Method for manufacturing anti-wear antibacterial pillowcase

A production method and pillowcase technology, applied in the textile field, can solve the problems that the pillowcase fabric does not have wear resistance and antibacterial properties, and achieve the effects of continuous and uninterrupted sewing operations, high production efficiency, and strong versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

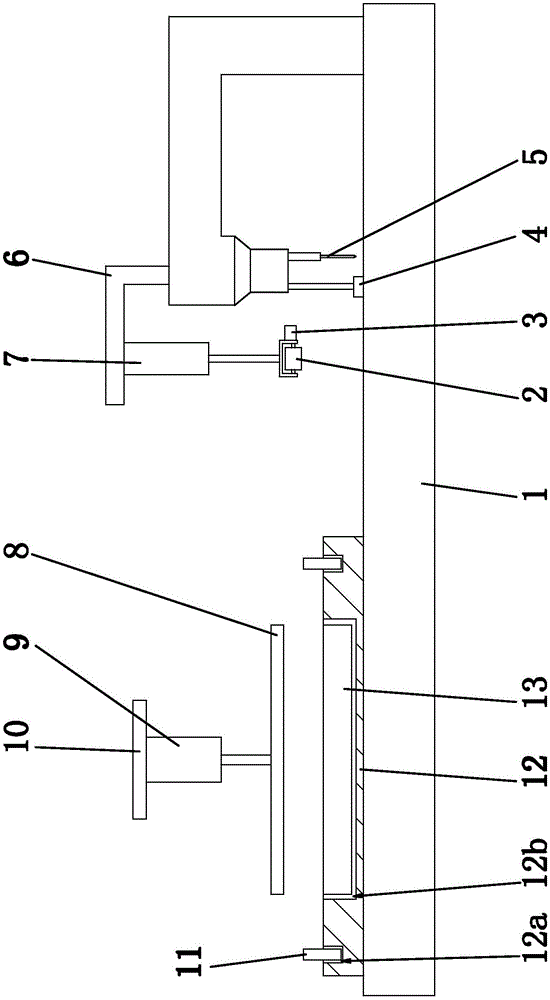

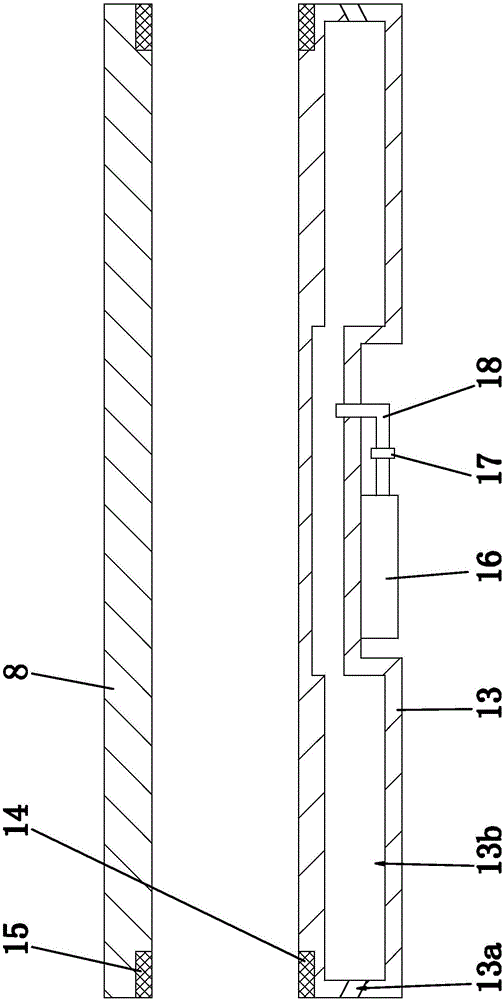

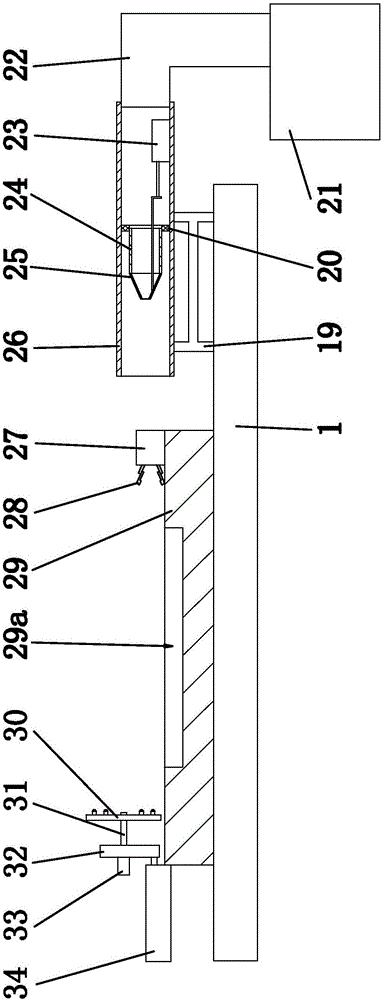

[0043] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

[0044] The manufacturing method of the wear-resistant and antibacterial pillowcase comprises the following steps:

[0045] a, make fabric coating liquid according to the formula of following weight ratio, polyvinyl alcohol tert-butyraldehyde 20-30 parts, dibutyl sebacate 12-15 parts, titanium dioxide 5-8 parts, deacetylated chitosin 6- 12 parts, 7-10 parts of magnesium oxide, 1-3 parts of zinc oxide, 10-14 parts of ammonium molybdate, 14-18 parts of sodium citrate, 3-5 parts of anti-aging agent and 16-24 parts of ethanol; In the example, weigh 25 parts of polyvinyl alcohol tert-butyraldehyde, 14 parts of dibutyl sebacate, 6 parts of titanium dioxide, 9 parts of deacetylated chitin, 8 parts of magnesium oxide, 2 parts of zi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com