater/sewage treatment by extractionDibutyl sebacateOrganic solvent

Owner:PEKING PUYUAN INST FOR ADVANCED MATERIALS & TECH

Iron-powder doped ceramic diamond grinding wheel

InactiveCN102814753AImprove adhesionAvoid deformationAbrasion apparatusGrinding devicesDibutyl sebacatePotassium

The invention discloses an iron-powder doped ceramic diamond grinding wheel which comprises the following components by weight: 50-60 parts of diamond abrasive, 15-20 parts of brown corundum abrasive, 4-6 parts of phenolic resin powder, 5-8 parts of iron powder, 1-3 parts of naphthyl grains, 1-3 parts of dibutyl sebacate, 1-2 parts of tricresyl phosphate, 4-8 parts of dolomite, 4-8 parts of borax, 2-4 parts of potassium feldspar and 1-3 parts of zinc oxide. Because the binding agents are ceramic materials, the grinding wheel is not easy to deform, has good heat resistance and high abrasion resistance. The various ceramic materials have good binding performance, can prevent the formation of cracks effectively and solves the problems that the existing grinding wheel has poor heat resistance and is easy to deform, the existing binding agents for producing the grinding wheel have poor performance, and the abrasives are easy to fall. Because the iron powder and other metal powders are added, the grinding wheel disclosed by the invention has high heat conducting performance, low grinding temperature and higher hardness and strength and can dissipate heat quickly, the cracks formed due to rigid grinding are reduced, the grinding efficiency and the service life of the grinding wheel are far higher and longer than those of the traditional grinding wheel, and the comprehensive benefit is improved by more than 50%.

Owner:安徽威铭耐磨材料有限公司

Super-thick soft rubber and preparation method thereof

The invention relates to the field of rubber industry and discloses super-thick soft rubber and the preparation method thereof. The super-thick soft rubber comprises the following components by weight portion: 100 portions of natural rubber 1#, 5-40 portions of carbon black N33, 1-4 portions of stearic acid, 0.75-2.5 portions of N-phenyl-alpha-naphthylamine, 1-4 portions of N-isopropyl-N'-steephenyl-para-phenylene diamine, 1-4 portions of paraffin 58#, 5-40 portions of talcum powder, 1.5-5 portions of brenstone, 2.5-7 portions of magnesium oxide, 4-11 portions of zinc oxide, 0.75-2.5 portions of accelerating agent D, 1-4 portions of solid coumarone, 10-60 portions of barium sulfate, 4-12 portions of dibutyl sebacate and 1.5-4 portions of pine tar. The preparation method comprises the following steps: plasticating the natural rubber 1# until the plasticity of the natural rubber 1# ranges from 0.6 to 0.65, adding other materials, mixing, forming rubber sheets, and molding and vulcanizing the rubber sheets, wherein . The assisting step of partial qualitative die clamping is carried out before vulcanization so as to obtain the super-thick soft rubber through one-step stable molding. The product is not easily deformed during vulcanization and can still maintain the dimensional stability and accuracy in the molding process.

Owner:SHANGHAI GUIGANG RUBBER PRODS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com